Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1419 results about "Corona treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Corona treatment (sometimes referred to as air plasma) is a surface modification technique that uses a low temperature corona discharge plasma to impart changes in the properties of a surface. The corona plasma is generated by the application of high voltage to an electrode that has a sharp tip. The plasma forms at the tip. A linear array of electrodes is often used to create a curtain of corona plasma. Materials such as plastics, cloth, or paper may be passed through the corona plasma curtain in order to change the surface energy of the material. All materials have an inherent surface energy. Surface treatment systems are available for virtually any surface format including dimensional objects, sheets and roll goods that are handled in a web format. Corona treatment is a widely used surface treatment method in the plastic film, extrusion, and converting industries.

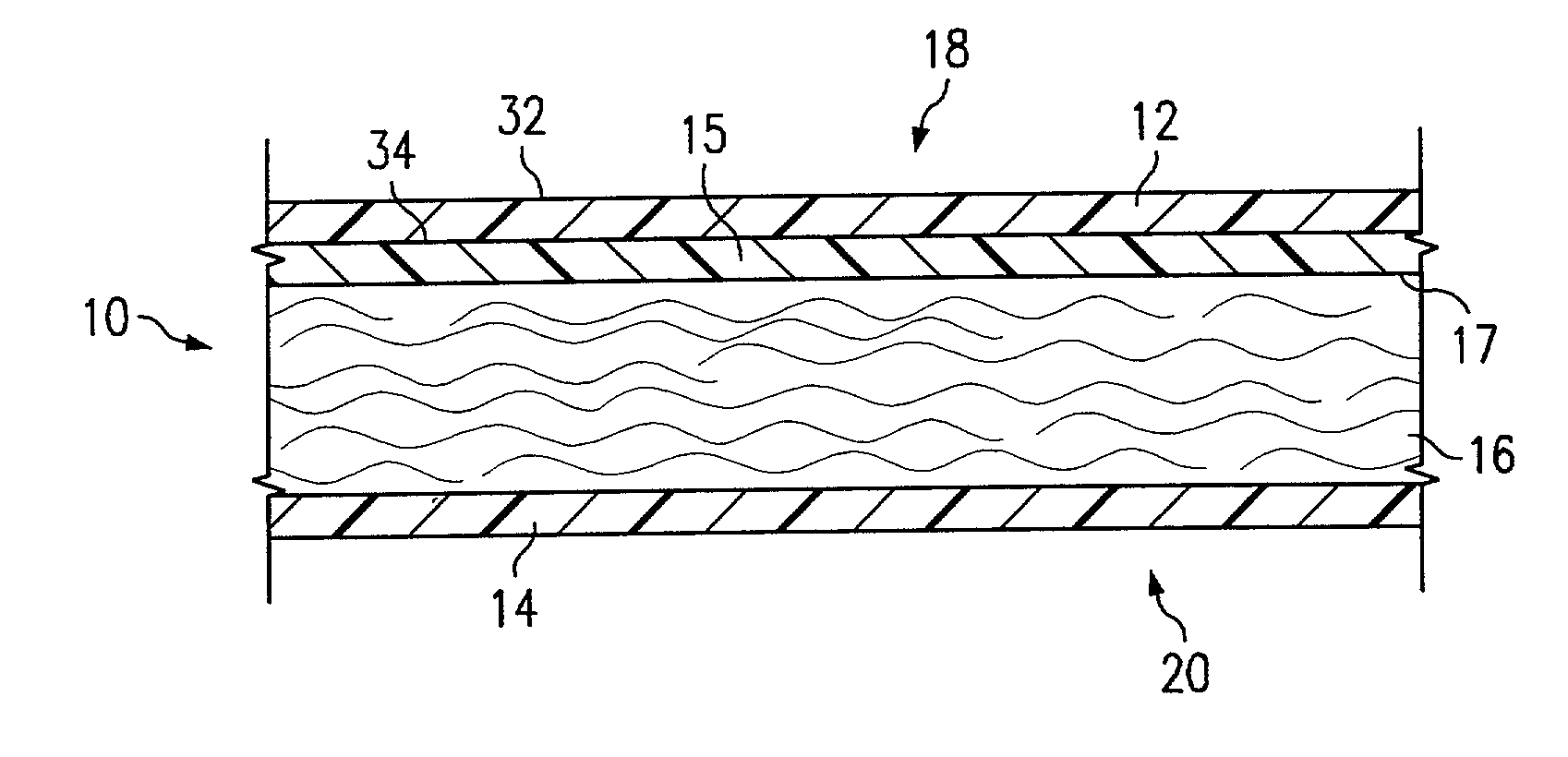

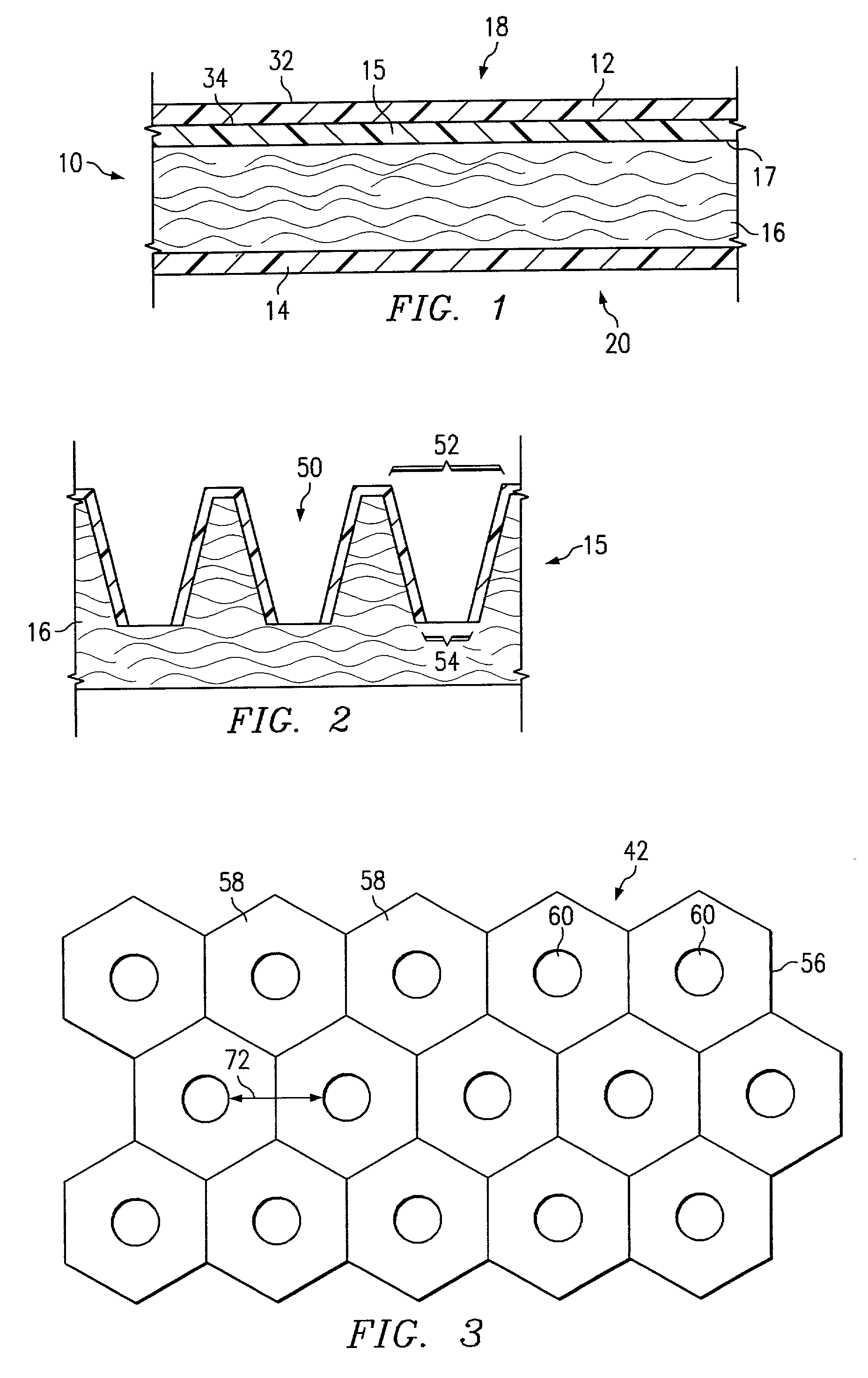

Electret filter media and filtering masks that contain electret filter media

InactiveUS6783574B1Reduce filtration efficiencyImprove filtering effectSynthetic fibresBreathing filtersFilter mediaRespiratory mask

Electret filter media comprising a nonwoven web of thermoplastic nonconductive microfibers having trapped charge, said charge provided by (1) subjecting the nonwoven web to a corona treatment, followed by (2) impingement of jets of water or a stream of water droplets on the web at a pressure sufficient to provide the web with filtration enhancing electret charge and (3) drying the web. This electret filter media may be used in a respiratory mask to provide extraordinarily good filtration properties.

