Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

740results about How to "Easy to remove dust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

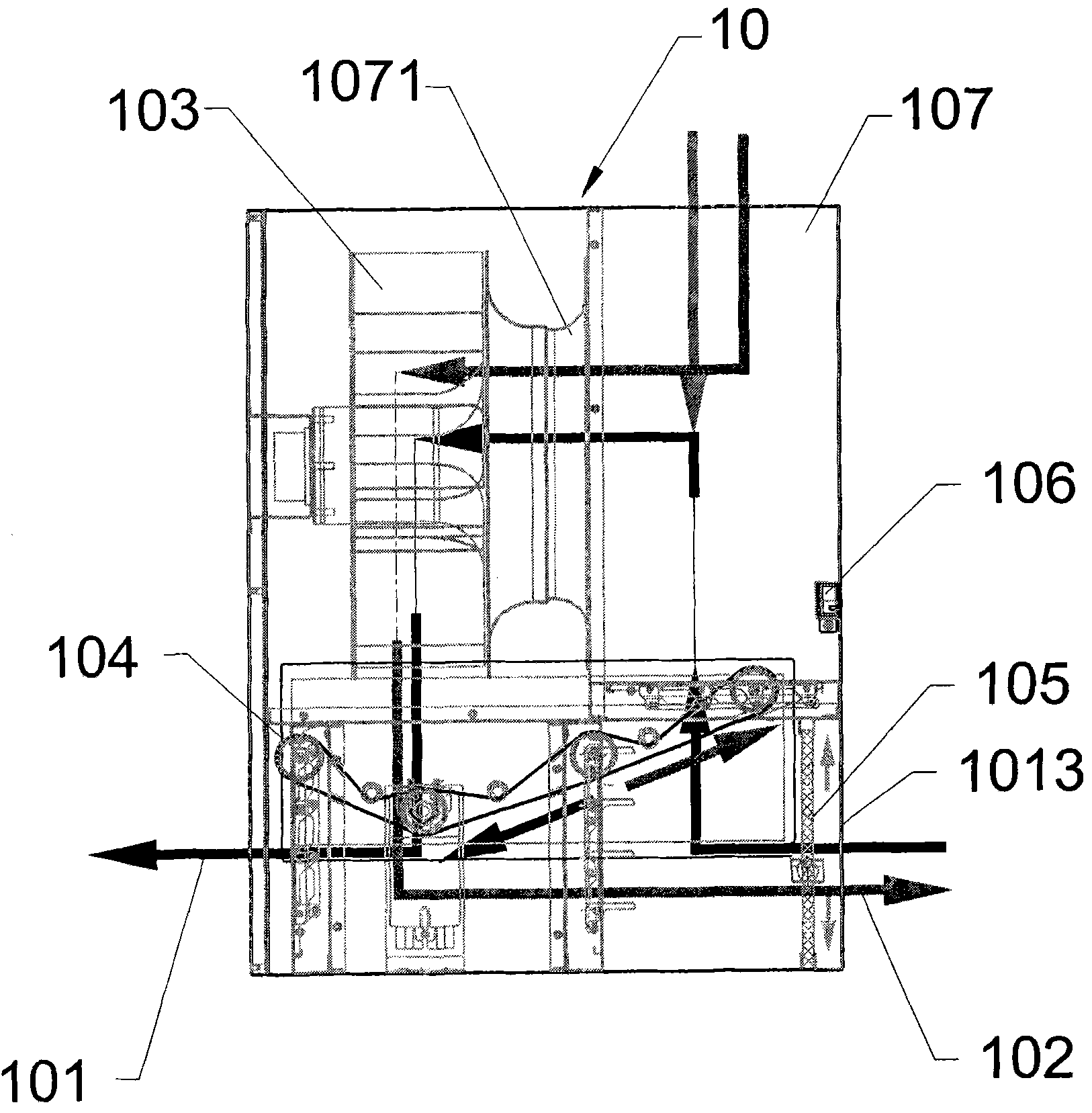

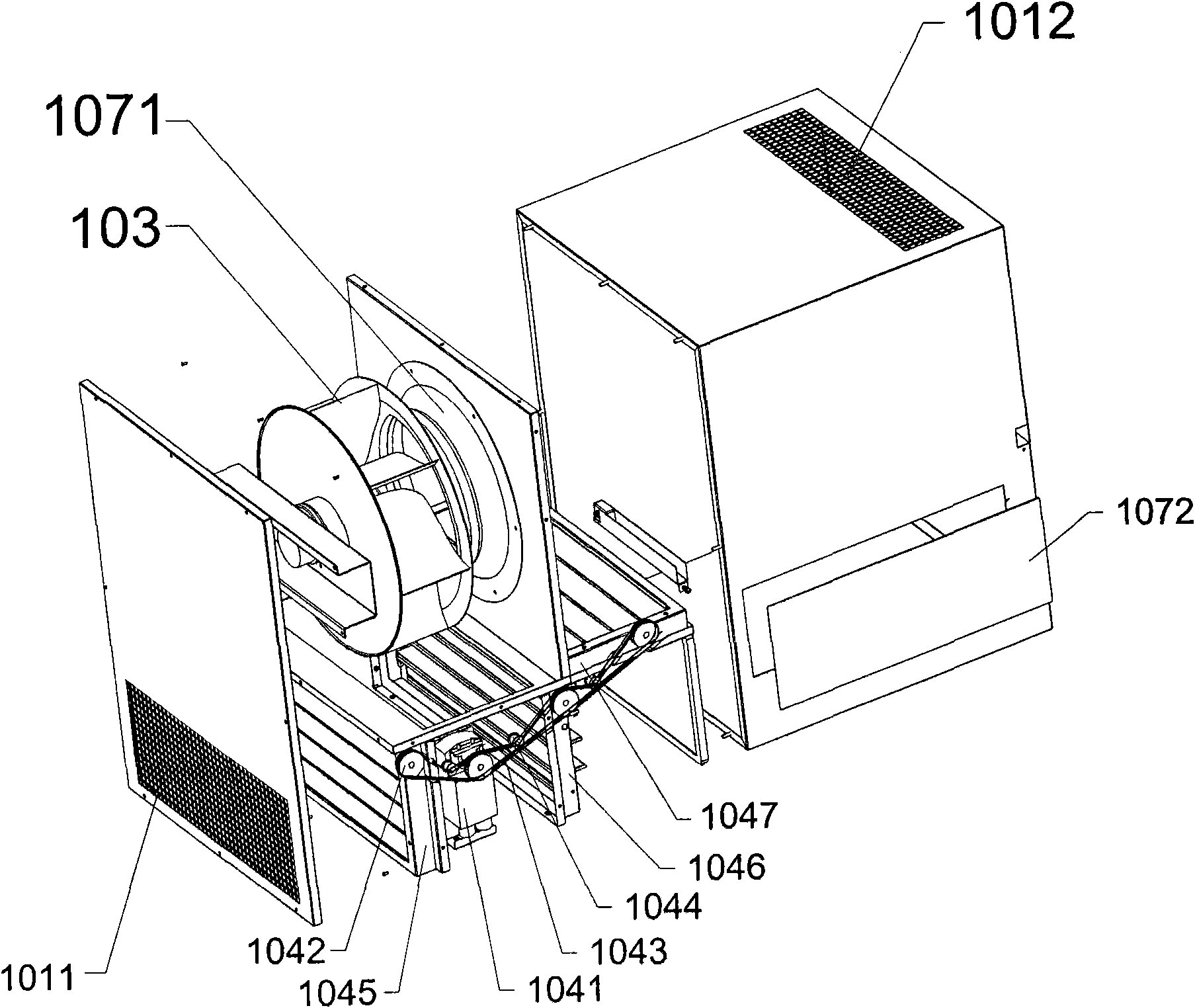

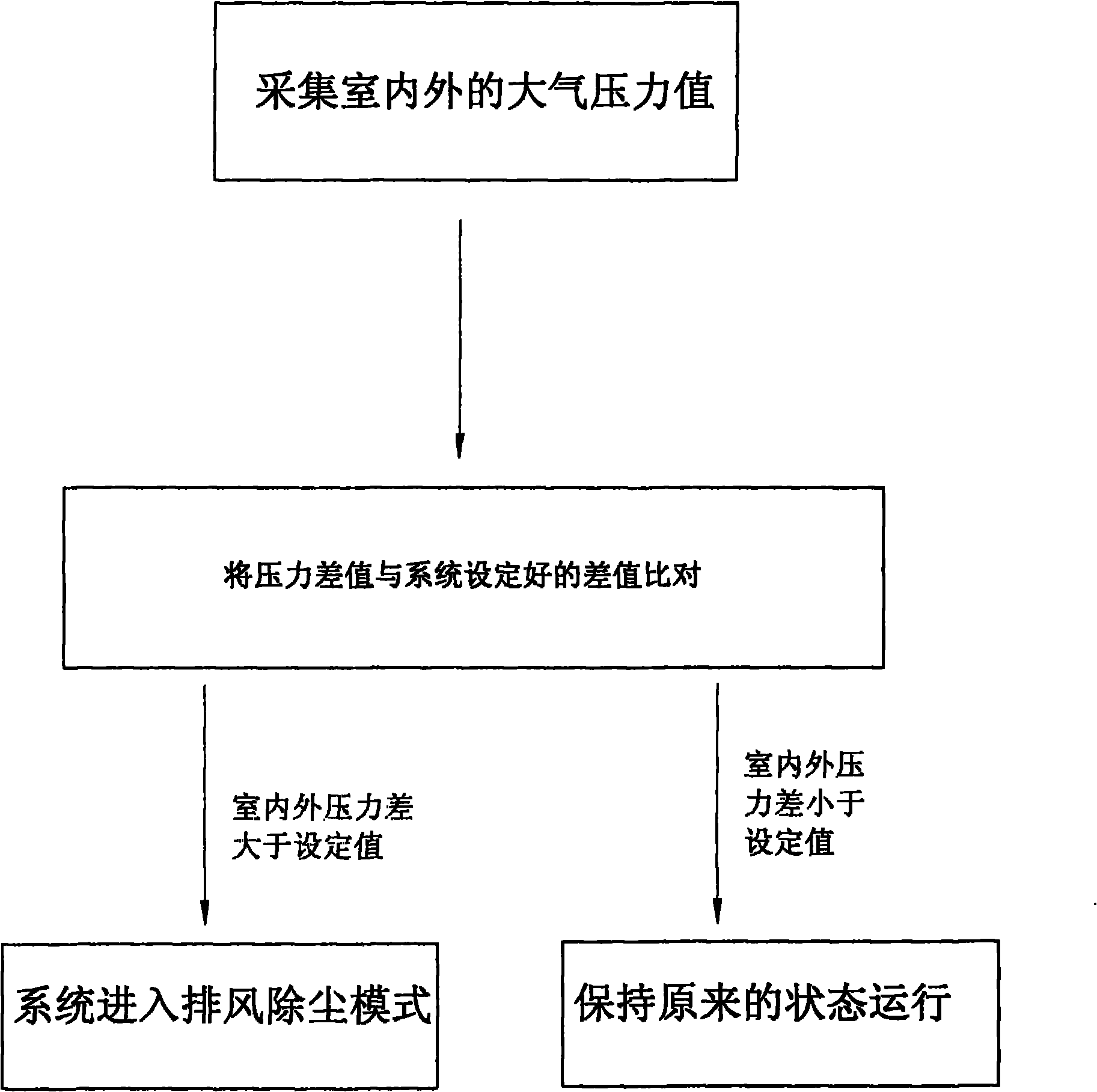

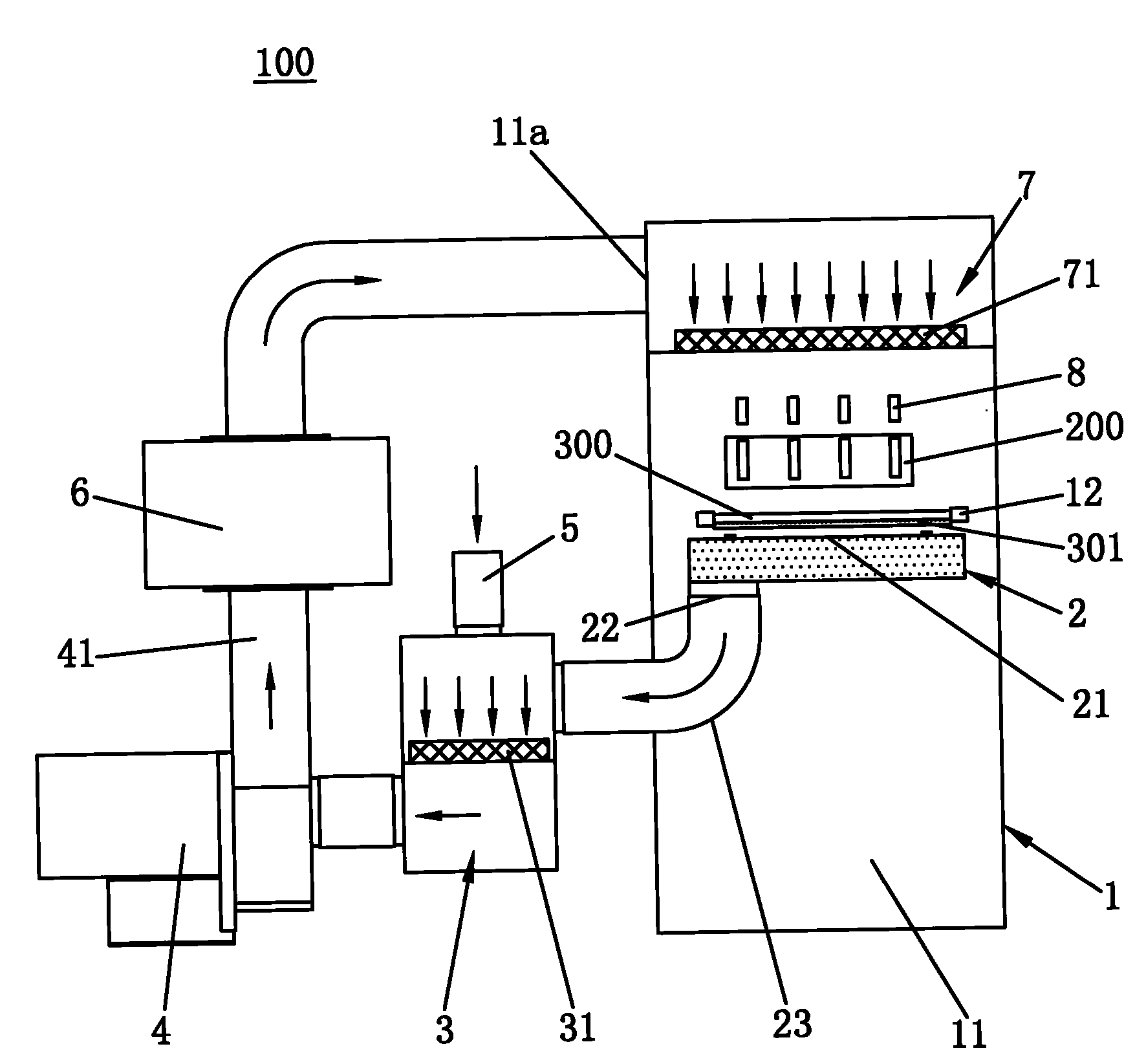

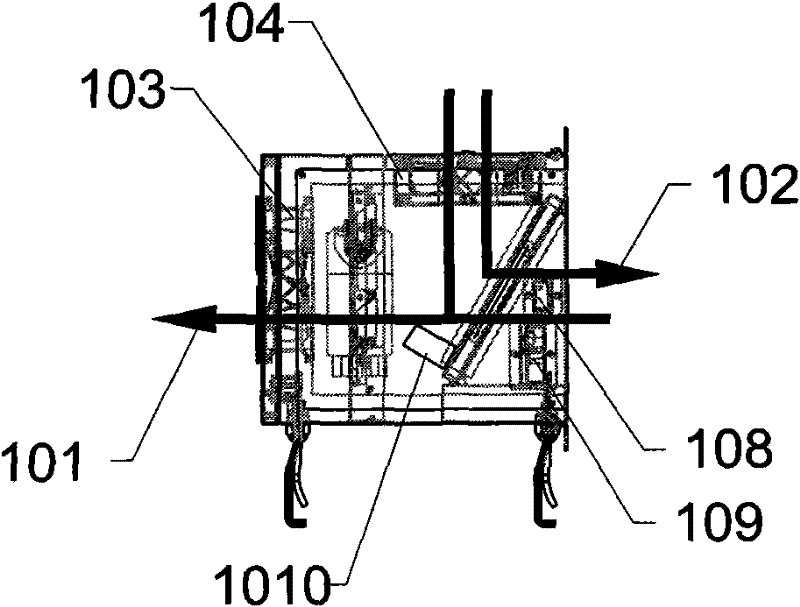

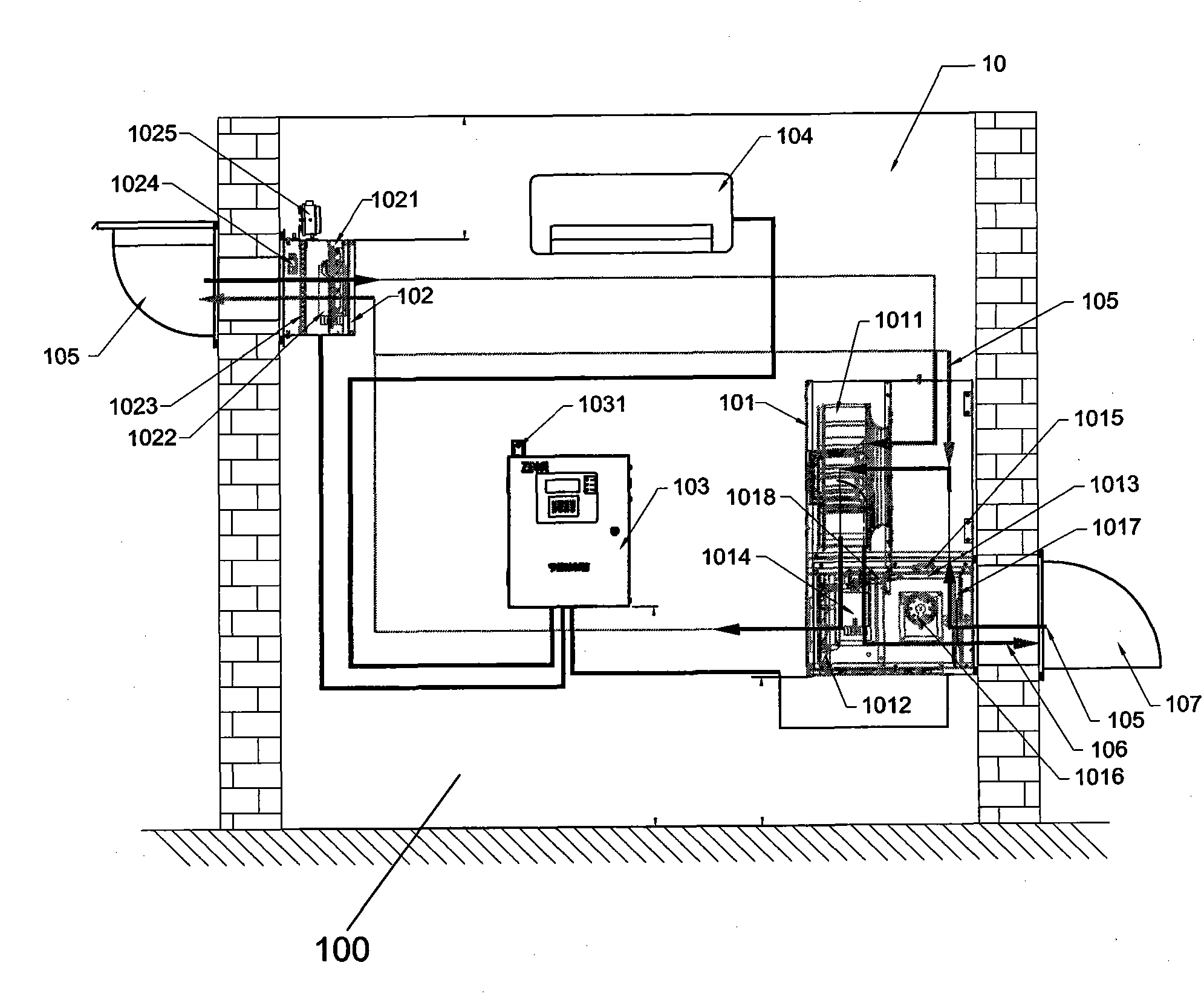

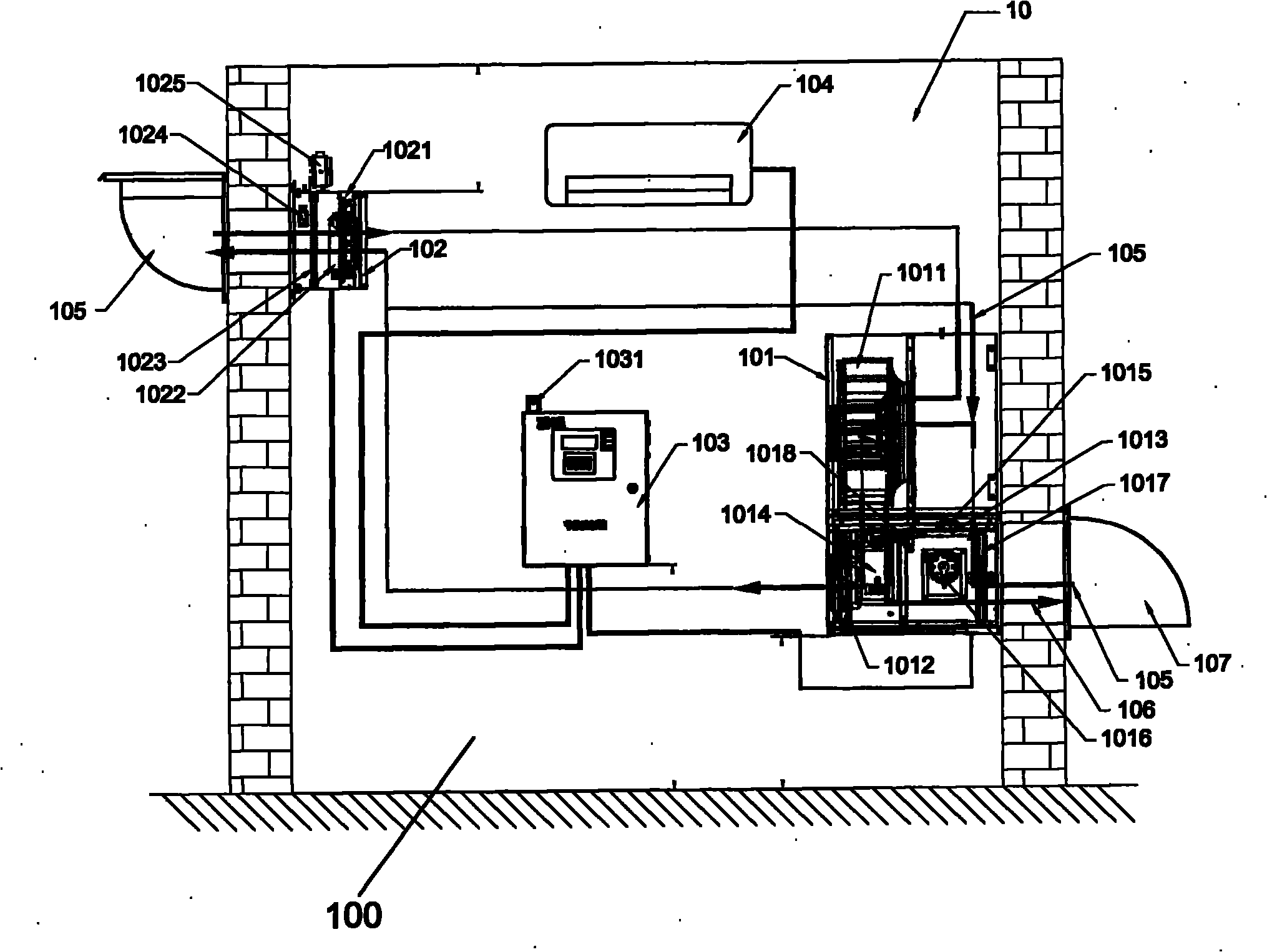

Efficient automatic dust-removing and intelligent ventilation system and automatic dust-removing method

InactiveCN101832612AGuarantee heat dissipation safetyImprove cooling effectSpace heating and ventilation safety systemsLighting and heating apparatusControl systemTime-sharing

The invention relates to the ventilation system field, in particular to an efficient automatic dust-removing and intelligent ventilation system and an automatic dust-removing method. The system comprises an intelligent energy-saving ventilation system housing component and a fan, wherein the intelligent energy-saving ventilation system housing component comprises a dual duct, a dust-discharging duct, a throttle actuating mechanism, a dust screen, a temperature and humidity sensor and a distributed pressure sensor, wherein the temperature and humidity sensor and the distributed pressure sensor are connected with a control system, and the control system drives the throttle actuating mechanism to realize time-sharing and smooth transition of the dual duct and the dust-discharging duct. The beneficial effects of the invention are as follows: the fans of the air feeder unit can be used for several purposes such as air supply and dust removing, thus reducing the equipment cost; the self-cleaning of the filtering screen can be realized, thus prolonging the service life of the filtering screen, reducing replacement frequency and lowering maintenance cost; and by turning on / off the automatic dust-removing and intelligent ventilation system, the normal operation of the devices in an equipment room can be ensured.

Owner:SHENZHEN ZHONGXING SINDI TECH CO LTD

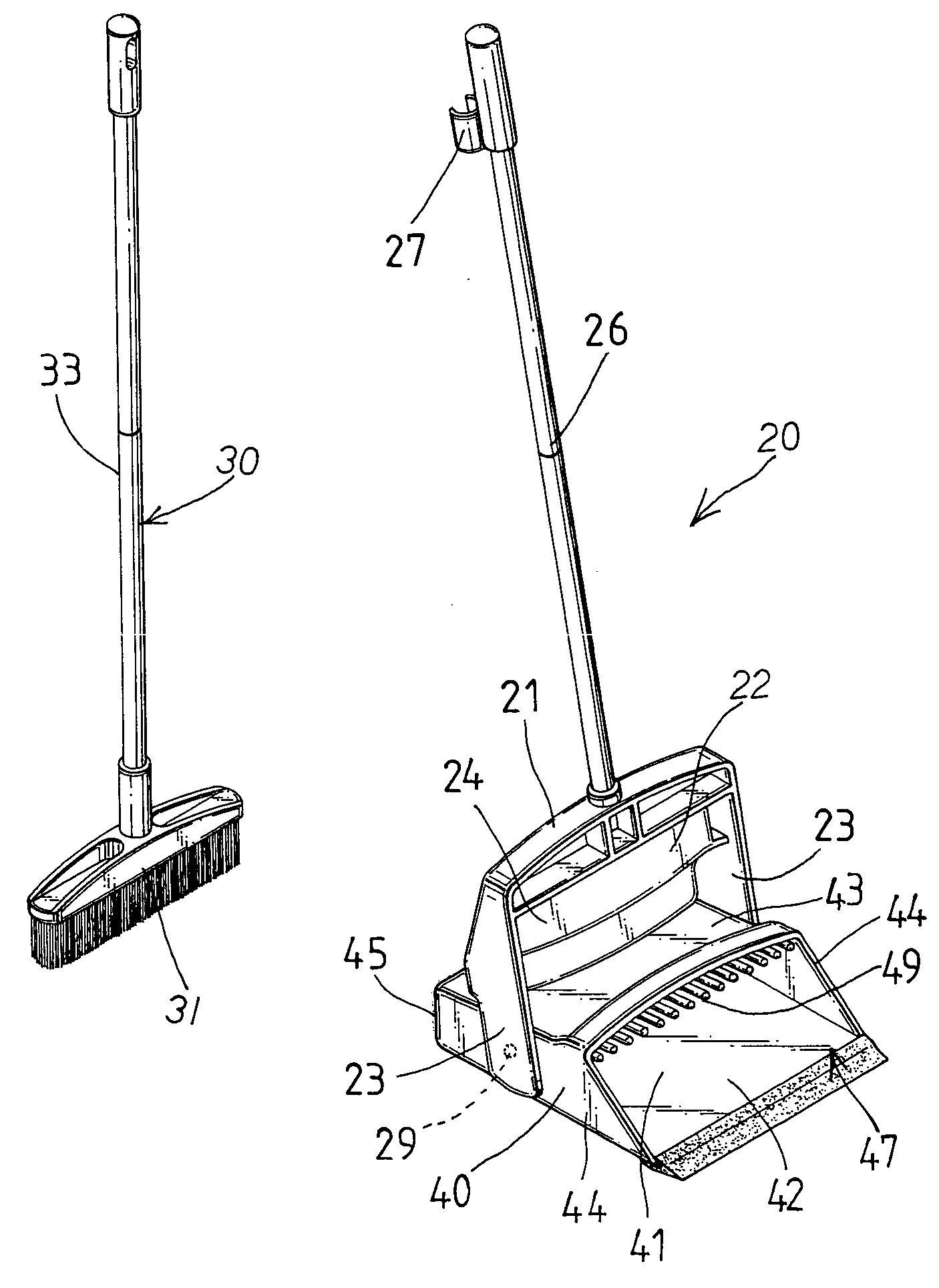

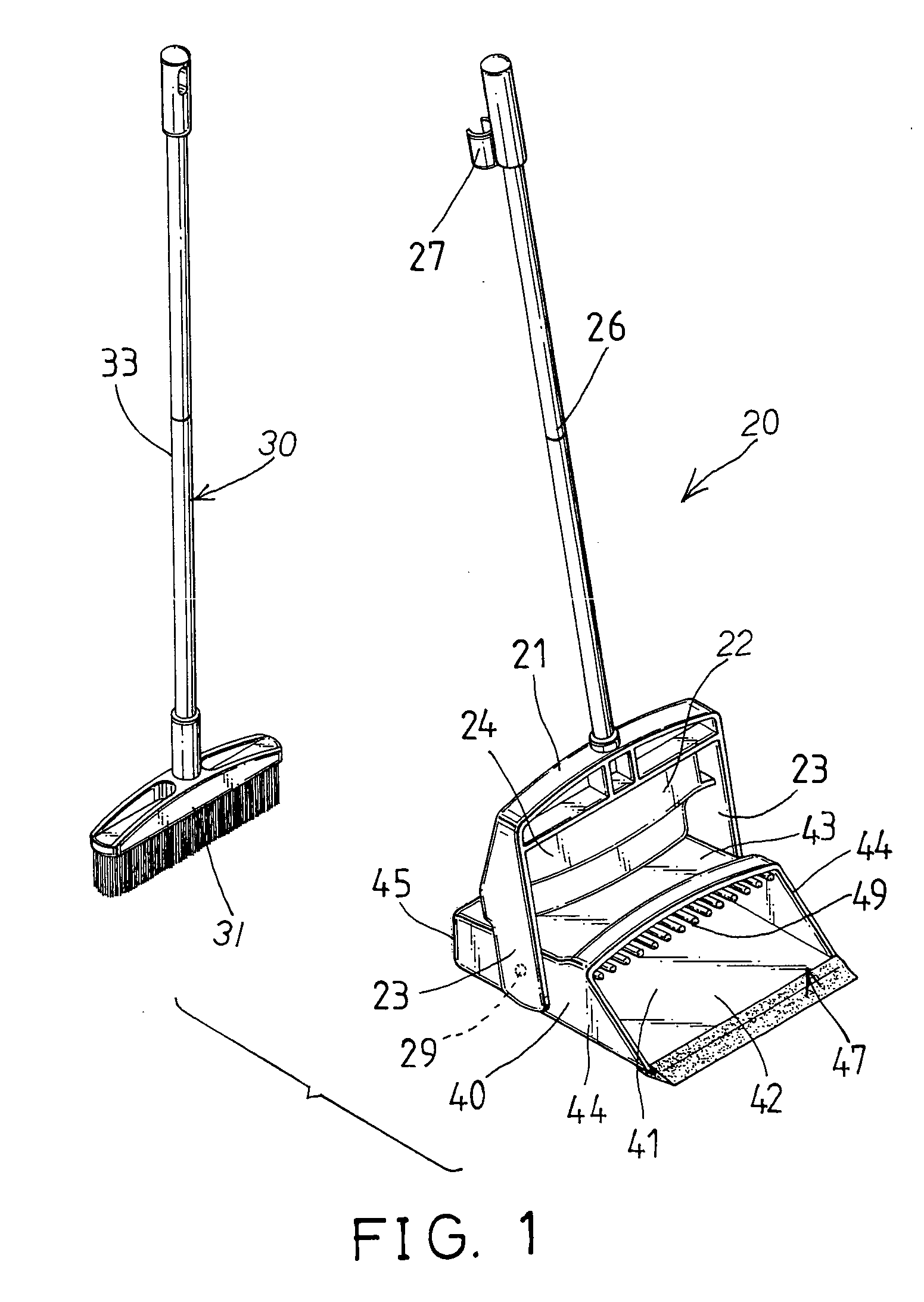

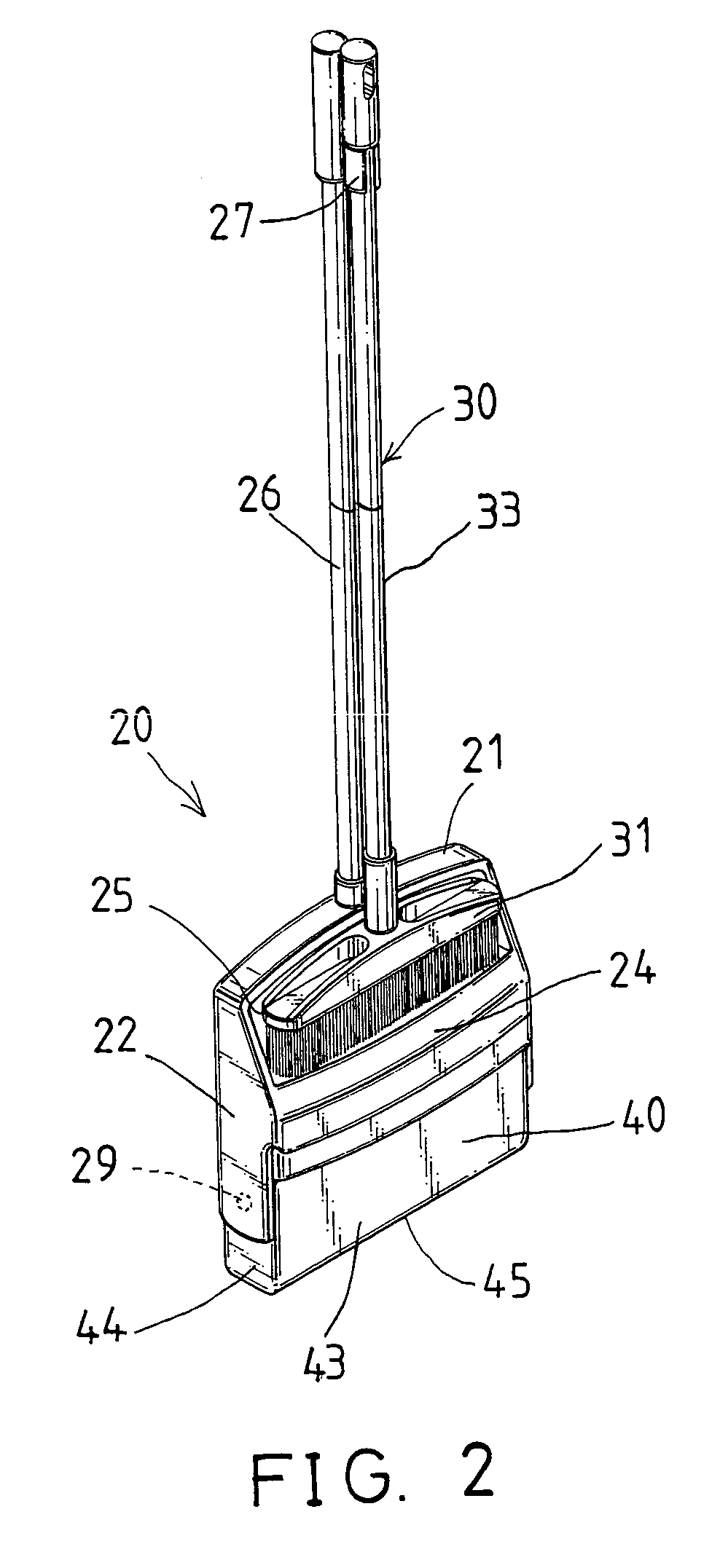

Dustpan having device for removing dust

InactiveUS20050071943A1Easy to remove dustEasy to disassembleCarpet cleanersFloor cleanersMechanical engineeringEngineering

A dustpan includes a casing pivotally attached to a housing, and rotatable relative to the housing between an upward folding position and a downward working position. The casing includes a chamber for receiving dirt, and defined by an upper panel, a bottom panel, and two side panels, and includes a front opening, and one or more projections extended forwardly from the upper panel of the casing, and extended into the front opening of the casing, for removing hairy members or fibers or threads or dirt from the broom, and thus for preventing the users' hands from being contacted with the brush member of the broom and the dirt or the hairy members.

