Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

159results about How to "Eliminate surface defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

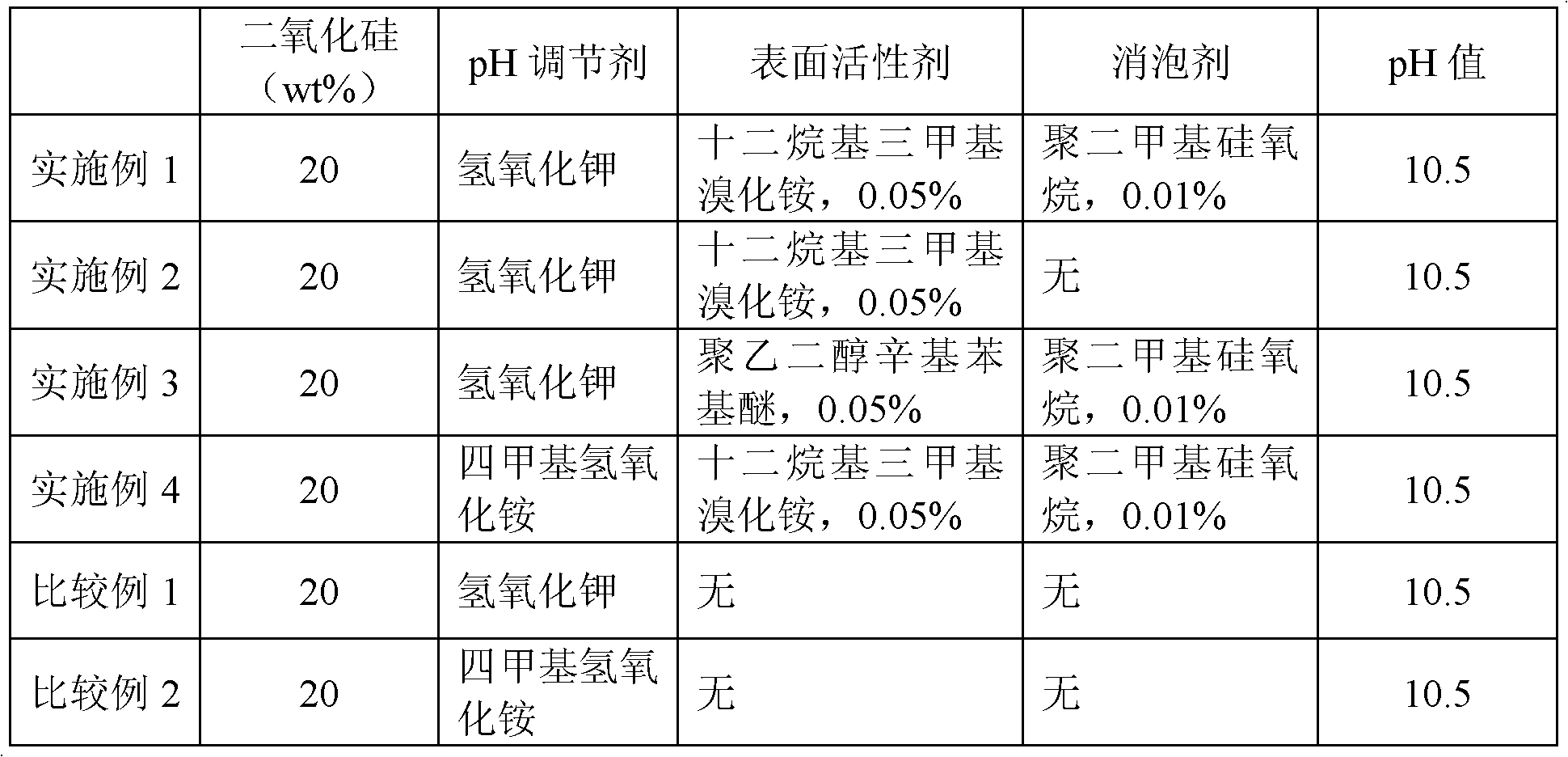

CMP (chemical mechanical polishing) liquid with high polishing rate for sapphire supporting base

ActiveCN102585705AReduce roughnessEliminate surface defectsPolishing compositions with abrasivesSurface-active agentsChemical-mechanical planarization

The invention discloses a CMP (chemical mechanical polishing) liquid with a high polishing rate for a sapphire supporting base. The CMP liquid comprises a grinding material, a pH value conditioning agent, a surface active agent, foam killer and deionized water, wherein taking the total weight of the CMP liquid as the criterion, the contents of the materials by weight percent are 1 to 50 percent of grinding material, 0.005 to 1 percent of surface active agent, and 20 to 200 ppm of foam killer respectively. Through the adoption of the CMP liquid, the sapphire supporting base can be polished in such a manner that the roughness of the sapphire supporting base is smaller than 0.2 nm, the polishing rate is larger than 5 MuM / h, and surface defects of concave pits, protrusions, scratches and the like can be eliminated effectively.

