Coating-type light conversion film and preparation method thereof

A light-converting film and coating technology, which is applied in the fields of botanical equipment and methods, chemical instruments and methods, and coatings, can solve the problems affecting the growth and final yield of crops in the greenhouse, and the loss of light, heat and temperature of crops in the greenhouse. environment, reducing the use of pesticides and chemical fertilizers, etc., to achieve the effect of shortening the growth period of crops, prolonging the service life and use value, and reducing the use of pesticides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

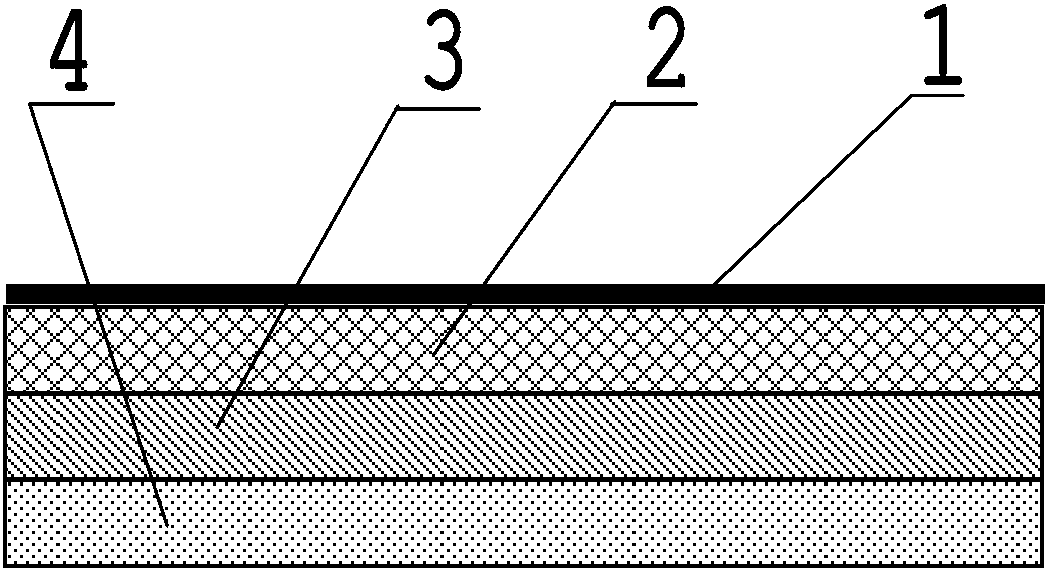

[0050] A coating-type light conversion film, which includes a four-layer structure of an inner layer, a middle layer, a sub-outer layer and an outer layer. The layered structure of the film from the inside to the outside is as follows: the inner layer is a mechanical property layer, and the middle layer is a high-strength layer. The thermal insulation and light conversion layer, the second outer layer is a coating carrier layer, and the outer layer is a thin film coating layer.

[0051] The inner layer and sub-outer layer include 7.5-12.5% long-life multifunctional masterbatch, the middle layer includes 7.5-12.5% high-efficiency light-changing longevity masterbatch containing high-strength nanometer multi-band light-changing agent, and the base material is 87.5-92.5%. in,

[0052] 1. Longevity multifunctional masterbatch formula (parts by weight):

[0053]

[0054] Heat the high-speed internal mixer to 130-140°C, add low-density polyethylene, dispersant, inorganic ult...

Embodiment 2

[0067] A coating-type light conversion film, which includes a four-layer structure of an inner layer, a middle layer, a sub-outer layer and an outer layer. The layered structure of the film from the inside to the outside is as follows: the inner layer is a mechanical property layer, and the middle layer is a high-strength layer. The thermal insulation and light conversion layer, the second outer layer is a coating carrier layer, and the outer layer is a thin film coating layer.

[0068] The inner layer and sub-outer layer include 7.5-12.5% long-life multifunctional masterbatch, the middle layer includes 7.5-12.5% high-efficiency light-changing longevity masterbatch containing high-strength nanometer multi-band light-changing agent, and the base material is 87.5-92.5%. in,

[0069] 1. Longevity multifunctional masterbatch formula (parts by weight):

[0070]

[0071] 2. Formula of high-efficiency light-changing and long-life masterbatch (parts by weight):

[0072]

...

