Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Improve tea production efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

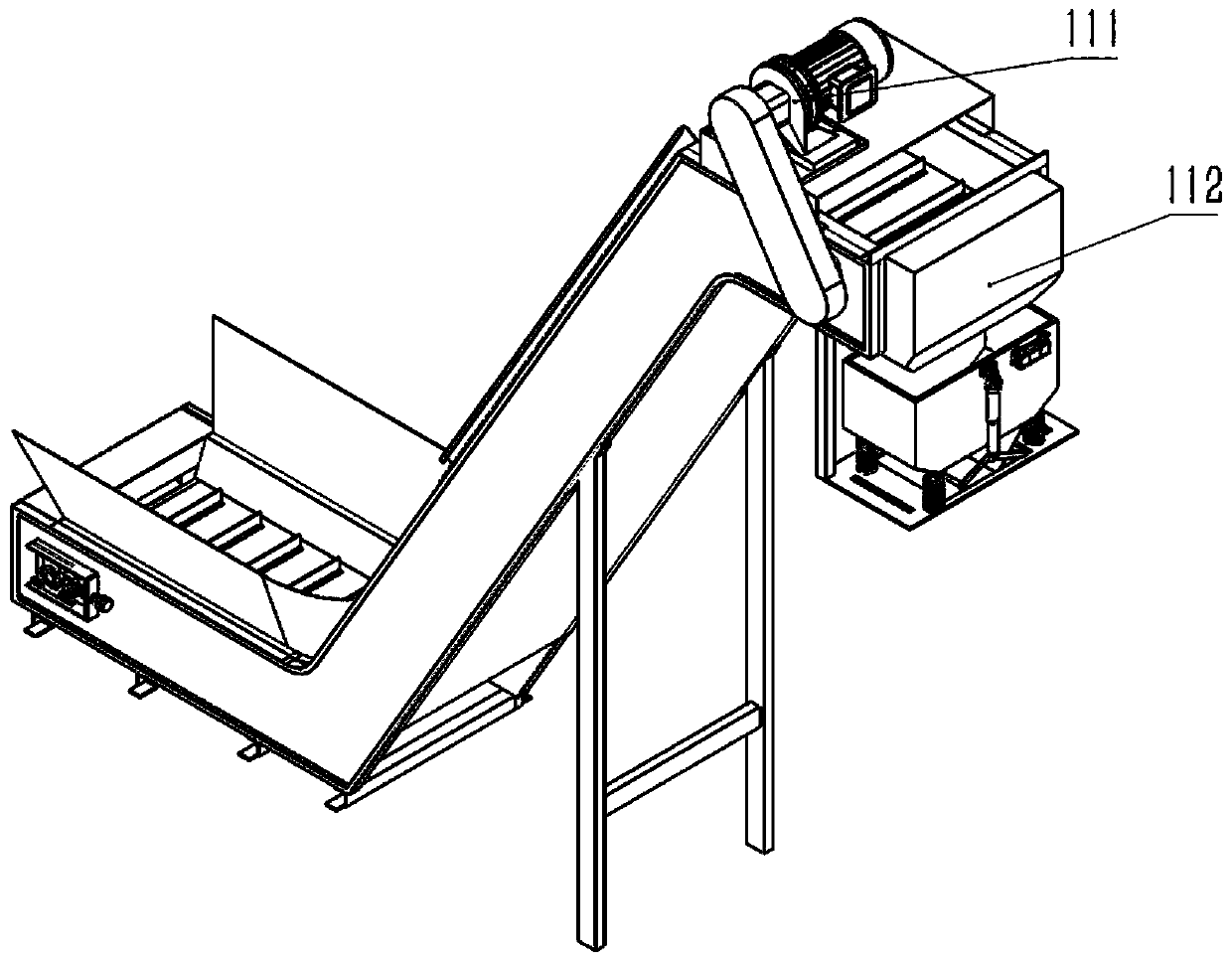

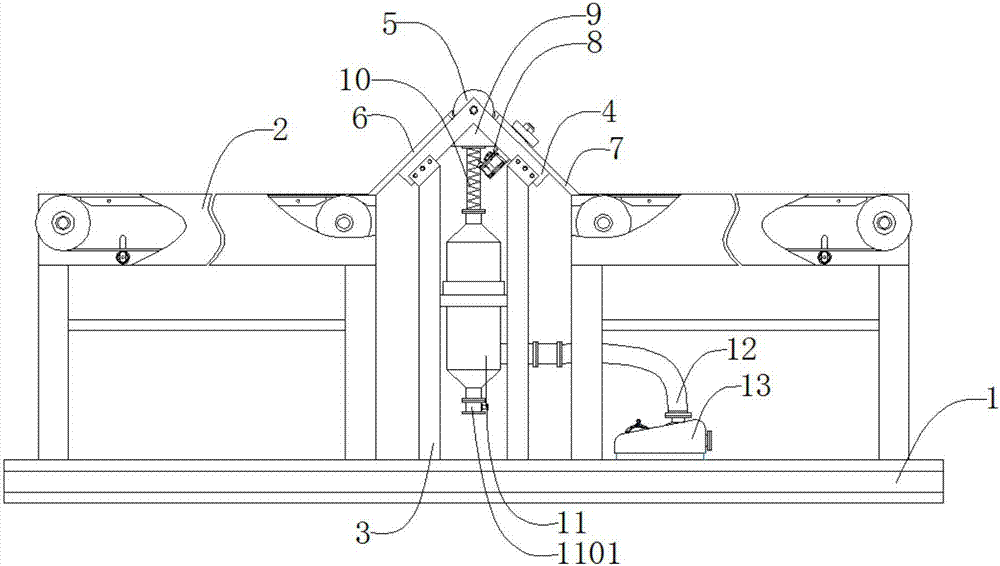

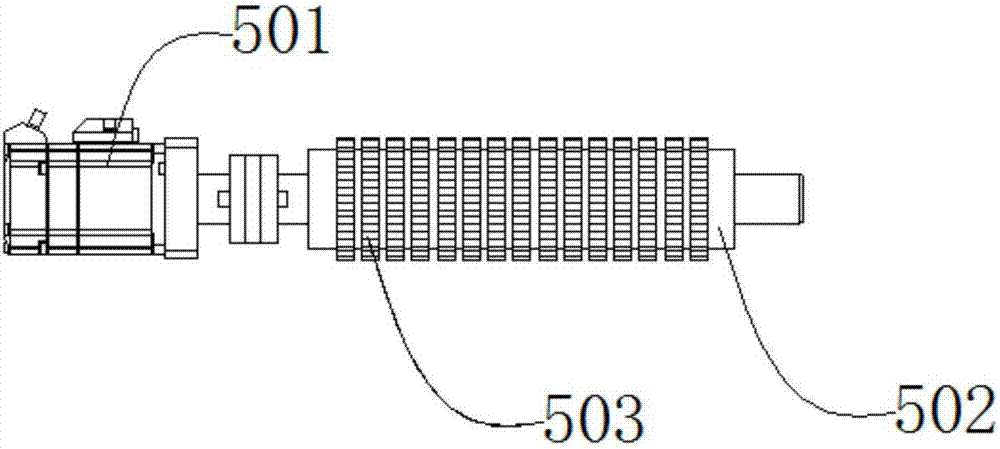

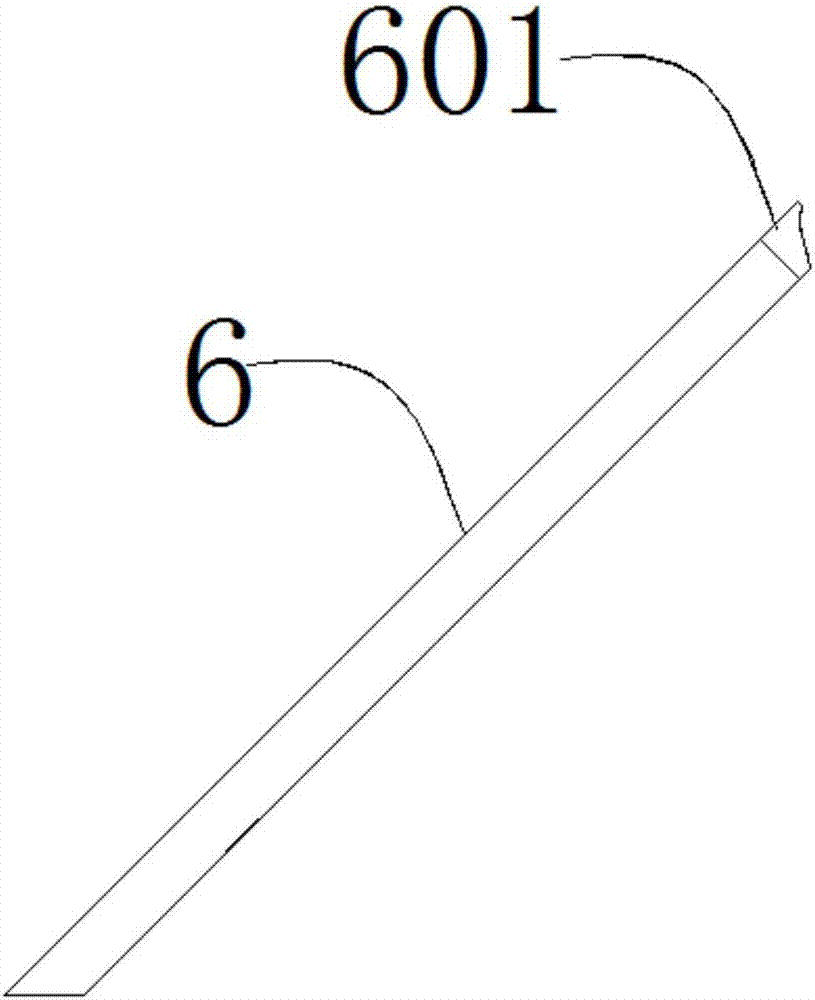

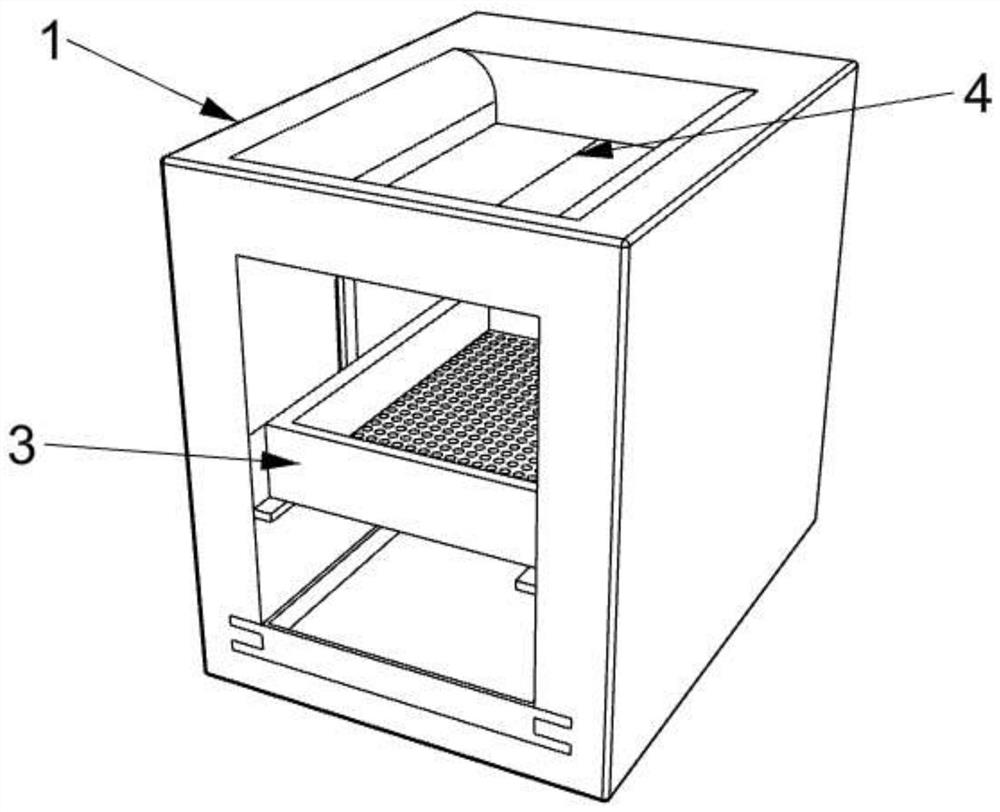

Multi-layer conveying belt tea leaf fragrance extraction machine and control method

PendingCN111217080AGuaranteed uniformityAchieve uniformitySievingConveyorsAgricultural engineeringTea leaf

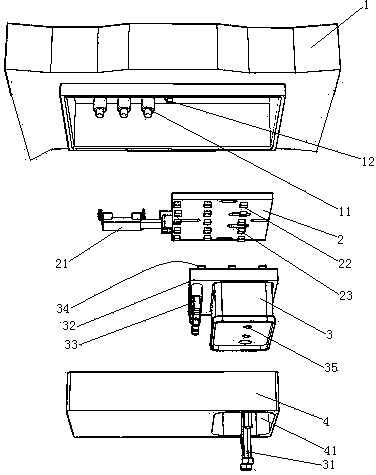

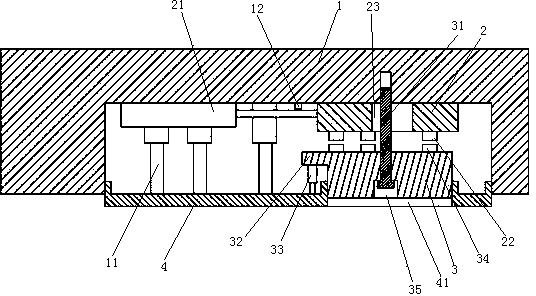

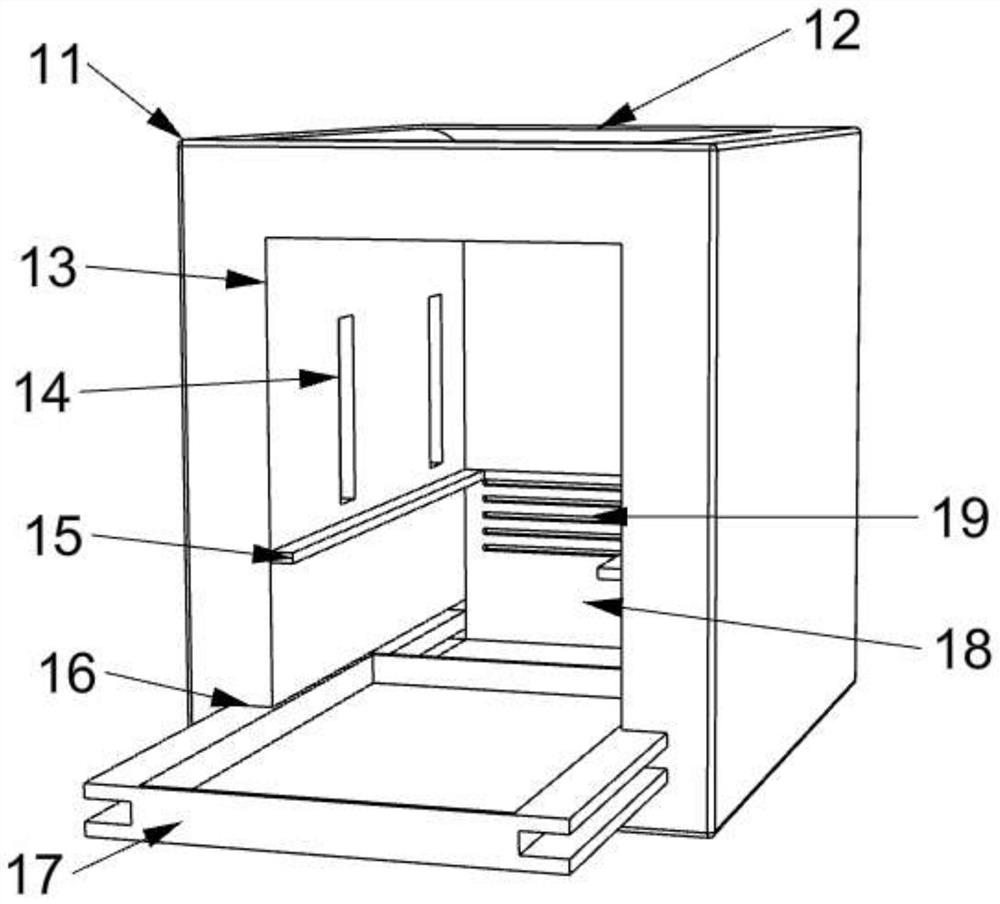

The invention relates to a multi-layer conveying belt tea leaf fragrance extraction machine and a control method. The fragrance extraction machine comprises a PLC control unit, an automatic tea leaf feeding unit, a fragrance extraction and baking unit and an automatic tea leaf discharging unit, wherein the automatic tea leaf feeding unit comprises a vertical elevator and an automatic tea leaf weighing device, and the fragrance extraction and baking unit comprises a transferring conveying belt, a transverse leaf evening device, a longitudinal leaf evening device and a multi-layer conveying beltbaking unit; and the transferring conveying belt is arranged below a discharge port of the automatic tea leaf weighing device and conveys tea leaves to the multi-layer conveying belt baking unit, thetransverse leaf evening device moves in the length direction of the transferring conveying belt to evenly scrape the tea leaves on the transferring conveying belt, the longitudinal leaf evening device moves in the width direction of the transferring conveying belt to evenly scrape the tea leaves on the transferring conveying belt, and the multi-layer conveying belt baking unit comprises a plurality of layers of conveying belts for conveying the tea leaves from top to bottom and heating baking units arranged on the two sides of the conveying belts. The multi-layer conveying belt tea leaf fragrance extraction machine and the control method solve the problem that the tea leaves are stacked on the conveying belts, and guarantees the tea leaf baking uniformity.

