Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

89results about How to "Reduce waviness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

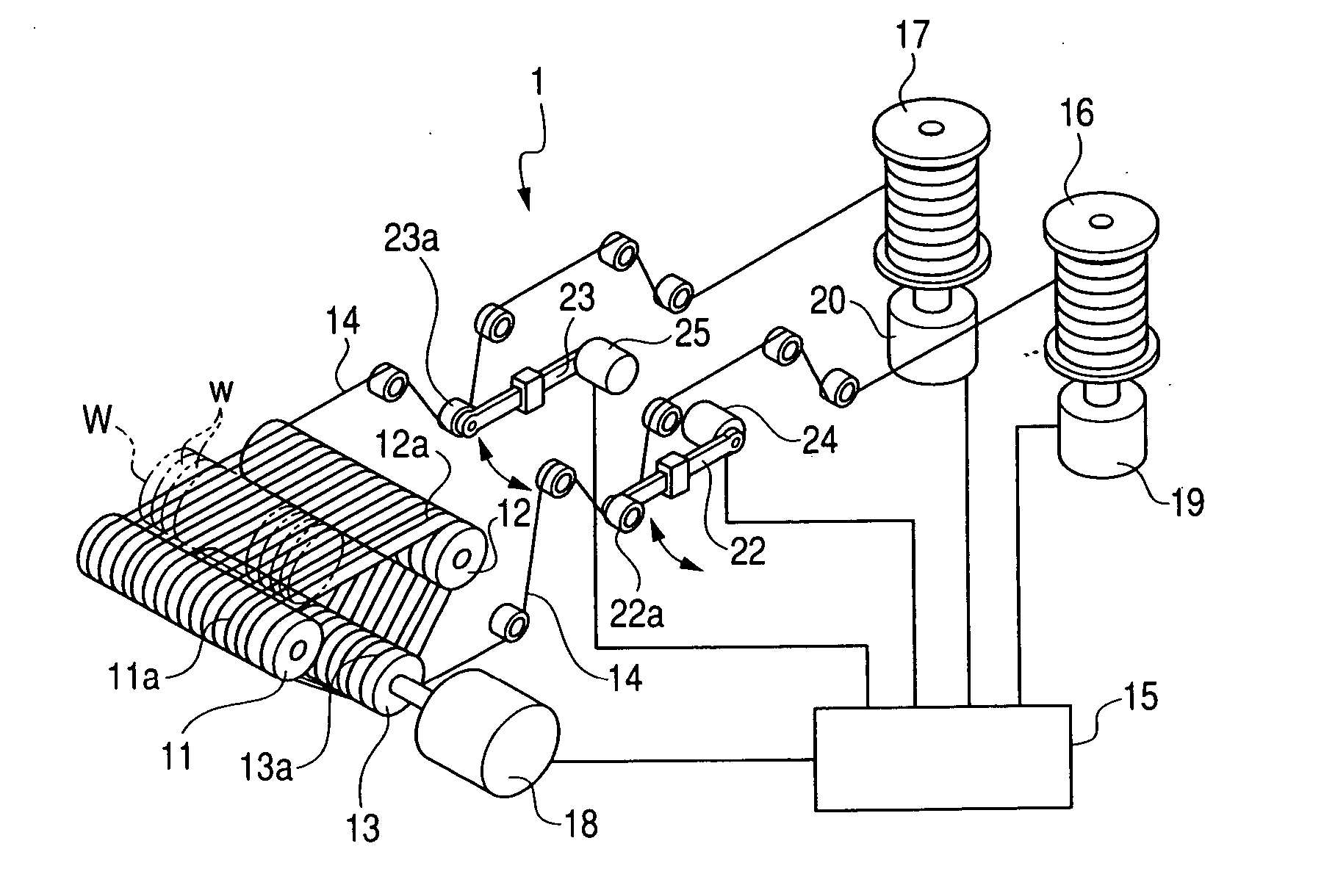

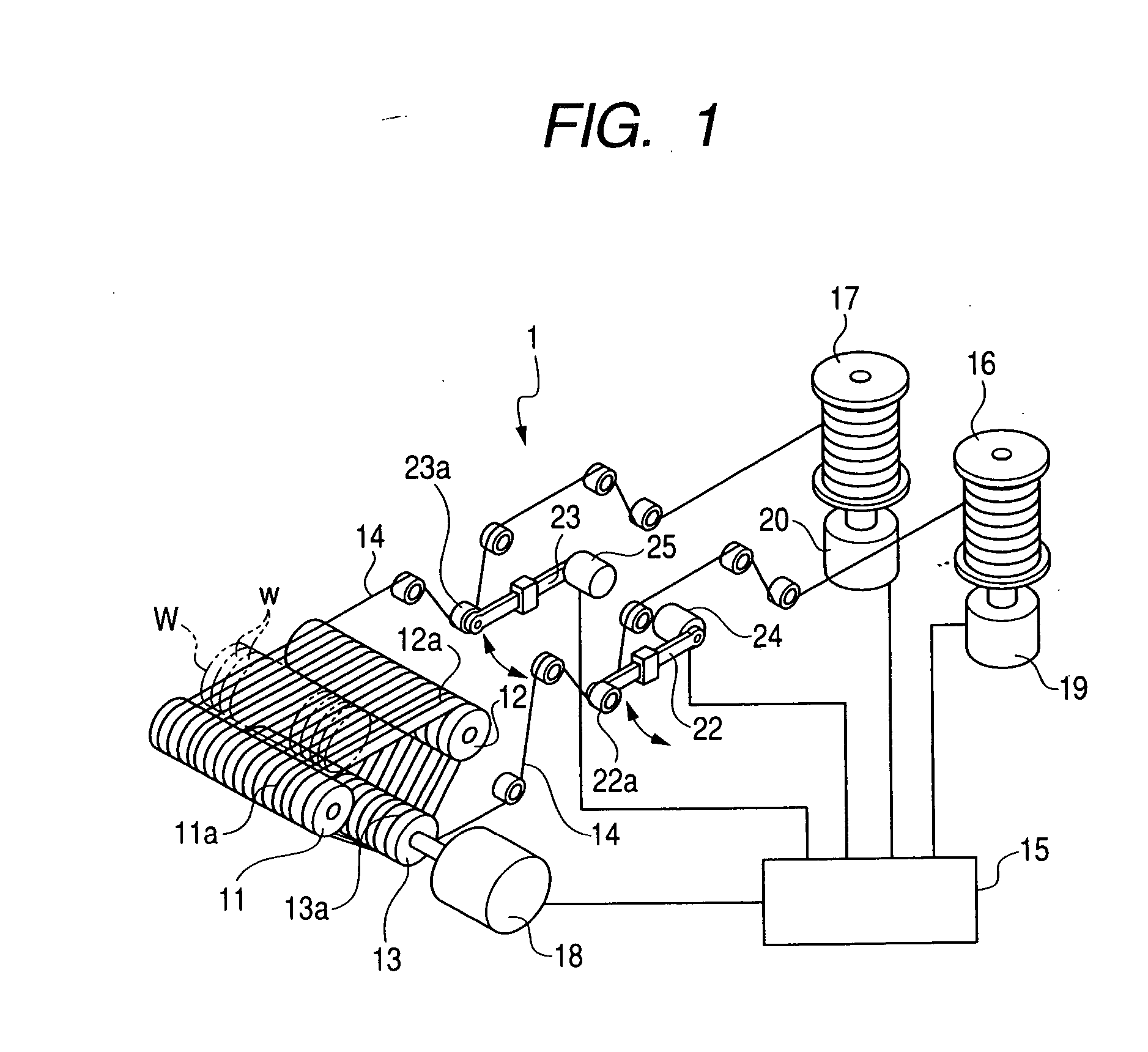

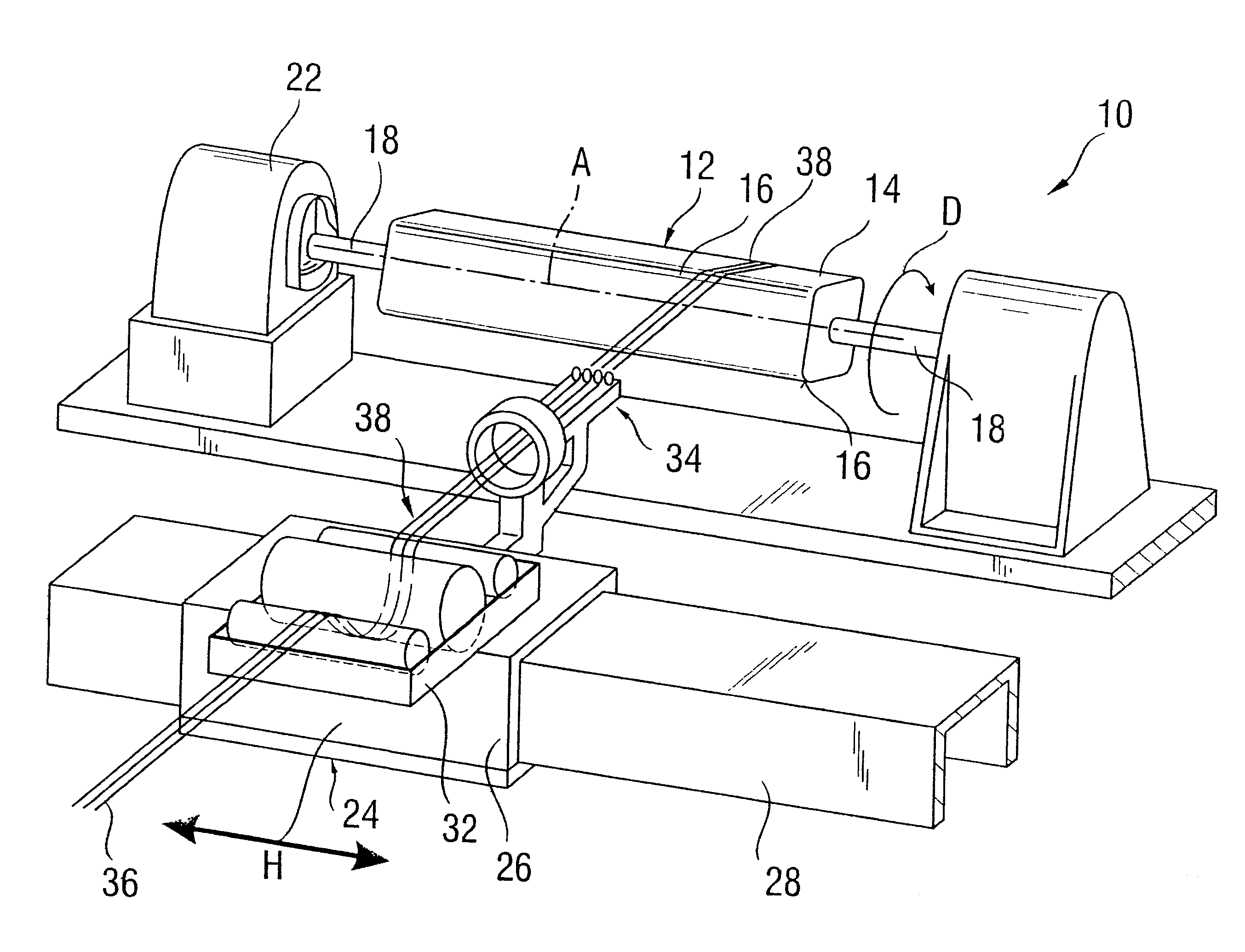

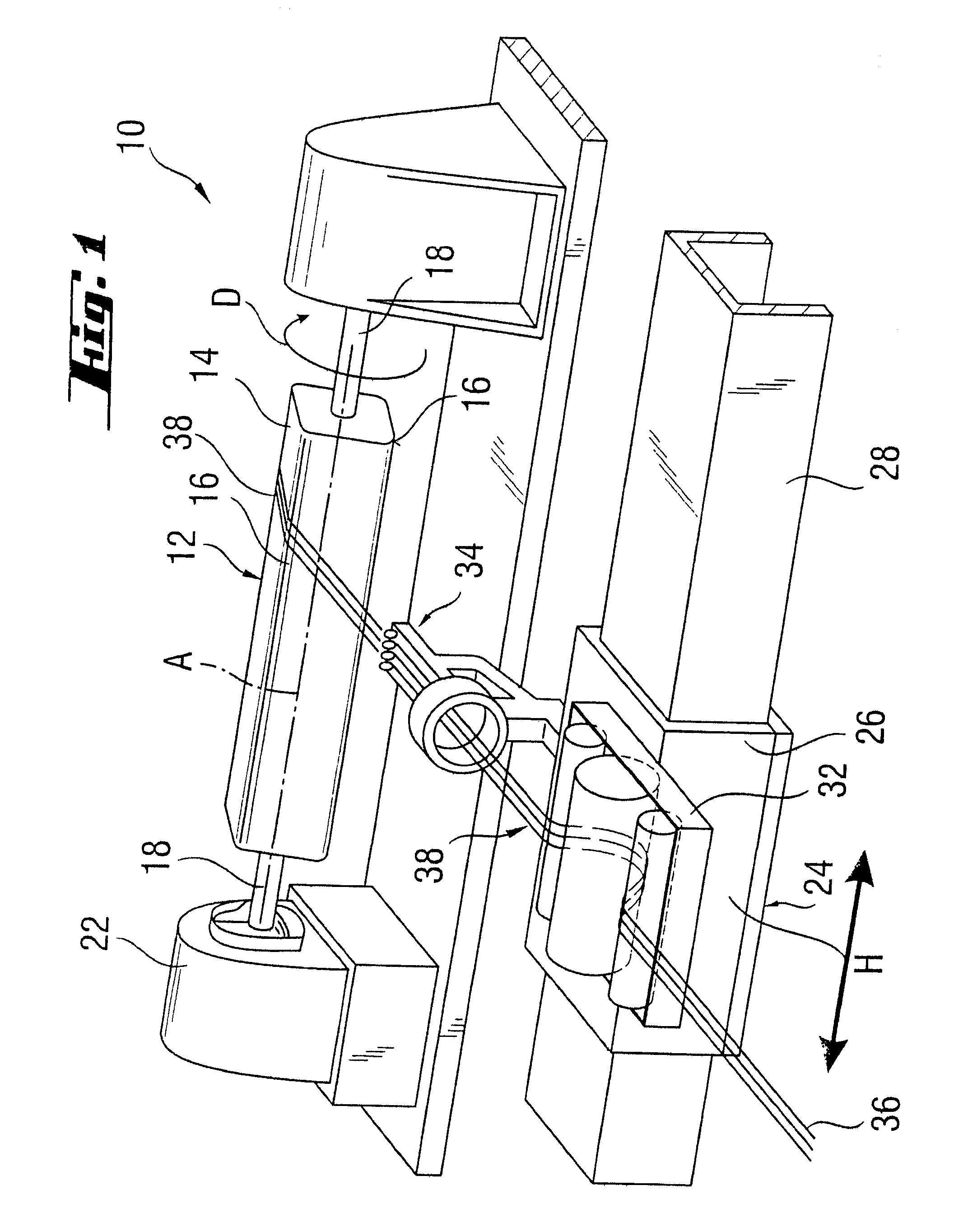

Manufacturing method for semiconductor wafers, slicing method for slicing work and wire saw used for the same

InactiveUS20060258268A1Reduce unevenness of thickness and warpReduce wavinessMetal sawing devicesEdge grinding machinesCompound (substance)Engineering

In order to omit a lapping process or a double disk grinding process by performing slicing operation so as not to generate long period waviness on the surface of the wafer in a slicing process and by completely removing short period waviness remaining in the surface of the sliced wafer during a polishing process, there is provided a manufacturing method includes a slicing process of slicing a work of the semiconductor wafer by reciprocating a wire of a wire saw at constant cycles of 3 or more and less than 8 per a minute a grinding process of grinding both sides of the sliced wafer by a grinding wheel, one-side by one-side and a polishing process of performing a chemical mechanical polishing on both sides of the ground wafer by a fixed abrasive grain polishing cloth, in which an abrasive grain is fixed, and a abrasive containing no abrasive grains.

Owner:KOMATSU NTC LTD +1

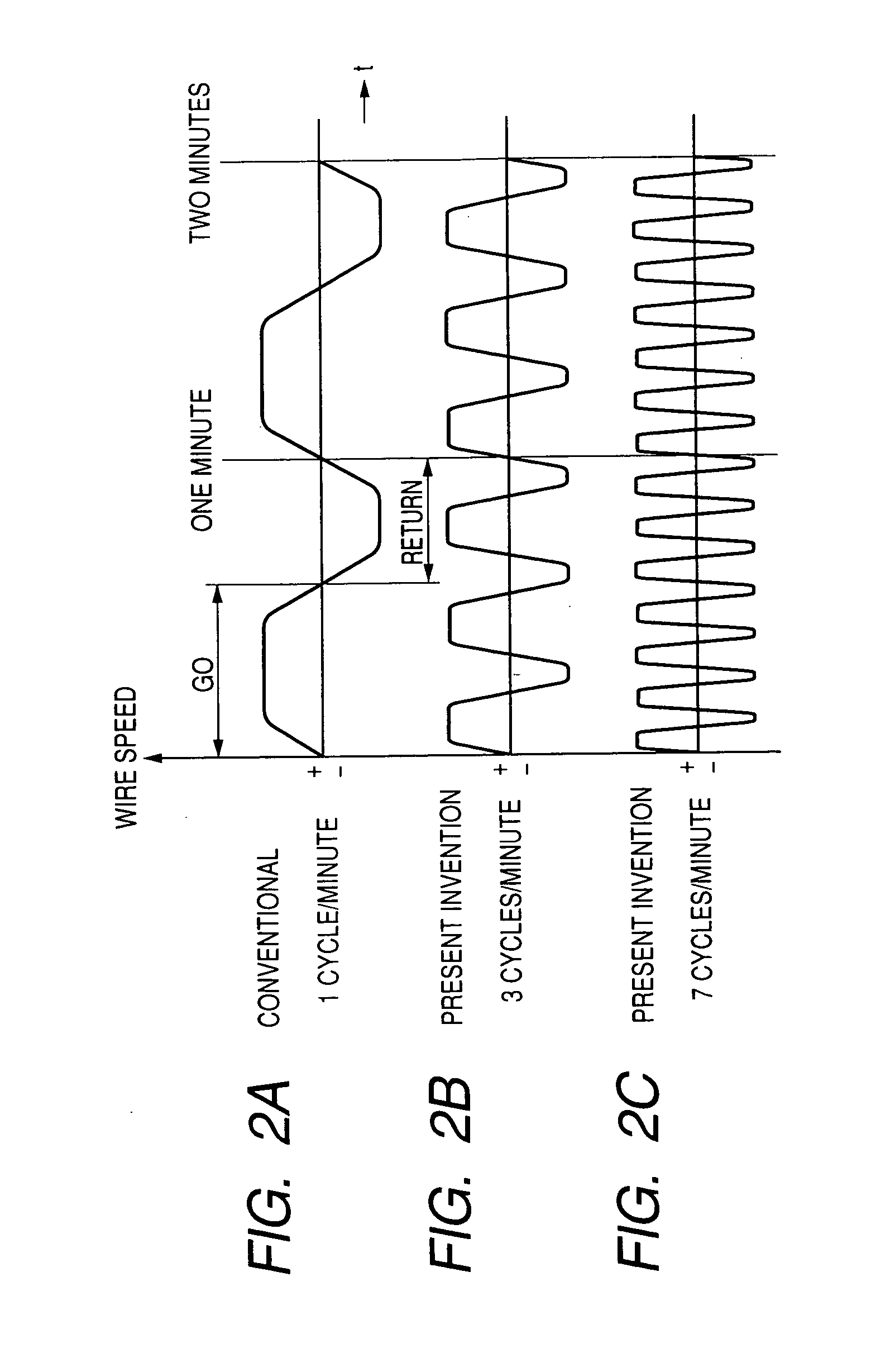

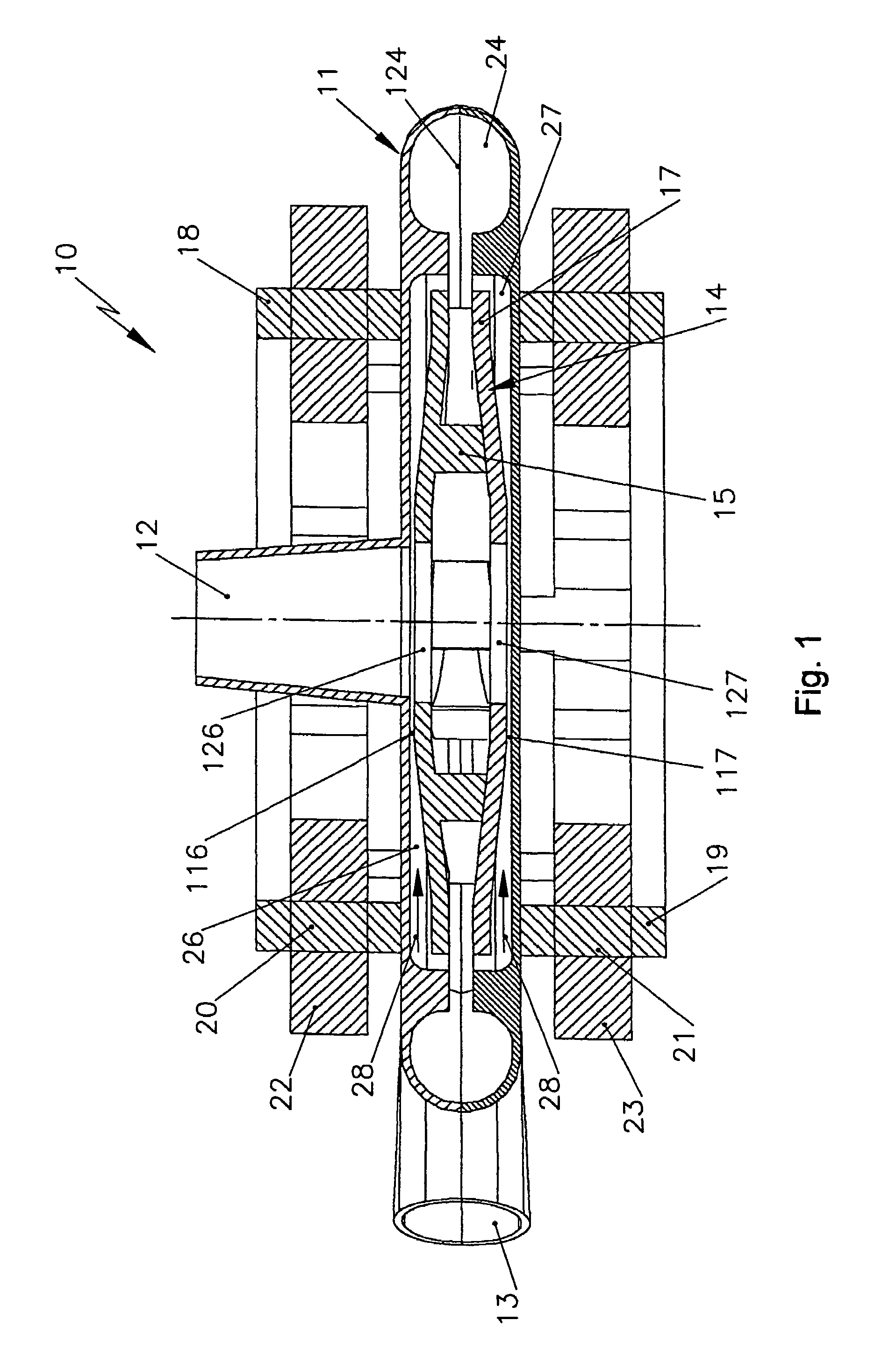

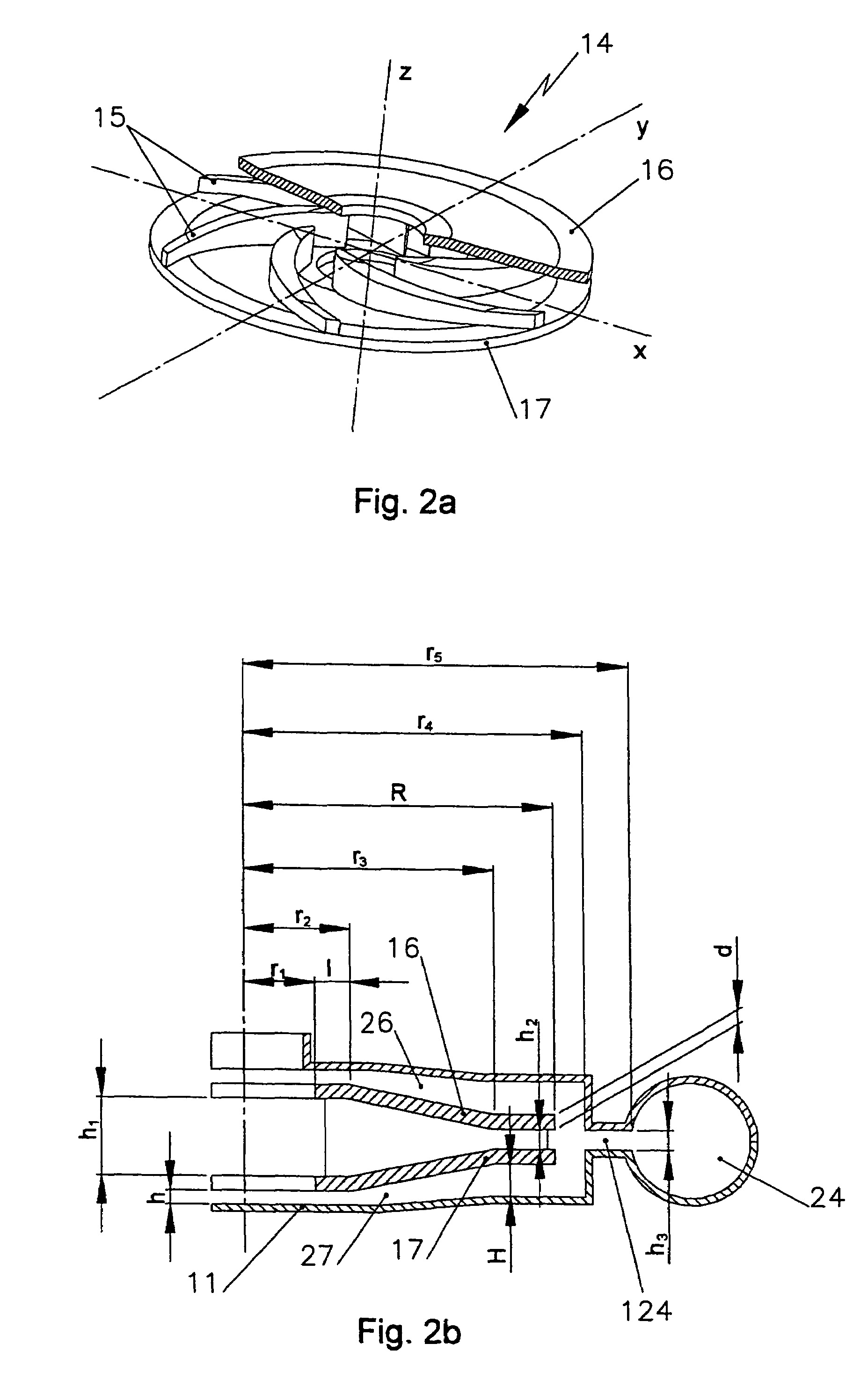

Centrifugal pump

InactiveUS7699588B2Improve efficiencyIncrease the projected areaPump componentsBlood pumpsEngineeringDrive motor

The invention relates to a centrifugal pump, especially for blood, comprising a pump rotor which is arranged in a rotational manner and without a bearing in a liquid-tight and gas-tight closed housing, except for at least one inlet opening and at least one outlet opening. The rotor is also the rotor of a drive motor. The rotor is symmetrical with respect to the centre plane thereof and comprises an upper and a lower covering. The rotor and / or the pump housing are formed in such a way that the axial distances between the upper and the lower coverings and the upper and lower housing walls are smaller in the radially inner region of the rotor than in the radially outer region. In the radially inner region of the rotor, each lateral rotor chamber comprises a flow-restrictor gap which, when in operation, influences back flows oriented in a radially inward manner in the lateral rotor chambers, such that during an axial deflection of the rotor above and below the rotor, various pressure distributions appear, enabling forces acting upon the predominant surface of the coverings to be produced, the forces bringing about an axial stabilisation of the rotor and acting, in the same manner, against tilting of the rotor inside the housing.

Owner:JOSTRA AG

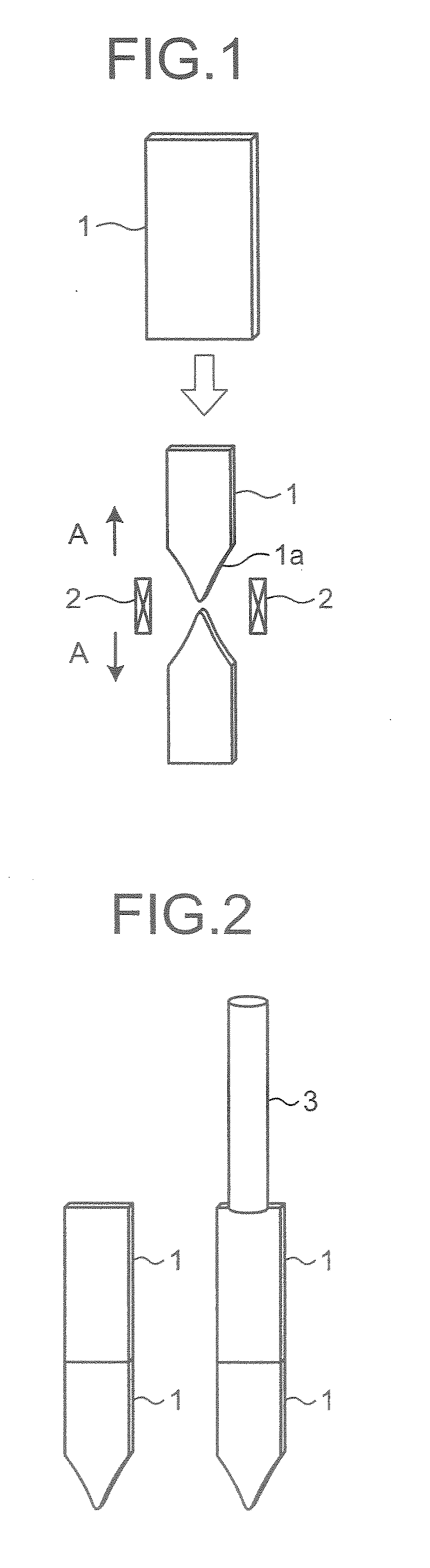

Process for Producing Glass Strip, Glass Strip and Glass Substrate

InactiveUS20070271957A1Improve flatnessReduce adhesionSynthetic resin layered productsGlass reforming apparatusInternal pressureSurface roughness

A manufacturing method of a glass strip, the method including a heating and drawing process of heating and softening a glass plate preform (1), drawing the glass plate preform to have a desired thickness and forming a glass strip (11), wherein at the heating and drawing process the glass plate preform (1) is drawn so that an internal pressure of a heating furnace (3) is kept positive relative to an atmospheric pressure and so that gas flows introduced to both surfaces of the glass plate preform (1) respectively are equal to each other within the heating furnace (3). It is possible to improve a surface roughness and obtain a desired surface roughness.

