Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3185 results about "Radian" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The radian is the SI unit for measuring angles, and is the standard unit of angular measure used in many areas of mathematics. The length of an arc of a unit circle is numerically equal to the measurement in radians of the angle that it subtends; one radian is just under 57.3 degrees (expansion at OEIS: A072097). The unit was formerly an SI supplementary unit, but this category was abolished in 1995 and the radian is now considered an SI derived unit.

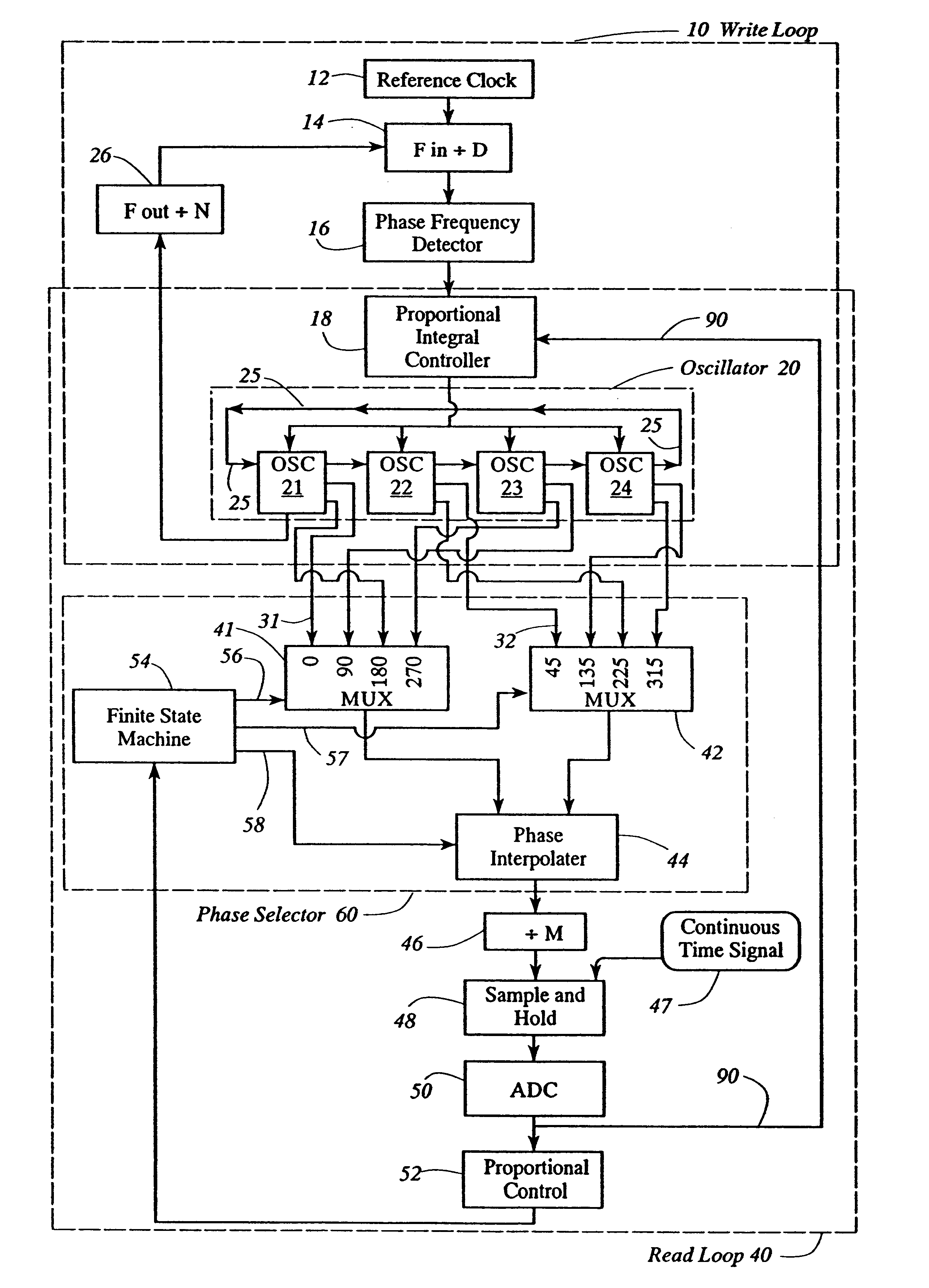

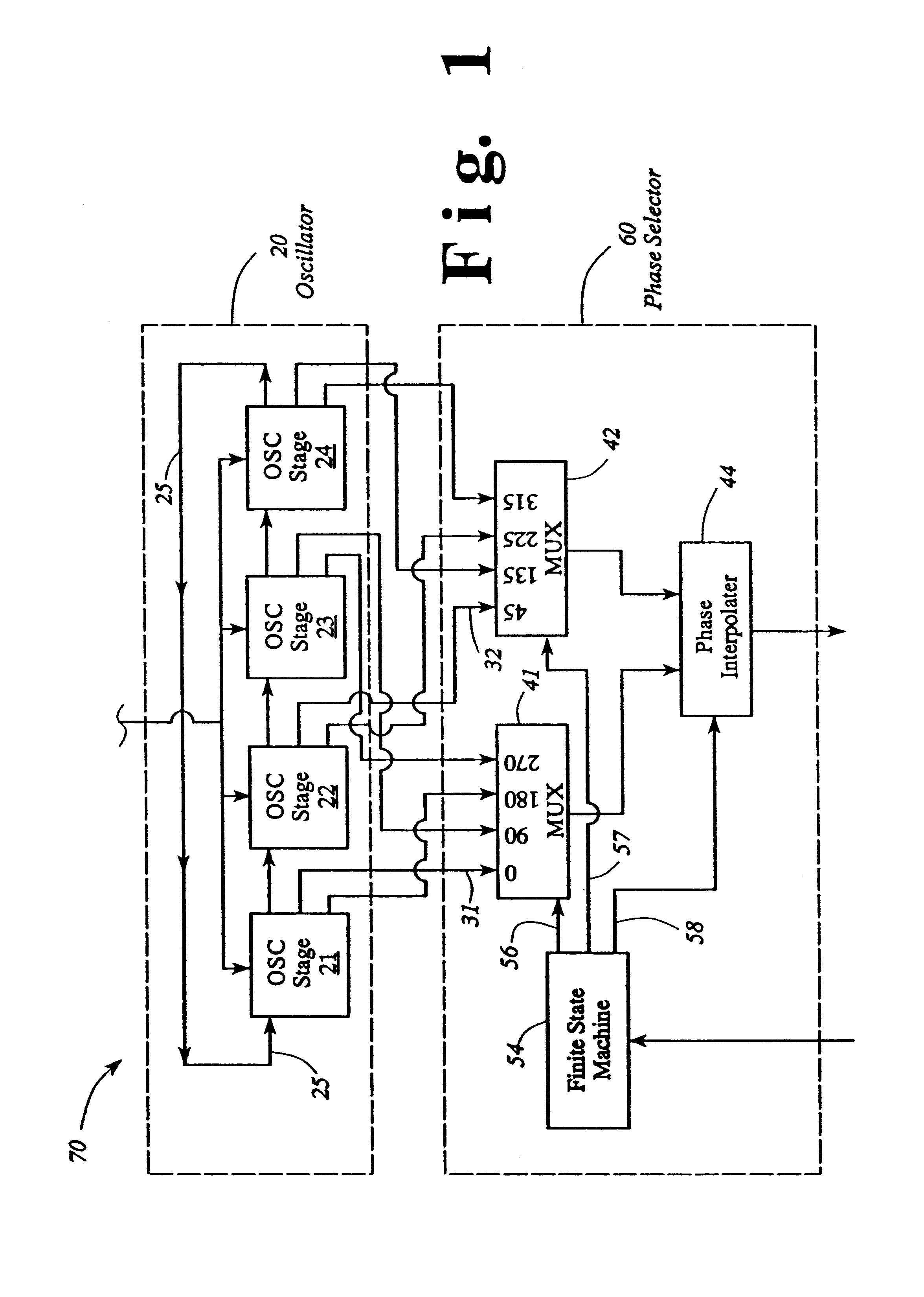

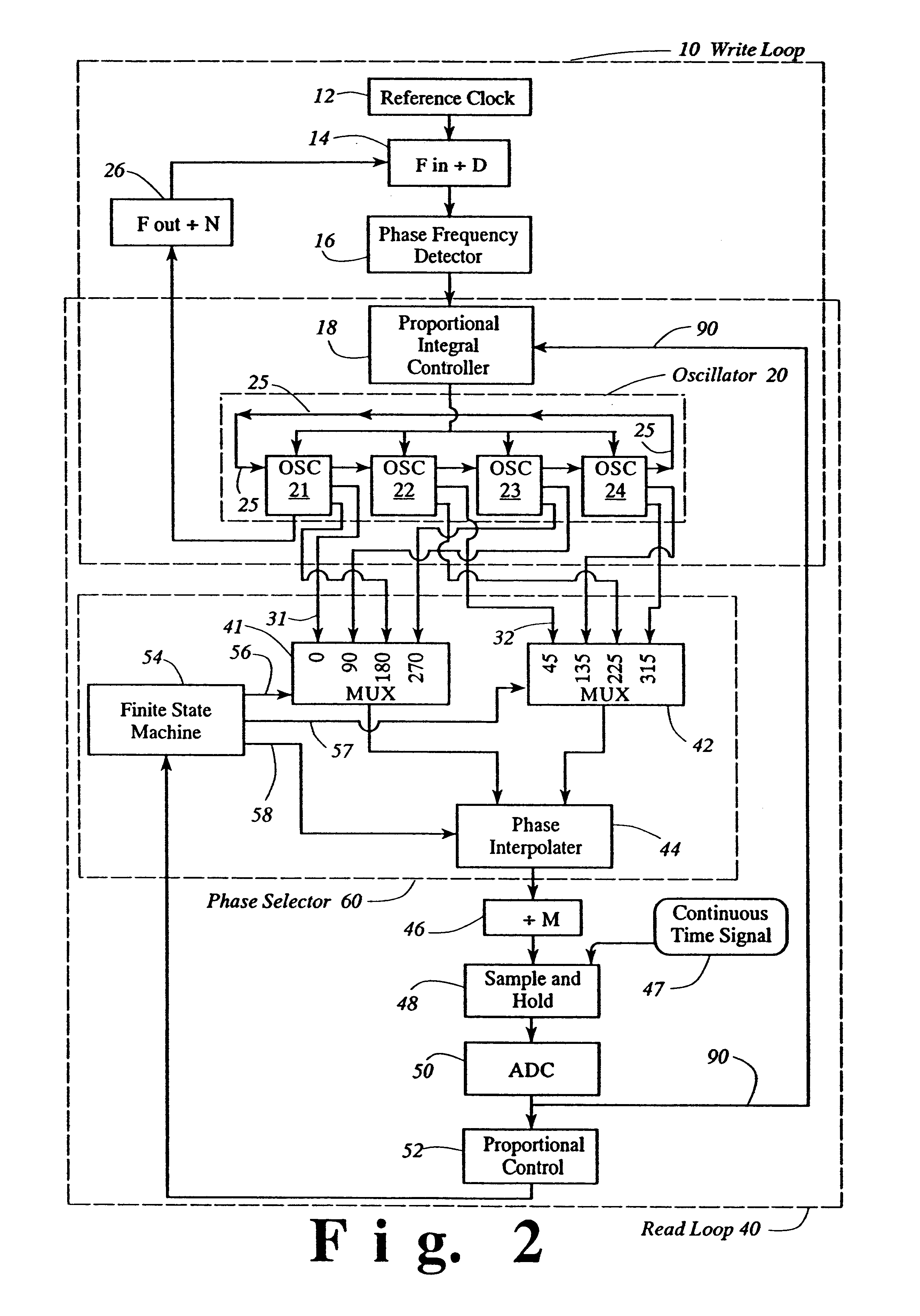

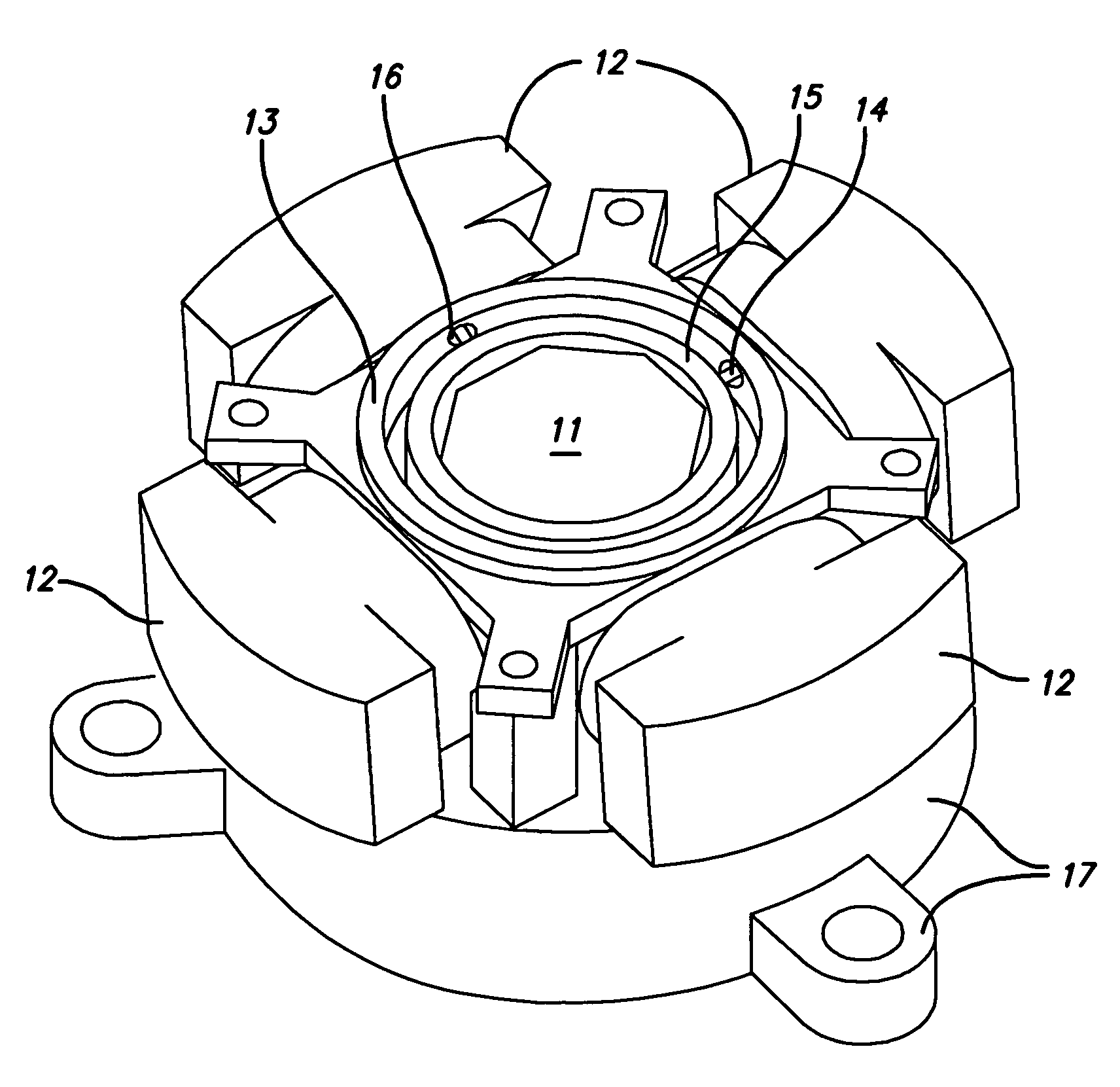

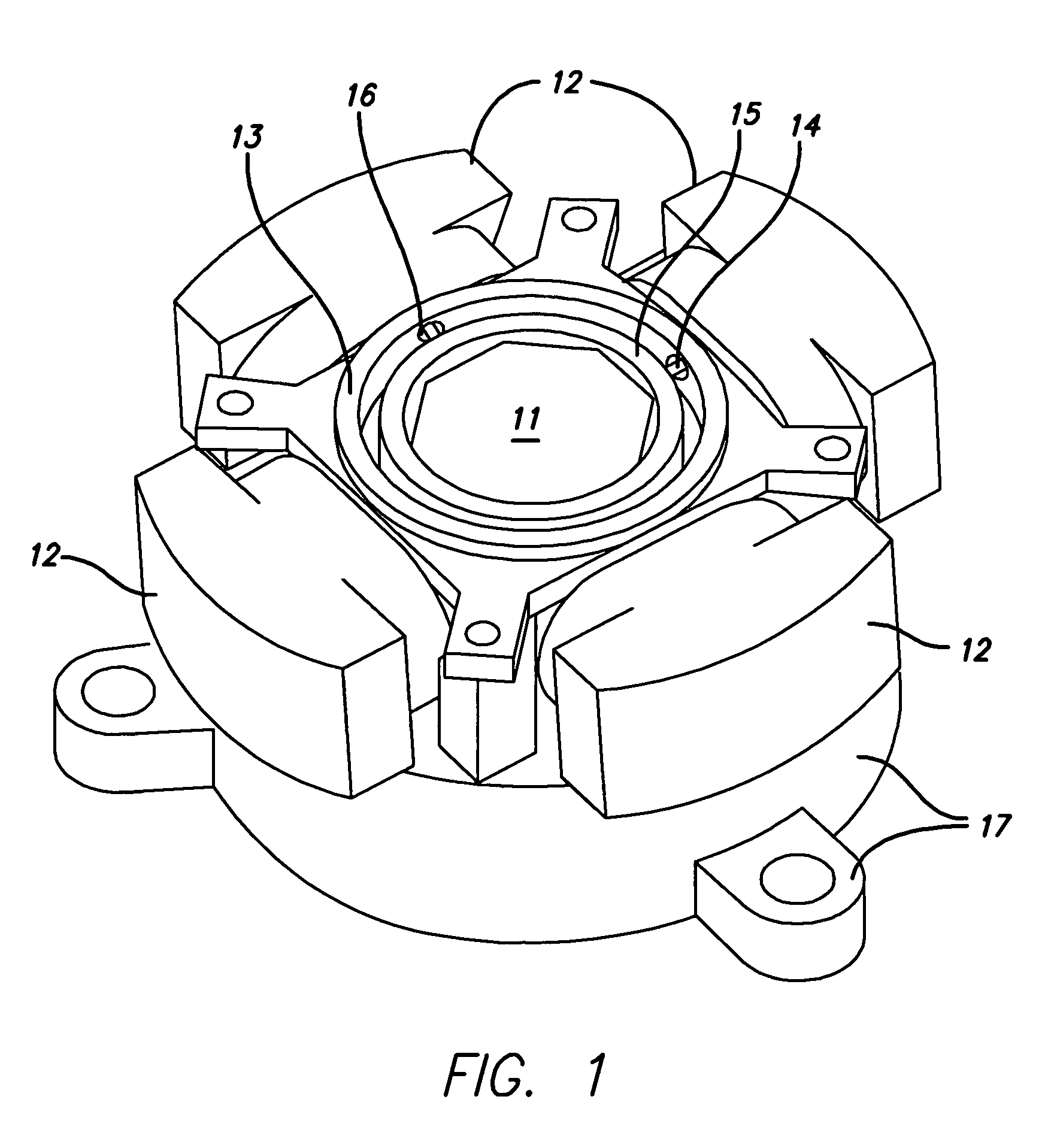

Oscillator with digitally variable phase for a phase-locked loop

InactiveUS6525615B1Disposition/mounting of recording headsPulse automatic controlMultiplexerImproved method

The present invention provides an improved method and apparatus for independently controlling phase and frequency using an oscillator having a plurality of stages in combination with a phase selector within a digitally controlled phase-locked loop, preferably, a read phase locked loop. The present invention provides a digitally controlled variable phase of the read timing loop in read channel integrated circuits associated with data storage devices. The phase selector has a digitally controlled fine interpolator with 12 states for further fine interpolation between at least two multiplexer phase outputs to provide a single phase output selected from a range comprising at least 2pi in selectable variable phase increments of 2pi / 96 radian. The combined oscillator with the phase selector within a phase locked loop controls phase by exact fractional increments of equally space phases of the operating frequency within the phase locked loop, therein controlling phase at all operating frequencies.

Owner:GLOBALFOUNDRIES INC

Sound judging device, sound sensing device, and sound judging method

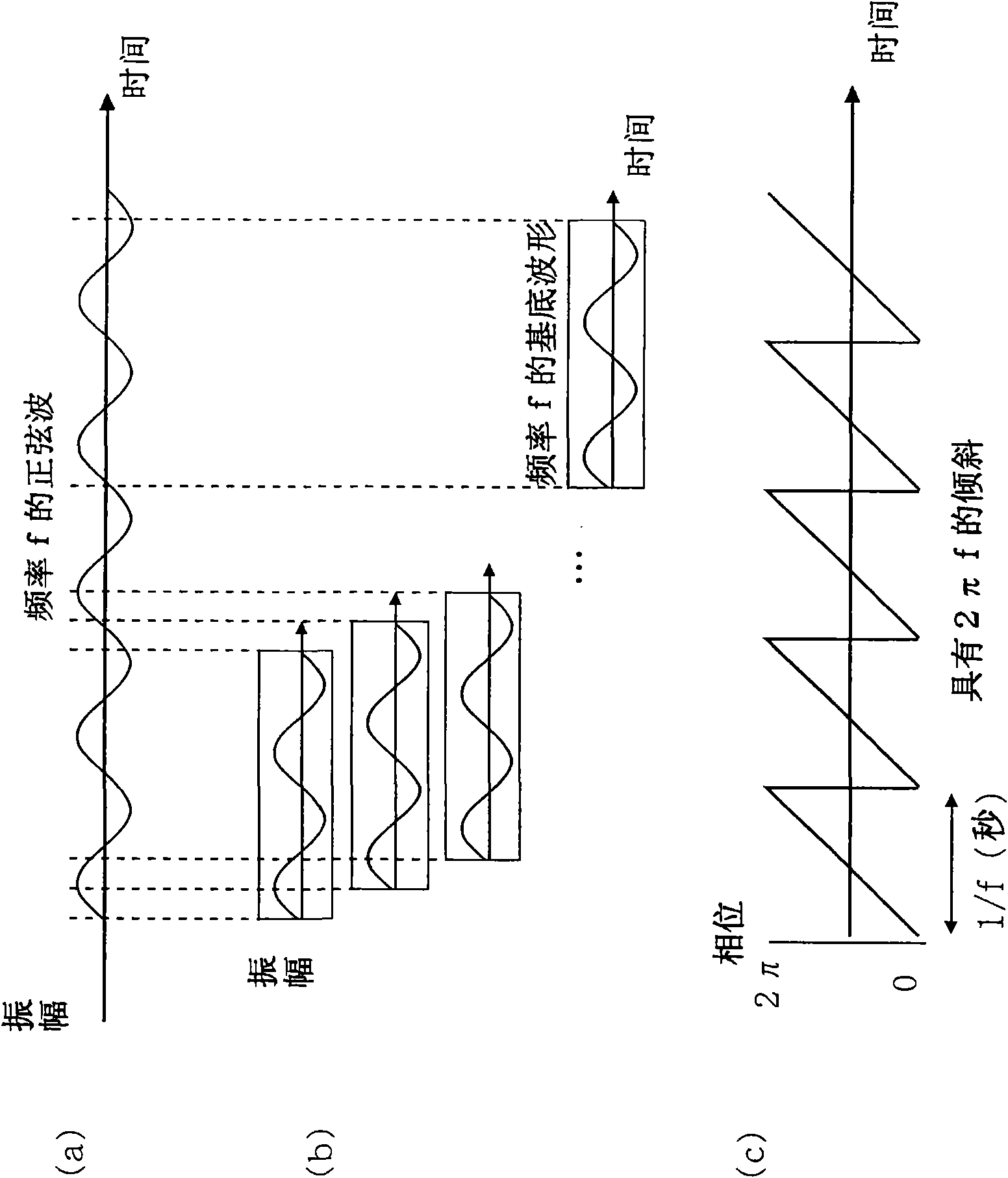

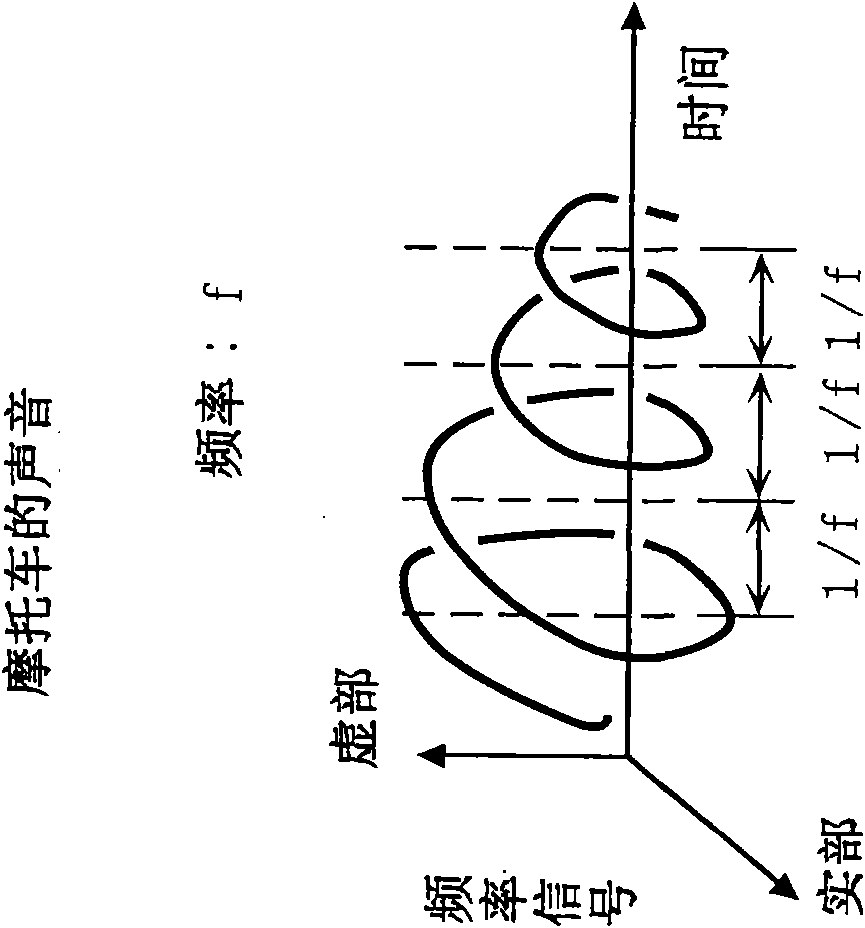

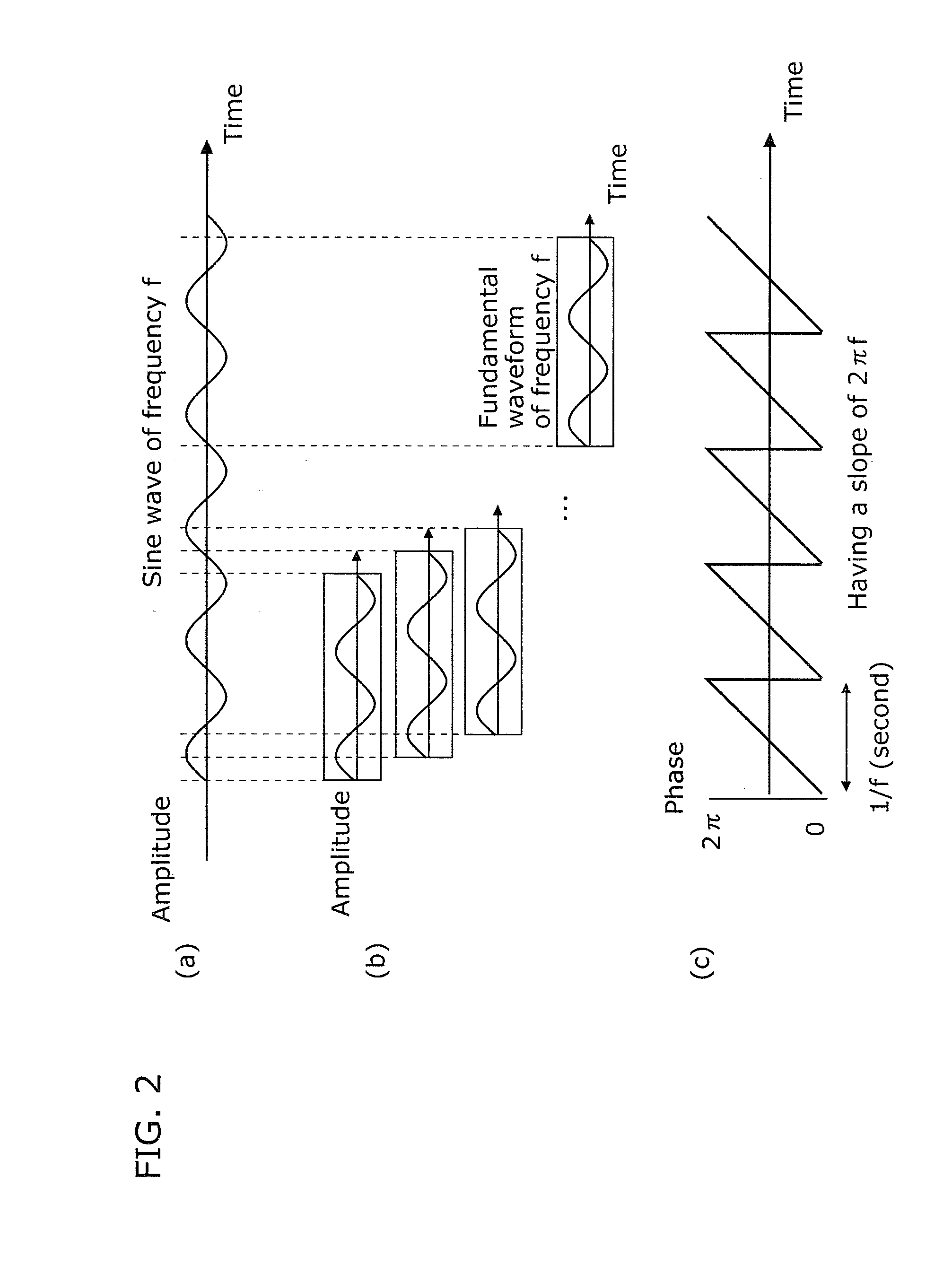

A sound determination device (100) includes: an FFT unit (2402) which receives a mixed sound including a to-be-extracted sound and a noise, and obtains a frequency signal of the mixed sound for each of a plurality of times included in a predetermined duration; and a to-be-extracted sound determination unit (101 (j)) which determines, when the number of the frequency signals at the plurality of times included in the predetermined duration is equal to or larger than a first threshold value and a phase distance between the frequency signals out of the frequency signals at the plurality of times is equal to or smaller than a second threshold value, each of the frequency signals with the phase distance as a frequency signal of the to-be-extracted sound. The phase distance is a distance between phases of the frequency signals when a phase of a frequency signal at a time t is psi (t) (radian) and the phase is represented by psi' (t) = mod 2 pi (psi (t) - 2 pi f t) (where f is an analysis-target frequency).

