Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

96results about How to "Small heat loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

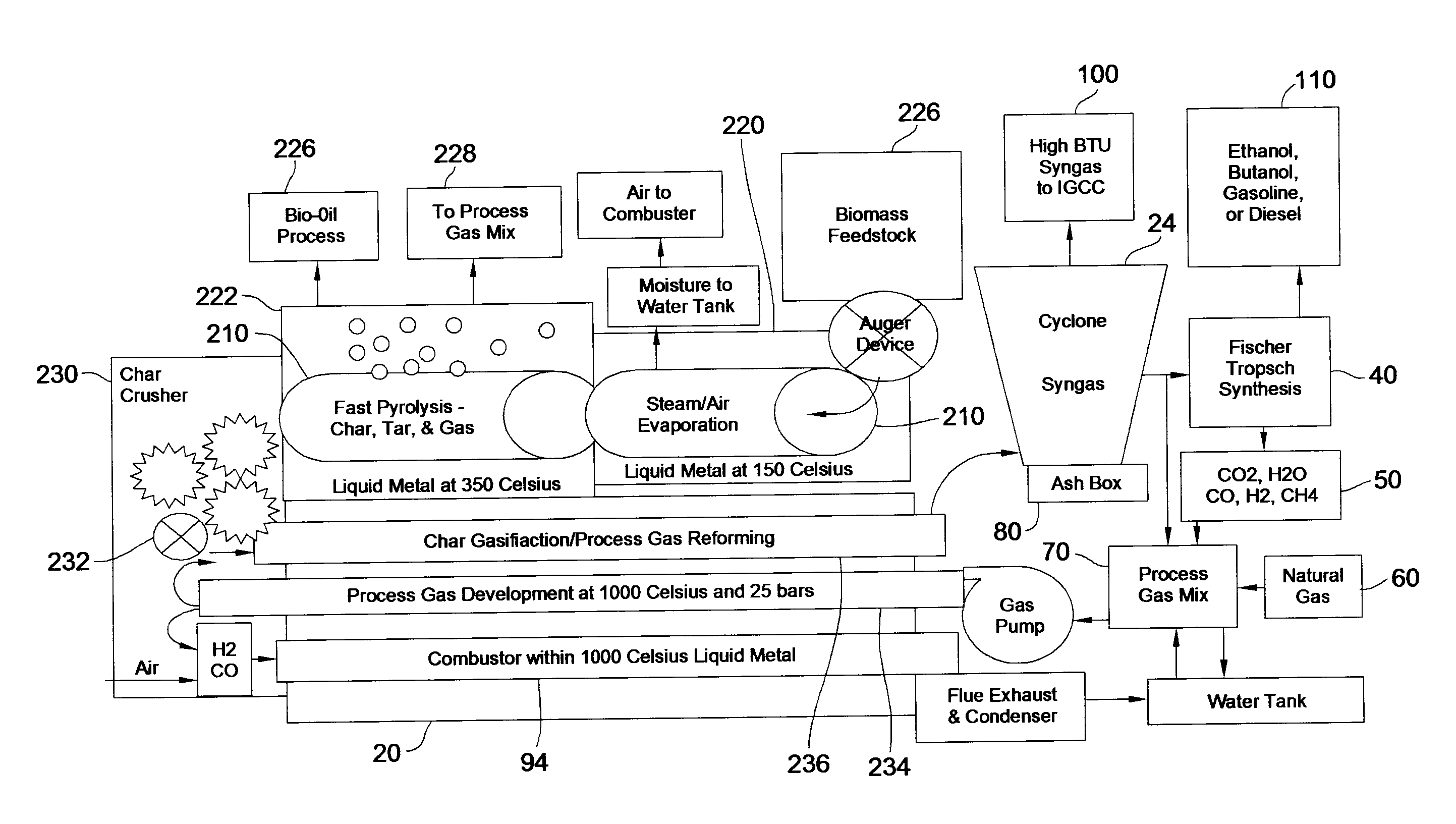

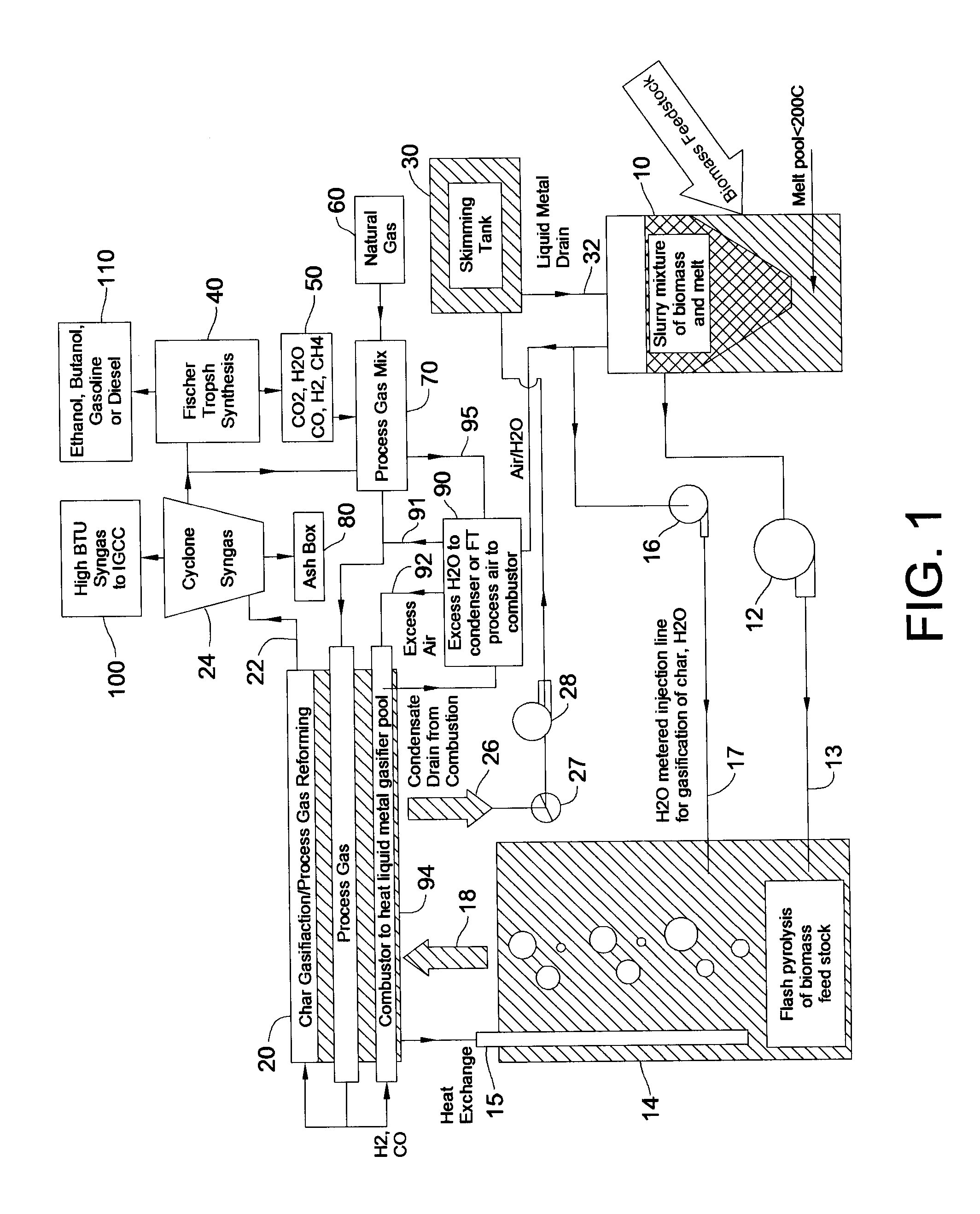

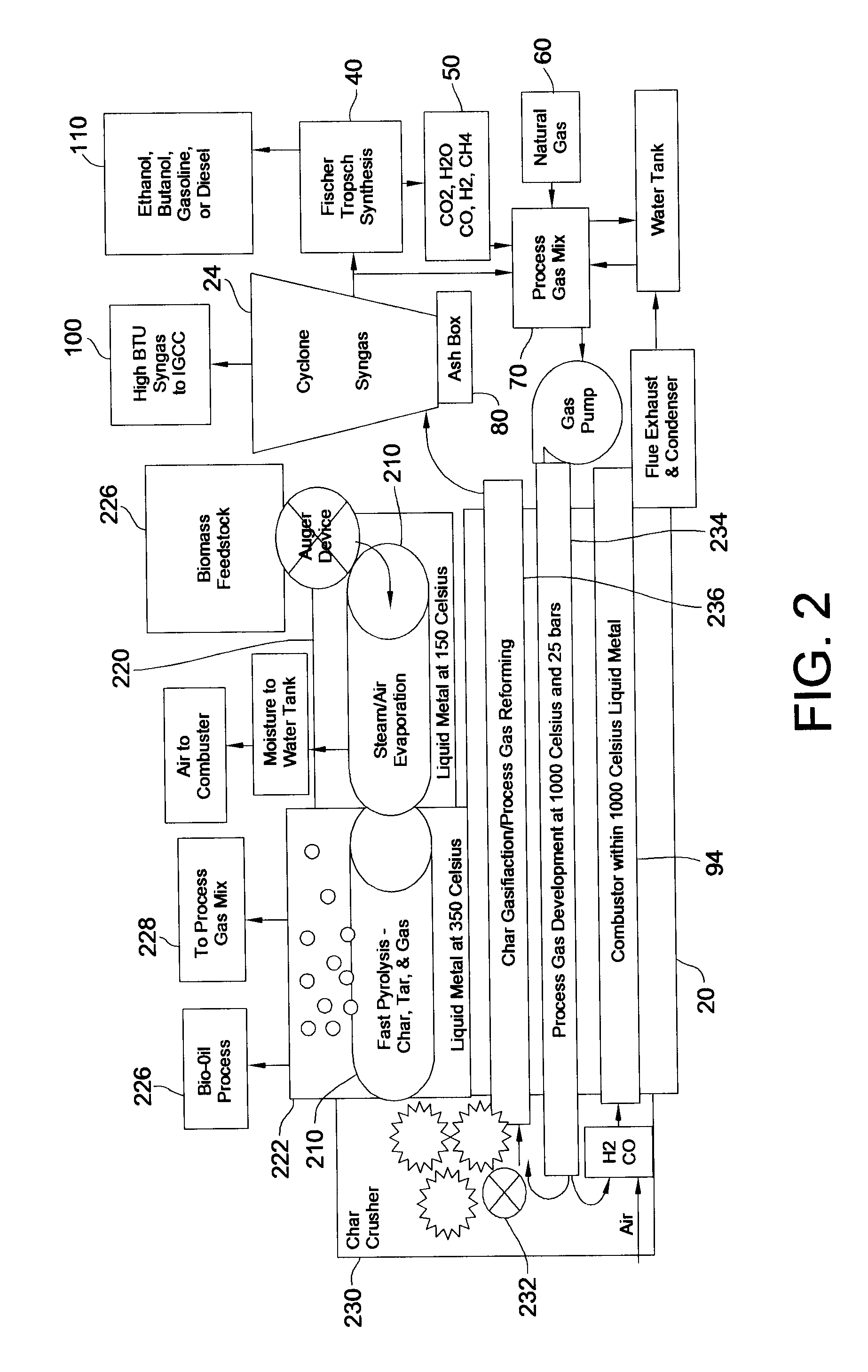

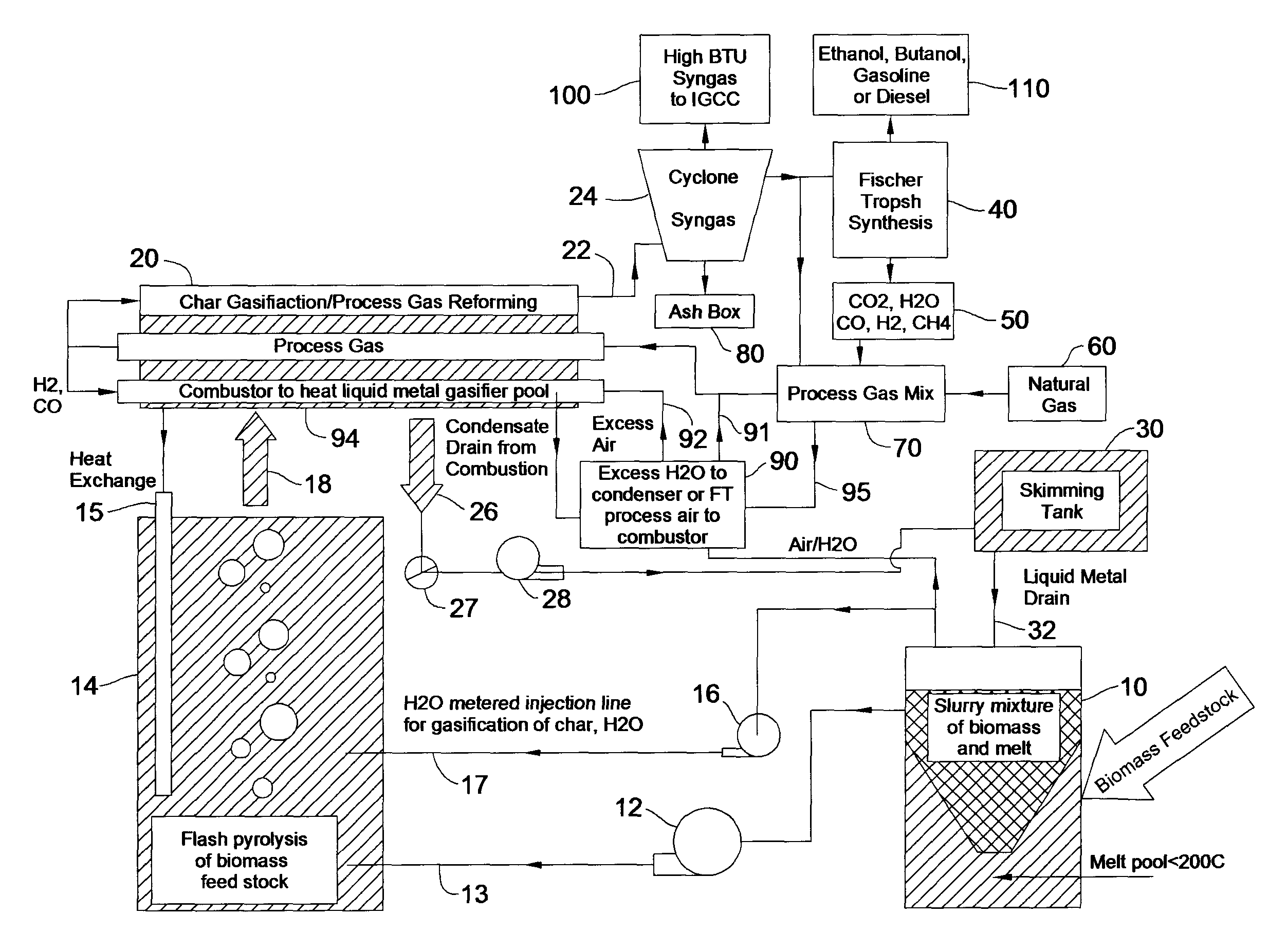

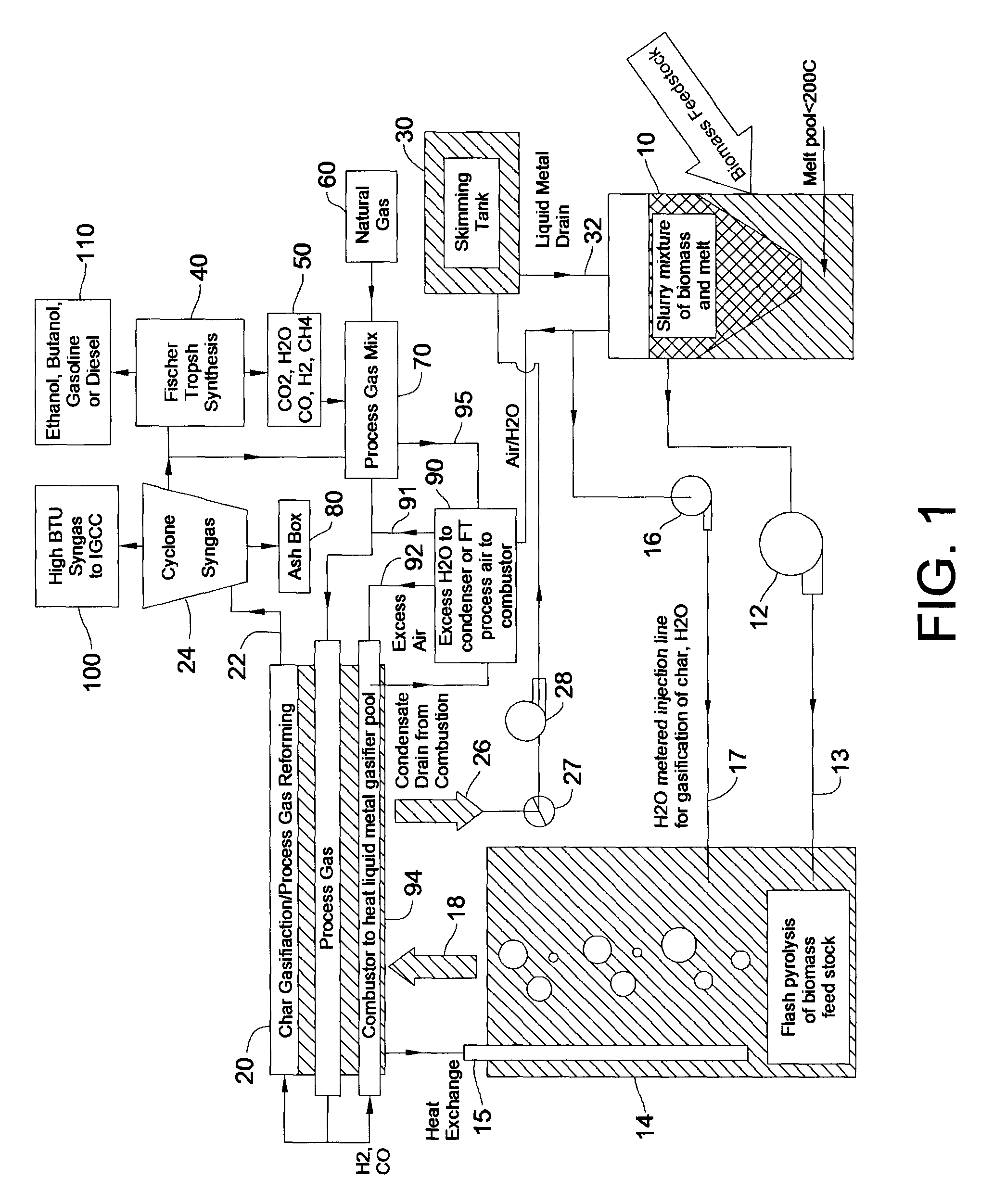

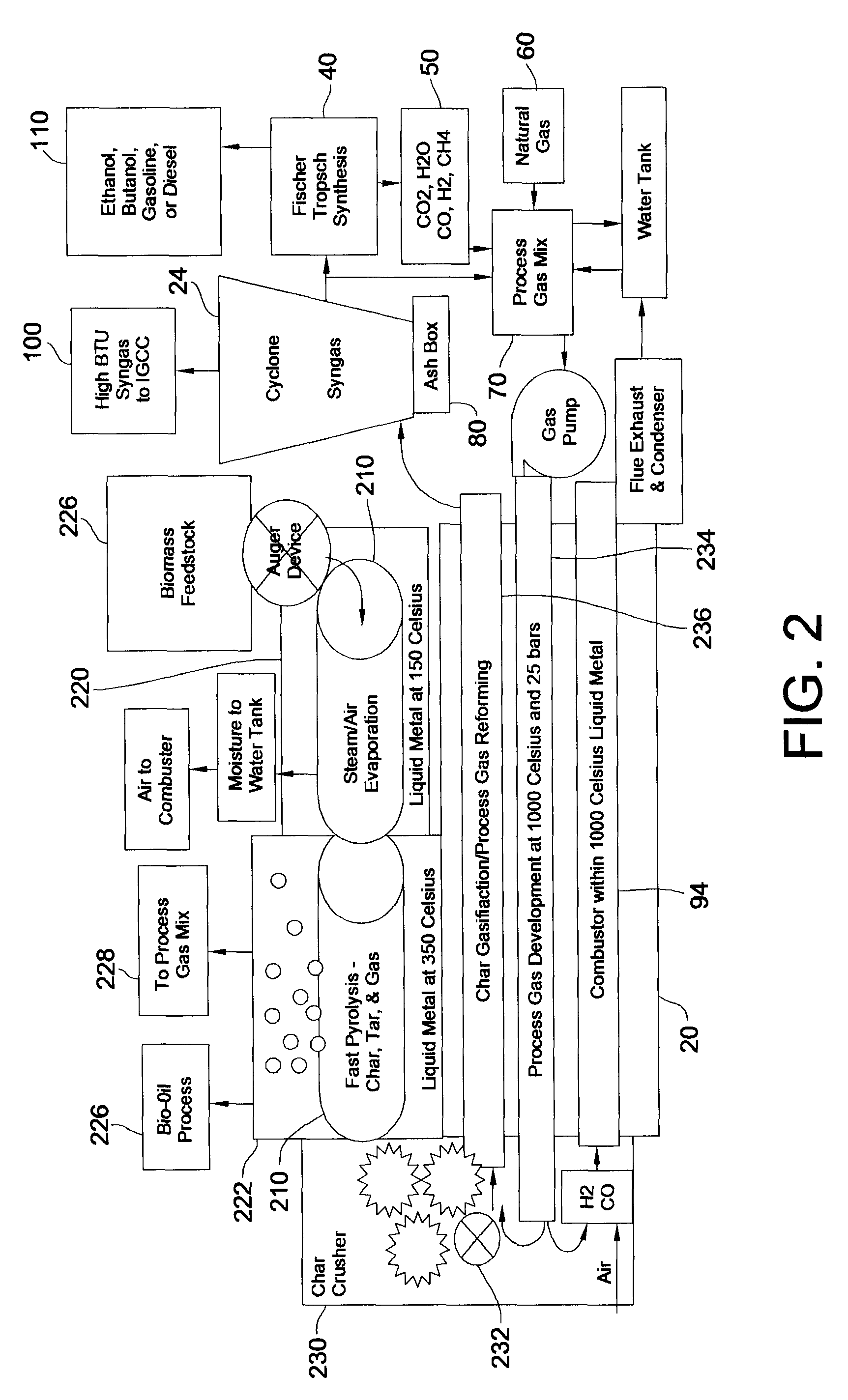

Method and apparatus to protect synthesis gas via flash pyrolysis and gasification in a molten liquid

InactiveUS20080307703A1Improve efficiencyLittle heating lossWaste based fuelRetortsSyngasThermodynamics

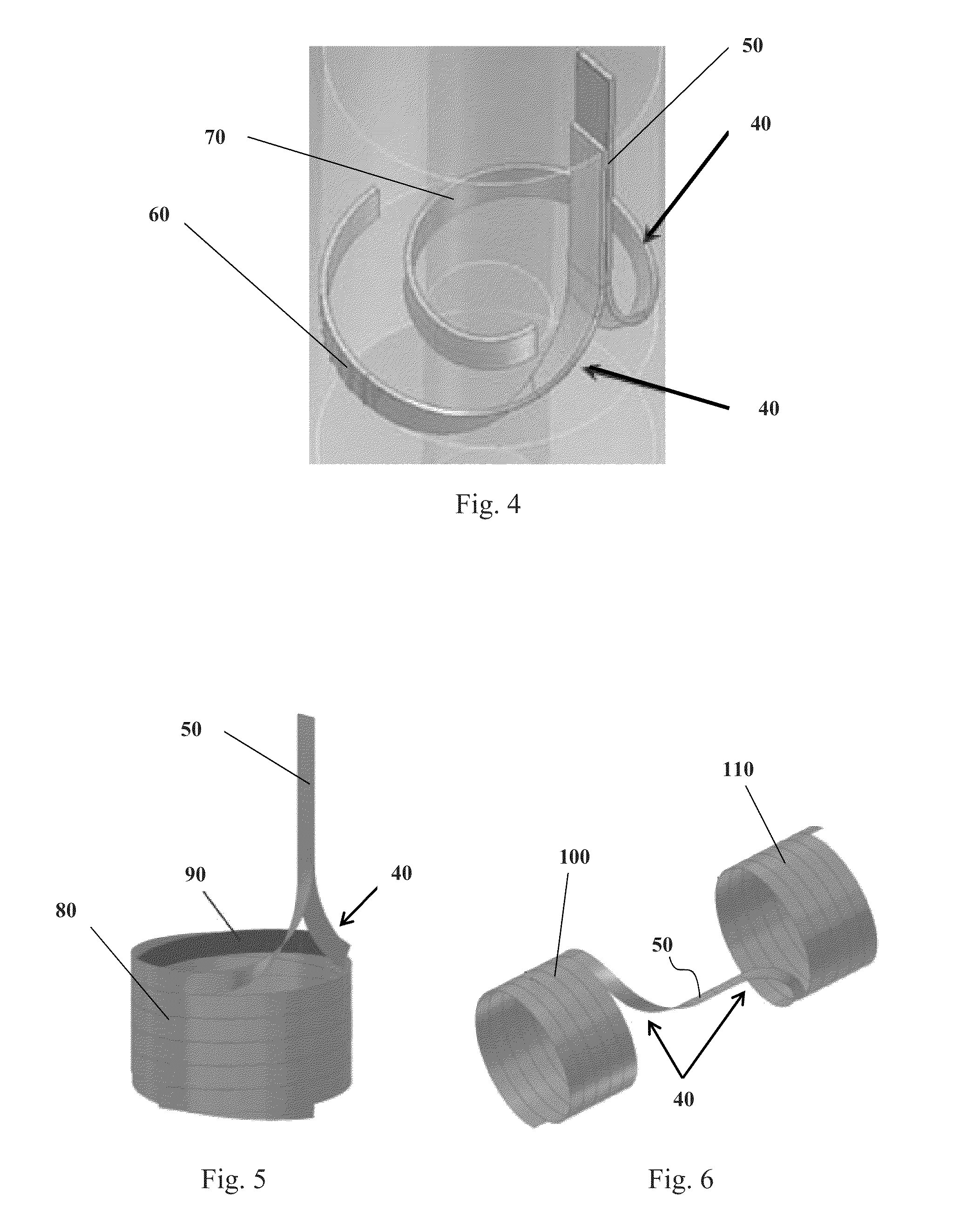

Disclosed are a method and a corresponding apparatus for converting a biomass reactant into synthesis gas. The method includes the steps of (1) heating biomass in a first molten liquid bath at a first temperature, wherein the first temperature is at least about 100° C., but less than the decomposition temperature of the biomass, wherein gas comprising water is evaporated and air is pressed from the biomass, thereby yielding dried biomass with minimal air content. (2) Recapturing the moisture evaporated from the biomass in step 1 for use in the process gas. (3) Heating the dried biomass in a second molten liquid bath at a second temperature, wherein the second temperature is sufficiently high to cause flash pyrolysis of the dried biomass, thereby yielding product gases, tar, and char. (4) Inserting recaptured steam into the process gas, which may optionally include external natural gas or hydrogen gas or recycled syngas for mixing and reforming with tar and non-condensable gases. (5) Further reacting the product gases, tar, and char with the process gas within a third molten