Tea turning apparatus capable of automatically removing crumbs

A tea and automatic technology, which is applied in the field of automatic crumb-removing tea turning devices, can solve the problems of long time consumption of tea leaves, low efficiency, long tea-making cycle, poor turning uniformity, etc., so as to shorten the tea-making cycle and improve the tea-making efficiency. , the effect of simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

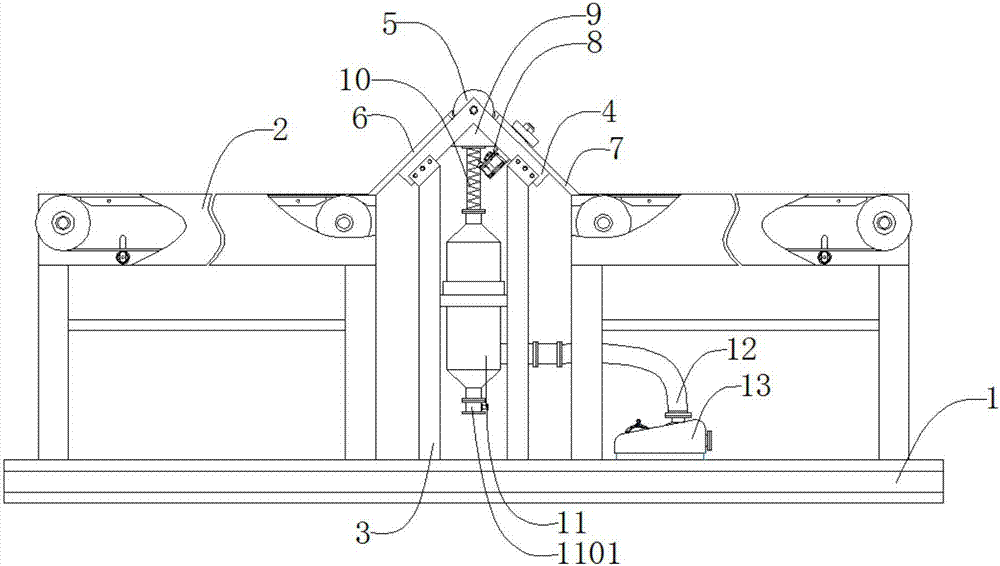

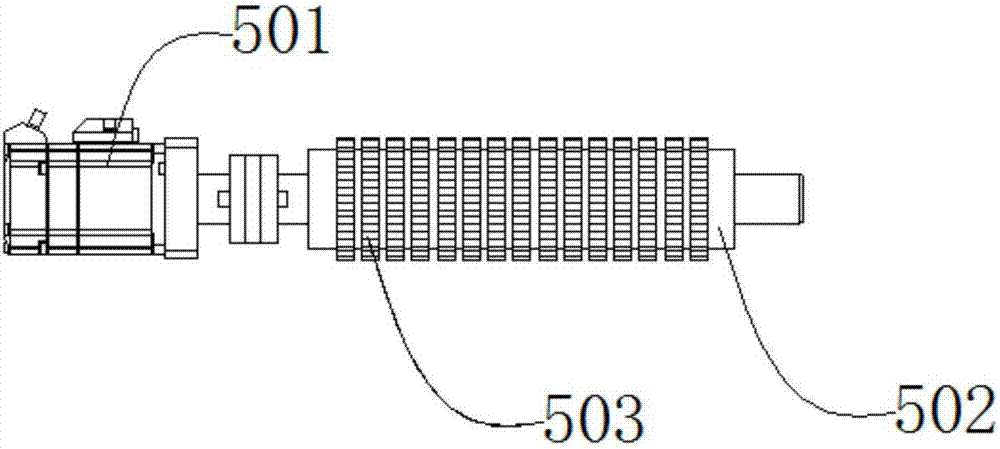

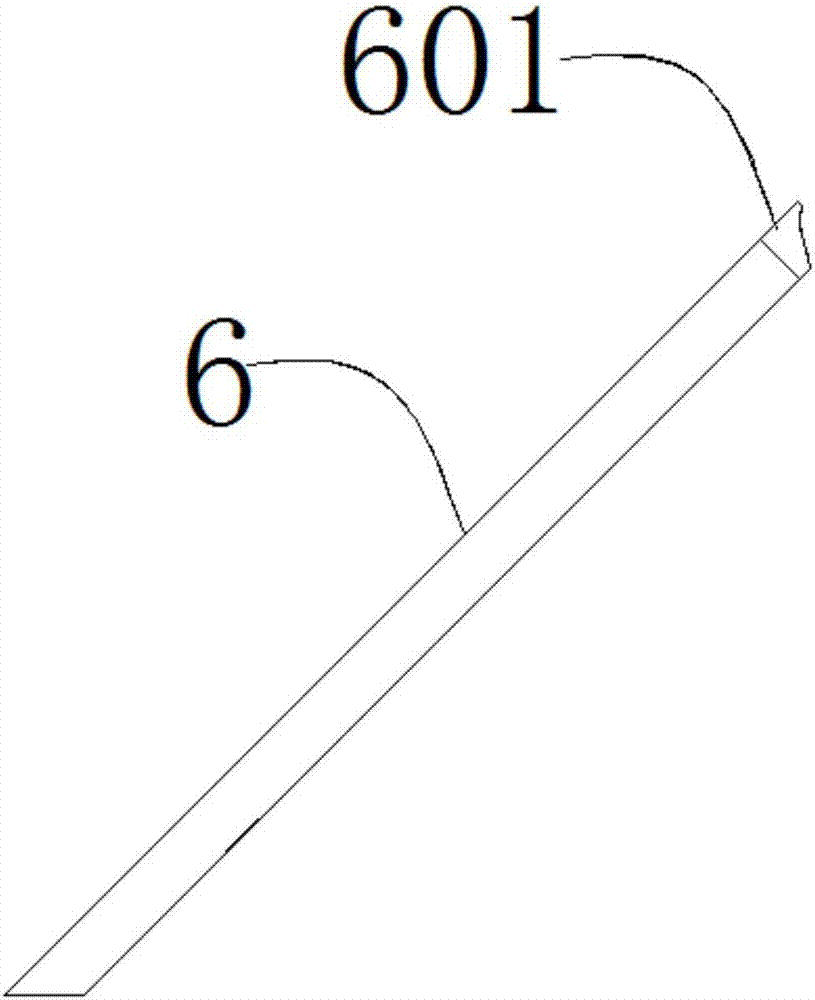

[0027] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6As shown, an automatic dust removal type tea leaf turning device includes a base 1, a mesh belt conveyor 2 arranged in parallel along the base 1, a bracket 3, a turning frame 4, a turning mechanism 5, and a left guide Material plate 6, right material guide plate 7, stirring mechanism 8 with no less than 2 pieces evenly distributed along the flip frame 4, dust collection box 9, soft connection 10, waste tank 11, air duct 12, Roots blower 13 , the mesh belt conveyor 2 is located at the upper end of the base 1, the mesh belt conveyor 2 is threadedly connected with the base 1, and the support 3 is located at the upper end of the base 1 and between two mesh belt conveyors 2 arranged in parallel Between, the support 3 is screwed to the base 1, the flip frame 4 is located at the upper end of the bracket 3, the flip frame 4 is screwed to the bracket 3, the flip mechanism 5 is located at the top of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com