Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

94 results about "Abrasive grinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Grinding is an abrasive machining process that uses a grinding wheel as the cutting tool. A wide variety of machines are used for grinding: Hand-cranked knife-sharpening stones (grindstones) Handheld power tools such as angle grinders and die grinders.

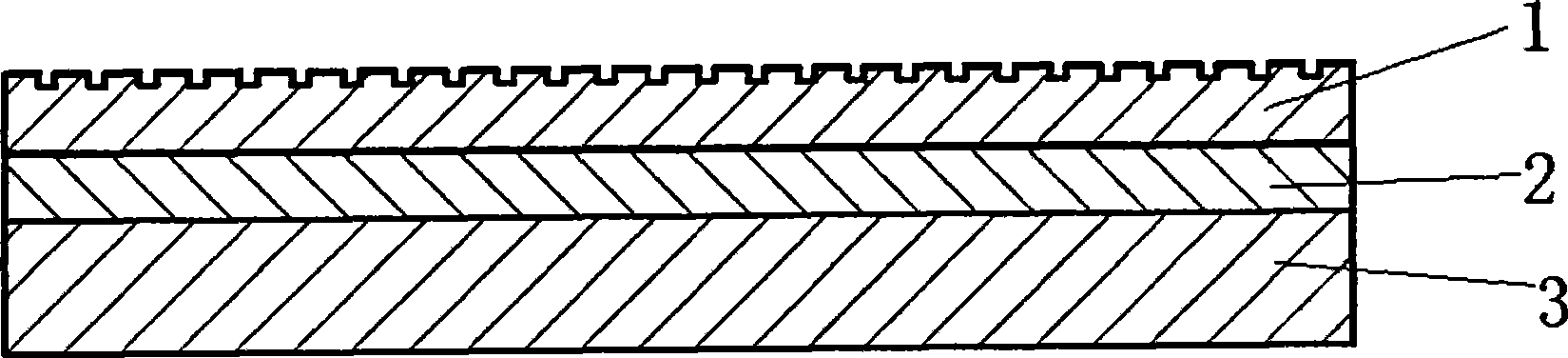

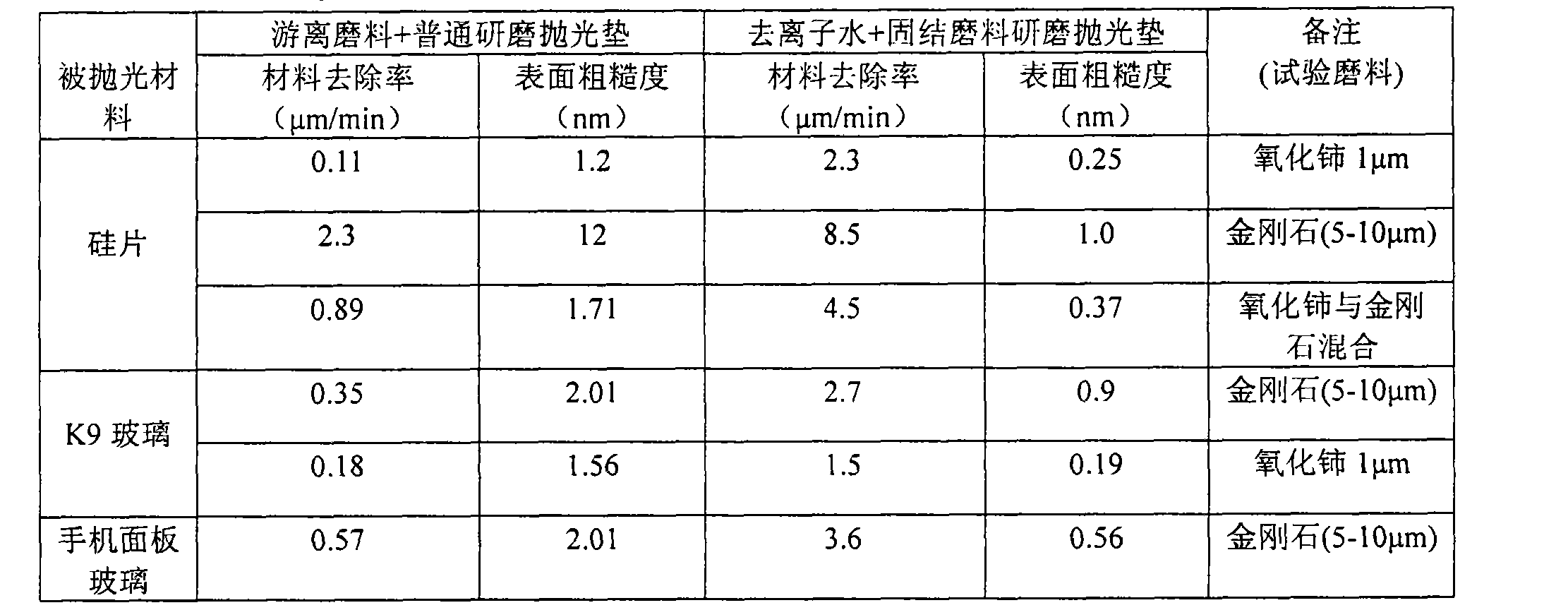

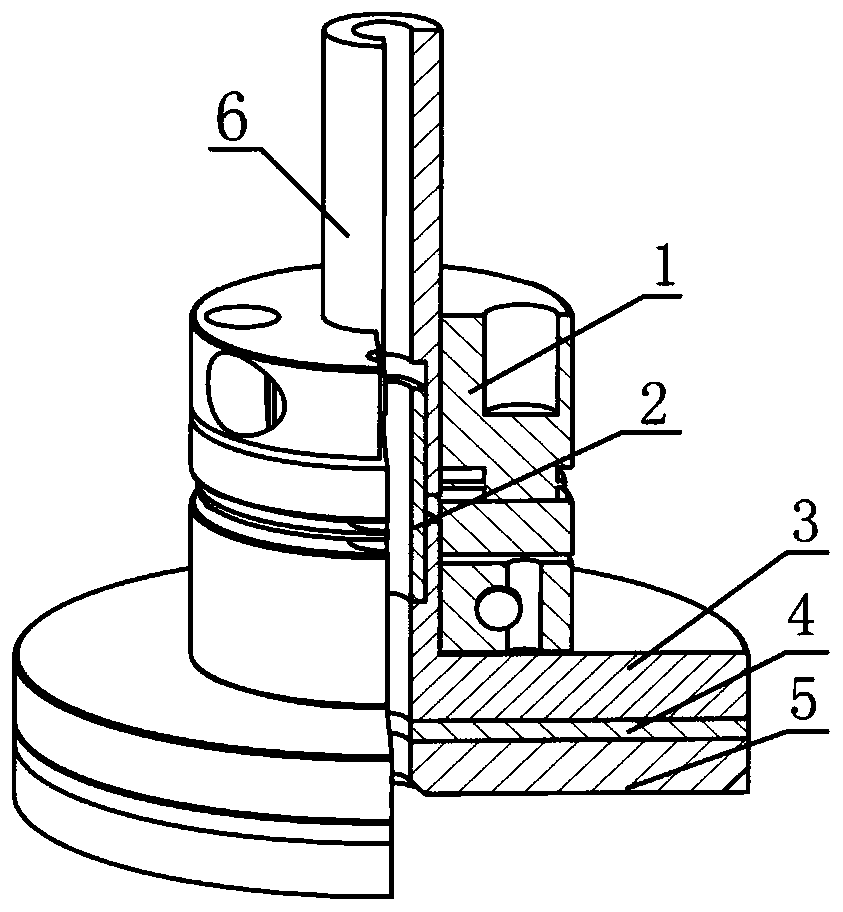

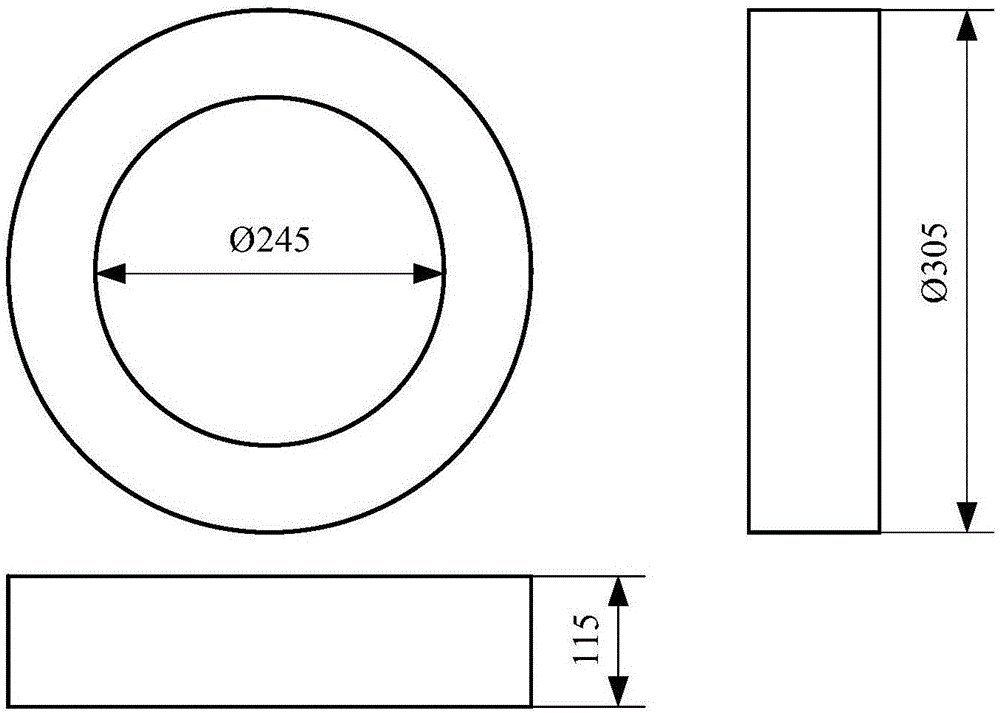

Fixed abrasive grinding polishing pad and method of manufacturing the same

InactiveCN101428404AImprove flatnessPlay a cutting roleAbrasion apparatusGrinding devicesReactive diluentEngineering

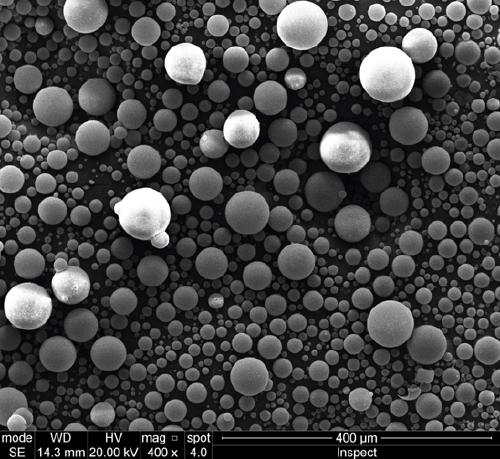

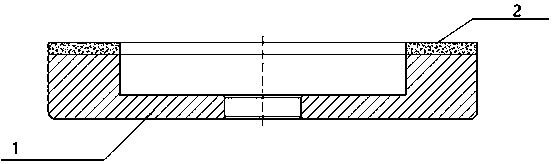

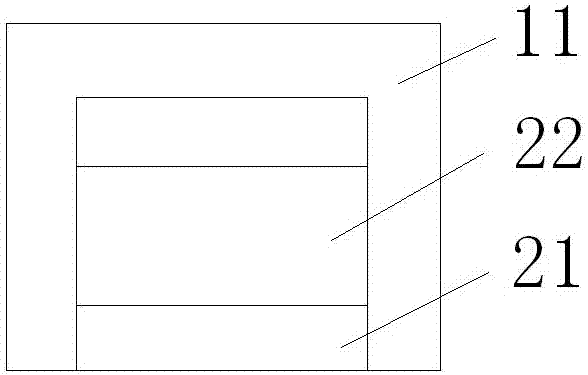

The invention provides a solidified abrading agent polishing pad and the preparation method thereof. The solidified abrading agent polishing pad comprises at least three layers, including an elastic layer (3), a rigid layer (2) and an abrading agent layer (1) sequentially arranged from the bottom layer to the top layer. The solidified abrading agent polishing pad is characterized in that the abrading agent layer (1) comprises the following components by the weight percentage: 1% to 40% of an abrading agent with the particle size being 1 nm to 40 Mum, 20% to 80% of polyacrylate prepolymer, 0.05% to 3% of free radical photoinitiator, 0% to 2% of poly-dimethylsiloxane / acrylic polymer, 0% to 20% of a performance adjusting addition agent, and 5% to 40% of esterified acrylic acid reactive diluent. The solidified abrading agent polishing pad which is prepared by the figure-transfer method has a series of advantages of stable grinding and polishing performance, high polishing efficiency, high surface texture of processed workpieces, and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method of roll grinding