Owner:LIU XIAN CHANG

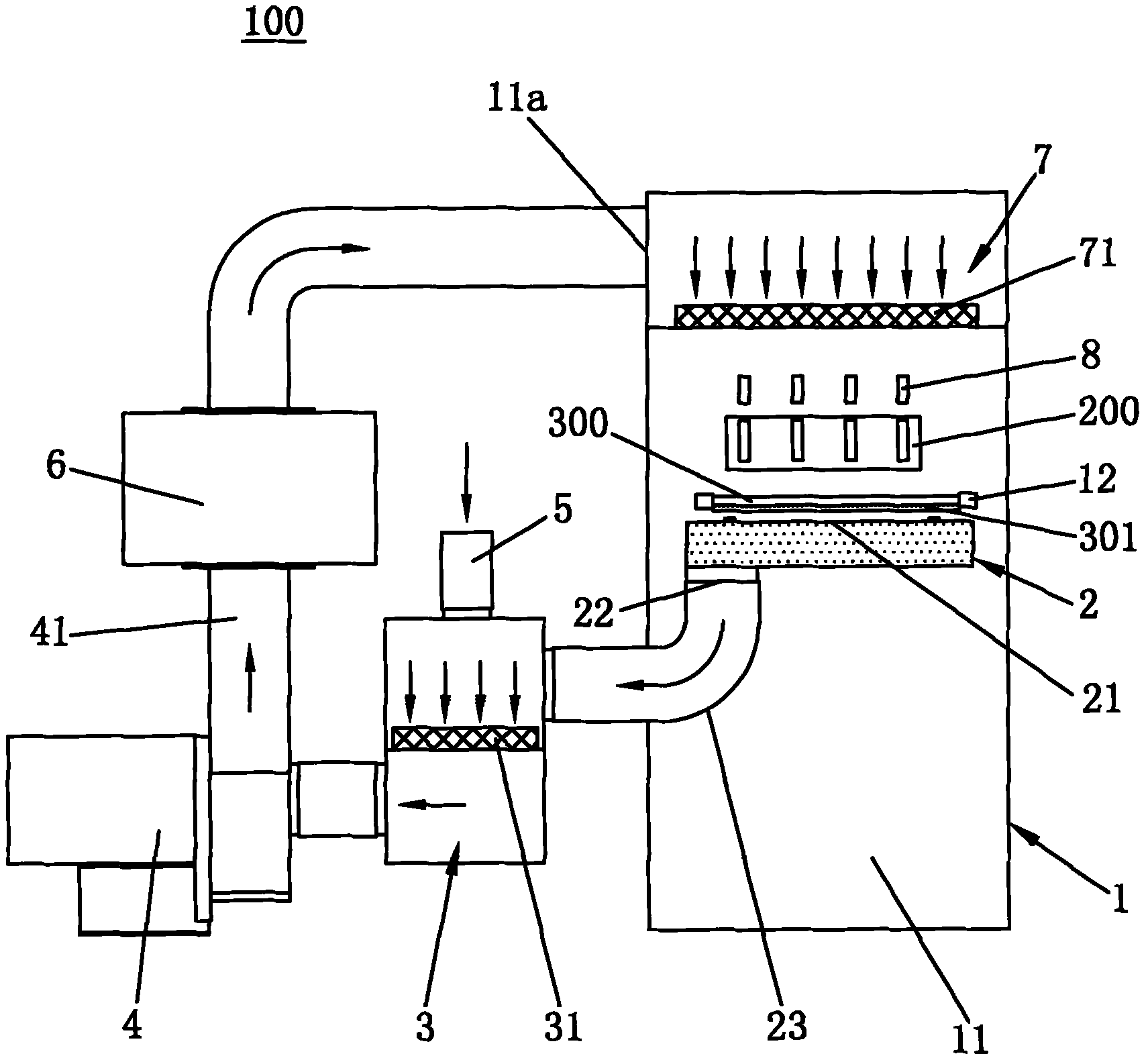

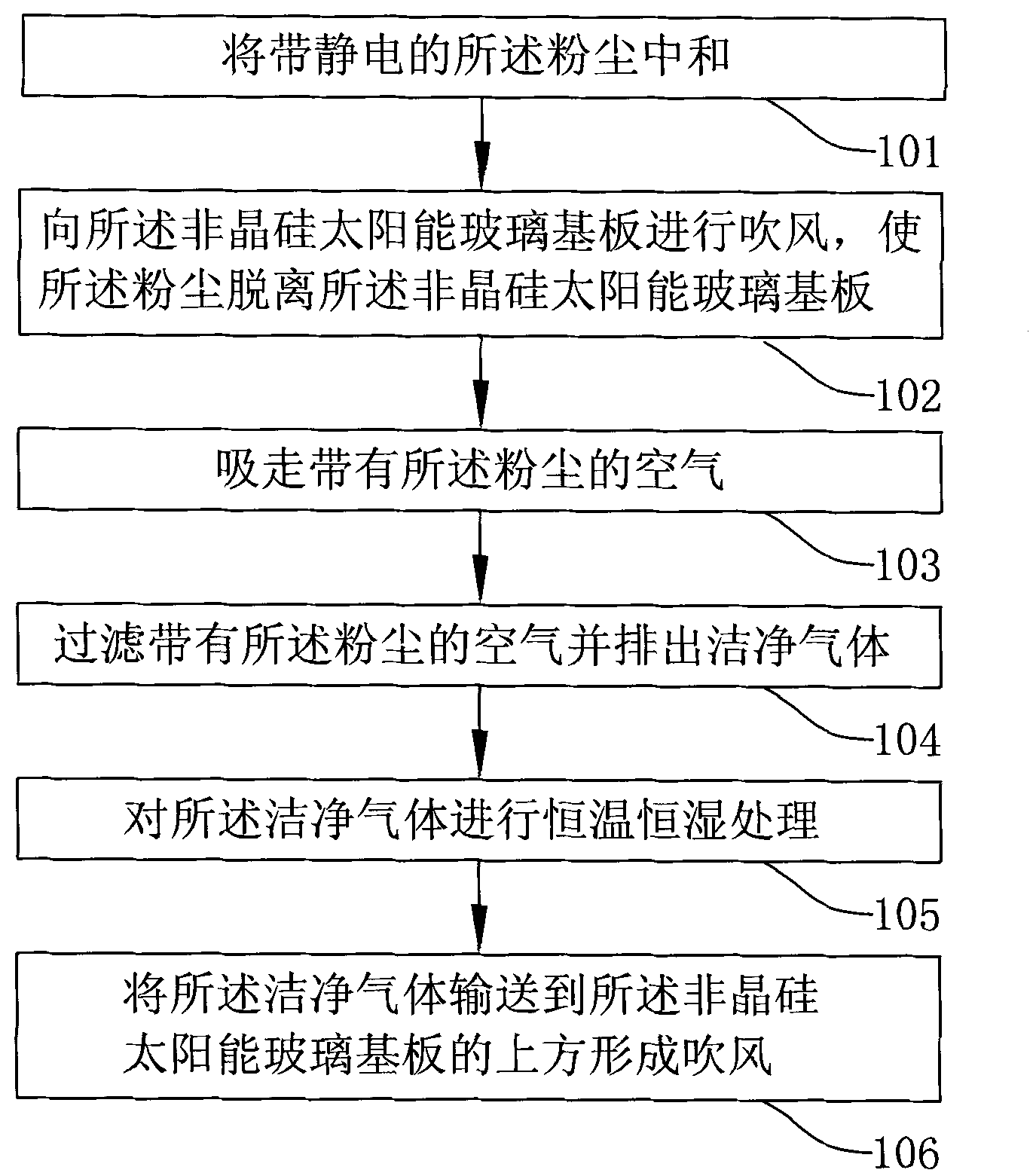

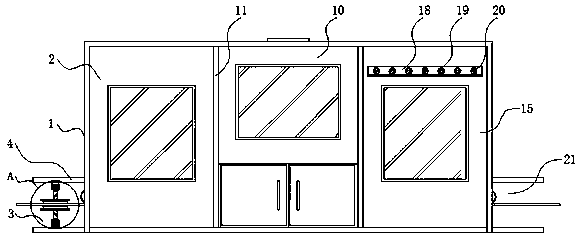

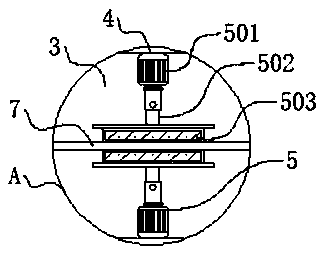

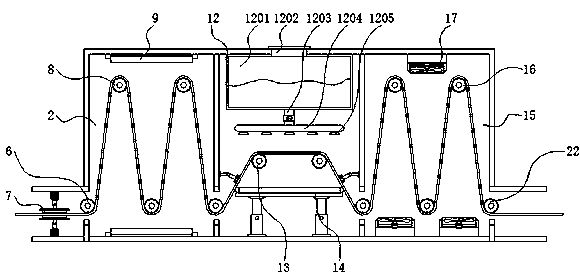

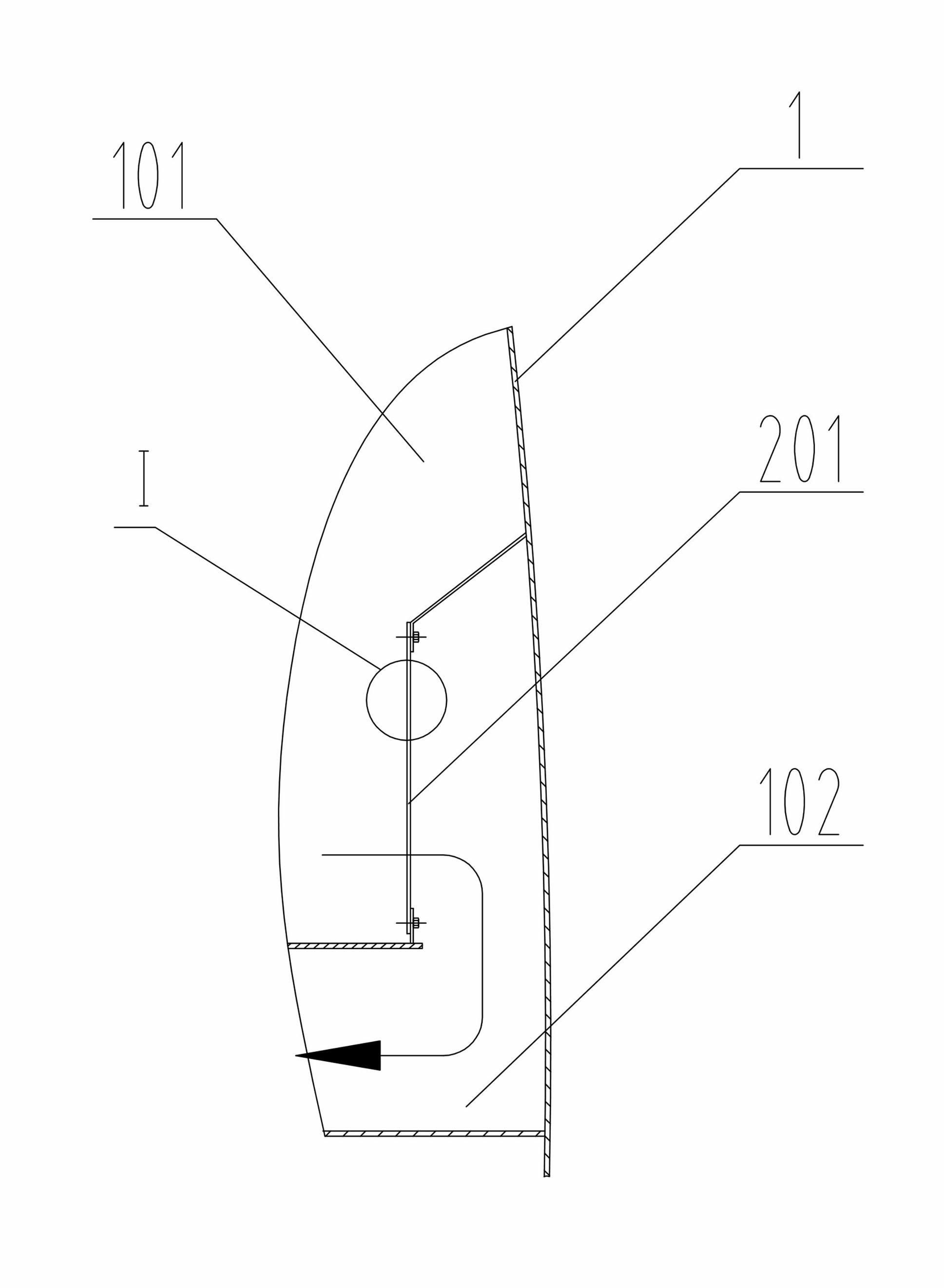

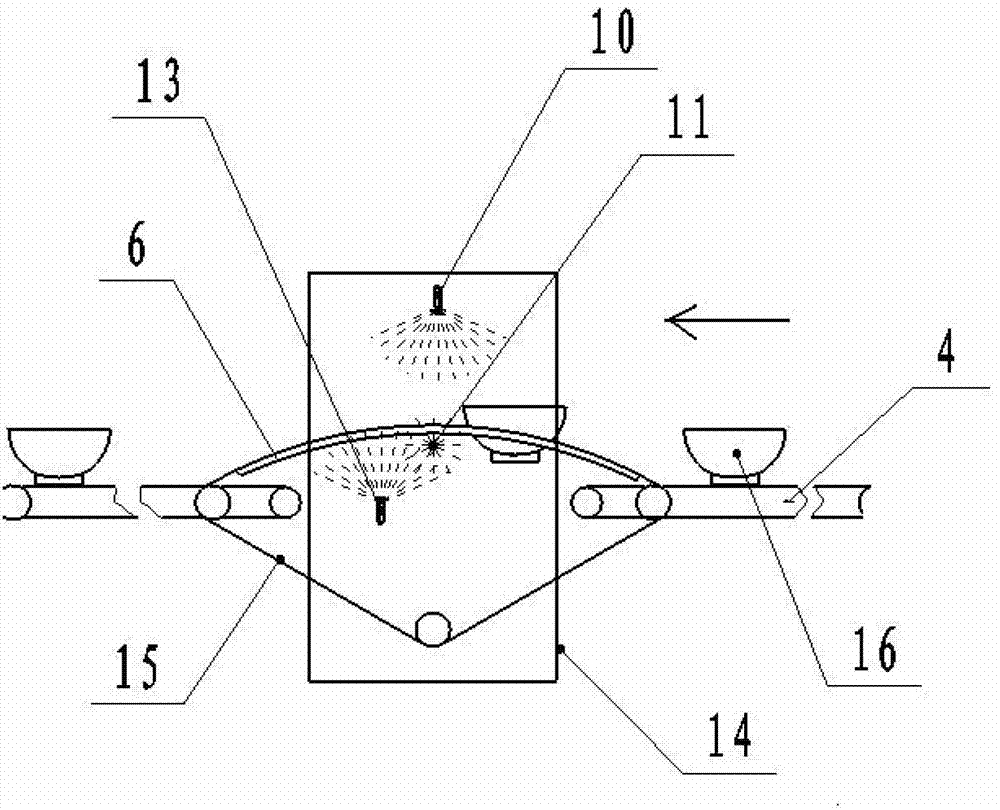

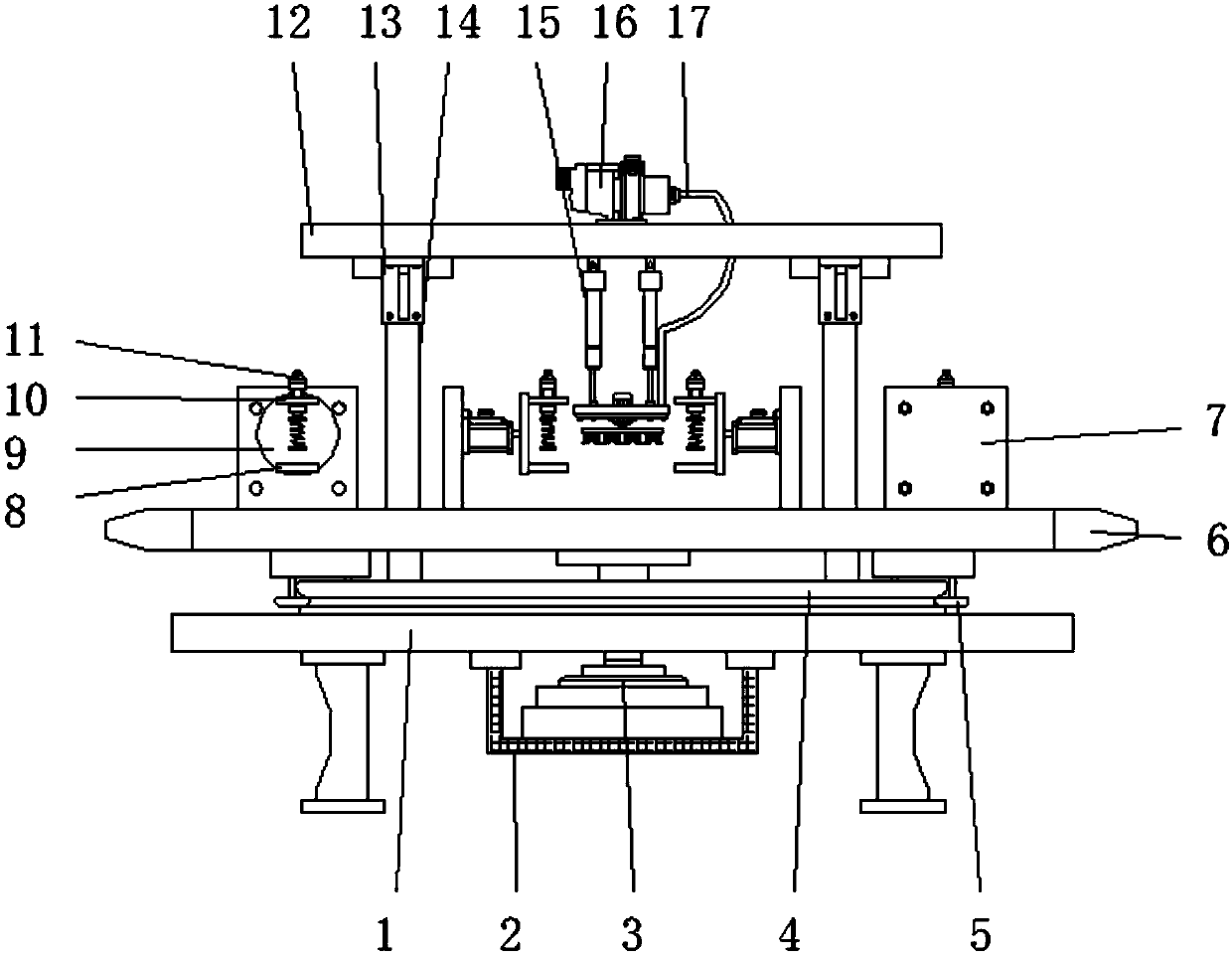

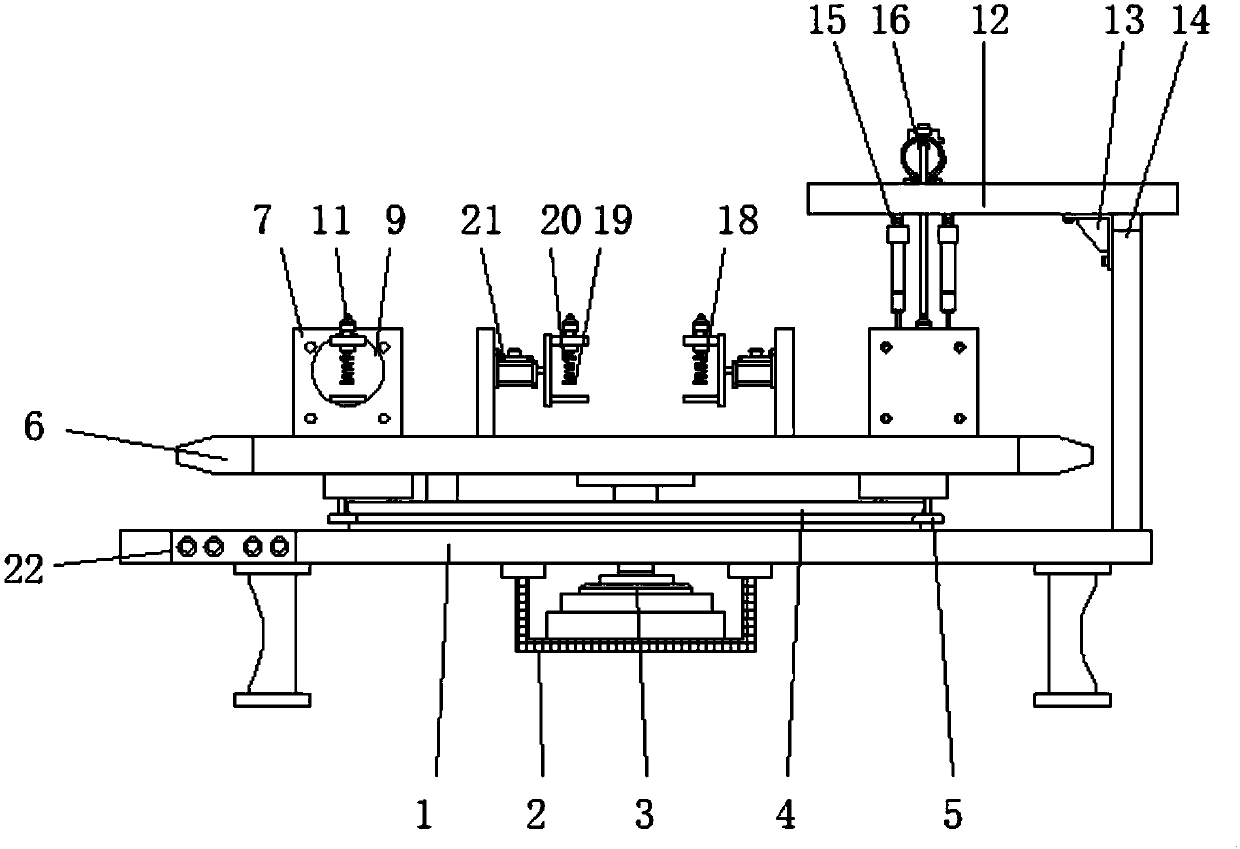

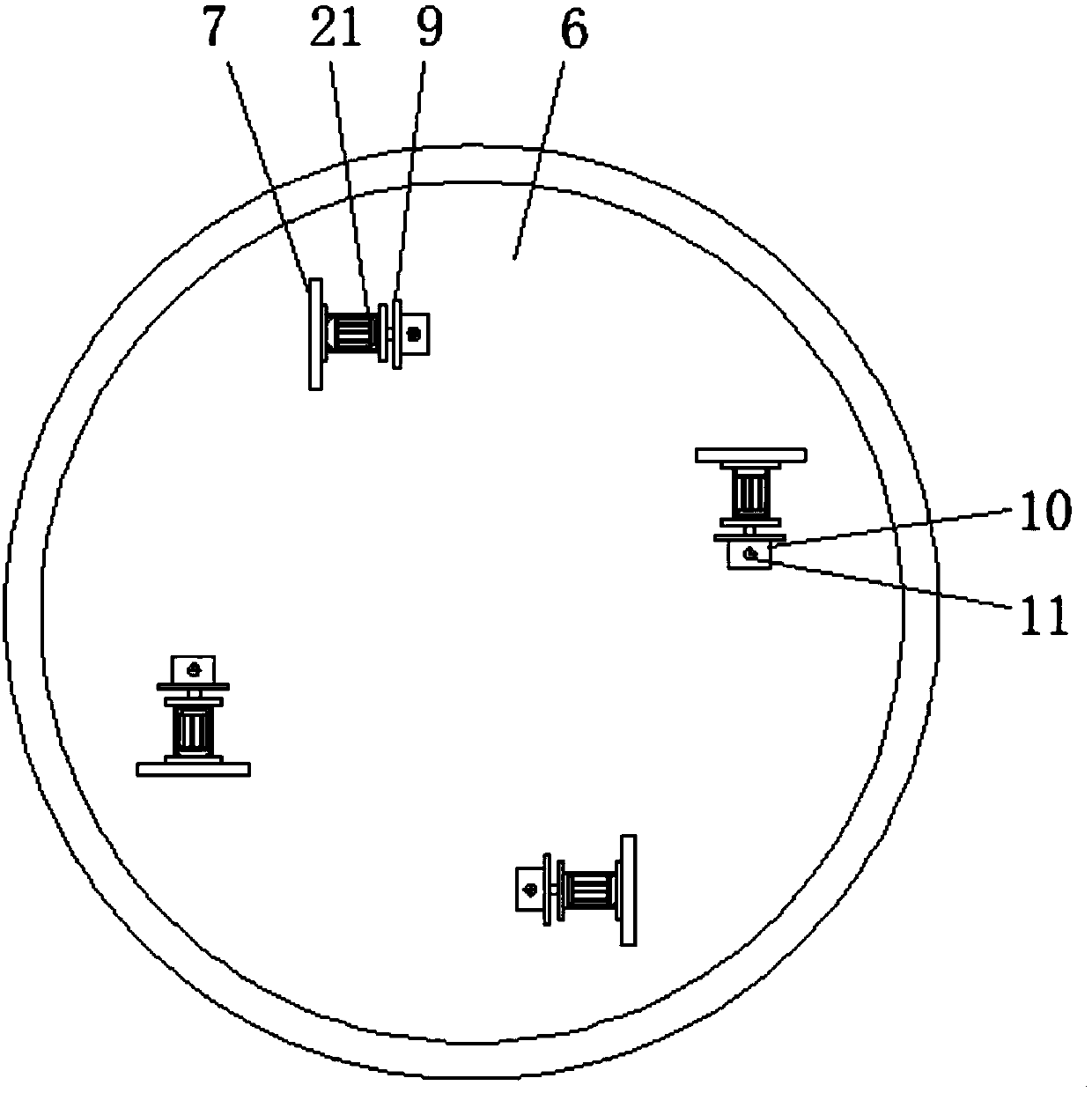

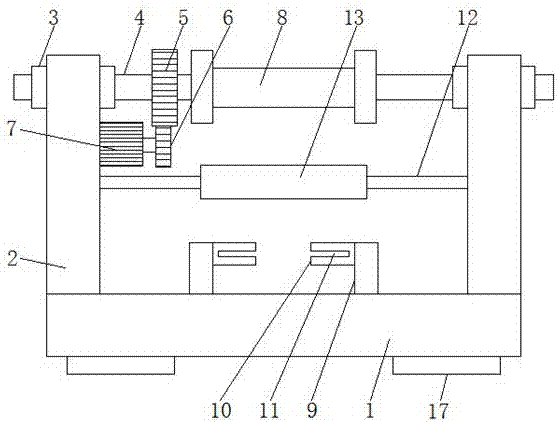

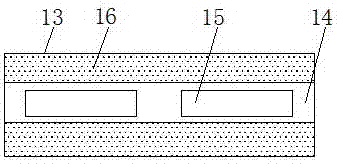

Laser recticle dedusting plant and dedusting method

InactiveCN101829848AEasy to remove dustImprove cleanlinessDirt cleaningAblative recordingLow noiseEngineering

