Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Prevent suction loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

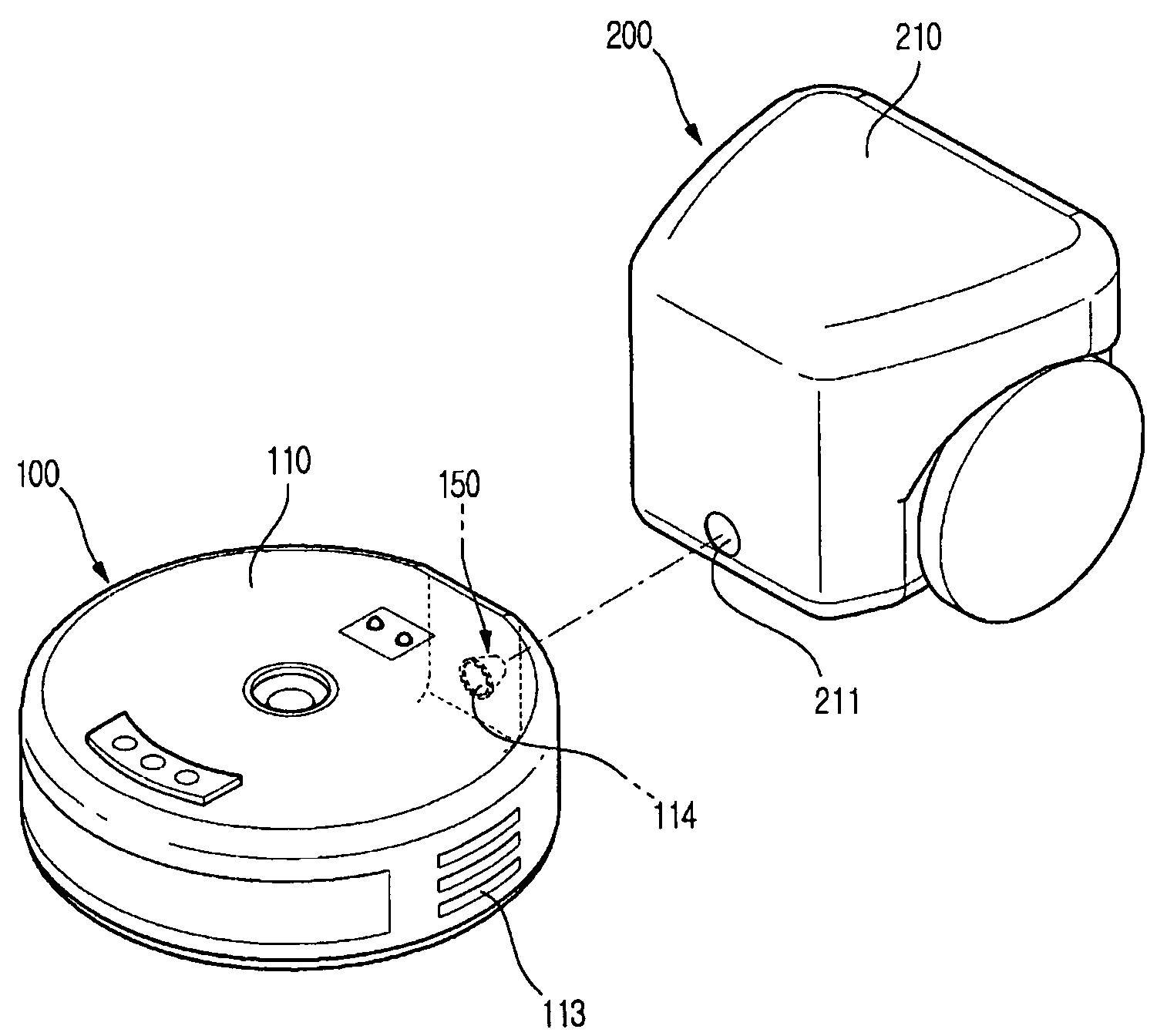

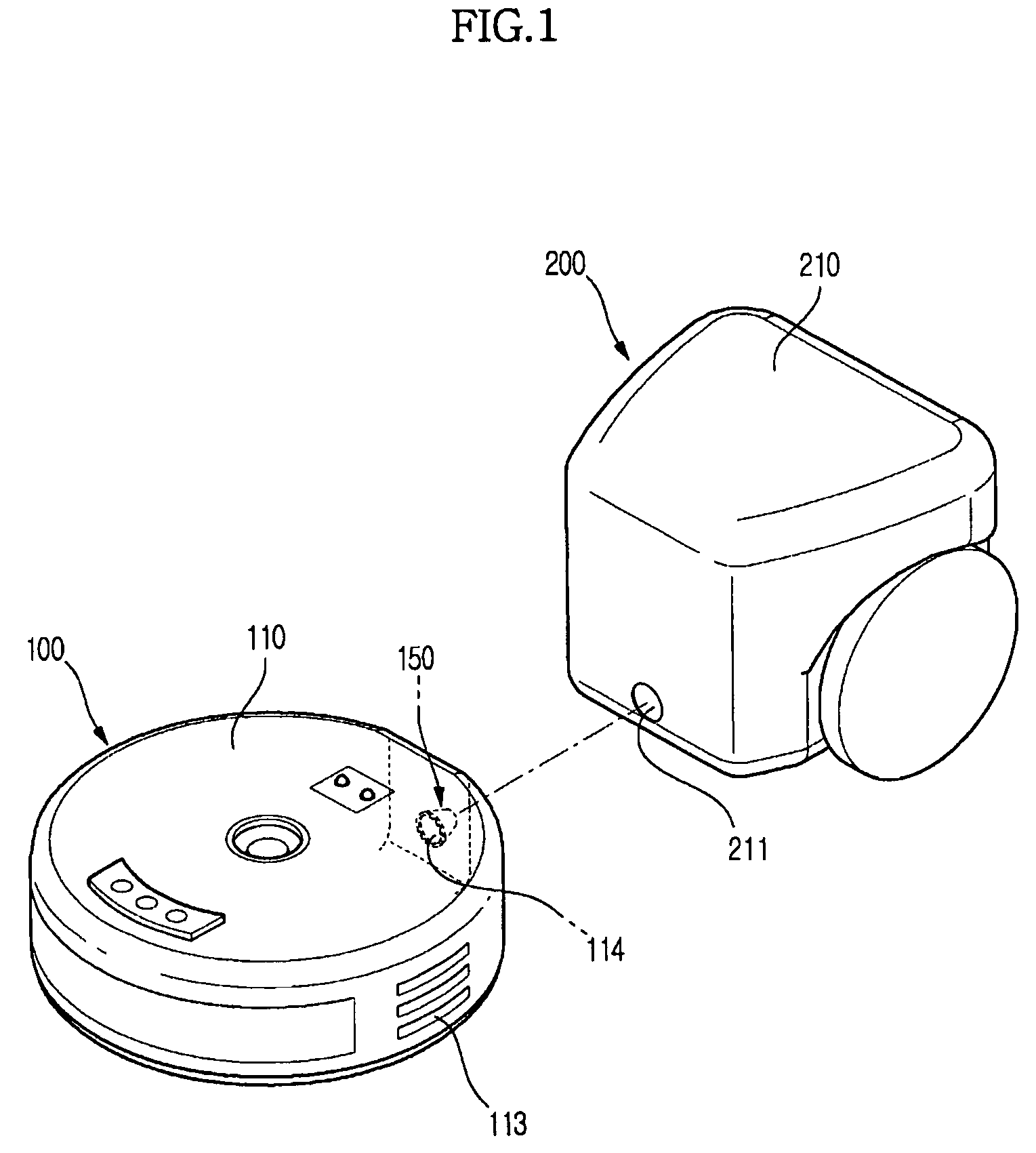

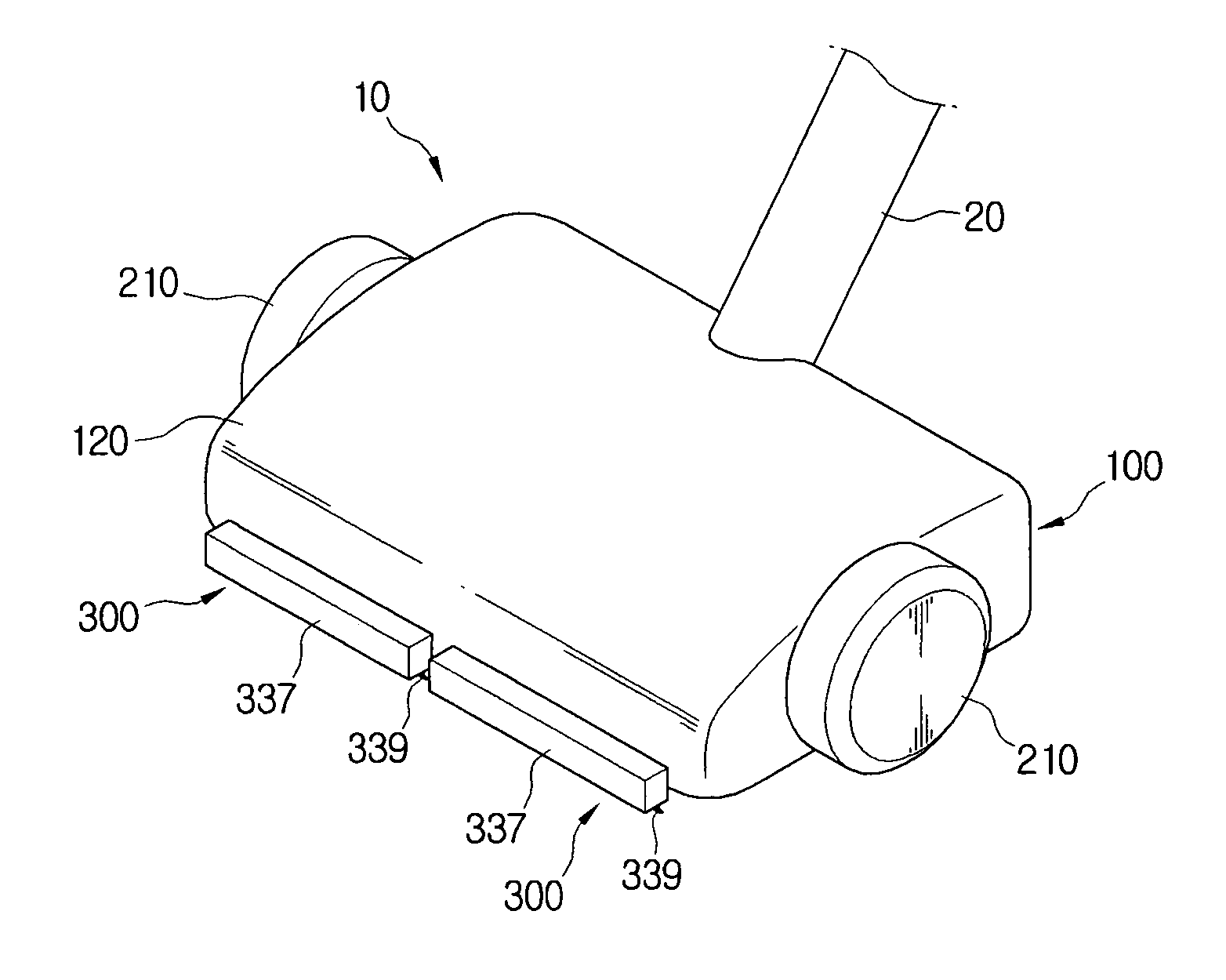

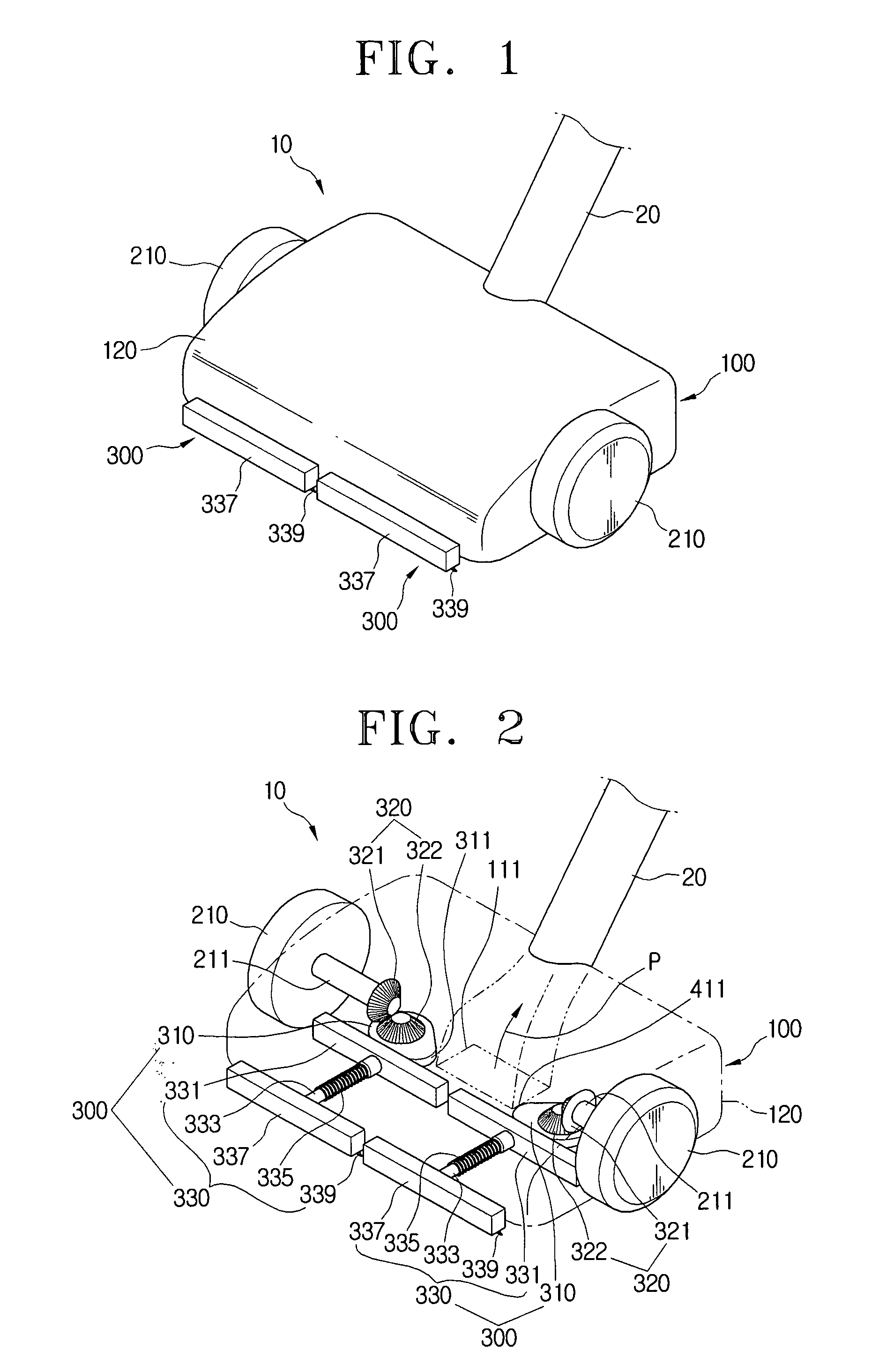

Robot cleaner system having robot cleaner and docking station

InactiveUS7861366B2Improved docking structurePrevent suction lossCleaning filter meansSuction filtersDocking stationSuction force

A robot cleaner system having an improved docking structure between a robot cleaner and a docking station, which is capable of an easy docking operation of the robot cleaner and preventing loss of a suction force generated in the docking station. The robot cleaner includes a docking portion to be inserted into a dust suction hole of the docking station upon a docking operation. The docking portion may be a protrusion, which protrudes out of a robot body to be inserted into a dust suction path defined in the docking station, the protrusion communicates a dust discharge hole of the robot cleaner with the dust suction path of the docking station. The robot cleaner system includes a coupling device to keep the robot cleaner and the docking station in their docked state. The coupling device is configured to have a variety of shapes.