Owner:FURUKAWA ELECTRIC CO LTD

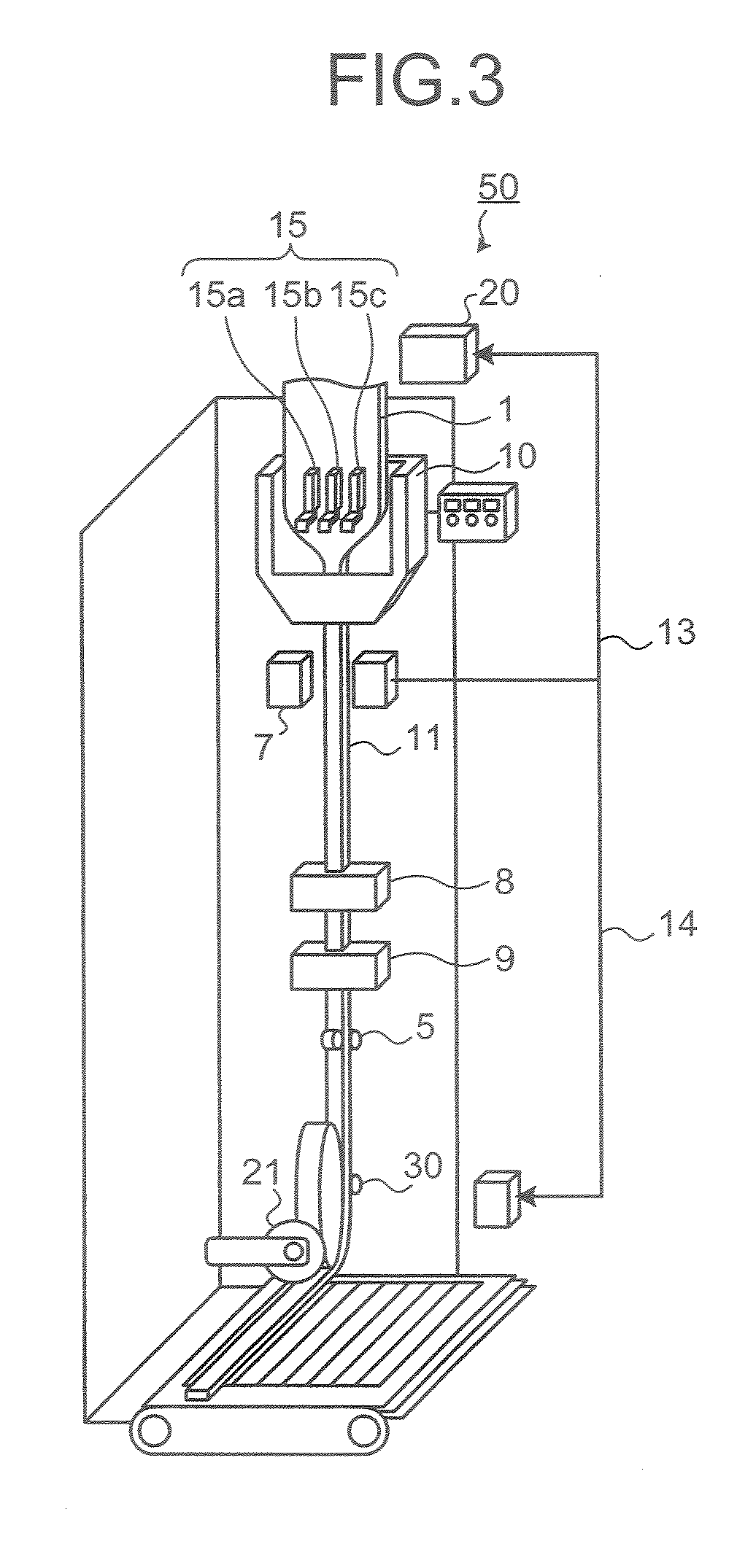

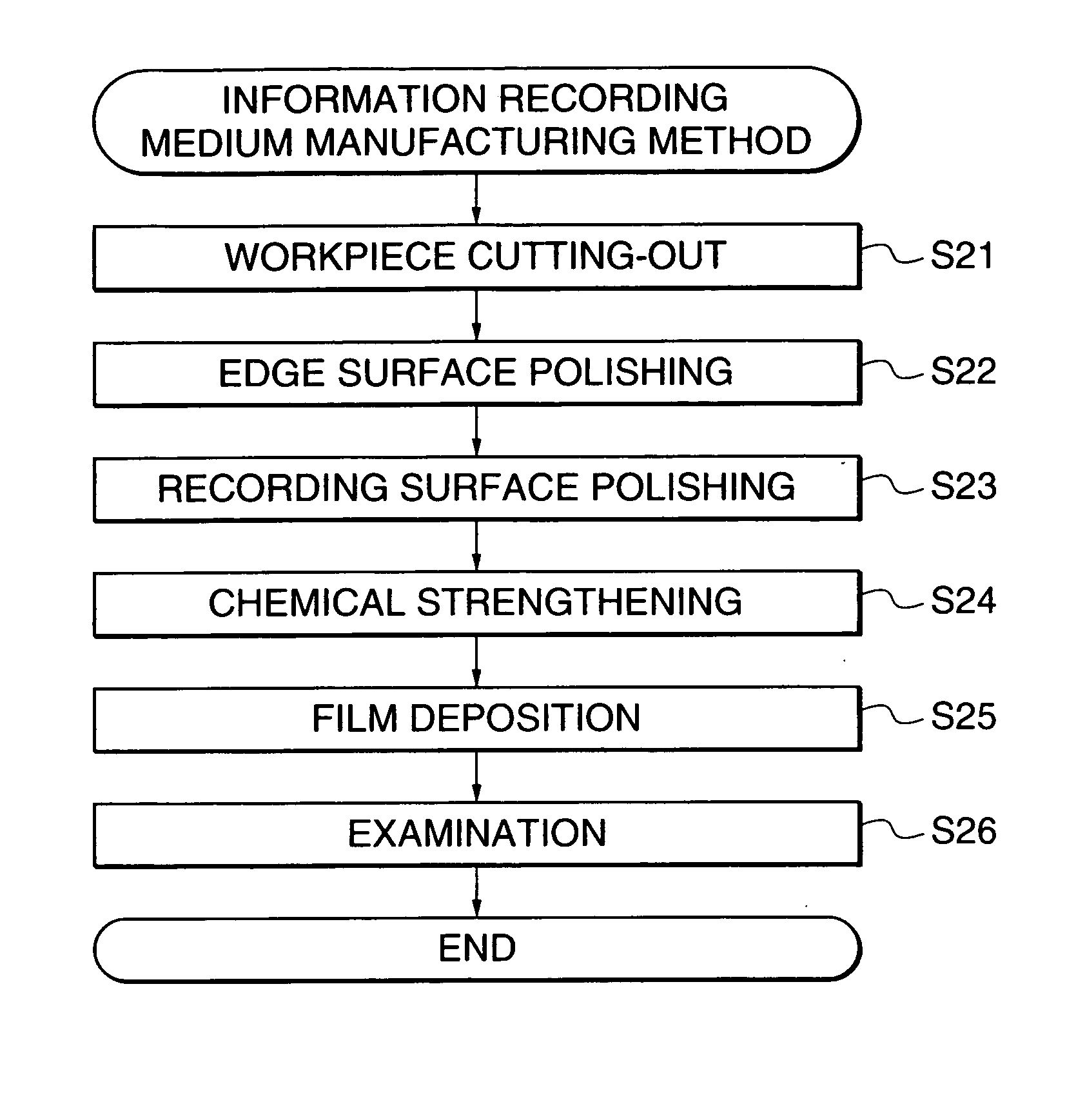

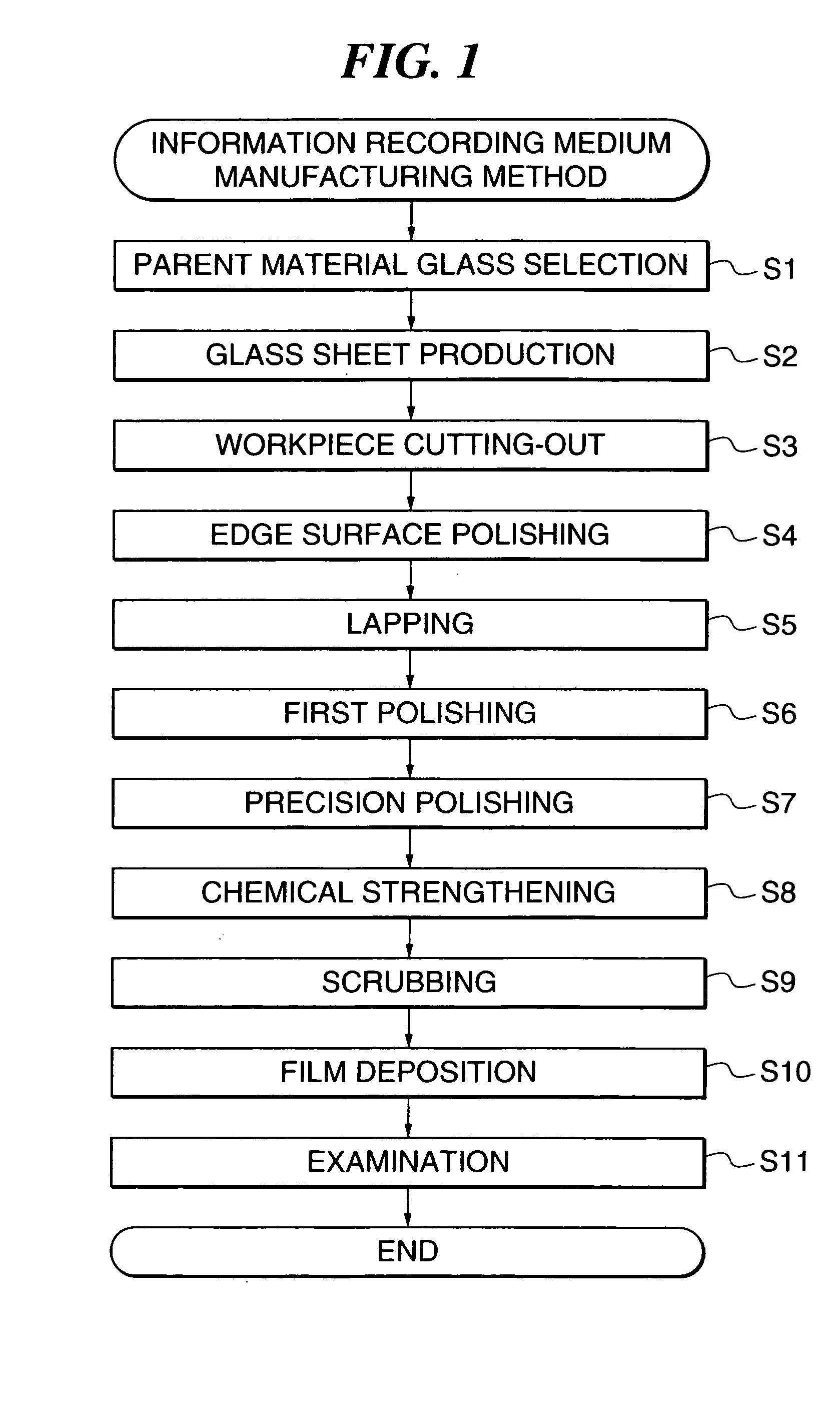

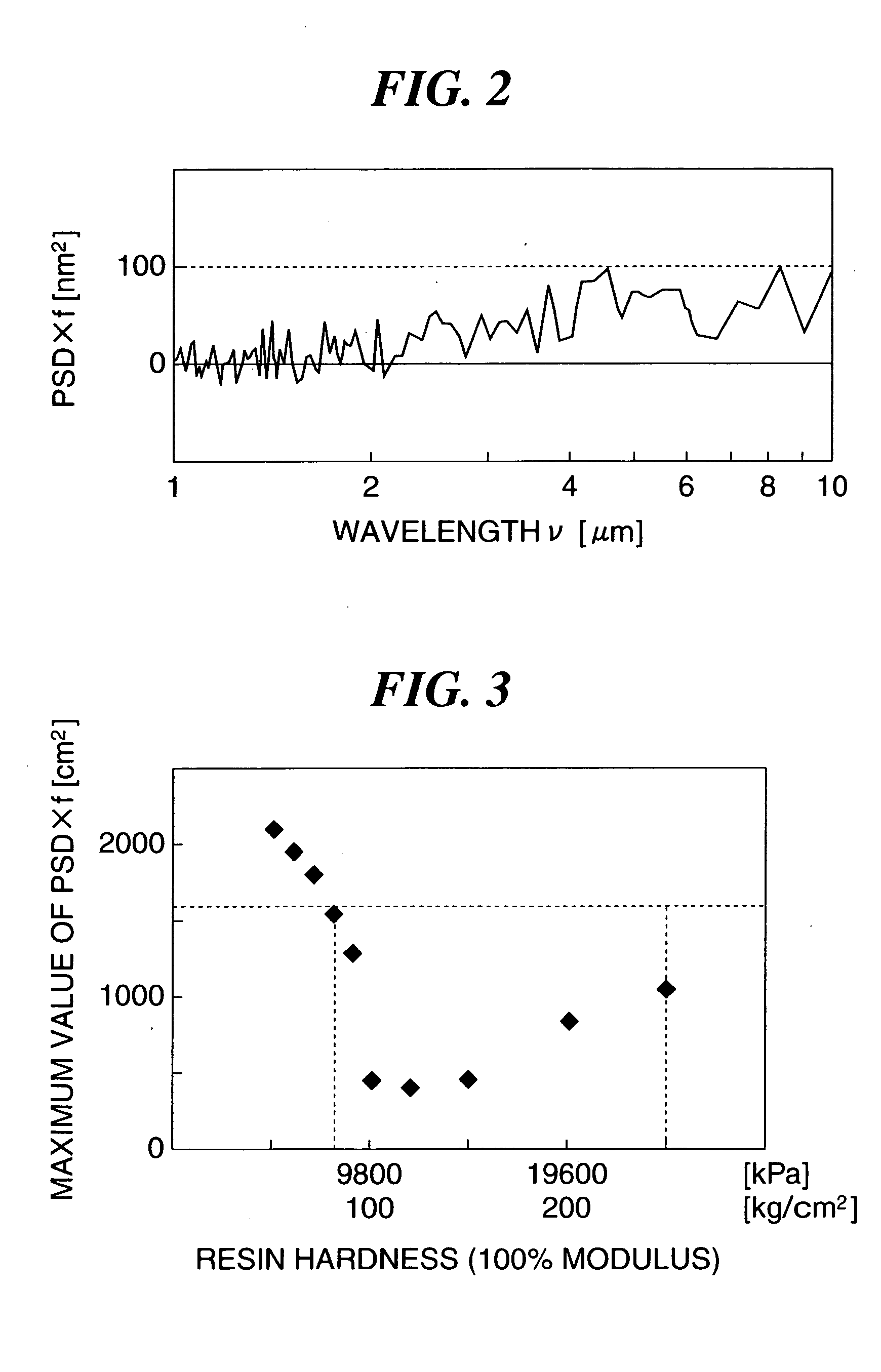

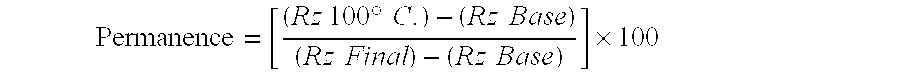

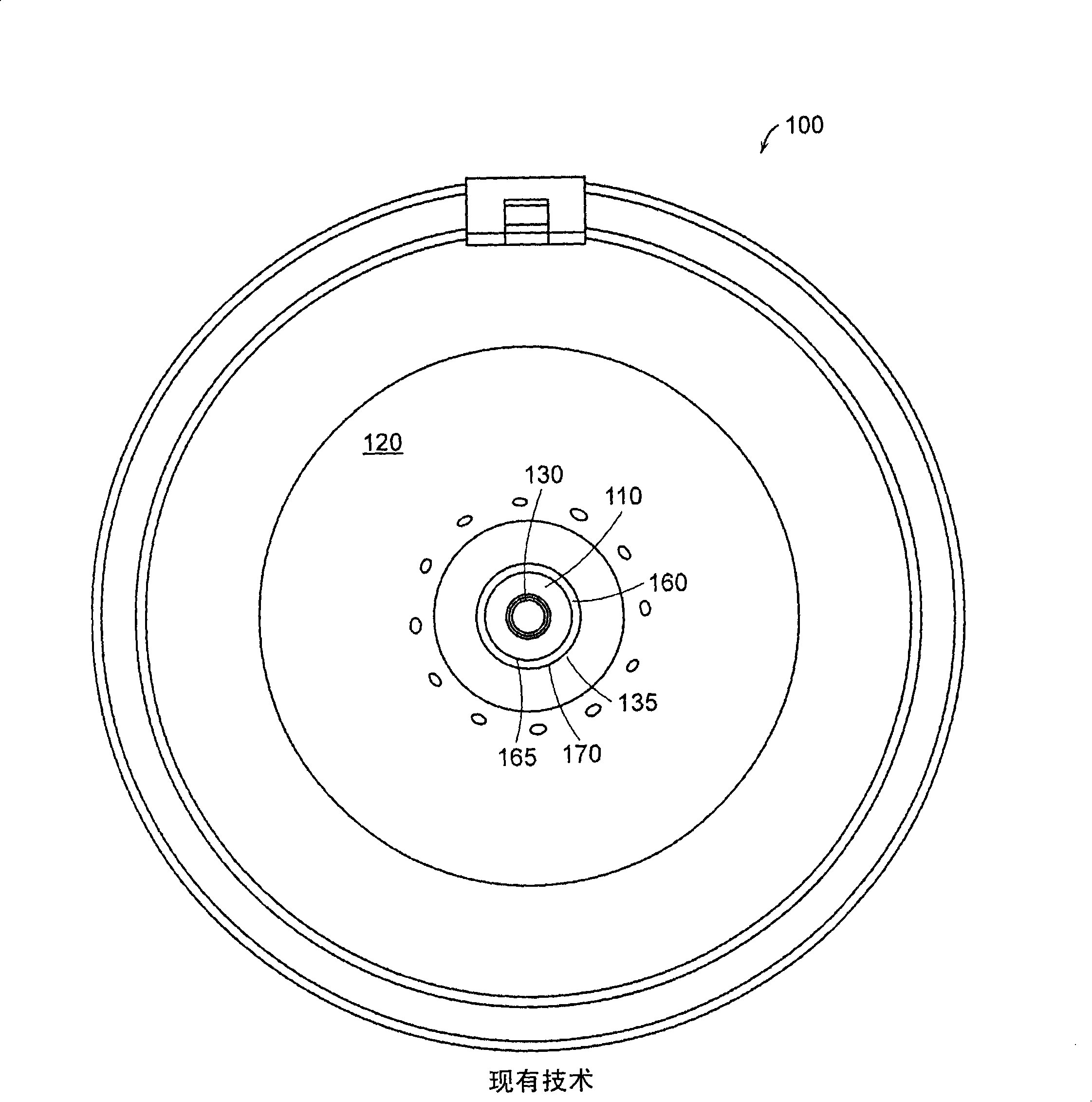

Information recording medium and method of manufacturing glass substrate for the information recording medium, and glass substrate for the information recording medium, manufactured using the method

InactiveUS20050074635A1Reduce wavinessStable flightCombination recordingMagnetic materials for record carriersEngineeringLength wave

There is provided an information recording medium and a method of manufacturing a glass substrate for information recording media as well as a glass substrate manufactured using the method, according to which the take-off height (TOH) of a HDD for example can be made low. The surface shape in a predetermined region of an information recording medium is measured using an optical interferometer or an atomic force microscope. The measured surface shaped is subjected to line analysis along the circumferential direction of the information recording medium. A calculation is made of the product PSD×f of PSD corresponding to a predetermined wavelength ν and the reciprocal of the predetermined wavelength ν. The maximum value of the calculated PSD is controlled to not more than a predetermined value. As a result, the TOH can be made low by reducing waviness which hinders the magnetic head of a HDD or the like from stably flying.

