Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

108results about How to "No surface defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Radiation-curable coating compounds

InactiveUS6605669B2Inhibition of polymerizationNo surface defectsPolyurea/polyurethane coatingsPrinting after-treatmentMeth-Functional monomer

Coating compounds curable by means of high-energy radiation, comprising as binderA) at least one (meth)acrylic copolymer containing olefinic double bonds capable of free-radical polymerization and hydroxyl groups with a C=C equivalent weight from 100 to 10,000 and an OH-value from 20 to 250 mg KOH / g, which is prepared from monomers comprising:A1) at least one olefinically unsaturated, epoxy-functional monomer capable of free-radical polymerization,A2) at least one olefinically unsaturated, carboxy-functional monomer capable of free-radical polymerization andA3) at least one further olefinically unsaturated monomer capable of free-radical polymerization which is different from A1) and A2), andB) at least one component with free isocyanate groups and process for multilayer coating using the coating compounds.

Owner:AXALTA COATING SYST IP CO LLC

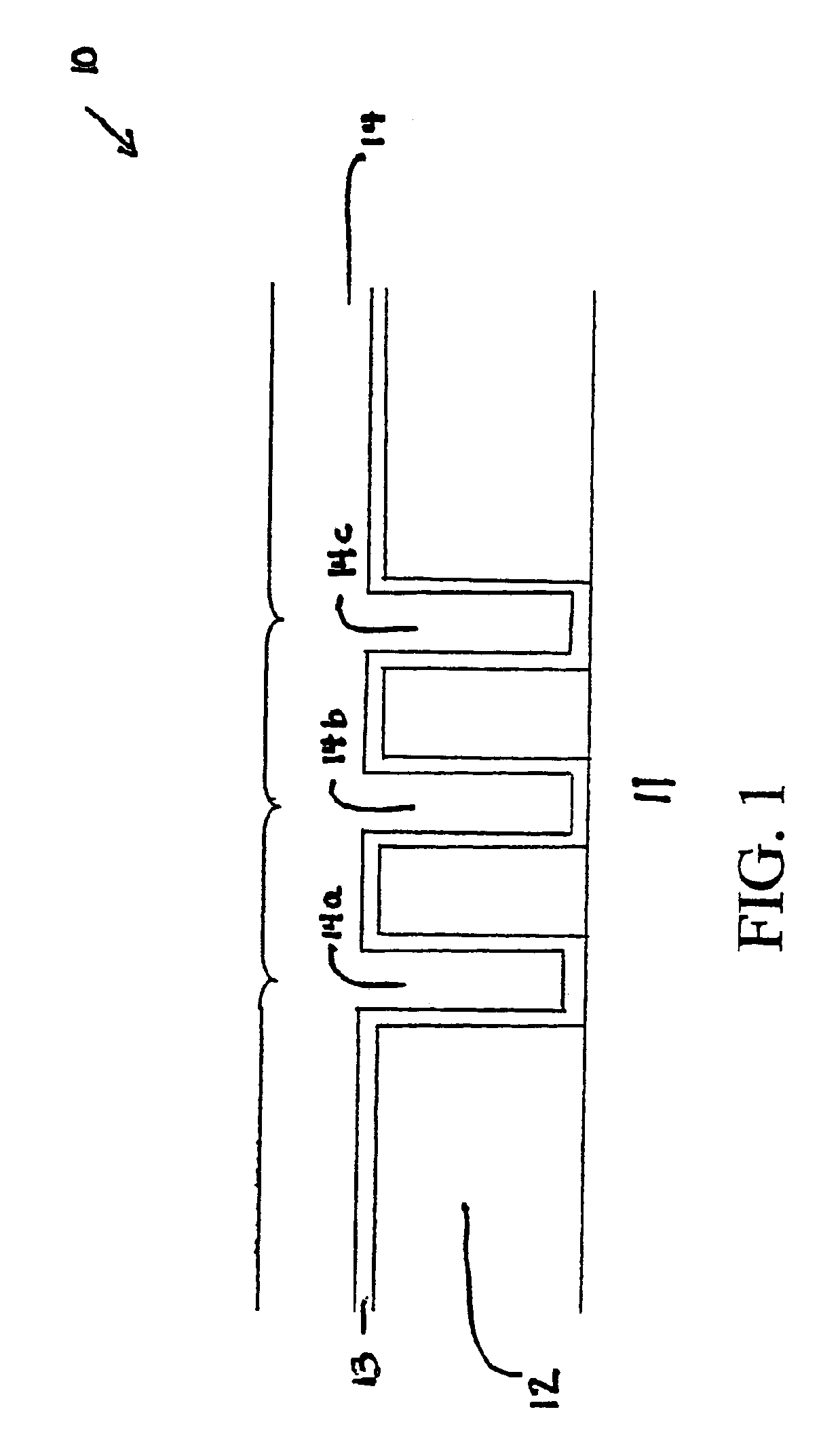

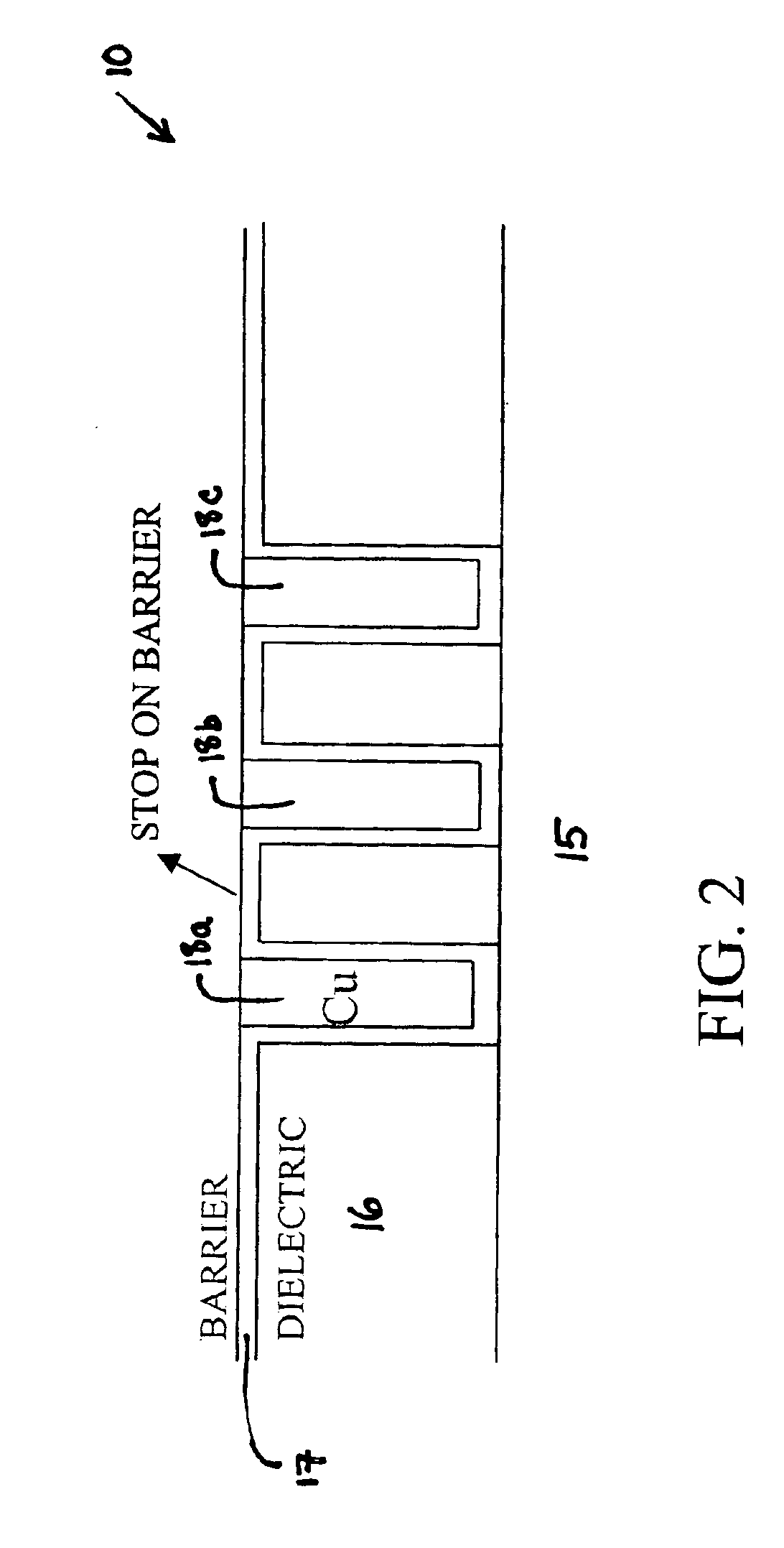

Chemical mechanical polishing compositions for metal and associated materials and method of using same

InactiveUS7029373B2High removal rateLow removal ratePigmenting treatmentOther chemical processesCompound (substance)Copper

A chemical mechanical polishing slurry composition and method for using the slurry composition for polishing copper, barrier material and dielectric material that comprises first and second-step slurries. The first-step slurry has a high removal rate on copper and a low removal rate on barrier material. The second-step slurry has a high removal rate on barrier material and a low removal rate on copper and dielectric material. The first slurry comprises at least an organic polymeric abrasive.

Owner:ADVANCED TECH MATERIALS INC

Polishing liquid for polishing monocrystalline silicon piece chemical machine

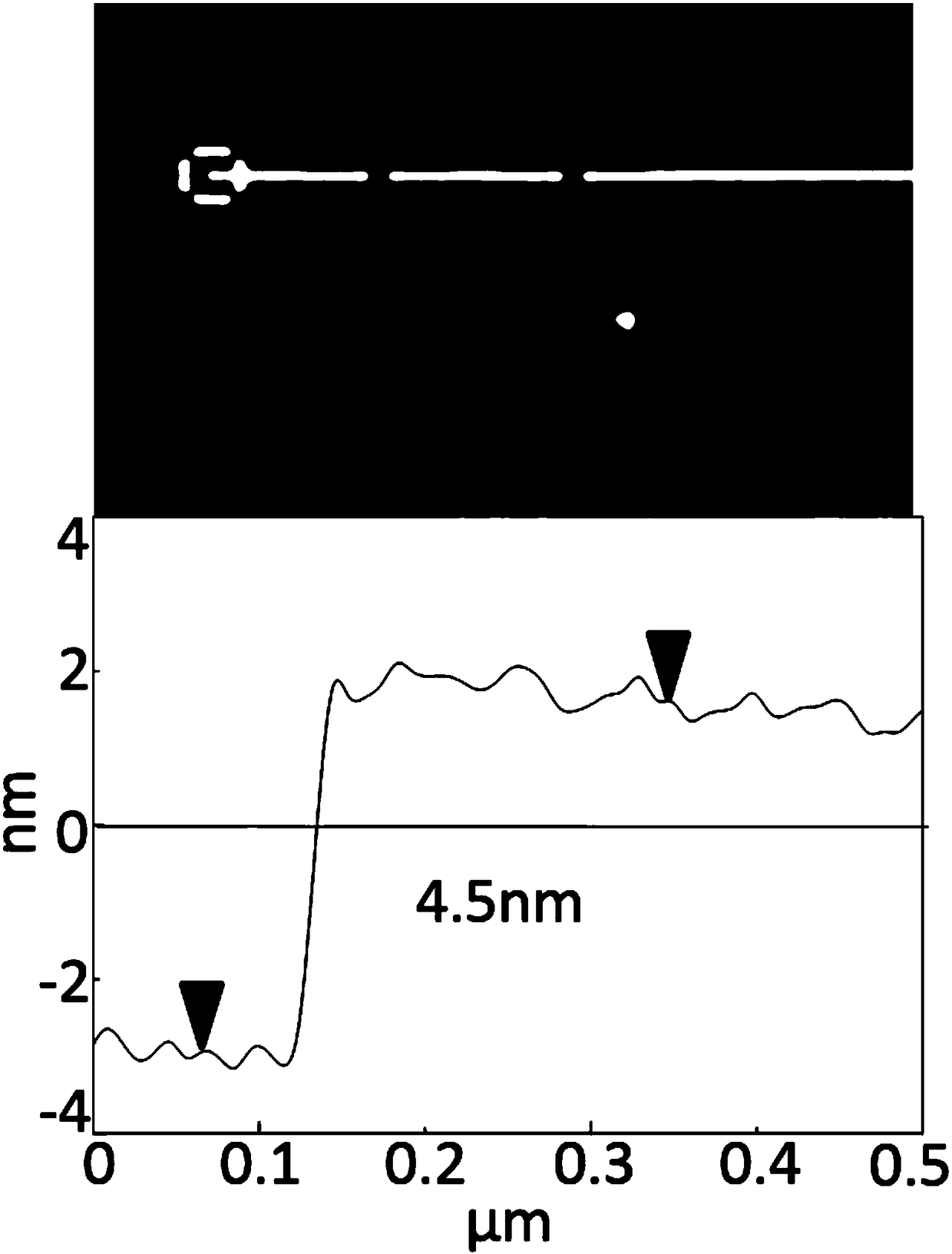

InactiveCN101671528ANo surface defectsEfficient ultrafine chemical mechanical polishingPolishing compositions with abrasivesActive agentSurface roughness

The invention discloses a polishing liquid for polishing a monocrystalline silicon piece chemical machine, comprising the raw materials by mass percent: 0.1-20% of grinding material, 0.1-2% of chelating agent, 0.1-5% of dispersing agent, 0.1-5% of active agent, 0.01-10% of pH regulator and less than or equal to 90% of purified water; and the pH value is 9.0-12.0. The polishing liquid can obviouslyimprove the polishing speed (removing rate reaching 710nm), generates lower surface defect for a monocrystalline silicon piece, and reduces the surface roughness (reaching 0.18nm), thus realizing topolish the high-efficiency ultra-precision chemical machine of the monocrystalline silicon piece, and ensuring the fine quality of the surface of the monocrystalline silicon piece. The polishing liquid is alkaline, so as to be conveniently cleaned after polishing; furthermore, the polishing liquid does not corrode equipment, thus prolonging the service life of the equipment and reducing the processing cost.

Owner:DALIAN SANDAAOKE CHEM

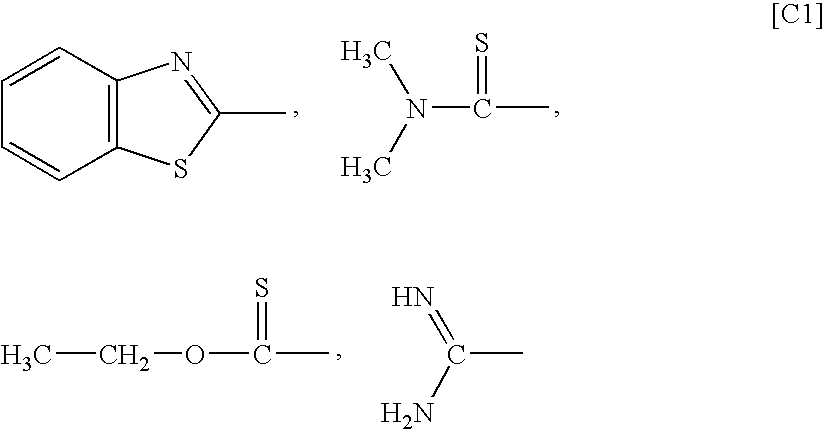

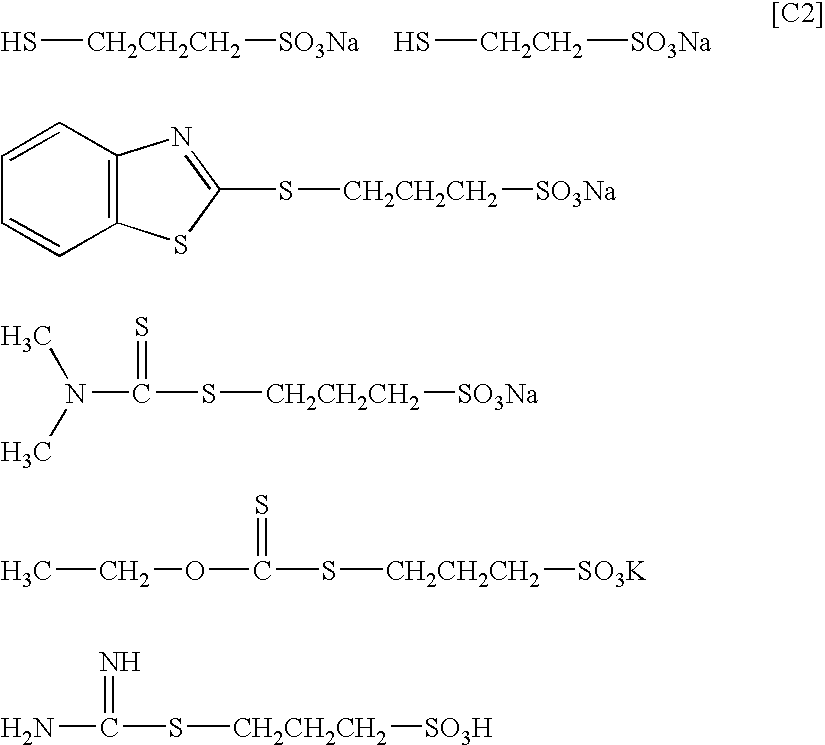

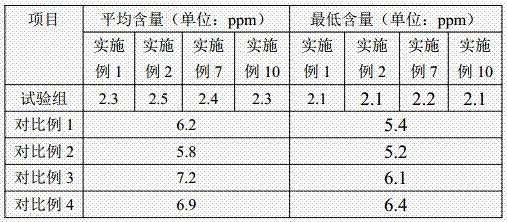

Copper electrolytic solution and two-layer flexible substrate obtained using the same

InactiveUS20100084275A1Excellent resist adhesivenessEliminate surface defectsDuplicating/marking methodsActive material electrodesFolding enduranceSulfur

To provide a two-layer flexible substrate having excellent folding endurance, etching properties, and resist adhesiveness with no surface defects.A copper electrolytic solution containing chloride ions, a sulfur organic compound and polyethylene glycol as additives, and the copper electrolytic solution preferably contains 5 to 200 ppm of chloride ions, 2 to 1000 ppm of a sulfur organic compound and 5 to 1500 ppm of polyethylene glycol. A two-layer flexible substrate having a copper layer formed using the copper electrolytic solution, wherein the MIT folding endurance is 100 or more, and the surface roughness (Rz) of the copper layer is 1.4 to 3.0 μm.