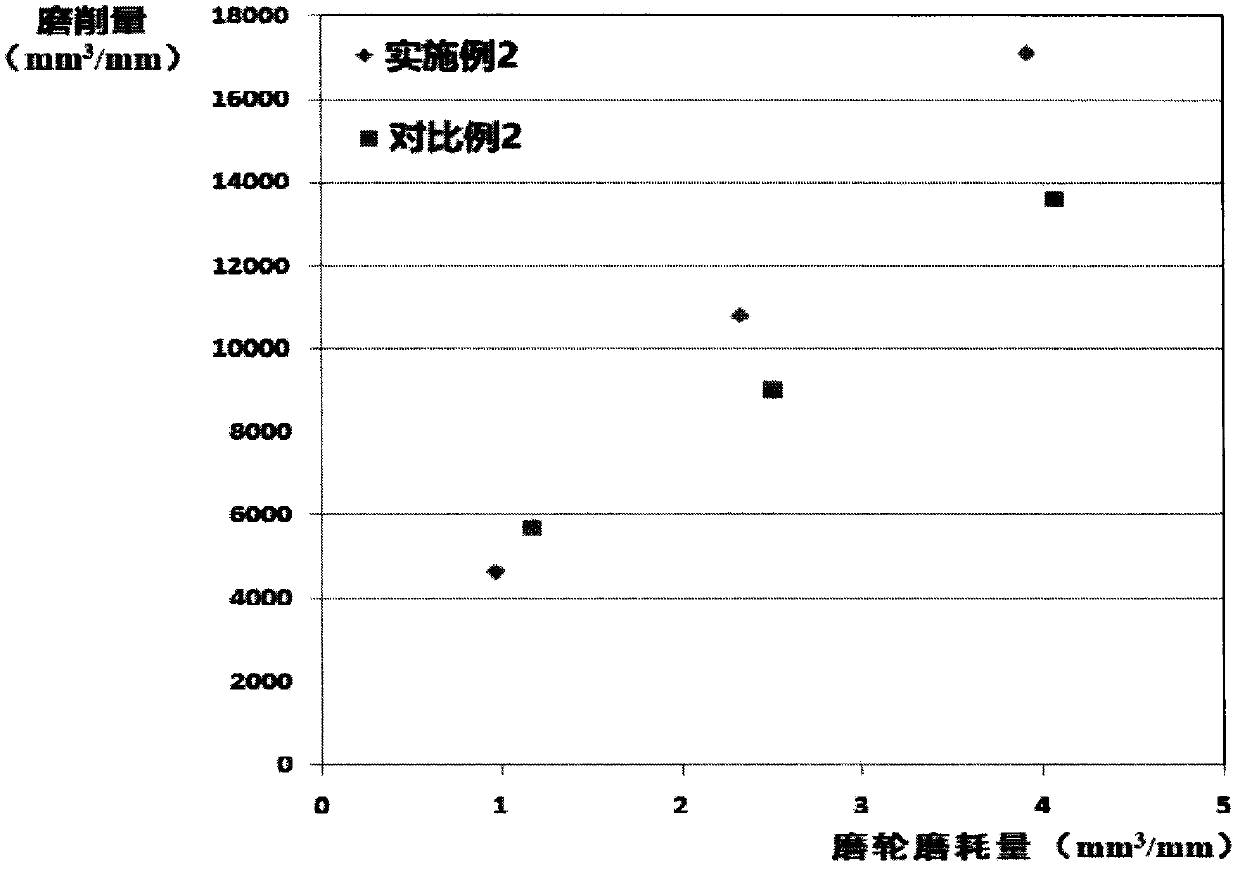

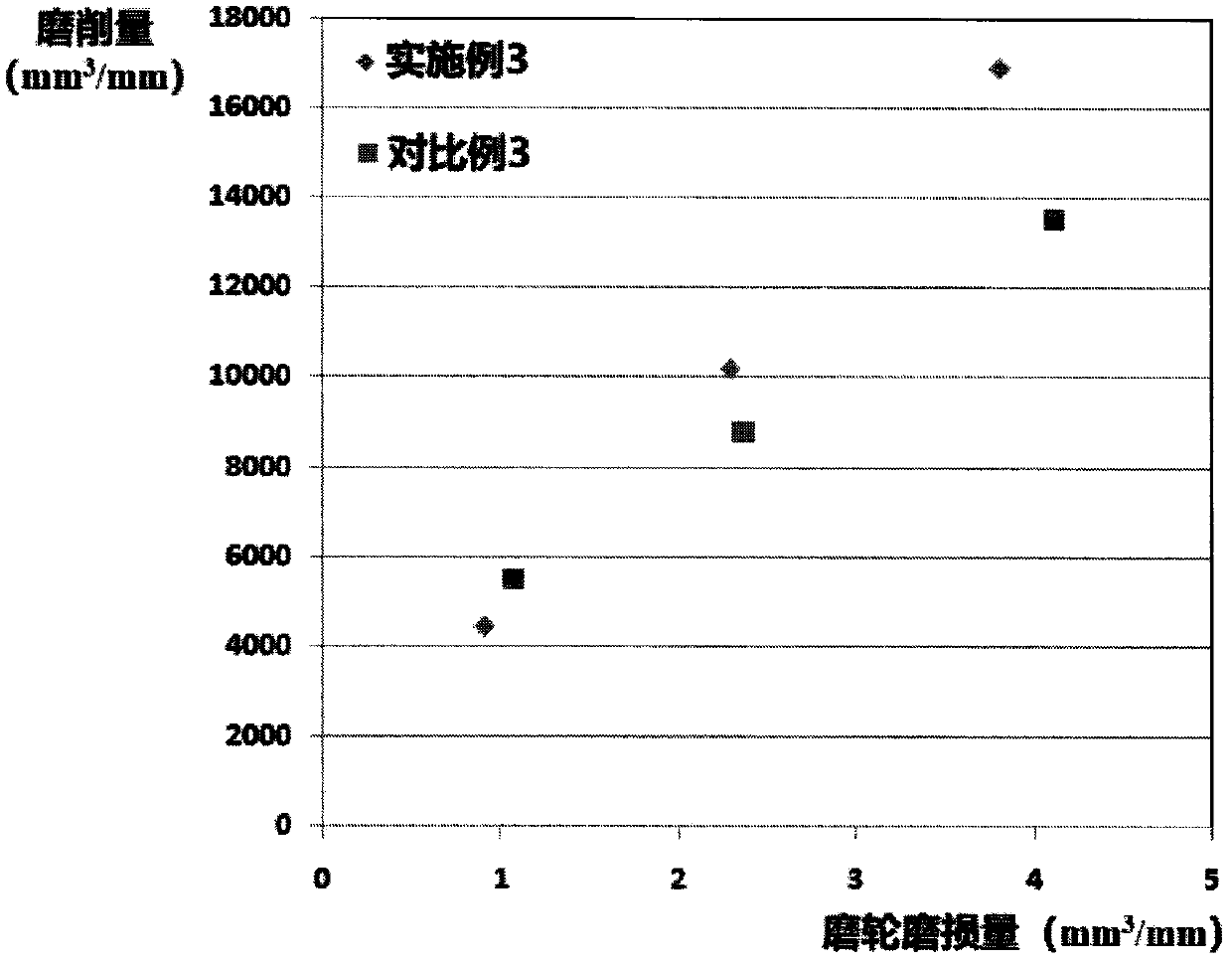

InactiveUS6988937B2Revolution surface grinding machinesOther chemical processesEngineeringGrinding wheel

Grinding of mill rolls is carried out with chatter resistant abrasive grinding wheels having relatively low elastic modulus values and relatively high burst speed values. Grinding operations may be carried out at high efficiency with controlled wheel vibration, thus generating optimum surface quality on the ground mill rolls.

Owner:SAINT GOBAIN ABRASIVES INC

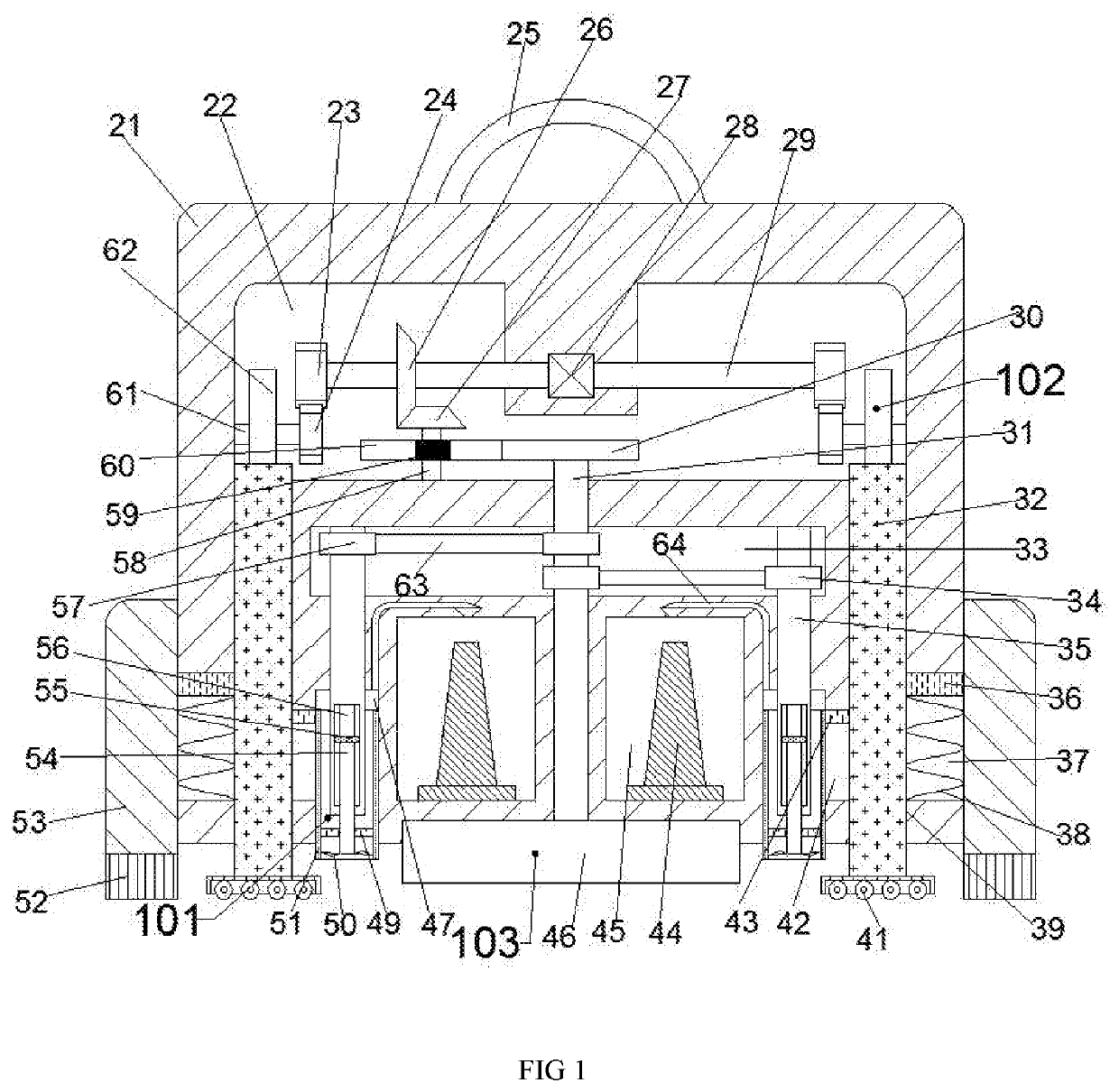

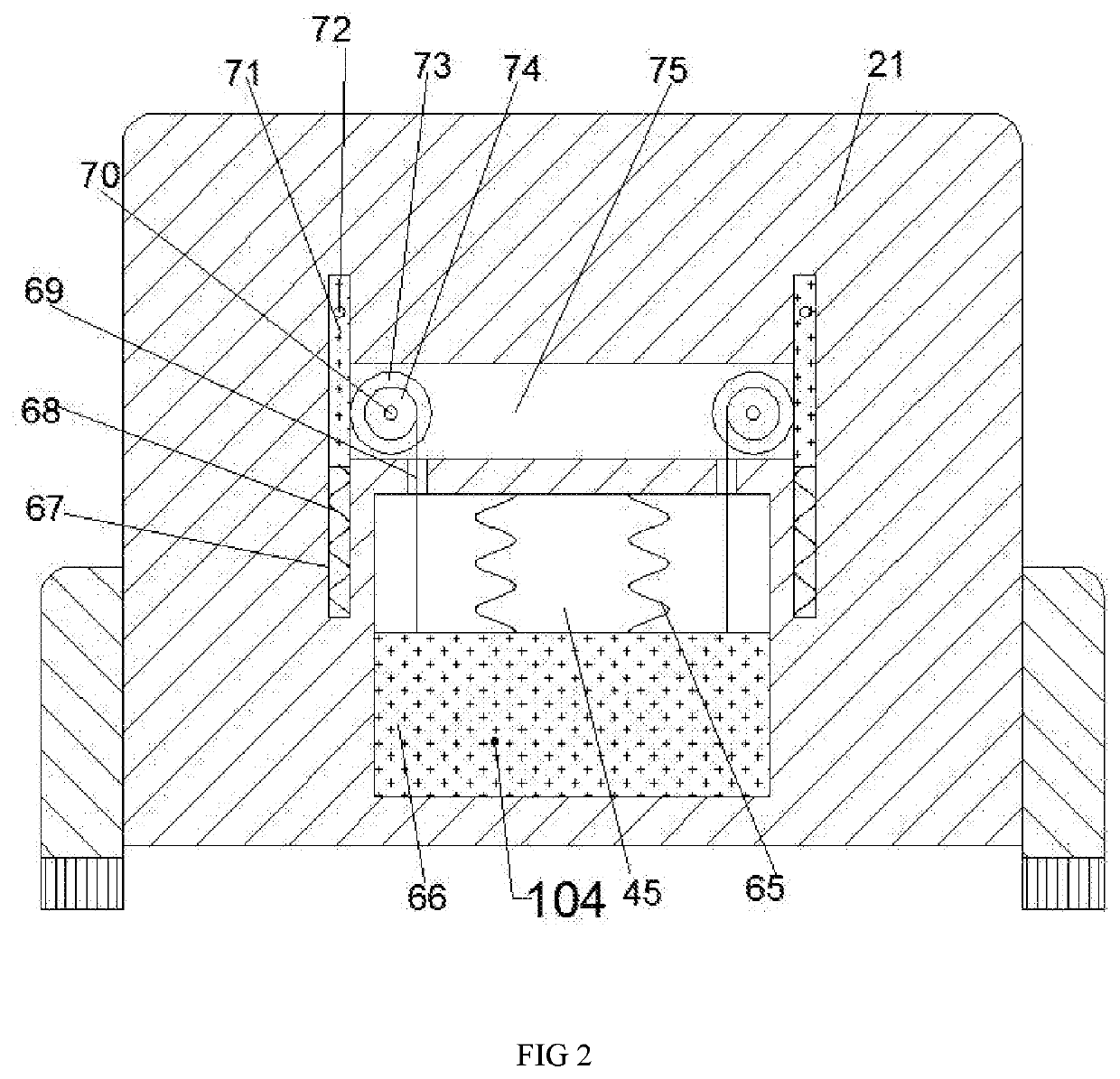

Environmentally-friendly abrasive grinding tool for grinding stones

InactiveUS20200122293A1Promote sportsImprove applicabilityGrinding drivesGrinding headsDrive wheelDust control

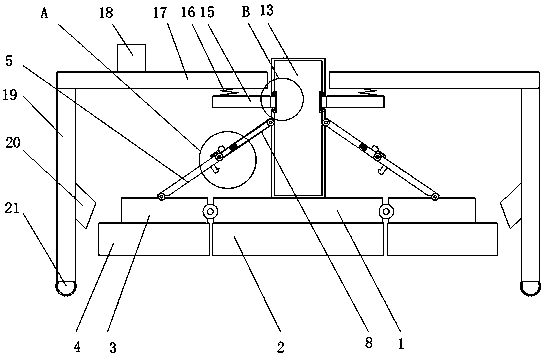

The invention discloses an environmentally-friendly abrasive dusting tool for grinding stones, comprising a machine body, wherein the machine body is provided with a dust removal cavity, and the left and right sides of the dust removal cavity are provided with sliding sleeve grooves symmetrically. The top wall of the sleeve is provided with a ventilation duct communicating with the dust removal chamber. The motor is first turned on in the opposite direction, so that the motor shaft and the main driving wheel are reversed, which drives the horizontal axis and cam to rotate. Compared with the transmission grinding tool, the device collects dust through a fan during the grinding process, which prevents the dust generated by the grinding from causing personal injury to the grinding personnel. At the same time, the device can automatically adjust the grinding height, so that it can adjust the polished stone to have different smoothness.

