Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3852results about How to "Improve dust removal efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

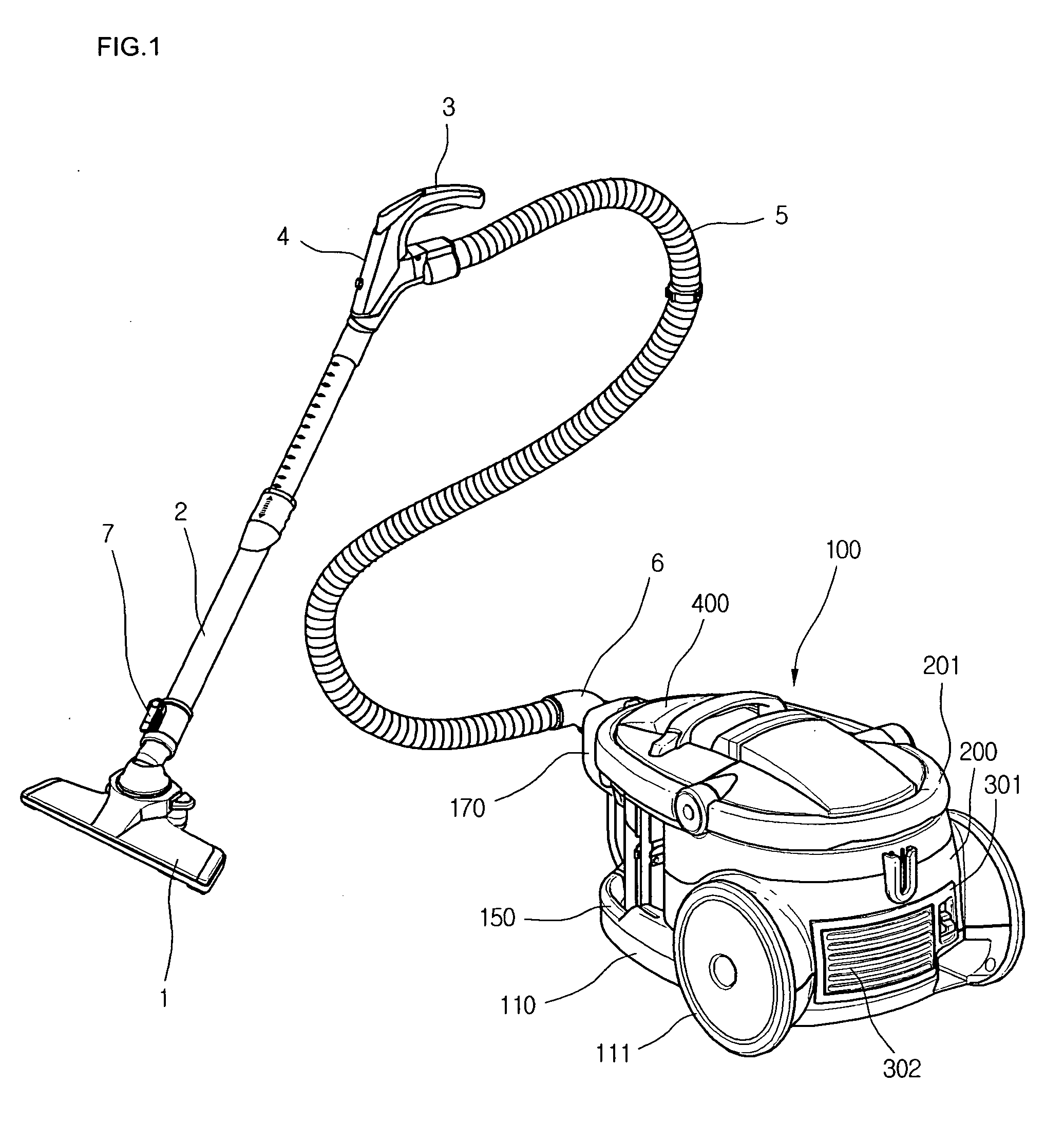

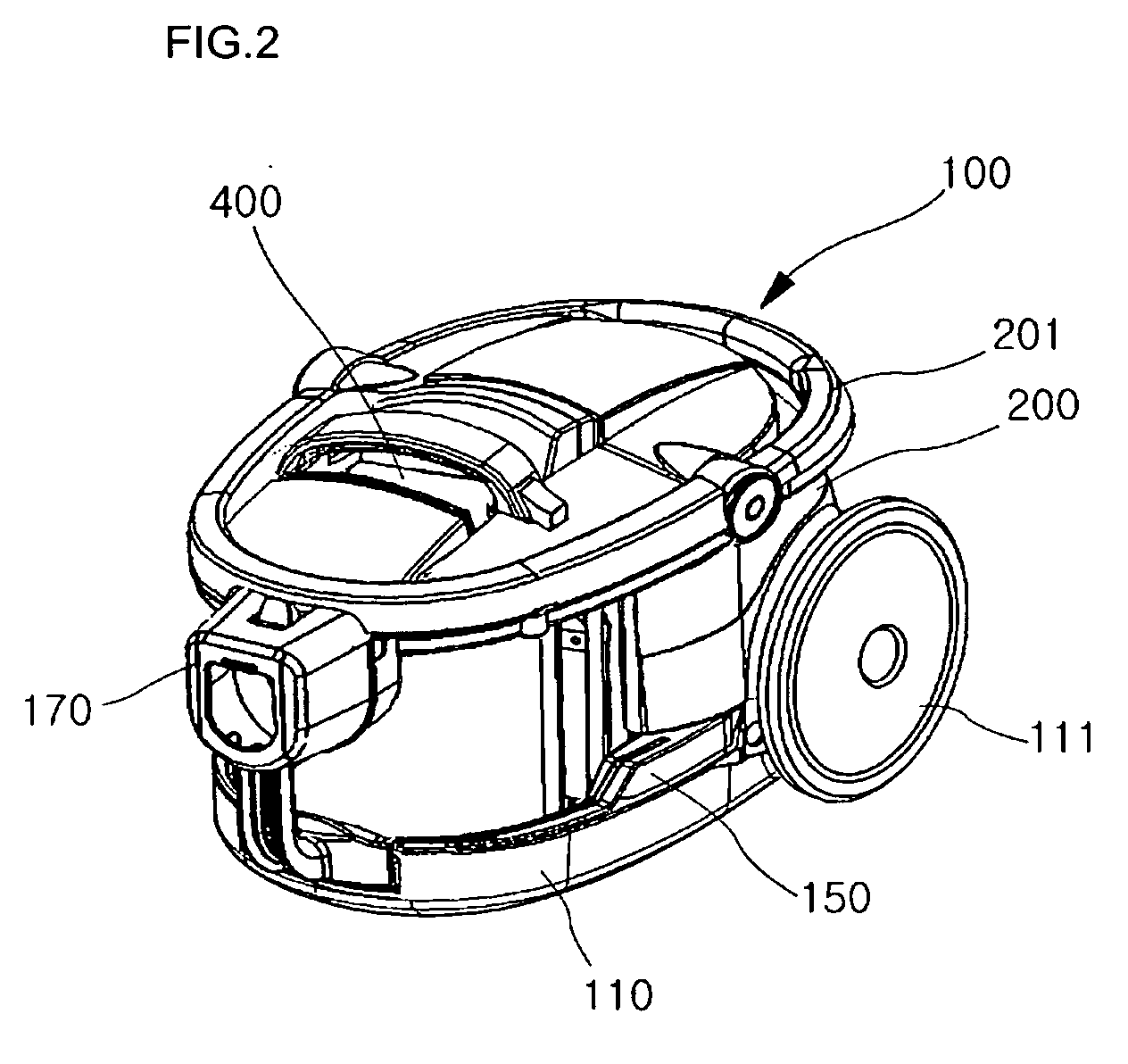

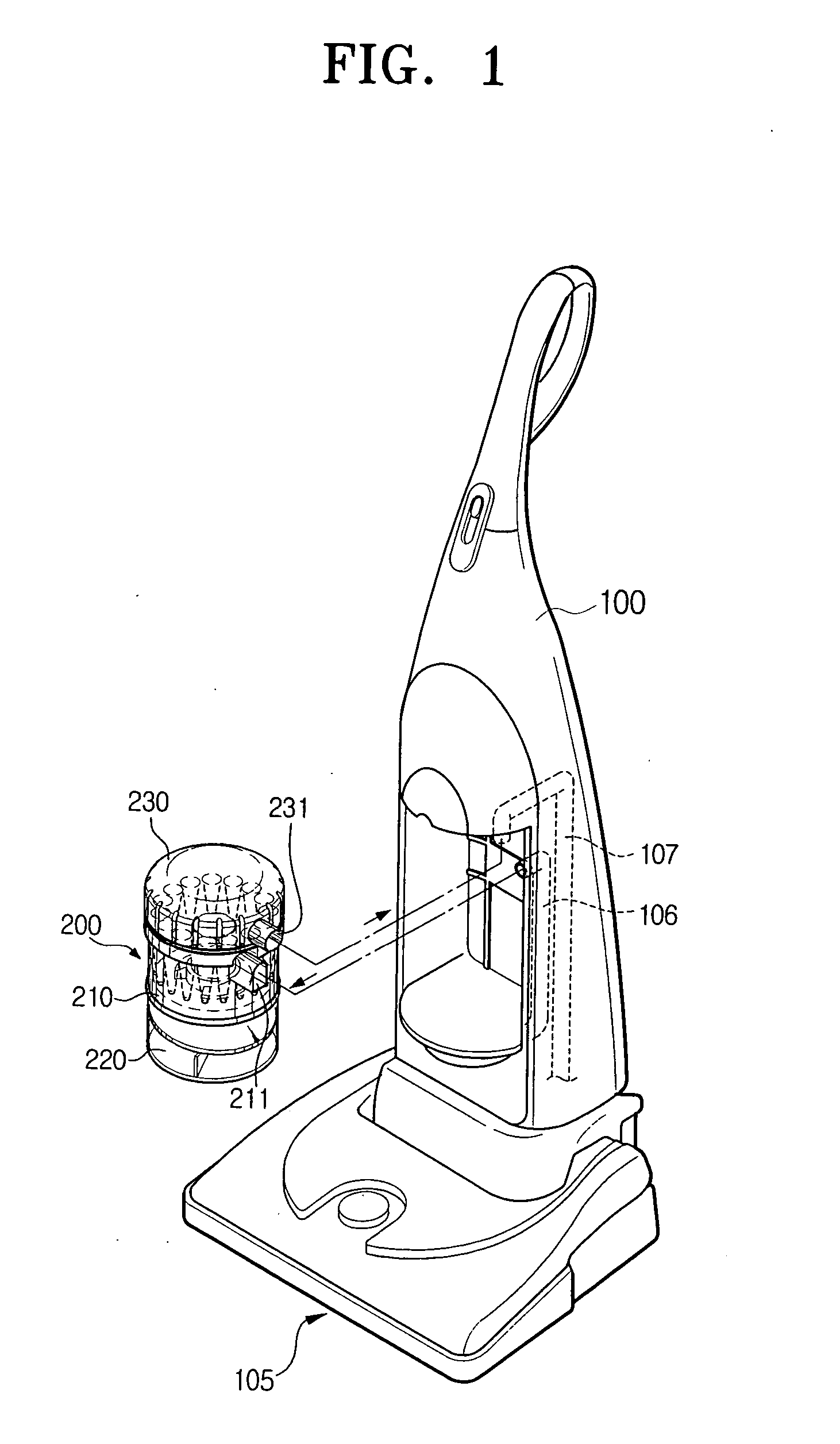

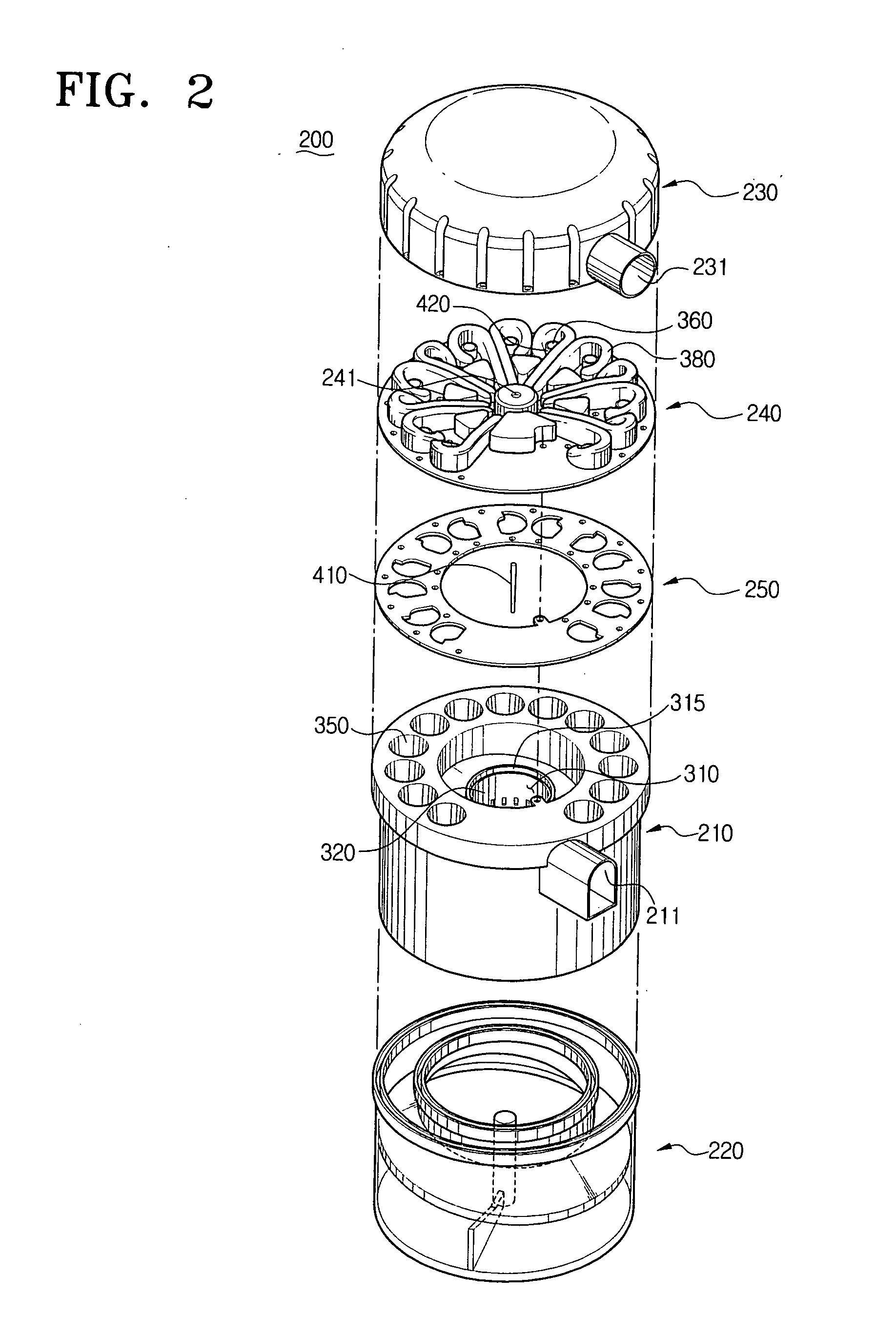

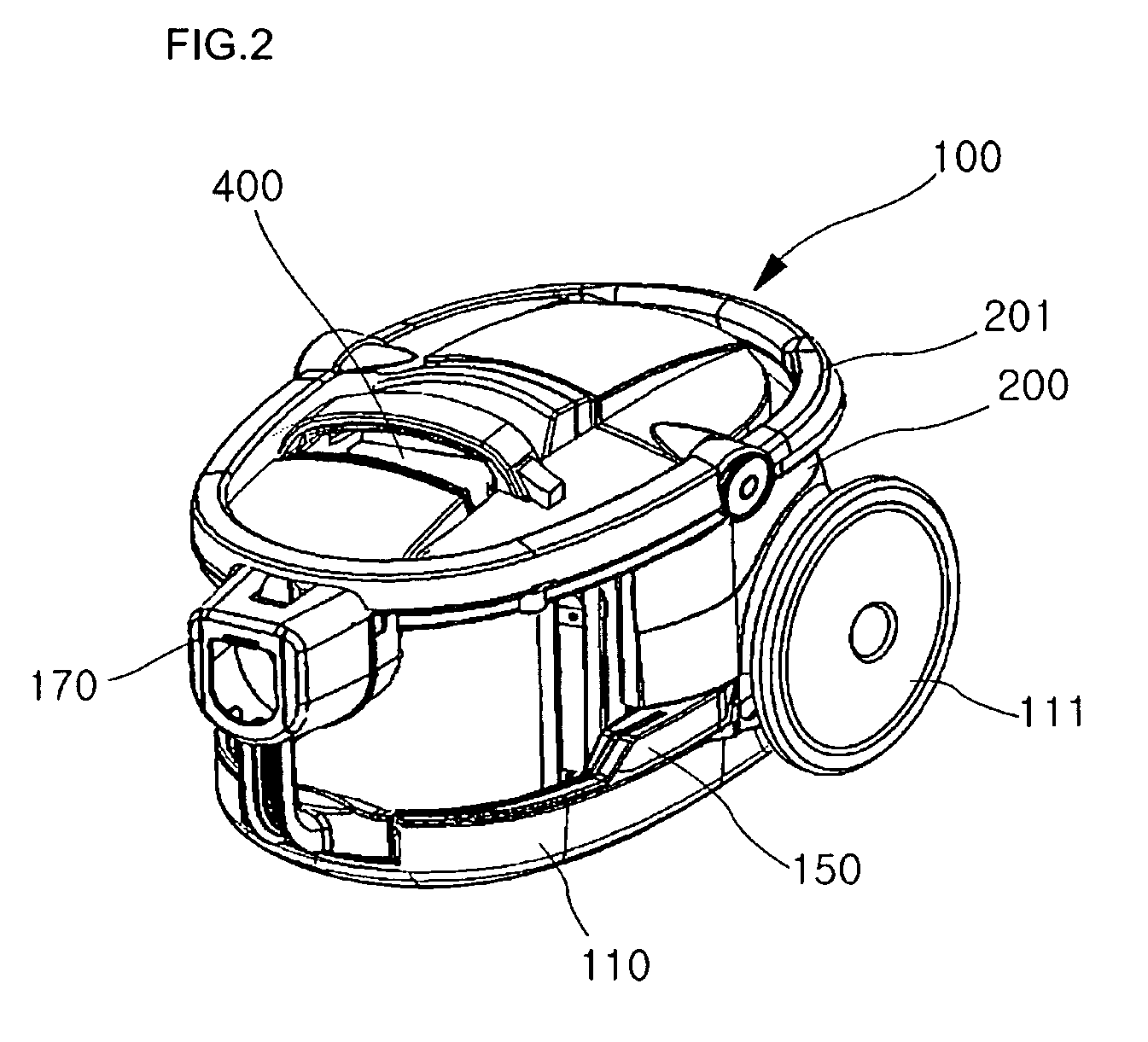

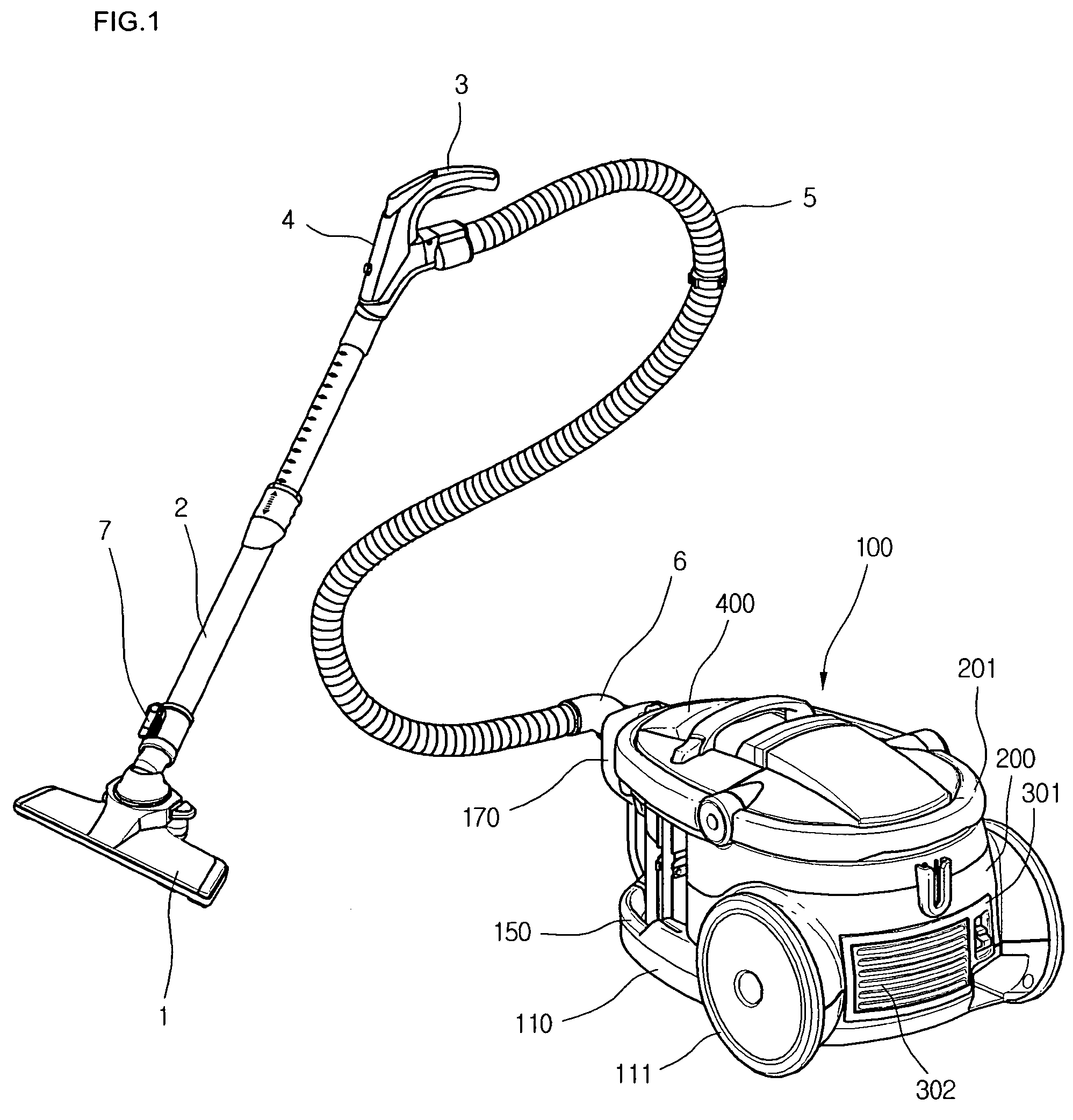

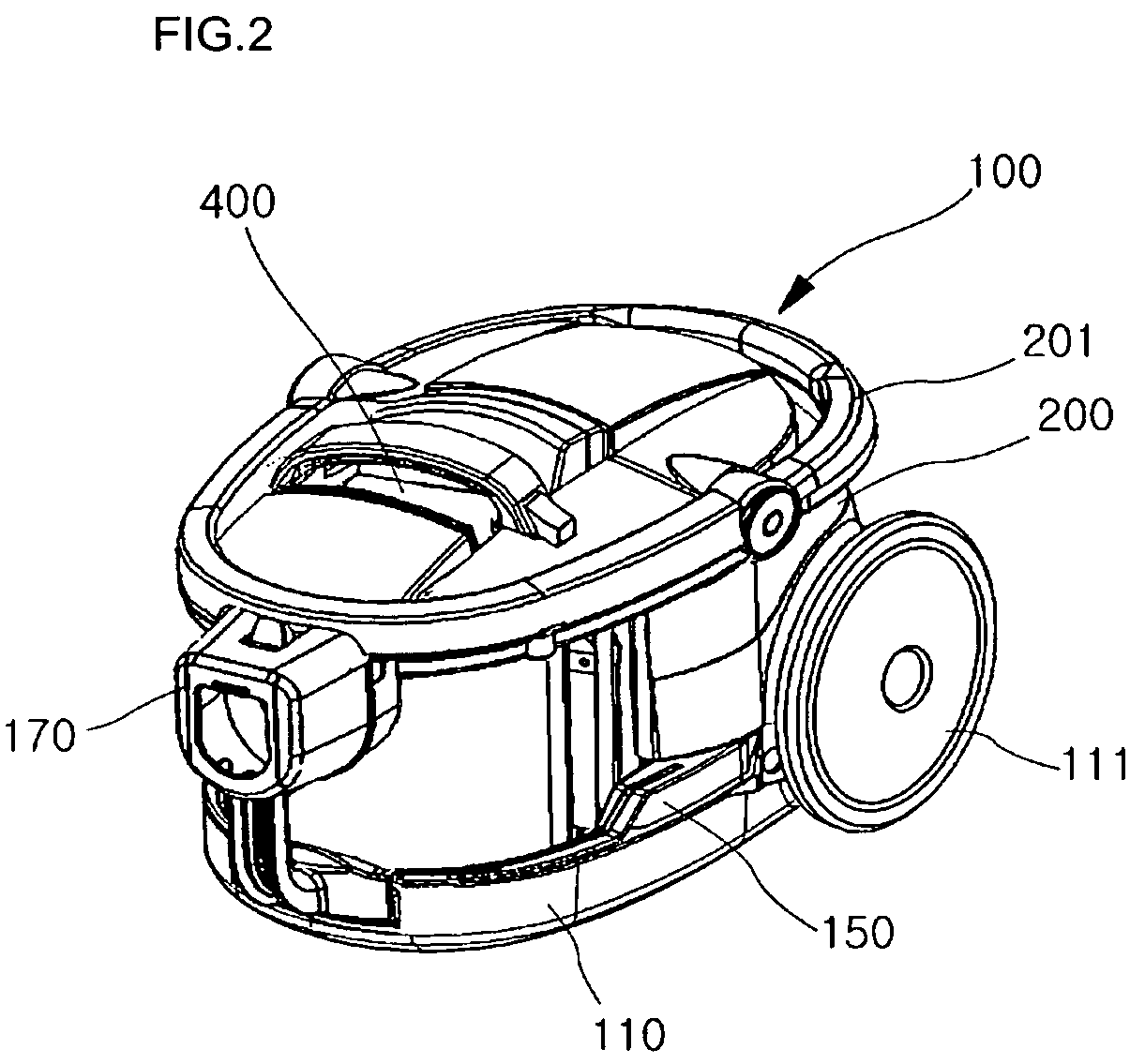

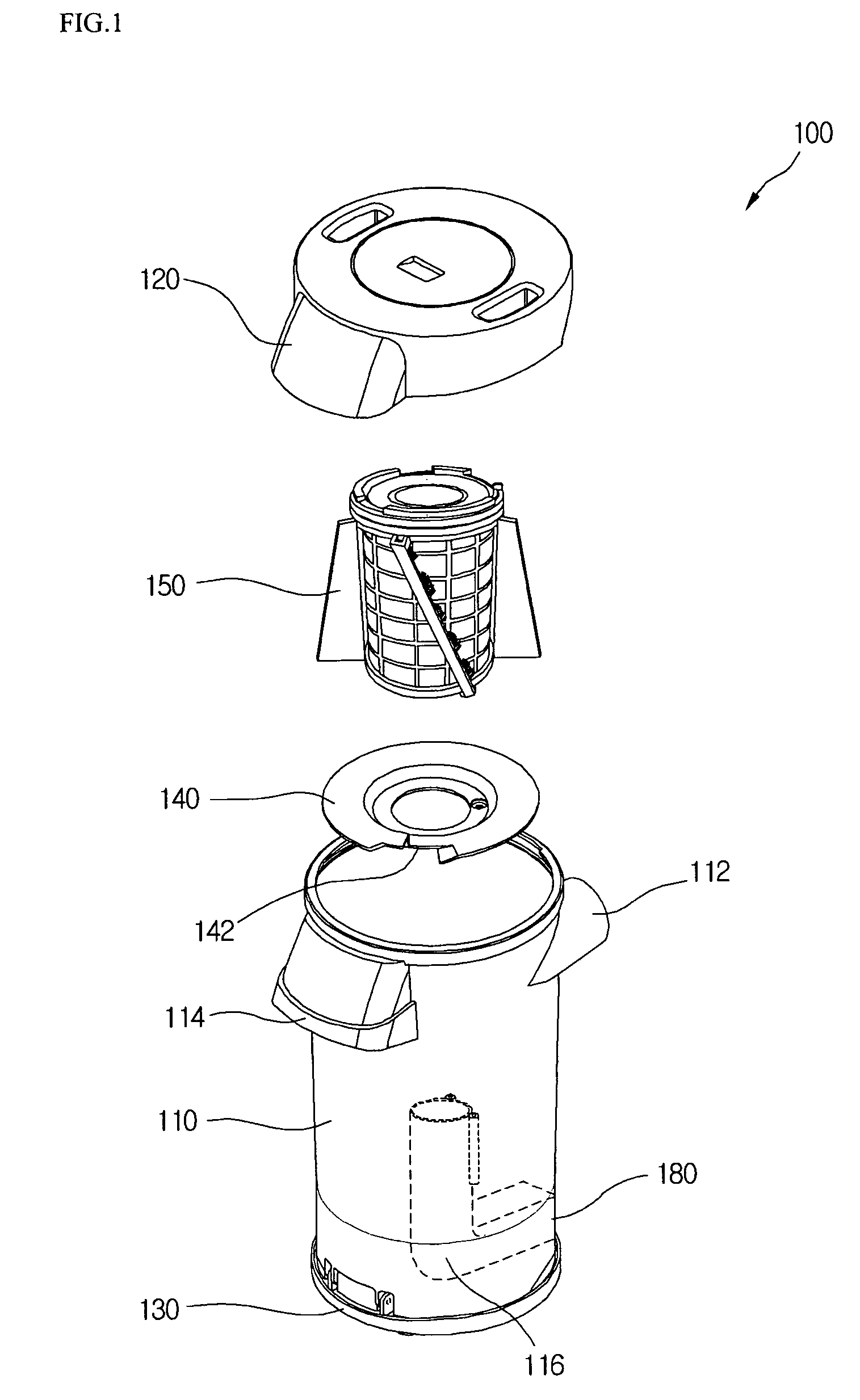

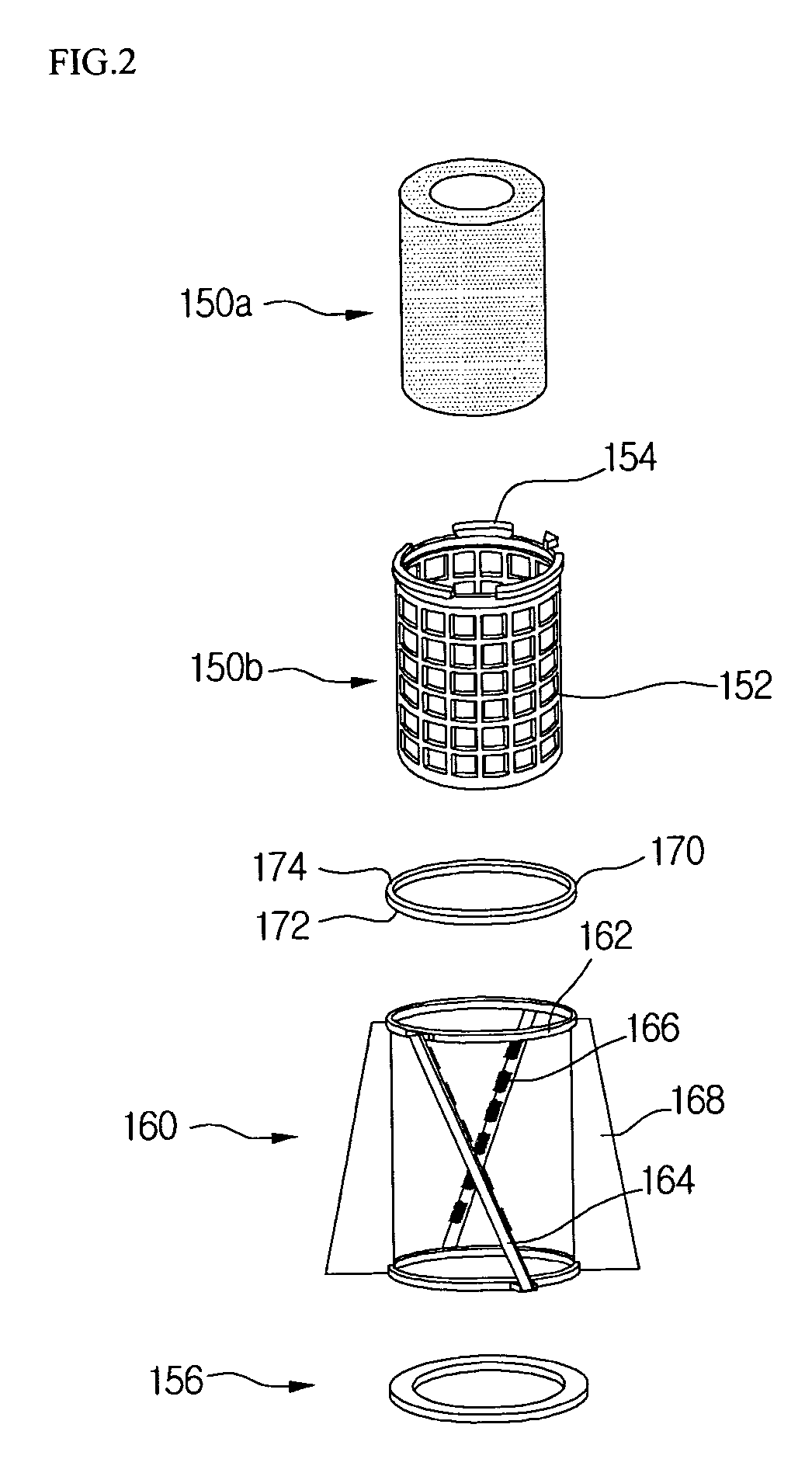

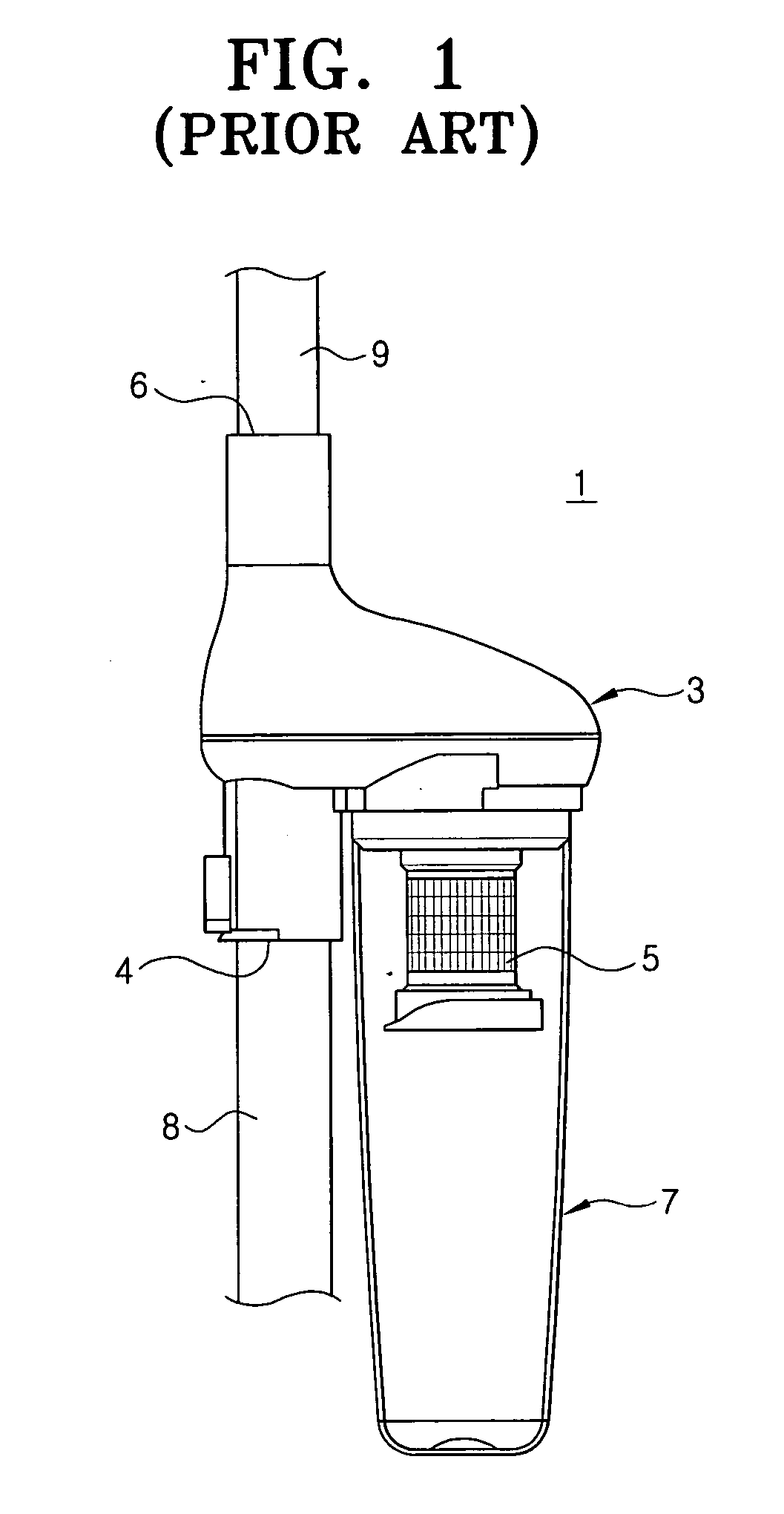

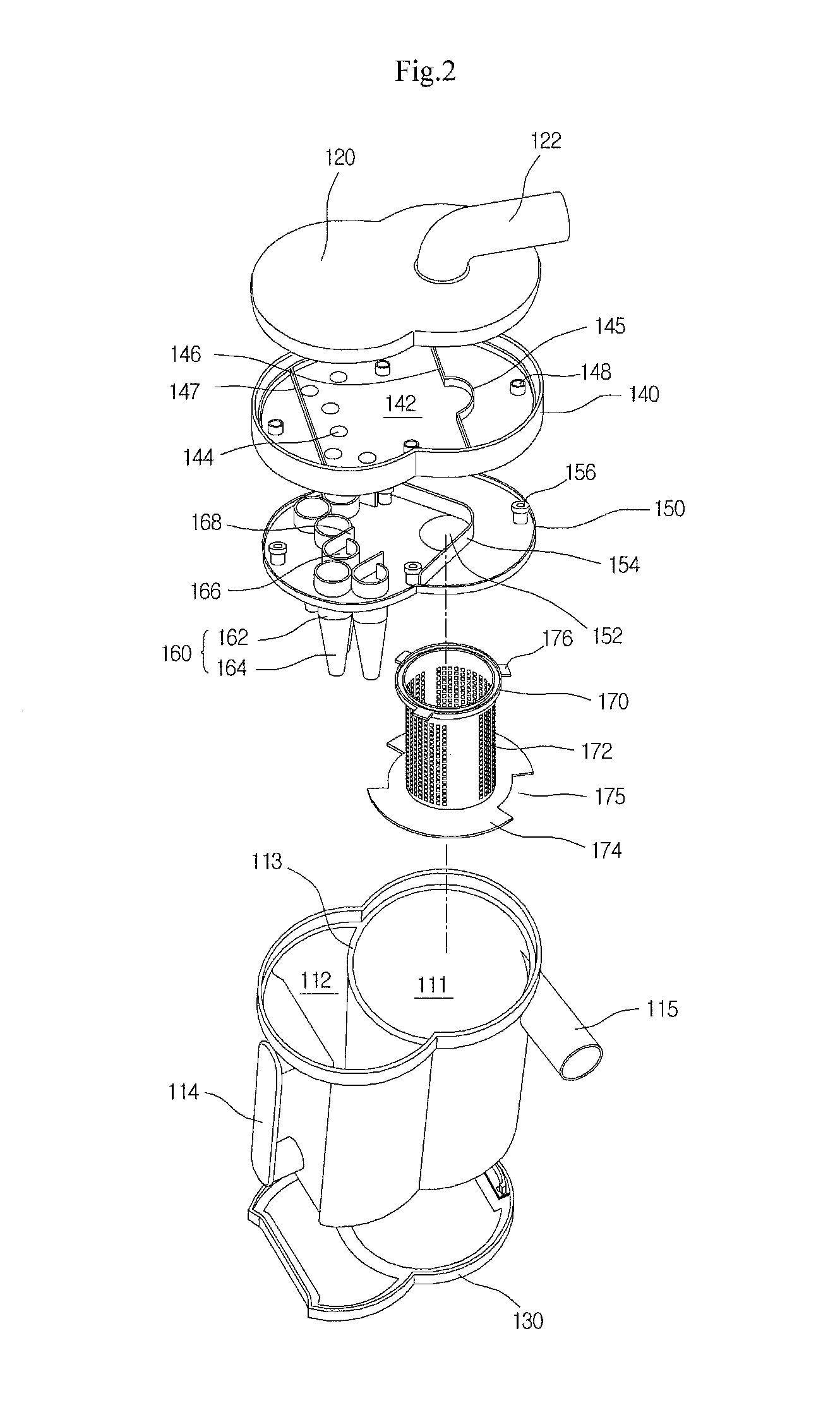

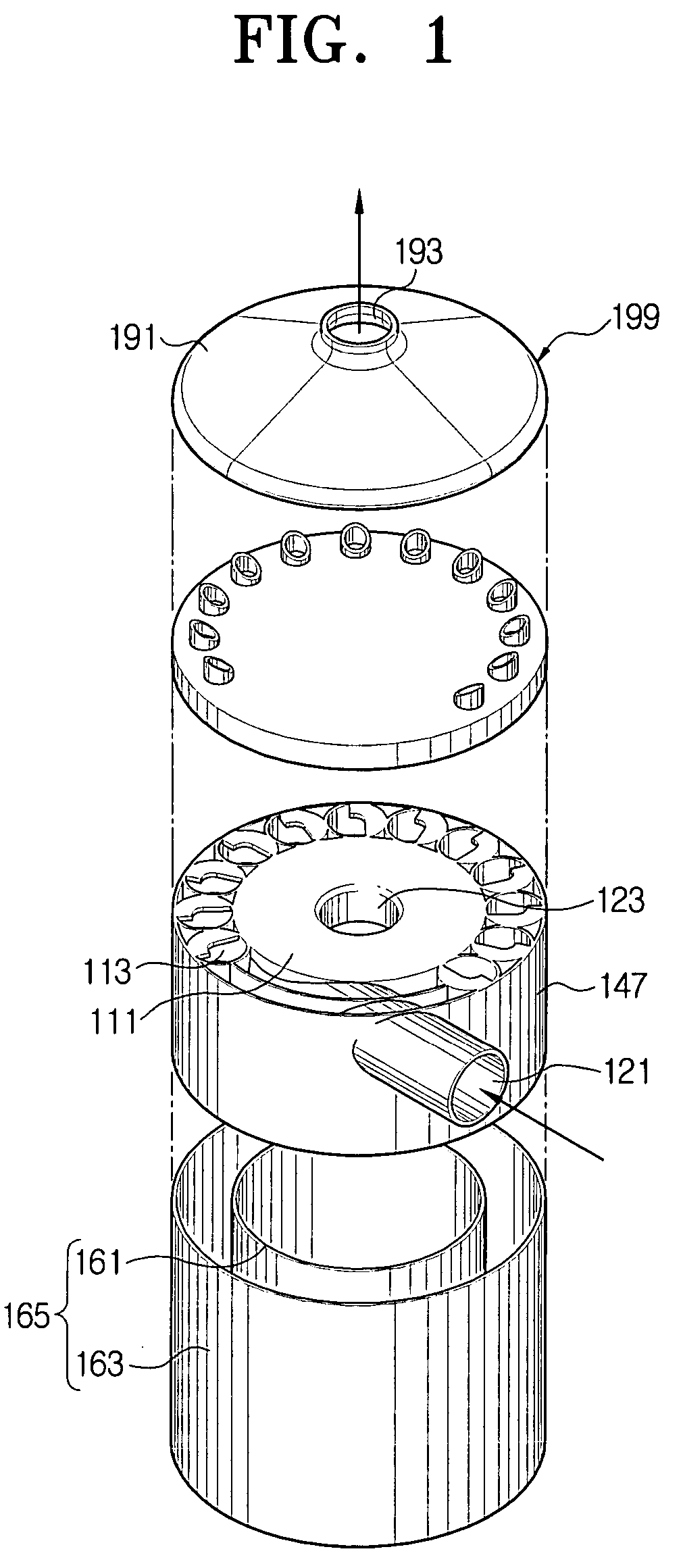

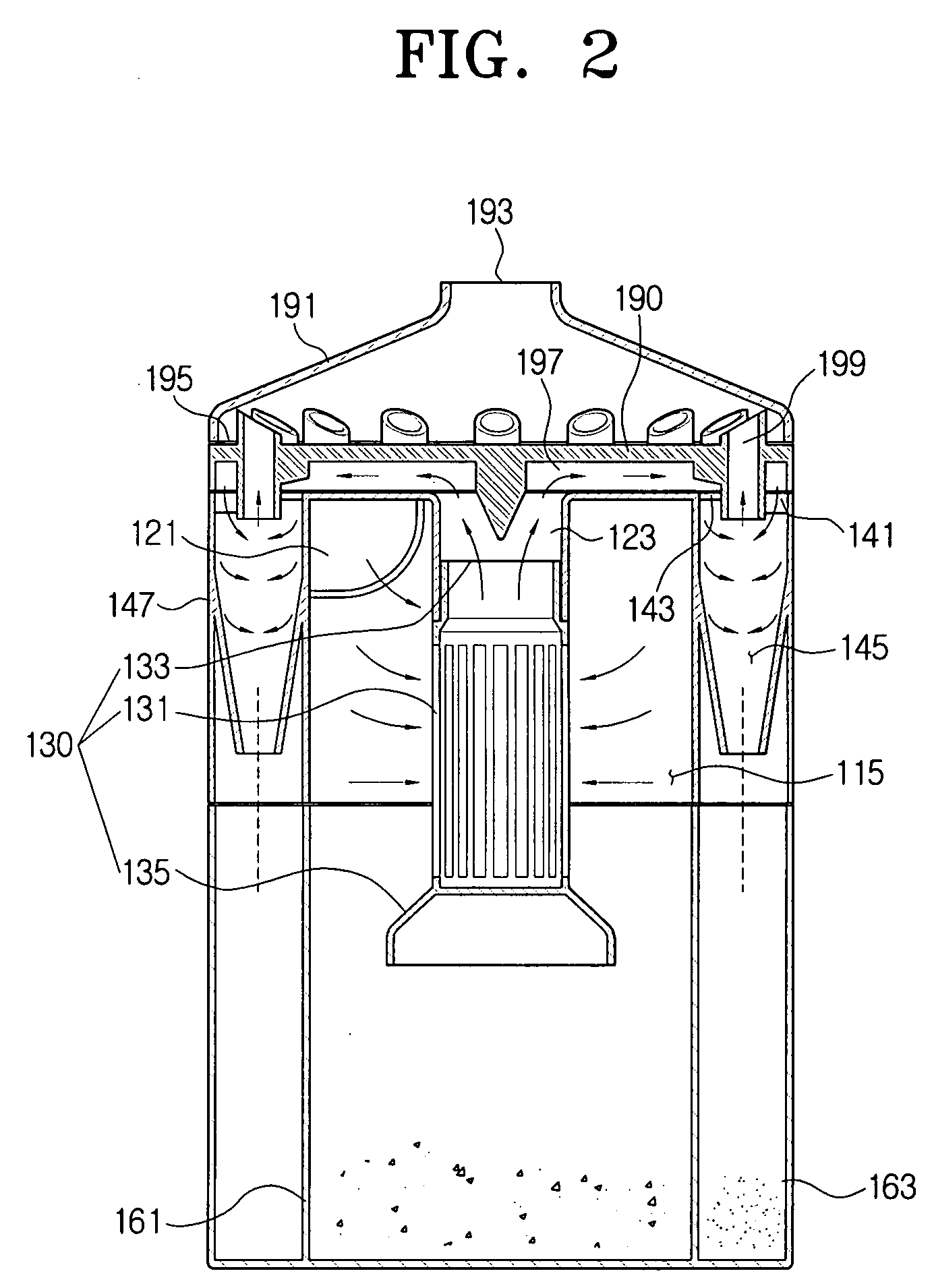

Dust collection unit and vacuum cleaner with the same

ActiveUS20060137309A1Improve foreign object removal efficiencyEasy to disassembleCombination devicesAuxillary pretreatmentForeign matterForeign object

A dust collection unit for a vacuum cleaner includes a first filtering chamber filtering foreign objects using a cyclone airflow, a separation plate defining a top surface of the first filtering chamber, a filter having a diameter that is reduced as it goes downward in response to airflow rate variation in the first filtering chamber, and a blocking member provided under the filter to prevent the foreign objects filtered in the first filtering chamber from flying.

Owner:LG ELECTRONICS INC

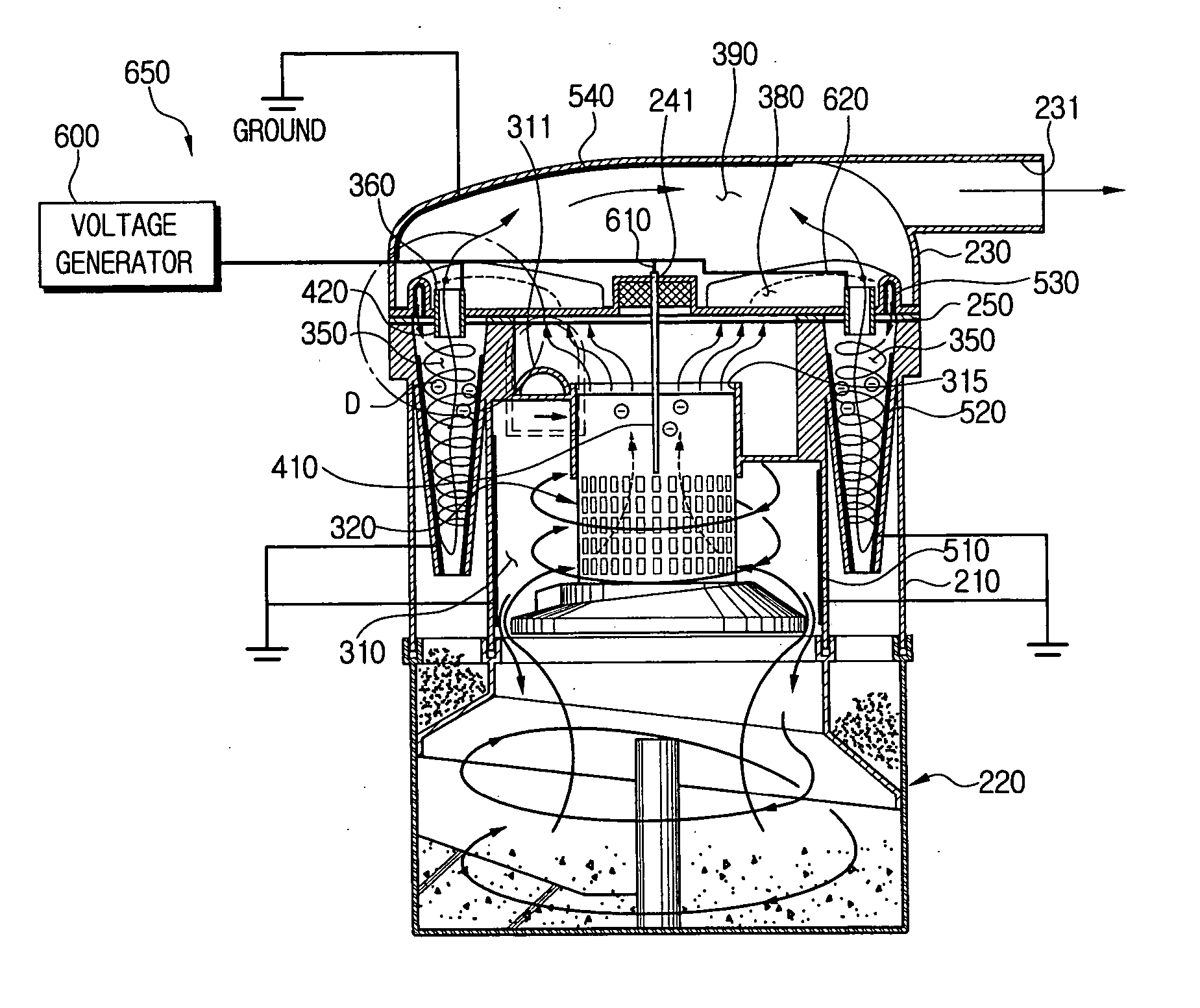

Cyclone dust collecting device for vacuum cleaner

InactiveUS20060278081A1Separation efficiency can be improvedIncreased durabilityCleaning filter meansSuction filtersCorona dischargeConductive materials

A cyclone dust collecting device using a corona discharge is provided. The cyclone dust collecting device includes a cyclone chamber rotating air drawn in from the outside to separate contaminants from the air, a discharge pipe guiding the air separated from the contaminants to the outside of the cyclone chamber and including a discharge electrode part with at least a part made of a conductive material and a power supply unit supplying a power to the discharge electrode part for the discharge electrode part to perform a corona discharge.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

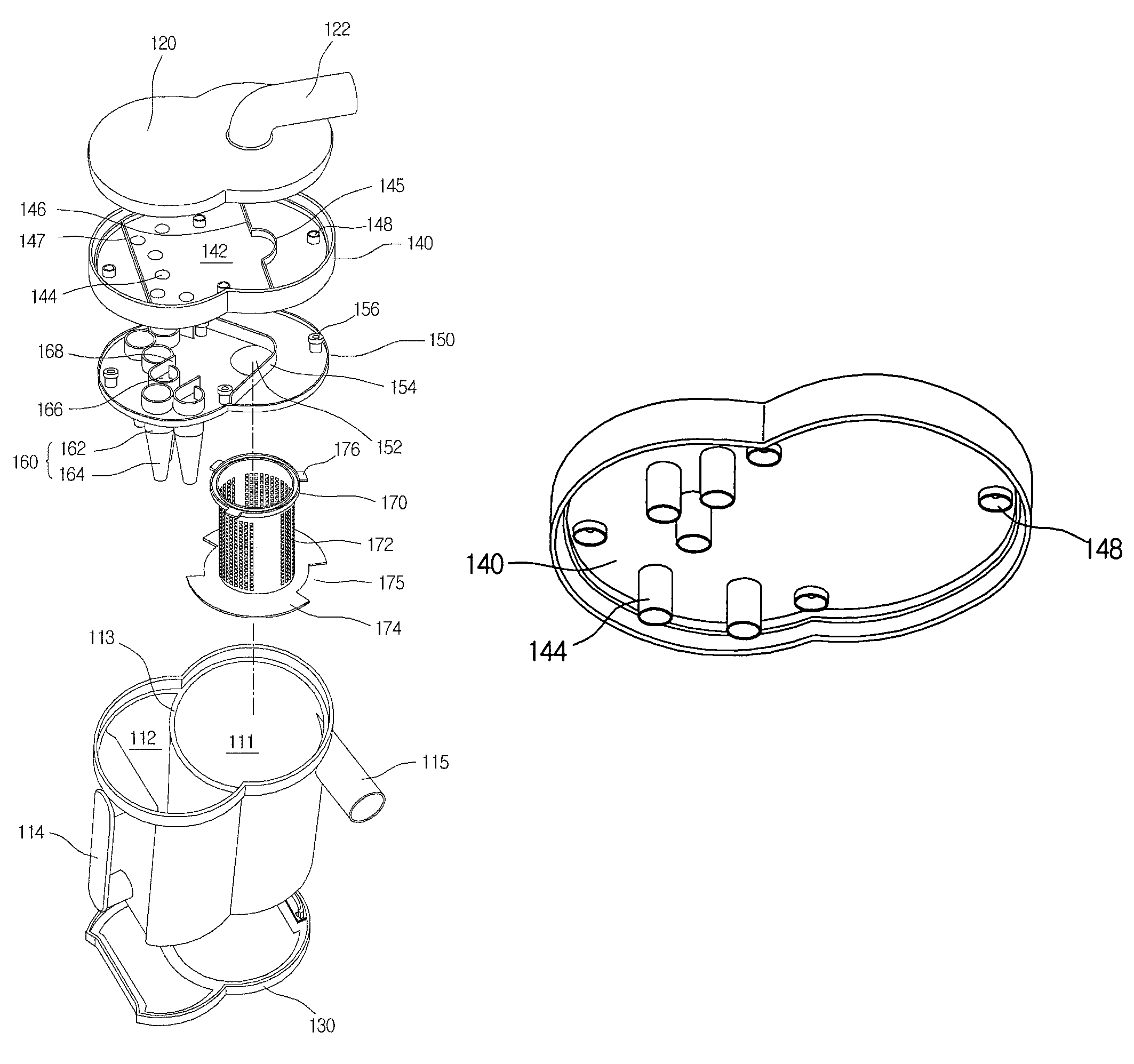