Owner:3M CO

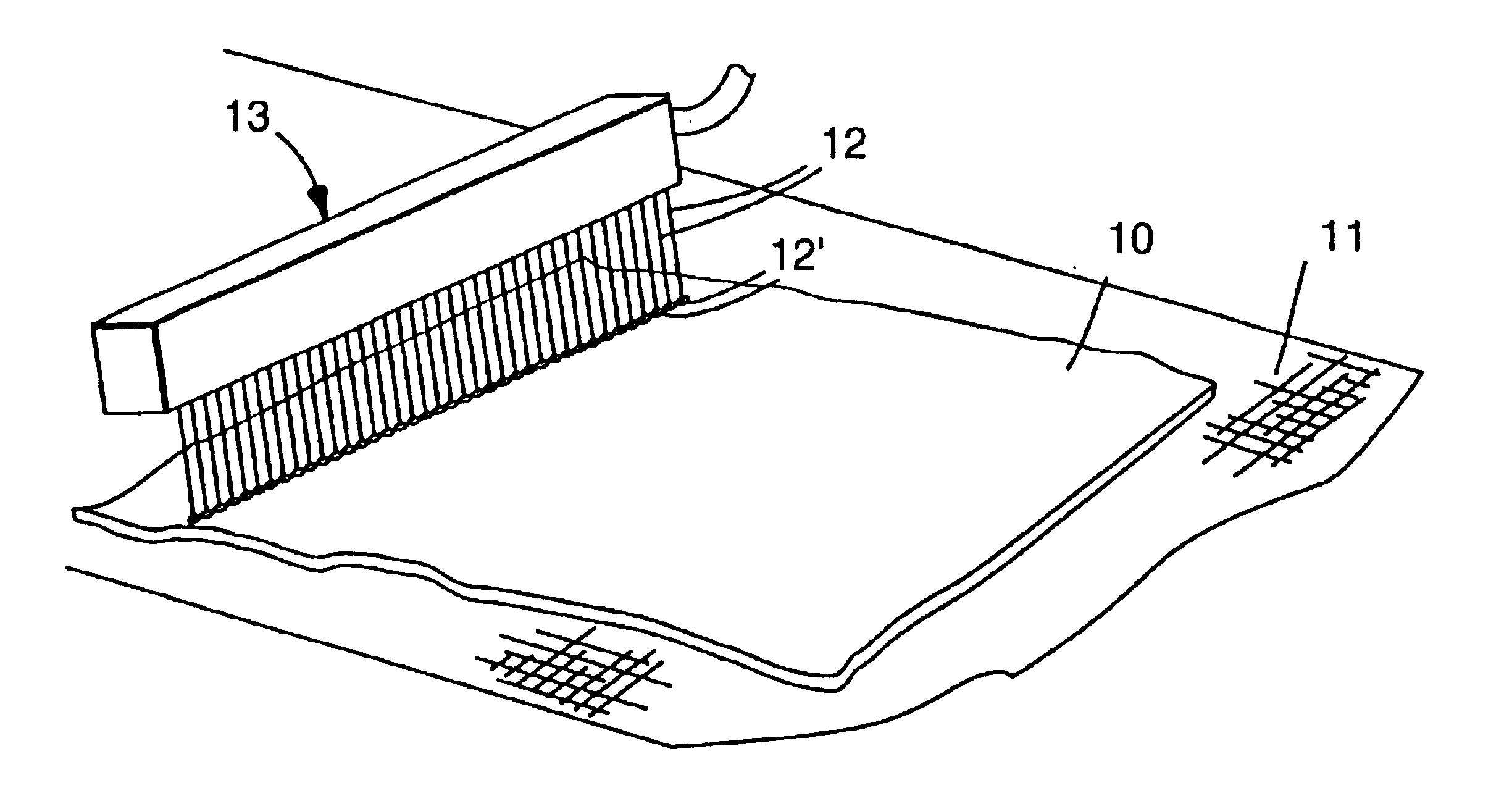

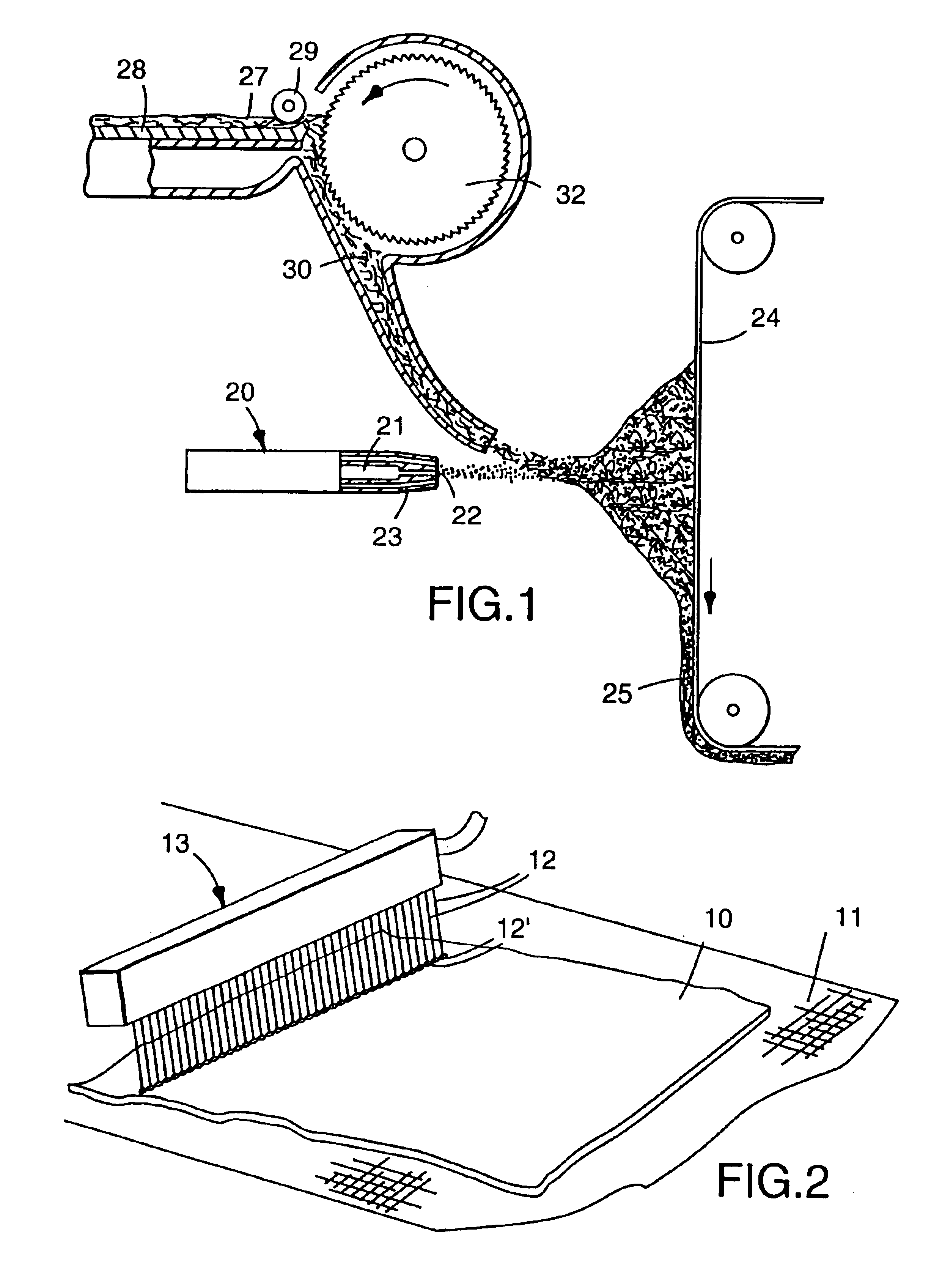

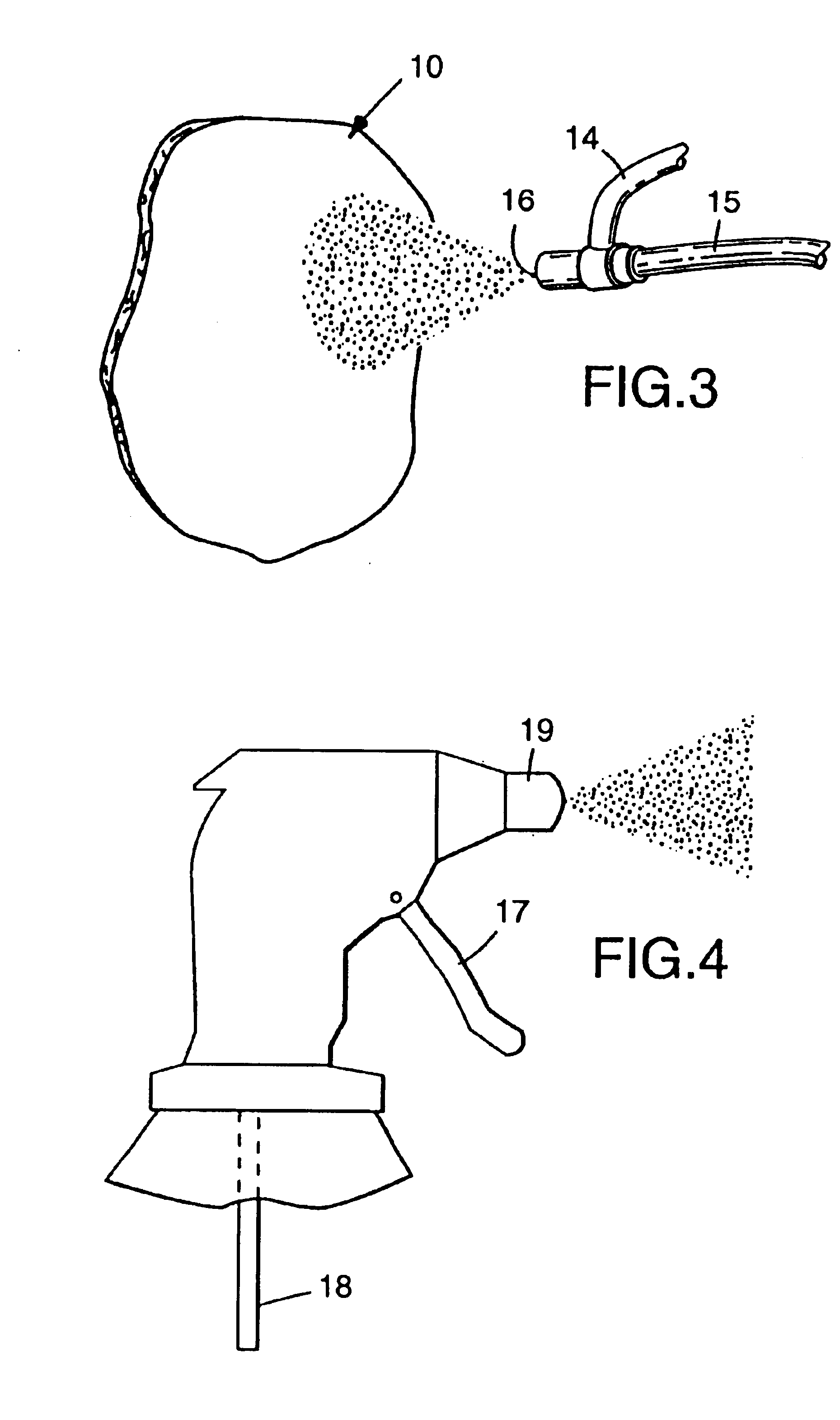

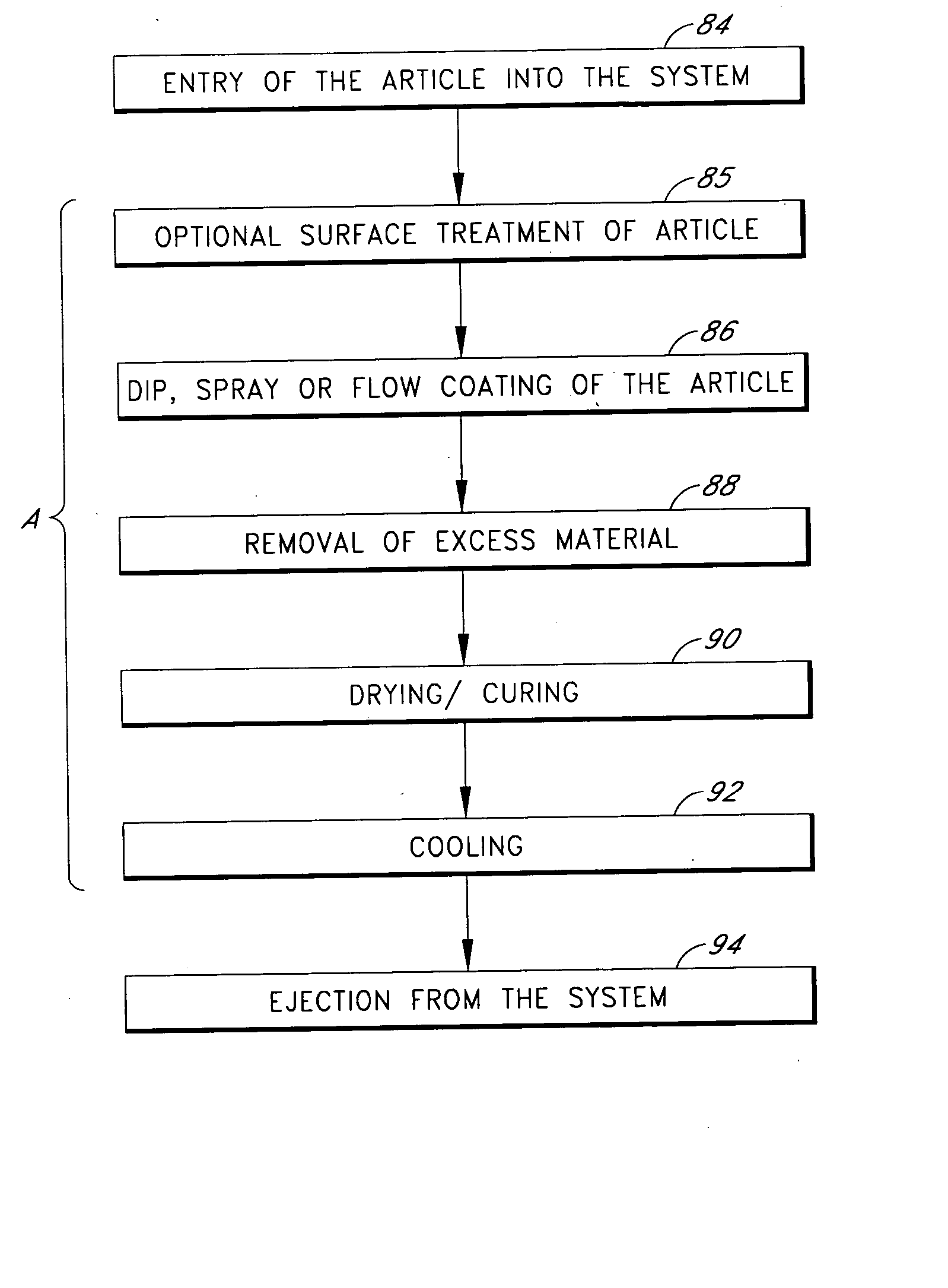

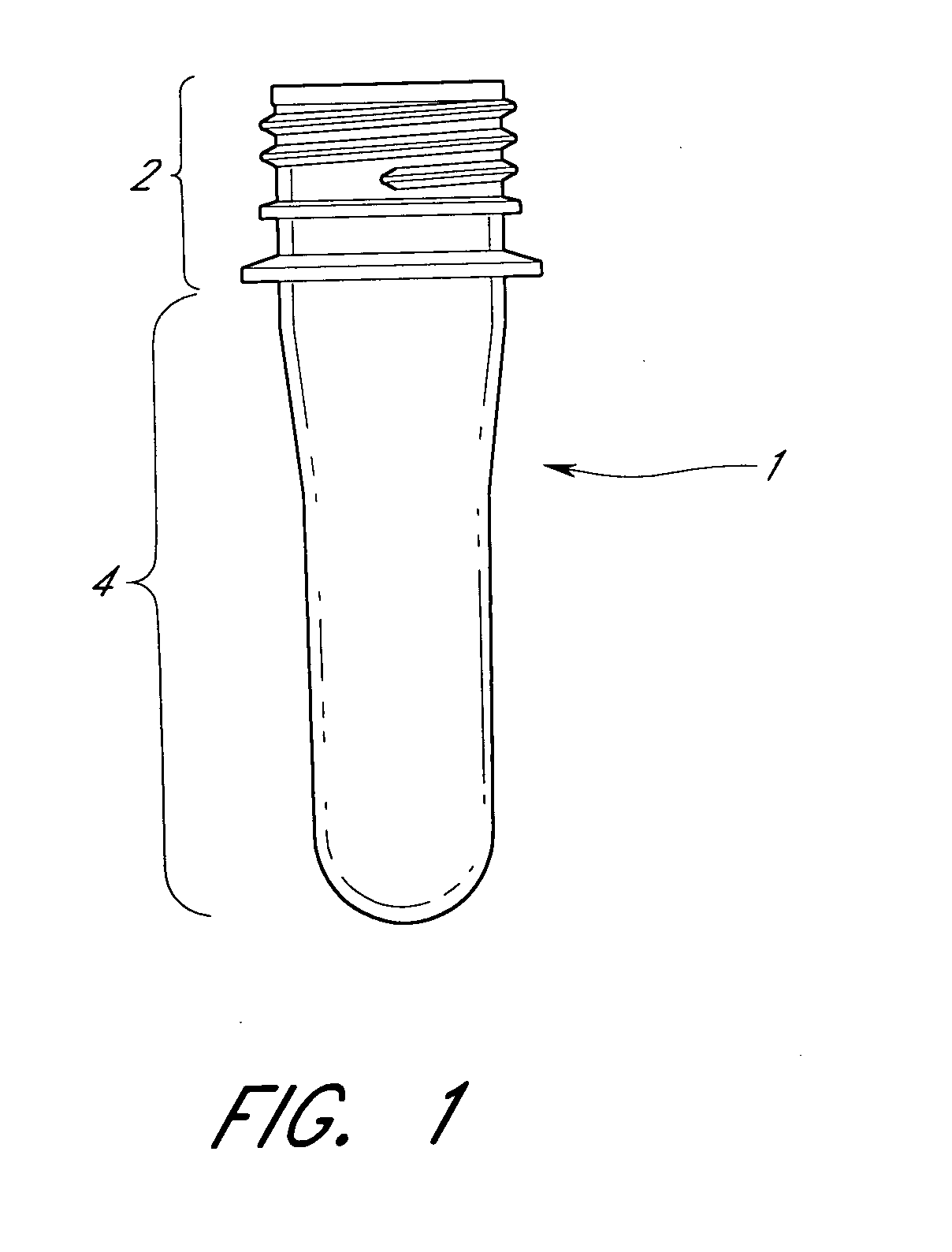

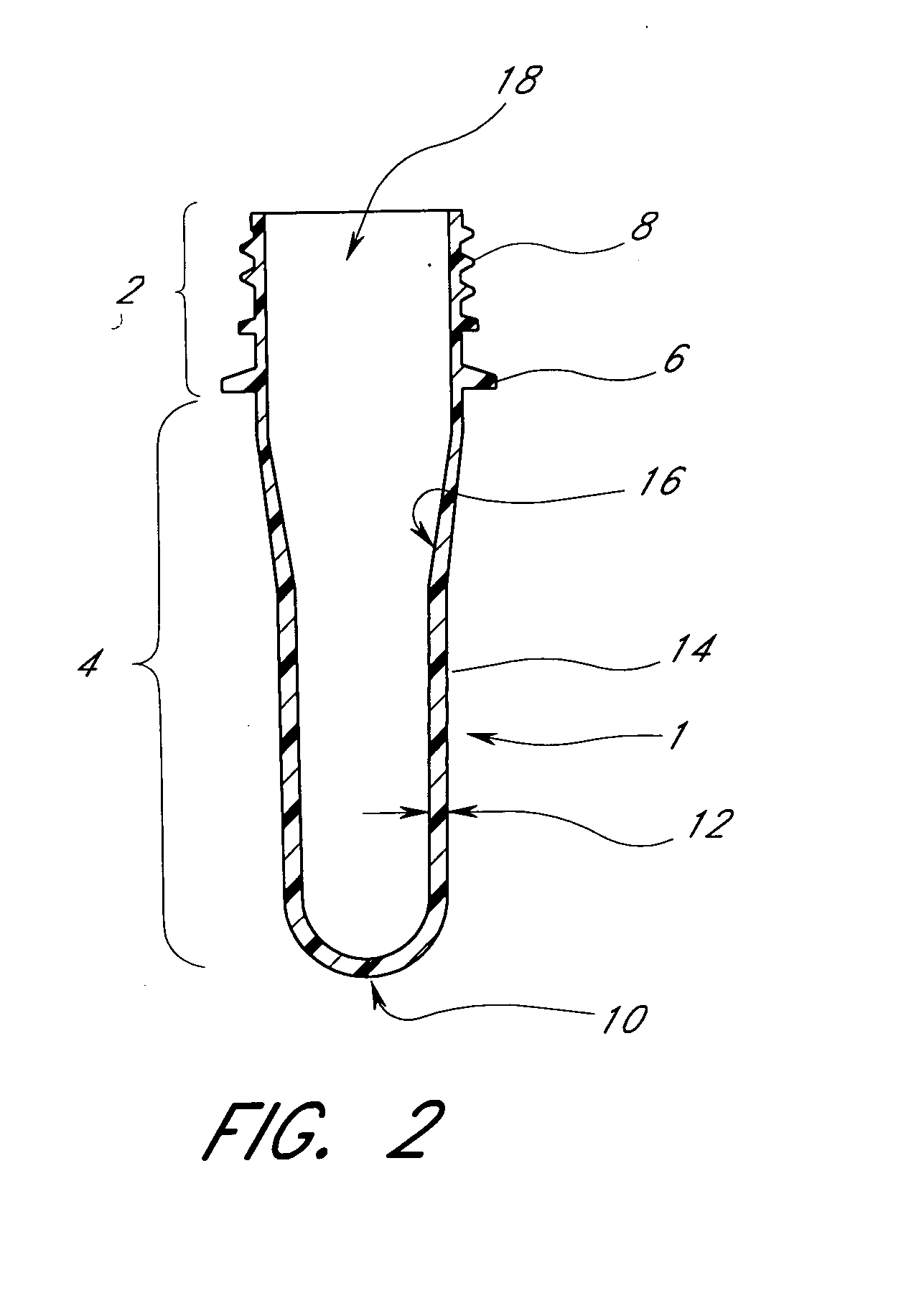

Methods of forming multilayer articles by surface treatment applications

InactiveUS20070087131A1Low water vapor transmission rateImprove adhesionPretreated surfacesCoatingsAir treatmentFlame treatment

Coated articles may comprise one or more coating layers, including water resistant coatings. A method comprises applying such coating layers by treating the article substrate by one or more methods selected from flame treatment, corona treatment, ionized air treatment, plasma air treatment and plasma arc treatment and dip, spray or flow coating. Additionally, a method comprises injection molding a first substrate material to form an article, treating the article surface by one or more methods selected from flame treatment, corona treatment, ionized air treatment, plasma air treatment and plasma arc treatment, and overmolding the article substrate with one or more barrier materials.