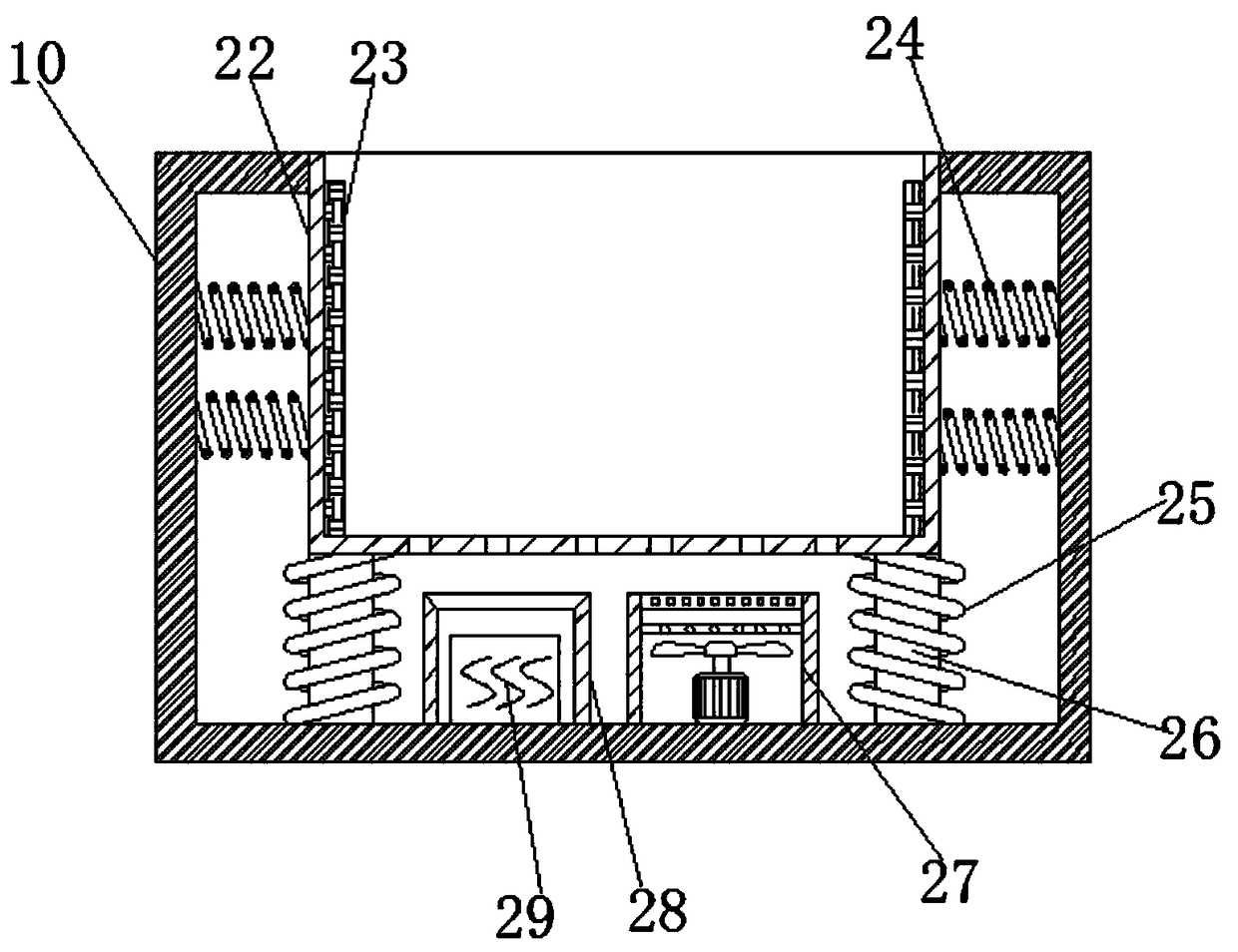

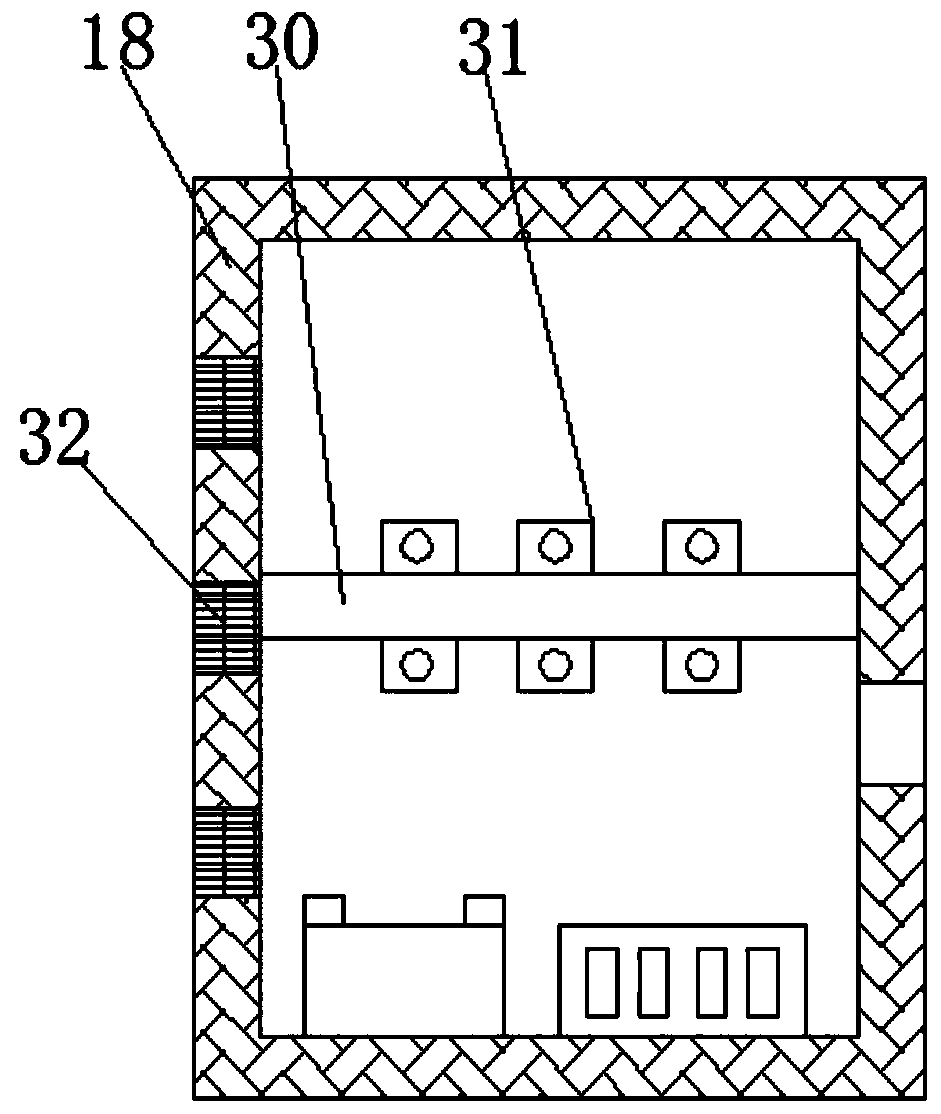

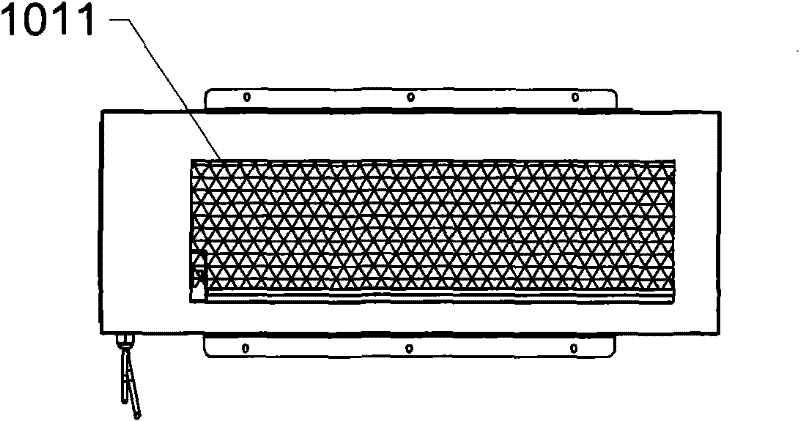

The invention discloses a laser recticle dedusting plant. The laser recticle dedusting plant comprises a processing unit, a dust exhaust apparatus, a first filter unit, a high pressure exhaust fan and a plurality of electrostatic cleaning bars, wherein the processing unit comprises an inner cavity and an operating platform arranged in the inner cavity; the dust exhaust apparatus comprises a dust suction port and a dust-discharging port, the dust suction port is positioned under the operating platform, the dust-discharging port of the dust exhaust apparatus is communicated with the upper end of the first filter unit, the lower end of the first filter unit is communicated with the suction opening of the high pressure exhaust fan, a first filter net core is arranged between the upper end andthe lower end of the first filter unit, the air outlet of the high pressure exhaust fan is communicated with the inner cavity, and the electrostatic cleaning bars are evenly arranged on the laser generator. The laser recticle dedusting plant has high dedusting efficiency, low noise and little energy consumption. The invention also discloses a laser recticle dedusting method.

Owner:东莞晨真光伏有限公司

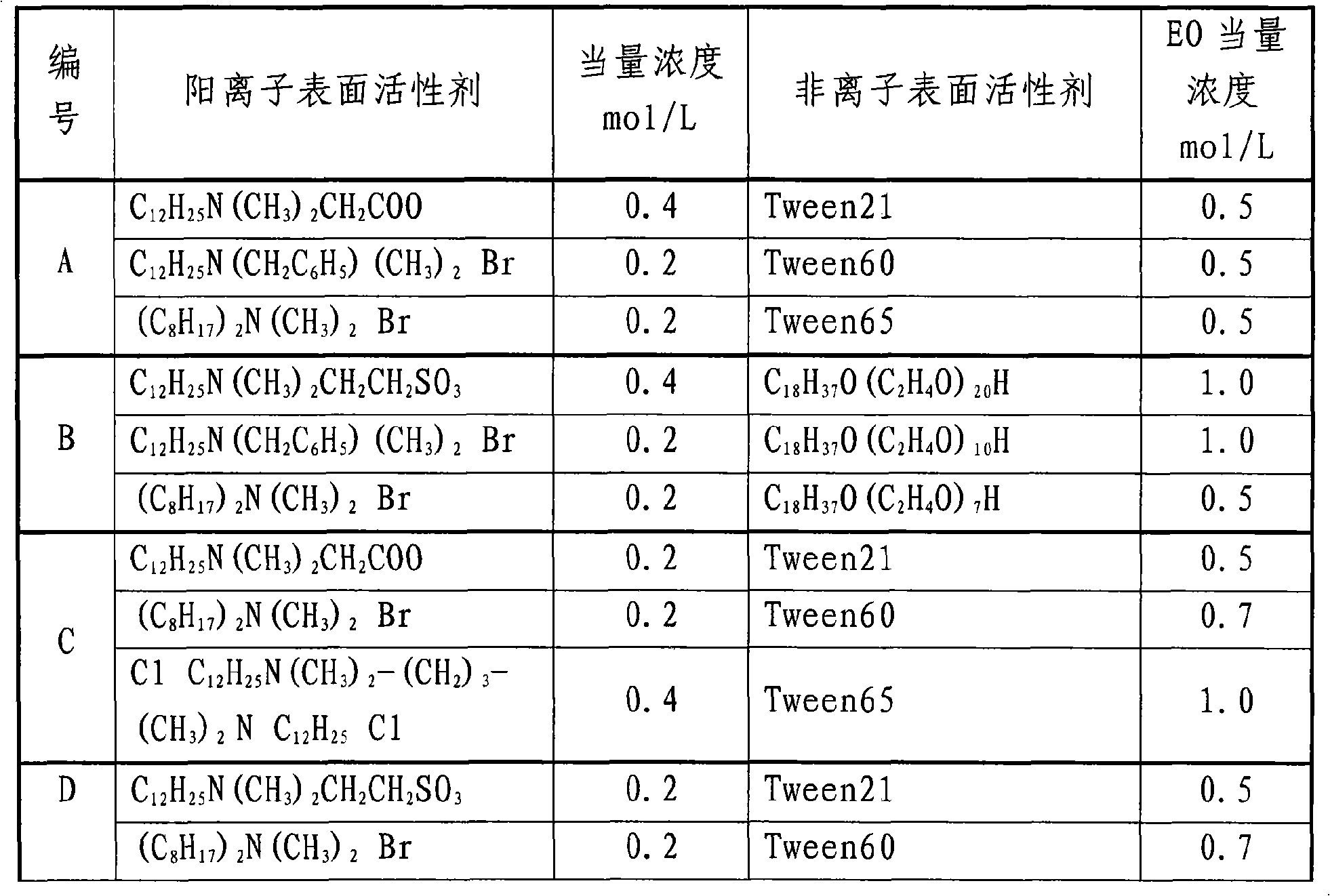

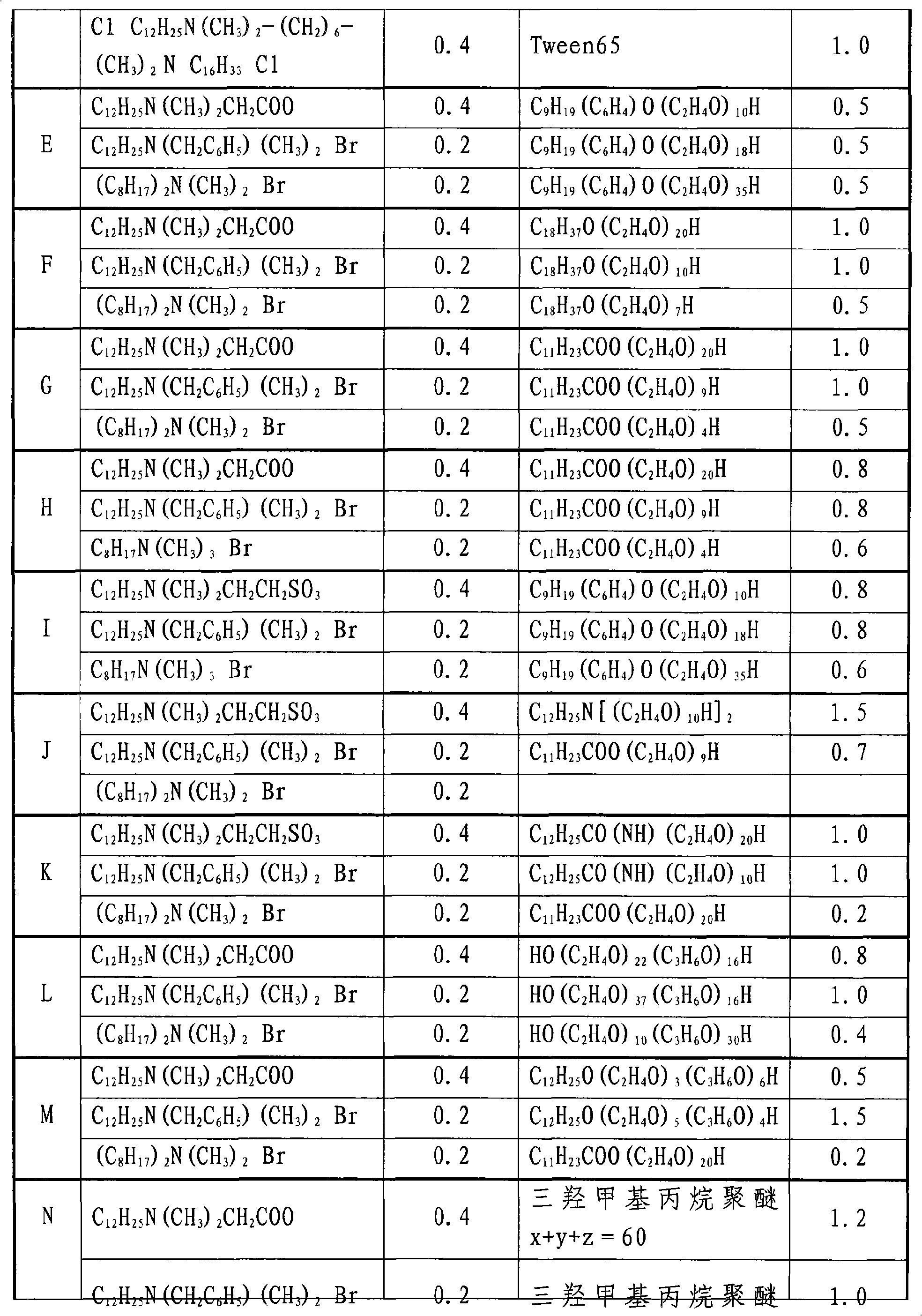

Multifunctional assistant plating additive for hot dip plating process, preparation and use method thereof

ActiveCN101328568AReduce lossImprove stabilityHot-dipping/immersion processesDissolutionLiquid metal

The invention relates to a multifunctional plating assisting additive for a hot dipping metallization process and a preparation and application method thereof, and belongs to the metal material anticorrosive technical field for providing multiple plating assisting efficacy. The technical proposal of the invention comprises that: a plurality of cations or an amphoteric surfactant ( an equivalent concentration of a quaternary ammonium group is between 0.1 and 2 mol / L) and nonionics (an equivalent concentration of a polyoxyethylene group is between 0.5 and 5 mol / L) are dissolved in deionized water. The method can improve the wetting quality between a liquid-state metal and a workpiece, and the adhesive uniformity and continuity of the plating assisting additive, reduces the drying time, prevents the liquid-state metal from falling and splashing, shortens the dipping and plating time, saves raw materials, improves a residue form, reduces an ash content, increases an ash discharge speed, isolates air, stops oxidation, disperses residual dirt and is suitable for a plurality of processes of hot galvanizing, hot plating zinc-aluminum alloy, hot plating aluminum, etc. The preparation steps comprise dissolution, cubage determination, cooling, keeping stand and filling; when the multifunctional plating assisting additive is used, the multifunctional plating assisting additive is directly added into a plating assisting additive solution and is evenly stirred.

Owner:JIANGSU FEITUO INTERFACE ENG TECH CO LTD

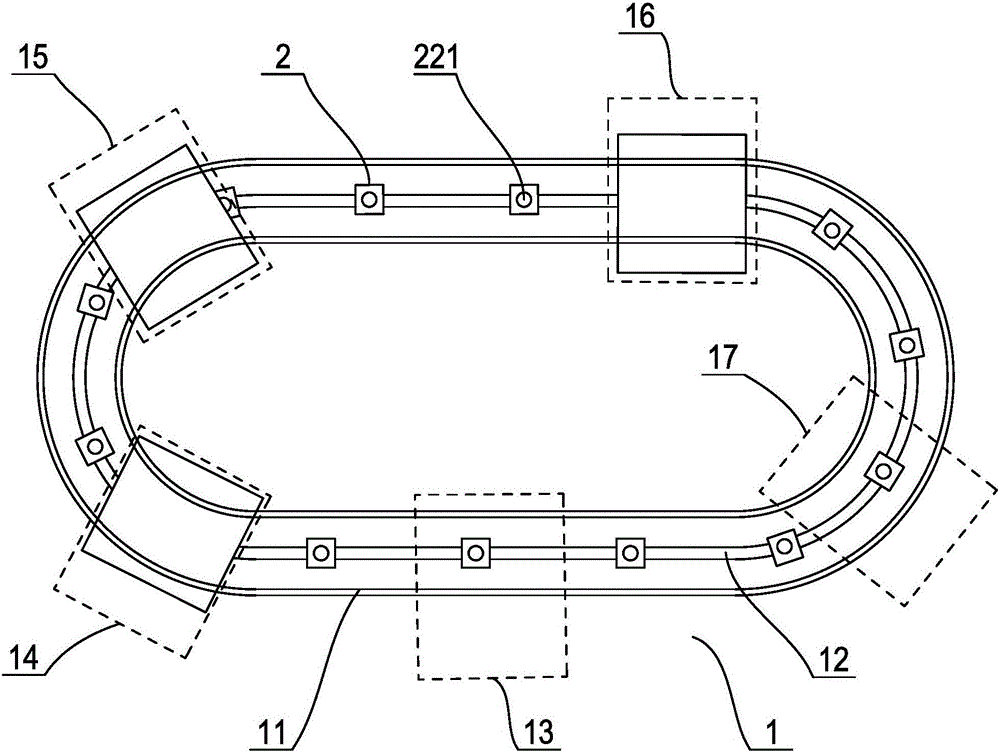

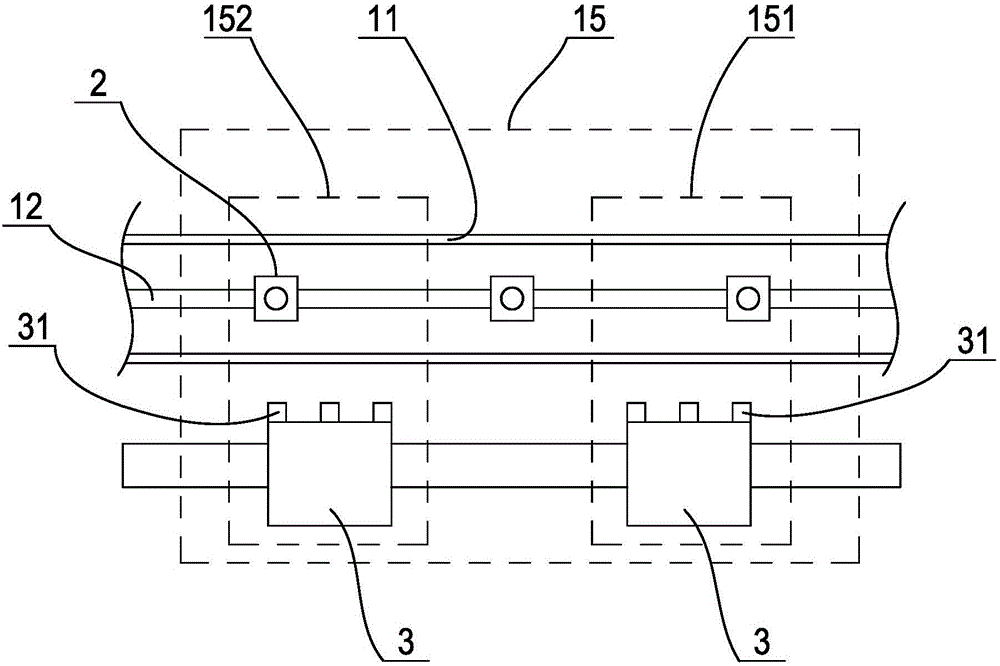

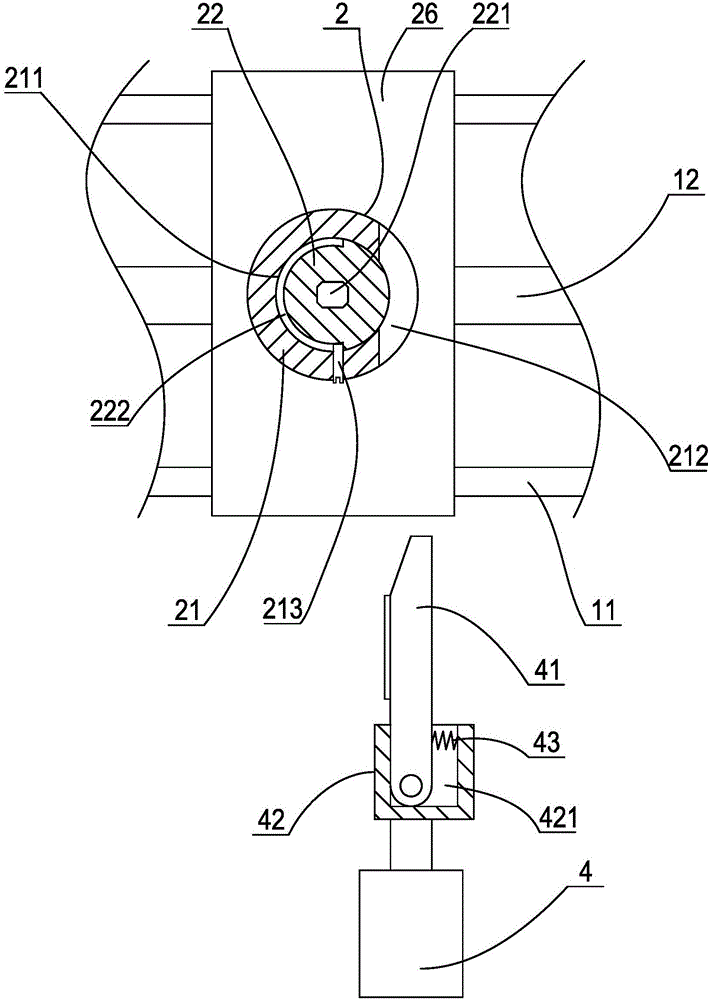

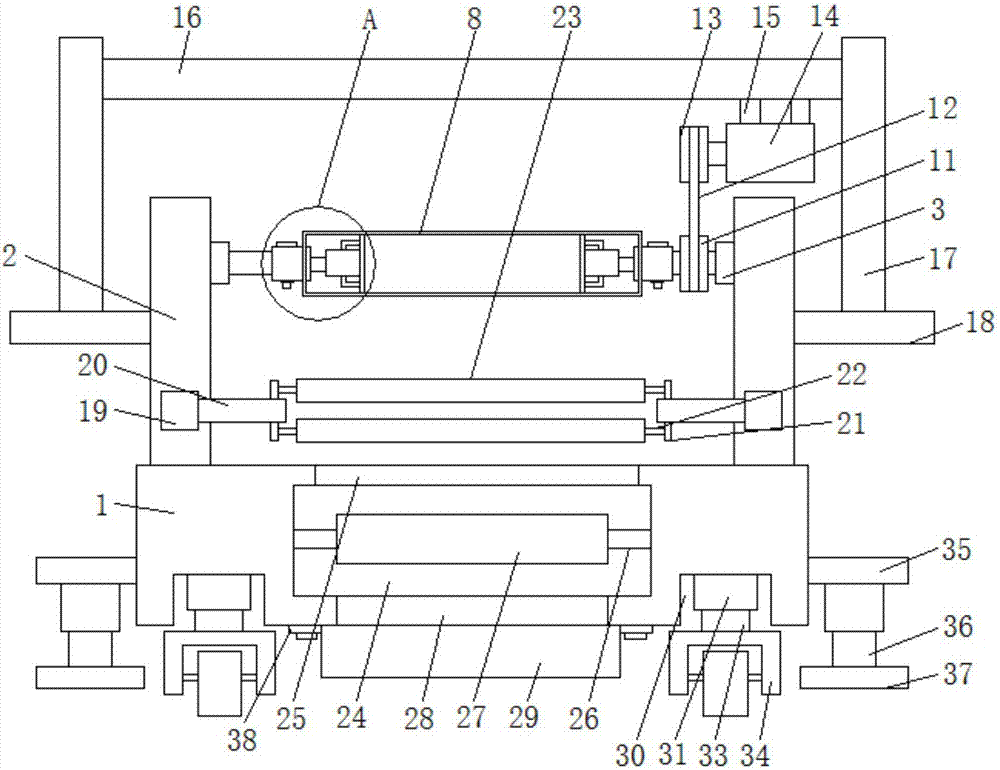

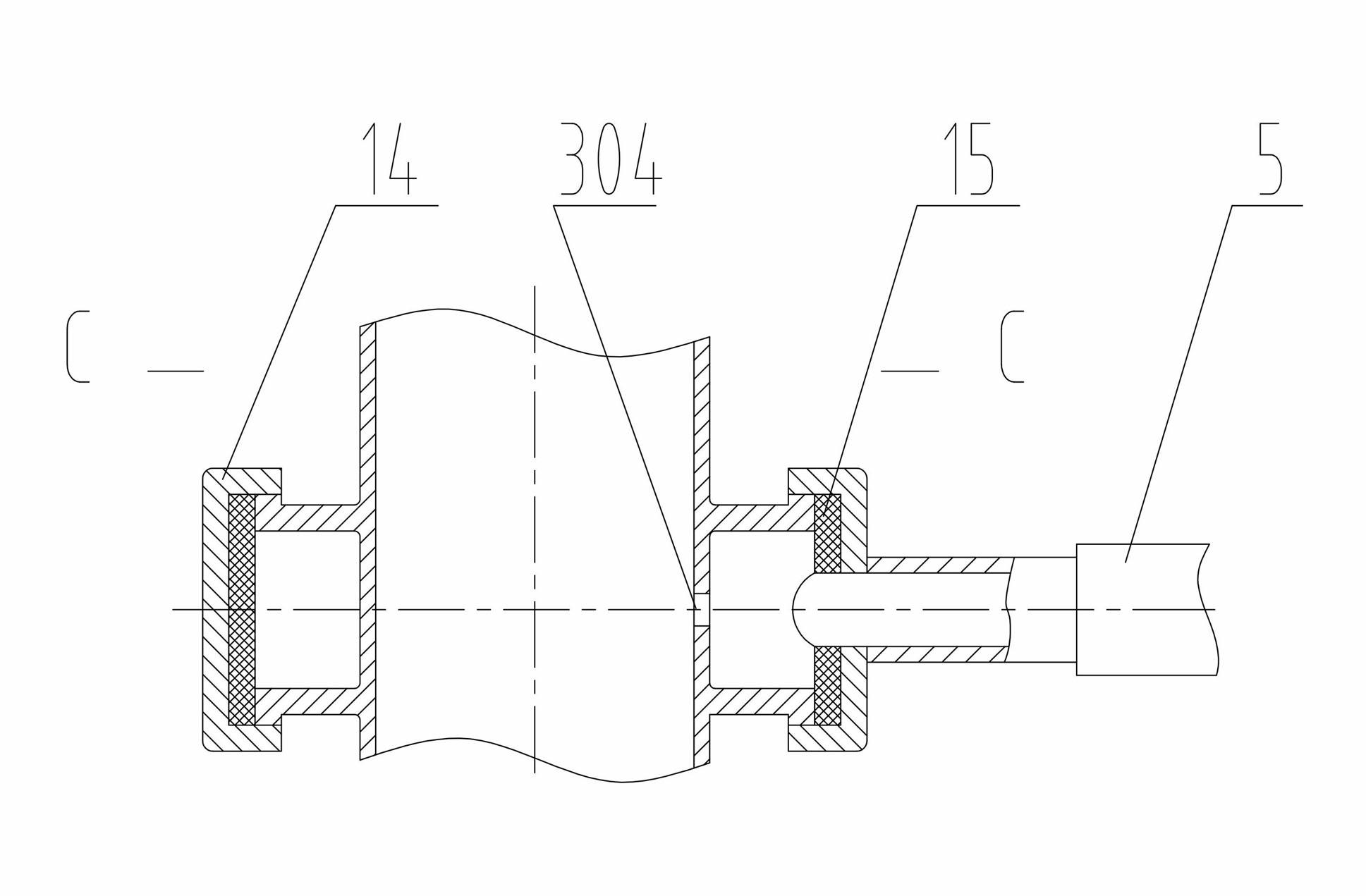

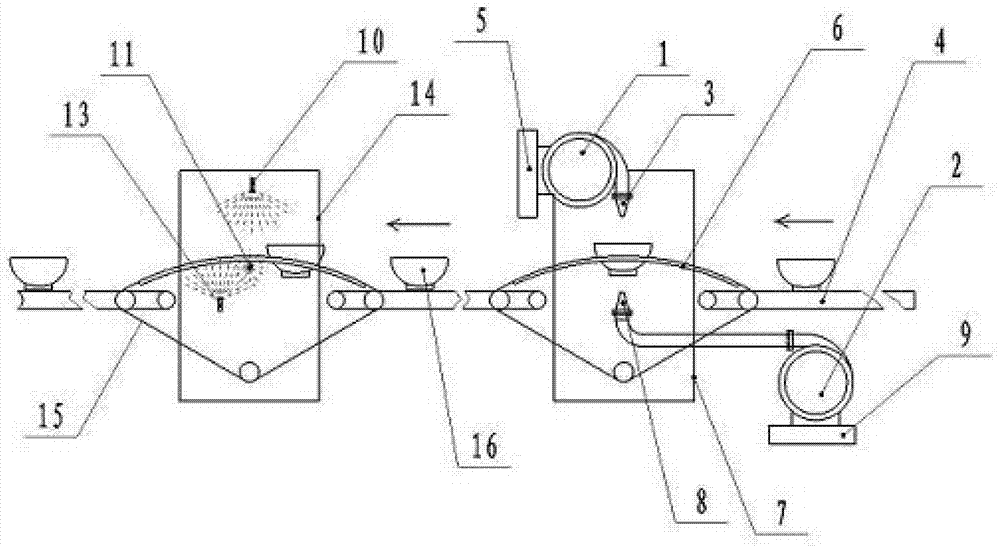

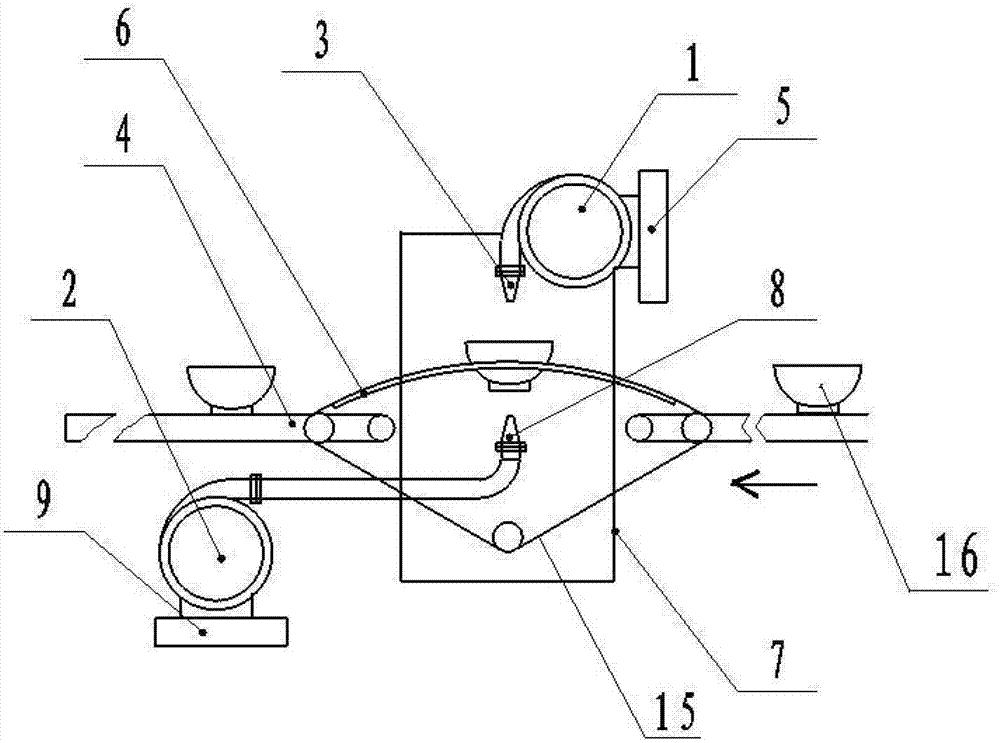

Racket automatic spraying system

ActiveCN106622771AAvoid mutual interferenceReduce movement distanceSpraying apparatusPretreated surfacesProduction lineControl signal

The invention discloses a racket automatic spraying system. The racket automatic spraying system comprises a loading station, a spraying station, a curing station and an unloading station arranged on a conveying production line in sequence; a driving chain of the conveying production line is provided with multiple racket fixed sleeves for inserting rackets; the spraying station is provided with a spraying manipulator; the spraying manipulator is provided with a combined spraying gun, a racket driving mechanism and a position detecting device; when the racket fixed sleeves move beside the spraying manipulator, the position detecting device sends a control signal; the spraying manipulator and the racket fixed sleeves keep synchronous movement; the combined spraying gun is controlled to automatically spray one surfaces of the rackets; after the combined spraying gun sprays one surfaces of the rackets, the racket driving mechanism acts to rotate the rackets on the racket fixed sleeves; and at this time, the combined spraying gun automatically sprays the other surfaces of the rackets by procedures. The racket automatic spraying system can realize full-automatic racket spraying to prominently improve the production efficiency, reduce the labor intensity of staff and effectively improve the spraying quality of the rackets.