Owner:ANHUI AGRICULTURAL UNIVERSITY

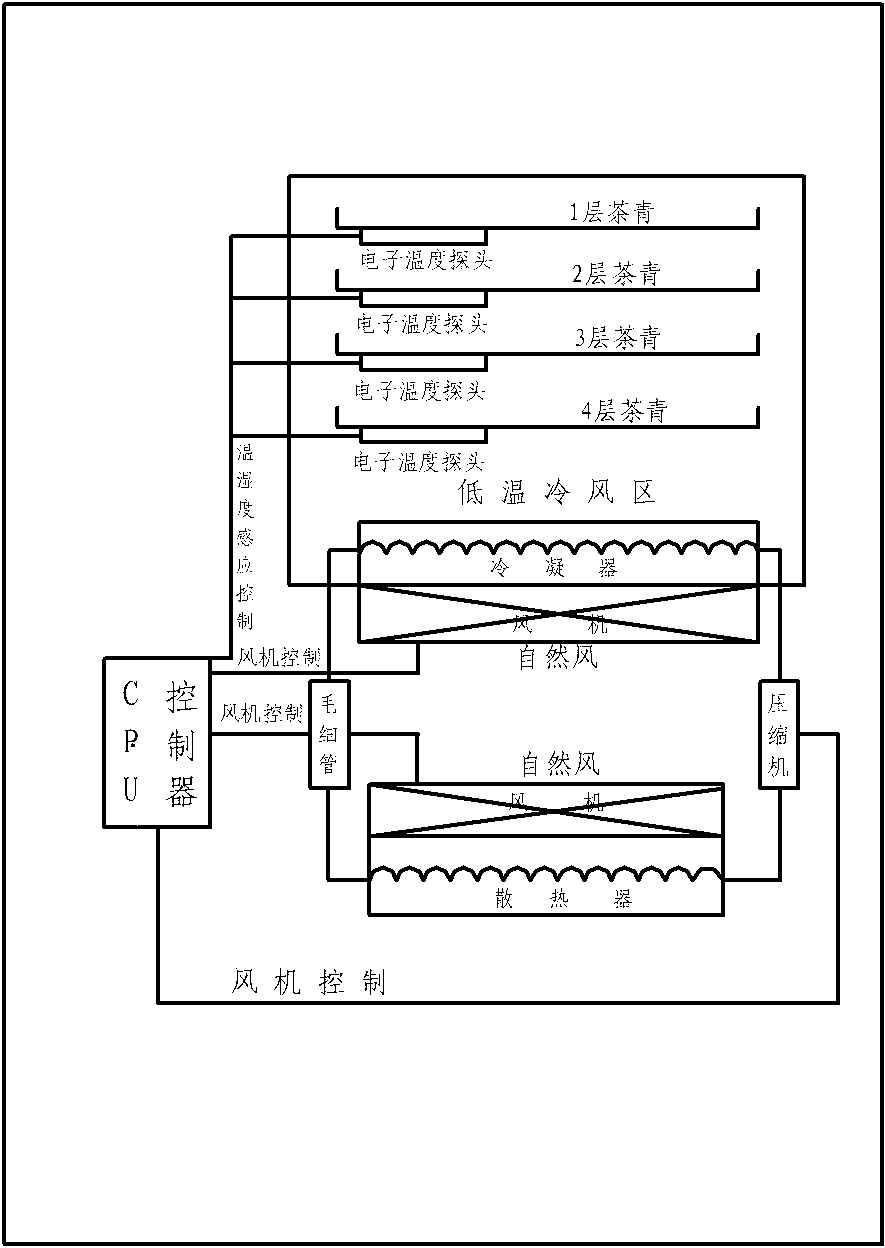

Low-temperature withering device for tea leaves

InactiveCN102835487AShorten withering timeImprove tea production efficiencyPre-extraction tea treatmentControl systemCapillary Tubing

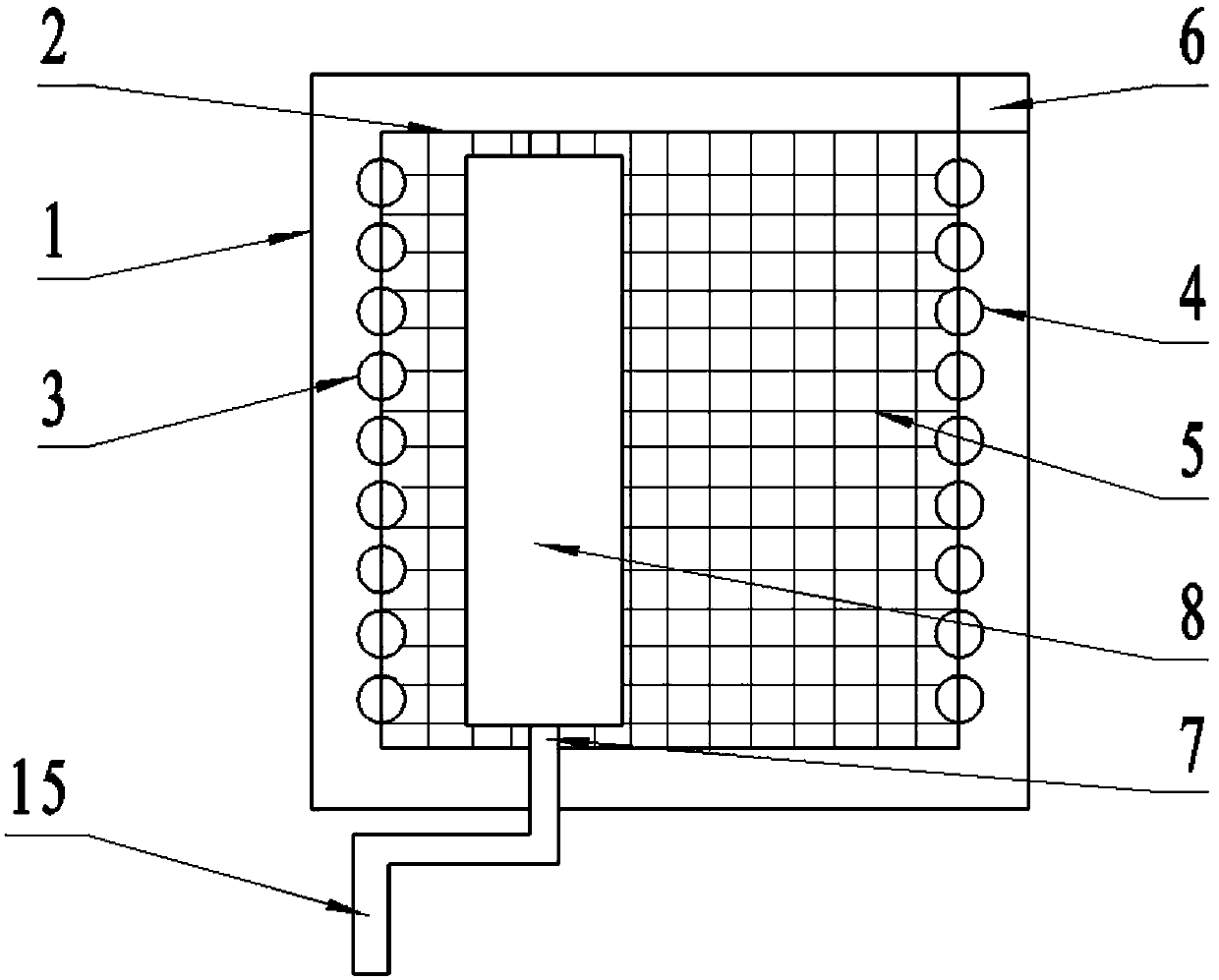

The invention relates to a low-temperature withering device for tea leaves, which mainly comprises a shell, a CPU (central processing unit) control system, a compressor, a capillary tube, a condenser, a radiator, electron temperature probes and a fan. The shell of the whole withering device is of a cabinet type structure; 4-6 layers of interlayers are arranged at the upper part of the shell and are used for placing the tea leaves; the electron temperature probes are uniformly arranged on the interlayers and are used for detecting the temperature of each interlayer; the compressor, the capillary tube, the condenser, the radiator and the fan are arranged at the lower part of the shell; the condenser is positioned above the radiator; the capillary tube is positioned between the condenser and the radiator; and the temperature in the whole withering device is controlled at 8 DEG C. According to the low-temperature withering device provided by the invention, the time for the tea leaves to wither is greatly shortened, the efficiency for making tea is improved, the risk of nonuniform quality of high-end brand-name tea is reduced, the quality of the tea leaves is improved, and the competition of the tea leaves in the market is enhanced.

Owner:贵州怡壶春生态茶业有限公司

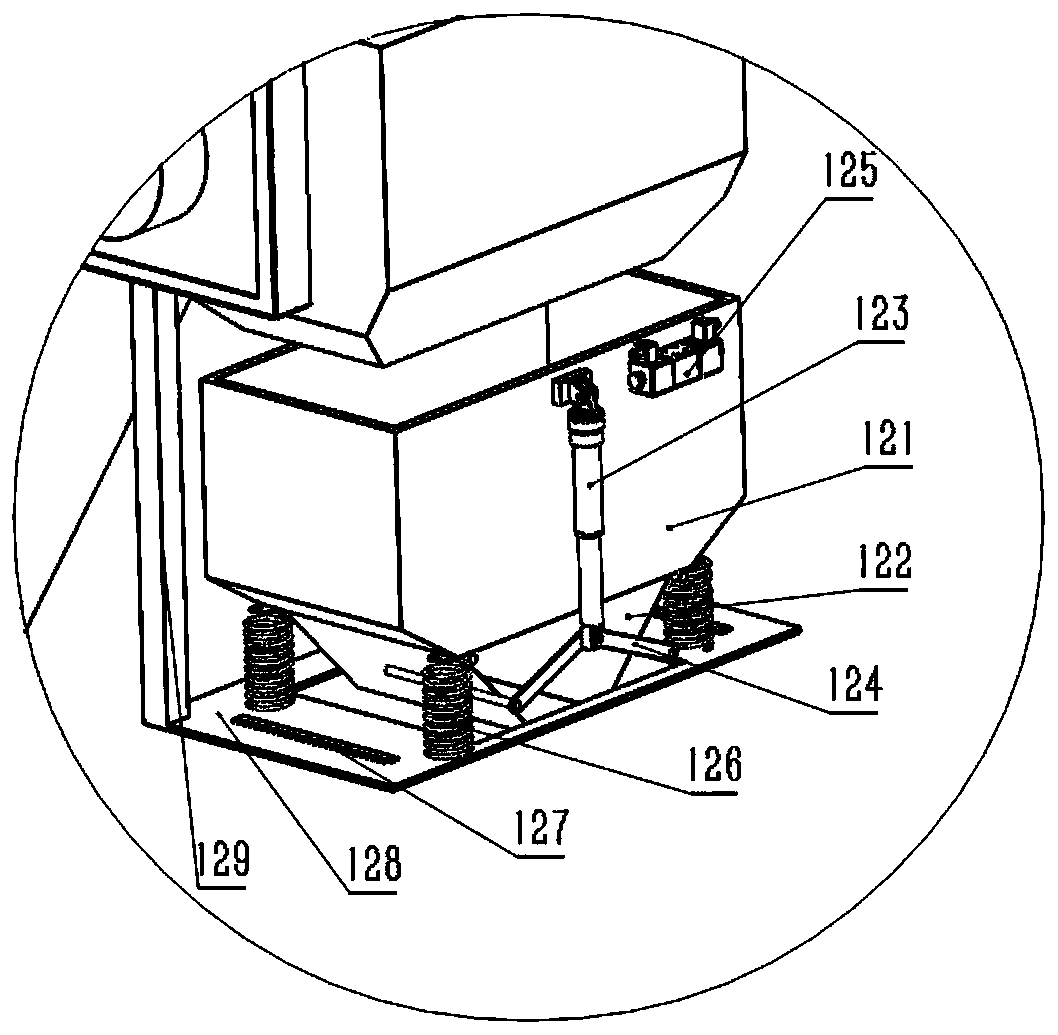

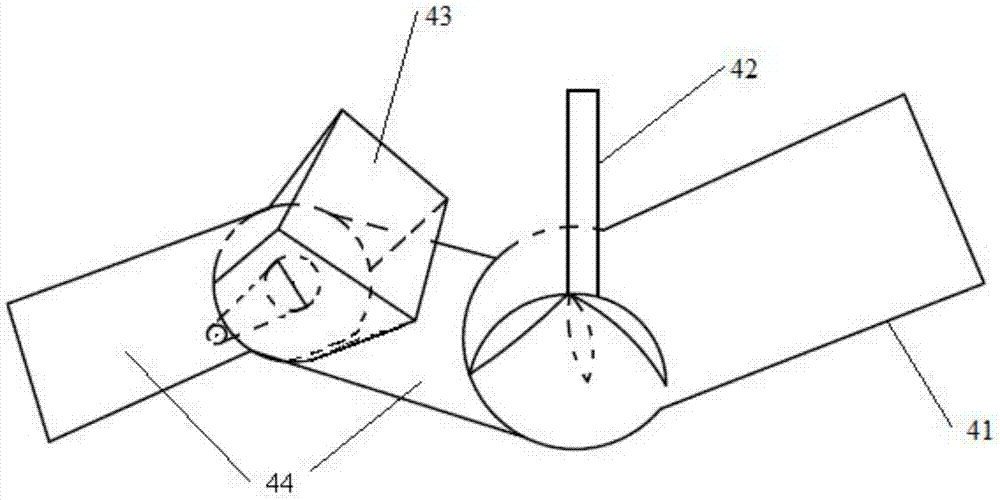

Automatic discharger of tea leaf firing machine

InactiveCN102630768AEliminates the hassle of manual retrievingImprove tea production efficiencyPre-extraction tea treatmentTemperature controlAgricultural engineering

The invention relates to a tea leaf firing machine, and in particular relates to an automatic discharger of a tea leaf firing machine. The automatic discharger comprises a stand, a tea leaf firing pot and a vibrative conveying slot, wherein the edge of the tea leaf firing pot is connected with the stand along the middle part of the tea leaf firing pot through a hinge, the hinge is fixed at the middle part of a cross beam at the upper part of the stand, the vibrative conveying slot is arranged in the stand below the tea leaf firing pot, the automatic discharger of the tea leaf firing machine further comprises an electric push rod, one end of the electric push rod is hinged with the middle-upper part of the edge of the tea leaf firing pot, the other end of the electric pushing rod is hingedwith the stand, and the automatic discharger further comprises an electric heater and a temperature controller, and the electric heater is fixed on one side of the middle part of the outer surface ofthe bottom of the tea leaf firing pot. The automatic discharger disclosed by the invention is additionally provided the electric push rod and the electric heater so as to be capable of automatically discharging materials without troubles of manually charging materials, largely improve tea leaf making efficiency and be clearer and more environmental-friendly.

Owner:信阳市华阳工贸有限公司

Automobile top cover die

The invention relates to equipment for automobile production, in particular to an automobile top cover die which comprises an upper die seat and a skylight puncher. A movable pushing plate and a switching cylinder driving the movable pushing plate to move in the horizontal direction are further arranged on the upper die seat, the skylight puncher is connected under the upper die seat in a lifting mode, the movable pushing plate is located between the upper die seat and the skylight puncher, a first jacking convex block is arranged on the lower surface of the movable pushing plate, and a second jacking convex block matched with the first jacking convex block is arranged on the upper end face of the skylight puncher. The automobile top cover die can meet production requirements of top covers with skylights and top covers without skylights, and solves the problem that two sets of dies are needed for top covers with skylights and top covers without skylights of the same automobile type.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

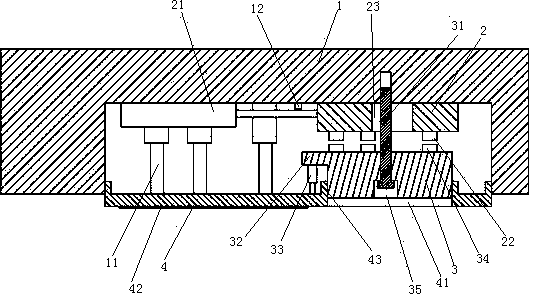

Dual-station chip test sorting machine

PendingCN109909180AIncrease productivityImprove tea production efficiencySortingElectrical and Electronics engineeringPull off test

The invention discloses a dual-station chip test sorting machine. The dual-station chip test sorting machine comprises a pair of feeding assemblies, a pair of test assemblies, a rotating disc assembly, a pressing assembly, and a pair of material dividing boxes which are installed on a working platform. The feeding assemblies are used for conveying to-be-tested chips to the test assemblies; the test assemblies are used for testing the to-be-tested chips; the rotating disc assembly is used for taking out the to-be-tested chips in the feeding assemblies and conveying the to-be-tested chips to thetest assemblies for testing, and finally conveying the to-be-tested chips to the material dividing box for sorting; The pressing assembly is used for controlling a suction nozzle on the rotating discassembly to move up and down and absorb the to-be-tested chips; and the material dividing boxes are used for separately collecting the tested chips. According to the dual-station chip test sorting machine, during the vibration process of the direct shock feeding track, adhered chips are separated through a blowing pipe, and the overlapped to-be-tested chips are separated through the pressing needle, so that it is ensured that the suction nozzle on the rotating disassembly can accurately absorb the to-be-tested chips, thus the production efficiency is improved, and the dual-station chip test sorting machine can be used for chip testing.

