Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1174 results about "Cyclonic separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

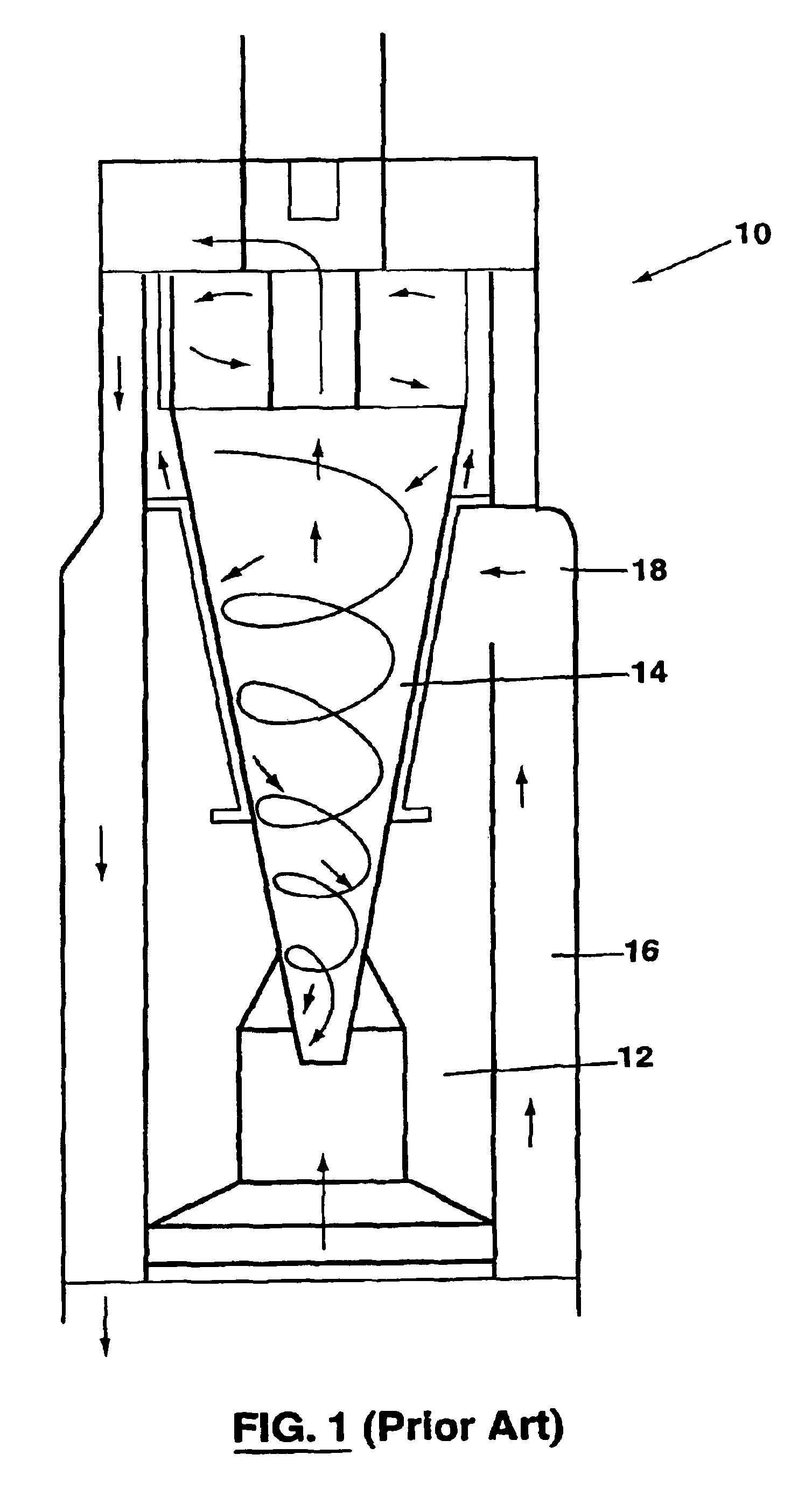

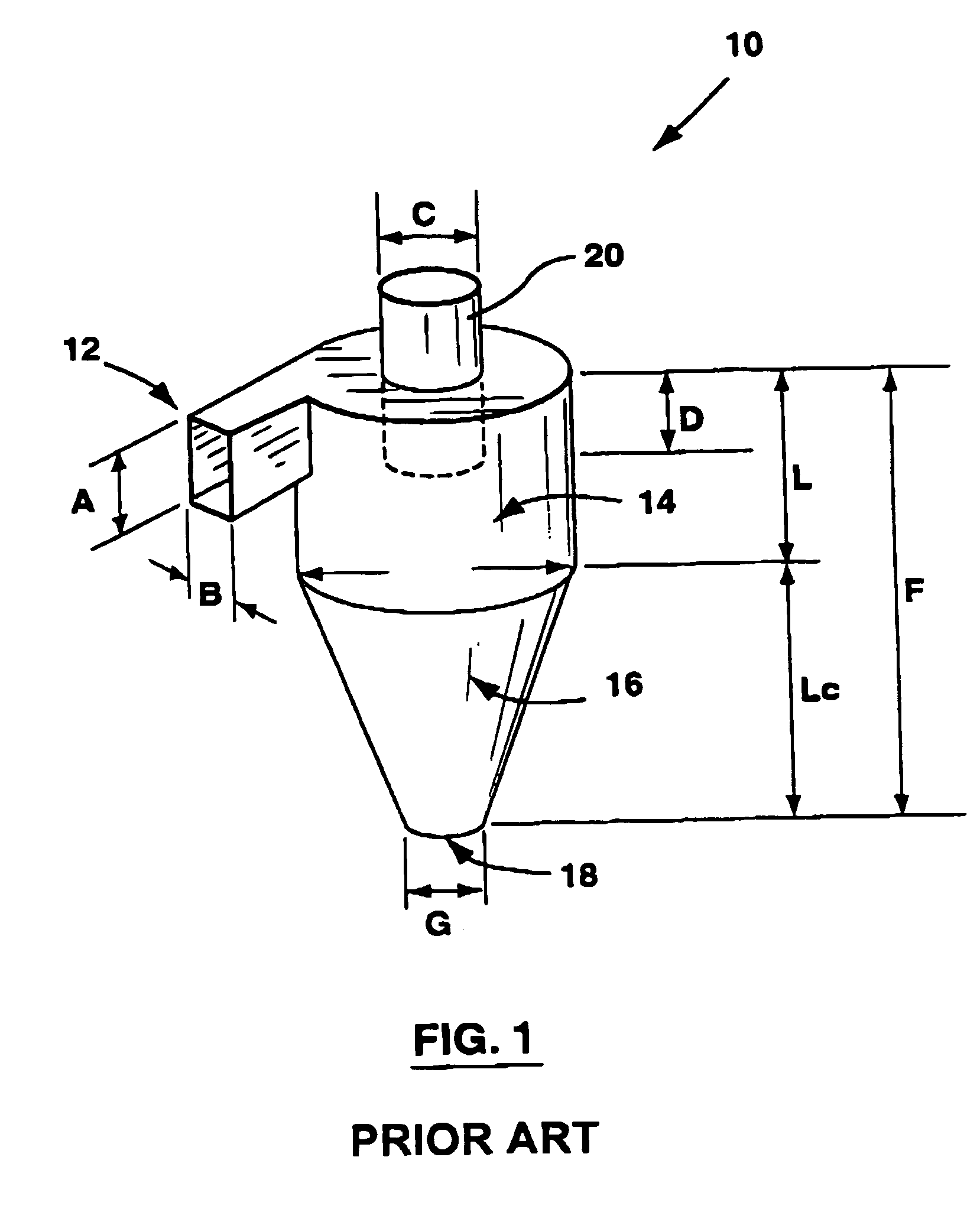

A cyclonic separation is a method of removing particulates from an air, gas or liquid stream, without the use of filters, through vortex separation. When removing particulate matter from liquid, a hydrocyclone is used; while from gas, a gas cyclone is used. Rotational effects and gravity are used to separate mixtures of solids and fluids. The method can also be used to separate fine droplets of liquid from a gaseous stream.

