Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6389results about "Domestic containers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compositions of ethylene/alpha-olefin multi-block interpolymer for blown films with high hot tack

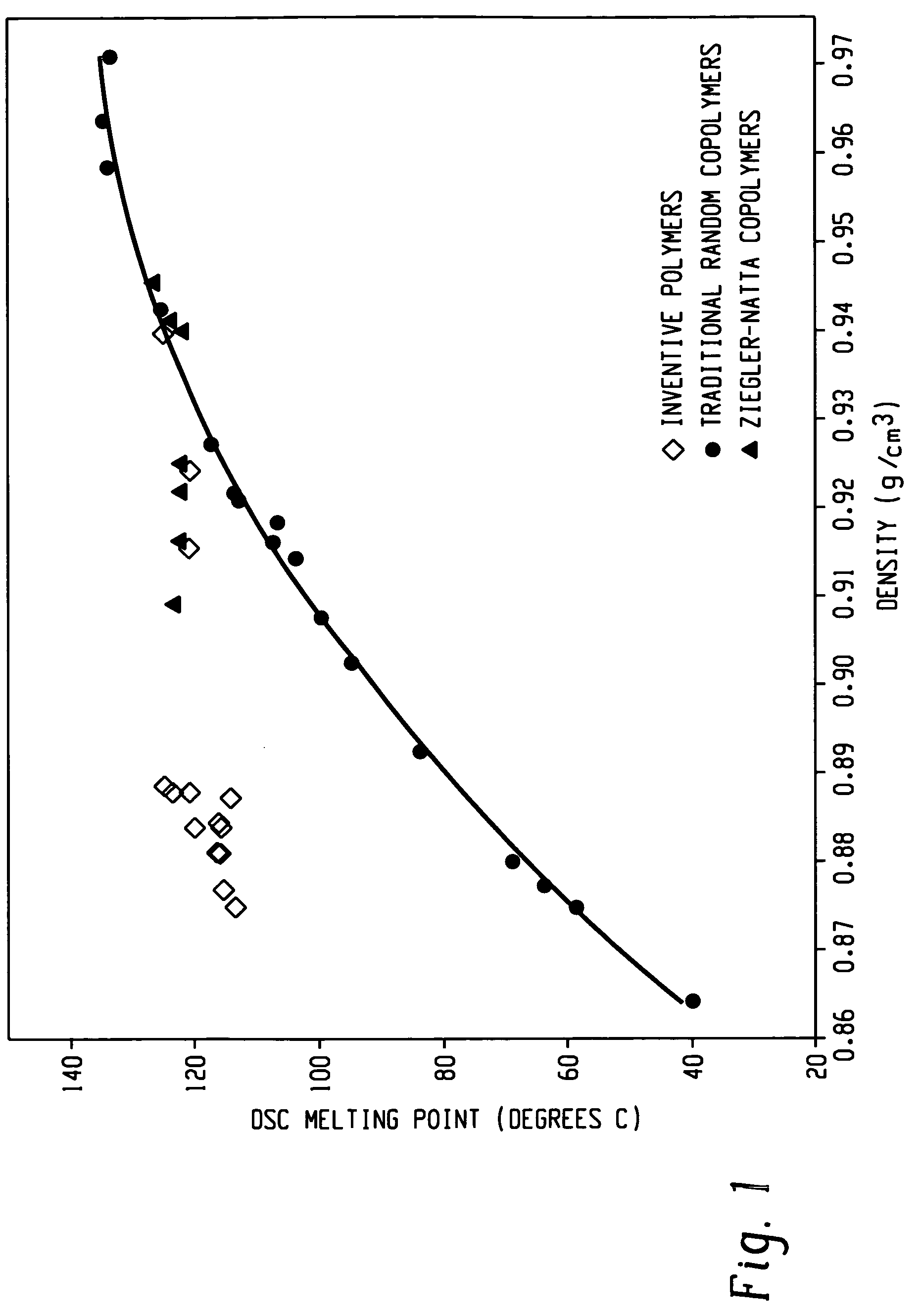

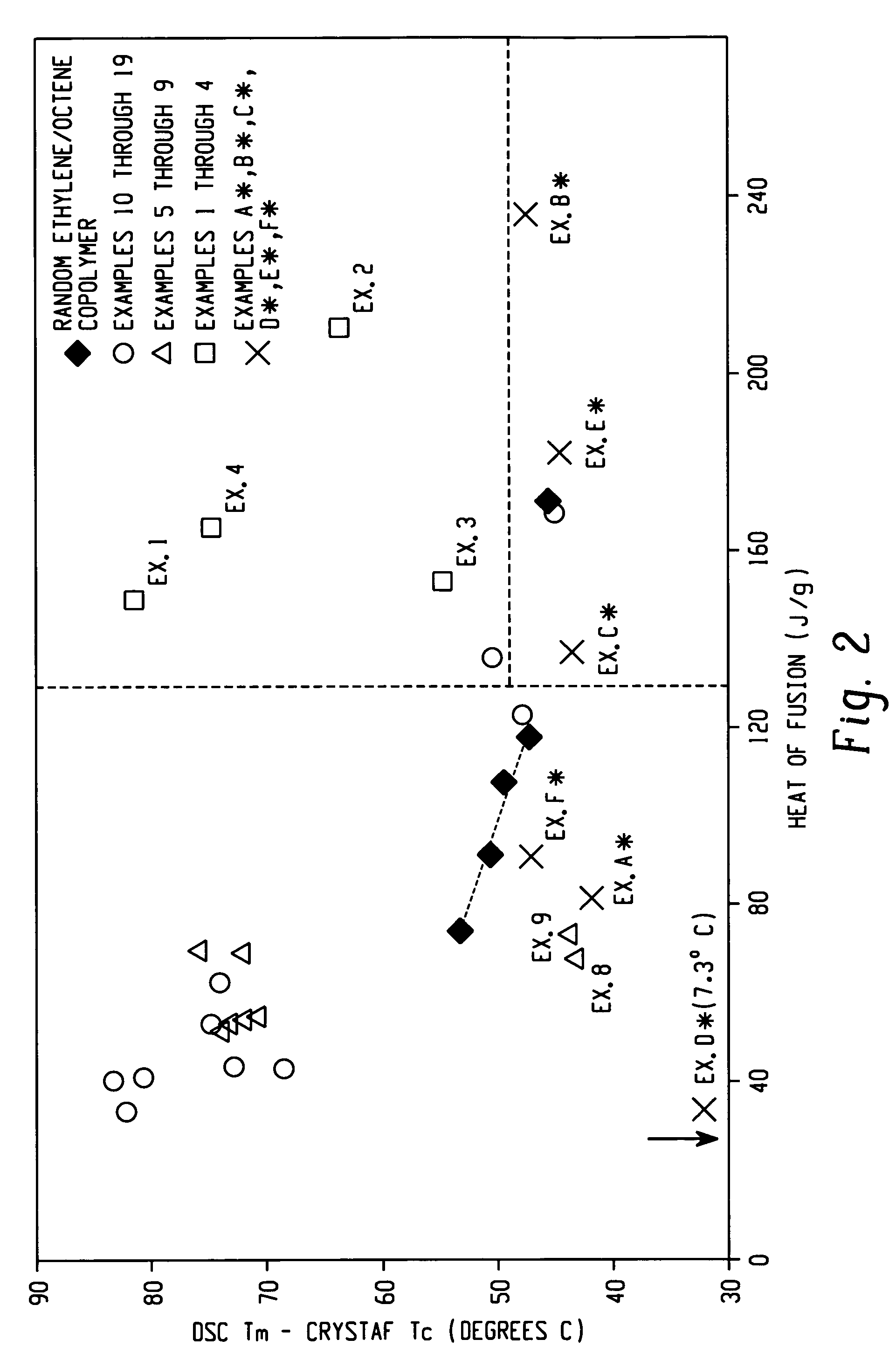

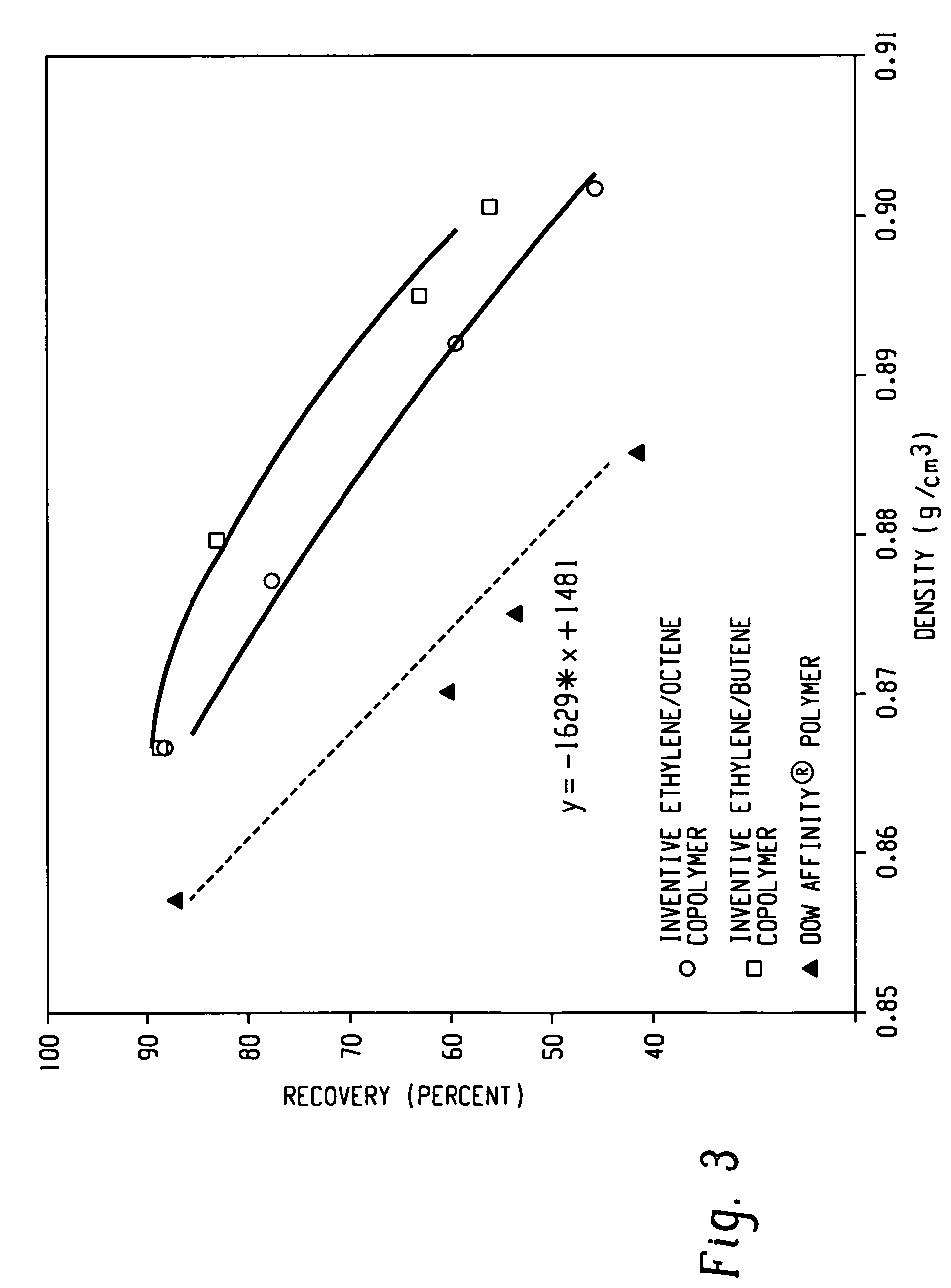

InactiveUS20060199030A1Superior hot tack propertyWider process windowSynthetic resin layered productsBagsCelsius DegreeVolumetric Mass Density

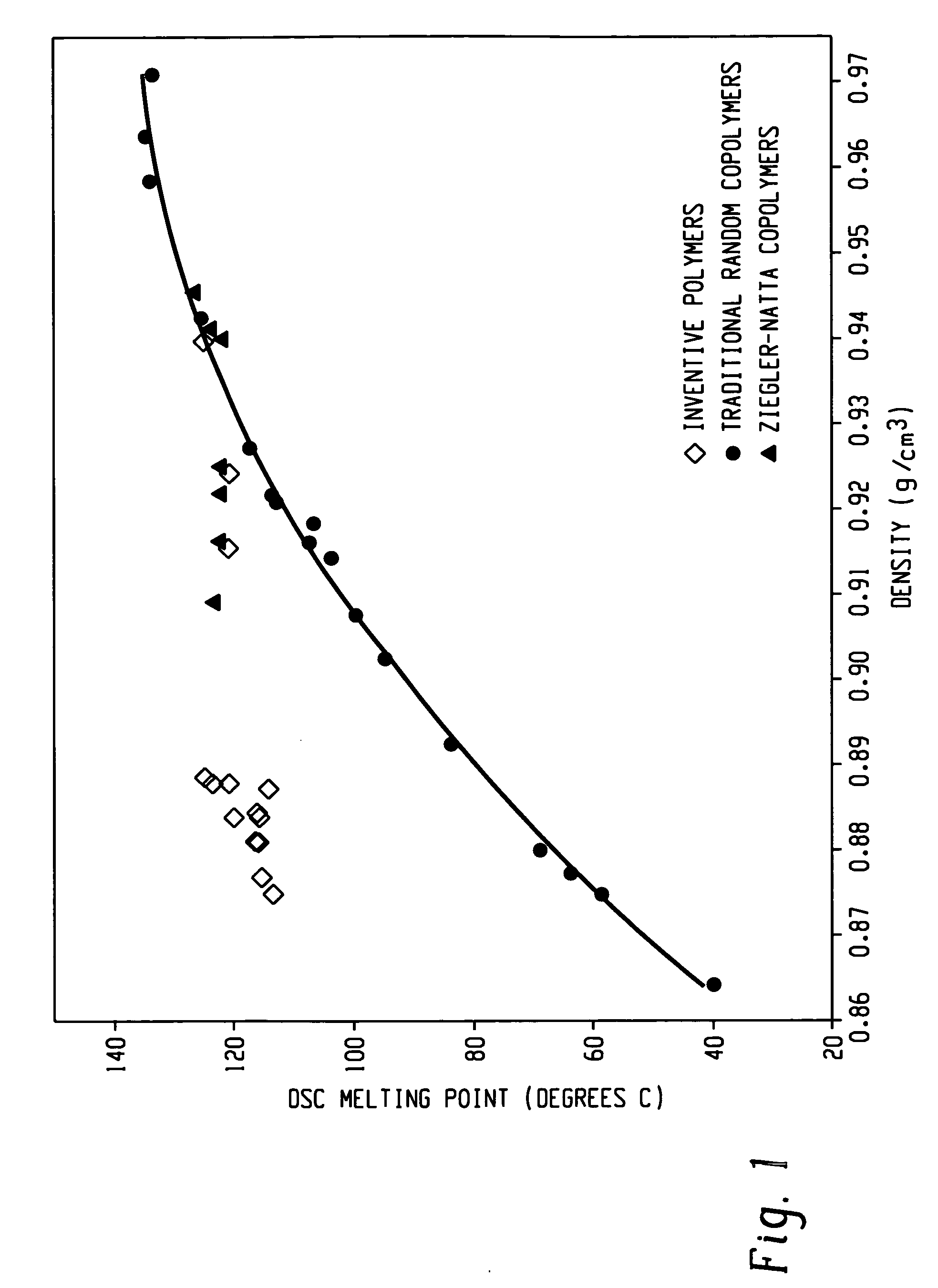

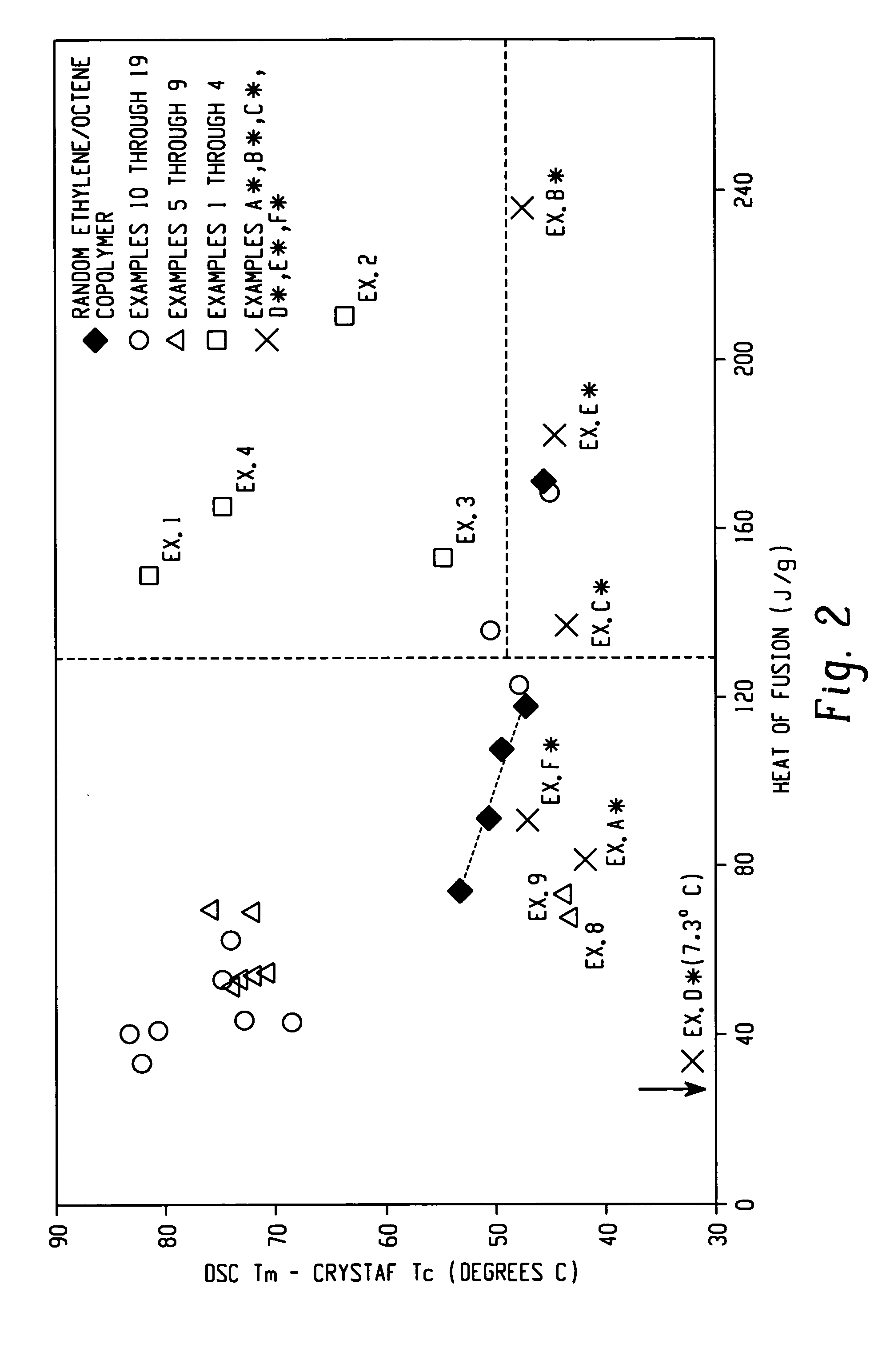

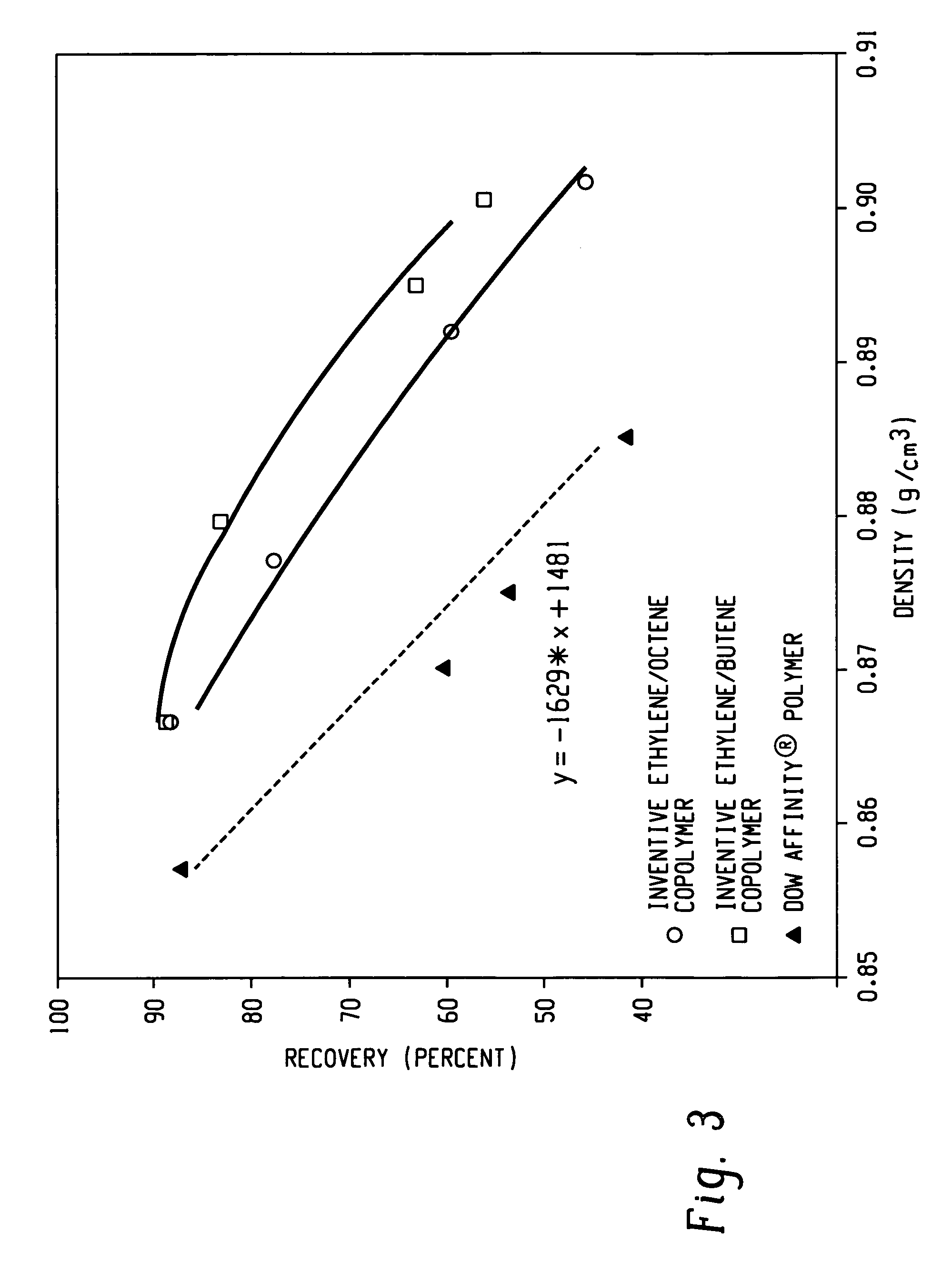

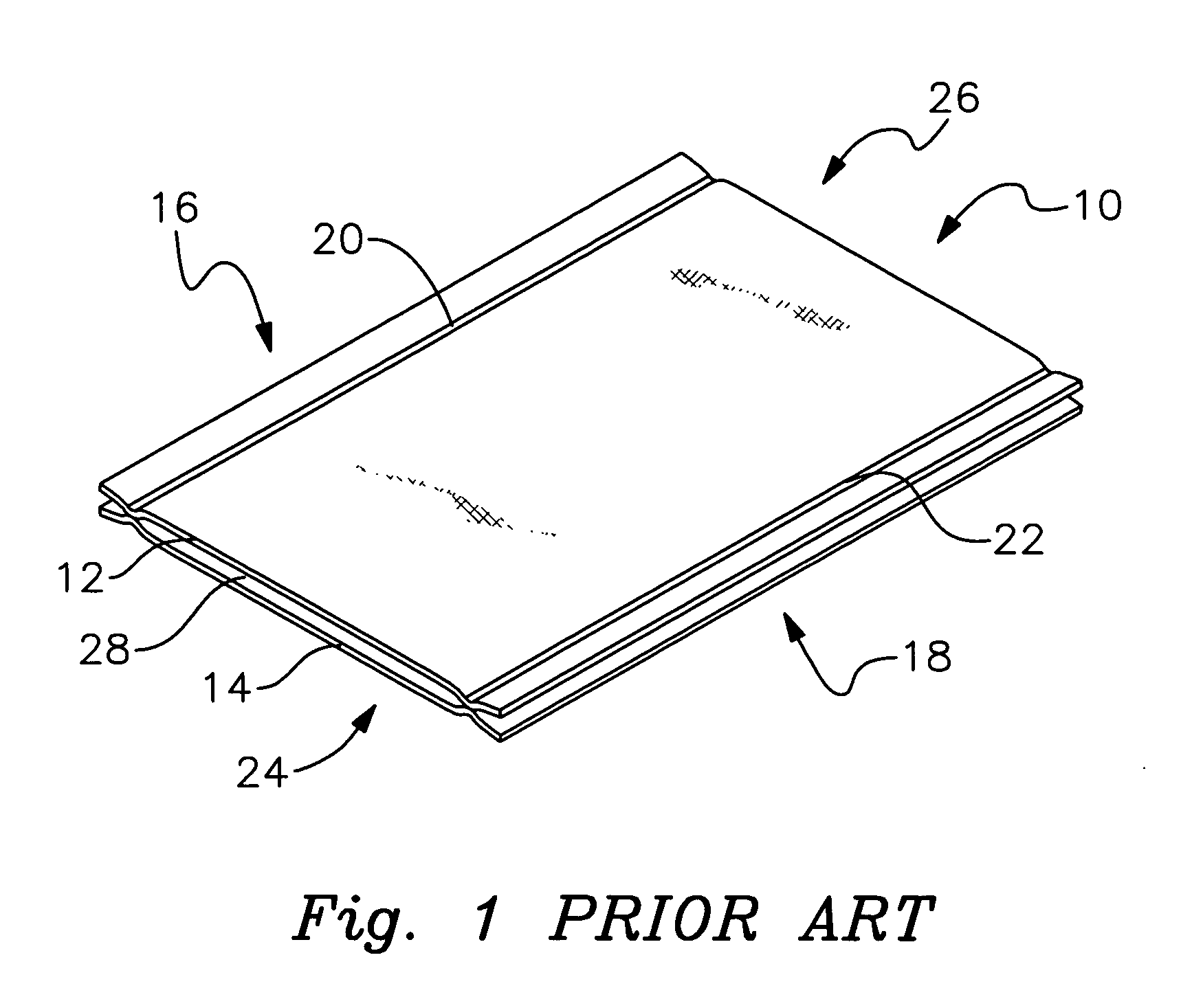

The present invention relates to film layers and compositions having improved hot tack properties. The compositions comprise at least one ethylene / α-olefin interpolymer, wherein the ethylene / α-olefin interpolymer may have, for example, a Mw / Mn from about 1.7 to about 3.5, at least one melting point, Tm, in degrees Celsius, and a density, d, in grams / cubic centimeter, wherein the numerical values of Tm and d correspond to the relationship: Tm>−2002.9+4538.5(d)−2422.2(d)2.

Owner:DOW GLOBAL TECH LLC

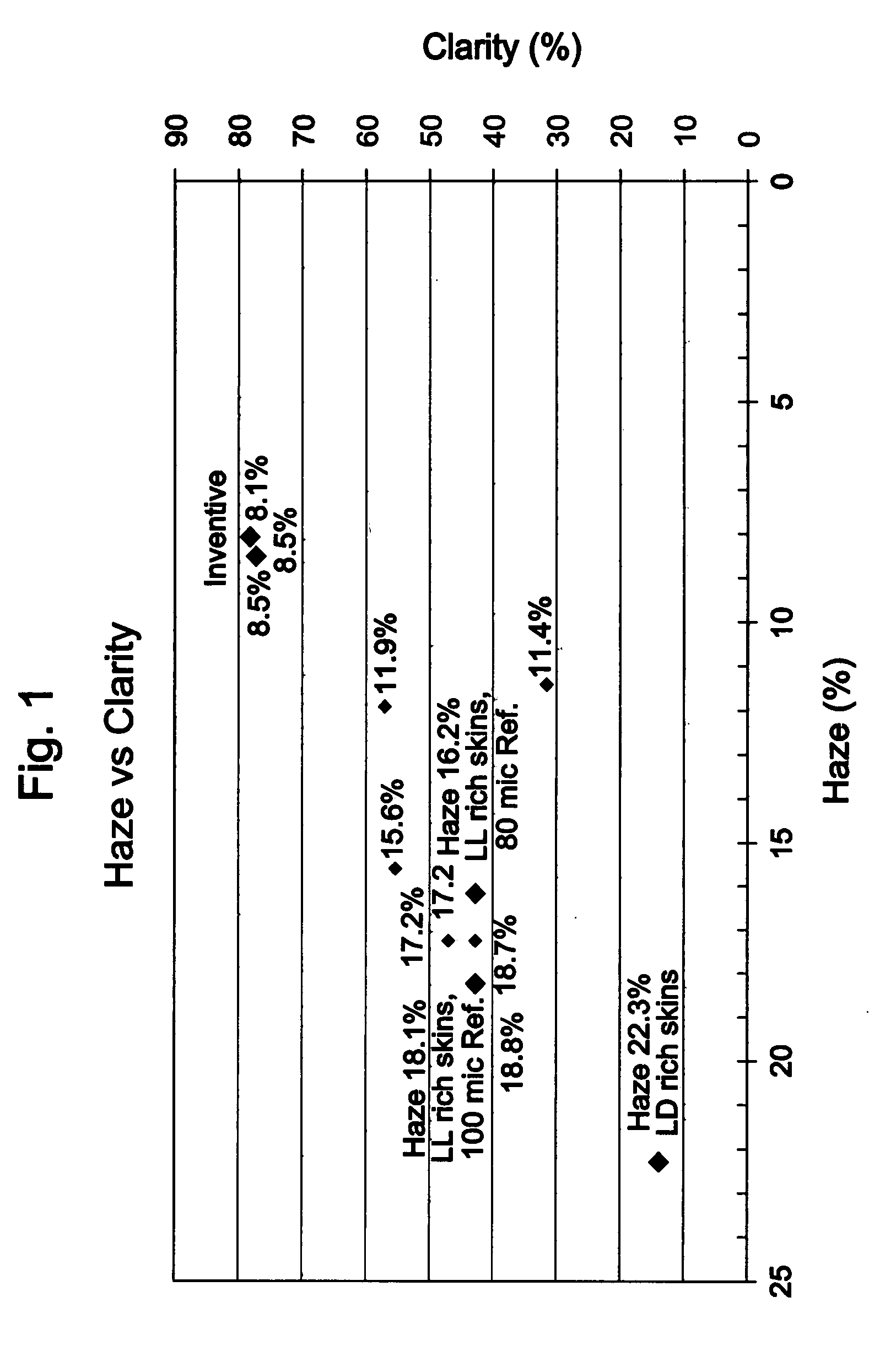

Linear low density polymer blends and articles made therefrom

ActiveUS20070260016A1Synthetic resin layered productsDomestic containersLow-density polyethyleneLinear low-density polyethylene

This invention relates to blends of linear low density polyethylene copolymers with other linear low density polyethylenes or very low density, low density, medium density, high density, and differentiated polyethylenes. The invention also includes articles produced from the linear low density polyethylene and polyethylene blends described.

Owner:EXXONMOBIL CHEM PAT INC

Films having a desiccant material incorporated therein and methods of use and manufacture

InactiveUS20070160789A1Improve efficacyExtended shelf lifeSurgical furnitureDiagnosticsDesiccantInsertion stent

Film structures, packages, films and methods of making the same are provided wherein the film structures have a desiccant material incorporated into at least one layer of the film structures and further wherein the film structures can comprise a material for making a peelable seal when the film structures are heat sealed to other film structures. The film structures are utilized for a package to hold a product that may be sensitive to the presence of moisture. The product may preferably be pharmaceutical products, nutraceutical products, or devices such as absorbable sutures or medical stents, although any moisture-sensitive product is contemplated by the present invention.

Owner:ALCAN PACKAGING FLEXIBLE FRANCE

Compositions of ethylene/alpha-olefin multi-block interpolymer for blown films with high hot tack

InactiveUS7582716B2Less energyLess timeSynthetic resin layered productsBagsCelsius DegreeAlpha-olefin

The present invention relates to film layers and compositions having improved hot tack properties. The compositions comprise at least one ethylene / α-olefin interpolymer, wherein the ethylene / α-olefin interpolymer may have, for example, a Mw / Mn from about 1.7 to about 3.5, at least one melting point, Tm, in degrees Celsius, and a density, d, in grams / cubic centimeter, wherein the numerical values of Tm and d correspond to the relationship:Tm>−2002.9+4538.5(d)−2422.2(d)2.