Owner:YANG CUIFANG

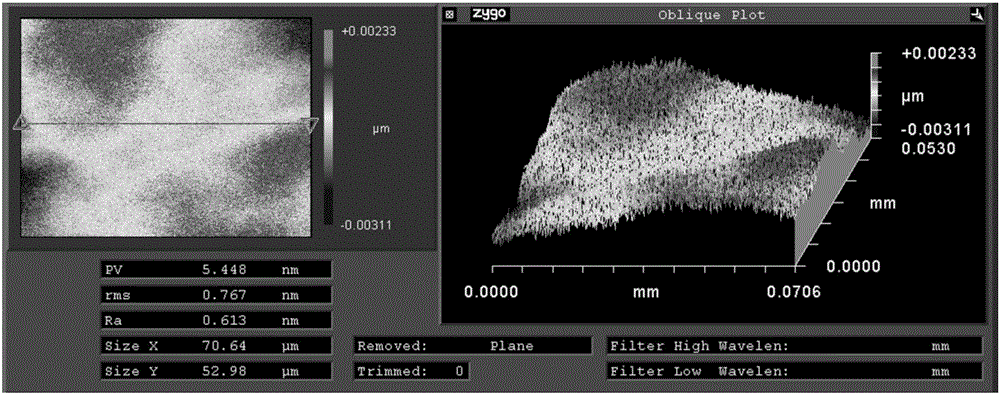

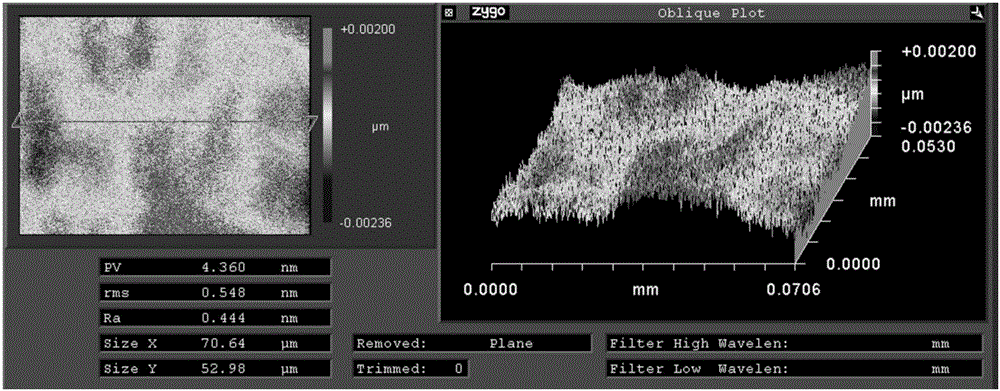

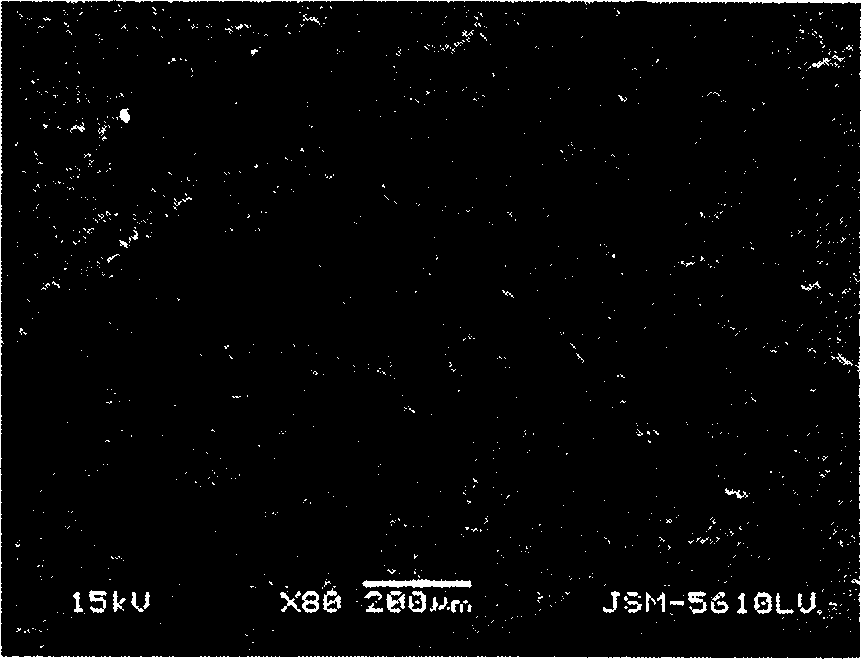

Fixed abrasive grinding and chemical-mechanical polishing method for nickel-base alloy

InactiveCN106078487AAchieve ultra-precision polishingLapping machinesPolishing compositions with abrasivesIonSandpaper

The invention discloses a fixed abrasive grinding and chemical-mechanical polishing method for nickel-base alloy, and belongs to the technical field of ultra-precision machining of alloy. Silicon carbide waterproof abrasive paper serves as a grinding tool, and grinding liquid is deionized water. A polishing pad is fuzzy damping cloth, the polishing pressure is 40-60 kPa, the polishing time is 5-12 min, and the rotation speed of a polishing plate and the rotation speed of a workpiece are 61 rpm and 59 rpm correspondingly. Chemical-mechanical polishing is divided into a rough polishing stage and a finish polishing stage. During rough polishing, polishing abrasive particles are aluminum oxide, the size is 60-100 nm, and polishing liquid is deionized water. During finish polishing, polishing liquid contains silica sol, malic acid, hydrogen peroxide and deionized water, and the pH value of the polishing liquid is 3-4. After chemical-mechanical polishing, the surface roughness Ra of the nickel-base alloy is 0.45 nm, and the PV value is 4.4 nm. The ultra-precision polishing method for the nickel-base alloy is realized, the silicon carbide waterproof abrasive paper serves as the fixed abrasive grinding tool, the silica sol, the malic acid, the hydrogen peroxide and the deionized water serve as the polishing liquid, and ultra-precision polishing for the nickel-base alloy is realized.

Owner:CHANGZHOU INST OF DALIAN UNIV OF TECH

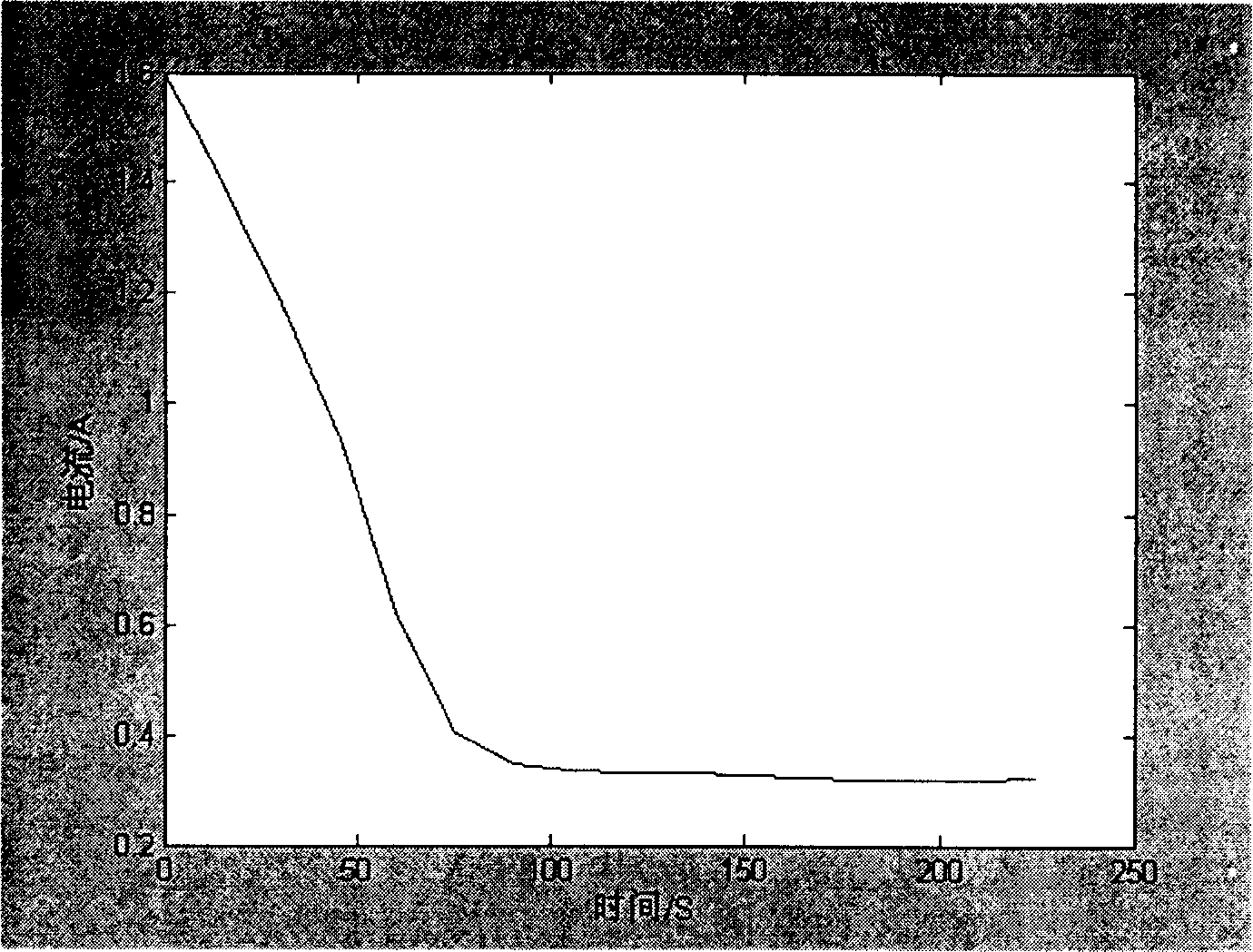

High speed on line electrolysis sharpening grinding liquid suitable for bronze binding agent ultra hard abrasive

InactiveCN1786131AGood electrolytic film forming abilitySmall stable currentAdditivesWater basedElectrolysis

The invention is applicable to a grinding fluid used in bronze anchoring agent super hard abrasive grinding wheel high speed electrolyzing dressing grinding. Its weight percentages are base fluid 87-89, sodium nitrite 9-11, saltier 0.25-0.40, disodium hydrogen phosphate 0.5-2.0, borax 0.1-0.2, propanetriol 0.28-0.32, and tributyl phosphate 0.1-0.3. The base fluid is normal water base high speed grinding fluid. It has great electrolysis film forming capability; the descending of the electrolysis current is quick; stable current is small; and the good oxide film can be formed at the superficial of the grinding wheel. The grinding cutter is as 3 / 4-2 / 3 of the common grinding; working superficial roughness is as 4 / 5-3 / 4.