Owner:SAMSUNG ELECTRONICS CO LTD

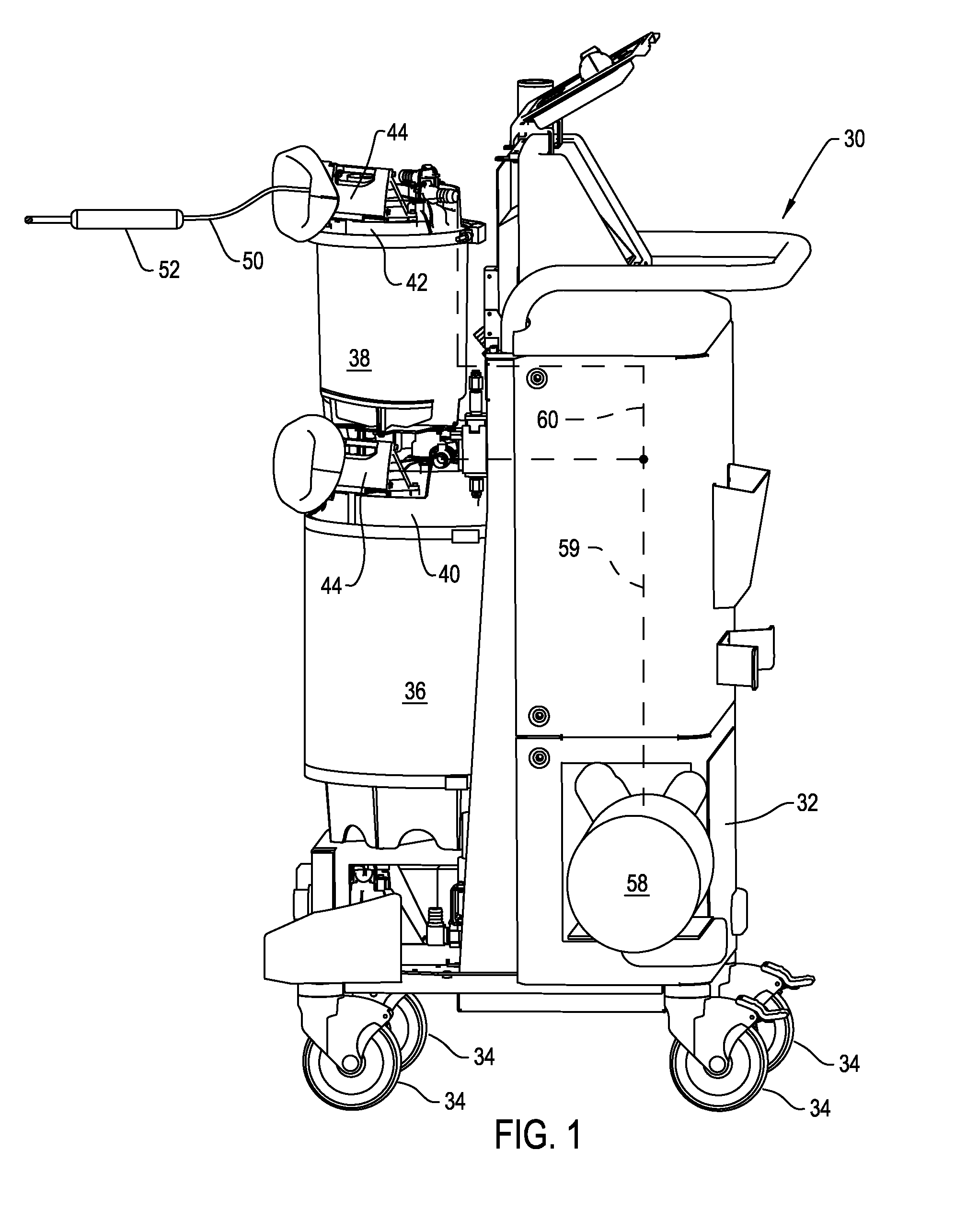

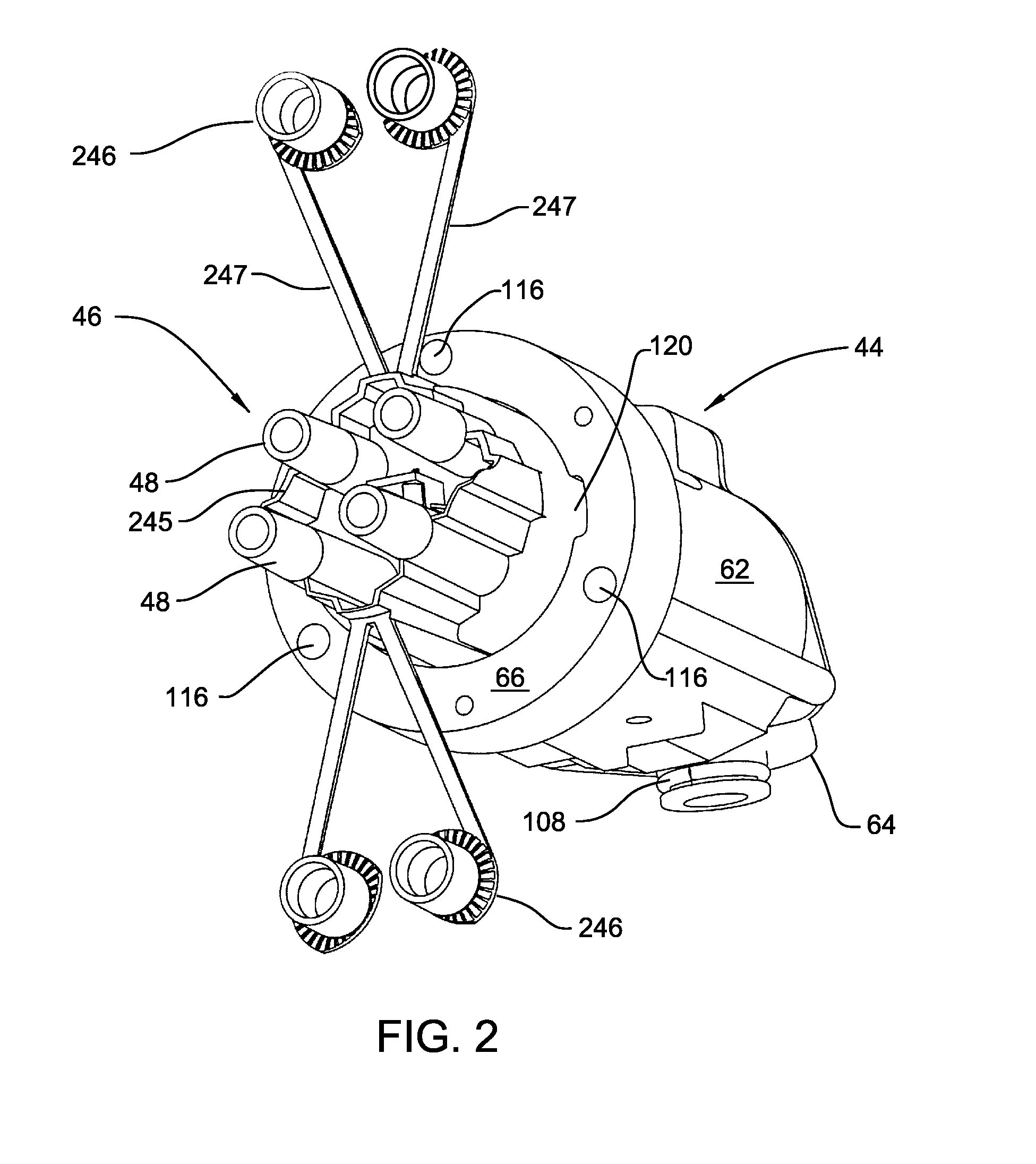

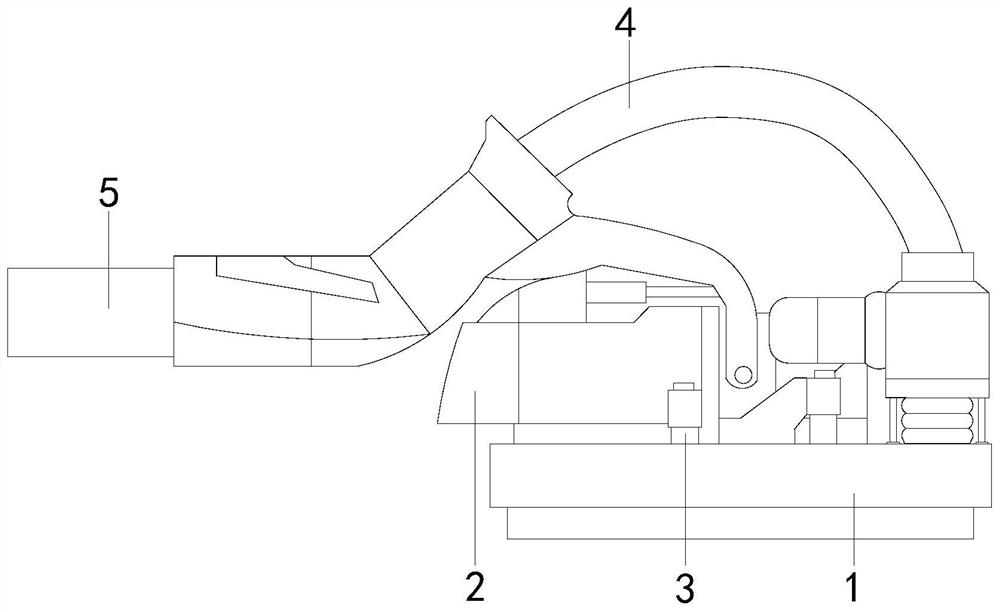

Removable inlet manifold for a medical/surgical waste collection system, the manifold including a driver for actuating a valve integral with the waste collection system

ActiveUS7615037B2Minimize releasePrevent leakageSurgical furnitureDiagnosticsCollection systemWaste collection

A removable manifold for a medical / surgical waste collection system. The manifold is dimensioned to be mounted to a receiver integral with the system. The manifold includes a driver for engaging a complementary valve internal to the receiver. The valve regulates flow between the receiver and the down line components of the waste collection system. The valve is normally closed. When the manifold is fitted to the receiver the driver engages the valve so as move the valve to the open position. This allows fluid flow from the manifold and receiver to the downstream components of the system.

Owner:STRYKER CORP

Removable inlet manifold for a medical/surgical waste collection system, the manifold including a driver for actuating a valve integral with the waste collection system

ActiveUS20070135778A1Minimize releasePrevent leakageSurgical furnitureDiagnosticsCollection systemWaste collection

A removable manifold for a medical / surgical waste collection system. The manifold is dimensioned to be mounted to a receiver integral with the system. The manifold includes a driver for engaging a complementary valve internal to the receiver. The valve regulates flow between the receiver and the down line components of the waste collection system. The valve is normally closed. When the manifold is fitted to the receiver the driver engages the valve so as move the valve to the open position. This allows fluid flow from the manifold and receiver to the downstream components of the system.