Owner:DOW GLOBAL TECH LLC

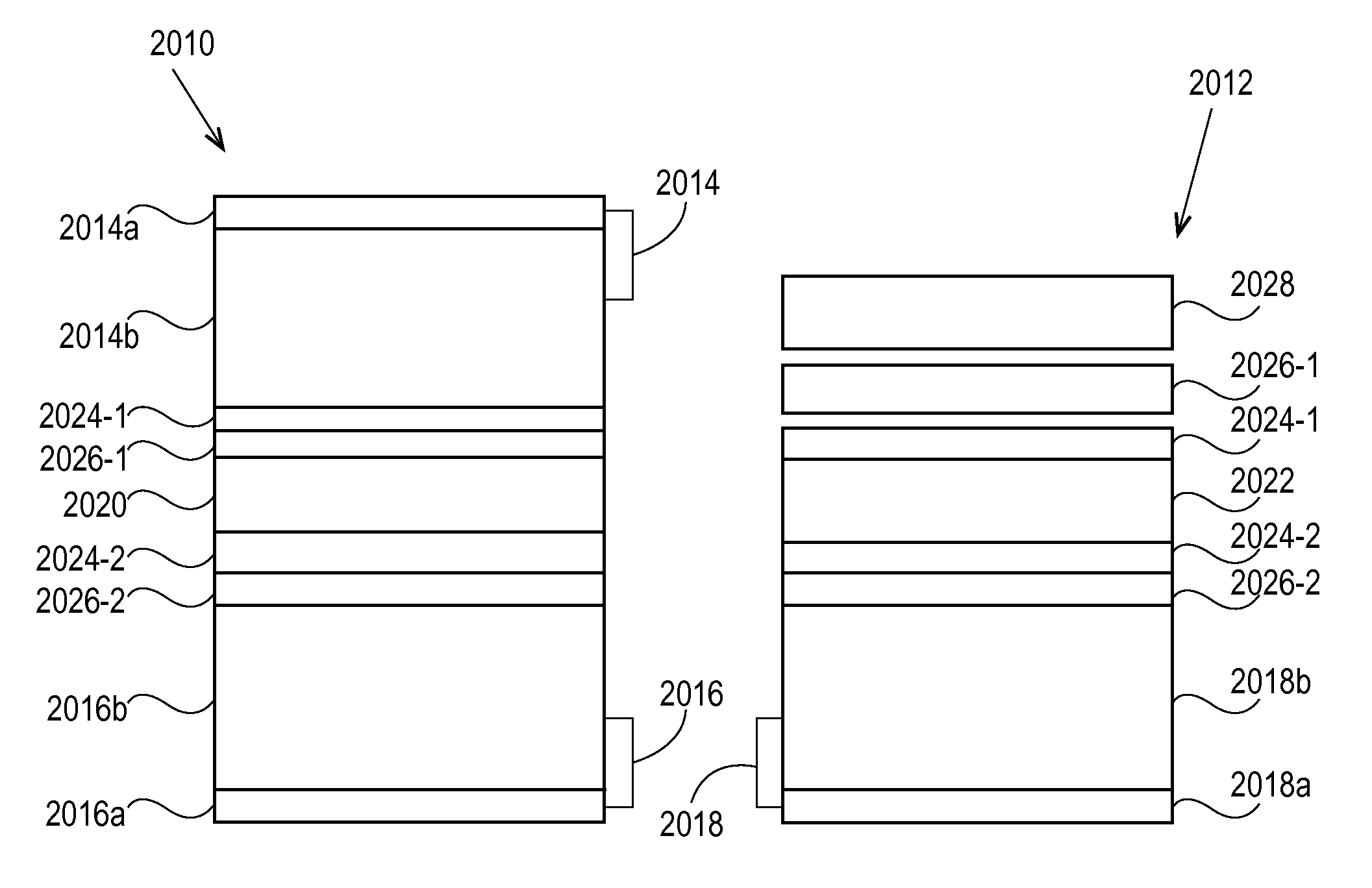

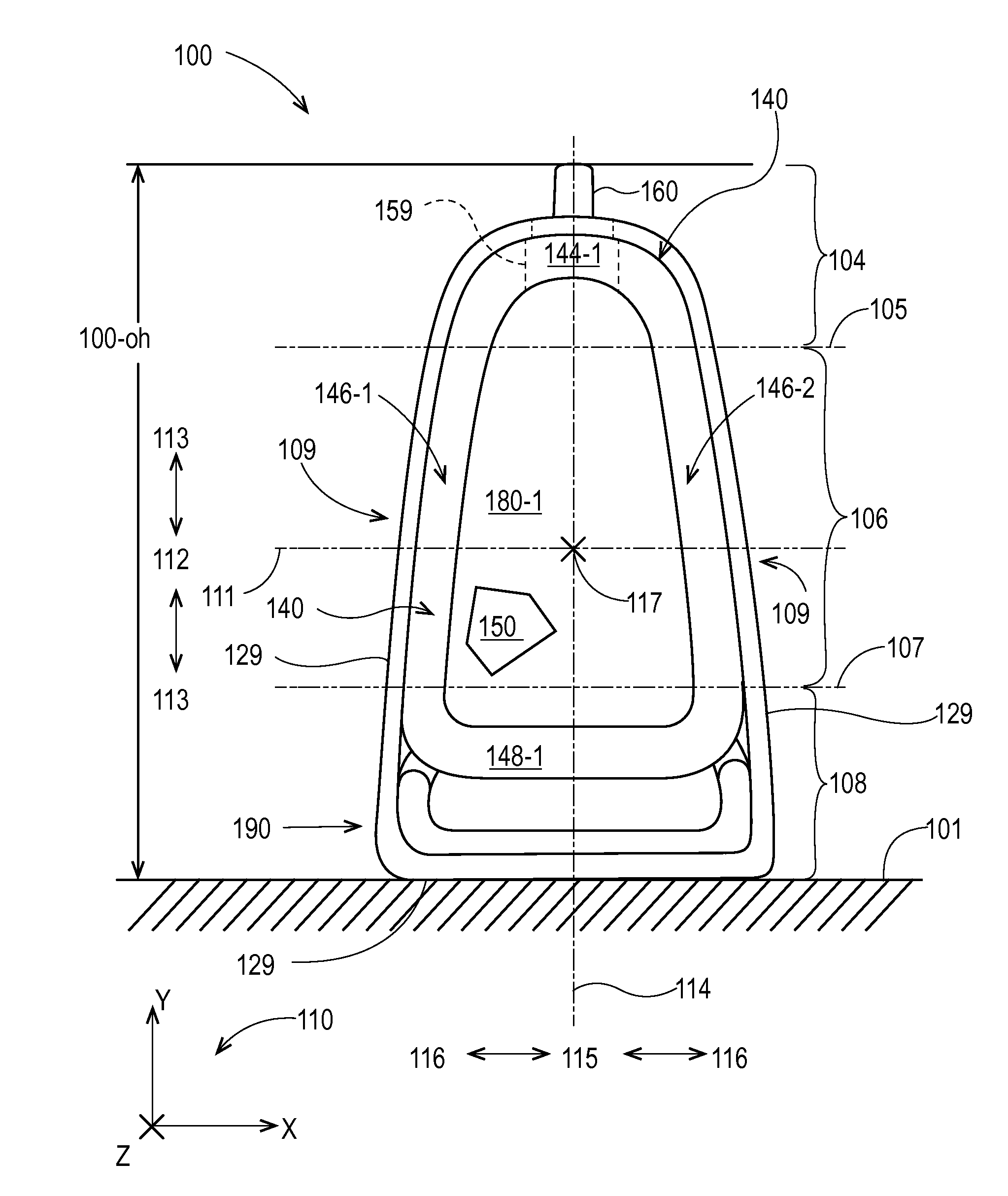

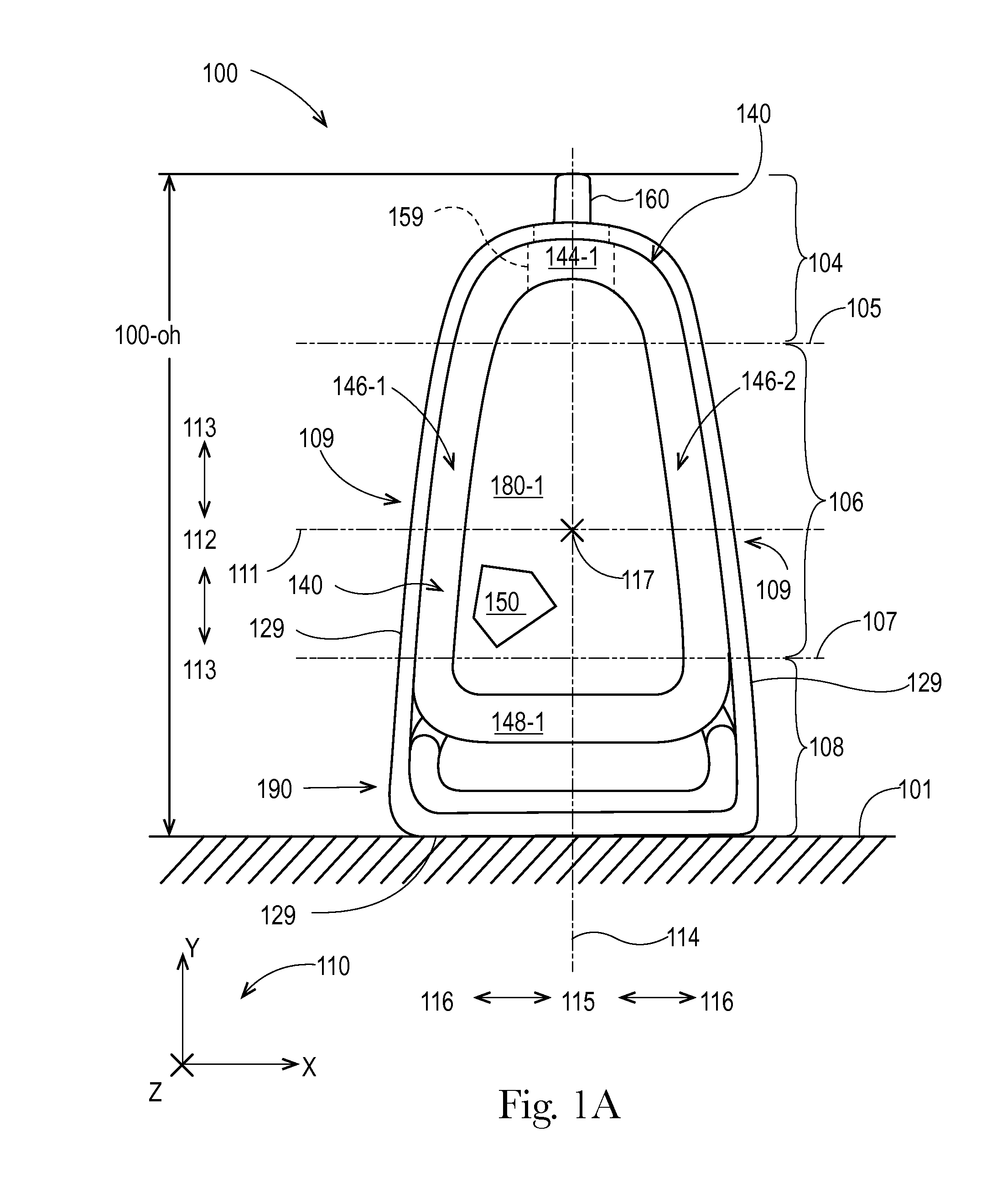

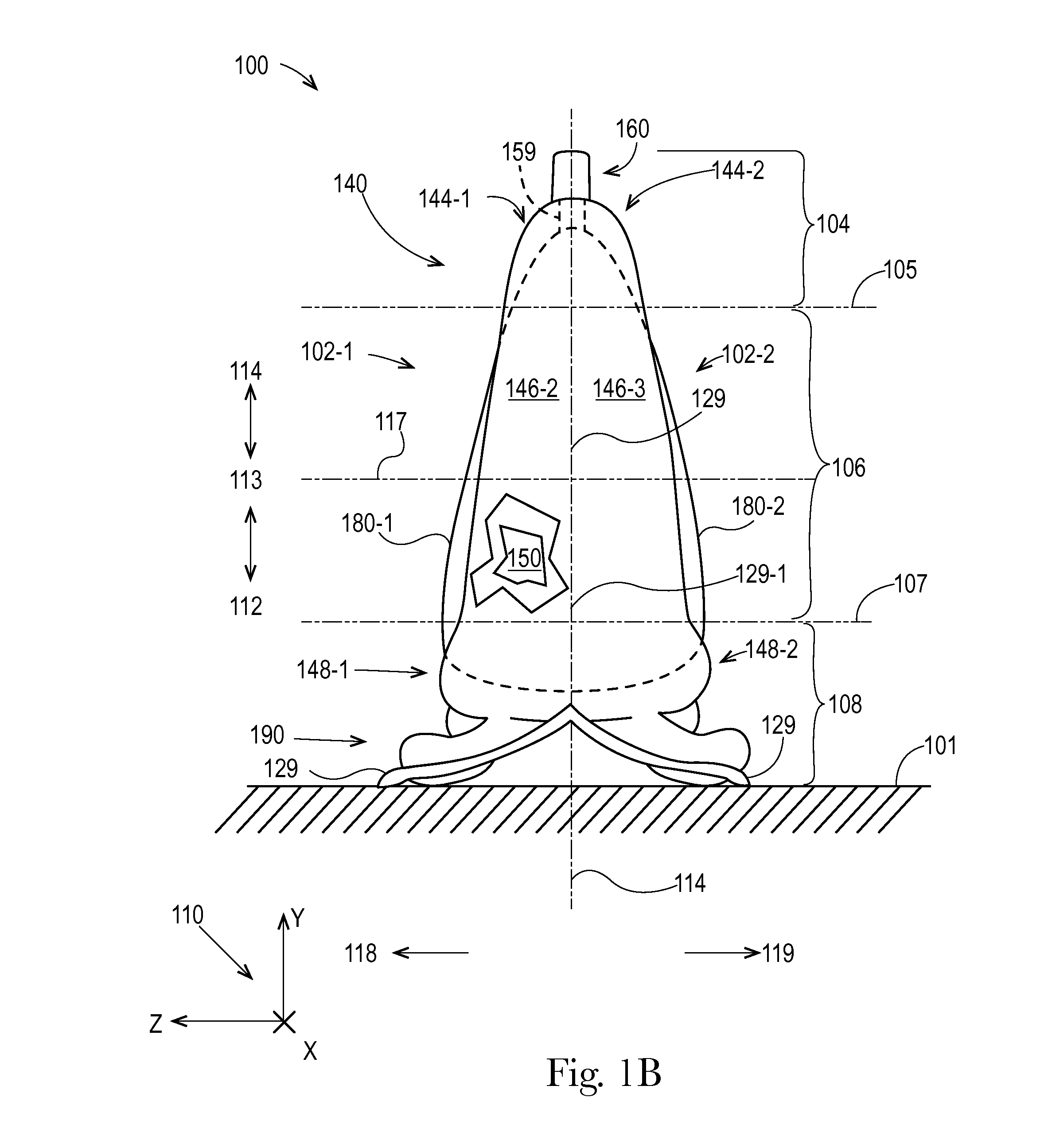

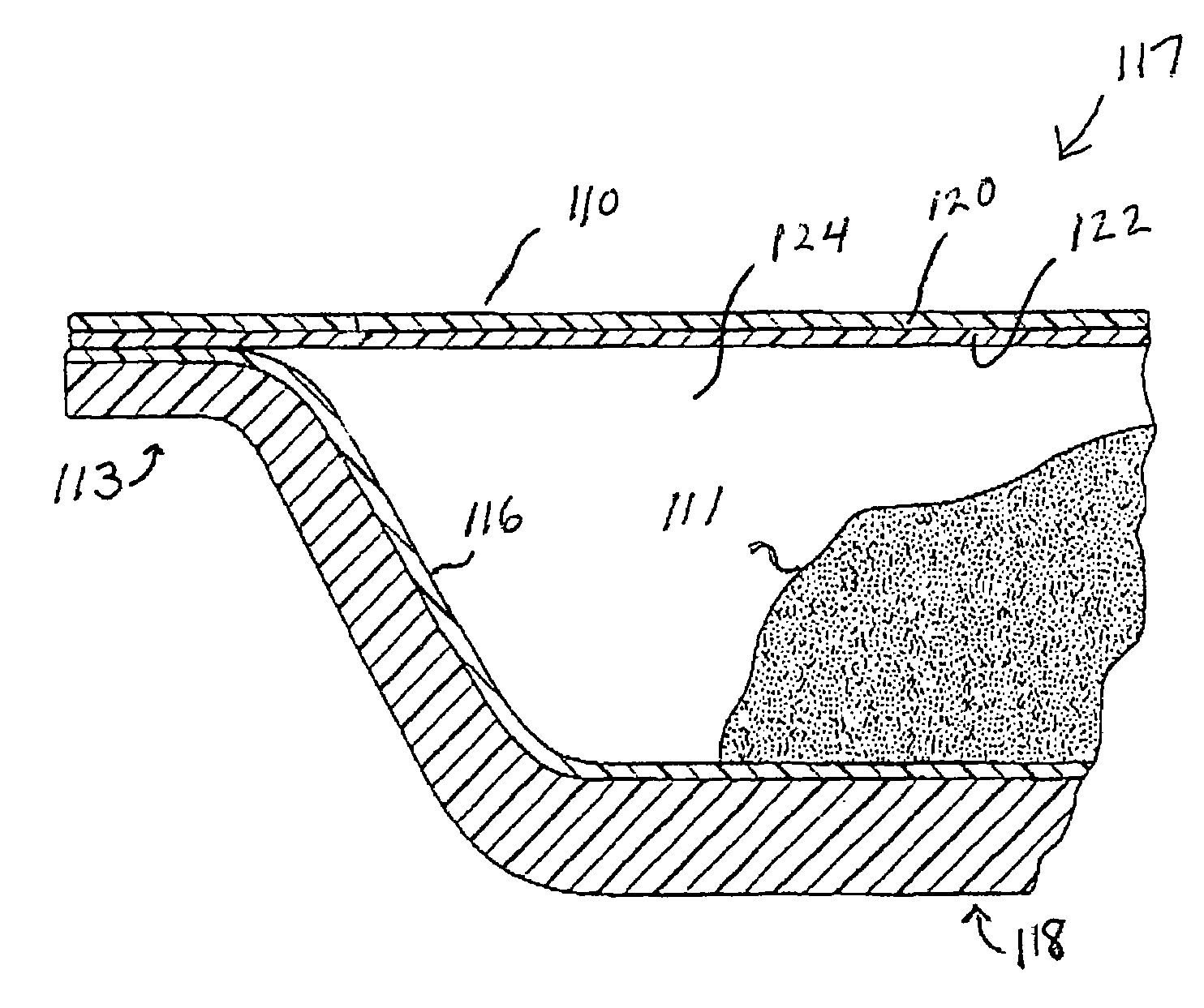

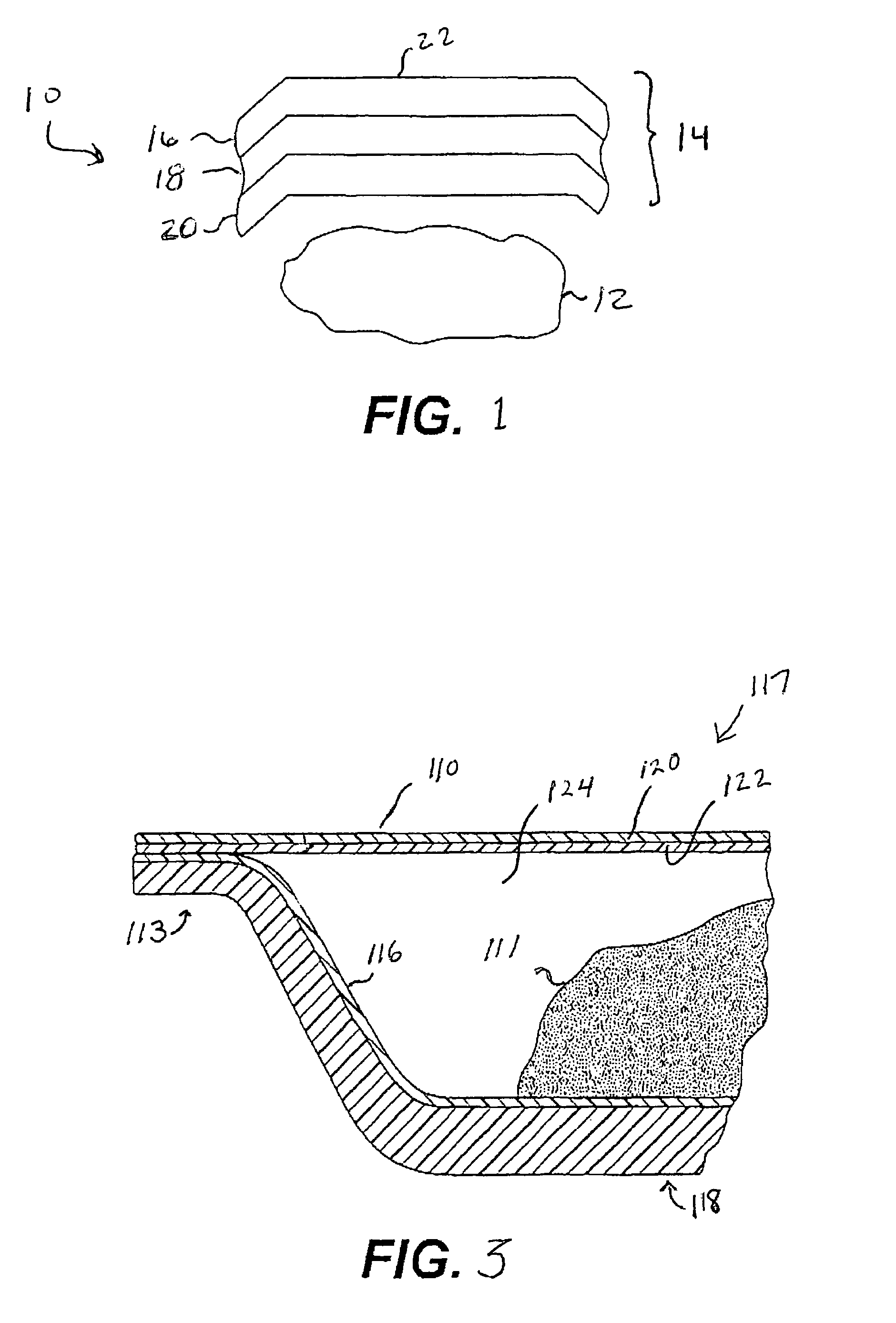

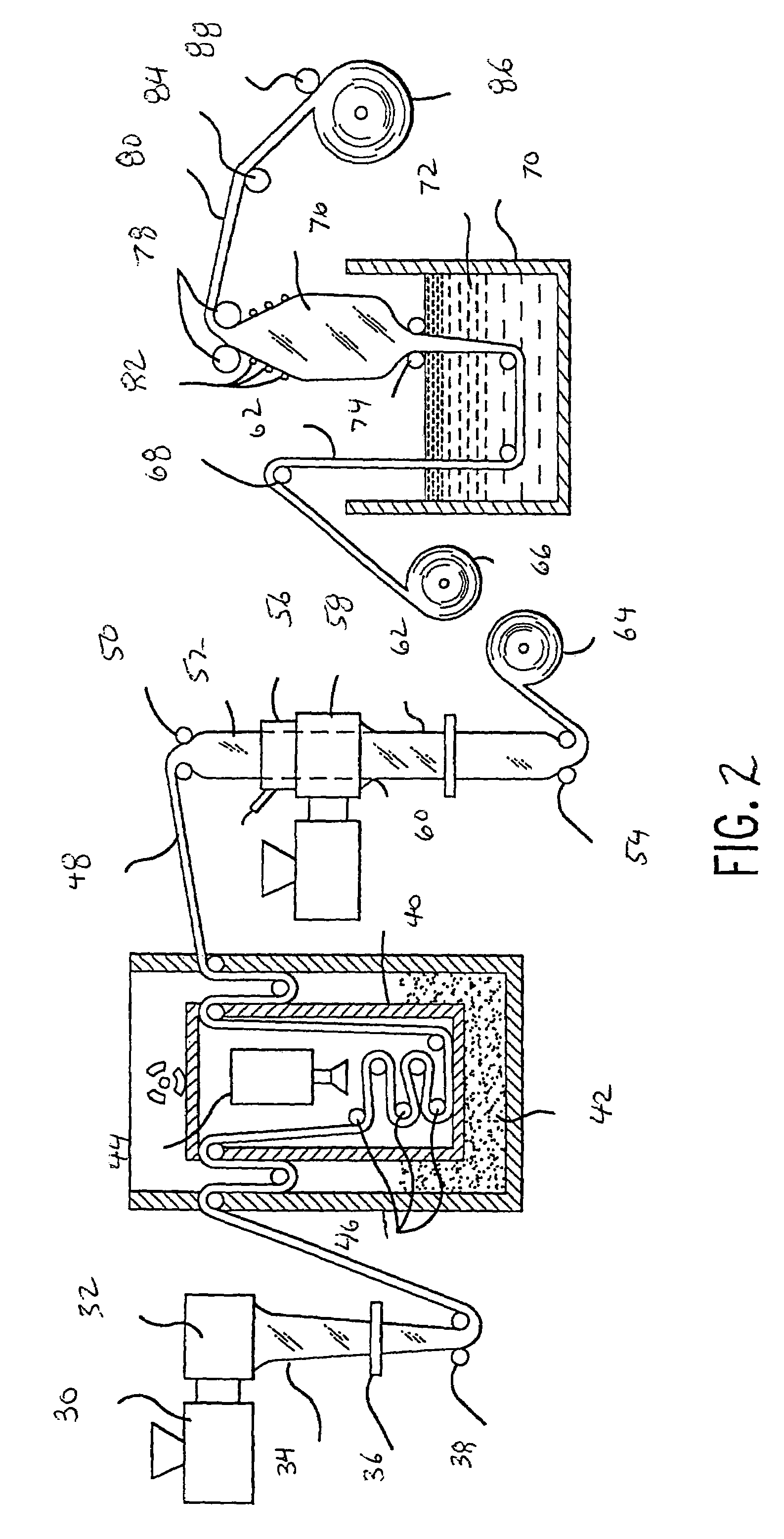

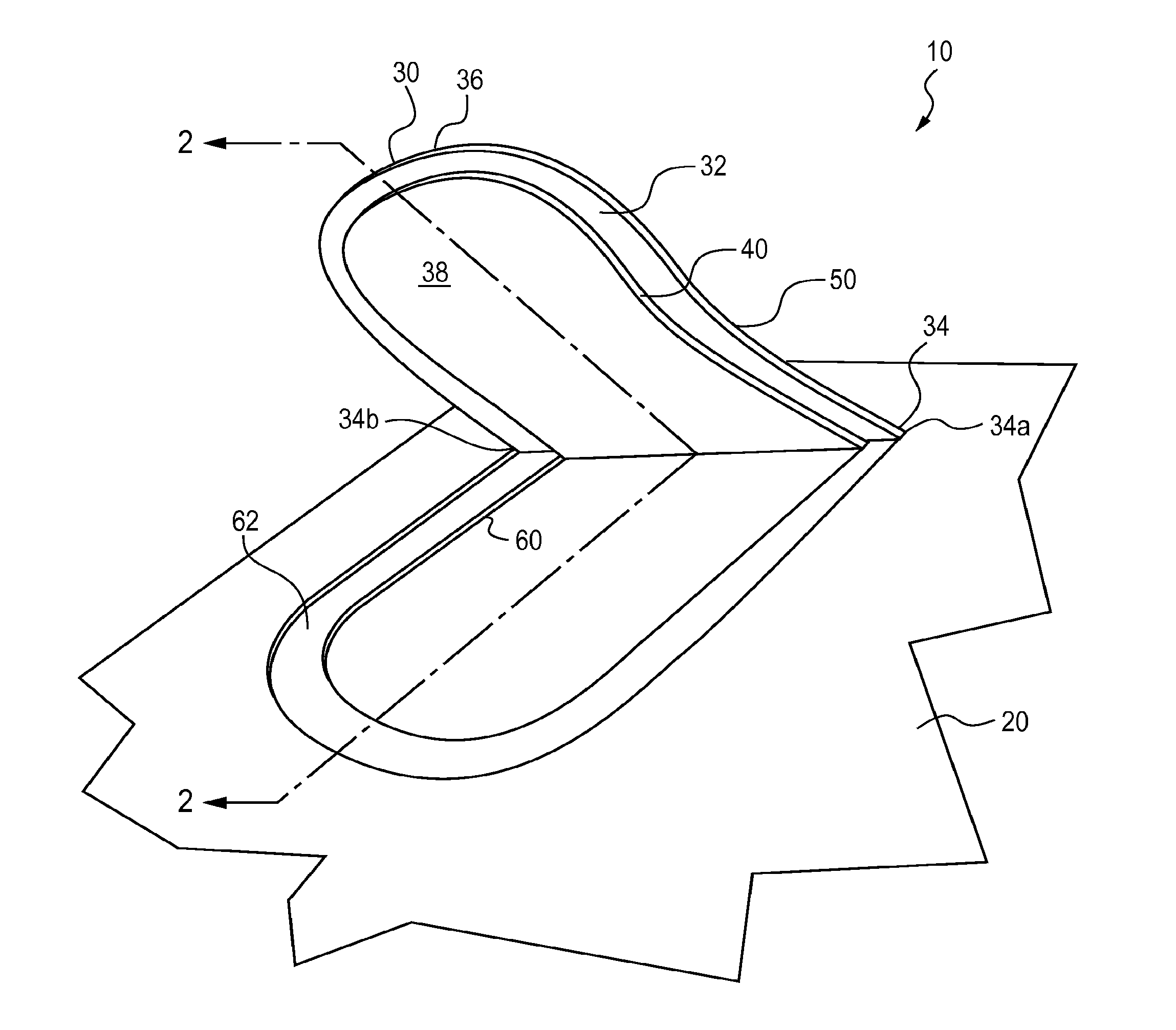

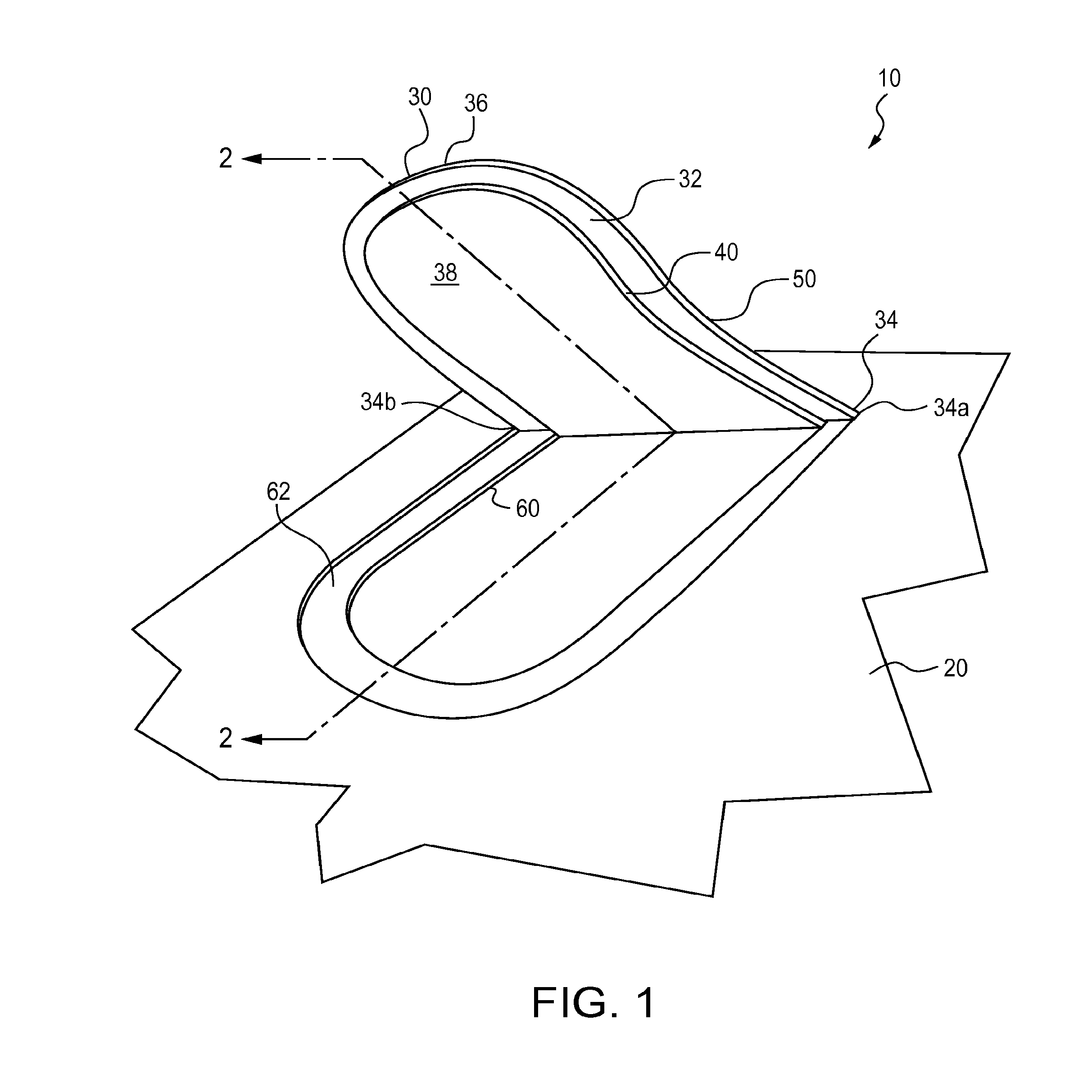

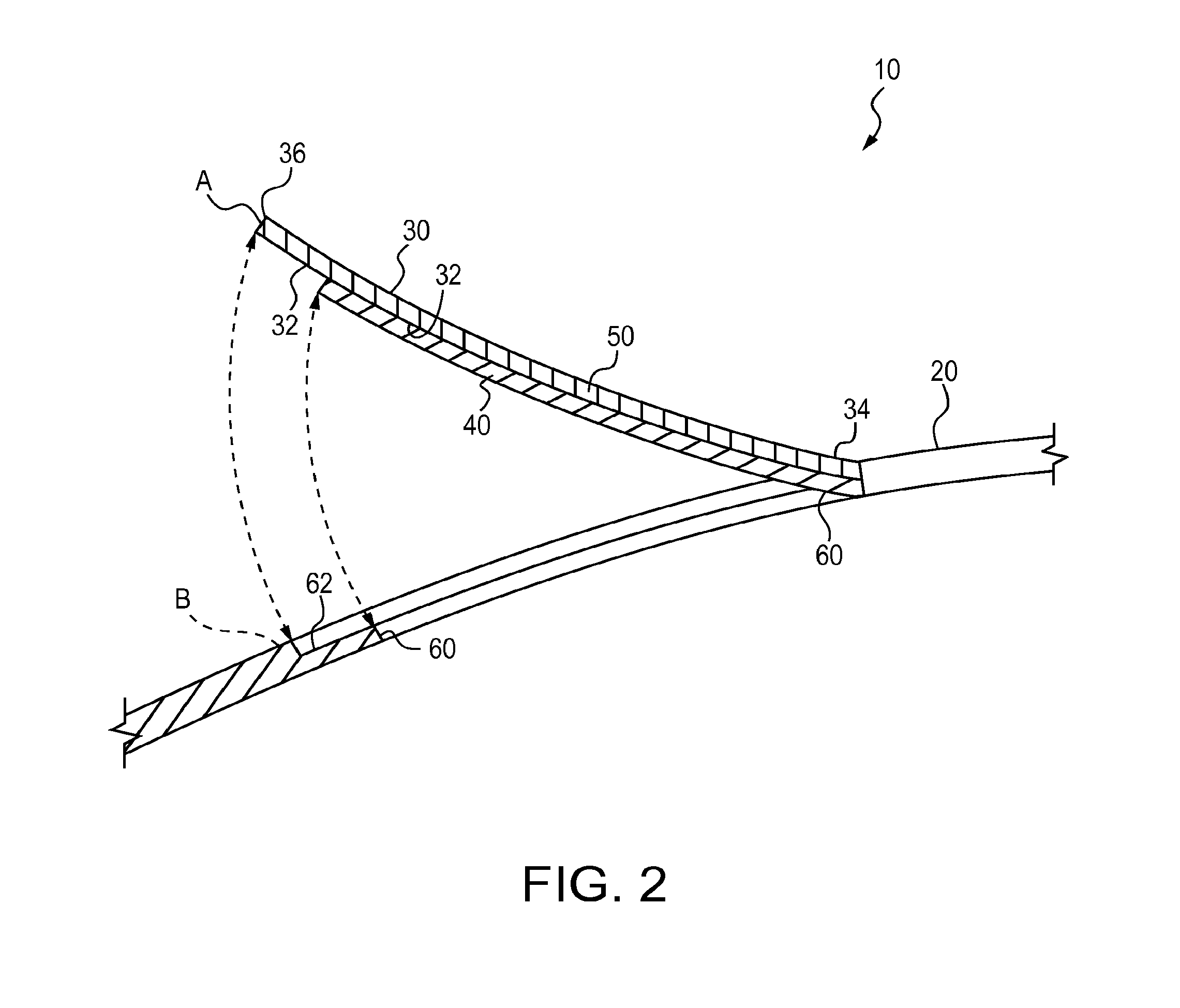

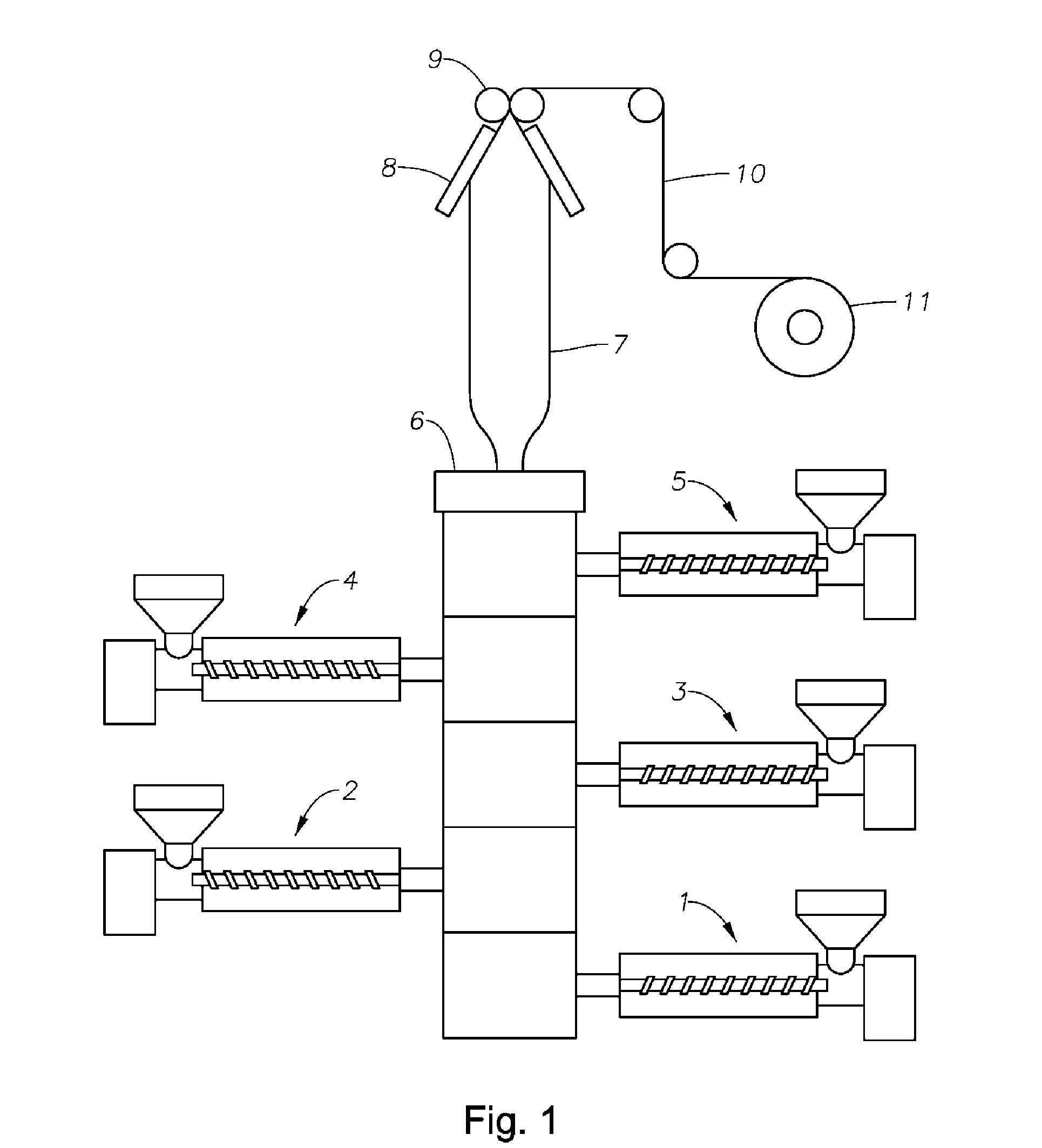

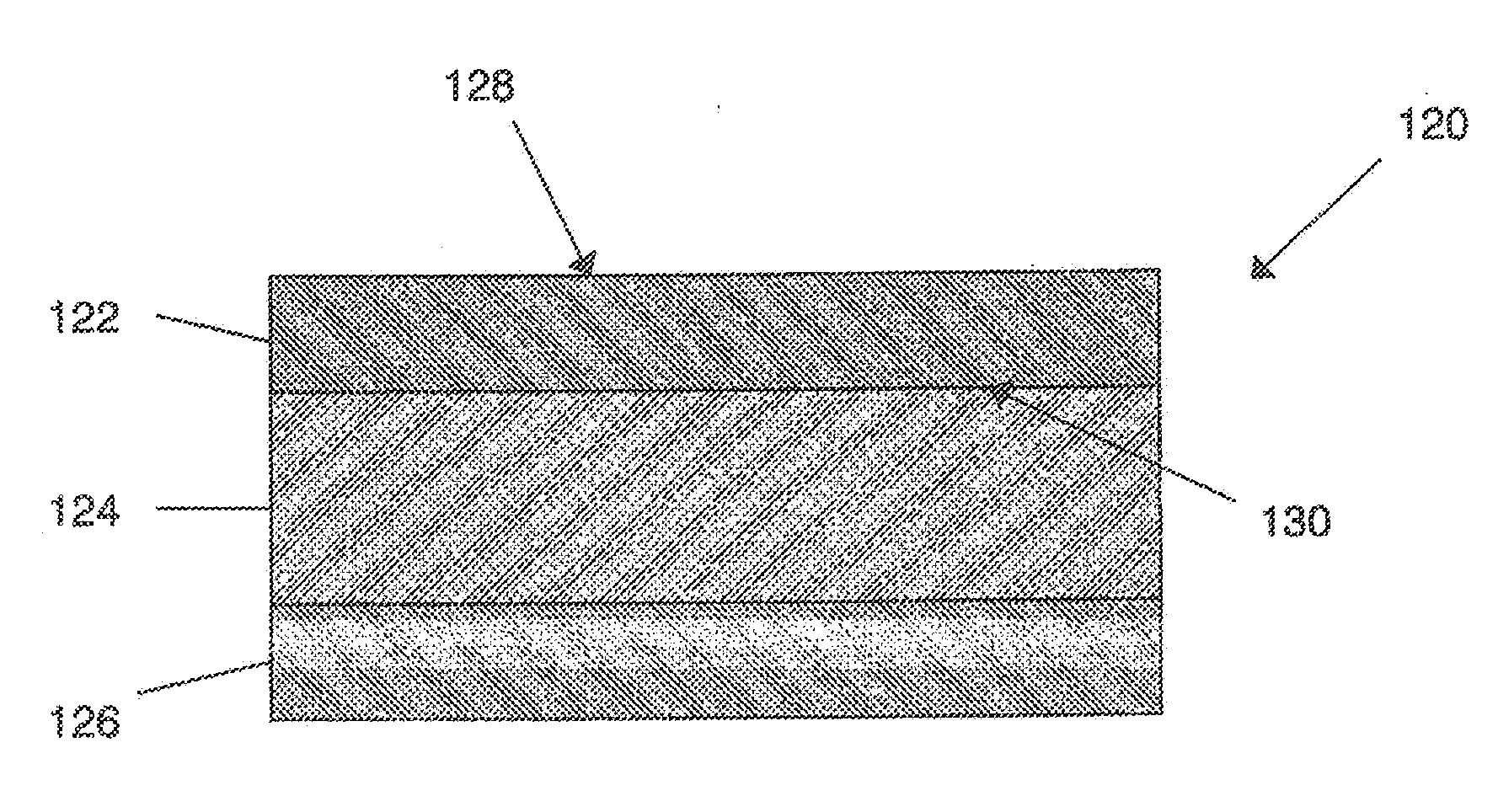

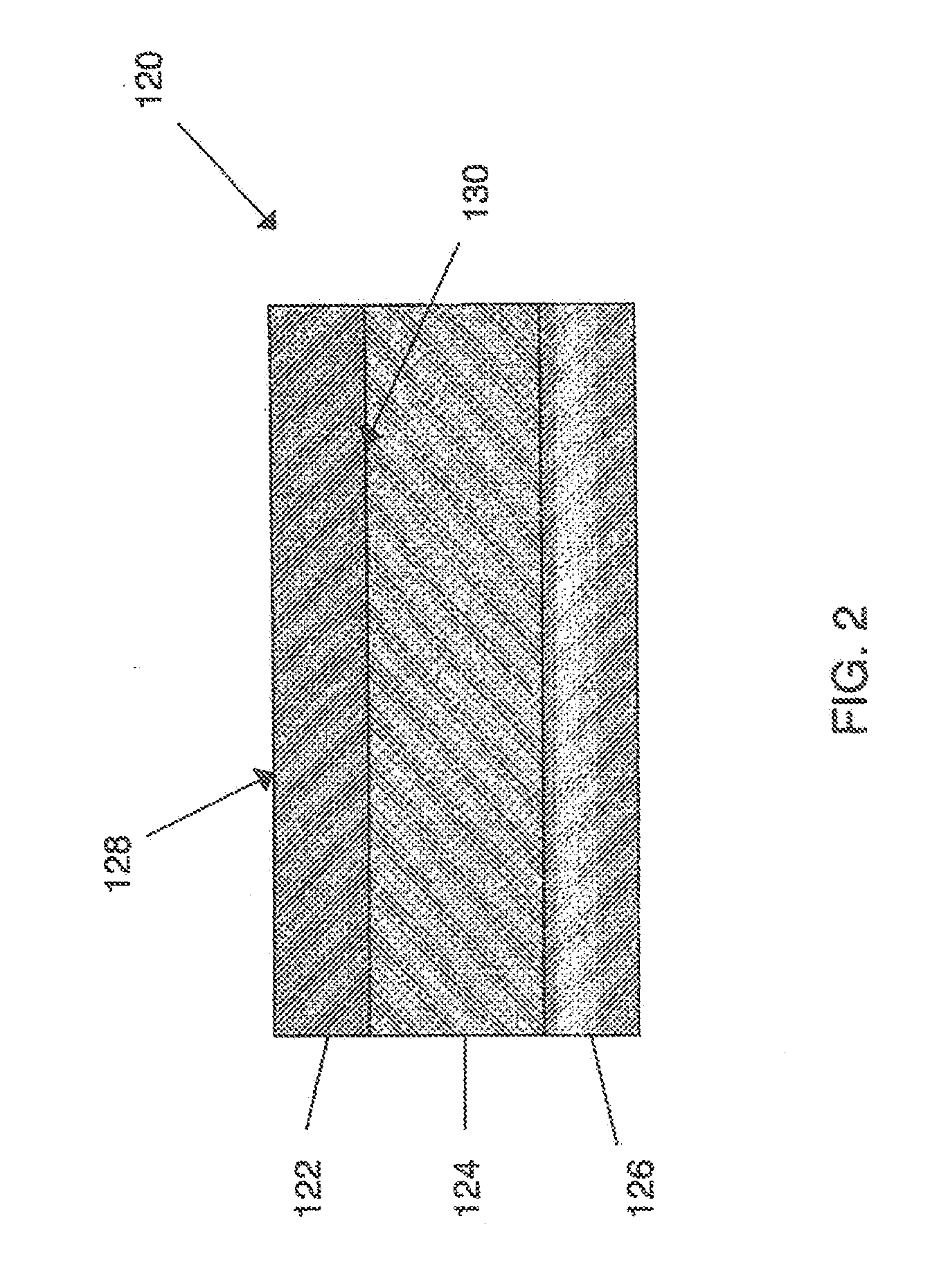

Flexible Materials for Flexible Containers

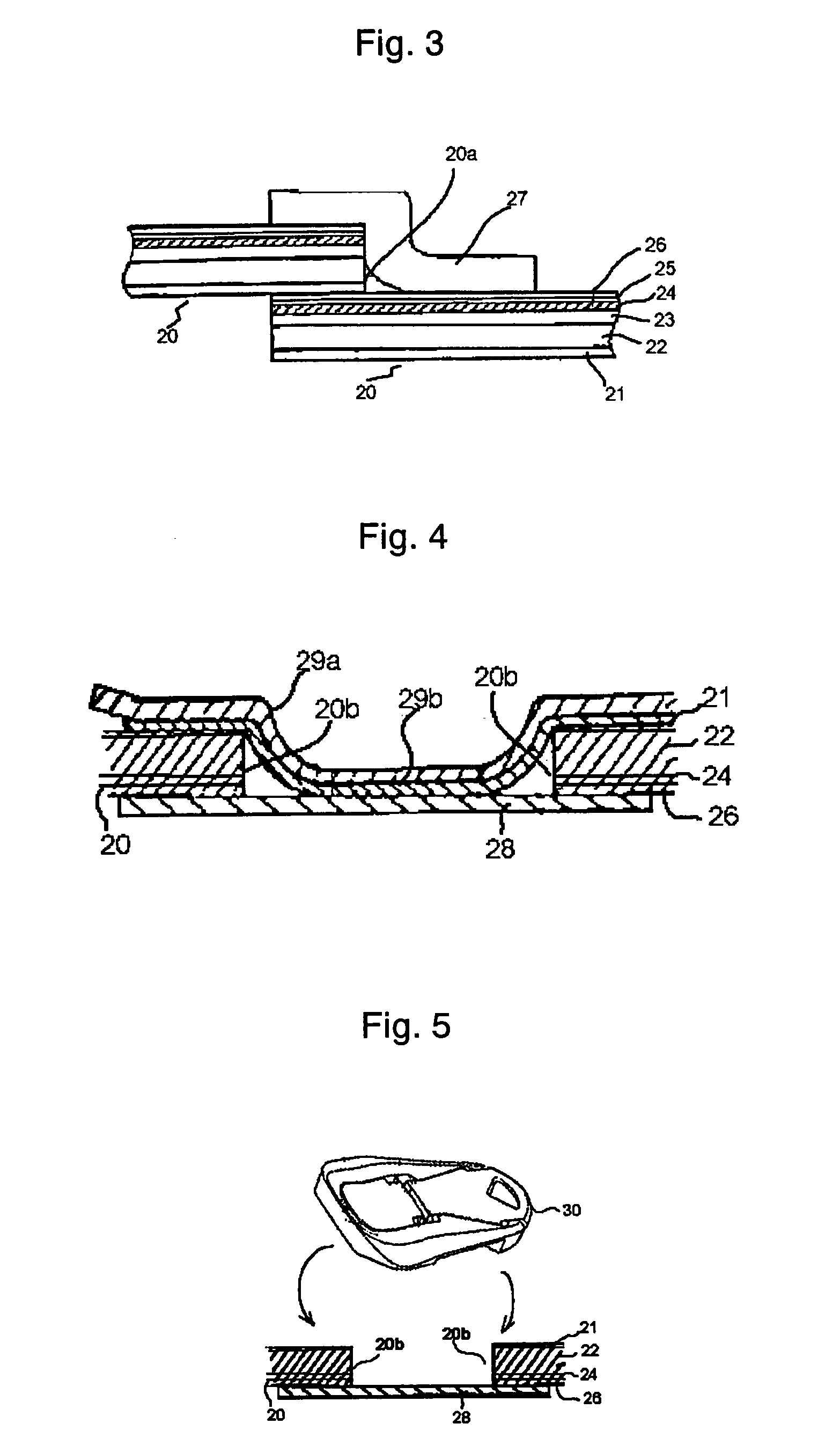

ActiveUS20130337244A1Less-expensiveImprove the decorative effectDomestic containersCoatingsEngineeringMechanical engineering

A flexible material for a flexible container can include a first laminate and a second laminate joined to at least a portion of the first laminate by at least one seal. The first laminate can include a first gas barrier layer disposed between first and second sealable layers, wherein the first and second sealable layers define opposed exterior layers of the first laminate. The second laminate can include a third sealable layer defining an exterior layer of the second laminate, and a second gas barrier layer. The at least one seal joins a portion of the third sealable layer to at least a portion of the second sealable layer.