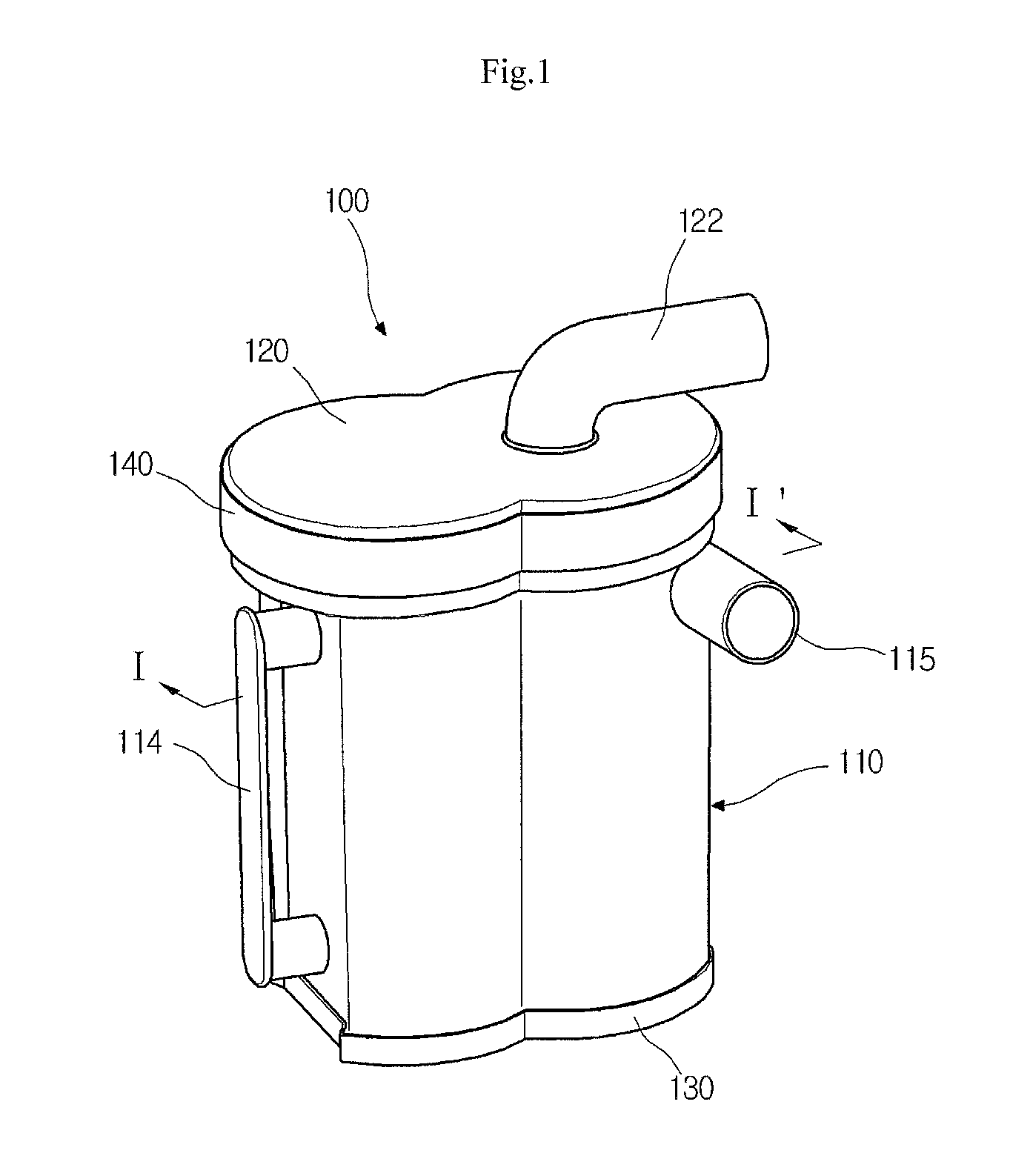

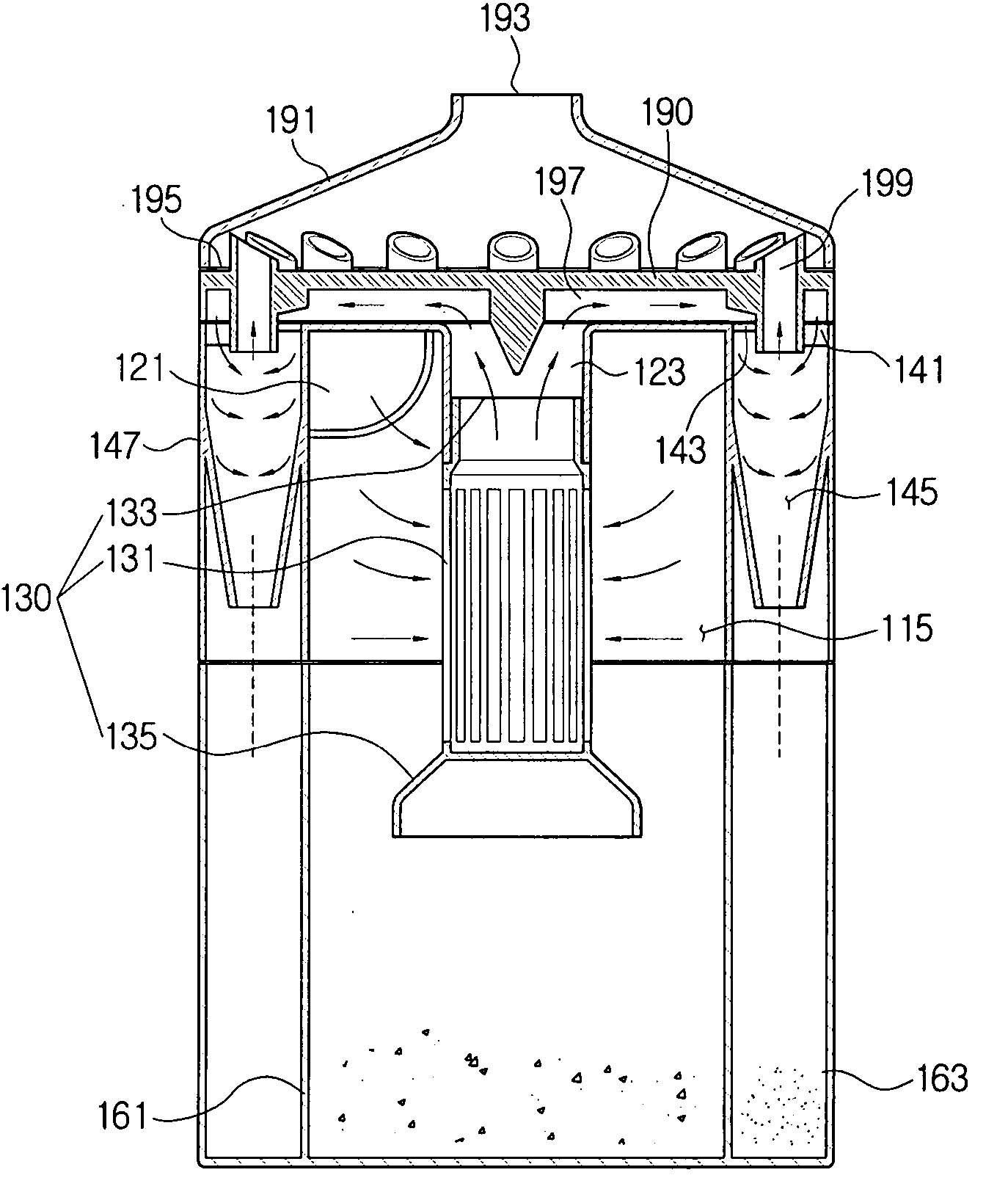

Dust collection unit for vacuum cleaner

InactiveUS7485164B2Easy to assembleImproved in strength and enduranceCombination devicesDispersed particle filtrationVacuum cleanerWaste management

A dust collection unit for a vacuum cleaner includes a collection body having a plurality of filtering chambers different from each in a volume and a plurality of storing chambers storing foreign objects filtered in the filtering chambers, a bottom seal member defining a bottom of the collection body, and an exhaust member guiding airflow in the filtering chambers. The exhaust member contacts tops of the filtering chambers as well as an outer circumference of the collection body.

Owner:LG ELECTRONICS INC

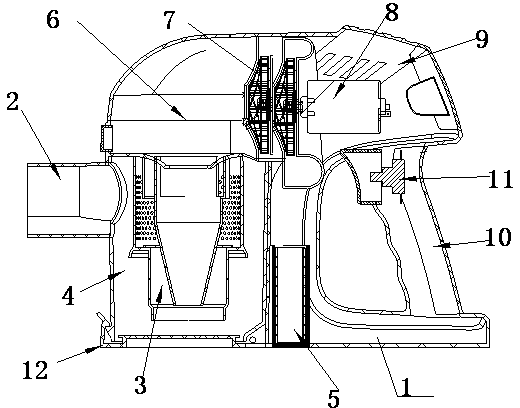

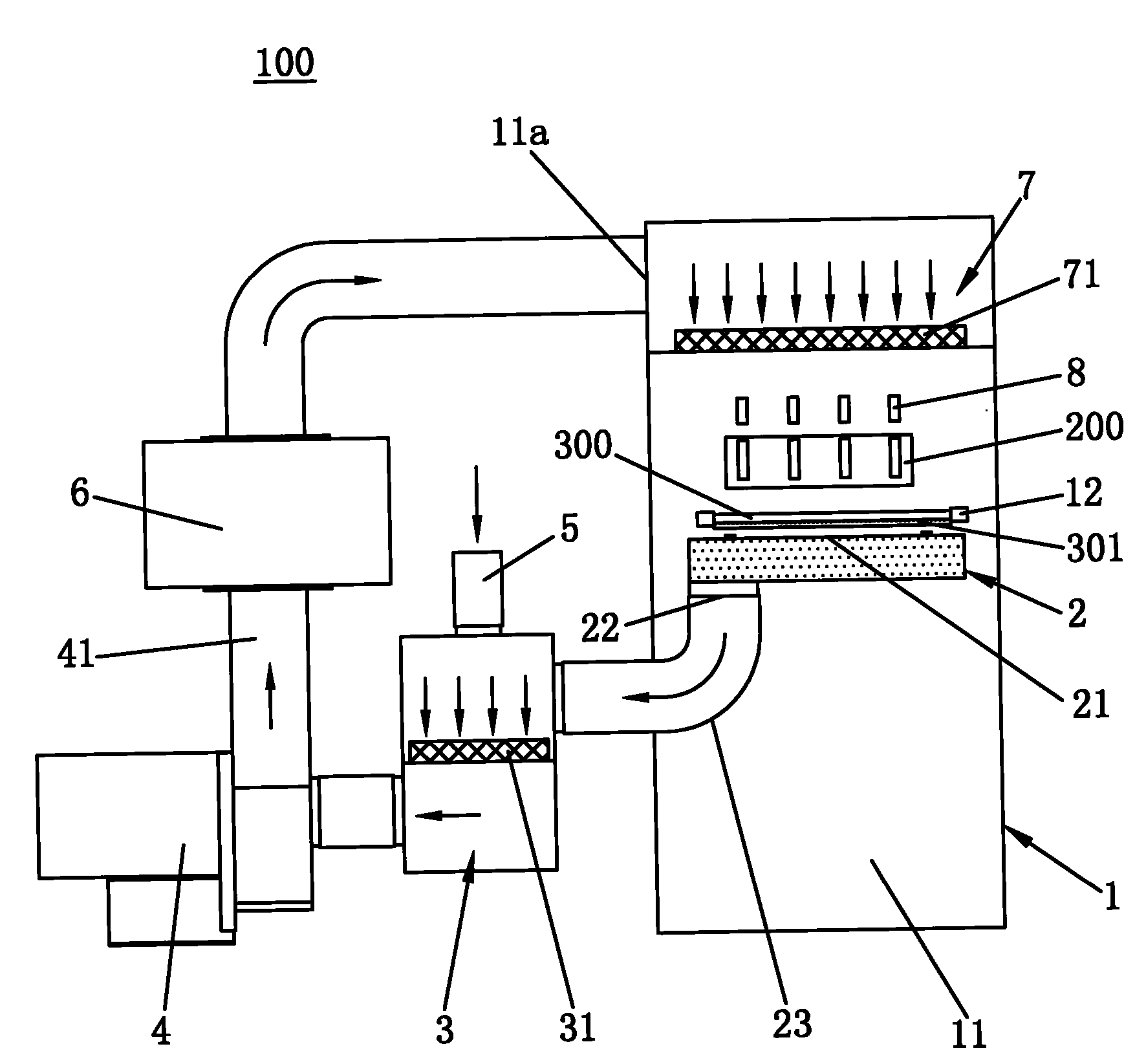

Handheld cleaning equipment

InactiveCN104172986AIncrease vacuumImprove dust removal efficiencySuction filtersHand heldWorking temperature

The invention discloses handheld cleaning equipment. The handheld cleaning equipment comprises an outer casing, a suction pipeline, a separation device, a dust cylinder, a power source, a filtering device, an airflow generator, a motor, an air outlet, a handle and a switch; the rear end of the outer casing is provided with the handle; the center at the front end of the outer casing is provided with the suction pipeline; the separation device is arranged behind the suction pipeline; the dust cylinder is arranged below the separation device; the filtering device is arranged above the separation device; the rear end of the filtering device is provided with the airflow generator; the rear end of the airflow generator is provided with the motor coaxially; the rear end of the motor is provided with the air outlet; the power source is arranged between the handle and the dust cylinder; the handle is provided with the switch. The handheld cleaning equipment has the advantages of being high in reliability, compact in structure, small and exquisite in size, strong in suction, good in filtering performance, low in working temperature, light in weight and convenient to use and having a wide market prospect in a dust collector market.

