Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

154results about How to "Precise suction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

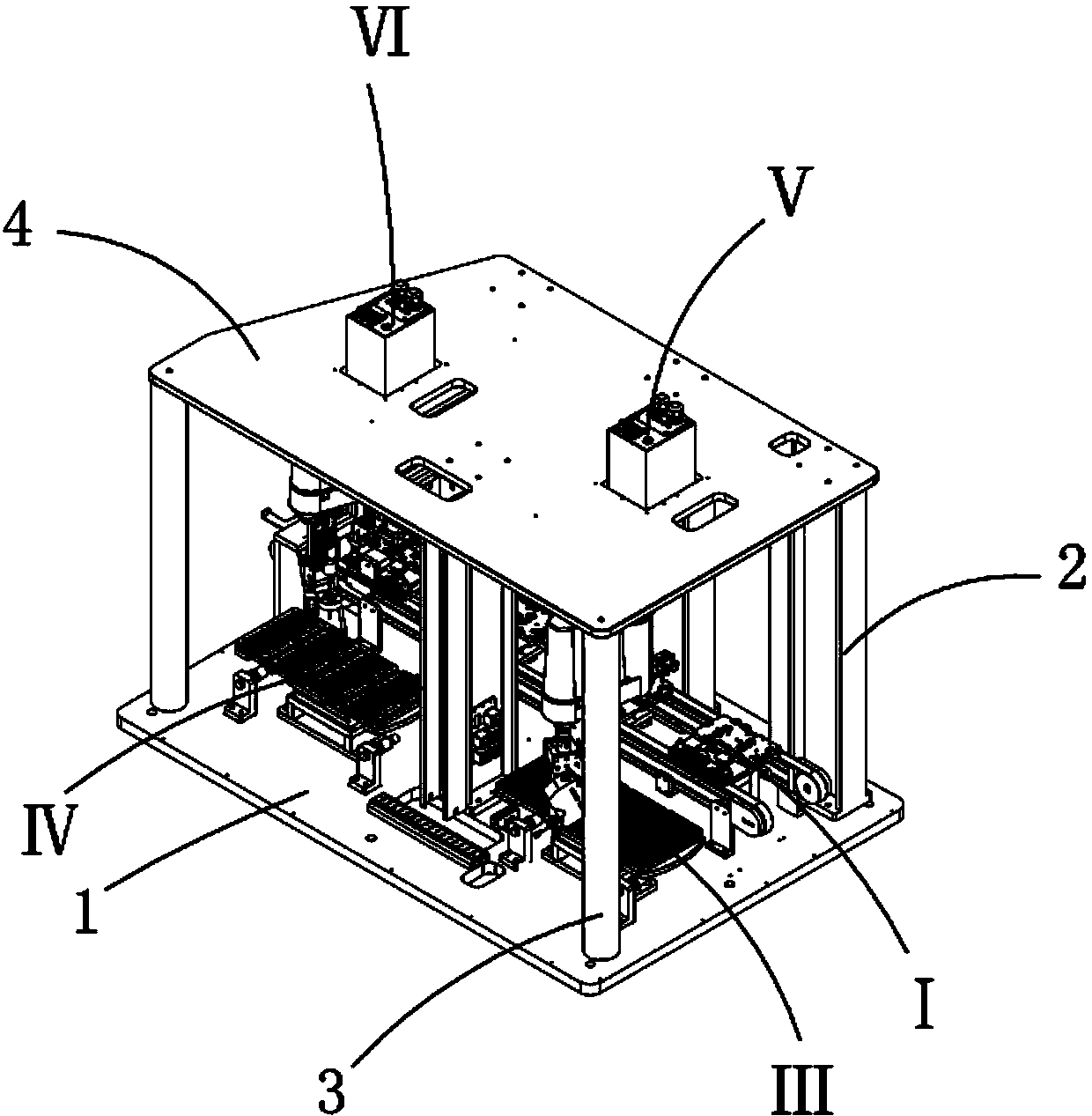

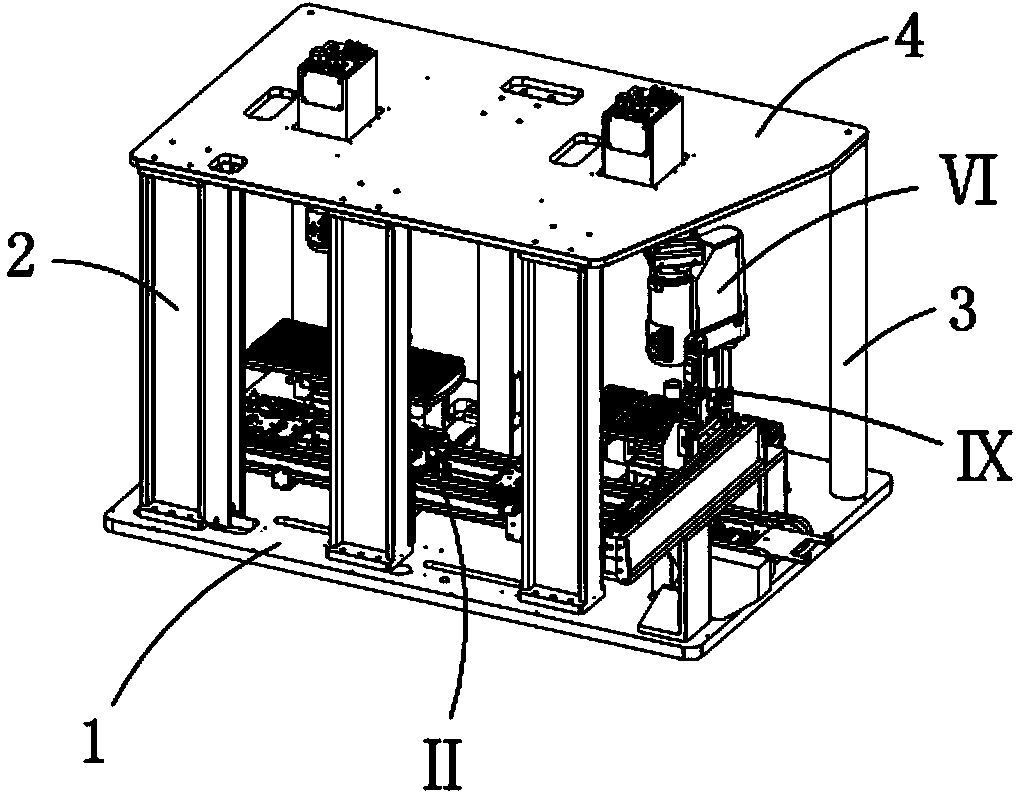

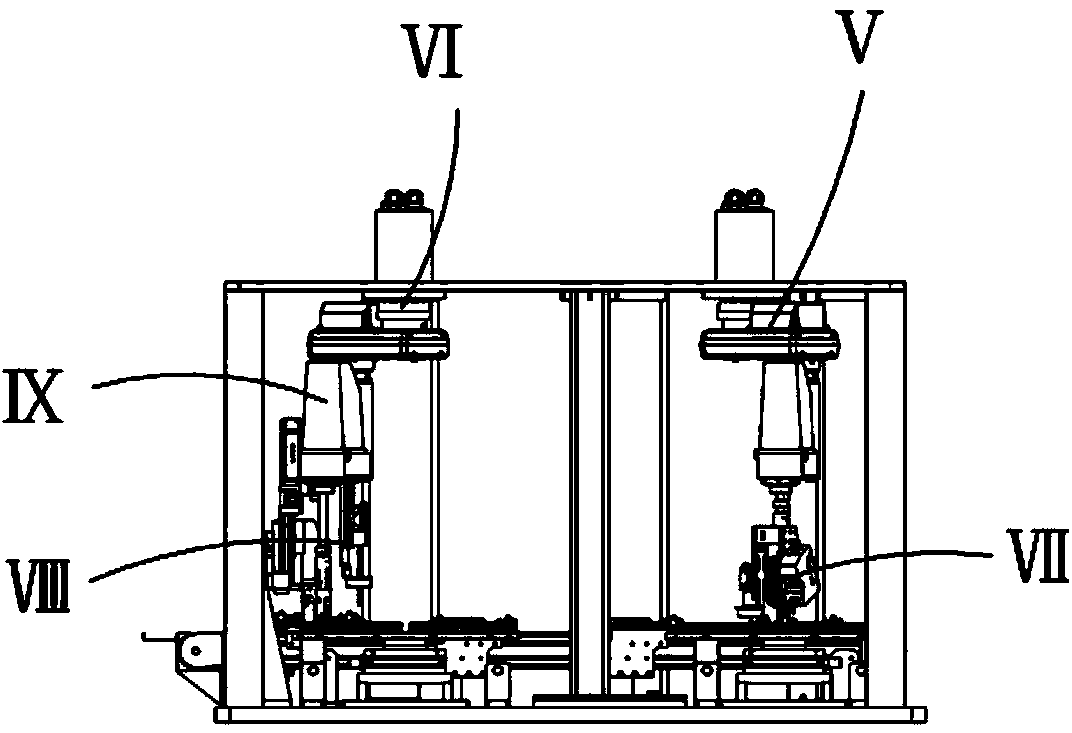

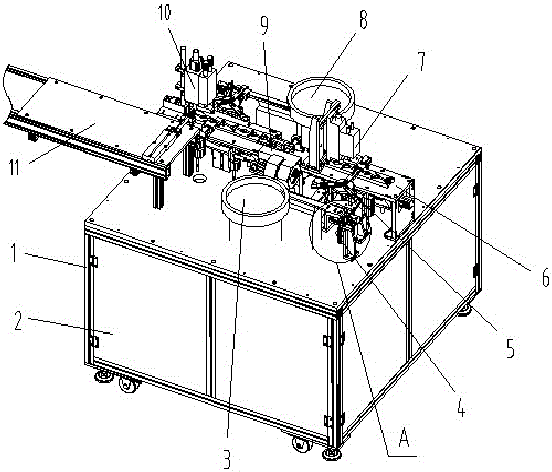

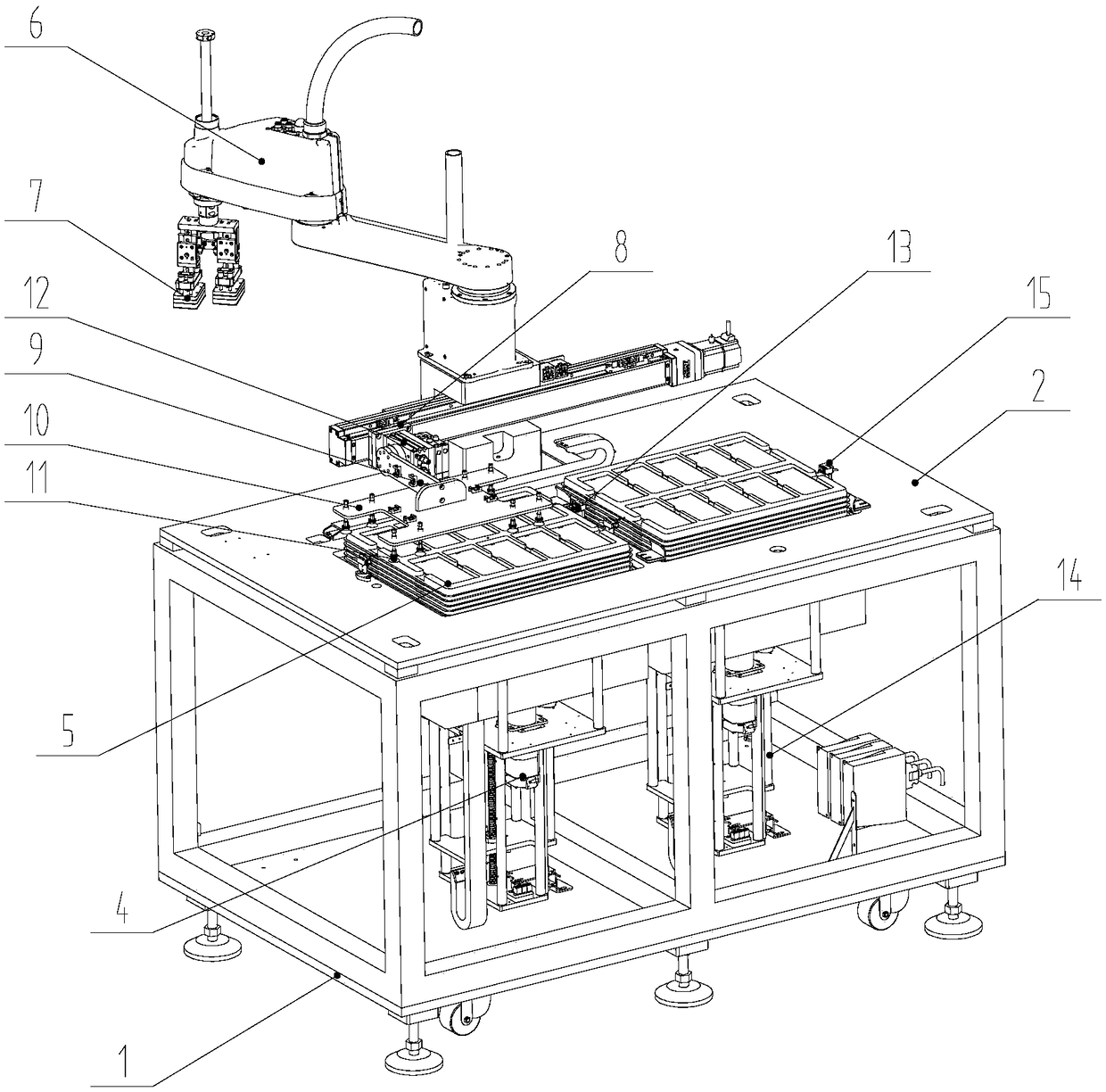

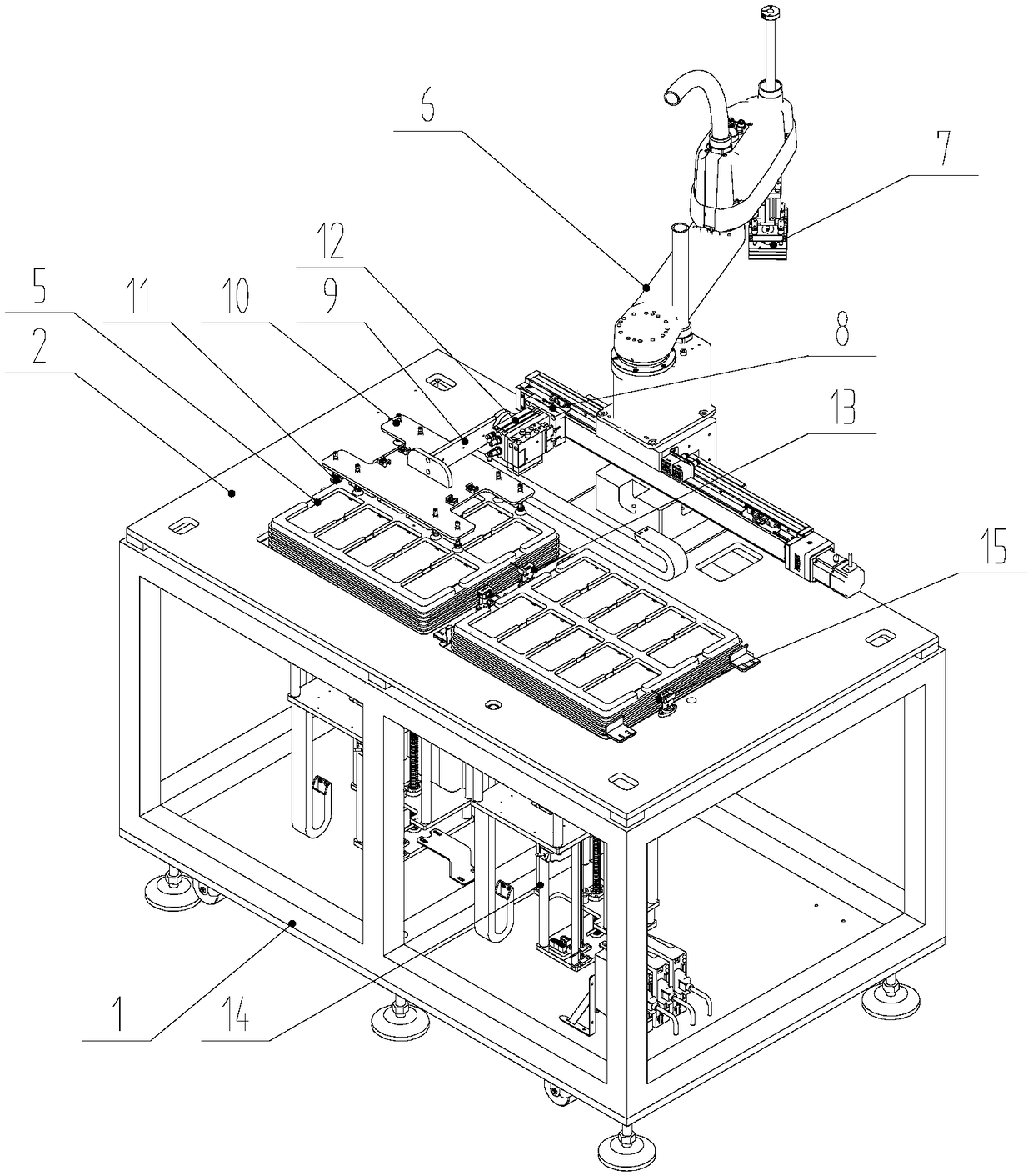

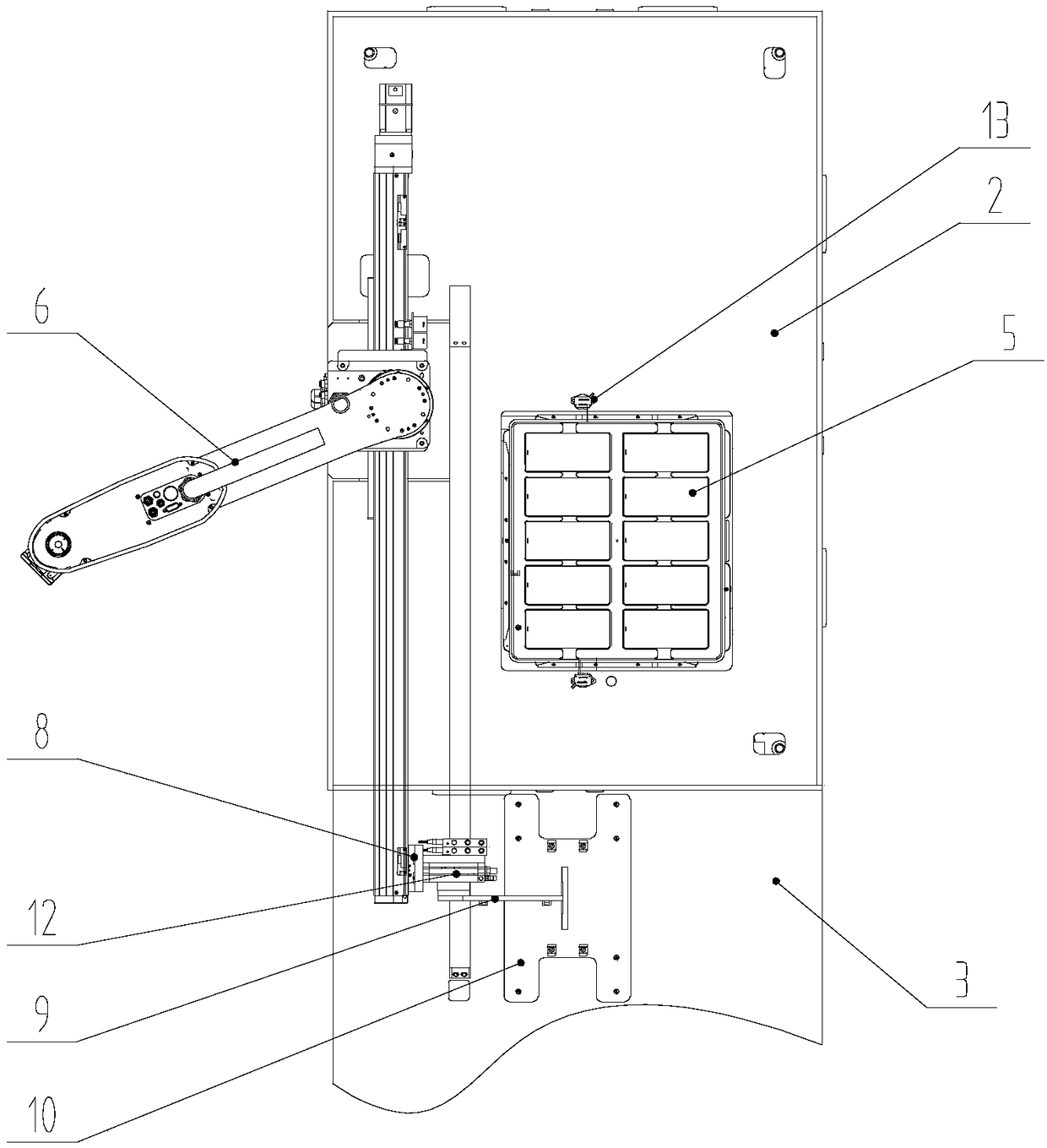

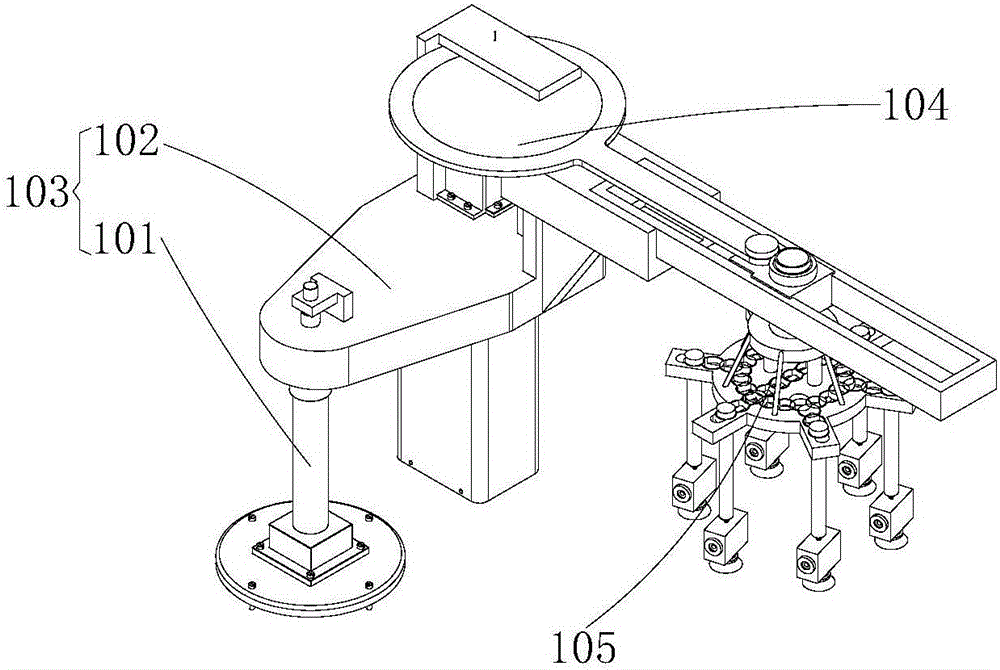

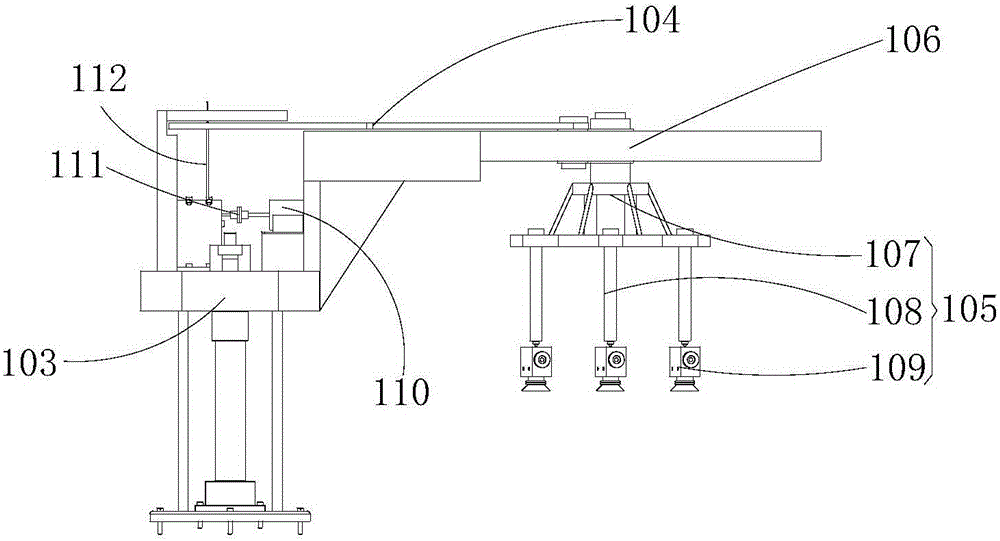

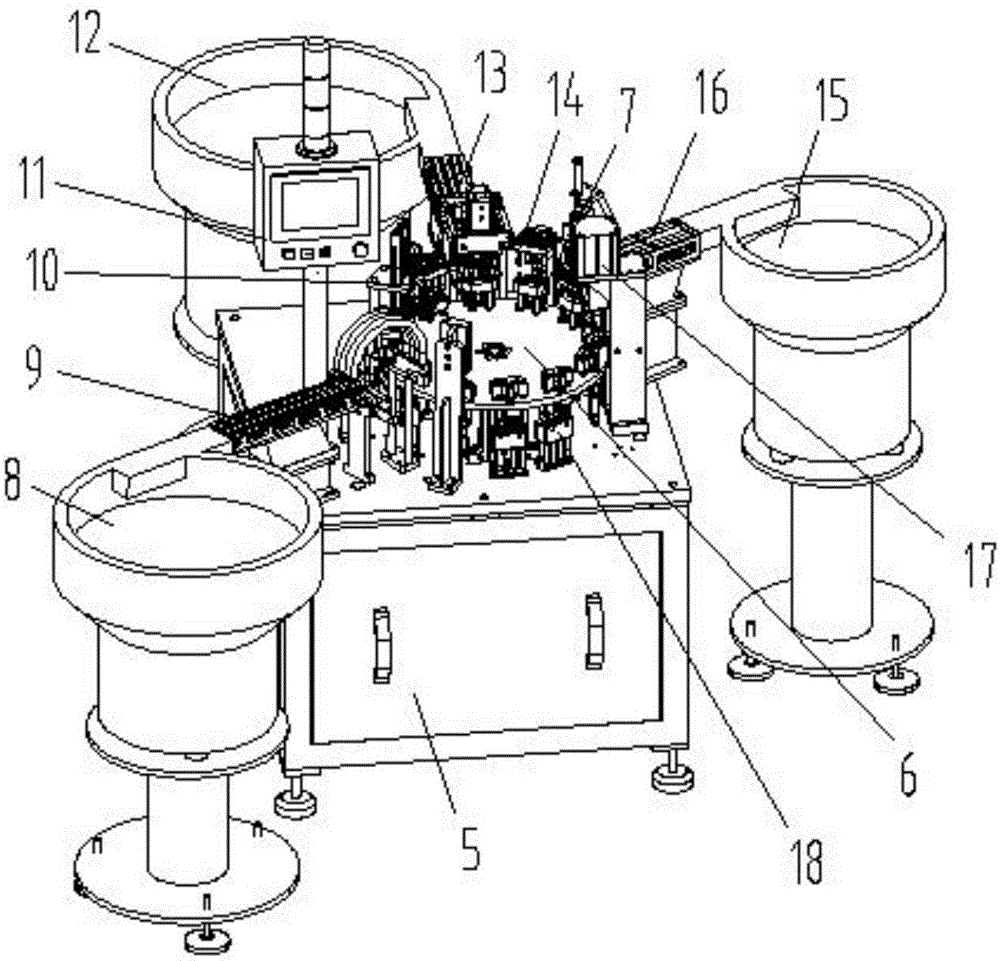

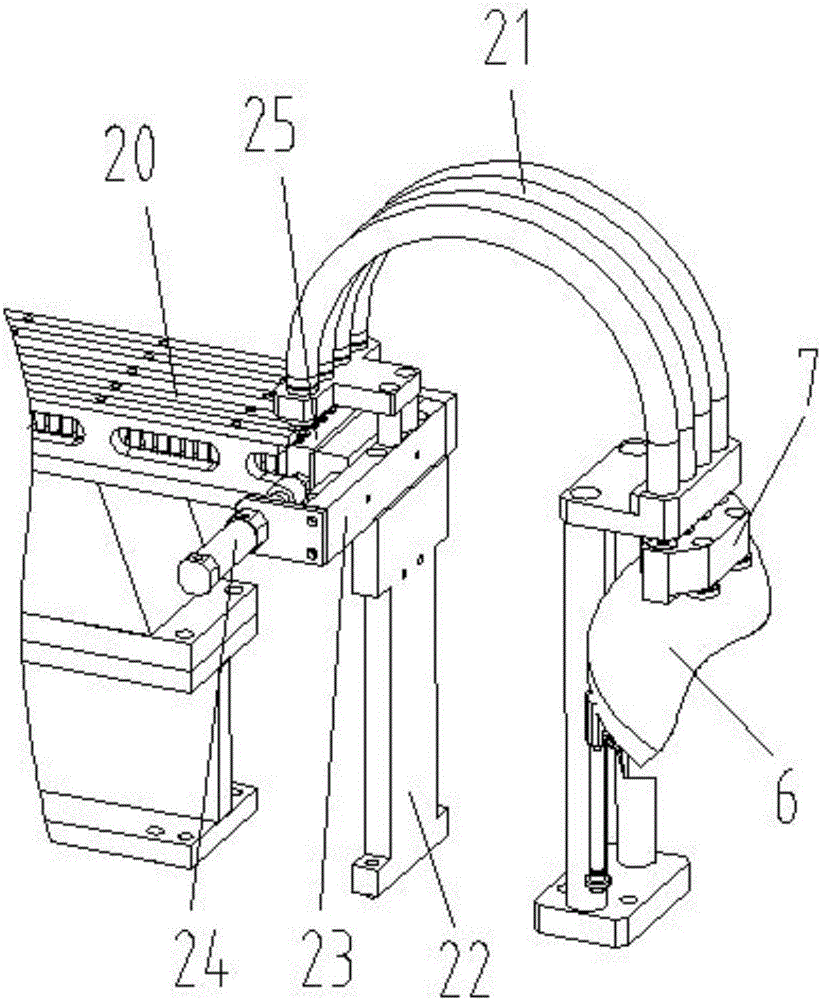

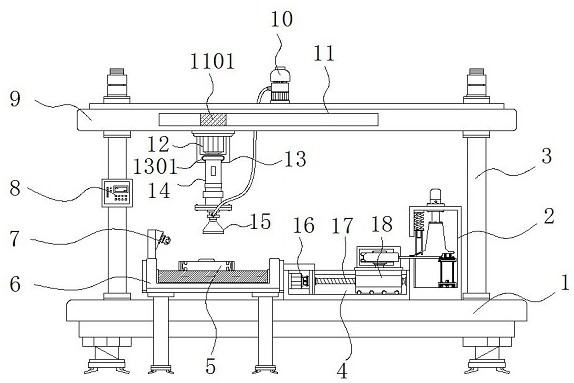

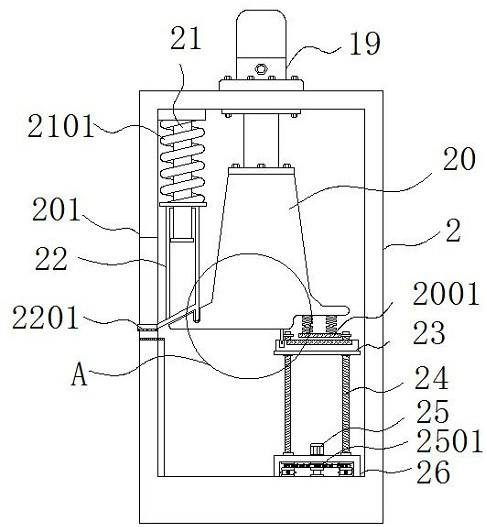

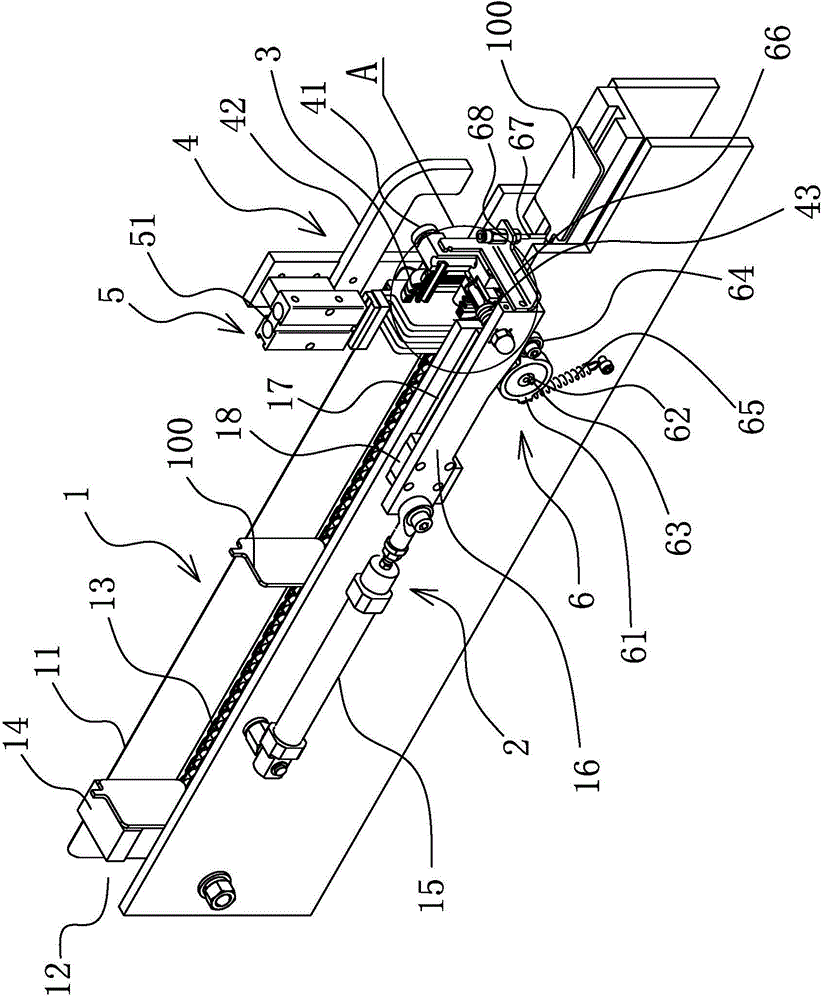

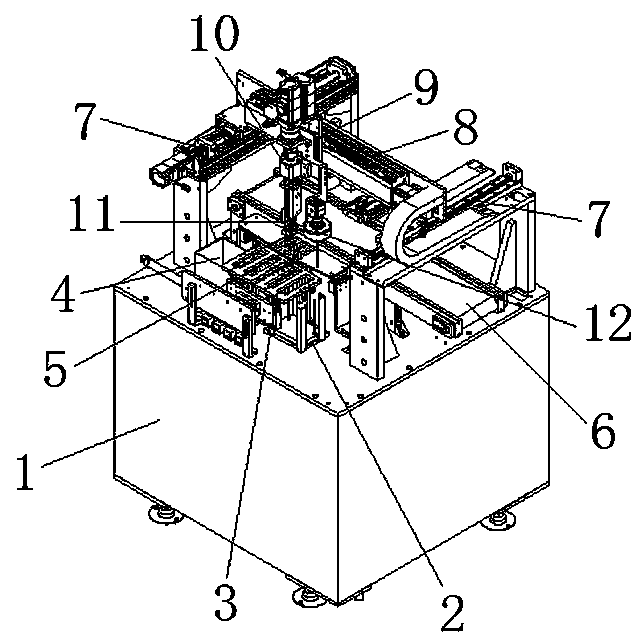

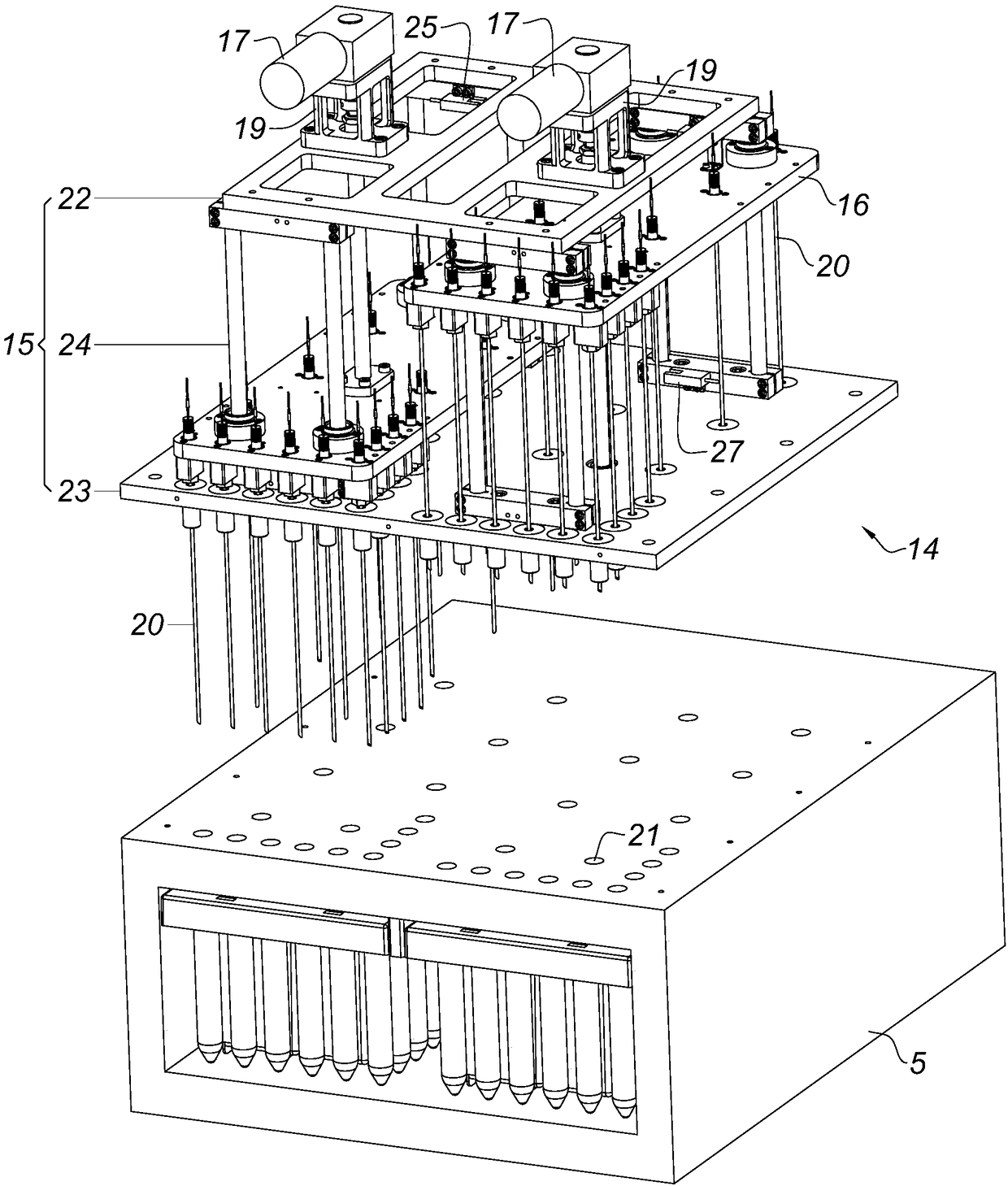

Full-automatic gasket assembler

The invention relates to a full-automatic gasket assembler. A top plate is connected on a baseplate via stand columns and support columns. An assembly line mechanism, a material disc mechanism a and a material disc mechanism b are mounted on the baseplate respectively. A mechanical arm a and a mechanism arm b are mounted on the top plate respectively. Products are placed on a product carrier which moves forwards via the assembly line mechanism. The mechanical arm a and the mechanical arm b respectively drive a gasket absorption mechanism a and a gasket absorption mechanism b to move, select needed gaskets from the material disc mechanism a and the material disc mechanism b and put the gaskets on the product carrier. The product carrier on the assembly line mechanism can be stopped in the process of a certain work, jacked up to be separated from the assembly line mechanism via a jacking mechanism on the assembly line mechanism and then detected and mounted relevantly. After detection and mounting, the product carrier is conveyed to be below a carrier carrying mechanism by the assembly line mechanism, and then clamped by a clamp on the carrier carrying mechanism to be transported to a preset place.