Owner:PANASONIC HLDG CORP KADOMA SHI

Optical system

ActiveUS8203702B1Reduce frictionEnormous difference potential speedAngle measurementAdditive manufacturing apparatusBeam divergencePiston

Method / system locate external articles using source, detector (PSD), entrance aperture, and magnifying / reducing afocal element—expanding FOR>90°, or refining precision. Between (1) source or detector and (2) aperture, at least one plural-axis-rotatable mirror addresses source / detector throughout FOR. ½- to 15-centimeter mirror enables ˜25 to ˜45 μradian beam divergence. Aperture, afocal element, and mirror(s) define source-detector path. Mirror(s) rotate in refractory- (or air / magnetic-) bearing mount; or mirror array. Auxiliary optics illuminate mirror back, monitoring return to measure (null-balance feedback) angle. To optimize imaging, auxiliary radiation propagates via splitters toward array (paralleling measurement paths), then focusing on imaging detector. Focal quality is developed as a PSF, optimized vs. angle; stored results later recover optima. Mirror drive uses magnet(s) on mirror(s). “Piston” motion yields in-phase wavefronts, so array dimensions set diffraction limit. Also: destructive reply; scaling optimizes acceleration vs. thickness; passive systems.

Owner:ARETE ASSOCIATES INC

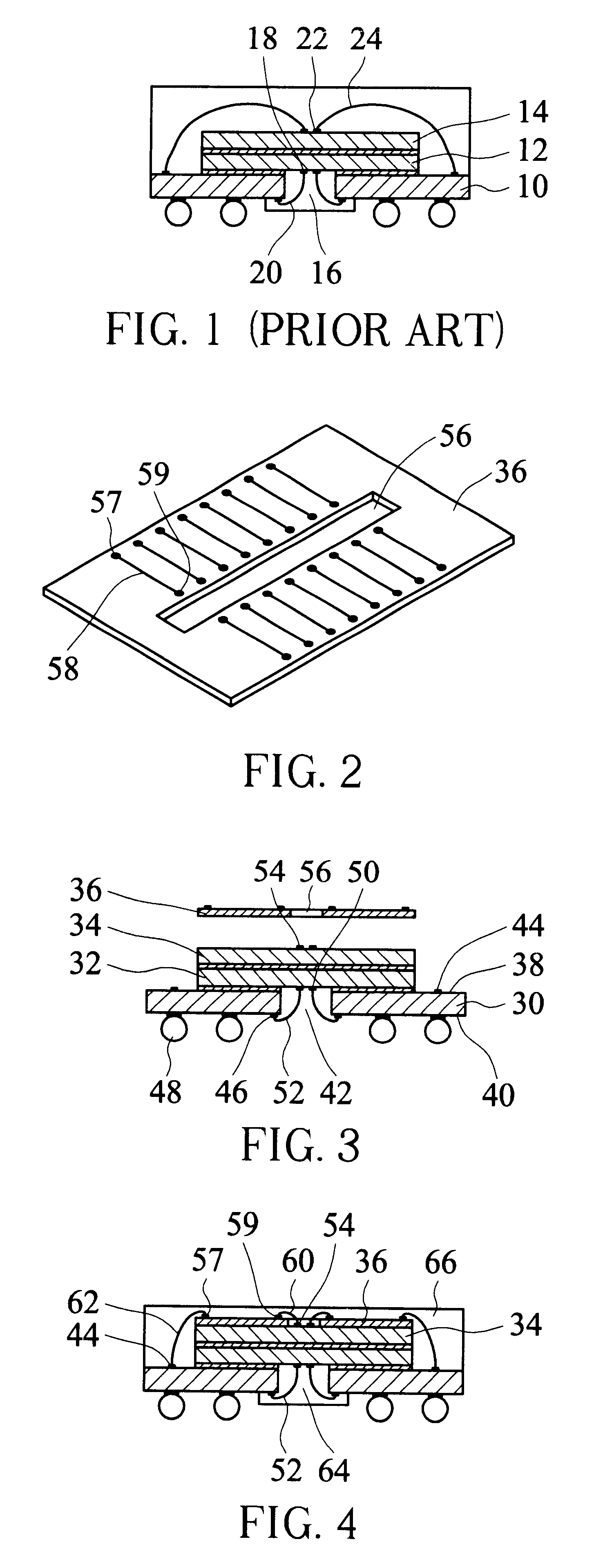

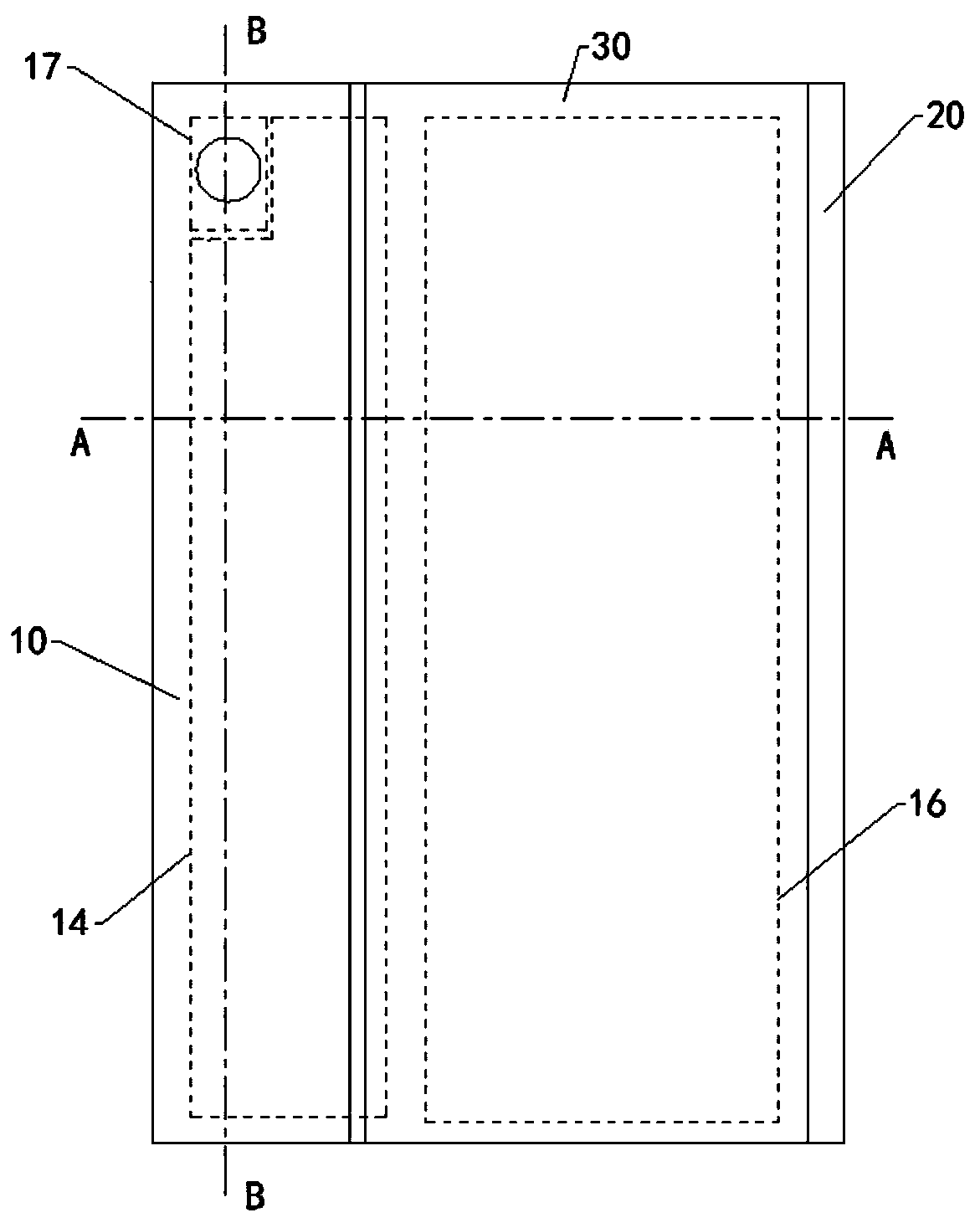

Stacked structure for memory chips

InactiveUS6472736B1Semiconductor/solid-state device detailsSolid-state devicesMemory chipEngineering

A stacked structure for memory chips includes a substrate, a lower memory chip, an upper memory chip, and an insulation medium. The substrate has an upper surface, a lower surface and a slot penetrating through the substrate from the upper surface to the lower surface. The lower memory chip has a central portion formed with a plurality of bonding pads. The lower memory chip is arranged on the upper surface of the substrate. The plurality of bonding pads is exposed via the slot of the substrate, and the bonding pads are electrically connected to the lower surface of the substrate via a plurality of wires. The upper memory chip has a central portion formed with a plurality of bonding pads. The upper memory chip is arranged on the lower memory chip in a back-to-back manner with respect to the lower memory chip so that the plurality of bonding pads of the upper memory chip faces upwards. The insulation medium has a central portion formed with a slot. The plurality of bonding pads of the upper memory chip is exposed via the slot of the insulation medium. The insulation medium is formed with a plurality of traces electrically connecting to the bonding pads of the upper memory chip and the upper surface of the substrate via a plurality of wires. Accordingly, the length and radian of each wire can be reduced so that a better signal transmission effect and a smaller package volume can be obtained.

Owner:KINGPAK TECH INC

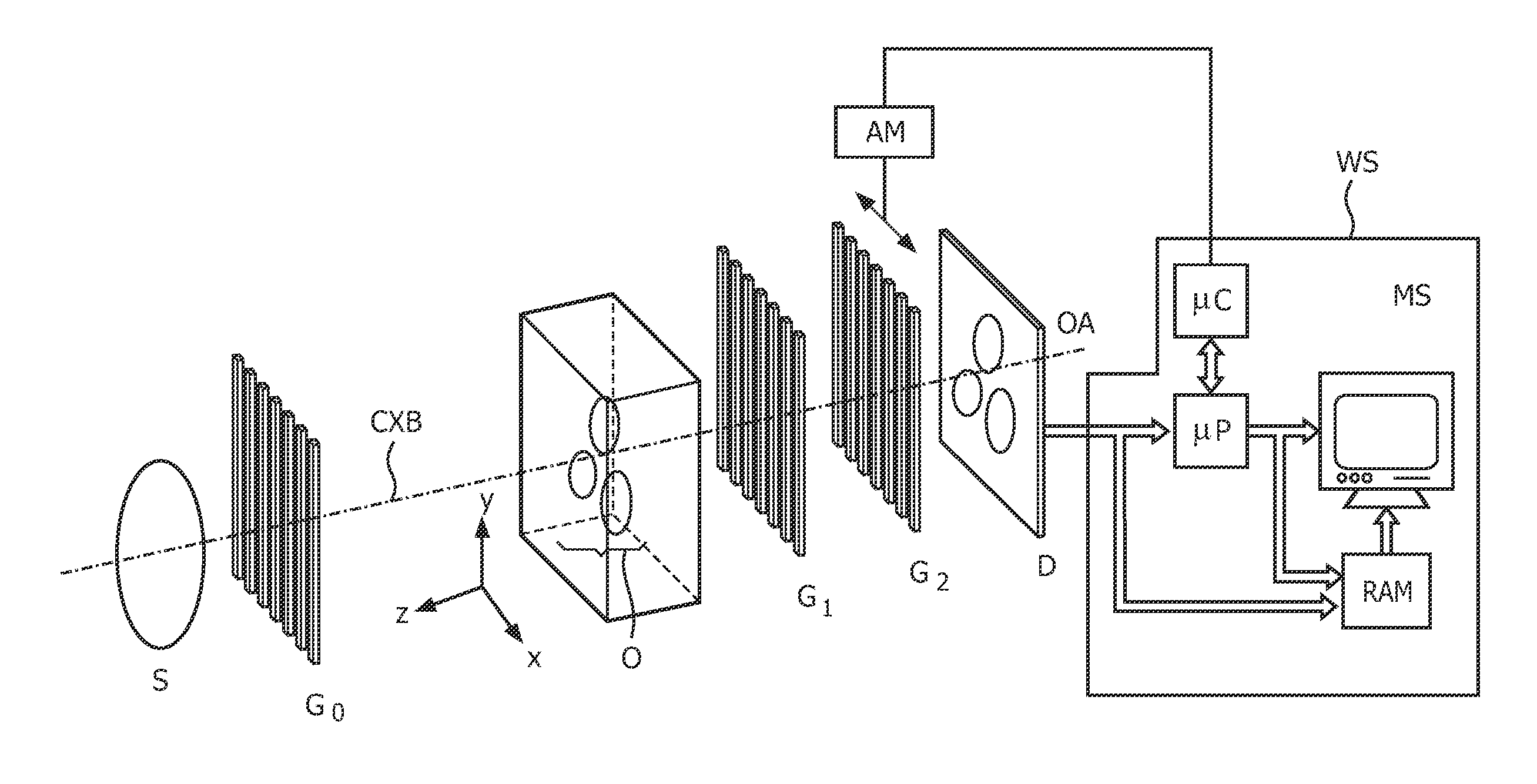

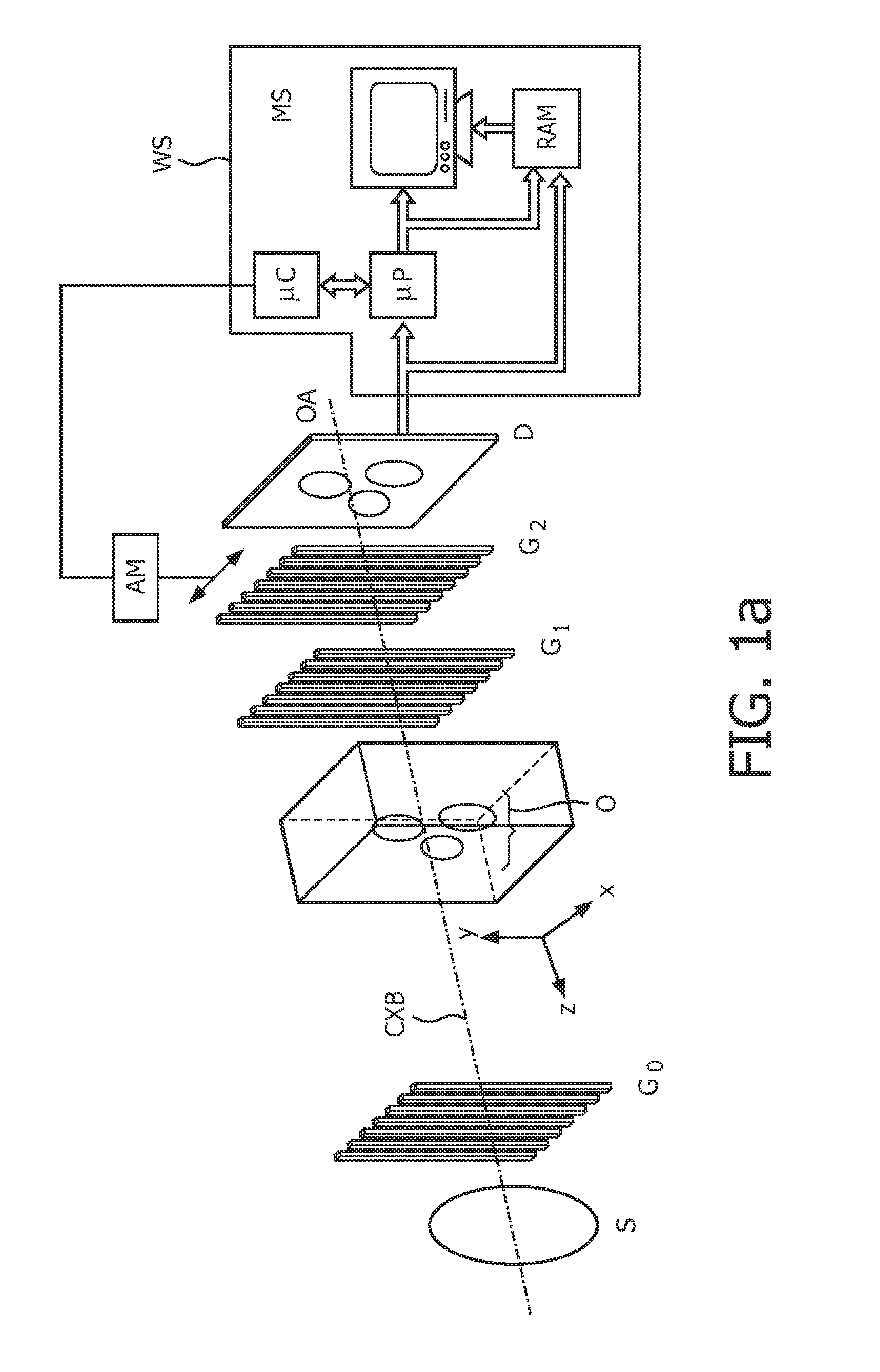

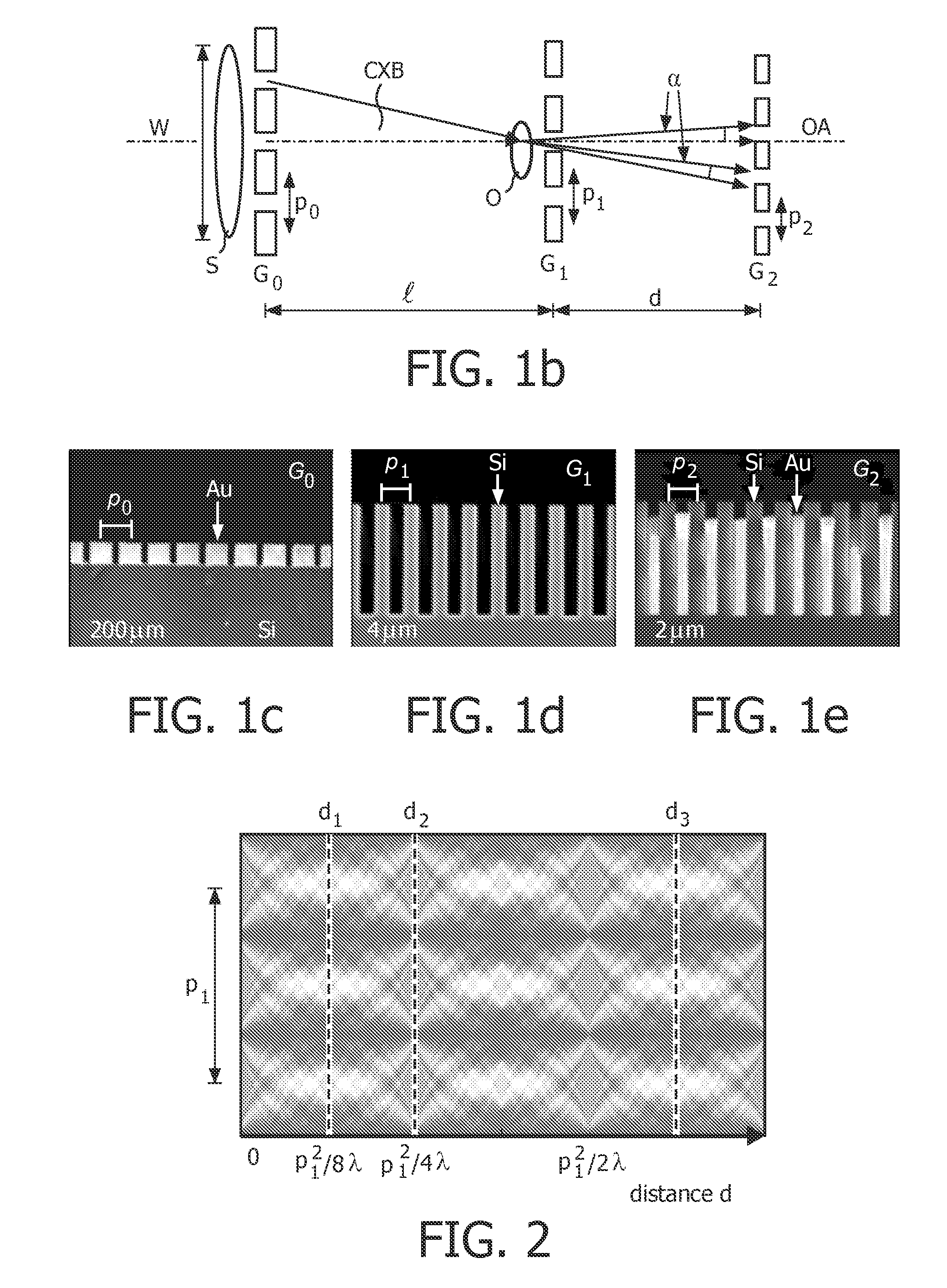

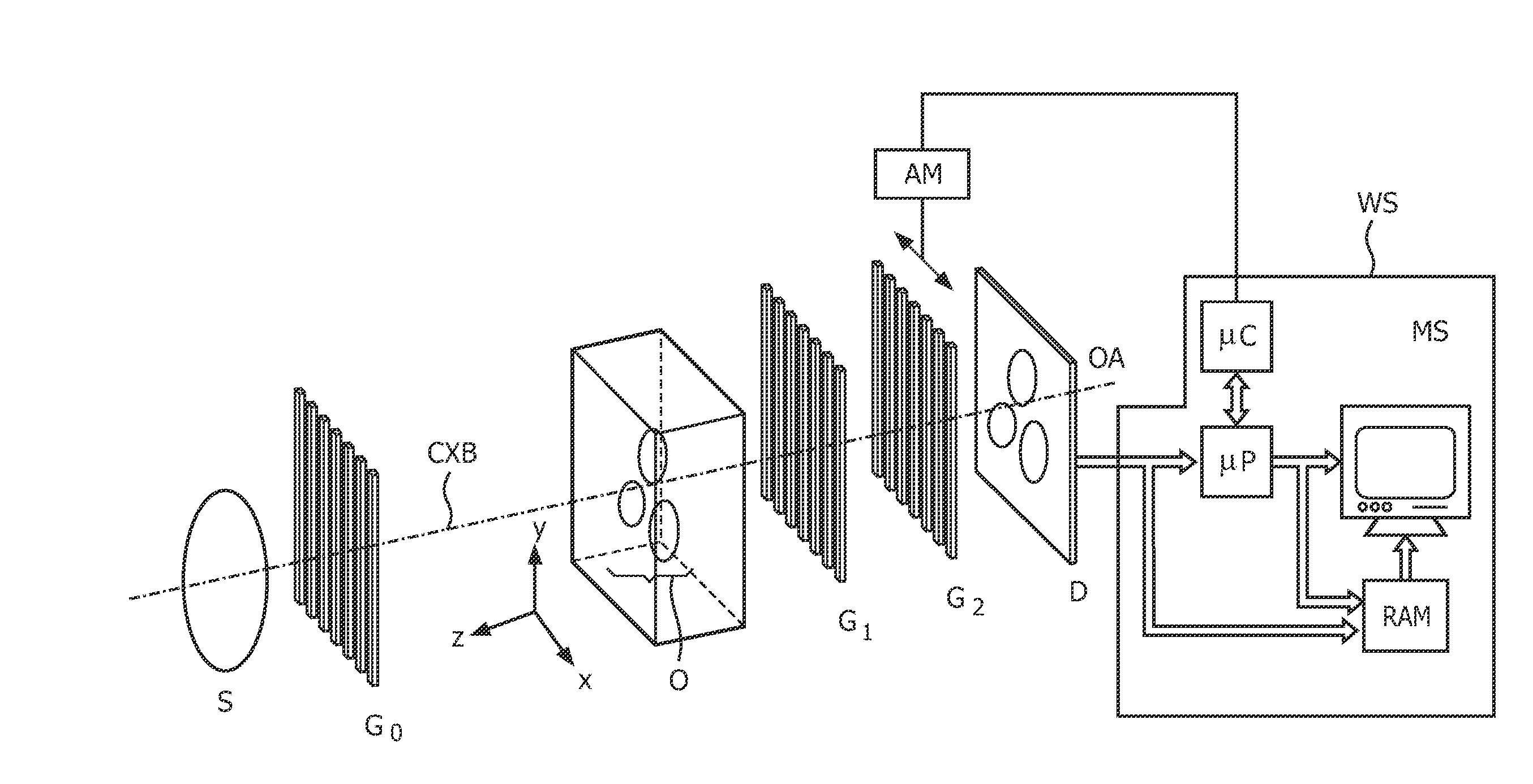

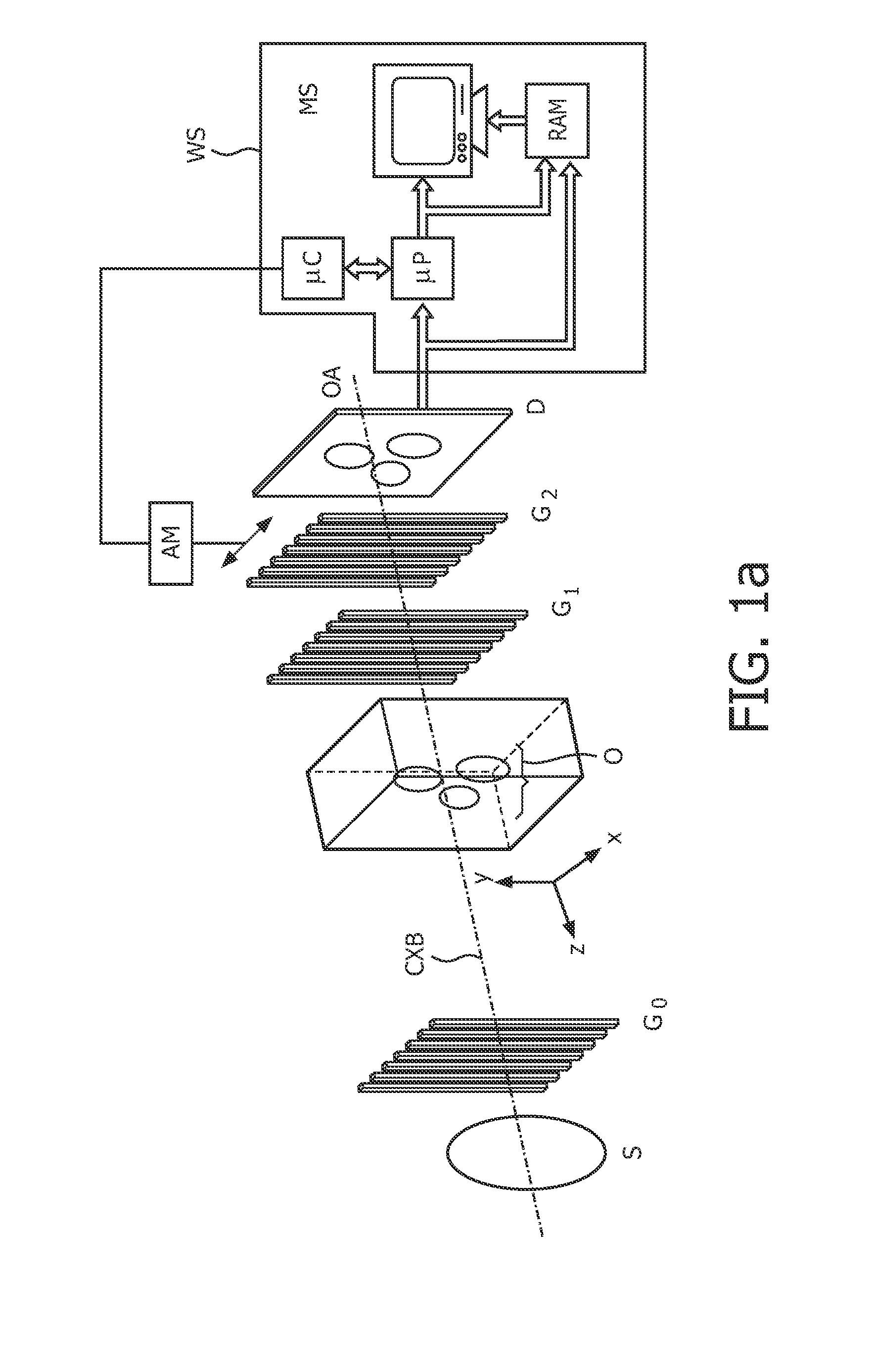

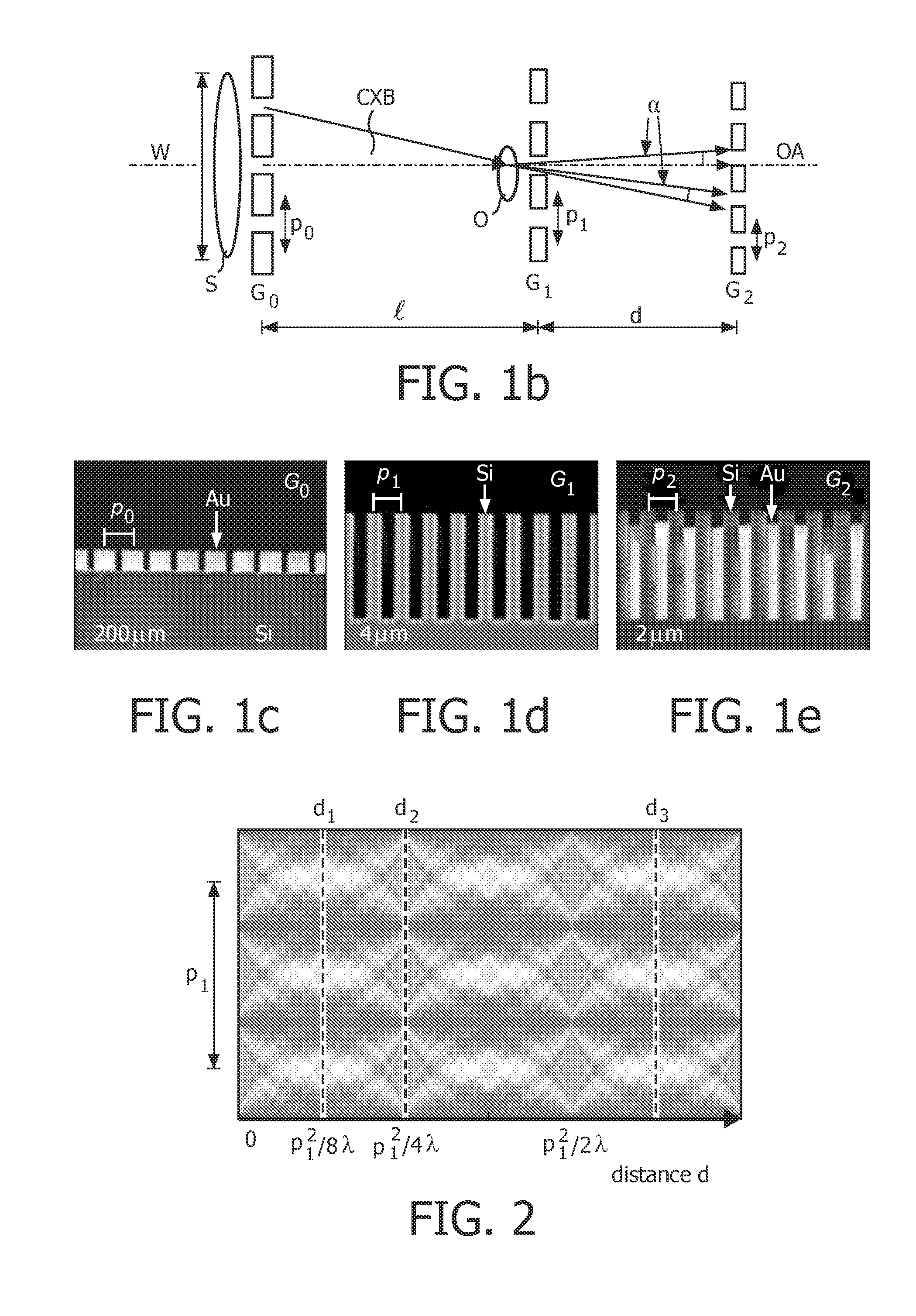

Correction method for differential phase contrast imaging

ActiveUS8855265B2Reduce impactImprove image qualityImaging devicesHandling using diffraction/refraction/reflectionHard X-raysBeam splitter

The present invention generally refers to a correction method for grating-based X-ray differential phase contrast imaging (DPCI) as well as to an apparatus which can advantageously be applied in X-ray radiography and tomography for hard X-ray DPCI of a sample object or an anatomical region of interest to be scanned. More precisely, the proposed invention provides a suitable approach that helps to enhance the image quality of an acquired X-ray image which is affected by phase wrapping, e.g. in the resulting Moiré interference pattern of an emitted X-ray beam in the detector plane of a Talbot-Lau type interferometer after diffracting said X-ray beam at a phase-shifting beam splitter grating. This problem, which is further aggravated by noise in the obtained DPCI images, occurs if the phase between two adjacent pixels in the detected X-ray image varies by more than π radians and is effected by a line integration over the object's local phase gradient, which induces a phase offset error of π radians that leads to prominent line artifacts parallel to the direction of said line integration.

