Ultraviolet light-cured hydrophilic coating and preparation method thereof

A hydrophilic coating, ultraviolet light technology, applied in polyamide coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of high cost, serious energy consumption, low efficiency and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

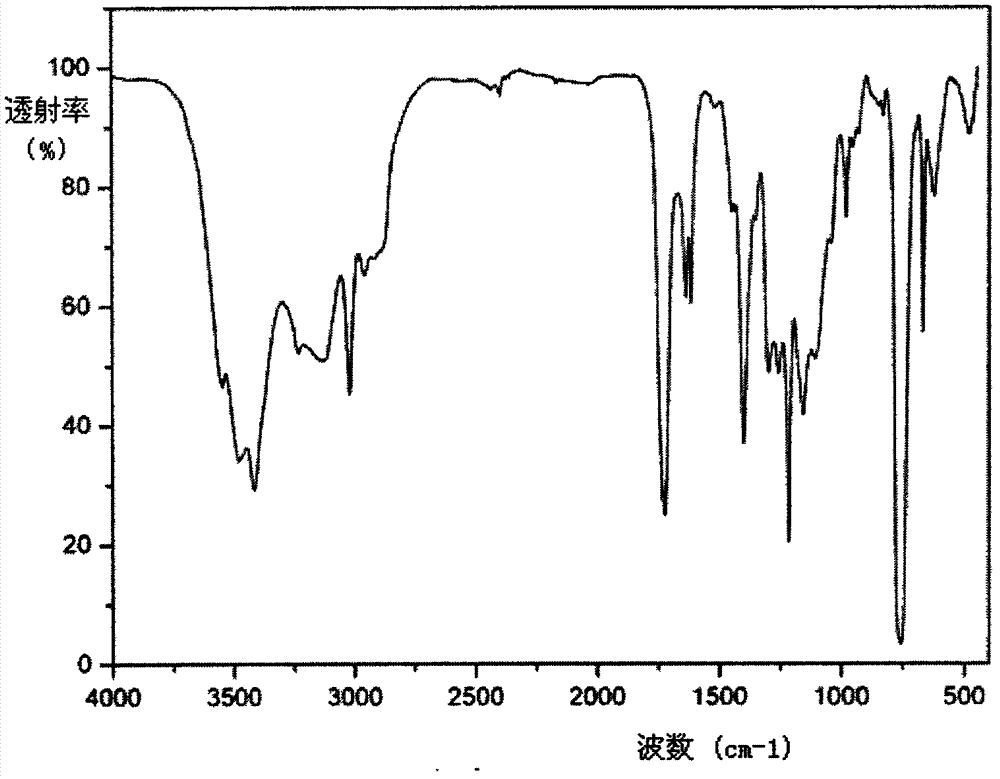

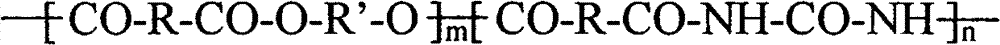

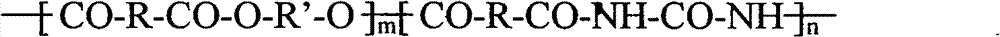

Image

Examples

Embodiment

[0027] Embodiment: the preparation of ultraviolet curing hydrophilic coating:

[0028] Mix the hydrophilic unsaturated polyester amide urea with the acrylate monomer and initiator 184 in a weight ratio of 20:10:1, then add 3% of total surfactant, 0.05% of defoamer and The total amount of 100% water is put into a container with a stirrer, placed in a water bath, protected by nitrogen, and stirred at 25°C for 30 minutes to prepare a brown-black liquid UV-curable hydrophilic coating with a certain viscosity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com