Owner:STRYKER CORP

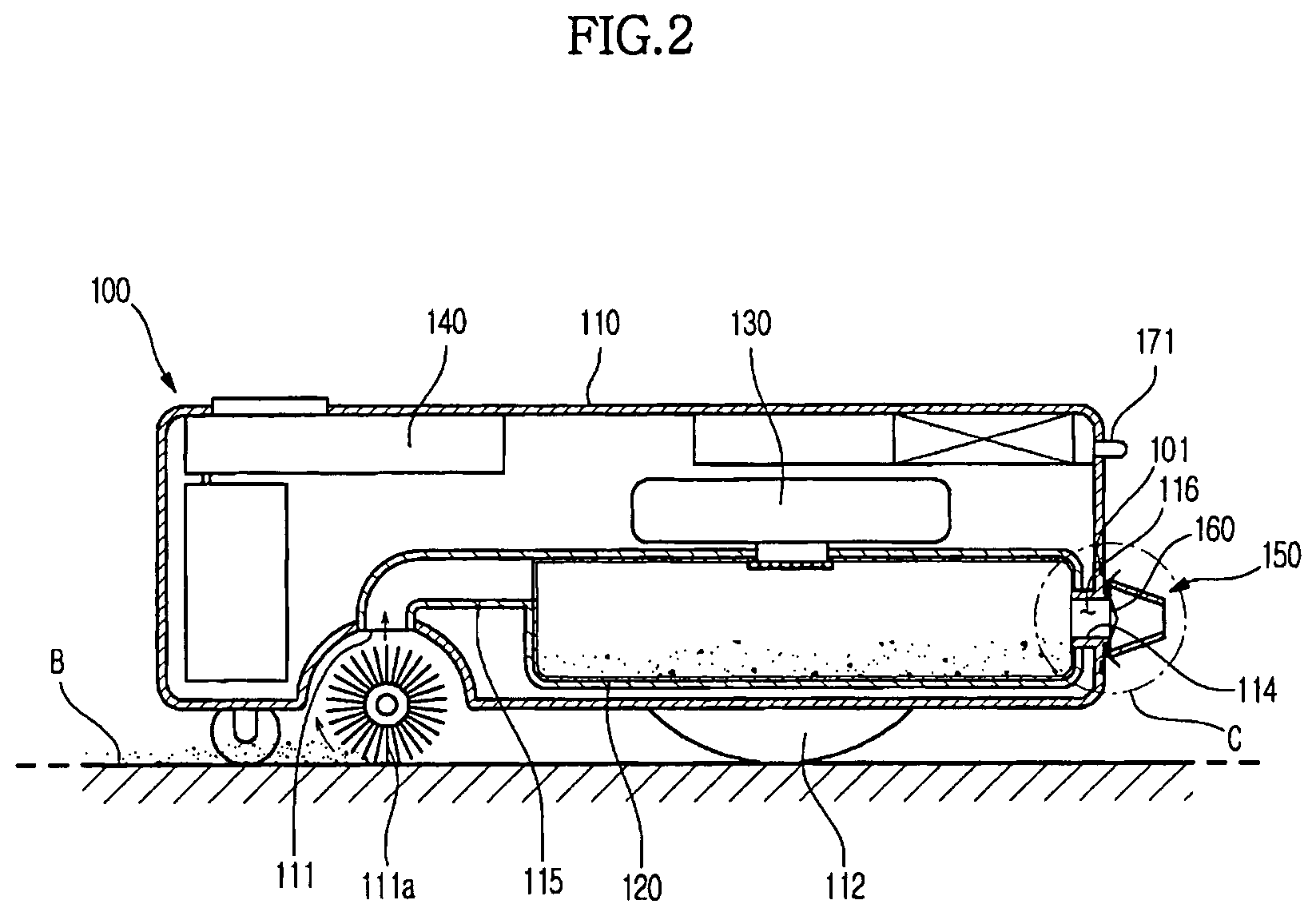

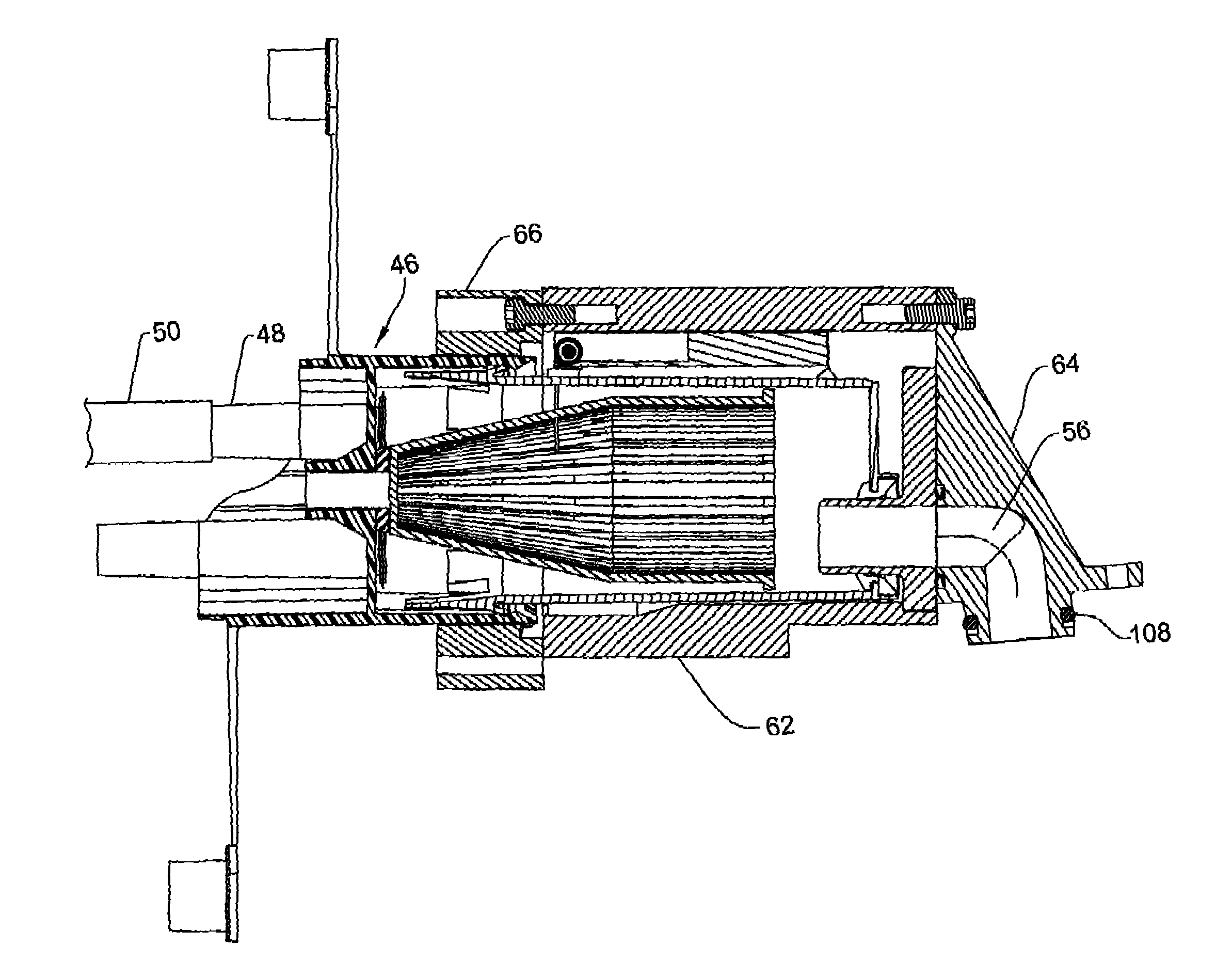

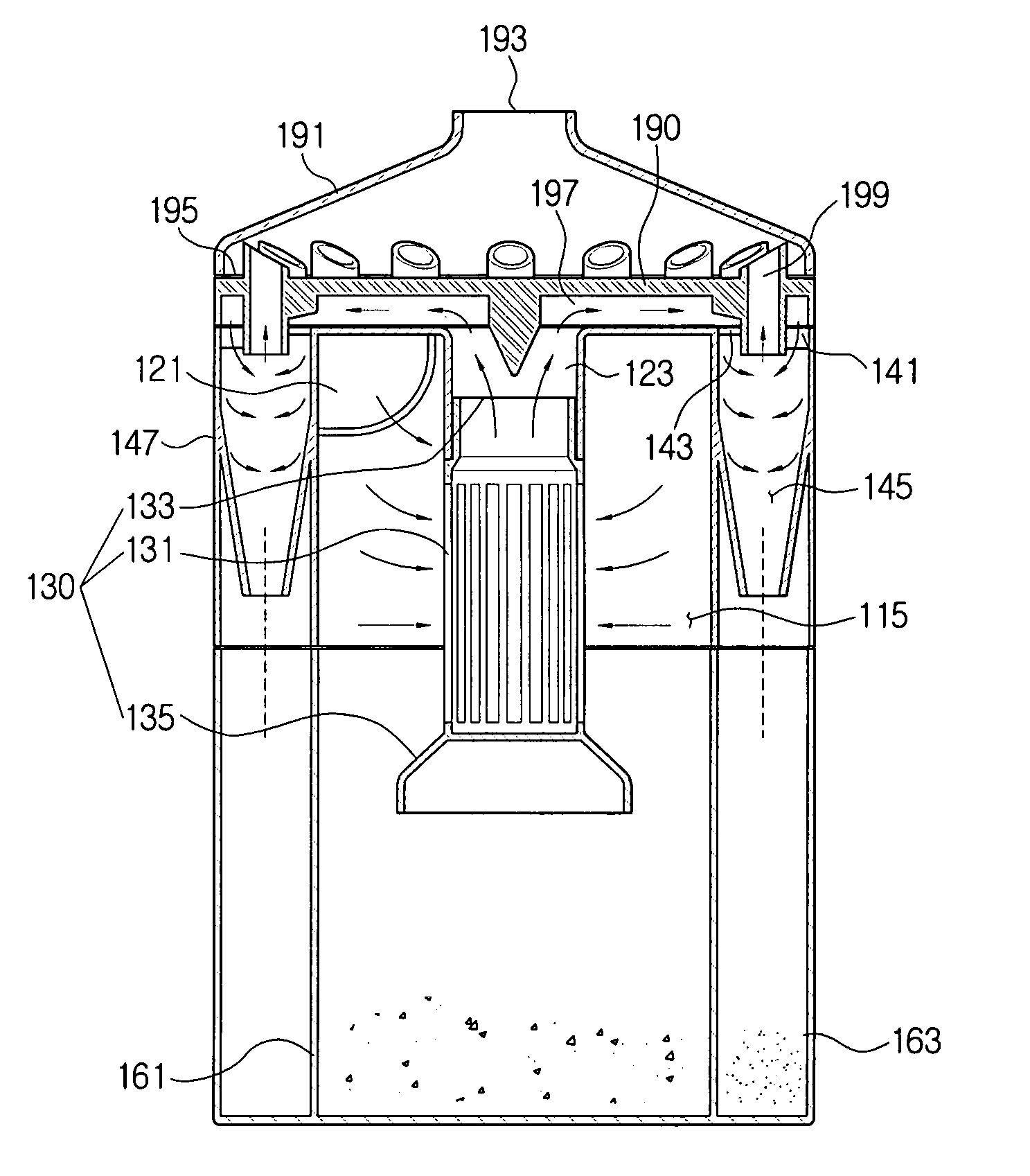

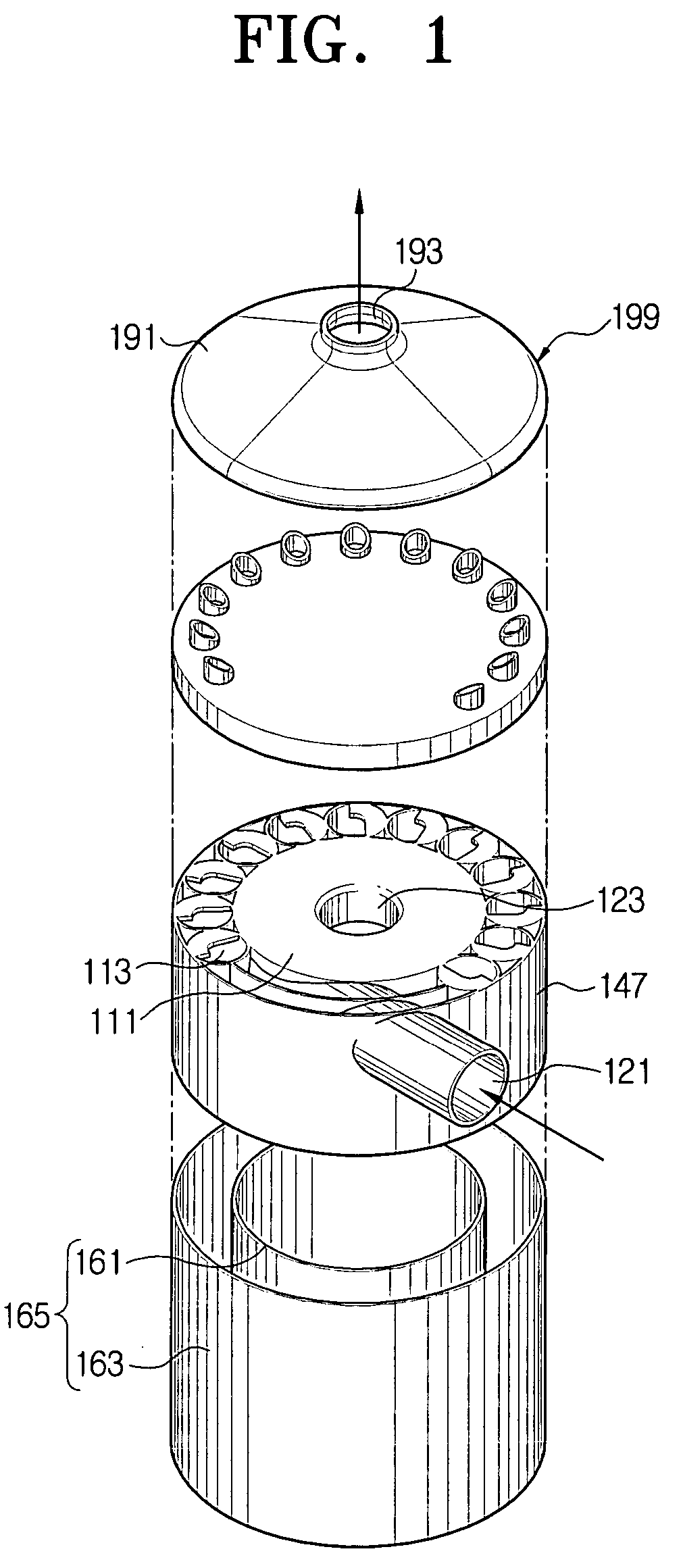

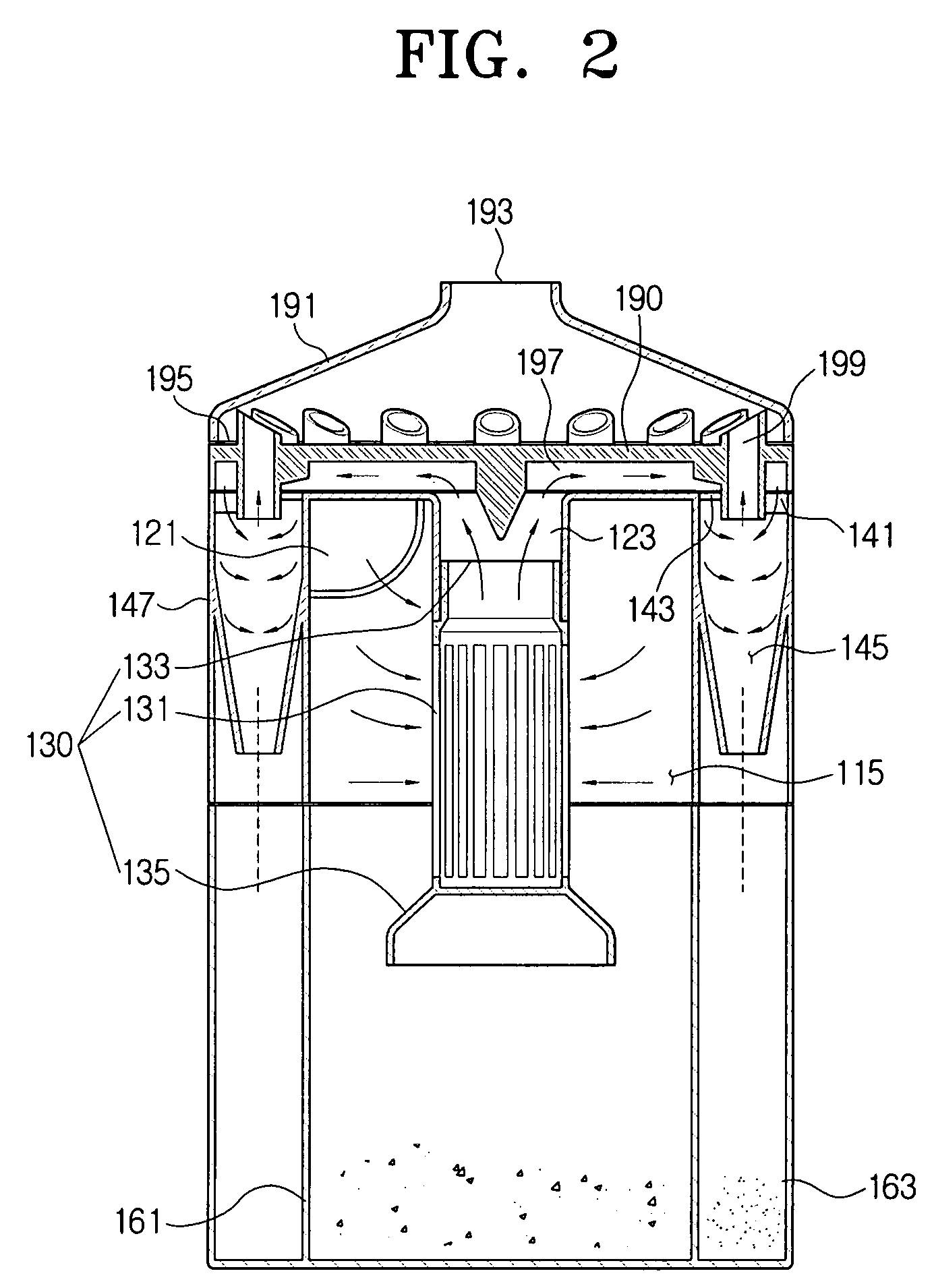

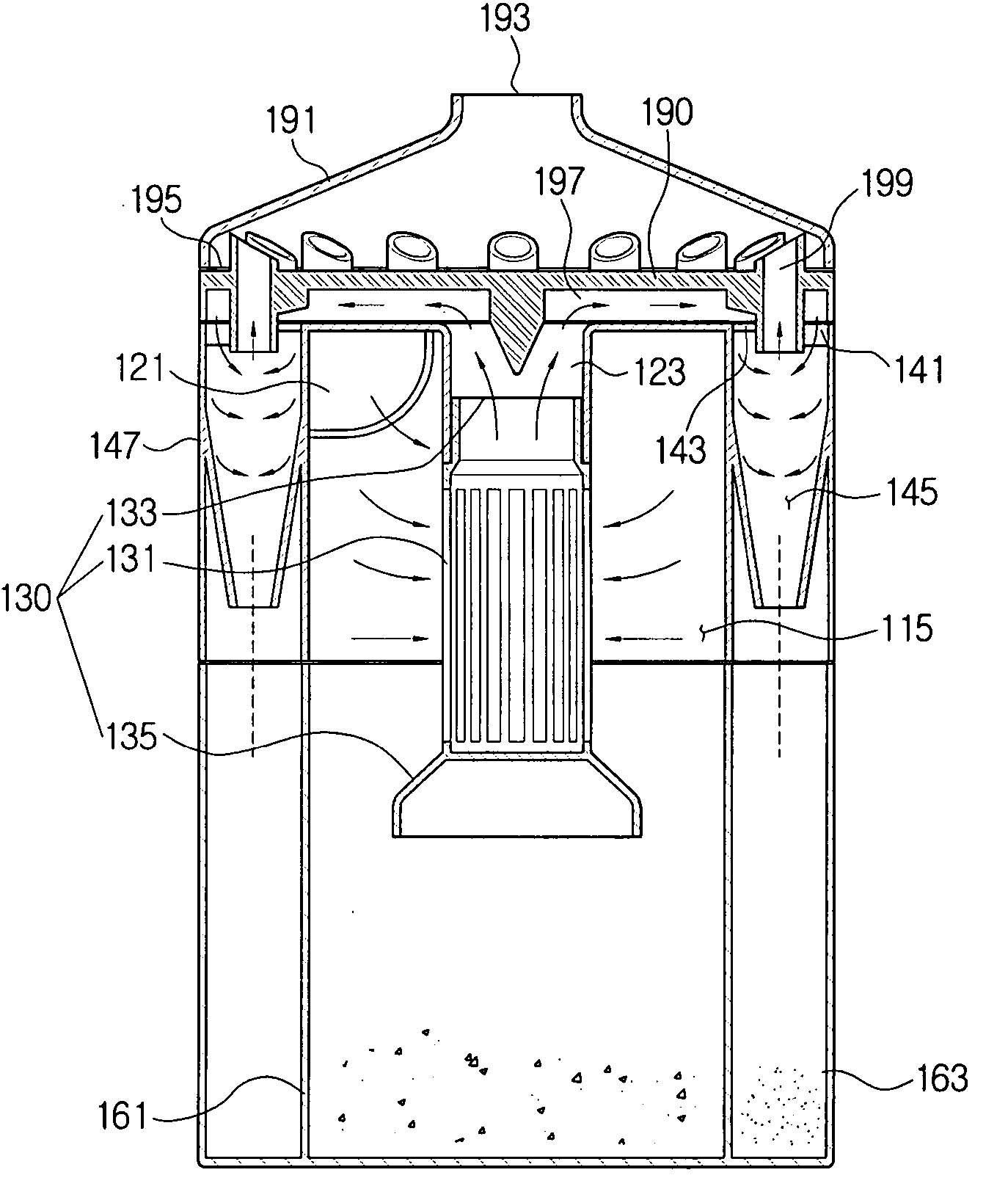

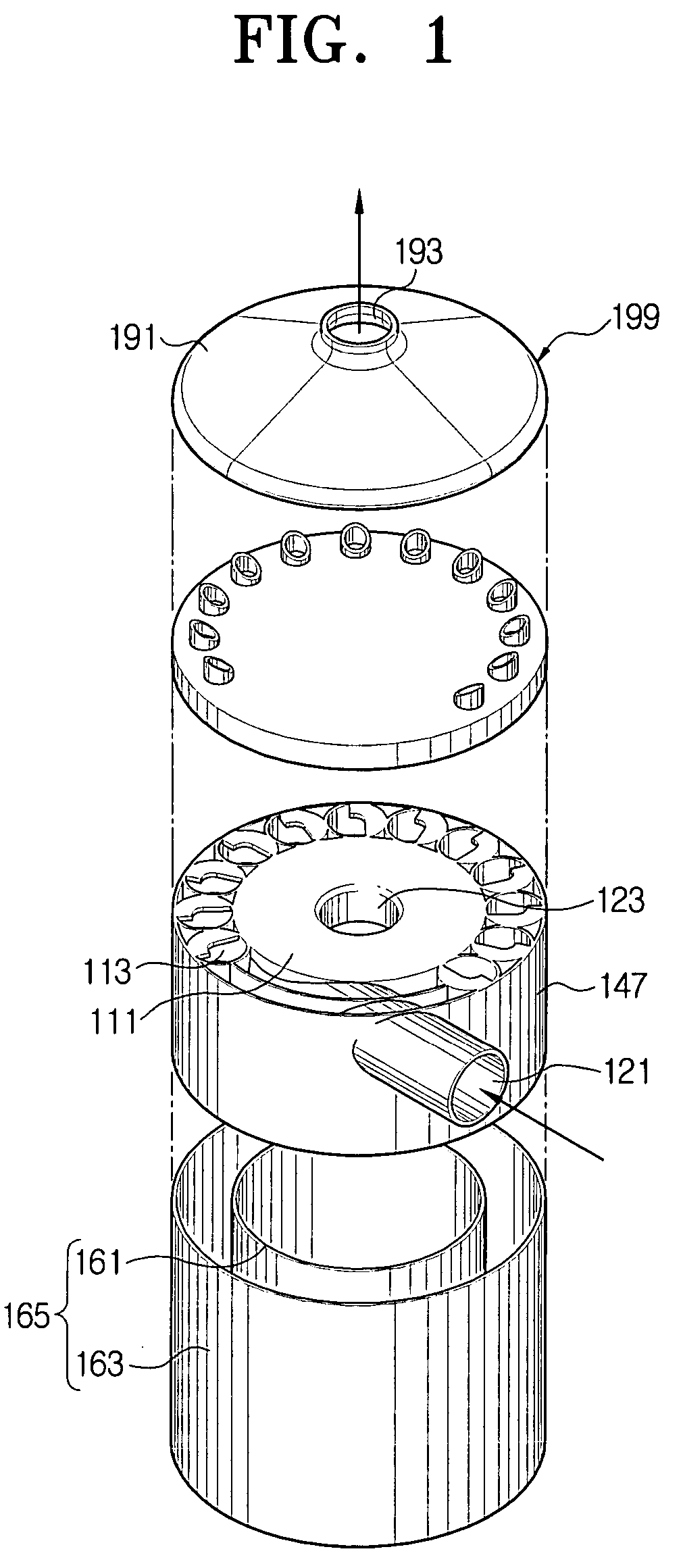

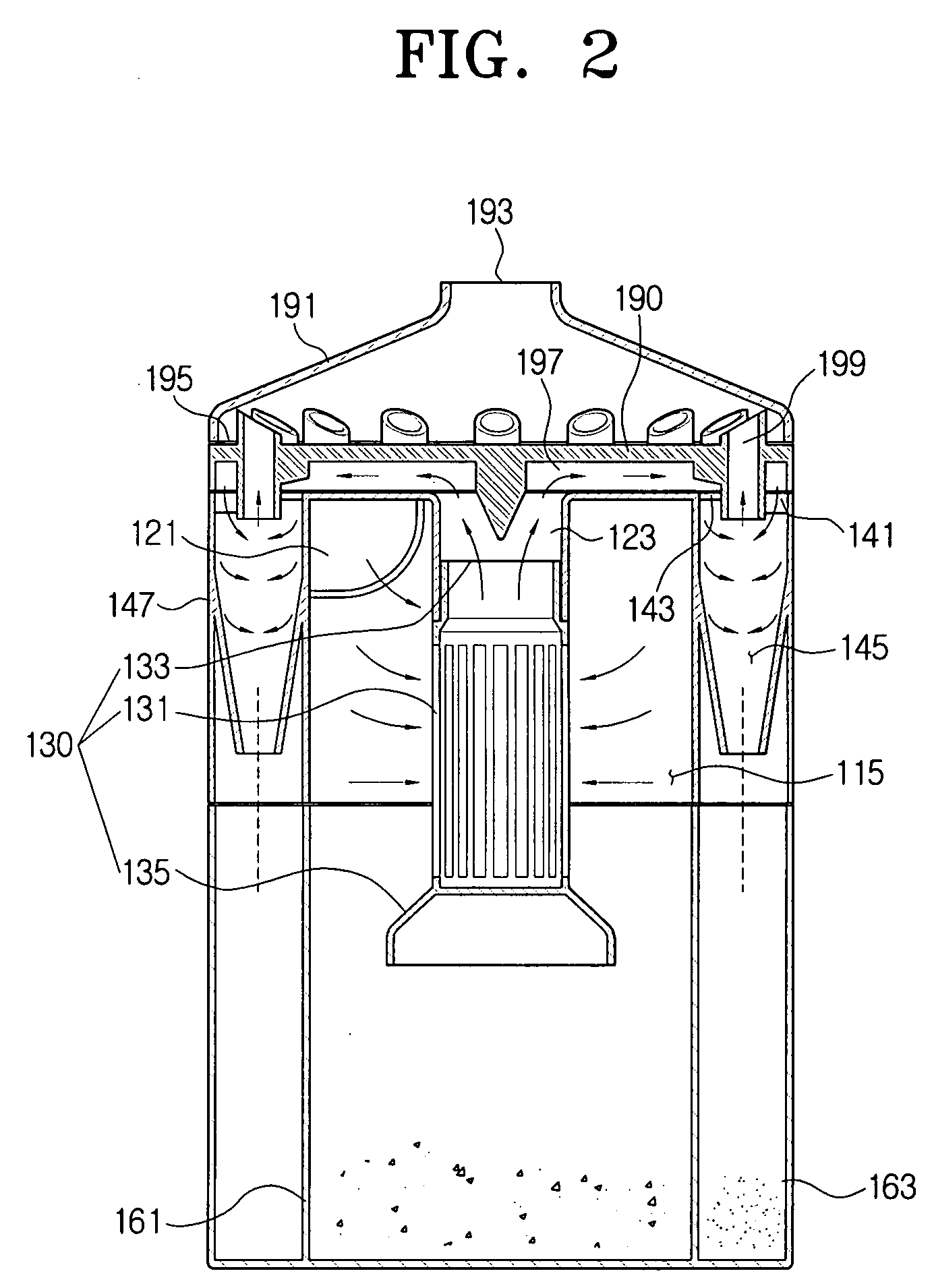

Cyclone separating apparatus and a vacuum cleaner having the same

InactiveUS7169201B2Improve dust removal efficiencyPrevent suction lossCleaning filter meansCombination devicesCycloneSuction force

A cyclone separating apparatus and a vacuum cleaner having the same are disclosed. More specifically, the cyclone separating apparatus for a vacuum cleaner comprises a first cyclone for separating drawn-in air, and a plurality of second cyclones installed on an outer periphery of the first cyclone to enclose the first cyclone. Accordingly, because a plurality of the cyclones separates dust, and a bulky structure is improved to a compact structure, suction force deterioration does not occur, and, dust-collecting efficiency is increased.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

