Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1980results about How to "Improve handling efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

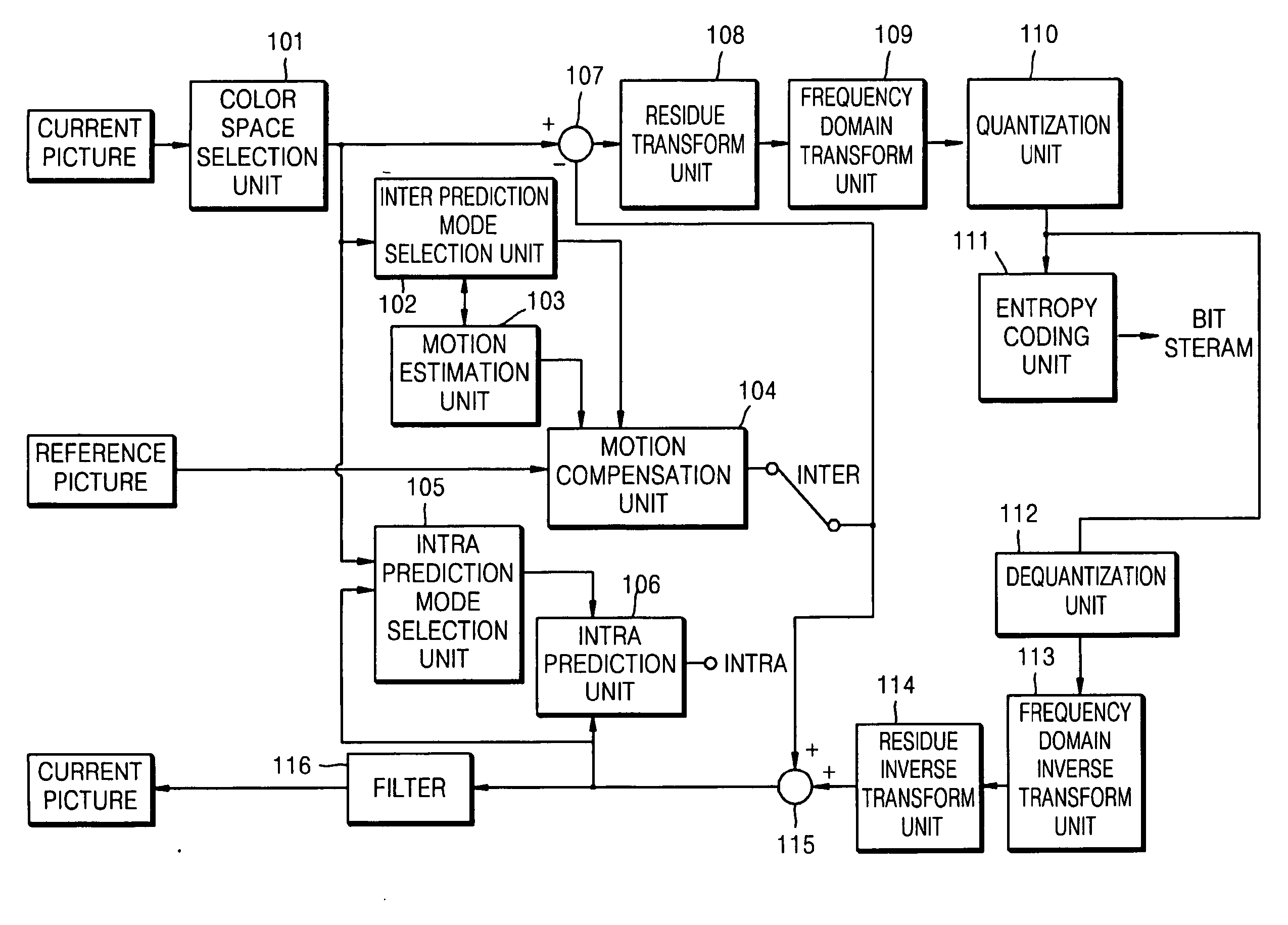

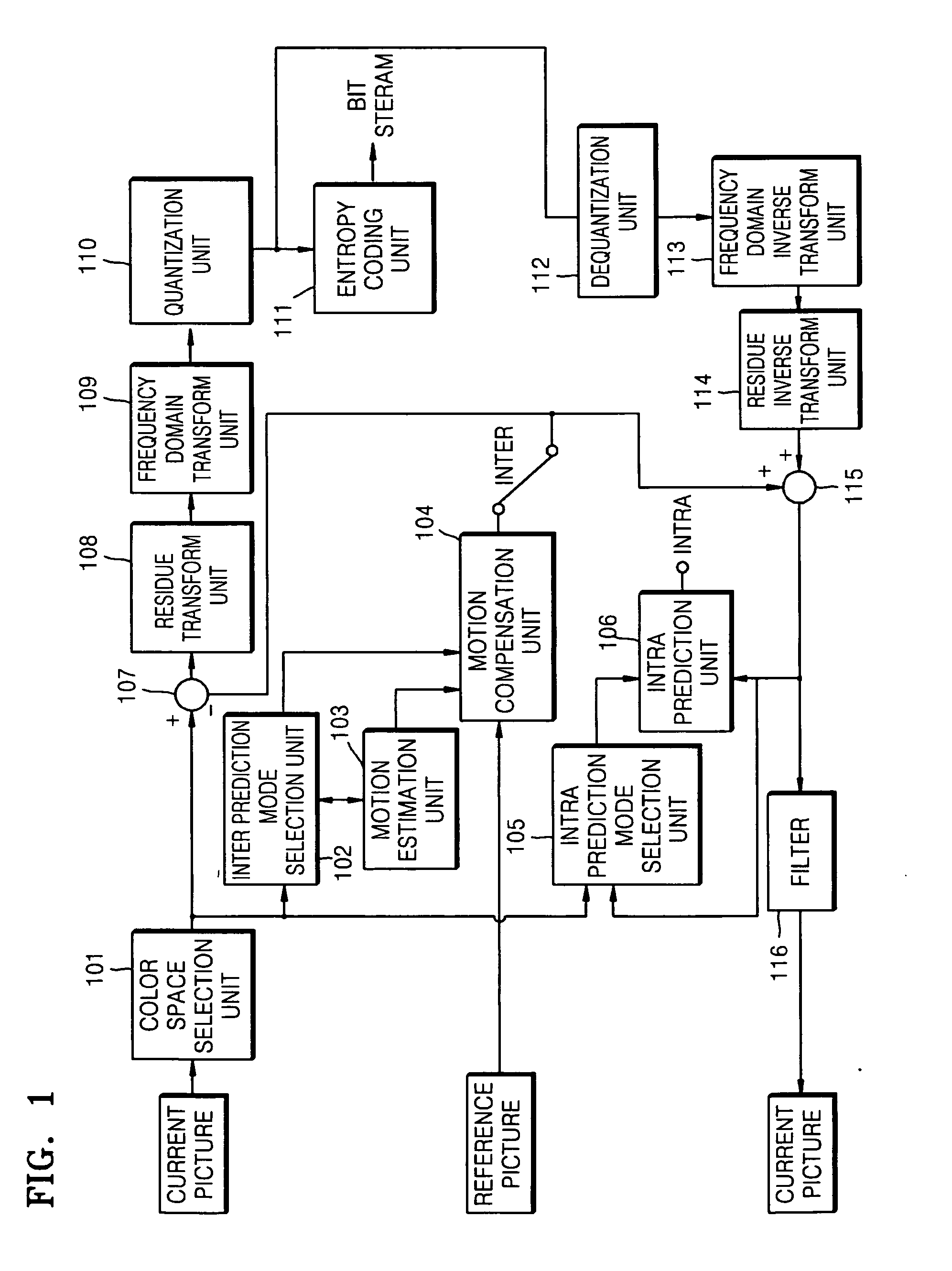

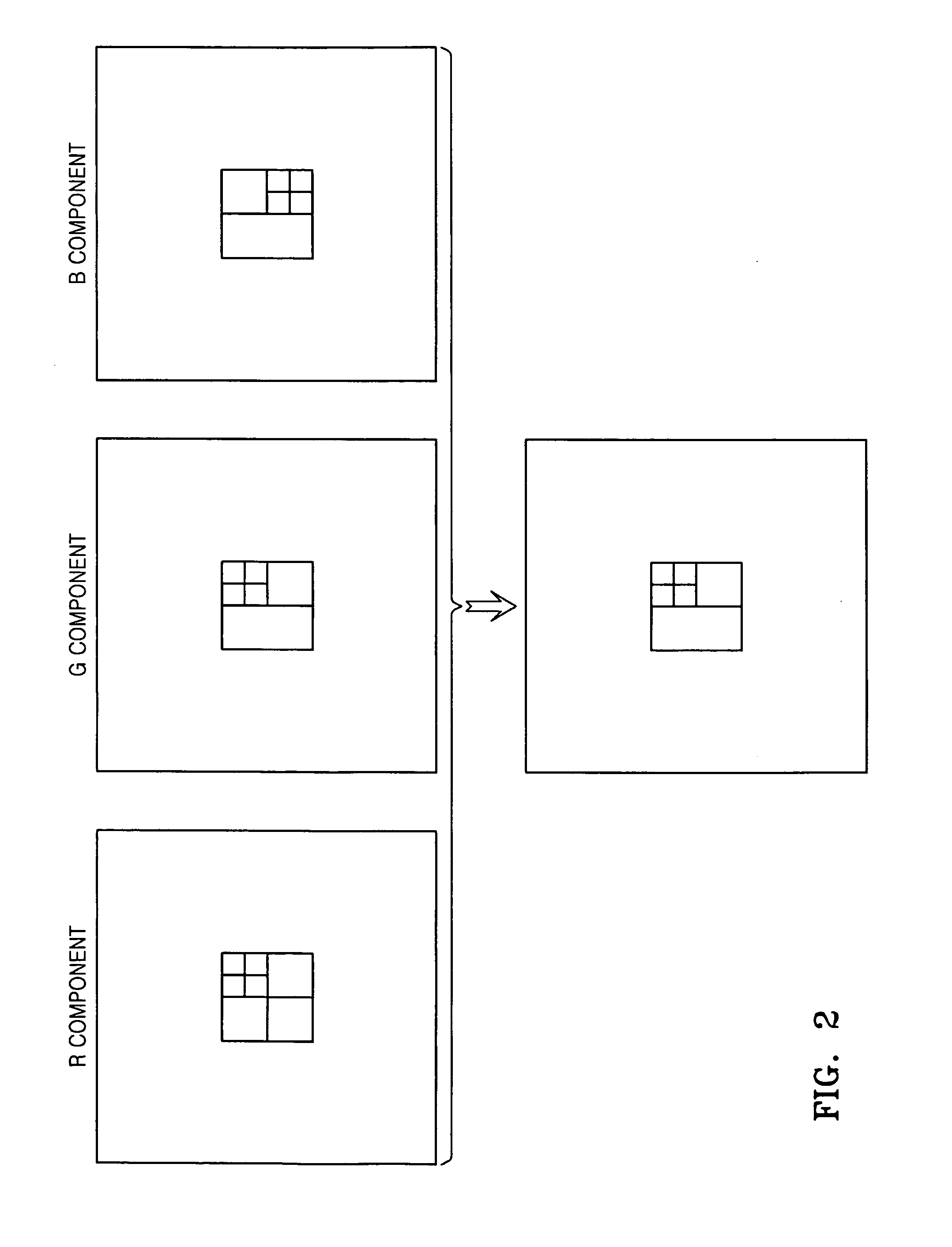

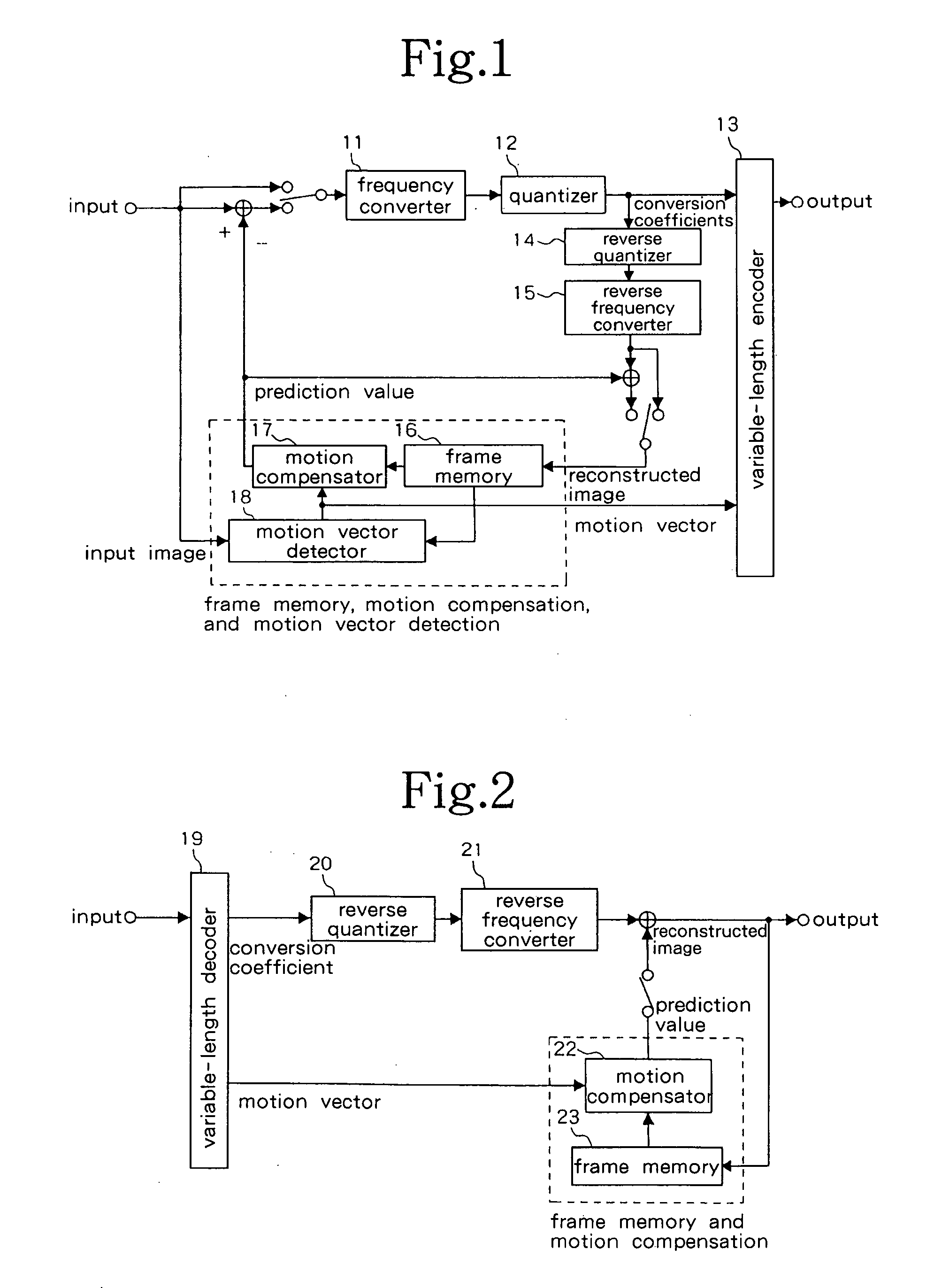

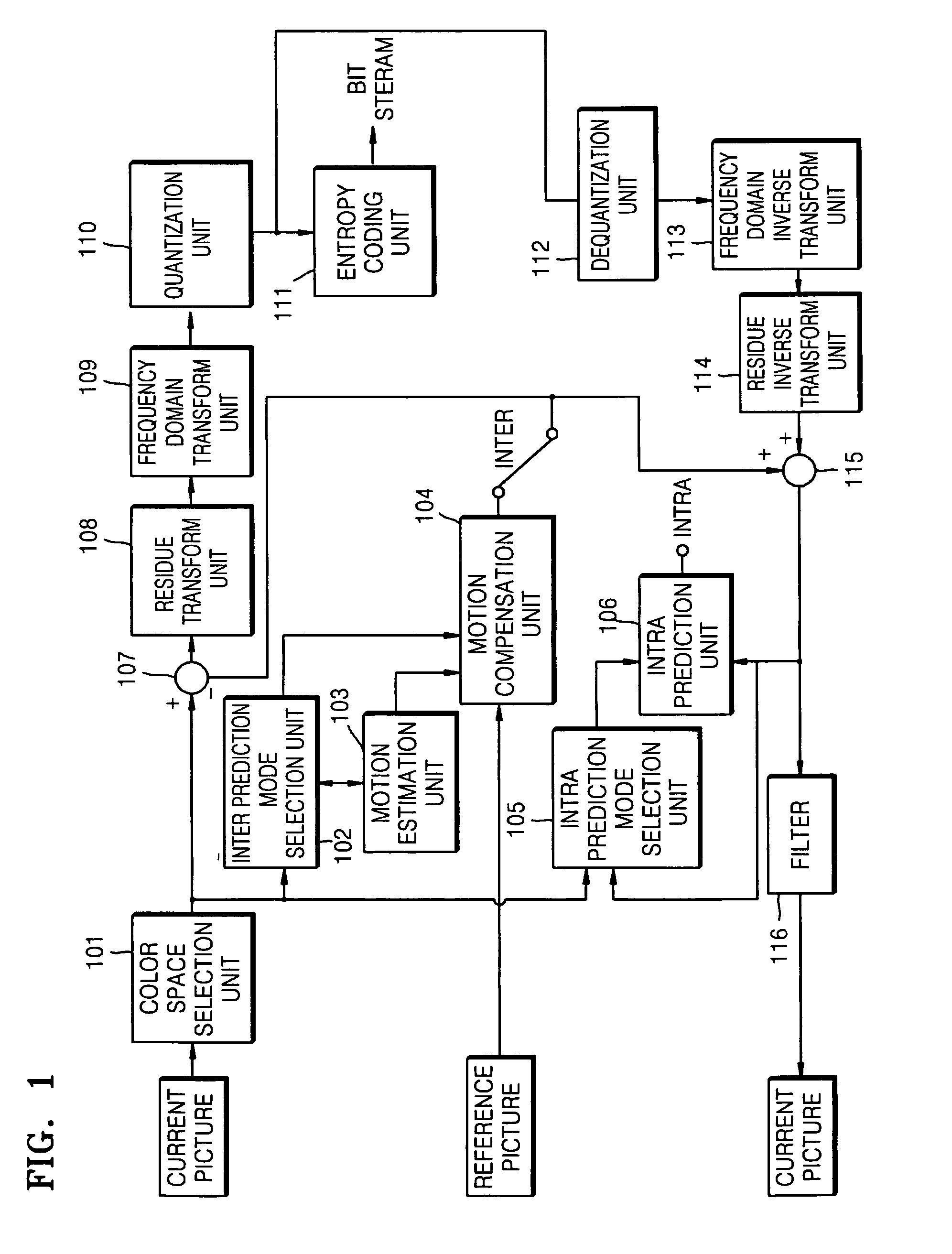

Moving picture coding/decoding method and apparatus

ActiveUS20060233251A1Improve handling efficiencyColor television with pulse code modulationPulse modulation television signal transmissionColor spaceDecoding methods

A moving picture coding / decoding method and apparatus with improved coding efficiency. A moving picture coding method includes selecting a color space from among a plurality of color spaces, selecting a prediction mode to be commonly applied to all the color components constituting the selected color space, generating first residual data corresponding to differences between a current picture and a predicted picture for each of the color components according to the selected prediction mode, generating second residual data corresponding to differences between the first residual data, and coding the second residual data.