Owner:杭州诚兴体育用品有限公司

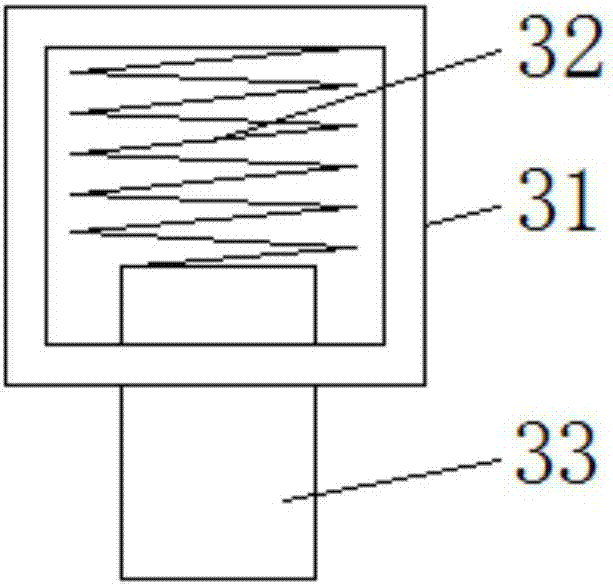

Cloth winding device capable of facilitating winding drum replacement and dust removal

InactiveCN107381168AEasy to change rollsEasy to remove dustCleaning using toolsCleaning using gasesEngineeringConductor Coil

Owner:梅明会

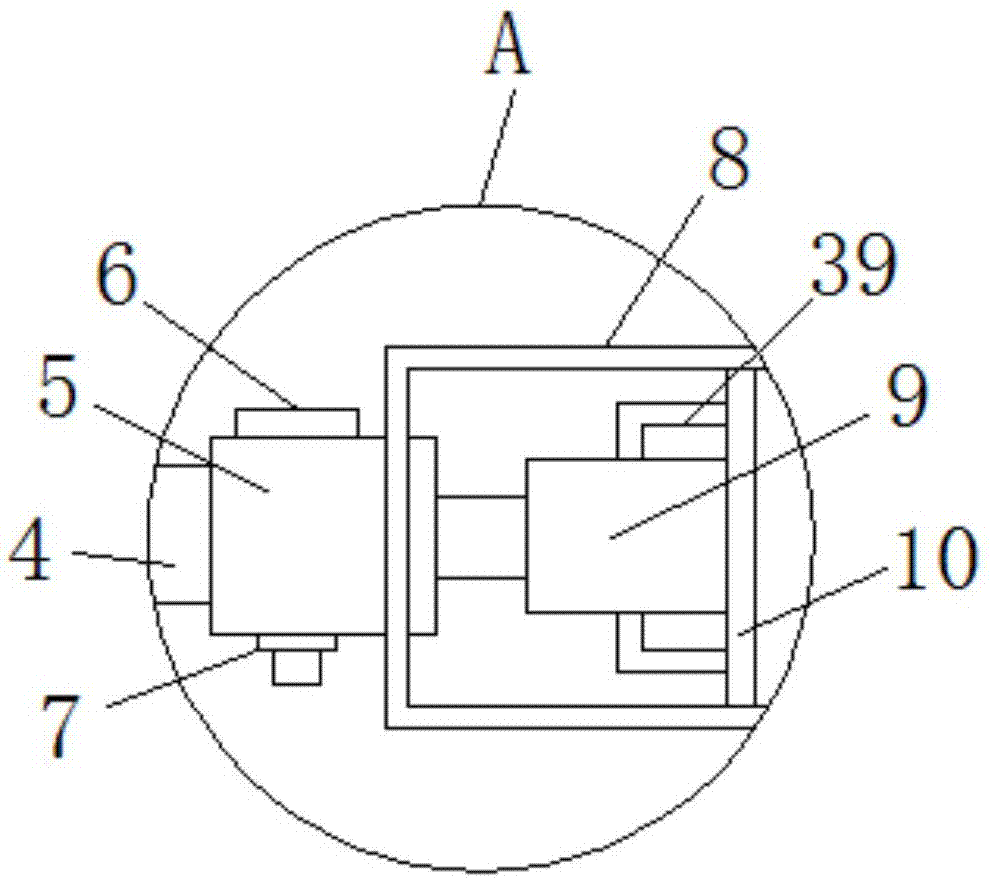

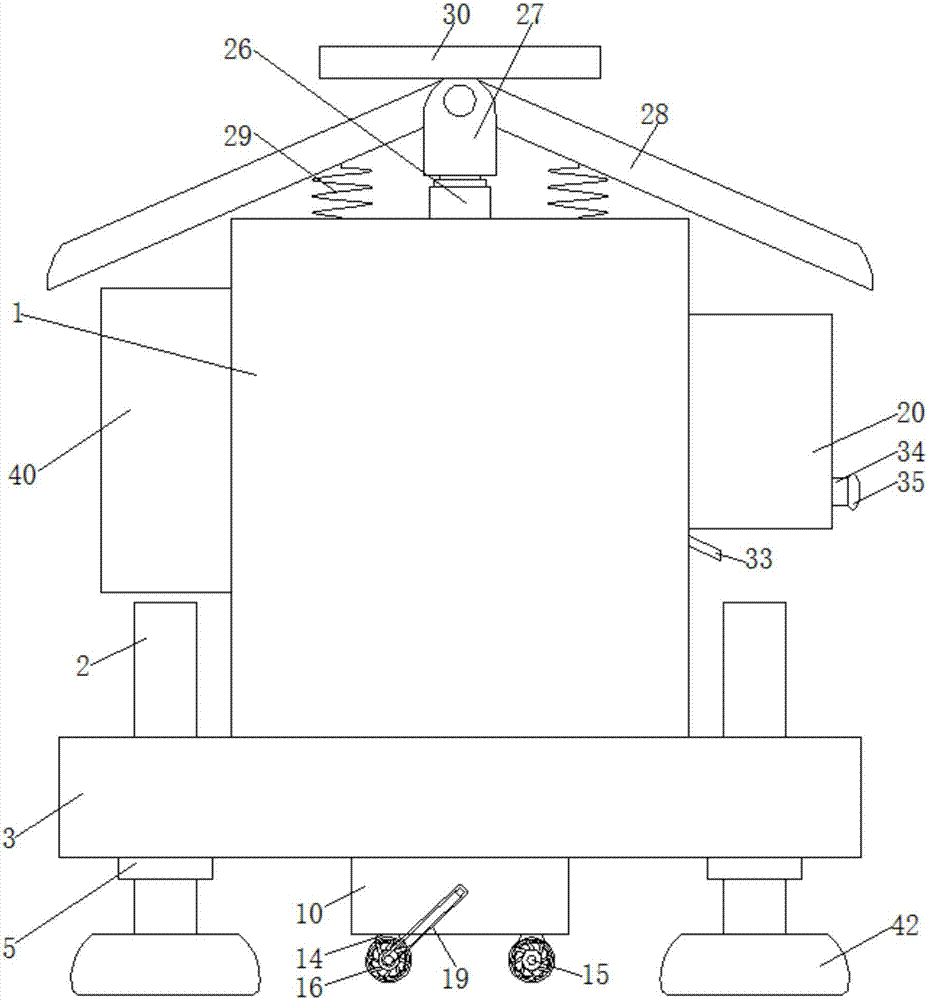

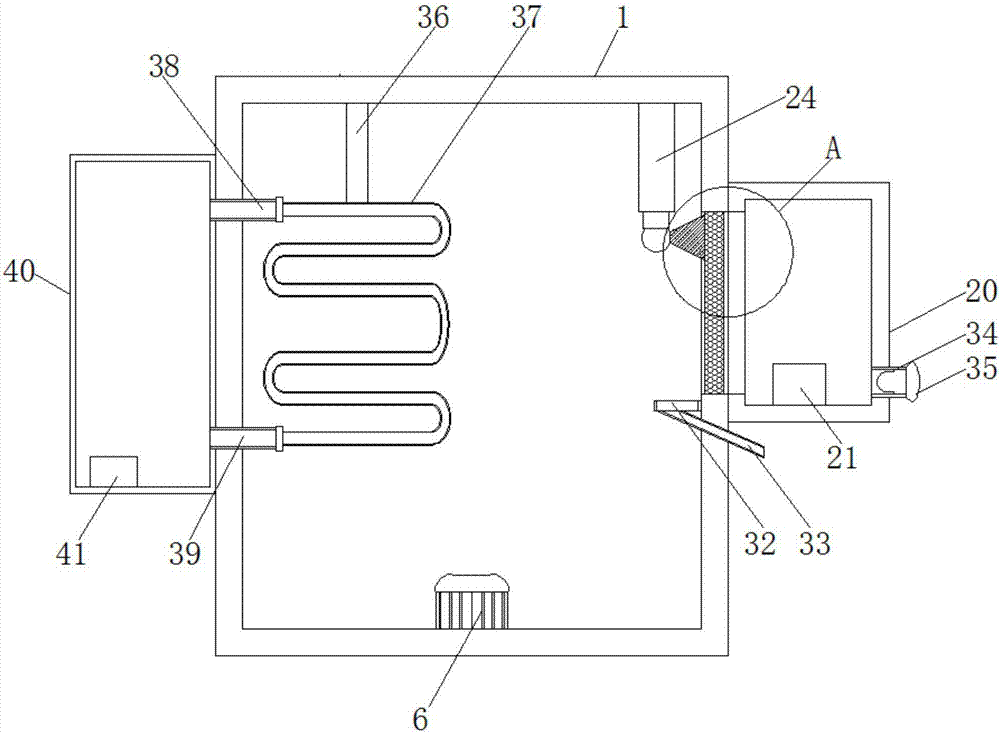

Electric power cabinet used for outdoor building engineering

ActiveCN107257096AAvoid damageAchieve moisture resistanceSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsTransverse planeControl engineering

The invention provides an electric power cabinet used for outdoor building engineering. The electric power cabinet comprises an electric power cabinet body, supporting legs and a transverse plate. There are two supporting legs. The two supporting legs are fixedly connected through the transverse plate. A bottom portion of the electric power cabinet body is fixedly installed on a top portion of the transverse plate. The electric power cabinet body is located between the two supporting legs. An internal portion of the transverse plate is provided with a cavity. Surfaces of the supporting legs are provided with threads. The electric power cabinet used for outdoor building engineering is provided with a condenser pipe, a water inlet pipe, a water outlet pipe, a water tank and a hydraulic pump. Condensate water in the condenser pipe carries out heat dissipation processing on an inner cavity of the electric power cabinet body. When the condensate water in the condenser pipe is used up, the hydraulic pump is started so that the condensate water in the water tank enters into the condenser pipe through the water inlet pipe and enters into the inner cavity of the water tank through the water outlet pipe; the condensate water in the condenser pipe is recycled; and heat dissipation is accelerated and heat dissipation efficiency is increased.

Owner:温州鼎高电器成套有限公司

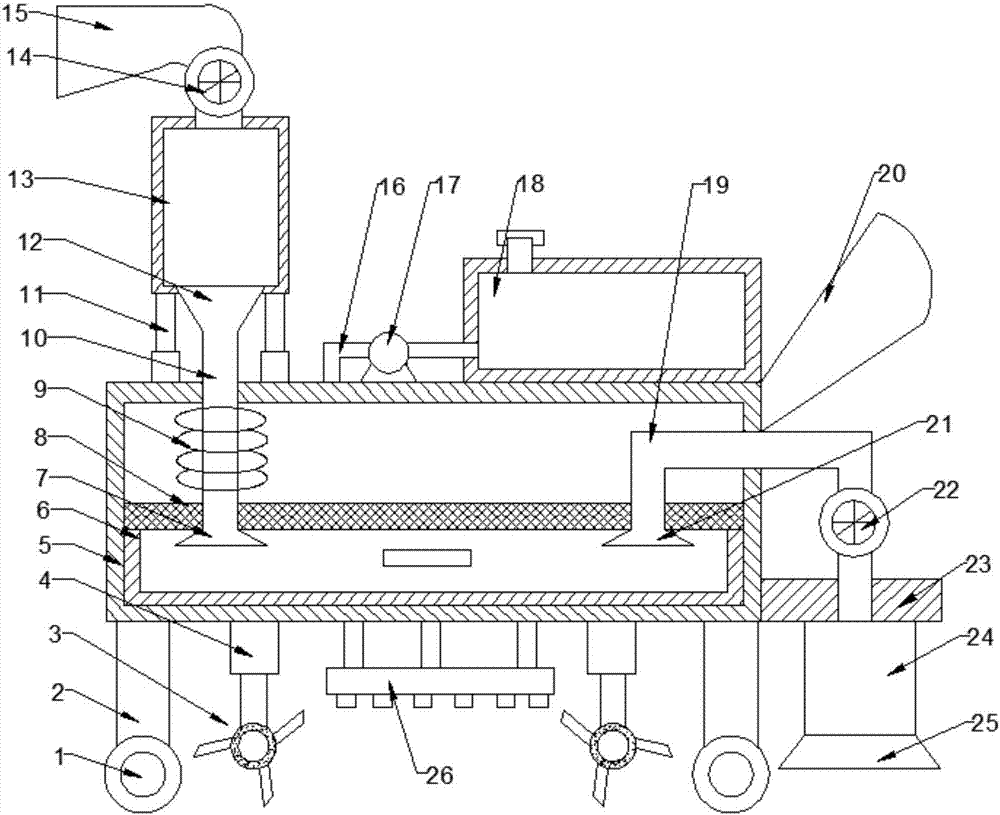

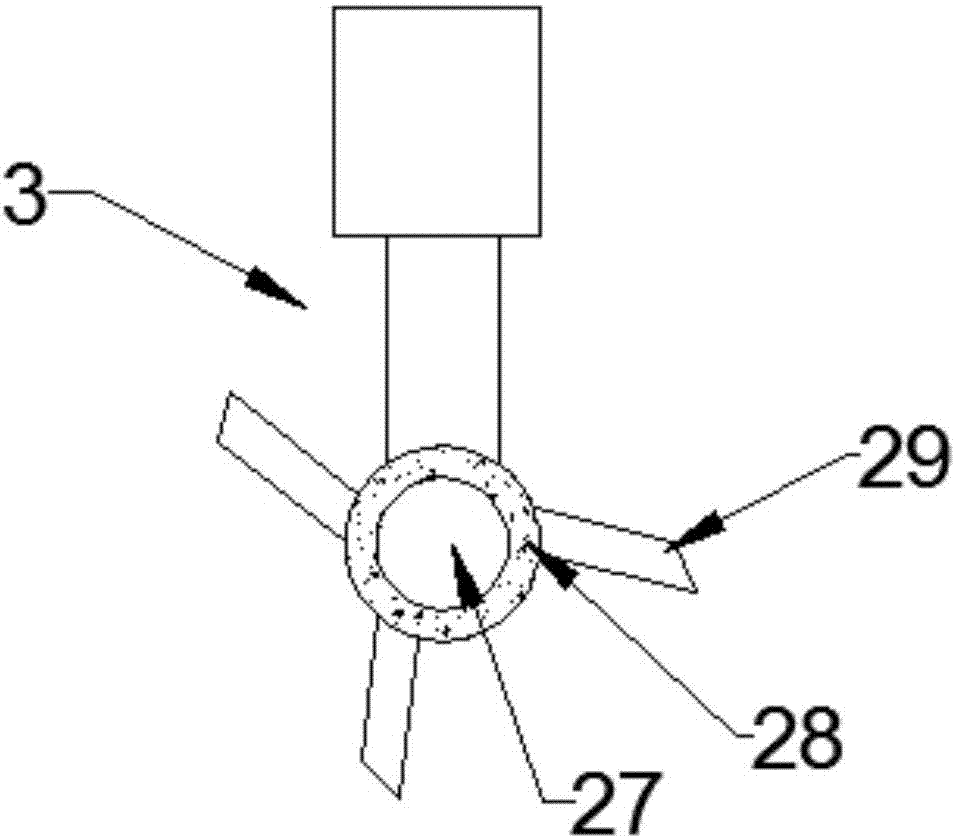

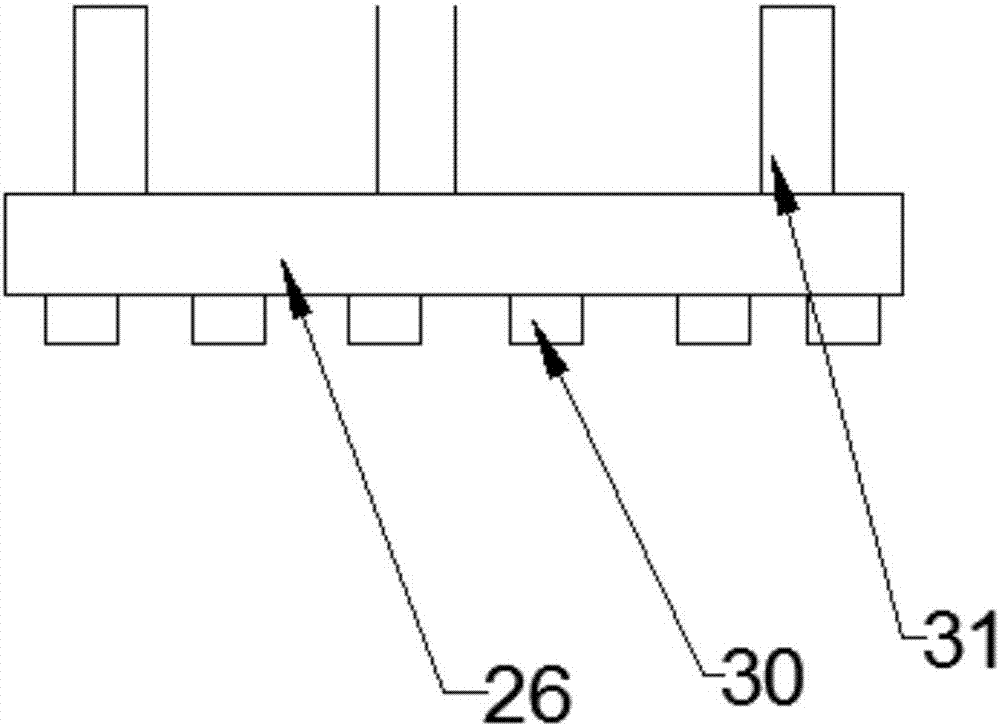

Dust removing and falling device for construction sites

InactiveCN107983724AEasy height adjustmentEasy to remove dustCombination devicesRoad cleaningArchitectural engineeringWater spray

The invention provides a dust removing and falling device for construction sites, and belongs to the technical field of construction dust removal. The dust removing and falling device comprises a dustremoving and collecting device, and a water spraying and dust falling device; a feed cylinder is fixedly arranged at the upper end of a hydraulic extension rod; a spring extension pipe is arranged ona connecting pipe; a collecting container is arranged at the bottom of an inner cavity of a collecting box; a cleaning device is arranged below the extension rod; a dust sucking cylinder is arrangedat the lower end of a fixed plate; the lower side of the left side of a water tank is connected with a water pump through a water outlet pipe; and the left end of the water pump is connected with a water spraying plate through a water outlet pipe. As the feed cylinder is fixedly arranged at the upper end of the hydraulic extension rod, the device achieves a function of conveniently adjusting the height of the feed cylinder to conveniently remove dust in the construction sites; the water spraying plate is arranged below the collecting box through a support rod to achieve functions of water spraying and dust falling; and the device has the characteristics of simple structure, high practicability and good dust removing and falling effects.

Owner:ZHENGZHOU CHENGHE INFORMATION TECH CO LTD

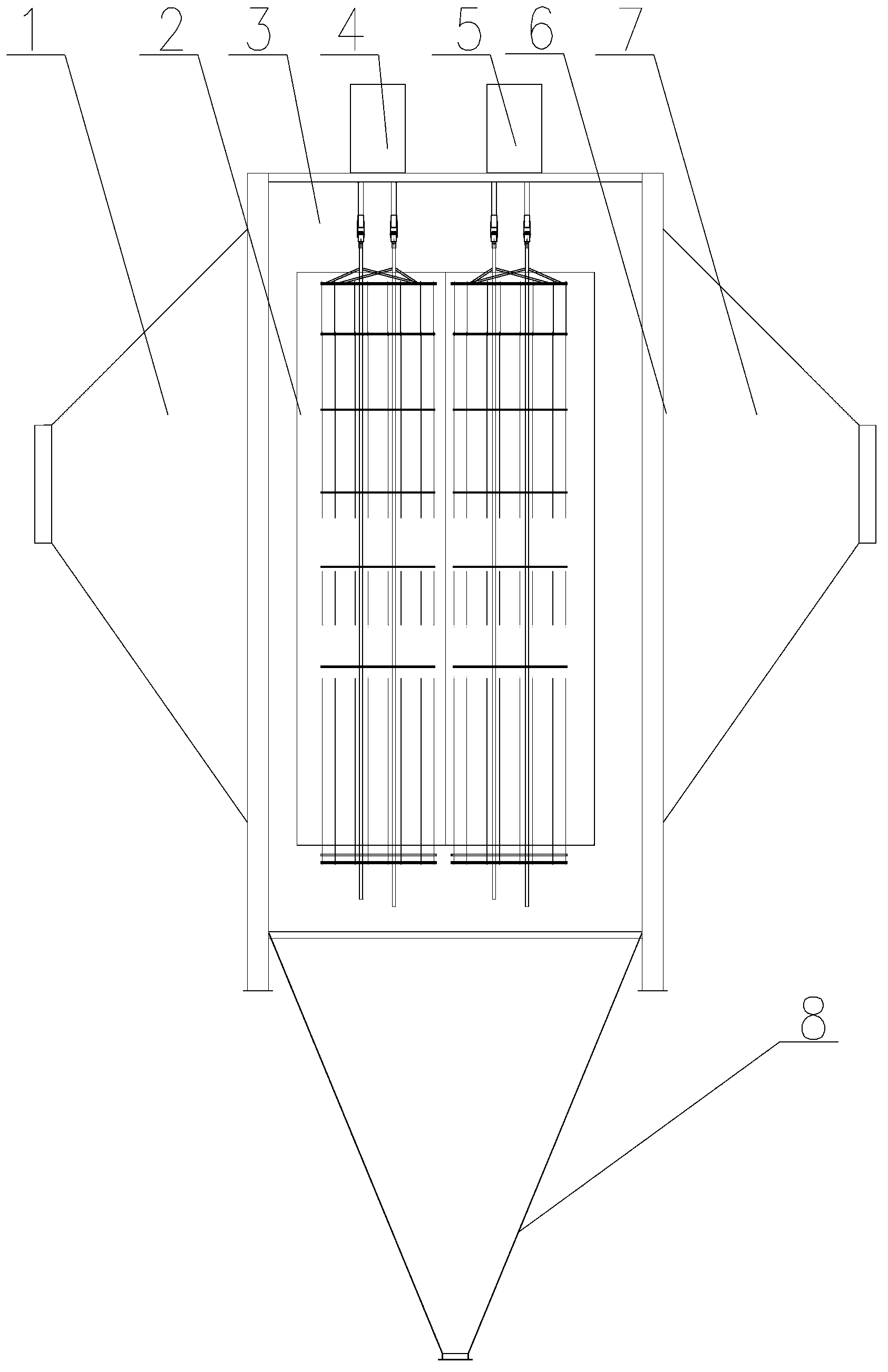

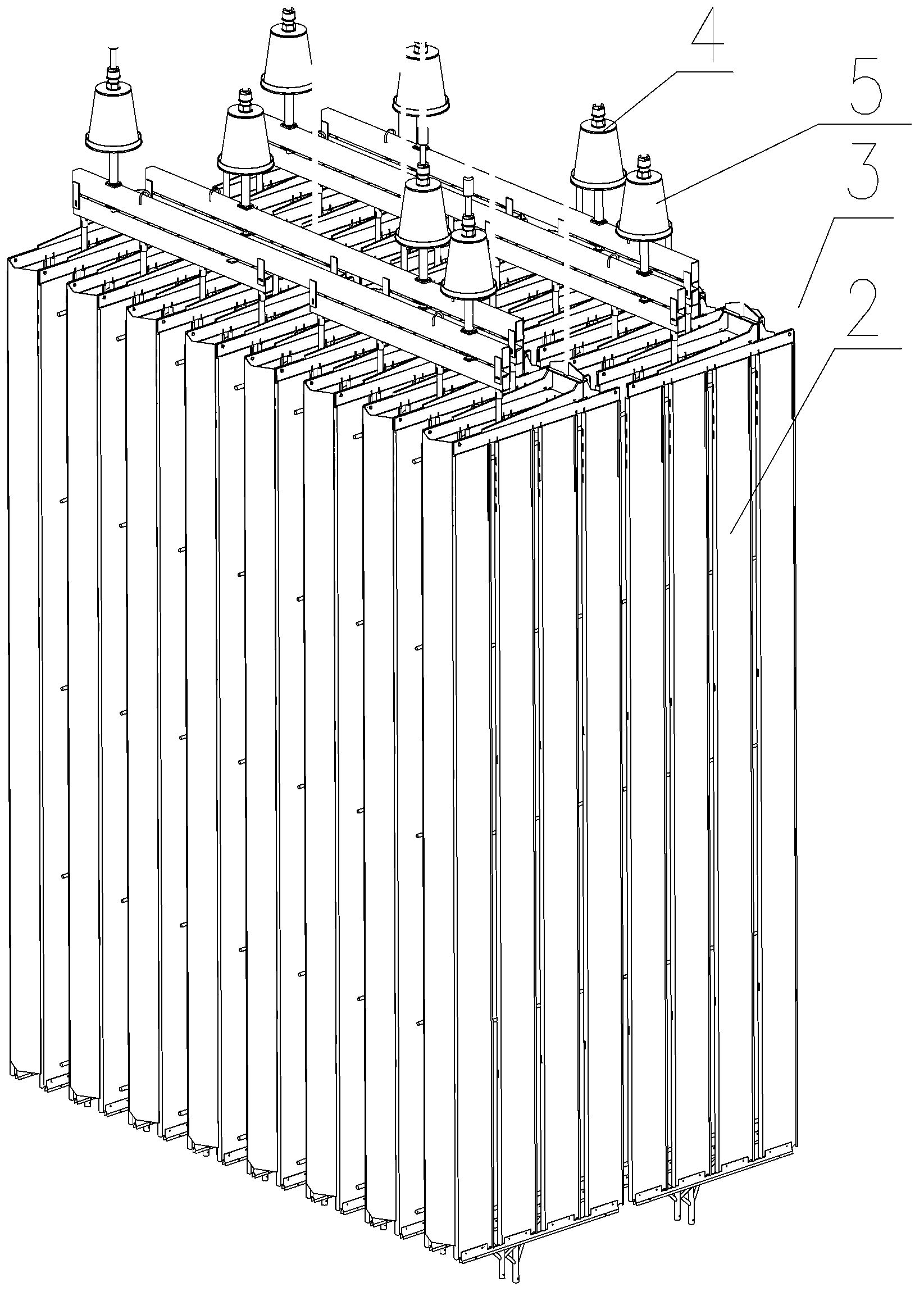

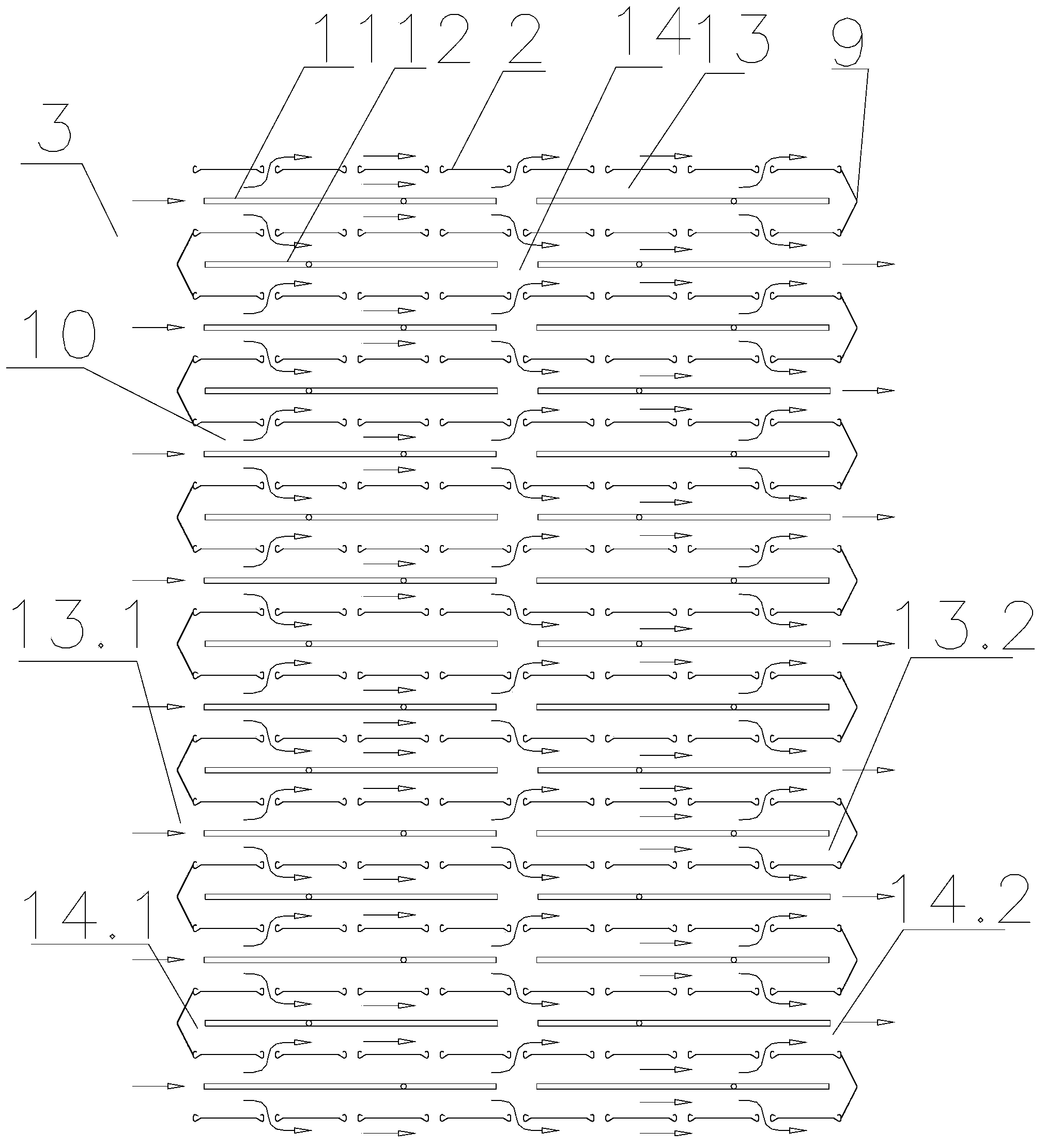

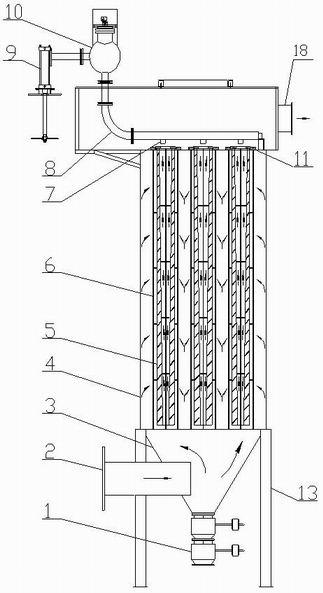

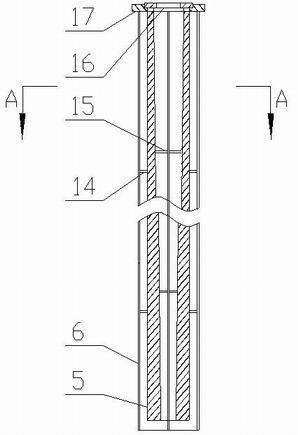

Electronic dust remover

InactiveCN103447153ALow costExtended service lifeExternal electric electrostatic seperatorElectrode constructionsElectric fieldElectricity

The invention discloses an electronic dust remover. The electronic dust remover comprises a shell (6) internally provided with a dust removing cavity (3), wherein multilayer grounded dust collection poles (2) are arranged inside the dust removing cavity (3); via the dust collection poles (2), the dust removing cavity (3) is divided into a plurality of smoke channels (10) which are arranged in parallel; an electrode is arranged inside each smoke channel (10); the electrodes in the two adjacent smoke channels (10) are respectively of a positive electrode (11) electrically connected with a positive power source (4) and a negative electrode (12) electrically connected with a negative power source (5); the both ends of the plurality of smoke channels (10) which are arranged in parallel are provided with wind screens (9) for blocking the end parts of the smoke channels (10) at intervals respectively; the wind screens (9) at the both ends of the plurality of smoke channels (10) which are arranged in parallel are arranged in a staggered manner. The electronic dust remover provided by the invention has the advantages of low cost, long service life, convenience in maintenance and good high-temperature tolerance. The defect that the dust removing property of a conventional electronic dust remover is greatly influenced by physical and chemical properties of dust can be overcome; therefore, not only can the dust be unlikely to release from an electric field, but also the composite efficiency of the dust is low.