Owner:JX NIPPON MINING & METALS CO LTD

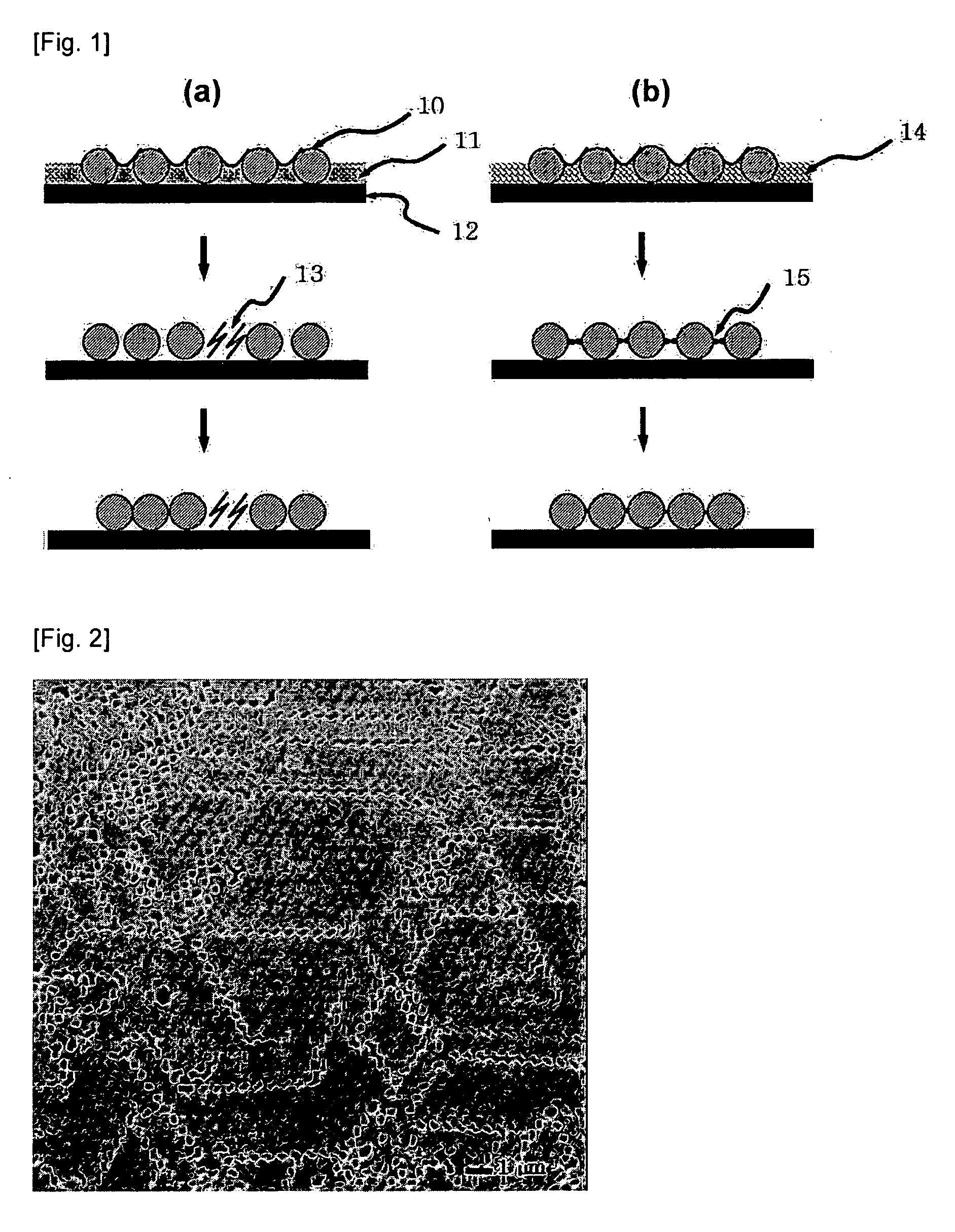

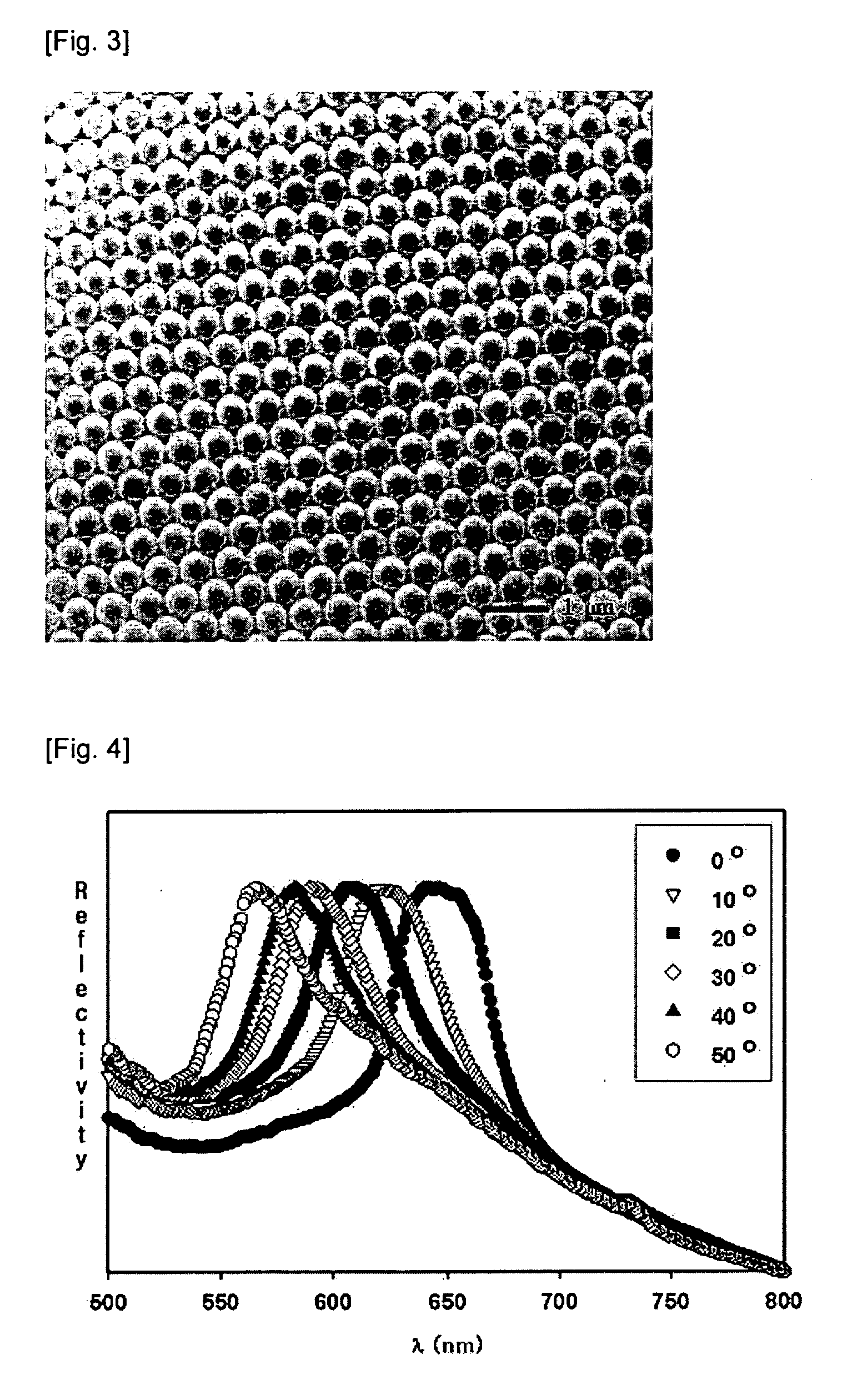

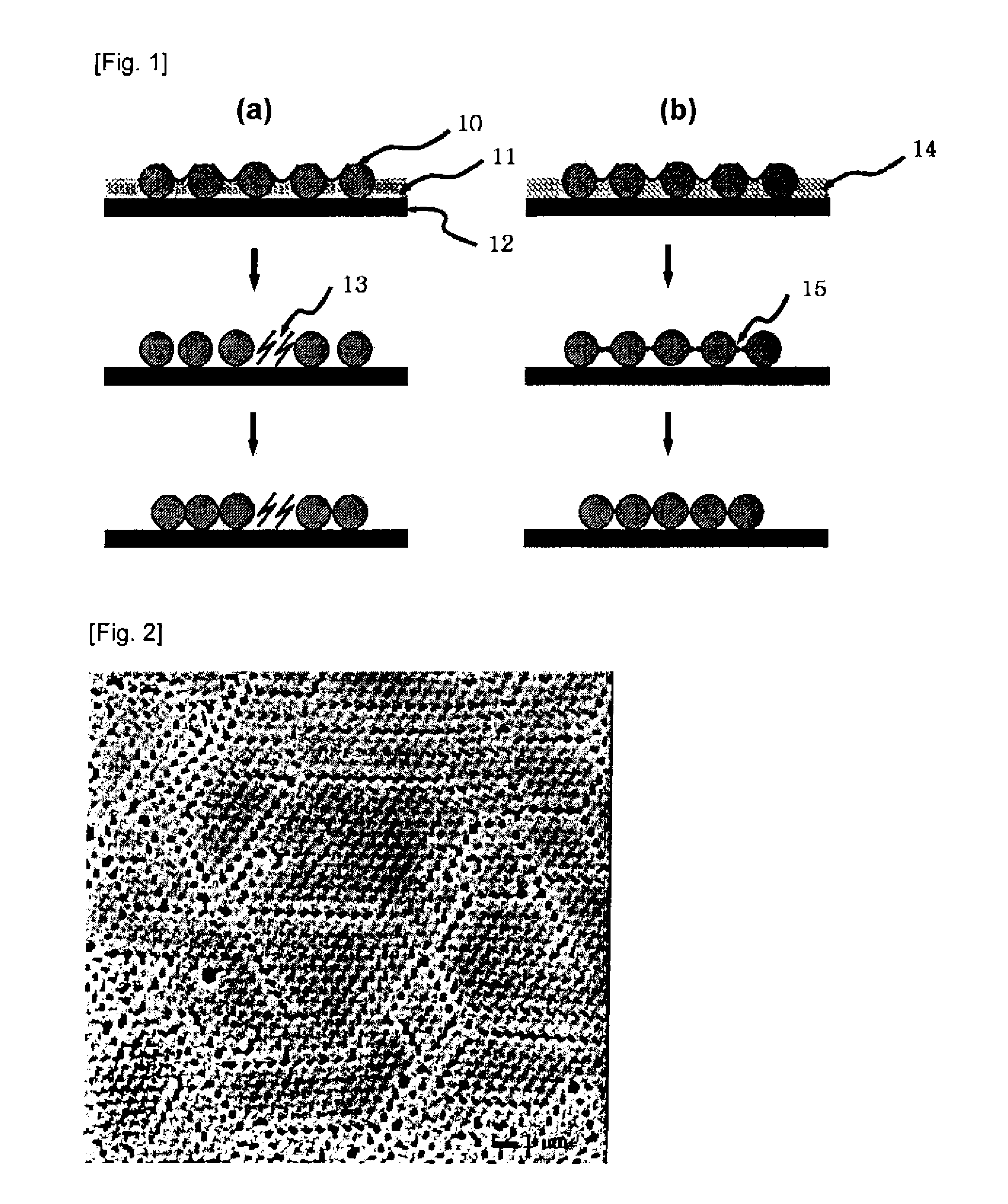

Colloidal photonic crystals using colloidal nanoparticles and method for preparation thereof

ActiveUS20070163486A1No surface defectsLess timeFrom gel statePolycrystalline material growthColloidal nanoparticlesColloidal particle

The present invention relates to colloidal photonic crystals using colloidal nanoparticles and a method for the preparation thereof, wherein by adding a viscoelastic material into a solution containing the colloidal nanoparticles when preparing the colloidal photonic crystals, a uniform volume contraction occurs due to the elasticity of the viscoelastic material even when a nonuniform volume contraction occurs while drying a dispersion medium in the colloidal solution. Thus, it is possible to prepare 2 or 3 dimensional colloidal photonic crystals of large scale with no defects in less time.

Owner:LG CHEM LTD

Metal-based composite material as well as preparation method and application thereof

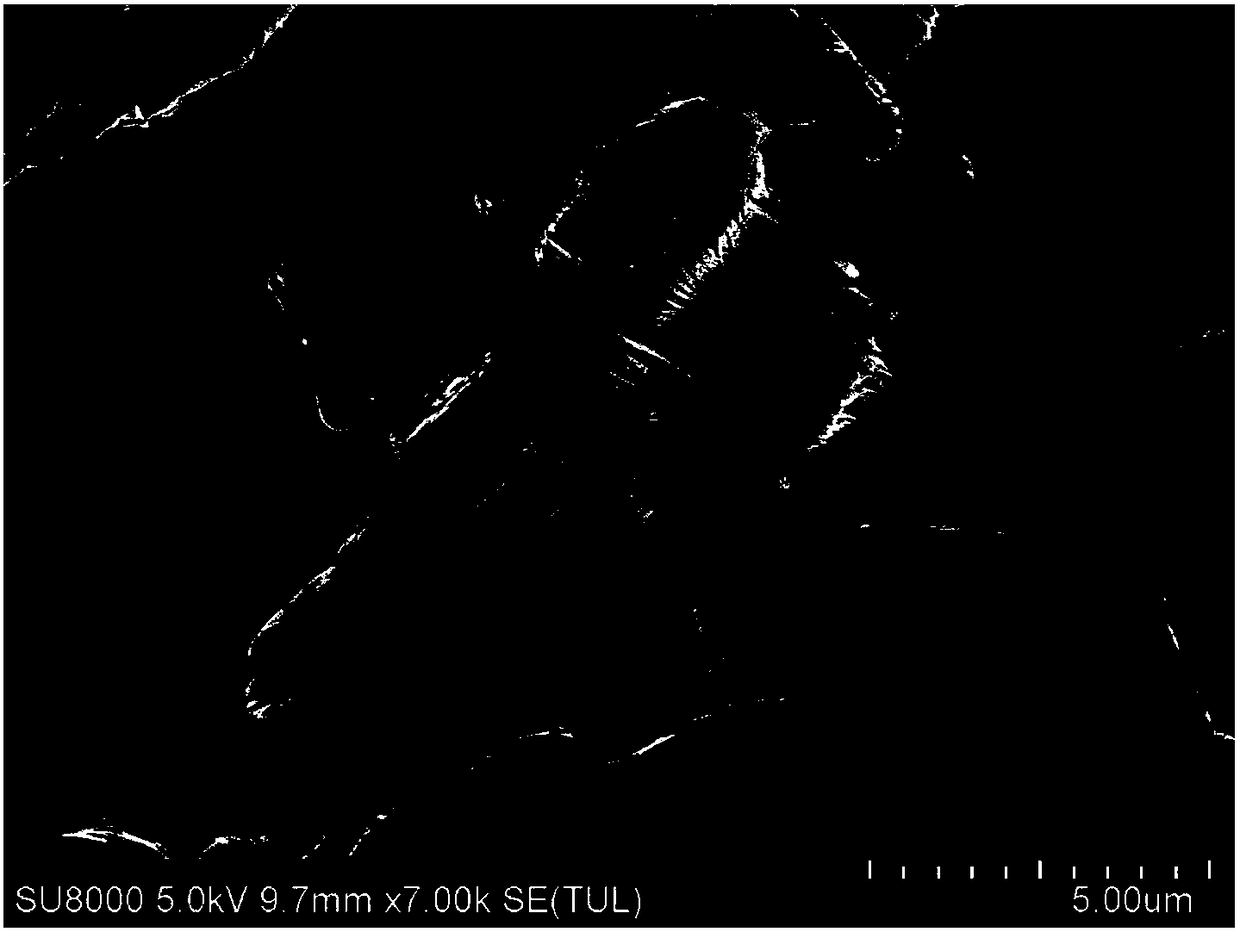

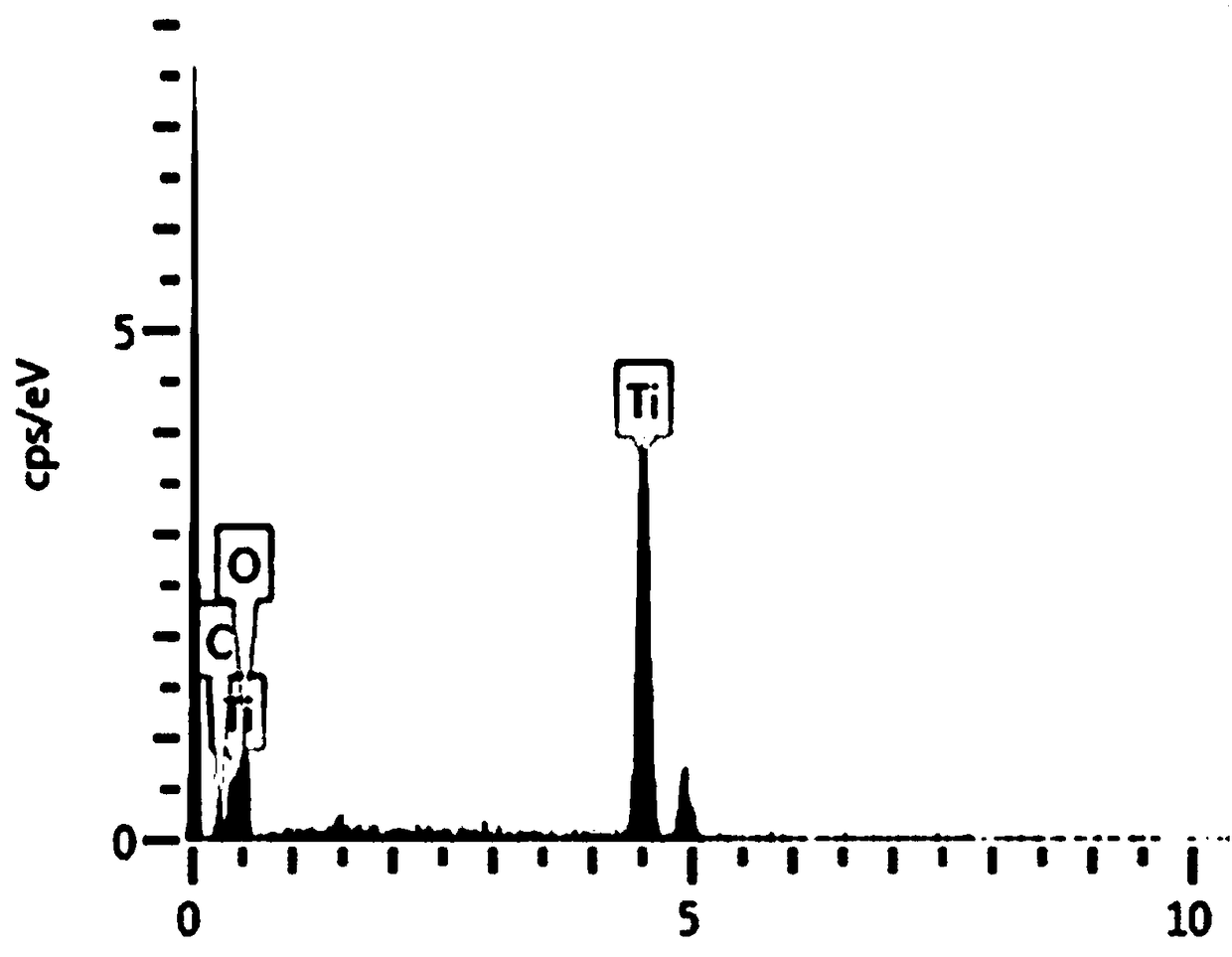

ActiveCN108275683ACoated evenlyUniform covering thicknessElectrolytic coatingsNitrogen-metal/silicon/boron binary compoundsMetal matrix compositeStructural formula

