Reinforced composite supported hollow fiber membrane and preparation method thereof

A reinforced composite and fiber membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of large coagulation bath depth, complicated winding process, limited adhesion, etc., and achieve easy control of process conditions , increase the specific surface area, enhance the effect of cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

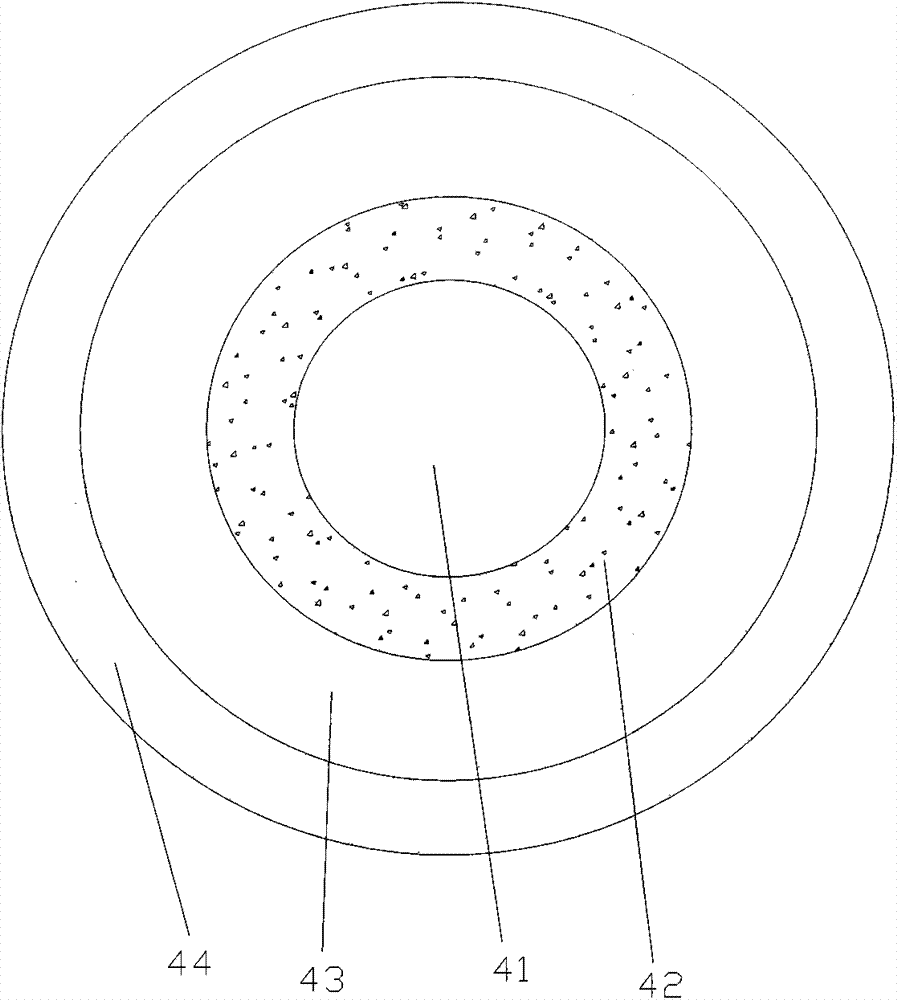

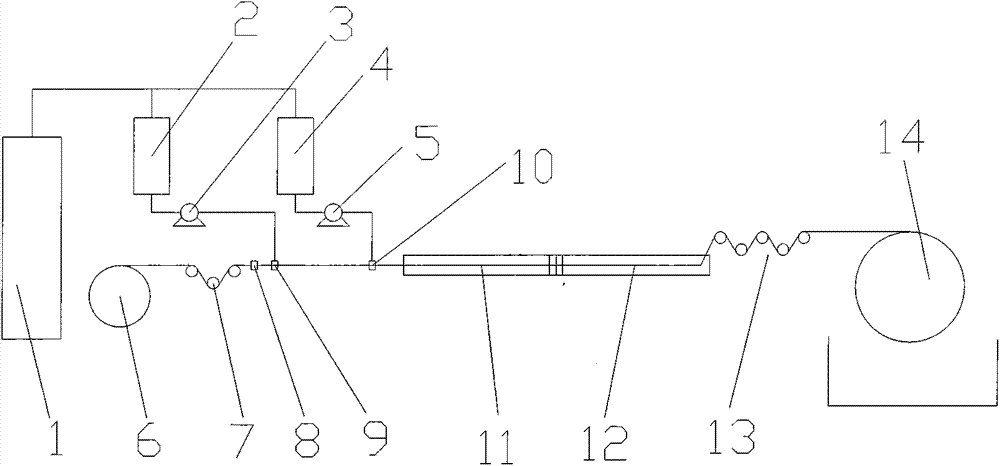

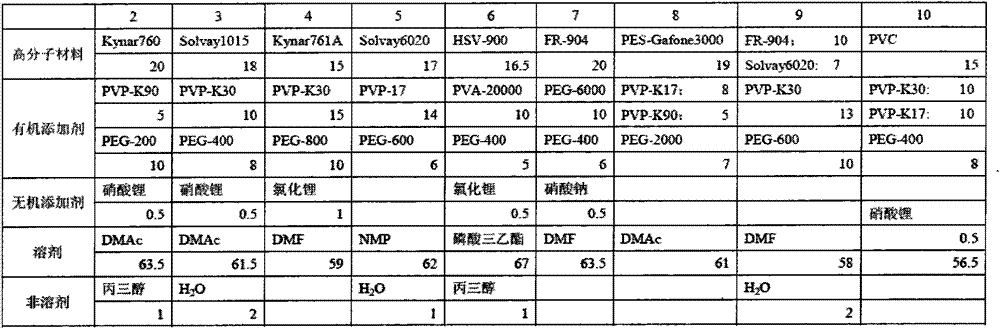

[0034] Such as Figure 1 to Figure 2Shown: a reinforced composite support hollow fiber membrane provided by an embodiment of the present invention, including a braided support tube 42, a transition layer 43 and a separation layer 44, the transition layer 43 is provided with the braided support tube 42 and the separation layer 44 Among them, the braided support tube 42 is a hollow braided fabric with a cavity 41 inside, its aperture is 0.3-1.5 mm, the cylindricity is greater than 0.8, the pre-elongation rate is less than 10%, and the shrinkage rate is less than 2%. The bonding force between the braided support tube 42 and the transition layer is 0.4-4N, the outer diameter of the hollow fiber membrane is 1-5 mm, the thickness of the separation layer 44 is 0.03-1 mm, and the braided support tube 42 is composed of The outer diameter of the braided s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com