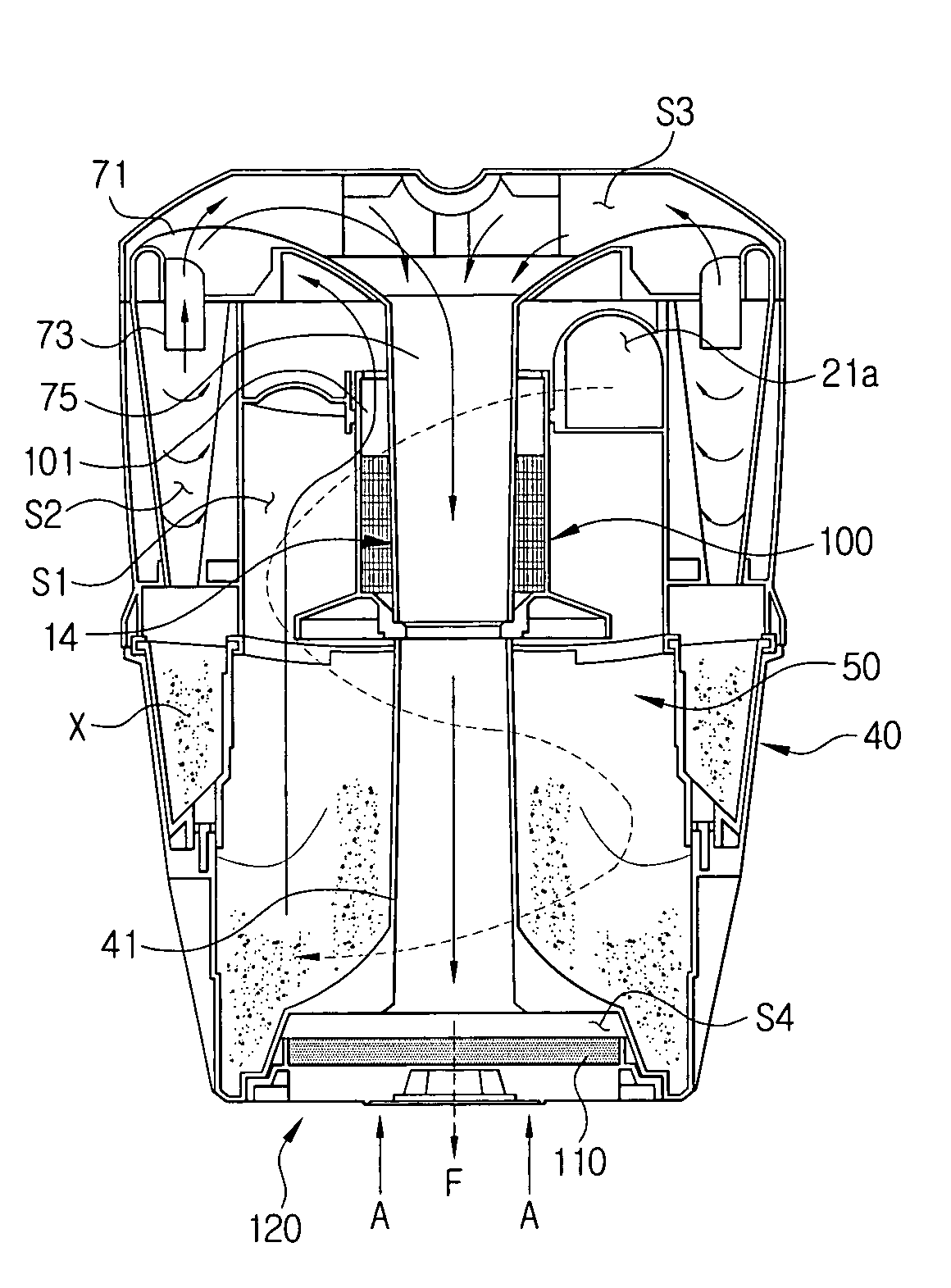

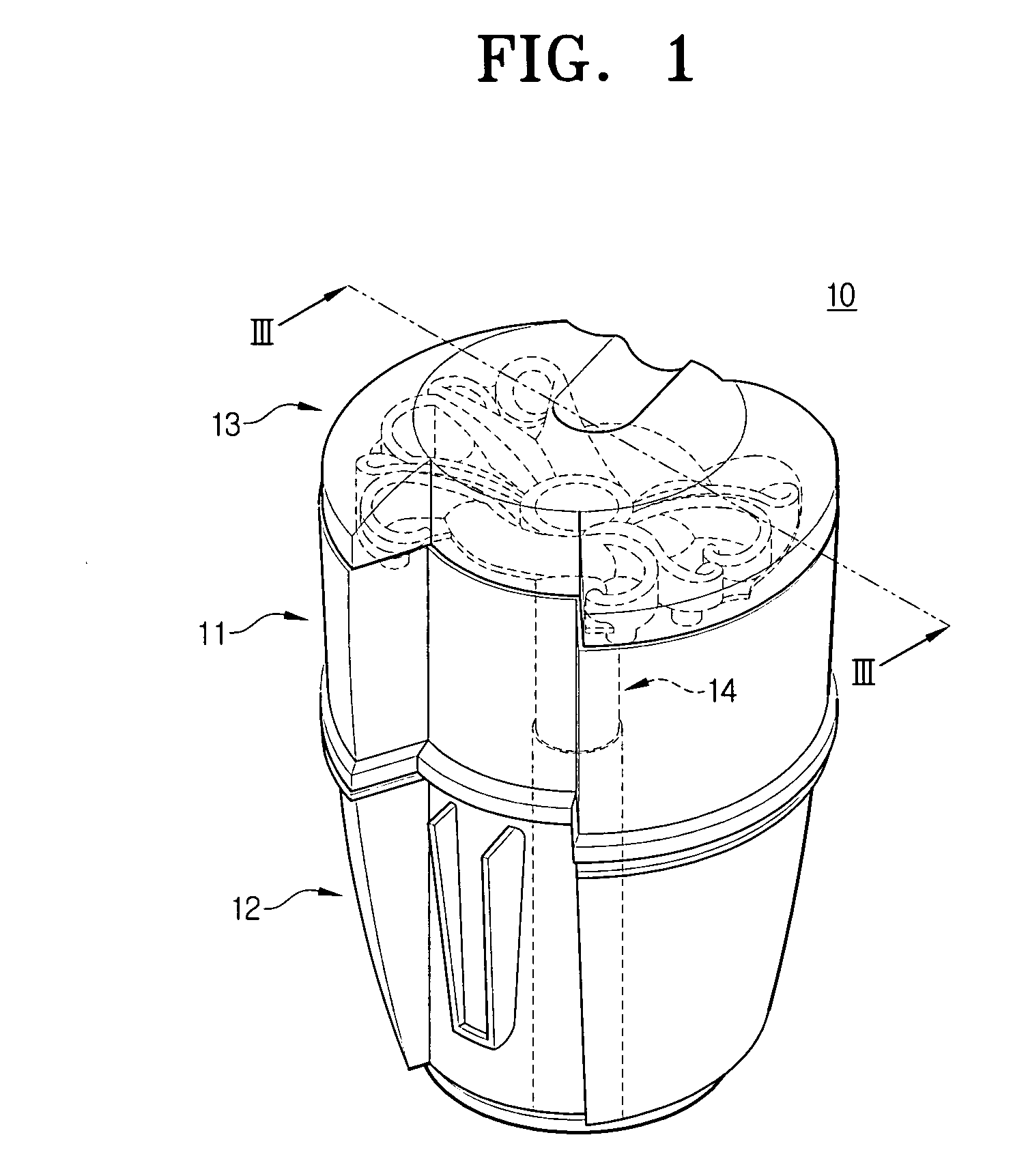

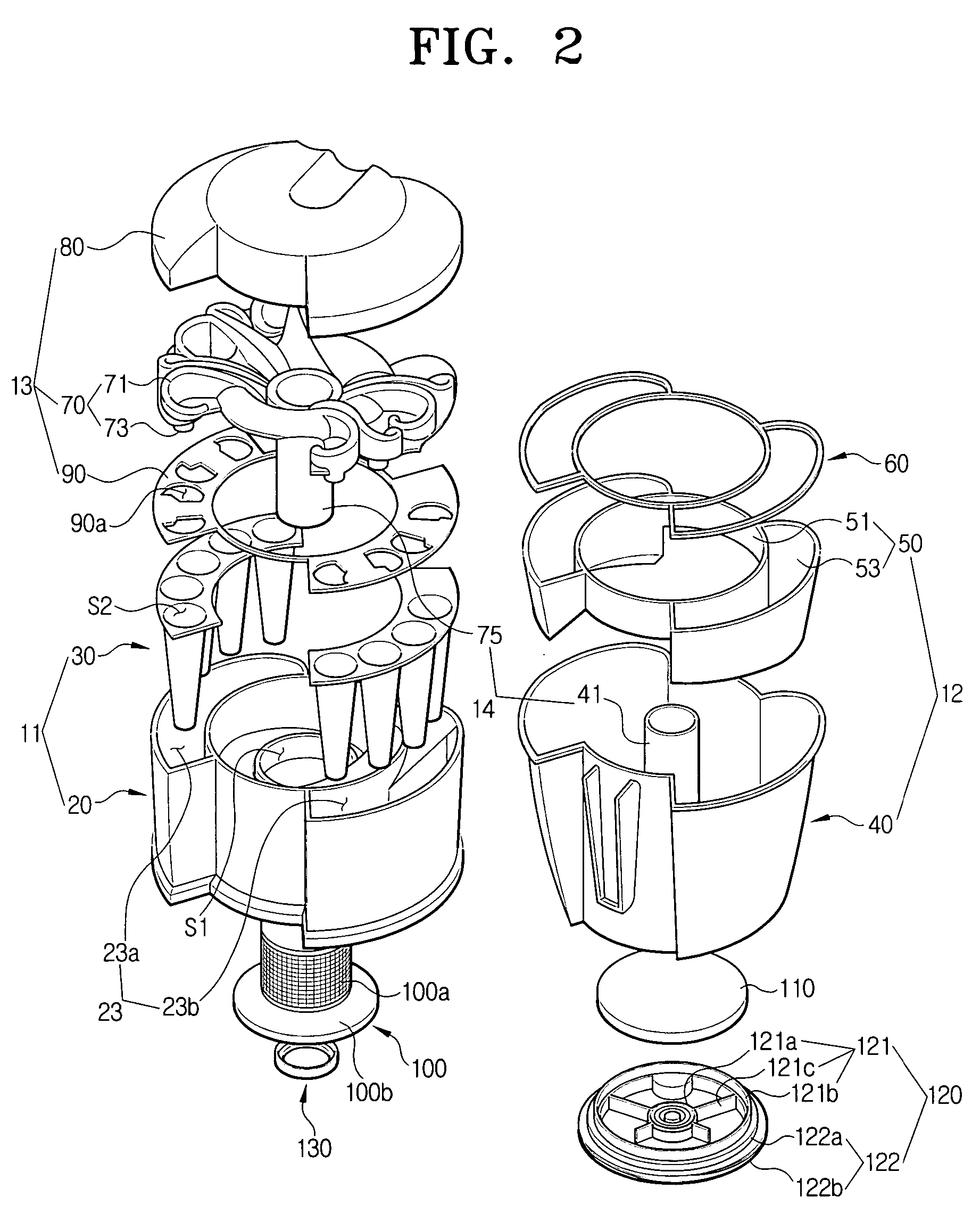

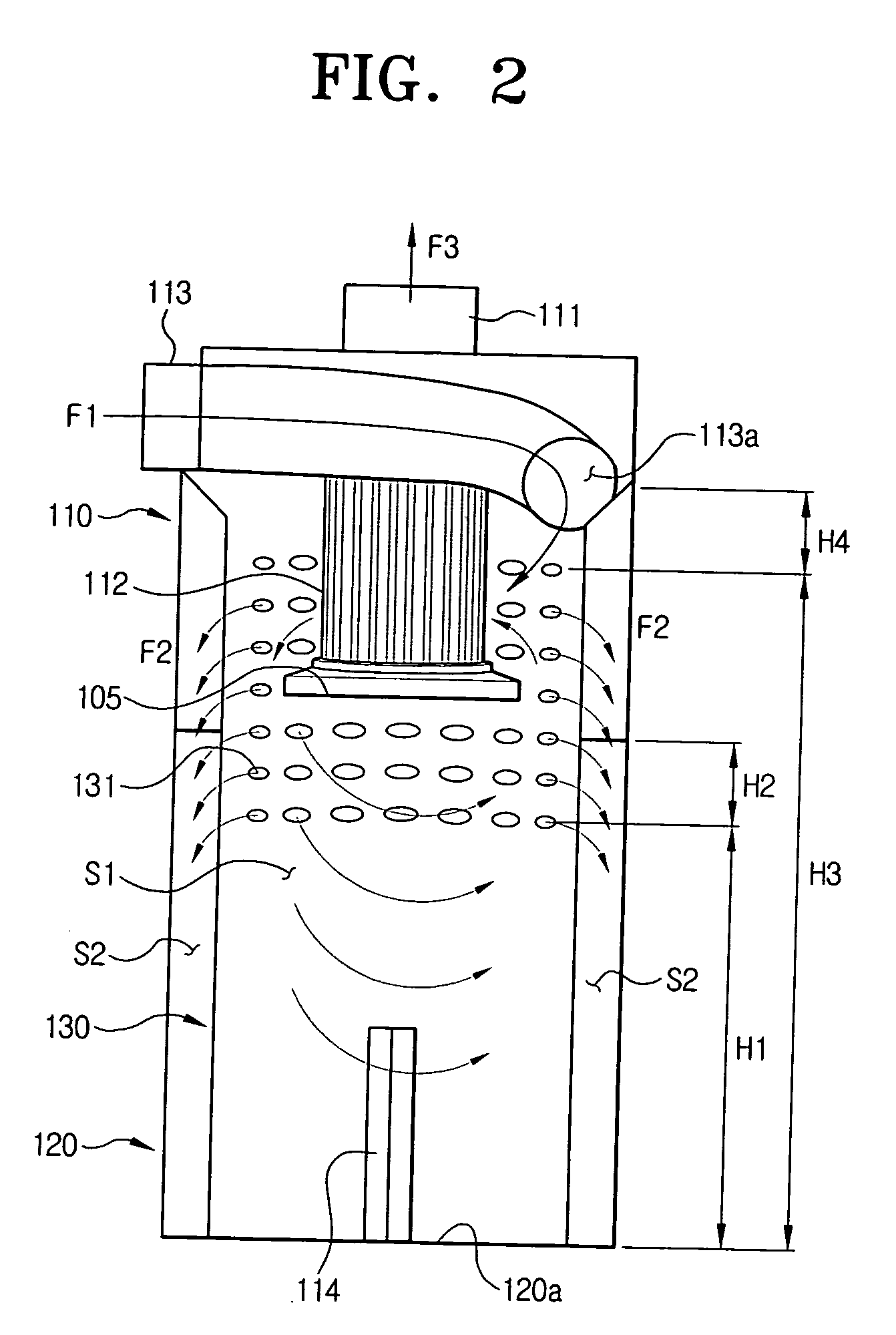

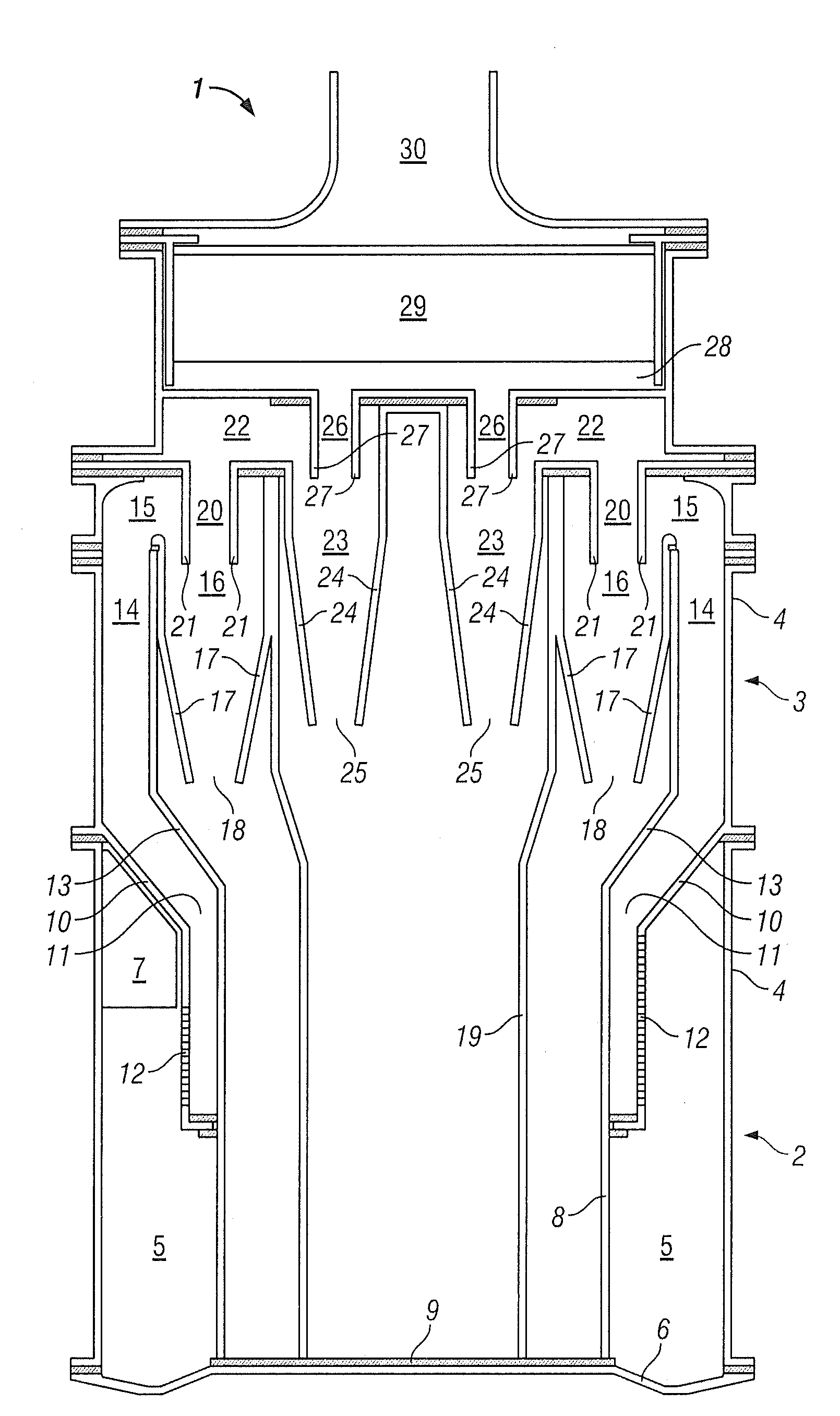

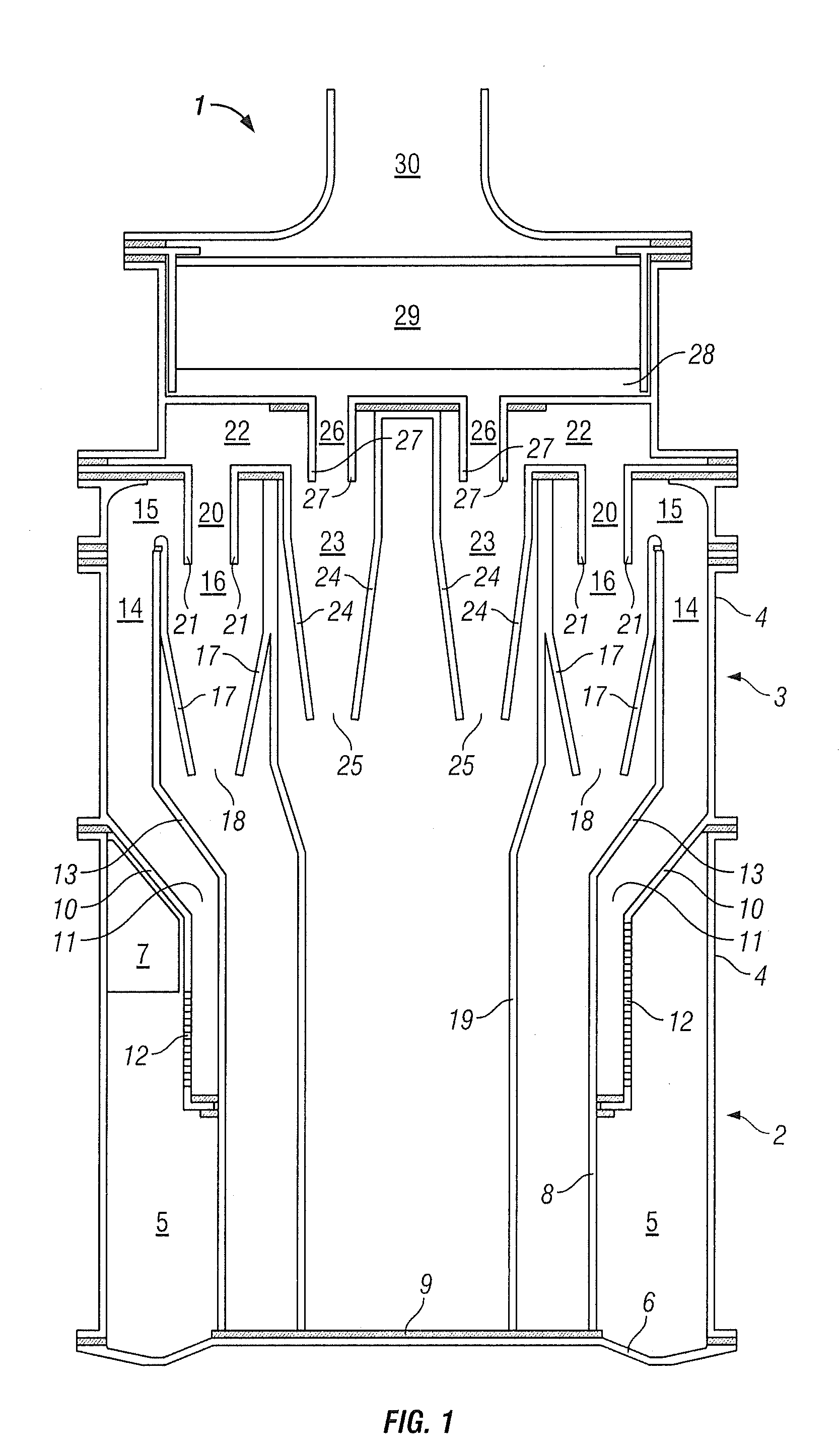

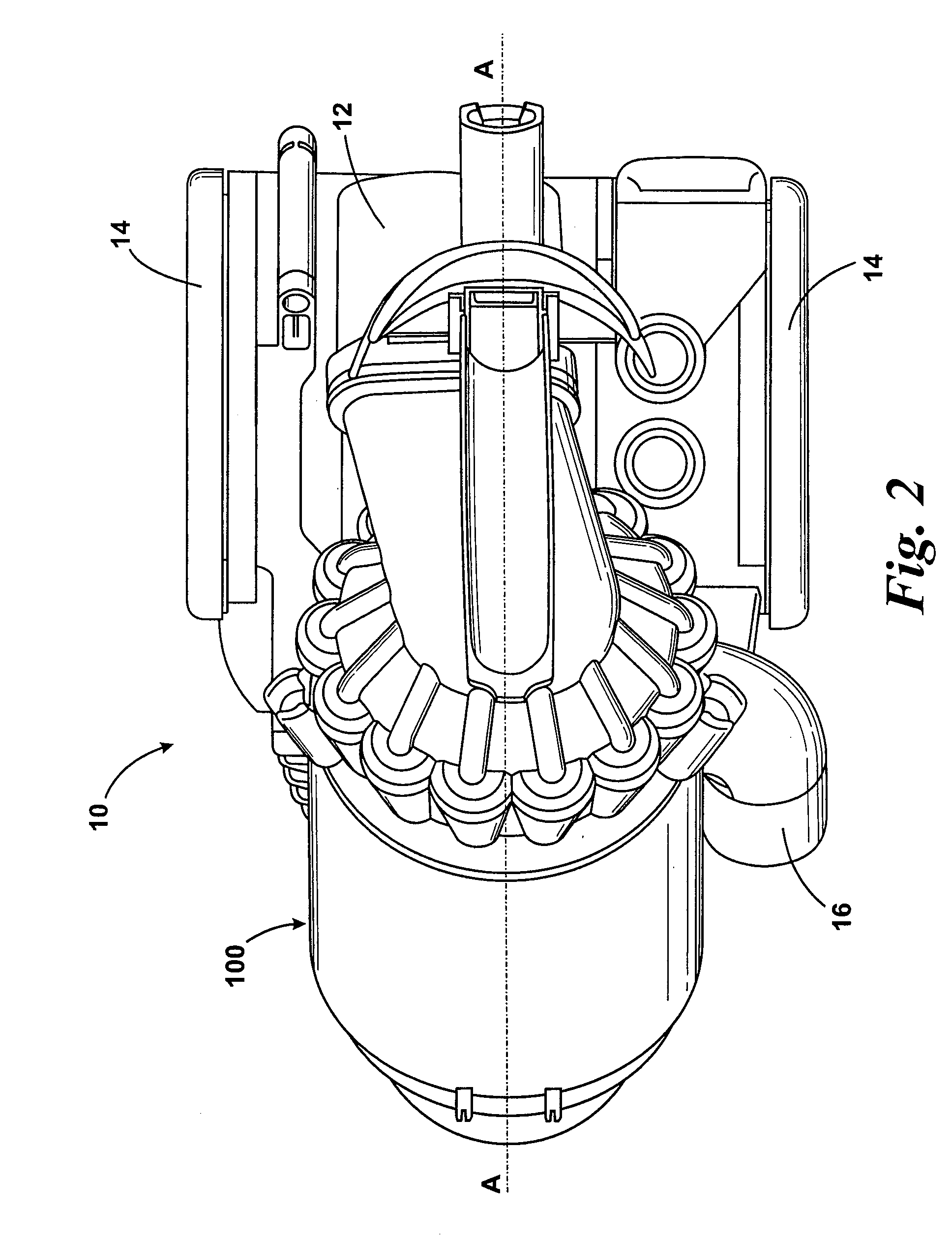

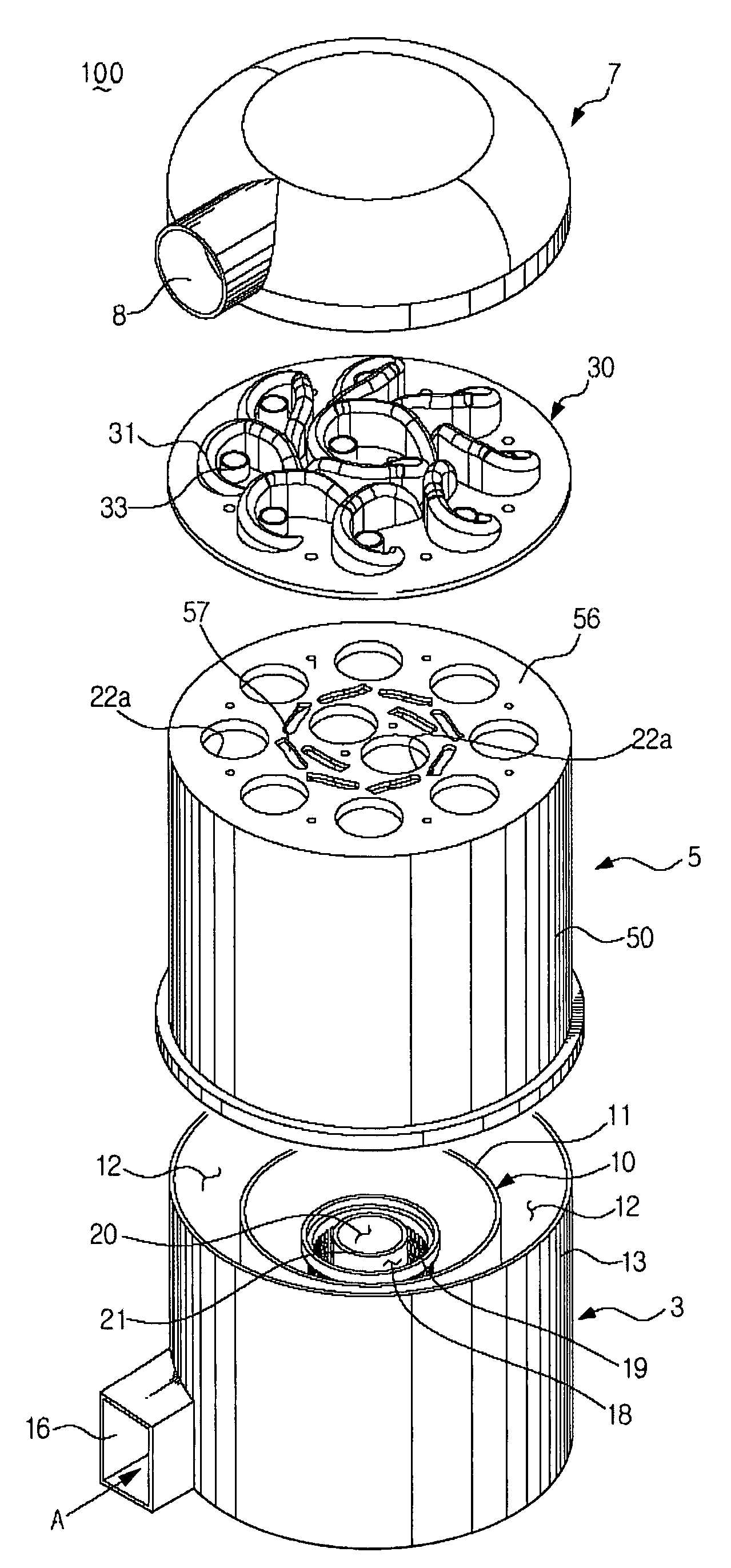

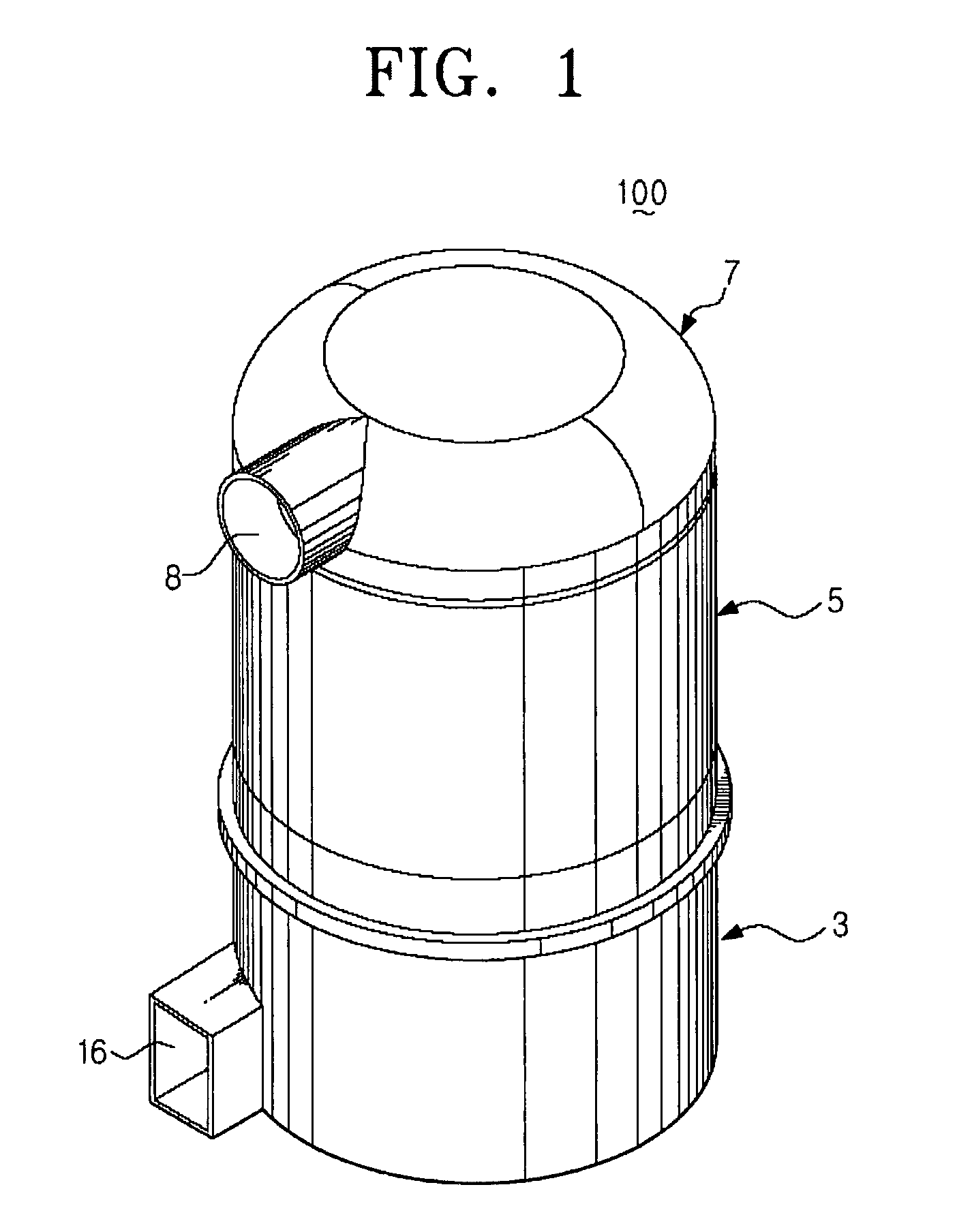

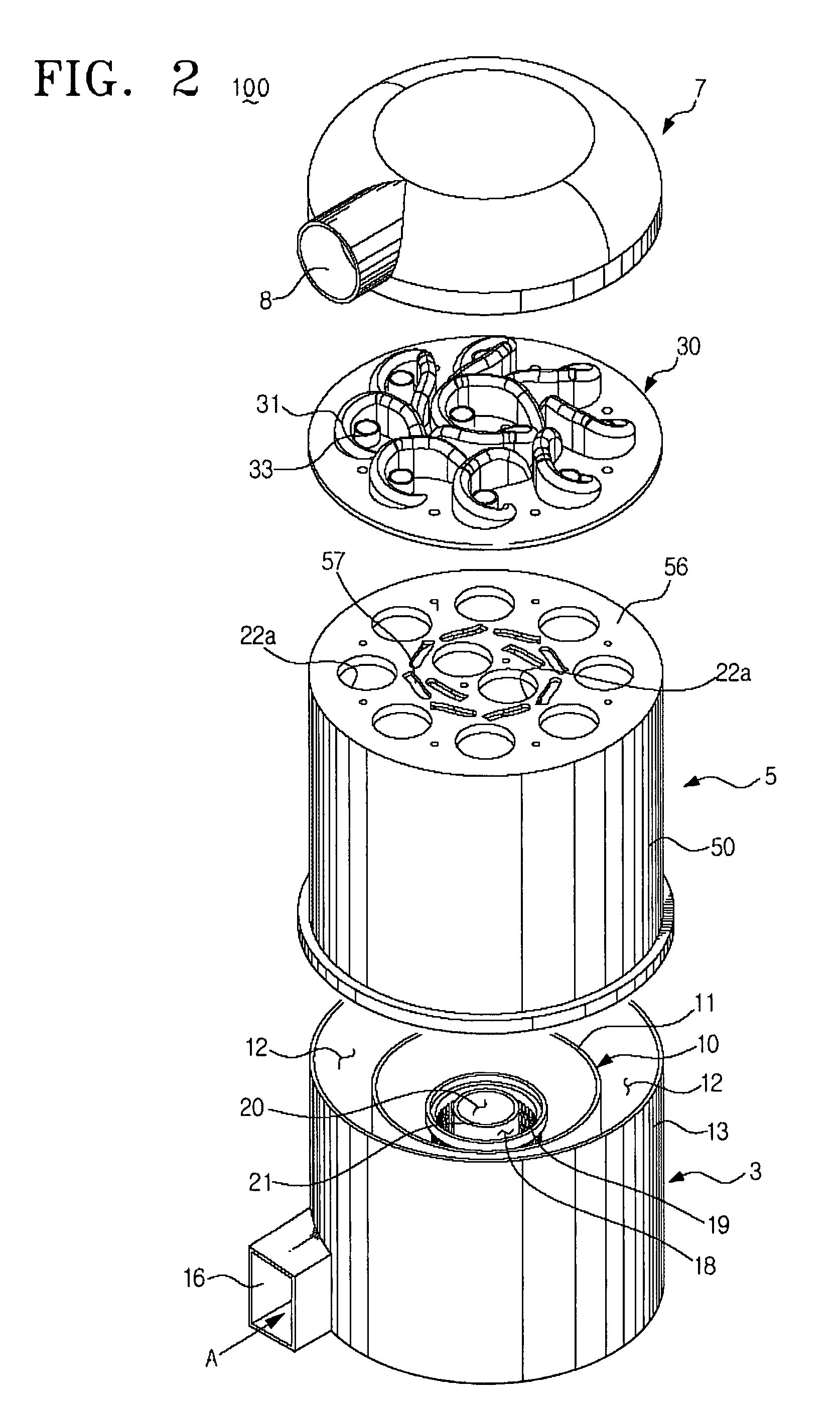

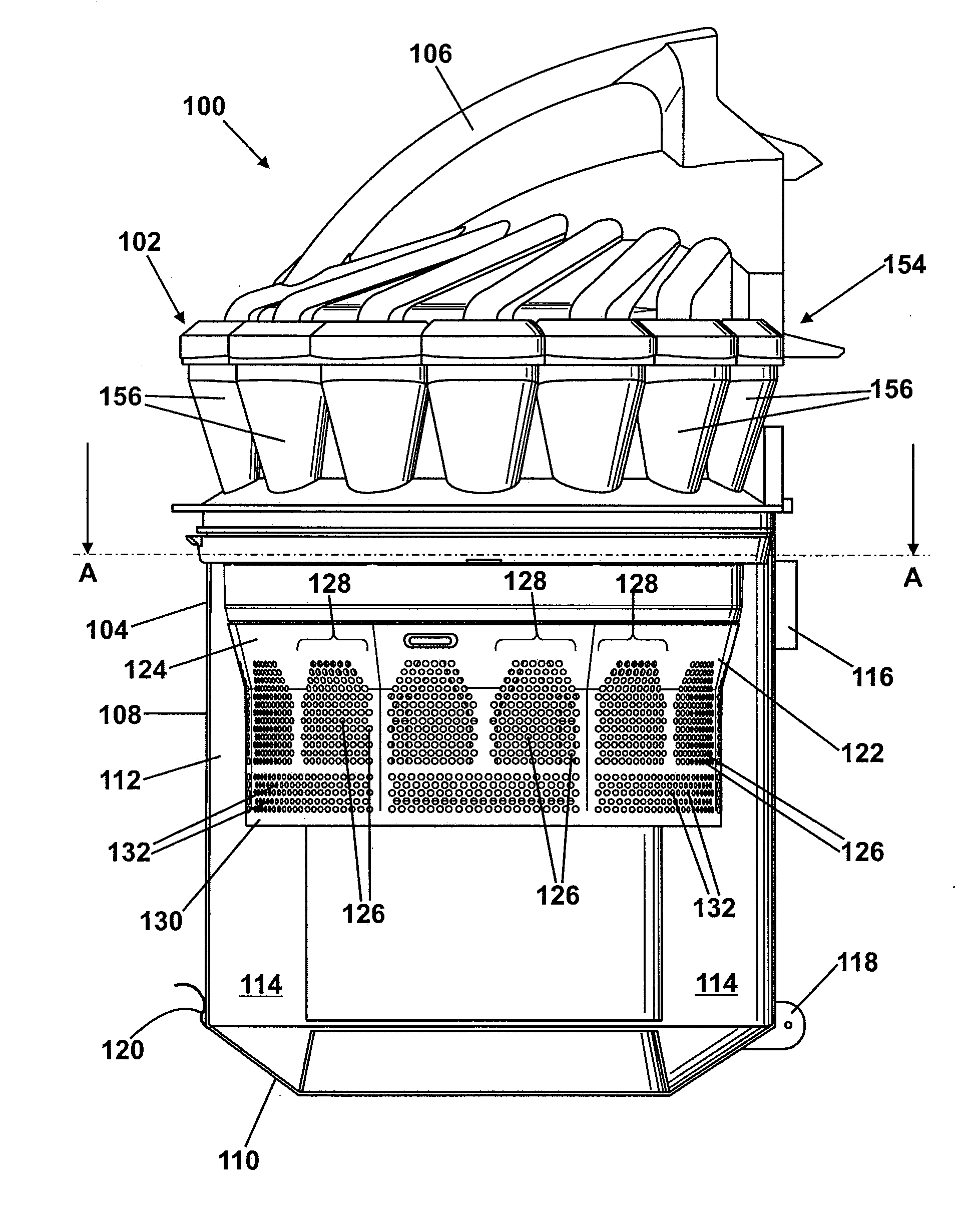

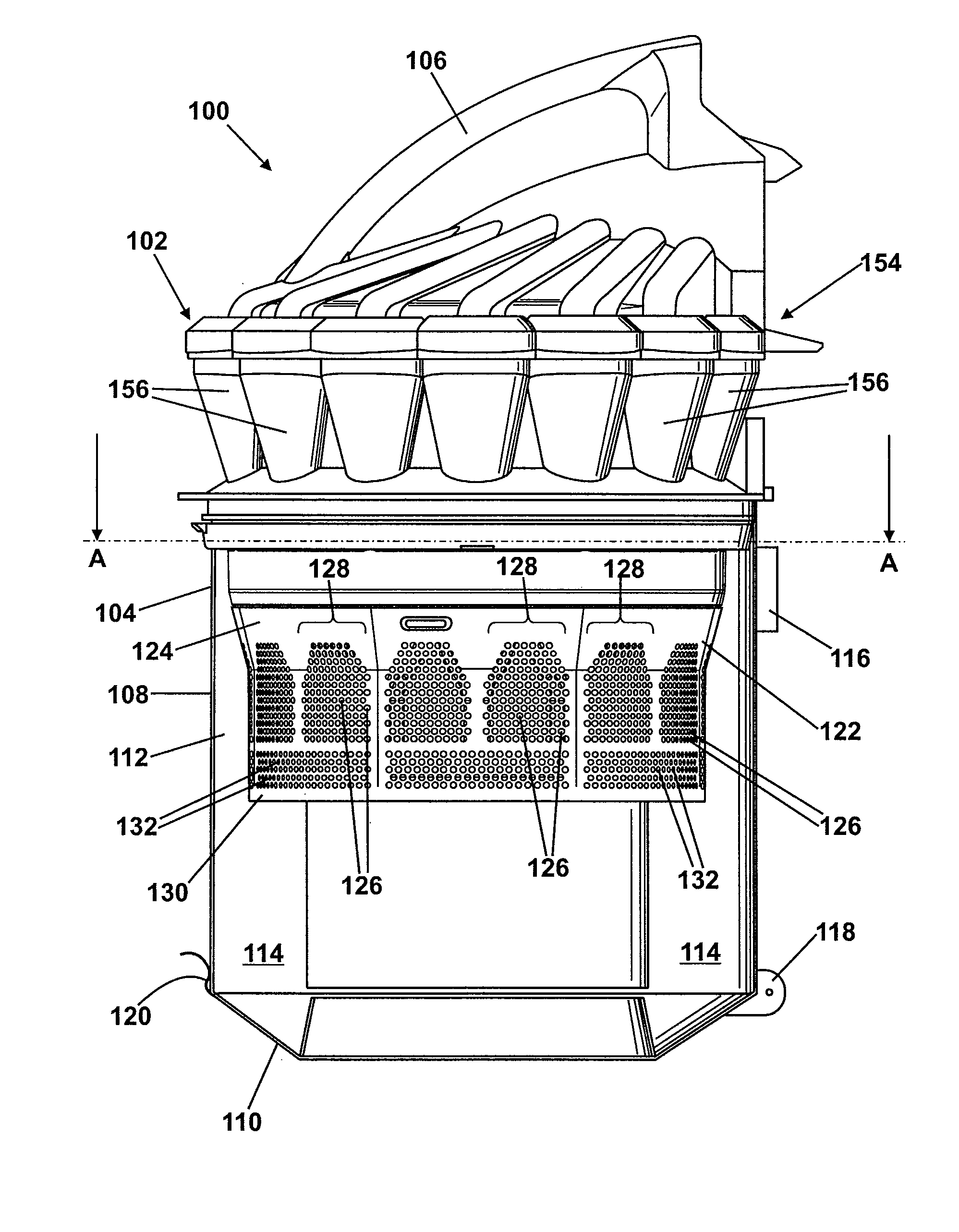

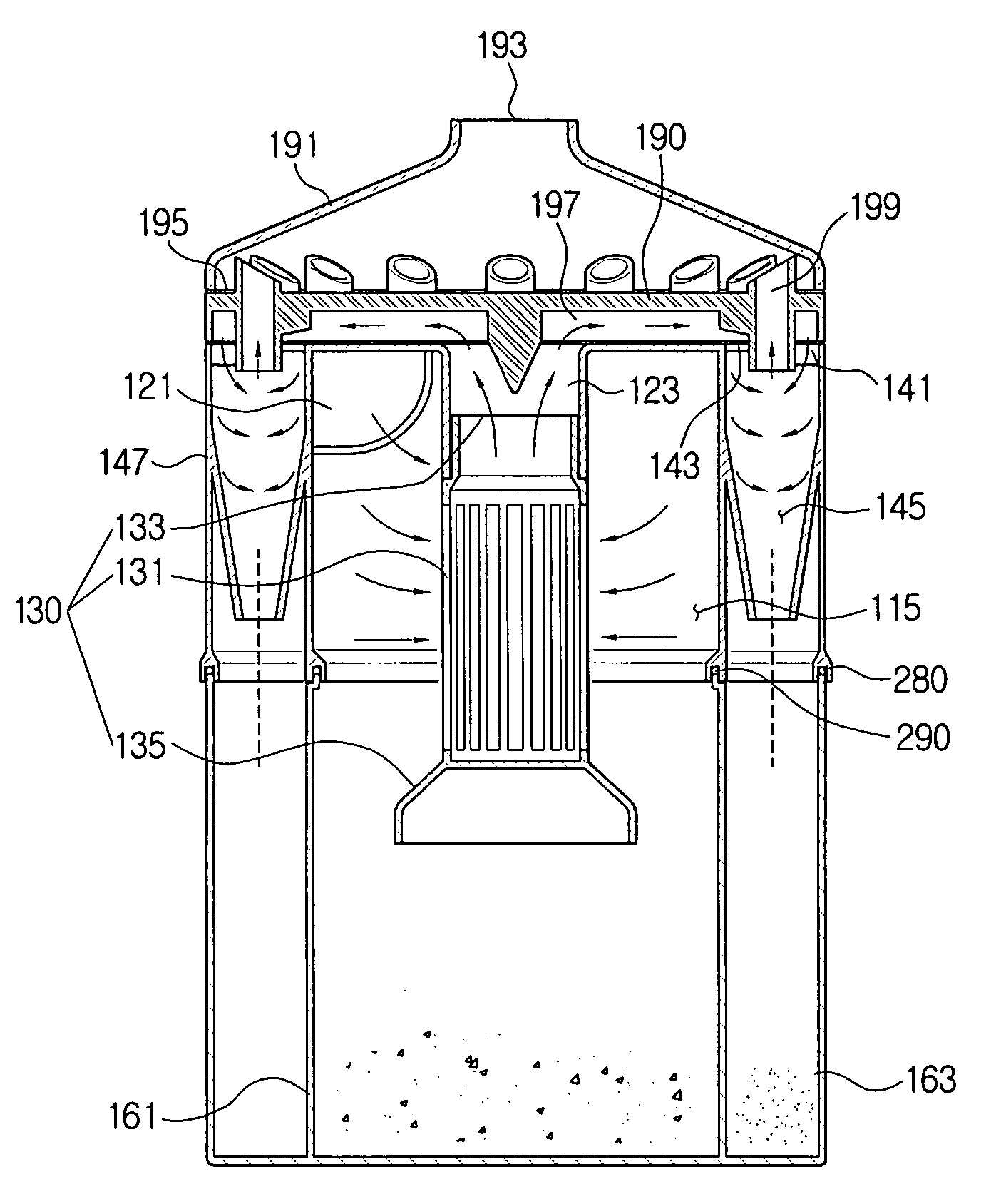

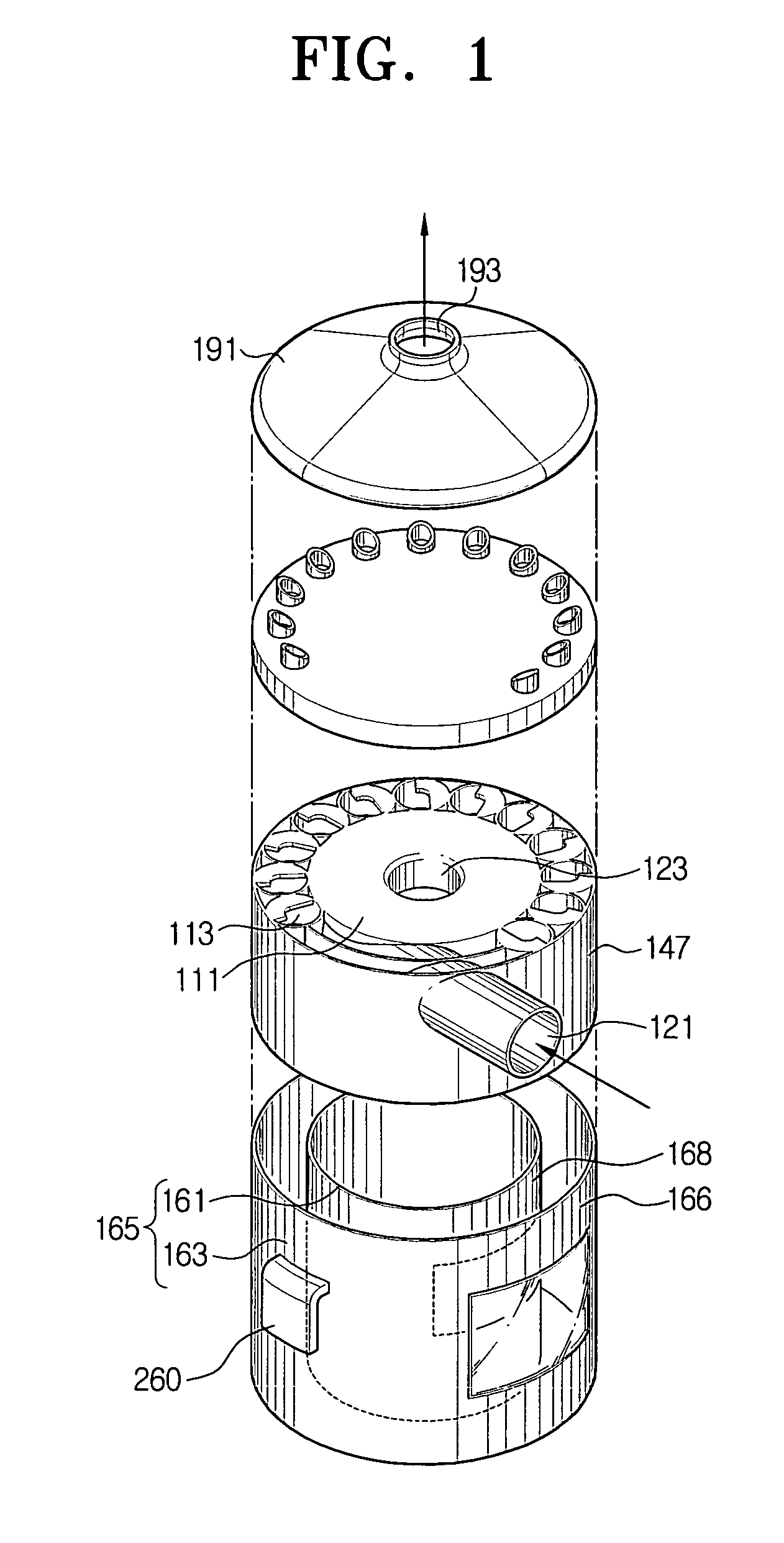

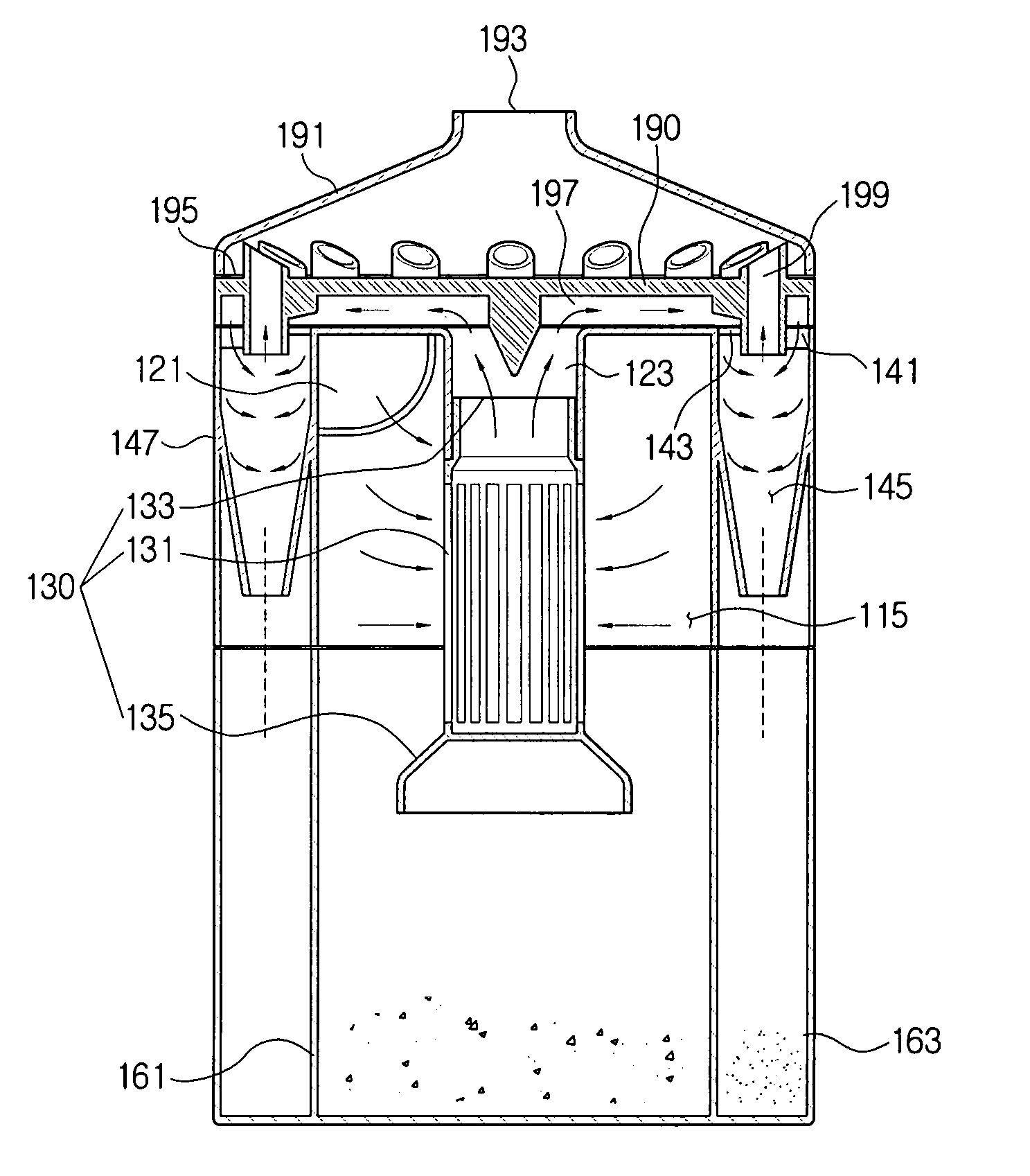

Multi-cyclone dust separating apparatus

A multi-cyclone dust separating apparatus includes: a multi-cyclone unit including a first cyclone chamber body having a first cyclone chamber and at least one protection chamber formed around at least a portion of an outer circumference of the first cyclone chamber, and at least one secondary cyclone chamber body disposed in the protection chamber, each secondary cyclone chamber body having at least one secondary cyclone chamber; a cover unit connecting an upper end of the multi-cyclone unit and guiding air discharged from the first cyclone chamber to the at least one secondary cyclone chamber; a dirt collecting unit adapted to connect to a lower end of the multi-cyclone unit and configured to collect dirt separated from the air in the first and secondary cyclone chambers; and an air discharge duct configured to discharge air that has passed through the multi-cyclone unit.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

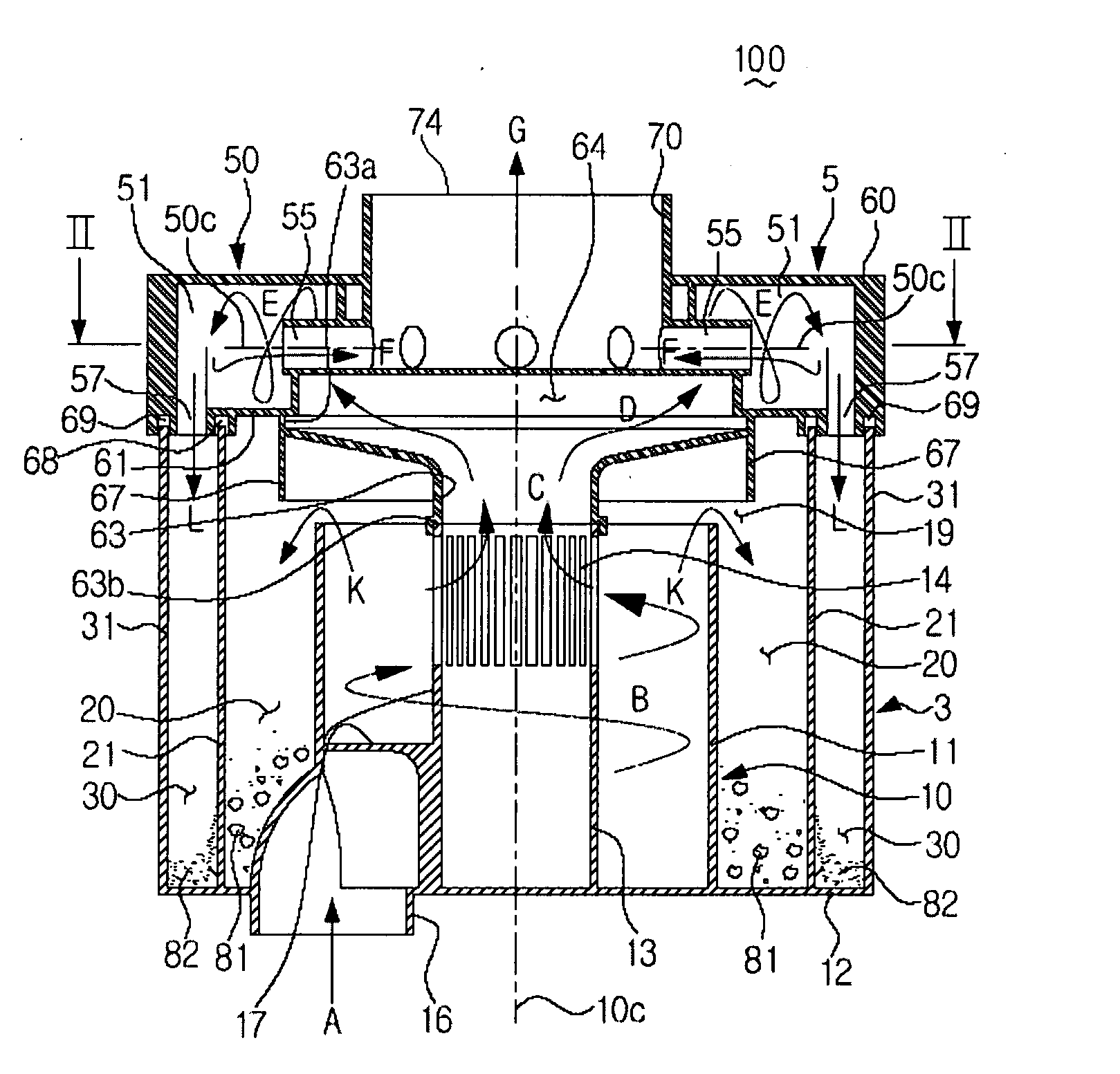

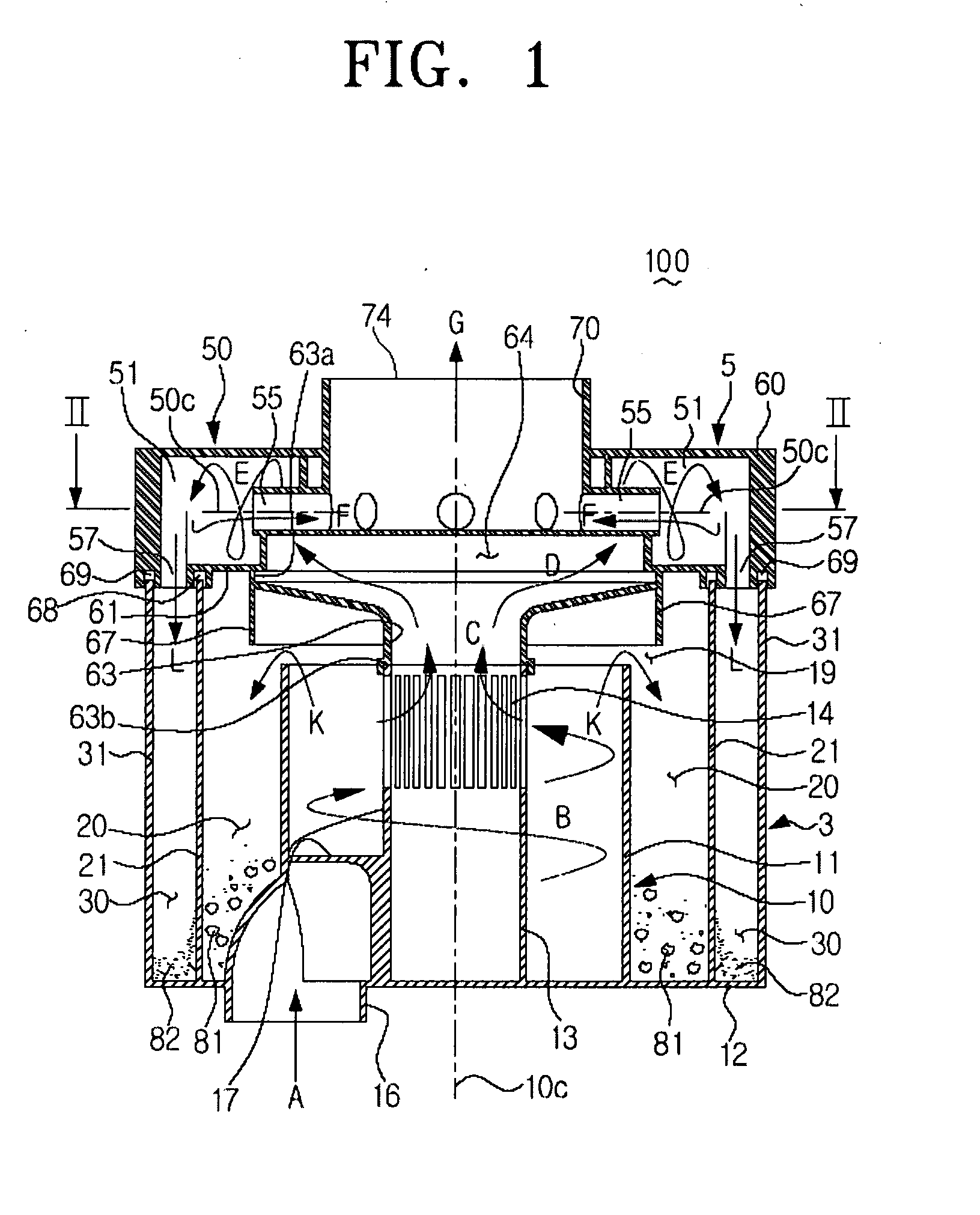

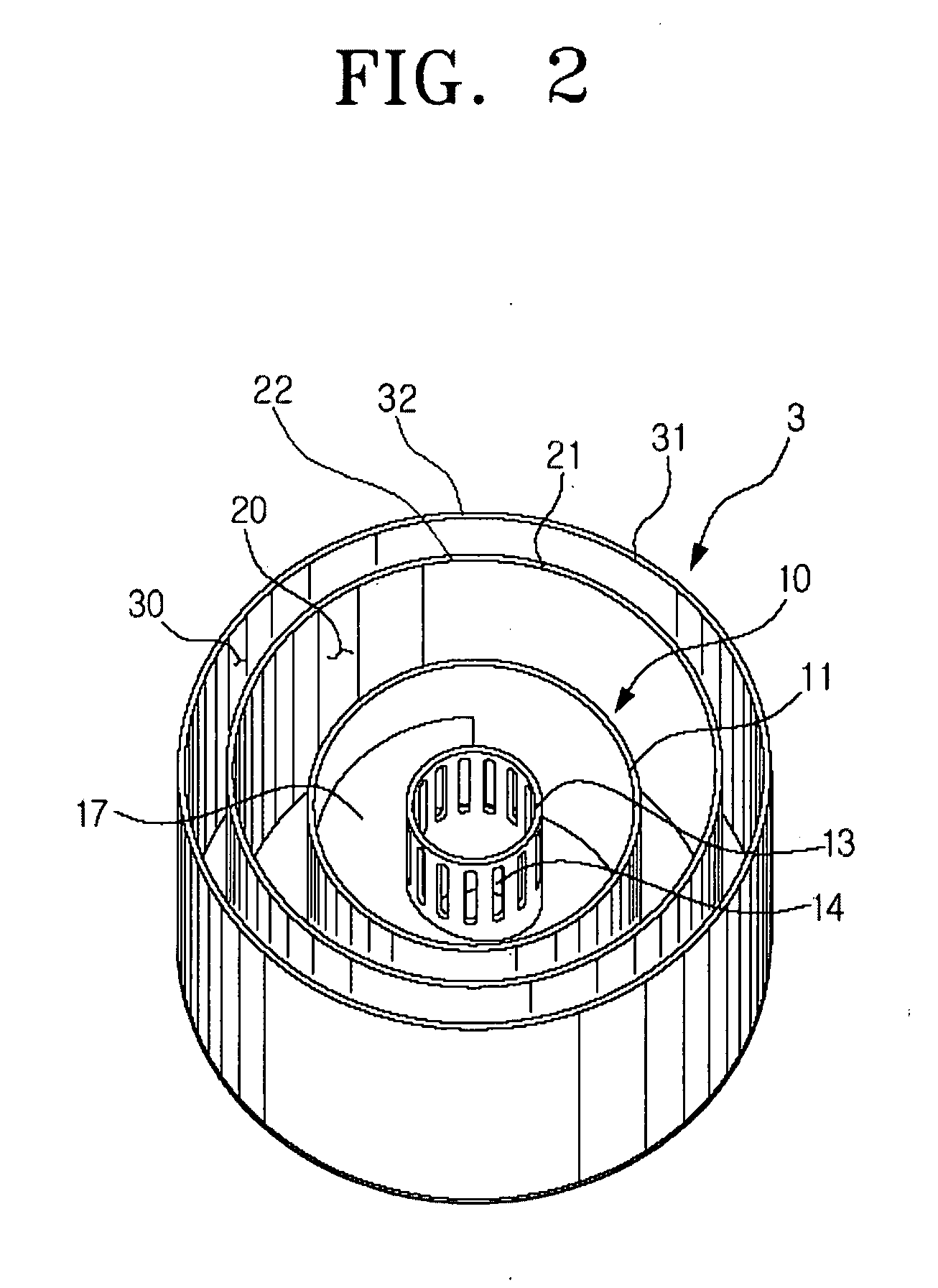

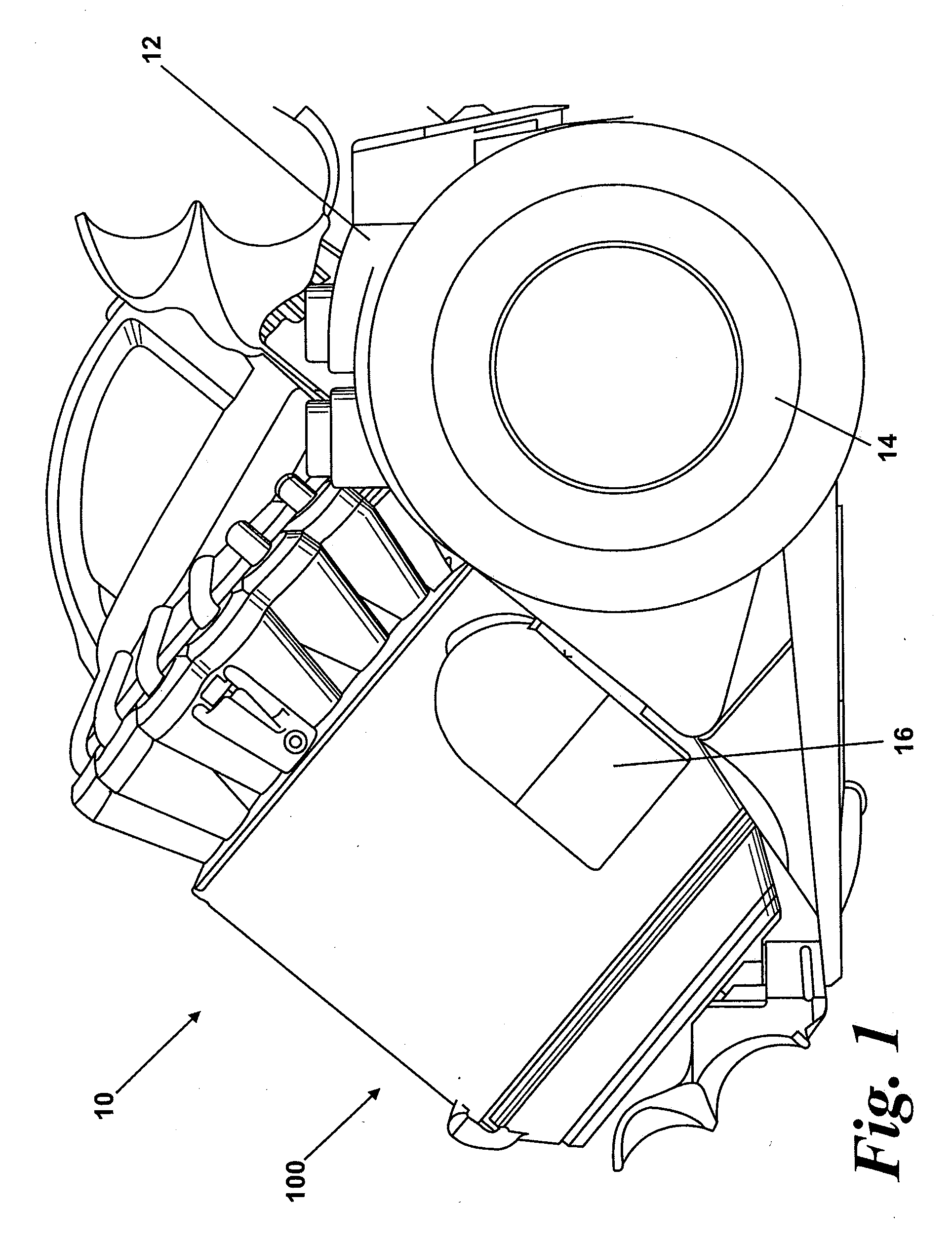

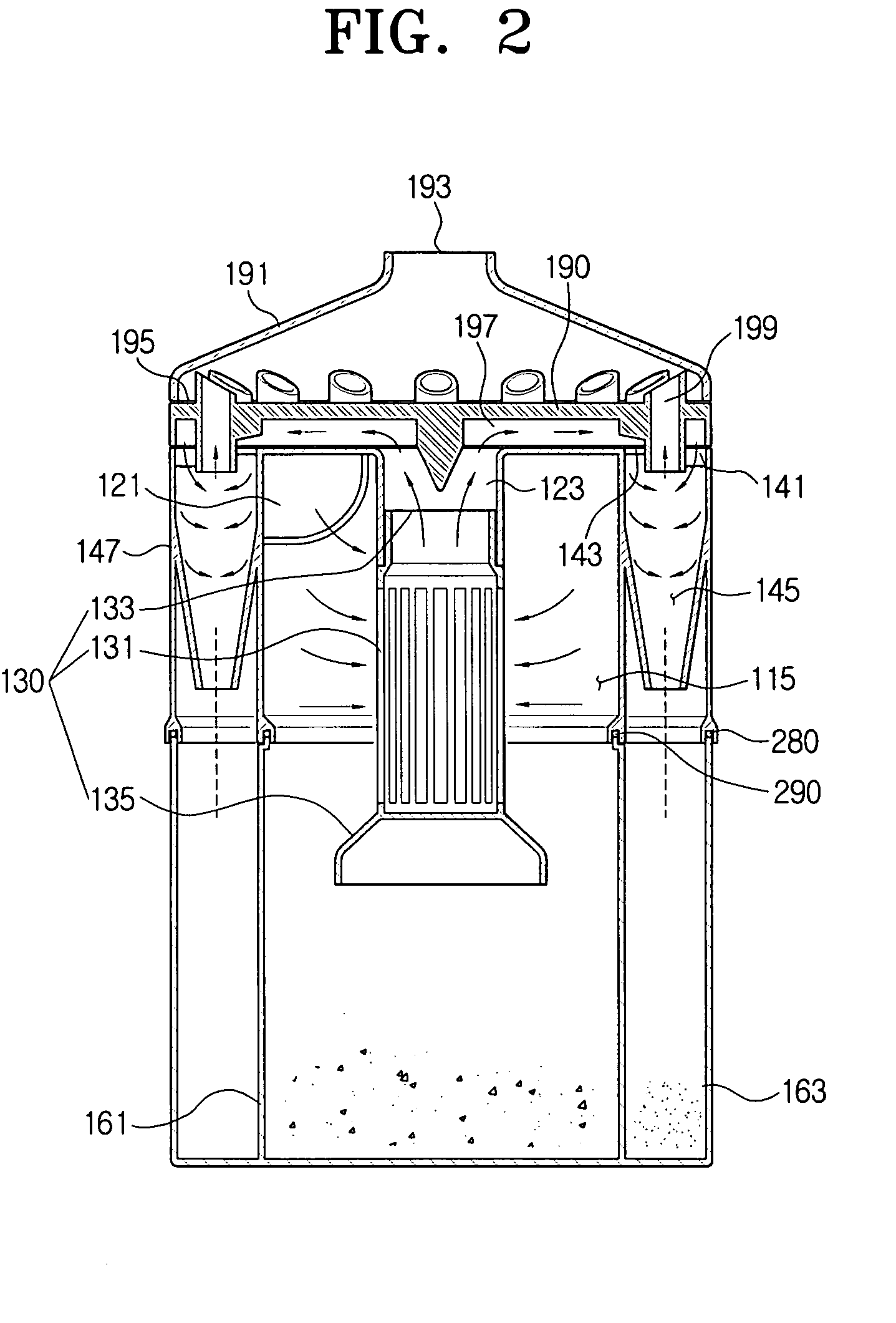

Cyclone separating apparatus for vacuum cleaner

InactiveUS20080190080A1High contaminant separating efficiencyProblem and drawbackCleaning filter meansCombination devicesCycloneCyclonic separation

A cyclone separating apparatus for a vacuum cleaner includes a first cyclone with an air entrance disposed on a lower portion of the first cyclone and an air exit disposed at an upper portion of the first cyclone; a first contaminants chamber substantially enclosing the first cyclone to collect contaminants discharged from the first cyclone; a plurality of second cyclones above the first cyclone, the plurality of second cyclones being substantially perpendicular to a center axis of the first cyclone; and a second contaminants chamber disposed outside the first contaminants chamber to collect contaminants discharged from the plurality of second cyclones.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