Owner:PROCTER & GAMBLE CO

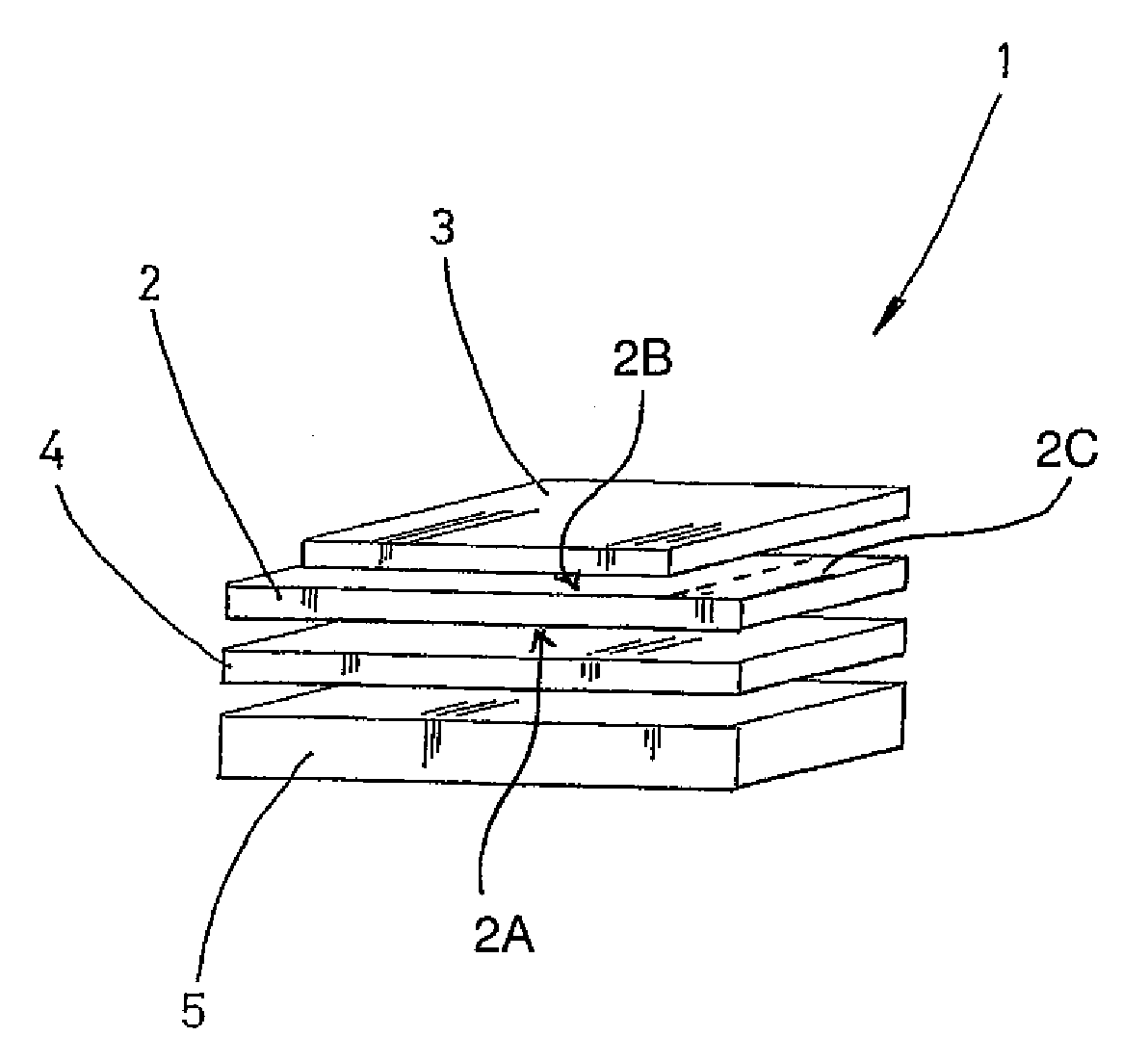

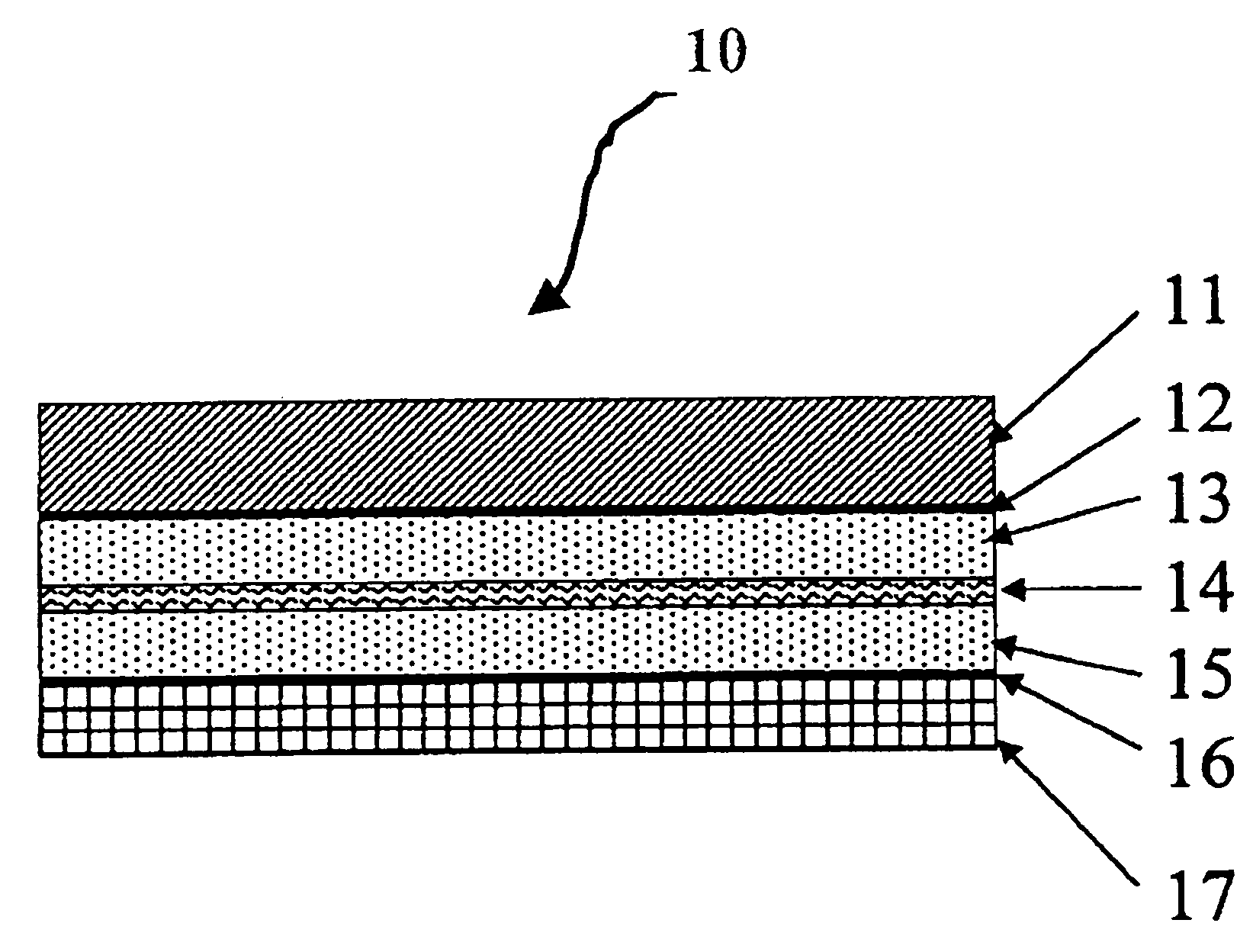

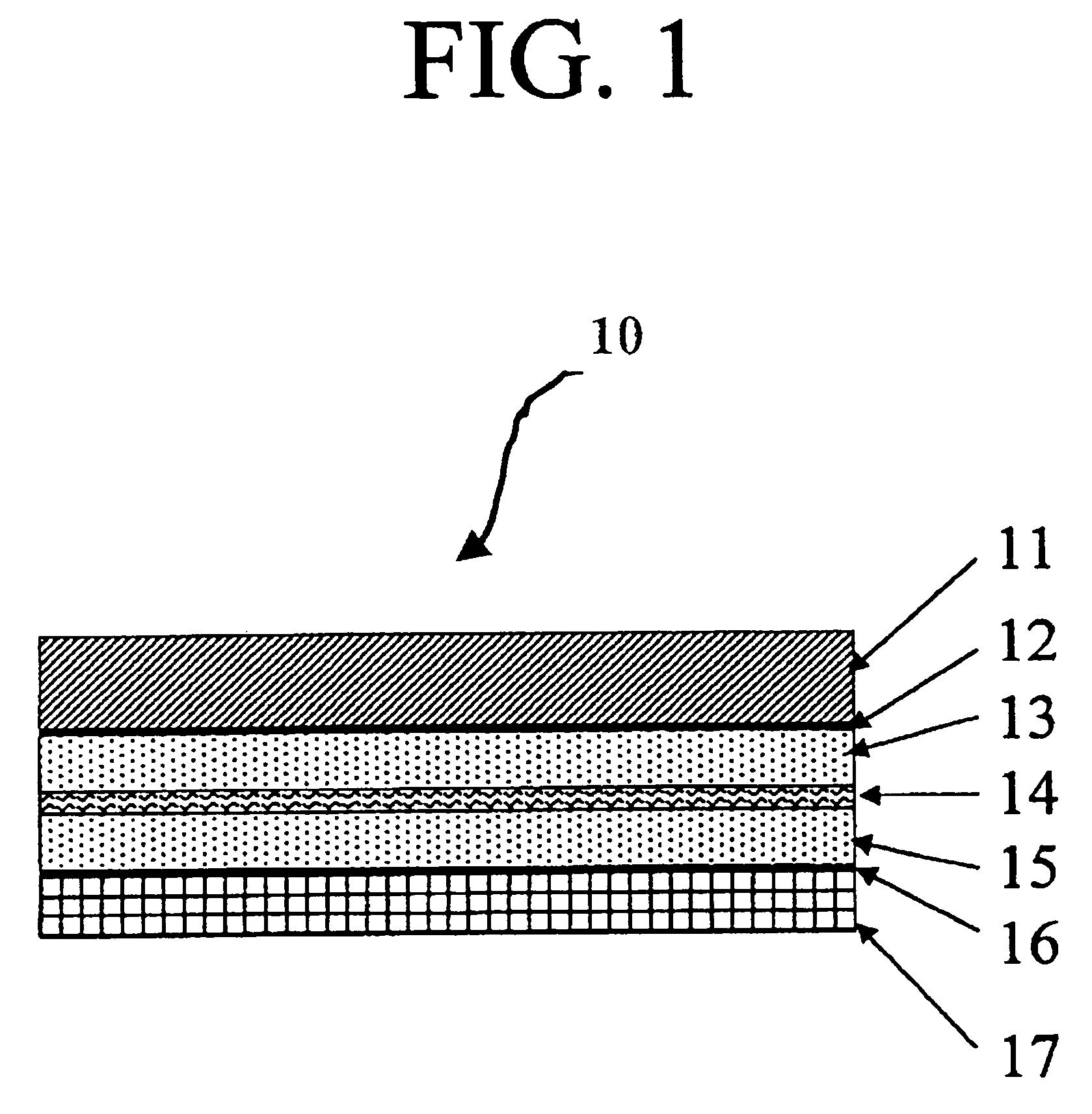

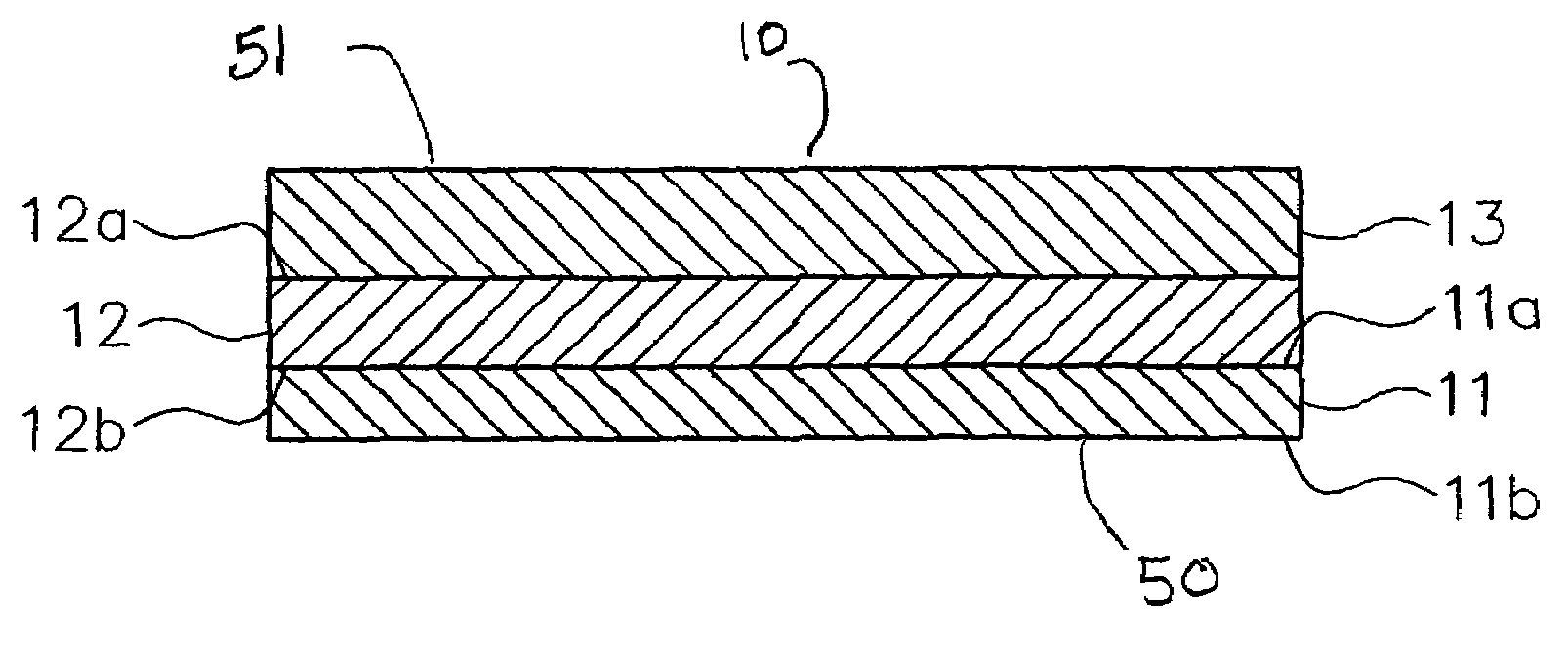

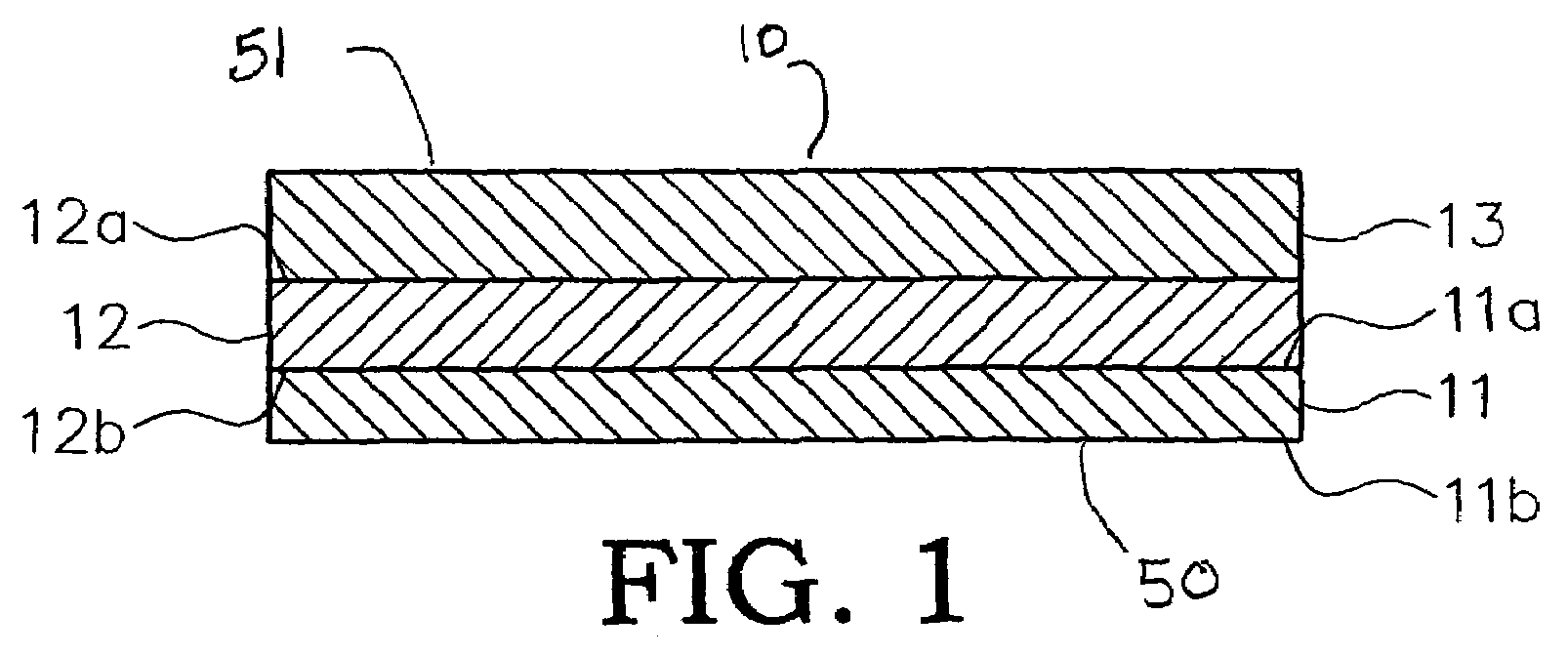

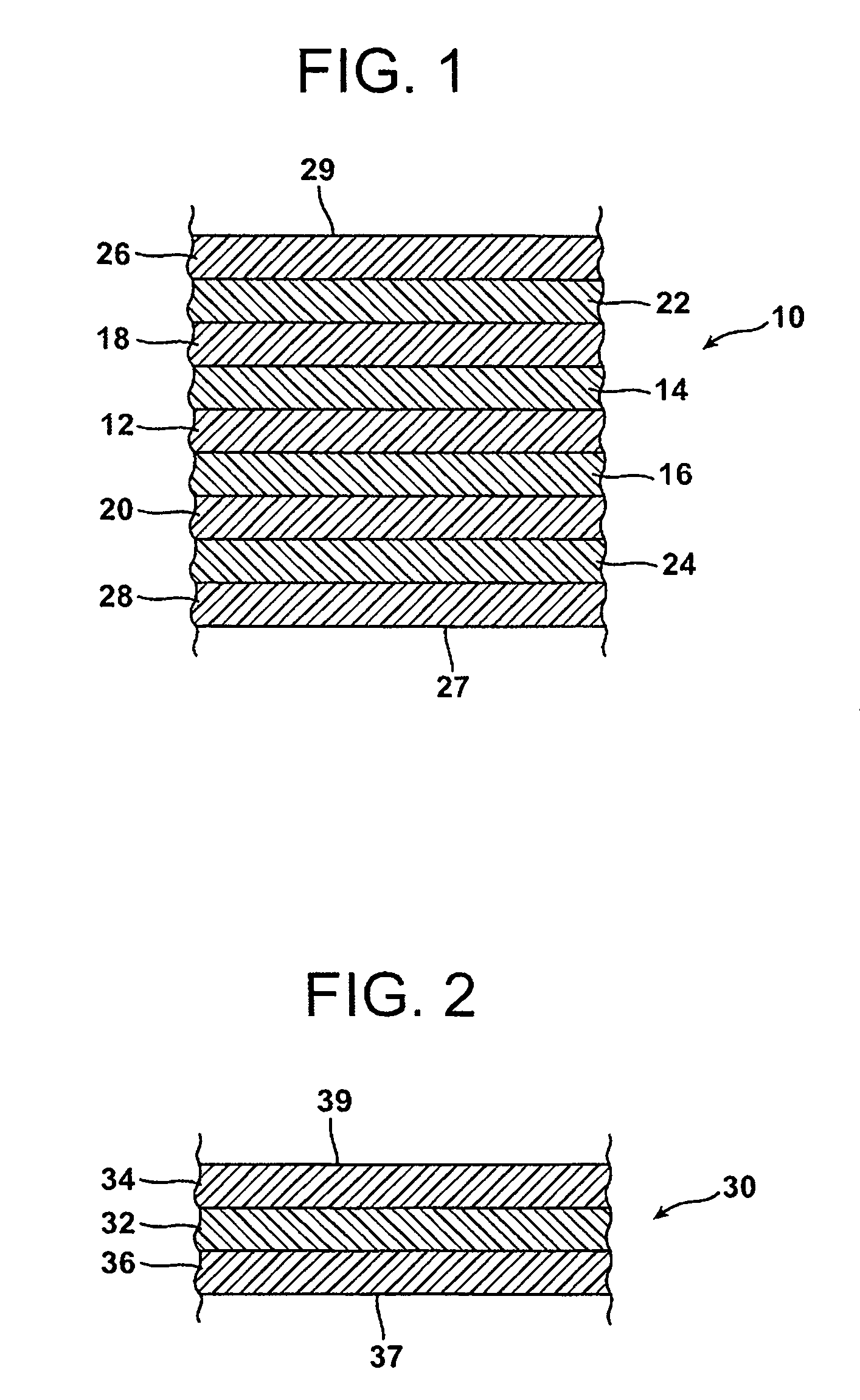

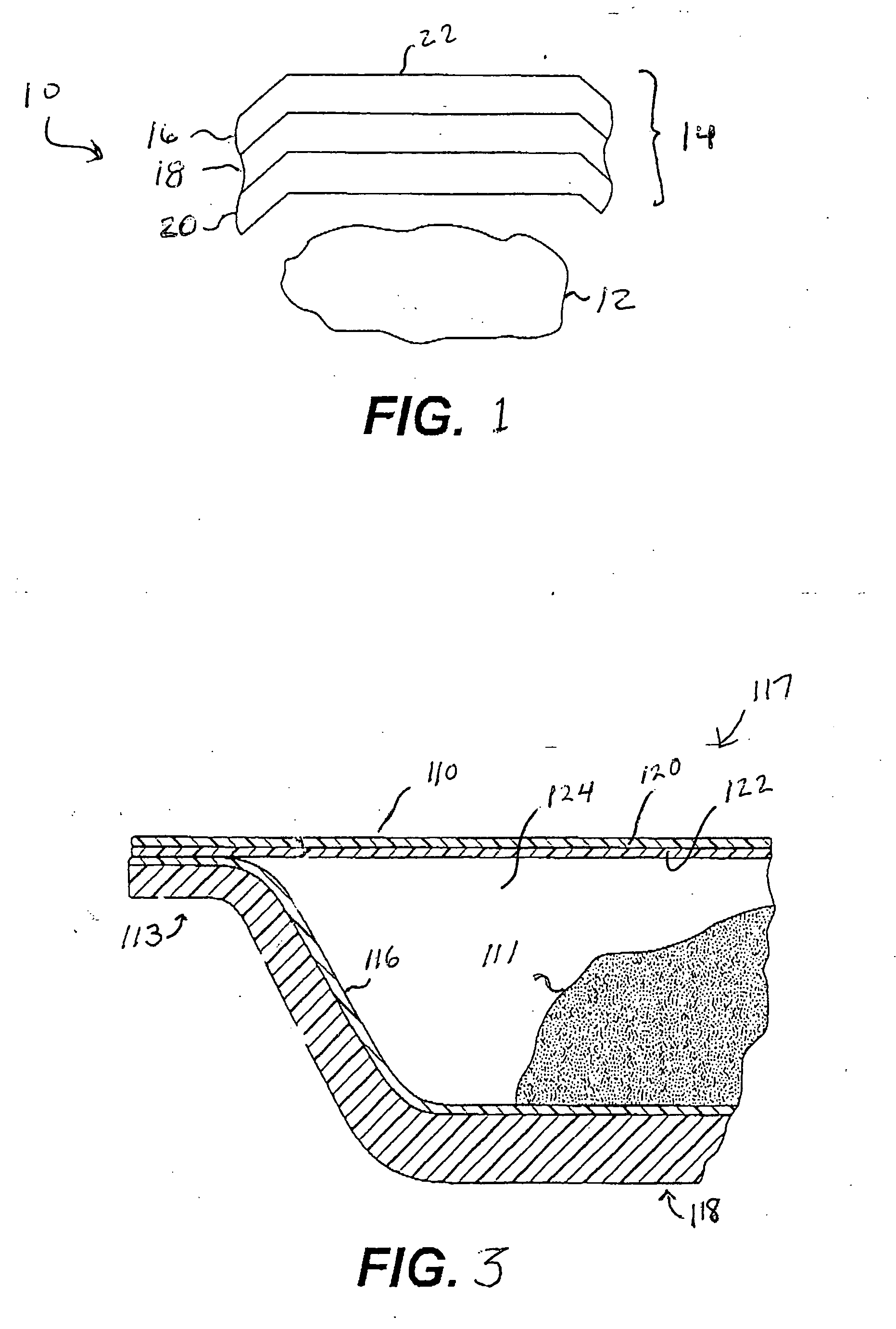

Multi-Layer Film Comprising a Barrier Layer and an Antistatic Layer

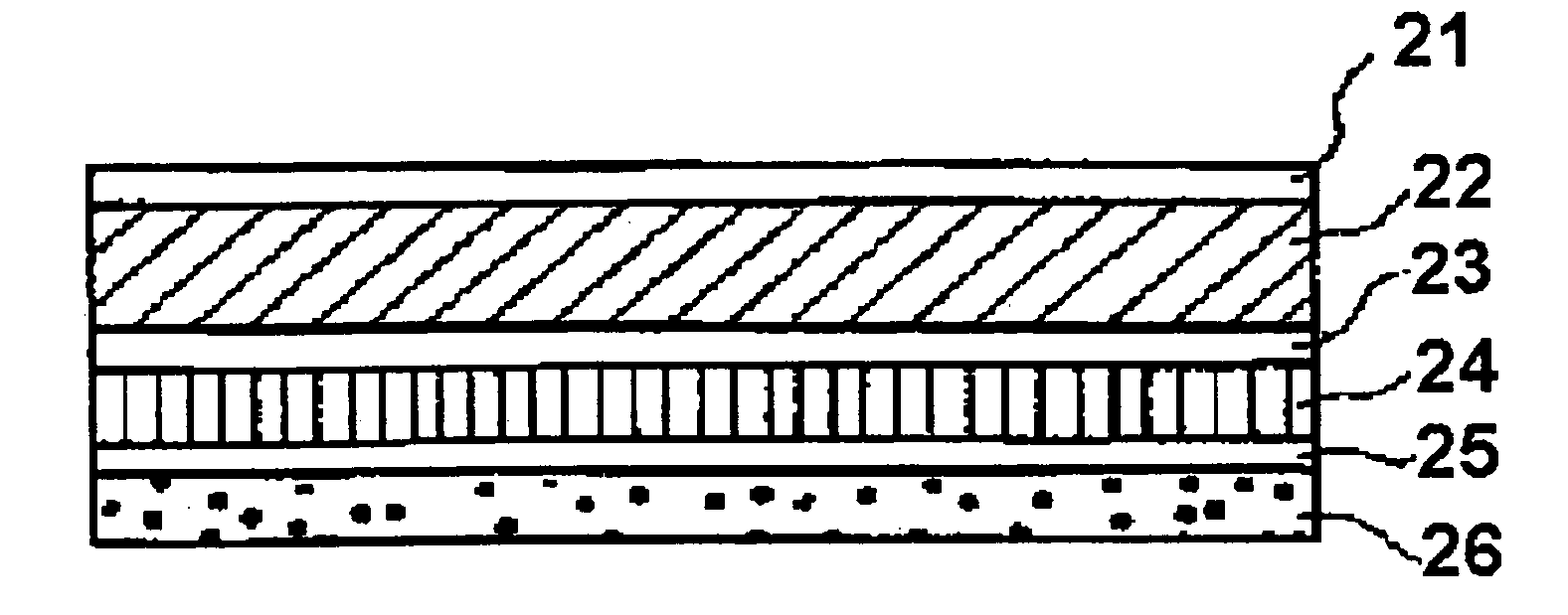

InactiveUS20100028637A1Guarantee capacityPrevent buildupSynthetic resin layered productsDomestic containersAntistatic agentEngineering

The invention relates to a multi-layer film comprising a barrier layer, a poorly extensible plastic layer, and an antistatic plastic layer arranged on the side of the barrier layer, opposing the poorly extensible plastic layer. According to the invention, either a layer of material that is generally recognised as safe in terms of food is arranged next to the antistatic plastic layer, opposing the barrier layer, said layer of material being between 5 and 20 μm thick, and the antistatic layer being approximately between 10 and 150 μm thick, or the antistatic plastic layer is embodied as a layer of material that is generally recognised as safe in terms of food, the antistatic plastic layer containing a plastic material that is generally recognised as safe in terms of food and an antistatic agent that is generally recognised as safe in terms of food.

Owner:SUNJUT DEUT

Flexible Materials for Flexible Containers

ActiveUS20130294711A1Less-expensiveImprove the decorative effectDomestic containersCoatingsEngineeringMechanical engineering

A flexible material for a flexible container can include a first laminate and a second laminate joined to at least a portion of the first laminate by at least one seal. The first laminate can include a first gas barrier layer disposed between first and second sealable layers, wherein the first and second sealable layers define opposed exterior layers of the first laminate. The second laminate can include a third sealable layer defining an exterior layer of the second laminate, and a second gas barrier layer. The at least one seal joins a portion of the third sealable layer to at least a portion of the second sealable layer.