Owner:ADVANCED PLASTICS TECH LUXEMBOURG SA

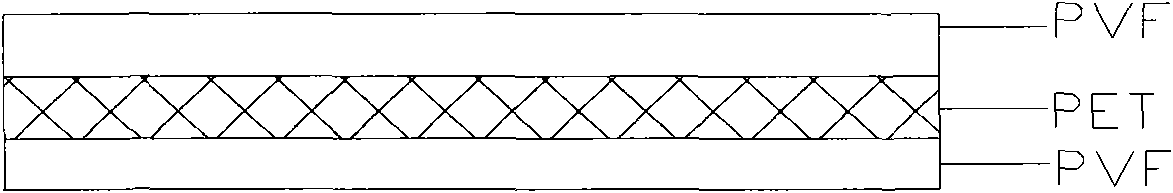

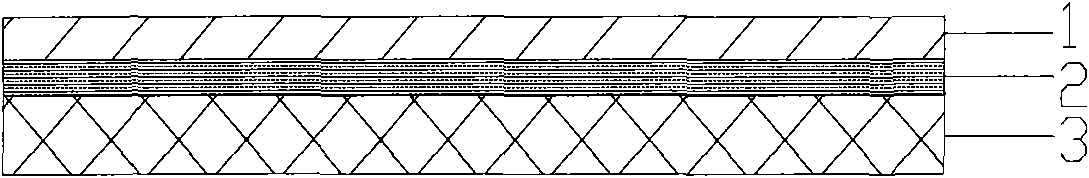

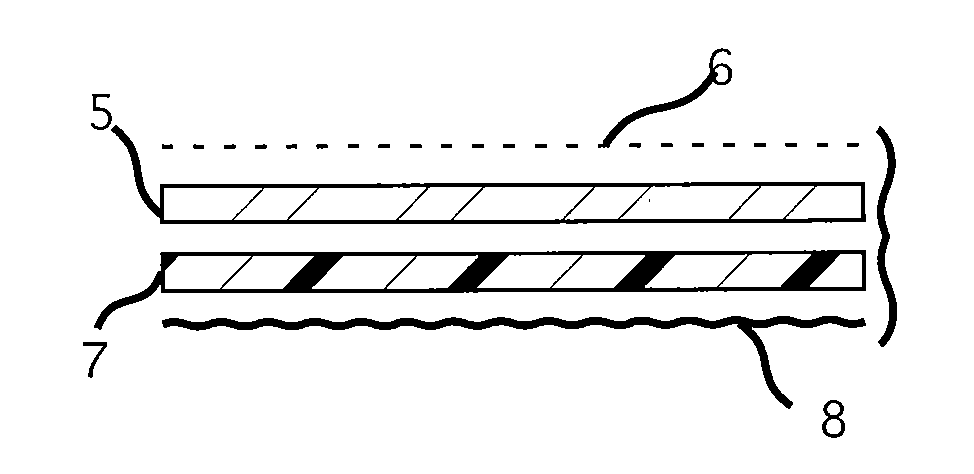

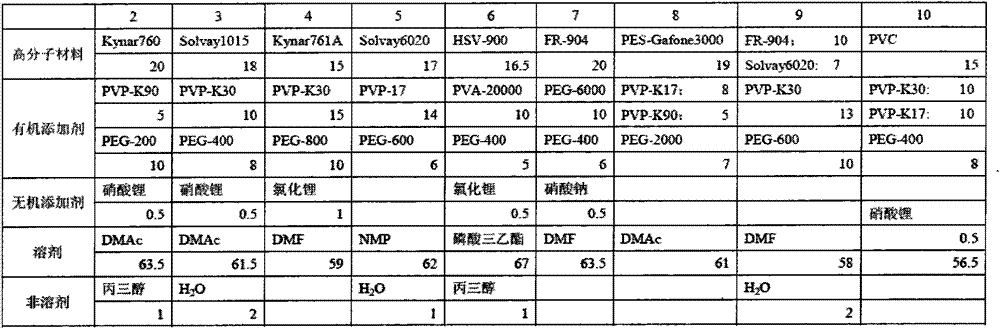

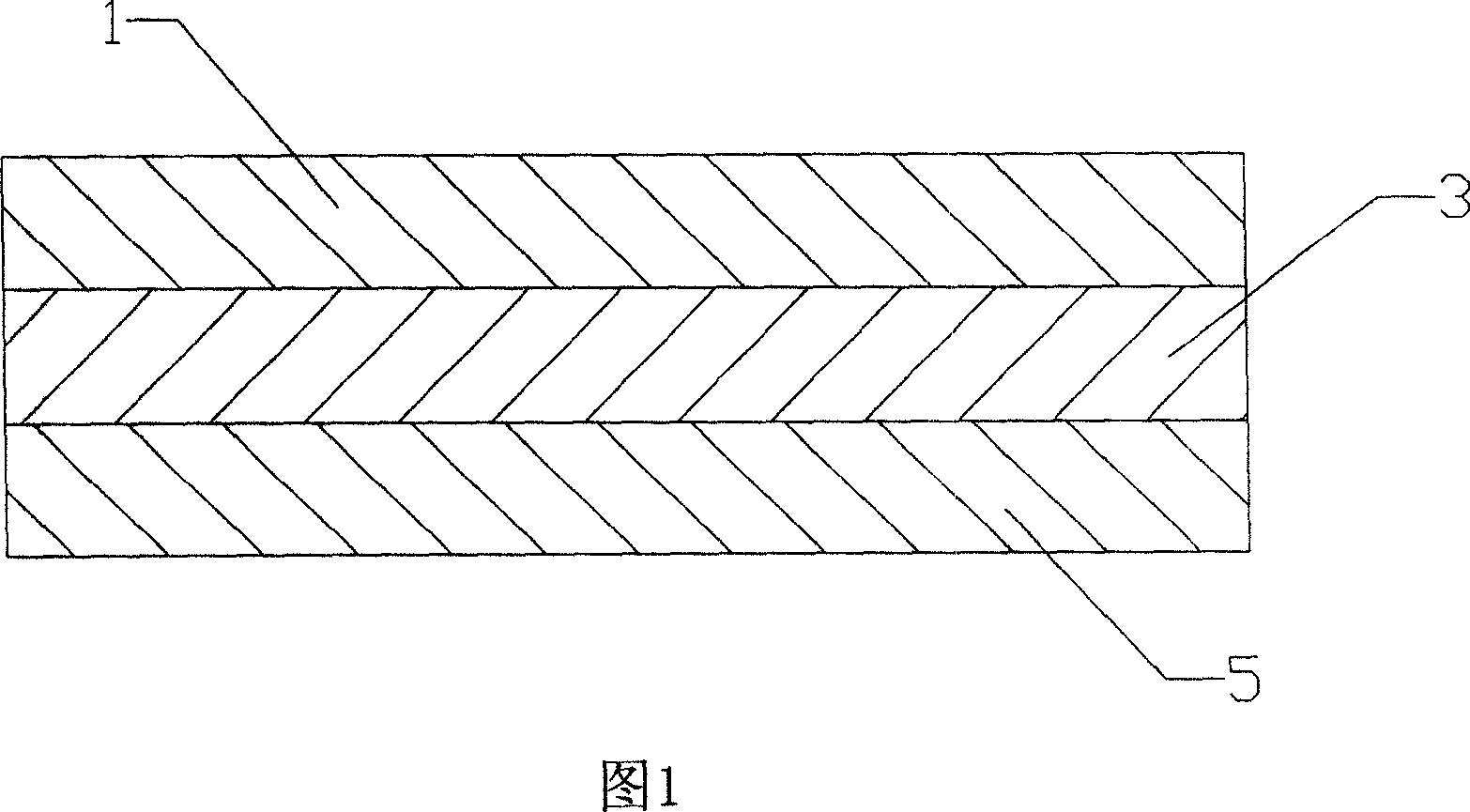

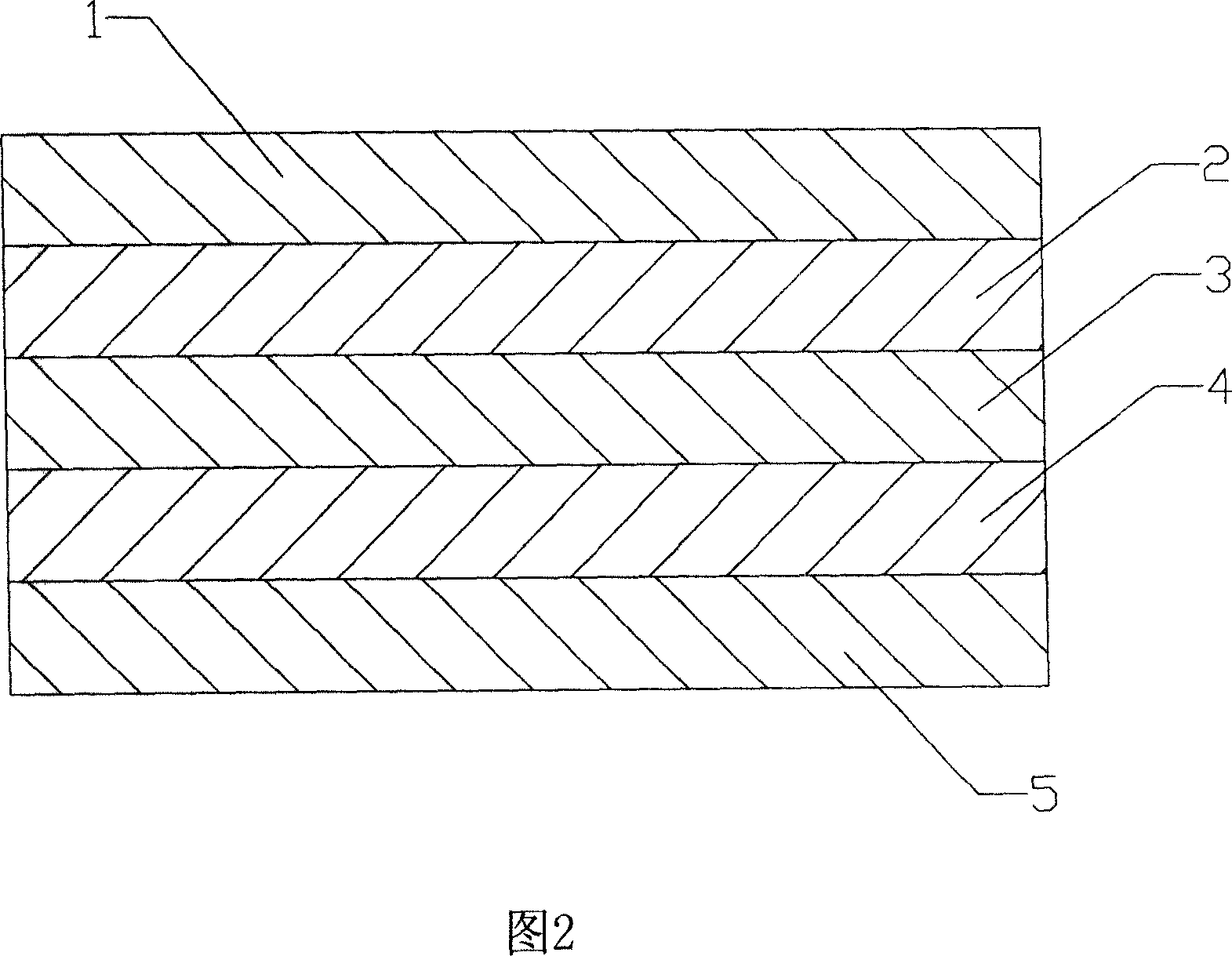

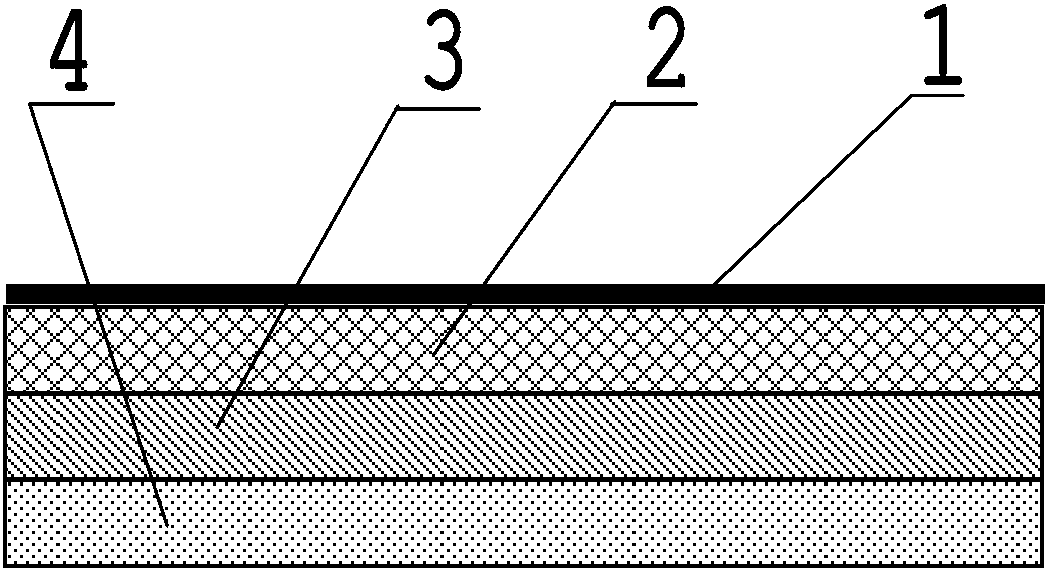

Solar battery back panel film and preparation method thereof

InactiveCN101997038AEasy to prepareGood weather resistanceLamination ancillary operationsFinal product manufactureAdhesiveElectric breakdown

The invention relates to a solar battery back panel film and a production method thereof. The solar battery back panel film comprises a PET (Polyethylene Terephthalate) thin film substrate layer and at least one polyvinylidene fluoride film layer, wherein the polyvinylidene fluoride film layer and the PET thin film substrate layer are compounded through an adhesive layer. The solar battery back panel film also comprises an EVA (Ethylene Vinyl Acetate Copolymer) film layer, and the EVA film layer and the PET thin film substrate layer are compounded by adopting a composite laminating process. The preparation method of the solar battery back panel film comprises the following steps of: carrying out surface corona treatment on the PET thin film substrate layer and the polyvinylidene fluoride film layer; coating an adhesive layer on the PET thin film substrate layer; and carrying out hot-pressing compounding on the adhesive-coated surface of the PET thin film substrate layer and the polyvinylidene fluoride film layer and then solidifying. The preparation method of the solar battery back panel film is simple, and the product has excellent weather fastness, higher lamination peel strength, good barrier property and good electric breakdown resistance.