Owner:WUHAN LONGKING ENVIRONMENTAL PROTECTION TECH

Method for purifying high-temp. smoke from garbage incinerator

InactiveCN1422689AHigh activityIncrease temperatureDispersed particle separationSolid reactionFlue gas

The method for cleaning high-temp. smoke produced by garbage incinerator is characterized by that in the flue gas with 600-800 deg.c discharged by garbage incinerator the sodium-alkali modified lime is added to make acid gas being in the flue gas react with sodium-alkali modified lime and be absorbed, then the solid reaction product and flyash carried by flue gas are collected by high-temp. dust-collector together, so that the solid reaction product can be separated from flue gas, and the cleaned flue gas can be fed into heated surface, and cooled, and the harmful substance de novo can not be synthesized in the flue gas, and the toxicity of the cleaned flue gas product and the flyash can be greatly reduced. Said invention is simple in process and good in effect.

Owner:TONGJI UNIV

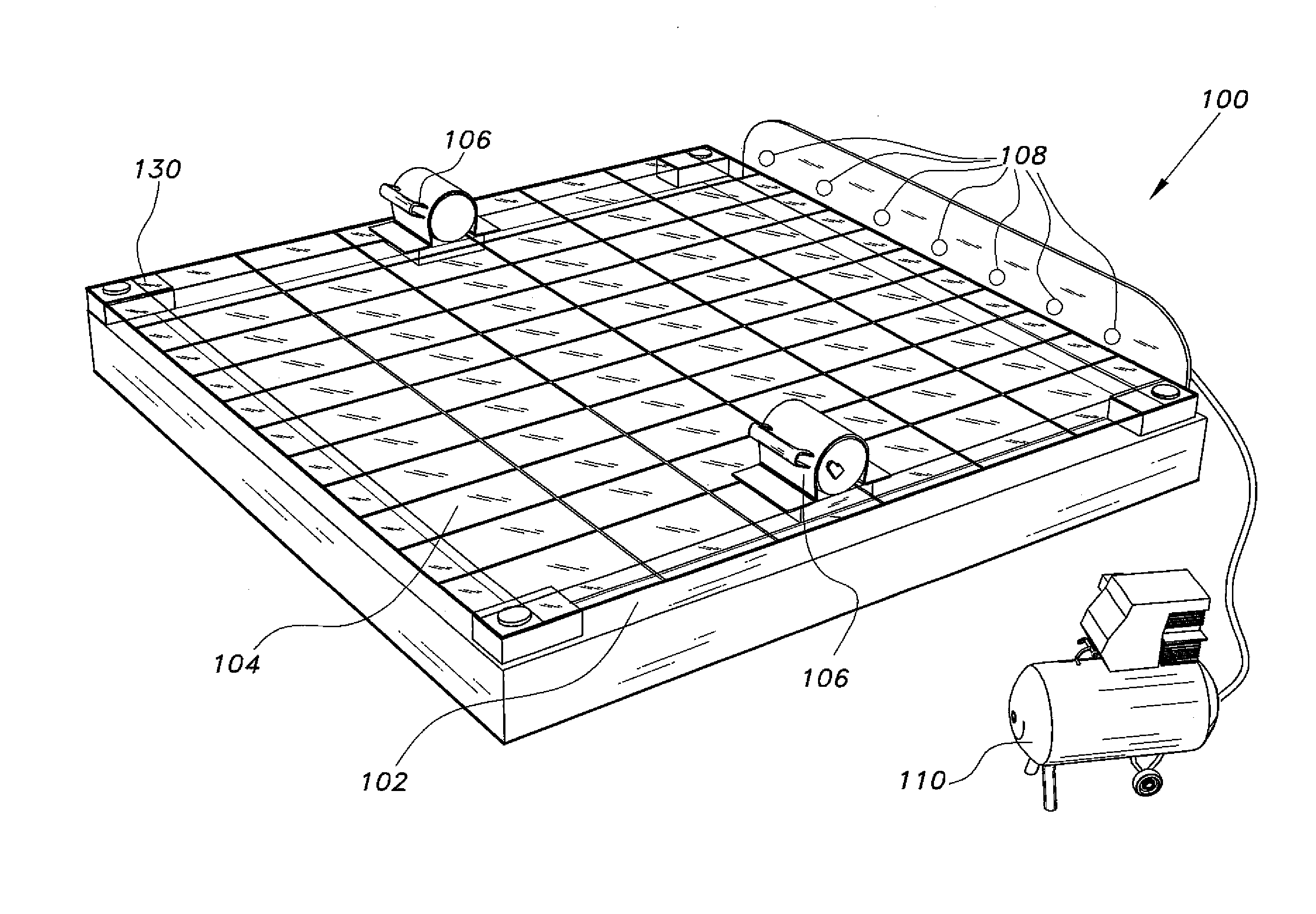

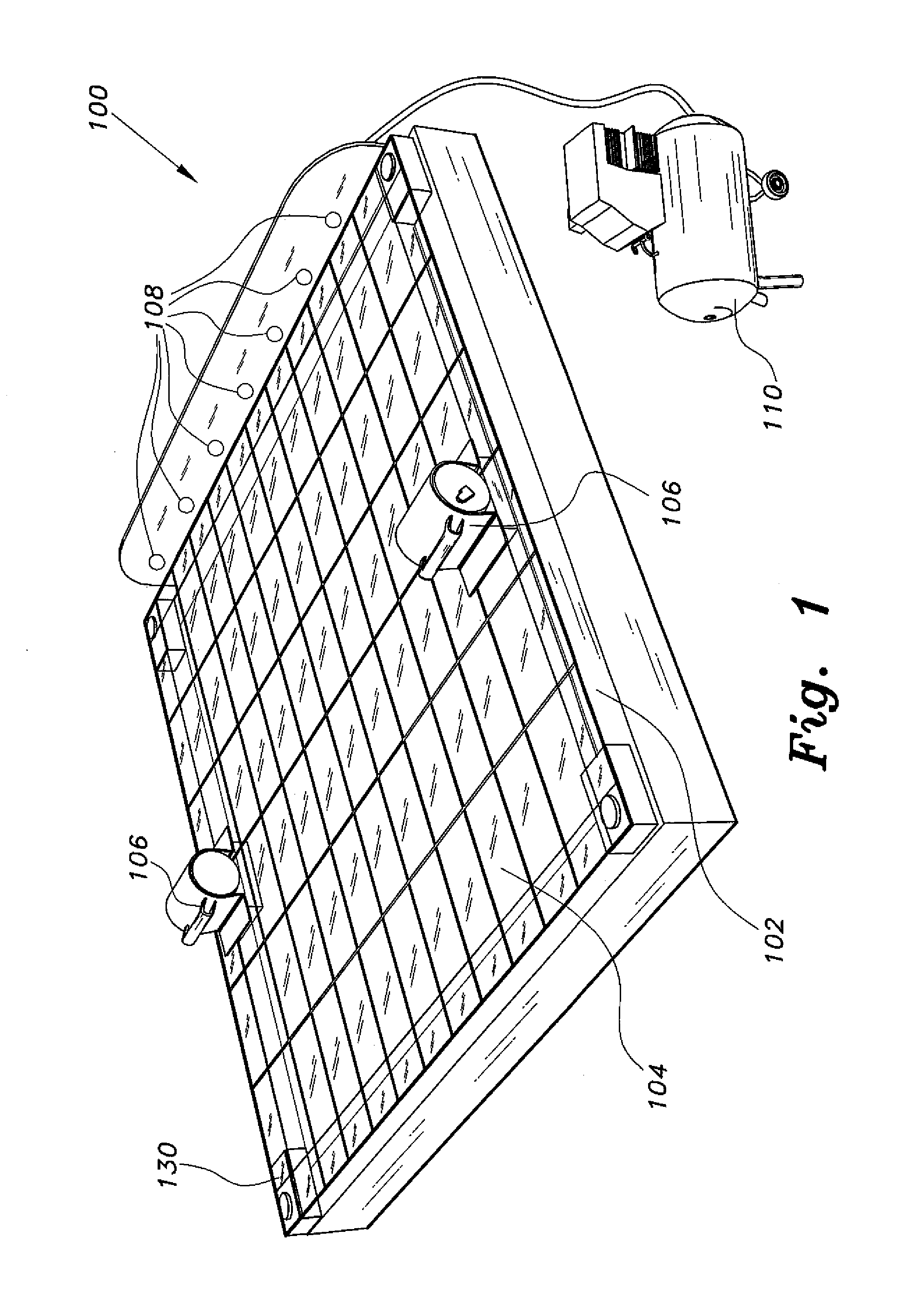

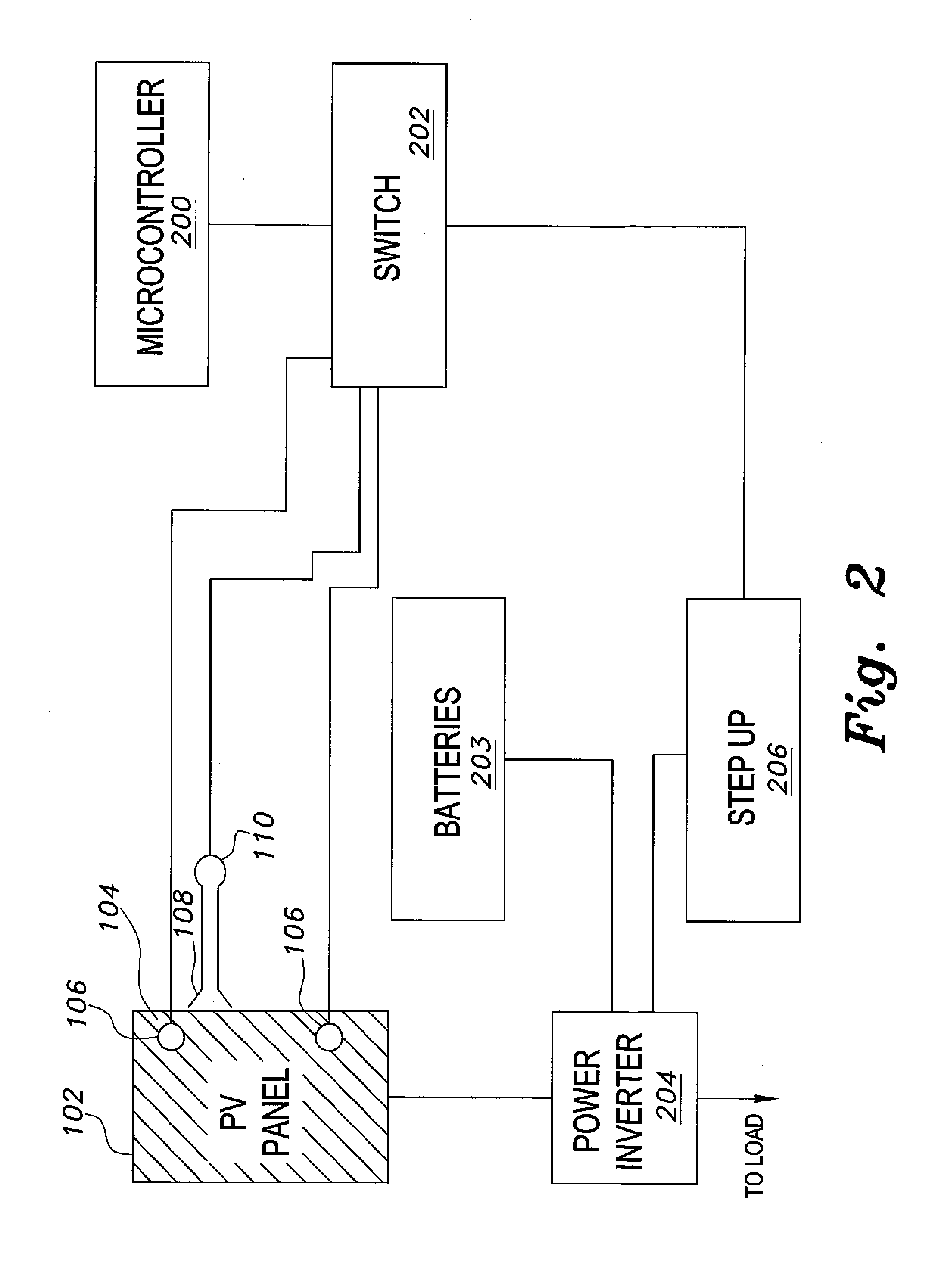

Smart dust-cleaner and cooler for solar pv panels

InactiveUS20150311859A1Easy to remove dustReduction factorSolar heating energyMechanical cleaningParticulatesDaily operation

The smart dust-cleaner and cooler for solar PV panels is a smooth transparent shield with low absorption coefficient (such as a plastic sheet) placed on the top of the panel to facilitate the removal of dust. Two Membrane Vibrators (MVs) are placed on opposite sides of the panel. The vibrators have the ability to shake and resonate the sheet, dislodging the dust particulates from their positions. A compressor powered by the PV panel compresses air before the cleaning process, which operates in short duration. Release of the compressed air creates an air stream over the panel that removes the loose dust and cools the panel to enhance performance. Using a microcontroller-based timer, the dust cleaning / cooling process is timed for daily operation before noon, when the panel temperature is at its peak to maximize panel efficiency at maximum irradiance time.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