Owner:扬州爱迪秀自动化科技有限公司

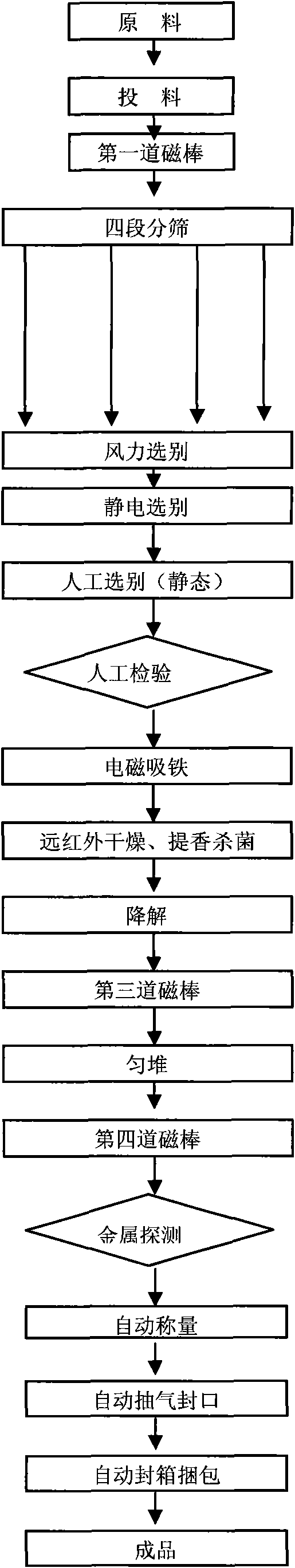

High-purification automatic impurity-removing and tea-sterilizing process

InactiveCN101647502ARaise the gradeImprove qualityPre-extraction tea treatmentFar infraredThermal effect

The invention discloses a high-purification automatic impurity-removing and tea-sterilizing process comprising the following steps: charging, fine processing, weighting and packaging. In the fine-processing step, tea is primarily screened by adopting a winnowing mode and residual impurities in the tea are removed by using a manual-selection mode; aroma-extracting and sterilizing working proceduresare set after the manual-selection step: tea moisture is removed, tea aroma is improved and bacteria in the tea are killed; far infrared rays are adopted to bake and heat the tea so as to greatly improve the tea quality; meanwhile, the far infrared rays have the thermal effect and the biological effect, and keep the activity of the tea and the nutrition and the luster of food to a maximum extent;and the automatic processing degree is high. The invention has the advantages of intelligently controlled technological process, compact connection, strong continuity, effectively controlled secondary pollution, little manpower consumption and high tea-making efficiency.

Owner:浙江茶乾坤食品股份有限公司

Method for low-temperature withering tea leaves

InactiveCN102813019AShorten withering timeImprove tea production efficiencyPre-extraction tea treatmentCold airPhysical chemistry

Owner:贵州怡壶春生态茶业有限公司

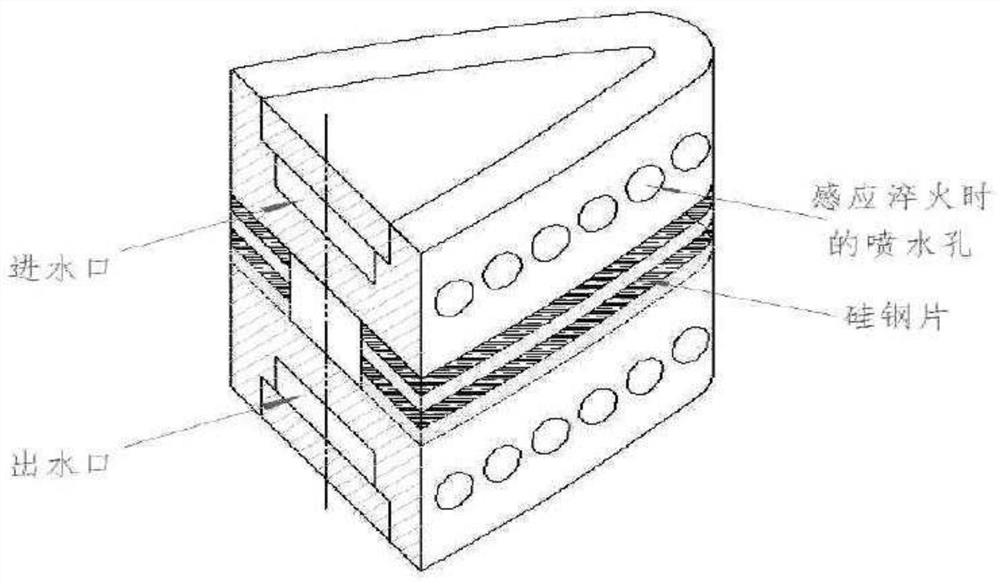

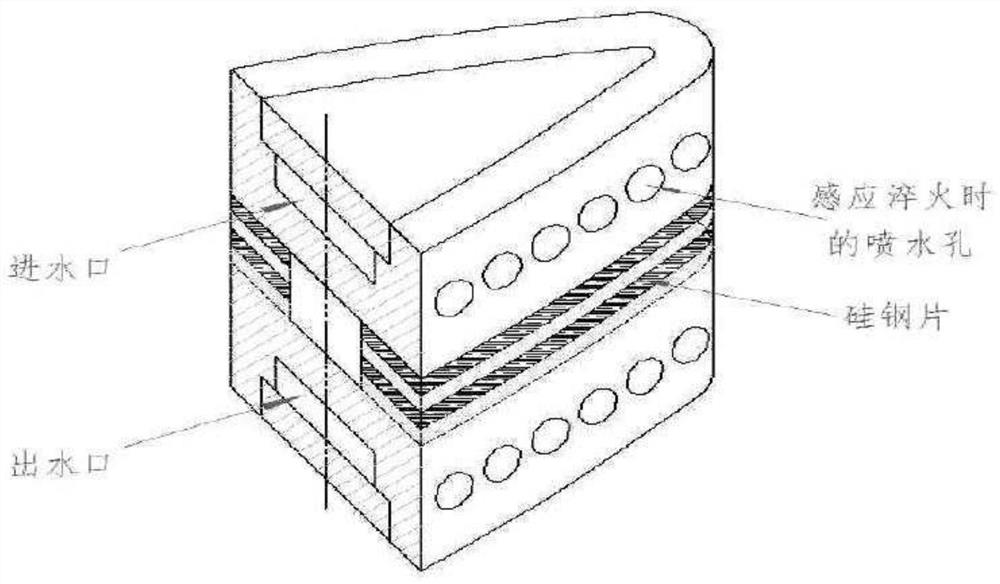

Carburizing and quenching large inner gear ring machining method

The invention discloses a carburizing and quenching large inner gear ring machining method. The method comprises the steps of removing of machining stress, semi-finish turning, gear milling, carburizing, induction quenching, finish turning and tooth grinding in sequence after tooth punching is completed; carburizing is carried out according to the set depth of a hardening layer; tooth-by-tooth induction quenching is carried out in a profiling mode in the induction quenching process; a vertical lathe is used during finish turning for clamping and machining the machining content including a tooth grinding and clamping benchmark; the alignment process of finish turning includes preliminary alignment and accurate alignment, preliminary alignment is carried out according to the alignment gear center and the leveling end surface, and gear deformation data are obtained by detecting gear reference circle run-out values of multiple sections in the tooth width direction; accurate alignment is conducted according to the obtained gear deformation data and the tooth grinding allowance uniform distribution principle; and according to tooth grinding, the tooth surface is ground to obtain a finished product. The method has the beneficial effects that the gear can be made of low-carbon alloy steel, and is long in service life, low in energy consumption, low in machining cost and high in production efficiency.

Owner:CHONGQING GEARBOX

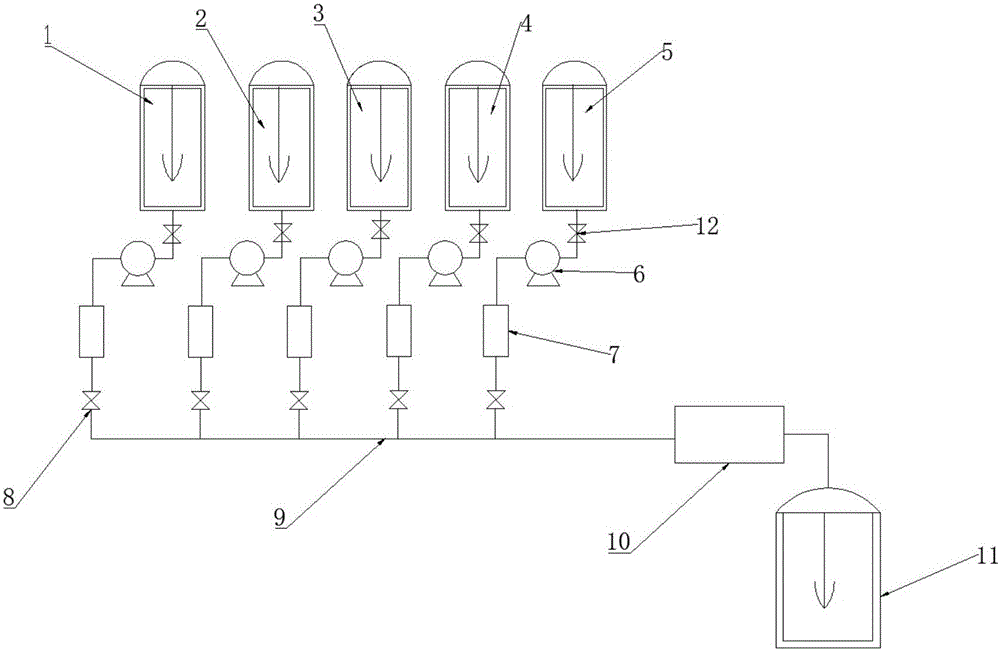

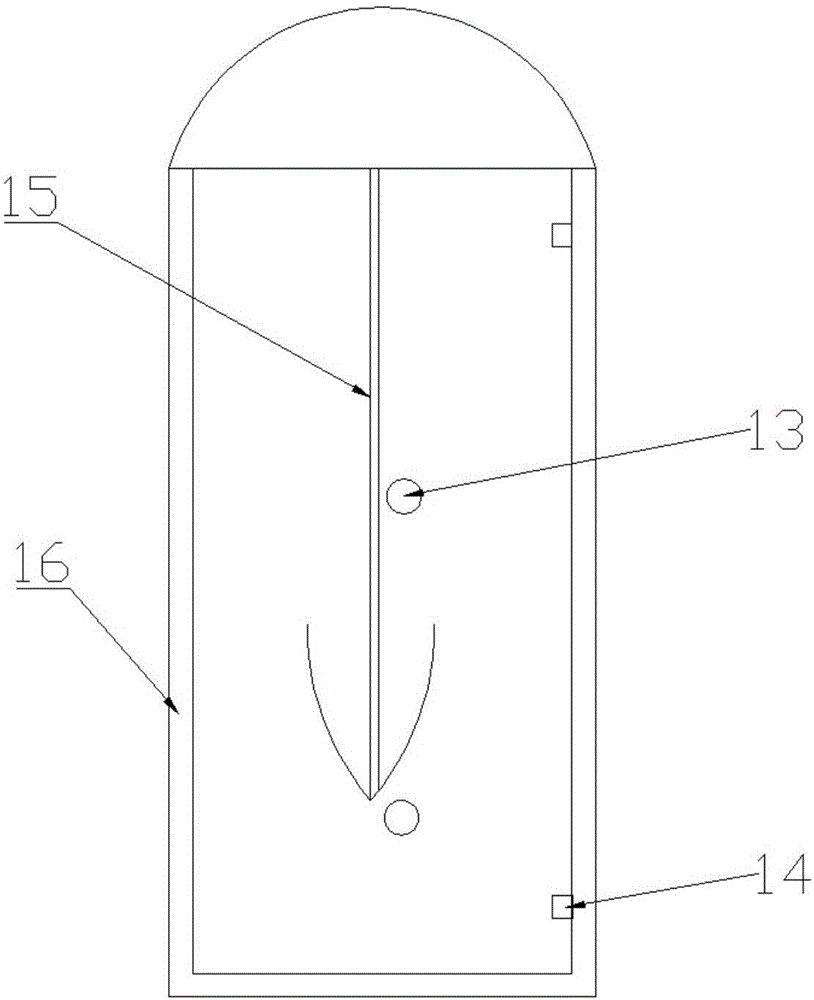

Continuous feeding system for polymerization of carbon fiber precursors

PendingCN106582451ARealize real-time continuous supplyPrecisely control the amount of feedFeed devicesFiberCarbon fibers

The invention discloses a continuous feeding system for the polymerization of carbon fiber precursors, belonging to the technical field of the production of carbon fibers. The continuous feeding system comprises a dimethyl sulfoxide storage tank, an acrylonitrile storage tank, a plurality of monomer storage tanks, an initiator storage tank, pumps, mass flow meters, regulating valves, a static mixer and a mixed liquid storage tank, wherein the dimethyl sulfoxide storage tank, the acrylonitrile storage tank, the monomer storage tanks and the initiator storage tank are independently connected with the pumps through independent pipelines; the pumps are respectively and sequentially connected with the mass flow meters and the regulating valves; each pipe connected with the regulating valve is communicated with the static mixer; and the static mixer is communicated with the mixed liquid storage tank through the pipeline. According to the continuous feeding system, each raw material storage tank is connected with the pump, respectively, the mass flow meters and the regulating valves are sequentially and respectively connected to the pipelines so as to independently and precisely control the feeding quantity of each storage tank, so that the real-time and continuous feeding of raw materials of different formulae can be realized; and meanwhile, the continuous product can be realized, so that the production efficiency is substantially improved, and the product quality is stable.

Owner:HARBIN TIANSHUN CHEM TECH DEV CO LTD

Tea leaf fixation method

InactiveCN103156007AShorten the timeImprove tea production efficiencyPre-extraction tea treatmentEngineeringTea leaf

Owner:贵州省凤冈县浪竹有机茶业有限公司

Preparation method of sea-buckthorn and gingko tea

The invention discloses a preparation method of sea-buckthorn and gingko tea, belonging to the field of drinking tea, in particular to the field of preparation of drinking tea. The sea-buckthorn and gingko tea with good quality is prepared by pickling sea-buckthorn leaves, processing the sea-buckthorn leaves, baking the sea-buckthorn leaves, and screening the sea-buckthorn leaves, and adding a gingko extracting solution. According to the preparation method, the influences of temperature and time on the active ingredients of the sea-buckthorn leaves during tea preparation process are reasonably considered, through reasonable matching of temperature, time and operation, the nutrition value and the active ingredients of the sea-buckthorn leave can be reserved, and meanwhile, through mixing of the sea-buckthorn leaves and gingko, the drinking tea with good effects of reducing blood pressure and blood fat and clearing away waste in blood vessels is obtained.

Owner:四川珍福堂商贸有限公司

Bridge vehicle top cover die

The invention relates to vehicle production equipment, in particular to a bridge vehicle top cover die comprising an upper die seat, a skylight punch and a pressure plate. The upper die seat is provided with a movable push plate and a switching cylinder driving the movable push plate to move horizontally; the skylight punch is connected onto the upper die seat in a lifting manner, the movable push plate is located between the upper die seat and the skylight punch, the lower surface of the movable push plate is provided with a first ejecting projection, the upper end face of the skylight punch is provided with a second ejecting projection matching with the first ejecting projection, the skylight punch is provided with a first air spring extending vertically, the first air spring is connected to the pressure plate, the lower surface of the pressure plate is provided with a rubber layer, and the skylight punch penetrates the pressure plate. The bridge vehicle top cover die is capable of meeting the requirements of producing top covers with skylight and without skylight, and the defects that the top covers with skylight and without skylight of vehicles in the same specification is produced through two sets of dies is solved.

Owner:泰州英格伟精密机械有限公司

Houkui tea making device and tea making technology

The invention belongs to the field of Houkui tea making and particularly relates to a tea making device automatically conducting deactivation of enzymes and tip pinching to make Houkui.The tea making device comprises a conveying device, an enzyme deactivation device, a tip pinching device and an output device.The conveying device is a crawler-type conveyor belt across the enzyme deactivation device and is provided with a transmission groove.The enzyme deactivation device combines far infrared and microwaves.The tip pinching device is provided with a material inlet and a tip pinching idler wheel.The tea making device has the advantages that the far infrared and the microwaves are adopted at the same time to conduct enzyme deactivation, tea aroma enhancing is benefited, and the color of tea leaves which are subjected to enzyme deactivation is superior to that of manually-made tea leaves; the tea leaves can not extrude or broken up, and the condition formed after tip pinching is better; enzyme deactivation and tip pinching are conducted on the same assembly line, the labor cost is saved, and the tea making efficiency is improved.

