Polyester film capable of being subjected to heat seal directly and preparation method

A polyester film and a direct technology, applied in the field of polyester film and its preparation, can solve the problems of incapability of self-heat sealing, etc., and achieve the effects of saving composite processes, reducing costs, and improving production and living standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A polyester film that can be directly heat-sealed, comprising an ABC three-layer structure, the B layer is an intermediate core layer, and the material is PET ultra-glossy polyester chips; the A layer is a surface heat-sealing layer, and the material is copolymerized PETG Polyester chips; C layer is an anti-blocking layer, and the materials include PET anti-blocking agent masterbatch chips and PET ultra-gloss polyester chips.

[0031] C layer anti-blocking layer, the material has the following components by mass percentage: 30%-60% of PET anti-blocking agent masterbatch chips and 40%-70% of PET ultra-gloss polyester chips.

[0032] The thickness of layer B accounts for 70% to 80%, the thickness of layer A accounts for 10% to 20%, and the thickness of layer C accounts for 10% to 20%.

[0033] The co-polymer PETG polyester chip of the surface heat sealing layer of the A layer is composed of dimethyl terephthalate (DMT), ethylene glycol (EG), silicon dioxide (SiO2) and 1,4-c...

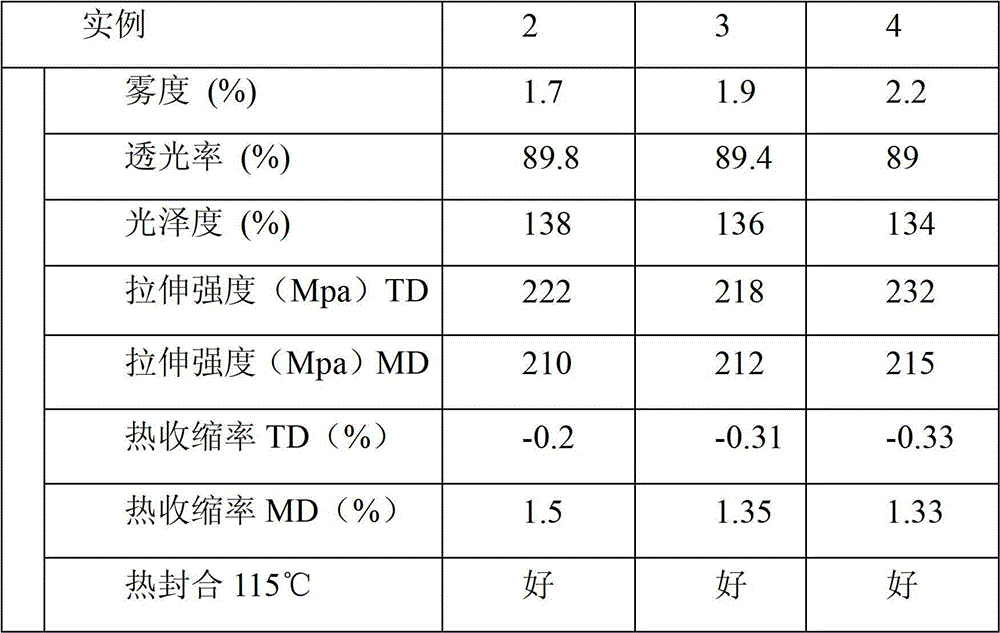

Embodiment 2

[0051] A preparation method of a polyester film that can be directly heat-sealed, in parts by weight: adding 22 parts by mass of 1,4 cyclohexanedimethanol (CHDM) and 3 parts by mass of silicon dioxide (SiO2) In 23 parts of ethylene glycol (EG), stir and disperse, then disperse and homogenize at high speed, and after using ultrasonic vibration and disperse, send into the main reaction system polymerization kettle; add 100 parts of dimethyl terephthalate (DMT) Stir and mix, then add 2 parts (PTA weight) of antimony trioxide and triphenyl phosphite, and replace with nitrogen (N2) 3 times after sealing. Under the pressure of 600Pa in the kettle, the temperature was raised to 180°C, and the esterification reaction was carried out for 0.8h. After the esterification reaction, the excess ethylene glycol (EG) was recovered; Cooling and dicing to obtain copolymerized PETG polyester chips.

[0052] The prepared copolymerized PETG polyester chips are weighed according to the mass percent...

Embodiment 3

[0054] The difference between this example and Example 2 is that the mass ratio of the extruded materials from the main extruder and the two auxiliary twin-screw extruders is 15:70:15, the thickness of the heat sealing layer of the 20um film A layer is 3.0um, and the thickness of the C layer is 3.0um. The thickness of the anti-stick layer is 3.0um.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com