Owner:NANJING NAQUAN HI TECH MATERIAL

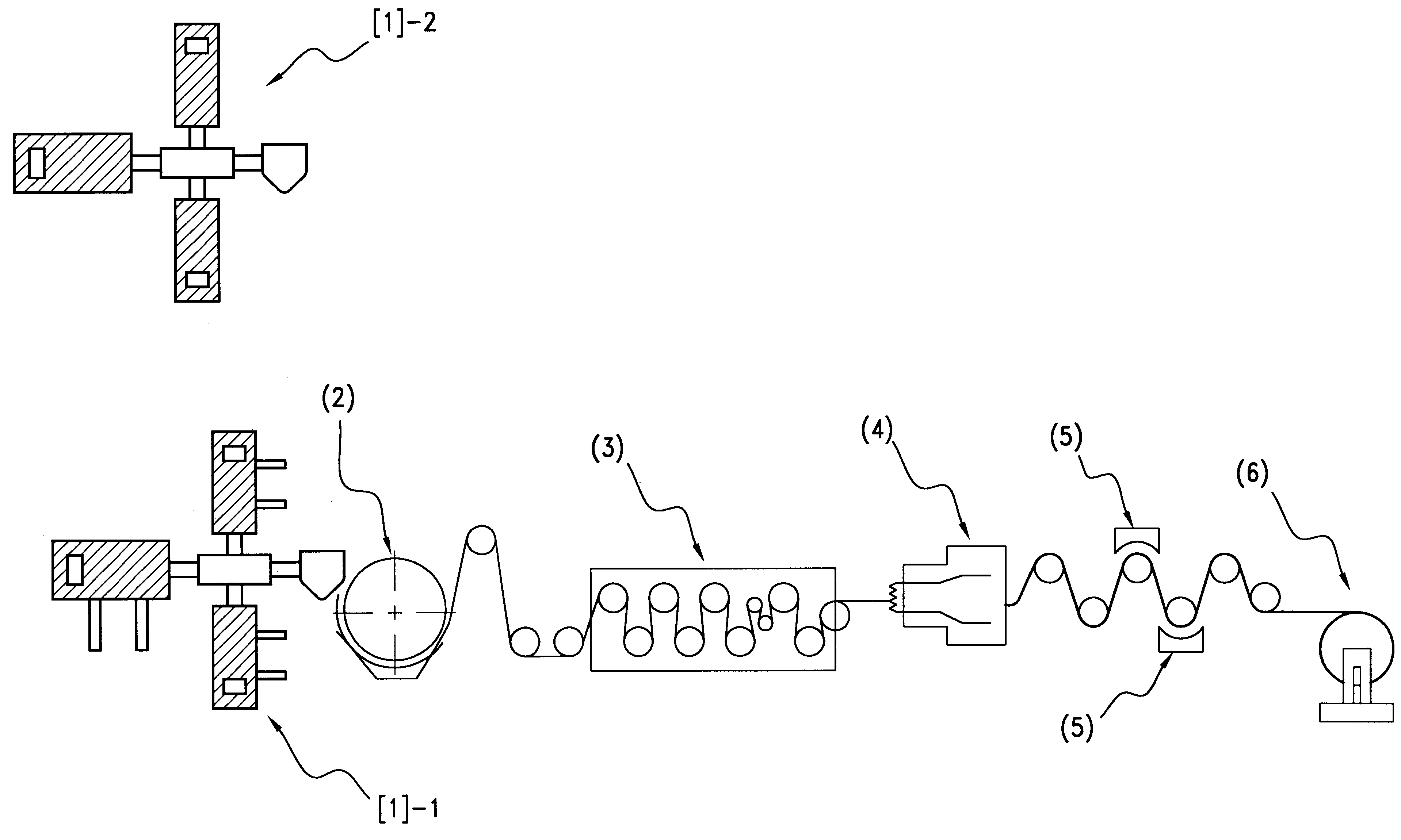

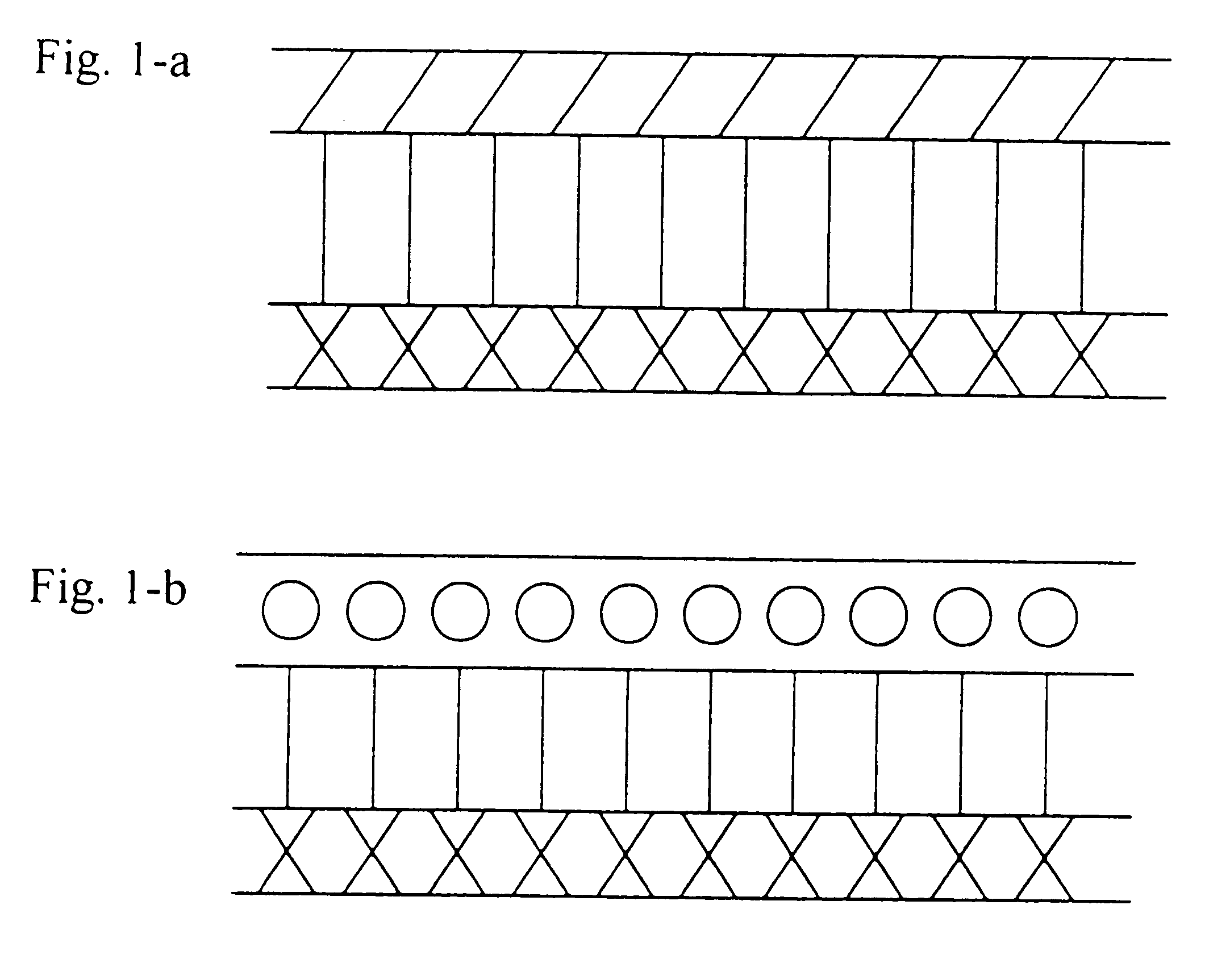

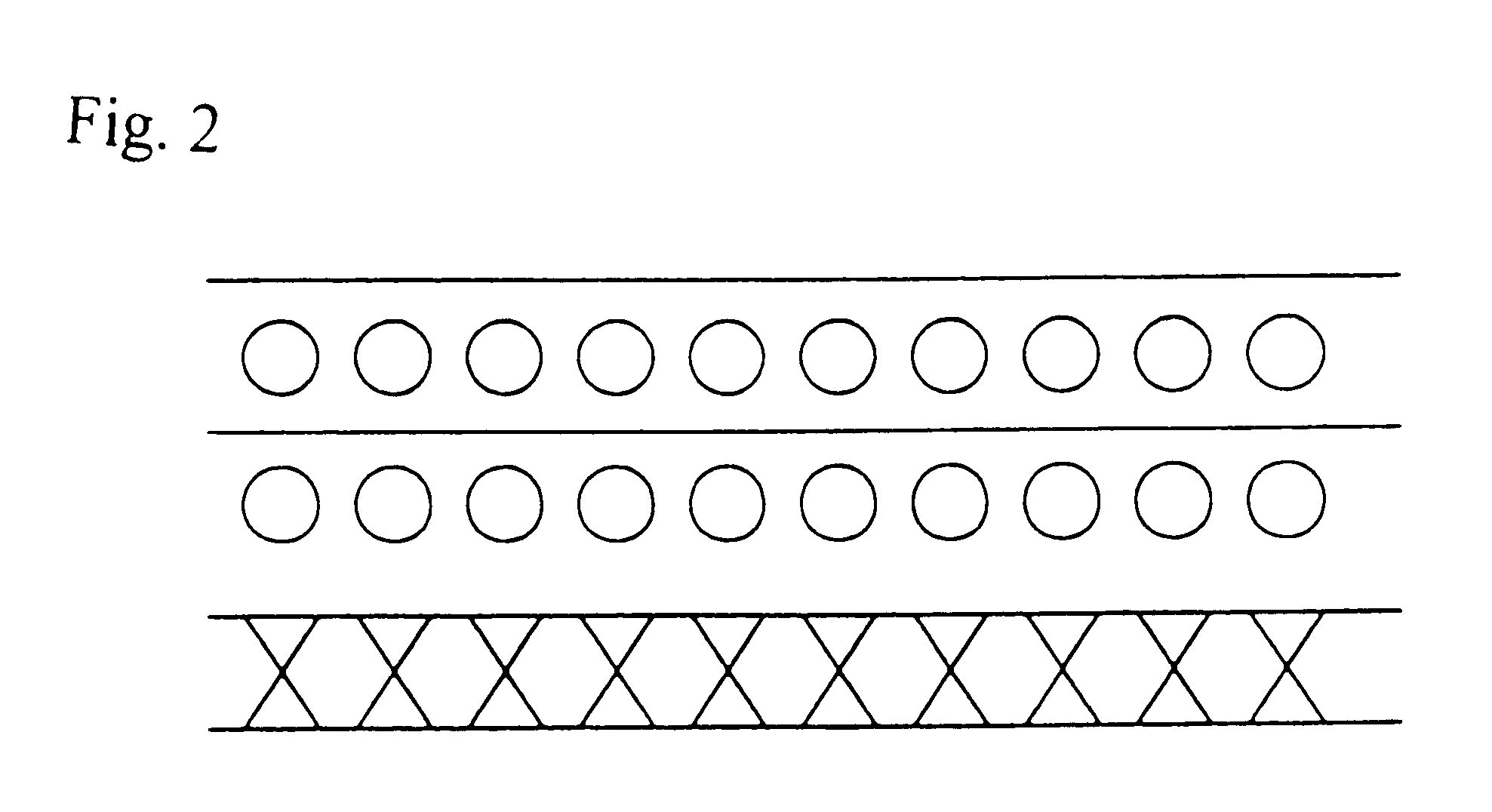

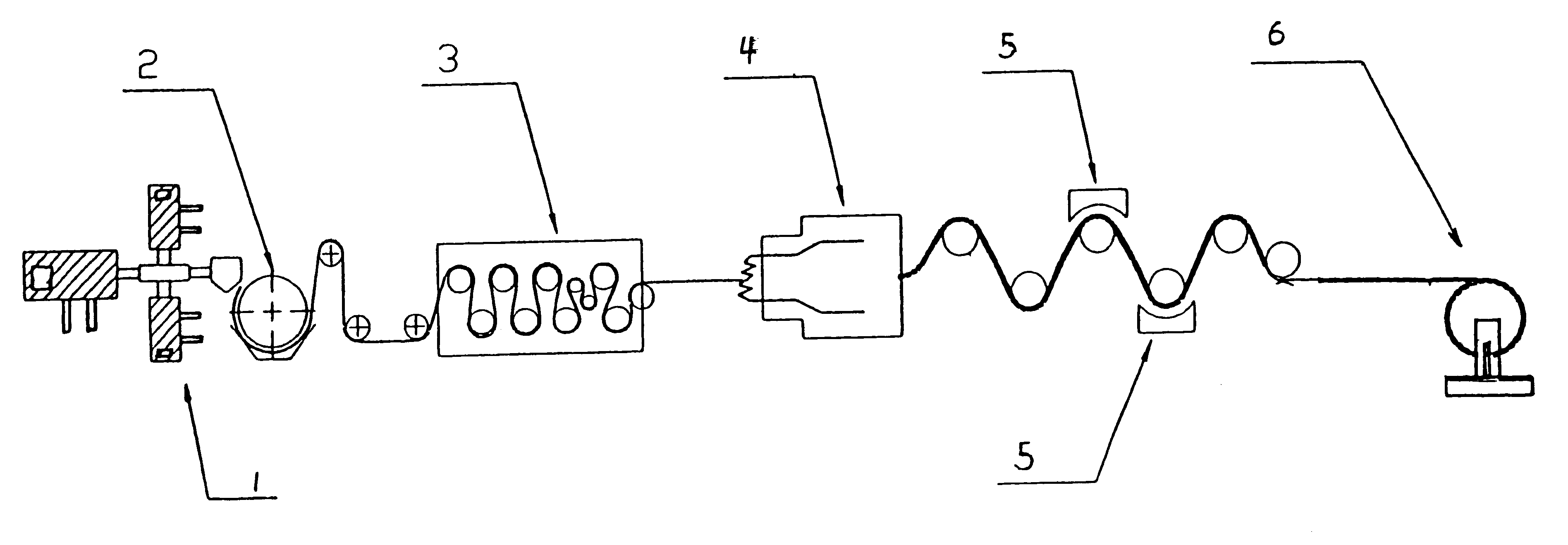

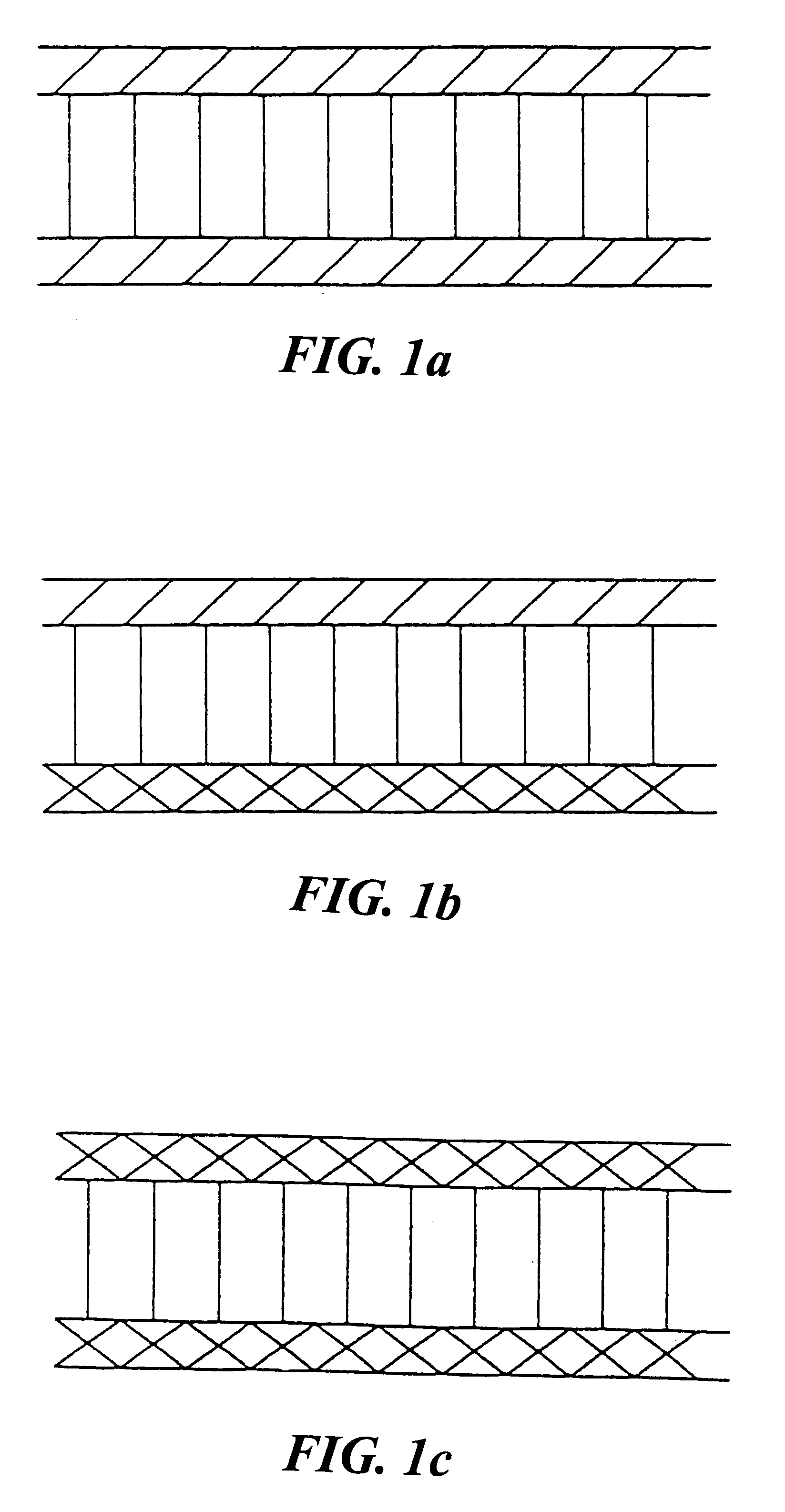

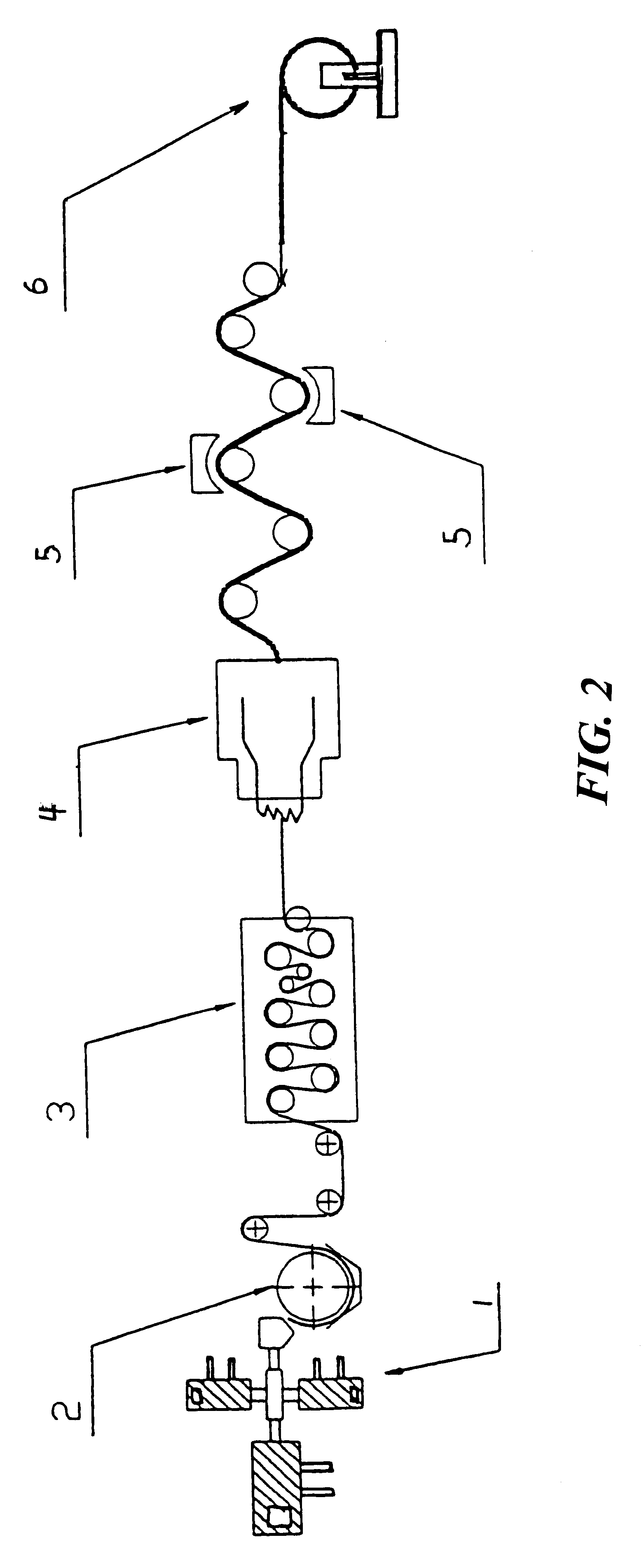

Process for producing a 3-layer co-extruded biaxial-oriented polypropylene synthetic paper and transparent film for in-mold label

InactiveUS6379605B1Low production costLow costLamination ancillary operationsElectric heatingCardboardEngineering

Disclosed is a process for producing a three layers co-extrusion biaxially oriented polypropylene (hereinafter as BOPP) synthetic paper and transparent film for in-mold label. More particularly, the invention relates to a process for producing a three layers biaxially oriented PP synthetic paper by means of three layers co-extrusion wherein three different PP resin compositions are separately extruded by one primary and two secondary extruders first, and then are co-flowed by a same T-die to form a three layers coating sheet. Thus, the three layers structure of said three layers co-extrusion coating sheet can be made into resin layer / foamed intermediate or resin layer / resin layer, and then through cooling, biaxial orientation, corona treatment and winding to form a three layers co-extrusion synthetic paper of haze paper sheet layer / foamed intermediate layer / adhesive layer, gloss paper sheet layer / foamed intermediate layer / adhesive layer, or a three layers co-extrusion synthetic transparent film of resin layer / resin layer / adhesive layer

Owner:NANYA PLASTICS CORP

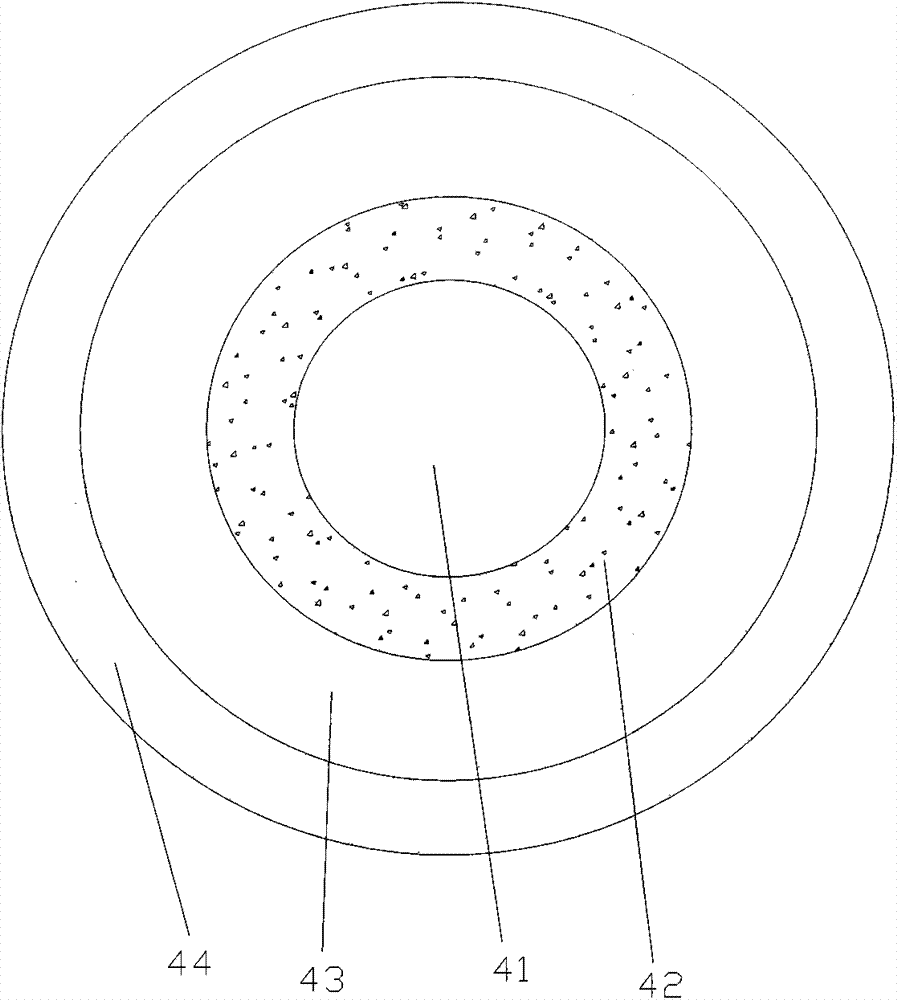

Preparation method of metalized film of induction cooker capacitor

ActiveCN103112169AImprove performanceGood removal effectVacuum evaporation coatingSputtering coatingMetallised filmRejection rate

The invention relates to the field of preparation of a capacitor, and in particular relates to a preparation method of a metalized film of an induction cooker capacitor. The preparation method comprises the following steps of: selection and preparation of raw materials, extruding a melt through an extruder, cooling the melt through a chilling roller and an air shower, drawing the melt in a vertical direction, drawing the melt in a transverse direction, testing the thickness of the drawn melt, performing procedures of trimming and corona treatment, rolling, time sequence treatment, slicing, and vacuum-evaporating the metalized film. Through the steps, the prepared metalized film is comparatively high in performance, comparatively low in rejection rate, low in cost and high in current carrying capability.

Owner:NINGBO GREAT SOUTHEAST WAN XIANG SCI & TECH

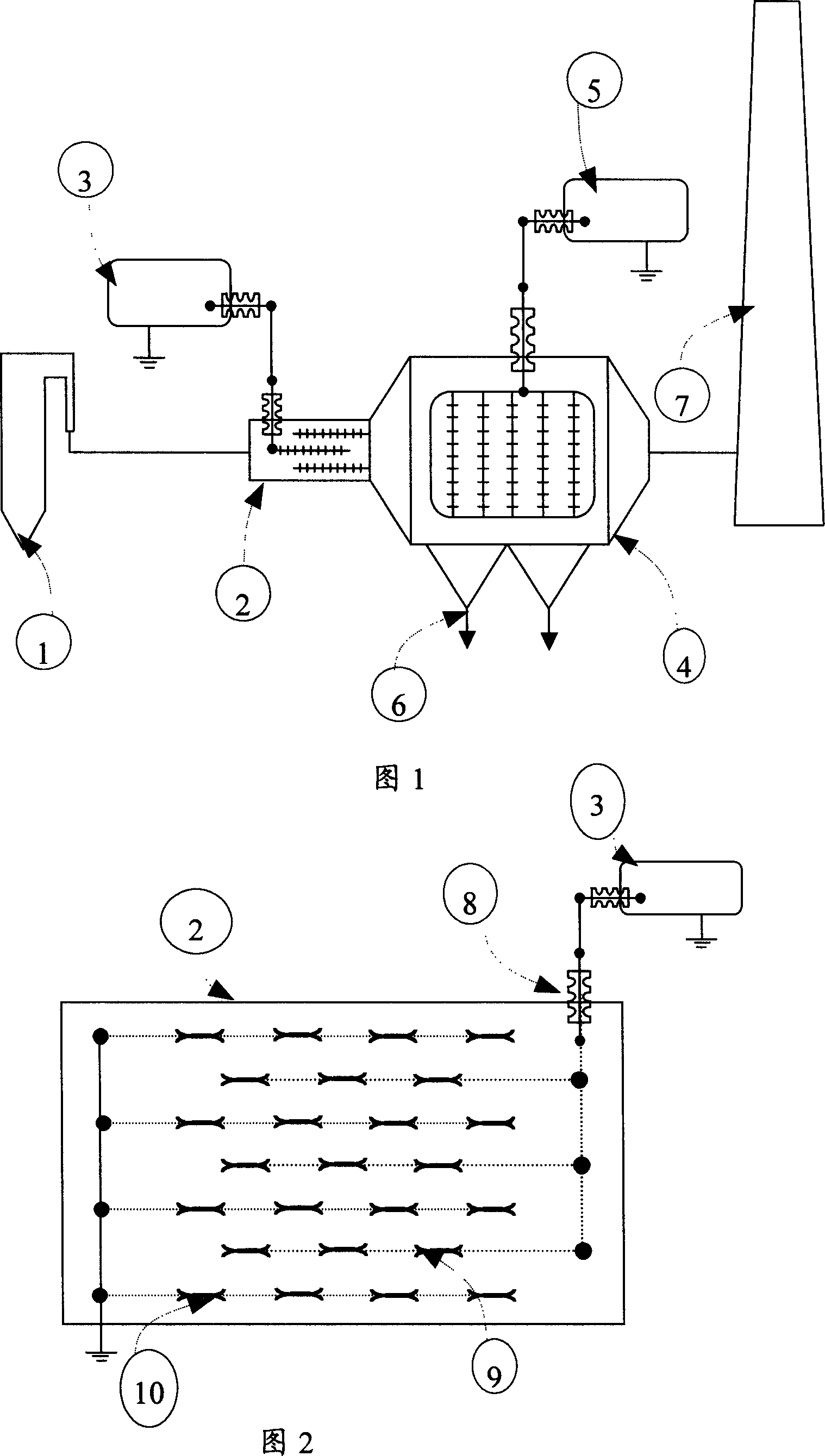

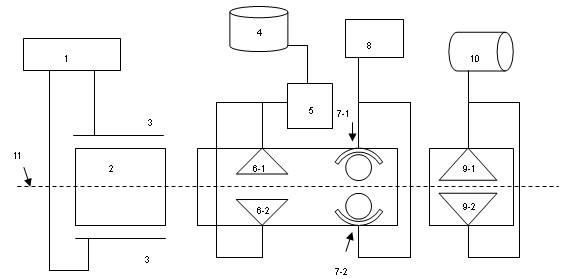

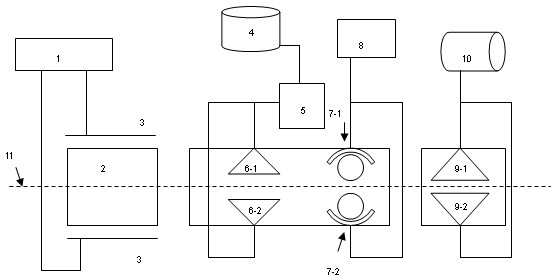

Bipolar corona discharge soot aggregation and electro dedust method and instrument

InactiveCN1603004AImprove charging efficiencyLow costExternal electric electrostatic seperatorElectric supply techniquesCorona dischargeEngineering

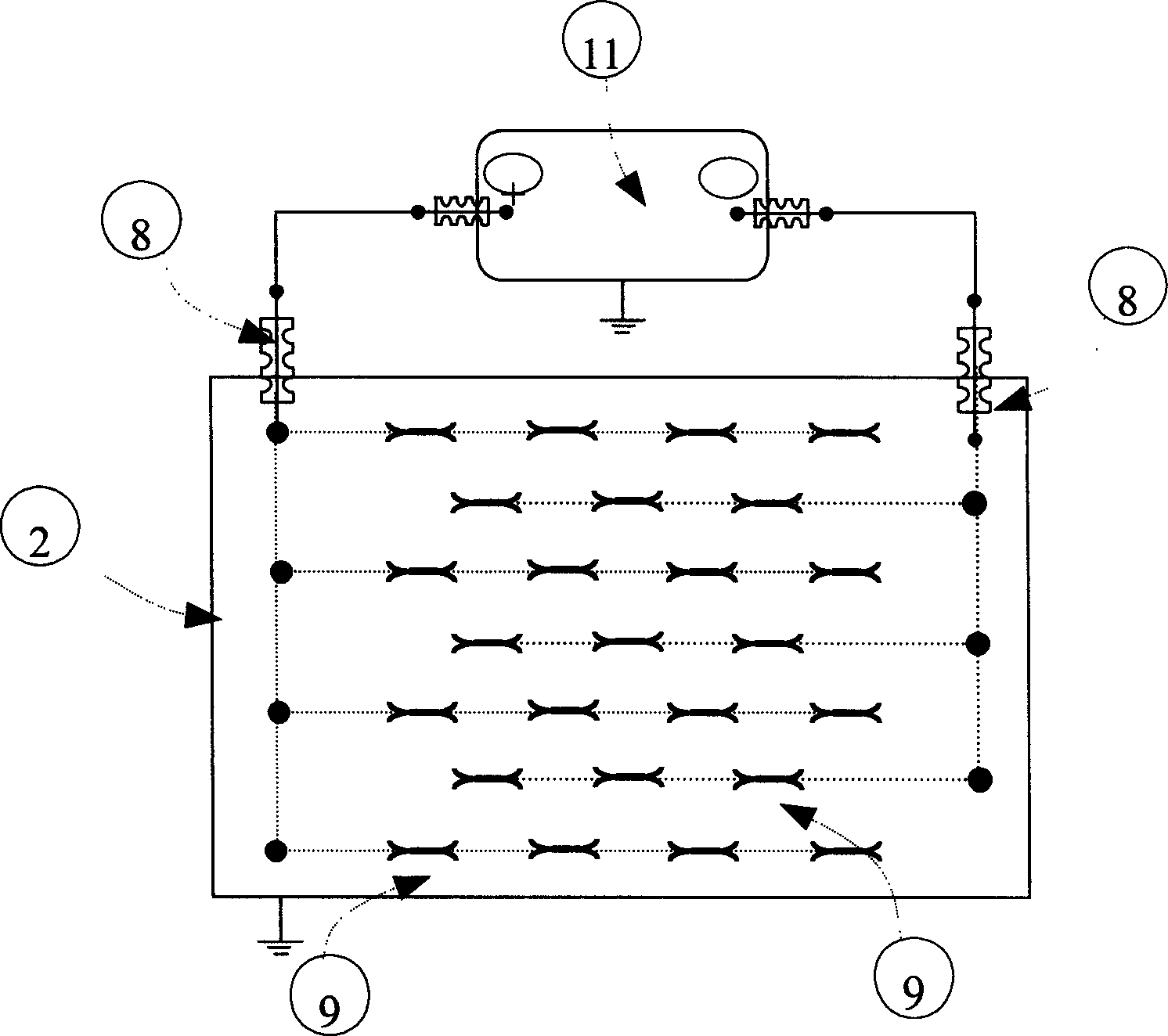

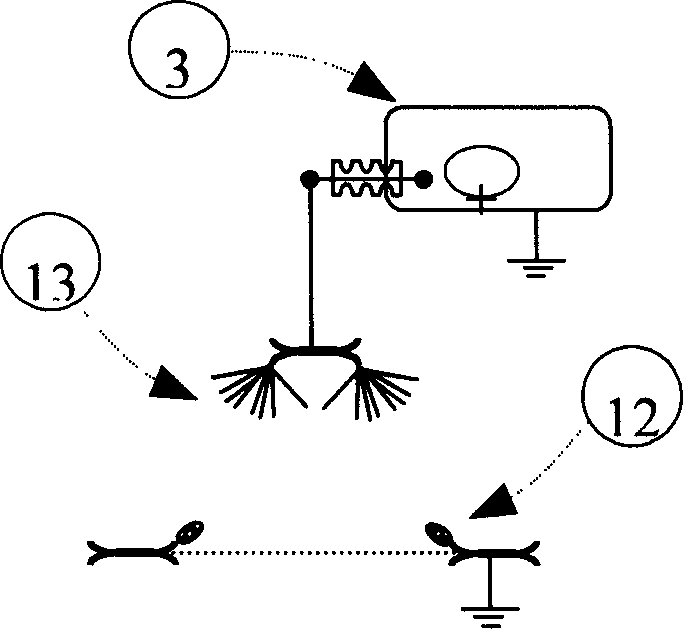

The invention discloses a kind of bipolarity corona discharge, dust smoke congeals gathers, the electricity dust removal method, it belonges to the haze dust removal technology domain, the containes dust smoke first passes through the positive and negative corona discharge area in haze,Causes the dust particle in the haze carry the positive and negative electric charge then mutually congeals and gathers into a bigger pellet,then put it into the electric precipitator to carry on the electricity dust removal.The invention also discloses the installment for implementating above method,including a smoke channel, the smoke channel is fixed in the front part of the electric precipitator, assembles at least group of corona discharge electrode and at least a group of negative corona discharge electrode in the internal, the positive and negative discharge electrode is separately connected with the high-pressured power source out-port and the output low pressure end.In this invention method the dust smoke in haze passes through positive and negative electronics corona processing to carry the electric charge then congeals, again enters the electricity dust removal installment to carry on the dust removal, enhances the dust removal efficiency.the stated installment use the single high-pressured power source, the positive and negative corona discharge simultaneously product, electrically charged congeals carries on in the identical room, the cost is low, the electrically charged efficiency is high.