Owner:BOZHON PRECISION IND TECH CO LTD

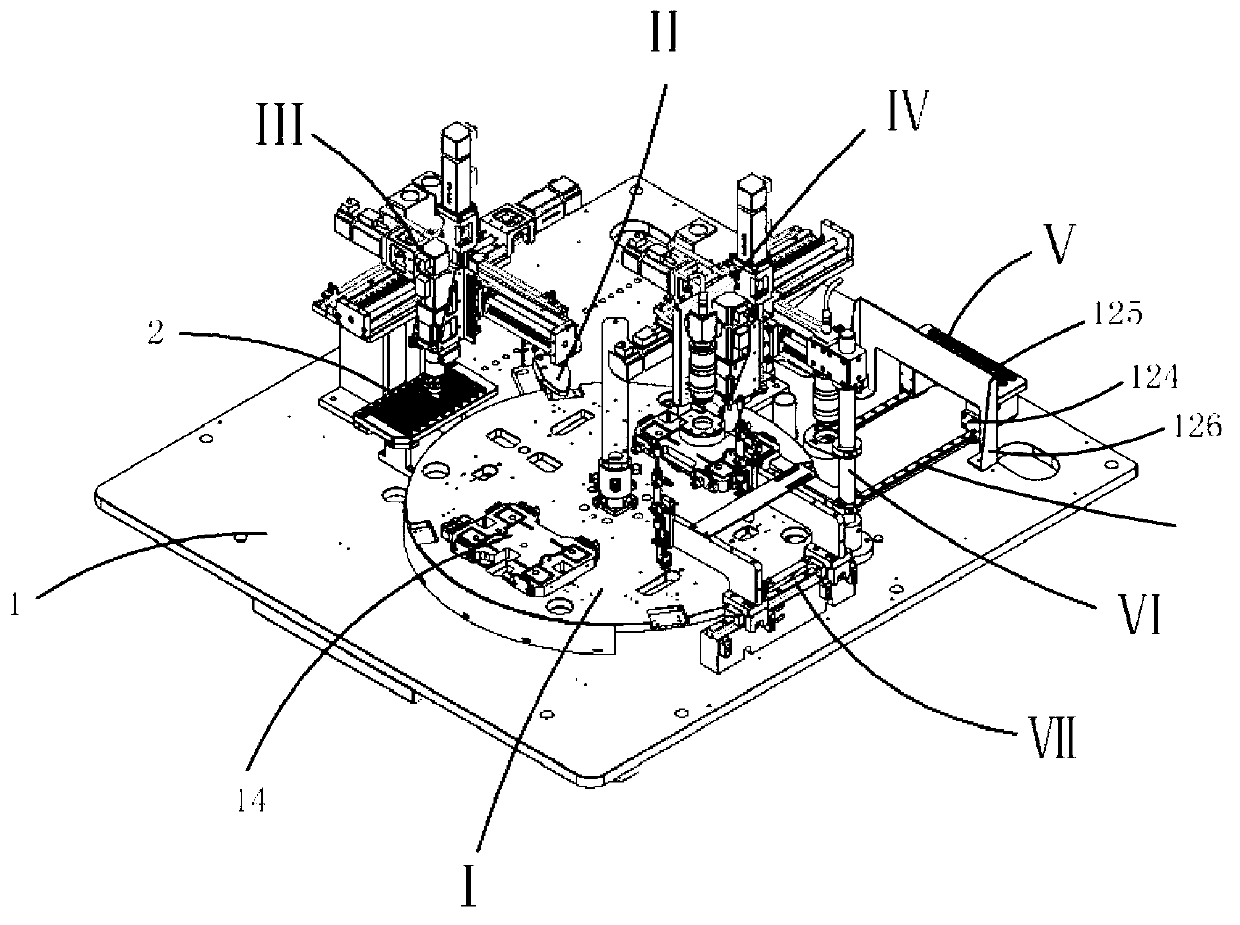

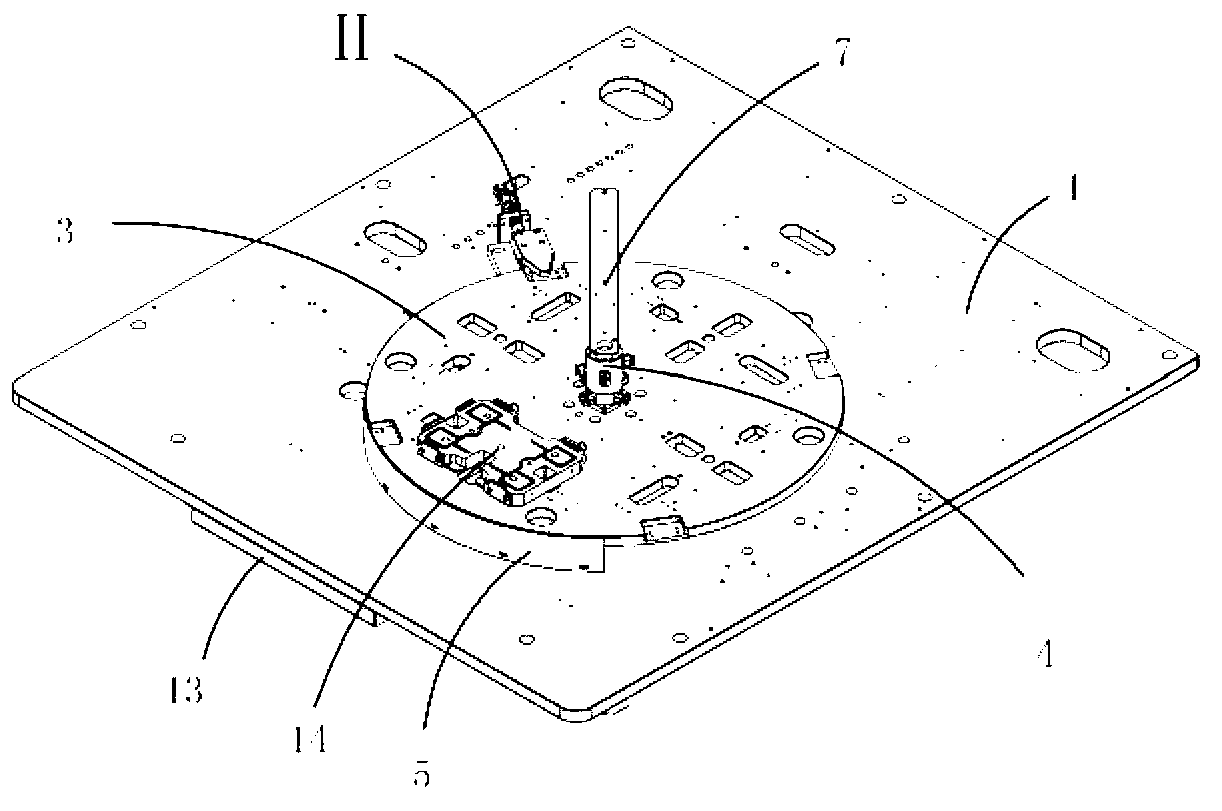

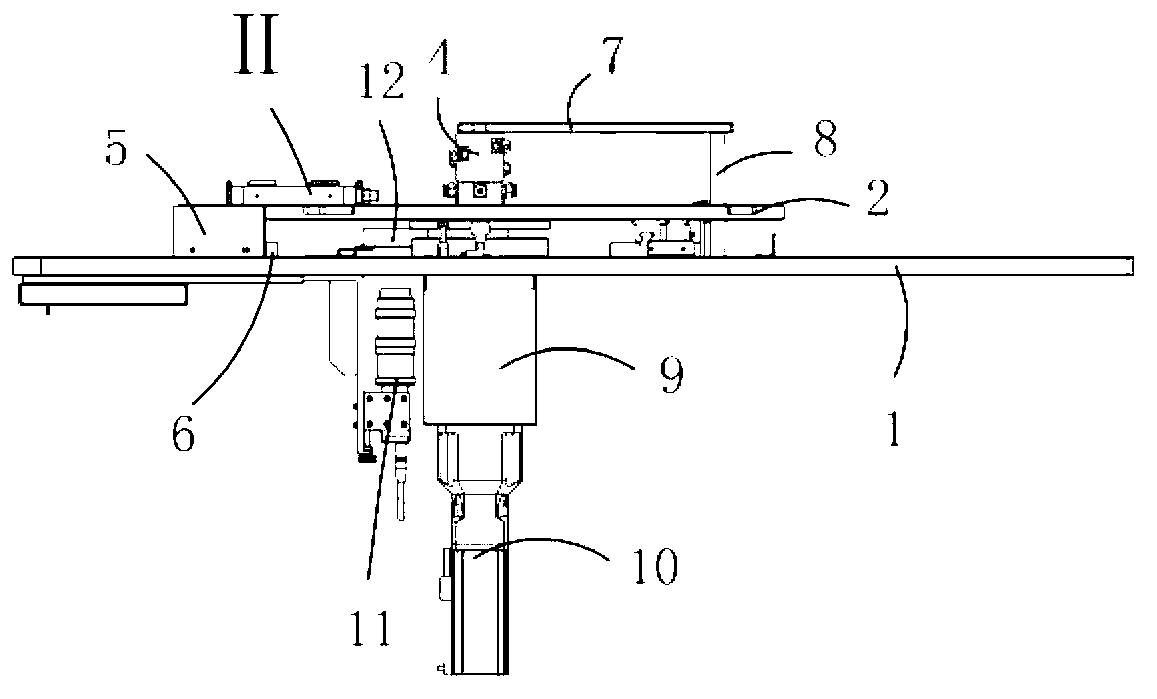

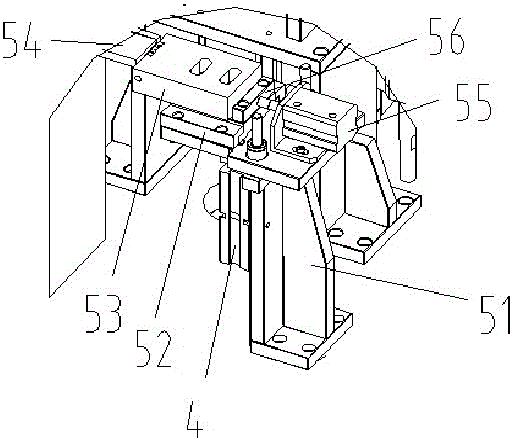

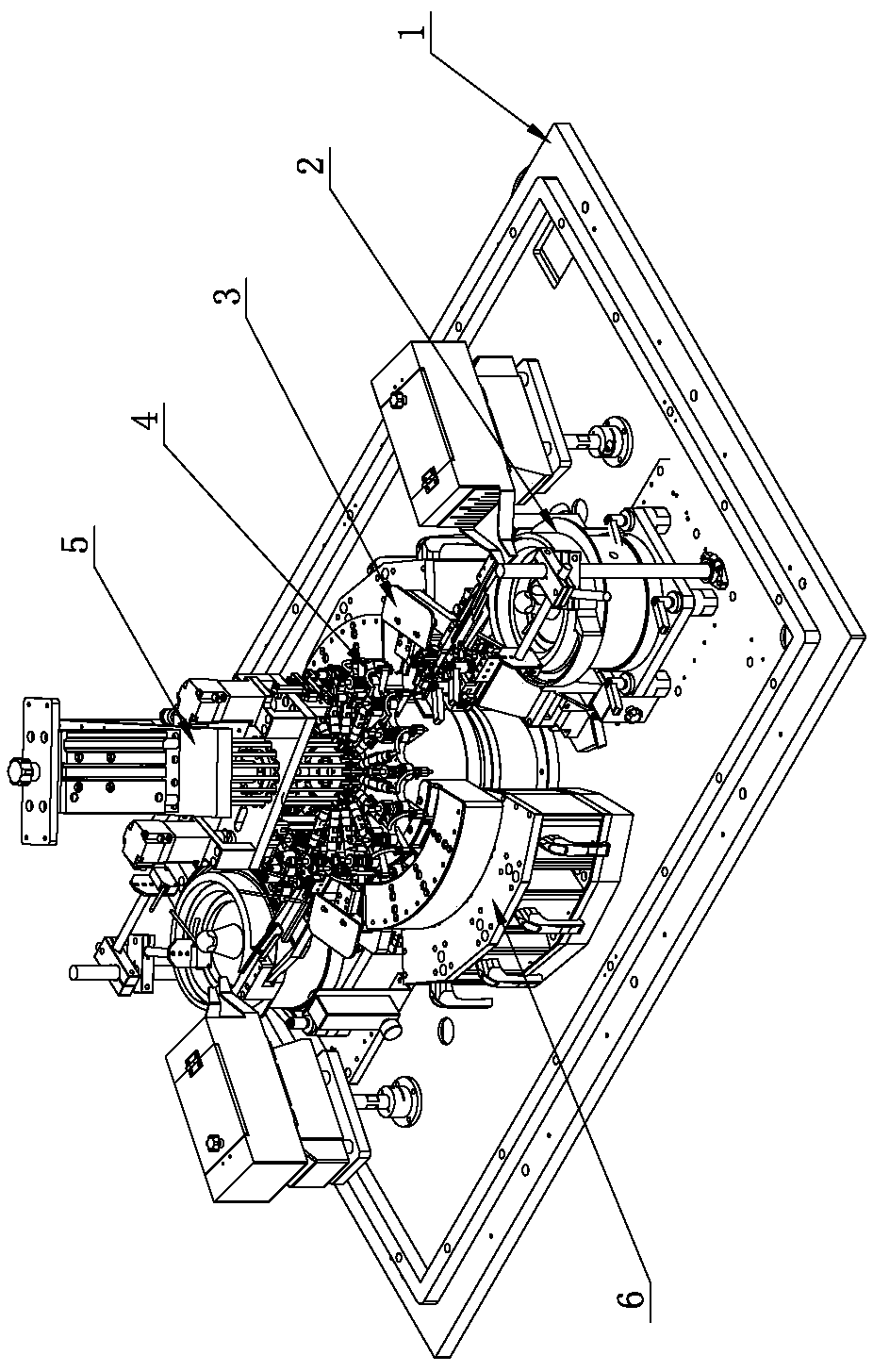

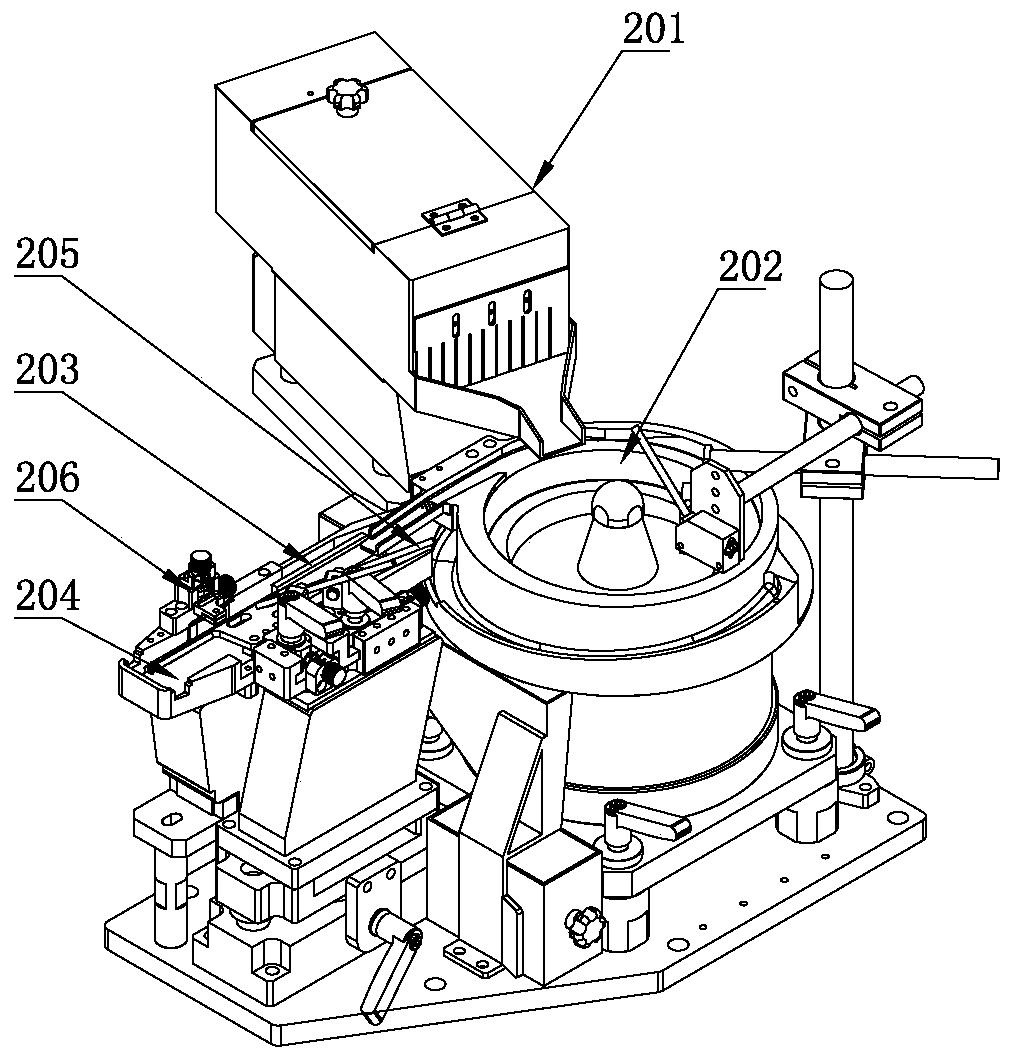

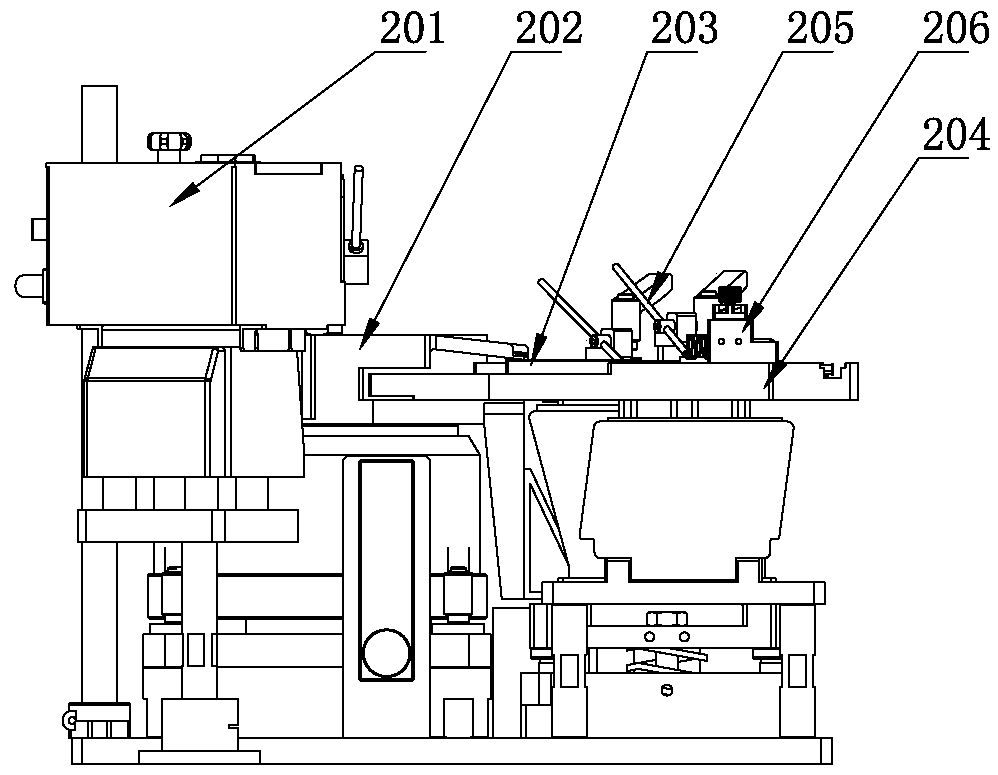

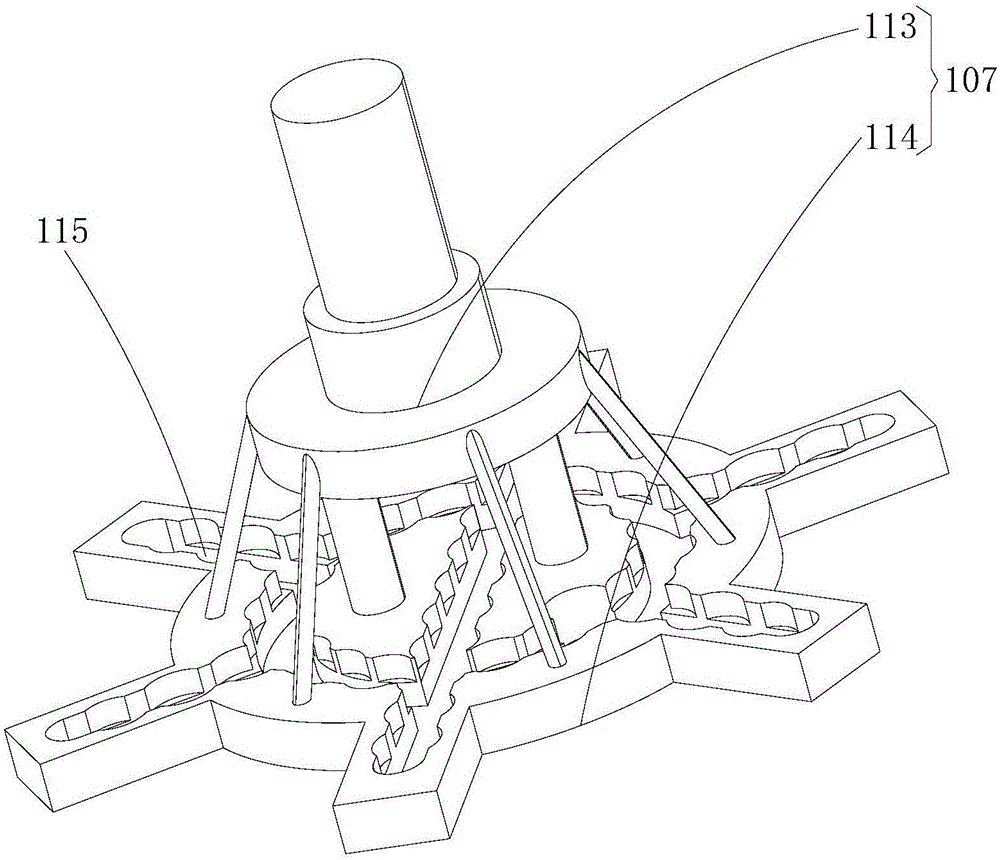

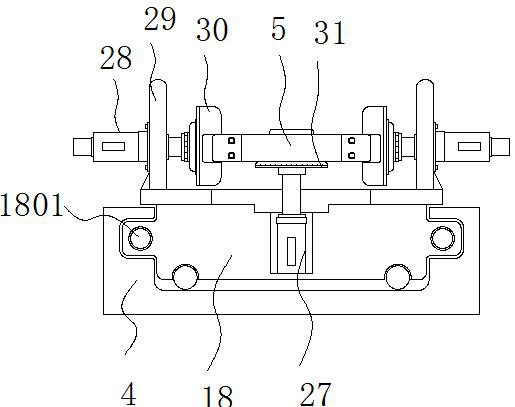

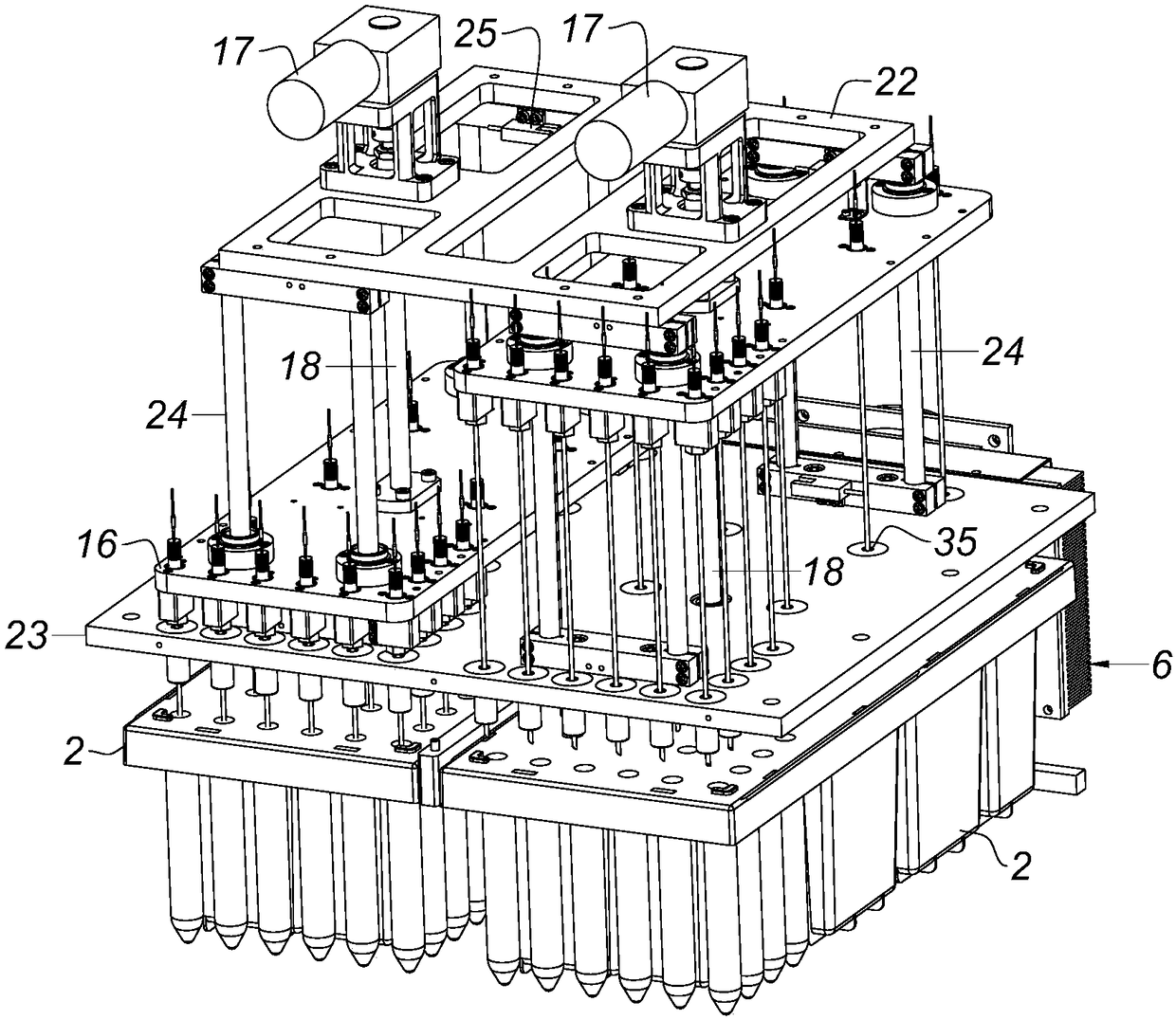

Part assembling machine

ActiveCN102990357AAccurate suctionMobile location is accurateAssembly machinesLarge buttonEngineering

The invention relates to a part assembling machine. The part assembling machine comprises a bottom plate, a turnplate mechanism, a turnplate locating mechanism, a button assembling mechanism, a fixing sheet assembling mechanism, a large button charging tray, a large fixing sheet charging tray component, a CCD (Charge Coupled Device) position correcting mechanism and a pressure maintaining mechanism, wherein the turnplate mechanism is arranged on the bottom plate; the button assembling mechanism is arranged at the left side of the turnplate mechanism; the large button charging tray is arranged on the bottom plate and is positioned below the button assembling mechanism; the turnplate locating mechanism is arranged above the left side of the bottom plate; the fixing sheet assembling mechanism is arranged at the upper end of the bottom plate, and the large fixing sheet charging tray component is arranged at the right side of the fixing sheet assembling mechanism; the CCD position correcting mechanism is arranged at the right upper side of the bottom plate; and the pressure maintaining mechanism is arranged at the right side of the bottom plate. The part assembling machine has the advantages that the turnplate is driven to rotate by a servo motor, parts can be assembled on standard operation positions by correction of the CCD position correcting mechanism and the turnplate locating mechanism, and the high automation of part assembling is completed through the coordination of all the mechanisms.

Owner:BOZHON PRECISION IND TECH CO LTD

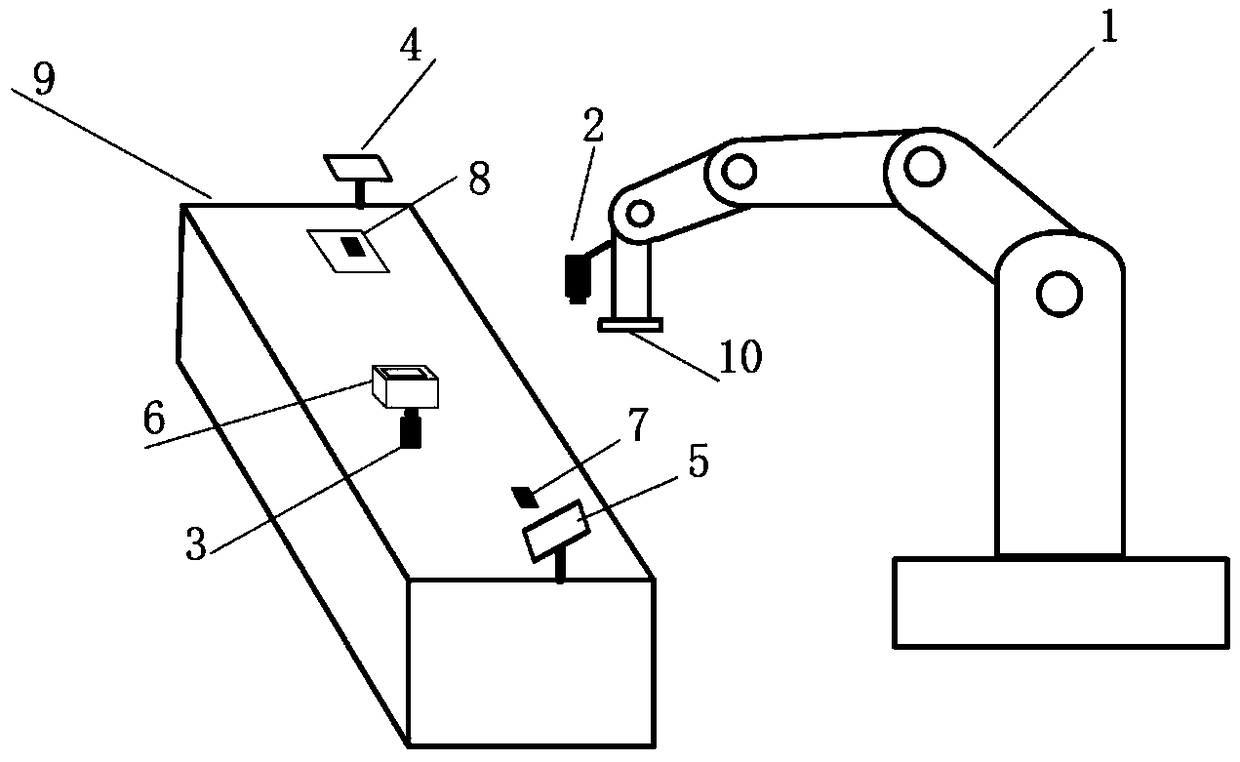

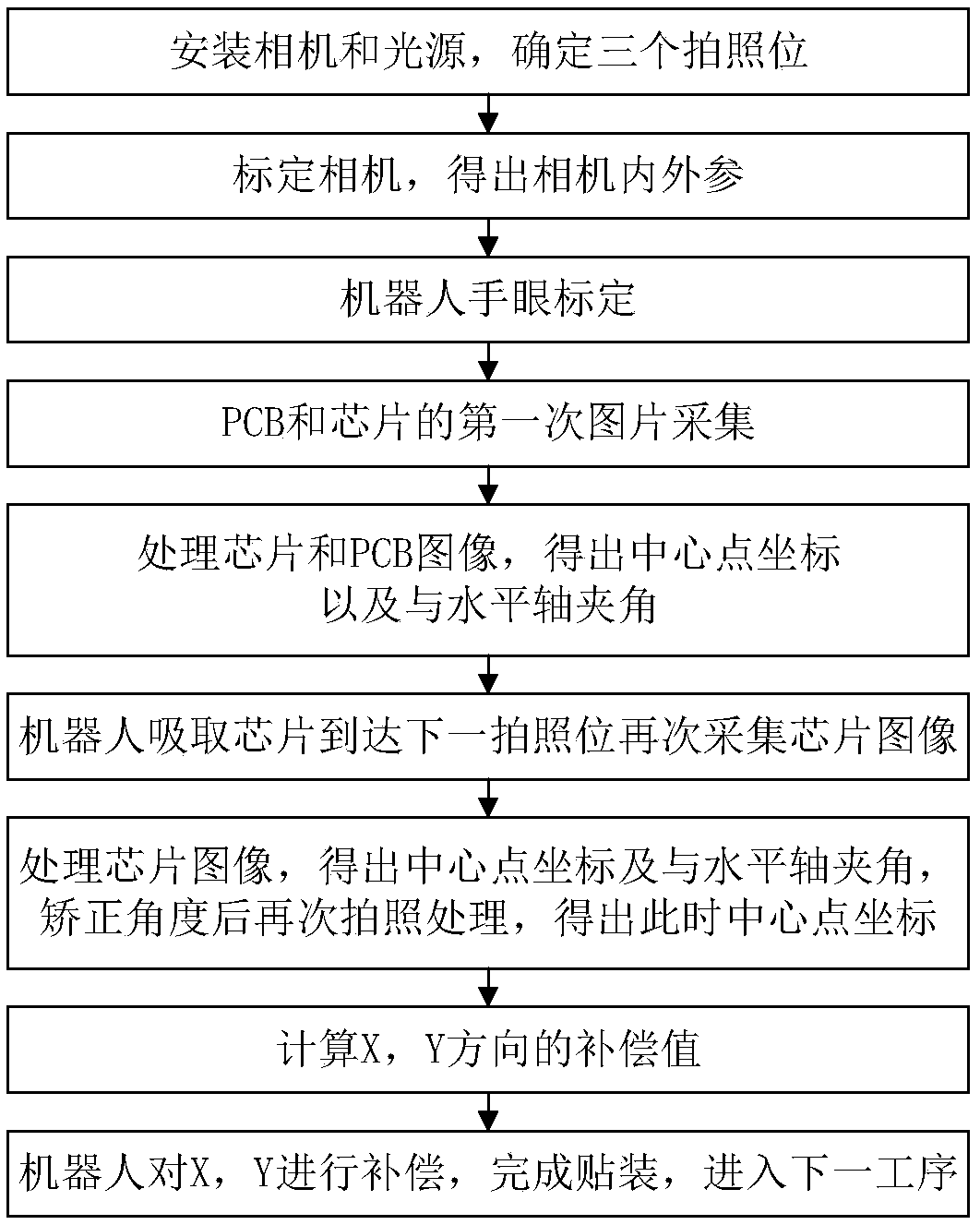

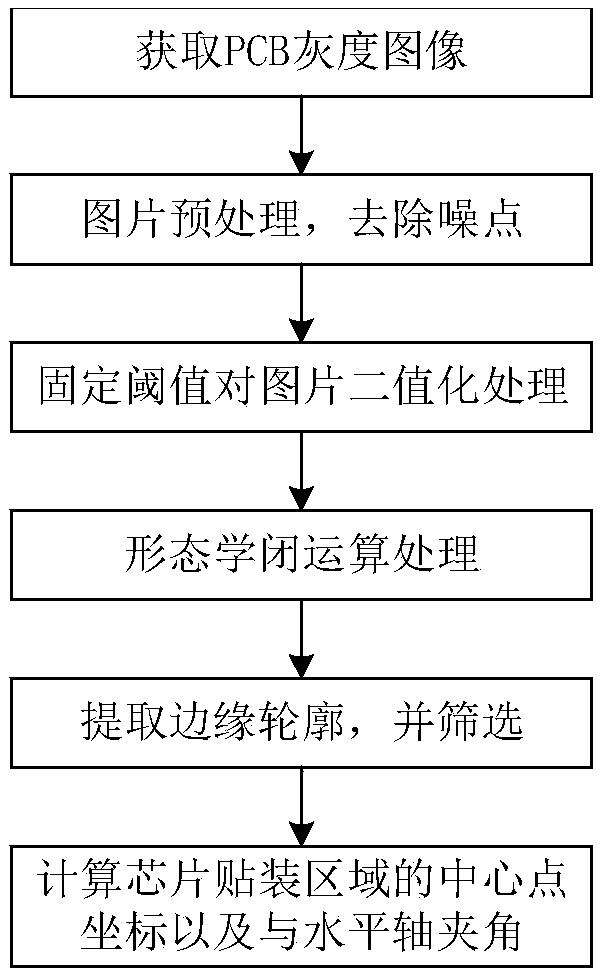

Chip mounting method and system for guiding robot vision

ActiveCN108766894AIncrease freedomIncrease flexibilitySemiconductor/solid-state device manufacturingAngular degreesHorizontal axis

The invention discloses a chip mounting method and system for guiding robot vision. A second industrial camera is additionally arranged in each of a PCB placing area and a chip placing area; a robot is used for absorbing chips to be moved to the positions of the second industrial cameras, the images of the absorbed chips are shot, and angular difference between the included angle of the chip mounting area and a horizontal axis and the included angle of the chips after the chips are absorbed and the horizontal axis is compared so that an end actuator rotates at the position of P3 in the angulardifference, angular compensation is carried out, compensation is carried out on X axis and Y axis, the sliding error generated when the chips are absorbed or in the moving process after the chips areabsorbed is improved, and the mounting precision is improved; moreover, a six-axis robot is adopted, due to the fact that the six-axis robot has higher degree of freedom and flexibility, the chip mounting inside workpieces such as cavities is realized, and flexible production is achieved; and then, first industrial cameras are arranged on the hands of the robot, and the robot is easier to move, so that the visual control method based on position is higher in flexibility and wider in range of application.

Owner:HUNAN UNIV

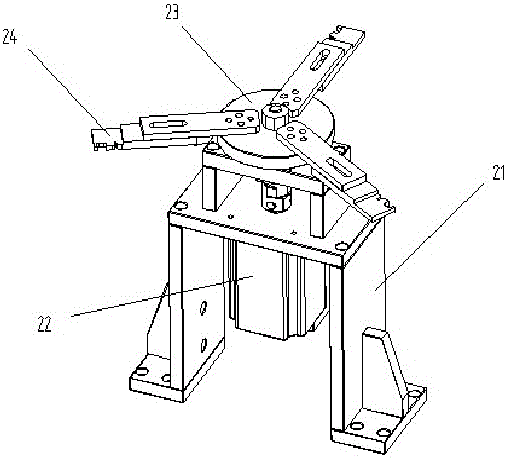

Reinforcing laminating device for flexible printed circuit board

ActiveCN103929889AImprove efficiencyReduce transit timePrinted circuit manufactureCcd cameraPrinted circuit board

The invention discloses a reinforcing laminating device for a flexible printed circuit board. The reinforcing laminating device for the flexible printed circuit board comprises a machine table, a reinforcing sheet manufacturing mechanism, a reinforcing sheet sucking mechanism and a locating assembly, wherein the reinforcing sheet manufacturing mechanism, the reinforcing sheet sucking mechanism and the locating assembly are all fixed to the table face of the machine table. The reinforcing sheet sucking mechanism comprises a rotation driving device, a rotating frame driven to rotate through the rotation driving device and at least three sucking assemblies for sucking reinforcing sheets, the rotating frame is mounted at the output end of the rotation driving device, the rotating frame is provided with ends, the number of the ends is identical to that of the sucking assemblies, and all the ends are symmetrically distributed relative to the rotating central axis of the rotating frame. Each sucking assembly is matched with one corresponding end in the vertical direction in telescopic sliding modes. A first CCD camera is further fixed to the table face of the machine table, and when one of the sucking assembly directly faces the first CCD camera, the other two sucking assemblies are located over the output end of the reinforcing sheet of the reinforcing sheet manufacturing mechanism and over the locating assembly respectively. The reinforcing laminating device for the flexible printed circuit board can efficiently laminate the reinforcing sheets on the flexible printed circuit board.

