Composite diaphragm, preparation method thereof and lithium ion battery

A composite diaphragm and deionized water technology, applied in secondary batteries, battery pack components, circuits, etc., can solve the problems of easy soft deformation of batteries, poor adhesion, and affecting battery cycle performance rate performance, etc., to achieve Facilitate continuous production, low cost, and ensure long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

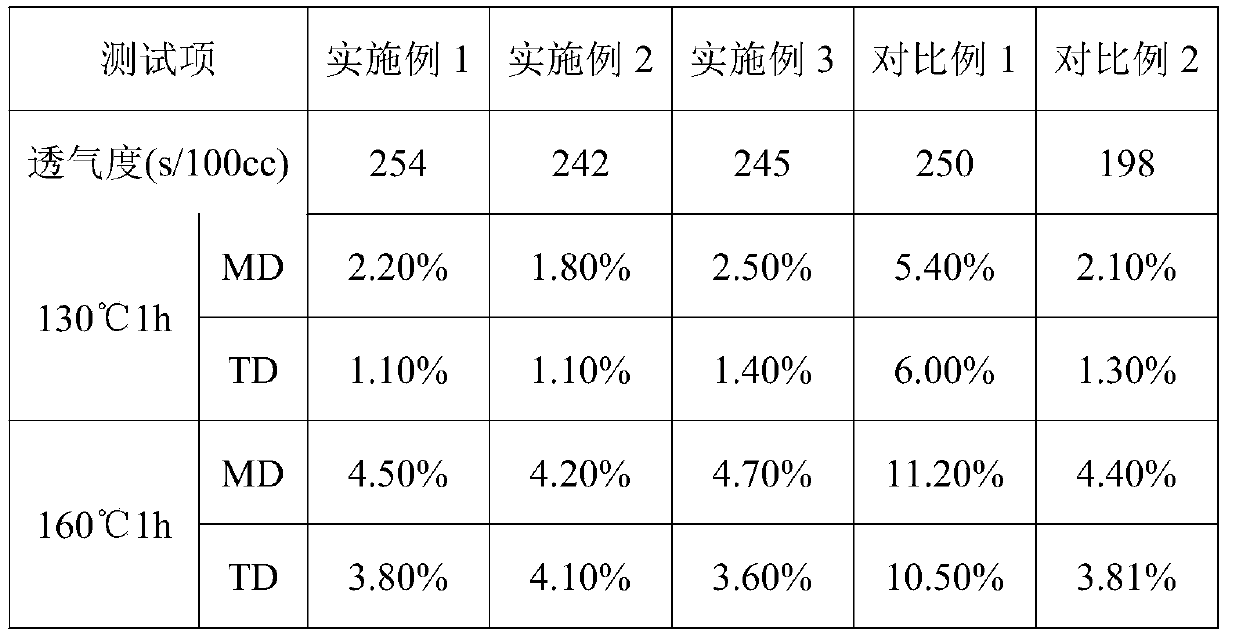

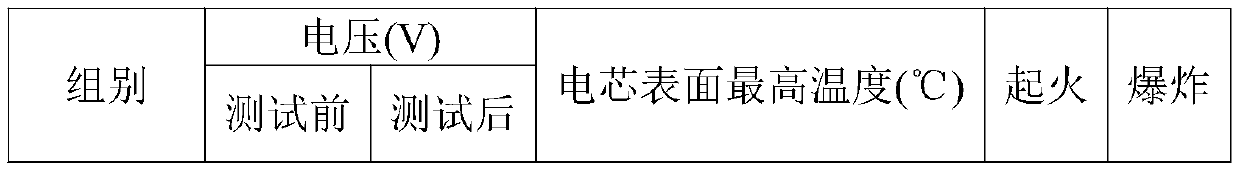

Examples

Embodiment 1

[0041] Preparation of composite diaphragm:

[0042] (a) Preparation of high-temperature resistant ceramic slurry: Add 35 parts of alumina and 0.46 parts of polyvinylpyrrolidone to 61.06 parts of deionized water, stir for 0.5 h, and then grind for 1 h to obtain a uniform ceramic dispersion, and then add 0.61 parts of sodium alginate , 2.84 parts of methacrylic acid-methyl methacrylate-vinyl carbazole terpolymer, 0.03 parts of sodium dodecylsulfonate were added to the ceramic dispersion, stirred at low speed, and dispersed for 2 hours to obtain a water-based high-temperature resistant ceramic slurry ;

[0043] (b) Preparation of water-based adhesive layer slurry: 10 parts of polymethylmethacrylate-polystyrene core-shell polymer particles, 0.05 parts of sodium alginate, 2.94 parts of polyvinyl alcohol, 0.01 parts of polyvinyl alcohol were added to 88 parts of water Polyether emulsified silicone oil defoamer, mixed and stirred for 60 minutes to obtain a water-based adhesive coati...

Embodiment 2

[0049] Different from Example 1, the preparation of composite diaphragm:

[0050] (a) Preparation of high-temperature resistant ceramic slurry: Add 40 parts of alumina and 0.51 parts of polyvinylpyrrolidone to 55.64 parts of deionized water, stir for 0.5 hours, and then grind for 1 hour to obtain a uniform ceramic dispersion, and then add 0.55 parts of carboxymethyl Sodium cellulose, 3.26 parts of methacrylic acid-methyl methacrylate-maleic anhydride terpolymer, and 0.04 parts of sodium dodecylsulfonate were added to the ceramic dispersion, stirred at a low speed, and dispersed for 1.5 hours to obtain a water-based high-temperature resistant Ceramic slurry;

[0051] (b) Preparation of water-based adhesive layer slurry: 15 parts of polymethylmethacrylate-polyvinylpiperidine core-shell polymer particles, 0.03 part of sodium carboxymethylcellulose, 1.96 parts of polyethylene were added to 83 parts of water Alcohol, 0.01 part of polyether emulsified silicone oil defoamer, mixed a...

Embodiment 3

[0055] Different from Example 1, the preparation of composite diaphragm:

[0056] (a) Preparation of high-temperature resistant ceramic slurry: Add 45 parts of alumina and 0.42 parts of polyvinylpyrrolidone to 50.75 parts of deionized water, stir for 0.5 hours, and then grind for 1 hour to obtain a uniform ceramic dispersion, and then add 0.48 parts of carboxymethyl Sodium cellulose, 3.53 parts of polyimide derivatives, and 0.05 parts of sodium dodecylsulfonate were added to the ceramic dispersion, stirred at a low speed, and dispersed for 1.5 hours to obtain a water-based high-temperature resistant ceramic slurry;

[0057] (b) Preparation of water-based adhesive layer slurry: 20 parts of polymethylmethacrylate-polystyrene core-shell polymer particles, 0.02 part of sodium carboxymethylcellulose, 1.57 parts of polyvinyl alcohol were added to 78.4 parts of water, 0.01 part of polyether emulsified silicone oil defoamer, mixed and stirred for 60 minutes to obtain a water-based adh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com