Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

106results about How to "Mobile location is accurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Contour recognition technology-based high-efficiency and low-cost automatic recharging system and method

InactiveCN107608358AHigh efficiency costLow costElectromagnetic wave reradiationPosition/course control in two dimensionsPhysicsMobile location

The invention discloses a contour recognition technology-based high-efficiency and low-cost automatic recharging system and a method. Only one feature module needs to be arranged on a charging seat, and a laser radar and a mobile mechanism are arranged on a mobile platform. A light beam emitted by the laser radar is reflected back when the light beam emitted by the laser radar touches an obstacle.The analysis is carried out through analysis units on the mobile mechanism, so that the contour line of the surrounding environment is obtained. The mobile platform is controlled to move and clean bythe mobile mechanism. Meanwhile, relevant line segments with a feature module are compared and then the position of the charging seat with the feature module is judged. In this way, the mobile platform is automatically returned to the charging seat for being charged according to the position information when the mobile platform needs to be charged. The whole structure is simple, and the control process method is simple. By adopting the laser radar and a radar reflection light analysis unit, the system is not prone to being influenced by dust and the like compared with infrared detection. Meanwhile, the contour recognition technology is adopted, so that the moving position of the mobile mechanism is more rapid and more accurate.

Owner:隆博科技(常熟)有限公司

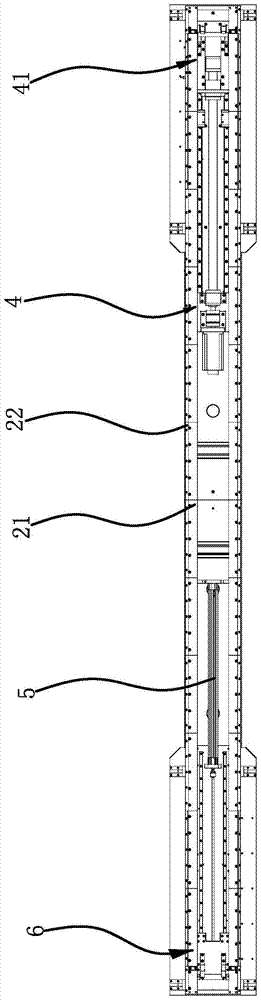

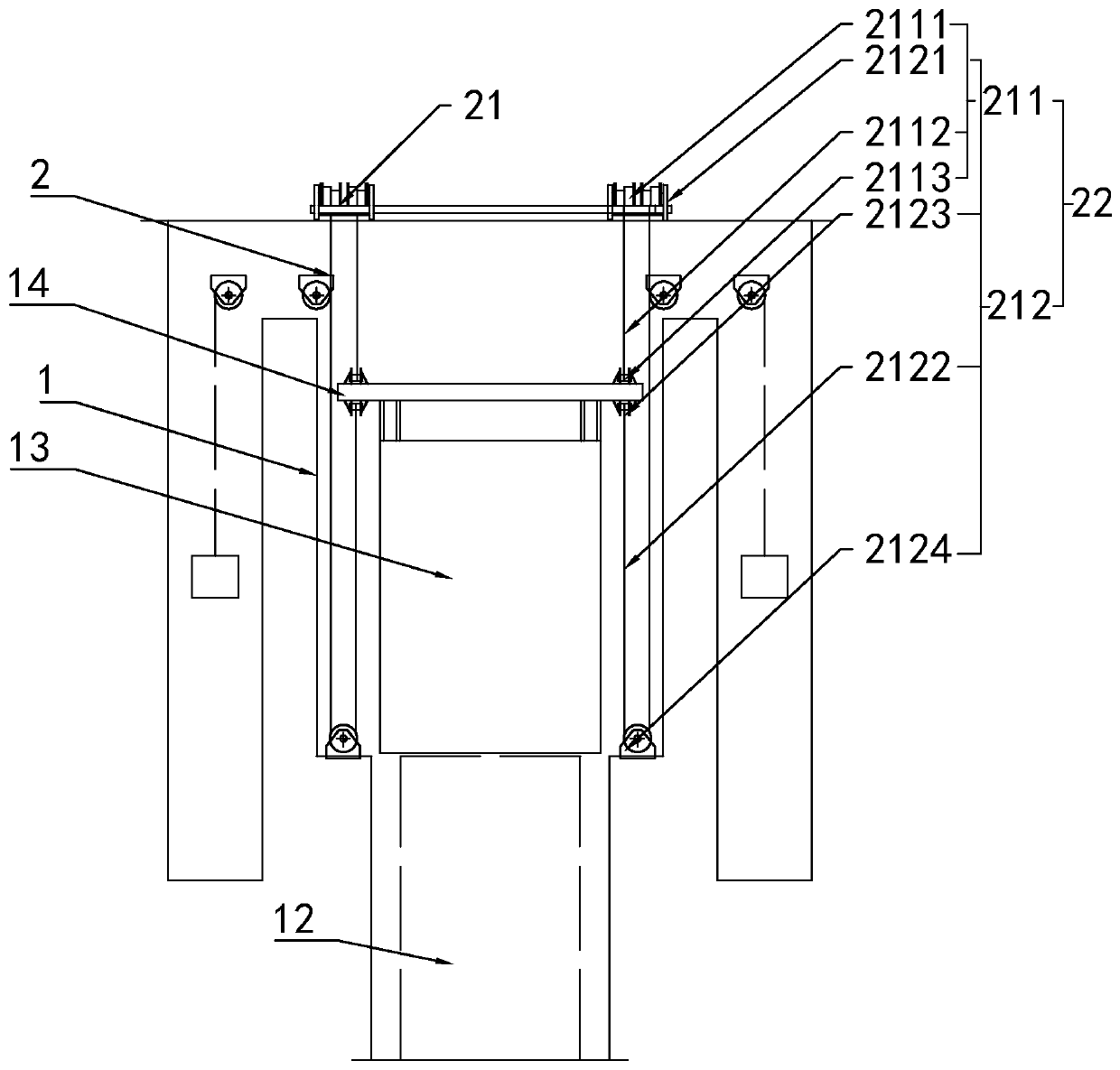

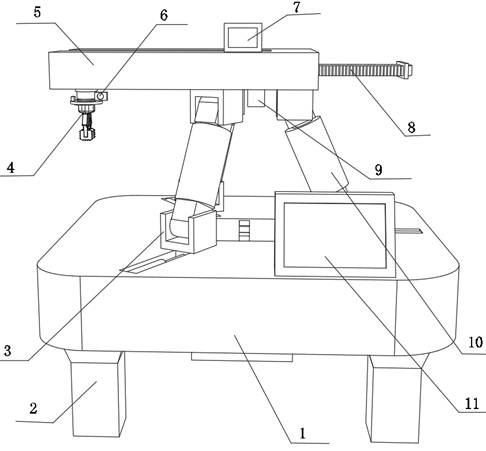

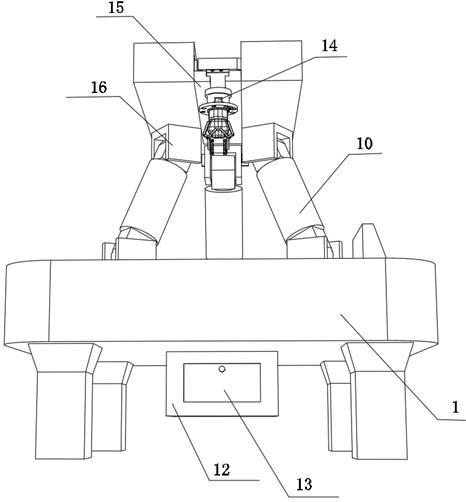

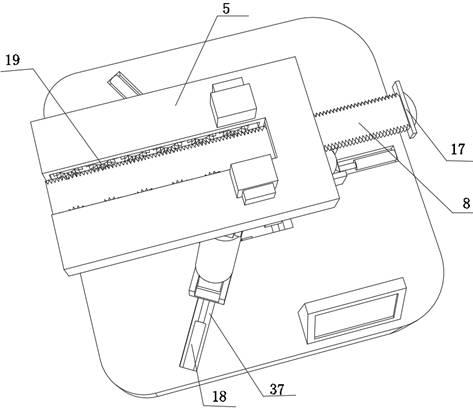

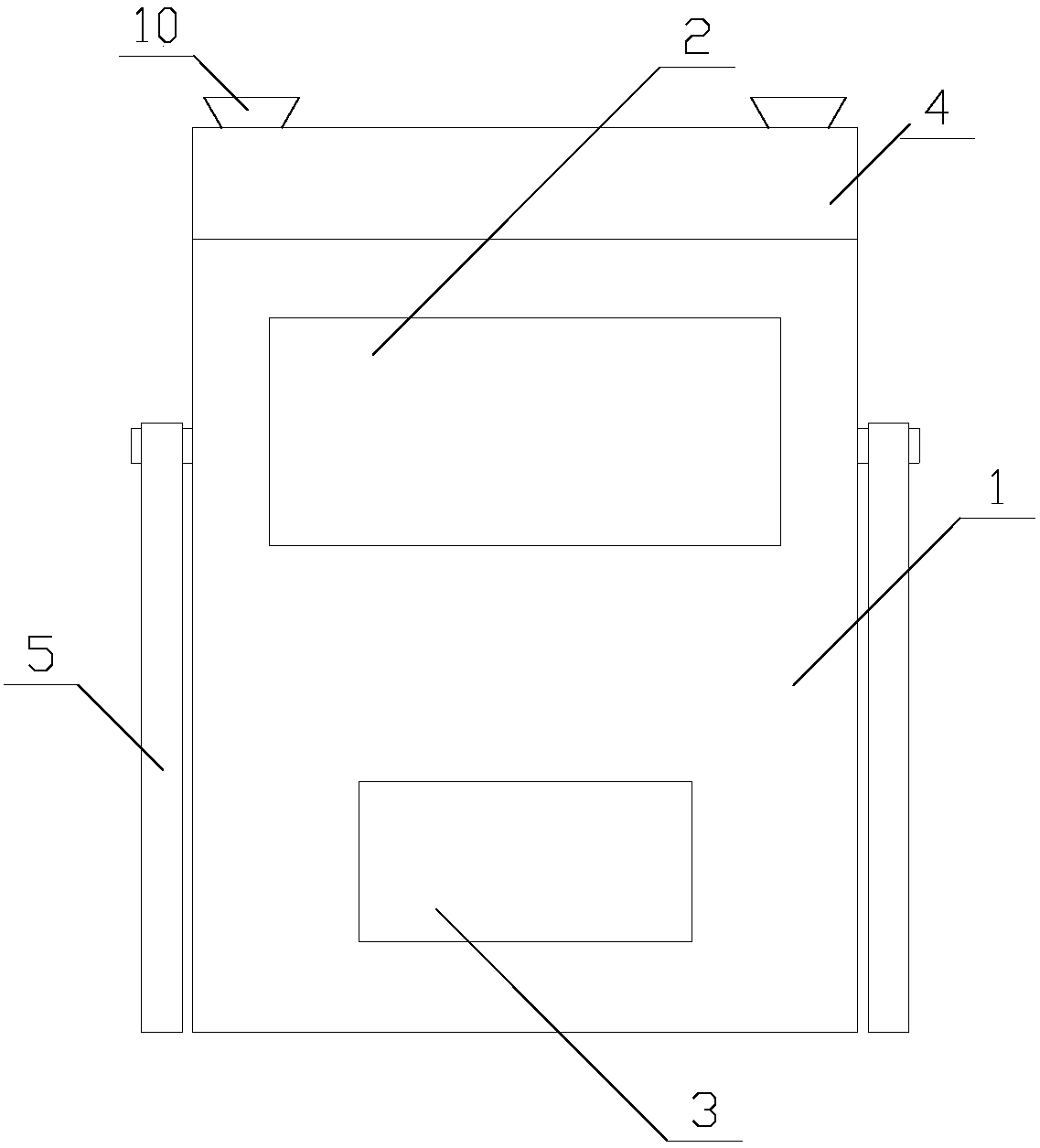

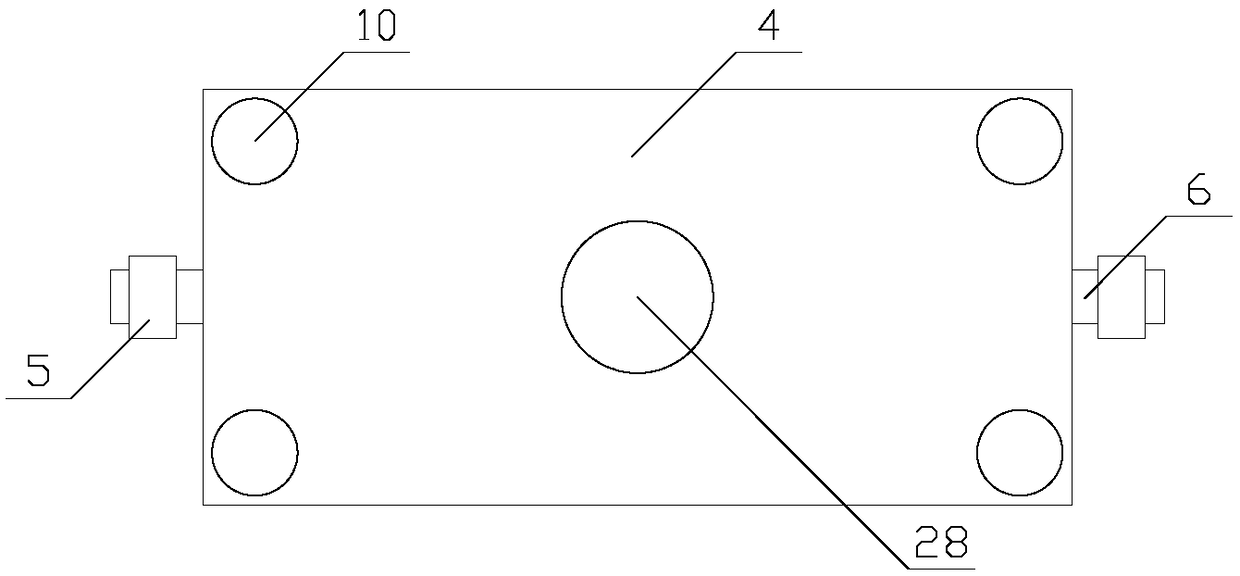

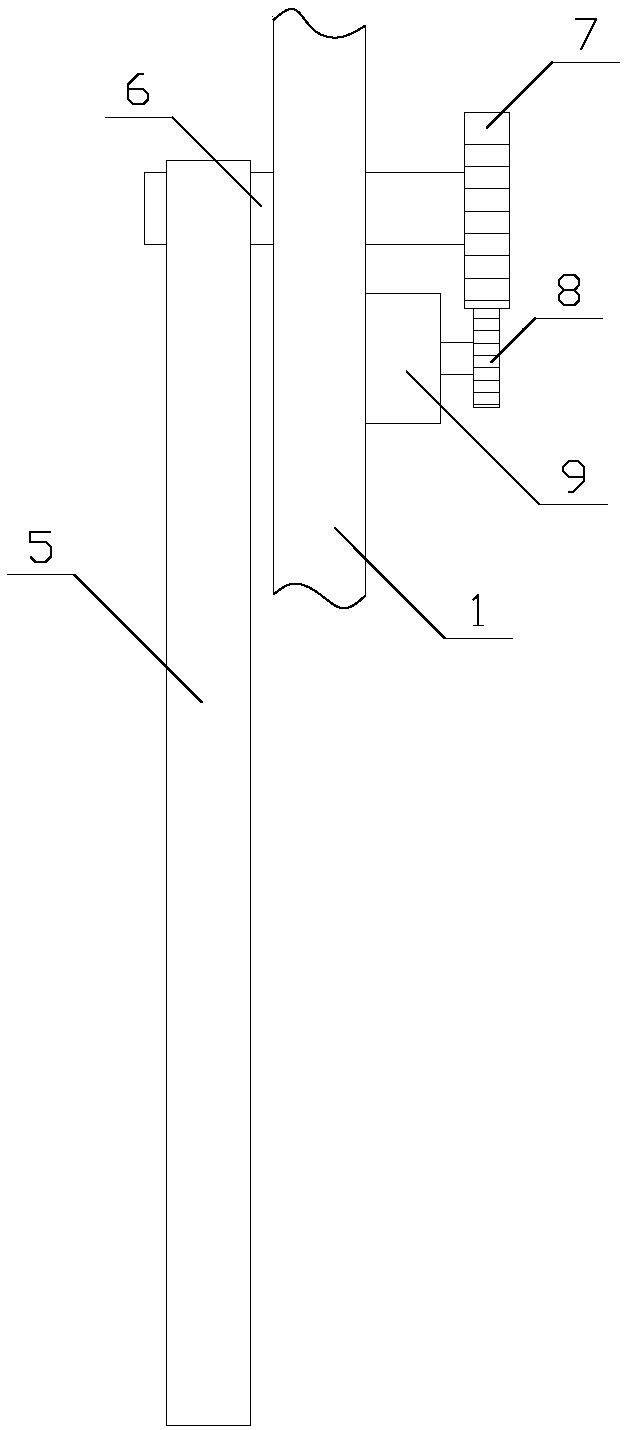

Automated drilling device for pipes of multiple specifications

ActiveCN106881472AReduce frictionPrecise rotational positionFeeding apparatusLarge fixed membersFriction reductionRolling resistance

The invention discloses an automated drilling device for pipes of multiple specifications. The automated drilling device comprises a base. The automated drilling device is characterized in that an output shaft of a longitudinal servo motor is linked with a ball screw, and the ball screw is supported by bearings and assembled onto the base; a workbench is further arranged above the base; a rolling guide rail is arranged between the workbench and the base; a mechanism for driving a conical clamp to rotate is arranged on the workbench; and the mechanism comprises support frames, a rotating servo motor, a reducer and a center height adjusting device. The device is provided with multiple adjustment mechanisms, and multiple holes can be drilled in the circumferential faces of the pipes large in length and diameter change range; the pipes move and rotate in the form of rolling friction, friction is reduced, rotation positions and movement positions are precise, and positional precision of all the holes drilled in the pipes is obviously improved; mounting of the pipes is completed one time, and the pipes do not need to be loosened in the intermediate process; and automation is achieved in the whole drilling process, and efficiency is obviously improved.

