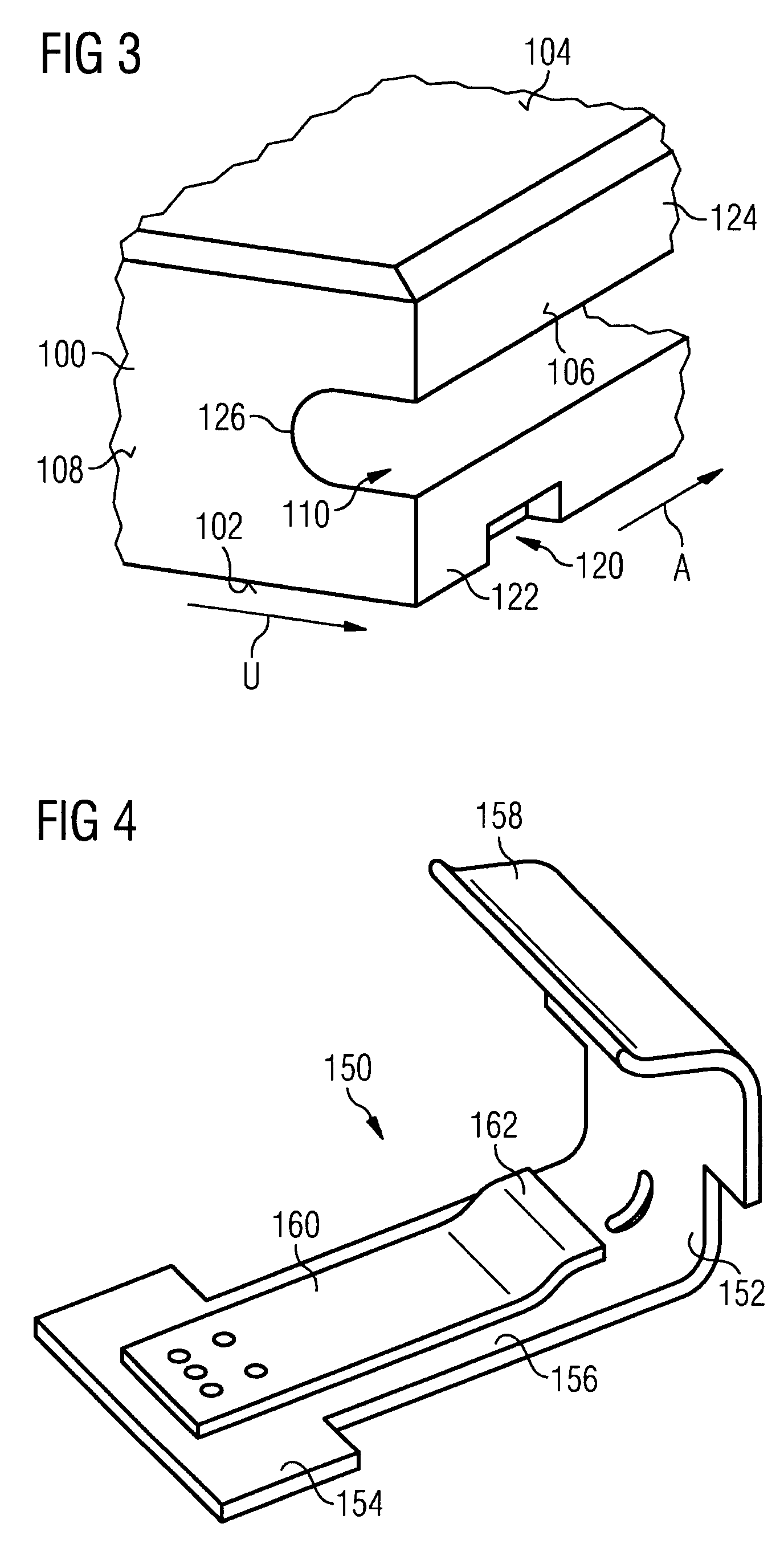

Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

190results about "Lining supports" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