Owner:超音速人工智能科技股份有限公司

Diaphragm installation device

ActiveCN103551842APrecise suctionImprove stabilityMetal working apparatusMetal-working hand toolsManufacturing technologyLiquid-crystal display

The invention relates to the technical field of manufacturing of liquid crystal display devices and discloses a diaphragm installation device. The diaphragm installation device comprises a carrying mechanism, a sliding rail, a mechanical arm, a driving device and a control device, wherein the mechanical arm is slidably assembled onto the sliding rail and is used for sucking and putting down a diaphragm; a sucking cup device of the mechanical arm is provided with sucking cups for sucking the diaphragm and a blowing device for bending the insertion side of the diaphragm; the driving device is used for driving the mechanical arm to slide; the control device is used for controlling the mechanical arm and the driving device. The diaphragm installation device has the beneficial effects that the diaphragm is moved by the mechanical arm, is sucked by the sucking cups and the blowing device of the sucking cup device and is bent, and the bent diaphragm can be inserted into a plastic frame; meanwhile, each execution motion is carried out through the control device, automation is realized, and the production efficiency of a backlight module is improved.

Owner:BOE TECH GRP CO LTD +1

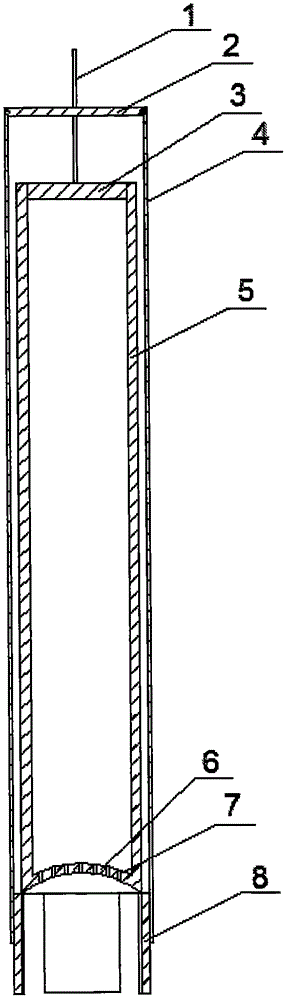

Thin tiny component sucking and placing device

InactiveCN105729438ASimple structureTechnically reasonableGripping headsEquipment useBiomedical engineering

The invention discloses a suction and release device for thin micro parts, which comprises a suction cylinder, a negative pressure pump is arranged at the top of the suction cylinder, a suction and release panel is arranged at the bottom of the suction cylinder, and several Suction hole, the suction hole is connected to the suction cylinder, and the suction and release panel is concave and has an arc surface structure. This device can not only freely suck and release thin and tiny parts, but also accurately position the sucked and released thin and tiny parts, so that It can accurately pick up and place thin and tiny parts during operation, which greatly reduces equipment failures caused by inaccurate placement of parts, improves the accuracy of equipment assembly, and thus greatly improves the use efficiency of the equipment; in addition, the suction at the bottom of the suction cylinder There are several suction holes on the placement panel, so that the suction cylinder can absorb thin and tiny parts of different structures, and a clamping device is added on the suction cylinder. The clamping device cooperates with the suction cylinder and can also clamp the suction cylinder with insufficient suction. Thin and tiny parts.

Owner:SUZHOU UNIV OF SCI & TECH

Button battery automatic butt-welding device

ActiveCN106808075ARealize the welding effectReduce human laborWelding/cutting auxillary devicesAuxillary welding devicesDistribution controlButt welding

The invention relates to a button battery automatic butt-welding device, which comprises a machine frame and a power distribution control box, wherein two groups of material conveying devices are arranged on the power distribution control box; in addition, an electrode butt-welding machine is arranged on each material conveying device; the two groups of material conveying devices are matched with an electrode piece feeding device; a turning device is arranged between the two groups of material conveying devices, and comprises a turning support frame arranged on the power distribution control box; a turning shaft is arranged on the turning support frame through a bearing seat; the two ends of the turning shaft are respectively connected with a mechanical hand clamping claw air cylinder and a gear in a sleeving way; a clamp post matched with a button cell arranged on the material conveying device is arranged on the mechanical hand clamping claw air cylinder; the gear is engaged with a pull strip arranged on the pull strip installing seat; the pull strip installing seat is connected with a turning air cylinder. The two groups of air conveying devices are installed; a negative electrode butt-welding part and a positive electrode butt-welding part are respectively arranged on the two groups of material conveying devices; in addition, the two groups of material conveying devices are combined through a turning device; the continuous material conveying welding effect is realized; the labor work is reduced; the production efficiency is improved.