Owner:SAMSUNG ELECTRONICS CO LTD

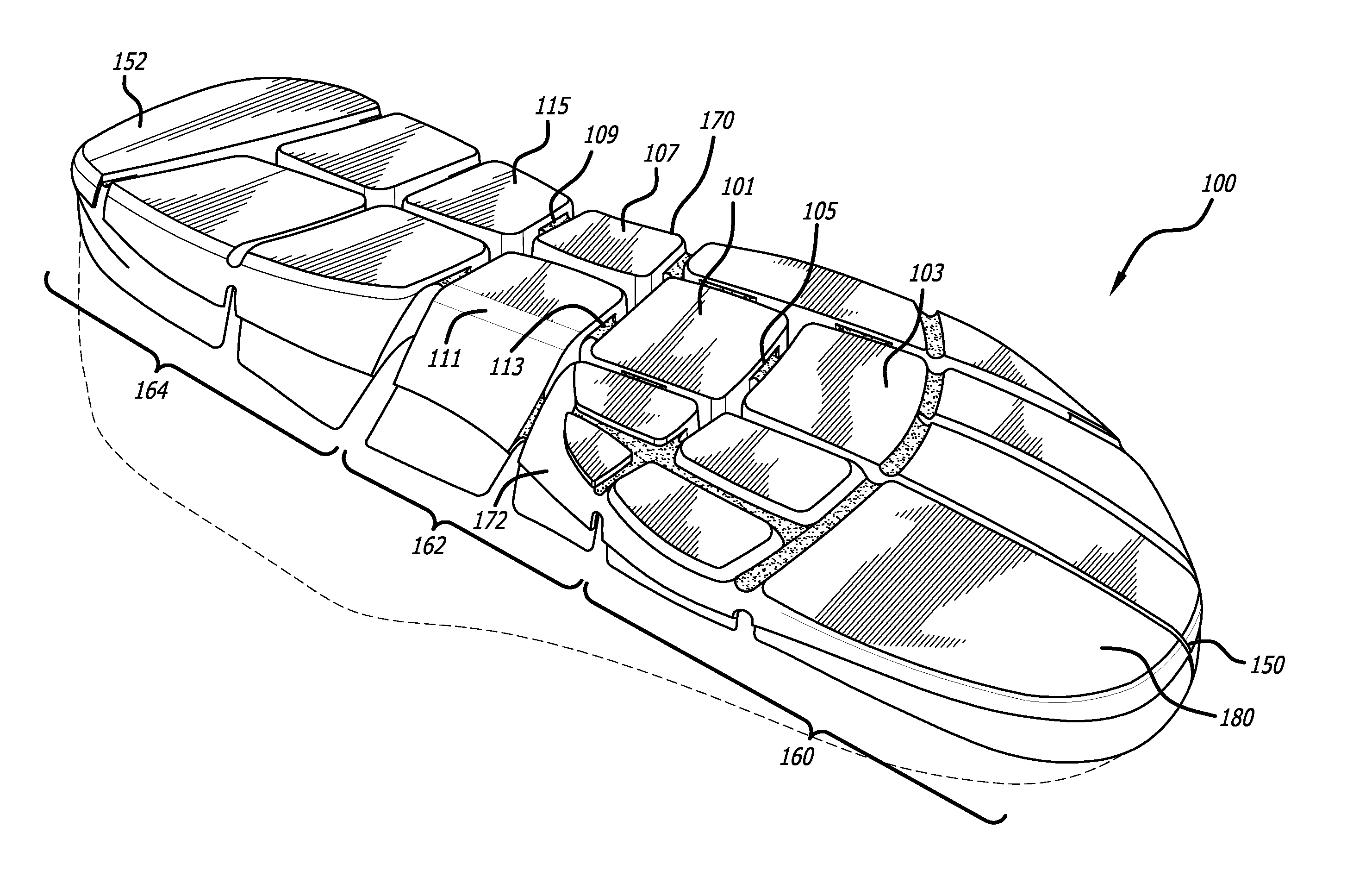

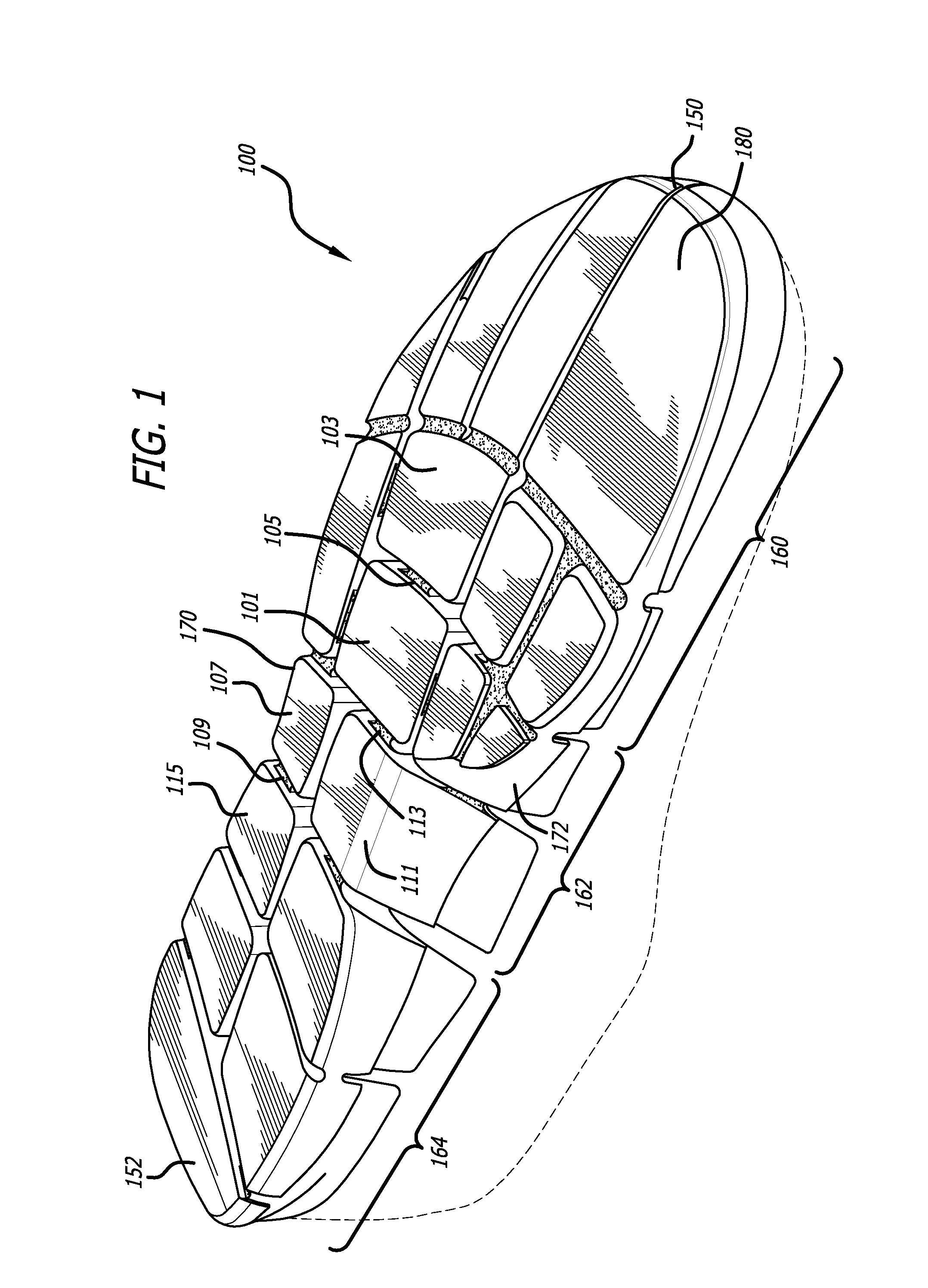

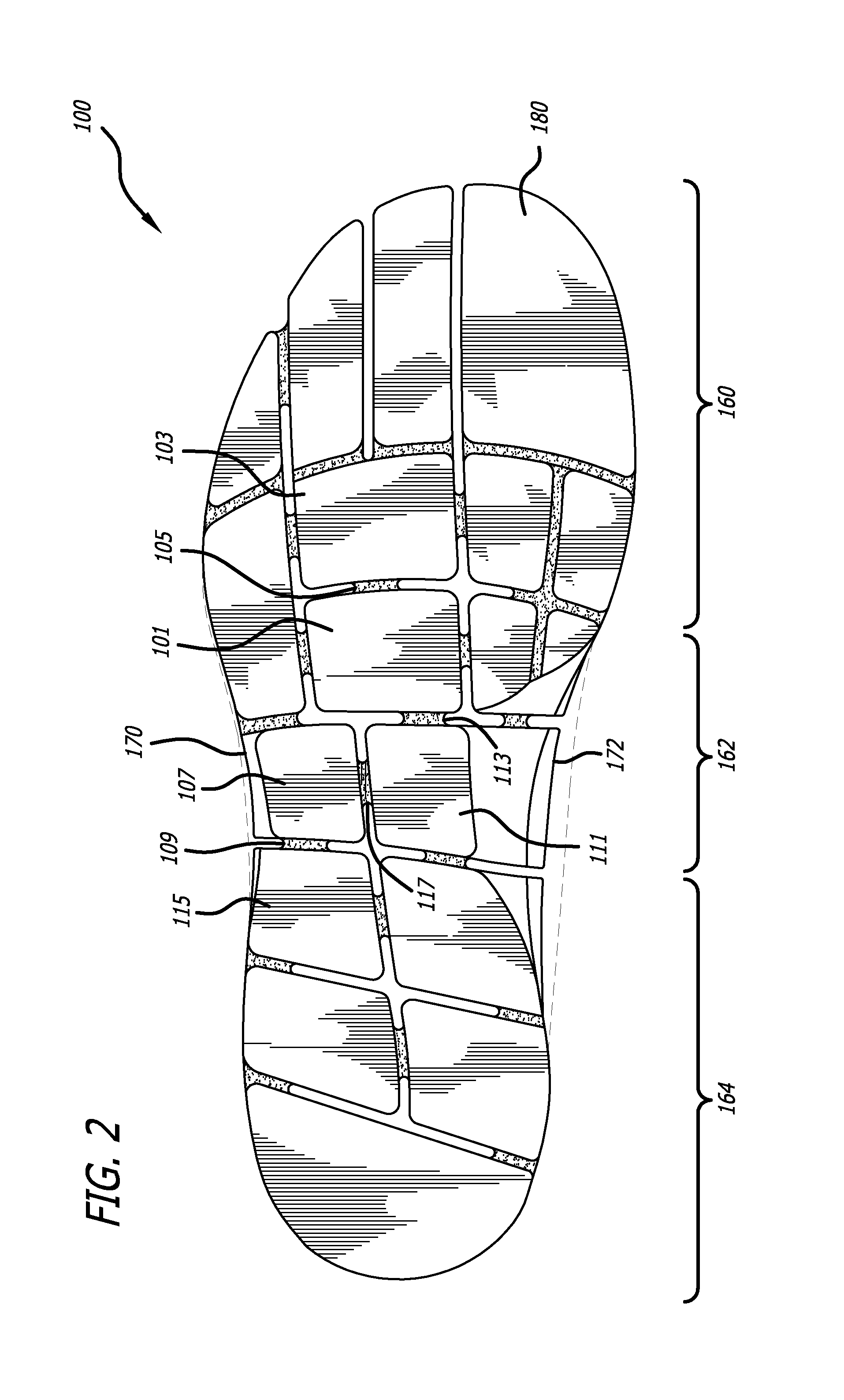

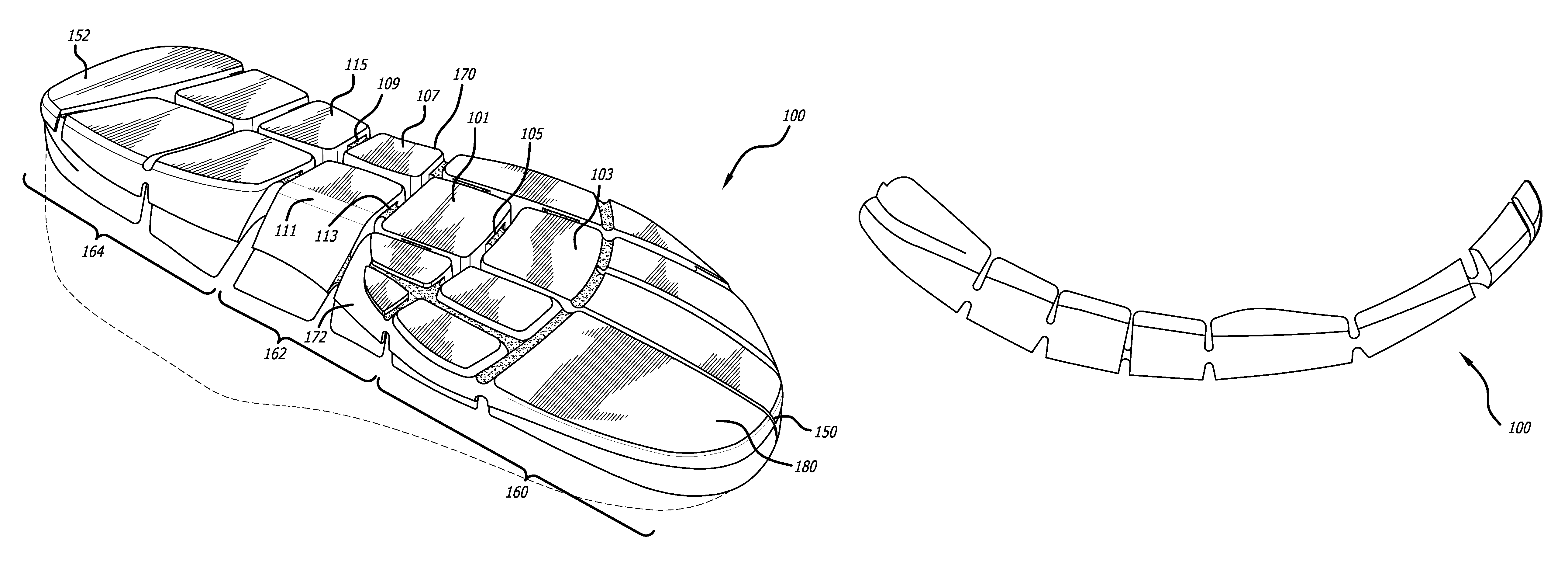

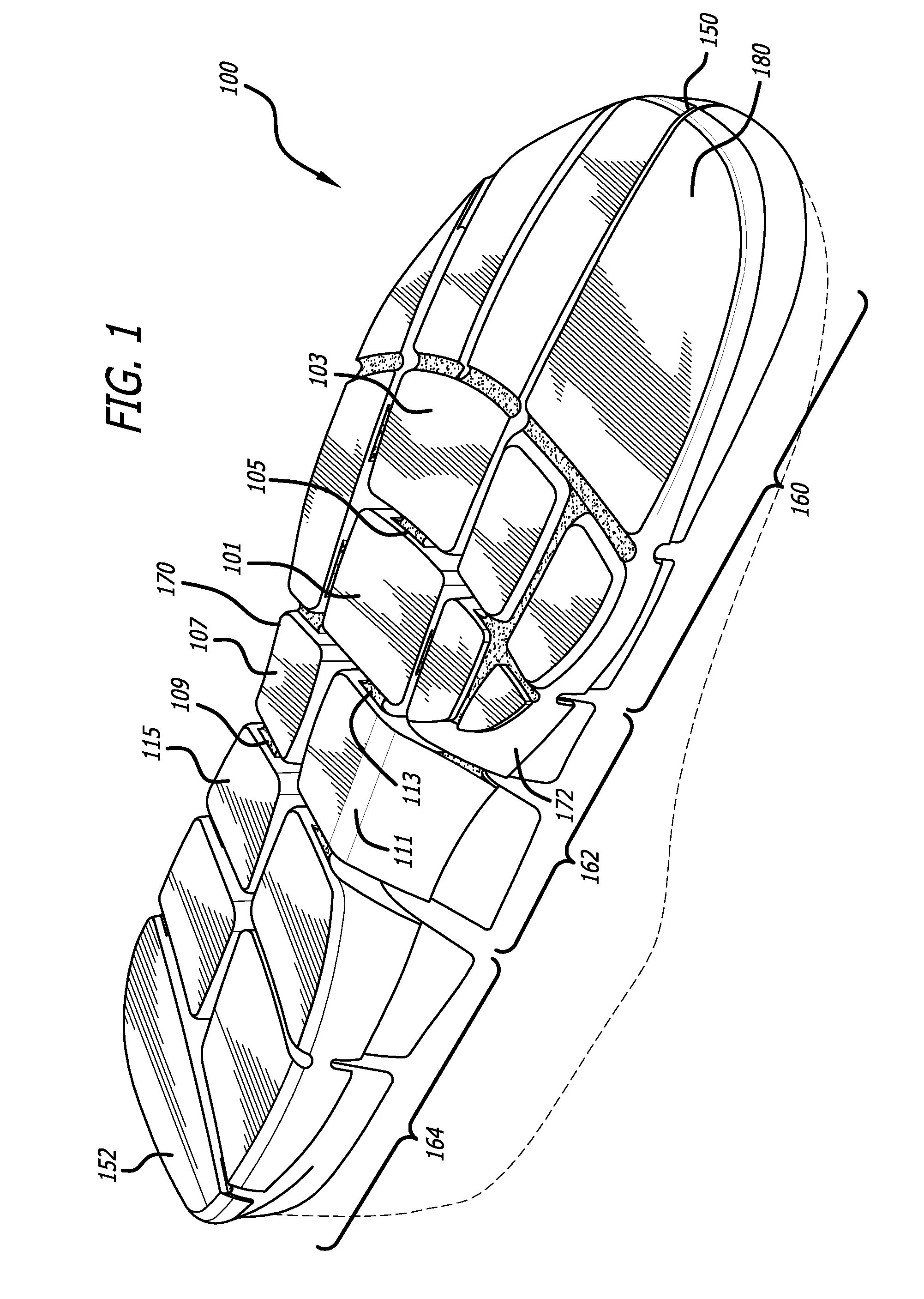

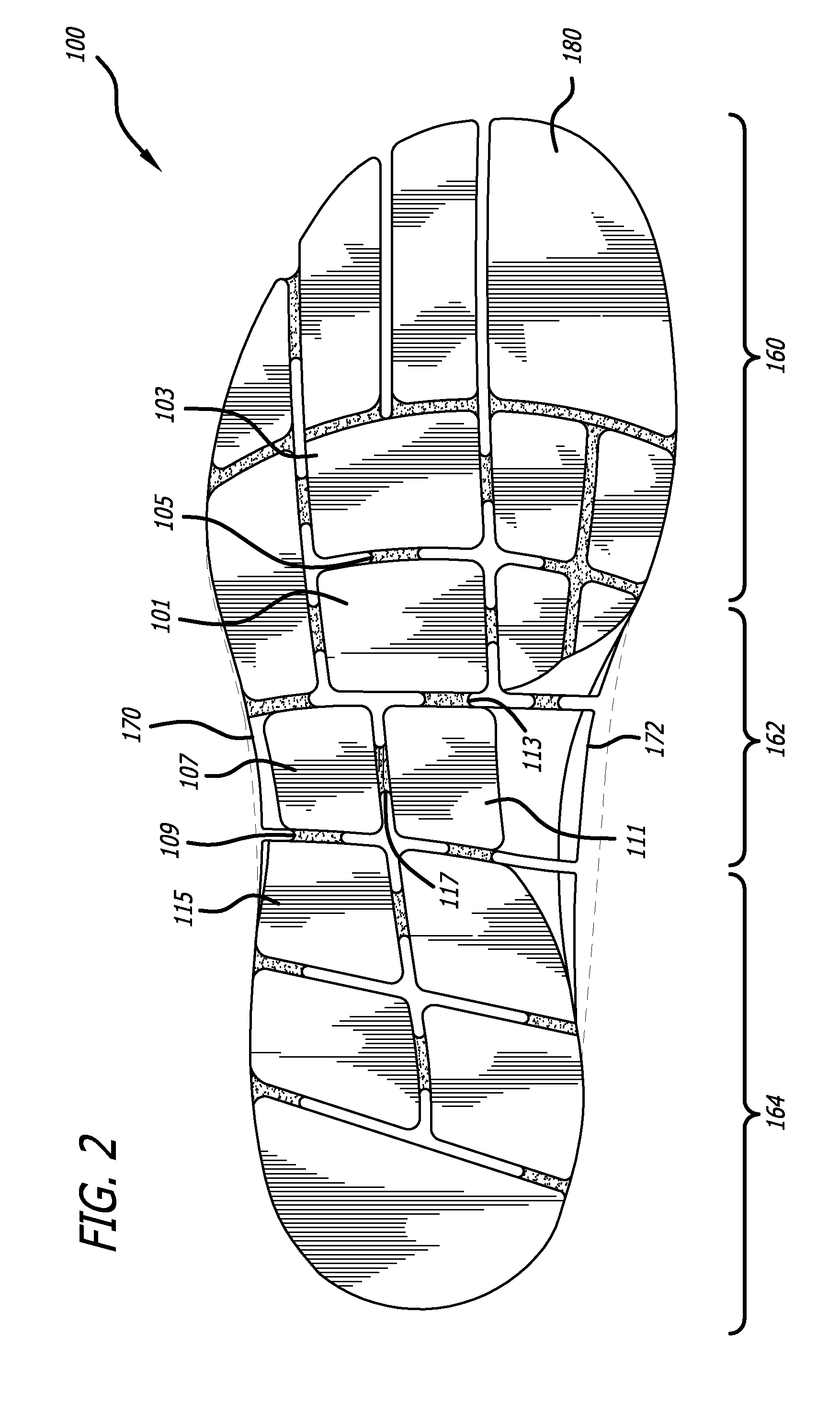

Article of footwear having articulated sole member

InactiveUS20140013624A1Improve handling efficiencyImprove comfortSolesEngineeringMechanical engineering

Owner:SKECHERS US II

Article of footwear having articulated sole member

Owner:SKECHERS US II

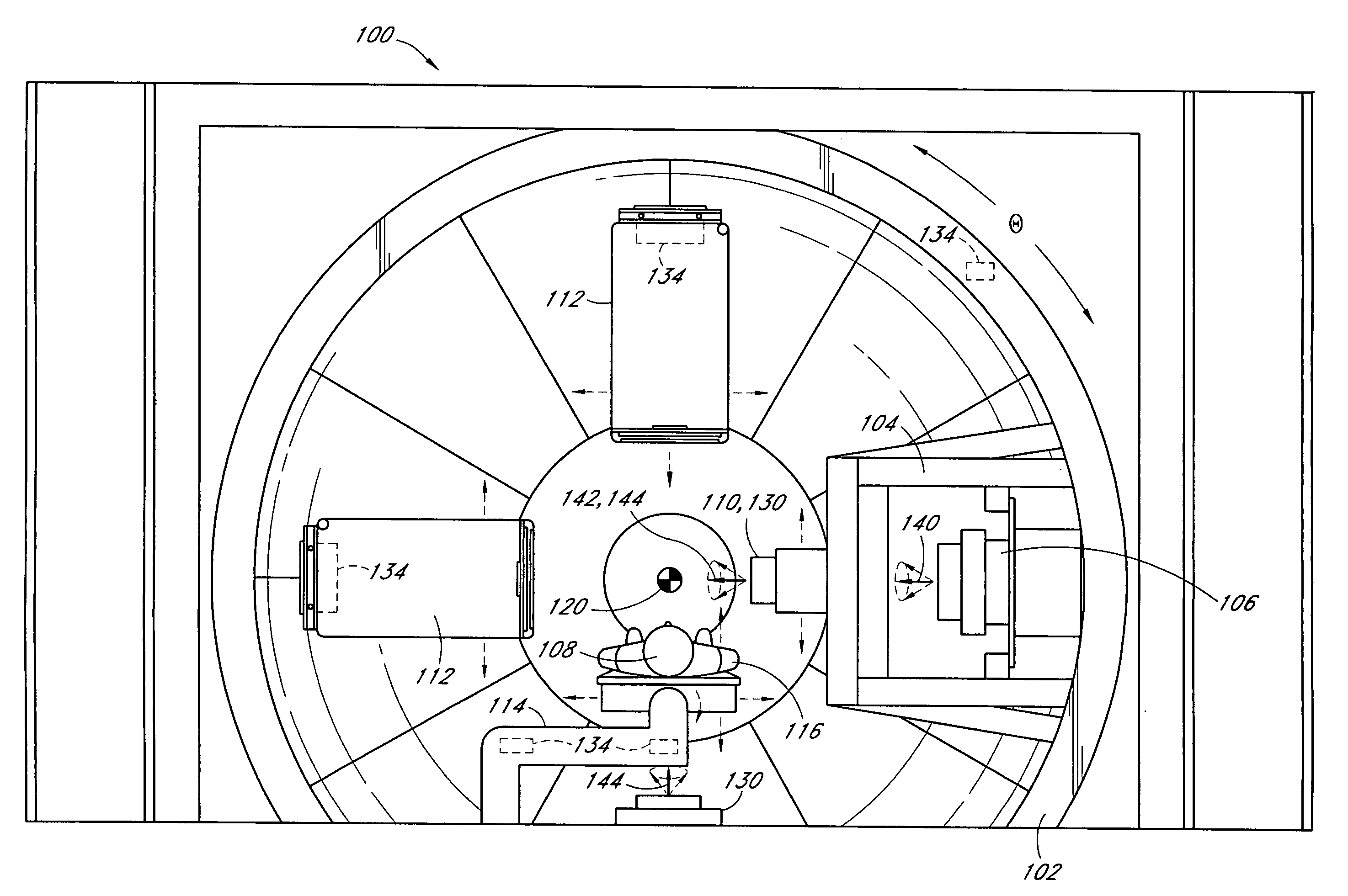

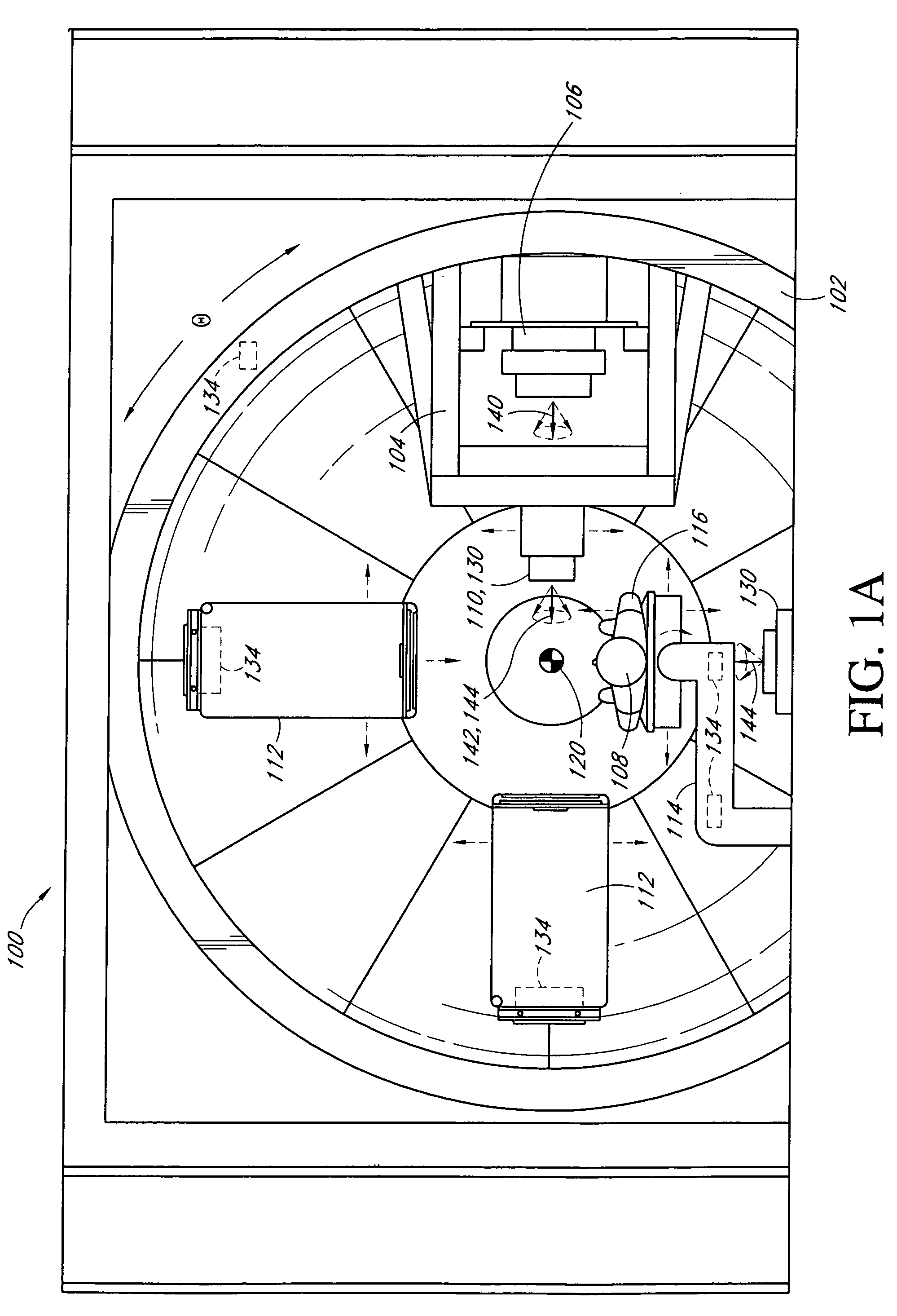

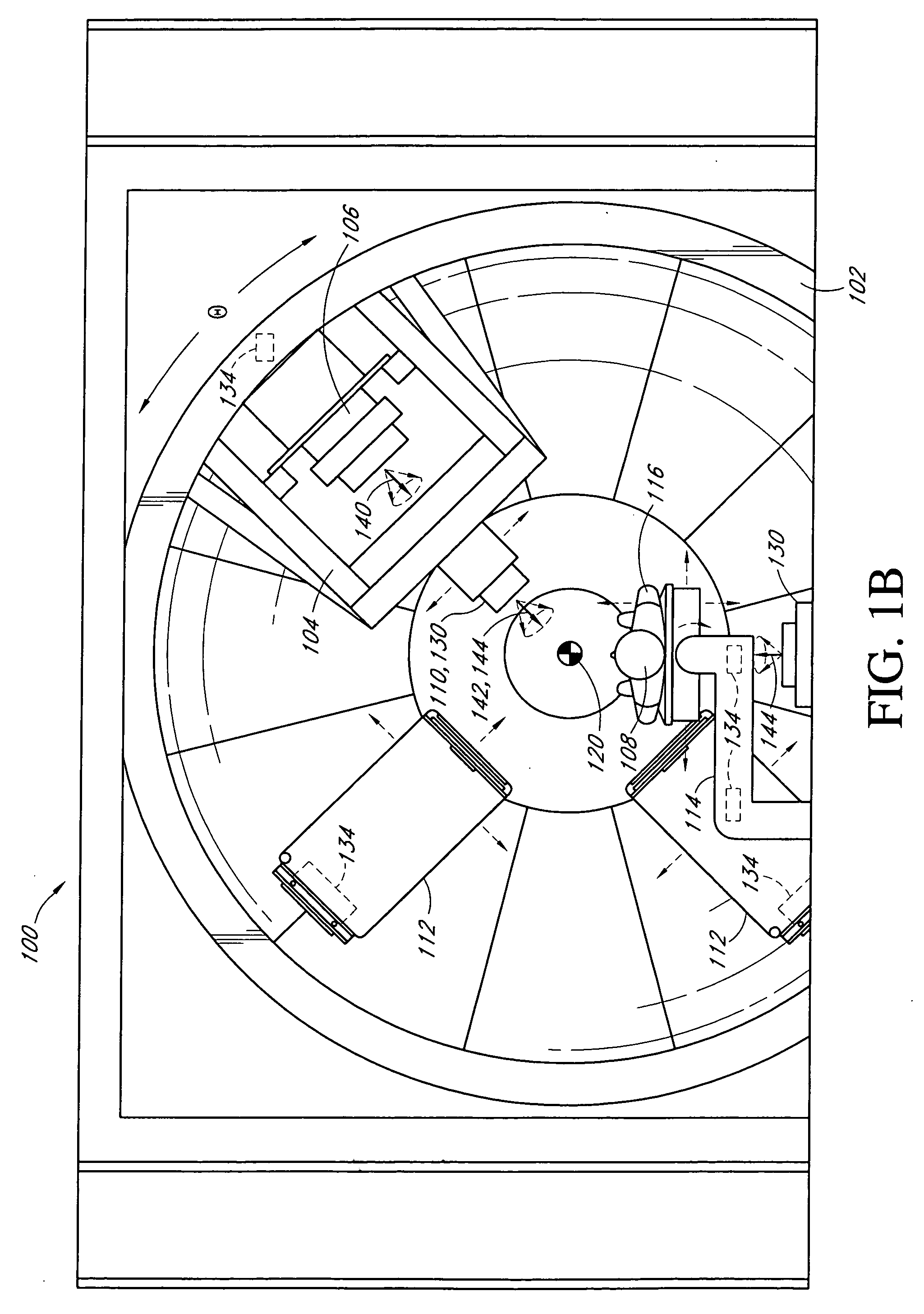

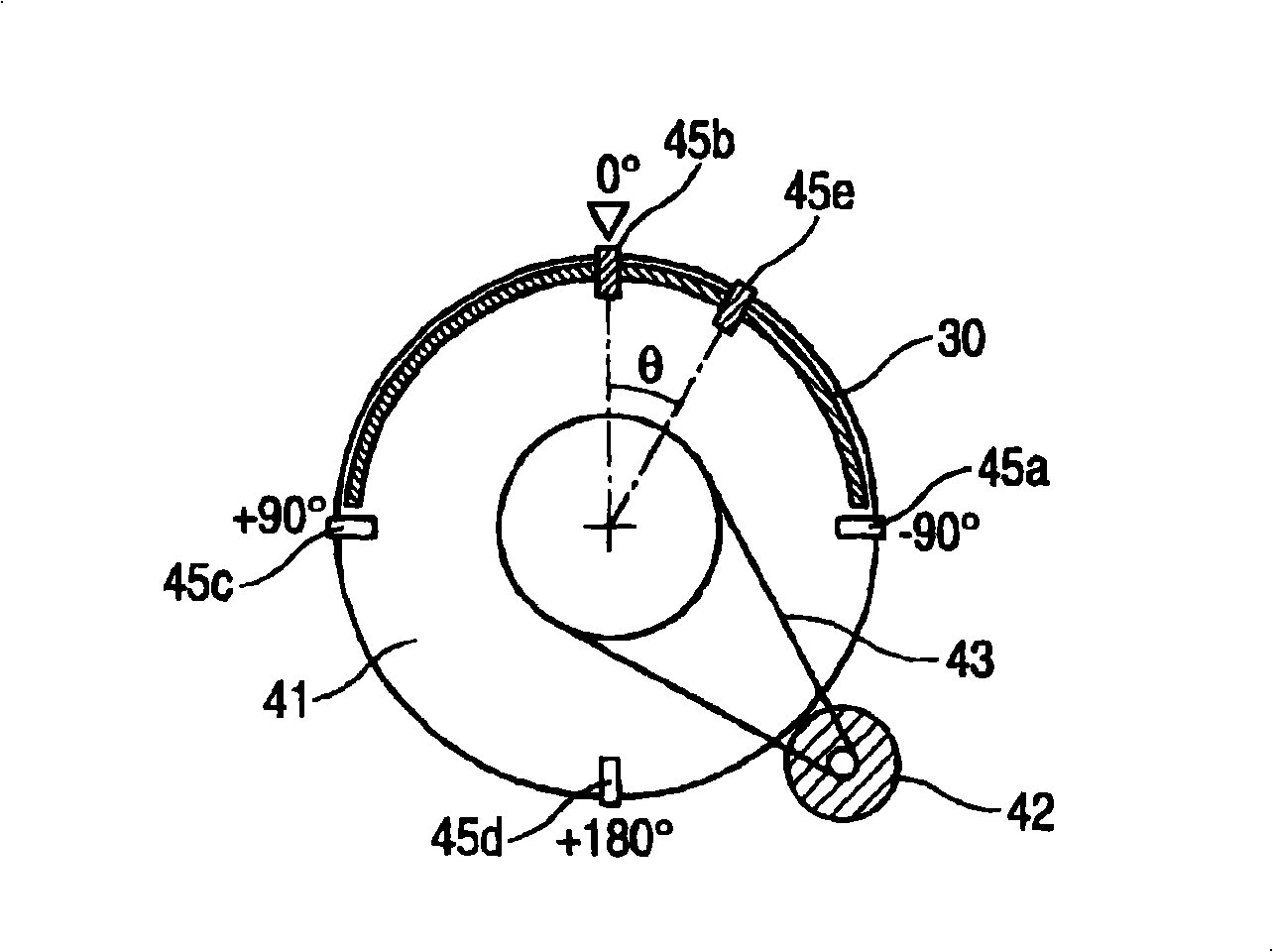

Path planning and collision avoidance for movement of instruments in a radiation therapy environment

ActiveUS20050281374A1Reduce latencyAvoid collisionThermometer detailsProgramme-controlled manipulatorMeasurement deviceOperational safety

A patient positioning system for use with a radiation therapy system that monitors the location of fixed and movable components and pre-plans movement of the movable components so as to inhibit movement if a collision would be indicated. The positioning system can also coordinate movement of multiple movable components for reduced overall latency in registering a patient. The positioning system includes external measurement devices which measure the location and orientation of objects, including components of the radiation therapy system, in space and can also monitor for intrusion into the active area of the therapy system by personnel or foreign objects to improve operational safety of the radiation therapy system.