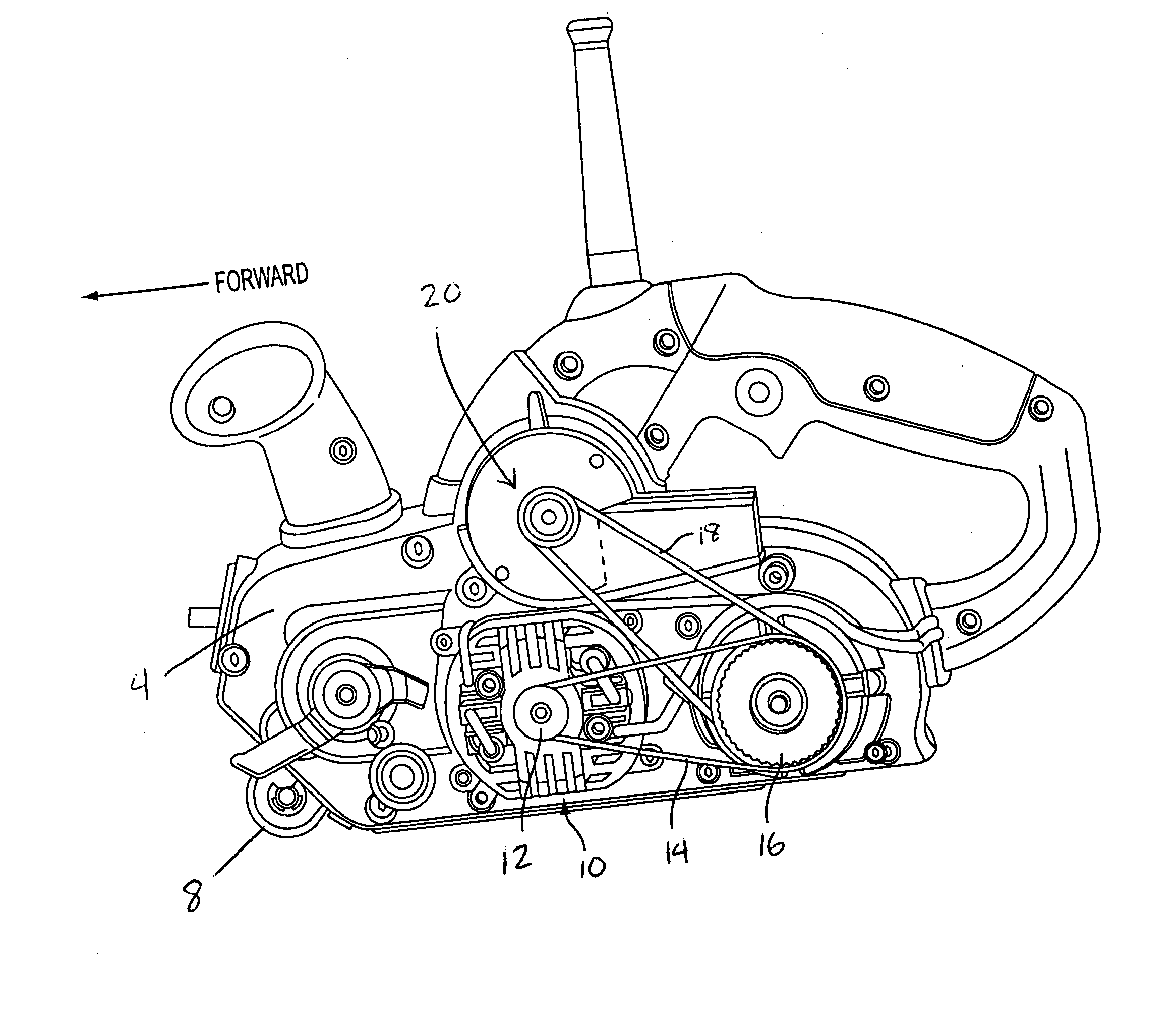

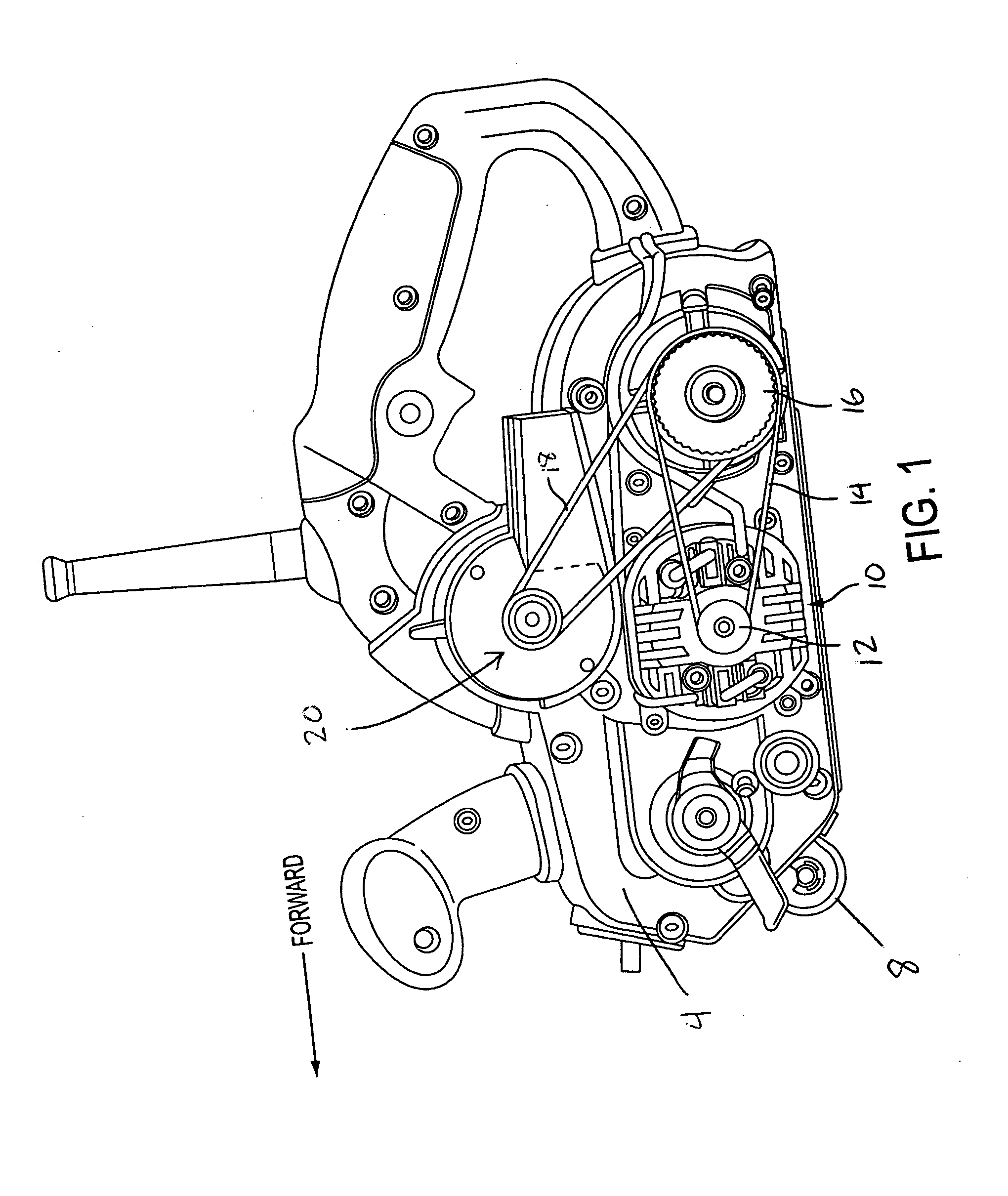

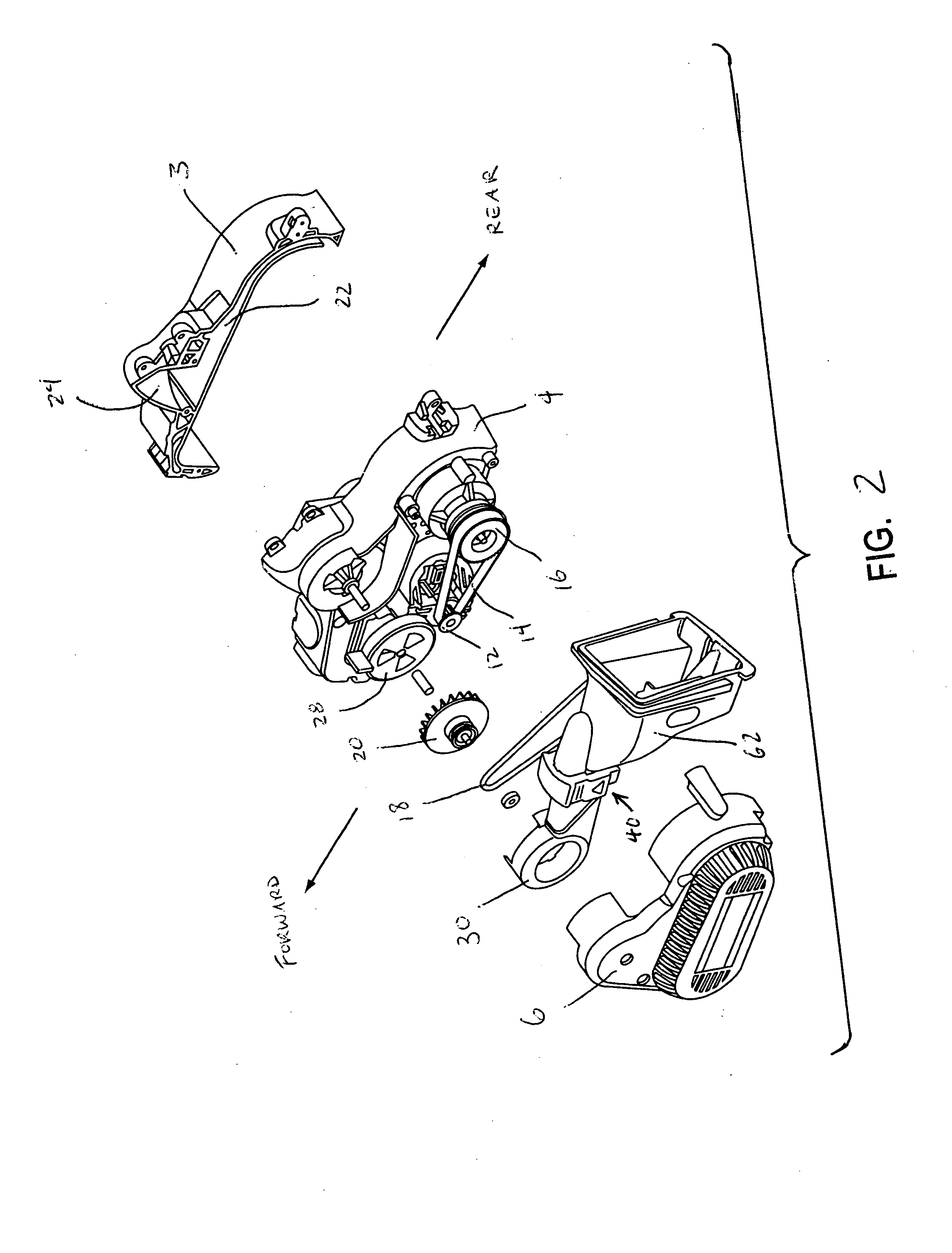

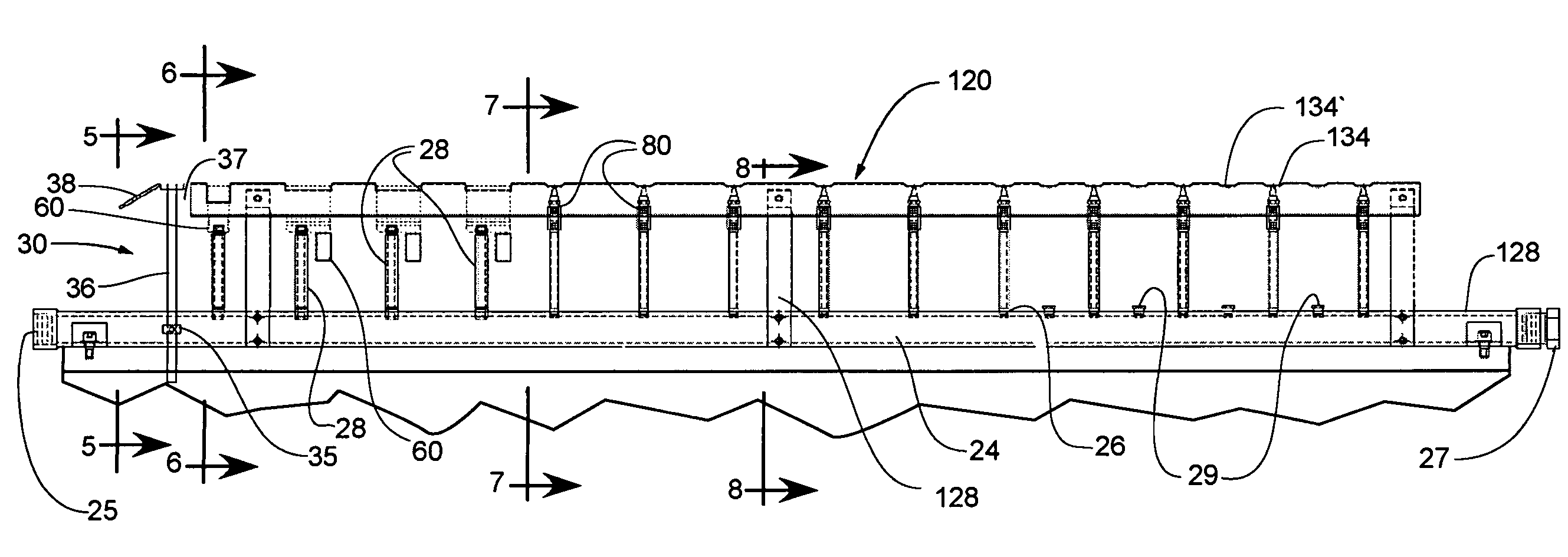

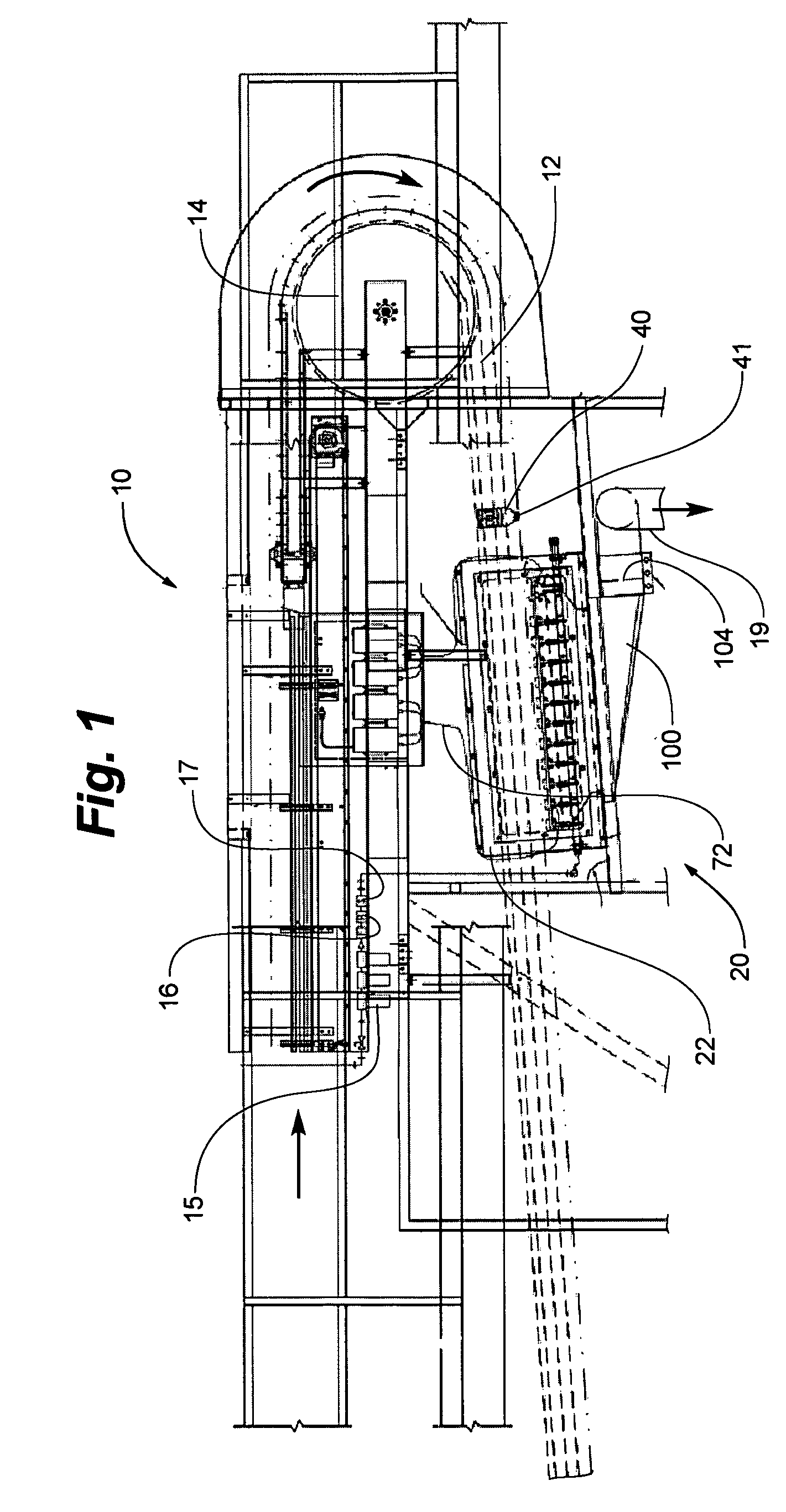

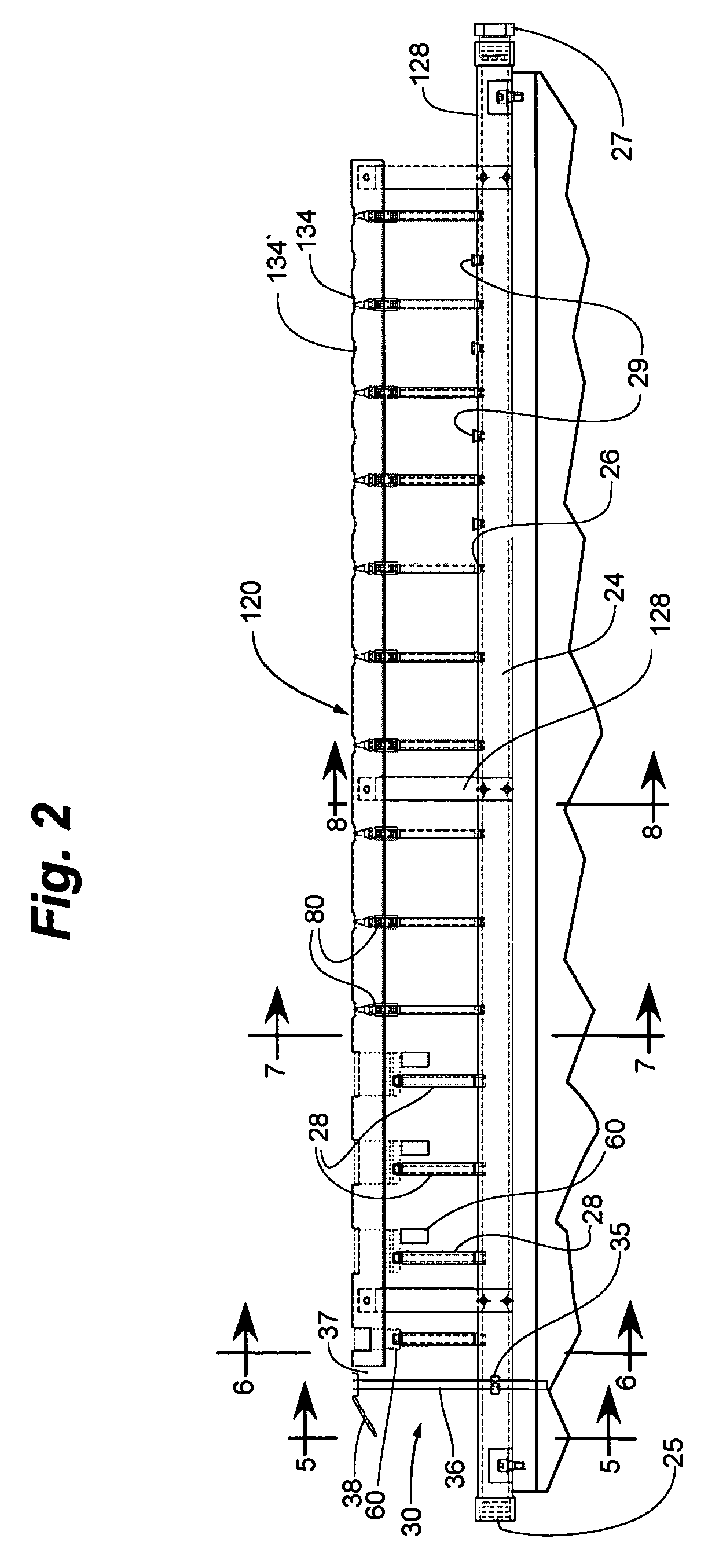

Dust collection system for a belt sander

InactiveUS20050048883A1Improved dust removal airflowEfficient dust removalPortable grinding machinesPlane surface grinding machinesEngineeringPower belt

An electrically powered belt sander comprising a housing, a dust flow path defined by the housing, a motor mounted in the housing at a first location and having an output shaft, a fan connectable to the motor output shaft and rotateably mounted in the housing at a second location a distance from the motor output shaft, a belt connectable between the motor output shaft and the fan whereby the rotation of the motor output shaft drives the rotation of the fan, and a damper located in the dust flow path and operable for blocking the dust flow path.

Owner:BLACK & DECKER INC

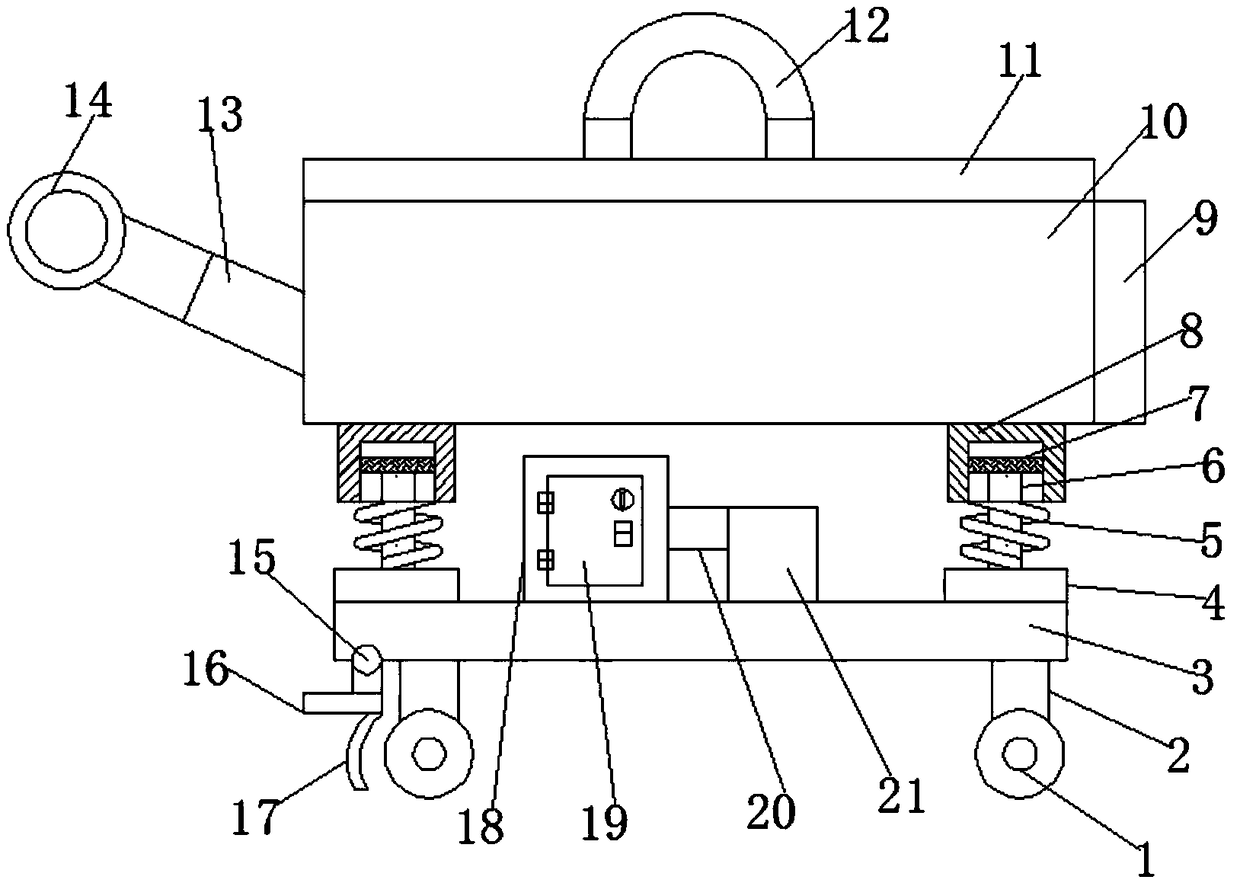

New material technological development superconducting material transporting device with good stability

ActiveCN108928370AAvoid damageImprove shock absorptionShock-sensitive articlesHand carts with multiple axesMechanical engineeringNew materials

The invention belongs to the technical field of transporting devices and in particular relates to a new material technological development superconducting material transporting device with good stability. In order to solve the technical problem that a superconducting material is easy to vibrate and collide during transportation to be damaged, the following scheme is provided. The new material technological development superconducting material transporting device with the good stability comprises a bottom plate, an internal box body and a transporting box body; a placing opening is formed in the external wall of the top of the transporting box body; a box cover is hinged to the internal wall of the placing opening through a hinge; two fixing blocks are welded on the external wall of the topof the box cover; the same pull handle is fixed on the external walls of the tops of the two fixing blocks through bolts; an internal box body is arranged in the transporting box body; and vent holeswhich are distributed in an equally spaced manner are formed in the external wall of the bottom of the internal box body. According to the new material technological development superconducting material transporting device with the good stability, as a second shock absorbing spring, a third shock absorbing spring and a shock absorbing rubber pad, a very good shock absorbing effect is realized toprevent the superconducting material from being damaged due to bumping and shaking during transportation; and a dehumidifier has a very good dehumidifying effect to prevent the superconducting material from being affected with damp to affect the quality of the superconducting material.

Owner:阜阳佰恩得新材料技术有限公司

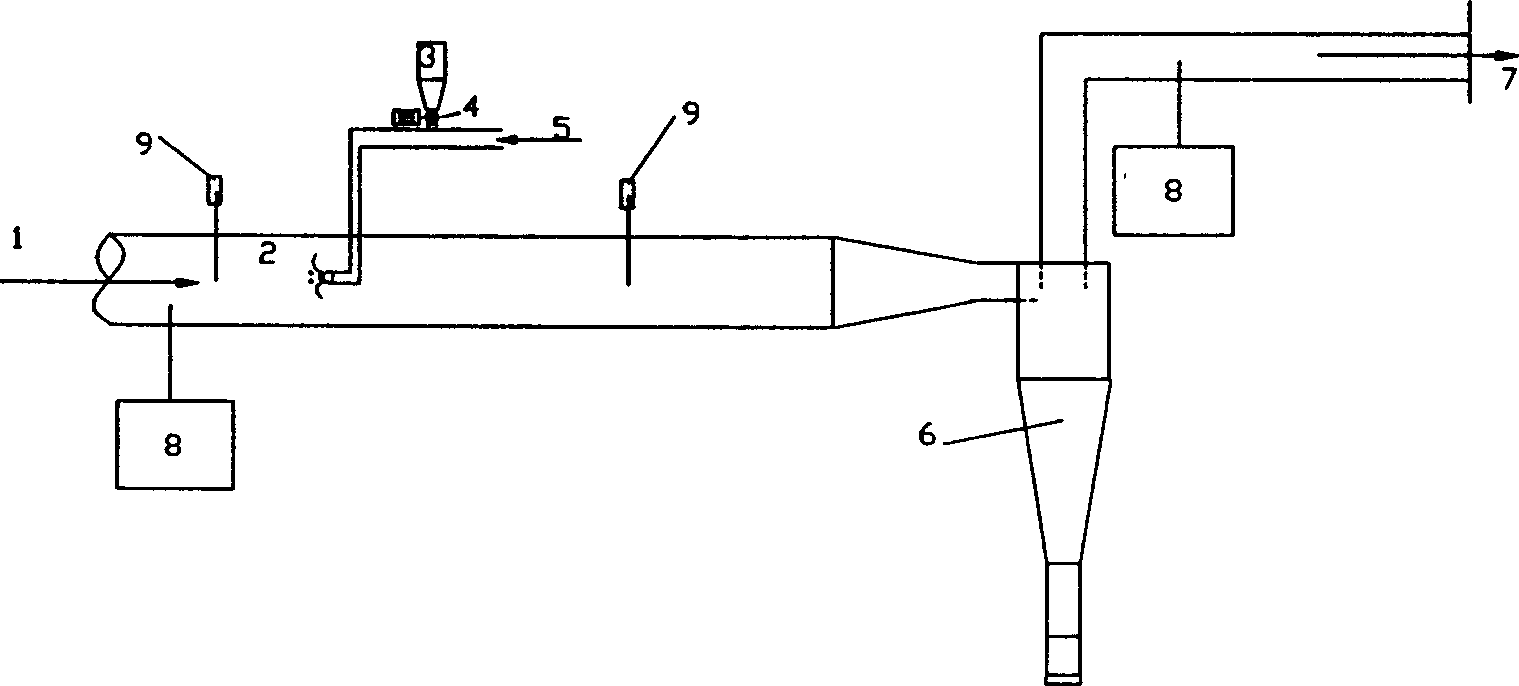

Technology for producing cooled coal gas with no discharge of phenolic water

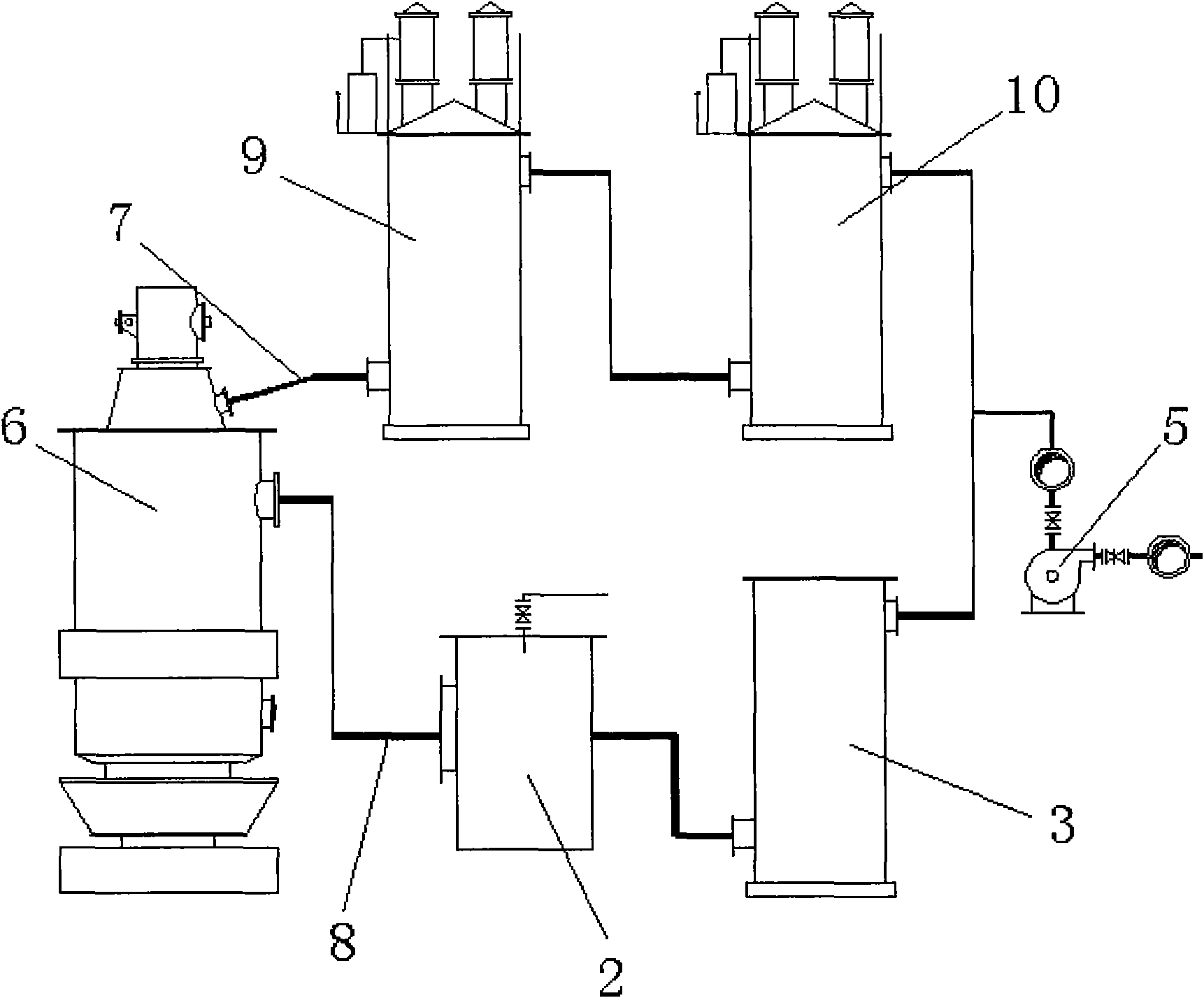

InactiveCN101613626ASolve the emission problemEasy to remove dustGas purification by treating with solidsGas dust removalTarProcess engineering

The invention relates to a technology for producing cooled coal gas with no discharging of phenolic water, belonging to the technical field of coal gas production and providing a technology for producing cooled coal gas with no discharging of phenolic water which has no contamination of the environment and can save energy and investment. The process flow of a single stage coal gas producer is as follows: the hot coal gas enters a ceramic filter deduster from the outlet of the coal gas producer; then enters an indirect cooling device to carry out heat exchange with phenolic water and the temperature drops to 40-50 DEG C; the cooled coal gas enters an electro detarrer to remove tar oil and small dust particles; the purified coal gas is supplied to users through a coal gas compresser; the phenolic water is heated into phenolic vapor and is used as gasification agent after being introduced into the bottom of the coal gas producer. The process flow of a two-stage coal gas producer is as follows: the lower-stage gas emerges out of the coal gas producer and passes through the ceramic filter deduster and the indirect cooling device; the upper-stage coal gas emerges, enters a rough electrical coke arrester and a refined electrical coke arrester, and is converged with the lower-stage coal gas to obtain purified coal gas, thus optimizing the dedusting and heat exchanging processes of hot coal gas, improving dedusting effect and hot exchange efficiency, being capable of saving investment of devices, protecting environmental and saving energy.

Owner:唐山雷浩能源技术装备有限公司

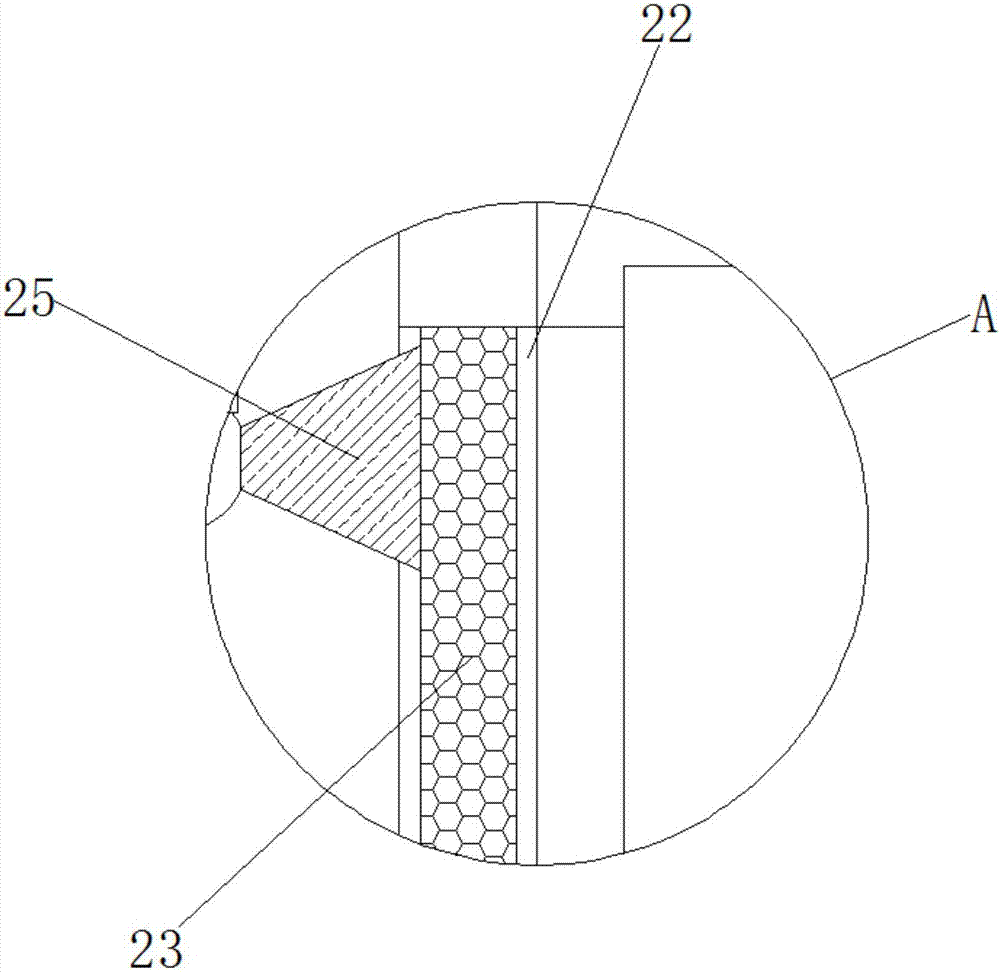

Automatic dust removal and intelligent ventilation system of fireproof linkage

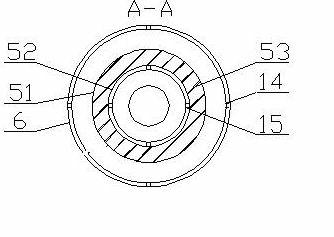

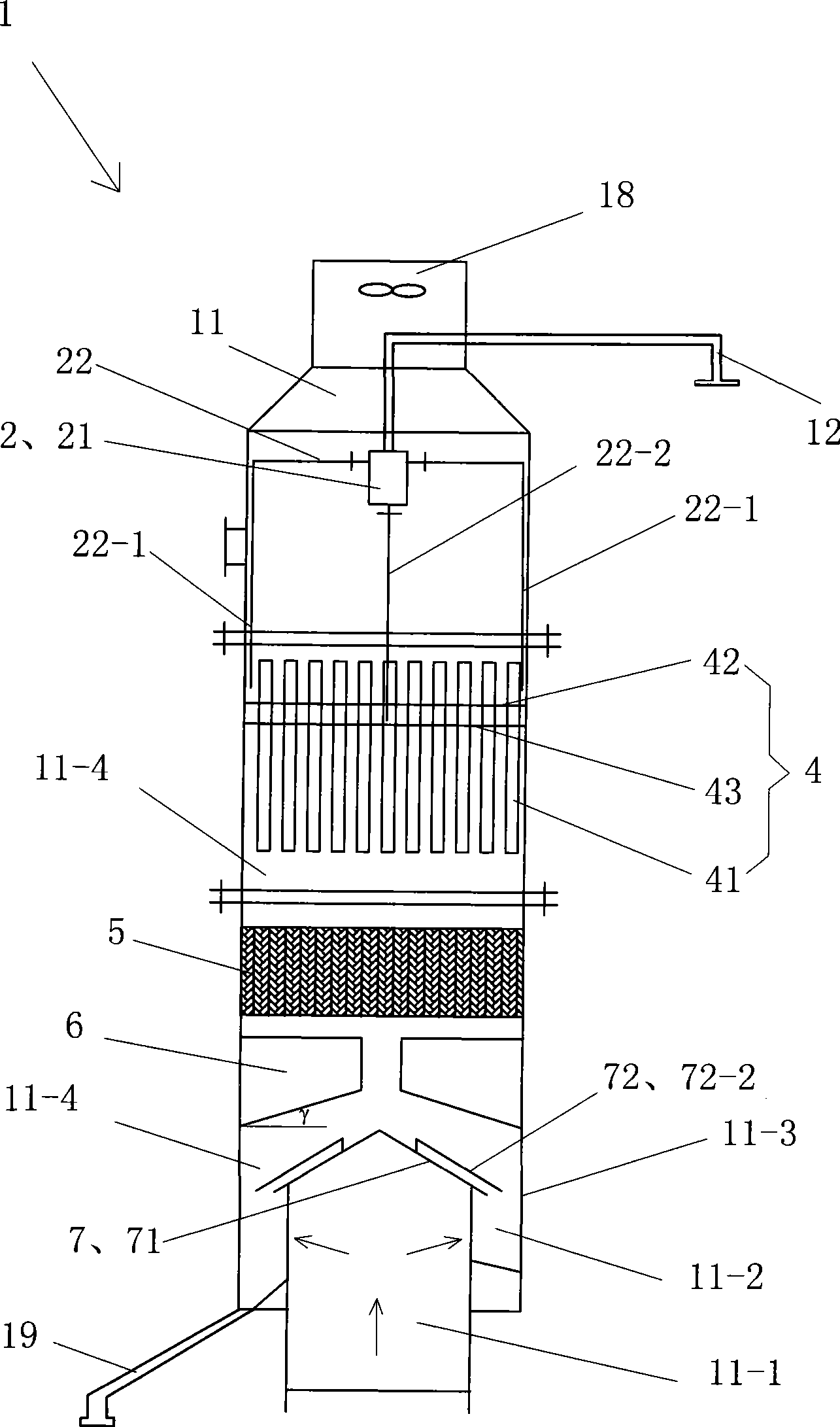

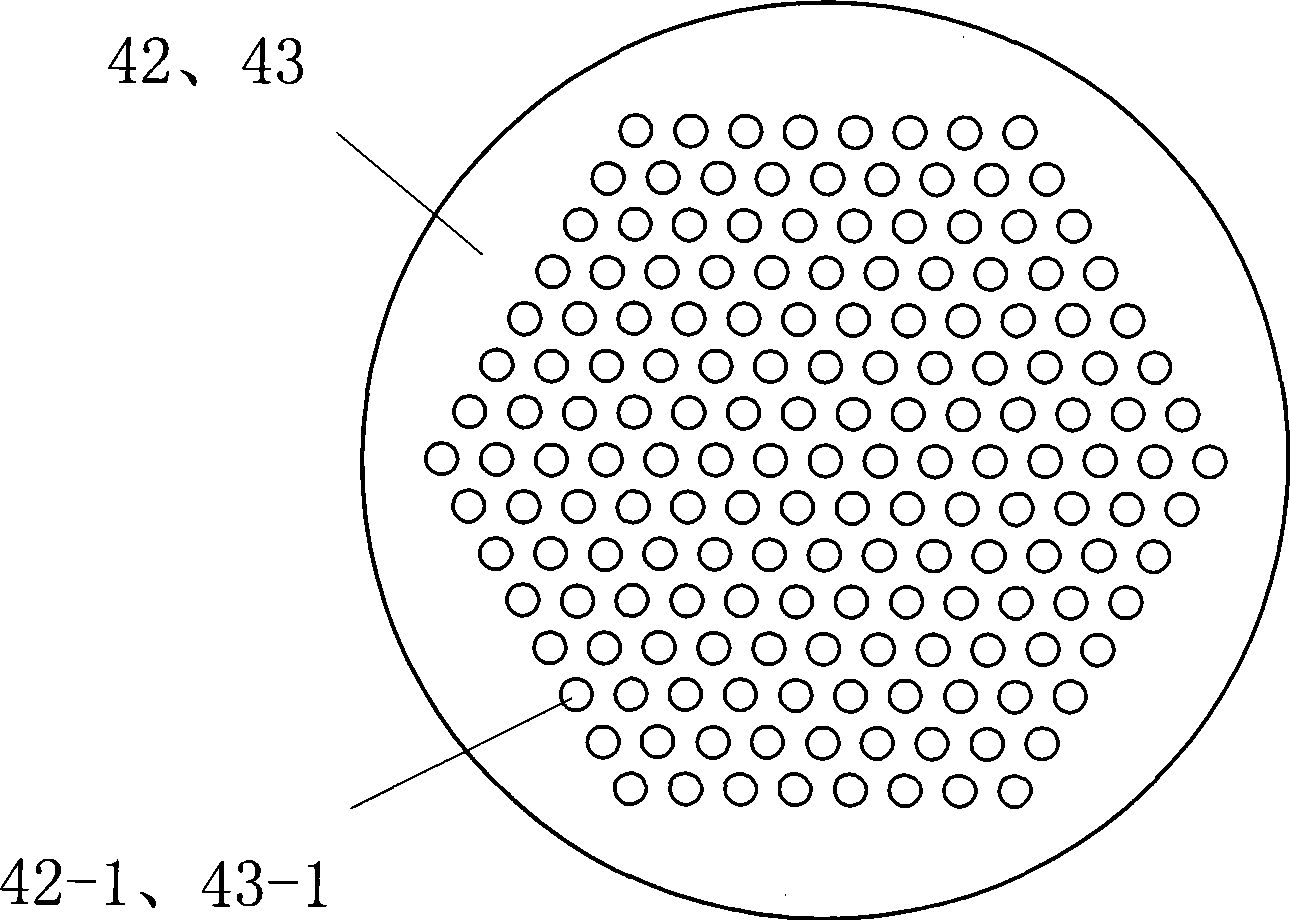

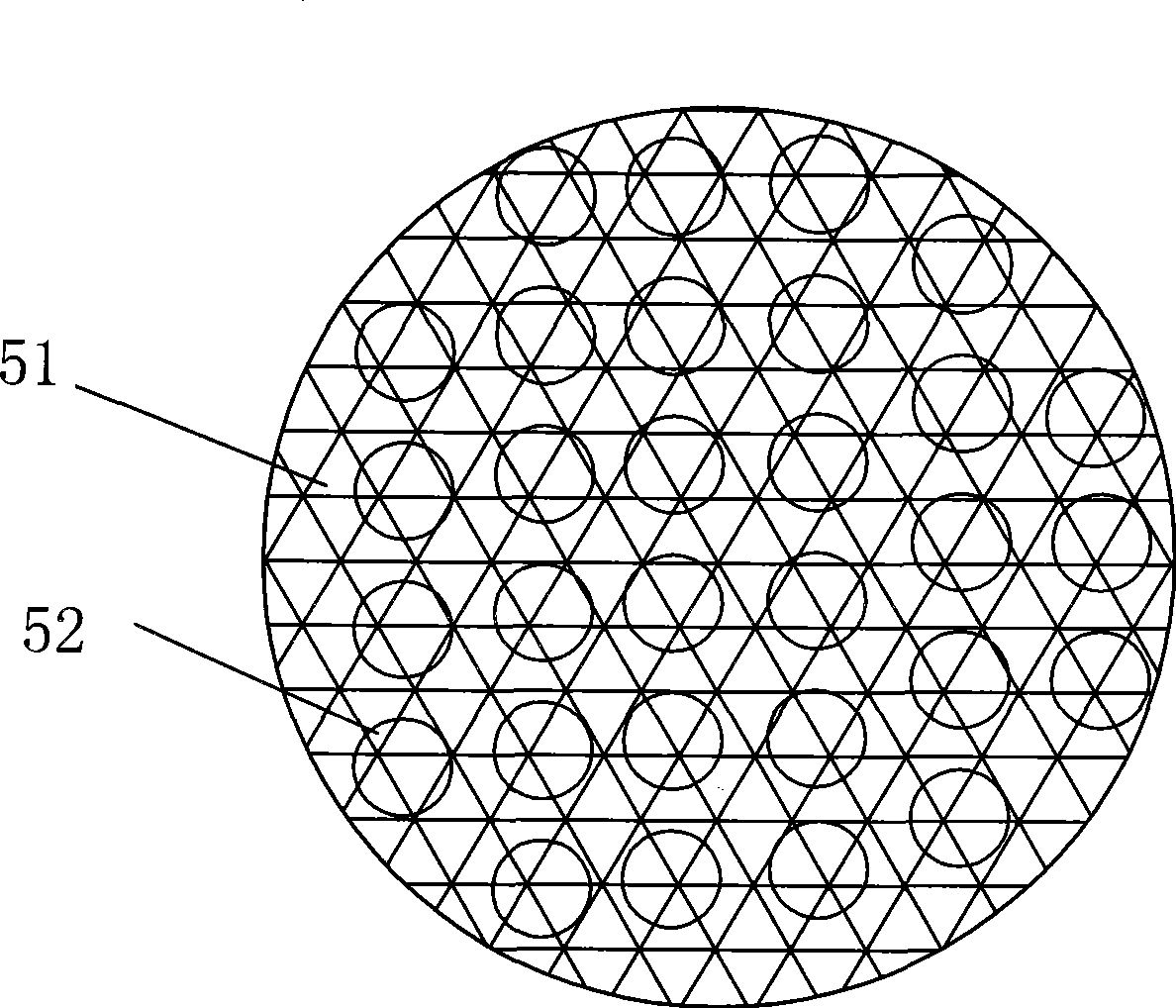

ActiveCN102175055AExtend the intervalExtended service lifeSpace heating and ventilation safety systemsLighting and heating apparatusSmokeMoisture sensor

The invention relates to the field of ventilation and heat exchange systems, in particular to an automatic dust removal and intelligent ventilation system of fireproof linkage. The system comprises an intelligent energy-saving ventilation system shell; the intelligent energy-saving ventilation system shell comprises a mixed air flue, a dust discharge air flue, an air door, a dust screen, temperature and humidity sensors, a dust sensor and an intelligent energy-saving ventilation system shell component; the dust screen filters the outdoor air; the temperature and humidity sensors are used for controlling start and stop of an indoor air conditioner and an intelligent energy-saving ventilation system; and the dust sensor is used for feeding the outdoor air cleanliness condition back to a control system, and the control system controls the start and stop of the intelligent ventilation system according to the feedback condition. The system has the advantages that: the intelligent ventilation system is associated with machine room safety key equipment such as a machine room power environment monitoring system, a machine room air conditioner, a smoke sensor and the like, so that new ignition points caused by electric faults of the air conditioner under the fire condition are prevented; and the air door of the intelligent ventilation system is closed to cut off the supply source of fresh oxygen so as to prevent supporting flames.