Owner:江苏瑞鑫数控装备有限公司

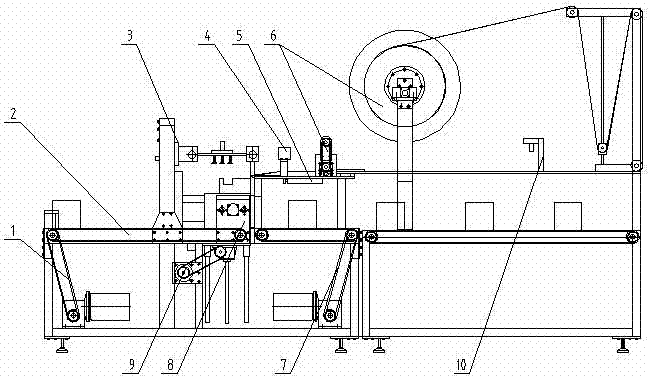

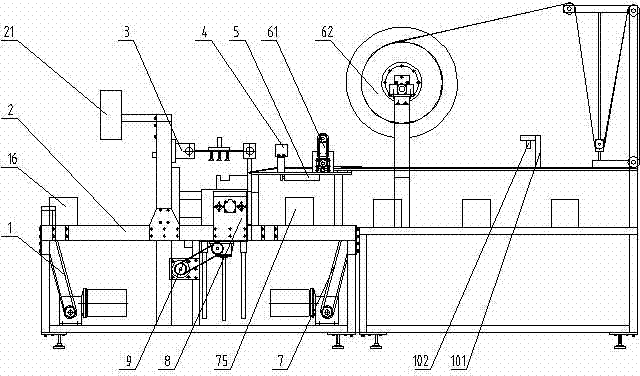

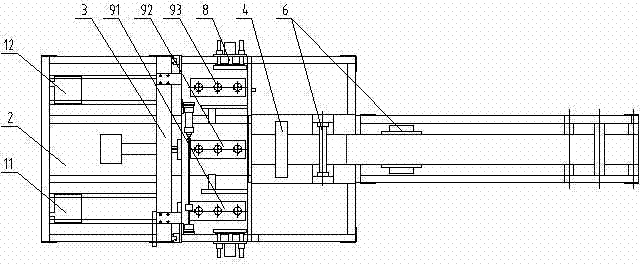

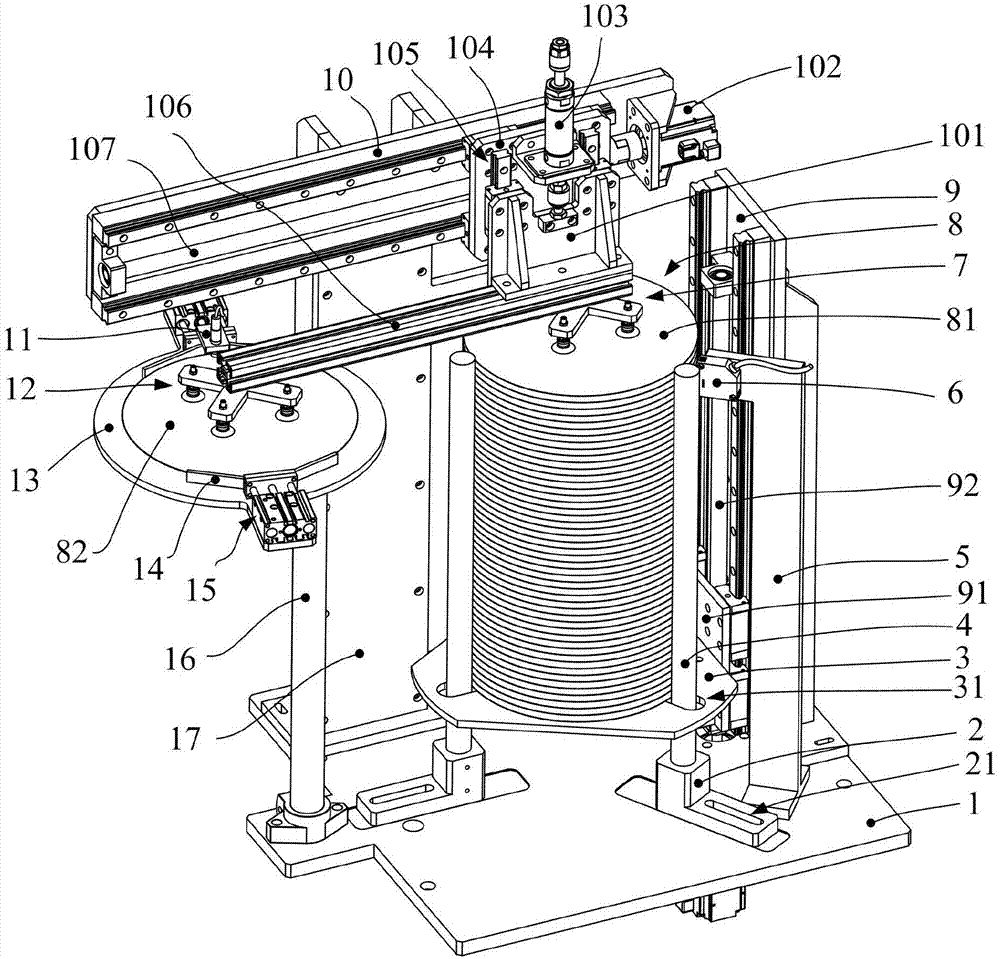

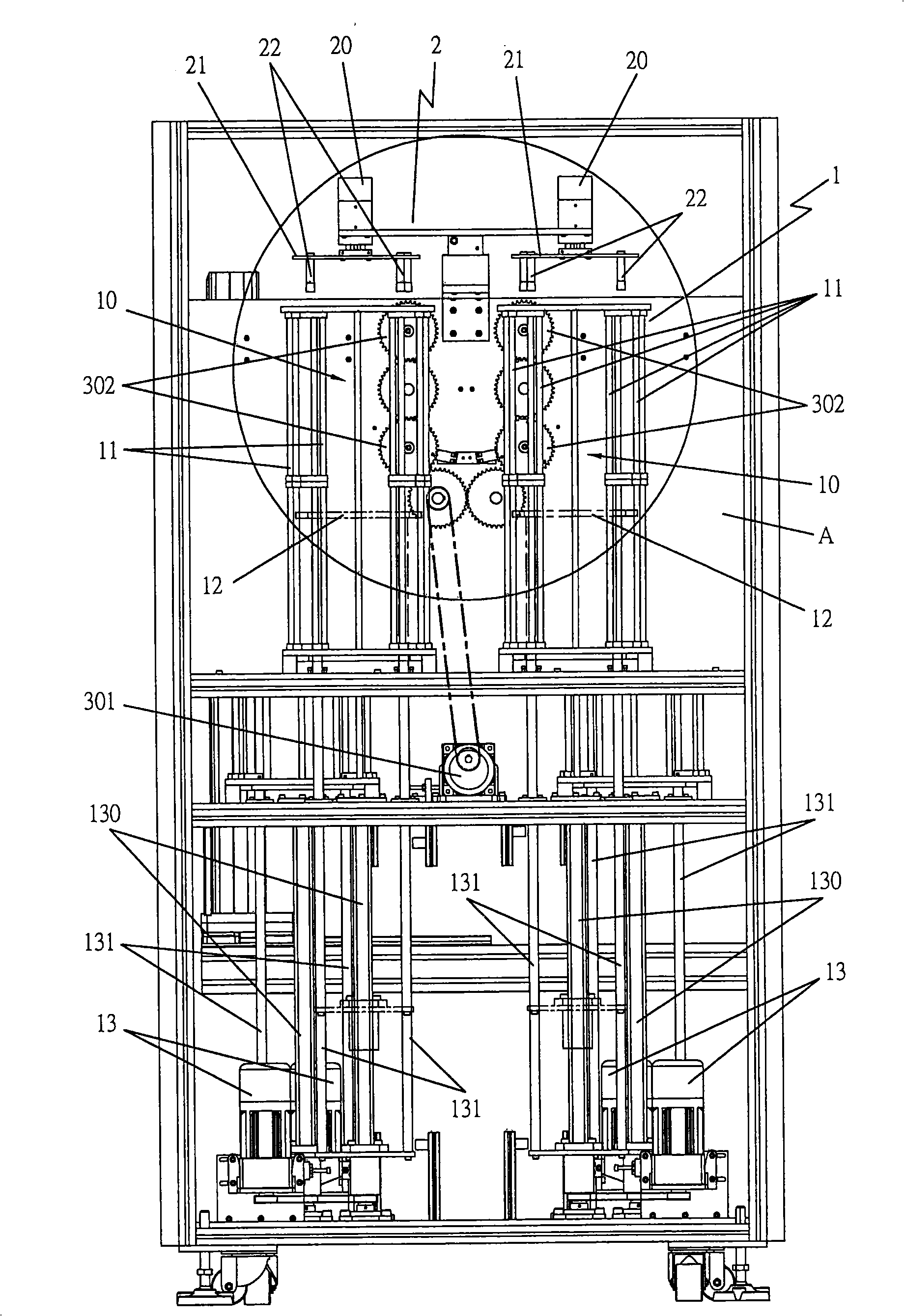

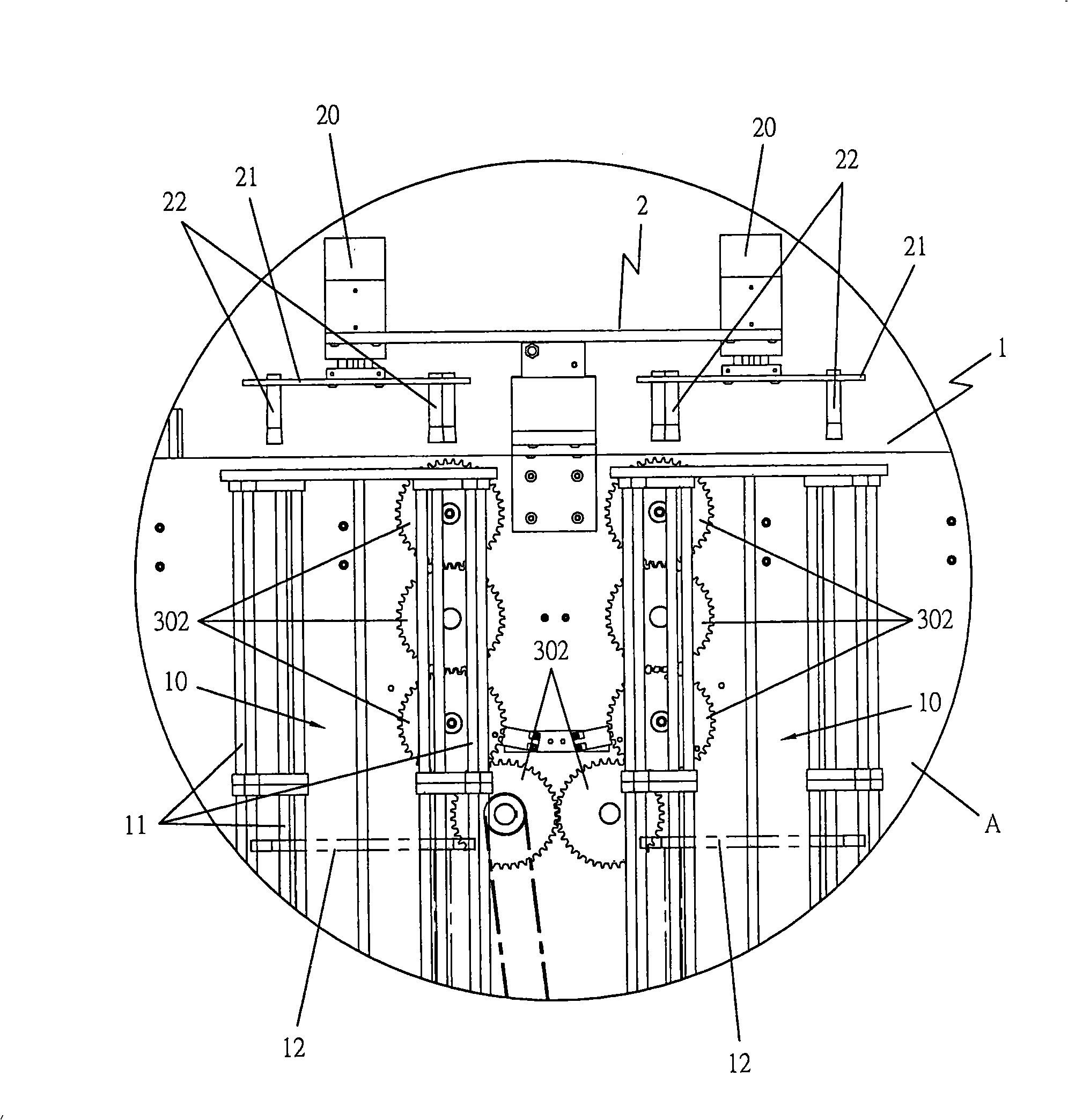

Novel full-automatic numerical control board packaging machine

InactiveCN103794823ASimple structureOverall small sizeFinal product manufactureLead-acid accumulators constructionNumerical controlSmall footprint

The invention relates to a novel full-automatic numerical control board packaging machine which comprises a pole plate conveying device, a pole plate finishing device, a pole plate lifting device, a pole plate absorbing device, a clapboard paper conveying device, a clapboard paper cutting device, a board packaging device, a pole plate group conveying device and a stand, wherein the pole plate conveying device is arranged at the left lower part of the stand; the tail end of the pole plate conveying device is provided with the pole plate finishing device; the pole plate lifting device is arranged under the stand; the pole plate absorbing device is arranged above the pole plate lifting device; the clapboard paper conveying device is arranged at the right upper part of the stand; the tail end of the clapboard paper conveying device is provided with the clapboard paper cutting device and the board packaging device; the pole plate group conveying device is arranged just under the clapboard paper conveying device. The novel full-automatic numerical control board packaging machine not only is simple in structure, compact in volume and small in occupied land area and improves the environment of a workplace, but also greatly improves the board packaging efficiency and the board packaging quality.

Owner:浏阳市联创机械设备制造厂

Feeding device of exposure machine

PendingCN109292450AEasy loadingReasonable structureConveyorsControl devices for conveyorsEngineeringManipulator

The invention discloses a feeding device of an exposure machine. The feeding device comprises a machine frame, a feeding platform is arranged on the machine frame, a supplement station and a finishedproduct storage station are arranged on the feeding platform, the supplement station is provided with a supplement passing hole, a lifting platform which can extend out of the supplement passing holeis vertically and slidably arranged at the supplement station, the lifting platform is driven by a supplement lifting power device, a plurality of trays used for placing to-be-exposed mobile phone shells are stacked on the lifting platform, a mechanical arm is arranged on the feeding platform, two first sucker assemblies used for sucking the mobile phone shells are arranged at the tail end of themechanical arm, and a working table is provided with a transferring device used for transferring the trays to the finished product storage station. The feeding device can realize automatic feeding ofthe mobile phone shells, the feeding efficiency is improved, and the labor cost is reduced.

Owner:JIANGSU GIS LASER TECH INC

Robot-based stamping automatic production line feeder

ActiveCN107457318AInhibit productionAvoid Scrap SituationsMetal-working feeding devicesMetal working apparatusProduction lineSurface mounting

The invention discloses a robot-based stamping automatic production line feeder which comprises a table surface mounting plate, guide shaft adjusting bases, stack positioning guide shafts, a stack tray, a first slide block and a sensor. A lifting servo motor is arranged on the bottom surface of the table surface mounting plate and drives a lifting lead screw to rotate. The top surface of the table surface mounting plate is connected with a feeding module mounting base with the top being fixedly connected with a second guide rail lead screw device. The second guide rail lead screw device is provided with a second slide block connected with an adjustable lifting air cylinder. The adjustable lifting air cylinder is connected with a sucking disc clamp support. The bottom end of the sucking disc clamp support is connected with a sucking disc clamp cross beam. The bottom surface of the sucking disc clamp cross beam is provided with a first sucking disc set and a second sucking disc set. A positioning disc is arranged under the second sucking disc set. The robot-based stamping automatic production line feeder provided by the invention further comprises a control system which is electrically connected with the sensor, the lifting servo motor, a horizontal moving servo motor and the adjustable lifting air cylinder. Compared with the prior art, by adopting the technical scheme, the production efficiency and the production safety of the stamping production line feeder can be improved, and the manpower cost can be lowered.

Owner:FOSHAN NANHAI GUANGDONG TECH UNIV CNC EQUIP COOP INNOVATION INST +1

Suction nozzle, and component mounting method and apparatus using the same

InactiveUS20060119118A1High bulk densitySmall widthPrinted circuit assemblingGripping headsEngineeringNozzle

In a suction nozzle (20), a sucking surface (60) is made larger in area than a to-be-sucked surface of a component (55) and is configured arbitrarily so long as a width (G1) between mutually-opposed sides parallel to a longer side (110) of the component to be sucked is smaller than a width (G2) in a direction parallel to a shorter side (111) of the component to be sucked. The suction nozzle sucks a component at its sucking surface, with a longitudinal axis (O) of the sucking surface (60) kept inclined with respect to a direction (J) in which the component is supplied.

Owner:HATA KANJI +3

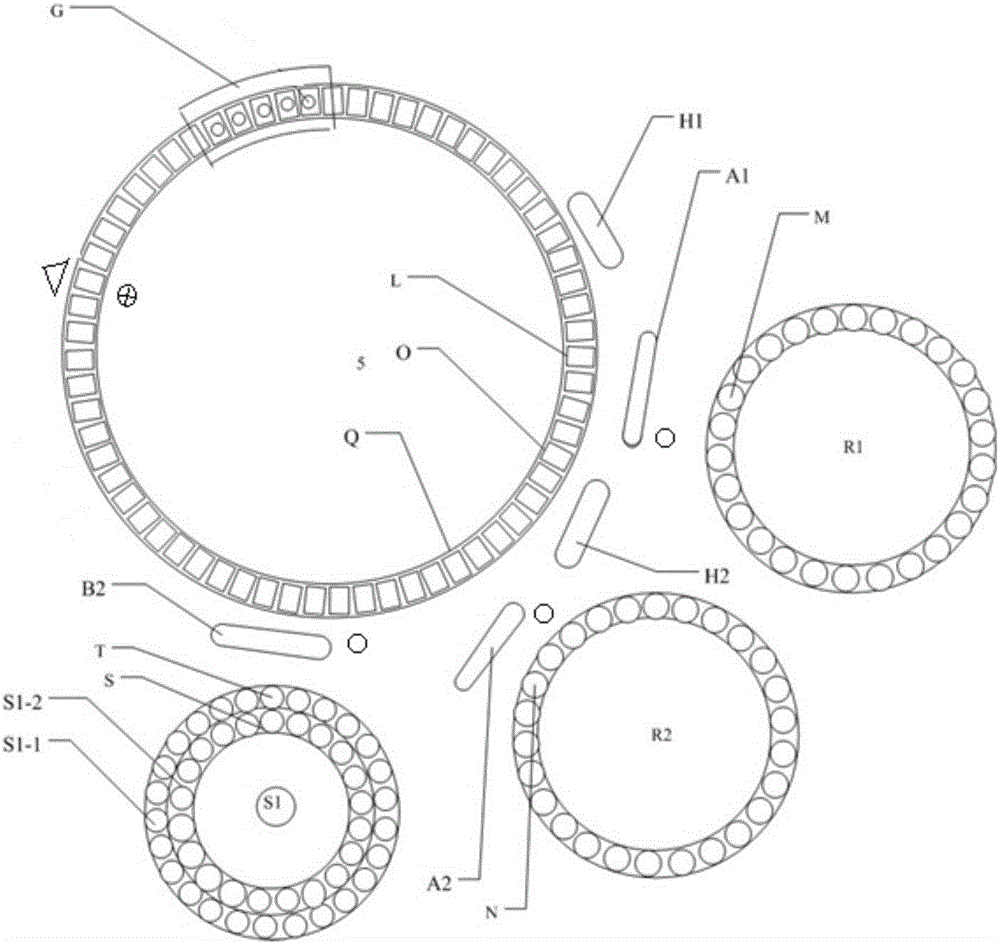

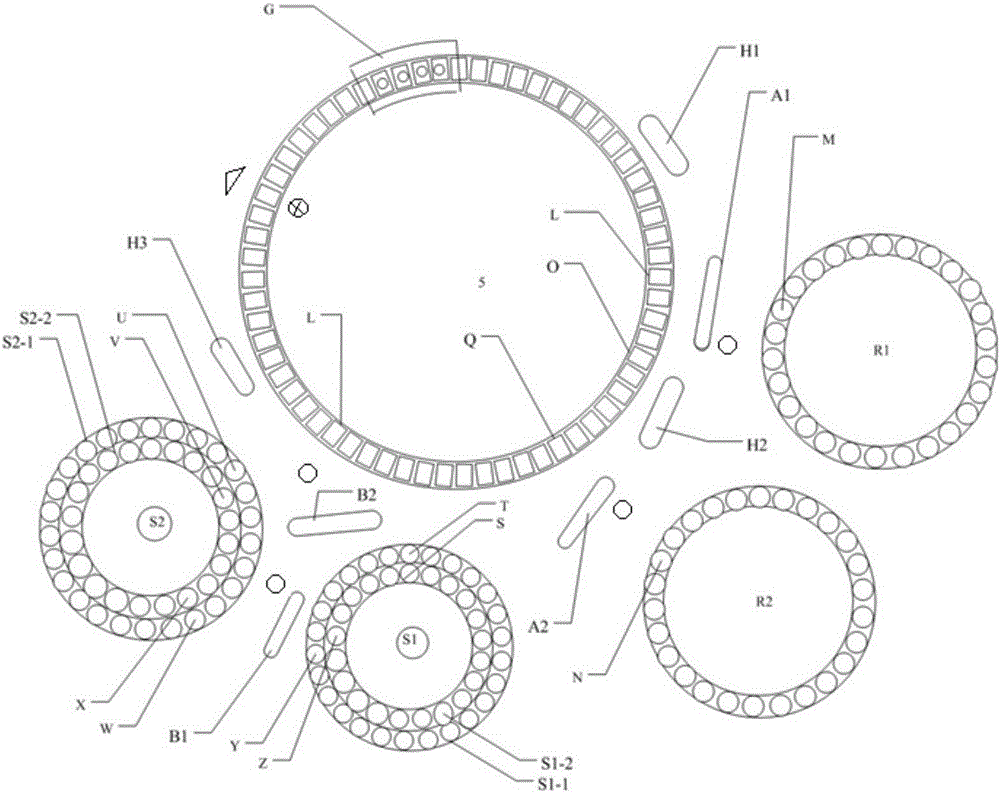

Dual-station chip test sorting machine

PendingCN109909180AIncrease productivityImprove tea production efficiencySortingElectrical and Electronics engineeringPull off test

The invention discloses a dual-station chip test sorting machine. The dual-station chip test sorting machine comprises a pair of feeding assemblies, a pair of test assemblies, a rotating disc assembly, a pressing assembly, and a pair of material dividing boxes which are installed on a working platform. The feeding assemblies are used for conveying to-be-tested chips to the test assemblies; the test assemblies are used for testing the to-be-tested chips; the rotating disc assembly is used for taking out the to-be-tested chips in the feeding assemblies and conveying the to-be-tested chips to thetest assemblies for testing, and finally conveying the to-be-tested chips to the material dividing box for sorting; The pressing assembly is used for controlling a suction nozzle on the rotating discassembly to move up and down and absorb the to-be-tested chips; and the material dividing boxes are used for separately collecting the tested chips. According to the dual-station chip test sorting machine, during the vibration process of the direct shock feeding track, adhered chips are separated through a blowing pipe, and the overlapped to-be-tested chips are separated through the pressing needle, so that it is ensured that the suction nozzle on the rotating disassembly can accurately absorb the to-be-tested chips, thus the production efficiency is improved, and the dual-station chip test sorting machine can be used for chip testing.