Owner:LOMA LINDA UNIV MEDICAL CENT

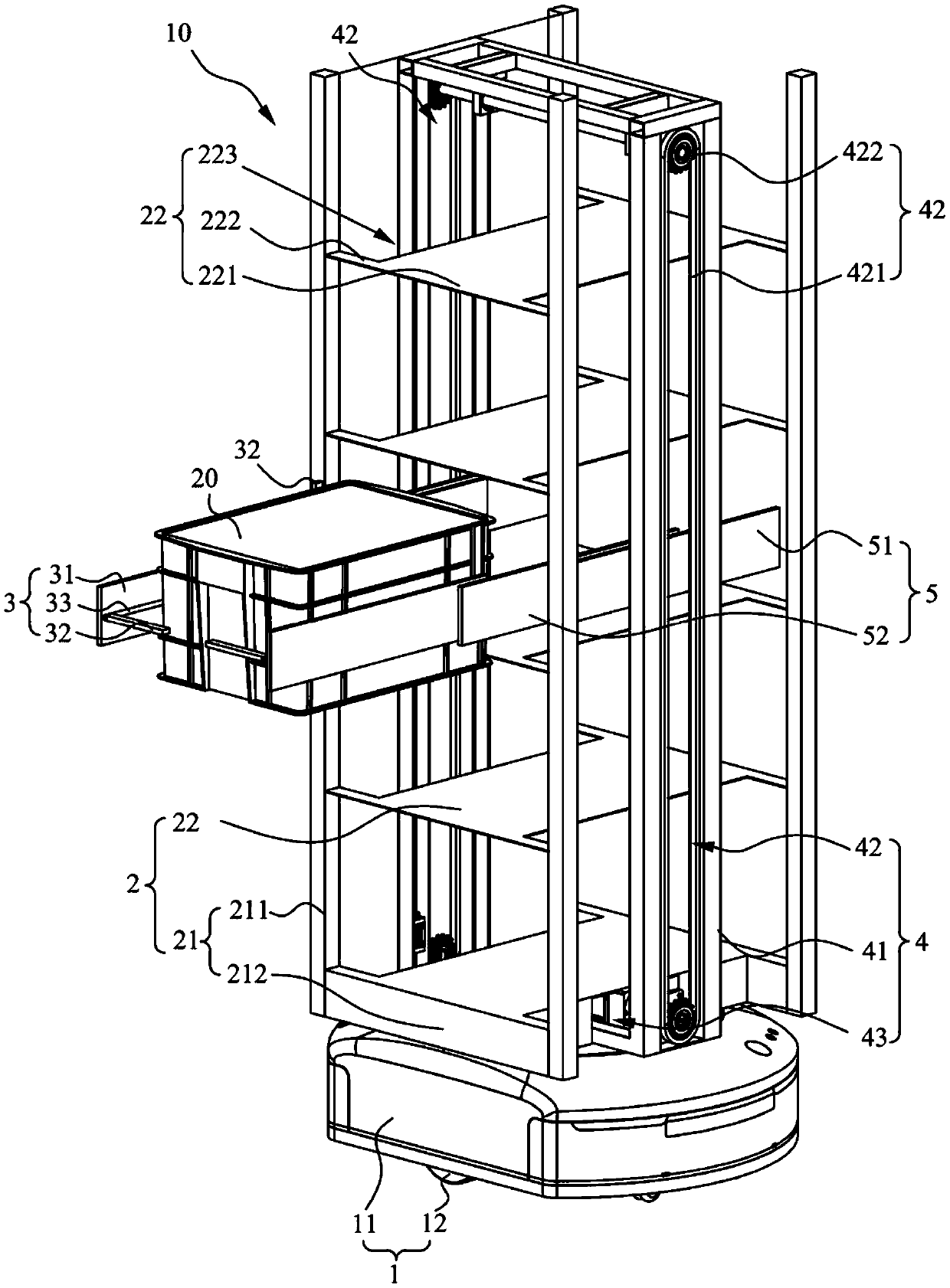

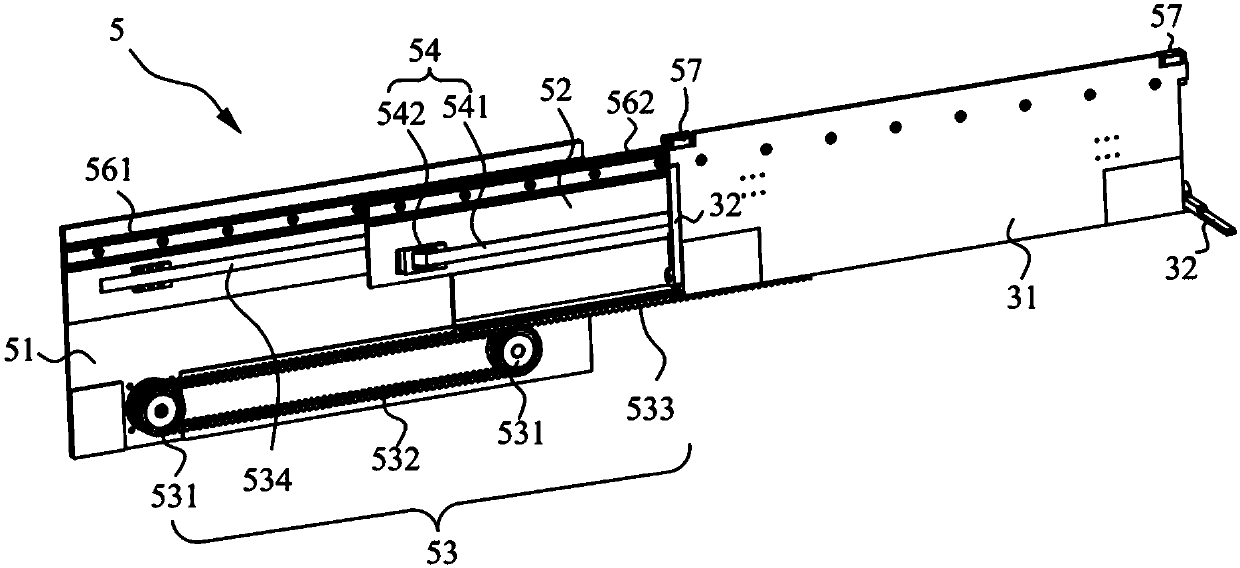

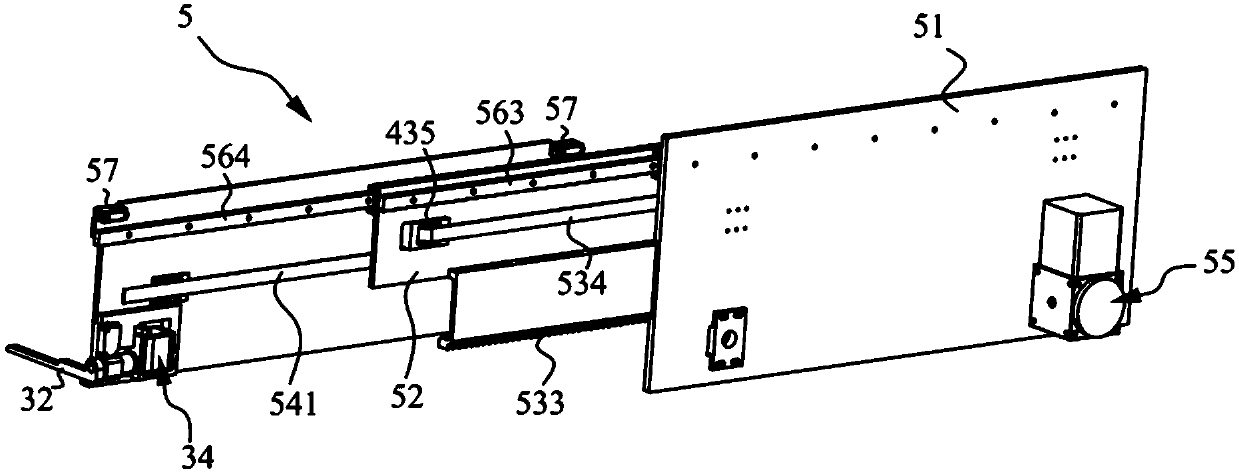

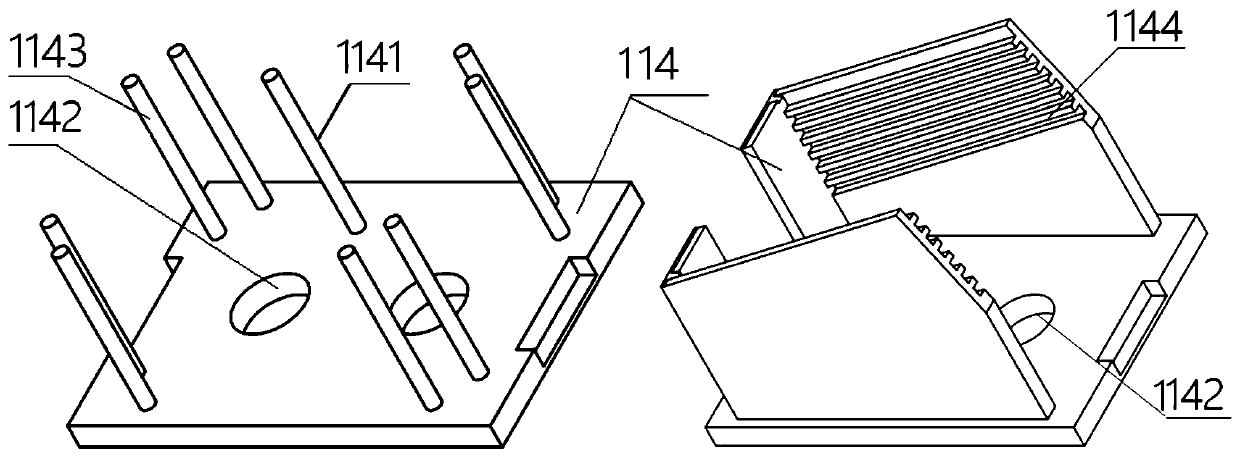

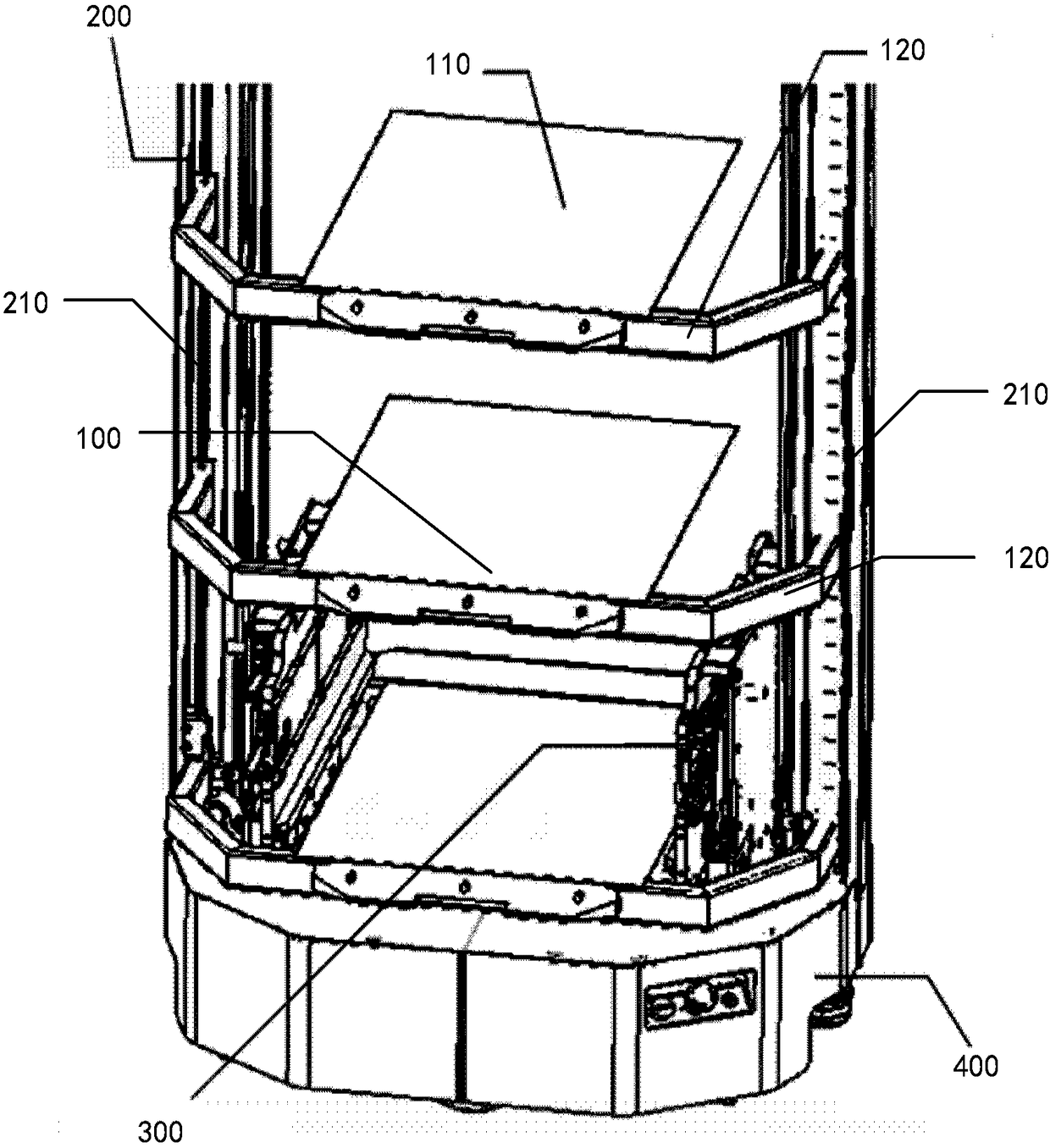

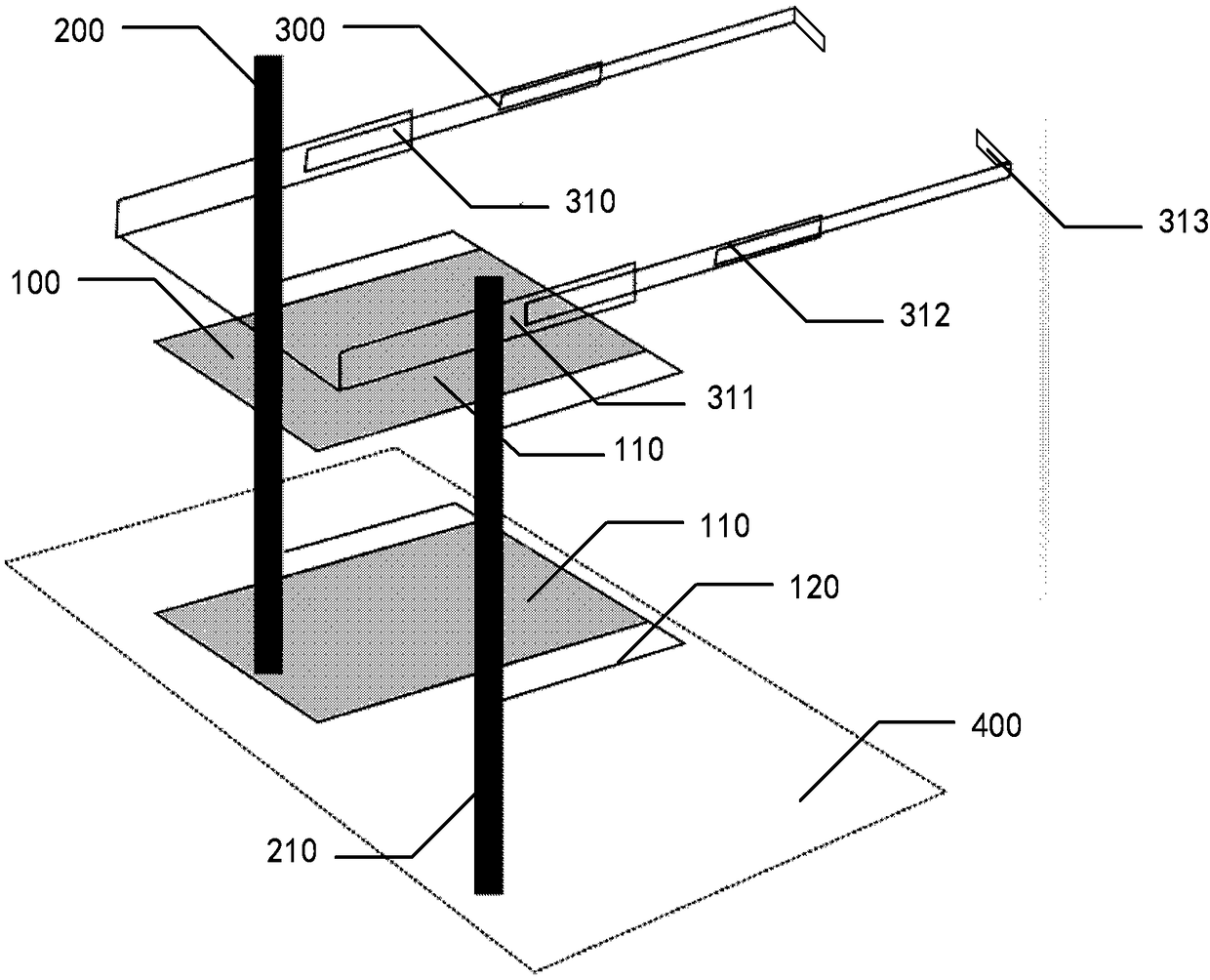

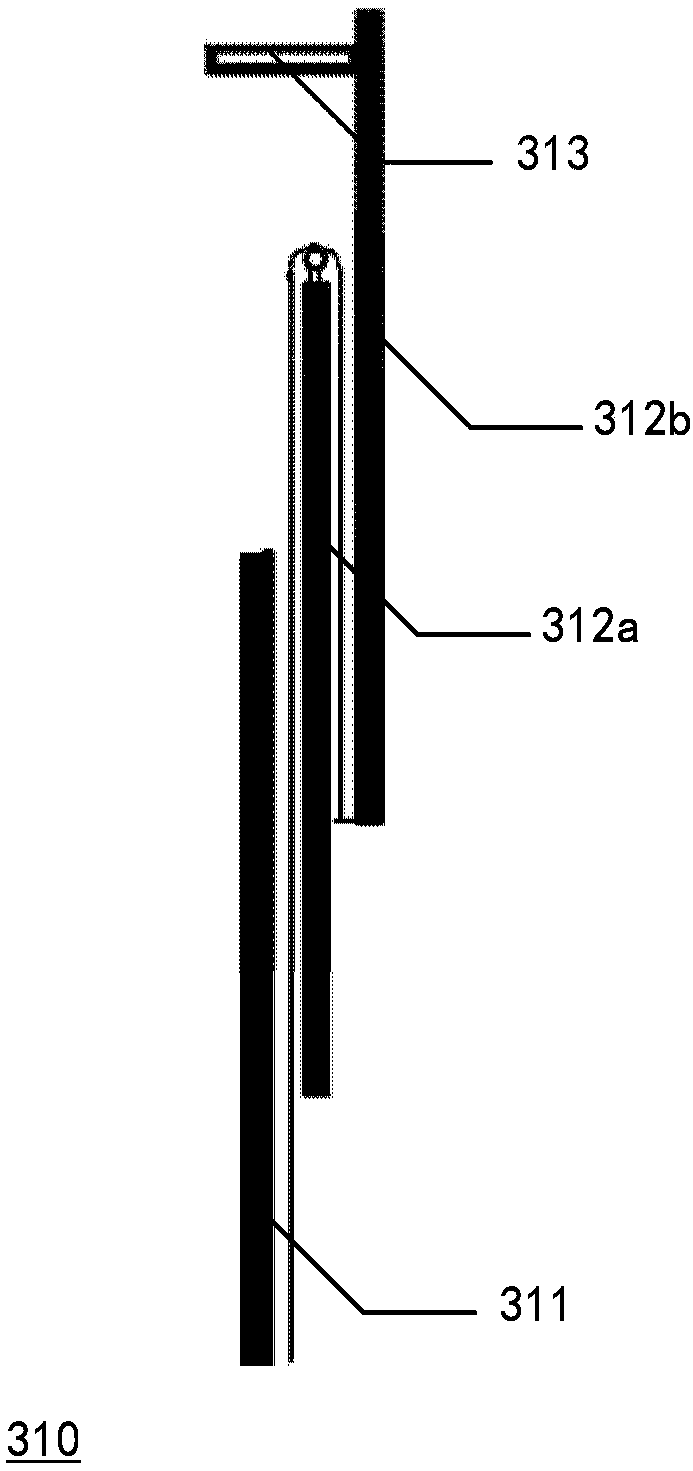

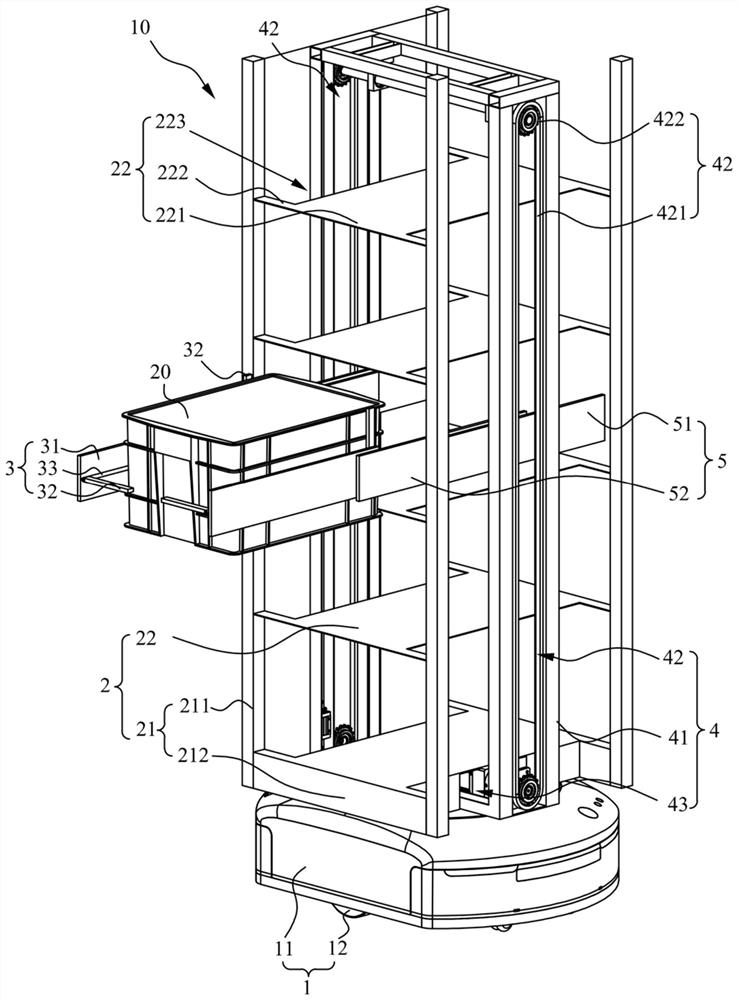

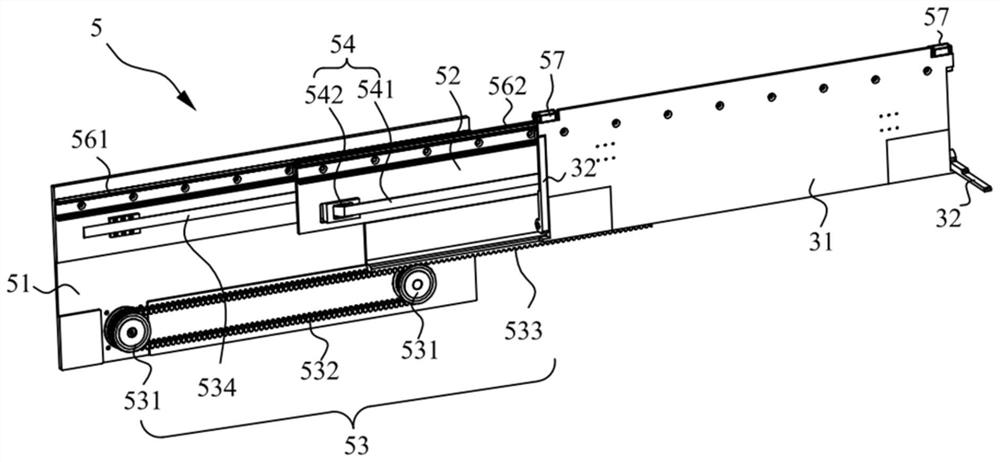

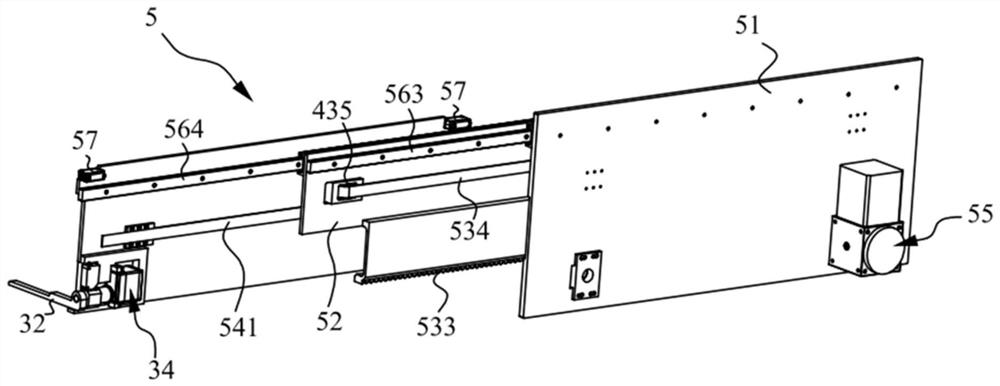

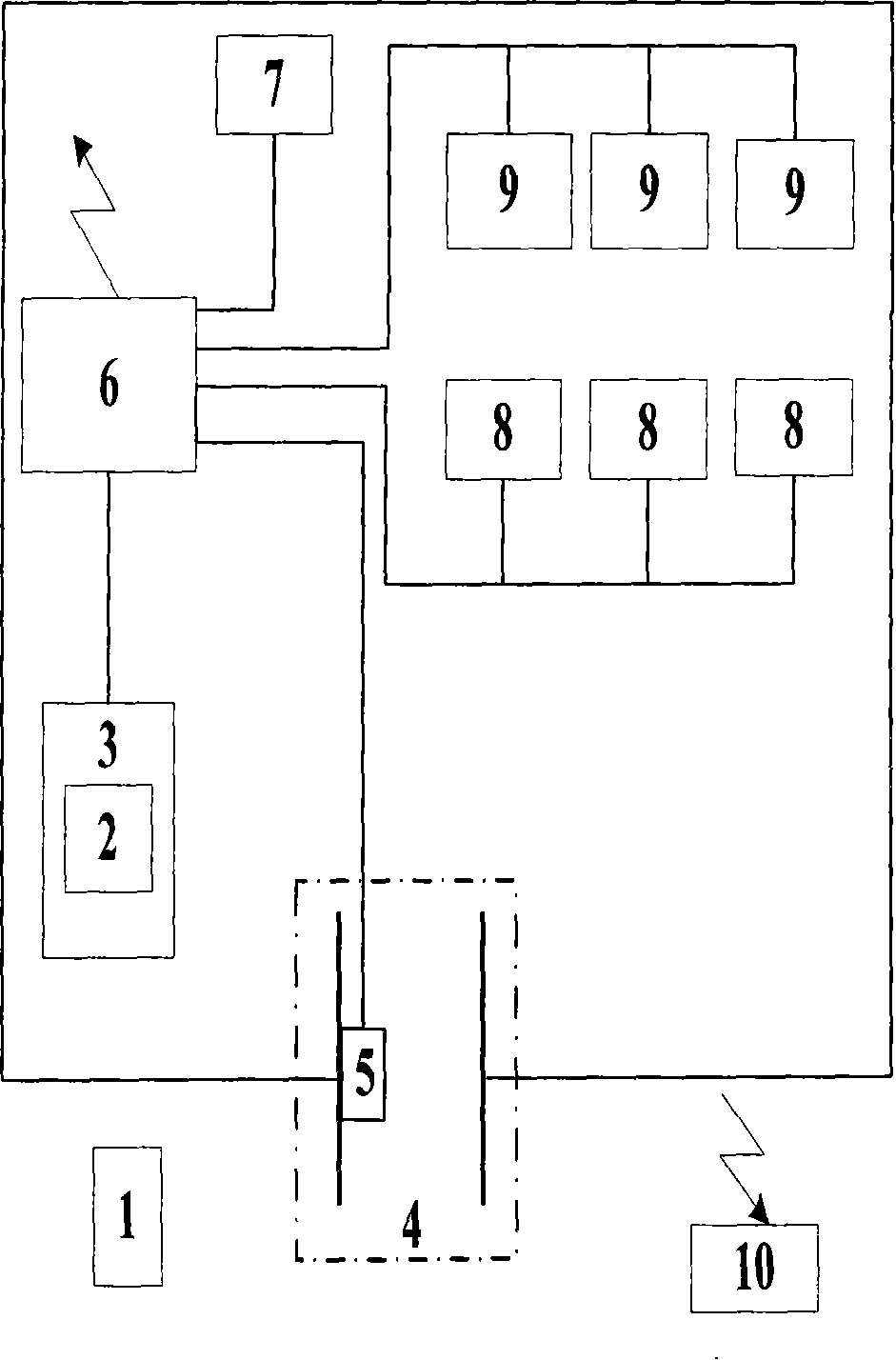

Handling robot, warehouse logistics system and packing box handling method

PendingCN109573449ALess room for movementIncrease profitStorage devicesLogistics managementMechanical engineering

The invention belongs to the technical field of warehousing logistics, and particularly discloses a handling robot, a warehouse logistics system and a packing box handling method. The handling robot comprises a movable base plate which can move along a channel between adjacent inventory containers, temporary storage racks which are arranged on the movable base plate and used for temporarily storing a target packing box, and box taking assemblies which are arranged on the movable base plate, wherein the box taking assemblies can horizontally stretch relative to the movable base plate so as to pick and place the target packing box between the inventory containers and the temporary storage racks, and the horizontal stretching direction of the box taking assemblies is perpendicular to the moving direction of the handling robot. The warehouse logistics system comprises the handling robot, and the packing box handling method adopts the handling robot to convey the target packing box. According to the handling robot, the warehouse logistics system and the packing box handling method, the occupied space of the handling robot on warehouse channels can be reduced, the utilization rate of thewarehouse can be improved, and meanwhile the handling efficiency of the packing box can be improved.