Owner:SHANGHAI XINANNA ELECTRONICS TECH

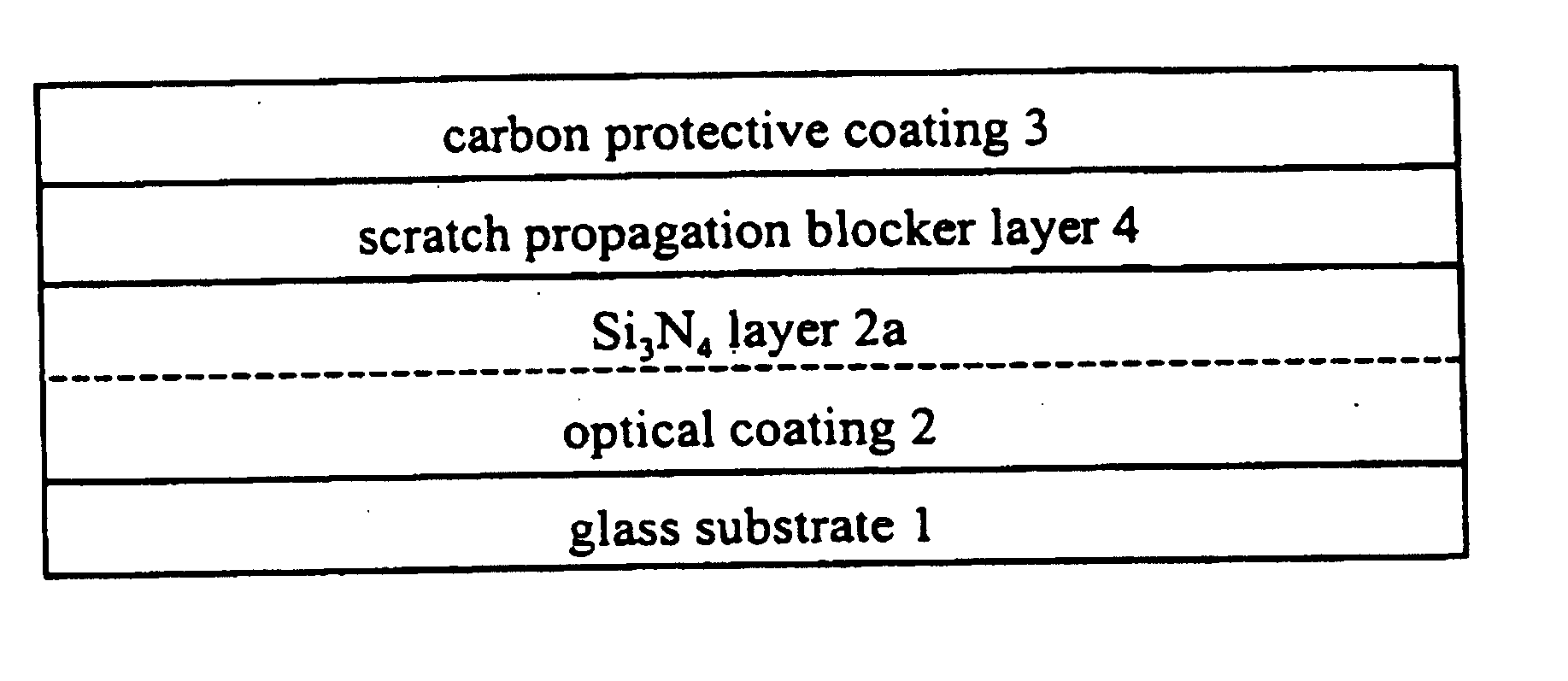

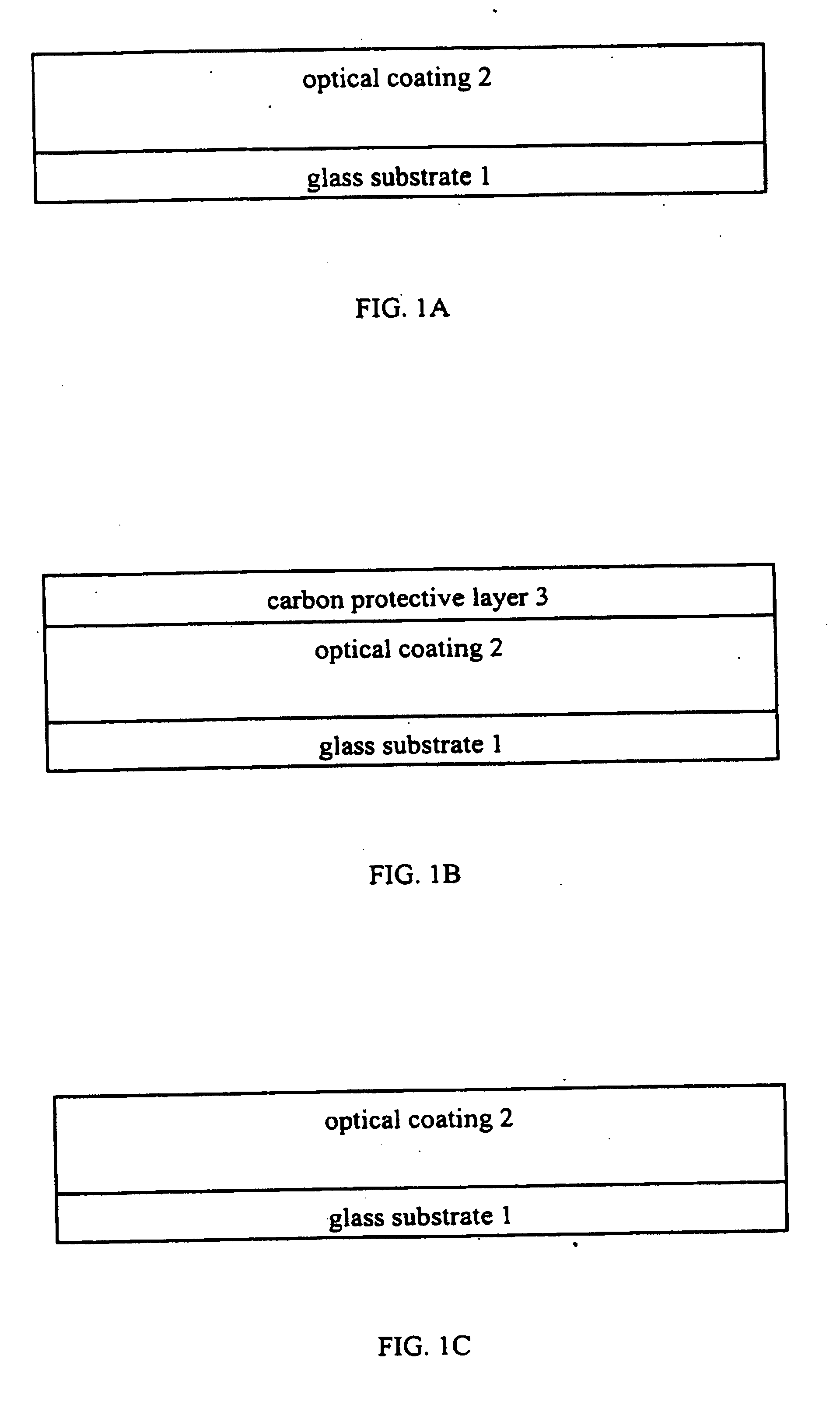

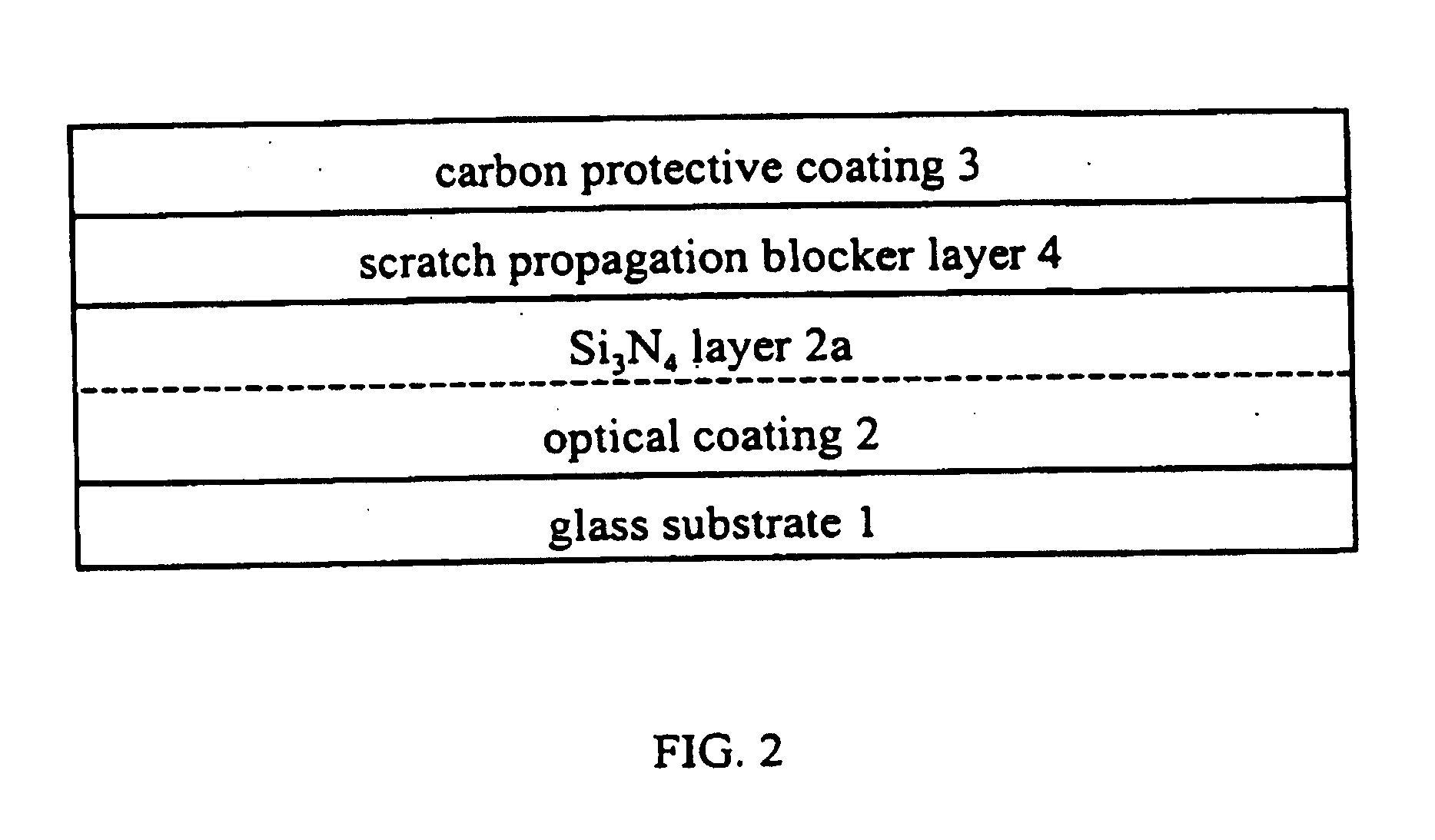

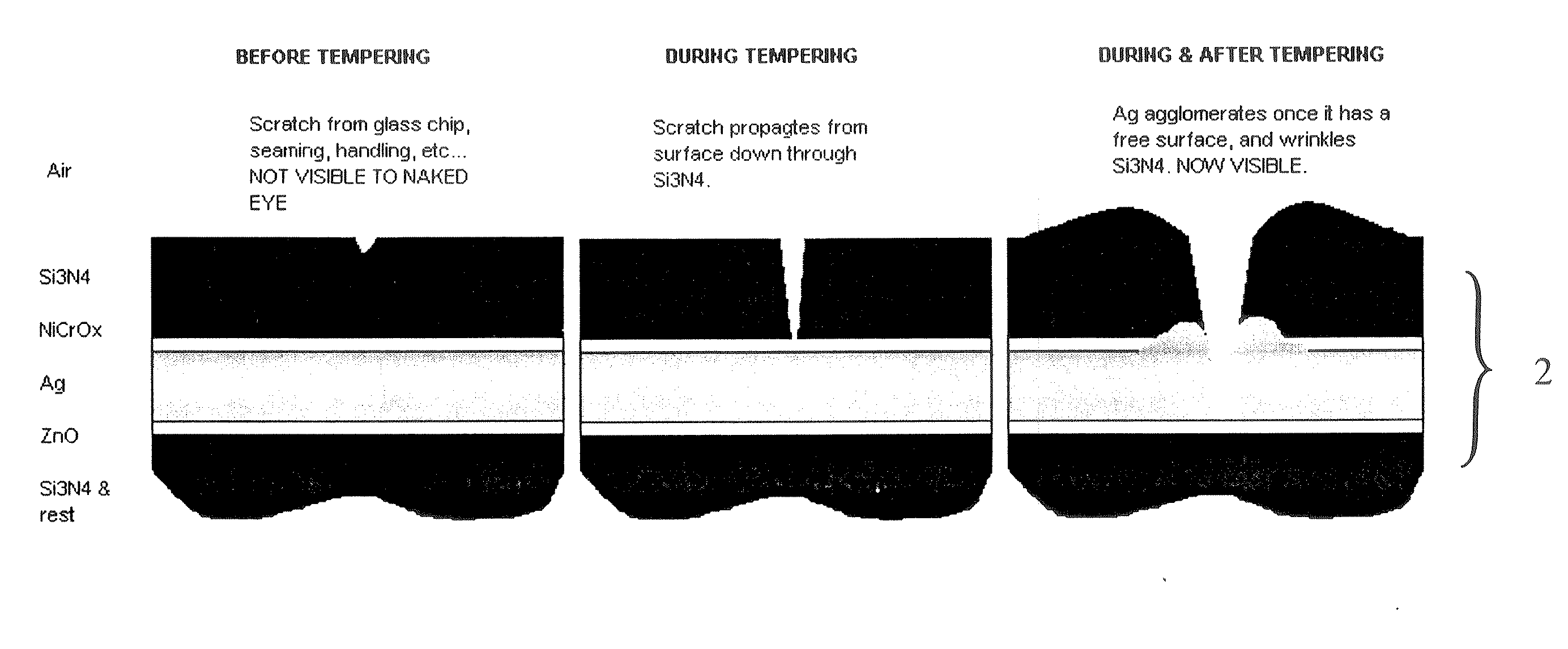

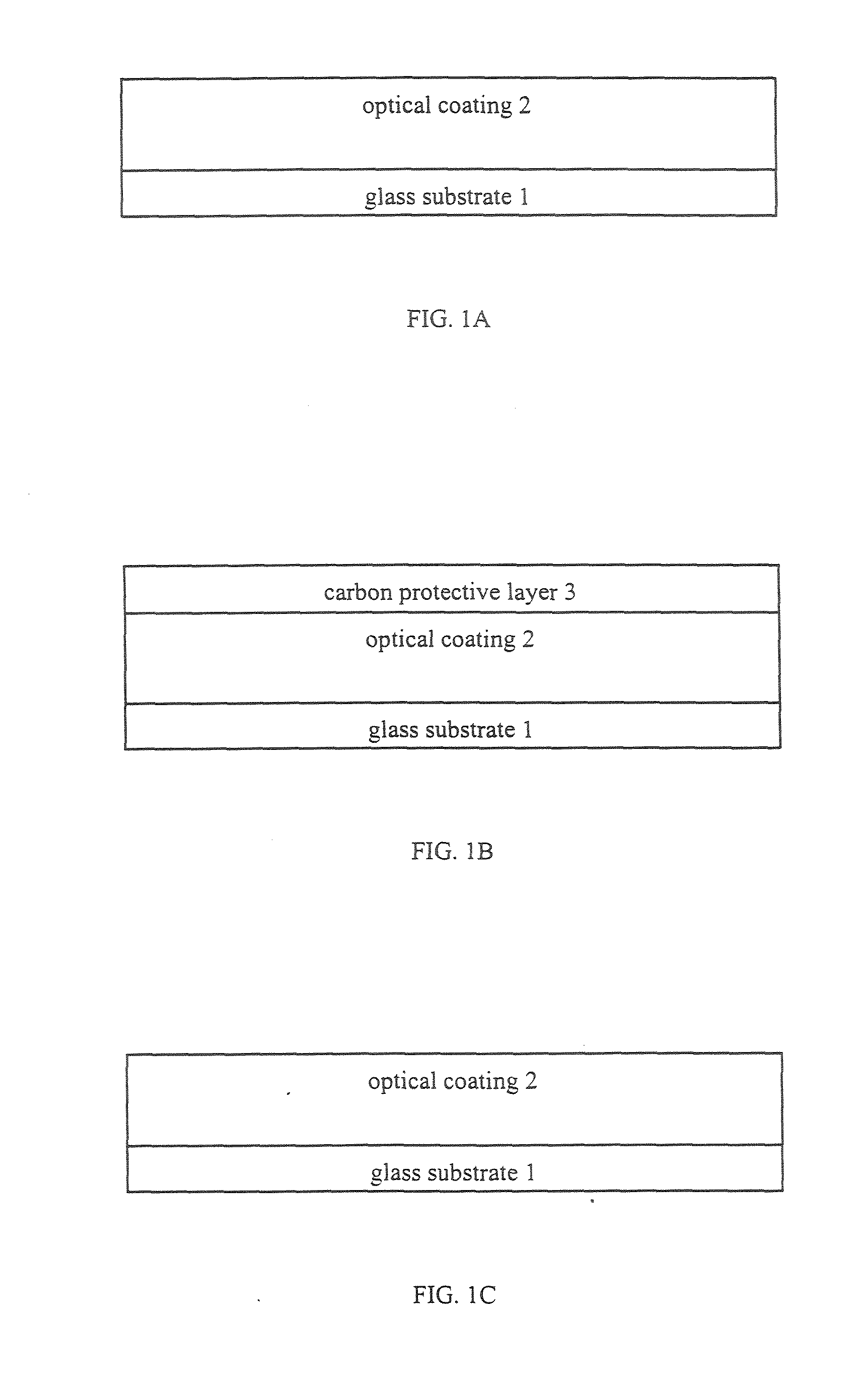

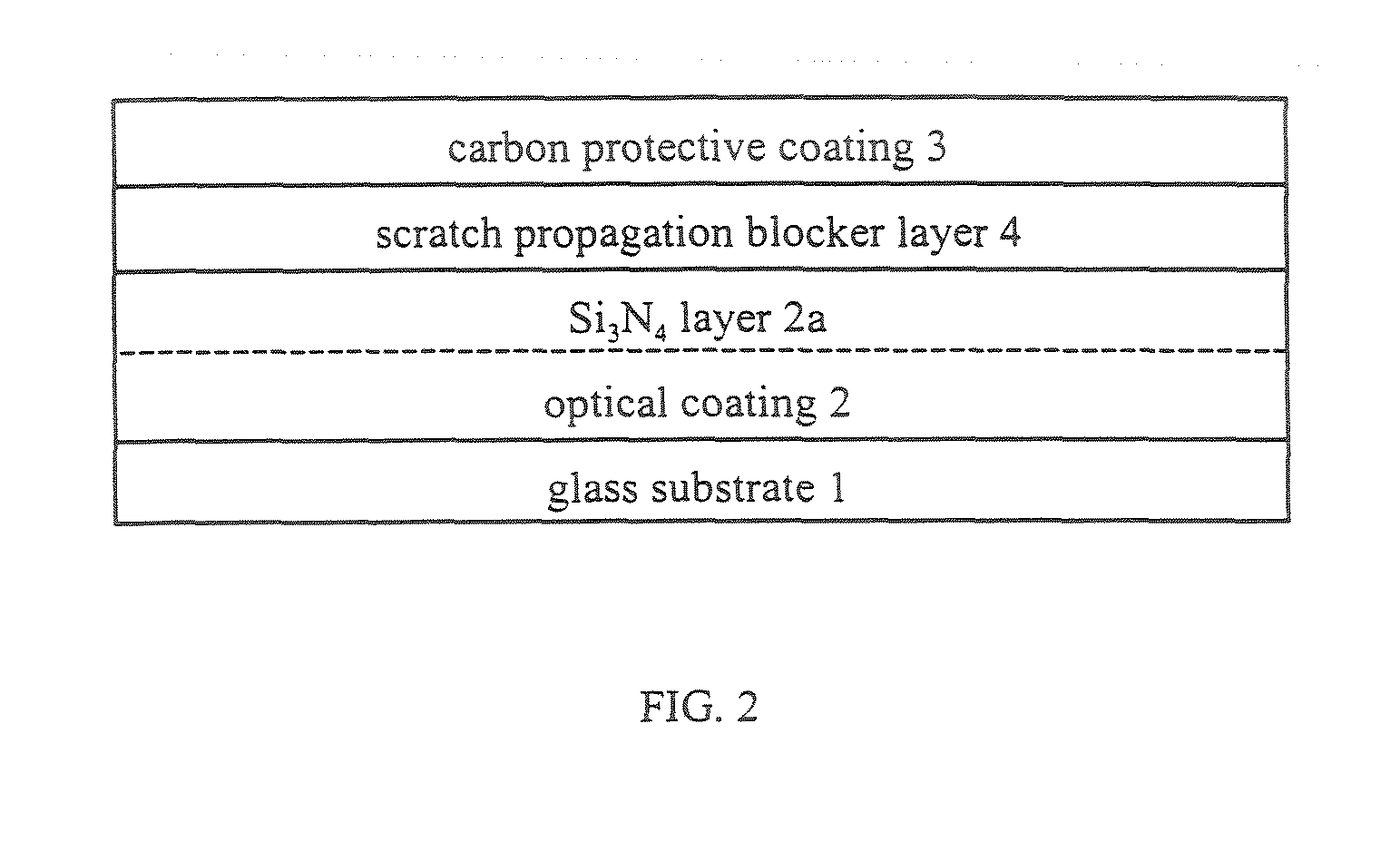

Protective layers for optical coatings

InactiveUS20050260419A1Reduce the numberReduce severityGlass/slag layered productsCoatingsOptical coatingOptoelectronics

An optical coating on a transparent substrate is provided with a temporary layer of carbon as protection during manufacturing against scratches and corrosive environments. When the optical coating and / or substrate are tempered in an atmosphere reactive to carbon, such as air, the layer of carbon is removed as a carbon-containing gas. For an optical coating with a brittle, glassy, outermost layer furthest from the substrate, additional protection is provided by a scratch propagation blocker layer between the outermost layer and the carbon protective layer.

Owner:AFG IND INC

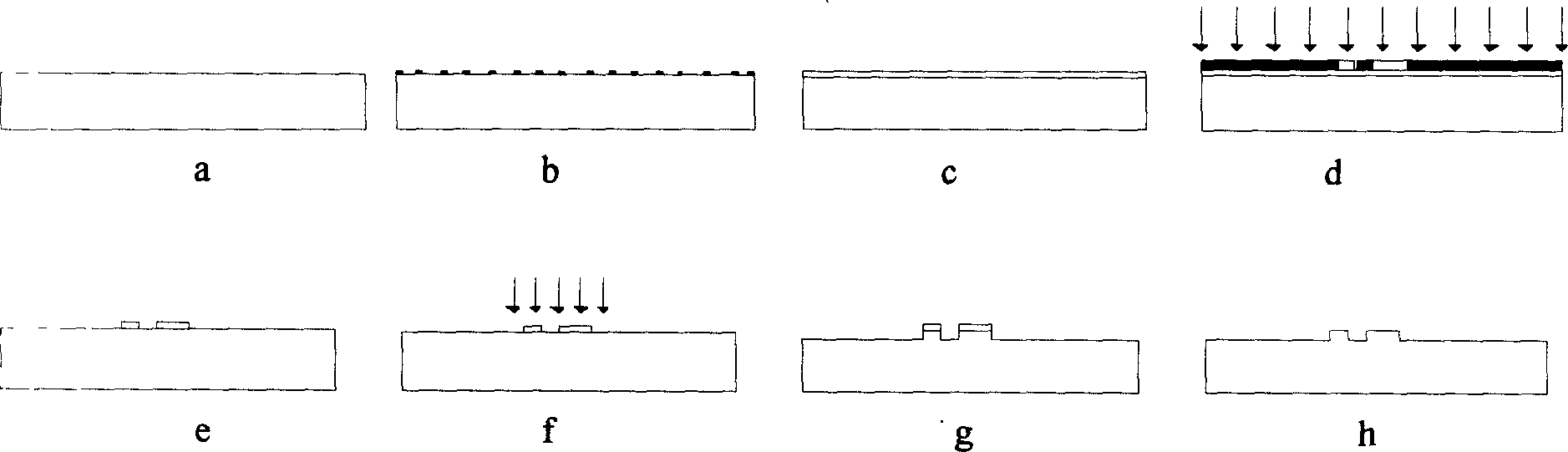

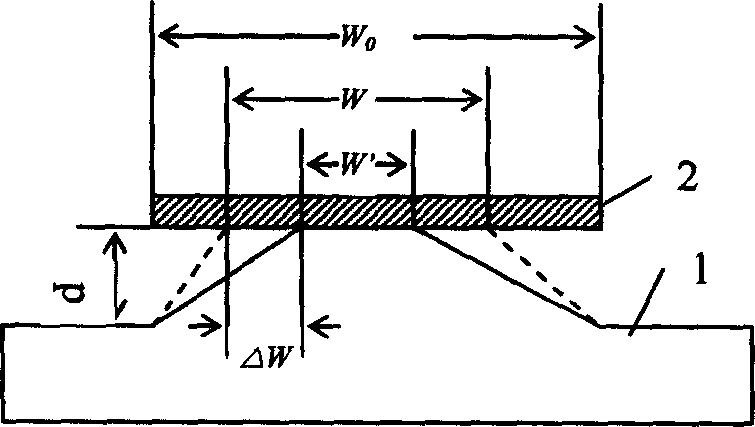

Manufacturing process of MEMS impression template based on wet etching

InactiveCN1731280AImprove adhesionReduce undercutting rateSemiconductor/solid-state device manufacturingPhotomechanical coating apparatusEtchingCoupling

The invention discloses a product design for using glass wet method to etch the coining etch mold, which comprises: cleaning the base material, depositing coupling agent, coating etch glue, exposing, purging, doing second solid, etching, extracting the glue and so on to obtain the coining mold. The method adopts single layer negative photoresist as etching mask, it adopts silane coupling agent to enhance the adherence between the etching mask and the surface of the glass, it uses depositing mode to coat the coupling agent to reduce the drilling rate, and it adopts HCI as etching liquid agent to improve the etching surface quality. The method is suit for preparing MEMS.