Owner:张秋红

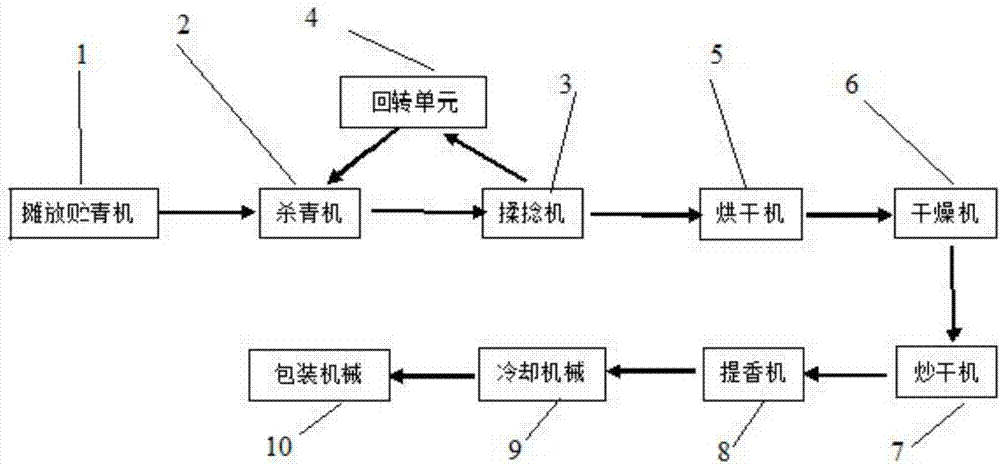

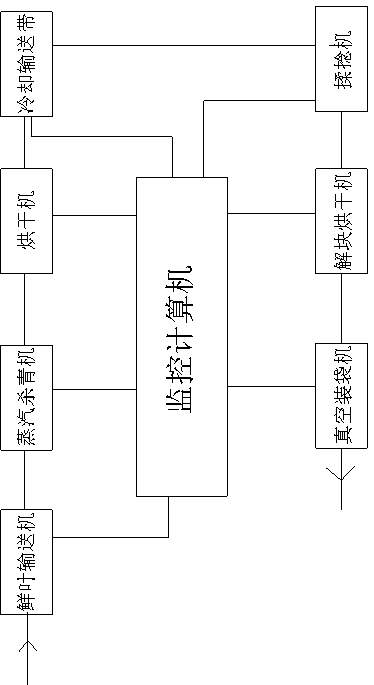

Processing system for high-mountain green tea

InactiveCN107279341ARealize multiple continuous finishing and kneading operationsStrong tastePre-extraction tea treatmentFlavorAgricultural engineering

The invention provides a processing system for high-mountain green tea. The processing system comprises a spreading and green-leaf storage machine, an enzyme deactivating machine, a rolling machine, a dryer, a drying machine, a stir-frying machine, a flavor distilling machine, a packaging machine, a rotary unit and a cooling machine, wherein the input end of the rotary unit is connected with the discharge outlet of the rolling machine, and the output end of the rotary unit is connected with feed inlet of the enzyme deactivating machine, so a circle is formed; the spreading and green-leaf storage machine is connected with the feed inlet of the enzyme deactivating machine; the discharge outlet of the rolling machine is connected with the dryer; the dryer is connected with the drying machine; the drying machine is connected with the stir-frying machine; the stir-frying machine is connected with the flavor distilling machine; the flavor distilling machine is connected with the cooling machine; and the cooling machine is connected with the packaging machine. The processing system for the high-mountain green tea can carry out two or more than two continuous enzyme deactivation and rolling operations on tea leaves; the prepared high-mountain green tea is free of astringent and grass taste; and compared with conventional processing system for green tea, the processing system provided by the invention saves energy by 30%, reduces production cost by 55% and increases output by 40%.

Owner:广西西林九龙山茶业有限公司

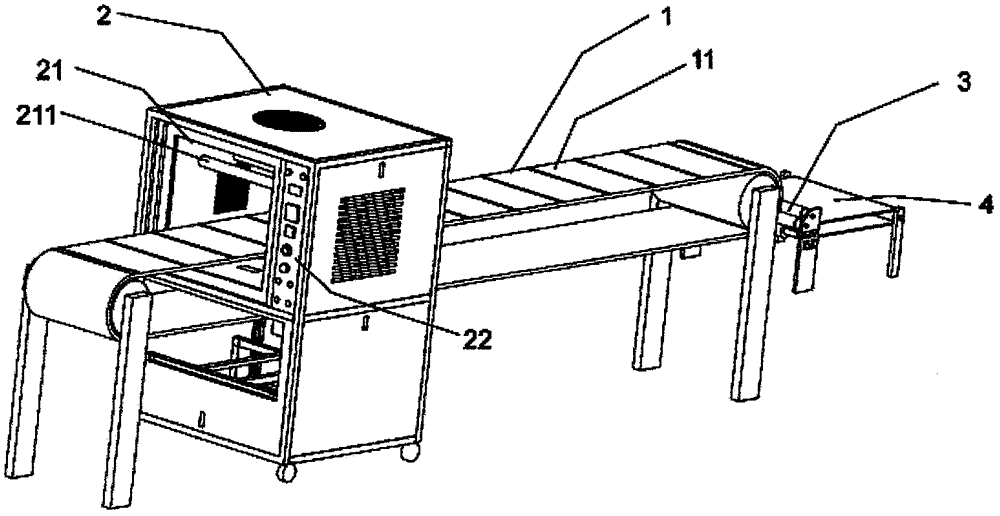

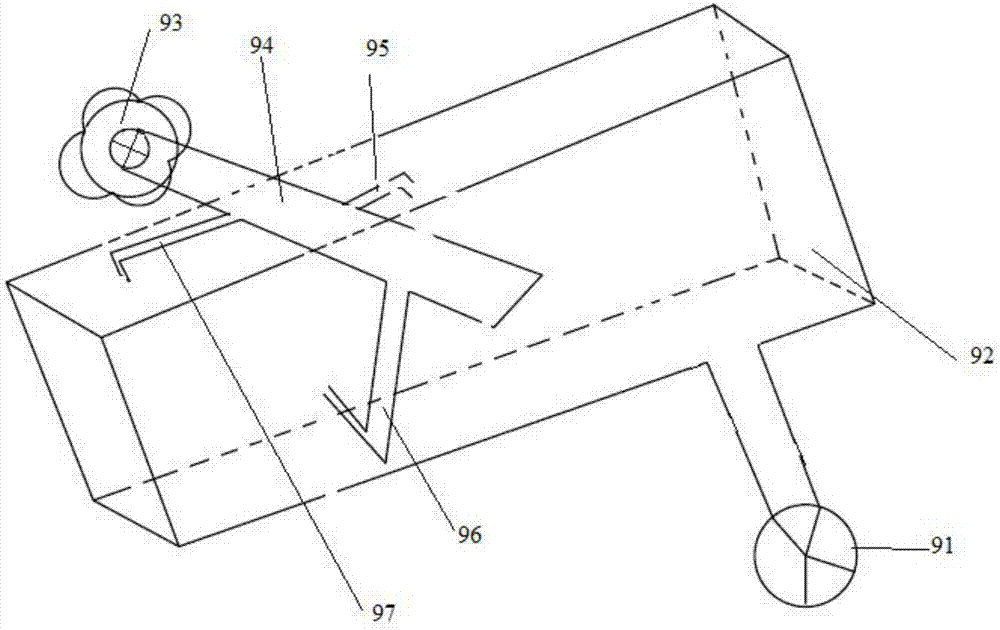

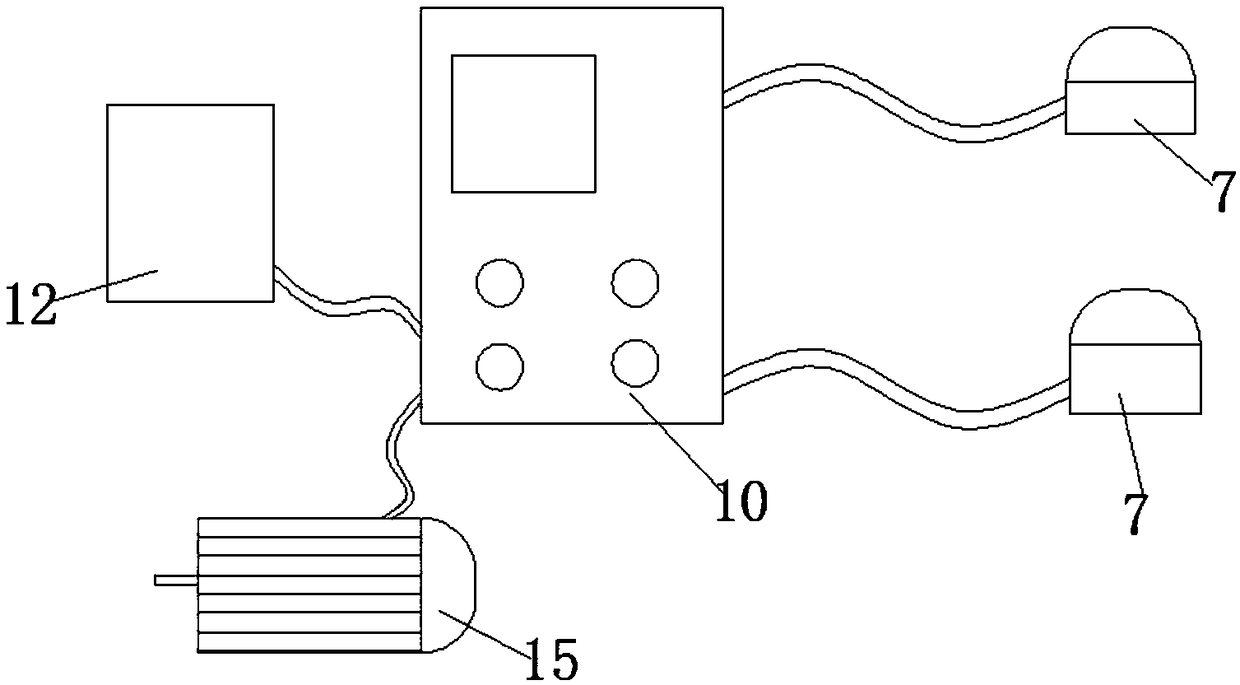

Tea-frying production line

InactiveCN103416513AImprove tea production efficiencyPre-extraction tea treatmentProduction lineSteam pressure

The invention relates to a tea-frying production line which comprises a fresh tea leaf conveyor, a steam enzyme-deactivating machine, a dryer, a cooling and conveying belt, a twisting machine, a vibrating and unblocking dryer and a vacuumizing and bagging machine in sequential arrangement. A steam pressure electromagnetic valve is arranged on a steam pipeline of the steam enzyme-deactivating machine, electric heating pipes are arranged in both the dryer and the vibrating and unblocking dryer, and driving motors are arranged on the fresh tea leaf conveyor, the cooling and conveying belt, the twisting machine and the vibrating and unblocking dryer. The tea-frying production line further comprises a monitoring control computer, and a control end of the monitoring control computer is connected with the motor of the fresh tea leaf conveyor, the steam pressure electromagnetic valve in the steam enzyme-deactivating machine, the electric heating pipe in the dryer, the motor of the cooling and conveying belt, the motor in the twisting machine, the motor and the electric heating pipe in the vibrating and unblocking dryer, and a controlled end of the vacuumizing and bagging machine. A novel steam-type tea-frying production line is provided, and tea making efficiency can be effectively improved by the production line.

Owner:SUZHOU XISHAN HONGYUN MATERIAL ARTICLES FACTORY

Device for withering and shaking tea leaves

The invention relates to the field of tea making, in particular to a device for withering and shaking tea leaves. The device comprises a support table. The cap is fixed at the geometric center position of the base surface of the support table. The base surface of the cap is provided with a hollow column, and the inner sleeve of the hollow column is connected with a rotating shaft. The end of the rotating shaft is fixedly connected with a three-way braced structure. The end of the three-way braced structure is fixed with a connecting rod. One end of the connecting rod away from the three-way arm structure is sleeved with a bearing. The outer wall of the bearing is jacketed with supporting arms. The ends of the arm away from the connecting rod are fixedly connected with a spring. The springis fixedly connected to the rocker plate at one end away from the arm. The inside of the rocker is provided with a winding pipe. Steel balls are built into the pipe around the wall. The invention perfectly simulates the manual shaking green, so that the efficiency is increased without lowering the quality.

