High-efficiency tea-acquisition temperature-controlled tea stir-frying machine

A high-efficiency technology for frying tea machines, which is applied in the field of temperature-controllable tea frying machines. It can solve the problems of affecting the tea output efficiency of the tea frying machine and easy accumulation of tea leaves, so as to save maintenance costs in the later stage, avoid excessive lifting, and improve work efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

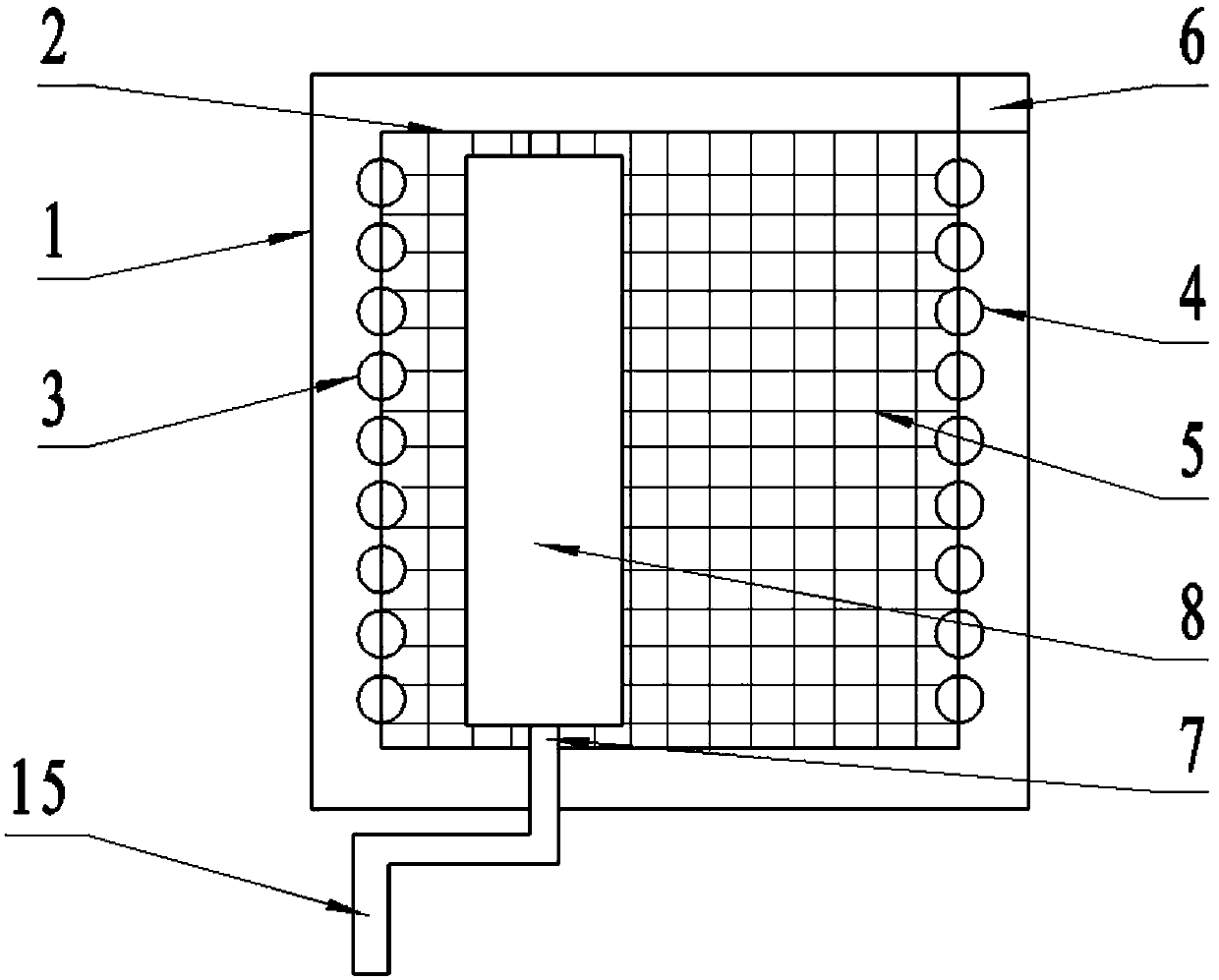

[0027] Such as figure 1 As shown, a high-efficiency temperature-controllable tea frying machine includes an outer furnace body 1, an inner furnace body 2, a tea twister 3 and a heater 4. The outer furnace body 1 is embedded with an inner furnace body 2, and the outer furnace body 2 A tea kneader 3 is provided on one side between the furnace body 1 and the inner furnace body 2, a sieve tray 5 is provided under the tea outlet of the tea kneader 3, and a stirring device is arranged between the tea outlet of the tea kneader 3 and the sieve tray 5 , the stirring device is close to the tea outlet side of the tea kneader 3, a heater 4 is provided on the side opposite to the tea kneader 3 in the inner furnace body 2, the heater 4 is connected with a temperature sensor, and a temperature display is arranged on the temperature sensor 6. Both the top of the outer furnace body 1 and the inner furnace body 2 are provided with mesh vents, and the bottom surface of the inner furnace body 2 i...