Owner:扬州爱迪秀自动化科技有限公司

Material taking device

Owner:何永刚

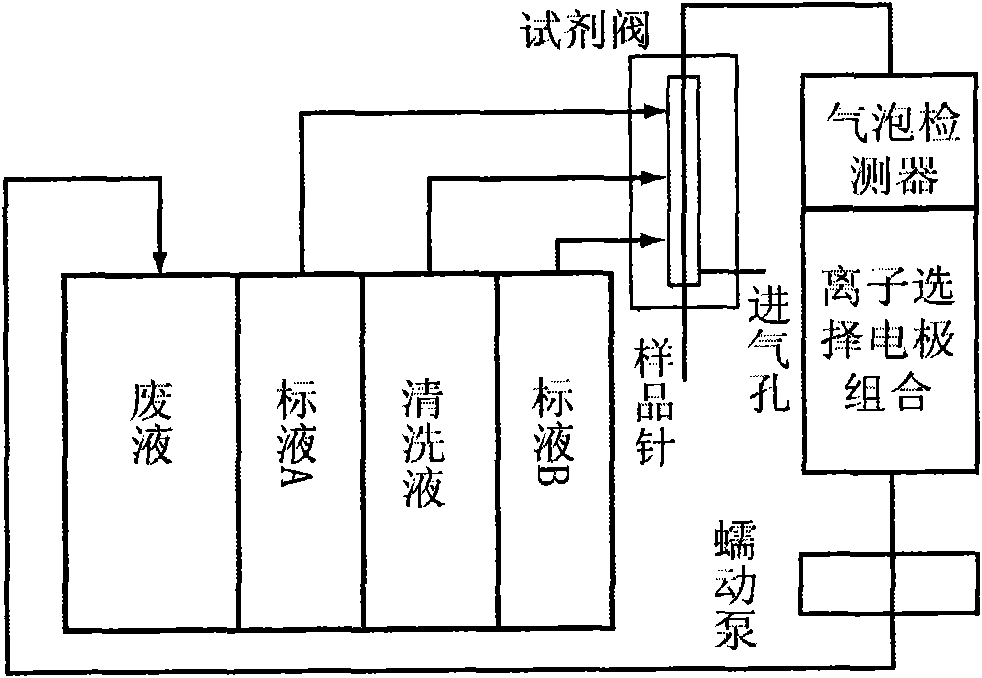

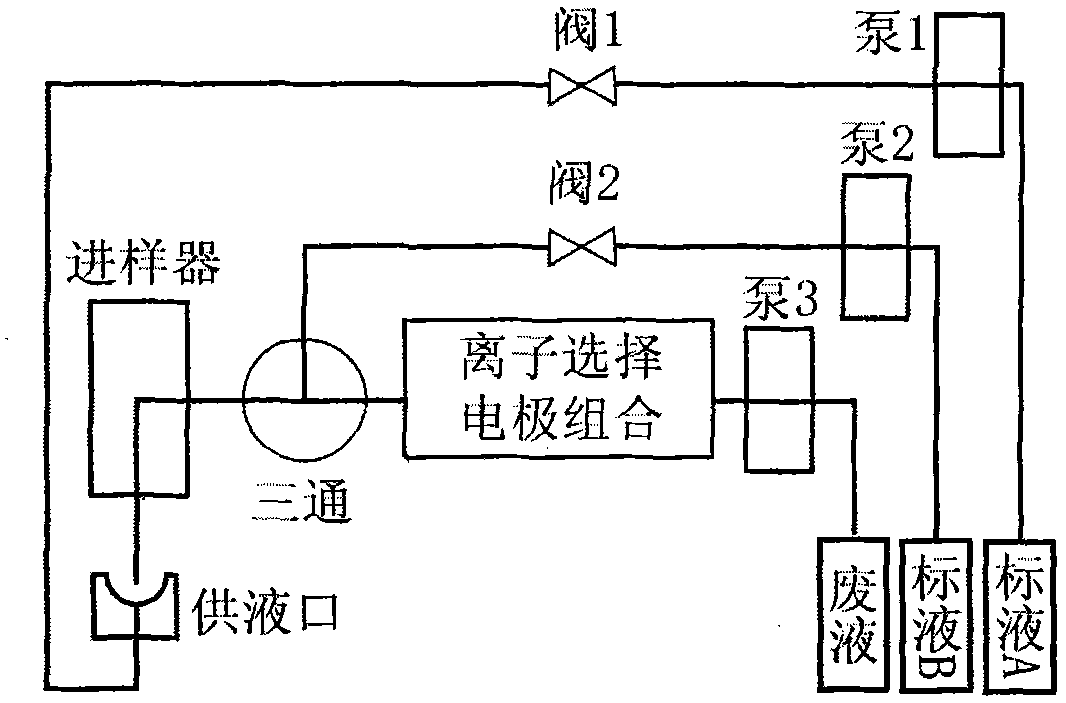

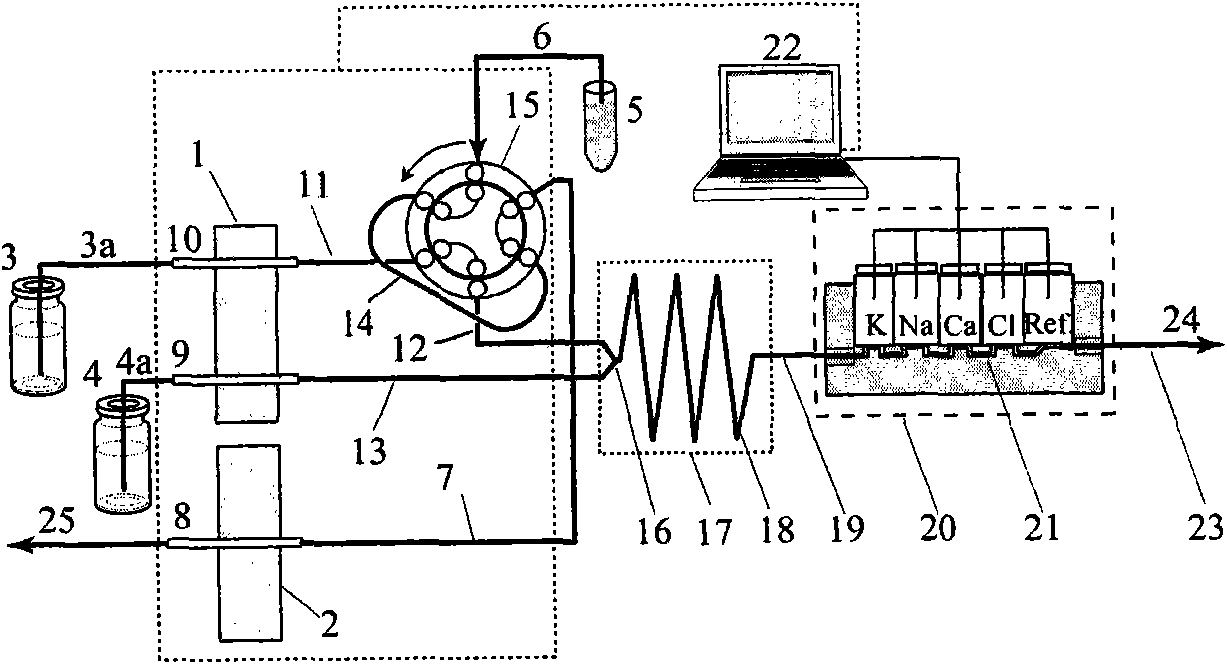

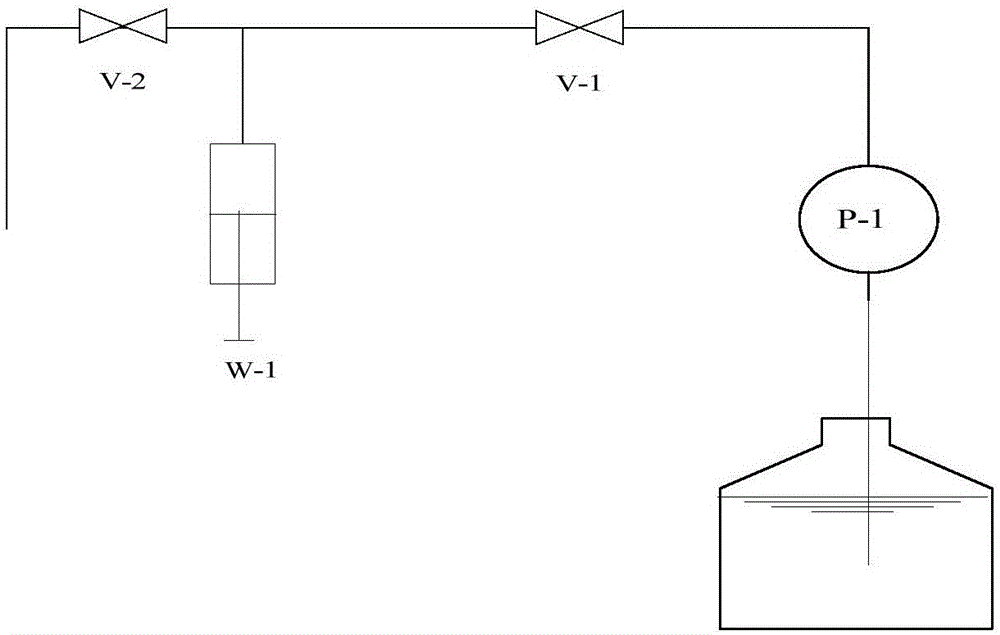

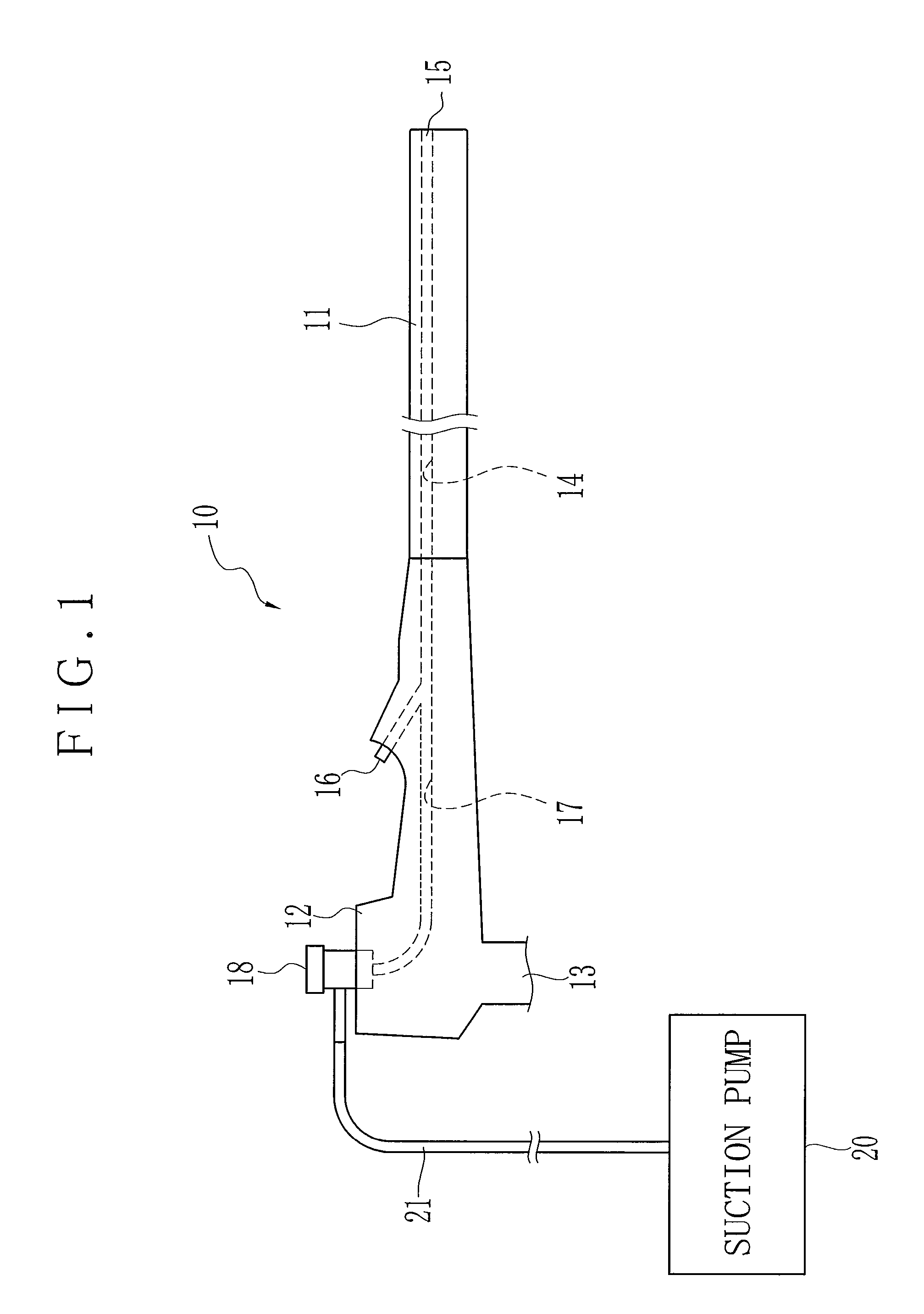

Flow injection serially connected microelectrode electrochemical automatic method and device for simultaneous measurement of various electrolytes in blood sample

InactiveCN102072930ASimple and efficient operationMany measurement parametersMaterial analysis by electric/magnetic meansMicroelectrodeEngineering

The invention discloses a flow injection serially connected microelectrode electrochemical automatic method and device for simultaneous measurement of various electrolytes in a blood sample, and belongs to the field of clinical examination. A multifunctional valve is arranged in a 'sampling' position, carrier flow is converged with an acidity regulator under the power action of a pump, continuously flows through a mixing coil and an electrochemical flow-through detector, and generates base line electrode potential signals; a blood sample simultaneously enters a sampling quantification ring for automatic precision quantification; a valve is switched to the 'injection' position, a quantified 'blood sample plug' is injected into the carrier flow in a high repetition manner, is mixed with the acidity regulator and flows into the electrochemical flow-through detector, respective potential signals can be obtained, and blood sample results can be obtained through a computer. Meanwhile, the carrier flow follows the 'blood sample plug' to automatically and timely clean an electrode sensitive membrane surface and a system. The invention has the advantages of high automation degree, fast measuring speed, good repeatability and less consumption of samples, and eliminates the system plugging caused by blood samples and the cross contamination.

Owner:SICHUAN UNIV

Die bonder

ActiveCN111370350AGuaranteed dispensing accuracyEnsure dispensing qualitySemiconductor/solid-state device manufacturingWaferingElectric machinery

The invention provides a die bonder. The die bonder comprises a rack; a dispensing device; a dispensing shifting mechanism; a feeding mechanism; a die bonding swing arm device; a crystal supply platform; a die bonding displacement mechanism; and a material receiving mechanism. The die bonding swing arm device comprises a rotating frame, a plurality of die bonding swing arms, a lifter and a die bonding motor, and each die bonding swing arm is provided with a suction nozzle; the dispensing device comprises a plurality of dispensing modules. The invention provides a die bonder. According to the invention, the plurality of dispensing modules are combined with the plurality of die bonding swing arms, so that the operation speeds of the plurality of dispensing modules can be adjusted to be matched with the operation speeds of the plurality of die bonding swing arms on the premise of ensuring the dispensing precision and quality and ensuring the wafer taking and placing precision, the idle time of each dispensing module and each die bonding swing arm is reduced, and the die bonding efficiency is greatly improved.

Owner:SHENZHEN XINYICHANG TECH CO LTD

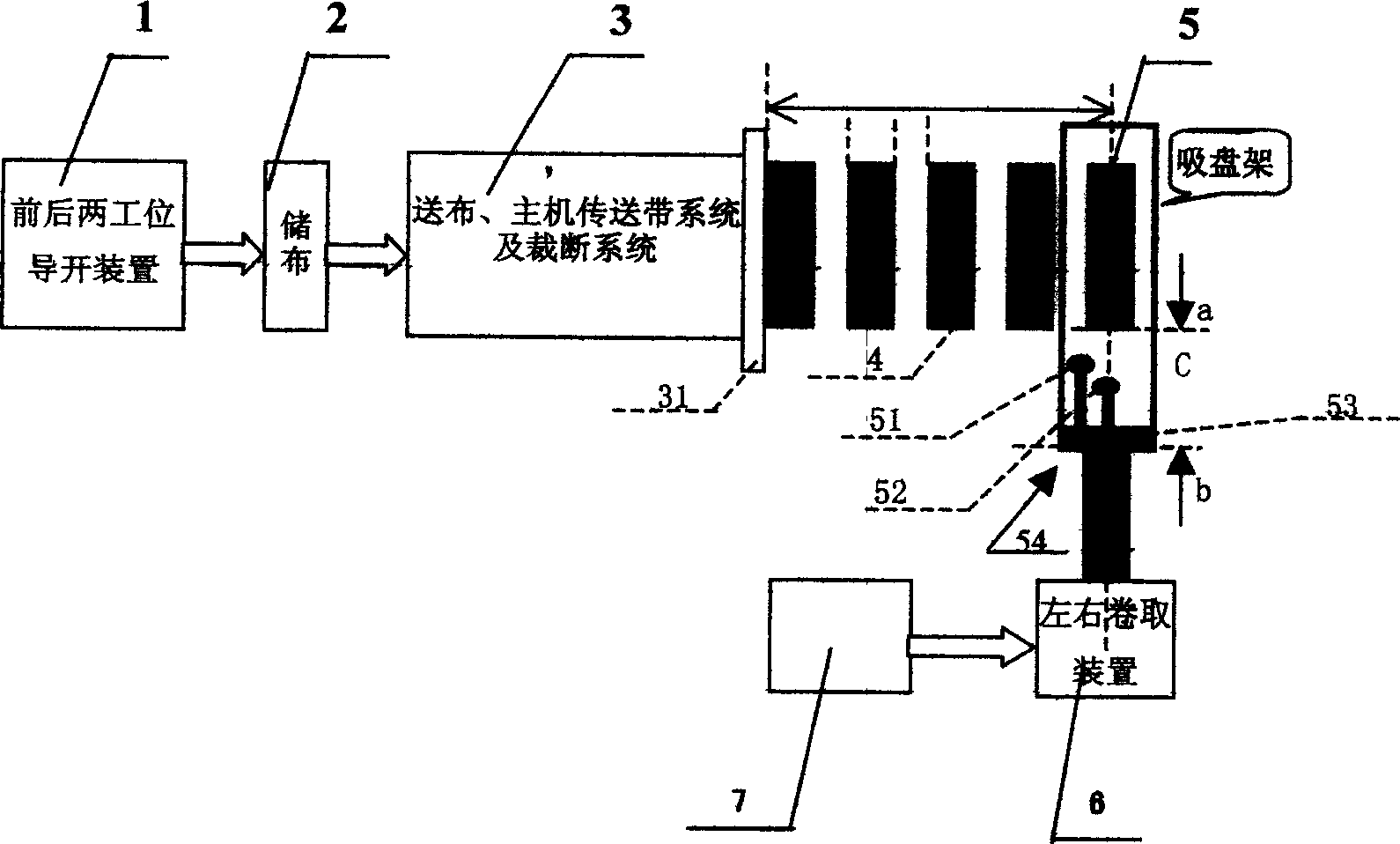

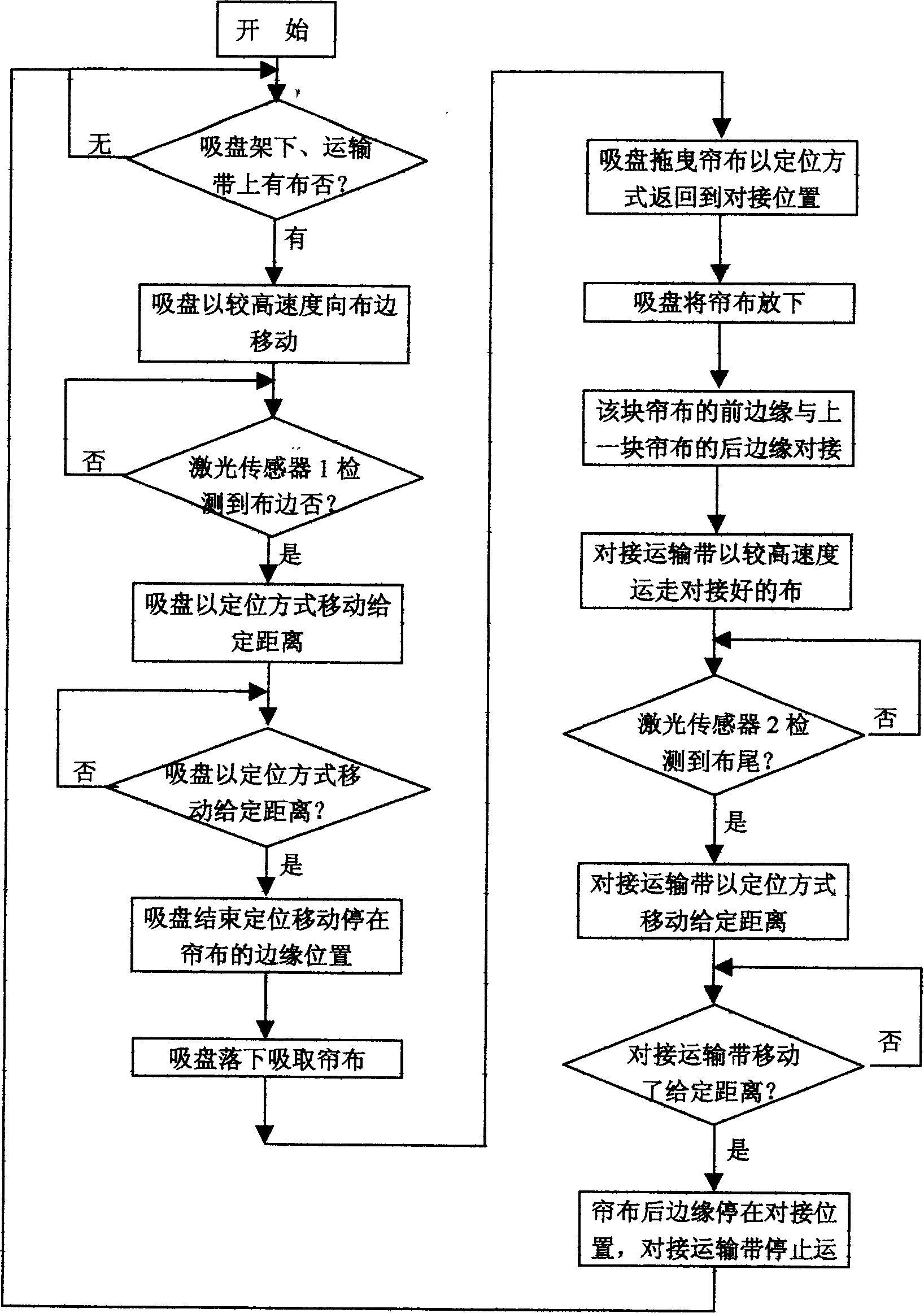

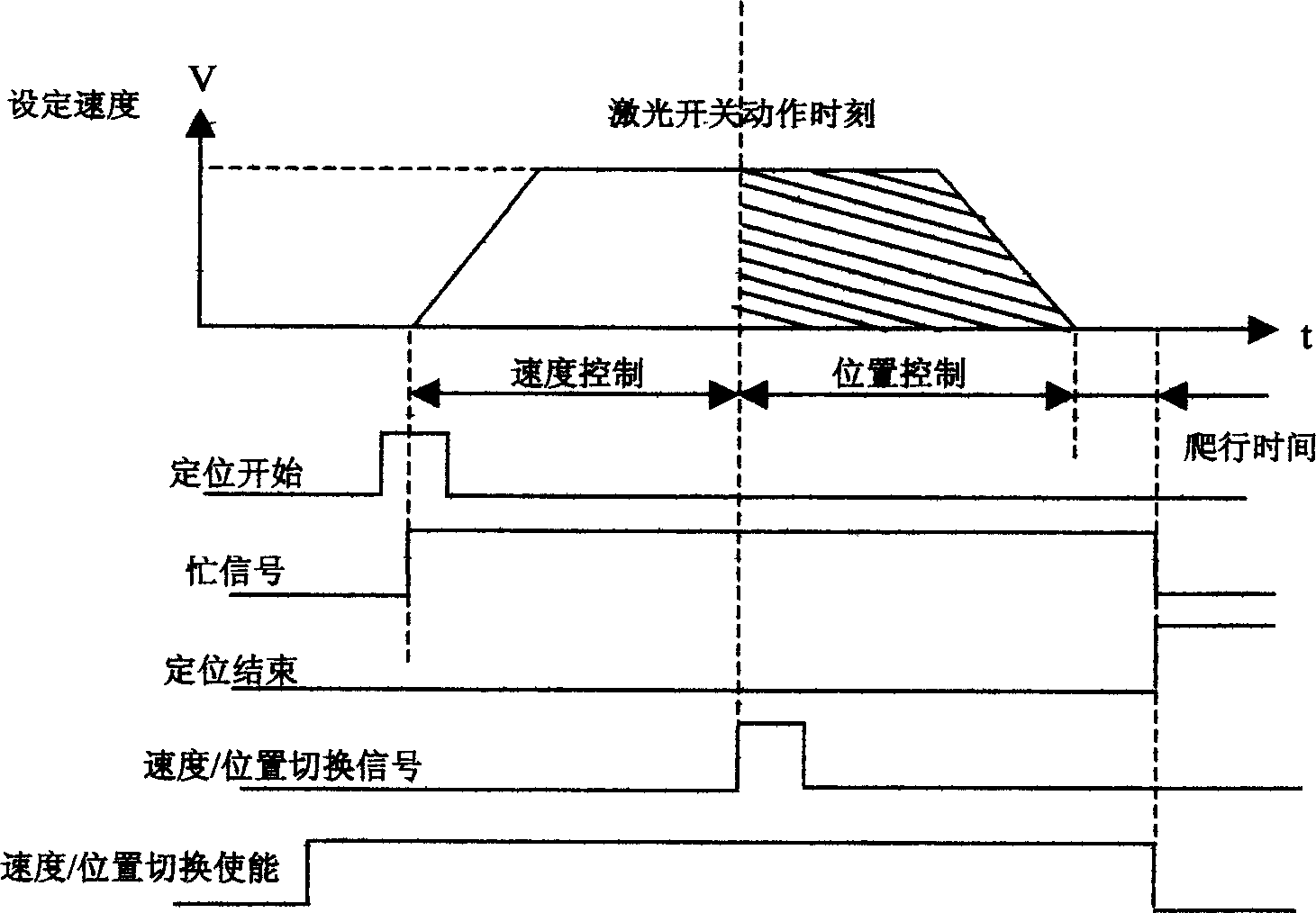

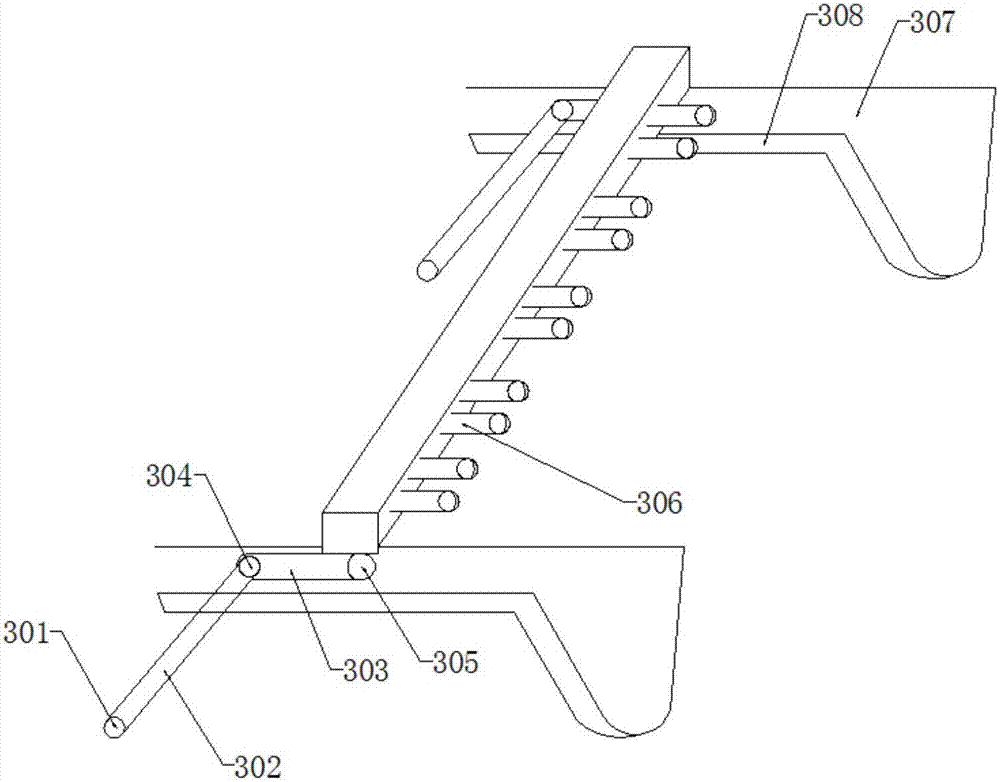

Method for controlling suction and abutment system for fully-automatic cutting machine of radial tyre fiber cord fabric

The invention discloses a kind fiber curtain cloth automation cut machine assimilate and meet system control method, the system including guide equipment, store cloth equipment, transmission and cut equipment, curtain, acetabula frame, assimilate and meet pull equipment, assimilate and meet control equipment, the control method is though the acetabula assimilate and test the curtain cloth by laser, the test signal drive the acetabula all data service mode change (speed mode and position mode)to achieve accumulate confirm length and pull slot, test edge automatism, to achieve accumulate assimilate and meet. This method is the integrate and comprehensive of the advanced technology. Its form is simple and run accumulatly and reliable, use and maintain easy.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY +1

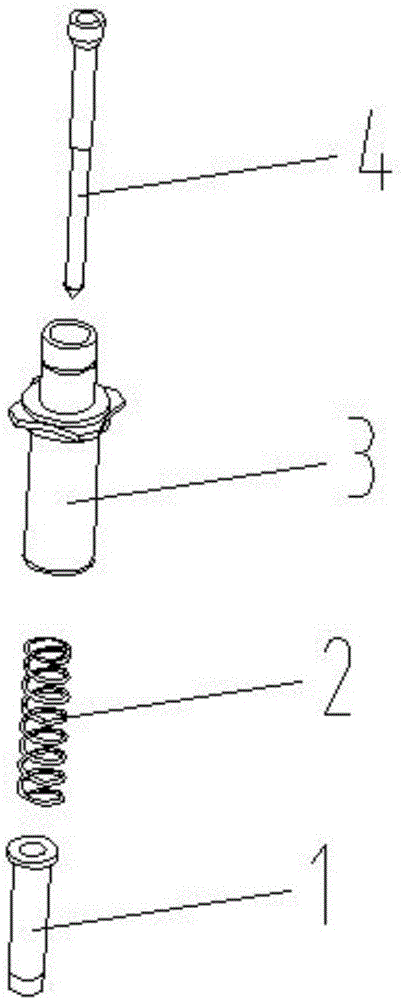

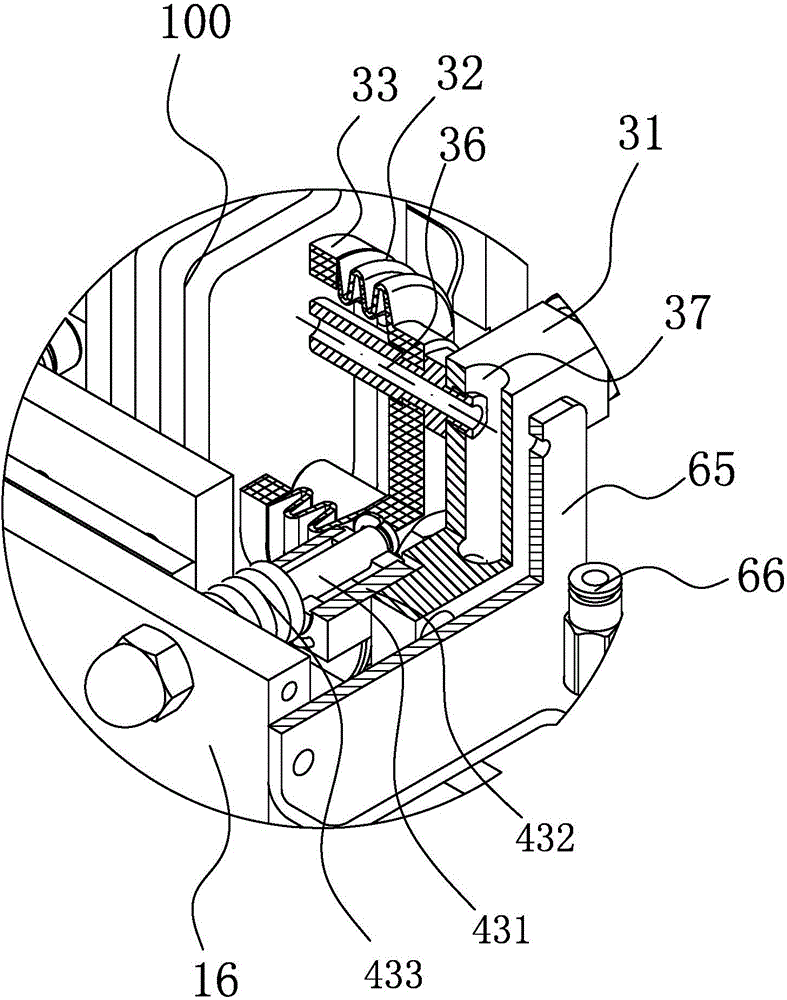

Integrated assembly machine of liquid shampoo gland

ActiveCN106826217ARealize integrated assemblyImprove assembly efficiencyAssembly machinesMetal working apparatusDistribution controlEngineering

The invention relates to an integrated assembly machine of a liquid shampoo gland. The integrated assembly machine comprises a power distribution control box, a rotary disc and an operation display screen, the rotary disc and the operation display screen are connected with the power distribution control box, carriers are evenly arranged on the rotary disc, each carrier comprises a carrier body arranged on the rotary disc, a matching hole matched with a spring base and a spring sleeve is arranged on each carrier body, and a guide rod penetrating out the rotary disc is fixedly connected to each carrier body; a spring base feeding device, a spring feeding device, a spring base feeding device, a thimble pipe feeding device and a pressing device which are matched with each carrier are sequentially arranged above the rotary disc in the anti-clockwise direction and are all connected to the power distribution control box; and each pressing device comprises a pressing base provided with a pressing air cylinder, a pressing block matched with the corresponding carrier is connected to the lower portion of each pressing air cylinder, and the pressing air cylinders are connected to the power distribution control box. By means of the integrated assembly machine, integrated assembling of the liquid shampoo gland can be automatically achieved, the assembling efficiency is greatly improved, the production hours are reduced, and the manpower consumption is reduced.