Owner:安徽香草茶业有限公司

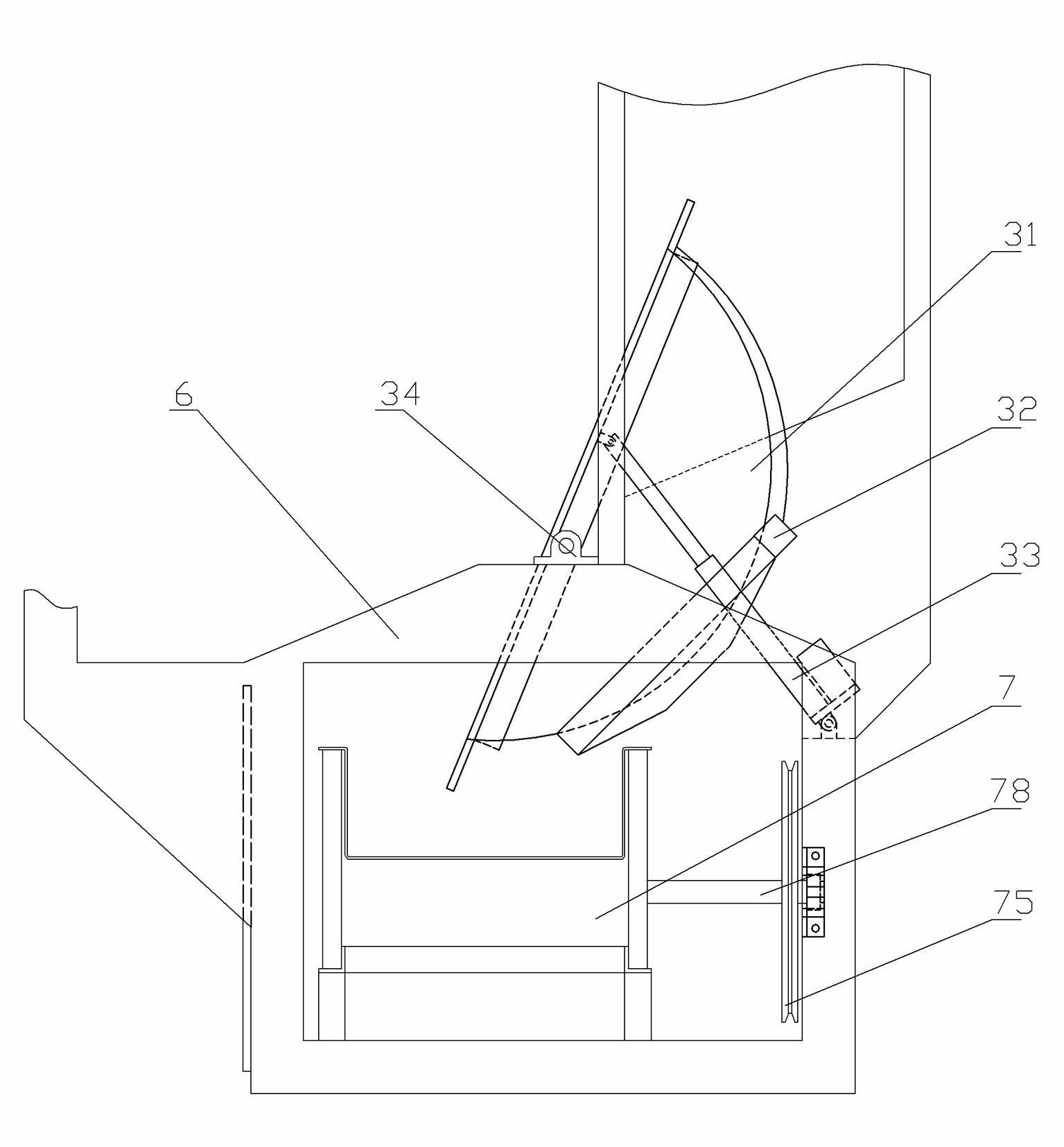

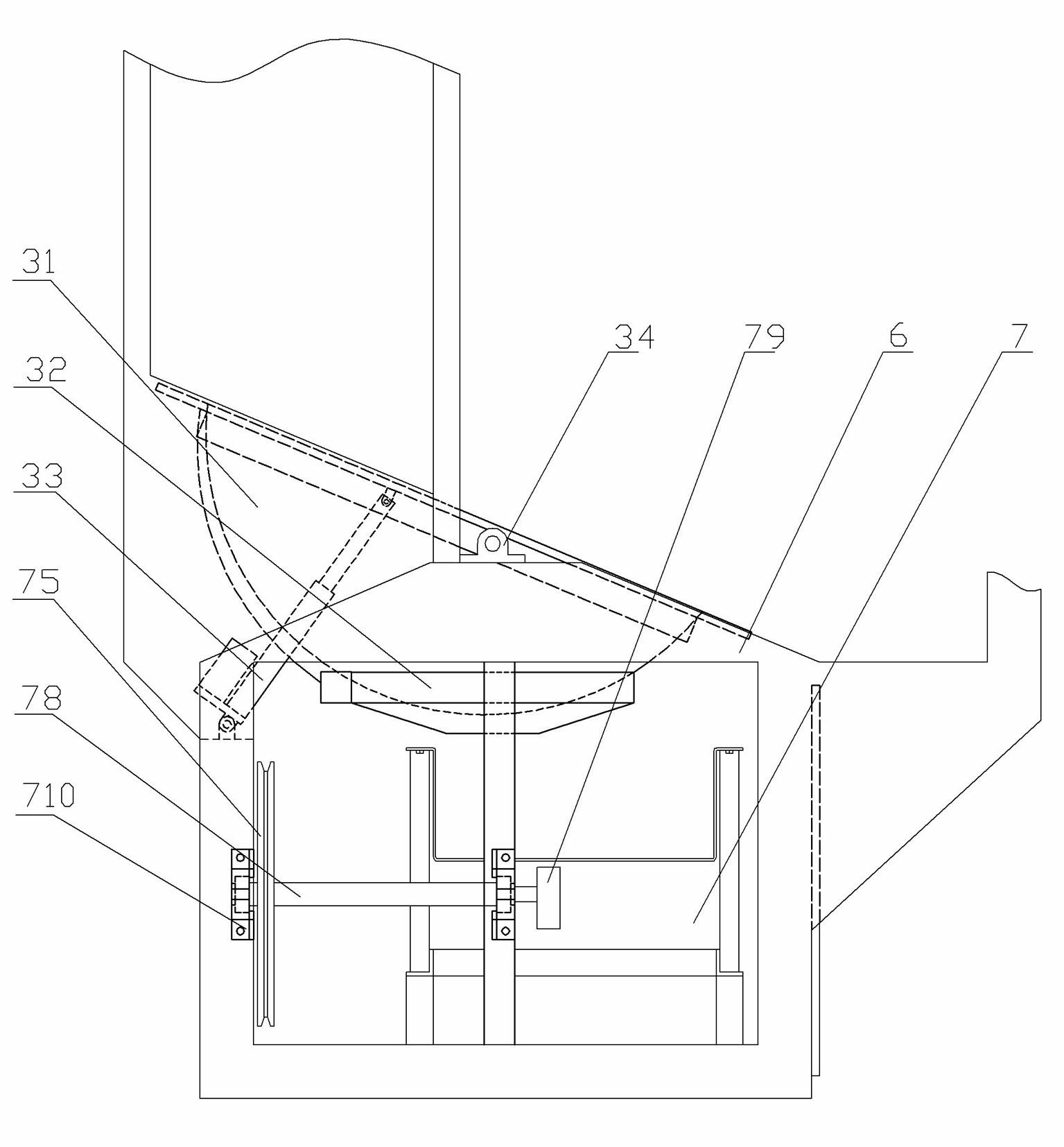

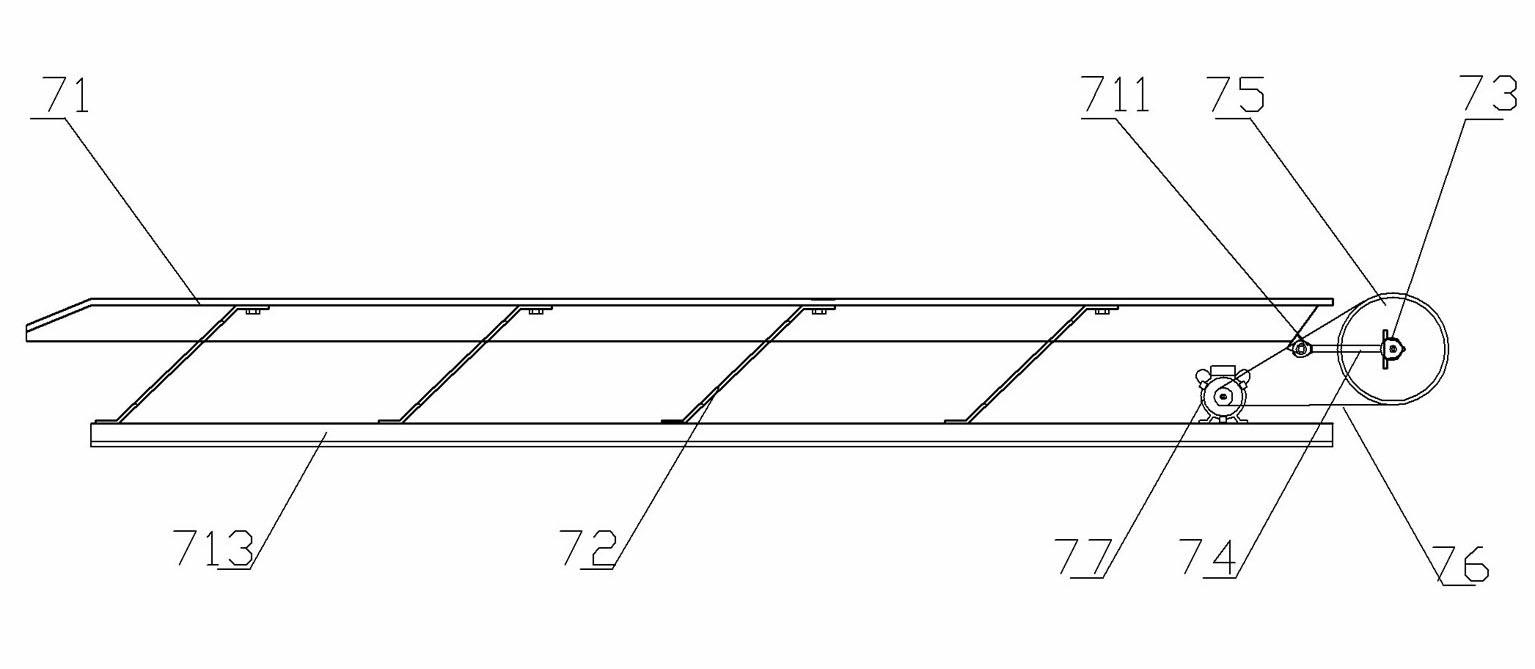

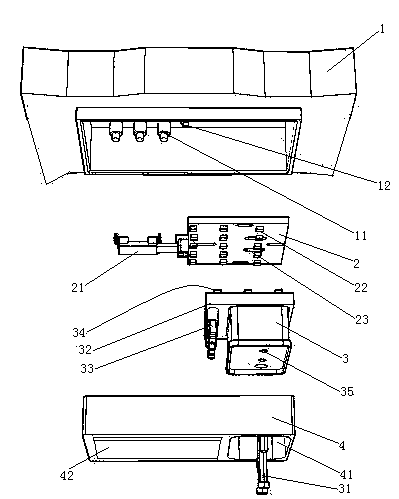

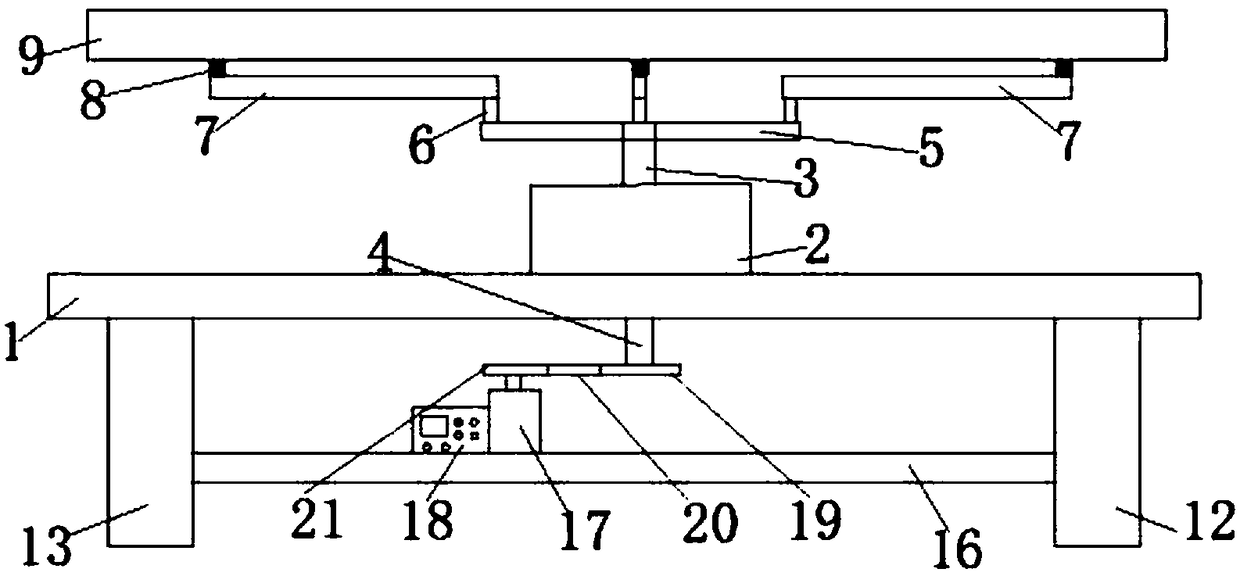

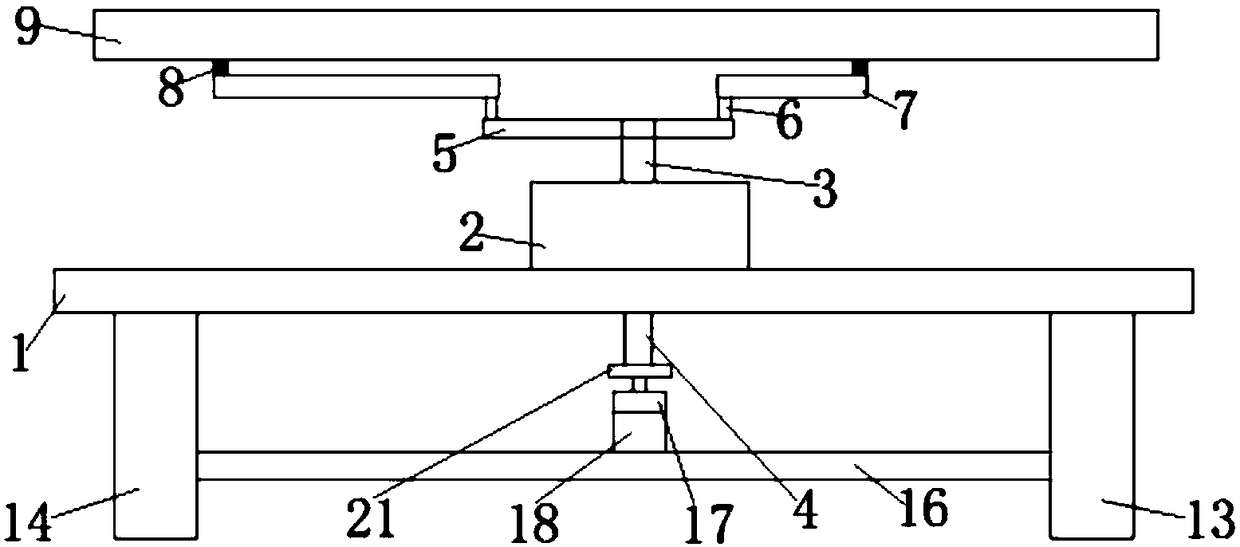

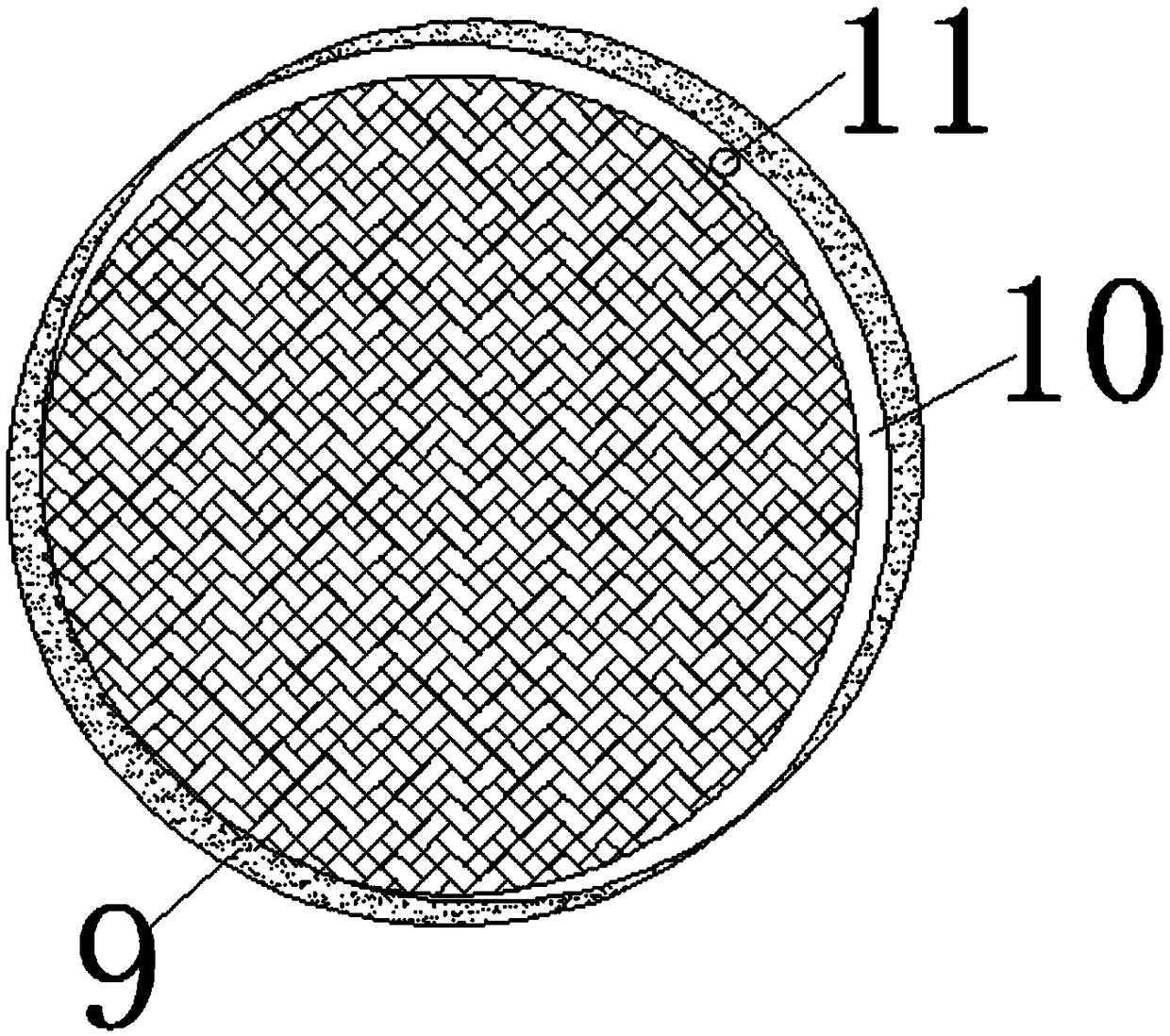

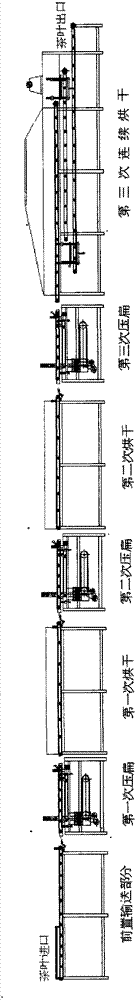

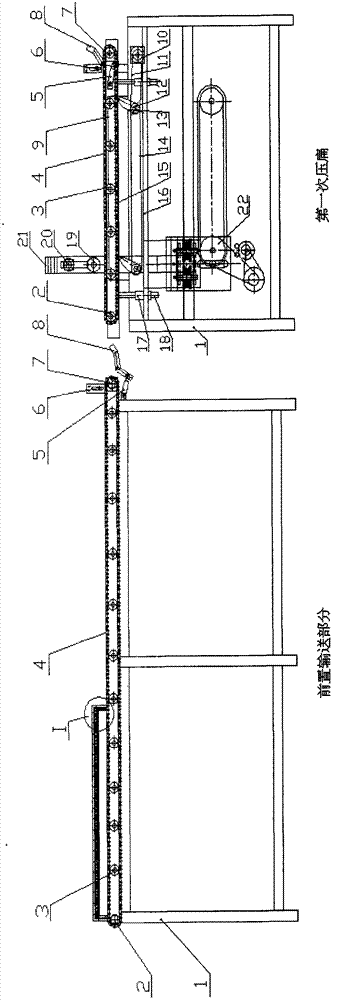

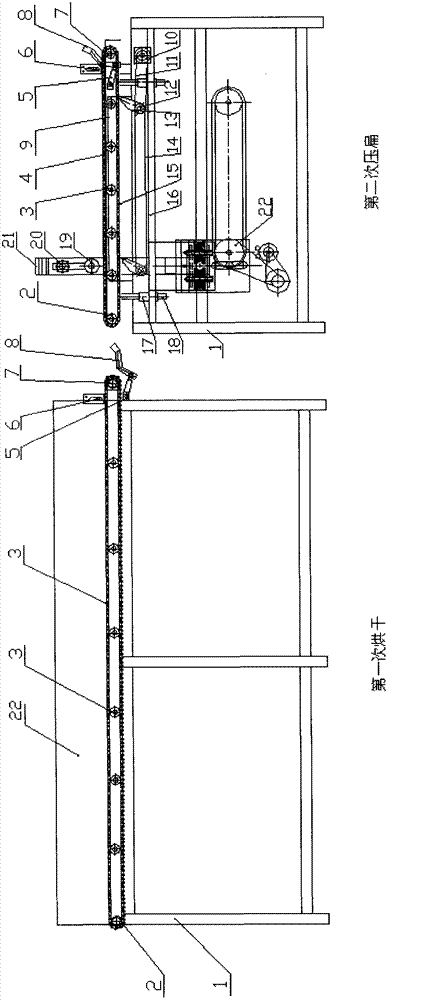

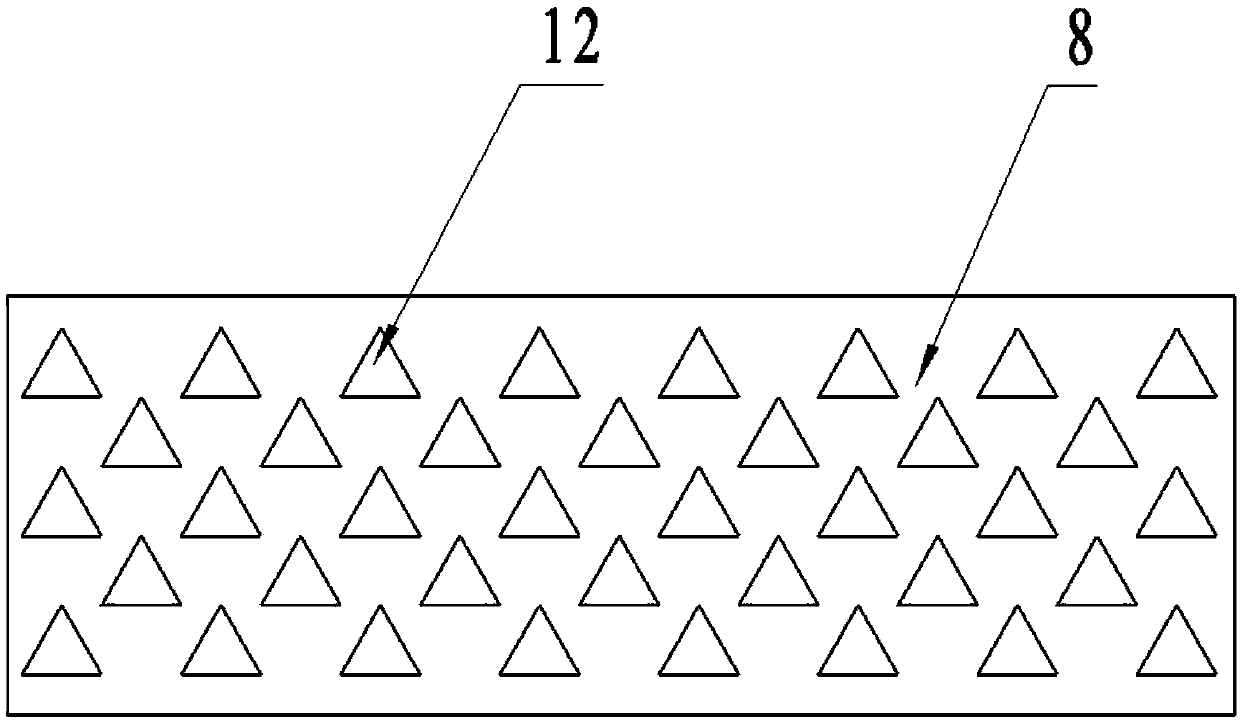

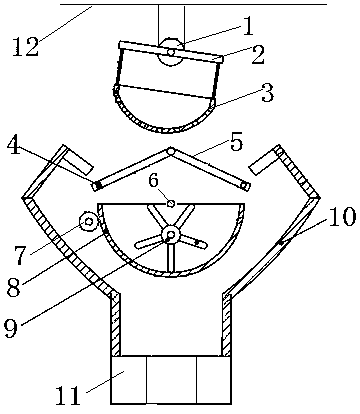

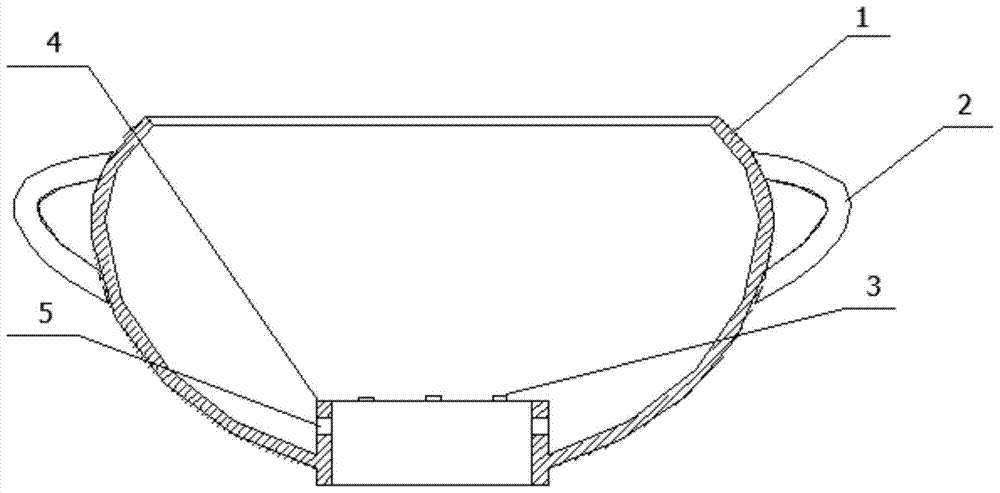

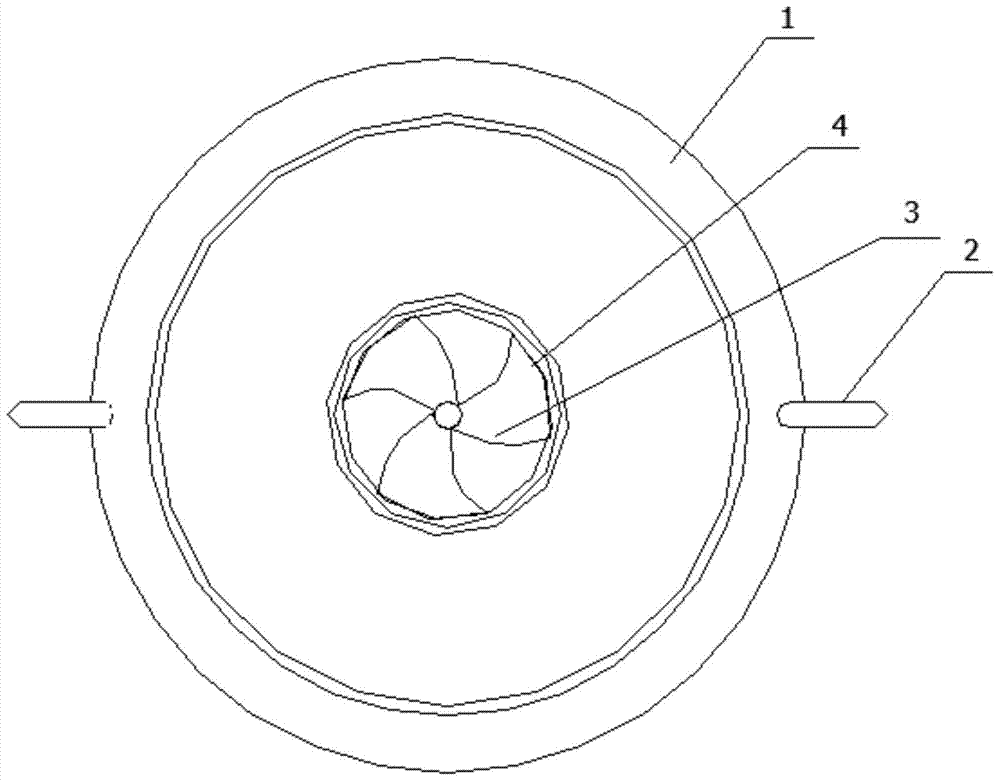

Fully-automatic tea flattening drying streamline

InactiveCN102813013AProcessing technology conforms toImprove qualityPre-extraction tea treatmentEngineeringCam

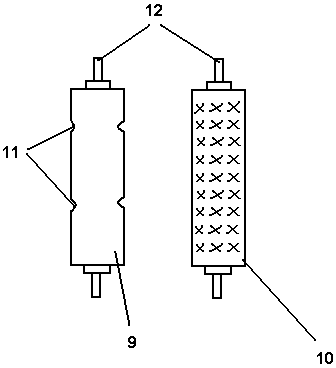

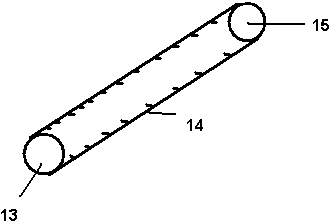

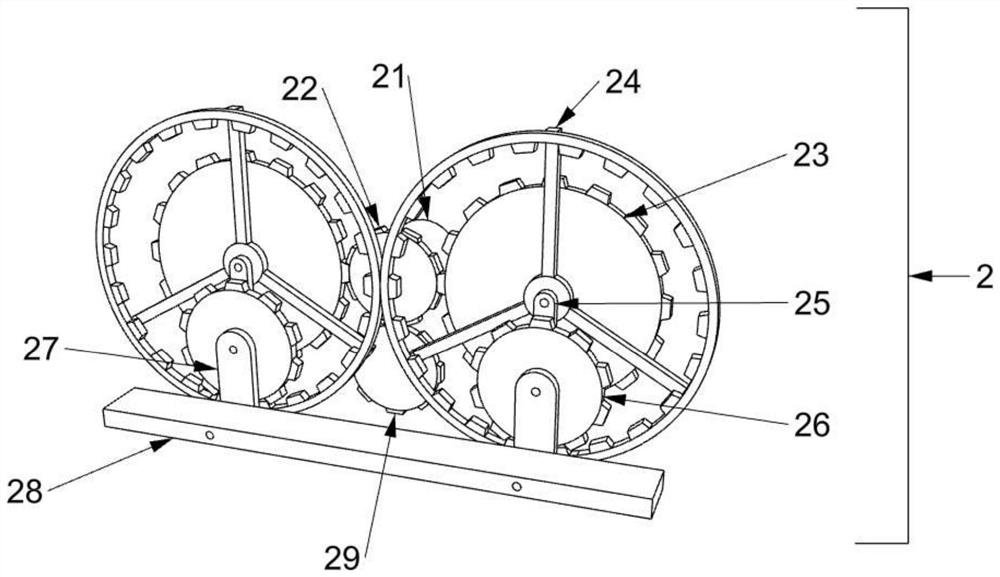

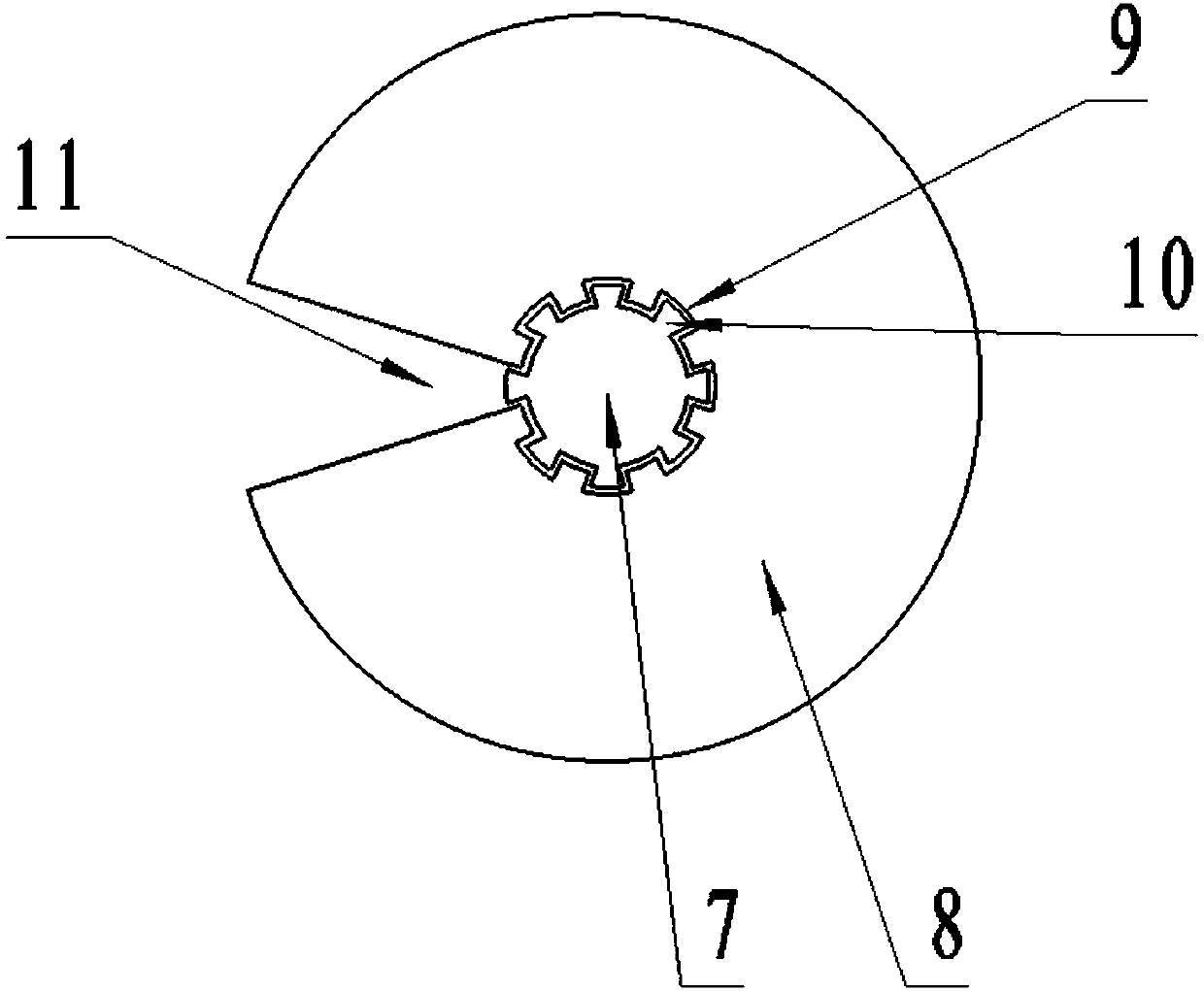

A fully-automatic tea flattening drying streamline is composed of a sieve part, a prepositioned conveying part, a first flattening part, a first drying part, a secondary flattening part, a secondary drying part, a third flattening part, a terminal continuous drying part, and a PLC control part, and mainly comprises frames (1), chain wheels (2), rollers (3), chains (4), cylinders (5), photoelectric switches (6), speed regulation motors (7), spacing baffle blocks (8), flattening workbenches (9), elevating motors (10), belts (11), camshafts (12), cams (13), belts (14), carriages (15), guide sleeve racks (16), guide sleeves (17), guide pillars (18), pressure rollers (19), pressure roller up-and-down movement mechanisms (20), moveable racks (21), pressure roller left-and-right movement mechanisms (22), an oven (23), a fan (24), cylinder supports (25), lifting cylinders (26), travel switches (27), supporting plates (28), guide sleeves (29), guide sleeve supports (30), guide pillars (31), a swing rod (32), a driving rod (33) and a limiting switch (34). A segment flattening and drying technology of tea leaves is carried out in the invention, and has the advantages of high tea preparation efficiency, good flatness and straightness of the tea leaves, and low labor intensity through the adoption of the fully-automatic line production.