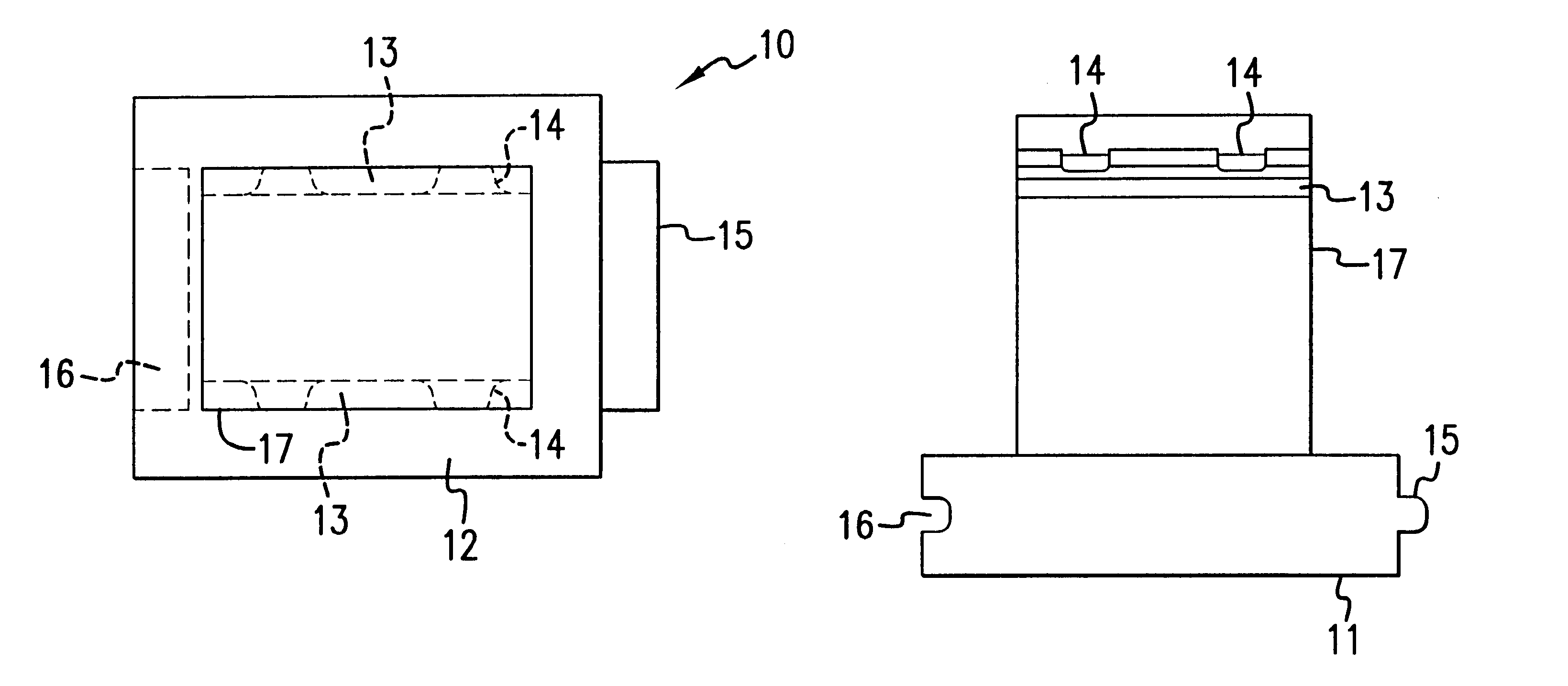

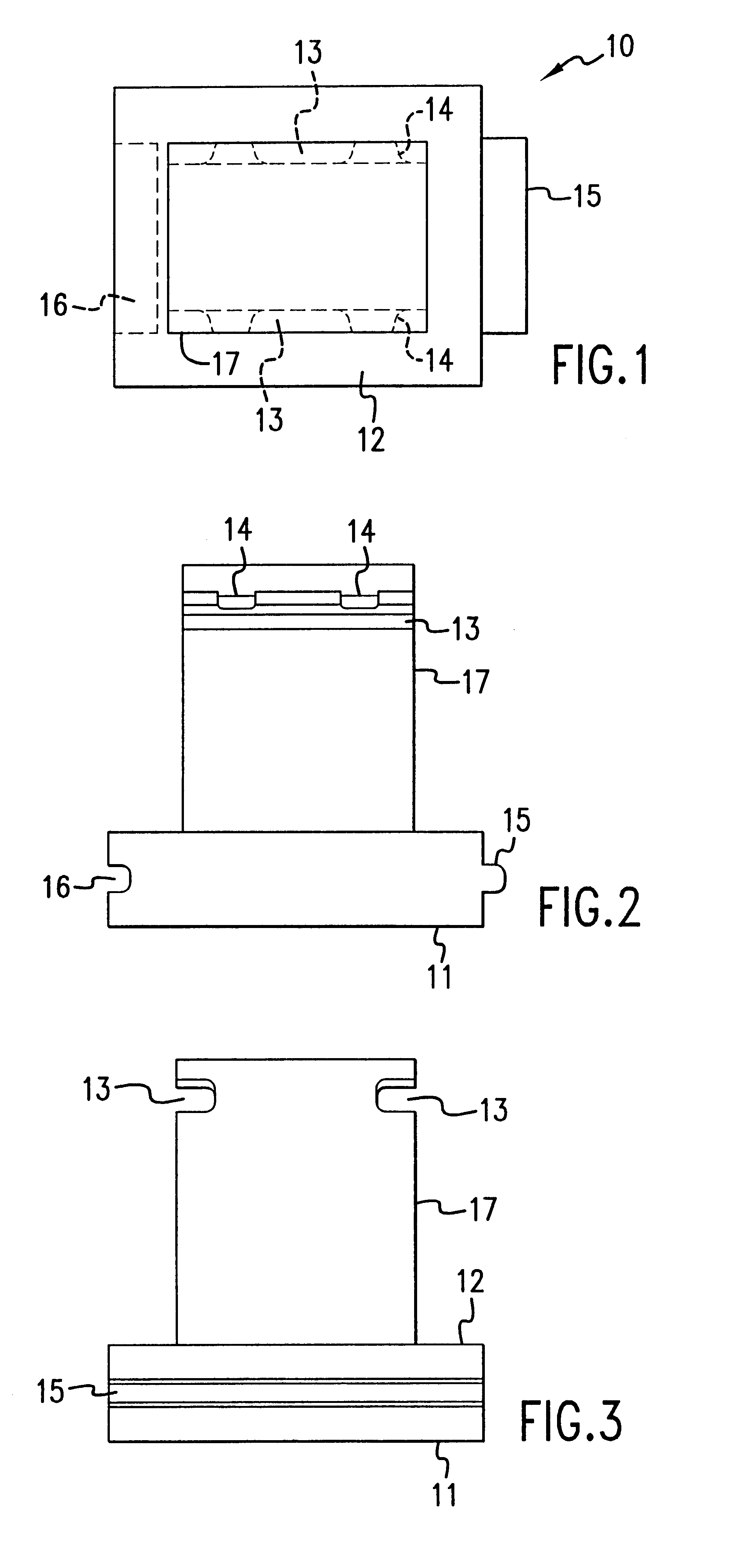

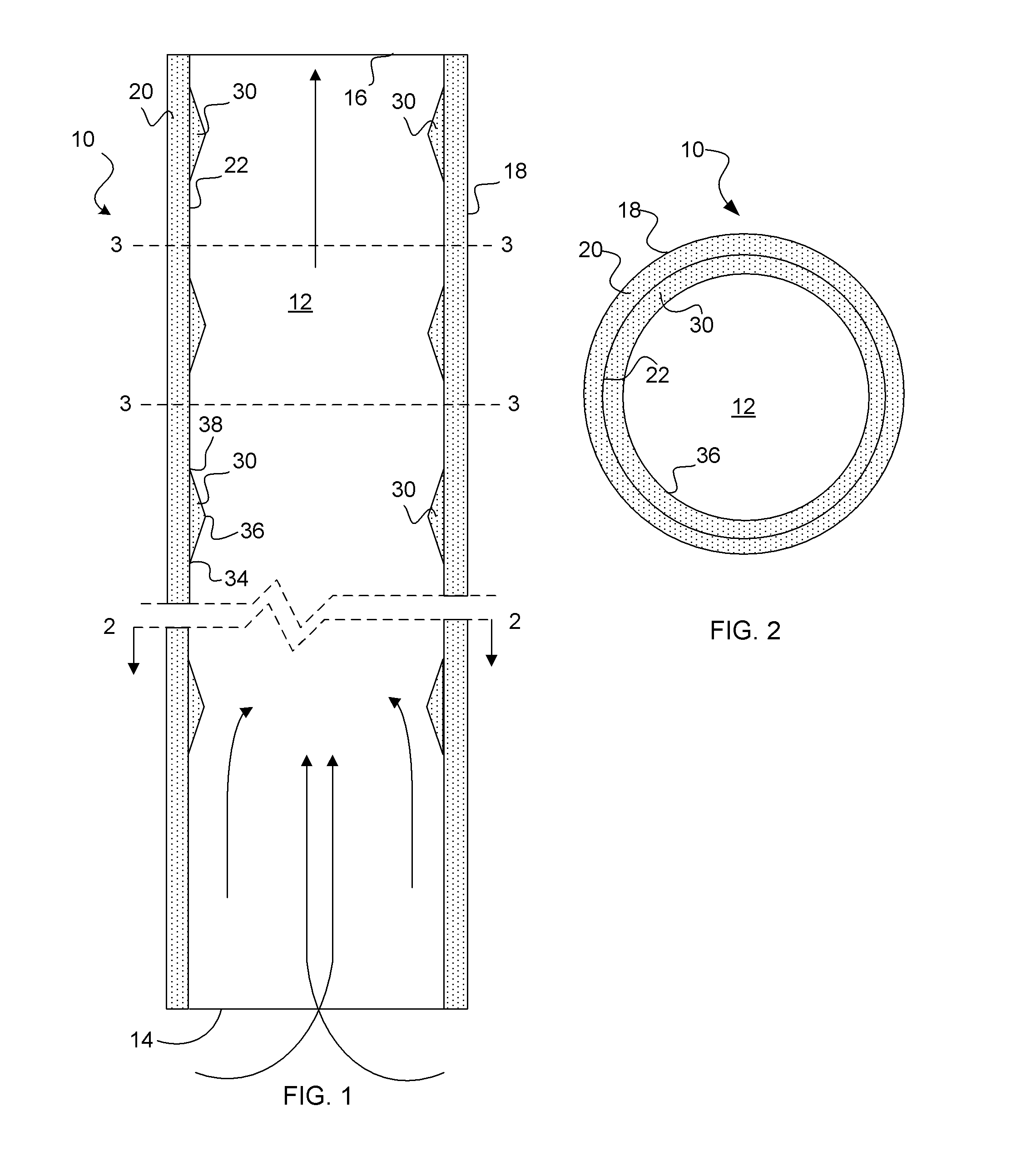

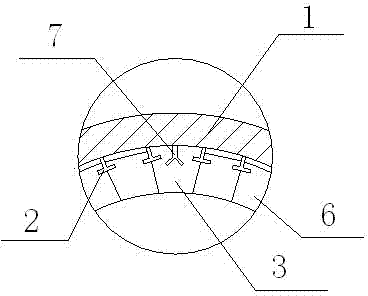

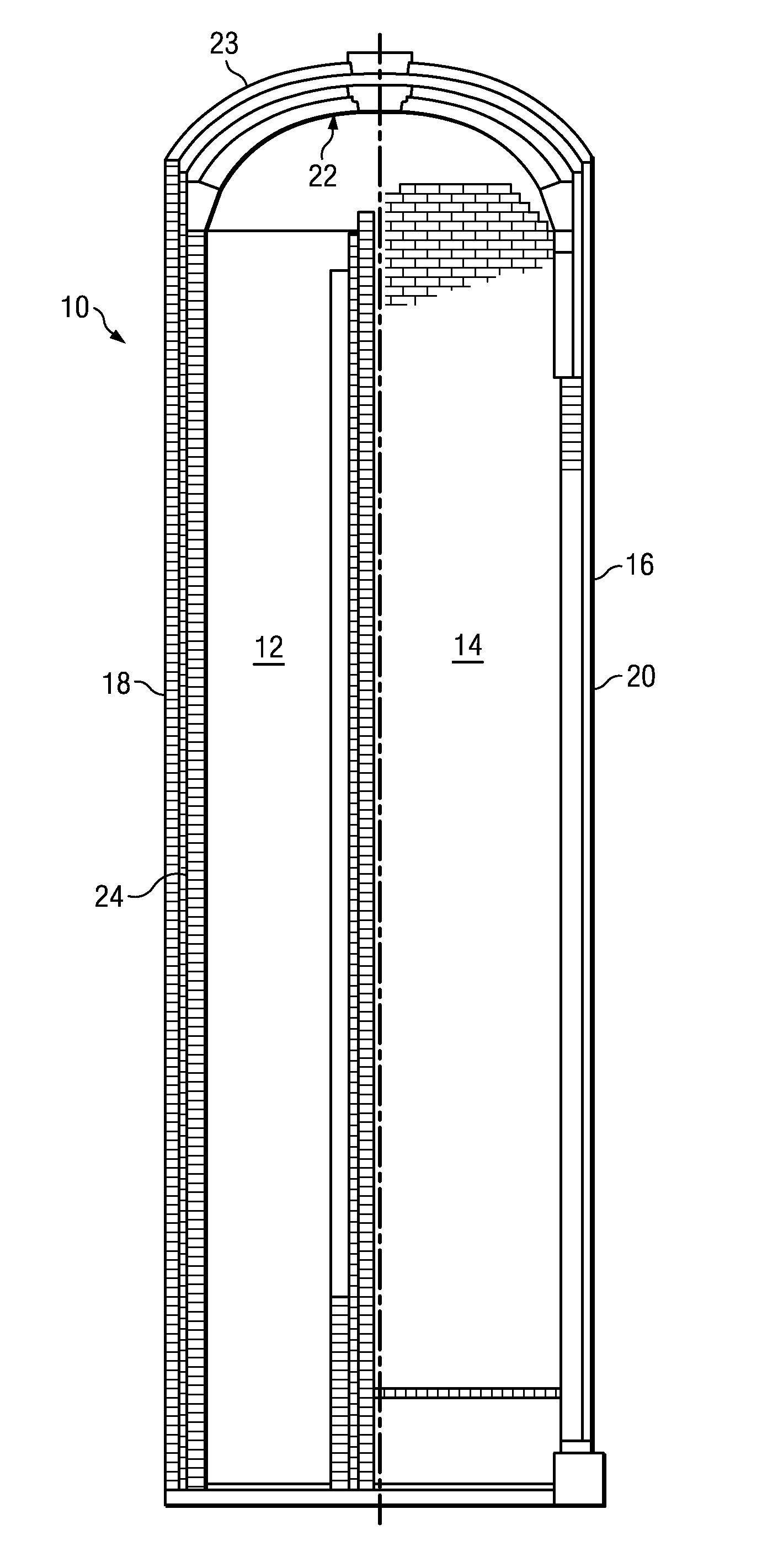

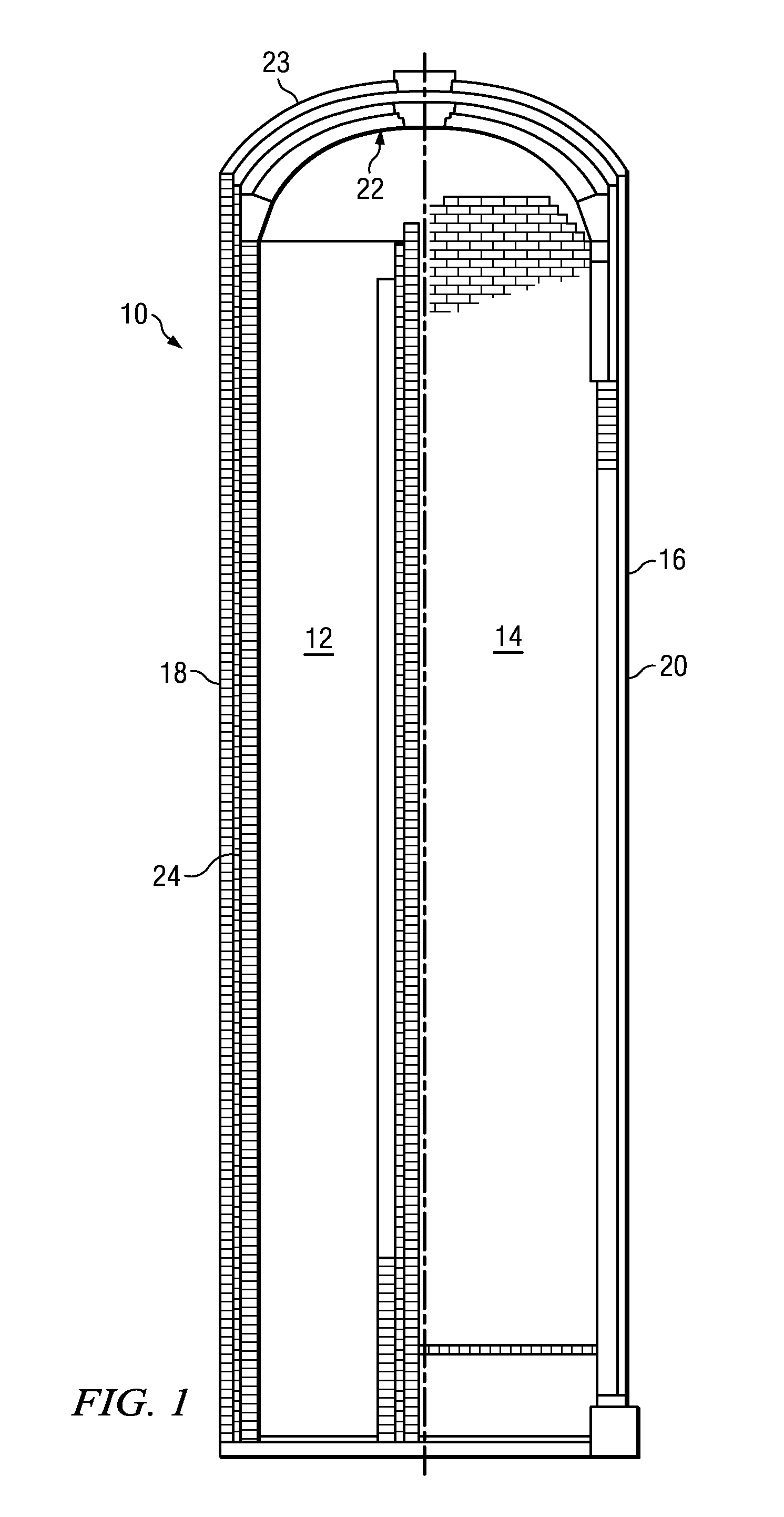

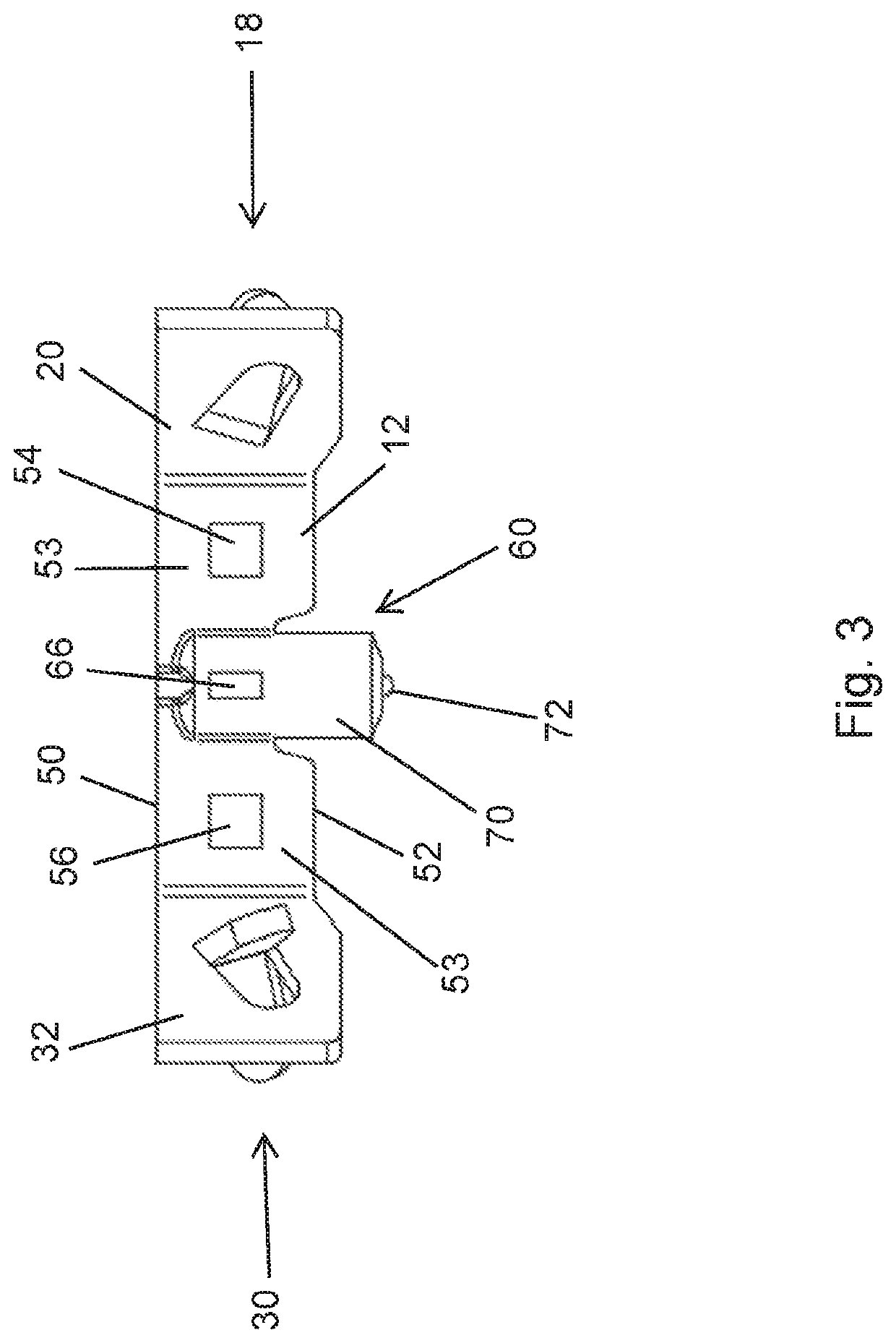

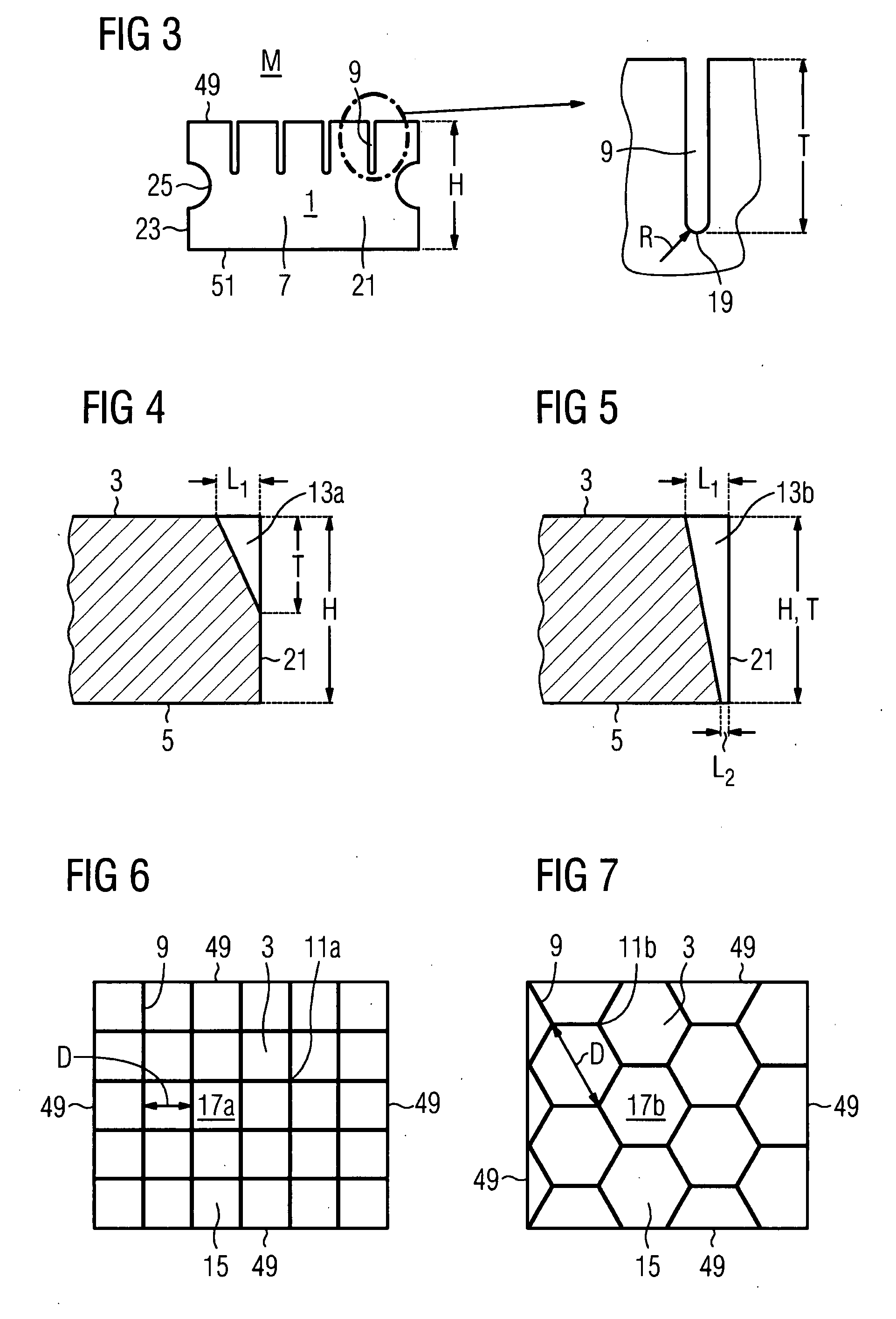

Molten metal containment structure having flow through ventilation

Exemplary embodiments of the invention provide a molten metal containment structure including a refractory molten metal containment vessel having an external surface, and a metal casing for the vessel having an internal surface at least partially surrounding the external surface of the vessel at a distance therefrom forming a spacing between the vessel and the casing. The spacing includes an unobstructed upwardly extending gap that is vented to the exterior of the structure by upper and lower openings in the casing. A layer of insulating material is preferably positioned in the spacing between the internal surface of the casing and the external surface of the vessel, with the layer of insulating material being narrower than the spacing at least at upwardly extending sides of the casing, thereby forming the unobstructed gap. The vessel may be a metal conveying trough, a housing for a metal filter, a container for a metal degasser unit, a crucible, or the like.

Owner:NOVELIS INC

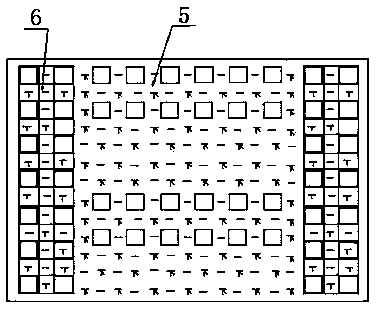

High temperature industrial furnace roof structure

InactiveUS6427610B1Reduces joint lengthImprove accessibilityLining supportsGlass furnace apparatusBrickEngineering

Owner:MERKLE ENGINEERS

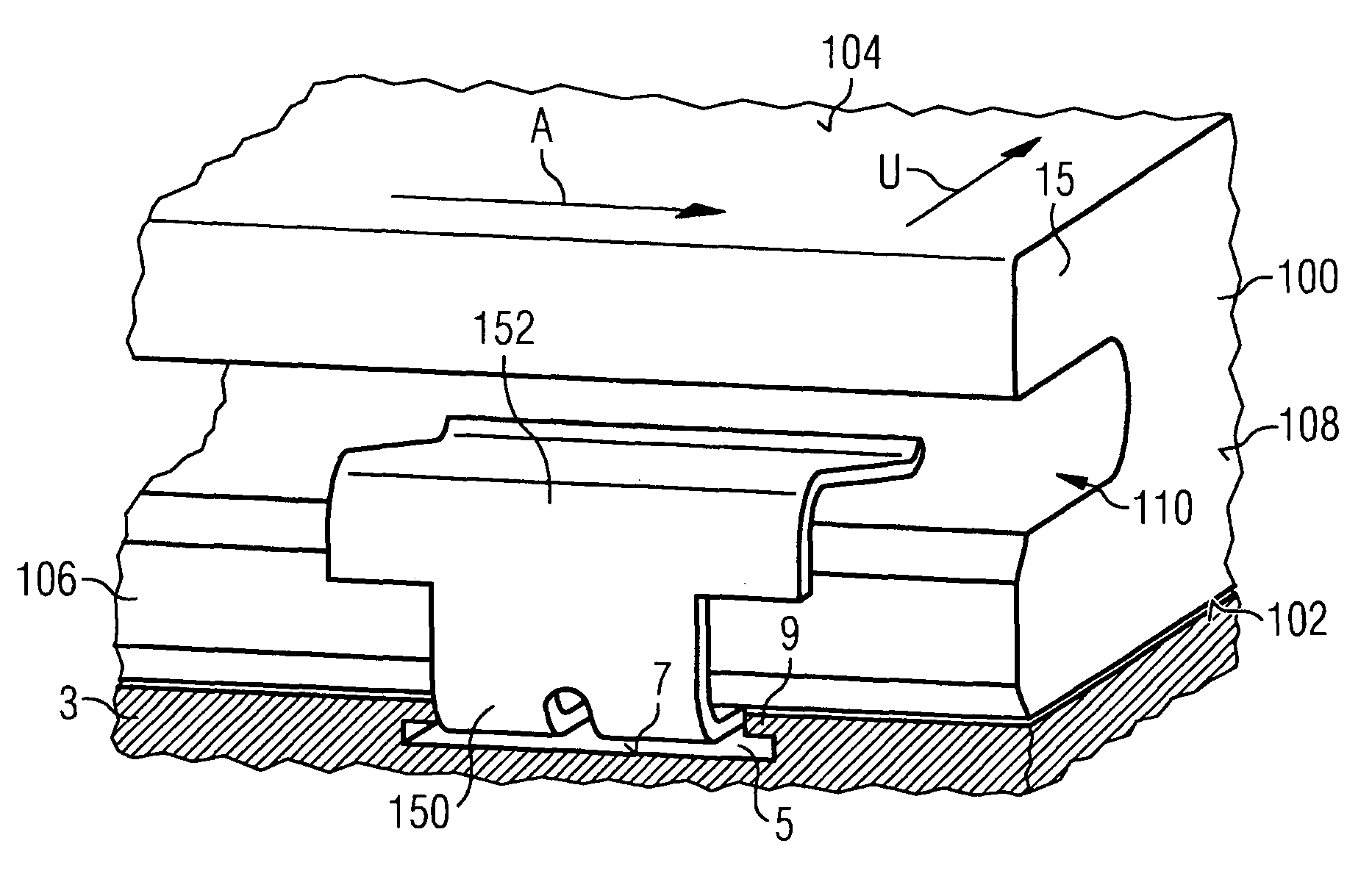

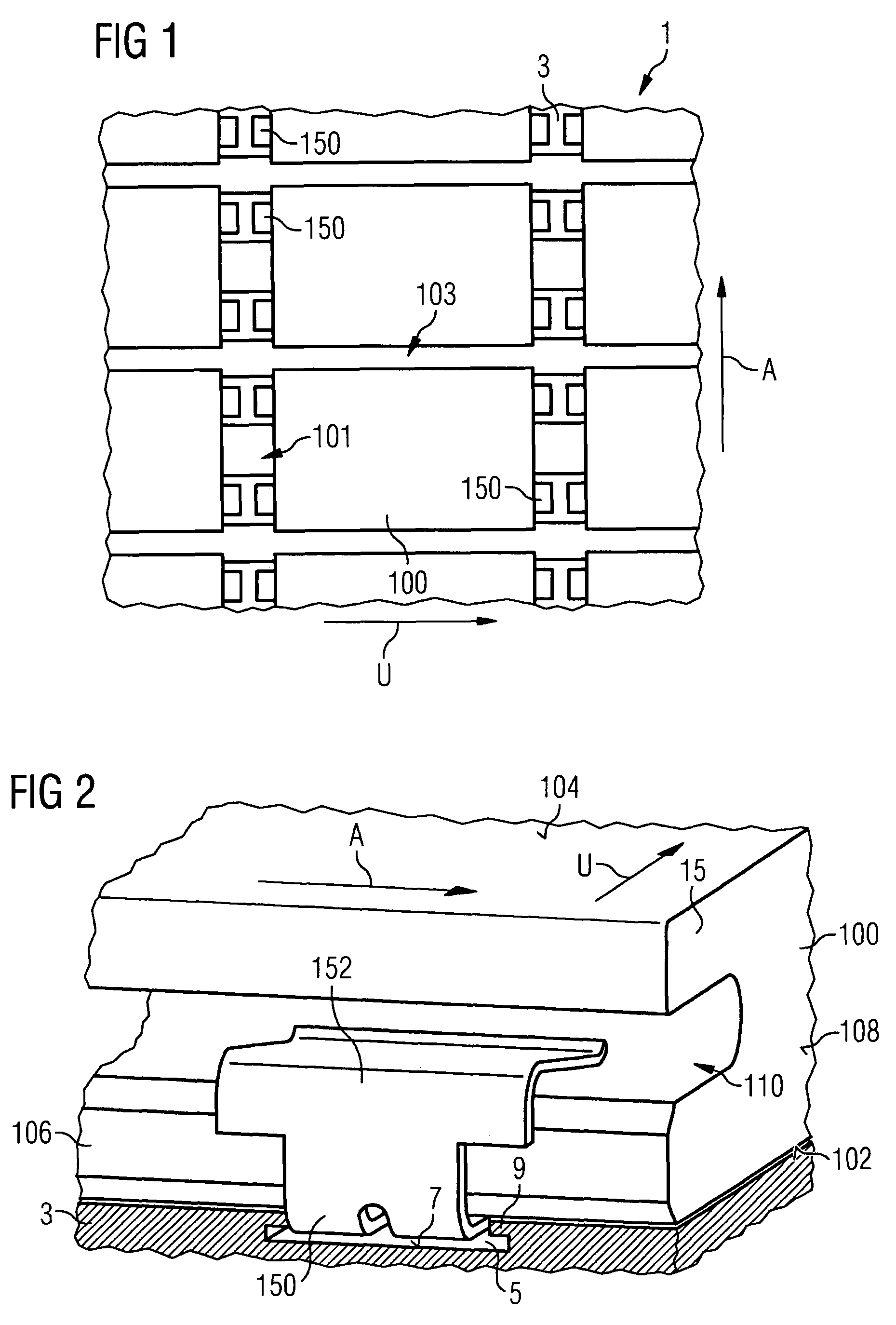

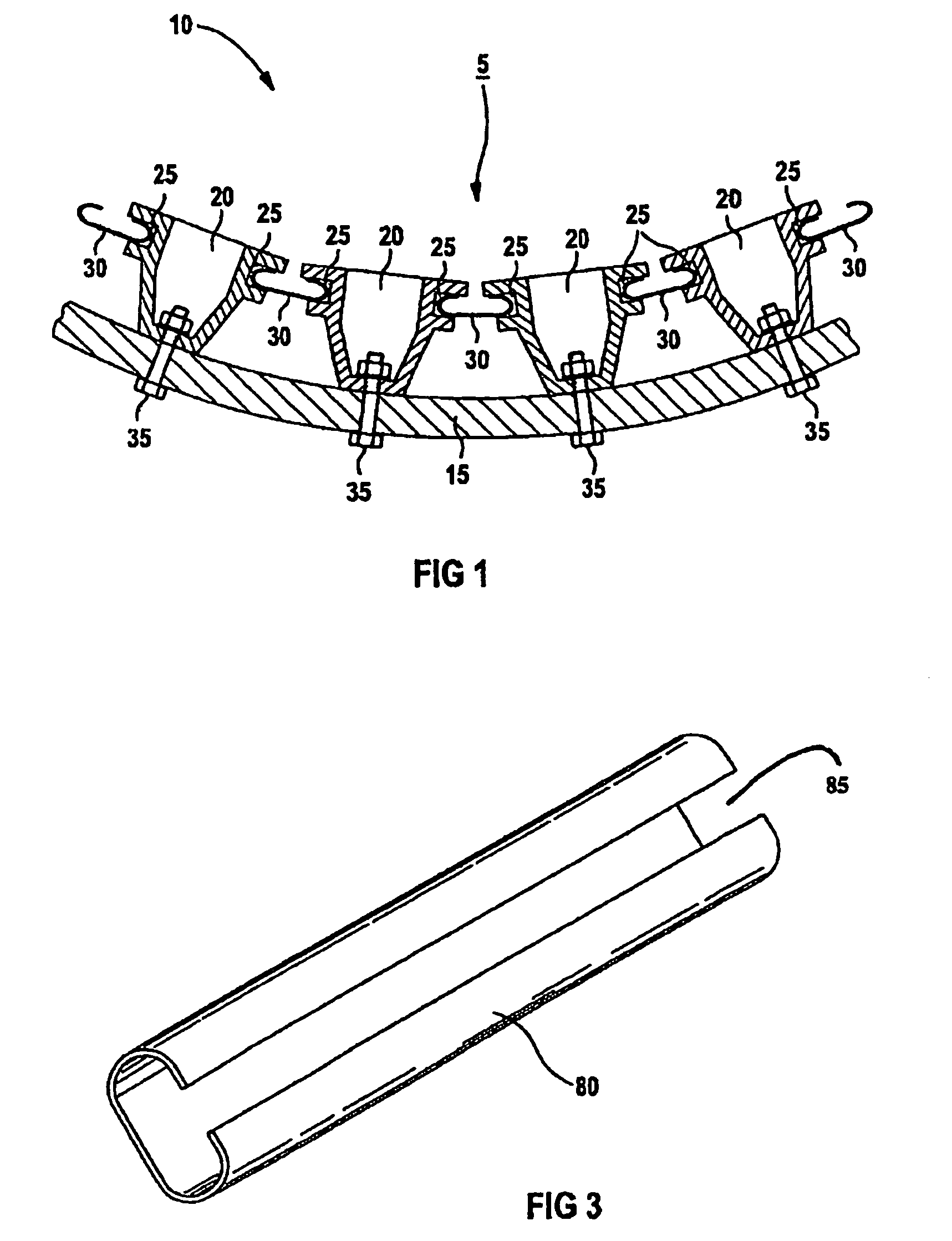

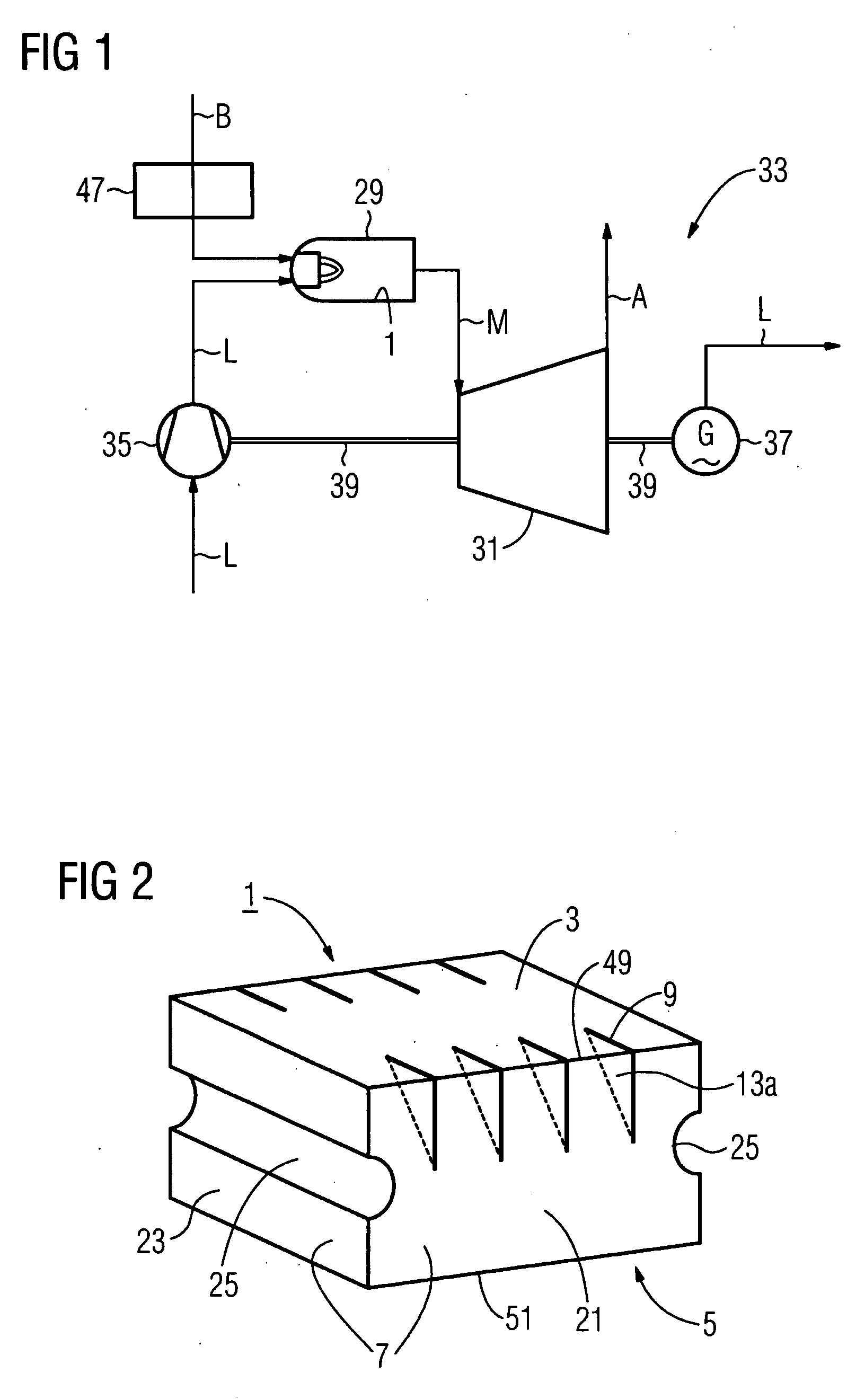

Retaining element and heat shield element for a heat shield and combustion chamber provided with a heat shield

A retaining element for retaining a heat shield element on a support structure comprises at least one fixing section adapted to fix the retaining element to the support structure and at least one retaining section adapted to engage with an engaging groove present on a periphery of the heat shield element. A projection is arranged on the retaining element in such a manner that it projects in the direction of the heat shield element when retaining a heat shield element.