Owner:KONINK PHILIPS ELECTRONICS NV

Correction method for differential phase contrast imaging

ActiveUS20120099702A1Good estimateImprove image qualityImaging devicesHandling using diffraction/refraction/reflectionHard X-raysBeam splitter

The present invention generally refers to a correction method for grating-based X-ray differential phase contrast imaging (DPCI) as well as to an apparatus which can advantageously be applied in X-ray radiography and tomography for hard X-ray DPCI of a sample object or an anatomical region of interest to be scanned. More precisely, the proposed invention provides a suitable approach that helps to enhance the image quality of an acquired X-ray image which is affected by phase wrapping, e.g. in the resulting Moiré interference pattern of an emitted X-ray beam in the detector plane of a Talbot-Lau type interferometer after diffracting said X-ray beam at a phase-shifting beam splitter grating. This problem, which is further aggravated by noise in the obtained DPCI images, occurs if the phase between two adjacent pixels in the detected X-ray image varies by more than π radians and is effected by a line integration over the object's local phase gradient, which induces a phase offset error of π radians that leads to prominent line artifacts parallel to the direction of said line integration.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

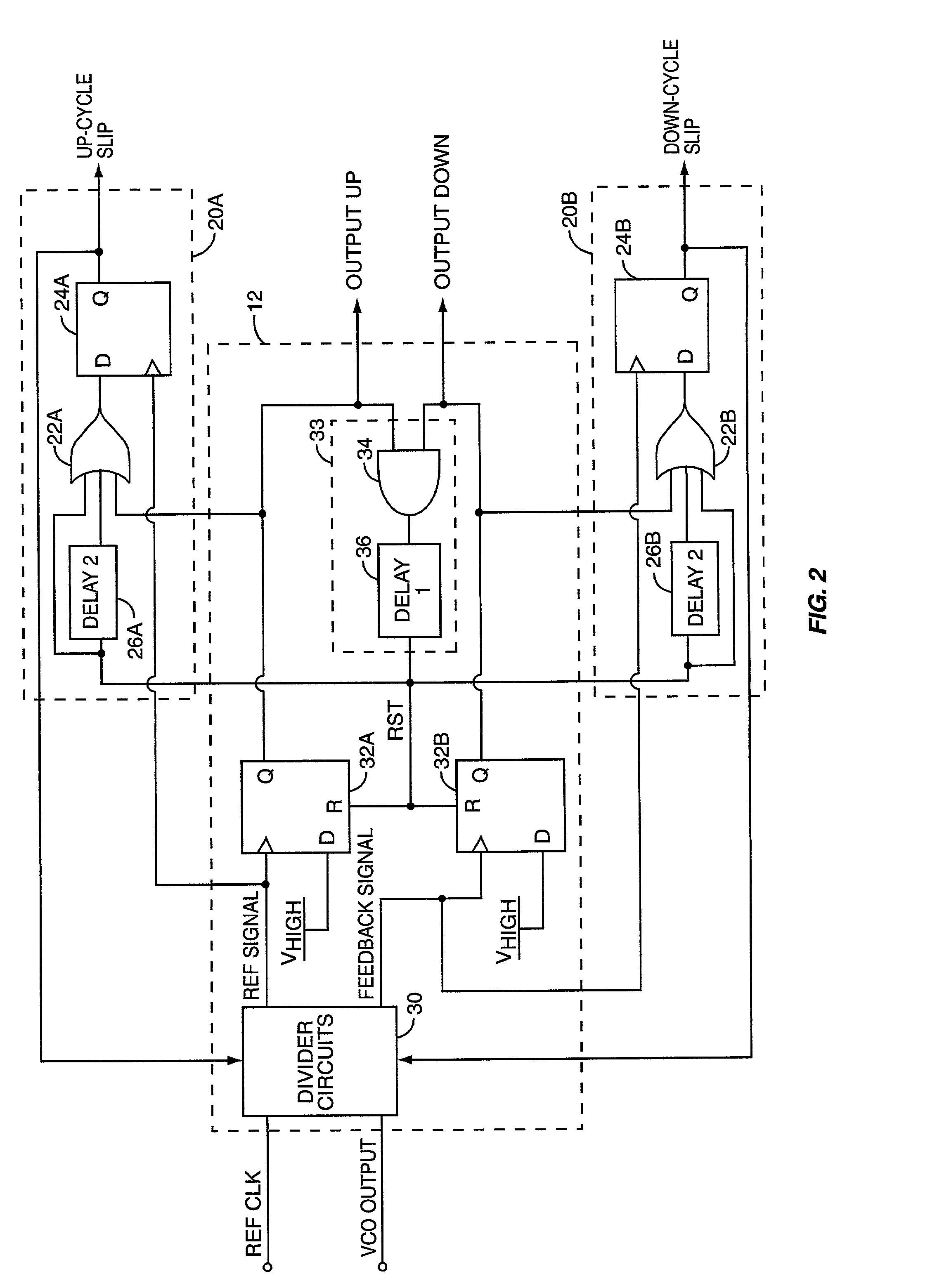

PLL cycle slip detection

InactiveUS7003065B2Pulse automatic controlVoltage-current phase angleControl signalPhase locked loop circuit

A cycle slip detector interfaces with a phase / frequency detector (PFD), such as might be used in a phase-locked loop circuit (PLL), and indicates when cycle slips occur in the PFD. Typically, the PFD generates output control signals as a function of the phase difference between first and second input signals, with the first input signal usually serving as a reference signal against which the PLL adjusts the second input signal. The PFD provides linear phase comparison between its input signals, provided their relative phase difference does not exceed ±2π radians. If one of the two signals leads or lags the other by more than that amount, a cycle slip occurs, and the PFD responds nonlinearly. The cycle slip detector provides logic for detecting and indicating leading and lagging cycle slips as they occur in the PDF, and is typically implemented as a minimal arrangement of logic gates and flip-flops.

Owner:ERICSSON INC

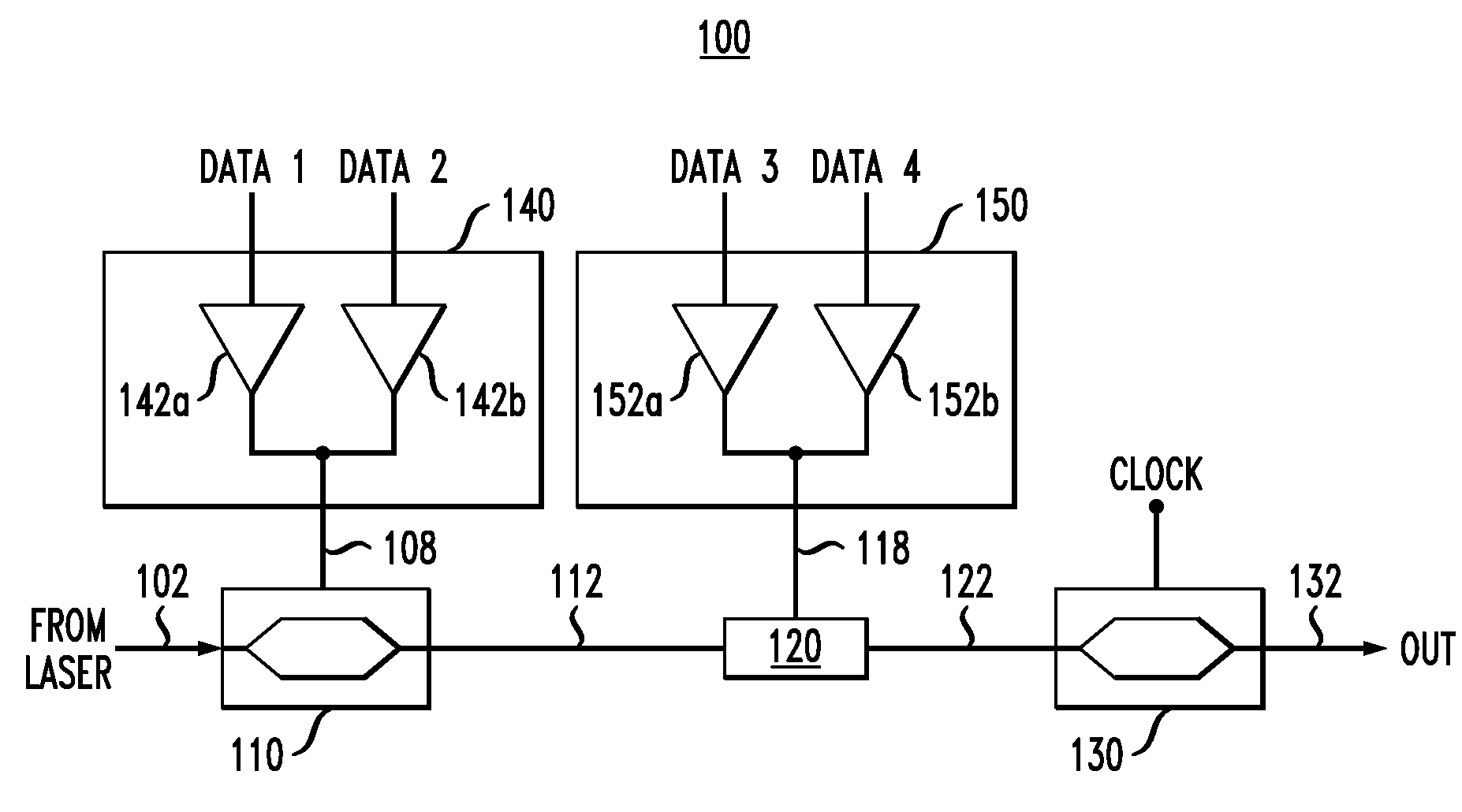

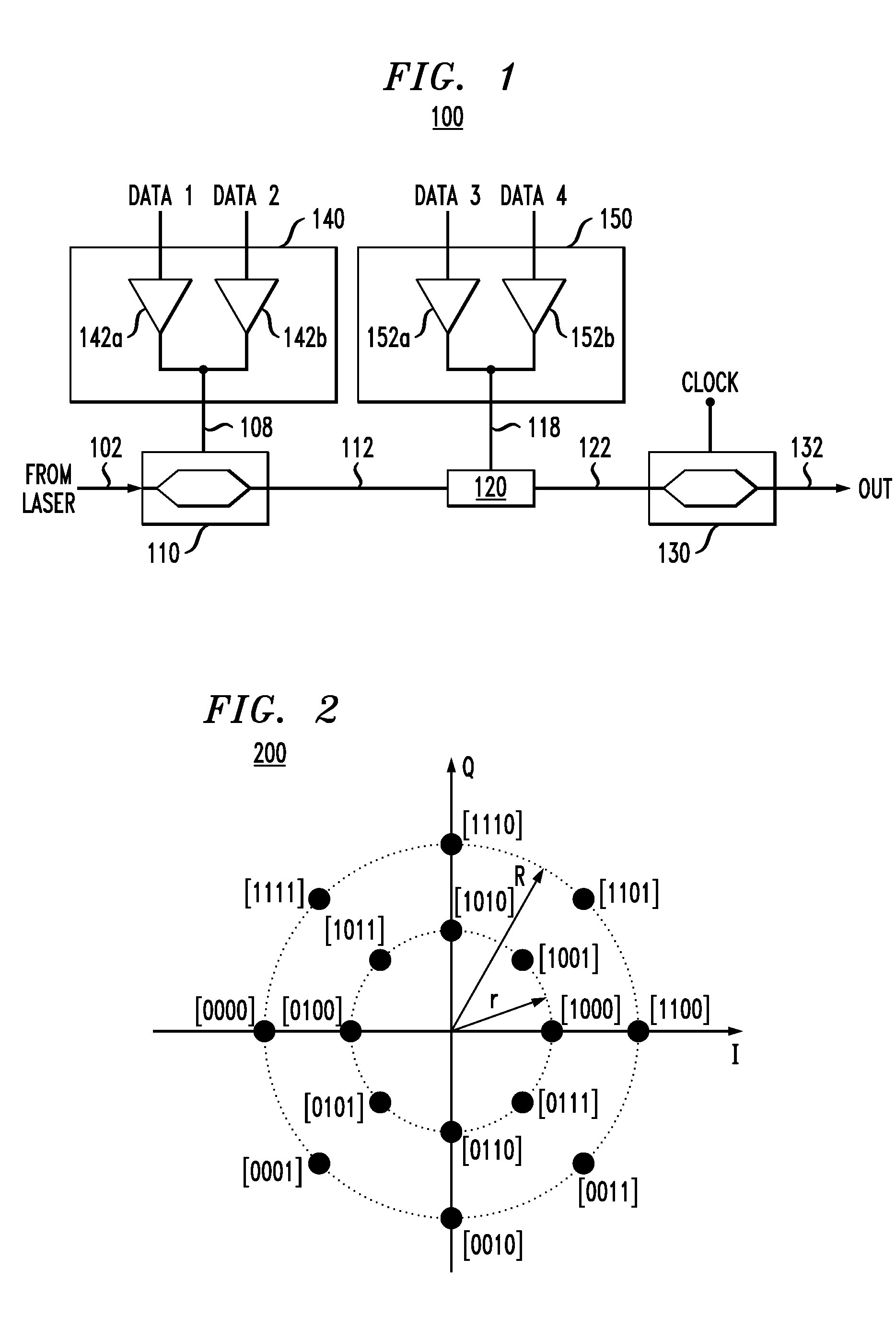

Optical modulator for higher-order modulation

According to one embodiment of the invention, a 16-QAM optical modulator has a Mach-Zehnder modulator (MZM) coupled to a drive circuit that drives the MZM based on two electrical binary signals. The output of the MZM corresponds to an intermediary constellation consisting of four constellation points arranged on a straight line in the corresponding in-phase / quadrature-phase (I-Q) plane. Two of these constellation points correspond to a zero phase, and the remaining two constellation points correspond to a phase of π radian. The 16-QAM optical modulator further has a phase shifter that modulates the output of the MZM based on two additional electrical binary signals. The resulting optical output signal corresponds to a star 16-QAM constellation, which is produced by incremental rotation of the intermediary constellation.

Owner:ALCATEL LUCENT SAS

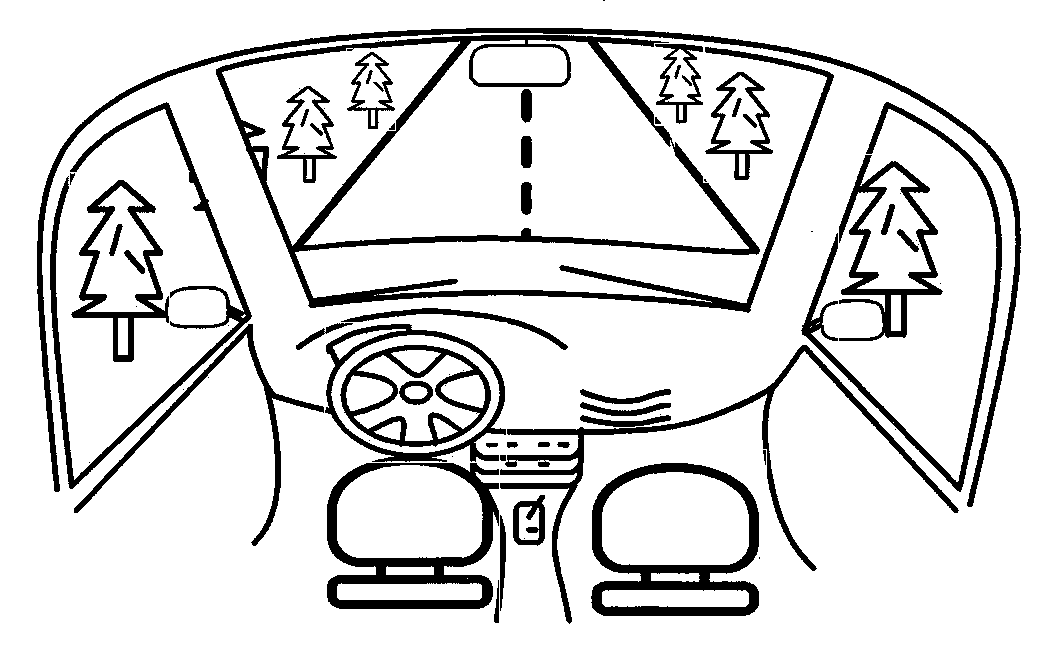

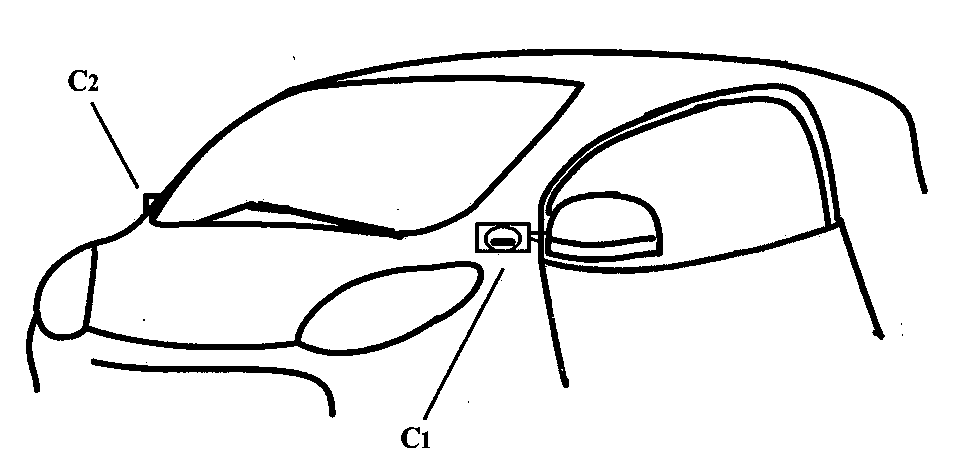

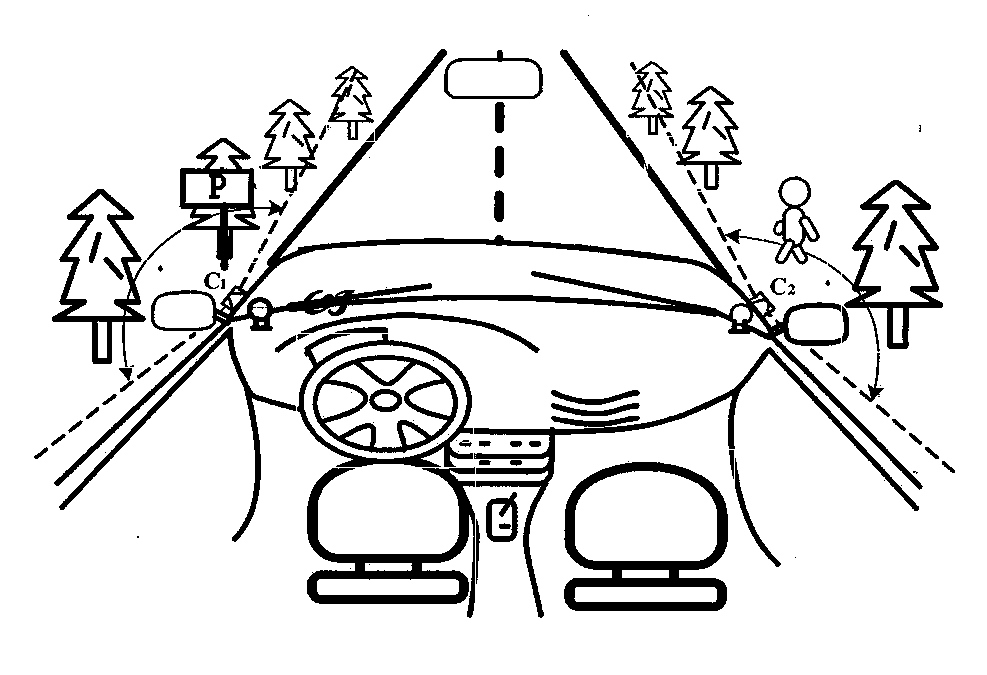

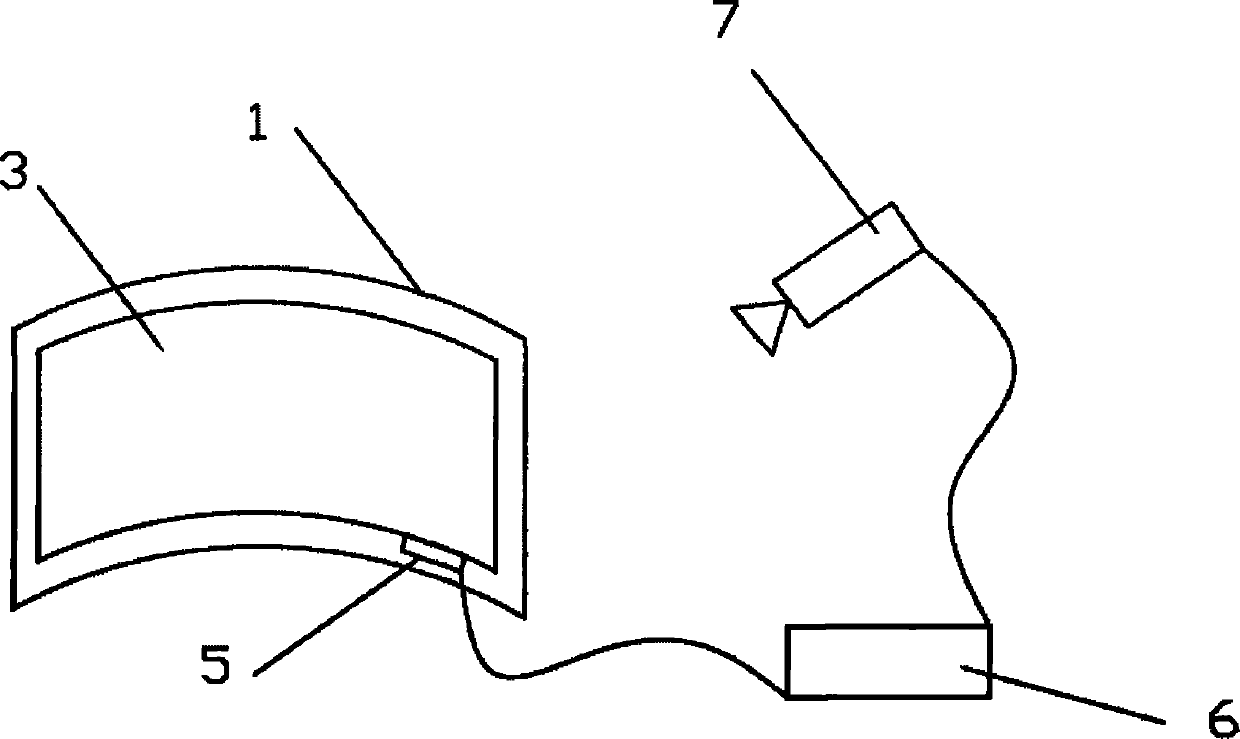

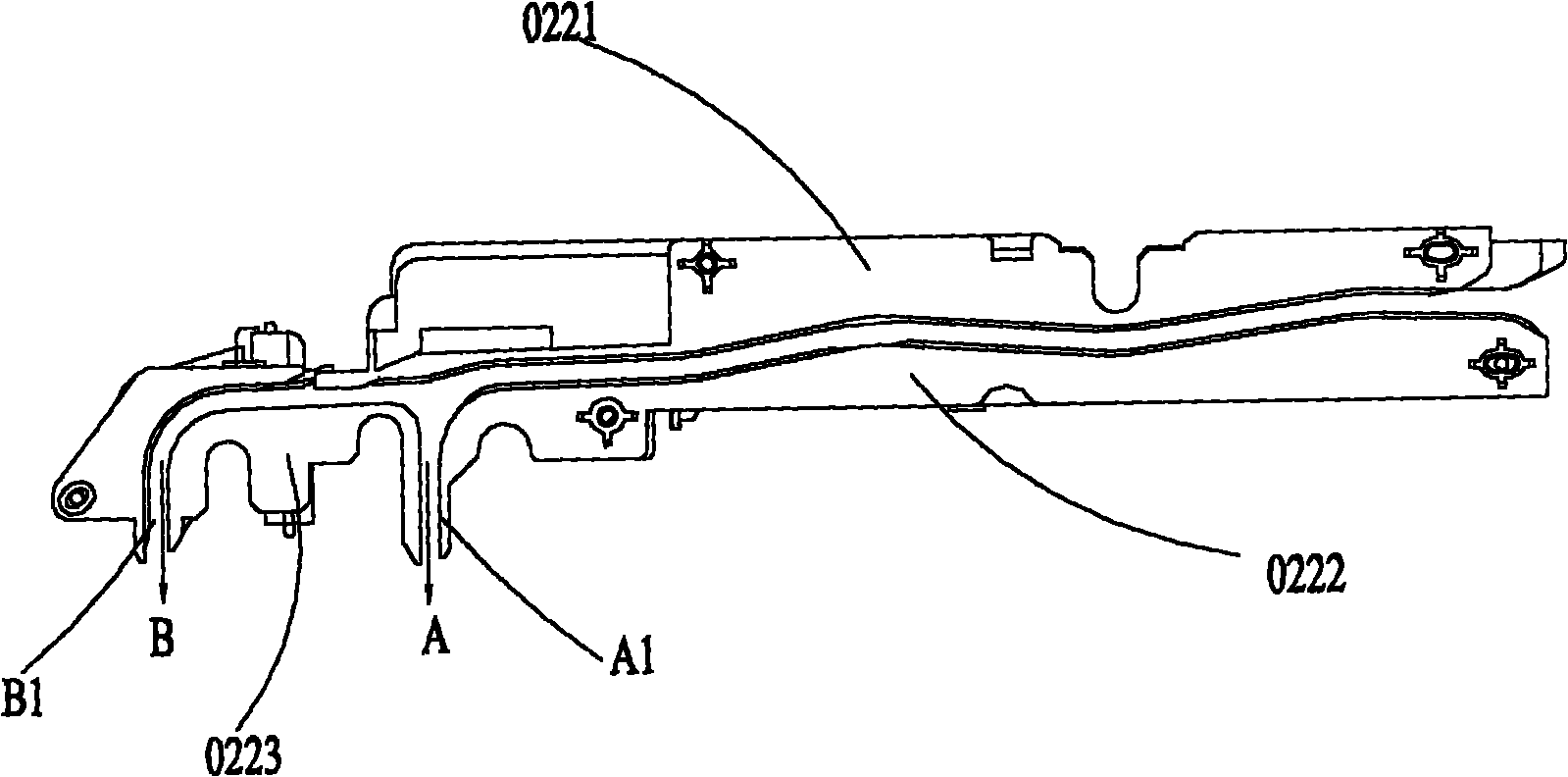

Automobile A pillar perspective vehicle-mounted display device

ActiveCN103358996ASolve occlusionEliminate the phenomenon of inconsistencyClosed circuit television systemsOptical viewingCar drivingLiquid-crystal display

The invention discloses an automobile A pillar perspective vehicle-mounted display device which reflects dynamic changes of driver sight angles. Cameras are arranged both inside an automobile and outside the automobile, the cameras outside the automobile are used for collecting surrounding sight information of a road ahead, and the cameras inside the automobile are used for obtaining driver vision information; according to driver sight concerning angles, images concerned by a driver are cut from images obtained by the cameras outside the automobile; flexible liquid crystal display screens are arranged on the inner side of an A pillar in an attaching mode according to the radian of the A pillar to display images; the images displayed on the flexible liquid crystal display screens inside the automobile are changed in real time according to driver sight angle change information collected by the cameras inside the automobile; the angle and the size of a driving scene image, collected by the cameras outside the automobile, at the position of a blind region are changed in real time, and an A pillar display system can be adjusted in a self-adaption mode according to sight needing regions detected through sight tracking. Therefore, external road traffic environment information which is more complete, more accurate and good in driver acceptability is provided for the driver, and the safety and the convenience of automobile driving are improved.