liquid bath at a third temperature which is equal to or greater than the second temperature within the second molten liquid bath, thereby yielding high quality and relatively clean synthesis gas after a relatively long residence time needed for char gasification. A portion of the synthesis gas so formed is combusted to heat the first, second, and third molten liquid baths, unless external natural or hydrogen gas is available for this use.

Owner:US SEC AGRI +1

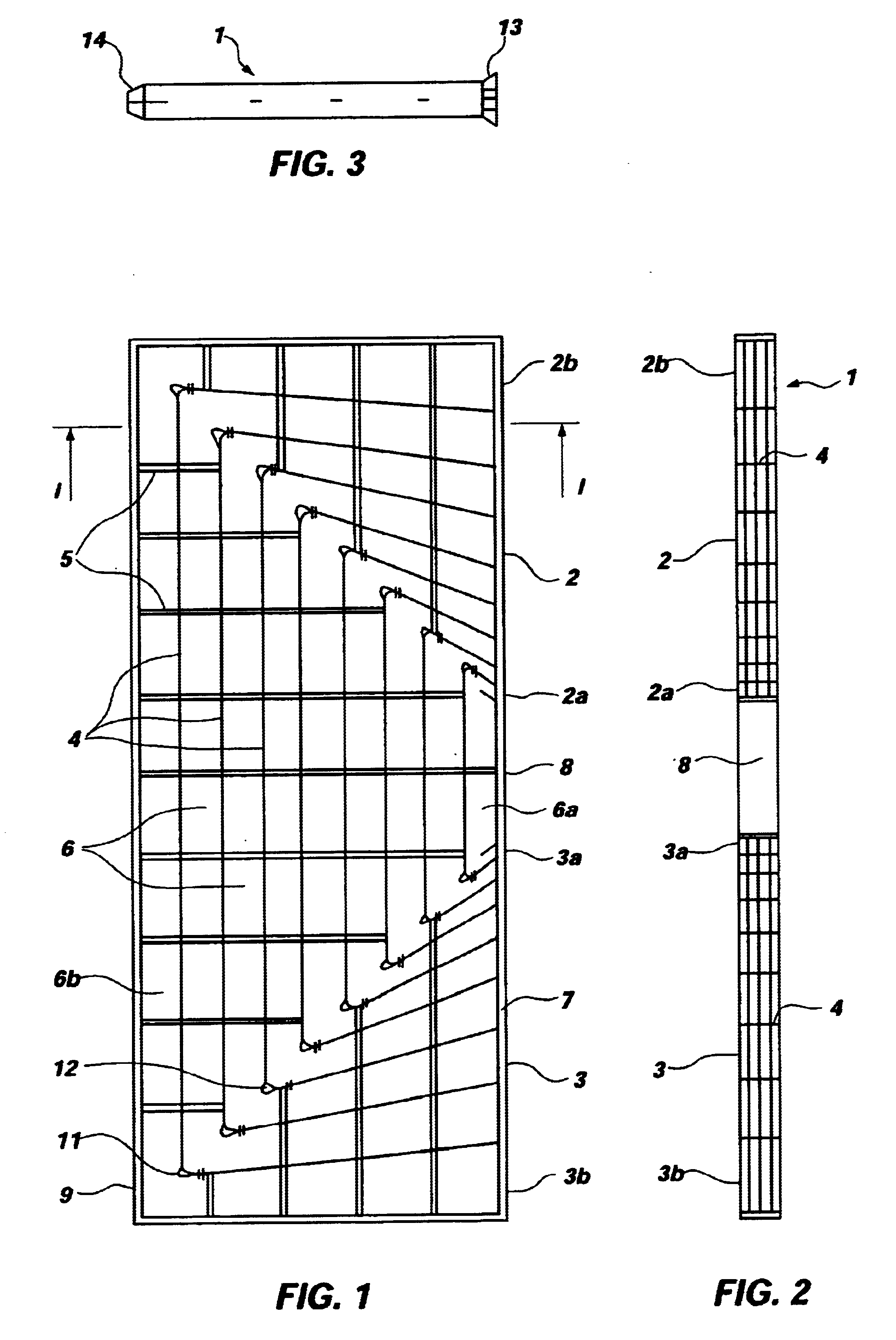

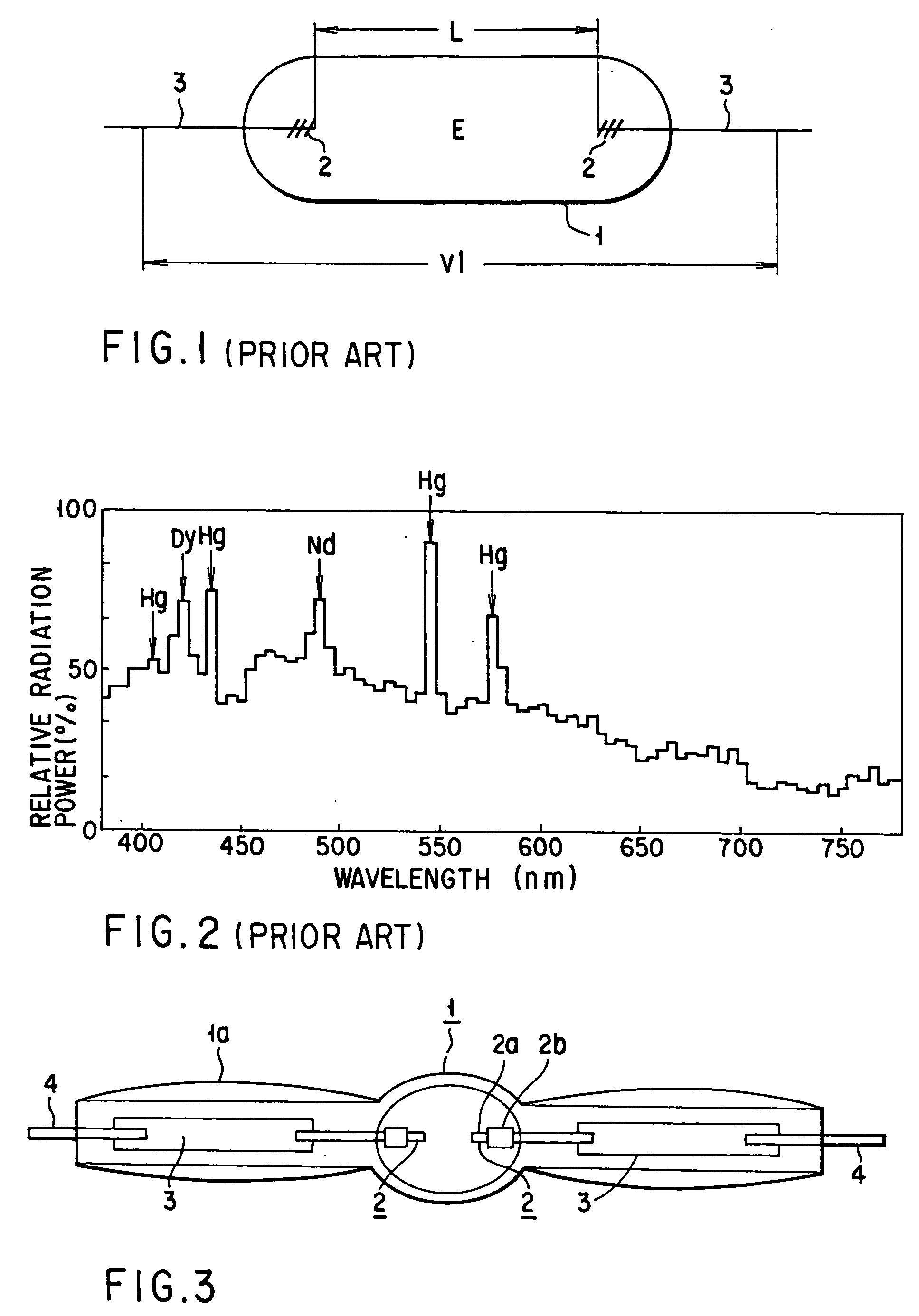

Heat exchanger

InactiveUS20020134087A1Small heat lossImprove performanceEnergy recovery in ventilation and heatingHeat recovery systemsGas passingHeat exchanger

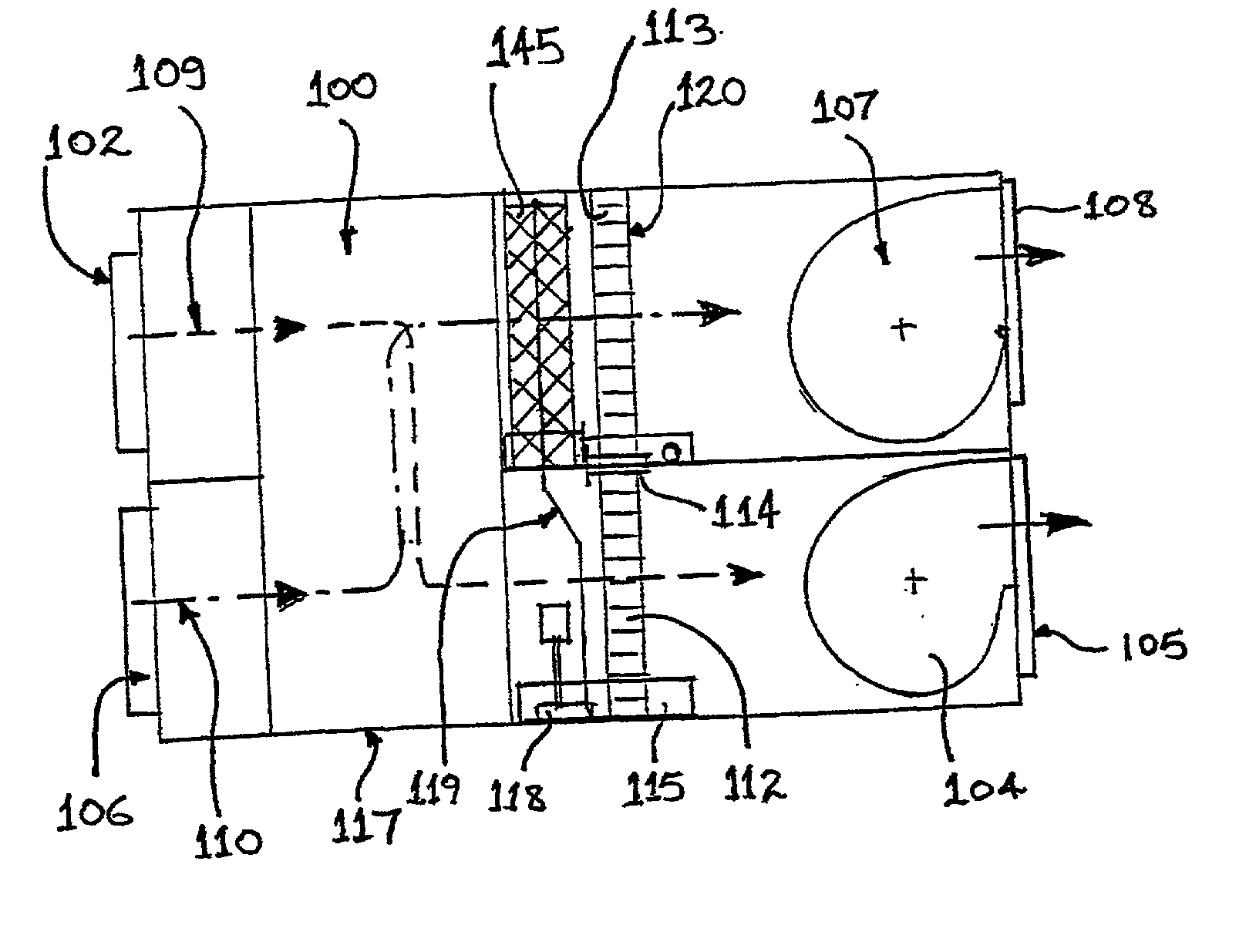

A gas-flow heat exchanger comprising a set of parallel, spaced, heat-conductive areas providing between them a stack of pockets each containing parallel baffles (24) which define a platen of passageways (26) guiding the gas-flow path through the pocket between inlet and outlet openings (22, 23). The openings being arranged in four parallel lines at the sides of the stack, two of the lines respectively containing the inlet and outlet openings (22, 23) associated with the gas flow paths of alternative pockets. The remaining two lines respectively containing the inlet and outlet openings associated with the remaining pockets. Each pocket containing a removable frame (21) formed with the openings provided at the ends of the gas flow path through it and supporting within the frame the parallel baffles (24) which divide the gas-flow path into the platen of passageways (26). All of the passageways (26) provide a substantially equal dwell time to gas passing therethrough.