Owner:SIEMENS AG

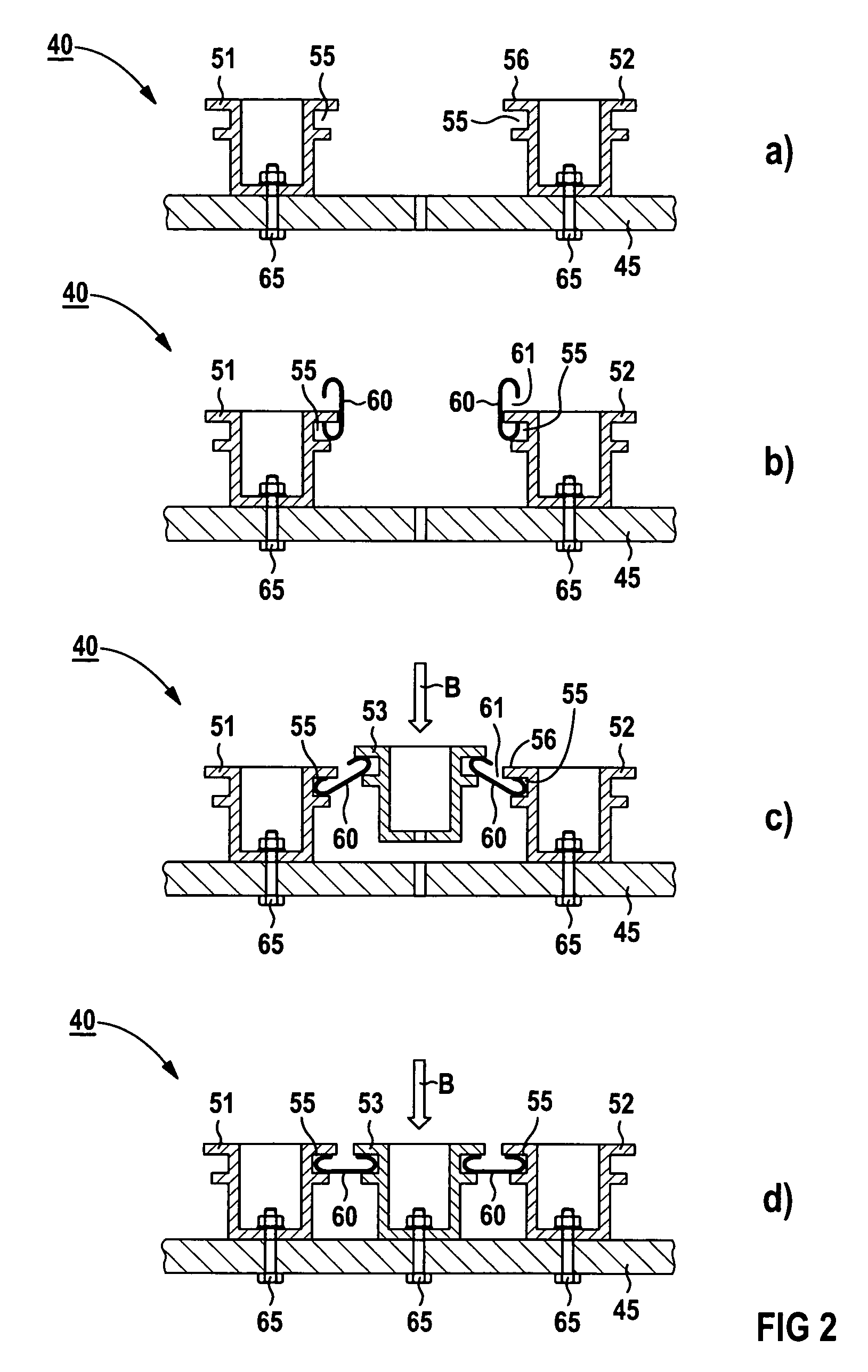

Heat shield arrangement for a hot-gas conducting component, in particular for structural pieces of gas turbines and method for production of said arrangement

InactiveUS7021061B2Flexible applicationEasily and quickly producedContinuous combustion chamberEngine sealsCombustion chamberProduct gas

The invention relates to a heat shield arrangement for a hot gas conducting structure, in particular a metal component of a gas turbine unit or combustion chamber, with the heat shield elements anchored adjacently on a support structure to cover a surface. Said heat shield elements each comprise a lateral groove, arranged in the region of the edge of the surface thereof facing the hot gas, at least two adjacent shield elements are connected by at least one seal element mounted in the groove. The seal element is embodied as a sealing flap, which may be displaced from a first position to a second position and vice versa, whereby the first position is an open position without a sealing effect and the second position is a closed position with a sealing effect. According to said method the sealing flap is moved from the first to the second position by the movement of a heat shield element.

Owner:SIEMENS AG

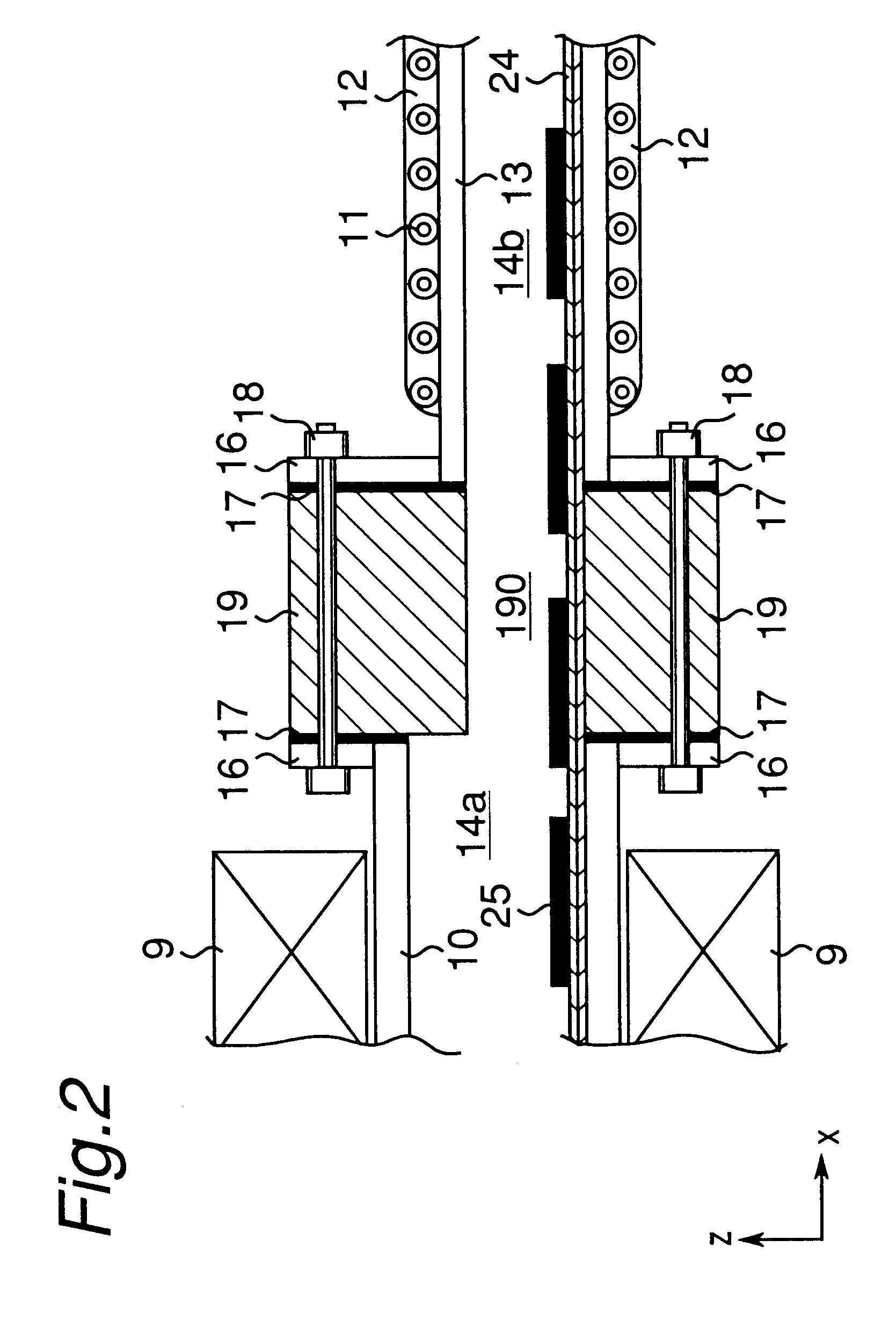

Thermal treatment apparatus

InactiveUS6623269B2Small heat lossAvoid heat conductionLining supportsGlass transportation apparatusThermal energyHeat losses

A thermal treatment apparatus has a plurality of thermal treatment chambers in which an object to be treated is thermally treated while being transported, and at least one pair of two adjacent thermal treatment chambers of which inside temperatures are different from each other. The thermal treatment chambers are connected through a thermal insulating structural member, whereby thermal conduction between the chambers, such as muffles, is prevented to reduce a heat loss caused in the thermal treatment apparatus. Therefore, input thermal energy which is necessary to carry out a predetermined thermal treatment is significantly reduced without affecting quality and yield of the object.

Owner:PANASONIC CORP

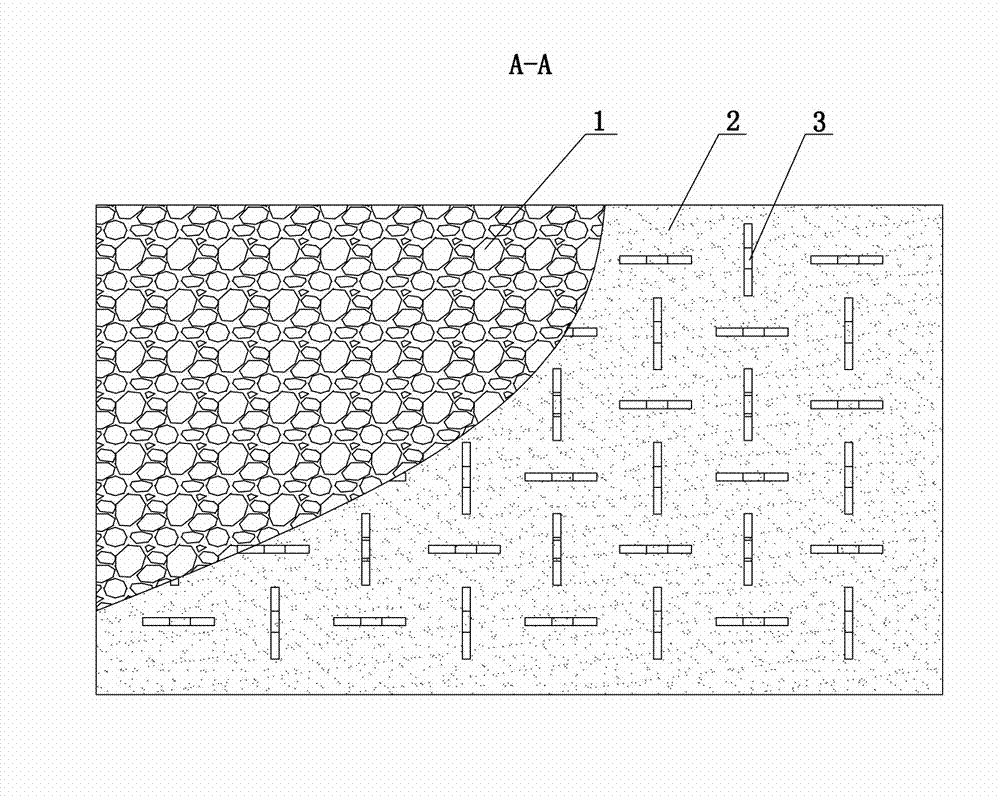

Large area air outlet fluidized calcining furnace refractory lining

ActiveCN101261079AGuaranteed reliabilityExtend your lifeLining supportsFluidised-bed furnacesCamber angleRefractory

The invention provides a large-area tuyere zone fluidizaton roasting furnace refractory lining. A steel fibrous reinforced castable or a high intensity low cement castable refractory is adopted to be cast with the furnace steel housing into a whole. The inside of the refractory lining is provided with a plurality of heat-proof stainless steel clips. The end surface of one end of each heat-proof stainless steel clip is welded with the furnace steel housing; the other end of each heat-proof stainless steel clip is lied inside the furnace refractory lining in a separated way or a ring-shaped link way. The heat-proof stainless steel clip is also applied by more than two layers of asphalt lac. A camber angle ring beam is arranged between the inner layer of the spherical vault and the combined furnace wall of the furnace body. The lower part of the furnace lining weight adopts the way of combing the bearing of an anchor ear beam and a furnace wall rivet clamping element. Under the condition that the roasting technology is not changed, the furnace body thins the furnace wall, and the furnace lining mass is reduced by 20 to 25 percent, thereby greatly lowering the cost, improving the leak tightness of the furnace body, preventing an isolated layer from being damaged, solving the problem that the insulating layer leaks SO2 to erode the furnace housing, improving the intensity, the air tightness and the stability of the furnace top and enhancing the whole structure of the furnace body.

Owner:洛阳市洛华粉体工程特种耐火材料有限公司

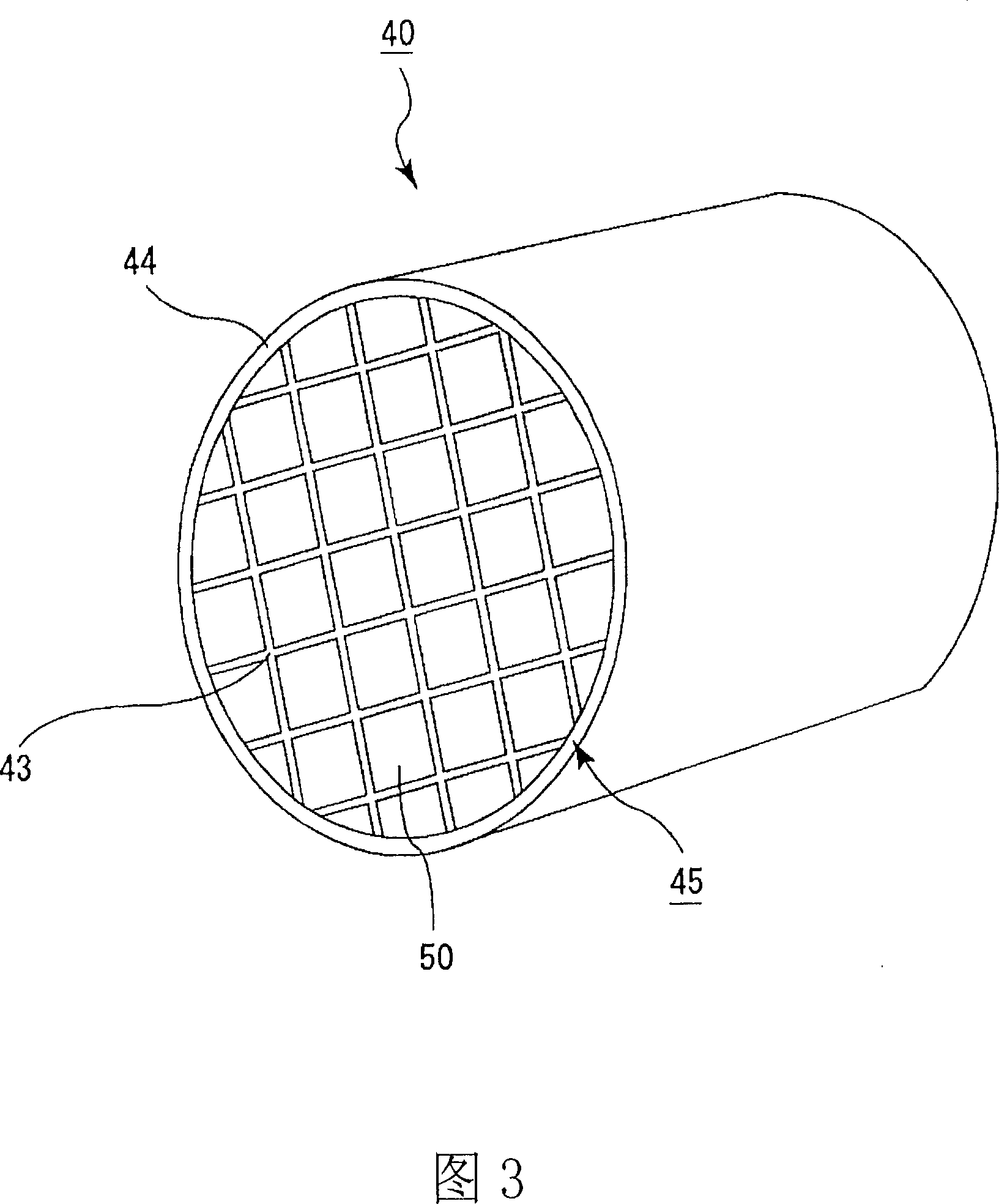

Riser reactor with flow disruptors

ActiveUS20130108519A1Reduce the risk of failureGaseous chemical processesCatalytic crackingRefractoryProcess engineering

An embodiment of the invention includes a riser reactor for reacting a feedstock and catalyst. The riser reactor wall defines an interior. A continuous refractory lining is attached to the reactor wall and defines a plurality of flow disruptors that extend inward from the wall into the reactor interior and disrupt flow patterns of the feedstock and catalyst.

Owner:UOP LLC

Masonry method for rotary kilns

ActiveCN103615884AIntegrity guaranteedSmall size errorLining supportsLinings repairStructural engineeringRotary kiln

The invention discloses a masonry method for rotary kilns. The masonry method includes steps of (1), dividing areas; (2), welding anchoring parts; (3), mounting precast bricks; (4), pouring mortar. The masonry method has the advantages that integral precast brick layers are divided into a plurality of areas, when the precast bricks in a certain area fall off, the integrity of the other areas can be guaranteed, accordingly, the cost can be saved, and workload on workers can be reduced; mortar joints are reserved among the various adjacent precast bricks, so that the integrity of the rotary kilns can be corrected, and accidents caused by the fact that only refractory mortar in joints is squeezed when existing precast bricks are heated and expanded, and the existing precast bricks are squeezed by one another, are broken and fall off can be prevented; the precast bricks are fixed to kiln bodies by the aid of the anchoring parts, so that joints among the precast bricks and the inner walls of the kiln bodies can be set and prevent the precast bricks from squeezing the inner walls of the kiln bodies when the precast bricks are radially expanded, and accidents caused by the fact that the inner walls of existing kiln bodies are squeezed by the existing precast bricks and anchoring parts are broken can be prevented.