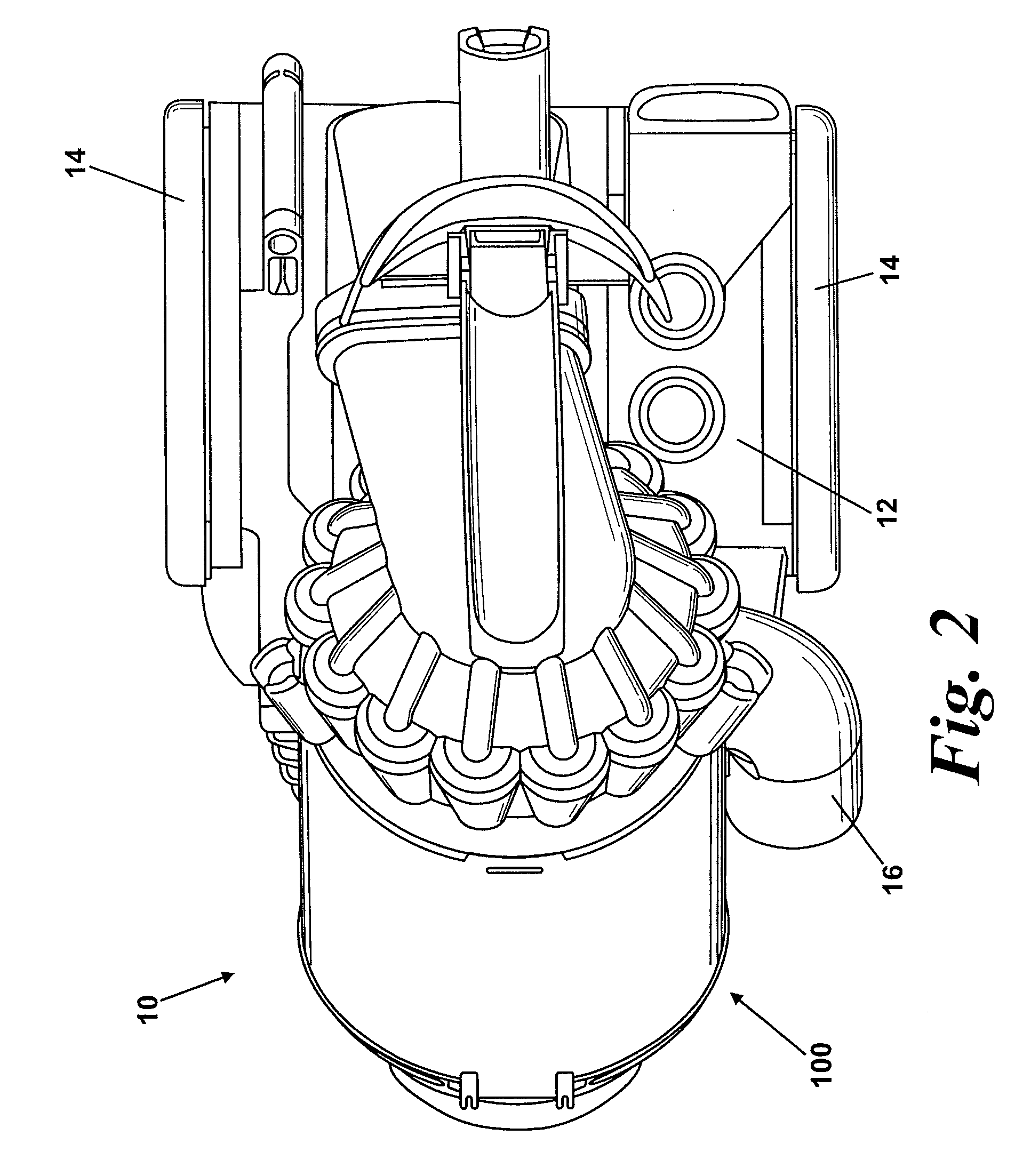

Cyclonic separating apparatus for vacuum cleaner which is capable of separately collecting water from dust

InactiveUS20060162298A1Easy to separatePreventing dispersion and subsequent backflowCombination devicesAuxillary pretreatmentInterior spaceCyclonic separation

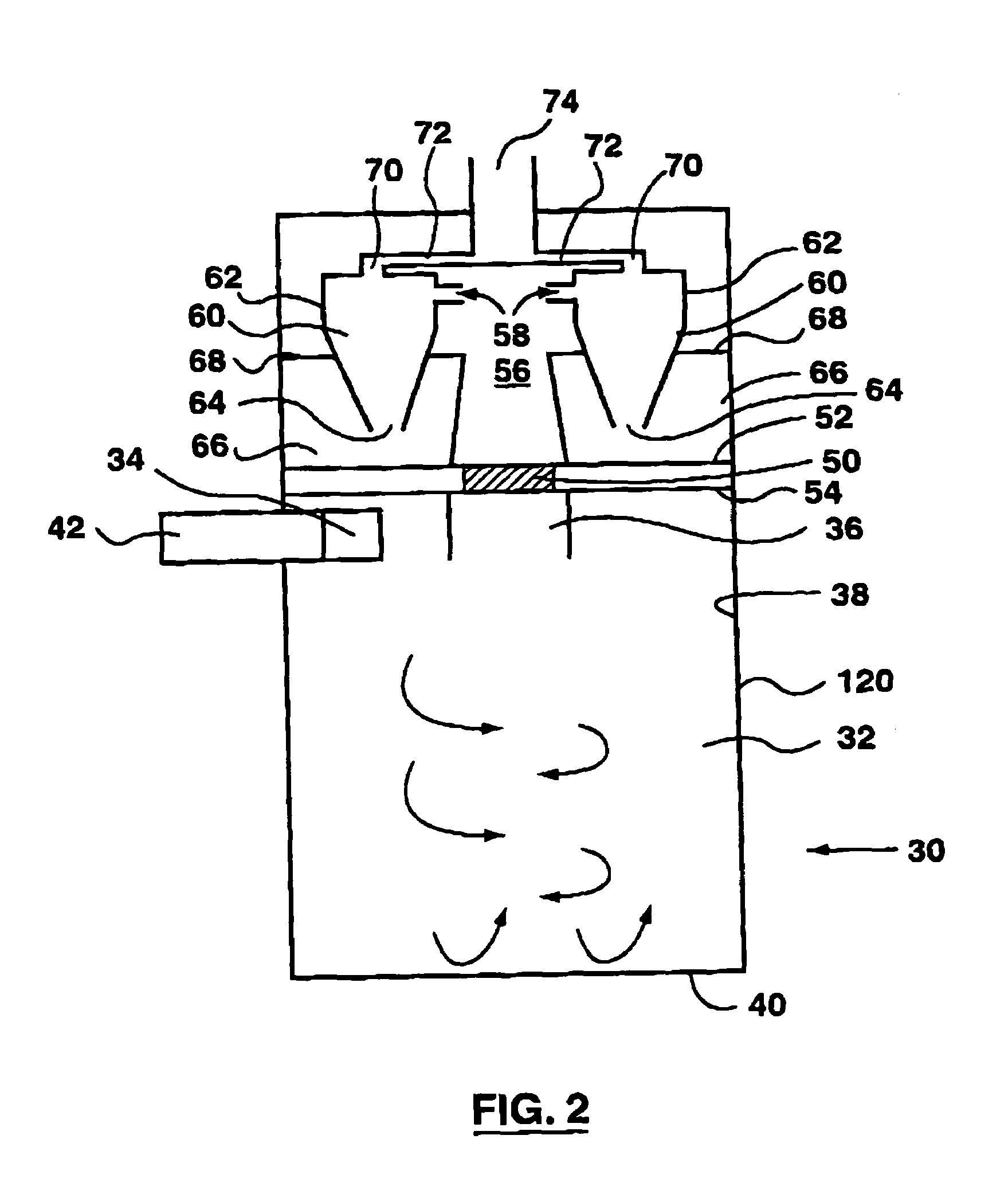

A cyclonic separating apparatus for a vacuum cleaner that can separately collect dust and water. The cyclonic separating apparatus includes: a cyclone body having an air inlet passage and an air discharge passage; a dust receptacle connected to a lower end of the cyclone body; and a screen dividing the cyclone body and interior space of the dust receptacle into a first chamber and a second chamber, the screen having a plurality of passing holes, wherein drawn air rotates in the first chamber and water separated from the air moves to the second chamber through the passing holes.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

