Round piece cutting device for beech

A disc and beech technology, applied in the field of beech disc cutting devices, can solve the problems of safety accident sawdust or wood thorns, sticking to hands, etc., and achieve the effect of consistent cutting thickness and accurate position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

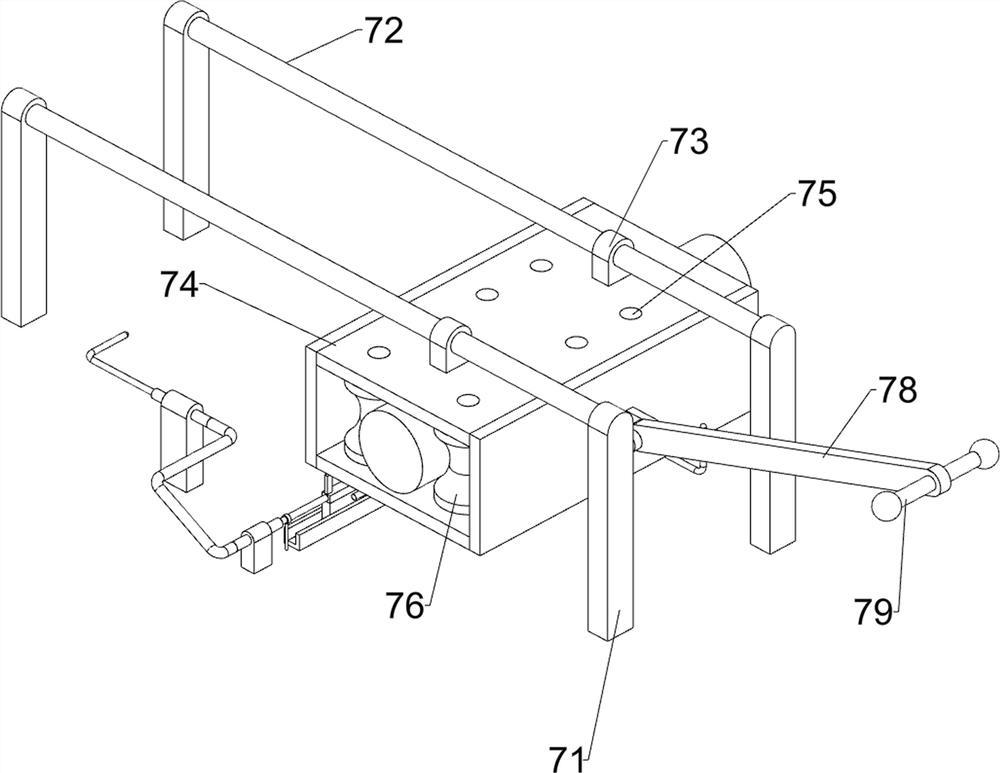

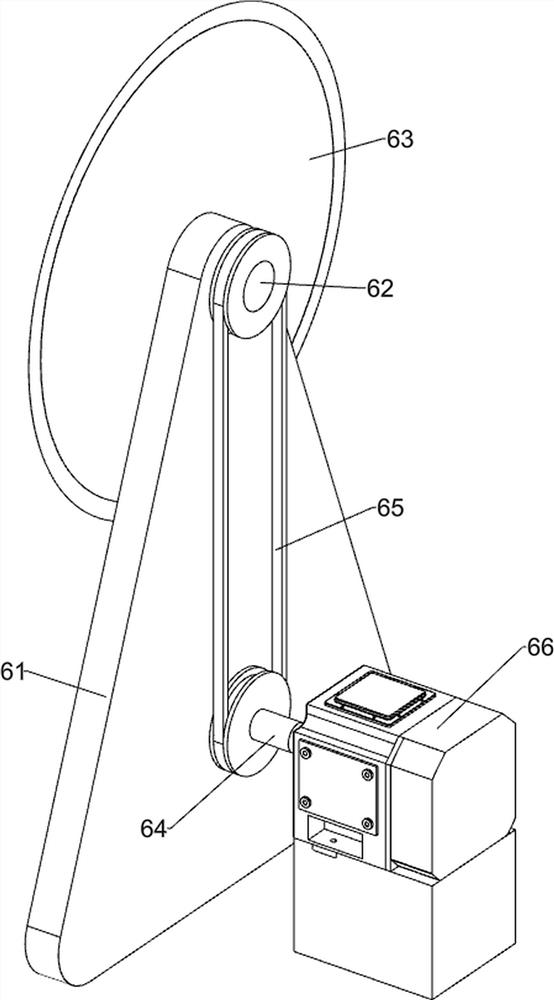

[0023] A beech wood disc cutting device, such as Figure 1-5 As shown, it includes a base 1, a support column 2, a workbench 3, a pad 4, a collection box 5, a cutting mechanism 6, and a push mechanism 7. There are five support columns 2 at the top edge of the base 1, and the top of the support column 2 There is a workbench 3 fixedly connected between them, a pad 4 is provided on the front side of the top of the workbench 3, a collection box 5 is placed on the right front side of the top of the base 1, a cutting mechanism 6 is arranged on the front side of the top of the base 1, and the cutting mechanism 6 is located on the left side of the collection box 5 Side, the top of the workbench 3 is provided with a push mechanism 7.

[0024] When people use this device, at first people put beech in the pushing mechanism 7, then start cutting mechanism 6, then just can promote pushing mechanism 7 to move to the right, treat that beech contacts with cutting mechanism 6, and cutting mech...

Embodiment 2

[0030] On the basis of Example 1, such as figure 1 with Figure 5 As shown, it also includes a fixed rod 8 and a rubber ring 9. The top of the workbench 3 is symmetrically fixedly connected with the fixed rod 8. The fixed rod 8 is provided with a rubber ring 9. The rubber ring 9 is slidably connected with the first piston 715.

[0031] When the first piston 715 moves back and forth, the rubber ring 9 can limit the movable position of the slider 712, thereby making the moving position of the push rod 713 more accurate, preventing the position deviation of the push rod 713 and not cooperating with the driving rod 77 .

[0032] Also include baffle plate 10 and guide plate 11, baffle plate 10 is provided on the rear side of the top of the pad 4, and guide plate 11 is provided on the right rear side of the top of the pad 4.

[0033] Baffle plate 10 can make the distance that beech wood moves forward consistent, and then makes the cutting thickness of disc consistent, and guide pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com