Owner:江苏三升信电子工程有限公司

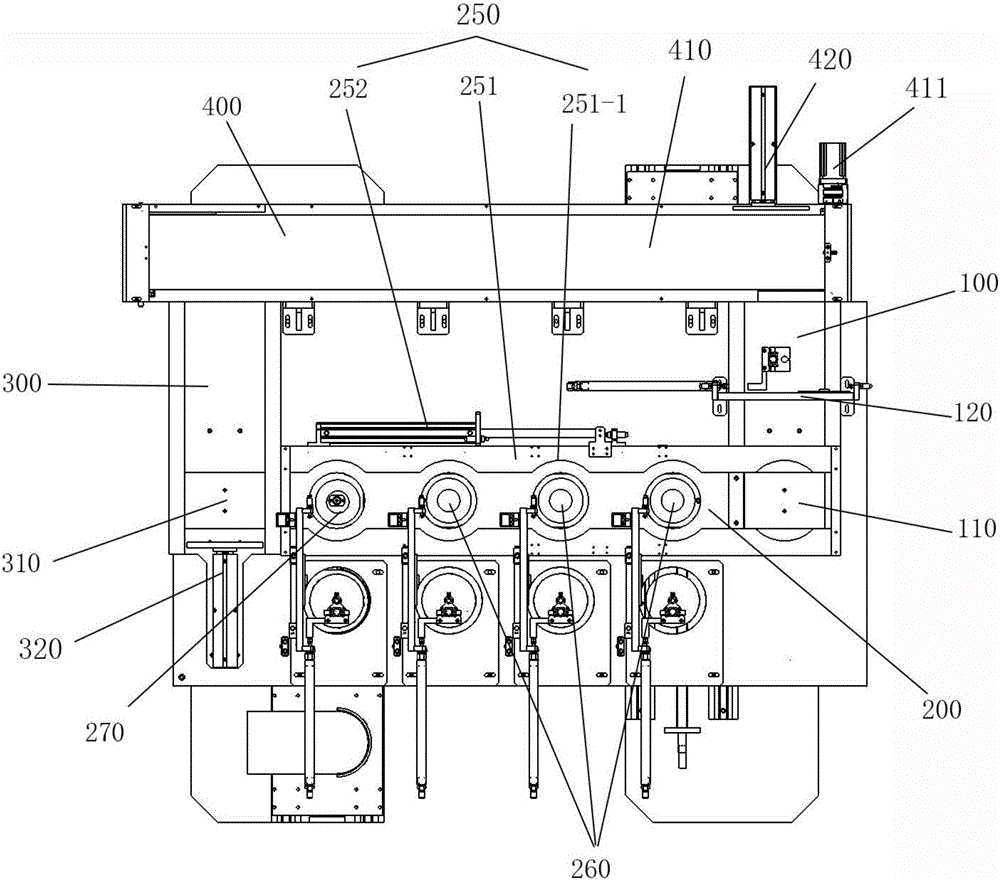

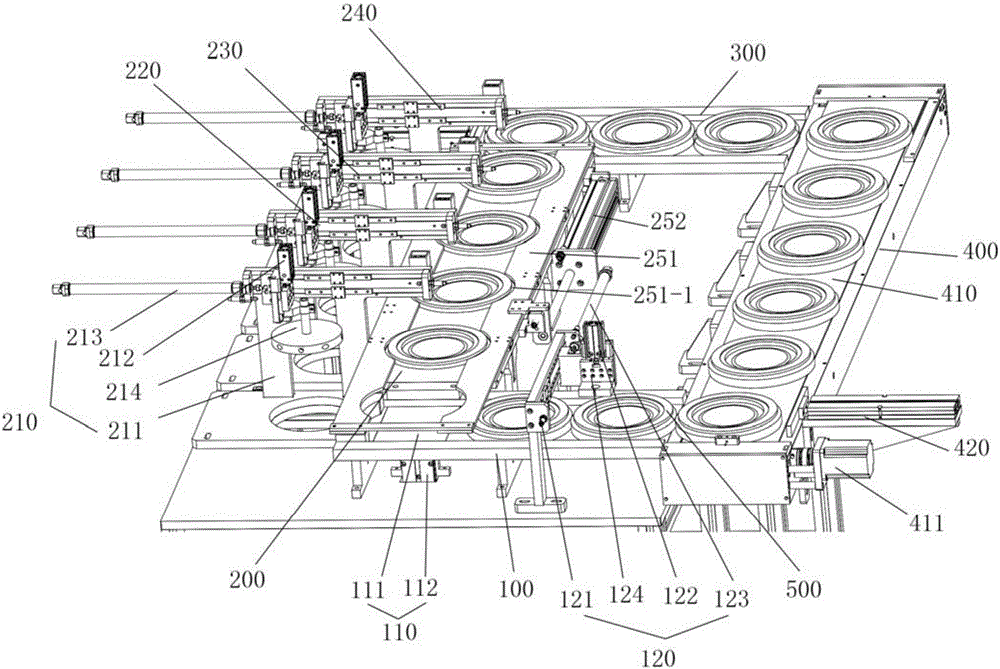

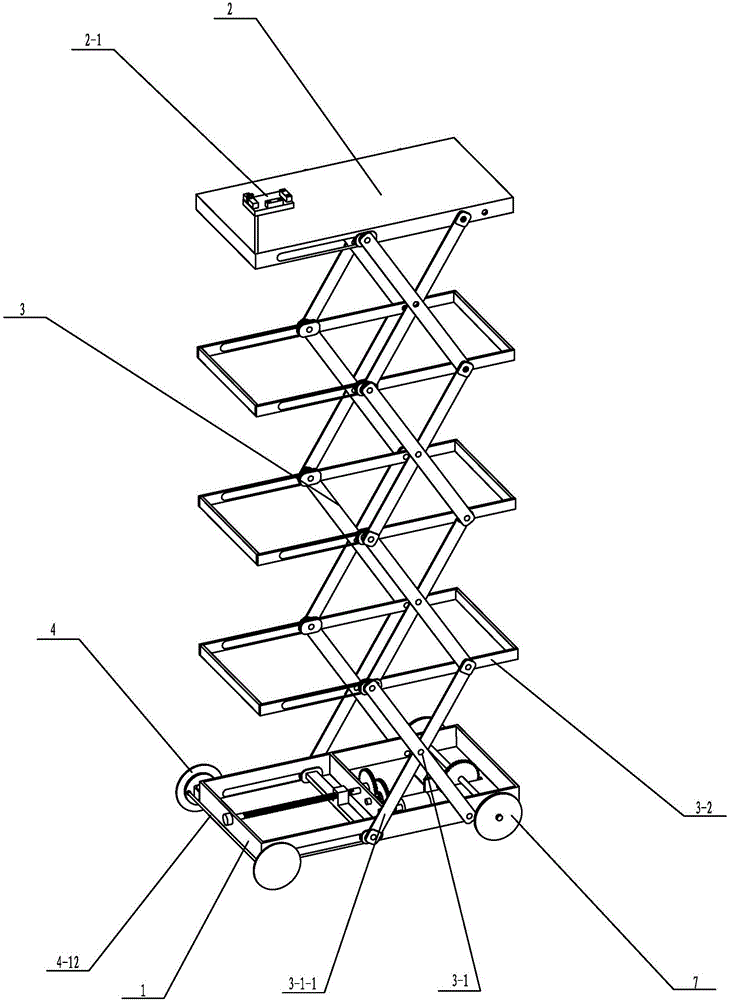

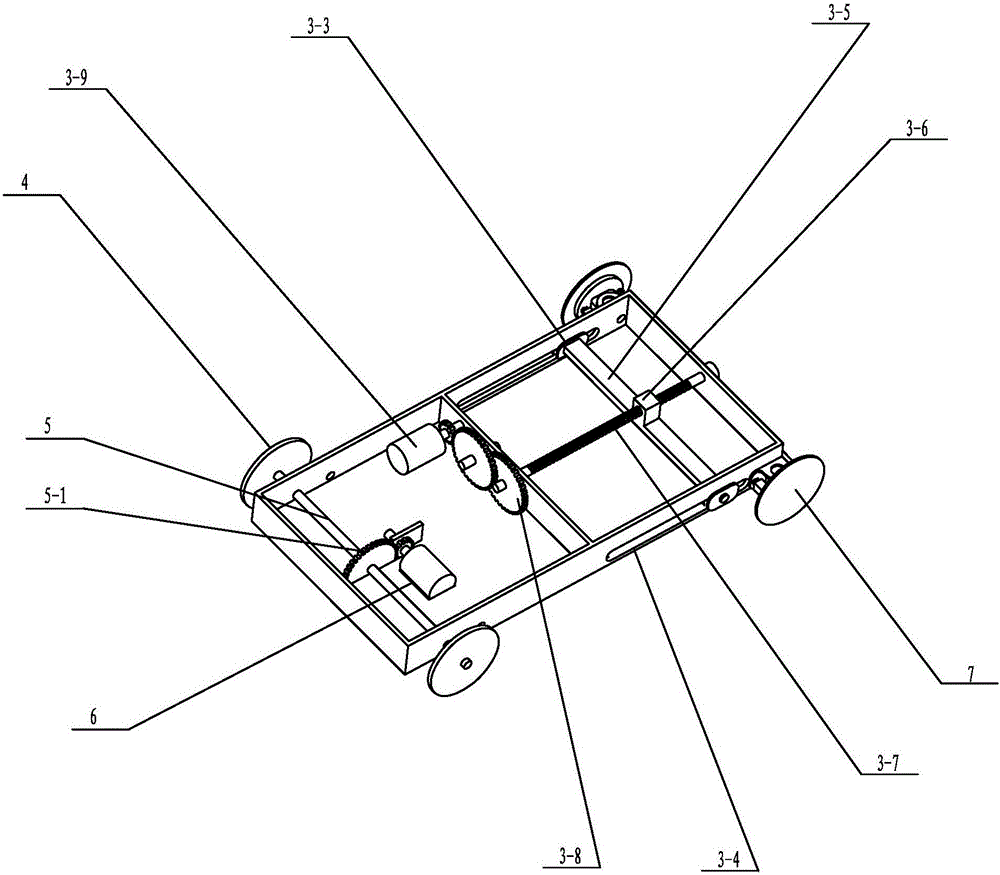

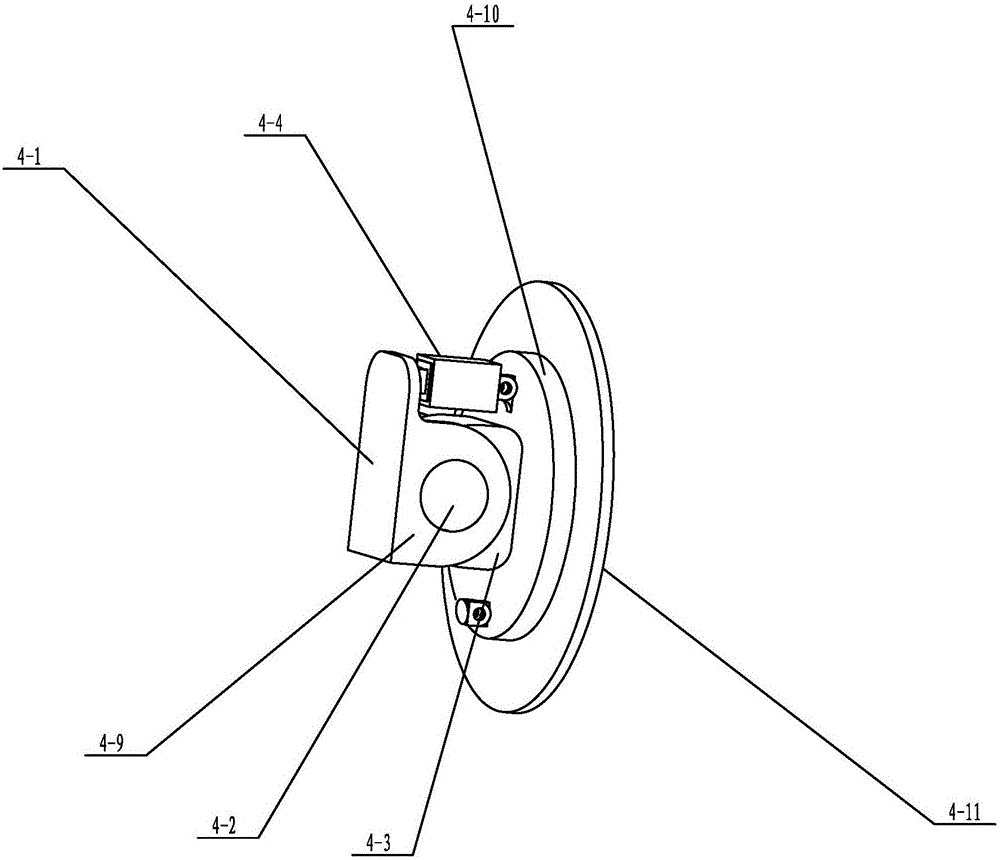

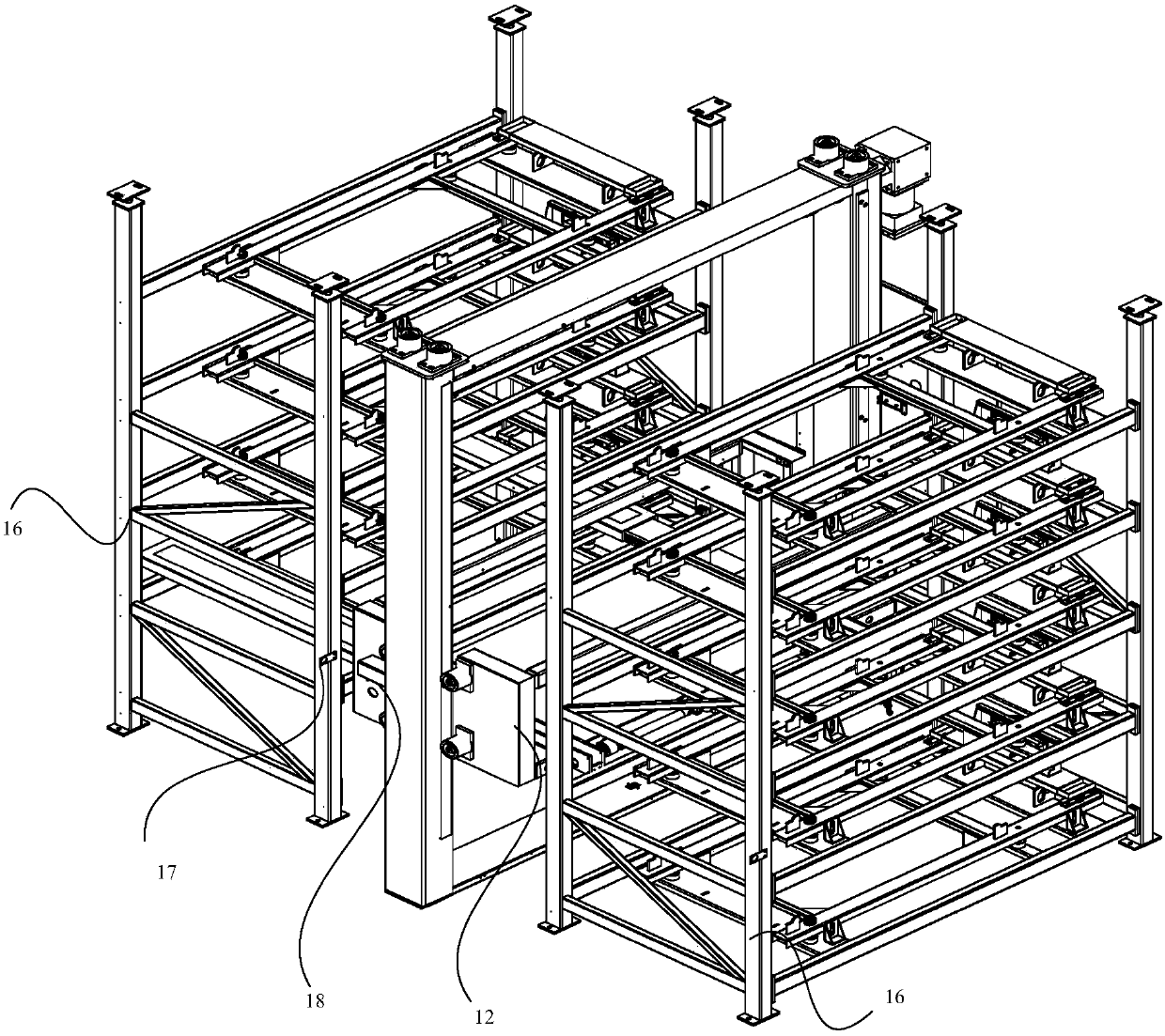

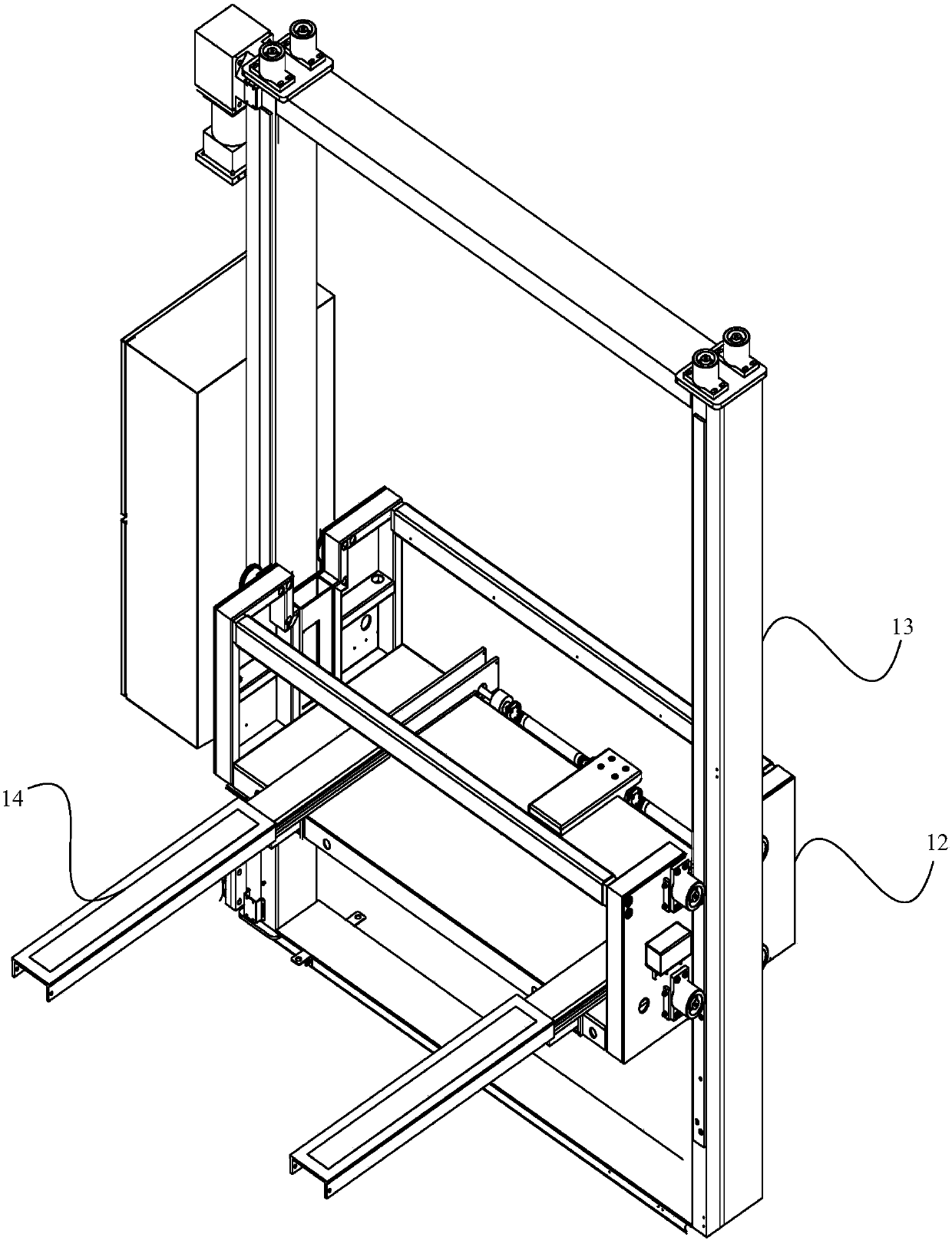

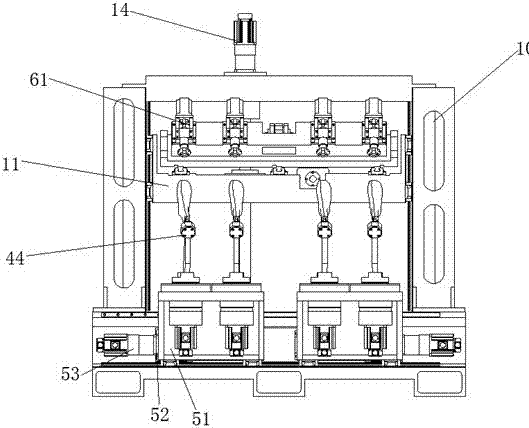

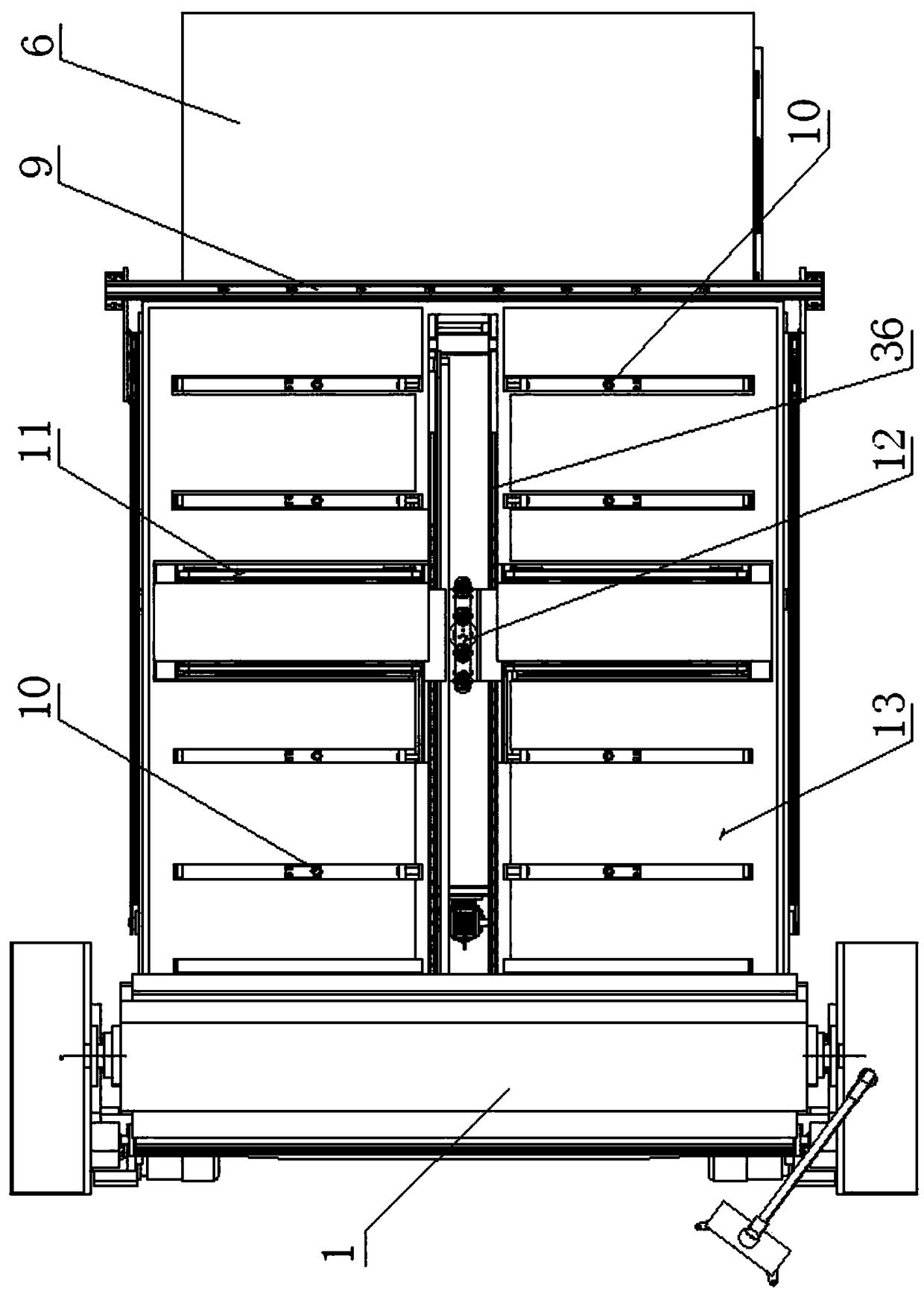

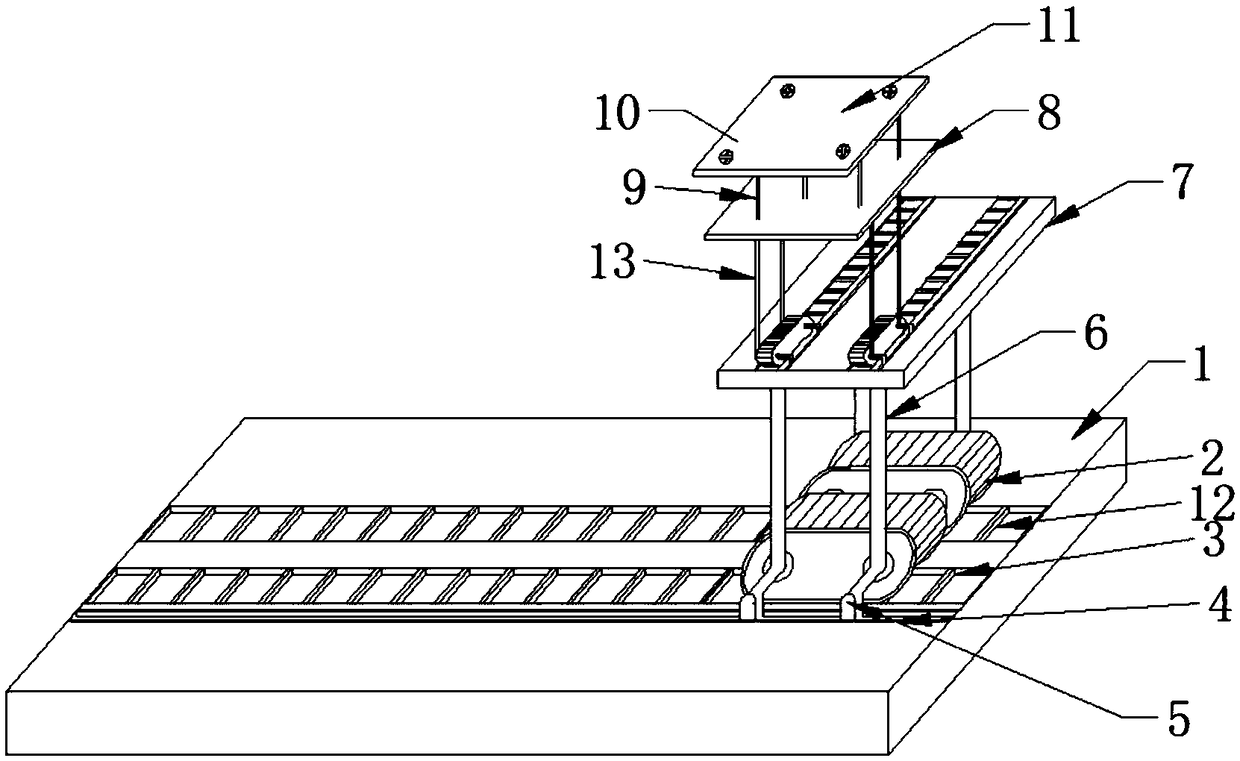

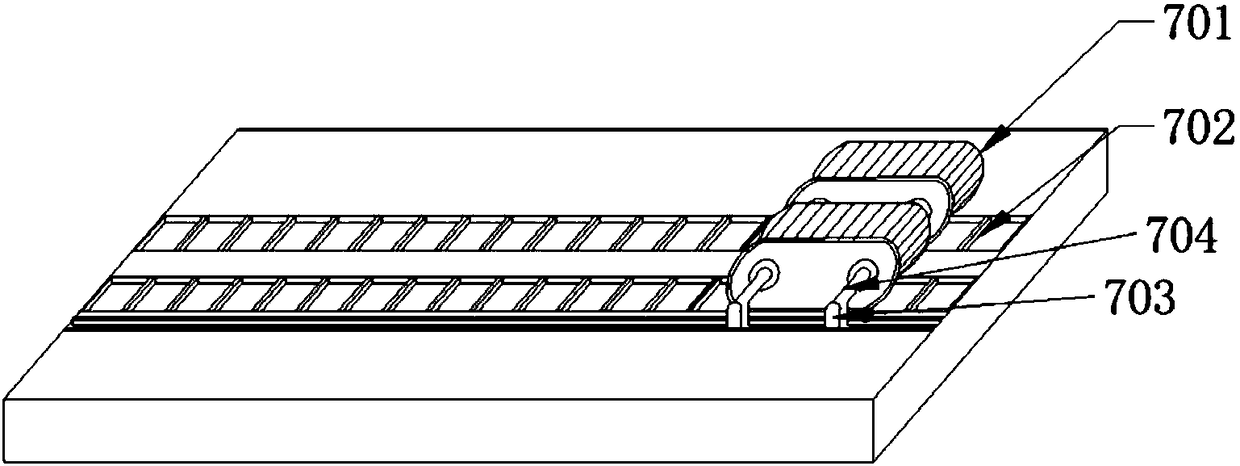

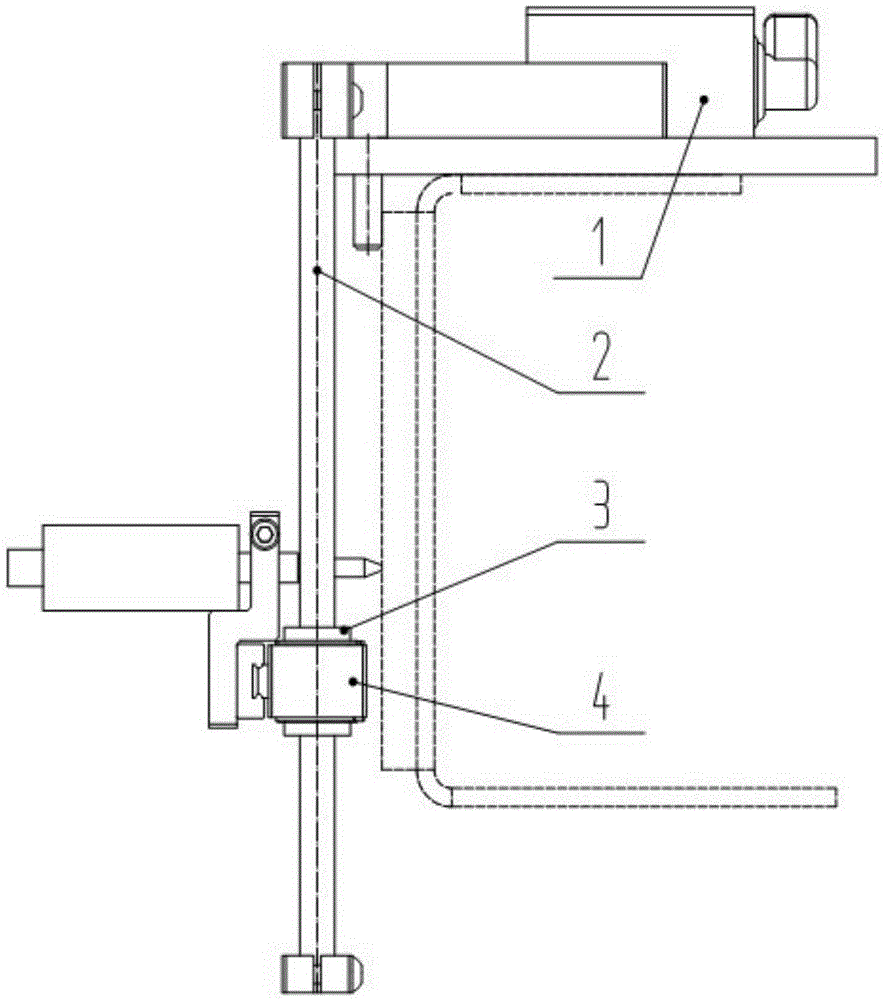

Automatic assembly equipment for LED panel lamp

ActiveCN106312549AReduce labor costsReduce manual labor intensityAssembly machinesLight guideEngineering

Automatic assembly equipment for an LED panel lamp comprises a worktable, wherein an unloading and loading track, an operation assembly track, a carrier turnover track and a carrier backflow track which are arranged rectangularly on the worktable in sequence; carriers are arranged on the tracks; a reflector paper assembly mechanism, a light guide plate assembly mechanism, a diffuser plate assembly mechanism and a face cover assembly mechanism are arranged sequentially in the direction of the operation assembly track; the operation assembly track is higher than the unloading and loading track and the carrier turnover track; a first lifting mechanism is arranged on the unloading and loading track; a second lifting mechanism and a first pushing mechanism are arranged on the carrier turnover track; a moving mechanism and a third lifting mechanism are arranged on the operation assembly track; the carrier backflow track comprises a conveyor belt and a conveyor belt motor and is provided with a second pushing mechanism. With adoption of the structure, automatic assembly of the LED panel lamp is realized, and the automatic assembly equipment has the characteristics of high production efficiency, stable assembly quality, small labor amount and low production cost.