Owner:THE PROCTER & GAMBLE COMPANY

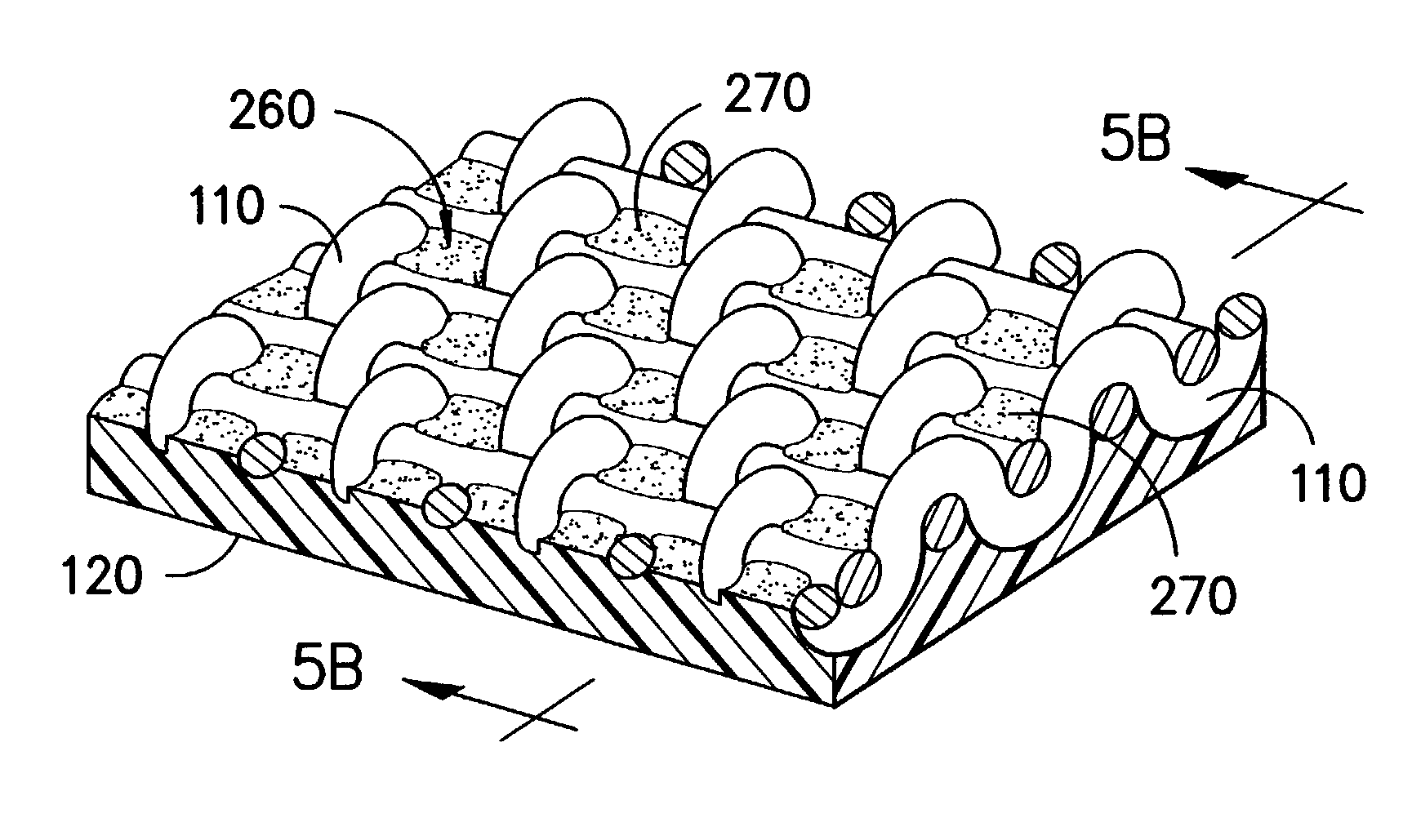

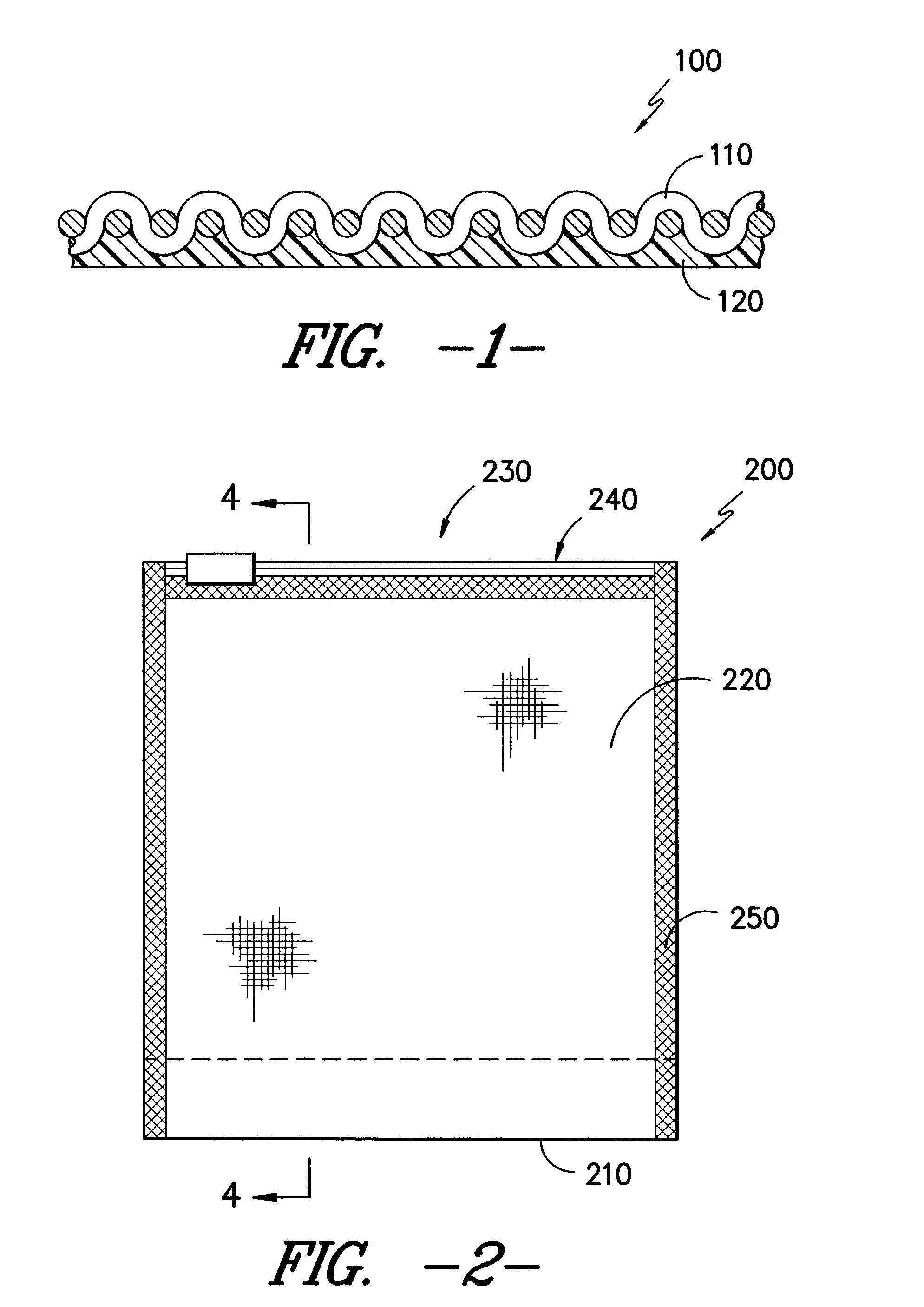

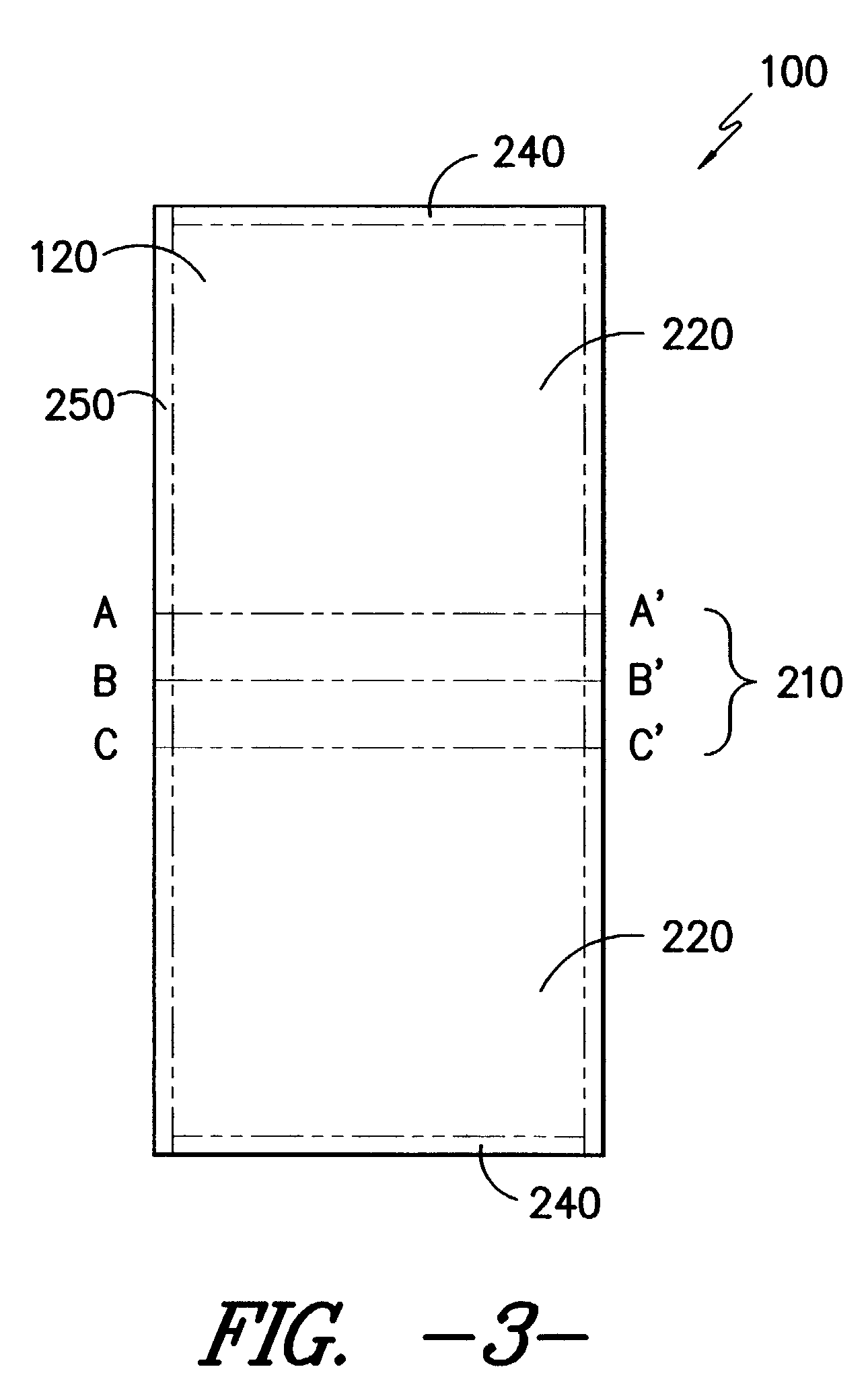

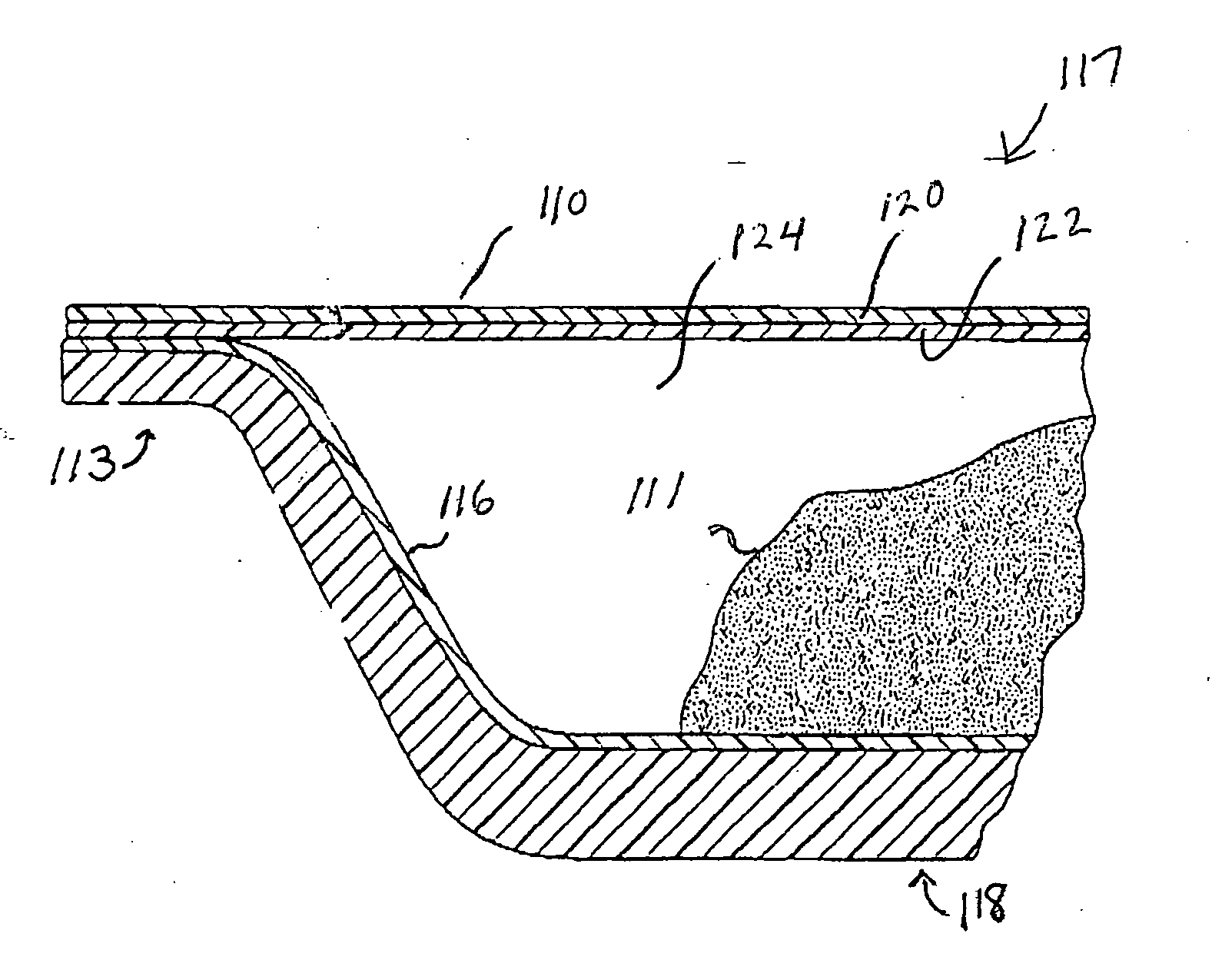

Packaging material and containers formed therefrom

The flexible, reusable packaging container of the present invention is comprised of a packaging material. The packaging material is comprised of one or more layers of coating disposed on one or more layers of textile substrate. The coating layer may be comprised of a stiffening agent for providing support to the packaging container. The stiffening agent may provide a gas and / or liquid impermeable barrier between the contents of the container and the textile substrate. The stiffening agent may also include chemicals which impart antifungal or antibacterial properties to container. The textile substrate typically provides an aesthetically pleasing feel and appearance to the outside of the packaging container, as well as providing functional attributes such as water repellence, stain resistance, and / or anti-static resistance. The resulting packaging container possesses increased strength, puncture resistance, and resistance to de-lamination over the current paper or plastic packaging containers.

Owner:MILLIKEN & CO

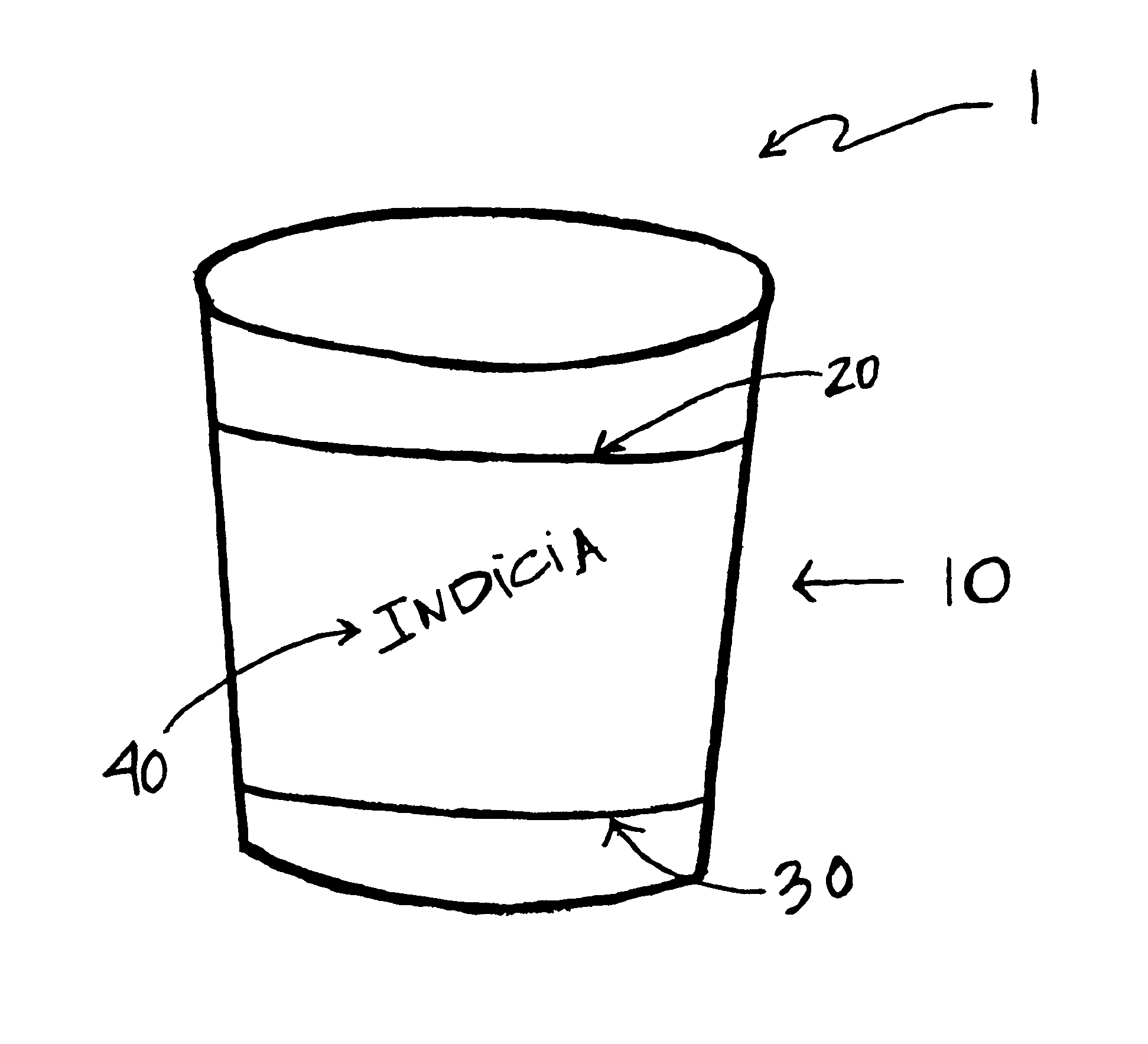

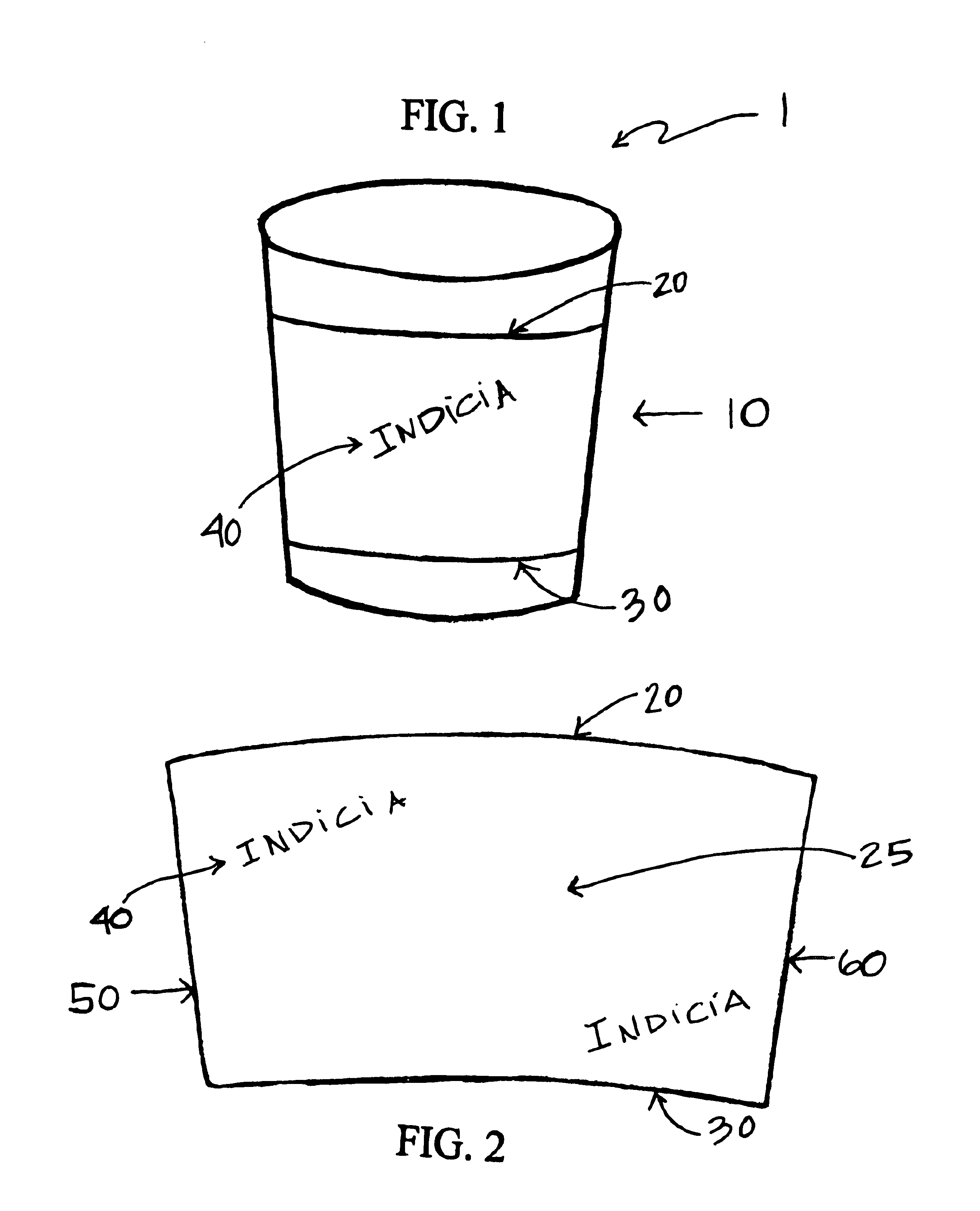

Insulating sleeve for grasping container and manufacturing method

InactiveUS6814253B2Easy to masterEasy to useSynthetic resin layered productsRefuse receptaclesPlastic materialsVolumetric Mass Density

Owner:DOUBLE TEAM

Packaging for primary and secondary batteries

InactiveUS20050112461A1Extended calendar lifeDeferred-action cellsSynthetic resin layered productsMetal foilEngineering

Owner:UCHICAGO ARGONNE LLC

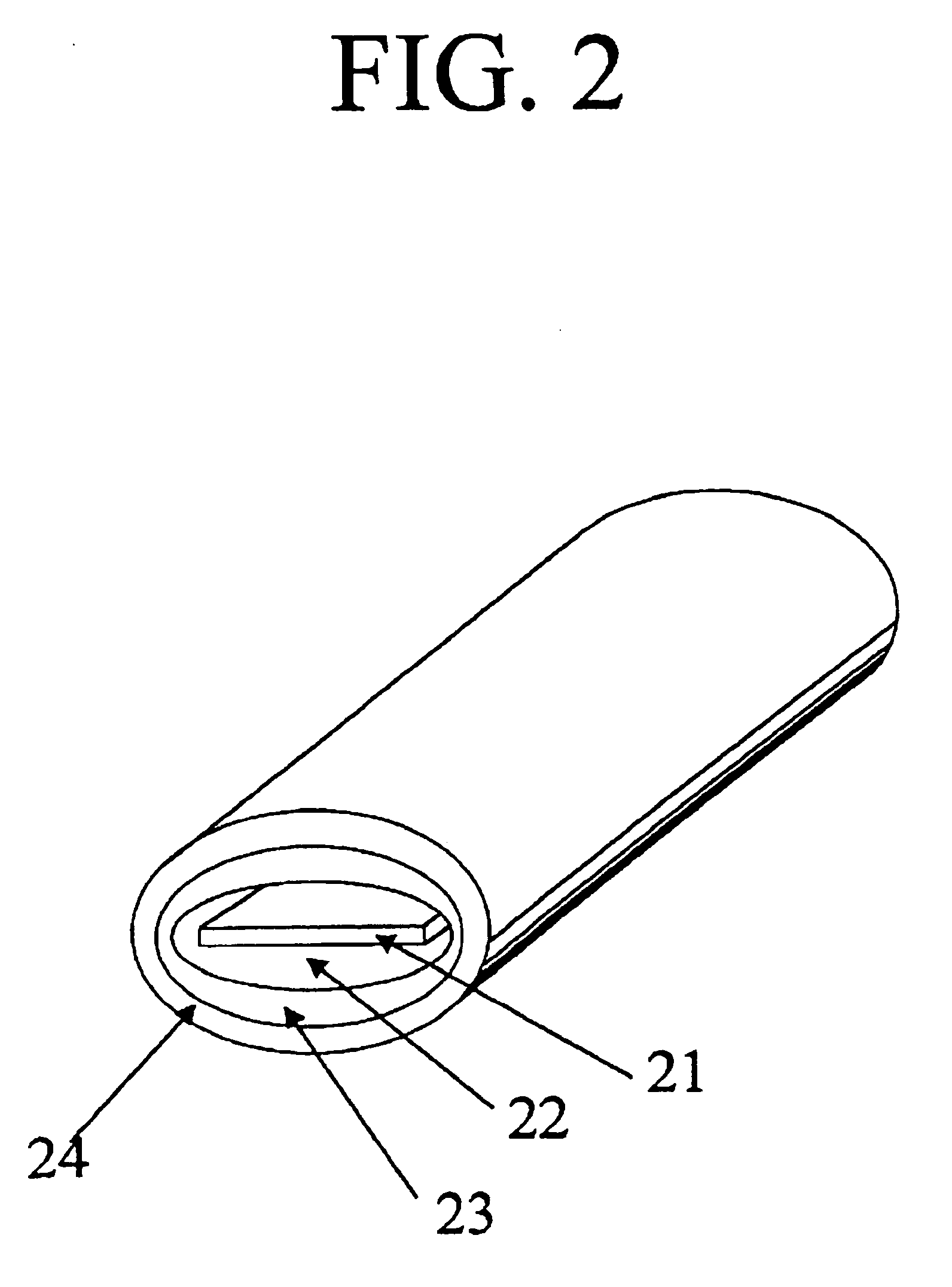

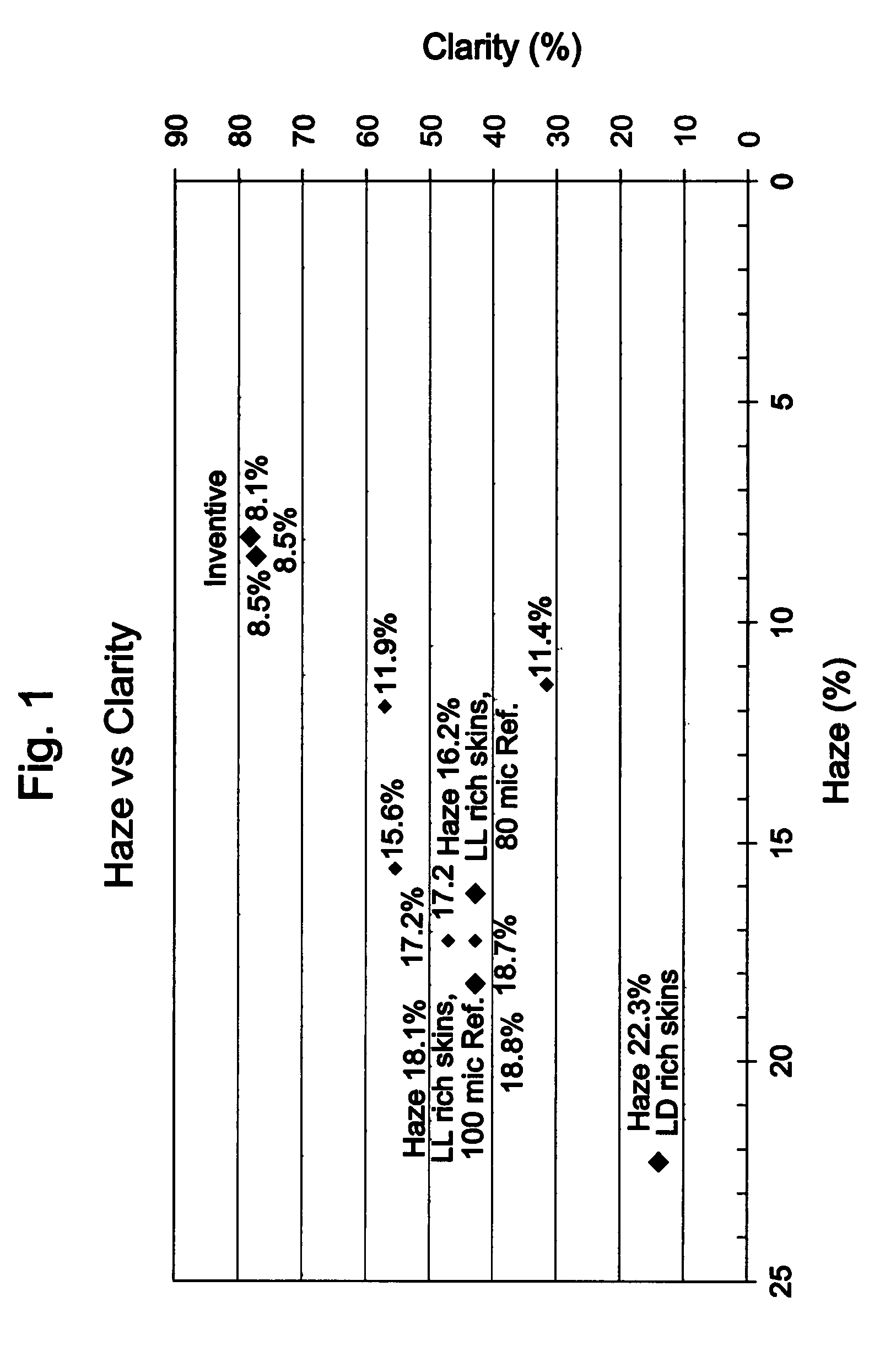

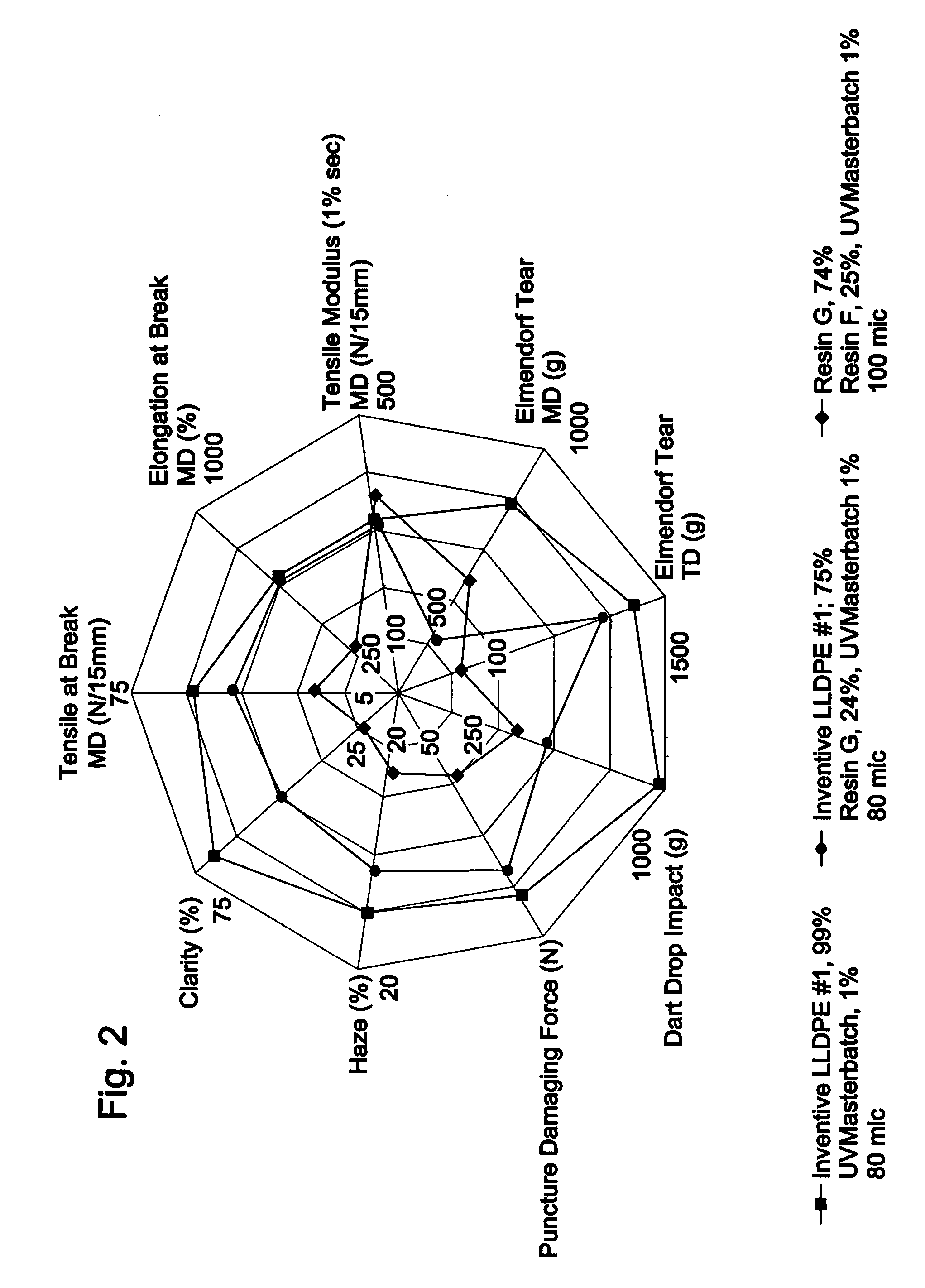

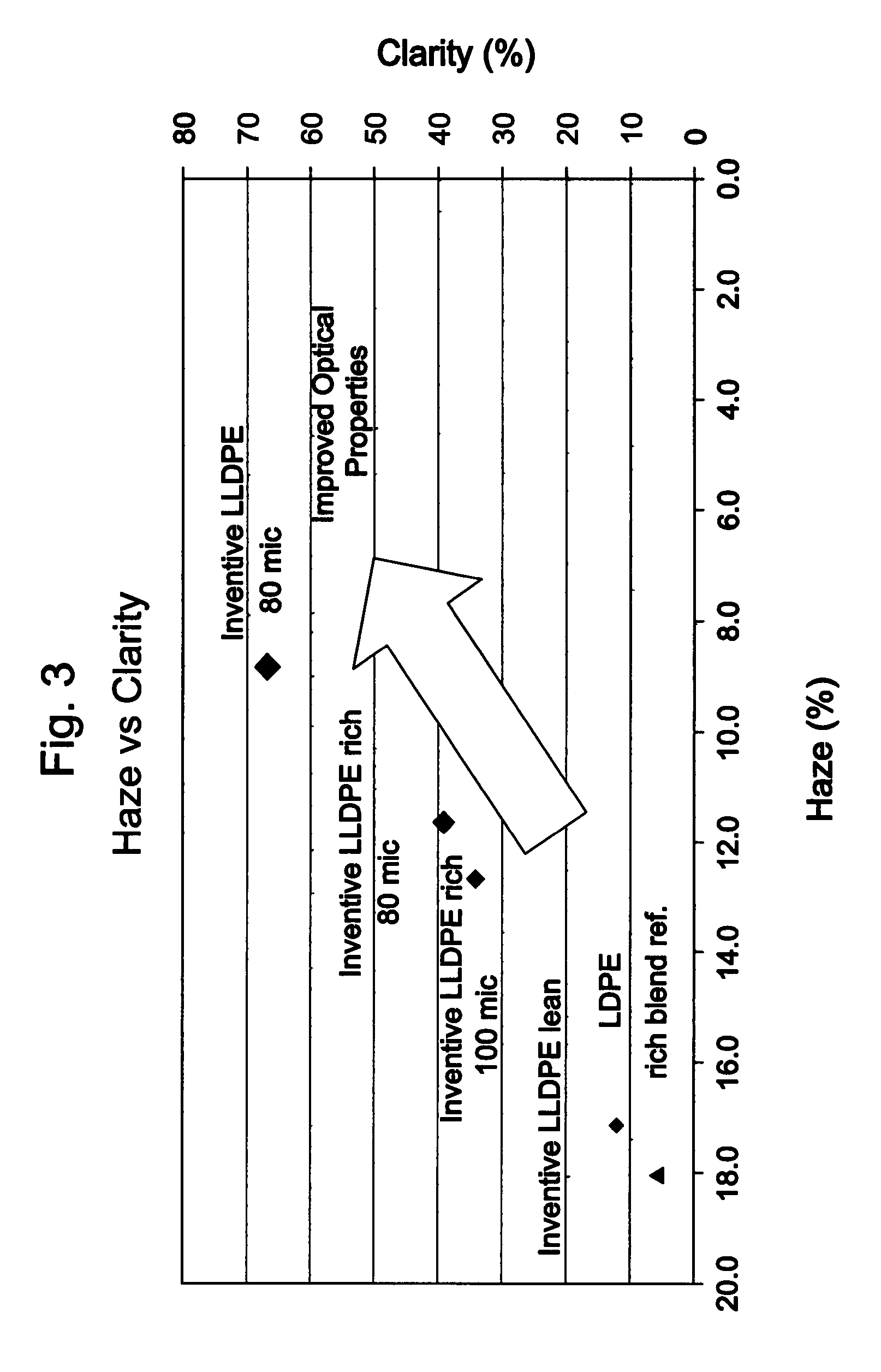

Linear low density polymer blends and articles made therefrom

ActiveUS7951873B2Synthetic resin layered productsDomestic containersLow-density polyethyleneLinear low-density polyethylene

This invention relates to blends of linear low density polyethylene copolymers with other linear low density polyethylenes or very low density, low density, medium density, high density, and differentiated polyethylenes. The invention also includes articles produced from the linear low density polyethylene and polyethylene blends described.

Owner:EXXONMOBIL CHEM PAT INC

Process for detecting leaks in sealed packages

InactiveUS7534615B2Analysis using chemical indicatorsChemiluminescene/bioluminescenceEngineeringLength wave

Owner:CRYOVAC ILLC

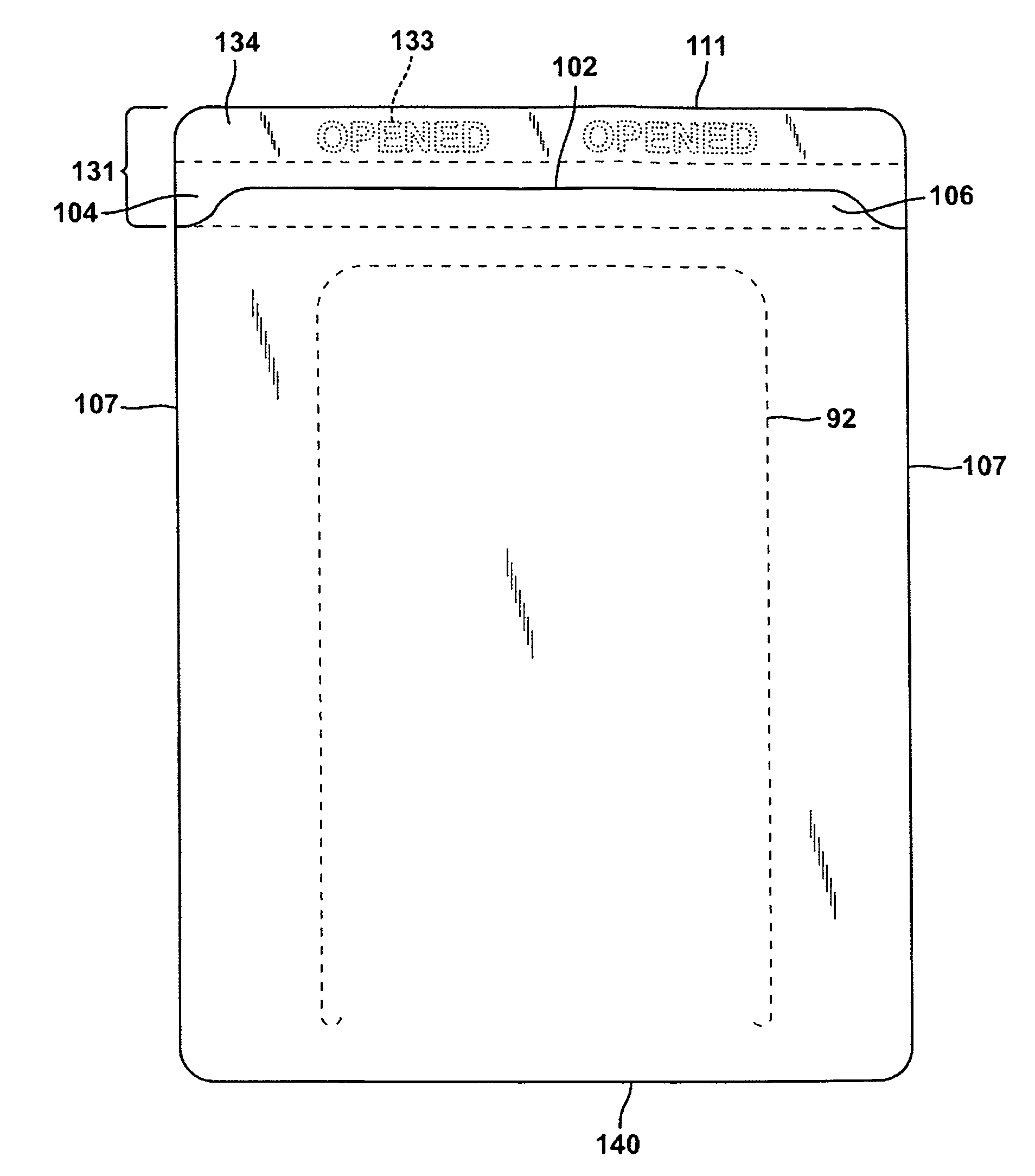

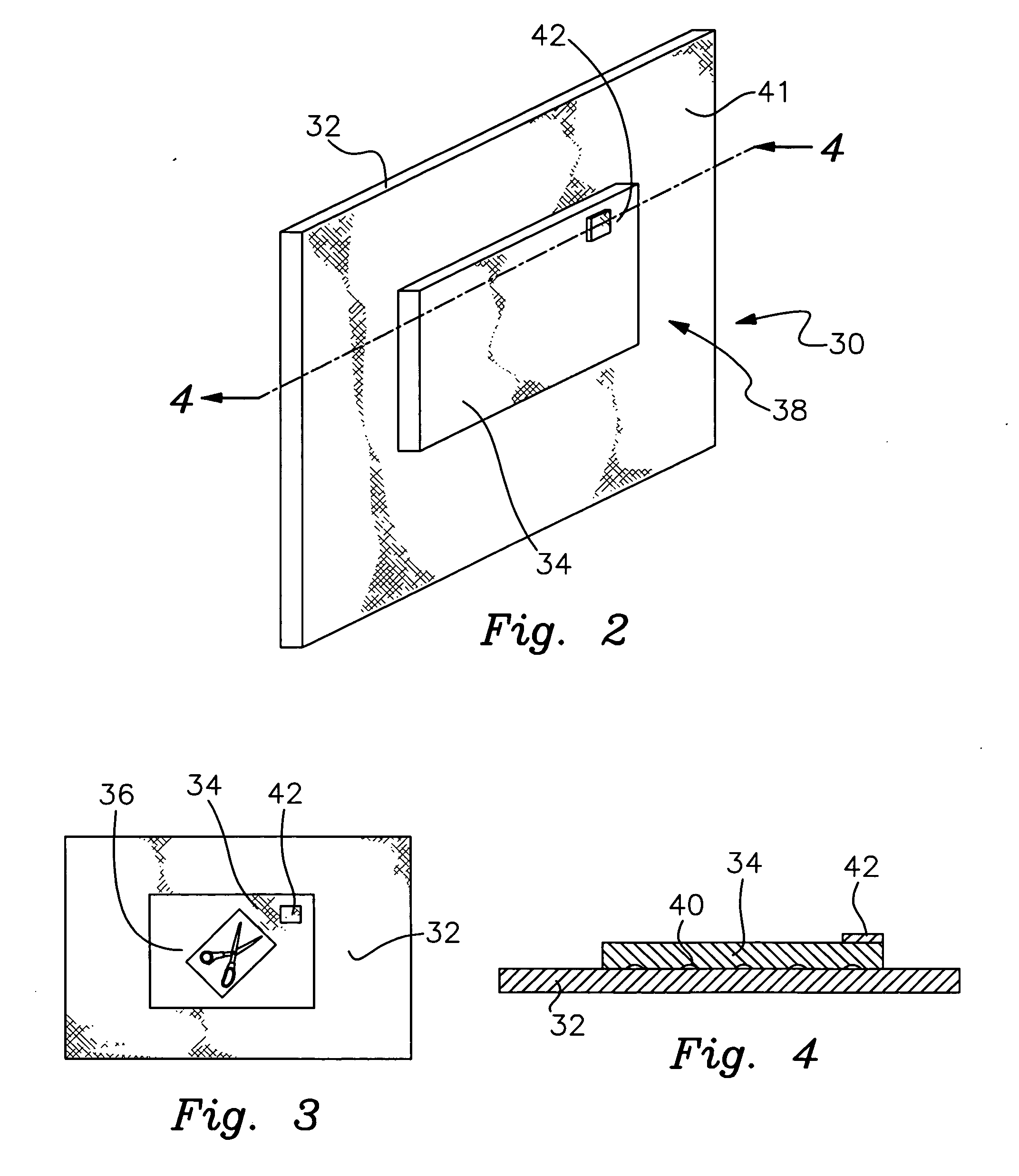

Resealable Laminate for Heat Sealed Packaging

A resealable package assembly is described. The package assembly includes a selectively positionable flap that covers an aperture or enables access through the aperture into the package. The flap and package include provisions for releasably engaging the flap to the package to seal the interior of the package. Provisions for grasping the tab and indicating whether tampering has occurred are also described.