Owner:HUNAN UNIV

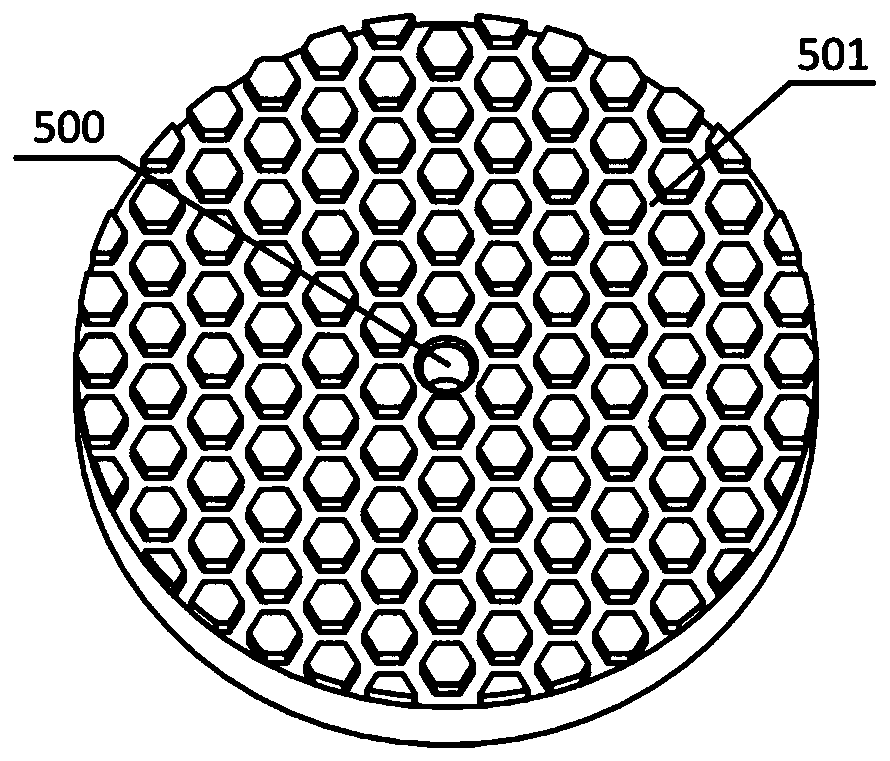

Iron-containing fixed abrasive grinding and polishing pad

An iron-containing consolidated abrasive grinding and polishing pad is characterized in that it is mainly composed of abrasives, iron powder and resin uniformly mixed and solidified, and the mass percentage of the abrasive, iron powder and resin is abrasive: iron powder: resin = 5 %-50%: 0.1%-30%: 20%-90%. The invention can not only increase the rigidity of the grinding and polishing pad, improve the surface shape accuracy of the workpiece, but also improve the self-repairing ability of the grinding and polishing pad by cooperating with the grinding and polishing liquid, which is beneficial to the continuous processing process for a long time, and improves the processing efficiency and the stability of the workpiece. Surface Quality.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Copper-Containing Fixed Abrasive Abrasive Polishing Pads

InactiveCN102267104AAvoid downtimeImprove surface accuracyAbrasion apparatusPolishingMaterials science

A copper-containing consolidated abrasive grinding and polishing pad is characterized in that it is mainly composed of abrasives, copper powder and resin uniformly mixed and solidified, and the mass percentage of the abrasive, copper powder and resin is abrasive: copper powder: resin = 5 %-50%: 0.1%-30%: 20%-90%. The invention is beneficial to improve the rigidity of the grinding and polishing pad, and improve the surface shape precision of the workpiece; cooperate with the grinding and polishing liquid, improve the self-repairing ability of the grinding and polishing pad, facilitate the long-term continuous processing process, and improve the processing efficiency and the surface quality of the workpiece.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

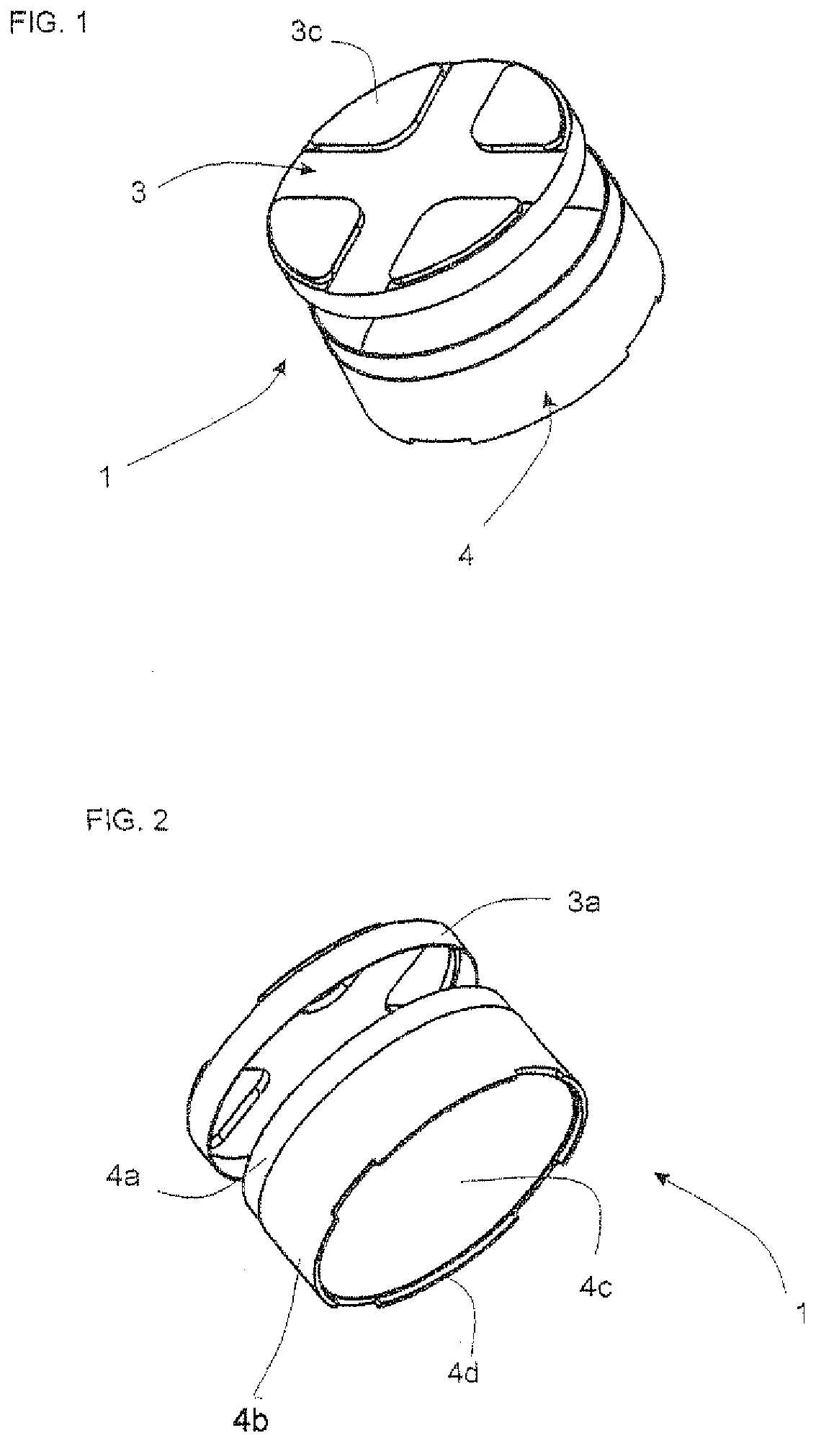

Package for abrasive grinding wheels

A package (1, 11) for abrasive grinding wheels that includes a cover (3) and a base (4) adapted to close, seal and insulate the grinding wheels from atmospheric agents, cover (3) and base (4) being made of insulating material from atmospheric agents, for example plastic material. Between base (4) and cover (3), it is possible to interpose a cylindrical body (7) made of cardboard or plastic or plasticized cardboard; the plasticizing being only internal, only external or on both surfaces. The base (4) can comprise a cylindrical mantle (4b) defining a space where grinding wheels can be inserted.

Owner:FICAI GIOVANNI

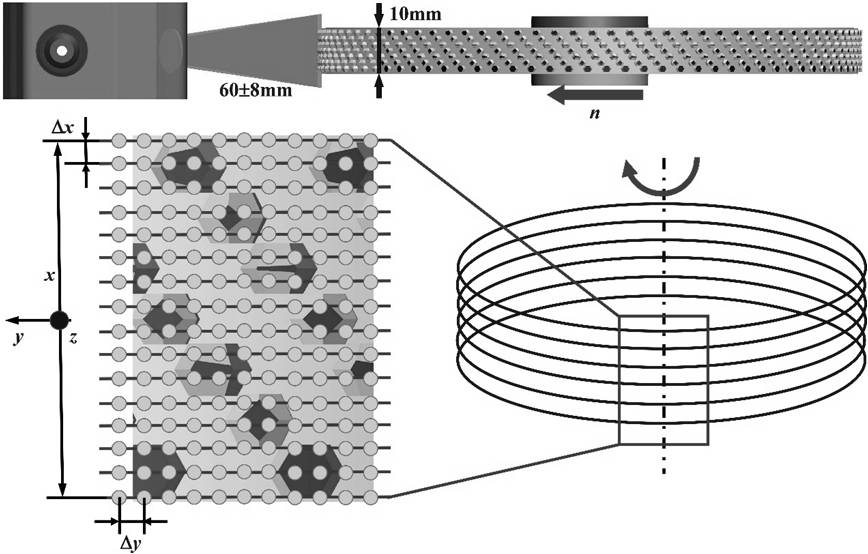

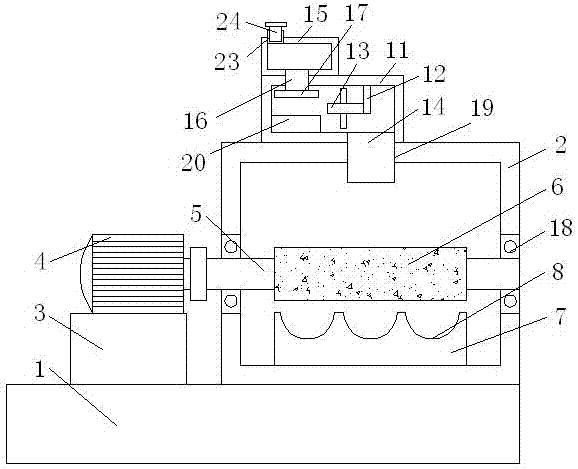

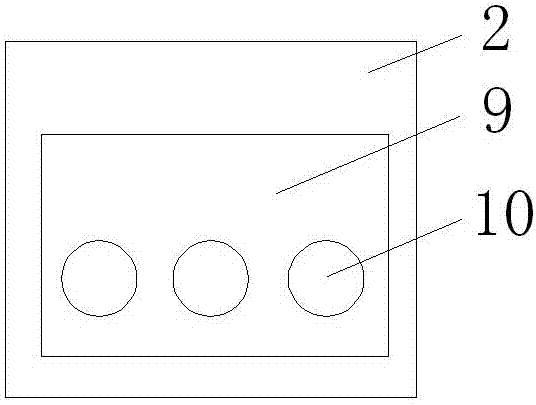

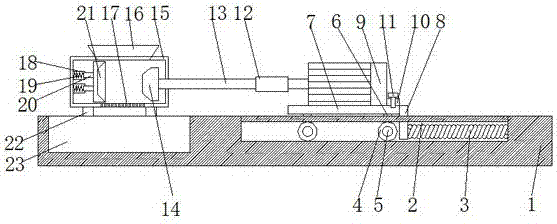

Method and device for detecting surface topography of fixed abrasive grinding tool

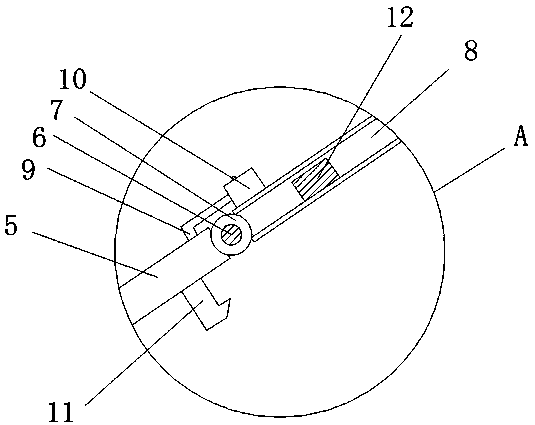

The invention discloses a method and device for detecting the surface topography of a fixed abrasive grinding tool. The method comprises the following steps that a CCD camera is connected to a computer through an image acquisition card, the CCD camera transmits the image of the fixed abrasive grinding tool to be detected to the computer and displays the image on a computer monitor, and the position of the CCD camera is changed and the fixed abrasive grinding tool to be detected is rotated so that a lens of the CCD camera can be aligned with a detected surface area of the fixed abrasive grinding tool to be detected; surface topography images of the detected area of the grinding tool are acquired continuously to form an image sequence, and the acquired surface topography images of the detected area of the fixed abrasive grinding tool to be detected are transmitted to the computer form image processing; and the acquired three-dimensional information of the surface topography of the fixedabrasive grinding tool is used for calculating the surface three-dimensional evaluation parameters in accordance with the international standard ISO25178-2, and the evaluation of the surface topography of the fixed abrasive grinding tool is realized. The method and device do not cause abrasion and damage to the grinding tool.

Owner:TIANJIN UNIV

Sub-aperture central liquid supply optical surface serial machining process and tool

ActiveCN111070080ASuppress low frequencySuppress IFOptical surface grinding machinesLapping machinesRotational axisPolishing

The invention discloses a sub-aperture central liquid supply optical surface serial machining process. The serial machining process is a systematic machining method from a blank surface to an ultra-smooth surface based on a hydrodynamic pressure principle and mainly comprises a hydrodynamic pressure consolidation abrasive grinding and polishing process, a central liquid supply small grinding headpolishing process and a disc-type hydrodynamic pressure polishing process. A sub-aperture central liquid supply optical surface machining tool comprises an elastic coupler, a polishing disc and a polishing pad, wherein the two ends of the flexible coupler are respectively connected with the polishing disc and a rotating shaft; and successive recursion inhibition processes of low-frequency, medium-frequency and high-frequency errors of the optical surface are achieved by replacing different grinding pads and polishing pads on the same machining tool. Meanwhile, in order to obtain a high-qualityand low-damage ultra-precision smooth surface, different grinding pads and polishing pads are combined to use, the residual sub-surface damage layer on the surface after being polished in premier polishing process is removed, no new sub-surface damage is generated any more, and the sub-surface damage is reduced to the minimum through multiple machining processes.

