Variable section double-channel air intake turbine

A double-channel, turbine technology, applied in the direction of gas turbine devices, jet propulsion devices, stators, etc., can solve the problems of poor efficiency and reliability, achieve good inheritance, meet the requirements of supercharging, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

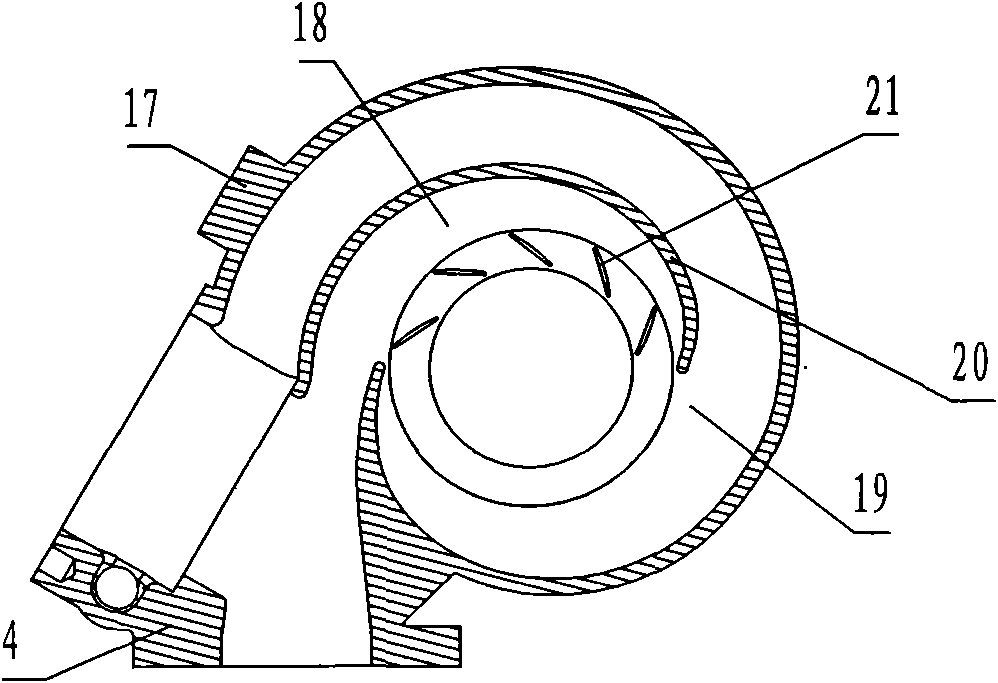

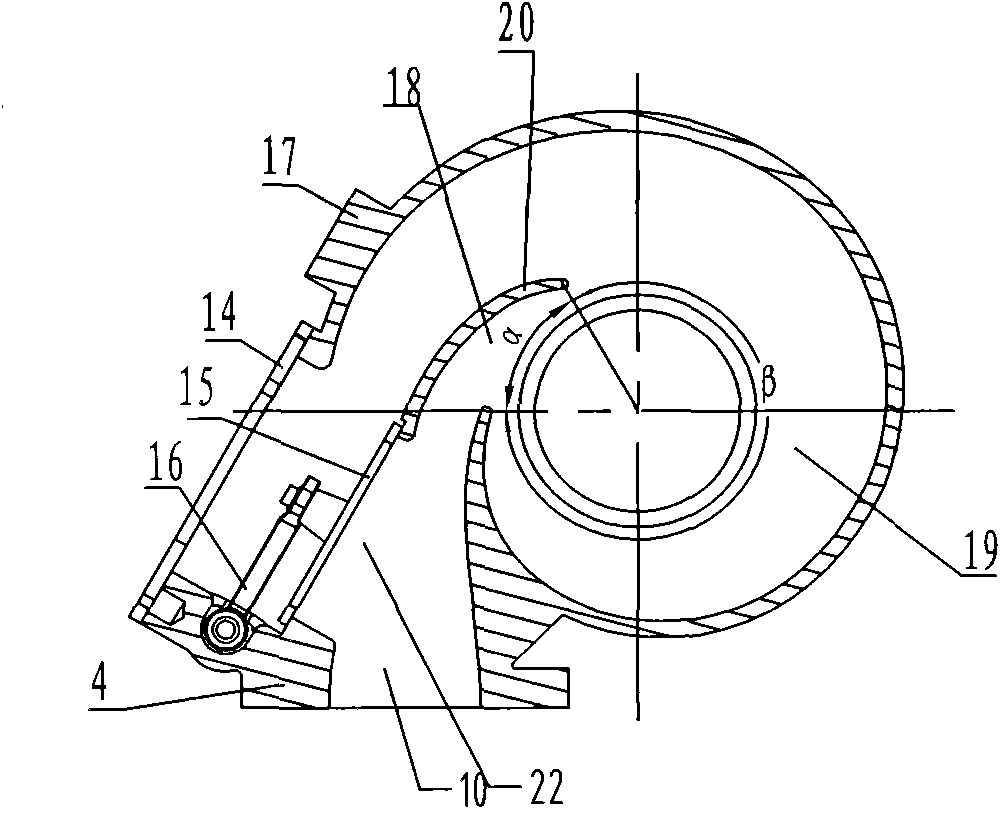

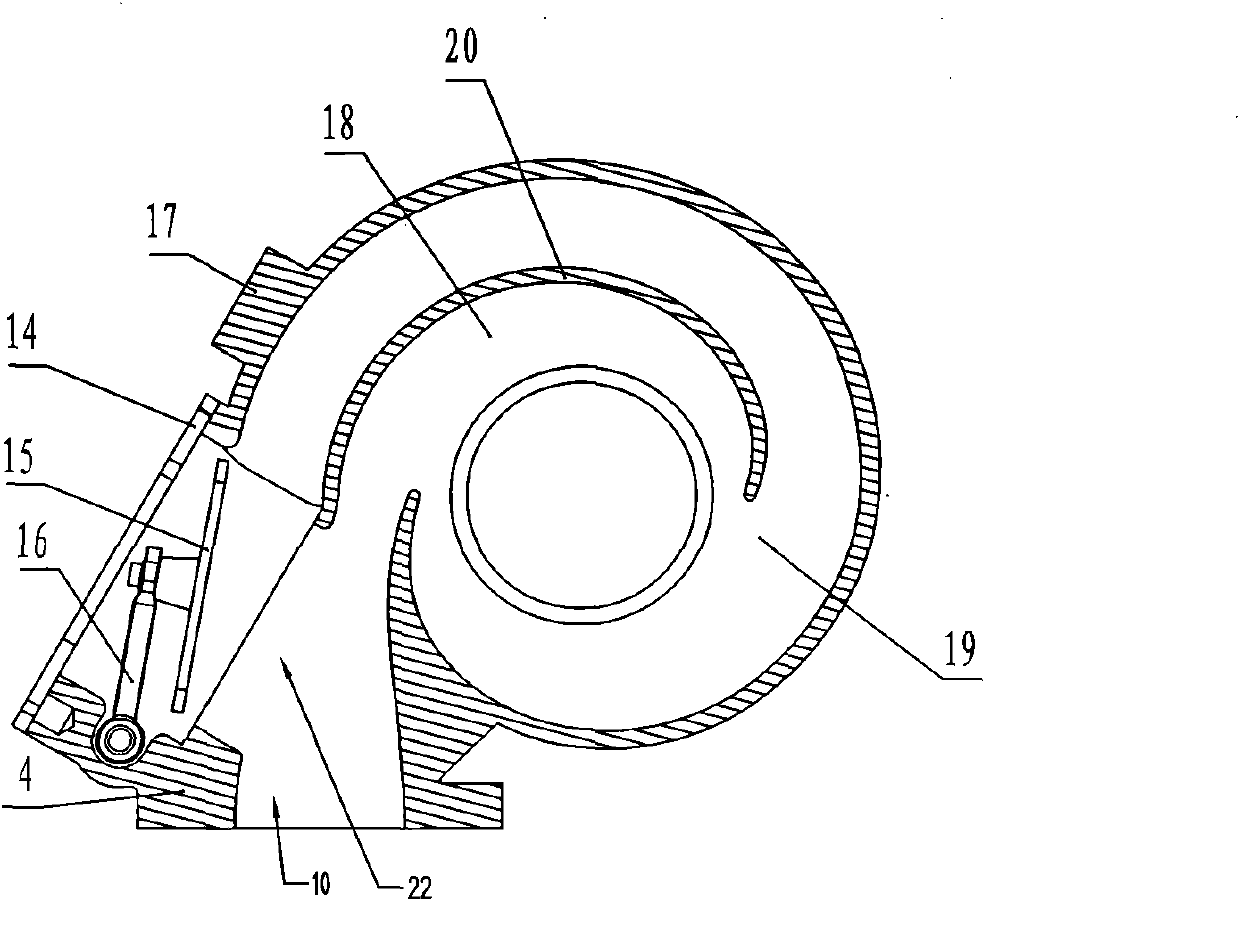

[0049] Example 1, such as figure 2 and image 3 As shown, a variable cross-section double-channel intake turbine includes a turbine volute 4, a volute nozzle 6 is provided on the turbine volute 4, a turbine impeller 8 is installed in the turbine volute 4, and the turbine volute 4 is provided with a volute inlet flow passage 10, and an intermediate wall 20 is arranged inside the volute inlet flow passage 10, and the intermediate wall 20 separates the volute inlet flow passage 10 into a small volute inlet flow passage 18 and a volute inlet flow passage. Air large flow channel 19, the flow area of the volute intake small flow channel 18 is less than the flow area of the volute intake large flow channel 19, the volute intake small flow channel 18 and the volute intake large flow channel 19 are both gas.

[0050] The radial section of the intermediate wall 20 is an arc-shaped structure, one end of the intermediate wall 20 is fixedly connected to the turbine volute 4, and the...

Embodiment 2

[0059] Example 2, such as Figure 7 As shown, in Embodiment 1, the positions of the large air intake channel of the volute and the small air intake channel of the volute can also be exchanged, and the position of the air intake adjustment control mechanism is readjusted, and the rest are the same.

[0060] The small volute air intake channel 18 is located outside the large volute air intake channel 19. When the engine is at low speed, only the small volute air intake channel 18 realizes air intake. When the engine is running at medium and high speeds, the air intake adjustment control mechanism 16 controls the intake air adjustment valve 15 to form different openings, and controls the gas flow entering the volute intake small flow channel 18 and the volute intake large flow channel 19 to realize flow Channel selection and flow capacity control to achieve matching with the engine at medium and high speeds.

[0061] The small volute intake flow channel 18 is located outside the...

Embodiment 3

[0063] Example 3, such as Figure 8 As shown, in Embodiment 1, several airflow guide vanes 21 can be provided at the nozzle of the volute intake large flow passage 19, and several airflow guide vanes 21 are arranged in a semicircular arc shape, and are installed obliquely along the turbine rotation direction, To ensure that the outlet airflow of the volute intake large flow channel 19 enters the turbine at a prescribed angle. Adopting this technical solution can improve the energy utilization efficiency of the exhaust gas at medium and high speeds of the engine, and effectively prevent the outlet airflow at the end of the small volute air intake channel 18 from entering the large volute air intake channel 19 at low engine speeds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com