Preparation technology of disposable paper cup

A preparation process, a one-time technology, applied in the direction of drinking utensils, etc., can solve the problem of the processing technology not passing the test, and achieve the effect of huge market potential, quality assurance, and broad prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

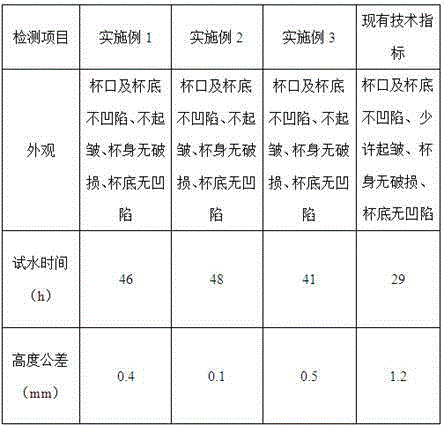

Examples

Embodiment 1

[0025] A preparation process of a disposable paper cup, comprising the following steps:

[0026] (1) Coating and slitting

[0027] The base paper is coated with PE film with a laminating machine, and then the coated paper is cut into rectangular sheets and roll paper with a slitting machine;

[0028] (2) Printing

[0029] Transfer the ink onto the rectangular paper sheet with a letterpress printing machine, and irradiate the ink with ultraviolet rays to make the ink nearly dry, and perform corona treatment on the rectangular paper sheet before printing, the surface tension after treatment is 40nM / m, and the printing temperature is 24 ℃;

[0030] (3) Drying

[0031] Put the printed rectangular paper sheet into an oven for drying, the temperature of the oven is 30°C, and the drying time is 8h;

[0032] (4) Die cutting

[0033] Use the die-cutting blade on the die-cutting machine to cut the dried rectangular paper sheet into fan-shaped sheets for making paper cups, and the di...

Embodiment 2

[0039] A preparation process of a disposable paper cup, comprising the following steps:

[0040] (1) Coating and slitting

[0041] The base paper is coated with PE film with a laminating machine, and then the coated paper is cut into rectangular sheets and roll paper with a slitting machine;

[0042] (2) Printing

[0043] Transfer the ink onto the rectangular paper sheet with a letterpress printing machine, and irradiate the ink with ultraviolet rays to make the ink nearly dry, and perform corona treatment on the rectangular paper sheet before printing, the surface tension after treatment is 45nM / m, and the printing temperature is 26 ℃;

[0044] (3) Drying

[0045] Put the printed rectangular paper sheet into an oven for drying, the oven temperature is 50°C, and the drying time is 10h;

[0046] (4) Die cutting

[0047] Use the die-cutting blade on the die-cutting machine to cut the dried rectangular paper sheet into fan-shaped sheets for making paper cups, and the die-cutt...

Embodiment 3

[0053] A preparation process of a disposable paper cup, comprising the following steps:

[0054] (1) Coating and slitting

[0055] The base paper is coated with PE film with a laminating machine, and then the coated paper is cut into rectangular sheets and roll paper with a slitting machine;

[0056] (2) Printing

[0057] Transfer the ink to the rectangular paper sheet with a letterpress printing machine, and irradiate the ink with ultraviolet rays to make the ink nearly dry, and perform corona treatment on the rectangular paper sheet before printing, the surface tension after treatment is 50nM / m, and the printing temperature is 28 ℃;

[0058] (3) Drying

[0059] Put the printed rectangular paper sheet into an oven for drying, the temperature of the oven is 70°C, and the drying time is 12h;

[0060] (4) Die cutting

[0061] Use the die-cutting blade on the die-cutting machine to cut the dried rectangular paper sheet into fan-shaped sheets for making paper cups, and the die...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com