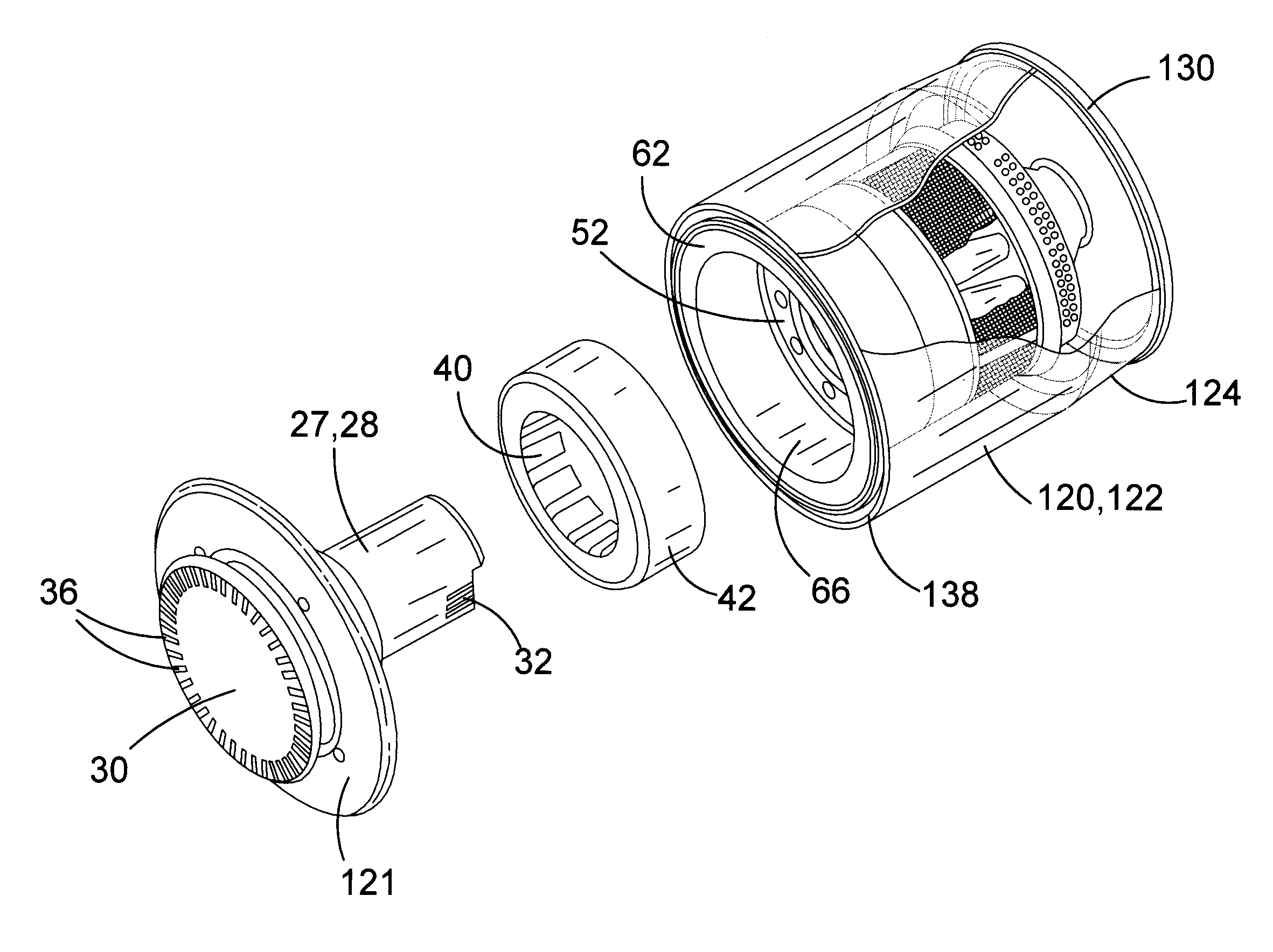

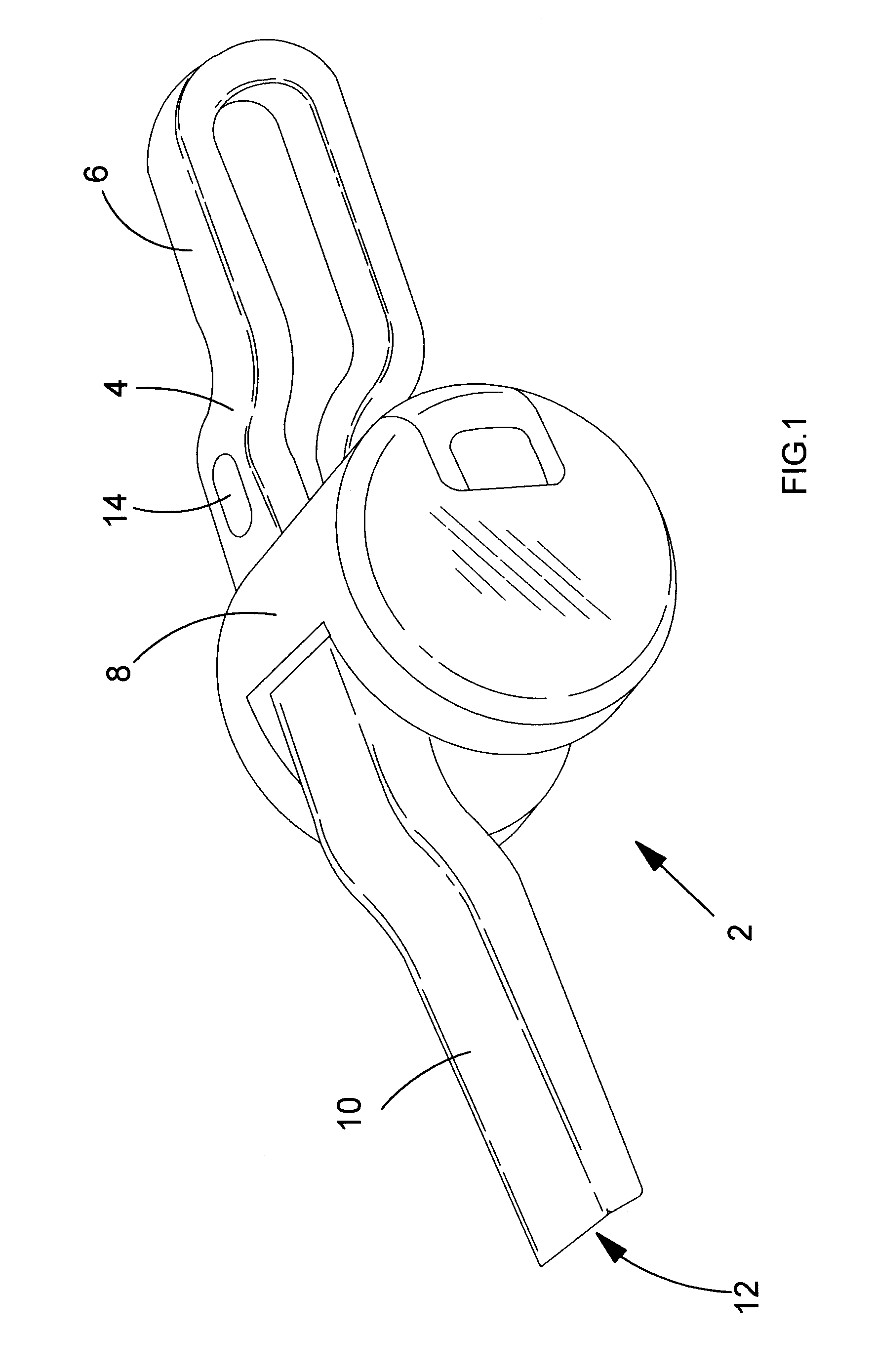

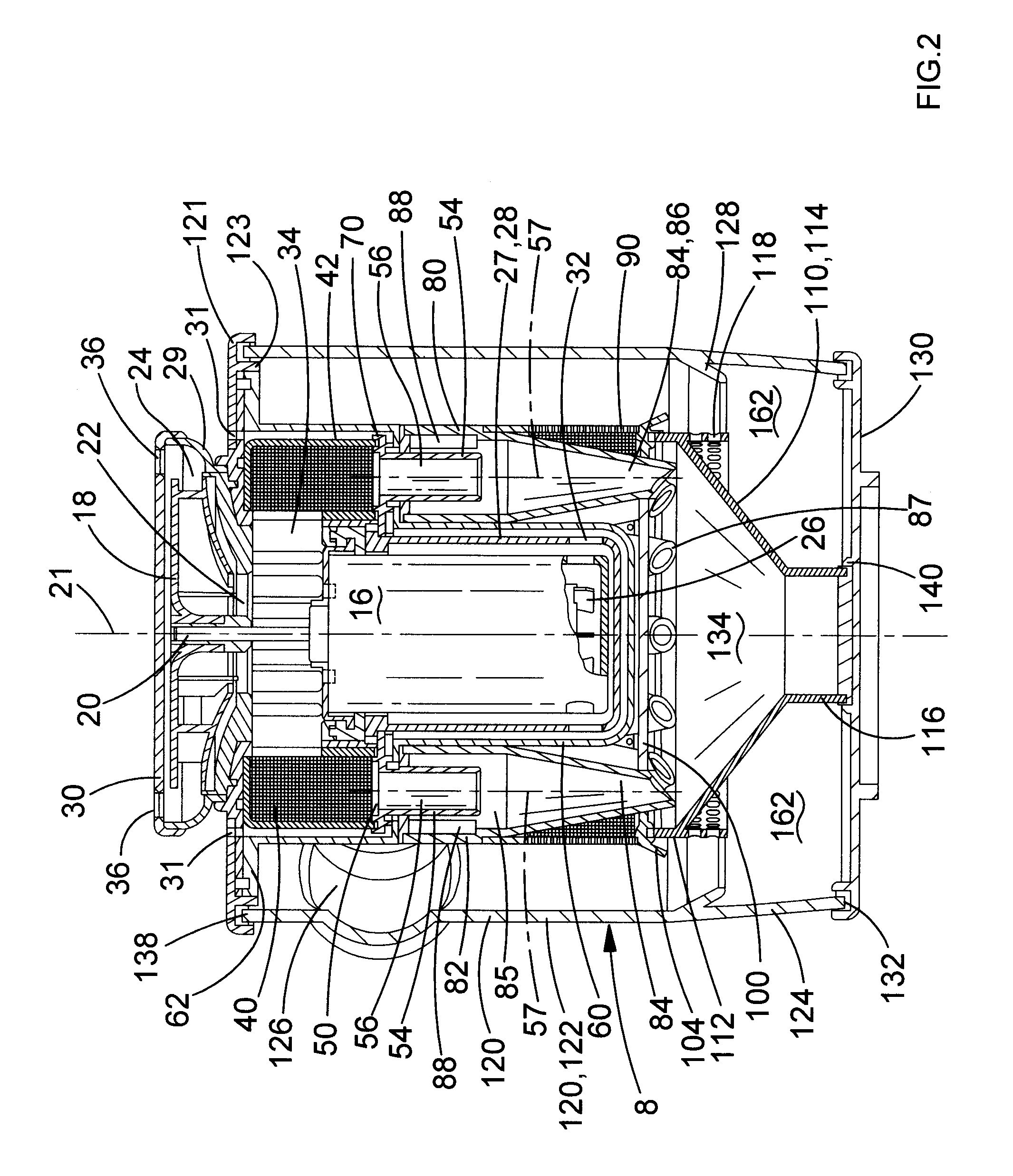

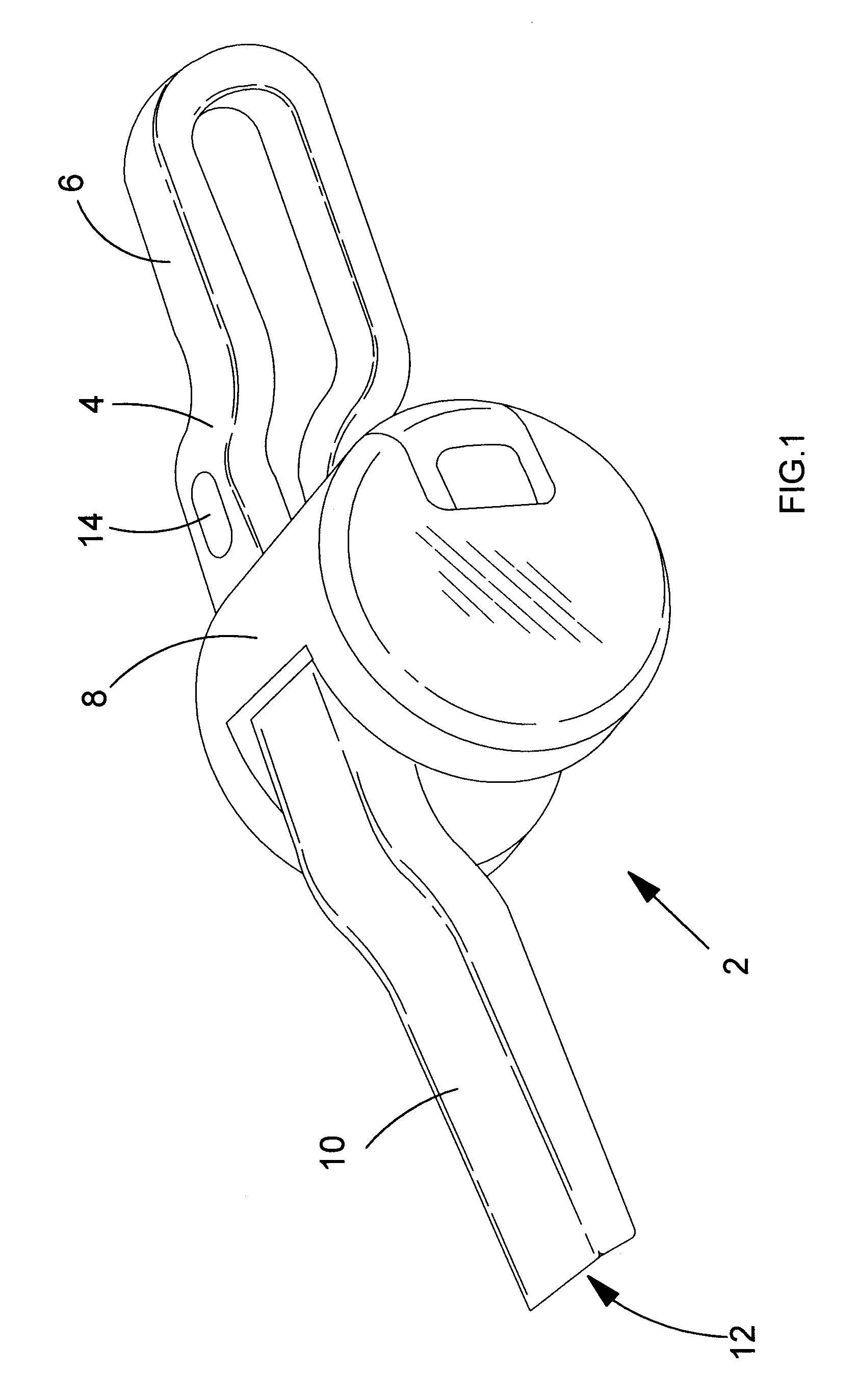

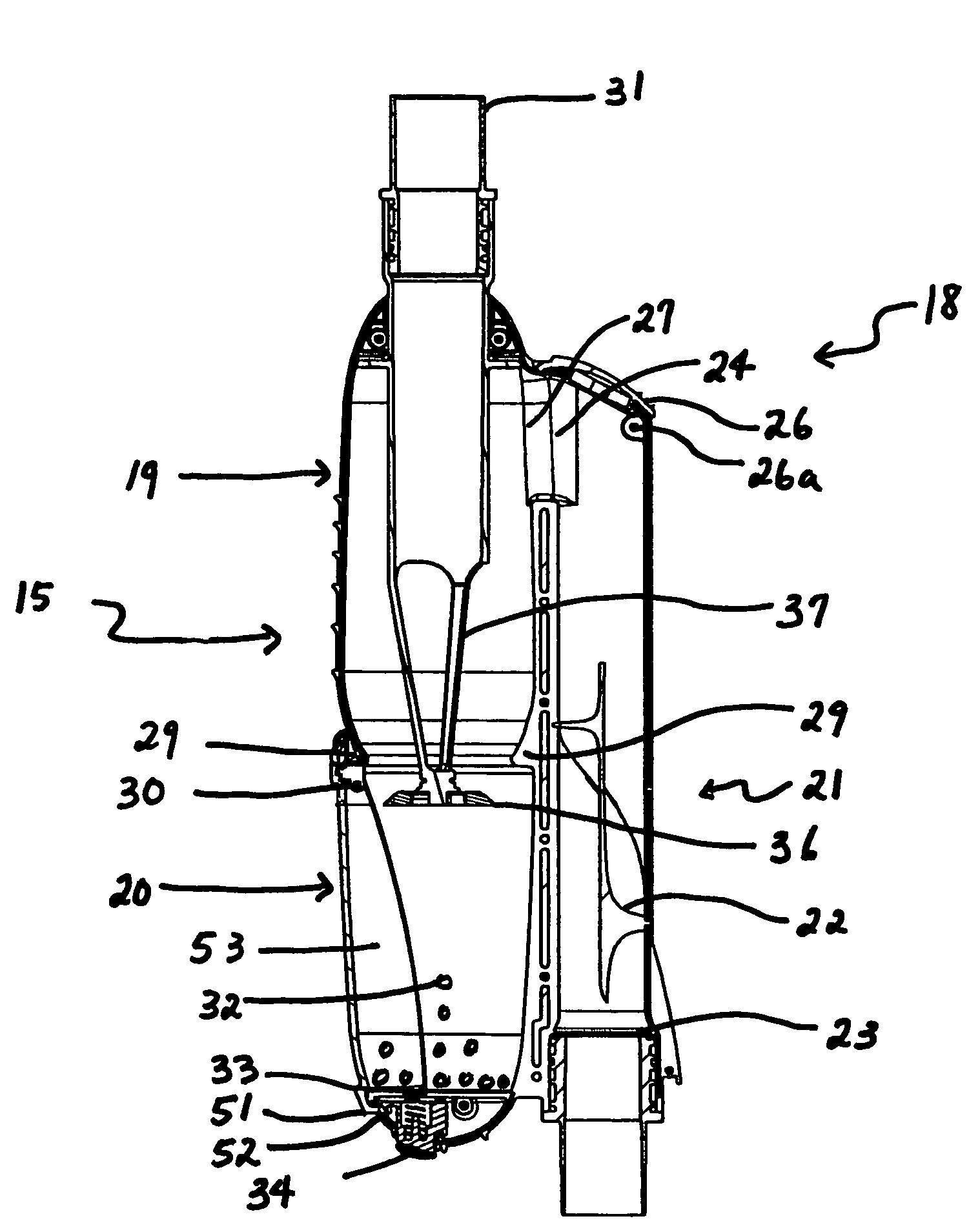

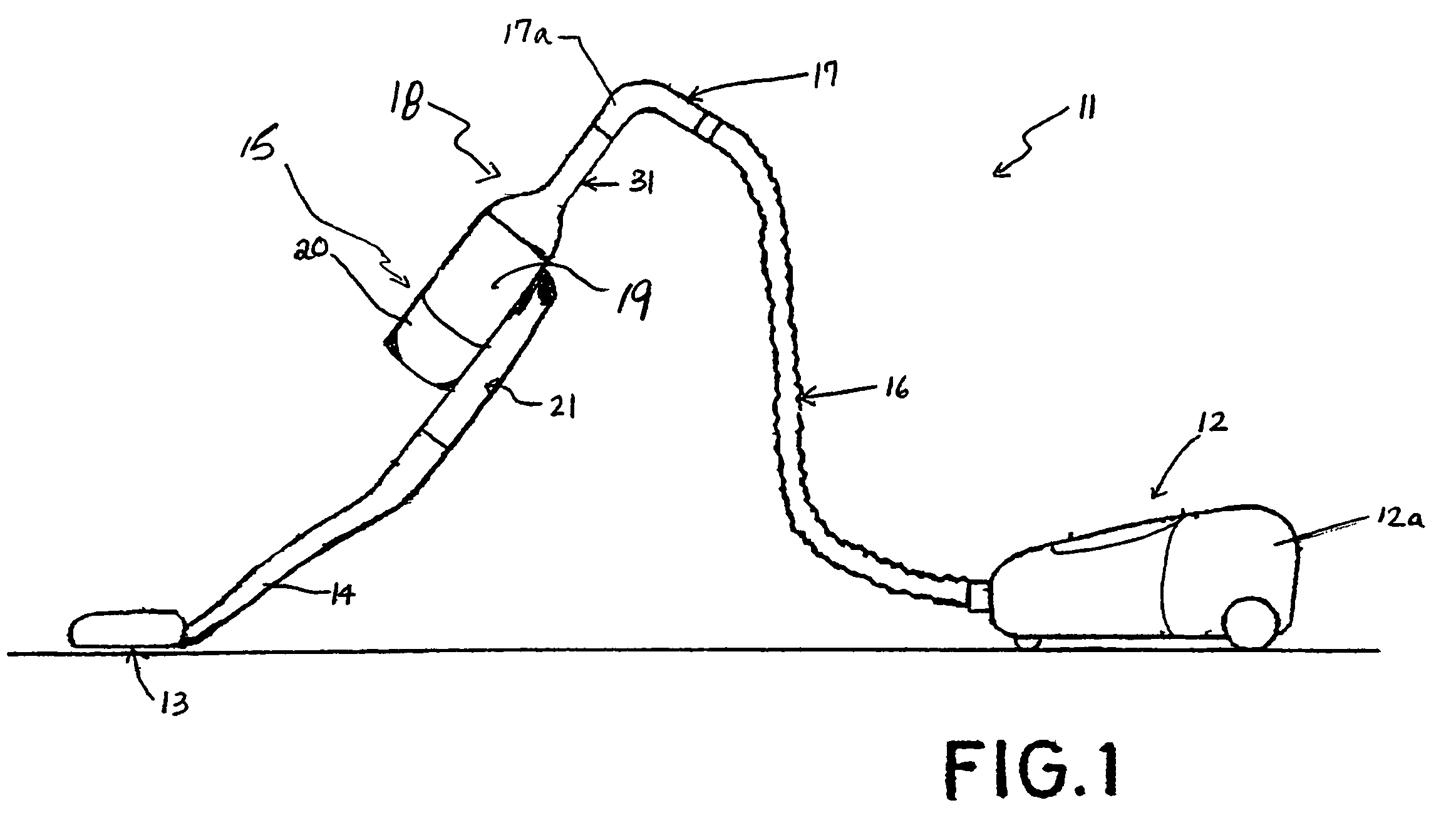

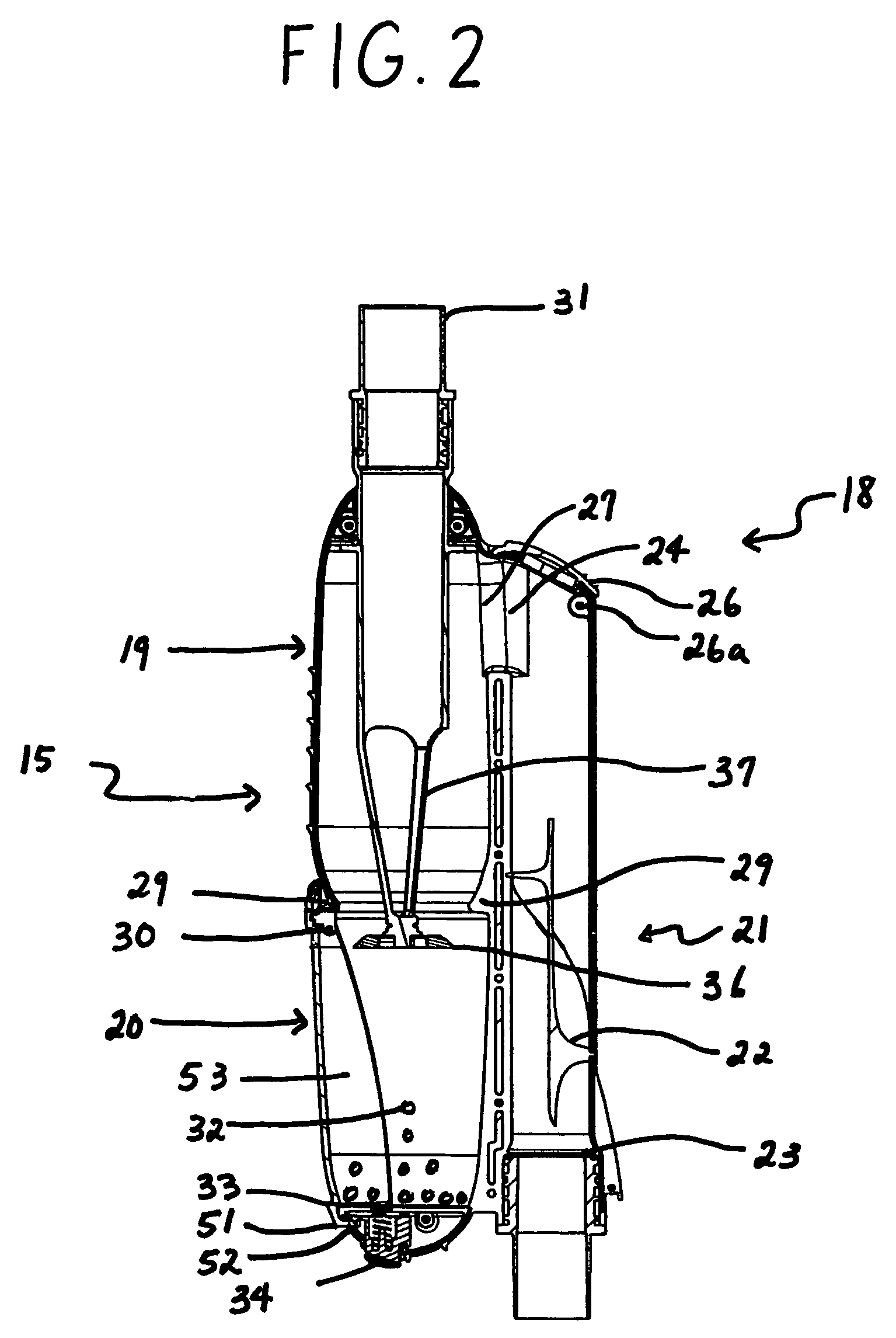

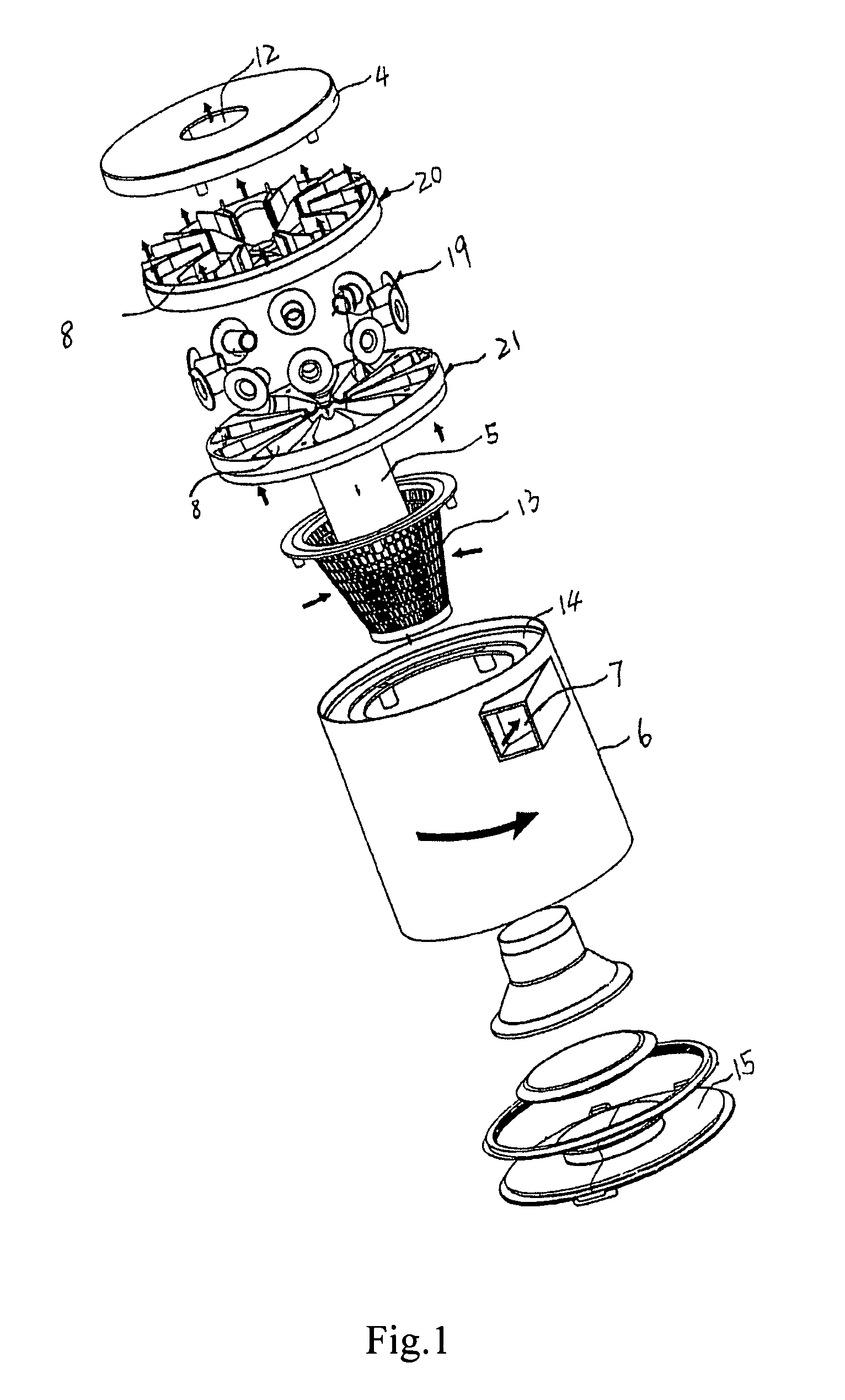

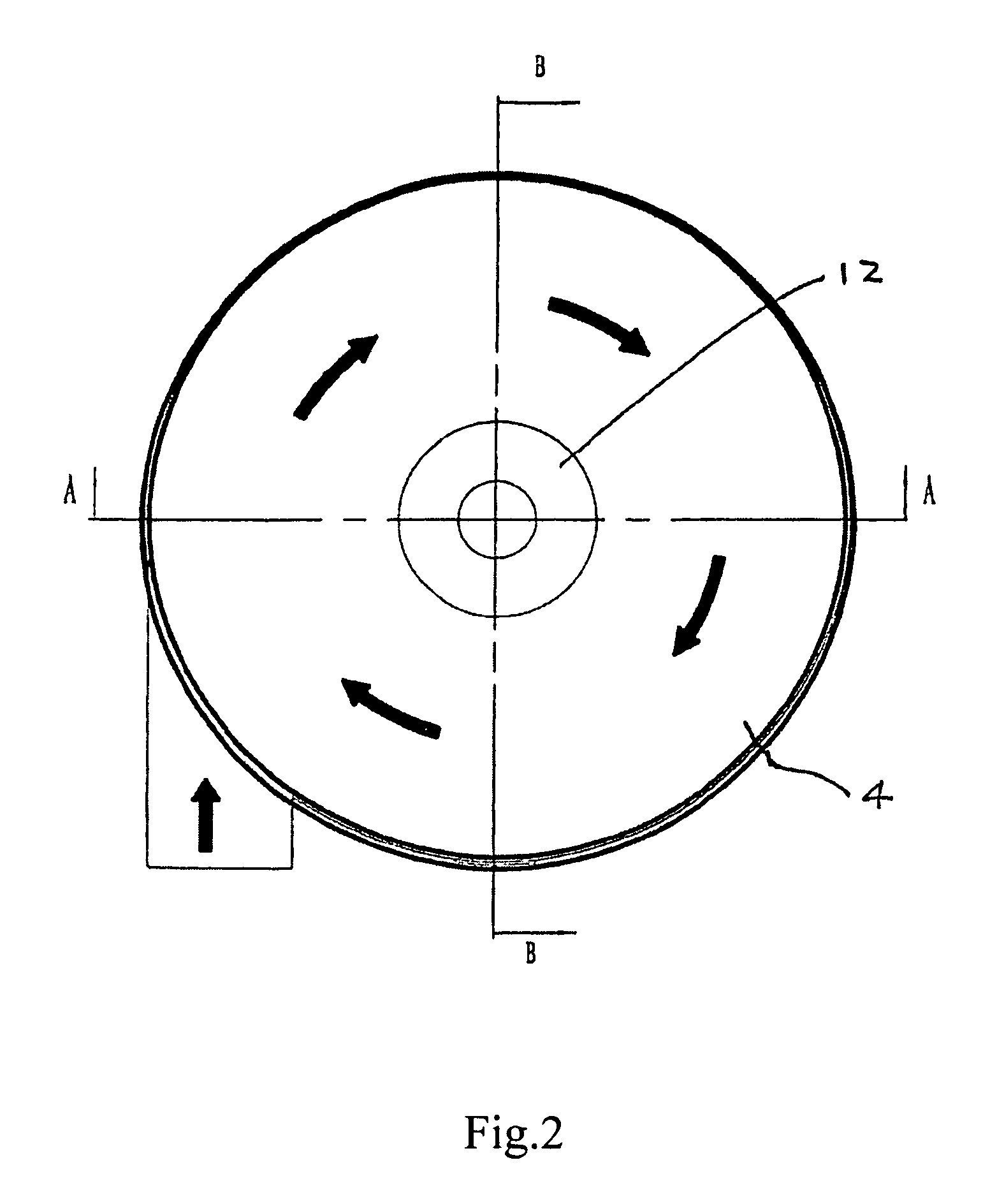

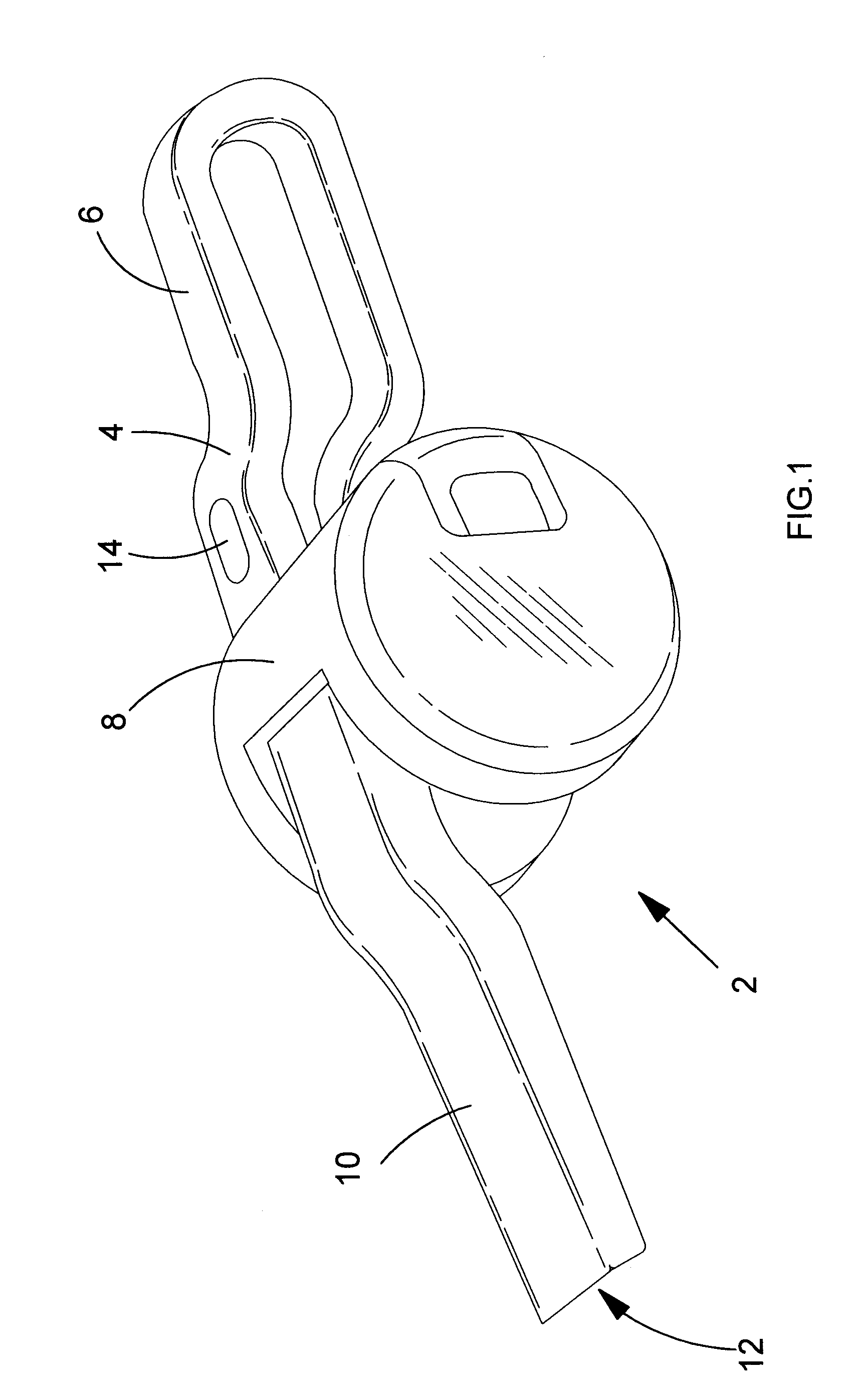

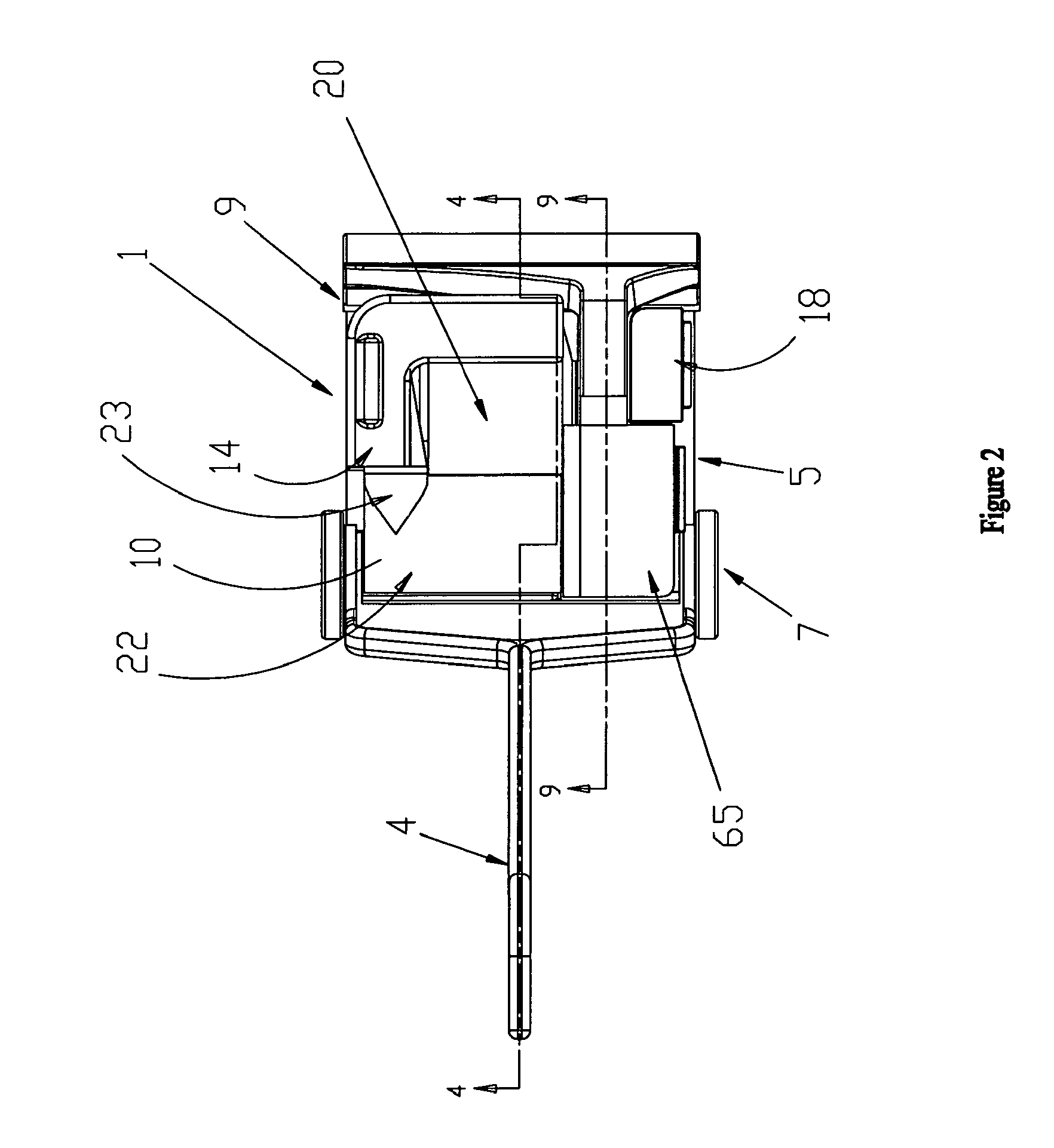

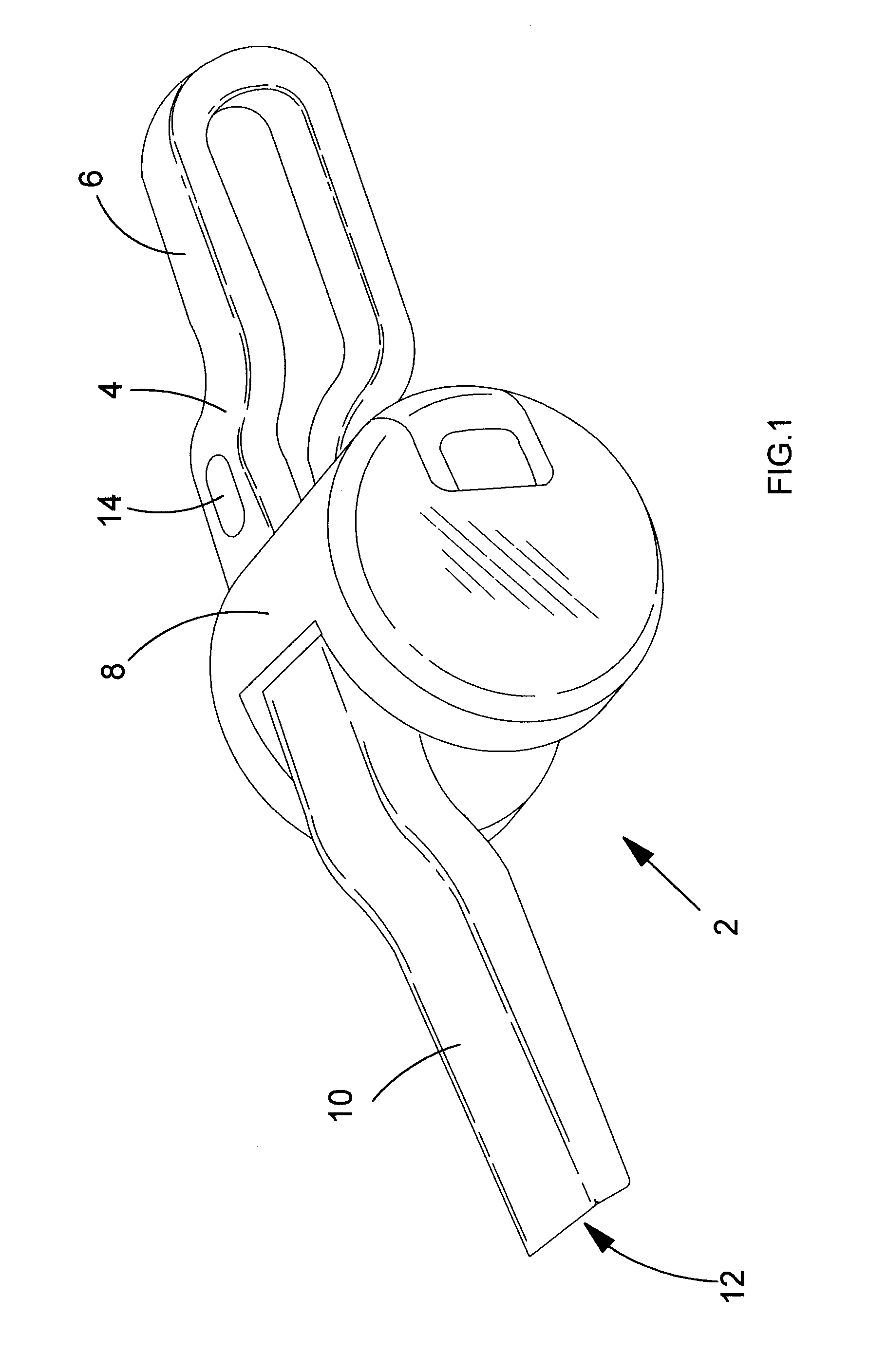

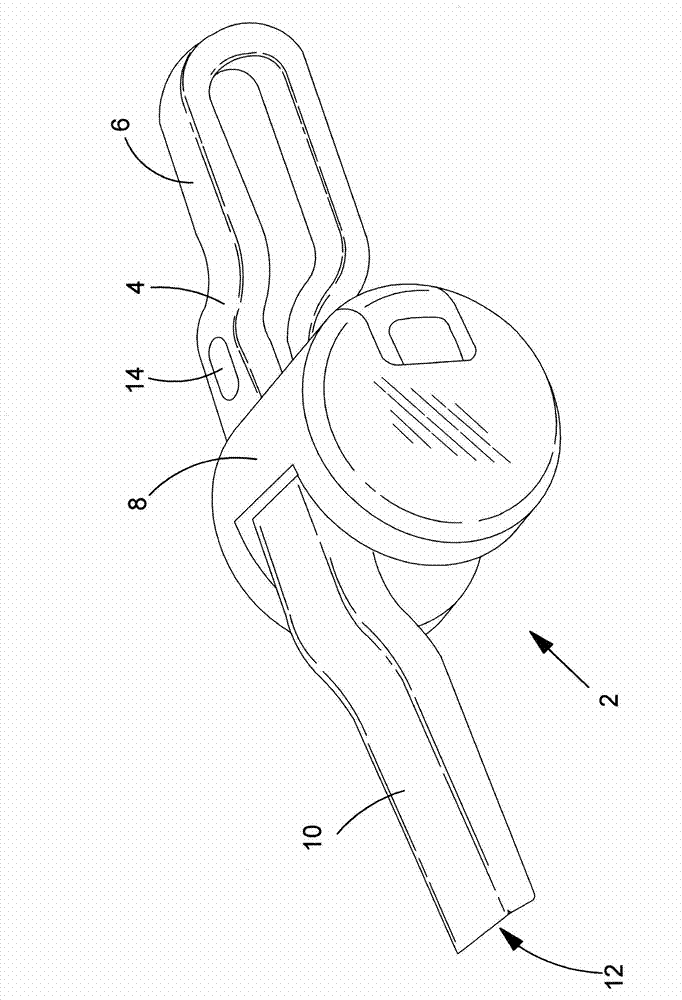

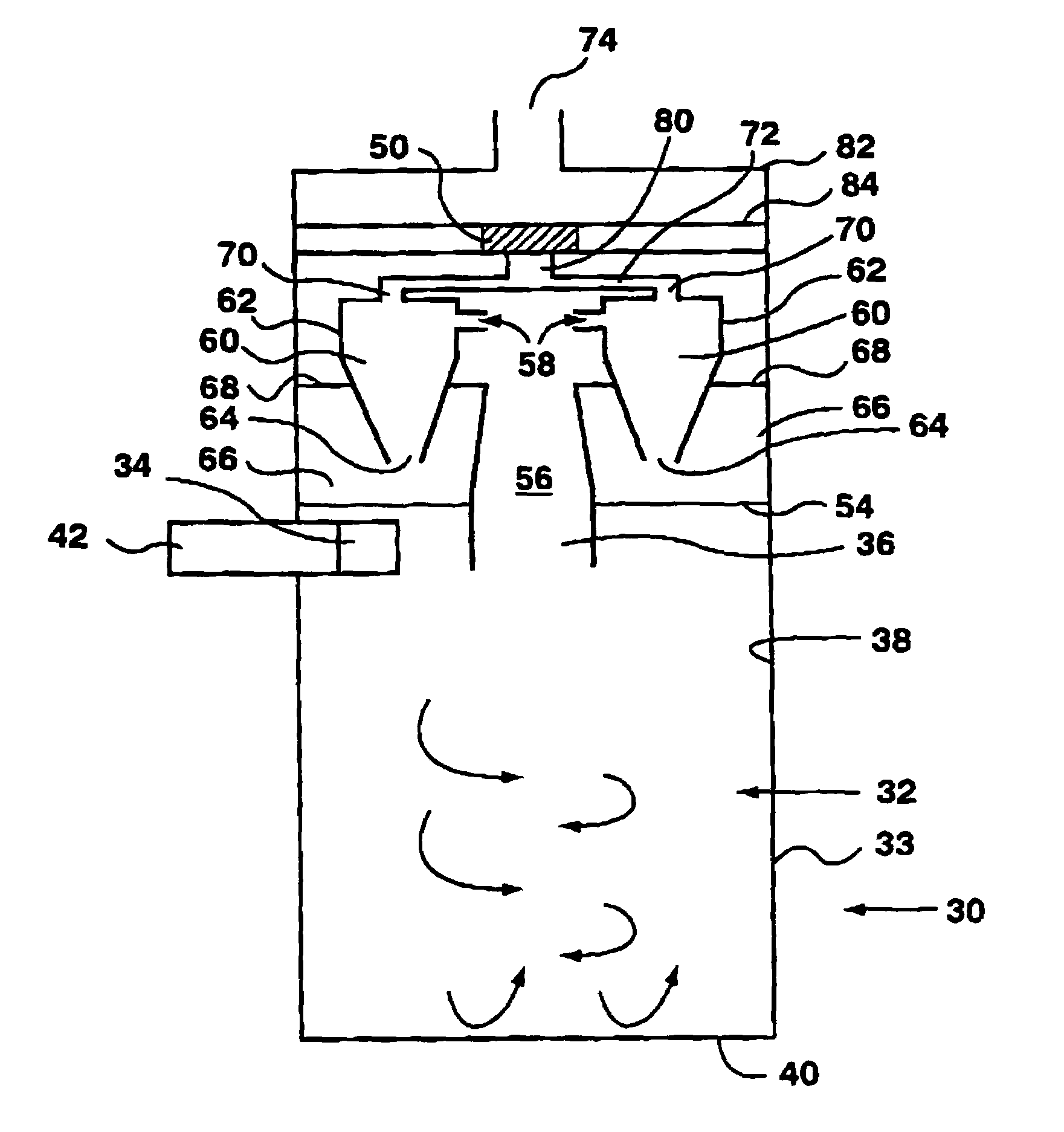

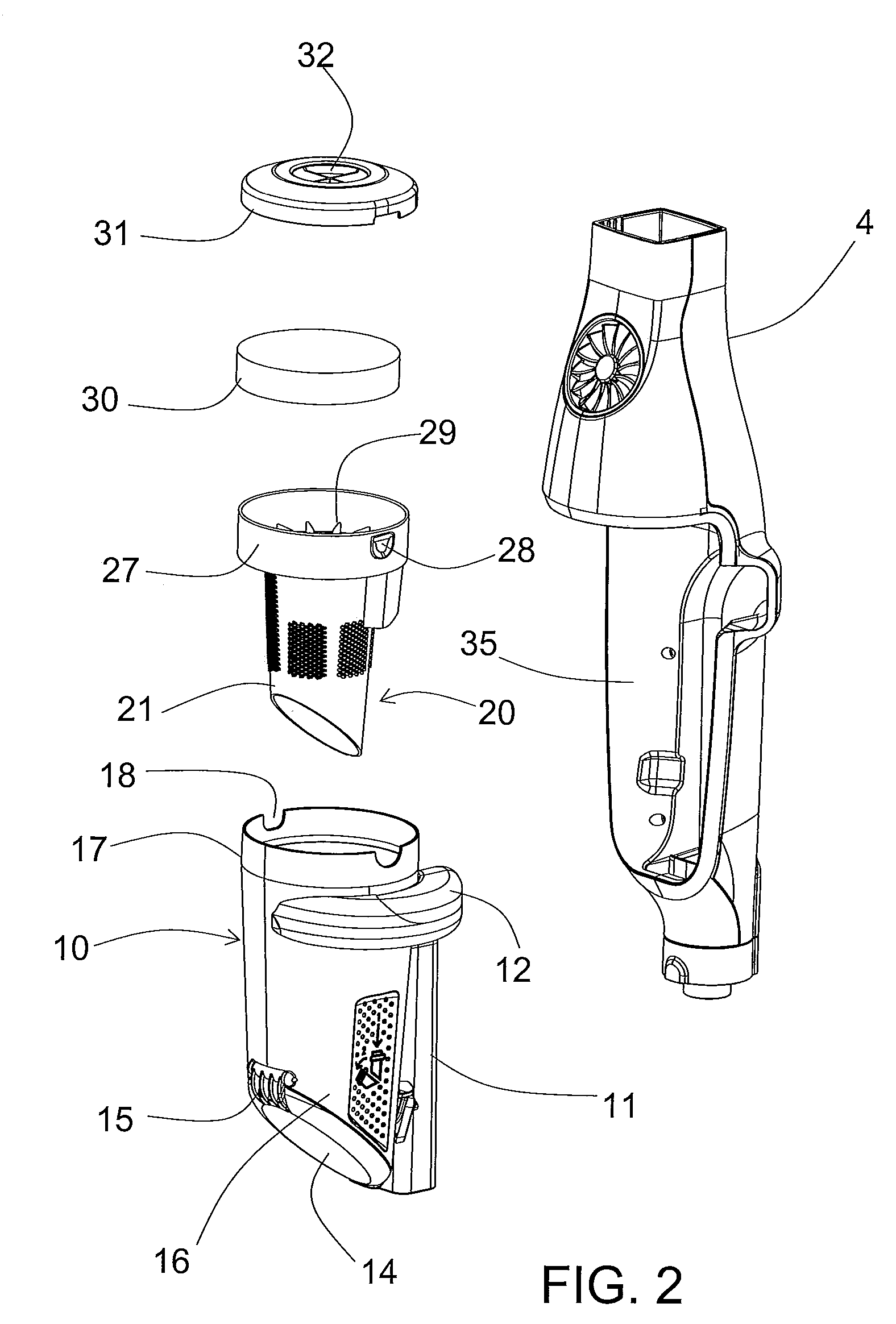

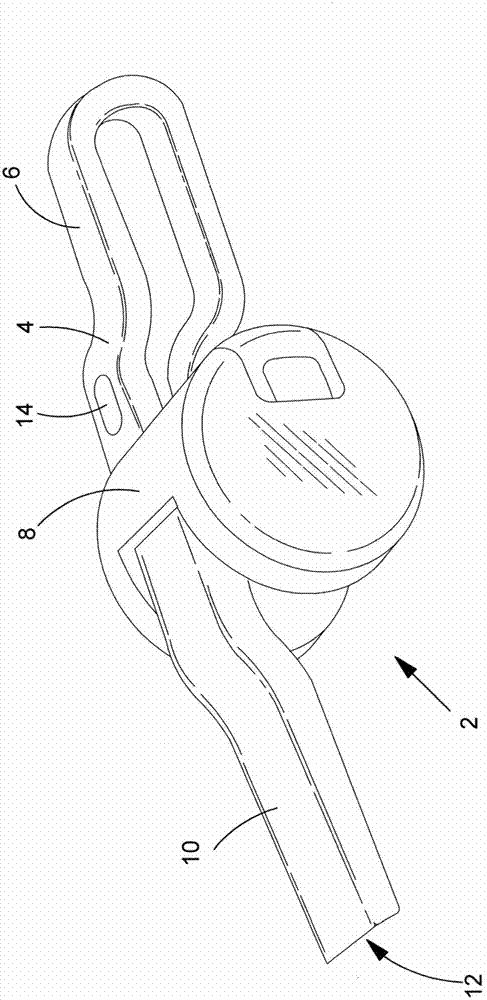

Compact cyclonic separation device

ActiveUS20060042206A1Easy to disassemblePrevent re-entrainmentCleaning filter meansCombination devicesCyclonic separationVacuum cleaner

A cyclonic separation device for a vacuum cleaner including a cylindrical housing, an inlet tube parallel to the axis of the housing having a vortex vane disposed axially in the inlet tube. Air rotates in one direction in the inlet tube, and preferably in the opposite direction in the housing. The housing includes a cylindrical sidewall with an upper central outlet tube and a closed bottom for collecting separated dirt. A disrupter ring located on the inside wall of the middle portion of the housing includes a curved surface and sharp edge for lifting air flow off the housing wall. An outlet tube disc spaced from the inlet of the outlet tube is located in the housing below the disrupter ring.

Owner:SHARKNINJA OPERATING LLC

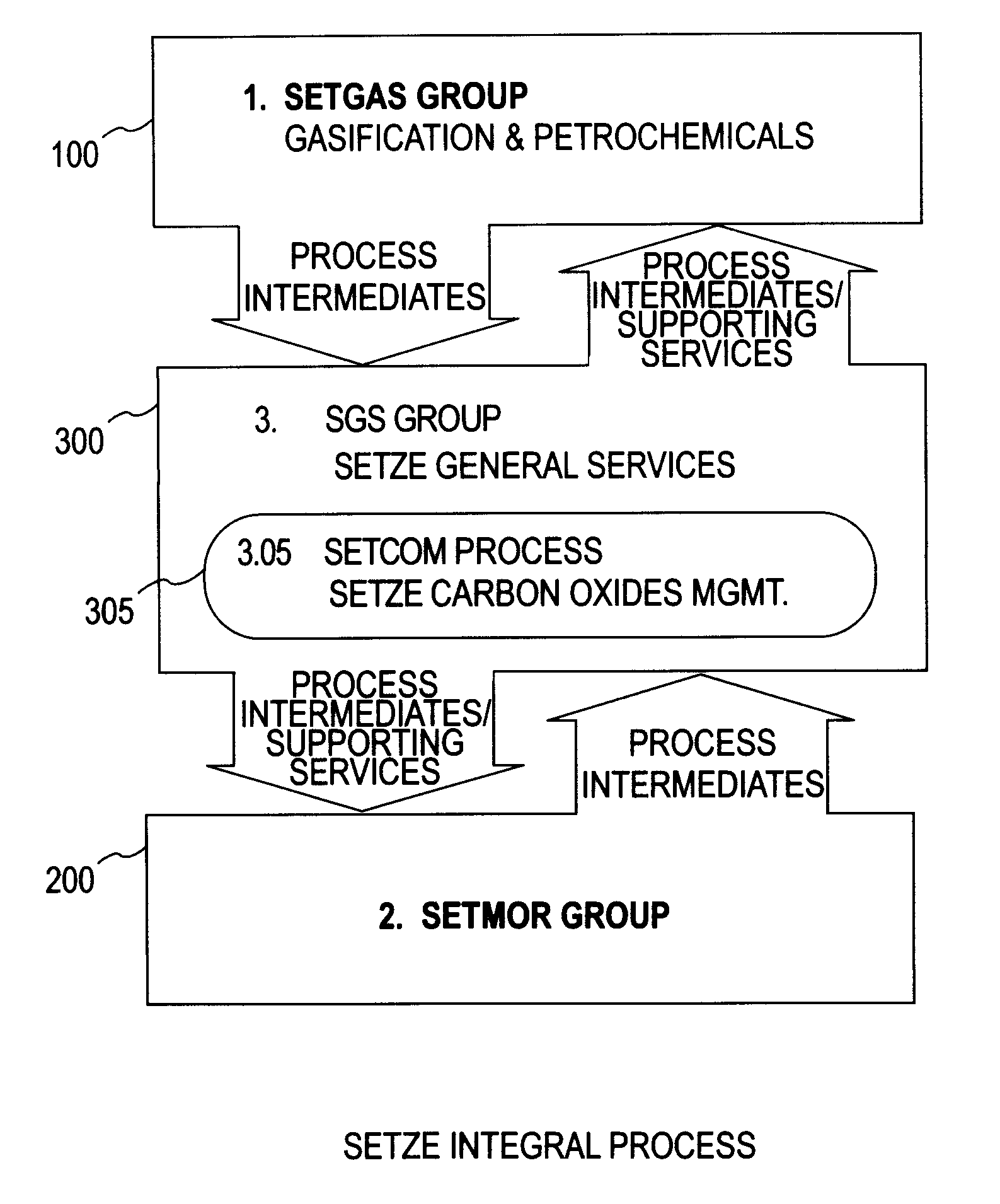

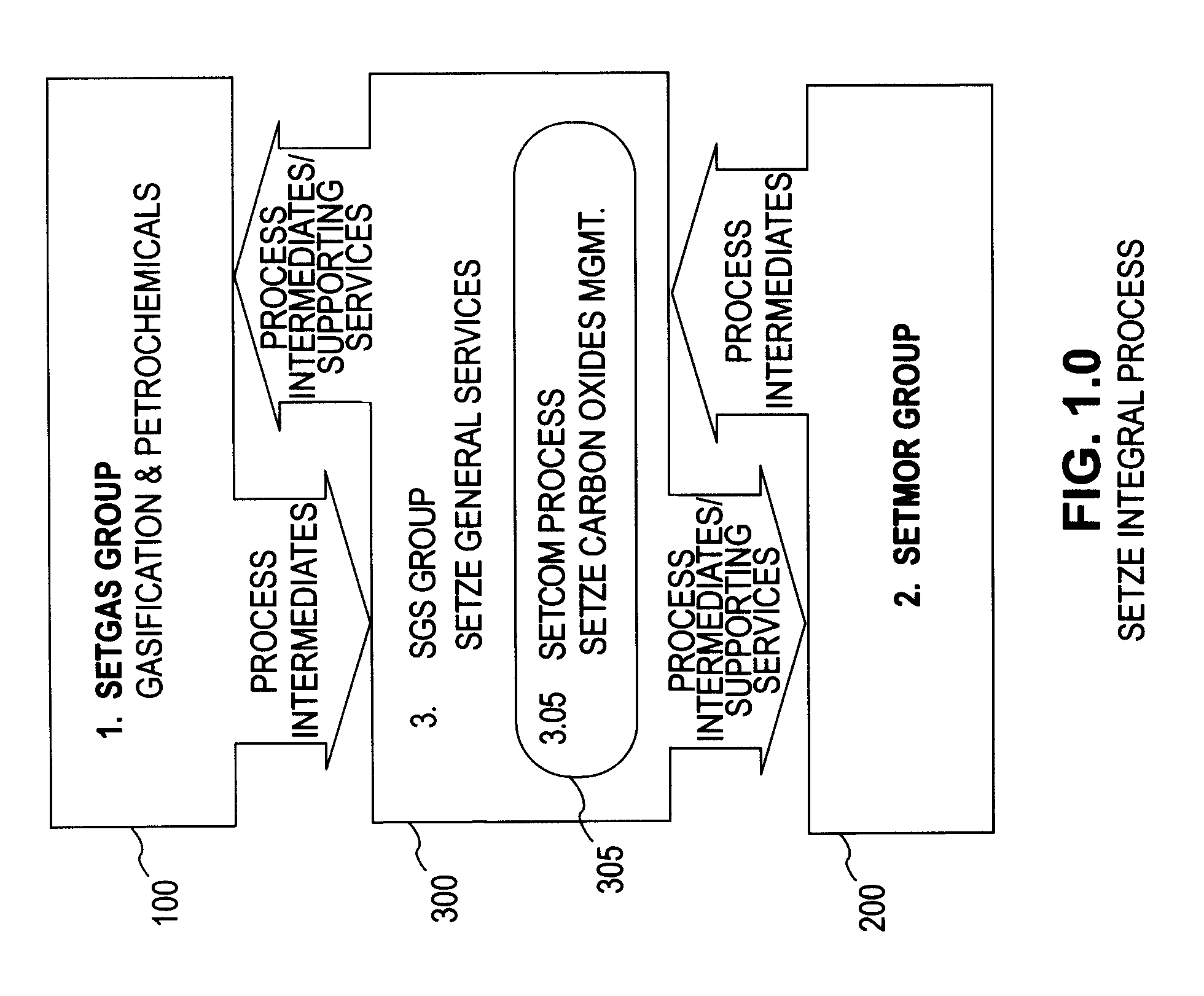

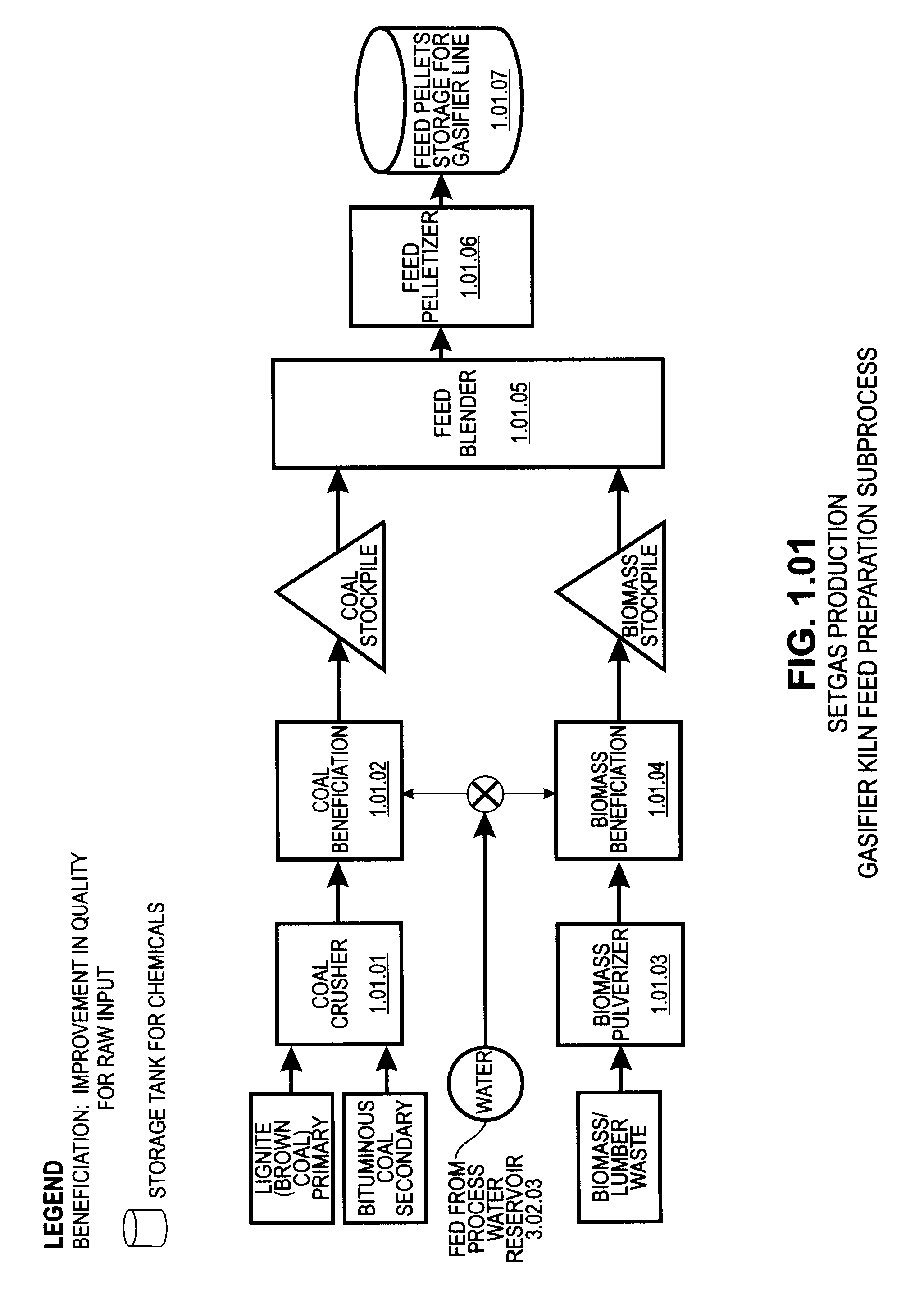

Zero emission gasification, power generation, carbon oxides management and metallurgical reduction processes, apparatus, systems, and integration thereof

ActiveUS7674443B1Improvement in individual technology componentEnhances economic performanceUsing liquid separation agentBiofuelsCyclonic separationOxygen

A system involving a two-step gasification of a carbonaceous source to produce bulk hydrogen that avoids the early formation of CO2 and obviates the traditional water gas shift (WGSR) step, carbochlorination of a metallic ore the production of metals found in the ore that utilizes carbon monoxide as an oxygen sink, rather than the traditional coke, and carbon oxides management that eliminates major impediments to emission-neutral power generation and the reduction of major metals. The gasification uses a rotary kiln reactor and gas-gas cyclonic separation process to separate synthesis gas into purified hydrogen and purified carbon monoxide. Purified bulk carbon monoxide issued in metallurgical reduction, and purified bulk hydrogen as fuel for an emission-neutral hydrogen combined cycle (HCC) turbine power generation station. The carbochlorination is integrated with: a) the concurrent separation and purification of all metal-chlorides (metchlors) and capture of CO2 for passage to the carbon oxides management system; b) the direct reduction of metchlors to nanoscale metallurgical powders and / or to dendritically-shaped particles, including metchlor reduction for the ultrahigh-performance semiconductor metals of the III-V group; and, c) the reforming of metal-oxides with improved crystalline structure from metchlors. The carbon oxides management collects, stores and directs to points of usage, carbon oxides that arise in various processes of the integrated system, and captures carbon monoxide for process enhancement and economic uses and captures carbon dioxide as a process intermediate and for economic uses.