Owner:金华市中荷环保科技有限公司

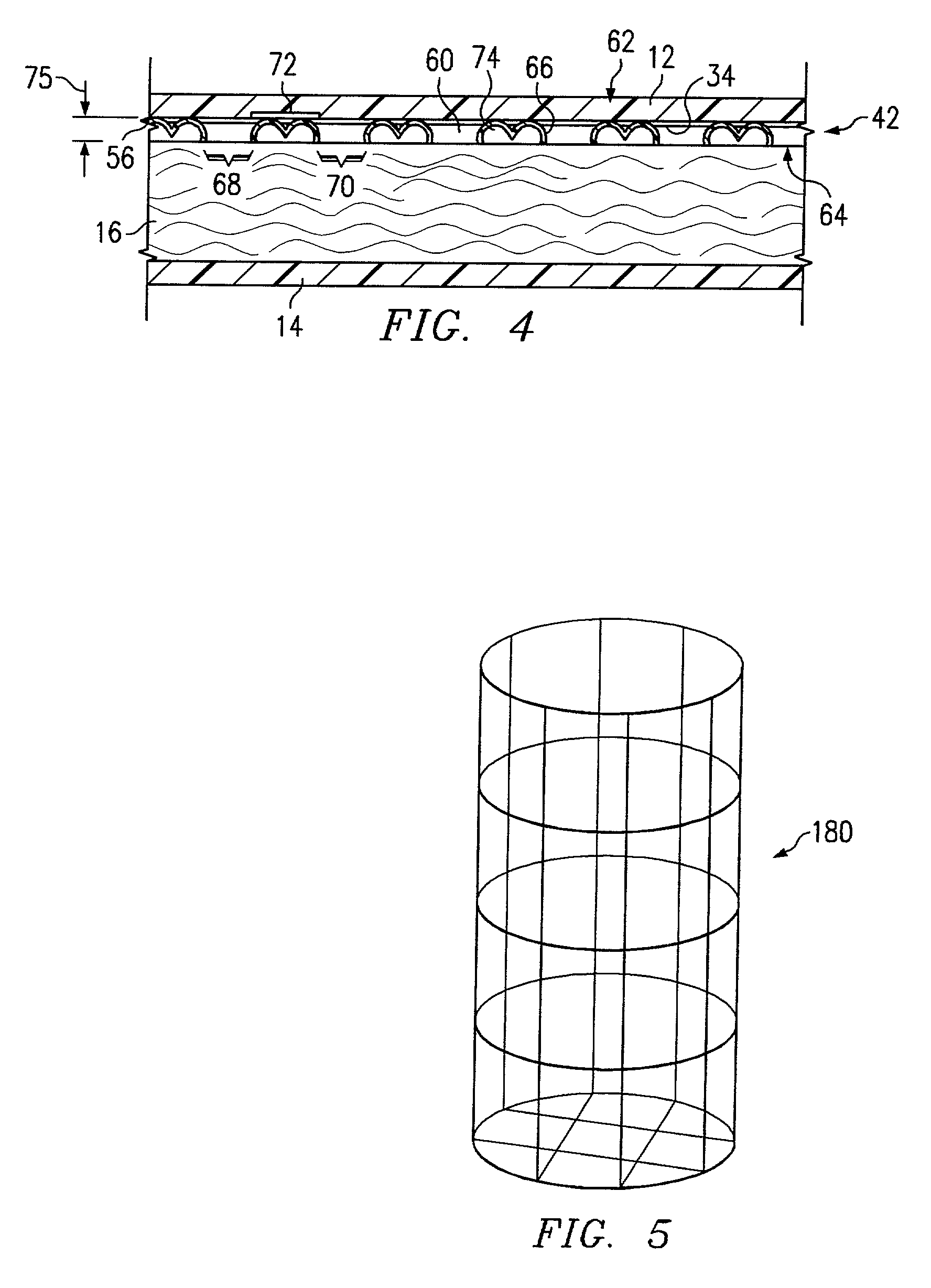

Absorbent article having a surface energy gradient between the topsheet and the acquisition distribution layer

An absorbent article has a topsheet, an absorbent core, and an acquisition distribution layer between the topsheet and the core. The topsheet has an affinity for water and is therefore philic, not phobic. The acquisition distribution layer is more philic than the topsheet, thereby creating a surface energy gradient between the topsheet and the acquisition distribution layer. The topsheet is preferably a formed film but may be nonwoven. The acquisition distribution layer is preferably of a high void volume type formed film but may be a standard formed film. The affinity to water of either the topsheet or the acquisition distribution layer may be created using surfactants, corona treatment, material selection or a combination of the above.

Owner:TREDEGAR FILM PROD CORP

Modification method for using low-temperature plasma to initiate gas-phase grafting on surface of polyethylene film

ActiveCN102432905AIncrease reaction rateSuitable for large-scale continuous productionReaction rateGas phase

The invention discloses a modification method for using low-temperature plasma to initiate gas-phase grafting on the surface of a polyethylene film. The modification method comprises the following steps of: 1) adopting a low-temperature plasma treatment machine with the power being 1KW-20KW and the voltage being 380V to carry out corona treatment on the polyethylene film; 2) after mixing liquid acrylic-acid monomer and an activating agent at the weight ratio being 100: (1-20), vaporizing by a vaporizing chamber with the temperature being 120-200 DEG C, and uniformly spraying on the surface ofthe polyethylene film after corona treatment by a spraying nozzle in a gaseous form; and 3) generating ultraviolet light for irradiation by a high-voltage mercury lamp with the wavelength being 365nmand the power being 500W-5000W, sensitizing the activating agent by the ultraviolet light, initiating the grafting of the acrylic-acid monomer on the surface of the polyethylene film, blowing by hot air with the temperature being 50-80 DEG C, removing the residual monomer and obtaining the polyethylene film with the gas-phase grafted surface. The modification method is high in reaction rate of gas-phase grafting on the surface, is suitable for large-scale continuous production, is lower in cost, the surface tension permanency is improved, and the problem of quality stability of the composite packaging film can be solved.

Owner:浙江粤海包装新材料有限公司

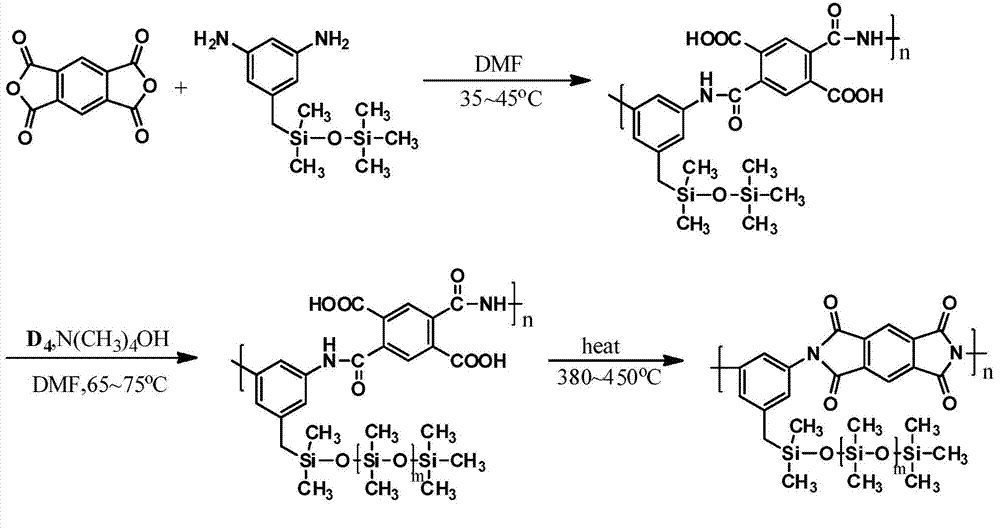

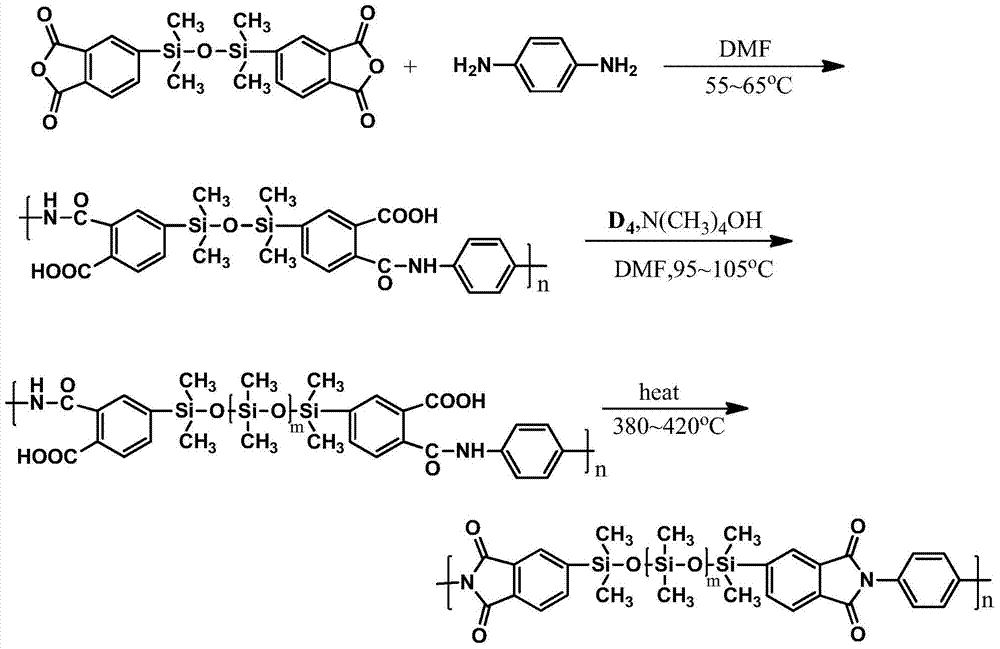

Novel electronic-grade polyimide film with low linear expansion coefficient and production method thereof

The invention relates to a preparation method of an electronic-grade polyimide film with low linear expansion coefficient. The method comprises the following steps that (1) the step-by-step condensation polymerization technology is used for obtaining polybasic block copolymerization polyamide acid glue solutions comprising one or more bar-shaped rigid chain sections containing para-benzene or biphenyl and one or more soft chain sections containing ether bonds or silicon-oxygen bonds and the like; (2) polyamide acid comprising one or more bar-shaped rigid chain structures containing para-benzene or biphenyl and polyamide acid comprising one or more soft chain structures containing ether bonds or silicon-oxygen bonds are independently compounded, and the two or more polyamide acid glue solutions different in rigidity and softness are mixed and compounded; (3) the compounded glue solutions are subjected to filtration, vacuum defoamation, casting filming, bidirectional stretching, chemical amidization or thermal amidization, infrared complete amidization, high-temperature thermal forming processing, corona processing and a reeling process, and therefore the electronic-grade polyimide film with the thickness being 7.5-125 micrometers, the linear expansion coefficient being 5-18ppm / DEG C, and good physical mechanical performance is obtained.

Owner:宏威高新材料有限公司 +1

Flexible packaging composites

ActiveUS20090047525A1Increased durabilityImprove biodegradabilityWrappersDomestic containersFiberDyne

The flexible packaging composites include one or more mineral-containing layers with a bonding agent. The composite structure is used as a primary or secondary packaging container or insulating material. In addition to the mineral-containing layer, the composite can contain one or more non-mineral containing layers, including various combinations of extruded resins, cast or blown films, and fibers. The mineral-containing layer is substantially and continuously bonded to the other layers. The present invention is an unexpectedly unique and environmentally friendly composite structure containing mineral layers with bonding agents as a key component. The material is designed to form flexible and semi-rigid storage articles at equal or lower costs to prior art solutions while providing a mineral containing layer that is a very smooth, has comparatively high plasticity, and having a high quality printing surface not requiring Corona Treatment. The composite structure is used as a primary or secondary packaging container or insulating material. In addition to the mineral containing layer, the composite could contain various combinations of extruded resins, cast or blown films, and fibers. The mineral containing layer is substantially and continuously bonded to the other layers. The polymer, fiber, and mineral containing layers can be shaped, sized and manufactured such that the composite structure formed is subsequently machined to form a storage article. The composite structure has advantages including a high degree of pliability and flexibility, a minimum 37 dyne level on the surface of the mineral containing layer; a mineral containing layer that is highly 86 opaque, and has a bright, white printing surface that readily accepts coating and inks, therefore, rendering it highly attractive to consumers. Further, the composite structure has tensile strength, dead-fold, stiffness, and other characteristics that allow it to be readily machined into desired storage article forms and storage article closures, therefore, the material can be used for as a variety of food, consumer, industrial, anti-static, and commercial uses. Other mineral containing layer advantages include environmentally attractive features such photo-degradability, recyclability, compost-ability, and bio-degradability.