Cyclone separating apparatus and a vacuum cleaner having the same

InactiveUS20050050865A1Improve efficiencyPrevents deterioration of suction forceCleaning filter meansCombination devicesCyclonic separationPhencyclone

A cyclone separating apparatus and a vacuum cleaner having the same are disclosed. More specifically, the cyclone separating apparatus for a vacuum cleaner comprises a first cyclone for separating drawn-in air, and a plurality of second cyclones installed on an outer periphery of the first cyclone to enclose the first cyclone. Accordingly, because a plurality of the cyclones separates dust, and a bulky structure is improved to a compact structure, suction force deterioration does not occur, and, dust-collecting efficiency is increased.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

Recording apparatus and line type liquid discharge recording apparatus

InactiveUS20110157288A1Prevent lowering of suction power for a recording sheetPrevent suction lossOther printing apparatusEngineeringRecording head

A recording apparatus includes a recording head performing recording onto a recording sheet; a platen section guiding the recording sheet to a position facing the recording head; a suction unit which includes a plurality of suction openings provided at the platen section and sucks and holds the recording sheet, a suction duct provided facing the suction openings, and a suction fan connected to the suction duct, and sucks and holds the recording sheet on the platen section through the suction openings; and a shutter mechanism which opens and closes the suction duct, wherein the shutter mechanism includes a shutter sheet in which at least one exposure opening portion exposing the suction duct is formed corresponding to the width of the recording sheet, and a shutter sheet movement mechanism which makes the shutter sheet travel between the suction duct and a back surface of the platen section.