Owner:AVERY DENNISON CORP

Peelable/resealable packaging film

ActiveUS7422782B2Strength of the heat-seal bondHigh strengthSynthetic resin layered productsBagsPolyesterWater insoluble

The present invention describes a multilayer film suitable for use in packaging applications comprising at least a polymeric first layer having a first surface and an opposing second surface wherein the polymeric first layer comprises a heat-sealable, water-insoluble polyester; a polymeric second layer having a first surface and an opposing second surface and comprising a pressure-sensitive adhesive, wherein the second surface of the polymeric second layer is in contact with the first surface of the polymeric first layer and forms a peelable / resealable bond therebetween; and a third layer in contact with the first surface of the polymeric second layer.

Owner:BEMIS COMPANY INC

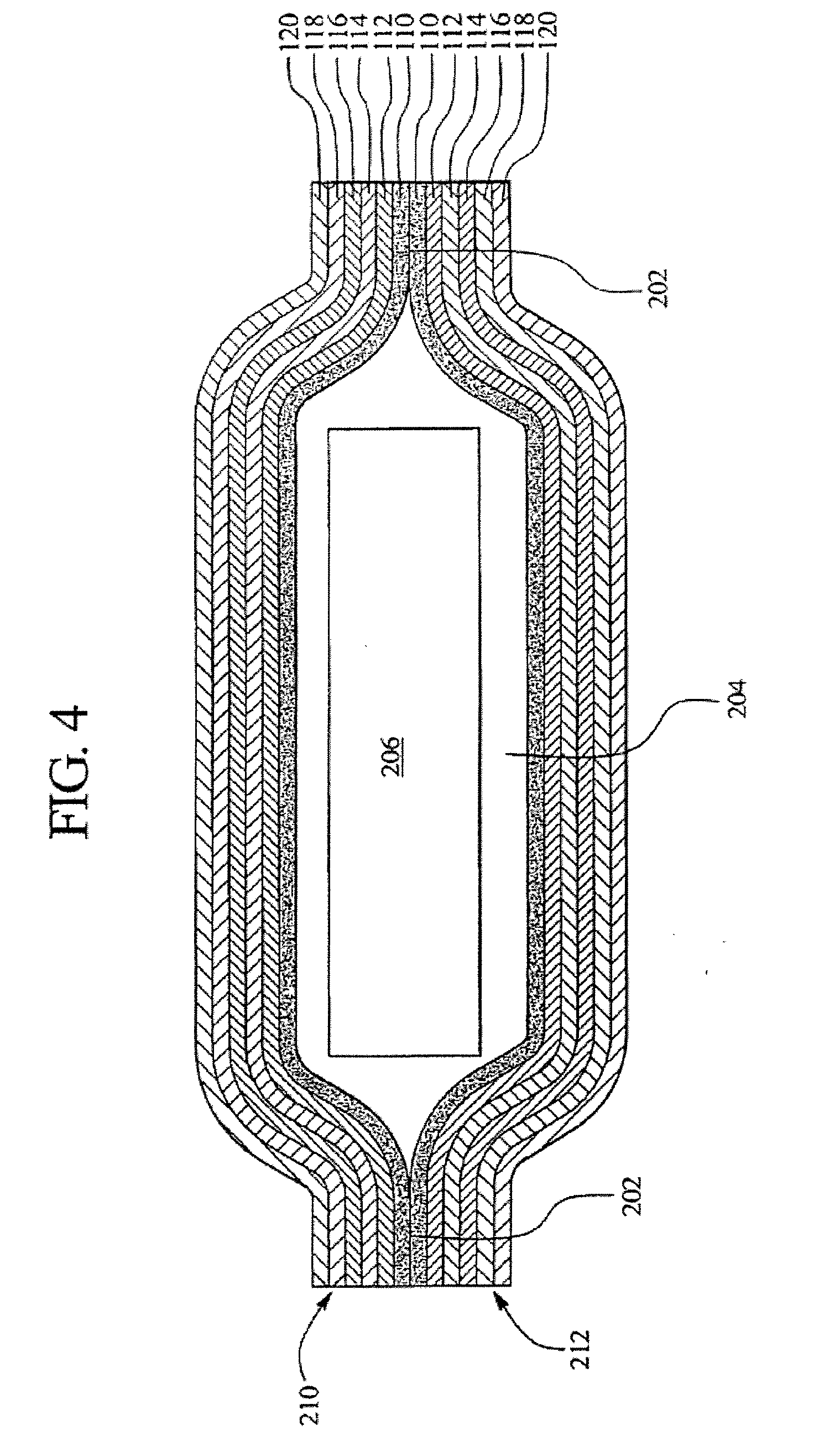

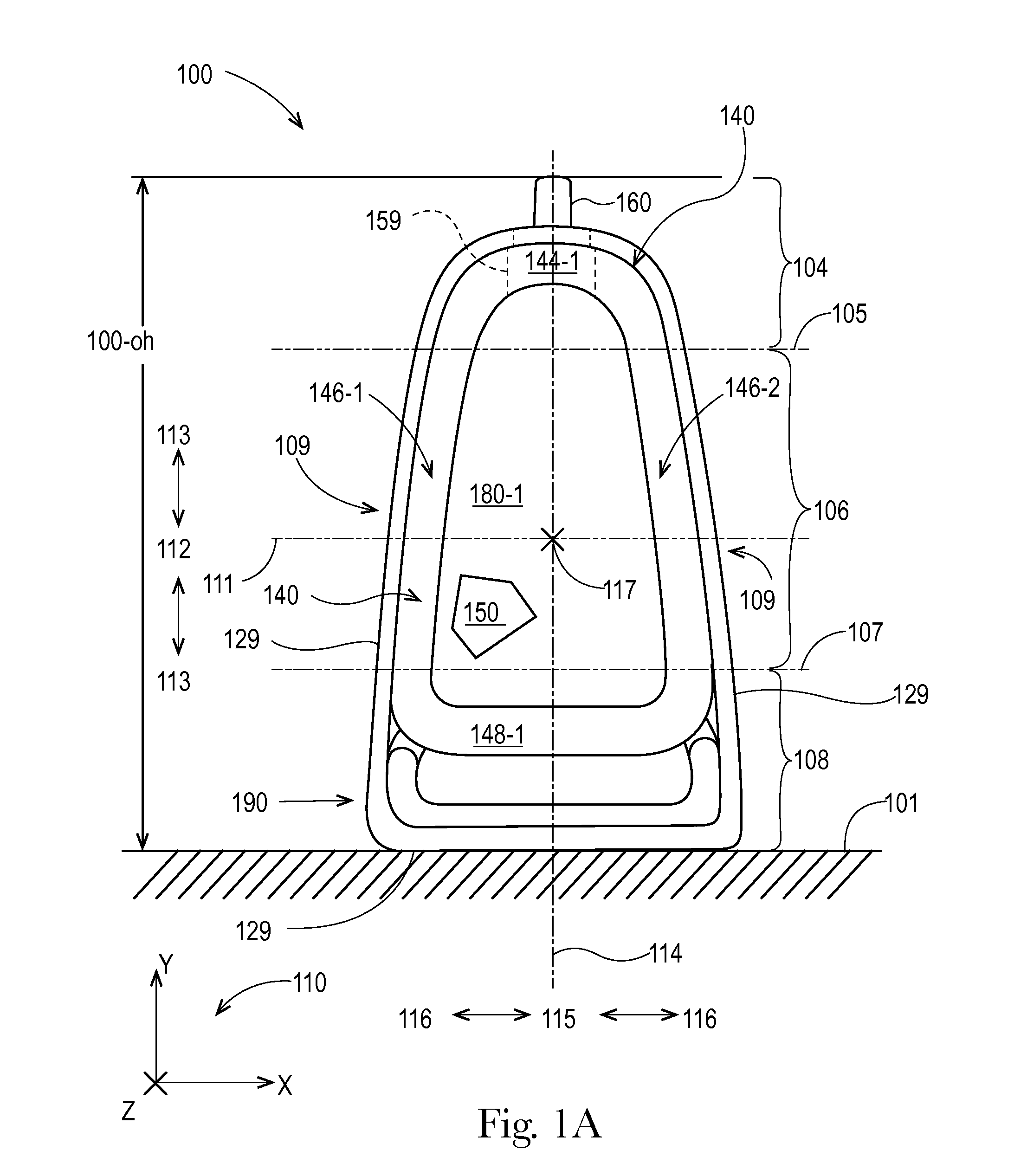

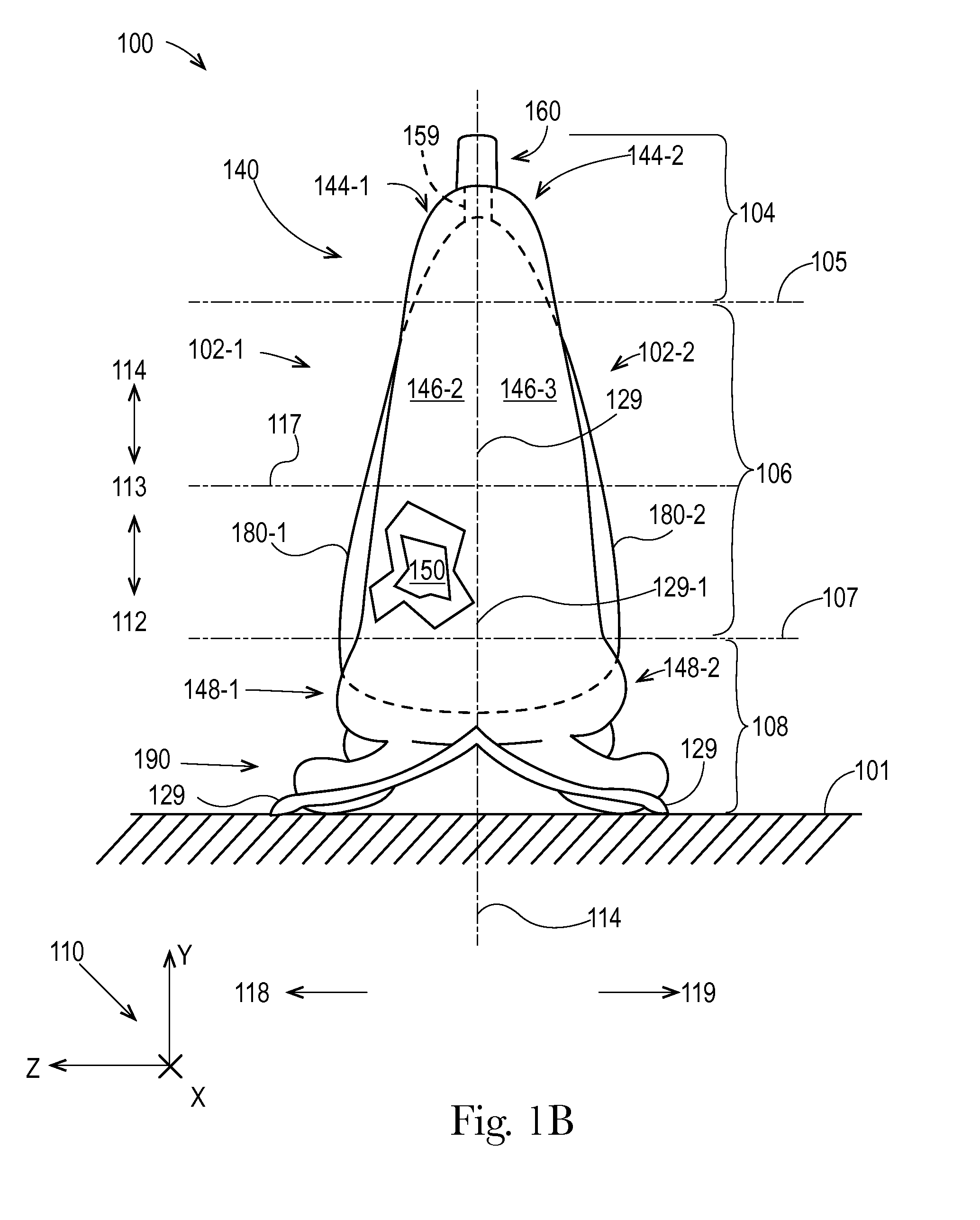

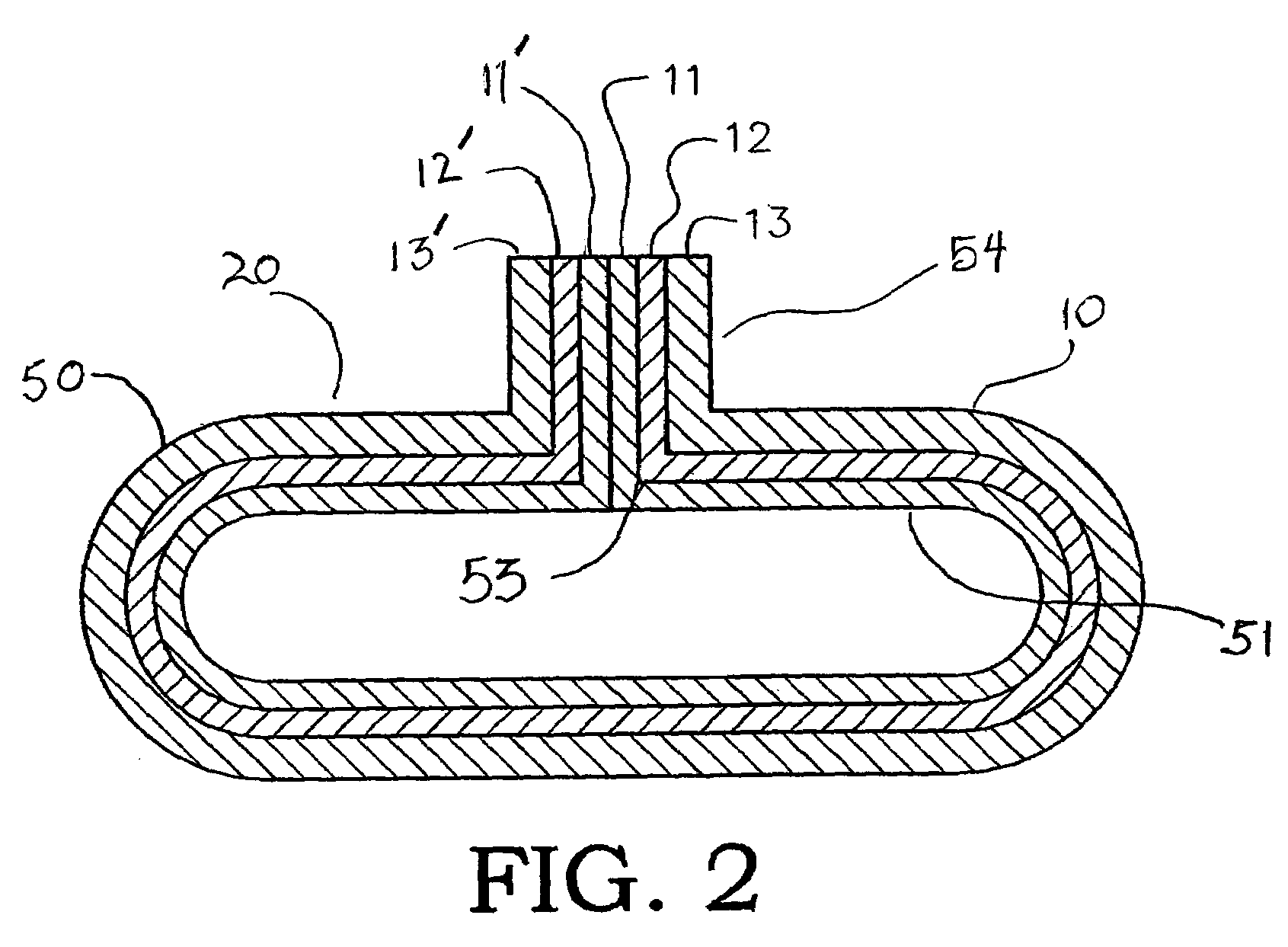

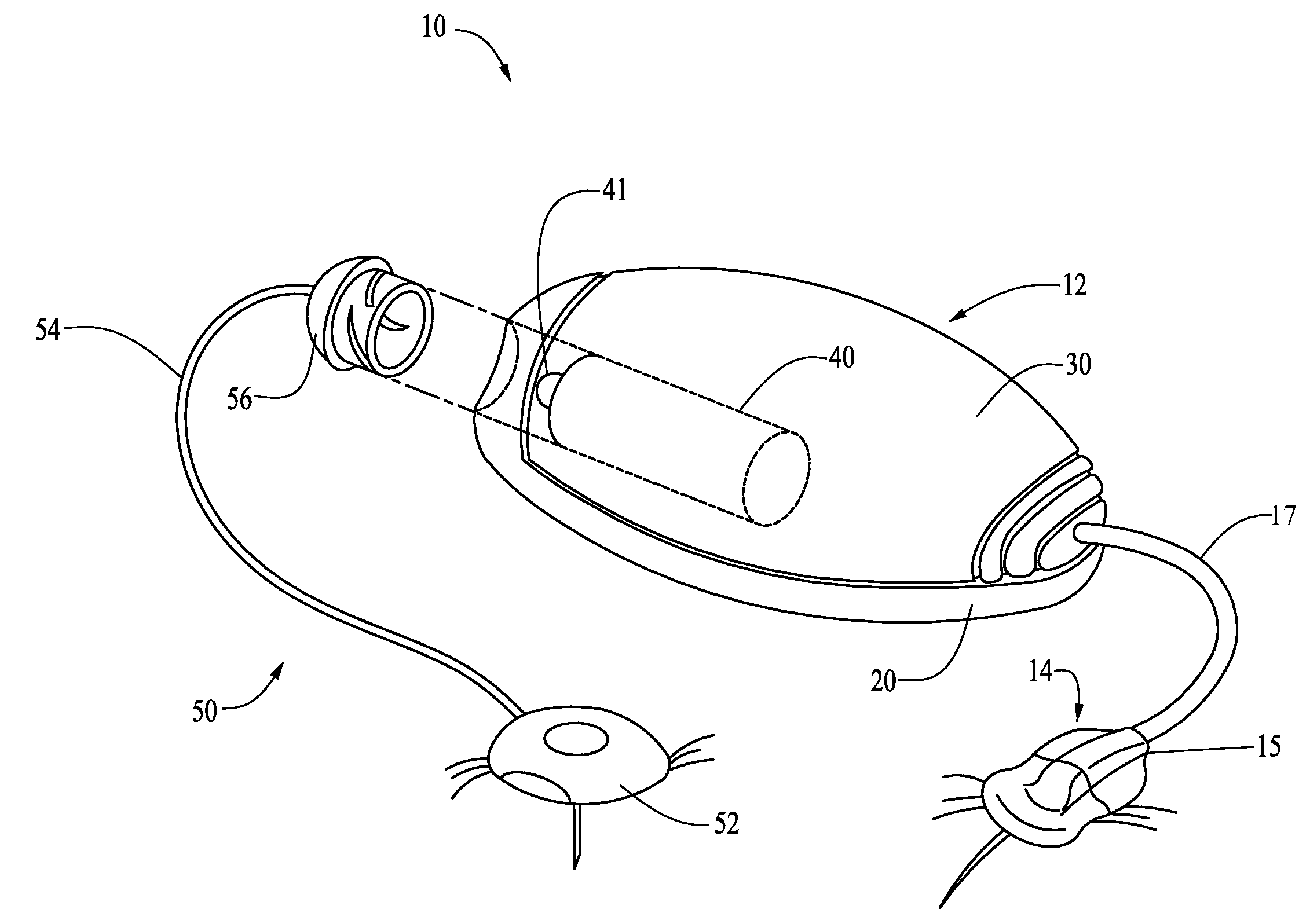

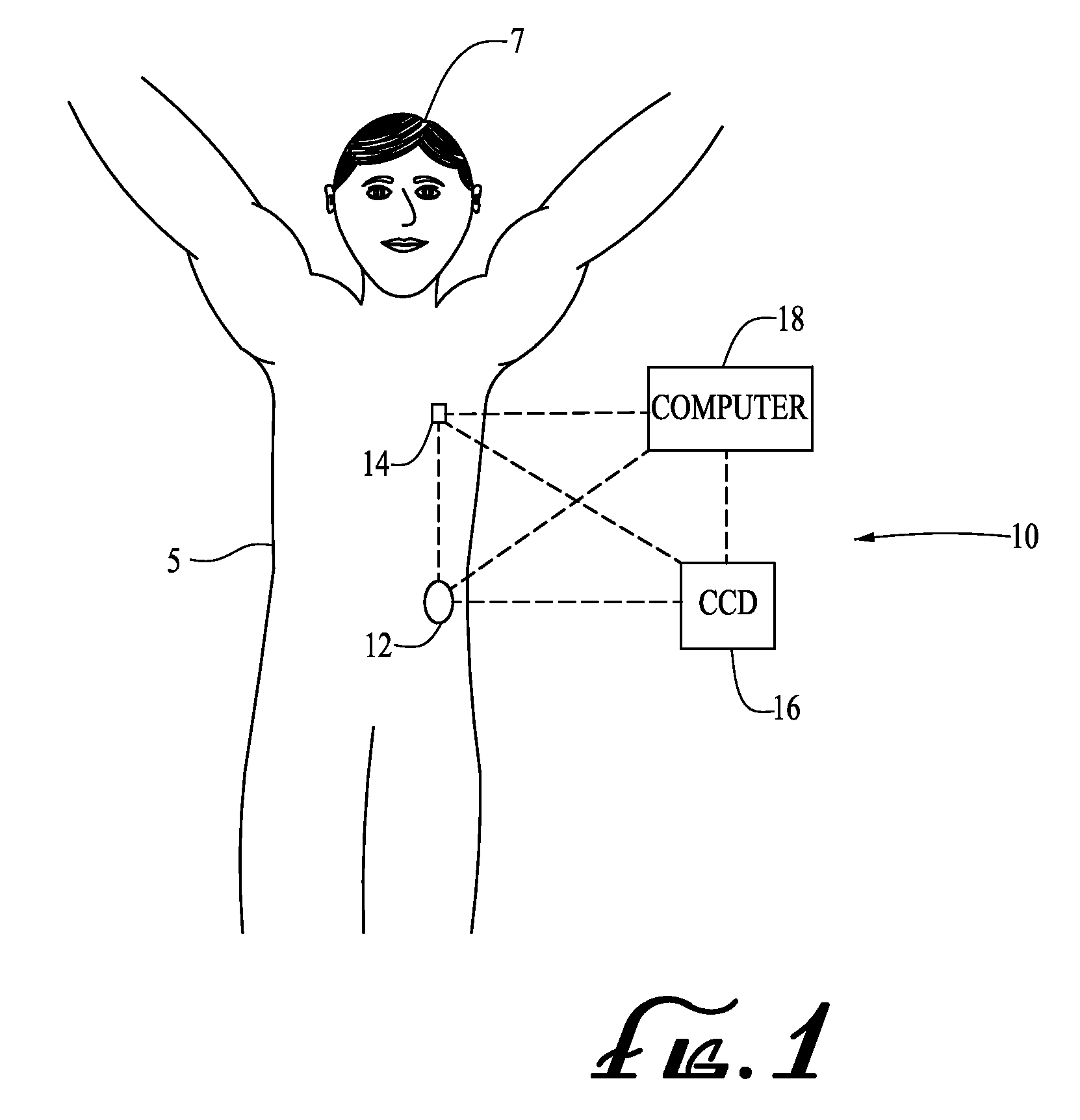

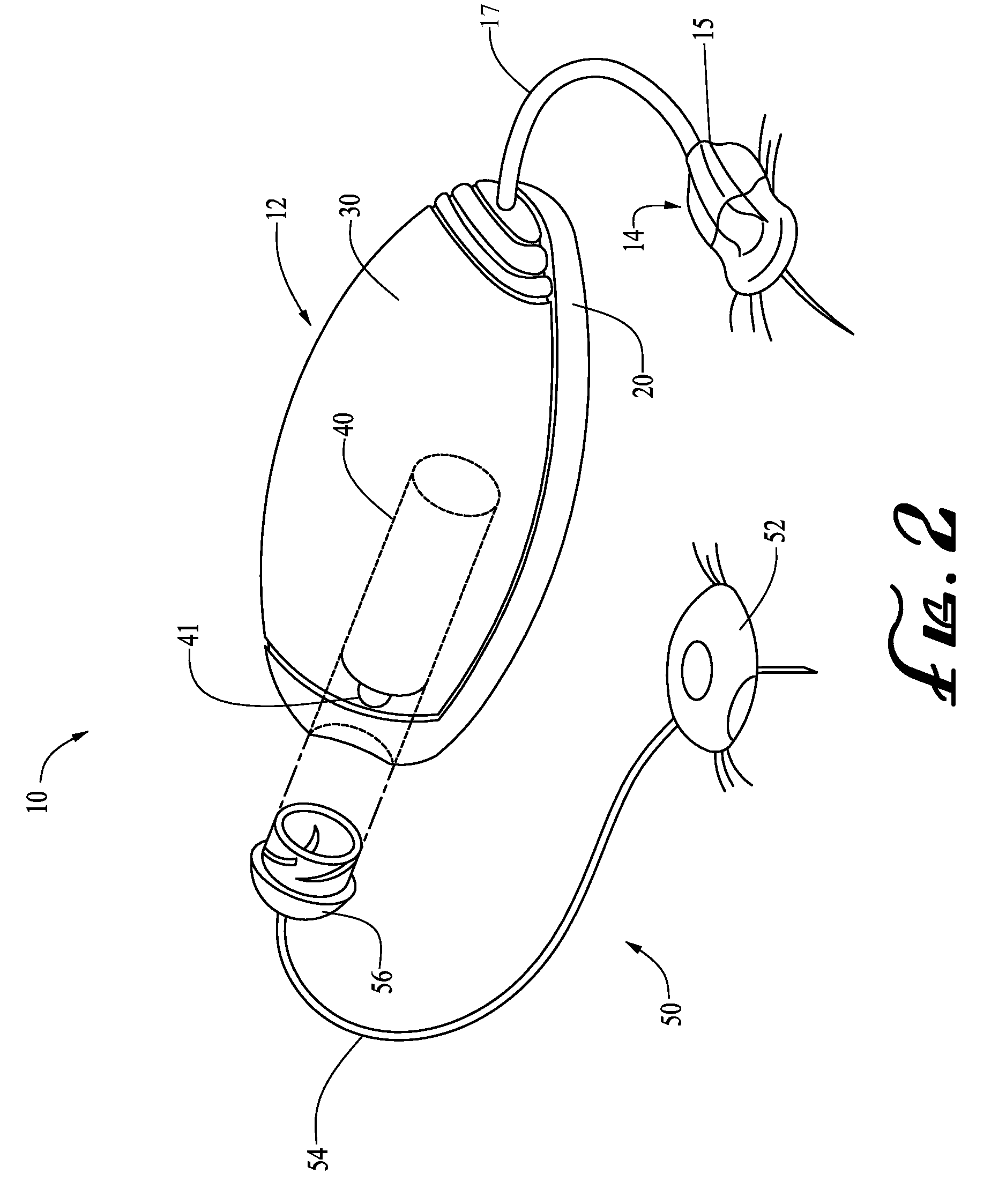

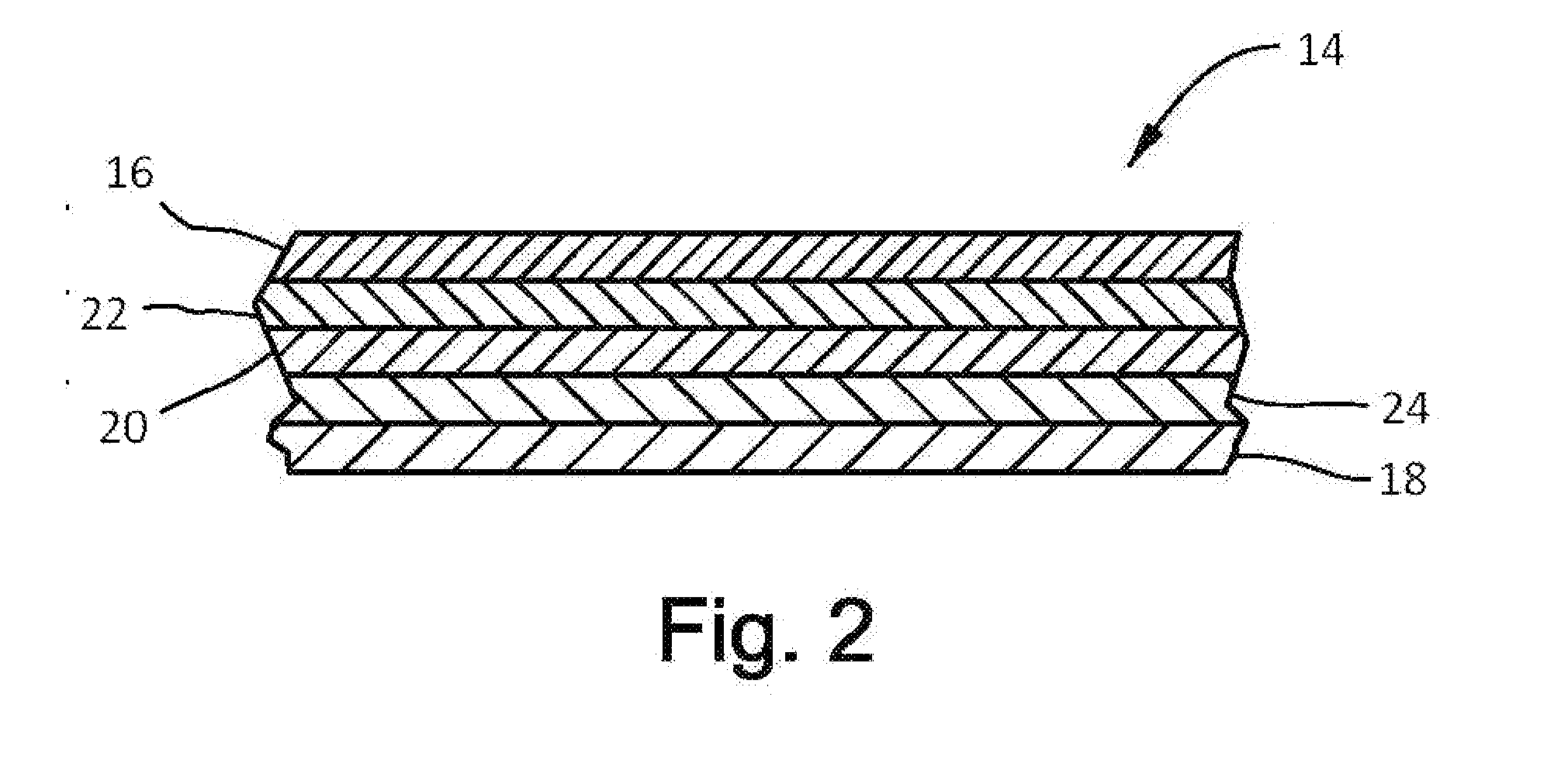

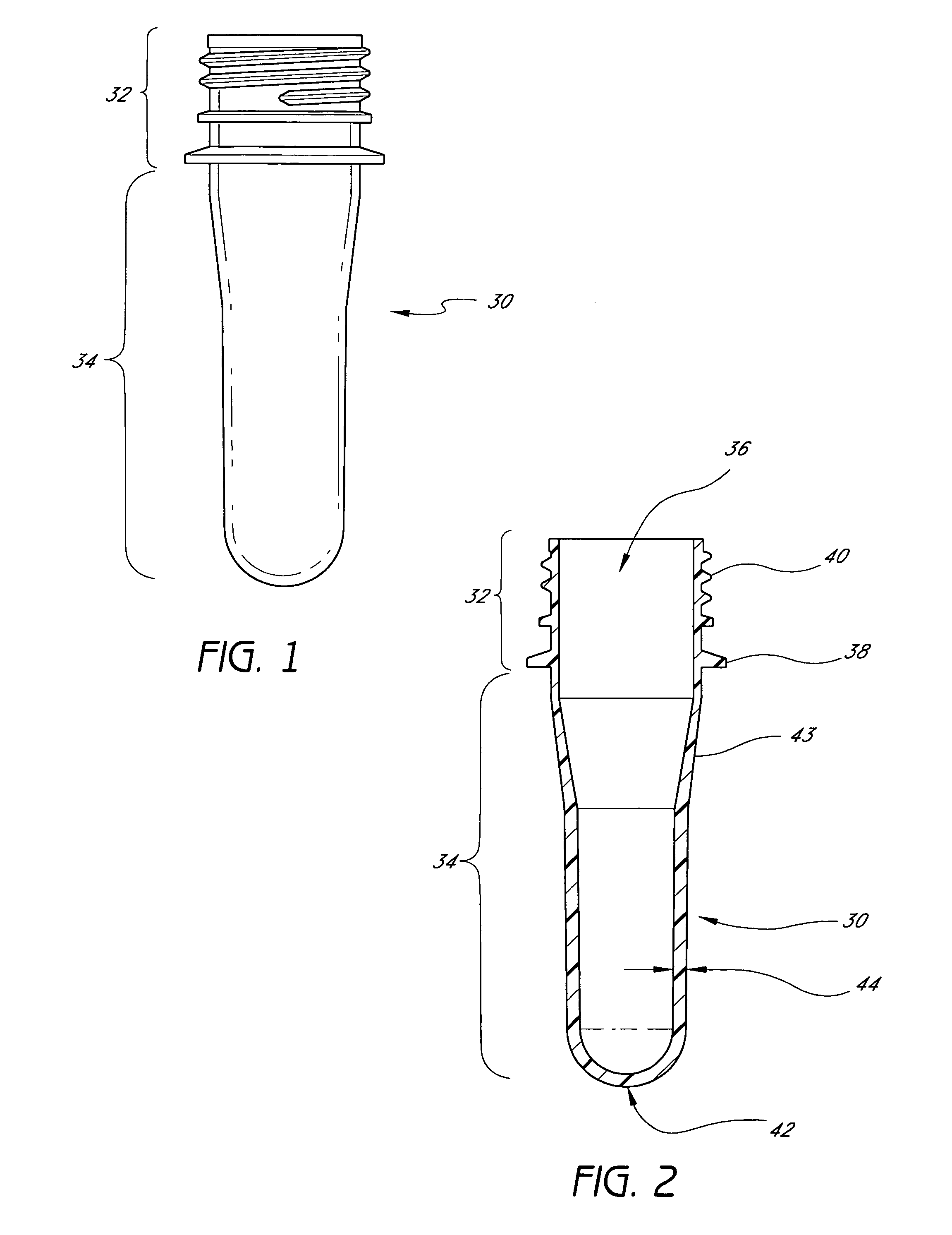

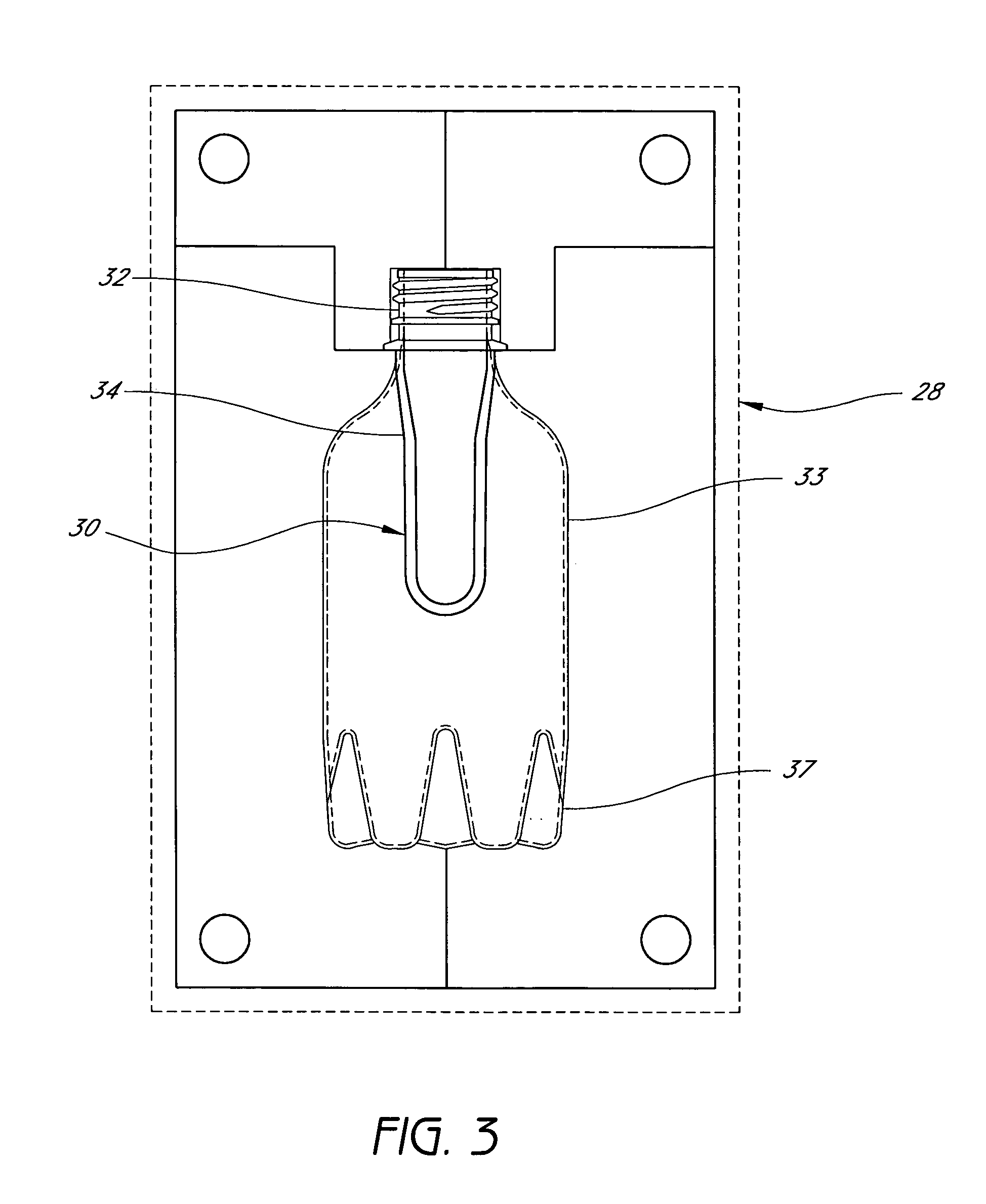

Reservoir barrier layer systems and methods

ActiveUS20090259183A1Reduce retentionAmpoule syringesSynthetic resin layered productsCyclic olefin copolymerBiomedical engineering

A reservoir and a plunger head contained within may be configured to move relative to each other in response to at least one of the reservoir being detached from a base, the base and / or the reservoir being removed from a packaging, and the base and / or the reservoir being moved relative to each other. A first layer may be configured to define a reservoir, the first layer, which may be made of a material compatible with fluidic media in the reservoir, may be adjacent a second layer for inhibiting a diffusion through the second layer. A first layer that may be less than 0.3 mm and made of a cyclic olefin copolymer may be configured to define a reservoir. A reservoir may be defined by a wall made of a cyclic olefin copolymer and the wall may be for substantially preventing light from passing through the reservoir.