Owner:AIR CHANGE PTY LTD

Method and apparatus to produce synthesis gas via flash pyrolysis and gasification in a molten liquid

InactiveUS7875090B2Improve efficiencyControlled heatingWaste based fuelRetortsFlash vacuum pyrolysisDecomposition

Disclosed are a method and a corresponding apparatus for converting a biomass reactant into synthesis gas. The method includes the steps of (1) heating biomass in a first molten liquid bath at a first temperature, wherein the first temperature is at least about 100° C., but less than the decomposition temperature of the biomass, wherein gas comprising water is evaporated and air is pressed from the biomass, thereby yielding dried biomass with minimal air content. (2) Recapturing the moisture evaporated from the biomass in step 1 for use in the process gas. (3) Heating the dried biomass in a second molten liquid bath at a second temperature, wherein the second temperature is sufficiently high to cause flash pyrolysis of the dried biomass, thereby yielding product gases, tar, and char. (4) Inserting recaptured steam into the process gas, which may optionally include external natural gas or hydrogen gas or recycled syngas for mixing and reforming with tar and non-condensable gases. (5) Further reacting the product gases, tar, and char with the process gas within a third molten liquid bath at a third temperature which is equal to or greater than the second temperature within the second molten liquid bath, thereby yielding high quality and relatively clean synthesis gas after a relatively long residence time needed for char gasification. A portion of the synthesis gas so formed is combusted to heat the first, second, and third molten liquid baths, unless external natural or hydrogen gas is available for this use.

Owner:US SEC AGRI +1

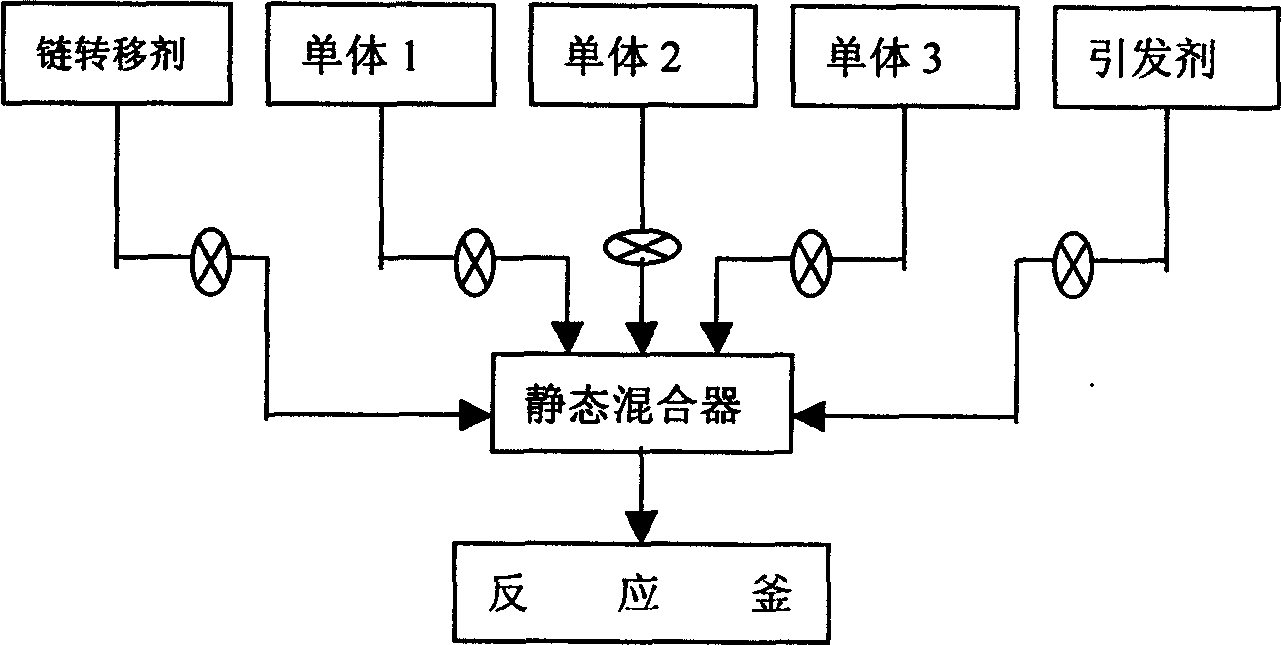

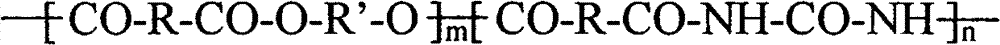

Acroleic acid/polyurethane transparent anode electrophoresis coating and its preparation method

InactiveCN1807528AControl molecular weightIncrease the degree of effective responsePaints for electrolytic applicationsMethacrylateSurface-active agents

The invention relates to an acroleic acid / polyurethane transparent anode electrophoresis coating and its preparation method, comprising the following raw materials (by weight ratio): cationic acrylic polymer 52-85, closed isocyanate cross linking agent 14.5-23.5, non-ionic or / and cationic surface active agent 4.6-8, catalyst 0.6-1.1, chain-transferring agent 0.5-0.8, deionized water 26-51. The cationic acrylic polymer comprises the following raw materials (by weight portions): isobutyl methacrylate 35-55, methyl acrylic ester 23-43, methyl methacrylic hydroxyl propyl ester 15-26, dimethyl amido propyl ester methacrylamide 13.5-23, 2-ethylhexyl methacrylate 13-28, azo-diisobutyronitrile 0.5-1.2, and dimethyl carbinol 35-89.

Owner:冯国贤

Heat exchanger

InactiveUS6829900B2Small heat lossImprove performanceEnergy recovery in ventilation and heatingDomestic cooling apparatusGas passingEngineering

Owner:AIR CHANGE PTY LTD

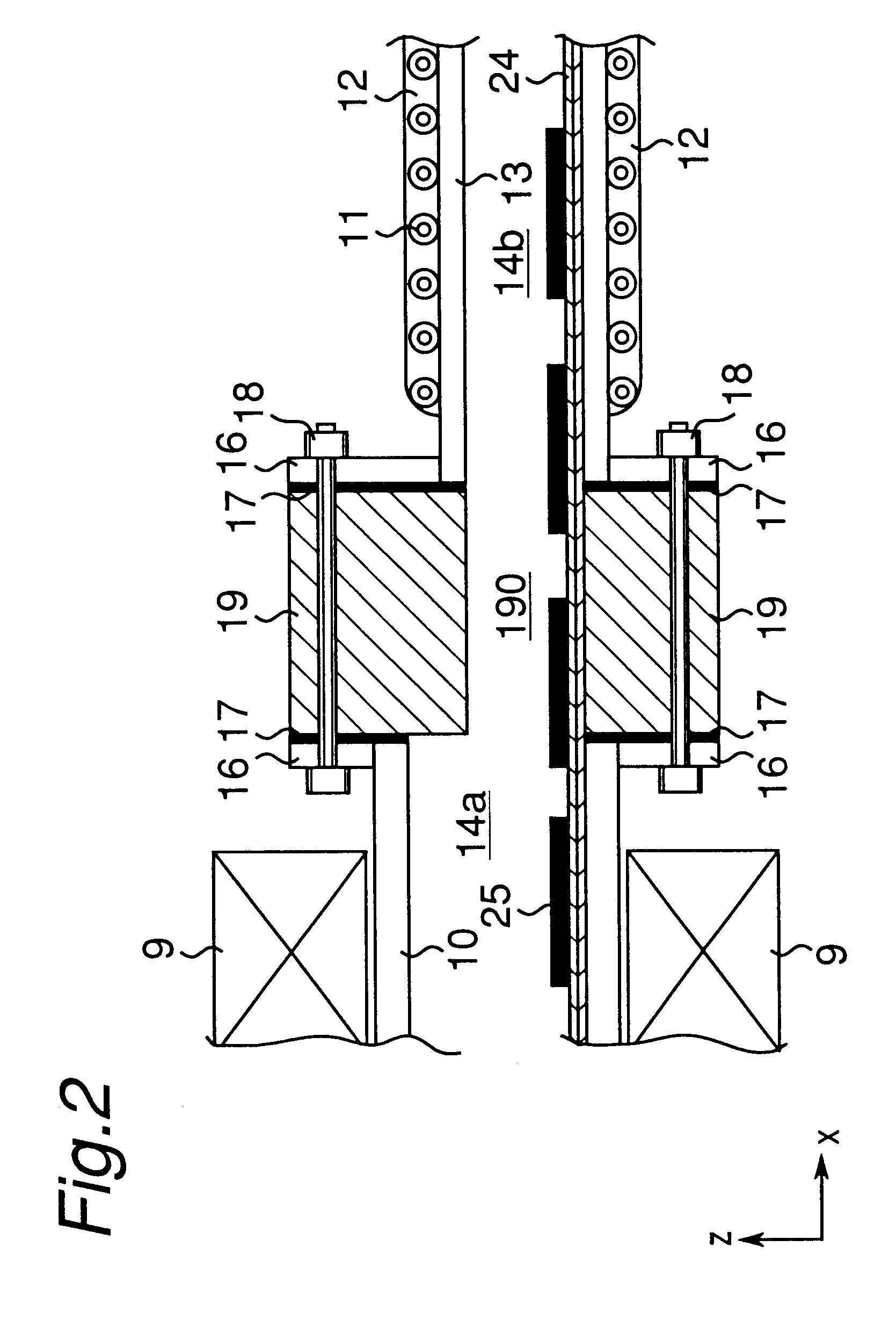

Thermal treatment apparatus

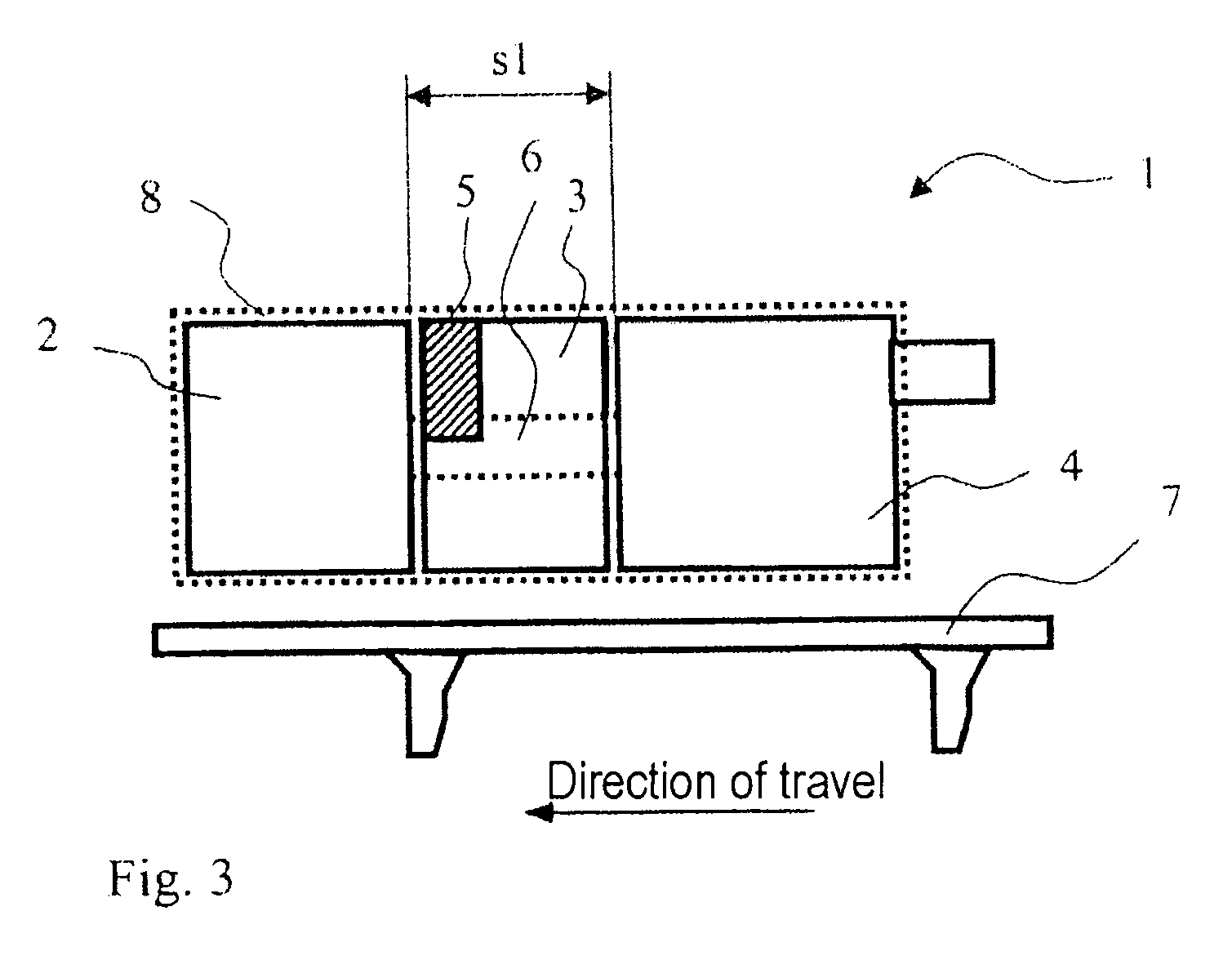

InactiveUS6623269B2Small heat lossAvoid heat conductionLining supportsGlass transportation apparatusThermal energyHeat losses

A thermal treatment apparatus has a plurality of thermal treatment chambers in which an object to be treated is thermally treated while being transported, and at least one pair of two adjacent thermal treatment chambers of which inside temperatures are different from each other. The thermal treatment chambers are connected through a thermal insulating structural member, whereby thermal conduction between the chambers, such as muffles, is prevented to reduce a heat loss caused in the thermal treatment apparatus. Therefore, input thermal energy which is necessary to carry out a predetermined thermal treatment is significantly reduced without affecting quality and yield of the object.

Owner:PANASONIC CORP

Local vapor fuel cell

InactiveUS20050164059A1Easy to assembleSmall heat lossFuel cell heat exchangeFuel cells groupingDigital cameraElectron device

A local vapor fuel cell, comprising (A) an anode receiving a liquid fuel from a liquid fuel source substantially through diffusion; (B) an electrolyte plate having a first surface adjacent to the anode; and (C) a cathode adjacent to a second surface of the electrolyte plate and opposite to the anode. The anode is provided with a heating environment to at least partially vaporize the liquid fuel inside the anode and the anode further comprises a catalyst phase to ionize the fuel in a vapor or vapor-liquid mixture form to produce protons. The electro-catalytic reaction at the anode is more efficient with a vapor phase or vapor-liquid mixture than with liquid fuel alone. The invented fuel cell is compact in size and light in weight and, hence, is particularly useful for powering small microelectronic devices such as a notebook computer, a personal digital assistant, a mobile phone, and a digital camera.