Owner:SONY CORP

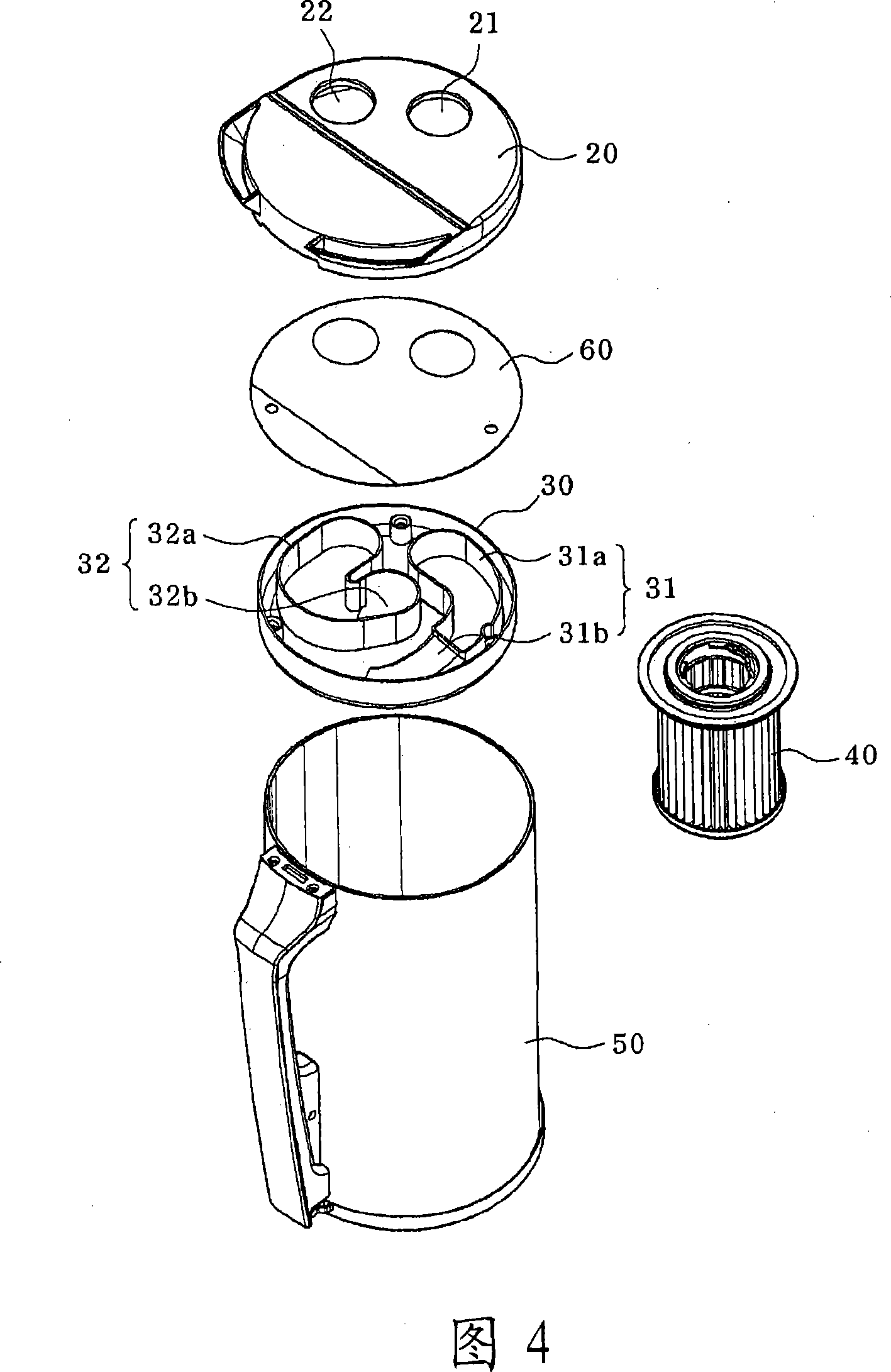

Dust container of upright type vacuum cleaner and supporting structure for cover thereof

InactiveUS7404231B2Prevent suction lossCleaning filter meansSuction filtersVacuum cleanerDust collector

A dust container of an upright type vacuum cleaner includes a circular cover having a suction port and an exhaust port, a guide member attached to a lower surface of the cover to guide an air flow, a filter attached to a lower surface of the guide member, and a cylindrical container body provided to the lower surface of the cover to receive the guide member and the filter. The guide member guides air induced into the dust container through a suction port to spirally rotate within the container body. A supporting member positioned within the container body supports the filter such that the filter supports the cover.

Owner:ACE ELECTRONICS CO LTD

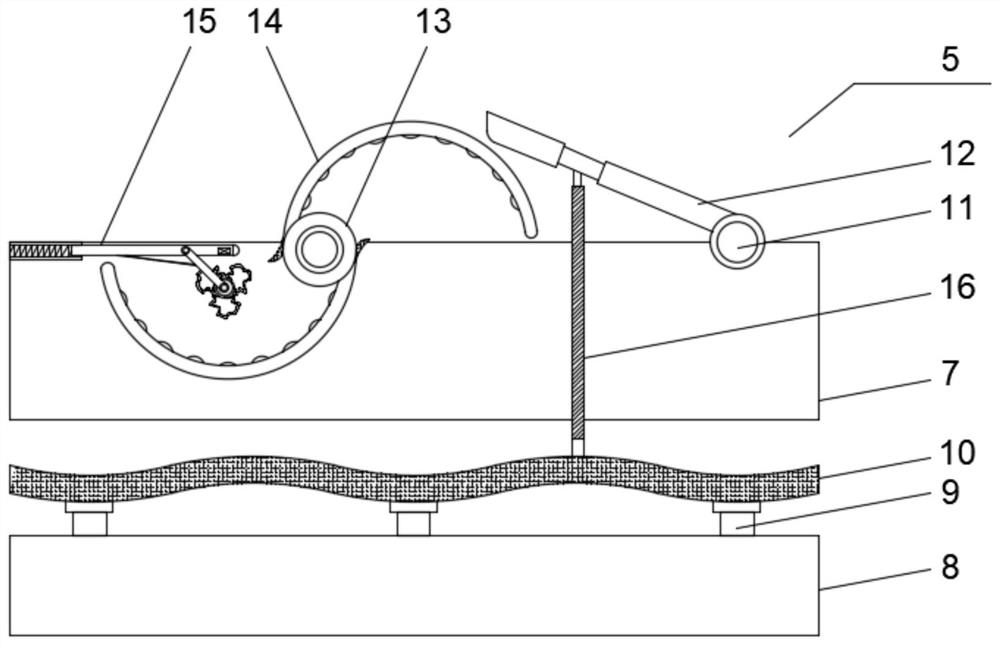

Suction brush for vacuum cleaner

ActiveUS8032985B2Prevent suction lossInhibit deteriorationMechanical cleaningPressure cleaningEngineeringMechanical engineering

A suction brush for a vacuum cleaner is provided. The suction brush a vacuum cleaner includes a brush main body connected to a cleaner main body and having a dust suction port provided on a bottom surface of the brush main body, first and second wheels rotatably engaged with both sides of the brush main body, and at least one hair removing unit, arranged in front of the suction port of the brush main body, for receiving rotation drive forces from the first and second wheels and raking up hair existing on a surface to be cleaned toward the dust suction port.

Owner:SAMSUNG ELECTRONICS CO LTD

Suction nozzle, and component mounting method and apparatus using the same

InactiveUS20060119118A1High bulk densitySmall widthPrinted circuit assemblingGripping headsEngineeringNozzle

In a suction nozzle (20), a sucking surface (60) is made larger in area than a to-be-sucked surface of a component (55) and is configured arbitrarily so long as a width (G1) between mutually-opposed sides parallel to a longer side (110) of the component to be sucked is smaller than a width (G2) in a direction parallel to a shorter side (111) of the component to be sucked. The suction nozzle sucks a component at its sucking surface, with a longitudinal axis (O) of the sucking surface (60) kept inclined with respect to a direction (J) in which the component is supplied.

Owner:HATA KANJI +3

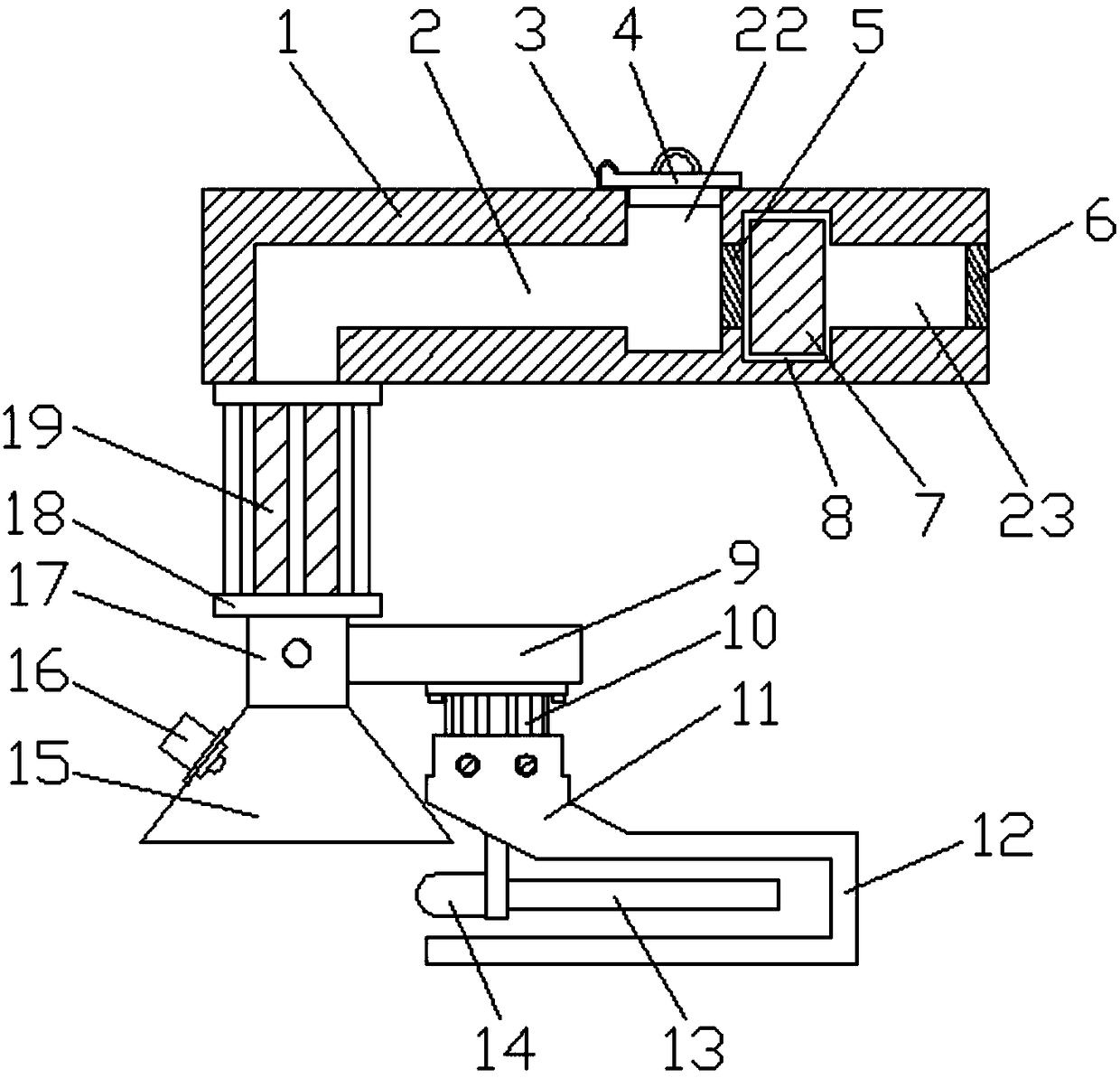

Edge trimming apparatus

PendingUS20210043473A1Prevent lowering of suction forceConstant depthEdge grinding machinesSemiconductor/solid-state device manufacturingWaferingKnife blades

An edge trimming apparatus includes a chuck table that causes a ring-shaped groove with an outer diameter smaller than the outer diameter of a wafer to communicate with a suction source to hold under suction a lower surface of the wafer by the ring-shaped groove, a cutting unit that rotates a cutting blade and annularly cuts a circumferential part of the wafer held by the chuck table, and a cleaning unit that cleans a region outside the ring-shaped groove in the upper surface of the table and the upper surface of the table including the ring-shaped groove. The cleaning unit is positioned to the region outside the ring-shaped groove in the upper surface of the table and the upper surface of the chuck table including the ring-shaped groove, and the chuck table is rotated to clean the ring-shaped groove and the upper surface.

