Cyclonic separation apparatus

一种分离装置、旋风分离器的技术,应用在吸尘器、胶体化学、化学仪器和方法等方向,能够解决分离效率低分离效率等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

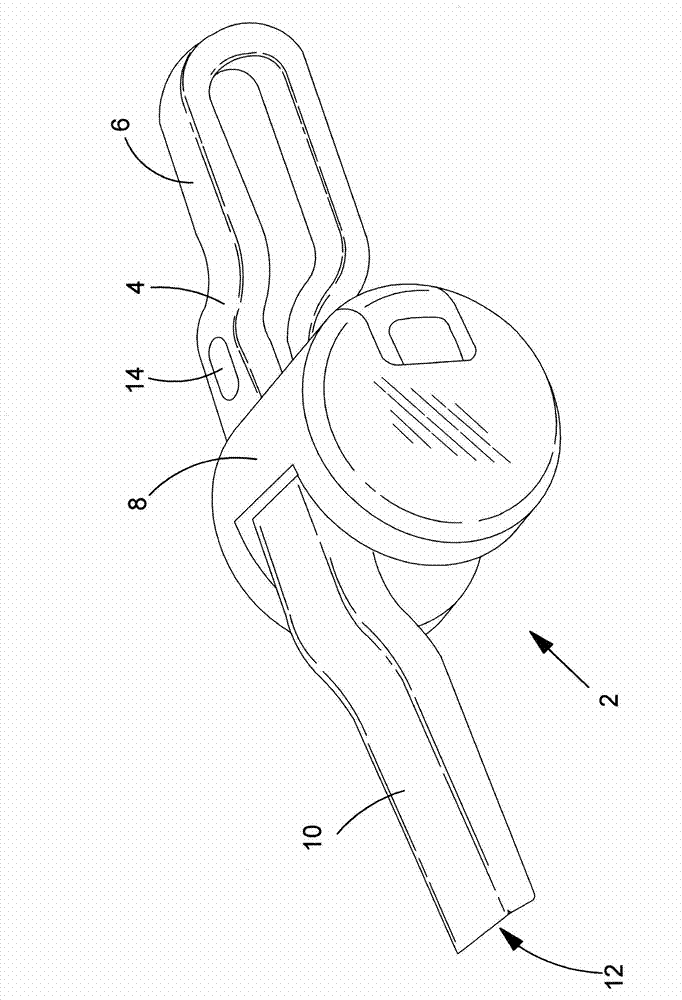

[0078] refer to figure 1 , which shows a first embodiment of a hand-held vacuum cleaner 2 comprising: a main body 4; a handle 6 connected to the main body 4; a cyclonic separation device 8 mounted on the main body and transversely across the main body; and a dirty air channel 10 having a dirty air inlet 12 at one end. The vacuum cleaner includes: an electric motor that engages a fan for generating air flow through the vacuum cleaner; and a rechargeable battery (not shown) Provides electrical energy to the motor when electrically connected to the motor.

