Method for blasting inclined thin ore body by dividing ores and rocks in area in drift driving

A technology of tunnels along veins and thin ore bodies, applied in blasting and other directions, can solve the problems of low driving efficiency, poor blasting effect, and low depletion rate of by-product ore.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

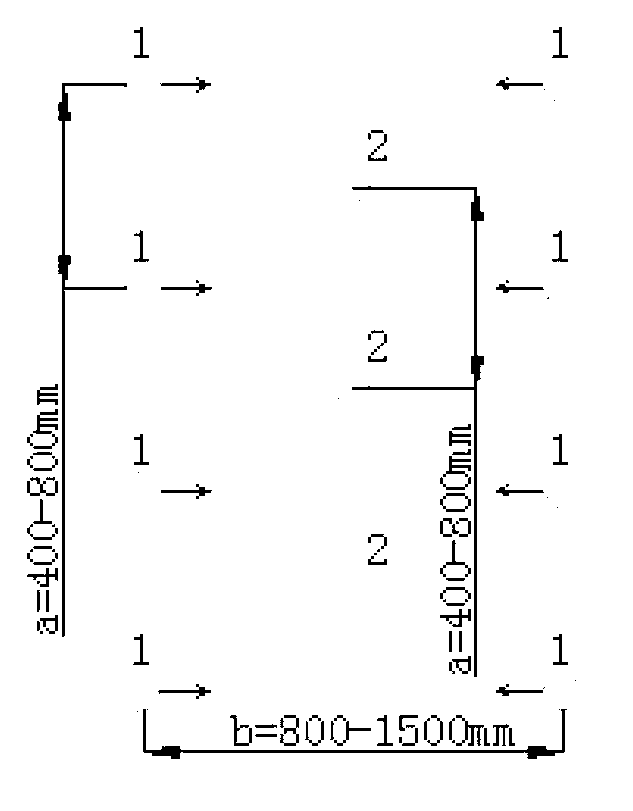

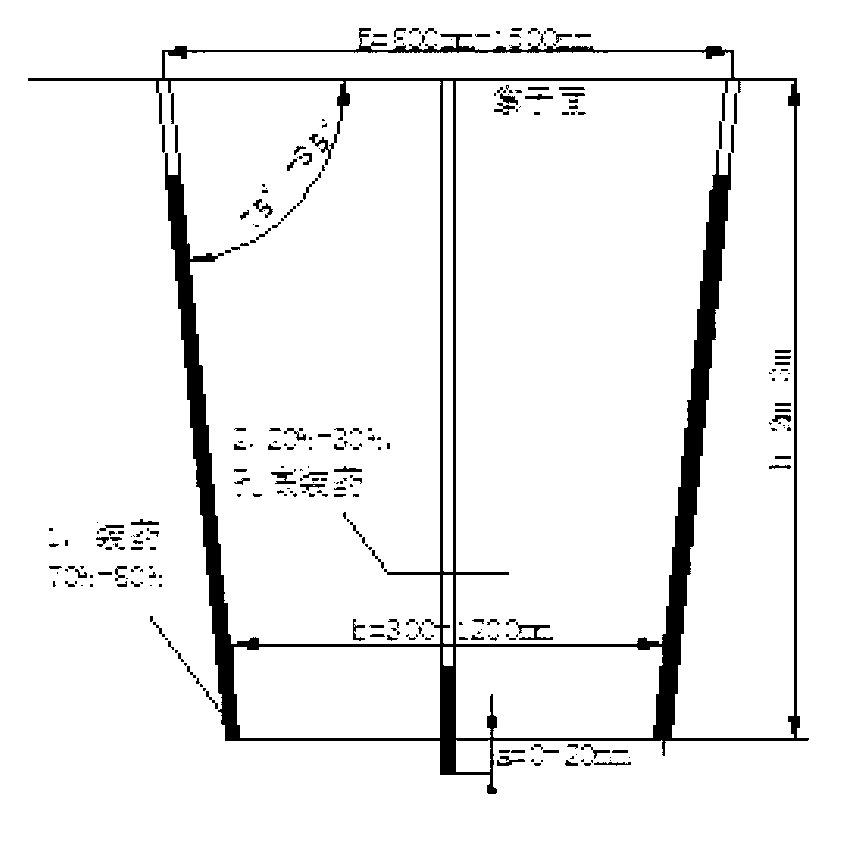

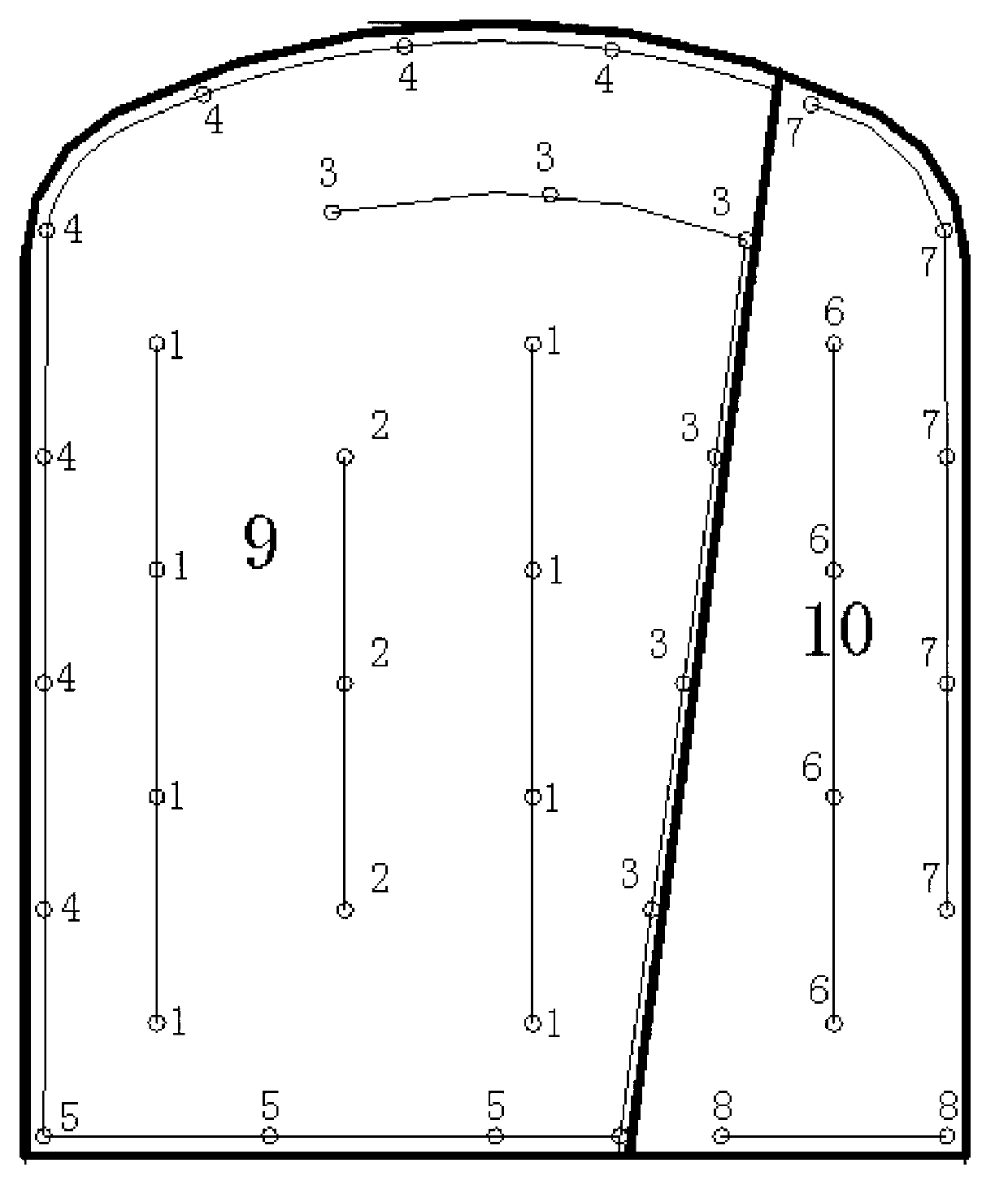

[0042] A gold mining area is divided into 6 gold ore belts from south to north. The exposed area of the ore belt is about 3.0km long from east to west and about 1.0km wide from north to south. The gold belt strikes near east-west, dips south, with steep dip angles and large gradual changes, generally between 45° and 75°, and the occurrence is consistent with the strata. The outcropping range of the ore belt is about 3.0km from east to west, and about 1.0km from north to south. The mining area is mainly composed of quartz veins, which are relatively developed. The vein width is generally 0.3-4.0m, and the average thickness is 1.0m. The roof is carbonaceous phyllite, and the floor is carbonaceous sericite quartz phyllite, which has good stability; the ore types are quartz vein type and structural alteration rock type. The roadway is arranged along the direction of the vein, as a prospecting and mining layout project, and the roadway through the vein is arranged at a certain di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com