Owner:HOYA CORP

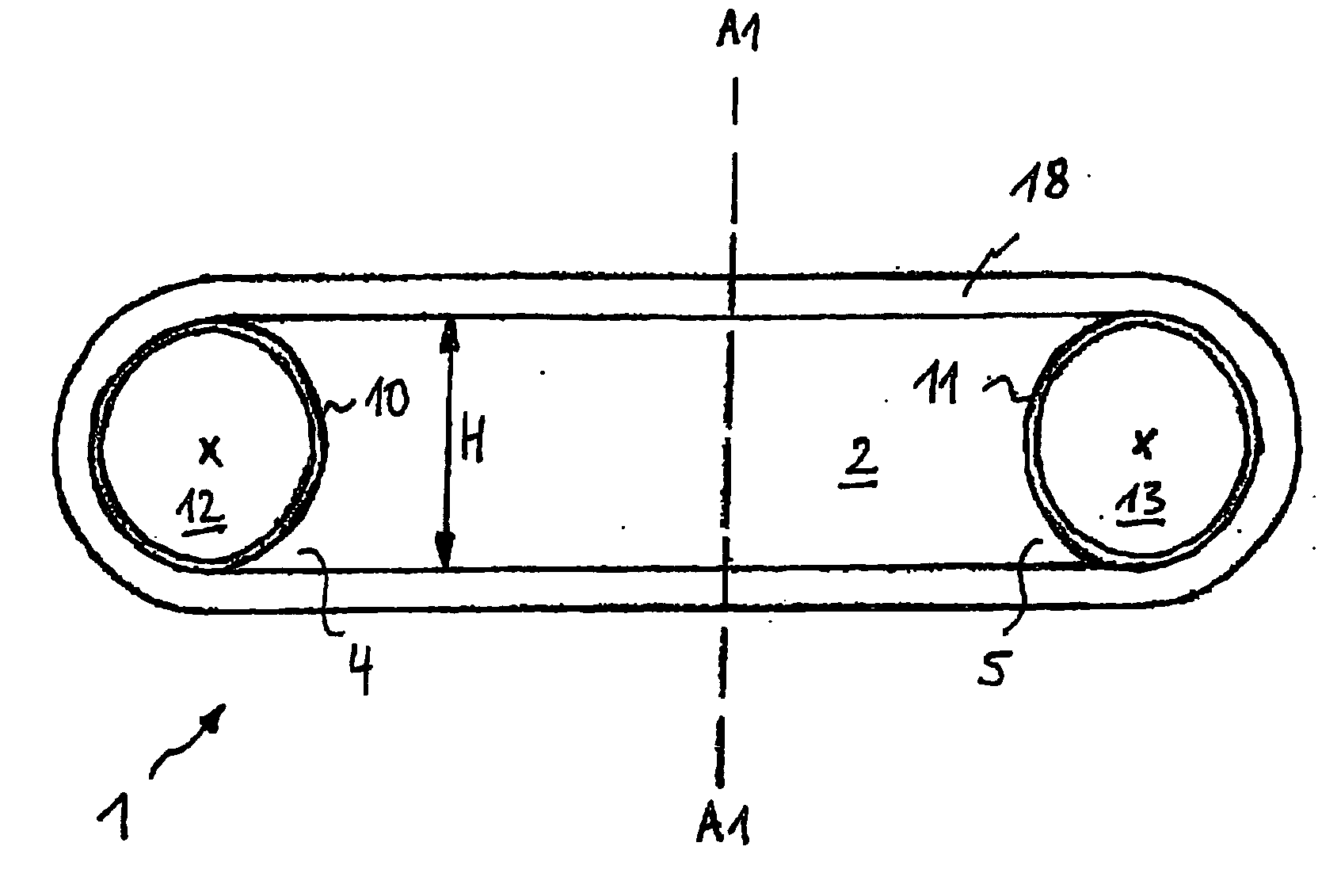

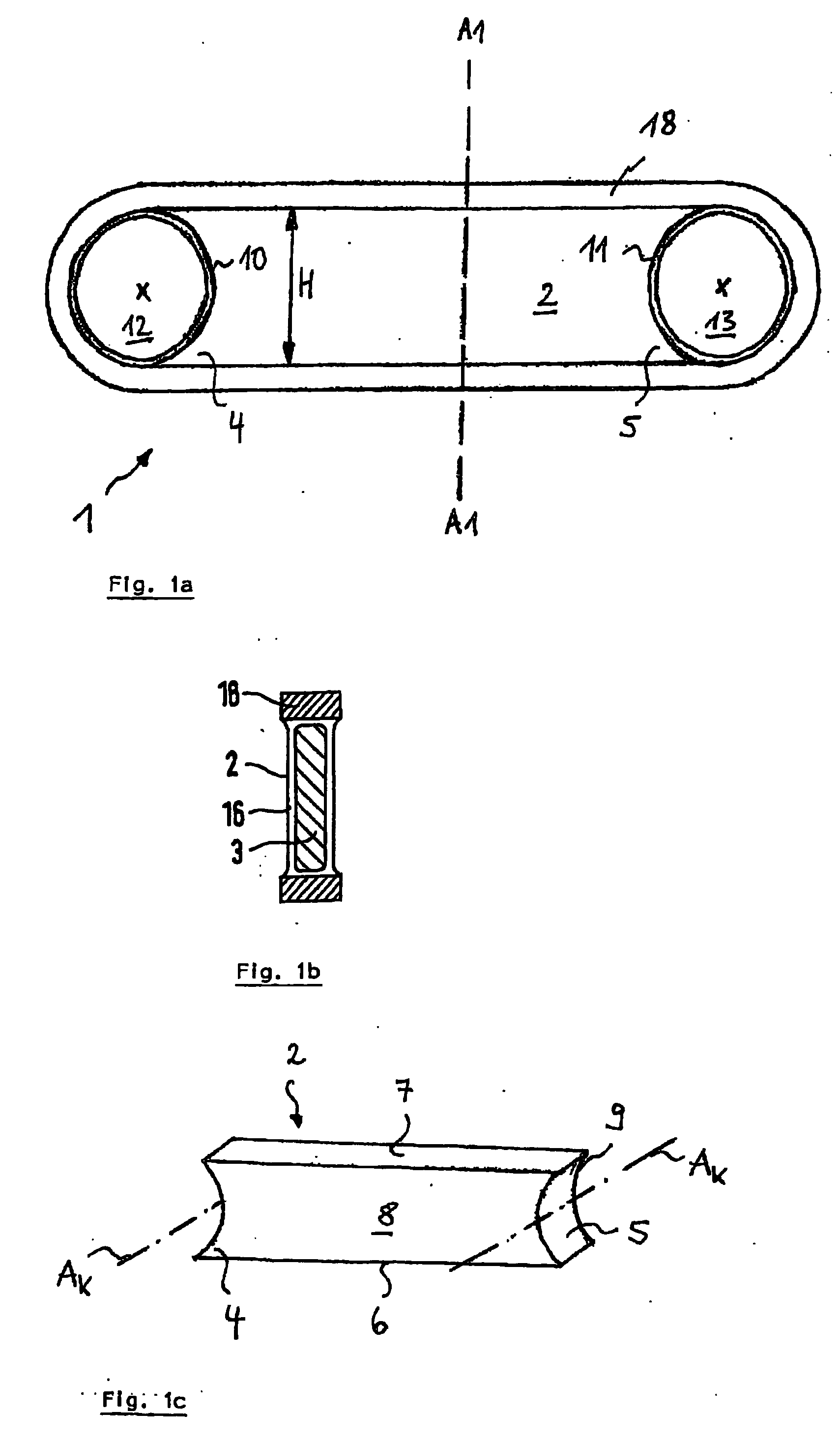

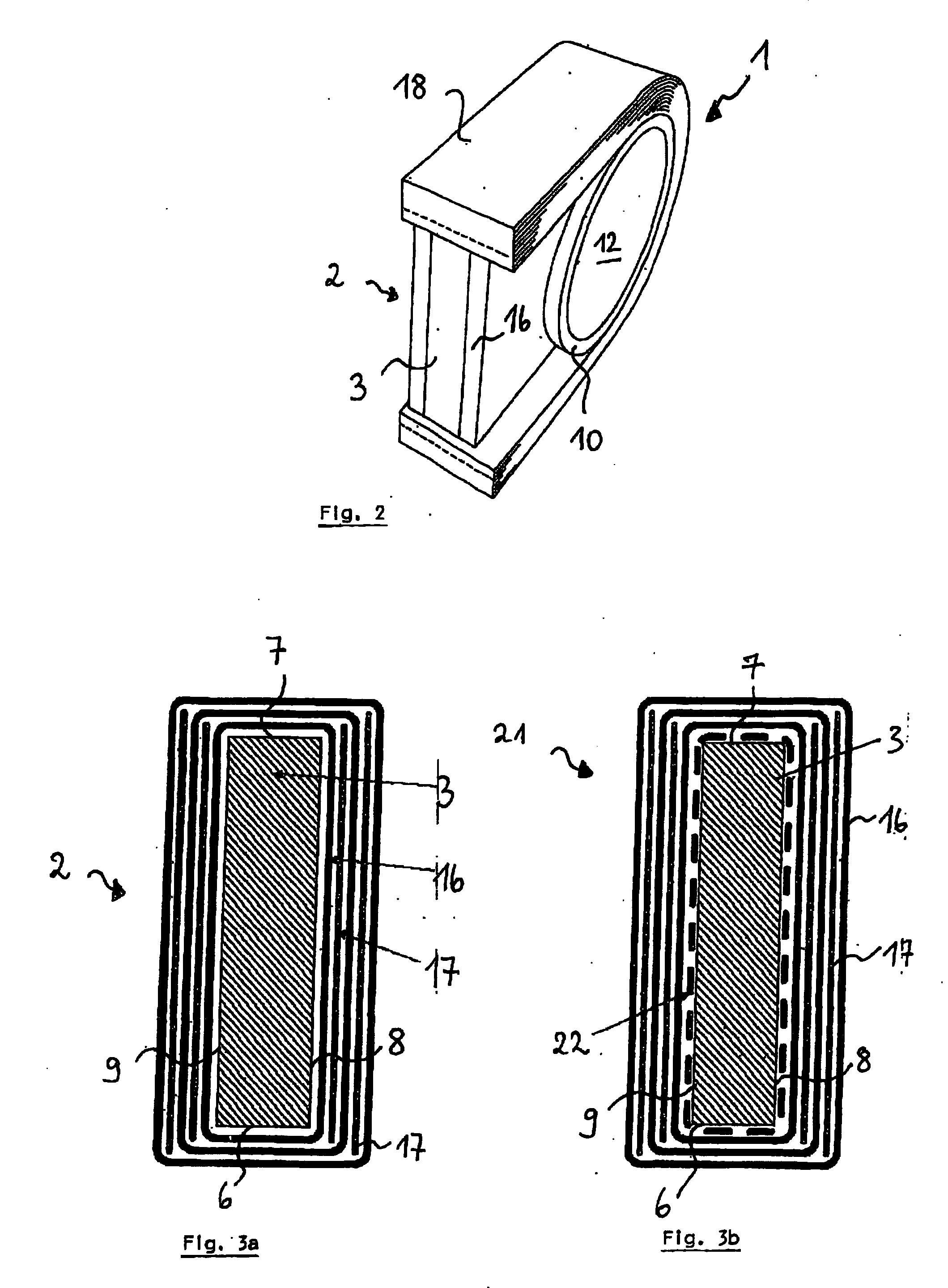

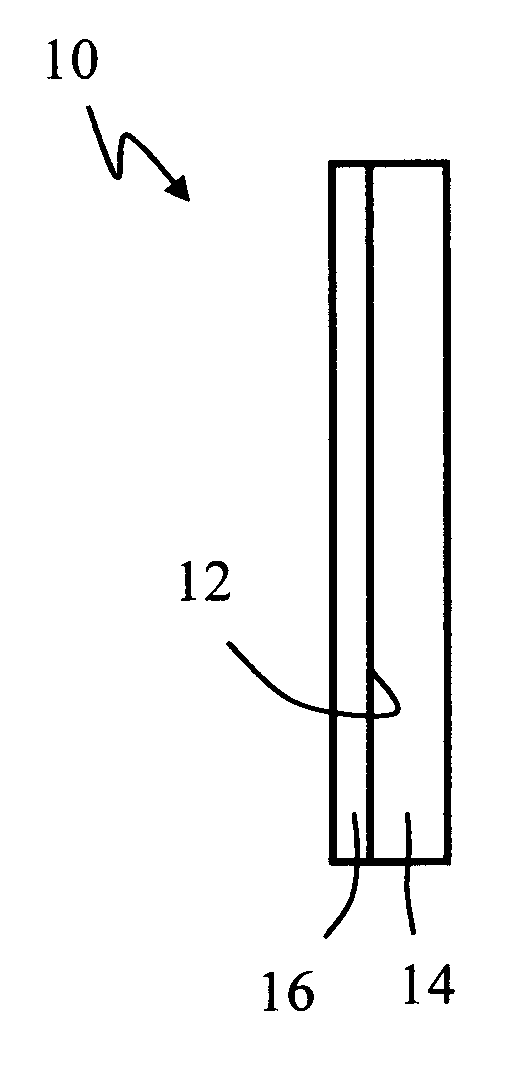

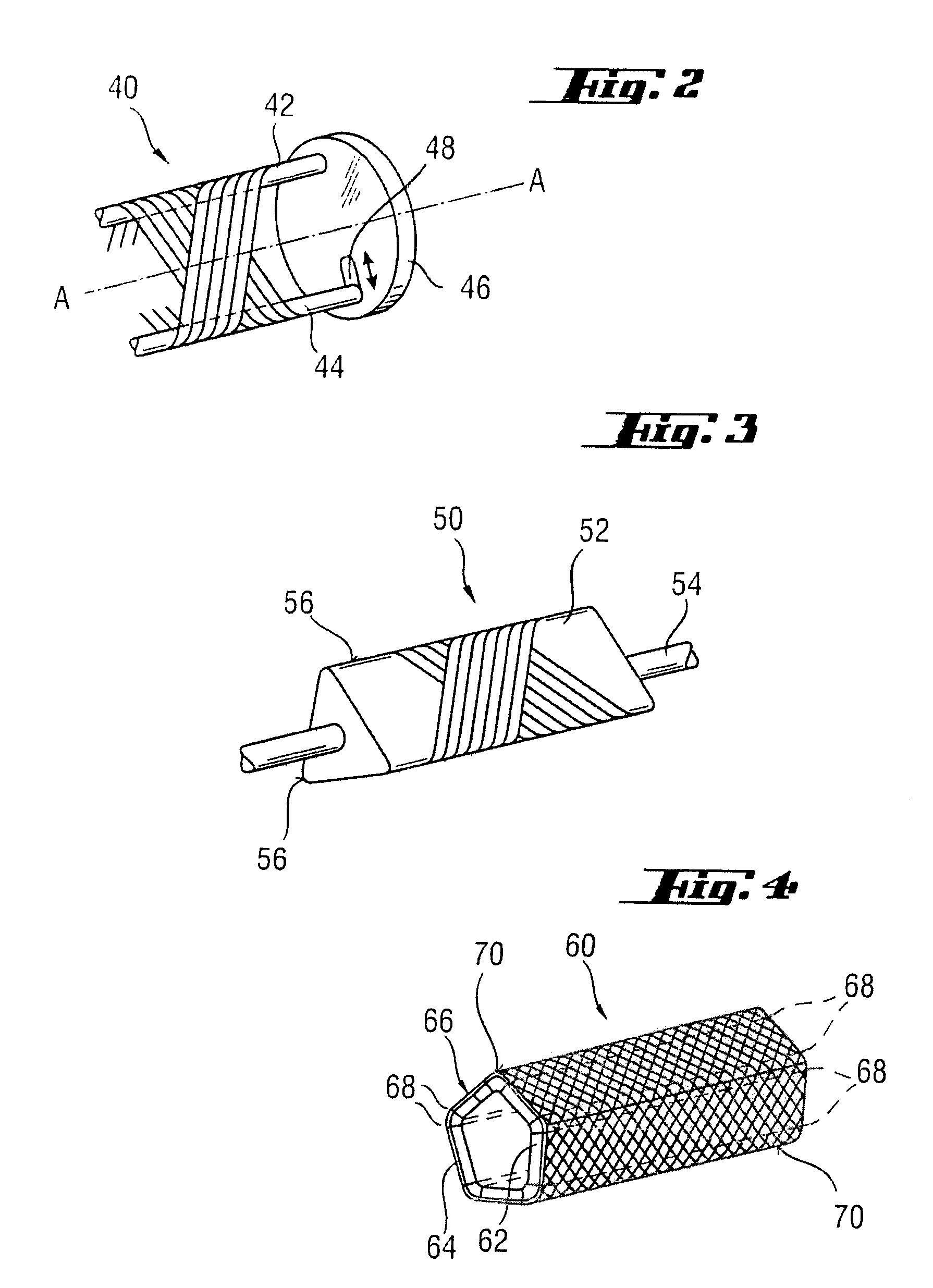

Composite fiber component produced by braiding

ActiveUS20070152105A1Reduce weightPromote absorptionConnecting rodsAircraft controlEngineeringFibrous composites

Owner:EADS DEUT GMBH

Low distortion interlayer

ActiveUS20060188695A1Low wavinessHigh roughness valueOrnamental structuresSpecial ornamental structuresEngineeringSurface plate

The present invention is in the field of multiple layer glass panels comprising a polymer sheet having desirable surface properties, and more specifically, the present invention is in the field of multiple layer glass panels comprising poly(vinyl butyral) having a finished surface of relatively low waviness and high roughness disposed in contact with poly(ethylene terephthalate) and / or other poly(vinyl butyral) type layers.

Owner:SOLUTIA INC

Polishing slurry for disk base sheet of memory hard disk

InactiveCN1417278AReduce roughnessReduce wavinessEdge grinding machinesPolishing compositions with abrasivesPolyolAlcohol

The present invention relates to the technology of manufacturing computer memory and hard disk. The polishing slurry contains abrasive, oxidant and water and is characterized by its water-soluble lubricant and polish balancing agent. The water-soluble lubricant is plyoxyethylenated fatly acid phosphate, plyoxyethylene fatty amide phosphate, fatty acid-polyol ester or their mixture and accounts for 0.2-20 wt%; and the polish balancing agent is water-soluble alcohol and accounts for 0.2-20 wt%. The polishing slurry can reduce the roughness and waviness of memory and hard disk surface to below 0.7 angstrom and eliminate effectively pit, lug, scratch and other faults.

Owner:TSINGHUA UNIV

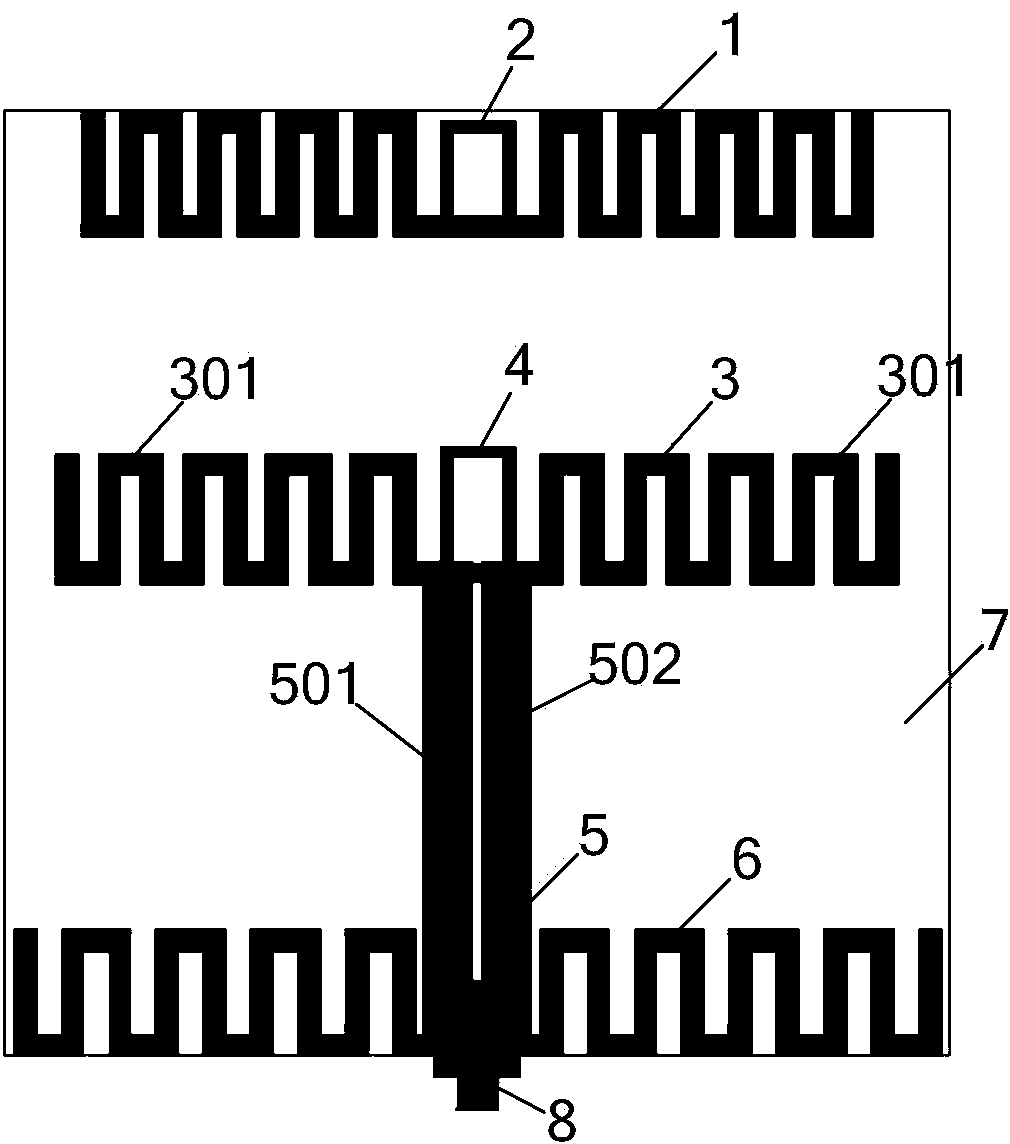

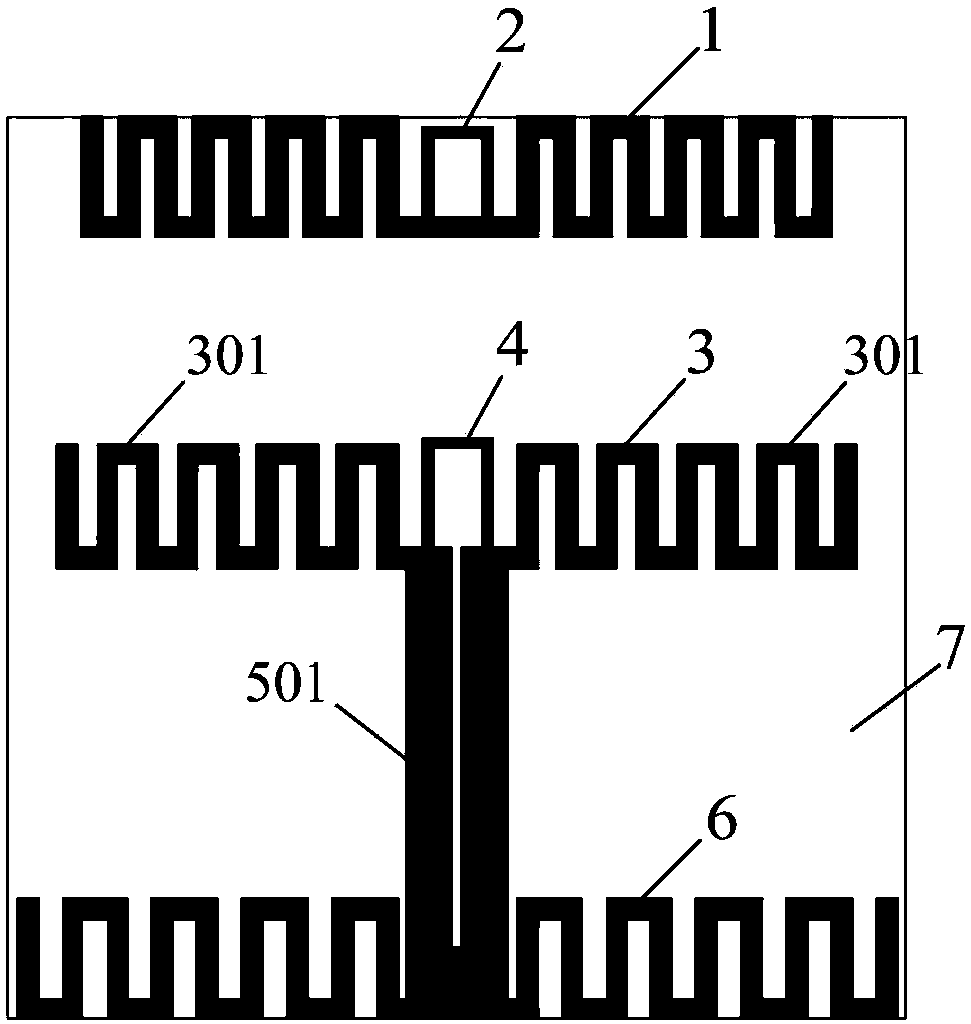

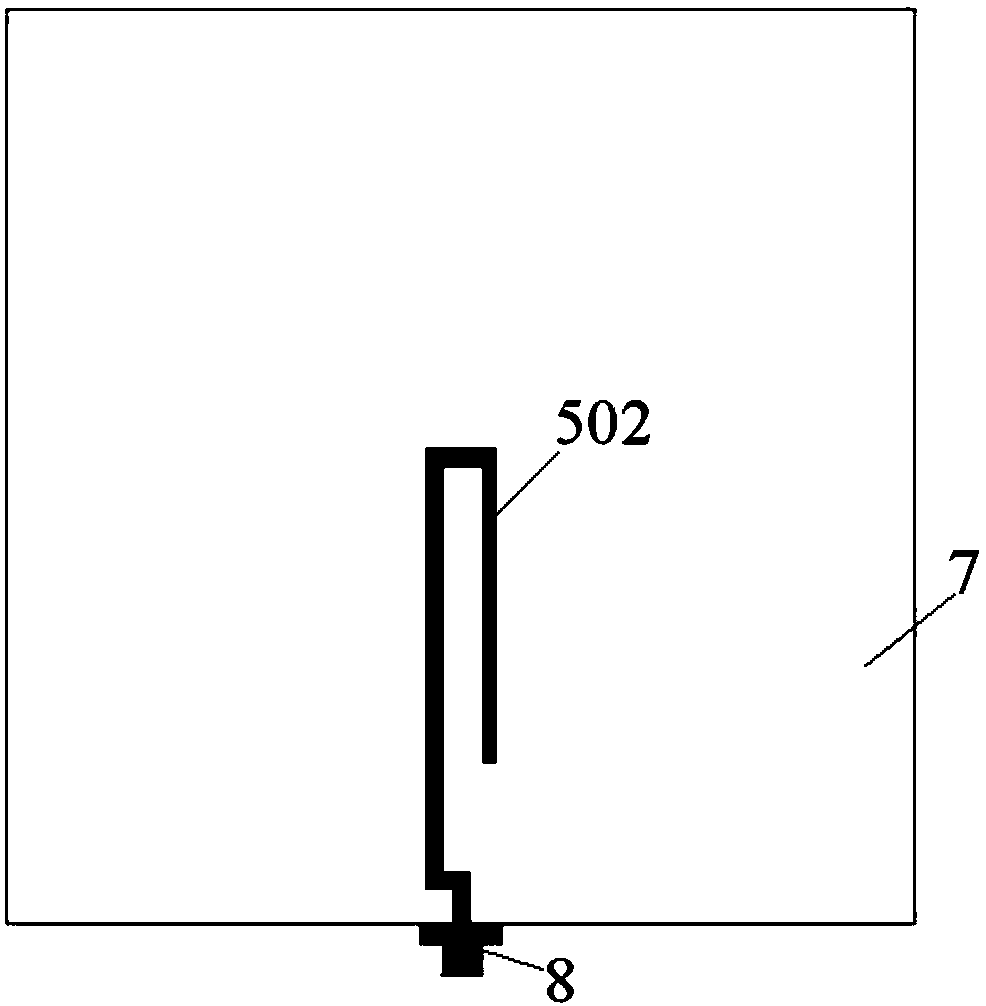

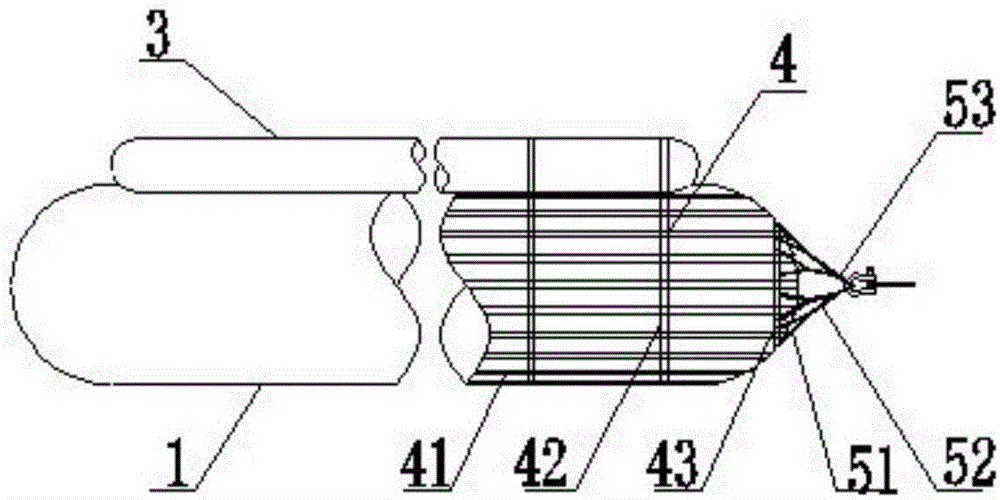

Small-sized broadband end-on-fire antenna

ActiveCN103531889AReduce horizontal sizeMatching impedance matchingAntenna supports/mountingsRadiating elements structural formsPolygonal lineDielectric substrate

The invention discloses a small-sized broadband end-on-fire antenna. The small-sized broadband end-on-fire antenna comprises a director, an exciter, a tuner, a feed balun, a reflector, a cable joint and a dielectric substrate, wherein the exciter is arranged opposite to the director in parallel and is of a two-arm vibrator structure; the two ends of the tuner are bridged on the inner side positions of the two-arm vibrator; the feed balun is of a micro-strip line-to-parallel double line structure; two output ends of the parallel double lines are connected with the inner side of the two-arm vibrator of the exciter respectively; the reflector is arranged opposite to the exciter in parallel and is connected with the parallel double lines of the feed balun; the director, the exciter and the reflector are all of bend line structures; the cable joint is connected with the feed balun; the director, a gain adjuster, the exciter, the tuner, the feed balun and the reflector are all arranged on the dielectric substrate. Small size, broad band and high gain of the antenna are simultaneously realized.

Owner:上海航空机械有限公司

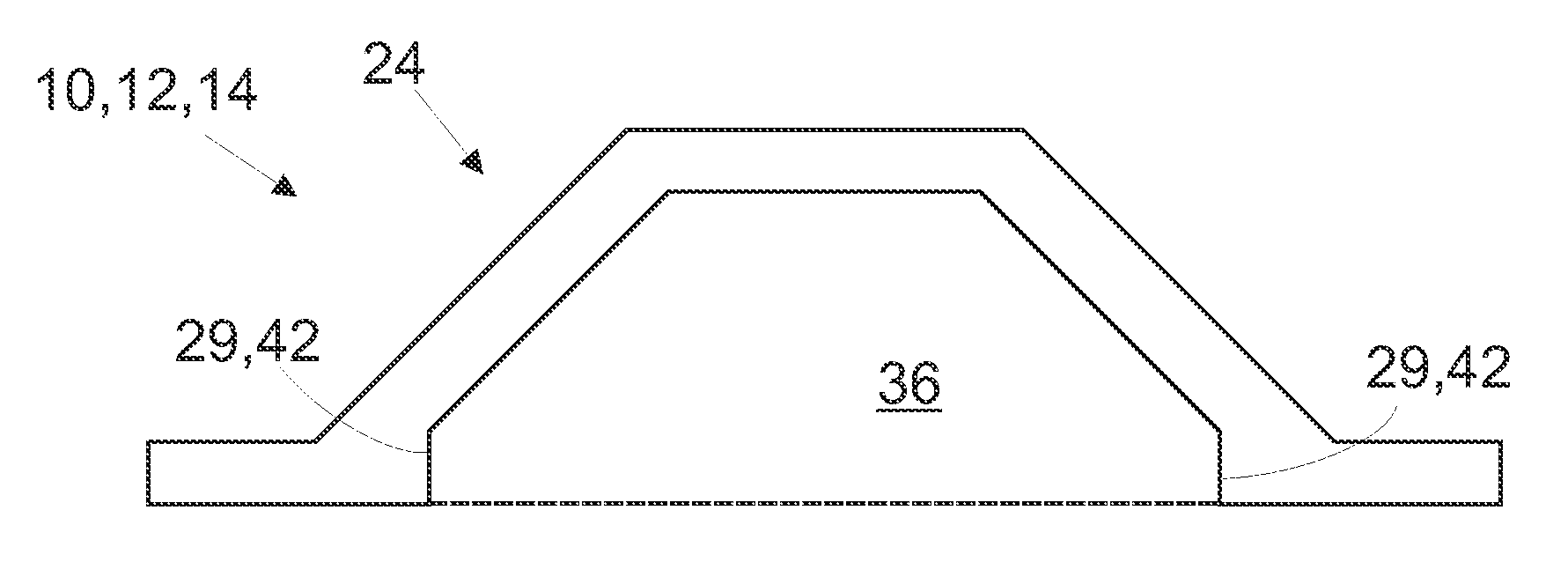

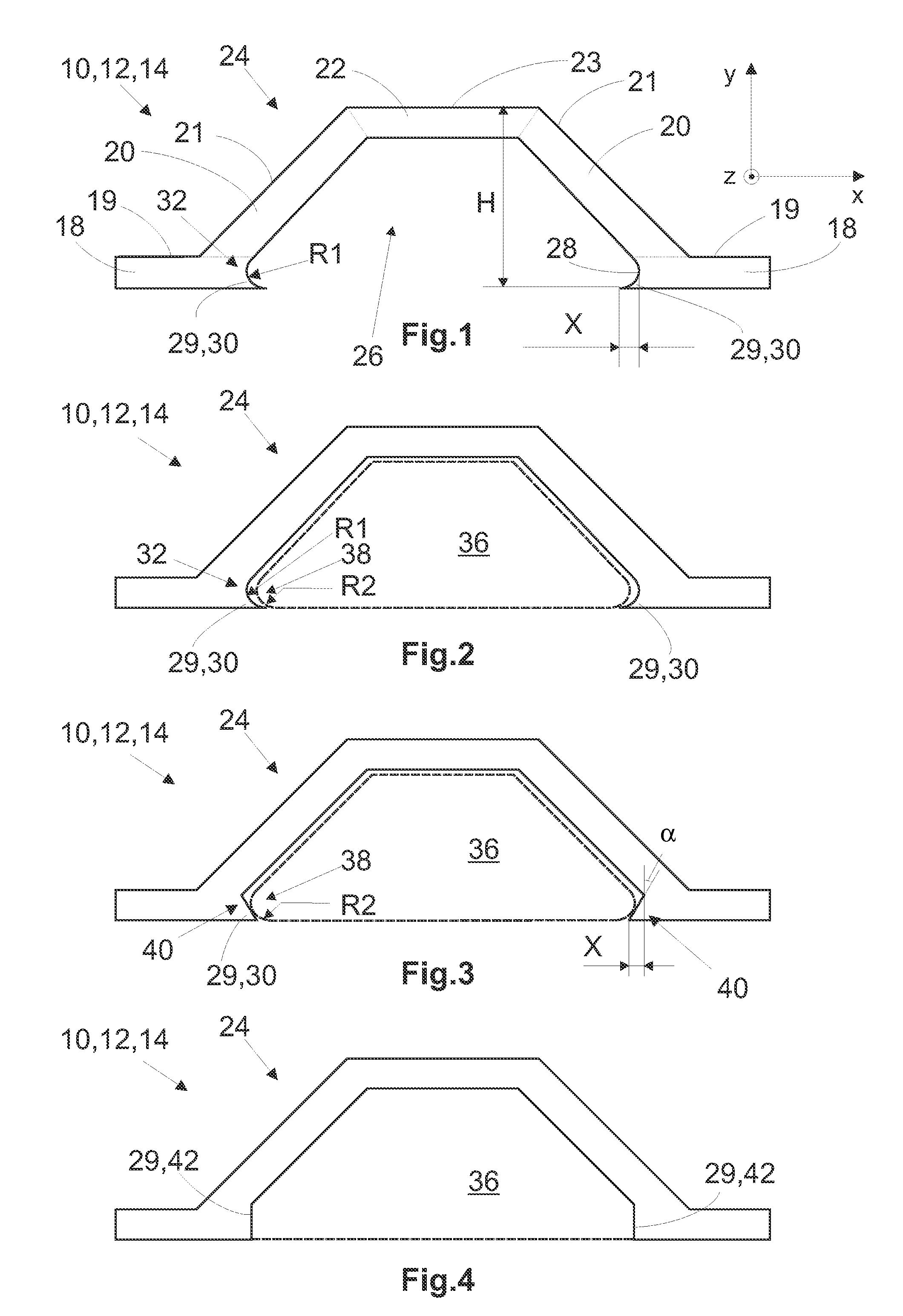

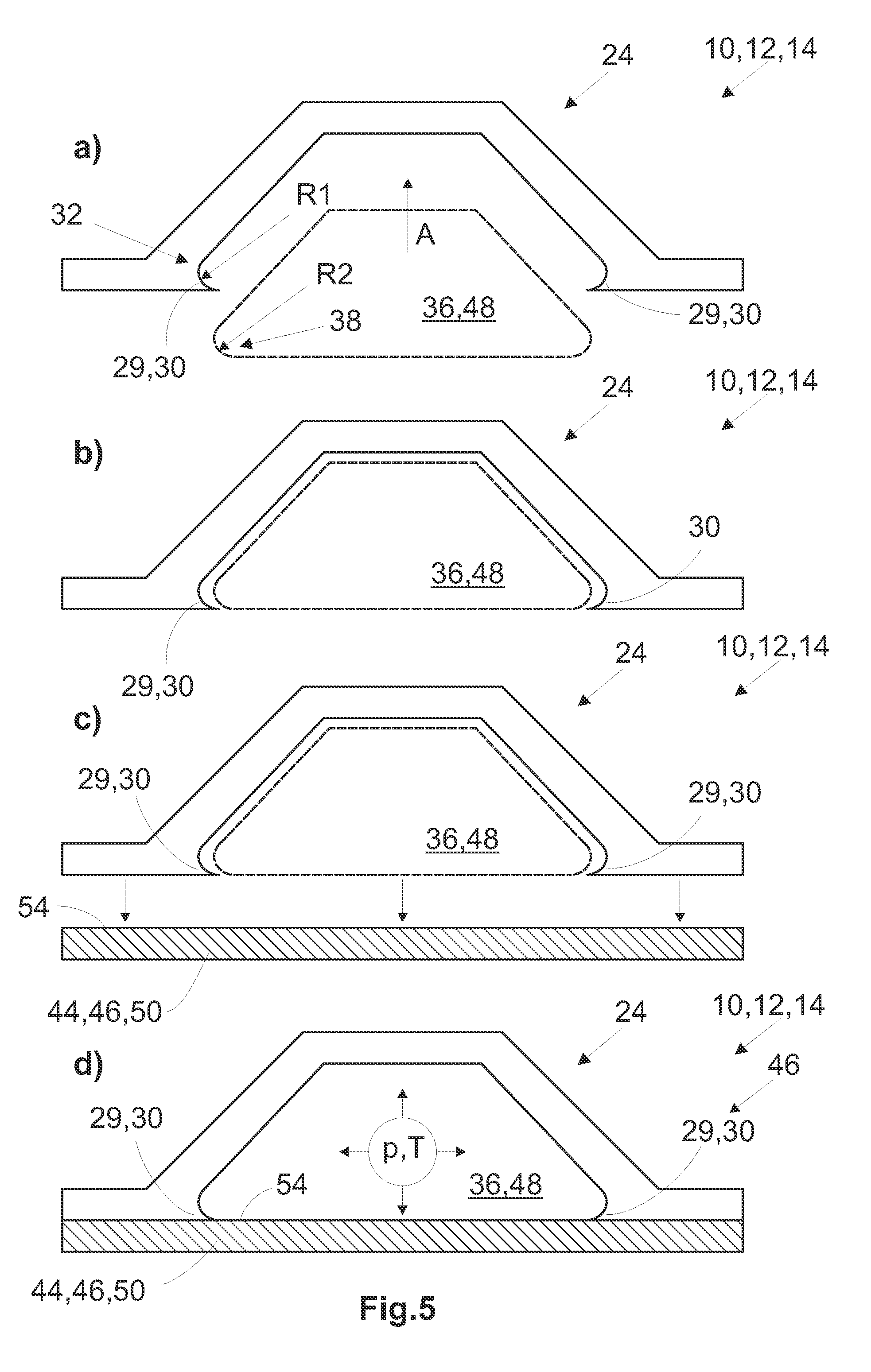

Clip Integration of Pressure Tube Mold Cores into Hardened Omega-Stringers for the Production of Stiffened Fiber Composite Skin Shells, in particular for Aeronautics and Astronautics

ActiveUS20100007056A1Simple componentsReducing and simplifying process stepNon-magnetic metal hullsEfficient propulsion technologiesComposite skinFibrous composites

The invention concerns a device for stiffening a flat component, a process for the production of a flat component, in particular a fiber composite component, and a fiber composite component. The device has a portion for producing a space for receiving a mold core for the transmission of a pressure for pressing the flat component and the device. It is characterised by means for positively lockingly and / or frictionally lockingly positioning the mold core in the space of the device. The process according to the invention includes the following steps: introducing the mold core into the portion of the device, positively lockingly and / or frictionally lockingly positioning the mold core in the portion of the device by means of the means, applying the device including the mold core to the non-hardened material layer or layers, pressing the material layers, and hardening the material layer or layers and joining the device to the material layer or layers.