Owner:NANOTEK INSTR

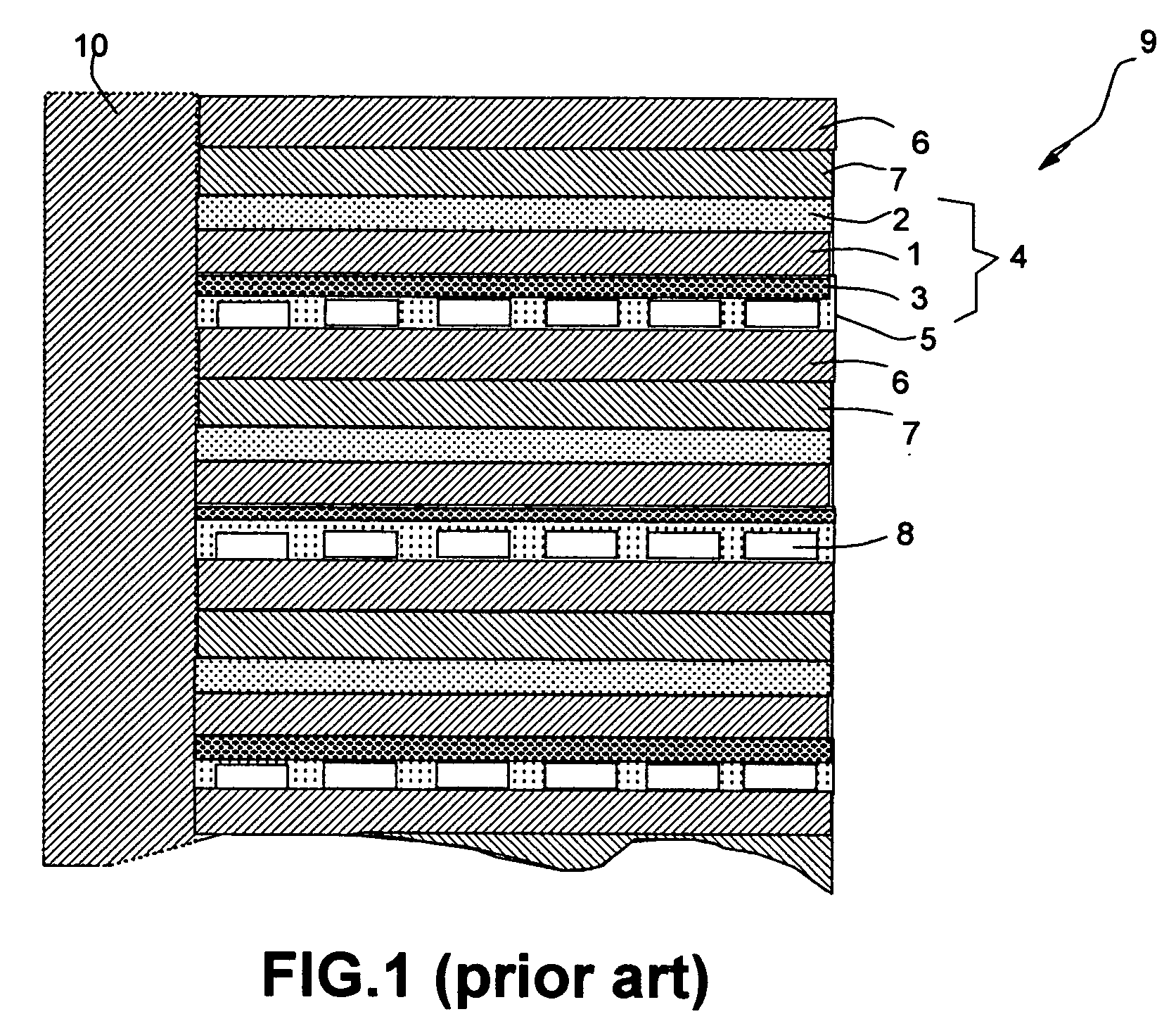

Lightening device for metal halide discharge lamp

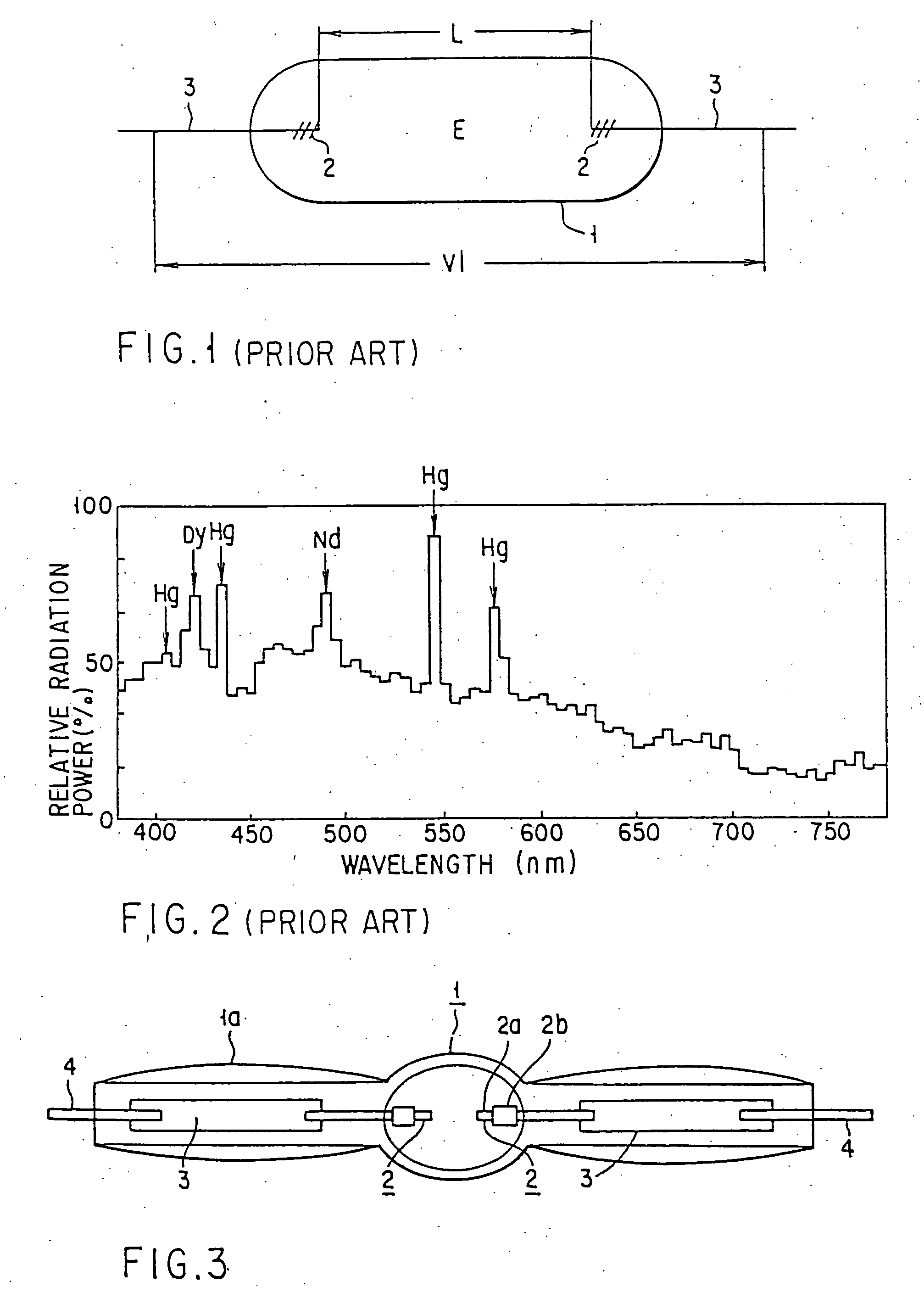

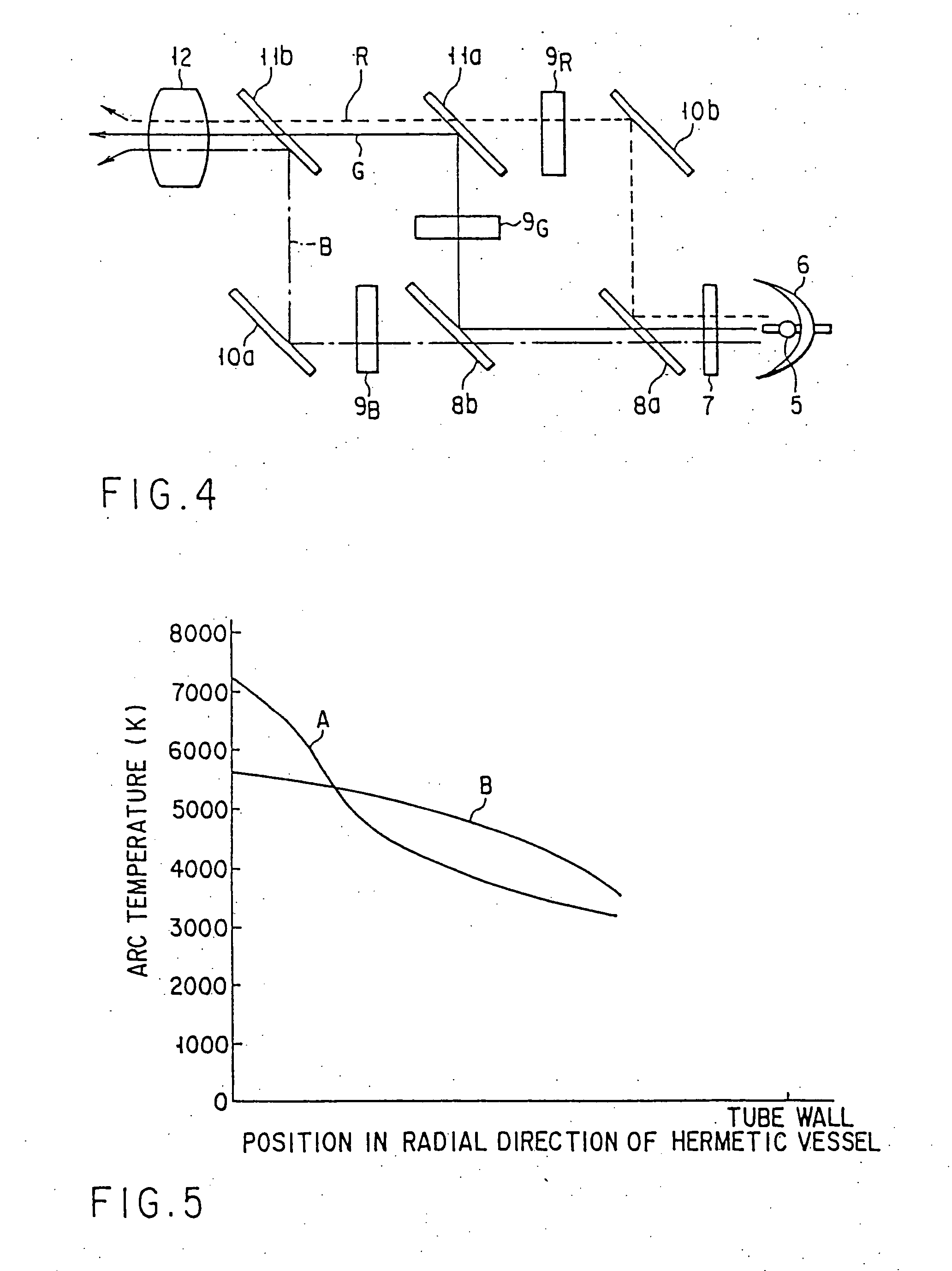

InactiveUS20060255741A1Good rising of chromaticitySmall in unevenness of characteristicVehicle headlampsElectric light circuit arrangementNoble gasElectric light

A metal halide discharge lamp with which essentially permits disusing mercury is provided. The metal halide discharge lamp comprises a refractory and transparent hermetic vessel, a pair of electrodes fixed to the hermetic vessel, and a discharge medium sealed in the hermetic vessel and containing a first halide, a second halide, and a rare gas. The first halide is a halide of metal which achieves a desired light emission. The second halide has a relatively high vapor pressure, being at least one halide of metal which is unlikely to emit a visible light compared with the metal of the first halide and acts as a buffer gas.

Owner:HARISON TOSHIBA LIGHTING CORP

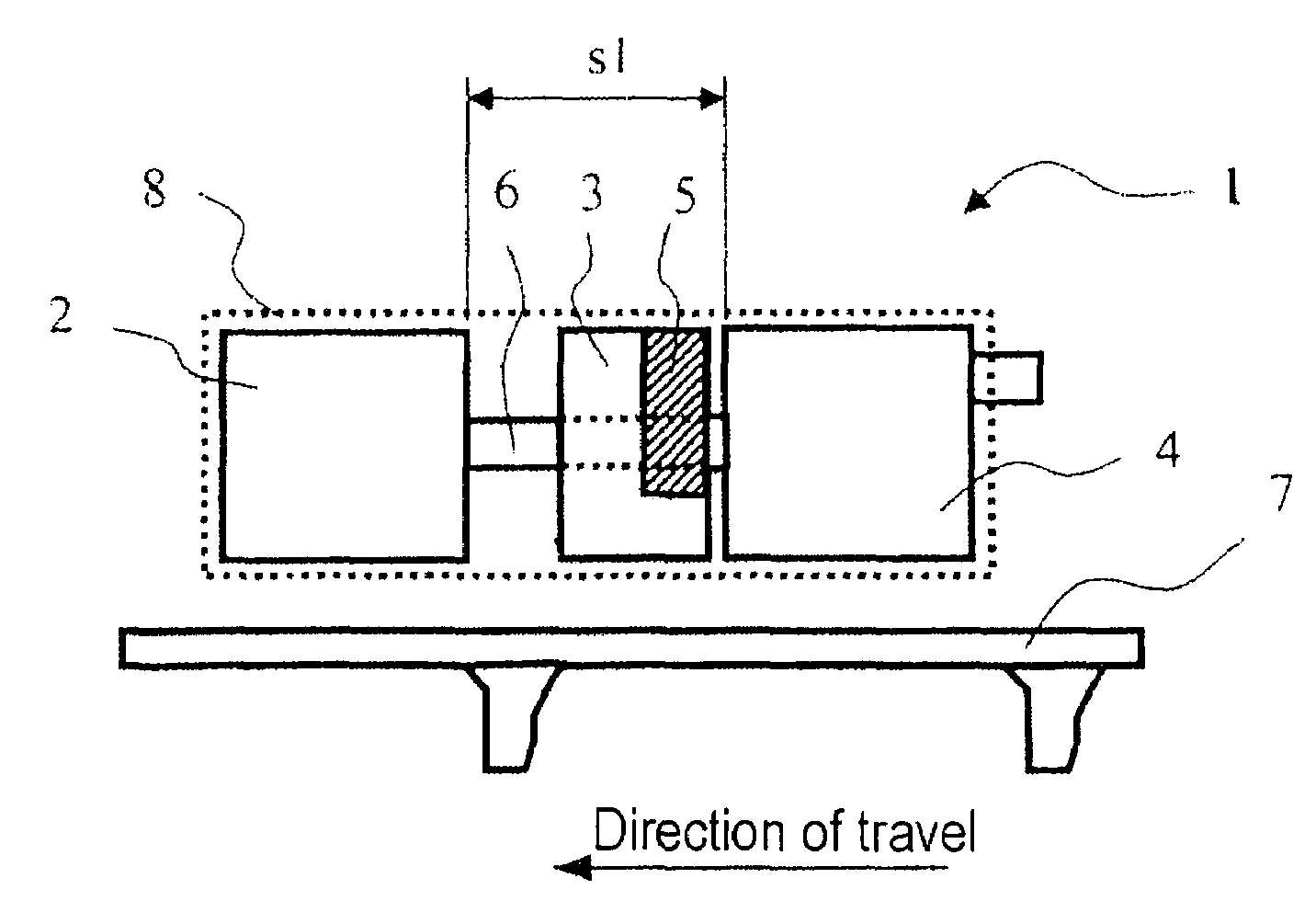

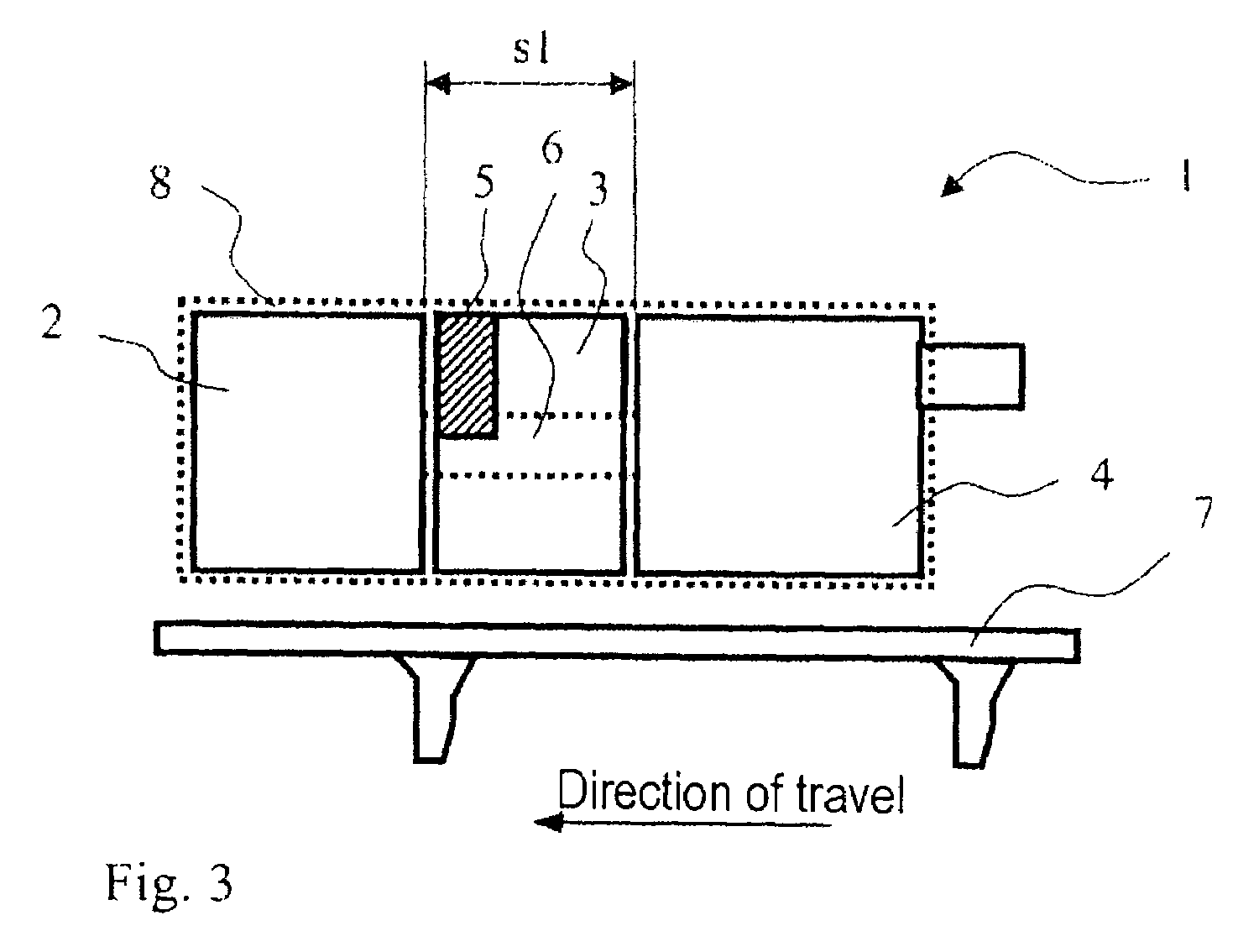

Exhaust gas treatment system and utility vehicle with an exhaust gas treatment system

InactiveUS7293408B2Line lengthEffective external surfaceInternal combustion piston enginesExhaust apparatusNitrogen oxidesExhaust fumes

Owner:DAIMLER AG

Method and device for the pneumatic operation of a tool

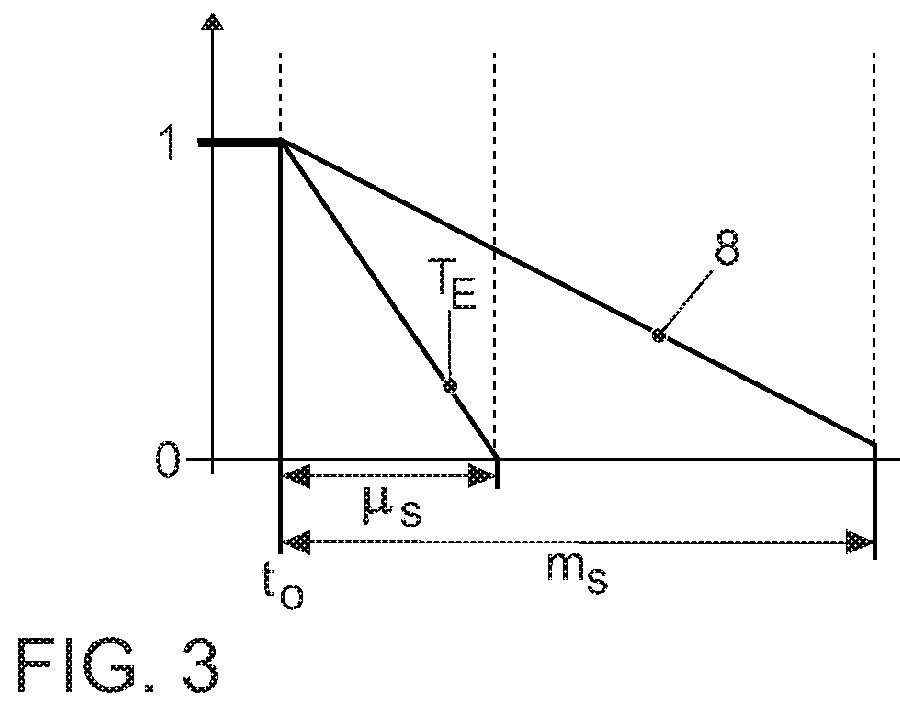

ActiveUS20060272324A1Reduce heat lossReduce capacityFluid parameterFluid couplingsEngineeringAtmosphere

A device for the pneumatic operation of a tool includes a generally closed pressure fluid circuit (2), at least one compressor (5), for increasing the pressure of the pressure fluid in the circuit, the compressor (5) having an inlet and an outlet, and a tool driven by the pressure fluid in the circuit, and through which the pressure fluid is transported in the circuit from the outlet to the inlet of the compressor (5). The pressure that is generated by the compressor and the load adopted by the tool (8) are adapted such that the pressure of the returning pressure fluid downstream the tool (8) is higher than the pressure of the surrounding atmosphere.