Owner:SUZHOU CLEANPLUS ELECTRIC APPLIANCE

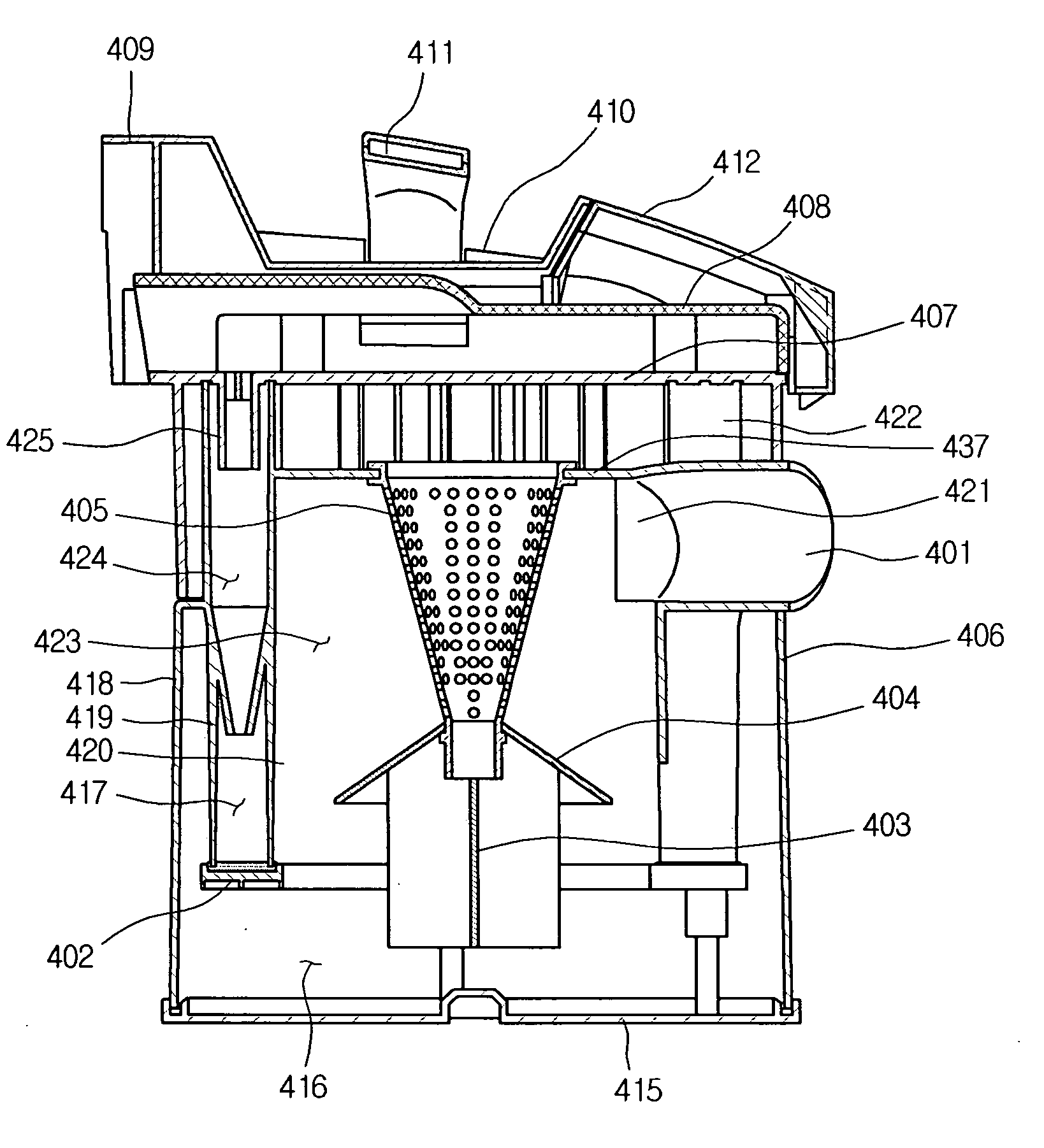

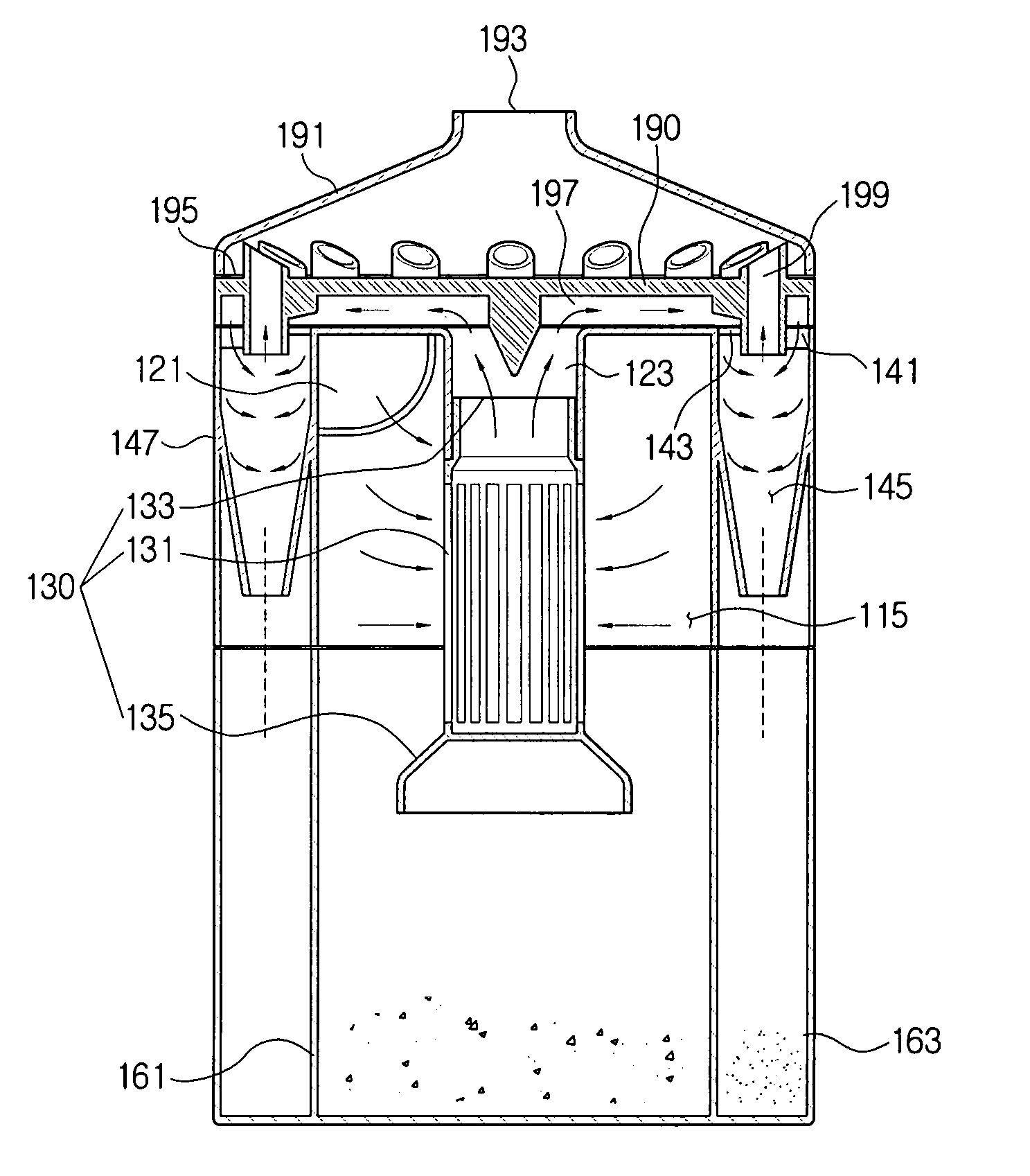

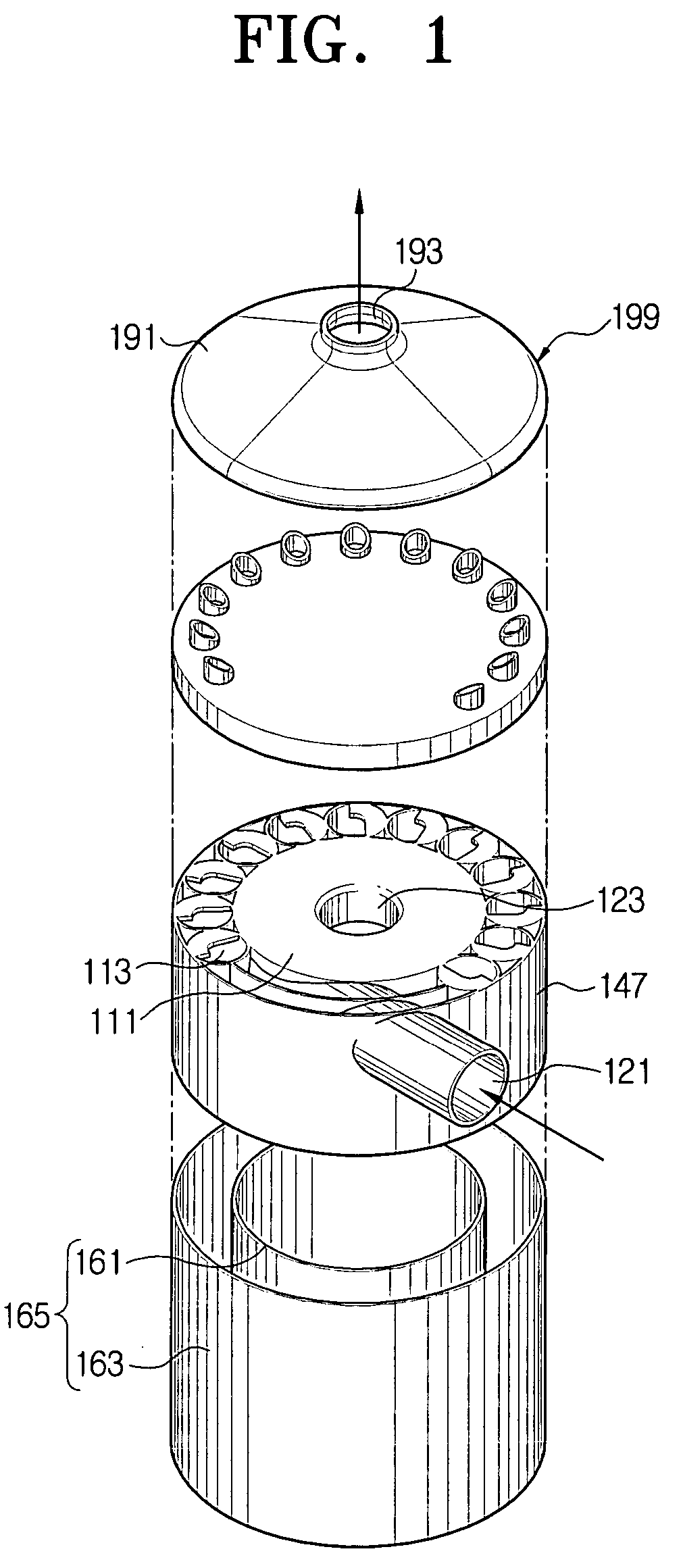

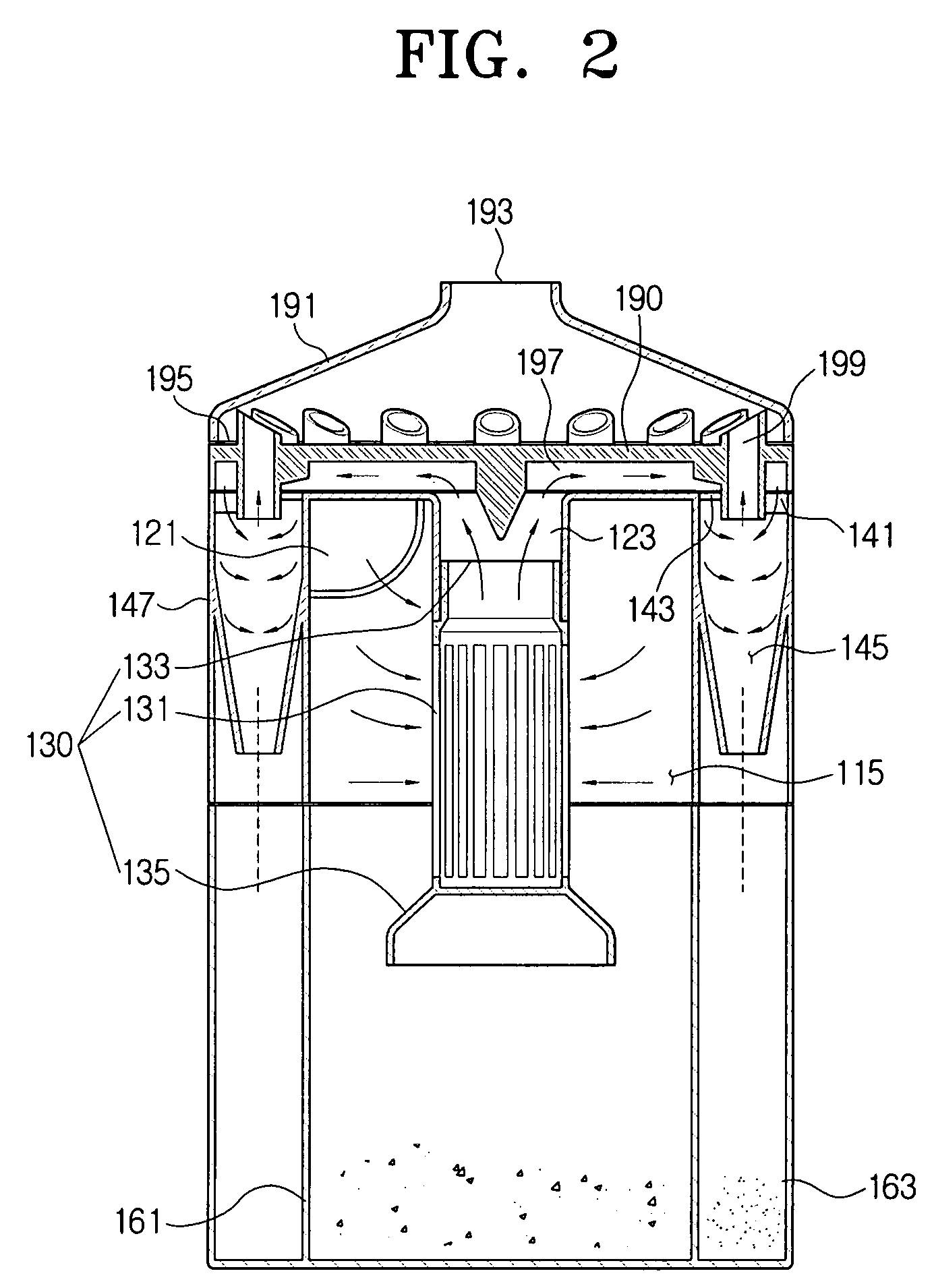

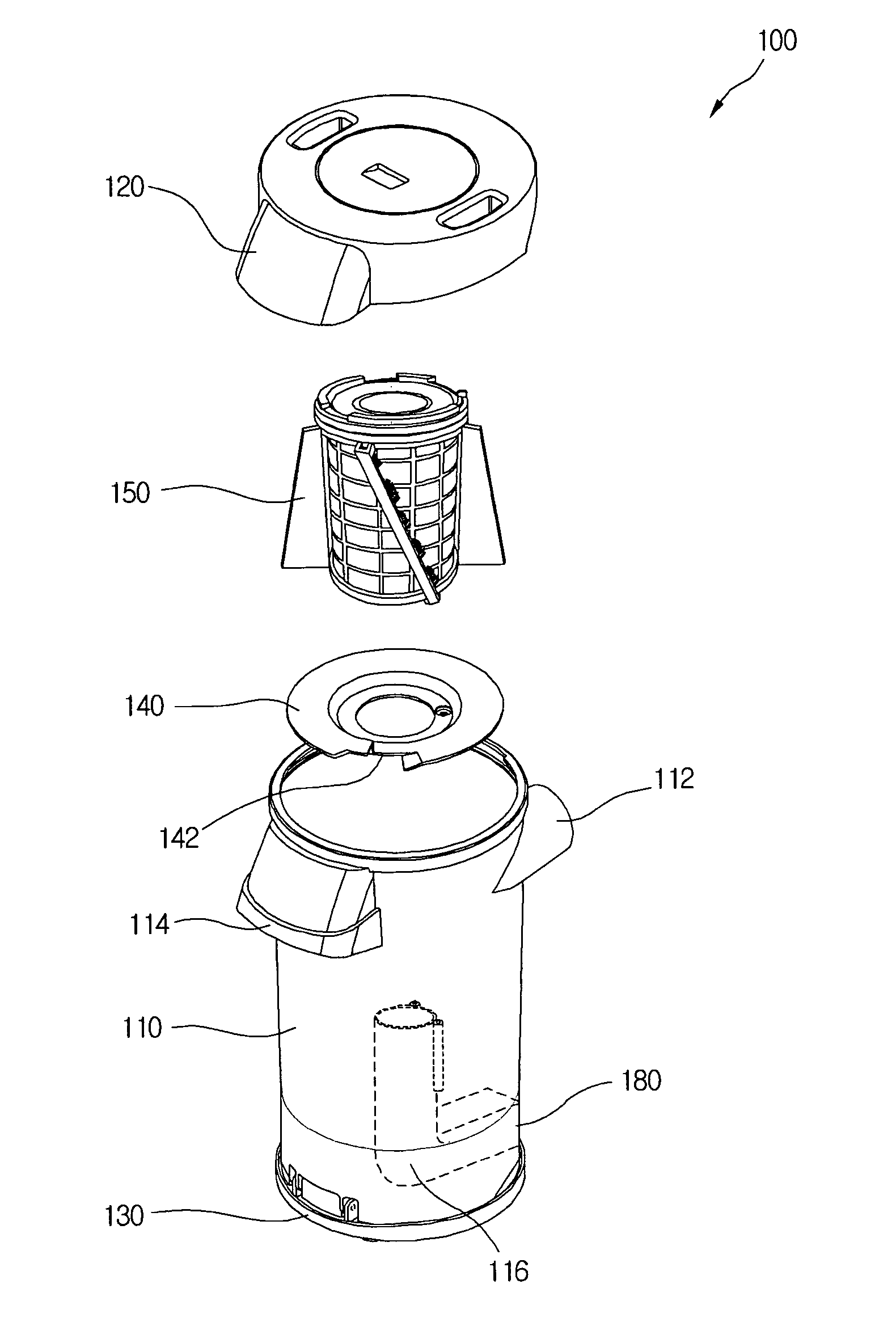

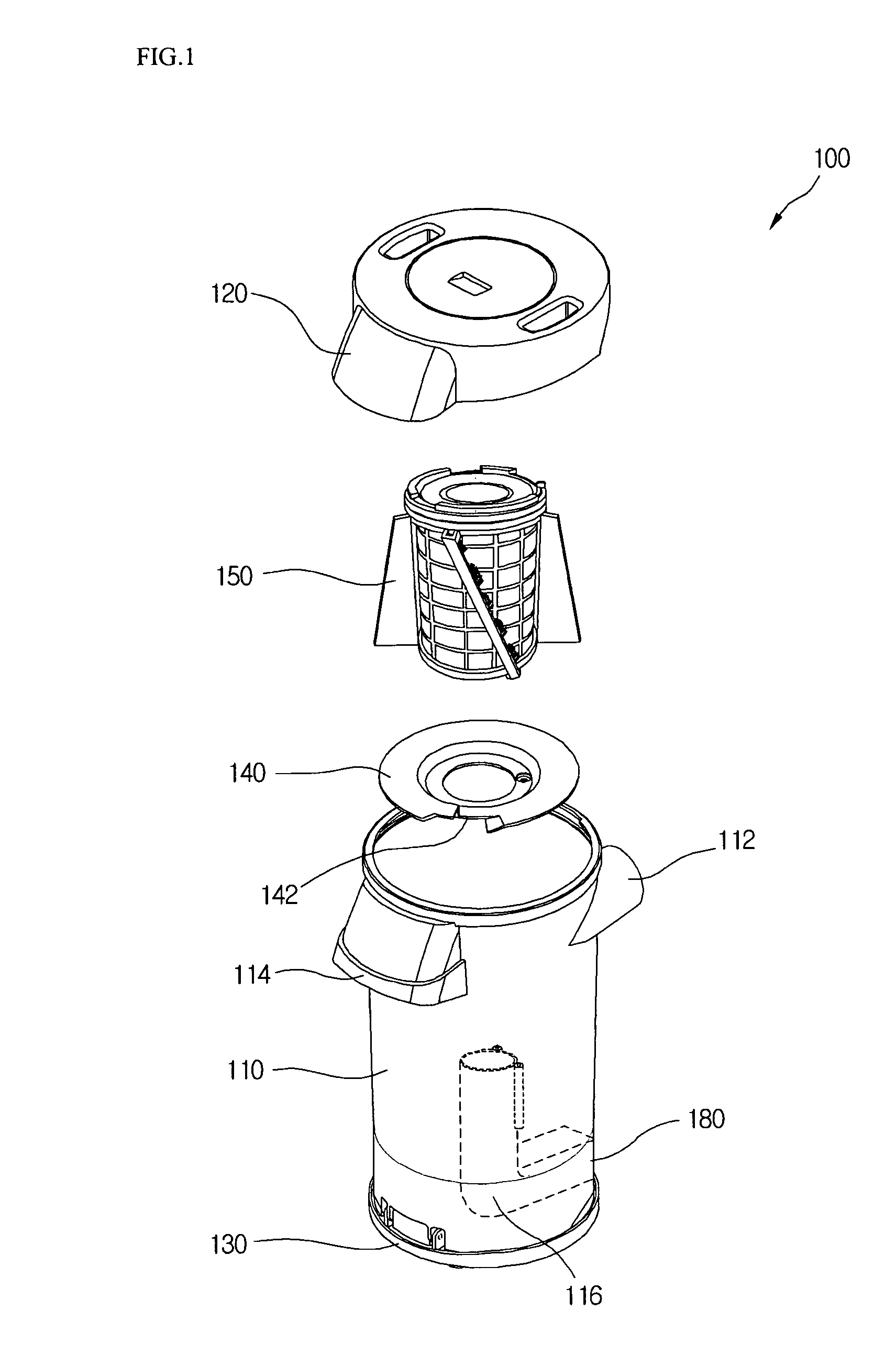

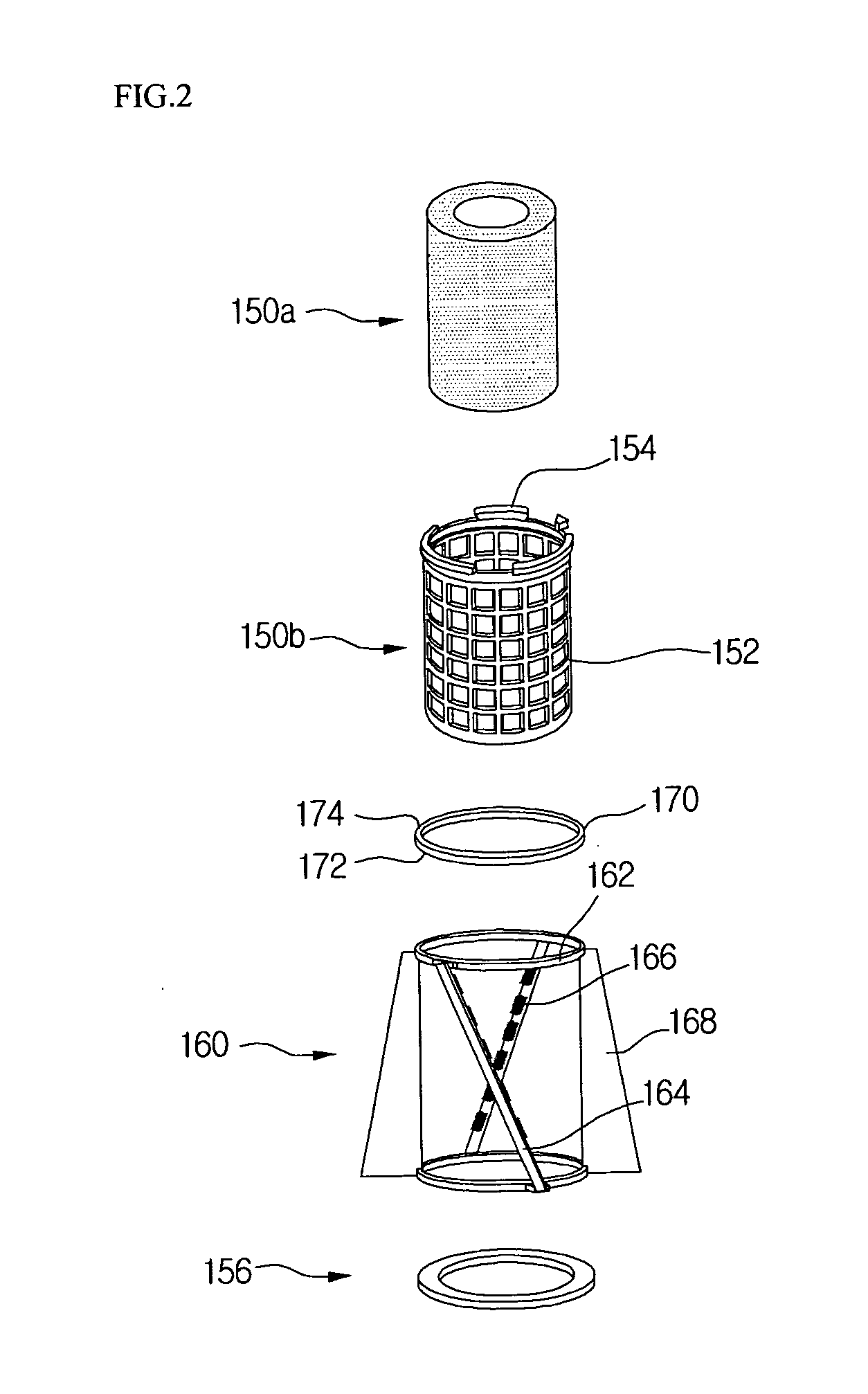

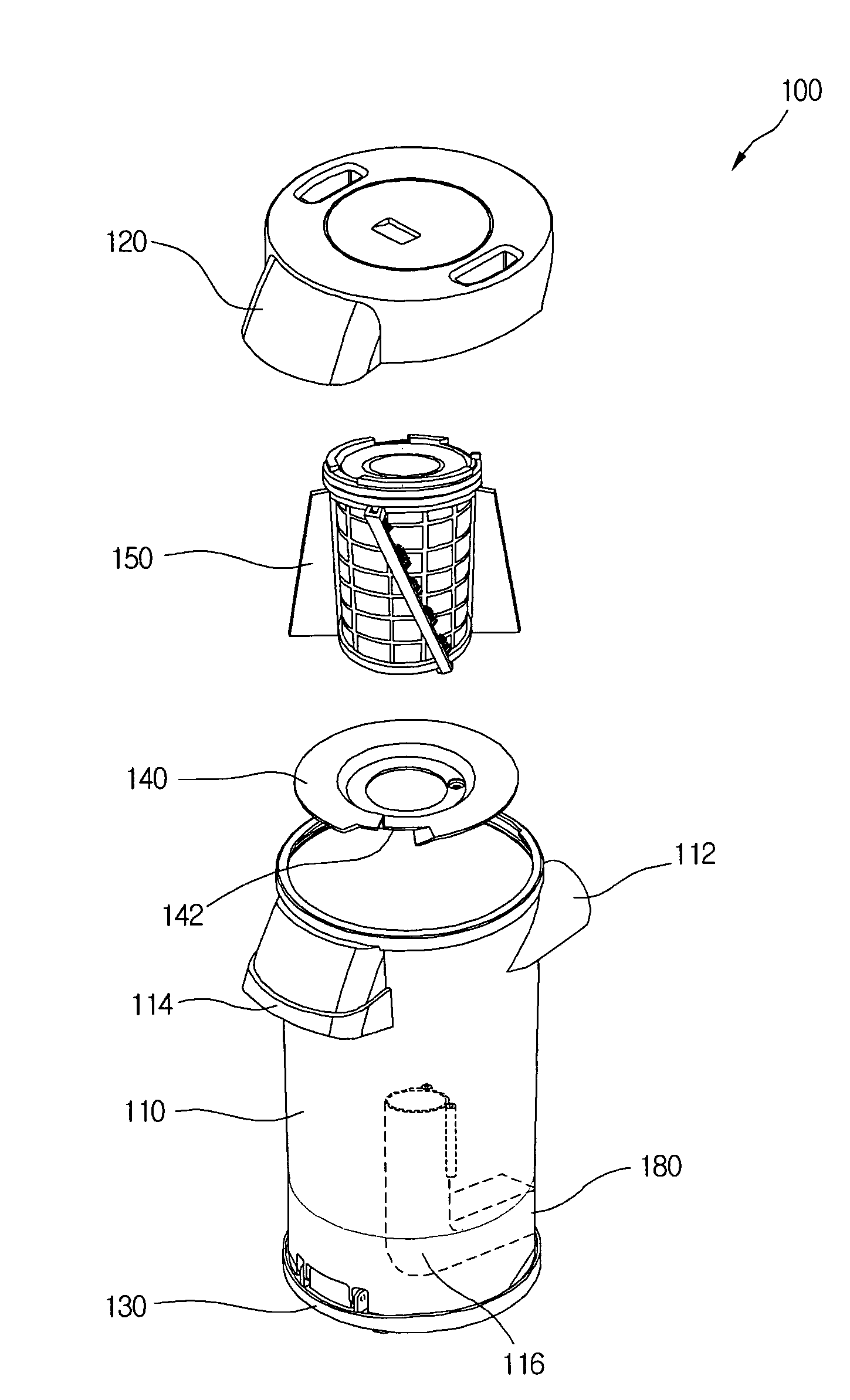

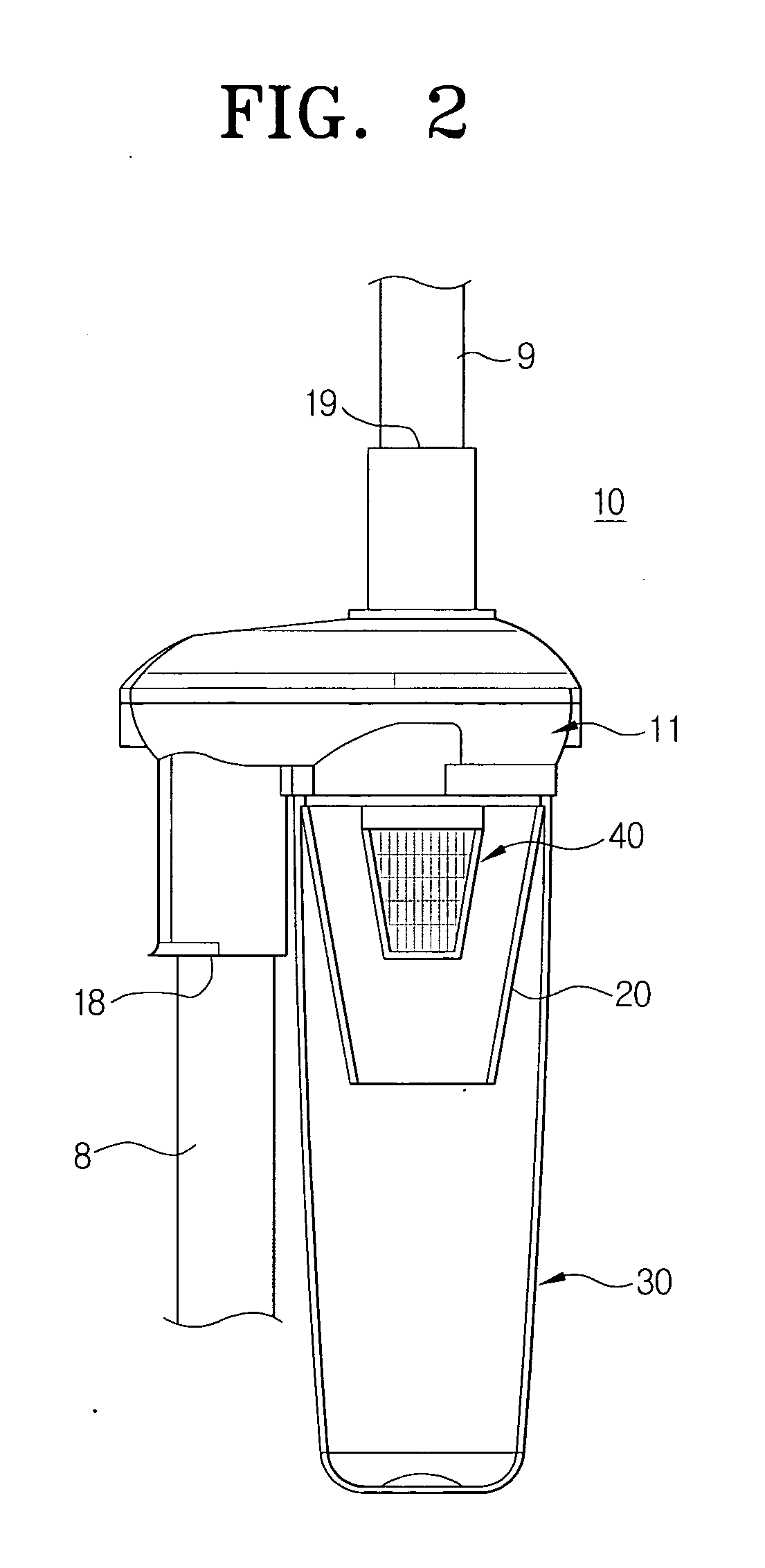

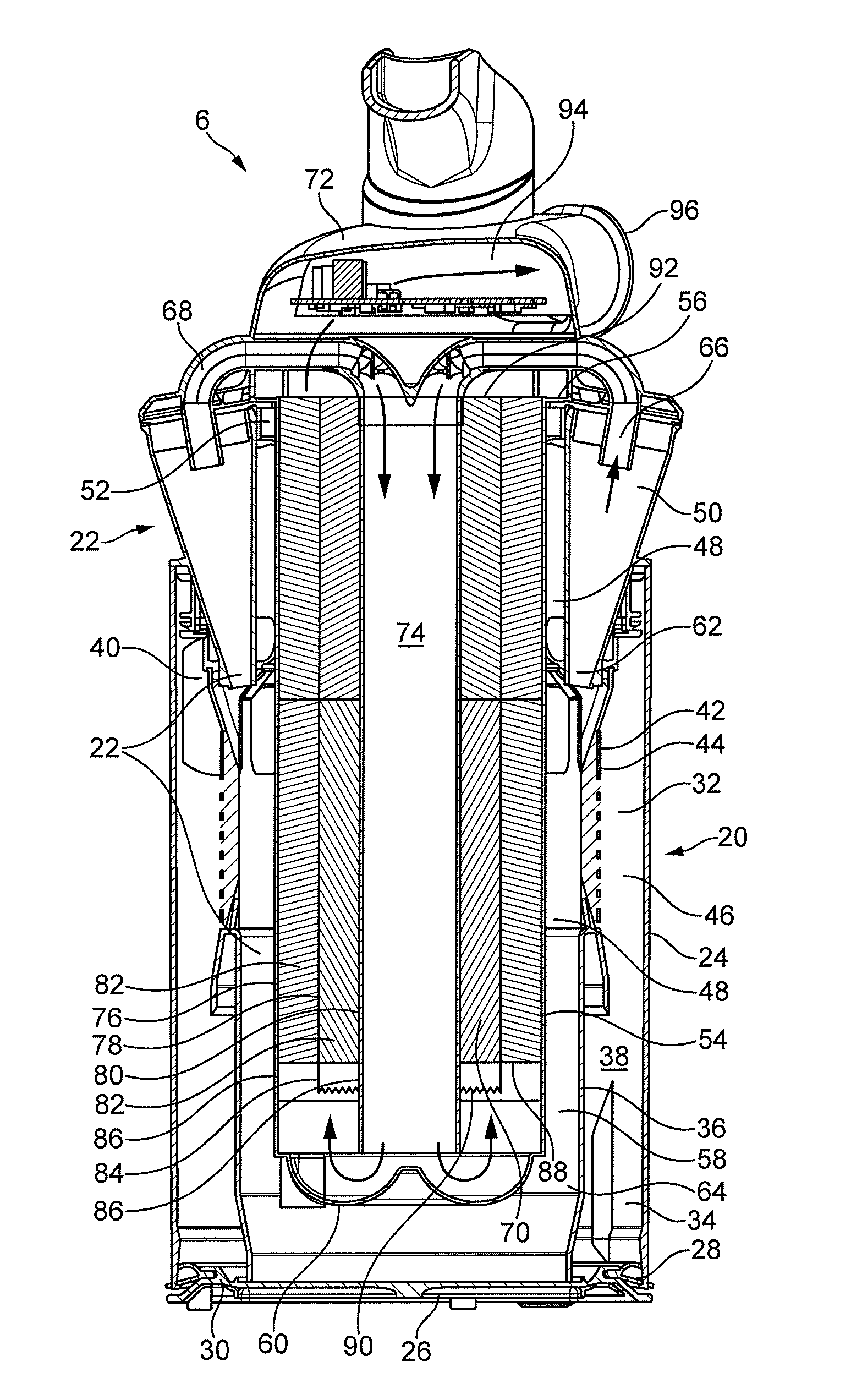

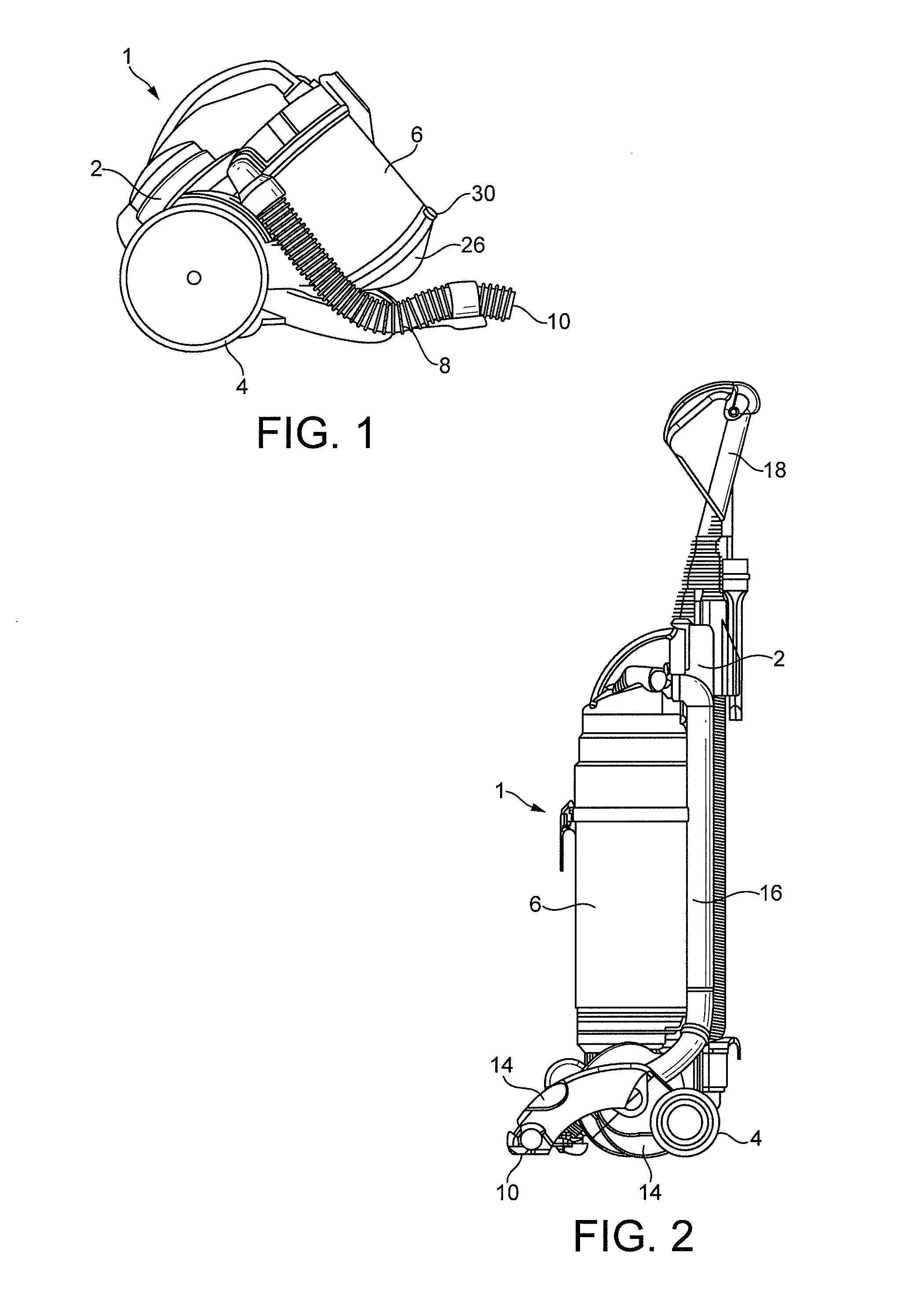

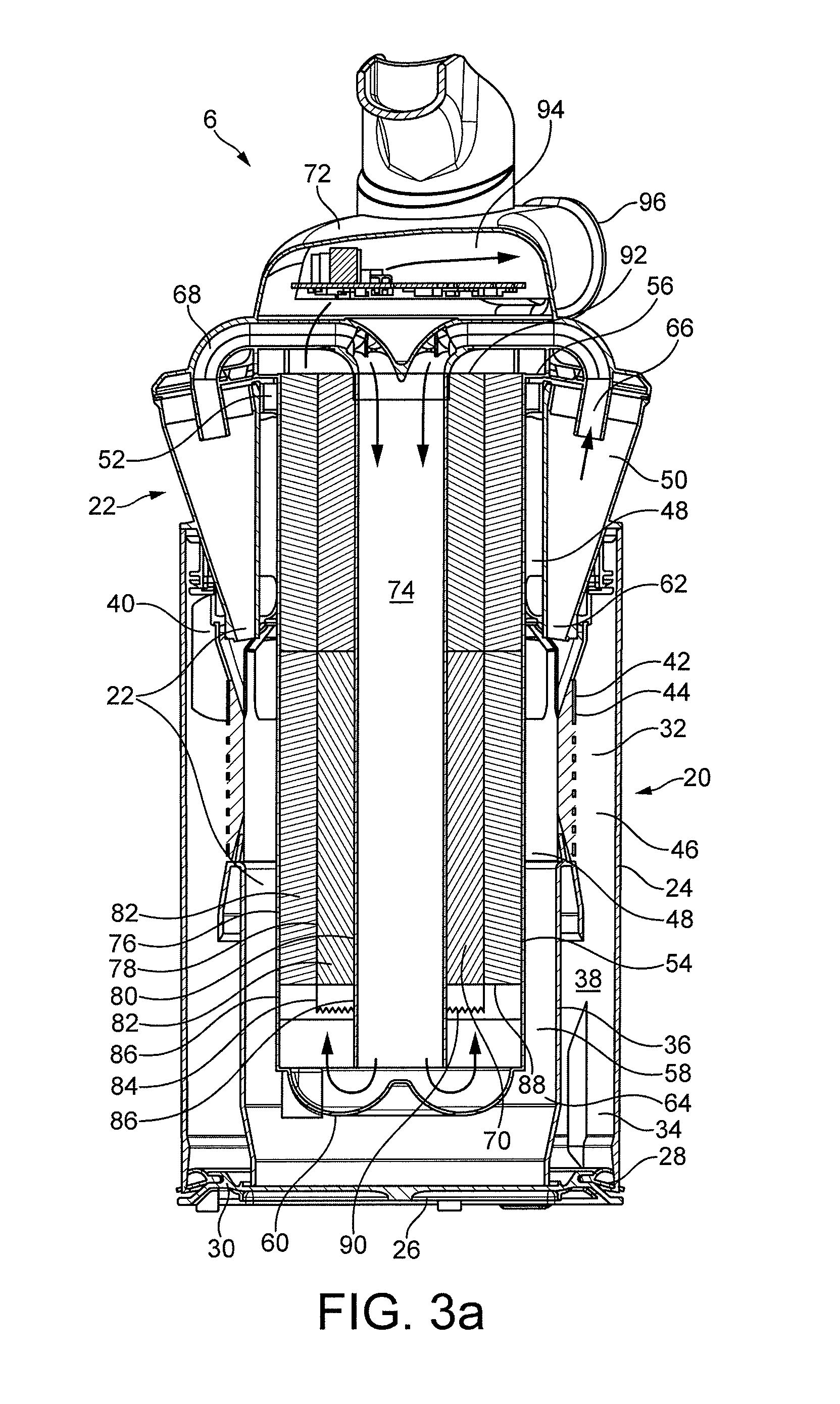

Dust collection unit and vacuum cleaner with the same

ActiveUS7645309B2Improve dust removal efficiencyEasy to cleanCombination devicesAuxillary pretreatmentForeign objectVacuum cleaner

A dust collection unit for a vacuum cleaner includes a first filtering chamber filtering foreign objects using a cyclone airflow, a separation plate defining a top surface of the first filtering chamber, a filter having a diameter that is reduced as it goes downward in response to airflow rate variation in the first filtering chamber, and a blocking member provided under the filter to prevent the foreign objects filtered in the first filtering chamber from flying.

Owner:LG ELECTRONICS INC

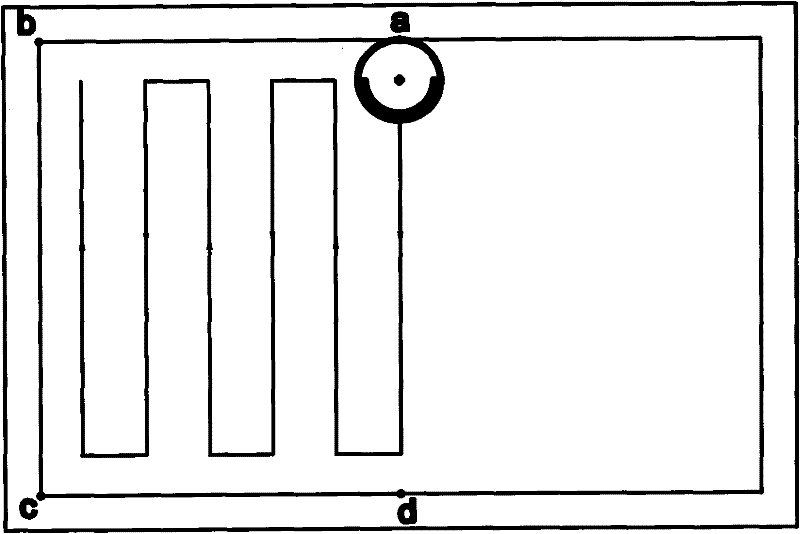

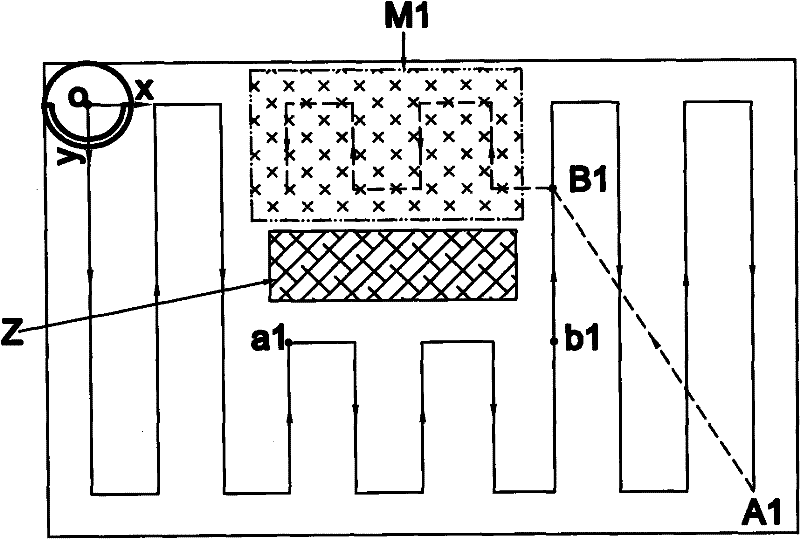

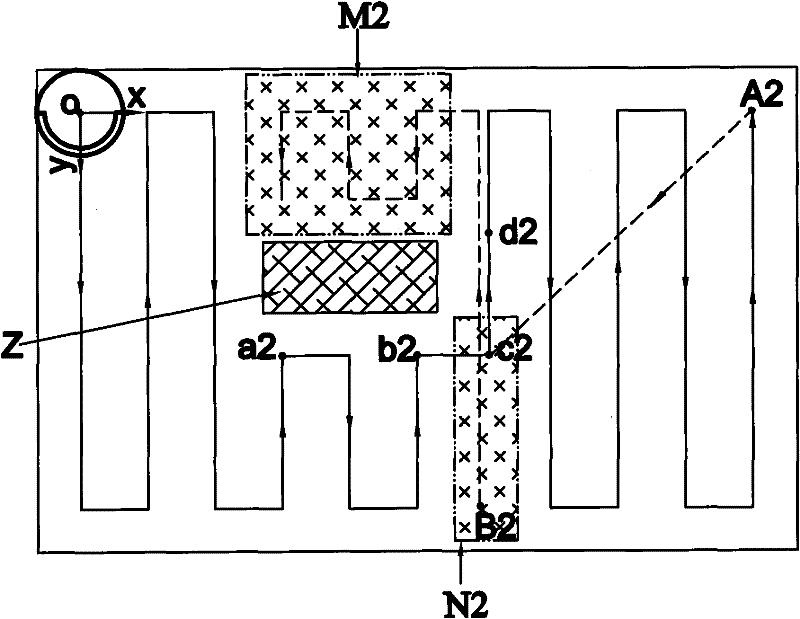

Obstacle processing method for robot

InactiveCN102541056AImprove dust removal efficiencyEfficient use ofPosition/course control in two dimensionsEngineeringRobot