Owner:AIRBUS OPERATIONS GMBH

Polishing composition

InactiveUS20050003746A1Reduce wavinessPigmenting treatmentOther chemical processesChemistryLiquid crystal

A polishing composition containing an α-alumina, an intermediate alumina, an oxidizing agent and water; a method for reducing waviness of a substrate to be polished, including the step of applying the polishing composition to the substrate to be polished; and a method for manufacturing a substrate, including the step of polishing a substrate to be polished with the polishing composition. The polishing composition is suitable for polishing substrates for precision parts such as substrates for magnetic recording media for magnetic discs, optical discs, opto-magnetic discs, and the like; photomask substrates; glass for liquid crystals; optical lenses; optical mirrors; optical prisms; and semiconductor substrates.

Owner:KAO CORP

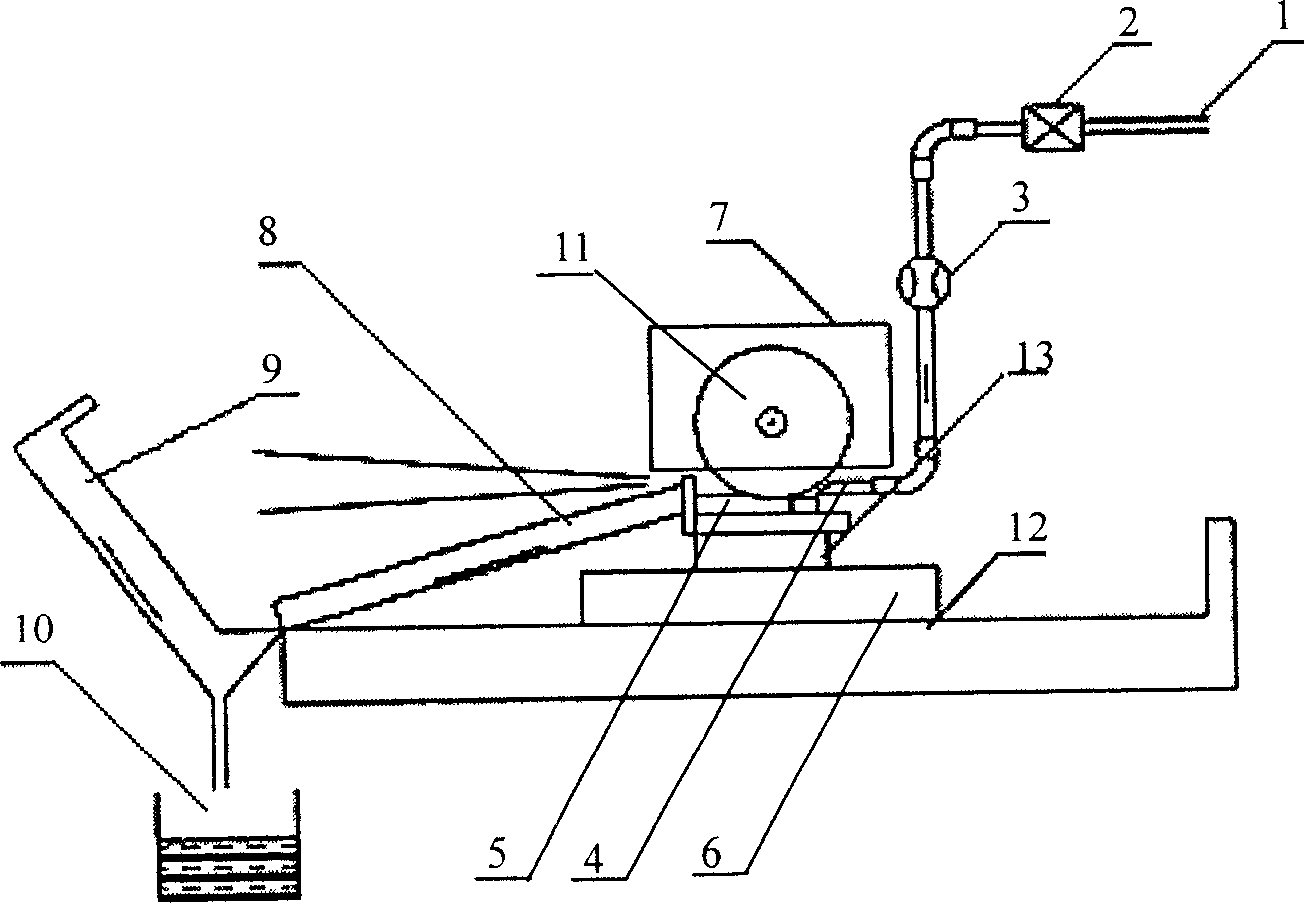

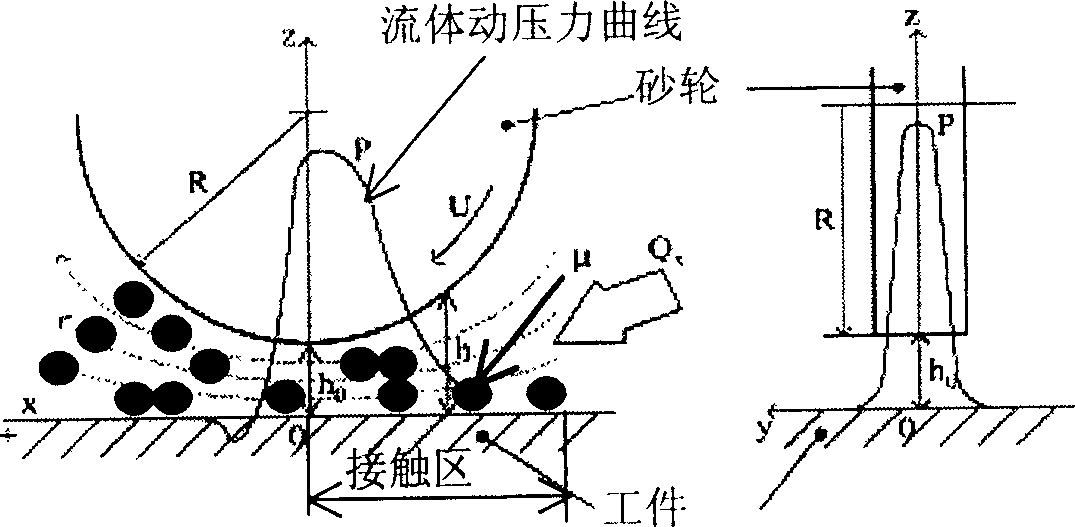

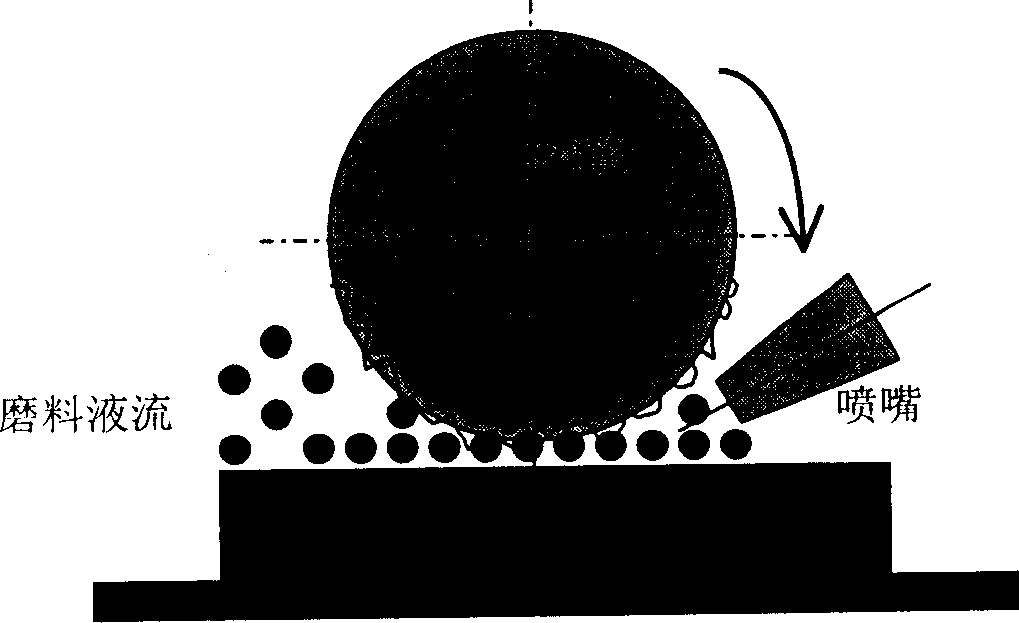

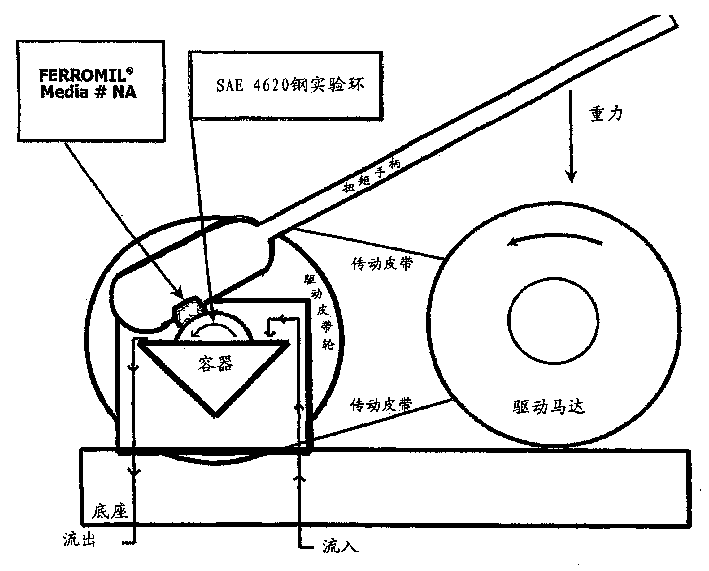

Grinding wheel constraining abrasive particle injection precise dressing processing method and device

InactiveCN1686668AUncomplicated design and manufactureEasy installationParticle injectionHigh pressure

A blasting precise machining technology by use of abrasive wheel to restrict the abrasive particles including grinding by adrasive wheel and blasting the abrasive particles. It features that after the abrasive particle stream is blasted by high-pressure pump, it can obtain the momentum under the action of the centrifugal force and attracting force of abrasive wheel, and the fluid pressure field and speed field between abrasive wheel and workpiece. Its apparatus is composed of grinder, abrasive wheel, bench, pump, control valve, flowmeter, nozzle, shielding cover, liquid collecting both, stop plate and liquid tank.

Owner:NORTHEASTERN UNIV

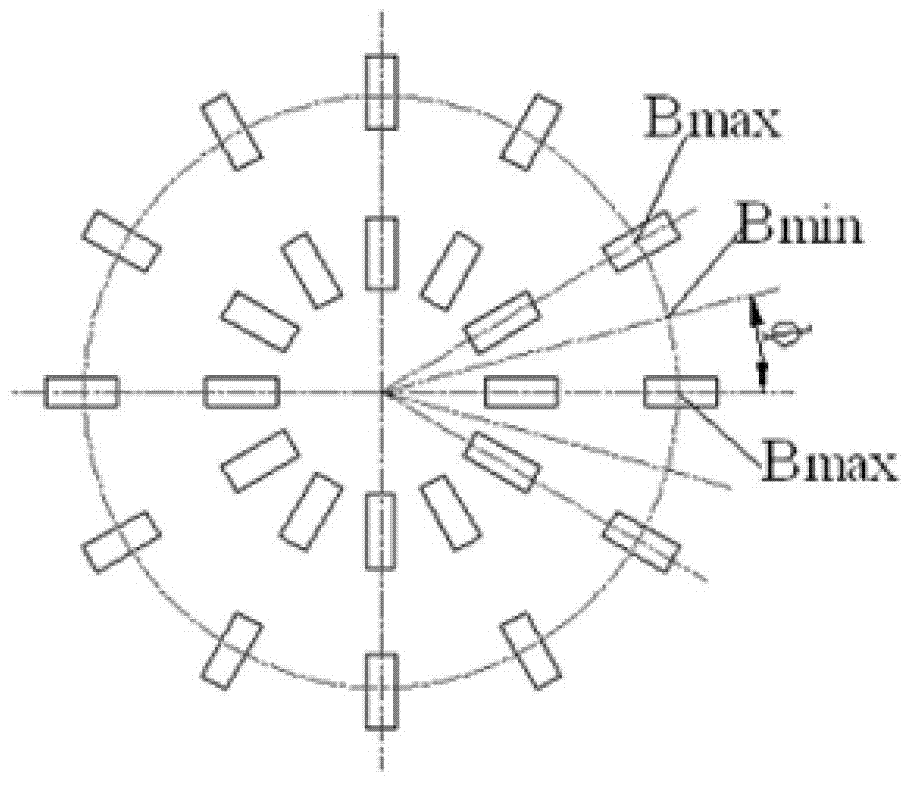

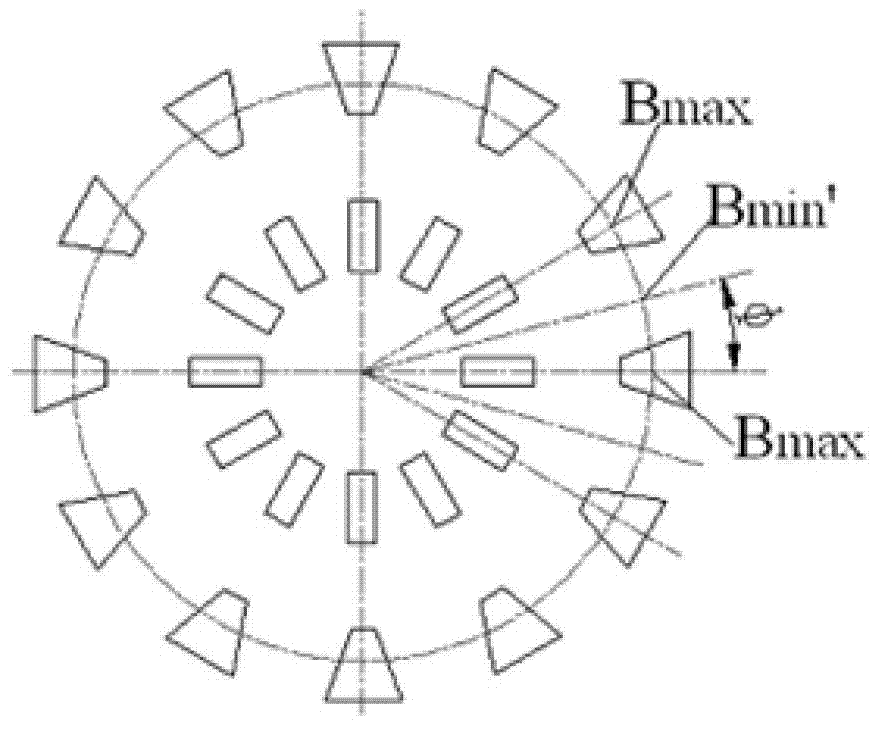

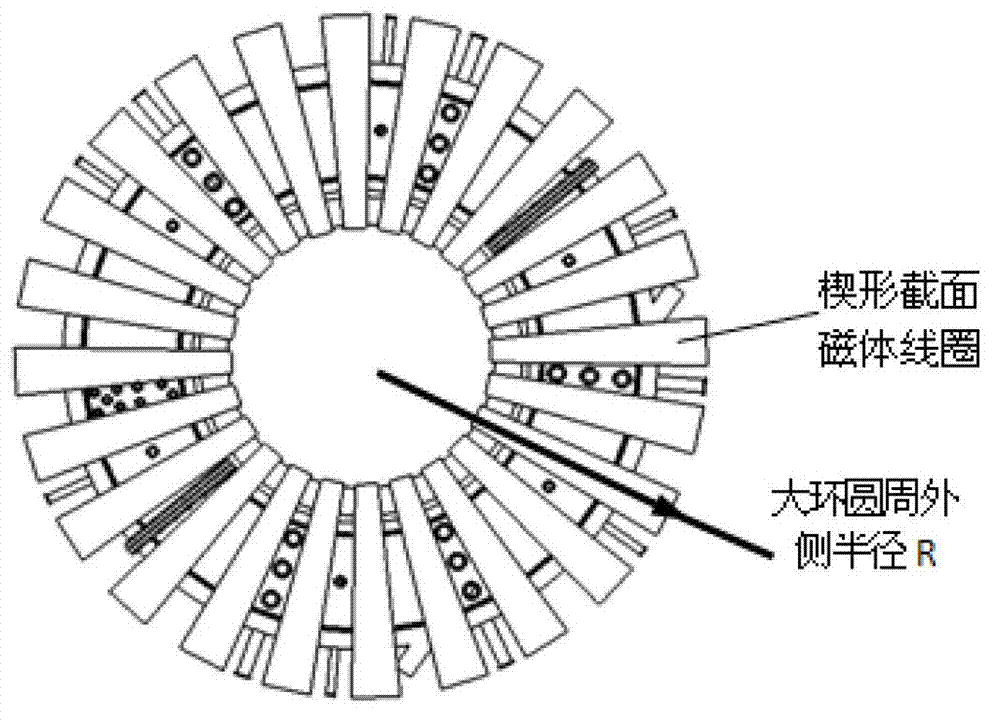

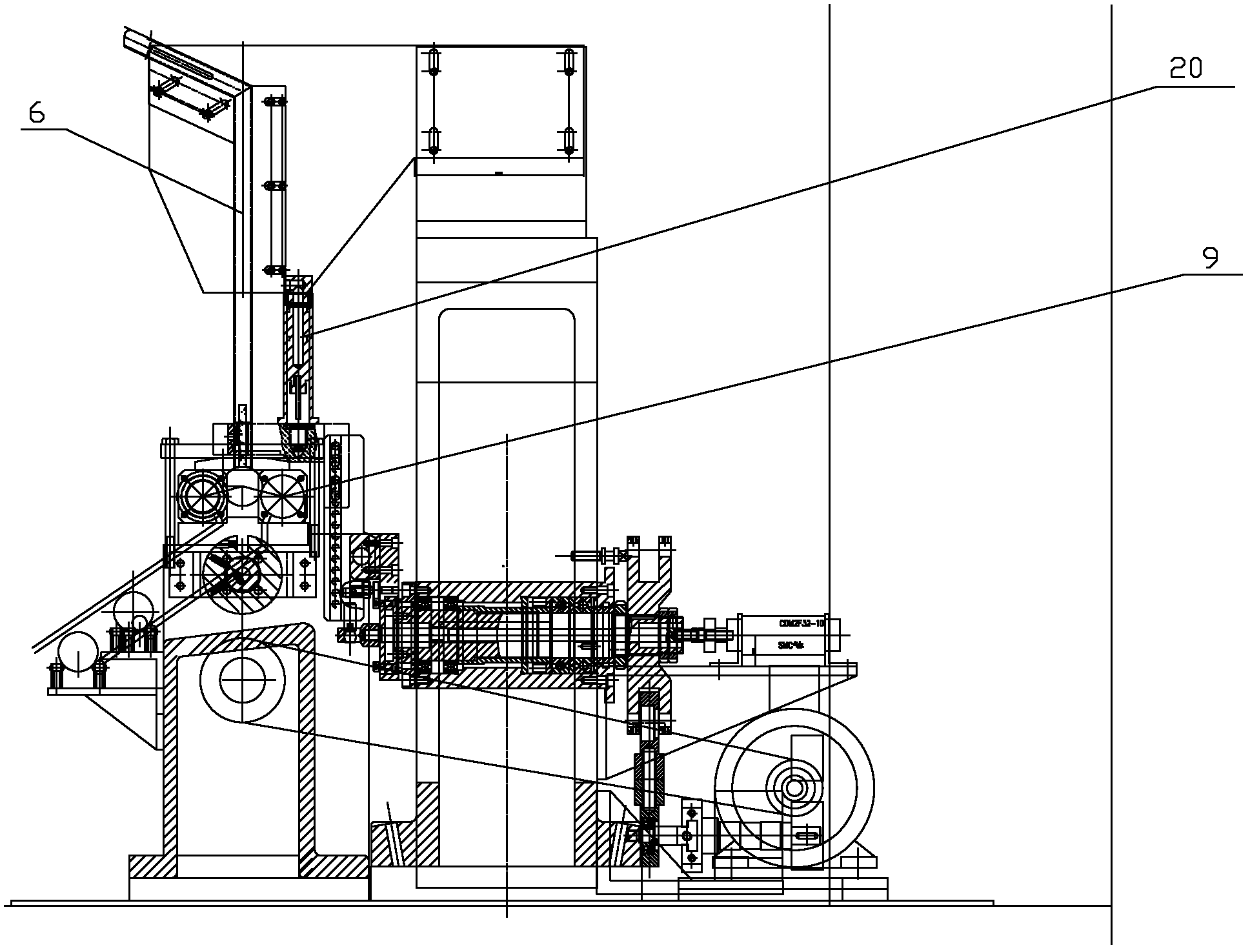

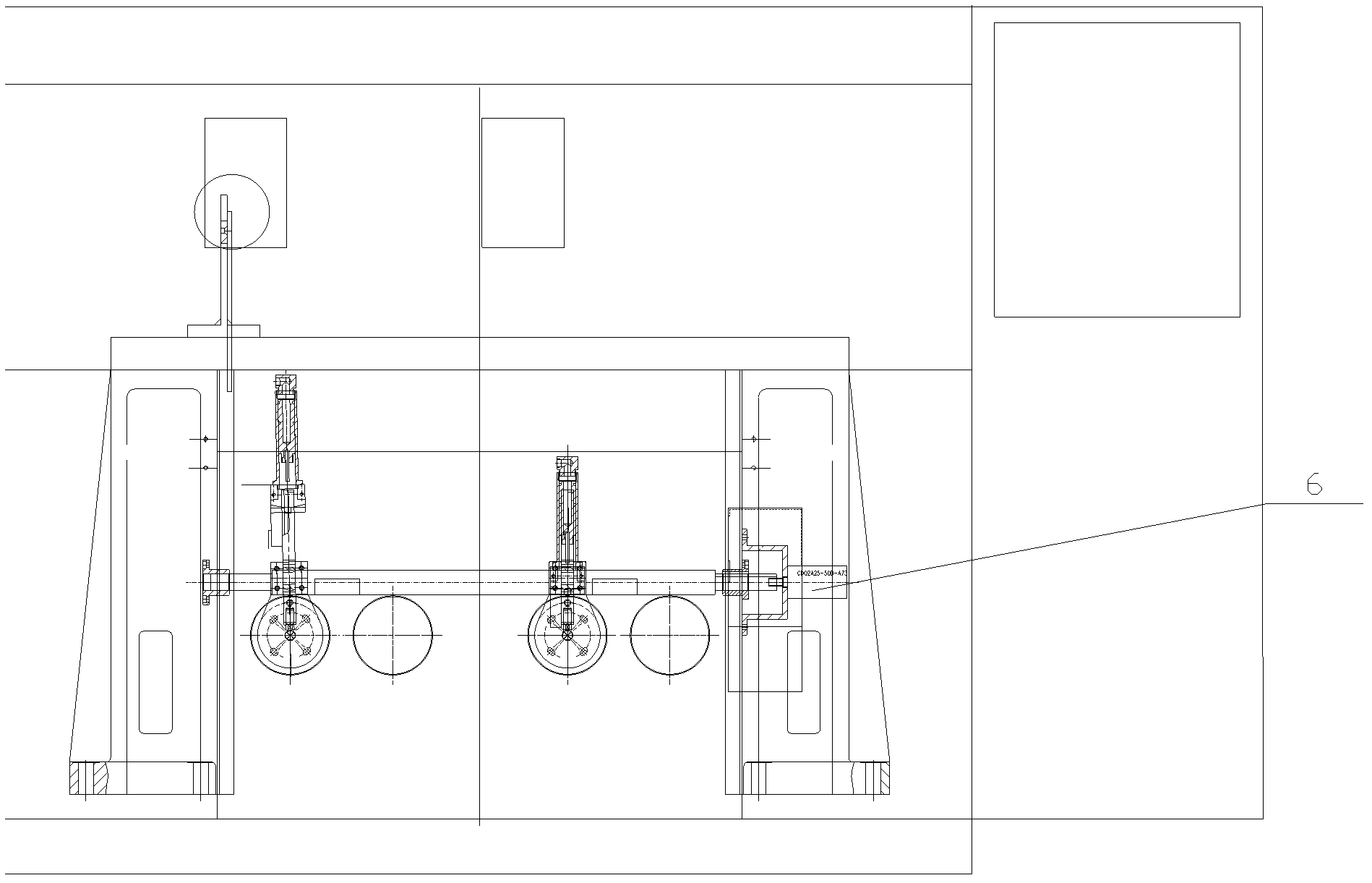

Superconducting magnet coil with wedge-shaped section for reducing waviness and conductor winding and forming method

InactiveCN102820117AUndamagedGuaranteed structural strengthSuperconducting magnets/coilsCoils manufactureElectrical conductorButt joint

The invention discloses a superconducting magnet coil with a wedge-shaped section for reducing waviness and a conductor winding and forming method. The superconducting magnet coil with a wedge-shaped section for reducing waviness comprises a mould which comprises a plurality of forming blocks and a central supporting column. Each forming block comprises two arc-shaped blocks in butt joint at one ends. An assembling hole is arranged in the inner wall of each arc-shaped block. A plurality of positioning blocks are respectively arranged on both sides of the central supporting column form top to bottom. Each positioning block is separated from the adjacent positioning blocks up and down. The pair of arc-shaped blocks of each forming block is respectively locked on the central supporting column from both sides of the central supporting column, and a wire is continuously winded and formed on the mould around the central supporting column along the gap between adjacent forming blocks. According to the superconducting magnet coil with a wedge-shaped section for reducing waviness and the conductor winding and forming method provided by the invention, under the premise of guaranteeing the assembling space and reducing the cost, the outermost waviness in the circumference of a large ring is effectively reduced so that the waviness in a rim area of a plasma in the center of the magnet coil is further reduced, the stable operation of the plasma is ensured, and the fabrication design and process of the coil conductor are reasonable and convenient to realize.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

Nano-silicon dioxide abrasive material polishing solution for polishing copper

InactiveCN101368068AGood dispersionGood chemical stabilityPolishing compositions with abrasivesCopperSURFACTANT BLEND

The invention provides nano-silicon dioxide abrasive polishing solution used for polishing copper, which comprises abrasive, surfactant, complexing agent, oxidizer, pH regulator and de-ionized water; the weight percent of the components is as follows: 10 to 40 percent of abrasive I, 5 to 20 percent of surfactant, 0.01 to 0.6 percent of complexing agent, 1 to 6 percent of pH regulator and the rest is de-ionized water. The pH value of the mixed liquid of the components is 10 to 12. The nano-silicon dioxide abrasive polishing solution can be used for surface polishing of copper quickly, which does not corrode equipment with high safety when being used.