Owner:XI AN JIAOTONG UNIV

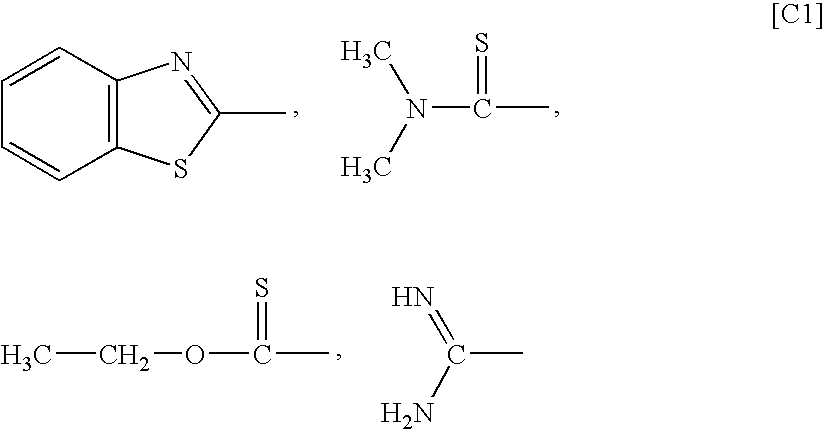

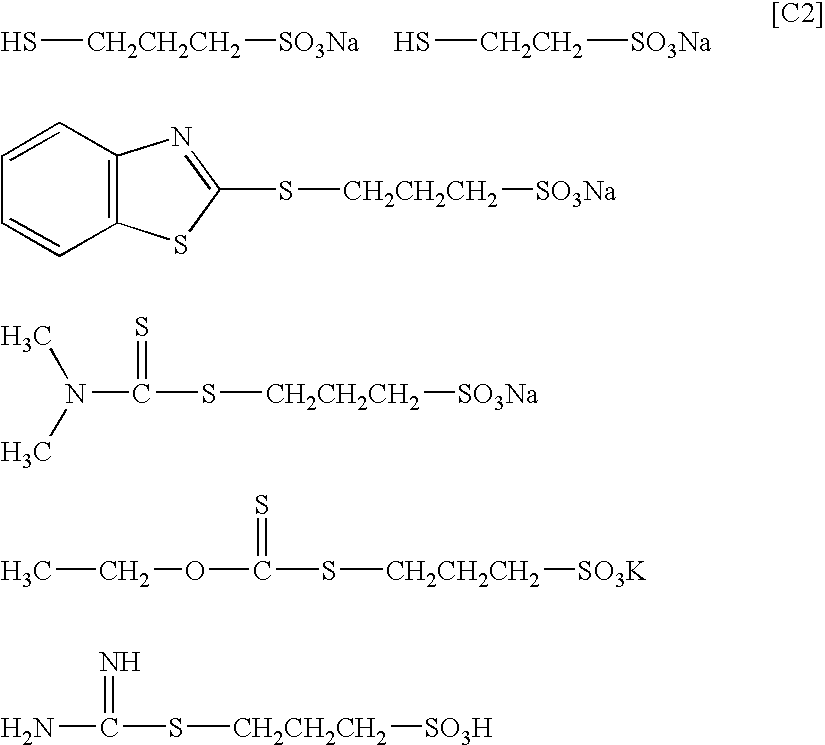

Copper electrolytic solution and two-layer flexible substrate obtained using the same

InactiveUS20100084275A1Excellent resist adhesivenessEliminate surface defectsDuplicating/marking methodsActive material electrodesFolding enduranceSulfur

To provide a two-layer flexible substrate having excellent folding endurance, etching properties, and resist adhesiveness with no surface defects.A copper electrolytic solution containing chloride ions, a sulfur organic compound and polyethylene glycol as additives, and the copper electrolytic solution preferably contains 5 to 200 ppm of chloride ions, 2 to 1000 ppm of a sulfur organic compound and 5 to 1500 ppm of polyethylene glycol. A two-layer flexible substrate having a copper layer formed using the copper electrolytic solution, wherein the MIT folding endurance is 100 or more, and the surface roughness (Rz) of the copper layer is 1.4 to 3.0 μm.

Owner:JX NIPPON MINING & METALS CO LTD

Weathering steel hot-rolled thin belt without P segregation and manufacturing method thereof

The invention discloses a weathering steel hot-rolled thin belt without P segregation and a manufacturing method thereof. The weathering steel hot-rolled thin belt comprises the following chemical components in percentage by mass: C: 0.07-0.12%; Si: 0.30-0.50%; Mn: 0.4-0.55%; P: 0.06-0.15%; S: not more than 0.02 % and more than 0; Cr: 0.6-0.8%; Ni: 0.03-0.11%; Cu: 0.2-0.5%; Al: not more than 0.046% and more than 0; B: not more than 0.003% and more than 0, and the balance of iron and impurity elements. The weathering steel hot-rolled thin belt disclosed by the invention is low in cost and free from central P segregation and flaky MnS inclusions.

Owner:SHAGANG GROUP +2

Polishing slurry for disk base sheet of memory hard disk

InactiveCN1417278AReduce roughnessReduce wavinessEdge grinding machinesPolishing compositions with abrasivesPolyolAlcohol

The present invention relates to the technology of manufacturing computer memory and hard disk. The polishing slurry contains abrasive, oxidant and water and is characterized by its water-soluble lubricant and polish balancing agent. The water-soluble lubricant is plyoxyethylenated fatly acid phosphate, plyoxyethylene fatty amide phosphate, fatty acid-polyol ester or their mixture and accounts for 0.2-20 wt%; and the polish balancing agent is water-soluble alcohol and accounts for 0.2-20 wt%. The polishing slurry can reduce the roughness and waviness of memory and hard disk surface to below 0.7 angstrom and eliminate effectively pit, lug, scratch and other faults.

Owner:TSINGHUA UNIV

Method for decreasing decarburized layers on surfaces of high-carbon-chromium bearing steel wires

The invention relates to a method for decreasing decarburized layers on surfaces of high-carbon-chromium bearing steel wires. The specific process comprises the steps that steel is molten to obtain molten steel which is subjected to continuous casting to form bearing steel, the bearing steel is subjected to continuous casting to form a bloom, and the bloom is rolled into square hot rolling billet with the section being 160mm*160mm; the surface of the square hot rolling billet is ground, and the grinding amount is 0.5-2mm; the square hot rolling billet is heated in a heating furnace, micro positive pressure control is adopted in the furnace, the pressure in the furnace is 5-40 Pa, the weak oxidizing atmosphere is adopted in the furnace, and the air-fuel ratio is adjusted to enable the oxygen remaining volume in the furnace to be 0-2%; and the spinning temperature is controlled to be 800-850 DEG C, cooling is performed at the rate of 5-10 DEG C / s after spinning to reduce the temperature to 500-600 DEG C, and then slow cooling is performed to obtain hot-rolled wire rods. According to the bearing steel wires obtained through the method, the surfaces are free of fully decarburized layers, and the depth of half decarburized layers is smaller than 50 microns; meanwhile, good component uniformity and internal structure uniformity are achieved, and the product quality requirement of downstream customers can be met; besides, the surface grinding amount of the downstream customers can be reduced, the cost is lowered, and a certain competitive advantage is provided.