The invention relates to a metal-based composite material which comprises a metal substrate and an MXene material membrane layer, wherein the MXene material membrane layer is arranged on the bottom surface of the metal substrate in a wrapping layer and is of a structural formula Mn+1Xn(Ts); an MXene material is prepared by removing A from a compound of a structural formula Mn+1AXn; in the formula,M, A and X are respectively three different elements; n is a positive integer; Ts is an end sealing group on the surface of the MXene material. The surface of the metal-based composite material provided by the invention is uniformly wrapped with the MXene material membrane layer, the number of sheet layers of the MXene material is only 1-15, the wrapping thickness is smaller than 250 nm, the thickness is uniform, the wrapped surface is smooth and flat, surface defects can be avoided, and the corrosion velocity of the obtained metal-based composite material is very low, that is, is only about0.06% of that of a conventional metal substrate; the invention further discloses a novel method for preparing the metal-based composite material, and by adopting the method, no complex instrument equipment is needed, and the metal-based composite material can be conveniently and rapidly prepared.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

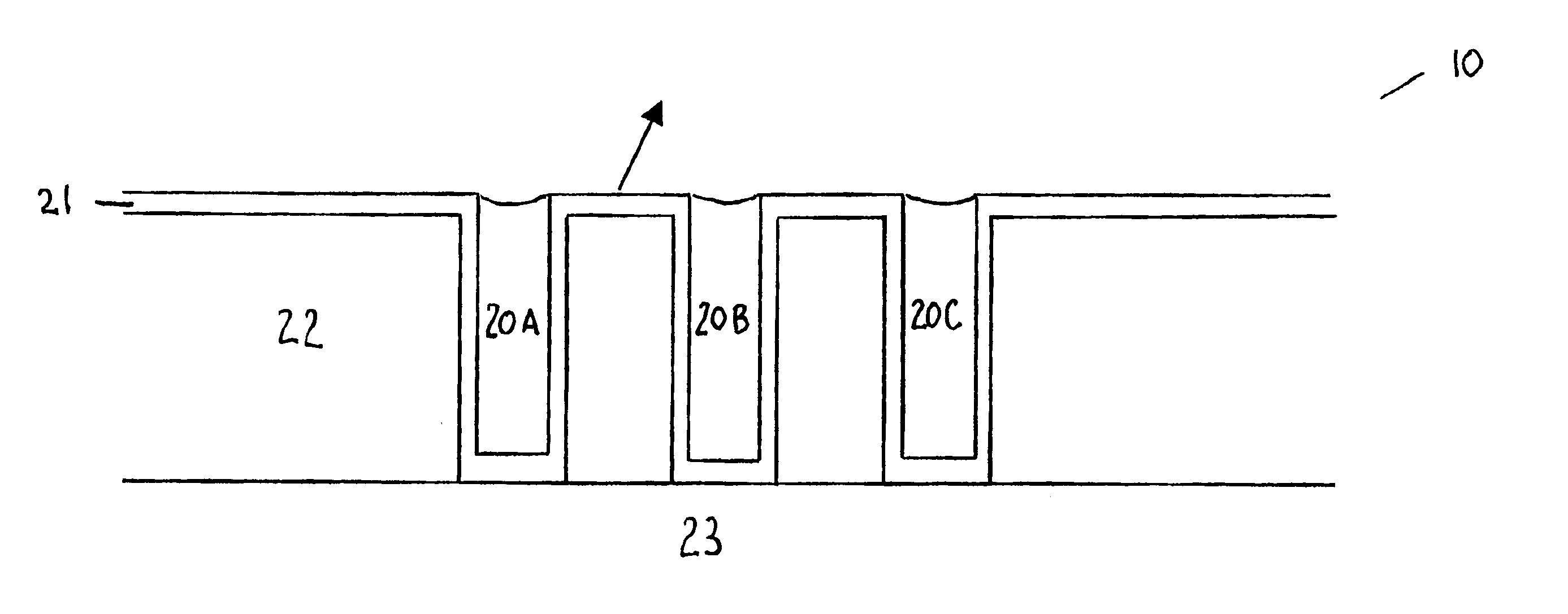

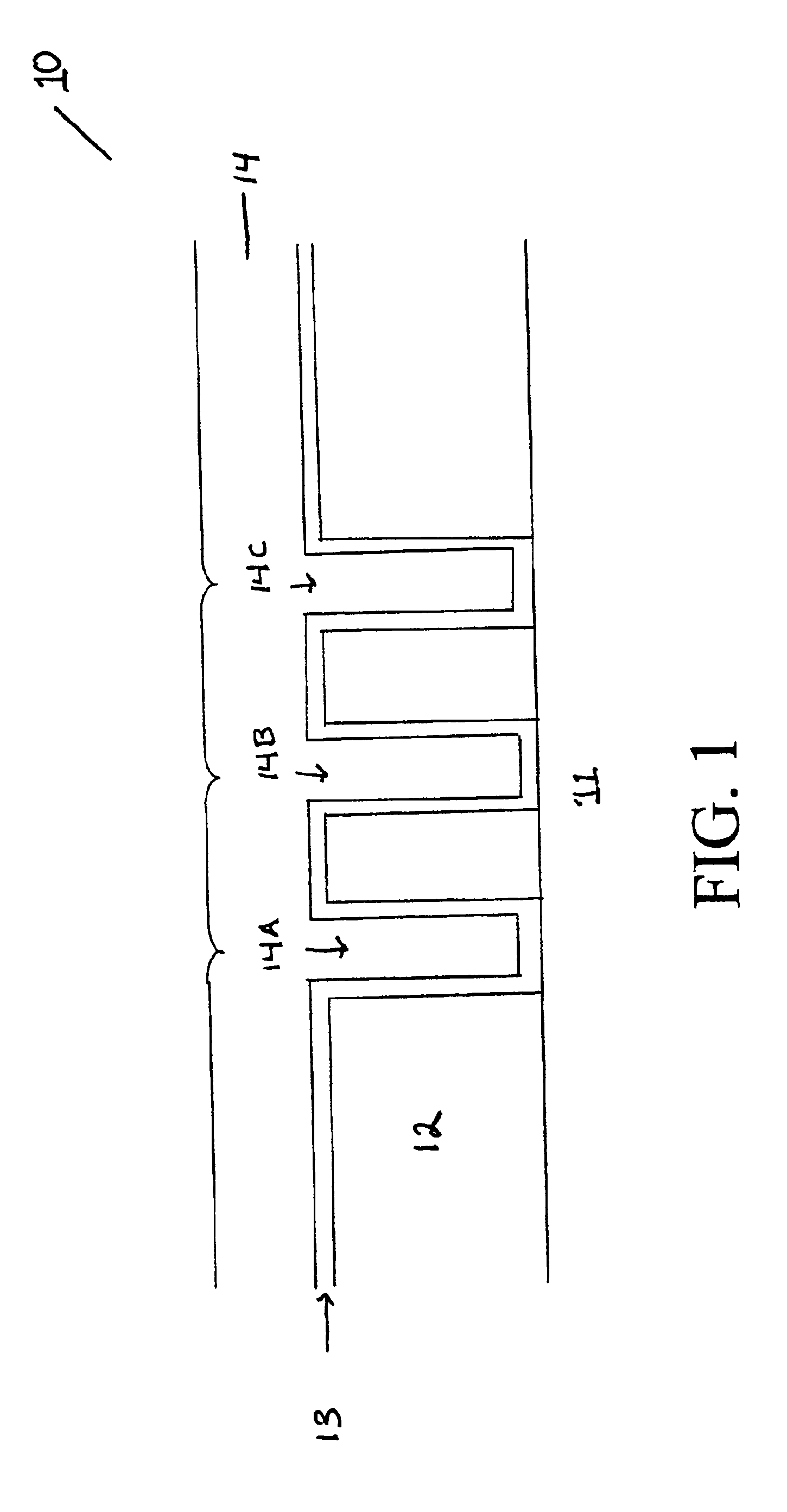

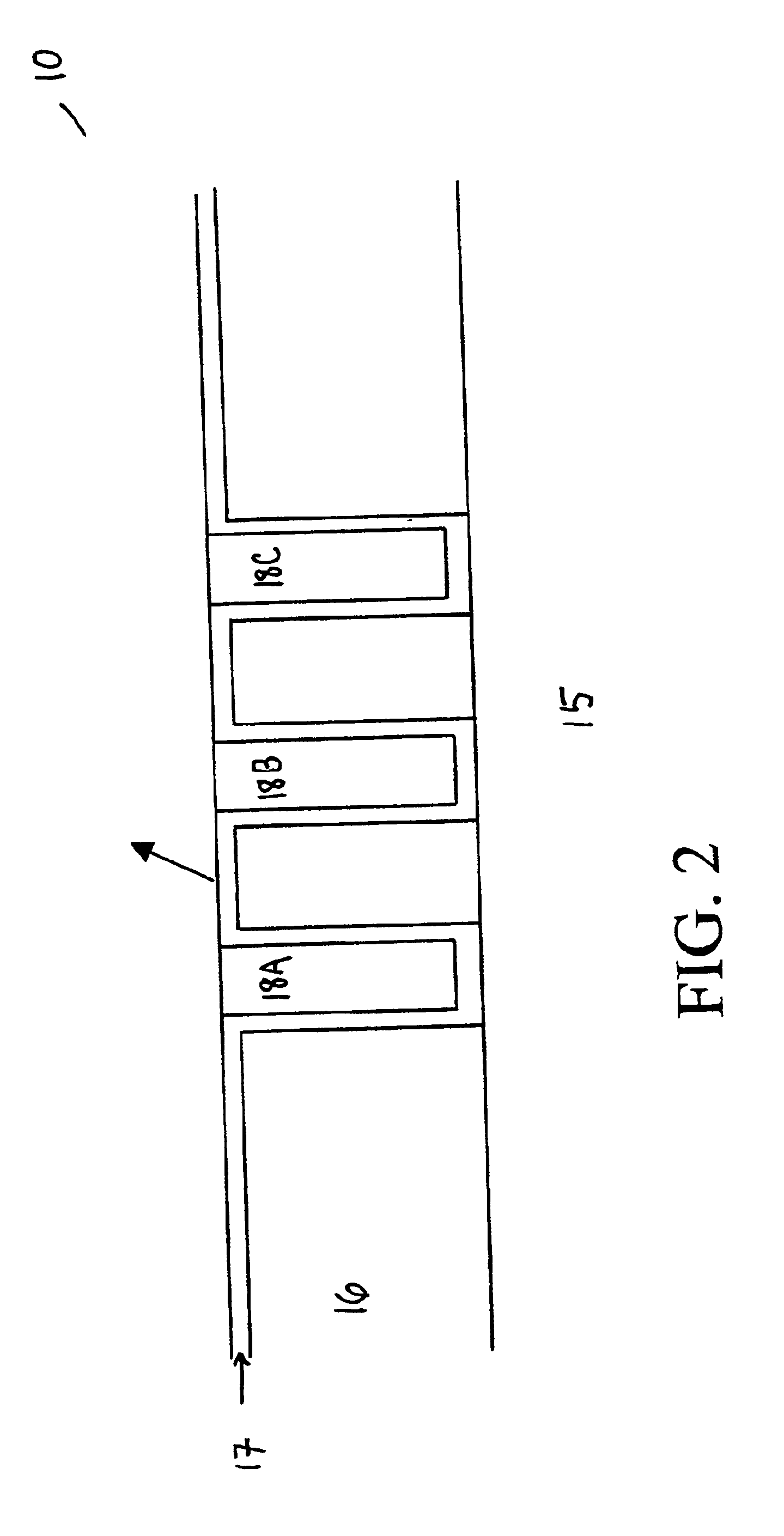

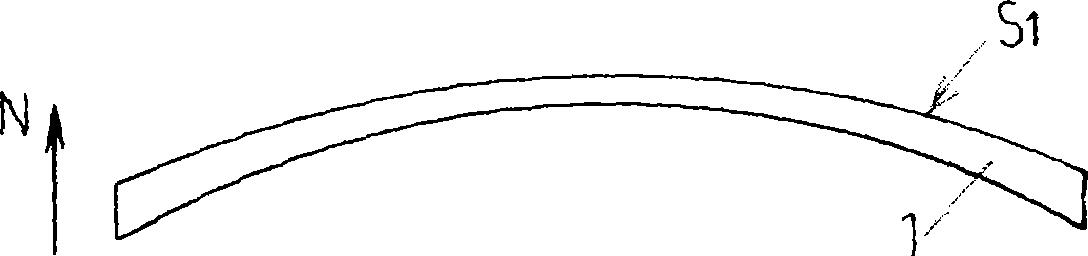

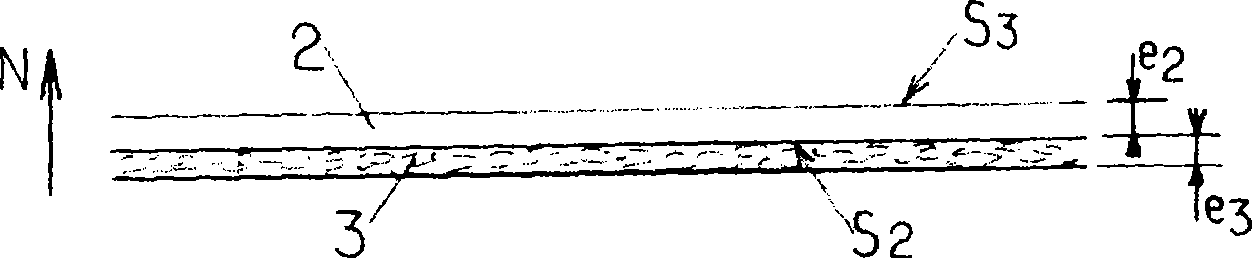

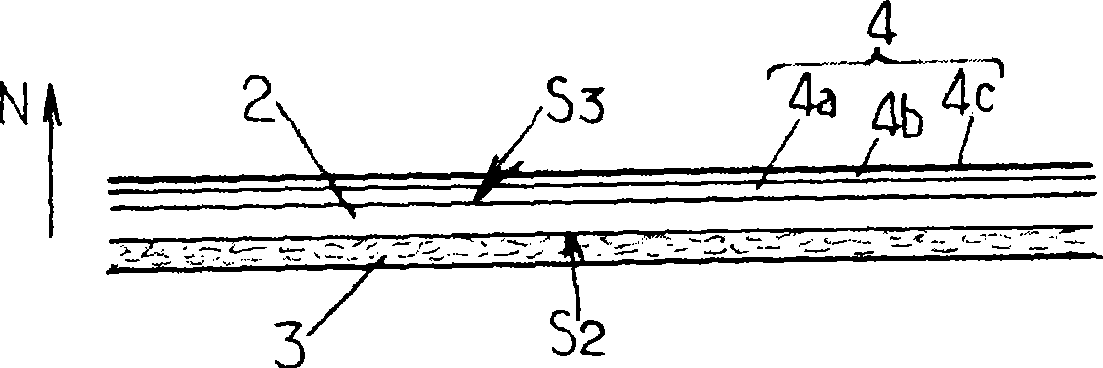

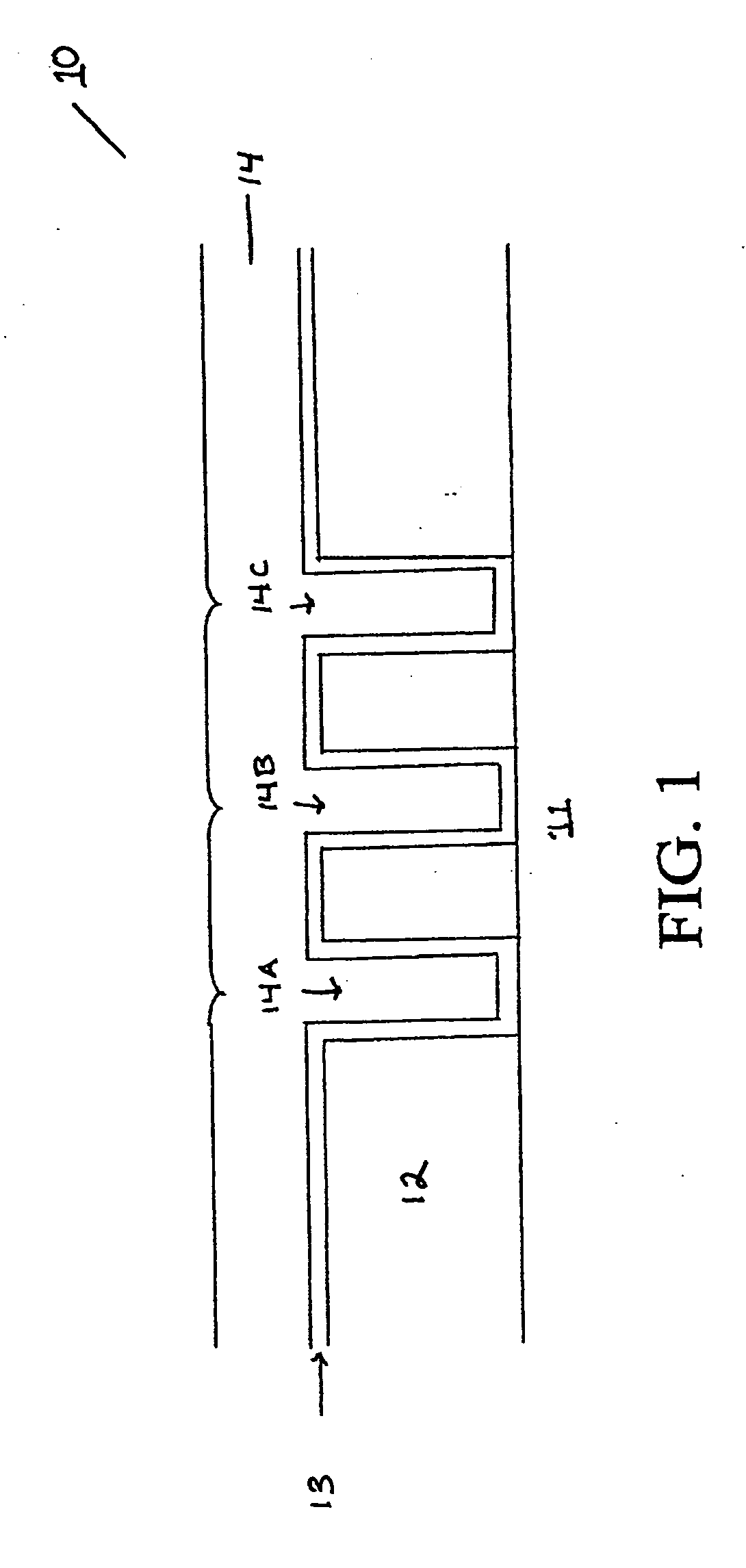

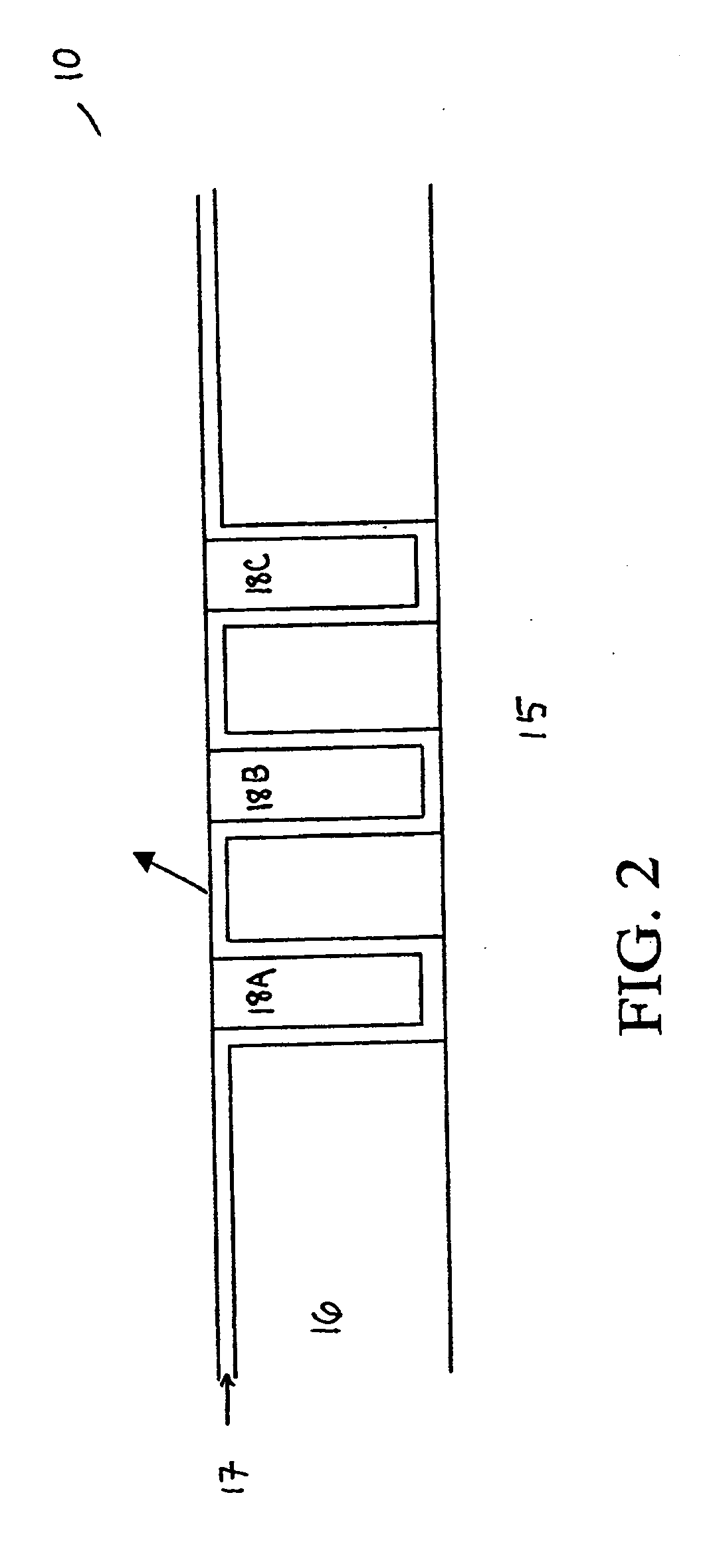

Method of bonding a film to a curved substrate

ActiveCN101466528ARelieve pressureNo surface defectsOptical articlesCoatingsEngineeringPressure difference

A method of bonding a film (2) to a curved substrate (1) comprises preforming the film by applying a pneumatic pressure difference between two sides of the film and by heating said film. An intermediate shape is then conferred on the film, which is suitable for applying the film against a curved face of the substrate. This application is carried out, on the one hand, by keeping the film m the intermediate shape by means of an adjusted pressure difference applied between the two sides of the film and, on the other hand, by pressing the substrate against the film by means of a movable support (12-14). Such a method is used to obtain a defect-free ophthalmic lens with a film bonded to it.

Owner:ESSILOR INT CIE GEN DOPTIQUE

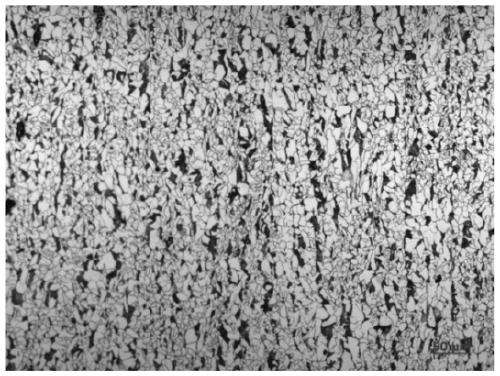

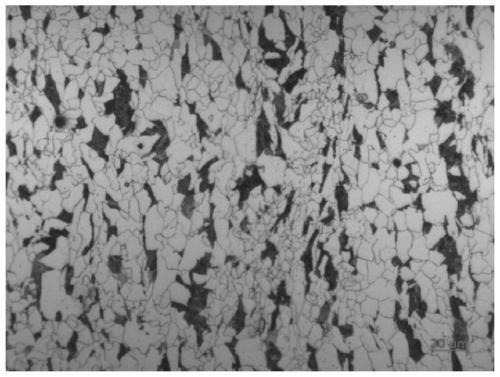

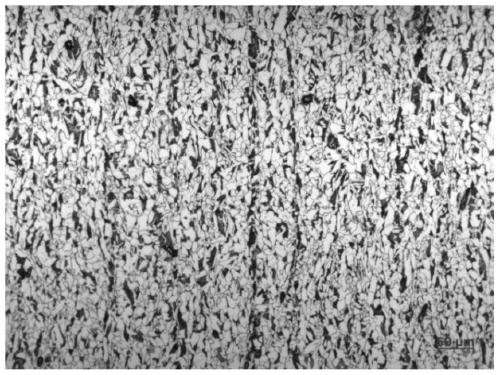

Preparation method of 80-100mm extra-thick EH36 steel for offshore wind power

ActiveCN111455255AGuaranteed StrengthGrain refinementFurnace typesHeat treatment furnacesMetallurgyOffshore wind power

The invention relates to a preparation method of 80-100mm extra-thick EH36 steel for offshore wind power. The preparation method comprises the following steps of: converter processing-LF refining-RH vacuum degassing-Ca treatment-continuous casting-casting blank hydrogen diffusion-heating-normalizing rolling-air cooling-steel plate stacking and slow cooling- unstacking, wherein the normalizing rolling adopts two stages of rough rolling and finish rolling; the initial rolling temperature of the rough rolling is 1050-1100 DEG C, the single-pass reduction rate of three passes after the rough rolling is greater than or equal to 15%, and the cumulative reduction rate in the rough rolling stage is greater than or equal to 50%; and the initial rolling temperature of the finish rolling is 860-890 DEG C, the austenite non-recrystallization interval is expanded by adding sufficient Nb, the initial rolling temperature of the finish rolling is above the austenite ferrite equilibrium transformationpoint Ac3, the total rolling pass is 8-12, air cooling is carried out after rolling, Nb is separated out in the steel plate in the air cooling process, and the triangular grain boundary, the grain boundary and the grain interior of ferrite grains are pinned to limit the rapid growth of the ferrite. Therefore, the normalized and rolled EH36 steel plate for offshore wind power is obtained.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

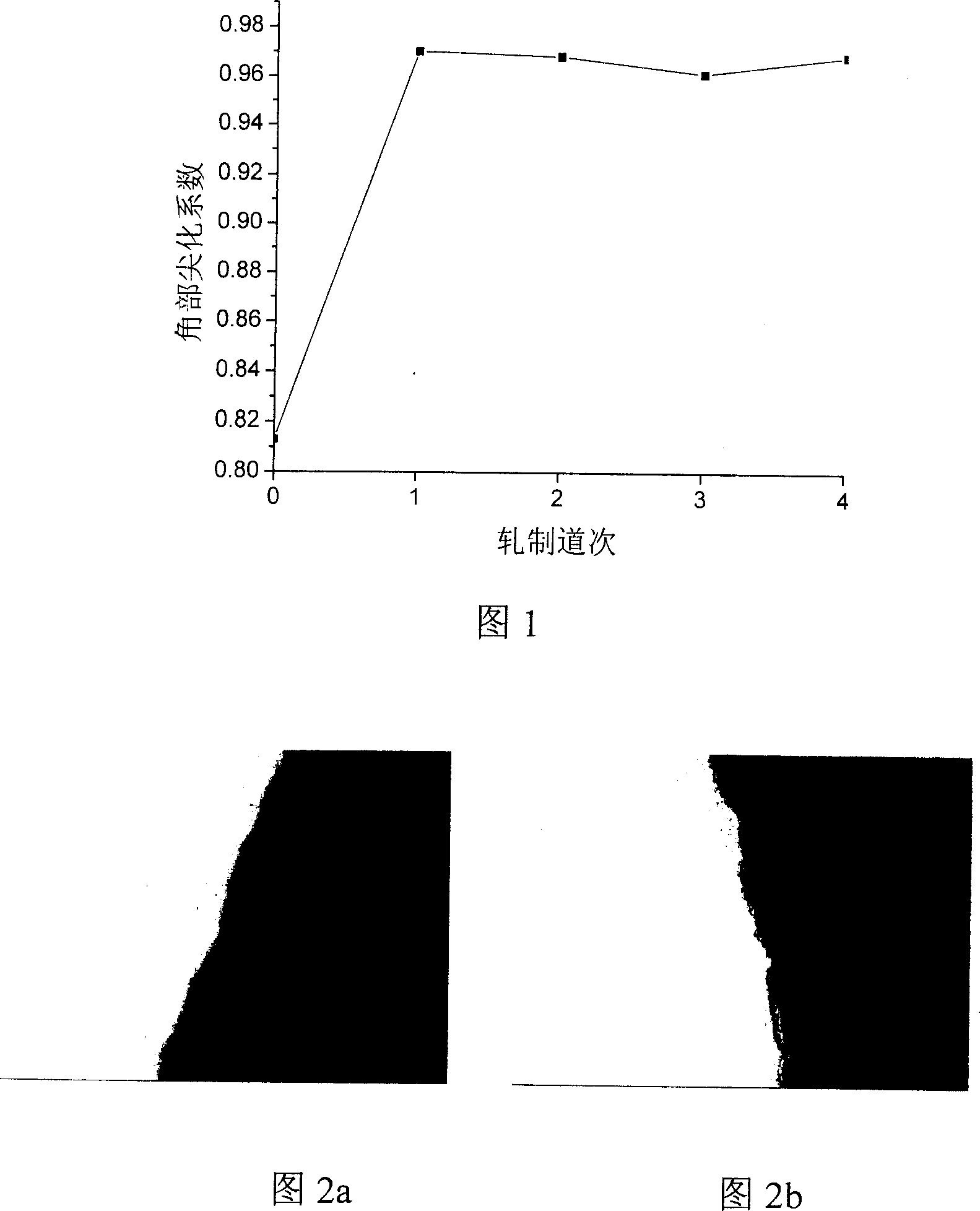

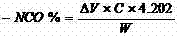

Non-groove rolling method for high speed wire bar intermediate rolling train

InactiveCN101152654AImprove work rateImprove productivityRoll force/gap control deviceTemperature control deviceReduction rateWire rod