Owner:固安海高汽车技术有限公司

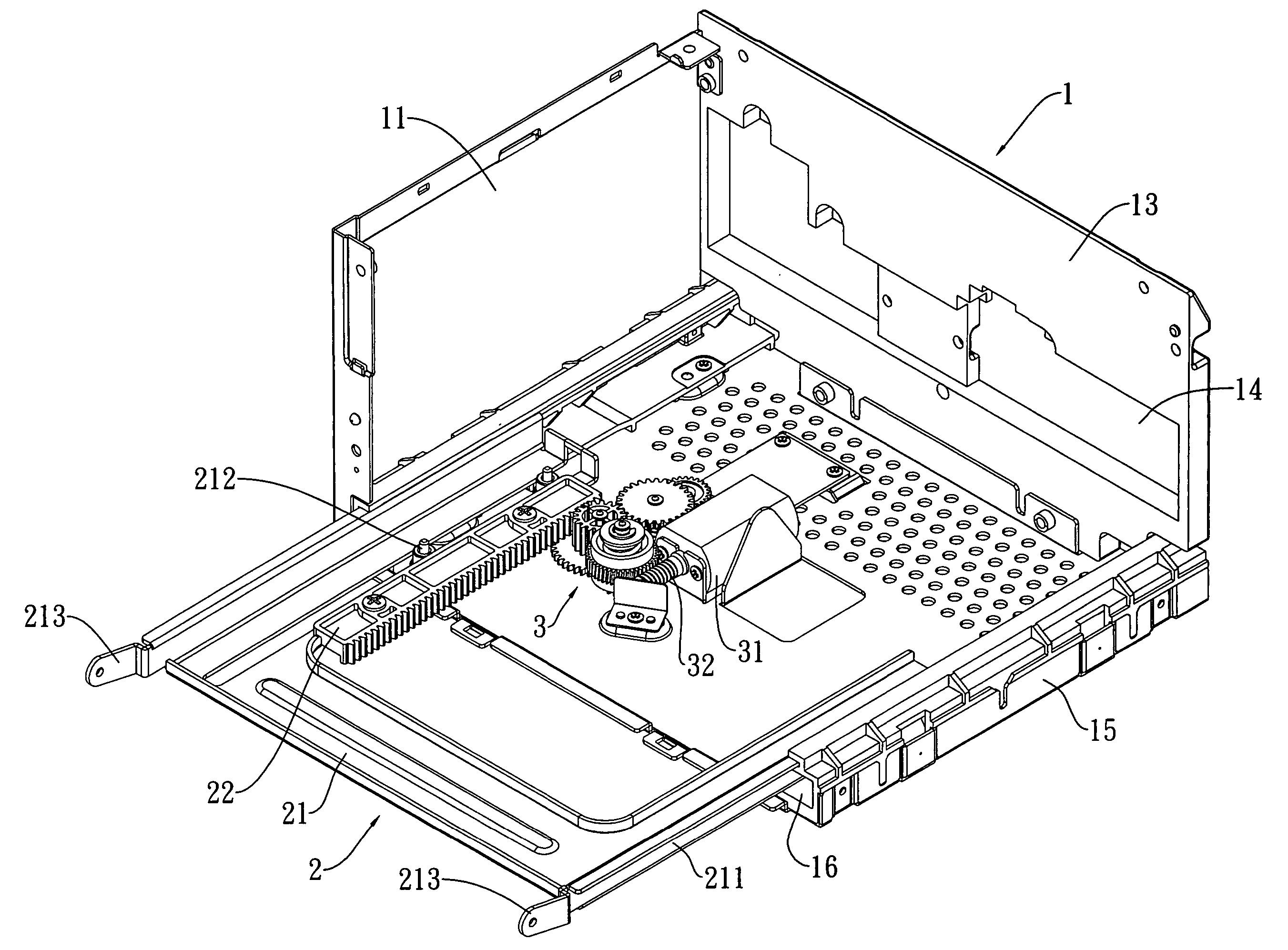

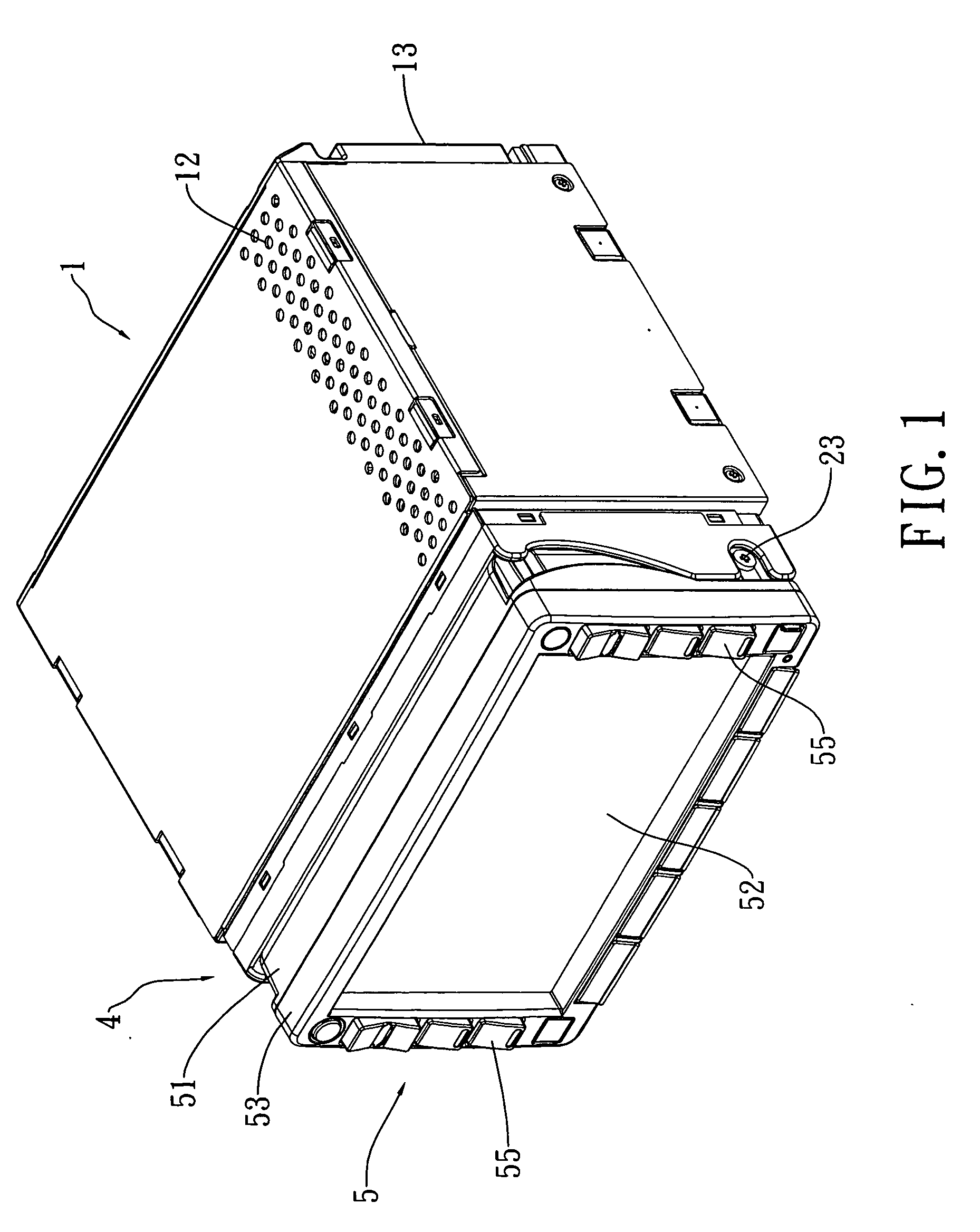

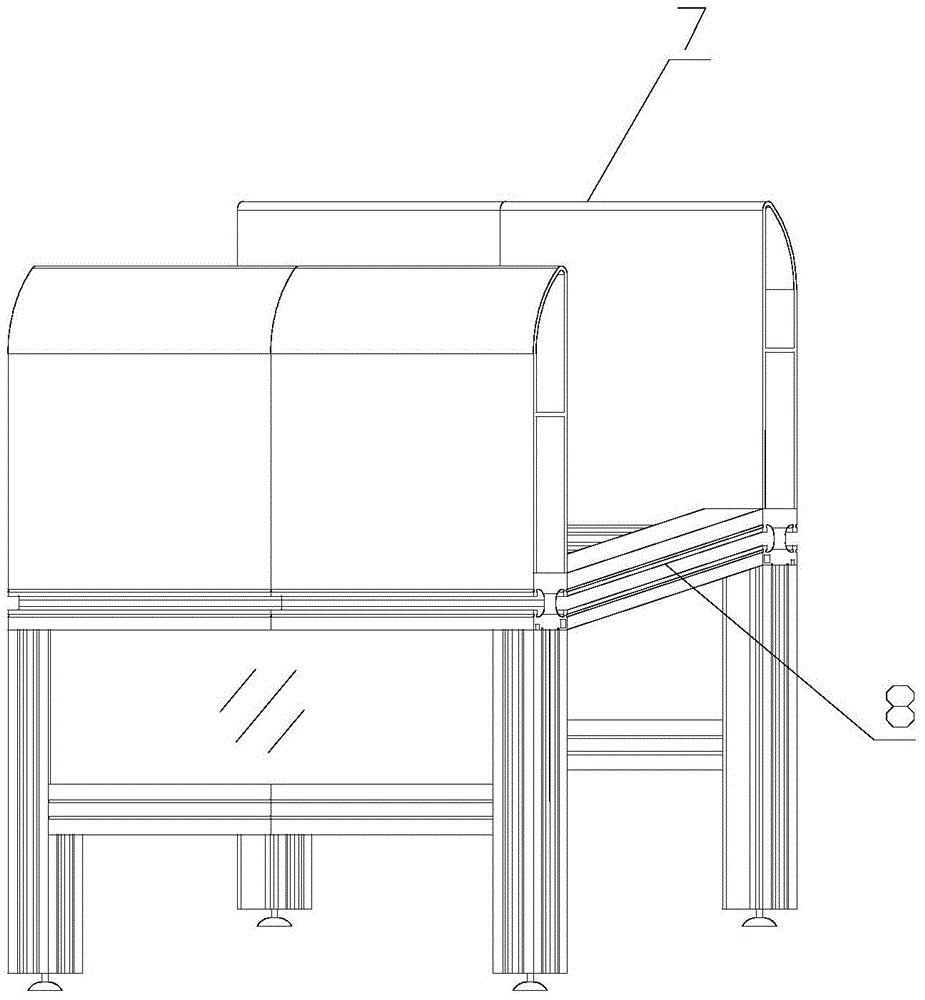

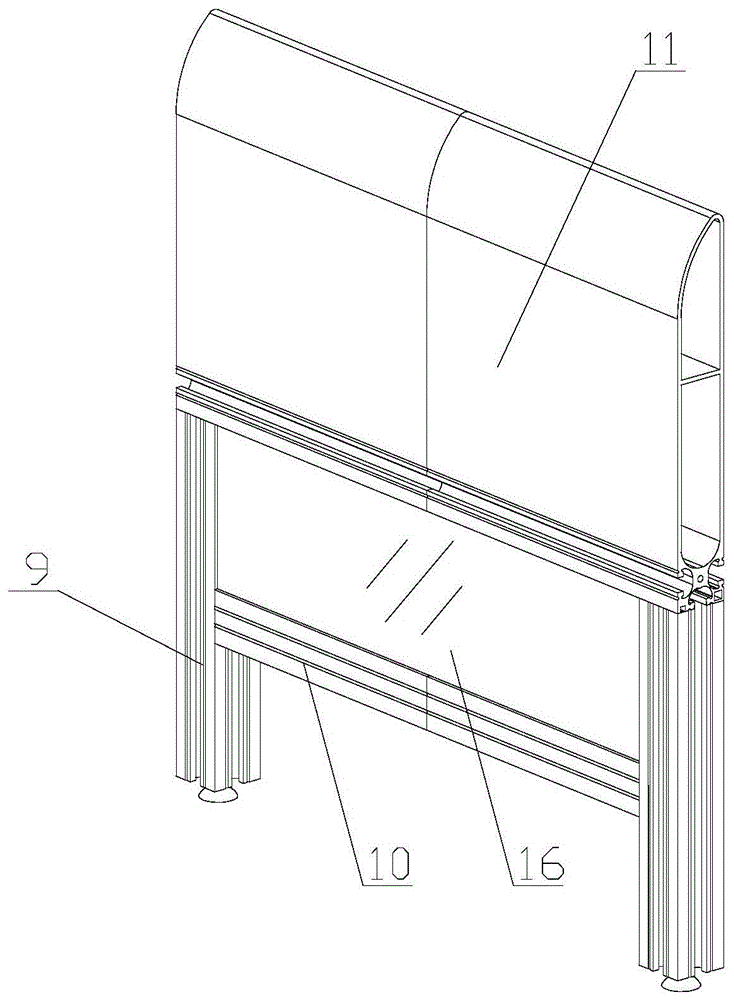

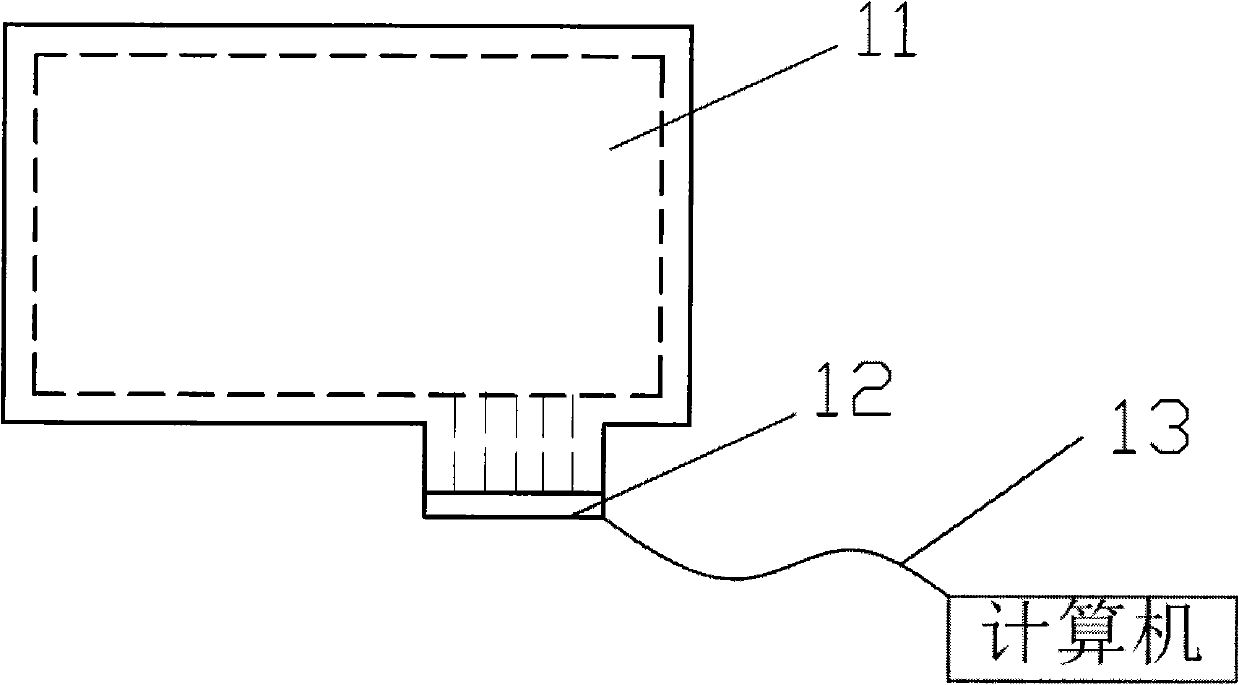

Automatic monitor sliding system

InactiveUS20070030647A1Inhibit inputHigh sliding radianRecord information storageGearing controlDisplay deviceEngineering

An automatic monitor sliding system comprises a machine case, a slidable structure, a monitor mounting plate, and a monitor structure. The slidable structure is mounted inside a reception chamber of the machine case. The monitor mounting plate is mounted in front of the machine case. The monitor structure is mounted in front of the monitor mounting plate. As a result, the slidable structure slides the monitor structure forward to slant the monitor structure downward for facilitating the user to insert and retrieve the audio-visual disk. Consequently, the automatic monitor sliding system provides the functions of protecting machine, preventing dust, water permeation, and mistouch input, and providing high sliding radian.

Owner:BCOM ELECTRONICS

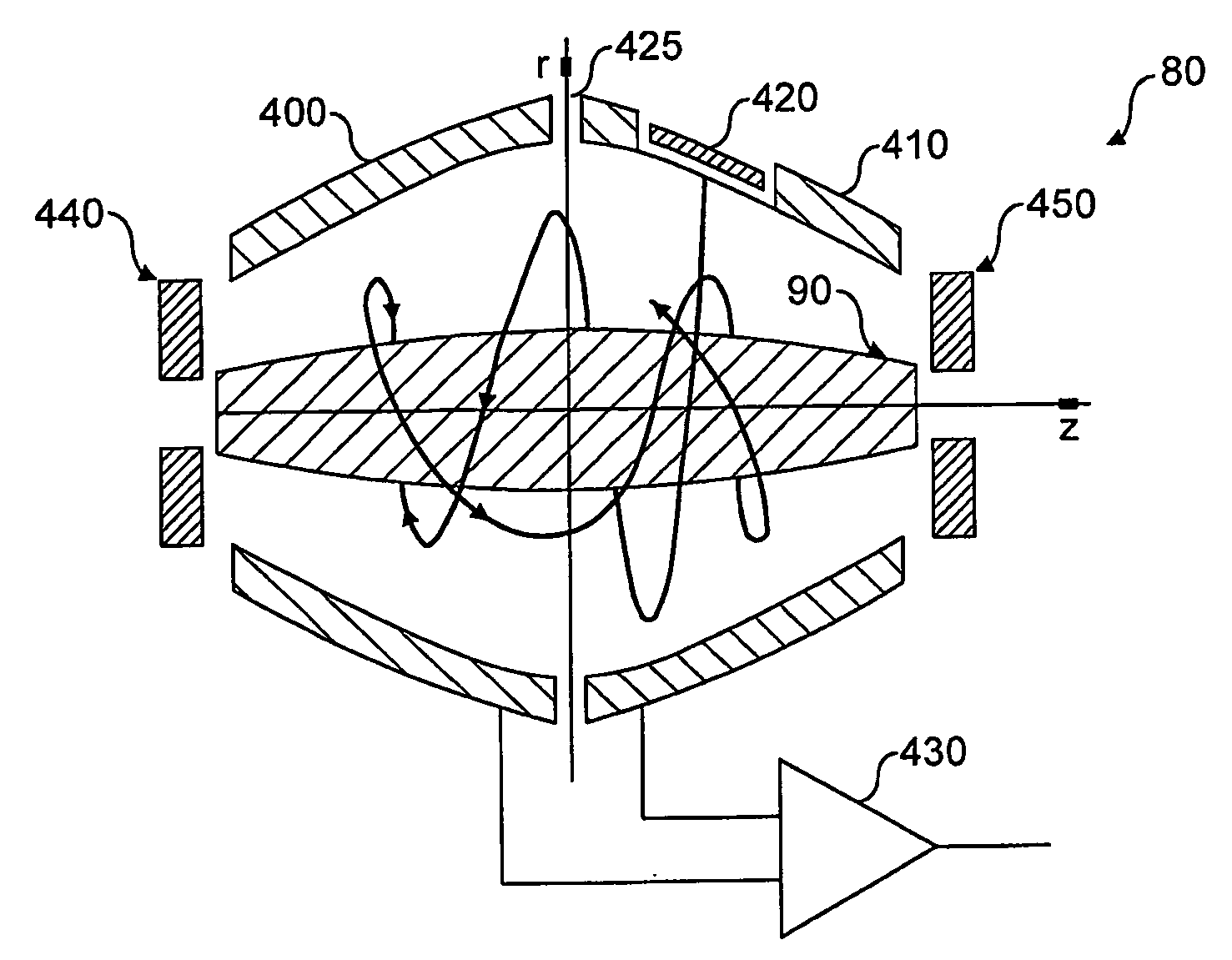

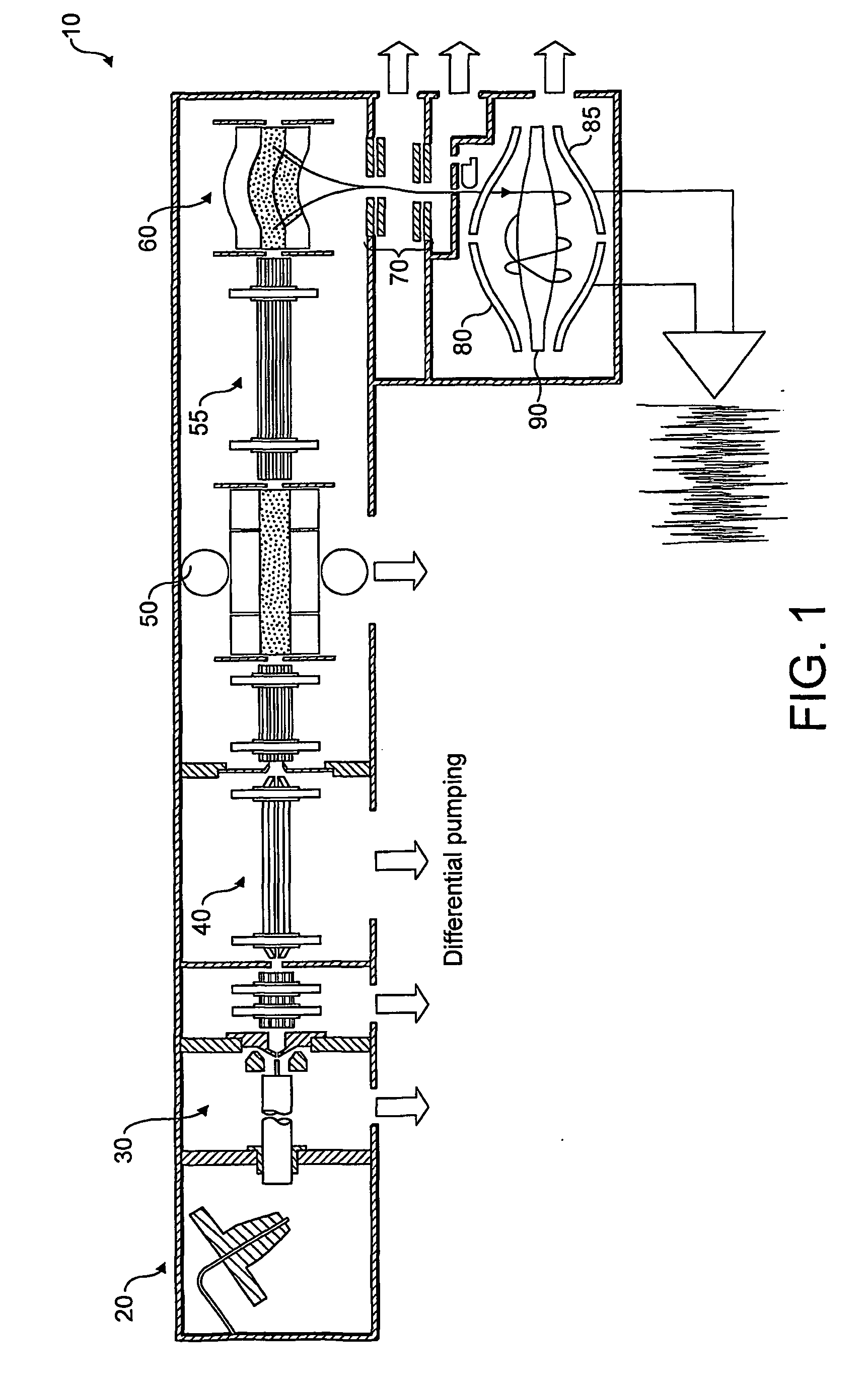

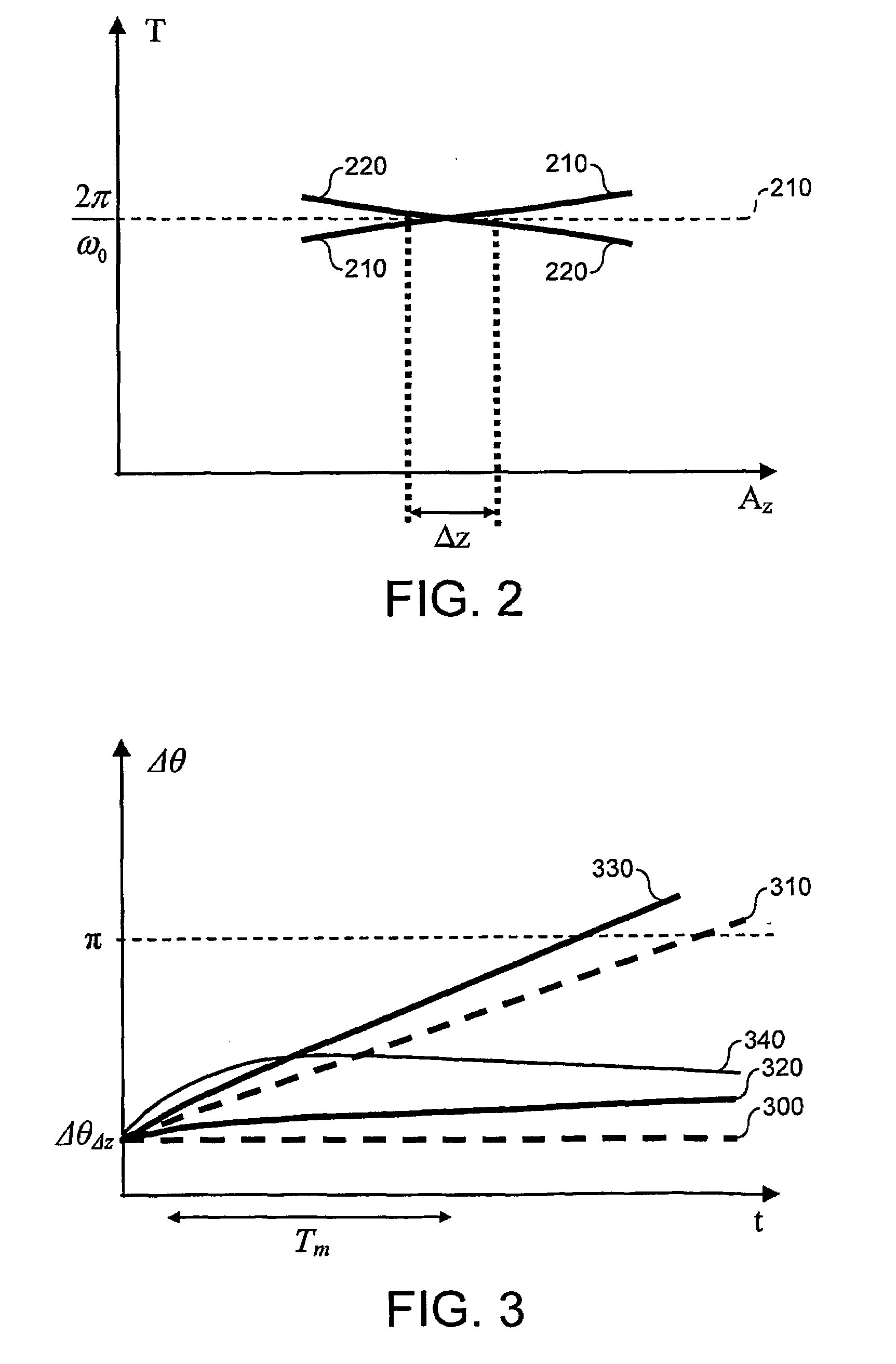

Electrostatic trap

An electrostatic trap such as an orbitrap is disclosed, with an electrode structure. An electrostatic trapping field of the form U′(r,φ,z) is generated to trap ions within the trap so that they undergo isochronous oscillations. The trapping field U′(r, φ,z) is the result of a perturbation W to an ideal field U(r, φ,z) which, for example, is hyperlogarithmic in the case of an orbitrap. The perturbation W may be introduced in various ways, such as by distorting the geometry of the trap so that it no longer follows an equipotential of the ideal field U(r, φ,z), or by adding a distortion field (either electric or magnetic). The magnitude of the perturbation is such that at least some of the trapped ions have an absolute phase spread of more than zero but less than about 2π radians over an ion detection period Tm.