Owner:安徽绿源机械科技股份有限公司

Production method of nutritional selenium-enriched soy sauce

InactiveCN110050983AMaintain nutrientsKeep the flavorFood ingredient as taste affecting agentFood ingredient as flavour affecting agentTotal nitrogenAspergillus sojae

The invention discloses a production method of nutritional selenium-enriched soy sauce and belongs to the technical field of fermentation engineering. The production method includes three steps: making koji, fermenting and processing to obtain the soy sauce. Total selenium content of the soy sauce is 2.2-2.4mg / L, and organic selenium content is 1.6-1.8mg / L, so that the soy sauce is rich in selenium content. Total acid of the soy sauce prepared through synergism of aspergillus oryzae, aspergillus sojae and saccharomyces soya is 1.70-1.72g / 0.1L, reducing sugar content is 6.38-6.41g / 0.1L, total nitrogen content is 1.83-1.86g / 0.1L, and the soy sauce is good in fresh taste, coordinated in flavor and good in fragrance and has better fermentation quality than that when one of aspergillus oryzae or aspergillus oryzae and aspergillus sojae or saccharomyces soya is used alone.

Owner:陇南中盛农业开发有限公司

Preparation method of sea buckthorn leaf honey tea

The invention discloses a preparation method of sea buckthorn leaf honey tea, belongs to the field of drinking tea, and particularly belongs to the field of preparation of drinking tea. The preparation method comprises the following steps: picking sea buckthorn leaves, processing the leaves, baking and sieving. The sea buckthorn leaf honey tea with good quality, comprehensive nutrients and relatively good mouth feel is obtained through a technical scheme of adding honey water in a leaf production process; the preparation method is simple and feasible; through reasonable cooperation of temperatures, time and operation in a preparation process, nutritive values and active ingredients of the sea buckthorn leaves can be guaranteed while the tea processing efficiency is improved and the drinking mouth feel of the tea is improved.