The invention discloses a non-groove rolling method for high speed wire rod roughing mill group and mainly solves rolling technical problem of the high speed wire rod roughing mill group. The non-groove rolling method comprises two pass non-groove rolling, four pass non-groove rolling or six pass non-groove rolling; the ratio of height and width of the rolling component is 0.90 to 1.58, reduction rate of pass is 15 percent to 45 percent, rolling temperature is 1000 celsius degree to 1100 celsius degree, the adaptation range of blank is 120*120mm to 180*180mm, and the absolute spread coefficient range is 0.25 to 0.45. The invention adopts a pass-free flat roller to replace a rough rolling pass roller of the prior art and realizes non-groove rolling of the high speed wire rod roughing mill group. The invention aims to provide the non-groove rolling method for the high speed wire rod roughing mill group adopting the flat roller to replace the rough pass roller, meanwhile, decreasing production cost, improving product quality and productivity of the mill and expanding the adaptation range of blank.

Owner:BAOSHAN IRON & STEEL CO LTD +1

SiC fiber reinforced polyurethane series skid-resistant coating and preparation method thereof

InactiveCN104710926AUniform appearanceGood adhesionAnti-corrosive paintsPolyurea/polyurethane coatingsDefoaming AgentsTitanium dioxide

The invention discloses a SiC fiber reinforced polyurethane series skid-resistant coating and a preparation method thereof. The skid-resistant coating is prepared from a component A, a component B, a component C, and other components through mixing, wherein the component A comprises polytetramethylene ether glycol, liquidated MDI, and E44 type epoxy resin; the B component comprises SiC short fiber, Al2O3 and a surface modifier; the component C comprises liquidated MDI, a chain extender, BaSO4, titanium dioxide and talcum powder; other components comprise a diluent, a defoaming agent and a levelling agent. The preparation method comprises the following steps: all components in the component A are mixed, so that the component A is prepared; all components in the component B are mixed, so that the component B is prepared; the component B, which accounts for 3-8% of the component C is mixed with the component C, and other components are added into the mixture so as to obtain a component D; finally, the component A and the component D are mixed according to the mass ratio of 1: (1-1.1), so that the skid-resistant coating is prepared. The skid-resistant coating disclosed by the invention is high in friction coefficient and adhesive force, excellent in comprehensive performance at low temperature and simple in preparation method.

Owner:NAT UNIV OF DEFENSE TECH

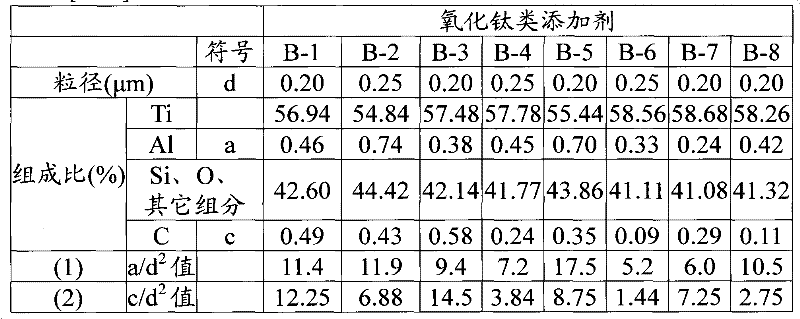

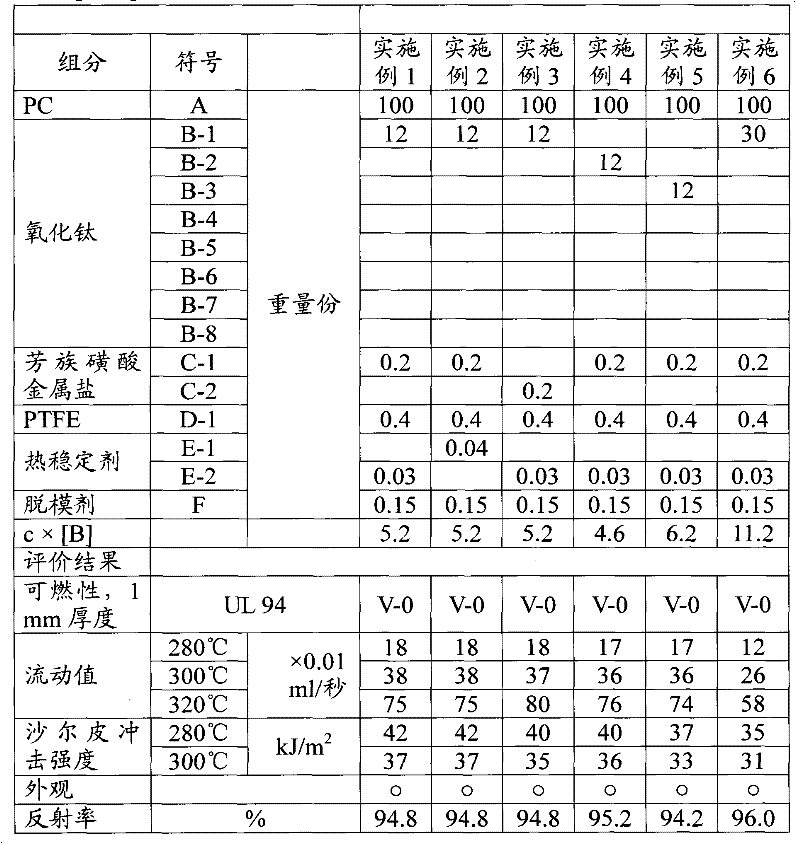

Aromatic polycarbonate resin composition, process for producing resin composition, and molded article

Disclosed is an aromatic polycarbonate composition having excellent thermal stability, excellent flame retardancy and excellent light reflectivity. Also disclosed is a light-reflecting member comprising a molded resin article produced from the aromatic polycarbonate composition. The aromatic polycarbonate resin composition is characterized by comprising 100 parts by mass of an aromatic polycarbonate resin (A), 3 to 30 parts by mass of a titanium oxide additive (B) having a surface treated with alumina and an organosiloxane, 0.05 to 0.9 part by mass of an aromatic sulfonic acid metal salt (C) and 0.01 to 1.5 parts by mass of polytetrafluoroethylene (D), wherein the content (a) (% by mass) of aluminum in the titanium oxide additive (B), the carbon content (c) (% by mass) and the average particle diameter (d) ([mu]m) of titanium oxide meet the requirements represented by formulae (1); and (2). Formula (1): 6.5 = (a / d2) = 15 Formula (2): 5 = (c / d2) = 25.

Owner:MITSUBISHI ENG PLASTICS CORP

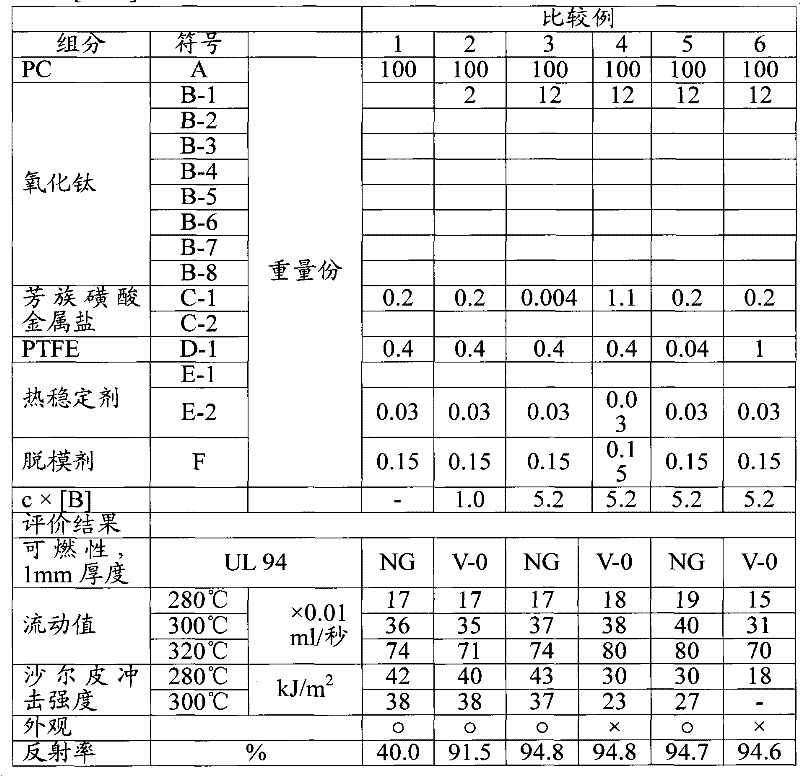

Steel sheet for enamelling, and a production method therefor

The present invention provides a steel sheet for enamelling which comprises, on a percent by weight basis, more than 0 and less than 0.005% carbon, 0.2-1.0% manganese, 0.04-0.08% sulphur, 0.005-0.02% phosphorus, 0.01-0.1% aluminium, 0.06-0.1% titanium and more than 0 and less than 0.003% nitrogen, and a balance of iron and unavoidable impurities, and in which there is a titanium sulphide or (titanium / manganese) sulphide precipitate having a size of 0.01-0.4 mm in an amount of at least 3*108 particles per cm2.