Owner:广州市柏亚化妆品有限公司

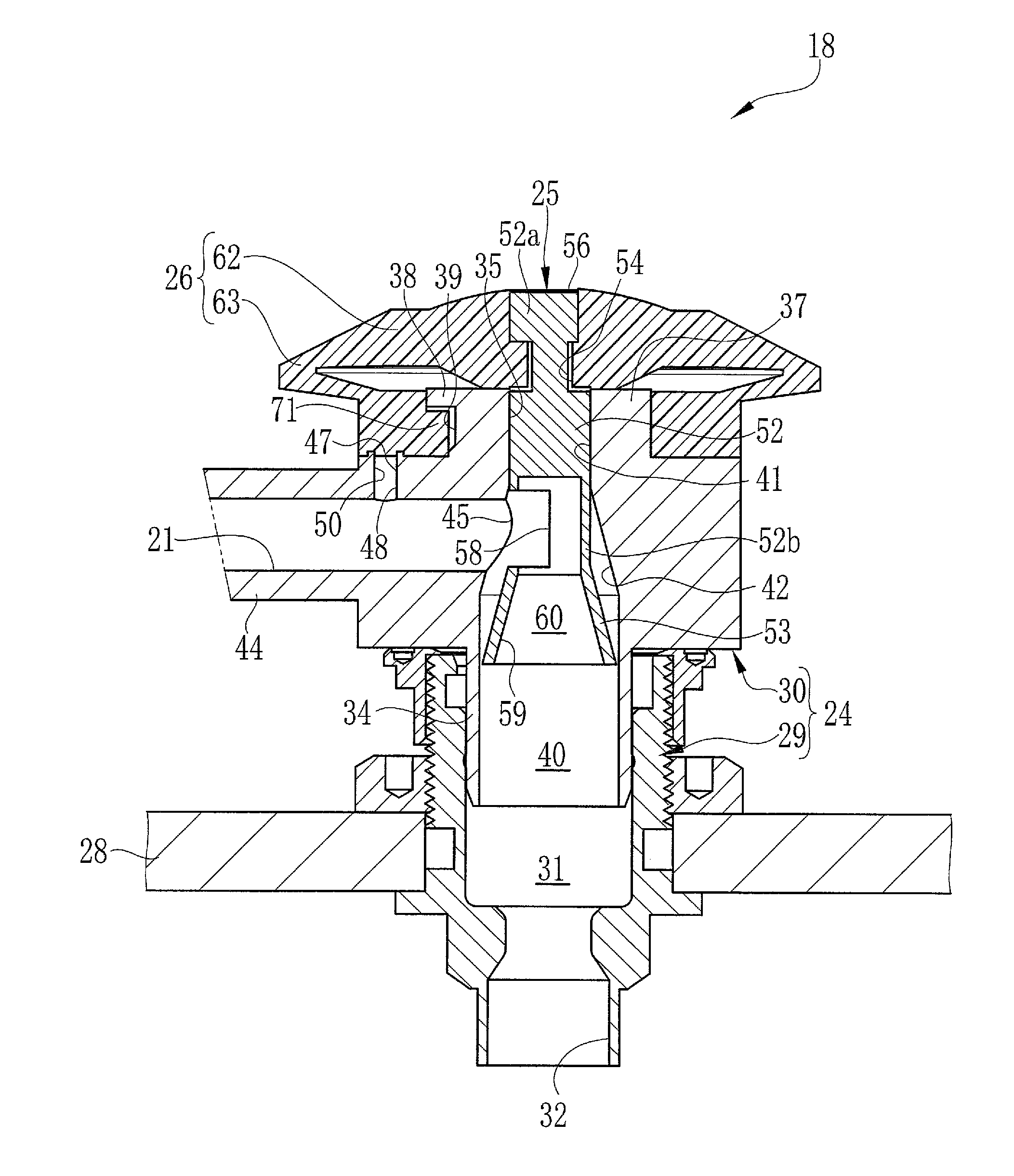

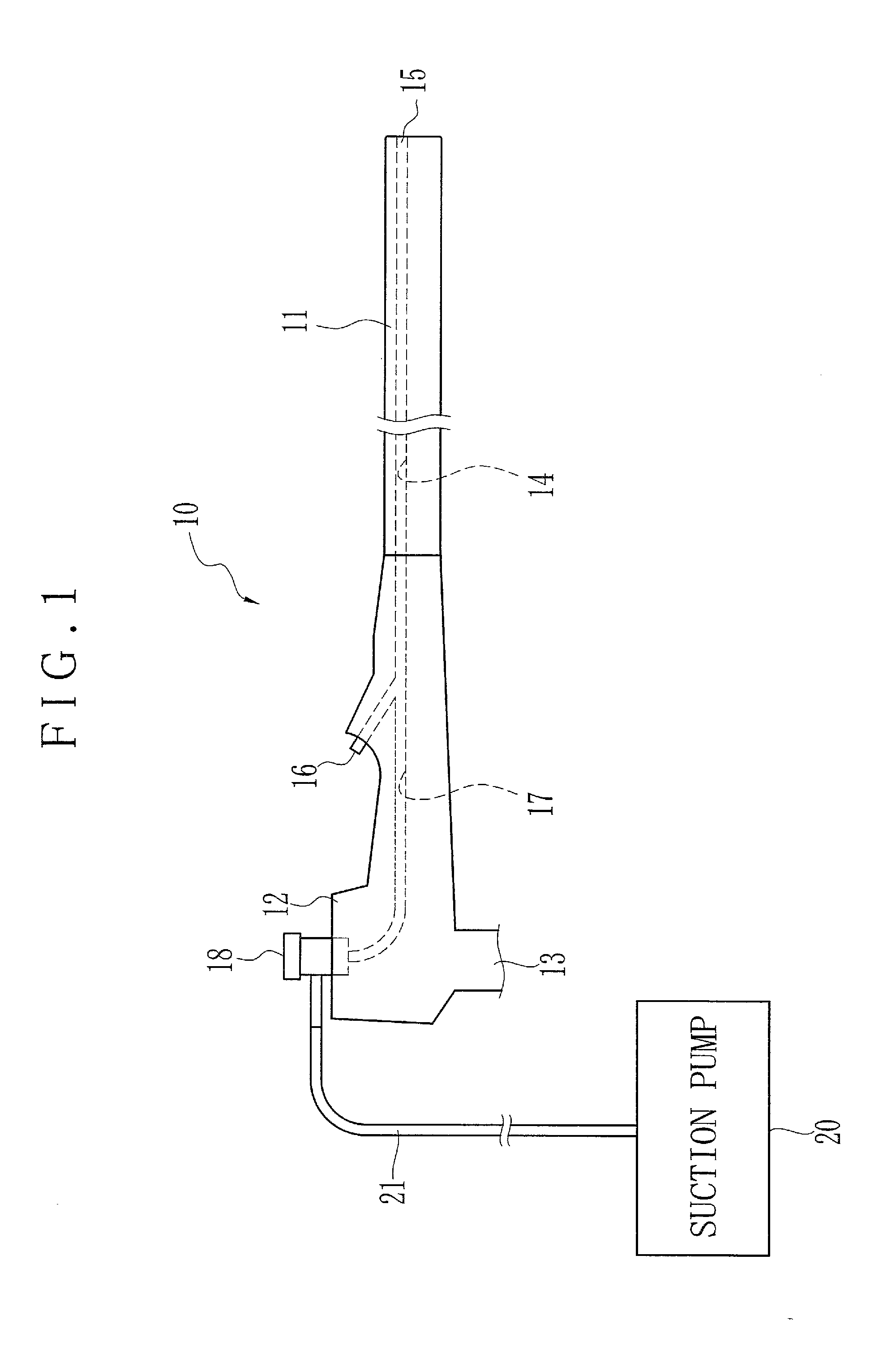

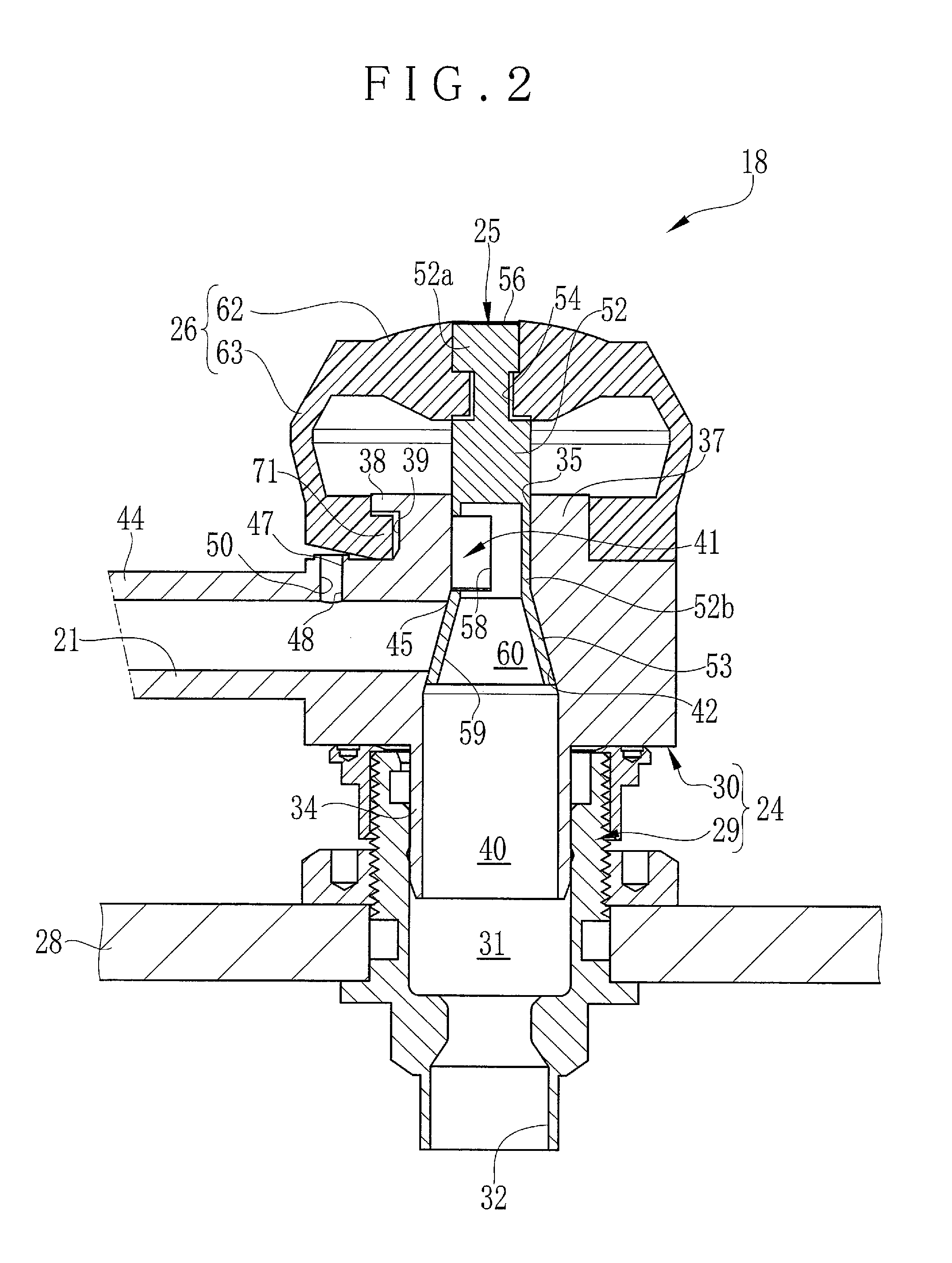

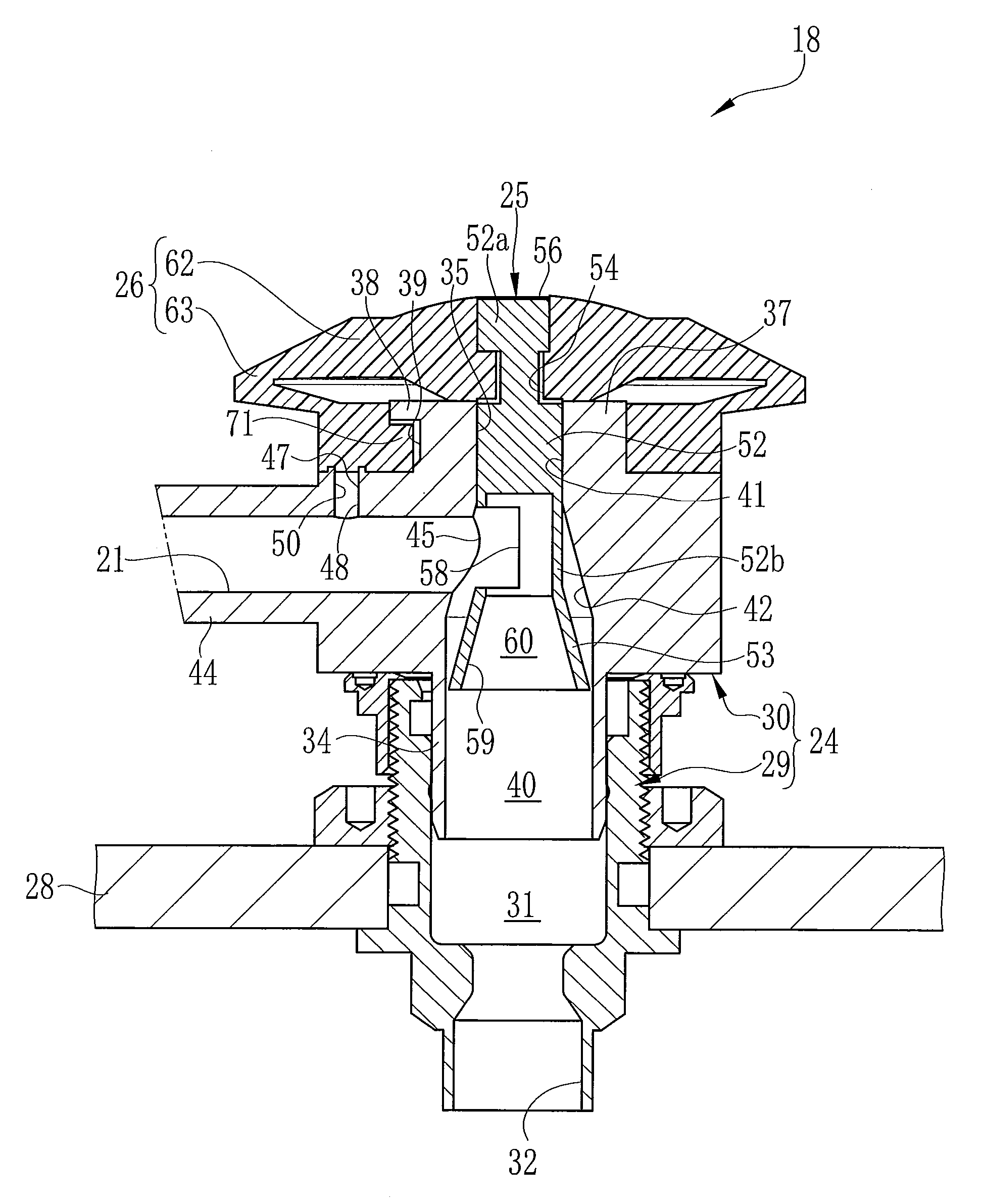

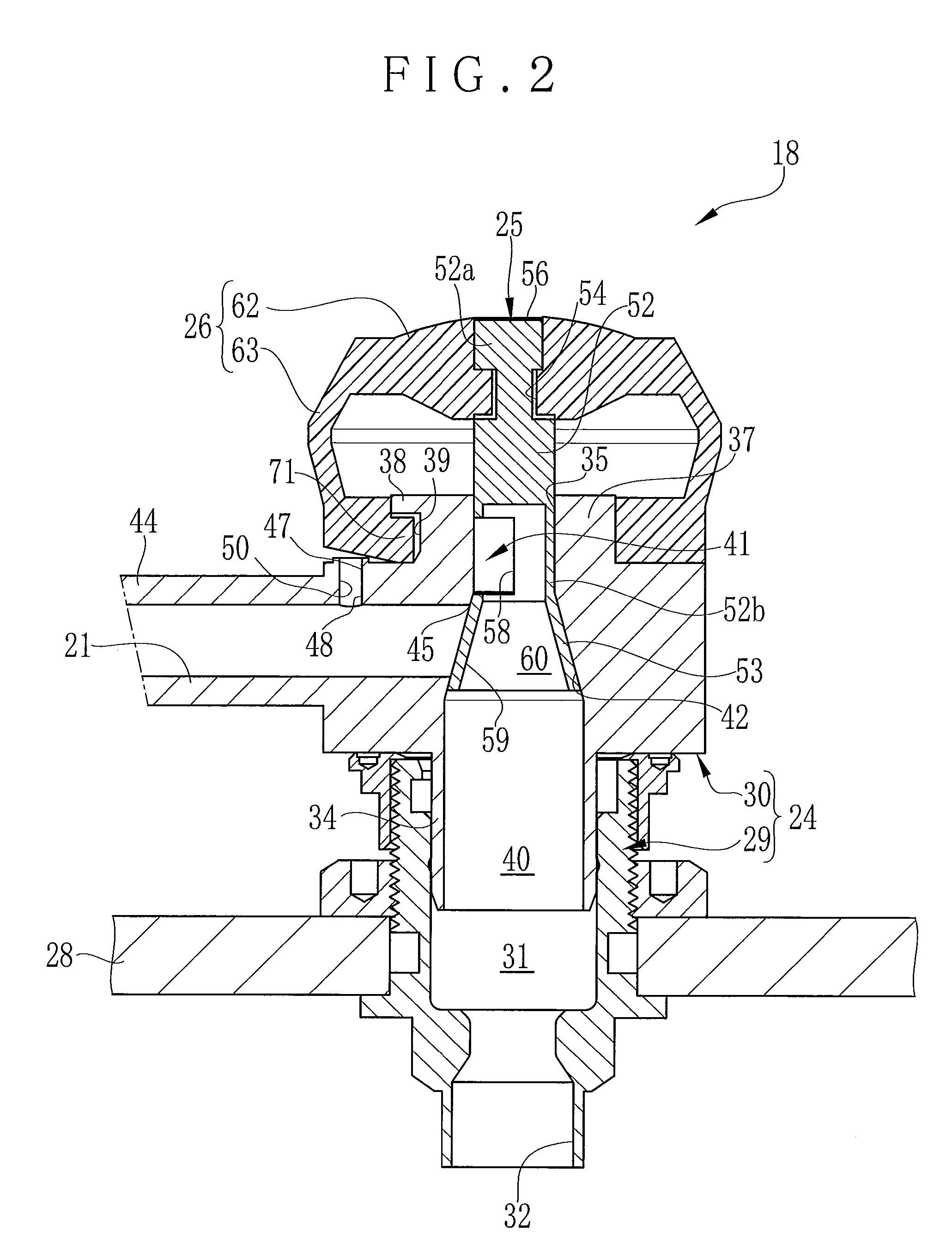

Suction button assembly for endoscope

A suction button assembly of a valve structure for an endoscope includes a cylinder housing, cylinder passage, plunger or piston unit, cylinder opening, plunger stem, flow opening, valve sleeve and flow channel. A valve opening is formed in a side surface of the valve sleeve at an end of the flow channel, closed by a wall of the cylinder passage when the plunger is in the closed position, for shut-off between the suction channel and the discharge conduit, and registered with the flow opening when the plunger is in the open position, for communication between the suction channel and the discharge conduit. A valve engaging surface is formed partially with the cylinder passage, has the flow opening, and has an inner diameter decreasing in an upward direction. The valve sleeve is tapered and tightly contacted on the valve engaging surface when the plunger is in the closed position.

Owner:FUJIFILM CORP

Automatic biochemical analyzer and analyzing method

The invention discloses an automatic biochemical analyzer and an analyzing method. The analyzer mainly structurally comprises a reagent disc, a reaction disc, a sample disc, a stirring unit, an optical detection unit, a control unit, a reagent needle, a sample needle and more than one reagent suction and diluting device; the analyzer has a function of automatically diluting the reagent gradually before the reagent is utilized; the effects of reducing the volume of the reagent and reducing the contact area between the analyzer and the inner part of the reagent needle are realized and the washing difficulty of residual reagents in the reagent needle is reduced; residues in the reagent needle are few so that crossed contamination can be reduced; the analyzer is further provided with a sample diluting unit; the sample is diluted to reduce the viscosity; sample suction errors are reduced, the sampling precision and detection precision are improved, and the sample needle is also convenient to wash. According to the automatic biochemical analyzer and the analyzing method, production, storage, transportation and dosage of the reagent are greatly reduced; the economical efficiency of a detection system is improved; meanwhile, the crossed contamination is reduced and the detection accuracy is improved.