Owner:DAVIS OLUMIJI B +1

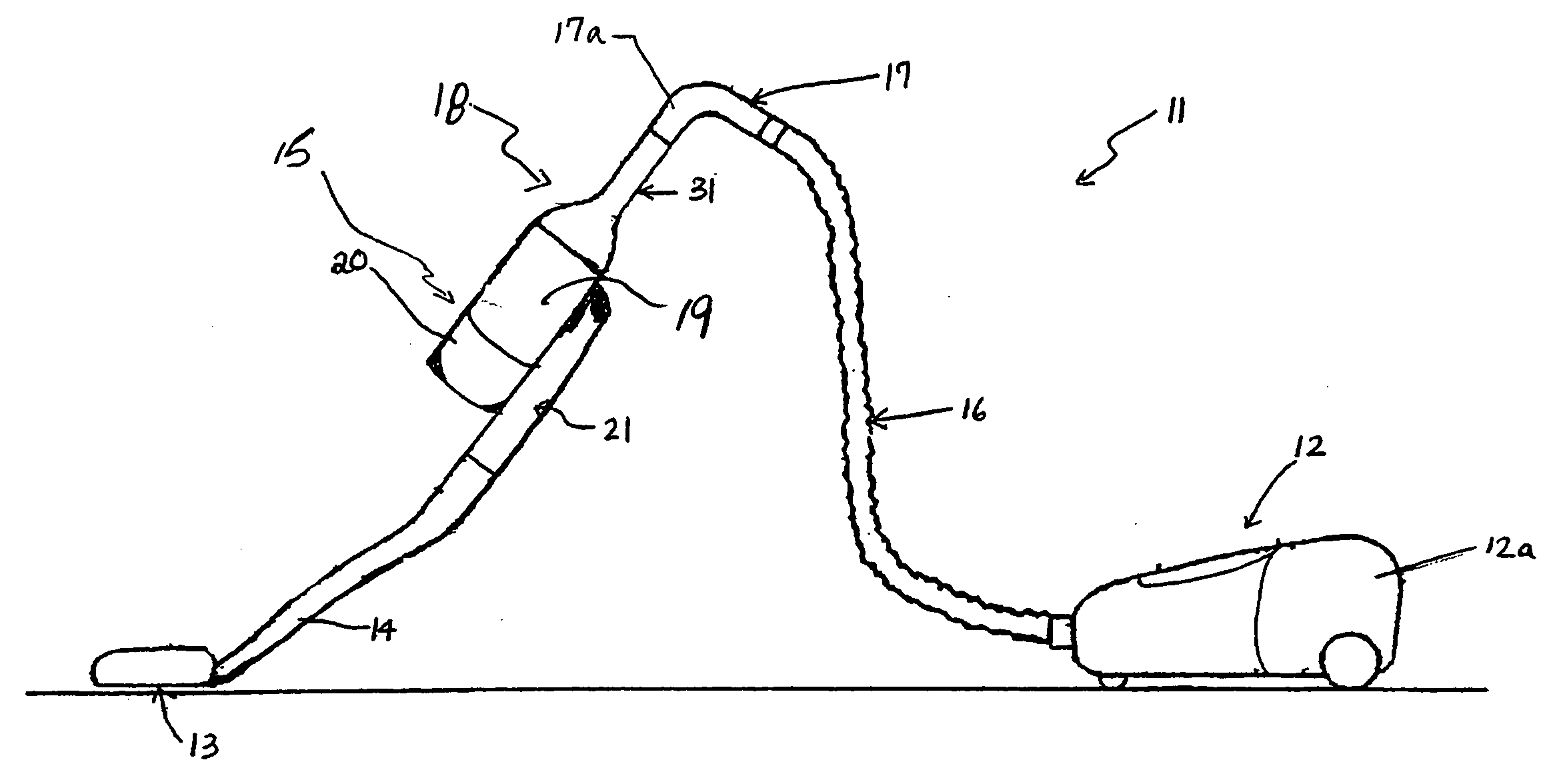

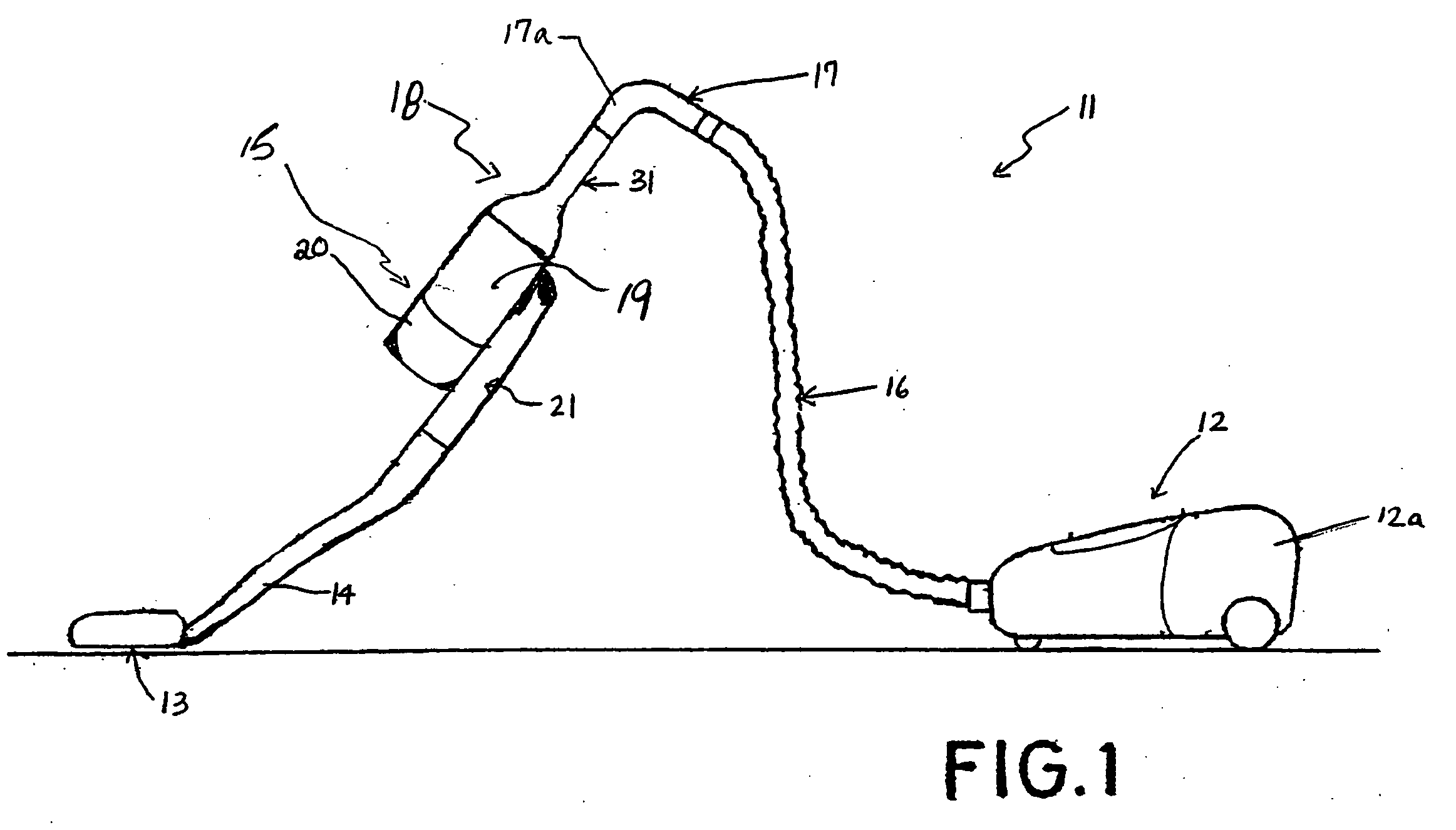

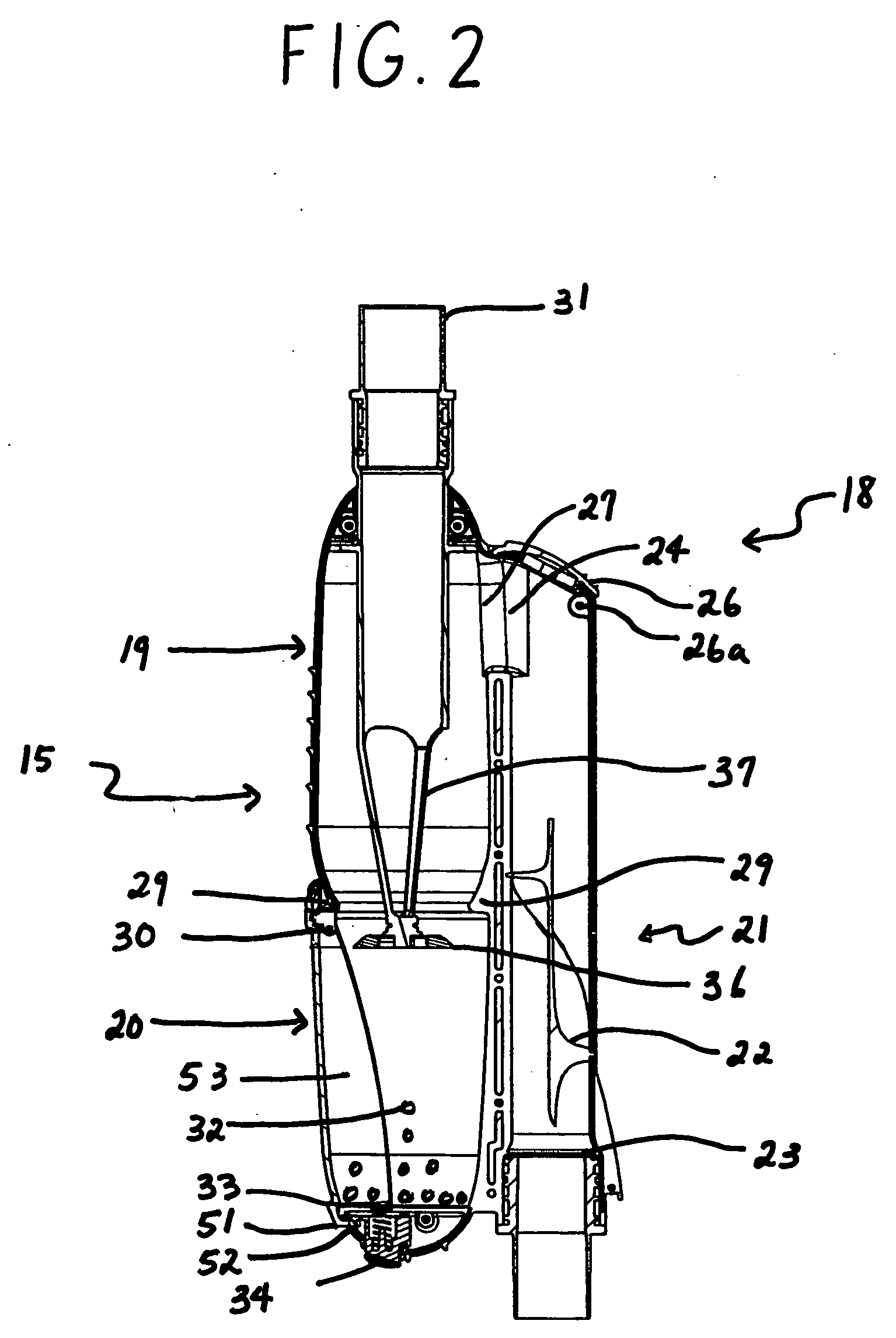

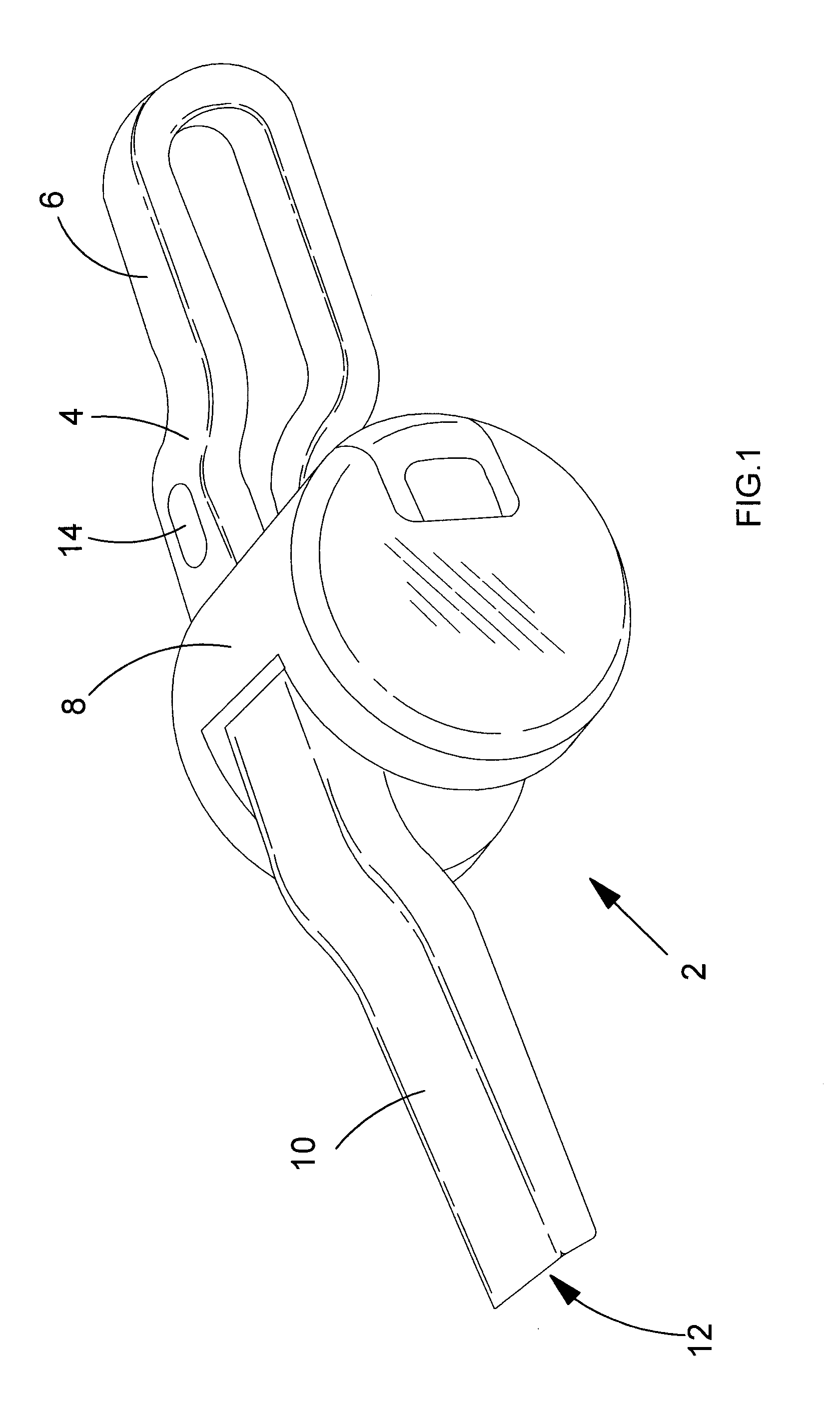

Cyclonic separation apparatus

ActiveUS20130091661A1Easy to carryEasy to useCleaning filter meansSuction filtersCyclonic separationEngineering

A cyclonic separation apparatus for a vacuum cleaner, the cyclonic separation apparatus comprising: a first cyclonic separating unit comprising a hollow cylindrical dirt container with a central axis and an air inlet port arranged tangentially through a side of the dirt container; a second cyclonic separating unit comprising at least one cyclone with an axial inlet port, an axial outlet port and a discharge nozzle and a substantially cylindrical intermediate wall surrounding the inlet port of the at least one cyclone, wherein the cyclonic separation apparatus comprises at least one protruding lip arranged to impede return of separated material from said longitudinal end of the dirt container and wherein the at least one lip protrudes radially inwardly from an inner surface of the dirt container or protrudes radially outwardly from the intermediate wall.