Owner:浦项股份有限公司

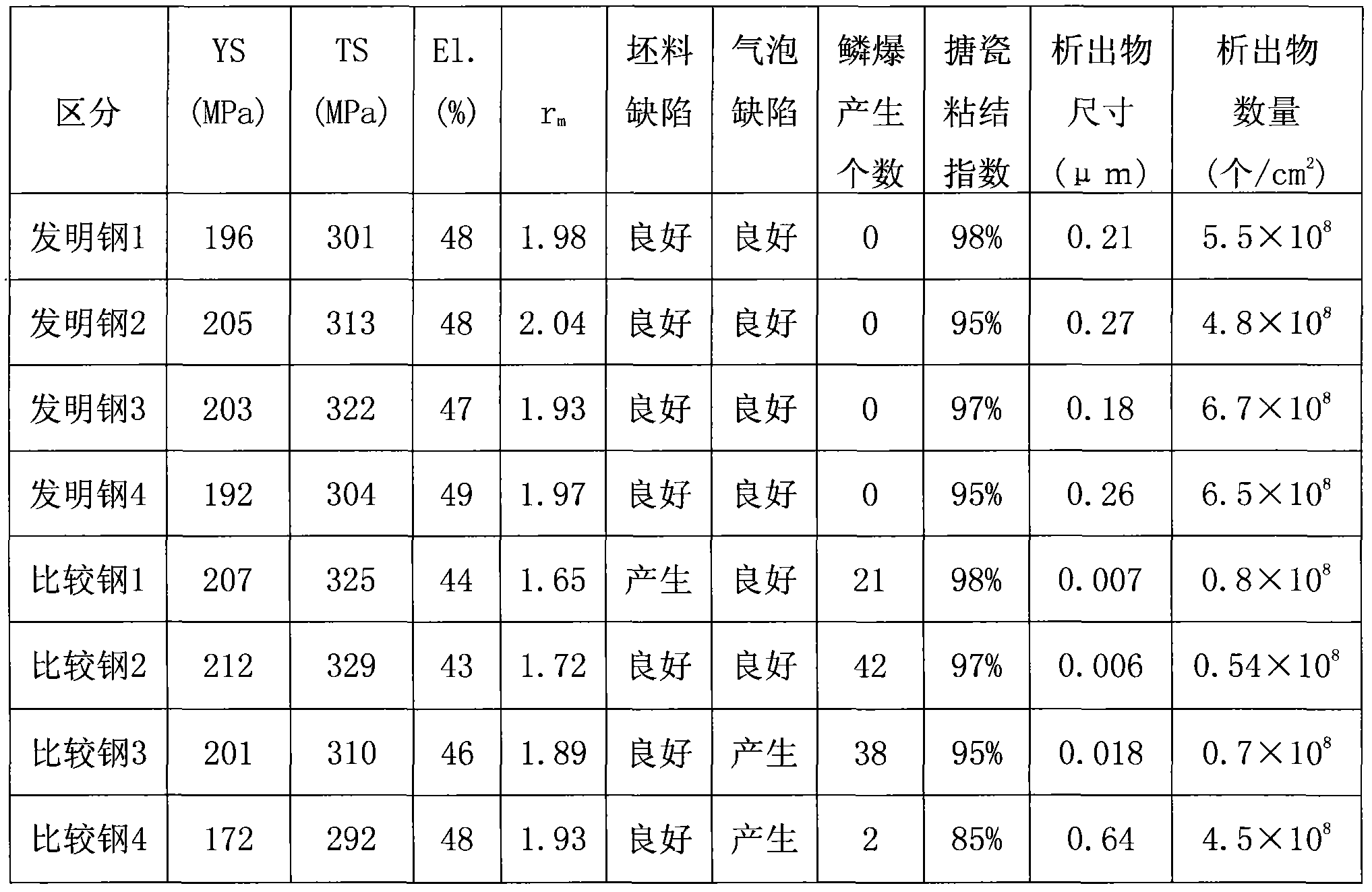

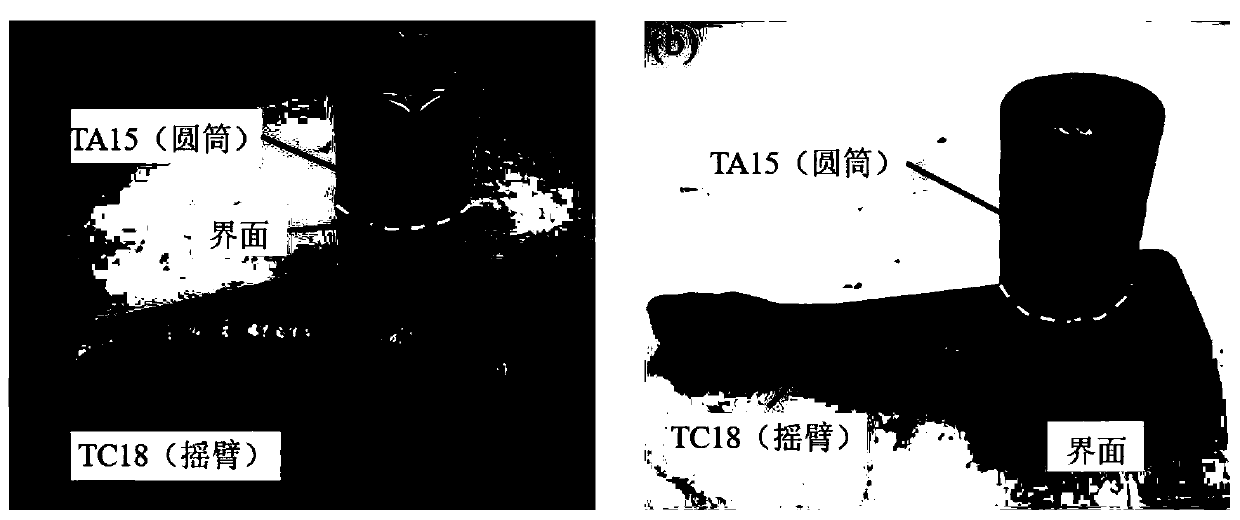

Electric arc additional material manufacturing method of multi-material integral structural component

ActiveCN110893503AMeet forming needsAvoid replacementAdditive manufacturing apparatusArc welding apparatusElectric arcManufacturing engineering

The invention provides an electric arc additional material manufacturing method of a multi-material integral structural component, and belongs to the multi-material integral structural component manufacturing technology field. The electric arc additional material manufacturing method of the multi-material integral structural component comprises the following steps of constructing a three-dimensional solid model of a target structural component, then carrying out slicing processing, generating a machining program, and importing the machining program into a control system; and using electric arcadditional material manufacturing equipment provided with n sets of wire feeders to carry out electric arc additional material manufacturing according to the machining program, and acquiring the multi-material integral structural component, wherein the n is an integer greater than or equal to 2. In an electric arc additional material manufacturing process, the n sets of wire feeders are divided into m sets, the m is the integer greater than or equal to 2, each set of wire feeders feeds one kind of wire at the same time, the m sets of wire feeders are continuously and alternately used, and a molten drop transition mode is a contact type transition mode. The method of the invention has no obvious defects at an interface, and has an advantage of high forming efficiency.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

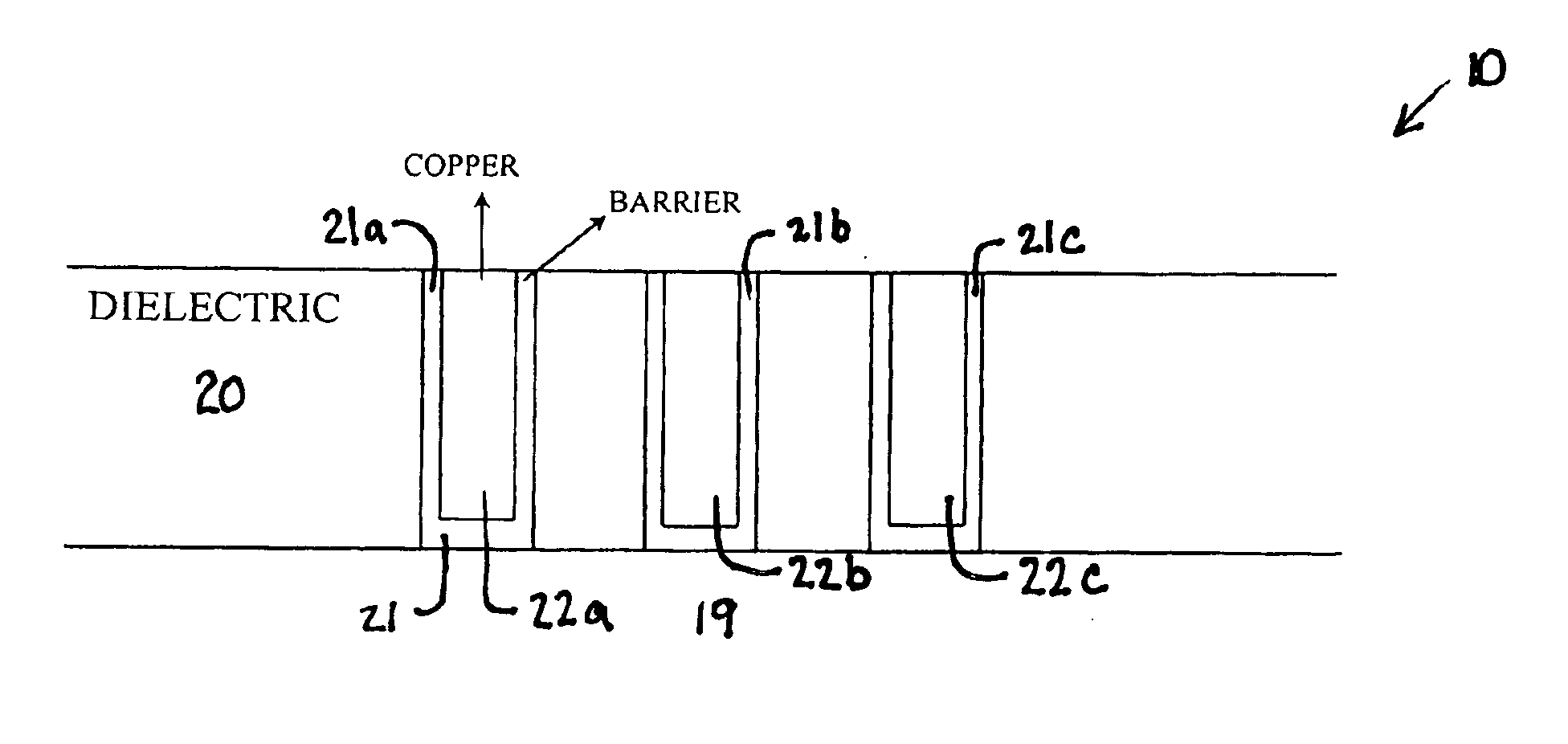

Chemical mechanical polishing compositions for metal and associated materials and method of using same

InactiveUS20060160475A1Low to moderate removal rateHigh removal rateSemiconductor/solid-state device manufacturingLapping machinesCompound (substance)Slurry

A chemical mechanical polishing slurry composition and method for using the slurry composition for polishing copper, barrier material and dielectric material that comprises first and second-step slurries. The first-step slurry has a high removal rate on copper and a low removal rate on barrier material. The second-step slurry has a high removal rate on barrier material and a low removal rate on copper and dielectric material. The first slurry comprises at least an organic polymeric abrasive.

Owner:MA YING +5

Method for mfg. magnetic drum of high resolution magnetic-encoded device

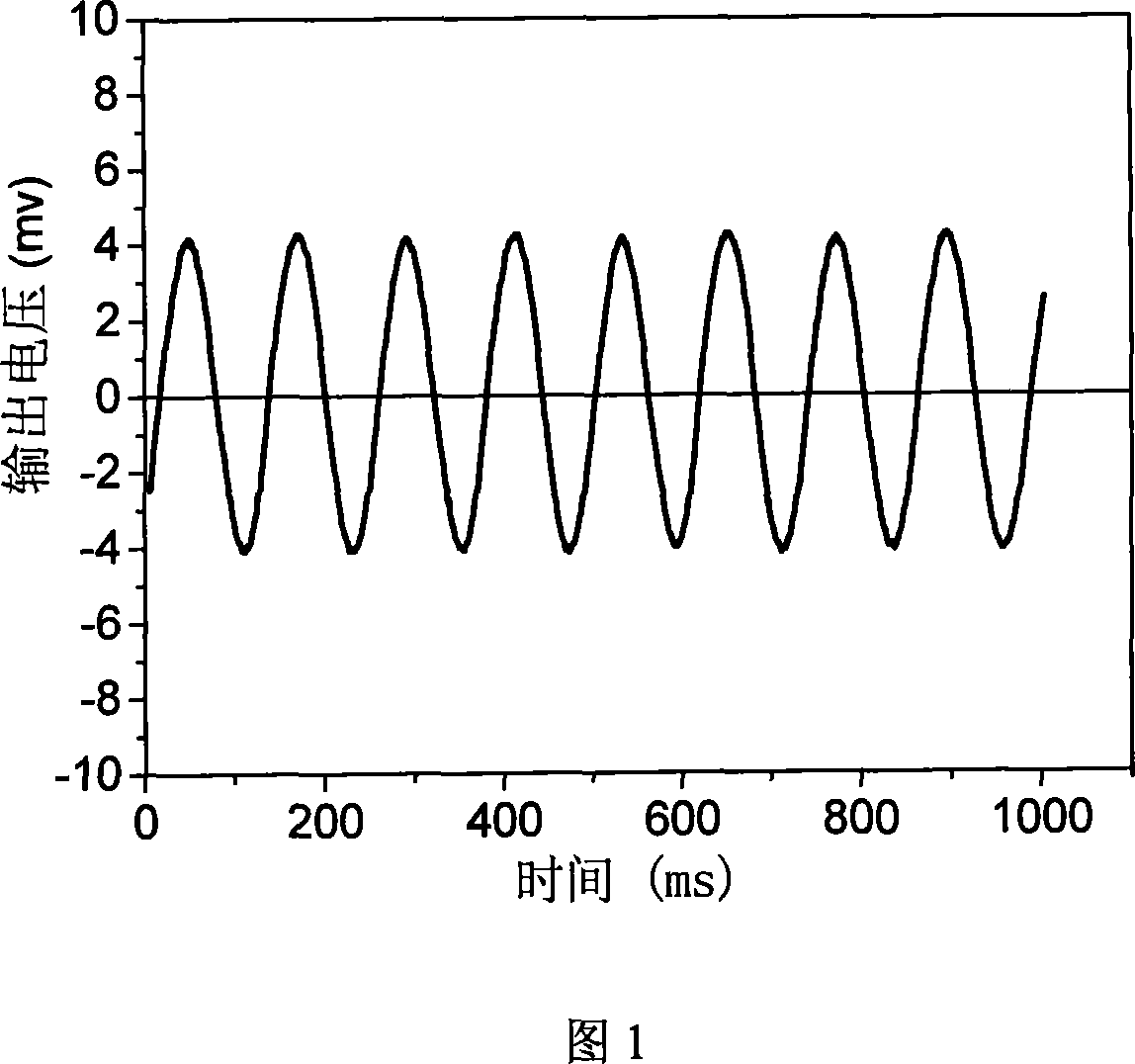

InactiveCN1598493AImprove performanceUniform thicknessConverting sensor output electrically/magneticallyImage resolutionEngineering

The invention discloses a manufacturing method for memory drum of high resolution magnetic coder. It uses coating process, and it is squeezed into shape and produces the memory drum materials. The magnetic powder, bonder, diluter, solidifier, dispersant is blended into magnetic pulp according to certain proportion, and then the pulp is pasted on the base of the memory drum. The pasted base is rotated and solidified, when the magnetic pulp is in half solidification state, it is squeezed into shape with high flat bearing, the thickness is 0.15-4mm. after it is fully solidified, it is filled with magnetism with high resolution optical coder pulse, the memory drum can be written with 128, 256 pairs of electrodes, the merits of the invention are: simple, good operation ability.

Owner:UNIV OF SCI & TECH BEIJING

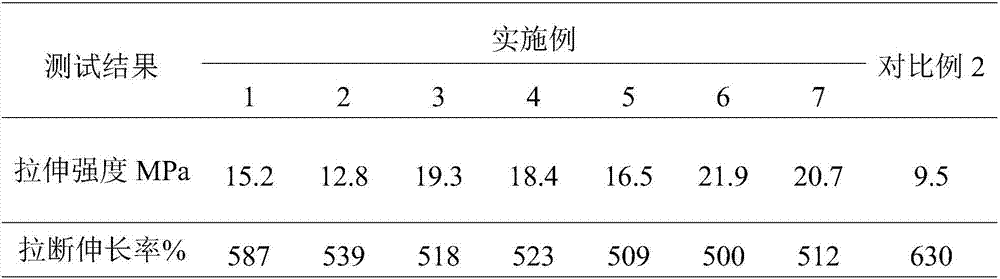

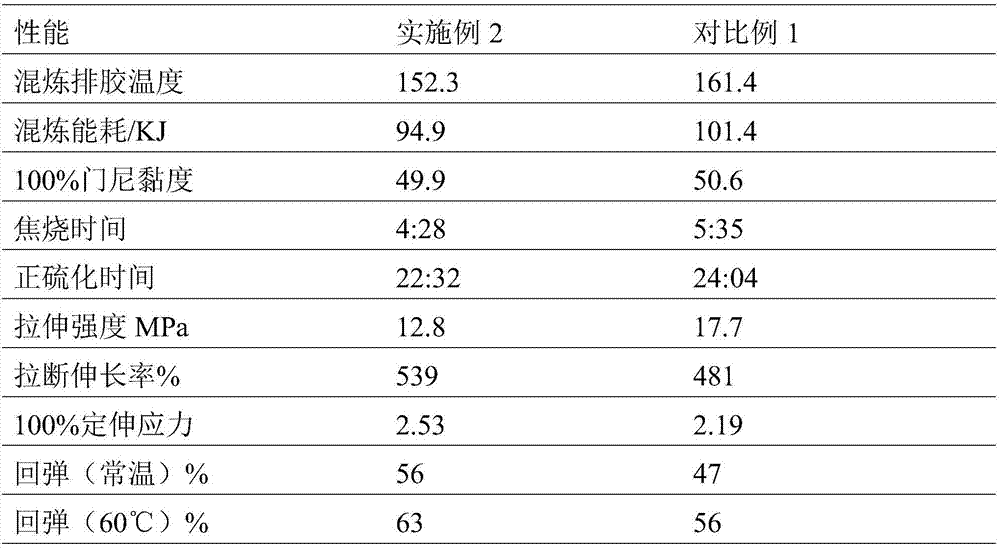

Preparation method of silicon carbon black / natural rubber composite material

ActiveCN107337815ASimple production processMeet the requirements of sustainable developmentSilicon dioxideBall mill

The invention discloses a preparation method of a silicon carbon black / natural rubber composite material, belongs to the technical field of composite materials, and solves the problems of high cost, non renewable resources, complex process, difficult processing and uneven dispersion of use of surface modified silica for filling natural rubber in the prior art. According to the method, first purified rice husks are added into a reaction device for pyrolysis to obtain pyrolysis gas and pyrolytic carbon, and after decoking, cooling and separation, tar-free pyrolysis gas and tar-free pyrolytic carbon are obtained; then tar-free pyrolytic carbon gas flow is pulverized, and ball-milled to the average particle size within 10 mu m to obtain silicon carbon black powder, and the silicon carbon black powder is further processed to obtain the modified silicon carbon black powder and silicon carbon black masterbatch; and finally the silicon carbon black / natural rubber composite material can be obtained by mixing and kneading technology. The preparation method has the advantages of low cost, saving energy, environmental-friendliness, full use of renewable resources, and broad application prospects in the rubber field.