Owner:TIANJIN UNIV

Graphite-Contained Abrasive Abrasive Polishing Pads

InactiveCN102275141AImprove wear resistanceImprove stabilityFlexible-parts wheelsPolishingSurface roughness

A graphite-containing consolidated abrasive grinding and polishing pad is characterized in that it is mainly formed by uniformly mixing and solidifying abrasives, graphite particles and resin, and the mass percentage of the abrasives, graphite particles and resin is abrasive:graphite particles:resin= 5%-50%: 0.5%-10%: 40%-90%. The invention is beneficial to improve the wear resistance and lubricity of the grinding and polishing pad, and improve the stability of processing; cooperate with the grinding and polishing liquid to improve the self-repairing ability of the grinding and polishing pad, which is beneficial to the continuous processing process for a long time and improves the processing efficiency; It is conducive to improving the lubricity of abrasives, reducing surface roughness, and improving surface quality. There is no need to add chemicals to the polishing liquid, which is conducive to environmental protection.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Disc grinding wheel with integrated mounting plate

A bonded abrasive grinding wheel is provided with a bonded abrasive disc including abrasive grain disposed within a bond matrix, and a mounting plate integrally fastened to the disc. In various embodiments, the mounting plate has a plurality of non-metallic first threaded fastener portions disposed in a predetermined pattern therein, and is fabricated from a composition including a polymetric material. The non-metallic first threaded fastener portions are each configured for respective engagement with a plurality of second threaded fastener portions disposed along a face plate of a grinding machine.

Owner:SAINT GOBAIN ABRASIVES INC +1

Super-hard abrasive grinding wheel for fingerprint identification lock substrate grinding and preparation method thereof

ActiveCN111283560AHigh strengthReduce intensityBonded abrasive wheelsGrinding devicesSurface finishHigh surface

The invention provides a super-hard abrasive grinding wheel for fingerprint identification lock substrate grinding. The super-hard abrasive grinding wheel comprises a grinding wheel base body and a super-hard grinding layer; and the super-hard grinding layer is of an annular structure and is bonded to the grinding wheel base body, the grinding wheel base body is a soft elastic base body with the medium-low elastic modulus, and the super-hard grinding layer is a layer prepared by mixing a super-hard abrasive, a functional filler and a resin binder. The soft elastic base body with the medium andlow elastic modulus can buffer the surface of a ground material well, during grinding, under the action of counter-acting force of a workpiece, elastic deformation can occur, thus the abrasive can well adapt to the change of the feed amount and is not so deep as to be pressed into a fingerprint substrate material, the effects of flexible grinding and polishing are achieved, and finally the fingerprint lock substrate material reaches the extremely high surface smoothness and the extremely low thickness deviation.

Owner:北京荣锋精密工具有限公司

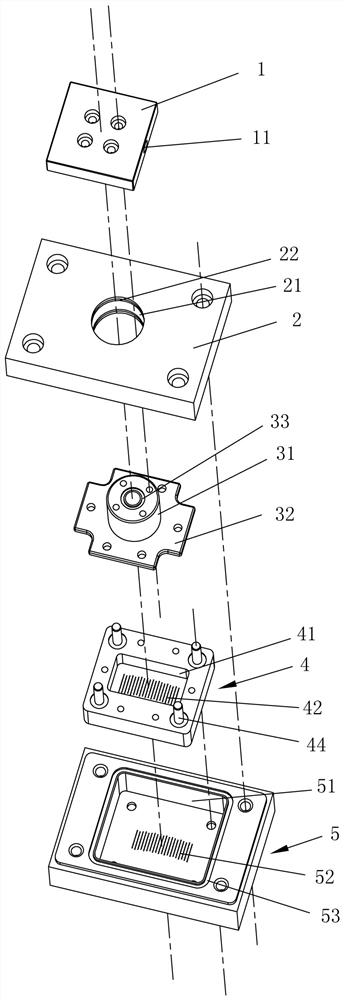

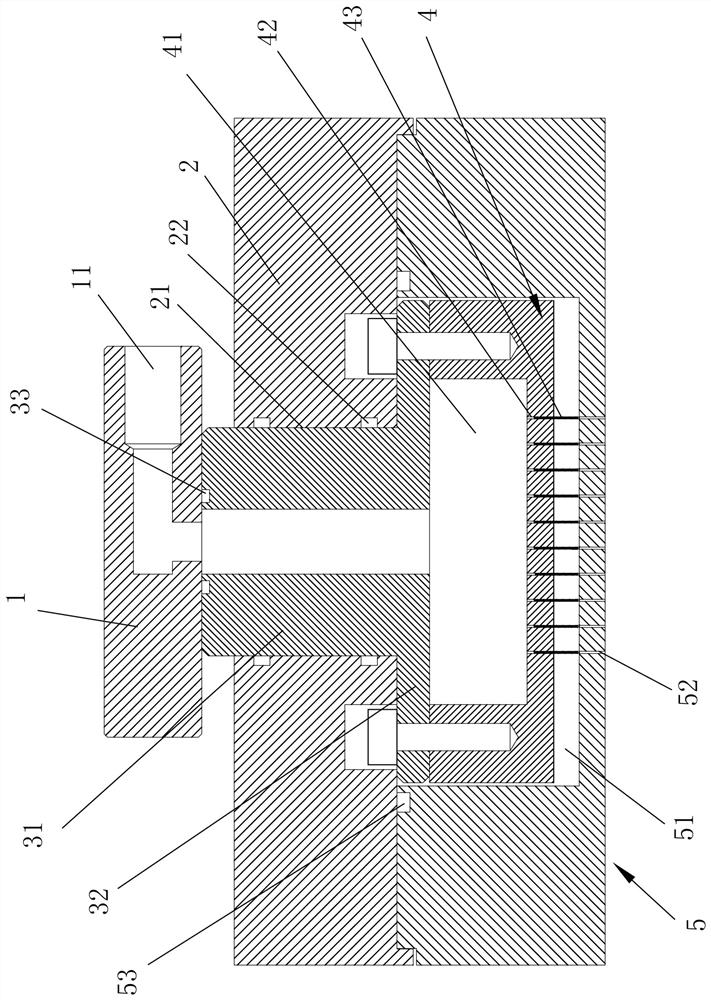

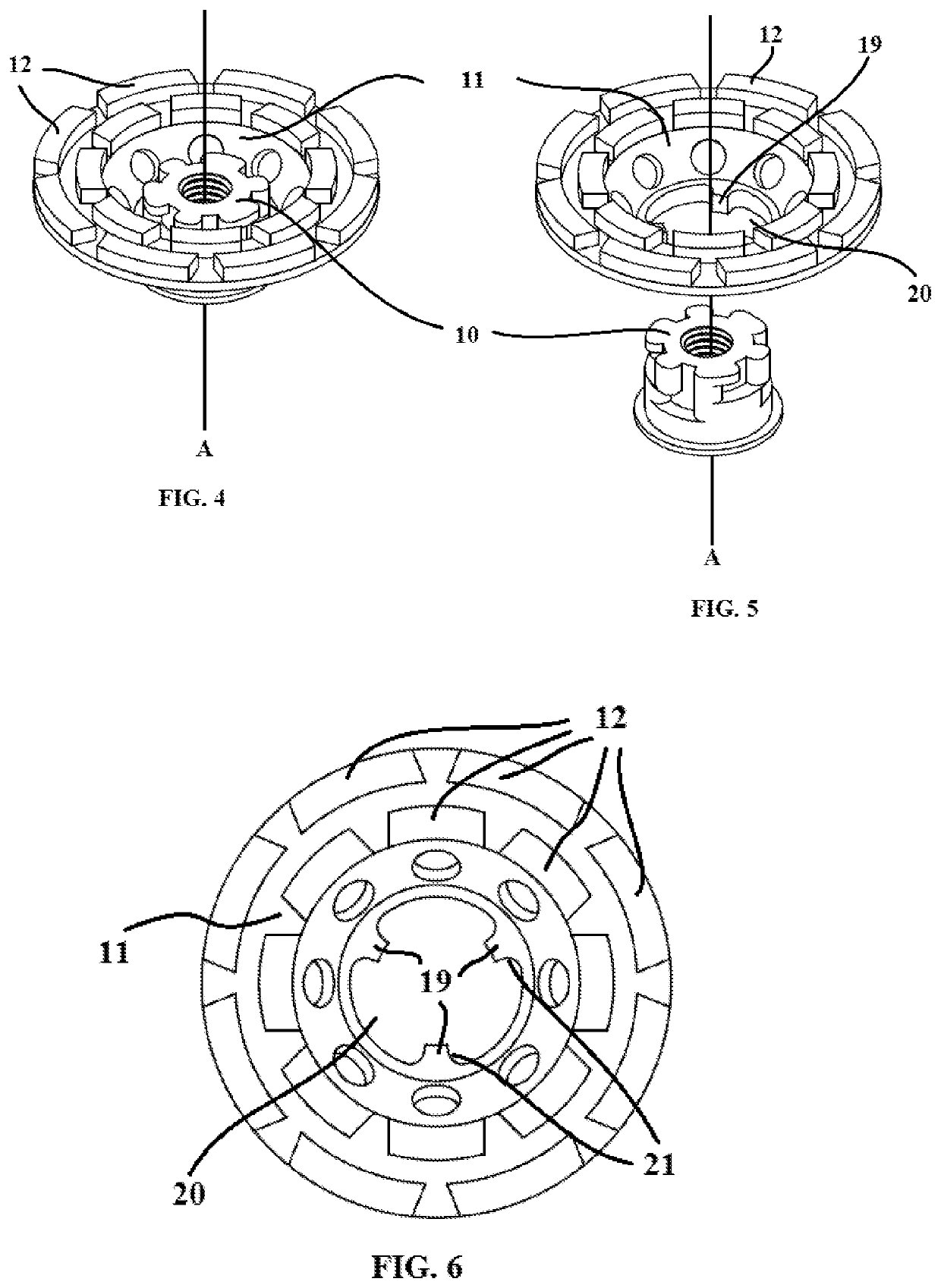

Three-dimensional ordered arrangement device and method for diamond particles

PendingCN112077754AReduce the probability of blocking the first viaRealize industrial processingGrinding devicesTool bitEngineering

The invention discloses a diamond particle three-dimensional ordered arrangement device and method, and relates to the field of diamond abrasive grinding tool manufacturing. The diamond particle three-dimensional ordered arrangement device comprises a fixed base, a connecting piece and a movable plate, the fixed base is provided with a mounting cavity, and the bottom of the fixed base is providedwith multiple first through holes communicating with the mounting cavity. The connecting piece is arranged on the fixed base in a vertically movable manner, the lower end of the connecting piece extends into the mounting cavity and is fixedly connected with a movable plate, the movable plate is provided with multiple tubular bodies which are used for adsorbing diamond particles and are in one-to-one correspondence with the first through holes, and the connecting piece is provided with an airflow channel for communicating with the tubular bodies and an air extractor. The diamond particle three-dimensional ordered arrangement device and method have the beneficial effects that a negative pressure state is formed in tubular parts to suck diamond particles, and after the negative pressure stateis relieved, the tubular parts arrange the diamond particles in order. Meanwhile, blocked holes of the tubular parts can be cleaned, the shutdown frequency of equipment is reduced, and production canbe conducted smoothly. According to the three-dimensional ordered arrangement device and method for diamond particles, industrialized machining of a diamond tool bit can be achieved, the automation degree is high, the equipment cost is low, and popularization is easy.

Owner:福建省泉州万龙石业有限公司

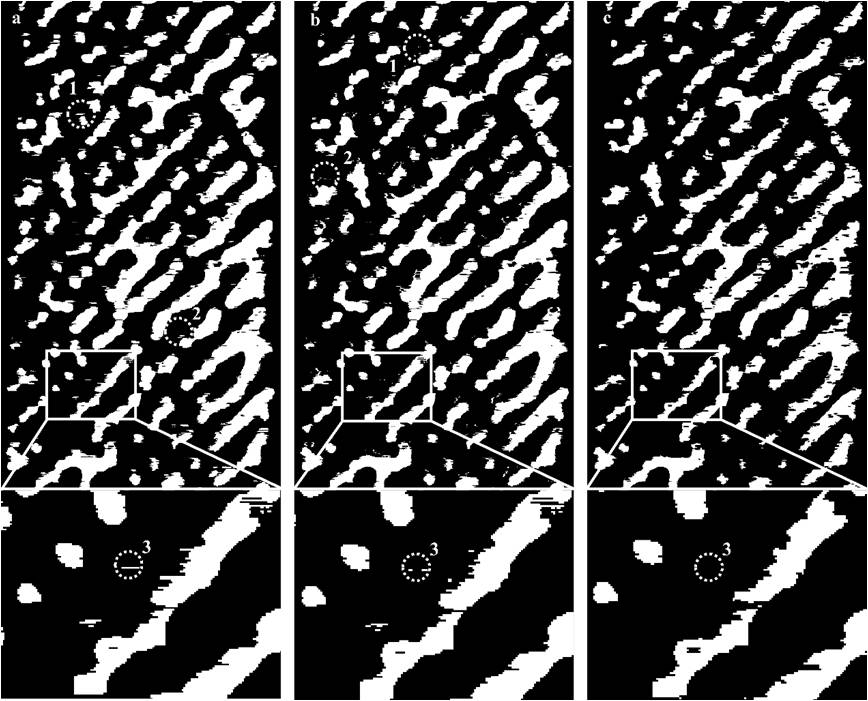

Abrasive particle contour evaluation method for large-abrasive-particle superhard abrasive grinding wheel

The invention discloses an abrasive particle contour evaluation method for a large-abrasive-particle superhard abrasive grinding wheel, and belongs to the technical field of grinding wheel dressing and image recognition processing. The method comprises the steps that firstly, three-dimensional data of the surface of the large-abrasive-particle super-hard abrasive grinding wheel are detected through an ultra-high-speed contour measuring instrument, and before detection, it is guaranteed that the circle run-out of the grinding wheel is within 10 micrometers by adjusting an installation clamp (a dial indicator is adopted for measurement); then, after binary image processing such as singular point and noisy point removal, connected domain analysis and image corrosion is carried out through Matlab software, the number of abrasive particles of the datum plane at the interval of the specific height is obtained; and finally, rule analysis and research are carried out on the abrasive particle exposure height information. According to the method, the laser detection technology, the data processing technology and the image processing technology are combined, and accurate evaluation of the abrasive particle contour of the large-abrasive-particle super-hard abrasive grinding wheel is achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