Owner:BLACK & DECKER INC

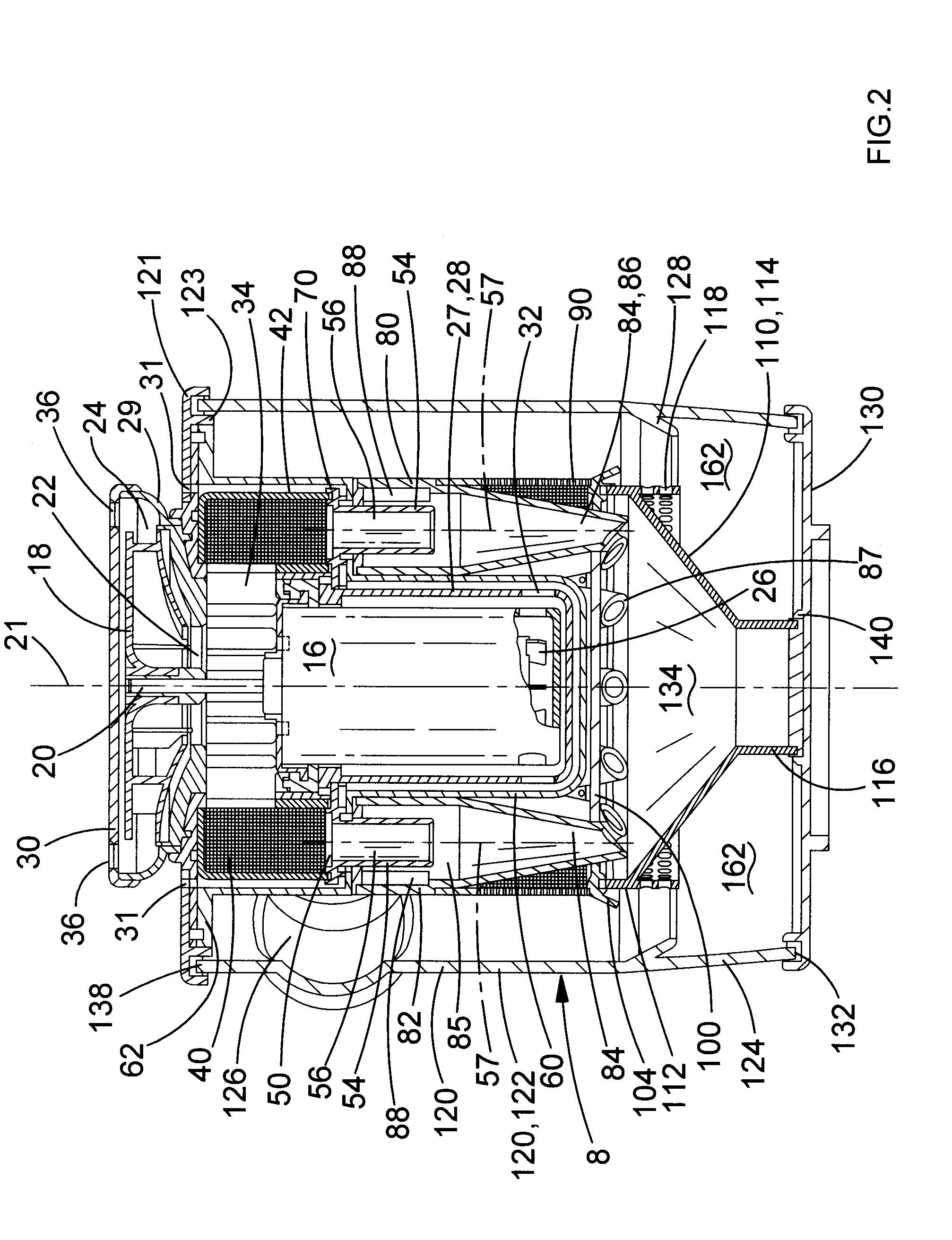

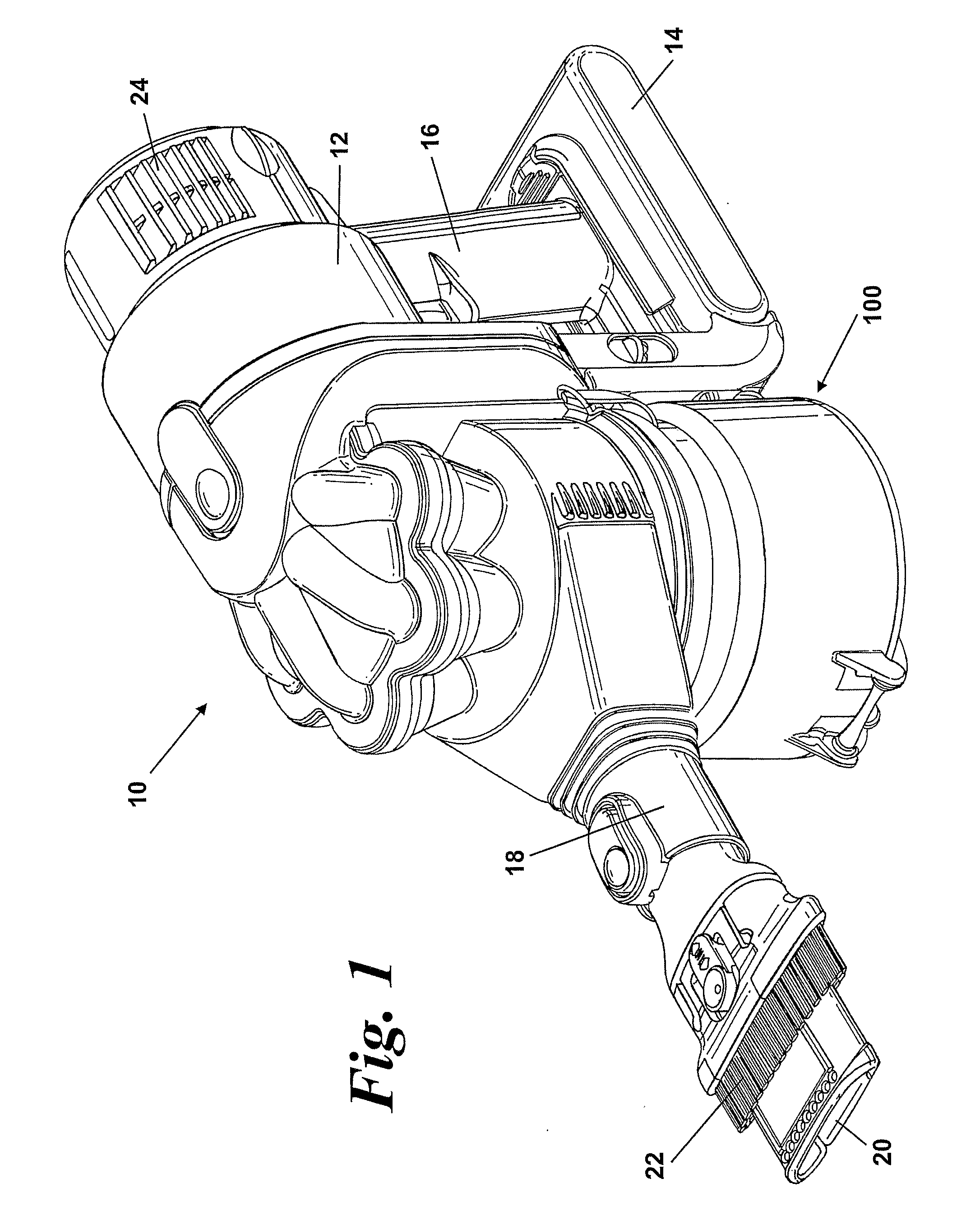

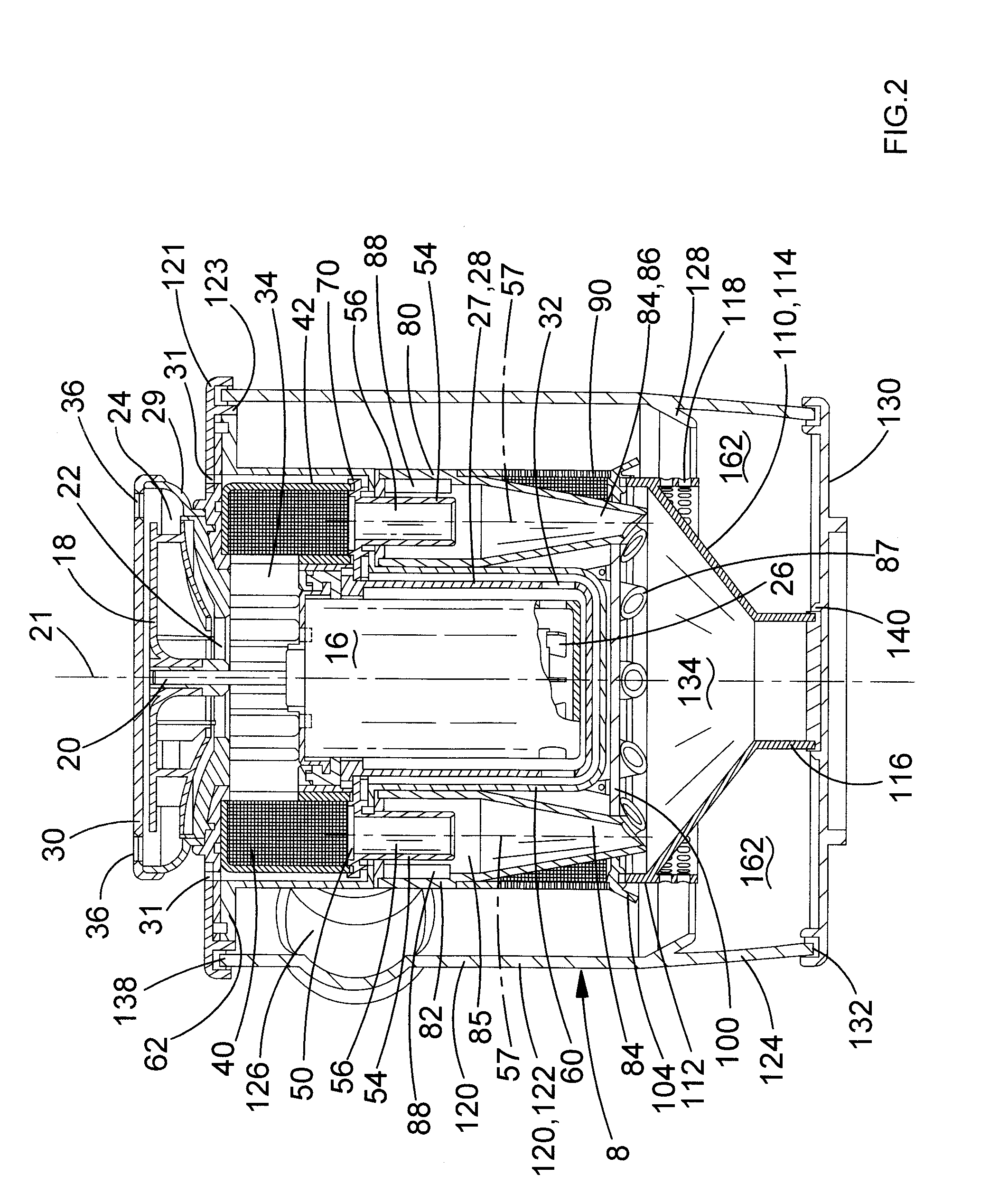

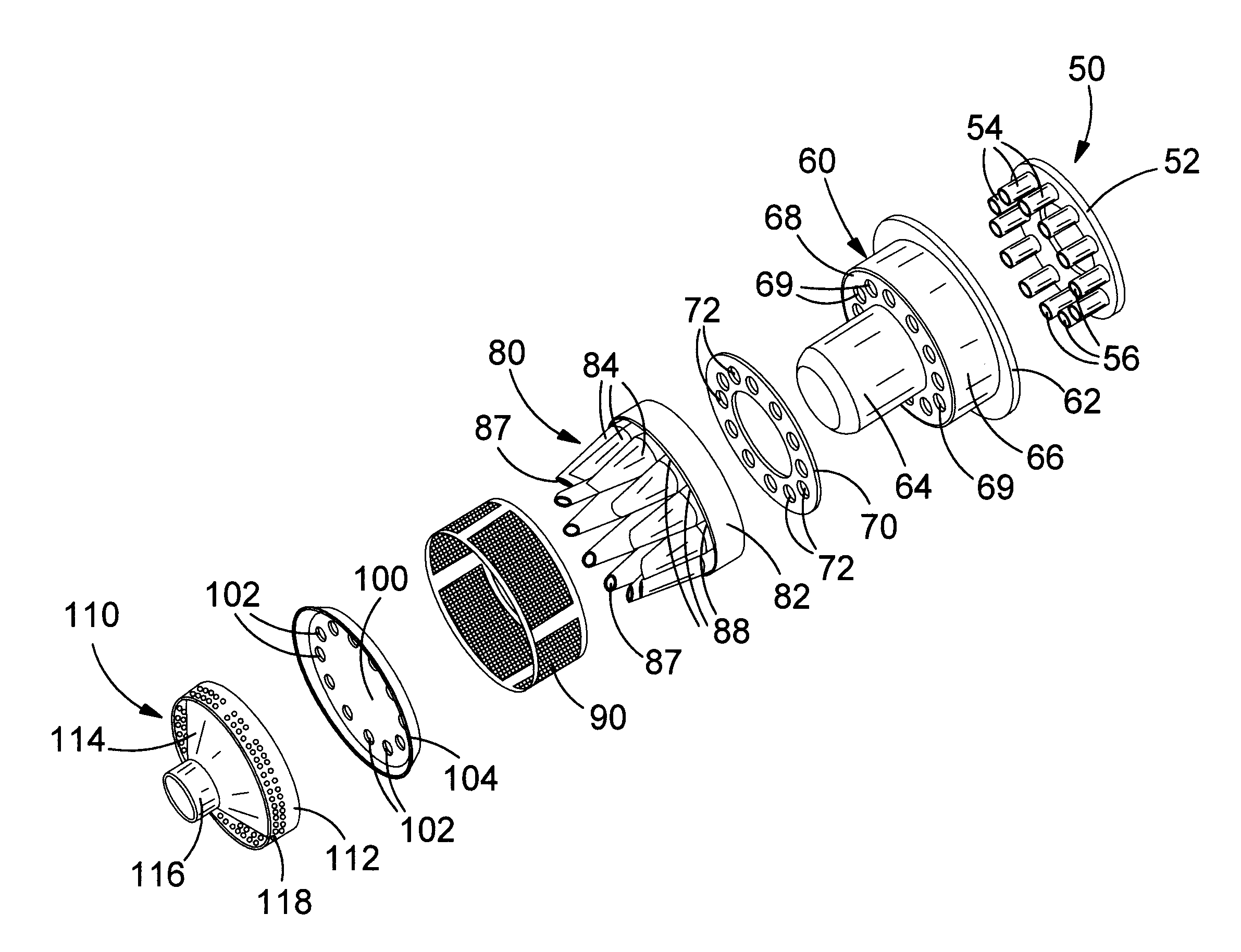

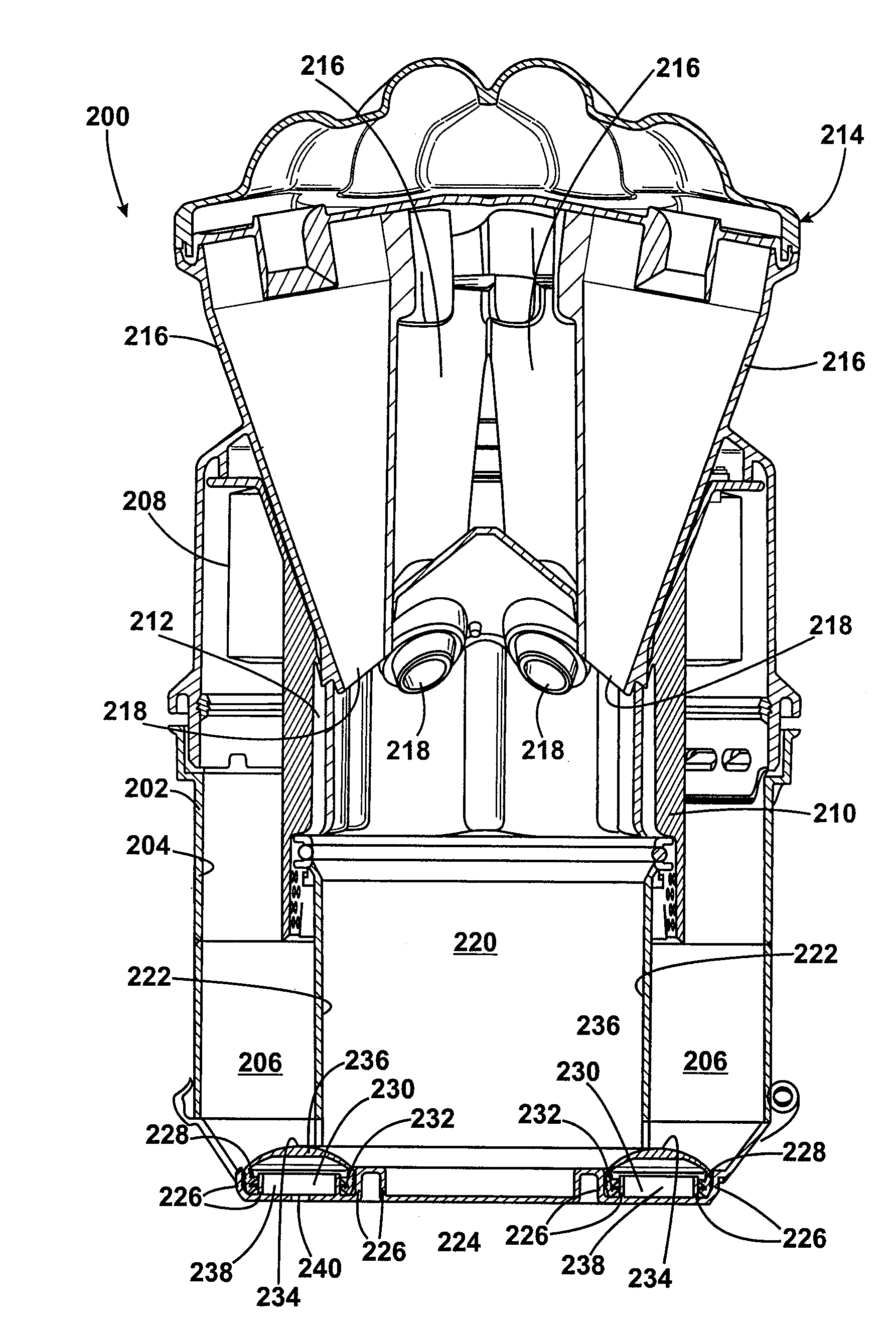

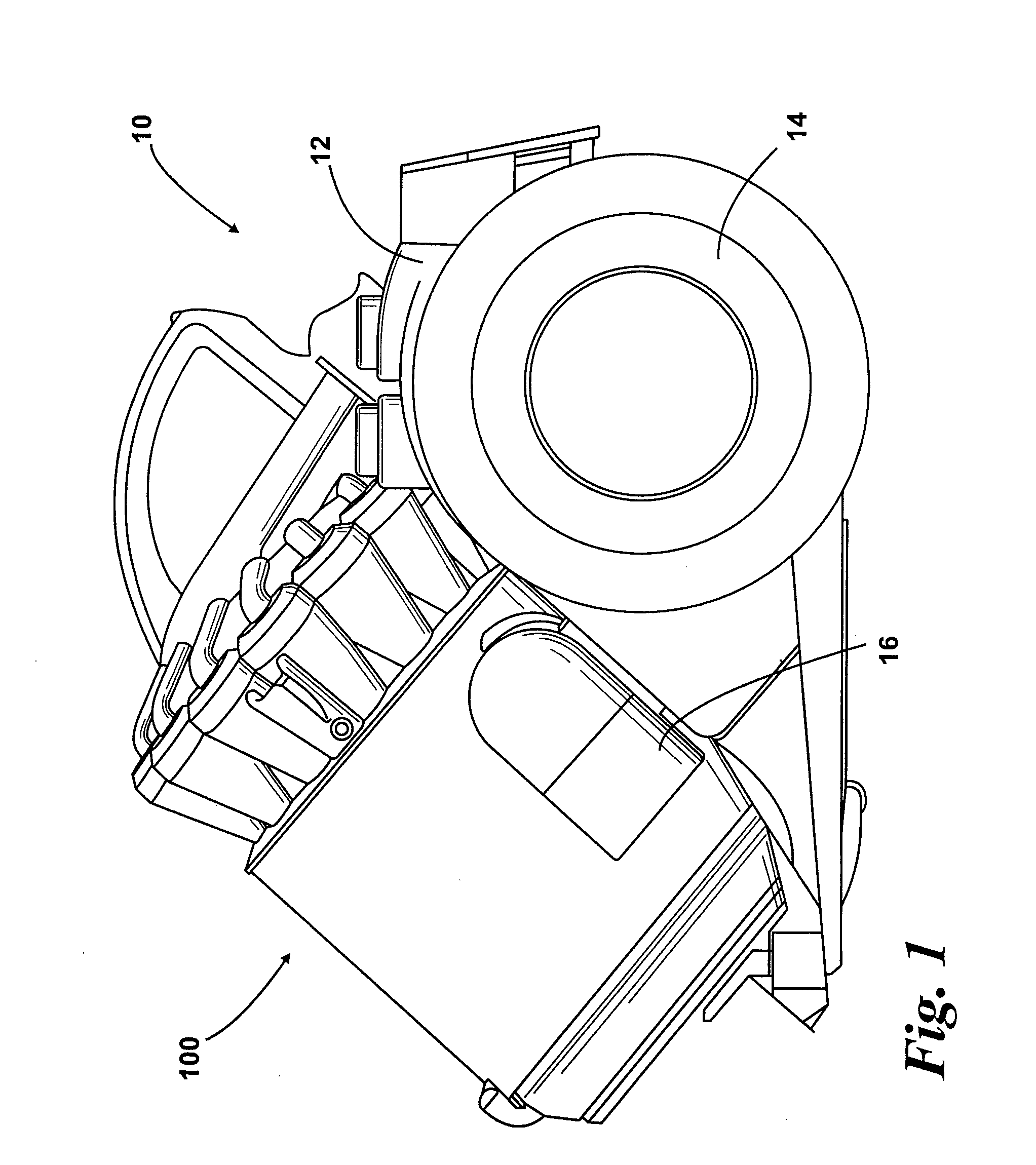

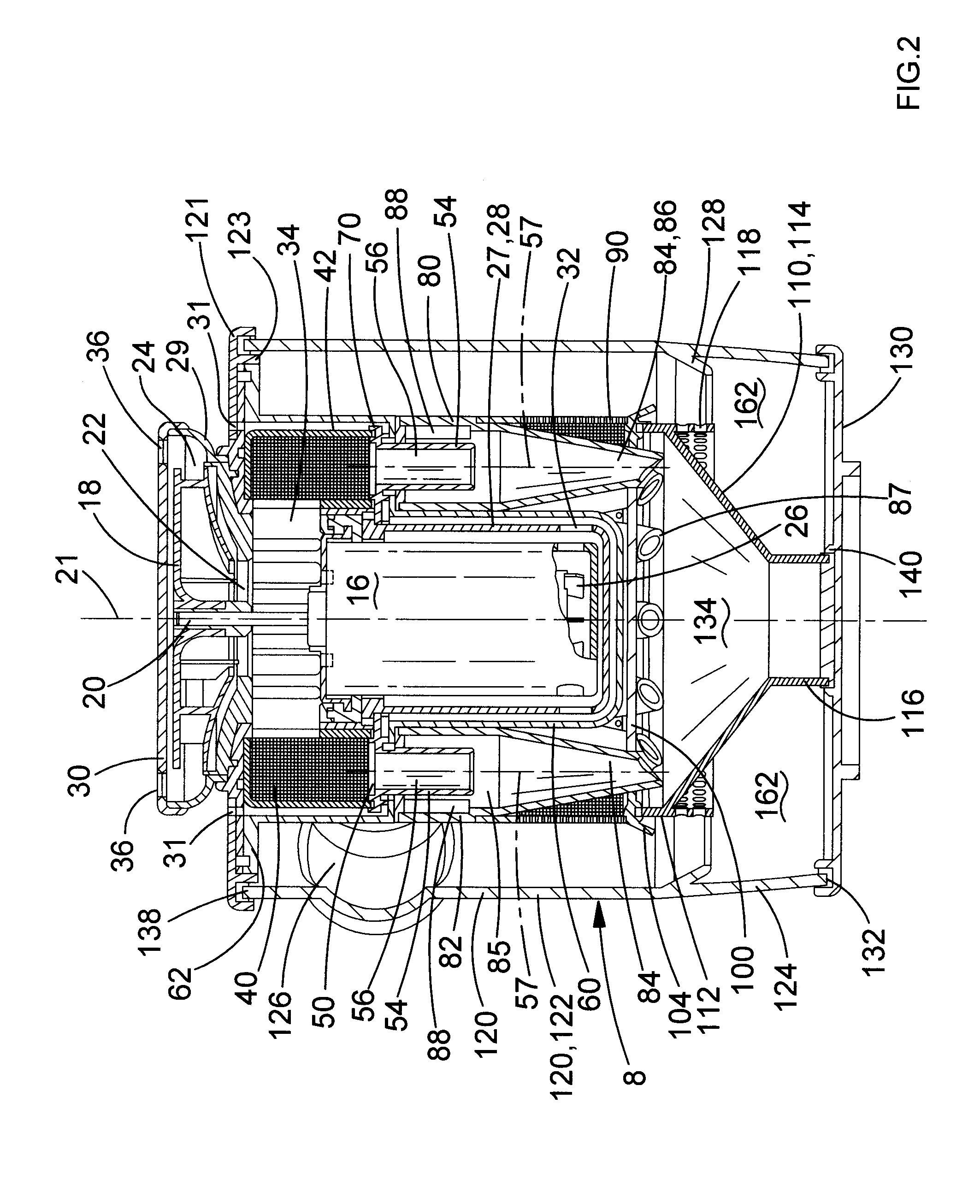

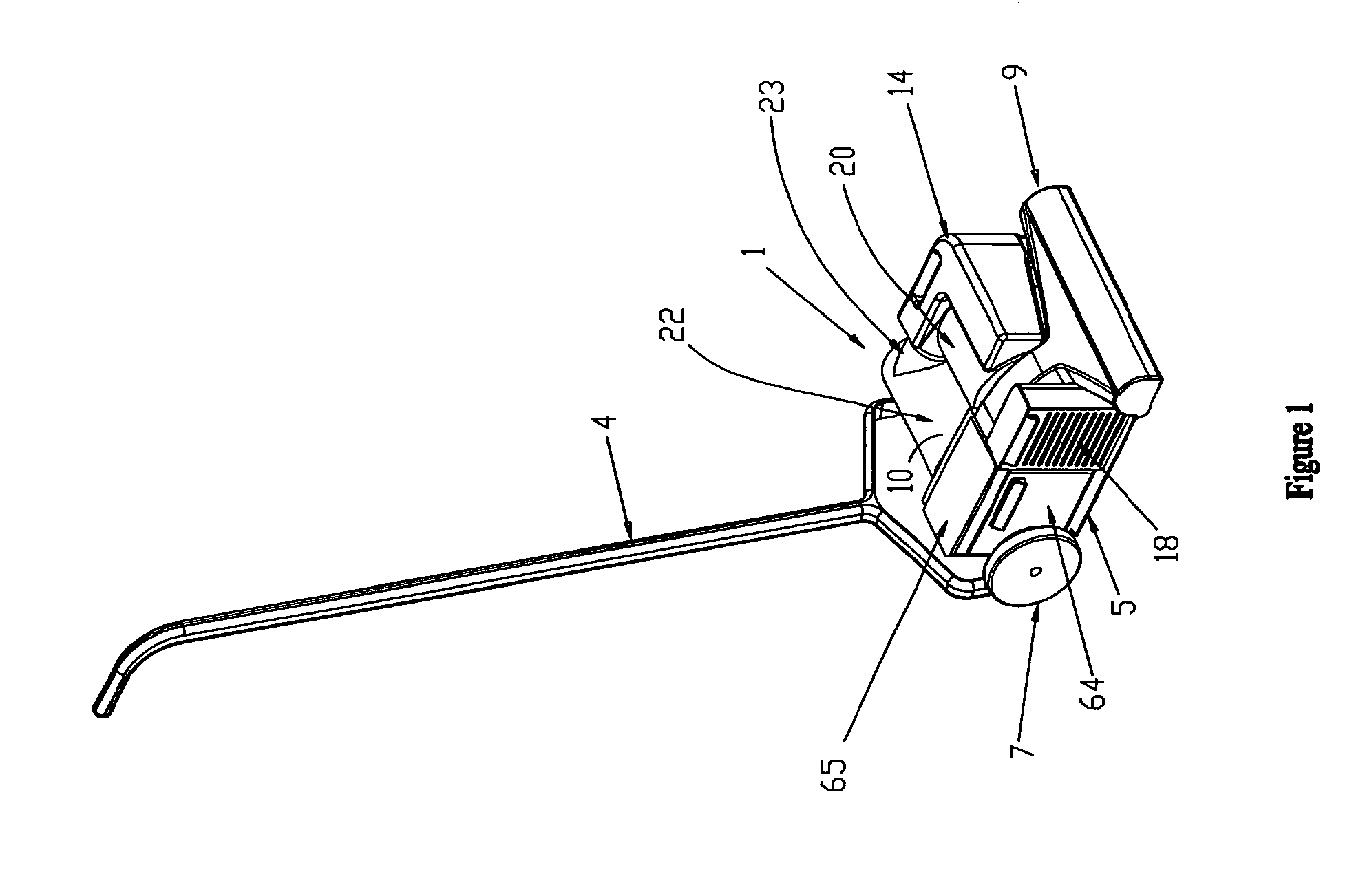

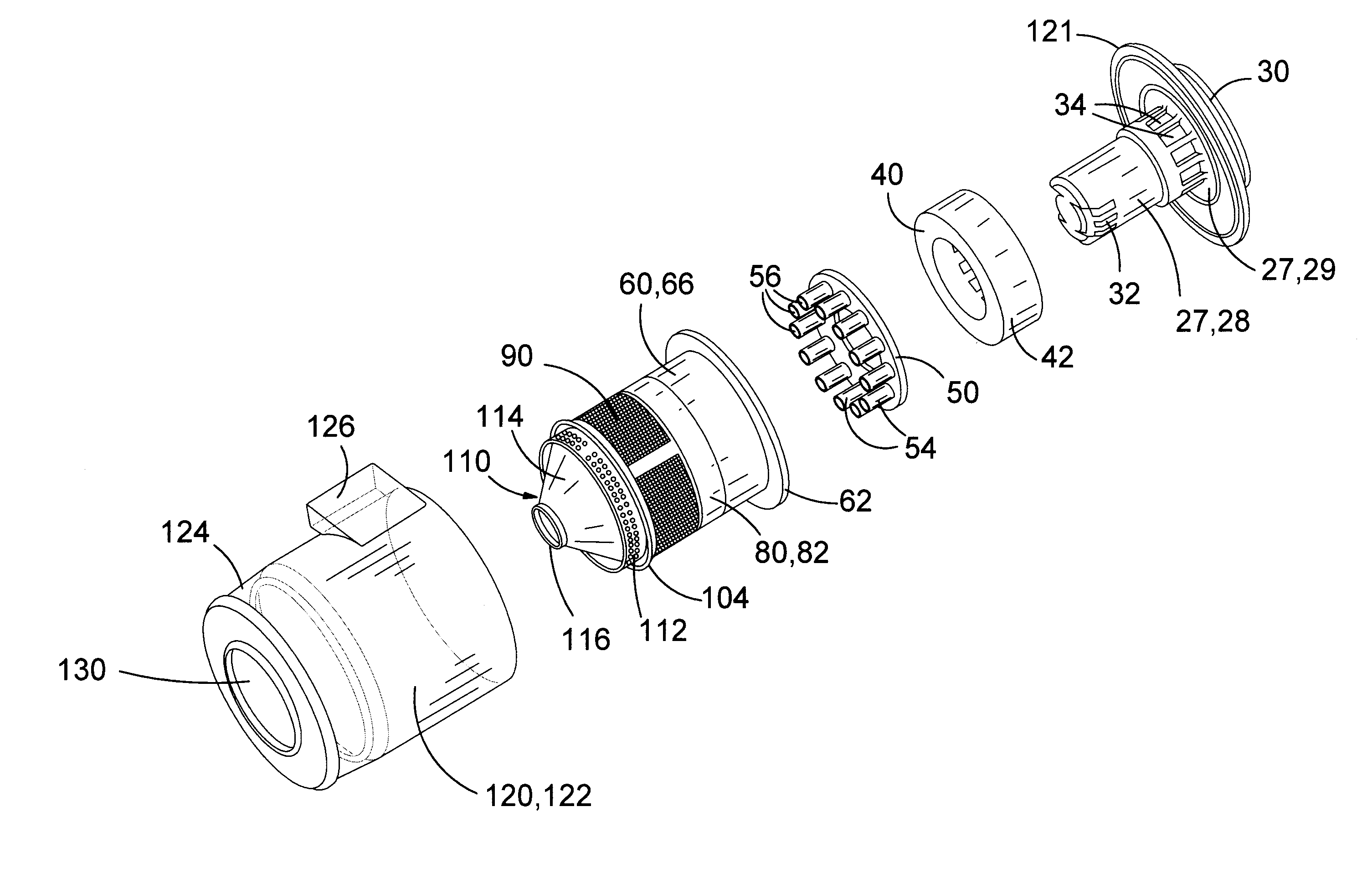

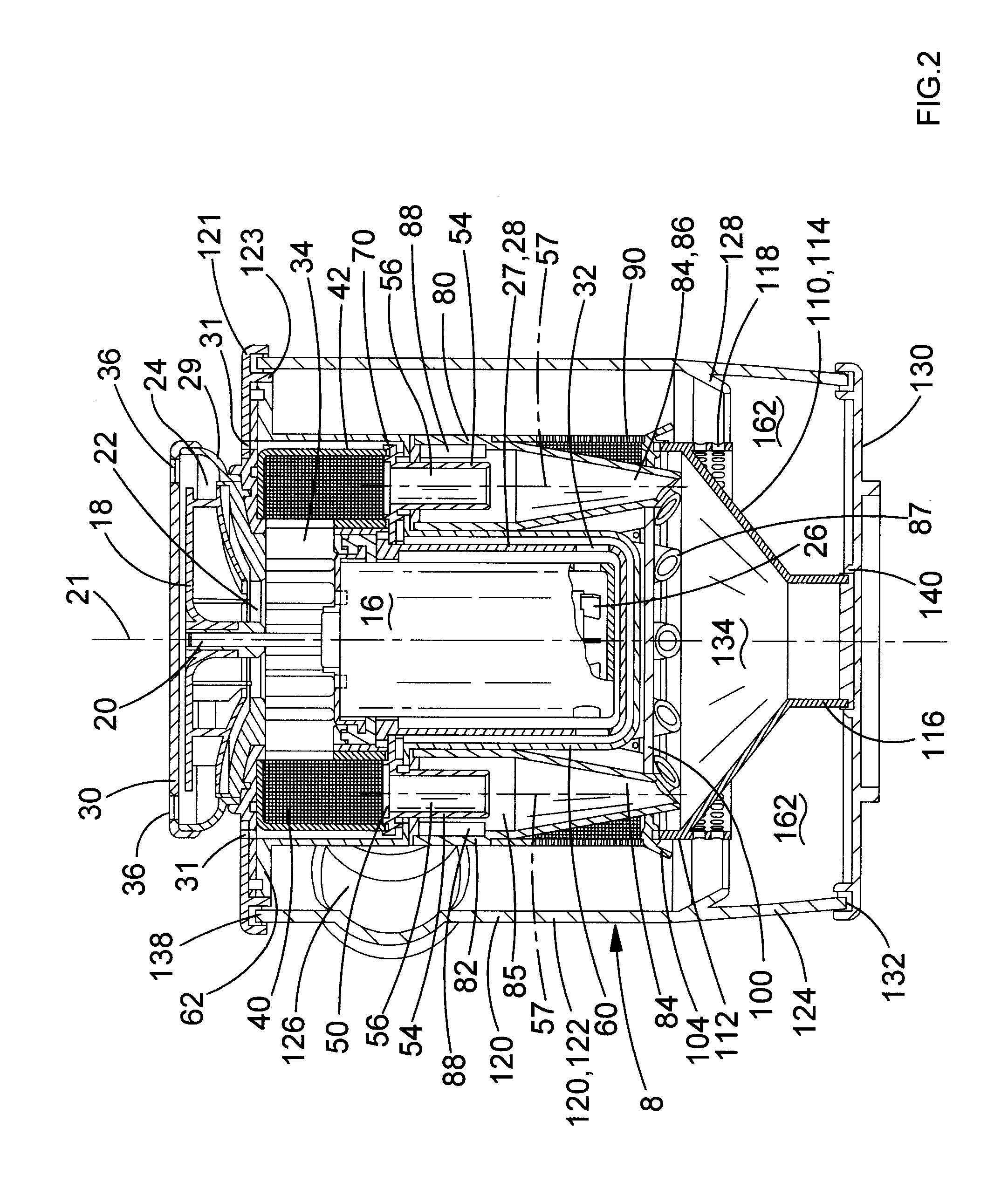

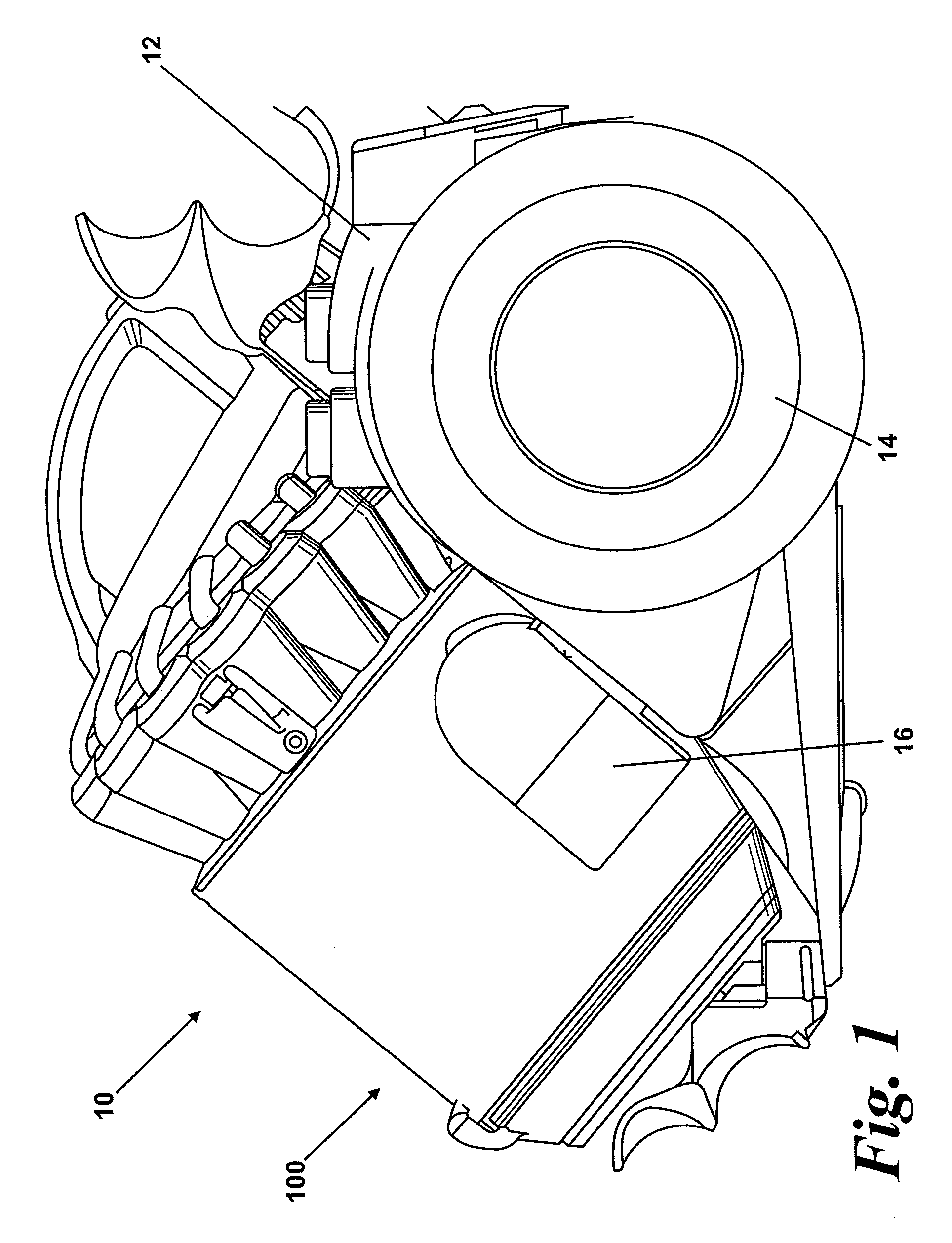

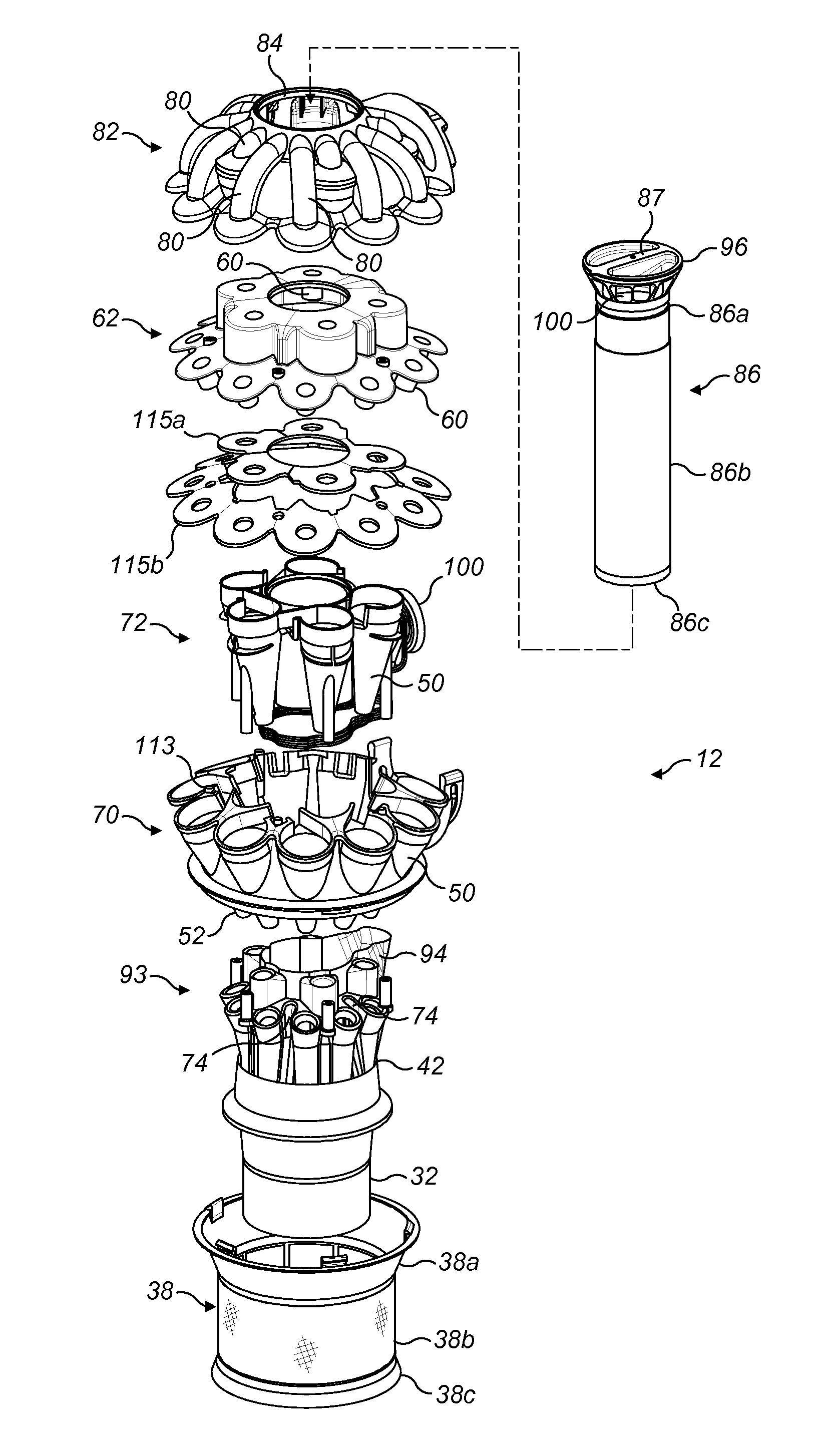

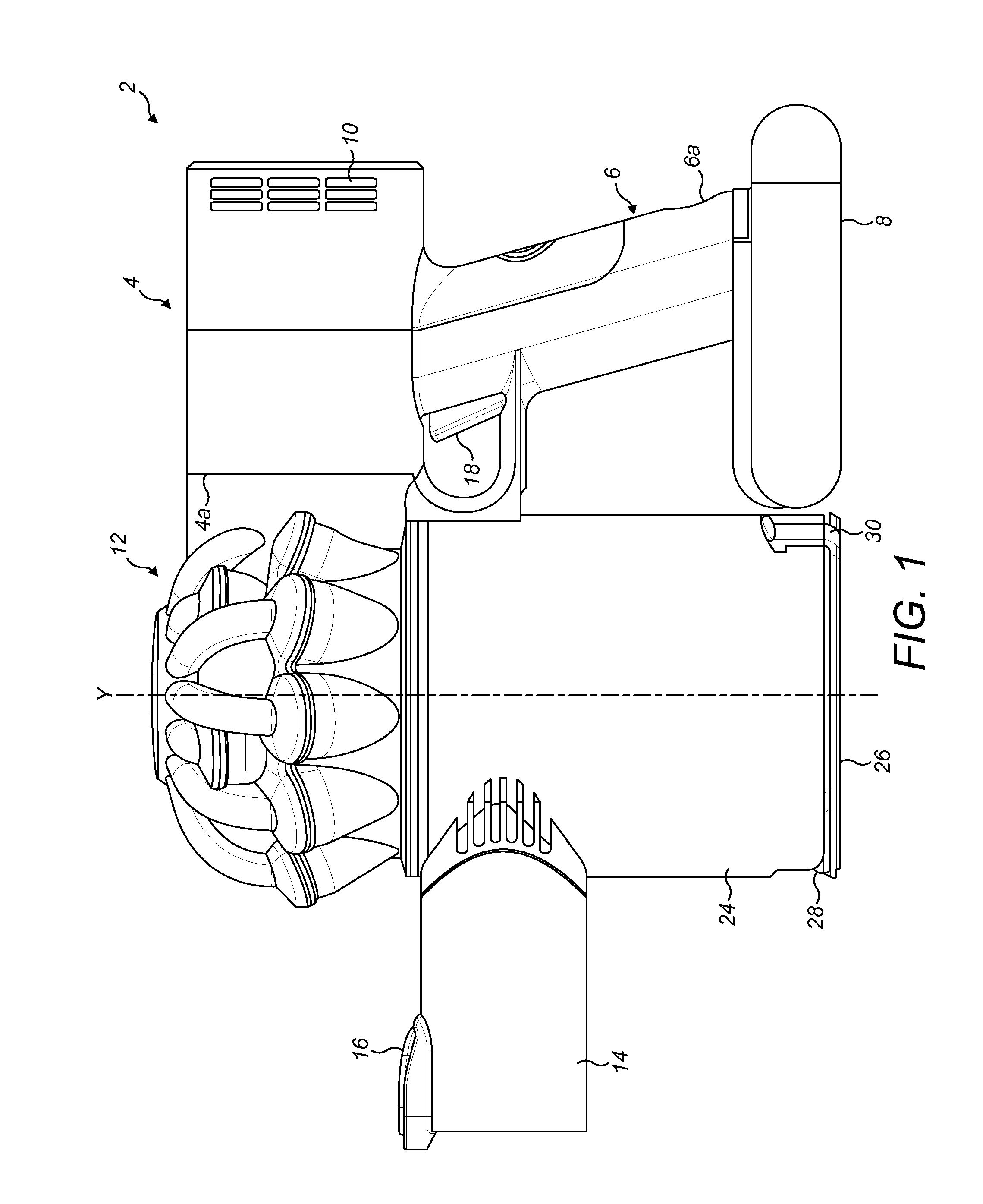

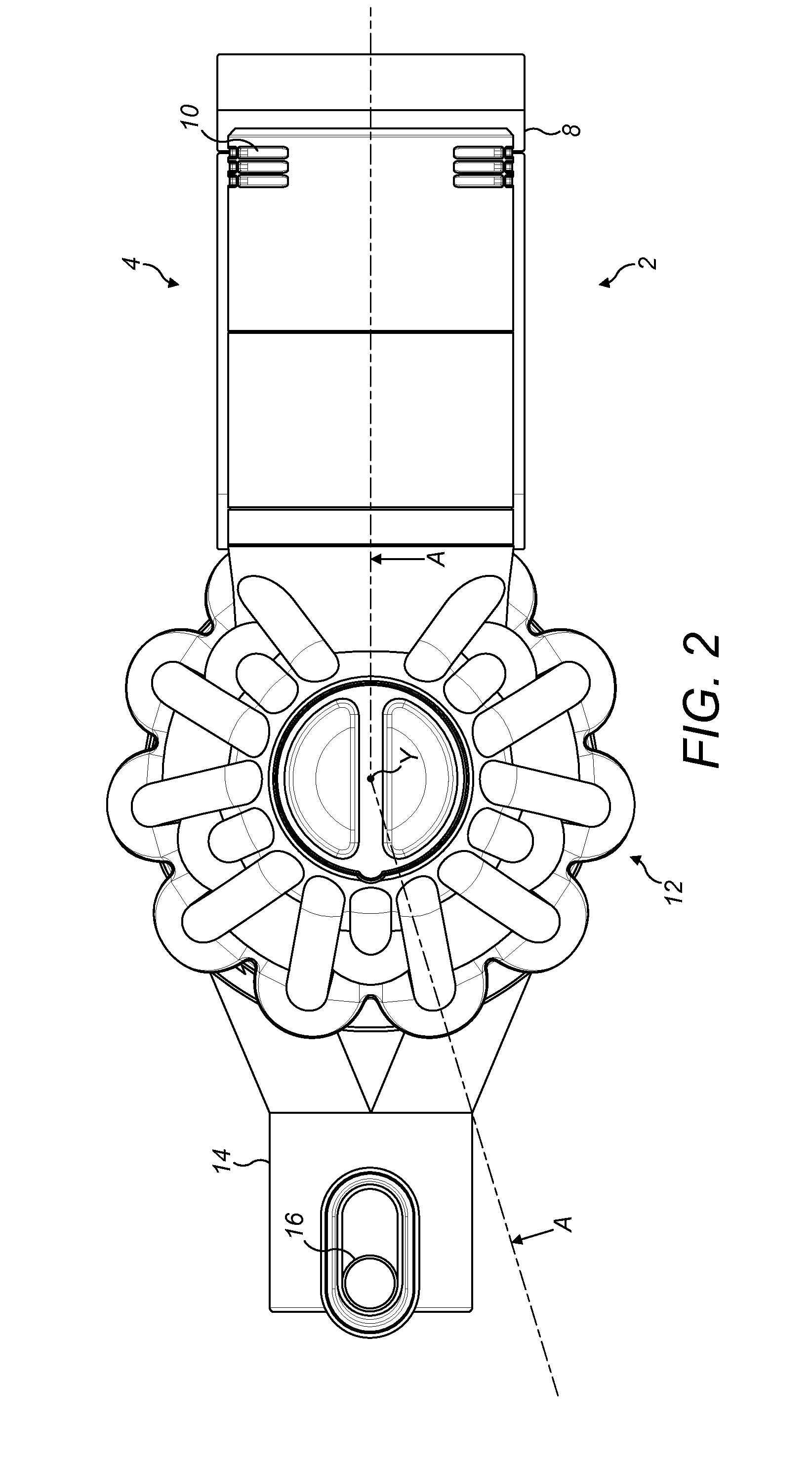

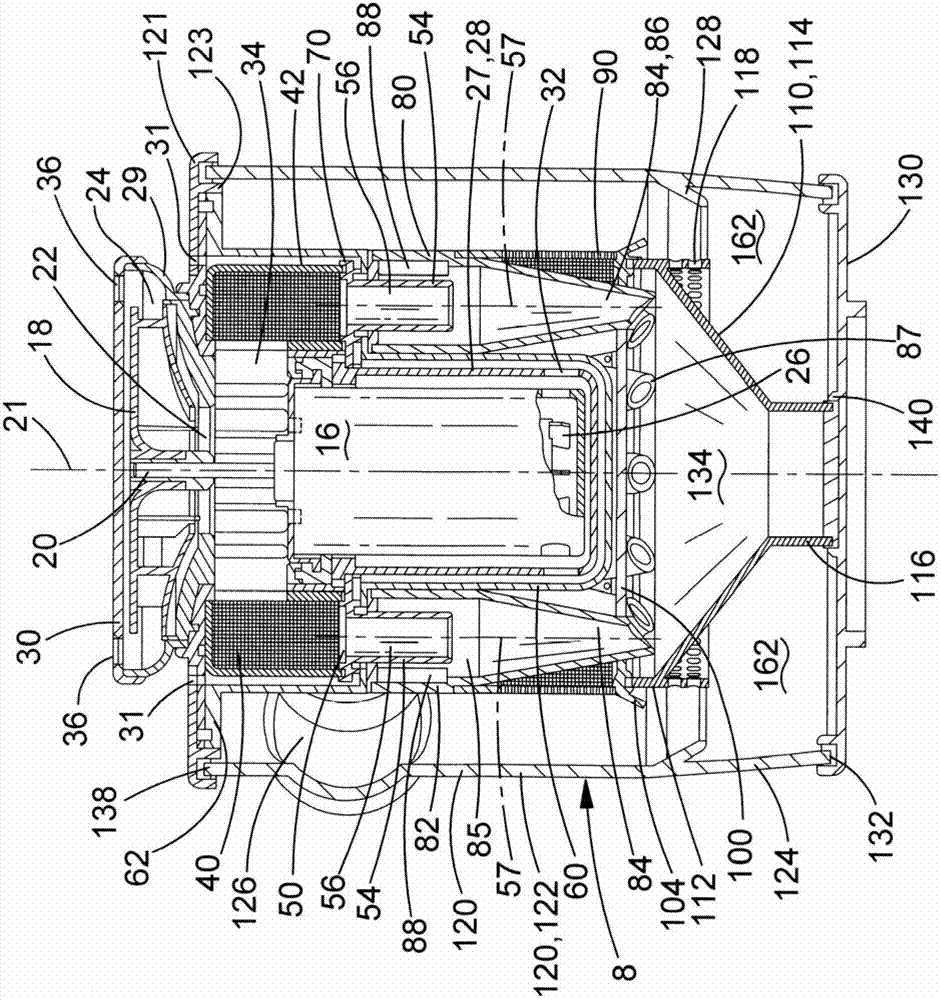

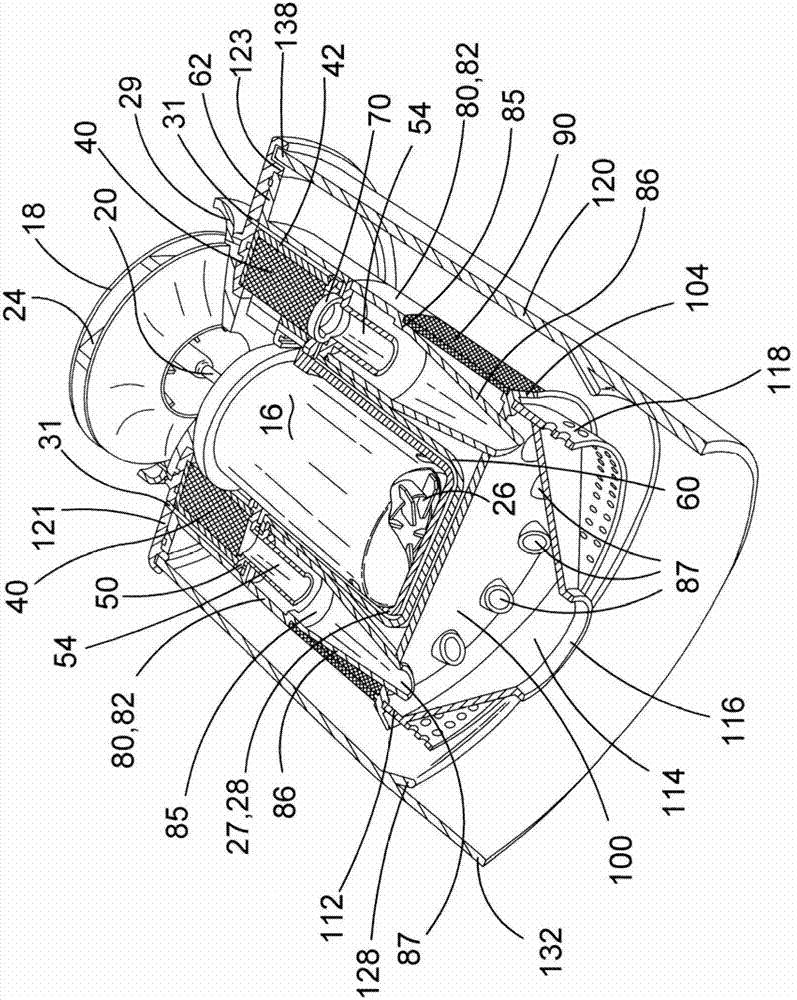

Motor, fan and cyclonic separation apparatus arrangement for a vacuum cleaner

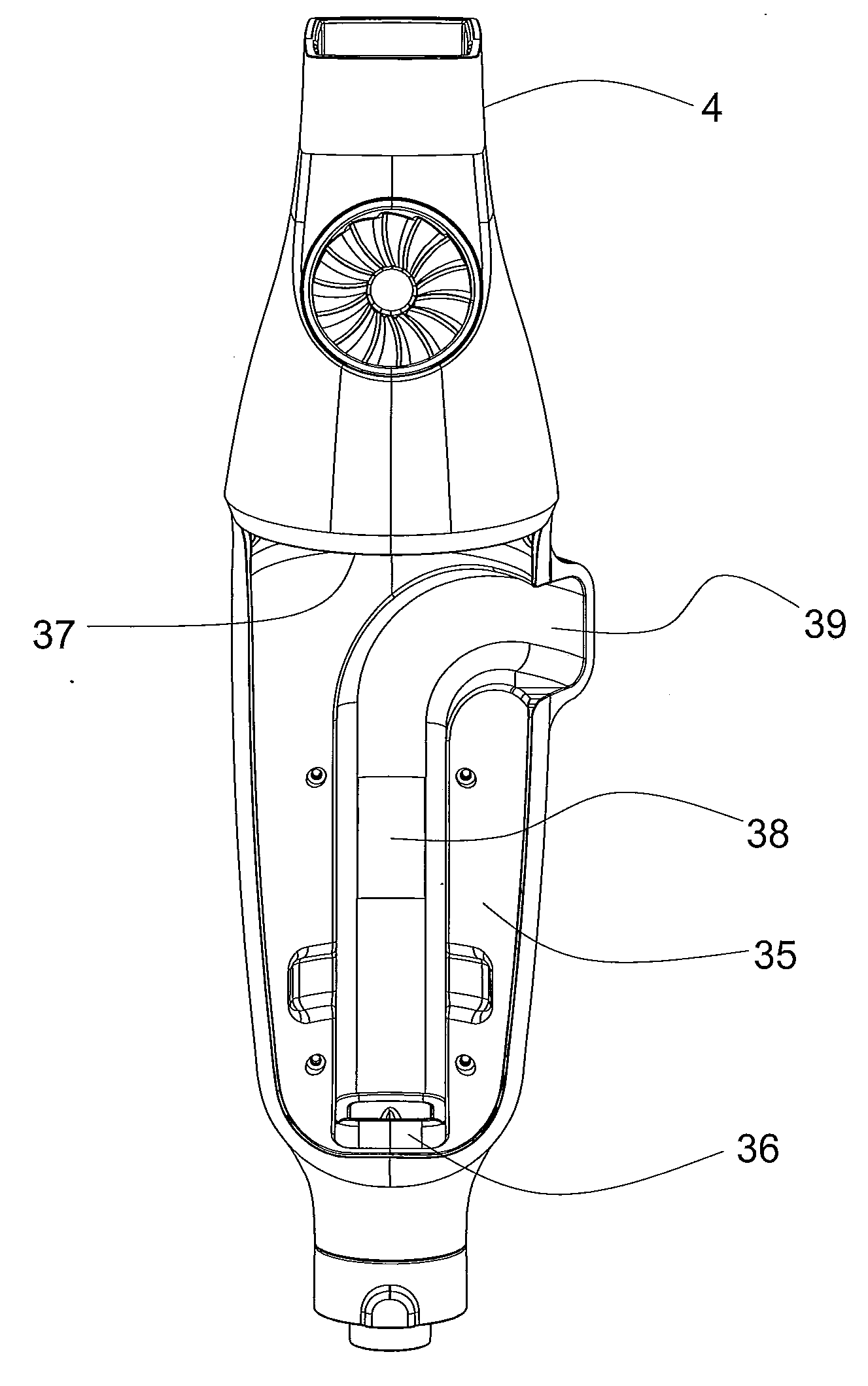

ActiveUS20130091813A1Reduce energy lossShorten the lengthMotor fan assembly mountingDispersed particle separationCycloneCyclonic separation

A motor, fan and cyclonic separation apparatus arrangement for a vacuum cleaner, the arrangement comprising: a motor coupled to a fan for generating air flow; and a cyclonic separation apparatus located in a path of the air flow generated by the fan, wherein the cyclonic separation apparatus comprises: a plurality of cyclones each with an air inlet port and an air outlet port wherein the cyclones are arranged in a generally circular array about a central axis of the cyclonic separation apparatus; and a cooling air flow path, wherein the motor is nested within the generally circular array of cyclones and wherein the motor is located in the cooling air flow path. A vacuum cleaner comprising the motor, fan and cyclonic separation apparatus arrangement.

Owner:BLACK & DECKER INC

Cyclonic separating apparatus

InactiveUS20090313958A1Reduces risk of re-entrainmentMinimize impactCombination devicesSuction filtersCycloneCyclonic separation

A cyclonic separating apparatus for separating particles from a dirt-laden airflow includes a cyclone for separating and collecting dirt and dust from the dirt-laden airflow. The cyclone has an air inlet, an air outlet, a longitudinal axis and a wall. The wall includes a first portion and a second portion spaced farther from the longitudinal axis than the first portion, the first and second portions being spaced along the longitudinal axis. The cyclone also includes at least one lip extending from the first portion of the wall into a portion of the cyclone surrounded by the second portion of the wall. By providing a cyclone with a wall having two portions of different sizes and a lip extending from the portion with the smaller size into the portion with the larger size, the risk of blockages due to re-entrainment and movement of dirt and dust within the cyclonic separating apparatus is reduced.

Owner:DYSON TECH LTD

Air flow passage for a vacuum cleaner

InactiveUS6902596B2Reduce back pressureImprove performanceCleaning filter meansSuction filtersCycloneCyclonic separation

A vacuum cleaner is provided having improved pressure loss characteristics. A fluid supply conduit in flow communication with an inlet to a cyclone is integrally formed as part of a cyclone bin. The present invention may be adapted for use with cyclonic separation devices of all types, including single- and multi-stage cyclonic separators.

Owner:OMACHRON INTPROP

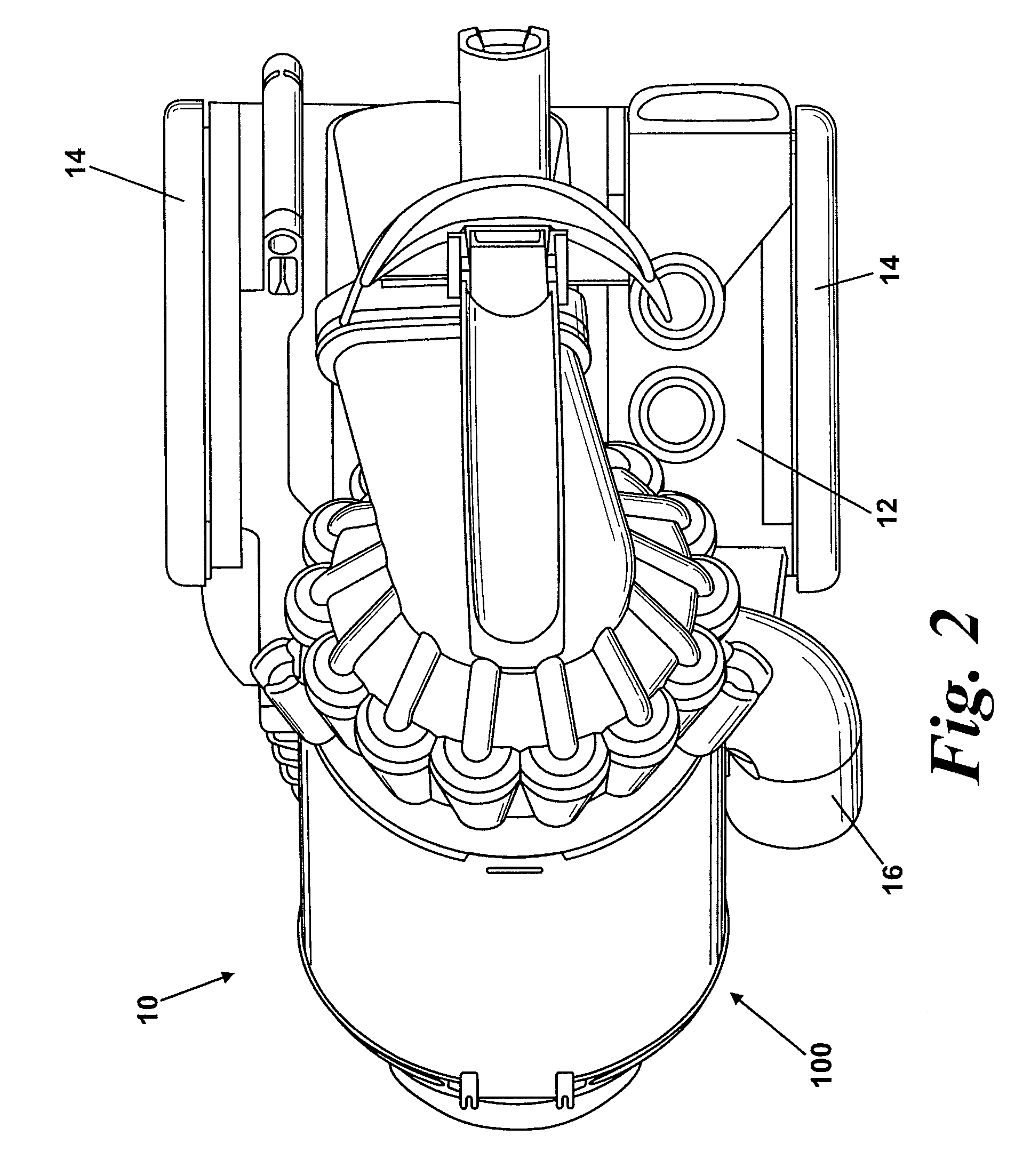

Motor, fan and cyclonic separation apparatus arrangement

ActiveUS20130091812A1Less spaceEasy to useMotor fan assembly mountingDispersed particle separationCycloneBrushless motors

A motor, fan and cyclonic separation apparatus arrangement for a vacuum cleaner comprising: a motor coupled to a fan for generating air flow; and a cyclonic separation apparatus located in a path of the air flow generated by the fan. The cyclonic separation apparatus comprises: a plurality of cyclones each with an air inlet port and an air outlet port; and a cooling air flow path. The motor comprises a permanent magnet brushless motor, a switched reluctance motor or a flux switching motor. The fan has an outer diameter the same or less than the diameter of the motor. The plurality of cyclones, the motor and the fan are arranged in a circular array about a central axis of the cyclonic separation apparatus. The arrangement comprises a baffle for directing air flow from the fan out of the circular array. The motor is located in the cooling air flow path.

Owner:BLACK & DECKER INC

Cyclonic separation apparatus

InactiveUS20130091814A1Easy maintenanceConvenience to workSuction cleanersDispersed particle separationCycloneCyclonic separation

A cyclonic separation apparatus for a vacuum cleaner, the cyclonic separation apparatus comprising: a first cyclonic separating unit comprising a hollow substantially cylindrical dirt container with a central axis, an air inlet port arranged tangentially through a side wall of the dirt container and an air outlet; and a second cyclonic separating unit comprising at least one cyclone with an air inlet port and an air outlet port, wherein the second cyclonic separating unit receives air flow downstream from the first cyclonic separating unit, wherein the second cyclonic separating unit is located within the dirt container and wherein the second cyclonic separating unit is detachably connected to the dirt container for removal through either longitudinal end of the dirt container. A vacuum cleaner comprising a motor coupled to a fan and the cyclonic separation apparatus.

Owner:BLACK & DECKER INC

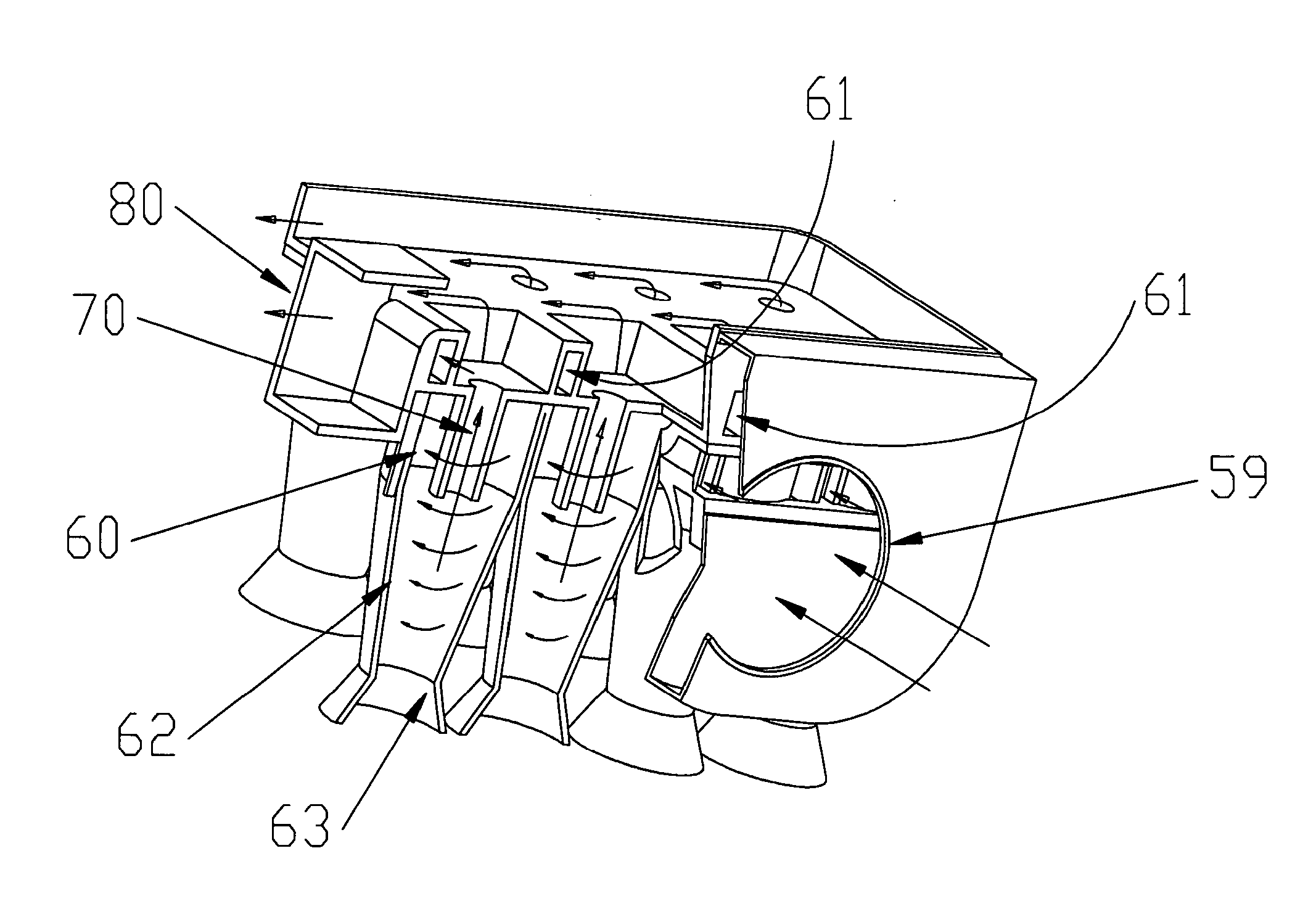

Compact cyclonic separation device

ActiveUS7354468B2Easy to disassemblePrevent re-entrainmentCombination devicesAuxillary pretreatmentCyclonic separationVacuum cleaner

A cyclonic separation device for a vacuum cleaner including a cylindrical housing, an inlet tube parallel to the axis of the housing having a vortex vane disposed axially in the inlet tube. Air rotates in one direction in the inlet tube, and preferably in the opposite direction in the housing. The housing includes a cylindrical sidewall with an upper central outlet tube and a closed bottom for collecting separated dirt. A disrupter ring located on the inside wall of the middle portion of the housing includes a curved surface and sharp edge for lifting air flow off the housing wall. An outlet tube disc spaced from the inlet of the outlet tube is located in the housing below the disrupter ring.