Owner:四川珍福堂商贸有限公司

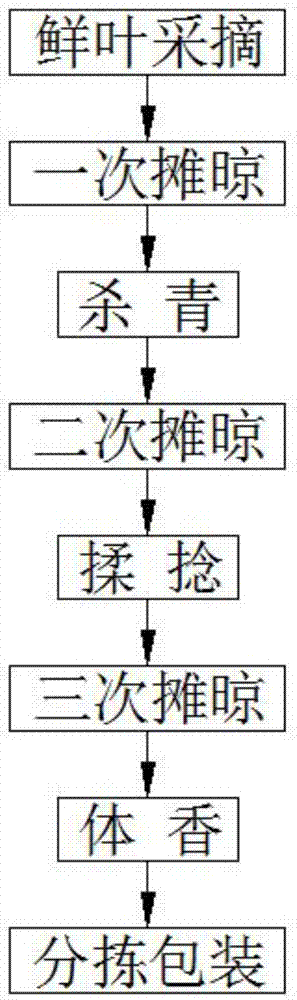

Preparation method of green tea

The invention discloses a preparation method of green tea. The preparation method comprises the following eight process steps: fresh leaf picking, primary spreading and airing, fixation, secondary spreading and airing, rolling, third spreading and airing, aroma enhancement and sorting and packaging. By carrying out secondary spreading and airing, residual moisture in tea leaf stalks is absorbed byfixed tea leaves, so that the moisture of the whole tea leaves is uniform; by carrying out third spreading and airing and aroma enhancement, the moisture in the tea leaves is effectively removed, teaaroma is stimulated, and the tea leaves have strong aroma; and meanwhile, by carrying out manual rolling formation, the complete forms of the tea leaves are furthest protected, and the produced tea leaves have complete forms. According to the preparation method, by combining mechanical production with manual production, the tea production efficiency is high, and furthermore, the produced tea leaves have strong aroma, complete form and good taste.

Owner:ANHUI PAOMAGANG TEA CO LTD

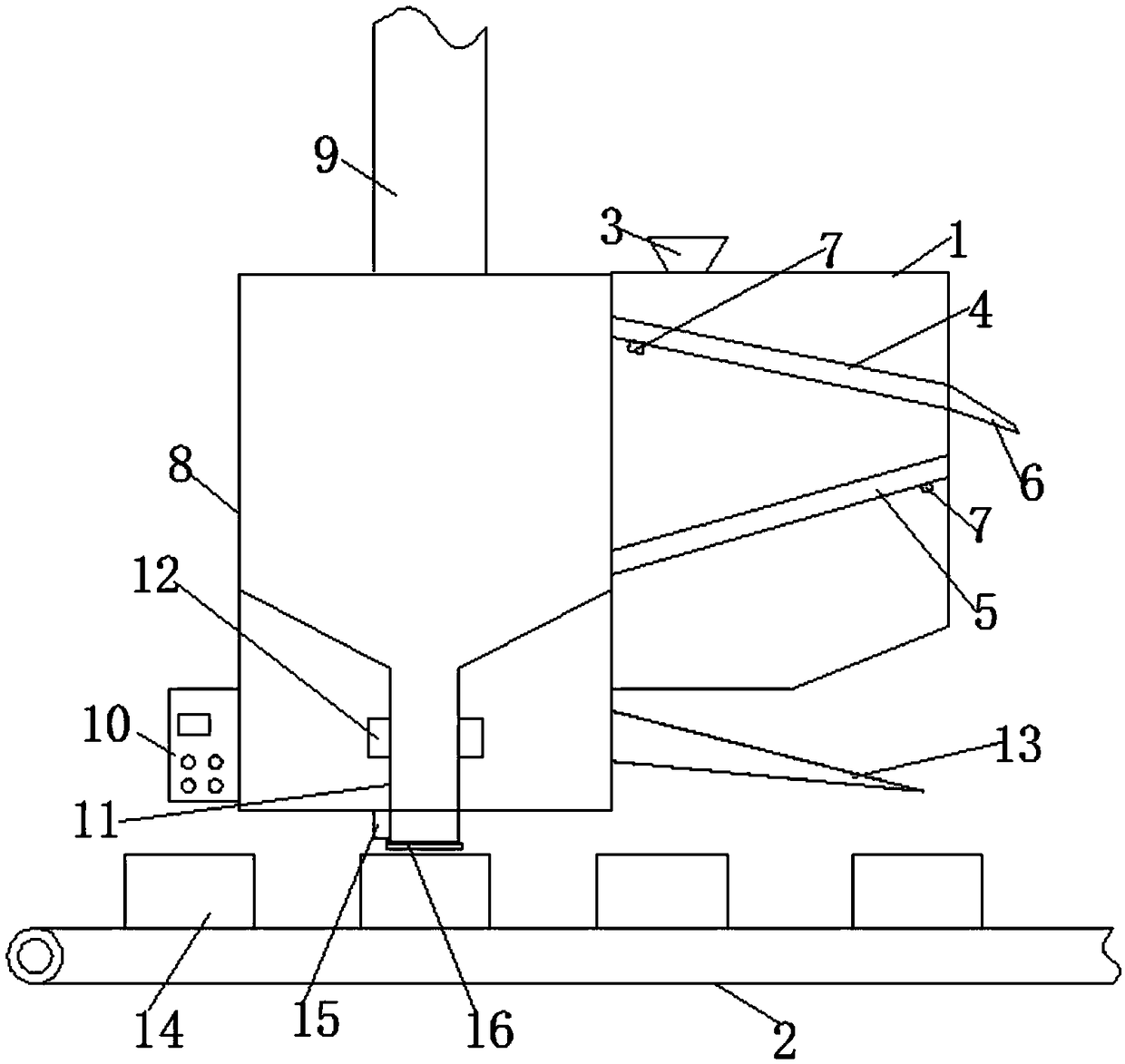

Integrated tea packing device

The invention relates to the technical field of tea manufacturing machinery, in particular to an integrated tea packing device. The integrated tea packing device comprises a screening box and a conveyor belt, a feeding inlet is formed in the base surface of the screening box, and a feeding hopper is arranged at the feeding inlet. A first screening net and a second screening net are arranged in thescreening box, a first discharging groove is fixedly connected to one end of the first screening net, and vibration motors are fixedly connected to the bottoms of the first screen net and the secondscreening net. A working box is fixedly connected to the surface, away from the first discharging groove, of the screening box, a hoisting column and a control electricity box are separately and fixedly connected to the base surface and the side wall of the working box, a tea discharging pipe is arranged in the working box, and ultraviolet ray sterilizing lamps are symmetrically arranged on the pipe wall of the tea discharging pipe. The integrated tea packing device integrates screening, sterilizing and packing, is more integrated, greatly saves labor, and the tea manufacturing efficiency is improved.

Owner:安徽凯盛茶业有限公司

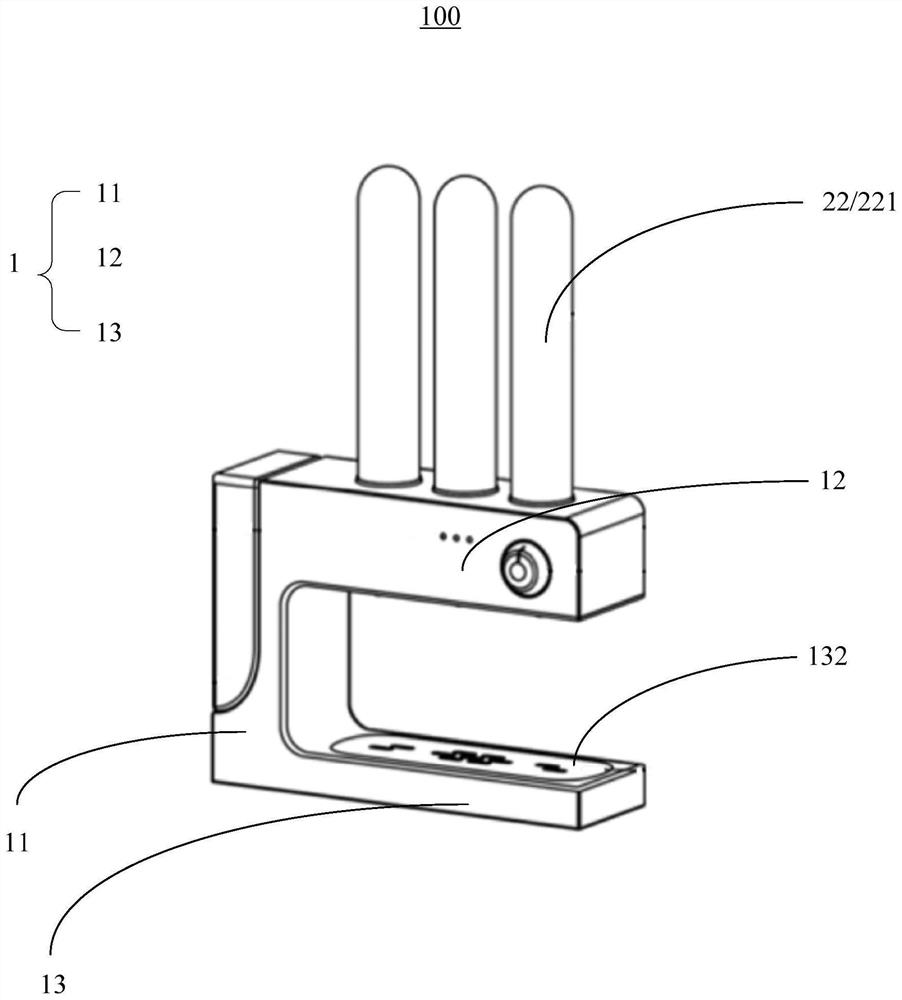

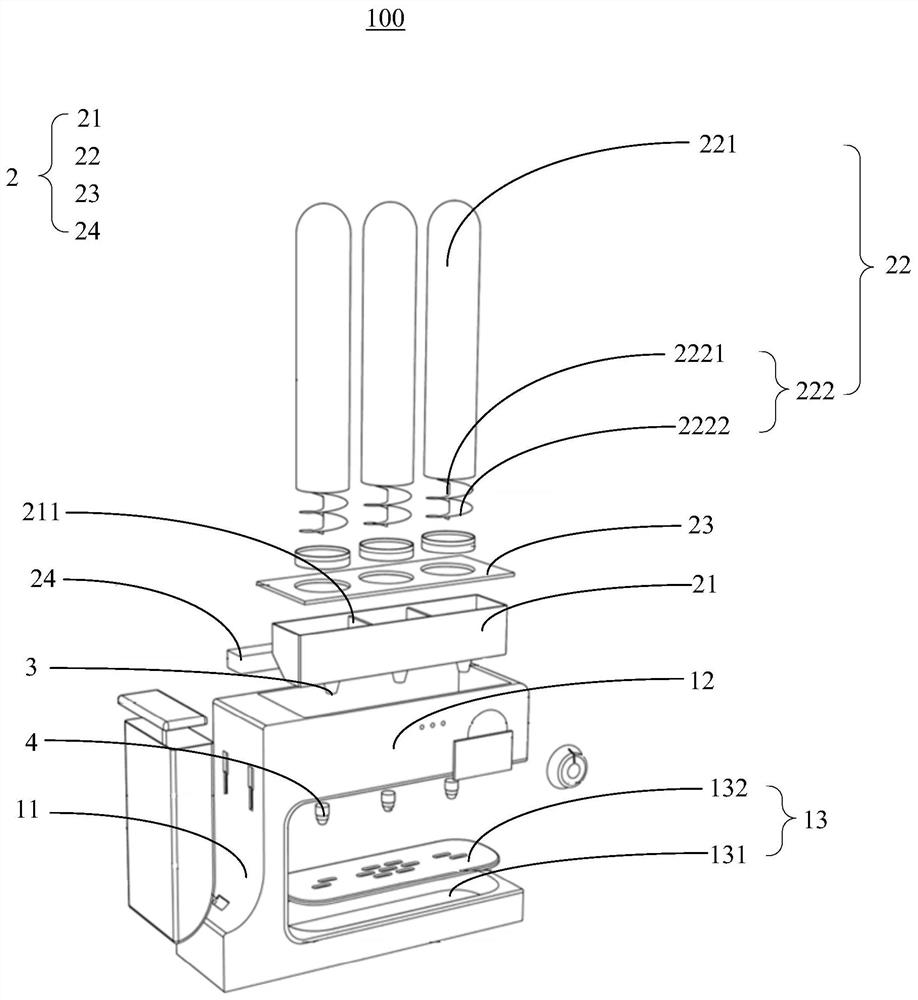

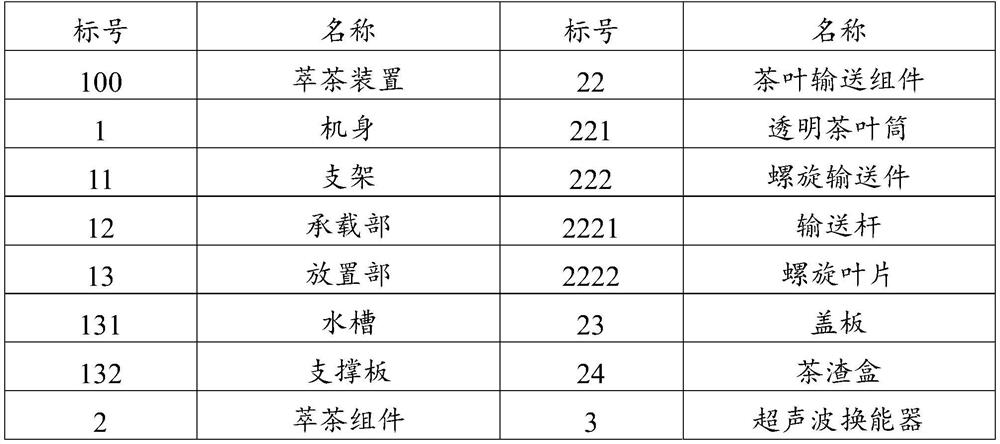

Tea extraction device

ActiveCN113598601AFast extractionReduce waiting timeBeverage vesselsProcess engineeringUltrasonic technology

The invention discloses a tea extraction device. The tea extraction device comprises a machine body, a tea extraction assembly and an ultrasonic transducer, wherein the tea extraction assembly comprises a tea extraction box, the tea extraction box is detachably installed on the machine body and used for containing tea leaves to be extracted and clear water, and the ultrasonic transducer is arranged on the machine body and used for vibrating the tea extraction box; the to-be-extracted tea leaves and the clear water are mixed in the tea extraction box, the ultrasonic transducer is arranged, so the tea extraction device drives the clear water in the tea extraction box to move for extraction through the ultrasonic technology, a user only needs to set parameters of the ultrasonic transducer, and then the vibration frequency is determined; therefore, the brewing operation process is reduced, rapid brewing of the to-be-extracted tea leaves is achieved, the extraction speed of the to-be-extracted tea leaves is increased, the tea extraction preparation time is shortened, tea extraction efficiency is improved, the waiting time of guests is shortened, and the sales volume is increased.

Owner:WUHAN POLYTECHNIC UNIVERSITY

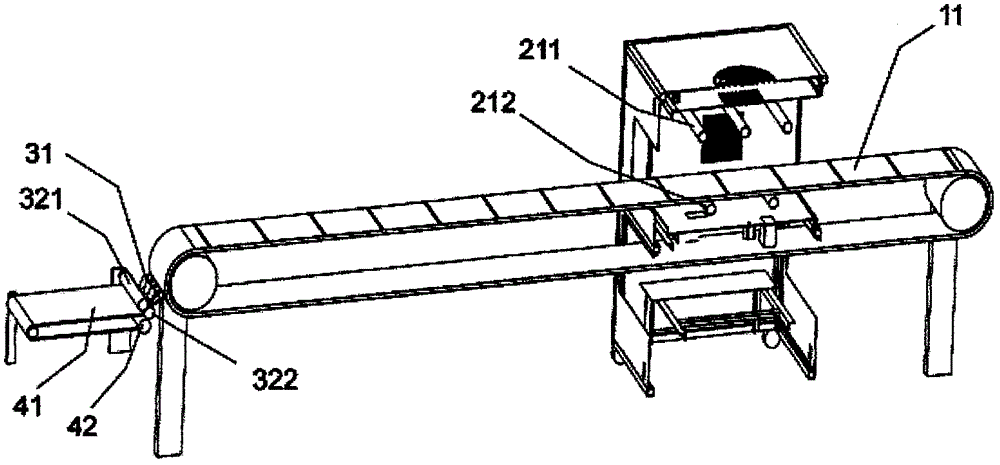

Tea turning apparatus capable of automatically removing crumbs

PendingCN107467244ASimple structureImprove tea production efficiencyPre-extraction tea treatmentEngineeringBelt conveyor

The invention discloses a tea turning apparatus capable of automatically removing crumbs. The tea turning apparatus capable of automatically removing the crumbs comprises a base, mesh belt conveyors, a support, a turning frame, a turning mechanism, a left material guide plate, a right material guide plate, a stirring mechanism, a crumb collecting tank, a soft connector, a waste tank, an air duct, and a Roots blower; the mesh belt conveyor at the left side continuously conveys tea leaves onto the left material guide plate; the turning mechanism works so as to turn over the tea leaves; the stirring mechanism continuously works so that a stirring head rotates so as to uniformly stir and mix the tea leaves under driven force of a second speed control motor; the turned tea leaves are pushed onto the mesh belt conveyor via the right material guide plate so as to carry out subsequent processing; the Roots blower synchronously works when the turning mechanism is working so as to pump the waste tank to realize negative pressure, and thus, fine crumbs fall into the crumb collecting tank through gap between interlocked rings; and then, the crumbs enter the waste tank through the soft connector so as to be stored. The tea turning apparatus is simple in structure, and is capable of automatically turning the tea leaves, as well as carrying out stirring and uniform mixing; moreover, fine crumbs in the tea leaves can be automatically removed so as to effectively improve tea production efficiency and shorten tea preparation cycle.