Owner:XINGTAI IRON & STEEL

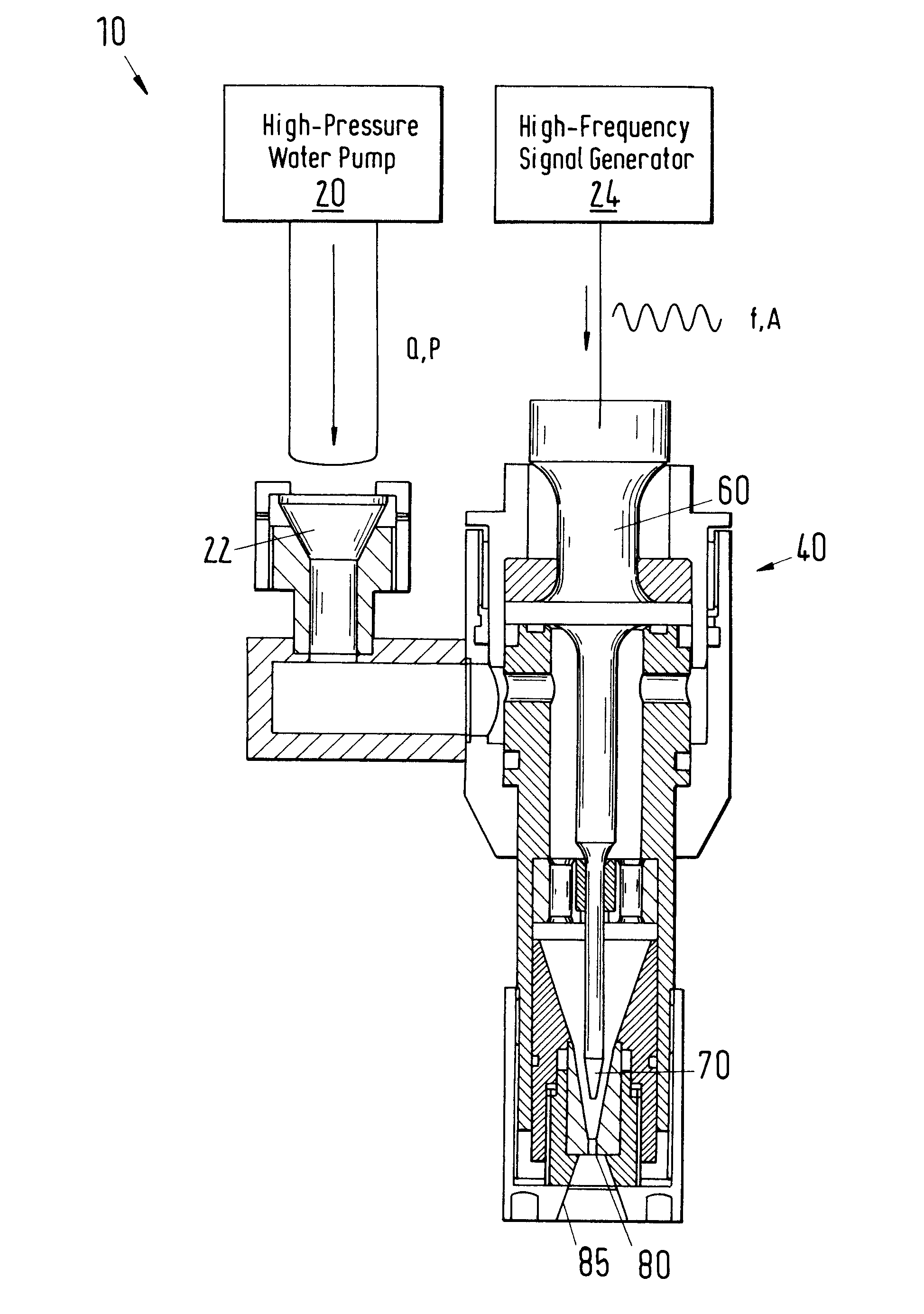

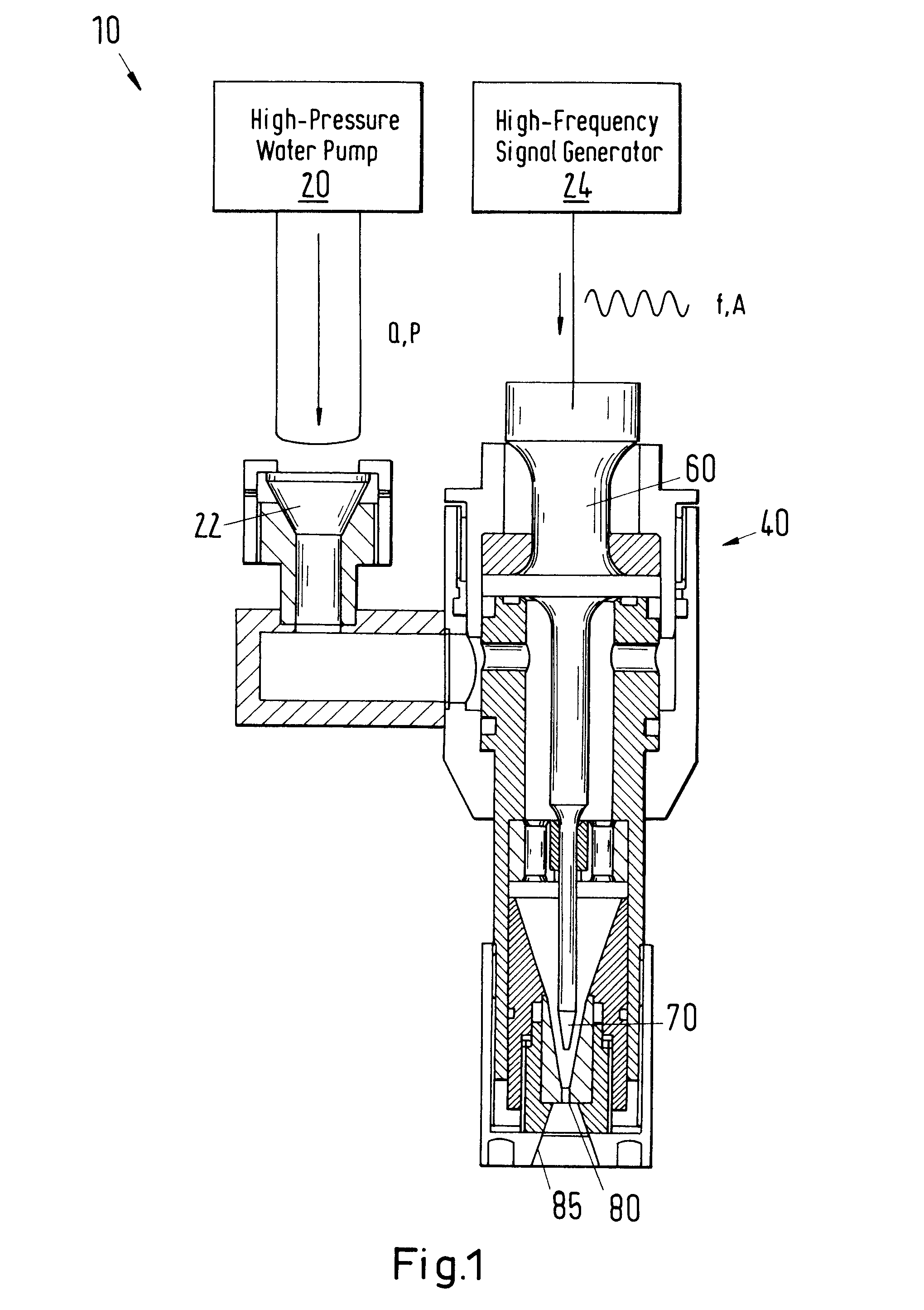

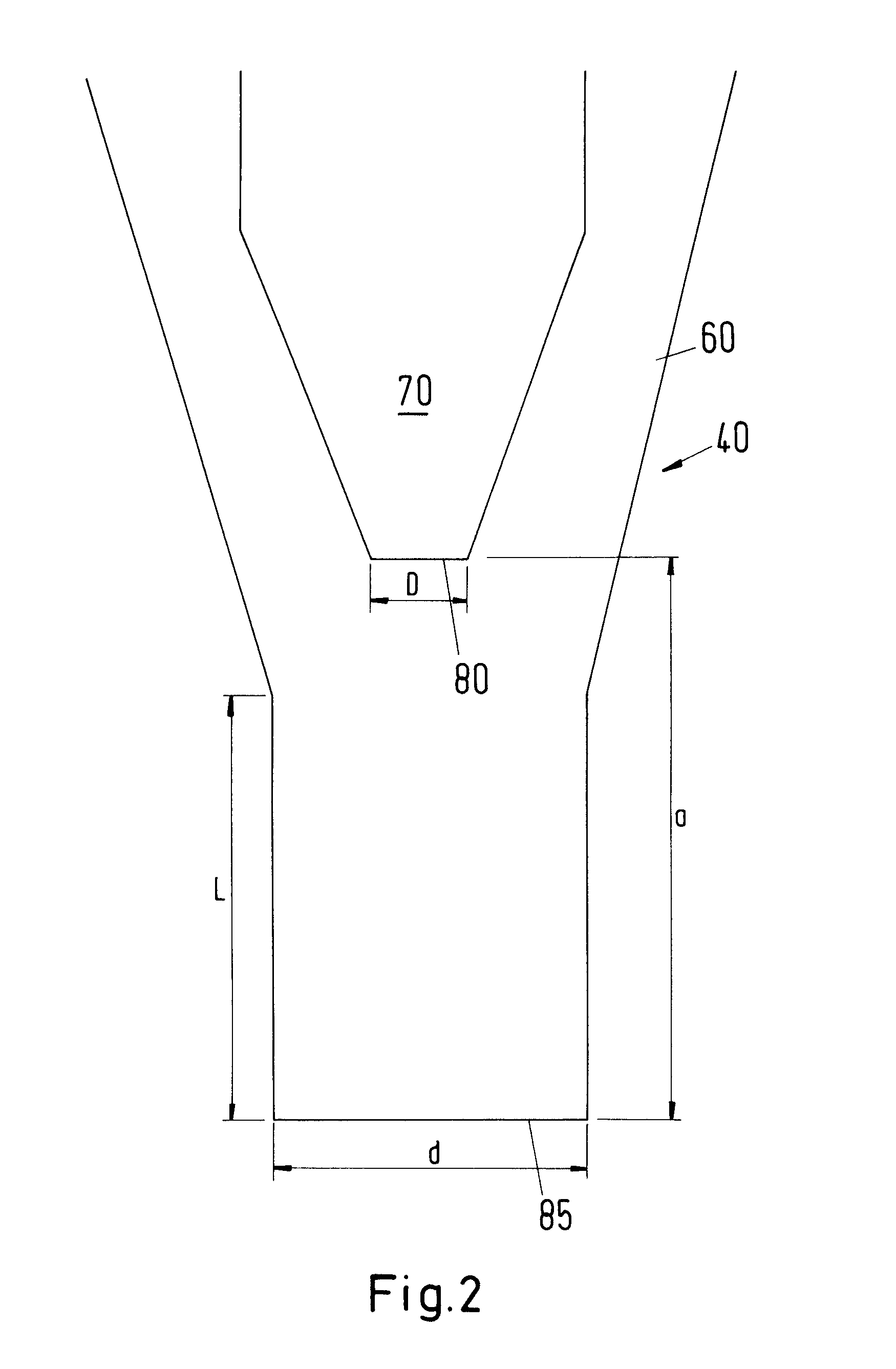

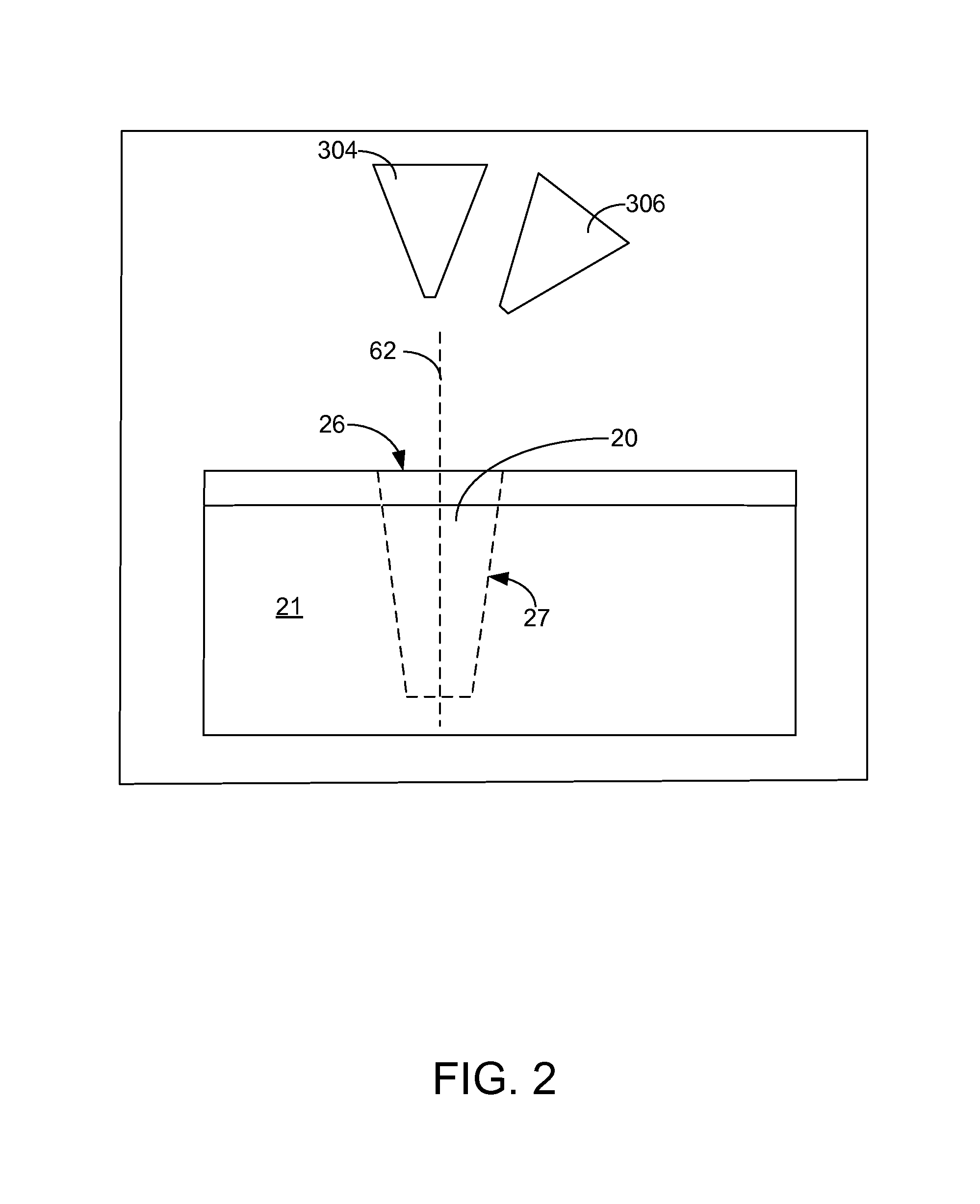

Method and apparatus for preparation of cylinder bore surfaces with a pulsed waterjet

InactiveUS20120322347A1Exact and highly uniform surface roughness characteristicHighly predictableBlast gunsMolten spray coatingSpray nozzleWater flow

An apparatus for and a method of prepping a surface of a cylinder bore using a pulsed waterjet entails generating a signal having a frequency f using a signal generator, applying the signal to generate a pulsed waterjet through an exit orifice of a nozzle having an exit orifice diameter d and a length L. The pulsed waterjet prepares the surface to within a predetermined range of surface roughness. The surface roughness is determined by selecting operating parameters comprising a standoff distance (SD), a traverse velocity VTR of the nozzle, a water pressure P, a water flow rate Q, a length-to-diameter (L / d) ratio, the frequency f, and an amplitude A of the signal.