Owner:THERMO FINNIGAN

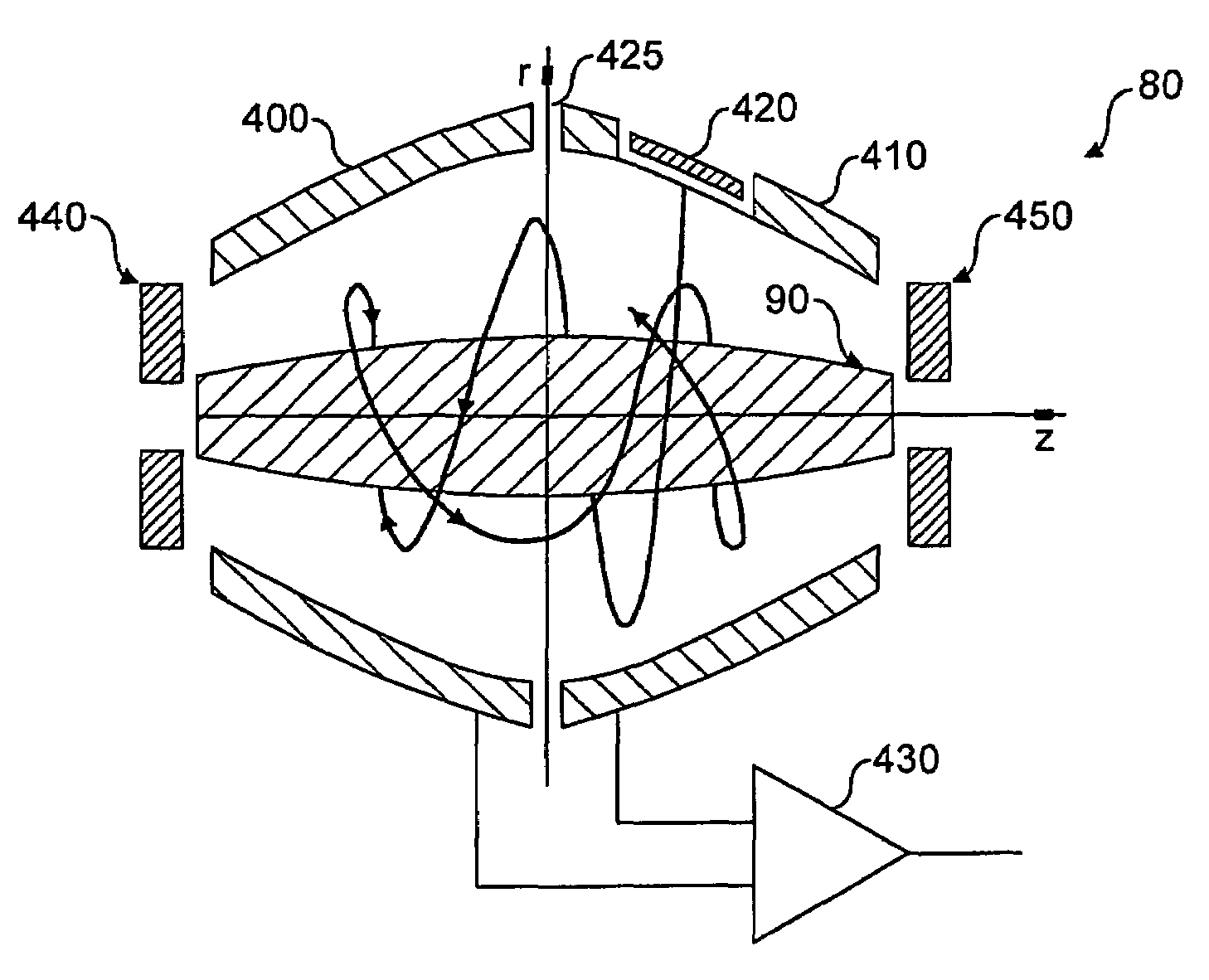

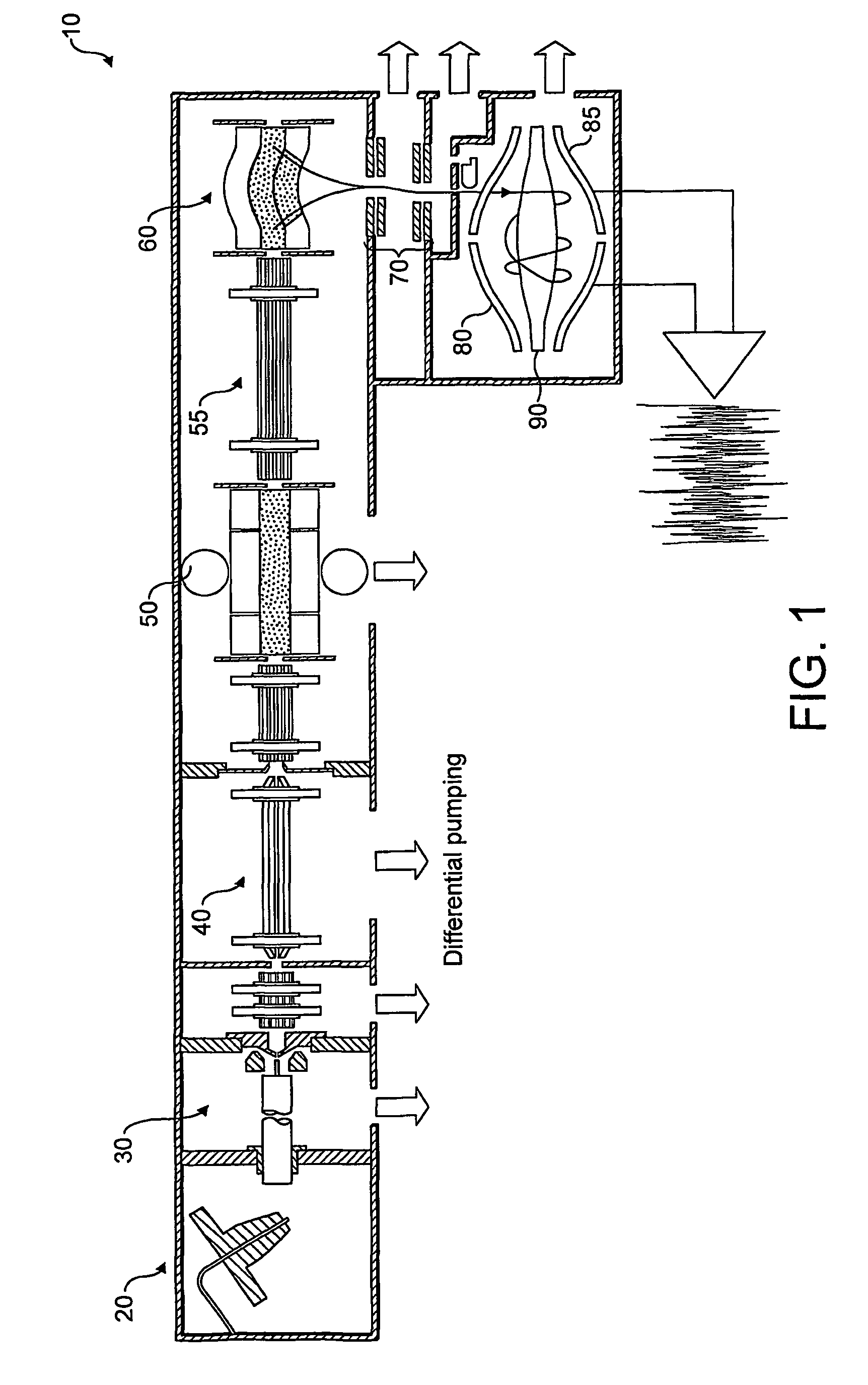

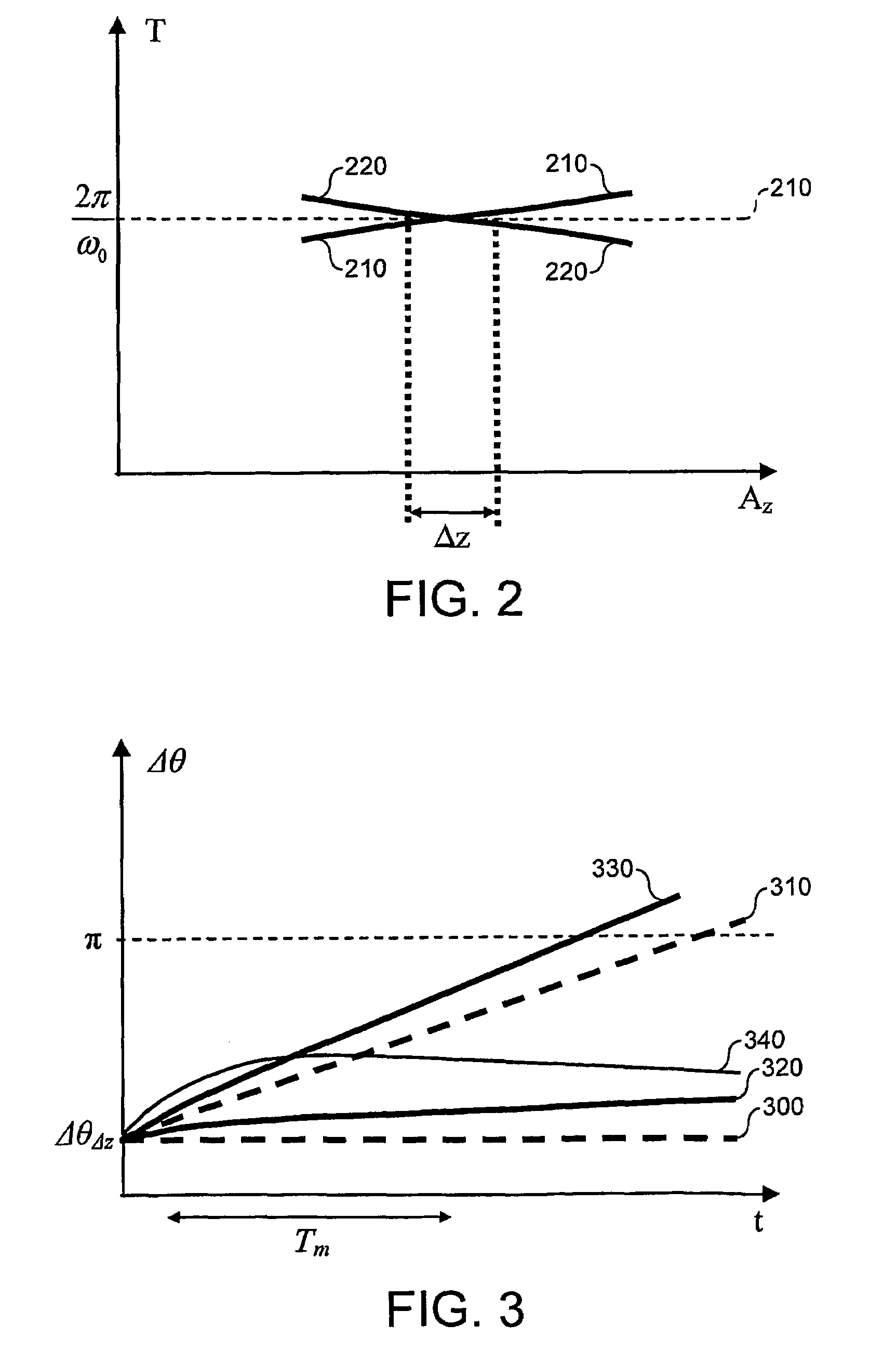

Electrostatic Trap

ActiveUS20080315080A1Growth be constrainStability-of-path spectrometersParticle spectrometer methodsTrappingEquipotential

An electrostatic trap such as an orbitrap is disclosed, with an electrode structure. An electrostatic trapping field of the form U′(r,φ,z) is generated to trap ions within the trap so that they undergo isochronous oscillations. The trapping field U′(r, φ,z) is the result of a perturbation W to an ideal field U(r, φ,z) which, for example, is hyperlogarithmic in the case of an orbitrap. The perturbation W may be introduced in various ways, such as by distorting the geometry of the trap so that it no longer follows an equipotential of the ideal field U(r, φ,z), or by adding a distortion field (either electric or magnetic). The magnitude of the perturbation is such that at least some of the trapped ions have an absolute phase spread of more than zero but less than about 2π radians over an ion detection period Tm.

Owner:THERMO FINNIGAN

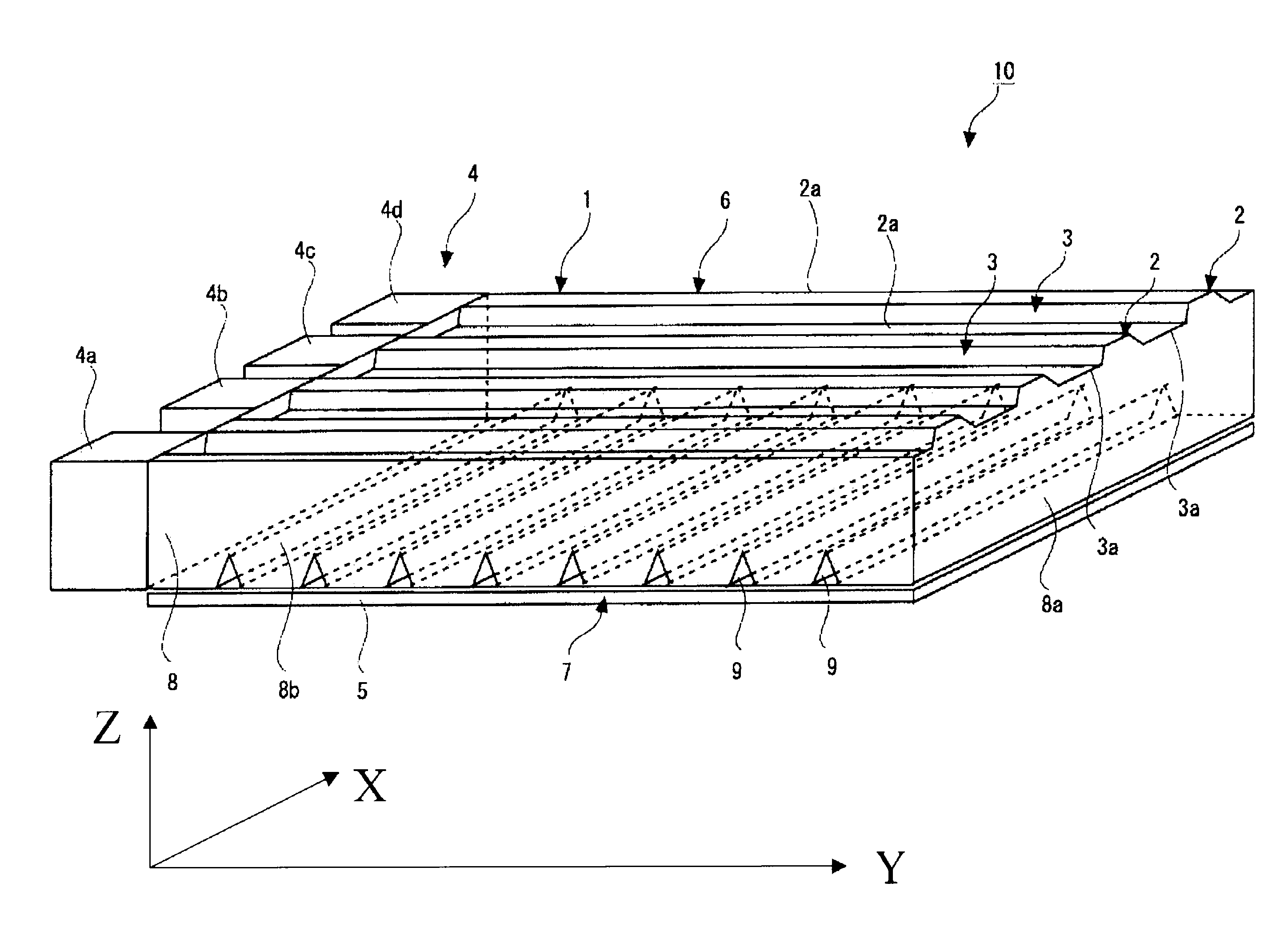

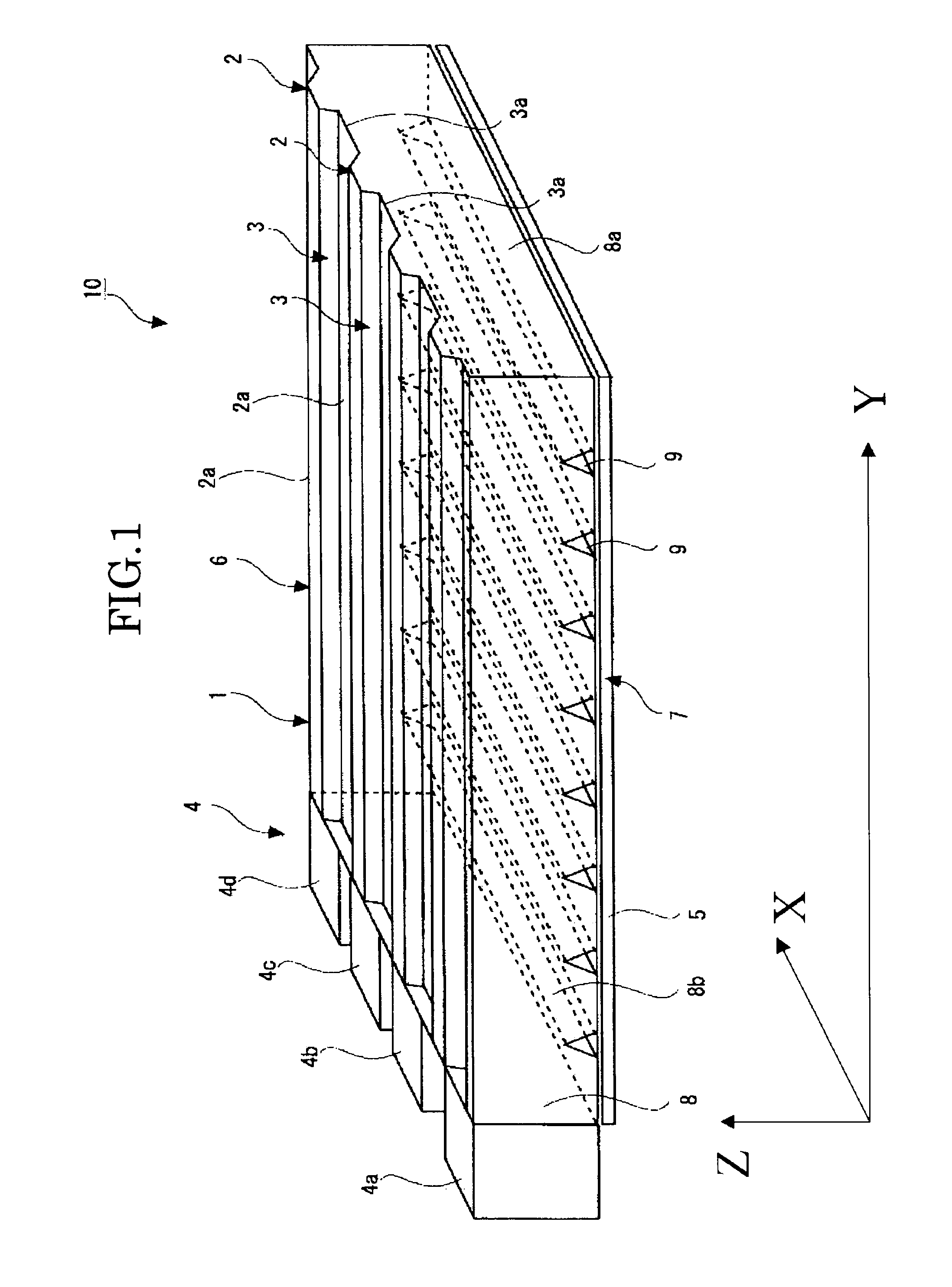

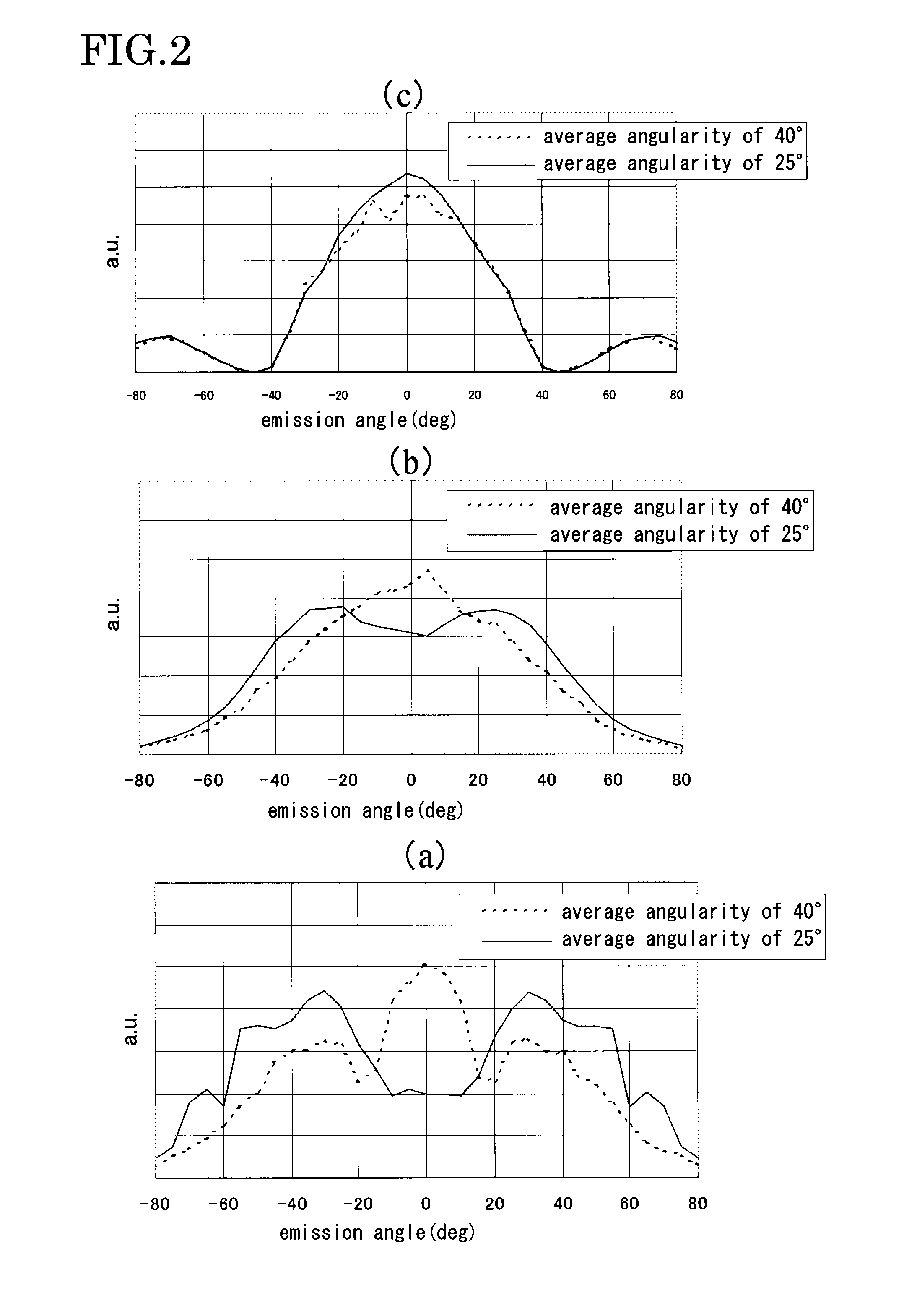

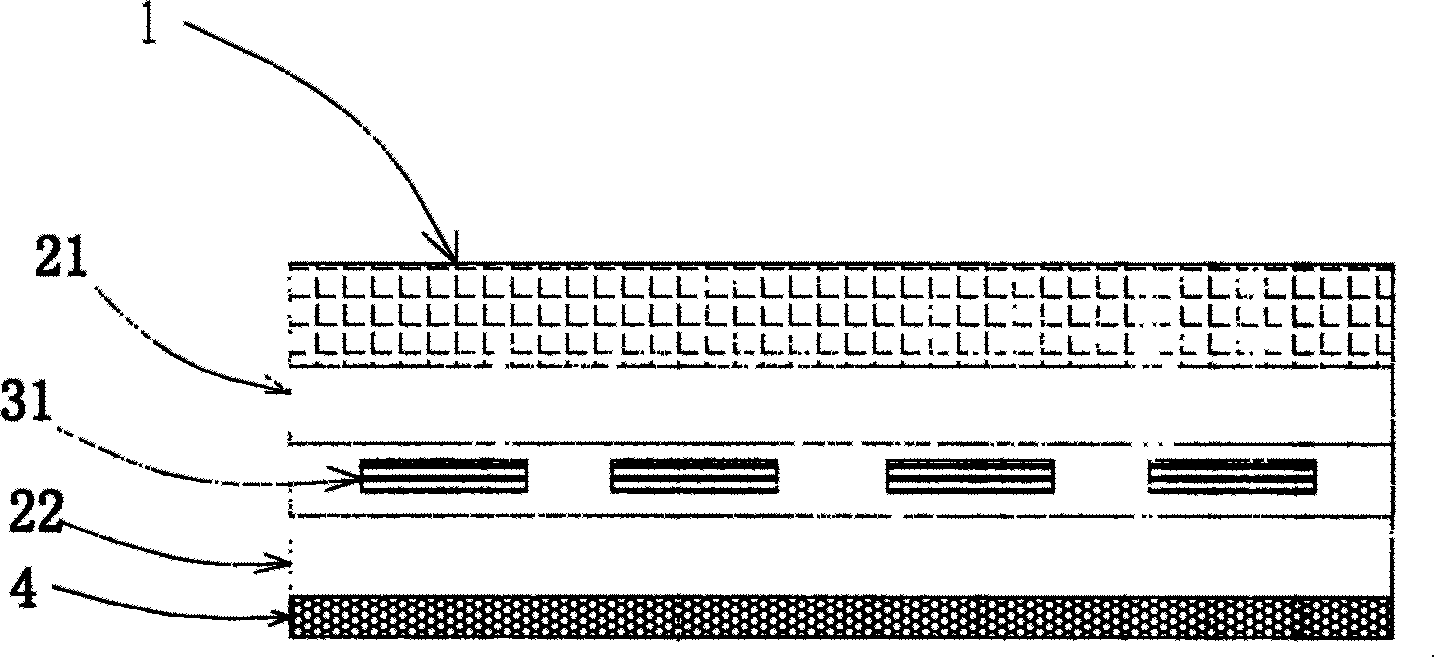

Surface light source element and image display including the same

InactiveUS20110255304A1Increase front brightnessRemarkable effectOptical light guidesReflectorsLight guideRefractive index

The present invention is objected to improve brightness in a front direction in a surface light source element including a light-guiding plate having a primary light source at least one side surface, a reflector and a prism sheet. In the surface light source element using the light-guiding plate (1) including a concave stripe (9) on a bottom surface (7) side, in order to emit light in the front direction after passing through the prism sheet of an optical sheet above the light-guiding plate (1), an average angularity R of an inclined surface of the concave stripe (9) to the bottom surface of the light-guiding plate is within the range described by the following condition,R≦[π / 2−sin−1(0.422 / nLGP)] / 2R≧sin−1(1 / nLGP)−sin−1(0.643 / nLGP)R: the average angularity (radian) to the bottom surface of the light-guiding plate (1),nLGP: a refractive index of a base material of the light guiding plate (1).

Owner:KURARAY CO LTD

Switching method of working modes of flexible screen and mobile terminal of flexible screen

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

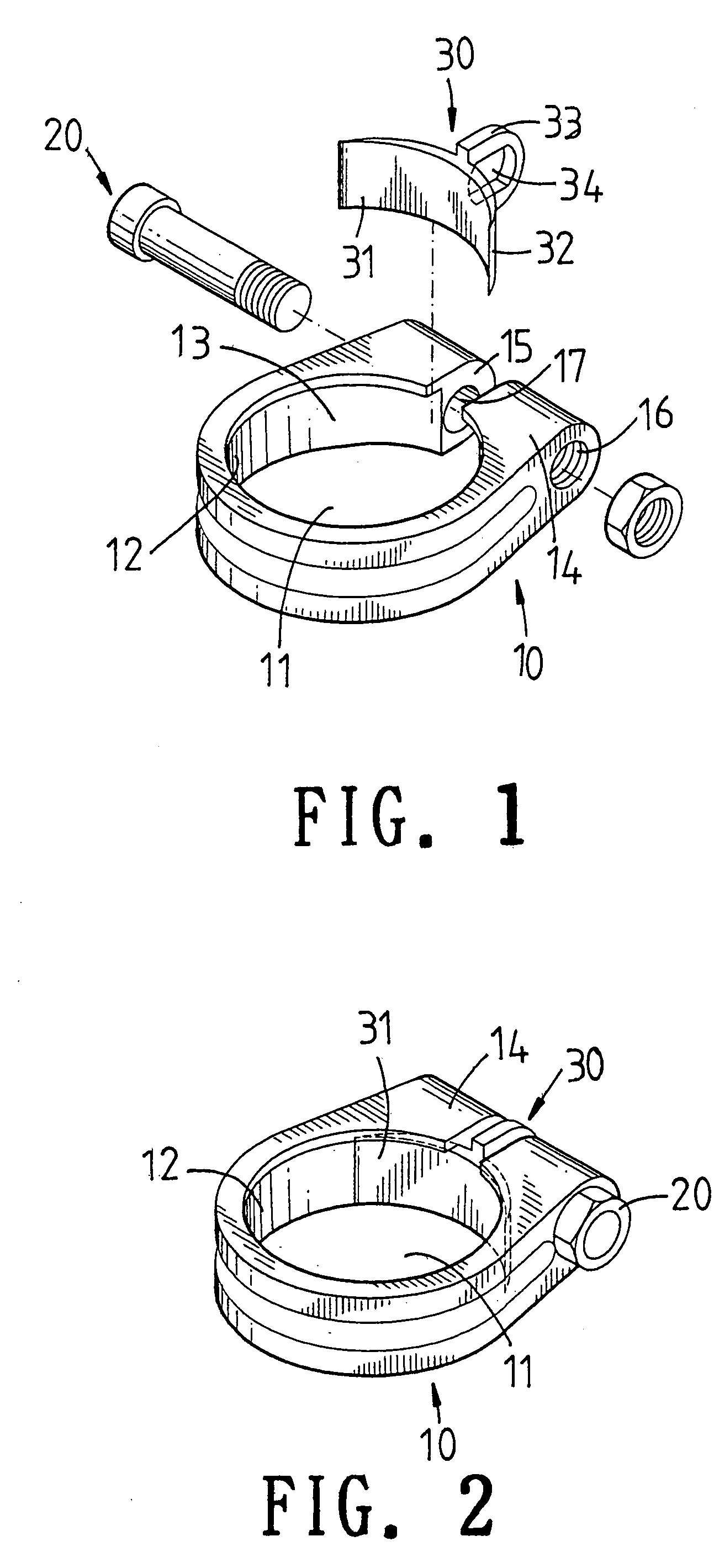

Tube retainer

InactiveUS6896438B1Easy to understandRod connectionsCouplings for rigid shaftsEngineeringScrew thread

A tube retainer comprises a tube body; a center of the tube body being formed with a receiving space; the receiving space being formed by a large cambered surface and a small cambered surface; one end of the tube body being formed with a tightening portion; the tightening portion being formed with a slot communicated with the receiving space and the outside of the tube body; a hole being formed in the tube body and the hole passing through the slot; a pad having a cambered surface which has the same radian as that of the receiving space; a protrusion protruding from the outer cambered surface; the protrusion having a through hole for retaining the screw fastener. The receiving space has a large cambered surface and a small cambered surface. A threaded hole is formed in the tightening portion and at one side of the through the slot and a via hole is formed in the tightening portion and at another side of the slot. The small cambered surface is at the tightening portion and is adhered to the pad.