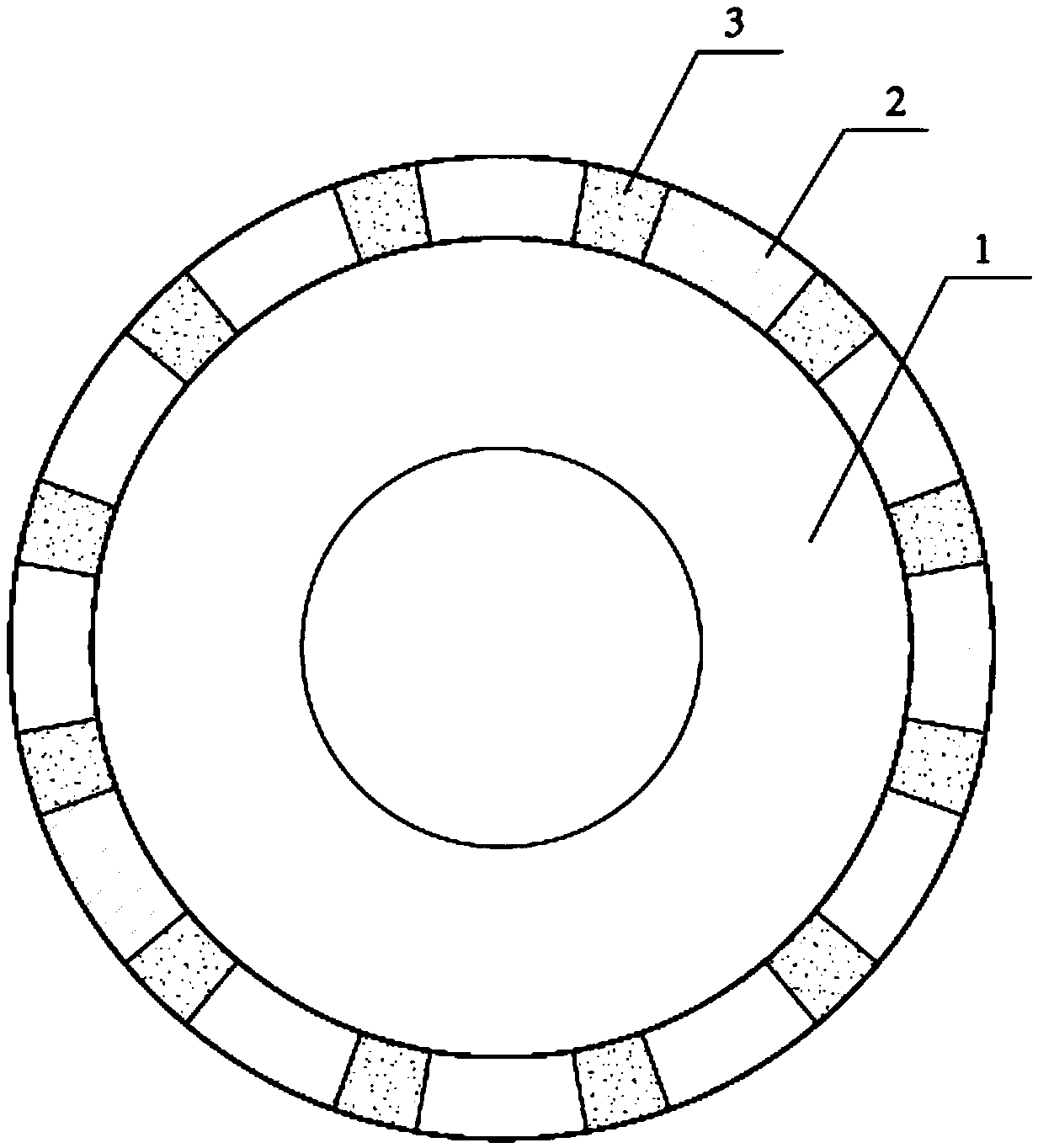

High-linear-speed self-sharpening CBN grinding wheel for processing unquenched alloy steel parts and preparation method thereof

ActiveCN108747857AImprove efficiencyDressing interval longBonded abrasive wheelsGrinding devicesProduction lineGrinding wheel

The invention discloses a high-linear-speed self-sharpening CBN grinding wheel for processing unquenched alloy steel parts and a preparation method thereof. The high-linear-speed self-sharpening CBN grinding wheel comprises a steel base body, abrasive blocks and auxiliary grinding self-sharpening blocks, wherein the abrasive blocks and the auxiliary grinding self-sharpening blocks are bonded to the steel base plate and alternately distributed. According to the high-linear-speed self-sharpening CBN grinding wheel, the auxiliary grinding self-sharpening blocks are added creatively so that the superhard CBN grinding wheel can replace a common abrasive grinding wheel for being used for processing the unquenched steel parts. The linear speed of the grinding wheel can reach 120 m / s during application. Scraps are not likely to adhere to the grinding wheel, and the unquenched parts are not likely to be burned. The high-linear-speed self-sharpening CBN grinding wheel has the advantages of beinglong in trimming interval and service life, high in efficiency and good in stability and is suitable for an automatic production line.

Owner:江苏赛扬精工科技有限责任公司

Non-API thread ring gauge electroplating super-hard abrasive molded grinding wheel matrix structure design method

ActiveCN106584296AAvoid grinding burnsImprove grinding efficiencyGrinding devicesEngineeringElectroplating

The invention provides a non-API thread ring gauge electroplating super-hard abrasive molded grinding wheel matrix structure design method. According to the non-API thread ring gauge electroplating super-hard abrasive molded grinding wheel matrix structure design method, a super-hard abrasive molded grinding wheel and a grinding machining method are aimed at a non-API thread ring gauge part; by adoption of the super-hard abrasive molded grinding wheel and the optimized form-grinding machining method, the phenomenon of non-API thread ring gauge grinding burn can be avoided; the super-hard abrasive molded grinding wheel structure design comprises the grinding wheel matrix structure design and the grinding wheel work profile structure design; the super-hard abrasive molded grinding wheel matrix structure design comprises the grinding wheel matrix outline structure design, the grinding wheel groove factor design, the grinding wheel intermittent period design and the sand grooving parameter design; the grinding wheel intermittent period design is equivalent to the groove quantity design; and the super-hard abrasive molded grinding wheel work profile structure design comprises the grinding wheel tooth structure design and the corner critical position structure design. By combination of optimized super-hard abrasive grinding wheel form-grinding machining parameters, the problem about grinding burn in a non-API thread ring gauge rough grinding machining can be solved and the efficient grinding machining demand can be met.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

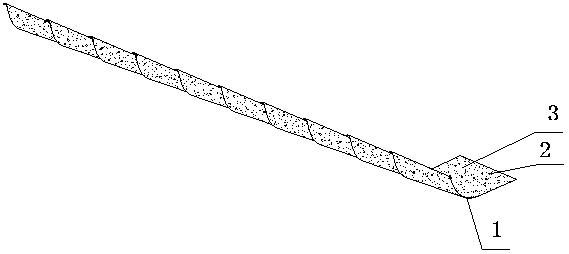

Coated abrasive tool based on fiber substrate sand rope, polishing and grinding wheel and manufacturing method thereof

InactiveCN103846825AImprove performanceImprove grinding and polishing effectFlexible-parts wheelsGrinding devicesFiberPolishing

The invention discloses a coated abrasive tool based on a fiber substrate sand rope. Fiber substrates containing abrasive grinding materials are twisted into a sand rope and are cured for obtaining the coated abrasive tool. The invention also discloses a polishing and grinding wheel manufactured by the coated abrasive tool based on the fiber substrate sand rope (or fiber substrate sand rope containing chopped fiber). The coated abrasive tool and the polishing and grinding wheel provided by the invention have the advantages that the three-dimension structure and the controllable degree in the processing process are sufficiently utilized for realizing the respective correspondence of different use environment and conditions, so the performance of the adhesive grounding materials and the fiber is sufficiently realized, the polishing and grinding performance is improved, and the use cost is reduced.

Owner:谢泽

Ceramic bond grinding tool

ActiveCN113894710AGuaranteed abrasive rateImprove high temperature sintering performanceAbrasion apparatusGrinding devicesPyrophylliteKaolinite

The invention relates to a ceramic bond grinding tool, and belongs to the technical field of abrasive grinding tools. A ceramic bond adopted by the ceramic bond grinding tool is composed of the following components of, by mass, 17%-27% of kaolinite powder, 1%-3% of low-melting-point glass powder, 1%-5% of nano-silica, 7%-12% of pyrophyllite and the balance feldspar powder. The ceramic bond grinding tool has high structure uniformity and quality stability, the pyrophyllite is hydroxyl-containing layered aluminosilicate, the chemical formula of the pyrophyllite is Al2[Si4O10](OH)2, the pyrophyllite has good pressure transmission capacity under large pressure, and the structure uniformity and the quality stability of the ceramic bond grinding tool can be further improved; and in addition, the nano-silica can improve the high-temperature sintering performance of the bond and improve the self-sharpening performance of the ceramic bond grinding tool, and therefore the cutting efficiency is improved.