Owner:广州力硕自动化设备系统集成有限公司

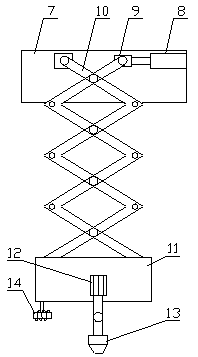

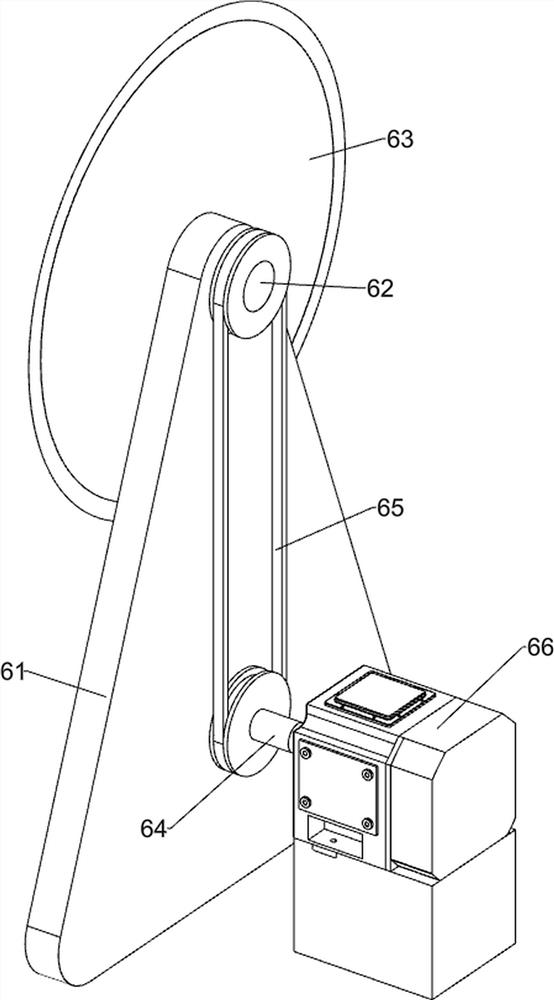

Lifting device for adjusting height based on ball screws

ActiveCN106044623AChanging Height Fixed DefectsHighly flexible adjustmentLifting framesBall screwIndustrial engineering

The invention discloses a lifting device for adjusting a height based on ball screws. The lifting device comprises a chassis, and a lifting platform arranged on the chassis; the chassis and the lifting platform are connected through a lifting module; the lifting module includes multiple lifting movable rod sets symmetrically arranged on two sides between a lifting plate and the chassis up and down; the adjacent lifting movable rod sets are hinged with each other, and lifting support frames are arranged in the hinged places; chutes capable of linearly sliding slide blocks are formed in two sides of the lifting plate, the lifting support frames and the chassis; the ball screws are arranged on the lifting module; and a lifting switch is arranged on the lifting platform. The lifting device can flexibly adjust the height, can be suitable for aerial operations with different heights, is wide in application range, can fold and compress a lifting system and reduce the size to bring convenience for carrying, in addition, can move on the horizontal plane in all directions, saves both time and labors, is convenient and fast in adjustment, effectively improves the working efficiency, is convenient and practical, and deserves wide popularization.

Owner:QINZHOU UNIV

Shared accompanying bed and commercial mode of shared accompanying bed

PendingCN109330266ASolve the occupation of activity spaceComfortable supine positionSofasCouchesState of artComputer terminal

The invention discloses a shared accompanying bed and a commercial mode of the shared accompanying bed. The shared accompanying bed comprises a main bed, a secondary bed arranged below the main bed, aconnector for connecting the main bed with the secondary bed, and an electronic lock arranged on the main bed; a commercial mode of the shared accompanying bed comprises the above shared accompanyingbed, a server, and a user terminal; a control terminal is arranged at the shared accompanying bed; and the step for executing the commercial mode comprises the following steps: user registration, usepermission acquisition; a user sends an instruction to the server, and starts the control terminal on the shared accompanying bed, and performs service charging; the user returns the shared accompanying bed, automatically stops charging and performing fee deduction. Compared with the prior art, the space use is reasonable, redundant activity space cannot be occupied, the use is quiet, stable andcomfortable, and the bedside table use cannot be influenced; the shared accompanying bed is provided with the electronic lock; and the commercial mode has the advantages of being reasonable in charging, fast in renting and returning, and easy to manage.

Owner:DONGTIE MECHANICAL & ELECTRICAL TECH CO LTD

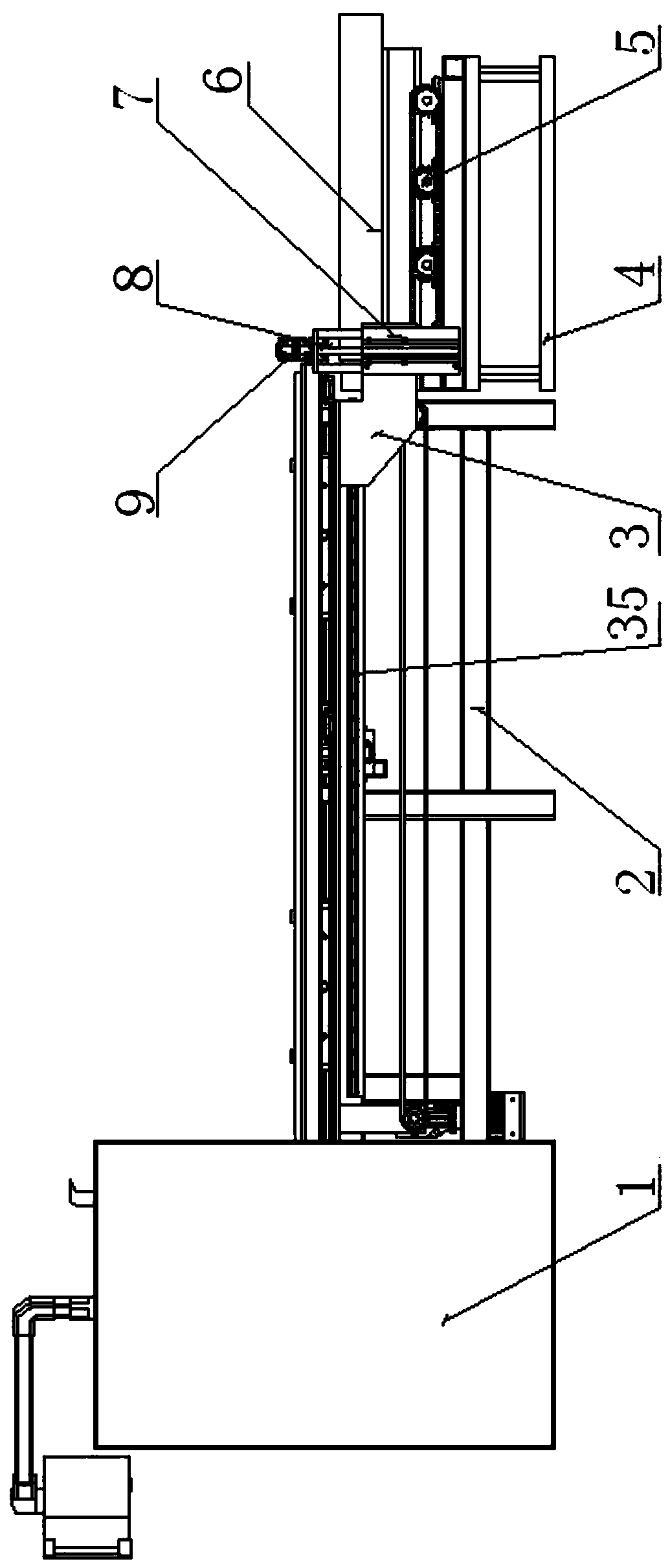

Battery placing and positioning system

PendingCN109849862AMobile location is accurateLow costElectric propulsion mountingElectric/fluid circuitAutomotive engineeringElectricity

The invention discloses a battery placing and positioning system which comprises a battery transfer device, a battery rack, a camera and a control unit; the battery transfer device comprises a lift car, a frame and a driving device; the lift car is arranged in the frame and can move up and down along the frame; the driving device is used for driving the lift car to move, and the camera is arrangedon the lift car; a positioning mark is arranged on the surface, facing the battery transfer device, of the battery rack; the control unit is electrically connected with the camera and the driving device and controls operation of the driving device according to images shot by the camera. According to the battery placing and positioning system, whether the lift car moves to an accurate position ornot is judged through pictures shot by the camera, so that the driving device is controlled to move the lift car to the accurate position; the moving position of the lift car is accurate, the cost ofthe camera is lower than that of laser equipment, and the cost of battery replacement equipment is reduced.

Owner:SHANGHAI DIANBA NEW ENERGY RESOURCES SCI & TECH +1

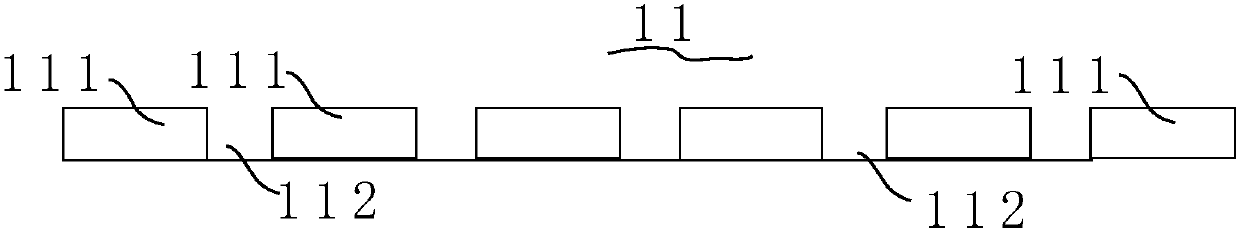

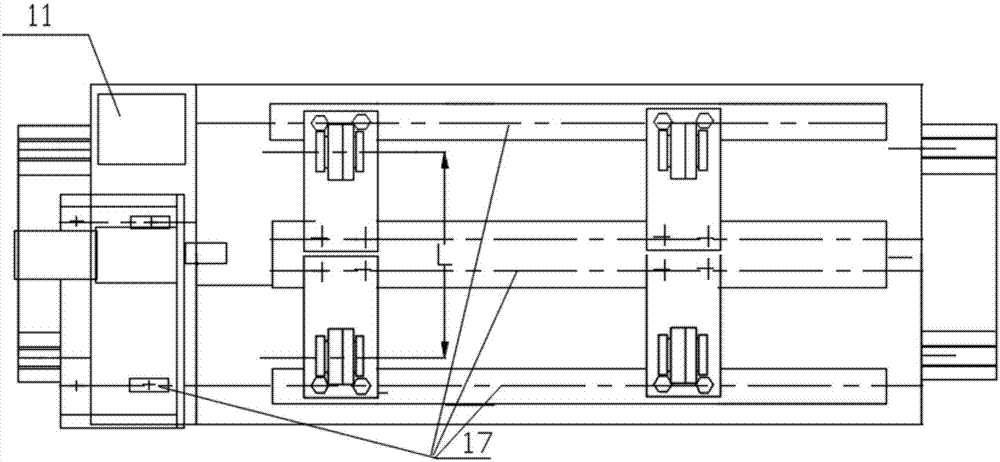

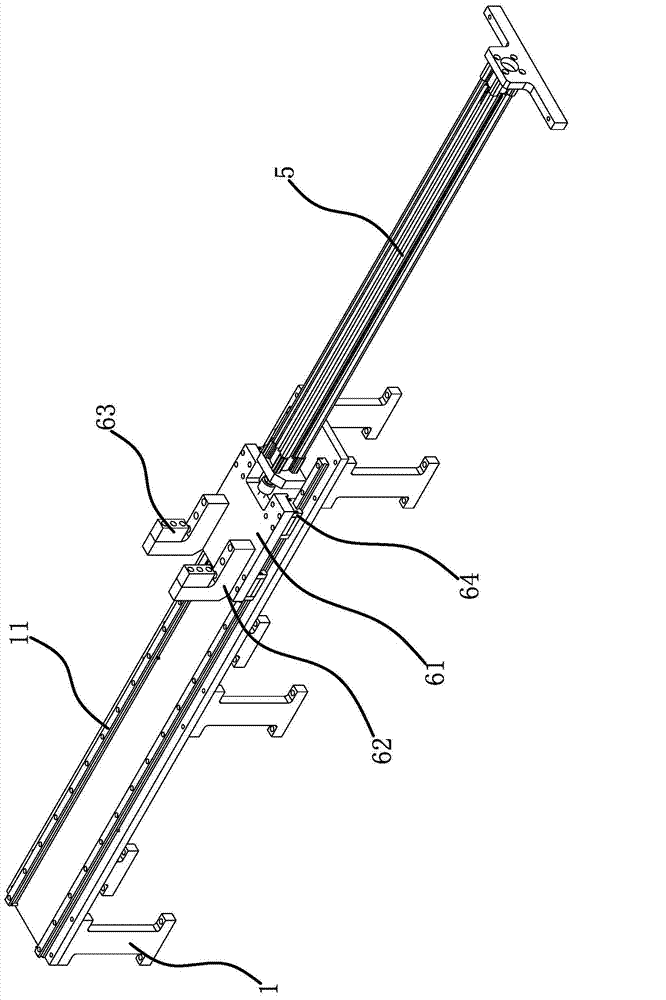

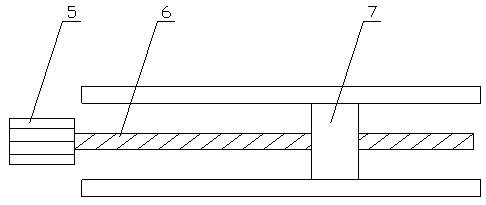

Conveying device for infusion set assembling machine clamp

The invention provides a conveying device for an infusion set assembling machine clamp and belongs to the technical field of medical accessory assembling machines. The conveying device solves the problem that the stopping position of an existing infusion set assembling machine clamp is not accurate. An infusion set assembling machine comprises a rack. The conveying device of the infusion set assembling machine clamp comprises a guide track and a moving supporting plate, wherein the moving supporting plate can be placed on the guide track, a driving mechanism is arranged at the end, provided with the guide track, of the rack, a first sliding rail is arranged at the other end of the rack, a buffer base is connected to the first sliding rail in a sliding mode, and the rack is provided with a buffer piece which can enable the moving supporting plate to gradually slow down and stop after the buffer base abuts against the moving carrying plate. The conveying device of the infusion set assembling machine clamp can enable the moving carrying plate with large weight and the clamp to be stopped at the appointed positions.