Owner:CHEN CHAO HU

Flexible display panel and display device

InactiveCN110518039AAvoid failureEasy to bendSolid-state devicesIdentification meansDisplay deviceEngineering

The invention discloses a flexible display panel and a display device. A plurality of bending adjustment patterns are arranged in a bending area, and each bending adjustment pattern is composed of a groove and / or an opening in at least one film layer. Moreover, the total area of the bending adjustment patterns far away from the center line is made to be greater than the total area of the bending adjustment patterns close to the center line, the bending stress can be dispersed in the direction from the center line to the non-bending area in the bending process, and therefore, the area, far awayfrom the center line, of the bending area can be bent more easily than the area, close to the center line, of the bending area. In the way, the radian of the bending area in the bending state can beincreased, the bending radius of the center line of the bending area in the bending state is increased, and the problem that the flexible display panel fails due to excessive bending in the bending process can be avoided.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

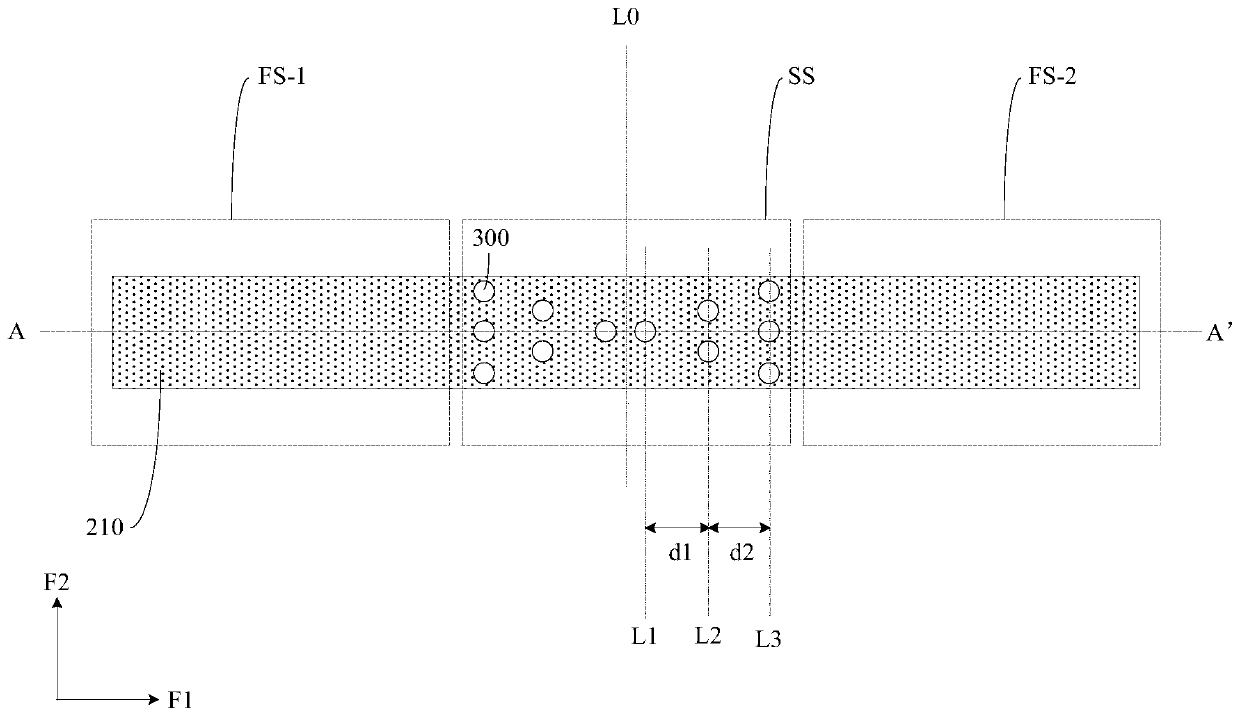

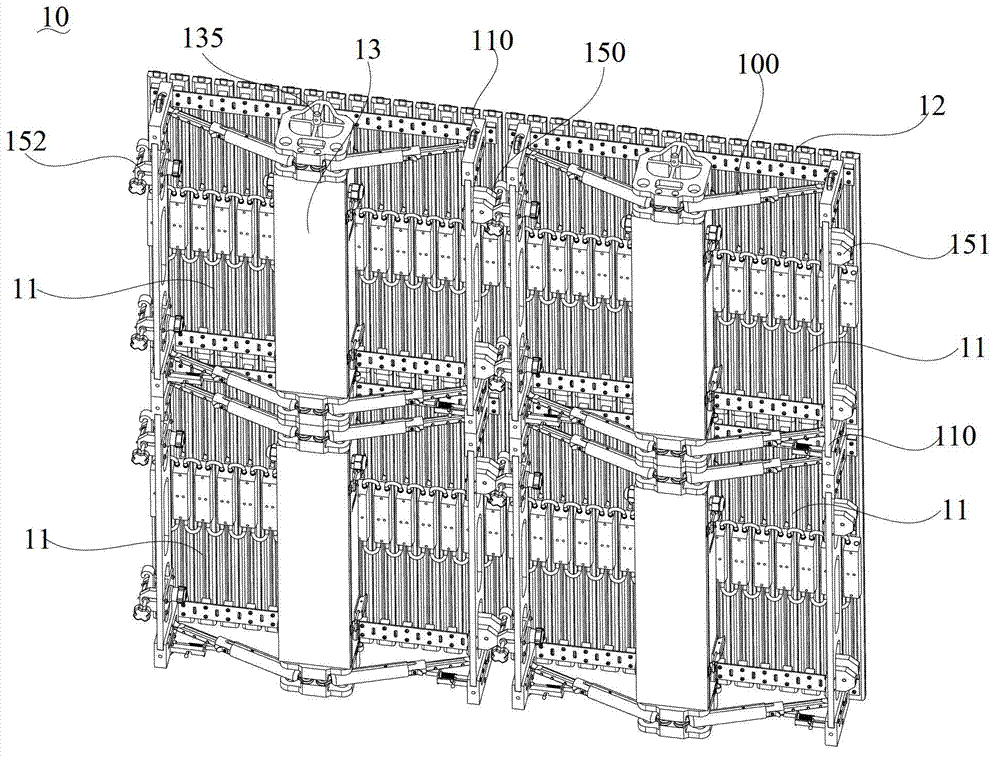

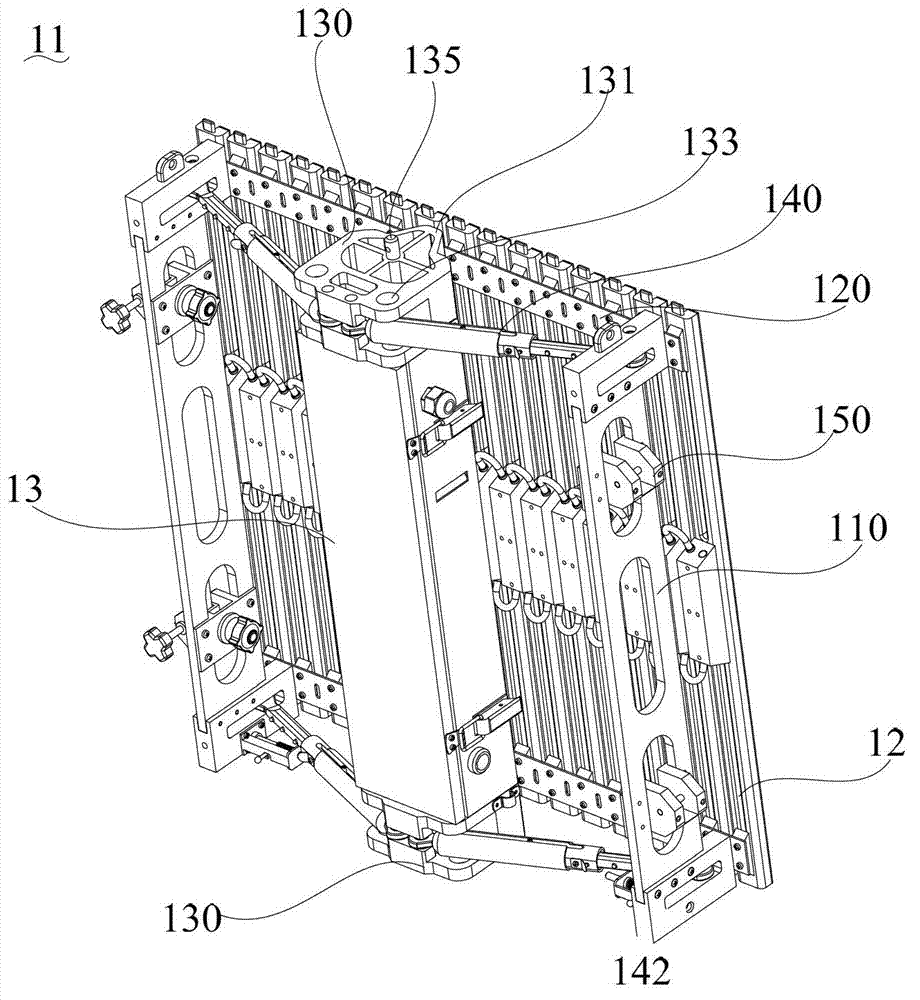

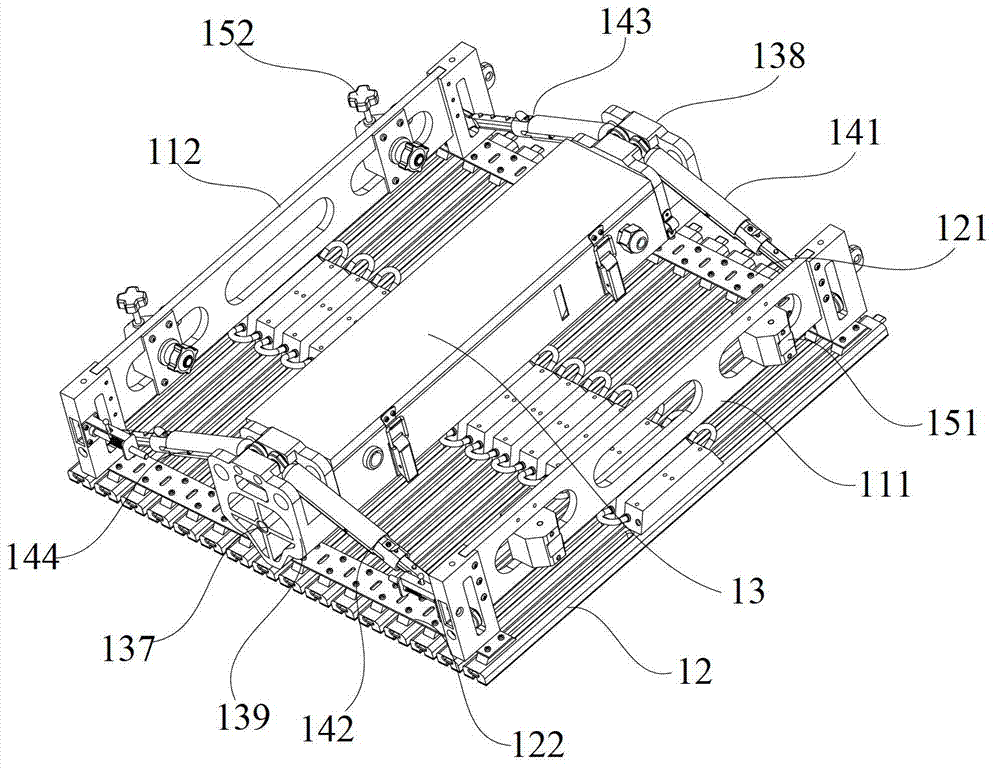

Display screen unit bracket, display screen unit and display screen box

InactiveCN102829305AImprove the display effectFlexible and diverse shapesStands/trestlesIdentification meansEngineeringRadian

The invention relates to a display screen unit bracket which comprises a frame, an elastic connector, a supporting platform and an adjusting element, wherein the elastic connector is of long and narrow shape; one end of the elastic connector is connected with the frame; the supporting platform is connected with the other end of the elastic connector; one end of the adjusting element is rotatably connected with the frame while the other end is rotatably connected with the supporting platform; a distance between the frame and the supporting platform is adjusted by the adjusting element, so as to bend the elastic connector; when the elastic connector is bent, a lamp strip component is bent following the elastic connector because the lamp strip component is arranged on the elastic connector, and a certain radian is formed by the lamp strip component; the certain radian is formed by the lamp strip component by adjusting the length of the adjusting element; and display screens of display screen boxes in different shapes can be formed by connecting a plurality of lamp strip components with certain radians in different modes. The invention also provides a display screen unit and a display screen box containing the display screen unit.

Owner:SHENZHEN TOP TECH

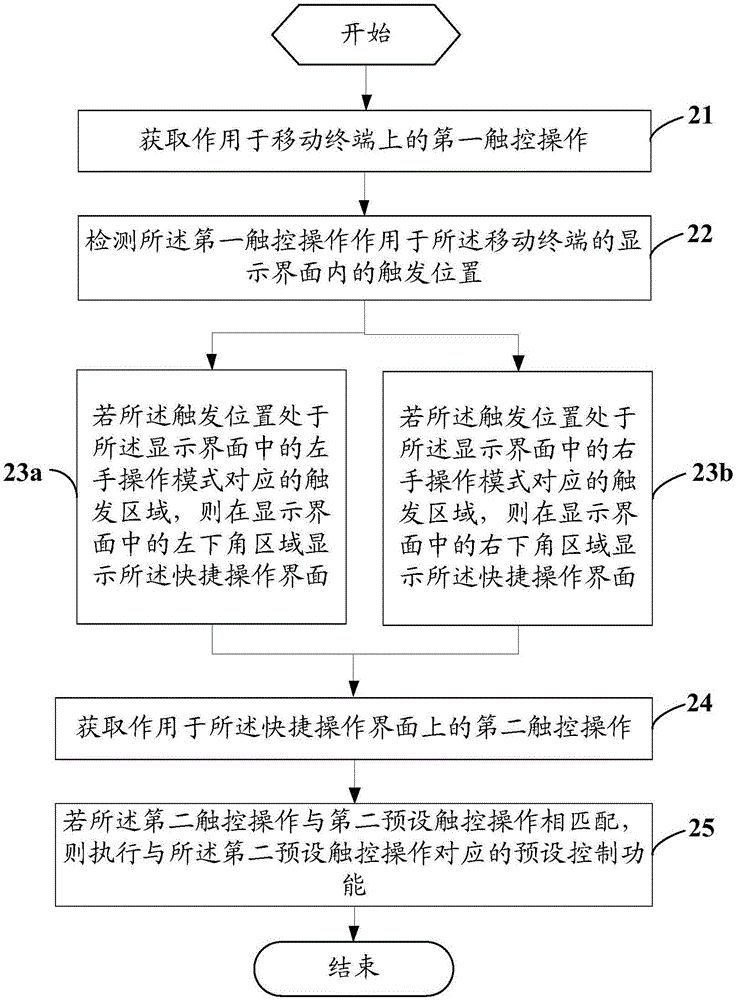

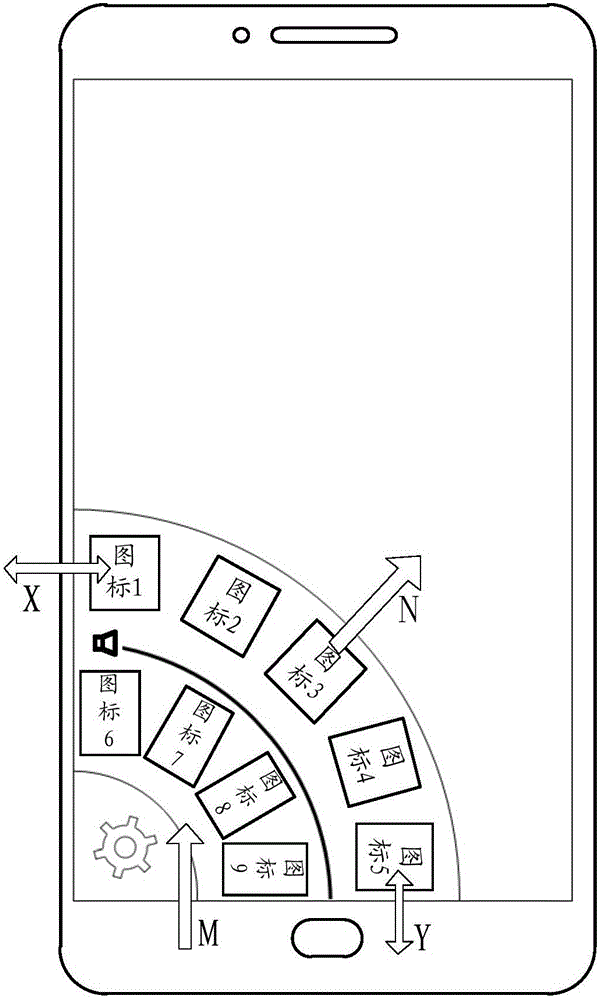

Display control method of mobile terminal and mobile terminal

ActiveCN106843739AImprove experienceIncrease profitSubstation equipmentInput/output processes for data processingComputer terminalComputer science

The invention discloses a display control method of a mobile terminal and the mobile terminal. The method comprises the steps as follows: first touch operation acting on the mobile terminal is acquired; if the first touch operation is matched with first preset touch operation, a fan-shaped shortcut operation interface is displayed on a display interface, multiple arc-shaped operation zones are sequentially arranged from the arc-shaped edge of the shortcut operation interface to the center direction, and at least one operable icon set according to the bending radian of the arc-shaped operation zone is arranged in each arc-shaped operation zone; second touch operation acting on the shortcut operation interface is acquired; if the second touch operation is matched with second preset touch operation, a preset control function corresponding to the second preset touch operation is executed. The fan-shaped shortcut operation interface increases the utilization rate of space, single-hand operation is facilitated, the operation manner is simple, and user experience is facilitated.

Owner:VIVO MOBILE COMM CO LTD

Developing device and image forming method using one component developer, and process cartridge using the developing device

InactiveUS20080227009A1Electrographic process apparatusElectrographic processes using charge patternWaxImage formation

A developing device including a developing roller and a developer layer forming member for forming a layer of a one component developer on the roller. The developing device satisfies the relationships (1) 20<X<65−14α, and (2) 12.7α−25>Q / M>13.1α−44.5, wherein X represents the ratio (% by weight) of the wax present on the surface of the developer to the total of the wax therein; α represents the angle formed by a tangent line to the member at a point B, which is the center of the contact zone of the member contacted with the roller, and another tangent line at a point A thereof 0.5 mm apart from the point B toward the tip of the member, wherein α is 0 to π / 2 radian; and Q / M represents the charge quantity (μC / g) of the toner per unit weight.

Owner:RICOH KK

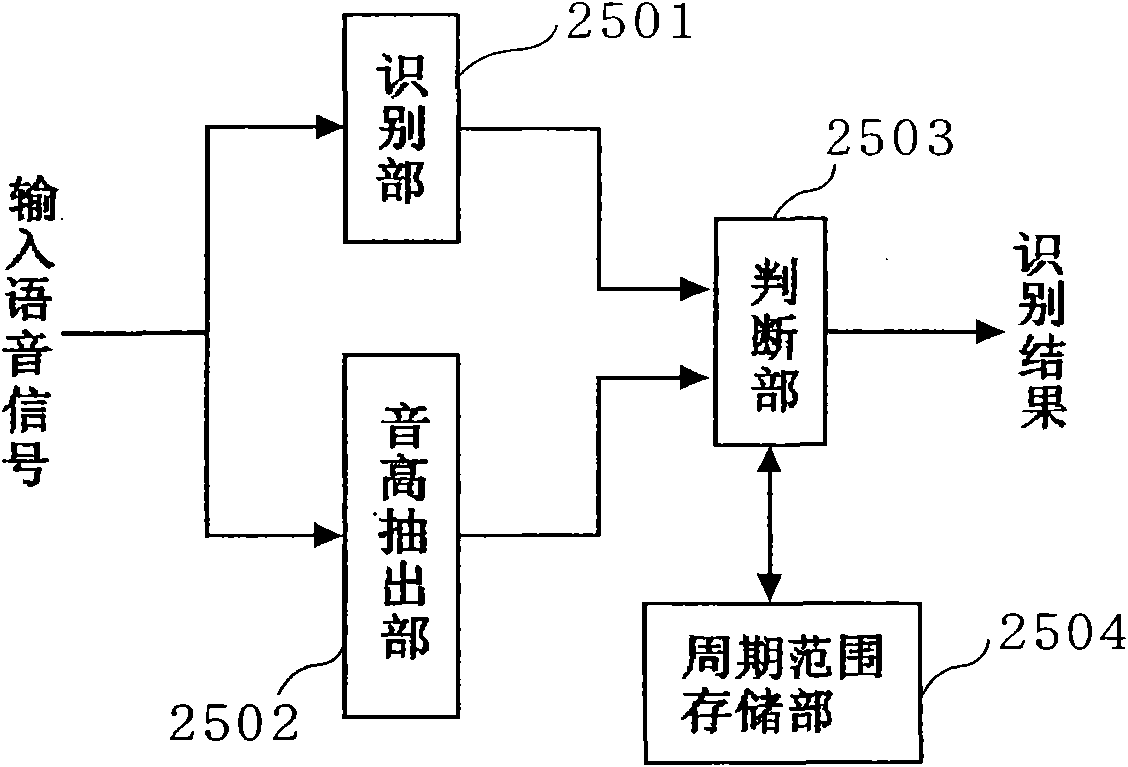

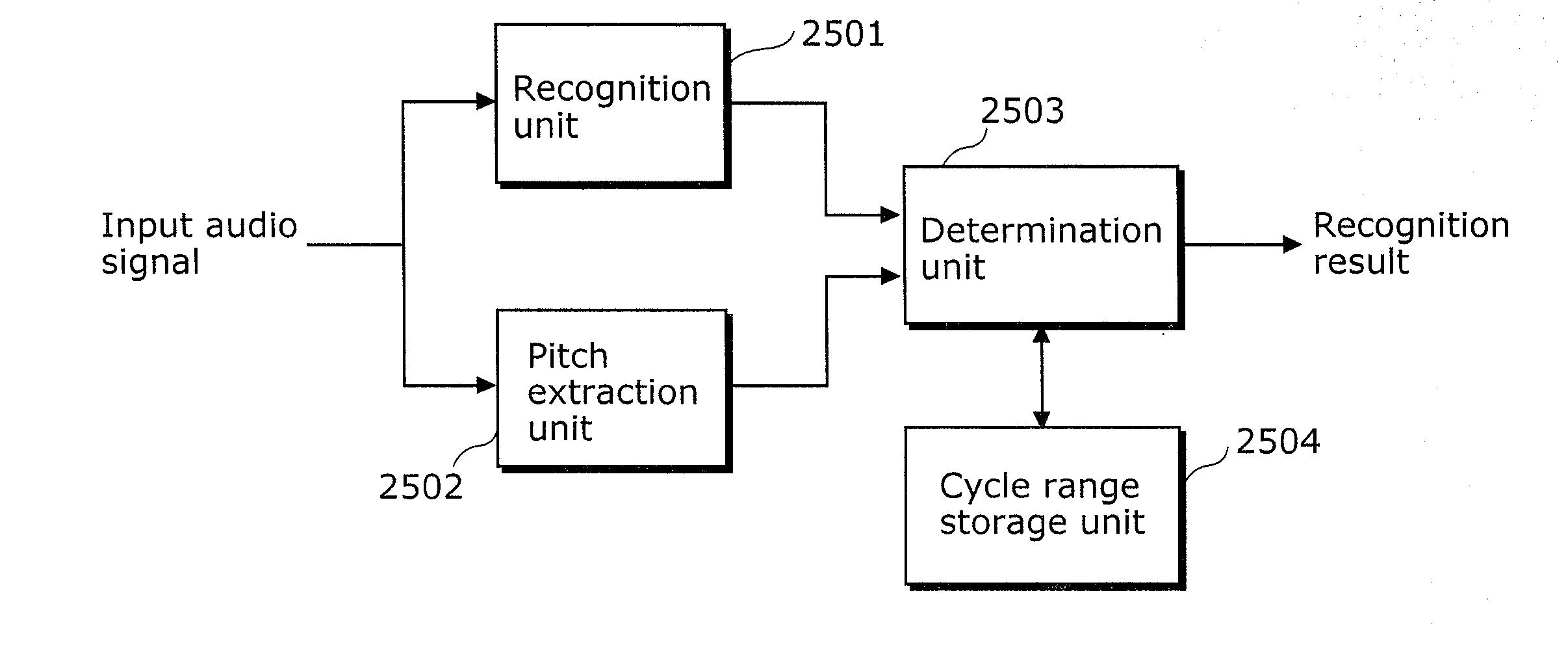

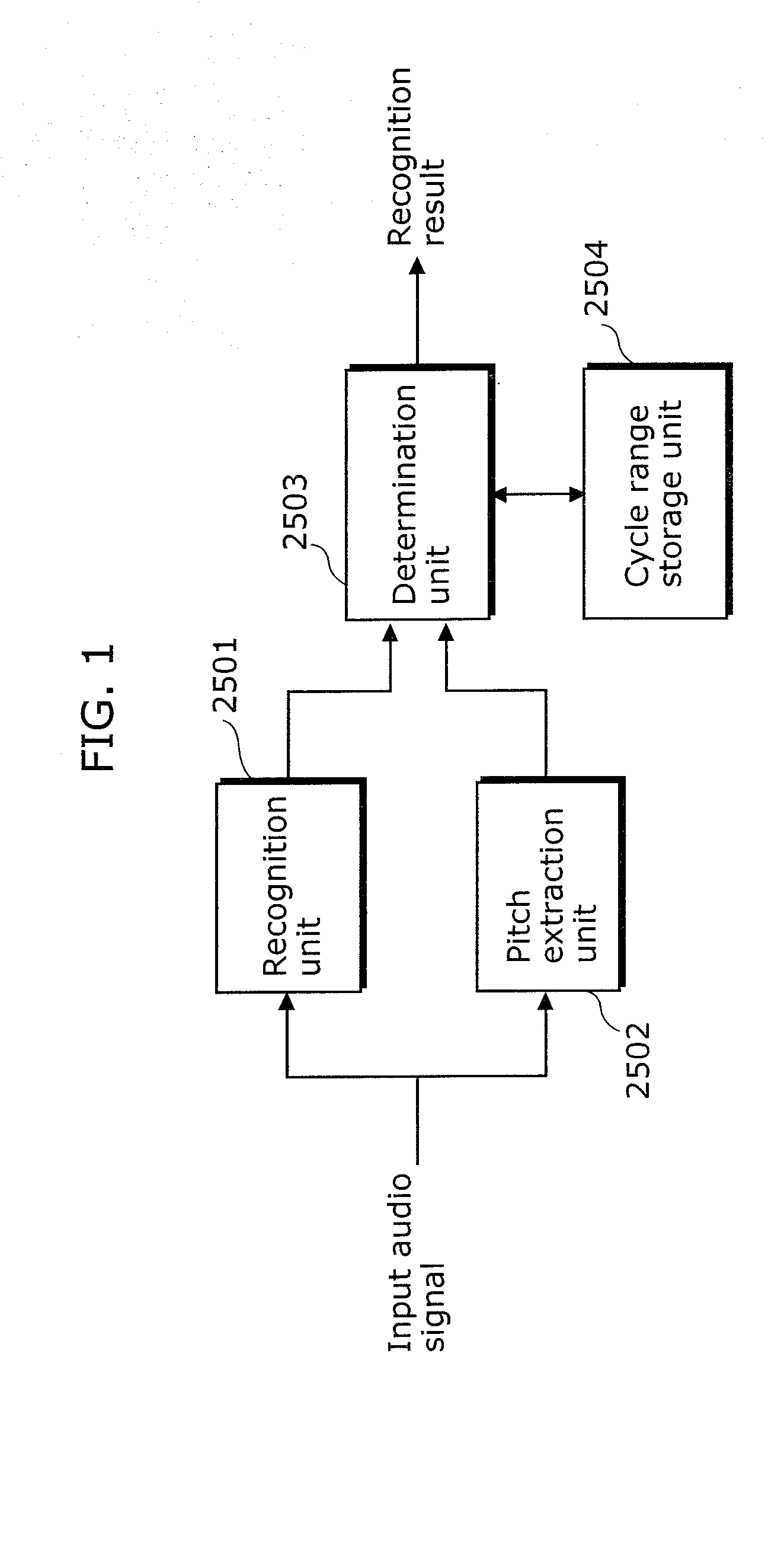

Sound determination device, sound detection device, and sound determination method

InactiveUS20100215191A1Accurate identificationAccurately determineSpeech analysisTransmission noise suppressionSound detectionNoise removal

A noise removal device includes: an FFT analysis unit which receives a mixed sound including to-be-extracted sounds and noises, and determines frequency signals at time points in a time width; and a to-be-extracted sound determination unit which determines, for each to-be-extracted sound, frequency signals at the time points, satisfying conditions of (i) being equal to or greater than a first threshold value in number and (ii) having a phase distance between the frequency signals that is equal to or smaller than a second threshold value, wherein the phase distance is a distance between phases ψ′(t) of the condition-satisfying frequency signals when a phase of a frequency signal at a current time point t is ψ(t) (radian) and the phase ψ′(t) is mod 2π(ψ(t)−2πft), f denoting a reference frequency, and the predetermined time width is within 2 to 4 times the time window widths of the window functions.