Owner:SULZER METCO (US) INC

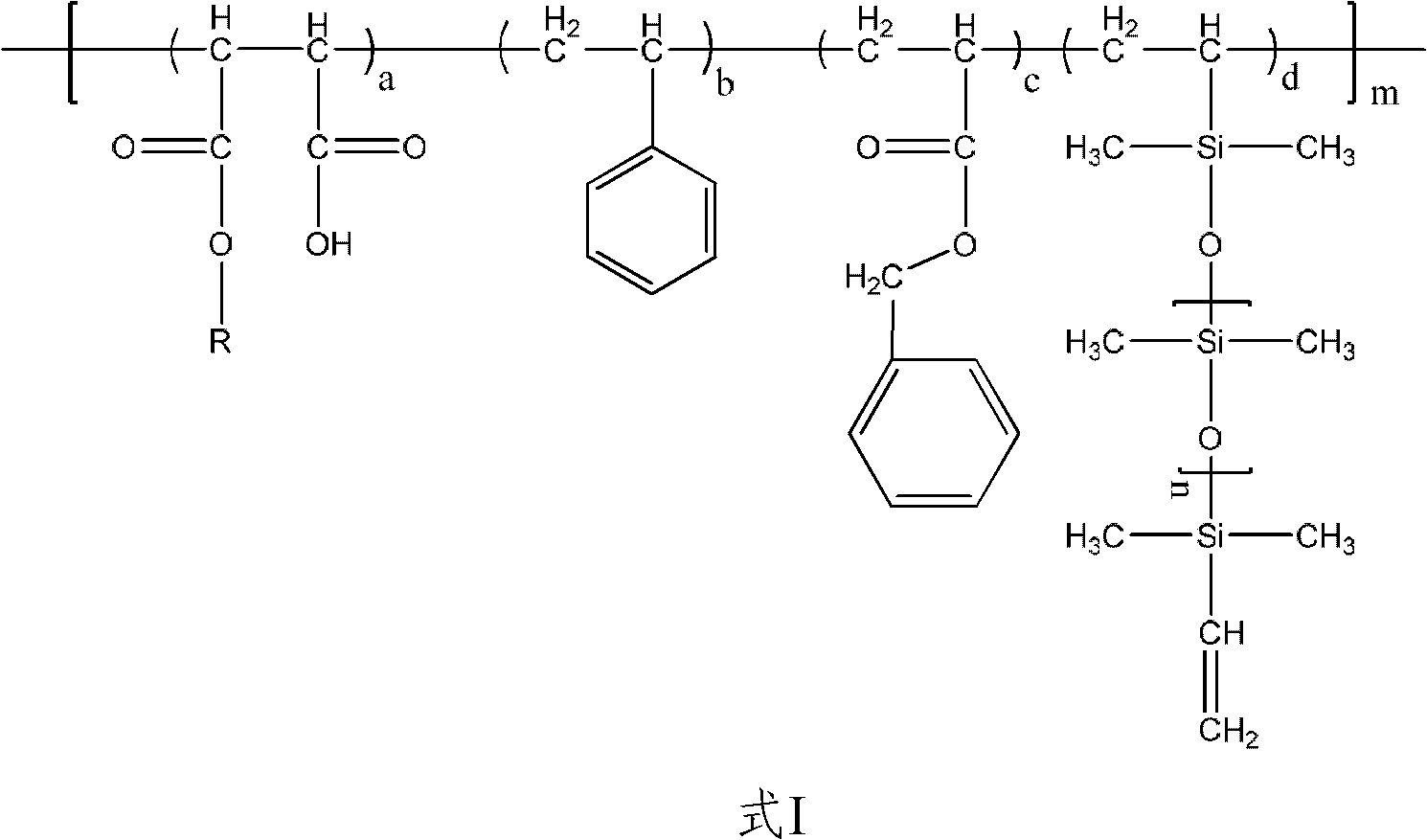

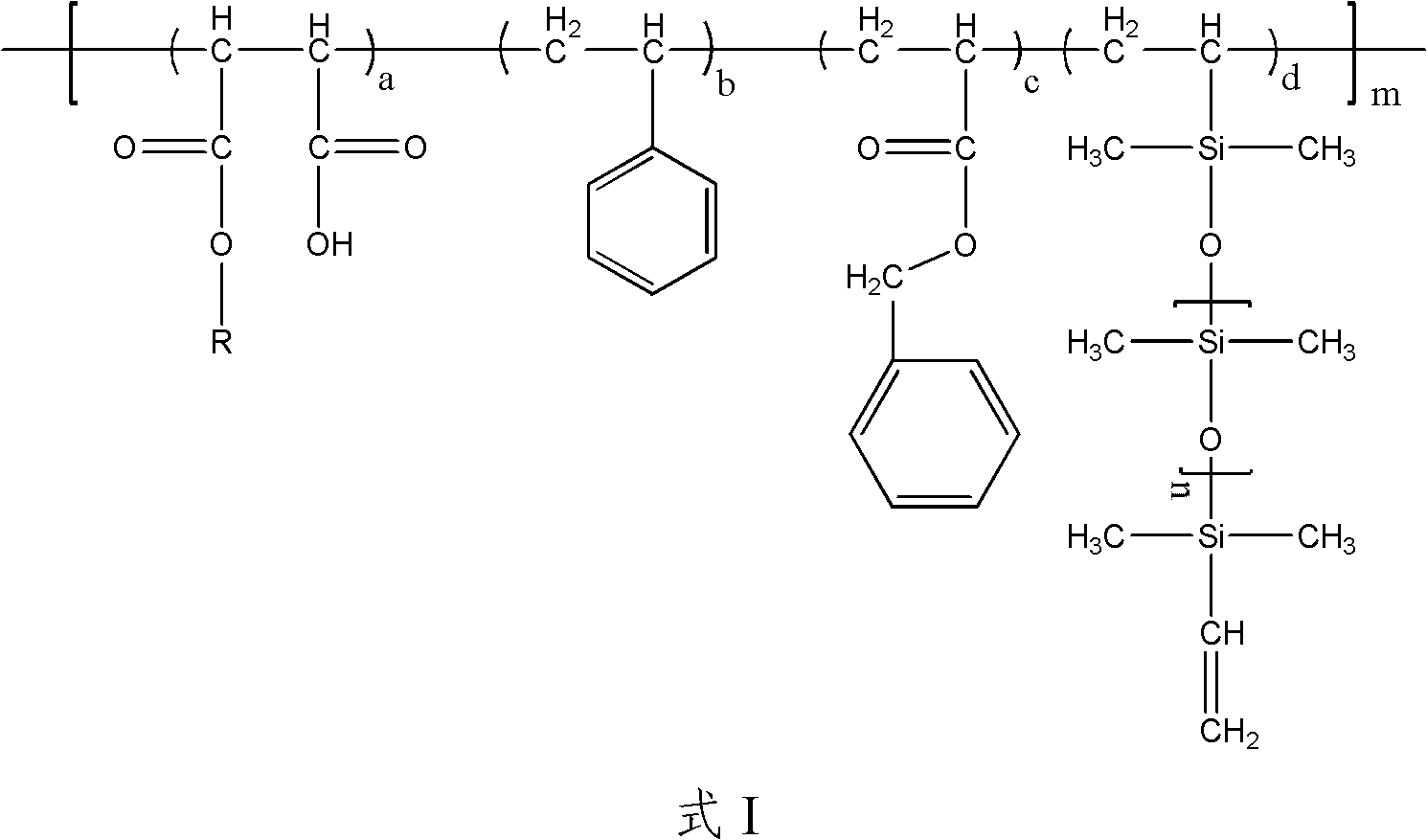

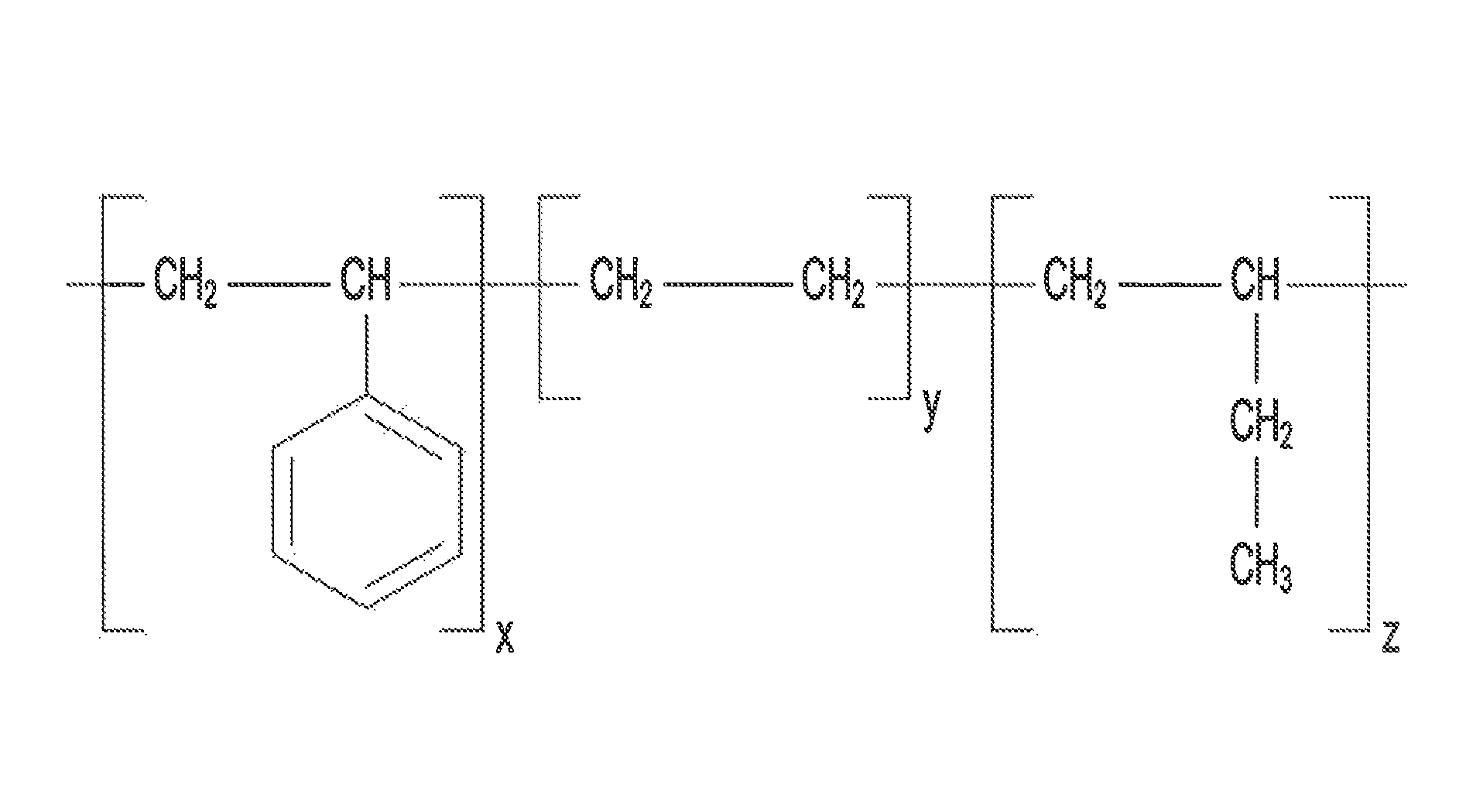

Alkali soluble resin, photosensitive resin composition containing it and application thereof

ActiveCN102875745ASmooth coating surfaceImprove flexibilityOptical filtersPhotomechanical apparatusHydrogenColor gel

The invention discloses an alkali soluble resin and its preparation method. The alkali soluble resin has a chemical structural formula shown in formula 1, wherein a is an integer ranging from 1 to 5, b is an integer ranging from 1 to 5, c is an integer ranging from 1 to 10, d is an integer ranging from 1 to 10, m is an integer ranging from 1 to 30, n is an integer ranging from 1 to 10, and R is hydrogen, alkyl, alkoxy or an acrylic group. The alkali soluble resin has a weight-average molecular weight of 3500-35000. The invention also discloses a photosensitive resin composition containing the alkali soluble resin, and a color photoresist glue that contains the photosensitive resin composition and is used for color filters, as well as a display device containing the color photoresist glue, which has the advantage of a level and smooth coating surface.

Owner:BOE TECH GRP CO LTD

Cold rolled strip steel for shadow mask and its making process

ActiveCN1888118AImprove performanceLow costMolten spray coatingCathode ray tubes/electron beam tubesChemical compositionStrip steel

The present invention is one kind of cold rolled strip steel for shadow mask and its making process. The making process of the cold rolled strip steel includes the following steps: smelting; casting; hot rolling with finishing temperature of 880-900 deg.c and winding temperature of 510-610 deg.c; acid pickling and cold rolling; cutting edge and eliminating edge faults; continuous annealing at 675-695 deg.c in the soaking duration of 20-35 s and flattening. The present invention has excellent product performance, high production efficiency and low production cost.

Owner:BAOSHAN IRON & STEEL CO LTD

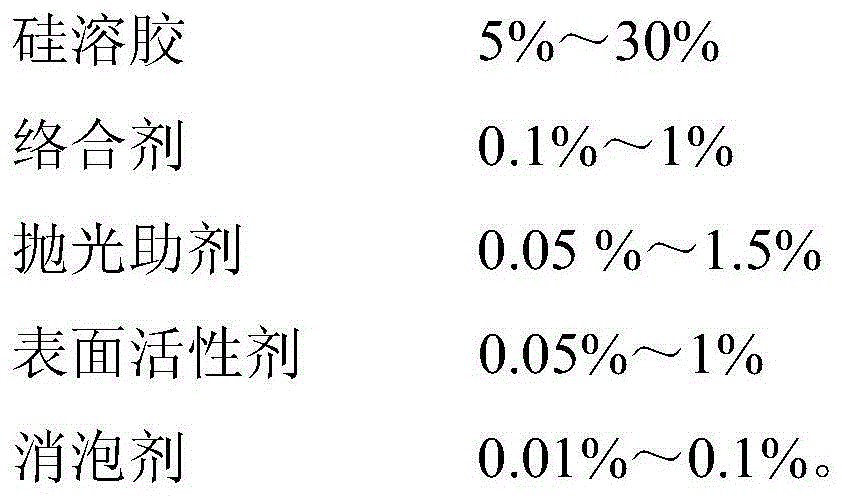

A-directional sapphire mobile phone cover plate polishing solution and preparation method thereof

InactiveCN104830234AEliminate surface defectsPolishing compositions with abrasivesMicrometerAgricultural engineering

The invention relates to an A-directional sapphire mobile phone cover plate polishing solution and a preparation method thereof. The polishing solution is a water fluid suspension and comprises ingredients shown in the following description according to a mass percent. The A-directional sapphire mobile phone cover plate polishing solution polishes an A-directional sapphire mobile phone cover plate so that surface roughness of the A-directional sapphire mobile phone cover plate is less 0.3nm, a polishing rate is more than 2 micrometers per hour, and scratch, orange-peel and concave-convex surface defects are effectively eliminated.

Owner:深圳杰明纳微电子科技有限公司 +1

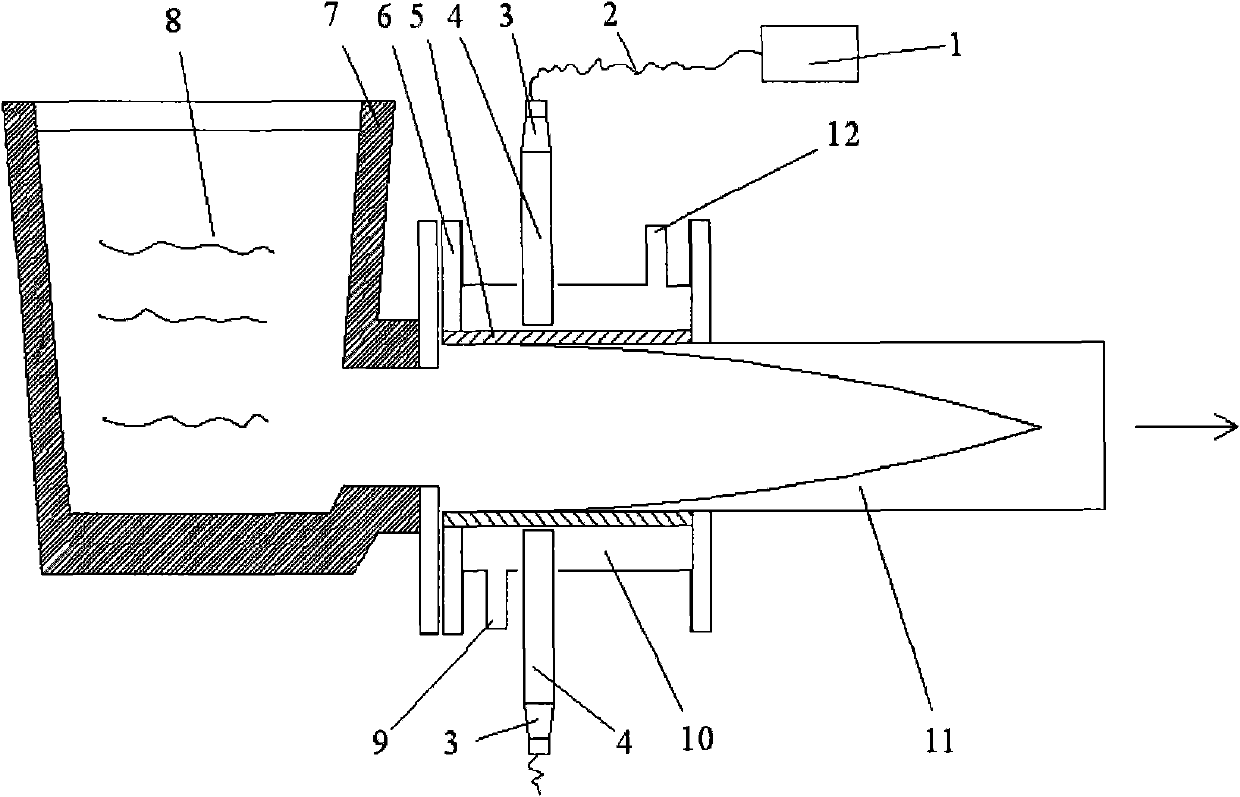

Continuous casting crystallizer device using ultrasonic vibration

InactiveCN101905295AEliminate stickingEliminate surface defectsUltrasonic vibrationUltrasonic guided wave

The invention provides a continuous casting crystallizer device using ultrasonic vibration, which belongs to the technical field of metallurgical casting. The device of the invention comprises a trough, a crystallizer, a crystallizer copper plate, ultrasonic guide rods, an energy converter and an ultrasonic power supply, wherein the crystallizer is directly connected with the trough; the ultrasonic guide rod is arranged on each reverse side of the crystallizer copper plate and connected with the energy converter; the energy converter is connected with the ultrasonic power supply; the ultrasonic guide rod passes through a cooling water tank and is vertically connected with the crystallizer copper plate; and the length of the ultrasonic guide rod is an integral multiple of the wavelength or half-wavelength of the used ultrasonic. The vibration mode of the ultrasonic vibration crystallizer provided by the invention breaks through the traditional mechanical vibration limit, and the continuous casting crystallizer device using the ultrasonic vibration is favorable for promoting the production of deflect-less continuous casting blanks without surface defects such as vibration marks and improving the quality of the casting blanks and steel.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

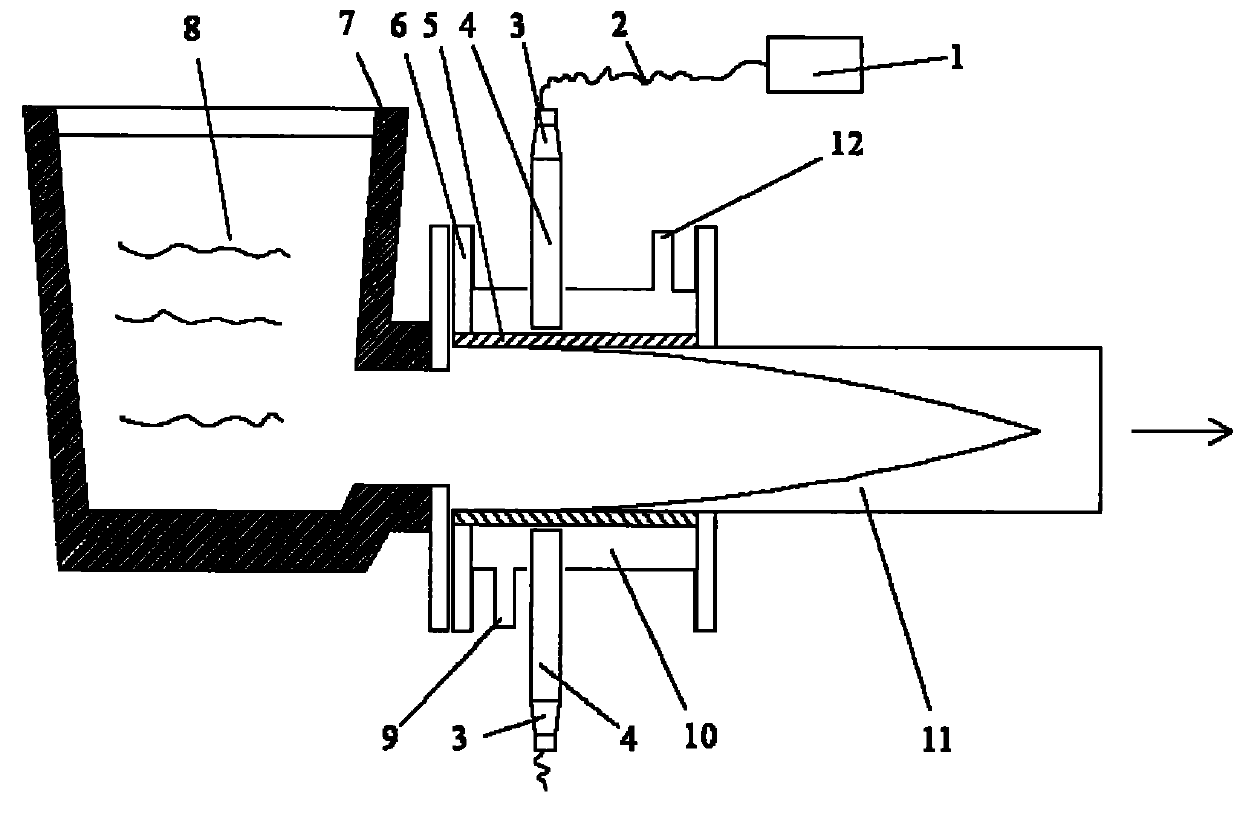

Germanium layer polishing

ActiveUS20110045654A1High removal rateReduce roughnessSemiconductor/solid-state device manufacturingLapping machinesMetallurgyGermanium

In order to polish a layer of germanium (121), a first step of chemical-mechanical polishing of the surface (121a) of the germanium layer (121) is carried out with a first polishing solution having an acidic pH. The first polishing step is followed by a second step of chemical-mechanical polishing of the surface of the germanium layer (121) carried out with a second polishing solution having an alkaline pH.