Owner:白鸽磨料磨具有限公司

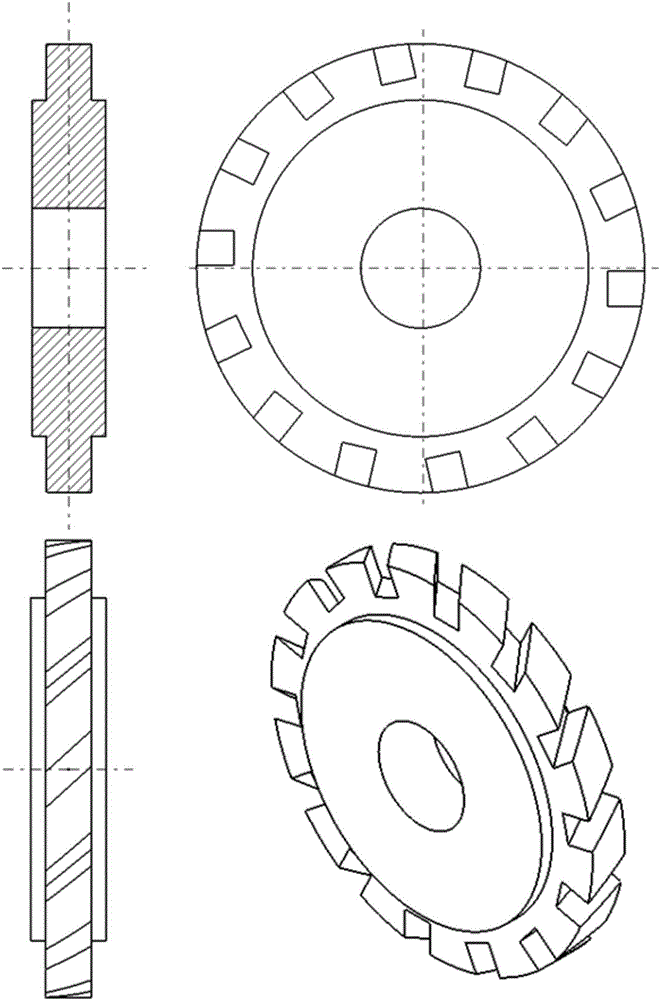

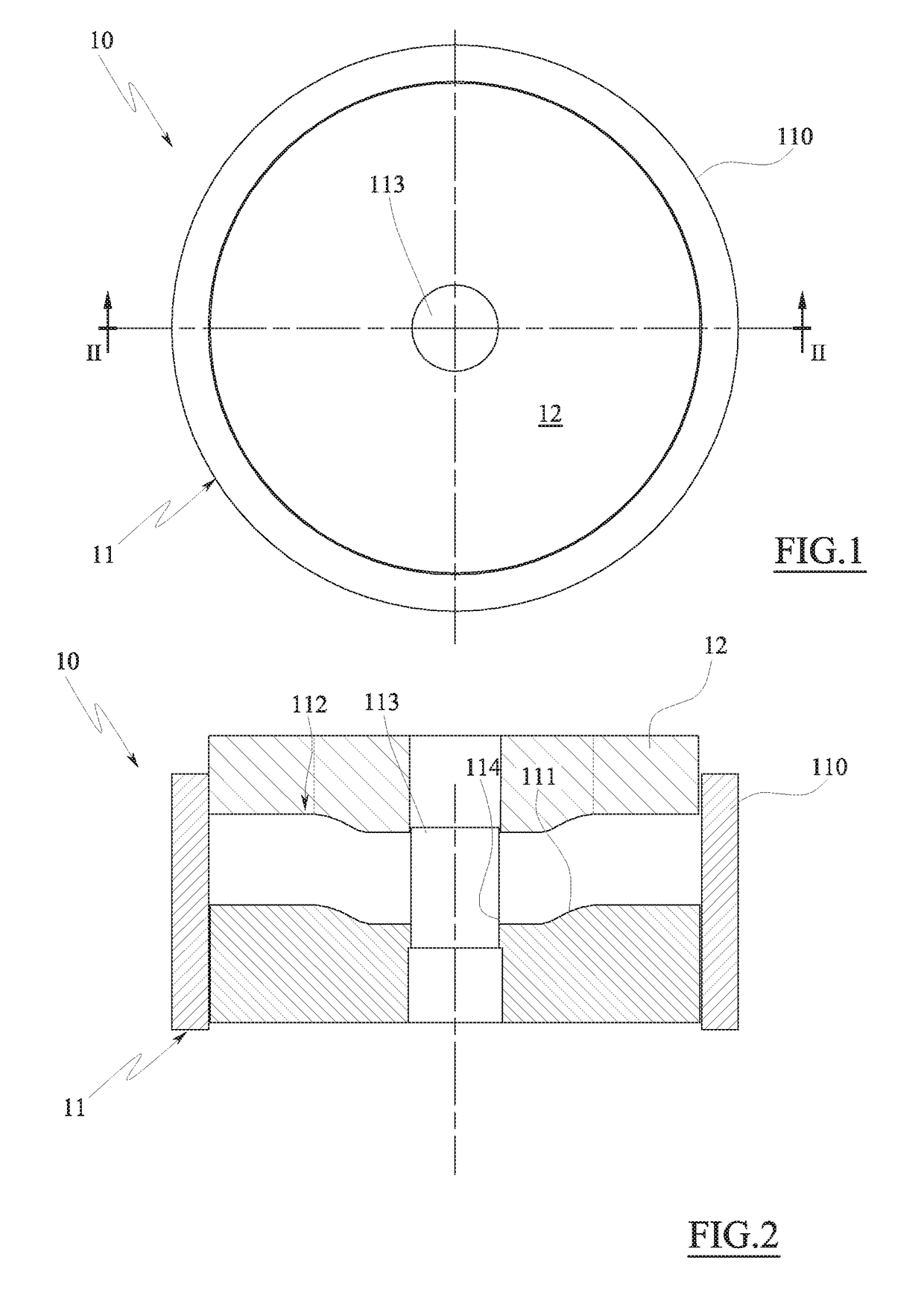

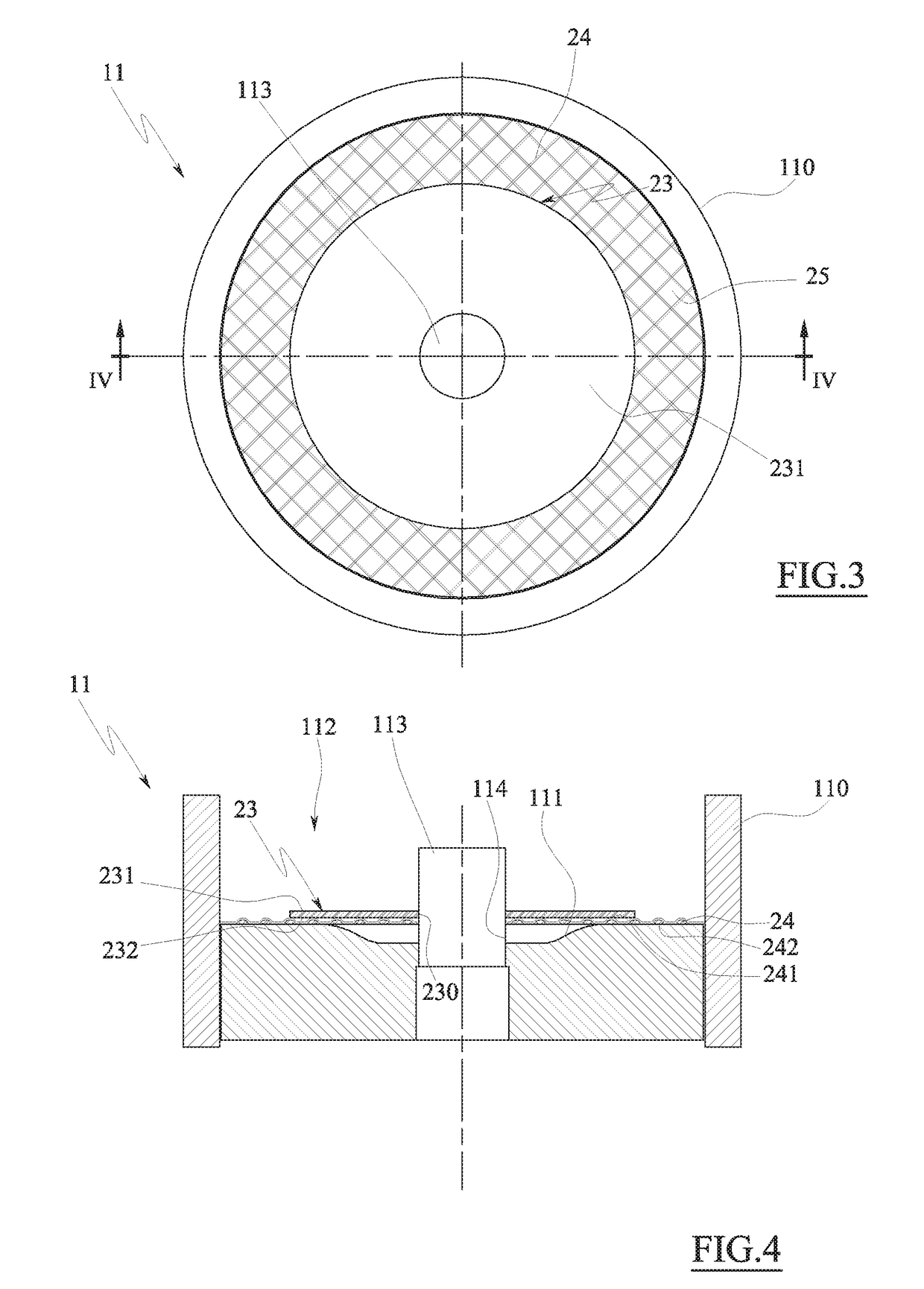

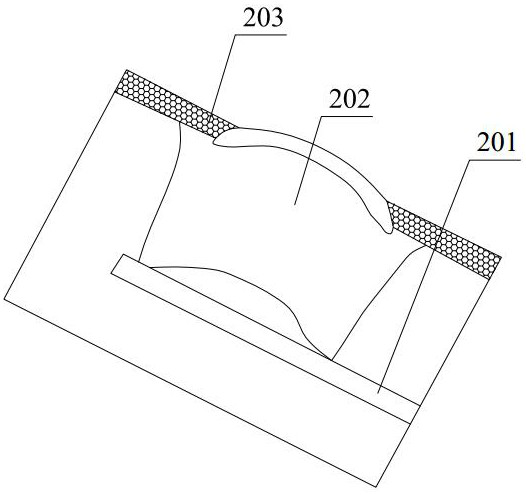

Grinding wheel

ActiveUS20170274502A1Reduce vibrationEasy to manufactureBonded abrasive wheelsMechanical engineeringAbrasive

An abrasive grinding wheel (20) comprising an annular body (200) defining an abrasive front face (202) at least partly made of a layer of an abrasive mixture (21) and an opposite rear face (203), which grinding wheel (20) comprises an annular damping element (23) made of a resilient yielding material and fixed to the annular body (200), wherein the damping element (23) comprises a first face (231) facing towards the abrasive front face (202) and an opposite free second face (232) which defines at least a portion of the rear face (203) of the annular body (200).

Owner:FICAI PAOLO

Grinding wheel, preparation method and application thereof

InactiveCN111070114AGive full play to the grinding effectReduce heat damageGrinding devicesAlloyMaterial distribution

The invention relates to a grinding wheel, a preparation method and application thereof, and belongs to the technical field of abrasive grinding tool manufacturing. The preparation method comprises the steps of burdening, material distribution, brazing sintering, reaming, paint spraying, edging and the like. The adopted alloy powder brazing filler metal is composed of 31wt%-35wt% of Ni, 23wt%-25wt% of Mn, 1.25wt%-2.5wt% of Si, 0.30wt%-1.0wt% of B, 1.0wt%-1.5wt% of Fe, 1.0wt%-5.0wt% of Cr and the balance Cu. The invention further relates to a grinding wheel obtained according to the preparationmethod and a preparation method of the grinding wheel. The alloy powder brazing filler metal adopted by the grinding wheel does not contain rare metal W, Co and precious metal components, the cost islow, the brazing sintering temperature is low, heat damage to diamond particles is small, the wettability is good, good holding force can be formed for abrasive materials, the grinding effect of theabrasive materials can be brought into full play, and the service life is remarkably prolonged.

Owner:江苏华昌工具制造有限公司

Abrasive grinding tool for grinding stone material convenient for dust removal

PendingCN107457652AEasy to remove dustEasy to removeGrinding machinesGrinding/polishing safety devicesDust controlElectric machinery

The invention discloses an abrasive grinding tool for grinding a stone material convenient for dust removal. The abrasive grinding tool for grinding stone material convenient for dust removal comprises an abutment. A grinding room is fixedly connected to the surface of the abutment, a base is fixedly connected to the surface of the abutment, a motor is fixedly connected to the surface of the base, the output shaft of the motor is fixedly connected to a rotary shaft through a coupling, one end of the rotary shaft penetrates through and extends into the grinding room, and a grinding roller is fixedly connected to the surface of the rotary shaft. According to the abrasive grinding tool for grinding stone material convenient for dust removal disclosed by the invention, when grinding work is performed, a draught fan is started to suck dust into a chassis through a dust suction pipe; then the draught fan then blows the dust to one end of a sprinkler; water in a water tank enters the sprinkler through a water pipe and then enters the chassis through the sprinkler; water wetting the dust falls into a dust accumulating box; therefore, an effect of eliminating dust in the grinding room conveniently is achieved, so that the problem that adverse effects are brought to physical health of operators to a certain extent as a lot of dust will be generated when a common stone material grinding tool is used is solved effectively.

Owner:FORTURE TOOLS CO LTD

Abrasive grinding tool with dust removing function

PendingCN107791148AWith dust removal functionAchieve dust removal effectGrinding wheel securing apparatusGrinding machinesArchitectural engineeringGrinding wheel

The invention relates to the technical field of abrasive grinding tools, and discloses an abrasive grinding tool with a dust removing function. The abrasive grinding tool with the dust removing function comprises a first fixing base. The bottom of the first fixing base is fixedly connected with the top of a first abrasive disk. One side of the first fixing base is hinged to one side of a second fixing base. The bottom of the second fixing base is fixedly connected with the top of a second abrasive disk. The top of the second fixing base is hinged to one end of a first connection rod, and the other end of the first connection rod is fixedly connected with a rotating rod. The rotating rod is sleeved with a rotating sleeve, and the rotating sleeve is fixedly connected to one end of a second connection rod. According to the abrasive grinding tool with the dust removing function, by means of a cover plate fixedly connected to the top of a spring and a connection pipe arranged on the top ofthe cover plate and by combining a dust suction opening fixedly connected to the inner wall of the cover plate and a rubber strip fixedly connected to the bottom of the cover plate, the abrasive grinding tool can be covered with a protection cover, fragments generated when the abrasive grinding tool works can be sucked, and so that the dust removing effect is achieved.

Owner:郑州博尔德磨料磨具有限公司

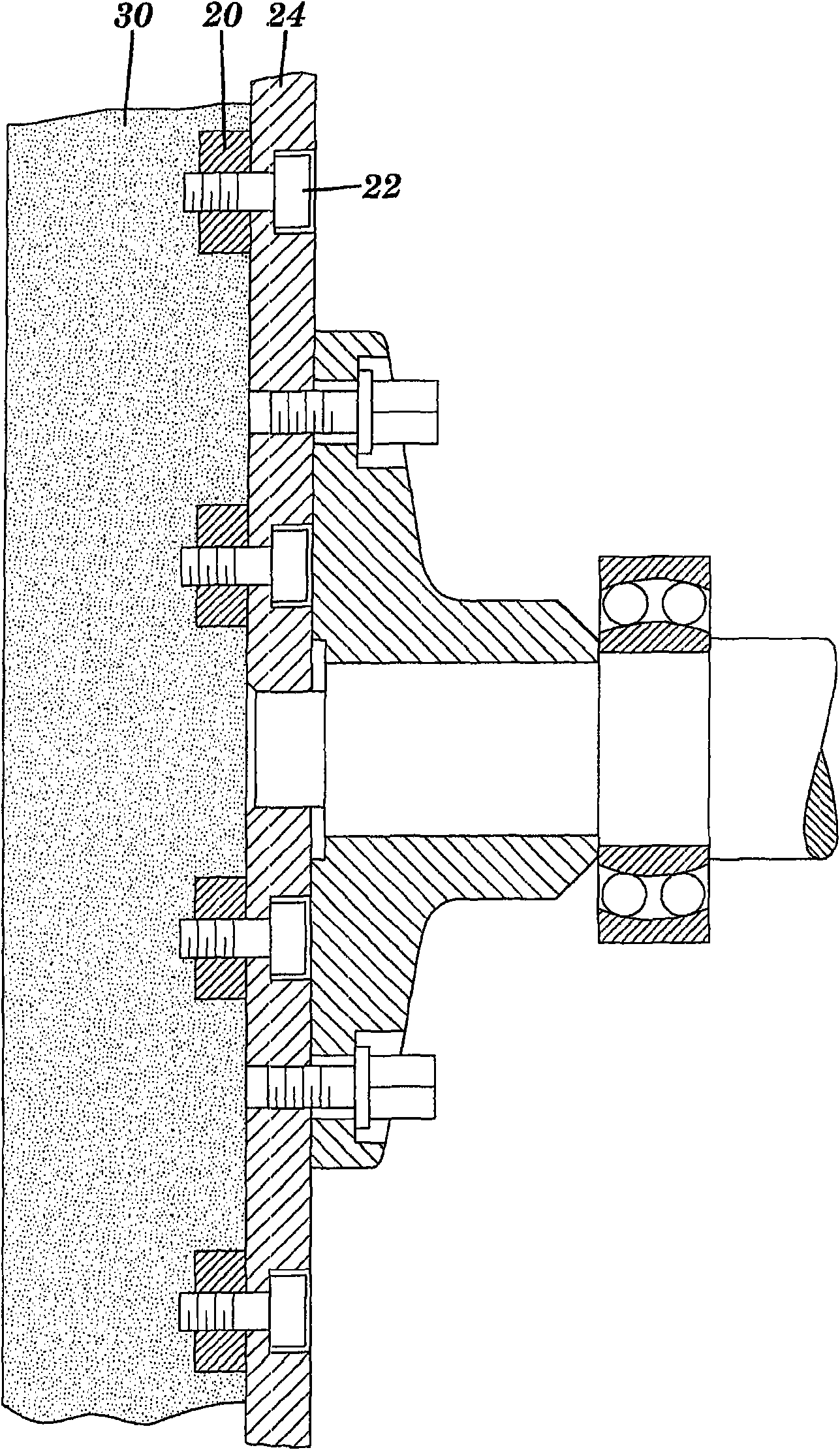

Depth adjustable hub for use with abrasive grinding tool

ActiveUS11123843B2Improve abilitiesLower areaGrinding wheel securing apparatusPortable grinding machinesEngineeringPower tool

An abrasive finishing article with an adapter or hub to attach to an appropriate power tool, wherein the hub contains sets of slots to receive ribs positioned on a grinding wheel to permit adjustment of the height of the hub to change the overall height of the grinding wheel and abrasive finishing article.

