Low-temperature plasma smoke compound pollutant control method

A low-temperature plasma and control method technology, which is applied in the field of environmental protection/exhaust gas purification, can solve the problems of low efficiency of electrostatic precipitator, low energy utilization efficiency, and high energy consumption, and achieves small footprint, low energy consumption, and oxidation efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

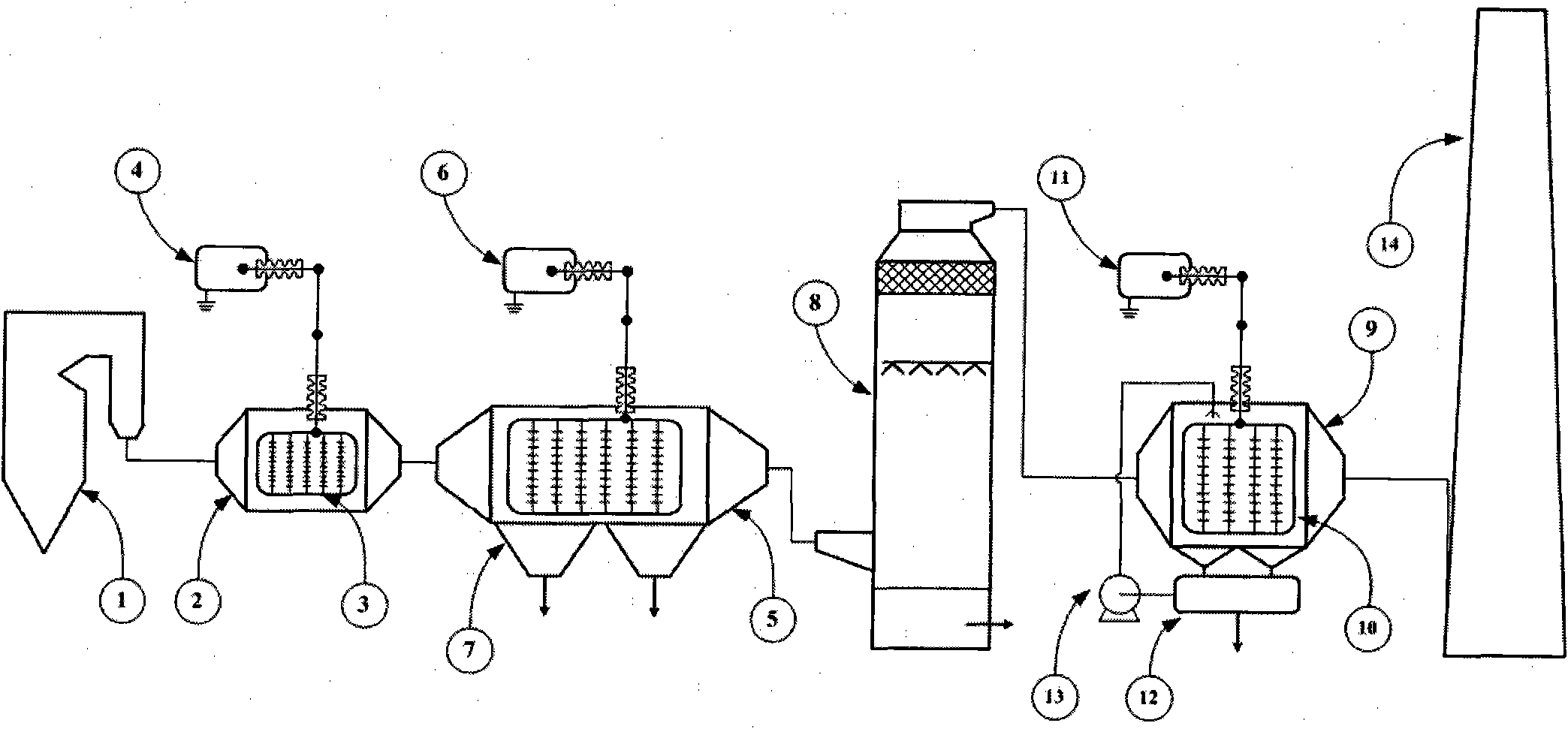

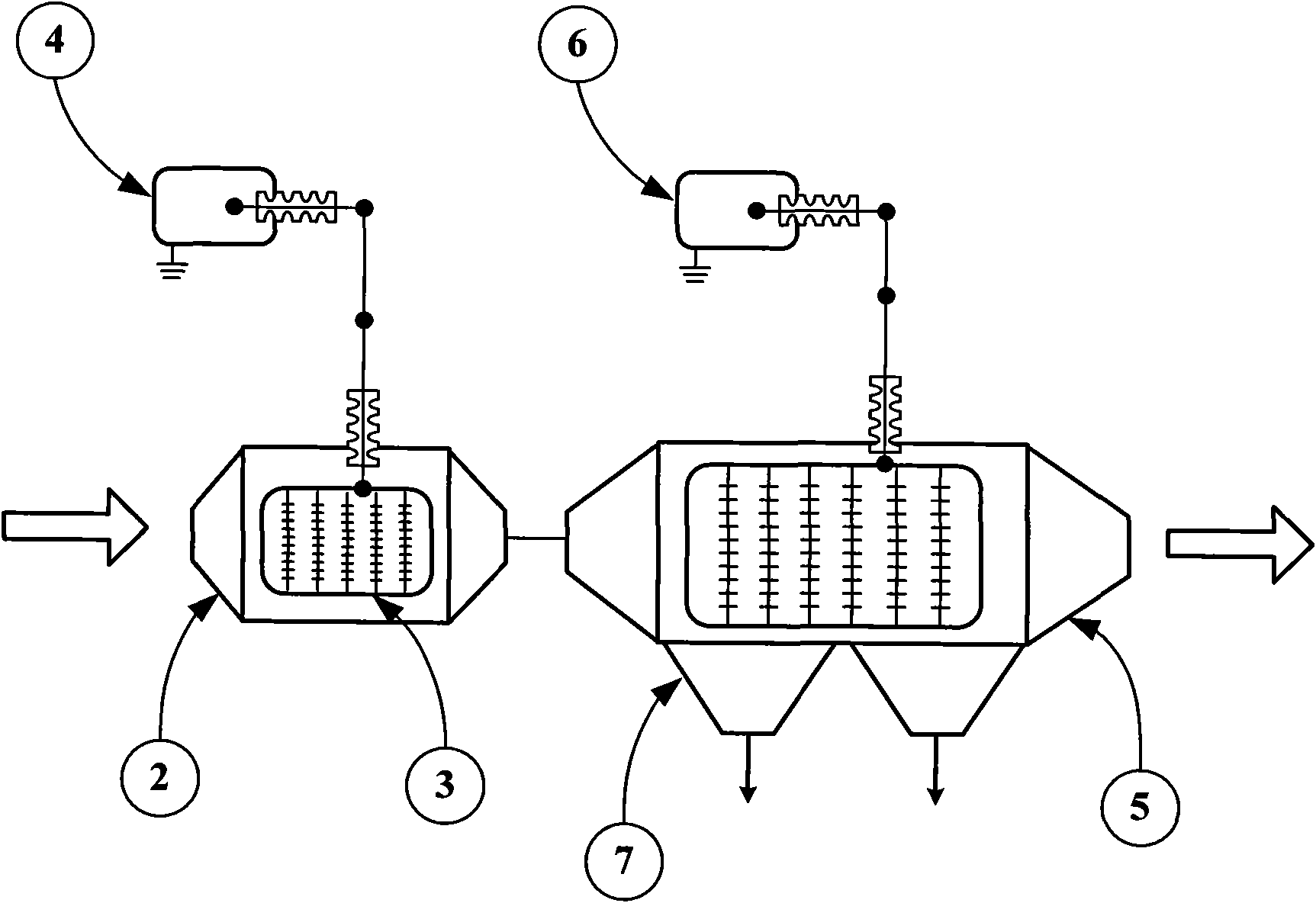