Owner:BEIJING JIZHIJIA TECH CO LTD

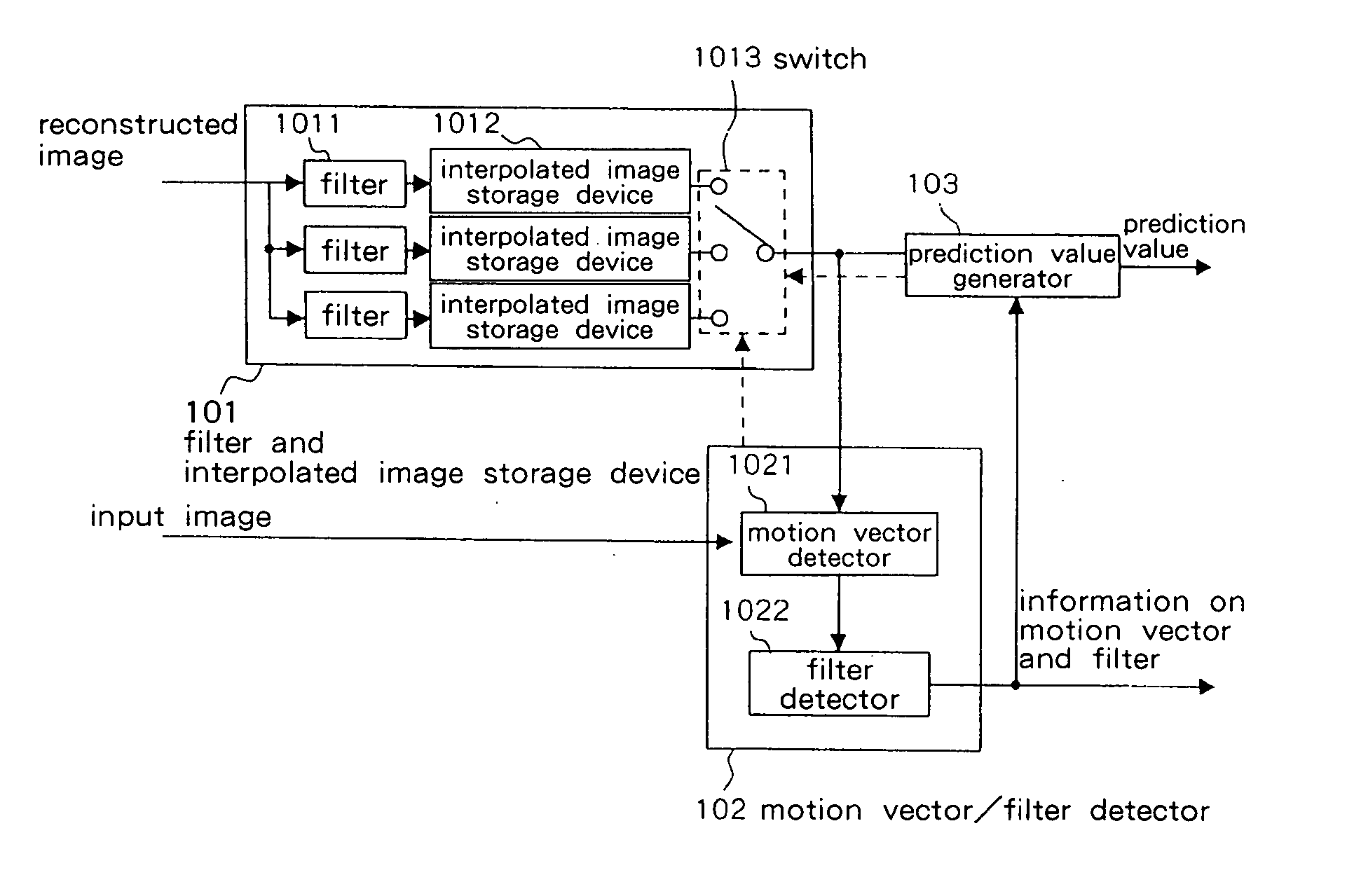

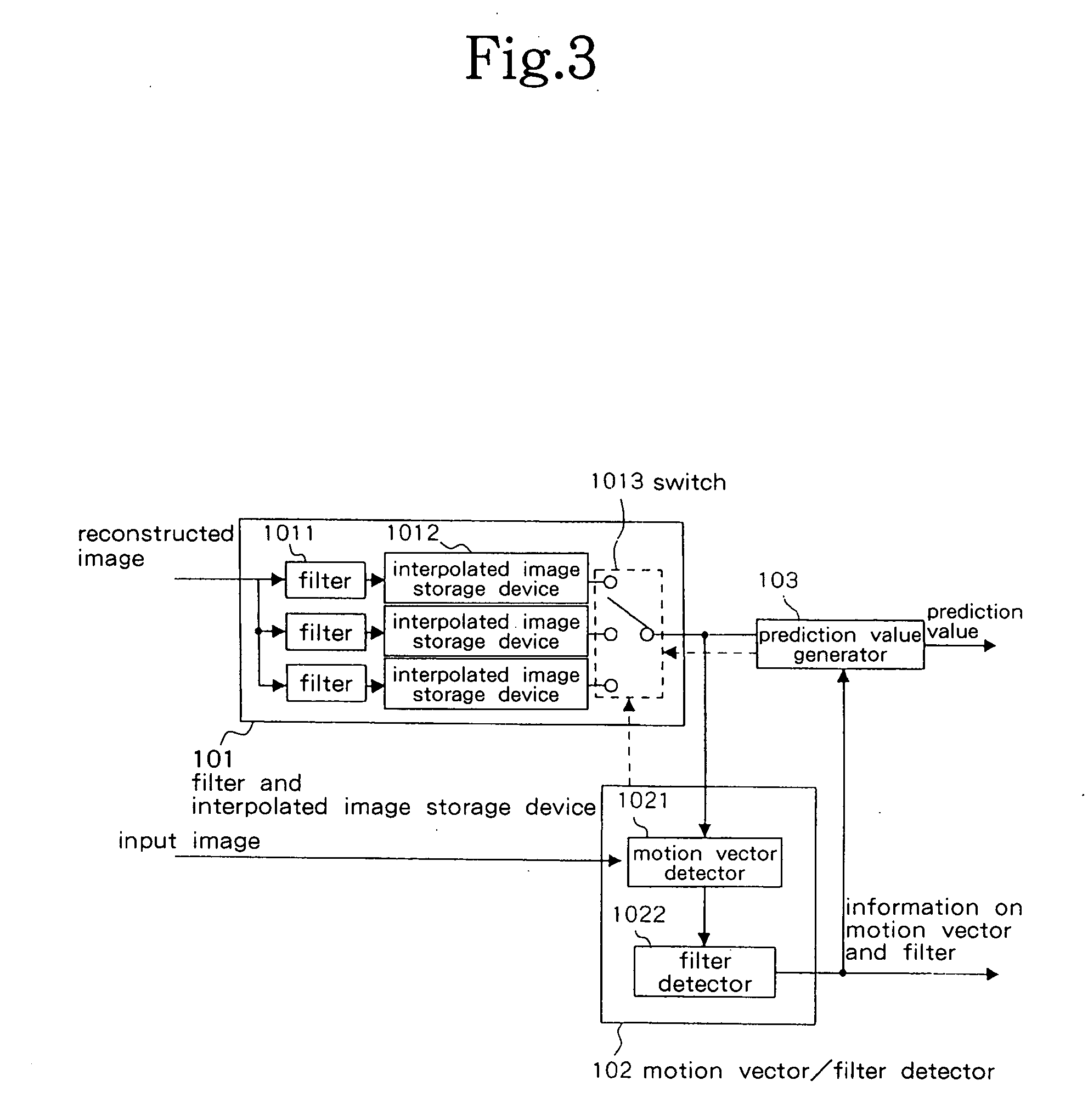

Moving picture coding method and decoding method, and apparatus and program using the same

ActiveUS20050105617A1Good effectEncoding efficiency can be improvedPicture reproducers using cathode ray tubesCode conversionDecoding methodsMotion vector

The present invention seeks to provide a solution to the problem that motion compensation in an encoding method of the prior art involves decimal point picture element interpolation by means of fixed filters and therefore cannot realize interpolation of decimal point picture elements that accords with the nature and bit rate of a moving picture. A filter / interpolated image memory (101) interpolates picture elements of decimal point positions in a reference image by means of a plurality of sets of filters, a motion vector, filter detector (102) detects the combination of filter and motion vector that realizes the highest encoding efficiency, a prediction value generator (103) uses the detected combination of filter and motion vector to generate a prediction value, and motion vector / filter detector (102) supplies as output the information of the filter and information of the motion vector that generated the prediction value; whereby decimal point picture element interpolation that corresponds to the nature and bit rate of the moving picture can be realized and encoding of a moving picture can be improved.

Owner:NEC CORP

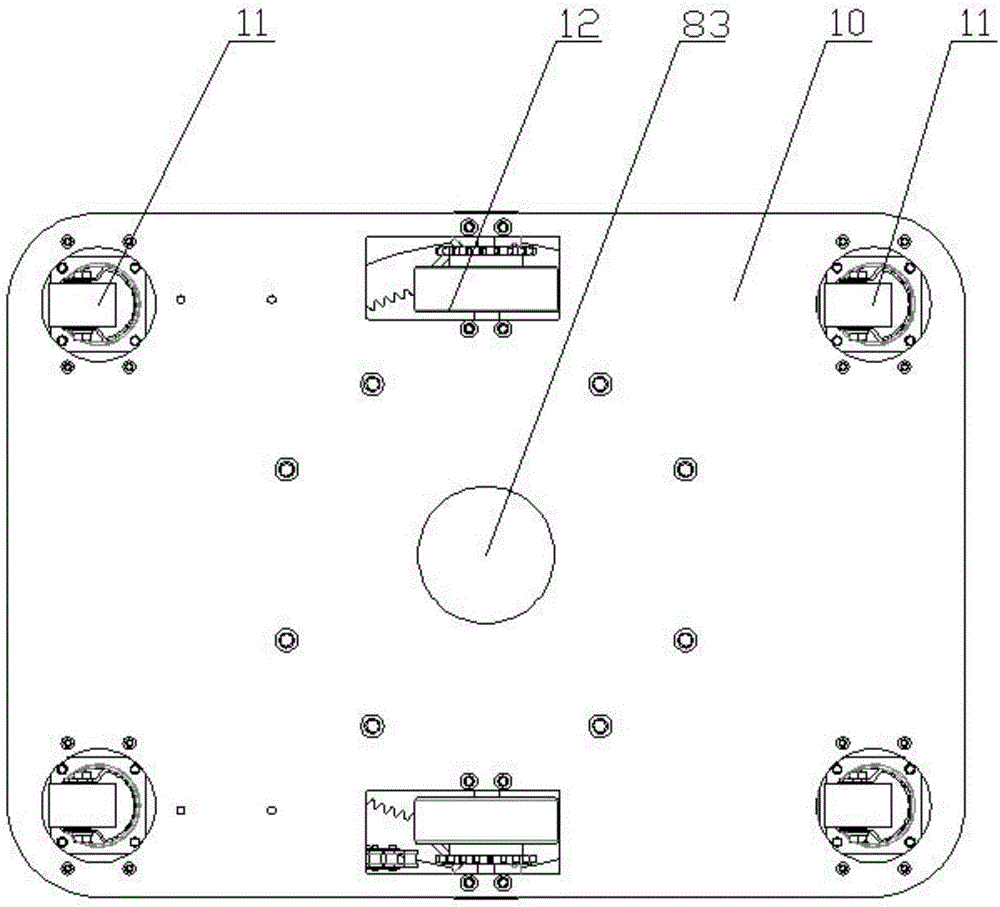

Sorting and carrying AGV

PendingCN106064717AIncrease flexibilityImprove logistics handling efficiencyControl devices for conveyorsStorage devicesEngineeringUltrasonic sensor

The invention relates to a sorting and carrying AGV comprising an underpan, a jacking mechanism, an infrared photoelectric sensor, an ultrasonic sensor, a control device and a power supply. Each of the front and rear ends of the underpan is provided with two driven wheels, and two sides of the middle part of the underpan are provided with driving wheels respectively and first driving mechanisms driving the driving wheels to rotate; the jacking mechanism comprises a lifting platform and a plurality of pillars supporting the lifting platform, wherein the lifting platform is provided with a tray and a rotating device for driving the tray to reversely rotate relative to the turning direction of the AGV, and the underpan is provided with a second driving mechanism for driving the lifting platform to go up and down; the infrared photoelectric sensor is arranged on the underpan and is used for detecting a pavement tracing line; the ultrasonic sensor is arranged on the underpan and is used for detecting a barrier; the control device is arranged on the underpan and is in communication connection with the first driving mechanisms, the rotating device, the second driving mechanism and the infrared photoelectric sensor and the ultrasonic sensor; and the power supply is used for supplying power to the first driving mechanisms, the rotating device, the second driving mechanism and the control device.

Owner:苏州小喇叭信息科技有限公司

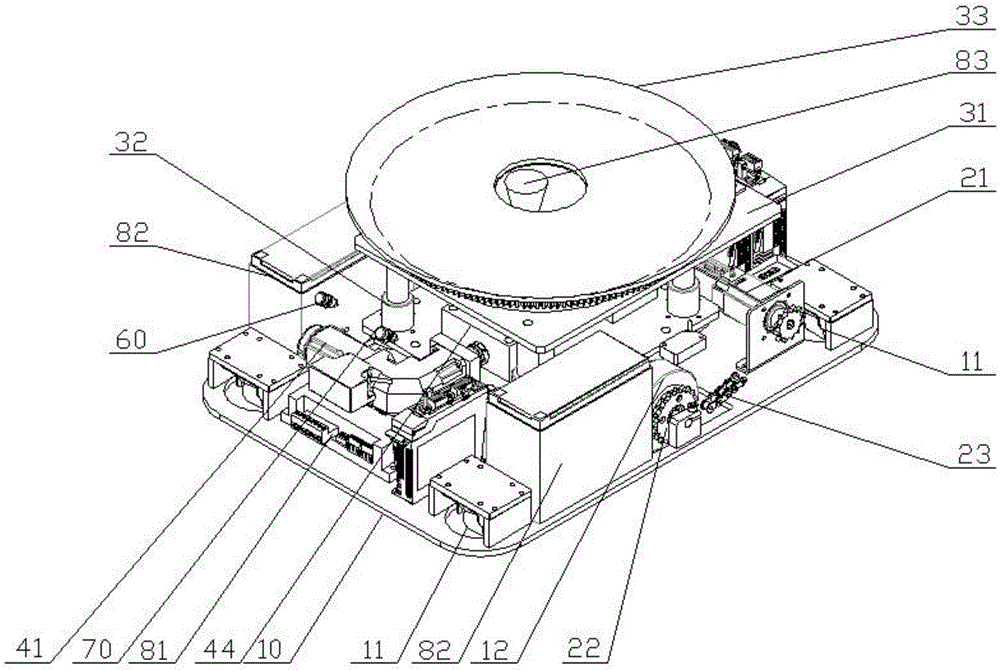

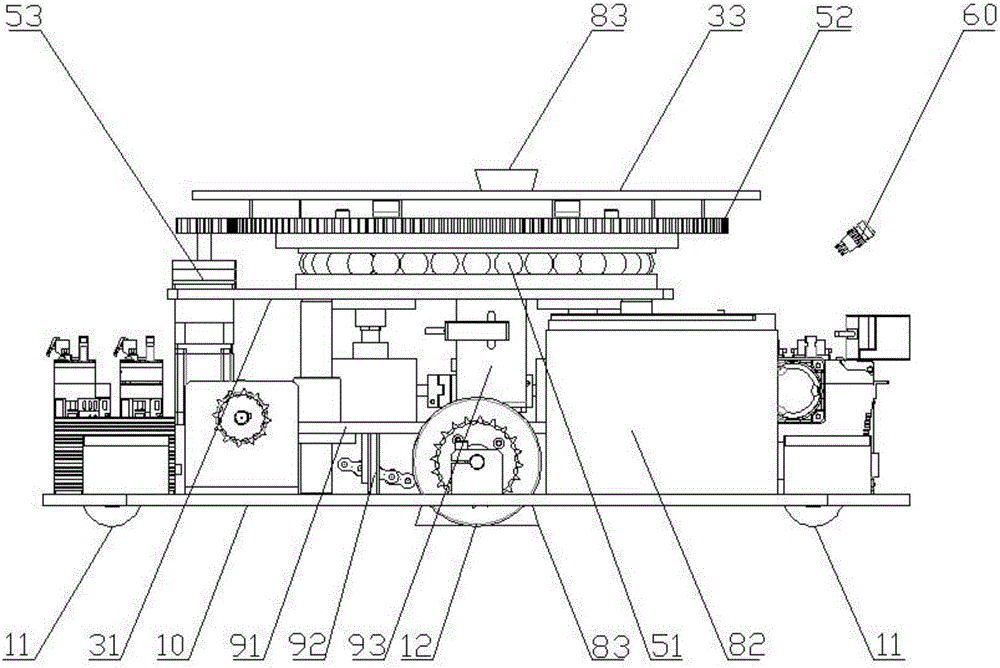

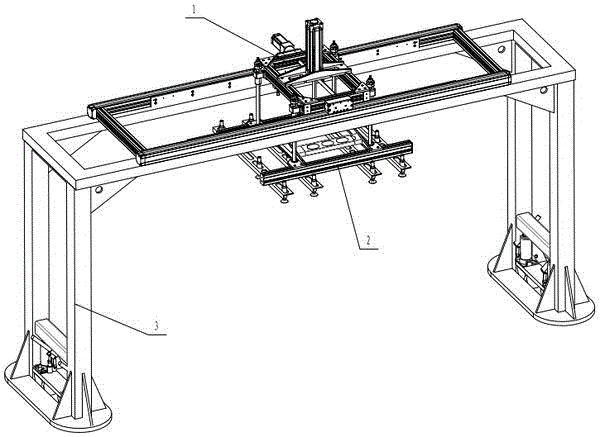

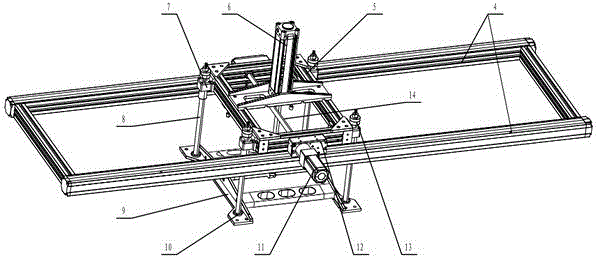

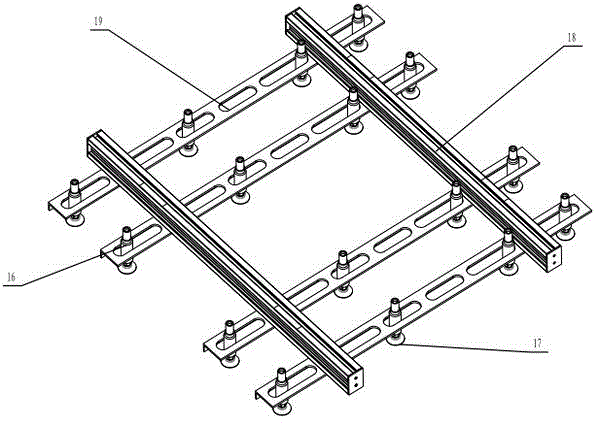

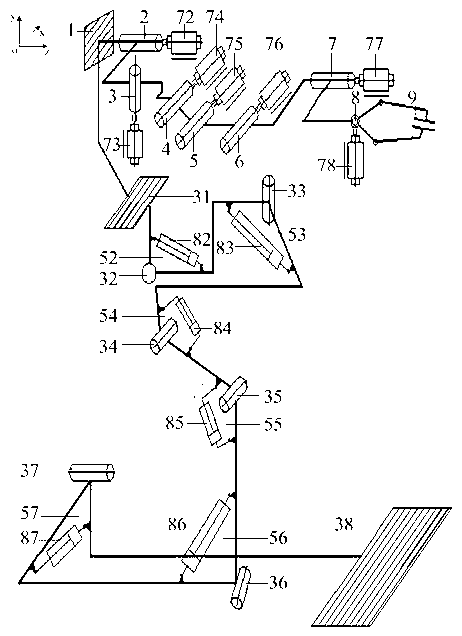

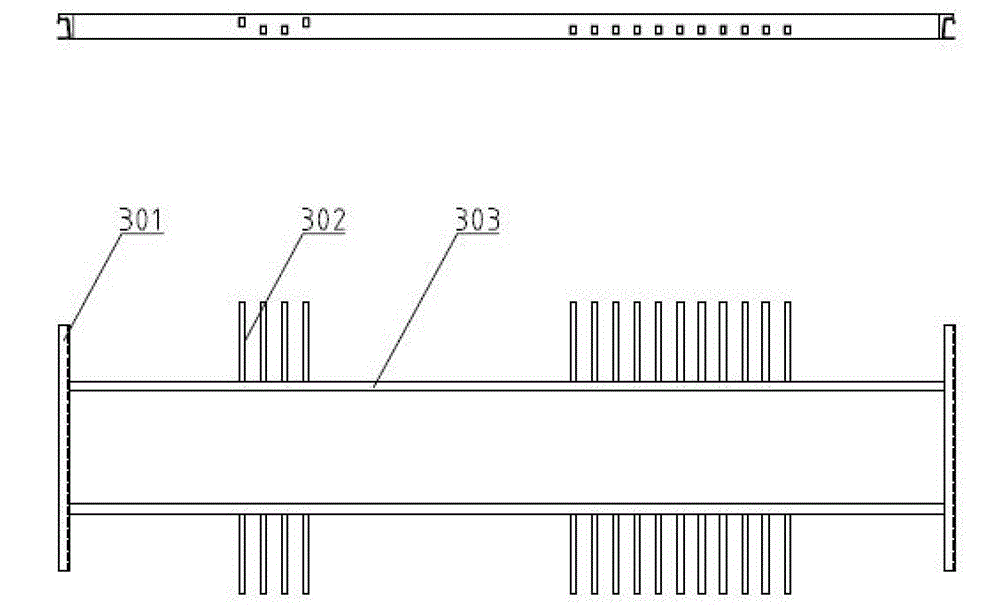

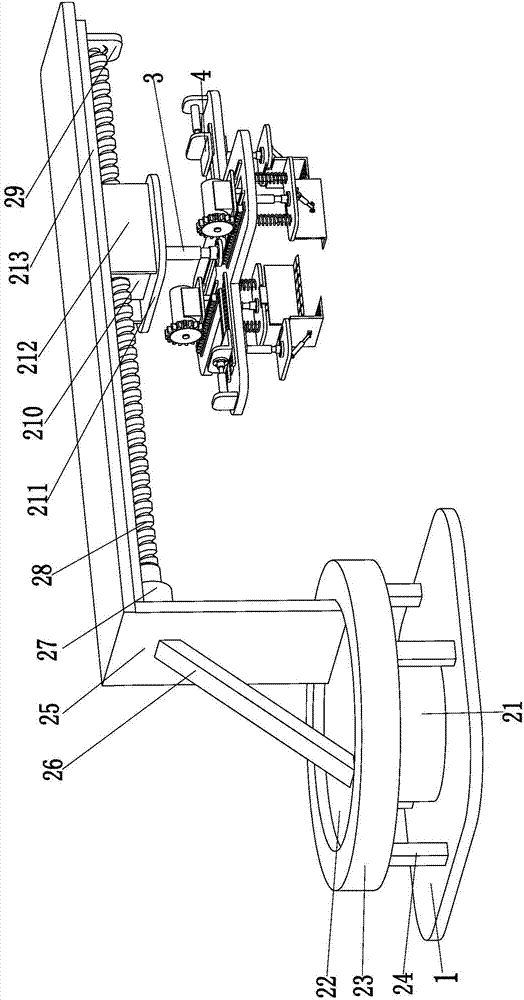

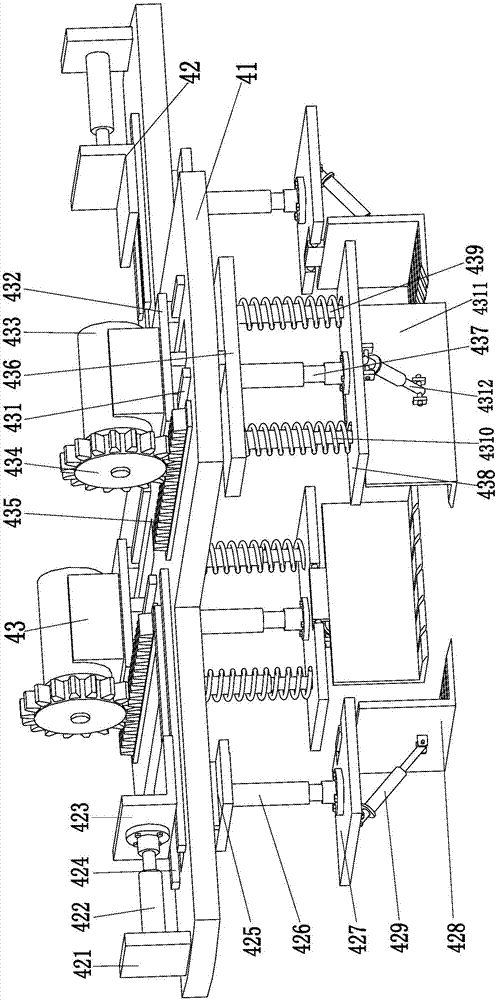

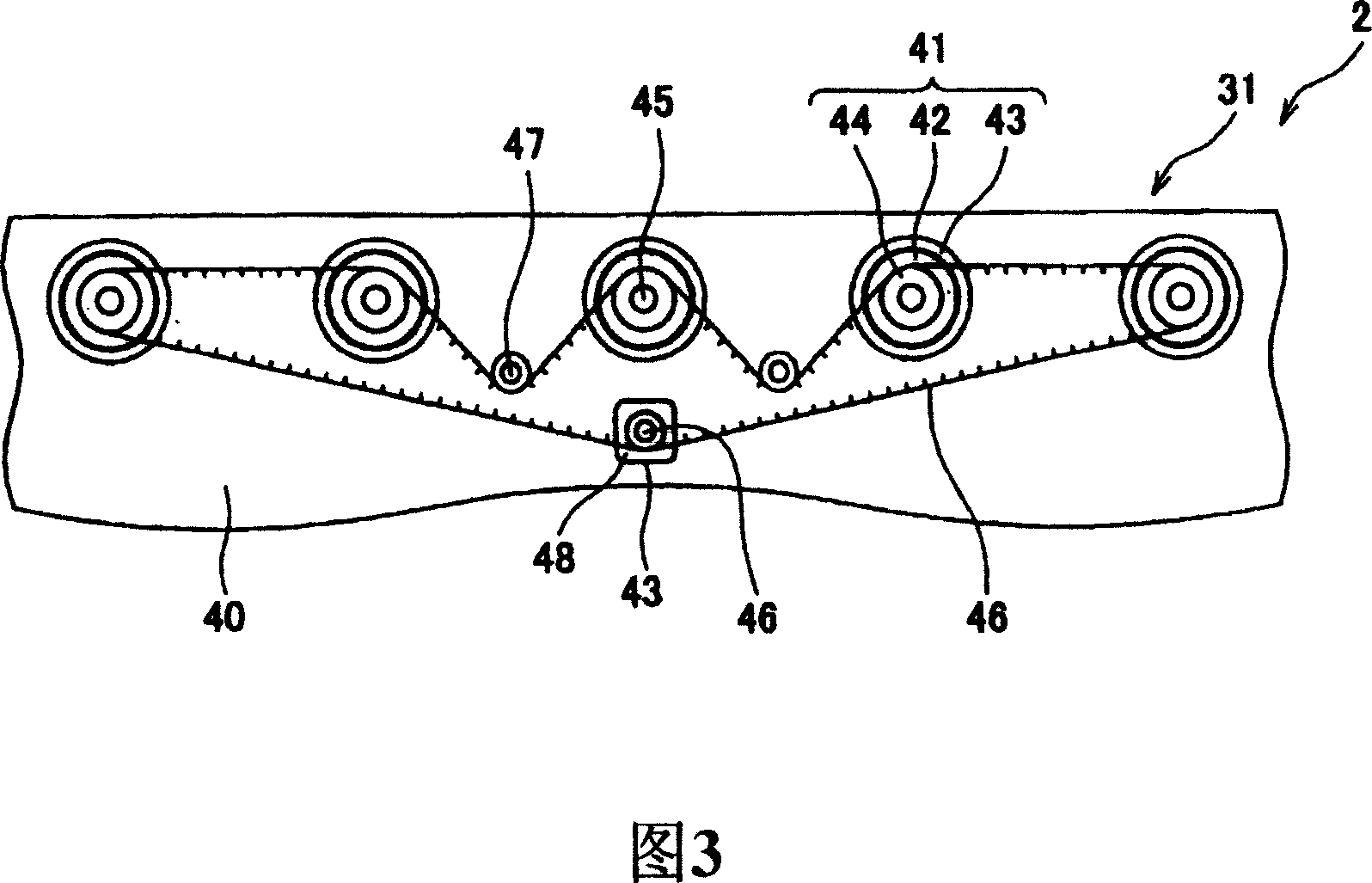

Automatic conveyer of work piece

ActiveCN104816945AIncrease stiffnessIncrease load capacityManipulatorConveyor partsPunch pressSilicon

The invention refers to the production field of automatic punching of a silicon steel sheet, and particularly relates to an automatic conveyer of a work piece. The automatic conveyer comprises a conveying robot, an absorbing system, and a mobile supporting mechanism; the absorbing system is arranged at the bottom part of the conveying robot, and the conveying robot is arranged on the mobile supporting mechanism. The conveying robot is a bi-axial robot, and the bi-axial robot comprises a horizontal movement mechanism and a vertical movement mechanism; the vertical movement mechanism is fixedly linked to the horizontal movement mechanism through a screw. The automatic conveyer of the work piece adopts a synchronous drive mode of a module with double synchronous belts in horizontal direction; during the horizontal conveying process, the automatic conveyer is high in speed, rigidity and bearing capacity and long in conveying distance; the automatic conveyer can be adapted to the high-speed production frequency of the existing punch press, and the production efficiency is improved.

Owner:中国东方电气集团有限公司

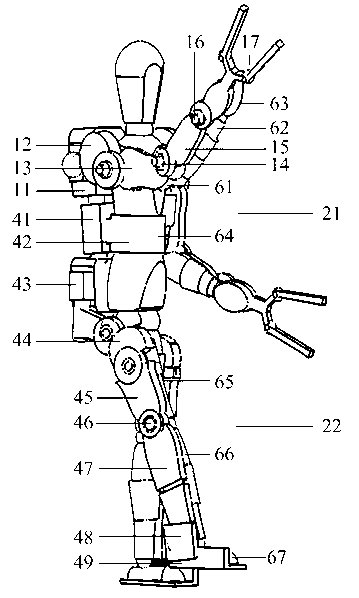

Wearable heavy material handling power-assisting bionic exoskeleton

InactiveCN102793595ASatisfy the rapidity of movementFulfil requirementsProsthesisMotor driveKnee Joint

The invention discloses a heavy material handling power-assisting bionic exoskeleton which can be worn on limbs of a human body. The heavy material handling power-assisting bionic exoskeleton can assist the human body in rapidly completing the task of carrying large-heavy materials under the harsh working condition and comprises an upper limb exoskeleton and a lower limb exoskeleton. The upper limb exoskeleton is a 7-degree-of-freedom system and consists of 3-degree-of-freedom shoulder joints, 1-degree-of-freedom elbow joints, 2-degree-of-freedom wrist joints, 1-degree-of-freedom hands and a motor driving system box of the back; and the 7 degrees of freedom are all driven by a motor. The lower limb exoskeleton is a 6-degree-of-freedom system and consists of a 3-degree-of-freedom hip joint, 1-degree-of-freedom knee joints, 2-degree-of-freedom ankle joints and an electrohydraulic driving system box of the back; and the 6 degrees of freedom are all driven by the hydraulic pressure. After the human body wears the complete set of exoskeleton equipment, when the materials are moved, the efficiency and the flexibility can be greatly improved by mechanical power such as the motor or the hydraulic pressure and the like so as to fulfill the aim of saving time and labor.

