Rotating table

A technology of rotating worktable and worktable, applied in the direction of conveyor control device, conveyor, storage device, etc., can solve the problem of start time delay and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

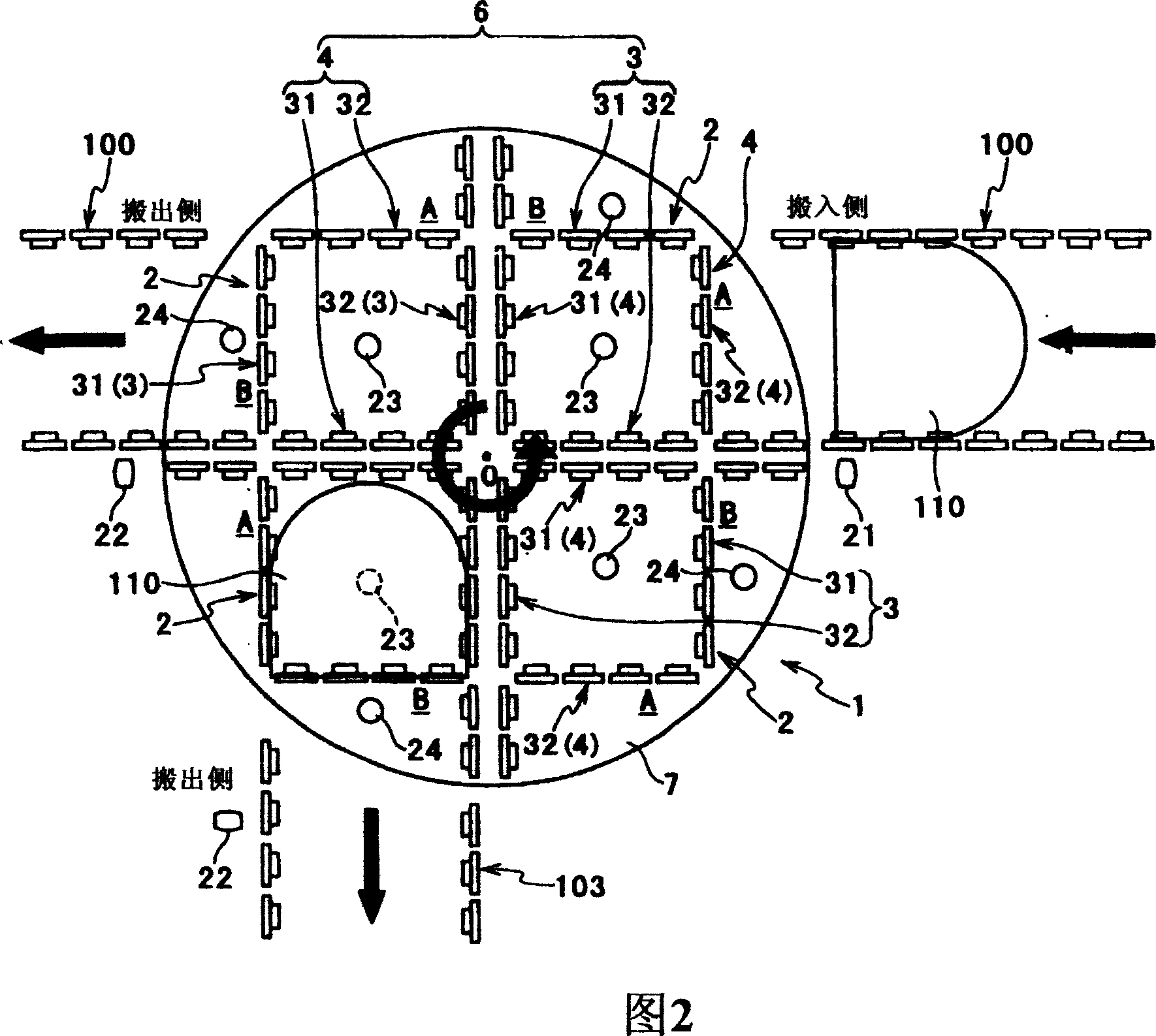

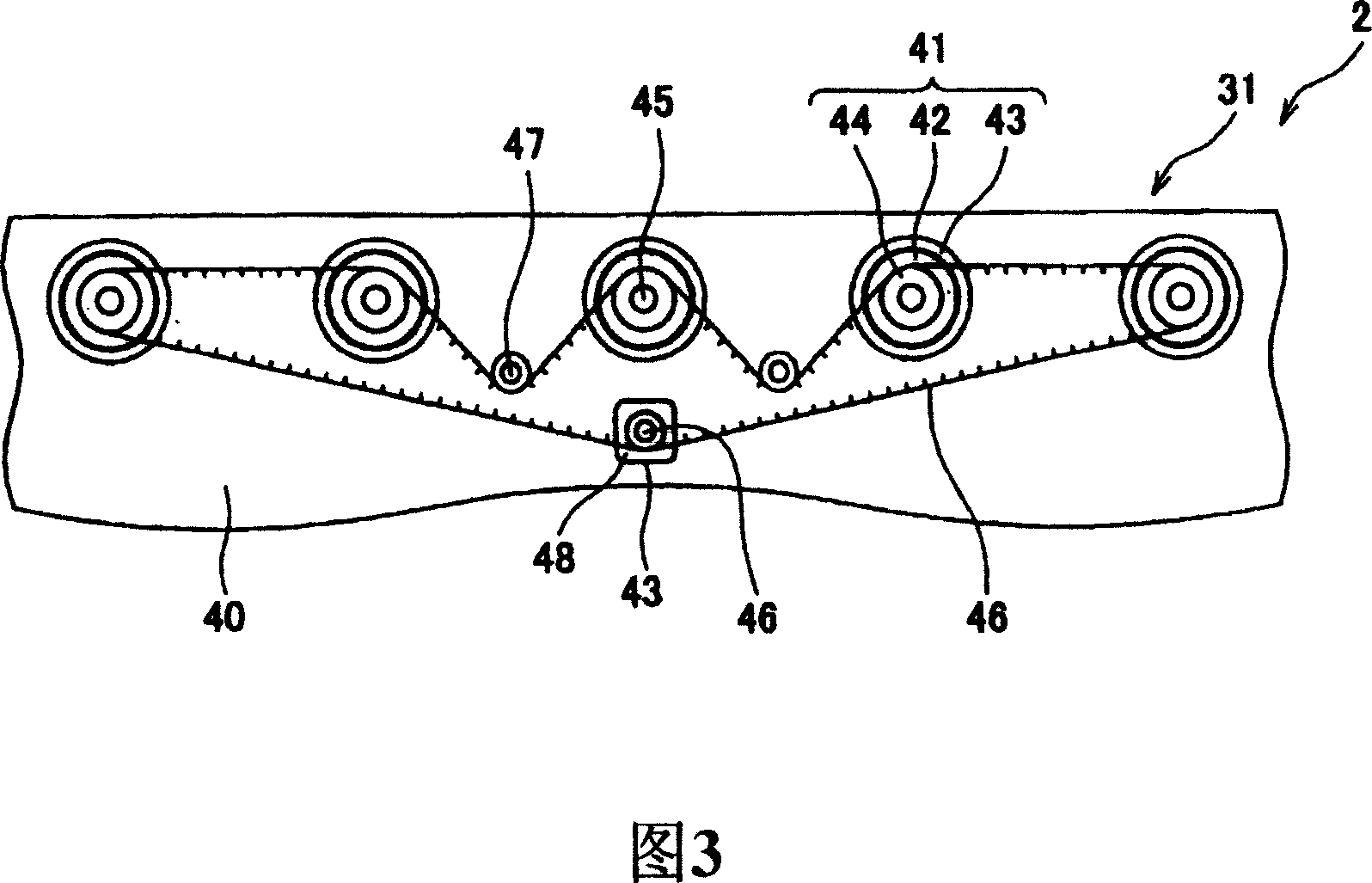

[0028] Hereinafter, an embodiment of the present invention will be described based on FIGS. 1 to 12.