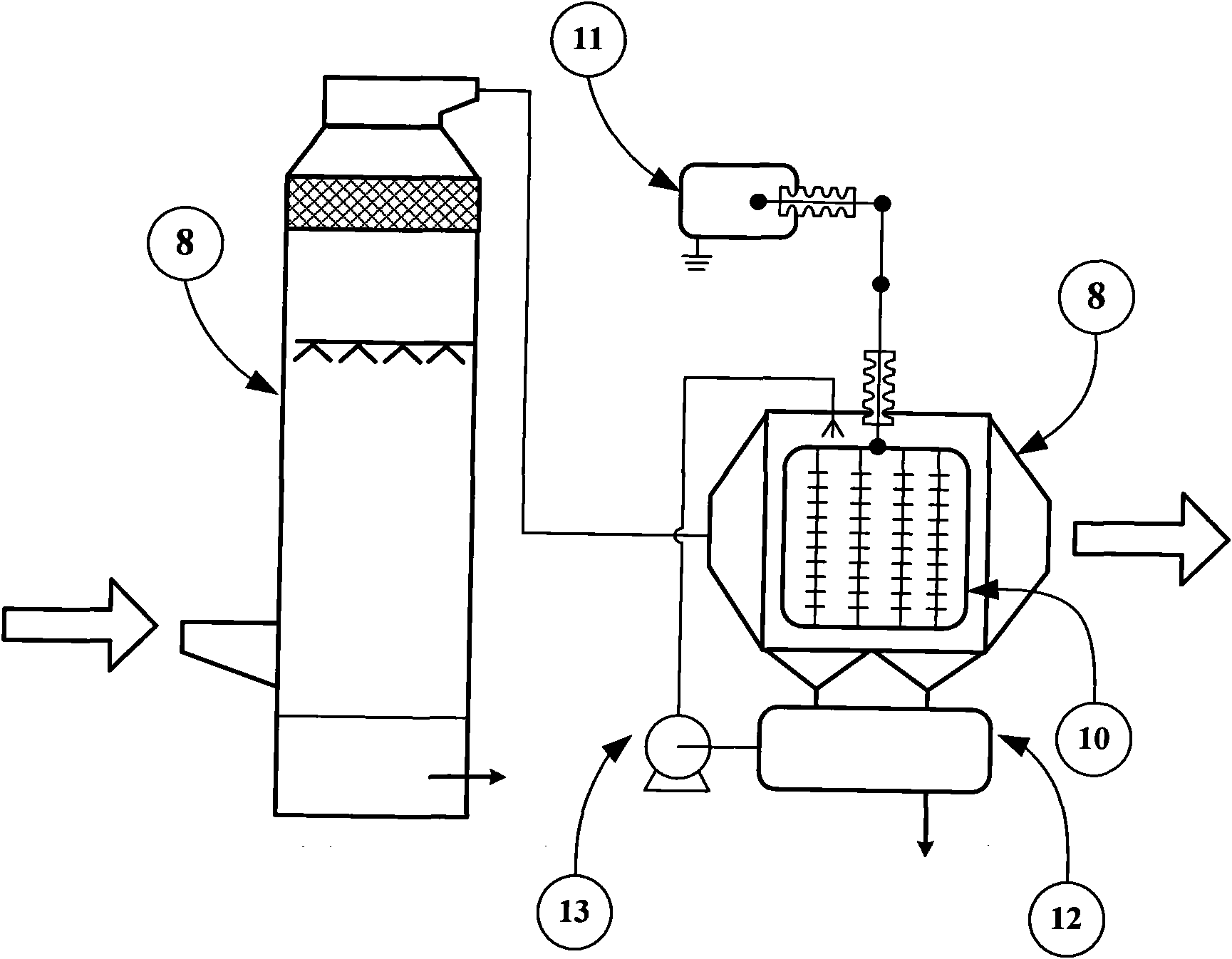

[0023] The low-temperature plasma flue gas complex pollutant control method is composed of multiple units mainly composed of dry and wet plasma reactors. The low-temperature plasma compound pollutant control method comprises the following steps:

[0024] 1) Introduce the high-temperature flue gas into the dry plasma reactor to pre-charge the particles, strengthen the coagulation and aggregation, and form coarse particles. At the same time, nitrogen oxides are oxidized, and nitric oxide is converted into high-priced and easy-to-absorb forms such as nitrogen dioxide;

[0025] 2) The condensed and oxidized flue gas enters the electrostatic precipitator, and the high voltage is provided by the power supply, and the particulate matter is captured and removed;

[0026] 3) The flue gas after dedusting enters the absorption device and is absorbed by alkaline substances (solution, slurry, powder) to generate absorption products sulfite and nitrate, and the absorption products flow int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxidation efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com