Owner:CHINA MCC5 GROUP CORP

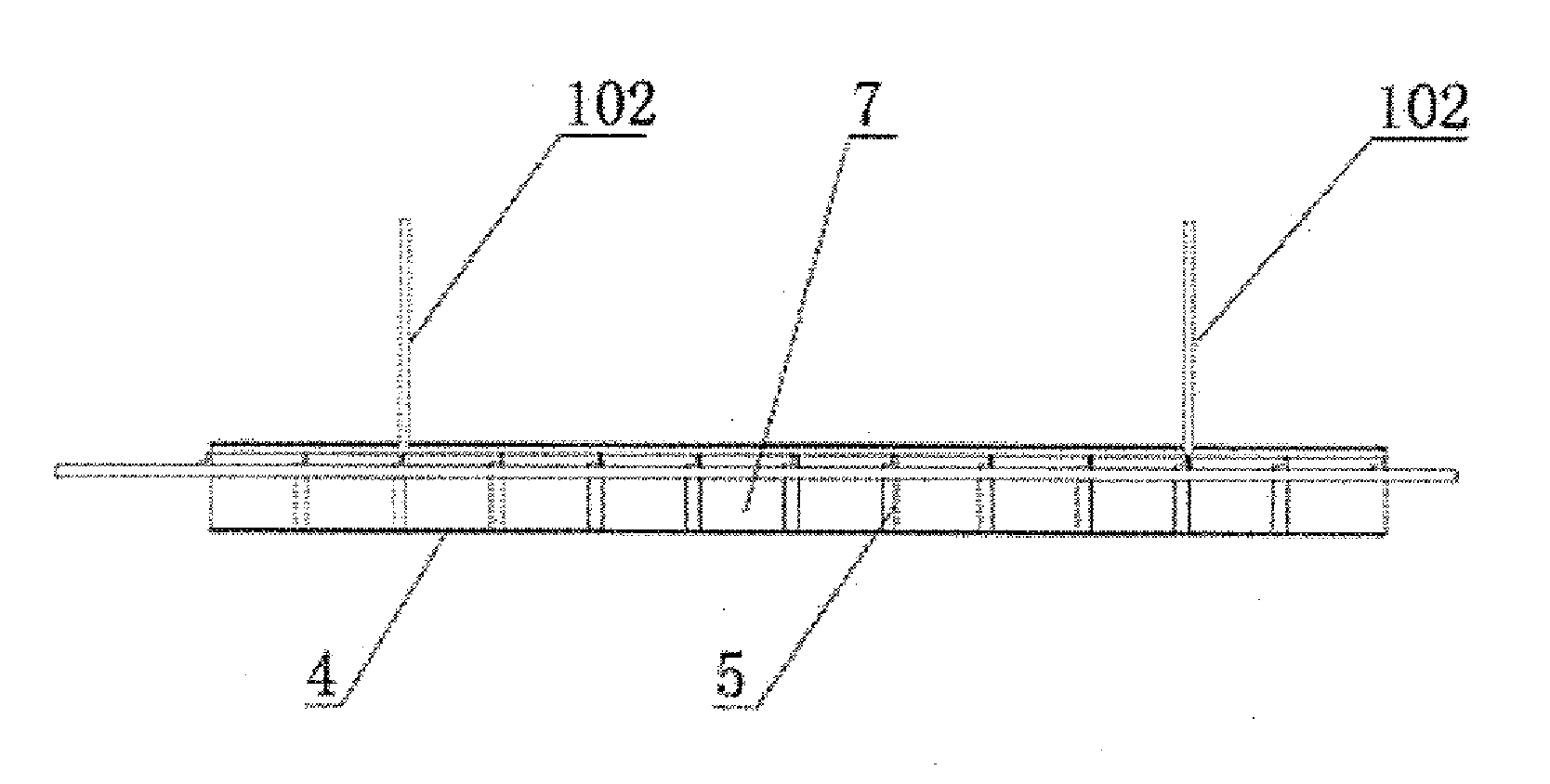

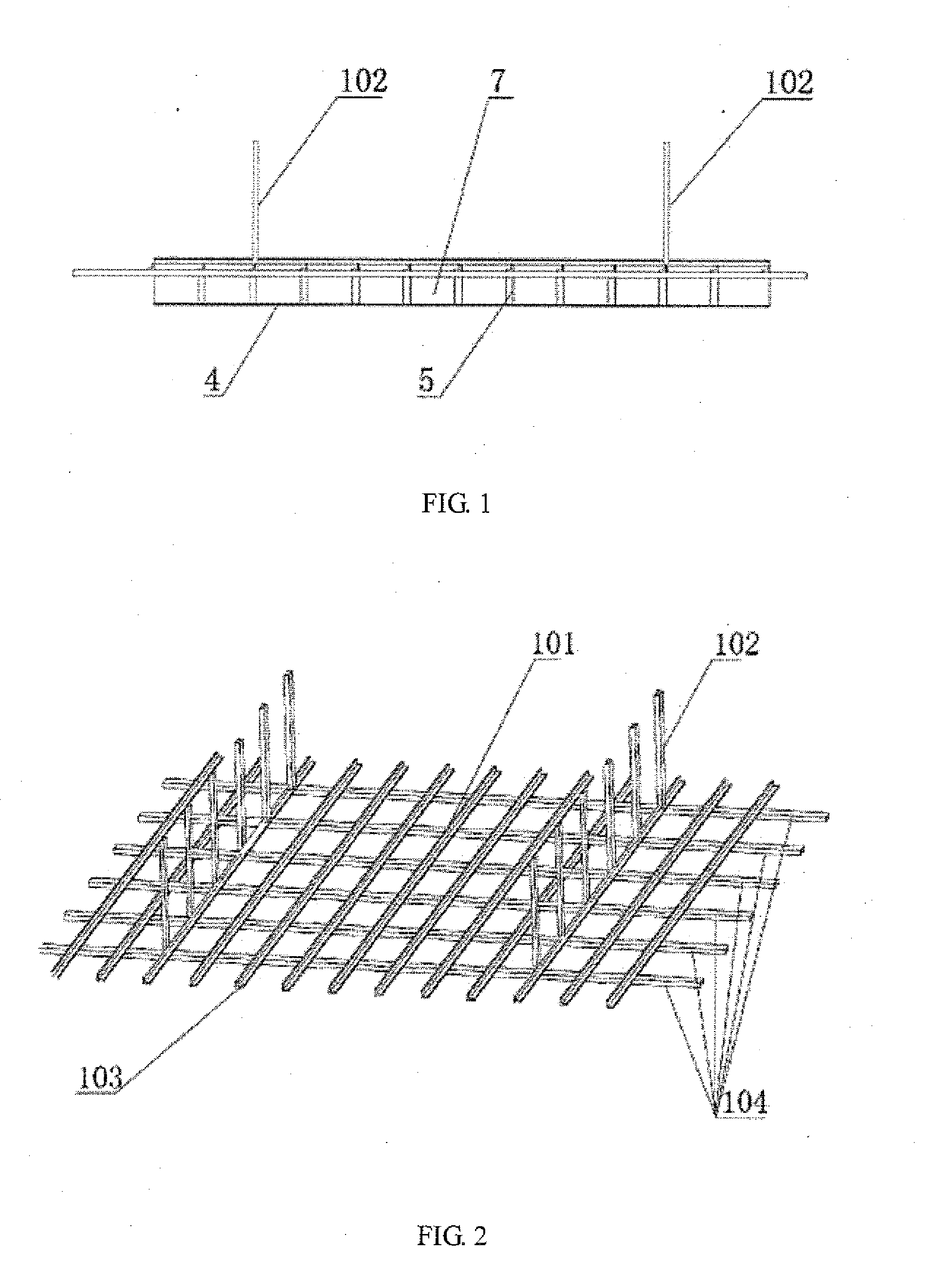

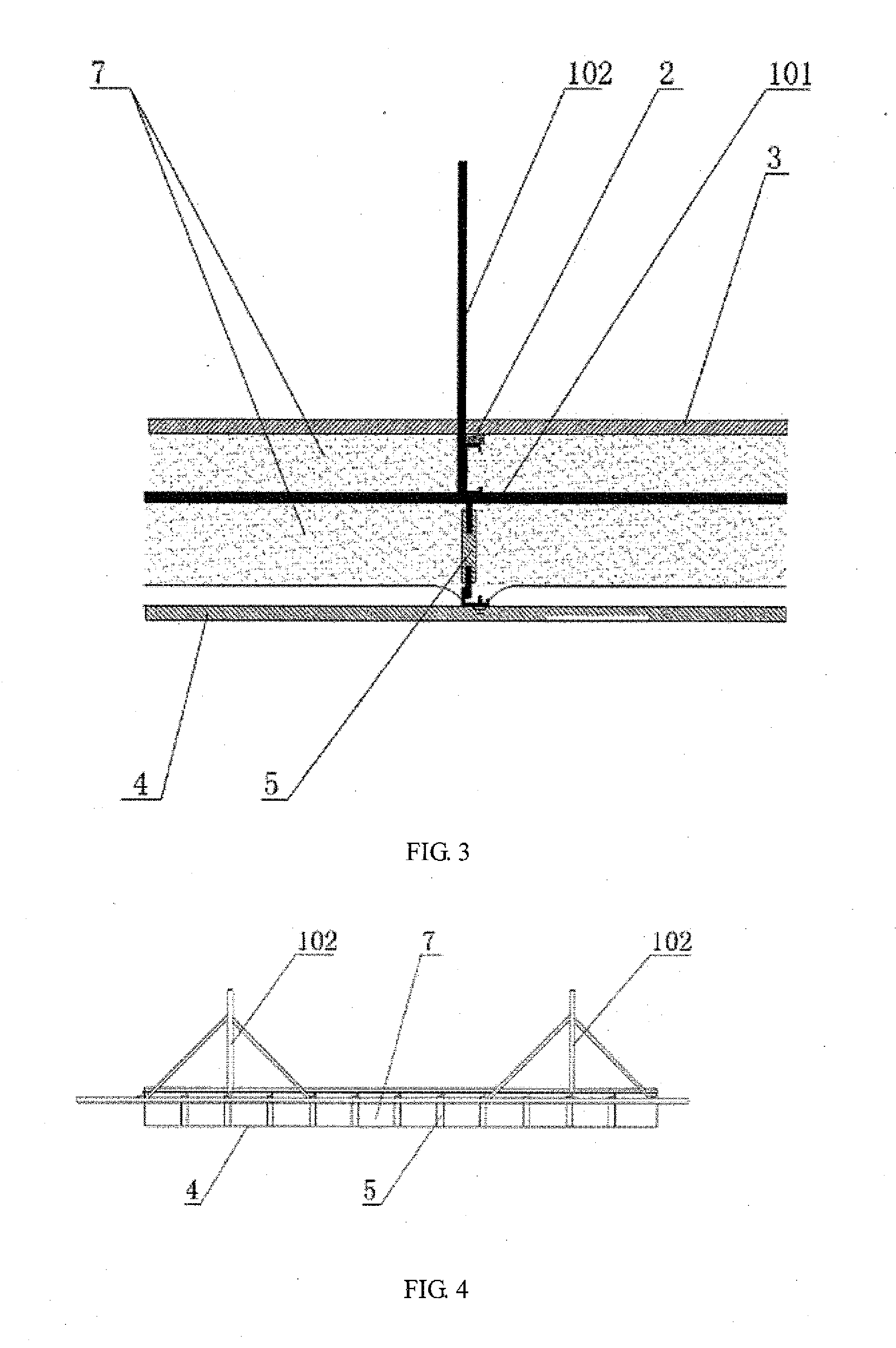

Suspended ceiling structure for refrigerated storage and construction method thereof

InactiveUS20120037582A1Good effectSave energyCeilingsLining supportsThermal breakStructural engineering

A suspended ceiling structure for a refrigerated storage and a construction method thereof are provided. The suspended ceiling structure comprises a ceiling grid which comprises a main grid, hanging members and an attachment grid. An insulating strip made of polyurethane foam is placed on the main grid so as to serve as a cushion block. An upper color-coated steel sheet is provided above the insulating strip and a lower color-coated steel sheet is arranged below the main grid. A thermal break component is arranged between the main grid and the lower steel sheet, and a polyurethane insulating material is sprayed in successive layers between the upper and lower color coated steel sheets. The ceiling structure can improve the insulation effect of the refrigerated storage and save energy.

Owner:GUANGZHOU BAIER COLD CHAIN POLYURETHANE TECH

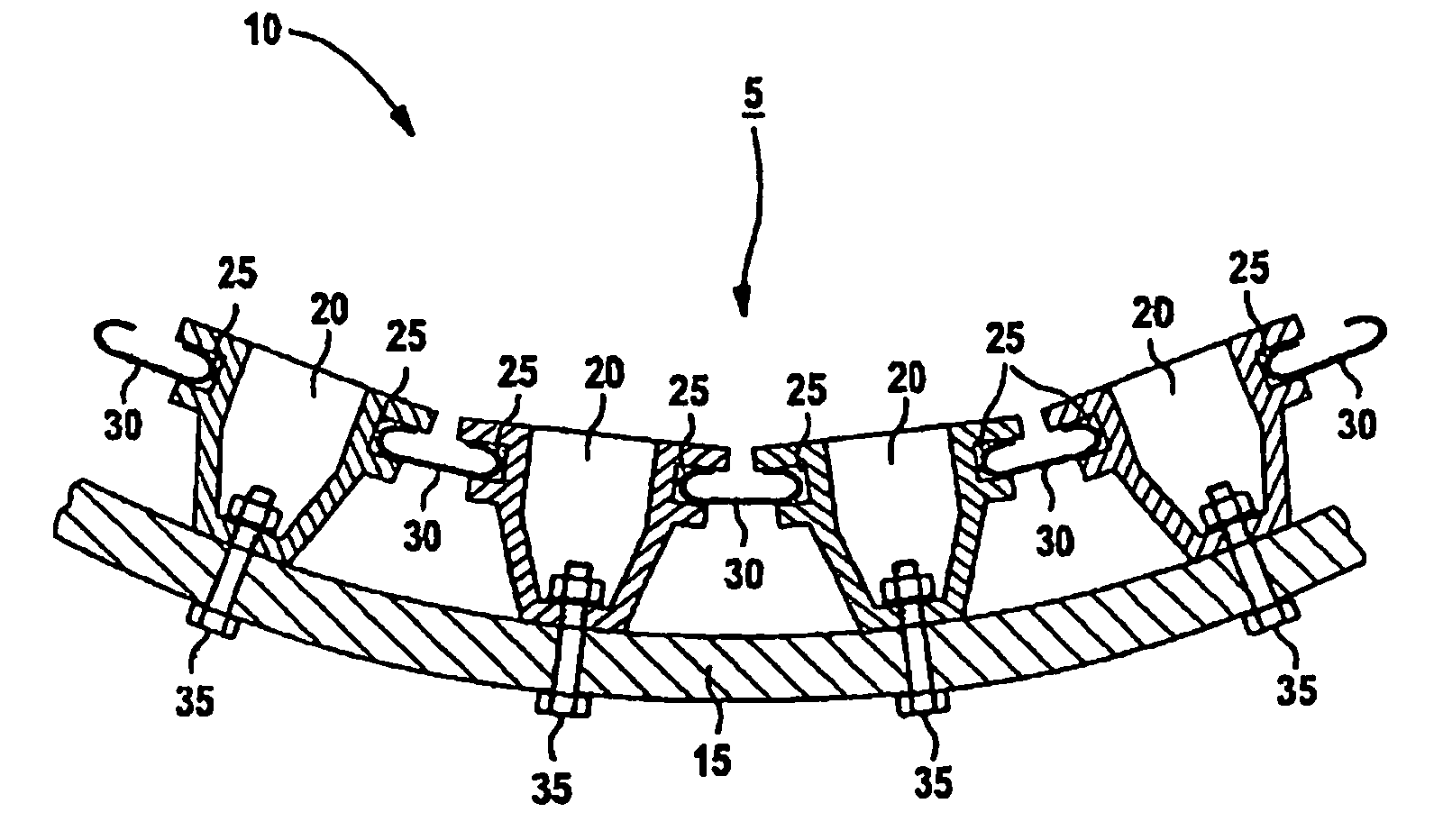

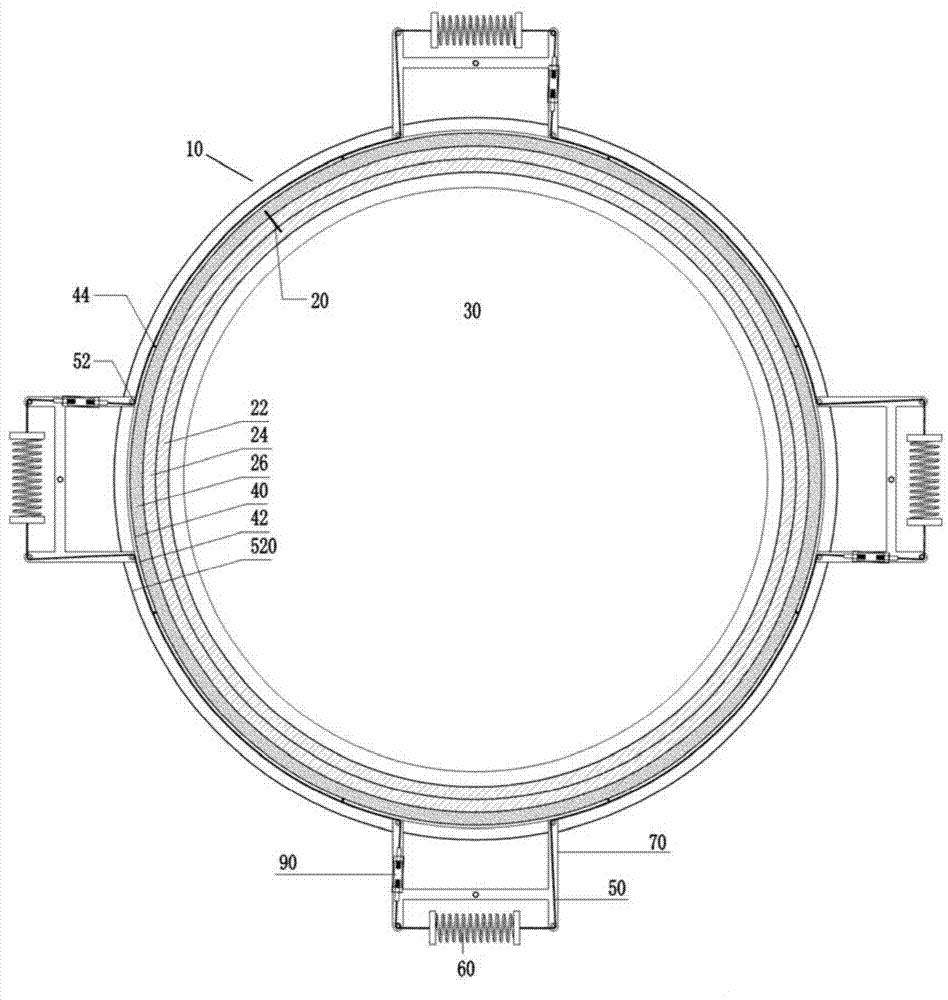

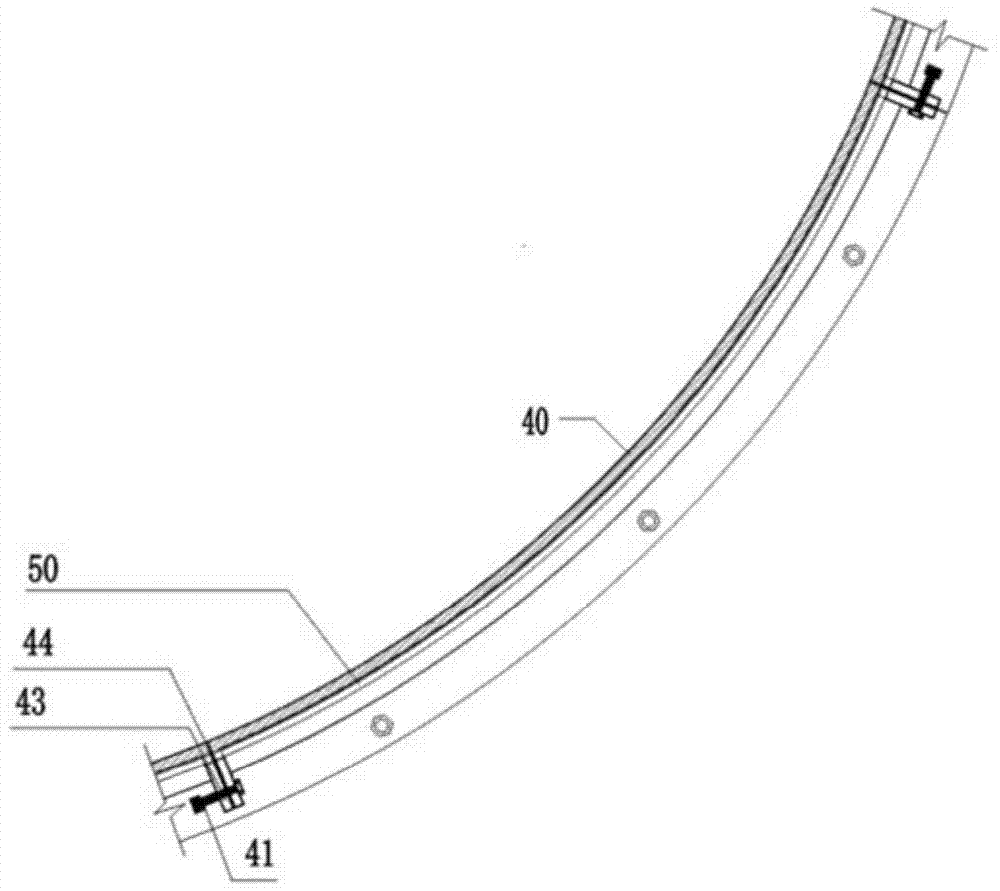

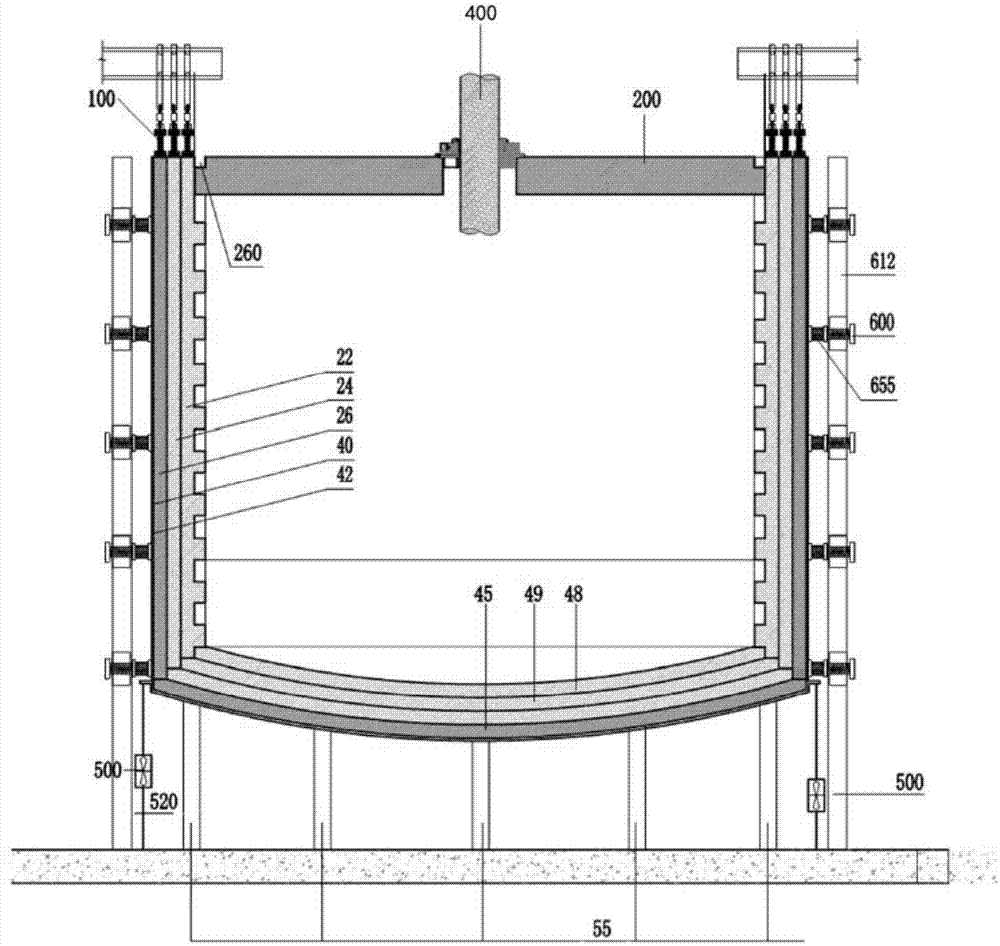

Elastically interconnected cooler compressed hearth and walls

ActiveUS20130099430A1Disallow leakIncrease pressureLining supportsManufacturing convertersBrickWorking pressure

An elastically interconnected cooler compressed hearth comprises a concave dished bottom lined with a sub-layer and a working layer of hearth bricks. Cylindrical walls that rise up from the rim of the concave dished bottom are constructed with one or more tiers of coolers shaped into arc segment blocks that are joined together by their flanges to form complete rings. The outer perimeter of the hearth brick within the ringed tiers is inwardly compressed toward the center to disallow any leaks from forming between the separate bricks. The coolers are elastically interconnected at their flanges by fasteners and springs. Each spring can be individually adjusted to obtain optimal working pressures on the whole of the core wall and hearth floor bricks.