Owner:JILIN UNIV

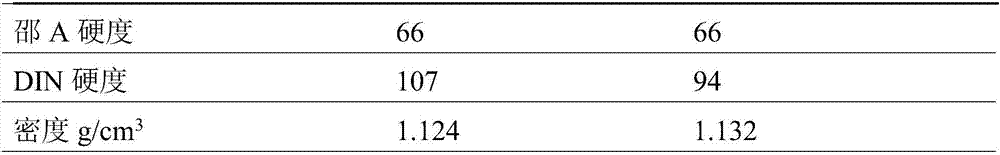

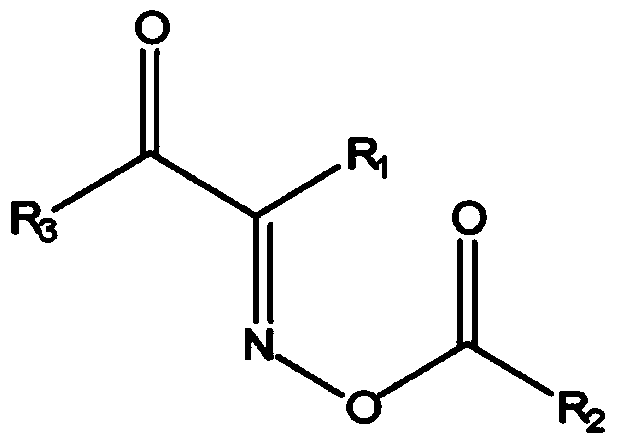

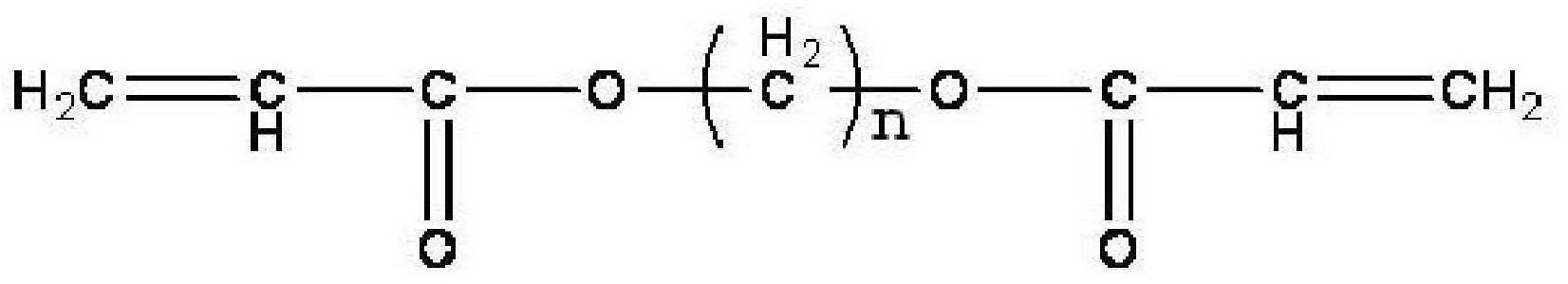

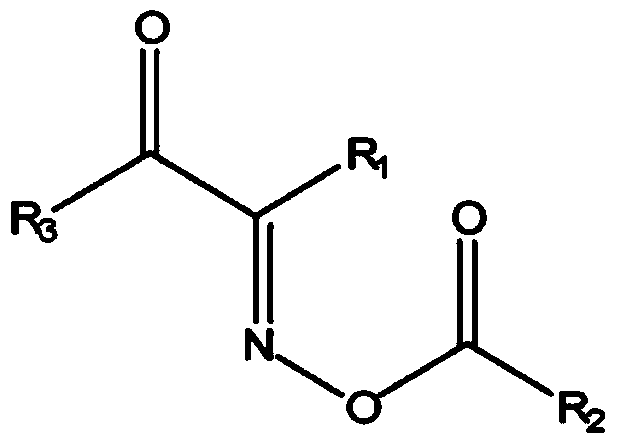

Colored photosensitive resin composition, color filter and liquid crystal display having the same

ActiveCN104345559AHigh sensitivity characteristicsExcellent sensitivity characteristicsOptical filtersPhotosensitive materials for photomechanical apparatusSolventColor gel

The invention discloses a colored photosensitive resin composition. The colored photosensitive resin composition comprises: coloring agent (A), alkaline soluble resin (B), photo-polymerizing compound (C), photo-initiator (D),solvent (E) and additive agent (F), wherein the photo-initiator (D) is a compound represented by the chemical formula (1), and the additive agent (F) is a compound represented by the chemical formula (3), wherein, in the chemical formula (1), R1 is represented by the chemical formula (2), R2 is C1-C8 alkyl group, substituted phenyl group or unsubstituted phenyl group, or substituted benzyl group or unsubstituted benzyl group, R3 is substituted diphenyl sulfide group or unsubstituted diphenyl sulfide group, and in the chemical formula (2), R4 is C1-C4 alkyl group, and R5 is C3-C8 alicyclic alkyl group or aromatic alkyl group, and in the chemical formula (3), n is an integer from 1 to 12, the chemical formula (2) -R4-R5.

Owner:DONGWOO FINE CHEM CO LTD

Photosensitive resin composition for black matrix

ActiveUS20110101268A1Good processing characteristicsFew defectLiquid crystal compositionsPhotosensitive materialsLiquid-crystal displayAlcohol

A photosensitive resin composition for a black matrix and a black matrix formed with the same are provided. The photosensitive resin composition for a black matrix includes a solvent consisting of 5-30 weight % of a first solvent having a boiling point of 110-159° C., 55-90 weight % of a second solvent having a boiling point of 160-200° C., and 3-15 weight % of a third solvent having a boiling point of 201-280° C., and the first solvent, the second solvent, and the third solvent are an aliphatic compound and use at least one solvent composition selected from a group consisting of alkyl ester, alkyl ketone, alkyl ether, and alkyl alcohol, and thus a uniform thin film having no surface defect can be obtained, and the photosensitive resin composition has an excellent process property while securing a high light shielding property and thus a black matrix pattern having a few defect can be obtained, and is thus useful for a liquid crystal display.

Owner:LG CHEM LTD

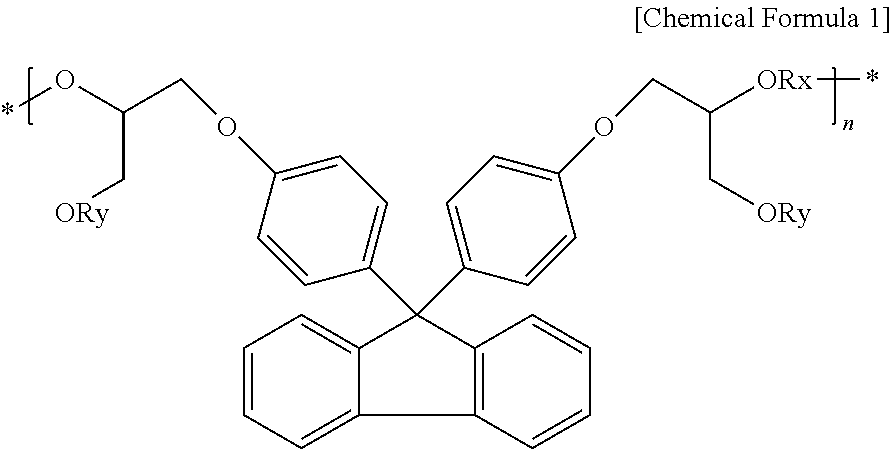

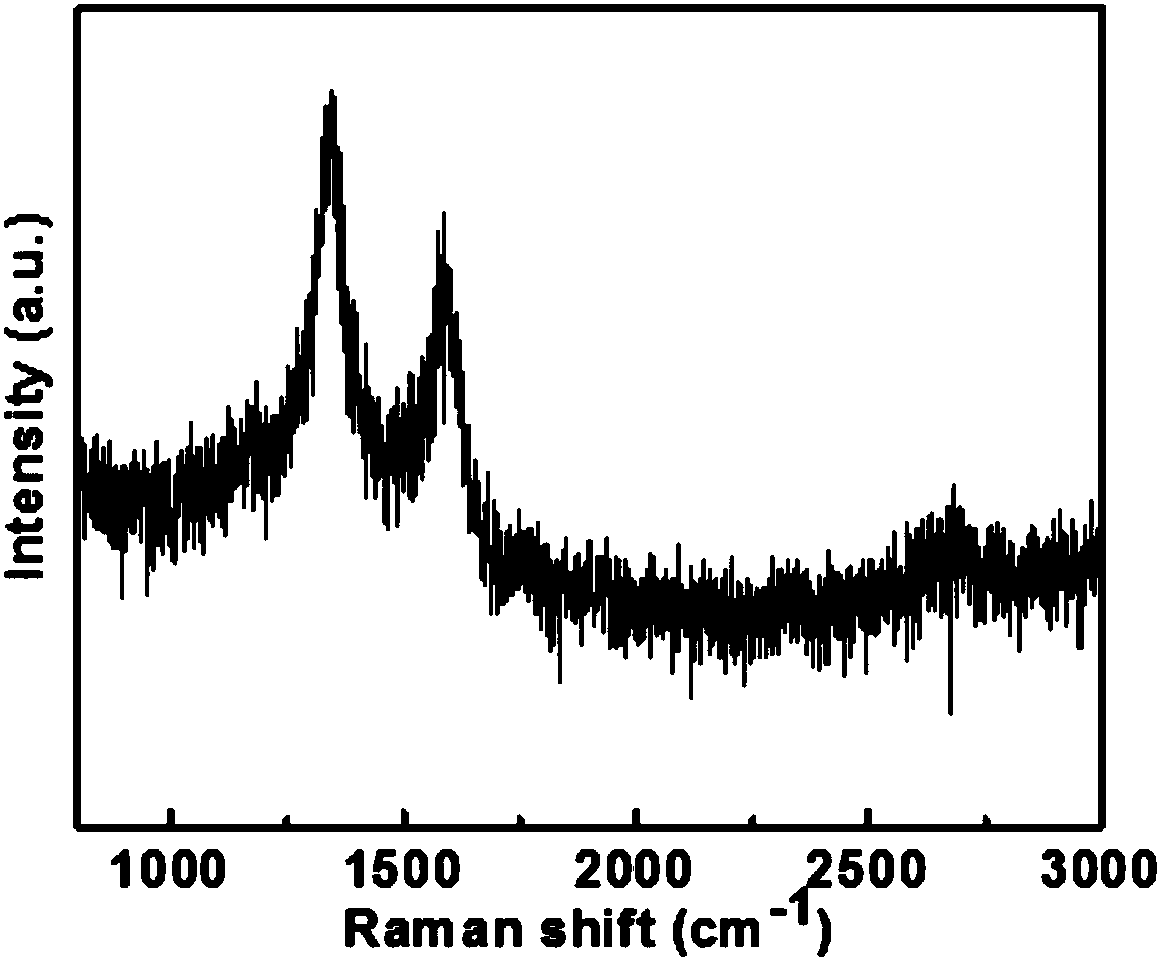

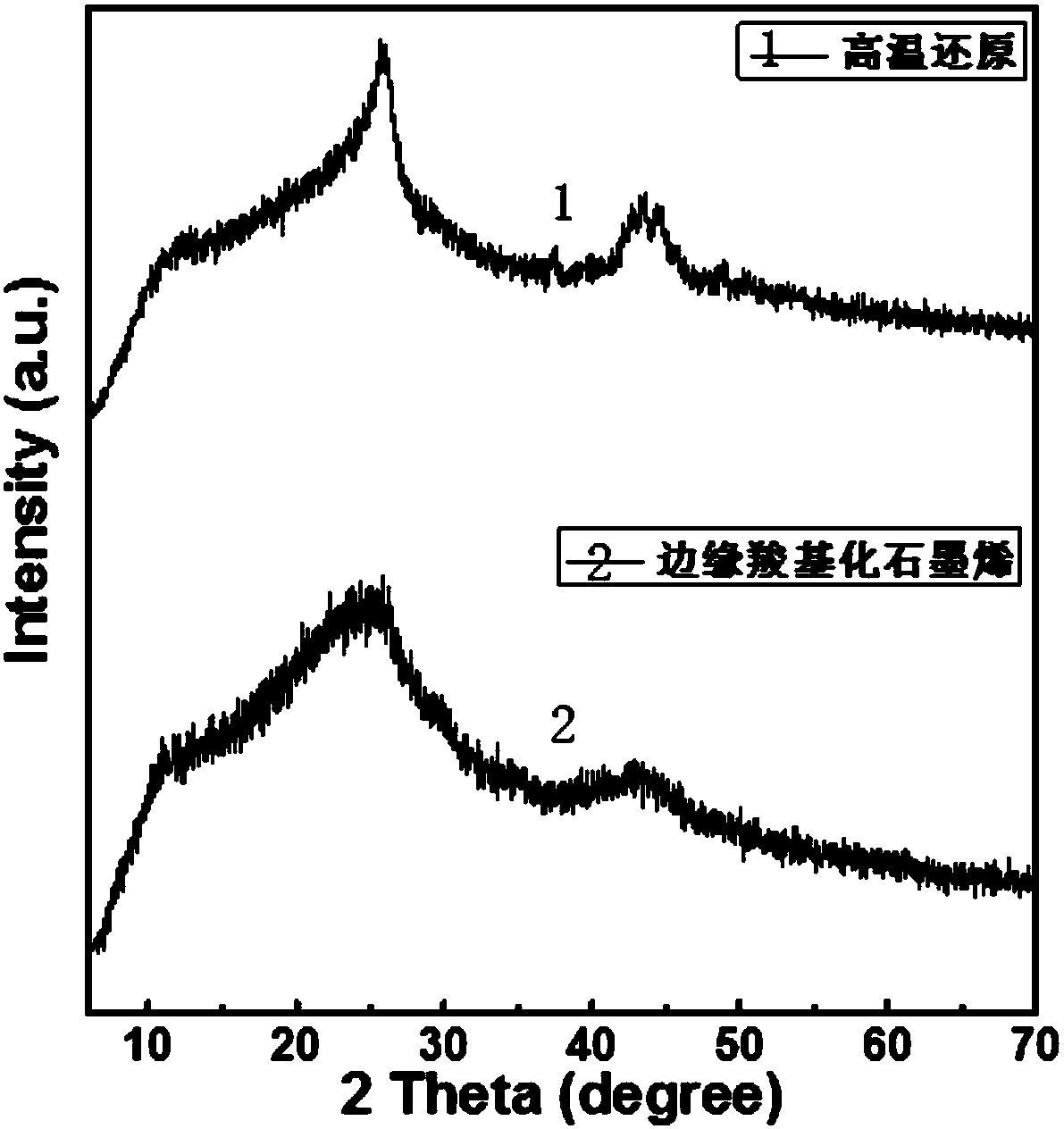

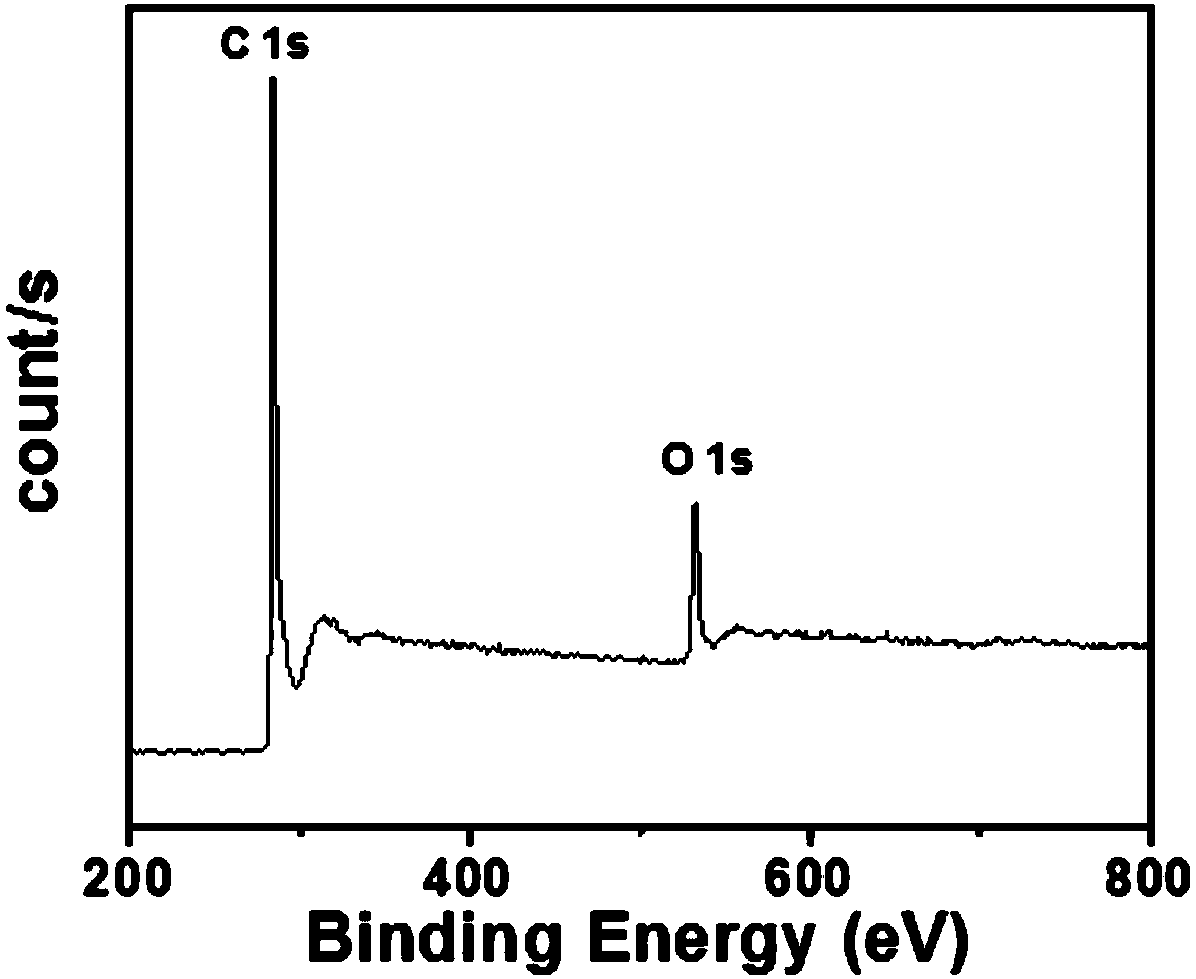

Method for preparing edge-carboxylated graphene and graphene through reaction milling technology

A method for preparing edge-carboxylated graphene and graphene through a reaction milling technology belongs to the field of novel nano-materials. The method comprises the following steps: placing graphite powder in a reaction milling device, sealing the reaction milling device, filling the reaction milling device with a carbon dioxide gas, starting the reaction milling device, performing reactionmilling at a certain speed for a certain time to obtain the edge-carboxylated graphene, reducing the edge-carboxylated graphene in an inert gas at a controlled temperature of 200-1200 DEG C to obtainthe graphene having a high quality, a large specific surface area and a high conductivity. The edge-carboxylated graphene and the graphene which are prepared through the method have the advantages oflarge specific surface area, high quality, good conductivity, low manufacturing cost, greenness, energy saving and environmental protection.