Owner:SHENZHEN ZHONGXING SINDI TECH CO LTD

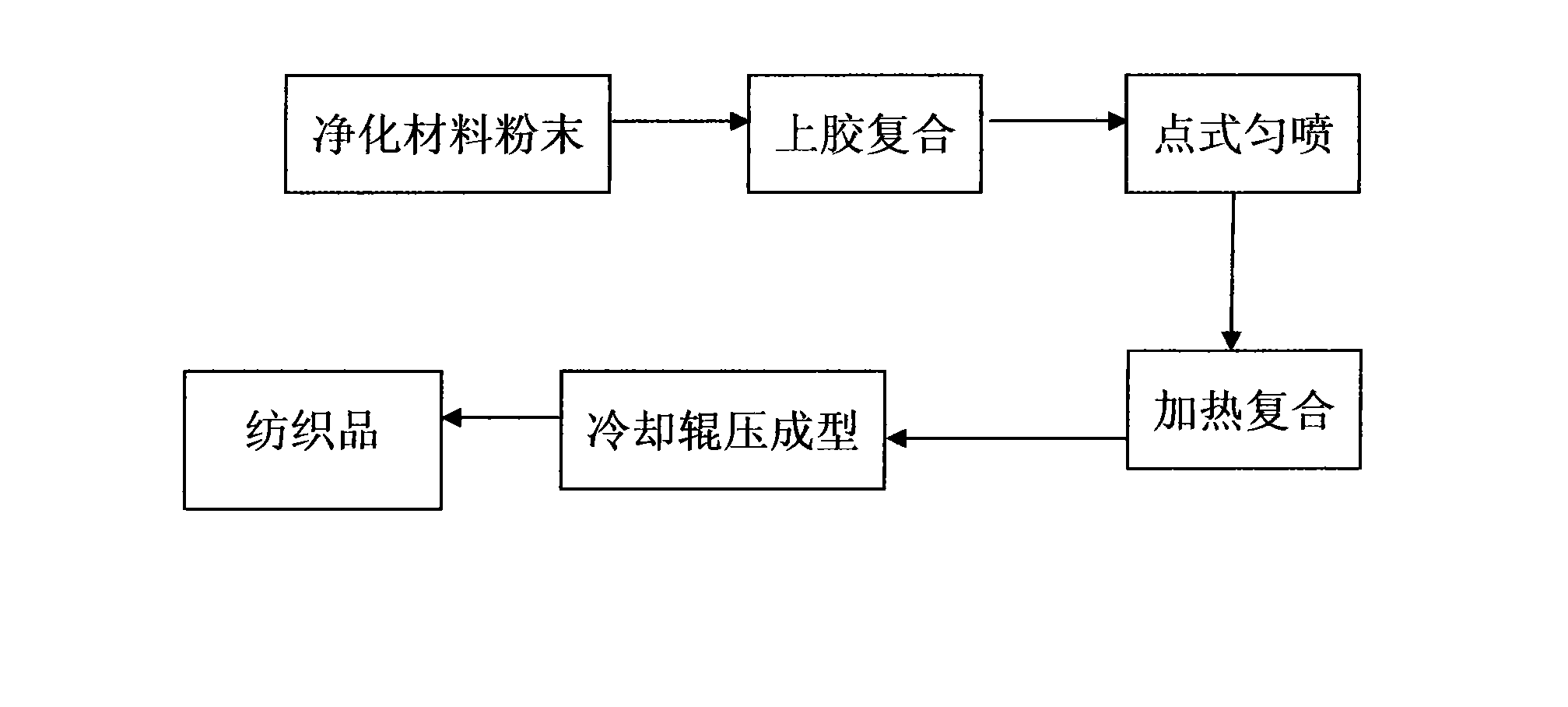

Inorganic air purification material

InactiveCN101249271AReduce air resistanceImprove sterilization efficiencyLighting and heating apparatusDeodrantsRare earthMicroparticle

The invention relates to a multifunctional material which has the functions of broad-spectrum and long-acting antibiosis and air purification, and a preparation method thereof. The material and the preparation method are characterized in that the air purification material is powdery and the basic component of the material is activated carbon with strong absorption property; the material comprises four constituents, wherein the first constituent is the mixture comprising nanometer silver particles and the activated carbon (antibiosis), and the second constituent is a mixture (photo catalyst) of nanometer titanium white powders (titanium dioxide) and the activated carbon, the third constituent is a mixture (far-infrared) comprising nanometer ceramic powders and the activated carbon, and the fourth constituent is a mixture (catalyst) comprising high rare earth and the activated carbon; the constituents are fully mixed after being prepared and are finely crushed into nanometer particles to be used. The purification material has the advantages of little air resistance, high bacterial efficiency, good purification effects of removing dust, harmful gas and ultra-fine particles, arbitrary shaping, longer service life, etc., and solves the problem of secondary environmental pollution caused by the former treatment using the chemical method and electric devices.

Owner:SHENGHONG GRP CO LTD

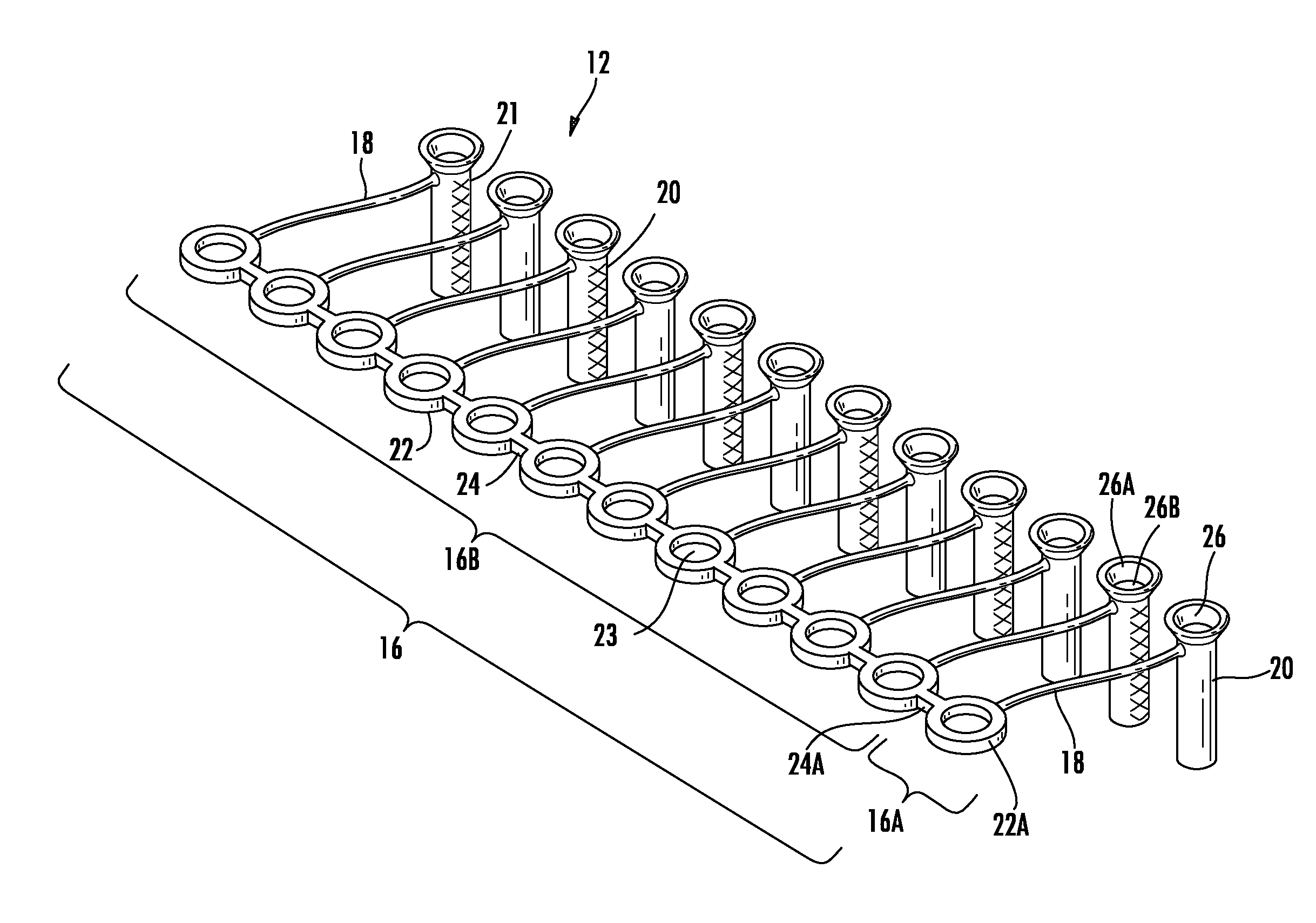

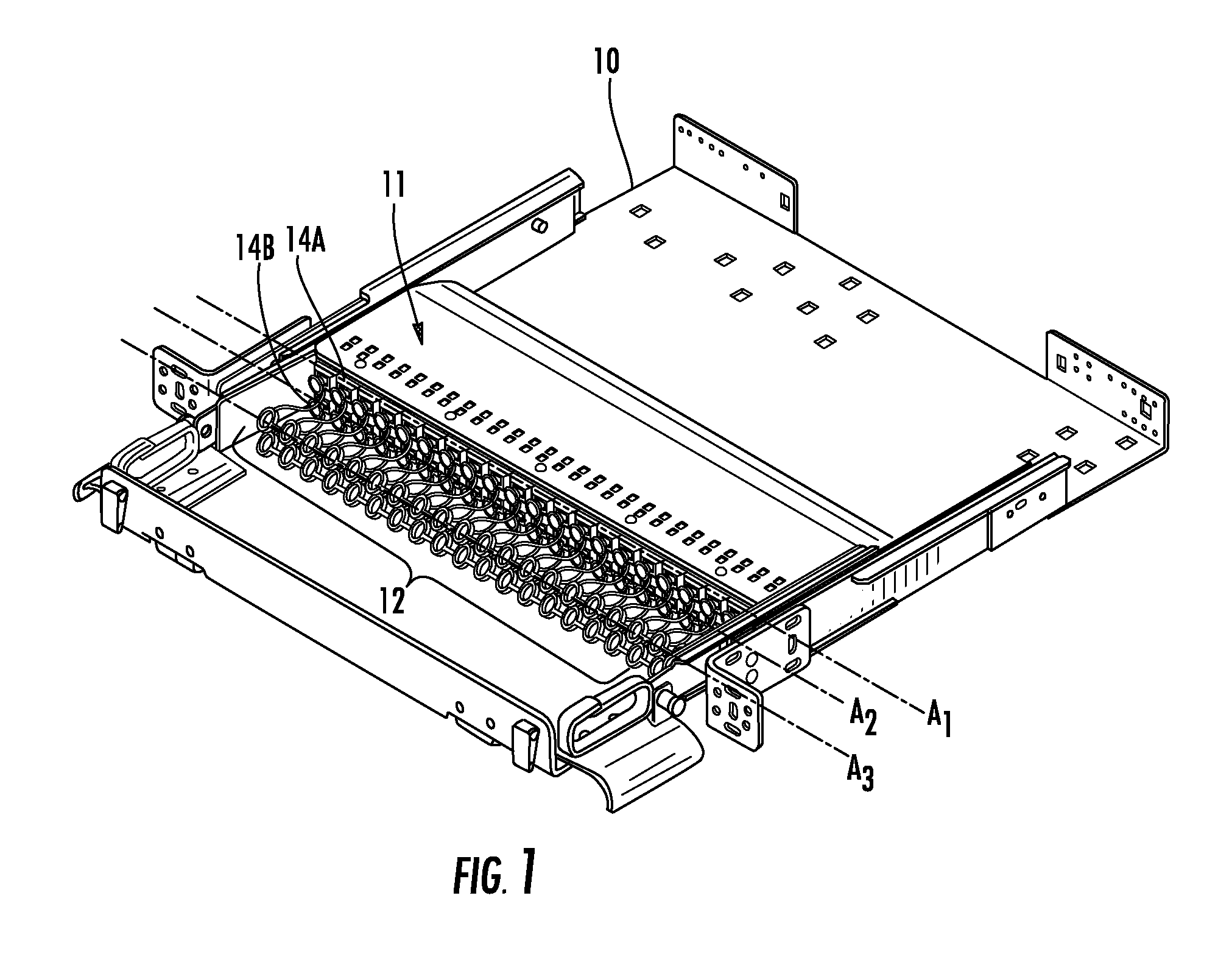

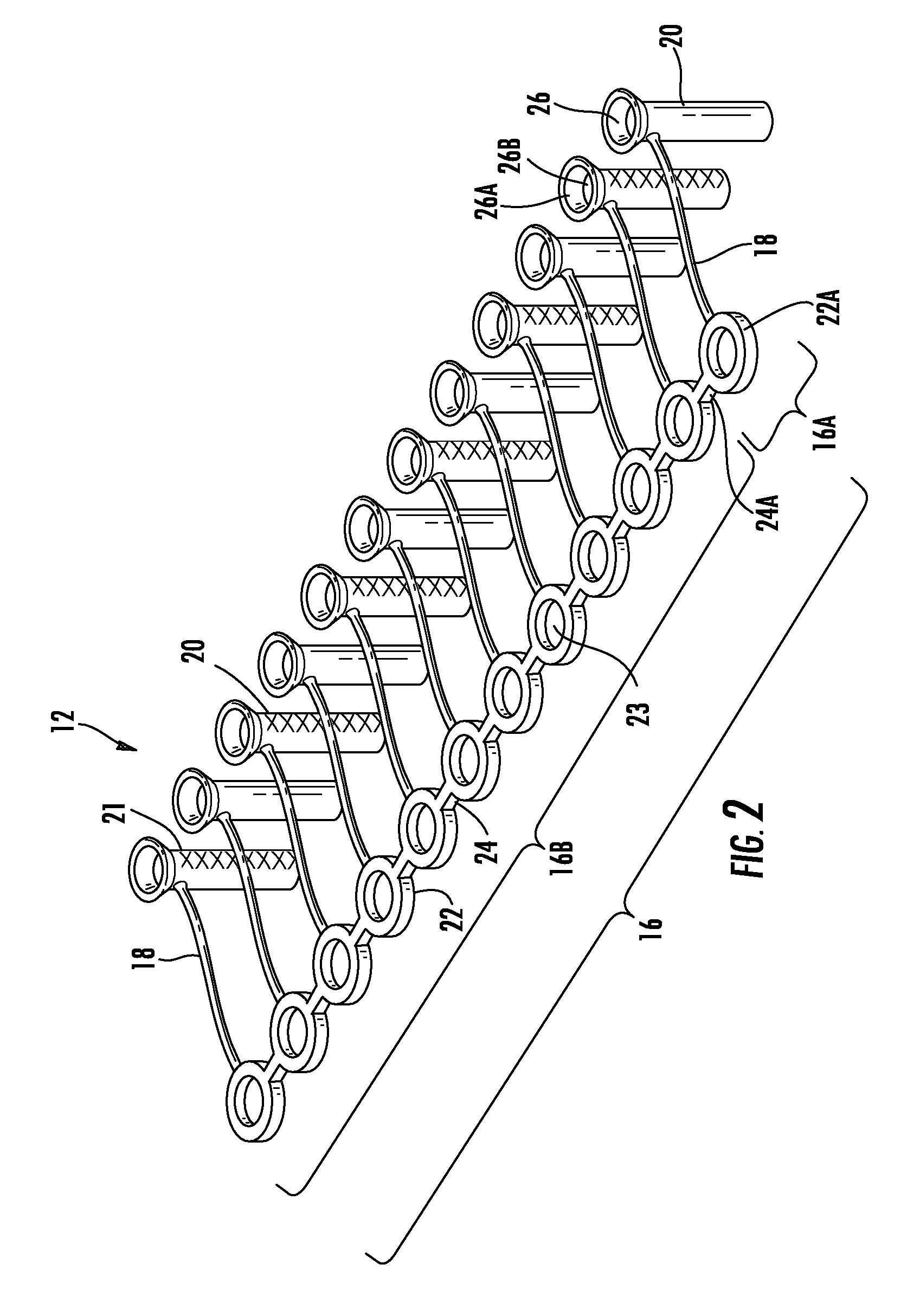

Fiber optic dust cap assembly and method

InactiveUS20100129043A1Easy to manageEasy to remove dustMountingsOptical light guidesFiberEngineering

A fiber optic dust cap assembly for protecting fiber optic components is provided. The protected fiber optic components may include fiber optic adapters and fiber optic connectors. The fiber optic dust cap assembly includes a plurality of dust caps each coupled to a lanyard. Each of the plurality of dust caps is configured for insertion into a fiber optic component. The lanyard is configured to facilitate management of the dust caps. The lanyard is also configured to facilitate removal of the dust caps from the fiber optic components. Each of the dust caps among the plurality of dust caps may be removed by pulling on the lanyard. The lanyard may also facilitate removal of each of the plurality of dust caps in one pulling action. Additionally, by the plurality of dust caps being connected to the lanyard, the plurality of dust caps coupled to the lanyard remain together after removal.

Owner:CORNING OPTICAL COMM LLC

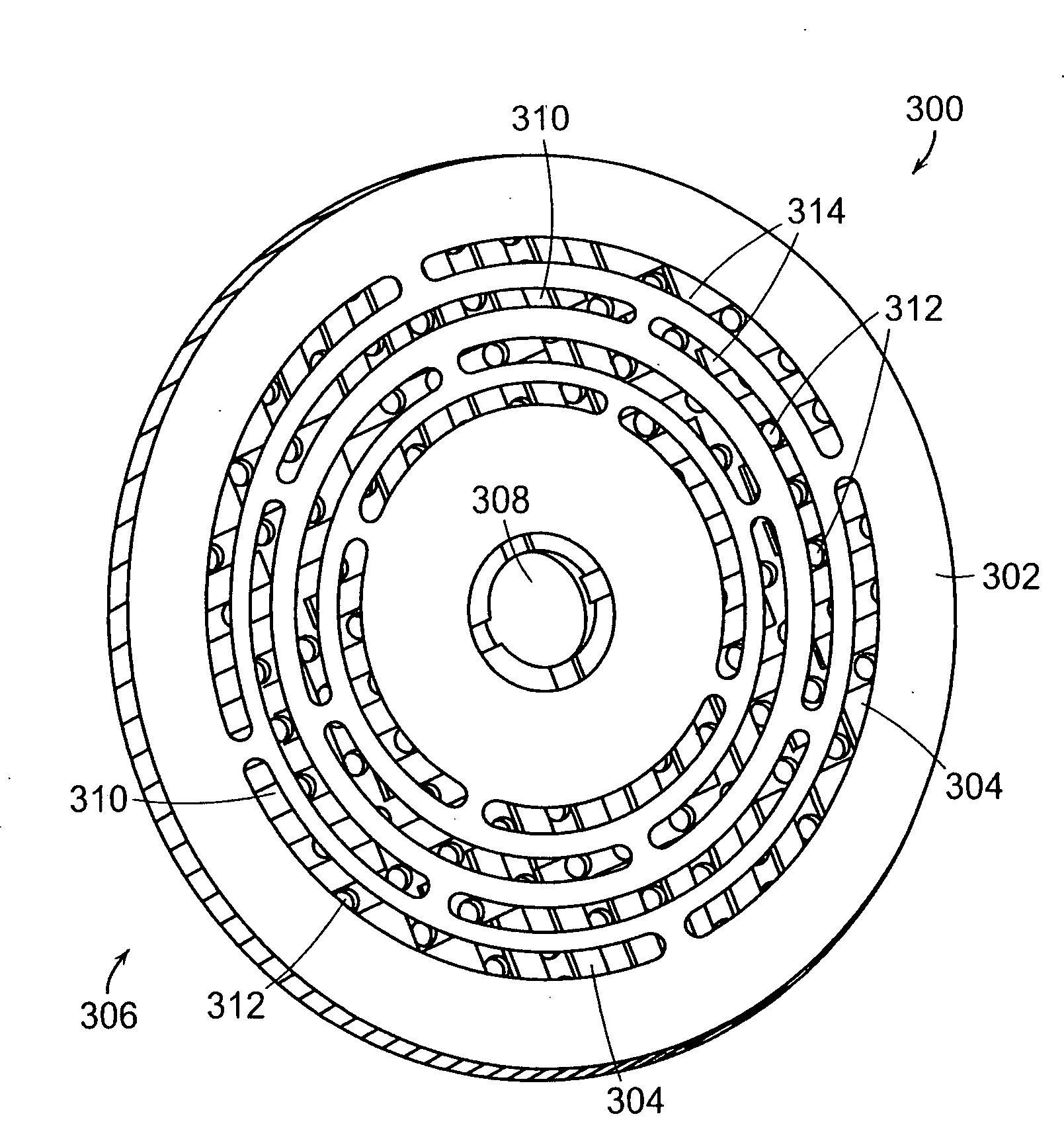

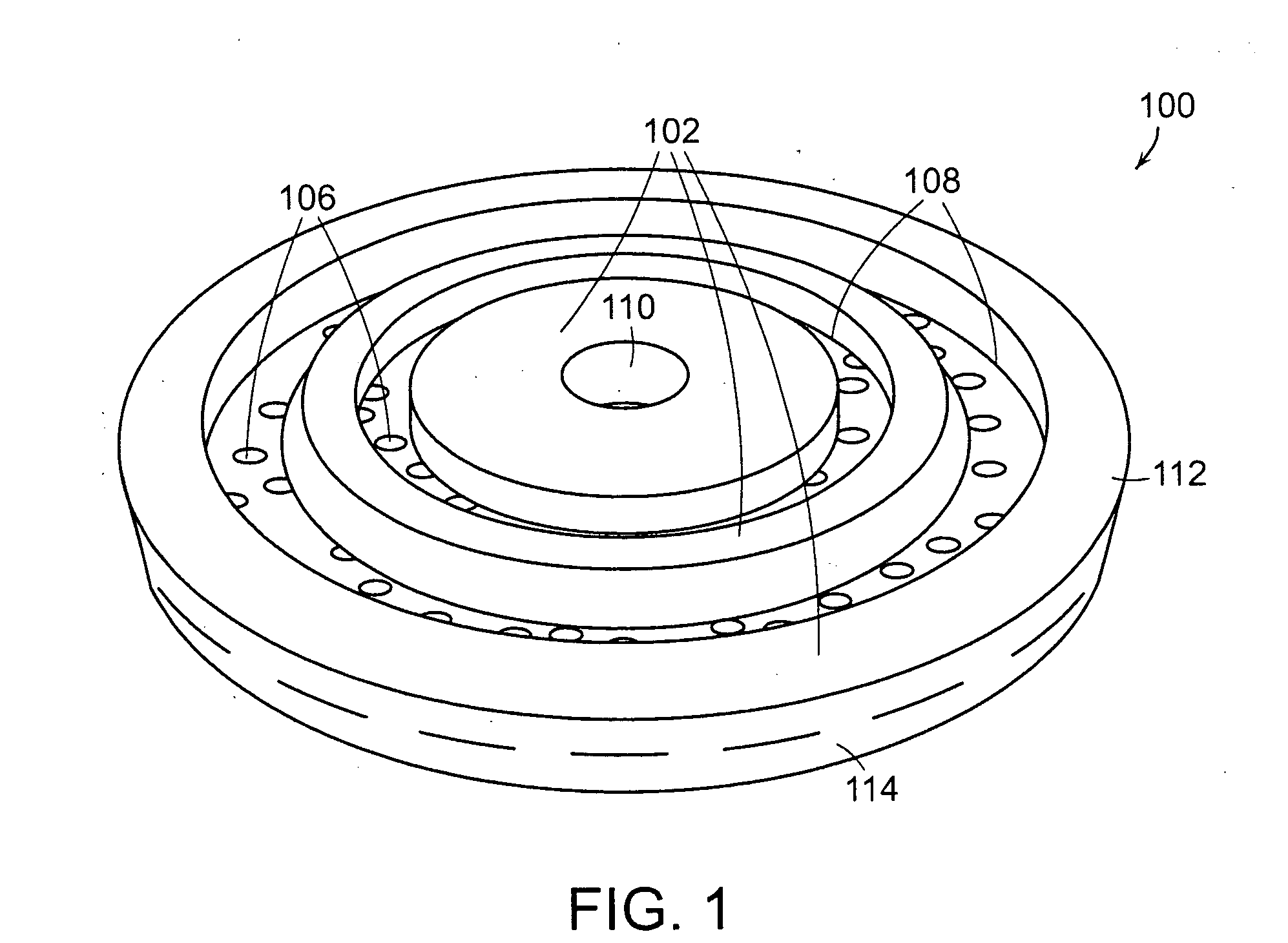

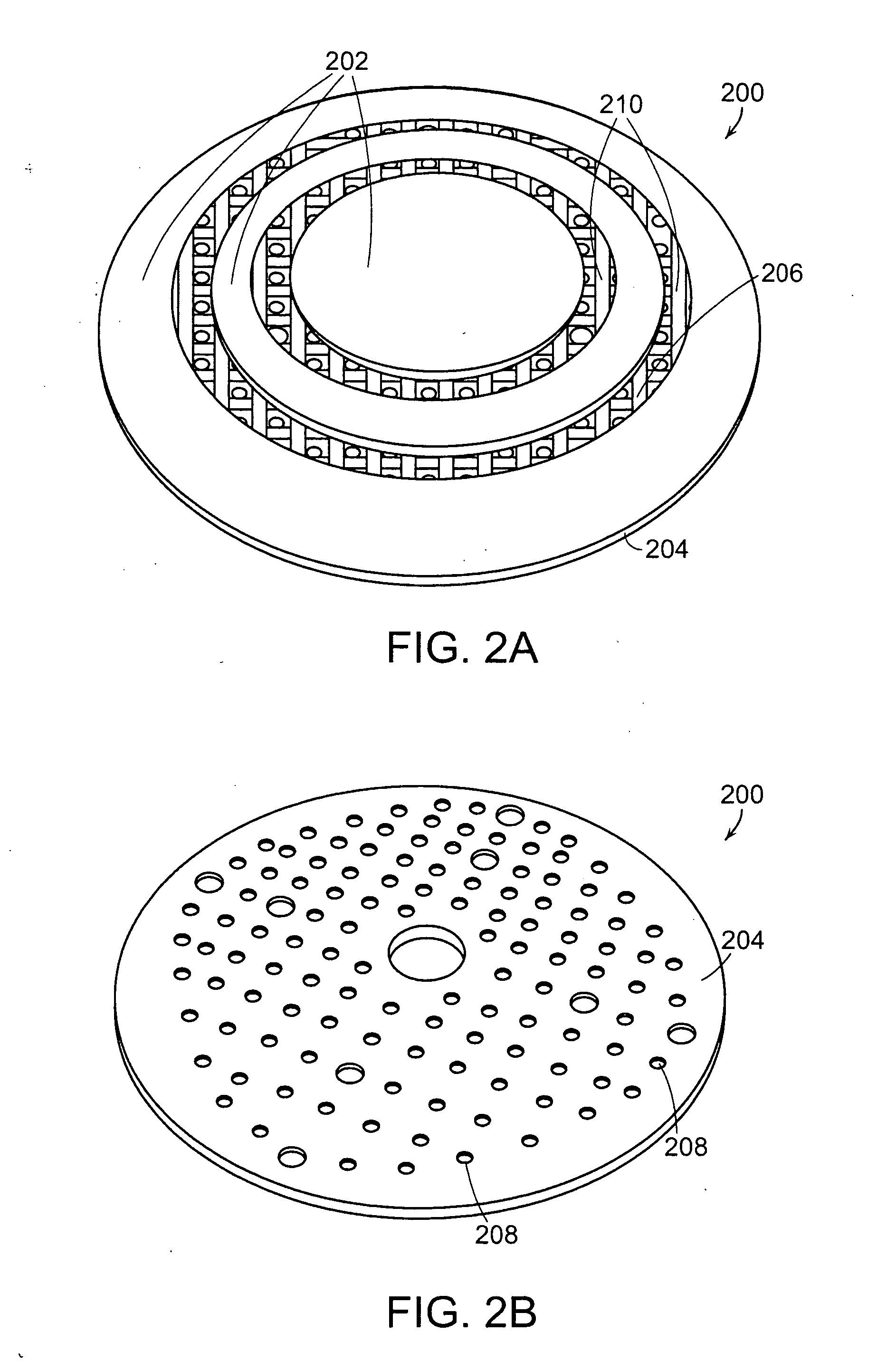

Interface pad for use between an abrasive article and a support tool

ActiveUS20090233527A1Decrease stockEasy to remove dustGrinding wheel securing apparatusLayered productsEngineeringAbrasive

The present invention relates to an interface pad for use between an abrasive article and a support tool. In one particular embodiment, an interface pad for use between a perforated abrasive article and a support tool is provided. In general, the interface pads described herein contain apertures and at least one channel configured such that an interface pad can be used between an abrasive article having a particular configuration of apertures and a support tool having different configuration of dust collection apertures. In one embodiment, the interface pads described herein contain apertures and at least one channel configured such that the interface pad can be used between any perforated abrasive article and any support tool with dust extraction capabilities. Abrasive tools which include an interface pad and methods for using the interface pads are also described.

Owner:SAINT GOBAIN ABRASIVES INC +1

Method of ionized air-rinsing of containers and apparatus therefor

InactiveUS7621301B2Easy to remove dustEasy to cleanMechanical cleaningLiquid fillingHigh velocityWaste management

A method and system for cleaning containers being transposed through a container cleaning line, including an open-ended housing, a predetermined container flow path defined by the line of moving containers traversing the enclosure defined by the housing longitudinally, a first set of ionizing air nozzles mounted within the housing for directing ionized compressed air toward the containers in the container flow path, with at least one of the nozzles directing air flow into an open side of each container as it passes the nozzle and a second set of high velocity air nozzles mounted within the housing for directing high velocity compressed air toward the container flow path, the second set of high velocity nozzles being disposed along a direction essentially parallel to the container flow path with at least one of the nozzles flows directing high velocity air flow into the open side of each container as it passes the nozzle. Nozzle guards are provided to prevent contact between the containers and the nozzles.

