A kind of preparation method of ultra-fine grain magnesium alloy extruded bar

A magnesium alloy and ultra-fine grain technology, which is applied in the field of magnesium alloy processing, can solve the problems of difficulty in ultra-fine grain crystallization, large internal stress, complex process, etc., so as to improve comprehensive mechanical properties, large strain, and shorten the preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Preprocessing:

[0029] After the magnesium alloy ZK60 was treated at 350°C for 12 hours, it was taken out of the furnace and air-cooled to room temperature;

[0030] 2) Deformation processing:

[0031] Start the extrusion device, under the condition of 380 ° C, the extrusion rod is extruded at the extrusion speed of 30 mm / s, and the extrusion ratio of 100:1 is extruded step 1) to obtain the pretreated magnesium alloy ZK60, and at the same time in the extrusion direction Twist the magnesium alloy ZK60 with a traction device for the axis, and the torsion speed is 0.27 r / s, so that the magnesium alloy is violently deformed, and the number of twisted turns per unit length of the ultra-fine-grained magnesium alloy extruded rod is 0.09 r / cm.

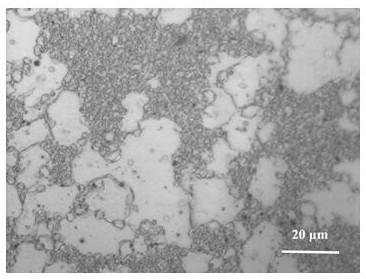

[0032] Using a metallographic microscope to observe the microstructure of the low-cost ultra-fine-grained magnesium alloy extruded rods, the results are as follows figure 1 shown.

[0033] From figure 1 It can be seen that the ...

Embodiment 2

[0037] 1) Preprocessing:

[0038] After the magnesium alloy AZ31 was treated at 450°C for 2 hours, it was taken out of the furnace and air-cooled to room temperature;

[0039] 2) Deformation processing:

[0040] Start the extrusion device, under the condition of 350 ° C, the extrusion rod is extruded at the extrusion speed of 28 mm / s, and the extrusion ratio of 25:1 is extruded step 1) to obtain the pretreated magnesium alloy AZ31, and at the same time in the extrusion direction The magnesium alloy AZ31 is twisted by traction equipment for the axis, and the twisting speed is 0.42 r / s, so that the magnesium alloy is violently deformed, and the number of twisted turns per unit length of the ultrafine grain magnesium alloy extruded rod is 0.15 r / cm.

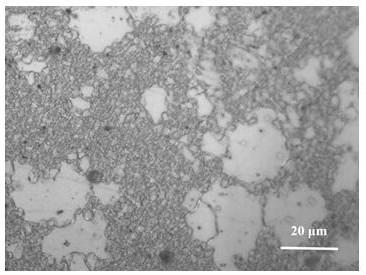

[0041] Using a metallographic microscope to observe the microstructure of the extruded rods of ultra-fine-grained magnesium alloys, the results are as follows: image 3 shown.

[0042] From image 3 It can be seen that the volu...

Embodiment 3

[0046] 1) Preprocessing:

[0047] cast magnesium alloy ingots without heat treatment;

[0048] 2) Deformation processing:

[0049] Start the extrusion device, under the condition of 380 ° C, the extrusion rod is extruded at the extrusion speed of 10 mm / s, and the extrusion ratio is 100:1. Step 1) to obtain the pretreated magnesium alloy AZ31, and at the same time in the extrusion direction Twist the magnesium alloy AZ31 with a traction device for the axis, and the twisting speed is 0.33 r / s, so that the magnesium alloy is violently deformed, and the number of twisted turns per unit length of the ultra-fine-grained magnesium alloy extruded rod is 5 r / cm.

[0050] Using a metallographic microscope to observe the microstructure of the extruded rods of ultra-fine-grained magnesium alloys, the results are as follows: Figure 5 shown.

[0051] From Figure 5 It can be seen that the volume fraction of the structure with grain size smaller than 1.2 μm in magnesium alloy accounts ...

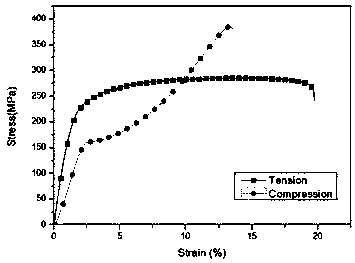

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com