Owner:CARGINE ENG AB

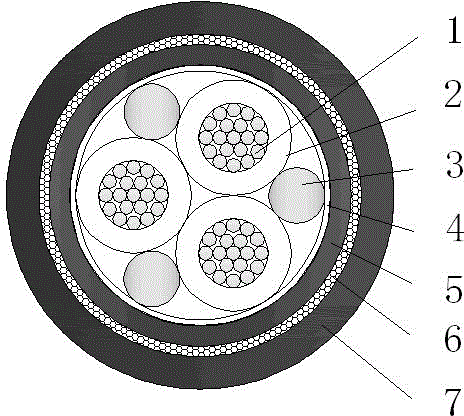

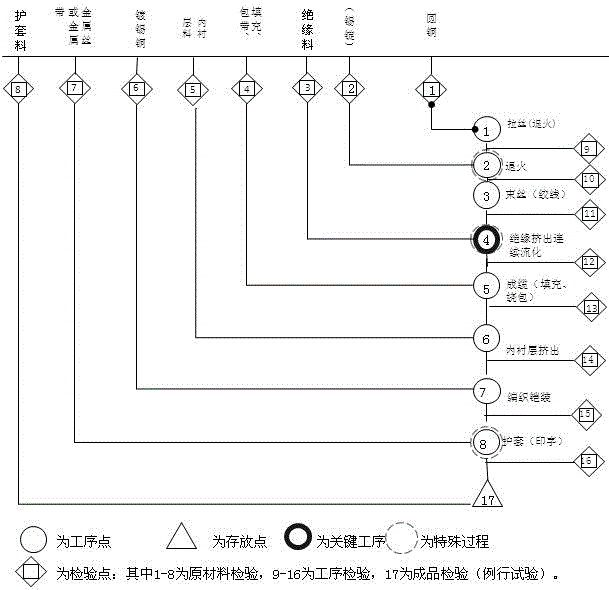

Lightweight flexible LSOH (Low Smoke Zero Halogen) fire-resistant low-voltage marine cable and process flow thereof

InactiveCN104681159ASmall heat insulationImprove insulation performanceFlexible cablesCable/conductor manufactureLow voltageShock resistance

The invention discloses a lightweight flexible LSOH (Low Smoke Zero Halogen) fire-resistant low-voltage marine cable and a process flow thereof. The lightweight flexible LSOH fire-resistant low-voltage marine cable comprises a tin-plated flexible conductor, a ceramic silicone rubber insulating layer, an LSOH flame-retardant filling material, an LSOH wrapping tape layer, an LSOH flame-retardant isolating sleeve, a metal braid armor shielding layer and an LSOH flame-retardant protection sleeve. The cable disclosed by the invention has the advantages of heat insulation, fire insulation, waterproofness, shock resistance, low thermal weight loss, low smoke, zero halogen, flame retardance and the like. In case of a fire, a hard shell formed by the insulating layer can take good effects of flame retardance, fire resistance, fire prevention and fire insulation and effectively ensures smoothness of a line. The cable has the advantages of being flexible, small in size, light in weight and excellent in mechanical property and electrical property, meets the requirement of a complex laying environment in a ship, can effectively save a ship space and reduce a light ship weight of the ship and improves a cargo dead weight of the ship.

Owner:ZHONGTIAN TECH IND WIRE&CABLE SYST CO LTD

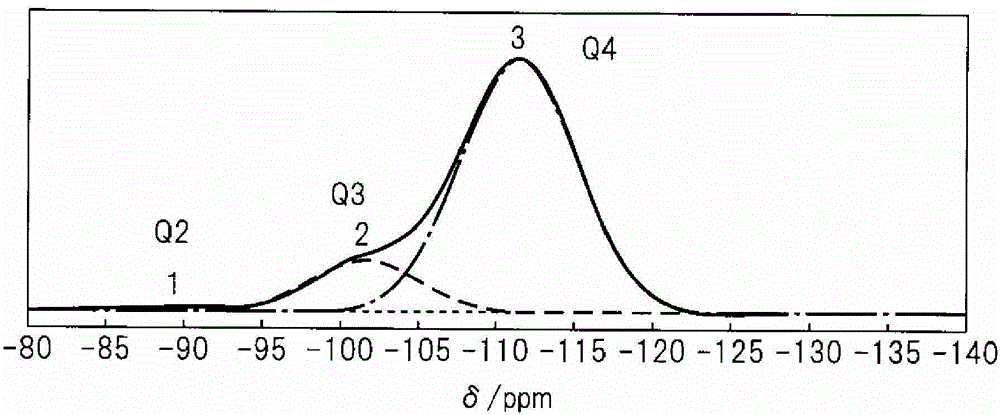

Photosensitive silicone resin composition

InactiveCN103068884AImprove crack resistanceSmall coefficient of linear expansionPhotomechanical apparatusSilica particleSilane compounds

Provided is a resin composition which gives a cured product of a photocurable resin having good crack resistance even when formed into a thick film, and capable of maintaining a low coefficient of linear expansion, low thermal weight loss, and a low shrinkage factor. This photosensitive silicone resin composition comprises (A) a silica particle-containing condensation reaction product and (B) a photopolymerization initiator, and is characterized in that the silica particle-containing condensation reaction product (A) is a condensation reaction product of a polysiloxane compound (a) comprising a hydrolytic condensation product of one or more silane compounds represented by the following general formula (1): R1 n1SiX1 4-n1 (wherein R1, n1, and X1 are defined in the claims) and / or the silane compound, and silica particles (b), and has a terminal structure: Si-O-Y (wherein Y is defined in the claims) which satisfies the following formula (2): 0 3 3] / ([Si-O-R2] + [Si-O-SiR3 3]) = 1 (wherein R2 and R3 are defined in the claims), and has a photopolymerizable functional group.

Owner:ASAHI KASEI KK

Solar Energy Absorber

InactiveUS20110259319A1Little heating lossEasy to getSolar heating energySolar heat collector controllersSolar lightEngineering

It aims to provide a solar heat collecting apparatus that can efficiently collect energy from solar light. The solar heat collecting apparatus comprises an opened container part 22 that accumulates heat, a closed part 25 that closes the container part 22 and has an opening part 26 to let the collected solar light in, and a light absorbing part 36 that absorbs the solar light dispersed by passing through the opening part 26 so that it is converted into heat.

Owner:ELECTRA HLDG CO LTD

Battery disconnecting device

ActiveUS20180097390A1Fast switching timeLimit power lossElectric devicesParallel/serial switchingEngineeringCircuit breaker

A battery disconnecting device has a first input and a second input to which a battery can be connected, whereby the disconnecting device also has a first output and a second output to which an electric component can be connected, whereby at least one first circuit breaker is arranged between the first input and the first output, and at least one second circuit breaker is arranged between the second input and the second output, whereby the first circuit breaker is at least a transistor and the second circuit breaker is a relay.

Owner:VOLKSWAGEN AG

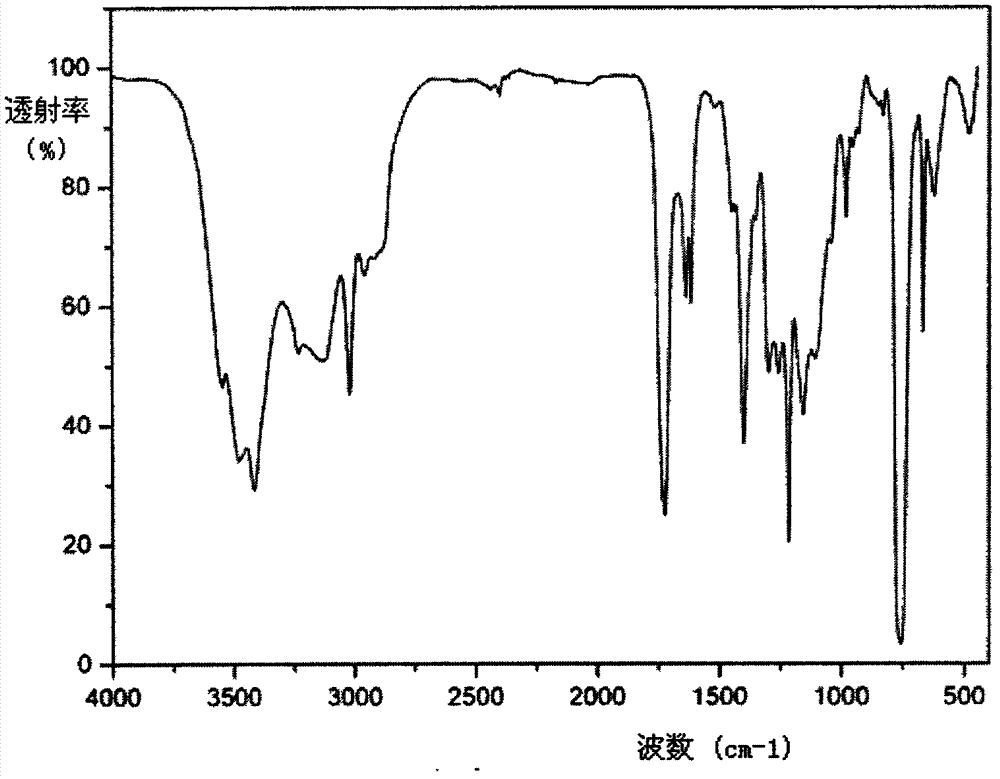

Ultraviolet light-cured hydrophilic coating and preparation method thereof

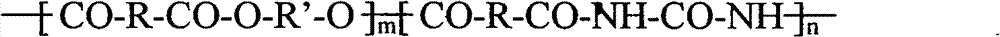

InactiveCN102816516ASmall heat lossImprove heat resistancePolyurea/polyurethane coatingsPolyamide coatingsAluminium foilUrea

The invention relates to an ultraviolet light-cured hydrophilic coating and a preparation method thereof. The method comprises the steps of mixing hydrophilic unsaturated polyester-urea amide, acrylic ester crosslinking monomers and an initiator according to a certain ratio; adding a proper amount of auxiliary agents and a diluent; stirring at a temperature of 25 DEG C, and thus the brownish black ultraviolet light-cured hydrophilic coating having a certain viscosity is obtained. The ultraviolet light-cured hydrophilic coating employs ultraviolet light to cure for film formation, has the characteristics of high efficiency, energy conservation and good hydrophilicity. The ultraviolet light-cured hydrophilic coating is expected to be used for hydrophilic coating of hydrophilic aluminium foil, plastic, glass, and the like, and provides excellent hydrophilic performance for the above.

Owner:郭文迅

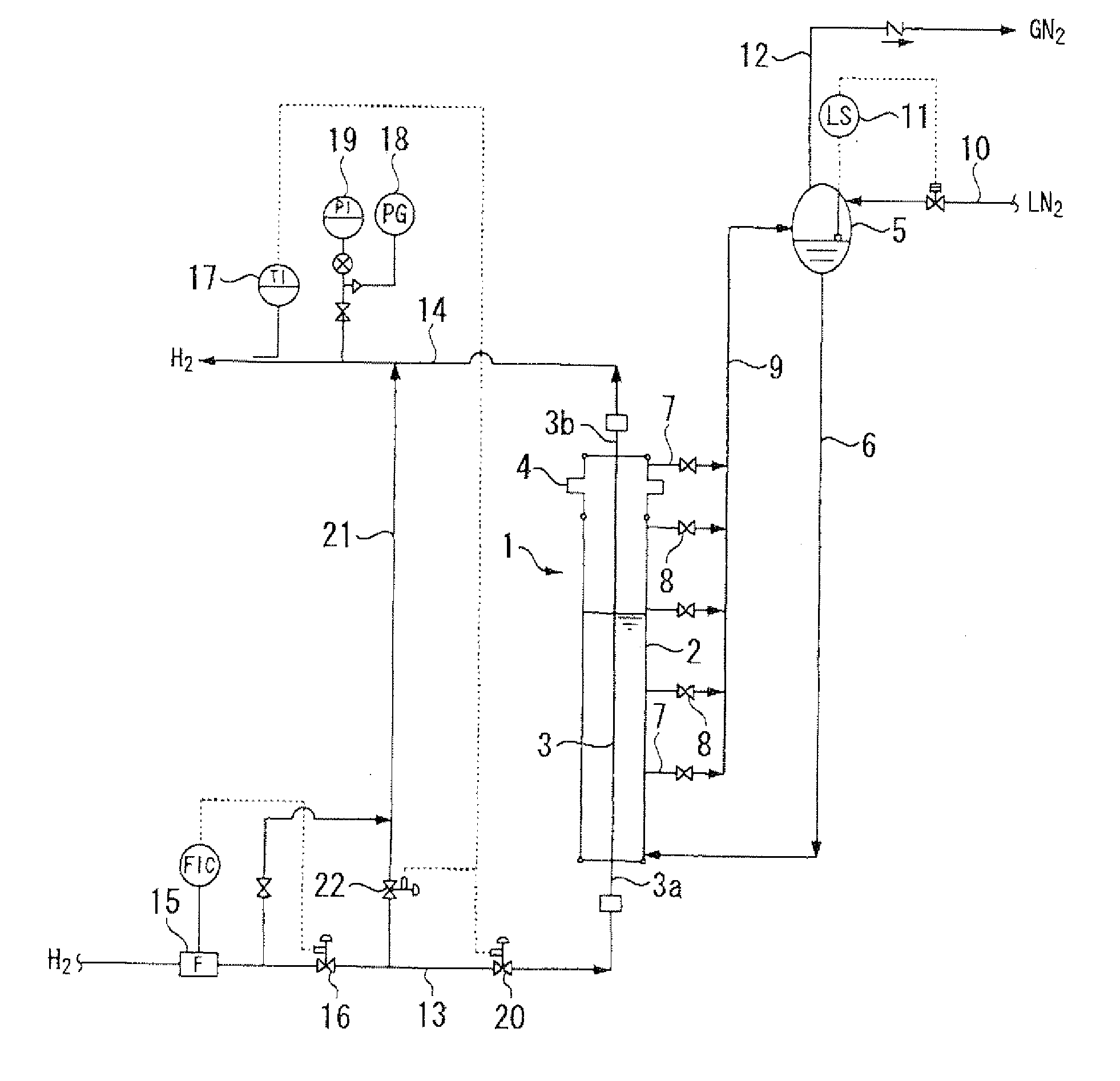

Hydrogen gas-cooling device

InactiveUS20100044020A1Low apparent densityImprove the overall coefficientDomestic cooling apparatusSolid materialHydrogenEngineering

A hydrogen gas-cooling device of the present invention includes, a heat exchanger that perform beat exchange between a hydrogen gas and a liquefied gas to cool a hydrogen gas; and a head tank that stores the liquefied gas supplied to the heat exchanger, wherein the heat exchanger has double pipe structure in which the hydrogen gas flows in an inner pipe, an outer pipe is filled with the liquefied gas, the pipe axis of the double pipe structure is vertically or obliquely arranged, a liquefied gas supply pipe that supplies the liquefied gas from the head tank is connected to a bottom part of the outer tube, and a return pipe that returns the liquefied gas to the head tank is provided at a position upper than that of the bottom part of the outer pipe.

Owner:TAIYO NIPPON SANSO CORP

Electric joint design to be used in electromagnetic coils made with high-temperature superconducting tape, aspected wire, or cable

ActiveUS8588876B1Little heating lossReduce contact resistanceSuperconductors/hyperconductorsCable fittings for cryogenic cablesMagnetic tension forceElectrical resistance and conductance

An electric joint design to be used in electromagnetic coils made with high-temperature superconducting tape, aspected wire, or cable. A terminal member contains an engraved twist-bend contour, which receives the coil and changes the direction of the coil by about 90 degrees without any hard-bends. A current lead is aligned with terminal section of the coil establishing an electric joint whose length is not limited by the coil geometry. Resistance is distributed along the length of the electric joint to reduce heat generation. The electric joint is placed away from the area where the magnetic forces are high to eliminate the problem of helium gas becoming trapped.

Owner:FLORIDA STATE UNIV RES FOUND INC

Lightening device for metal halide discharge lamp

InactiveUS20050179391A1Good rising of chromaticitySmall in unevenness of characteristicElectric lighting sourcesGas discharge lamp usageNoble gasElectric light

Disclosed is a metal halide discharge lamp which essentially permits disusing mercury. The metal halide discharge lamp comprises a refractory and transparent hermetic vessel, a pair of electrodes fixed to the hermetic vessel, and a discharge medium sealed in the hermetic vessel and containing a first halide, a second halide and a rare gas, the first halide being a halide of a metal which achieves a desired light emission, the second halide having a relatively high vapor pressure, being at least one halide of a metal which is unlikely to emit a visible light compared with the metal of the first halide, and acting as a buffer gas.

Owner:HARISON TOSHIBA LIGHTING CORP

Lightening device for metal halide discharge lamp

InactiveUS20070069655A1Good rising of chromaticitySmall in unevenness of characteristicVehicle headlampsElectric light circuit arrangementNoble gasElectric light

A metal halide discharge lamp with which essentially permits disusing mercury is provided. The metal halide discharge lamp comprises a refractory and transparent hermetic vessel, a pair of electrodes fixed to the hermetic vessel, and a discharge medium sealed in the hermetic vessel and containing a first halide, a second halide, and a rare gas. The first halide is a halide of metal which achieves a desired light emission. The second halide has a relatively high vapor pressure, being at least one halide of metal which is unlikely to emit a visible light compared with the metal of the first halide and acts as a buffer gas.