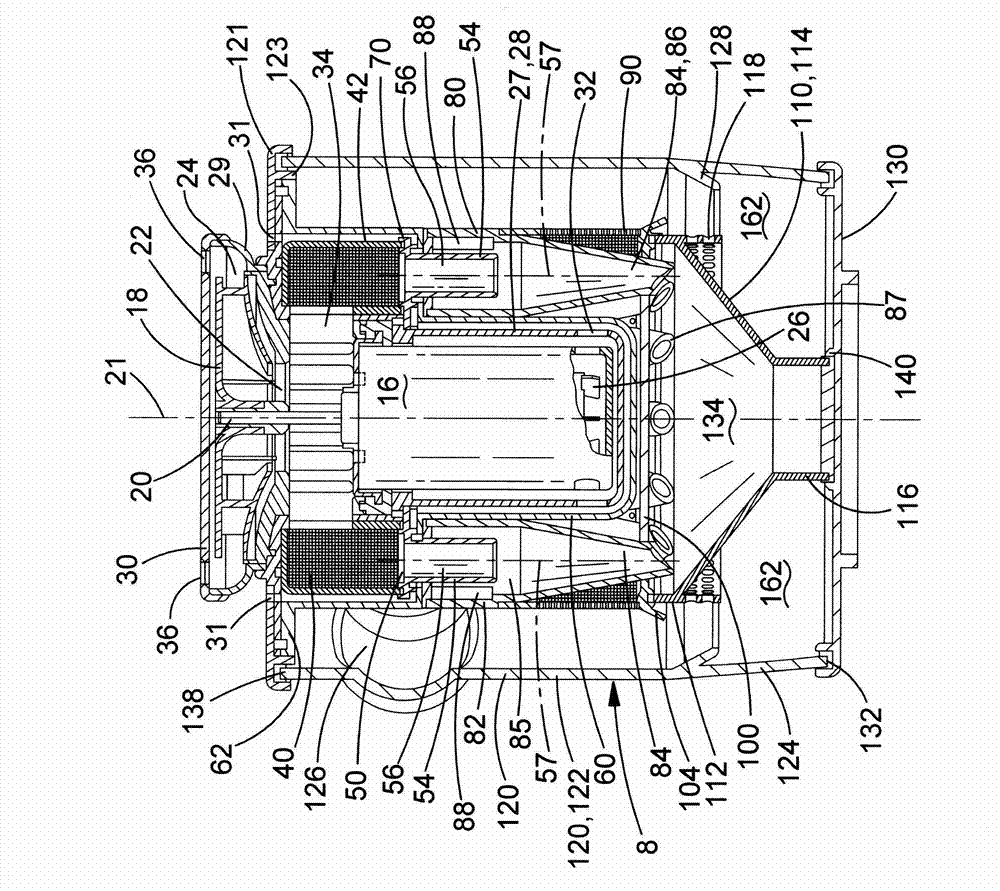

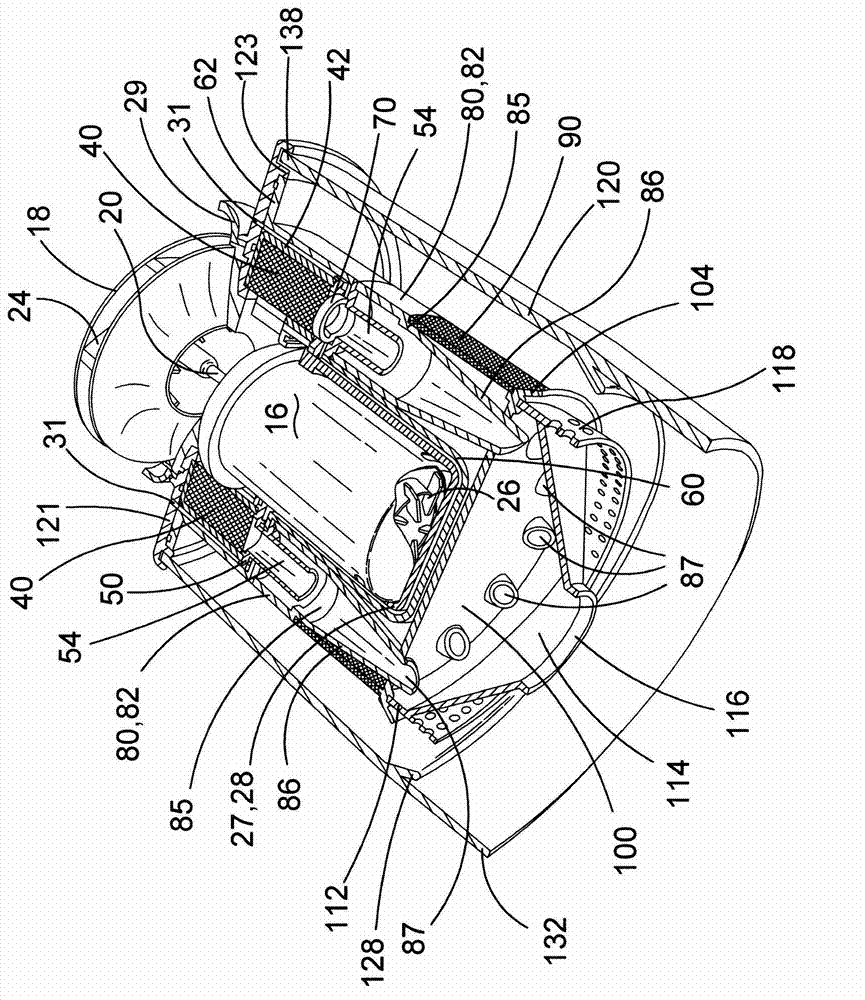

[0079] refer to Figure 2 to Figure 8 , which shows a structure including a motor 16, a fan 18 and a cyclonic separation device 8. The electric motor has a drive shaft 20 with a central axis 21 . The fan is a centrifugal fan 18 with an axial inlet 22 facing the motor and a tangential outlet 24 . The diameter of the fan is 68mm. The fan is mounted on the drive shaft that sits on top of the motor. In use, an electric moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com