Owner:MACRAE ALLAN

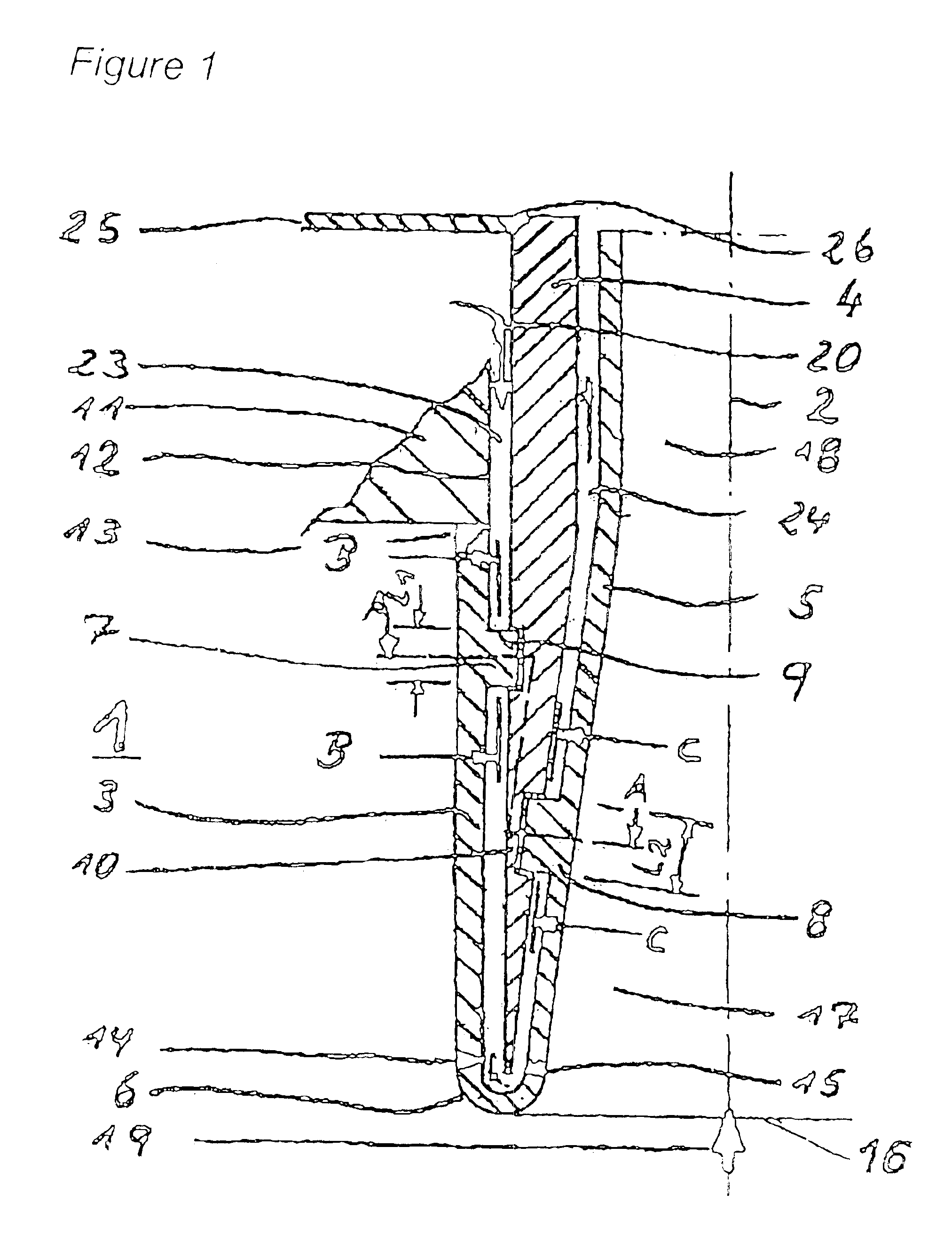

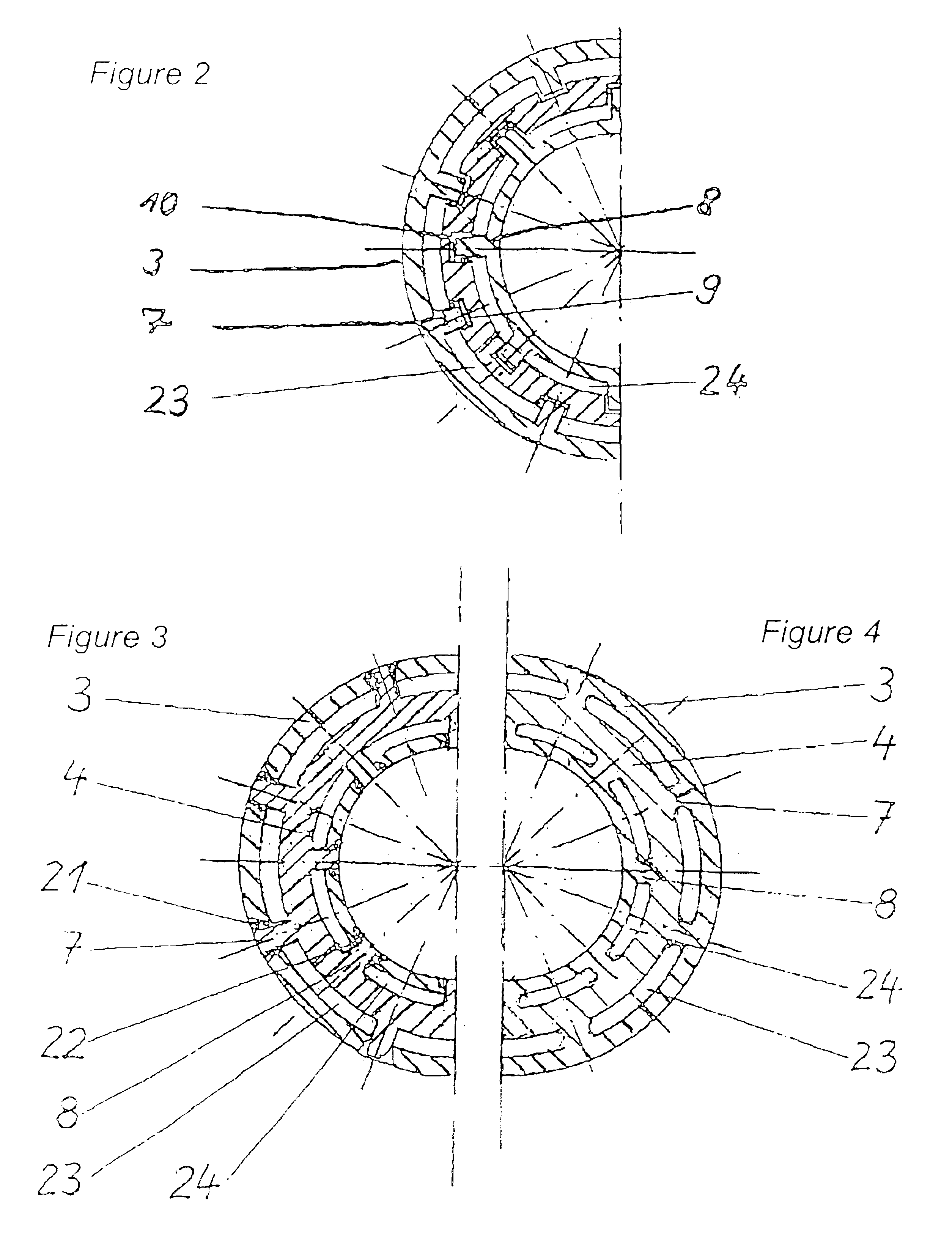

Device for introducing hot gas into a heating surface pipe of a waste heat boiler

InactiveUS6880492B2Increase mass flowEasy to moveLining supportsGasifier mechanical detailsEngineeringWaste heat

A device for introducing hot gas into a heating surface pipe of a waste heat boiler includes an outer pipe that is connected to the boiler wall, preferably to the bottom of the pipe. The device also includes an inner pipe or entry pipe that has an admission section that is cylindrical or conically narrows and also has a discharge section that is connected to the heating surface pipe. The inner pipe is connected to the outer pipe via a rounded reversible cap while forming an entry opening for the hot gas. The inner pipe is surrounded by the outer pipe at a distance. The device also includes a coolant guiding pipe, which is placed between the outer pipe and the inner pipe and which extends into the proximity of the reversible cap. The guiding pipe is provided in the form of a force-transmitting component and is connected, in a removable or fixed manner, both to the inner pipe as well as to the outer pipe each time with at least three connecting ribs which are uniformly distributed over the periphery and which are provided for introducing or transferring forces.

Owner:ARVOS GMBH

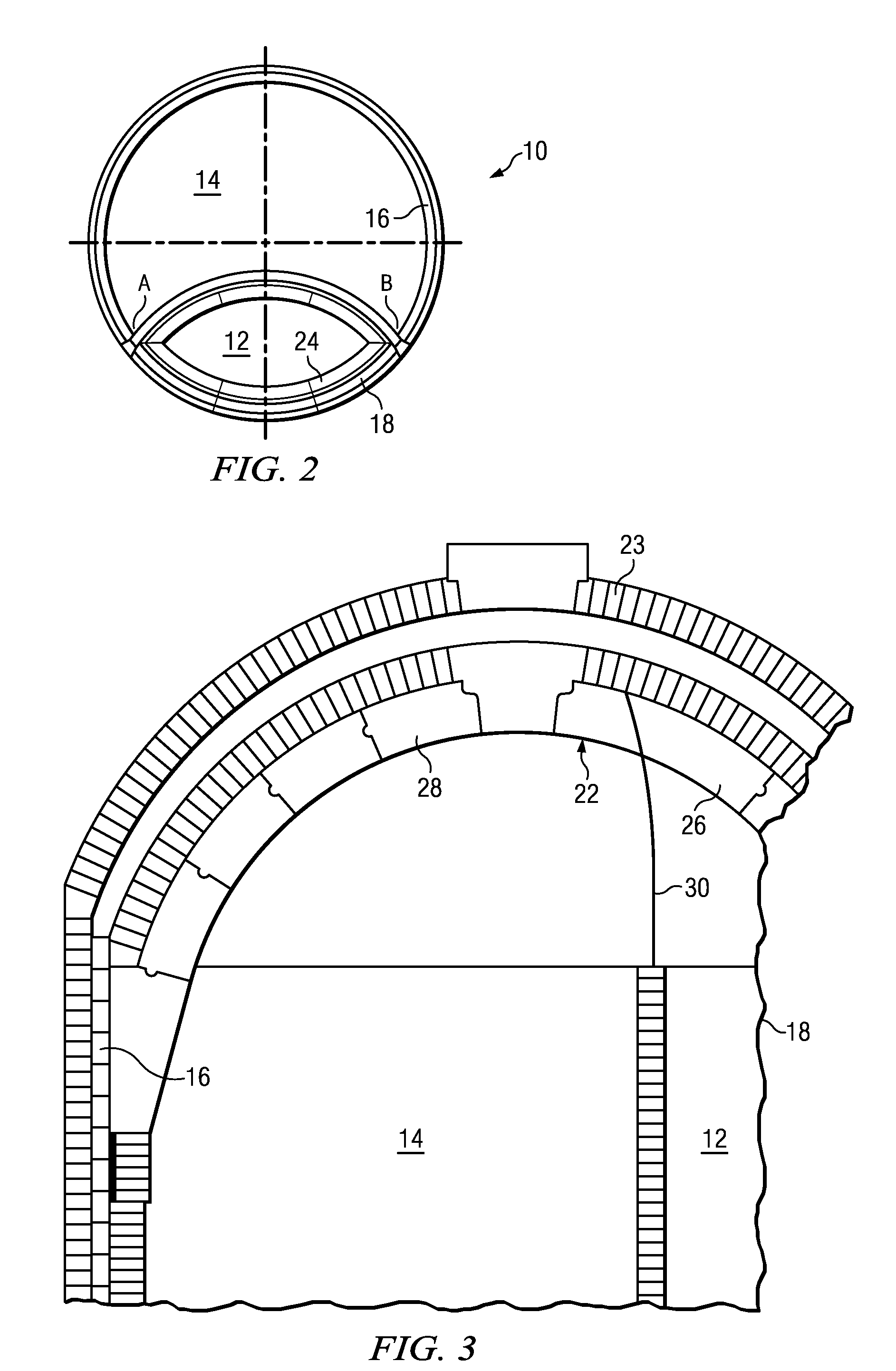

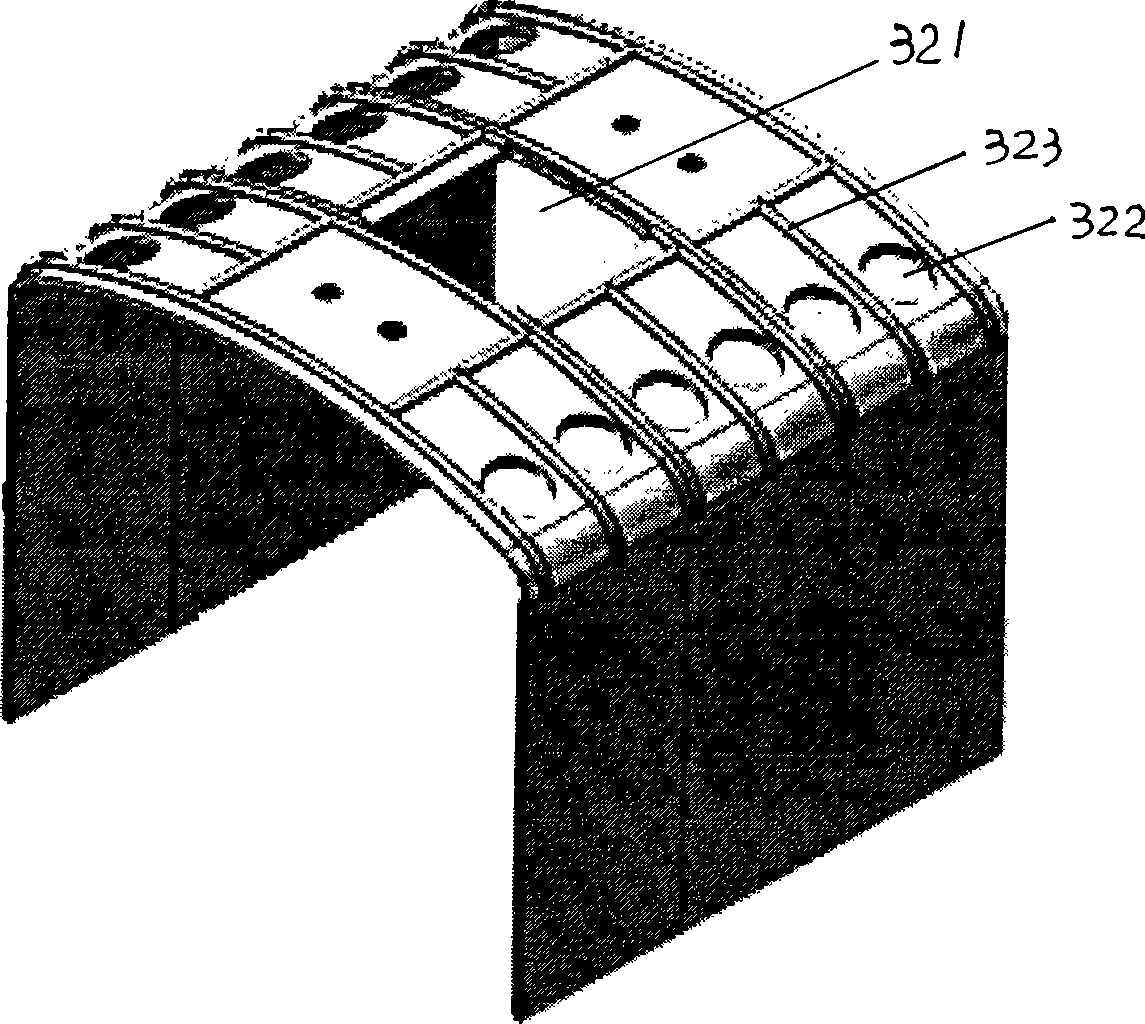

Hot Blast Stove Dome and Hot Blast Stove

ActiveUS20110200958A1Significant engineeringSignificant materialBrick-hot blast stovesLining supportsCombustion chamberEngineering

A hot blast stove dome comprises a first dome portion adapted for support on a combustion chamber wall of a hot blast stove, and a second dome portion adapted for support on a checker chamber wall of a hot blast stove, wherein a vertical expansion joint is provided between the first dome portion and the second dome portion and is adapted to allow the first dome portion and the second dome portion to independently accommodate vertical expansion of their respective supporting walls. The dome is suitably provided in a hot blast stove which comprises a combustion chamber, a checker chamber, a cylindrical housing comprising a combustion chamber wall and a checker chamber wall.