Owner:SHARKNINJA OPERATING LLC

Cyclonic separation apparatus

InactiveUS20090100810A1Separation efficiency is highCleaning filter meansCombination devicesCyclonic separationVertical axis

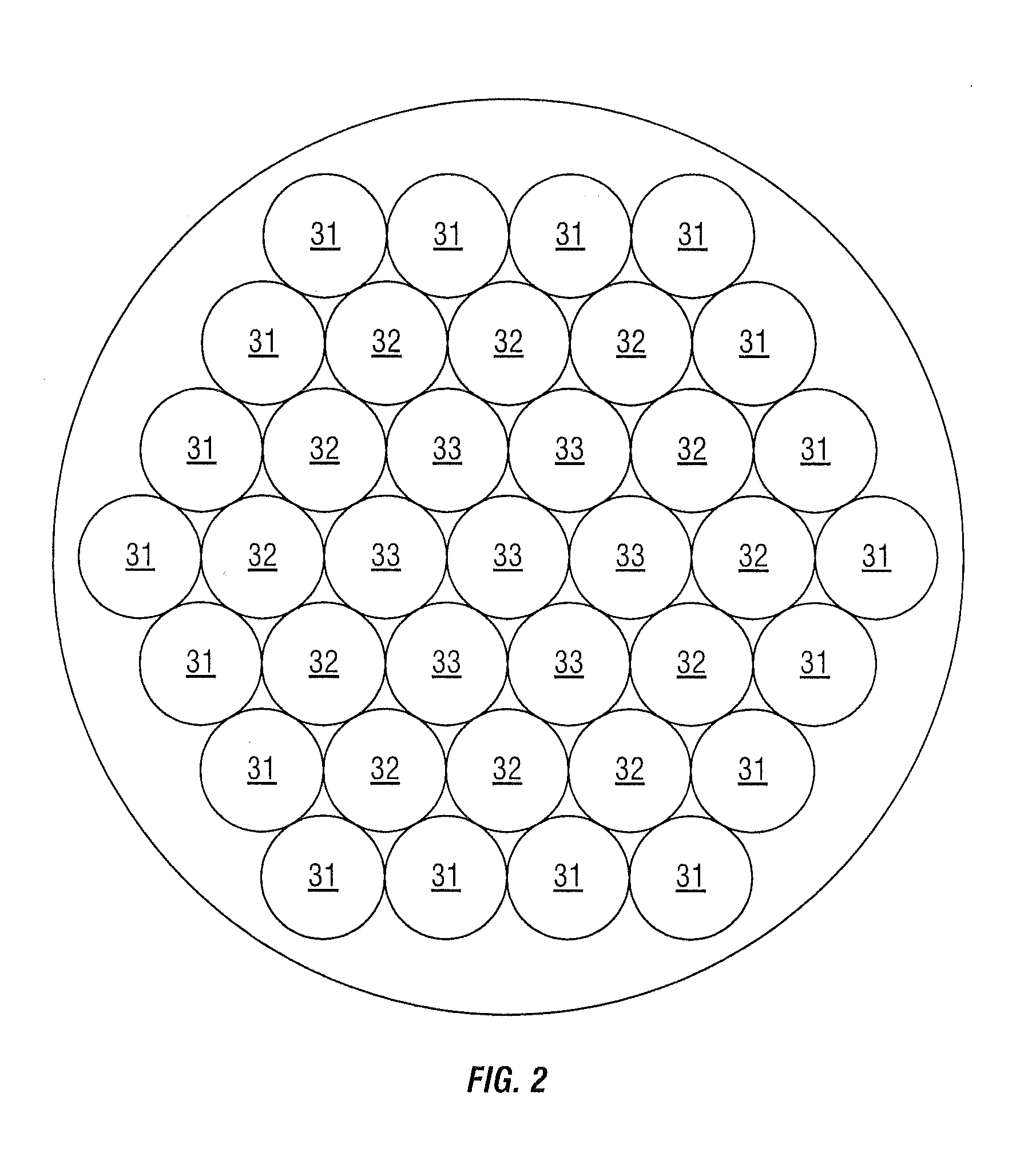

A cyclonic separation apparatus comprises a plurality of series-connected separation stages 50,51, each comprising a plurality of cyclone separators 16 / 23 connected in parallel and disposed in a generally annular arrangement about a main vertical axis of the apparatus, with their respective longitudinal cyclone axes extending parallel to the main axis. The successive separation stages 50,51 in the direction of fluid flow are disposed radially inwardly of each other with respect to the main axis of the apparatus and are also vertically staggered upwardly, so that the outlet 20 of one separation stage 50 leads directly into the inlet 22 of the next downstream stage 51. The multi-stage, series connected cyclone separators of the apparatus provide a high separation efficiency, yet the annular arrangement of the stages 50,51 makes the apparatus compact and enables the apparatus to be utilised in a vacuum cleaner.

Owner:HOOVER LIMITED

Cyclone separating device of a cleaner

ActiveUS8101001B2Reduce radial sizeReduce the overall heightCleaning filter meansCombination devicesCycloneCyclonic separation

A cyclone separating device of a cleaner includes an upstream cyclone separating device and a downstream cyclone separating device. The upstream separating device communicates with the downstream cyclone separating device through a gas passage. The upstream cyclone separating device has a first cyclone barrel, while the downstream cyclone separating device has at least one second cyclone barrel. The downstream cyclone separating device is lying and set above the upstream separating device. The size of the cyclone separating device of the present invention is small in radial direction. The height of the cyclone separating device which is the sum of the height of the upstream cyclone separating device plus the height of the lying downstream cyclone separating device lying down is low.

Owner:ECOVACS ROBOTICS (SUZHOU ) CO LTD

Cyclonic separating apparatus for a cleaning appliance

ActiveUS20090100633A1Improve sealingEasy to separateCleaning filter meansSuction filtersCyclonic separationEngineering

A cyclonic separating apparatus for a cleaning appliance includes a plurality of cyclonic separators arranged in series for separating particles from a dirt- and dust-laden airflow, at least two or three collectors for collecting separated dirt and dust, and a closure member movable between a closed position in which the closure member closes an end of each collector and an open position in which separated dirt and dust can be emptied from the collectors. The ends of the collectors are separated by dividing walls. A expandable seal is provided between the closure member and the dividing walls to seal when the closure member is in the closed position. The expandable seal is able to seal effectively even if the closure member is misaligned, incorrectly fitted or if dirt and dust is present between the surfaces to be sealed.

Owner:DYSON TECH LTD

Cyclone separating apparatus for a vacuum cleaner

InactiveUS20080184681A1Efficient separationSuction filtersDispersed particle filtrationCycloneCyclonic separation

A cyclone separating apparatus for a vacuum cleaner includes a first cyclone having an inclined part and adapted for separating dust and air; a first dust chamber adapted to be disposed substantially around the first cyclone and to be in fluid communication with the first cyclone; at least one second cyclone for separating dust and air adapted to be disposed above the first cyclone and to be in fluid communication with the first cyclone; and a second dust chamber adapted to be in disposed within the first cyclone and to be in fluid communication with the second cyclone.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

Cyclonic separation apparatus

ActiveUS20130091660A1Easy to separateImprove performanceCleaning filter meansSuction filtersCycloneCyclonic separation

A cyclonic separation apparatus for a vacuum cleaner, the cyclonic separation apparatus comprising: a cyclone with a hollow cylindrical body, a hollow frustro-conical body tapering away from the cylindrical body and a longitudinal central axis through the cylindrical body and the frustro-conical body; a discharge nozzle through the frustro-conical body at a longitudinal end; an air inlet port arranged tangentially through a side of the cylindrical body; and an air outlet port through the cylindrical body at an opposite longitudinal end; a dirt container in communication with the cyclone; and a deflector fin arranged within the cyclone to deflect, in use, air flow from the air inlet port in a helical path around the cyclone and towards the discharge nozzle. A vacuum cleaner comprising a motor coupled to a fan and the cyclonic separation apparatus.

Owner:BLACK & DECKER INC

Cyclonic separating apparatus

A cyclonic separating apparatus includes a cyclonic separator for separating dirt and dust from an airflow, an inlet to the cyclonic separator and a shroud comprising a wall having a multiplicity of through-holes forming an outlet from the cyclonic separator. The apparatus also includes a plurality of separate passageways provided immediately downstream of the through-holes. By providing this arrangement, the separate passageways can be located around other parts of the cyclonic separating apparatus inwardly of the shroud, allowing for better packaging of the components of the cyclonic separating apparatus. The shroud may be reduced in size because some of the space previously required for a single, large passageway can be used for other components of the cyclonic separating apparatus such a collector or a cyclone. The reduction in size of the shroud in turn allows for the cyclonic separating apparatus to be more compact.

Owner:DYSON TECH LTD

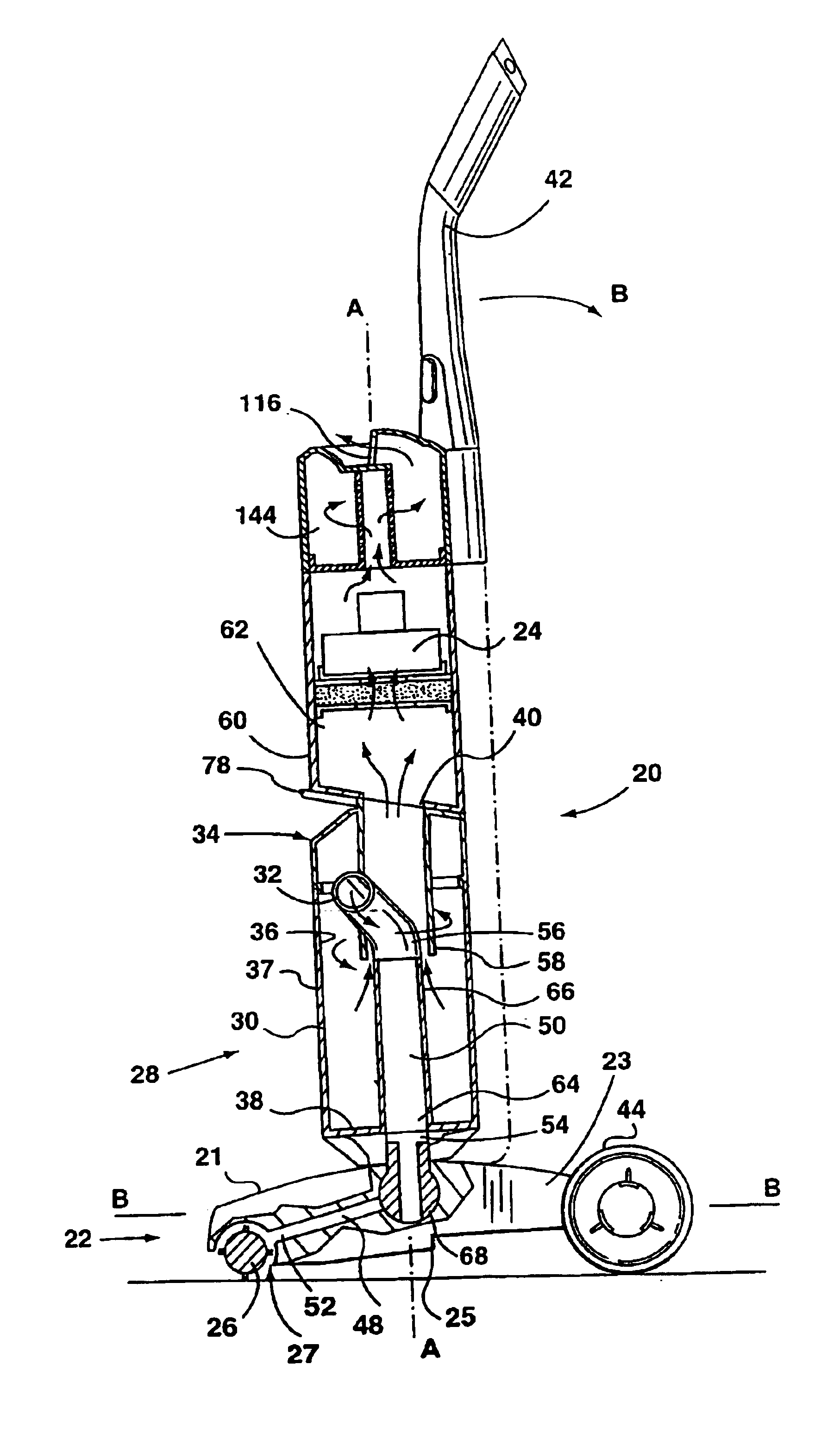

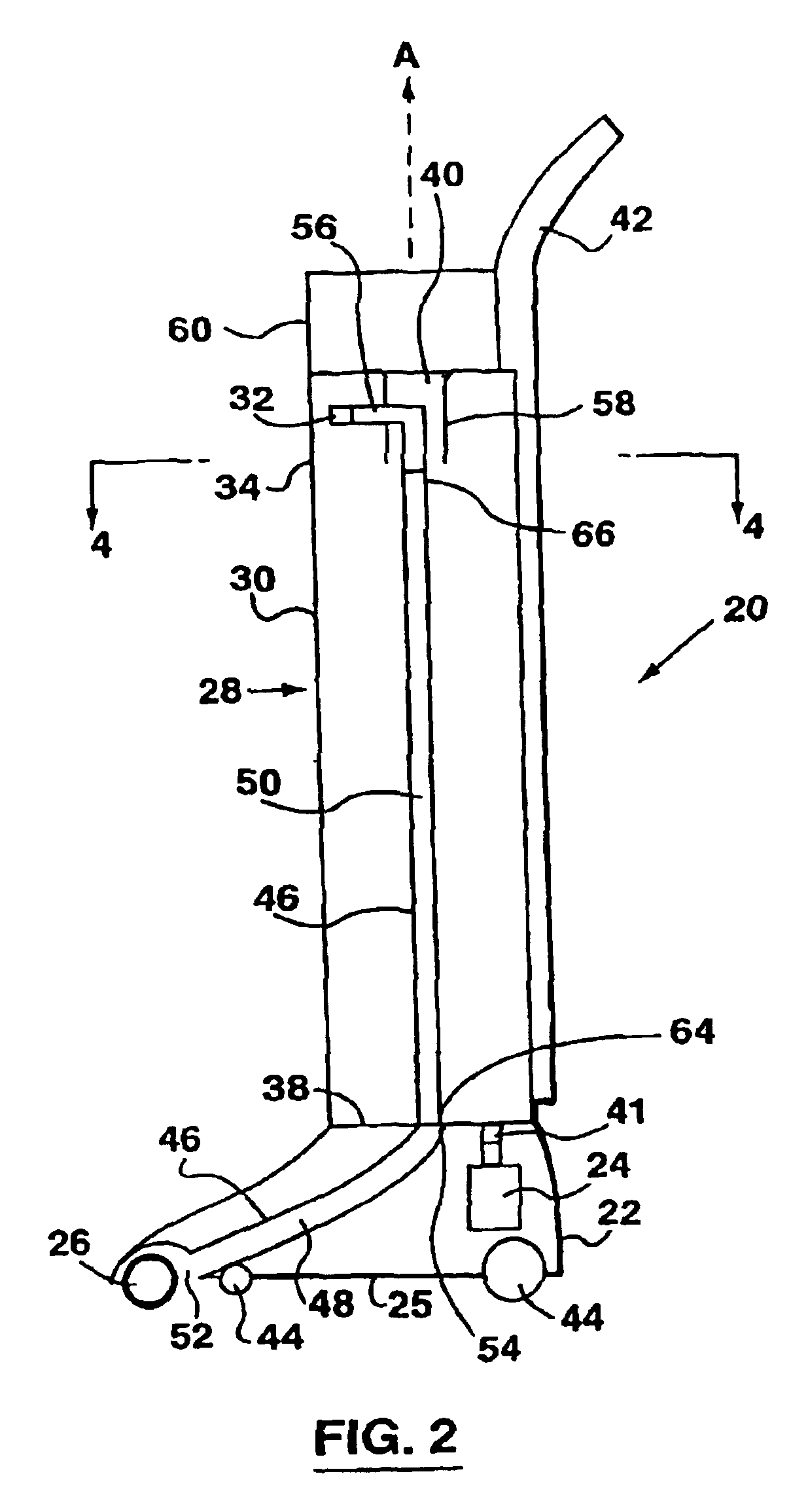

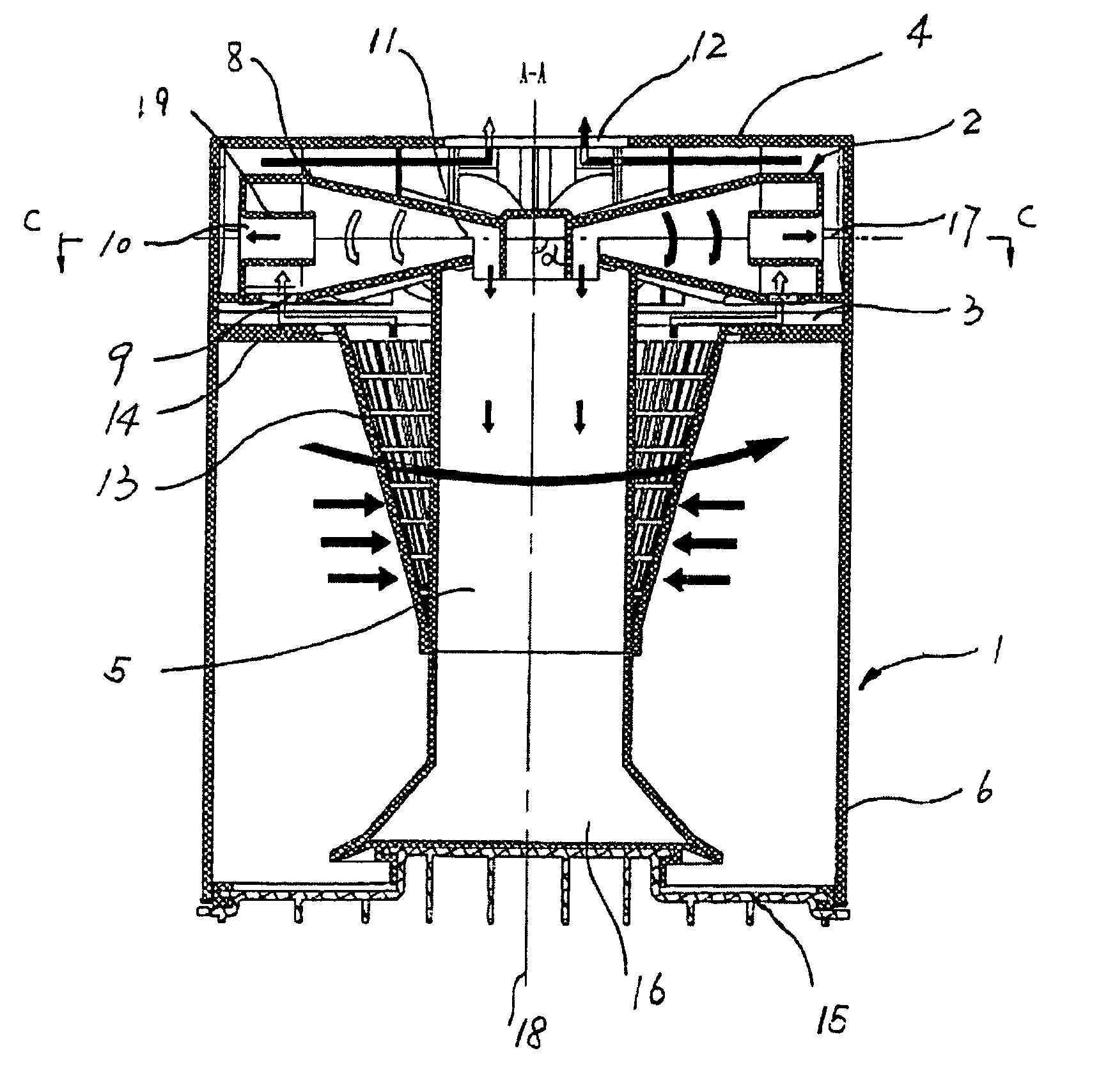

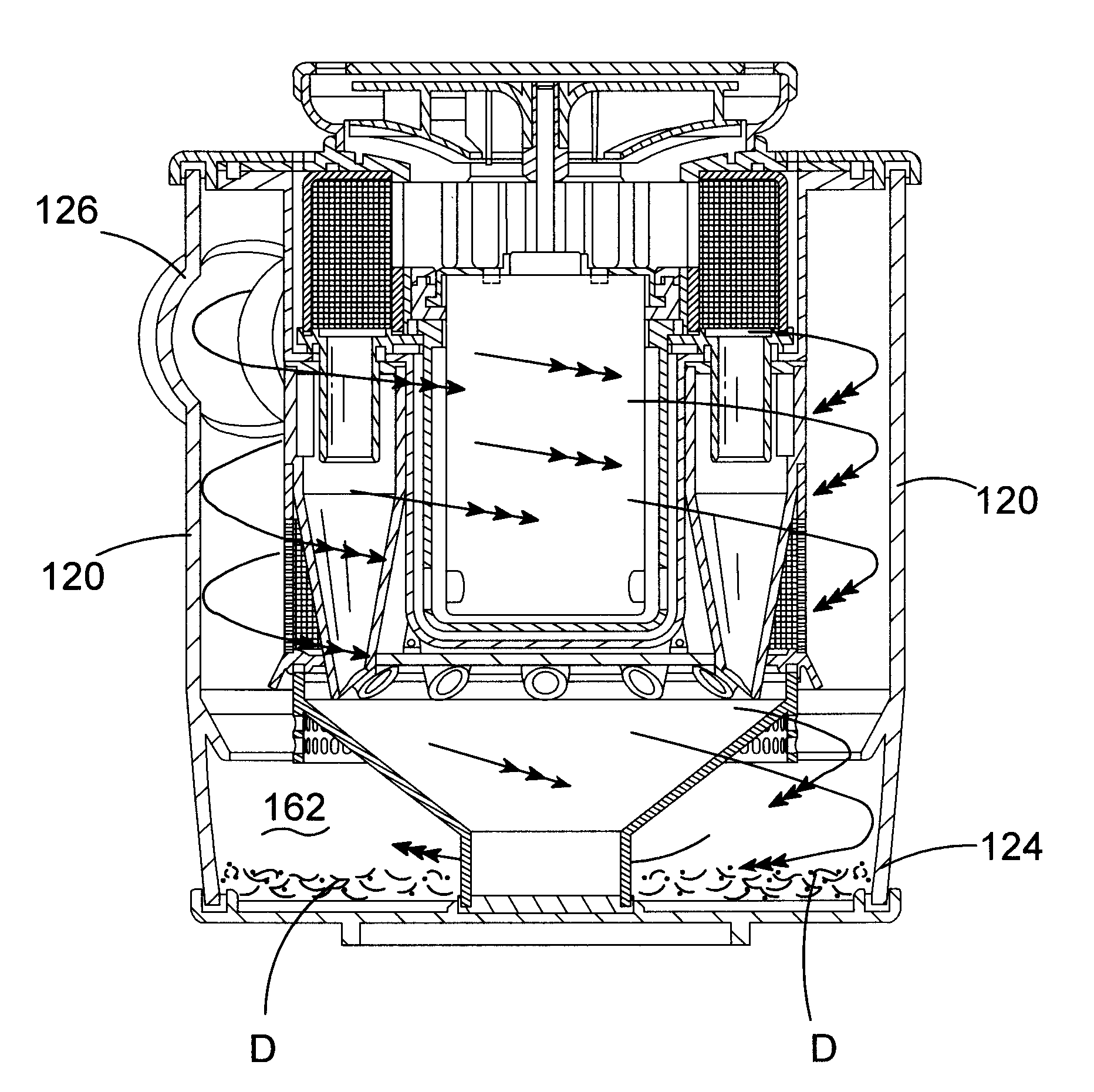

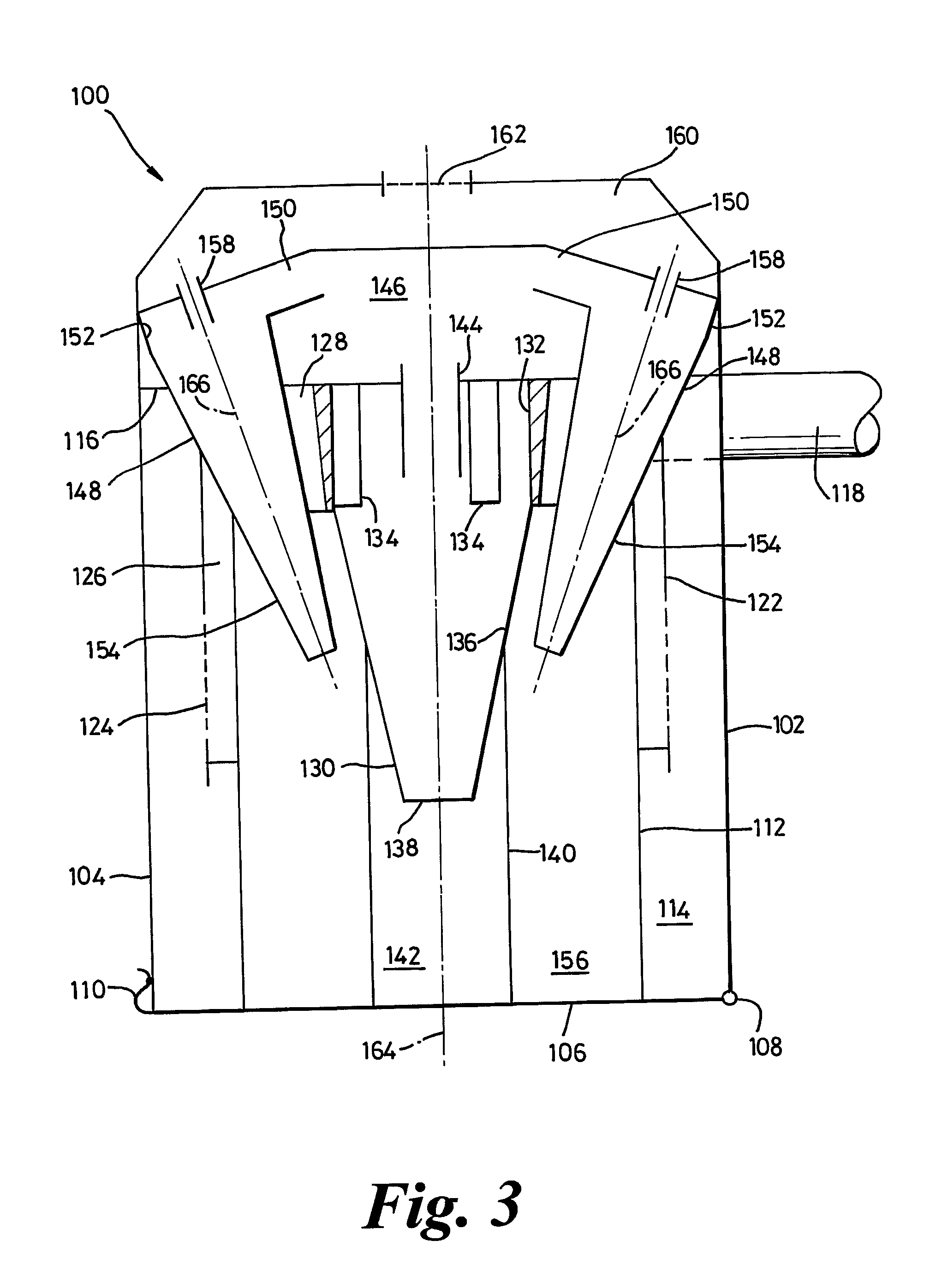

Centrifugal dirt separation configurations for household-type and shop-type vacuum cleaners

ActiveUS20110296648A1Easy maintenanceThe process is compact and efficientCleaning filter meansCombination devicesCycloneParticle flow

A cyclonic separation device in accordance with an embodiment of the present application preferably includes a first cyclone chamber having a cylindrical shape with a predetermined diameter, the first cyclone chamber including, a tangential inlet positioned on a first longitudinal end of the first cyclone chamber, a baffle plate positioned in the first cyclone chamber a predetermined distance from the tangential inlet, a tangential dirt outlet positioned on a second end of the cyclone chamber, opposite the inlet and on an opposite side of the baffle plate from the tangential inlet and a center exit duct mounted in the center of the cyclone chamber having an inlet opening positioned upstream from the baffle plate such the centrifuged fluid without particles flows into the center exit duct and out of the cyclone chamber.

Owner:KAH JR CARL L C

Cyclonic separation apparatus for a vacuum cleaner

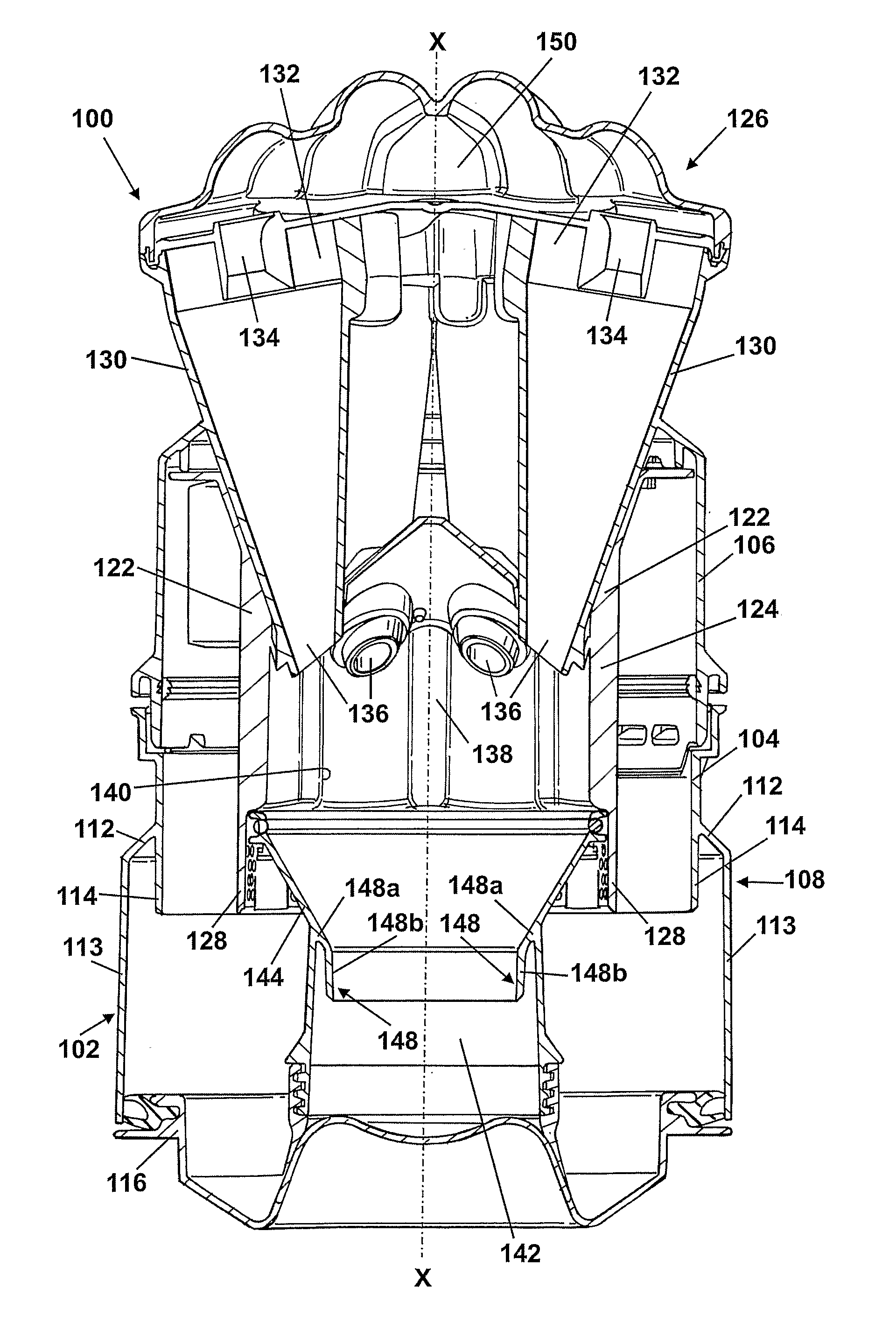

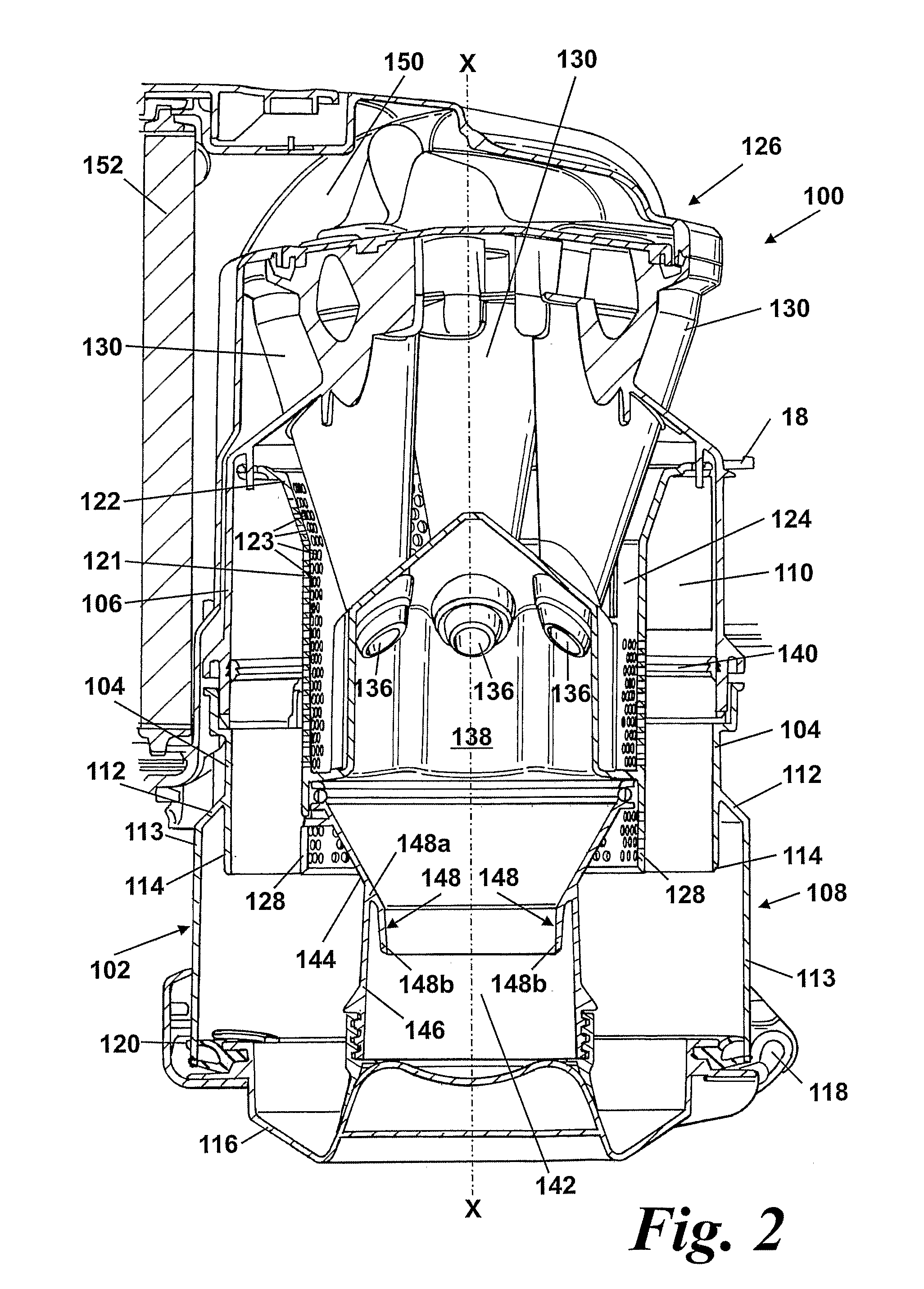

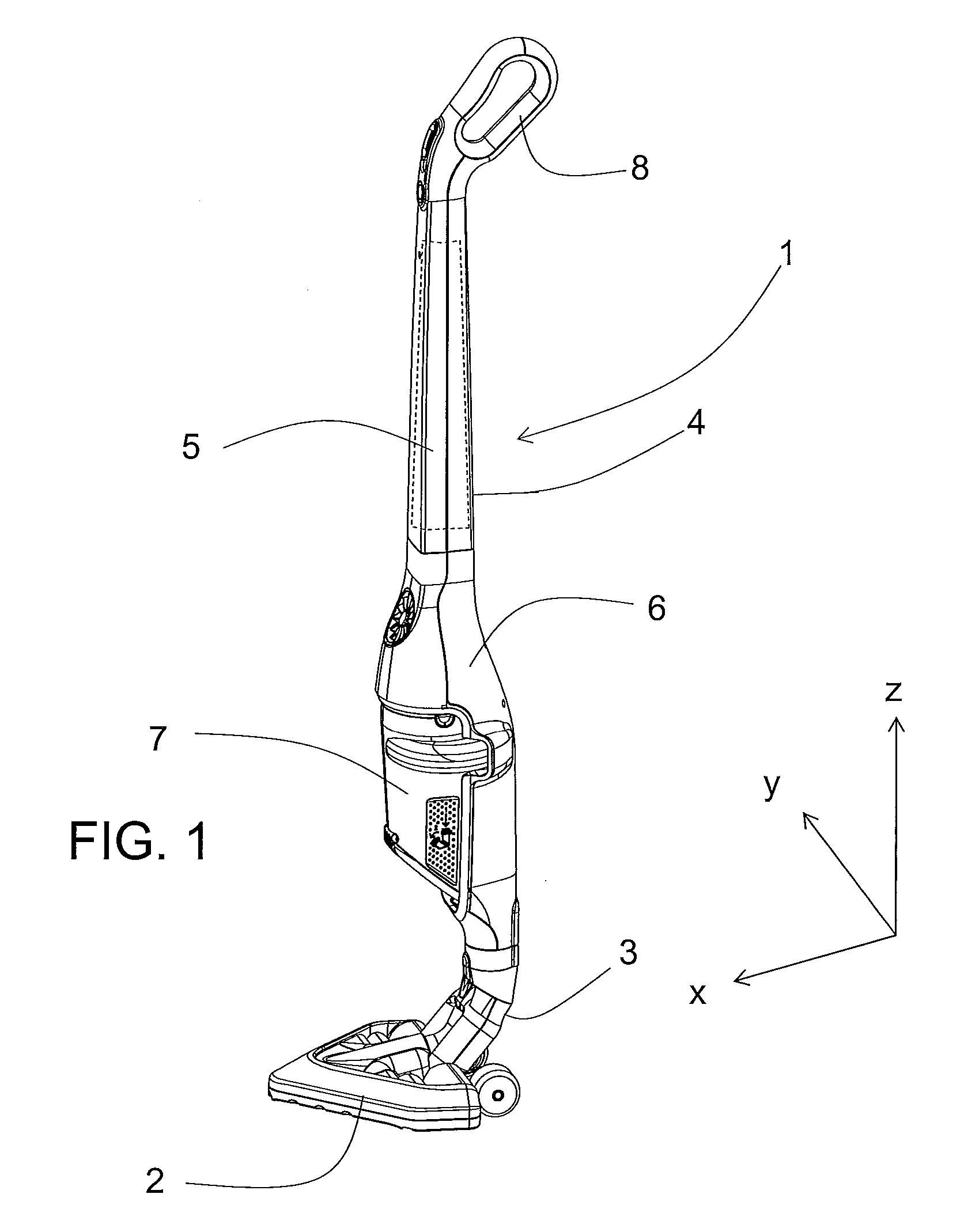

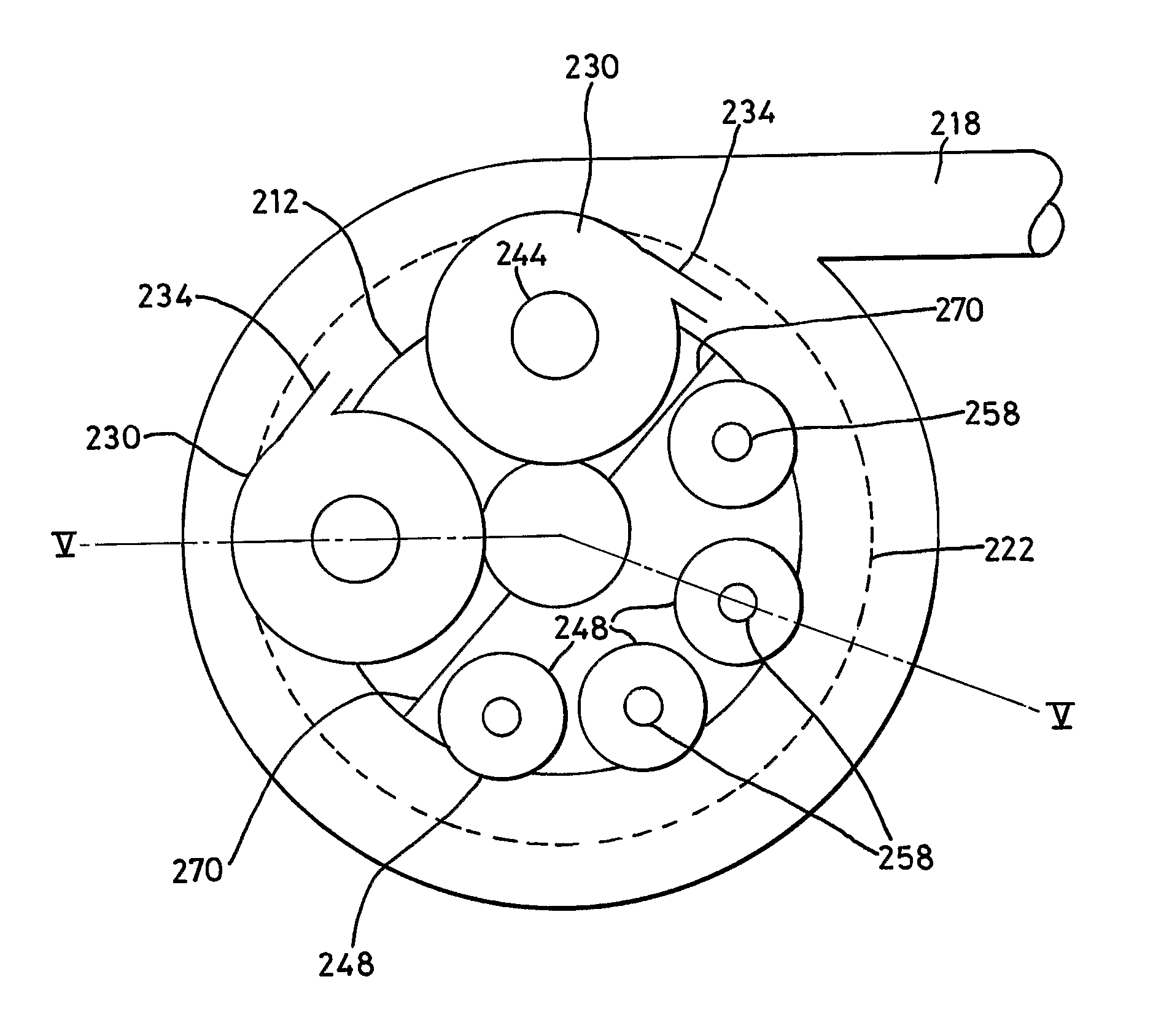

ActiveUS20130091654A1Easy to carryEasy to useCleaning filter meansSuction filtersCycloneCyclonic separation

A cyclonic separation apparatus for a vacuum cleaner, the cyclonic separation apparatus comprising: a first cyclonic separating unit comprising a hollow cylindrical dirt container with a central axis and an air inlet port arranged tangentially to the dirt container; and a second cyclonic separating unit comprising a plurality of cyclones arranged in a circular array about the central axis, wherein each cyclone has an air inlet port and an air outlet port, wherein the second cyclonic separating unit receives air flow downstream from the first cyclonic separating unit and wherein the second cyclonic separating unit has a higher separation efficiency than the first cyclonic separating unit, wherein the second separating unit is located within the dirt container. A vacuum cleaner comprising: a main body, a motor coupled to a fan and the cyclonic separation apparatus.