Owner:SOITEC SA

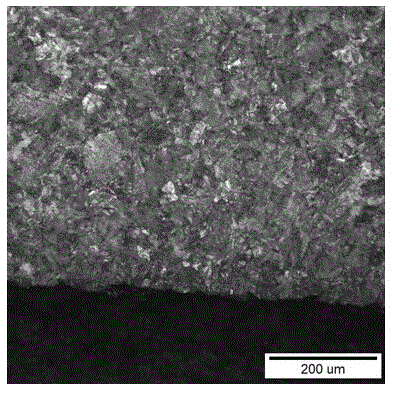

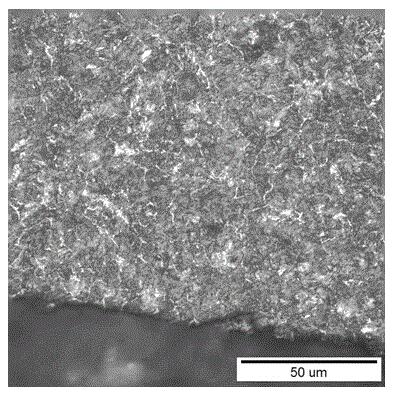

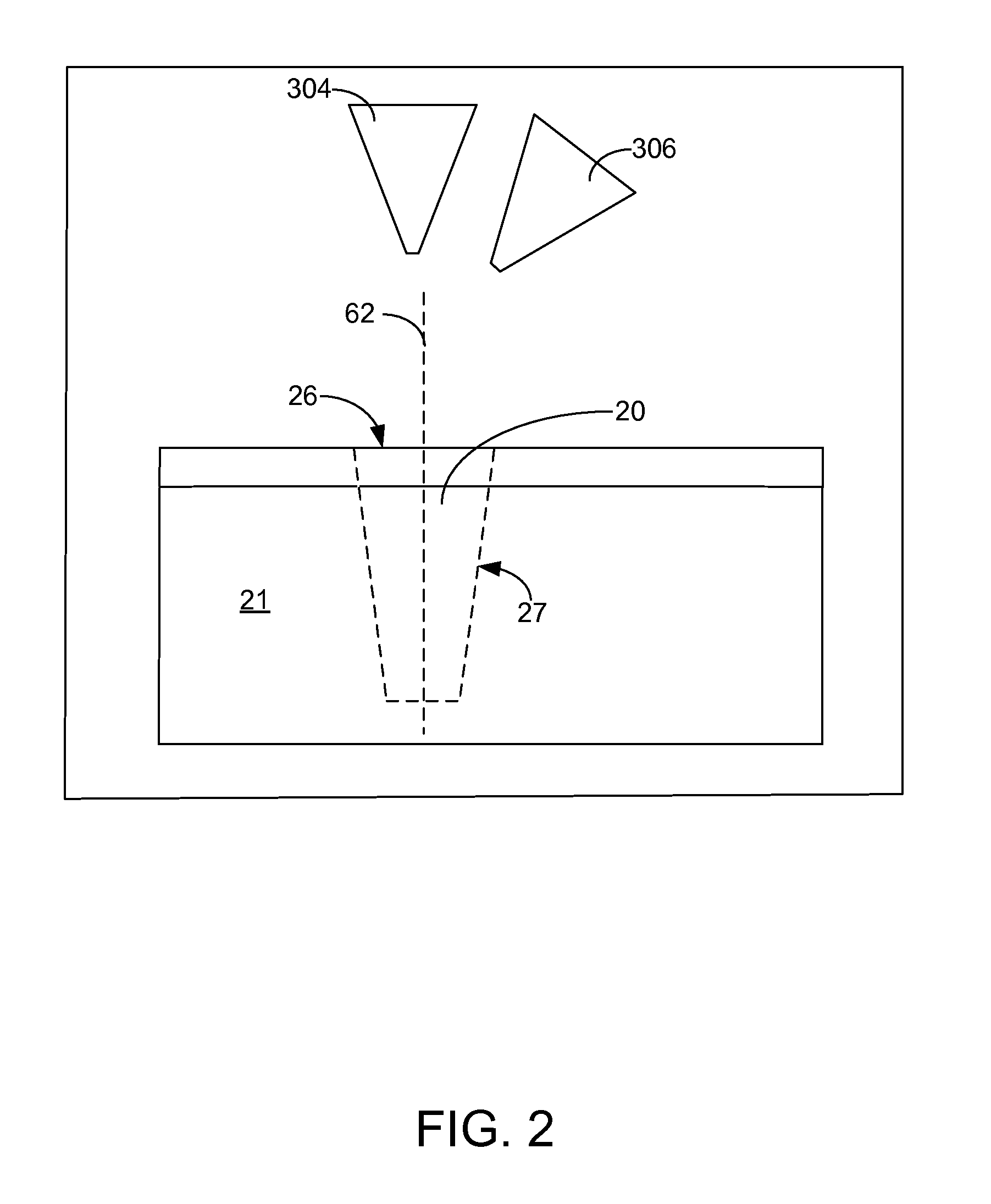

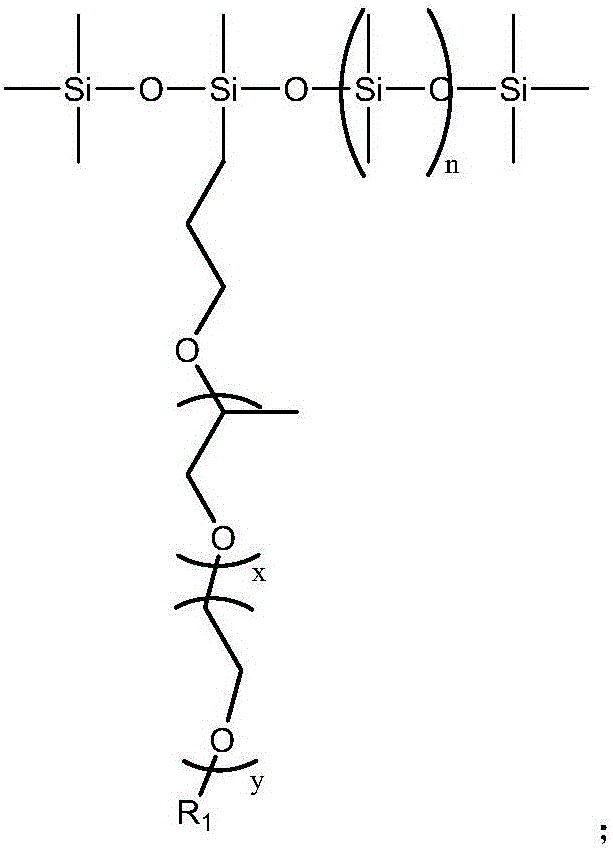

TEM sample preparation

ActiveUS8859998B2Eliminate surface defectsReliable and robust preparationSamplingElectric discharge tubesThinningImproved method

An improved method of preparing ultra-thin TEM samples that combines backside thinning with an additional cleaning step to remove surface defects on the FIB-facing substrate surface. This additional step results in the creation of a cleaned, uniform “hardmask” that controls the ultimate results of the sample thinning, and allows for reliable and robust preparation of samples having thicknesses down to the 10 nm range.

Owner:FEI CO

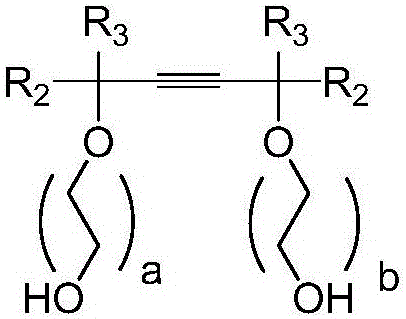

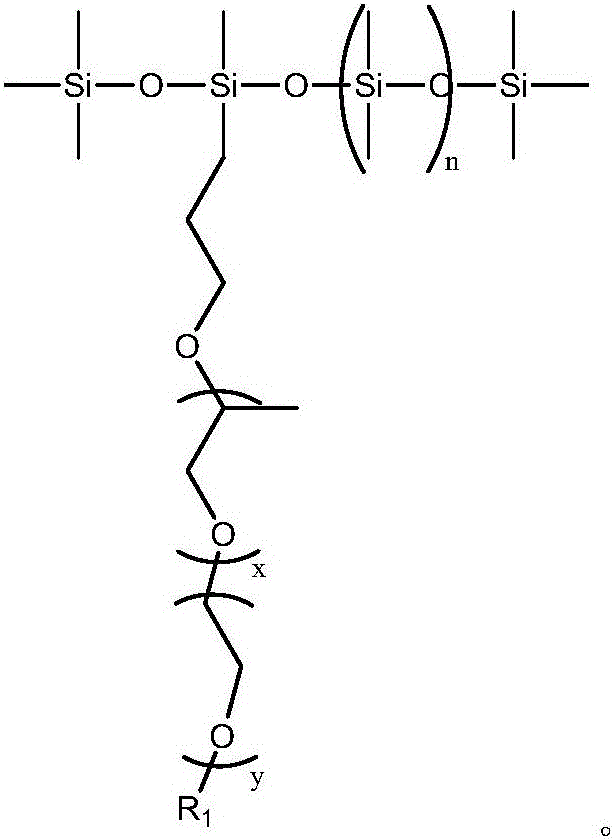

Compound wetting agent and coating formed by same

InactiveCN106084975AGood foam stabilization effectSolve the problem of poor wettingPolyurea/polyurethane coatingsChemistryOrganosilicon

The invention provides a compound wetting agent and a coating formed by the same. The compound wetting agent mainly comprises, by weight, 5-40% of polyether modified organosilicon surfactant, 50-90% of alkynediol surfactant and 1-10% of isomerized low-foam special polyether solubilizer. The compound wetting agent has low static surface tension and dynamic surface tension and good system compatibility, foam stability of polyether modified organosilicon is remarkably improved, and the compound wetting agent can be suitable for water-based wood paint of different resin systems such as an acrylic resin system and a polyurethane system.

Owner:岳阳凯门水性助剂有限公司

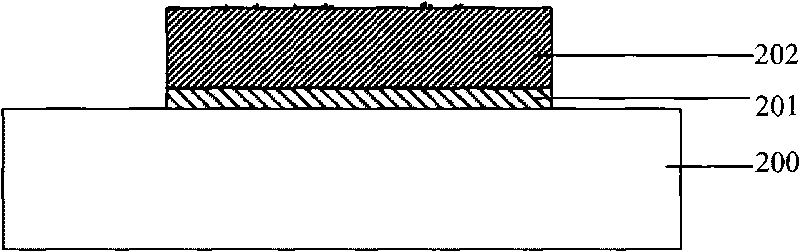

Method for eliminating surface defect of semiconductor device and semiconductor device

ActiveCN101740379AEliminate surface defectsReduce pollutionSemiconductor/solid-state device manufacturingImpuritySemiconductor device

The invention relates to a method for eliminating the surface defect of a semiconductor device and a semiconductor device. The method for eliminating the surface defect of a semiconductor device comprises the following steps of: providing a semiconductor substrate and forming an impure polycrystalline silicon layer on the semiconductor substrate, wherein impurities are adhered to the surface of the polycrystalline silicon layer; forming an oxide sacrificial layer on the polycrystalline silicon layer, wherein the impurities are dissolved in the oxide sacrificial layer; and removing the oxide sacrificial layer in which the impurities are dissolved. By removing the impurities originally attached to the surface of the semiconductor element, the pollution to the subsequent process is reduced, and the fine rate of the products is relatively raised.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Removable spray coating and application method

According to the present invention, sprayable liquid solvent-based compositions for removable coatings are provided along with methods of applying those compositions to a surface for protecting and improving the appearance of the surface. Solvent-based compositions may be applied to a surface as a liquid and undergo evaporation and / or drying to form a “rubberized” material, forming a substantially uniform protective coating on a surface.

Owner:FIGLIOZZI MARK

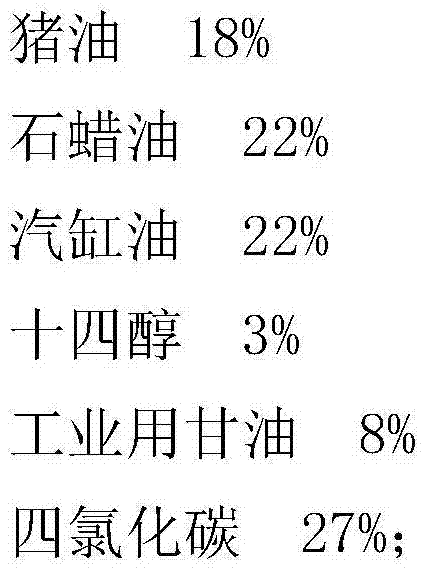

Lubricating liquid for lubricating surface of aluminum alloy material and preparation method thereof

InactiveCN104119995AEliminate surface defectsEliminates oil and scaleBase-materialsParaffin oilsOxide

The invention discloses a lubricating liquid for lubricating the surface of an aluminum alloy material and a preparation method thereof, and relates to the technical field of lubricating liquids. The lubricating liquid is composed of the following components: lard, paraffin oil, steam cylinder oil, tetradecyl alcohol, industrial glycerin, and carbon tetrachloride. The lubricating liquid can eliminate the surface defects of an aluminum alloy material, oil stains and oxide scales, so the lubricating effect is better, the fluidity and lubricity of aluminum alloy products are better during the extrusion process, and the part quality is improved.