Owner:SMART PLANET TECH

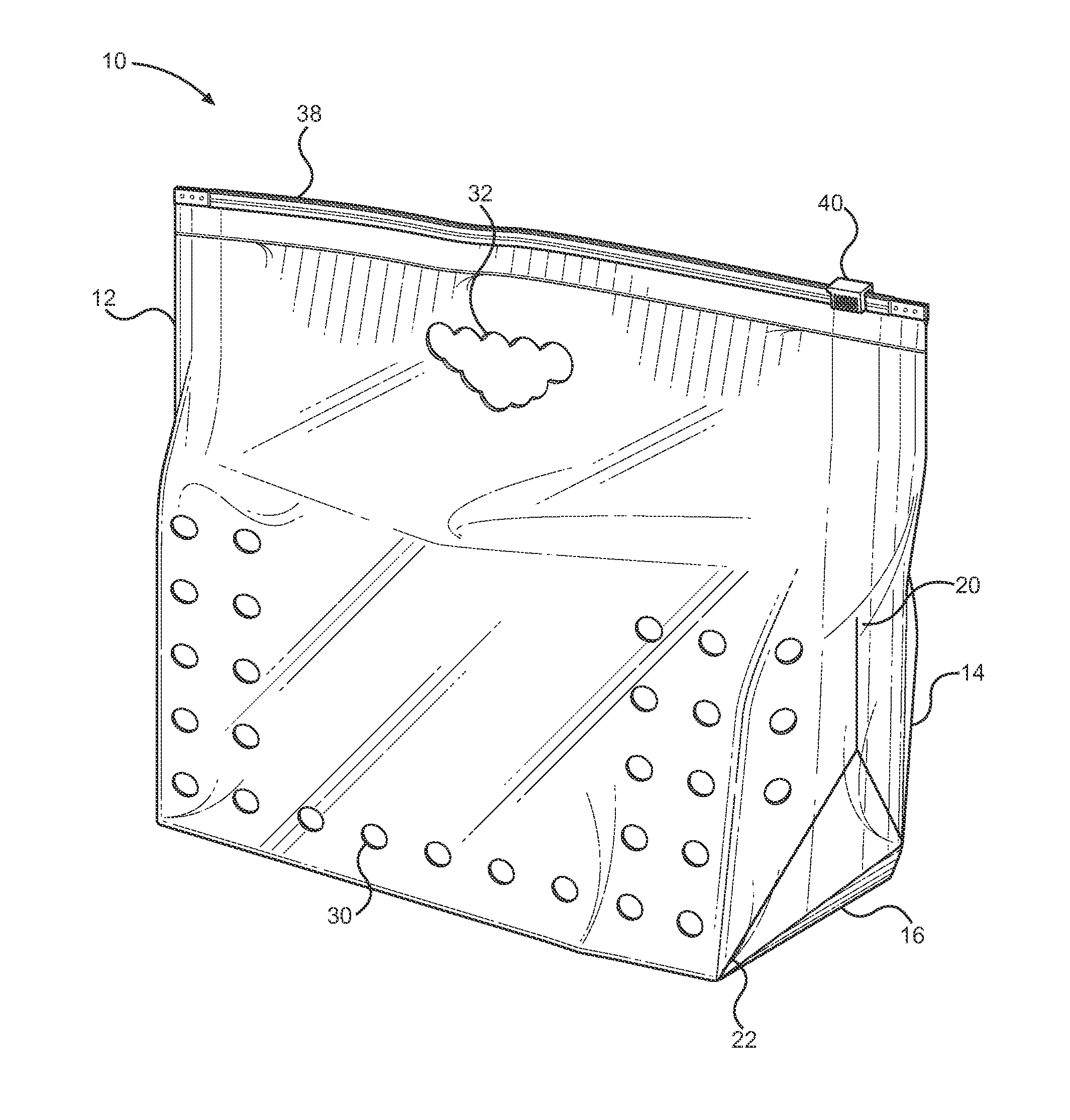

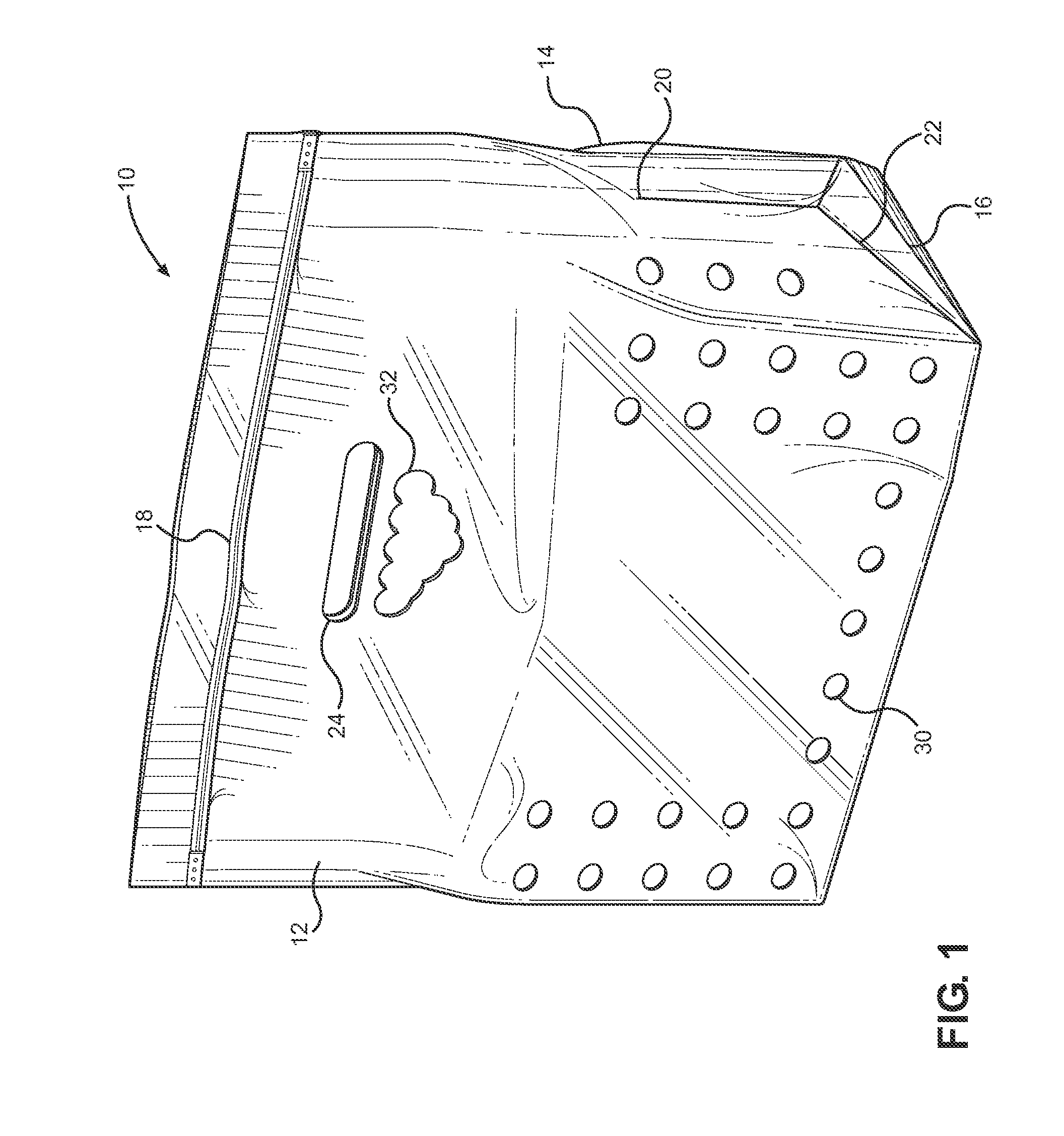

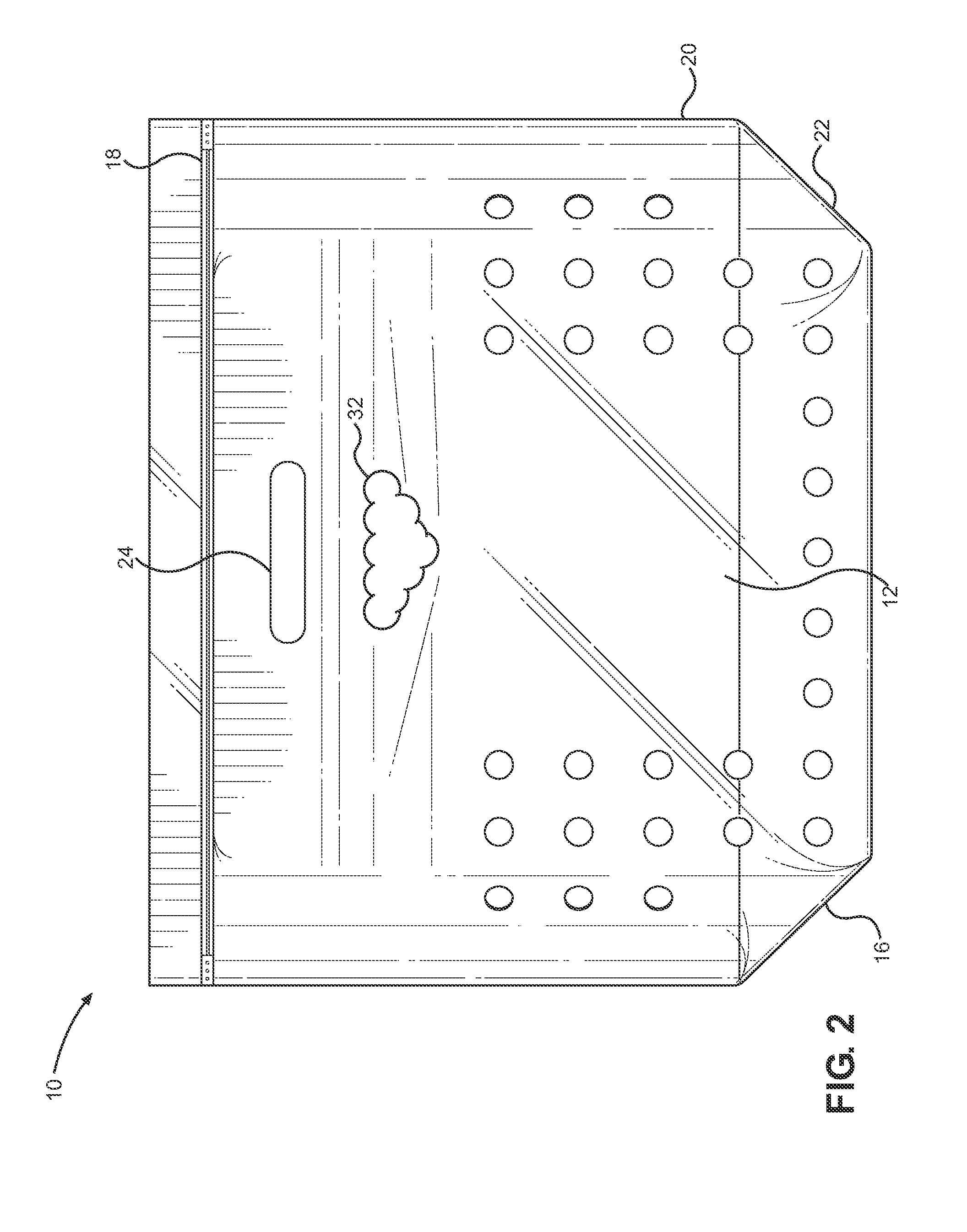

High-Clarity, Cast Polypropylene Produce Pouch and Method

A high-clarity, cast polypropylene produce pouch with first and second sidewalls and a bottom panel joined to form a pouch wherein the first and second sidewalls and the bottom panel are formed from cast polypropylene. The bottom panel can be a bottom gusset panel. The first and second sidewalls and the bottom gusset panel can have edges joined by side welding or heat sealing. Zipper or slide closures can close the first and second sidewalls. A method for forming a high-clarity, cast polypropylene produce pouch comprises creating a polypropylene (PP) resin, passing the polypropylene (PP) resin through a cast extruding machine and extruding molten polypropylene (PP) to produced extruded polypropylene (PP), rolling the extruded polypropylene (PP) in a cooling roller, and applying a surface-modifying corona treatment to the extruded polypropylene (PP).

Owner:DUPAK

Ink-jet recording material and preparation method thereof as well as method for preparing ink absorption layer coating liquid

ActiveCN102092209ALow priceIncrease polarityStarch dervative coatingsConjugated diene hydrocarbon coatingsPolymer scienceAdhesive

The invention provides an ink-jet recording material and a preparation method thereof as well as a method for preparing an ink absorption layer coating liquid, and relates to an ink-jet material and a preparation method thereof as well as a method for preparing an ink absorption layer coating liquid, so that the problems of poor ink absorption effect, nonuniform color distribution of printed images, unclear printed images and higher preparation cost of the existing ink-jet recording material can be solved. The ink-jet recording material is prepared from the ink-jet layer coating liquid which is prepared from PVC (polyvinyl chloride) serving as a base material, a 20-30% polyacrylic acid emulsion serving as a primer, an inorganic nano-pigment with the thickness of 10-100nm, a dispersing agent, acetic acid, deionized water and an adhesive aqueous solution. The prepared ink-jet recording material prepared through PVC material corona treatment, PVC substrate glue coating, drying, ink absorption layer coating and drying has the advantages that that the printed image is clear, the ink droplet does not diffuse, and the color is distributed uniformly; and the ink-jet recording material has excellent performances of color definition, color saturation, glossiness and the like. The raw material cost and the manufacture cost are low, so the ink-jet recording material is advantageous to industrial production, popularization and application.

Owner:HARBIN INST OF TECH

Process for producing a 3-layer co-extruded biaxially oriented polypropylene synthetic paper of thickness 25-250 mum

InactiveUS6364988B1High glossGood printabilityLamination ancillary operationsLayered product treatmentPolymer scienceBoPET

Disclosed is a process for producing a 3-layer co-extruded biaxially polypropylene (hereinafter as BOPP) synthetic paper of thickness 25-250 mum. More particularly, the invention relates to a process for producing a 3-layer biaxially-oriented PP synthetic paper by means of 3-layer co-extrusion wherein two different PP resin compositions are separately extruded by one primary and two secondary extruders first, and then are co-flowed by a same T-die to form a three layers coating sheet, and through cooling, biaxial orientation, corona treatment and winding to form a 3-layer co-extrusion synthetic paper of thickness 25-250 mum. The 3-layer structure of said 3-layer co-extrusion synthetic paper of thickness 25-250 mum can be made into three kinds, such as: paper sheet layer / foamed intermediate layer / paper sheet layer with double side paper sheet layer, paper sheet layer / foamed intermediate layer / resin layer with single side paper sheet layer and resin layer / foamed intermediate layer / resin layerwith double side high gloss resin layer.

Owner:NANYA PLASTICS CORP

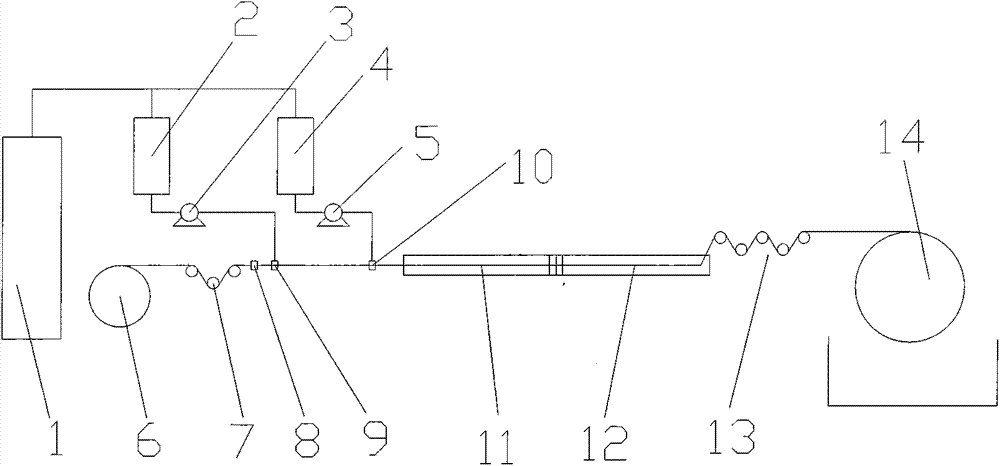

Reinforced composite supported hollow fiber membrane and preparation method thereof

ActiveCN104117289APrevent peelingAvoid foulingSemi-permeable membranesProcess conditionsTransition layer

The invention relates to a reinforced composite supported hollow fiber membrane and a preparation method thereof. The reinforced composite supported hollow fiber membrane comprises a weaving support tube, a transition layer and a separating layer, wherein the support tube is a hollow braided fabric; the adhesive strength between the weaving support tube and the transition layer is 0.4-4N; the weaving support tube is made of synthetic fiber through weaving. The reinforced composite supported hollow fiber membrane and the preparation method thereof have the beneficial effects that as the support tube is subjected to corona treatment, the surface of the support tube is relatively rough, and the specific surface area of the support tube is improved, so that the adhesive strength between the transition layer and the support tube of the hollow fiber membrane is improved; due to adoption of a macromolecule polymer added in the transition layer, the adhesive strength between the support layer and the separating layer is improved, and the hollow fiber membrane is effectively prevented from being stripped in the use process. The preparation method comprises the following step that the weaving tube passes through a corona machine, a pre-coating machine head, a coating machine head and a coagulating bath respectively in a horizontal manner. The preparation method is simple to operate, the process condition is easy to control and production efficiency is high.

Owner:枫科(北京)膜技术有限公司

Paper plastic glue-free composite bidirectional stretching polypropylene film and its preparation method

ActiveCN101058247ASimple structureHigh heat sealing strengthSynthetic resin layered productsFlat articlesThick plateEngineering

The invention relates to a paper plastic glue free compound bi-directional stretch polypropylene film, which has coextruded surfaced, core layer, functional layer being able to compound with paper, pre-print paper or thin film, with upper sub surface between the surface and core layer, and lower sub surface between the core layer and the functional layer. All of them are extruded through bi-directional stretch. It feeds formulated material into the extruder to melt, which is co-extruded into thick plates through slip cast, then the thick plates being stretched in both directions into thin film, which are processed through corona and flame into mother film, through effective treatment to get the final thin film product. It is simple in structure, strong in thermal sealing, high in stripping strength.

Owner:GUANGDONG DECRO PACKAGE FILMS +1

Biaxial tension polypropylene synthetic paper and manufacture method thereof

InactiveCN101015974AReduce adhesionLow densityFlexible coversWrappersPolypropylene compositesPolymer science

A method for producing bidirectional drawing polypropylene composite paper is characterized in foam or specific porous thin layer. The inventive bidirectional drawing polypropylene composite paper has three-layer extrusion, while two surface layers are pearl layer or extinction layer, the pearl layer is PP and adhesive resistant, the extinction layer is extinction mother material, the corn layer is inorganic foaming layer which comprises polypropylene resin, pearl mother material and static resistant. The invention fuses and extrudes corn layer and surface layer, while the extruded corn layer fusion is extruded via a metering pump to be filtered via a filter network to enter into mould head, and the extruded surface material fusion is directly fed into the mould head, to be cooled and shaped via a cooling roller, and the sheets are fed into longitudinal drawer and transverse drawer, the membrane enters into a drawer to be flattened and on-line measured at thickness, to adjust the thickness, cut edge, and corona, to be coiled, cut, checked and packed.

Owner:QUANZHOU LICHANG PLASTIC

Biaxially oriented matte BOPA (Biaxially oriented polyamide film) thin film and preparation method thereof

ActiveCN102924905AOvercome stabilityOvercome yieldSynthetic resin layered productsBoPETThin membrane

The invention discloses a biaxially oriented matte BOPA (Biaxially oriented polyamide film) thin film which is formed by a single frosted surface layer, or is formed by laminating the frosted surface layer and a smooth surface layer, or is formed by sequentially laminating the frosted surface layer, a middle layer and the frosted surface layer or is formed by sequentially laminating the frosted surface layer, the middle layer and the smooth surface layer. A method for preparing the biaxially oriented matte BOPA thin film comprises the following steps of: 1, placing the raw materials on each layer into a corresponding extruder to carry out melting and carrying out coextrusion by a die head to form a layer structure; 2, cooling and forming to obtain a crude product nylon thin film; and 3, carrying out biaxial stretching, heat setting, corona treatment and winding on the crude product nylon thin film to obtain the matte BOPA thin film product. The invention can overcome the defects of unstable quality of a conventional process, low yield, fussy process and high cost of the product; and the produced biaxially oriented matte BOPA thin film has a high quality.

Owner:FSPG HI TECH

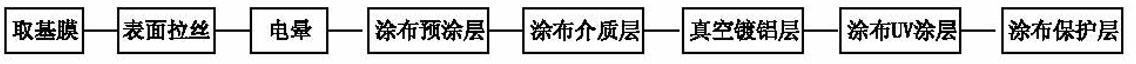

Manufacture process of imitation stainless steel metal drawbench film

InactiveCN102642439AIncrease the dyne coefficientHigh fastnessLamination ancillary operationsSynthetic resin layered productsPolyesterAcrylic coating

The invention discloses a manufacture process of an imitation stainless steel metal drawbench film, which comprises the following steps: 1 taking a base film which is a polyester (PET) film; 2 conducting surface drawbench and surface polishing one surface of the base film; 3 conducting surface corona and conducting corona processing on two surfaces of the base film, 4 conducting precoat coating and conducting network roller coating on the surface of the base film receiving surface drawbench and corona processing through methyl methacrylate coating, 5 conducting media layer coating and conducting network roller coating on a precoat through acrylic coating, 6 conducting vacuum aluminizing on the media layer, 7 conducting ultraviolet (UV) coating coating and conducting network roller coating on one face of the base film without surface drawbench through colored translucent UV coating, and 8 conducting protection layer coating and preventing an aluminizing layer from being oxidized. The manufacture process improves product structure firmness, and ensures optimum using effects of products. The products can show different gloss effects from dumb light to high light, thereby meeting requirements for environment protection.

Owner:DONGGUAN GUODING OPTICAL MEMBRANE TECH

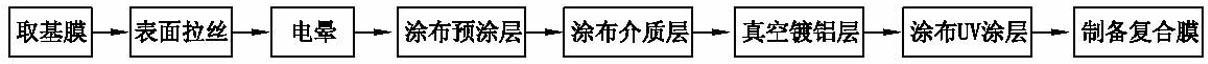

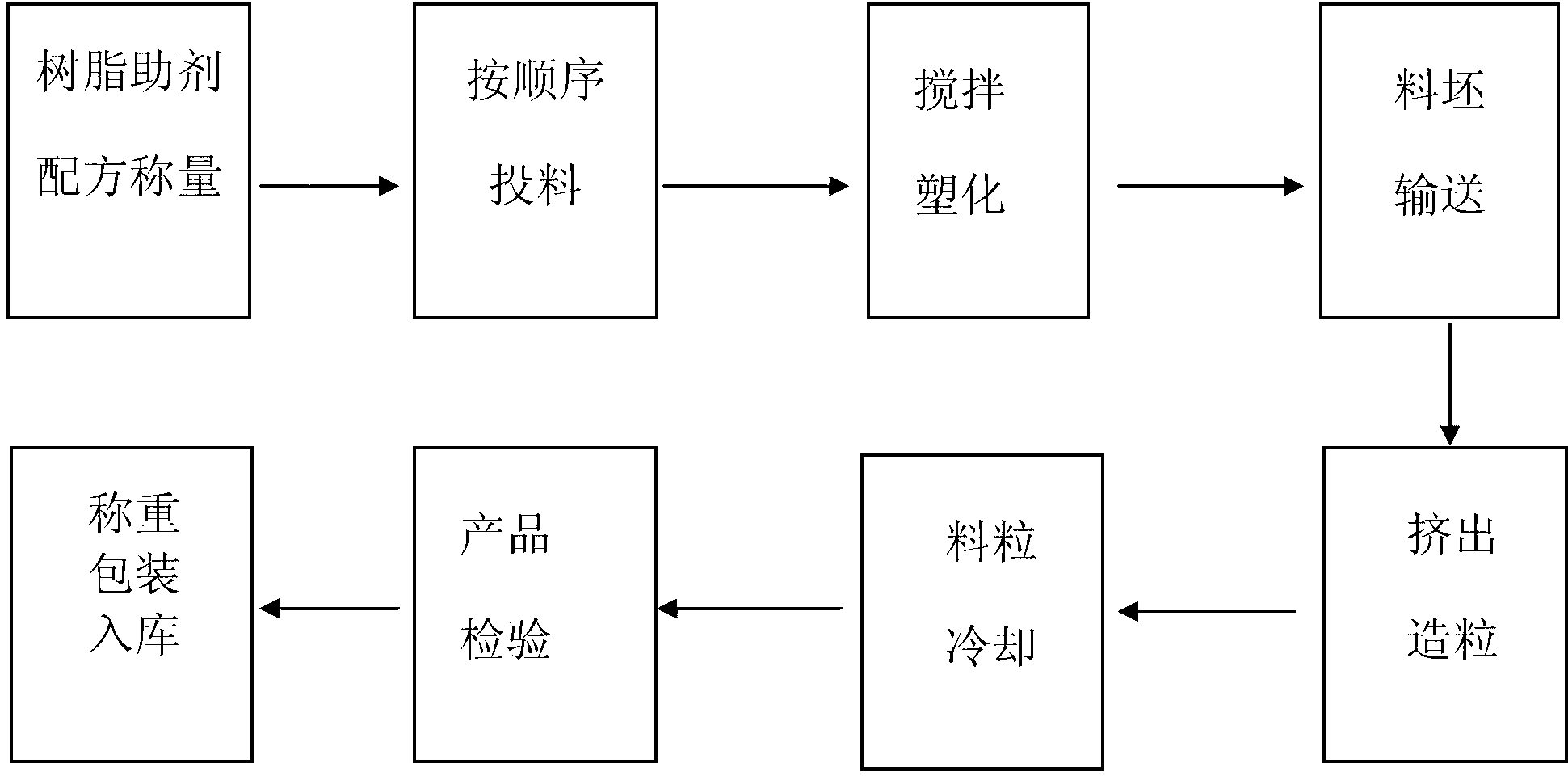

Stone water-free paper-making method and flow

InactiveCN101701433AFast productionIncrease productionSpecial paperPaper/cardboardPrinting inkInorganic materials