Owner:MAIDER MEDICAL IND EQUIP

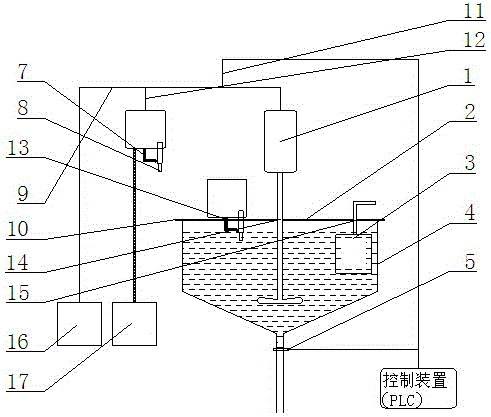

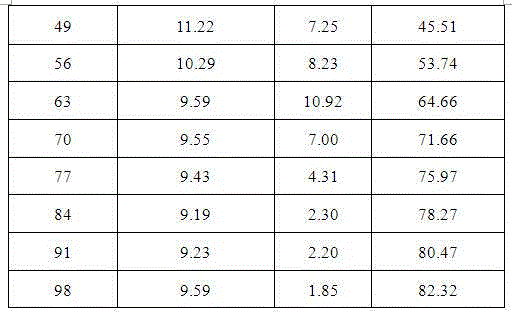

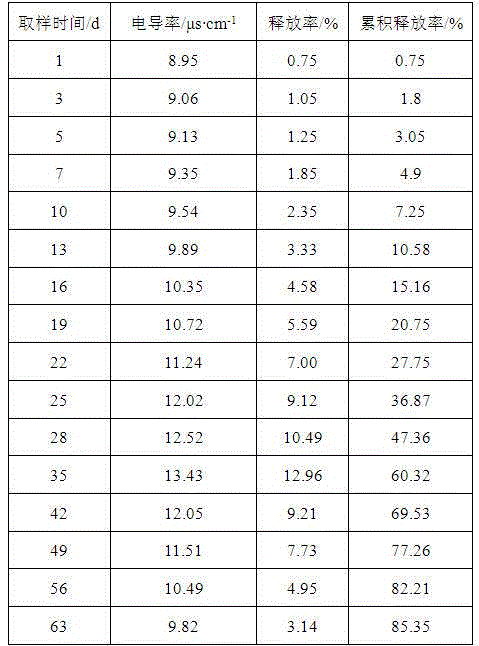

Device and method for rapidly detecting nutrient releasing rate of controlled-release fertilizer based on electric conductivity method

InactiveCN105116021AAutomatic conductivity data recordingEasy to operateMaterial resistanceSoil scienceControl system

The invention belongs to the technical field of a test for detecting the nutrient releasing rate of a controlled-release fertilizer, relates to a device and method for rapidly detecting the nutrient releasing rate of the controlled-release fertilizer based on an electric conductivity method, and particularly relates to a device and method for rapidly detecting the still water dissolution rate and the accumulation releasing rate of the controlled-release fertilizer based on the electric conductivity method. The device comprises a bracket, a water feeding device, a glass container, a digital display electric conductivity instrument, an electronic stirrer, a PCL control system for controlling detection steps and the like. With the adoption of the special device, an uneven concentration distribution phenomenon caused by external temperature fluctuation and long-time standing of a solution to be detected is avoided; and the detected electric conductivity value of a nutrient solution is relatively reliable and accurate, and meanwhile, the operation time is greatly shortened.

Owner:SHANDONG AGRI UNIV FERTILIZER TECH CO LTD

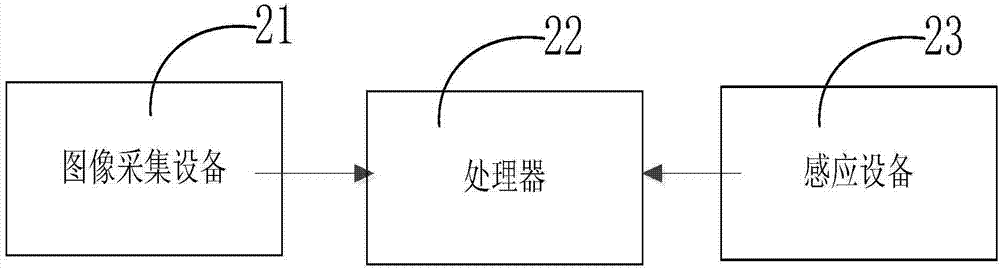

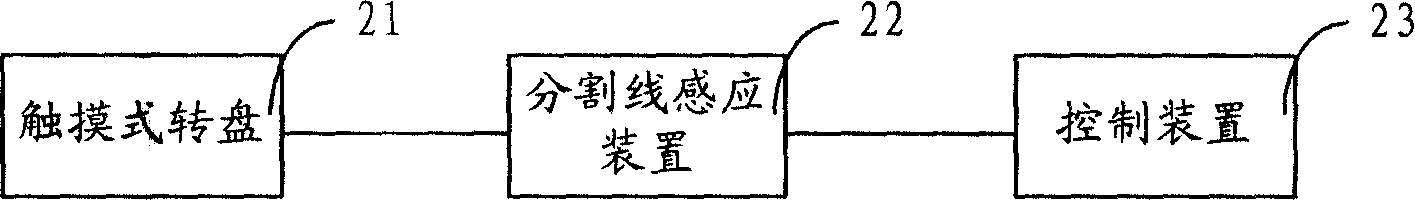

Pointing device and processing method in rotation

InactiveCN103529956AMobile location is accurateInput/output for user-computer interactionTelevision system detailsPointing deviceComputer science

The invention discloses a pointing device and a processing method in rotation. The pointing device comprises a sensing device, an image acquisition device and a processor. The sensing device senses whether the pointing device rotates or not at any time, and transmits the degree and the direction of a deflection angle to the processor when the pointing device rotates. The image acquisition device acquires an image of a display screen with a preset light source and transmits the image to the processor. The processor firstly confirms actual coordinates of the preset light source in the mage, calculates standard coordinates of the preset light source according to the degree and the direction of the deflection angle when the pointing device does not rotate, and then transmits the standard coordinates to a host. By the aid of the pointing device and the processing method in rotation, the coordinates of the preset light source transmitted to the host by the pointing device are the standard coordinates when the pointing device does not rotate regardless of whether the pointing device rotates or not, and accuracy of the moving position of a cursor of the display screen is ensured when the pointing device is operated to move.

Owner:GUANGZHOU SHIRUI ELECTRONICS

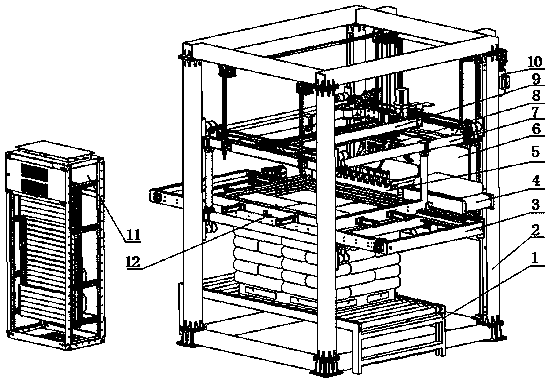

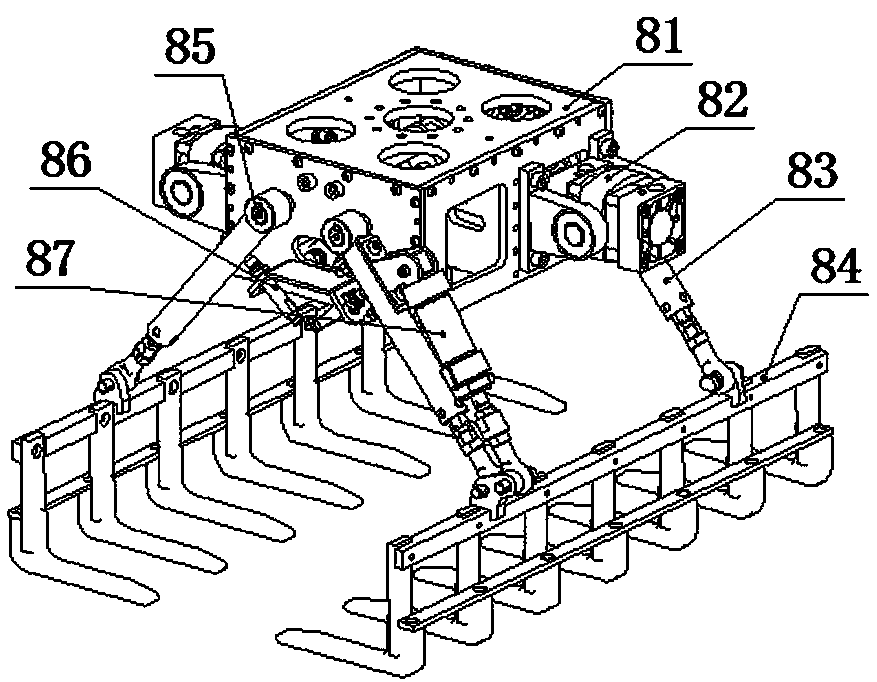

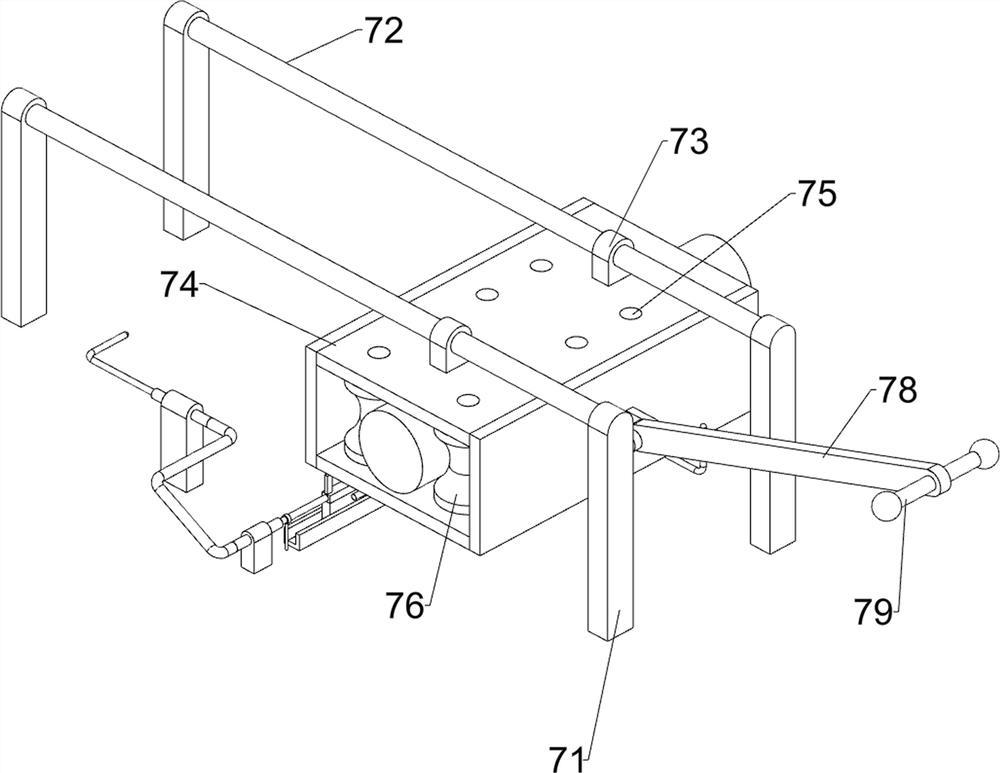

High-speed bagged material stacking machine

PendingCN108438927AAchieve compactionImprove handling efficiencyStacking articlesDe-stacking articlesEngineeringHeavy load

The invention discloses a high-speed bagged material stacking machine. The machine comprises a frame; a heavy-load conveying mechanism is arranged at the lower part of the frame; a stacking layer shaping mechanism and a working frame are arranged at the middle part of the frame; a stacking layer frame of the stacking layer shaping mechanism is fixedly connected with the working frame through a stand column; the working frame is connected with a lifting power mechanism; a fed bag conveying mechanism and a grabbing mechanism are arranged on one side of the stacking layer frame; a shaping mechanism is arranged on the other side of the stacking layer frame; and a cross beam moving mechanism is arranged on the working frame, and is connected with a join gripper mechanism. The machine is excellent in stack shaping capacity and high in automation degree, realizes overall monitoring and detection in the use process, and is suitable for production in general manufacturing industry, high in stacking capacity in unit time, easy to popularize and apply and excellent in economical benefit.

Owner:ZHENGZHOU DATANG GRAIN MASCH CO LTD

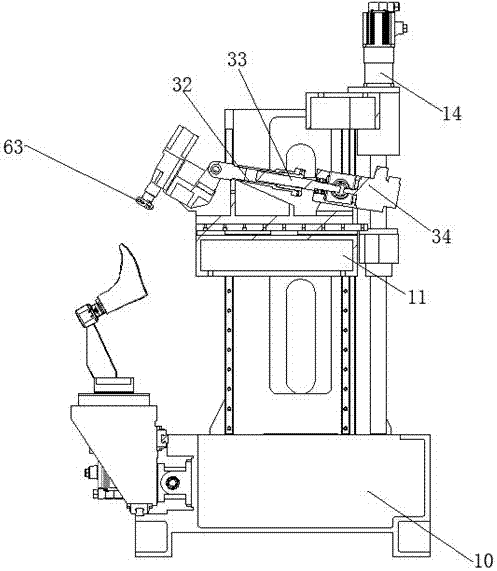

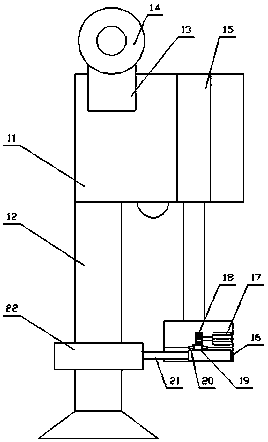

Numerical-control shoe-last carving machine capable of hydraulically clamping cylinder verge

PendingCN107052860AImprove stabilityEasy to installPositioning apparatusMetal-working holdersTool bitElectric machinery

The invention discloses a numerical-control shoe-last carving machine capable of hydraulically clamping a cylinder verge. The numerical-control shoe-last carving machine comprises a base and a main bracket arranged on the base, wherein a processing feeding mechanism is arranged on the main bracket; a swinging tool apron is arranged on the processing feeding mechanism; a processing motor is arranged on the swinging tool apron; the processing motor is connected with a directly-connected tool bit; a shoe-last rotating mechanism and a shoe-last feeding mechanism are arranged on the base; the shoe-last feeding mechanism comprises a motor base, a fourth drive motor and a fourth lead screw nut pair; the fourth drive motor is arranged on the base through the motor base; an output shaft of the fourth drive motor is connected with a lead screw and is in threaded connection with the fourth lead screw nut pair; and the fourth lead screw nut pair is connected with the shoe-last rotating mechanism. In this way, the numerical-control shoe-last carving machine has the advantages of achieving a plurality of axial processing stations, being capable of processing out shoe-lasts once, being free of manual grinding, being high in processing efficiency and being high in production quality.