Owner:CLINDIAG SYSTEMS CO LTD

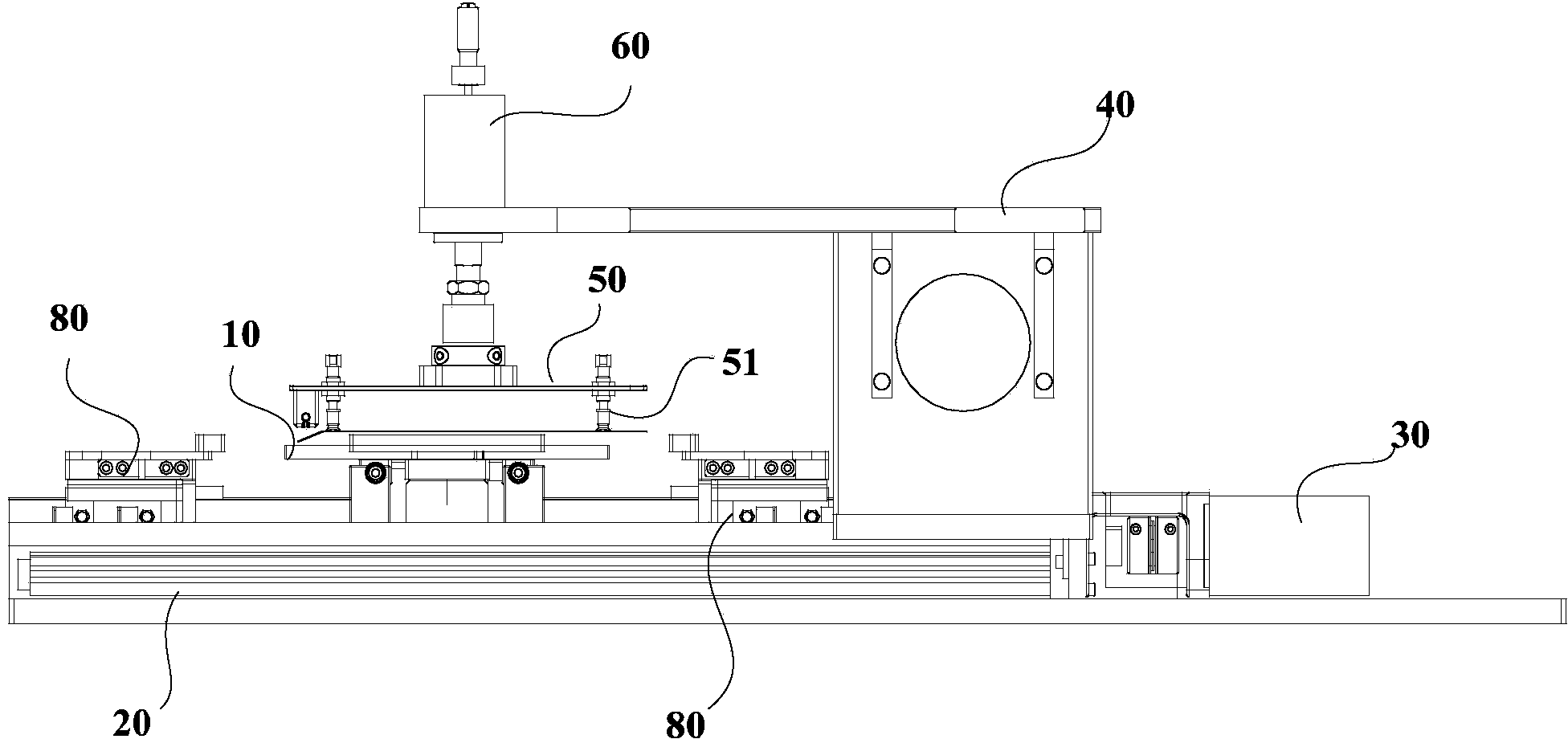

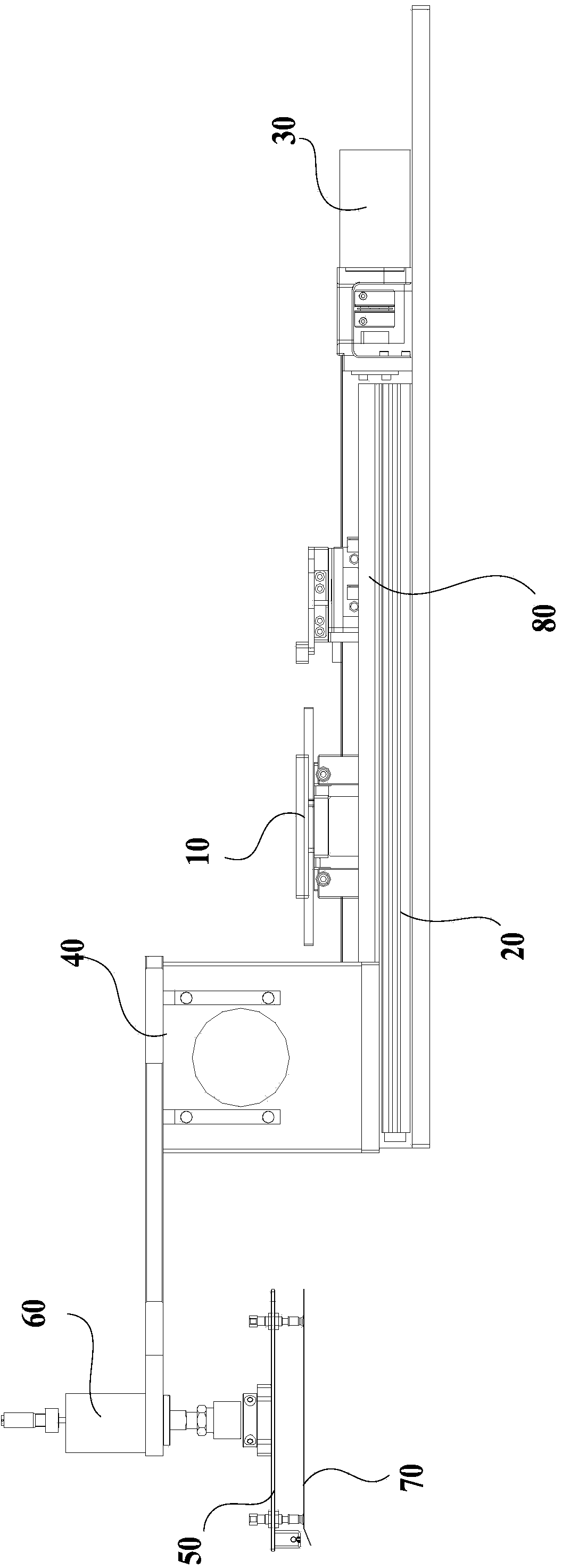

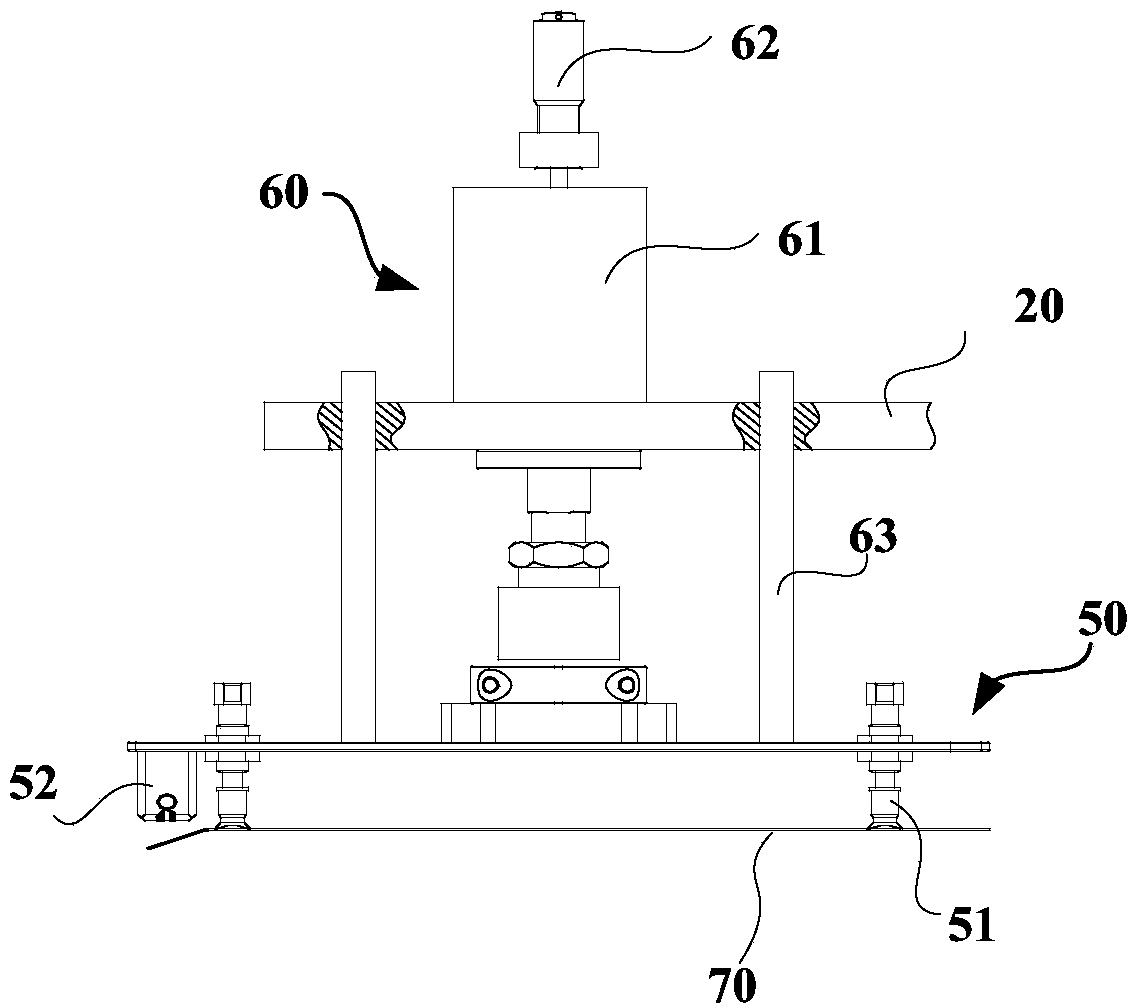

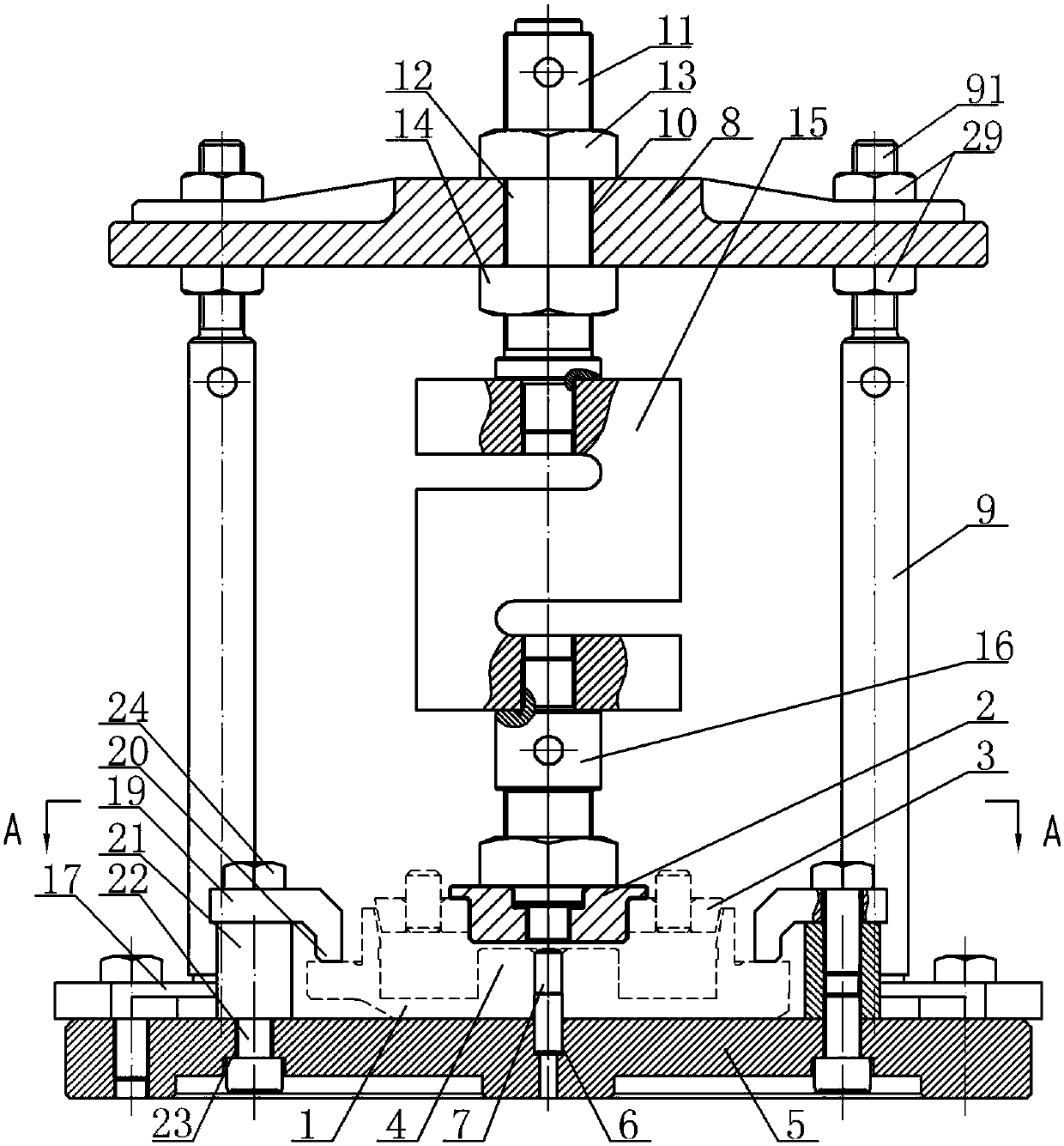

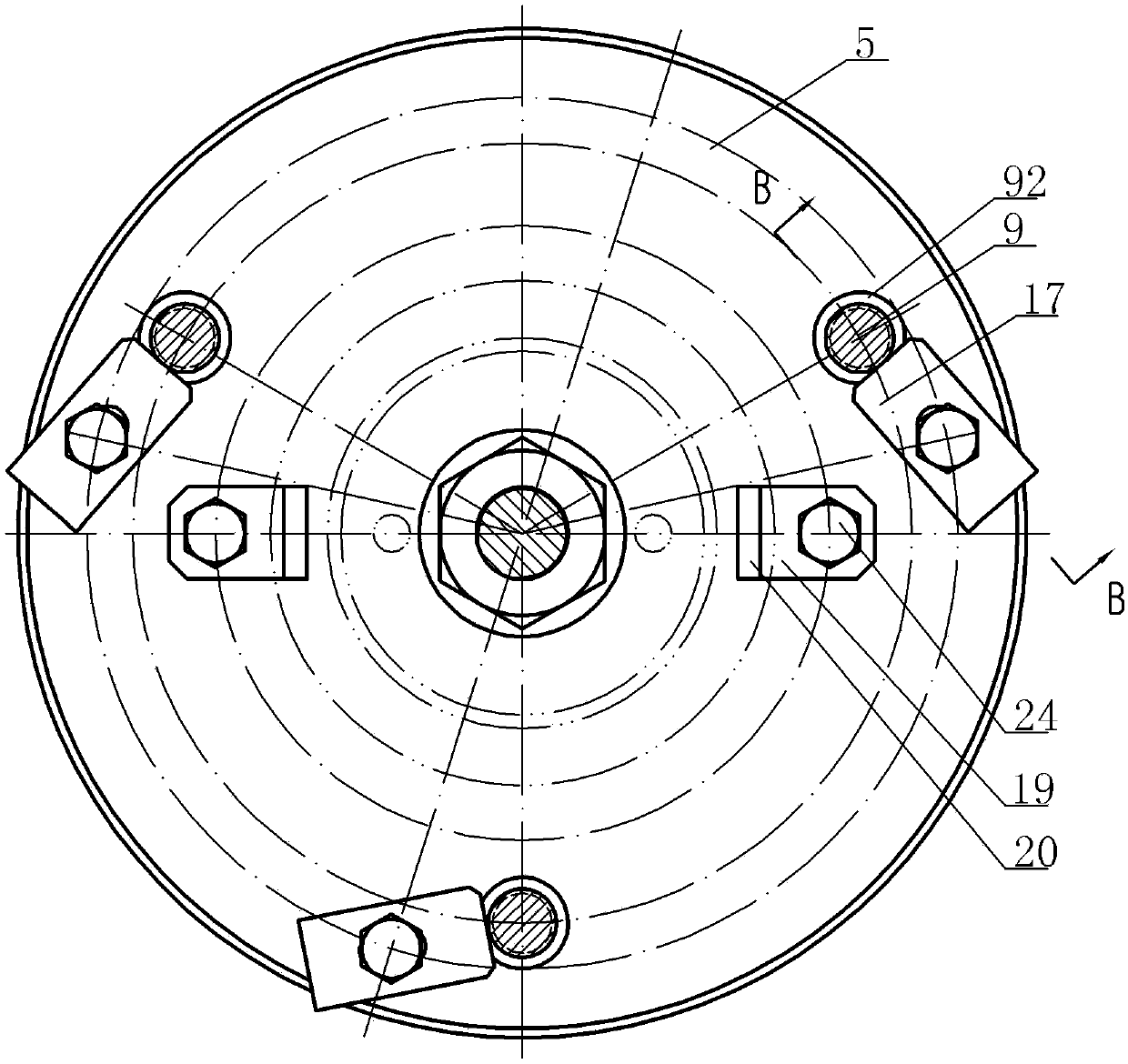

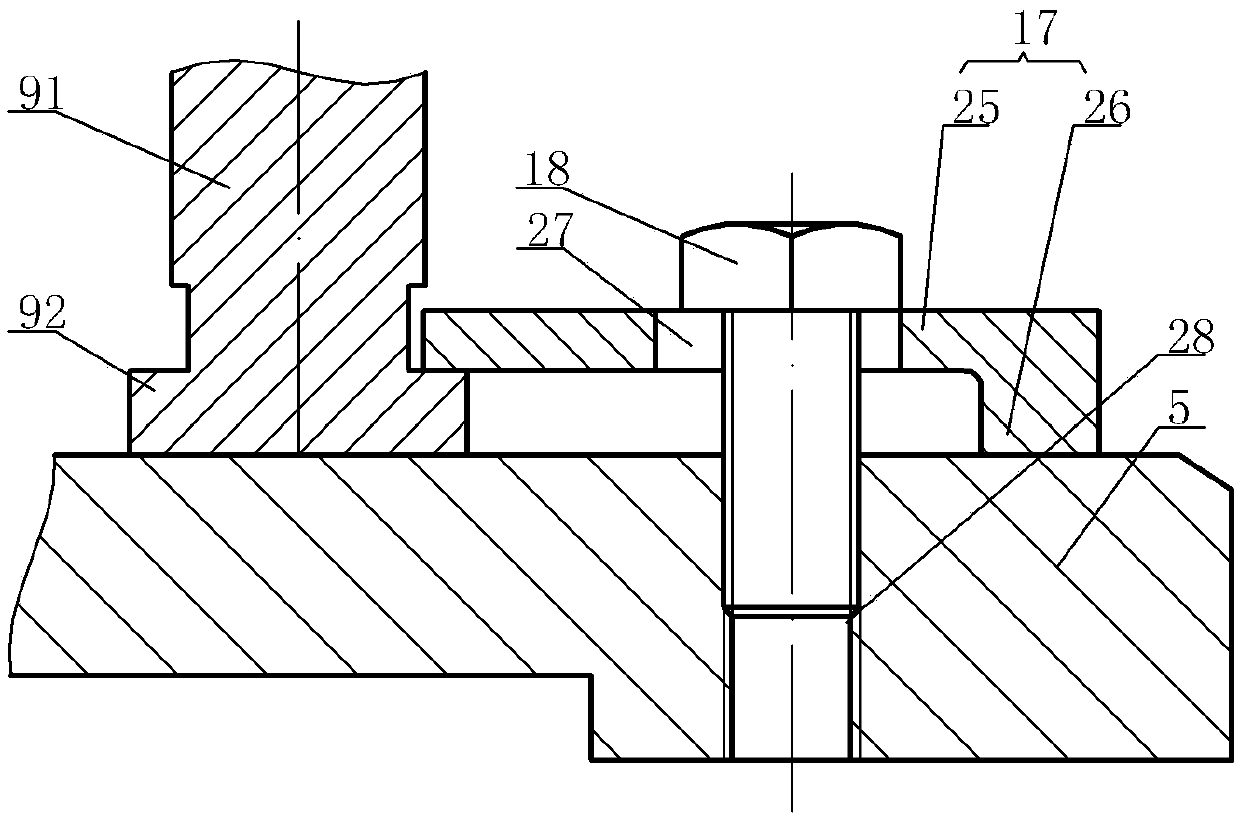

Electromagnet attraction detecting device

PendingCN107748340APrecise suctionSuction Accurately AcquiredMagnetic property measurementsPull forceControl theory

The invention provides an electromagnet attraction detecting device capable of accurately obtaining an electromagnet attraction value by controlling an air gap value between an armature and an armature core so as to accurately display the electromagnet attraction, thereby eliminating laborious calculation and saving time. An electromagnet to be tested comprises a magnetic yoke, an armature and a coil. A convex armature core is arranged at the center of the magnetic yoke. The electromagnet attraction detecting device is characterized in that the electromagnet attraction detecting device comprises a base, a center positioning through hole is arranged in the center of the base; the central position of the magnetic yoke to be tested is fixedly installed in the center positioning through hole by a step pin; an upper plate is disposed right above the bas and is supported right above the base by a plurality of support rods; a vertical through hole is disposed right above the upper plate relative to the center positioning through hole; the middle screw portion of a upper pull rod passes through the vertical through hole and then is fixed to the upper plate by a upper nut and a lower nut; and the lower end of the upper pull rod is fixedly connected with the upper end of a tension sensor.

Owner:SUZHOU LVKON TRANSMISSION TECH CO LTD

Pin machining and production equipment capable of detecting lengths of capacitor pins

InactiveCN112077227AImprove work efficiencySimple structureMeasurement devicesSortingCapacitanceStructural engineering

Owner:东莞市夯牛机电科技有限公司

Suction button assembly for endoscope

An endoscope includes an operation unit, an elongated tube, a distal opening, a suction channel, and a discharge conduit. A suction button assembly has a valve structure for changing over between the discharge conduit and the suction channel for communication and shut-off. The suction button assembly includes a plunger, a first stem end, and a valve opening of the plunger. A cap device is coupled to the first stem end and to the first cylinder end of a cylinder housing in the operation unit, and around the first stem end. A first regulating device prevents the plunger from rotating in the cap device. A second regulating device prevents the cap device from rotating about an axis of the cylinder housing, to keep the valve opening aligned with a flow opening of a cylinder passage of the cylinder housing.

Owner:FUJIFILM CORP

Suction disc separation mechanism for lead storage battery plate

ActiveCN104868153AThe overall mechanism is simpleWork reliablyAssembling battery machinesFinal product manufactureEngineeringMechanical engineering

Owner:NINGBO UNIV

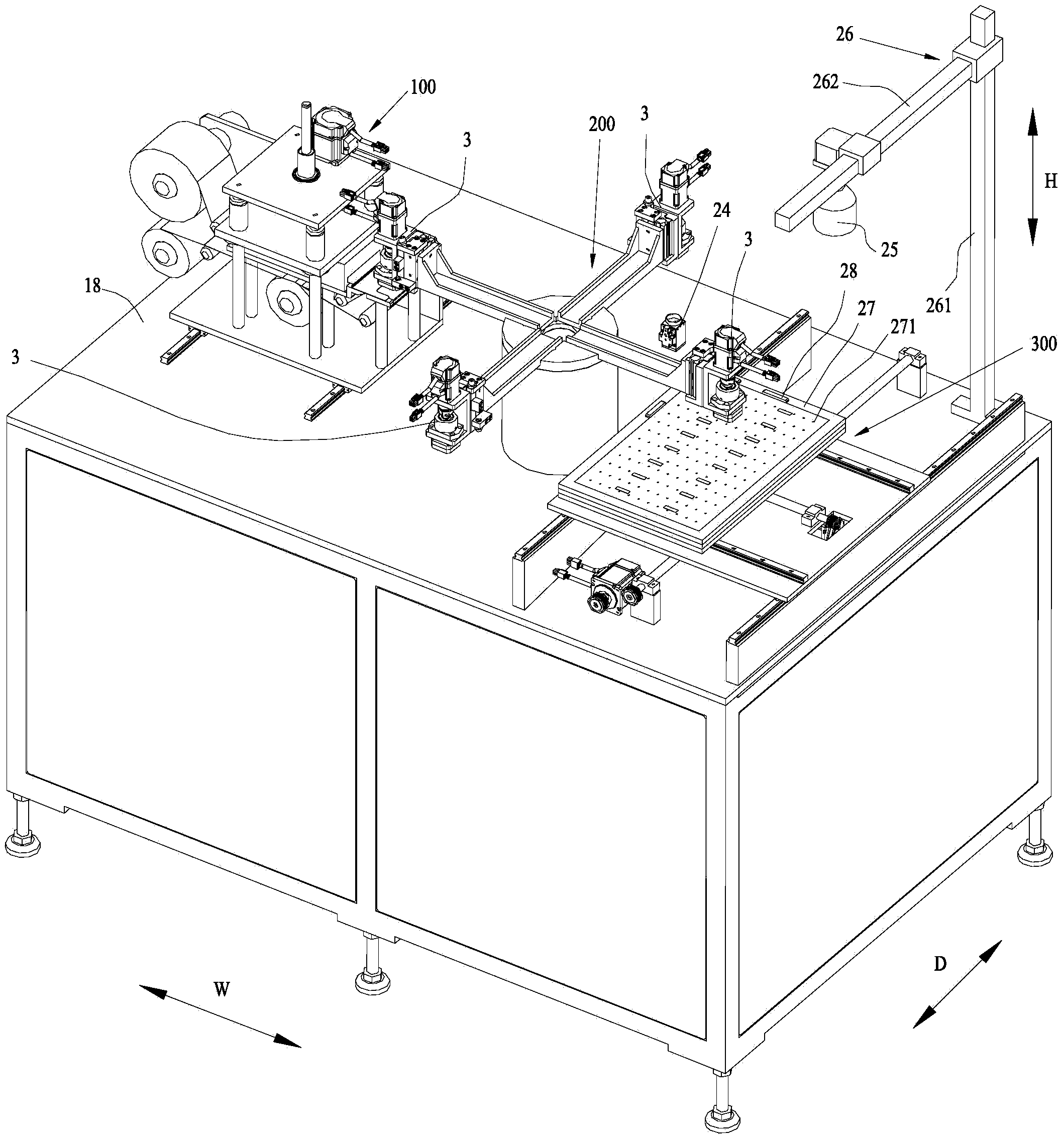

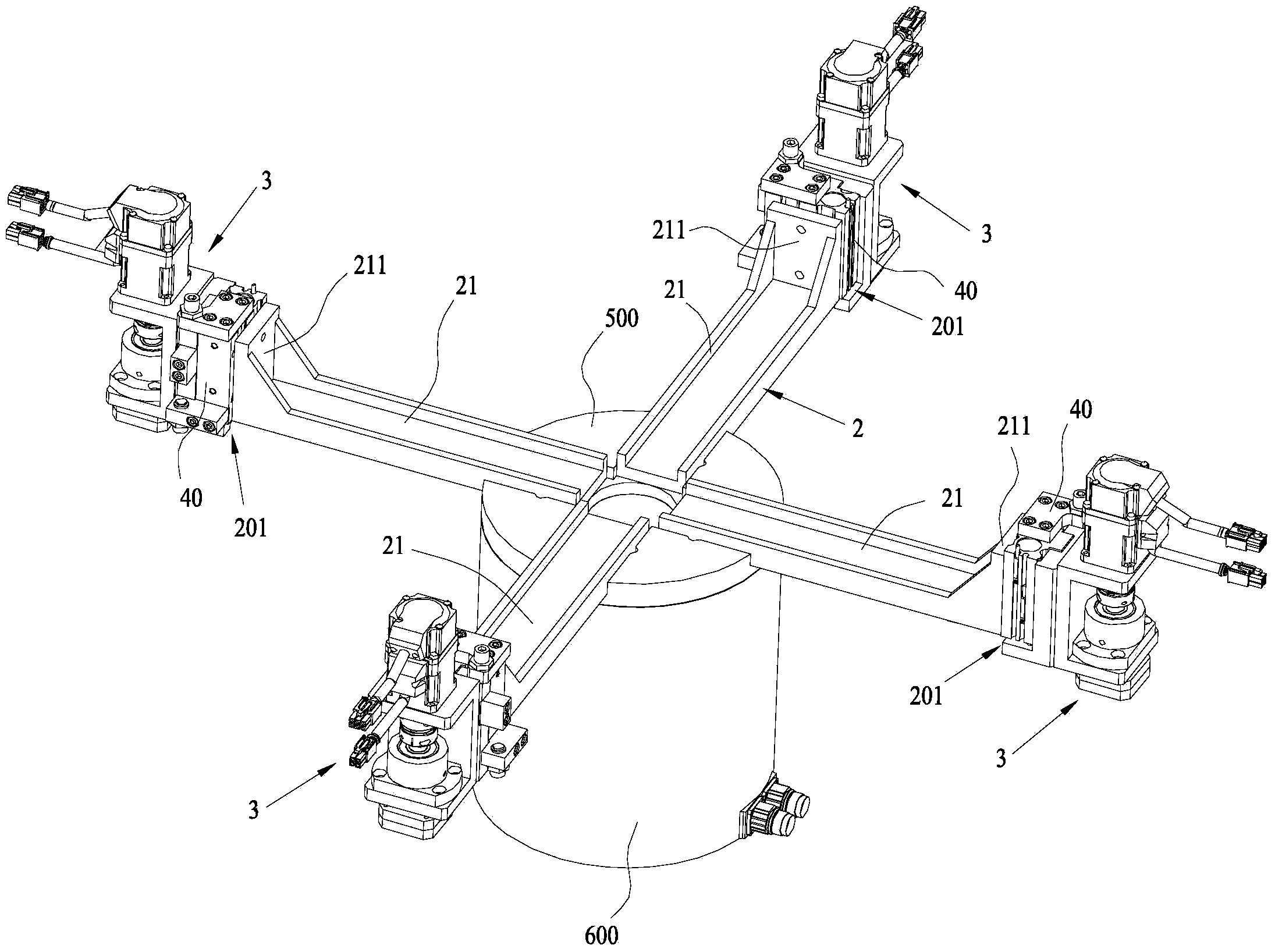

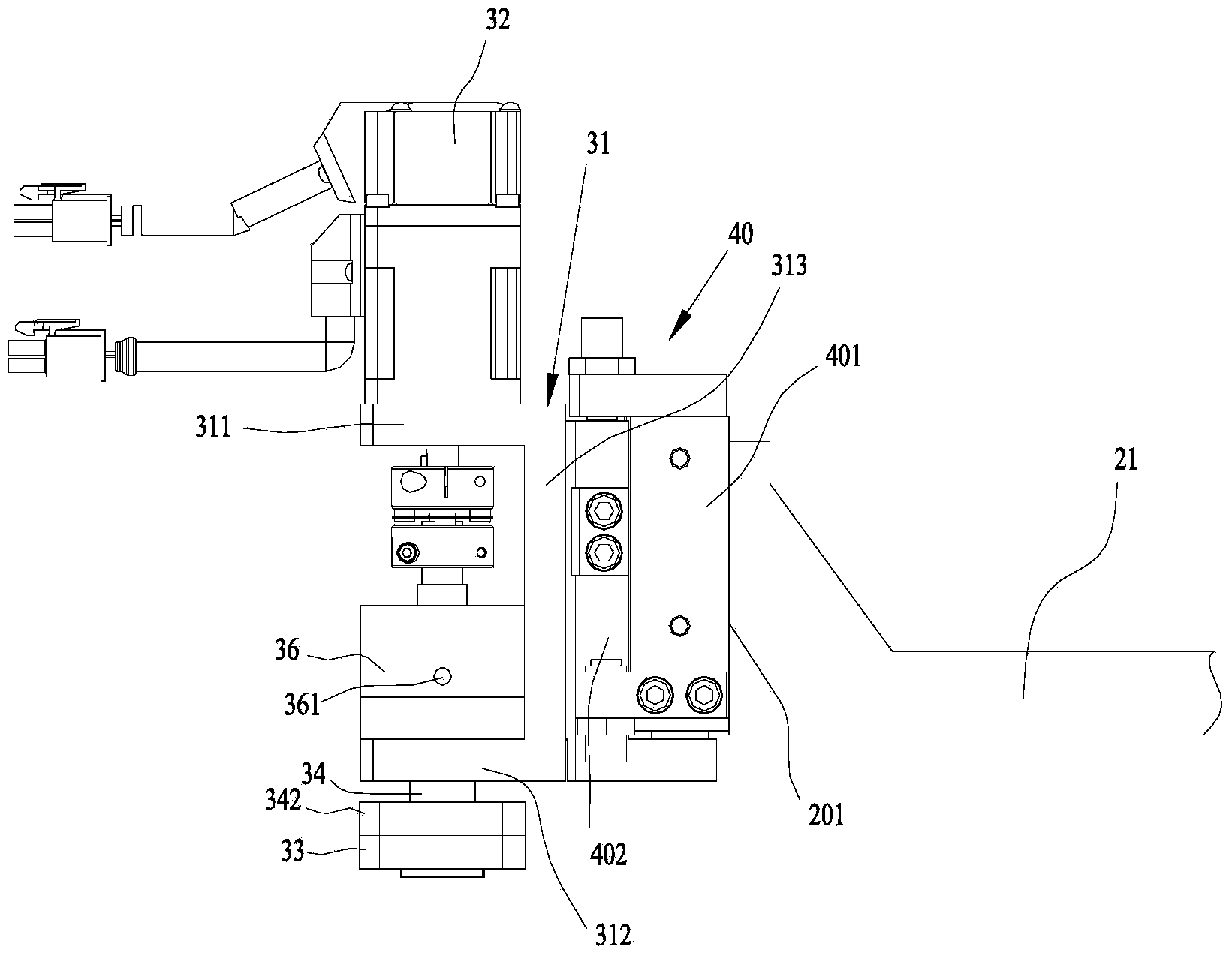

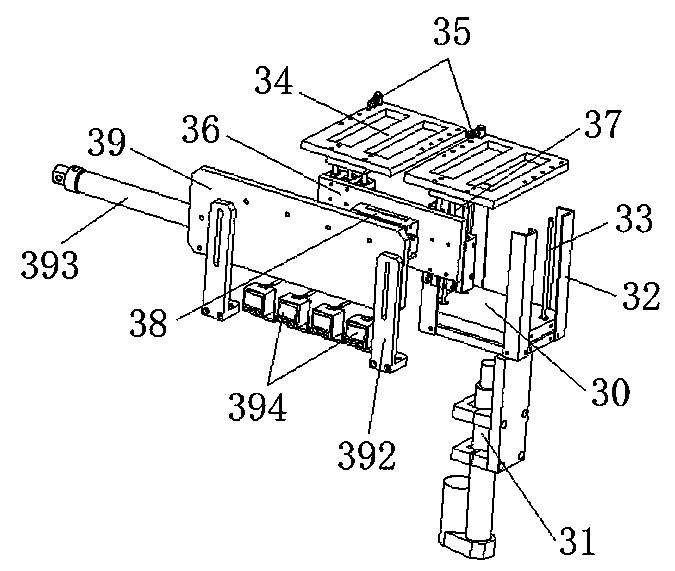

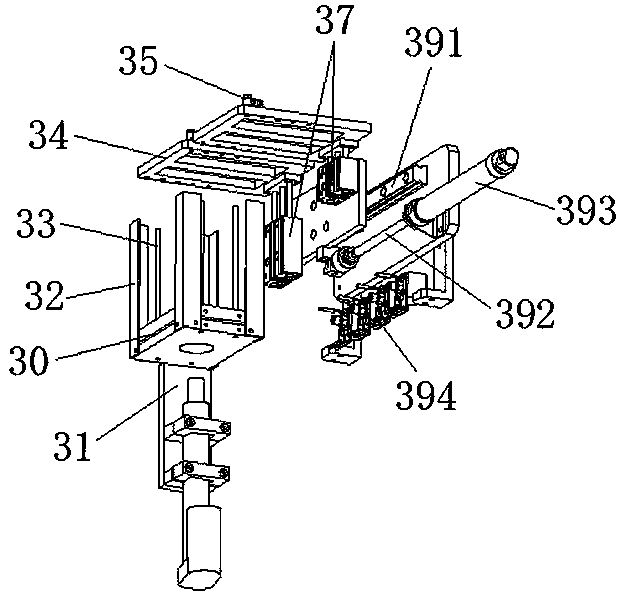

Automatic sheet foot pad laminating machine

PendingCN109130448APrecise suctionAvoid misalignmentLamination ancillary operationsLaminationAssembly lineEngineering

The invention discloses an automatic sheet foot pad laminating machine, which comprises a feeding mechanism, a conveying mechanism, longitudinal transmission modules, a bilateral transmission module,a vertical transmission module, a laminating rotary module, a clamping mechanism, a CCD visual positioning system and the like. A series of operations including jacking, sucking, planar transferring,clamping, CCD shooting, three-dimensional spatial foot pad grabbing position regulation, accurate foot pad grabbing, three-dimensional spatial movable conveying, three-dimensional spatial movable positioning, three-dimensional spatial spinning lamination, discharging and the like are completed on the top surface of a case. The problem of large floor area of traditional assembly line operating equipment is solved while sheet conveying time can be shortened, so that production efficiency and productivity are improved; the production process is free of artificial operations, so that labor cost ofenterprises is reduced; by joint use with the CCD visual positioning system and the transmission modules in different moving directions, high laminating precision, excellent laminating effects and the like are achieved.