Owner:BLACK & DECKER INC

Cyclonic separating apparatus

A cyclonic separating apparatus includes a cyclonic separator for separating dirt and dust from an airflow, an inlet to the cyclonic separator and a shroud comprising a wall having a multiplicity of through-holes forming an outlet from the cyclonic separator. The apparatus also includes a plurality of separate passageways provided immediately downstream of the through-holes. By providing this arrangement, the separate passageways can be located around other parts of the cyclonic separating apparatus inwardly of the shroud, allowing for better packaging of the components of the cyclonic separating apparatus. The shroud may be reduced in size because some of the space previously required for a single, large passageway can be used for other components of the cyclonic separating apparatus such a collector or a cyclone. The reduction in size of the shroud in turn allows for the cyclonic separating apparatus to be more compact.

Owner:DYSON TECH LTD

Cyclonic separation apparatus for a vacuum cleaner

ActiveUS8657904B2Easy to useUse cleanCleaning filter meansCombination devicesCyclonic separationProcess engineering

A cyclonic separation apparatus for a vacuum cleaner, the cyclonic separation apparatus comprising: a first cyclonic separating unit comprising a hollow cylindrical dirt container with a central axis and an air inlet port arranged tangentially to the dirt container; and a second cyclonic separating unit comprising a plurality of cyclones arranged in a circular array about the central axis, wherein each cyclone has an air inlet port and an air outlet port, wherein the second cyclonic separating unit receives air flow downstream from the first cyclonic separating unit and wherein the second cyclonic separating unit has a higher separation efficiency than the first cyclonic separating unit, wherein the second separating unit is located within the dirt container. A vacuum cleaner comprising: a main body, a motor coupled to a fan and the cyclonic separation apparatus.

Owner:BLACK & DECKER INC

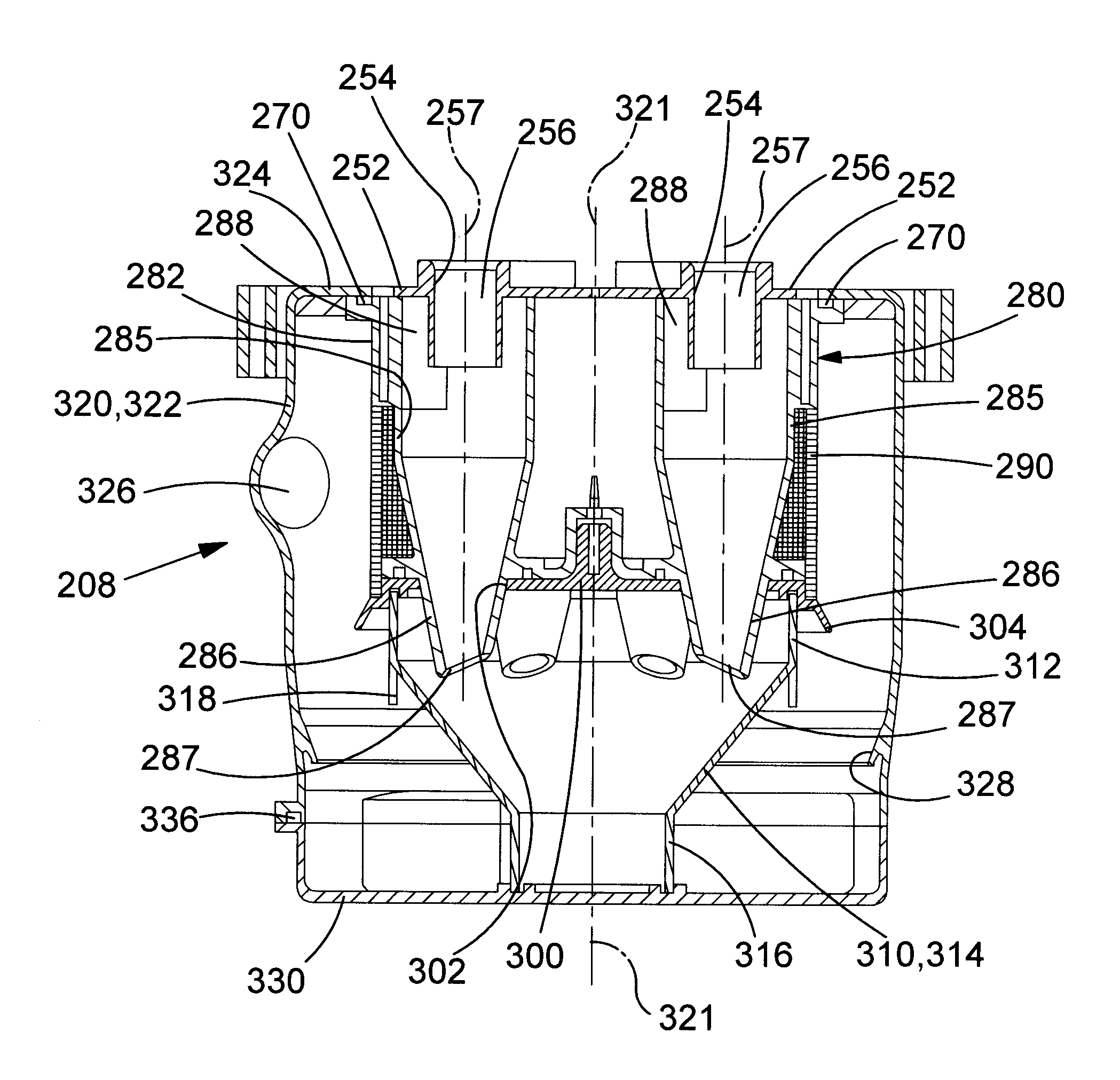

Cyclonic separation apparatus

A cyclonic separation apparatus (208) for a vacuum cleaner (202), the cyclonic separation apparatus (208) comprising: a first cyclonic separating unit (360) comprising a hollow cylindrical dirt container (320) with a central axis (321) and an air inlet port (326) arranged tangentially through a side of the dirt container (320); a second cyclonic separating unit (350) comprising at least one cyclone (284) with an axial inlet port (288), an axial outlet port (256) and a discharge nozzle (287); a substantially cylindrical intermediate wall (290) surrounding the inlet port (288) of the at least one cyclone (284); and at least one protruding lip (304, 328) arranged to impede return of separated material from a longitudinal end of the dirt container (320), wherein the at least one lip (304, 328) protrudes radially inwardly from an inner surface of the dirt container (320) and / or radially outwardly from the intermediate wall (290).

Owner:BLACK & DECKER INC

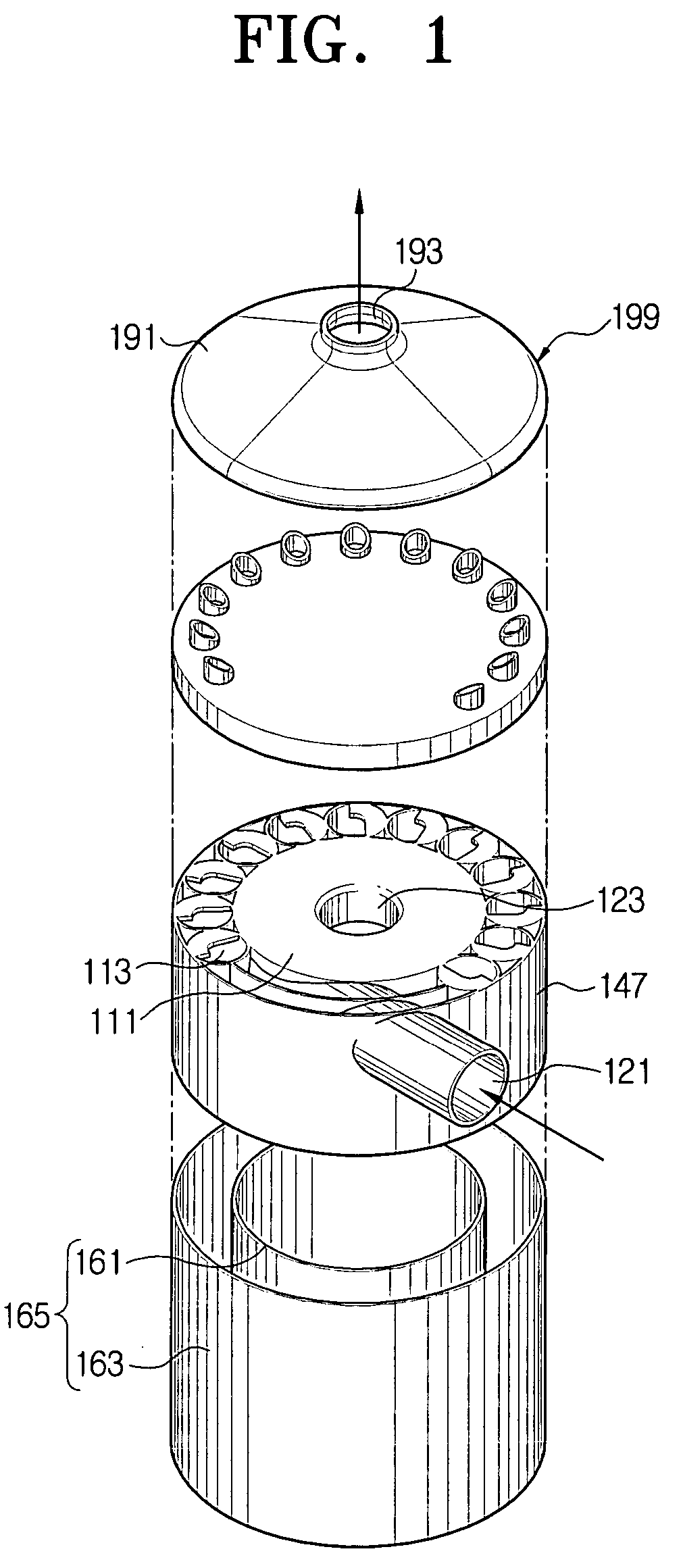

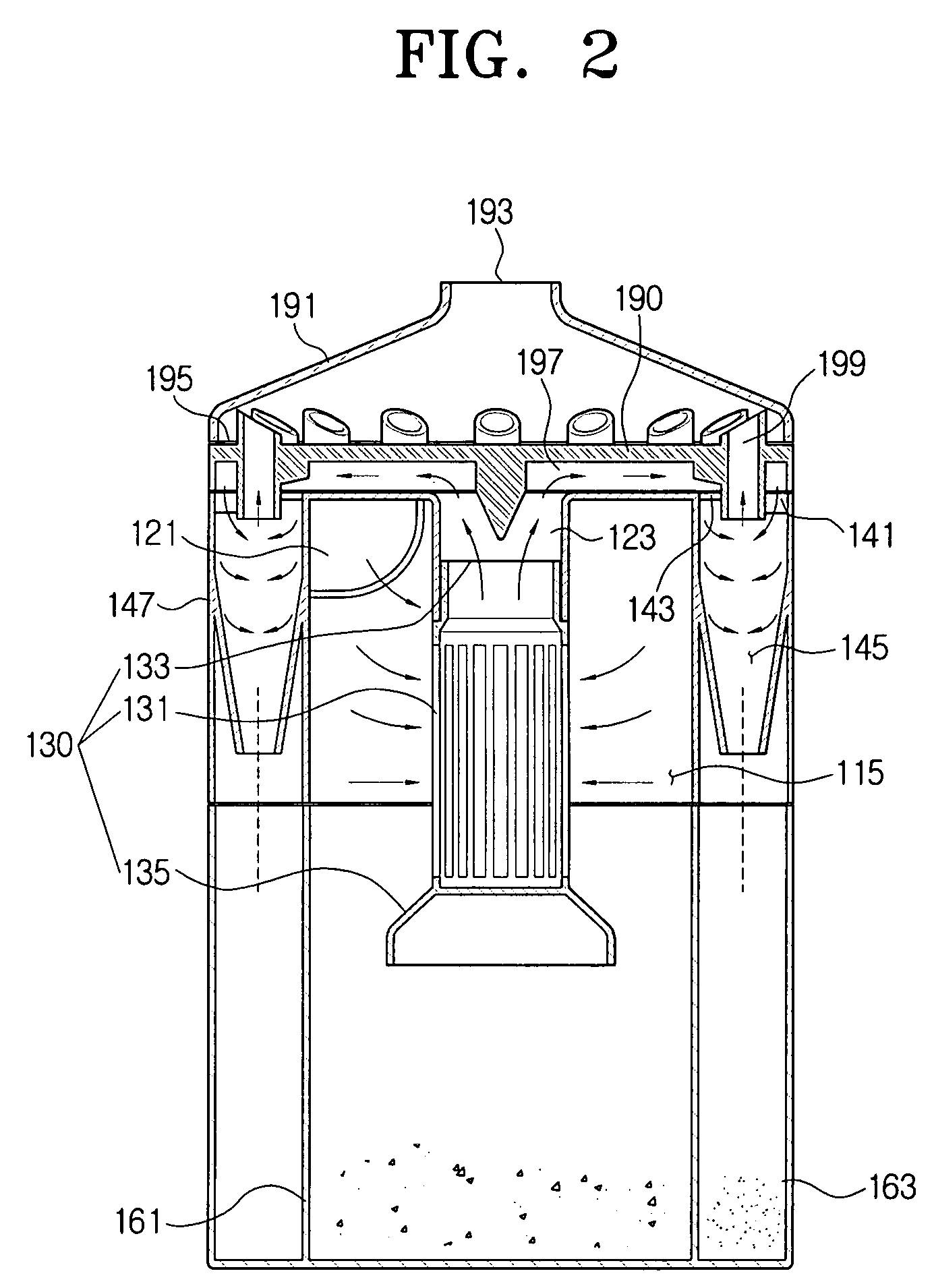

Cyclone separating apparatus and vacuum cleaner equipped with the same

InactiveUS7097680B2Inhibit deteriorationImprove suction efficiencyCleaning filter meansCombination devicesCycloneCyclonic separation

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

Vacuum cleaner

InactiveUS7179314B2Improve the level ofLarge resistanceCleaning filter meansCombination devicesCyclonic separationFiltration

A method for filtering a dirty air stream in a vacuum cleaner to obtain a clean air stream comprises subjecting the dirty air stream to a first cyclonic separation stage to obtain a partially cleaned air stream and subjecting the partially cleaned air stream to an electronic filtration stage and optionally a second cyclonic separation stage to obtain the clean air stream. The electronic filtration stage is optionally removable with a cyclonic cleaning stage from the vacuum cleaner. The electronic filtration stage is optionally an electrostatic precipitator which utilizes air flow through the vacuum cleaner to generate the voltage used by the electrostatic precipitator.

Owner:POLAR LIGHT

Cyclonic Separation Device With Acceleration Ramp

InactiveUS20100175219A1Streamlining assembly costStreamlining manufacturing costCleaning filter meansAuxillary pretreatmentCyclonic separationEngineering

A cyclonic separation device for dust and debris in vacuum cleaners, comprising a roughly cylindrical interior cyclonic chamber connected to an air intake, as well as a separator filter located in the central part of the interior chamber, comprising a tube segment to direct airflow to the air intake with this tube segment located around the roughly cylindrical interior cyclonic chamber, from a starting point to an end point near the air intake, with the cross-section of this tube segment near the end point being smaller than that near the starting point in order to form an acceleration ramp for the airflow between these two points.

Owner:SEB SA

Cyclonic separating apparatus

InactiveUS20140366495A1Improve consistencyPrevent materialSuction filtersDispersed particle separationCyclonic separationEngineering

A cyclonic separating apparatus comprising a first cyclonic separating unit and, downstream from the first cyclonic separating unit, a second cyclonic separating unit comprising a plurality of cyclones arranged fluidly in parallel about a first axis and a dust collector arranged to receive dust from each of the plurality of cyclones. Each of the plurality of cyclones in the second cyclonic separation unit comprise a fluid inlet and a fluid outlet, the plurality of cyclones being divided into at least a first set of cyclones and a second set of cyclones, the fluid inlets of the first set of cyclones arranged in a first group and the fluid inlets of the second set of cyclones arranged in a second group spaced along said axis from the first group. Each outlet of the plurality of cyclones in the second cyclonic separation unit is provided by a common plate-like vortex finder member.

Owner:DYSON TECH LTD

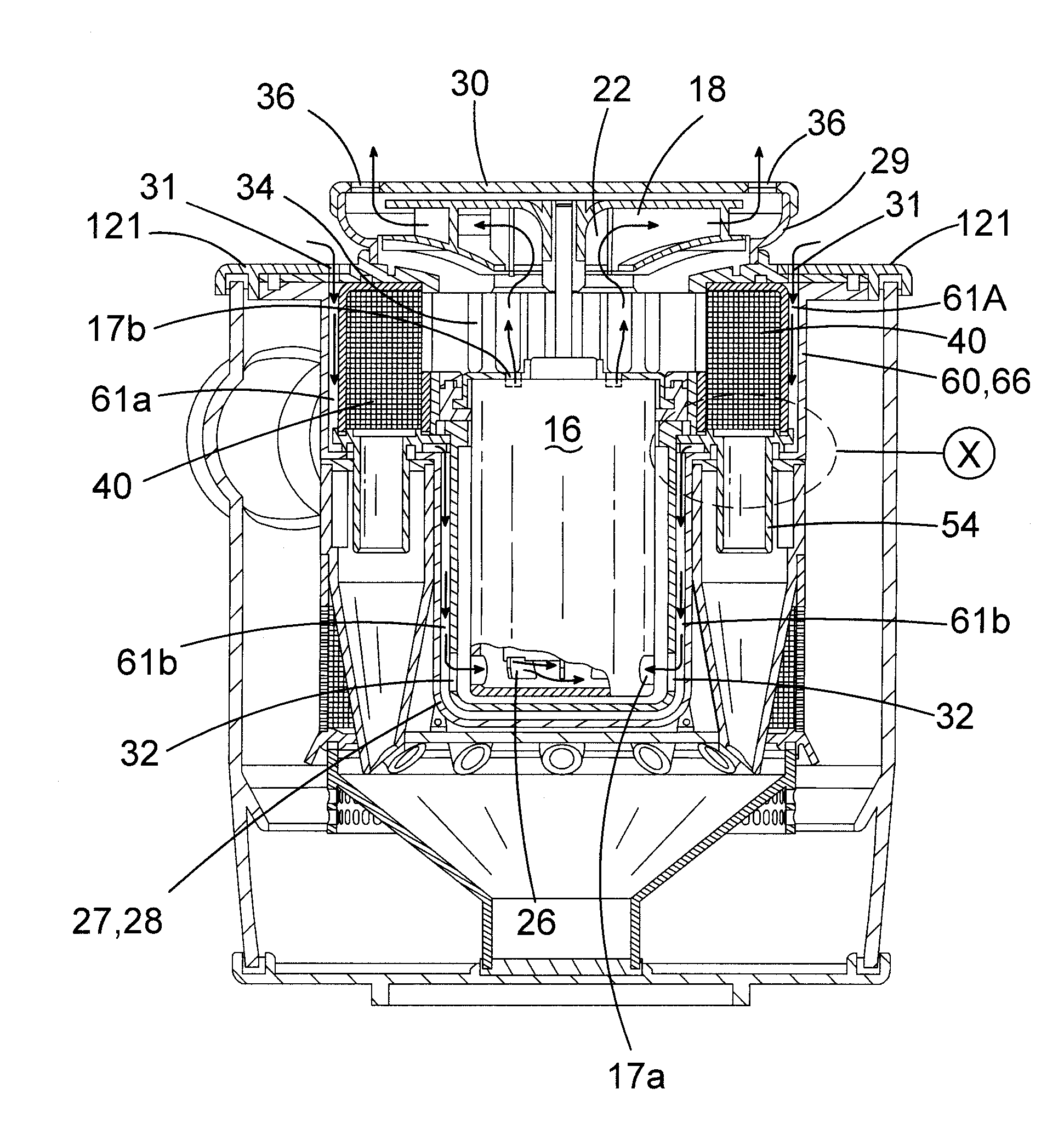

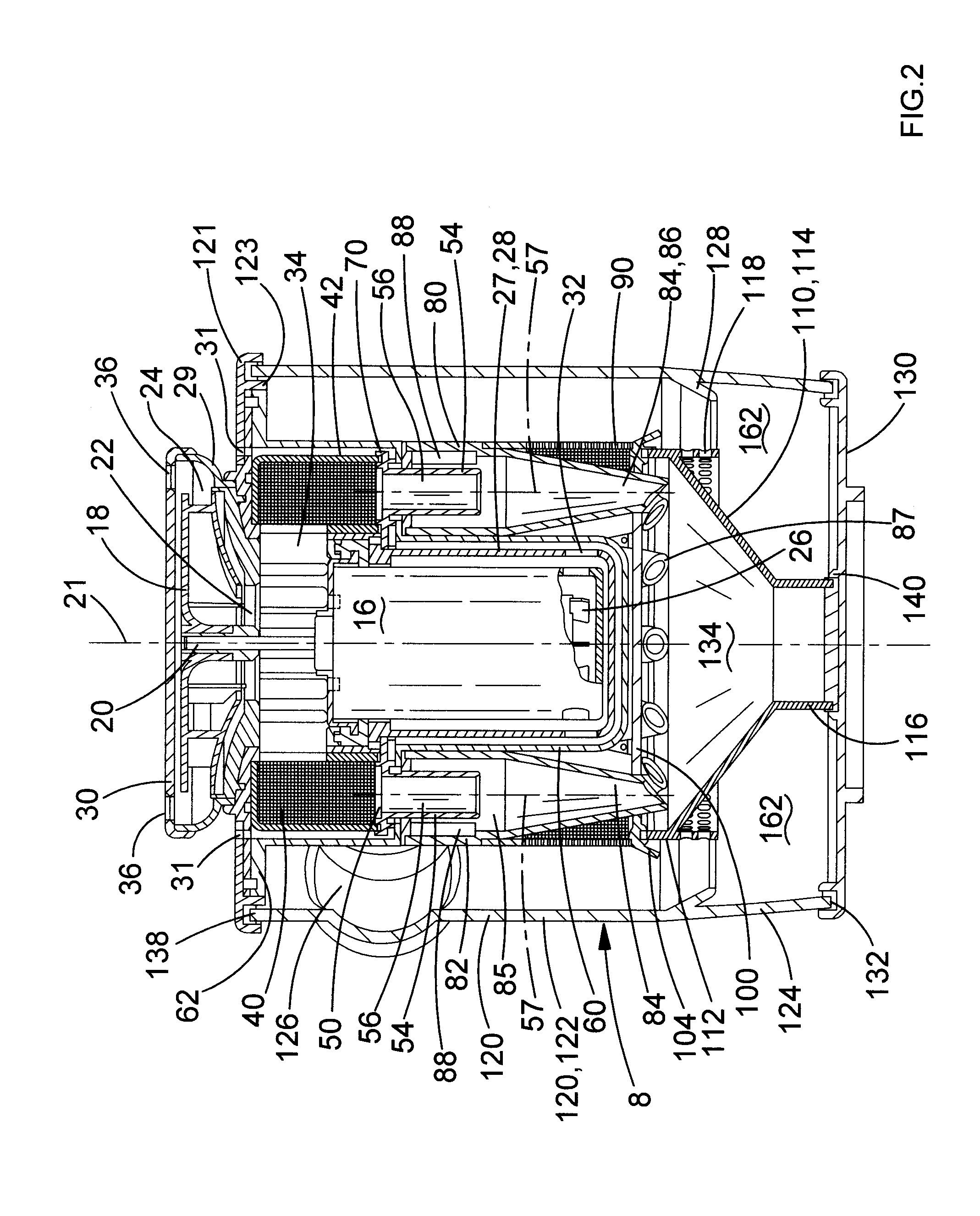

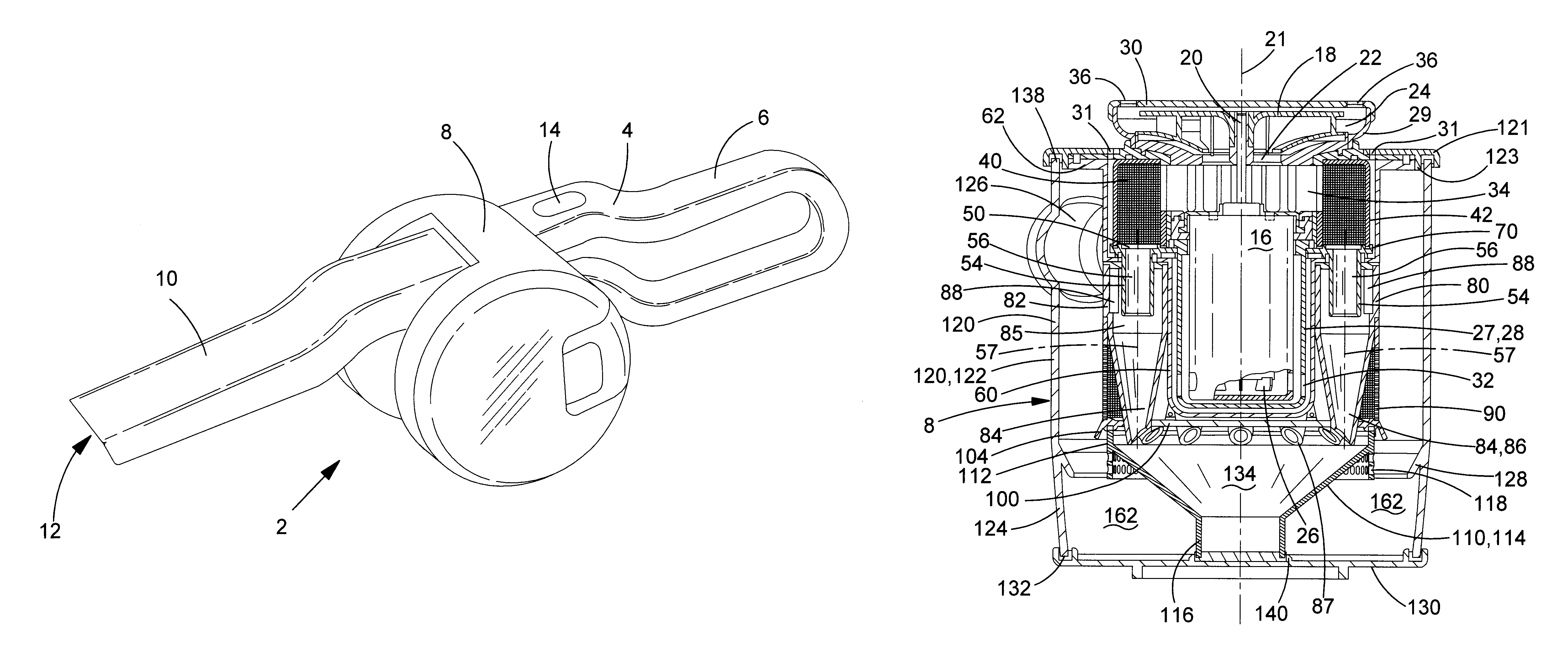

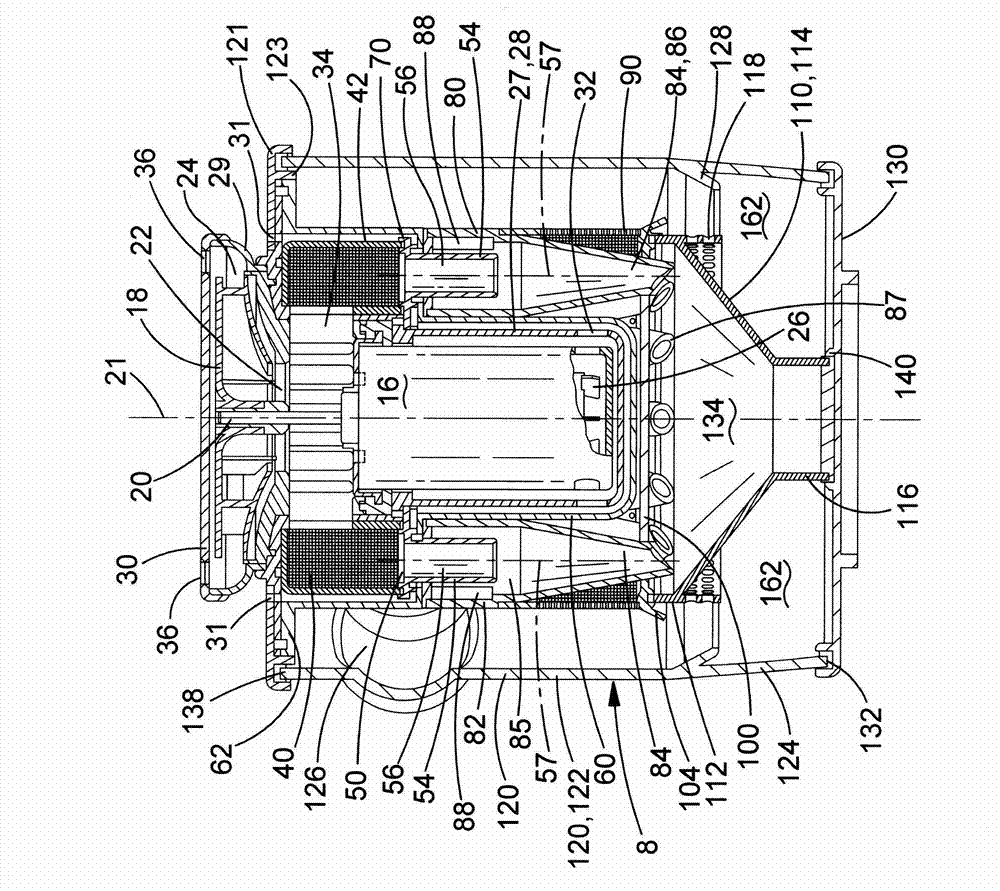

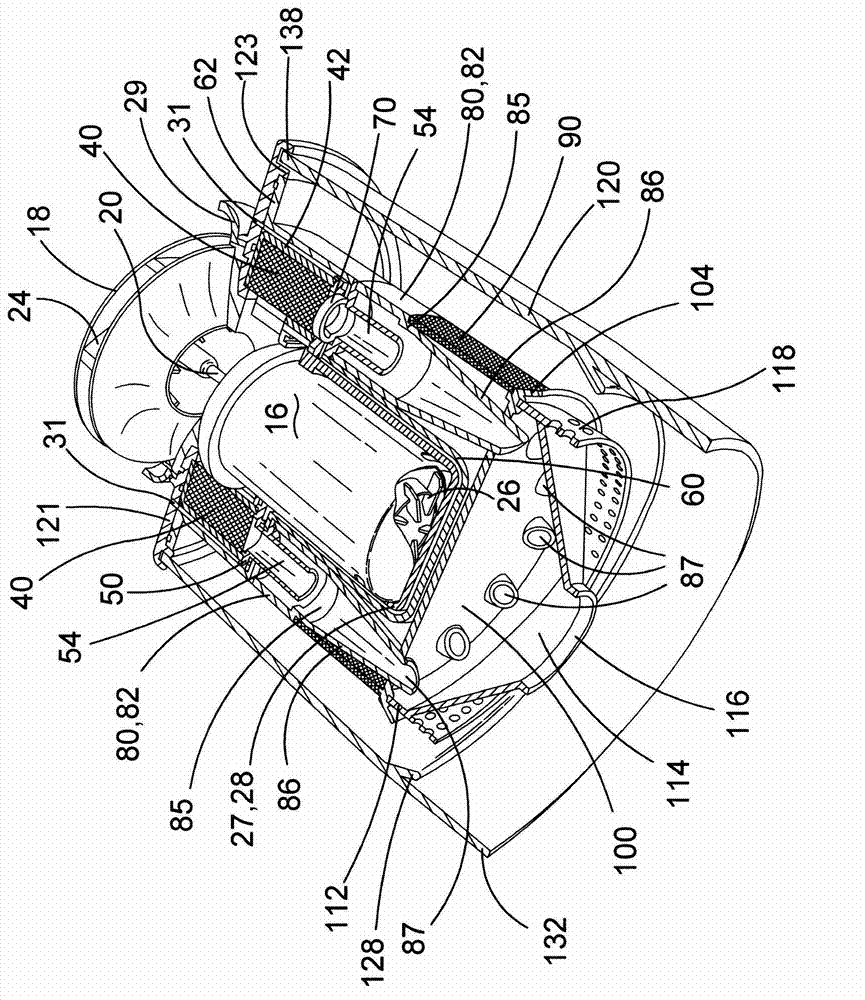

Structure for motor, fan and cyclonic separation apparatus

InactiveCN103040412AShortened fluid communicationReduce in quantitySuction filtersMotor fan assembly mountingCycloneCyclonic separation

A motor, fan and cyclonic separation apparatus arrangement for a vacuum cleaner, the arrangement comprising: a motor (16) coupled to a fan (18) for generating air flow,a cyclonic separation apparatus (8) located in a path of the air flow generated by the fan,and a pre-fan filter (40) located in the path of the air flow downstream of the cyclonic separation apparatus and upstream of the fan (18), wherein the cyclonic separation apparatus comprises at least one cyclone (84) comprising: a cyclone body (85,86) with a longitudinal axis (57),an air inlet port (88) arranged tangentially through a side of the cyclone body,and an air outlet port (56) through a longitudinal end of the cyclone body, wherein the pre-fan filter (40) is arranged upon the air outlet port of the or each cyclone.

Owner:BLACK & DECKER INC

Cyclonic Separating Apparatus

InactiveUS20080289140A1Reduce riskReliable collectionCleaning filter meansSuction filtersCycloneCyclonic separation

A cyclonic separating apparatus includes a first cyclonic separating unit including at least one first cyclone, a second cyclonic separating unit located downstream of the first cyclonic separating unit and including at least one second cyclone, and a third cyclonic separating unit located downstream of the second cyclonic separating unit and including a plurality of third cyclones arranged in parallel. The separation efficiency of the first cyclonic separating unit is lower than the separation efficiency of the second cyclonic separating unit and the separation efficiency of the second cyclonic separating unit is lower than the separation efficiency of the third separating unit, thus achieving a higher separation efficiency than known separation apparatus.

Owner:DYSON TECH LTD

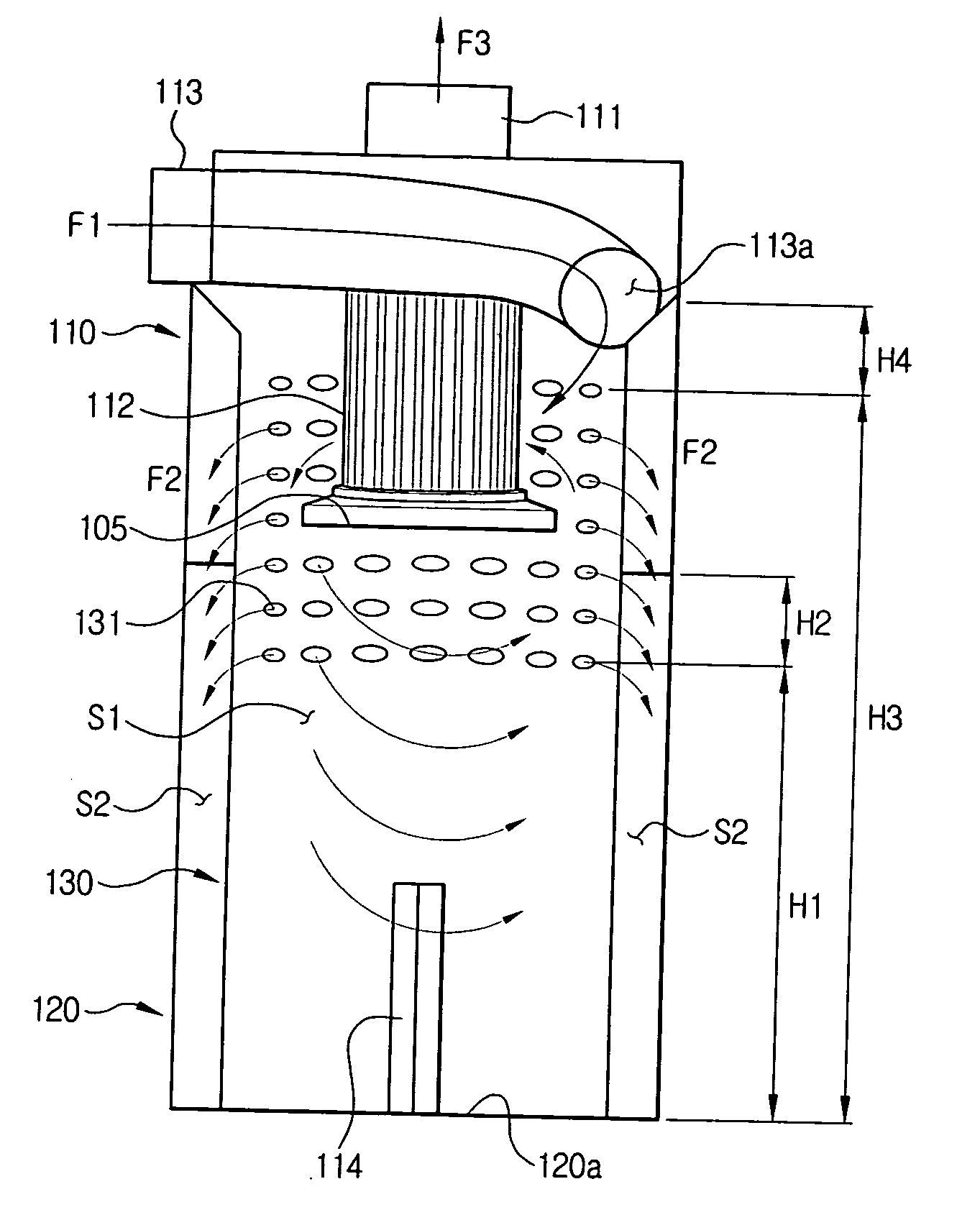

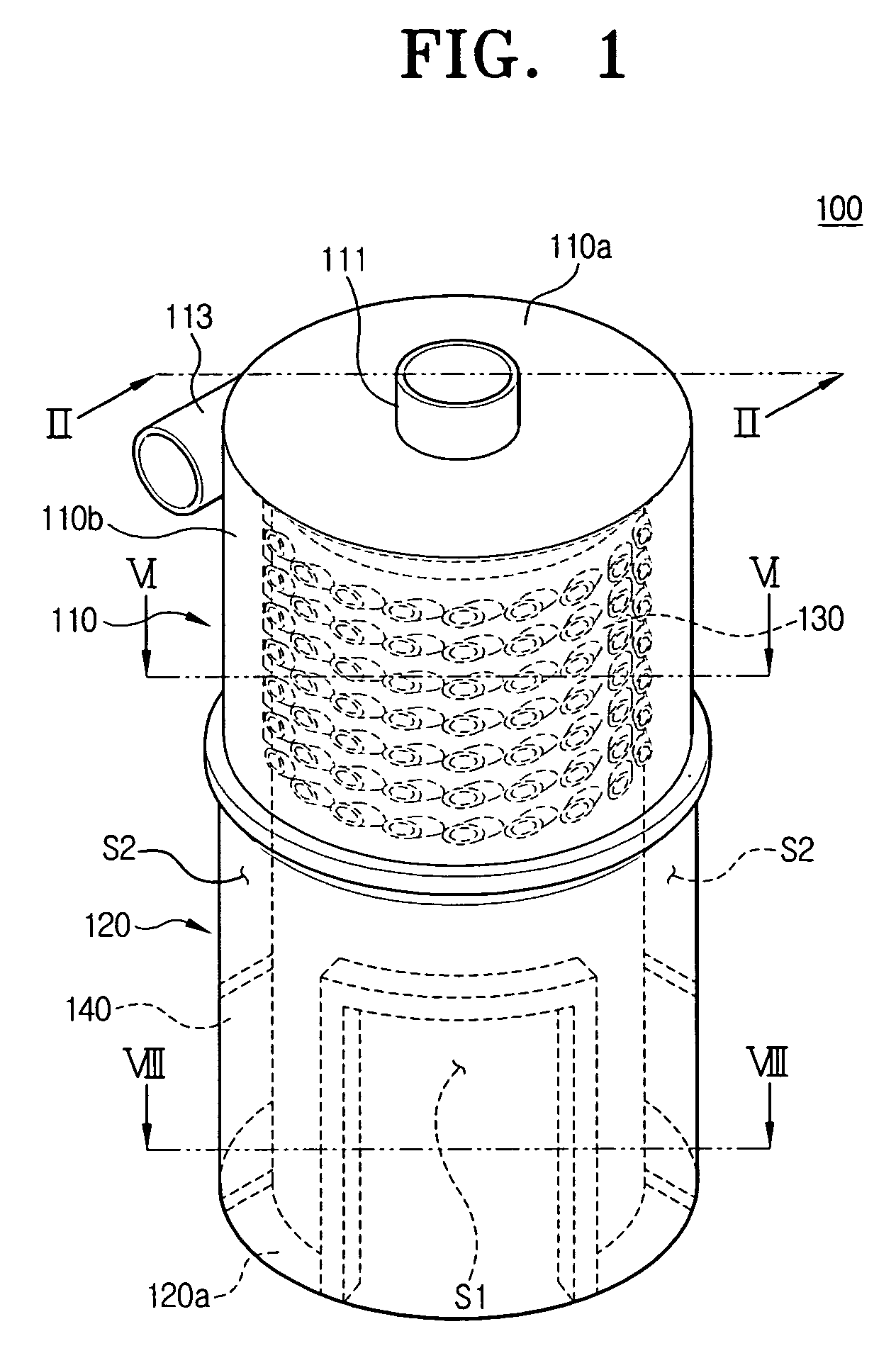

Cyclone separating apparatus and a vacuum cleaner having the same

InactiveUS7169201B2Improve dust removal efficiencyPrevent suction lossCleaning filter meansCombination devicesCycloneSuction force

A cyclone separating apparatus and a vacuum cleaner having the same are disclosed. More specifically, the cyclone separating apparatus for a vacuum cleaner comprises a first cyclone for separating drawn-in air, and a plurality of second cyclones installed on an outer periphery of the first cyclone to enclose the first cyclone. Accordingly, because a plurality of the cyclones separates dust, and a bulky structure is improved to a compact structure, suction force deterioration does not occur, and, dust-collecting efficiency is increased.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com