Owner:ANHUI CHENGYOU AUTO PARTS MFG

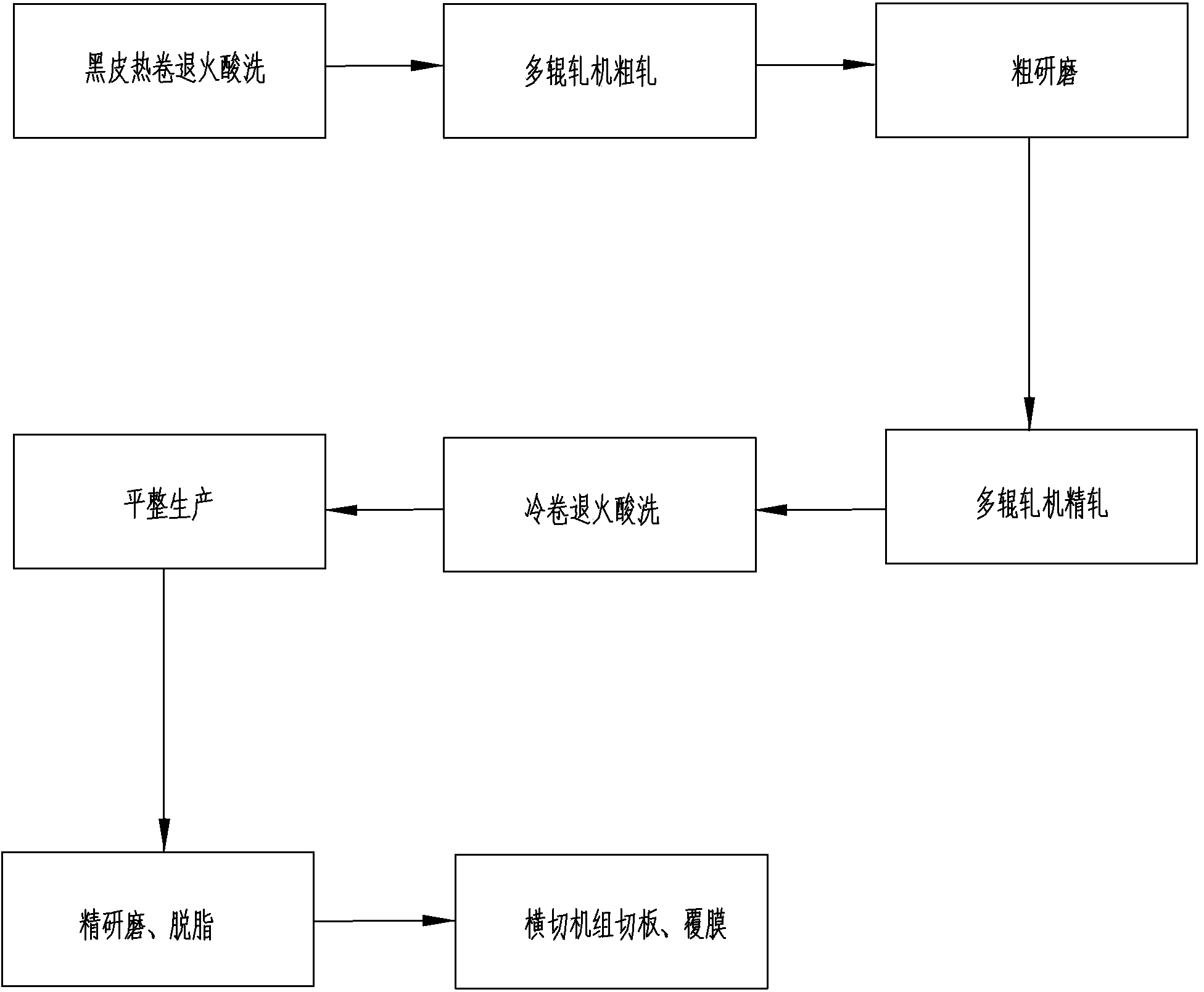

Manufacture method of stainless steel external wall panel for rail vehicle

ActiveCN103433319AGuaranteed product performanceGuaranteed surface qualityMaterials scienceRolling mill

The invention discloses a manufacture method of a stainless steel external wall panel for rail vehicle. The method sequentially comprises the following steps: firstly, annealing and pickling of a black hot coil, secondly, rough rolling by using a multi-roll mill, thirdly, rough grinding, fourthly, finish rolling by using the multi-roll mill, fifthly, annealing and pickling of a cold coil, sixthly, leveling production, seventhly, finish grinding, and eighthly, cutting plates by a transverse cutting unit. The method has the advantages that the product performance and the surface quality are guaranteed through the reasonable arrangement and collocation of all production processes, the processes of rough rolling and rough grinding are adopted, so as to eliminate the surface defect of raw material and guarantee the surface quality of final products, specified yield strength, tensile strength and elongation are achieved through a leveling mode, and the grinding time of all racks is controlled during grinding, so that required surface requirements are achieved.

Owner:NINGBO BAOXIN STAINLESS STEEL

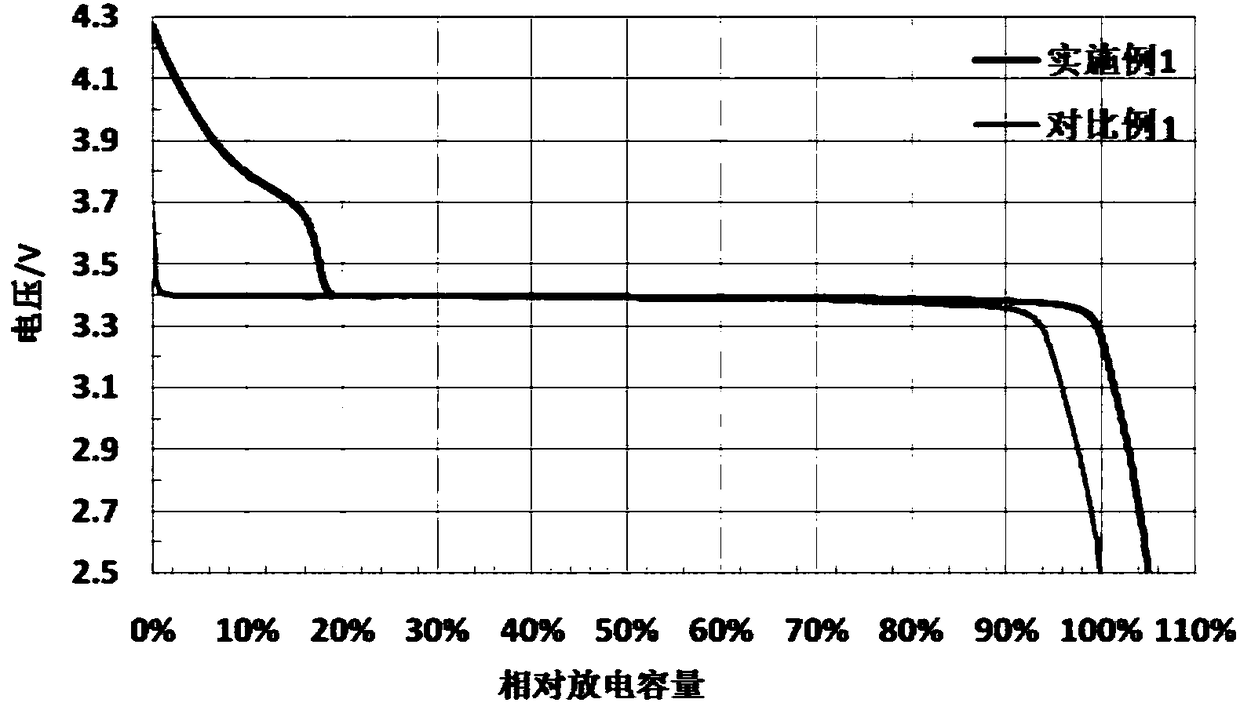

Compound lithium iron phosphate material and preparing method thereof, positive electrode piece and lithium ion battery

InactiveCN108288699AIncrease compaction densityReduce porositySecondary cellsPositive electrodesPorosityLithium iron phosphate

The invention relates to a compound lithium iron phosphate material and a preparing method thereof, a positive electrode piece and a lithium ion battery, and belongs to the technical field of lithiumion batteries. The compound lithium iron phosphate material is prepared from, by mass, 75-85% of lithium iron phosphate, 10-25 parts of nickel cobalt lithium manganate, 1-2% of carbon nano tube and 1-2% of conductive black. The prepared compound lithium iron phosphate material is a high high-energy density compound lithium iron phosphate material, lithium iron phosphate, nickel cobalt lithium manganate, carbon nano tube and conductive black fill one another, the porosity among materials is lowered, and the compaction density of the materials is increased.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG +1

Explosive welding manufacturing method of high-purity niobium-oxygen-free copper composite plate

InactiveCN109604806AGuaranteed SuperconductivityReduce oxygen contentNon-electric welding apparatusNiobiumMechanical stability

The invention discloses an explosive welding manufacturing method of a high-purity niobium-oxygen-free copper composite plate. The method comprises the following steps that a high-purity niobium plateserves as a composite plate, an oxygen-free copper plate is used as a substrate, and high-purity niobium is manufactured in an explosive welding mode; and the quality purity of the high-purity niobium plate is not less than 99%, the thickness of the high-purity niobium plate is not larger than 2 mm, the oxygen content in the oxygen-free copper plate is less than 2 ppm, and the thickness of the oxygen-free copper plate is larger than 10 mm. According to the method, the composite surface of the high-purity niobium plate and the oxygen-free copper plate are subjected to high-speed collision through explosion welding to form a solid-phase metallurgical bonding to be combined, the defect that the oxidation of the high-purity niobium plate and oxygen absorption of the oxygen-free copper plate in the heating rolling process are avoided, the problem that the high-purity plates with relatively large elongation rates are difficult to cold rolling and rolling is solved, and the excellent superconducting performance of the high-purity niobium material is kept, and meanwhile, the thickness of a superconducting cavity is increased by the oxygen-free copper plate, and thus the mechanical stability of the superconducting cavity is enhanced.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH +1

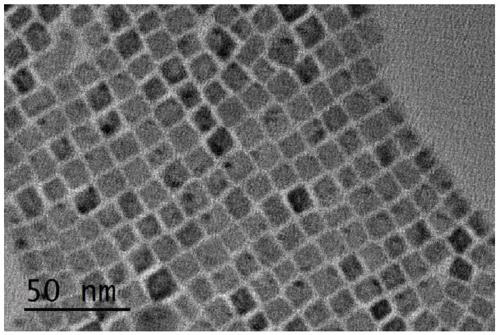

Perovskite quantum dot ligand and preparation method and application thereof

InactiveCN110041906AGood dispersionAvoid contactOrganic compound preparationLuminescent compositionsSide chainQuaternary ammonium ions

The invention provides a perovskite quantum dot ligand. The ligand is an acrylate-based quaternary ammonium salt ligand, wherein a quaternary ammonium ion is positively charged, and the ligand can becombined with an unstable site on the surface of a quantum dot to improve the stability; on the other hand, an acrylate side chain can be polymerized into a long chain under the action of an initiator, and crosslinked by a crosslinking agent to make the ligand be coated onto the surface of the quantum dot, so that a network-crosslinked polymer structure coated onto the surface of the quantum dot prevents water and oxygen from being in contact with the surface of the quantum dot, and protects the crystal structure of the quantum dot from being destroyed by the water and oxygen in environment, thereby improving the optical stability; secondly, the ligand is fixed onto the surface of the quantum dot, and an adsorption-desorption process of the ligand on the surface of the quantum dot is eliminated, thereby eliminating surface defects caused by the adsorption-desorption process, and improving the optical property and stability of the quantum dot.

Owner:SHENZHEN INSTITUTE OF INFORMATION TECHNOLOGY

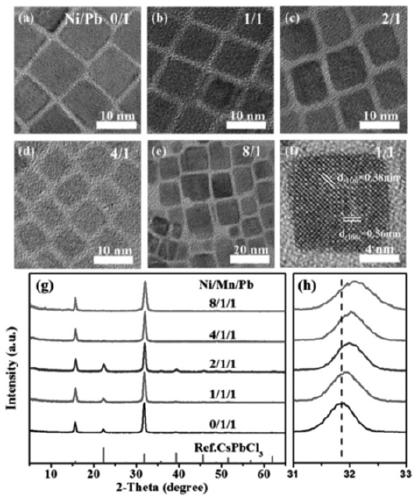

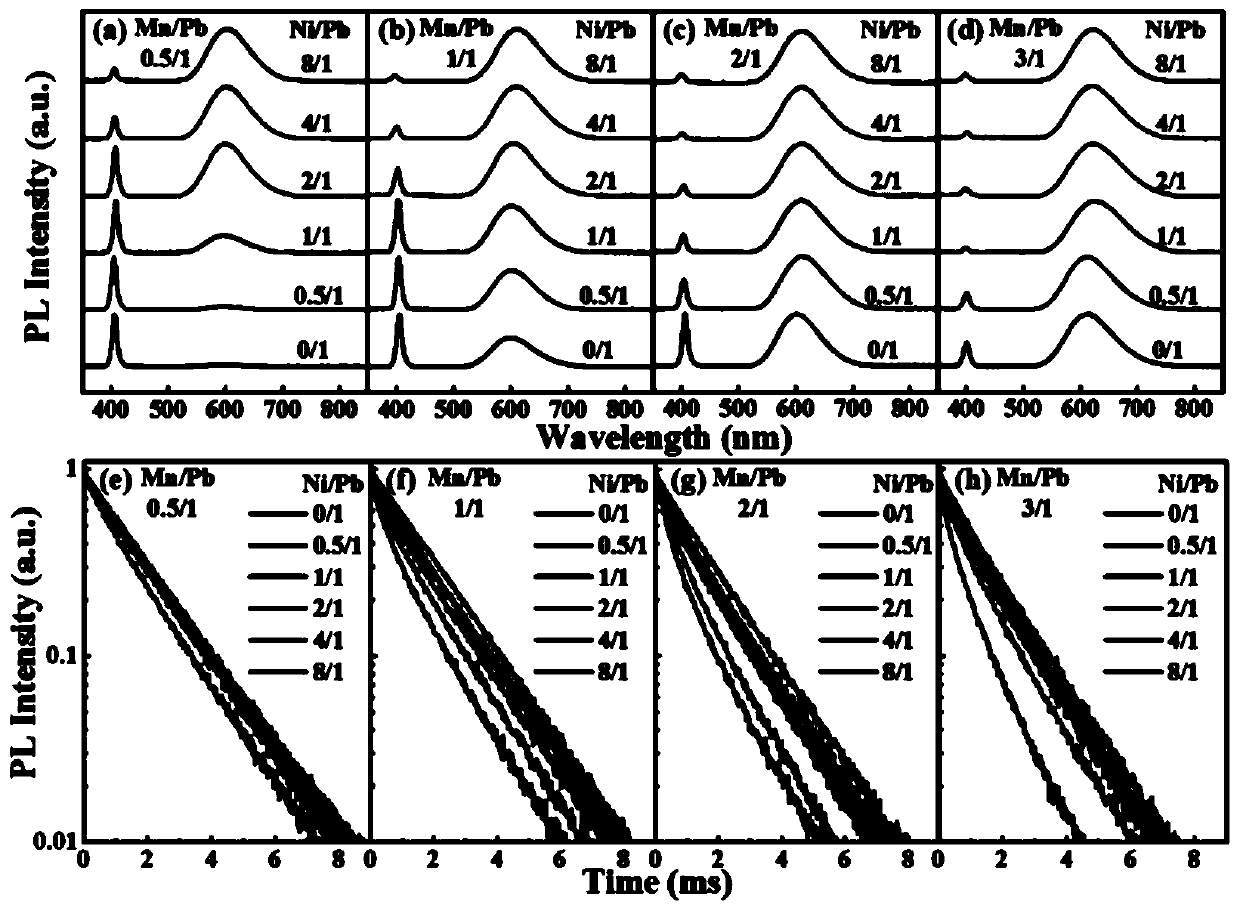

Method for increasing manganese doping concentration and light emission efficiency of manganese-doped CsPbCl3 nanocrystal

ActiveCN110218561AImprove luminous efficiencyIncrease the doping concentrationMaterial nanotechnologyNanoopticsTrioctylphosphineCrystallinity

The invention relates to the technical field of CsPbCl3 nanocrystal material preparation and in particular to a method for increasing the manganese doping concentration and the light emission efficiency of a manganese-doped CsPbCl3 nanocrystal. The method comprises the following steps: preparing a caesium precursor solution; mixing octadecene, oleic acid, oleylamine, tri-n-octylphosphine, lead chloride, lead chloride, manganese chloride and nickel chloride; and forming a Ni-Mn double-doped CsPbCl3 nanocrystal, so as to obtain a Ni-Mn double-doped CsPbCl3 nanocrystal solution. By adopting the method, by adding NiCl2, the crystallinity and the surface defect state of a Mn-doped CsPbCl3 nanocrystal can be improved, the doping concentration of Mn in the manganese-doped CsPbCl3 nanocrystal canbe increased, and the light emission efficiency of the manganese-doped CsPbCl3 nanocrystal can be improved.