The invention discloses an obstacle processing method for a robot. The robot performs X-axis or Y-axis scanning cleaning in a cleaning area for the first time, and records a non-cleaned area behind an obstacle; after finishing performing the X-axis or Y-axis scanning cleaning for the first time, the robot returns to the non-cleaned area behind the obstacle, and performs X-axis or Y-axis scanning cleaning for the second time; and the robot records X-axis coordinates and Y-axis coordinates when touching the obstacle and detecting that the obstacle disappears to adjust a walking route. According to the obstacle processing method, the number of walking routes is small during identification of obstacles; the obstacles can be judged accurately; and an effect of automatically cleaning by a dust remover is achieved.

Owner:KINGCLEAN ELECTRIC

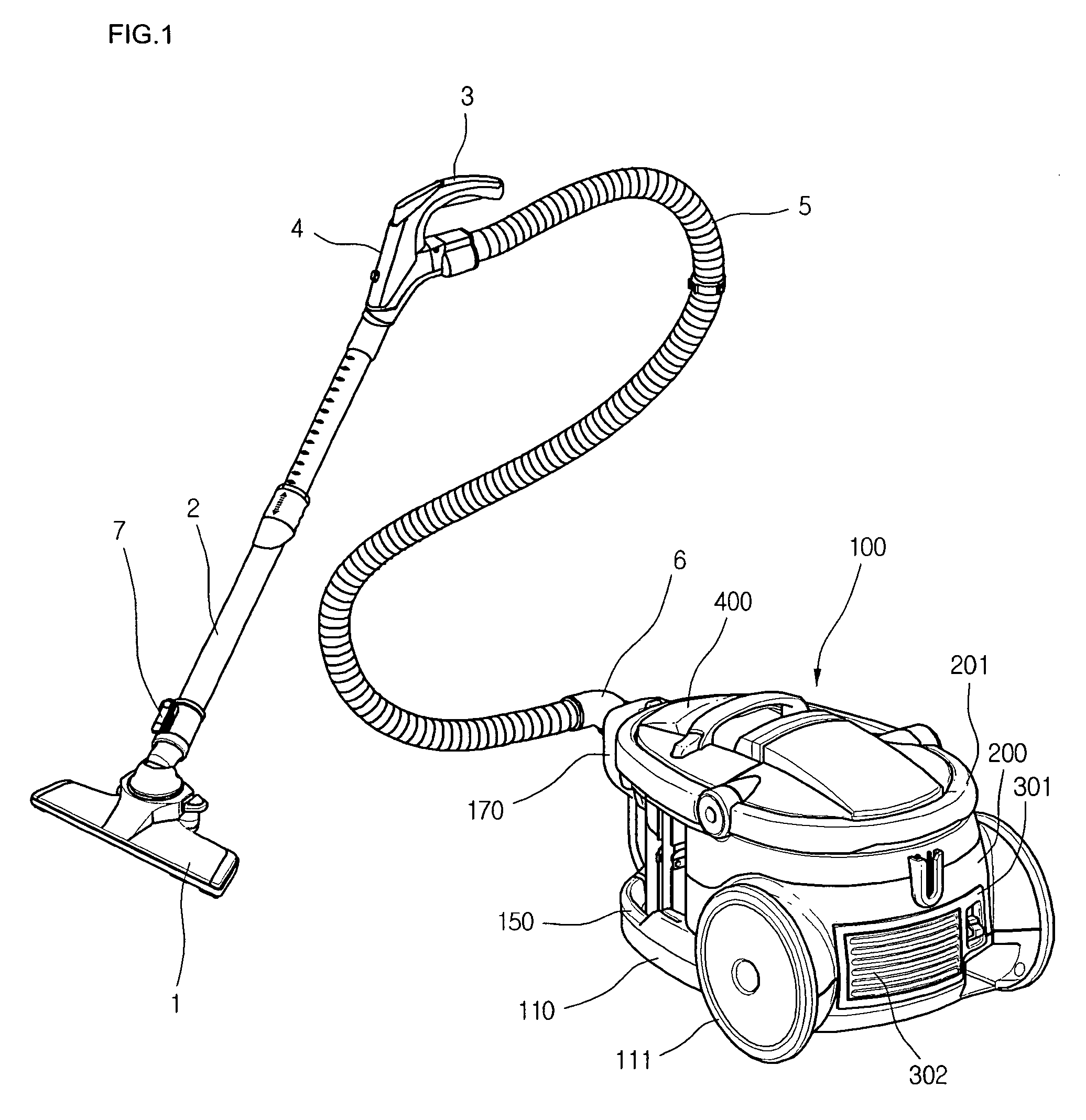

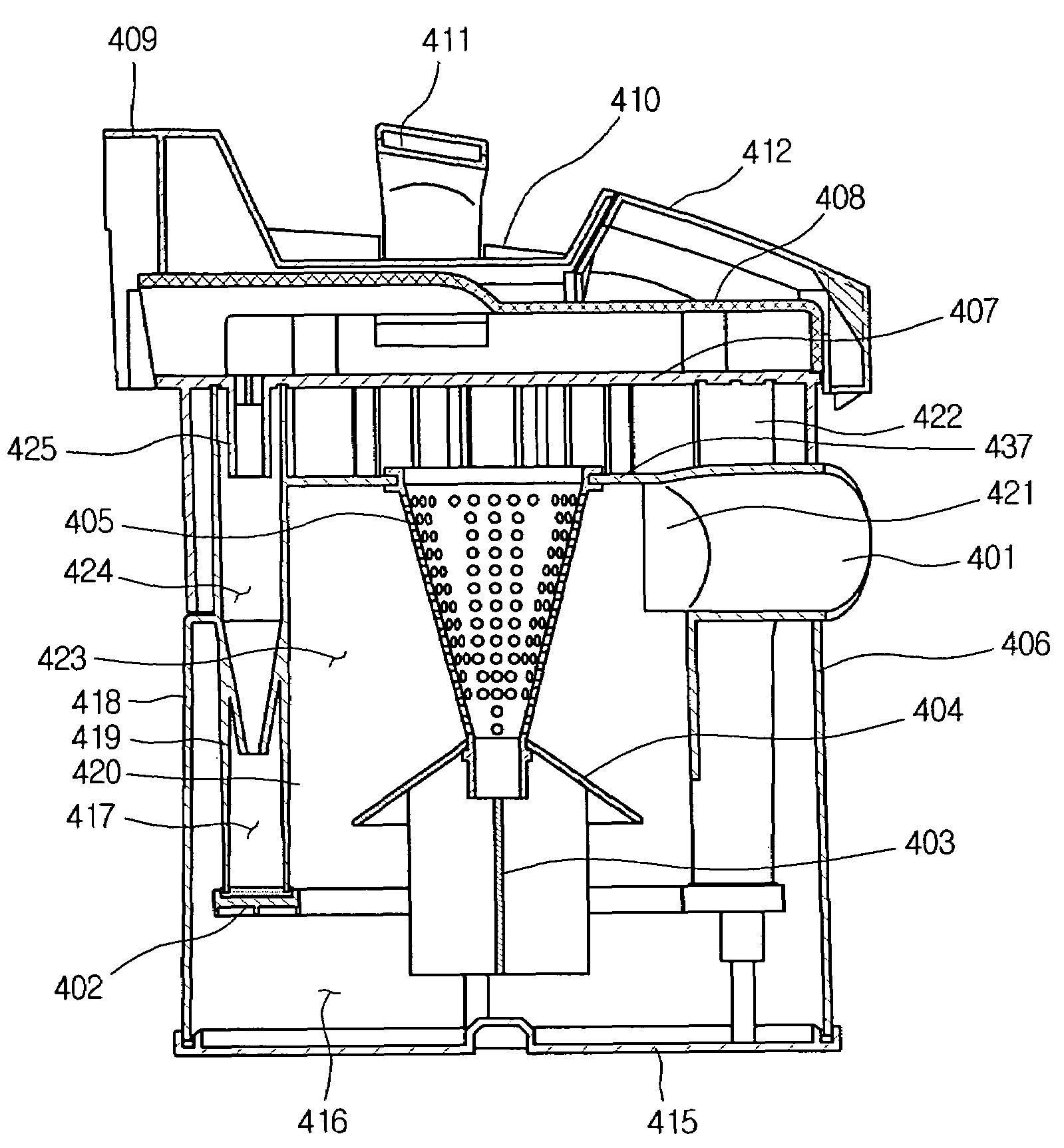

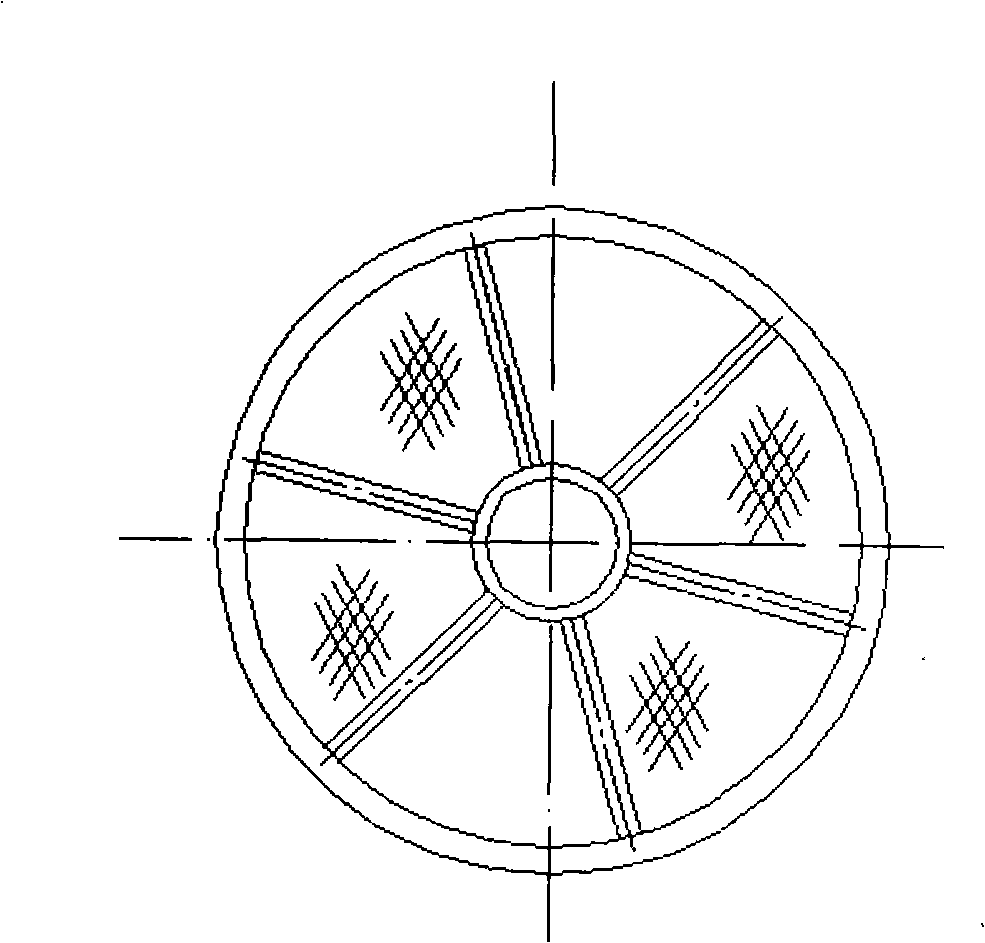

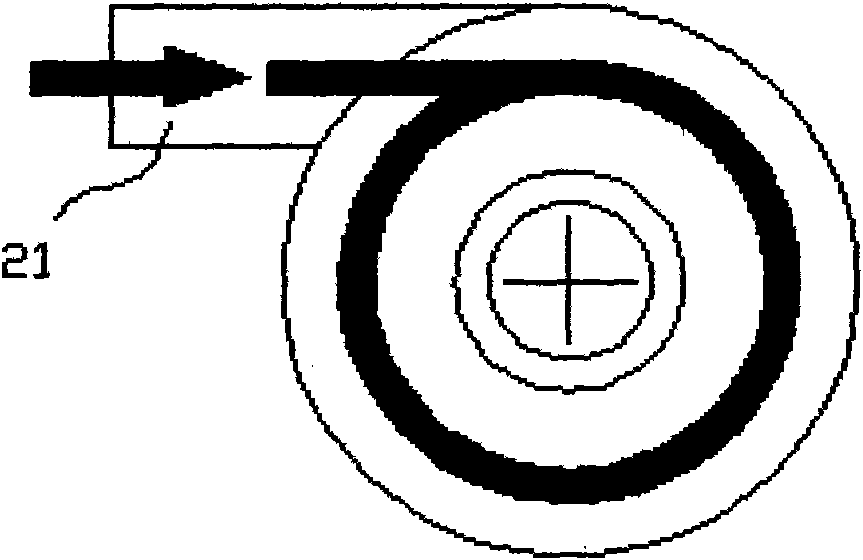

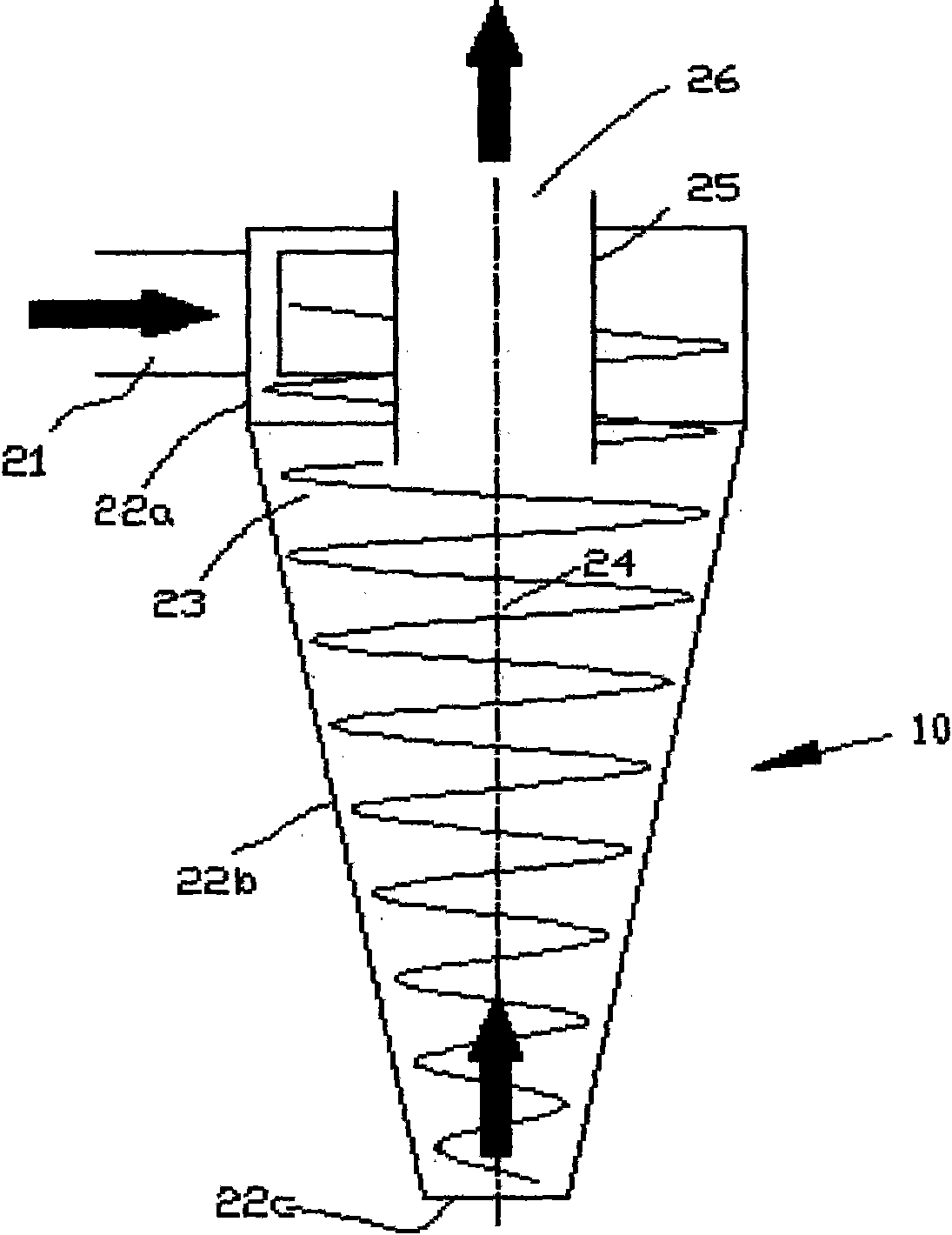

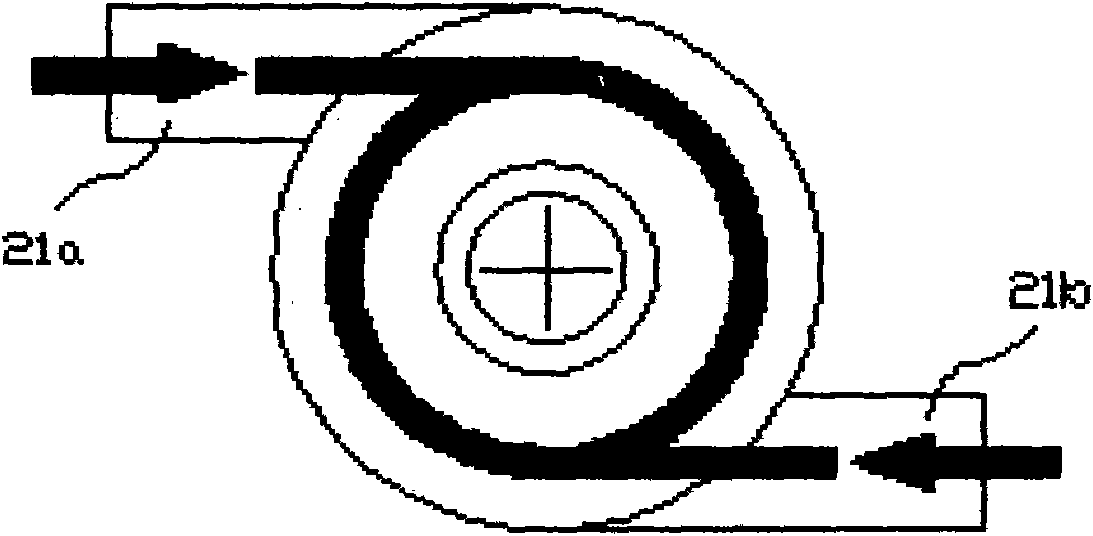

Cyclone separating apparatus and a vacuum cleaner having the same

InactiveUS7169201B2Improve dust removal efficiencyPrevent suction lossCleaning filter meansCombination devicesCycloneSuction force

A cyclone separating apparatus and a vacuum cleaner having the same are disclosed. More specifically, the cyclone separating apparatus for a vacuum cleaner comprises a first cyclone for separating drawn-in air, and a plurality of second cyclones installed on an outer periphery of the first cyclone to enclose the first cyclone. Accordingly, because a plurality of the cyclones separates dust, and a bulky structure is improved to a compact structure, suction force deterioration does not occur, and, dust-collecting efficiency is increased.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