Owner:MEDTRONIC MIMIMED INC

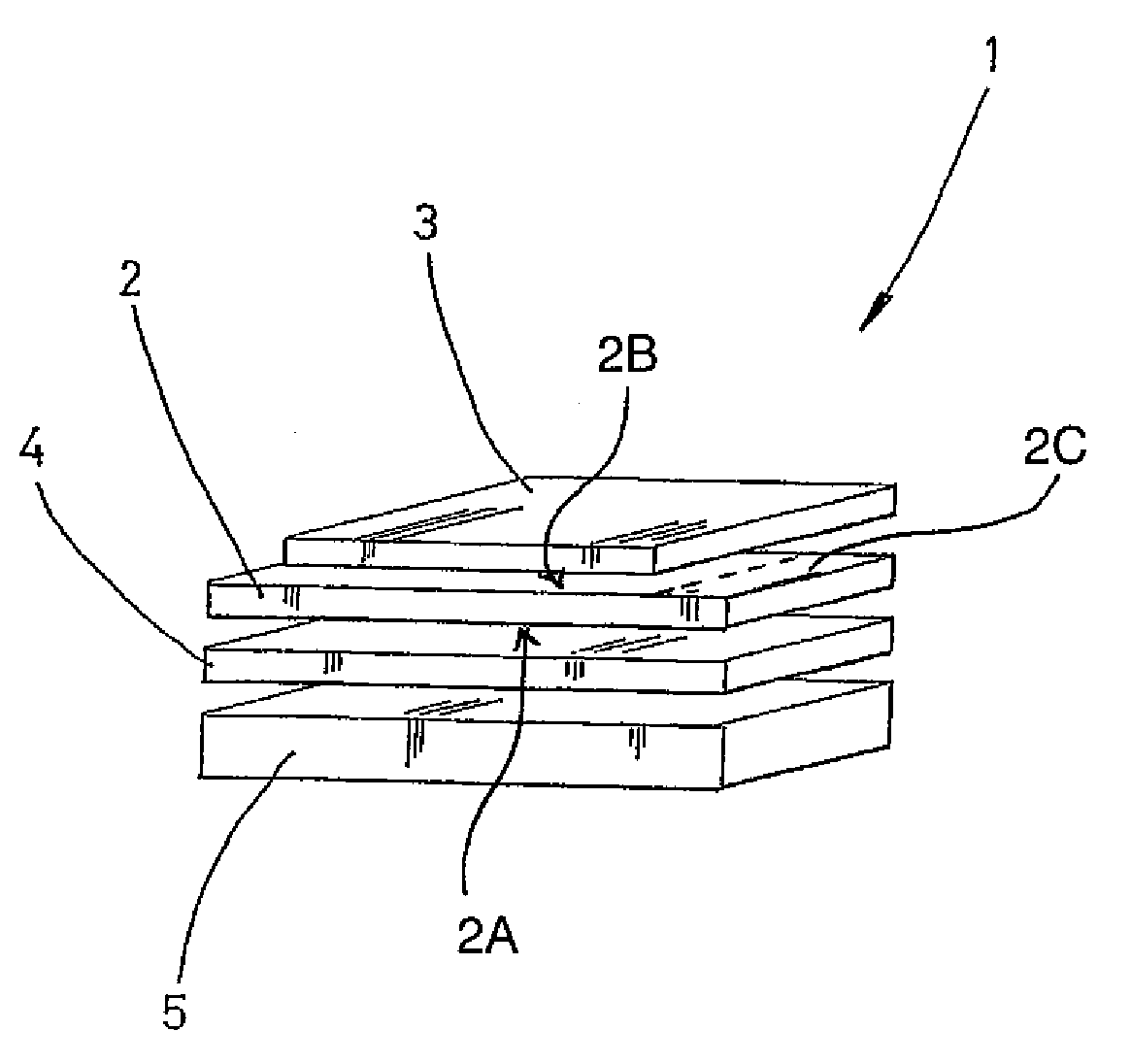

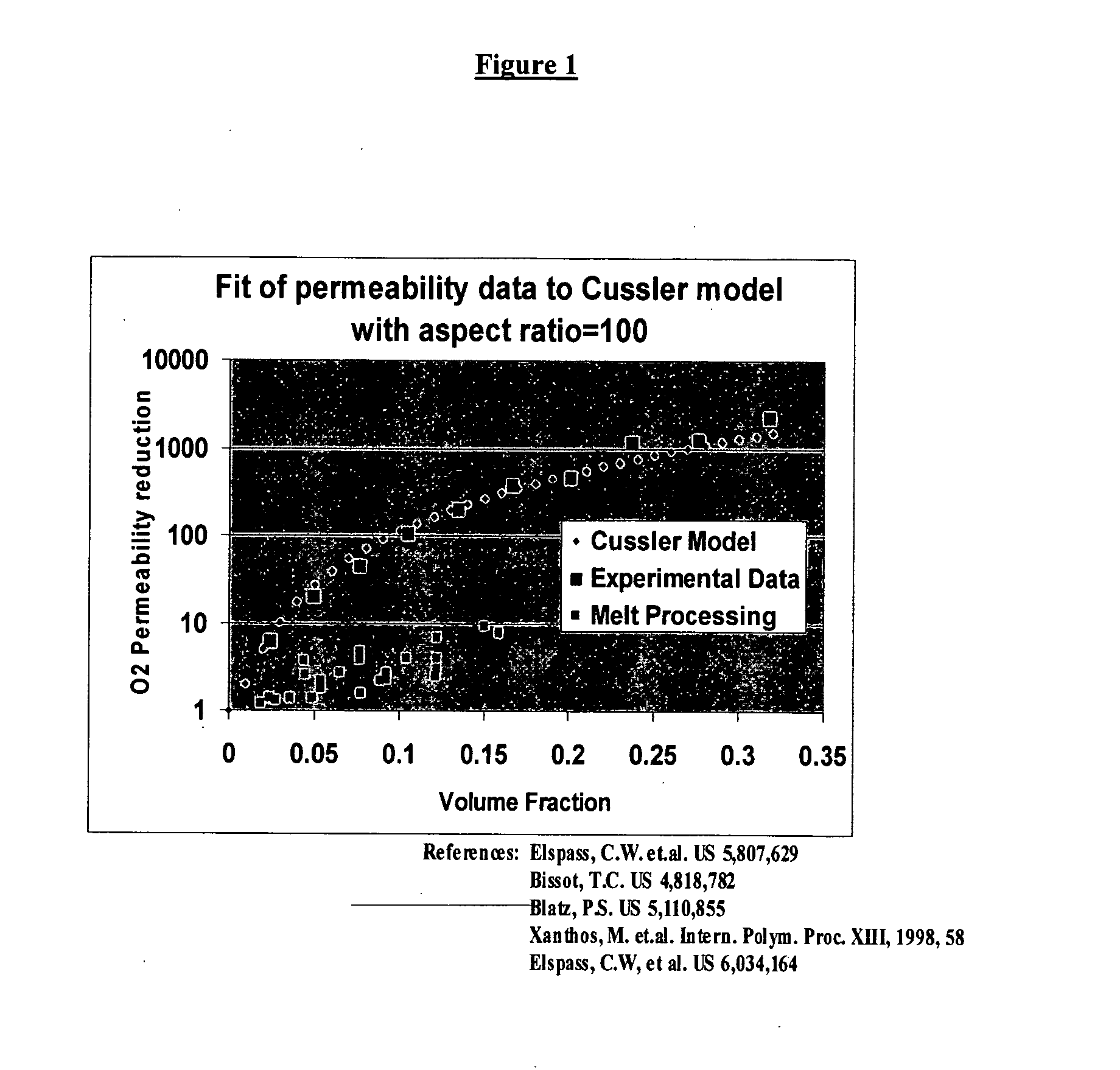

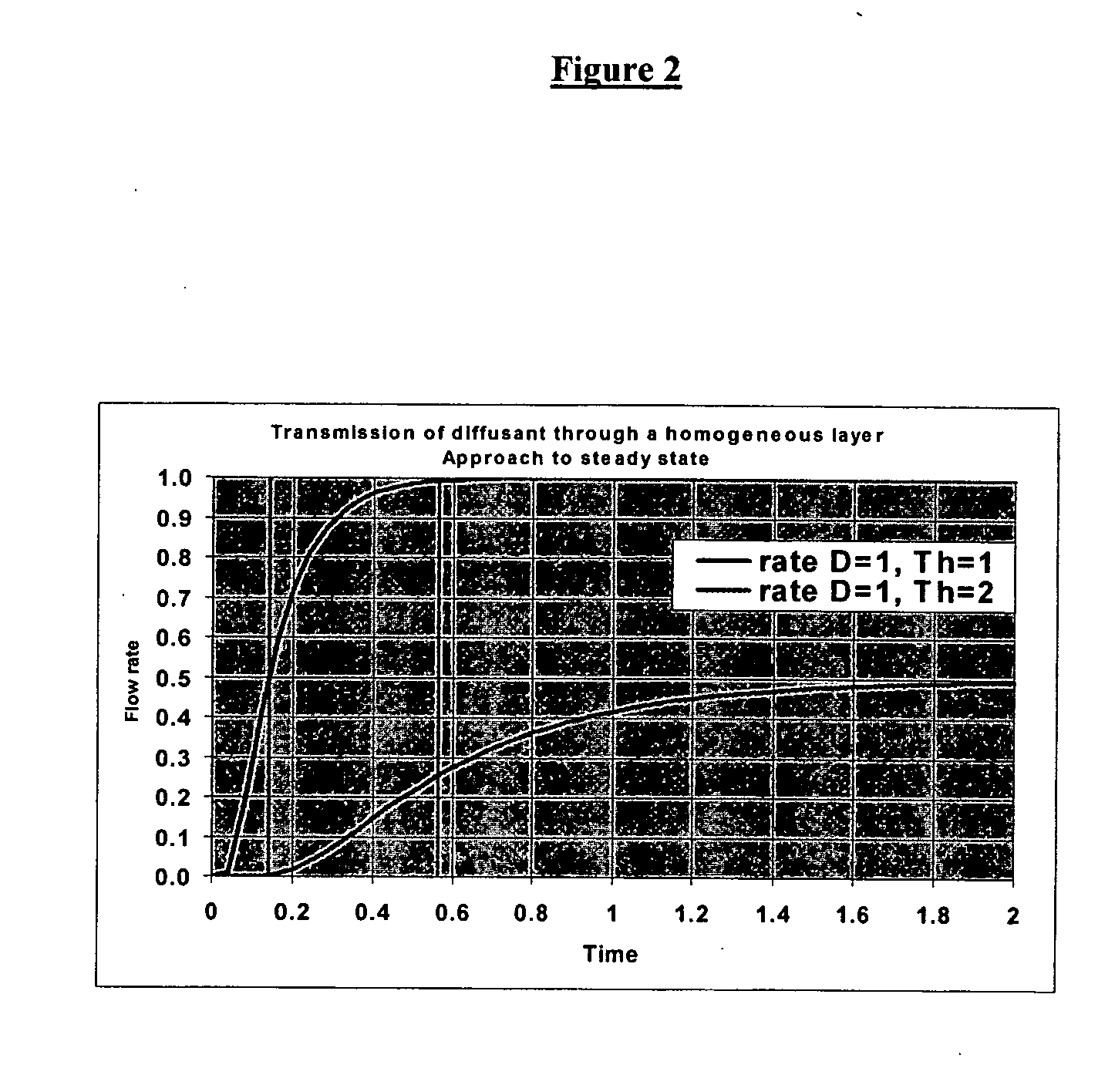

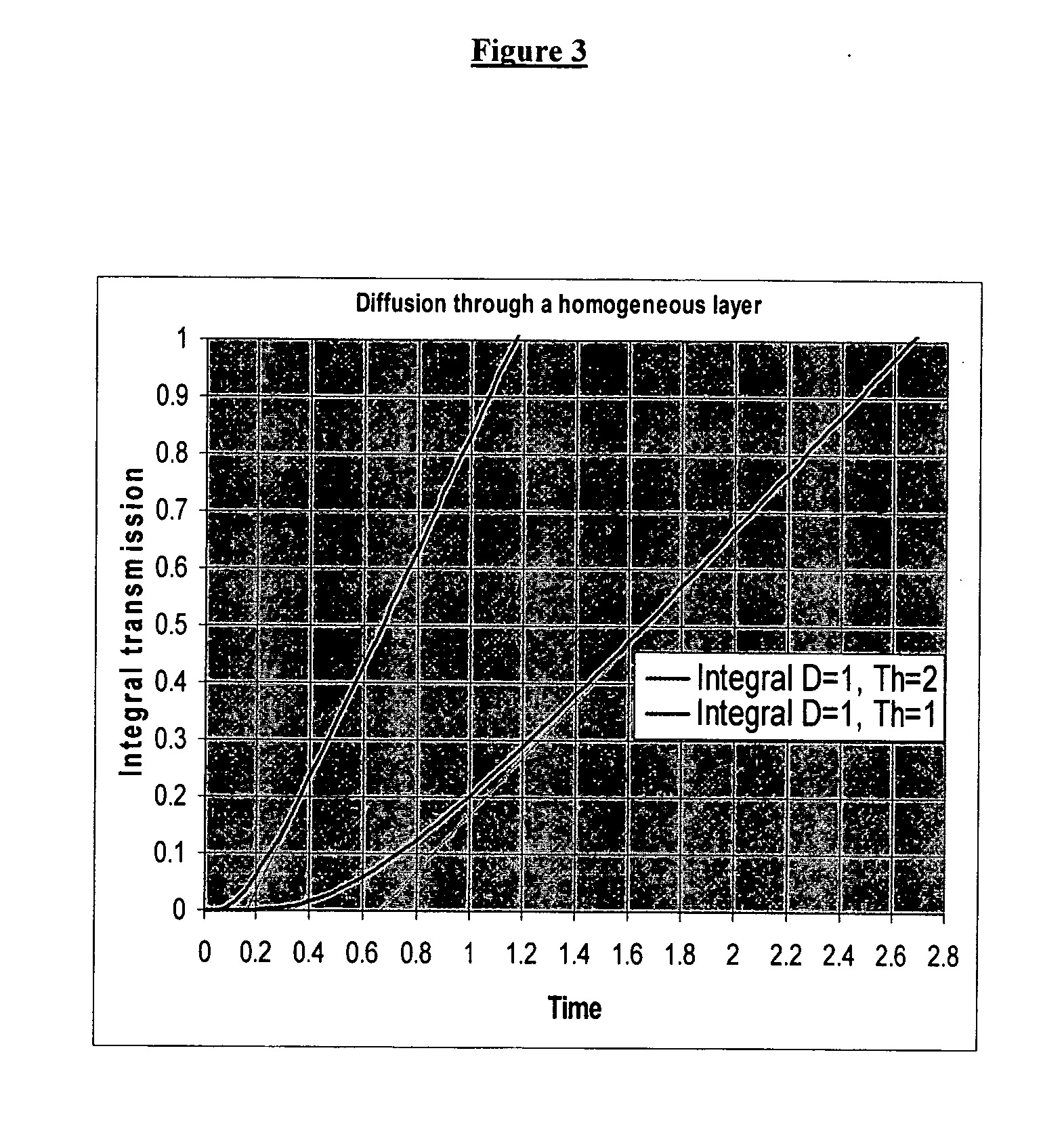

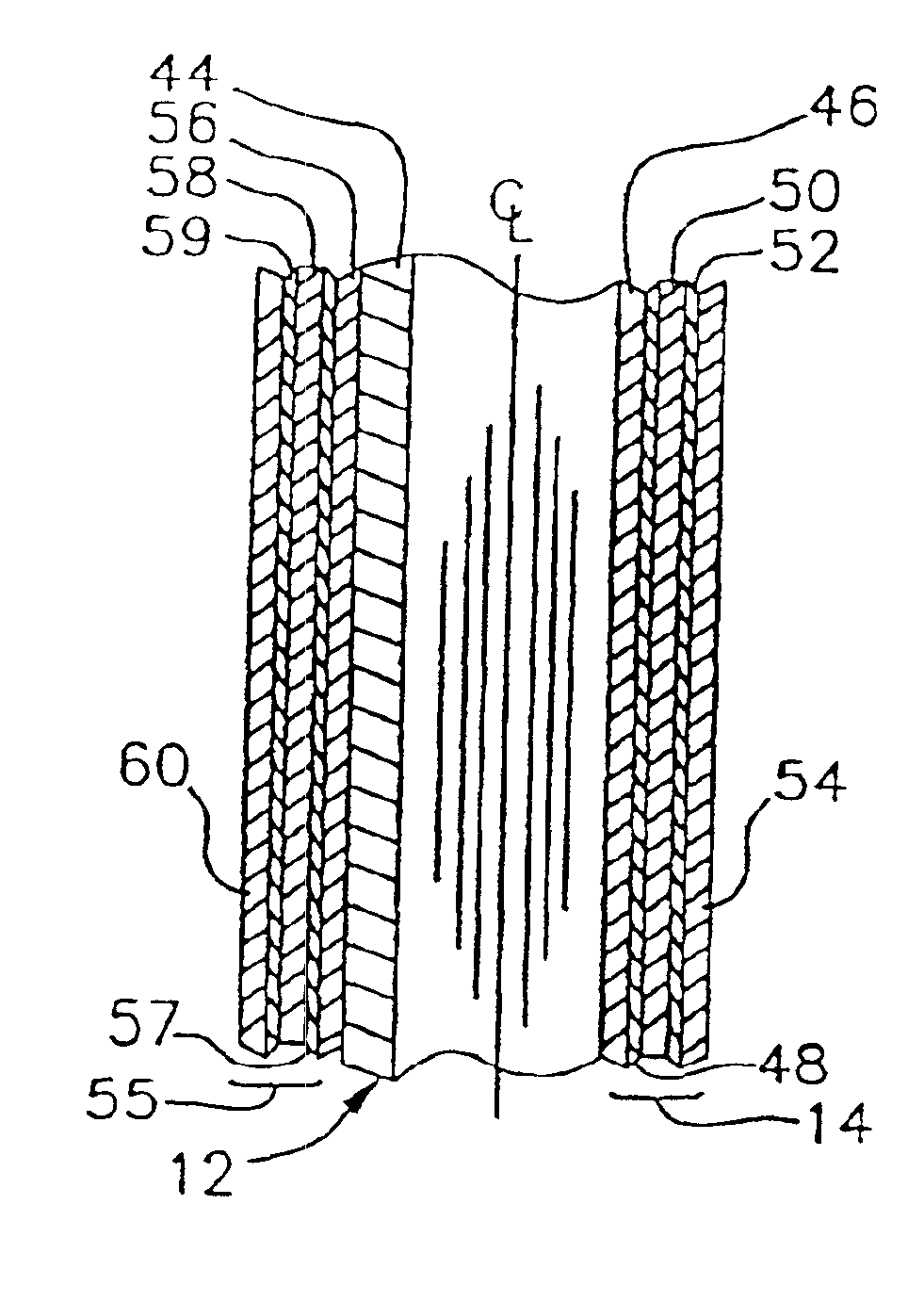

Multilayer nanocomposite barrier structures

InactiveUS20060110615A1Reduce penetrationInhibited DiffusionSynthetic resin layered productsDomestic containersElastomerNanometre

A multilayer barrier structure includes a plurality of relatively thin nanocomposite layers separated by one or more relatively thick intermediate layers selected from synthetic elastomers or non-elastomeric polymers. The composites exhibit remarkably long breakthrough and lag-times and are useful for packaging or protective apparel.

Owner:INMAT INC

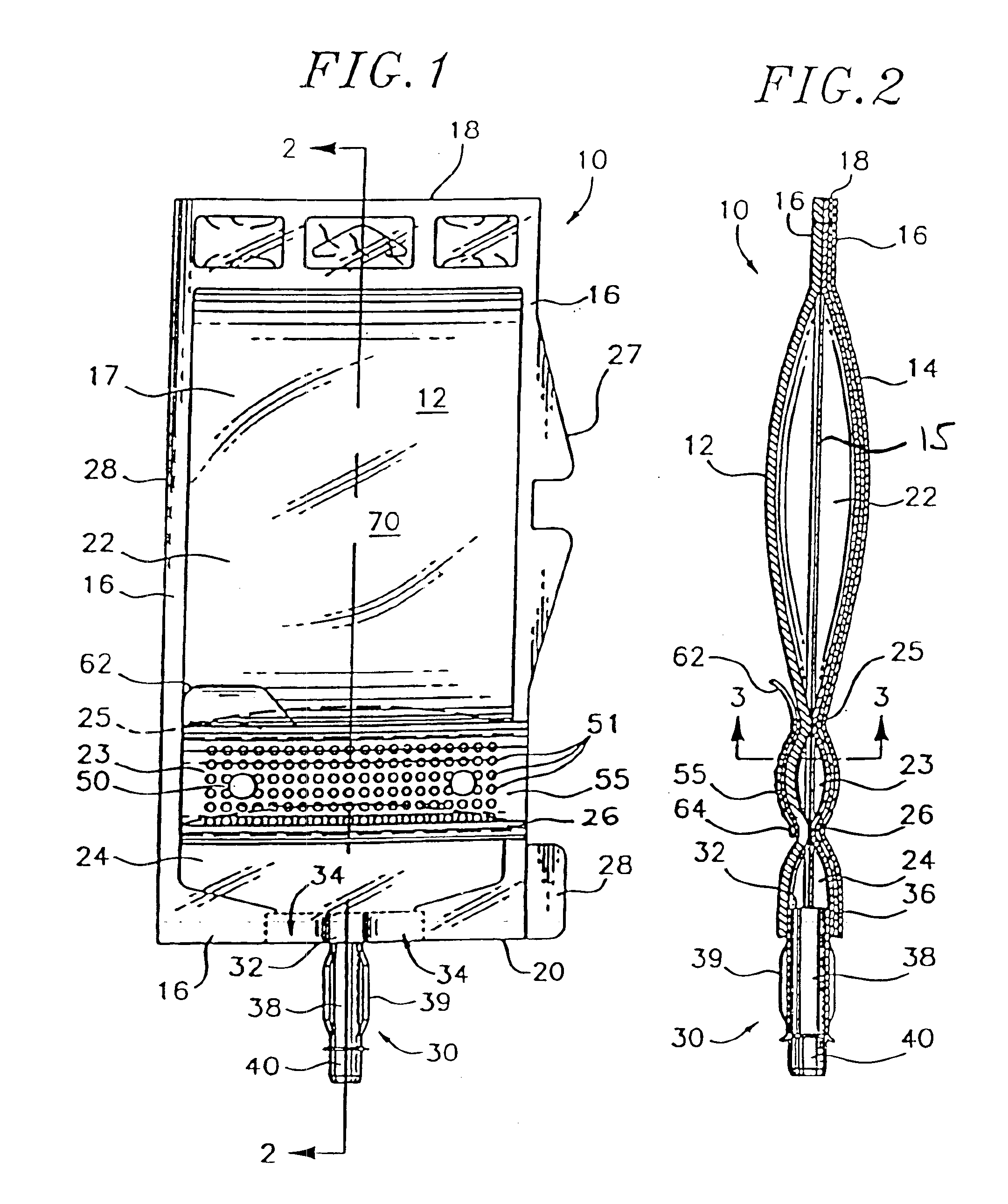

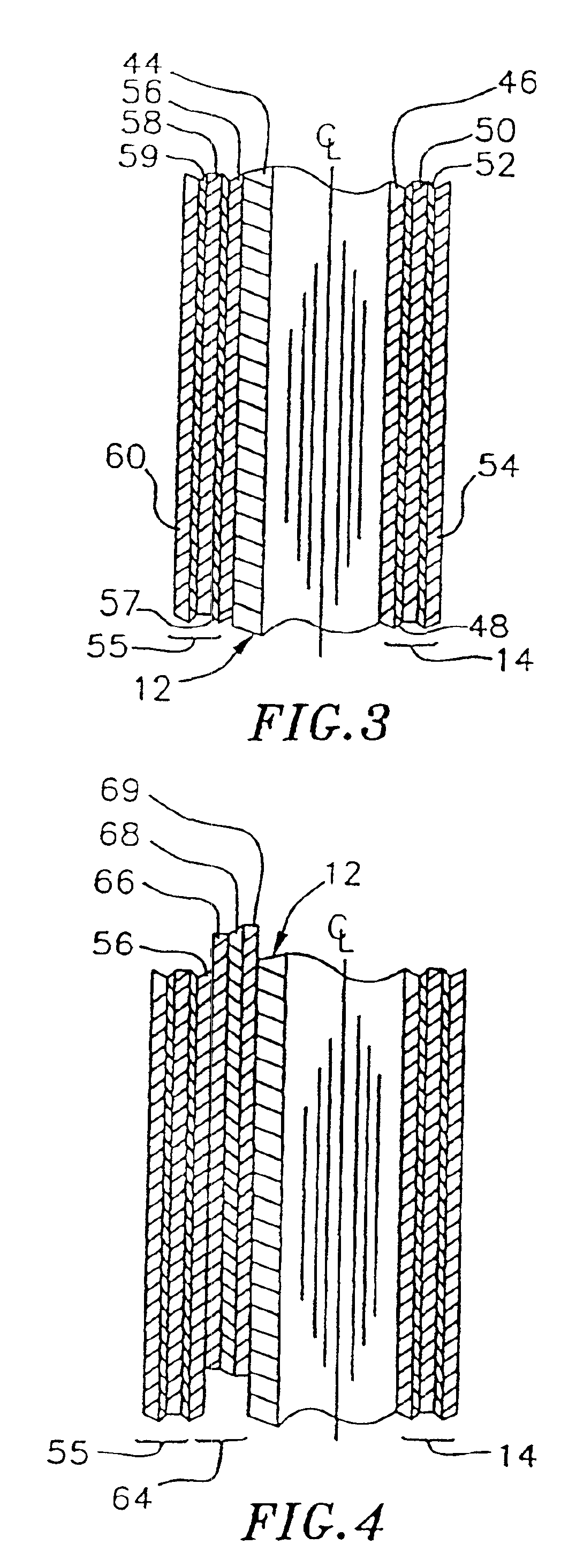

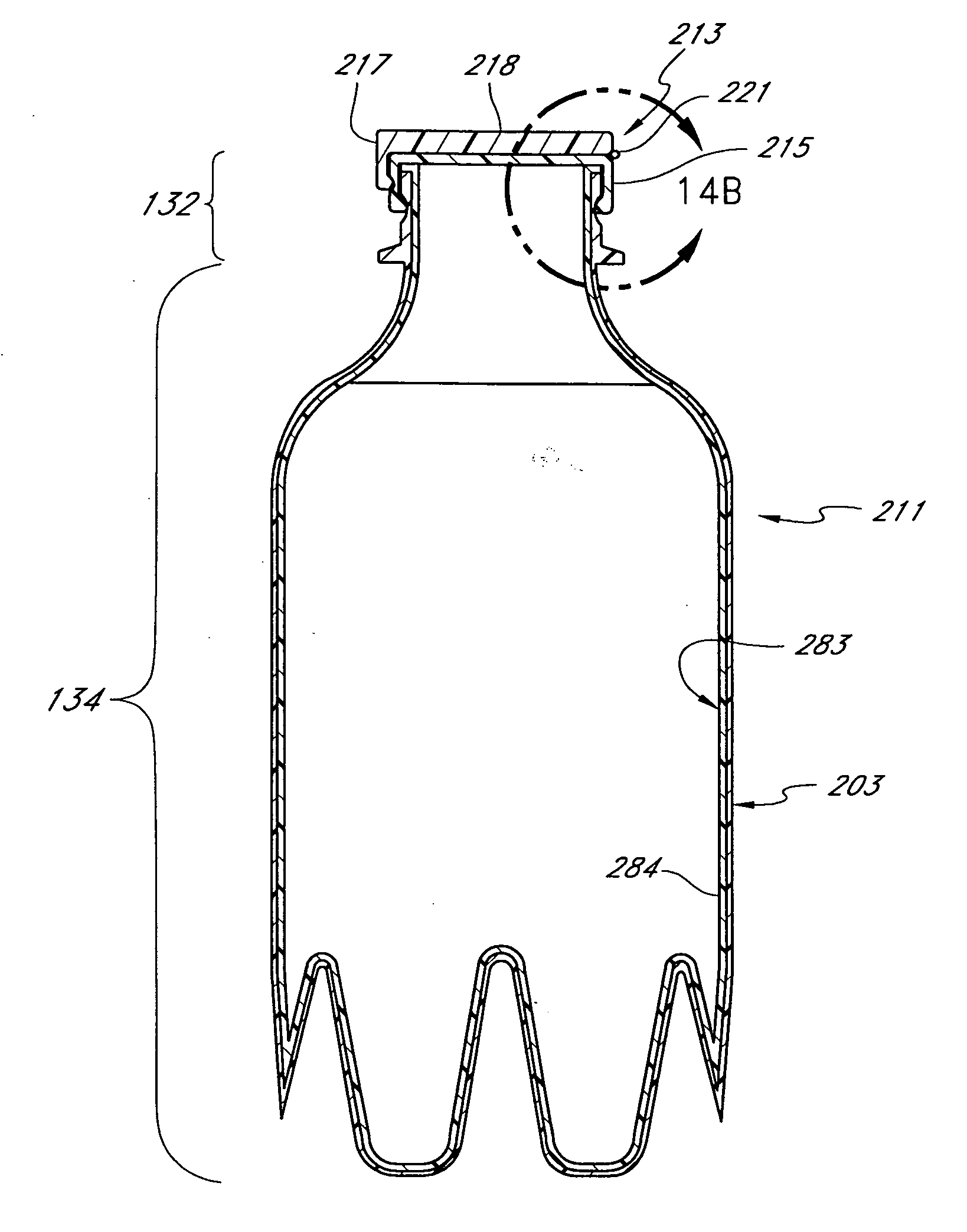

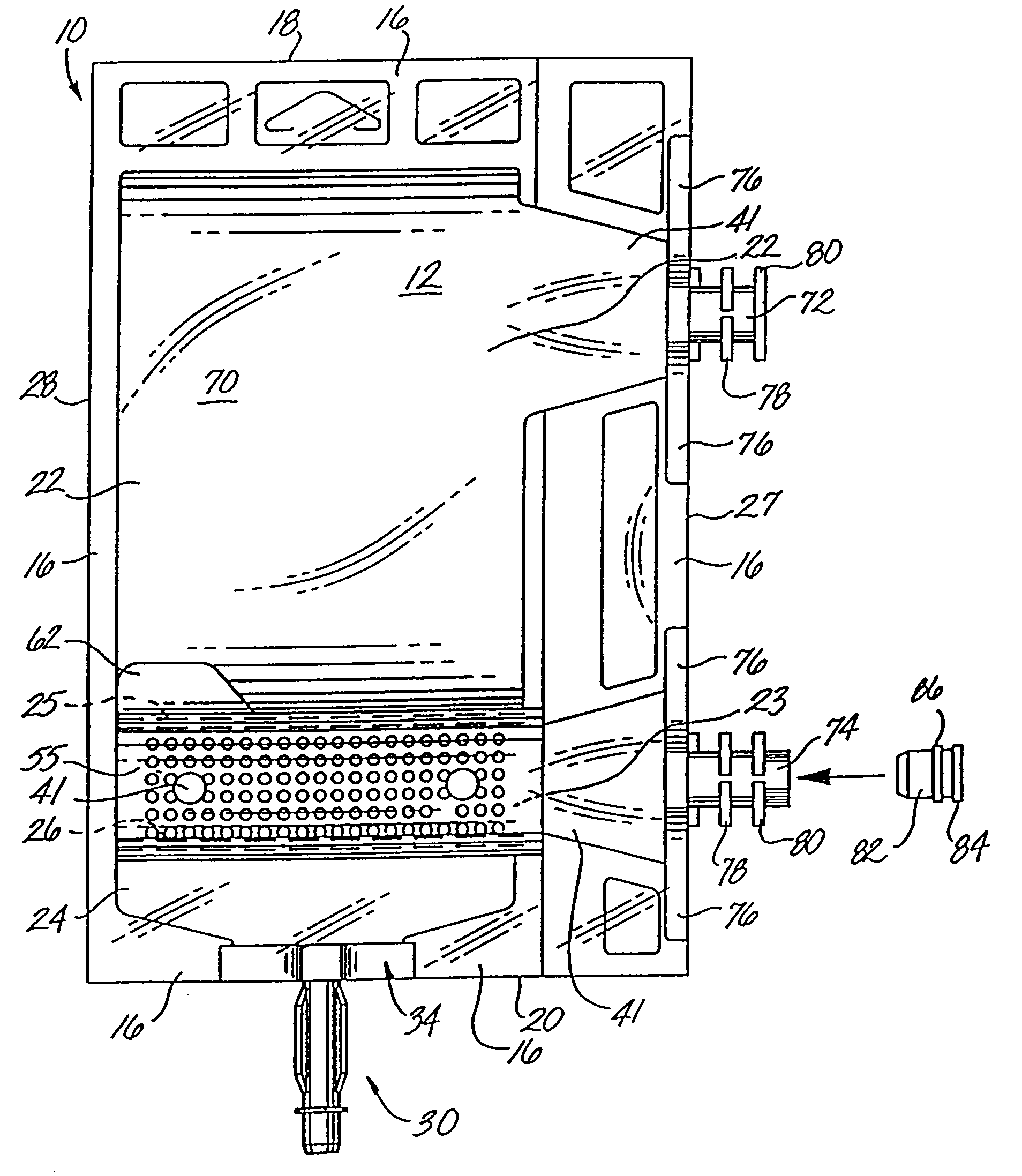

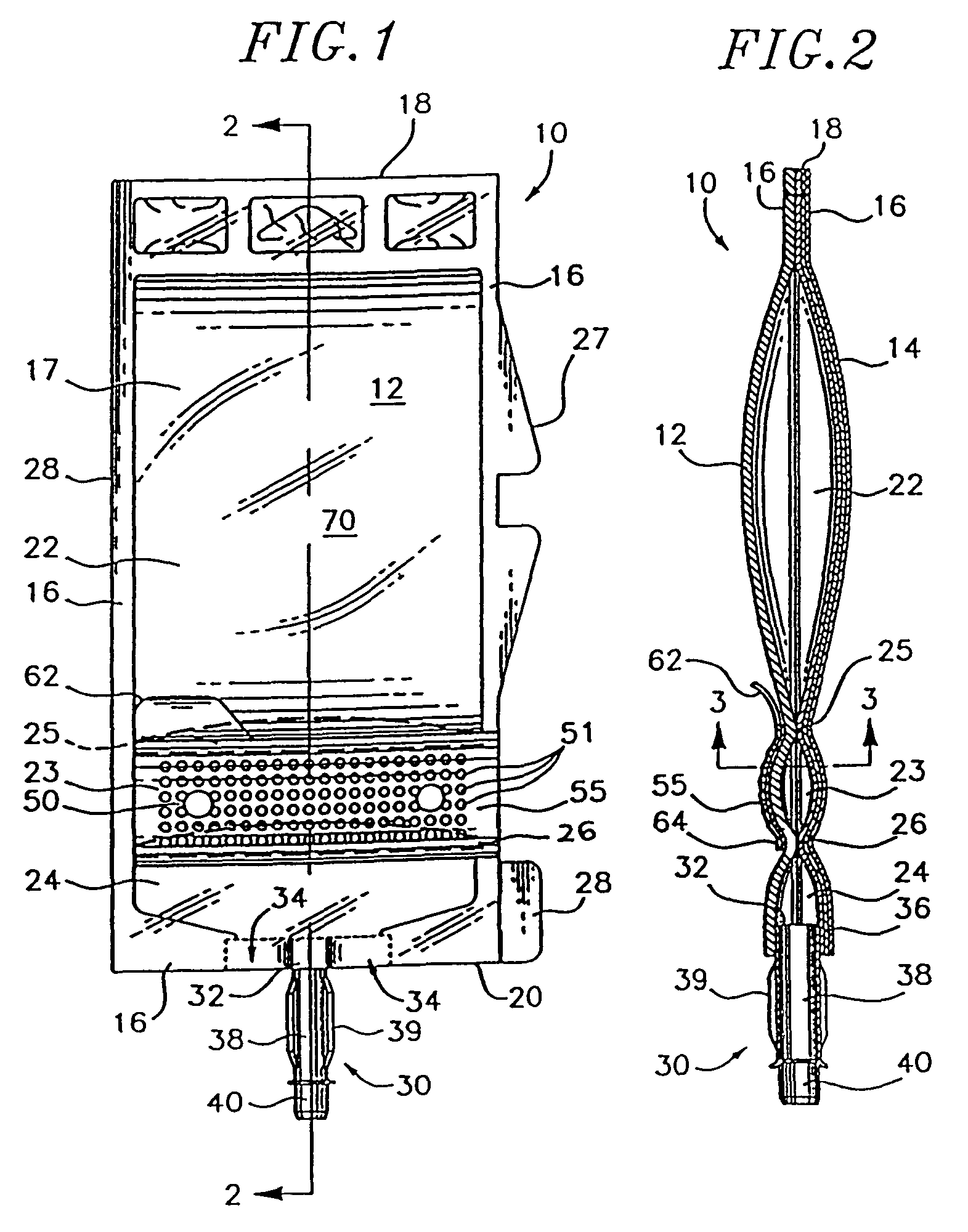

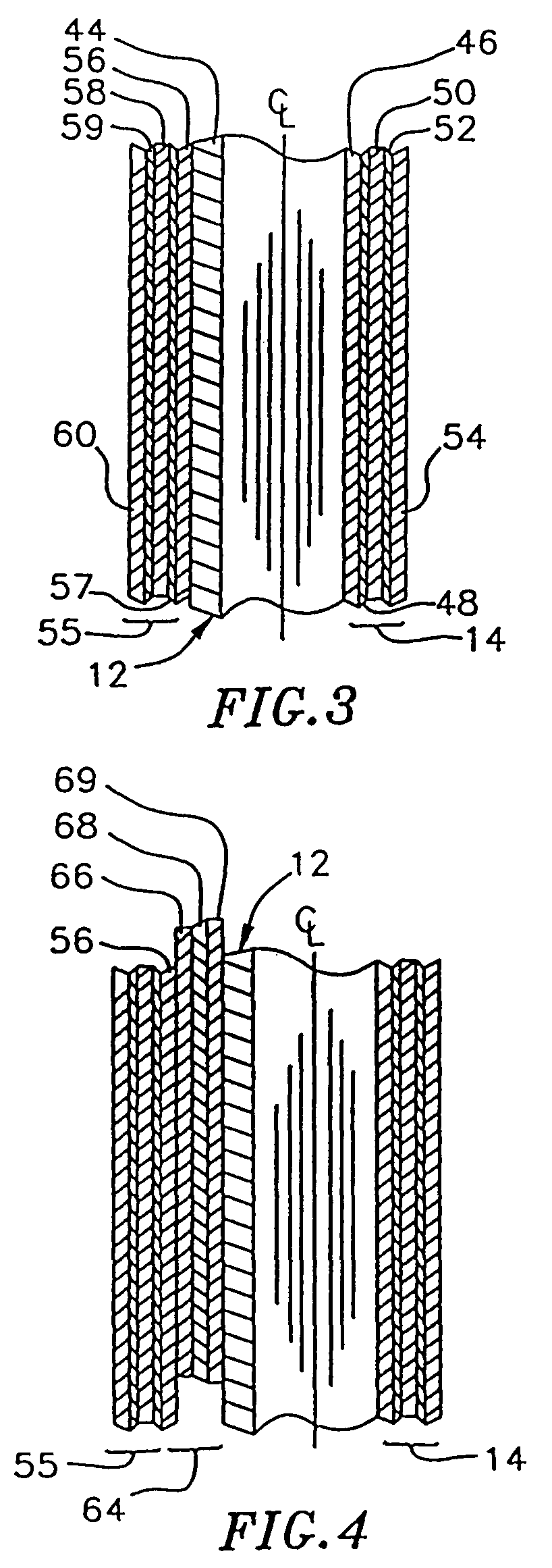

Flexible multi-compartment container with peelable seals and method for making same

InactiveUS6846305B2Increase capacityIncrease storage capacityWrappersMedical devicesThermoplasticDiluent

A flexible container is provided for the storage and administration of medical solutions. The container incorporates a transparent front sheet made from a planar layer of a polymer and an opposing rear sheet. The rear sheet is made from a planar laminate layer. The front and rear sheets are sealed together along a common peripheral edge to form a volume enclosure. The volume enclosure is constructed of materials having high oxygen and moisture barrier properties which allows the container thermoplastic to be stored for extended periods of time without degrading the contents. The volume enclosure is then inflated with a pressurized gas to permanently stretch the front and rear sheets outwardly and to thereby increase the volume capacity of the container. An alternative embodiment of the container incorporates multiple compartments, separated by peelable seals, for containing a diluent and a medicament. The seals are ruptured by manipulation of the container to thereby mix the contents together for delivery through standard IV arrangement to a patient.