Owner:ZHEJIANG UNIV

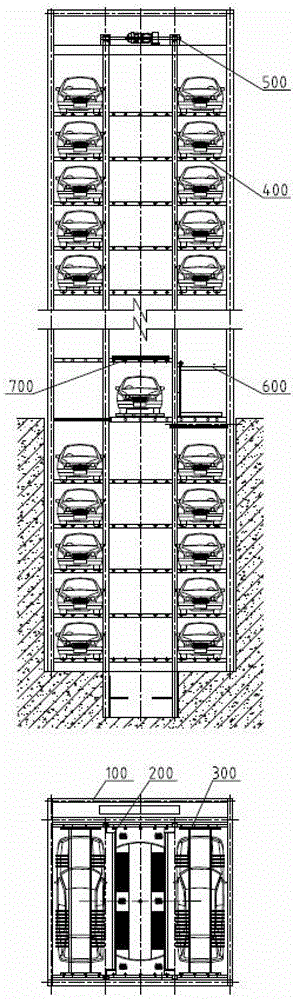

Comb-shaped exchange type vertical-lifting type mechanical stereoscopic parking garage

ActiveCN103334615AReduce weightReduce energy consumptionParkingsAutomatic controlAutomotive engineering

The invention relates to a comb-shaped exchange vertical-lifting type mechanical stereoscopic parking garage. The garage comprises a lifting system, a transverse conveying system, a lifting comb platform, a transverse comb platform, a passing storehouse room, a protecting platform and an automatic control system. The garage is characterized in that operations of lifting, transversely conveying, turning around by rotating of automobiles can be smoothly linked through comb exchange of the lifting comb platform, the transverse comb platform and a rotary plate steel frame; meanwhile, each link is individually driven, each sub-system only carries out one-dimensional movement in space, that is to say, the lifting system is only responsible for conveying the automobile to vertically move up and down, the transverse conveying system is only responsible for conveying the automobile to parallel move left and right, and a rotating platform in the passing storehouse room is only responsible for turning the automobile around; and in addition, the protecting platform arranged above the passing storehouse room can shield objects falling from high altitudes, and prevent fallen objects from hurting people to ensure that the passing storehouse room is at a safety protection state. The comb-shaped exchange vertical-lifting type mechanical stereoscopic parking garage disclosed by the invention has the advantages of scientific design, ingenious structure, small floor area, high automobile parking and take-out speeds, good safety and the like.

Owner:SHENZHEN YEEFUNG AUTOMATION TECH CO LTD

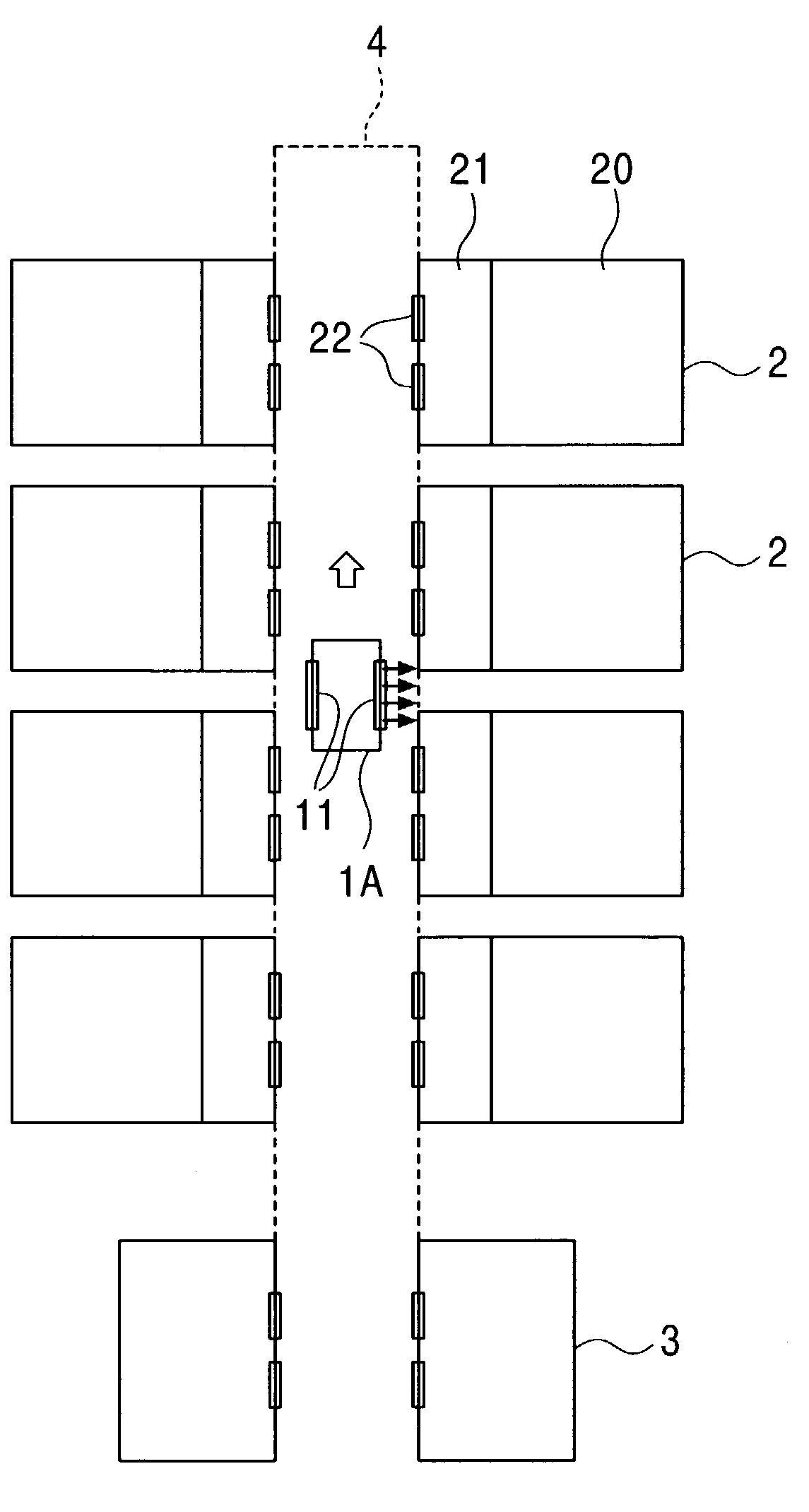

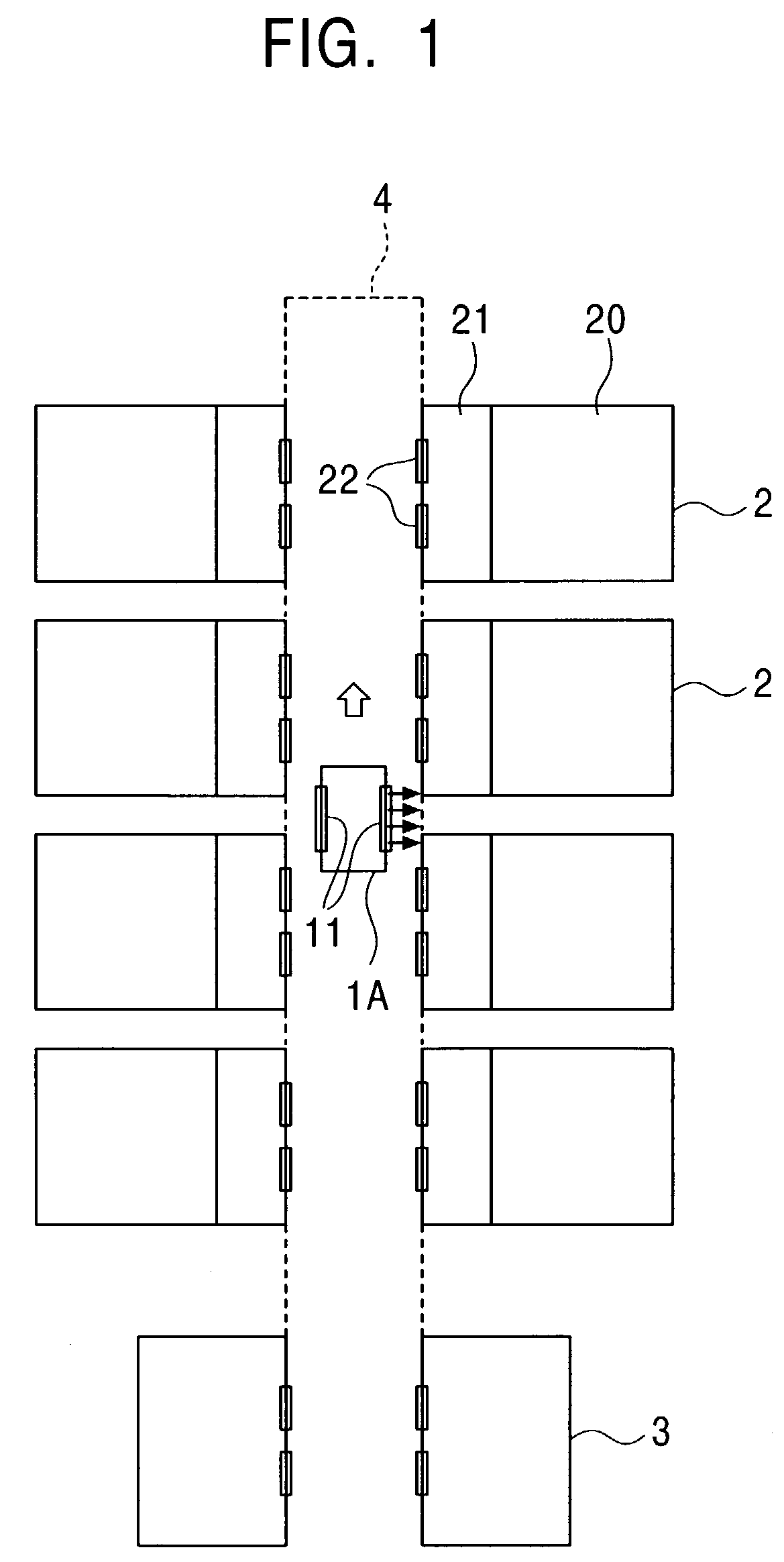

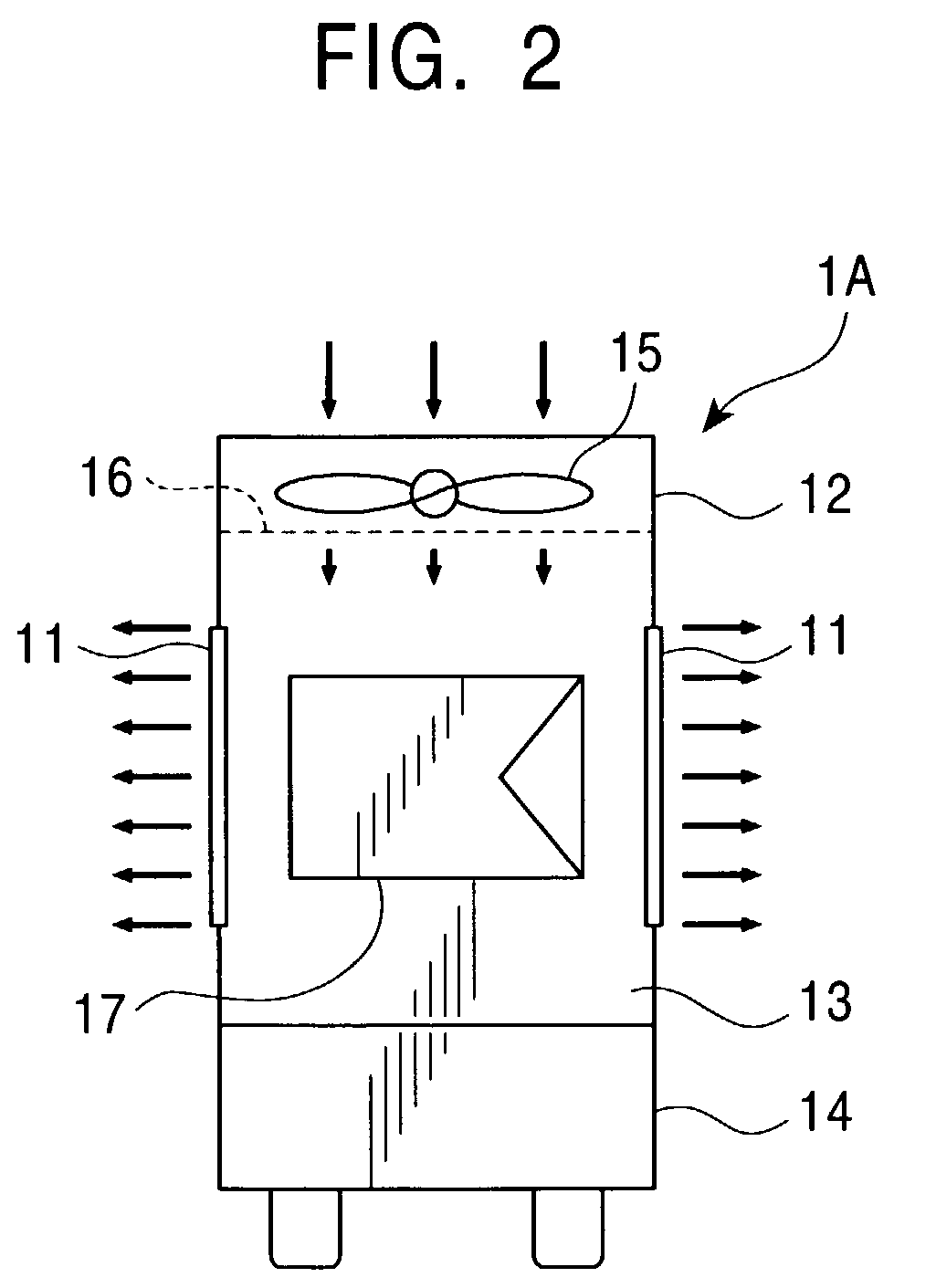

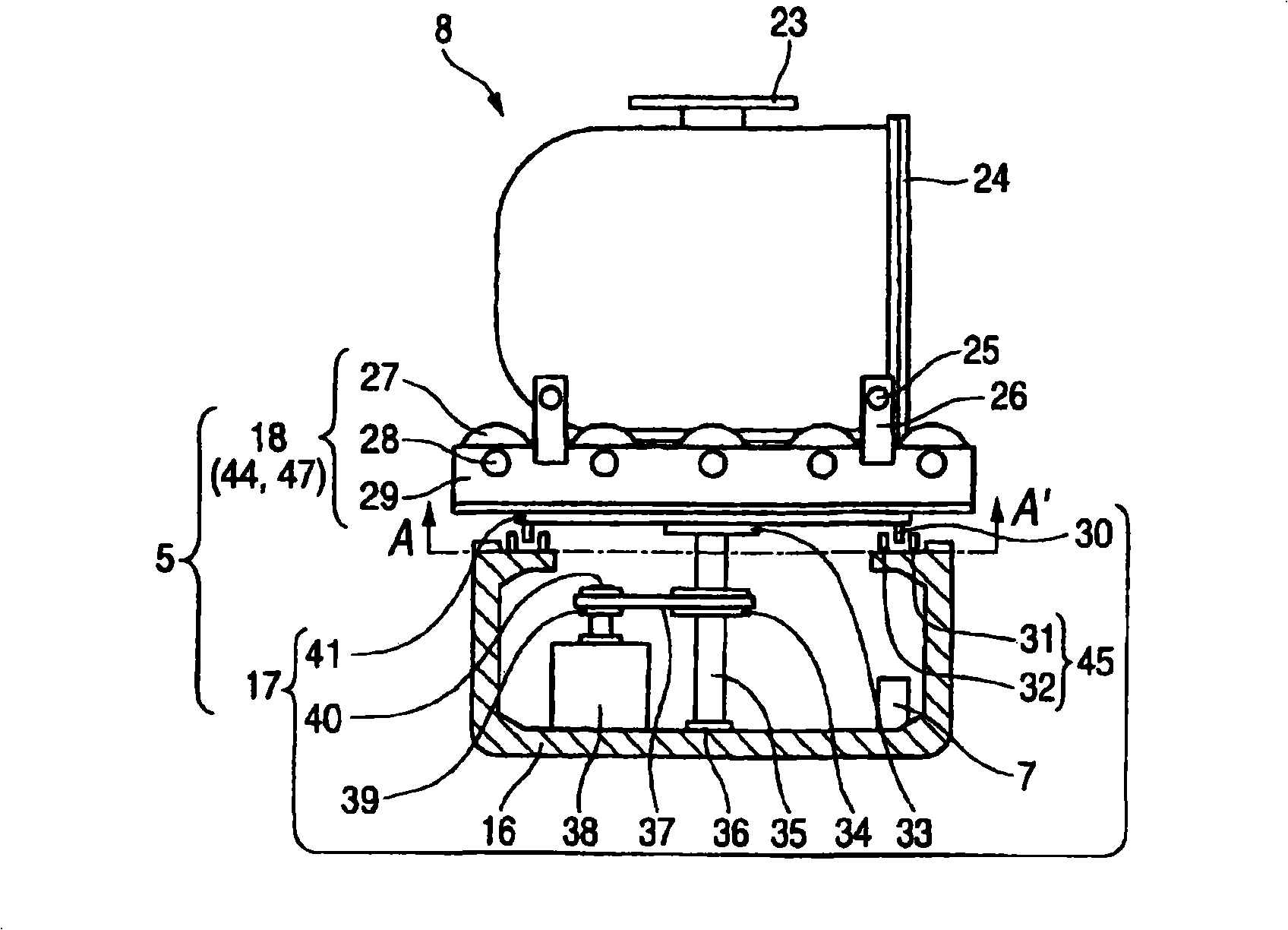

Carrying vehicle, manufacturing apparatus, and carrying system

InactiveUS7014672B2Improve handling efficiencyAvoid dustCombination devicesDomestic stoves or rangesForeign matterEngineering

According to the present invention, in a carrying system comprising a carrying vehicle and a manufacturing apparatus the interior of which is kept cleaner than a surrounding environment, manufactured articles to be transferred are prevented from being contaminated by foreign matter or the like attached to transfer ports. A carrying vehicle includes a running unit 14 that runs along a predetermined carrying path, a cleaning unit 12 that supplies cleaned air, a housing section 13 to which the cleaned air is supplied and in which manufactured articles are housed, a transfer port 11 which is formed in a side of a housing and through which a manufactured article is loaded into or unloaded from the housing section 13, and an air injecting section 19A that blows out air toward the transfer port 11.

Owner:MURATA MASCH LTD

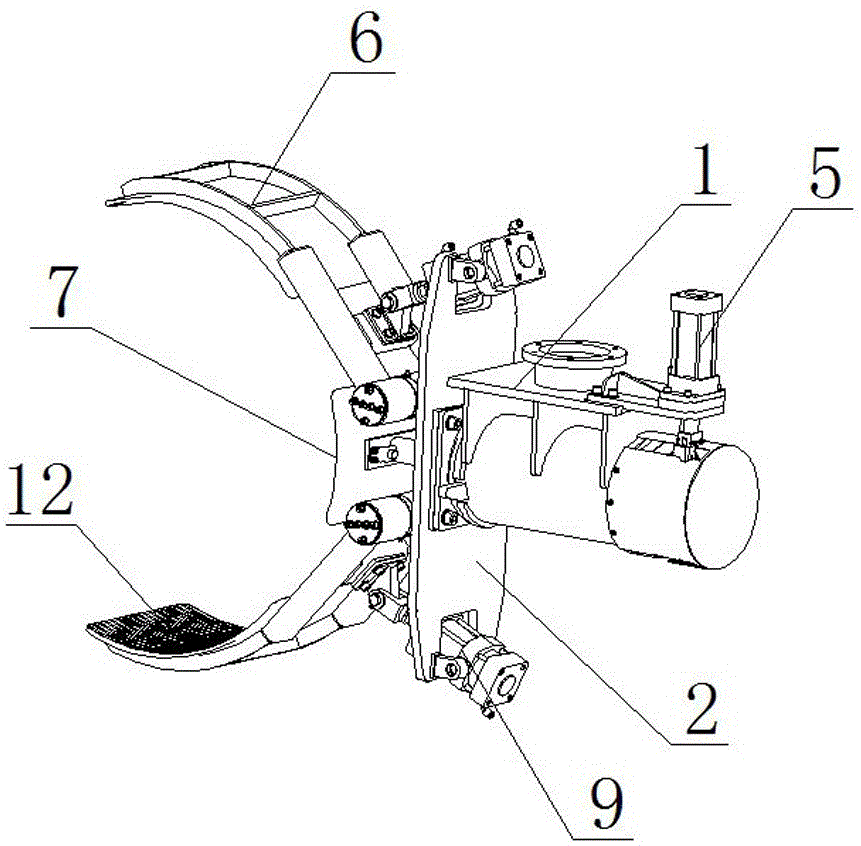

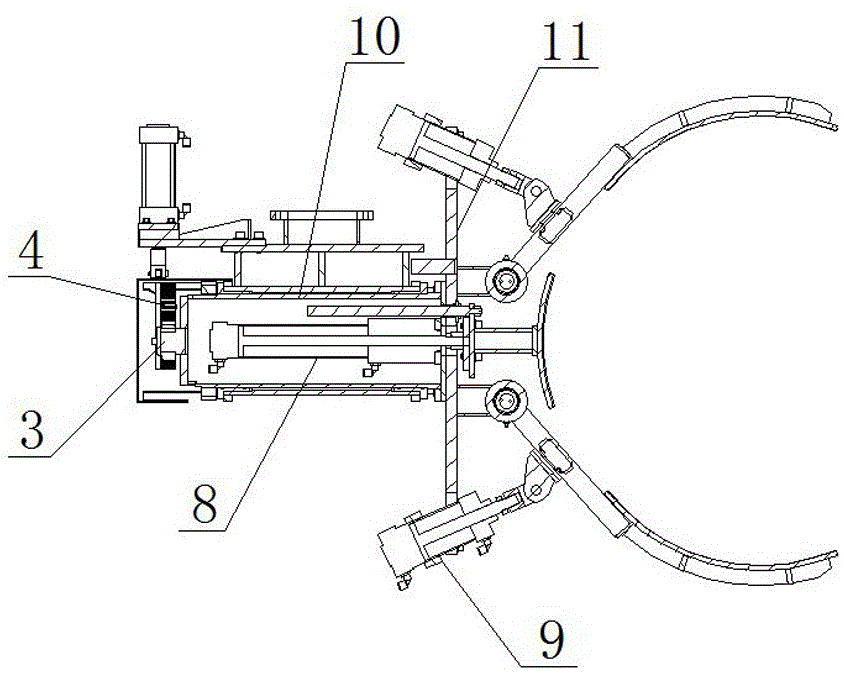

Solid tire carrying manipulator and tire transfer device with same

ActiveCN106395363ASmall footprintCompact structureProgramme-controlled manipulatorConveyorsManipulatorEngineering

The invention discloses a solid tire carrying manipulator. The solid tire carrying manipulator comprises a fixing rack, a rotating rack, a gear wheel, a gear rack, a vertical driving cylinder, two clamping jaws, a pushing jaw, a locking cylinder and two clamping cylinders; the rotating rack comprises a roller and a clamping jaw support, the roller is fixed at one side of the clamping jaw support, the roller is rotationally arranged in the fixing rack, and the gear wheel is fixed at one end of the roller; the gear rack is vertically arranged at one side of the gear wheel and meshed with the gear wheel, the upper end of the gear rack is connected with the vertical driving cylinder, and the gear rack is driven by the vertical driving cylinder; the two clamping jaws are oppositely arranged, and one end of each clamping jaw is hinged to one end of the clamping jaw support; each clamping cylinder is arranged corresponding to one clamping jaw, one end of each clamping cylinder is hinged to the clamping jaw support, and the other end of each clamping cylinder is hinged to the outer side of the corresponding clamping jaw; the locking cylinder is fixed in the roller, and the pushing jaw is fixed to the locking cylinder and driven by the locking cylinder. According to the solid tire carrying manipulator, the occupied space is small, the structure is compact, manual carrying is replaced, and therefore the tire carrying efficiency is greatly improved.

Owner:NANTONG RAINBOW HEAVY MACHINERIES

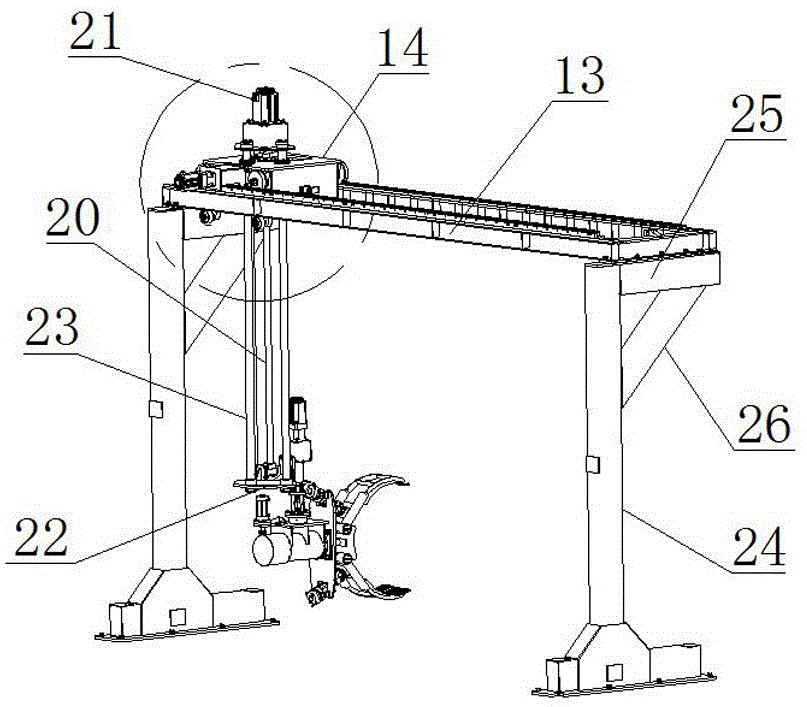

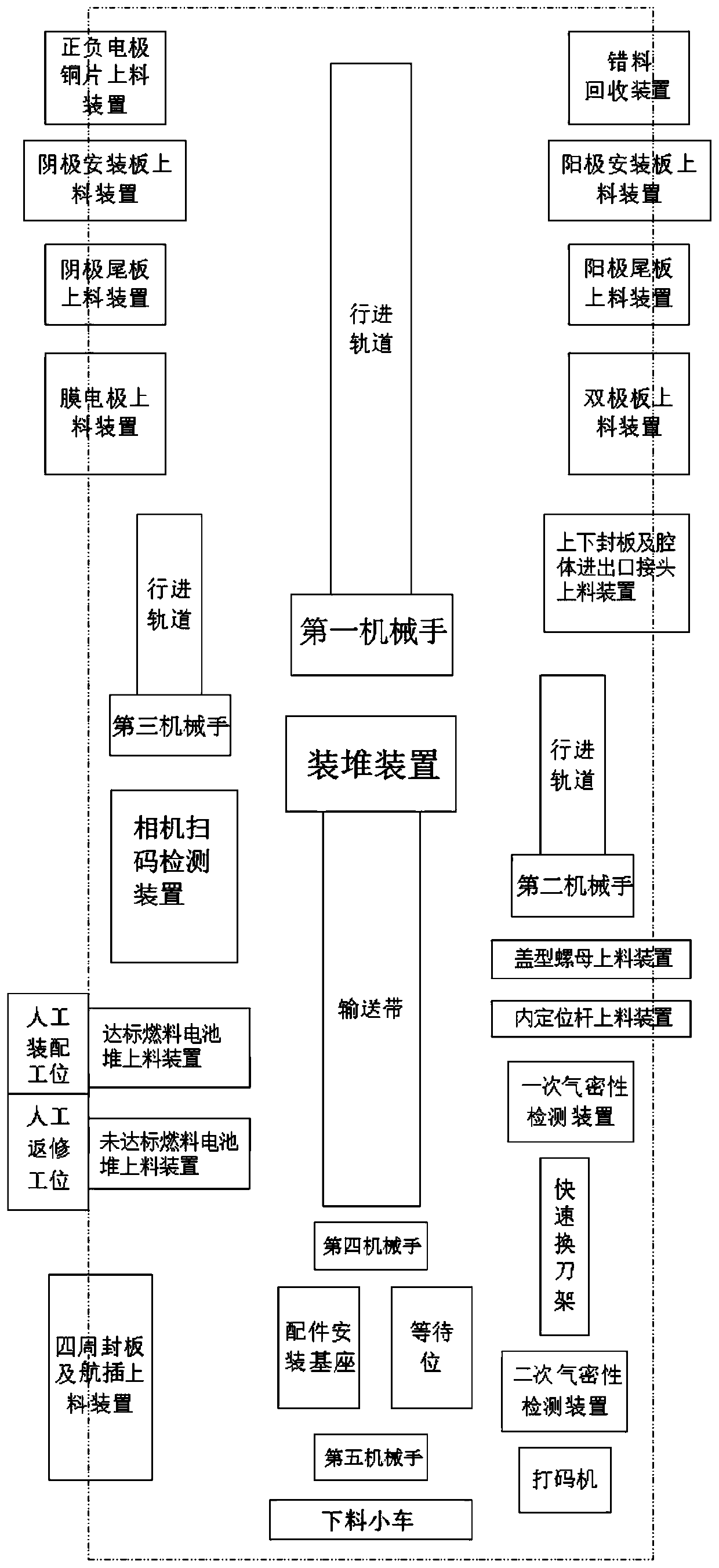

Automatic production line of fuel cell stack

PendingCN110021772AIncreased load-bearing capacityImprove handling efficiencyFinal product manufactureFuel cellsProduction lineFuel cells

The invention relates to an automatic production line of a fuel cell stack. The automatic production line comprises a material taking and placing region, a stack lamination fastening region, a primaryperformance test region, an artificial assembly region, an artificial rework region, a part installation region, a secondary performance test region, a product off-line region, a manipulator and a control server, wherein the manipulator comprises a first manipulator, a second manipulator, a third manipulator, a fourth manipulator and a fifth manipulator, and the manipulators can slide along respective rails in a reciprocating way to take and place materials. In the automatic production line, a large part of production operation is completed by a mechanical program, high automation is achieved, modular and large-scale production of a fuel cell is easy to achieve, the continuity of production links is maintained, the production efficiency is substantially improved, the production cost is reduced, the automatic production line is suitable for producing different specifications of cell panels, is wide in application range and is flexible and simple to adjust, each production equipment isindependent, the production line is compact in layout, high in design flexibility, and compatibility, upgrading and transformation are easily achieved.

