In-mold label multifunctional conveying system

A multi-functional conveying and in-mold labeling technology, which is applied in the directions of transportation, packaging, object stacking, etc., can solve the problem of lack of initial positioning function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

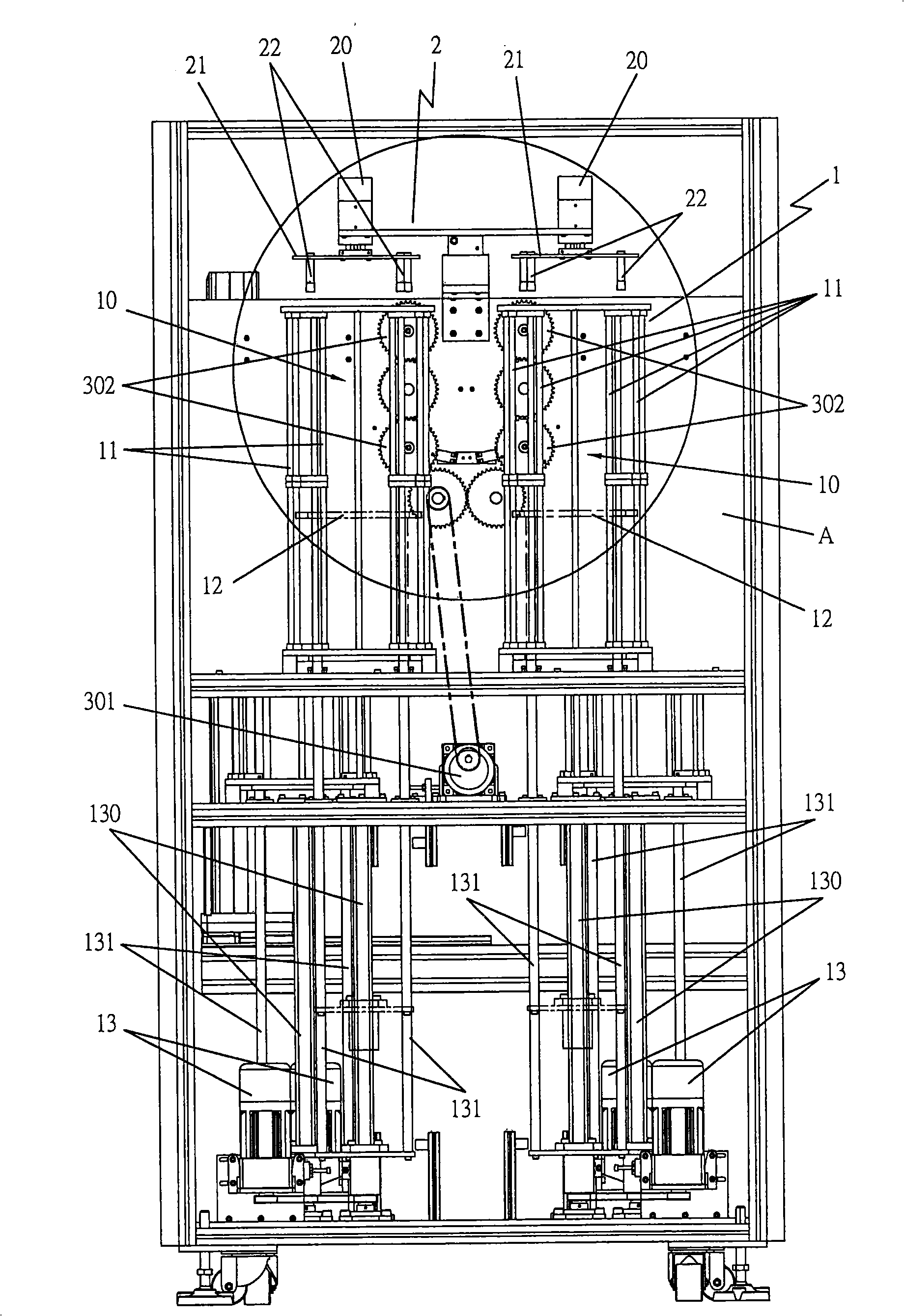

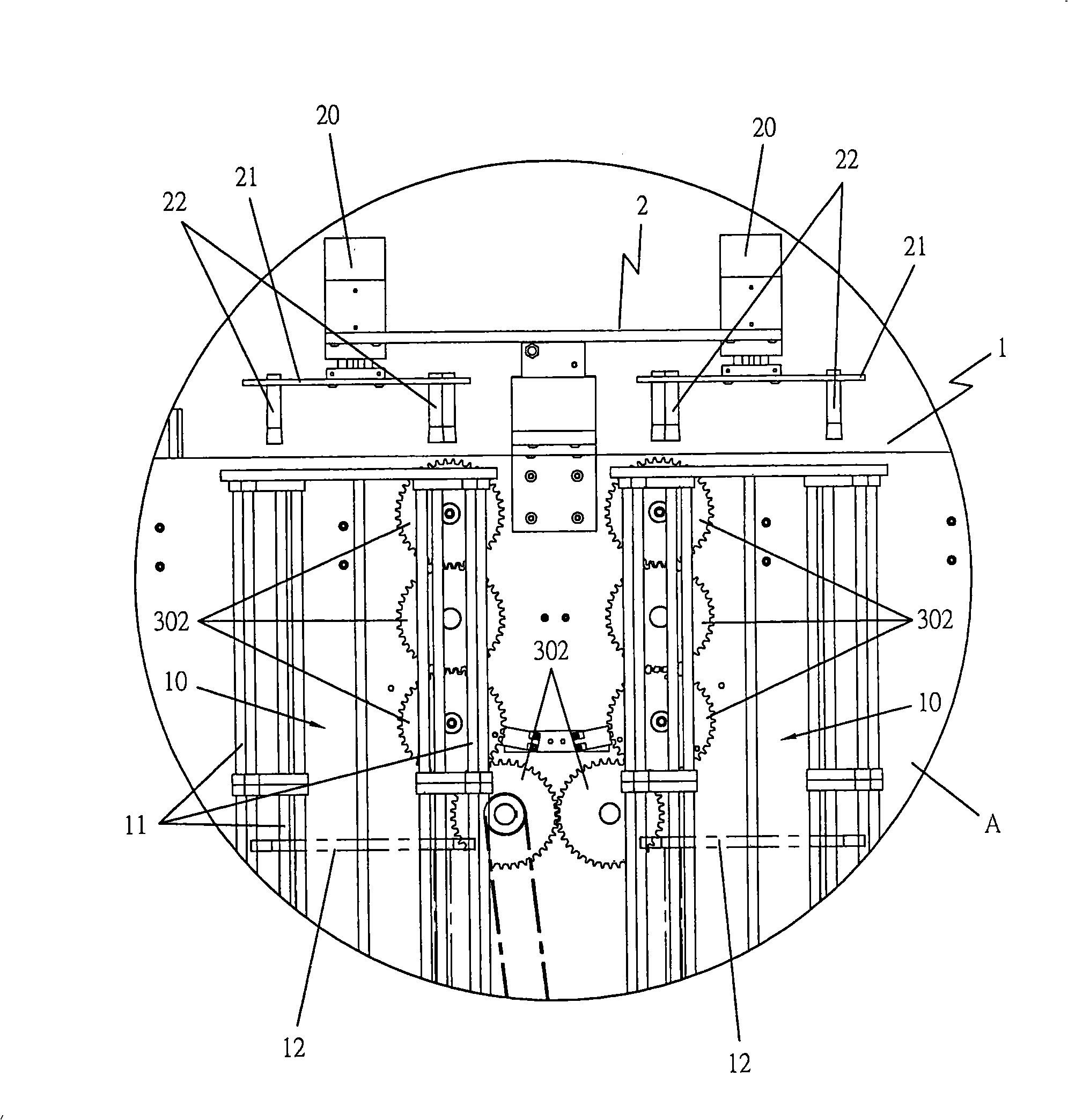

[0047] Such as Figure 1~3 As shown, the in-mold labeling multifunctional conveying system of the present invention at least includes:

[0048] Label placement device 1, the embodiment of the present invention is provided with multiple groups, and the groups are arranged on the front and rear sides of the machine base A (as shown in Figure 21), thereby saving space, of course, it is also possible to set only one group or the Multiple groups are set on one side of the base, as long as it is set according to the work to be done, it is not limited to Figure 1~3setting method. The label placement device 1 is provided with a label groove 10 to accommodate a large number of labels. The label groove 10 is surrounded by a plurality of rods 11, or if it is not surrounded by rods 11, it can also be composed of a sealed wall. Label groove 10, and in order to allow the label to be placed flatly, it is necessary that the label groove 10 has the same or similar shape as the label. And a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com