Embodiment 2

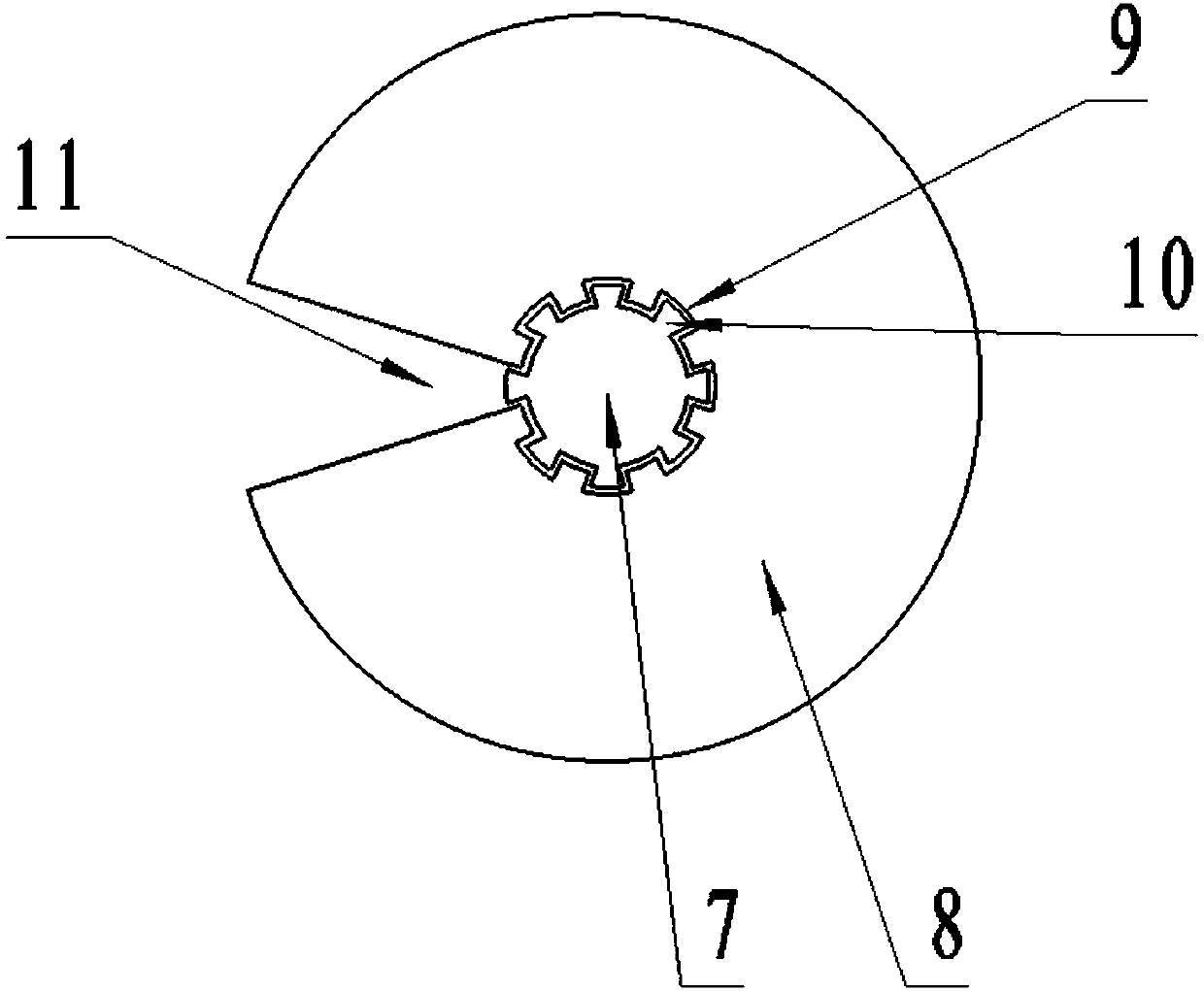

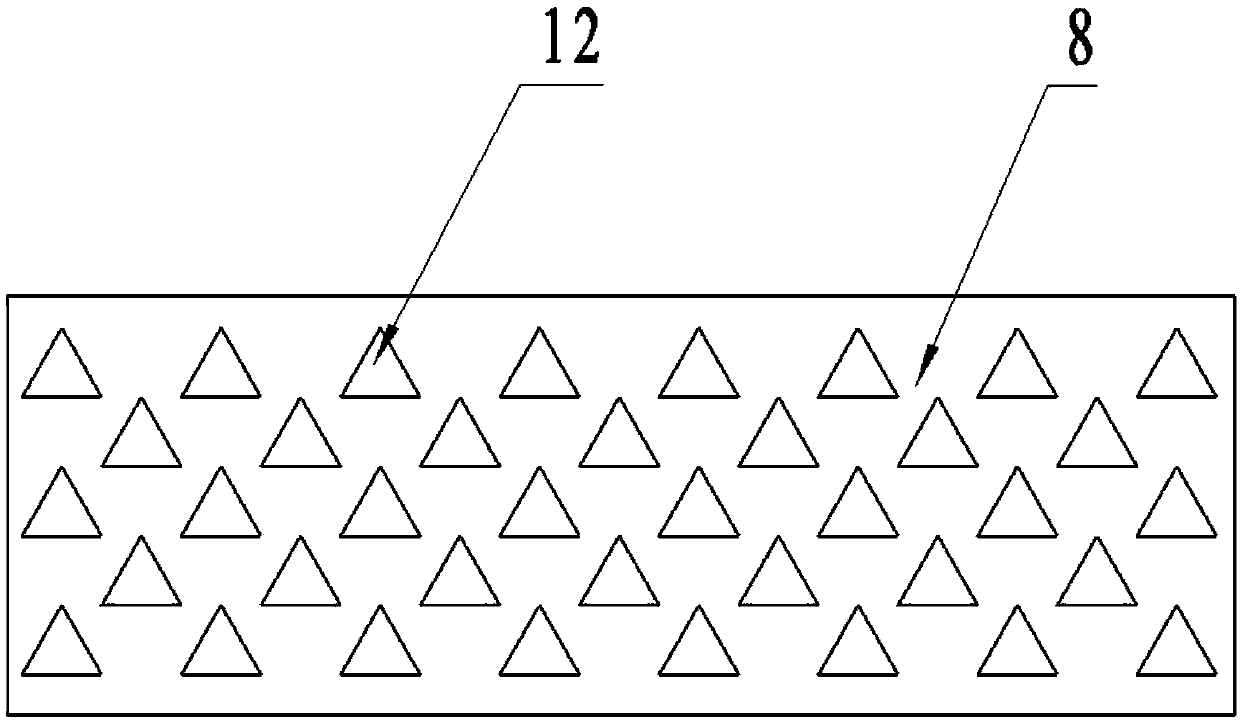

[0032] Such as figure 2 and image 3 As shown, the stirring part 8 is a hollow cylinder, the inner surface of the hollow cylinder is uniformly provided with a plurality of grooves 9 along the axial direction, and the outer surface of the rotating rod 7 is provided with a plurality of protrusions 10 corresponding to the grooves 9 There is a slit 11 on one side of the stirring part 8, the stirring part 8 is made of rubber material, the inner diameter of the hollow cylinder is smaller than the outer diameter of the rotating rod 7, and a plurality of break-up structures are uniformly arranged on the outside of the stirring part 8.

[0033] The dispersing structure is a triangular prism 12, one bottom surface of the triangular prism 12 is fixed on the outside of the hollow cylinder, the distance between the other bottom surface of the triangular prism 12 and the sieve tray is 0.1-1 mm, and one edge of the triangular prism 12 faces the stirring part 8 In the direction of rotation,...

Embodiment 3

[0037] Such as Figure 4 As shown, the breaking structure includes a first breaking plate 13 and a second breaking plate 14 with the same width as the stirring part 8, and one end of the first breaking plate 13 is fixedly connected to the outside of the stirring part 8 and connected to the stirring part 8. 8 The tangent at the joint is vertical, the other end of the first breaking plate 13 is connected to one end of the second breaking plate 14, and the angle formed by the first breaking plate 13 and the second breaking plate 14 is rotated towards the stirring part 8 direction, the angle between the first breaking plate 13 and the second breaking plate 14 is 90°, and the distance between the second breaking plate 14 and the sieve tray is 0.1-1mm.

[0038] The structural setting of the first breaking plate 13 and the second breaking plate 14 can make the tea leaves on the sieve tray 5 be turned up more fully, and then pass through the sieve tray 5 better again, and will not be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com