Owner:林勇

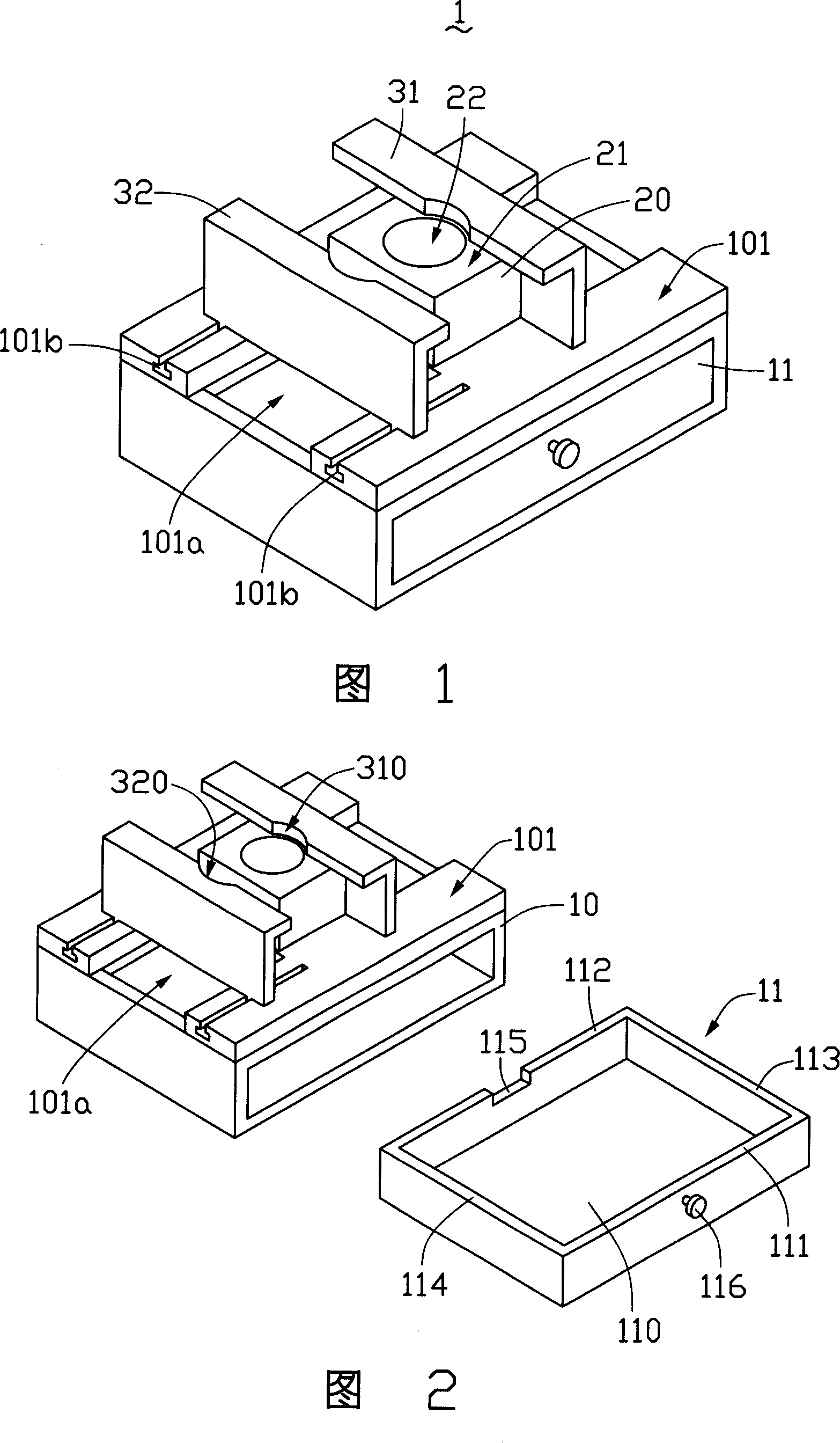

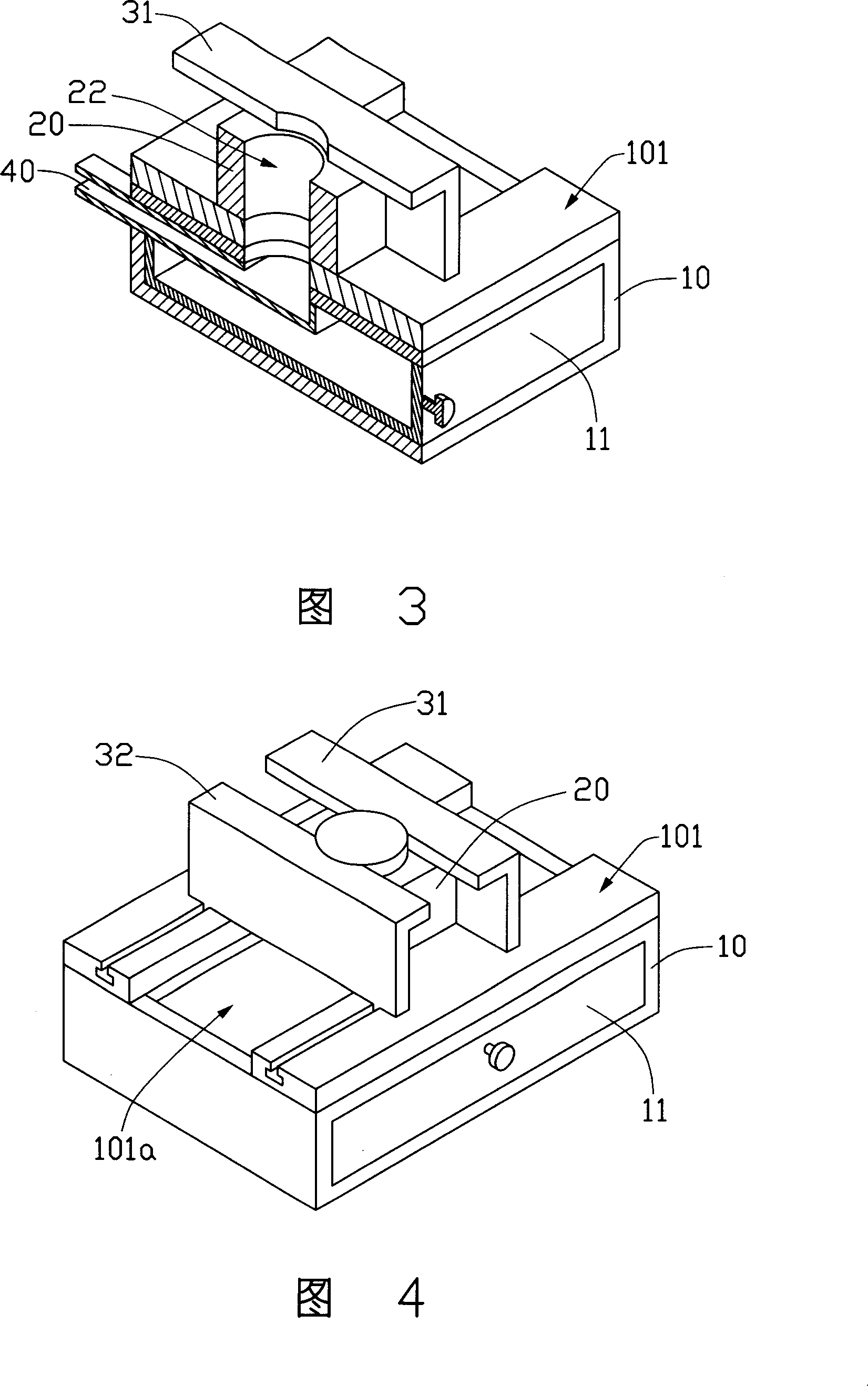

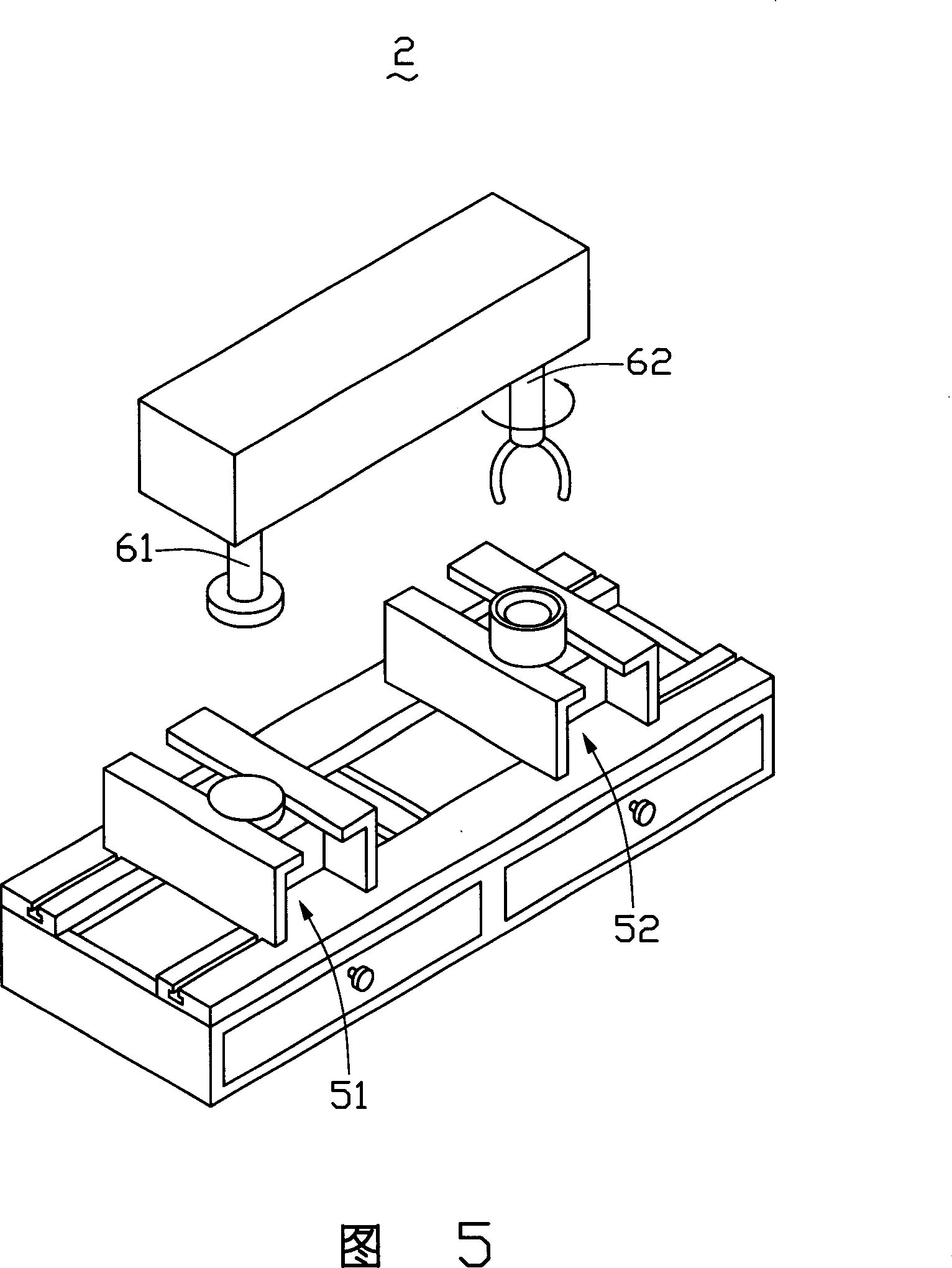

Positioning device and lens module assembling apparatus

A positioning device for lens module component and lens cone comprises a base, a bearing body on the surface of the base for the lens module component or lens cone, and the first and the second positioning block for the lens module or the lens cone, a storage drawer inside the base with its surface with notch connected to the storage drawer. It also provides a lens module assembly device for the said positioning device.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Facial mask folding and conveying device and facial mask folding equipment with same

The invention belongs to the technical field of facial mask production equipment and relates to a facial mask folding and conveying device and facial mask folding equipment with the same. The facial mask folding and conveying device provided by the invention comprises a rack, a moving and overturning mechanism and a lifting mechanism; the lifting mechanism is arranged at one side of the rack and is used for upwards moving a facial mask layer; the moving and overturning mechanism is arranged on the rack and can be used for overturning and moving the facial mask layer on the lifting mechanism; and the moving and overturning mechanism comprises a first driving assembly, a first connecting rod, a second connecting rod, a suction cup rack and a sliding chute. The facial mask folding and conveying device is simple in structure, convenient to operate, use and maintain, capable of effectively reducing manual operation and the possibility of artificial product pollution and guaranteeing more stable quality of the produced product, high in automation degree and production efficiency and low in production cost.

Owner:宋福文

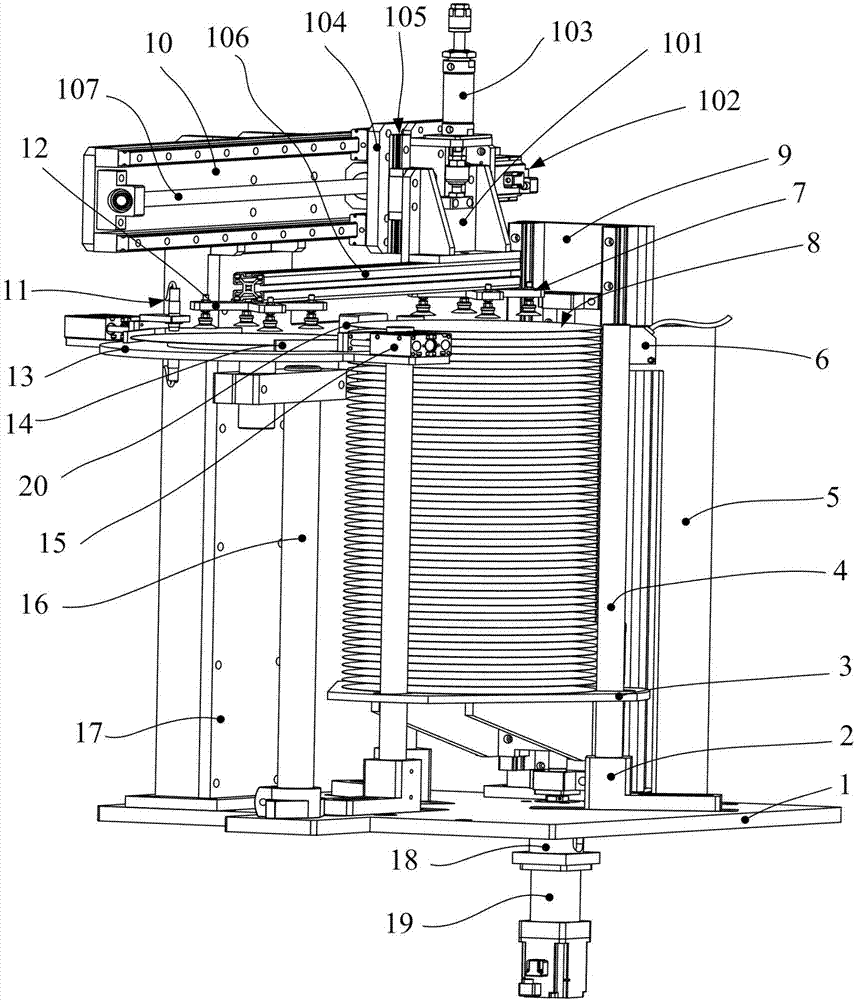

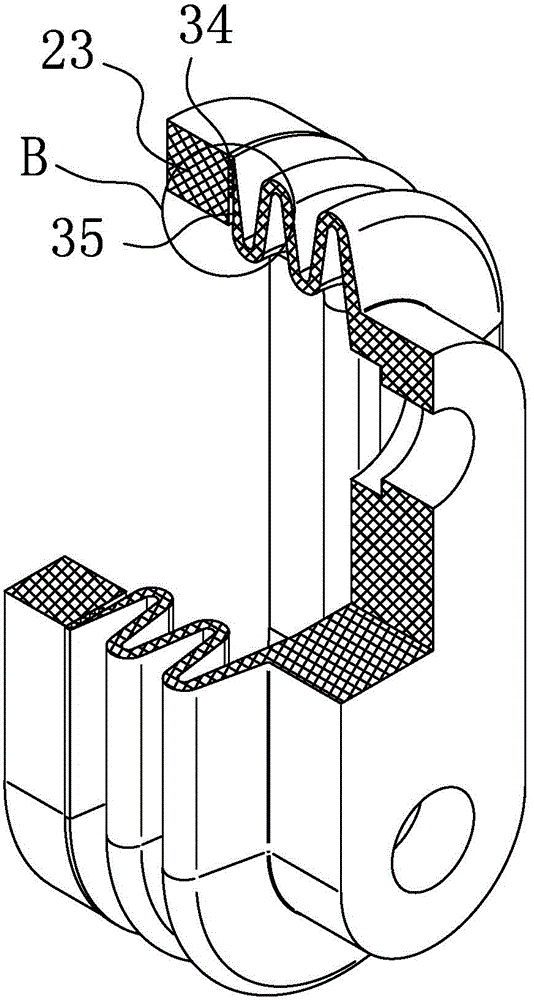

In-mold label multifunctional conveying system

InactiveCN101337406APrecise suctionPrecise windingStacking articlesPlastic forming machineEngineering

The invention relates to a multi-functional in-mould label conveying system, which comprises a volume label positioning device, a volume label sucking device, a rolling bar, a detecting component, a manipulator and a stacking device. The volume label positioning device is provided with a volume label tank to contain a large quantity of volume labels; a power component is arranged under the volume label tank to drive a pushing plate and push the volume labels upward; the volume label sucking device is arranged on the front side of the machine support, and is also provided with a power component to drive a moving part; the moving part is provided with a sucking component, which can be used for sucking the volume labels from the volume label positioning device to a rolling device; the rolling device is provided with the rolling bar; the rolling bar is provided with a C-shaped rolling tank, and can adsorb the volume labels first; after the rolling bar starts rotating, the C-shaped rolling tank is utilized to roll the volume labels into appropriate shape smoothly; the rolling device is provided with the detecting component to control the rotating radian and distance of the rolling bar of the rolling device; the manipulator is used for clamping rolled volume labels and is positioned into the cavity of the forming die of a plastic forming machine; plastic end products are taken out from the forming die of the plastic forming machine; the stacking device receives the plastic end products from the manipulator and conveys the end products to a packing place after the end products are stacked on a conveying belt.

Owner:黄胜昌 +1

Method for improving homologous recombination efficiency and recombination virus screening of pseudorabies virus

InactiveCN106544367AAvoid influenceShorten screening timeBioreactor/fermenter combinationsBiological substance pretreatmentsEnzyme digestionFluorescence

The invention discloses a method for improving homologous recombination efficiency and recombination virus screening of pseudorabies virus. According to the method, a pseudorabies virus AH strain transfer vector containing an EGFP gene complete expression box is subjected to enzyme digestion linearization, and then subjected to homologous recombination with the pseudorabies virus AH strain; and the obtained recombination virus screening method comprises the steps of separating fluorescent single host cells with pathological changes, and then performing further screening by improved plaque experiment. After recombinant plasmid enzyme is subjected to digestion linearization, the enzyme is subjected to cell transfection; next, virus homologous recombination is performed, so that the homologous recombination efficiency is improved; by virtue of the method in combination with single cell absorption and plaque purification, the screening and purifying time of the recombination viruses is greatly shortened; and therefore, the method is of great significance to improvement of the virus homologous recombination efficiency, has high application prospect in single cell separation, particularly recombination virus screening, and can be widely applied to the recombination virus screening.

Owner:SOUTH CHINA AGRI UNIV

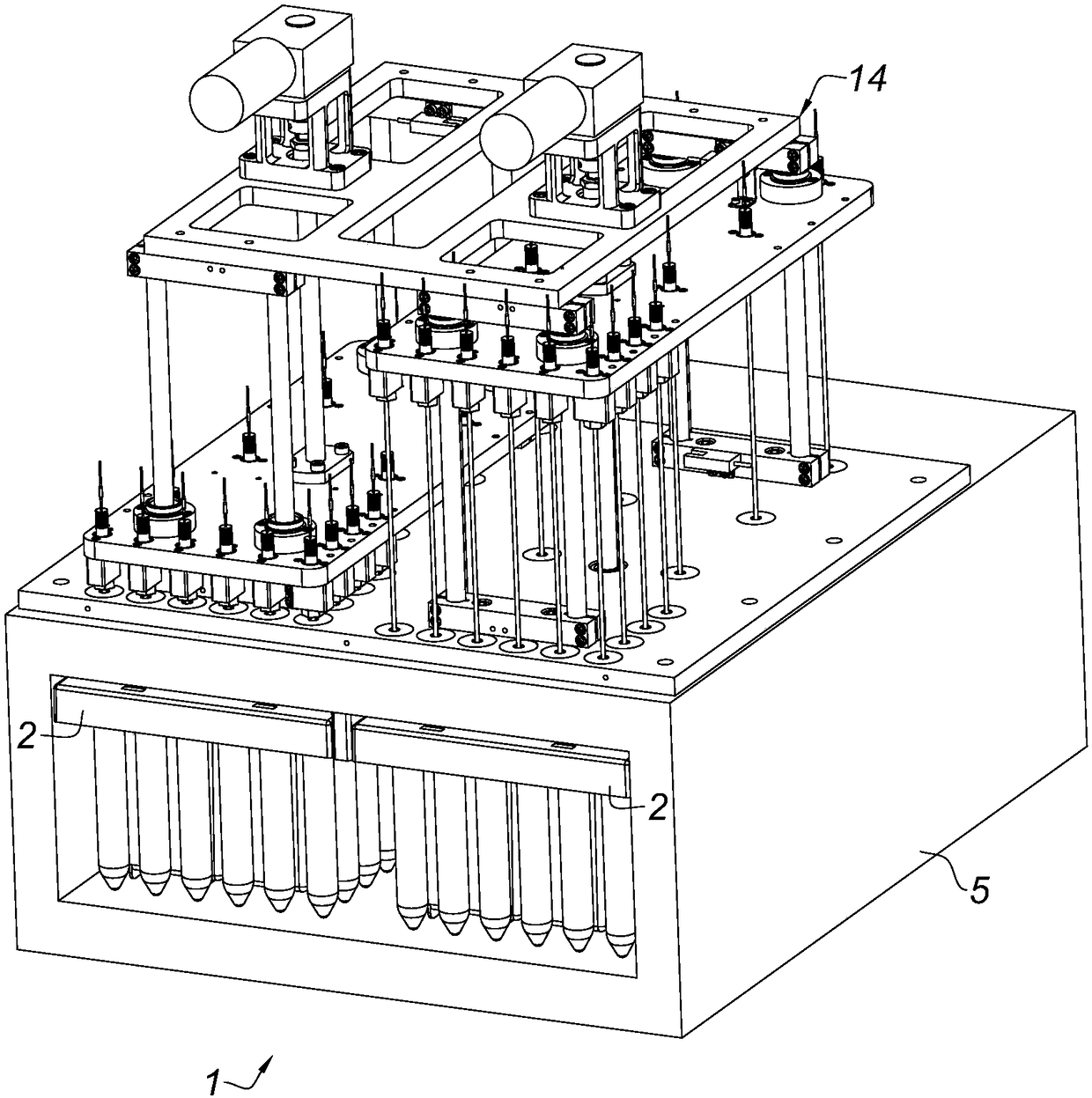

Reagent storage device

ActiveCN108100491AHigh degree of automationPrecise suctionDomestic cooling apparatusLighting and heating apparatusTemperature controlReagent

The invention belongs to the technical field of biochemical appliances, and provides two types of reagent storage device. A first type reagent storage device includes a reagent box, a thermal insulating box, a temperature control module, and a motion module; the reagent box has a seal film and is placed in the thermal insulating box; a temperature sensor is arranged in the thermal insulating box;a temperature control module is arranged on the thermal insulating box; the temperature control module adopts a Peltier effect principle to work; a motion module body is arranged outside the thermal insulating box; and the motion module can drive a reagent needle to puncture the seal film of the reagent box to suck a reagent. The second type of reagent storage device is similar to the first type of reagent storage device, and the main difference between the first type reagent storage device and the second type of reagent storage device is that a motion module of the second type reagent storagedevice is arranged in the thermal insulating box, and a door is arranged on the thermal insulating box. The reagent storage device is simple in structure, facilitates assembly and later maintenance,can be transplanted on different appliances, and is wide in compatible range; the temperature control module can avoid noise and vibration, is safe to use, can rapidly achieve cooling and heating, andis excellent in temperature control effect.

Owner:MGI TECH CO LTD

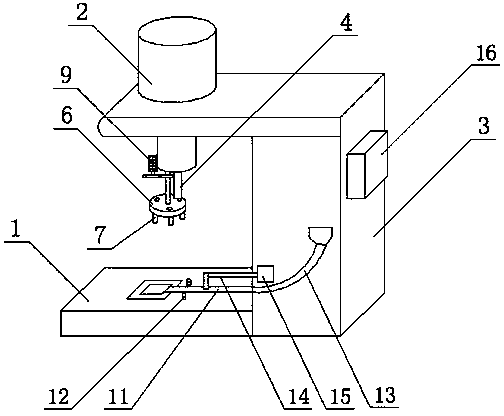

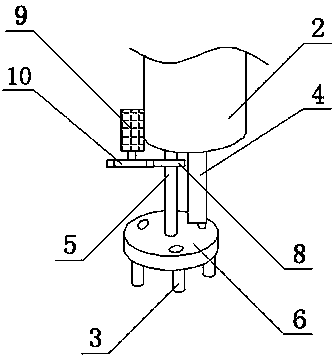

Full-automatic machine for sewing trouser buttons

InactiveCN103653472AImplement the switching operationRealize buttoning operationClothes making applicancesEngineeringUltimate tensile strength

Provided is a full-automatic machine for sewing trouser buttons. The full-automatic machine for sewing the trouser buttons comprises a base (1), wherein a stand column (3) is fixed to the base (1), a machine head (2) is installed at the upper end of the stand column (3), a strike driving device is installed in the machine head (2), a strike rod (4) is perpendicularly fixed to the lower end, in the axis direction, of the bottom of the strike driving device, a rotary disk (6) is installed at the position, arranged on the outer side of the strike rod (4), of the bottom of the strike driving device through a rotary shaft (5), more than one rotary die head (7) is fixed to the circumference of the bottom surface of the rotary disk (6), a rotation driving device is installed on the rotary disk (6), and a button conveying slide way (11) is arranged between the stand column (3) and a button sewing working position arranged on the base (1). The full-automatic machine for sewing the trouser buttons is compact in structure, button placement, button locating and button sewing are automatically accomplished, labor intensity of operators is greatly reduced, processing efficiency is high, safety performance is good, the buttons are sewed accurately and firmly, and large-scale button sewing is facilitated.

Owner:JIHUA 3506 TEXTILE & APPL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com