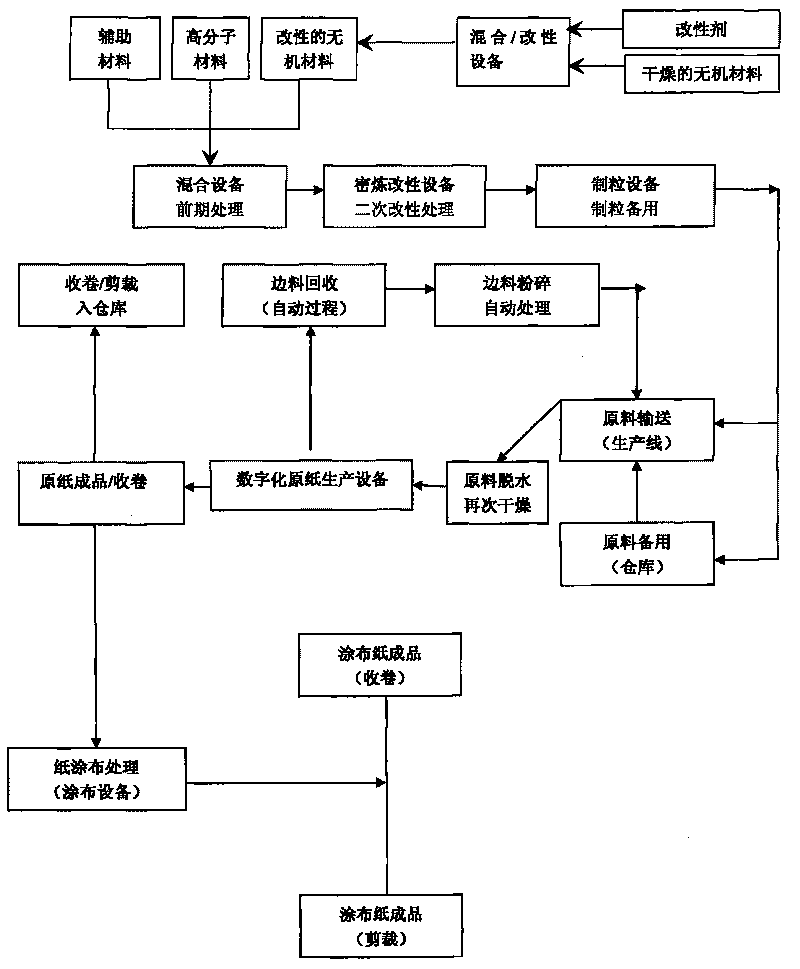

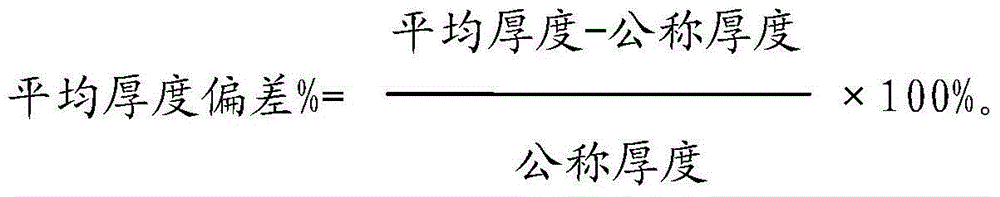

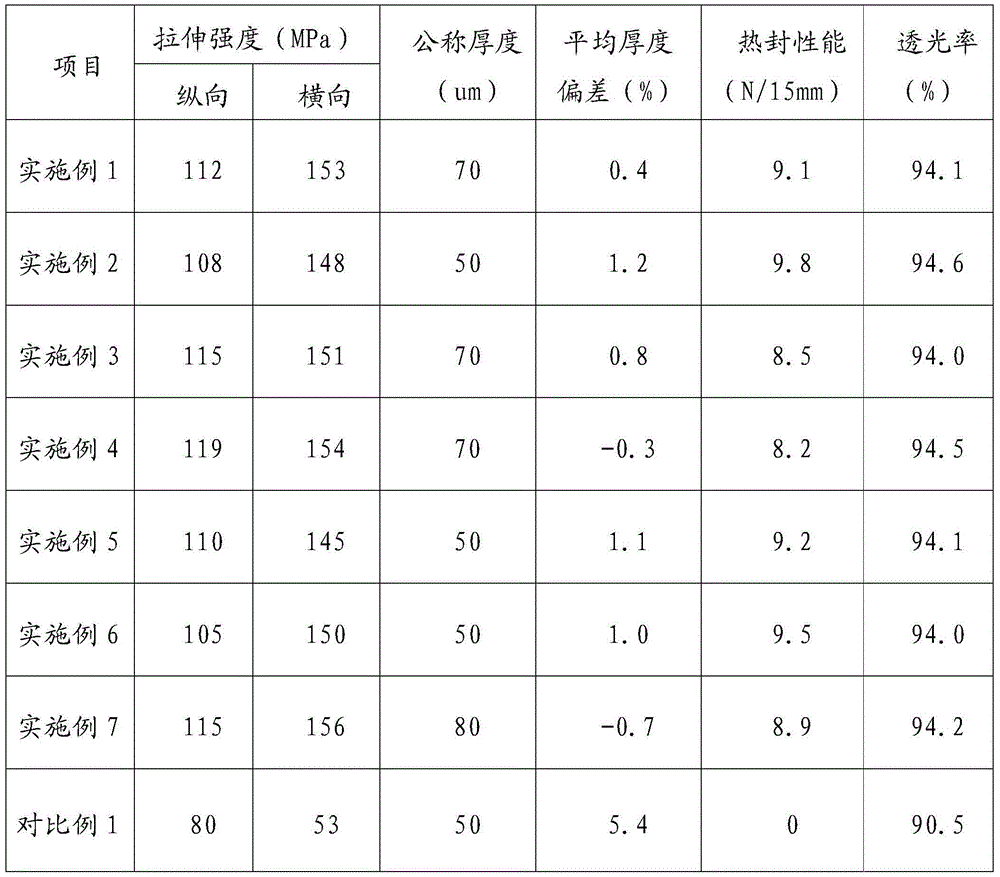

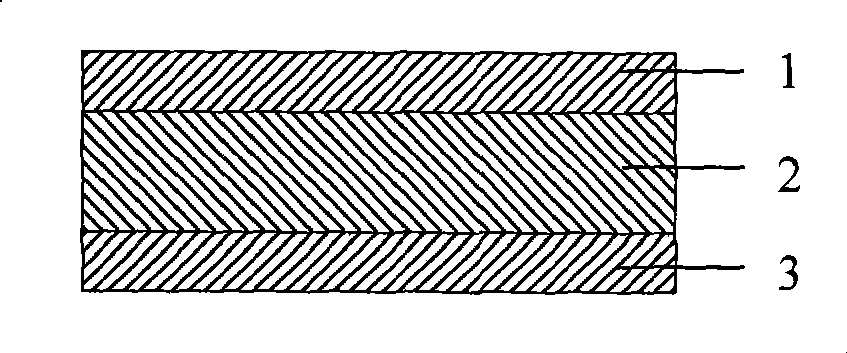

The invention relates to a stone water-free paper-making method and a flow thereof; the process method and the flow are that: after inorganic material is dried, a modifier is added in the inorganic material to carry out mixing modification in mixing / modifying equipment, and then the inorganic material which is activated and modified and organic material and accessory ingredients are mixed and are conveyed to the modifying equipment to carry out secondary modifying treatment (banburying), and then extrusion granulation is carried out to form granulated raw material, and the granulated raw material is conveyed to raw material drying equipment to carry out secondary drying by raw material conveying equipment, and the dried raw material is directly conveyed to a film casting and laminating machine and a drawing mill to be produced into body paper, and then the body paper is cut and rolled for spare, and the cut rim charge is recycled; corona treatment is carried out to the body paper, and then surface coating treatment is carried out in a coating machine, so as to obtain coated paper; by adopting the method to produce stone paper, the production speed is rapid, the output is high, the flatness and smooth finish of the finished paper are good, the product quality is high, and various printing modes and printing inks are suitable for the paper. The process in the invention is simple and rational, the product quality is stable and the effect is good.

Owner:蔡茂友

Two-way stretch polylactic acid film capable of being directly thermally sealed and preparation method of two-way stretch polylactic acid film

ActiveCN104608448AUniform thicknessHigh tensile strengthLamination ancillary operationsSynthetic resin layered productsBoPETPolylactic acid

The invention discloses a two-way stretch polylactic acid film capable of being directly thermally sealed and a preparation method of the two-way stretch polylactic acid film. The two-way stretch polylactic acid film comprises an A layer, a B layer and a C layer, which are sequentially arranged, wherein the A layer is a surface layer heat-seal layer, the B layer is a middle core layer, the C layer is an anti-adhesion layer. The preparation method comprises the steps of melting and extruding raw material sections of the layer A, the layer B and the layer C respectively at the temperature of 180 to 220 DEG C by virtue of a double-screw extruder, placing fused mass in a three-layer co-extrusion die head, casting the fused mass to form PLA sheets, preheating the PLA sheets, carrying out longitudinal stretch and cooling stereotyping on the PLA sheets, re-preheating the PLA sheets after the longitudinal stretch and cooling stereotyping, then transversely stretching the PLA sheets, carrying out stereotyping crystallization and cooling stereotyping on the PLA sheets, carrying out the pulling sectioning and corona treatment on the PLA sheets, and carrying out the coiling to prepare the two-way stretch polylactic acid film capable of being directly thermally sealed with thickness of 20 to 100 micrometers. The two-way stretch polylactic acid film capable of being directly thermally sealed can be directly produced on a BOPET production line, the prepared film can be directly thermally sealed, and the application range of the polylactic acid film can be enlarged.

Owner:SHANDONG SHENGHE PLASTIC DEV

Biaxial stretching polypropylene film and preparation method thereof

ActiveCN101362388AReduce usageReduce production processSynthetic resin layered productsSurface layerCo extrusion

The invention discloses a biaxial stretching polypropylene film which is a composite layer structure. One surface layer is a binding layer, and the material of the binding layer adopts polyethylene, vinyl copolymer and ionic polymer. The invention also provides a preparation method for the biaxial stretching polypropylene film, which comprises the following process steps: firstly, the raw material of the intermediate layer is put into an extruding machine; secondly, the raw material of the binding layer is put into an auxiliary extruding machine; thirdly, the raw material of the bottom layer is put into another auxiliary extruding machine; fourthly, the raw materials are fused and plasticized and then extruded out for confluence, to form a composite layer co-extrusion thick piece by a T-shaped die head; fifthly, the obtained thick piece is molded by cooling, then biaxially stretched, and then coiled into a 12-80 Mum multi-layer co-extrusion biaxial stretching polypropylene film at a recoiling machine by thickness measuring, edge cutting and single sided or two sided corona treatment, and the thickness of the binding layer is 0.8-10 Mum.

Owner:QUANZHOU LICHANG PLASTIC

Polyester film capable of being subjected to heat seal directly and preparation method

ActiveCN102873954AReduce wasteLow costSynthetic resin layered productsPolyethylene terephthalate glycolPolyethylene terephthalate

The invention relates to a polyester film and a preparation method thereof and particularly discloses a polyester film capable of being subjected to heat seal direction and a preparation method. The polyester film comprises a layer A, a layer B and a layer C, wherein the layer B is a middle core layer and made of a PET (polyethylene terephthalate) ultra-glazed polyester slice, the layer A is a surface heat-seal layer and made of a copolymerized PETG (polyethylene terephthalate glycol) polyester slice, and the layer C is an anti-blocking layer and made of a PET anti-blocking agent master batch slice and a PET ultra-glazed polyester slice. The preparation method includes steps of preparing corresponding polyester slices, extruding and drawing via an extruder, forming with cooling, crystallizing, drawing to remove scrap edges, treating coronas, detecting the thickness and the like.

Owner:ZHEJIANG QIANGMENG IND

Liquid packaging composite film and manufacturing method thereof

ActiveCN101638159AImprove barrier propertiesHigh composite fastness of coatingFlexible coversWrappersComposite filmPolyvinyl alcohol

The invention relates to a liquid packaging composite film which comprises a film layer, a coating layer and a bonding layer, wherein the film layer and the coating layer are used as base materials; the bonding layer is arranged between the film layer and the coating layer; the coating layer is a polyvinylidene chloride copolymer layer or a polyvinyl alcohol layer; the polyvinylidene chloride copolymer layer comprises polyvinylidene chloride copolymers; and the polyvinyl alcohol layer comprises a polyvinyl alcohol dispersion system. The manufacturing method of the liquid packaging composite film comprises the following steps: treating the base material film by corona discharge; coating the bonding layer on the base material film which is treated by corona discharge, and drying and coolingthe bonding layer; coating the polyvinylidene chloride copolymer dispersion system or the polyvinyl alcohol dispersed system on the base material film which is coated with the bonding layer; and then,drying and cooling the coating layer. The liquid packaging composite film has the characteristics of good barrier property, high firmness of the coating layer and long service life.

Owner:ZHEJIANG BILI PACKAGING

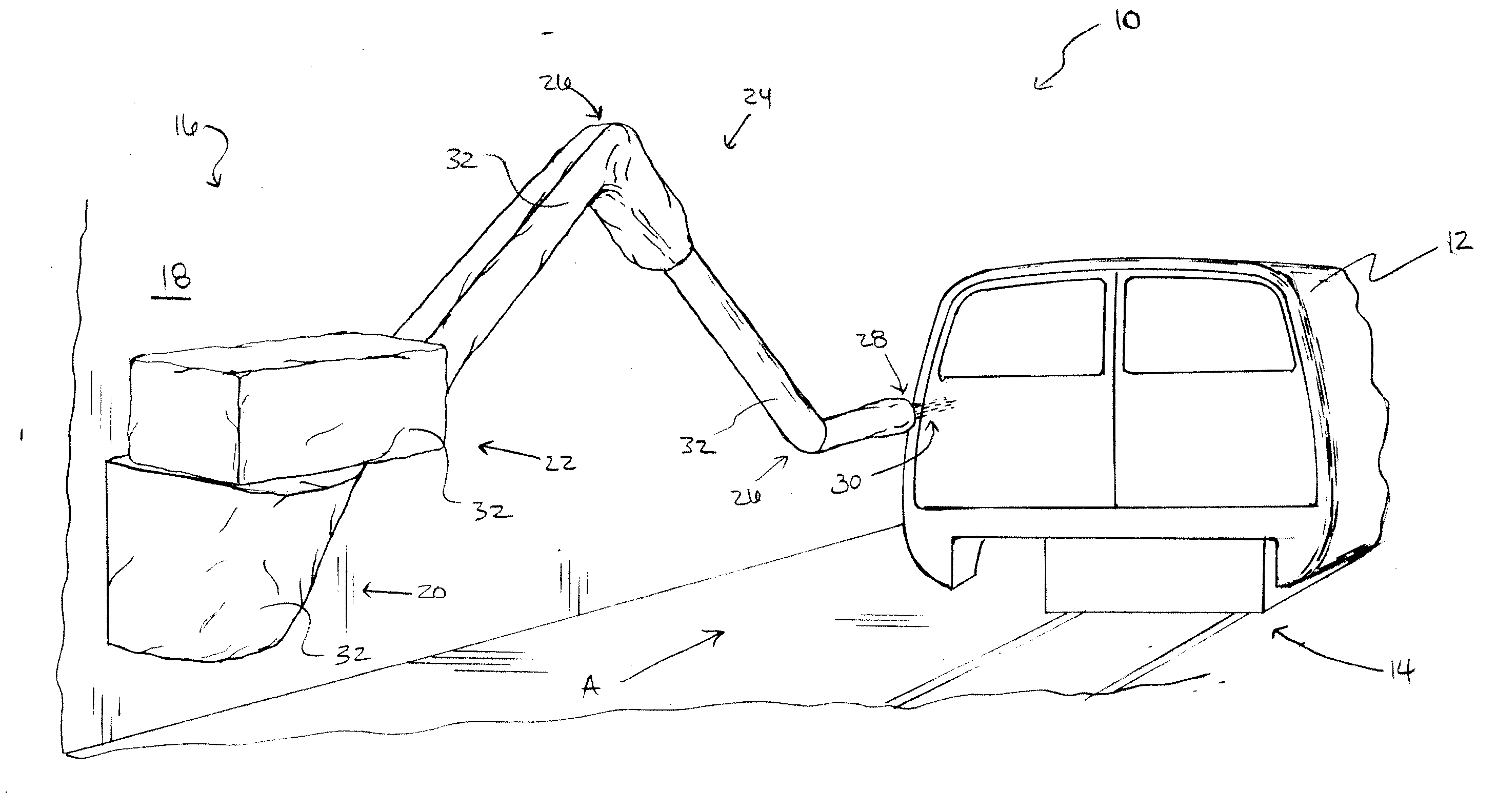

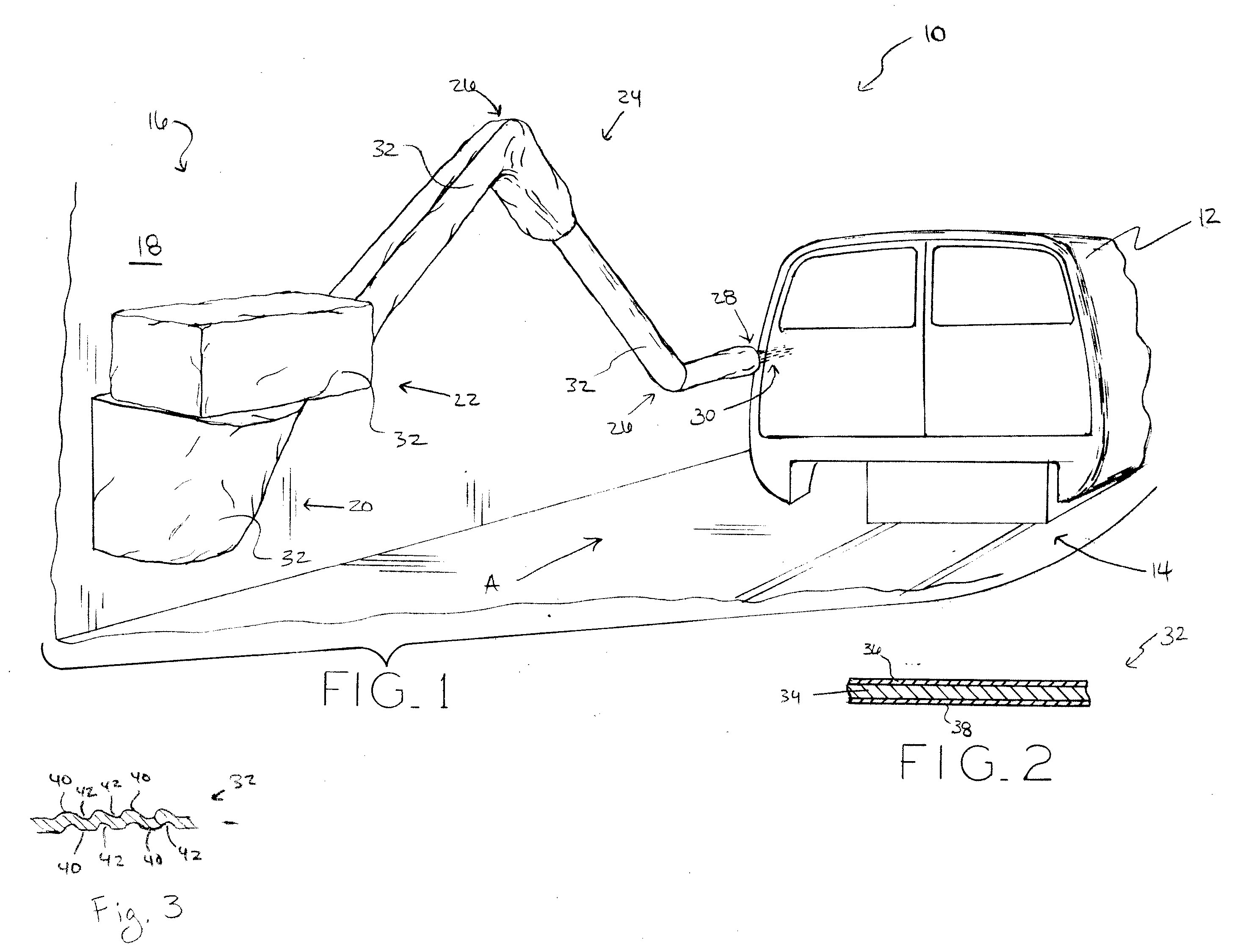

Polymeric cover for robots

ActiveUS20080237921A1Improve abilitiesAdhesivity increasedProgramme-controlled manipulatorLiquid surface applicatorsEngineeringPolymer

The present invention involves a cover for a spraying device of a robot which is formed from a polymer with enhanced residue retention properties. The polymer may be processed to increase the surface energy of the polymer. For example, the polymer may be subjected to a corona treatment in order to increase its surface energy. The corona treatment process may be performed on the polymer as received, prior to cutting or otherwise manipulating the polymer. Also, the polymer may be embossed to provide the enhancement. To assemble the polymer into a robot cover, the polymer as received may be cut into individual sections for assembly. The sections may then be assembled to one another by heat sealing the sections together. The heat sealing provides a bond between the individual sections of polymer that secures the individual sections together to create the robot cover. The polymer may also be formed into tubular sections for securing to the spraying device.