Owner:JIANGSU HAIXUN IND GROUP SHARE

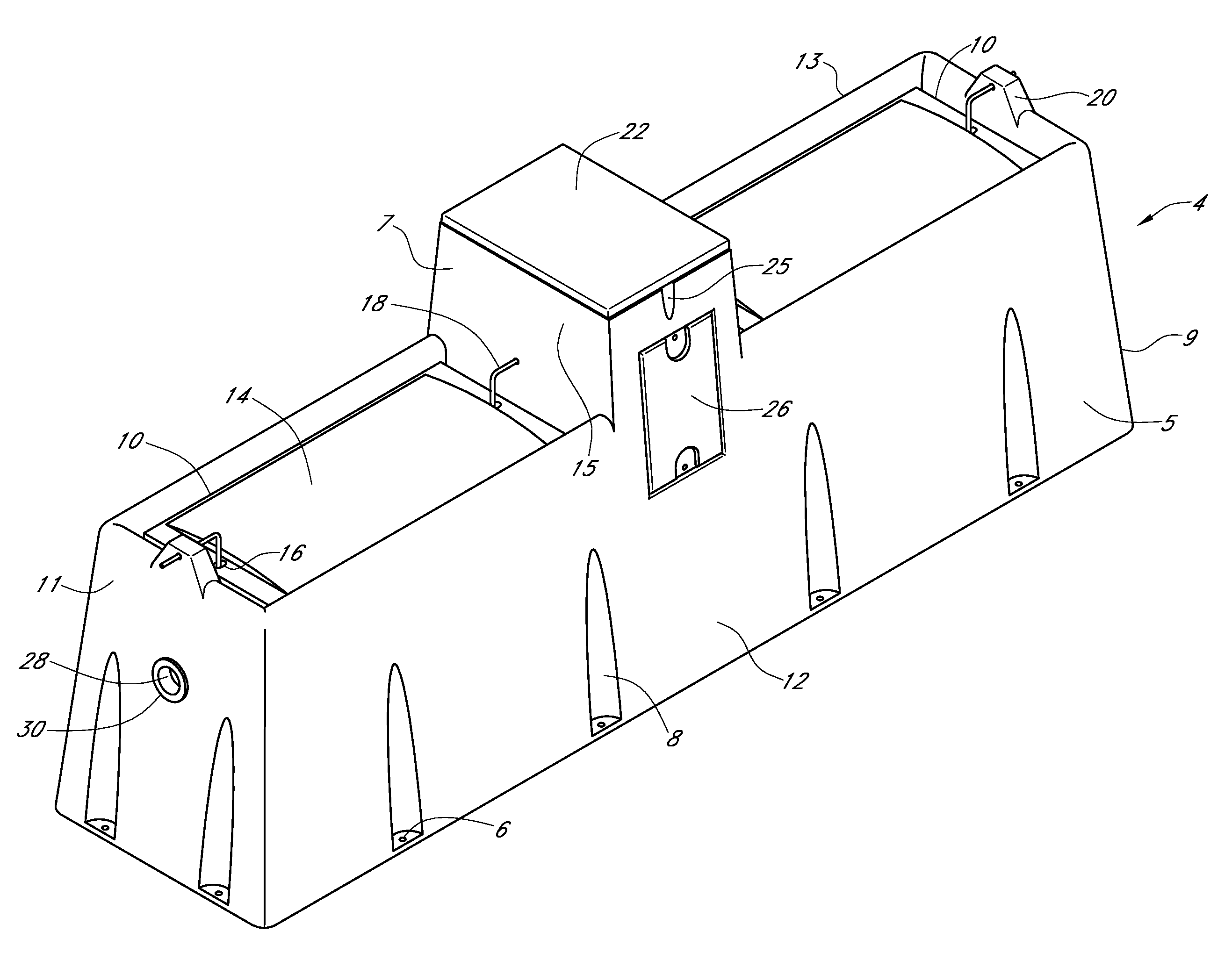

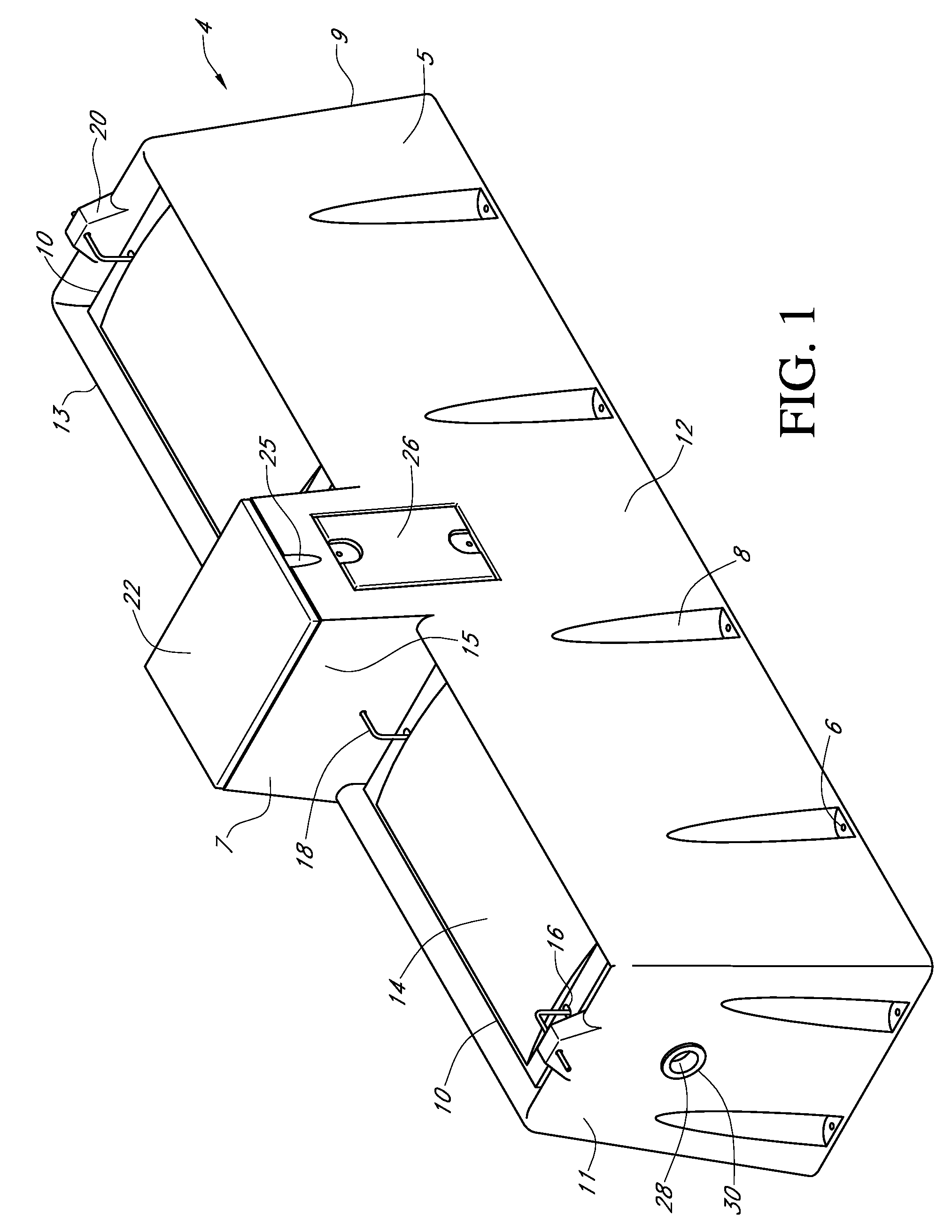

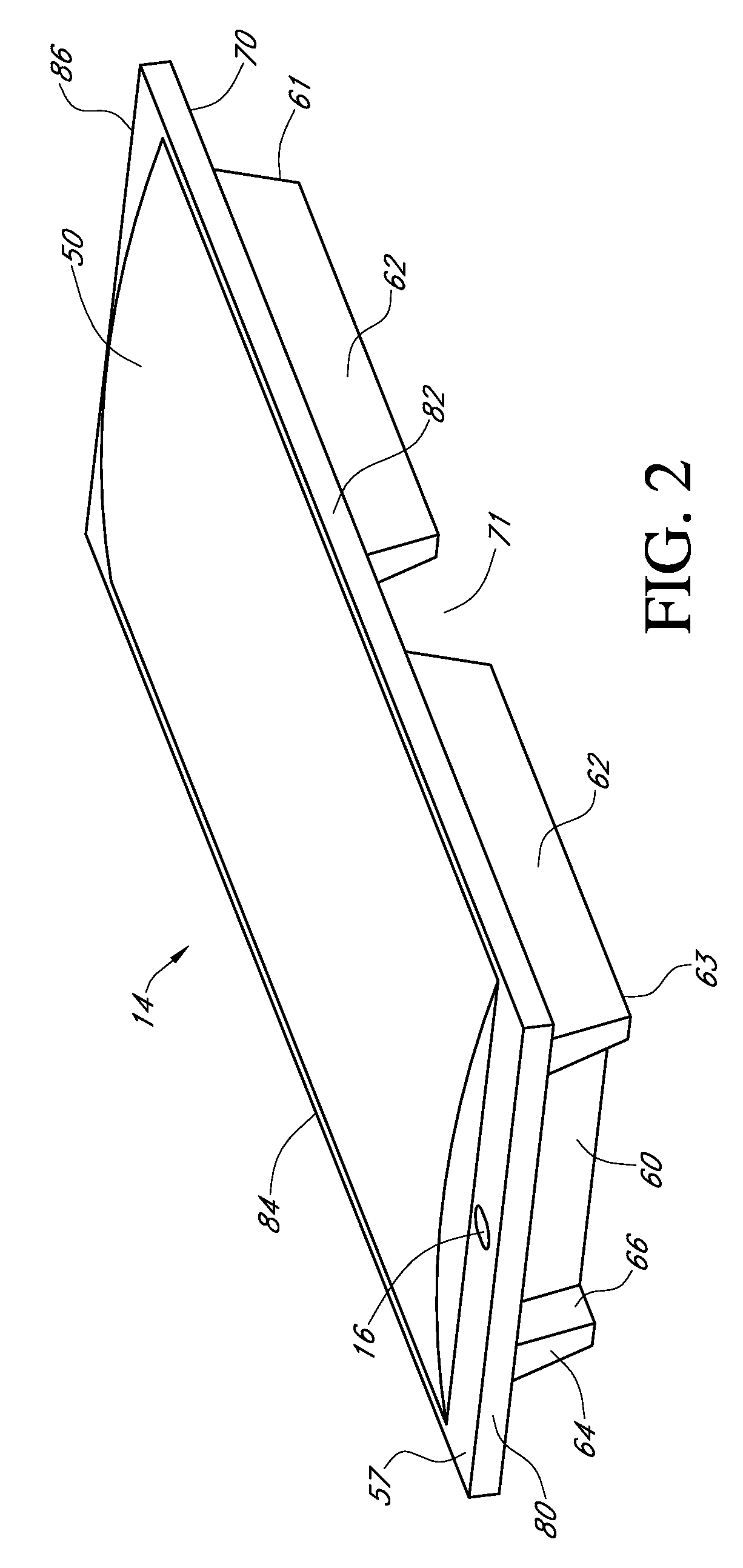

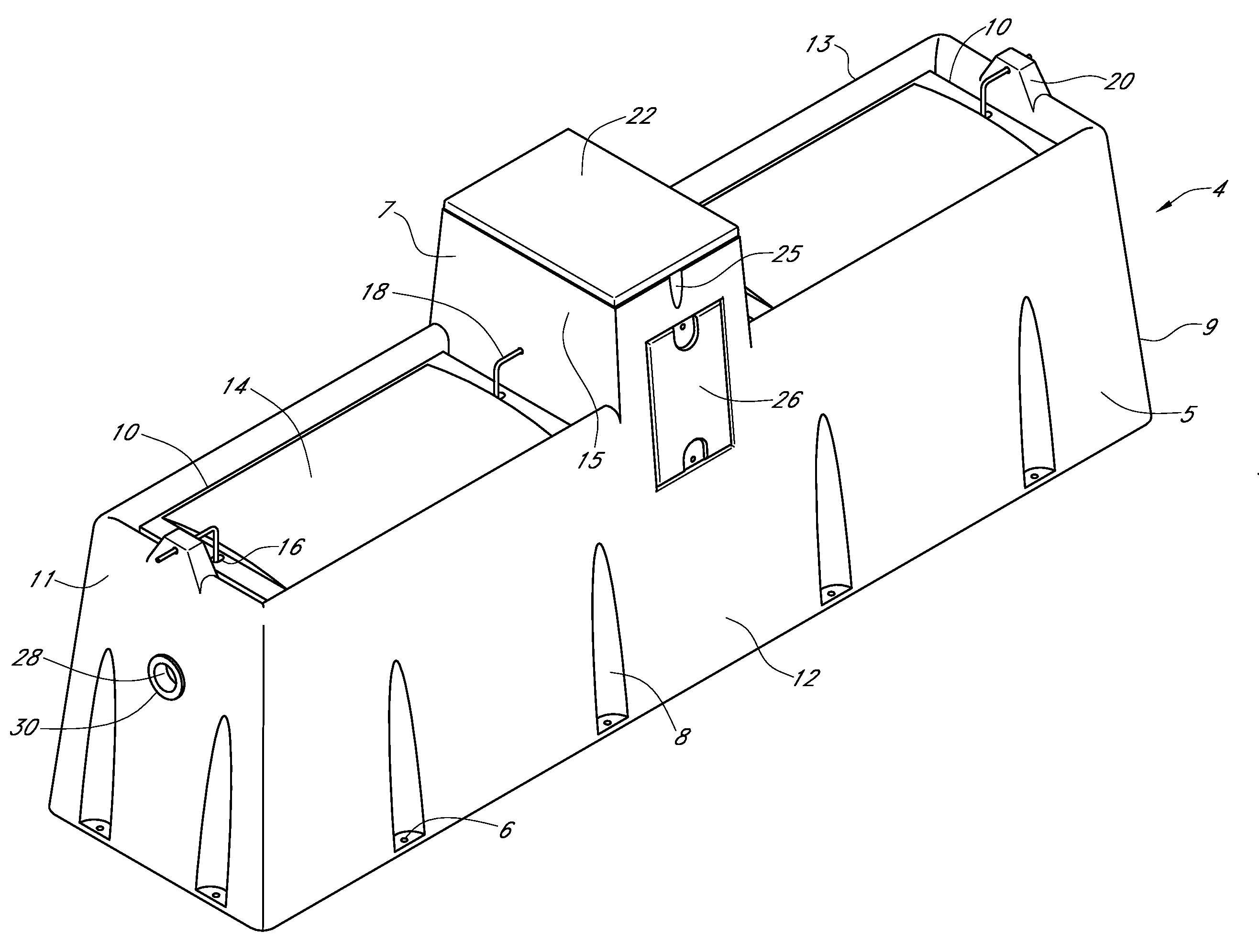

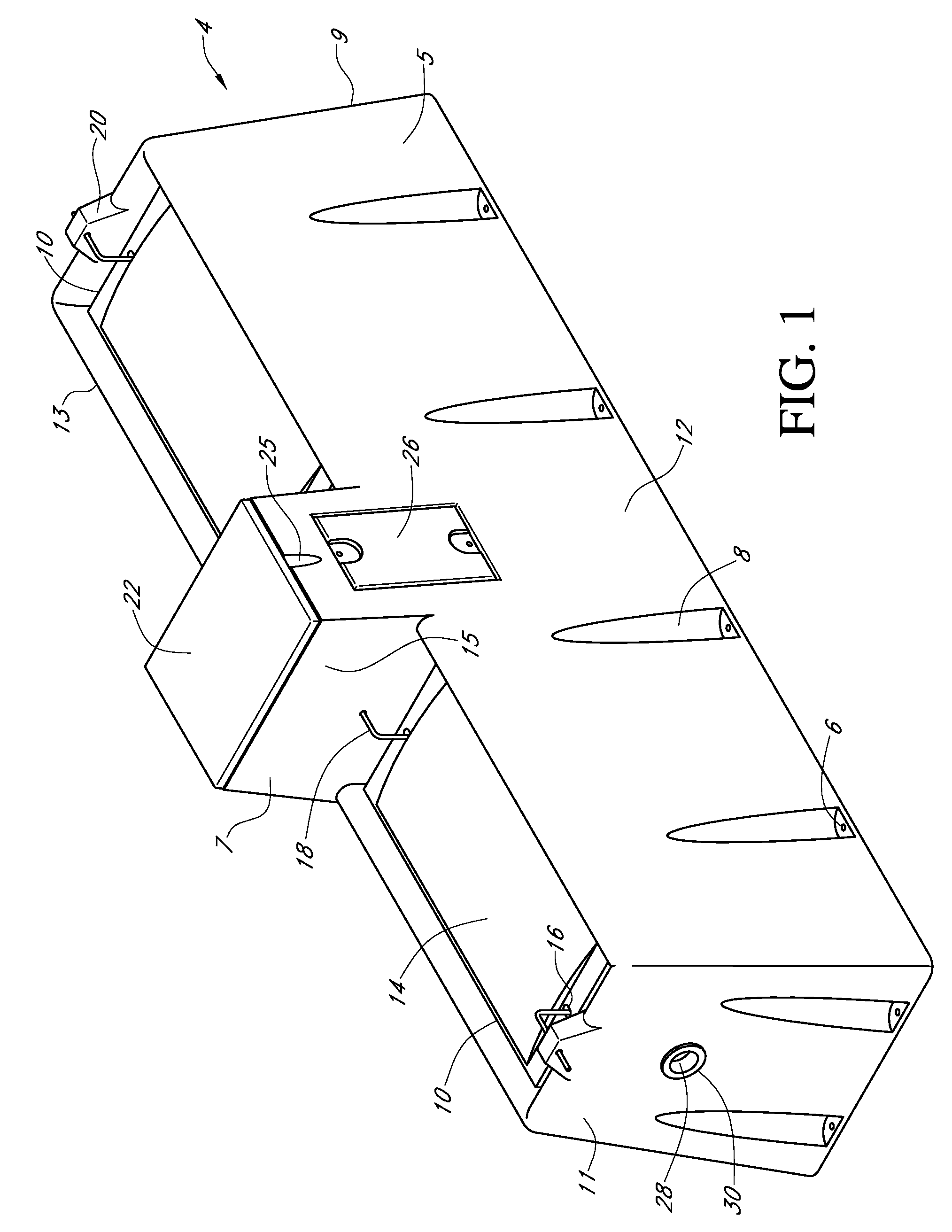

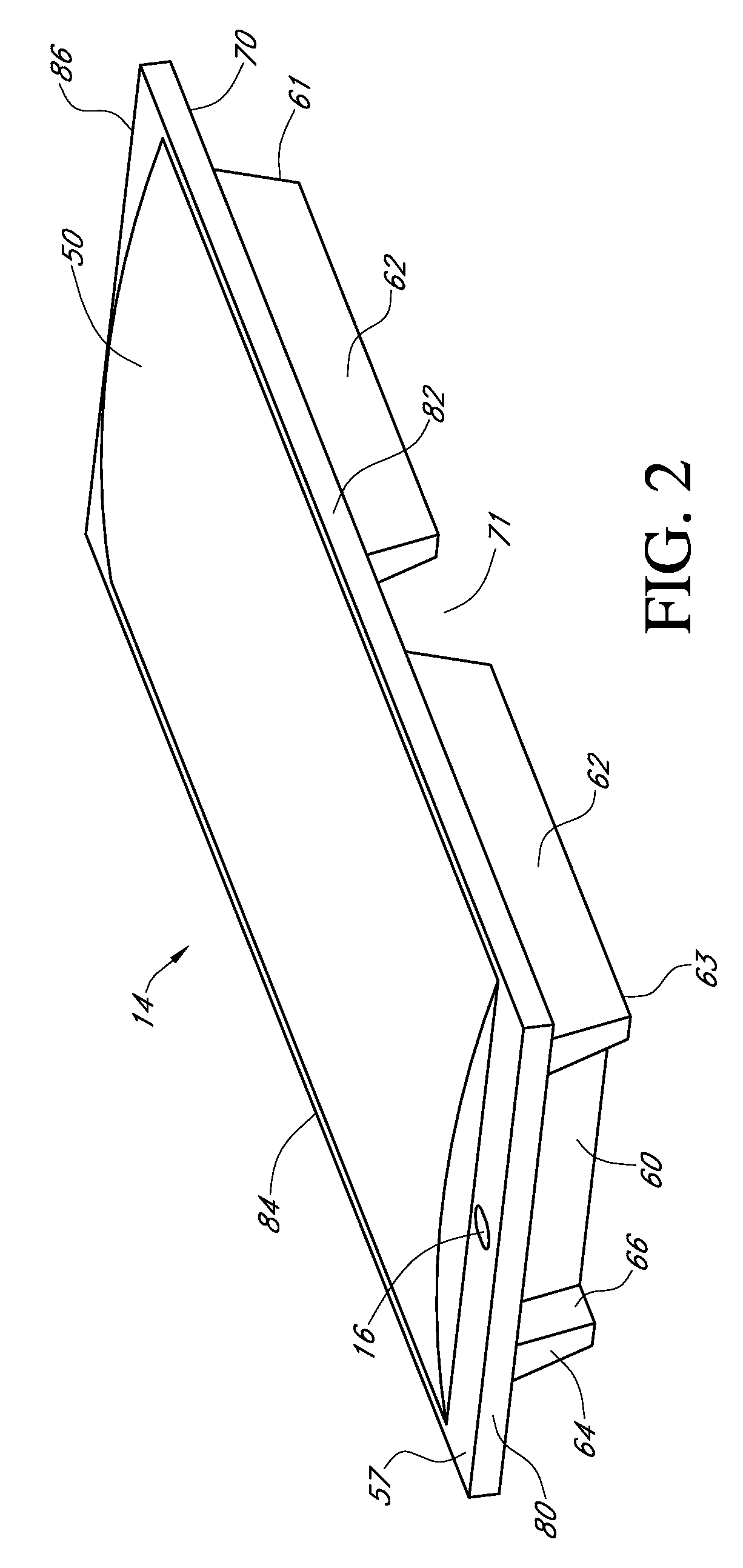

Livestock waterer

InactiveUS7975649B2Reduce wavinessReduce turbulenceAnimal watering devicesAnimal feeding devicesEngineeringLivestock

A livestock waterer for use in frigid climates includes a lid which floats on the surface of the water in each basin of the waterer. The lid is hollow with a convex upper surface and with baffle walls depending from the underside of the lid. The baffle walls interrupt wave action on the surface of the water created by depression of the lid into the water when an animal presses down on the lid to gain access to the water. The floor of each basin is provided with an integrally formed mounting post to support a heater within the basin. The baffles walls prevent exhaustion of water within the basin thereby preserving submersion of the heater at all times.

Owner:BARKER RUHL A

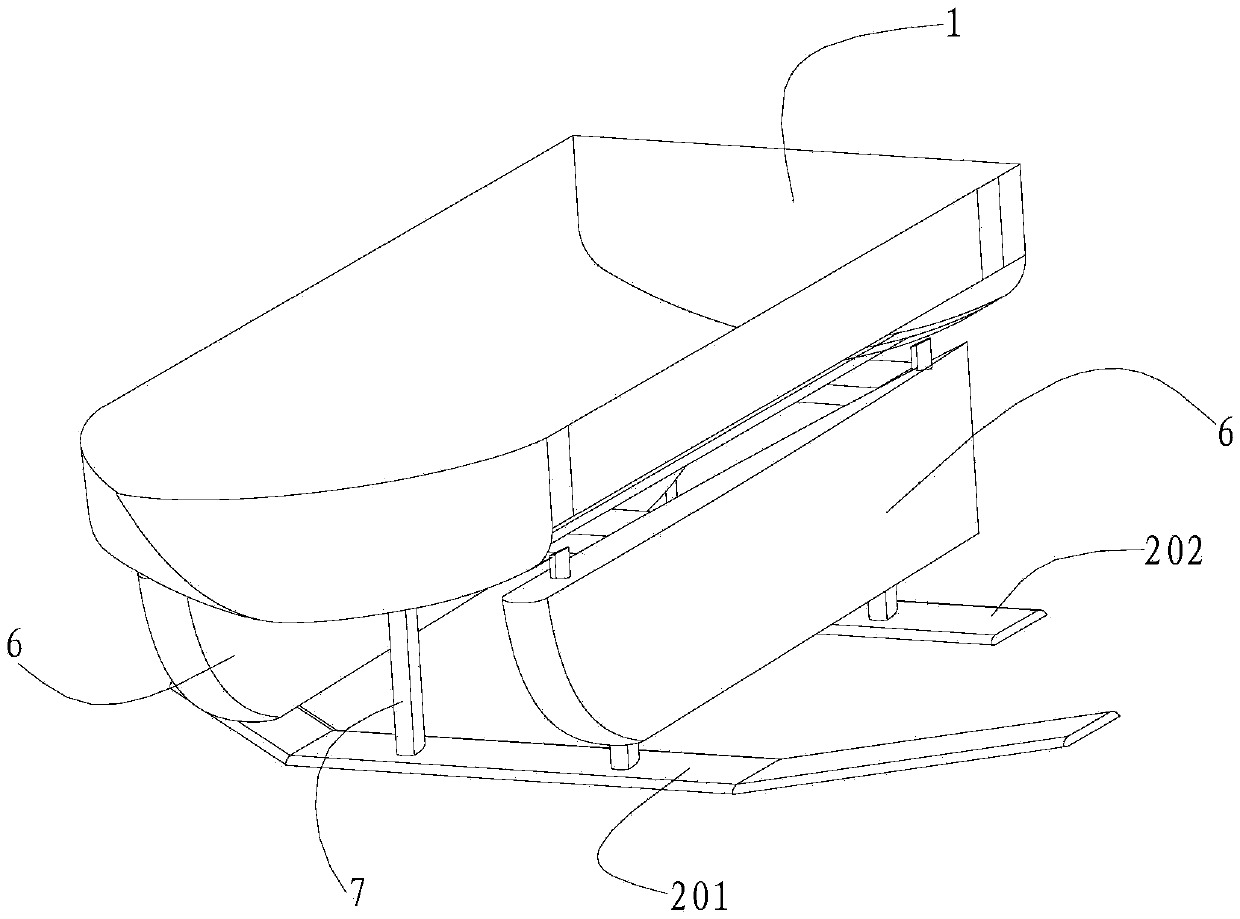

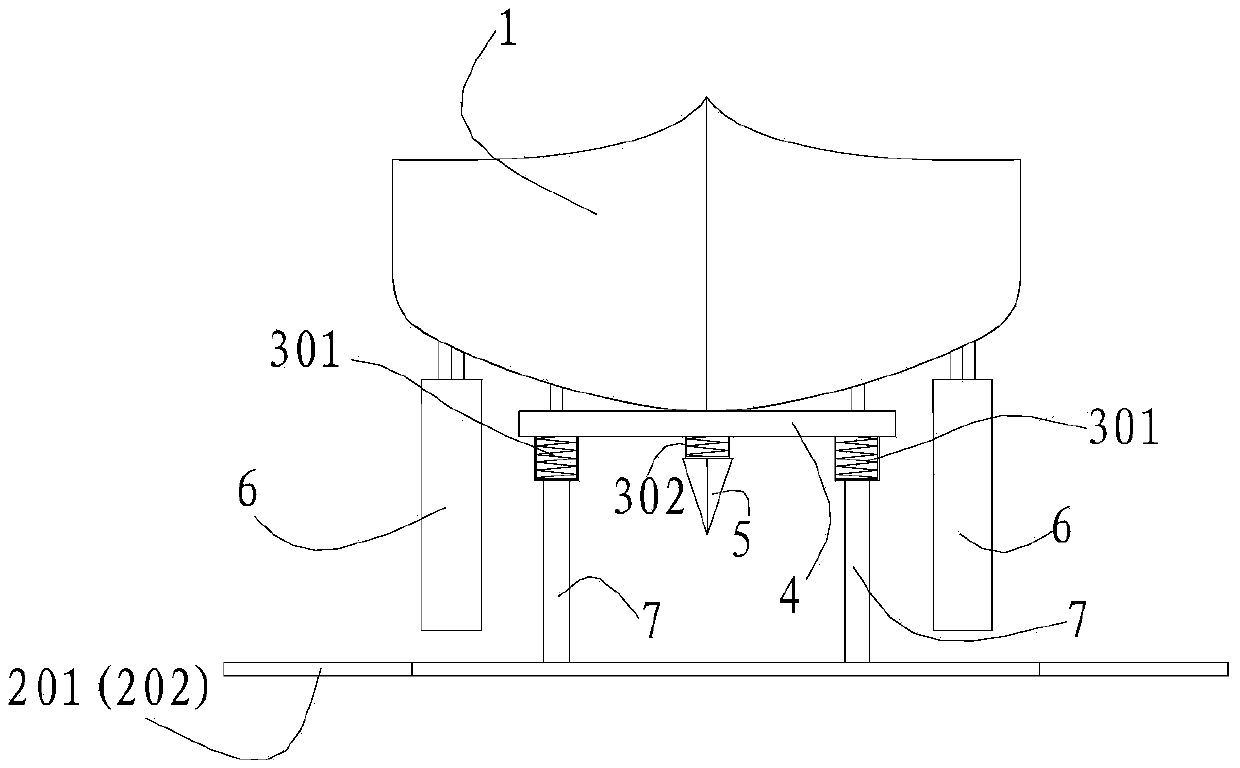

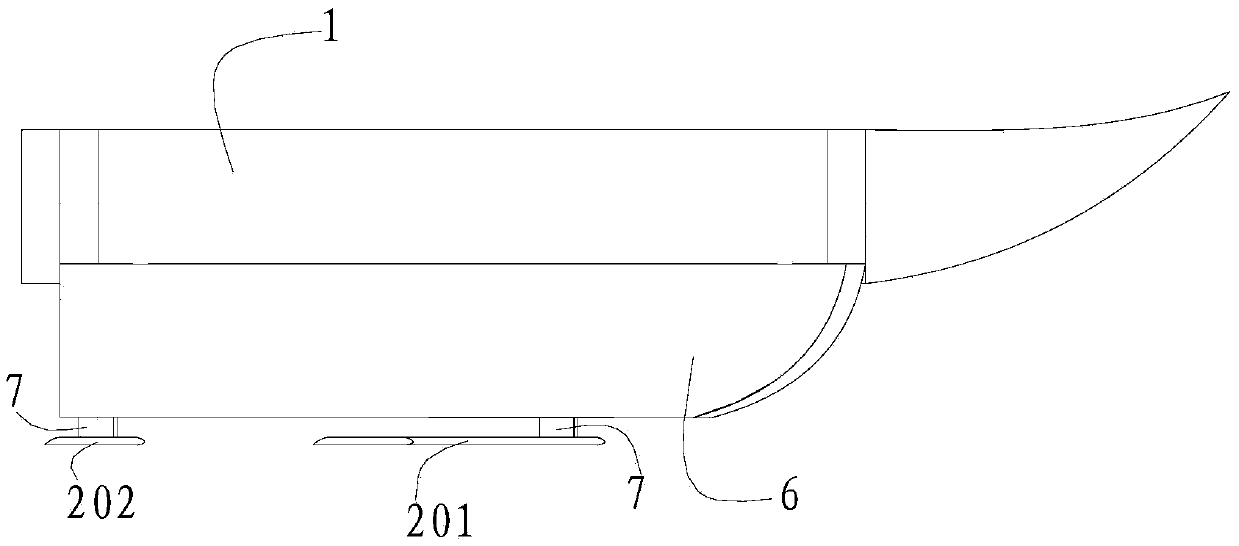

Hull structure with underwater appendage

InactiveCN105365998AReduce shockImprove seakeepingHydrodynamic/hydrostatic featuresHull structureMarine engineering

A hull structure with an underwater appendage comprises an underwater appendage structure arranged below the hull; a suspension is arranged between the underwater appendage structure and the hull; the hull structure arranges the suspension between the hull and the underwater appendage structure so as to buffer the wave impact load on the underwater appendage structure; the suspension can attenuate impact vibrations, can weaken refloating motions caused by posture adjustment, and comprises an elastic piece, a damper and a guide mechanism respectively providing buffering, damping and force transmission effects; the underwater appendage structure receives the impact transferred by the waves; the guide mechanism transfers force and moment between the underwater appendage structure and the bottom of the hull; the elastic piece can be deformed; the damper can provide damping effect for the elastic piece so as to prevent the elastic piece from swinging back and forth, so the impact on the bottom of the hull can be greatly reduced, thus improving hull sea-keeping, and improving passenger comfort level on the hull.