Owner:HARISON TOSHIBA LIGHTING CORP

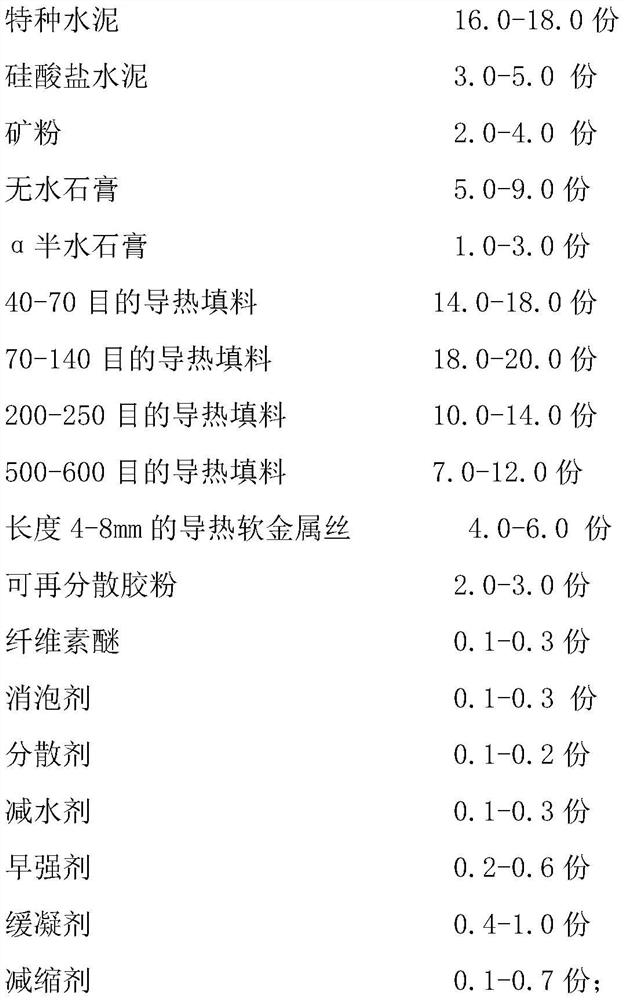

Special cement-based self-leveling mortar for indoor floor heating and preparation method thereof

The invention relates to special cement-based self-leveling mortar for indoor floor heating and a preparation method thereof. The special cement-based self-leveling mortar is prepared by mixing powder and water according to the mass ratio of 1:(0.22-0.25), wherein the powder is prepared from the following components in parts by weight: cement, anhydrite, alpha semi-hydrated gypsum, 40-70-mesh heat-conducting filler, 70-140-mesh heat-conducting filler, 200-mesh heat-conducting filler, 500-mesh heat-conducting filler, heat-conducting soft metal wires with the length of 6mm, redispersible rubber powder, cellulose ether and the like. The invention overcomes the defects that: cement-based self-leveling needs to be used for leveling when the existing indoor floor heating is laid, however, no cement-based self-leveling special for floor heating exists in the market at present, common cement-based self-leveling is mostly used, the heat conductivity coefficient is low, the heat conduction rate is slow, the heat loss amount is large and the like. The method is based on special cement and Portland cement which cooperate with the heat-conducting filler with higher heat conductivity coefficient, the heat-conducting soft metal wire and other preferable additives, so that the mortar has the advantages of high heat conductivity coefficient, high heat-conducting rate and low heat-conducting loss.

Owner:上海三棵树防水技术有限公司

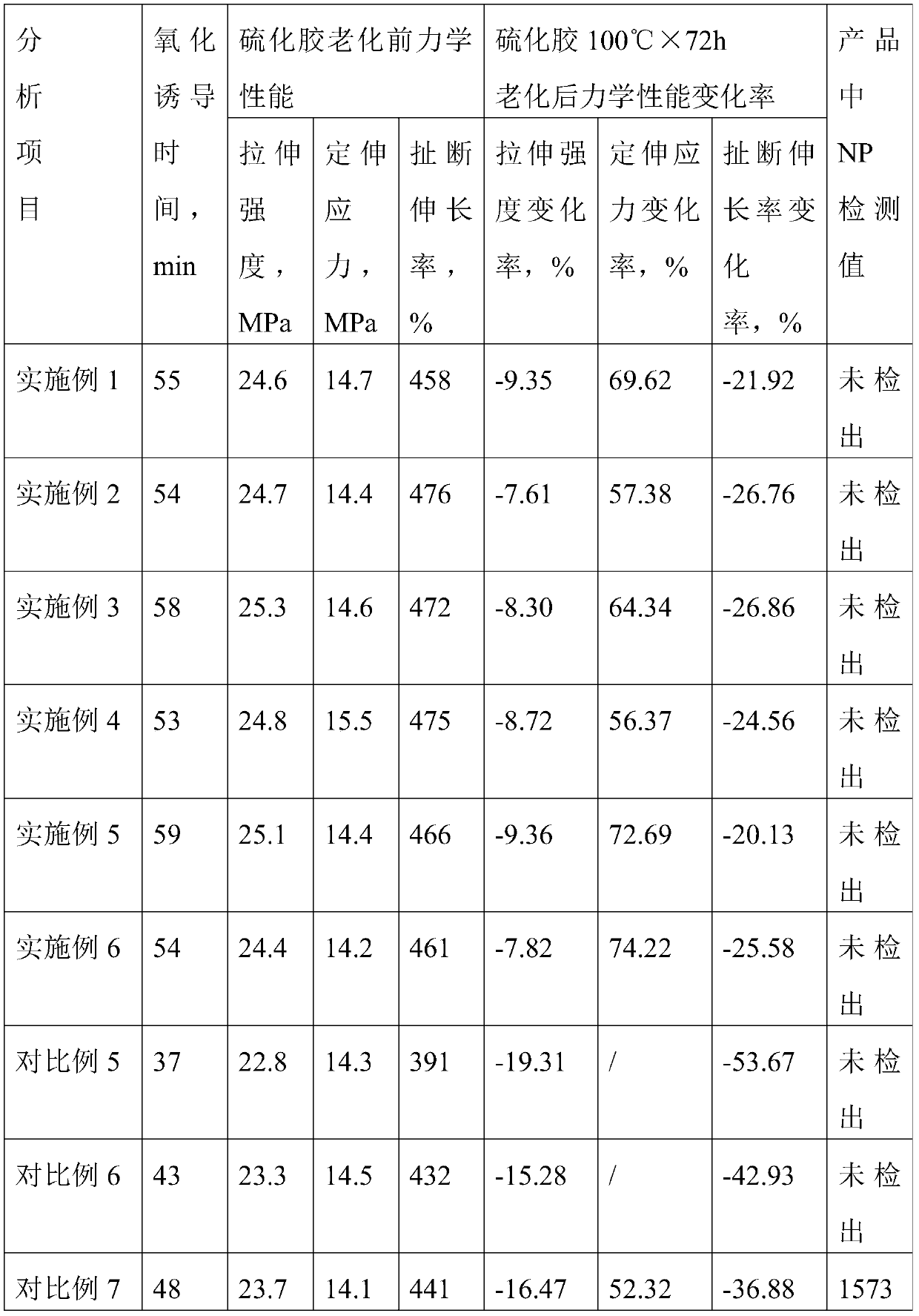

Preparation method of antioxidant for nitrile rubber

The invention relates to the technical field of preparation methods of antioxidants, in particular to a preparation method of an antioxidant for nitrile rubber, which comprises the following steps: proportionally mixing phenols, amines and phosphite antioxidants, stirring and heating to obtain a molten liquid, and emulsifying by using a composite emulsifier to form an antioxidant microemulsion with the particle size of less than 600nm and the viscosity of less than 500Pa. S. The antioxidant emulsion prepared by the invention has the advantages of good anti-aging effect, high activity, small thermal weight loss, high storage stability, environmental protection and the like.

Owner:PETROCHINA CO LTD

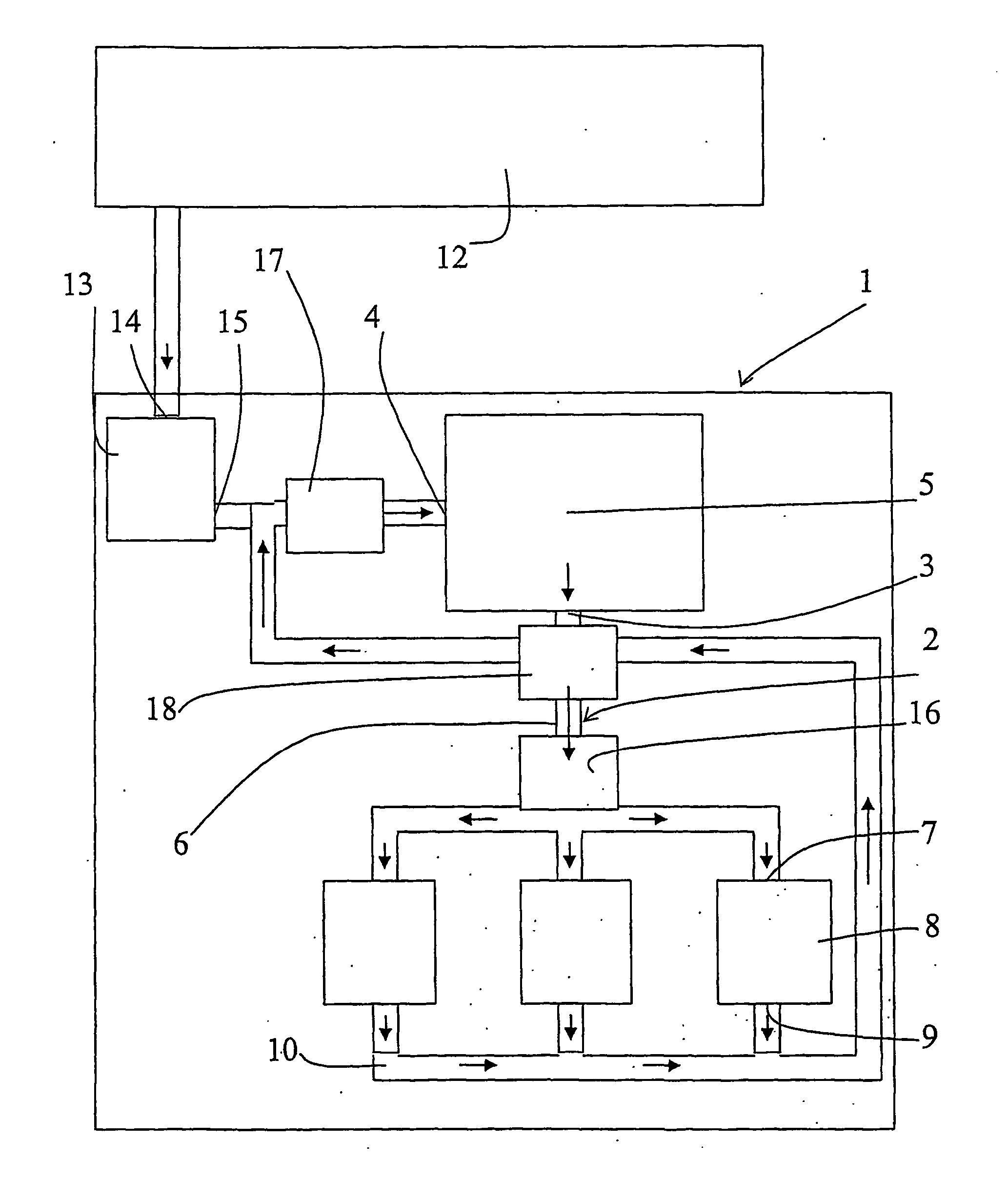

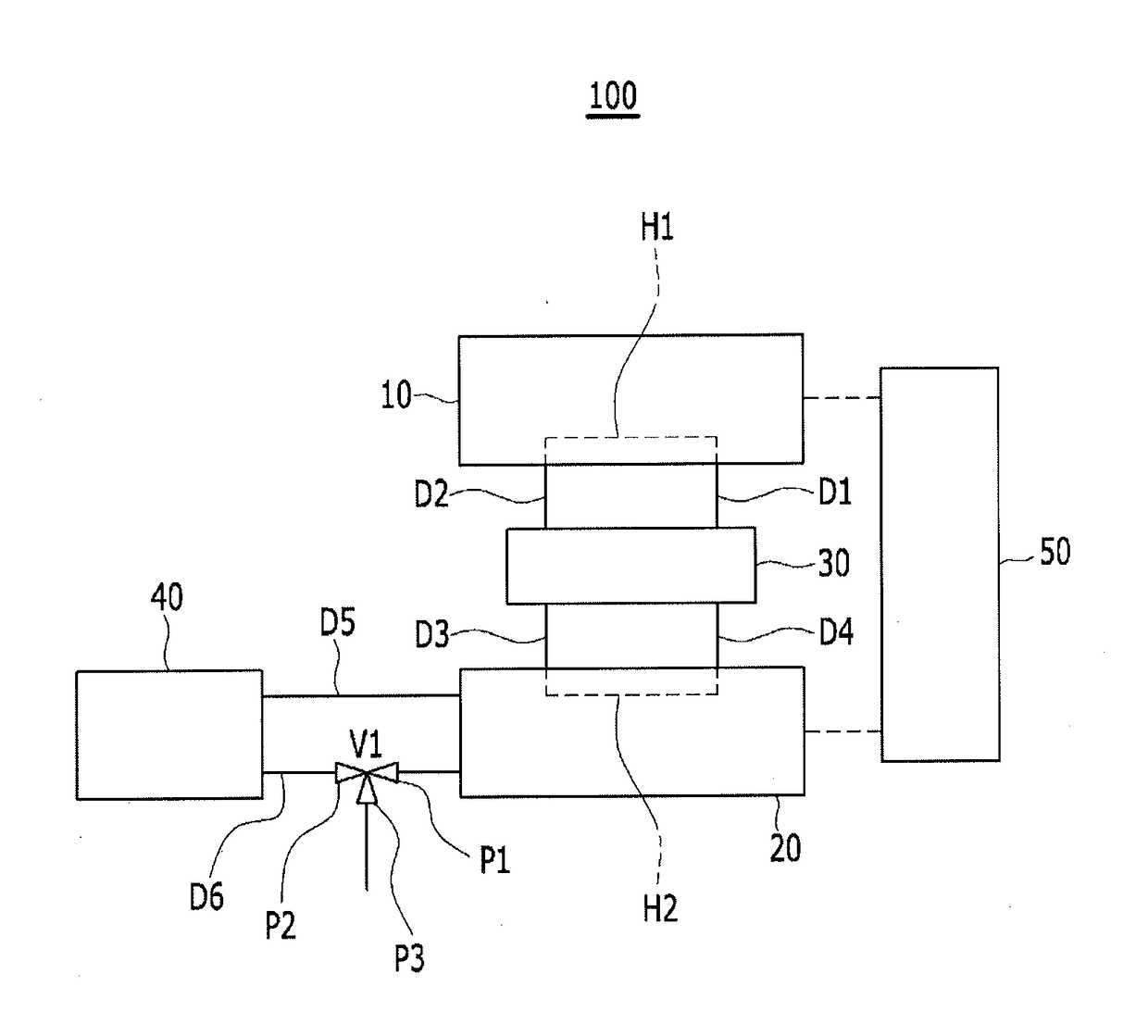

Thermal management system for fuel cell vehicle

ActiveUS20180233753A1Improve fuel efficiencyGood reversibilityHybrid vehiclesFuel cell heat exchangeElectricityThermal energy storage

A thermal management system for a fuel cell vehicle may include a fuel cell stack, a solid-state hydrogen storage device, and a hydrogen supply pipe, wherein the fuel cell stack receives hydrogen and air configured to generate electricity and discharge water, wherein the solid-state hydrogen storage device includes a first container accommodating a solid-state hydrogen storage material, a second container accommodating a thermochemical thermal energy storage material, a third container accommodating a heat transfer medium, and pipes connected to the first container, the second container, and the third container to circulate the heat transfer medium, and wherein the hydrogen supply pipe is connected to the first container and the fuel cell stack.

Owner:HYUNDAI MOTOR CO LTD +1

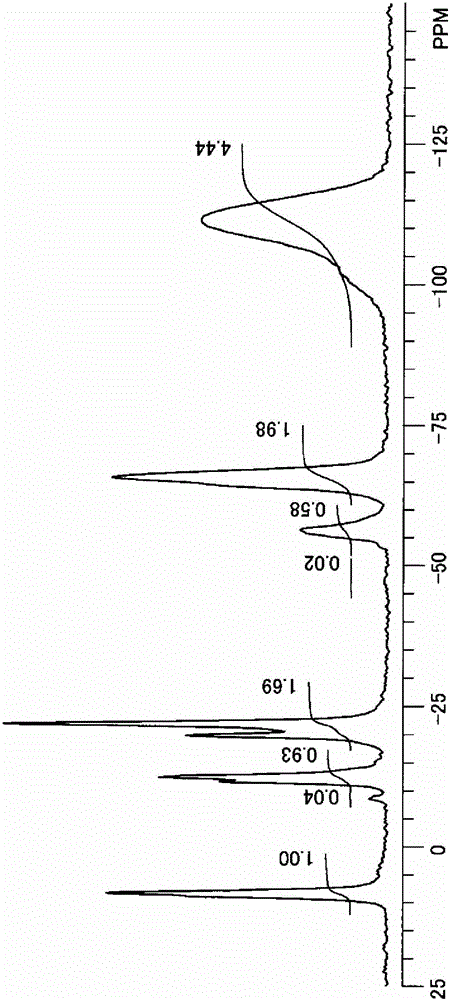

Method for raising heat-resistance property of organic silicon resin adopting polyheadral oligo-sesqui silione

This is the method of improving the thermal stability of organosilicon resin adopting polyhedral oligomeric silsesquioxane (POSS). It relates to a kind of method of improving the thermal stability of organosilicon resin. The invention solves the problem of reducing the wave-transmissivity of the organosilicon resin by all the methods that changes the structure of the pendent groups of polysiloxane or changes the structure of main chain or adds thermostable padding to improve the thermal stability of the organosilicon resin. It includes following steps: a. adopt methyl methoxy silane monomer as raw material, prepare organosilicon resin through hydrolyzation and polyesterification reaction; b. add alcohol solvent into the prepared organosilicon resin to prepare the organosilicon resin with alcohol as solvent; besides it also includes Step c.: add 0.5 -10% POSS of the weight of the organosilicon resin into the organosilicon resin produced in Step b., the reaction temperature is 60 -90 Deg. C, the reaction time is 4 -8 hours, and vacuum membrane distillation. The modified organosilicon resin produced by the method has high heat-resisting performance.