Owner:DISCO CORP

Dust container of upright type vacuum cleaner and supporting structure for cover thereof

InactiveUS20070039127A1Reduce suction forcePrevent suction lossCleaning filter meansSuction filtersSuction forceEngineering

A dust container of an upright type vacuum cleaner, and a supporting structure for a cover of the dust container are disclosed. The dust container comprises a circular cover having a suction port and an exhaust port, a guide member attached to a lower surface of the cover to guide an air flow, a filter attached to a lower surface of the guide member, and a cylindrical container body provided to the lower surface of the cover to receive the guide member and the filter. The supporting structure for the cover comprises a supporting member positioned within the container body to support the filter such that the filter supports the cover. The cover has the suction port and the exhaust port, respectively, enhancing a suction force of the vacuum cleaner, and preventing deformation of the cover even when a vacuum degree is increased by operation of the vacuum cleaner.

Owner:ACE ELECTRONICS LTD

Adjustable wand for cleaning apparatus

ActiveUS9204774B1Prevent suction lossComfortable areaCarpet cleanersSuction hosesLocking mechanismSpray nozzle

An embodiment of this invention is an adjustable wand for a carpet cleaning apparatus wherein the upper tube telescopes within a lower tube and allows lengthening of the wand. The lower nozzle is adjustable in that it allows rotation about the wand axis and allows removal of the nozzle. The preferred means for adjustment is a cam lock mechanism that tightens an adjustment clamp around the wand upper tube or nozzle neck.

Owner:JACKSON CRAIG A

Suction brush for vacuum cleaner

ActiveUS20090019661A1ResistanceDrag minimizationMechanical cleaningPressure cleaningEngineeringMechanical engineering

A suction brush for a vacuum cleaner is provided. The suction brush a vacuum cleaner includes a brush main body connected to a cleaner main body and having a dust suction port provided on a bottom surface of the brush main body, first and second wheels rotatably engaged with both sides of the brush main body, and at least one hair removing unit, arranged in front of the suction port of the brush main body, for receiving rotation drive forces from the first and second wheels and raking up hair existing on a surface to be cleaned toward the dust suction port.

Owner:SAMSUNG ELECTRONICS CO LTD

Nozzle assembly of vacuum cleaner

A nozzle assembly of a vacuum cleaner is provided that includes a casing, a suction port, a drum brush, a fan, and a blocking plate. The drum brush is rotatably disposed in the casing so drum bristles hit a surface being cleaned. The fan is disposed in the casing to be rotated by air drawn in through the suction port so that the fan rotates the drum brush. The blocking plate is adjacent to the front of the fan to screen most of the fan except for a lower portion of the fan. The fan includes a circular fan body, a shaft member, and a plurality of blades. The inside edge of each of the blades is at a distance from the shaft member so that the drawn-in air passes through a space defined between the inside edge of each of the blades and the shaft member.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

Cleaner having brush height control apparatus

InactiveCN1572214APrevent suction lossImprove vacuuming effectSuction nozzlesForeign matterSuction force

A cleaner includes a suction motor mounted in a cleaner main body, and generating a suction force; a filter for collecting dust or filth sucked by the suction force generated at the suction motor; a suction head connected with the filter by a suction tube, and sucking dust and filth on a floor; a brush installed in the suction head so as to ascend / descend in a vertical direction, and sweeping dust and foreign substances into the suction head; and a brush height control apparatus installed in the suction head, and making the brush ascend / descend in a vertical direction. The cleaner having a brush height control apparatus can prevent deterioration of a suction force and improving cleaning performance by constantly maintaining a gap between the suction head and the floor.

Owner:LG ELECTRONICS INC

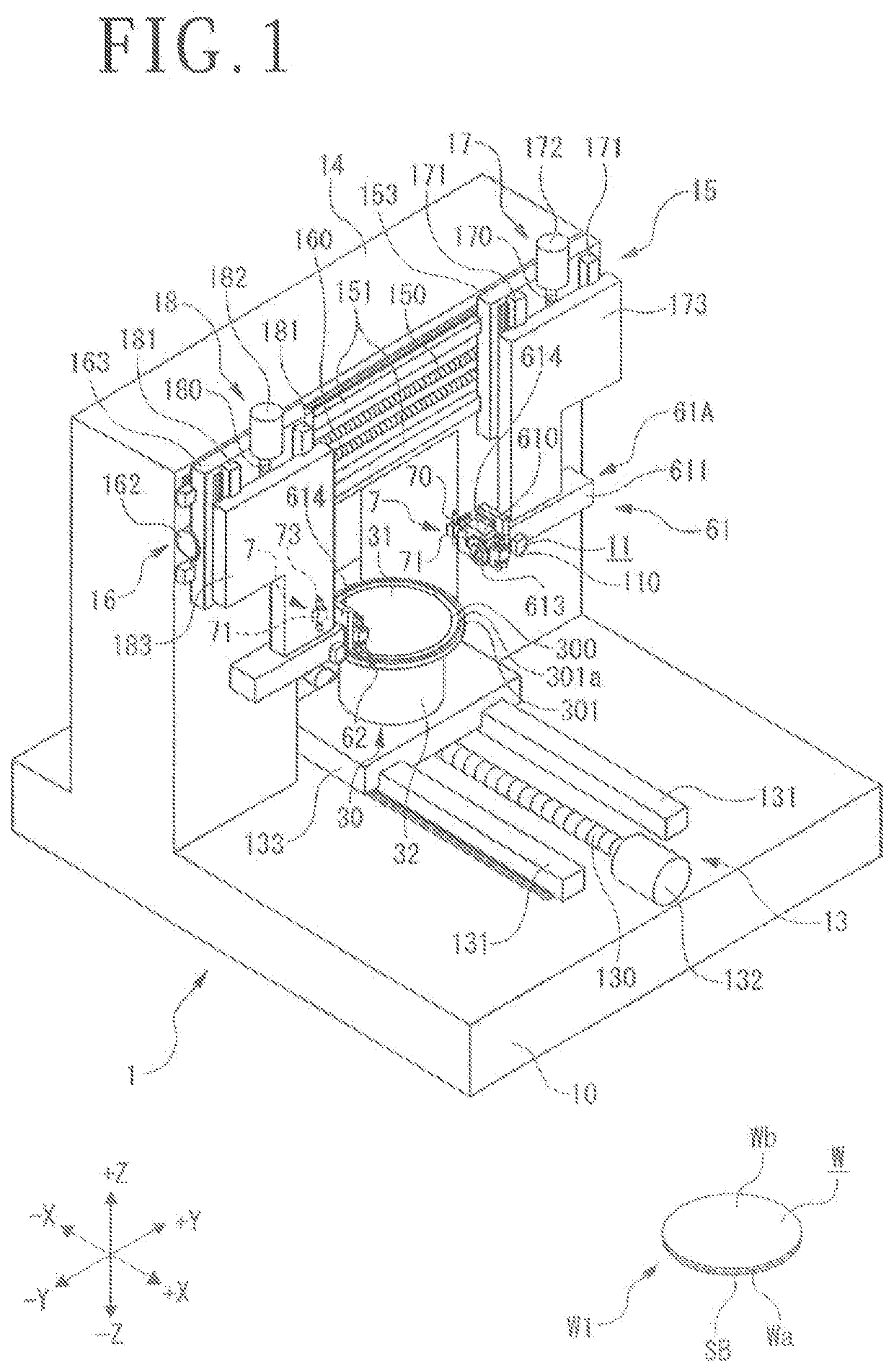

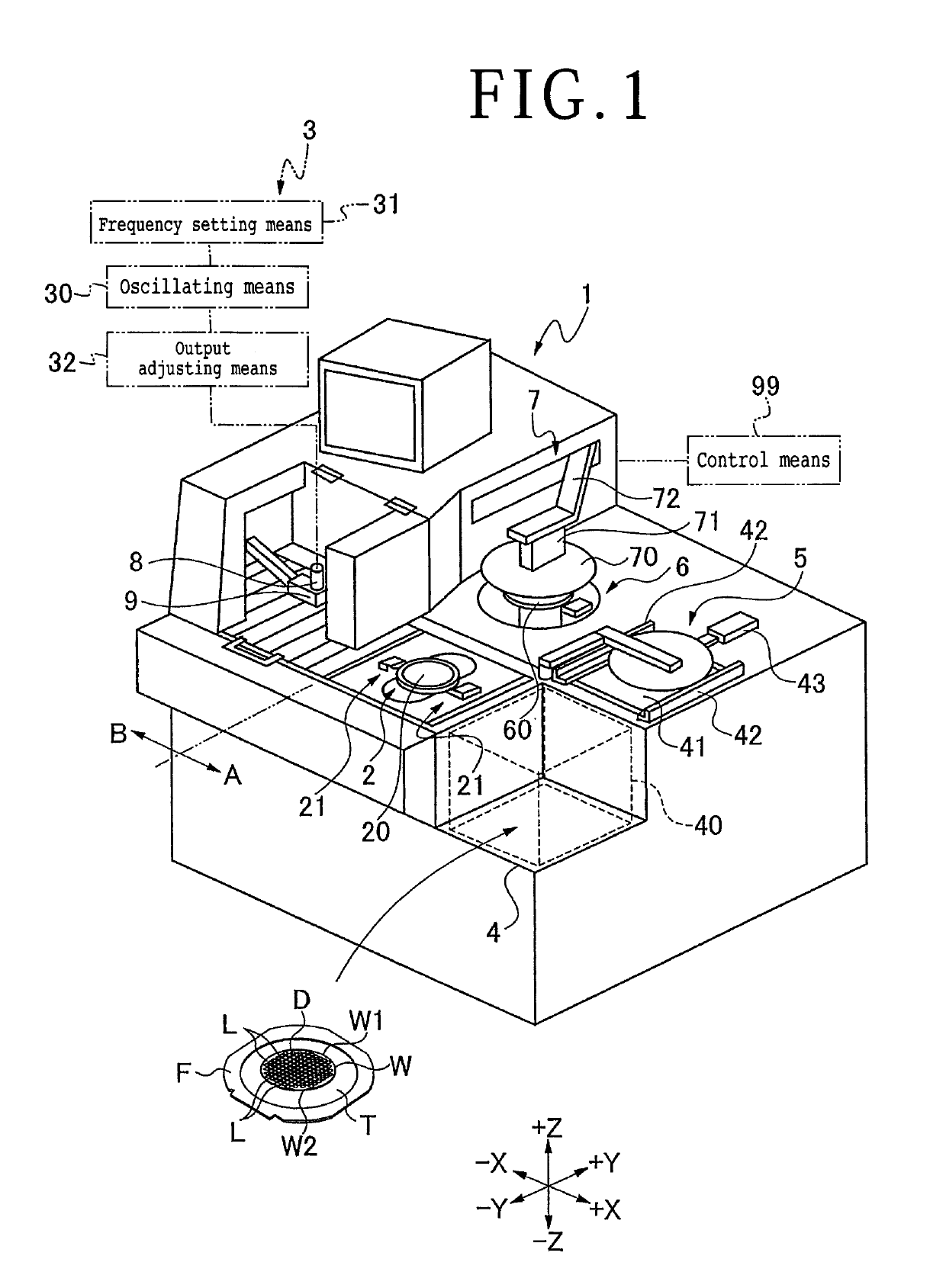

Laser processing apparatus

ActiveUS20170043432A1Suctioning capability of suction is prevented being loweredSolve the lack of suctionLaser beam welding apparatusLaser processingTrapping

A laser processing apparatus has a suction unit for suctioning debris. The suction unit includes a debris trapping chamber and a cleaning unit for cleaning the inside of the debris trapping chamber. The cleaning unit includes a shutter for closing an opening of the debris trapping chamber and a cleaning water supply port for supplying cleaning water to the debris trapping chamber when the opening thereof is closed. The shutter closes the opening of the debris trapping chamber, the suction unit exerts a suction through the suction port, and cleaning water is supplied from the cleaning water supply port to the debris trapping chamber and suctioned through the suction port to clean the inside of the debris trapping chamber.

