Carburizing and quenching large inner gear ring machining method

A technology of carburizing and quenching and processing methods, which is applied in the field of gear processing, can solve problems such as failure to achieve design accuracy and life, and achieve good comprehensive mechanical properties, low energy consumption, and avoid process waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

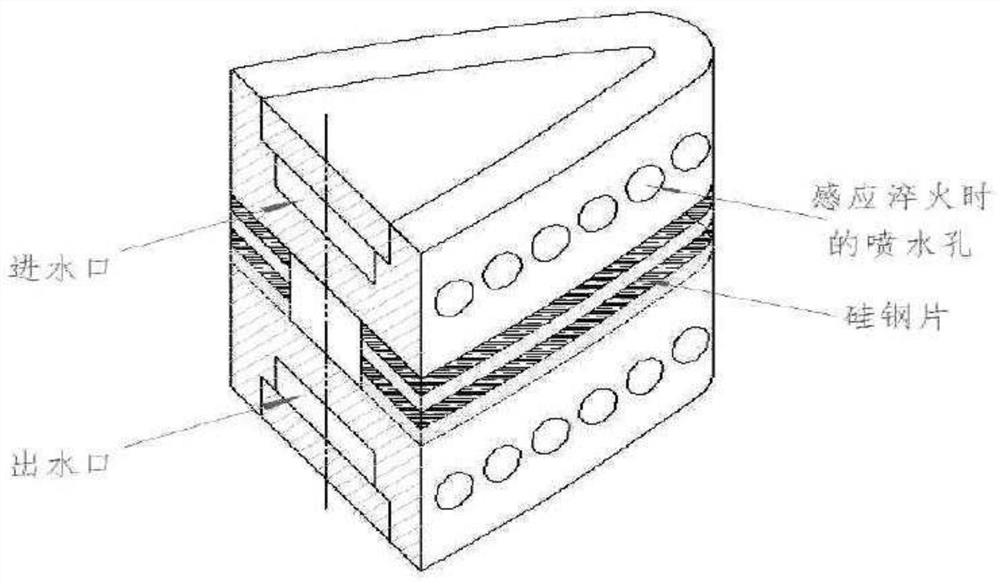

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

[0029] A method for processing a carburized and quenched large internal gear ring, comprising the following steps:

[0030] The first step, forging: including controlling the forging ratio as required, and testing the bulk grain size, mechanical properties and forging defects with samples;

[0031] The second step, normalizing: to refine the grain and eliminate the forging stress;

[0032] The third step is to remove the black skin rough turning: according to the principle of roughness of Ra3.2 and retaining the maximum physical size, the black skin is removed by turning;

[0033] The fourth step, flaw detection: use an ultrasonic flaw detector to conduct ultrasonic flaw detection to detect internal defects of the gear blank, so as to eliminate gear blanks with internal defects that ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com