Owner:THE QUAKER OATS CO

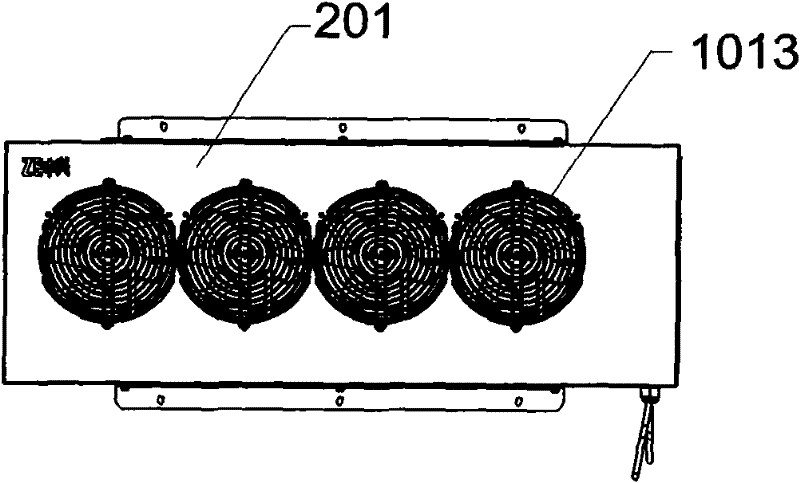

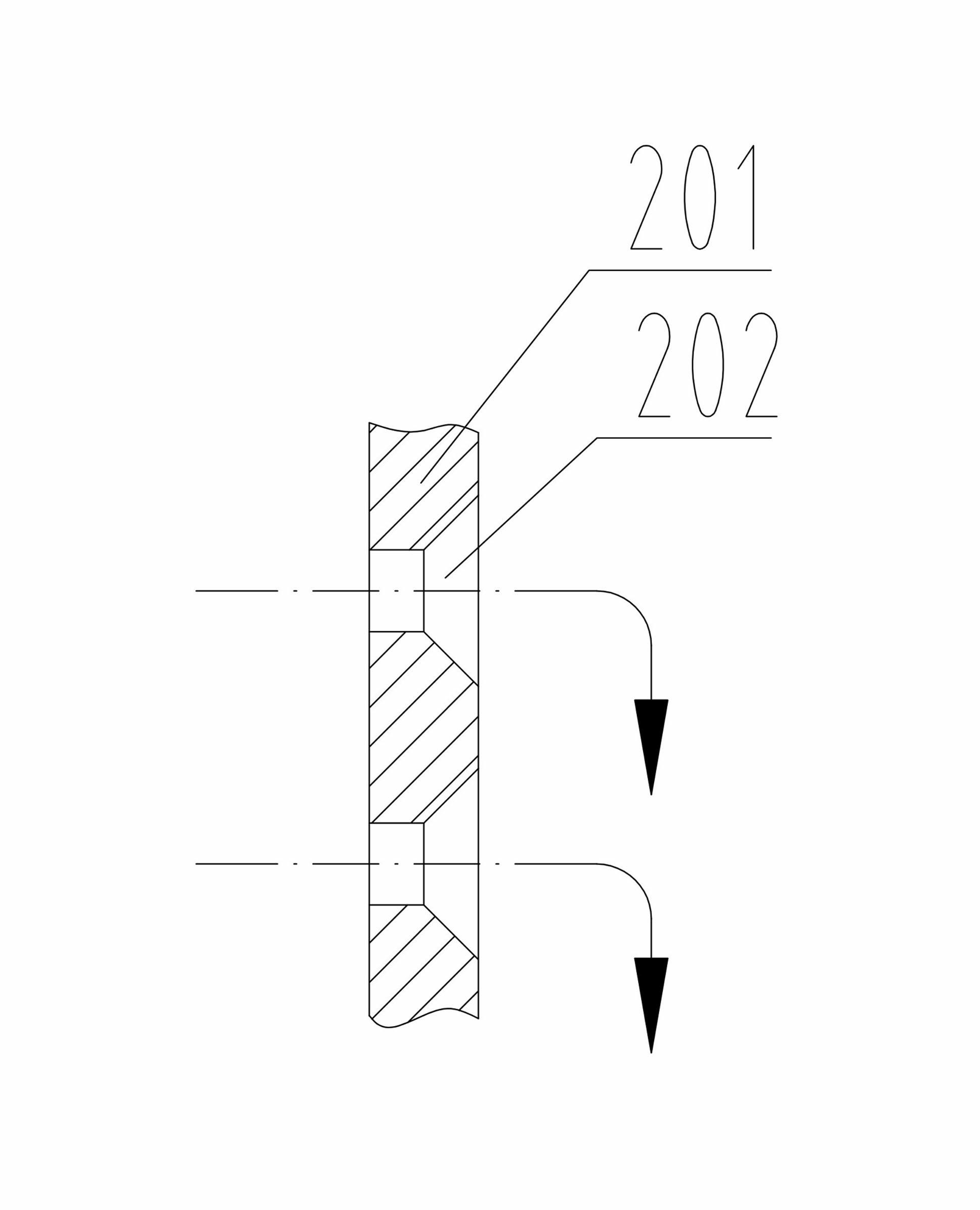

Bidirectional automatic dust removal and intelligent ventilation system and bidirectional dust removing method

InactiveCN101896057ALow failure rateReduce consumptionCooling/ventilation/heating modificationsFailure rateCold air

The invention relates to the field of ventilation systems, in particular to a bidirectional automatic dust removal and intelligent ventilation system and a bidirectional dust removing method. The bidirectional automatic dust removal and intelligent ventilation system is arranged in a communication computer room and is provided with a dust removing outlet and an air supply outlet. The bidirectional automatic dust removal and intelligent ventilation system comprises an air supply unit, a dust removing unit, a control system, an air conditioner, a mixed air supply duct, an air exhaust duct and an air hood. The air supply unit brings a micro positive pressure environment for the computer room during air supply so as to automatically exhaust hot air of the communication computer room and remove dust of a strainer at the same time; and the air supply unit brings a micro negative pressure environment for the communication computer room during air exhaust and dust removal so as to pump outdoor cold air into the communication computer room. The bidirectional automatic dust removal and intelligent ventilation system has the advantages of reducing the hardware cost of the system, and reducing the use cost and maintenance cost of the system. The air exhaust unit is not provided with an air blower, so that the failure rate of the air exhaust unit due to the damage of the air blower is reduced, the energy efficiency ratio of the whole system is improved, and the energy consumption of the whole system in normal use is reduced.

Owner:SHENZHEN ZHONGXING SINDI TECH CO LTD

Integrated device for removal of dusts and gaseous pollutants

InactiveCN102091484ALess investmentLow running costDispersed particle filtrationAir quality improvementEnvironmental engineeringSmall footprint

The invention relates to an integrated device for the removal of dusts and gaseous pollutants, which comprises a bracket and a bag-type dust remover, wherein the bag-type dust remover consists, from top to bottom, of an ash cleaning device, a box body, an ash compartment and an ash unloading device, the box body is internally provided with a plurality of filter bags installed vertically, the filter bags are internally or externally provided with adsorbers corresponding to the filter bags one by one, and the adsorbers are installed inside the box body via an adsorber support cage. The adsorber is internally filled with carbon-based adsorbent through which the gaseous pollutants are adsorbed. According to the invention, the integrated device is formed by integrating dust removal with the gaseous pollutant removal, the carbon-based adsorbent having large surface area can be regenerated many times and repeatedly used to lower the operating expenditure, and the integrated device of the invention can effectively remove particles, SO2, Nox, Hg and toxic and harmful organic pollutants resulting from industrial discharge in the same device, and has the advantages of simple structure, small floor area and excellent dust removal and adsorption effects.

Owner:HARBIN INST OF TECH AT WEIHAI

Desulfurization dust removing method of industrial furnace

InactiveCN101362043AIncrease contact timeImprove dust removal efficiencyUsing liquid separation agentFlue gasLiquid water

The invention discloses a desulfurization and dust removal method for an industrial furnace, which comprises the followings steps: 1. a flue gas inlet of a desulfurization and dust removal device of the industrial furnace is communicated with a flue gas outlet of the industrial furnace; 2. cooling water is pumped into a water inlet pipe, enters a contact type cooling spraying device through a flow partitioning device, falls into a spraying area in spraying shape and then is discharged along a blowdown pipe; 3. flue gas generated from the industrial furnace enters the desulfurization and dust removal device of the industrial furnace from bottom to top from the flue gas inlet of a shell, is contacted with cooling water between a barrier cap and an annular bottom plate firstly and then with the cooling water in the spraying shape and falling down from the contact type cooling spraying device to carry out heat exchange; 4. after the heat exchange, phase change is carried out to steam so as to cause the steam to turn into liquid water drops, during the phase change, adjacent sulfur dioxide is absorbed by the water drops and adjacent minimal dust grains are adsorbed by the water drops effectively. The desulfurization and dust removal method for the industrial furnace has good dust removal effect, high desulfurization efficiency, as well as low energy consumption, low equipment investment and low operation cost.

Owner:姚立猛

Shell fabric disinfection equipment used for mask processing

InactiveCN111228528AEasy to cleanSmooth rotationMechanical cleaningPressure cleaningUltraviolet lightsDust control

The invention discloses shell fabric disinfection equipment used for mask processing, and relates to the technical field of mask processing. The shell fabric disinfection equipment comprises a machinebody, a disinfection mechanism and a drying chamber, wherein the inner left side of the machine body is provided with a sterilization chamber; a material inlet is arranged on the left lower part of the sterilization chamber; the upper side and the lower side of the outer part of the material inlet are independently fixedly provided with an outer baffle plate; the inner side of each outer baffle plate is provided with a dust removal mechanism; the inner side of the material inlet is provided with a fed material guide roller; the outer side of the fed material guide roller is provided with a shell fabric main body; a first traction roller is installed in the sterilization chamber; the upper side and the lower side of the inner wall of the sterilization chamber are independently provided with an ultraviolet lamp; and a disinfection chamber is arranged in the middle of the machine body. The shell fabric disinfection equipment has the beneficial effects that the arrangement of the dust removal mechanisms is convenient to clean the surface of the shell fabric main body, the position height of a soft hairbrush can be conveniently flexibly regulated through a telescopic rod to enable thesoft hairbrush to be laminated with the surface of the shell fabric main body, and therefore, the outer surface of the shell fabric main body can be subjected to dust removal through two groups of symmetric soft hairbrushes.

Owner:DONGGUAN RONGGONG AUTOMATION TECH CO LTD

Suction pipe dust suppression device and road sweeper for suction sweeping road sweeper

A dust collecting system includes a suction means, a dustbin (10), a suction tube (20) and a suction nozzle (30). They are connected in turn. There are water inlets (23) on the suction tube (20). The dust collecting system also includes a water supply device, which supplies water for the suction tube (20) through said water inlets (23). By supplying water to the suction tube, inner wall of the suction tube is moistened by said dust collecting system, besides dust and waste carried by airflow are further moistened, therefore friction between airflow with dust and the inner wall of the suction tube can be decreased, and stick and clog can be avoided or reduced. A road sweeping vehicle including said dust collecting system is also provided.

Owner:ZOOMLION ENVIRONMENTAL IND CO LTD

Automatic dust removal and spray system for household ceramic blank

The invention discloses an automatic dust removal and spray system for the surface of a household ceramic blank. An automatic dust removal device and an automatic spray device are sequentially arranged along the conveying direction of a conveyor belt. The system is characterized in that the automatic dust removal device and the automatic spray device are provided with conveyor belt transition bridges which support the blank overhead, and the two ends of the conveyor belt transition bridges are connected with conveyor belts; a material blank enters the dust removal device by a material blank conveyor belt through a material blank through cavity of a bellows, and gas nozzles of upper and lower middle pressure fans send air to the material blank conveyor belt to remove the dust on the surface of the material blank; and after the completion of dust removal, the material blank conveyor belt enters a watering device through a material blank through cavity of an atomizing chamber, and atomizing nozzles at the upper and lower ends of the atomizing chamber, connected with a water pump, directly spray atomizing water onto the surface of the material blank to wet the surface of the material blank. Compared with the prior art, the system has the advantages of full automation of production of dust removal and spray processes and the like, labor cost saving, improvement on production efficiency, and good dust removal and spray effects on the surface of the blank.

Owner:GUANGXI BEILIU CITY ZHICHENG CERAMIC AUTOMATION TECH

Cleaning equipment for improving efficiency

ActiveCN107626629AEasy to remove dustAvoid damageCleaning using toolsCleaning using gasesEngineering management

The invention discloses cleaning equipment for improving efficiency. The cleaning equipment comprises a first supporting plate, a rotating plate, a second supporting plate and a soft brush; a motor support is installed at the middle portion of the bottom of the first supporting plate, a first motor is installed at the middle portion of the interior of the motor support, a control panel is installed at one end of one side of the first supporting plate, an annular sliding rail is installed at the middle portion of the upper portion of the first supporting plate, the rotating plate is installed on the annular sliding rail through an annular sliding rail sliding device, and four sets of first installing plates are installed above the rotating plate. According to the cleaning equipment, the gradual dust removing manner is adopted for conducting dust removal on a circuit board, the dust removal effect is better compared with in-batch dust removal, influences of follow-up machining operationare avoided, rework is avoided, operation efficiency is improved, and meanwhile, damage caused by in-batch dust removal to the circuit board can be avoided.

Owner:常熟市董浜科技创业投资发展有限公司

Cloth winding device having dust removal function and used for textiles

ActiveCN106915644AWith dust removal functionEasy to remove dustCleaning using toolsCleaning using gasesBristleEngineering

The invention relates to the technical field of textiles, and discloses a cloth winding device having a dust removal function and used for textiles. The cloth winding device comprises a supporting base. The top of the supporting base is fixedly connected with a supporting frame. Bearings are connected to the supporting frame in a clamping manner. A rotating shaft is connected in the bearings in a sleeving manner. The surface of the rotating shaft is fixedly connected with a first gear. The first gear is engaged with a second gear. The second gear is fixedly connected to an output shaft of a motor. The motor is fixedly connected to one side of the supporting frame. According to the cloth winding device having the dust removal function and used for the textiles, by arranging a supporting rod, a brush plate, an empty groove, air blowers and bristles, dust removal can be better conducted when cloth is wound, the problem that an existing cloth winding device does not have the dust removal function when the cloth is wound is solved, and therefore the situation that dust is attached to the back face of the cloth after the cloth is wound is avoided, and appearance of the cloth can be better when the cloth is sold in the later period.

Owner:SANYANG TEXTILE

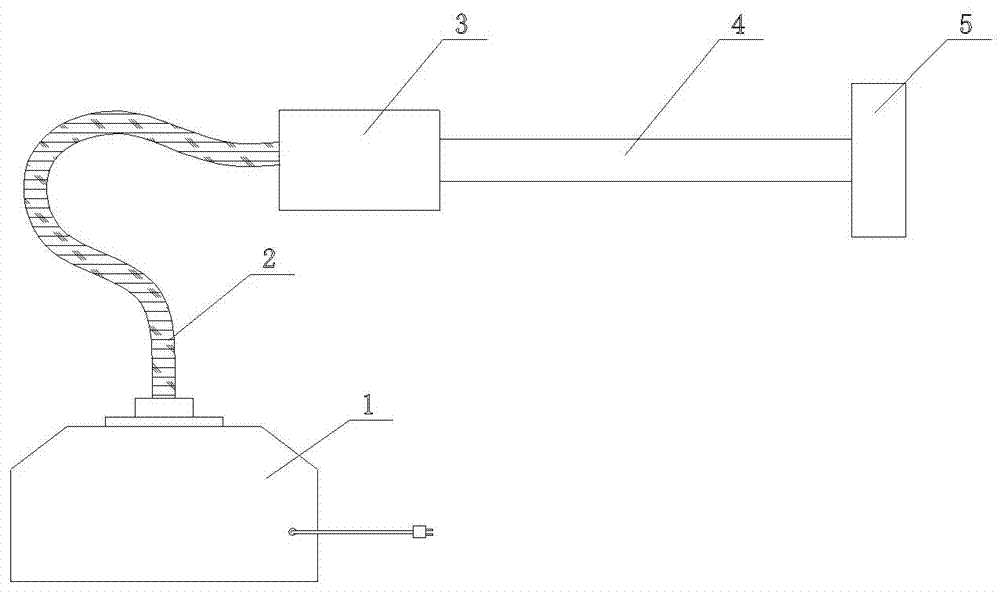

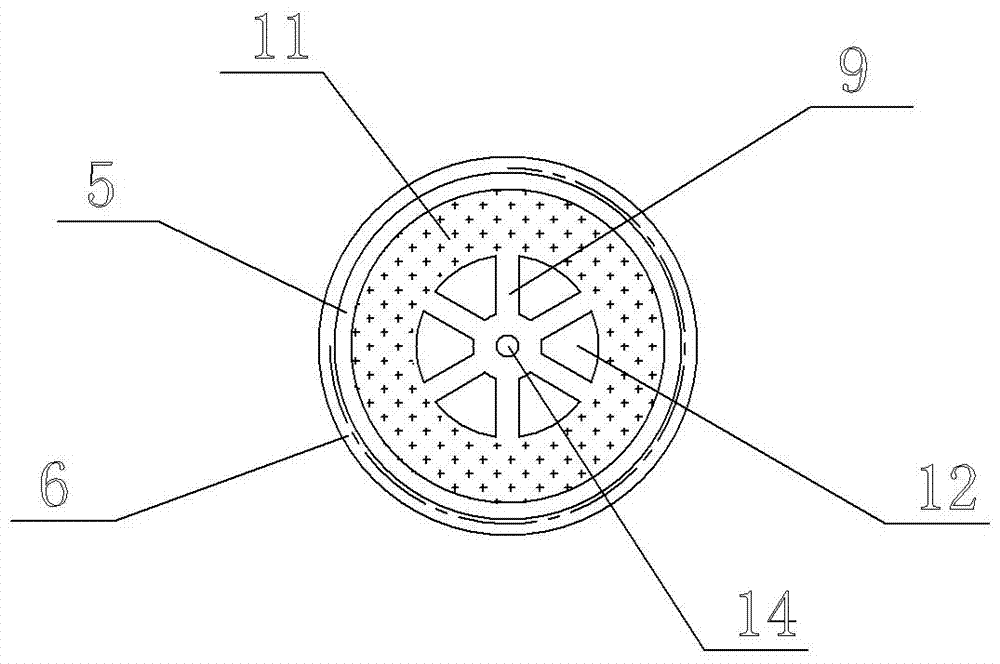

Handheld dust sucking brush

PendingCN106964582AInvisible absorptionAdd cleaning functionCleaning using toolsCleaning using gasesElectric machineDust control

The invention discloses a handheld dust sucking brush. The handheld dust sucking brush comprises a collecting device, a connecting hose, a handheld device, a dust sucking pipe and a brush head which are connected in sequence, and further comprises a switch and a power supply wire; a motor is mounted in the handheld device; after a rotating shaft of the motor penetrates through the dust sucking pipe, the tail end of the rotating shaft is mounted in a center hole of a spoke in the brush head; fan blades for exhausting are mounted at one section, positioned on the inner side of the handheld device, of the rotating shaft of the motor; and a brush disc is arranged on the edge of the spoke, and is provided with a brush. Compared with a traditional dust sucker, the handheld dust sucking brush is smaller, adds a cleaning function, and is more convenient to remove dust during working. The handheld dust sucking brush is simple in structure and convenient to manufacture. The brush head adopts a wheel structure, can achieve a cleaning effect, and cannot influence suction of the dust by the device. A transmission device adopts an extension form to achieve adjustment.

Owner:STATE GRID CORP OF CHINA +2

Distribution cabinet convenient for heat dissipation and dust removal

PendingCN108767708ADischarge in timeReduce the temperatureSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsElectromagnetic lockThree phase asynchronous motor

The invention discloses a distribution cabinet convenient for heat dissipation and dust removal, including pillars, a distribution cabinet body, a baffle, a bearing, an electromagnetic lock, a cabinetdoor, a gasket, a first linear motor, a fixing rod, a first slider, a top plate, a first vent, a first drive motor, a first screen, a slide slot, a fan blade, a mounting rod, a second screen, a second vent, a lead screw, a second slider, a second linear motor, a second drive motor, a brush, a fixing plate, a dust box, a base, a fixing block, a three-phase asynchronous motor, a winding wheel, a spring, a bracing wire and a magnet block. The first linear motor is arranged, so that the fan blade at one end of the output shaft of the first drive motor rotates and moves laterally, the first ventilation outlet and the second ventilation outlet are matched, air convection is facilitated and the heat is discharged with the air in time, the temperature in the cabinet is effectively reduced, and the brush is driven to move transversely by a second driving motor and a lead screw, so that the dust is quickly accumulated on the surface of the baffle plate and discharged, and is worth popularizing.

Owner:高邮市电塑厂

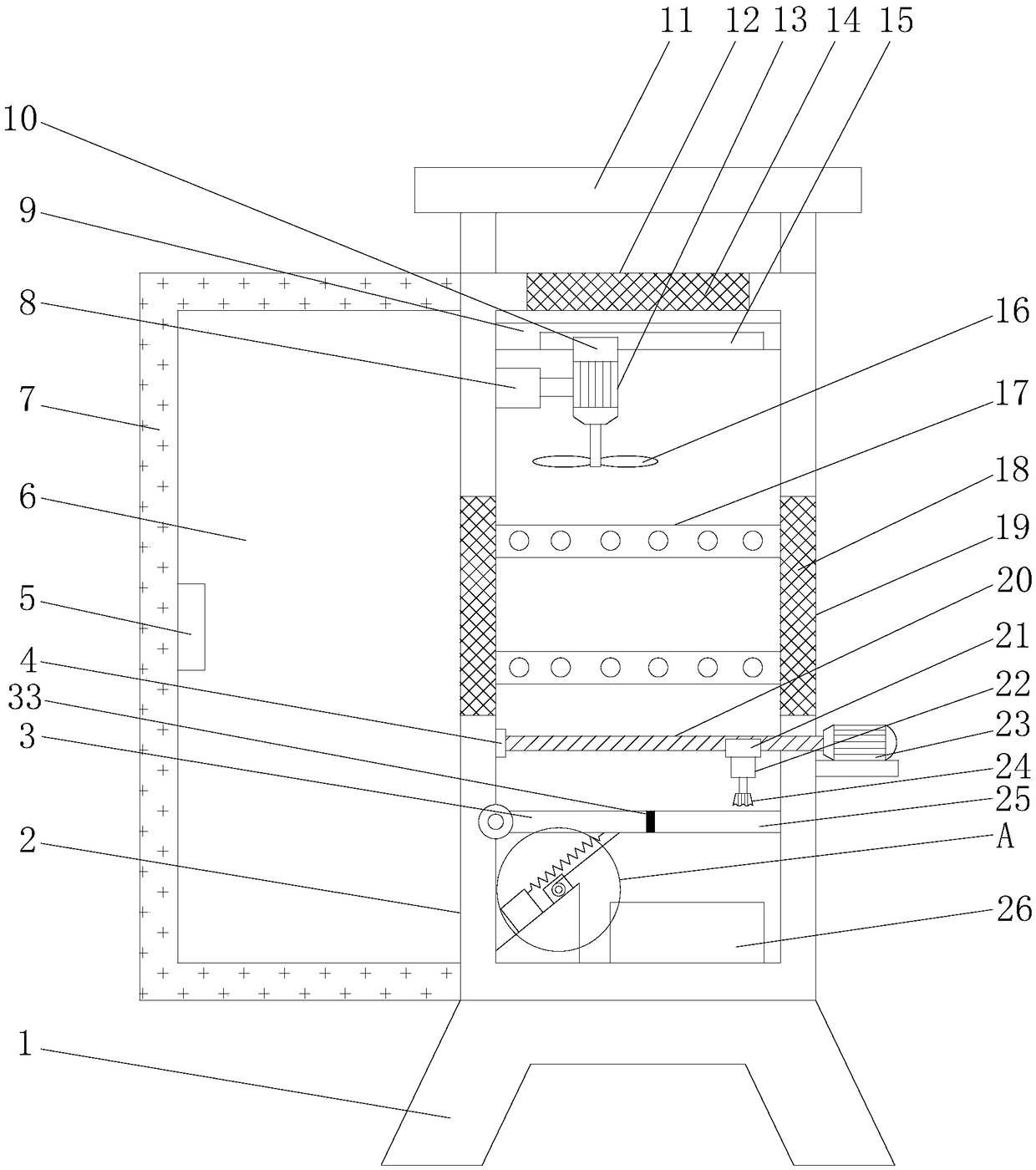

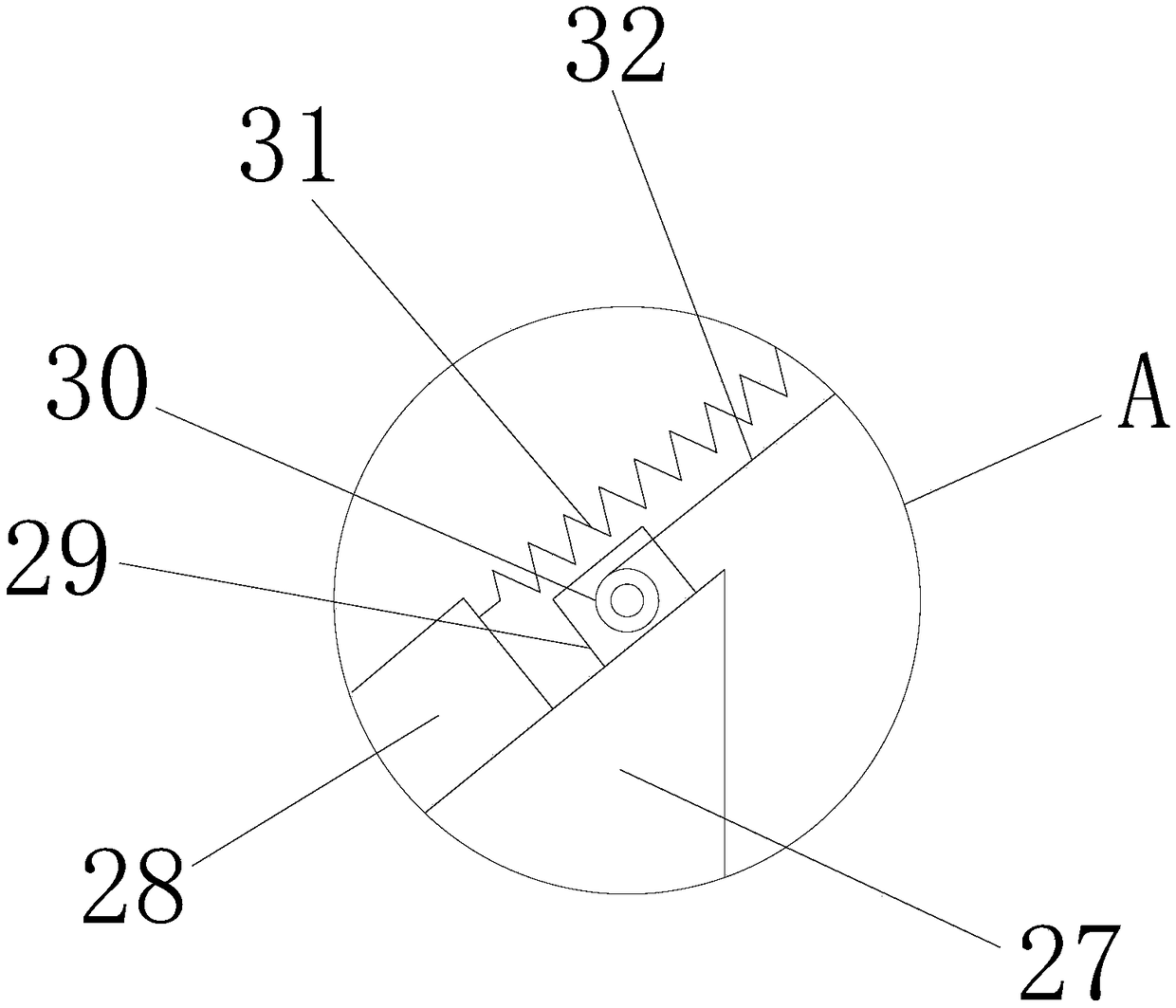

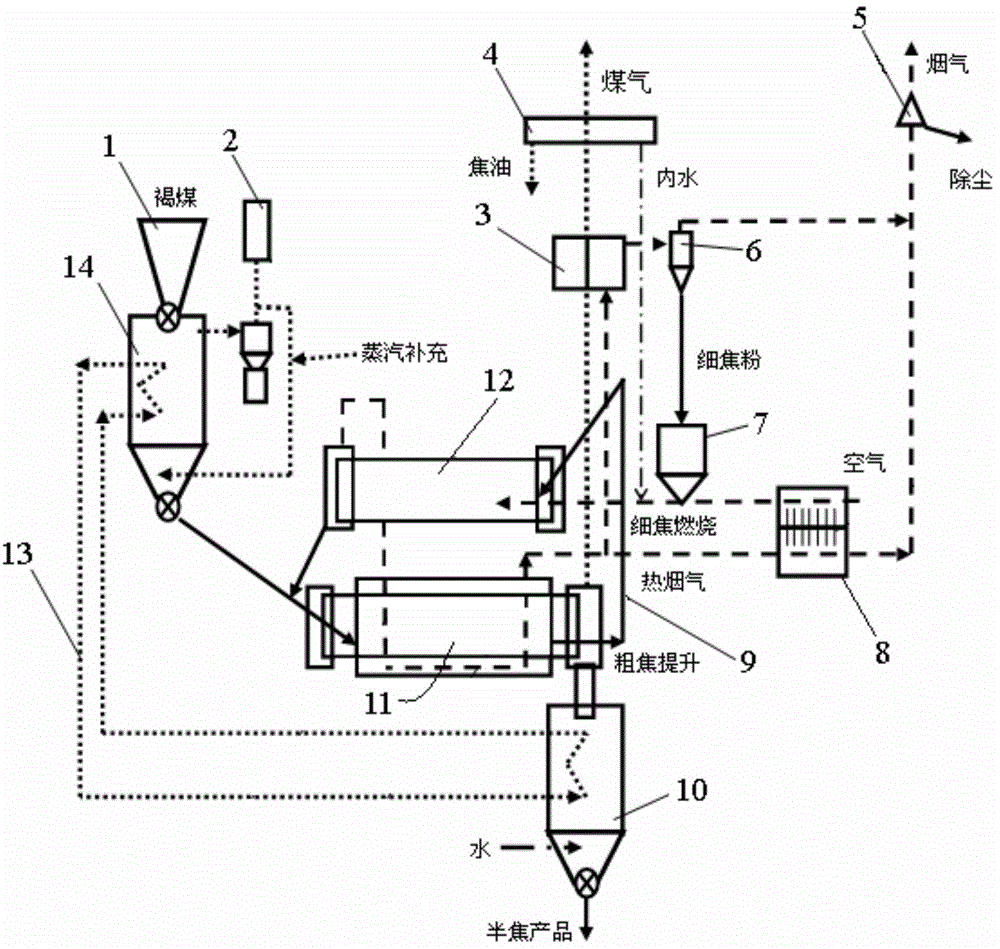

Destructive distillation method and device for brown coal

InactiveCN103980912ANon-flammableImprove drying efficiencyCoke quenchingChemical industryBrown coalCoke oven

The invention relates to a destructive distillation method and device for brown coal. The destructive distillation method for brown coal comprises the following steps: fluidizing, drying and heating raw coal by circular steam; indirectly heating the preheated and dried raw coal by hot smoke and directly heating the preheated and dried raw coal by a hot carrier; taking one part of coal after destructive distillation as a semicoke product while the other part as circulating semicoke; sieving the circulating semicoke into coarse and fine cokes; heating the coarse semicoke by combusting the fine coke powder, and taking the heated coarse coke as the hot carrier, wherein the hot smoke required by destructive distillation of coal is from smoke generated by combusting fuel; and generating steam for drying the raw coal when semicoke is cooled. The device comprises a drying furnace, a destructive distillation furnace combining external heat with the hot carrier, a coal gas dedusting device of a coke oven, a semicoke cooling and lifting device and the like. The destructive distillation method for brown coal provided by the invention transfers heat comprehensively, and the energy consumption of brown coal for destructive distillation and pyrolysis is less, the content of coal gas dust is low, the heat efficiency is high and the ash content of coke powder is low.

Owner:CHANGAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com