Owner:BEIJING NOWOGEN TECH CO LTD

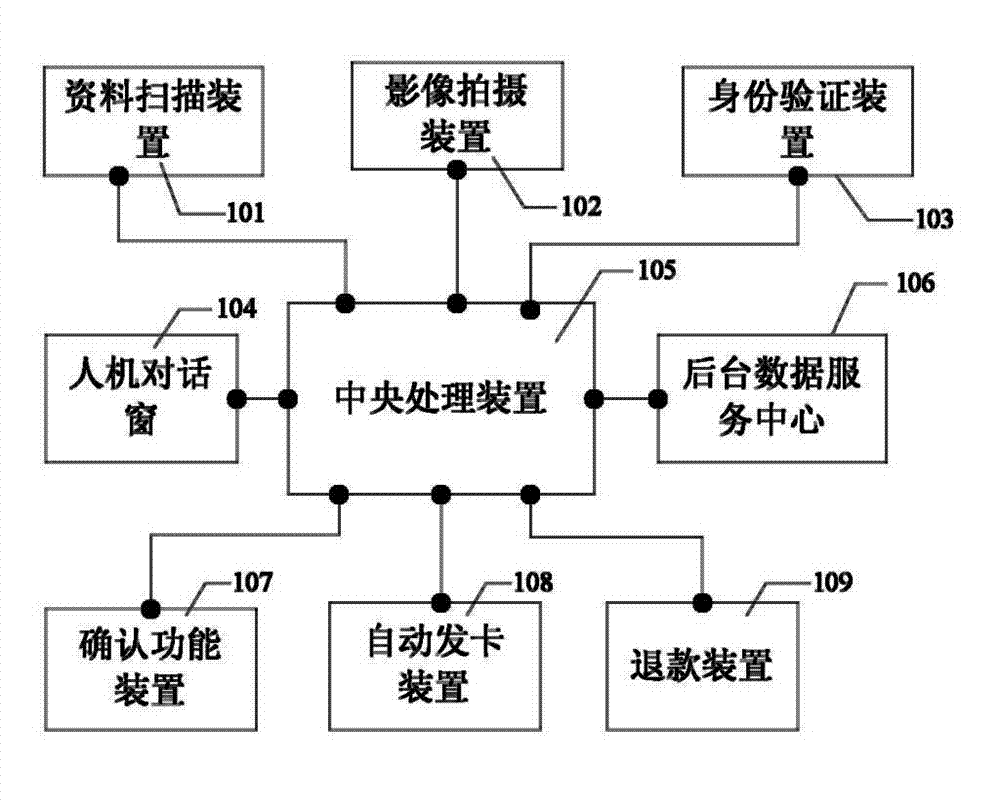

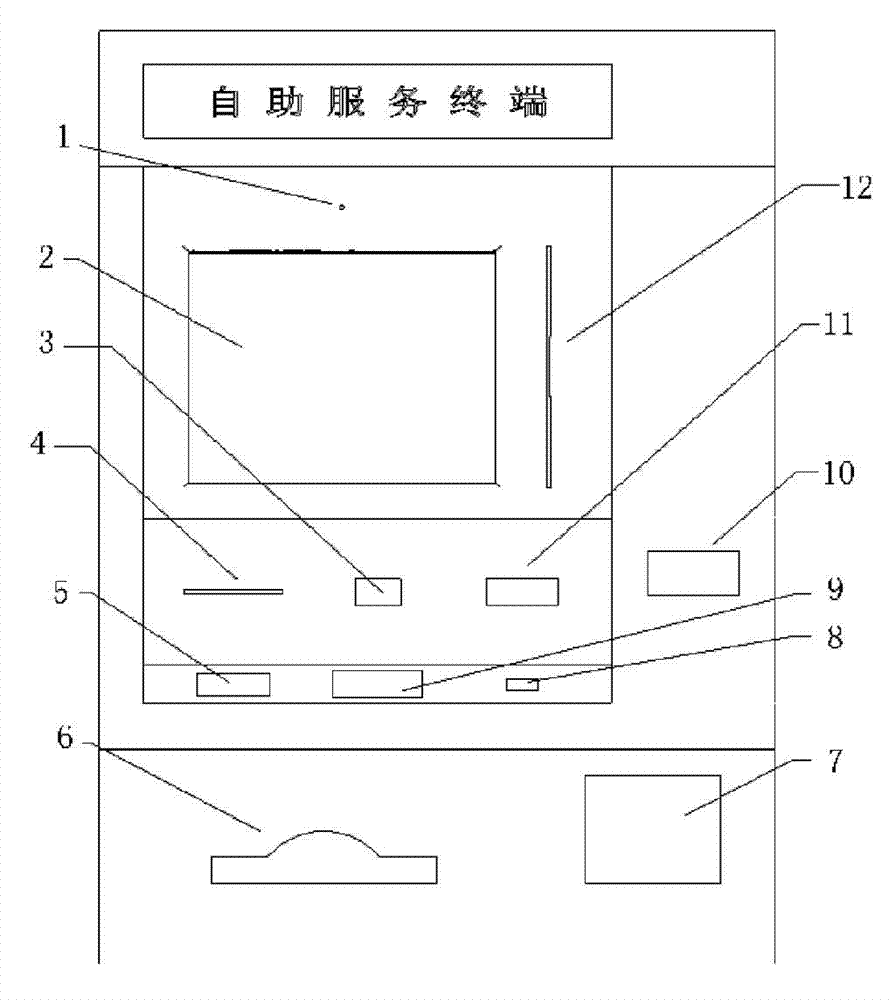

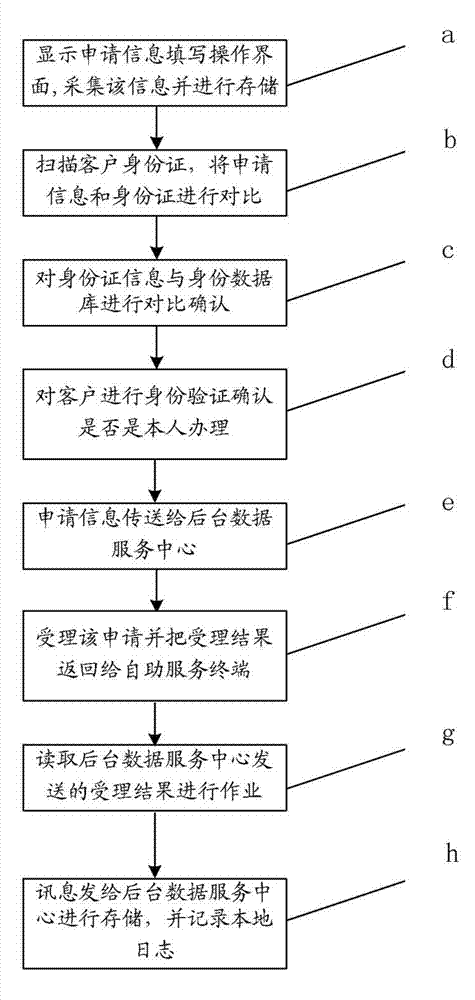

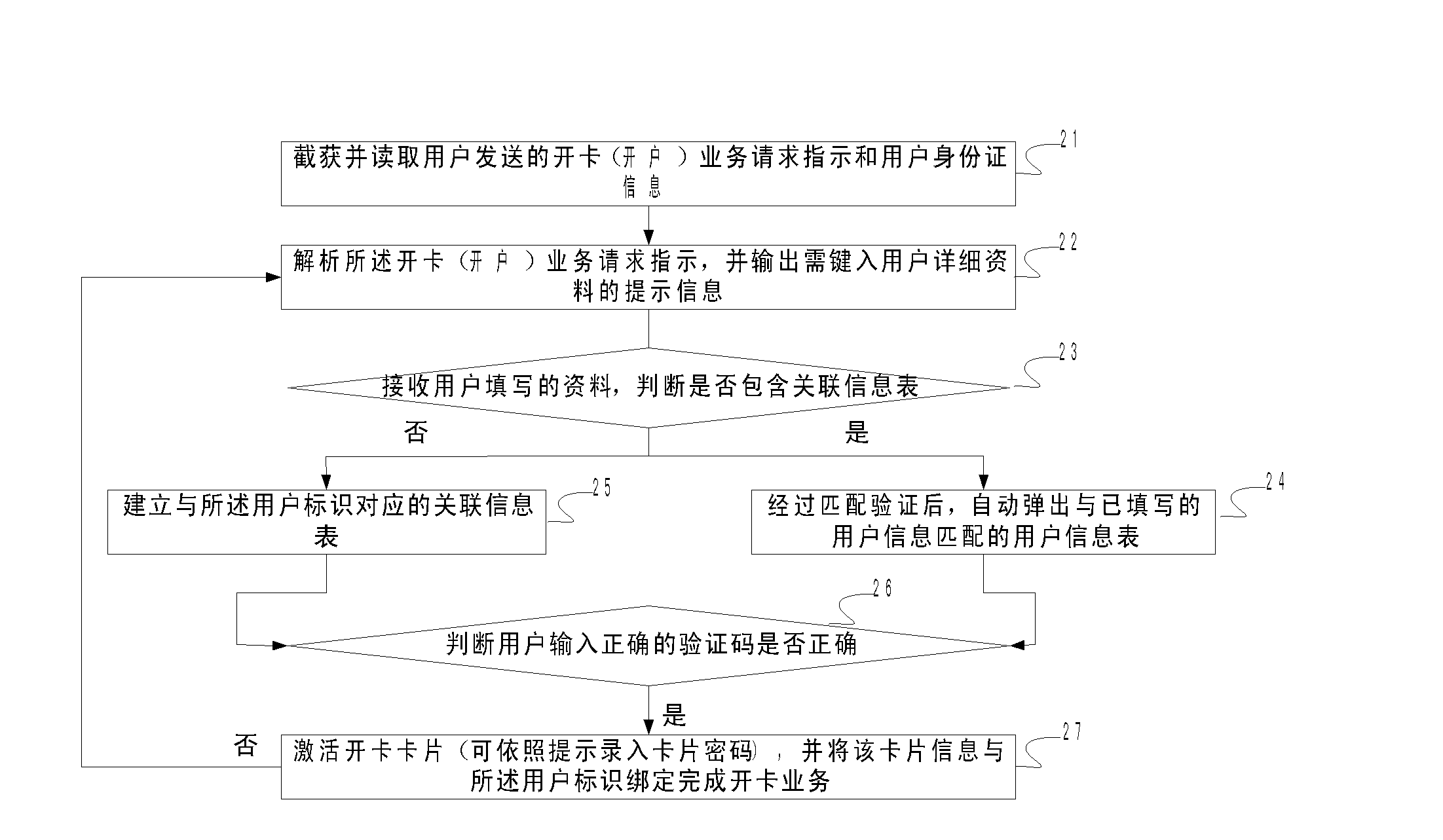

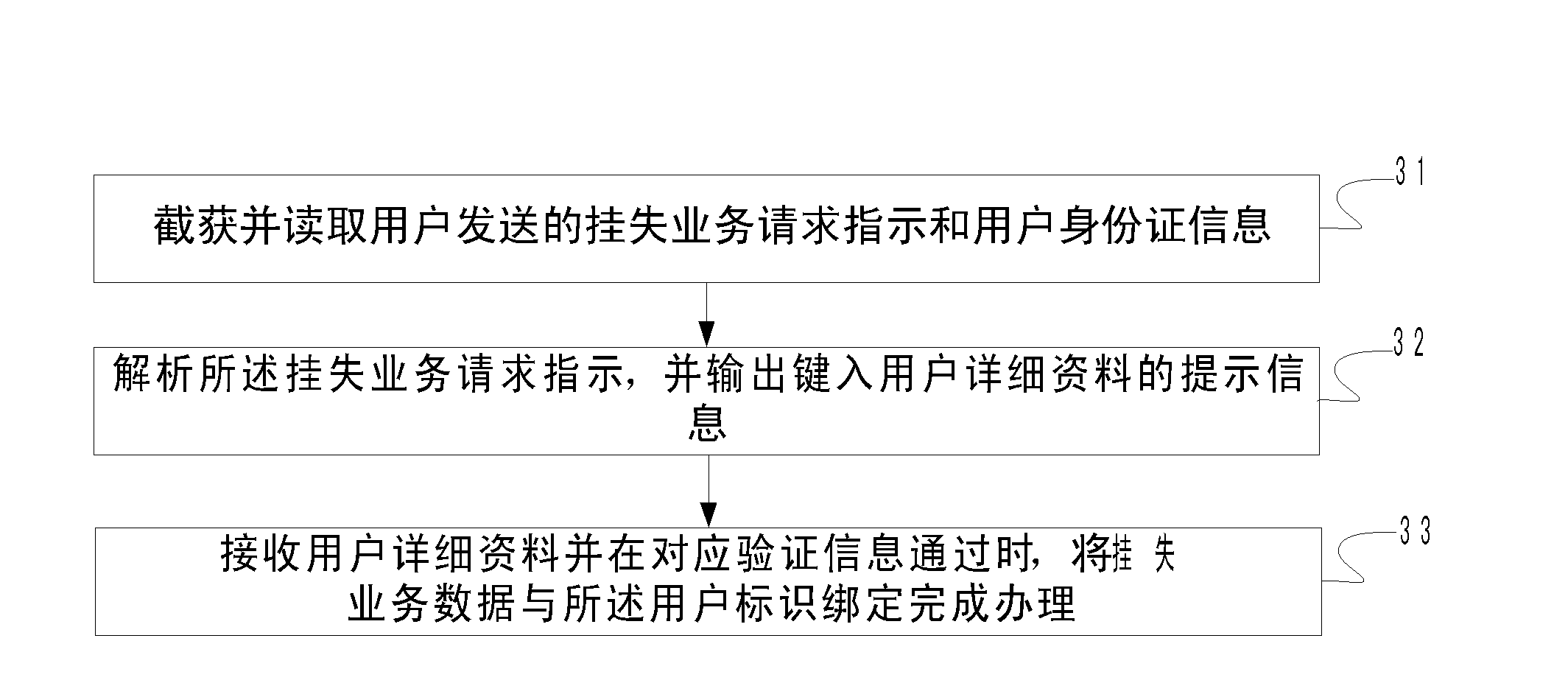

Self-service terminal and self-service card-issuing system and method applying same

InactiveCN103208015AReduce workloadReduce manpowerCo-operative working arrangementsComputer networkEngineering

The invention relates to a self-service terminal and an intelligent witness identification self-service card-issuing system and method applying the same. According to the system, account opening, account cancellation and loss reporting application information is filled for clients through the self-service terminal, the self-service terminal receives the account opening, account cancellation and loss reporting application information of the clients to be connected with a background data service center so as to perform identity verification, issues card containing card number information to the account opening clients, or cancels cards for card cancellation clients and recycles the cards, or performs loss reporting processing for the loss reporting clients and reissues news cards to the clients. The intelligent witness identification self-service card-issuing system can be used for account opening, account cancellation and loss reporting operation according to cards of different types, not only reduces workload and manpower for business processing, but also saves time for consumers, improves business processing efficiency, and is convenient and swift. Simultaneously, the cancelled cards can be recycled in the card cancellation business process, resource waste is reduced, and personal information safety in card using is also guaranteed.

Owner:刘小云 +2

Robot

The invention provides a robot which comprises a storage rack structure, a lifting mechanism and an operation mechanism. The storage rack structure comprises a plurality of storage rack plates with different heights, the lifting mechanism is connected with the storage rack structure and is used for determining one storage rack plate to be an available storage rack plate, and the operation mechanism is connected with the lifting mechanism and is used for storing cargoes.

Owner:HAI ROBOTICS CO LTD

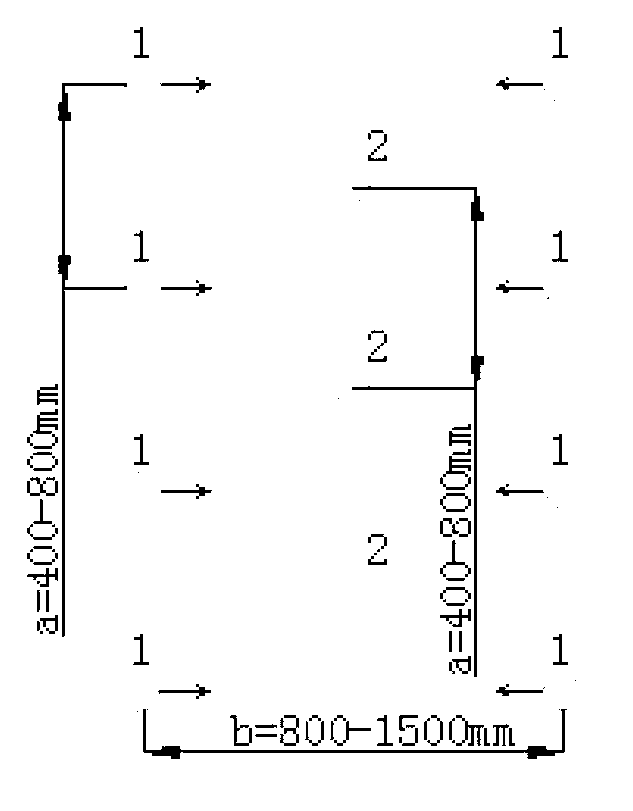

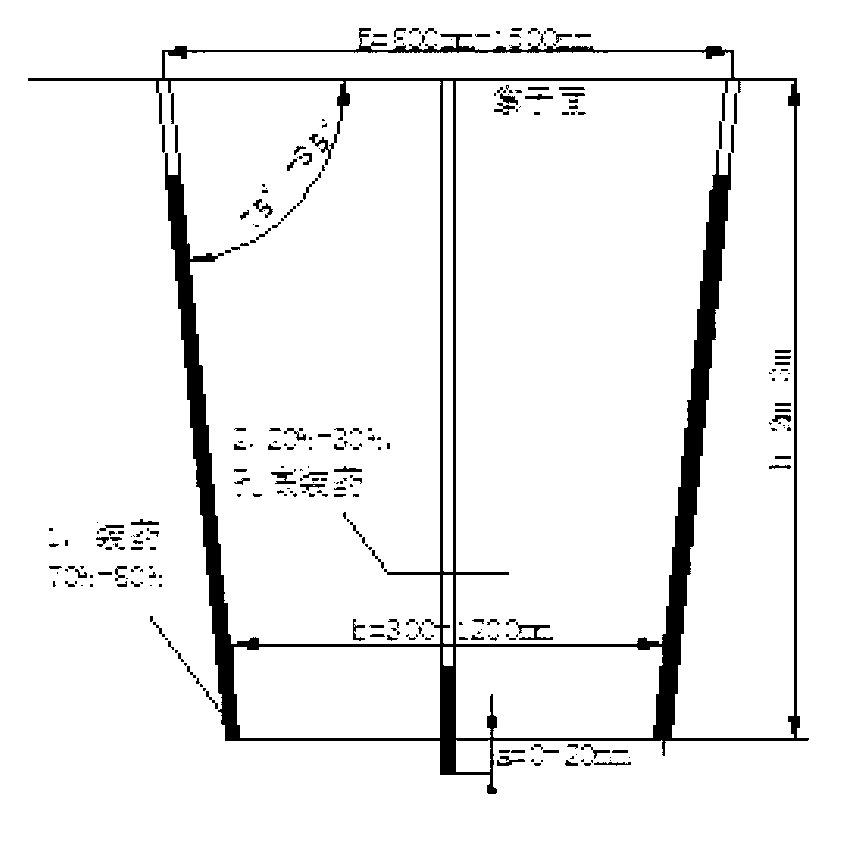

Constructional engineering grab bucket capable of grabbing and carrying bagged cement of different specification

ActiveCN106946035AImprove handling efficiencySolve labor intensityConveyor partsManual handlingFlange

The invention relates to a constructional engineering grab bucket capable of grabbing and carrying bagged cement of different specifications. The grab bucket comprises a bottom plate, a regulating device is installed on the bottom plate, the lower end of the regulating device is provided with a hydraulic lift cylinder, the bottom end of the hydraulic lift cylinder is installed on a gripping device by flanges, the regulating device can drive the gripping device mounted on the hydraulic lift cylinder to adjust positions, the gripping device can grab bagged cement, and the regulating device, the hydraulic lift cylinder and the gripping device cooperate with each other to complete the process of gripping bagged cement. According to the grab bucket provided by the invention, the existing problems, such as high labor intensity, low handling efficiency and complicated operation, caused during manual handling of bagged cement are solved, the operation complication being caused by different requirements on workers by different specifications of bagged cement. And the function of automatic gripping of bagged cement can be realized.

Owner:福建兴旺建设发展有限公司

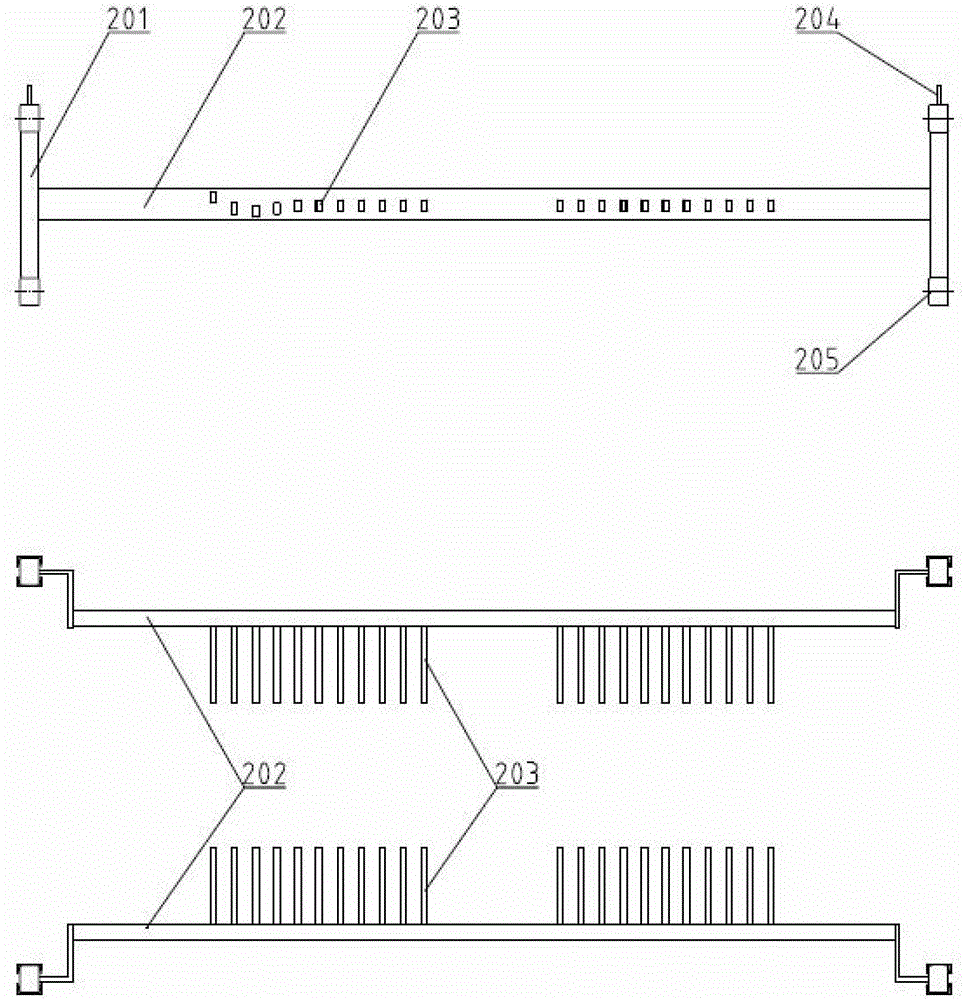

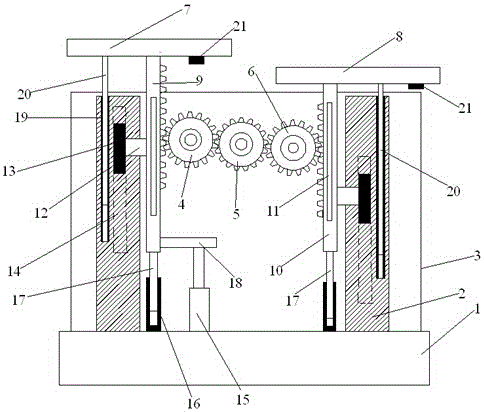

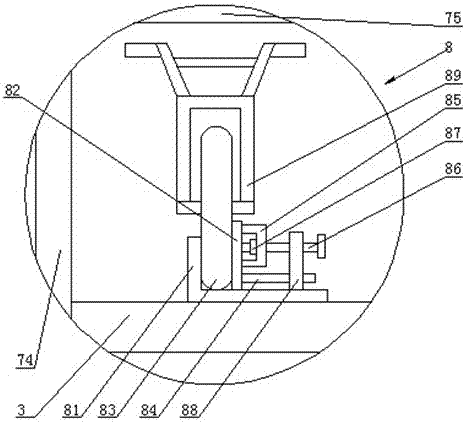

Reversing lifting device for gear transmission

ActiveCN105836653ARealize alternate liftingImprove stabilityLifting framesManipulatorIndustrial engineering

The invention discloses a reversing lifting device for gear transmission. A first lifting table and a second lifting table are in transmission connection through a gear transmission assembly. A linear drive assembly is connected with the gear transmission assembly so as to provide power for the gear transmission assembly. The first lifting table and the second lifting table ascend and descend relative to a base through the gear transmission assembly, the lifting direction of the first lifting table and the lifting direction of the second lifting table are opposite, and the first lifting table and the second lifting table are both provided with at least two guide assemblies. By means of the gear transmission assembly, the two lifting tables can well ascend and descend alternately, so in the lifting process of one lifting table, articles can be placed on the other lifting table by a carrying manipulator, and carrying efficiency is improved. In order to improve operation stability of the lifting tables, the guide assemblies are arranged at different angles, lifting stability of the lifting tables is improved, lifting efficiency is guaranteed, and meanwhile carrying safety is improved.

Owner:ANHUI SCI & TECH UNIV

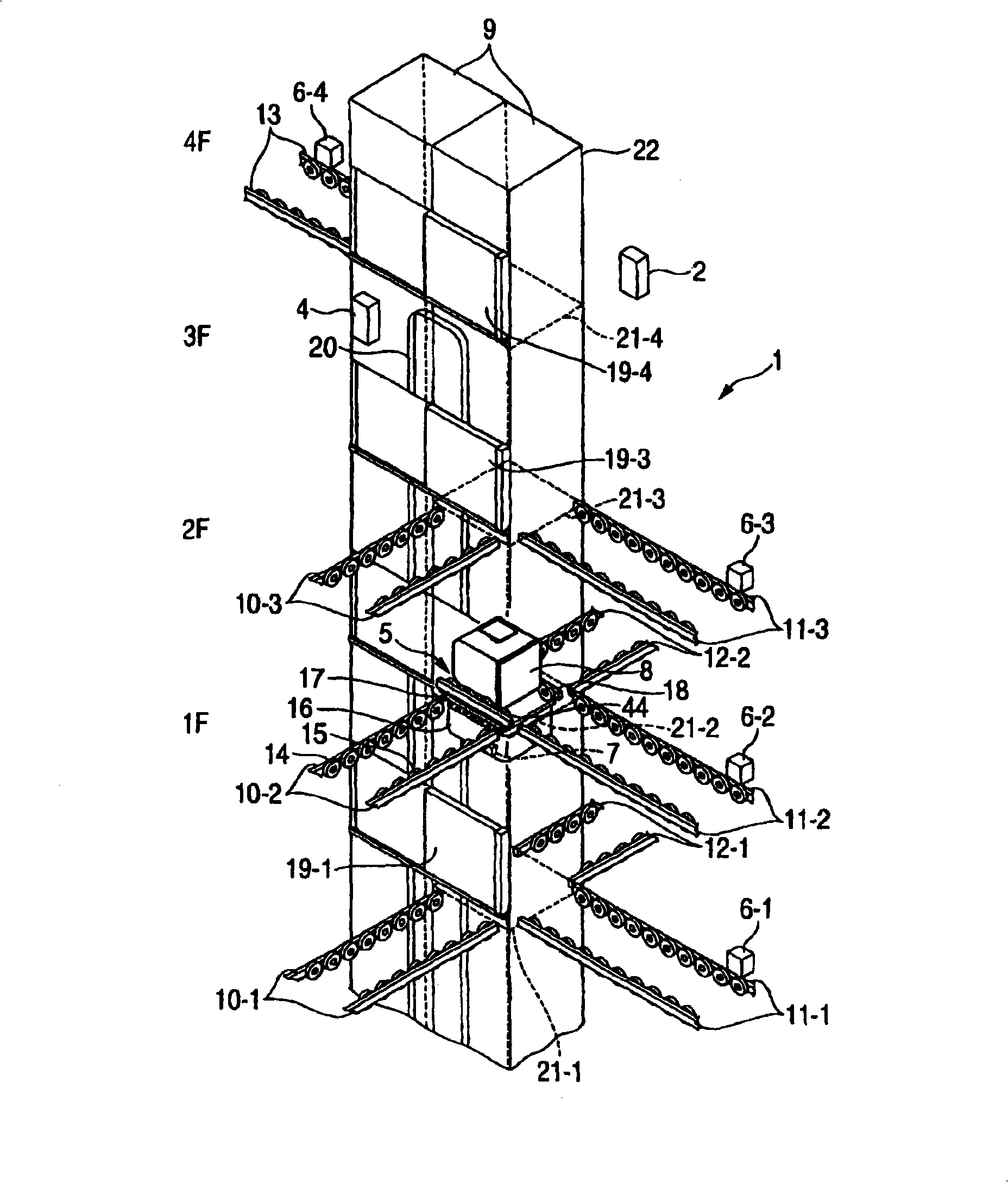

Vertical conveyance device

InactiveCN101331074AImprove handling efficiencyRealize handlingSemiconductor/solid-state device manufacturingThin material handlingEngineeringMechanical engineering

Provided is a vertical conveyance deivce. A lifting conveyor (5) is constructed from a turntable (17) and a roller conveyor (18). The roller conveyor (18) is supported on the turntable (17). A conveyor rail performs delivery or reception of a load. The turntable (17) is turned by a turntable controller (7) to align the conveyance direction of the conveyor rail with the roller conveyor (18), and after that, the conveyor rail and the roller conveyor (18) are driven to deliver or receive a FOUP (8). The lifting conveyor (5) is supported by a cable (20a) placed in a hoistway space (9) by a joint member (20b) of a cable bearer (20), and the cable bearer (20) is vertically circulated in a reciprocating manner by a lifting conveyor controller (4). In association with the movement of the cable bearer (20), the lifting conveyor (5) stops in a vertically movable manner at a port (21) placed at each floor.