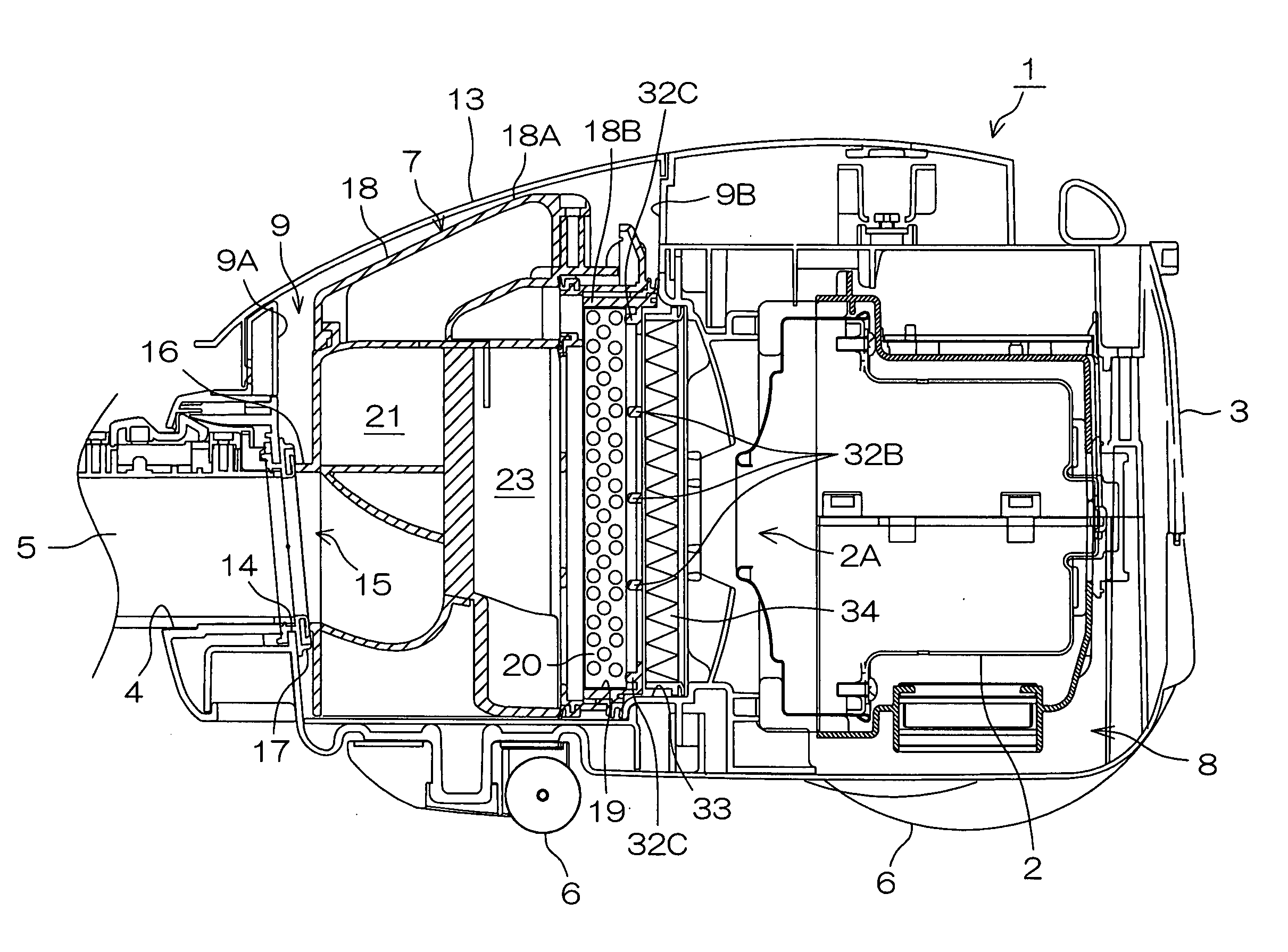

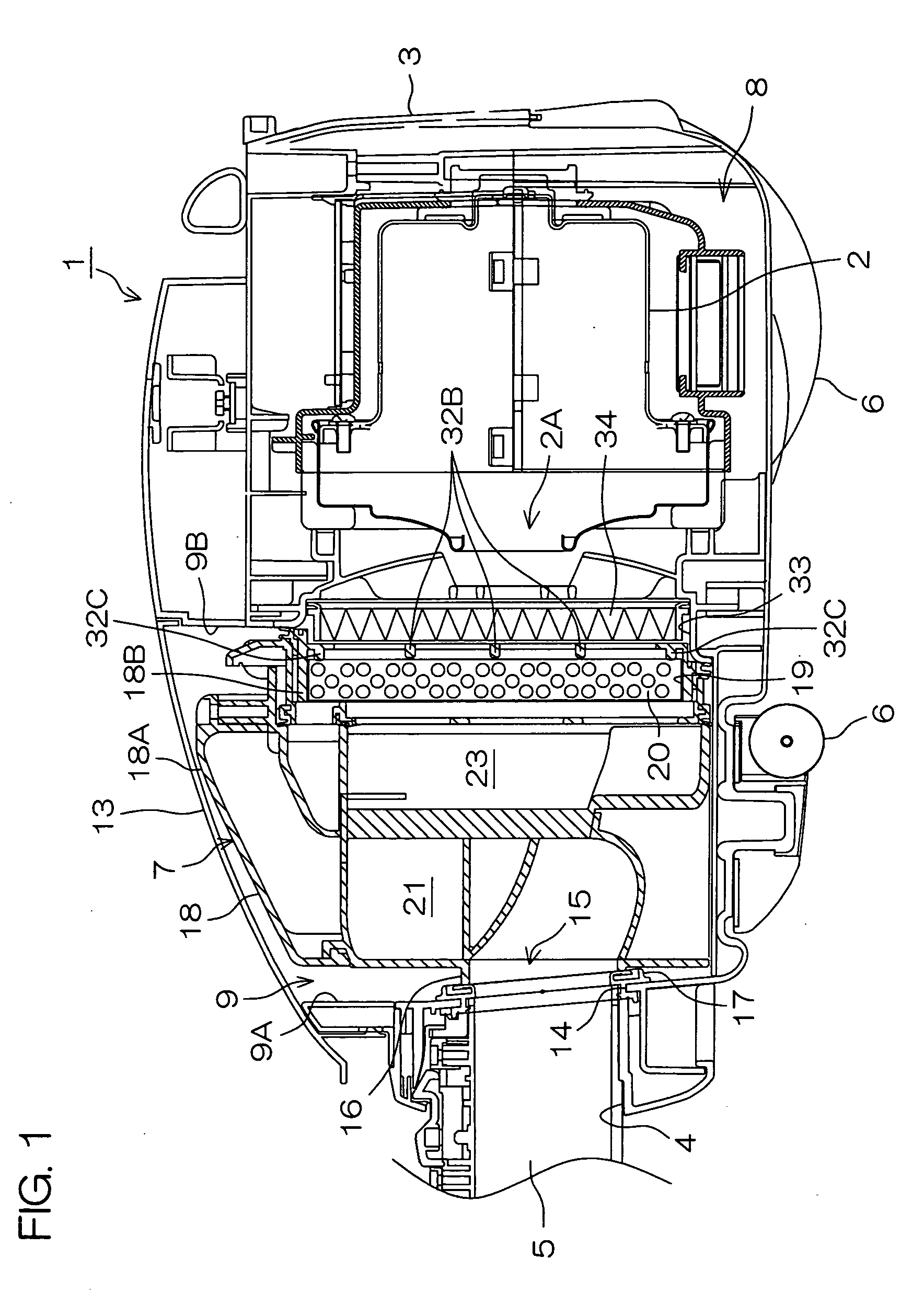

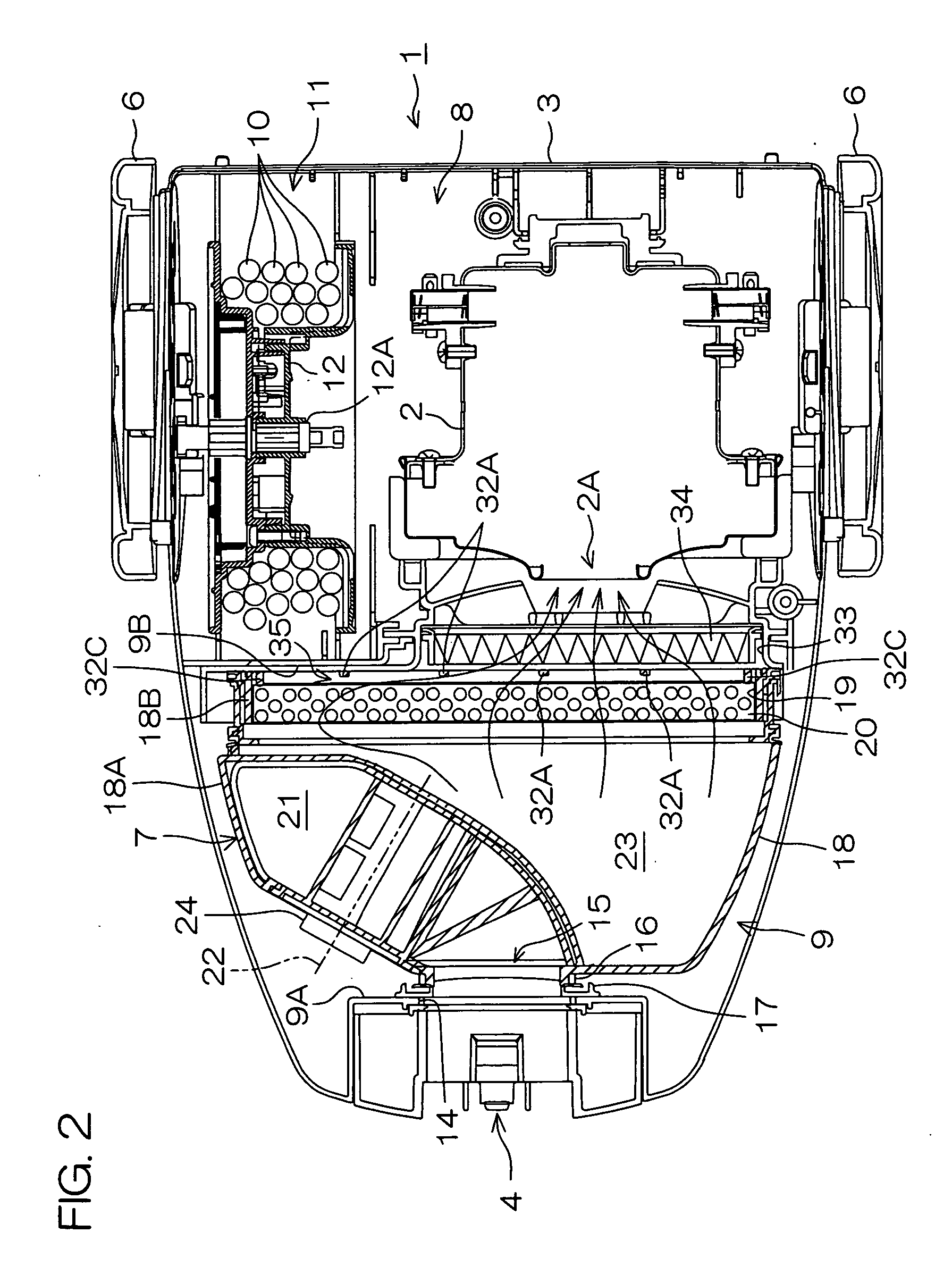

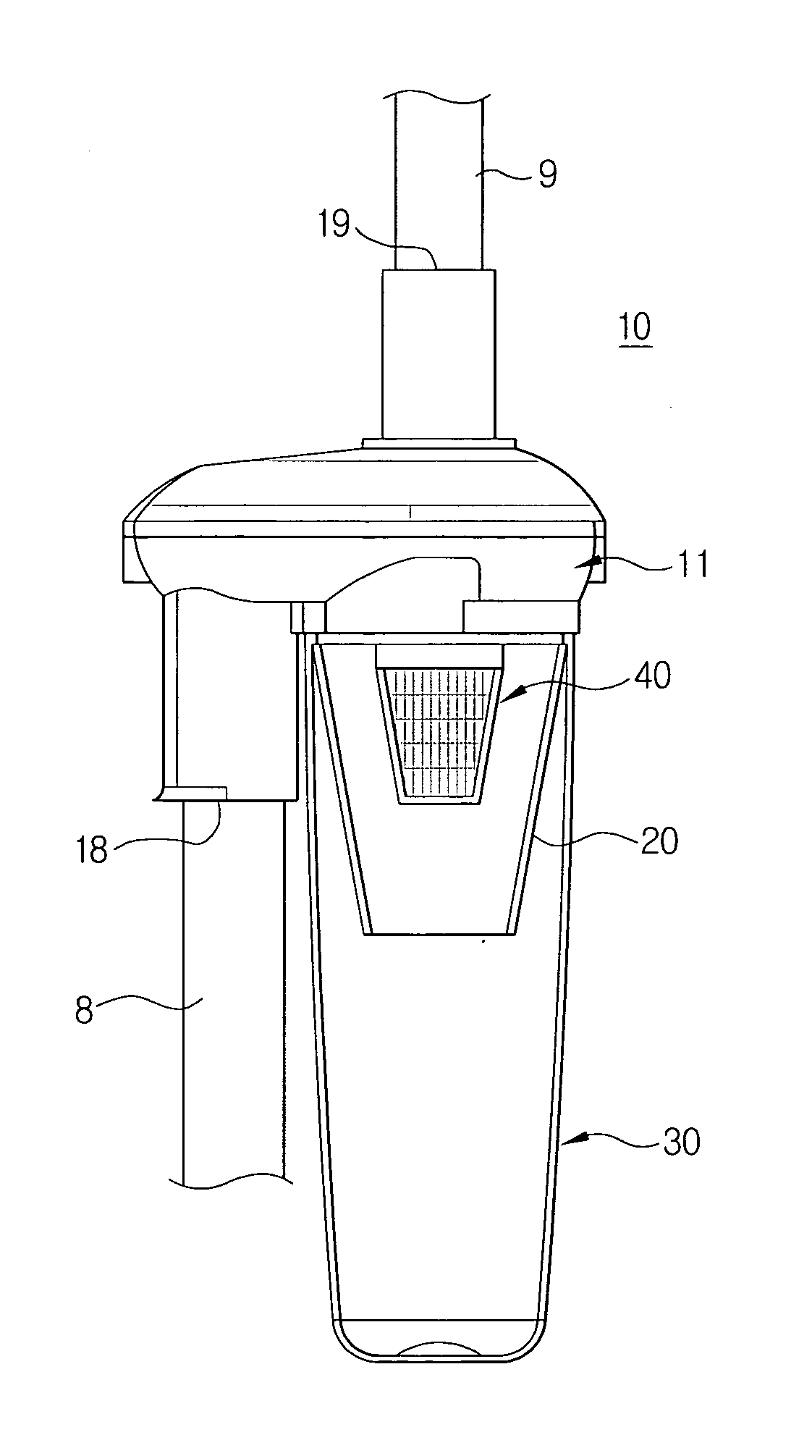

Electric vacuum cleaner and cyclonic dust collecting apparatus

InactiveUS20060016043A1Improve dust removal efficiencyImprove convenienceCleaning filter meansSuction filtersEngineeringMechanical engineering

In an inventive electric vacuum cleaner, a filter 20 through which air discharged from an air outlet port 19 is passed is provided on a rear face of a casing 18 of a cyclonic dust collecting apparatus 7, and held by a filter holder 18B. A rear face of the filter 20 is spaced from vertical ribs 32A of the filter holder 18B to define a guide passage 35 for guiding air discharged from a portion of the air outlet port 19 not opposed to an opening 33 through the filter 20 toward the opening 33. The guide passage 35 allows the air to pass through the portion of the air outlet port 19 not opposed to the opening 33.