Embodiment 3

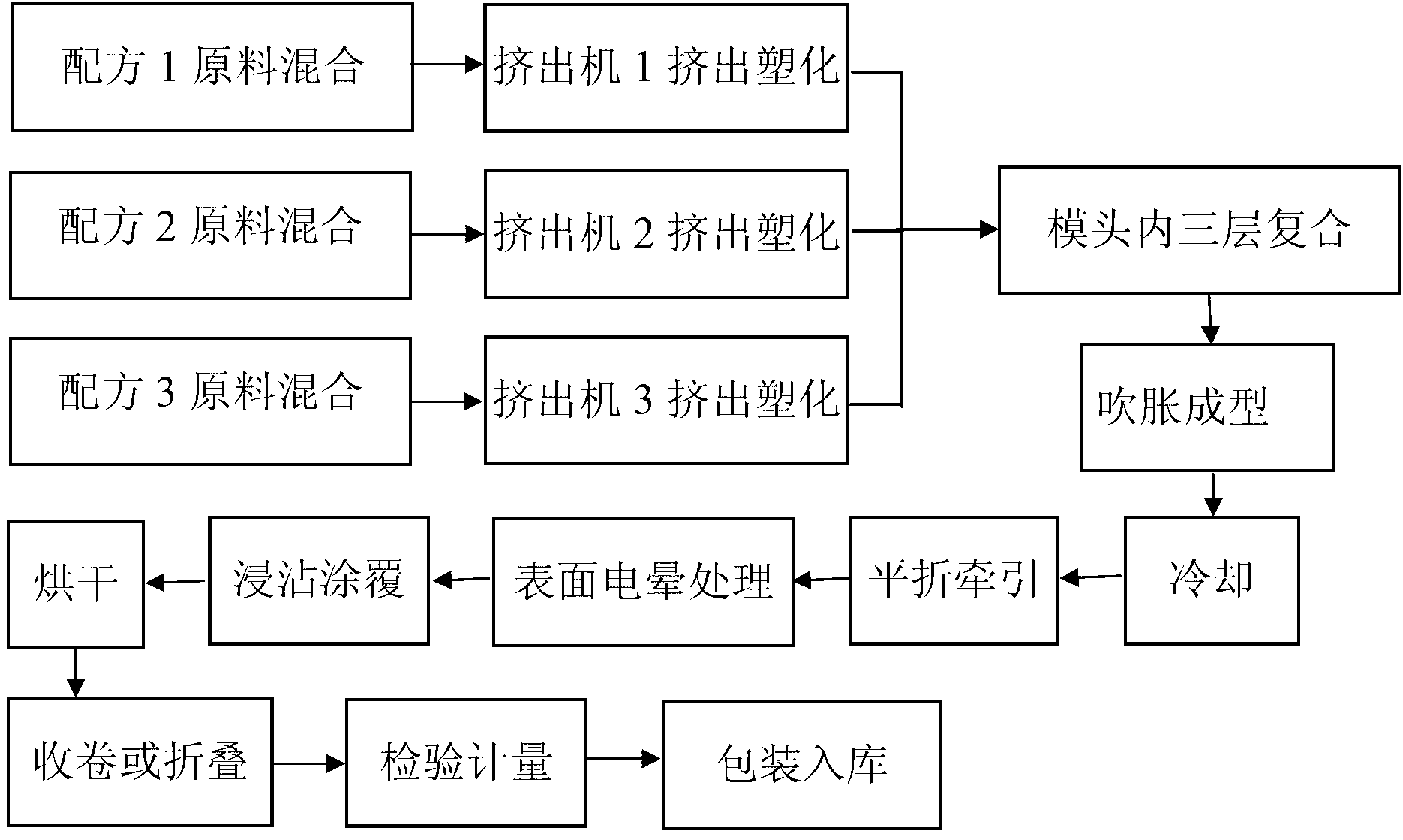

[0083] A method for preparing a coating-type light conversion film, comprising the following process:

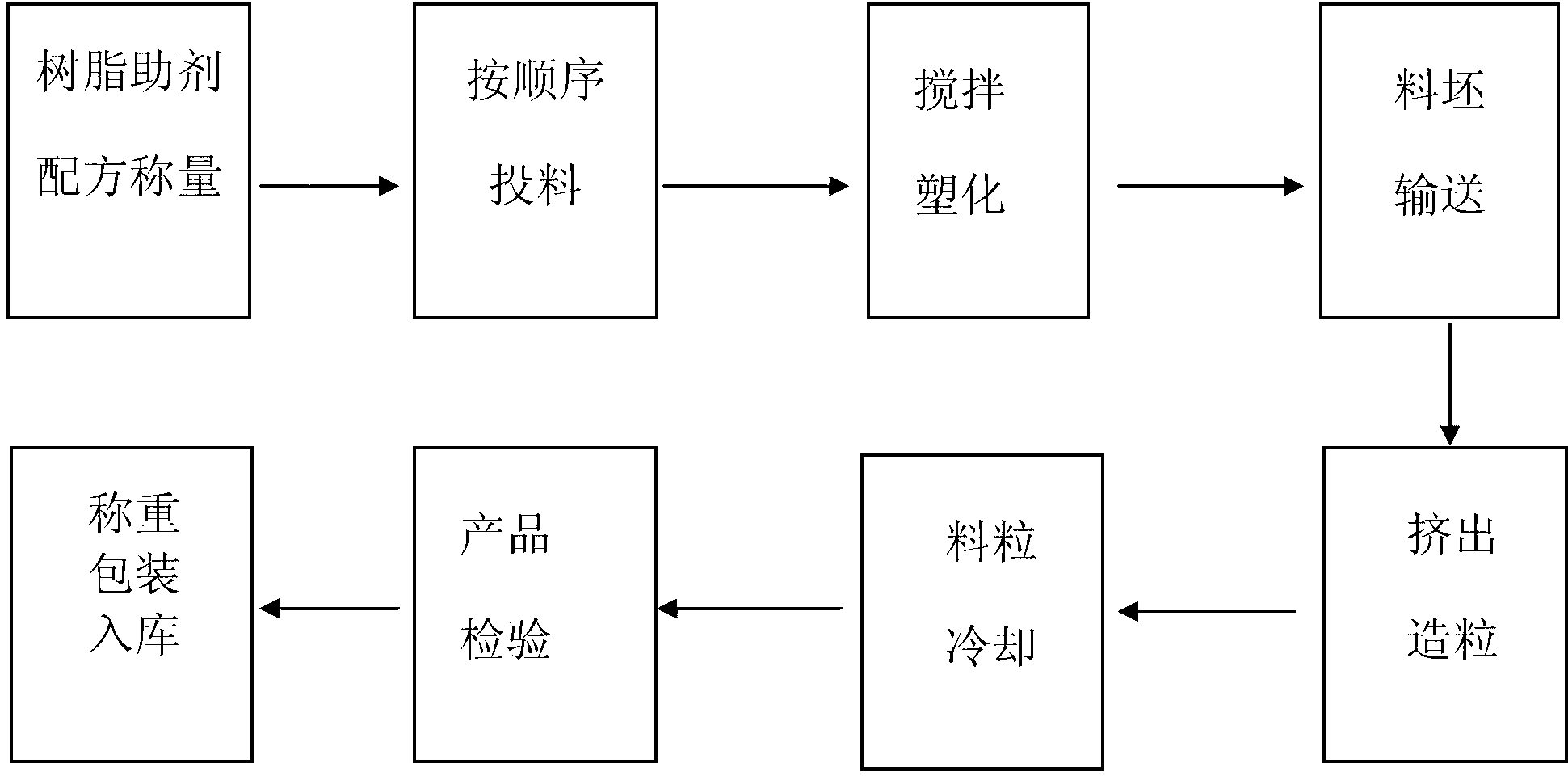

[0084] 1. Preparation of Longevity Multifunctional Masterbatch:

[0085] Weigh the components according to the formula described in Example 1, raise the temperature of the internal mixer to 130-140°C, and put in low-density polyethylene, dispersant, inorganic ultrafine slow-release heat preservation agent, hindered amine light stabilizer, ultraviolet absorber agent, composite antioxidant, stirred for 7-12 minutes, discharged and cooled, and then put into a granulator for granulation;

[0086] 2. Preparation of high-efficiency light-changing and long-life masterbatch:

[0087] Weigh the components according to the formula described in Example 1, raise the temperature of the high-speed internal mixer to 130-140°C, and put in low-density polyethylene, dispersant, slip agent, nanometer multi-band light-changing agent, inorganic ultrafine Slow-release heat preservation agent,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com