Owner:HARBIN INST OF TECH

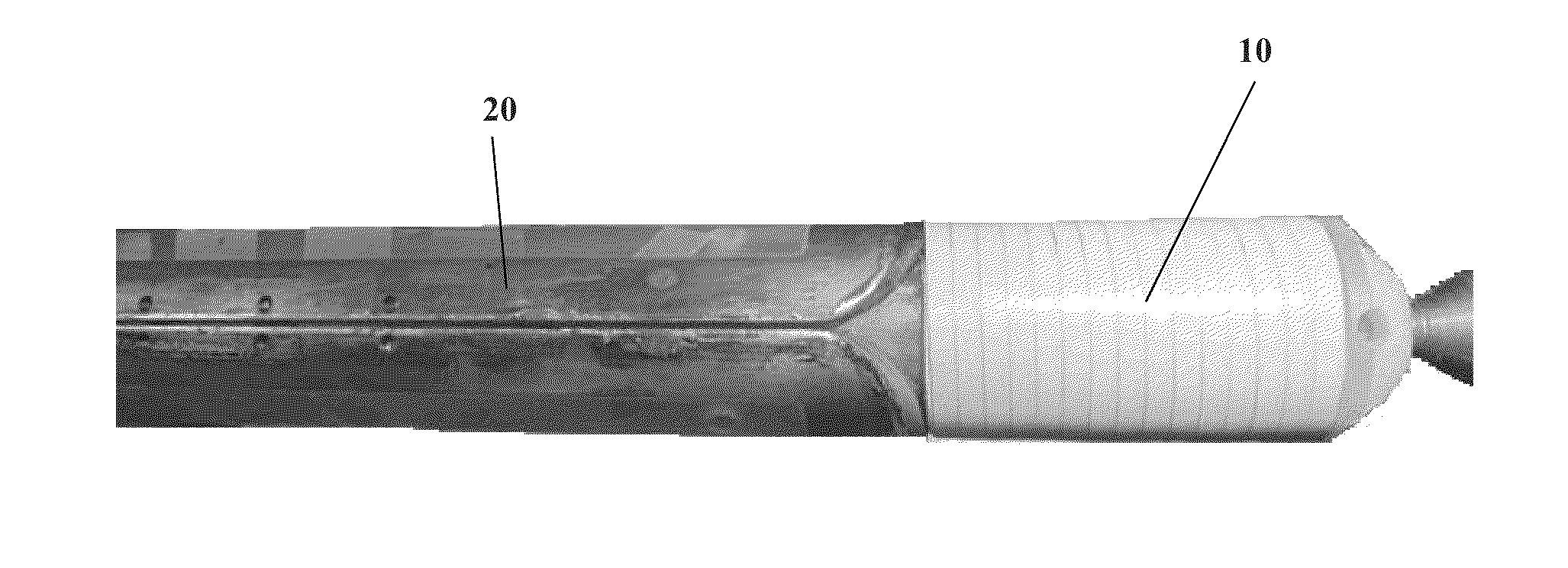

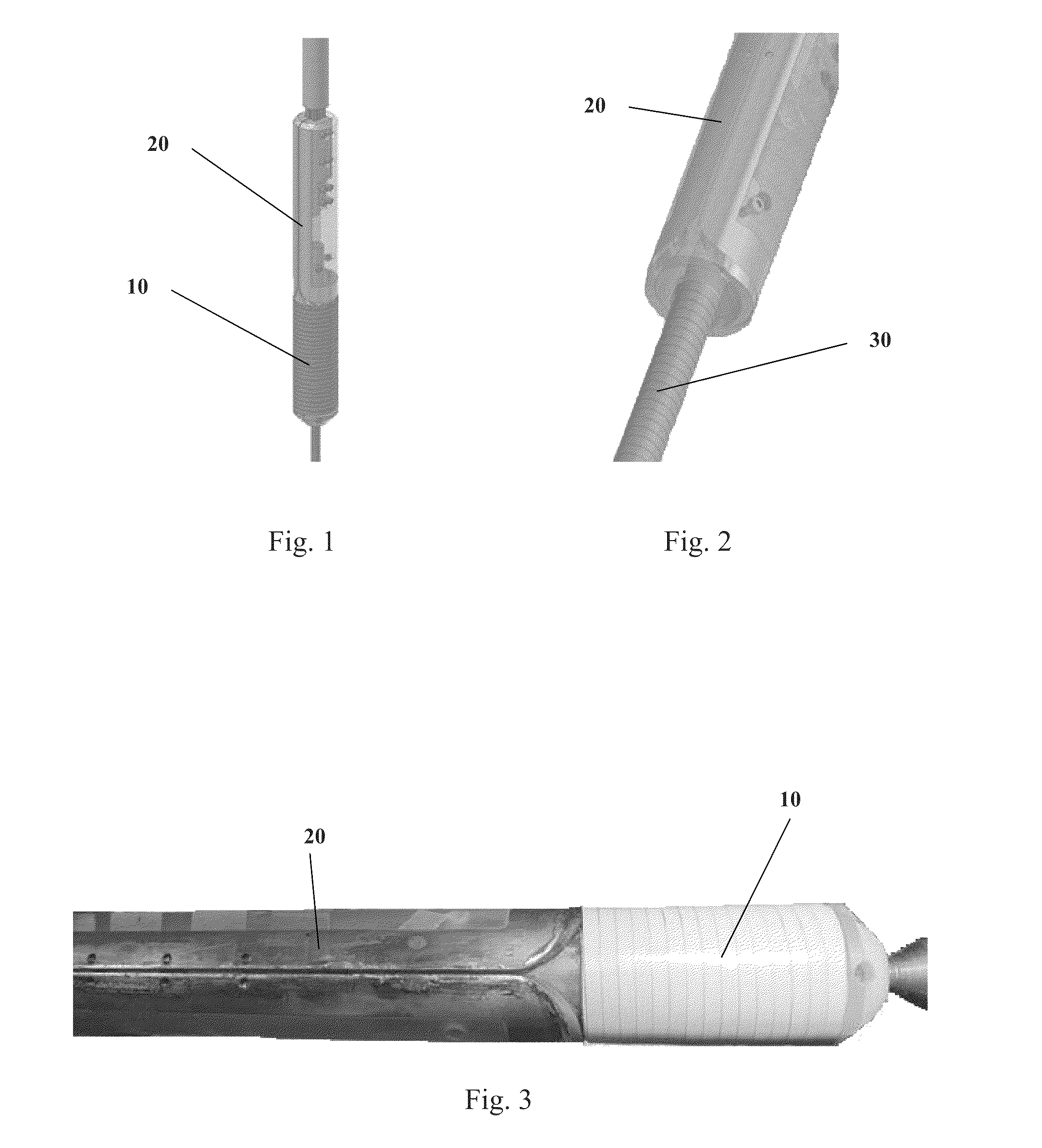

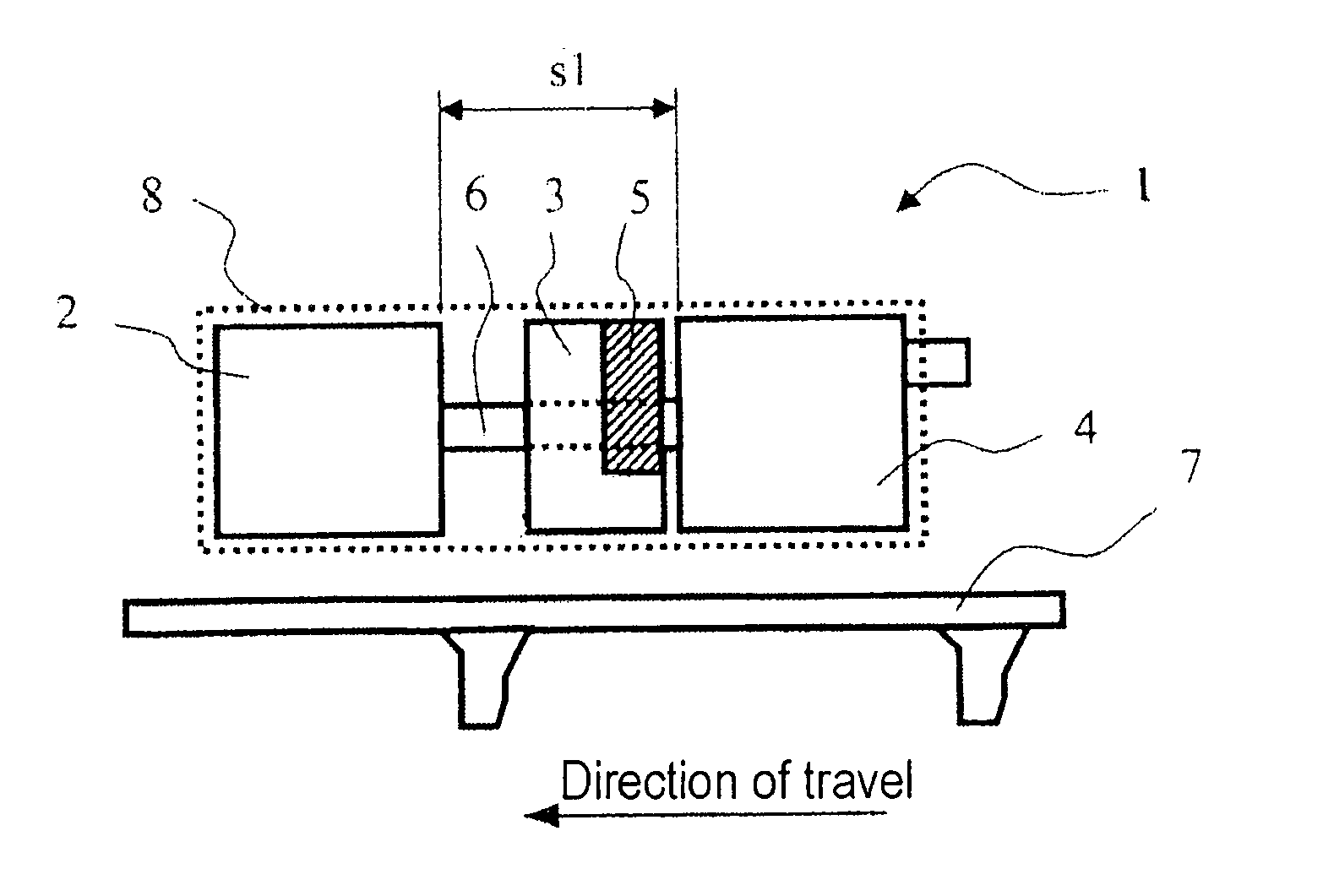

Exhaust gas treatment system and utility vehicle with an exhaust gas treatment system

InactiveUS20060010858A1Line lengthEffective external surfaceInternal combustion piston enginesExhaust apparatusNitrogen oxidesExhaust fumes

In an exhaust gas treatment system and a utility vehicle having an exhaust gas treatment system, the exhaust gas treatment system includes a particle reduction unit, a reducing agent tank and a nitrogen oxide reduction unit of a modular design, wherein the reducing agent tank is arranged between the particle reduction unit and the nitrogen oxide reduction unit and extends around a connecting line extending between the particle reduction unit and the nitrogen oxide reduction unit, and in a utility vehicle, the associated exhaust gas treatment system is arranged within a predefined cuboid envelope volume on a support structure which is attached to a frame member of the vehicle.

Owner:DAIMLER AG

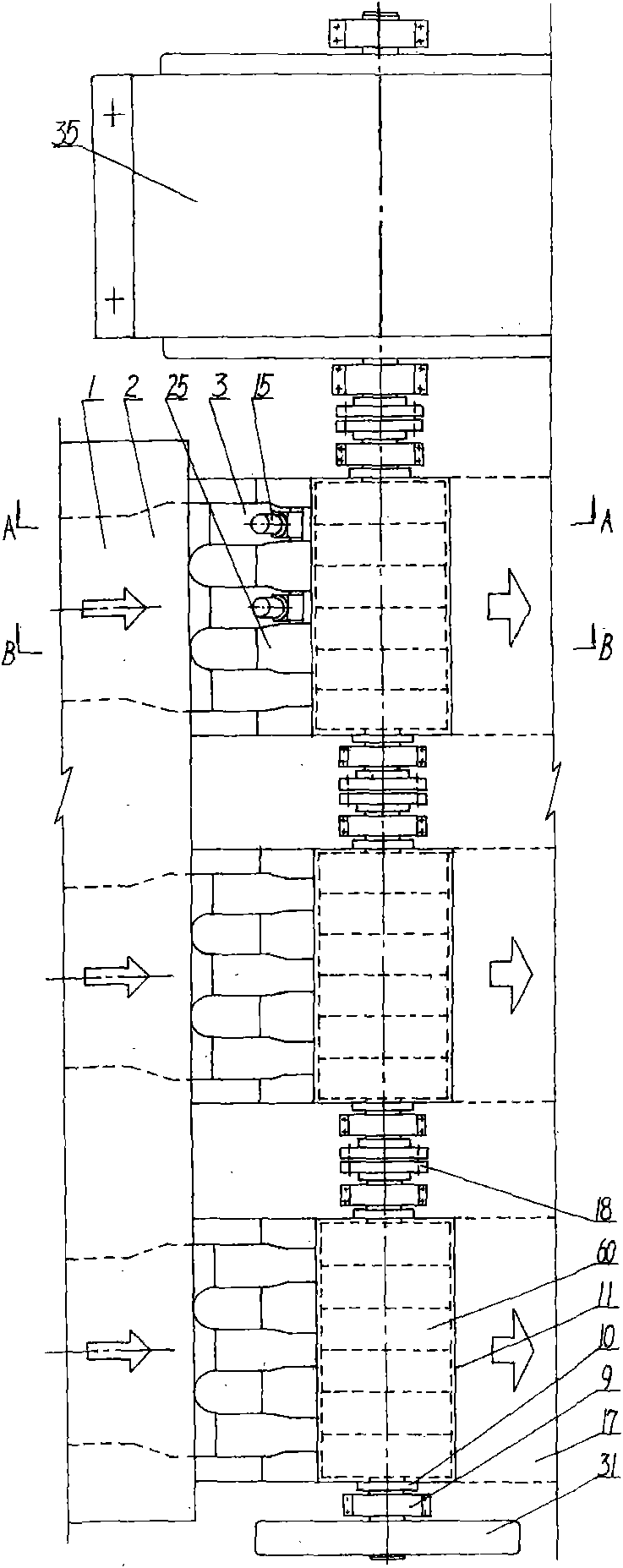

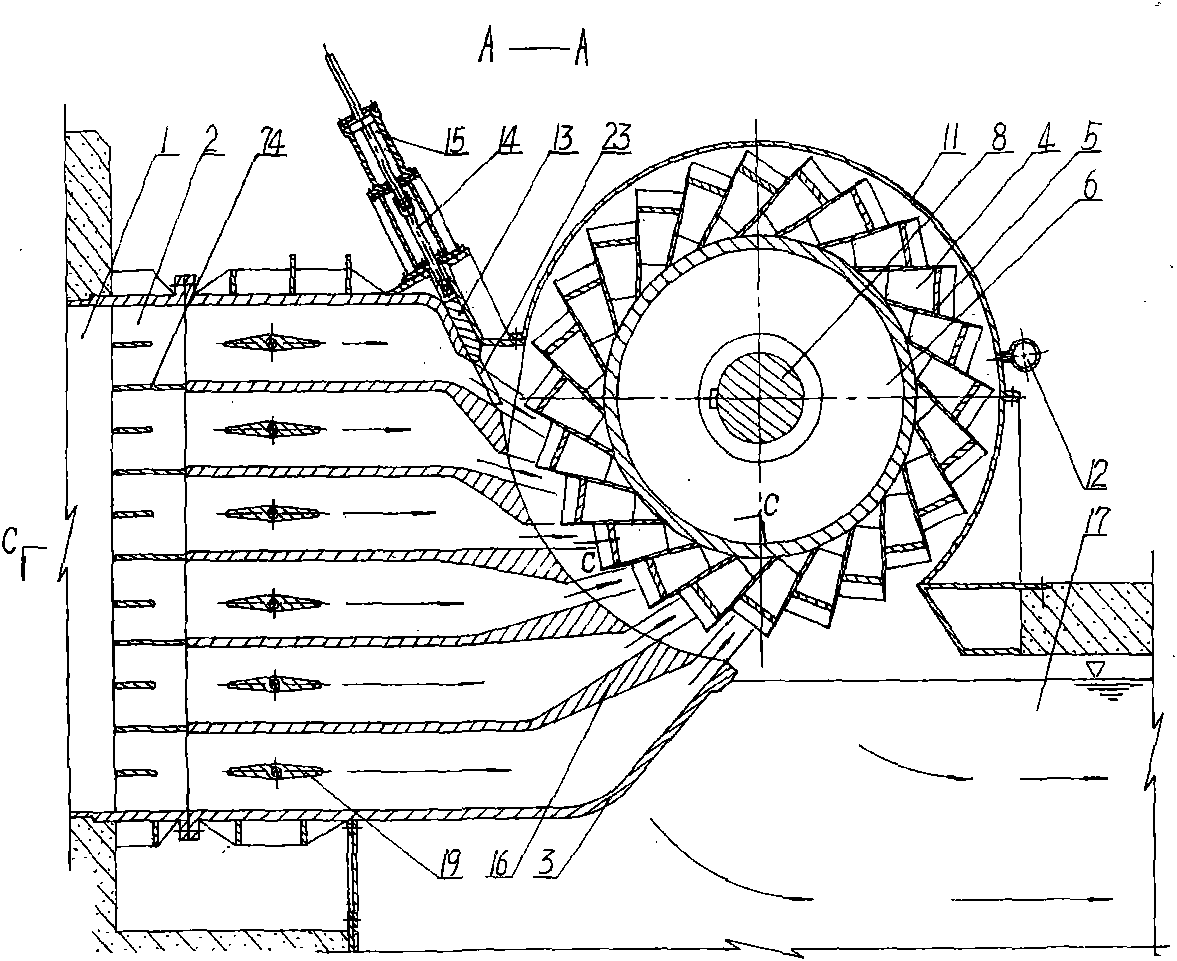

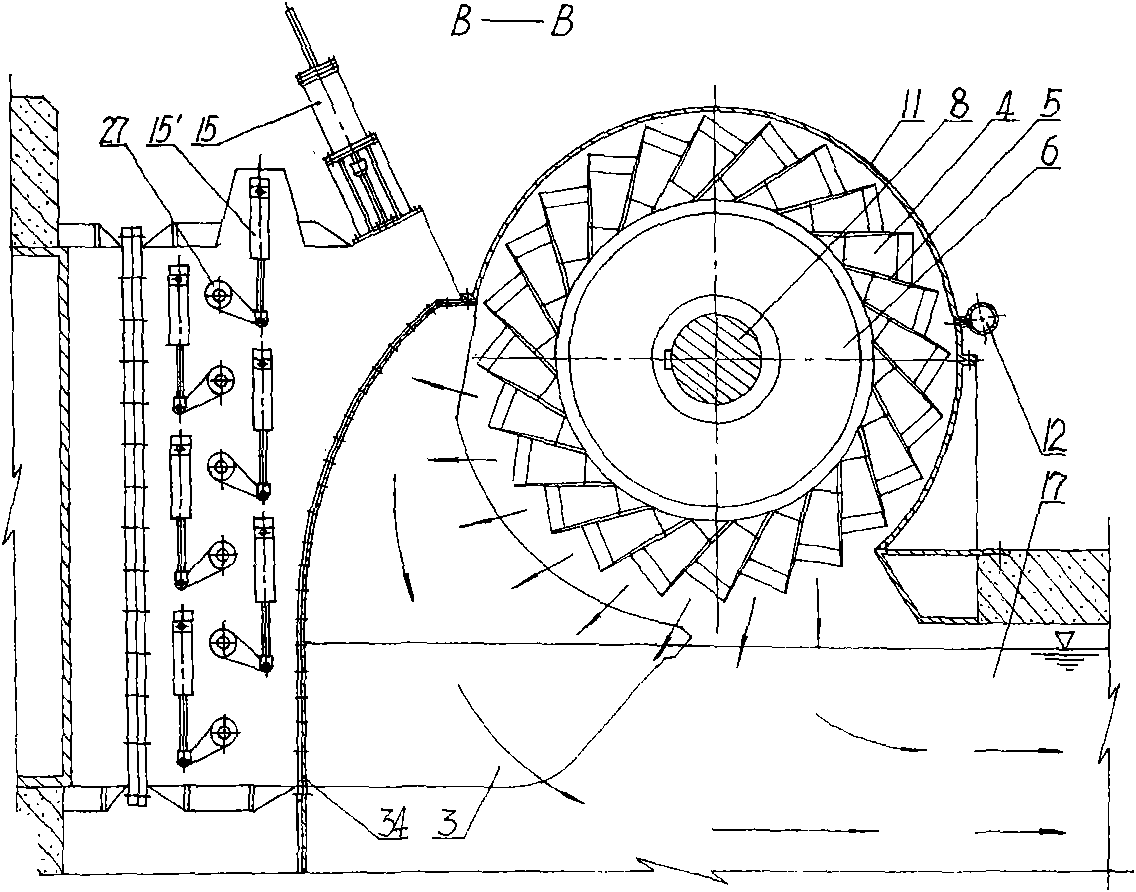

Universal fully-effective generating power machine

InactiveCN101871415AImprove efficiencyNo leakage lossFrom solar energyFinal product manufactureTidal waterWind force

The invention relates to a universal fully-effective generating power machine belonging to generating power equipment which can fully and effectively convert conventional energy resources such as water energy, steam energy and the like and new energy resources such as wind energy, steam energy formed by solar heating, tidal water energy and the like into rotating mechanical energy. The machine mainly comprises one or a plurality of jet orifices, a regulating mechanism of the jet orifices, one or a plurality of universal fully-effective rotating wheels, a speed regulator and the like, wherein, the universal fully-effective rotating wheels correspond to the jet orifices and are arranged on a main shaft. The machine can fully develop and utilize water energy, steam energy and wind energy of all types, can fully and effectively convert the utilized water energy, steam energy and wind energy into rotating mechanical energy, can fully replace all current water turbines, steam turbines and wind turbines, and has the advantages of simple structure, reliable performance, low manufacturing cost and easy implementation. Thus, the universal fully-effective generating power machine can replace equipment of hydraulic, thermal and wind power generation industries, and can promote rapid development of new energy resource generating industries such as hydraulic fully-effective power generation, hydraulic wind power generation, solar steam power generation and the like to become main energy source power generating modes.