Owner:SANYO ELECTRIC CO LTD

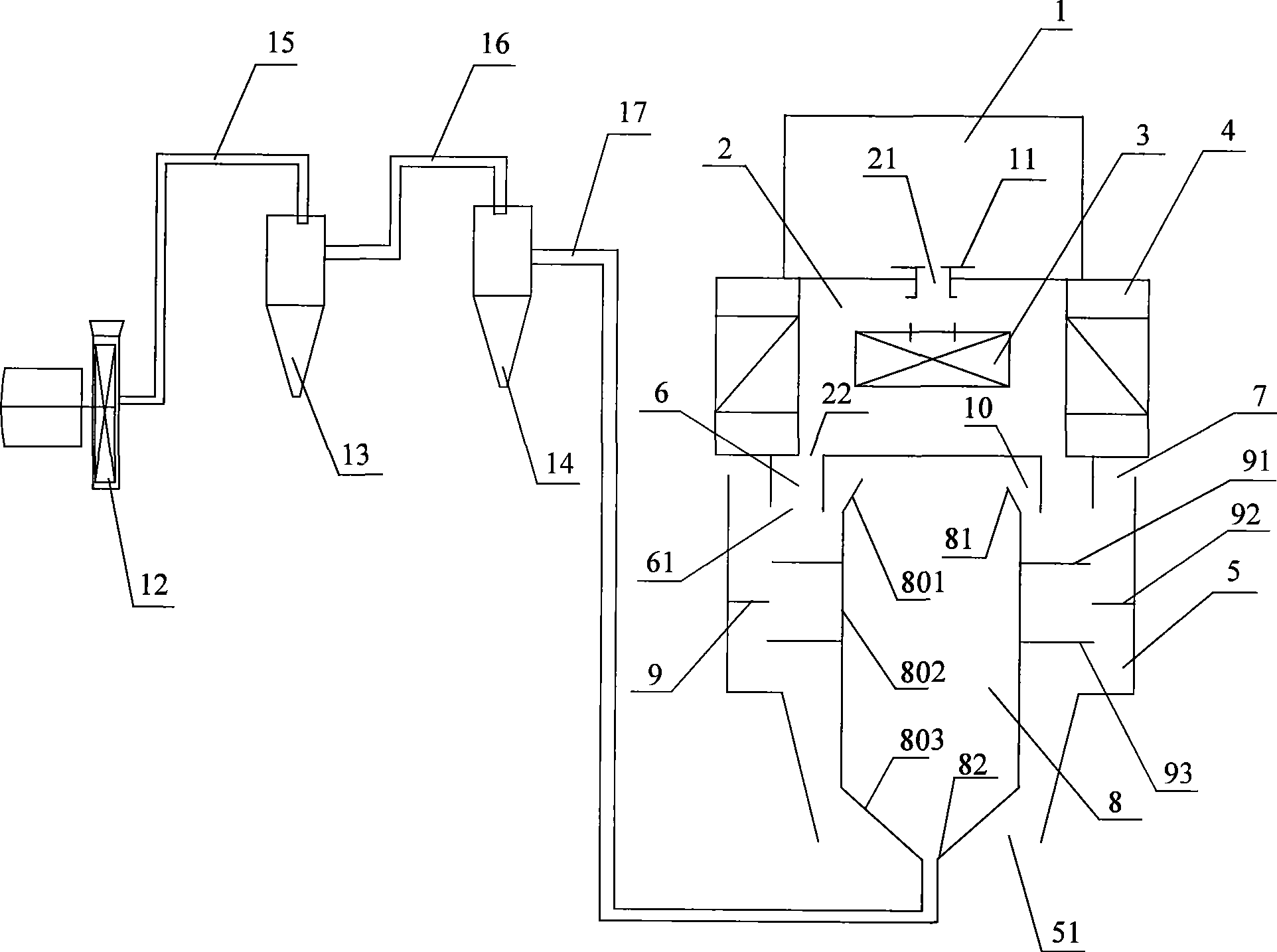

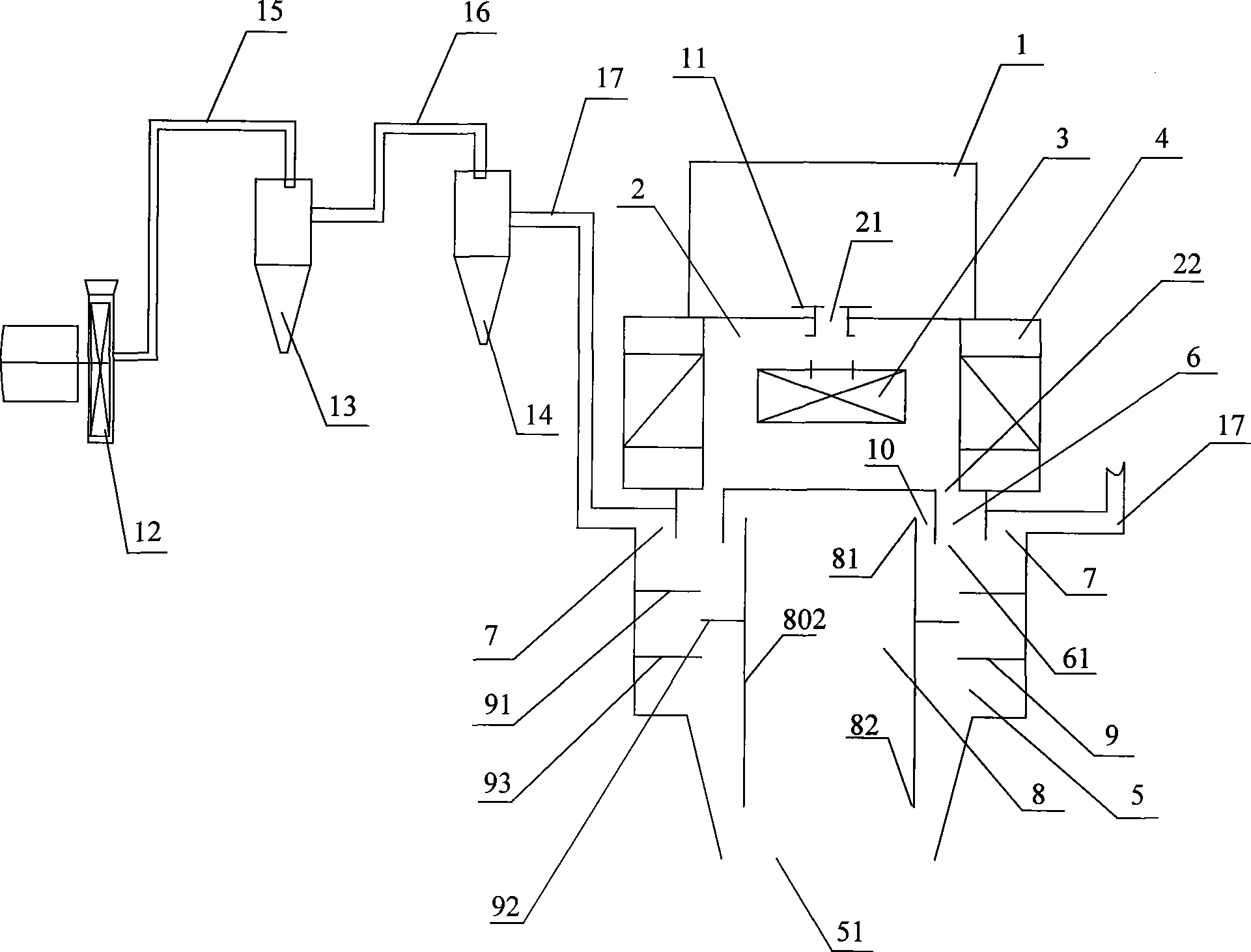

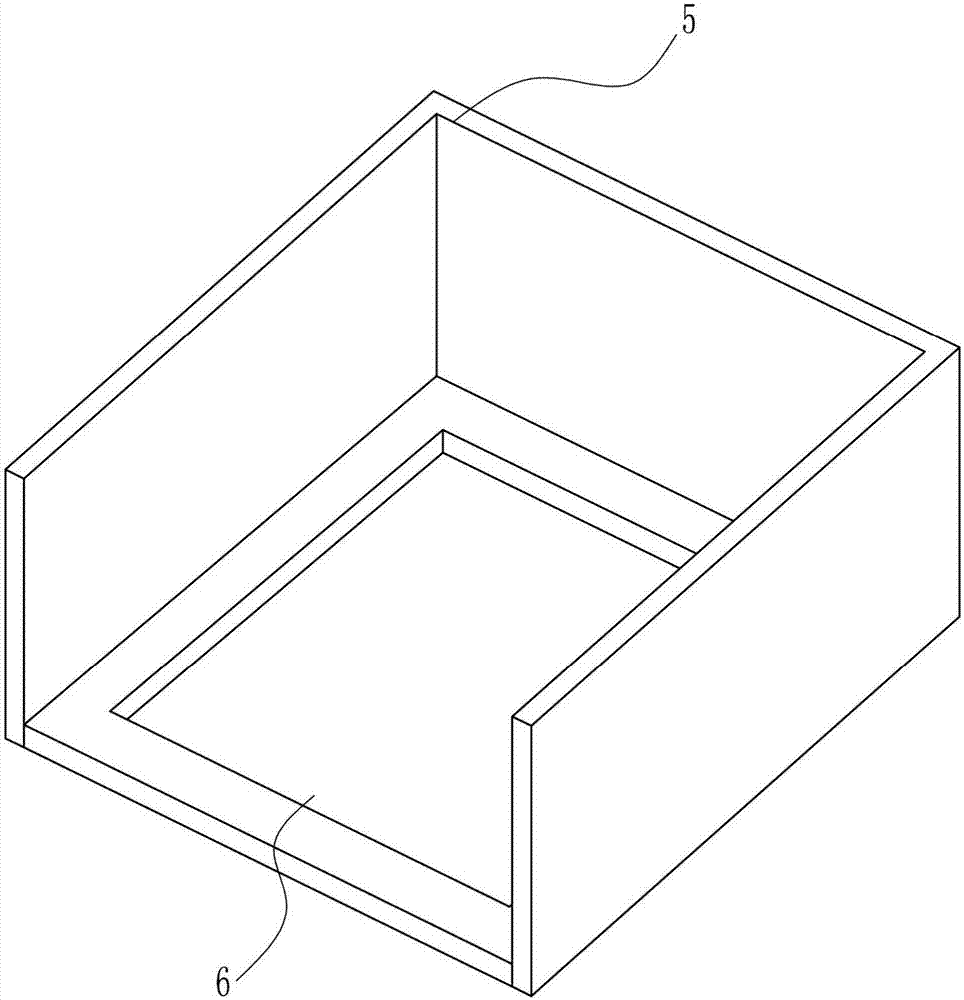

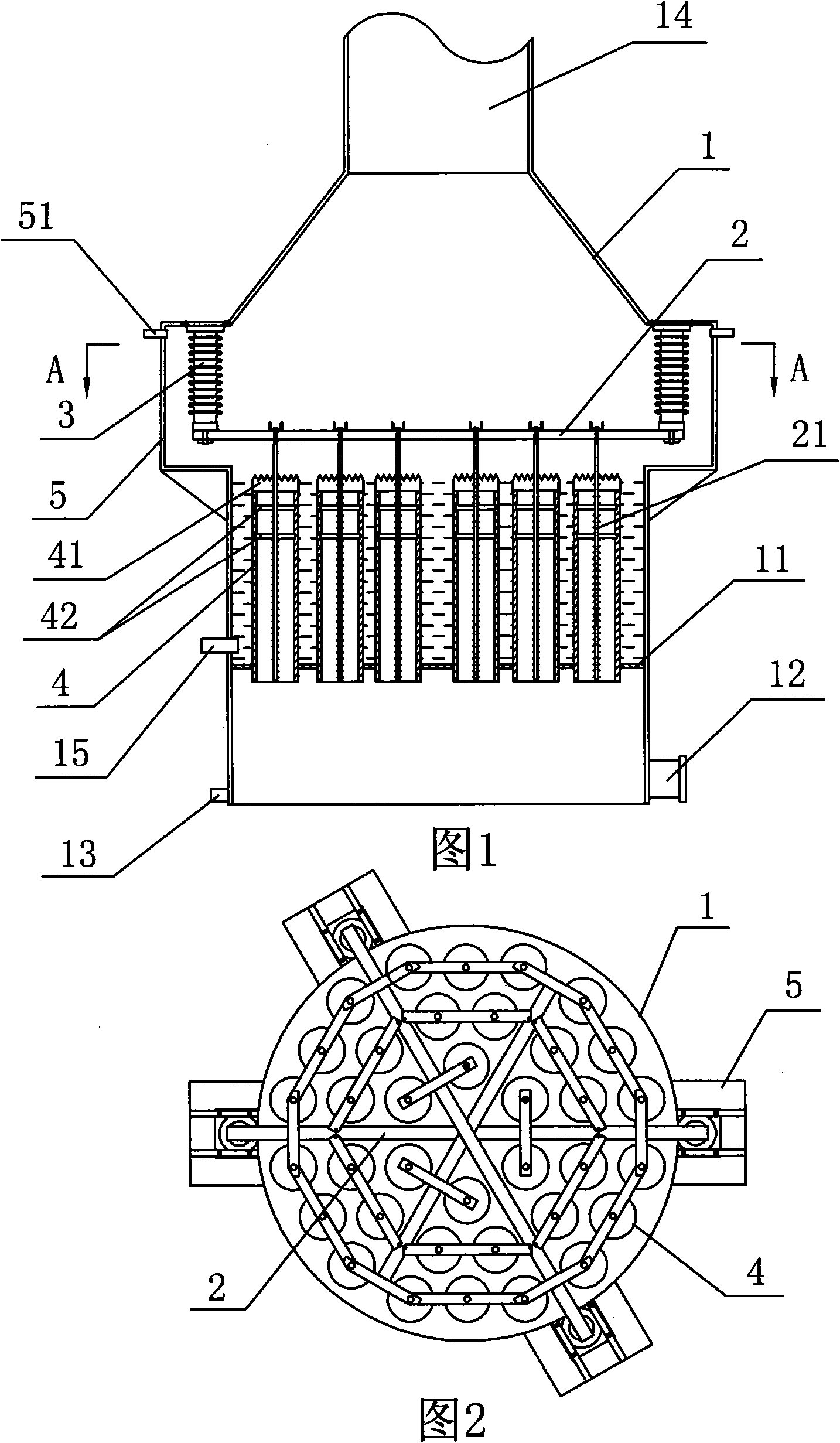

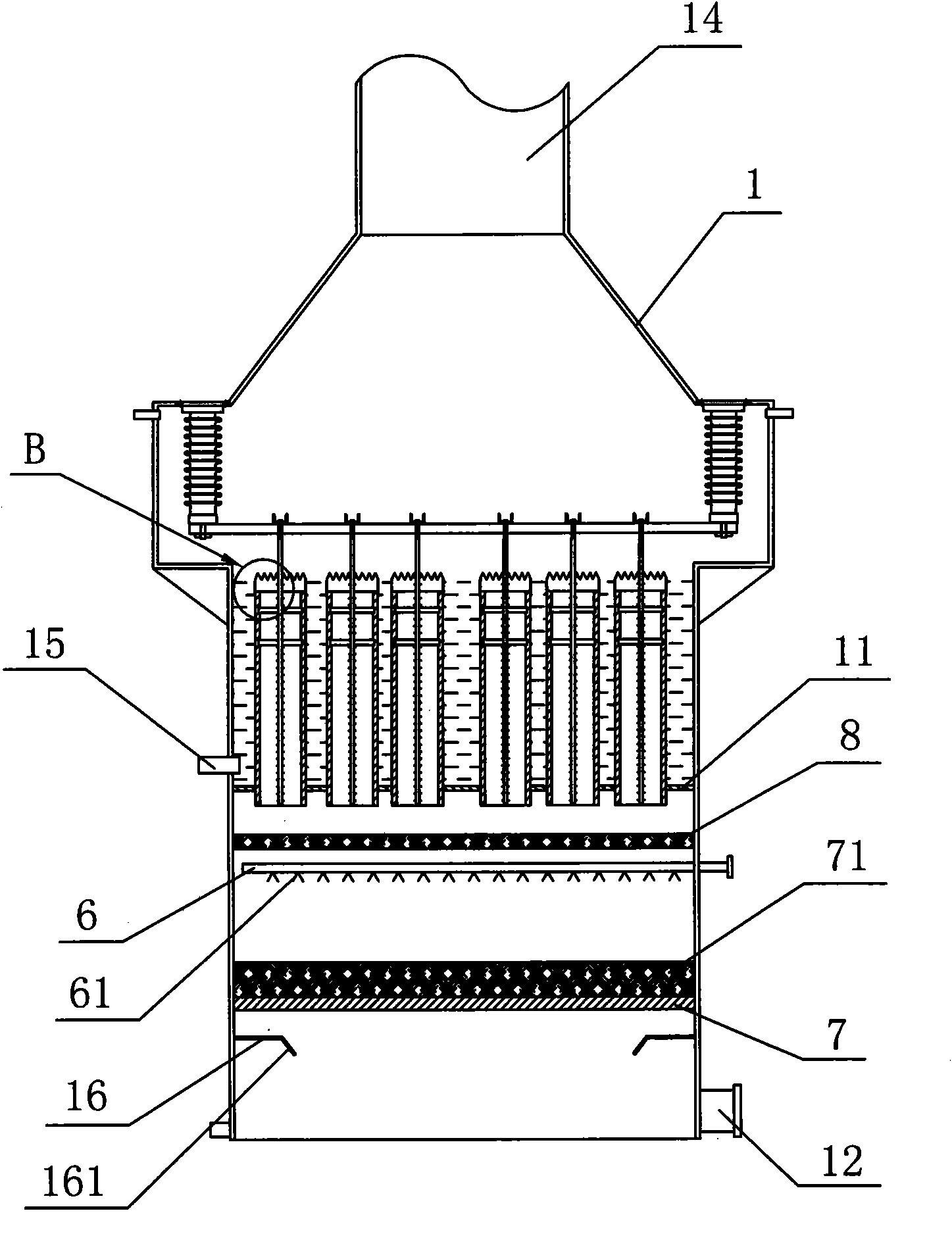

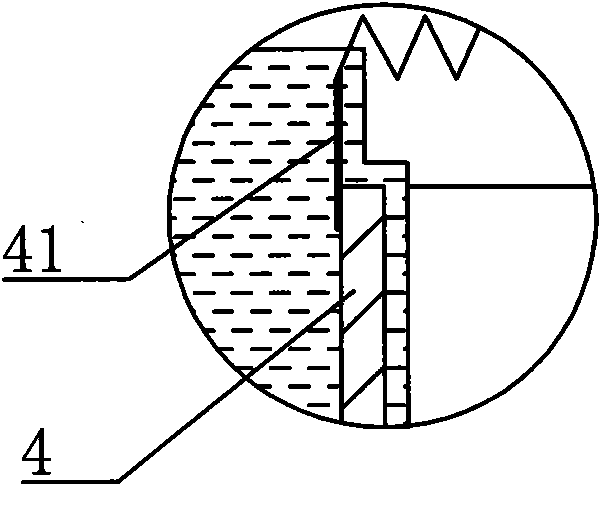

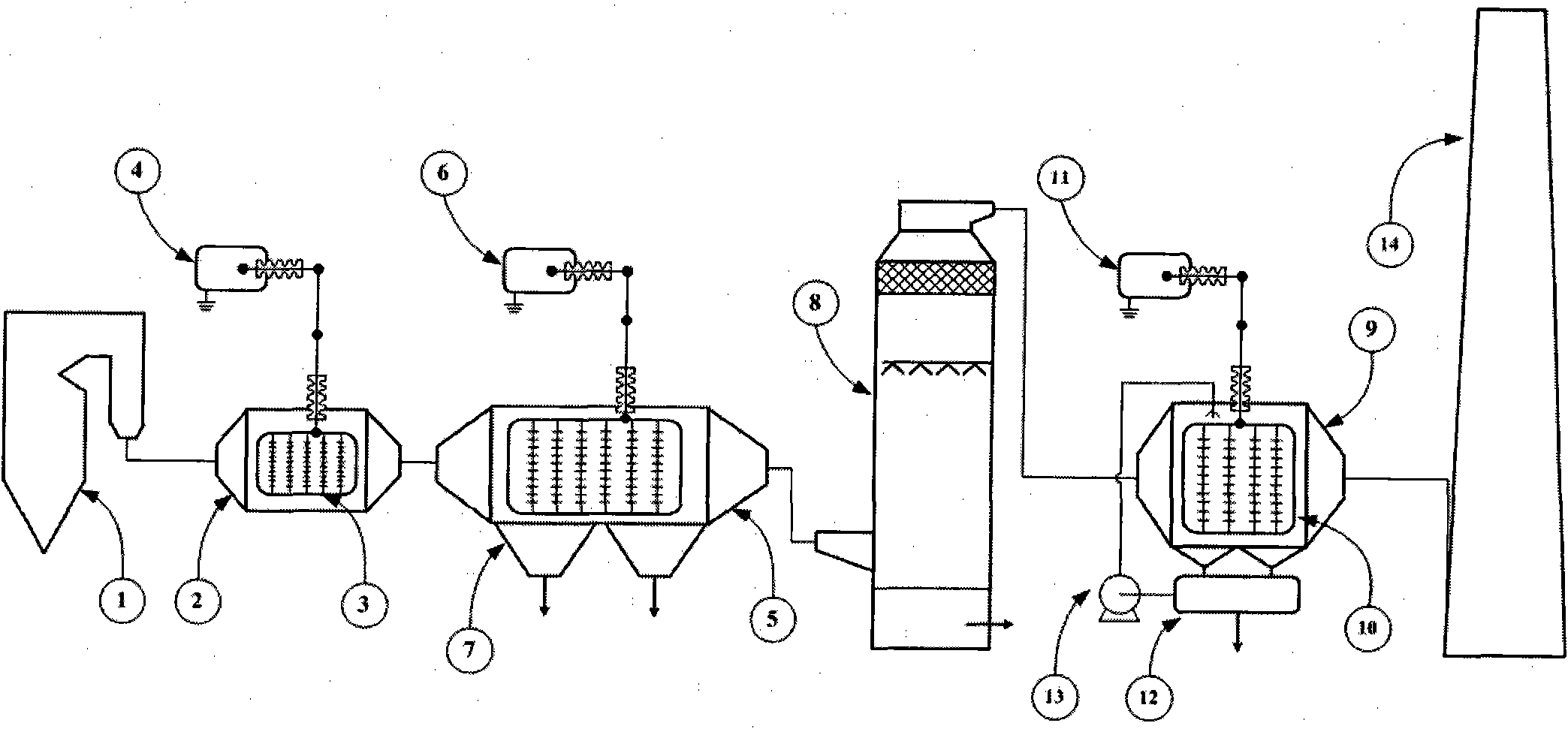

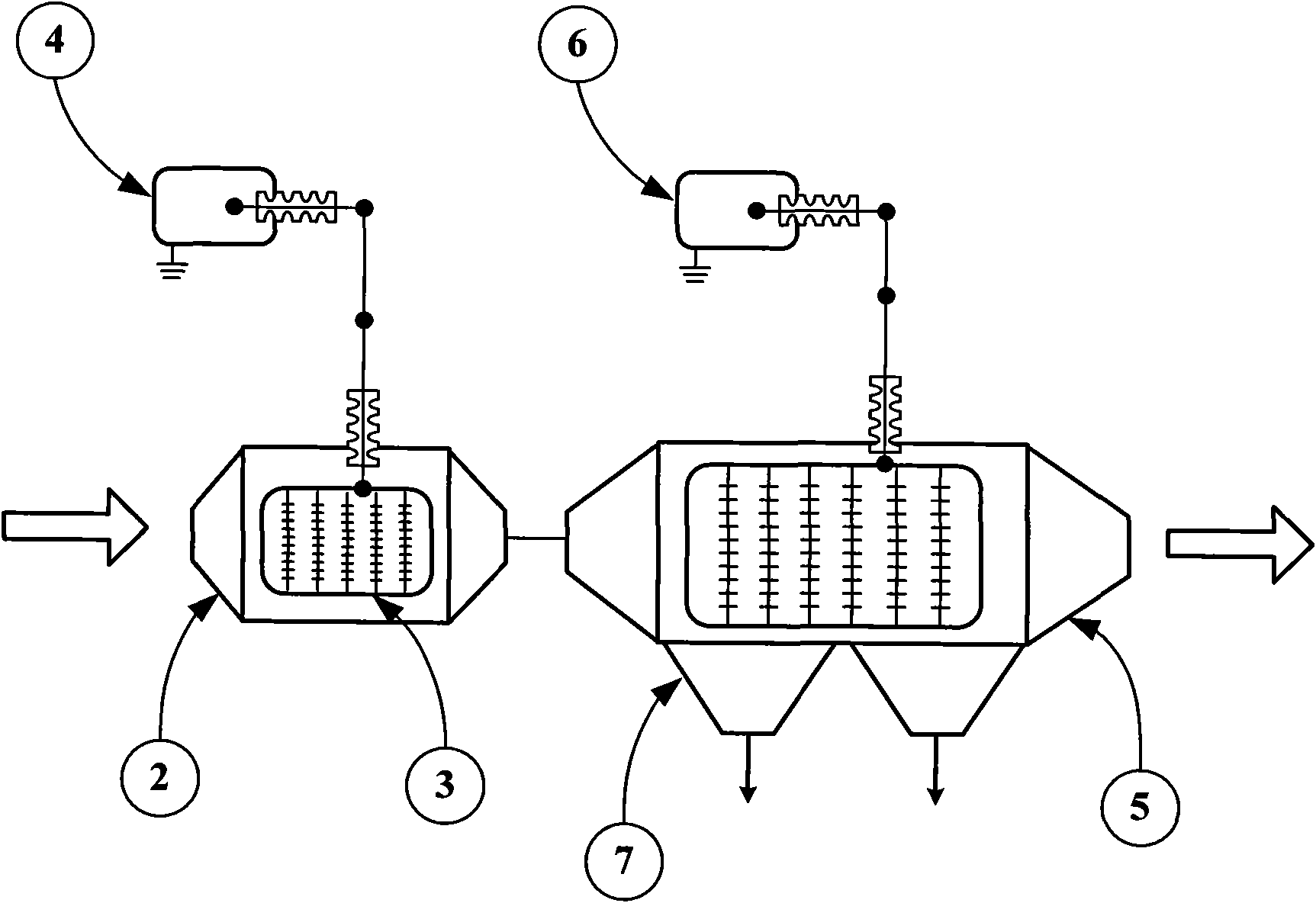

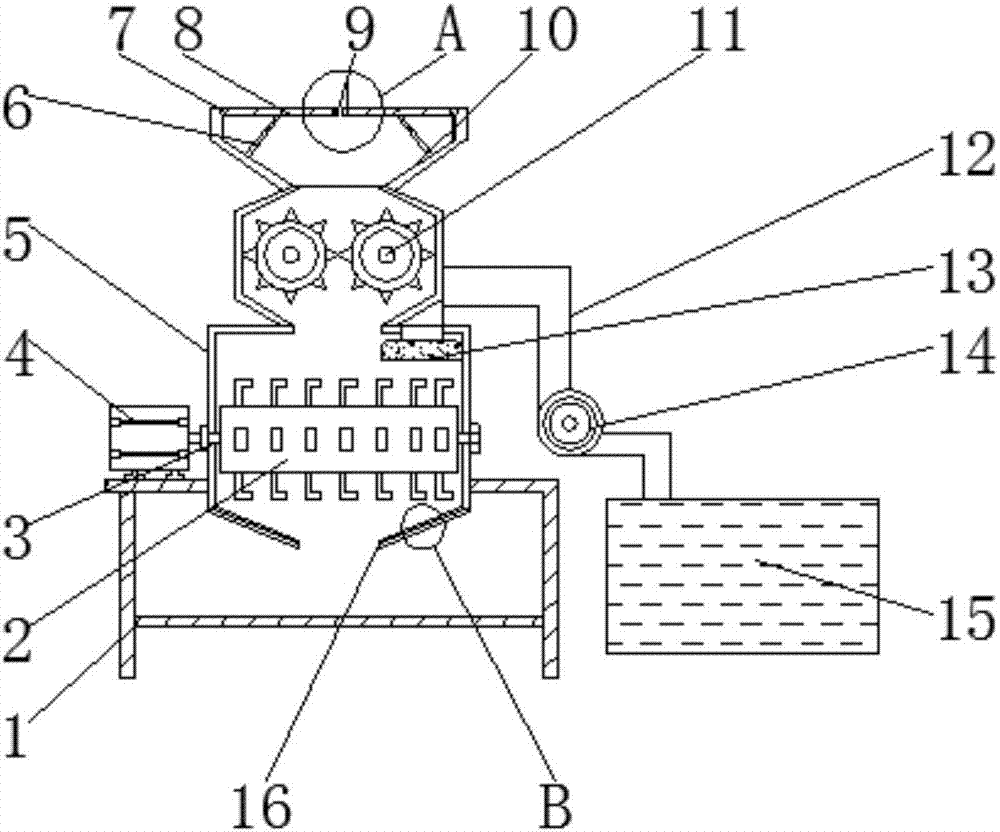

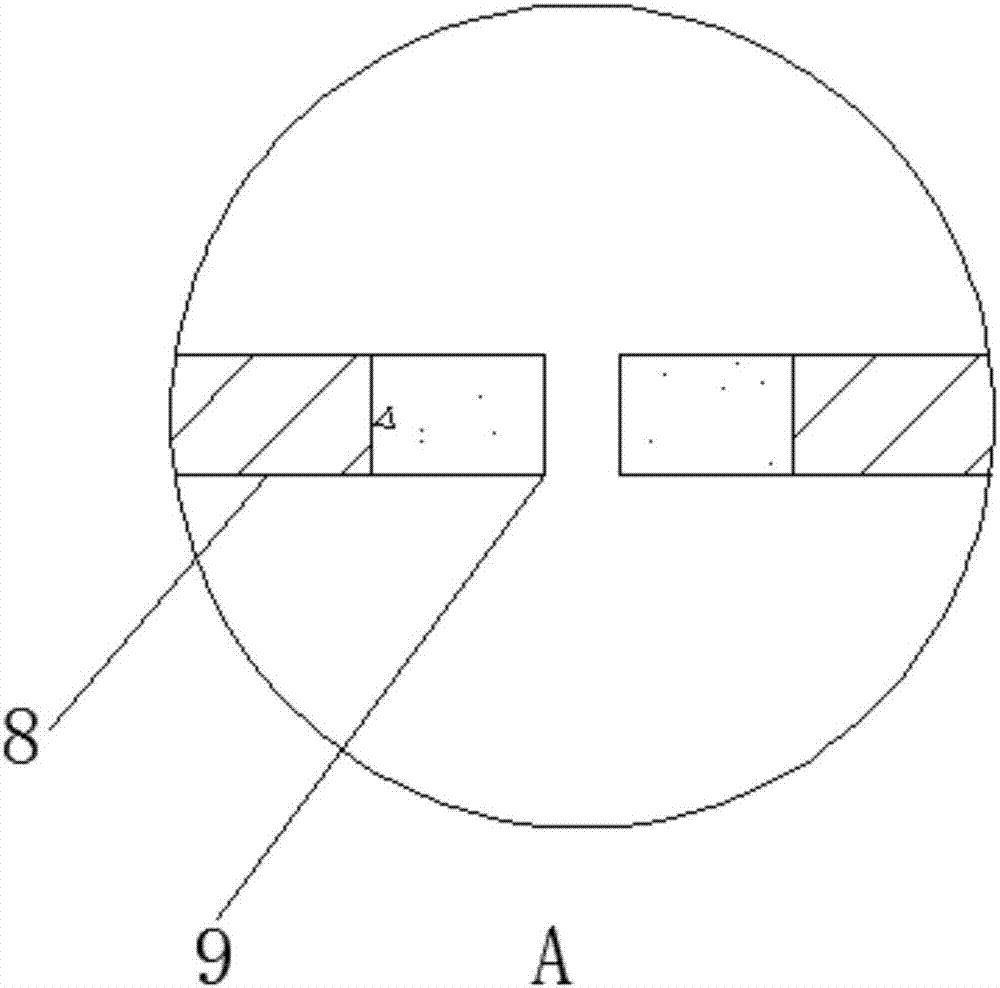

Dry-type sand making method and dry-type sand making machine thereof

The invention discloses a dry sand maker which comprises a hollow crushing cavity (2). A hollow dust removal cavity (5) is arranged under the hollow crushing cavity (2); the upper end of a feeding channel (6) is hermetically connected with a feeding mouth (22) and the lower end (61) thereof is positioned in the dust removal cavity (5) on which an air vent (7) is also arranged; an air duct (8) is arranged in the dust removal cavity (5); the lower end (61) of the feeding channel (6) is staggered with the upper end (81) of the air duct (8) in the horizontal direction; the bottom surface of the dust removal cavity (5) is provided with an outlet (51); a dust absorption component is hermetically connected with the lower end (82) of the air duct (8) or the air vent (7) after passing through the outlet (51). The invention also provides a method for drying sand making simultaneously. By adopting the dry sand maker, the drying sand making can have the advantages of high production efficiency and low environmental pollution.

Owner:吴核明

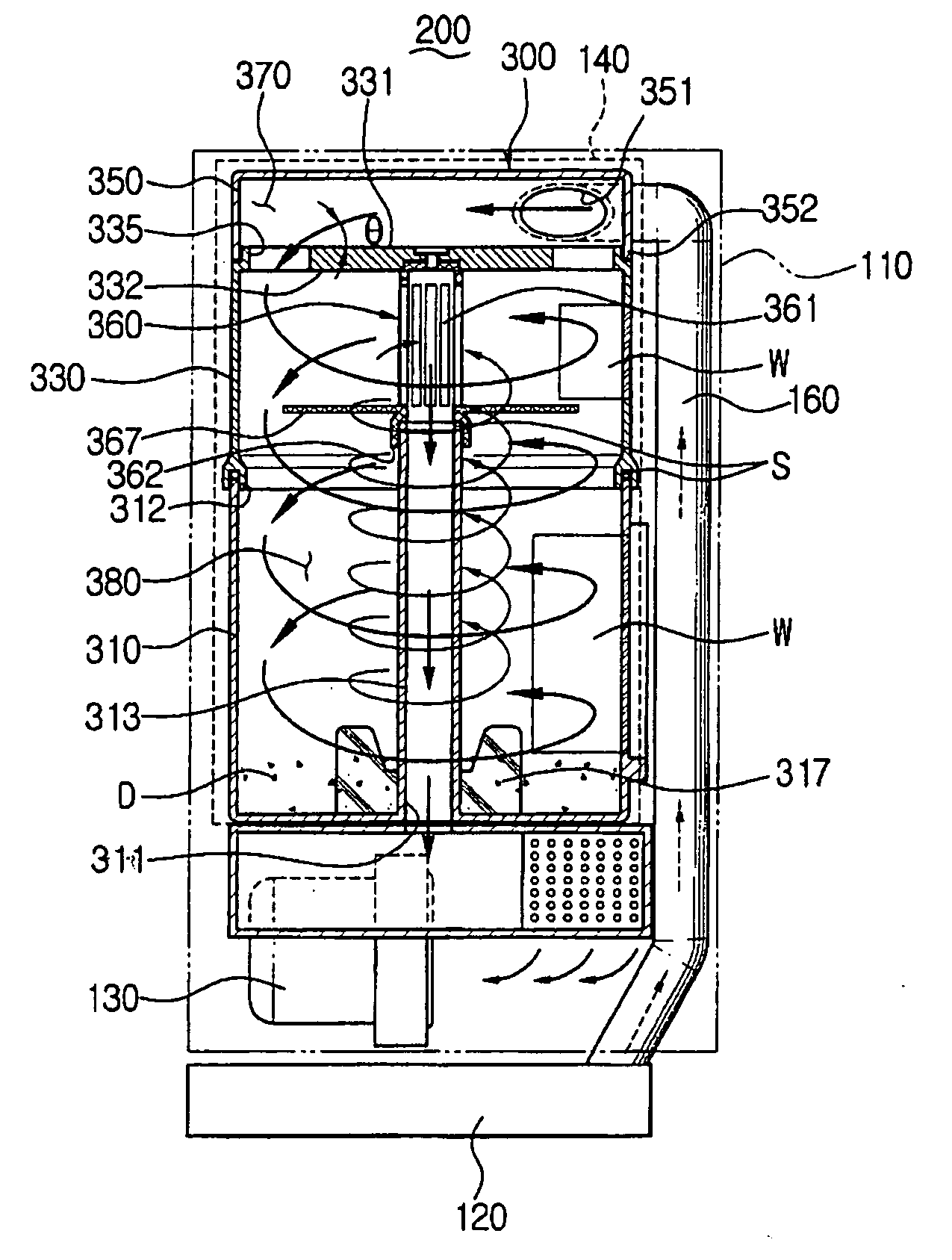

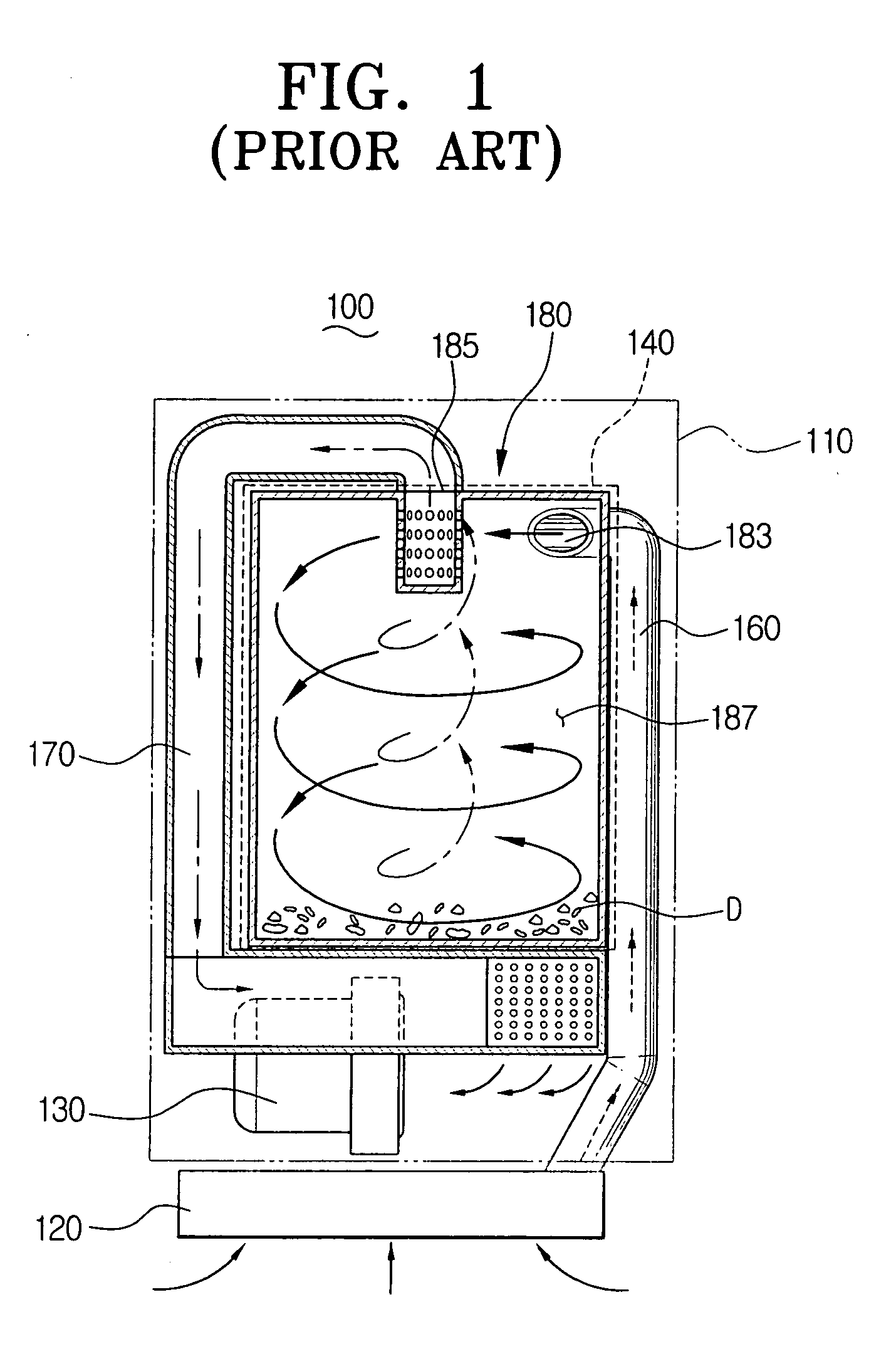

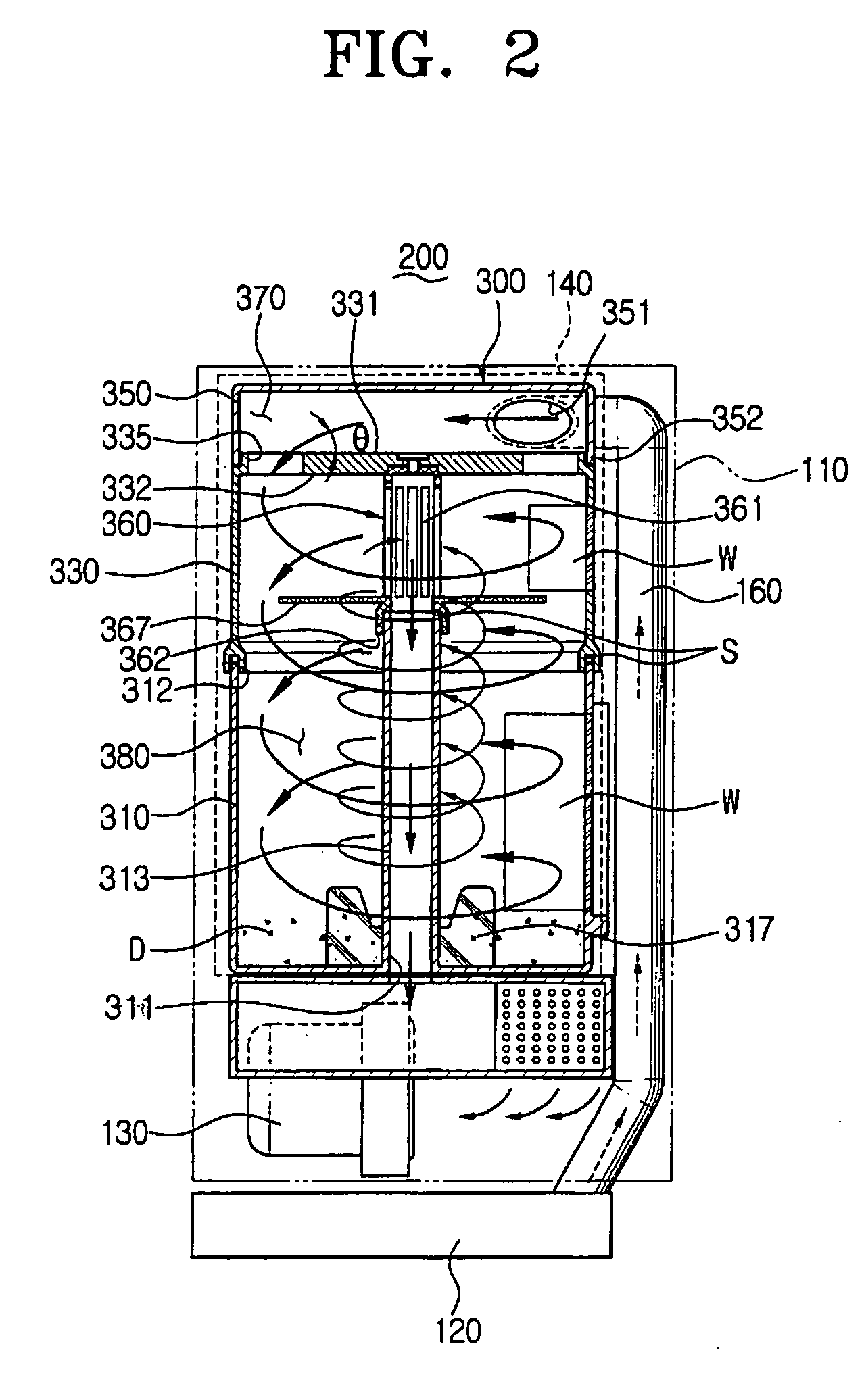

Dust collection unit and vacuum cleaner with the same

ActiveUS20060042202A1Improve dust removalPrevent overloadCleaning filter meansCombination devicesEngineeringForeign matter

A dust collection unit for a vacuum cleaner includes a dust collection container for collecting foreign objects contained in air introduced therein, covers defining a top and bottom of the dust collection container, and a filter-cleaning unit having a plurality of brushes rotating around the porous filter unit to remove the foreign objects clogging the outer surface of the porous filter unit.

Owner:LG ELECTRONICS INC

Dust collection unit and vacuum cleaner with the same

ActiveUS7419520B2Prevent overloadImprove dust removal efficiencyCleaning filter meansCombination devicesForeign matterEngineering

A dust collection unit for a vacuum cleaner includes a dust collection container for collecting foreign objects contained in air introduced therein, covers defining a top and bottom of the dust collection container, and a filter-cleaning unit having a plurality of brushes rotating around the porous filter unit to remove the foreign objects clogging the outer surface of the porous filter unit.

Owner:LG ELECTRONICS INC

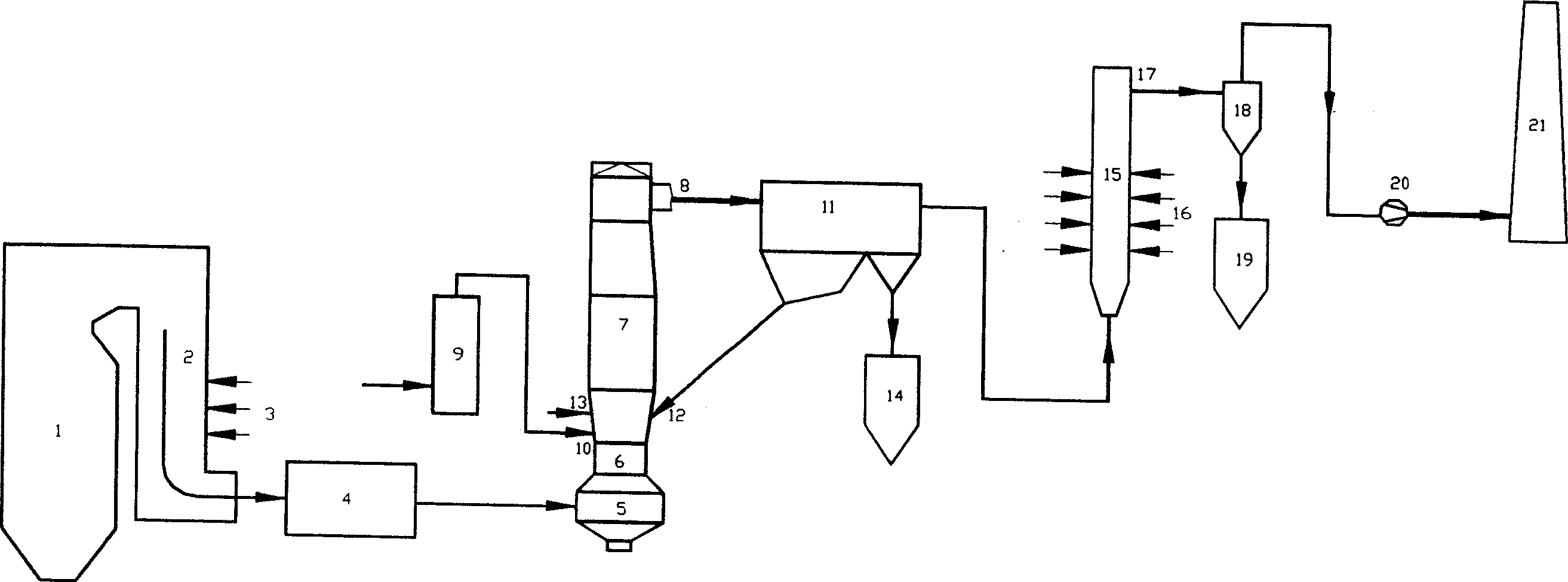

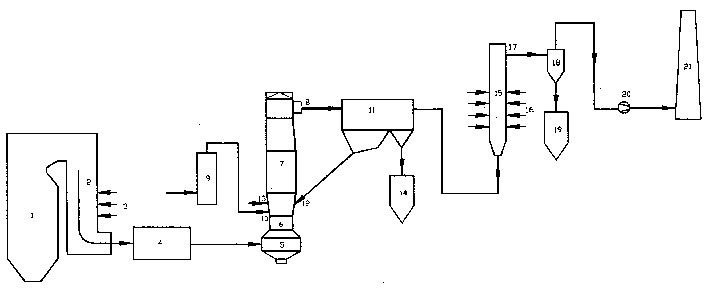

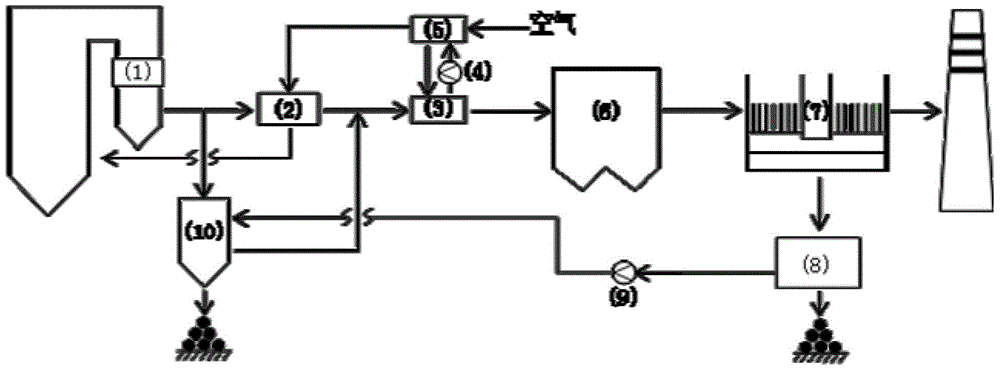

Dry smoke cleaning process for desulfurizing and denitrating simultaneously and its system

InactiveCN1589954ASimplify stand-alone removal systemsSimple processDispersed particle separationSprayerNitric oxide

A dry method for simultaneously desulfurizing and denitrating fume includes using H2O2 or methanol to convert the NO in fume to NO2, using Ca-base particles as desulfurizing agent to react with SO2 to obtain calcium sulfate, and using ammonia water or urea as denitrating agent to react with NO2 to obtain ammonium nitrate and clean fume. Its apparatus is composed of additive sprayer, desulfurizing system and denitrating system.

Owner:WUHAN KAIDI ELECTRIC POWER CO LTD

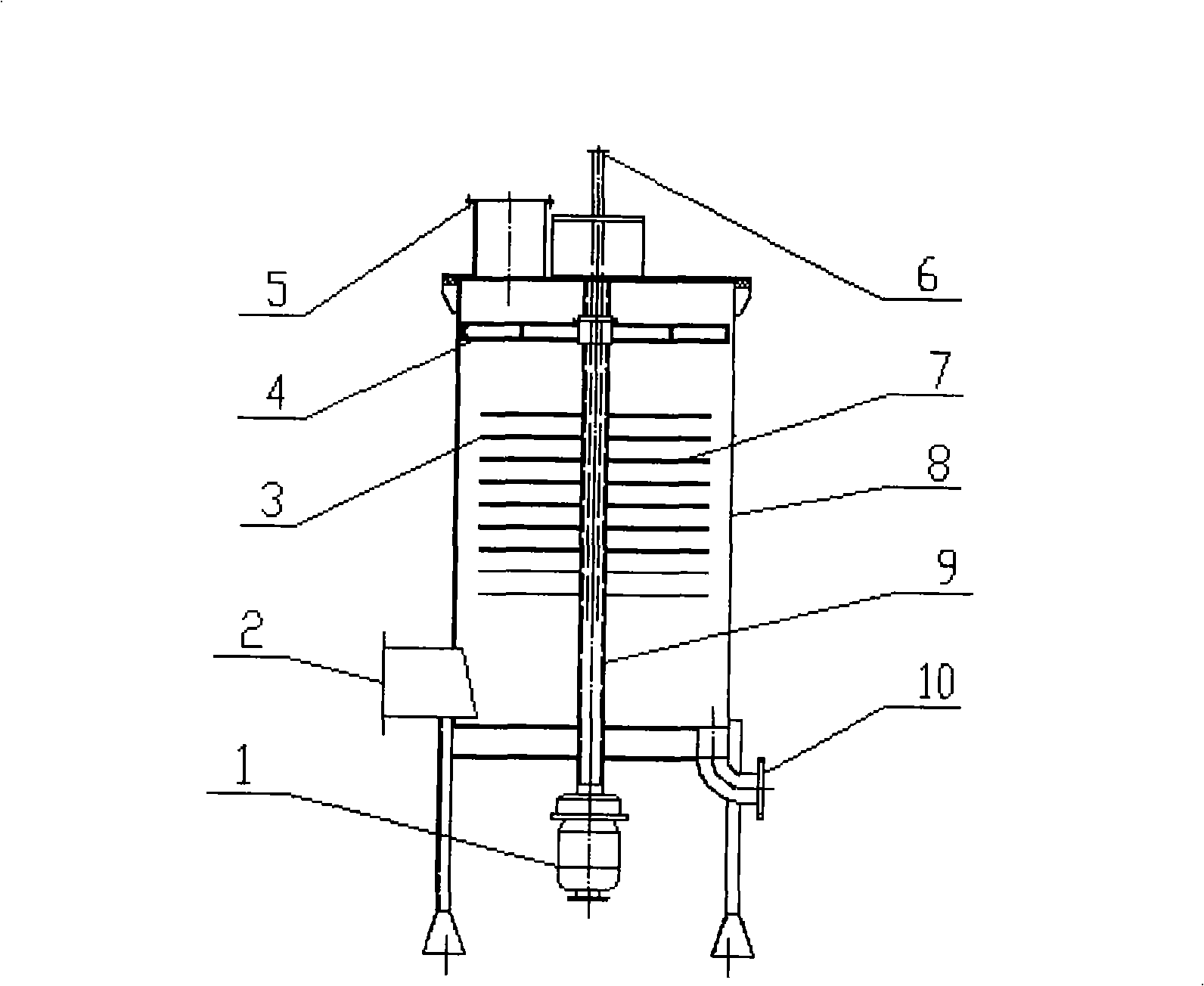

Plane material otter board stuffing type cross flow type hypergravity swinging bed and uses thereof

InactiveCN101254355ALow gas resistanceEnhanced mass transferUsing liquid separation agentFractional distillationHypergravityEngineering

The invention discloses a planar otter board packing type crossflow super-gravity rotating packed bed, as well as the application thereof. The rotating packed bed comprises a rotating packed bed shell, a motor and a rotating shaft; the rotating shaft positioned in the shell is of a hollow structure, the middle of the rotating shaft is inserted with a middle water pipe with an opening, the water pipe is provided with a liquid inlet, and small holes are distributed on the rotating shaft. Planar otter boards are fixed on the rotating shaft, and are horizontally arranged, and axial distances are kept among the otter boards. The planar otter board packing type crossflow rotating packed bed can achieve the mass transfer and the heat transfer between gas and liquid, and improved dust removal efficiency, and can avoid the high loss of gas resistance , so as to obtain higher heat transfer and mass transfer coefficients and higher dust removal efficiency under the lower gas resistance, thereby having the value of being widely spread and applied in the industry.

Owner:SOUTH CHINA UNIV OF TECH

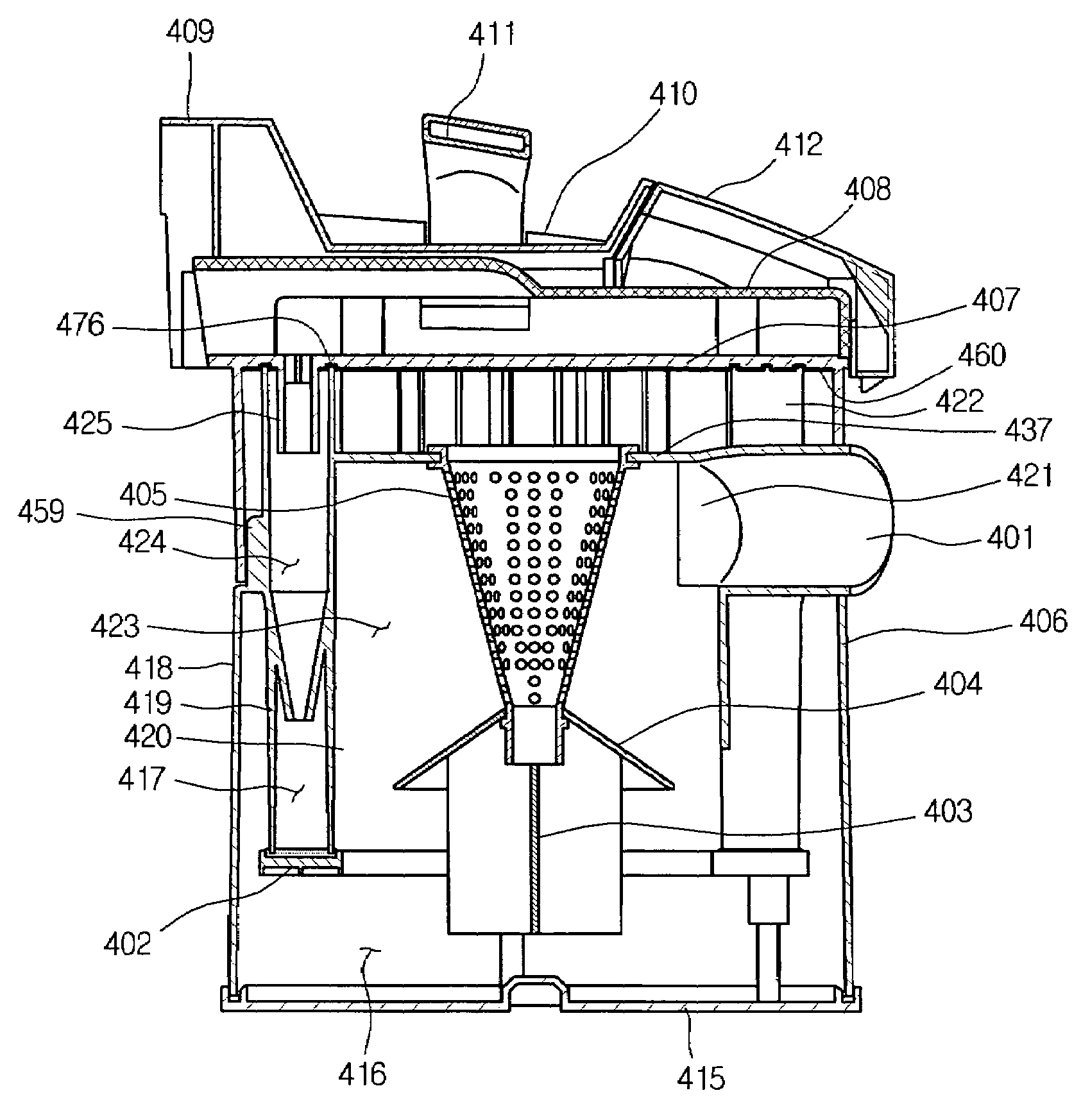

Cyclone dust collecting apparatus for vacuum cleaner

InactiveUS20070039292A1Reduce loadSave electricityCombination devicesSuction filtersEngineeringVacuum cleaner

The present invention is a cyclone dust collecting apparatus for a vacuum cleaner in which an air-whirling space and a contaminant collecting space are separated from each other. The cyclone dust collecting apparatus for the vacuum cleaner according to the present invention comprises a cyclone body connected to an extension tube; an inner cover provided at a lower side of the cyclone body, the inner cover having a hollow conical shape with an opened upper and lower ends; a grill unit through which the air is discharged, the grill unit being provided at a lower end of an air discharge tube of the cyclone body in the inner cover; and a contaminant receptacle for receiving a contaminant fallen from the inner cover, the contaminant receptacle being provided at a lower side of the inner cover.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

Dust collection unit for vacuum cleaner

InactiveUS7857878B2Improve dust removal efficiencyEfficient removalCleaning filter meansCombination devicesForeign matterForeign object

A dust collection unit for a vacuum cleaner includes a first dust collection part for filtering foreign objects in air, a second dust collection part for filtering foreign objects in the air that has passed through the first dust collection part, and a dust collection container having first and second dust collection chambers that correspond to the first and second dust collection parts, respectively. The first and second dust collection chambers store the foreign objects filtered by the respectively first and second dust collection parts in a state where parts of the respective first and second dust collection parts are received in the respective first and second dust collection chambers and the first and second dust collection chambers are provided in a line.

Owner:LG ELECTRONICS INC

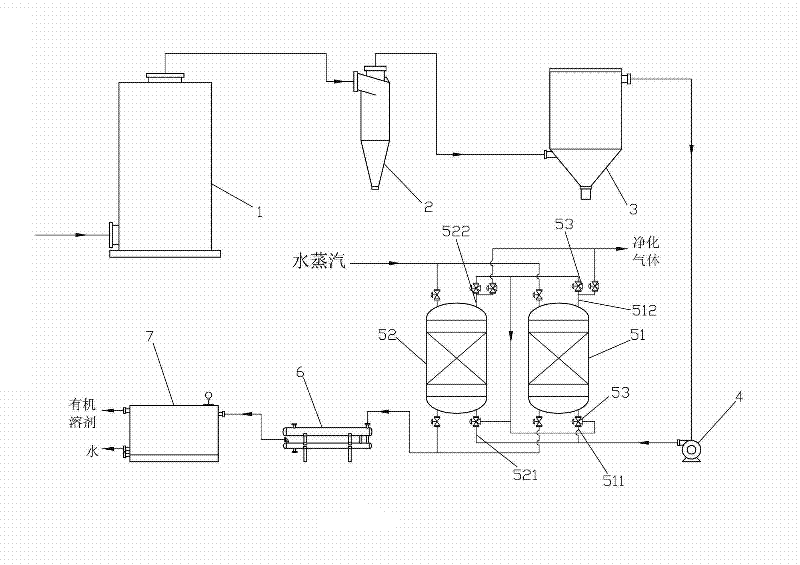

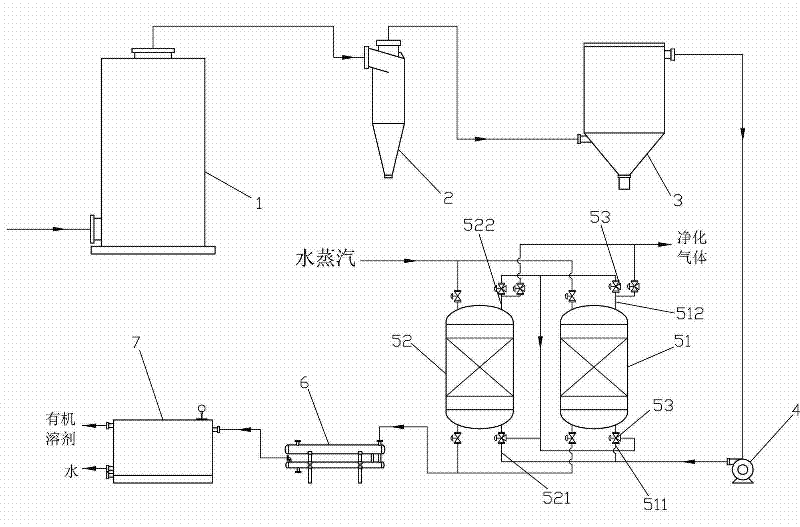

Recycling device for exhaust gas of painted organic solvent and method for recycling organic solvent

The invention discloses a recycling device for an exhaust gas of a painted organic solvent. The recycling device comprises a painting fog removing device, a fan, an absorbing jar, a condenser and an oil-water separator which are connected in turn, wherein the painting fog removing device comprises a gas collecting tank, a cyclone dust collector and a bag type dust collector; the gas collecting tank is used for temporarily storing the exhaust gas of the organic solvent; and the gas collecting tank, the cyclone dust collector and the bag type dust collector are connected in turn. All componentsof the recycling device are reasonably and compactly jointed; collection efficiency is high; and the painting fog is efficiently removed while a trouble in frequently exchanging filter cotton is avoided. The invention also discloses a method for utilizing the recycling device for the exhaust gas of the painted organic solvent to recycle the organic solvent. The method comprises the following steps: removing the painting fog; absorbing; desorbing steam; condensing; and separating oil from water, wherein the step of removing the painting fog is carried out by changing the painting fog into painting powder and then efficiently removing the painting fog. Compared with a traditional process, the method is more reasonable, compact and labor-saving.