Owner:INST OF IND TECH GUANGZHOU & CHINESE ACADEMY OF SCI

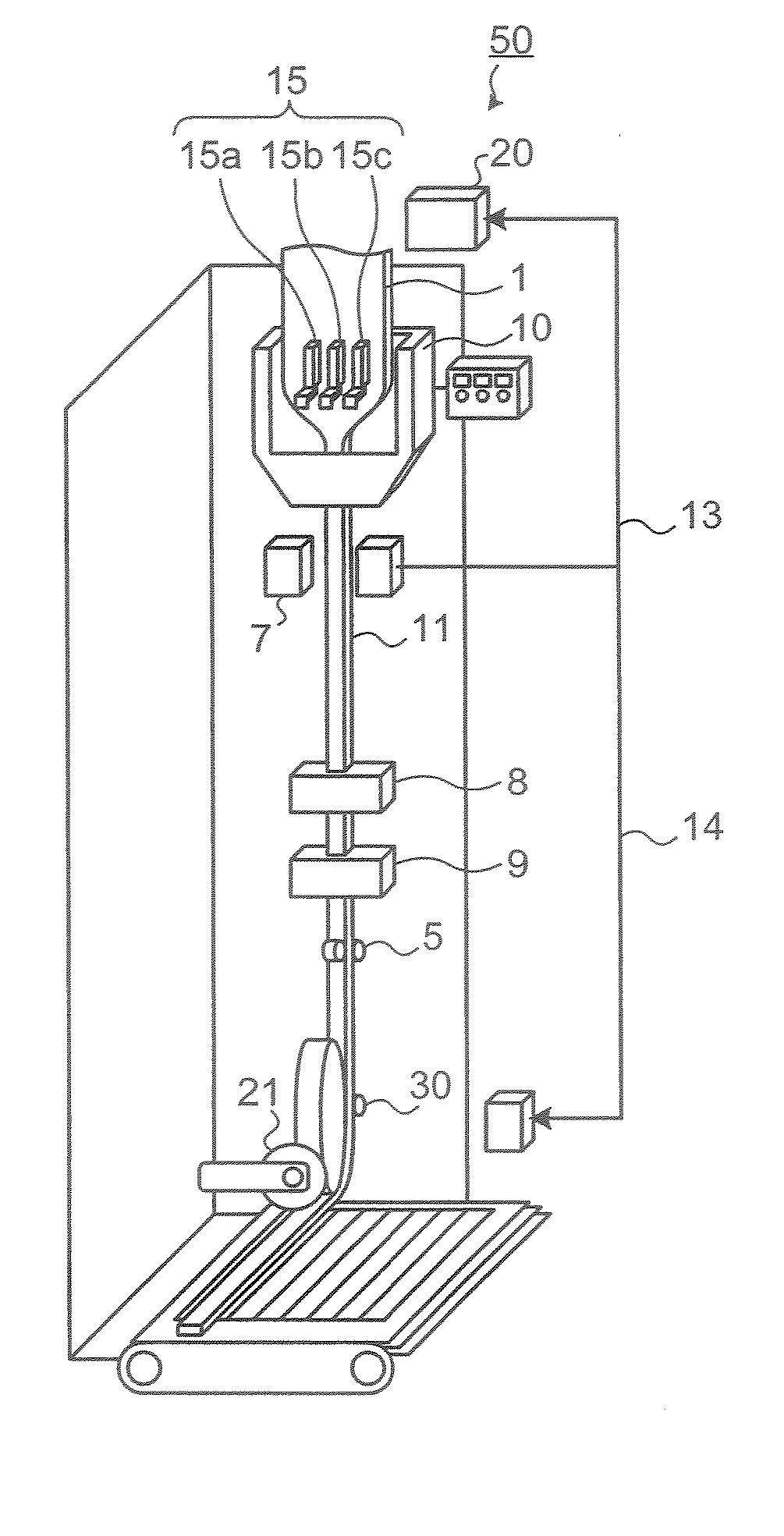

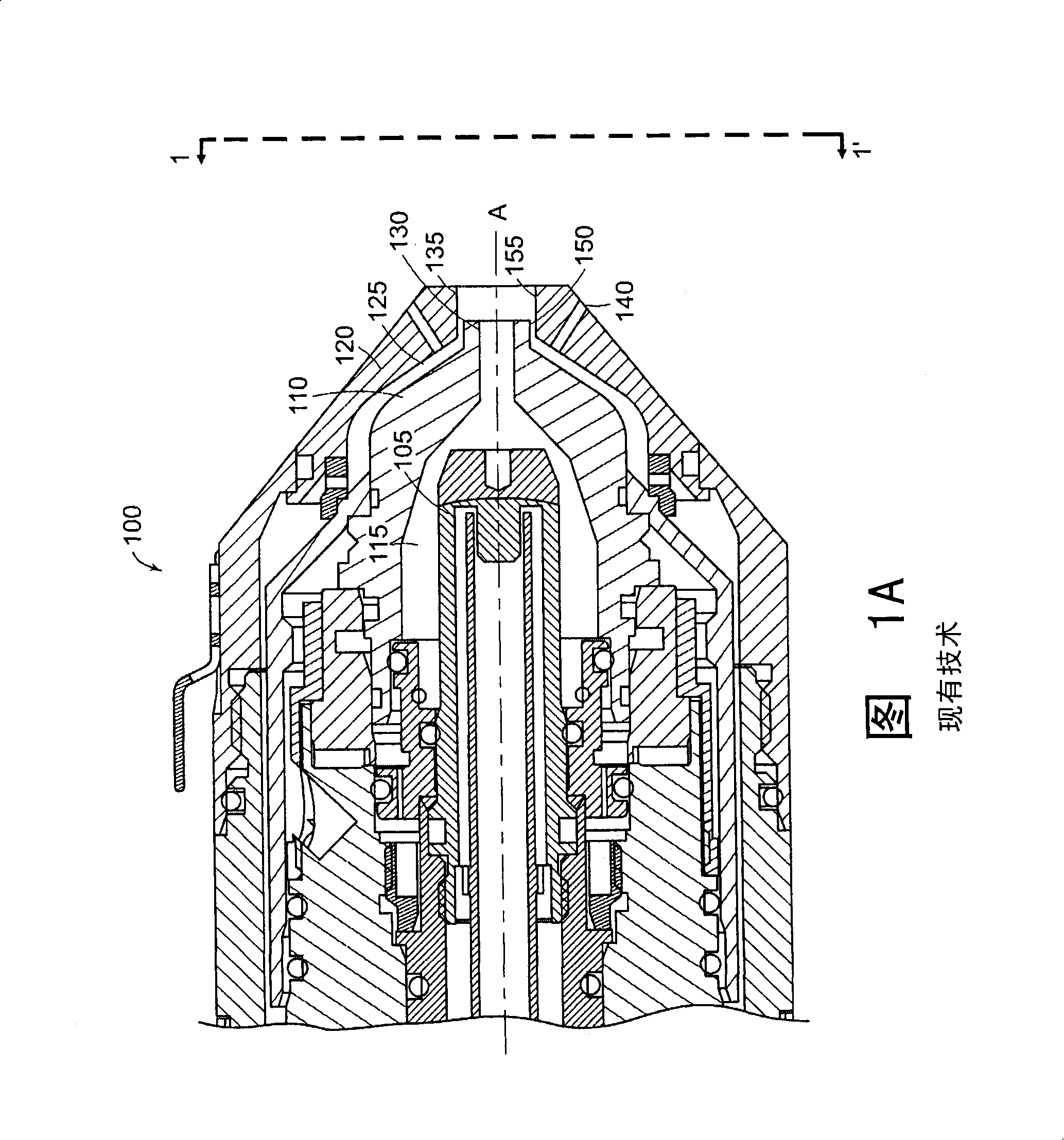

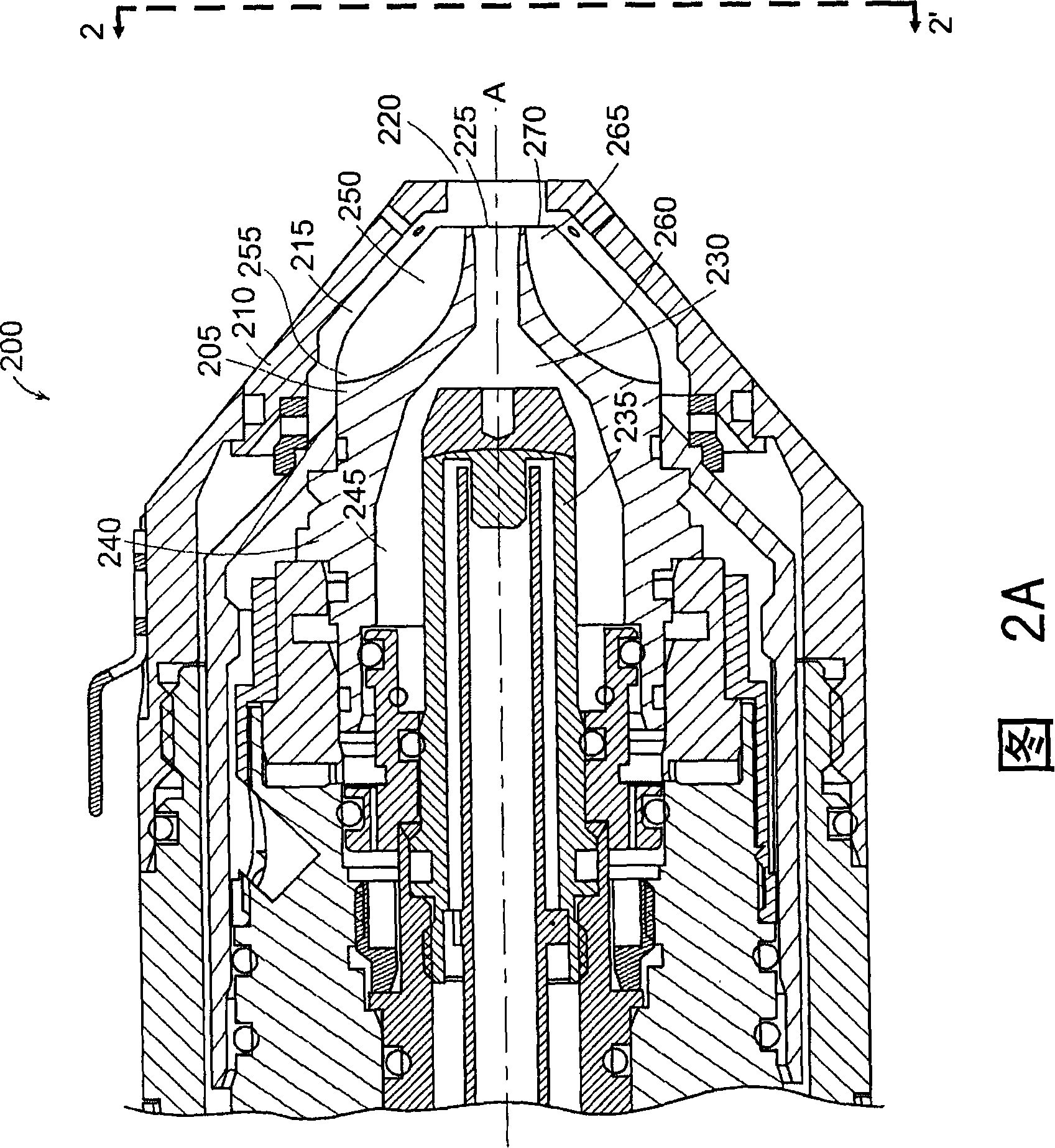

Generating discrete gas jets in plasma arc torch applications

ActiveCN101176387AExtended service lifeImprove cooling effectPlasma welding apparatusPlasma techniquePlasma jetProduction rate

The present invention is generally directed to a nozzle for a plasma torch, the nozzle having a rear portion that defines at least a portion of a plasma chamber and a front portion that includes a first end and a second end. The first end is adjacent the rear portion, and the second end defines a plasma exit portion. One or more fluid passageways are disposed within the front portion and extend from the first end to the second end. The fluid passageways have passageway exit portions that provide one or more discrete jets of a secondary fluid to surround a plasma jet that is ejected from the plasma exit portion. Features of the invention include faster cutting, thicker workpiece piercing capability, reduced noise, improved arc stability, and increased consumable life, all of which improve productivity associated with plasma arc torch workpiece processing.

Owner:HYPERTHERM INC

Polishing solution for magnesium alloy

The invention provides a polishing solution applied to the magnesium alloy. The polishing solution comprises an abrasive, a strong oxidant, a pH regulator and deionized water; the components are as follows by weight percentage: 10 percent to 40 percent of the abrasive I, 0.1 percent to 3 percent of the strong oxidant, 1 percent to 10 percent of the pH regulator and the balance is deionized water. The polishing solution can be used for polishing treatment of magnesium-alloy surface, effectively improve surface finish of the magnesium alloy, effectively reduce surface scratch after polishing, and reduce surface roughness after polishing; simultaneously, polishing debris is dissolved in the polishing solution, the magnesium-alloy surface is easy to be cleaned, the polishing speed is rapid, the polishing solution has no harm to equipment, and the usage security is high.

Owner:JIANGSU HAIXUN IND GROUP SHARE

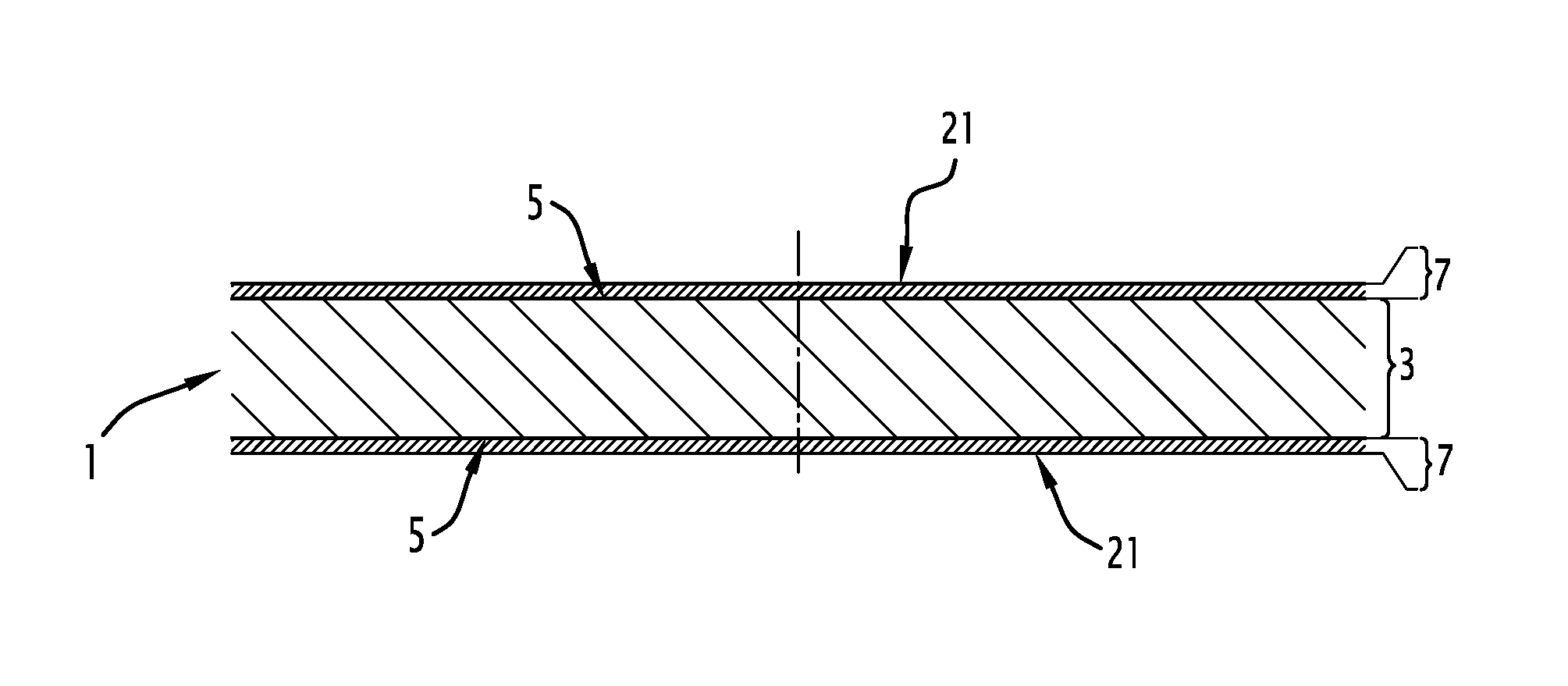

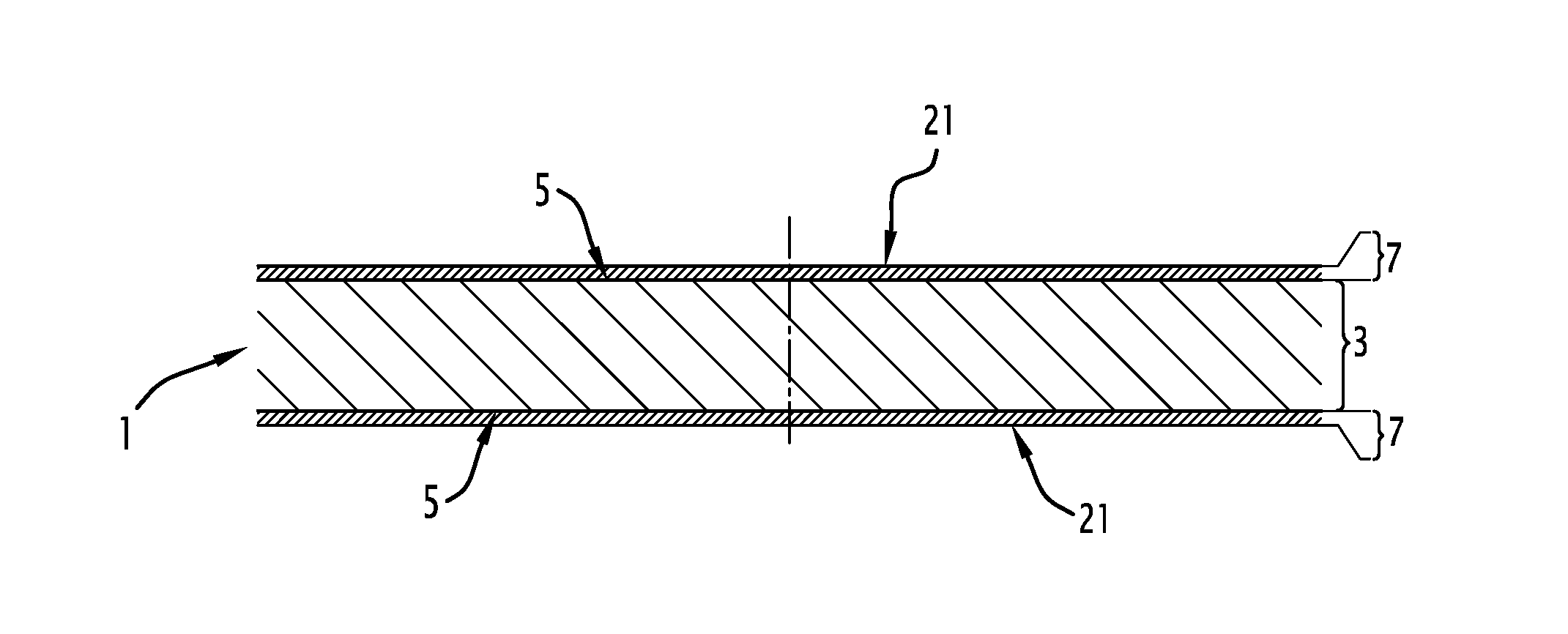

Sliding element procedure and device for its production

InactiveUS20080240634A1Low costEfficient productionLinear bearingsBearing bushesEngineeringConductor Coil

A method and a device is provided for producing a flat or arc-shaped sliding element with a very large radius of curvature. The sliding element has a sliding layer based on a fiber reinforced plastic with a plastic matrix and a reinforcing element containing at least one thread. The reinforcing element is deposited on a polygonal winding core by means of a guide with the addition of a synthetic resin forming the plastic matrix. The flat or arc-shaped segments formed between the edges are separated from the tubular, polygonal winding body thus formed after it has set.

Owner:FEDERAL MOGUL DEVA

Method for Manufacturing Parts with a Low Waviness from an Electrogalvanized Metal Sheet, Corresponding Part and Vehicle

ActiveUS20160339491A1Reduce thicknessQuality improvementHot-dipping/immersion processesElectrophoretic coatingsMetal coatingMetallurgy

A method for manufacturing parts is provided. The method includes cold rolling a substrate with work cylinders whose work surface has a roughness Ra2.5 of less than or equal to 3.6 μm, depositing the metal coating on at least one face of the annealed substrate by electrodeposition to form the metal sheet and deforming the cut metal sheet to form the parts. The outer surface of the metal coating has a waviness Wa0.8 of less than or equal to 0.5 μm after the deformation step. A part and vehicle are also provided.

Owner:ARCELORMITTAL INVESTIGACION Y DESARROLLO SL

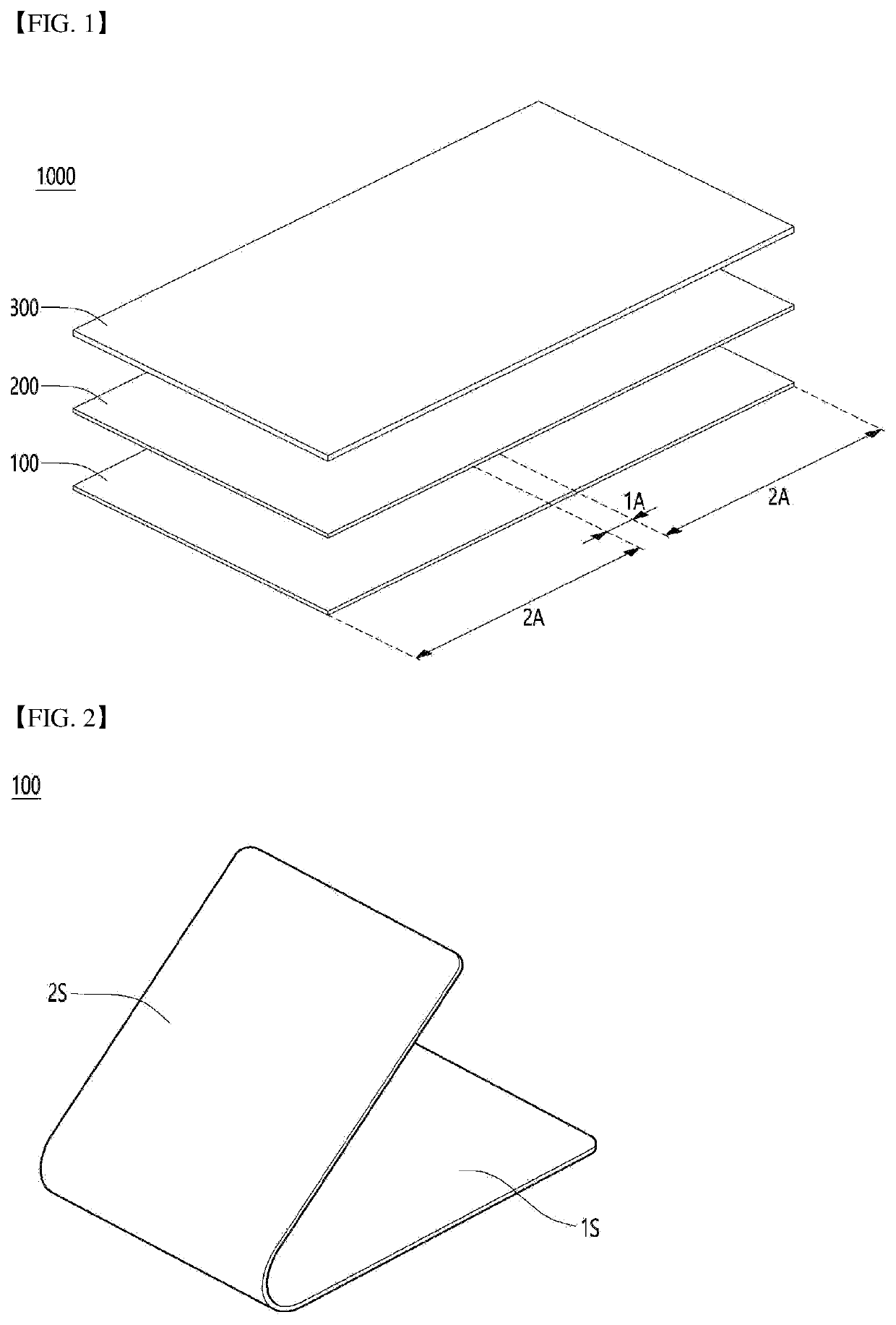

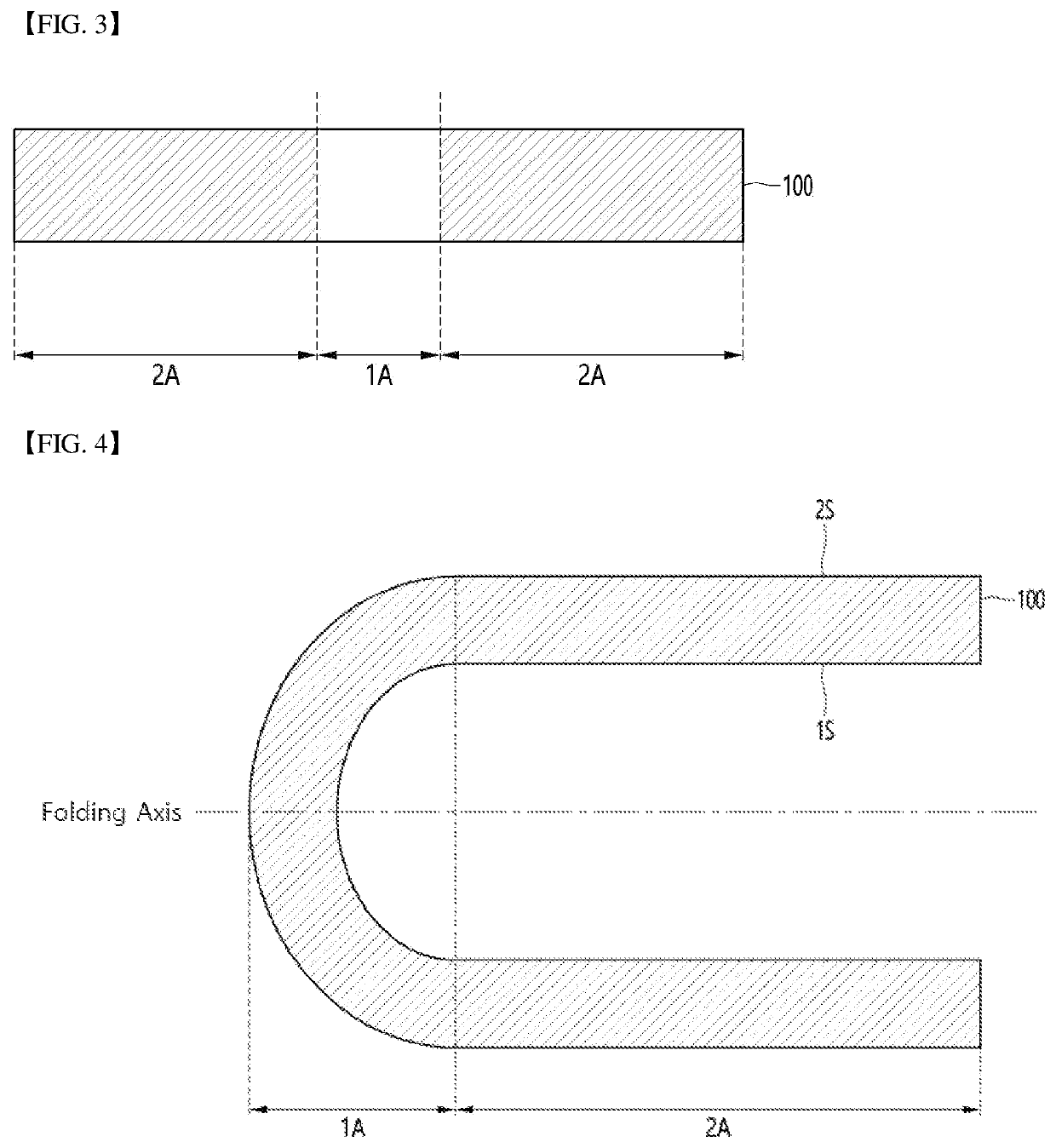

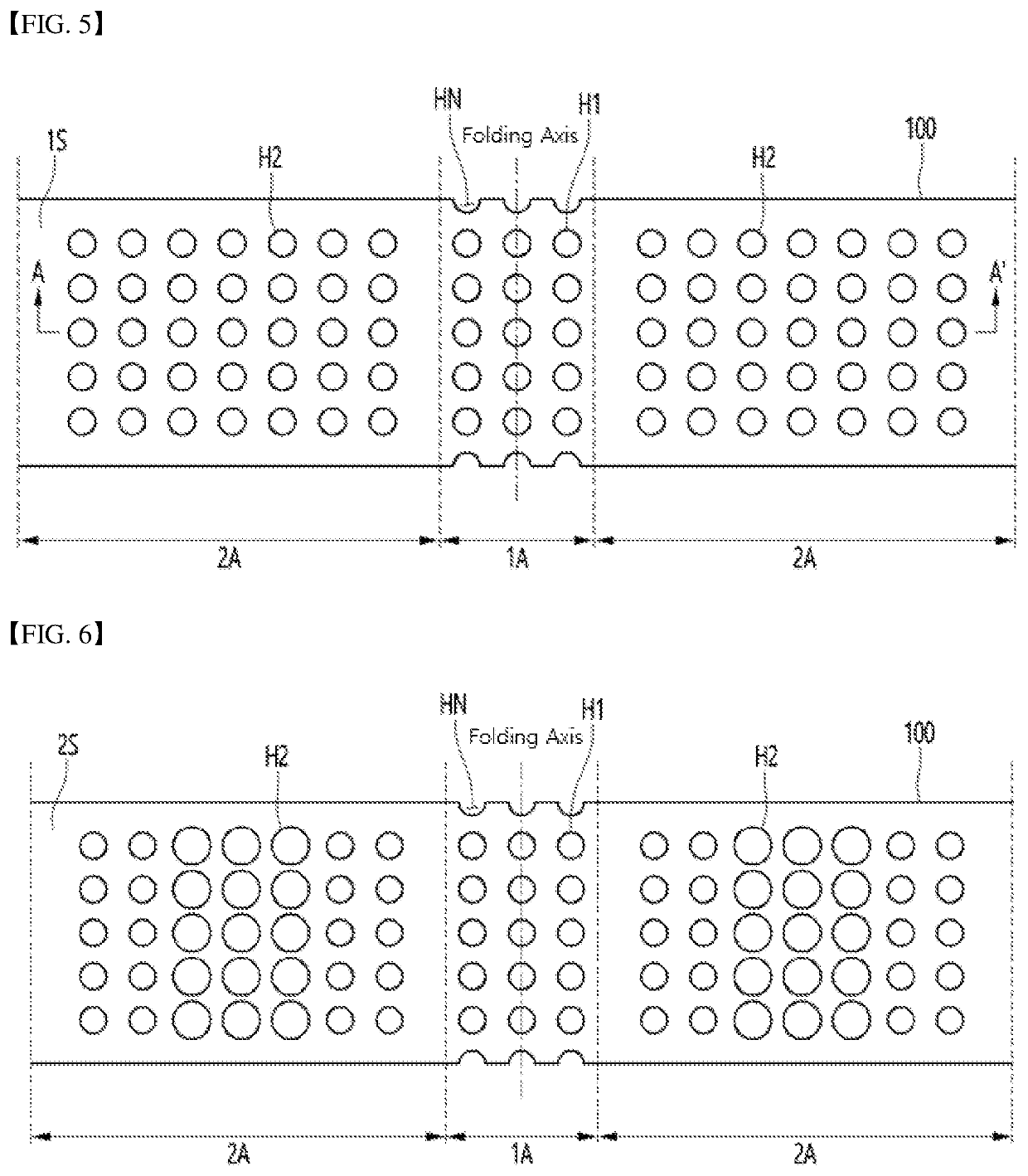

Substrate for display

PendingUS20220206537A1Reduce wavinessHigh surface flatnessDigital data processing detailsPivotal connectionsEngineeringMechanical engineering