Owner:B BRAUN MEDICAL

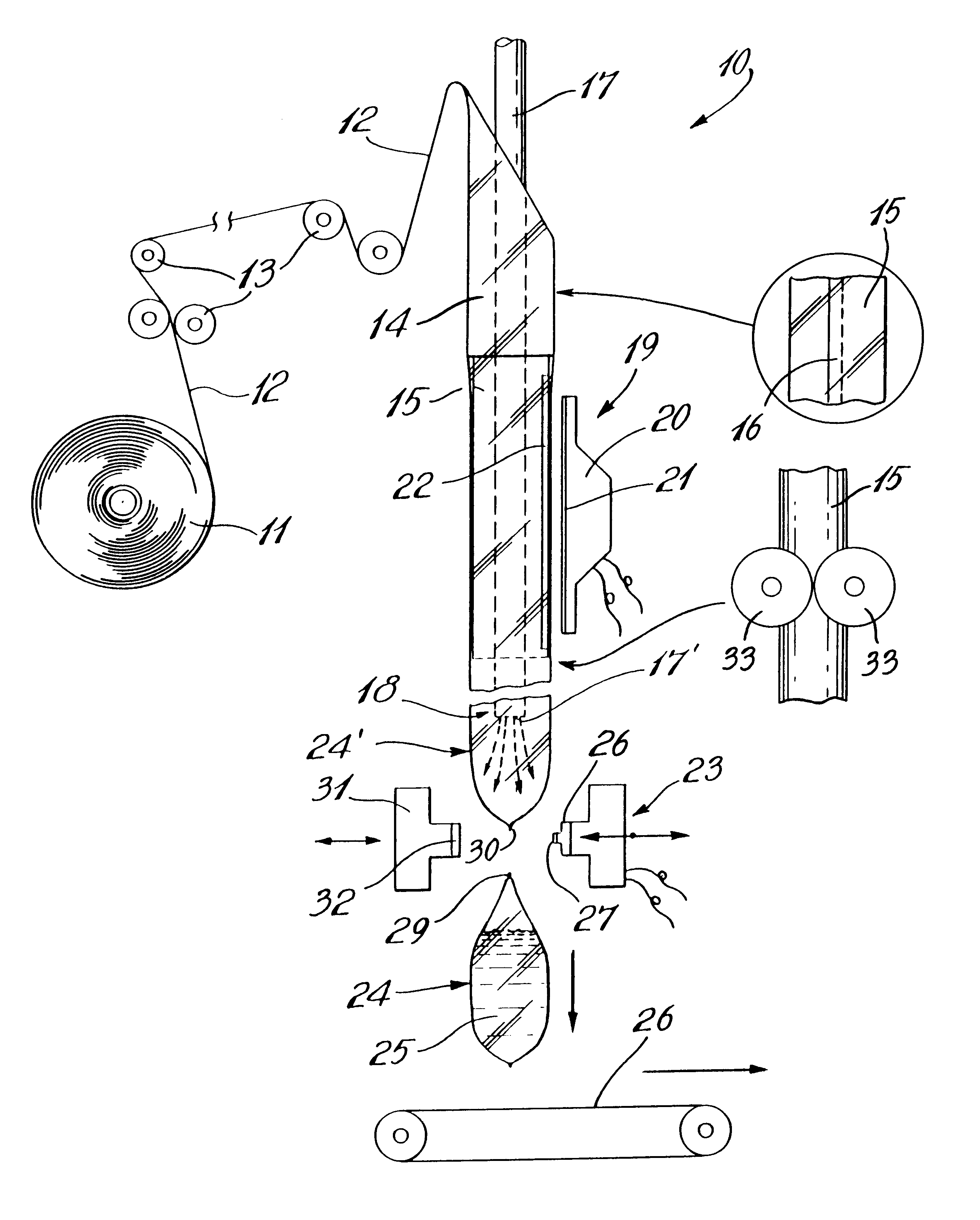

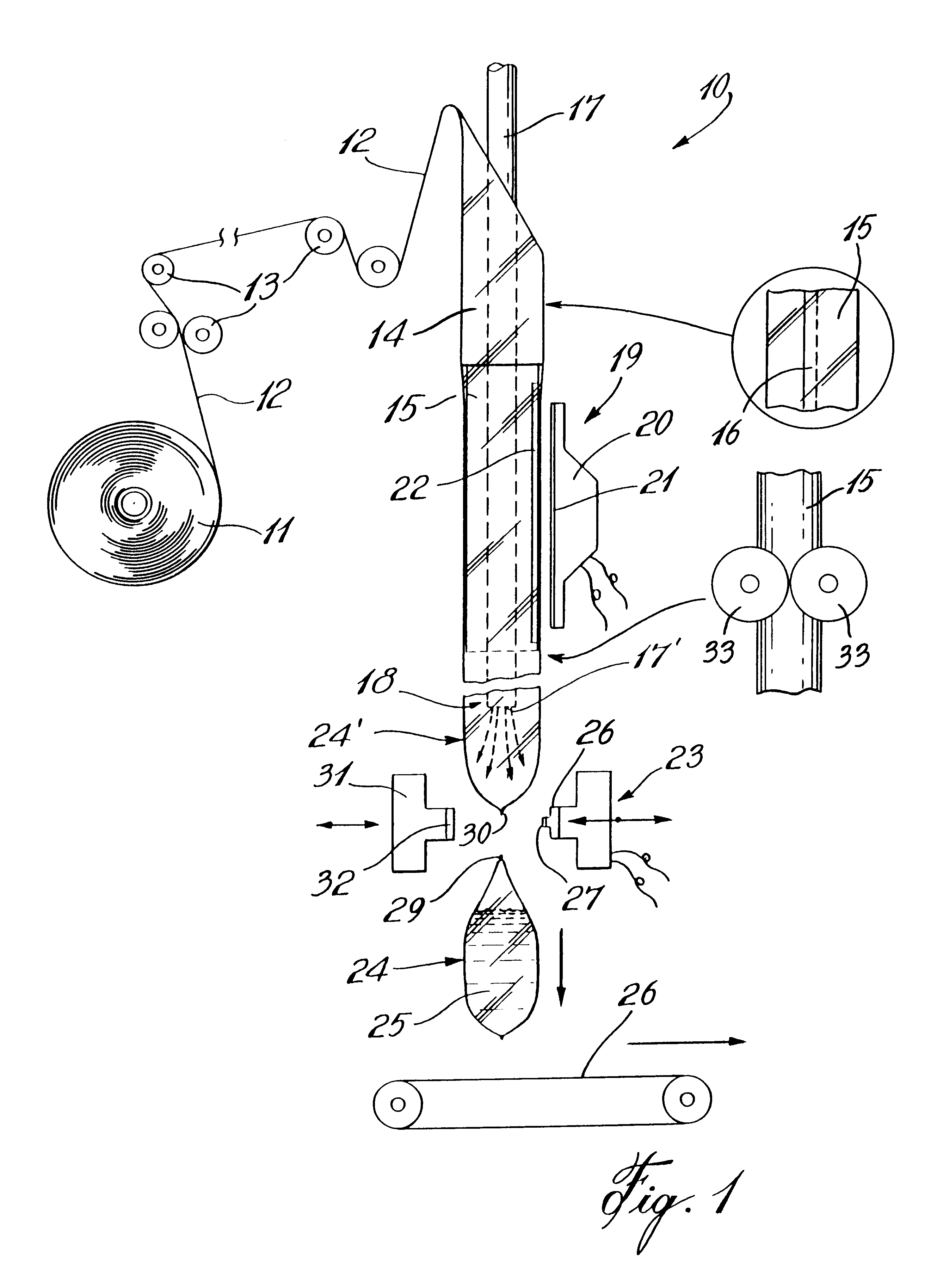

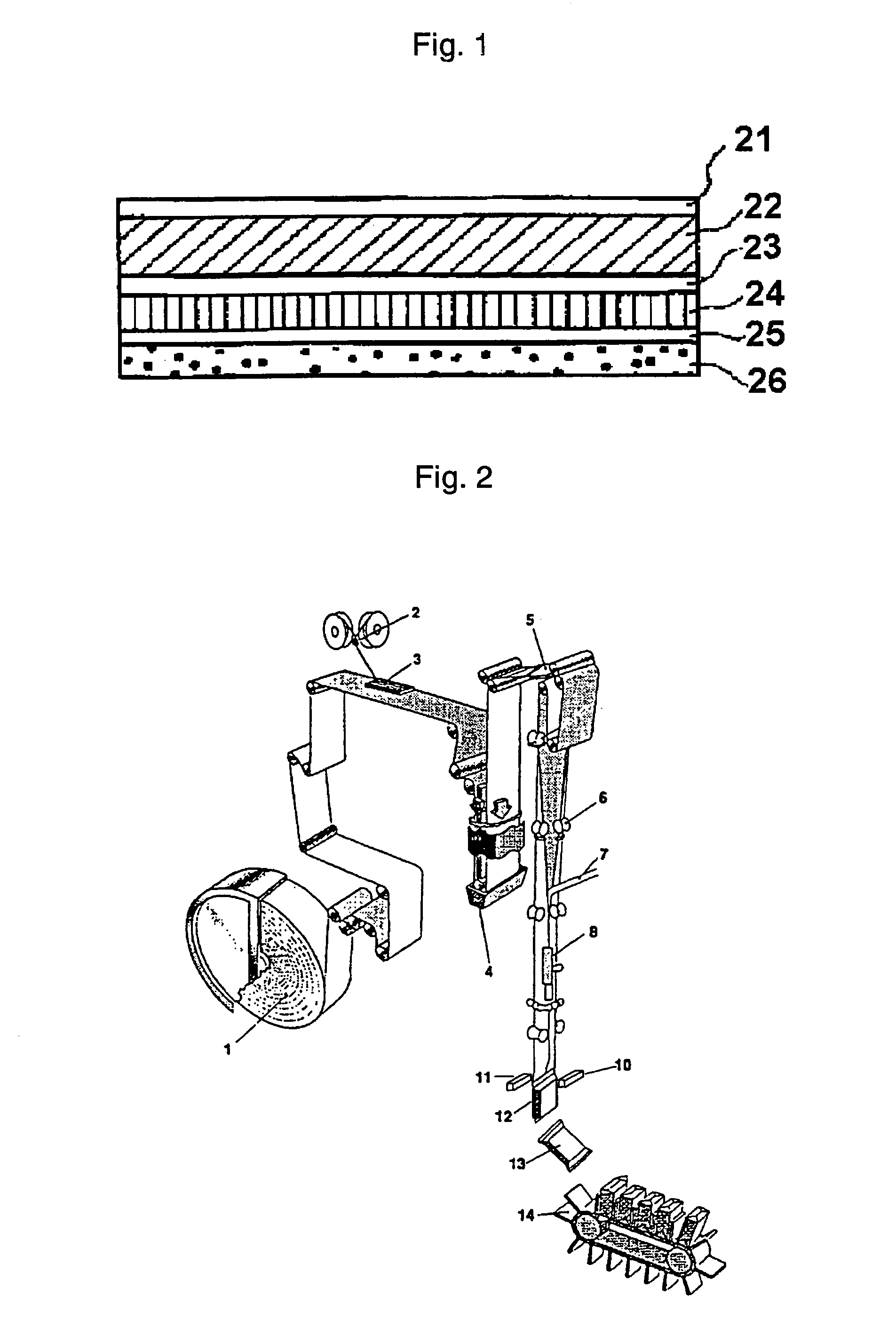

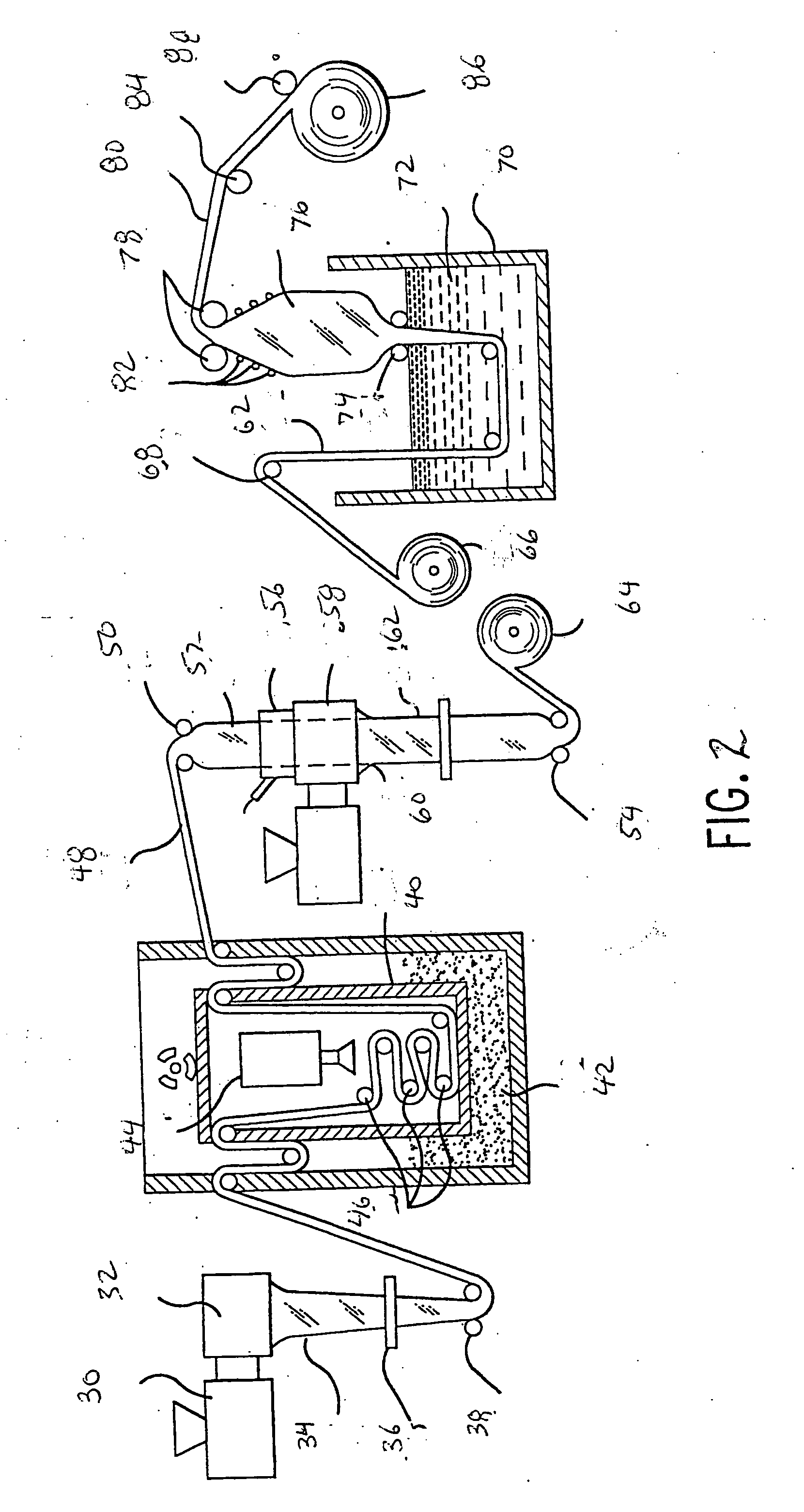

High-speed pouch forming, sealing and filling machine, method of operation, and multi-layer film therefore

InactiveUS6237308B1Improve methodImprove throughputSynthetic resin layered productsWrapper twisting/gatheringPuncture resistanceEngineering

The multi-layer film structure having an inner sealing layer which comprises metallocene resin, a core which includes polypropylene copolymer and an outer layer and wherein the multi-layer film structure has a thickness within a range between about 50 and 70 microns (2.0-2.75 mil). By utilizing this thin film with specific properties the sealers may be operated at lower temperatures thereby resulting in an energy saving and they produce seals having improved seal strength of 30% to 50% as compared with known prior mono-layer polyethylene film. The seal initiation temperature is reduced by 10° C. to 15° C. and the film exhibits an improved machine direction tensile strength of 25% to 40% and an improvement of 30% to 50% in puncture resistance as compared with a 76 microns (3 mil) mono-layer polyethylene film. This results in a reduction in the sealing cycle time and an increase in the throughput of the machine. This results in a liquid pouch having a substantial improvement in drop test performance, puncture resistance and seal strength. The machine accomplishes better seals with less energy, requires less downtime for roll changes and maintenance and increase throughput.

Owner:GLOPAK INC

Laminated lidstock

ActiveUS7681732B2Container/bottle contructionDomestic containersMechanical engineeringPressure sensitive

Owner:CRYOVAC ILLC

Mono and multi-layer articles and extrusion methods of making the same

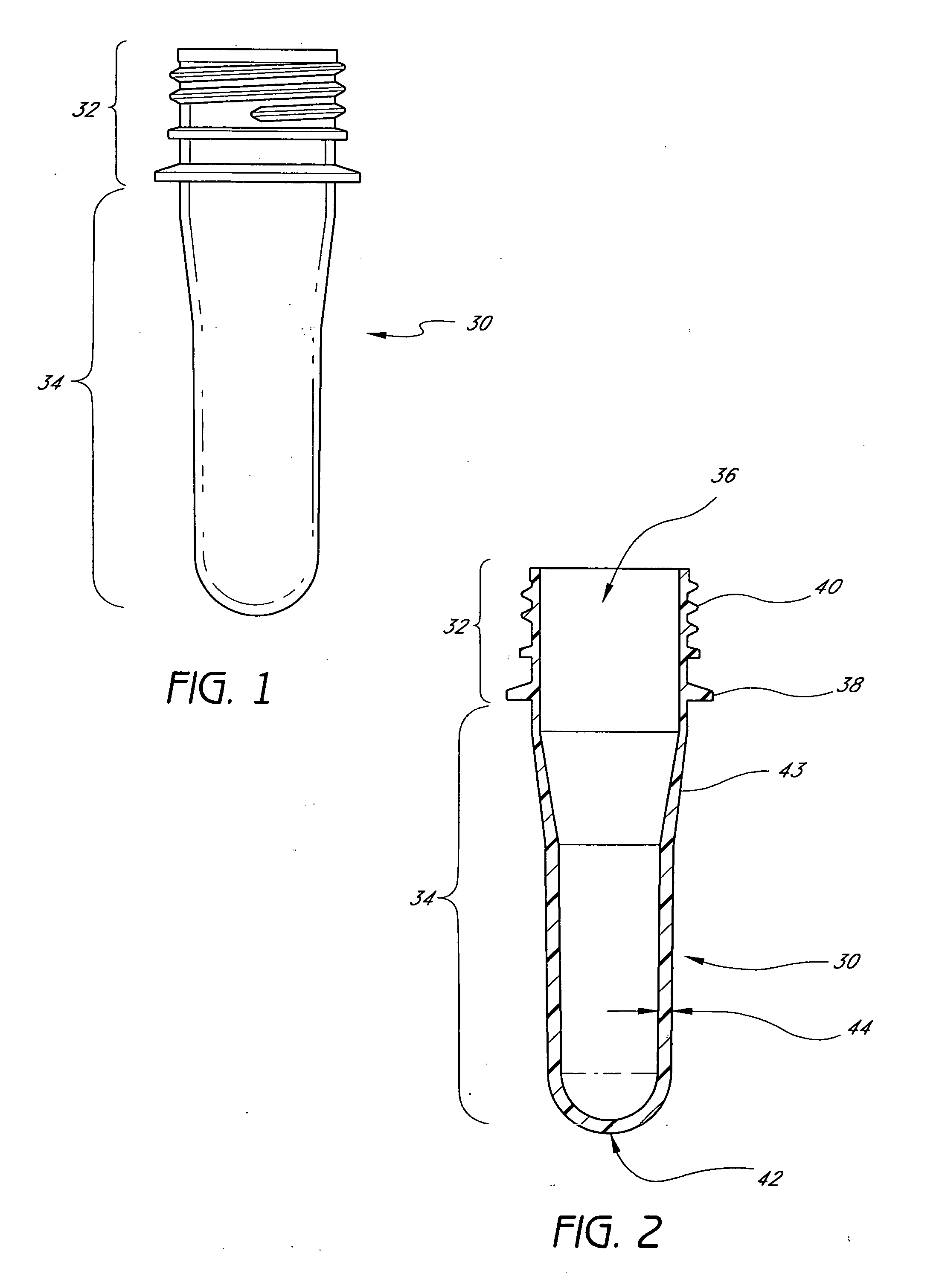

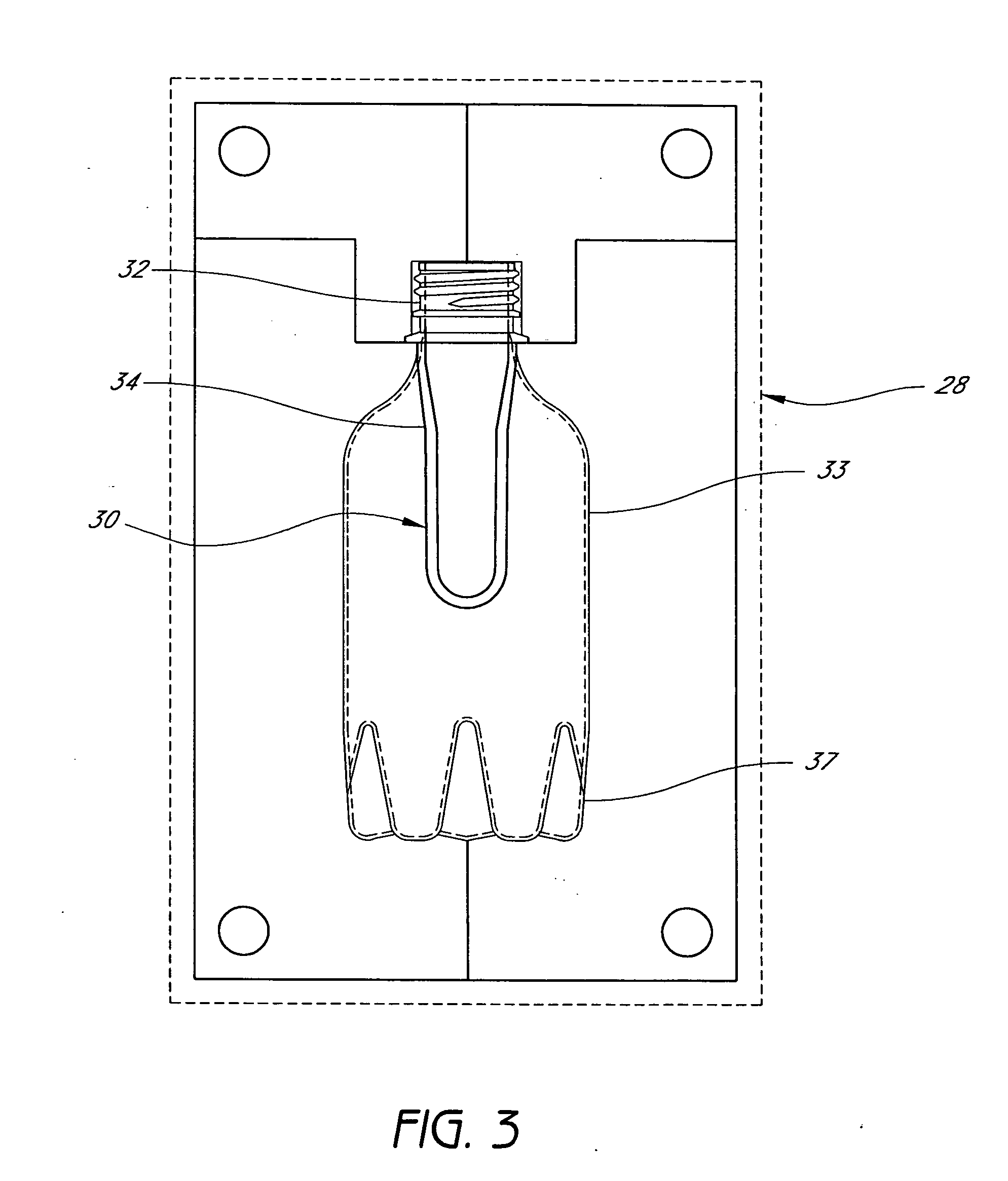

InactiveUS20060073298A1Easy to processImprove melt strengthBottlesSynthetic resin layered productsThermoplasticPolyester

An extruded blow molded bottle comprises a neck portion and a body portion. The body portion comprises a first inner layer and a second layer. The first inner layer comprises a first material selected from a group consisting of polyester, phenoxy type thermoplastics, phenoxy-polyolefin thermoplastic blends, and combinations thereof. The second layer comprises a second material selected from a group consisting of virgin PET, recycled PET, PETG, foam, polypropylene, polyester, polyolefins, phenoxy type thermoplastic, phenoxy-polyolefin thermoplastic blends, regrind scrap materials, and combinations thereof. The second material is different from the first material.

Owner:PEPSICO INC +1

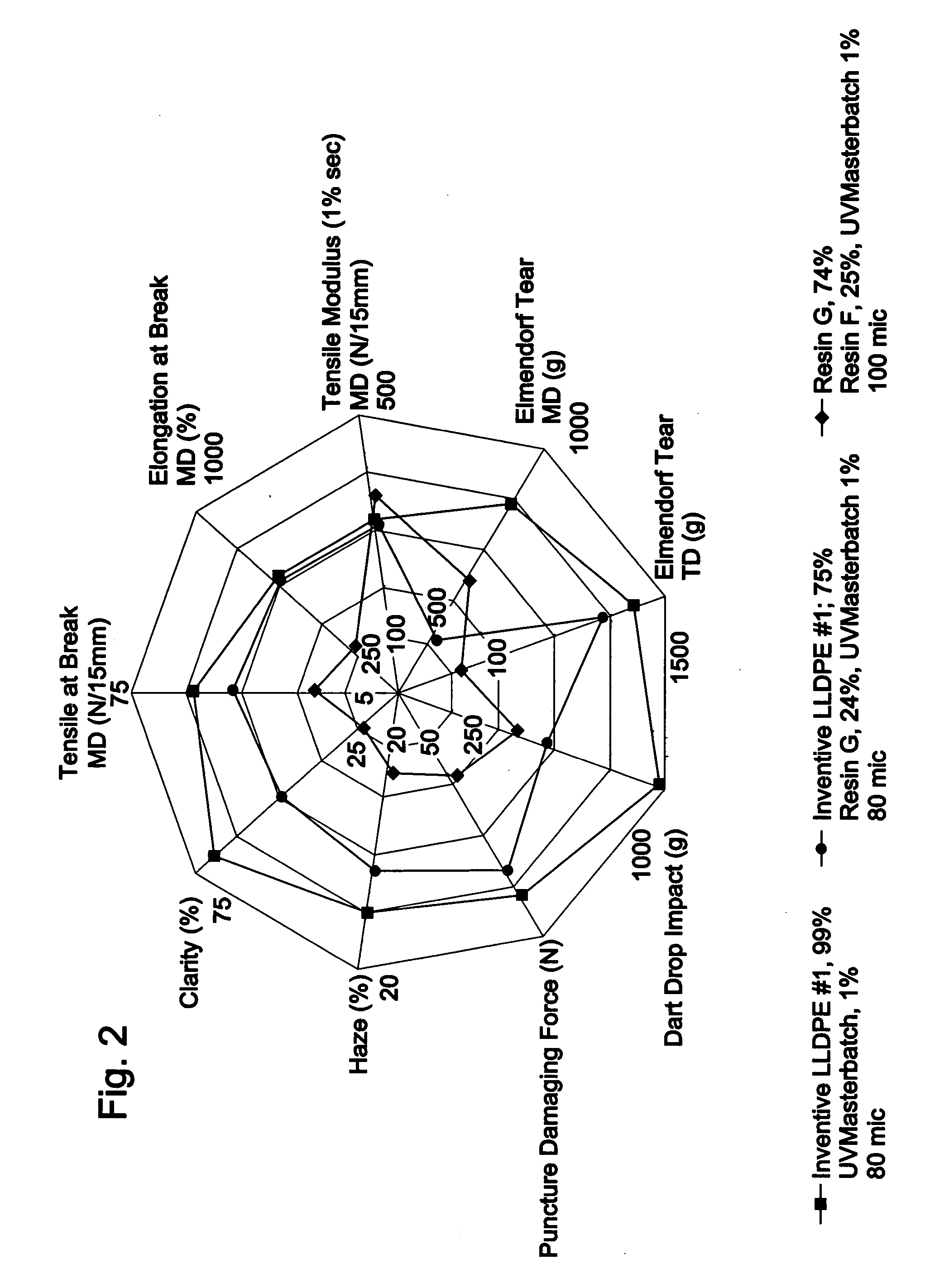

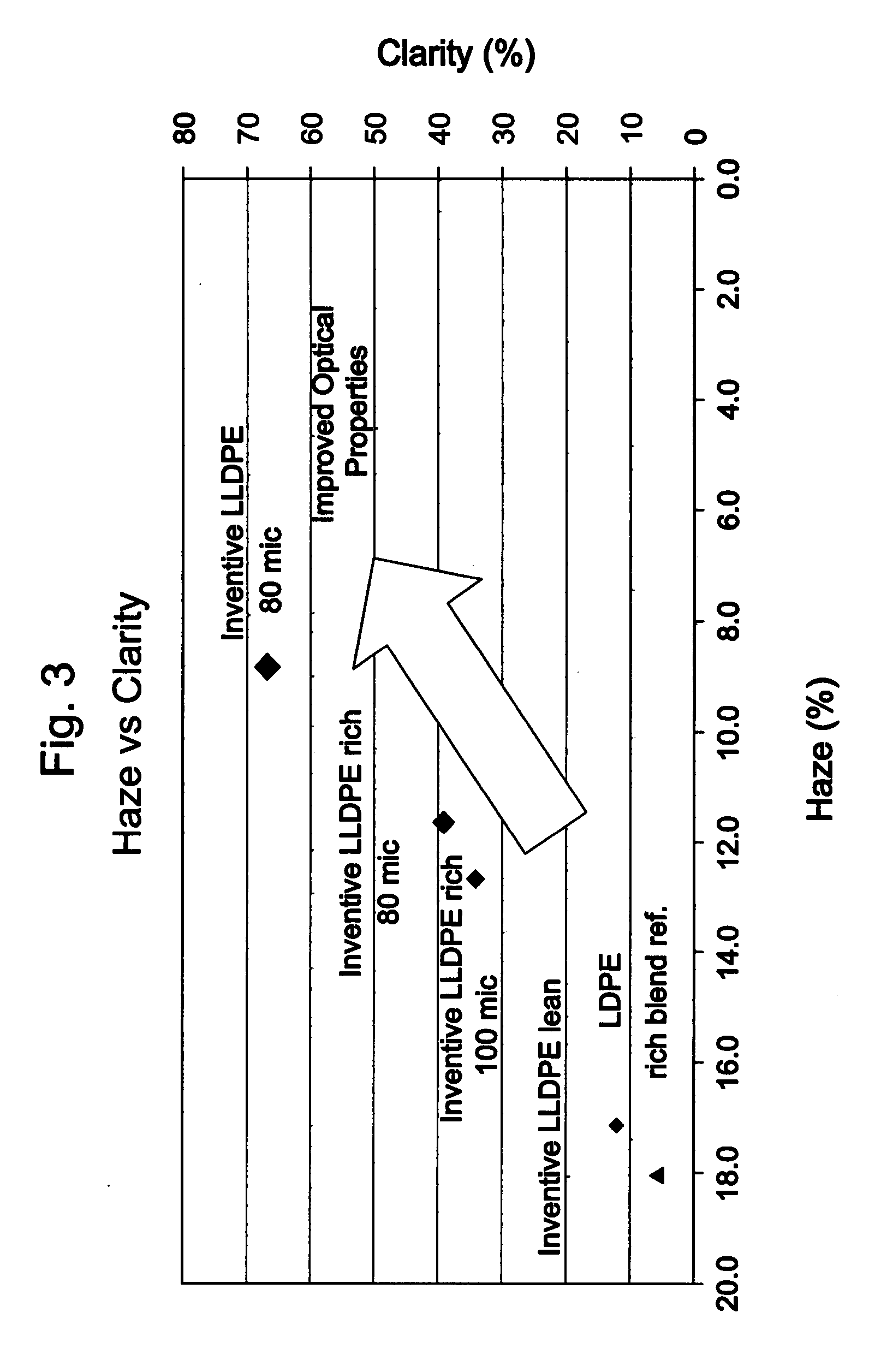

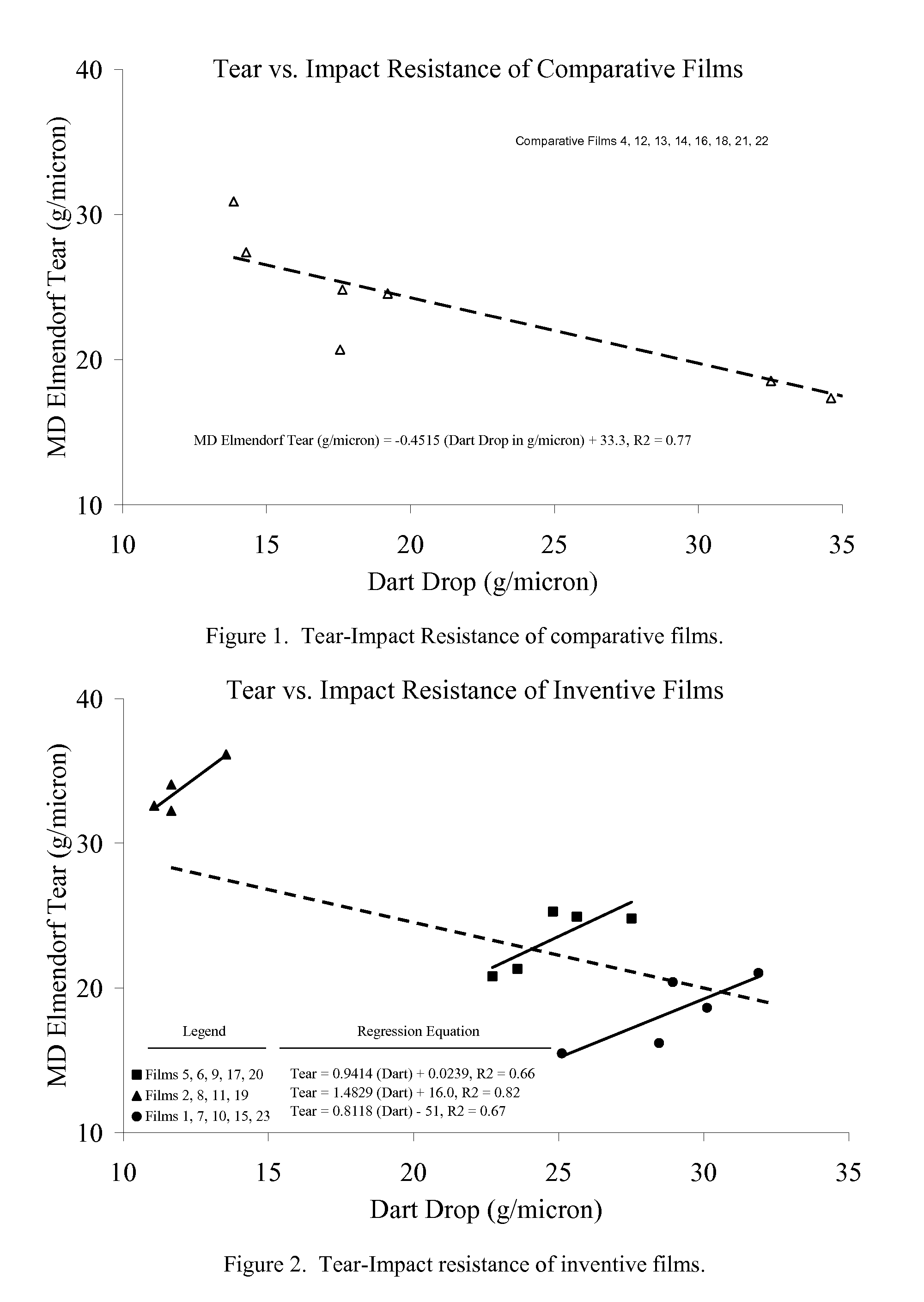

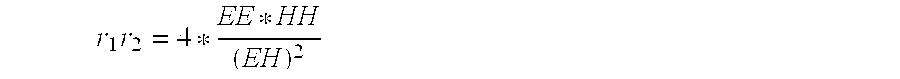

Polyethylene Films and Process for Production Thereof

This invention relates to a polyethylene film having a MD 1% Secant Modulus of 220 MPa or more and an MD Elmendorf Tear of Y g / micron, where Y≧−0.4515(Dart Drop in g / micron)+33.3 g / microns, wherein the MD Elmendorf tear is at least 11.8 g / micron.