Owner:佛山市盈胜智造科技有限公司

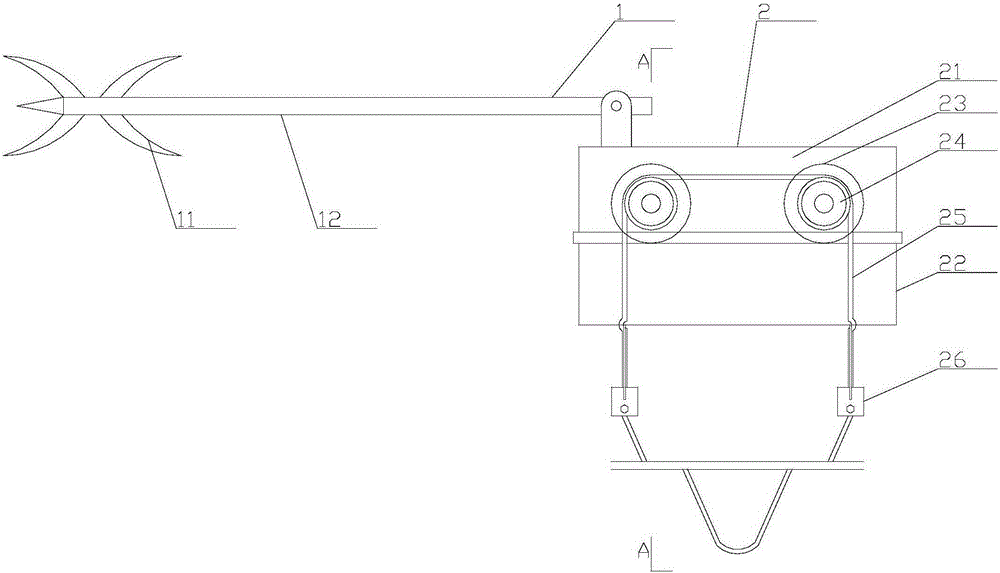

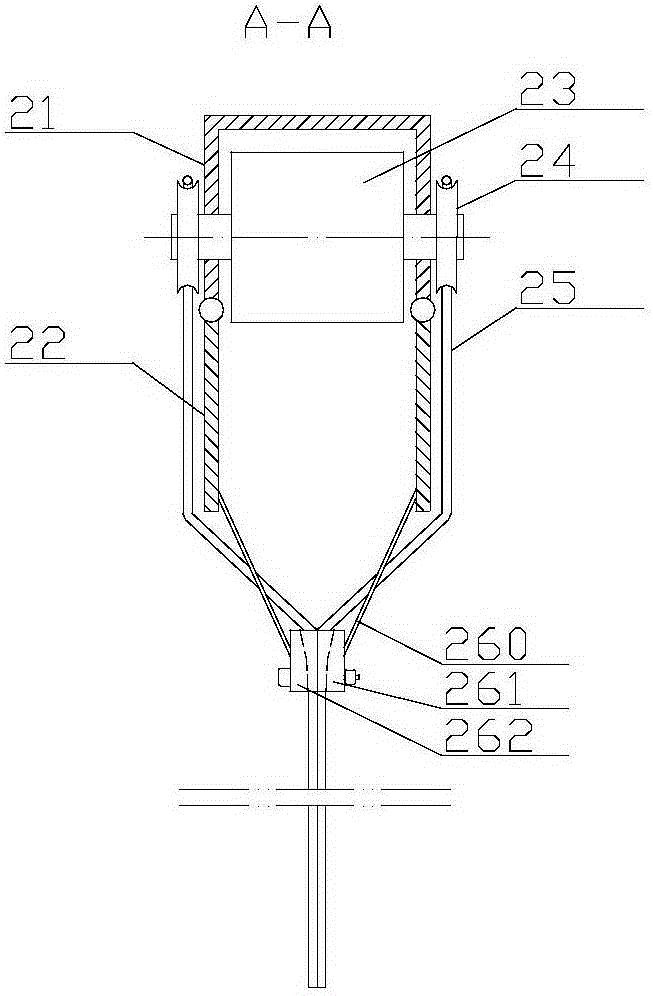

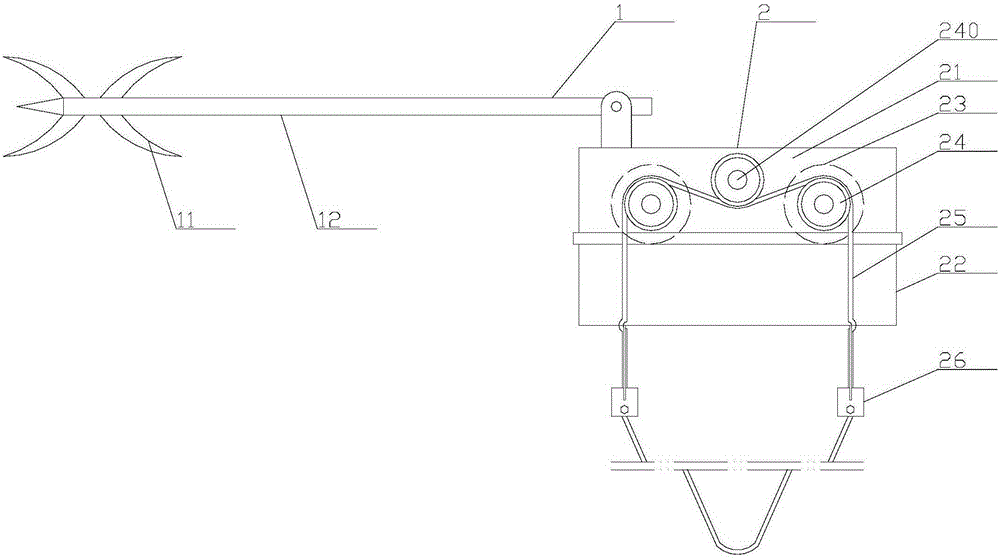

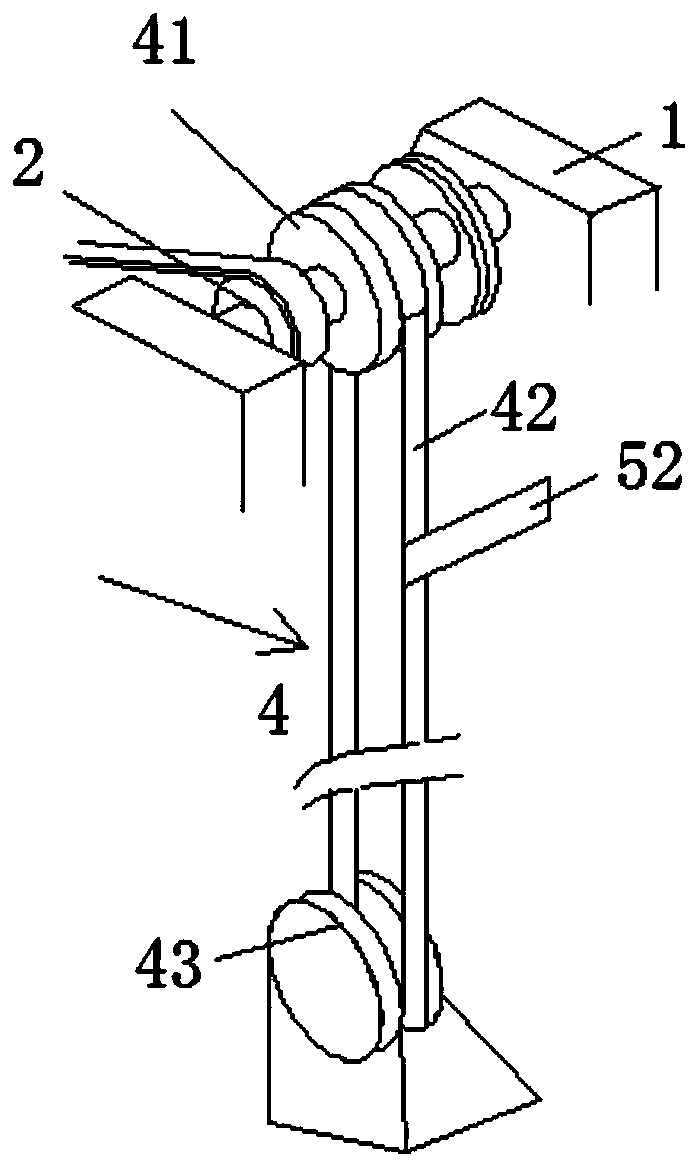

Cleaning device and cleaning method for foreign matters on different-layer overhead cable

InactiveCN105244803AEasy to moveMobile location is accurateApparatus for overhead lines/cablesForeign matterDrive wheel

The invention discloses a cleaning device and a cleaning method for foreign matters on a different-layer overhead cable, and relates to improvement of a high-voltage cable device and an operation method thereof. The cleaning device is delicate in structure, convenient to use and good in stability, can conveniently move on the cable in a reciprocating manner in use and can keep stable. The cleaning device comprises a cleaning component and a mobile component, wherein the mobile component comprises a body, a pair of clamping plates, at least one pulley, at least one pair of driving wheels, two driving ropes and two rope lacing devices, wherein the body is in a frame body with an opening in the bottom; the clamping plates are hinged to two sides of the bottom of the body; the pulley is hinged in the body; the driving wheels are fixed at one end far away from the pulley; the driving ropes are in a closed loop form and respectively wind the driving wheels; the cleaning component comprises a cleaning claw and a cleaning rod; the cleaning rod is connected to the body; and the cleaning claw is fixed at one end of the cleaning rod. The cleaning device is convenient to move, accurate in moving position, and extremely stable in movement. The stability in movement is greatly improved. The cleaning device is convenient to move, efficient, good in stability, high in foreign matter cleaning efficiency and good in cleaning effect.

Owner:YIZHENG POWER SUPPLY OF JIANGSU ELECTRIC POWER +2

Gate opening-closing device and control method

ActiveCN111236174ASolve problems that cannot be completely closedMake sure to closeBarrages/weirsWinchElectrical and Electronics engineering

The invention discloses a gate opening and closing device. According to the technical scheme, the gate opening and closing device comprises a dam body, a drainage channel is formed in the lower end ofthe dam body, and a gate for opening and closing the drainage channel is longitudinally arranged on the dam body in a sliding manner; and opening and closing equipment for controlling the gate to longitudinally reciprocate is mounted on the gate opening and closing device. The gate opening and closing device is characterized in that an opening and closing beam is fixed above the gate, and the opening and closing equipment comprises a winch and traction mechanisms which are used for connecting the winch and the gate and are correspondingly mounted on two sides of the gate, wherein the winch ismounted above the dam body; and each traction mechanism comprises a first traction part used for pulling the gate upwards and a second traction part used for helping the gate to be closed. Accordingto the gate opening and closing device, the problem that the gate cannot be completely closed by means of self weight is effectively solved, and the safety performance of the dam body is improved.

Owner:浙江九州治水科技股份有限公司

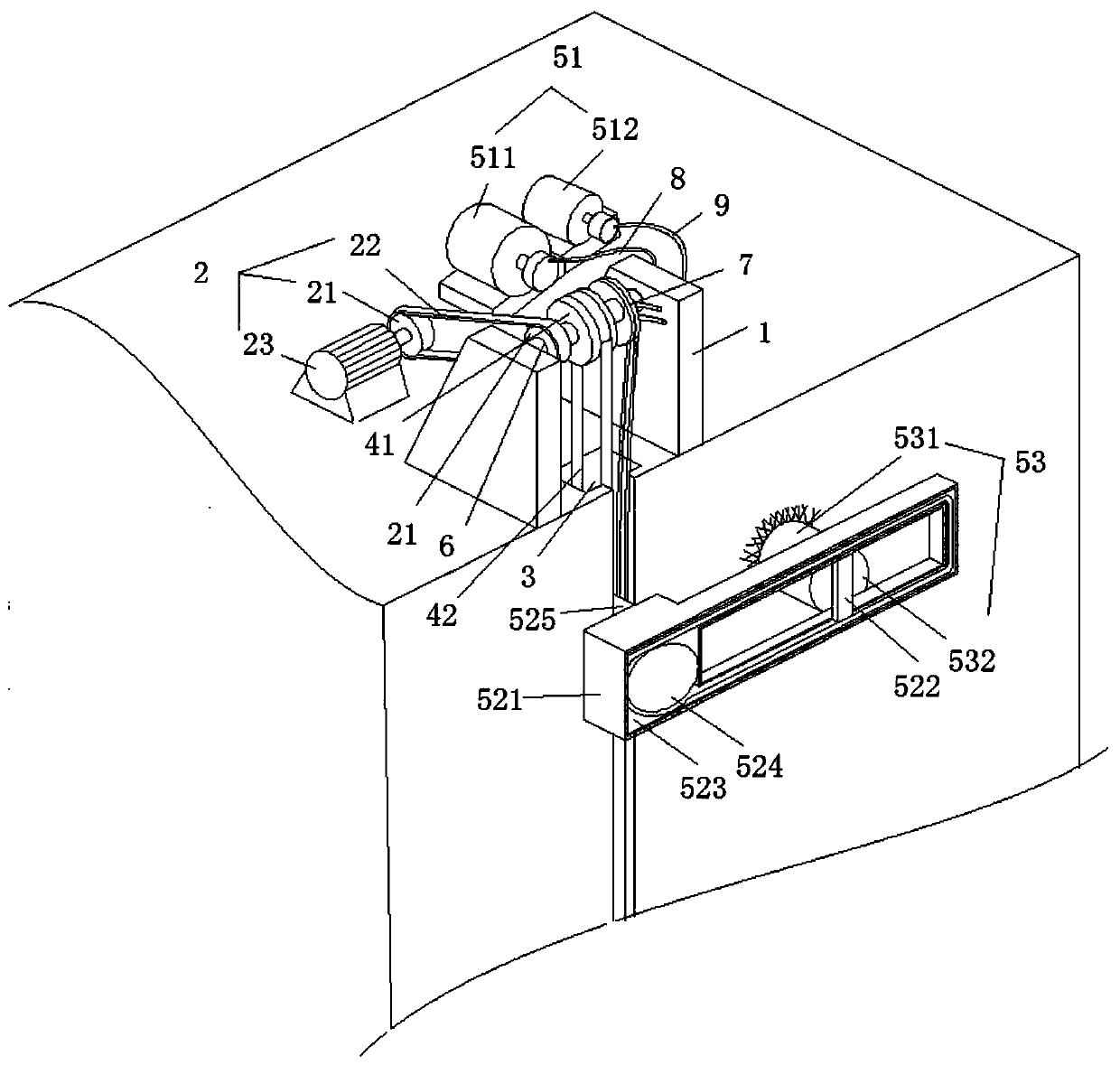

Robot for scrubbing glass and wall surface on building facade

InactiveCN111513621AMobile location is accuratePrecise control of spraying timeAutomatic obstacle detectionTravelling automatic controlArchitectural engineeringEngineering

The invention discloses a robot for scrubbing glass and a wall surface on a building facade, which comprises two supports which are fixed on the top surface of a building and are oppositely arranged,and water pipe holes are formed in the side walls of the supports so that a first water pipe and a second water pipe penetrate through the water pipe holes; a rotating shaft is connected between the two supports, a water pipe winding drum is rotatably connected to the rotating shaft, a first water pipe and a second water pipe are wound on the water pipe winding drum, the robot further comprises apower mechanism, a track, a lifting mechanism and a scrubbing mechanism, and the action of the robot is controlled through a PLC system. The robot for scrubbing the glass and the wall surface on the building facade is simple in structure, stable in system and low in cost, the scrubbing structure can flexibly move in the horizontal direction and the vertical direction, the whole scrubbing operationis controlled through the PLC system, the scrubbing position can be accurately controlled, the accuracy is high, and the scrubbing efficiency is high.

Owner:宁波巨谷智能装备有限公司

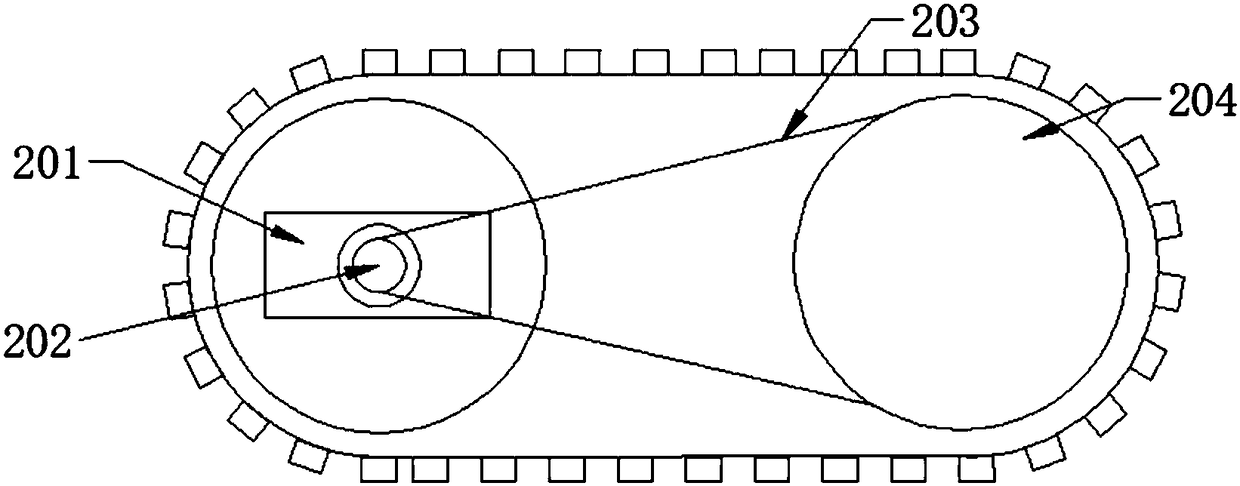

Automatic stamping equipment for thin-walled annular workpieces

ActiveCN105921612AImprove continuityRealize processingShaping toolsMetal-working feeding devicesPunchingEngineering

The invention discloses automatic stamping equipment for thin-walled annular workpieces and belongs to the technical field of stamping dies. The automatic stamping equipment comprises a stamping die, wherein the stamping die comprises an upper die part and a lower die part, the upper die part comprises an upper die holder, a connecting plate and a stamping plate, and the lower die part comprises a lower die holder and a lower die plate which are fixed and mounted together; a drawing male die, a punching male die and a shaping male die are sequentially mounted on the connecting plate of the upper die part, stamping convex rings surrounding all of the drawing male die, the punching male die and the shaping male die are arranged on the stamping plate, and a drawing elastic ejector, a blanking hole and a shaping elastic ejector are sequentially and correspondingly arranged on the lower die plate of the lower die part; and a molding die plate mounted on a circulating chain is arranged between the stamping plate and the lower die plate, and a drawing female die, a blanking female die and a shaping female die are sequentially arranged on the molding die plate. The automatic stamping equipment can realize the processing of the annular workpieces with different cross areas on the progressive stamping die, improves the production efficiency and the finished product rate and is widely applied to the manufacture of the annular workpieces with different cross areas.