Owner:LG INNOTEK CO LTD

Magnesium-aluminum alloy polishing solution and its preparation method and polishing method

The invention discloses a magnesium-aluminum alloy polishing solution. Each 1000g of the magnesium-aluminum alloy polishing solution comprises 5 to 12g of sodium coco-sulfate, 1 to 8g of sodium tripolyphosphate, 1 to 2.5g of sodium hydroxide, 4 to 11g of fatty alcohol polyoxyethylene ether, 0.4 to 2.5g of sodium citrate and the balance distilled water. The invention also discloses a preparation method of the magnesium-aluminum alloy polishing solution and a polishing method of the surface of a magnesium-aluminum alloy material. The magnesium-aluminum alloy polishing solution can improve surface brightness of a polished magnesium-aluminum alloy material.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

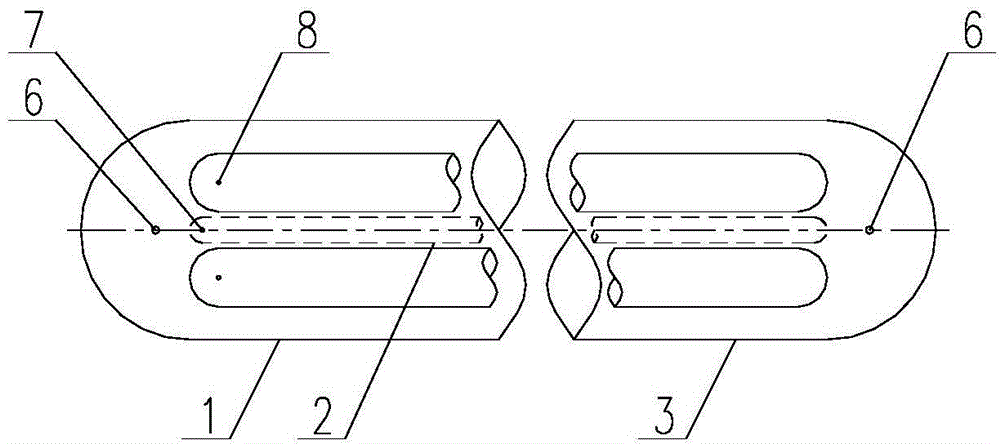

Flexible floating breakwater and containing device thereof

ActiveCN104790344AImprove adaptabilityReduce wavinessBreakwatersQuaysOpen waterBiomedical engineering

The invention discloses a flexible floating breakwater. The flexible floating breakwater comprises a first capsule body, a second capsule body, a third capsule body and an outer net structure, wherein the first capsule body is made of flexible materials, and the first capsule body is internally provided with gastight space capable of being filled with water; the second capsule body is made of the flexible materials, the second capsule body is internally provided with gastight space capable of being filled with gas, and the second capsule body is arranged on an inner surface of the first capsule body in the length direction of the first capsule body; the third capsule body is made of the flexible materials, the third capsule body is internally provided with gastight space capable of being filled with gas, and the third capsule body is arranged on an outer surface the first capsule body in pairs in the length direction of the first capsule body; the whole capsule body is wrapped by the outer net structure. The flexible floating breakwater can be installed quickly and anchored by a matched anchoring system, the flexible floating breakwater floats and is unfolded on water, when the flexible floating breakwater is arranged at an open water area, the function of reducing the wave effect can be achieved, and after work is finished, the flexible floating breakwater can be recovered, stored, transported quickly and recycled.

Owner:CCCC SECOND HARBOR ENG

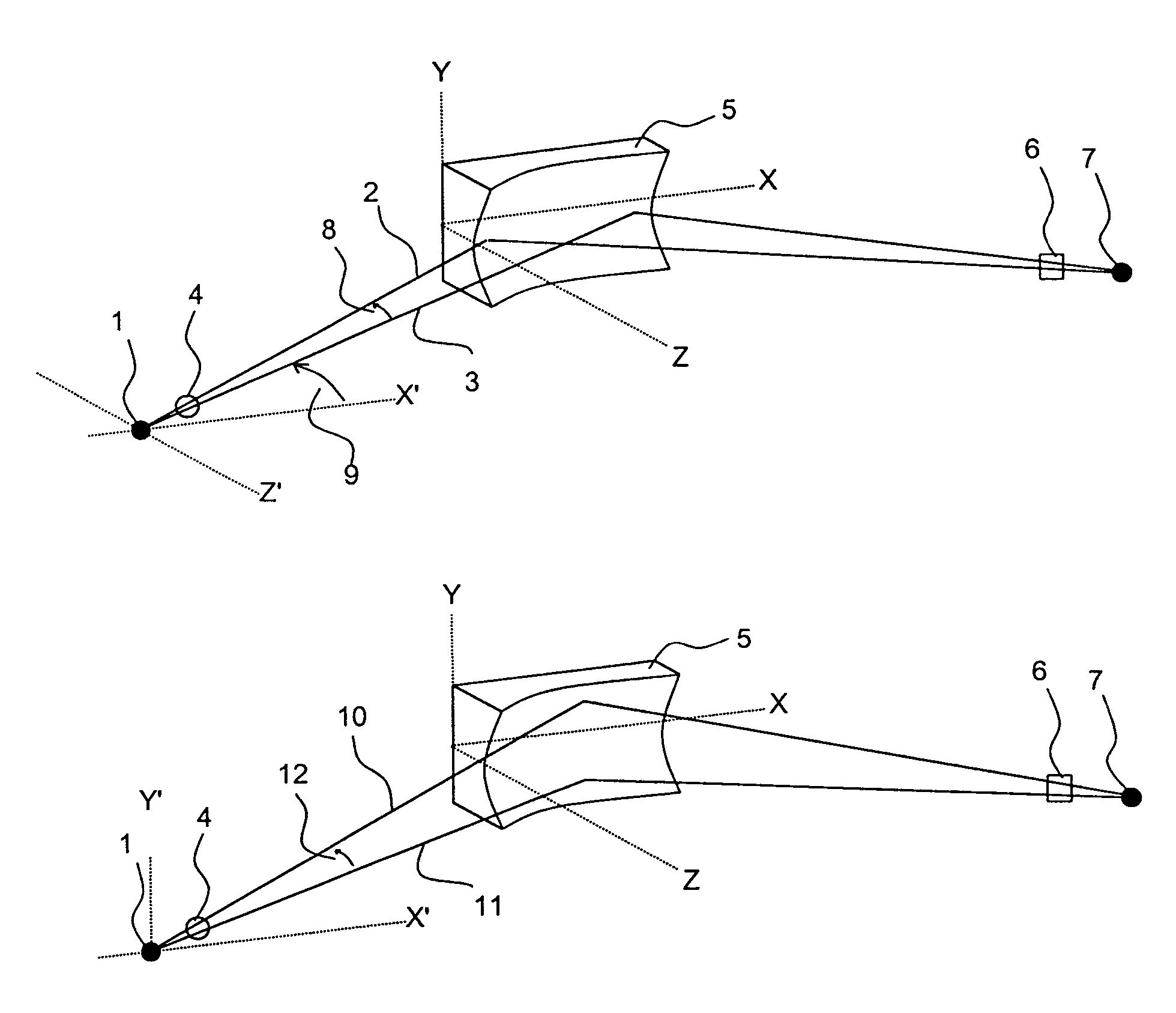

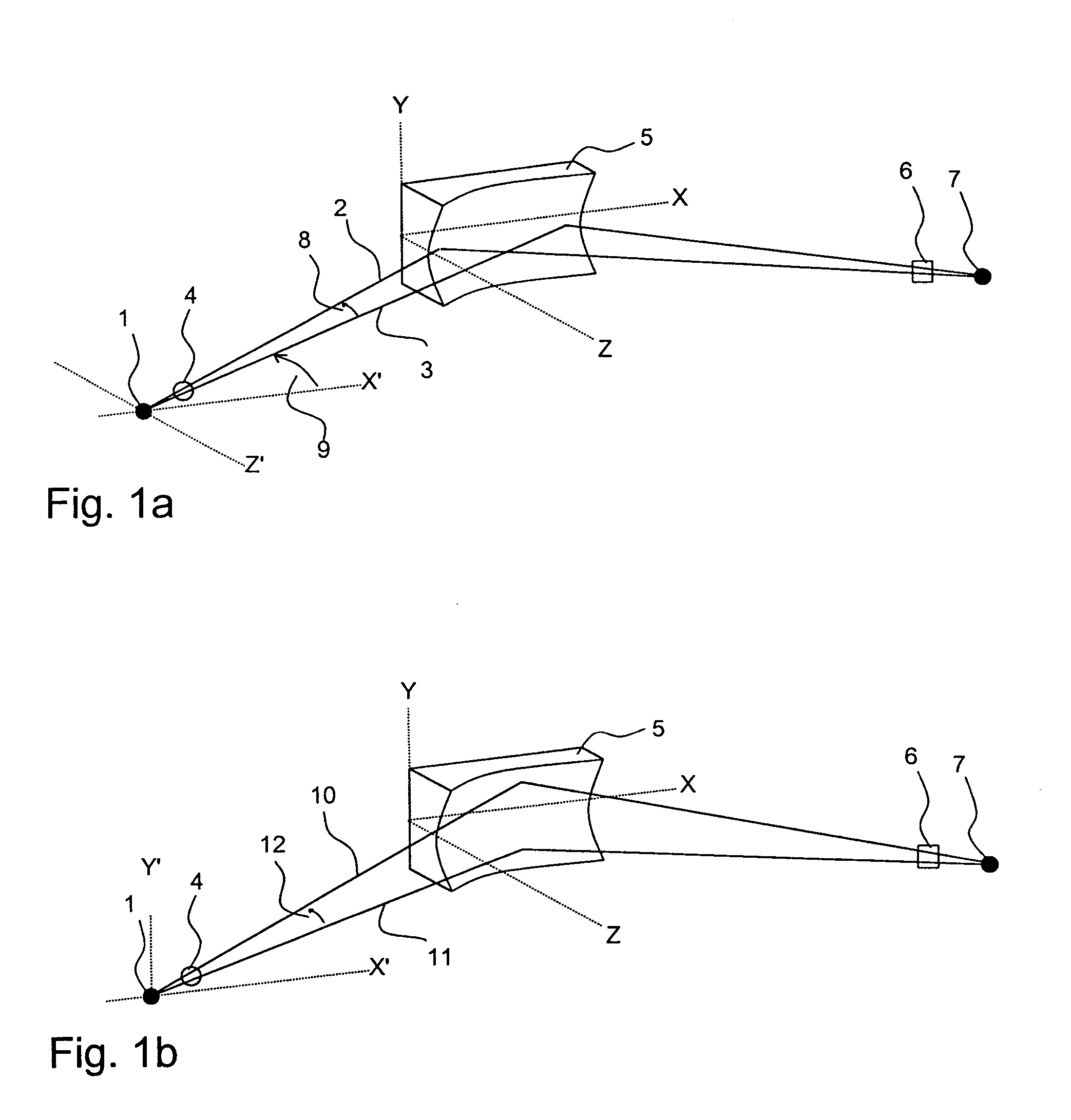

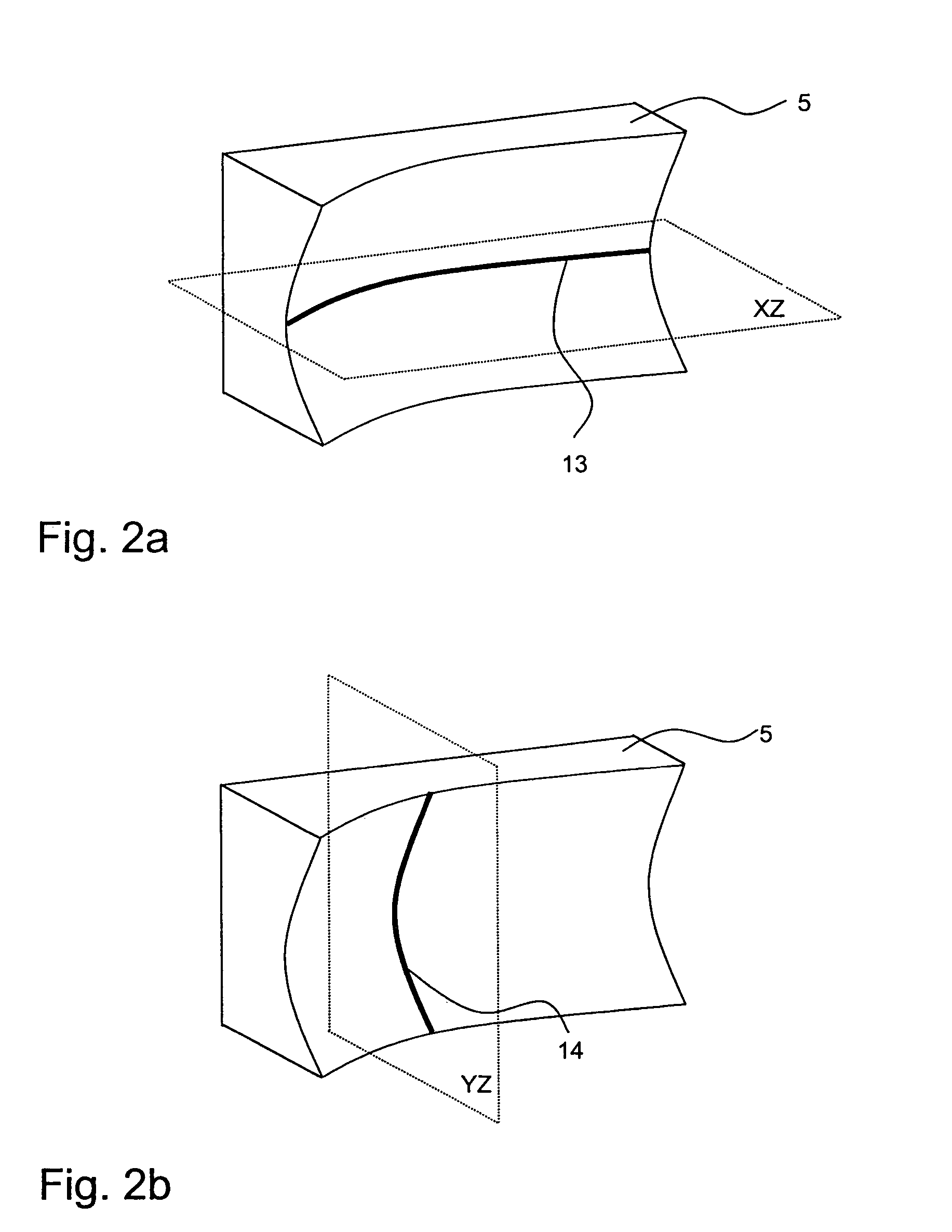

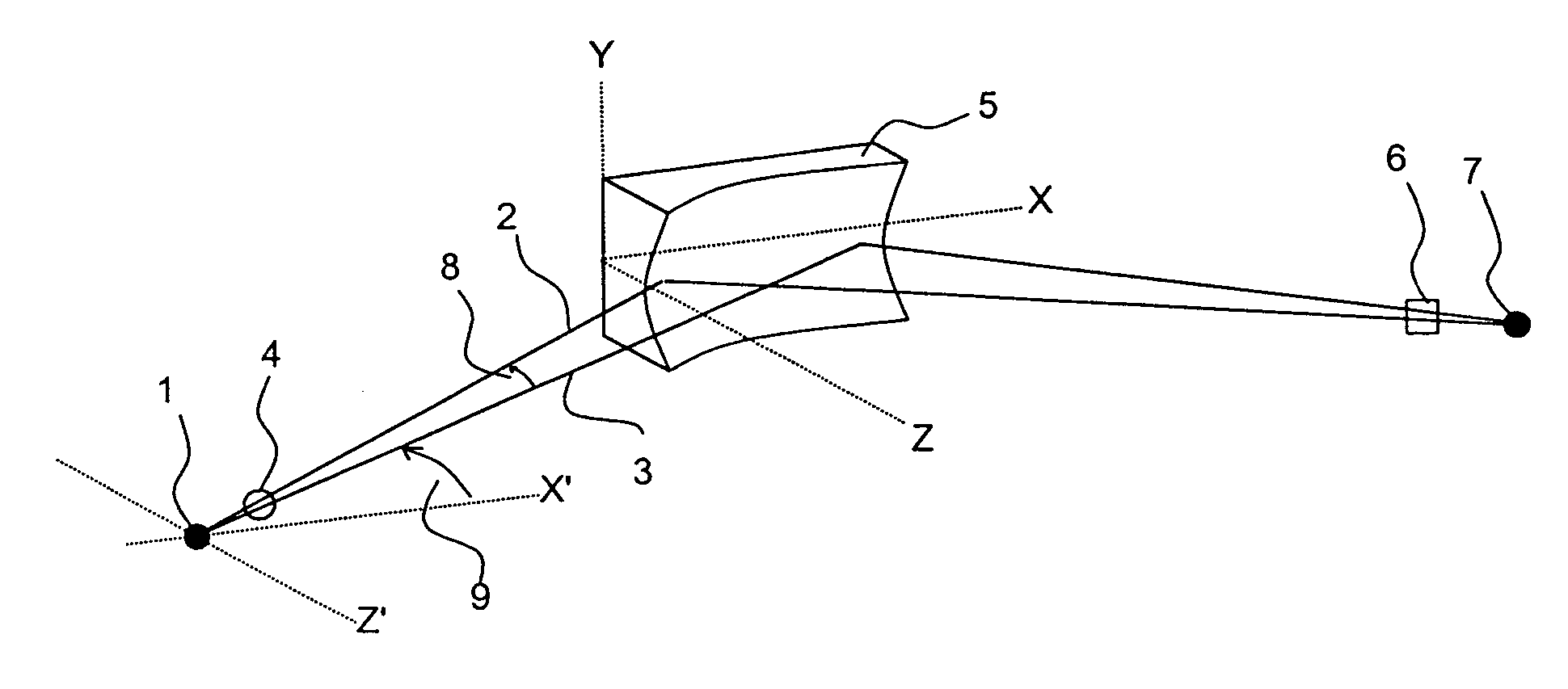

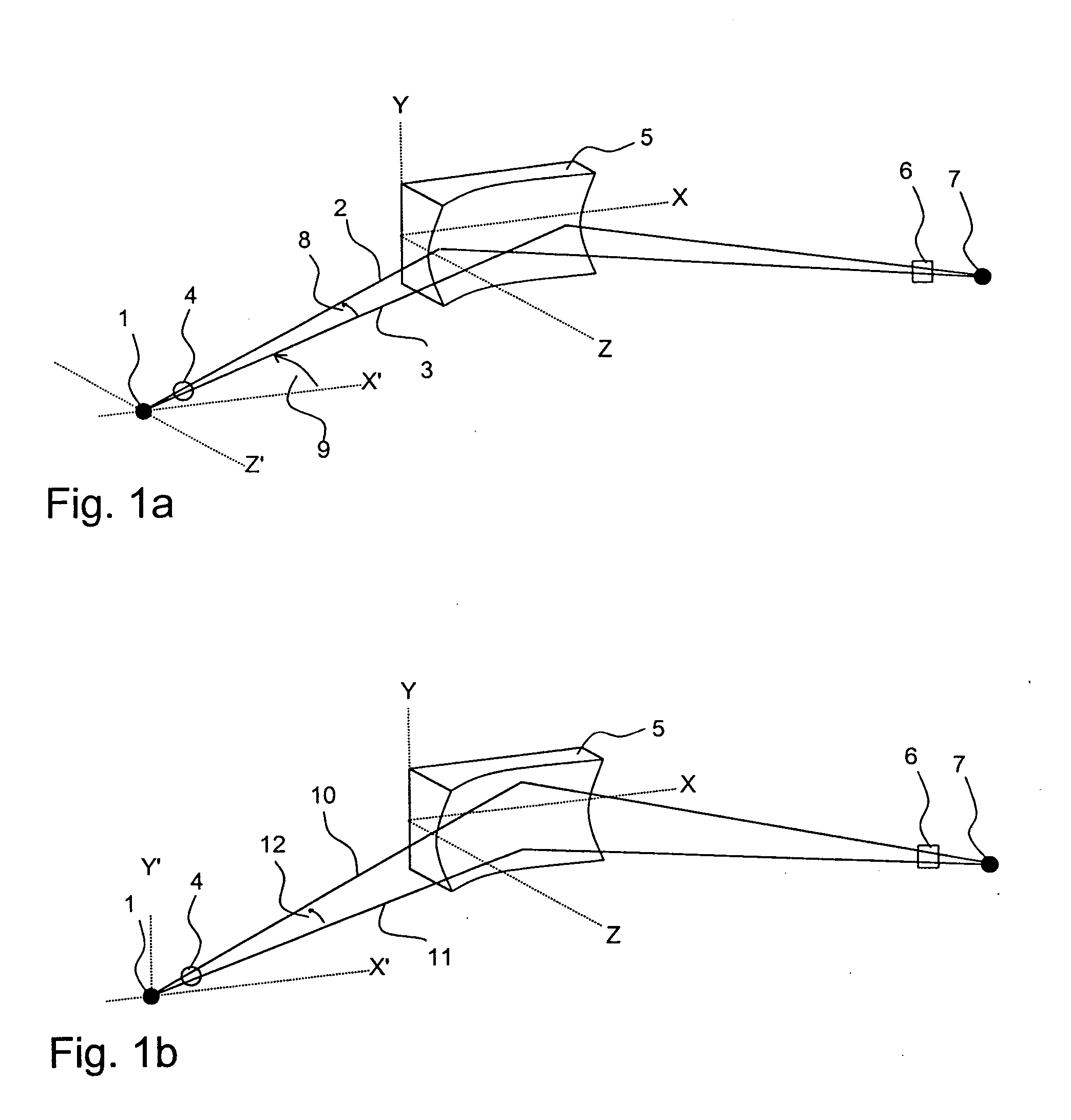

Method for manufacturing a reflector for X-ray radiation

InactiveUS7242746B2Reduce curvatureReduce roughnessX-ray spectral distribution measurementElectrode and associated part arrangementsX-rayLight beam

A method for manufacturing a reflector (5) for X-ray radiation (2, 3, 10, 11) which is curved in a non-circular arc shape, along a first cross-section (13) in a plane (XZ) which contains a x-direction, wherein the reflector (5) is also curved along a second cross-section (14) in a plane (YZ) which is perpendicular to the x-direction, is characterized in that the reflector (5) has a curvature along the second cross-section (14) which also differs from the shape of a circular arc. This makes the design of X-ray mirrors and the beam profile of reflected X-ray radiation more flexible, facilitates production of X-ray mirrors and at the same time provides high reflection capacity and good focusing properties for X-ray mirrors.

Owner:INCOATEC

Livestock Waterer

InactiveUS20100064977A1Reduce morbidityOptimize the installation structureAnimal watering devicesAnimal feeding devicesEngineeringLivestock

A livestock waterer for use in frigid climates includes a lid which floats on the surface of the water in each basin of the waterer. The lid is hollow with a convex upper surface and with baffle walls depending from the underside of the lid. The baffle walls interrupt wave action on the surface of the water created by depression of the lid into the water when an animal presses down on the lid to gain access to the water. The floor of each basin is provided with an integrally formed mounting post to support a heater within the basin. The baffles walls prevent exhaustion of water within the basin thereby preserving submersion of the heater at all times.

Owner:BARKER RUHL A

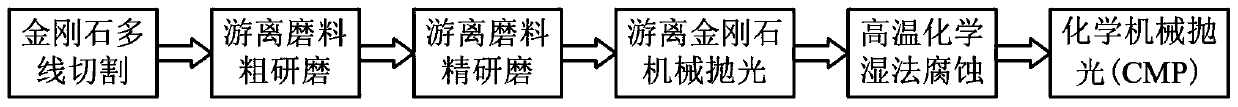

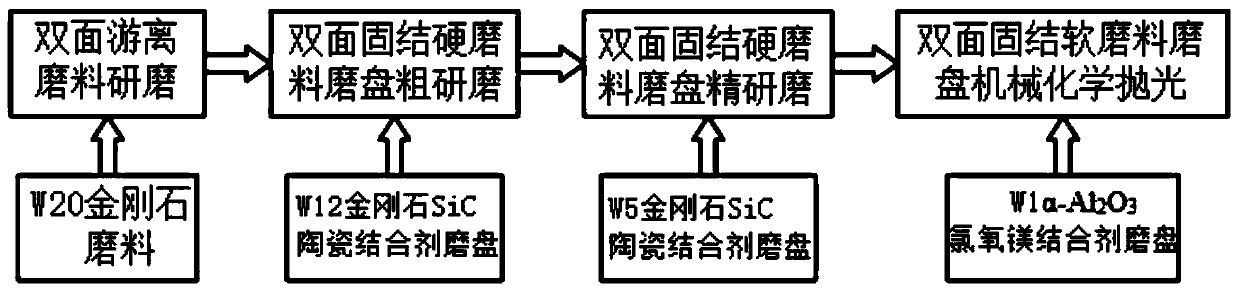

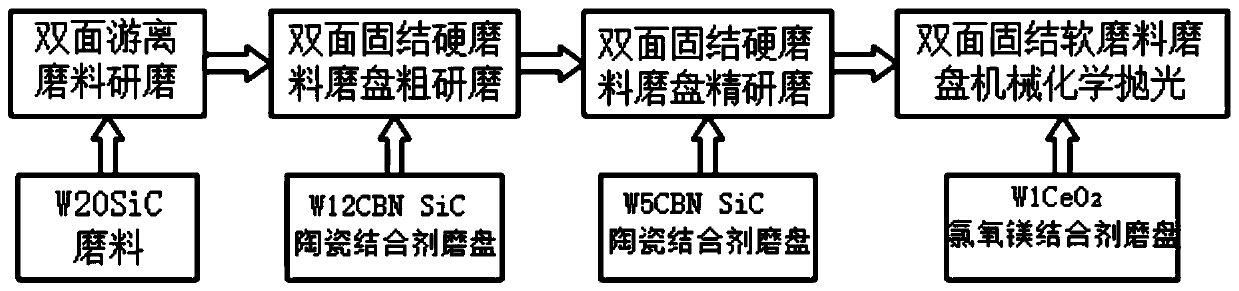

Processing method of thin plate-shaped sapphire wafer

ActiveCN110539209AGood surface accuracyStrong machining accuracyLapping machinesMaterial removalSapphire wafer

The invention discloses a processing method of a thin plate-shaped sapphire wafer. The processing method is characterized by comprising the following steps that a thin plate-shaped sapphire wafer is sequentially subjected to double-sided free abrasive grinding, double-sided consolidation hard abrasive grinding disc coarse grinding, double-sided consolidation hard abrasive grinding disc fine grinding and double-sided consolidation soft abrasive grinding disc mechanical polishing treatment. The double-sided grinding of the free abrasive is mainly used for reducing the ripple degree of the thin plate-shaped sapphire wafer and controlling the flatness. The grinding pressure can be increased by the double-sided consolidation abrasive grinding disc grinding, the material removal rate is improved, the processing precision and the surface quality controllability are high, and the processing efficiency is high. The double-sided consolidation soft abrasive grinding disc mechanical polishing treatment can greatly improve the grinding and polishing efficiency of the wafer, avoids a large amount of loss of the traditional silica sol polishing solution, reduces the cost, and is green and environment-friendly. According to the processing method, the thin plate-shaped sapphire wafer can be processed and manufactured with high precision, high quality and high efficiency.