Owner:ALLIED MINERAL PROD LLC

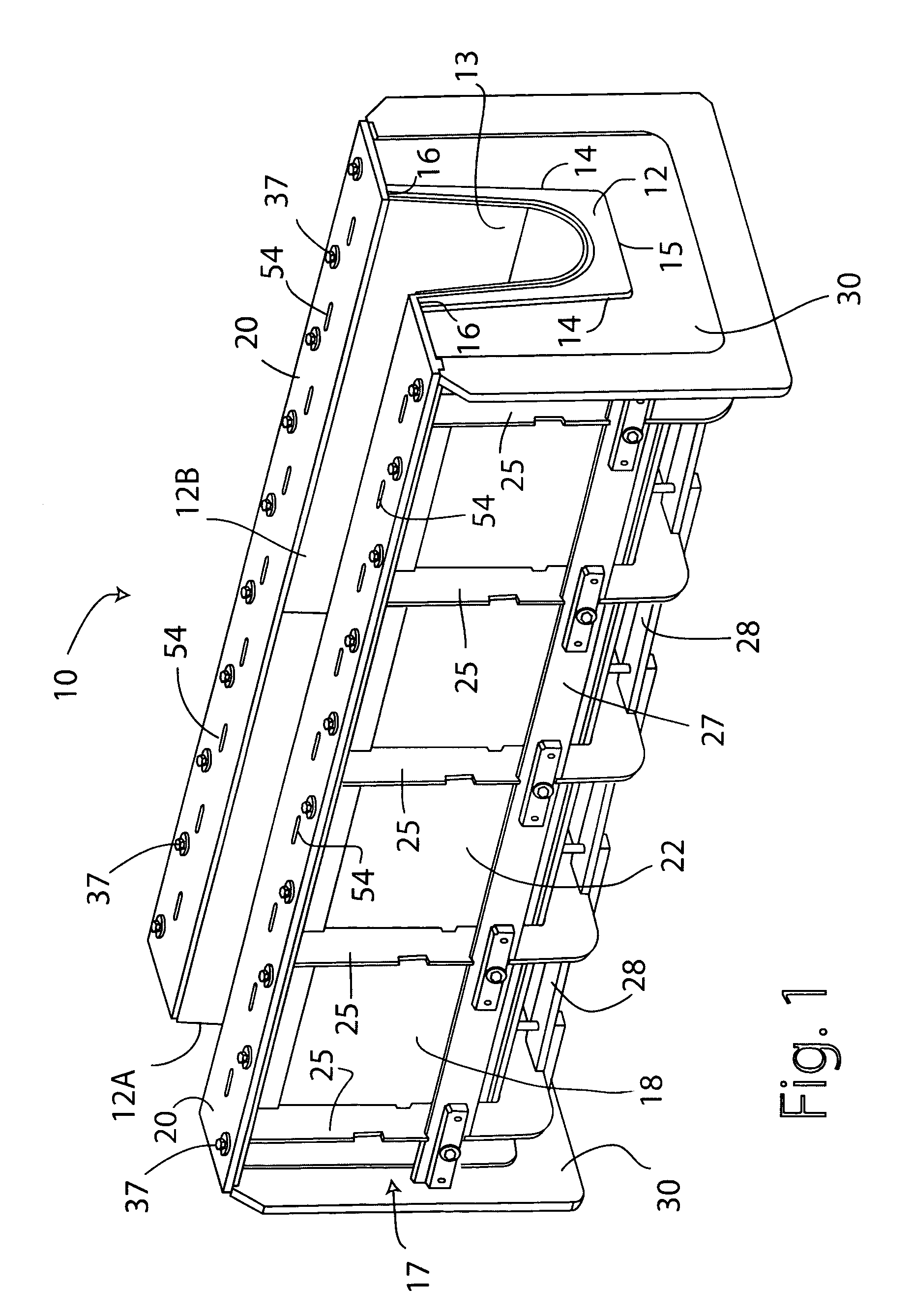

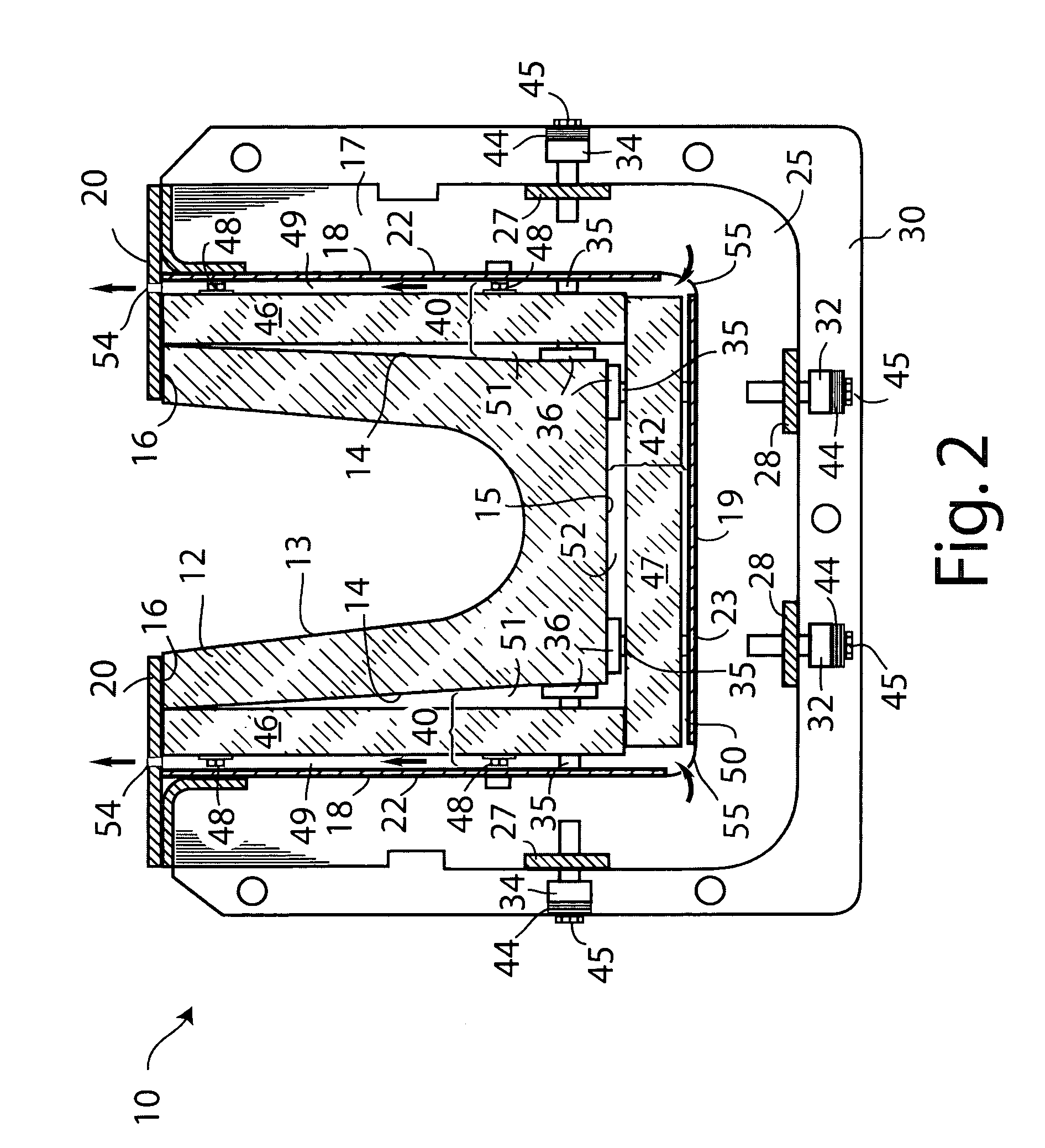

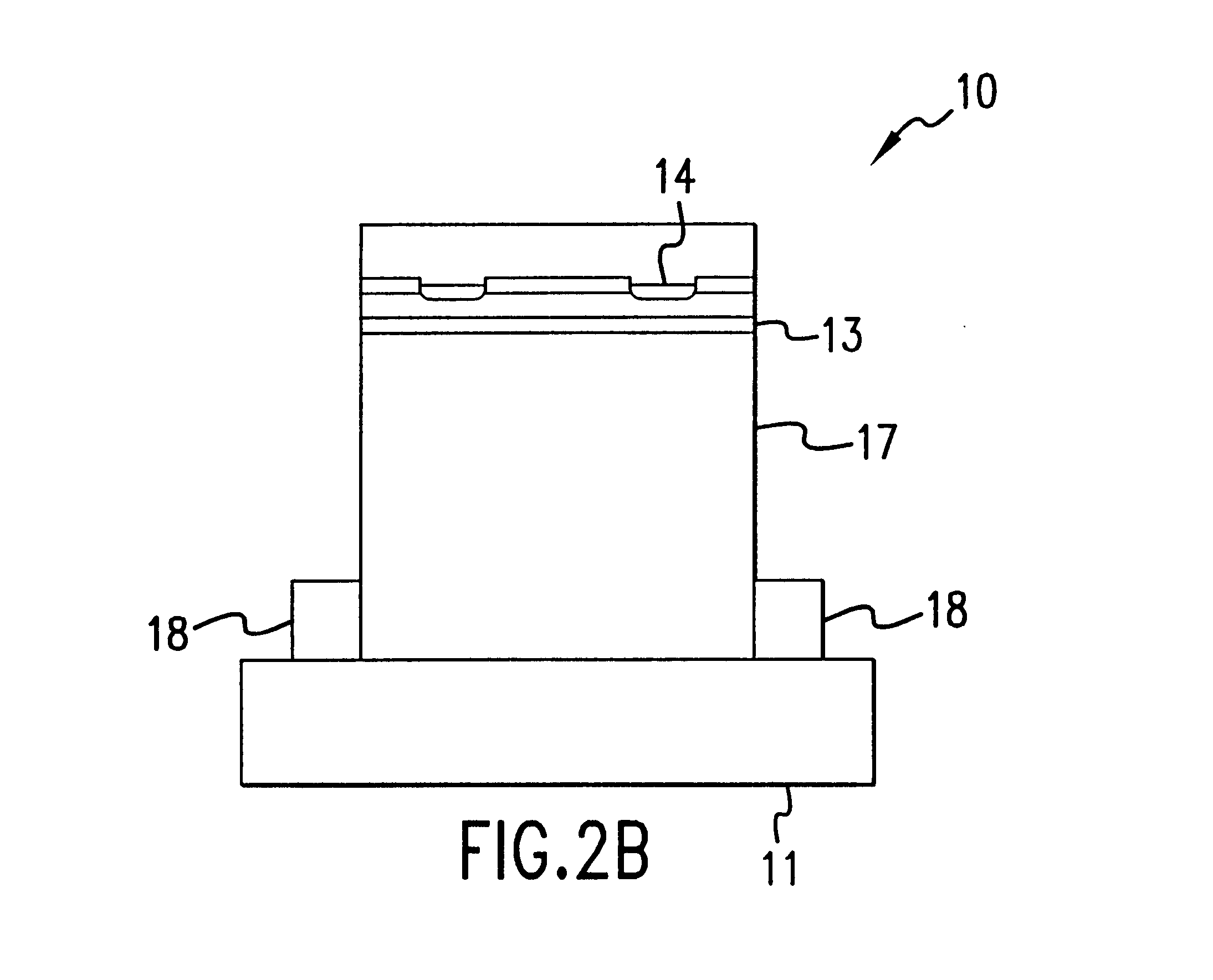

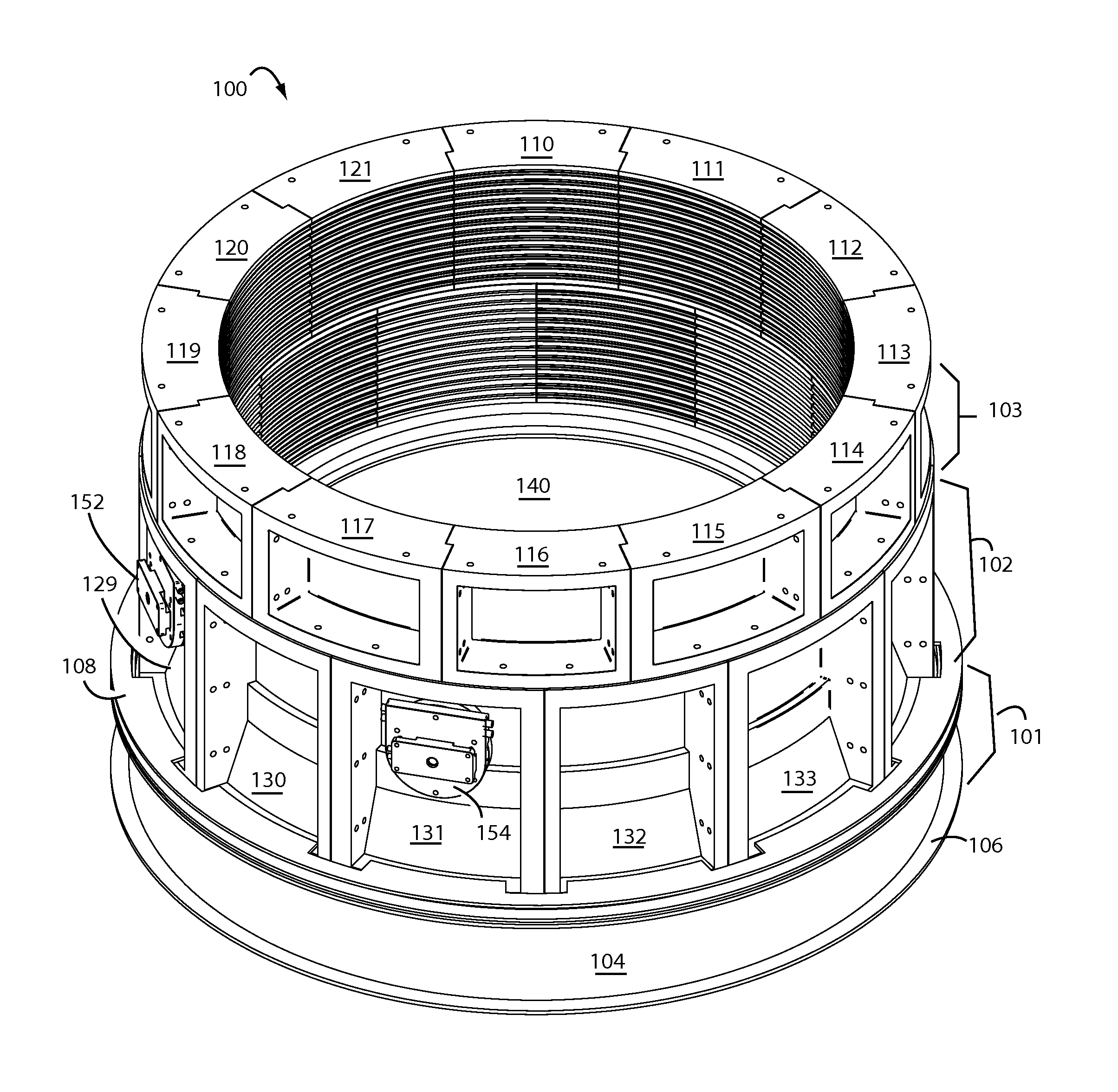

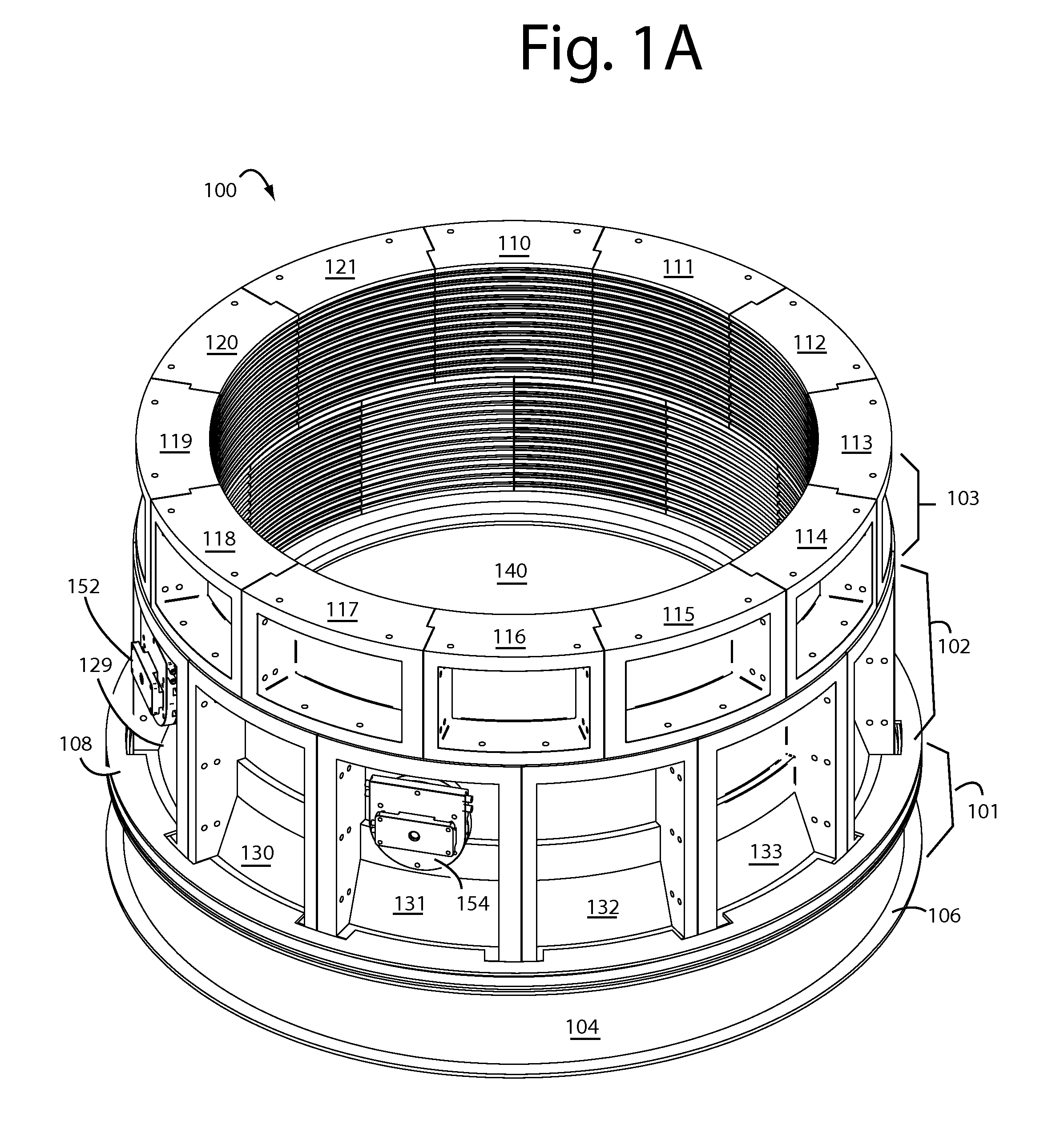

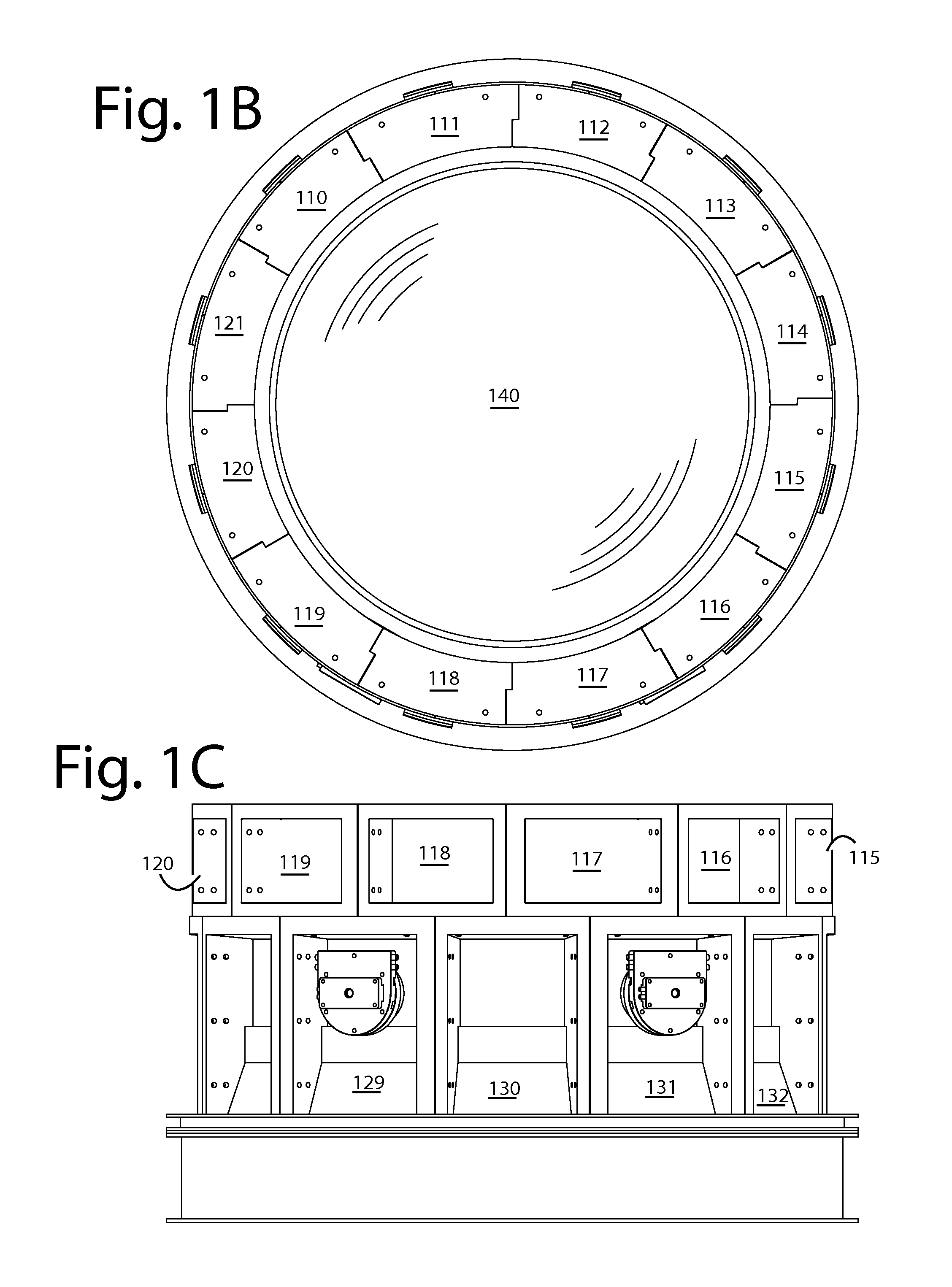

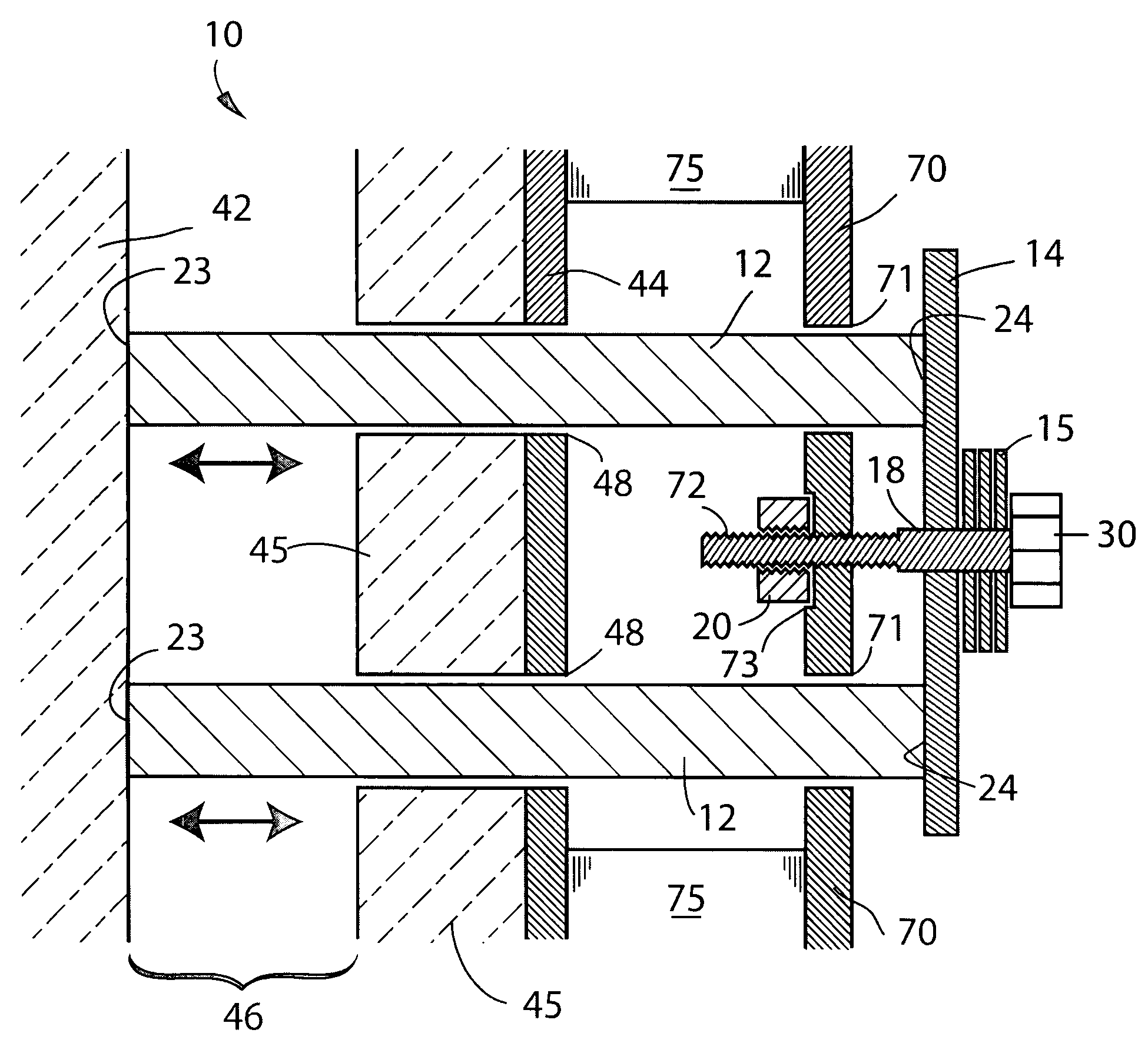

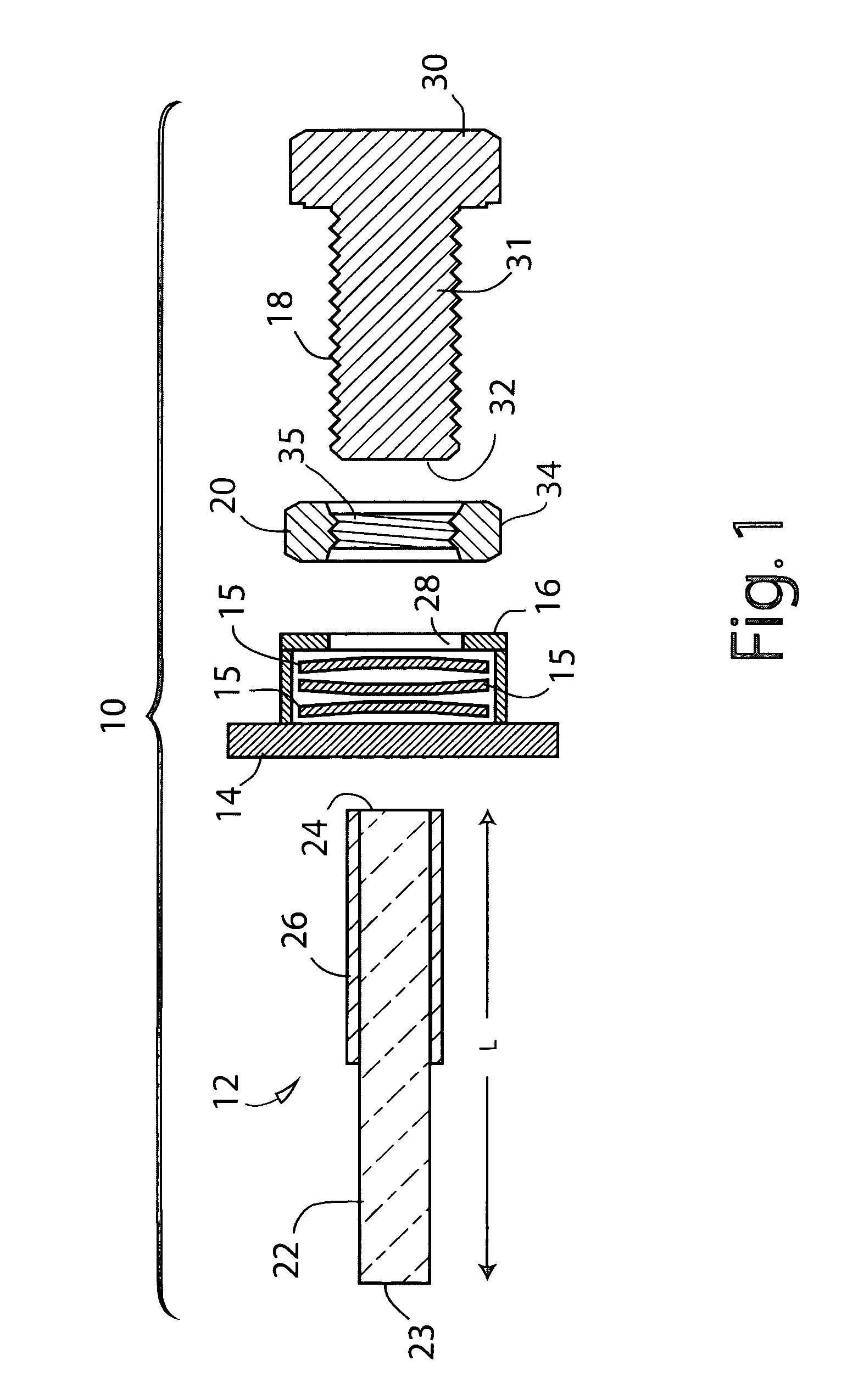

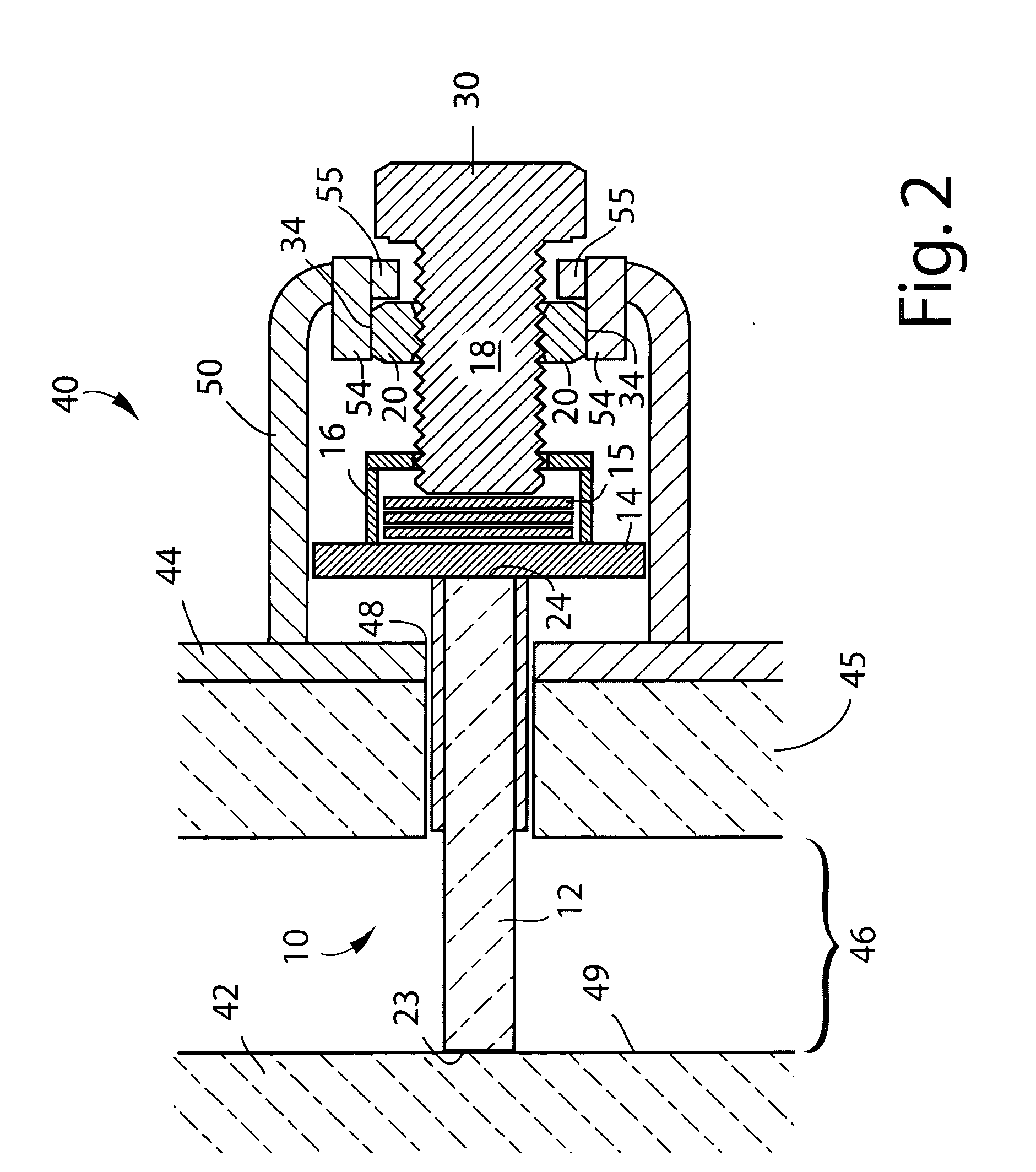

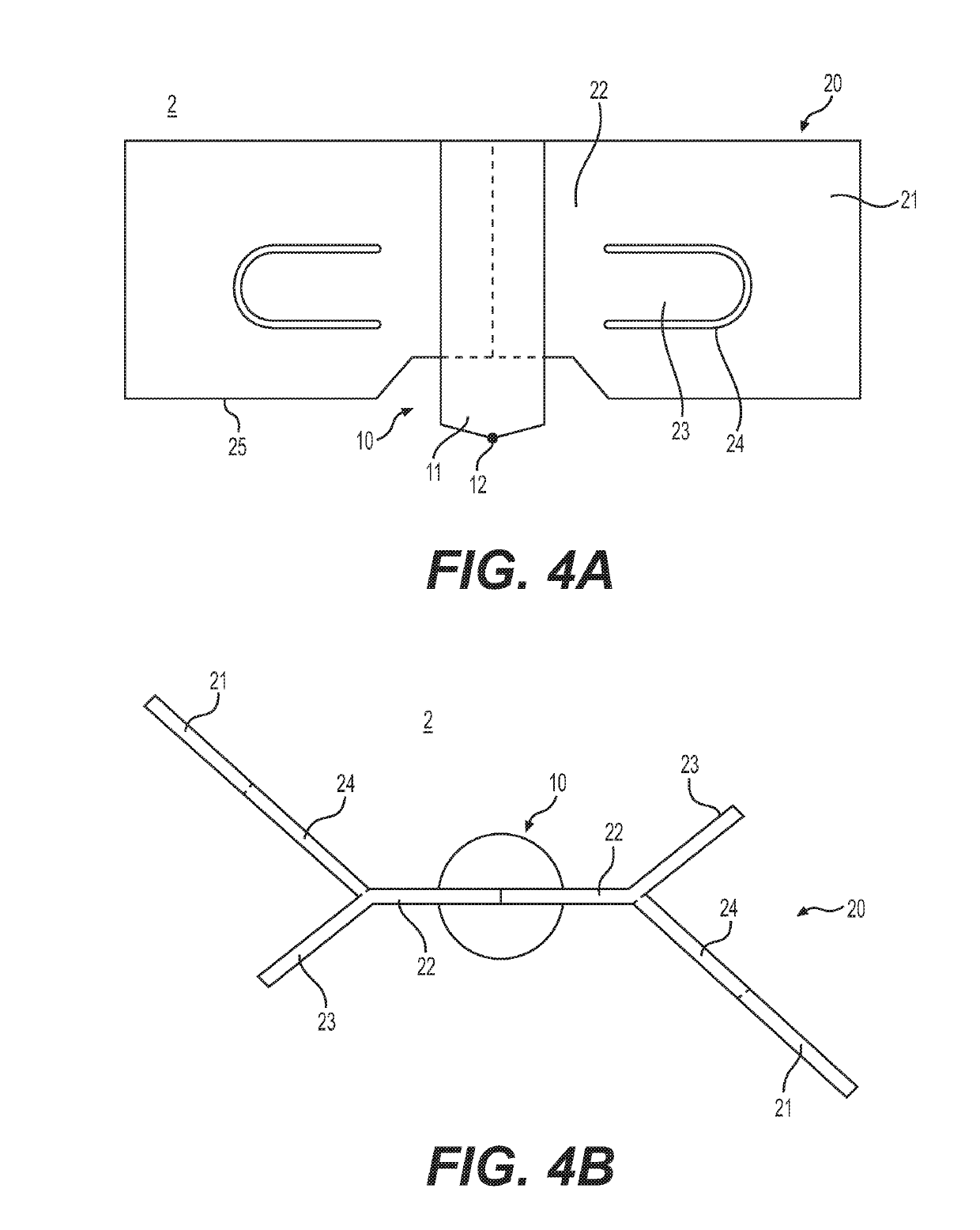

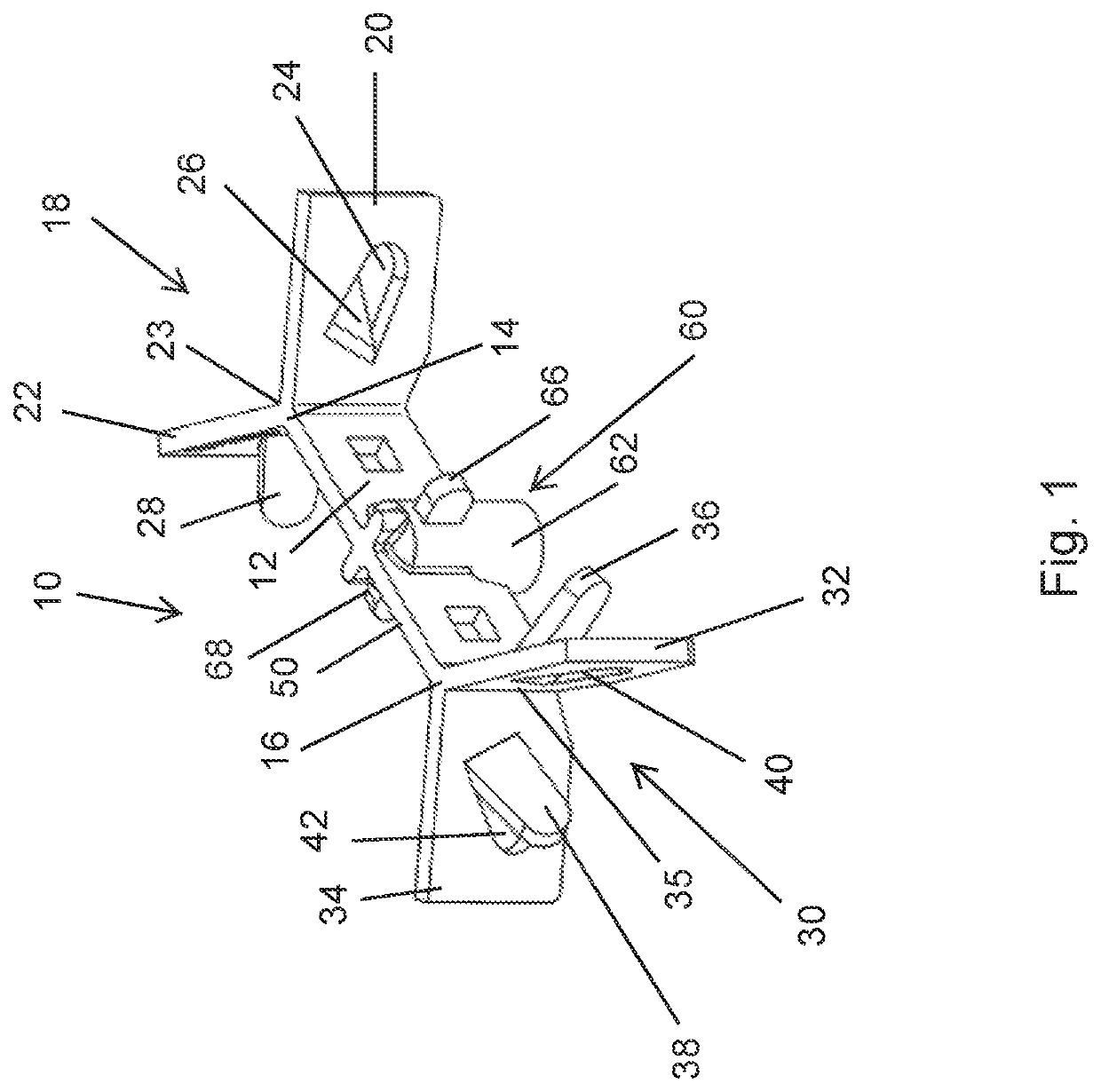

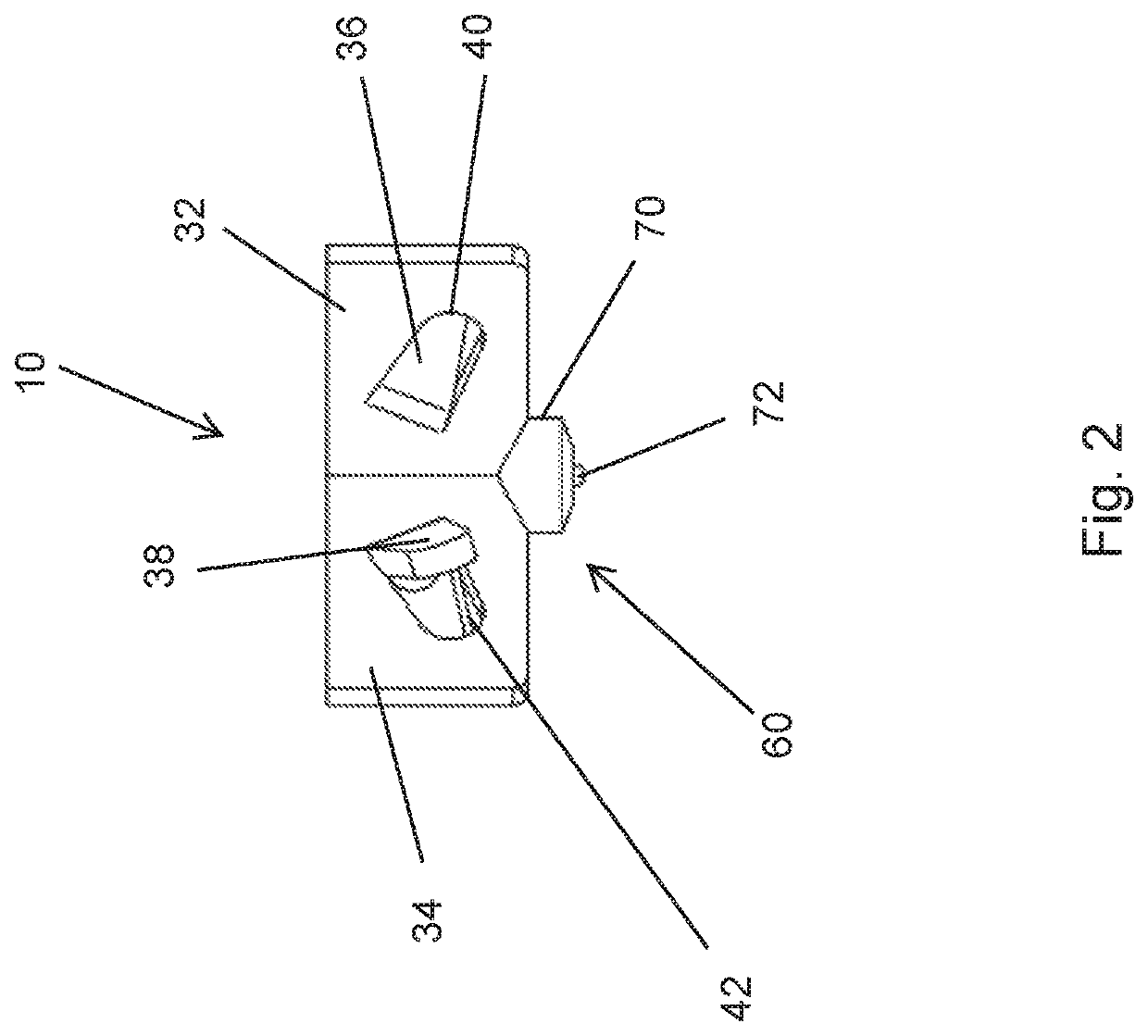

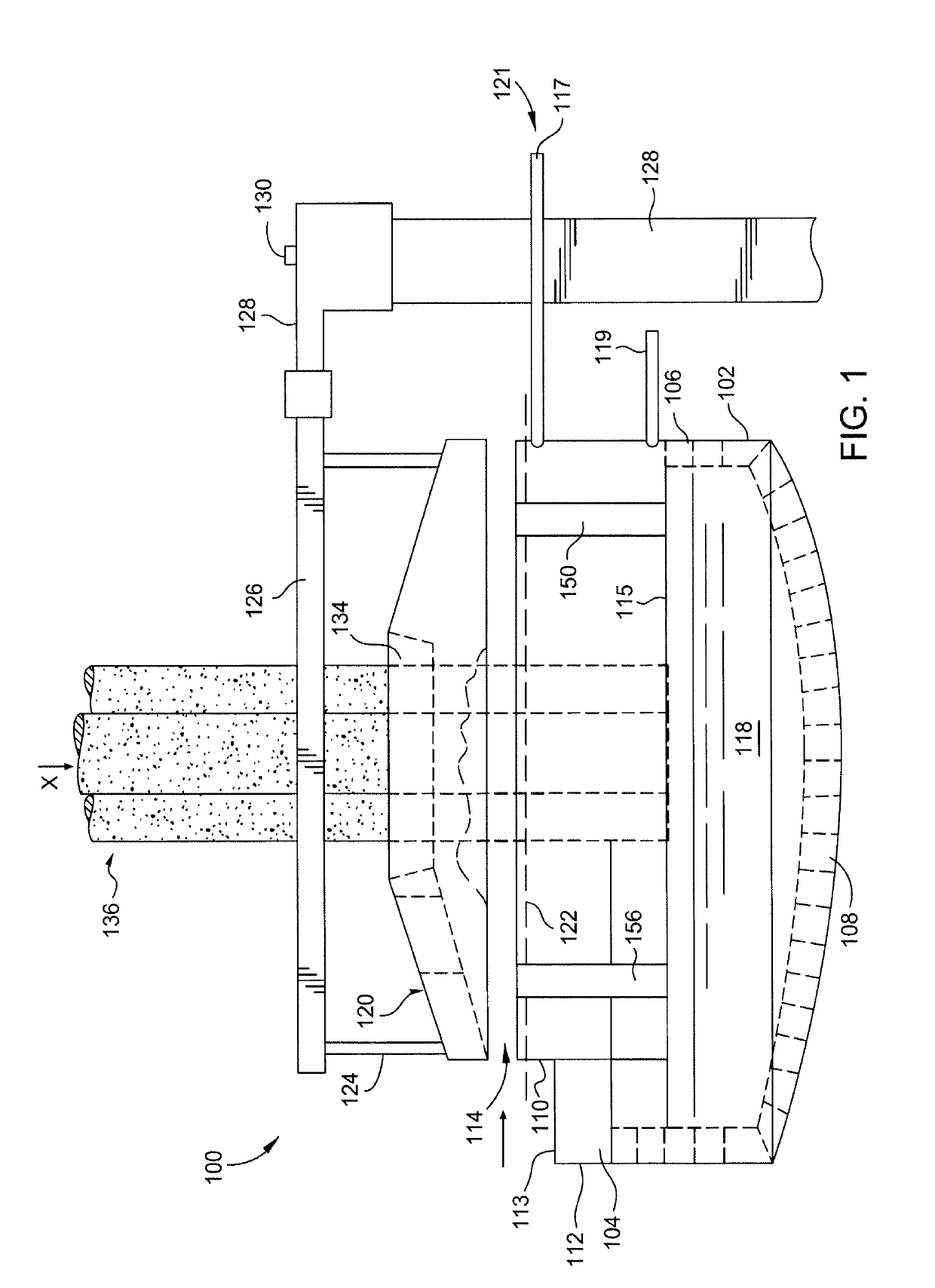

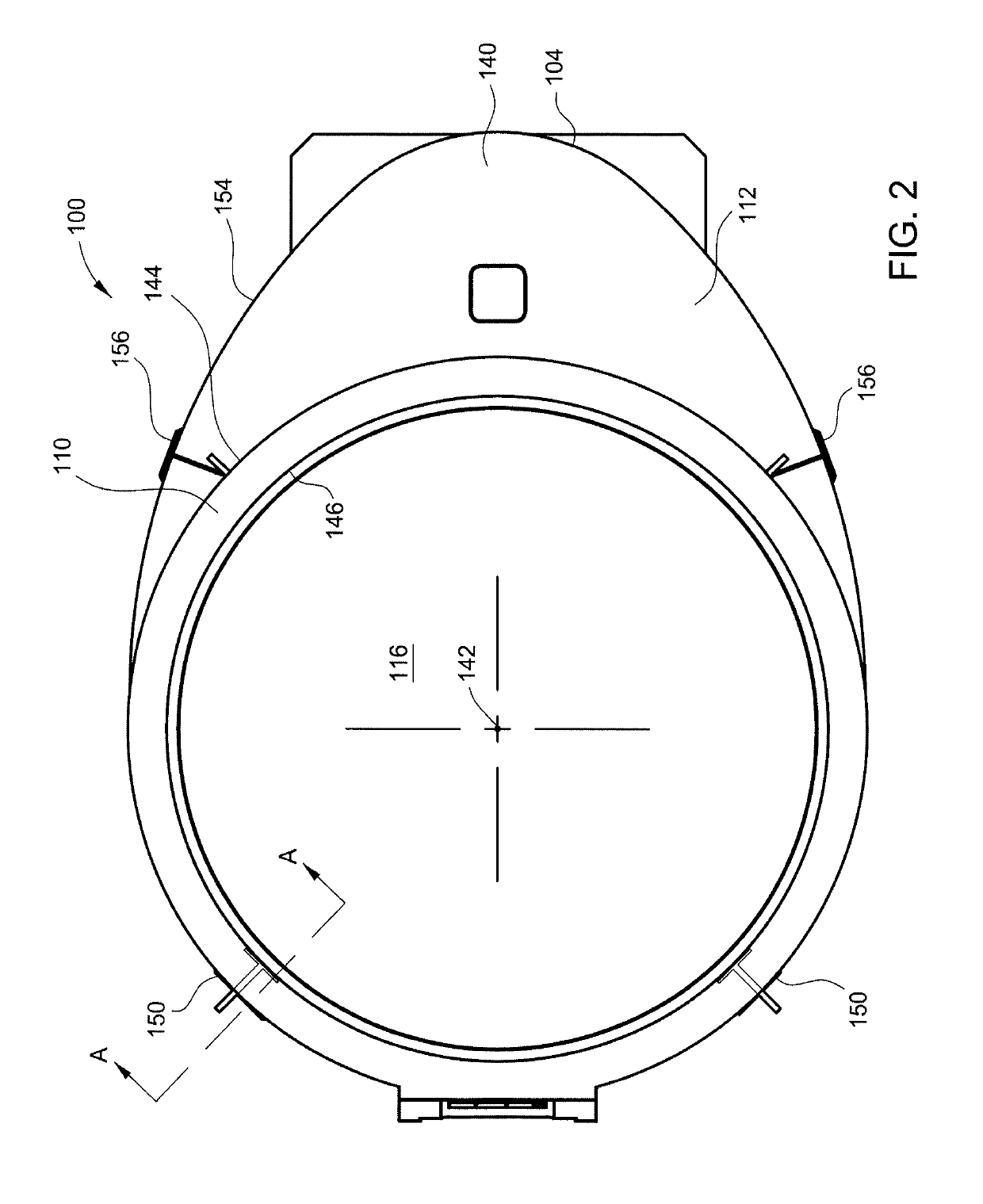