Owner:DISCO CORP

Vacuum cleaner

InactiveUS7306640B2Reduce the possibilityRapid of suction forceCleaning filter meansCombination devicesSuction forceEngineering

A vacuum cleaner includes a first dirt separation unit and a second dirt separation unit. The first dirt separation unit has a first inlet port through which a suction air stream including dirt particles is introduced thereinto, and the second dirt separation unit has a second inlet port through which the air stream introduced into the first dirt separation unit is introduced into the second dirt separation. The first and the second inlet port are disposed such that they are not registered with each other. Accordingly, the dirt particles suctioned are separated in two stages, thereby decreasing the possibility of occlusion of a filter and rapid deterioration of a suction force.

Owner:PANASONIC CORP

Plant protection unmanned aerial vehicle for plant sampling

ActiveCN108750106AGuaranteed stabilityAvoid breakingWithdrawing sample devicesAircraftsPlant tissueDevices fixation

The invention discloses a plant protection unmanned aerial vehicle for plant sampling. The plant protection unmanned aerial vehicle includes a sample recovery case, a sample transporting slot, a driving motor, a blade protection rack fixing base, a sample collection shield, a camera and an unmanned aerial vehicle main body. Sample recovery case fixing racks are welded to bottom two sides of the unmanned aerial vehicle main body. The sample recovery case is welded to bottoms of the sample recovery case fixing racks. A device fixing rack is welded to one side of the bottom of the sample recoverycase. The bottom of the device fixing rack is provided with a device fixing base. The unmanned aerial vehicle main body can carry the sample recovery case and fly to a position above the center of anexperimental field, the driving motor drives a cutting blade to rotate so as to cut a plant and separate plant tissue from the plant, a draught fan works to generate rising air stream in a connectionpipe so as to inhale a sample into the sample recovery case, and through the structure, damage to plants in a sampling process for obtaining plant samples of an experimental field can be avoided.

Owner:QINGYUAN JUJIN TECH CO LTD

Intelligent dust collector convenient for cleaning filter net

InactiveCN108771511AEasy to cleanAvoid reduced suctionCleaning filter meansSuction cleaner storing devicesHydraulic cylinderEngineering

The invention discloses an intelligent dust collector convenient for cleaning a filter net. The intelligent dust collector comprises a dust collector body, a first reset spring and a collection box, wherein a motor is arranged in the dust collector body, an exhaust hole is formed in the upper part of the motor, an air inlet pipe is arranged on the right side of the motor, an air inlet is formed inthe left side of a filter box, a hydraulic cylinder is arranged above the filter box, and a movable plate is arranged below the hydraulic cylinder; the first reset spring is arranged inside the lowerend of a movable rod, a rotating shaft is arranged on the inner side of a movable block and penetrates through a rolling brush, and the rolling brush is arranged on the side surface of the filter net; and a second reset spring is arranged in the lower side wall of the dust collector body, and the collection box is arranged on the lower side of the filter box. According to the intelligent dust collector, the extrusion block extrudes the dust collector body by the through the second reset spring and is clamped with a clamping slot, so that the stability of the collection box is improved.

Owner:安徽省皖太电器有限公司

Vacuum cleaner

InactiveUS7311742B2Maintaining suction performancePreventing deterioration of suctioning forceCleaning filter meansCombination devicesEngineeringInhaled air

An electric vacuum cleaner includes an inlet port through which a suctioned air stream including dirt particles pass and a centrifugal separation member having a substantially circular space therein. The centrifugal separation member has a swirl portion to swirl the dust-laden suction air stream along an inner surface of the centrifugal separation member. By forming swirl passageway between the swirl portion and the inner surface of the centrifugal separation member, the high velocity swirling air stream can be made and consequently an efficiency of separating the dirt particles from the suction air and collecting the dirt particles can be improved.

Owner:PANASONIC CORP

Laser processing apparatus

ActiveUS10315273B2Improve rendering capabilitiesSolve the lack of suctionLaser beam welding apparatusLaser processingTrapping

A laser processing apparatus has a suction unit for suctioning debris. The suction unit includes a debris trapping chamber and a cleaning unit for cleaning the inside of the debris trapping chamber. The cleaning unit includes a shutter for closing an opening of the debris trapping chamber and a cleaning water supply port for supplying cleaning water to the debris trapping chamber when the opening thereof is closed. The shutter closes the opening of the debris trapping chamber, the suction unit exerts a suction through the suction port, and cleaning water is supplied from the cleaning water supply port to the debris trapping chamber and suctioned through the suction port to clean the inside of the debris trapping chamber.

Owner:DISCO CORP

Rotary compressor

ActiveUS20180340534A1Improve compressor performanceFlow loss minimizationRotary/oscillating piston combinations for elastic fluidsPositive displacement pump componentsInterior spaceRotary compressor

A rotary compressor includes a cylinder that is coupled to an inner space of a casing and that defines a compression space, a first bearing and a second bearing located at upper and lower sides of the cylinder, a roller disposed eccentrically with respect to an inner circumferential surface of the cylinder to vary a volume of the compression space based on rotation, and a vane inserted into the roller to rotate together with the roller, and drawn out toward the inner circumferential surface of the cylinder during the rotation of the roller to partition the compression space into a plurality of compression chambers. A suction passage communicating with the compression space is defined in the first bearing or the second bearing, and a suction port communicating between the suction passage and the compression space is defined on a side surface of the cylinder.

Owner:LG ELECTRONICS INC

Vertical type vacuum cleaner dust collector and the dust collector lid support structure

InactiveCN101242771APrevent suction lossImprove assembly efficiencySuction filtersEngineeringSuction force

A dust container of an upright type vacuum cleaner, and a supporting structure for a cover of the dust container are disclosed. The dust container comprises a circular cover (20) having a suction port (21) and an exhaust port (22), a guide member (30) attached to a lower surface of the cover 20 to guide an air flow, a filter (40) attached to a lower surface of the guide member (30), and a cylindrical container body (50) provided to the lower surface of the cover to receive the guide member (30) and the filter (40). The supporting structure for the cover comprises a supporting member (201) positioned within the container body to support the filter such that the filter supports the cover. The cover has the suction port and the exhaust port, respectively, enhancing a suction force of the vacuum cleaner, and preventing deformation of the cover even when a vacuum degree is increased by operation of the vacuum cleaner.

Owner:DAEWOO ELECTRONICS CO LTD

Milk box pricking needle assembly and milk suction method

The invention provides a milk box pricking needle assembly and a milk suction method. The milk box pricking needle assembly is provided with a pricking needle; a first oblique cut opening which can pierce a milk box is formed in the lower end of the pricking needle; and a plurality of strip-shaped receding surfaces in the vertical direction are arranged at the end, adjacent to the first oblique cut opening, of the outer wall of the pricking needle in the circumferential direction. When the pricking needle pierces the milk box, the first oblique cut opening pierces the milk box to form a pierced opening in the milk box; and a gap is formed between the receding surfaces and the pierced opening for air to enter, so that the suction is prevented from reducing when the pricking needle sucks milk in the milk box.

Owner:NINGBO MEROL COFFEE MACHINE

Processing apparatus

ActiveUS20160016331A1Increase in numberSuction force be lowerSemiconductor/solid-state device manufacturingGrinding feed controlProduct gasCheck valve

A processing apparatus includes a chuck table for holding a plate-like workpiece under suction. A suction unit is connected to the chuck table, and a processing unit is configured to process the workpiece while supplying processing water to the workpiece. The suction unit includes a first suction source, a first pipe providing fluid communication between the first suction source and the chuck table, a separator arranged in the first pipe, for separating a gas and a liquid drawn in from the chuck table, and a water discharging unit configured to discharge the liquid separated by the separator. The water discharging unit includes a second suction source, a second pipe providing fluid communication between the second suction source and a water discharge port of the separator, and a check valve arranged in the second pipe, for preventing a fluid from flowing from the second suction source to the separator.

Owner:DISCO CORP

Processing apparatus

ActiveUS9975274B2Increase the number ofAvoid flowSemiconductor/solid-state device manufacturingGrinding feed controlWater dischargeEnvironmental engineering

Owner:DISCO CORP

Nozzle assembly of vacuum cleaner

A nozzle assembly of a vacuum cleaner is provided that includes a casing, a suction port, a drum brush, a fan, and a blocking plate. The drum brush is rotatably disposed in the casing so drum bristles hit a surface being cleaned. The fan is disposed in the casing to be rotated by air drawn in through the suction port so that the fan rotates the drum brush. The blocking plate is adjacent to the front of the fan to screen most of the fan except for a lower portion of the fan. The fan includes a circular fan body, a shaft member, and a plurality of blades. The inside edge of each of the blades is at a distance from the shaft member so that the drawn-in air passes through a space defined between the inside edge of each of the blades and the shaft member.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

Milk box puncturing needle component and milk suction method

The invention provides a milk box puncturing needle component and a milk suction method. The milk box puncturing needle component comprises a puncturing needle, a first oblique notch can puncture a milk box and is formed in the lower end of the puncturing needle, and a first circular flange is formed at the position, close to the first oblique notch, of the outer wall of the puncturing needle. When the milk box is punctured by the puncturing needle, the first oblique notch punctures the milk box, so that a puncturing opening is formed in the milk box, the puncturing opening is enlarged when the first flange passes the puncturing opening, so that a gap is formed between the puncturing opening and the outer wall of the puncturing needle after the first flange enters the milk box, air entersthe milk box through the gap, and suction falling is avoided when milk in the milk box is sucked by the puncturing needle.

Owner:NINGBO MEROL COFFEE MACHINE

Wall surface polishing device for building decoration

InactiveCN112440169AAvoid Suction DropsImprove dust collection efficiencyGrinding machine componentsDispersed particle filtrationFiberSuction force

The invention discloses a wall surface polishing device for building decoration. The wall surface polishing device structurally comprises a polishing disc, a driving motor, a damping frame, a dust suction pipe and a holding handle, wherein the polishing disc is fixed at the bottom of the driving motor, the middle of the polishing disc is connected by the damping frame, the dust suction pipe penetrates through the center of the holding handle and is connected with the polishing disc, and a movable lug on the right side of the holding handle is fixed to the surface of the upper end of the polishing disc through welding. The wall surface polishing device has the beneficial effects that first-order rotary blades and second-order rotary blades are arranged in a staggered mode to form blades, the blades rotate along a positioning rotating shaft and a driving middle shaft under the action of wind power, a plurality of protrusions are arranged on the surfaces of the first-order rotary blades,the first-order rotary blades are hooked up when passing through the inner wall of a filter screen with attached fibers, the second-order rotary blades collect the hooked fibers and guide the fibers into a containing cavity, so that the dust suction efficiency is improved, and the situation that too much dust is generated inside due to the fact that the suction force is reduced due to long-time use is avoided.

Owner:吴碧江

Cyclone dust removal device for industrial dust removal

PendingCN112973997AGuaranteed cleanlinessAvoid stayingReversed direction vortexThermodynamicsEngineering

The invention provides a cyclone dust removal device for industrial dust removal, and relates to the field of industrial dust removal. The cyclone dust removal device comprises a dust removal barrel, one side of the dust removal barrel is provided with an air inlet pipe, the other side of the dust removal barrel is provided with an air outlet pipe, the top end of the dust removal barrel is provided with an air cylinder, and the inner side of the dust removal barrel is provided with an inner rotating pipe; the top end of the inner rotating pipe is fixedly connected with the air outlet pipe, the bottom end of the dust removal barrel is open, a separation layer is installed at the inner side of the dust removal barrel and comprises a contact layer and a stable layer, a plurality of connecting frames are installed at the inner side of the contact layer, and an isolation curtain is installed between the contact layer and the stable layer; and the outer side of the isolation curtain is fixedly connected with the connecting frames. According to the cyclone dust removal device, the problem that when the dust removal device is used, a large amount of dust is attached to the surface of the dust removal barrel, so that the dust cannot be separated through the gravity of the dust in the later period, and the equipment effect is reduced is effectively solved.

Owner:程婉莹

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com