Owner:DALIAN UNIV OF TECH

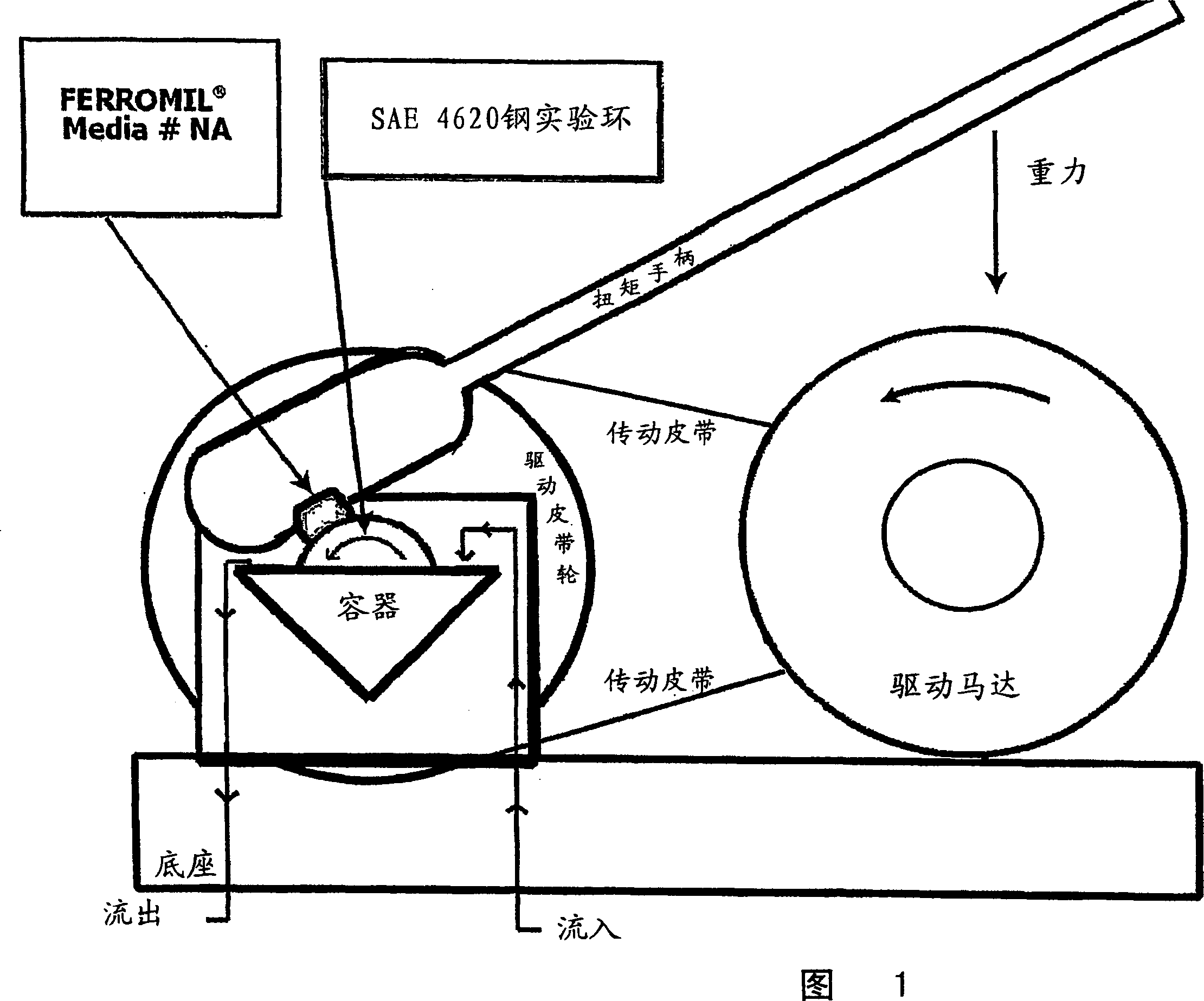

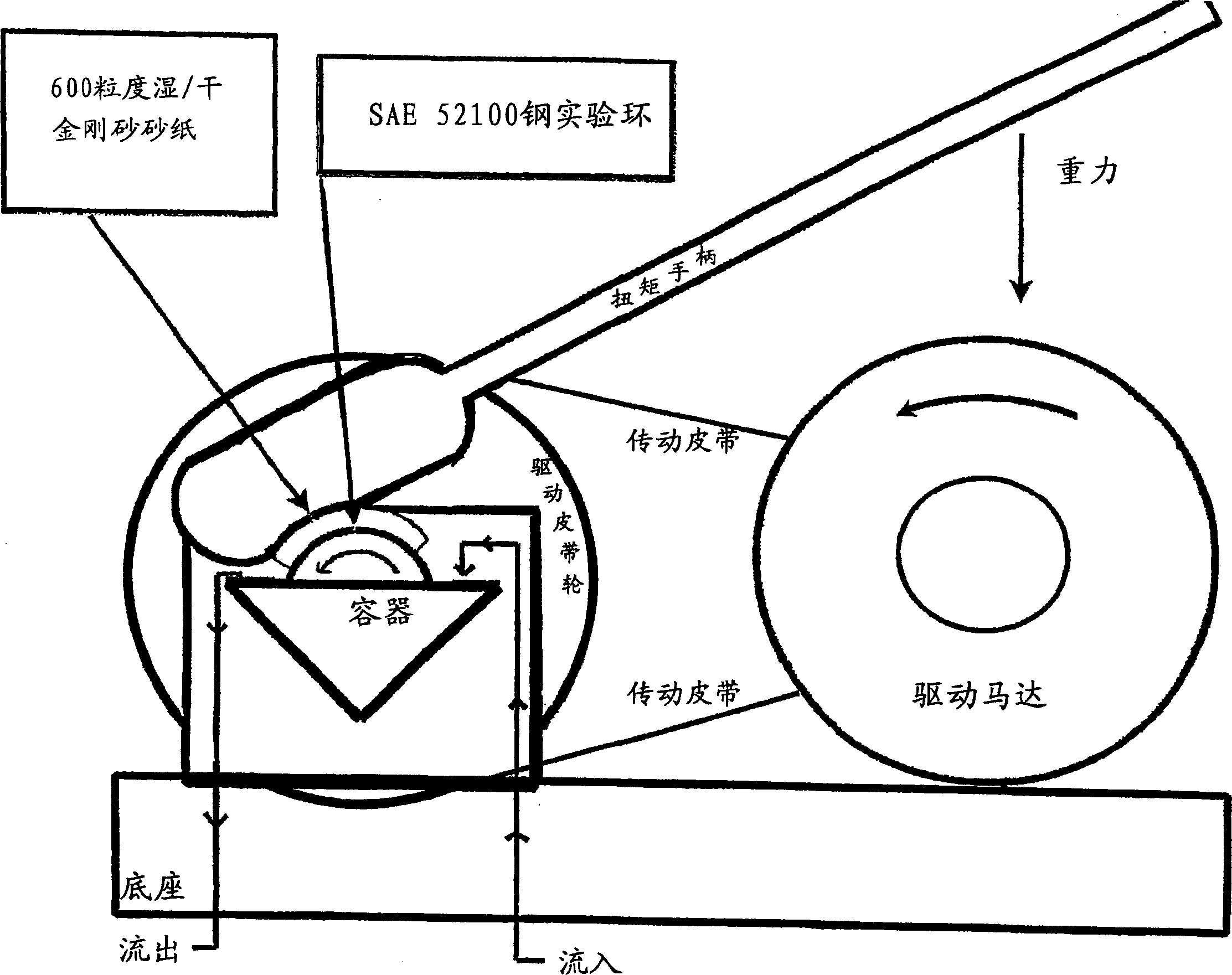

Chemical mechanical machining and surface finishing

InactiveCN1491146AReduce wearEliminate temperingRevolution surface grinding machinesLapping machinesSurface finishRelative motion

Owner:REM TECHNOLOGY INC

Numerical control milling machine spindle box structure

ActiveCN108526495APrevent PitchingImprove anti-overturn performanceMetal-working apparatusNumerical controlSurface roughness

The invention discloses a numerical control milling machine spindle box structure. The numerical control milling machine spindle box structure comprises a first box body, a second box body, a guide rail and a sliding block; the rear end face of the first box body is arranged on a stand column, the guide rail and the second box body are arranged on the front end face of the first box body, one endof the sliding block is fixed to the second box body, the other end of the sliding block is connected with the guide rail, and the sliding block slides along the guide rail along with rotation of thesecond box body. Through connection of the guide rail and the sliding block, a spindle box has the higher overturning-prevention capacity, the whole structural rigidity of the spindle box can be improved, meanwhile, avoiding of a tool fluttering condition is assisted, the surface roughness and the waviness of blades are reduced, machine tool machining precision is improved, and the blade machiningquality is improved.

Owner:TSINGHUA UNIV

Method for manufacturing a reflector for X-ray radiation

InactiveUS20060133569A1Reduce curvatureReduce roughnessX-ray spectral distribution measurementElectrode and associated part arrangementsSoft x rayLight beam

A method for manufacturing a reflector (5) for X-ray radiation (2, 3, 10, 11) which is curved in a non-circular arc shape, along a first cross-section (13) in a plane (XZ) which contains a x-direction, wherein the reflector (5) is also curved along a second cross-section (14) in a plane (YZ) which is perpendicular to the x-direction, is characterized in that the reflector (5) has a curvature along the second cross-section (14) which also differs from the shape of a circular arc. This makes the design of X-ray mirrors and the beam profile of reflected X-ray radiation more flexible, facilitates production of X-ray mirrors and at the same time provides high reflection capacity and good focusing properties for X-ray mirrors.

Owner:INCOATEC

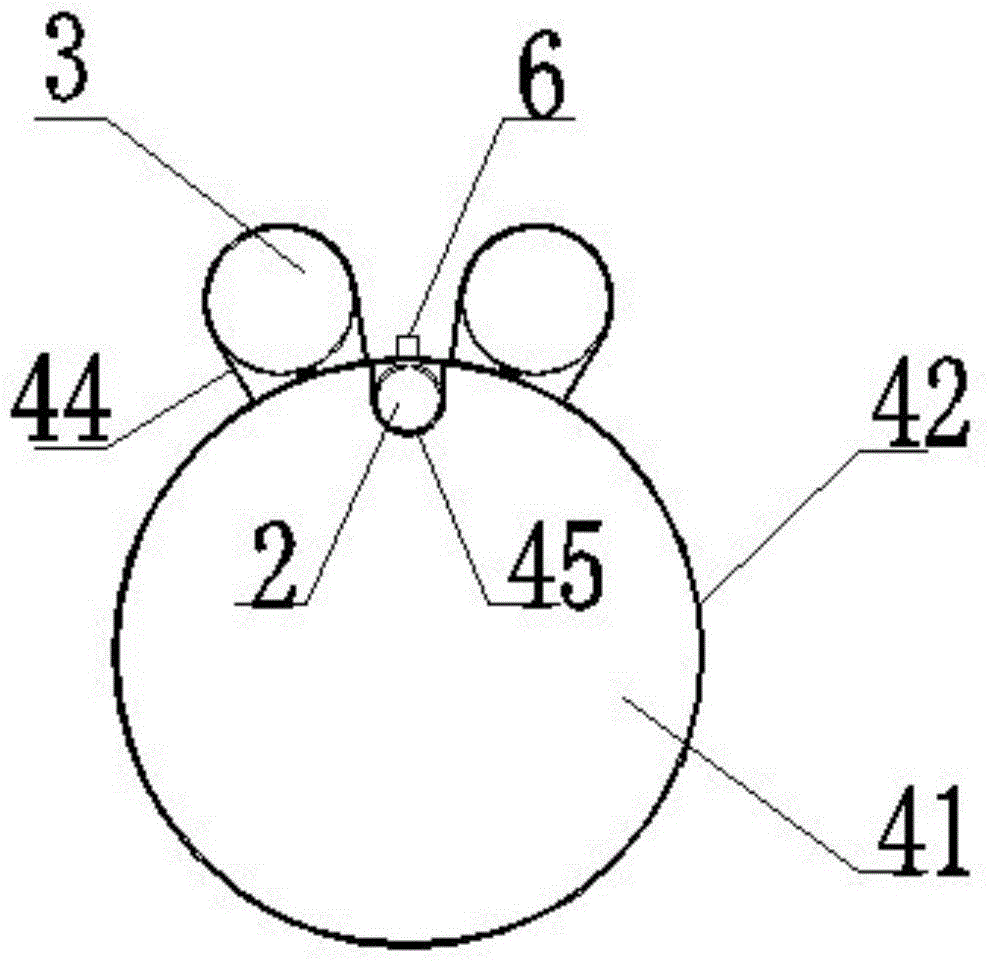

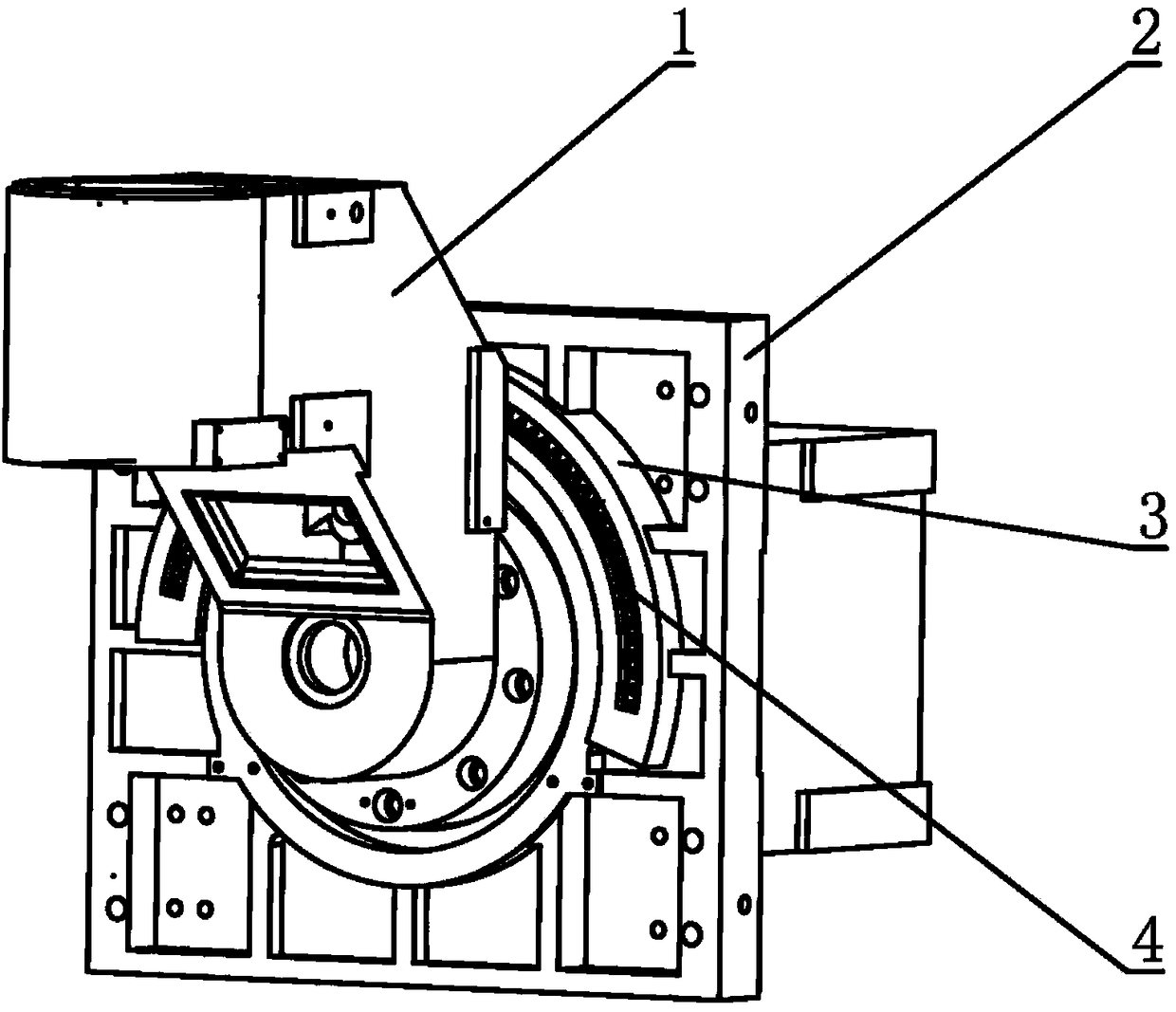

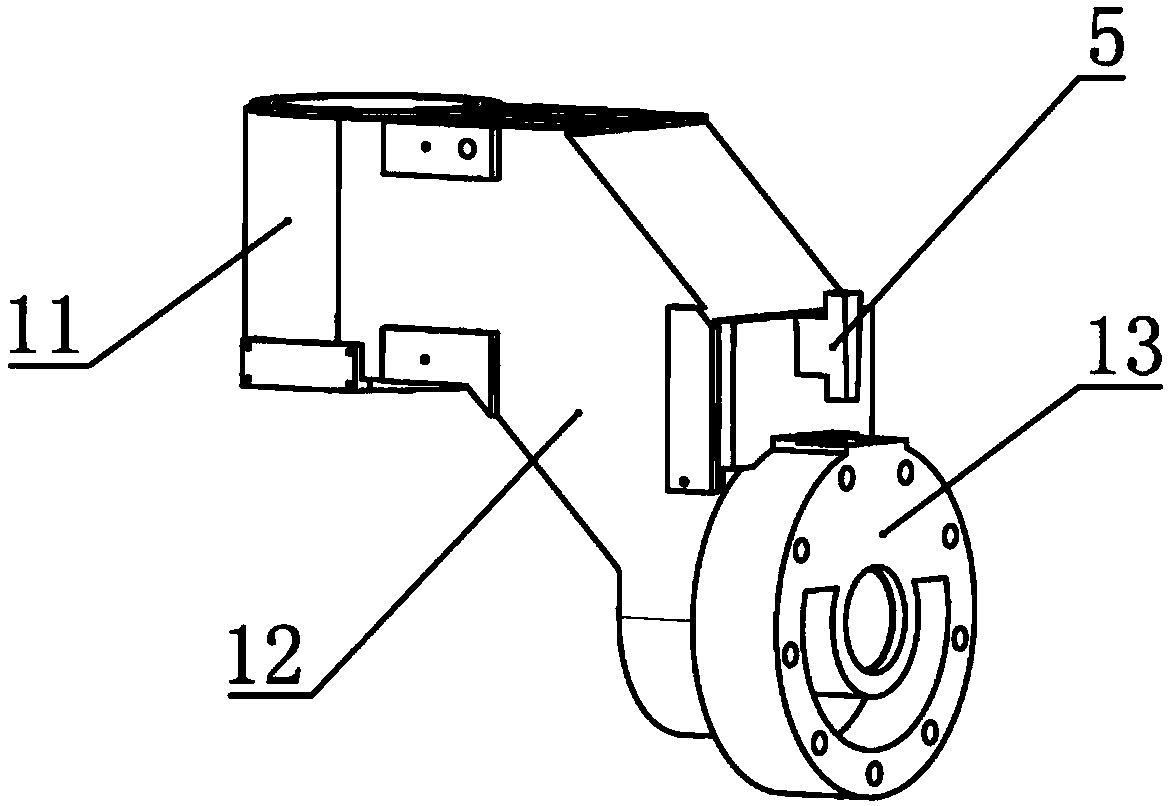

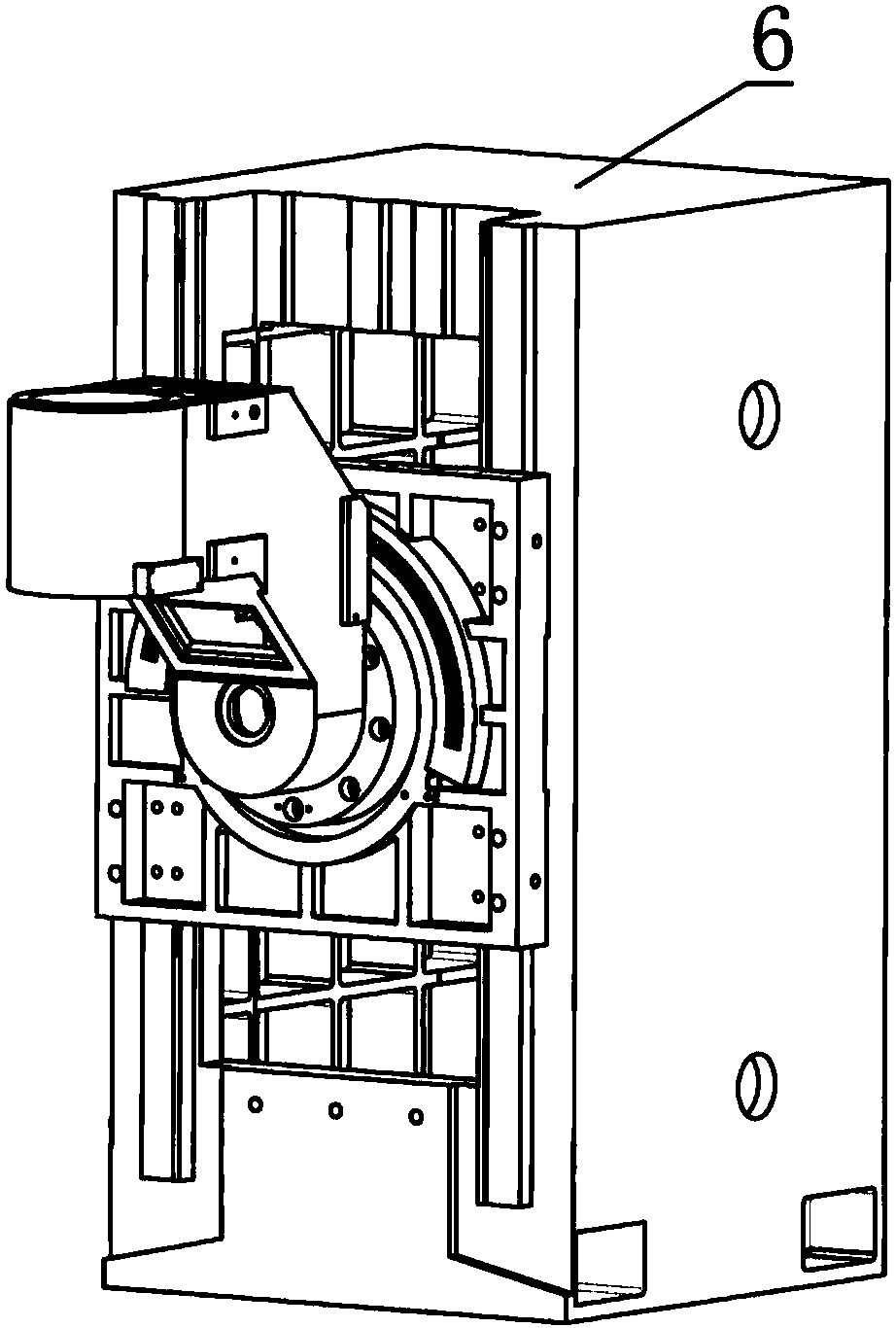

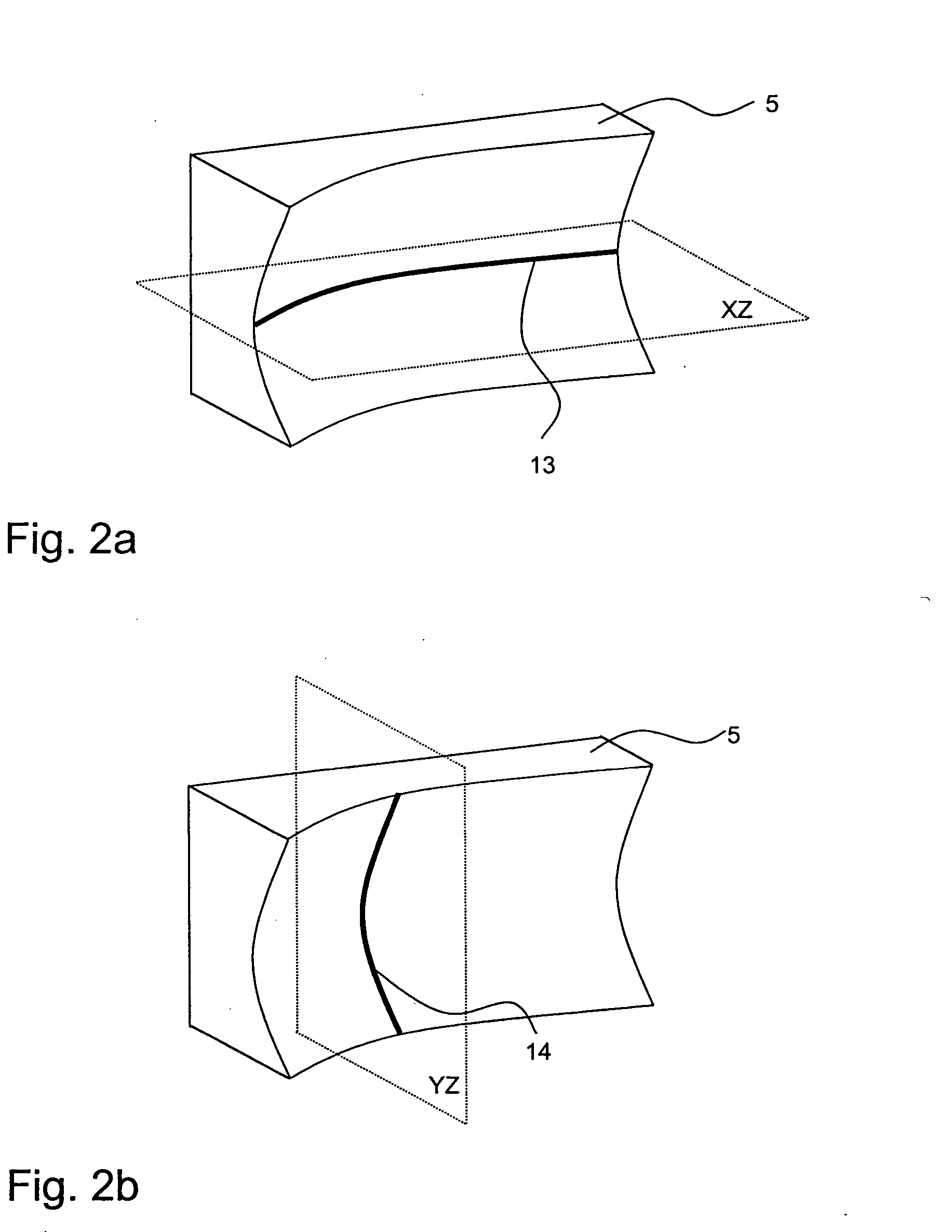

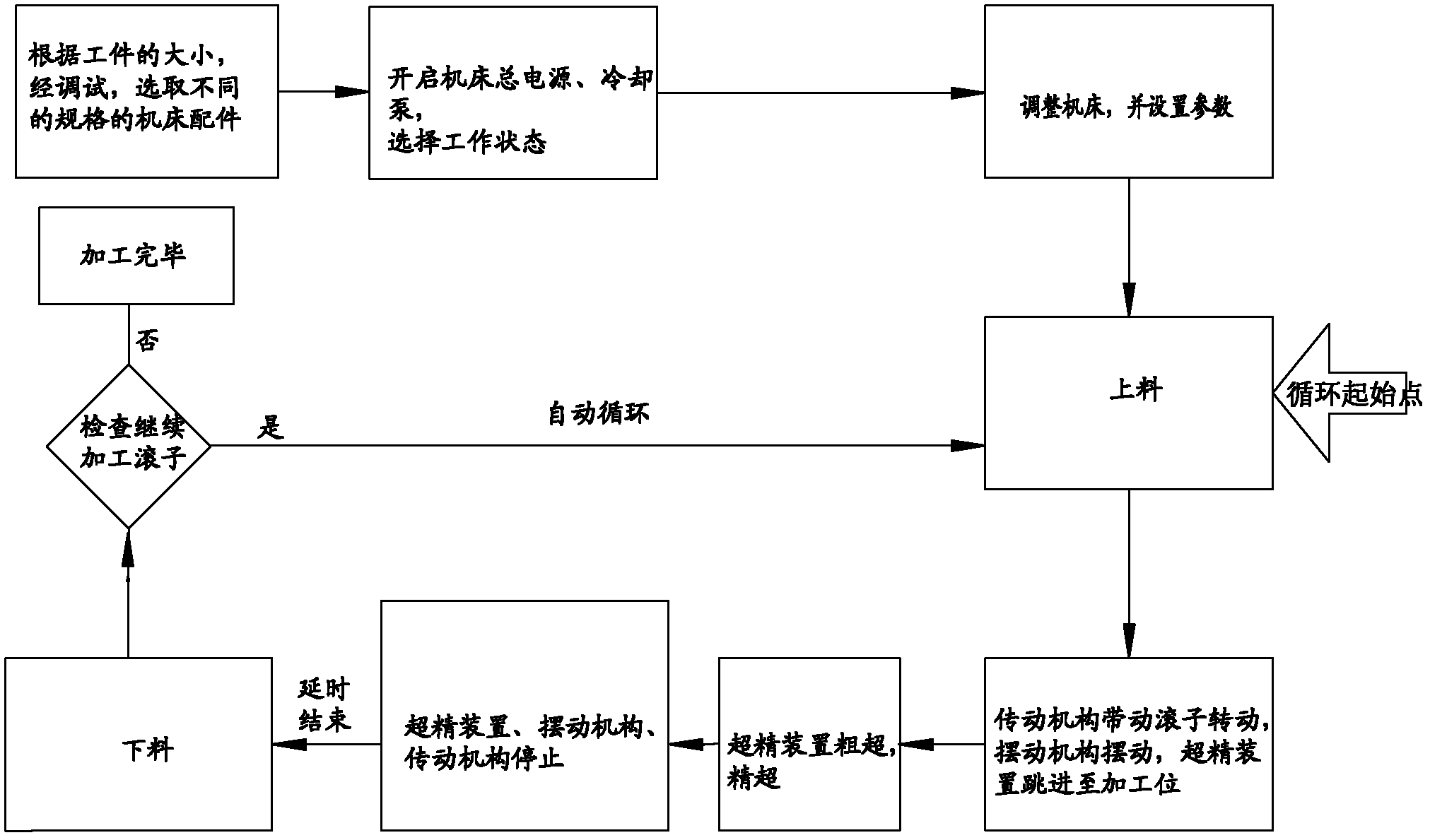

Spherical Roller Outer Diameter Superfinishing Technology

ActiveCN102294645ANot easy to rustExtended service lifeHoning machinesMachine toolIndustrial engineering

The invention discloses a superfine process for the outer diameter of a spherical roller. The superfine process comprises the following specific steps of: 1, debugging according to the size of a workpiece and selecting machine tool fittings of different specifications; 2, switching on a general power supply of a machine tool and a cooling pump and selecting a working status; 3, adjusting the machine tool and setting parameters thereof; 4, feeding with a blanking cylinder of a feeding / blanking mechanism; 5, driving the roller to rotate with a workpiece transmission mechanism, making an oscillating mechanism oscillate and making a superfine mechanism jump into a processing position; 6, performing rough processing and superfine processing with the superfine mechanism; 7, stopping the superfine mechanism, the oscillating mechanism and the workpiece transmission mechanism; and 8, blanking with the feeding / blanking mechanism. The invention has the advantages: the spherical roller has a long service life; the roughness value is small, the Ra is 0.05 mum after superfine processing, the circular degree is increased by 30 percent and is less than 1 mum, and the corrugation is reduced by 30 percent and is less than 1 mum; and the spherical roller is arranged on an elevator bearing after superfine processing, so that the noise is lowered by 30 percent and meets the user requirement in comparison to the noise before superfine processing.

Owner:WUXI RUIDING MACHINE TOOLS

Polishing fluid of Nano silicon dioxide grinding material in use for processing microcrystalline glass, and preparation method

InactiveCN101050338AGood dispersionUniform particle size distributionPolishing compositions with abrasivesIonCorrosion

This invention provides nanoscale SiO2-abrasive polishing solution used for processing glass ceramics. The polishing solution comprises: abrasive I 10-40 wt.%, abrasive II 5-20 wt.%, surfactant 0.01-0.6 wt.%, pH regulator 1-6 wt.%, and deionized water as balance. The pH value of the polishing solution is 10-12. The polishing solution can be used for polishing glass ceramics, and can reduce surface scratches and surface toughness of polished glass ceramics, which can be used for fabricating computer hard disk substrates. The polishing solution has such advantages as high polishing speed, no corrosion to apparatus, and high safety.

Owner:江苏海迅实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com