Owner:中科天龙(厦门)环保股份有限公司

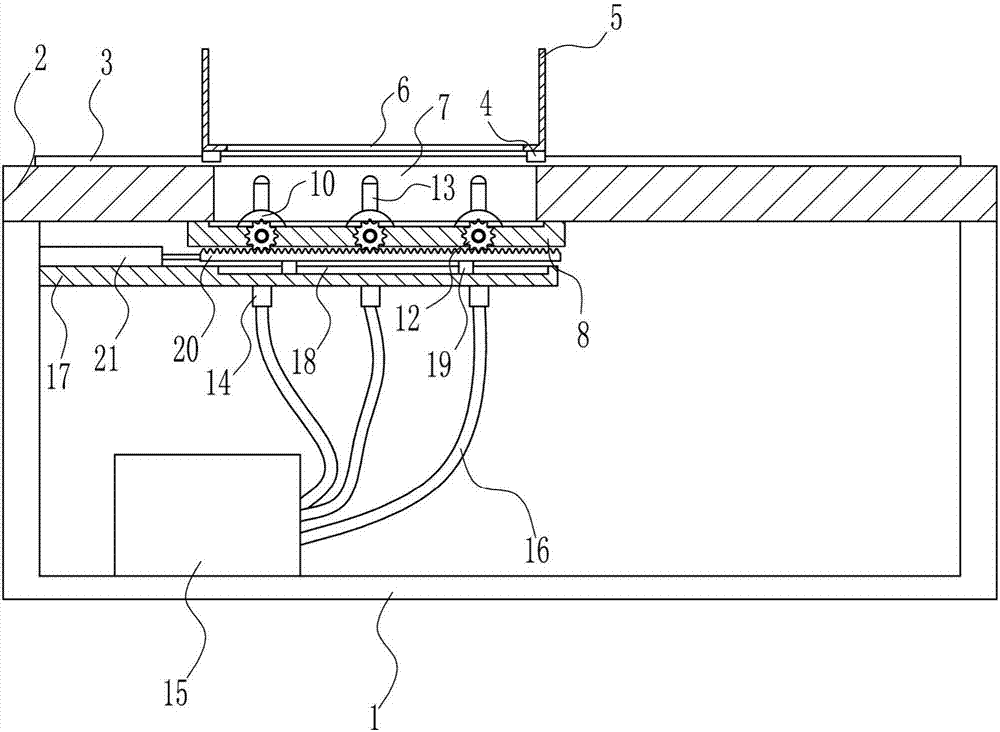

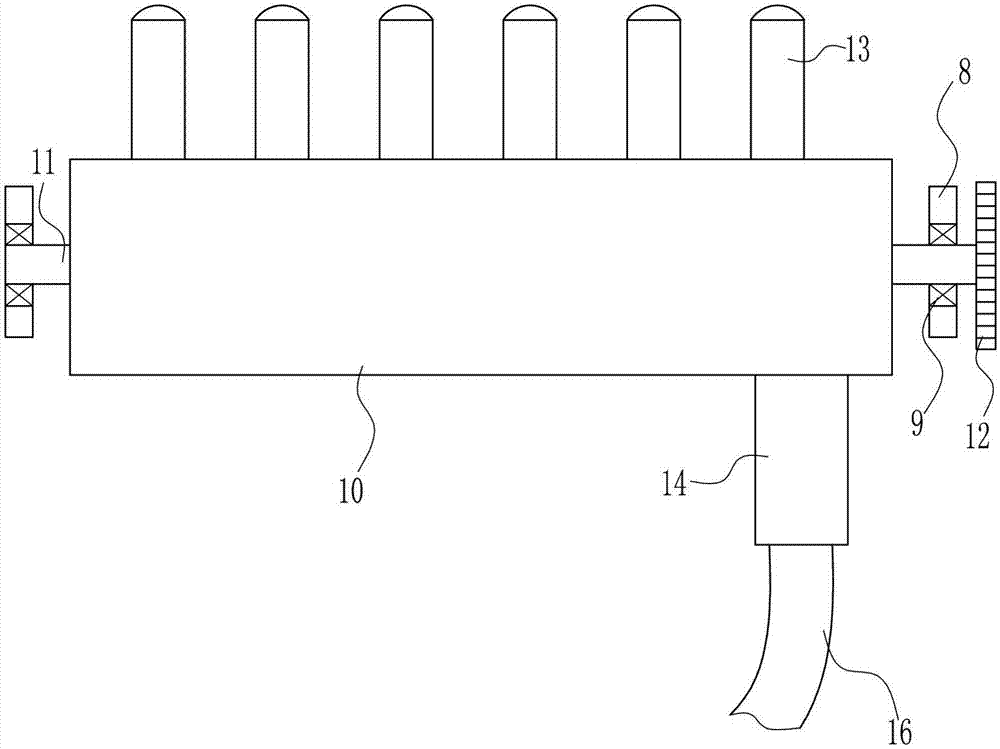

Dust control unit used after assembling of mainframe box of computer

InactiveCN106944416AAvoid inhalationAvoid driftingDirt cleaningDigital processing power distributionDust controlBolt connection

The invention belongs to the field of computer assembly, in particular to a dust removal device after assembly of a computer main case. The technical problem to be solved by the present invention is to provide a dust removal device after assembly of the computer main case which can reduce the labor intensity, improve the dust removal efficiency and improve the quality of the case. In order to solve the above-mentioned technical problems, the present invention provides such a dust removal device after the computer main case is assembled, which includes a first bracket, a workbench, a first slide rail, a first slider, a placement frame, a support plate, and a first bearing seat , main air pipe, rotating shaft, gear, air spray head, joint, etc.; the top of the first bracket is provided with a workbench, and the top of the workbench is horizontally connected with the first slide rail by means of bolt connection. The present invention blows air to the cabinet by swinging the air spray head left and right to blow away the dust in the cabinet, so that the dust in the cabinet can be removed, the labor intensity can be reduced, and the dust removal efficiency can be improved.

Owner:汪国栋

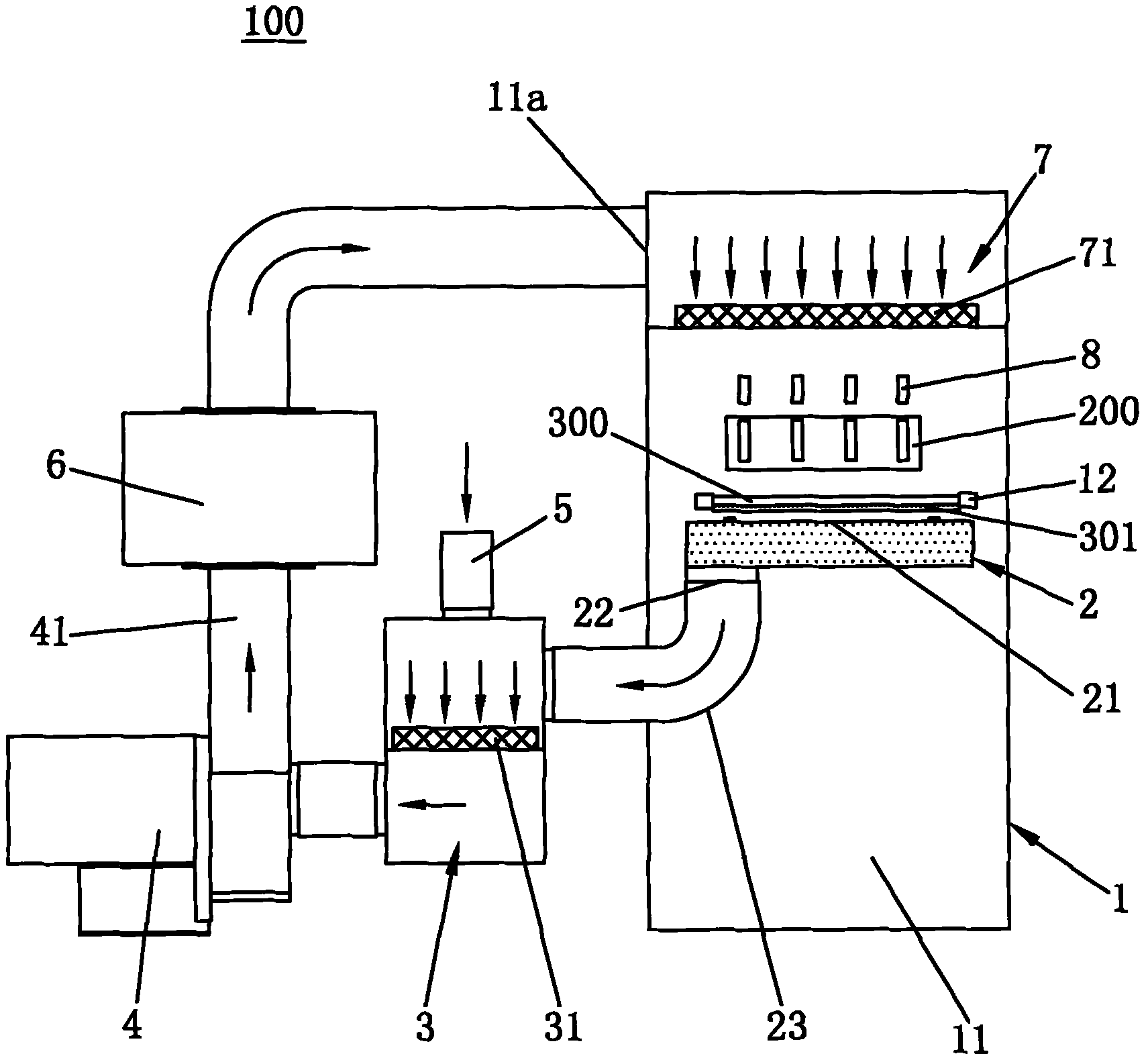

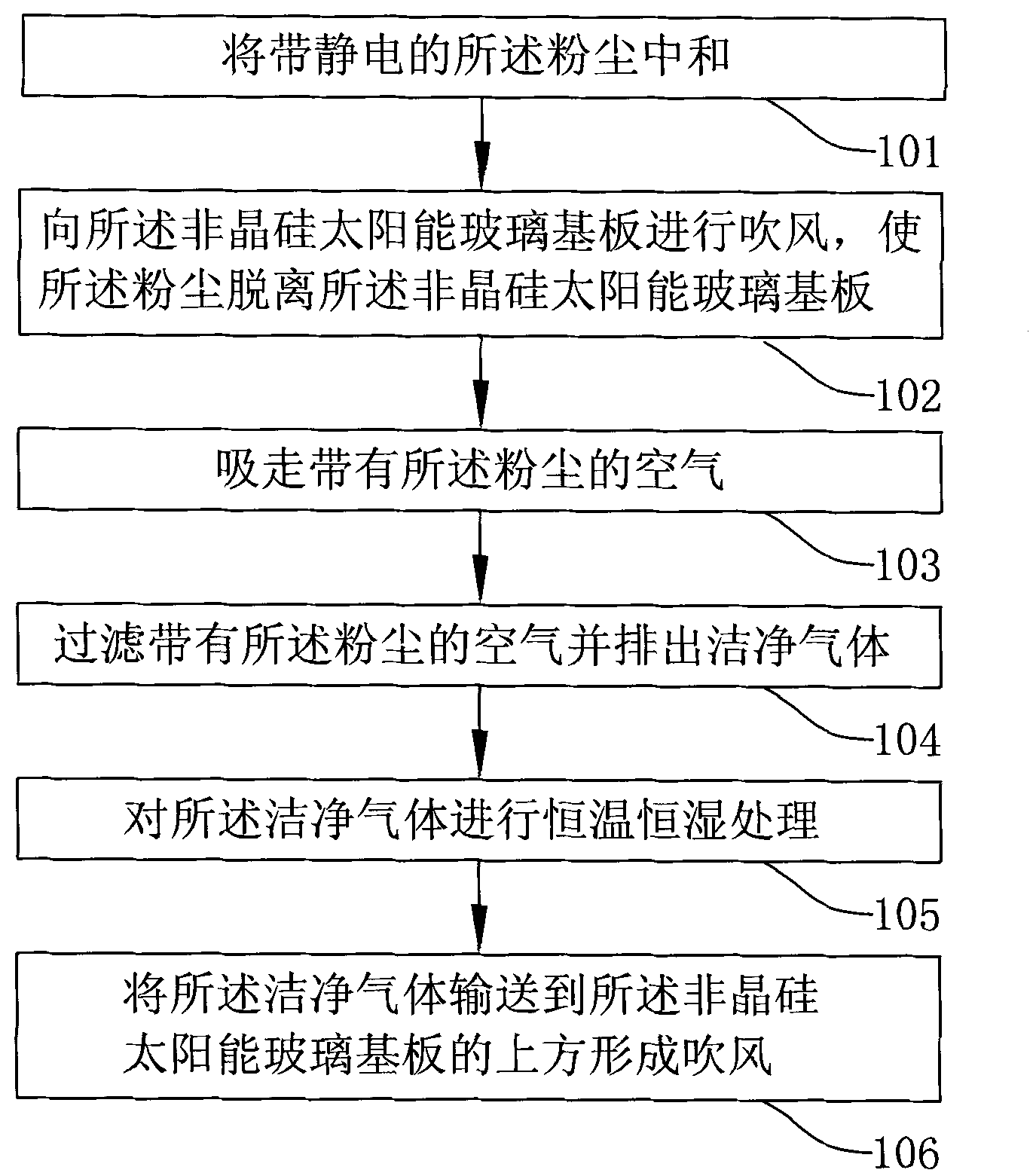

Laser recticle dedusting plant and dedusting method

InactiveCN101829848AEasy to remove dustImprove cleanlinessDirt cleaningAblative recordingLow noiseEngineering

The invention discloses a laser recticle dedusting plant. The laser recticle dedusting plant comprises a processing unit, a dust exhaust apparatus, a first filter unit, a high pressure exhaust fan and a plurality of electrostatic cleaning bars, wherein the processing unit comprises an inner cavity and an operating platform arranged in the inner cavity; the dust exhaust apparatus comprises a dust suction port and a dust-discharging port, the dust suction port is positioned under the operating platform, the dust-discharging port of the dust exhaust apparatus is communicated with the upper end of the first filter unit, the lower end of the first filter unit is communicated with the suction opening of the high pressure exhaust fan, a first filter net core is arranged between the upper end andthe lower end of the first filter unit, the air outlet of the high pressure exhaust fan is communicated with the inner cavity, and the electrostatic cleaning bars are evenly arranged on the laser generator. The laser recticle dedusting plant has high dedusting efficiency, low noise and little energy consumption. The invention also discloses a laser recticle dedusting method.

Owner:东莞晨真光伏有限公司

Cyclone dust collecting apparatus for vacuum cleaner

InactiveUS20050066469A1Increase swirl speedImprove dust removal efficiencyCleaning filter meansSuction filtersEngineeringVacuum cleaner

A cyclone dust-collecting apparatus comprises a first chamber fluidly communicated with a suction port, a second chamber fluidly communicated with the first chamber and a vacuum generating source, in which dirt is centrifugally separated form the air drawn in from the first chamber, and a partition having at least one penetrating hole connecting the first and the second chambers and at least one guide member disposed adjacent to the penetrating hole, the partition being formed between the first and the second chambers. Accordingly, when the air dispersed from the first chamber due to the penetrating hole and the guide member, flows into the second chamber, a speed of the swirling air in the second chamber increases. Therefore, the dust-collection efficiency of the cyclone dust collecting apparatus is improved.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

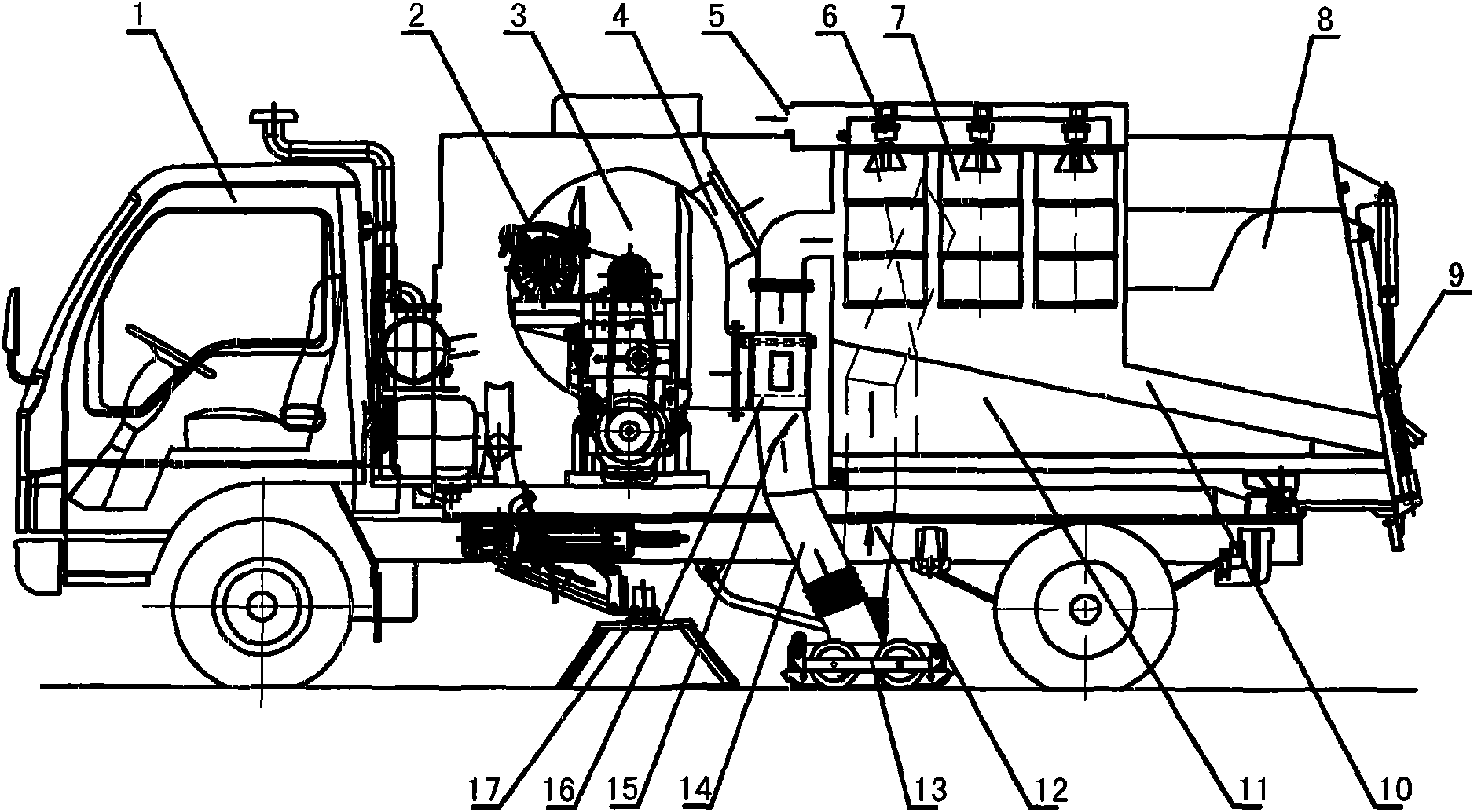

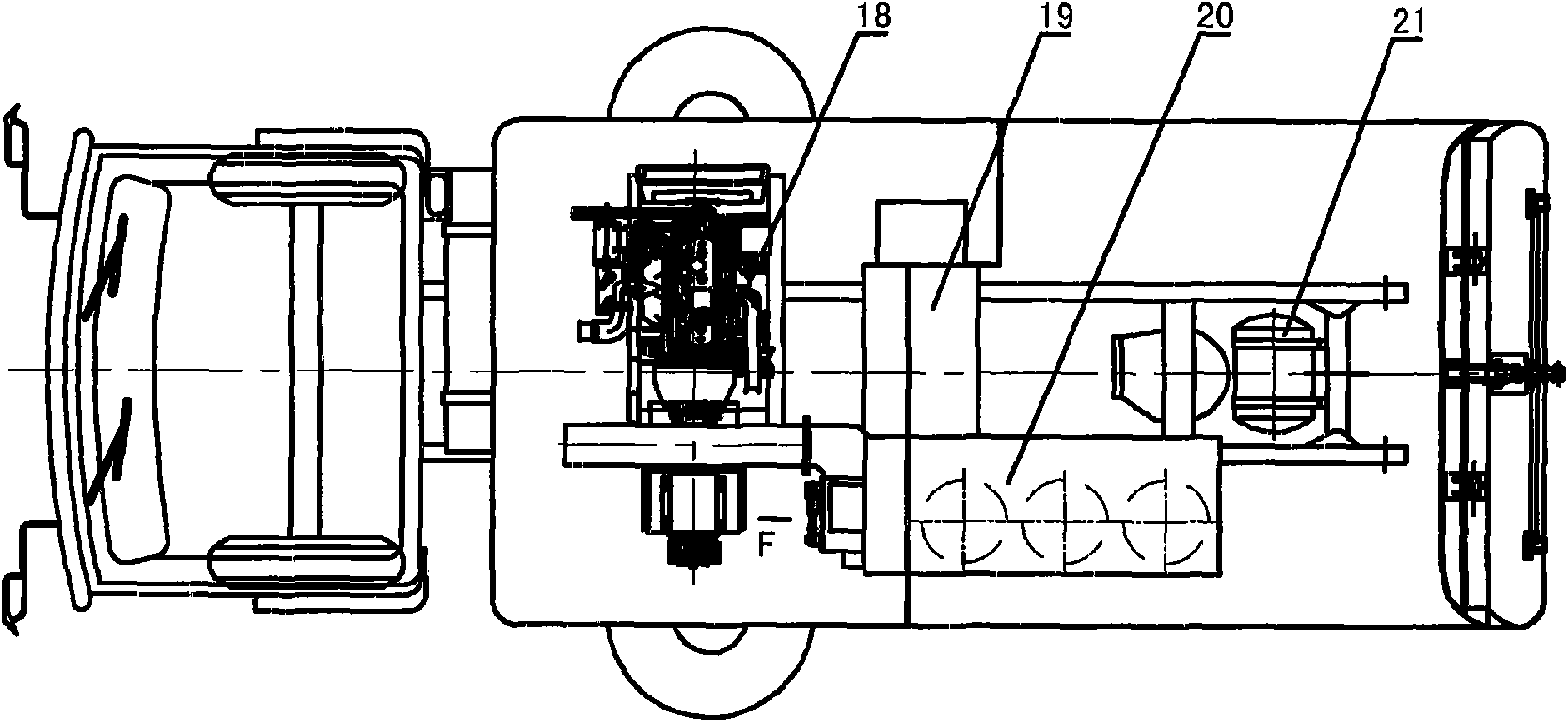

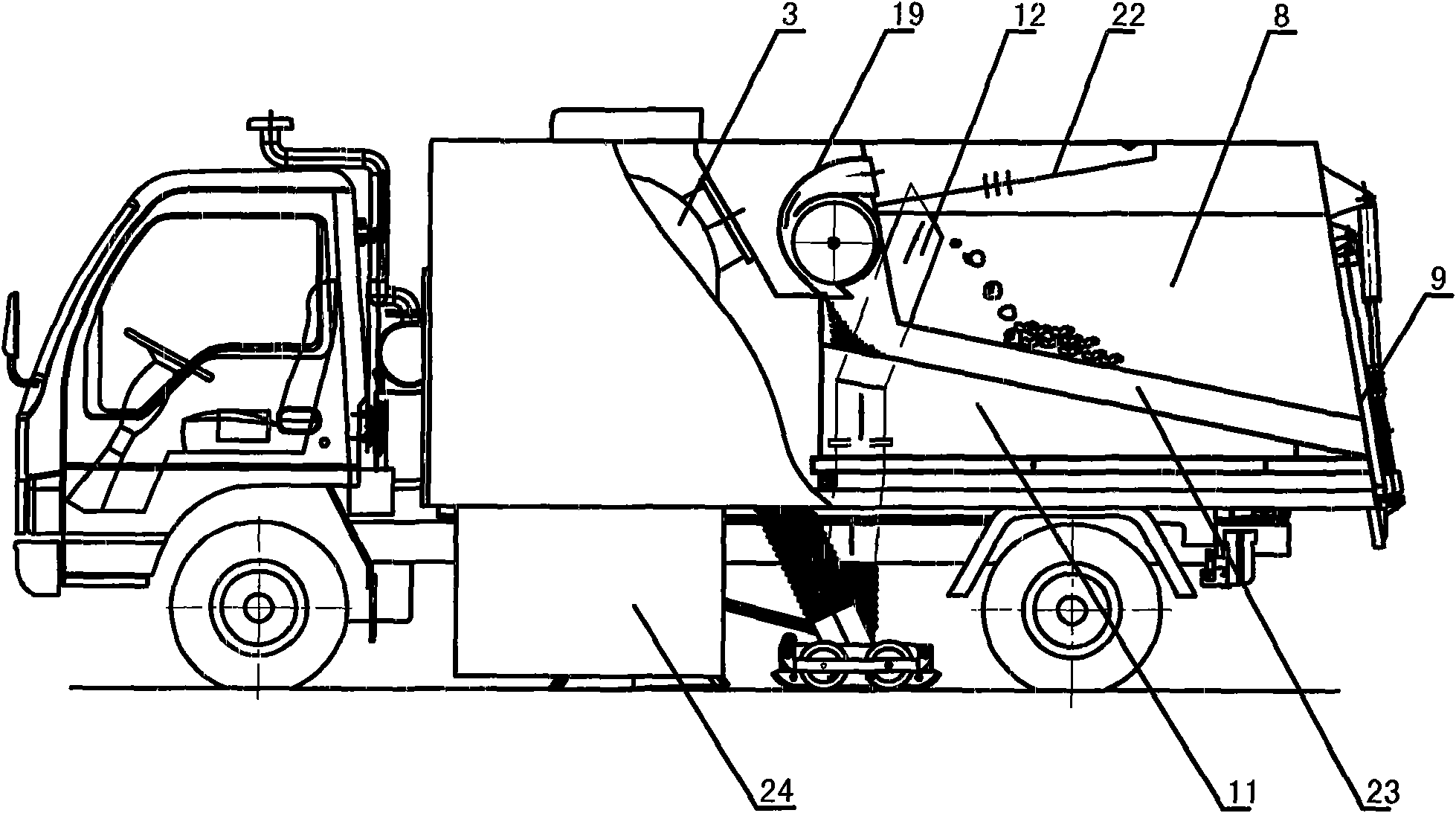

Sweeping and sucking type wet and dry road sweeper

The invention relates to a sweeping and sucking type wet and dry road sweeper, belonging to the special-purpose vehicle technology field. The road sweeper comprises an automobile chassis. A main fan is arranged at the upper part of the beam in the middle of the chassis and a rotary sweeper brush is installed at the lower part. A blowback type suction nozzle is arranged at the back of the rotary sweeper brush. The upper part at the back of the chassis is provided with a dedusting and dust collecting device and a water tank. The water tank is connected with nozzle at the rotary sweeper brush. The dedusting and dust collecting device comprises a dustbin and a dust filtering chamber. One part of the dustbin is communicated with the suction nozzle through a dust pipe and the other part is connected with an air inlet of the centrifugal separator through a filter screen. The air outlet of the centrifugal separator is communicated with the inlet of the main fan. The dust outlet goes to the back door of the dustbin. The outlet of the main fan is communicated with the blowback mouth at the suction nozzle by the blowback pipe and is communicated with the air outlet and the dust filtering chamber. The upper part of the dust filtering chamber is communicated with the air by a filter barrel. The road sweeper can sweep in a dry way or a wet way, is not limited by the climatic condition, combines suction and sweeping, has high cleaning rate, simple structure and easy sanitary tipping.

Owner:AEROSUN CORP

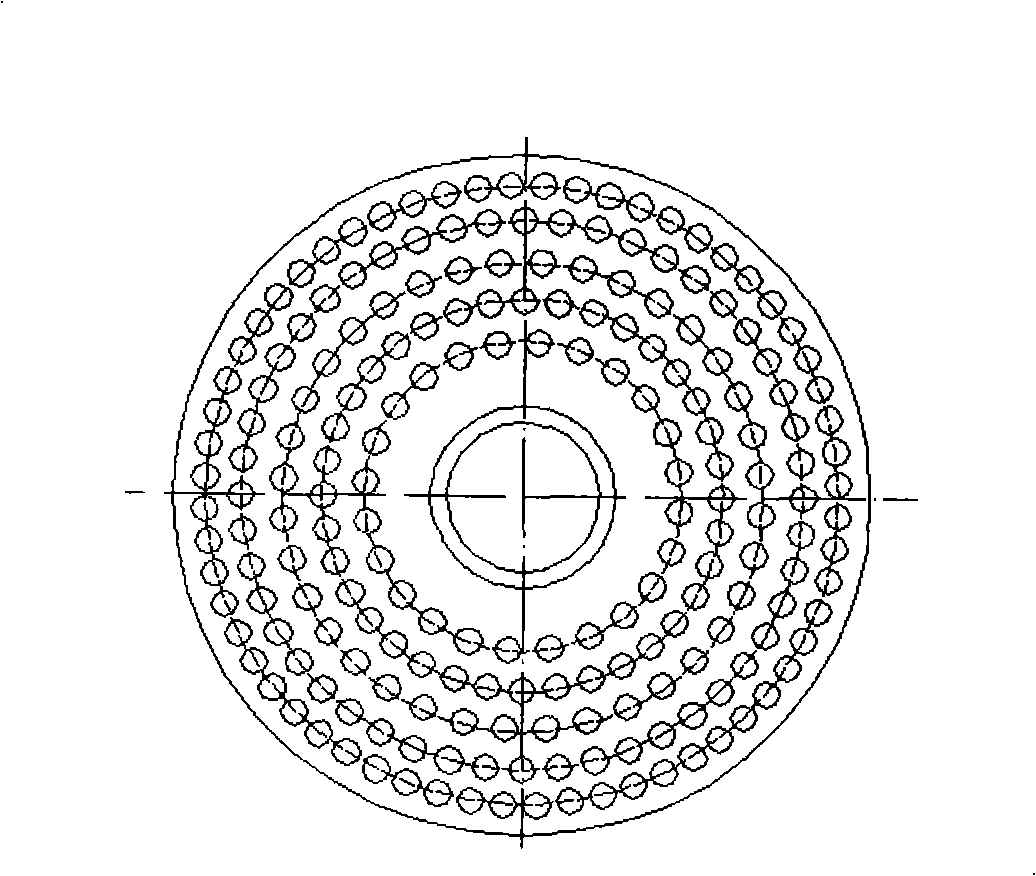

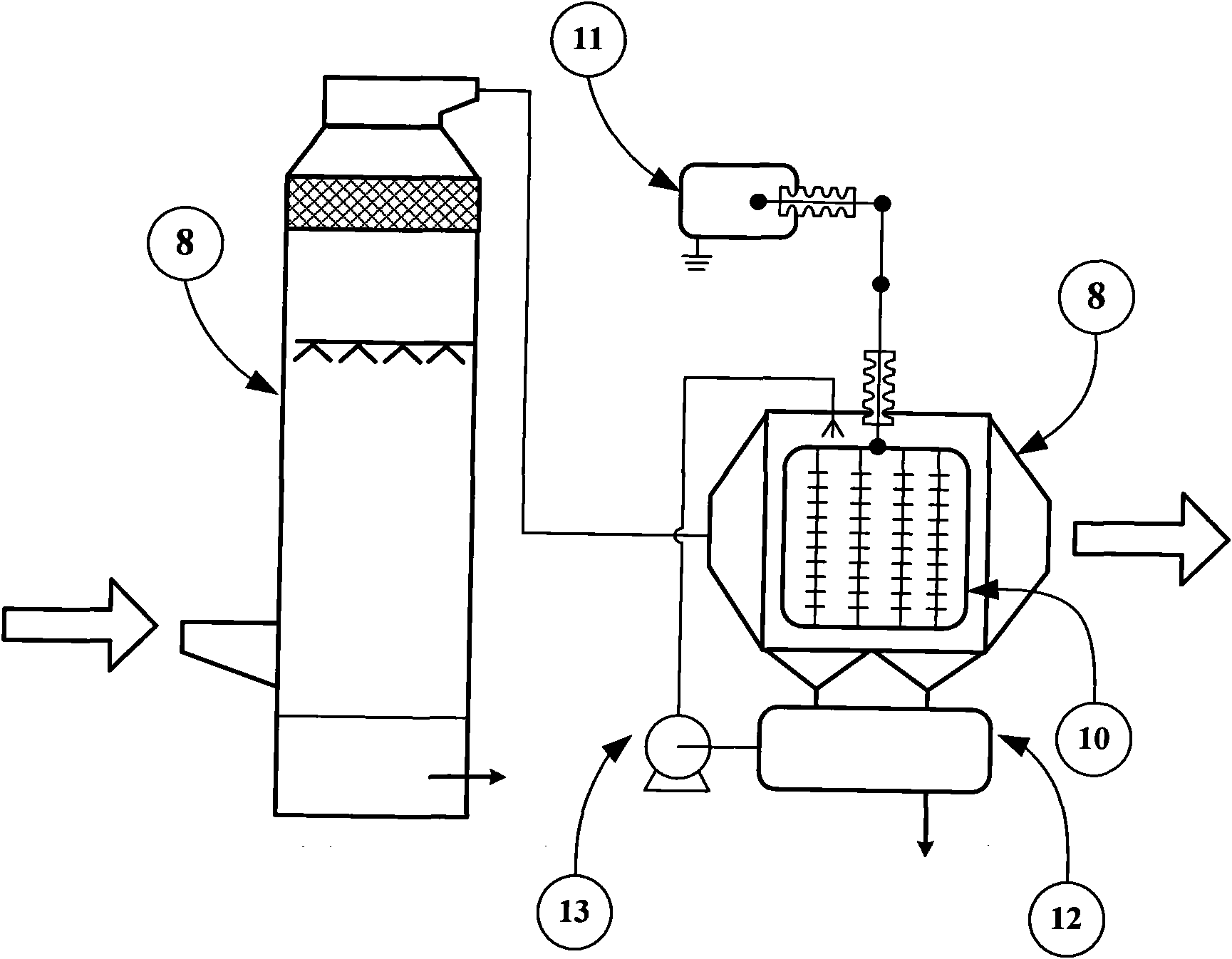

Wet static dedusting device

InactiveCN101780435AAvoid failureExtended service lifeExternal electric electrostatic seperatorHazardous substanceEngineering

The invention discloses a wet static dedusting device which comprises a tower body, an electrode support and an insulated pillar, wherein the electrode support is installed in the tower body. The wet static dedusting device is characterized in that a plurality of suspended electrode rods are fixedly arranged on the electrode support; a hollow condenser tube is sleeved outside the electrode rods; a clapboard is sealed and fixedly arranged in the tower body; the condenser tube is fixedly arranged on the clapboard, with the lower end running out of the clapboard; a water inlet is arranged on the tower body; one end of the insulated pillar is fixedly connected with the electrode support, and the other end of the insulated pillar is fixedly connected with the tower body; a waste gas inlet and a dirt drain port are arranged at the lower end of the tower body; and a gas exhaust port is arranged at the upper end of the tower body. The wet static dedusting device has the advantages that a uniform water film renewed constantly is formed on the inner wall of the condenser tube and serves as a dust collecting electrode when the electrode rods discharge so that a uniform electrostatic field can be formed in the condenser tube; charges of the high voltage electrostatic electrons generated by the electrode rods adhere to the harmful particles in the exhaust gas, and under the action of the high voltage electric field, the harmful particles directionaly migrate to the wall of the condenser tube and then flow down with the water film to be drained; the ozone or plasma free radicals generated when the electrode rods discharge can oxidize and remove the fetid substances in the exhaust gas, so the exhaust gas can get deep purification treatment; and the wet static dedusting device has good dedusting and purifying effects and the whole equipment can operate safely for a long period.