[0029] (Overview of the transportation system)

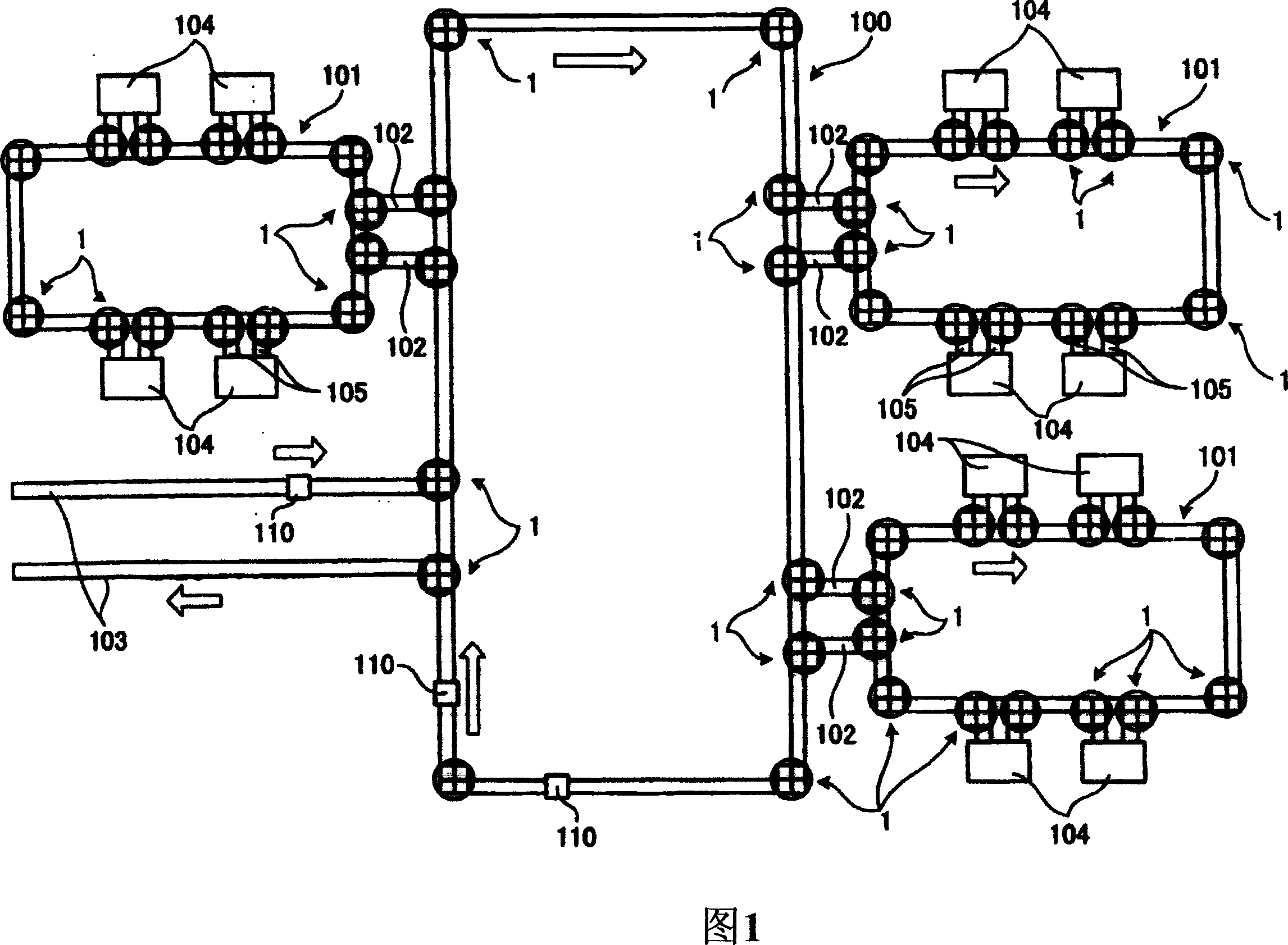

[0030] The rotary table according to this embodiment can change the conveying direction of the carriage 110 (object to be conveyed) conveyed on the conveying rail, and is installed in the conveying system shown in FIG. 1, for example. The conveying system includes: an inter-process roller conveyor track 100 arranged in a predetermined area to communicate between processes, an in-process roller conveyor track 101 arranged around the inter-process roller conveyor track 100, and a connection The other process shown in the figure (including the roller conveyor track 100 between the processes) and the roller conveyor track 103 communicate with the roller conveyor track 100 between the processes.

[0031] The roller conveyor track 101 and the inter-process roller conveyor track 100 in the above-mentioned process communicate with each oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com