Owner:PANASONIC CORP

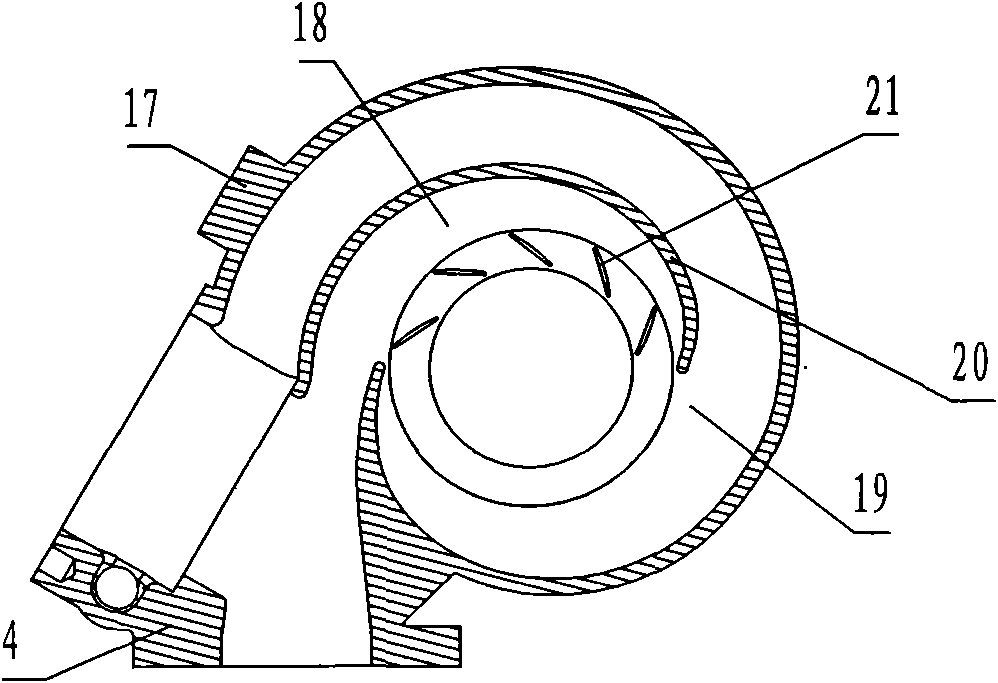

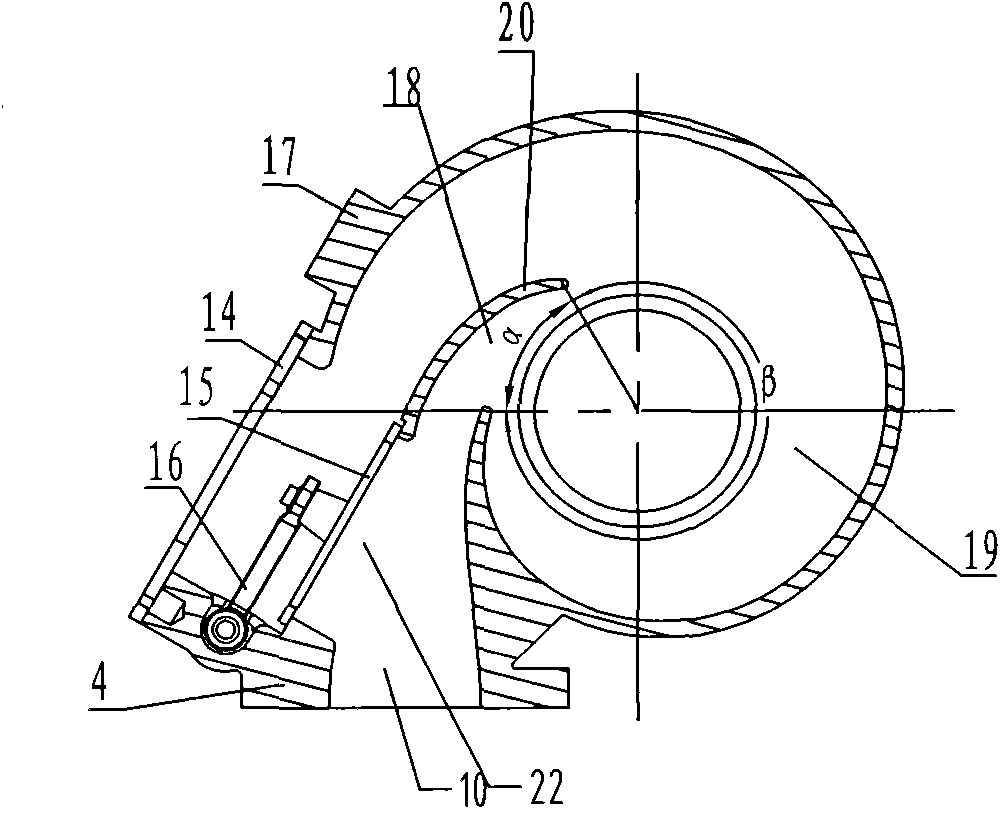

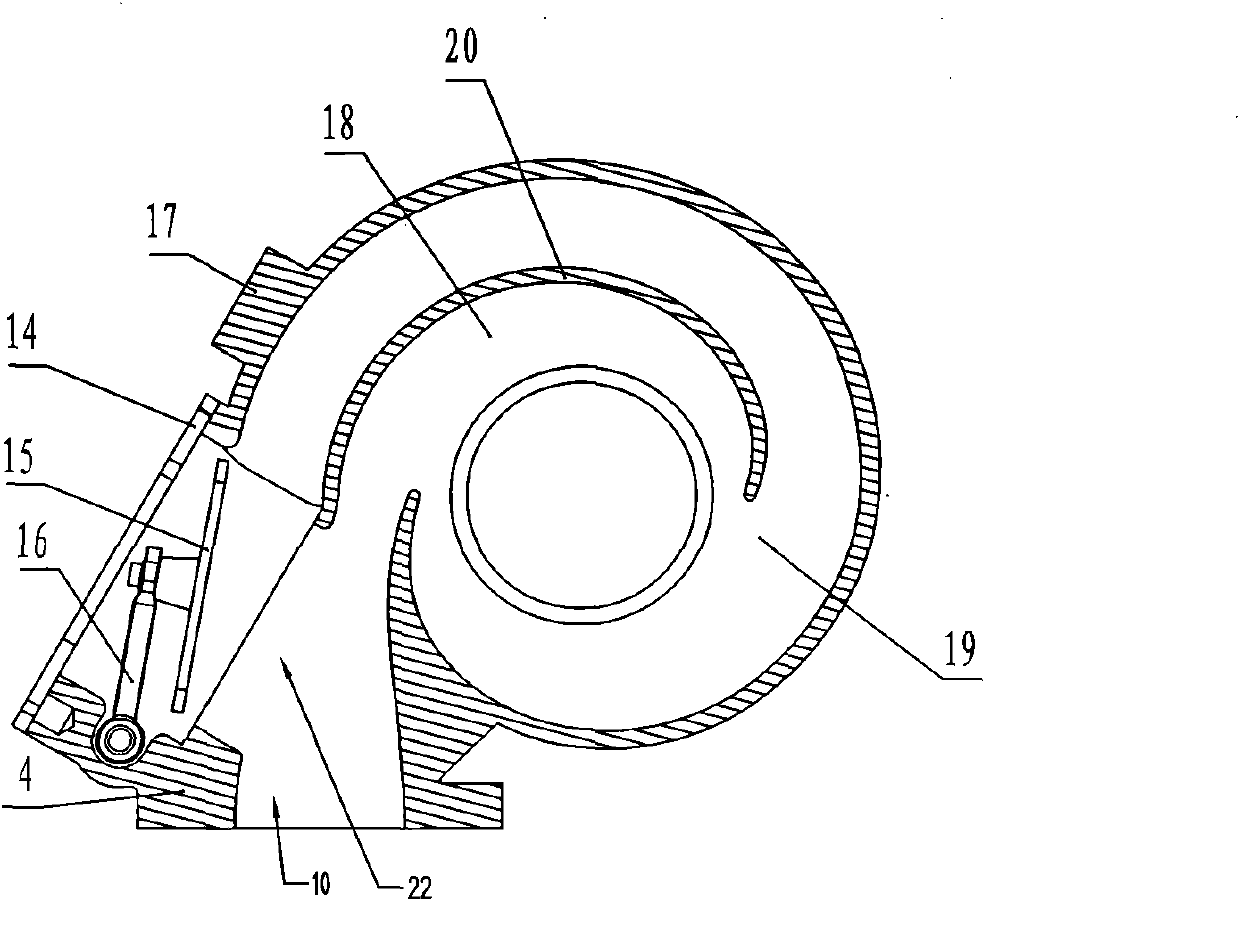

Variable section double-channel air intake turbine

InactiveCN101949326AChanging the angle of the intake areaMeet supercharging requirementsInternal combustion piston enginesGas turbine plantsTurbine wheelTurbine

The invention discloses a variable section double-channel air intake turbine, comprising a turbine volute, wherein the turbine volute is provided with a volute nozzle; a turbine wheel is installed in the turbine volute; the turbine volute is provided with a volute air intake channel; a middle wall is arranged in the volute air intake channel and separates the volute air intake channel into a small volute air intake channel and a big volute air intake channel; and the radial section of the middle wall is of arc structure, with radian of 60-180 degrees. The turbine changes the position of the end of the middle wall on the circumference through reasonable separation of the middle wall, thus changing the corresponding air intake area angles of the big and small channels and being capable of realizing that the air intake area angle of the small volute air intake channel changes between 60 degrees and 180 degrees and the corresponding air intake area angle of the big volute air intake channel changes between 300 degrees and 180 degrees.

Owner:KANGYUE TECH

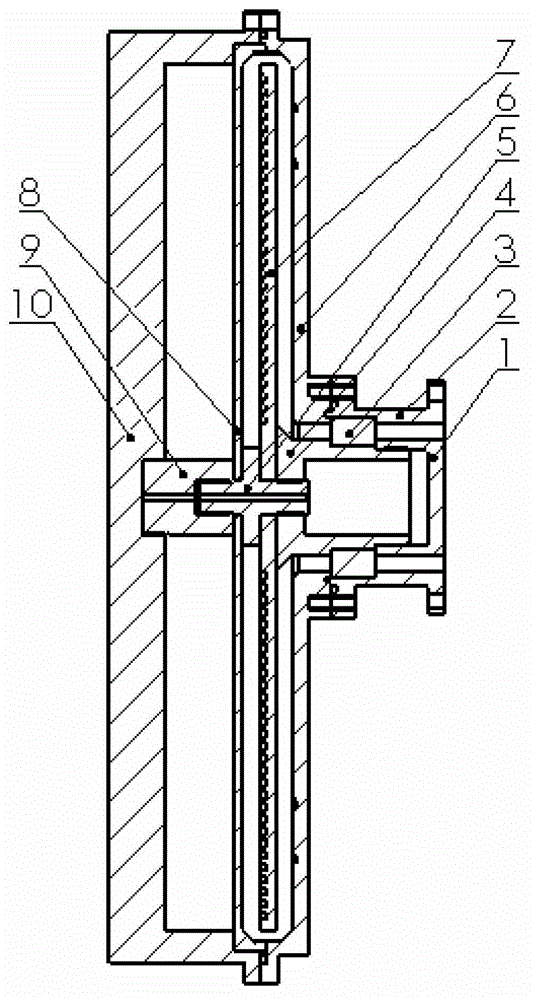

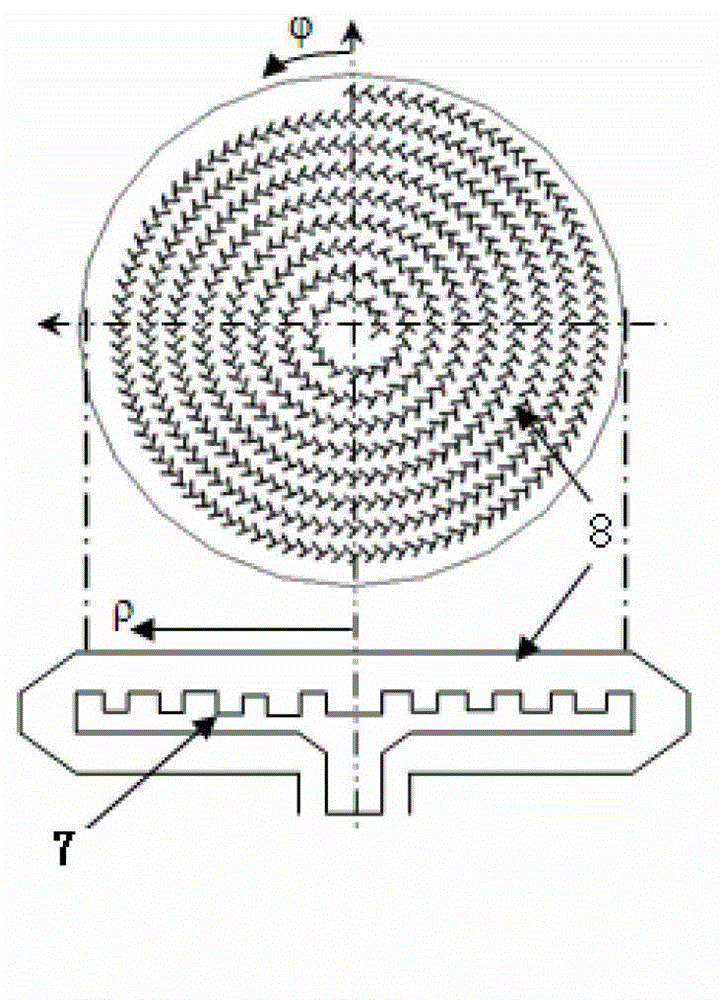

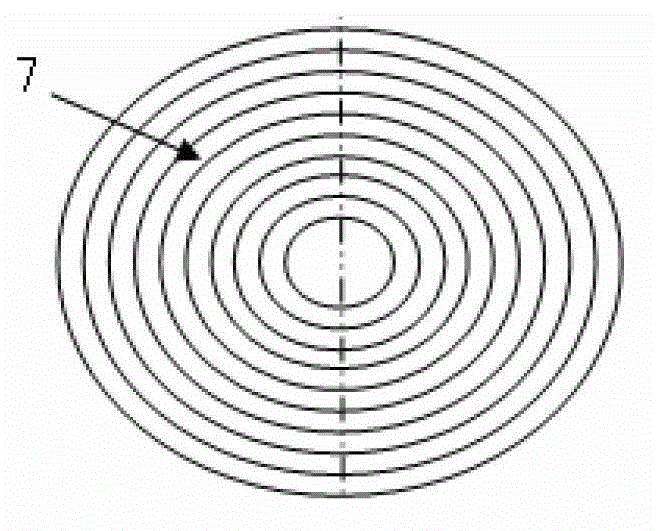

High power microwave radial line slit array antenna

InactiveCN103151620AImprove radiation efficiencyInhibitionAntenna arraysRadiating element housingsWave structureMicrowave

The invention relates to a high power microwave radial line slit array antenna which comprises a coaxial input waveguide, a radial line leaky wave waveguide and an antenna housing, wherein an output port of the coaxial input waveguide is connected with an input port of the radial line leaky wave waveguide, and an output port of the radial line leaky wave waveguide is sealed through the antenna housing. Microwaves are inputted through a coaxial over-mode waveguide in a transverse electronic and magnetic (TEM) mode, folding conversion is carried out through a double layer radial line waveguide, and microwave radial inner feedback is achieved on a waveguide upper layer. Slit unit arrays arranged on an antenna aperture cut a radial electric field, distant field same-phase superimposed circular polarization radian is achieved, the whole axial dimension is small, and the structure is compact. Due to action of a radial line slow wave structure, the wavelength of the radial line waveguide is reduced, and generation of slit array grating lobes is restrained. Due to the fact that a high order reflection mode excited by a wide slit array is restrained through a reflection offset spiral groove in a lower layer waveguide, the whole antenna has high radiant efficiency. Due to the improvement on the slit unit structure and vacuum sealing of the antenna housing, the whole radiating system has high power capacity, and application requirements in the high power microwave field can be met.

Owner:NAT UNIV OF DEFENSE TECH

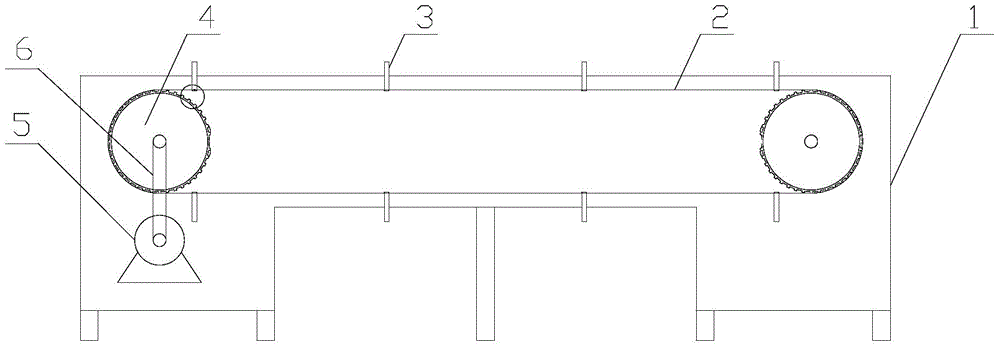

A belt type circular transmission device

ActiveCN104139962BReduce consumptionFlexible and easy to disassembleSupporting framesTransmission beltFuselage

Owner:SUZHOU TRANSPARENT TECH CO LTD

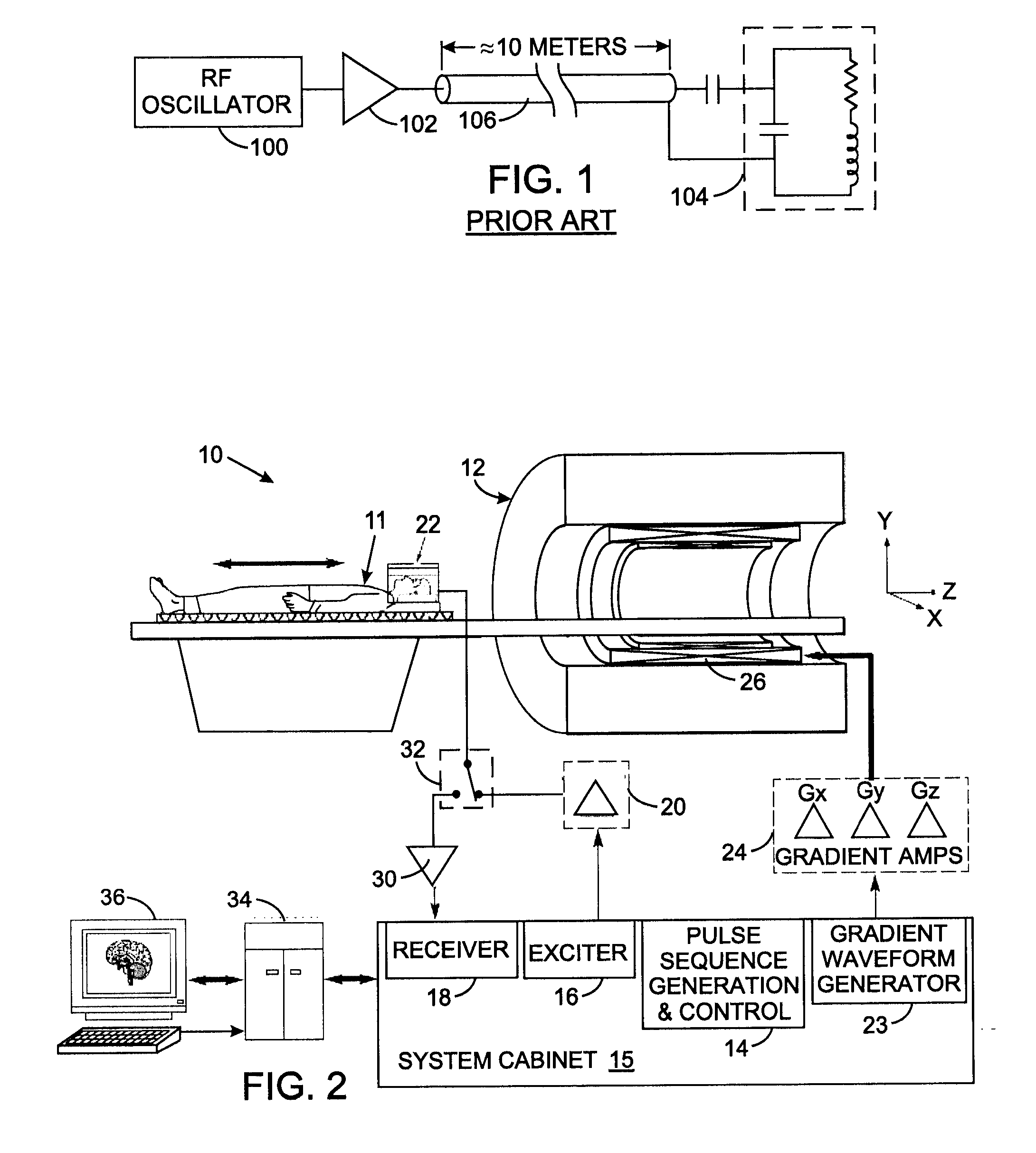

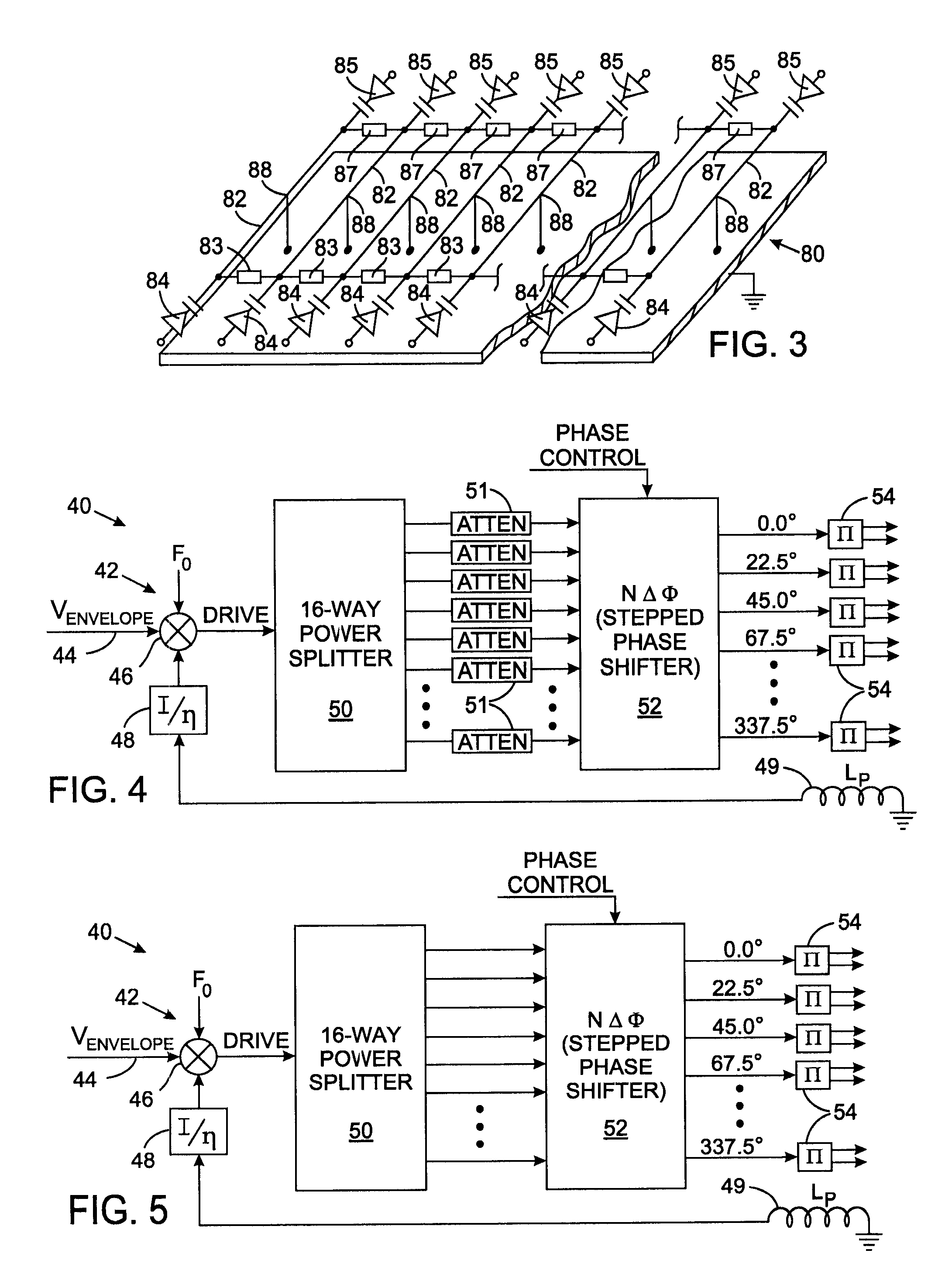

Magnetic resonance imaging system with a class-e radio frequency amplifier

InactiveUS20070279058A1Electric/magnetic detectionDc amplifiers with modulator-demodulatorShunt capacitorsAudio power amplifier

A Class-E amplifier has bee adapted for use in the radio frequency section of a magnetic resonance imaging (MRI) system. A drive signal is produces by modulating the envelope of a radio frequency carrier signal and then applied to a switch in the Class-E amplifier. The switch is connected in series with a choke between a supply voltage terminal and circuit ground with an output node formed between the choke and the switch. The output node is coupled to circuit ground by a shunt capacitor. In a preferred embodiment, a pair of such amplifiers, that are Π radians out of phase, are connected to each rung of a transverse electromagnetic transmit array type radio frequency coil of the MRI system.

Owner:KENERGY INC

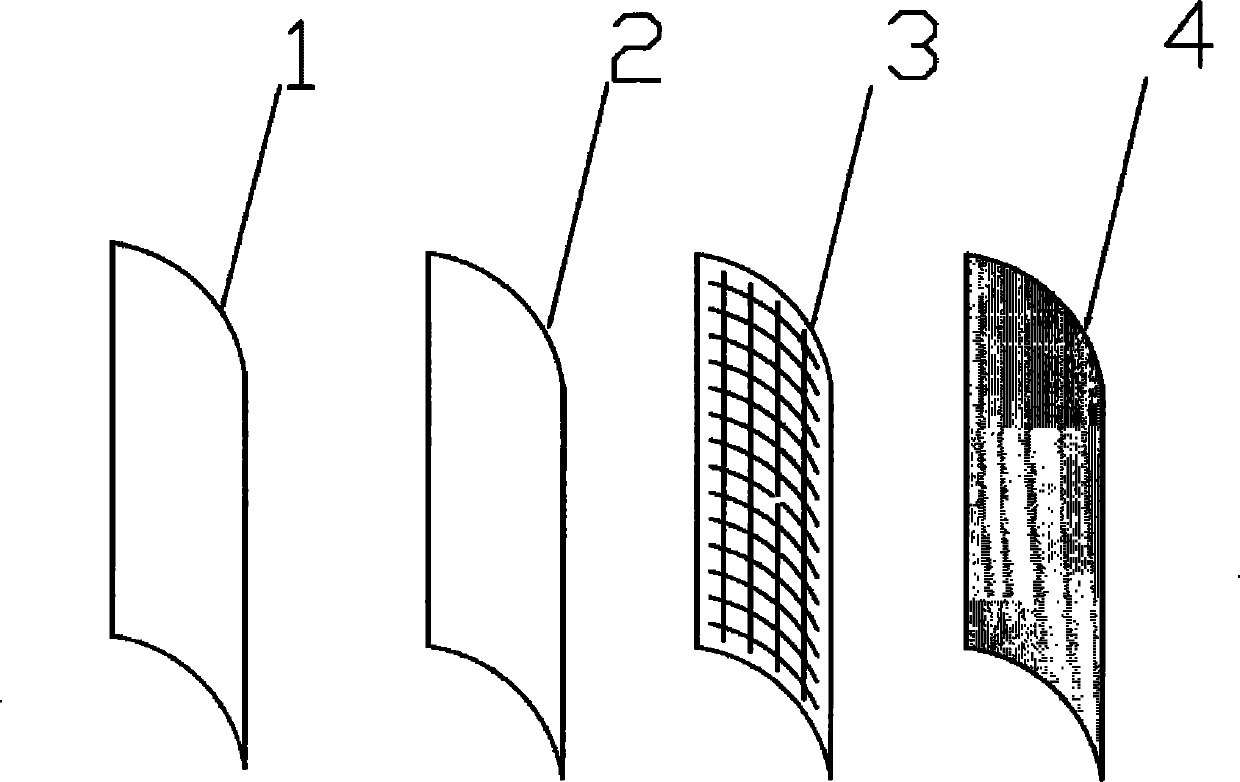

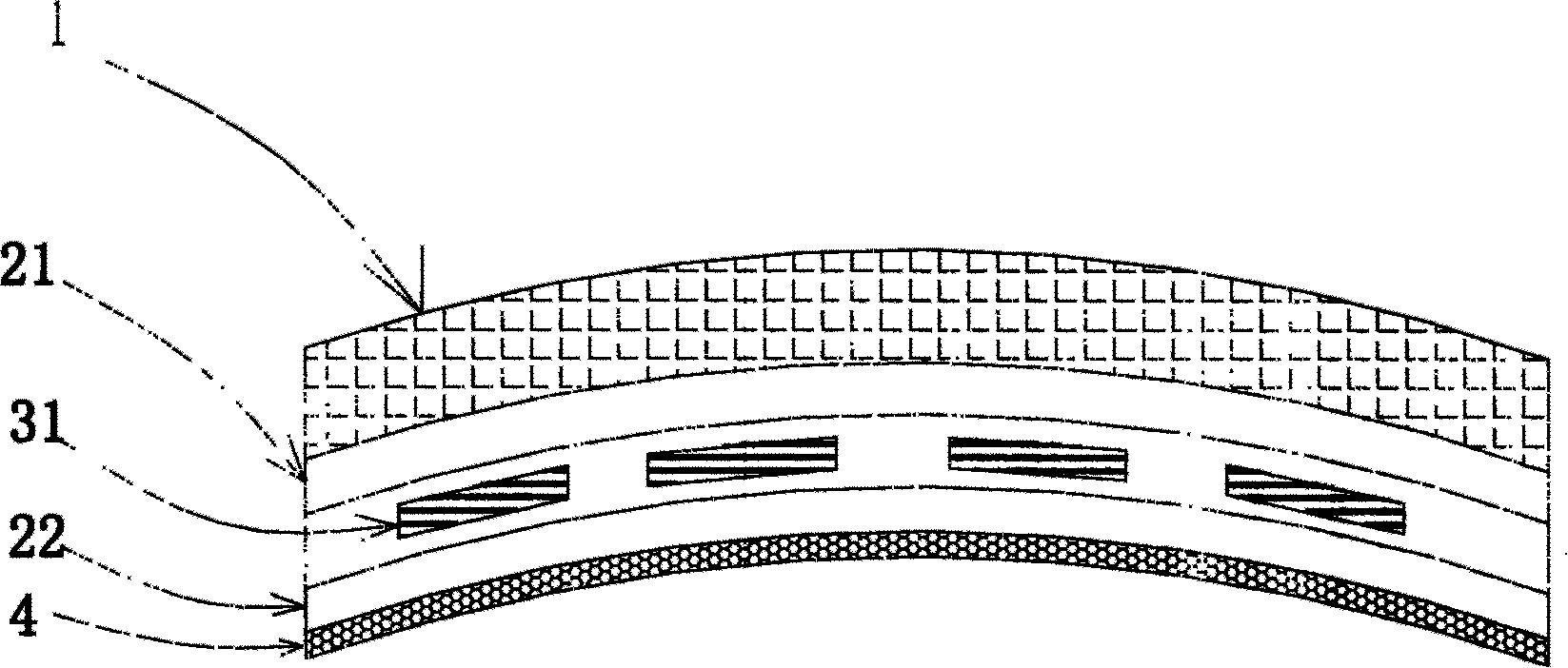

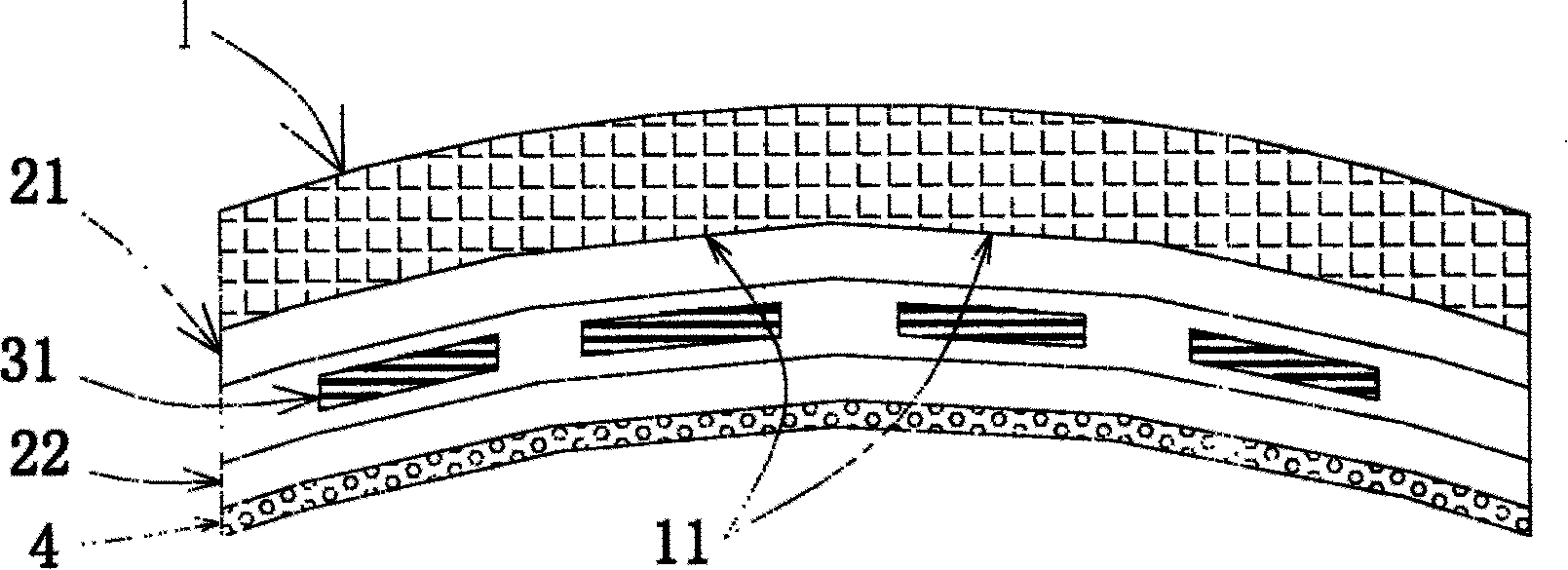

Curve screen based on nanometer touch-control membrane technique and manufacturing method thereof

ActiveCN102169388AImprove mechanical propertiesMalleableInput/output processes for data processingSystem integrationCarbon product

The invention discloses a curve screen based on nanometer touch-control membrane technique and a manufacturing method thereof. The curve screen comprises a curve substrate, wherein the curve substrate is an arc-shaped imaging device; the radian of the curve substrate is 0-180 degrees; the curve substrate is adhered to a nanometer touch-control membrane having flexibility; a sensing signal acquisition control integrated circuit is arranged on the nanometer touch-control membrane and is connected to a computer control unit through an interface; and the computer control unit is connected to the curve substrate in a wired or wireless communication manner. In the invention, the touch control technique is realized on the curved surface. The curve screen provided by the invention is suitable fordisplay devices in different sizes. The unit cost is low, the system integration is simple, and the operation is easy, thereby ensuring that the curve screen provided by the invention is a low energy-consumption and low-carbon product.