Owner:NINGBO UNIV

Low-temperature plasma smoke compound pollutant control method

InactiveCN102059050ALow costImprove space utilizationCombination devicesAir quality improvementNitric oxideHigh pressure

The invention discloses a low-temperature plasma smoke compound pollutant control method. By discharging at a high voltage to generate low-temperature plasmas in a dry reactor and a wet reactor, the method controls pollutants and oxidized by-products in the smoke, such as smoke dusts, sulfur dioxide, oxynitride, hydrogen sulfide, hydrogen chloride, heavy metal and the like, by combination with the conventional dedusting method, the ammonia method desulfuration, the limestone / gypsum wet method, the rotary atomization drying method and the like, wherein the dry plasma reactor is used together with a dedusting device to improve the dedusting efficiency and oxidize the nitric oxide; and an absorbing device is used together with the wet plasma reactor to remove gaseous pollutants, oxidize ammonium sulfite, namely a desulfurized product of an ammonia absorber, demist and purify the tail gas. The method can be used for controlling smoke compound pollutants of boilers or incinerators.

Owner:ZHEJIANG UNIV

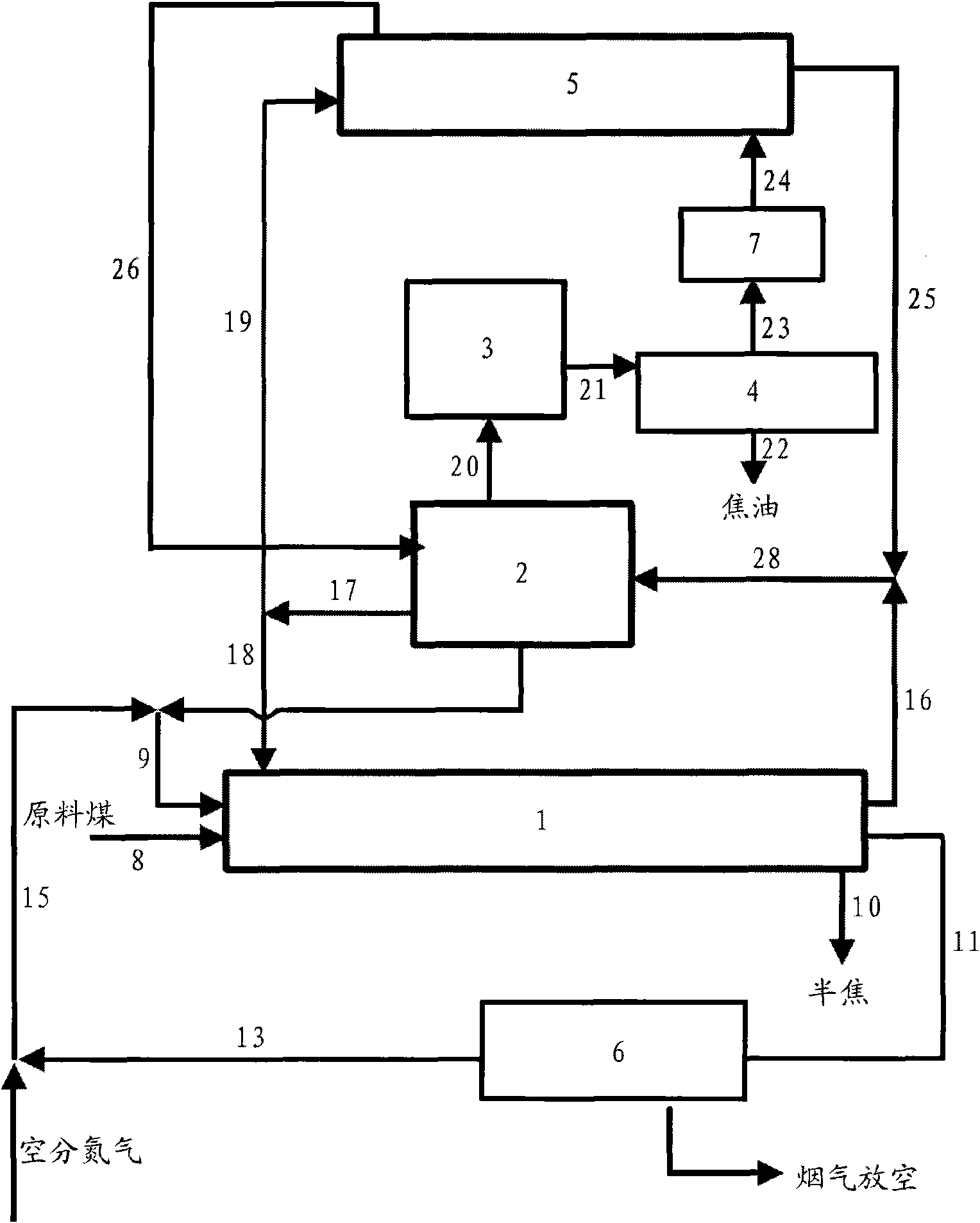

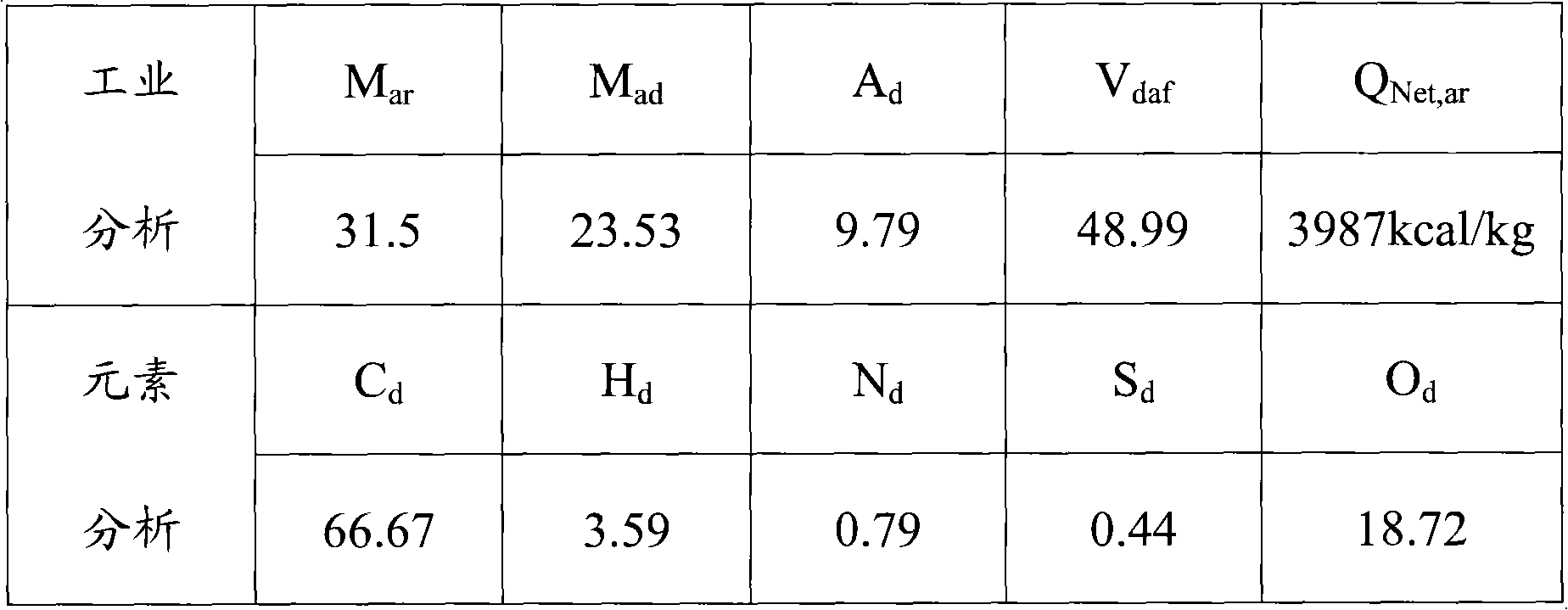

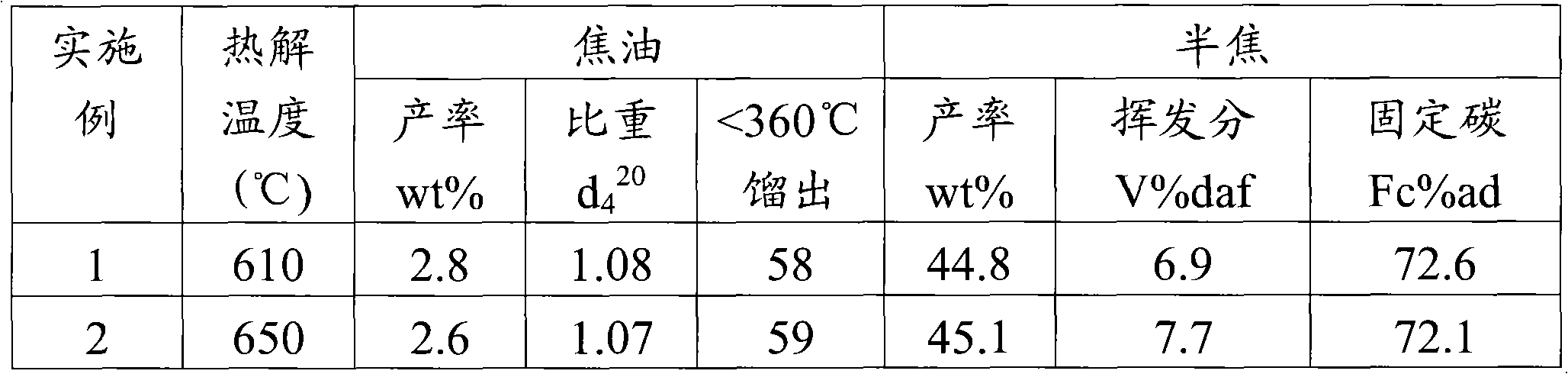

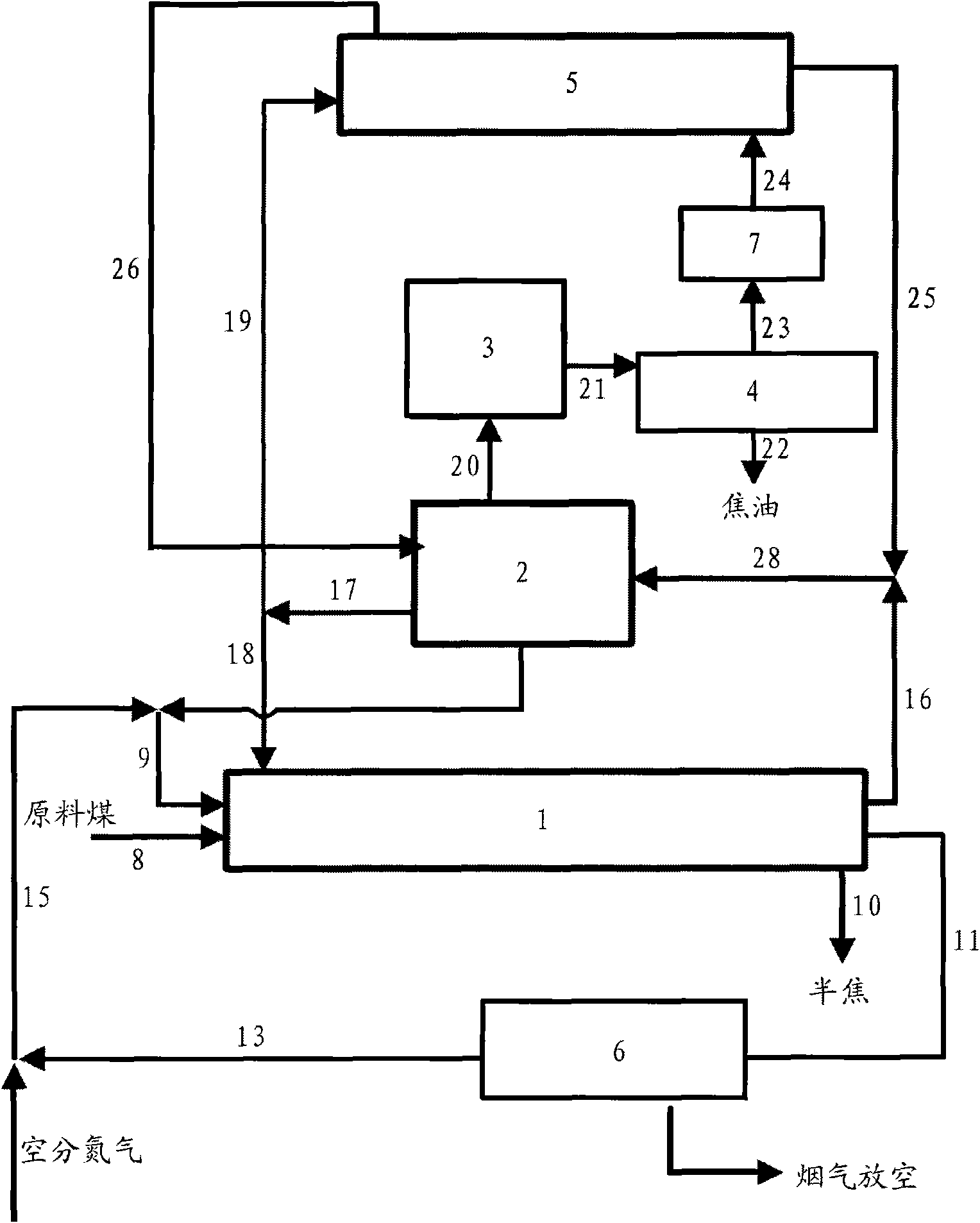

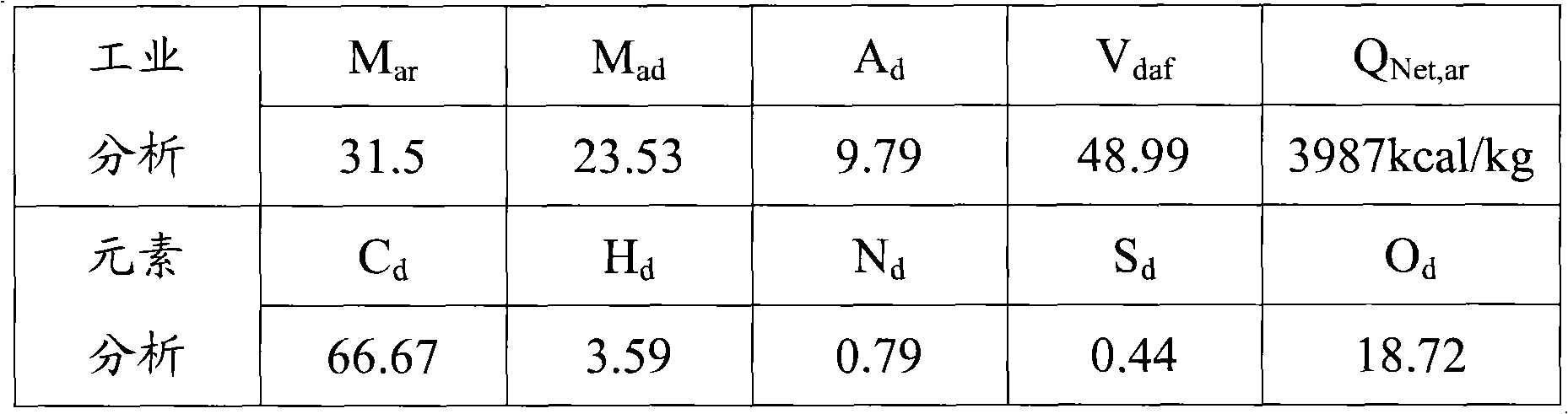

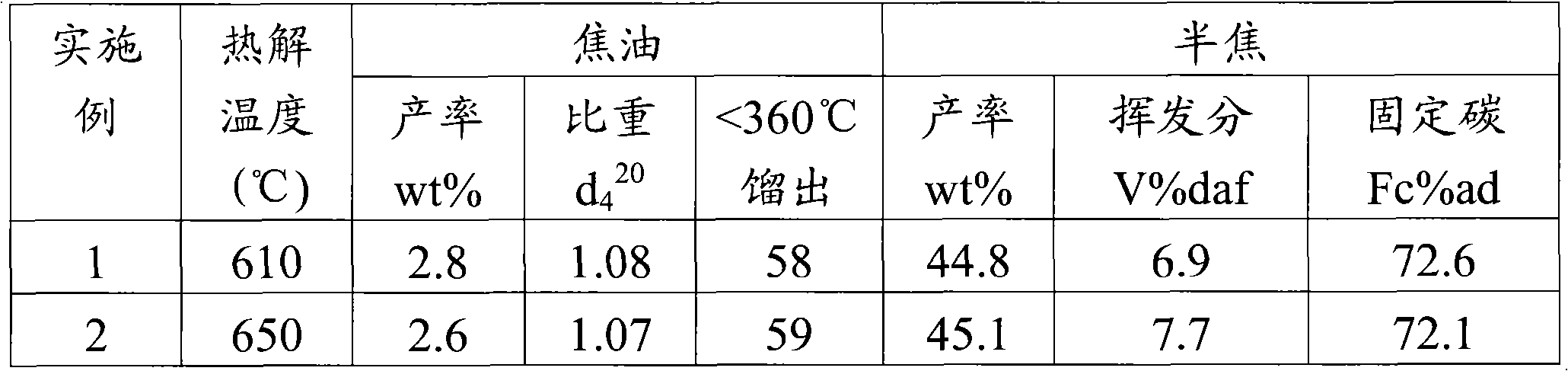

Method for upgrading coal pyrolysis

ActiveCN101608125AAvoid enteringReduce separation loadDirect heating destructive distillationOven incrustations prevention/removalGranularityFlue gas

The invention provides a method for upgrading coal pyrolysis, comprising the following steps: (a) sending raw coal with granularity being less than and equal to 30mm into a rotary drier, so that the raw coal and hot flue gas are connected with each other by the means of parallel flow and directly change heat, and the raw coal exchanges heat indirectly with hot semicoke from a pyrolyzer in the rotary drier, to dry the raw coal; (b) mixing the dried raw coal with the high-temperature semicoke from a heating rotary kiln and sending the mixture into the pyrolyzer, wherein the coal material directly changes heat with the high-temperature semicoke and pyrolyzes to generate hot semicoke, tar steam and coal gas, wherein final pyrolyzing temperature is 500 DEG C-700 DEG C; and (c) sending a part of the hot semicoke generated into the heating rotary kiln for processing by means of heating, and sending the rest part of the hot semicoke into the rotary drier for exchanging heat directly with the raw coal. The method for upgrading coal pyrolysis has flexible operation, wide granularity range of the coal material, good quality of the generated semicoke and the generated tar, high cascade utilization of energy and high system thermal efficiency, properly solving the technical problems such as dust and tar blocking, high dust content in the tar, etc.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Device for improving quality of coal by pyrolysis

ActiveCN101608126AAvoid enteringReduce separation loadDirect heating destructive distillationOven incrustations prevention/removalGranularityFlue gas

The invention provides a device for improving the quality of the coal by pyrolysis, comprising a rotary drier, a pyrolyzer and a heating rotary kiln. The rotary drier is used for receiving and drying raw coal with granularity being less than and equal to 30mm, and is provided with a sleeve structure to directly change heat between the raw coal and the hot flue gas and indirectly change heat between the raw coal and hot semicoke; the pyrolyzer receives mixture of the dried raw coal and the high-temperature semicoke by a feed line of solid material, directly changes heat between the raw coal and the hot semicoke, pyrolyzes the mixture, and is further provided with a heat clamping sleeve accompanied with high-temperature flue gas; and the heating rotary kiln is used for receiving the hot semicoke from the pyrolyzer and processing the hot semicoke by the means of heating. The device for improving the quality of the coal by pyrolysis has flexible operation, good quality of the generated semicoke and the generated tar, high cascade utilization of energy and high system thermal efficiency, properly solving the technical problems such as dust and tar blocking, high dust content in the tar, etc.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Cyclone separating apparatus and a vacuum cleaner having the same

InactiveUS20050050865A1Improve efficiencyPrevents deterioration of suction forceCleaning filter meansCombination devicesCyclonic separationPhencyclone

A cyclone separating apparatus and a vacuum cleaner having the same are disclosed. More specifically, the cyclone separating apparatus for a vacuum cleaner comprises a first cyclone for separating drawn-in air, and a plurality of second cyclones installed on an outer periphery of the first cyclone to enclose the first cyclone. Accordingly, because a plurality of the cyclones separates dust, and a bulky structure is improved to a compact structure, suction force deterioration does not occur, and, dust-collecting efficiency is increased.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

Building rubbish crusher

InactiveCN106925378ACause wasteImprove dust removal efficiencyCombination devicesGas treatmentArchitectural engineeringCrusher

The invention discloses a building rubbish crusher which comprises a rack and baffles. An electromotor is mounted at the upper end of the left side of the rack. A machine body is arranged at the upper end of the rack. A feeding opening is fixed to the upper end of the machine body. The lower end of the feeding opening is connected with the baffles through supporting rods. A sealing ring is arranged on the outer side of each baffle. Crushing rollers are mounted in the machine body. An exhaust opening is formed in the upper end of the right side in a cavity of the machine body and located below the crushing rollers. A filter screen is mounted in the exhaust opening. The upper end of an air suction motor is connected with the exhaust opening through an air outlet pipe. The machine body is mounted on the left side of the exhaust opening. A water tank is fixed below the air suction motor and located on the right side of the rack. A discharging opening is mounted below the machine body. A shock absorption mat is arranged at the upper end in the discharging opening. The building rubbish crusher is provided with the water tank, sucked-out building rubbish dust can be removed through water in the water tank, the dust removal efficiency is high, and water resources cannot be wasted.

Owner:THE FOURTH OF CHINA CONSTR SEVENTH ENG

Multistage cyclone separation device of dust collector

InactiveCN101862165AExcellent vortex nuclear deformationReduce resistanceSuction filtersCycloneCyclonic separation

The invention relates to a multistage cyclone separation device of a dust collector, which comprises an upstream first-stage cyclone separation device (1), a downstream second-stage cyclone separation device (2) and a gas flow channel (3), wherein the gas flow channel (3) is used for connecting the upstream first-stage cyclone separation device (1) and the downstream second-stage cyclone separation device (2), the downstream second-stage cyclone separation device (2) comprises a cyclone filter (5), a dust-gas separation cover (6) and a central cylinder (8), at least two tangential air inlets are arranged on the cylindrical later surface of a cyclone cylinder body (20), an exhaust pipe (504) is positioned on the cylindrical top surface of the cyclone cylinder body (20), and the tangential air inlets have equal cross sectional area, are positioned on the same horizontal surface and are arranged relatively to the central shaft of the cyclone cylinder body (20) according to equal phase difference. The invention has the advantages that the short-circuit flow of the exhaust pipe is less than that of a single-gas inlet cyclone separation device, the axial symmetry of a flow field is more excellent, and the proportion that small-granule dust directly enters an exhaust port without cyclone separation after entering a separation chamber is reduced.

Owner:马吉

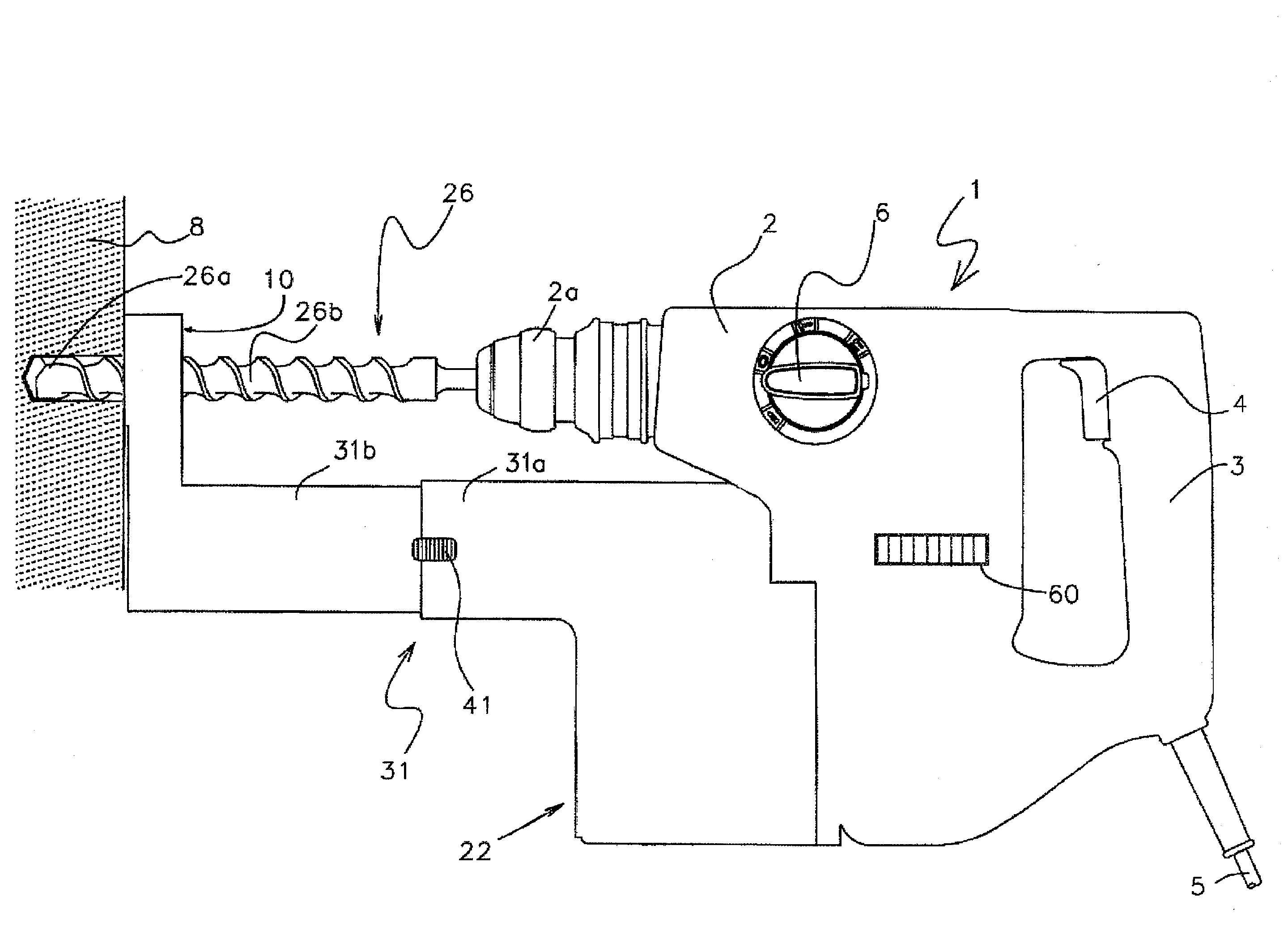

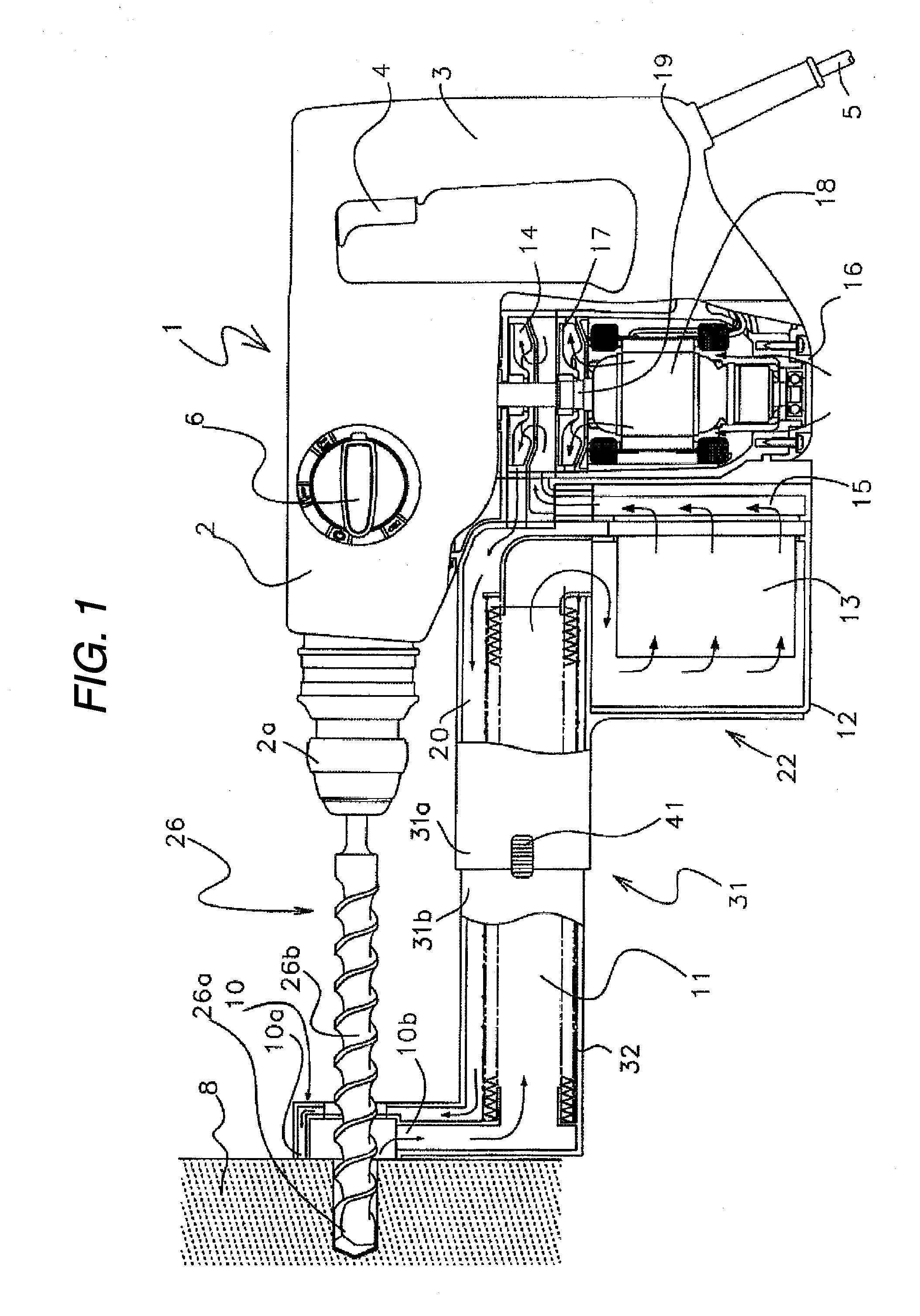

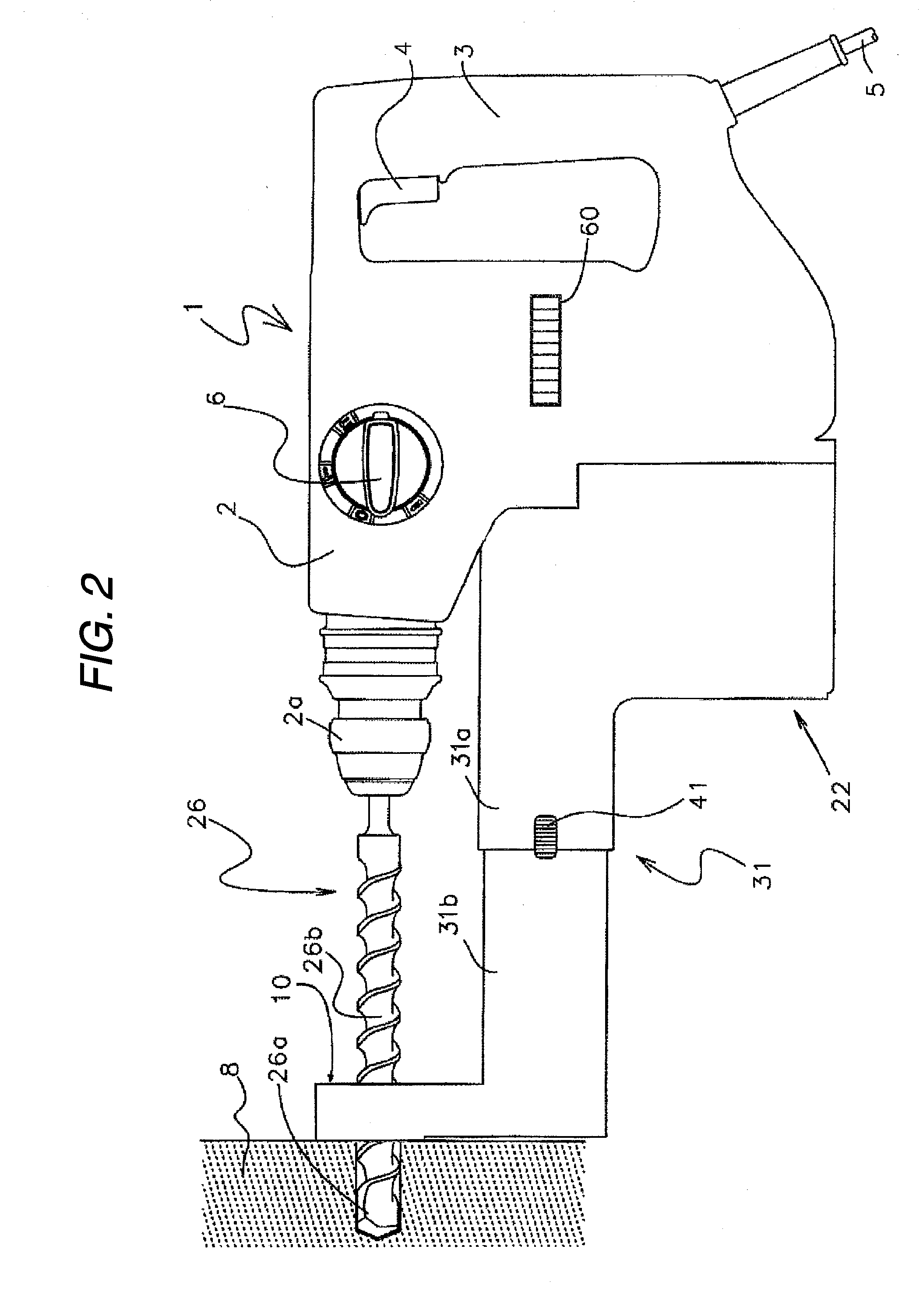

Drilling tool with dust collector

InactiveUS20090148248A1Improve dust removal efficiencyImprove workabilityThread cutting feeding devicesBoring/drilling componentsEngineeringDrill bit

According to the invention, a drilling tool includes: a motor; a transmission drive unit for transmitting a rotation force of the motor to rotate a drill bit; and a dust collector for collecting dust produced from a workpiece drilled by the drill bit, wherein the dust collector is provided with a pierced portion pierced by the drill bit, a dust collection port for sucking the produced dust and its surrounding air, and a blowoff port for blowing air against a vicinity of the piercing drill bit.

Owner:HITACHI KOKI CO LTD

System and method for treating tail end waste water by using smoke waste heat

ActiveCN103982903AAchieve recyclingLower smoke temperatureLighting and heating apparatusWater/sewage treatmentAir preheaterCoal

The invention discloses a system and a method for treating tail end waste water by using smoke waste heat. The system comprises a coal economizer, an air preheater, a smoke cooler, an electric deduster, a desulfurization tower, a waste water preprocessor and a waste water spraying evaporator which are communicated in sequence; a waste water pump is arranged on the pipeline for communicating the waste water processor and the waste water spraying evaporator; the smoke inlet of the waste water spraying evaporator is communicated with the pipeline between the coal economizer and the air preheater; the hot water outlet of the smoke cooler is communicated with a waste heat air heater by a circulation pump; the hot air outlet of the waste heat air heater is communicated with the air preheater. The smoke outlet of the waste water spraying evaporator is communicated with the electric deduster by the smoke cooler. The invention provides the method for treating tail end waste water by using the smoke waste heat. The smoke tampering is performed and the smoke temperature is reduced while the tail end waste water is treated, so the dedusting efficiency is improved, the low-temperature dedusting is realized, the desulfurization water consumption is reduced, the method has benefits of three aspects of energy saving, water saving and environment friendliness, and the zero emission of the waste water from a power station is truly realized.

Owner:XIAN THERMAL POWER RES INST CO LTD

Separating apparatus

InactiveUS8409335B2Improve dust removal efficiencyEasy to separateCombination devicesAuxillary pretreatmentEngineering

The present invention relates to a separating apparatus for separating particles from a fluid flow. Particularly, but not exclusively, the invention relates to a domestic vacuum cleaner having such a separating apparatus for removing dust particles from a dust laden airstream. The separating apparatus includes a first cyclonic cleaning stage including at least one cyclone, and an electrostatic filter, wherein the electrostatic filter is in fluid communication with the at least one cyclone via an air passage, at least a portion of the air passage being formed longitudinally through the separating apparatus, wherein at least a portion of the first cyclonic cleaning stage, the electrostatic filter and the air passage are arranged concentrically.

Owner:DYSON TECH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com