Owner:河北昊天滤清器制造有限公司

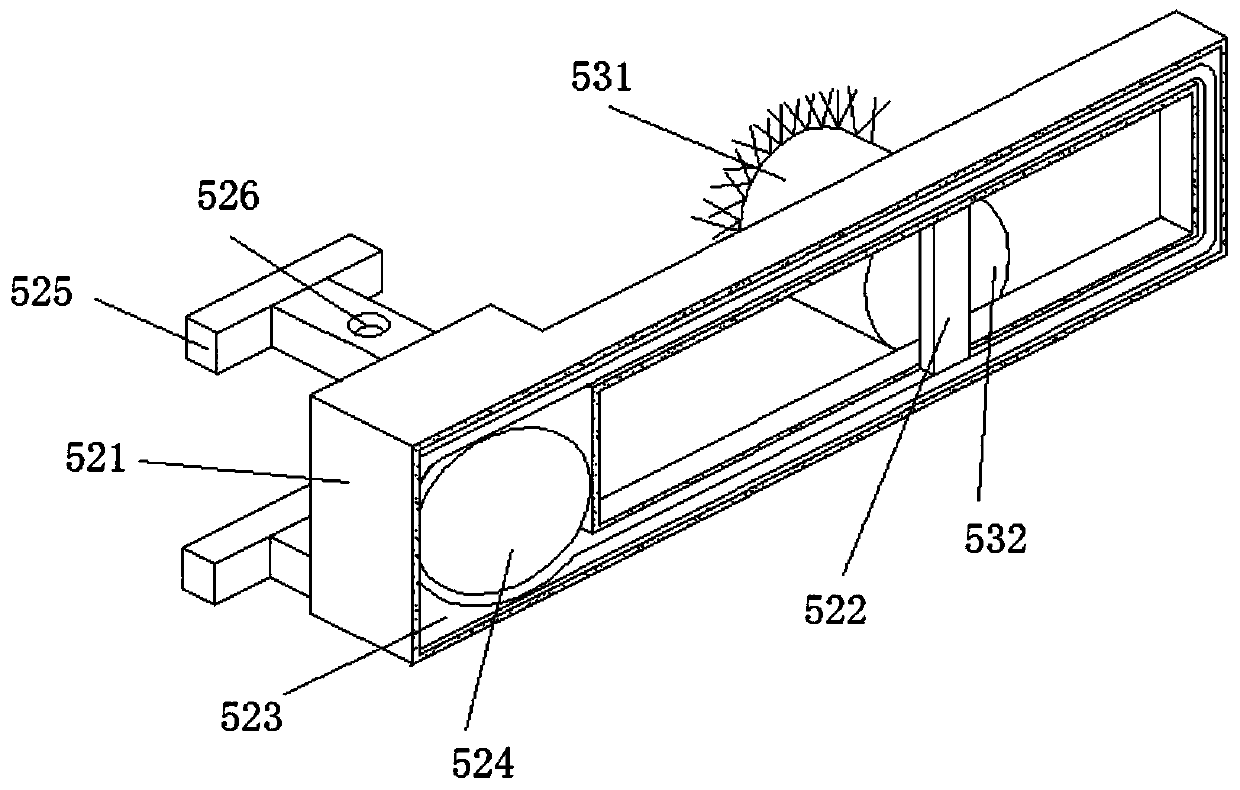

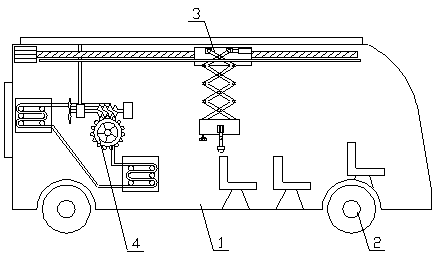

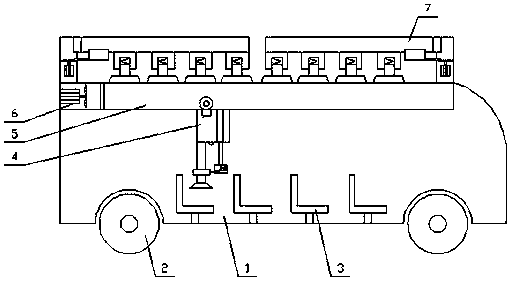

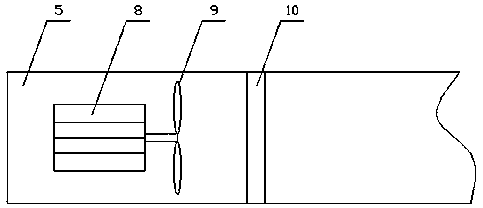

Bus with carriage sterilizing and efficient heat dissipation functions

InactiveCN107839566AWill not polluteMobile location is accurateVehicle arrangementsChemicalsSpontaneous combustionCooling effect

The invention relates to a bus with carriage sterilizing and efficient heat dissipation functions. The bus with carriage sterilizing and efficient heat dissipation functions comprises a bus body, a moving mechanism, a sterilizing mechanism, a heat dissipation mechanism, a heat dissipation opening and a plurality of seats, wherein the sterilizing mechanism comprises a moving assembly, a lifting assembly and a rotating assembly; the heat dissipation mechanism comprises a water-cooling assembly and an air-cooling assembly; and the water-cooling assembly comprises a water pump, a connecting tube,a heat absorbing unit and a heat dissipation unit. In the bus with the carriage sterilizing and efficient heat dissipation functions, a disinfectant is sprayed to a carriage through the sterilizing mechanism and a sprayer for sterilizing treatment, thus, the integral environment of the carriage is clean, the influenza virus spreading range is reduced as much as possible, health of passengers who go out is ensured, by the heat dissipation mechanism and combination of air cooling and water cooling, the heat dissipation effect is good, the possibility of spontaneous combustion of the tail of thebus due to over-high temperature is reduced, and the practicality and safety of the bus are greatly improved.

Owner:NANJING LENIAS PHOTOELECTRIC EQUIP

Plate machining center

PendingCN109047398AImprove processing efficiencyWide range of processingShaping toolsMetal-working feeding devicesEngineeringCam

The invention discloses a plate machining center. The plate machining center comprises a hydraulic lifting platform, a feeding table machine frame and an edge folding main machine which are sequentially arranged; a roller moving trolley and a raw material table are arranged on the hydraulic lifting platform, a liftable sucker lifting cross beam is arranged above the feeding table machine frame ina straddling mode, and two ends of the liftable sucker lifting cross beam are movably arranged on guide rails A on two sides of the feeding table machine frame; a brush work table is arranged above the feeding table machine frame, sucker devices allowing ascending, descending and rotating of suckers are arranged in the middle of the feeding table machine frame, and the sucker devices are arrangedon guide rails B which are arranged along the longitudinal direction of the feeding table machine frame in a sliding mode; a plurality of movable stop fingers are arranged, on two sides of each suckerdevice, on the feeding table machine frame respectively, and lateral moving belts capable of ascending and descending are arranged on two sides of the feeding table machine frame respectively; and the edge folding main machine comprises an edge folding machine frame, a rotatable upper sliding block, a lower knife, a turnover plate capable of rotating, ascending and descending, the upper sliding block which can vertically move is arranged above the edge folding machine frame, two ends of the upper sliding block are connected with a cam lifting mechanism, and the turnover plate drives the uppersliding block to ascend and descend through the lifting mechanism.

Owner:姜云峰

Three-direction-moving type medical detection device rack

The invention discloses a three-direction-moving type medical detection device rack. The three-direction-moving type medical detection device rack comprises an x-axis moving device, a y-axis moving device and a z-axis moving device, wherein rail bars are arranged on the top end of the x-axis moving device; horizontal bars are arranged at the inner sides of the rail bars, and the space between thehorizontal bars is less than 5mm; moving tracks are arranged on the top ends of the rail bars, and micromotors are arranged in the moving tracks; a fixing bar is arranged at one end of each micromotor, and fixed rails are arranged at two sides of the micromotors; the other end of each fixed bar is inverted T shaped, and each fixed bar is embedded into the corresponding fixed rail; steel beads arearranged in the fixed rails, and fixing arms are arranged at two sides of the steel beads. The three-direction-moving type medical detection device rack is simple in structure, low in noise, and low in cost, and facilitates people in use.

Owner:王月招

High-speed jacking transfer machine

InactiveCN109911581ARealize transferImprove efficiencyConveyor partsHeight differenceMechanical engineering

The invention provides a high-speed jacking transfer machine. The high-speed jacking transfer machine comprises a suppressing mechanism, a roller conveying mechanism, a crank connecting rod lifting mechanism, and a transfer belt mechanism, the suppressing mechanism is of a gantry structure, arranged above the roller conveying mechanism, and across the roller conveying mechanism; the roller conveying mechanism is rubber coating rollers arranged in parallel, and arranged below the suppressing mechanism, the roller conveying mechanism is installed on the crank connecting rod lifting mechanism, thus the crank connecting rod lifting mechanism can drive the roller conveying mechanism to do lifting movement, the transfer belt mechanism is arranged on an empty space of the roller conveying mechanism, rollers can produce a certain height difference with transfer belts during lifting, when the position of the rollers is higher than that of the transfer belts, plates are in contact with the rollers so as to move in the rotating direction of the rollers, thus the plates on the high-speed jacking transfer machine can move in different directions, the position and quantity of rubber coating press wheels correspond to the position and quantity of the transfer belts, and during steering of the plates, the rubber coating press wheels on the suppressing mechanism move downwards, and the plates are pressed through the rubber coating press wheels.

Owner:广州宁基智能系统有限公司

Sorting machine

ActiveCN109178866ASmooth motionIncrease contact areaConveyor partsMechanical engineeringPerpendicular distance

The invention provides a sorting machine, and relates to the technical field of article conveying. The sorting machine comprises a buckling plate, a bracket, a deflection wheel module, a conveying driving mechanism and a deflection driving mechanism, wherein the deflection wheel module comprises a plurality of deflection wheels and a plurality of flat belts; a plurality of through holes are formedin the buckling plate; each through hole corresponds to one deflection wheel of the deflection wheel module or one flat belt of the deflection wheel module; the perpendicular distance between a center shaft of each deflection wheel and the upper surface of the buckling plate is less than the radius of each deflection wheel; the upper end surface of each flat belt is higher than the upper surfaceof the buckling plate; the conveying driving mechanism is used for driving the deflection wheels and the flat belts to rotate, so that articles move on the buckling plate in the extension direction ofthe buckling plate; and the deflection driving mechanism is used for driving the deflection wheels and the flat belts to turn, so that the articles turn in a moving process. The upper end surfaces ofthe flat belts make contact with the articles, so that the contact area of the articles and the deflection wheel module can be increased, the articles stably move, and the moving position is precise.

Owner:WEIHAI NEWBEIYANG ZHENGQI ROBOT

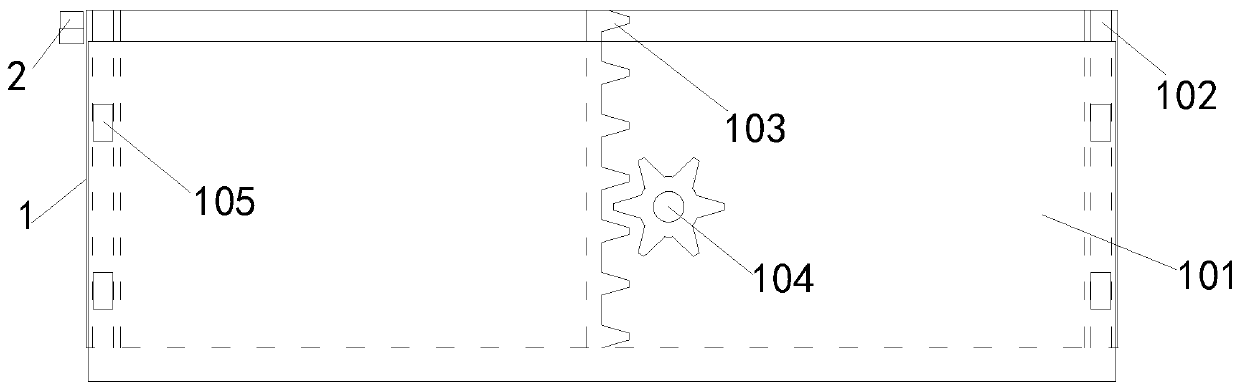

Browsing information item block positioning method and device

InactiveCN101236473AControl mobile positionPrecise positioningInput/output processes for data processingSplit linesComputer science