Owner:MURATA MASCH LTD

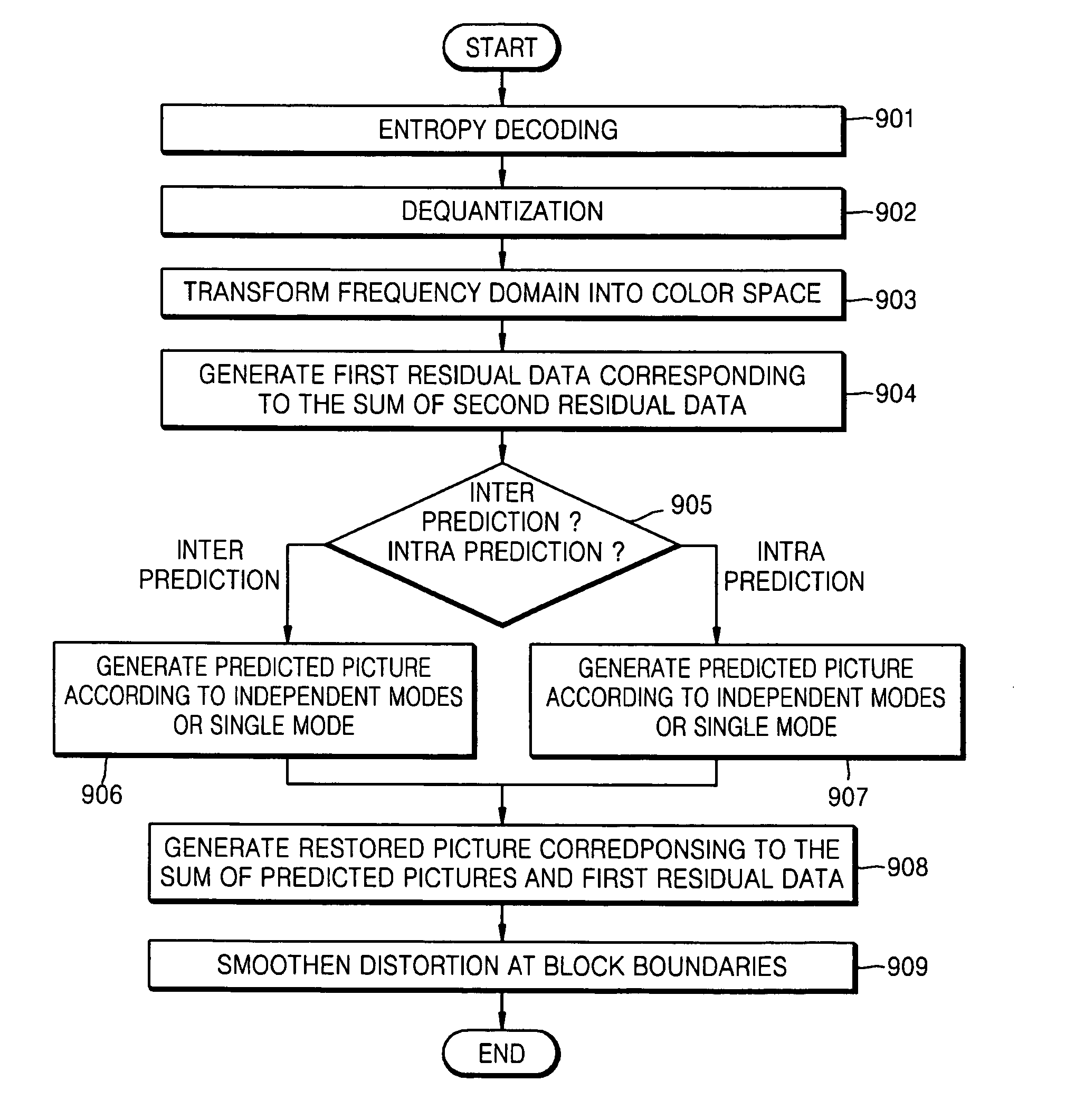

Moving picture coding/decoding method and apparatus

ActiveUS8958476B2Improve handling efficiencyPulse modulation television signal transmissionPicture reproducers using cathode ray tubesDecoding methodsColor space

A moving picture coding / decoding method and apparatus with improved coding efficiency. A moving picture coding method includes selecting a color space from among a plurality of color spaces, selecting a prediction mode to be commonly applied to all the color components constituting the selected color space, generating first residual data corresponding to differences between a current picture and a predicted picture for each of the color components according to the selected prediction mode, generating second residual data corresponding to differences between the first residual data, and coding the second residual data.

Owner:SAMSUNG ELECTRONICS CO LTD

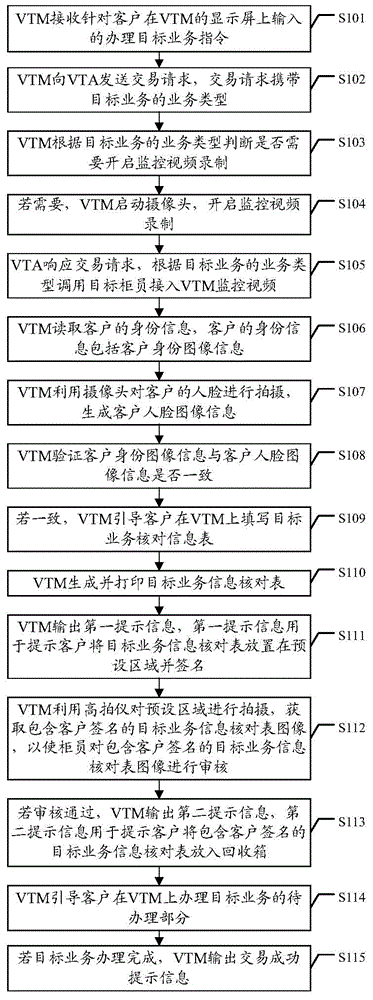

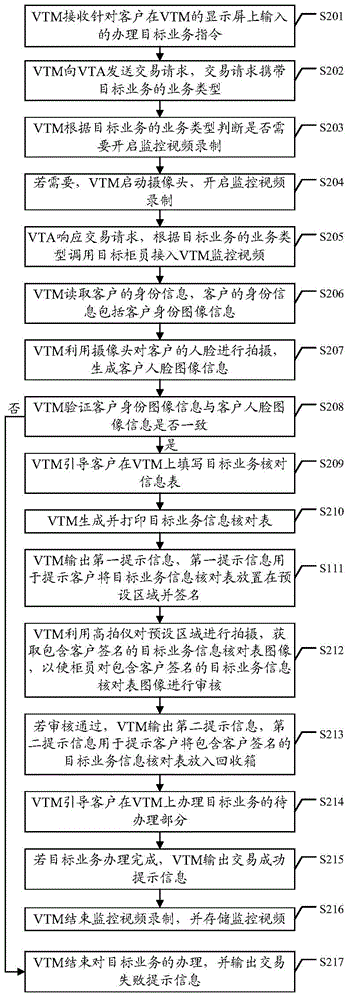

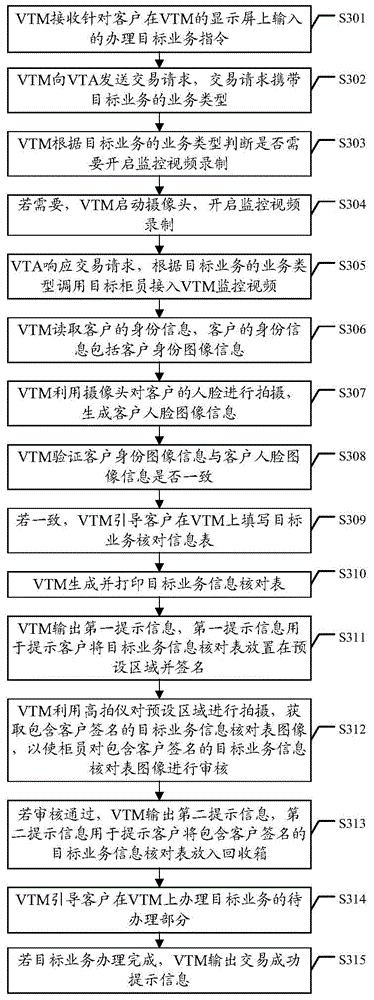

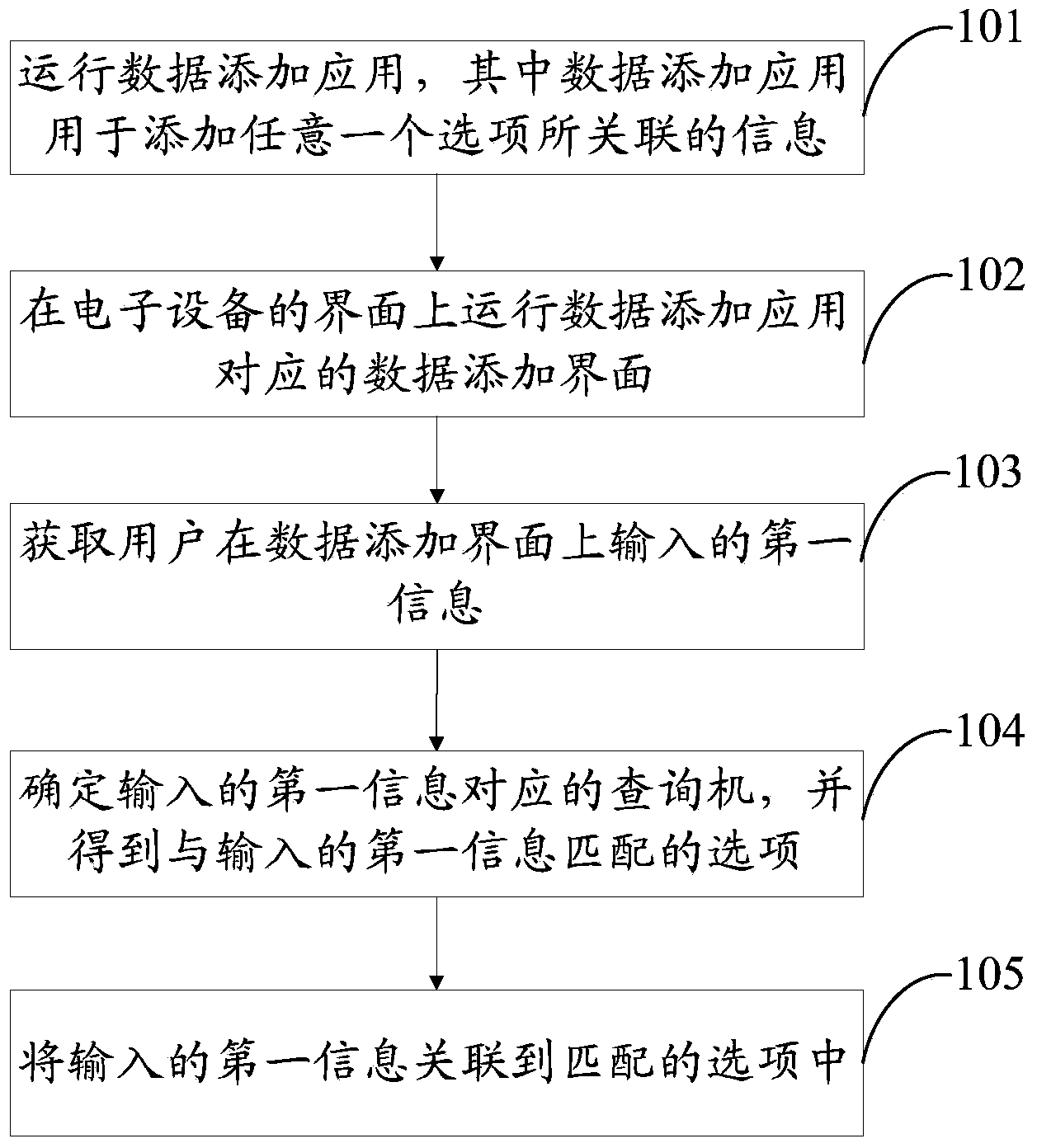

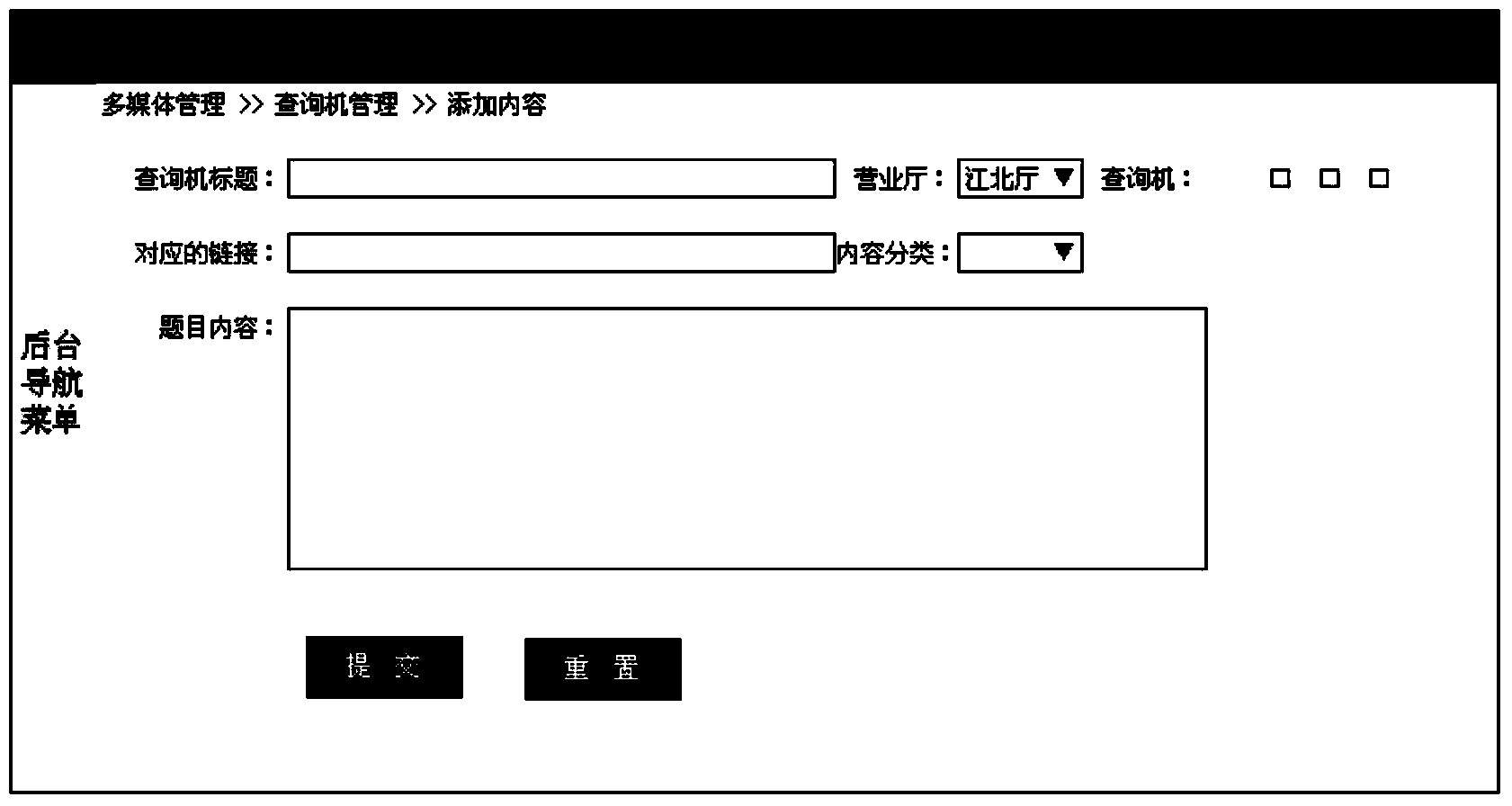

Business handling method and system of VTM

ActiveCN104835266AImprove handling efficiencyComplete banking machinesDigital data authenticationFinancial transactionVideo recording

The embodiment of the invention discloses a business handling method and a system of a VTM. The method comprises following steps of receiving the instruction of handling target business inputted on a display screen of the VTM by a customer, sending a transaction request to a VTA by the VTM, determining the necessity of starting monitor video recording by the VTM, starting a camera to start monitor video recording if necessary, a target teller is utilized for access to a VTM monitor video by a VTA, verifying information of client identities by the VTM, guiding a client to fill the check list of target business information after authentication, producing and printing the check list of target business information, utilizing a high-shooting instrument to shot the pre-set area in order to acquire an image for the check list of target business information including a client's signature such that the target teller audits the image for the check list of target business information including the client's signature, guiding the client to handle the portion to be handled on the VTM for handling target business after a review, and outputting the prompt message of successful trade by the VTM if the target business finishes handling. By applying the embodiment of the method and the system, handling efficiency of banking business is boosted.

Owner:CHINA CONSTRUCTION BANK

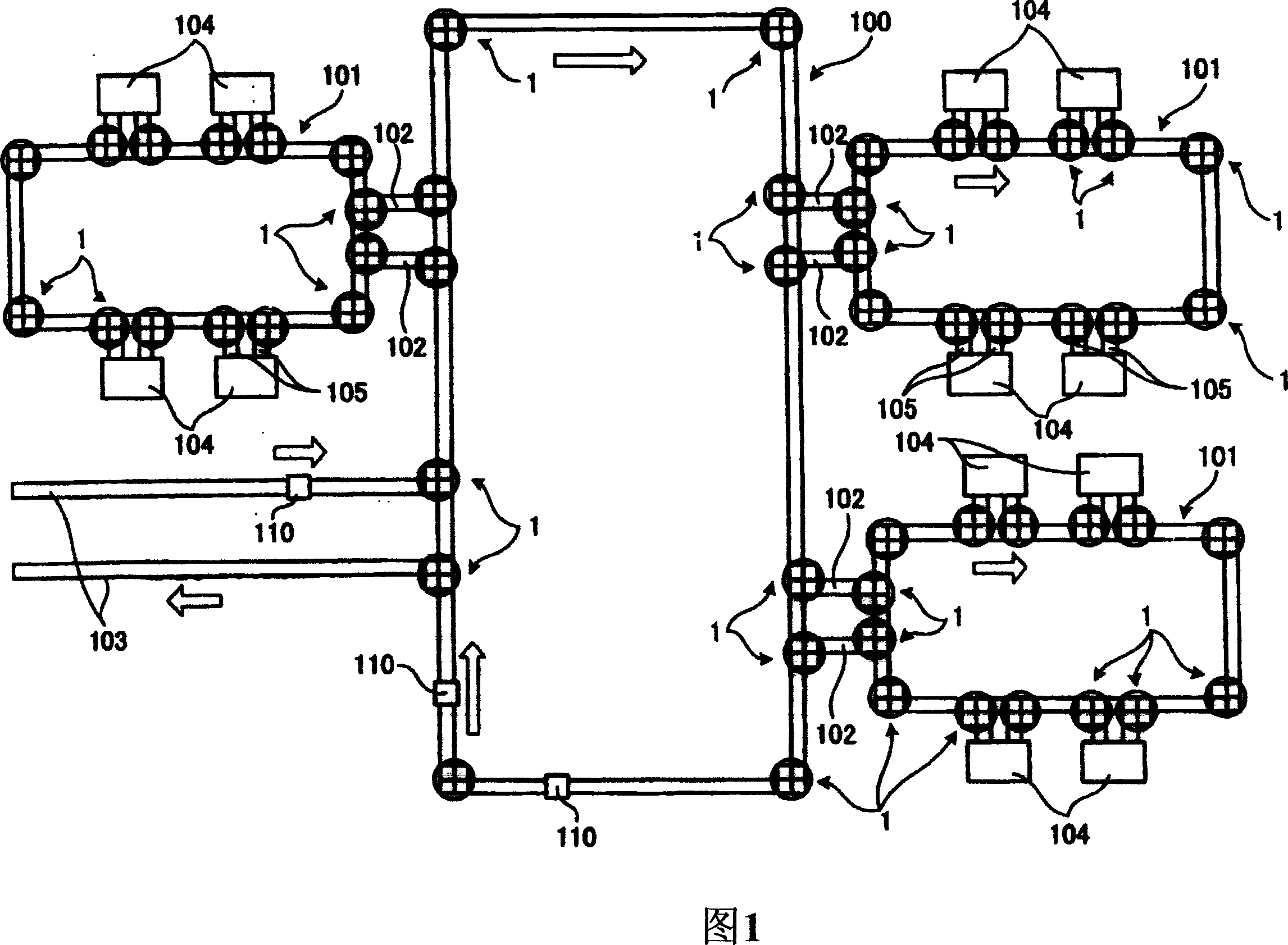

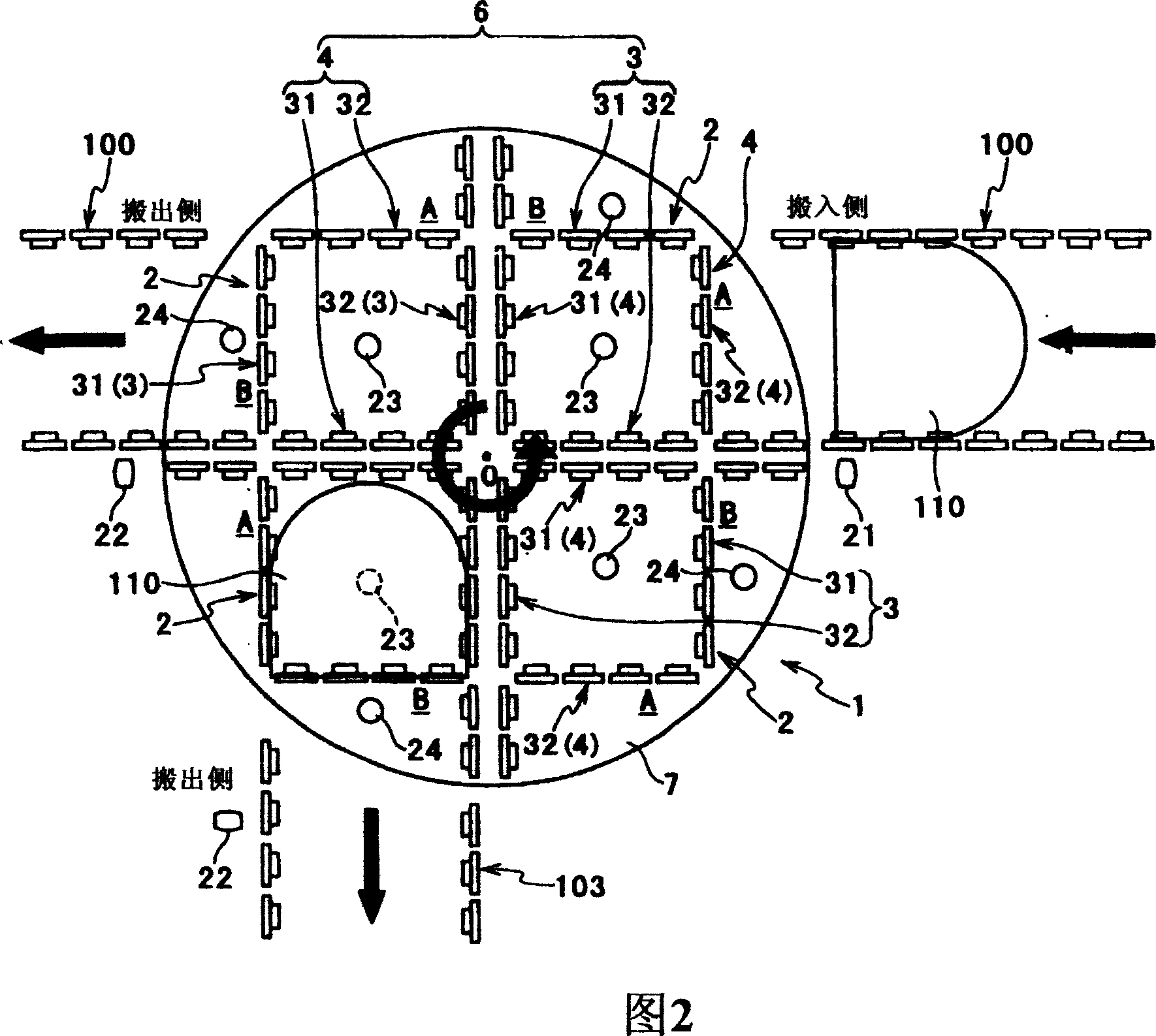

Rotating table

InactiveCN101020538AImprove handling efficiencyEliminate waiting timeControl devices for conveyorsStorage devicesEngineeringRotation control

The invention provides a revolving table, which can start to change the direction of the movement of a conveyed object in a very short time. The revolving table is provided with inlet side ends (A) and outlet side end (B) respectively communicating with the inlet side and the outlet side of a conveying track; a first track (3) and a second track (4) used for conveying the conveyed object from the inlet side ends (A) to the outlet side ends (B); a worktable component (7) for arranging the first track (3) and the second track (4); a worktable rotation mechanism (8) used for rotating the worktable component (7) and stopping the worktable component at any angle of rotation; a worktable rotation control mechanism used for controlling the rotation of the conveyed object on the first track (3) and the second track (4) in the conveying direction. The first track (3) and the second track (4) are arranged on the worktable component (7) in the following way: when the conveying direction is set, either the inlet side end (A) of the first track (3) or the inlet side end (A) of the second track communicates with the inlet side of the conveying track.

Owner:ASYST SHINKO INC

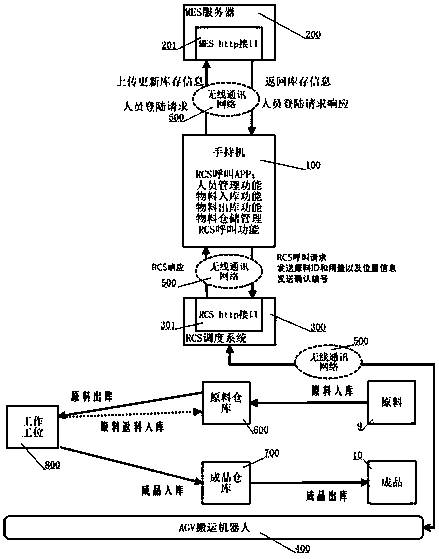

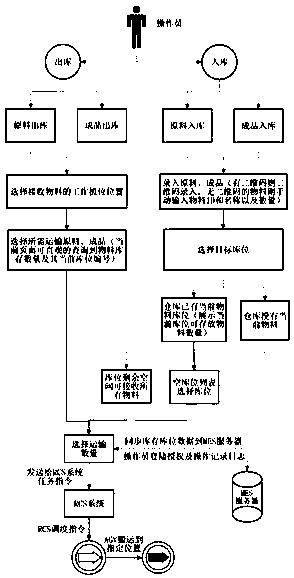

Wool-spinning material carrying call system for intelligent AGV

InactiveCN107844940AImprove material handling efficiencyReduce labor costsCo-operative working arrangementsResourcesHandsetWool

The invention discloses a wool-spinning material carrying call system for an intelligent AGV, and the system consists of a handset, an MES server, an AGV conveying robot, an RCS robot dispatching system, a wireless communication network, a material warehouse, and a work station. The system achieves the automatic conveying of wool-spinning materials in wool-spinning production management through the AGV robot, the informationization data management of material warehousing and delivery and the flexible call dispatching for material conveying in a production process, greatly improves the materialconveying efficiency, reduces the manpower cost, reduces the failure rate of manual operation, improves the informationization degree of workshop production management, is easy to deploy, and greatlyreduces the production management cost of material conveying and dispatching.

Owner:JIANGSU DANMAO TEXTILE

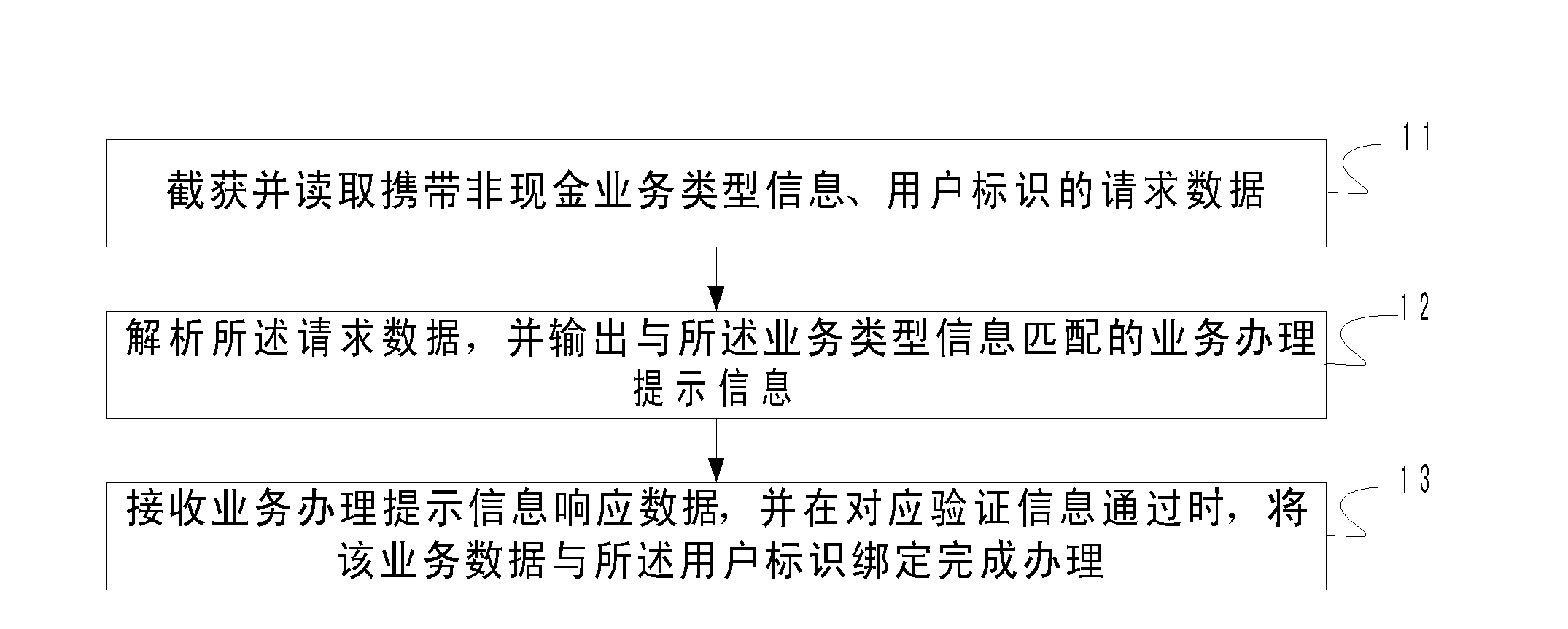

Bank non-cash business processing method, apparatus and system

InactiveCN102509238AReduce waiting timeImprove handling efficiencyFinanceBusiness dataBusiness transactions

The embodiment of the invention discloses a bank non-cash business processing method, apparatus and system. The bank non-cash business data processing method is characterized by comprising the following steps: capturing and reading request data carrying non-cash business type information and a user identification; analyzing the request data, and outputting business transaction prompting information matched with the business type information; and receiving response data of the business transaction prompting information, and binding the business data and the user identification to finish the transaction when corresponding authentication information passes. The embodiment of the invention integrates multiple non-cash business models, indicates the user to operate further by outputting the business transaction information matched with the business type information in the request data in accordance with the request data sent by the user, and finishes the transaction of the non-cash business when the authentication information is authenticated. As an auxiliary or alternative mode for bank window business data processing, the method reduces the waiting time of the user in a business hall and improves the transaction efficiency.