Owner:河北烯创科技有限公司

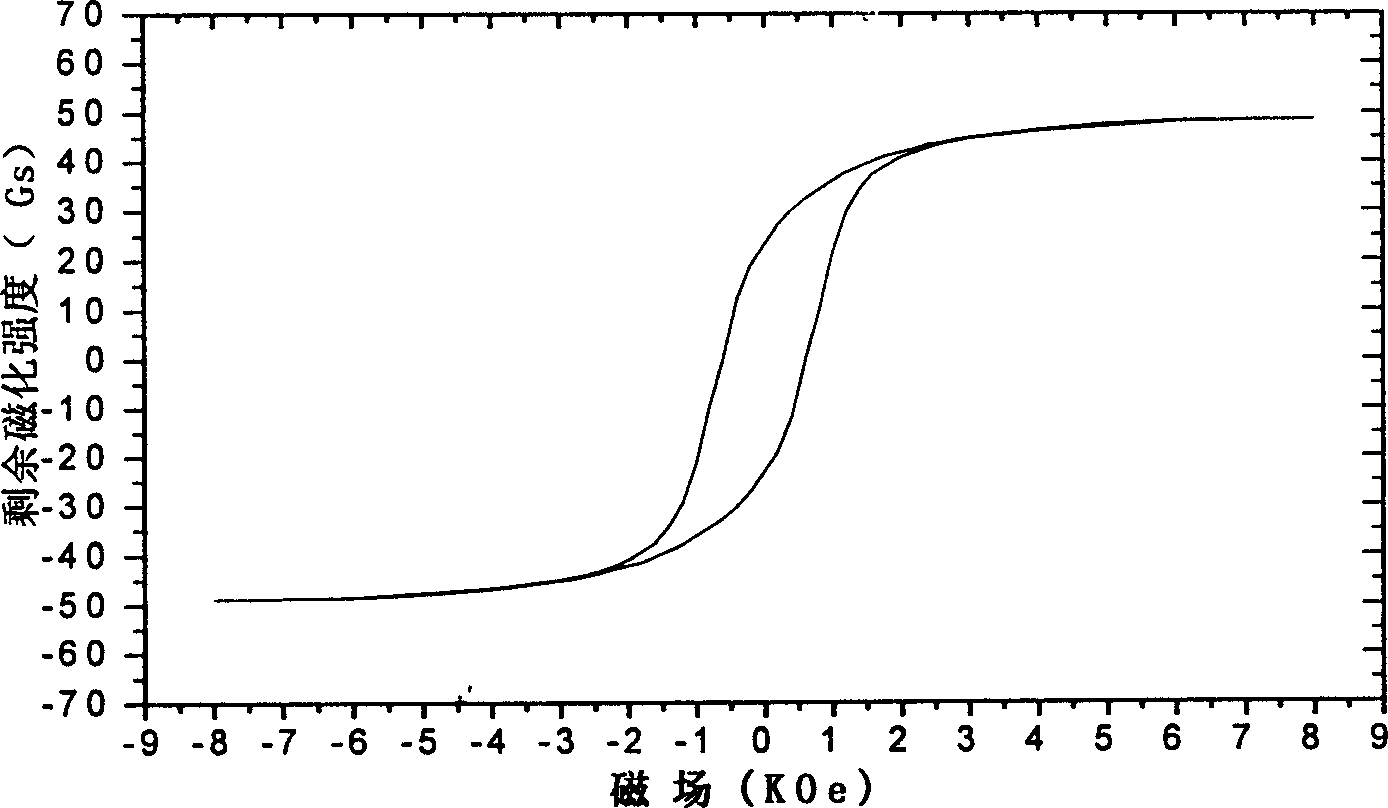

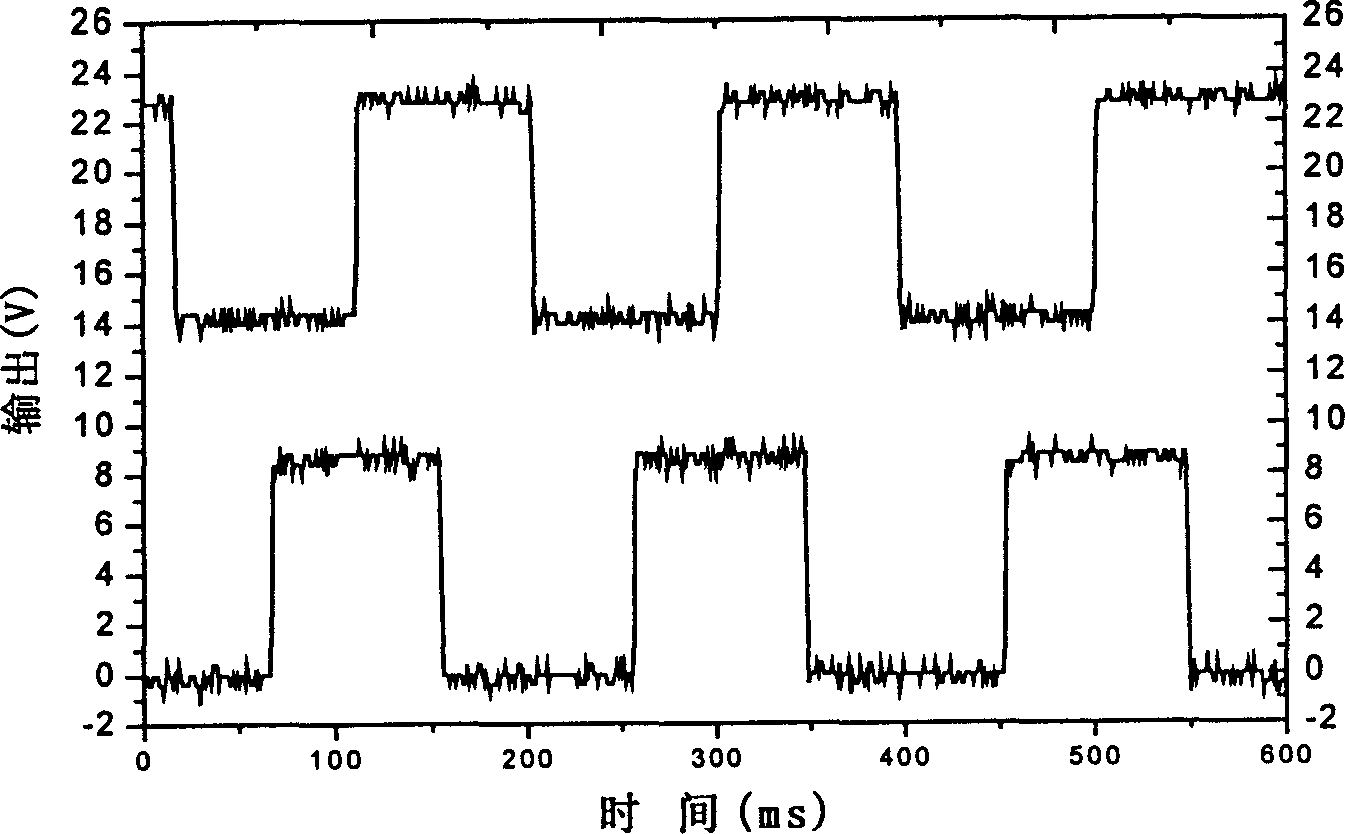

Process of preparing magnetic drum for high precision magnetic coder

InactiveCN101046394AImprove performanceUniform thicknessConverting sensor outputChemical platingMagnetic poles

The process of preparing magnetic drum for high precision magnetic coder belongs to the field of magnetic coder technology. Co-P or Co-Ni-P film as record medium of magnetic drum is prepared through a chemical plating process on an aluminum alloy base with the solution compounded with cobalt salt, reductant, complexing agent and buffering agent in certain weight proportion. The film is crystalline and magnetic, and has P content of 5-10 wt% and thickness of 1-10 microns. Thus prepared magnetic drum may have 1024-2500 pairs of N and S magnetic pole written. The present invention has the advantages of excellent performance, stable preparation process and easy use in industrial production, and the magnetic drum has high resolution and may be combined with anisotropic magnetoresistor film probe to form high precision rotary magnetic coder.

Owner:UNIV OF SCI & TECH BEIJING

Polishing slurries for copper and associated materials

InactiveUS6936542B2High removal rateLow removal ratePigmenting treatmentOther chemical processesCorrosion inhibitorOxidizing agent

A chemical mechanical polishing slurry and method for using the slurry for polishing copper, barrier material and dielectric material that comprises a first and second slurry. The first slurry has a high removal rate on copper and a low removal rate on barrier material. The second slurry has a high removal rate on barrier material and a low removal rate on copper and dielectric material. The first and second slurries at least comprise silica particles, an oxidizing agent, a corrosion inhibitor, and a cleaning agent.

Owner:CABOT MICROELECTRONICS CORP

Radiation-curable coating compounds

InactiveUS20020143078A1Inhibition of polymerizationNo surface defectsPolyurea/polyurethane coatingsPrinting after-treatmentPolymer scienceFunctional monomer

Coating compounds curable by means of high-energy radiation, comprising as binder A) at least one (meth)acrylic copolymer containing olefinic double bonds capable of free-radical polymerization and hydroxyl groups with a C=C equivalent weight from 100 to 10,000 and an OH-value from 20 to 250 mg KOH / g, which is prepared from monomers comprising: A1) at least one olefinically unsaturated, epoxy-functional monomer capable of free-radical polymerization, A2) at least one olefinically unsaturated, carboxy-functional monomer capable of free-radical polymerization and A3) at least one further olefinically unsaturated monomer capable of free-radical polymerization which is different from A1) and A2), and B) at least one component with free isocyanate groups and process for multilayer coating using the coating compounds.