Owner:YINGHUADA (SHANGHAI) ELECTRONIC CO LTD

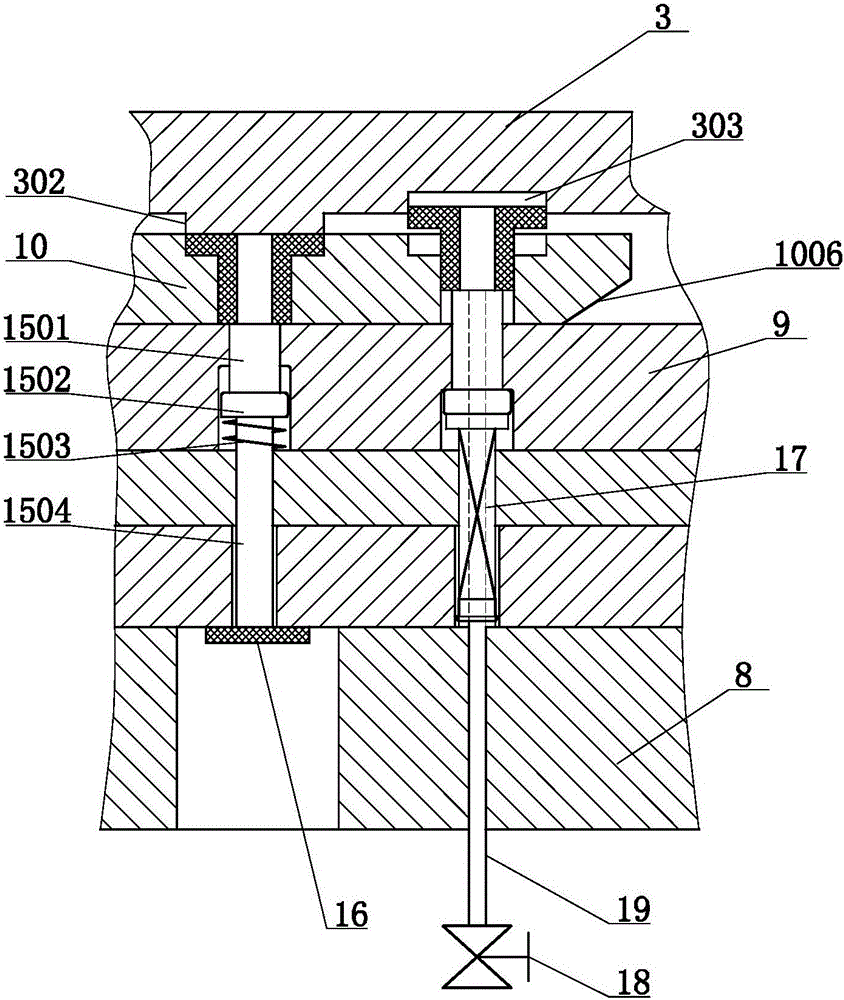

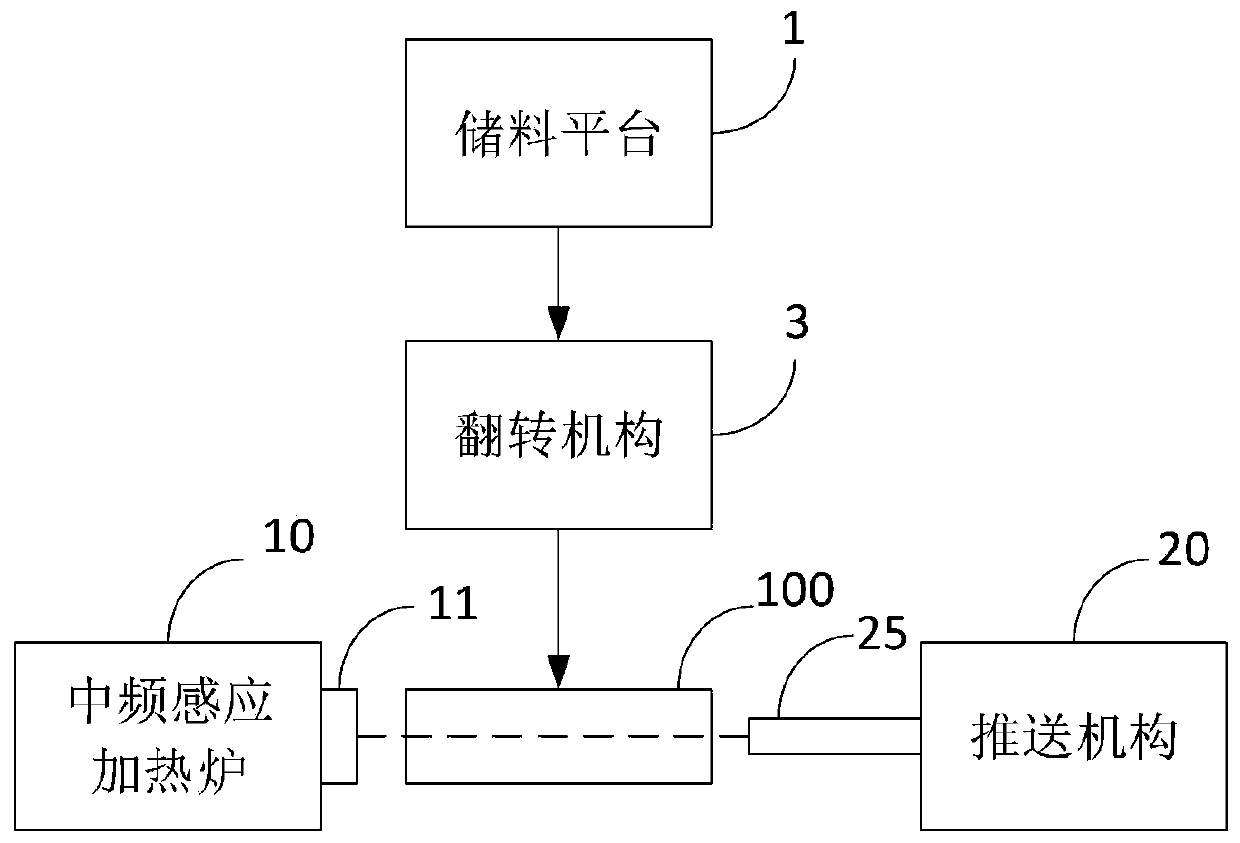

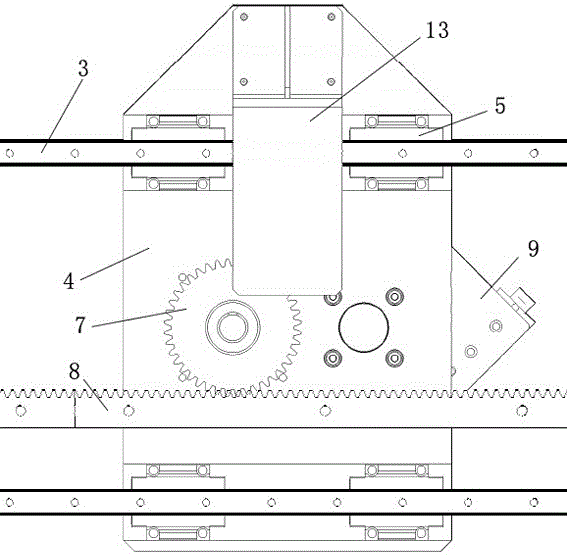

Heating system for forging

The invention provides a heating system for forging. The heating system comprises a medium frequency induction heating furnace and an automatic feeding device, and the automatic feeding device comprises a storage platform, a turnover mechanism and a pushing mechanism; the storage platform, the turnover mechanism and the pushing mechanism are installed on a base; the height of the base is designedsuch that a pushing rod of the pushing mechanism, round steel blanks and an inlet of the medium frequency induction heating furnace are in a straight line when the round steel blanks are conveyed to the termination position, the round steel blanks are disposed on the storage platform, and the bottom surface of the storage platform is an inclined plane; the turnover mechanism comprises a containinggroove and a support shaft, and one end of the support shaft is connected with the base in a coupling mode; the other end of the support shaft is connected with the containing groove fixedly, and a turnover cylinder is arranged at the bottom of the end, connected with the containing groove, of the support shaft; and the bottom surface of the support shaft is further provided with an auxiliary cylinder. The heating system for forging is simple in structure and low in cost; one hundred kilograms, even hundreds kilograms, of round steel blanks can be moved through the turnover mechanism reliably; and the reliability is high, and the service life is long.

Owner:QINGDAO ZHONGTIANPENG FORGING MFG CO LTD

Feeding device of plate shearing machine

InactiveCN106694996AGuaranteed reliabilityReduce labor intensityConveyor partsShearing machine accessoriesSlide platePiston rod

The invention provides a feeding device of a plate shearing machine. The feeding device comprises a framework. A clamping mechanism is arranged on the framework, guide rails are arranged on the framework, the clamping mechanism comprises a traversing slide plate, sliders which are matched with the guide rails are arranged on the traversing slide plate, the traversing slide plate is mounted on the framework under the matching effects of the sliders and the guide rails, a gear motor is mounted at the lower end of the traversing slide plate, an output shaft of the gear motor upwardly penetrates the traversing slide plate, a gear is mounted on the output shaft, a rack which is parallel to the guide rails is arranged on the framework and meshes with the gear, the traversing slide plate can be driven by the gear motor to move along the guide rails, a cylinder is vertically downwardly arranged at the lower end of the traversing slide plate, a sucker mounting plate is fixed to an end of a piston rod of the cylinder, a sucker is mounted at the lower end of the sucker mounting plate, a conveying platform is arranged below the sucker and is connected with the plate shearing machine, and plate loading tanks are arranged on the front side and the rear side of the conveying platform. The feeding device has the advantages that the feeding device is reasonable in structure, good in safety and high in movement accuracy, plates can be carried to be fed, the production efficiency can be improved, and the labor intensity can be relieved for workers.

Owner:WUXI MINGZHU STEEL BALL

Intelligent teaching device and teaching board

InactiveCN110421997AInterpretation of heightMobile location is accurateWriting boardsFurniture partsPhysicsSelf adjusting

The invention discloses an intelligent teaching device and a teaching board, wherein the intelligent teaching device comprises a lifting blackboard and an infrared distance measuring sensor; the lifting blackboard is connected with a wall body in a sliding manner; the infrared distance measuring sensor is used for measuring the distance to a user; the infrared distance measuring sensor is arrangeddownwards; the infrared distance measuring sensor is arranged at the upper part of the side edge of the lifting blackboard; the lifting blackboard comprises a blackboard main body and a moving mechanism; the infrared distance measuring sensor is electrically connected with a controller, and the controller is electrically connected with the moving mechanism; and the controller is used for controlling the movement of the moving mechanism according to the numerical value monitored by the infrared distance measuring sensor. The invention also discloses an intelligent teaching board, and the moving mechanism comprises a slide rail, a gear, a rack and a roller; wherein, the slide rail is arranged on the wall body up and down; the rack is arranged in parallel with the sliding rail, the rack is fixedly connected with the wall body, the gear is fixedly connected with the blackboard main body, and the gear is meshed with the rack; and the back of the blackboard body corresponding to the slide rail is provided with the roller. The invention has the advantages of self-adjusting blackboard height and high moving reliability.

Owner:江苏万喜至工业设计有限公司

Mechanical arm with high precision and control method thereof

InactiveCN112809688AWon't shakeSave human effortProgramme-controlled manipulatorArmsHydraulic cylinderRobot hand

The invention discloses a mechanical arm with high precision and a control method thereof, and relates to the technical field of mechanical arms. The mechanical arm aims to solve the problems that a mechanical arm is prone to shaking and being unstable, and quite manpower is consumed. The mechanical arm comprises a machine body, and four supporting legs are arranged on the outer wall of the bottom of the machine body. Three containing grooves are formed in the outer wall of the top of the machine body, hydraulic cylinders are arranged on the inner walls of the three containing grooves, lower connecting bases are arranged at the extending ends of the three hydraulic cylinders, the three lower connecting bases are in sliding fit with the three containing grooves correspondingly, the lower connecting bases are of C-shaped structures, and an electric telescopic assembly is arranged on the inner wall of one side of each of the three lower connecting bases. The control method of the mechanical arm comprises the following steps that objects needing to be conveyed are loaded into a collecting box; and two first motors which do not rotate synchronously are controlled to be started. By means of the mechanical arm, the situation that the stable conveying structure shakes due to the fact that the carrying range is too large can be avoided, manpower is saved, and the adjusting operation efficiency is greatly improved.

Owner:柳斯

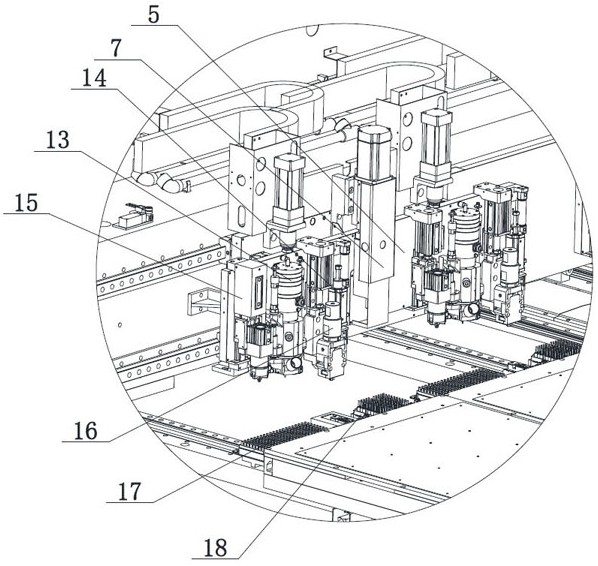

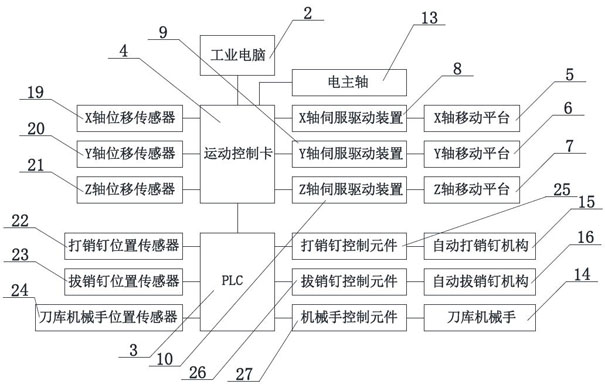

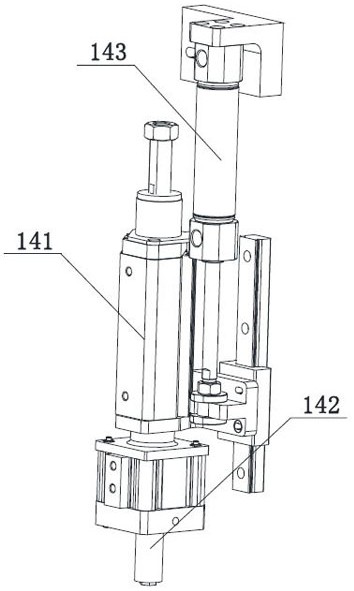

PCB automatic machining device and automatic machining process with automatic pin driving and pulling function

ActiveCN112296392ARealize three-axis linkageMobile location is accuratePrinted circuit manufactureMetal working apparatusRobot handControl engineering

The invention discloses a PCB automatic machining device with an automatic pin driving and pulling function. The PCB automatic machining device comprises a device body, an industrial computer, a motion control card, a PLC, an X-axis moving platform, a Y-axis moving platform, a Z-axis moving platform, an X-axis servo driving device, a Y-axis servo driving device and a Z-axis servo driving device. An electric main shaft, a tool magazine mechanical hand, an automatic pin driving mechanism and an automatic pin pulling mechanism are arranged on the Z-axis moving platform. A pin magazine and a toolmagazine are arranged at the end, close to the X-axis moving platform, of a work table. The industrial computer is connected with the motion control card, and the PLC is connected with the motion control card. The PLC is connected with the automatic pin driving mechanism, the automatic pin pulling mechanism and the tool magazine mechanical hand, and the electric main shaft is connected with the motion control card. By means of the PCB automatic machining device, automation and precision of the whole process of pin driving and pulling are achieved, and the automation degree of the PCB machiningdevice can be greatly improved.

Owner:CHENGDU JINDALI TECH

Smart bus with snow removal and garbage cleaning functions

The invention relates to a smart bus with snow removal and garbage cleaning functions. The smart bus comprises a bus body, a moving mechanism, seats, a cleaning mechanism, a fixing plate, a heating mechanism and a snow removing mechanism. The cleaning mechanism comprises a moving block, a hose, a lantern ring, a moving component, a telescopic component and an angle adjusting component. The snow removing mechanism comprises a fixing block, a swinging lever, a control component and a plurality of cleaning components. The control component comprises a power unit and a swinging unit. According tothe smart bus with snow removal and garbage cleaning functions, the cleaning mechanism can automatically absorb and treat the garbage inside the bus body, thereby reducing the workload of a driver. The snow removing mechanism makes a cleaning brush always in contact with the snow to avoid incapability of cleaning the snow at some places, and avoids a safety hazard of climbing to the roof of the bus through automatic snow cleaning. The mechanisms greatly improve the practicability and safety of the bus.

Owner:JIANGSU HUAXIA INTPROP SERVICE CO LTD

Tool for measuring verticality of side plate of elevator framework

PendingCN105403130AAvoid displacementAvoid errorsMechanical measuring arrangementsEngineeringMeasurement precision

The invention discloses a tool for measuring verticality of a side plate of an elevator framework. The tool comprises an electromagnetic base. At least two positioning pins are arranged on the electromagnetic base. A guide post which is perpendicular to the electromagnetic seat is arranged on one side, near the positioning pins, of the electromagnetic base. A linear guide rail is slidably connected with the guide post and connected with the positioning pins in a linear parallel manner. A dial indicator is slidably connected to the linear guide rail. The tool is capable of precisely measuring data of the verticality of the side plate of the elevator framework, so measurement precision is ensured and inaccuracy caused by quite big errors caused by tedious operation of workers can be avoided.

Owner:HANGZHOU KANGTEER ELEVATOR COMPONENTS CO LTD

Round piece cutting device for beech

InactiveCN112077945AQuick sliceMobile location is accurateProfiling/shaping machinesEngineeringWorkbench

The invention relates to a round piece cutting device, in particular to a round piece cutting device for a beech. According to the round piece cutting device for the beech, the beech does not need tobe fixed and moved manually, and the safety is high. The round piece cutting device for the beech comprises a base, a workbench, a cushion table, a collecting box, a cutting mechanism and a pushing mechanism, wherein a plurality of supporting columns are arranged at the top of the base; the workbench is arranged between the tops of the supporting columns; the cushion table is arranged on one sideof the top of the workbench; the collecting box is placed on the side, close to the cushion table, of the top of the base; the cutting mechanism is arranged on the side, close to the collecting box, of the top of the base; and the pushing mechanism is arranged on the workbench. According to the round piece cutting device, rotation of a cutter is achieved by starting a servo motor, then through cooperation of the cutting mechanism and the pushing mechanism, the pushing mechanism drives the beech to move rightwards, meanwhile, the cutting mechanism cuts the beech into round pieces, and then rapid slicing of the beech is achieved; and through cooperation of a shifting rod and an ejector rod, the beech automatically moves forwards, so that people do not need to push the beech manually.

Owner:陈幼琳

Concrete carbonization depth measuring equipment convenient and fast to operate and accurate in measurement

ActiveCN108279231AReduce loadMinimize impact on measurement resultsMaterial analysis by observing effect on chemical indicatorControl using feedbackData displayHand shakes

The invention relates to concrete carbonization depth measuring equipment convenient and fast to operate and accurate in measurement. The concrete carbonization depth measuring equipment comprises a main body, a data display screen, an operation panel, an adsorber and two supporting mechanisms, wherein the data display screen and the operation panel are arranged on the main body; the two supporting mechanisms are arranged on the two sides of the main body respectively; the adsorber is fixed to the upper side of the main body; a measuring mechanism is arranged inside the main body; the adsorbercomprises a box body and four adsorbing mechanisms; the four adsorbing mechanisms are arranged at four corners of the box body respectively. The concrete carbonization depth measuring equipment convenient and fast to operate and accurate in measurement enables a measuring instrument to be adsorbed onto a measuring surface through the supporting mechanisms and the adsorbing mechanisms, so that influence of hand shake of a surveyor on a measurement result is reduced, and thus the measurement accuracy is improved; furthermore, measuring steps are sequentially completed through a moving assemblyand telescopic assemblies, so that the measurement efficiency is improved.

Owner:广东海业岩土工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com