Owner:JILIN NORMAL UNIV

TEM Sample Preparation

ActiveUS20140217283A1Eliminate surface defectsReliable and robust preparationMaterial analysis using wave/particle radiationSamplingThinningImproved method

An improved method of preparing ultra-thin TEM samples that combines backside thinning with an additional cleaning step to remove surface defects on the FIB-facing substrate surface. This additional step results in the creation of a cleaned, uniform “hardmask” that controls the ultimate results of the sample thinning, and allows for reliable and robust preparation of samples having thicknesses down to the 10 nm range.

Owner:FEI CO

High-strength and high-plasticity hollow aluminum profile and preparation method thereof

InactiveCN110453111AAvoid overheatingImprove mechanical propertiesAnodisationElectrophoretic coatingsMechanical propertyToughness

The invention discloses a high-strength and high-plasticity hollow aluminum profile and a preparation method thereof, and belongs to the field of aluminum profile preparation. The high-strength and high-plasticity hollow aluminum profile comprises the following raw materials of, in percentage by weight (wt%), 2.0-4.0 of Mg, 2.0-4.0 of Cu, 0.4-0.8 of Si, 0.4-1.0 of Gu, 0.8-1.0 of As, 0.2-0.6 of Ti,0.4-1.0 of Mn, 1.0-3.0 of Fe, 0.4-0.6 of Cr, 0.4-0.6 of Zn, 0.6-0.8 of Li, and the balance aluminum and inevitable impurities. By controlling the content of elements in aluminum alloy components, strengthening phases such as Al2Cu, Al2CuMg, Mg2Si and MgZn2 are formed in an aluminum alloy, the strengthening phases act synergistically, so that the effects of deoxidizing and refining grains are achieved, the obvious strengthening effect on the aluminum profile is achieved, the cracking sensitivity of a material is effectively reduced, the mechanical properties such as plasticity, toughness and fatigue resistance of the aluminum profile and the good machining performance are improved, and the performance requirement of the aluminum profile for alternate transportation can be met.

Owner:ANHUI XIN FA ALUMINUM PROD

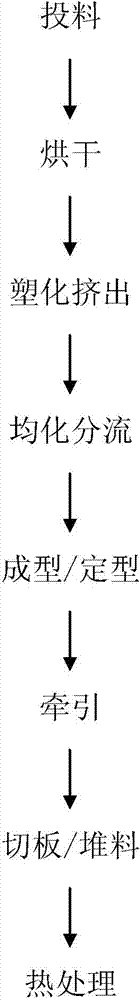

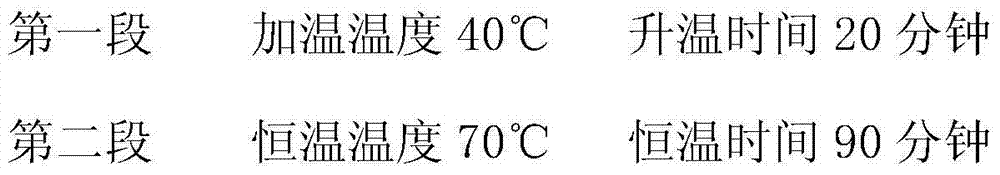

PPS plastic rod production device and production method

The invention discloses a PPS plastic rod production device and a production method. The PPS plastic rod production device comprises a main machine and an auxiliary machine; the main machine is an extruder comprising an extrusion system, a rotating system, and a controlling system; the extrusion system is a gun barrel screw; the rotating system comprises a motor and a reduction box; the controlling system comprises electrical instruments and an executing mechanism; the auxiliary machine comprises a mould, a tractor, an oil temperature machine, a cutting machine, and a baking box; the mould comprises a main mould, a flow deflector, a thermal insulation gasket, a moulding shaping barrel, and a cooling water tank; the oil temperature machine is arranged on a setting segment of a moulding pipe; the tractor comprises a transmission device, a roller compressing device, and a brake device, and is arranged behind a thermal insulation device; the cutting machine is arranged behind a mould outlet; and the baking box is a sealed box. The production method comprises steps of feeding, drying, plastifying extrusion, homogenizing distribution, moulding / setting, traction, plate cutting / stockpiling, and thermal treatment.

Owner:深圳市恩欣龙特种材料股份有限公司

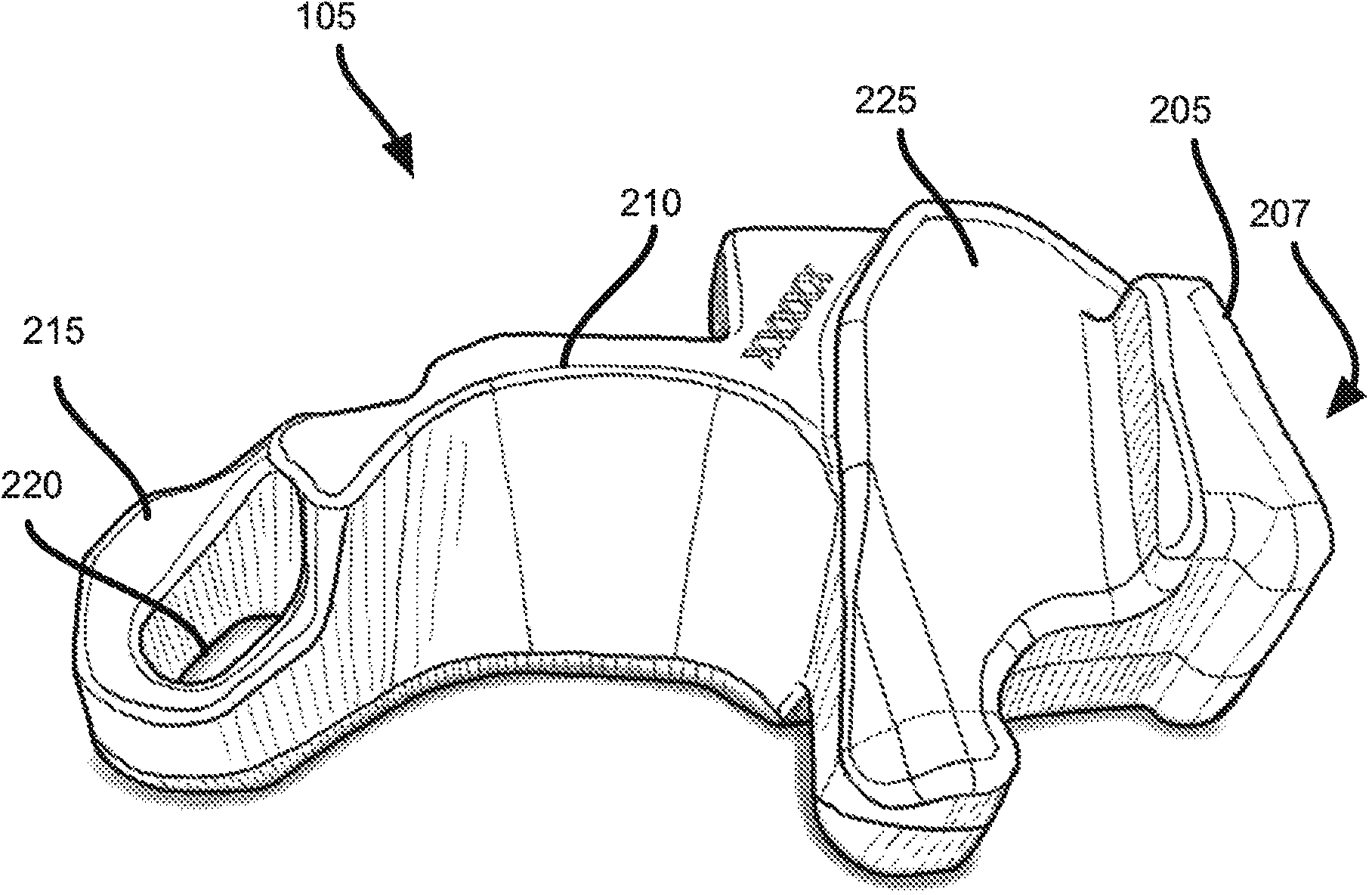

Method and system for manufacturing railcar coupler locks

InactiveCN103492101AEliminate surface defectsSmall sizeFoundry mouldsMoulding machinesCasting moldMechanical engineering

A casting assembly for manufacturing a lock of a railcar coupler includes drag and cope portions of a first mold that defines exterior surfaces of the lock, wherein the first mold comprises a first molding material. The casting assembly also includes a second mold formed of a second molding material. The second mold defines a cavity with an interior surface that substantially complements an exterior surface of the first mold. A down sprue is formed in the second mold. A gating system is formed in the second mold that and is in fluid communication with the down sprue. An in-gate is formed in the second mold and is in fluid communication with the gating system and the first mold.

Owner:BEDLOE IND LLC

Protective layers for optical coatings

InactiveUS20100266823A1Reduce in quantityIncreased durabilityRecord information storageMagnetic recordingOptical coatingOptoelectronics

Owner:CARDINAL CG

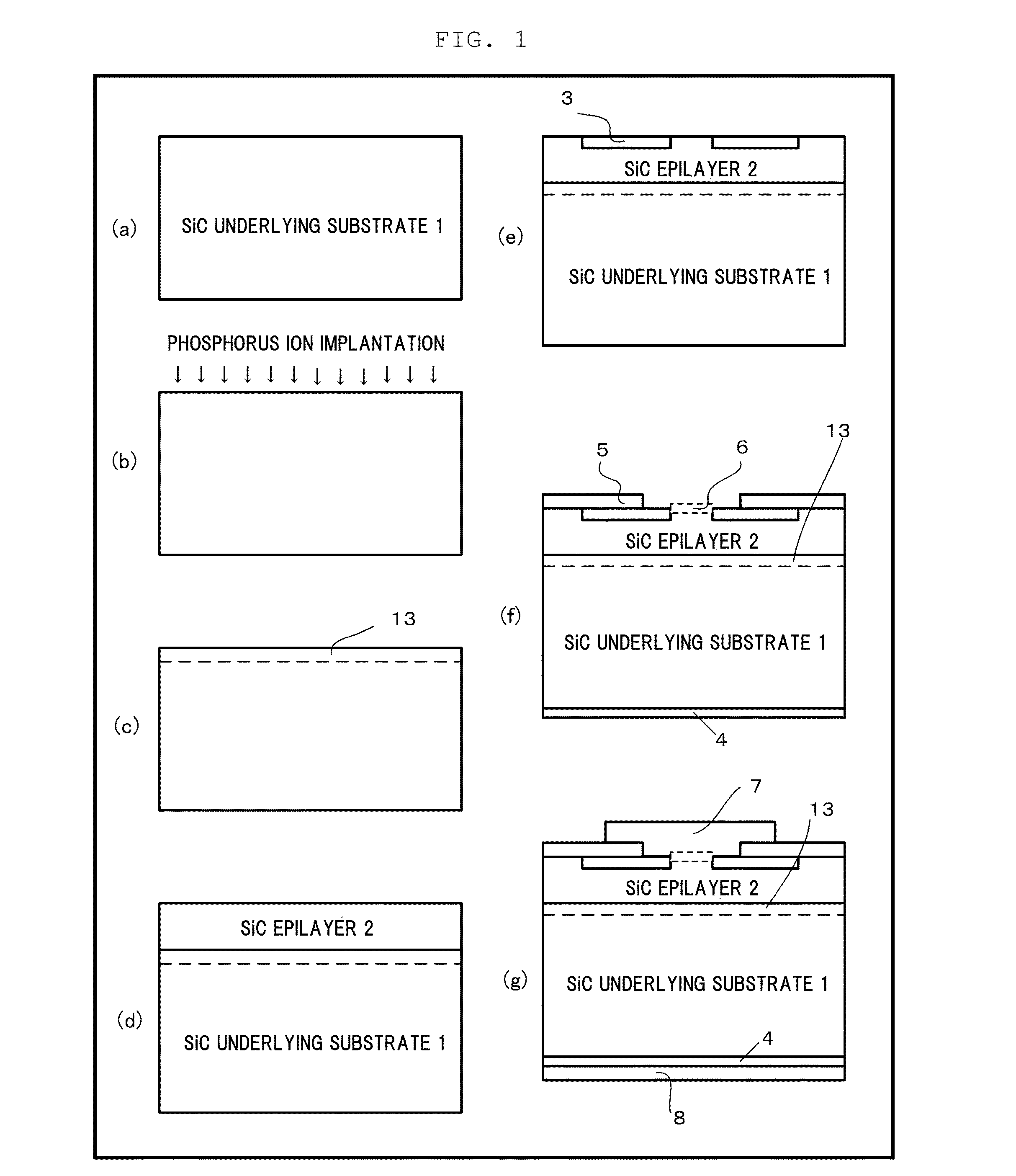

Silicon carbide semiconductor device and manufacturing method for same

InactiveUS20160254148A1Outstanding electrical characteristicEliminate surface defectsSemiconductor/solid-state device manufacturingSemiconductor devicesCarbon filmSurface layer

A method of manufacturing a silicon carbide semiconductor device in which a first-conductivity-type silicon carbide semiconductor epitaxial layer is formed on a main surface of a first-conductivity-type silicon carbide semiconductor substrate, wherein the silicon carbide semiconductor device manufacturing method includes: a step for supplying strain energy to at least one of (i) a surface layer of the surface of the silicon carbide semiconductor substrate on which the silicon carbide semiconductor epitaxial layer is formed, and (ii) the surface of the silicon carbide semiconductor epitaxial layer, a step for forming a carbon film on the surface layer, and a step for forming a recrystallized layer by adding a heat treatment for recrystallizing the surface layer to which the strain energy is supplied.

Owner:FUJI ELECTRIC CO LTD

Bimetal Laminate Structure And Method Of Making The Same

ActiveUS20090269562A1Low costIncreased durabilityAdhesive processesLaminationAdhesiveMetallic materials

The present invention provides a bimetal laminate structure and improved method for manufacturing the same. The method includes: applying a layer of adhesive to a metallic substrate; and laminating a decorative metallic sheet to the metallic substrate in such a manner that substantially all surface defects and all read through appearance along an outer surface of the decorative metallic sheet are eliminated. The resultant bimetal laminate includes a decorative metallic layer consisting of a first metallic material, and a metallic substrate consisting of a second metallic material that is different from the first metallic material. The metal substrate has a thickness that is greater than the thickness of the decorative metallic layer. An adhesive layer is disposed between, and spans substantially the entirety of the decorative metallic layer and metallic substrate to rigidly attach the same.

Owner:MATERIAL SCIENCES CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com