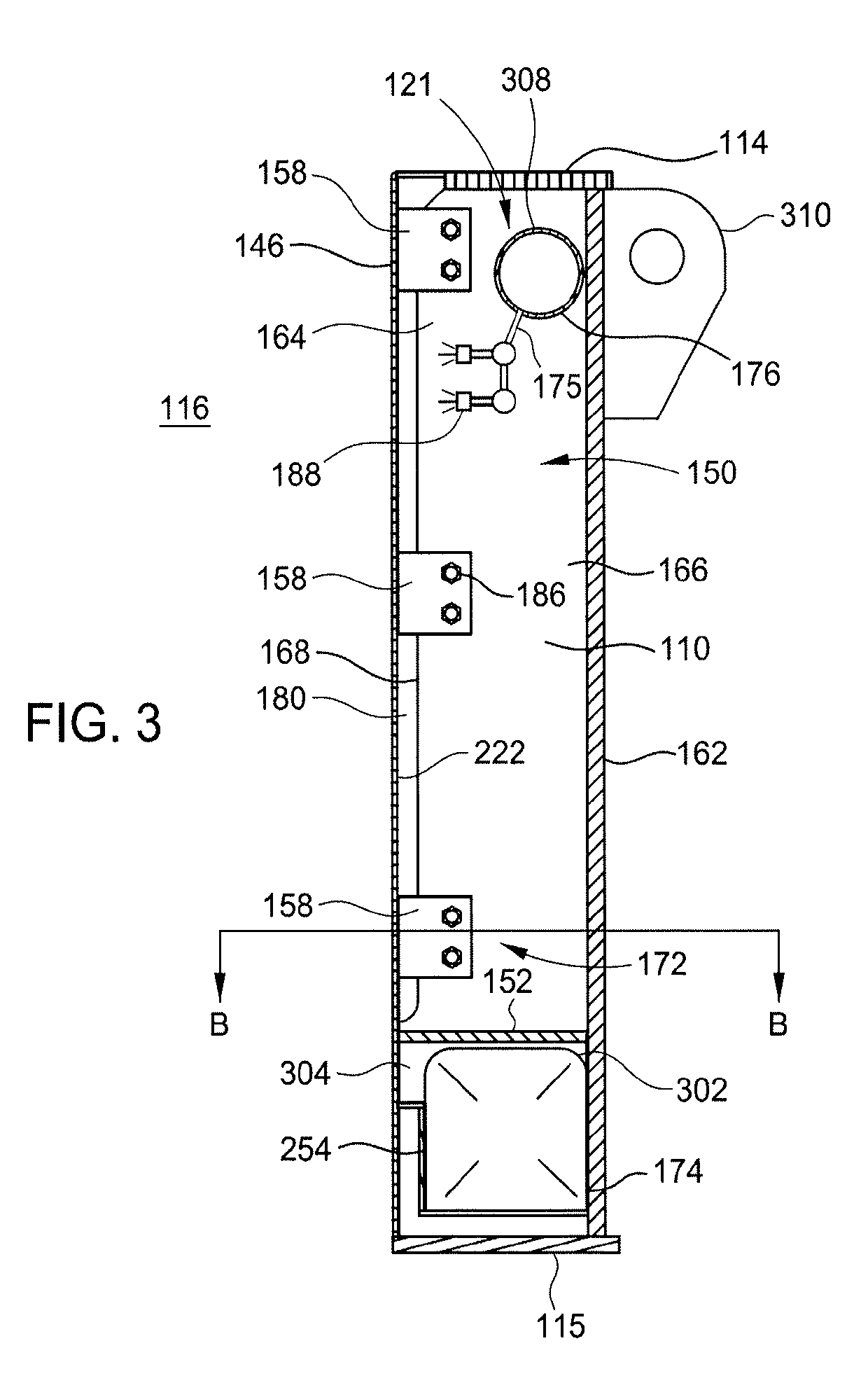

Compressive rod assembly for molten metal containment structure

ActiveUS20110140322A1Limit longitudinal movementReduces instanceMelt-holding vesselsConnecting rod bearingsEngineeringMolten metal

Exemplary embodiments of the invention relate to a compressive rod assembly for applying force to a refractory vessel positioned within an outer metal casing. The assembly includes a rigid elongated rod having first and second opposed ends, a threaded bolt adjacent to the first opposed end of the elongated rod, and a compressive structure positioned operationally between the elongated rod and the