Two-way stretch polylactic acid film capable of being directly thermally sealed and preparation method of two-way stretch polylactic acid film

A technology of biaxial stretching and polylactic acid, which is applied in the direction of chemical instruments and methods, lamination, layered products, etc., can solve the problems of low tensile strength, brittle characteristics of PLA materials, and low transparency, so as to improve tensile strength and Uniformity of thickness, reduction of intermolecular stress, and widening of the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

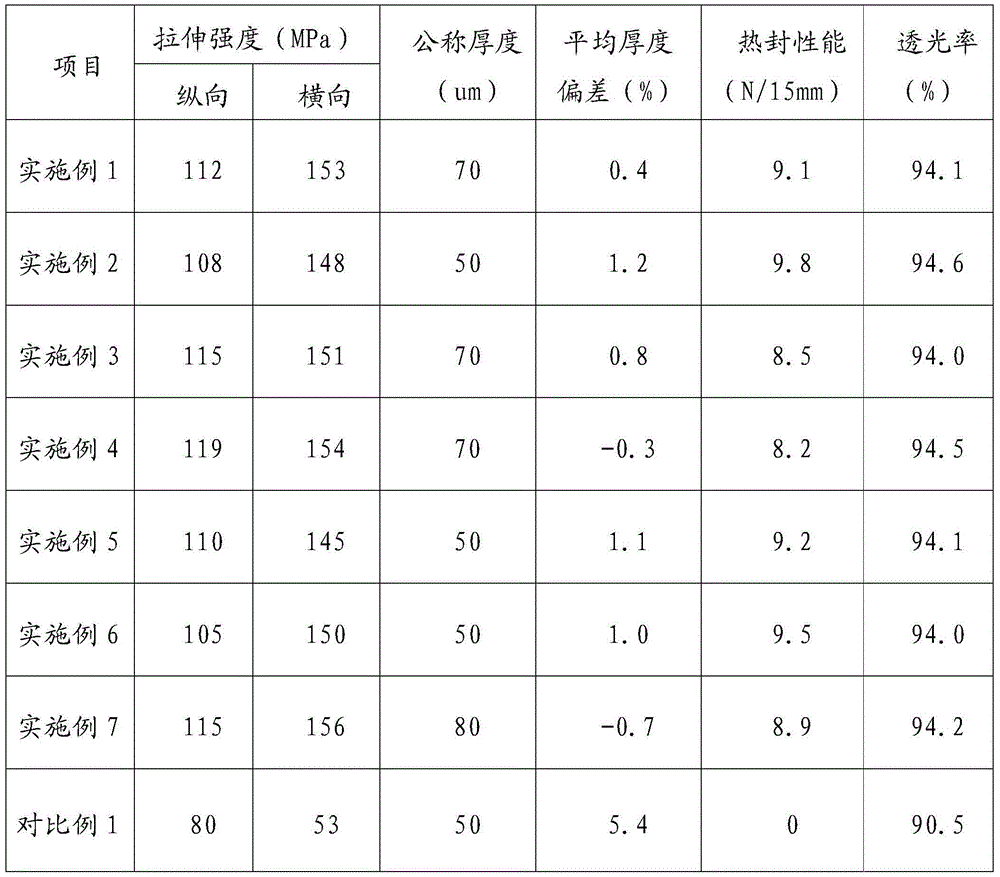

Embodiment 1

[0042] A biaxially stretched polylactic acid film that can be directly heat-sealed, including ABC three-layer structure arranged in sequence, wherein layer A is the surface heat-sealing layer, and the raw material of the layer A is heat-sealable PLA chips; layer B is the middle core Layer, the raw material of the B layer is crystalline PLA slices; the C layer is an anti-blocking layer, and the raw materials of the C layer are 45wt% crystalline PLA slices and 55wt% PLA anti-blocking agent masterbatch slices.

Embodiment 2

[0044] A biaxially stretched polylactic acid film that can be directly heat-sealed, including ABC three-layer structure arranged in sequence, wherein layer A is the surface heat-sealing layer, and the raw materials of the layer A are 85wt% crystalline PLA slices and 15wt% non- A heat-sealed PLA slice composed of crystalline PLA slices; B layer is the middle core layer, and the raw material of the B layer is a crystalline PLA slice composed of 98wt% crystalline PLA slices and 2wt% amorphous PLA slices; C layer is an anti- Adhesion layer, the raw materials of the C layer are 50wt% crystalline PLA slices and 50wt% PLA anti-blocking agent masterbatch slices, and the PLA anti-blocking agent masterbatch slices are crystalline PLA containing 5wt% anti-blocking agent slice.

Embodiment 3

[0046] A biaxially stretched polylactic acid film that can be directly heat-sealed, including ABC three-layer structure arranged in sequence, wherein layer A is a surface heat-sealing layer, and the thickness of layer A accounts for 15% of the thickness of the film. The raw material of layer A is It is a heat-sealed PLA slice composed of 90wt% crystalline PLA slices and 10wt% non-crystalline PLA slices; B layer is the middle core layer, and the thickness of B layer accounts for 70% of the thickness of the film, and the raw material of the B layer is 99wt % crystalline PLA slices and 1wt% non-crystalline PLA slices; the C layer is an anti-adhesion layer, and the thickness of the C layer accounts for 15% of the thickness of the film, and the raw material of the C layer is 60wt% crystalline Type PLA slices and 40wt% PLA anti-blocking agent masterbatch slices, the PLA anti-blocking agent masterbatch slices are crystalline PLA slices containing 6wt% anti-blocking agent, and the anti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com