Owner:黄国宏

Preparation method of asphalt material, asphalt material prepared by the same and application thereof

InactiveCN106520166ALow alpha benzopyrene contentReduce PAH contentWorking-up pitch/asphalt/bitumen by chemical meansBuilding insulationsBituminous materialsReaction temperature

The invention discloses a preparation method of an asphalt material, an asphalt material prepared by the method and application thereof. The preparation method comprises: carrying out purging reaction on an aromatic compound-containing raw material under inert gas purging to obtain an asphalt material. Specifically, based on the total mass of the aromatic compound-containing raw material, the flow rate of the inert gas is 0.5-10L / (min.kg), the purging reaction temperature is 380-440DEG C, and the purging reaction time is 1-10h. The asphalt material prepared by the preparation method provided by the invention can be applied to preparation of waterproof materials, anti-corrosion materials, electrode binders and automobile damping materials, and has very excellent environmental protection performance.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Binary graphitization furnace

The invention relates to the technical field of graphite preparation, in particular relates to a binary graphitization furnace which is combined by adopting a parallel connection way. The binary graphitization furnace comprises a first furnace body (1) and a second furnace body (2), wherein a middle combination part of the first furnace body (1) and the second furnace body (2) forms waste heat flue space (3); a circulating tube is arranged in the waste heat flue space; the circulating pipe enters the waste heat flue space (3) from an inlet (4) formed in the front surface of the middle combination part and stretches out of the waste heat flue space (3) from an outlet (5) formed in the front surface of the middle combination part; an axial flow fan is arranged at the position of the outlet of the waste heat flue space (3). The binary graphitization furnace disclosed by the invention is reasonable in design; compared with an existing graphitization furnace kiln, the actual effects of high heat efficiency, good safety, capability of implementing forced cooling and the like are obtained; meanwhile, the binary graphitization furnace is clear in structure and energy-saving purpose, has very good practical performances of safety, easiness in operation and the like and has very obvious economic benefit after implementation.

Owner:SHANXI BEITERUI NEW ENERGY TECH

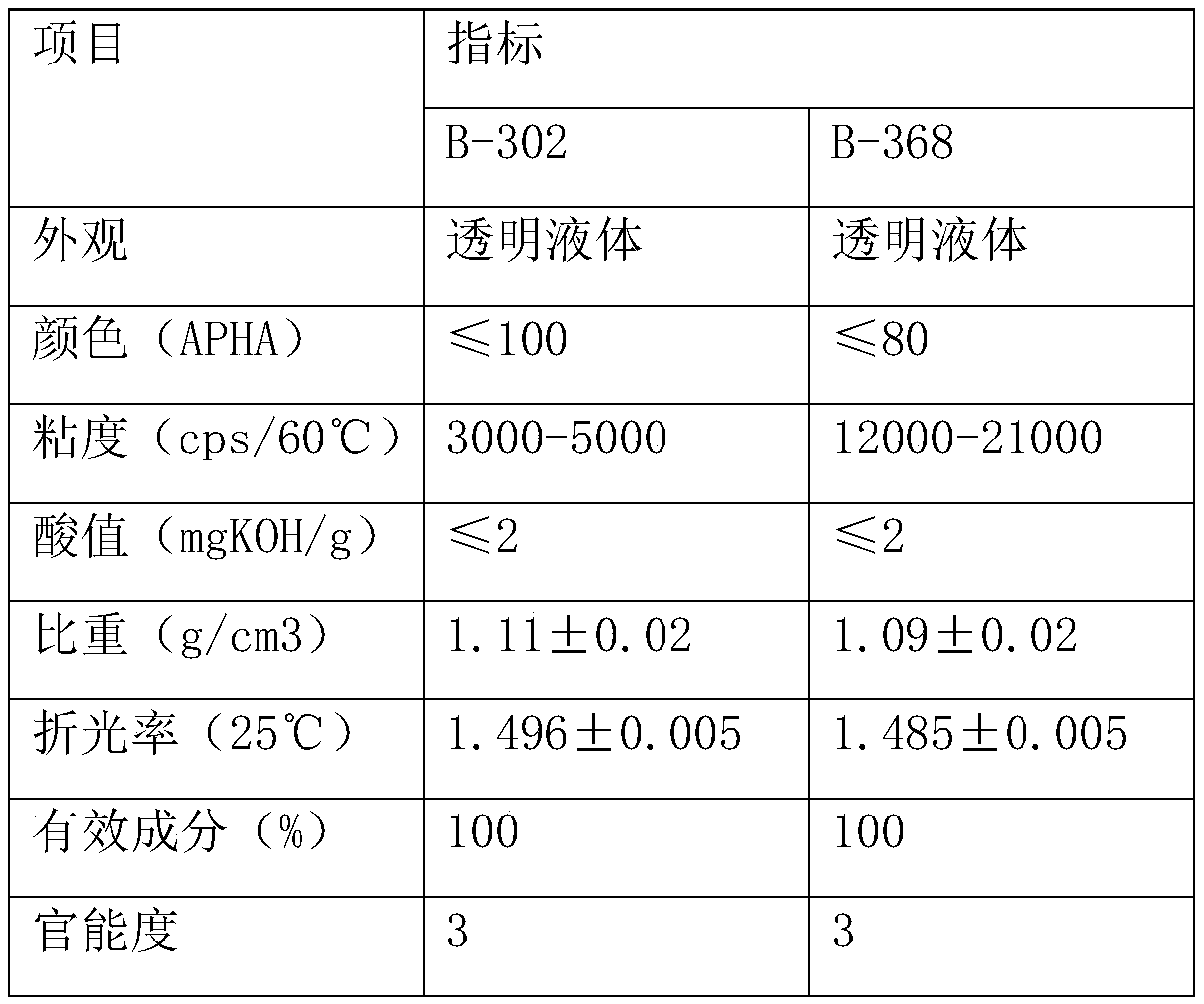

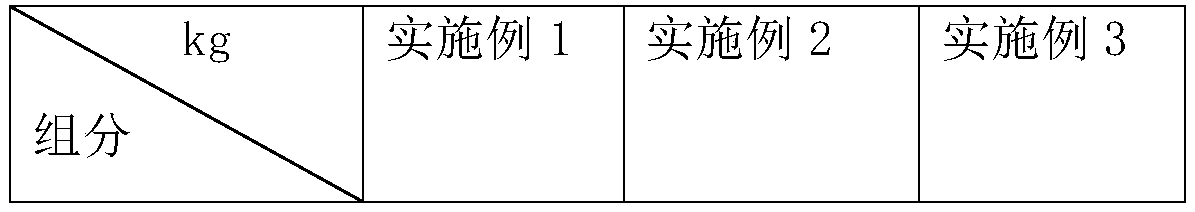

Asphalt resin anti-sloughing agent for drilling fluid, and preparation method of asphalt resin anti-sloughing agent

ActiveCN111303844AImprove high temperature resistanceStrong epoxy indexDrilling compositionPolymer sciencePtru catalyst

The invention discloses an asphalt resin anti-sloughing agent for a drilling fluid, and a preparation method of the asphalt resin anti-sloughing agent. The asphalt resin anti-sloughing agent for the drilling fluid comprises the following components in parts by weight: 40-60 parts of sulfonated asphalt, 10-20 parts of castor oil triglycidyl ether, 15-30 parts of a filtrate reducer, 5-15 parts of aseparant, 15-25 parts of a modifier, 3-7 parts of a compatibilizer, 1-3 parts of 1,4-butanediol, 1-3 parts of a coupling agent and 0.5-1.5 parts of an organic tin catalyst, wherein the modifier comprises trifunctional polyurethane acrylate, a urea formaldehyde resin and a trifunctional epoxy resin in a mass ratio of 1:(0.3-0.5):(0.5-0.7). The asphalt resin anti-sloughing agent for the drilling fluid has the advantages of high-temperature resistance, high-pressure resistance, high rigidity, good adsorbability, strong stabilizing effect on a well wall, salt resistance and calcium resistance.

Owner:北京宏勤石油助剂有限公司

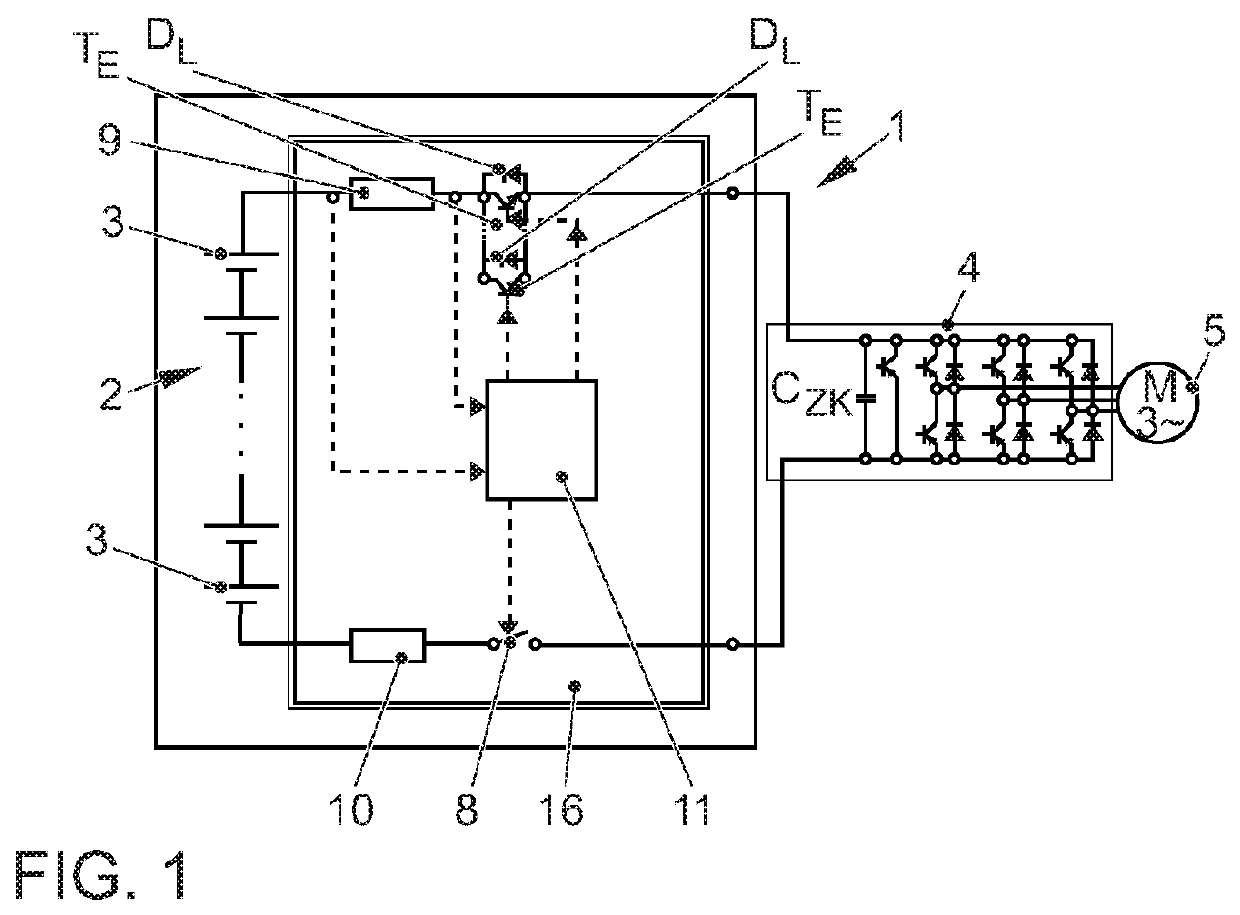

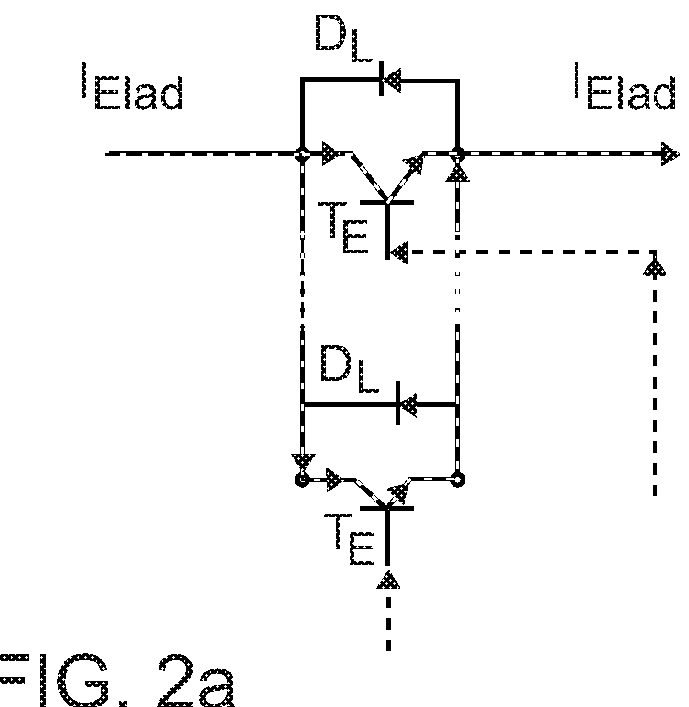

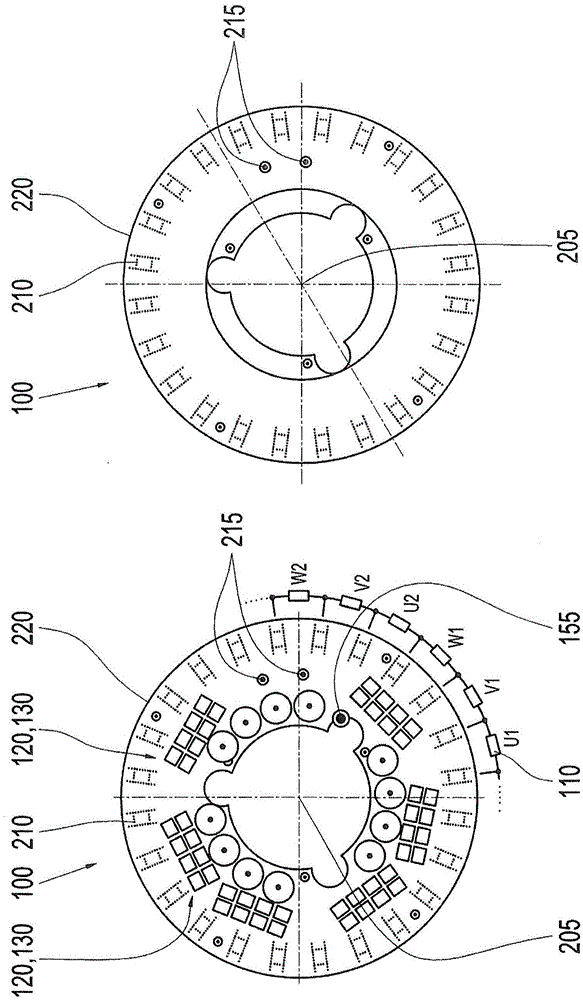

Control of rotating field machine

InactiveCN105811850ASmall heat lossReduce lossAC motor controlElectric motor controlEngineeringControl equipment

The invention relates to control of a rotating field machine. The rotating field machine comprises a plurality of phase and each phase includes a plurality of parallel windings. The invention also relates to a control device used for the rotating field electric machine. The device used for the rotating field electric machine comprises a half-bridge for each phase, a processing device for controlling the half bridge according to phase current passing through one of the phases, and a current sensor. The current sensor is set as winding current for flowing through one of the windings of the phase and the processing device is configured to determine phase current on the basis of the winding current.

Owner:ZF FRIEDRICHSHAFEN AG

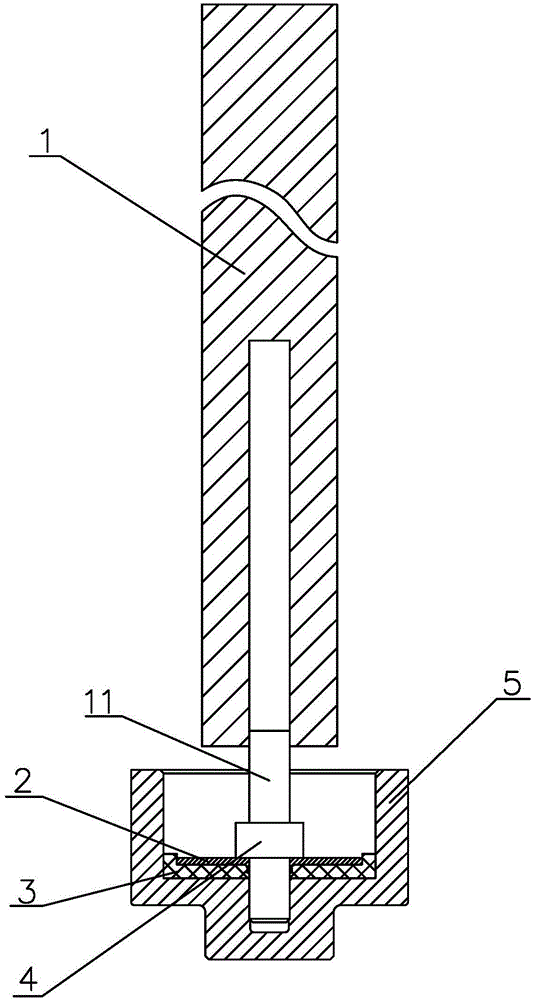

Magnesium rod assembly of water storage type water heater

The invention discloses a magnesium rod assembly of a water storage type water heater. The magnesium rod assembly comprises a magnesium rod (1), one end of the magnesium rod (1) stretches into an inner container (7), the other end of the magnesium rod (1) makes tight contact with a magnesium rod base (2), the magnesium rod base (2) make tight contact with the end face of a drain outlet (6), the drain outlet (6) is welded to the inner container (7), and a drain cover (5) matched with the drain outlet (6) is arranged on the outside of the drain outlet (6). The magnesium rod of the magnesium rod assembly makes tight contact with the magnesium rod base, the magnesium rod base makes tight contact with the end face of the drain outlet, the drain outlet is welded to the inner container, the magnesium rod is electrically communicated with the inner container, the structure is simple, assembly and disassembly are convenient, simple transformation only needs to be carried out on an existing magnesium rod assembly, new components do not need to be additionally arranged, cost is low, the magnesium rod assembly is easy to achieve, heat diffusion amount is small, and heat preservation performance of the water heater can be improved.

Owner:成都前锋电子有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com