Owner:GENERAL TOOLS

Double-deflection light beam shaping device for concave surface forming grinding wheel and machining method

ActiveCN113231963AEfficient removalImprove dressing efficiencyOther manufacturing equipments/toolsAbrasive surface conditioning devicesLight beamElectric machinery

The invention discloses a double-deflection light beam shaping device for a concave surface forming grinding wheel and a machining method. The double-deflection light beam shaping device comprises a supporting base assembly, a vertical displacement motion table and deflection laser trimming devices, wherein the vertical displacement motion table is fixed to the supporting base assembly and used for installing a to-be-trimmed concave grinding wheel, the two deflection laser trimming devices are fixed to the left side and the right side of the vertical displacement motion table correspondingly, laser heads are arranged on the deflection laser trimming devices so as to trim the concave face of the to-be-trimmed concave face grinding wheel, and each deflection laser trimming device comprises a rotating plate direct drive motor, a rotating plate and a laser horizontal adjusting assembly. According to the technical solution, the two laser beams with the deflectable angles are used for conducting concave surface forming trimming on the concave surface super-hard abrasive grinding wheel, and the forming contour precision and trimming efficiency of concave surface trimming are improved.

Owner:HUNAN UNIV

Dry type flexible grinding and polishing method and matching cutter and device thereof

PendingCN107855886AImprove insulation performanceGood heat insulationGrinding machinesGrinding headsPolishingElectric machinery

The invention discloses a dry type flexible grinding and polishing method and a matching cutter and device of the dry type flexible grinding and polishing method. The dry type flexible grinding and polishing method involves application of dry type grinding and polishing cutters and flexible copying elastic mats to a dry type flexible grinding and polishing device. The invention further provides the dry type flexible grinding and polishing device comprising a ring flow grinding mechanism. The ring flow grinding mechanism comprises a grinding head support, a main shaft, a revolution disk, a revolution motor and grinding tool modules. Each grinding tool module comprises a rotation blank polishing motor and a dry abrasive grinding wheel. The dry abrasive grinding wheels are provided with dry type grinding and polishing cutters and flexible copying elastic mats. According to the cutter, a ceramic bond wraps diamond or cubic boron carbide or the like, an abrasive material good in grinding and polishing performance is obtained through sintering, after the abrasive material is smashed so as to obtain abrasive particles, the abrasive particles are mixed with a binding agent, and then the wear-proof heat-insulating cutter good in holding effect and used for dry grinding and polishing is manufactured. The problem that during dry type grinding and polishing, generated high temperature shortens the service life of the cutter is solved. The dry grinding and polishing theory is converted into an operable machining manner, and then a traditional wet grinding and polishing manner can be thoroughly abandoned.

Owner:广东工科机电有限公司

Chopped carbon fiber reinforced resin binder-ultrahard abrasive grinding wheel and preparation method thereof

ActiveCN111482906AGood shape retentionHigh line speed limitAbrasion apparatusGrinding devicesFiberAl powder

The invention discloses a chopped carbon fiber reinforced resin binder-ultrahard abrasive grinding wheel and preparation method thereof. A matrix is prepared from chopped carbon fiber reinforced aluminum powder by pressing, and a grinding layer is prepared from a chopped carbon fiber reinforced resin binder and an abrasive by pressing. The resin binder of the grinding wheel is formed by mixing high temperature resin and low temperature resin. The ultrahard abrasive is formed by mixing coating diamond and coating cubic boron nitride. Compared with the conventional grinding wheel, the ultrahardabrasive grinding wheel has higher limit linear velocity and improved rotating speed, thereby improving production efficiency; meanwhile, shape retention of the grinding wheel can be enhanced, so thatthe grinding wheel can bear higher stress, and the application range of a resin grinding wheel is expanded; as the working temperature of the grinding wheel is higher, burning of the grinding wheel is avoided, and the service life of the grinding wheel is prolonged; the processing technology of the grinding wheel is simpler, and the grinding wheel can process different welding materials, and is more suitable for industrial production.

Owner:江苏赛扬精工科技有限责任公司

Brazed diamond combination abrasive belt, finishing device and finishing method of device

PendingCN112123210AReduce difficultyReduce dressing efficiencyAbrasive surface conditioning devicesSteel beltMaterials science

The invention provides a brazed diamond combination abrasive belt, a finishing device and a finishing method of the device, wherein the brazed diamond combination abrasive belt comprises an annular steel belt and a plurality of brazed combination blocks uniformly distributed on the annular steel belt along the circumferential direction, a mounting groove for clamping the brazing combination blockon the annular steel belt is arranged at the bottom of each brazing combination block, the middle position of the top of each brazing combination block is sunken downward to form a transverse bucklinggroove protruding forward or backward, and brazing abrasive particle layers are arranged in positions, on two sides of the transverse buckling groove, of the top of each brazing combination block. According to the invention, a superhard abrasive grinding wheel is finished by adopting the improved brazed diamond combination sand belt, the defects of single-point finishing and line finishing adopted in a conventional finishing process are overcome, the finishing difficulty and finishing efficiency of the superhard abrasive grinding wheel are greatly reduced by adopting a small-area fitting finishing method, the sharpening effect of the superhard abrasive grinding wheel is enhanced, and the finishing difficulty of the superhard abrasive grinding wheel is reduced.

Owner:HENAN UNIV OF SCI & TECH

Abrasive grinding tool device convenient for grinding

PendingCN107457646AEasy to GrindEasy to polishGrinding machinesGrinding work supportsElectric machineryEngineering

The invention provides an abrasive grinding tool device convenient for grinding and relates to the field of grinding tools. The abrasive grinding tool device convenient for grinding comprises a grinding tool base. A chute is formed in the top of the grinding tool base; a roller is slidably connected in the chute; a wheel axle fixedly sleeves an inner ring of the roller; a connecting block is fixedly connected to the outer surface of the wheel axle; a fixed plate is arranged above the grinding tool base; one side, far from the wheel axle, of the connecting block penetrates through the chute and is fixedly connected to the fixed plate arranged above the grinding tool base; a first supporting spri9ng is fixedly connected to the right side of the inner wall of the chute; and one side, far from the right side of the inner wall of the chute, of the first supporting spring is fixedly connected to a fixed block. According to the abrasive grinding tool device convenient for grinding, the fixed plate can slide left and right through the chute and the roller arranged in the bottom of the fixed plate, so that a grinding motor drives a grinding block to apply a uniform leftward acting force to a processed objected, and the grinding operation is more convenient as the object is uniformly stressed by the grinding block.

Owner:FORTURE TOOLS CO LTD

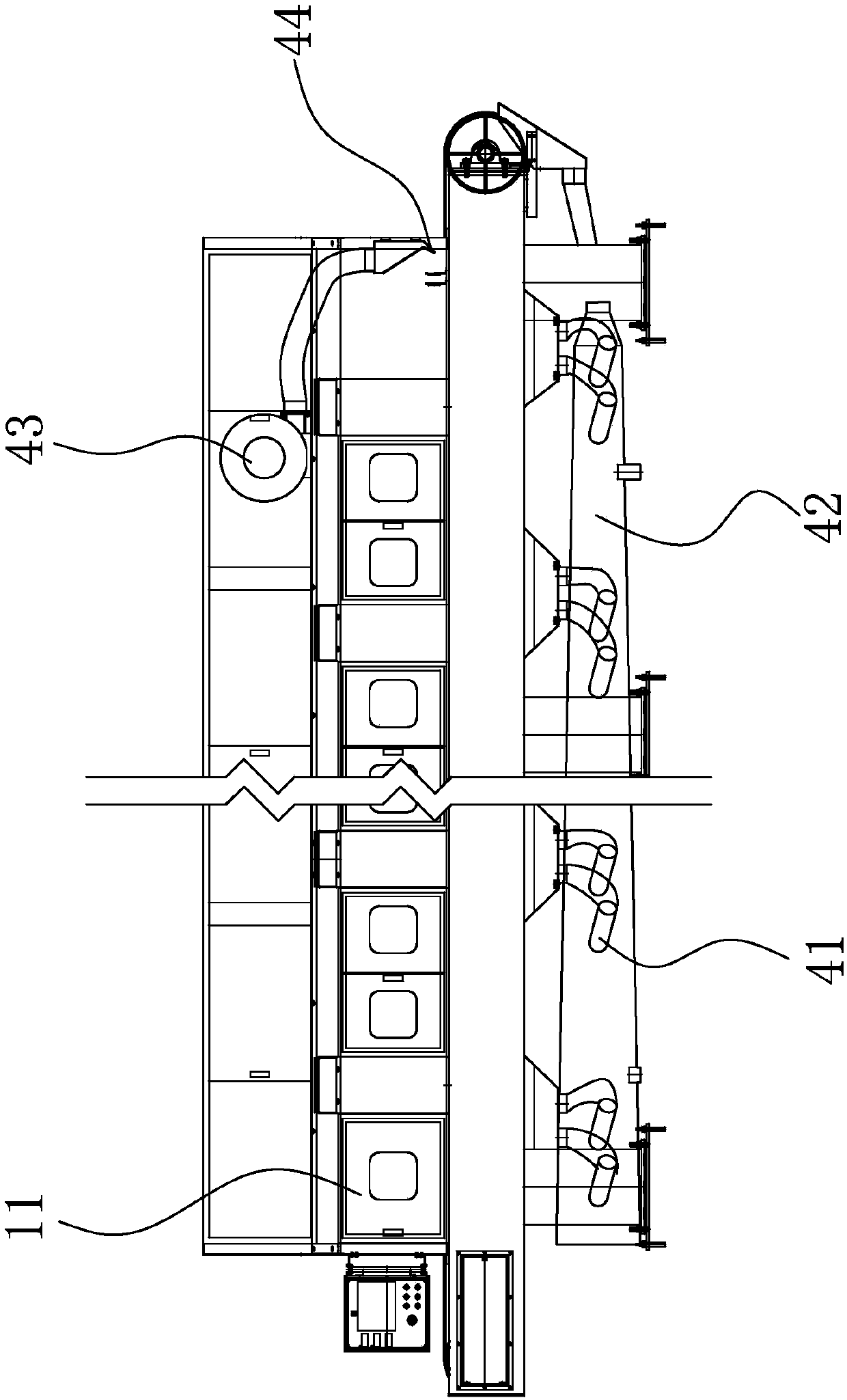

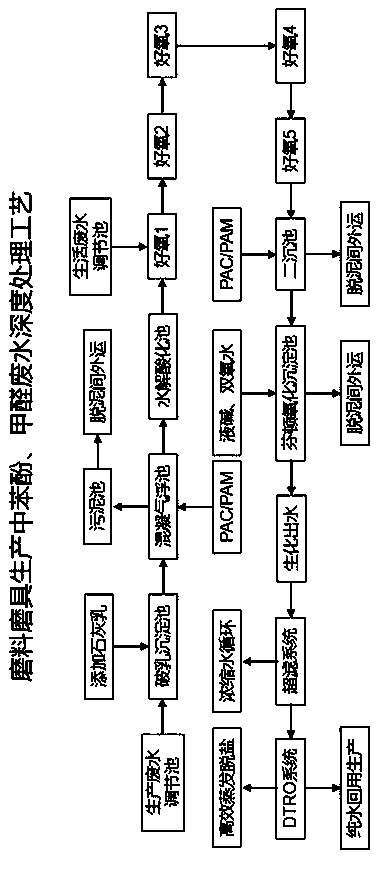

Advanced treatment process for phenolic resin production wastewater in abrasive grinding tool production

ActiveCN111484209AUpdate controlUpdate runabilityFatty/oily/floating substances removal devicesWater treatment compoundsWater treatment systemUltrafiltration

The invention discloses an advanced treatment process of phenolic resin wastewater in abrasive grinding tool production. The method comprises the steps of sedimentation, demulsification, flocculation,hydrolytic acidification, aerobic treatment, secondary flocculation, Fenton oxidation, ultrafiltration and ultrahigh-pressure reverse osmosis. The invention provides a whole set of process combiningmultiple treatment modes to solve the problems of long treatment flow, poor treatment effect and large occupied area in the existing process. The problem of secondary pollution is solved; the wastewater treated by the process disclosed by the invention can reach the discharge standard required by the country; the process advantages of efficient biological treatment, energy saving, consumption reduction, land occupation saving, simple operation and maintenance and the like are realized, and the control and operation modes of the existing biological sewage treatment system are thoroughly updated. The biochemical wastewater is treated by adopting a ultrafiltration system, pure physical filtration is performed, the effluent quality is stable, produced water is ensured to completely reach the discharge standard, and pretreatment is performed for a subsequent DTRO system.

Owner:ZHENGZHOU UNIV MULTI-FUNTIONAL DESIGN & RES ACAD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com