Owner:成都安朗电气自控设备有限公司

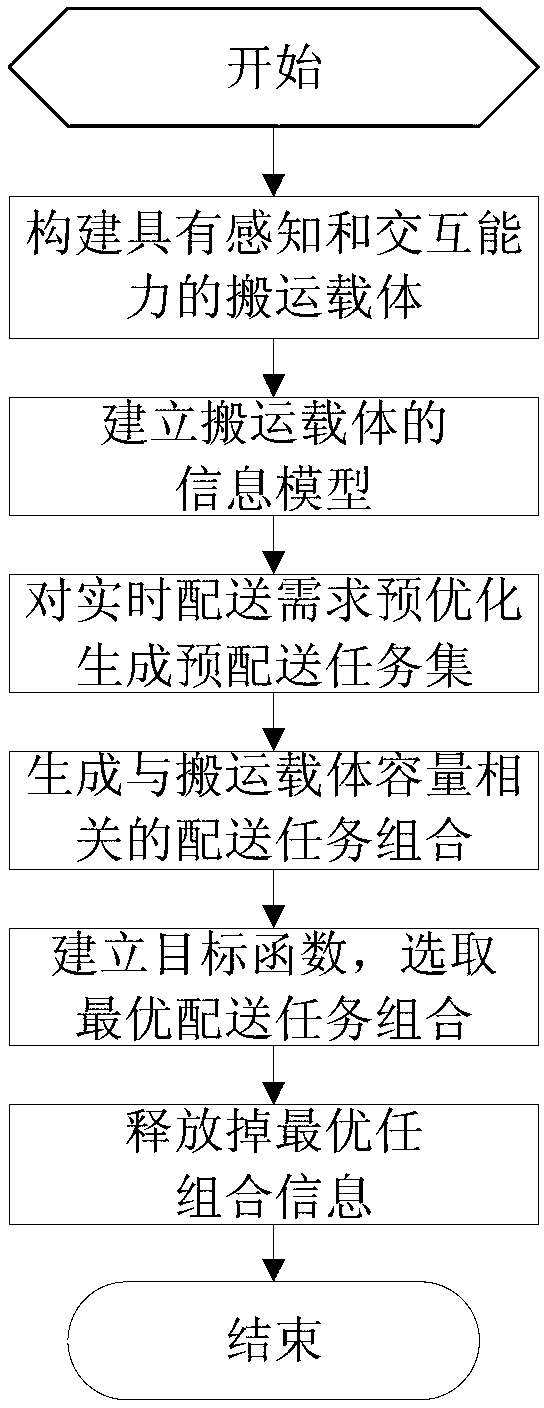

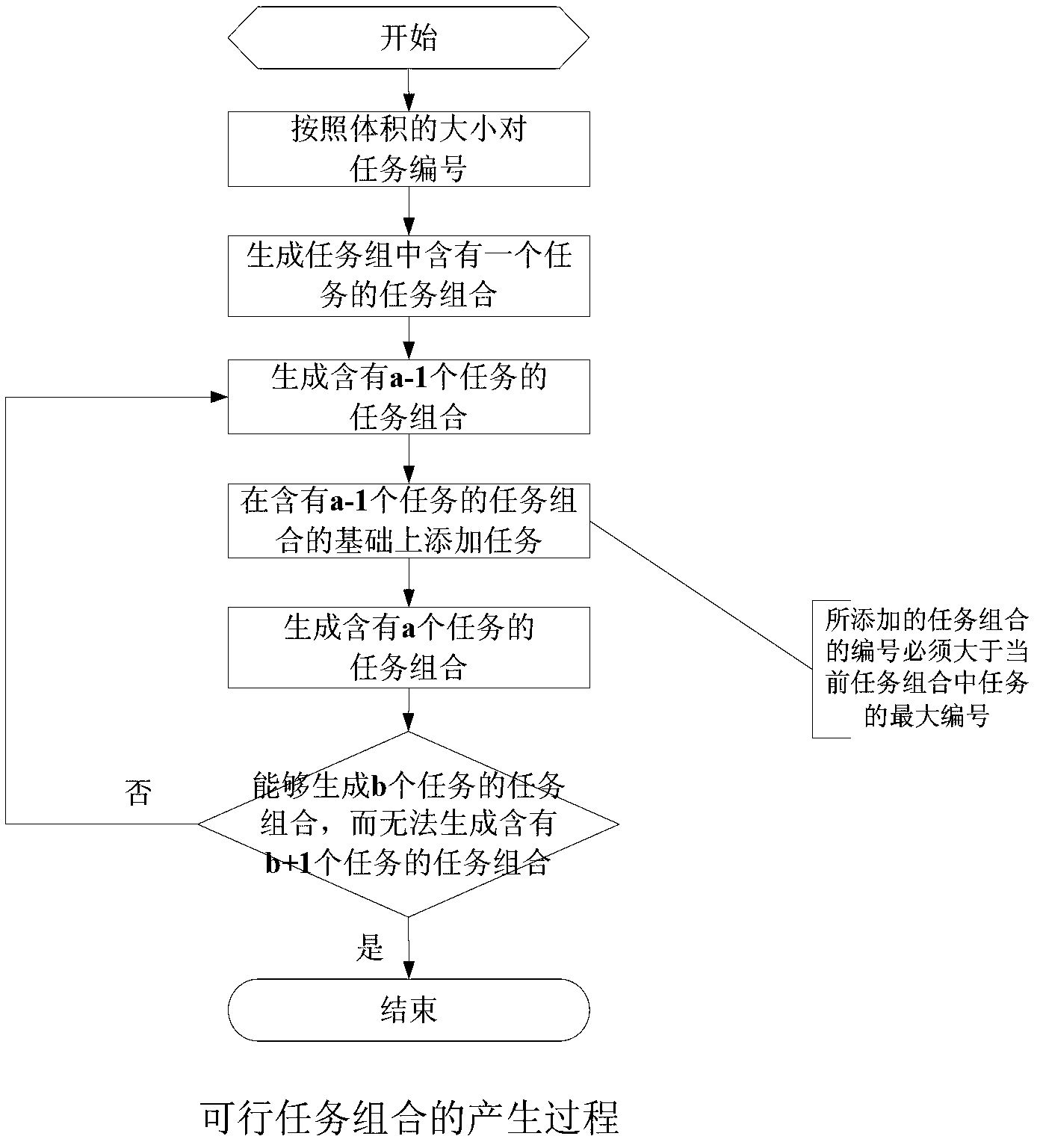

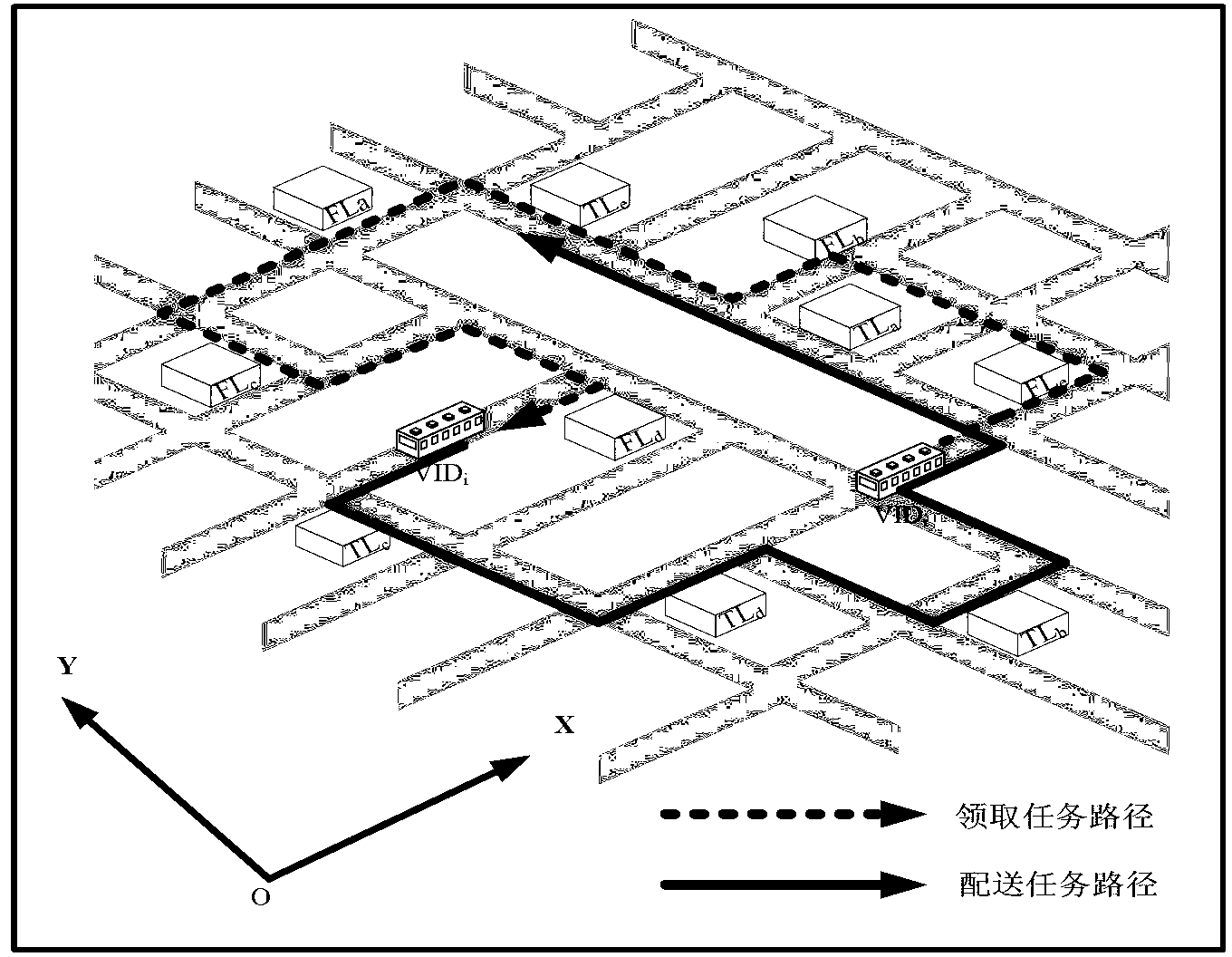

Material delivery task dynamic distribution method based on internet of things technology

InactiveCN103310321AAdapt to task dynamic optimizationAdapt to the delivery situationLogisticsComputation complexityDistribution method

The invention provides a material delivery task dynamic distribution method based on an internet of things technology. Based on the real-time state information of carrying carriers and the work mode that the carrying carriers scramble for tasks, the most suitable material carrying task set is actively obtained, and an efficient and feasible task distribution model and method are provided for the timely distribution of production materials from the three aspects of the dynamic distribution strategy of the tasks, the task dynamic distribution method based on the real-time state of the carrying carriers and the combinatorial optimization of the tasks,. As the real-time position information after the carrying carriers unload, the task dynamic combinatorial optimization facing to the capacity of the carrying carriers and the like are fully considered in the method, compared with the traditional material delivery task optimization method, the method has the advantages that the defects that the computation complexity of an original distribution strategy is high, the optimization time is long, and the change of material delivery tasks is difficultly dynamically responded are overcome, the efficiency of workshop distribution is improved, the carrying cost is saved, and the digital precise distribution and the intellectualization of material distribution management are better realized.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

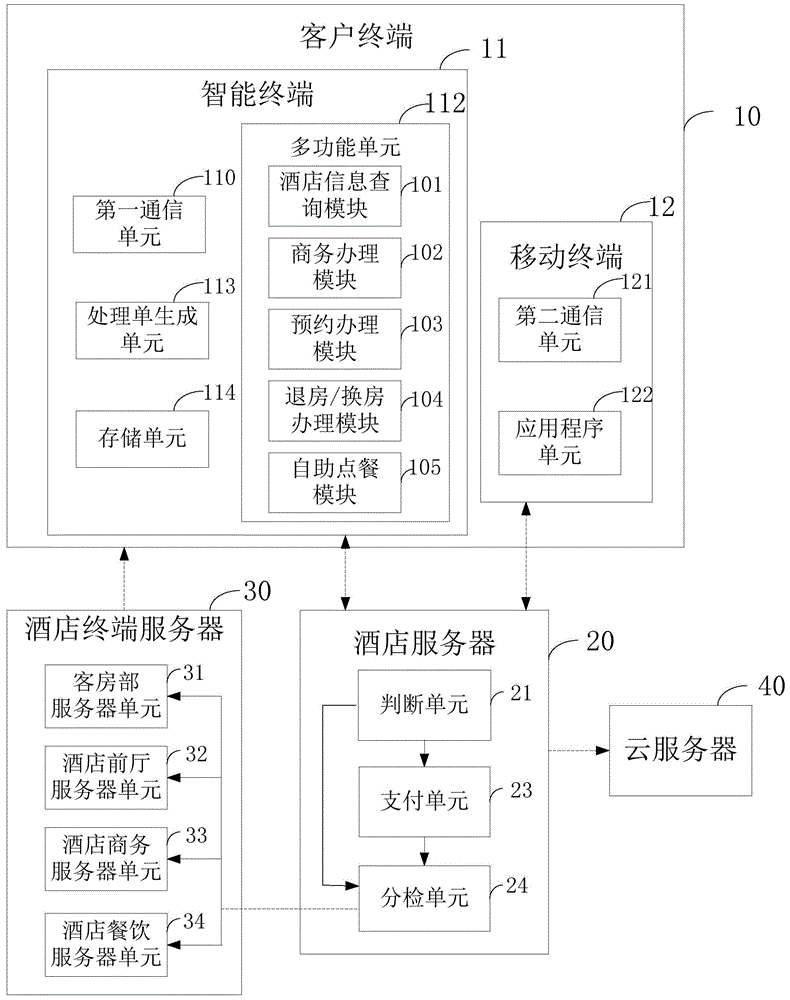

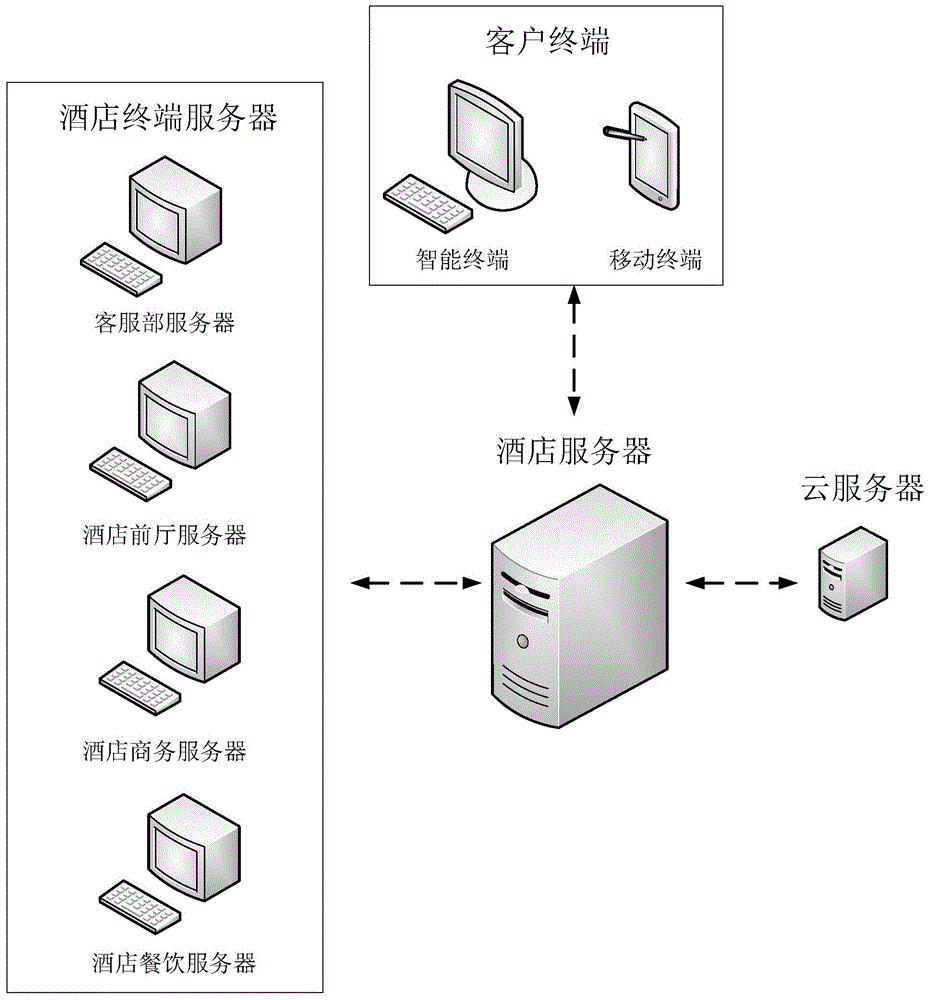

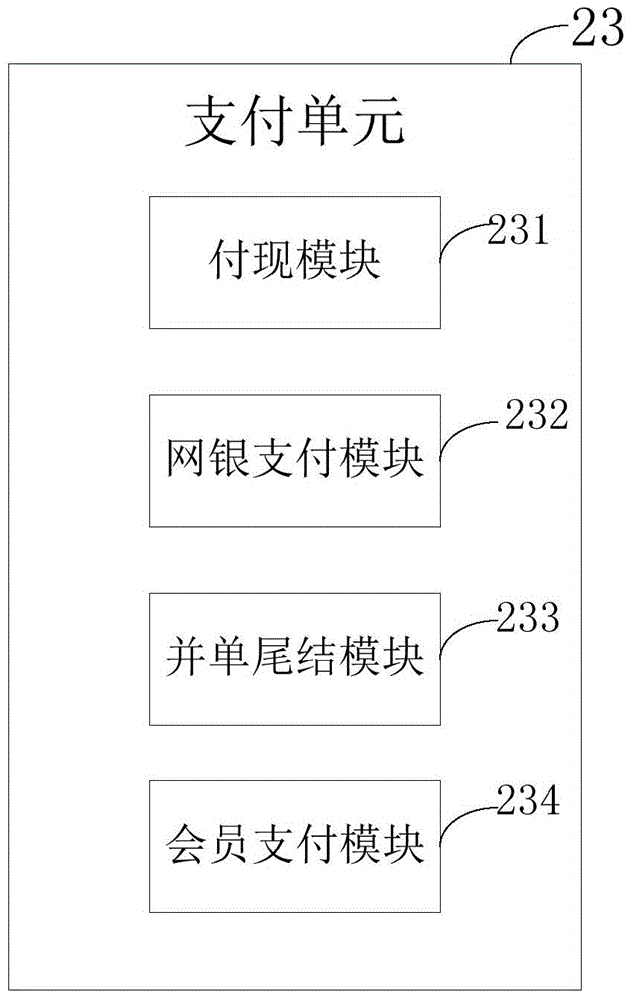

Hotel self-service system and method thereof

The invention discloses a hotel self-service system and a method of the hotel self-service system. The method comprises the steps that a service item is selected by a client in a self-service mode through a client terminal according to requirements and corresponding operation is conducted, wherein the client terminal comprises an intelligent terminal and a mobile terminal, the intelligent terminal is installed in a hotel, and the mobile terminal is provided with an application program; after a process sheet is generated by data of self-service operation, the process sheet is sent to a hotel server; after payment requests are processed by the hotel server preferentially, the processed payment requests are sorted to corresponding units of a hotel terminal server; after the sorted payment requests are received by the units of the hotel terminal server, specific content is executed, and a processing result is pushed to the client terminal. The method overcomes the shortage that according to an existing hotel, a client cannot deal with multifunctional items such as room reservation, check-out, business treatment and ordering of the hotel in a self-service mode in the hotel or through remote control. According to the hotel self-service system and the method of the hotel self-service system, the client does not need to wait when hotel services need to be treated in passenger-flow rush hours and the working efficiency of the hotel is improved to a certain degree.

Owner:邓昊

Queue calling method and queue server

InactiveCN103440698AAchieve independent distributionFamiliar with the processChecking apparatusSelf-serviceDistributed computing

The invention provides a queue calling method and a queue server. The queue calling method is applied to the queue server of a queue calling system. The queue calling system further comprises a self-service touch screen. The queue calling method comprises the following step: after receiving a number taking request sent by the self-service touch screen, extracting a service identifier in the calling request for identifying the service type to be handled by the user so as to further generate a service handling sequence number corresponding to the service identifier in the current number taking request. The service handling sequence number is the service handling sequence number corresponding to handled service identifier plus 1, namely, the service types identified by different service identifiers have a set of independent service handling sequence numbers. When the service handling sequence number is generated, the handled service handling sequence number corresponding to the service handling sequence number is just taken into consideration, so that the service handling sequence numbers are independently distributed based on service types.

Owner:STATE GRID CORP OF CHINA +2

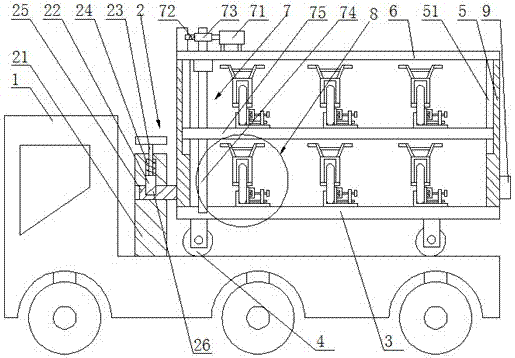

Transport vehicle of bicycles

InactiveCN107380045AIncrease capacityEasy to disassembleItem transportation vehiclesVehicle carriersVehicle frameSingle vehicle

The invention discloses a transport vehicle of bicycles. The transport vehicle comprises a transport vehicle body and a bottom plate, wherein a frame locking device is fixedly connected to the upper end of the transport vehicle body; rolling wheels are fixedly connected to the lower end of the bottom plate; a supporting frame is fixedly connected to the upper end of the bottom plate; a supporting plate is fixedly connected to the upper end of the supporting frame; a lifting device is fixedly connected to the upper end of the supporting plate; wheel locking devices are fixedly connected to the upper end of the bottom plate; and a switch is fixedly connected to the right end of the supporting frame. According to the transport vehicle of the bicycles disclosed by the invention, the wheel locking devices are adopted, so that wheels of each bicycle can be fixed, and in the transporting process, the situation that the bicycles are collided caused by random rocking can be avoided; the frame locking device is adopted, so that the supporting frame can be easily disassembled, and after the bicycles are fixed, a whole vehicle frame is fixed on the transport vehicle body, so that the carrying efficiency is improved; and the lifting device is adopted, so that the double-layer placing of the bicycles can be realized, and the transport capacity of the transport vehicle is improved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

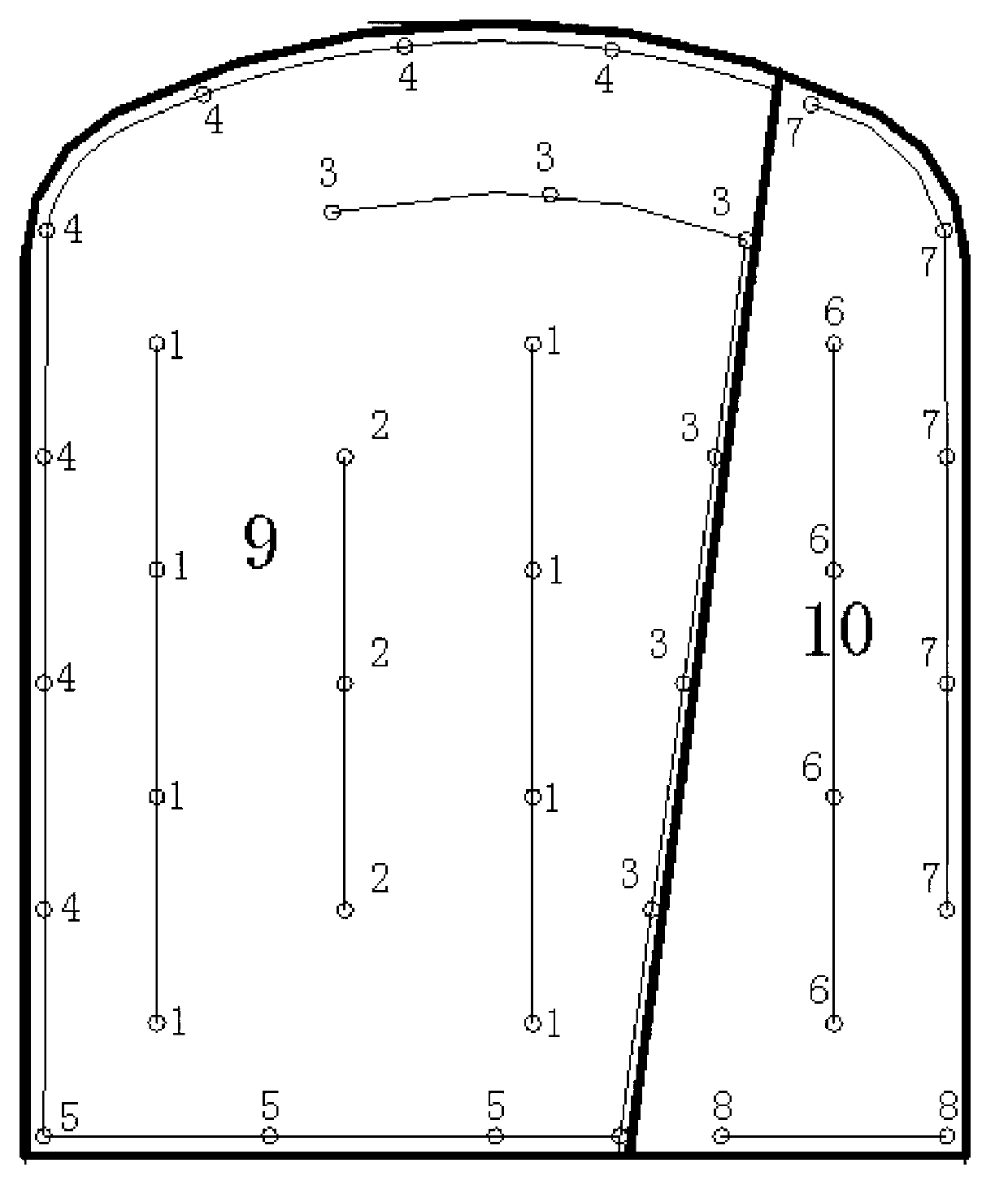

Method for blasting inclined thin ore body by dividing ores and rocks in area in drift driving

The invention provides a technology for blasting an inclined thin ore body by dividing ores and rocks in area in drift driving, belonging to the field of mining engineering. A design process comprises the steps of: 1, dividing a waste rock area (9) and an ore area (10) according to an ore body and a rock distribution condition of a tunnel cross section; 2, arranging a main easer (1) and a secondary easer (2) at the lower part in the waste rock area; 3, arranging an auxiliary hole (3) in the waste rock area according to the size of the cross section; 4, arranging a breaking hole (6) in the ore area according to an inclination angle of the ore body and the size of the cross section; 5, arranging rim holes (4 and 7) and bottom holes (5 and 8) in the circumference edge and the bottom edge of a tunnel; 6, charging each blast hole; 7, sequentially initiating the blast holes; and 8, clearing slag after blasting, and respectively transporting the ores and the waste rocks. With the adoption of the technology provided by the invention, the quantity of the blast holes can be reduced, the use ratio of the blast holes can be improved, a blast effect can be enhanced, the driving efficiency and the ore and rock transportation efficiency can be improved, the dilution rate of the byproduct ores and the engineering cost can be reduced, and the economical benefits of a mine can be improved.

Owner:QINGHAI SHANJIN MINING

Carrying robot, container taking method and container placing method

ActiveCN111620024ALess room for movementIncrease profitStorage devicesLogistics managementIndustrial engineering

The invention belongs to the technical field of storage logistics, and particularly discloses a carrying robot, a storage logistics system and a container carrying method. The carrying robot comprisesa movable chassis, a temporary storage frame and a container taking assembly, wherein the movable chassis can move along a channel between adjacent inventory containers, the temporary storage frame is arranged on the movable chassis and used for temporarily storage target containers, the container taking assembly is arranged on the movable chassis, the container taking assembly can stretch and retract horizontally relative to the movable chassis so as to take and place target containers between the inventory containers and the temporary storage frame, and the horizontal stretching direction of the container taking assembly is perpendicular to the motion direction. The storage logistics system comprises the carrying robot. The container carrying method adopts the carrying robot for carrying target containers. According to the carrying robot, the storage logistics system and the container carrying method, the occupied space of the carrying robot in a warehouse channel can be reduced, the warehouse utilization rate is increased, and meanwhile the target container carrying efficiency can be improved.

Owner:BEIJING JIZHIJIA TECH CO LTD

Intelligent queuing system

InactiveCN101149845ASolve the problem of empty numbersImprove handling efficiencyChecking apparatusComputer hardwareHand held devices

The smart queuing system solves the blank number problem in a queuing machine. When a user takes a number card from a number-taking machine, a control computer reads the information of the number card through the reader at the number-taking machine and stores the information in association with the number card whose state is set as in effect; When a user passes a check device to get into business site, the control computer reads the information of the number card through the reader on the check device and revises the number card state as 'in effect' or 'no effect'; The control computer only distributes 'in effect' number to business window. The control computer is fitted with a short message sending software which can send message to users to provide prompting service.

Owner:王丽婵

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com