Owner:BUTTERWORTH INDS

Coating-type light conversion film and preparation method thereof

InactiveCN102848683AAvoid degradationHas acid resistanceClimate change adaptationSynthetic resin layered productsCooking & bakingMechanical property

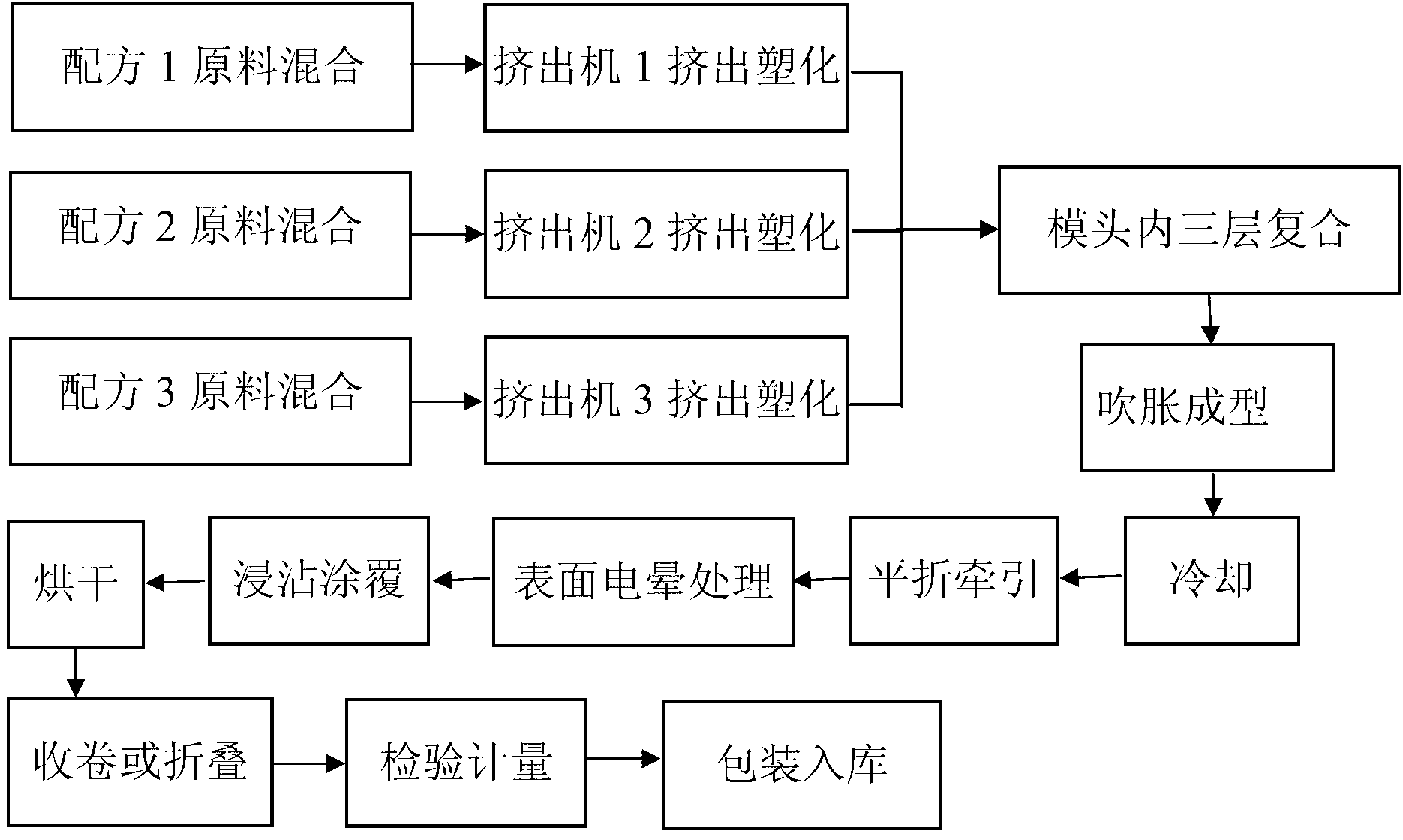

The invention relates to a coating-type light conversion film and a preparation method of the coating-type light conversion film. The invention belongs to the technical field of an agricultural film. An inner layer of the coating-type light conversion film is a mechanical property layer; a middle layer is a heat-insulating light conversion layer; a secondary outer layer is a coating carrier layer, and the outer layer is a film coating layer. The preparation method of the coating-type light conversion film comprises the following steps of: (1) preparing a multifunctional master batch with a long service life, heating an internal mixer, charging and agitating, discharging and pelletizing; (2) preparing the master batch with the long service life and efficient light conversion, heating the internal mixer, charging and agitating, discharging and pelletizing; (3) manufacturing the coating light conversion film, weighing the inner layer, the middle layer and the secondary outer layer according the prescription, respectively adding to a blender mixer to agitate and extrude, wherein a die head is of a three-layer composite center feeding form; the material is fused and plastified by three extruders, and coextruded by a round opening die; carrying out corona treatment on the film surface, coating on line, baking and sizing. The coating-type light conversion film has the advantages that the coating-type light conversion film is high in strength, high in impact resistance, high in tear resistance, high in light conversion, high in heat preservation, high in light transmittance, and long in lasting period of drip fog dissipation and the like.

Owner:TIANJIN TIANSU SCI & TECH GROUP

High performance ballistic composites and method of making

ActiveUS20130059494A1Protective equipmentSynthetic resin layered productsRoom temperatureBallistic resistance

Fabrication of ballistic resistant fibrous composites having improved ballistic resistance properties and retained or improved ballistic penetration resistance properties. The composites are formed from high tenacity fibers having a tenacity of at least about 33 g / denier at ambient room temperature after being modified by a plasma treatment or by a corona treatment, without tenacity loss due to said treatments.

Owner:HONEYWELL INT INC

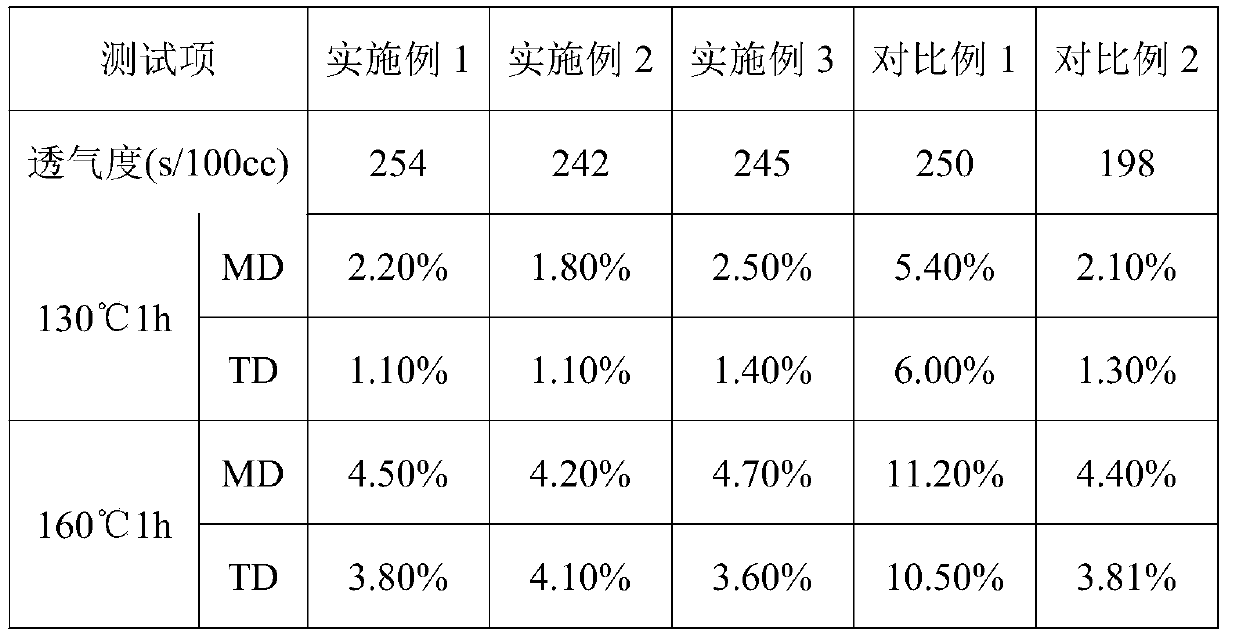

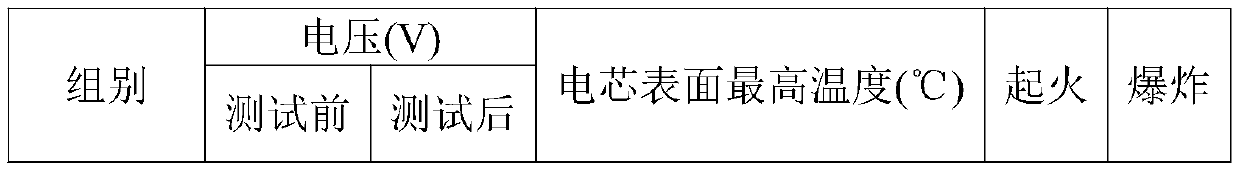

Composite diaphragm, preparation method thereof and lithium ion battery

ActiveCN111244362AImprove thermal stabilityImprove securitySecondary cellsCell component detailsCeramic coatingPhysical chemistry

The invention belongs to the technical field of batteries, and particularly relates to a composite diaphragm which comprises a base membrane subjected to corona treatment, a high-temperature-resistantceramic coating is arranged on one surface of the base membrane, and water-based bonding layers are arranged on the other surface of the base membrane and the surface of the high-temperature-resistant ceramic coating; and the high-temperature-resistant ceramic coating comprises a ceramic material, a high-temperature-resistant binder, a dispersing agent, a thickening agent, a wetting agent and deionized water. In addition, the invention also provides a preparation method of the composite diaphragm and a lithium ion battery containing the composite diaphragm. Compared with the prior art, the composite diaphragm has the advantage that the cycle performance and the safety performance of the lithium ion battery can be improved on the premise of ensuring the air permeability.

Owner:HUIZHOU LIWINON NEW ENERGY TECH CO LTD

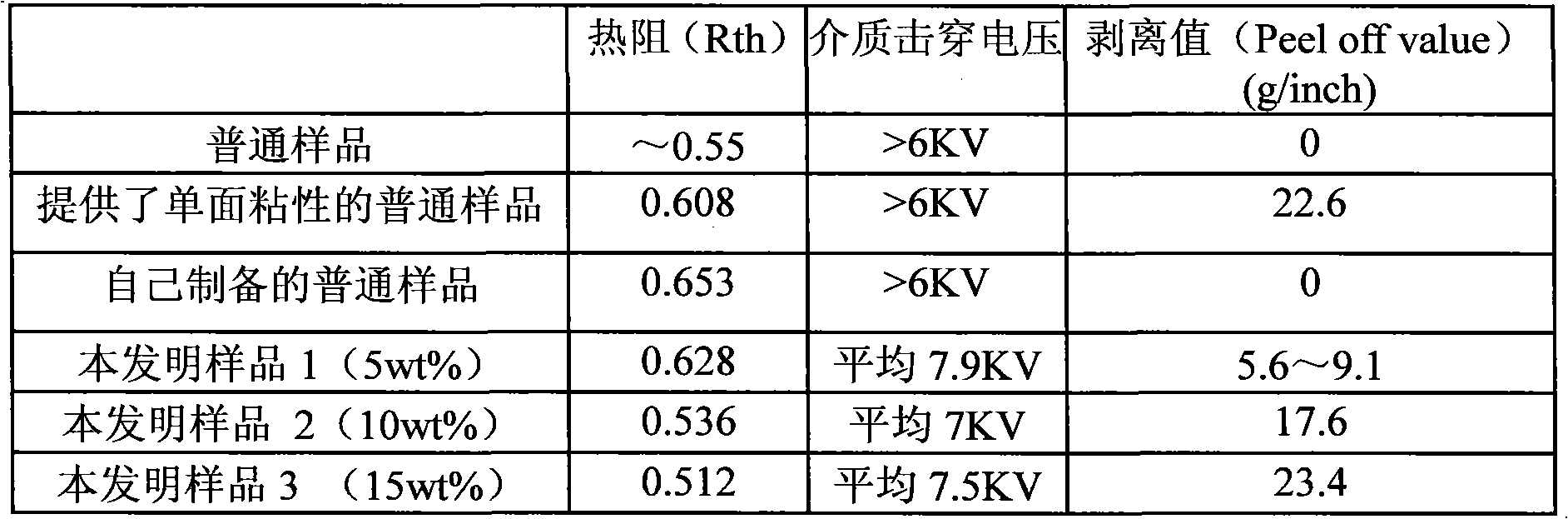

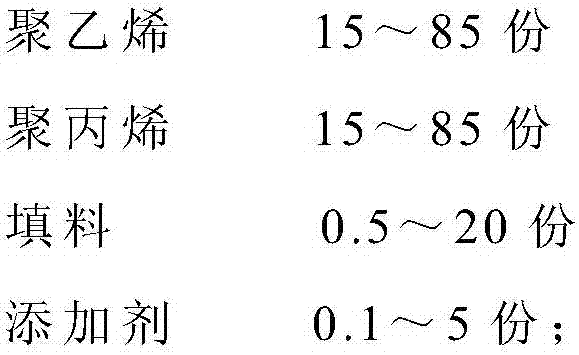

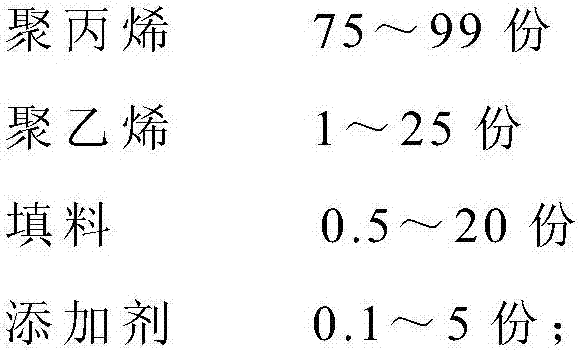

Heat conduction insulating material, heat conduction insulating strip and preparation method thereof

ActiveCN102372925AImprove insulation performanceStickyHeat-exchange elementsModifications by conduction heat transferElectricityElectronic component

The invention provides a heat conduction insulating material, a heat conduction insulating strip and a method for preparing the heat conduction insulating material and the heat conduction insulating strip. The heat conduction insulating material comprises the following components by weight part: 4-40 parts of high-molecular base material; 1-20 parts of tackifying additive, wherein the tackifying additive contains a reaction group which is identical or analogous with at least one solidified active group in the high-molecular base material; and 40-85 parts of heat conduction insulating particles. The heat conduction insulating material of the present invention has good heat conduction insulating property and viscosity, and can adhere between a radiator and an electronic component without using a double faced adhesive tape or corona treatment.

Owner:TIANJIN LAIRD TECH LTD

Extrusion type solar energy backboard and manufacturing method thereof

InactiveCN107275429AGuaranteed bonding performanceImprove adhesionSynthetic resin layered productsElectrical equipmentEngineeringSilica gel

The invention discloses an extrusion type solar energy backboard. The extrusion type solar energy backboard sequentially comprises an inner layer, a middle layer and an outer layer from inside to outside, wherein mass ratios of the inner layer, the middle layer and the outer layer are respectively 10-40:40-80:10-40, and total thickness of the extrusion type solar energy backboard is 0.1-0.6mm. The extrusion type solar energy backboard is advantaged in that polypropylene having relatively large rigidity is added to the inner layer, not only can adhesion stress between the backboard and a glue film be guaranteed, but also interlayer adhesion force between the inner layer and the middle-layer polypropylene material is further improved, moreover, polyethylene or copolymer of the polyethylene is added between the middle layer and the outer layer material, excellent adhesion with polyethylene of the inner-layer material can be realized, and interlayer adhesion force and low temperature impact strength of the backboard are further improved; the grafting material is added, uniformity and interlayer adhesion stress of products can be improved, surface tension of the backboard after corona processing can be improved, adhesion force between the backboard and sealing silica gel employed during solar energy cell frame sealing can be enhanced, and sealing performance is better.

Owner:SUZHOU DUCHAMPS ADVANCED MATERIALS CO LTD

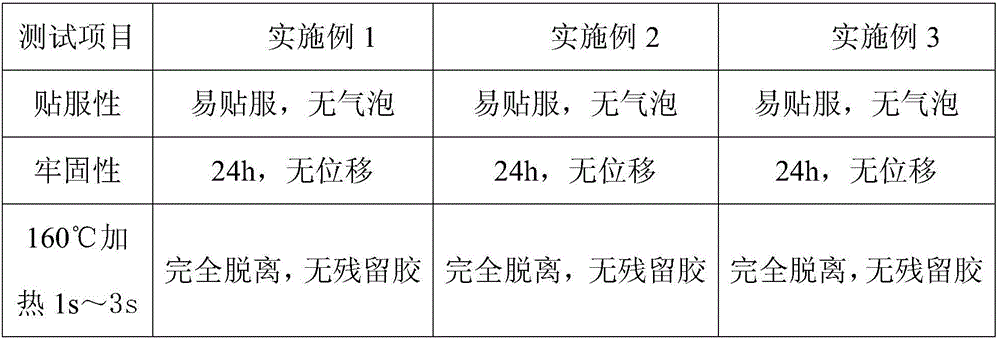

Protective film with heating-reducible adhesion and preparation method thereof

InactiveCN106433506AImprove adhesionEasy to prepareFilm/foil adhesivesPolyureas/polyurethane adhesivesTectorial membranePolyethylene terephthalate

The invention discloses a protective film with heating-reducible adhesion, comprising a PET (polyethylene terephthalate) base material and heating-reducible adhesion glue applied to the surface of the PET base material; the heating-reducible adhesion glue is made from, by weight, 20-90% of resin, 0.01-15% of a curing agent, 9-90% of a solvent and 0.1-10% of self-expanded microsphere foaming agent. The heating-reducible adhesion glue has high adhesive power, and can automatically peel off after being heated to 160 DEG C with no residue left. The protective film with heating-reducible adhesion is prepared in the steps of 1) cleaning and drying the surface of the PET base material; 2) subjecting the surface of the PET base material treated in step 1) to corona treatment; 3) preparing the heating-reducible adhesion glue; 4) applying the heating-reducible adhesion glue prepared in step 3) evenly to the surface of the PET base material subjected to corona treatment, and drying to obtain the protective film with heating-reducible adhesion. The preparation method of the protective film with heating-reducible adhesion is simple and easy to perform.

Owner:苏州旭泽新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com