Owner:UNIVATION TECH LLC

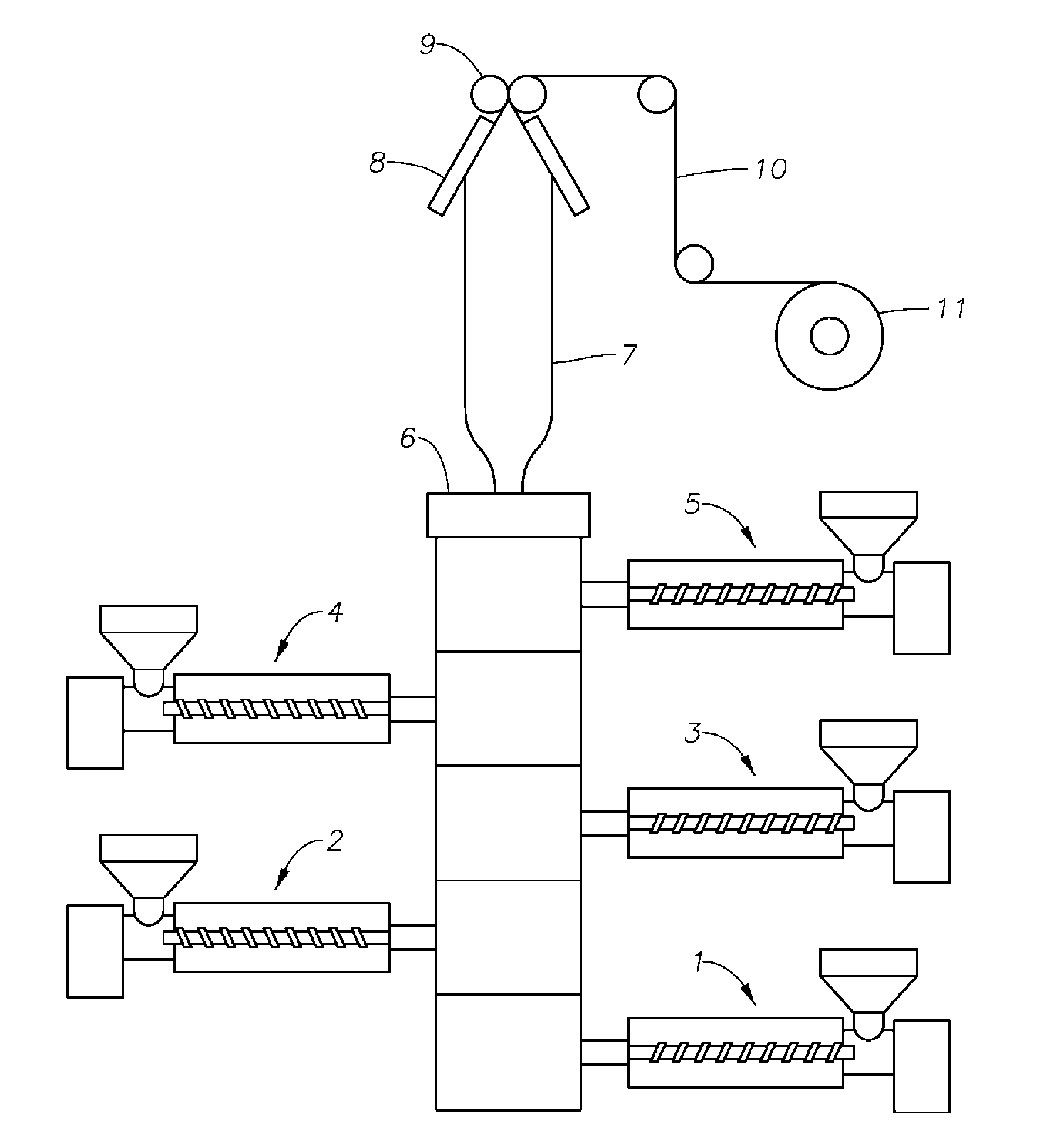

Multilayer Polyolefin Blown Film

ActiveUS20120100356A1Improve mechanical propertiesSynthetic resin layered productsTurning toolsProduction ratePolyolefin

A multilayer blown film with improved strength or toughness comprising a layer comprising a metallocene polyethylene (mPE) having a high melt index ratio (MIR), a layer comprising an mPE having a low MIR, and a layer comprising a HDPE, and / or LDPE. Other embodiments have skin layers and a plurality of sublayers. At least one sublayer includes an mPE, and at least one additional sublayer includes HDPE and / or LDPE. The mPE has a density from about 0.910 to about 0.945 g / cm3, MI from about 0.1 to about 15, and melt index ratio (MIR) from about 15 to 25 (low-MIR mPE) and / or from greater than 25 to about 80 (high-MIR mPE). A process is related to supplying respective melt streams for coextrusion at a multilayer die to form a blown film having the inner and outer skin layers and a plurality of sublayers, wherein the skin layers and at least one of the sublayers comprise mPE and at least one of the sublayers comprise HDPE, LDPE or both. Draw-down, blow-up ratios and freeze-line distance from the die are controlled to facilitate a high production rate.

Owner:EXXONMOBIL CHEM PAT INC

Mono and multi-layer articles and injection molding methods of making the same

ActiveUS20060073294A1Reduce heat transferInhibit transferBottlesSynthetic resin layered productsEngineering

Owner:CONCENTRATE MFG OF IRELAND +1

Renewably sourced films and methods of forming same

Mono- and multi-layer films having film layers at least partially formed from a polymer (A) wherein polymer (A) is at least partially derived from a renewable resource such that the mono- or multi-layer film has a bio-based content of about 10% to about 100% using ASTM D6866-10, method B. Methods of forming high biocontent mono- and multi-layer films are also provided.

Owner:THE PROCTER & GAMBLE COMPANY

Flexible multi-compartment container with peelable seals and method for making same

InactiveUS6996951B2Increase storage capacityIncrease capacityEnvelopes/bags making machineryBoxes/cartons making machineryThermoplasticDiluent

A flexible container is provided for the storage and administration of medical solutions. The container incorporates a transparent front sheet made from a planar layer of a polymer and an opposing rear sheet. The rear sheet is made from a planar laminate layer. The front and rear sheets are sealed together along a common peripheral edge to form a volume enclosure. The volume enclosure is constructed of materials having high oxygen and moisture barrier properties which allows the container thermoplastic to be stored for extended periods of time without degrading the contents. The volume enclosure is then inflated with a pressurized gas to permanently stretch the front and rear sheets outwardly and to thereby increase the volume capacity of the container. An alternative embodiment of the container incorporates multiple compartments, separated by peelable seals, for containing a diluent and a medicament. The seals are ruptured by manipulation of the container to thereby mix the contents together for delivery through standard IV arrangement to a patient.

Owner:B BRAUN MEDICAL

Laminated packaging material for paper container

InactiveUS6974612B1Easy to manufactureQuick heat sealEnvelopes/bags making machineryFlexible coversLow-density polyethyleneLinear low-density polyethylene

A paper packaging container is formed from the packaging material comprising constitution layers of at least an outside thermoplastic material layer, a paper substrate layer, and an inside thermoplastic material layer, wherein the inside thermoplastic material layer contains at least a linear low density polyethylene, and has properties parameters of an average density of 0.900–0.930, a predetermined peak melting point, a melt flow index of 5–15, and a swelling ratio of 1.3–1.8. The use of the packaging material allows easy filling and packaging to the packaging container and quick heat sealing, and results in more toughly and strongly sealed container, and the material can be used for achieved good sealing independently of the temperature of food contents and thus maintaining the non-scalping and quality preservability of the content product.

Owner:TETRA LAVAL HLDG & FINANCE SA

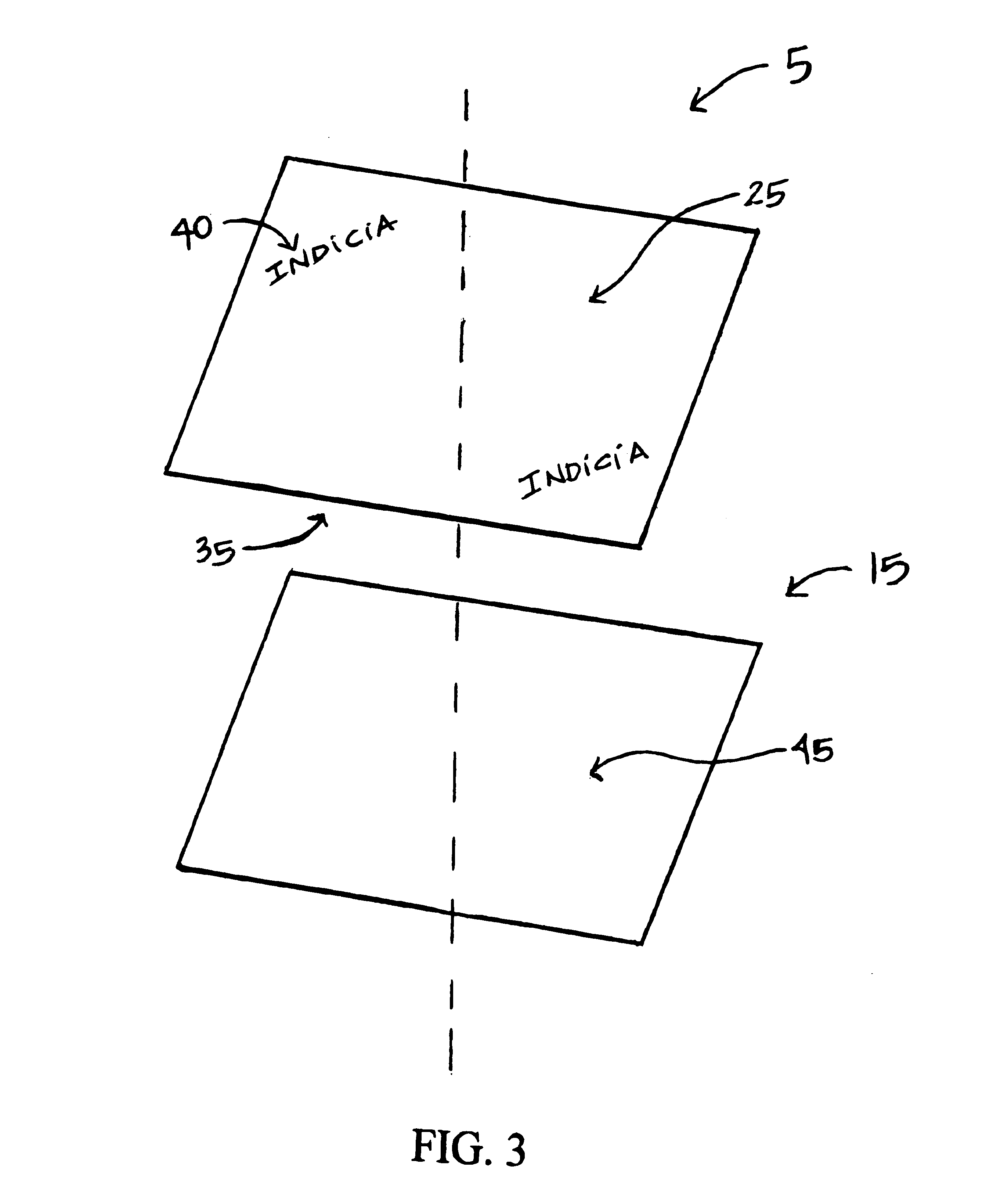

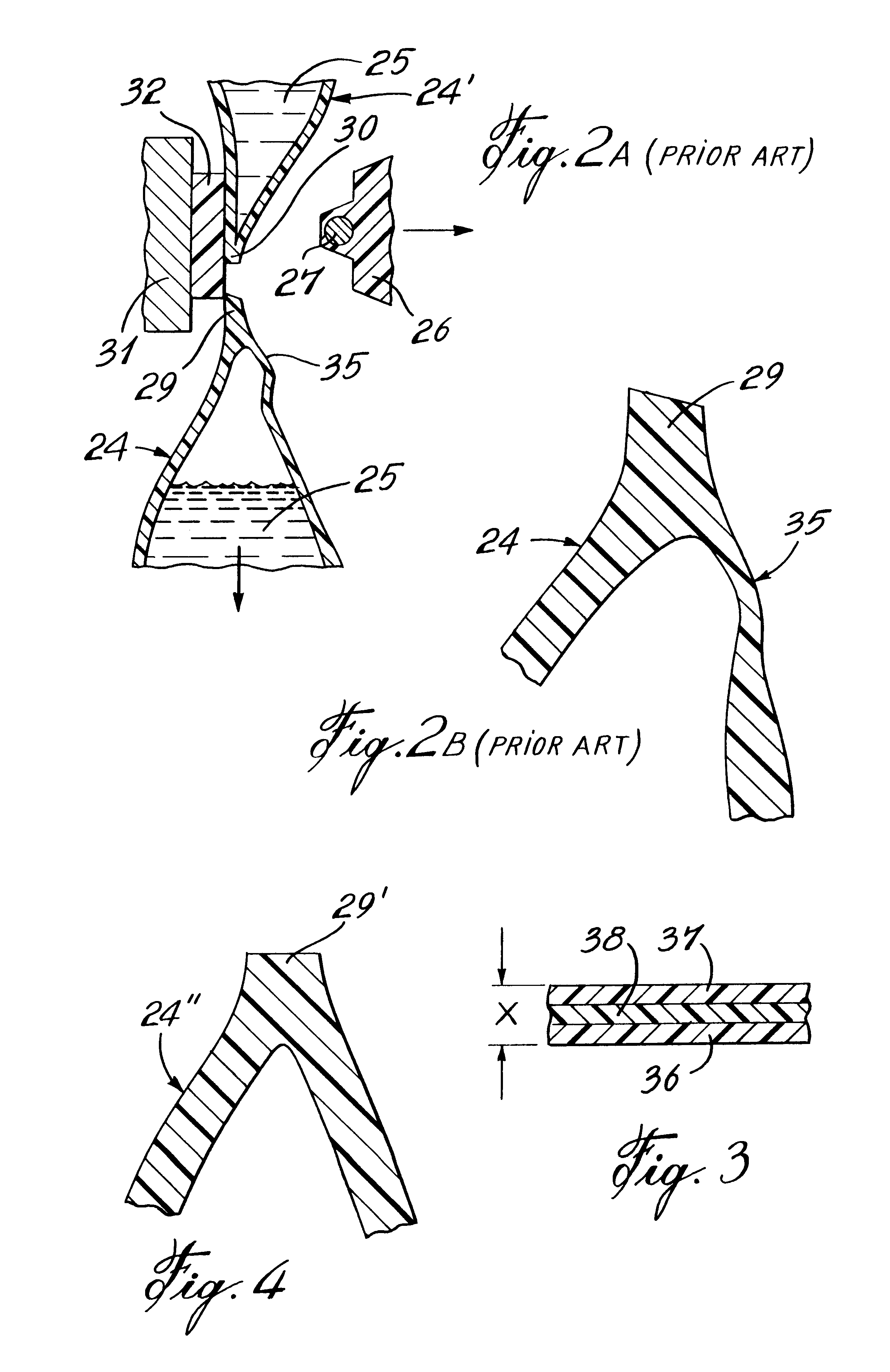

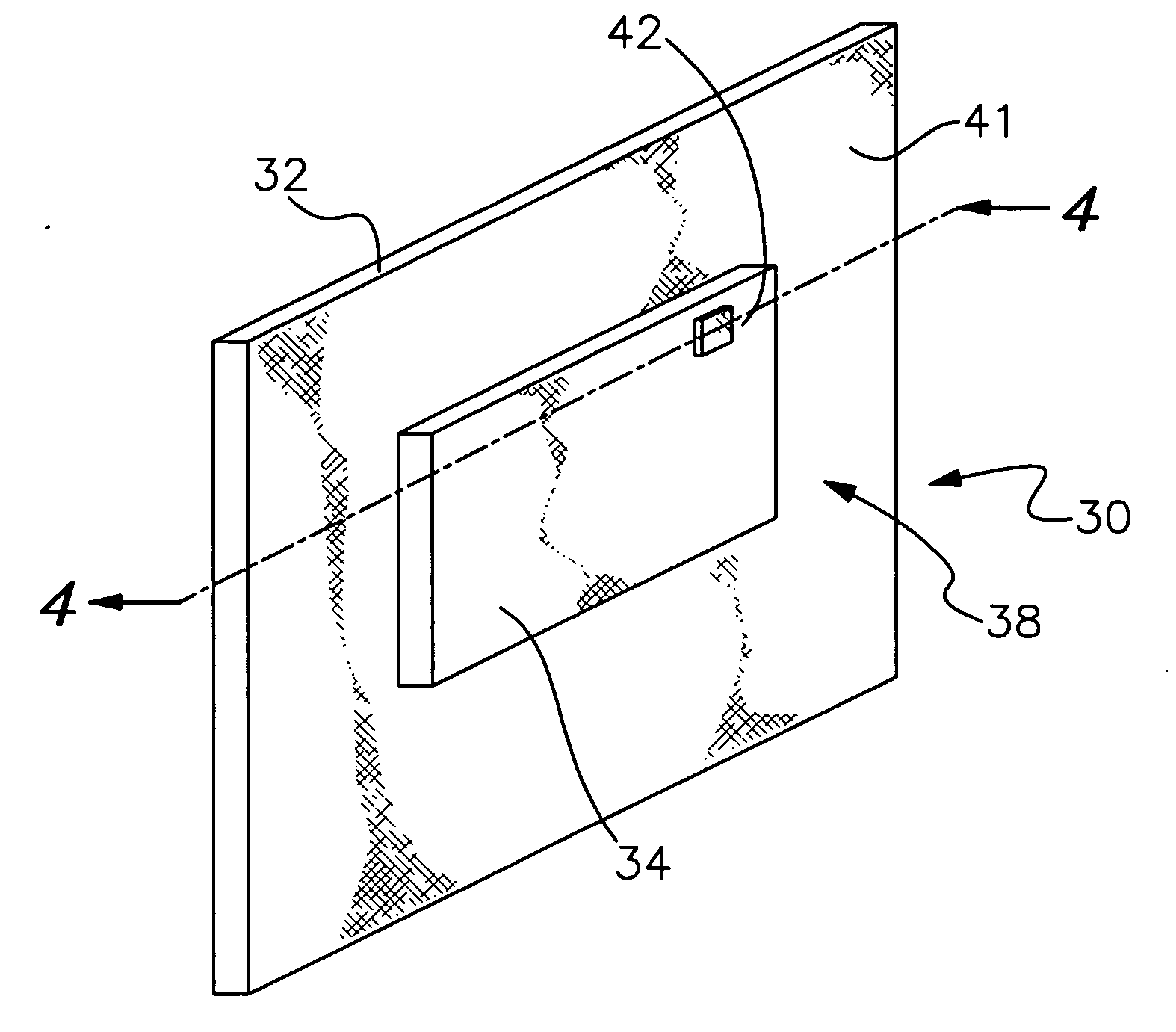

Sterilization wraps and methods for sterilizing articles

There is provided an improved sterilization wrap and a method for using the improved sterilization wrap to sterilize an article. The wrap is made of at least a first panel of sterilization material and includes an additional panel of material. The first panel is multi-layered and includes at least one pathogen filtration layer. The first panel is rectangular and has an outer periphery and a central portion. The outer periphery includes first, second, third and fourth edges. The additional panel of material is bonded to the first panel, approximately at a forty-five degree angle to the first panel, with a substantial portion of the additional panel being adjacent to the central portion of the first panel. The perimeter of the additional panel is smaller than the perimeter of the first panel. Portions of the additional panel are bonded to the first panel along the first, second, third and fourth edges of the first panel. The article to be sterilized is placed on the additional panel, is wrapped, and sterilant is applied to the wrapped article. A chemical visual indicator is provided to indicate whether or not the article has been exposed to adequate sterilization conditions.

Owner:ALLEGIANCE CORP

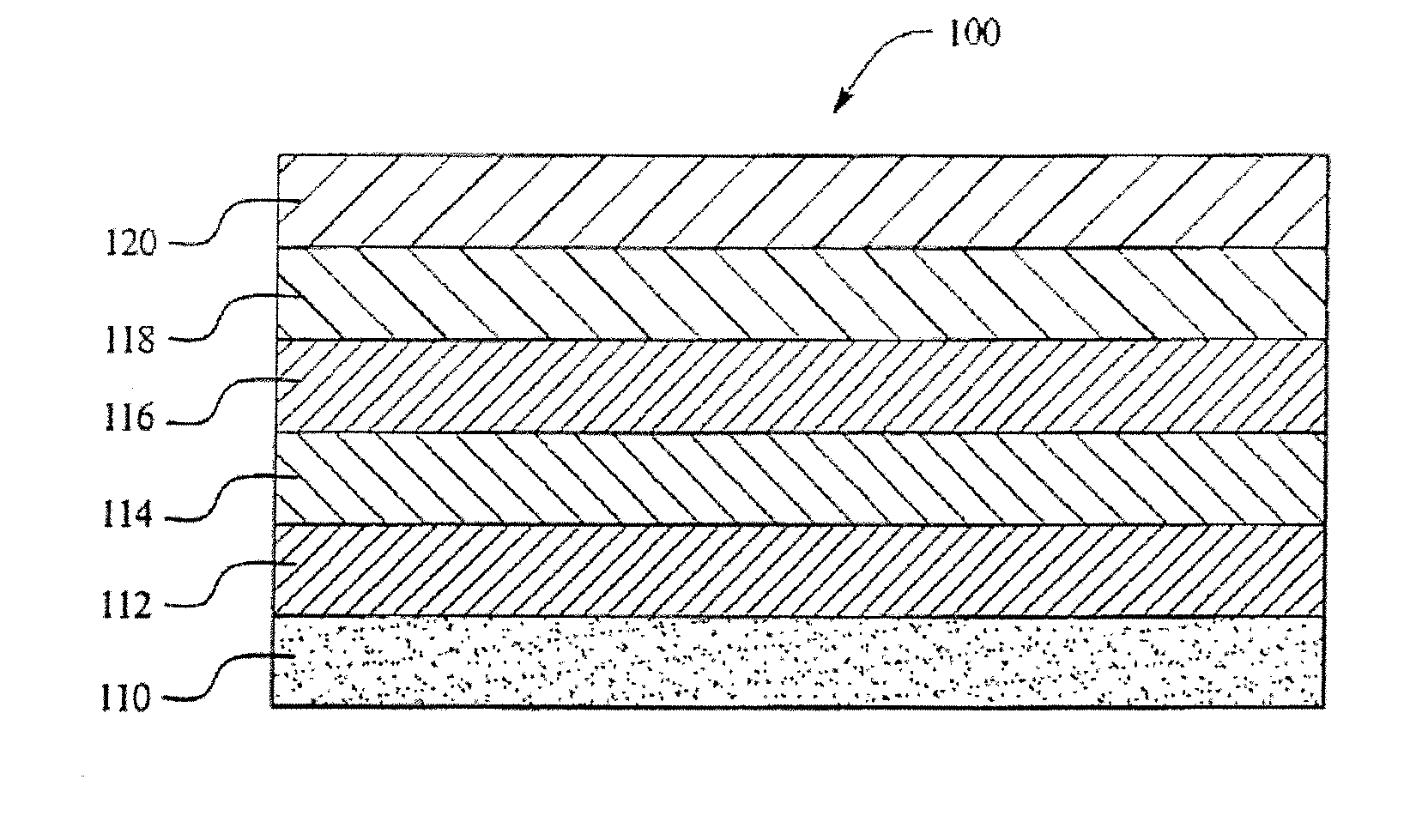

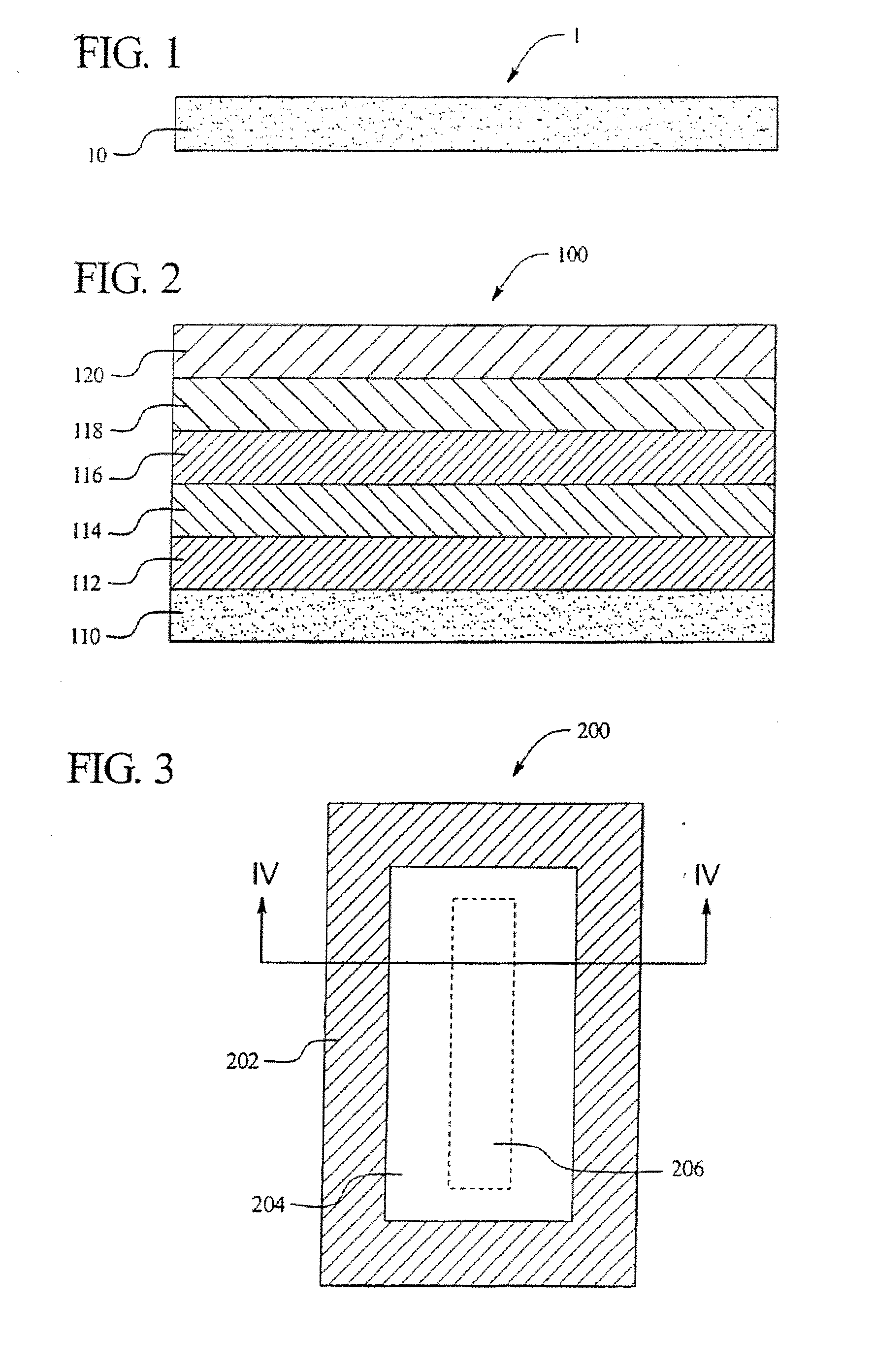

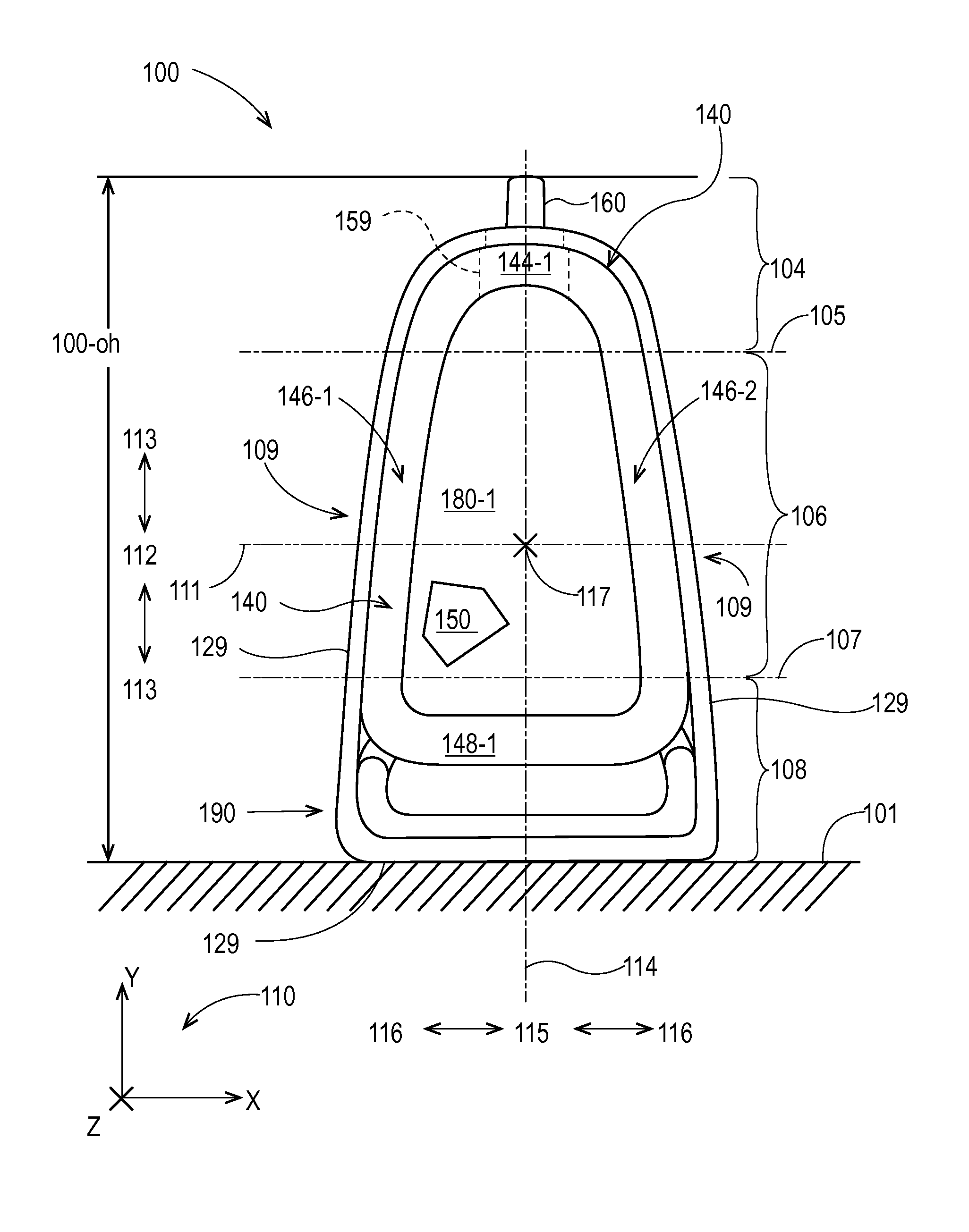

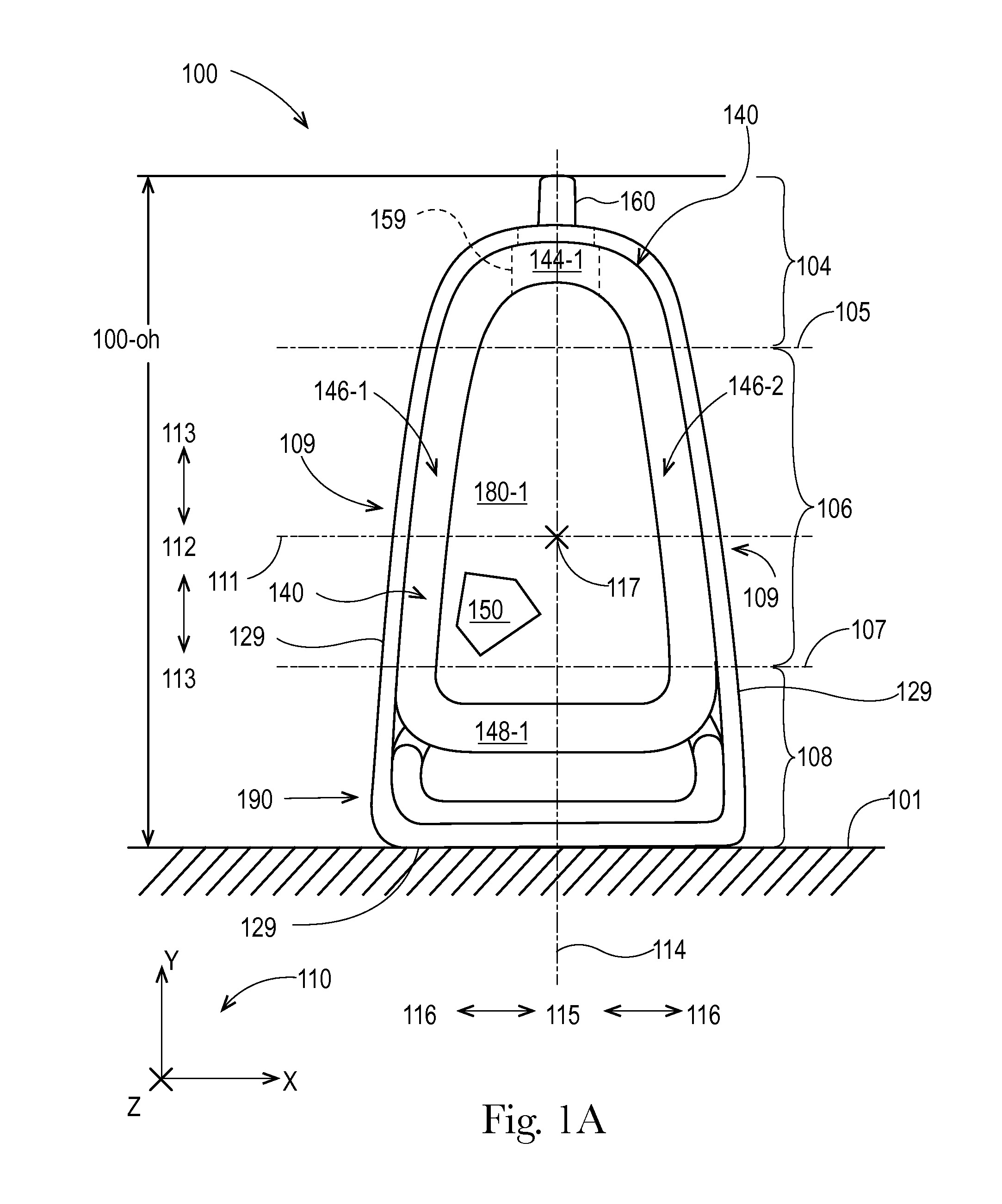

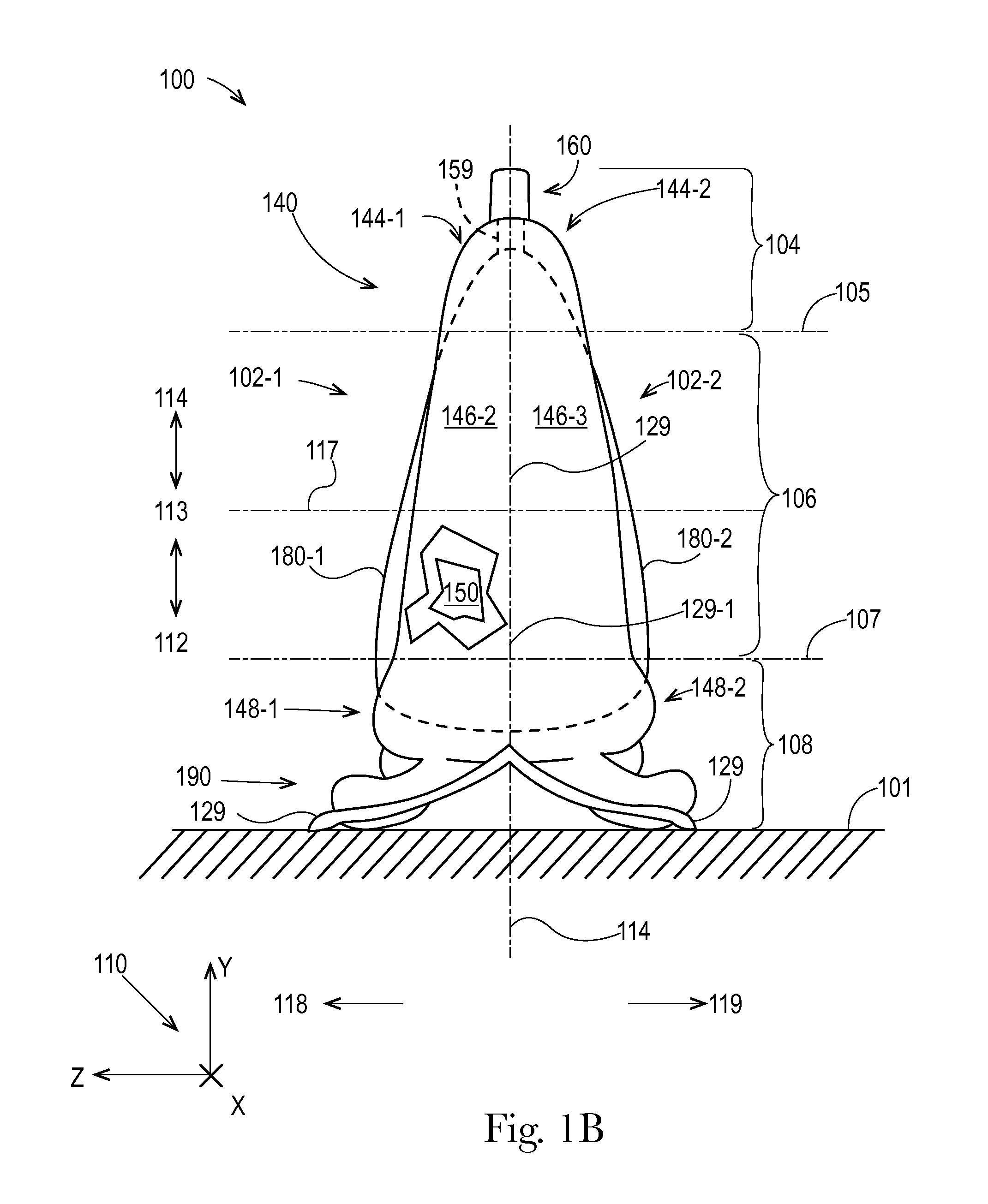

Flexible materials for flexible containers

ActiveUS9469088B2Less-expensiveImprove the decorative effectDomestic containersCoatingsMechanical engineeringGas barrier

A flexible material for a flexible container can include a first laminate and a second laminate joined to at least a portion of the first laminate by at least one seal. The first laminate can include a first gas barrier layer disposed between first and second sealable layers, wherein the first and second sealable layers define opposed exterior layers of the first laminate. The second laminate can include a third sealable layer defining an exterior layer of the second laminate, and a second gas barrier layer. The at least one seal joins a portion of the third sealable layer to at least a portion of the second sealable layer.

Owner:PROCTER & GAMBLE CO

Process for detecting leaks in sealed packages

InactiveUS20060121613A1Chemiluminescene/bioluminescenceSynthetic resin layered productsLength waveChemistry

The present invention relates to a process for detecting a leak in a package. The process comprises preparing a package by covering at least a portion of an O2-sensitive product with a multilayer film comprising (i) a leak-indicator layer in which a O2-sensitive indicator is present throughout the leak-indicator layer; and (ii) an O2-barrier layer outward of the leak-indicator layer. A low O2-environment is provided within the package. The leak-indicator layer is then illuminated with light containing a wavelength absorbed by the O2-sensitive indicator, so that the O2-sensitive indicator produces an emission of radiation in an amount inversely proportional to a level of O2 present with the O2-sensitive indicator. Then the multilayer film is scanned while the O2-sensitive indicator is emitting radiation, the scanning being carried out by sensing and comparing the amount of radiation emitted from at least two different regions of the multilayer film.

Owner:CRYOVAC ILLC

Oxygen-scavenging filled polymer blend for food packaging applications

InactiveUS6037022AOxygen transmission propertyLow oxygenDomestic containersThin material handlingPaperboardFood packaging

The specification discloses a polymer blend especially well-suited for coating paperboard substrates used in food packaging, particularly acidic or acid-generating foods such as fruit and vegetable juices. The blend contains an acid-activatable oxygen scavenger dispersed in a film-forming synthetic polymer such as an EVOH copolymer. When placed as a film or layer on the side of the substrate inside the container in contact with the food the blend is effective to reduce the oxygen in the container over time to a very low concentration, replacing the same with carbon dioxide, for an excellent preservative effect.

Owner:INT PAPER CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com