Owner:ANHUI PAOMAGANG TEA CO LTD

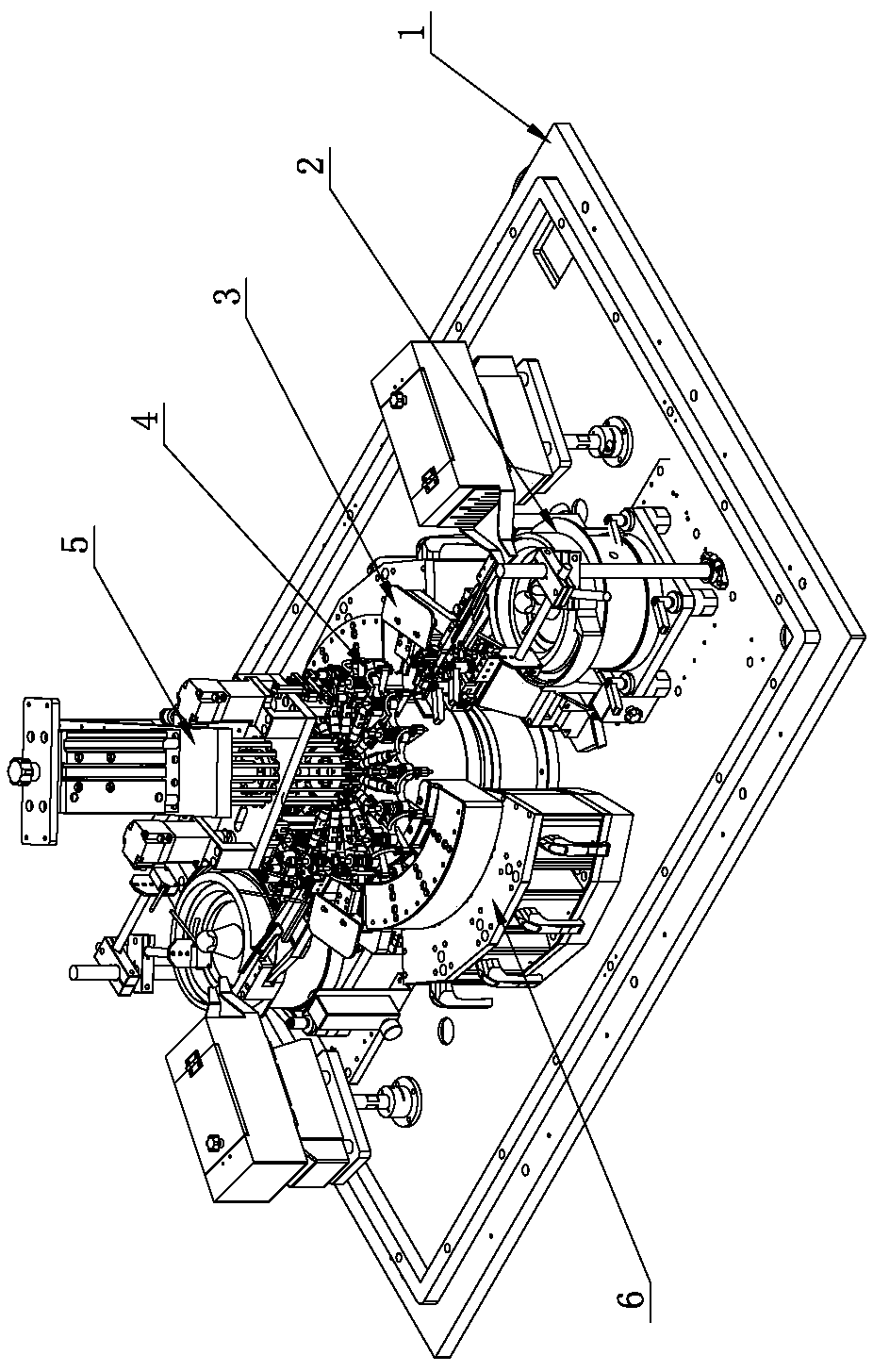

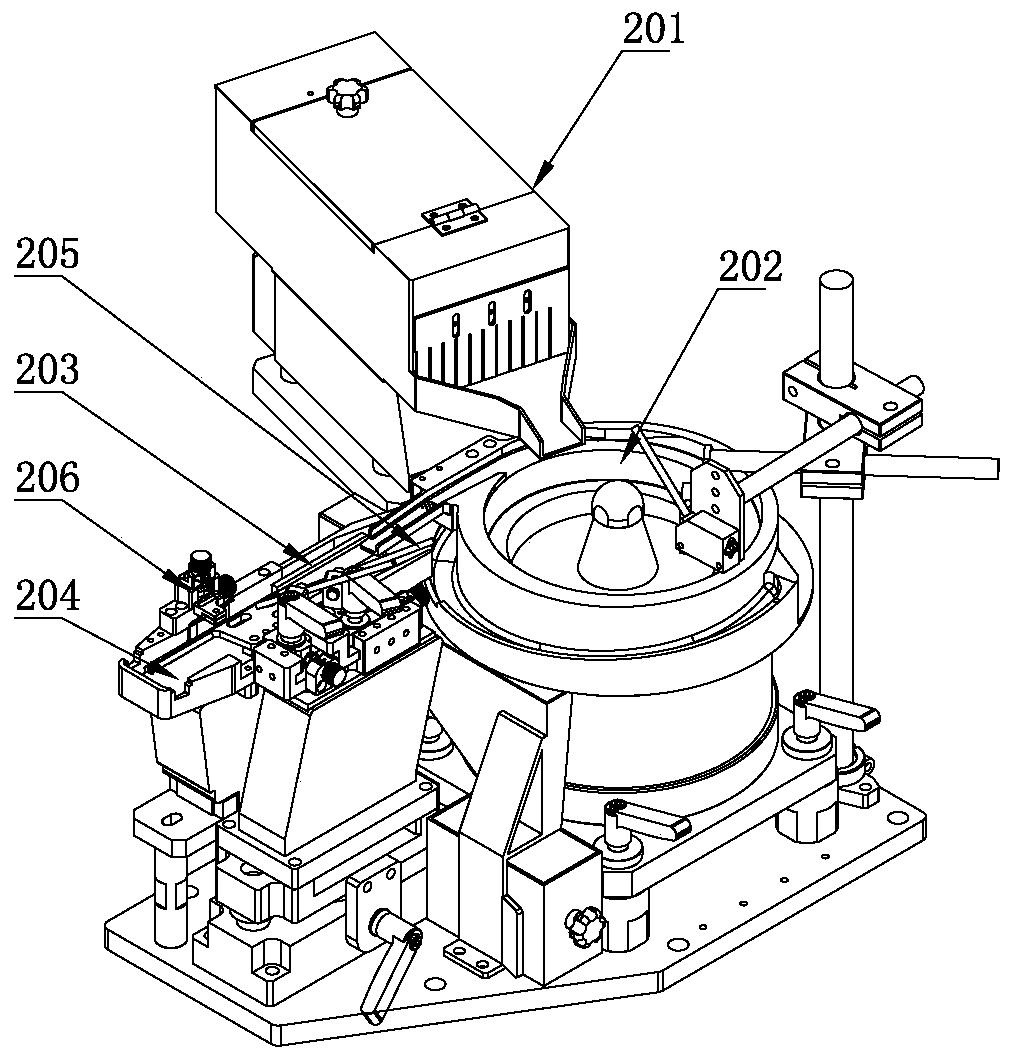

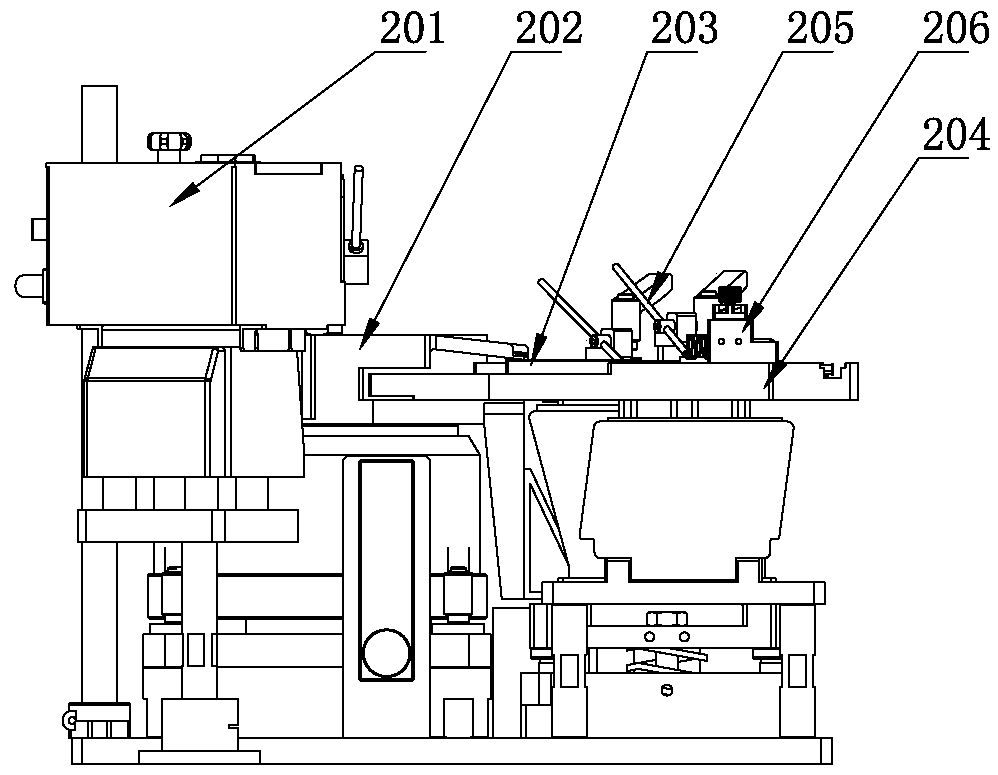

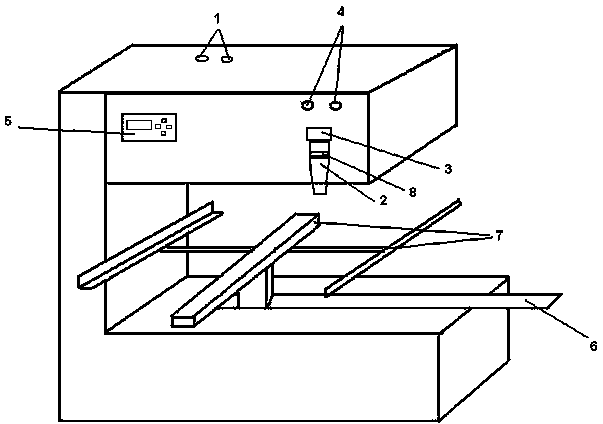

Numerical control tea leaf pinching and forming machine

InactiveCN103416493AConsistent qualityImprove stabilityPre-extraction tea treatmentNumerical controlProgrammable logic controller

The invention discloses a numerical control tea leaf pinching and forming machine which mainly comprises a tea leaf feeding device, an internal tea leaf pressing and transporting device and an external receiving and adjusting device, wherein the tea leaf feeding device is composed of two external interfaces, the internal tea leaf pressing and transporting device comprises a pressing roller, an inner interface and a transporting device, the external receiving and adjusting device comprises a photoelectric induction system, a PLC (programmable logic controller) and an adjustable receiving frame, the feeding device is mounted at the top of the machine, the internal tea leaf pressing and transporting device is mounted inside the machine, the adjusting device is mounted on a surface of the machine, and the receiving frame is horizontally mounted under the machine. According to the invention, with the combination of a modern intelligent controller according to the principles of procedures such as carding and shaping in the tea leaf processing process, an efficient and modern tea manufacturing machine is made, the machine overcomes the difficulty in manual tea leaf pinching, the tea manufacturing efficiency is improved, time and labor are saved, and the operation is convenient.

Owner:赵翠花 +1

Hippophae rhamnoide tea and preparation method thereof

InactiveCN105010589ARetain nutritional valueRetain activityPre-extraction tea treatmentTea substituesBiotechnologyHippophae

The invention discloses a hippophae rhamnoide tea and a preparation method thereof, and belongs to the field of drinking teas. The hippophae rhamnoide tea which is excellent in quality, disclosed by the invention, is prepared through the following steps: picking hippophae rhamnoides, making the picked hippophae rhamnoides, roasting the made hippophae rhamnoides, and screening the roasted hippophae rhamnoides. The preparation method of the hippophae rhamnoide tea disclosed by the invention is simple and easy to operate, through the cooperation of reasonable temperature, reasonable time and reasonable operation during preparation, the tea making efficiency can be improved, and besides, the nutrient value and the active component of the hippophae rhamnoides are ensured.

Owner:四川珍福堂商贸有限公司

A processing method of carburizing and quenching large internal tooth ring gear

Owner:CHONGQING GEARBOX

Efficient tea drying equipment for tea processing

InactiveCN113598237AIncreased baking contact areaImprove tea production efficiencyPre-extraction tea treatmentConveyor partsTea leafRotating disc

The invention discloses efficient tea drying equipment for tea processing. The efficient tea drying equipment for tea processing comprises a tea drying equipment part, wherein the tea drying equipment part comprises an equipment body, a tea placing groove, a tea drying cavity, a plurality of groups of movable grooves, sliding plates, clamping grooves, a charcoal fire placing part, a baffle plate and an air outlet, the tea placing groove is formed in the middle of the upper end of the equipment body, and the tea drying cavity is formed in the middle of the equipment body; and the movable grooves are symmetrically formed in the left and right sides of the tea drying cavity, and the sliding plates are fixedly mounted in the middles of the wall surfaces of the left side and the right side of the tea drying cavity. When the efficient tea drying equipment is used, rotating discs are driven by driven teeth to rotate, a driven piece II is driven by fixing rods to rotate, linkage wheels are driven by small fixing wheels to slowly rotate, then a fixing block continuously triggers a rotating rod in a timing mode, a tea placing bottom plate part rotates towards the lower end, tea leaves are put in the timing mode, and the time for manual tea putting is shortened.

Owner:张强

High-efficiency tea-acquisition temperature-controlled tea stir-frying machine

InactiveCN109924272AAvoid cloggingGreat tastePre-extraction tea treatmentTemperature controlWave shape

The invention relates to a high-efficiency tea-acquisition temperature-controlled tea stir-frying machine, which comprises an outer furnace body, an inner furnace body, a tea rolling device and a heater, the tea rolling device is arranged on one side between the outer furnace body and the inner furnace body, a sieve tray is arranged under a tea outlet of the tea rolling device, a stirring device is arranged between the tea outlet of the tea rolling device and the sieve tray, the heater is arranged on the opposite side of the inner furnace body and the tea rolling device, the heater is connected with a temperature sensor, the temperature sensor is provided with a temperature display device, the outer furnace body and the inner furnace body are provided with a mesh venting opening, and the bottom surface of the inner furnace body is a wave-shaped bottom surface. The setting of the stirring device on the sieve tray can make the tea leaves that are not on the bottom of the inner furnace body and stay on the sieve tray to be changed after being stirred, the tea leaves are more easily dropped to the bottom of the inner furnace body, and obstruction of the tea leaves on the sieve tray canbe prevented, and the working efficiency of the tea stir-frying machine and the taste of the final tea can be improved.

Owner:谷约飞

Tea leaf stir-drying device

InactiveCN109105553AAvoid spillingEven heat transferPre-extraction tea treatmentEngineeringMechanical engineering

The invention discloses a tea leaf stir-drying device, which comprises a housing, and a screening mechanism, a guide mechanism and a tea leaf stir-drying mechanism are sequentially arranged on the housing; the screening mechanism comprises a screening basket, a rocker, and a first rotating gear; the middle point of the rocker is connected to the rotary shaft of the first rotating gear, and both ends of the rocker are fixed with the screening basket; the tea leaf stir-drying mechanism comprises a wok and a recovery cavity; the wok is arranged in the opening of the recovery cavity through a shaft rod fixed on the wok brim, the bottom is engaged with a second rotating gear, and stirring plates are arranged in the wok; the guide mechanism comprises a pair of pouring rods, the tops of which abut against each other and the bottoms of which are respectively driven by third rotating gears, forming an inverted V to cover the top of the work brim; and the first rotating gear, the second rotatinggear and the stirring plates are respectively driven by a controller. The structure is simple, the tea leaf stir-drying device is convenient to use, automatic operation can be further realized, the steps of tea leaf production are reduced, the efficiency of tea leaf production is increased, and the tea leaf stir-drying device has wide applicability.

Owner:句容市下蜀镇窑业自立茶场

A kind of kang tea and its preparation method, and pottery pot for preparing kang tea

InactiveCN104365897BUnique and strong fragranceBright golden colorPre-extraction tea treatmentGreen teaSweet taste

The invention provides a kang tea, a preparation method thereof, and a pottery pot for preparing the kang tea. The preparation method of kang tea is as follows: heating the tea making pot to 70-150°C; putting raw tea leaves into the heated tea making pot, stirring and kneading at 70-150°C to obtain shaped tea leaves; The shaped tea leaves are baked until the color is light yellow to obtain a product. A pottery pot for preparing kang tea comprises: a pottery pot body; a pot handle arranged on the outside of the pottery pot body; a kneading device fixed on the inner wall of the pottory pot body, and the kneading device consists of a plurality of protruding The ribs are composed of a plurality of ribs distributed radially. The process of the method of the present invention is simple and suitable for industrialized production. The prepared kang tea has the characteristics of rich and unique fragrance, golden and bright color after brewing, strong and sweet taste, etc.; There are three steps of roasting, and you can also brew Kang tea.

Owner:王戎

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com