Owner:AXALTA COATING SYST IP CO LLC

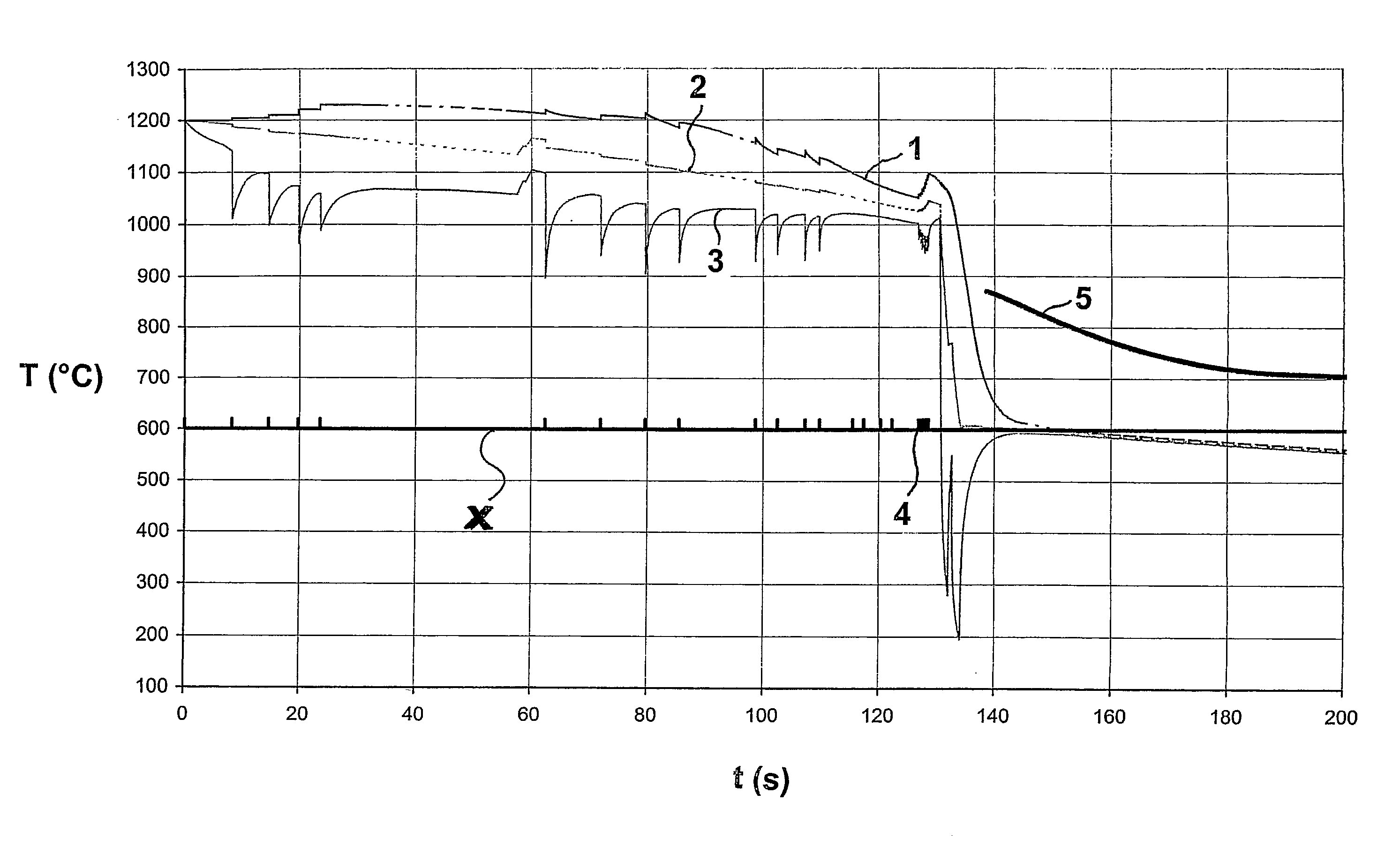

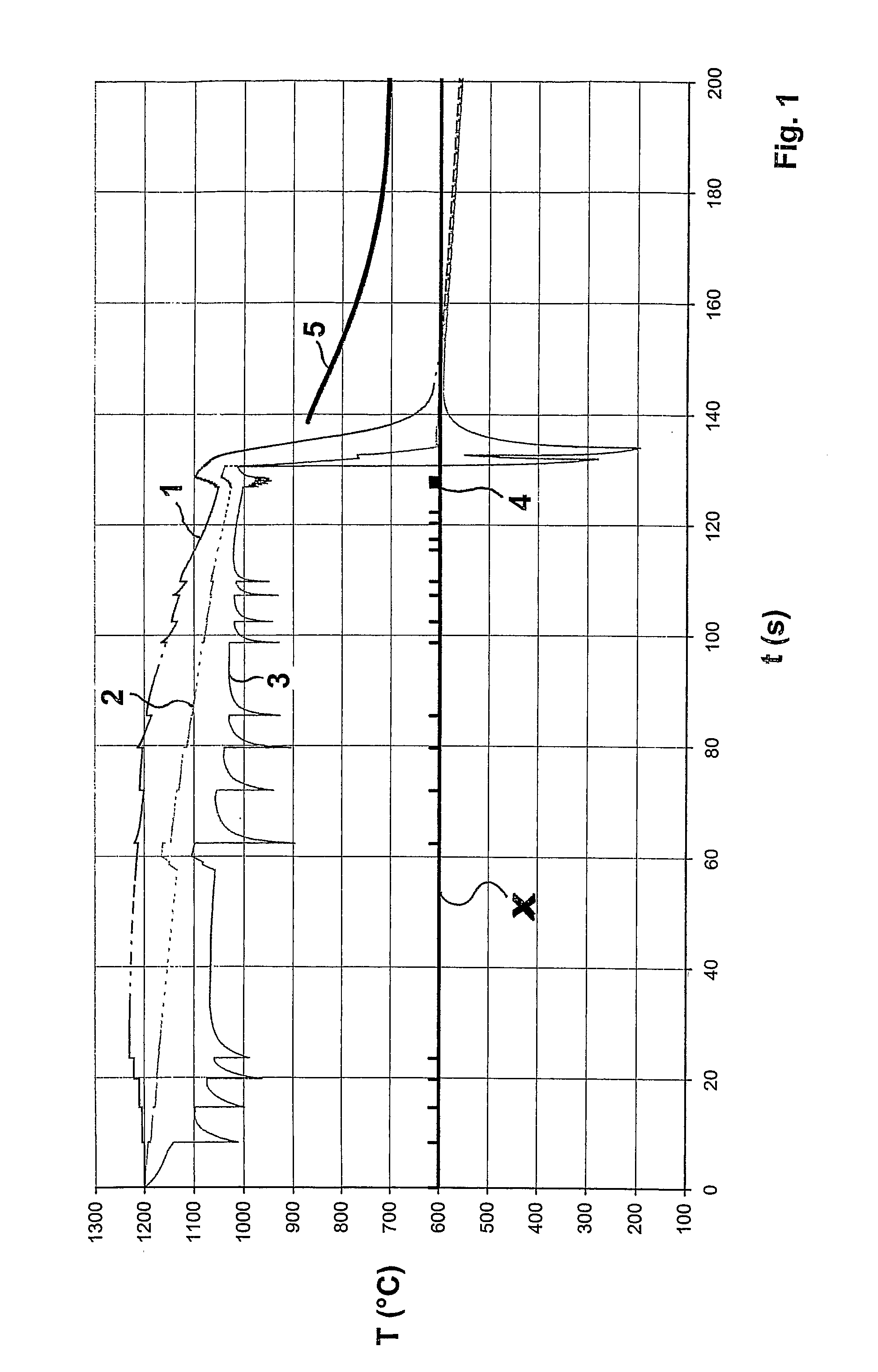

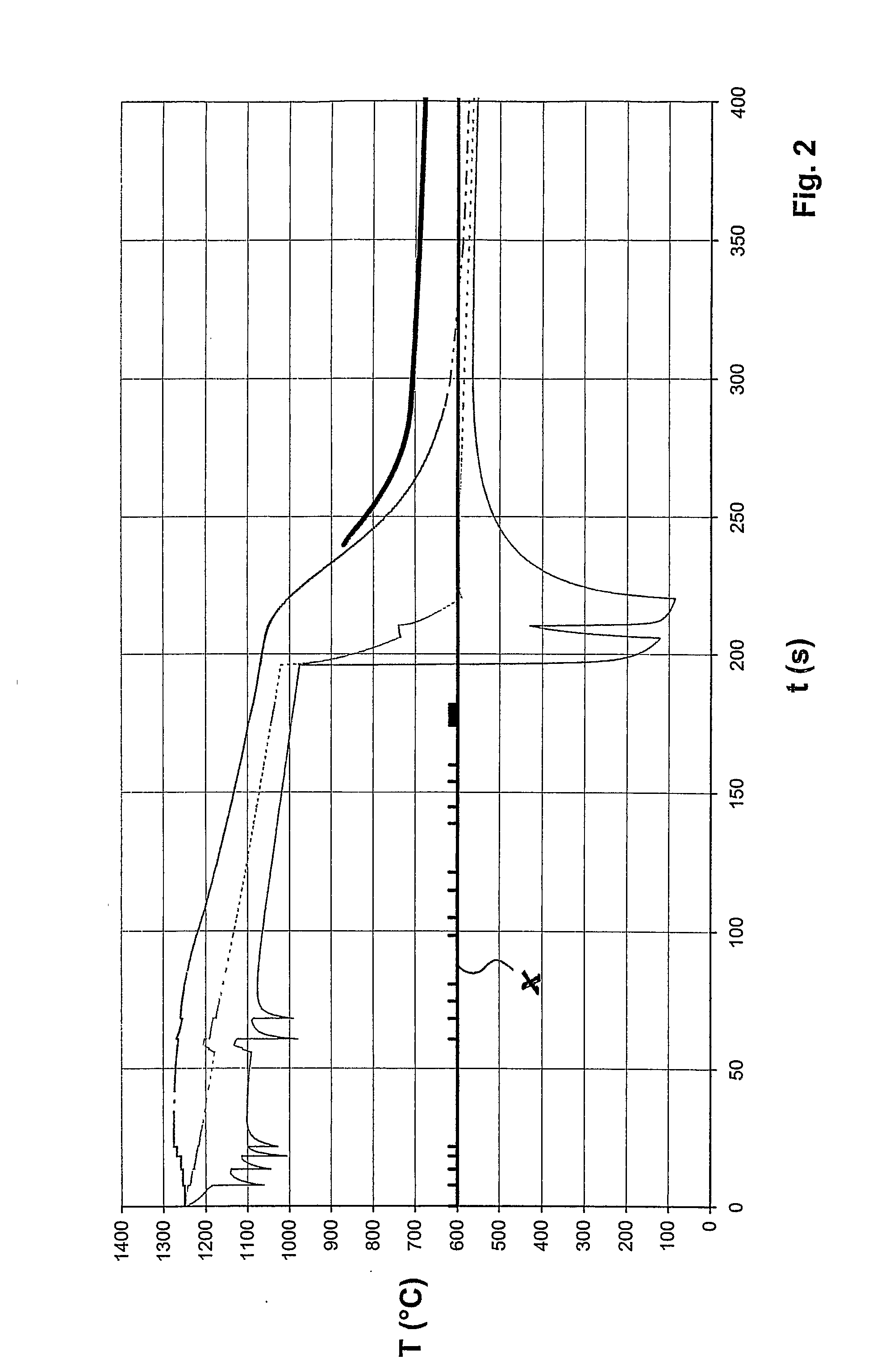

Treatment Process for Bars

InactiveUS20090044884A1Not require straighteningQuality improvementFurnace typesHeat treatment furnacesProduction rateSteel bar

Treatment process for stainless steel bars, in particular a solution quenching, to be performed directly in-line downstream of the rolling mill which makes it possible to obtain a material devoid of intergranular corrosion and with microstructural characteristics suitable for subsequent uses. Advantageously, said process also makes it possible to improve the productivity of the entire rolling plant. The treatment is suitable to be performed on austenitic, ferritic, or austeno-ferritic stainless steel bars, Al—Cu alloy bars, Nickel alloy bars, and all other alloys requiring rapid cooling in order to prevent undesired phase precipitations. Prevention of intergranular corrosion obtained with the treatment process of the invention makes it possible to prevent problems, and relative costs, during surface treatment of the bars and those that could occur in final use.

Owner:DANIELI & C OFF MEC SPA

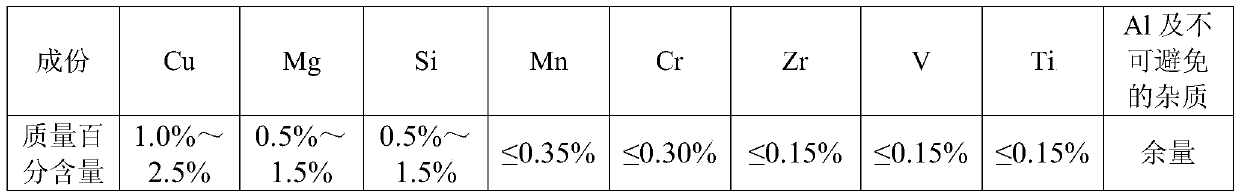

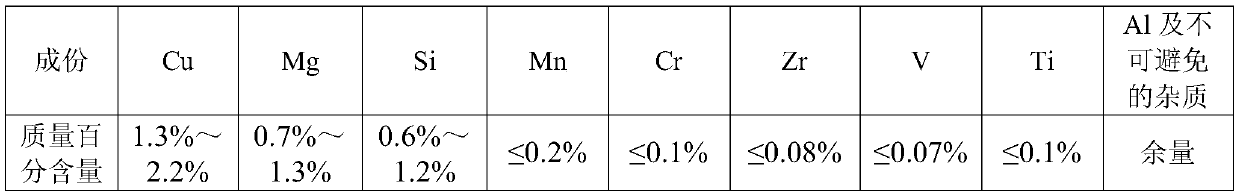

2000 aluminum alloy profile and manufacturing method thereof

The invention relates to a 2000 aluminum alloy profile and a manufacturing method thereof, and belongs to the field of aluminum profiles. Through the steps of preparation of aluminum alloy raw materials in proportion and casting into an aluminum alloy cast ingot, homogenization, extrusion, softening annealing, cold processing, solution treatment and artificial aging, the processed aluminum alloy material has excellent bendability and high strength, does not have surface defects, can be manufactured without a straightening step, and does not generate surface defects such as orange peel in bending processing. According to the scheme, the straightening step is omitted, so that the manufacturing process is simplified, and the manufacturing cost is saved.

Owner:CHINA ZHONGWANG

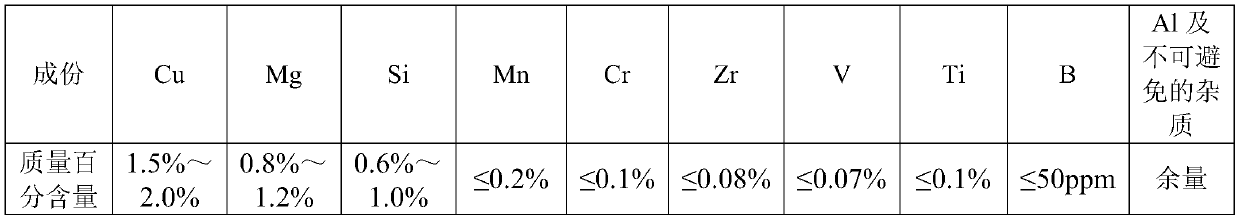

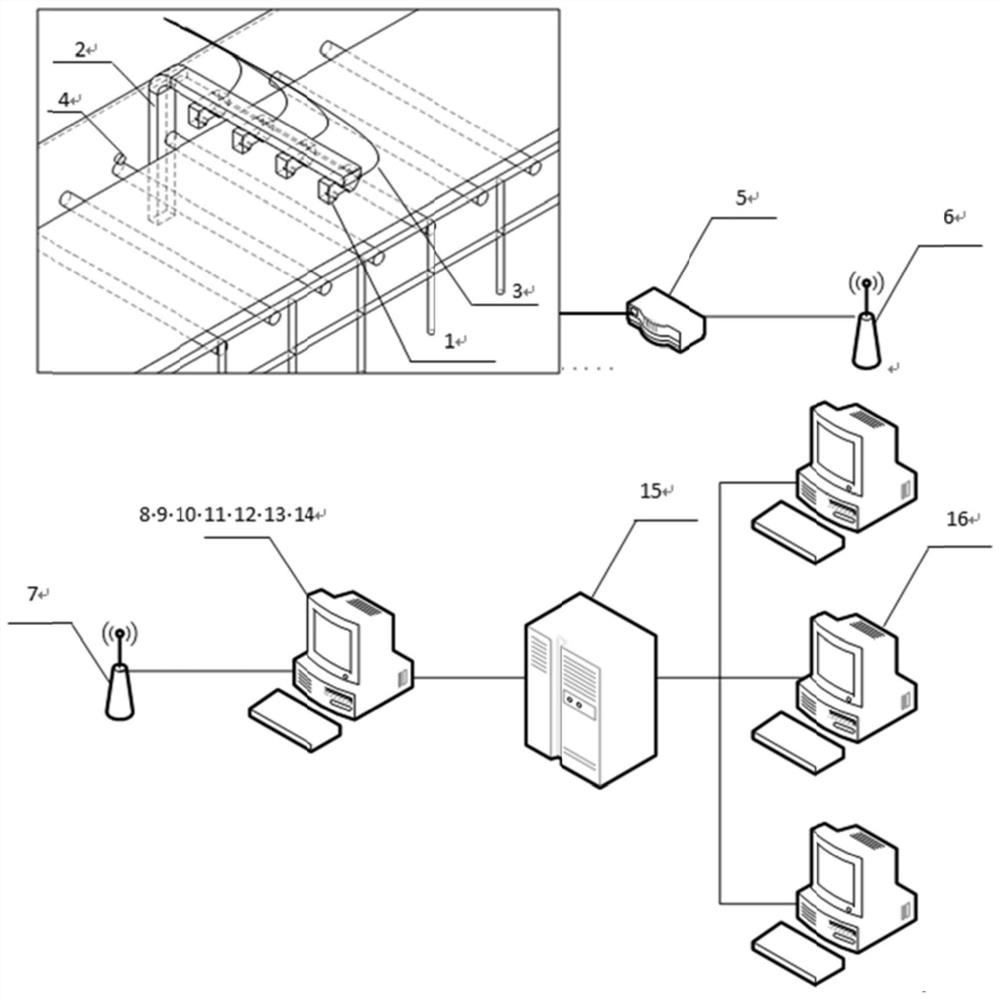

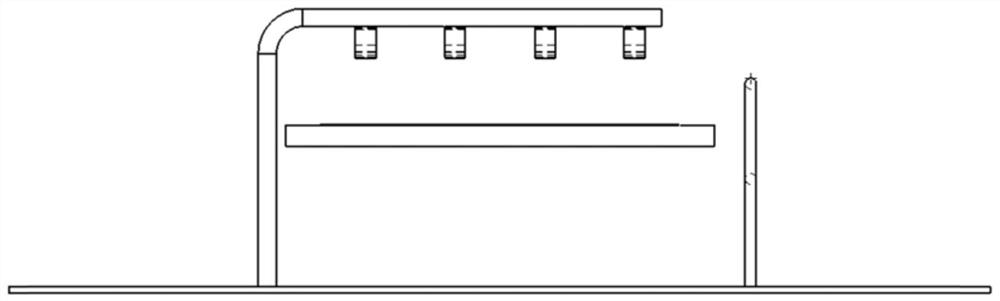

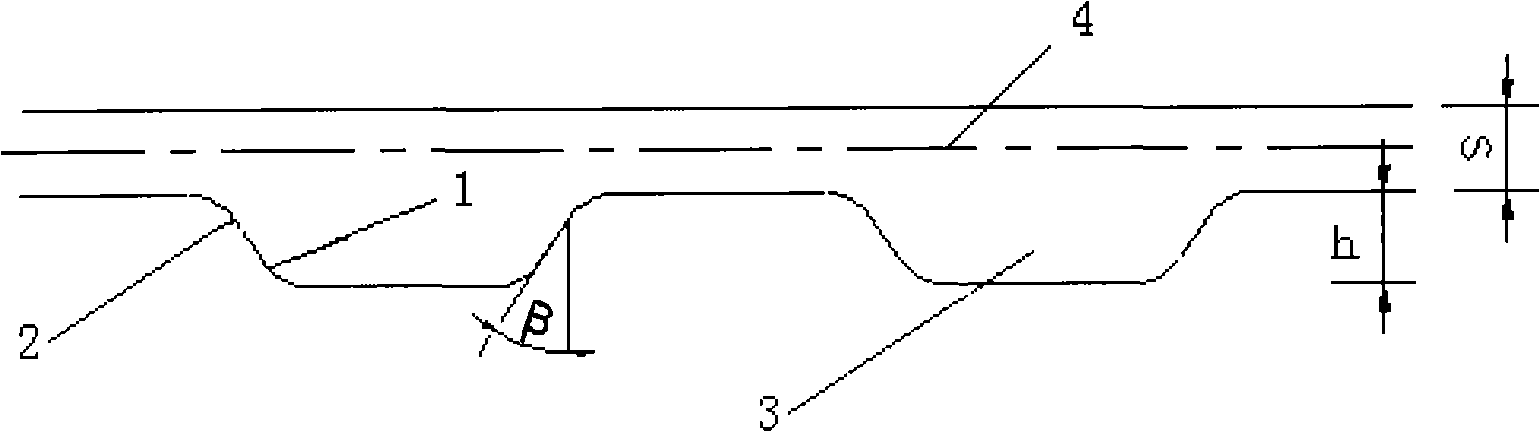

Online detection method and device for plate shape defects of oriented silicon steel finished product

PendingCN112113963AIncrease material rateLow costInvestigating moving sheetsOptically investigating flaws/contaminationHeight differenceEngineering

The invention discloses an online detection method and device for plate shape defects of oriented silicon steel finished products, and belongs to the technical field of measuring equipment. The devicecomprises a detection end, a processing end and a network end; the detection end is used for measuring the vertical height from each point on a steel belt to a laser head, calculating the height difference between each point and the reference surface by taking a unit roller way as the reference surface, and drawing steel belt contour data according to the difference value; the processing end is used for processing the steel belt contour data to obtain steel belt full-length contour data, correcting the steel belt contour information into plate shape information, storing the plate shape information into a plate shape database, automatically classifying defects and generating a slitting instruction according to the plate shape information, and uploading the slitting instruction to the network end; and the network end is used for checking the slitting instruction of a to-be-produced steel coil so as to carry out production through the slitting instruction. A non-contact laser contour scanning method is combined with steel strip jitter suppression suitable for oriented silicon steel, contour information is corrected into the plate shape defect information through laser joint correction, the manufacturing cost is low, and a steel strip coating layer cannot be damaged.

Owner:武汉钢铁有限公司

Heat treatment technology for low-temperature high impact toughness medium-thickness steel plate

InactiveCN101892373AShorten heat treatment cycleNo high temperature phase transition stressFurnace typesHeat treatment furnacesSheet steelEnergy consumption

The invention discloses heat treatment technology for a low-temperature high impact toughness medium-thickness steel plate. The heat treatment technology comprises the following steps of: putting the steel plate into a furnace and heating, wherein the heating temperature is 50 to 100 DEG C lower than the Al temperature; keeping the temperature for 40 to 80 minutes; and discharging and performing air cooling to obtain the low-temperature high-toughness medium-thickness steel plate. The heat treatment technology can effectively solve the problems of plate warp, high heat treatment energy consumption, high maintenance cost of heat treatment equipment, low production efficiency and the like due to high heating temperature when normalizing heat treatment is performed on a TMCP steel plate, and also can obtain the low-temperature high-toughness steel plate at the temperature of 40 DEG C below zero.

Owner:NANJING IRON & STEEL CO LTD +1

Roll caliber for rolling special-shaped wide steel strip

InactiveCN101314165AReasonable metal flowReasonable flowRollsMetal rolling arrangementsStrip millStrip steel

The invention relates to a roll pass used to roll a special wide steel band, which belongs to the steel rolling technical field. A roll comprises an upper roll and a lower roll of a final stand of a strip mill, the roll pass of the upper roll or the lower roll is of a long narrow rectangle, and lug bosses of the upper edge or the lower edge of the rectangle are arranged equidistantly. The special wide steel band which meets the requirement can be rolled through the roll pass, and the size and the service performance meet the requirement; and the steel band rolled by the roll pass has reasonable metal flow, good strip shape, and no surface defects.

Owner:KUNMING IRON & STEEL

Colloidal photonic crystals using colloidal nanoparticles and method for preparation thereof

ActiveUS20100255192A1No surface defectsLess timeFrom gel statePolycrystalline material growthColloidal nanoparticlesColloidal particle

The present invention relates to colloidal photonic crystals using colloidal nanoparticles and a method for the preparation thereof, wherein by adding a viscoelastic material into a solution containing the colloidal nanoparticles when preparing the colloidal photonic crystals, a uniform volume contraction occurs due to the elasticity of the viscoelastic material even when a nonuniform volume contraction occurs while drying a dispersion medium in the colloidal solution. Thus, it is possible to prepare 2 or 3 dimensional colloidal photonic crystals of large scale with no defects in less time.

Owner:LG CHEM LTD

Multicomponent crosslinking acrylate compound paint

The invention discloses multicomponent crosslinking acrylate compound paint which comprises unsaturated acrylate compound resin, a crosslinking monomer, an initiator, an accelerator and an assistant, wherein the unsaturated acrylate compound resin is prepared by polymerizing and synthesizing terpolymer MBG resin with conventional free radical solutions of methyl methacrylate or hydroxyethyl methylacrylate, butyl acrylate and glycidyl methacrylate and then allowing an epoxy group of glycidyl methacrylate and a carboxyl group of acrylic acid to perform ring-opening reaction. The multicomponent crosslinking acrylate compound paint has the benefits that the multicomponent crosslinking acrylate compound paint has the advantages of high rigidity, good luster, no surface defect and the like, has good adhesion on the surface of ABS (acrylonitrile butadiene styrene) and PC (poly carbonate) plastic and the like, is particularly suitable for plastic vacuum coating of an automobile spot lamp reflector, a cosmetic packing box and the like as a primer, can be widely applied to various plastic finishing, is a relatively novel paint system and has wide development prospects.

Owner:王帅

Electroslag remelting slag and production technology thereof

The invention provides electroslag remelting slag and a production technology thereof, and belongs to the technical field of electroslag remelting. The electroslag remelting slag comprises, by mass percent, 2%-5% of CaF2, 40%-50% of Al2O3, 20%-30% of SiO2, 10%-20% of MgO and 5%-15% of CaO. The producing and machining performance of the electroslag remelting slag is stable and reliable, the content of harmful elements in a steel ingot is obviously reduced, no obvious surface flaws exist in the steel ingot, product components are stable and uniform, the yield of the steel ingot is increased by 15%-20%, and the power consumption of a single furnace is reduced by more than 20%.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com