Owner:UC NANO TECH CO LTD

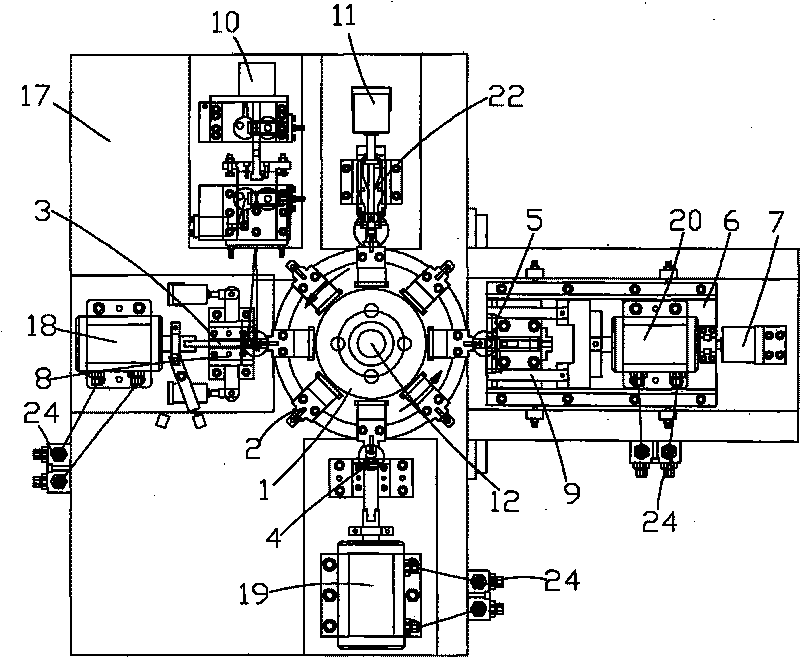

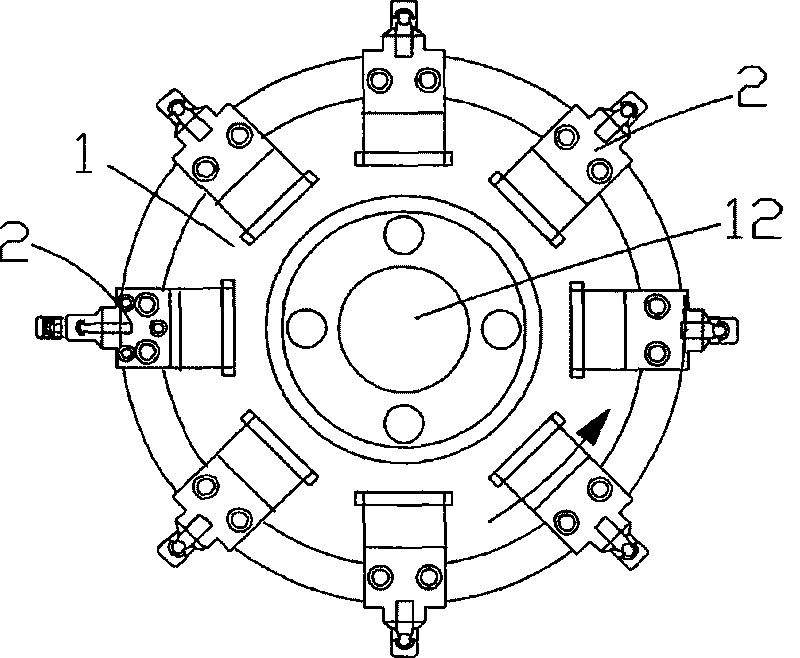

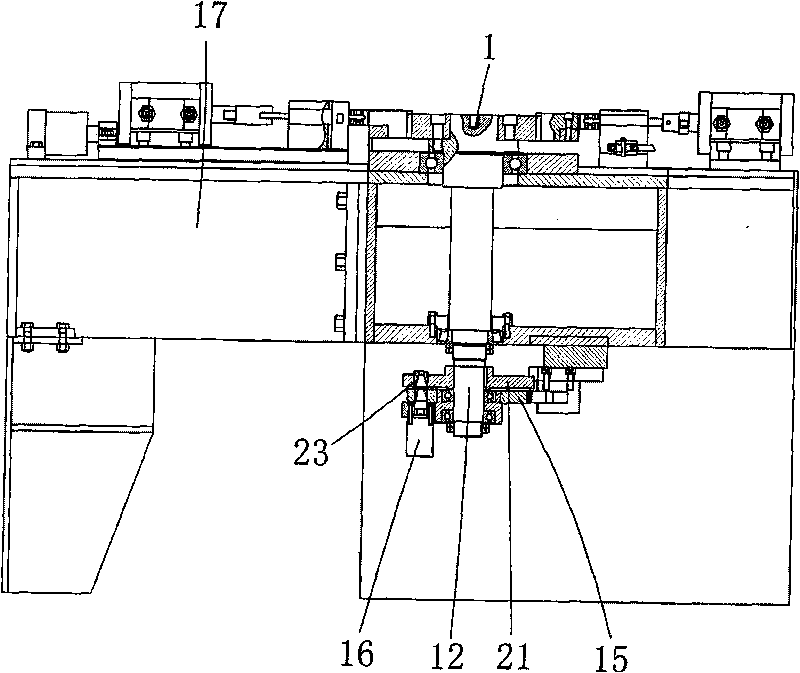

Four-position full automatic locker moulding machine and method thereof

InactiveCN101745806AIncrease profitImprove production efficiencyOther manufacturing equipments/toolsPosition shiftRadian

The invention relates to a four-position full automatic locker moulding machine and a method thereof. The four-position full automatic locker moulding machine comprises a feeding mechanism, a cutting mechanism, a moulding mechanism, a discharging mechanism and a position shifting mechanism all mounted on a platform. The position shifting mechanism comprises a core turntable arranged above the platform and an edge trimming mechanism, and the edge trimming mechanism, the discharging mechanism, the cutting mechanism and the moulding mechanism are distributed anticlockwise with the same radian according to the core turntable. The feeding mechanism is arranged on the corner between the discharging mechanism and the cutting mechanism, and the discharge end of the feeding mechanism is arranged just opposite the charging end of the cutting mechanism. Eight core seats are fixed on the periphery of the core turntable with the same radian, and the core seats can be matched with the edge trimming mechanism, the discharging mechanism, the cutting mechanism and the moulding mechanism face to face in turn after being rotated. The method of the four-position full automatic lock moulding machine comprises steps of charging, cutting, position shifting, moulding, edge trimming and discharging. The four-position full automatic lock moulding machine can manufacture finished products of high unity, can produce engine lockers of various specifications through replacing cores and moulding cavities, and has the advantages of simple replacement and high production efficiency.

Owner:蒋正启 +1

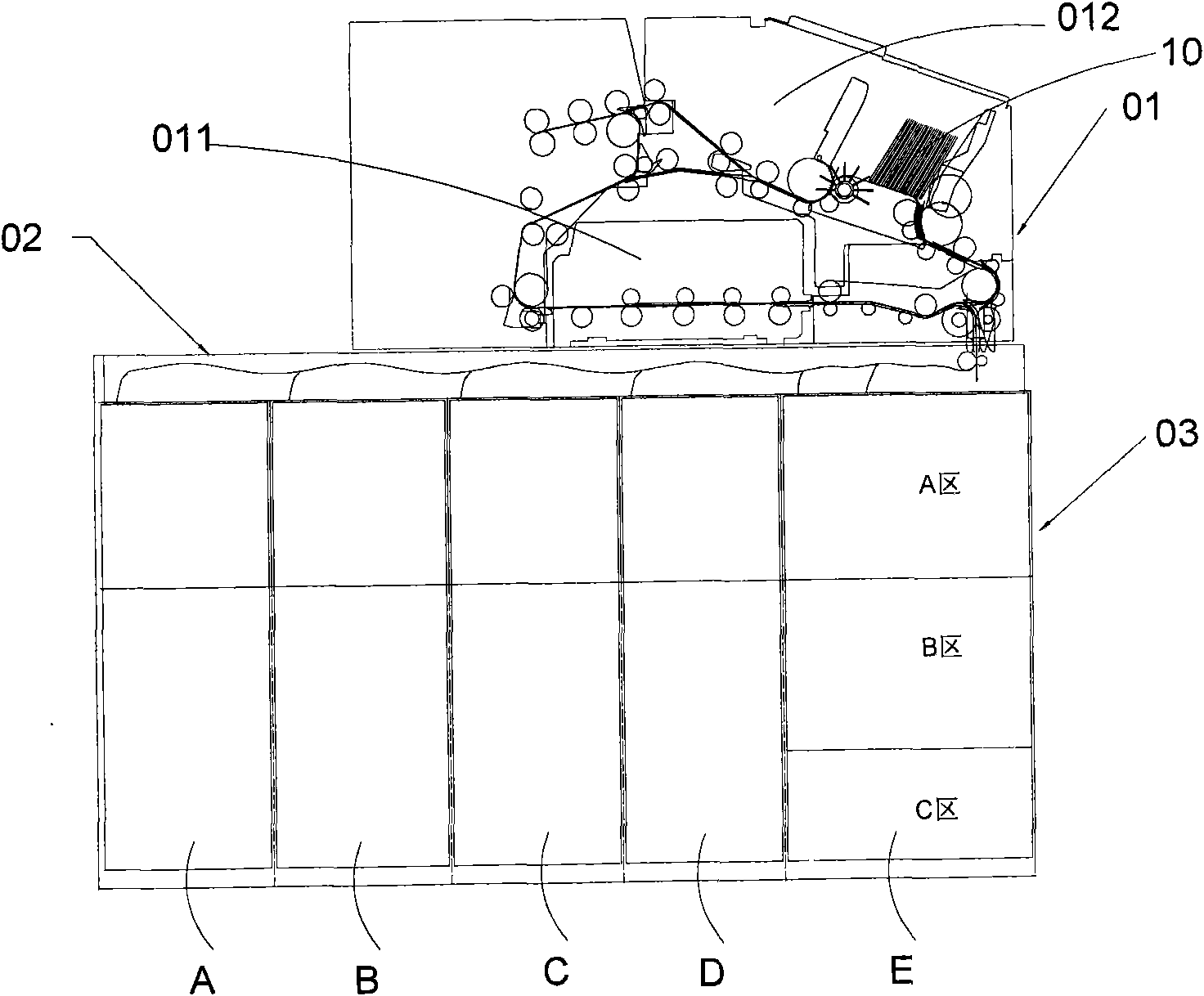

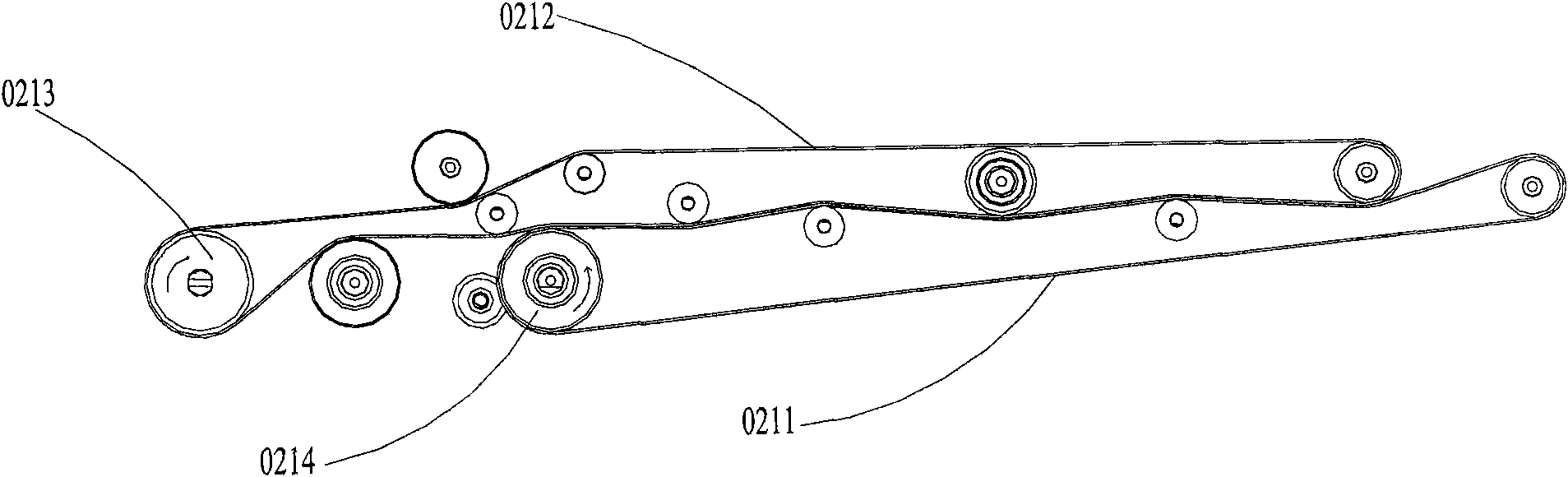

Reversible paper money transmission path device

ActiveCN102044107AAvoid cloggingCoin/currency accepting devicesArticle feedersTransmission beltMagnetic valve

The invention relates to a paper money transmission device, in particular to a multipath reversible paper money transmission path device. The paper money transmission path device is arranged between an upper machine core with functions of paper money identification and division and a lower machine core for storing paper money and is used as a transmission path for reversely transmitting and dividing the paper money. The device comprises a support, a pair of transmission belts, a first path board, a second path board, a third path board and a reversing mechanism. In the device, the reversing mechanism comprises a reversing shaft, a plurality of reversing pieces and a magnetic valve, wherein the reversing pieces are sleeved with the reversing shaft in parallel and are mutually spaced for a certain distance; the magnetic valve is used for controlling the reversing pieces to be switched between a first position and a second position; each reversing piece is shaped like a '<' and comprises two ends and an inner concave surface between the two ends; and a convex edge which is basically in accordance with the radian of the inner concave surface is arranged on the inner concave surface.

Owner:GRG BAKING EQUIP CO LTD

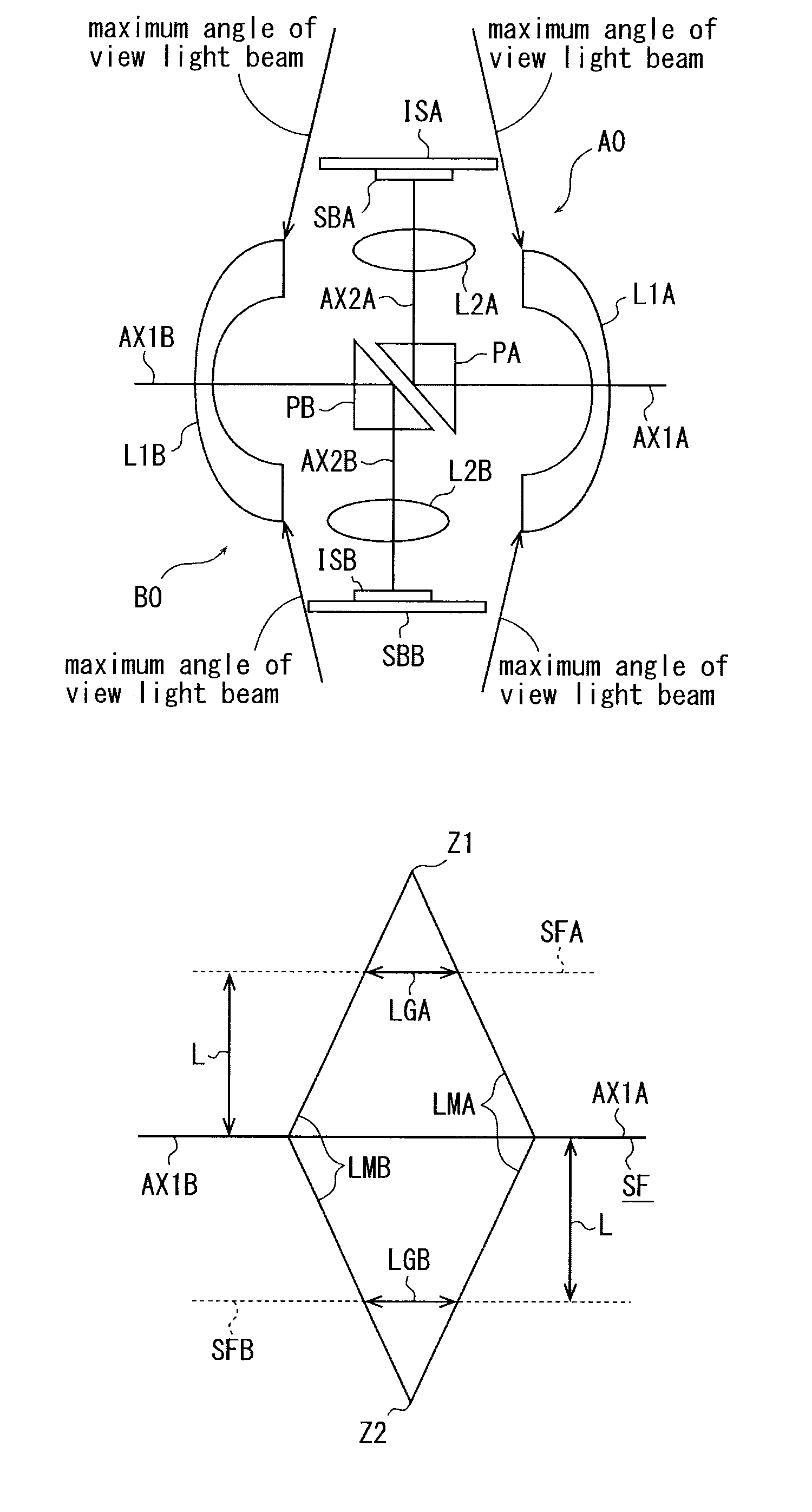

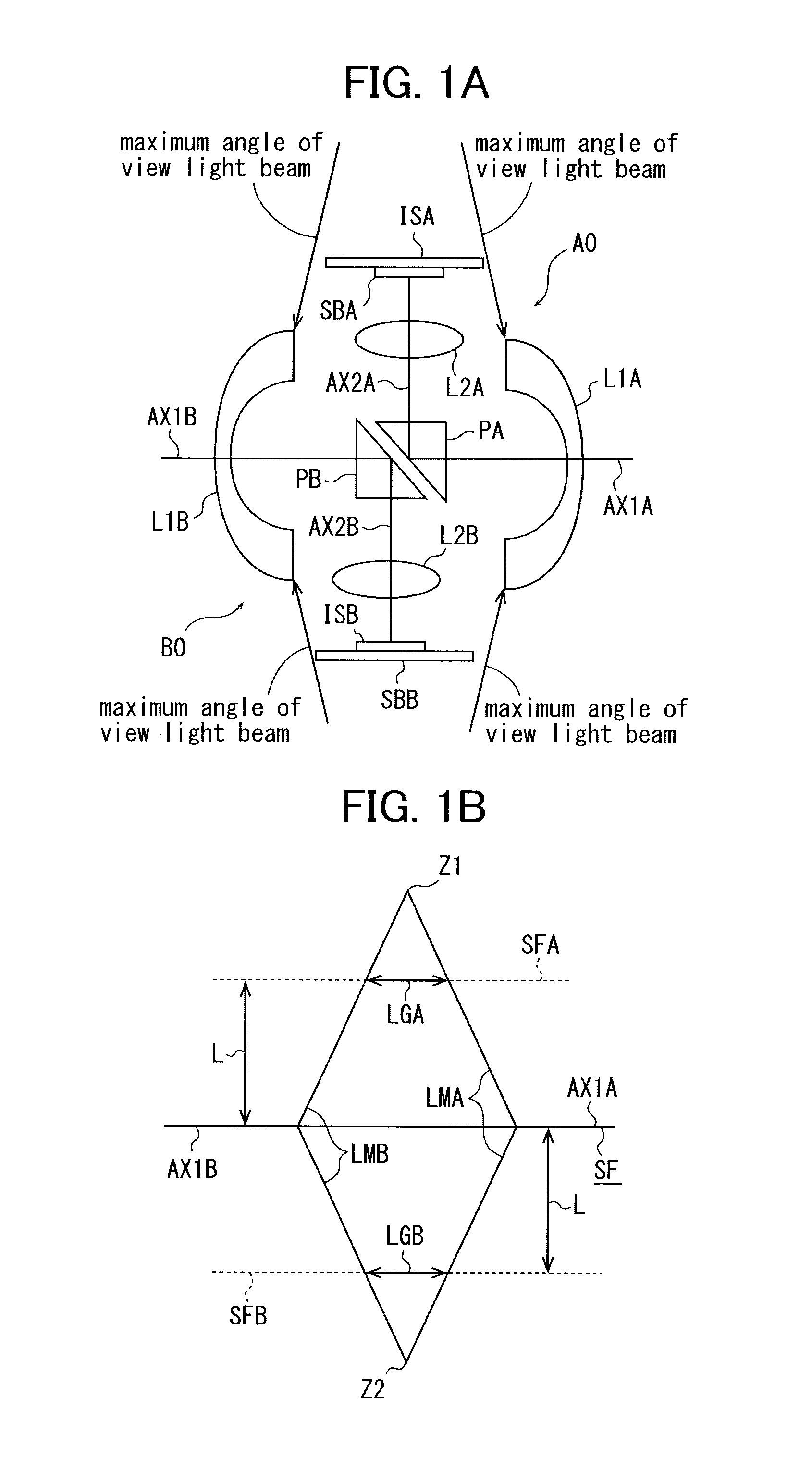

Imaging optical system, imaging device and imaging system

An imaging device includes two imaging optical systems each of the imaging optical systems including a wide-angle lens having an angle of view wider than 180 degrees, and an imaging sensor configured to image an image by the wide-angle lens, so as to obtain an image in a solid angle of 4π radian by synthesizing the images by the respective imaging optical systems, wherein the wide-angle lens of each of the imaging optical systems includes, in order from an object side to an image side, a front group having a negative power, a reflection surface and a back group having a positive power, and is configured to bend an optical axis of the front group by the reflection surface at 90 degrees toward the back group.

Owner:RICOH KK

Solar cell louver and method of manufacture

The invention provides a solar cell skylight, which comprises skylight glass and at least one solar cell. The skylight glass is provided with a convex arched exterior surface and a concave interior surface. The interior surface has at least one plane and at least one solar cell is connected with the plane. As the exterior surface of the skylight glass has the same radian with a car roof, the car looks more attractive. As the interior surface of the skylight glass has the same shape plane with the solar cell, when the arched skylight glass and the solar cell are laminated together, the solar cell is unlikely to be broken due to deformation or displaced corresponding to the skylight glass. The invention also provides a method for manufacturing the solar cell skylight glass.

Owner:BYD CO LTD

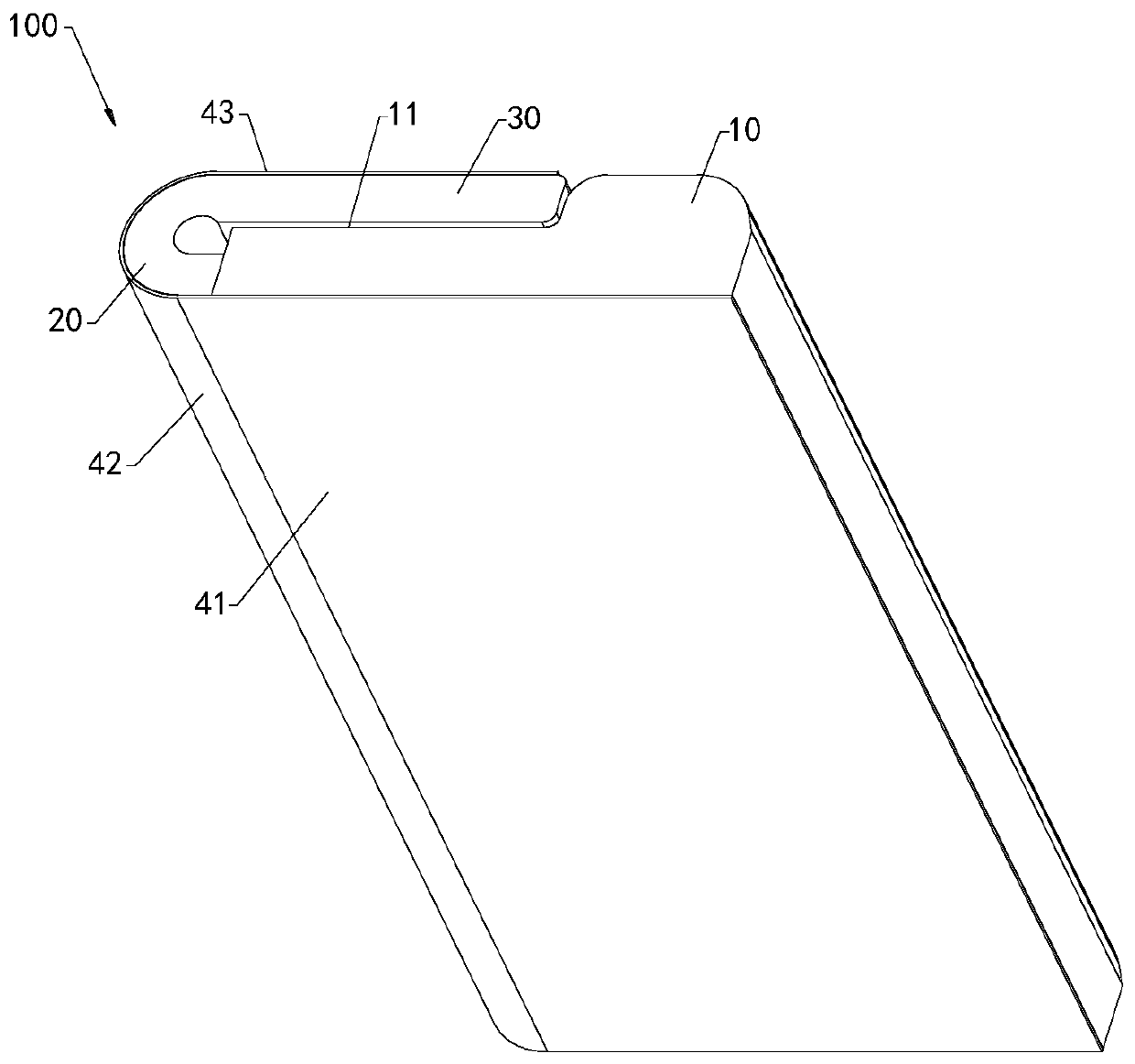

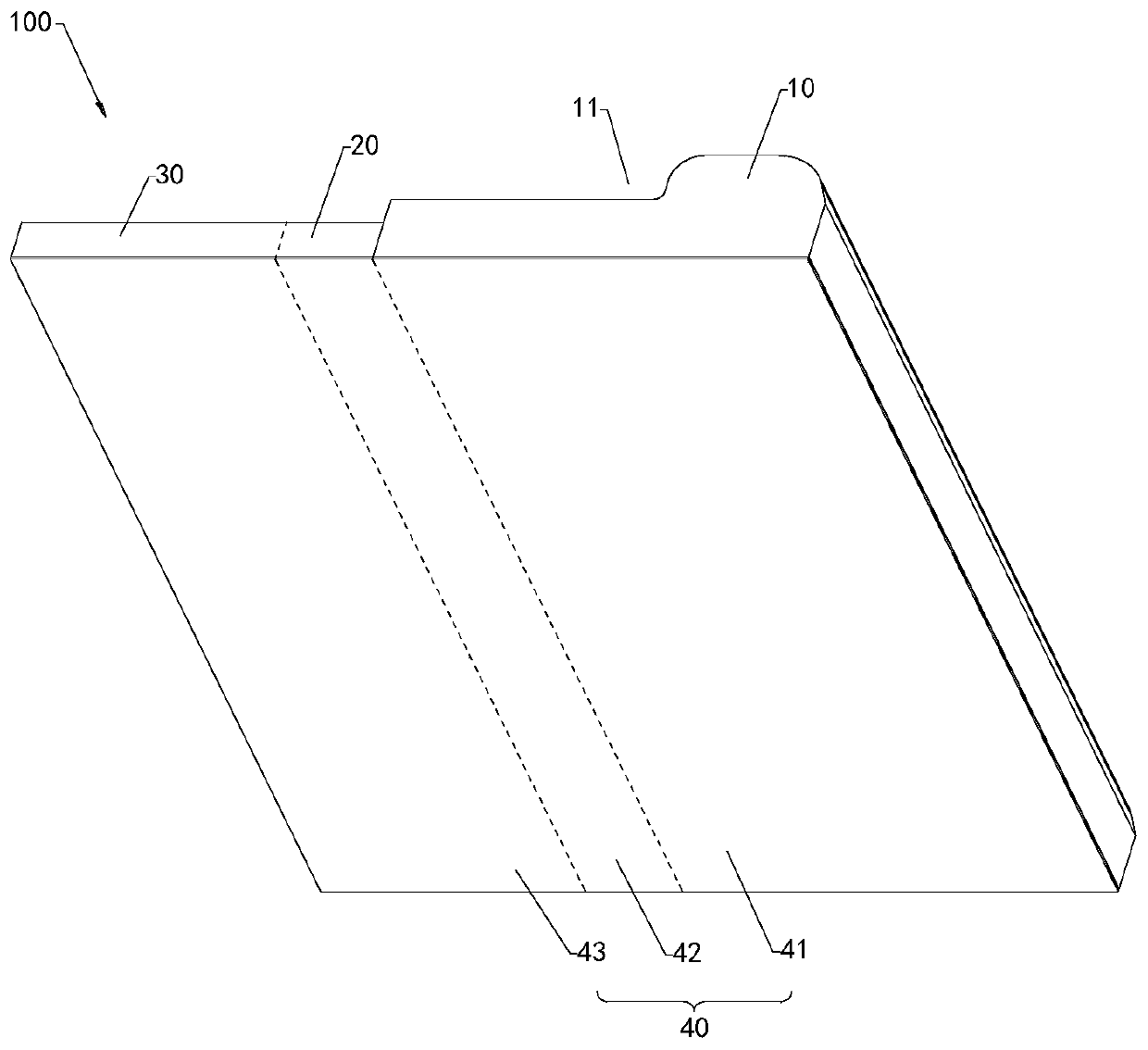

Flexible display screen and terminal comprising same

InactiveCN110277022AStrong rigidityImprove visual experienceTelephone set constructionsIdentification meansEngineeringFlexible display

The invention provides a flexible display screen and a terminal comprising the same. The flexible display screen comprises a display layer and a supporting layer, wherein the supporting layer is located on the back face of the display layer so as to improve the rigidity of the display screen; the supporting layer comprises one or more bent areas and one or more non-bent areas; and the bent areas can be bent or curved relative to the non-bent areas so as to enable the supporting layer to be bent or curved. The flexible display screen has the high rigidity, when the display screen is folded or curled, bending can be conducted at the certain radian, folds or arches or creases caused by folding or curling are avoided, and the visual experience of a user is improved.

Owner:HUAWEI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com