bolt. Compressive force applied by the bolt to the elongated rod passes through the compressive structure which allows limited longitudinal movements of the elongated rod to be accommodated by the compressive structure without requiring corresponding longitudinal movements of the bolt. Exemplary embodiments also relate to rod structure forming a component of the assembly, and to a metal containment structure having a vessel supported and compressed by at least one such assembly.

Owner:NOVELIS INC

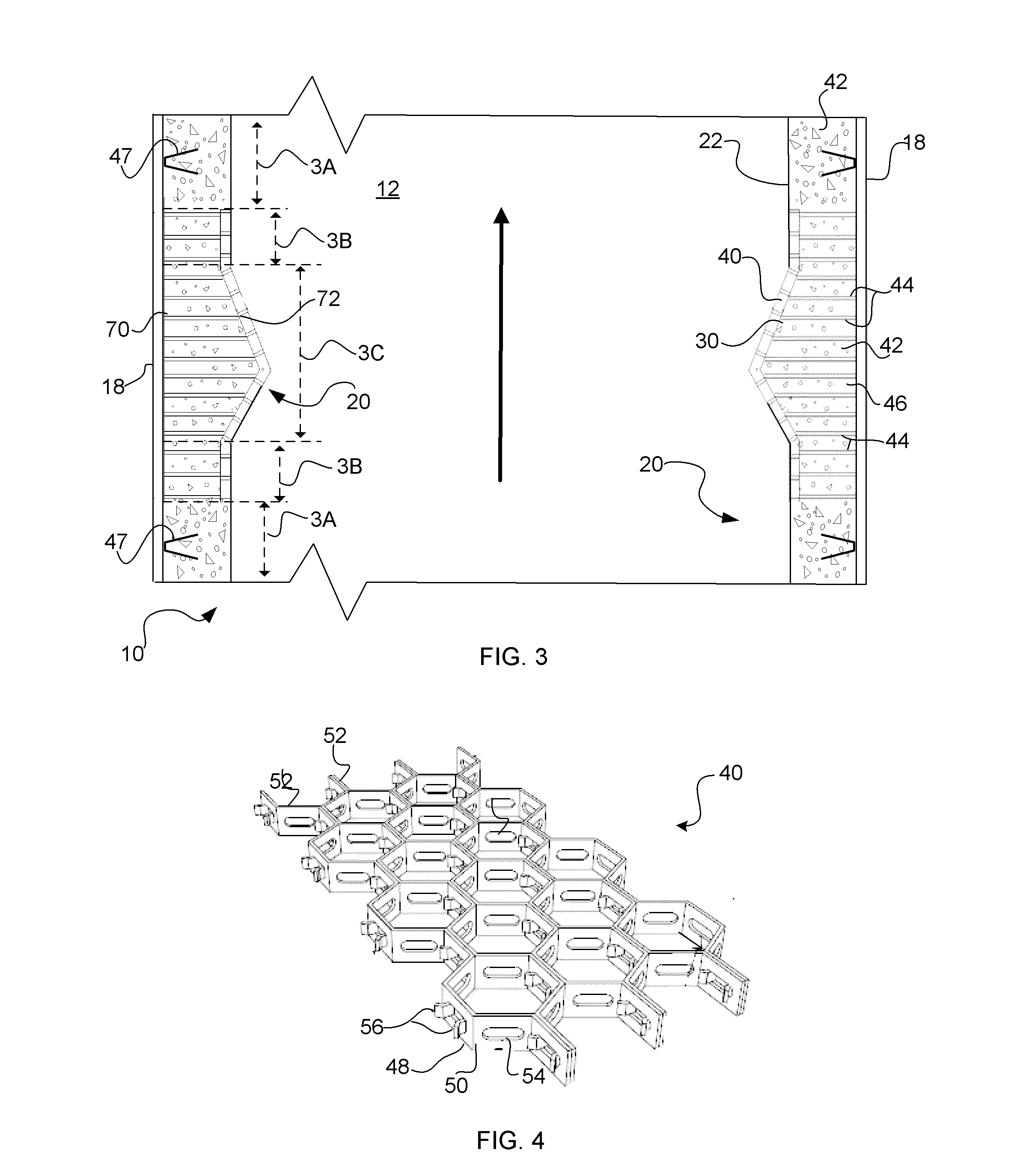

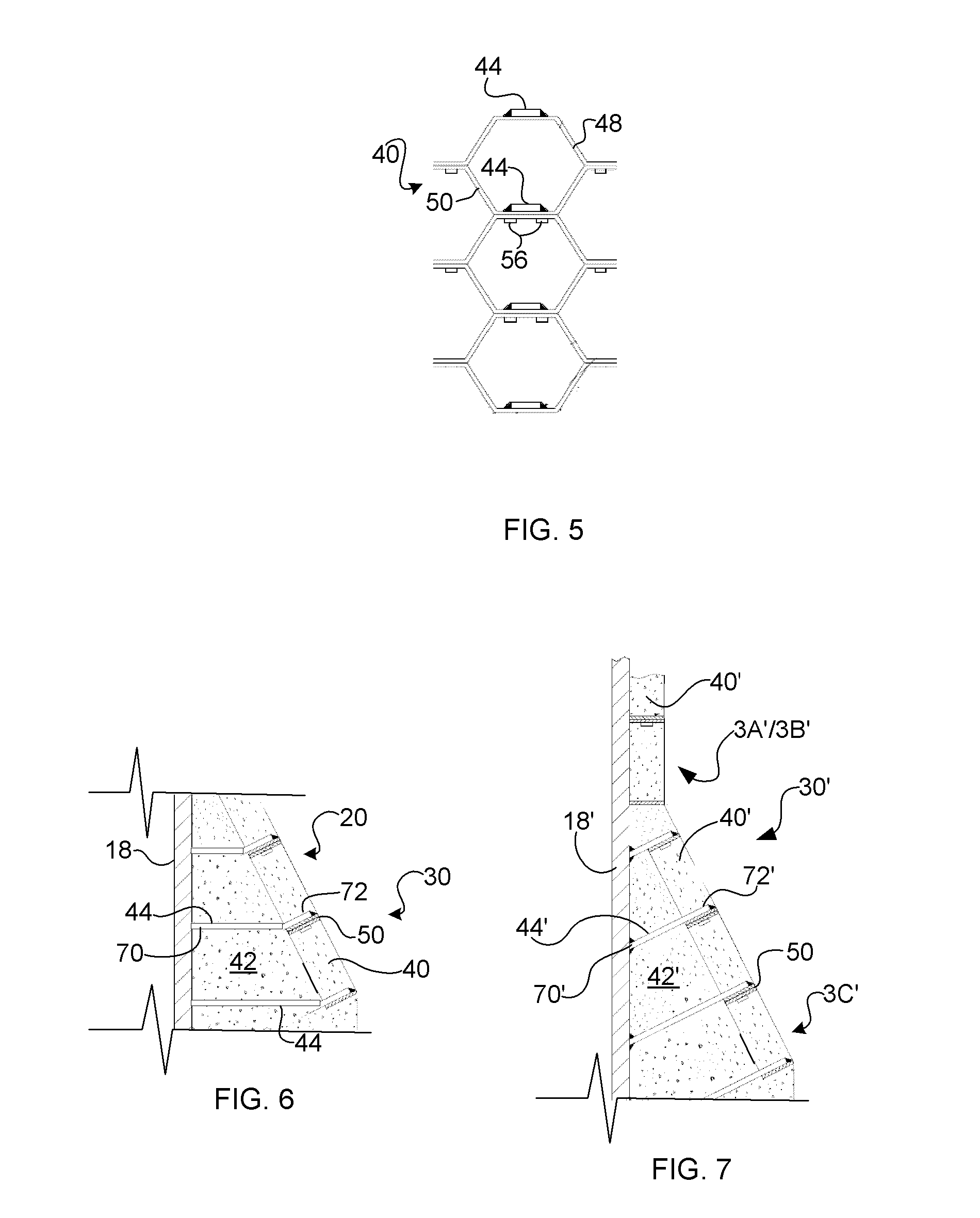

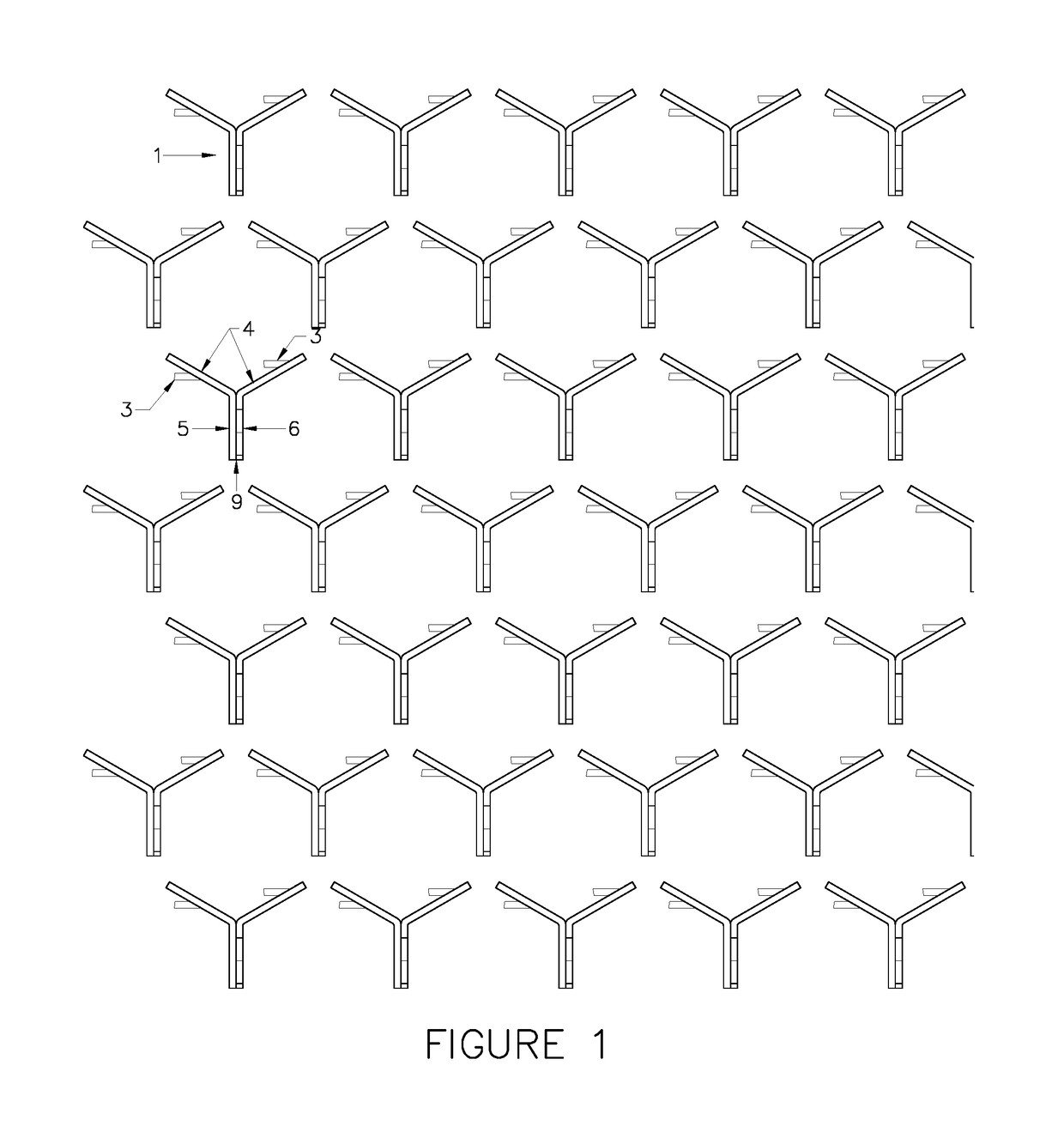

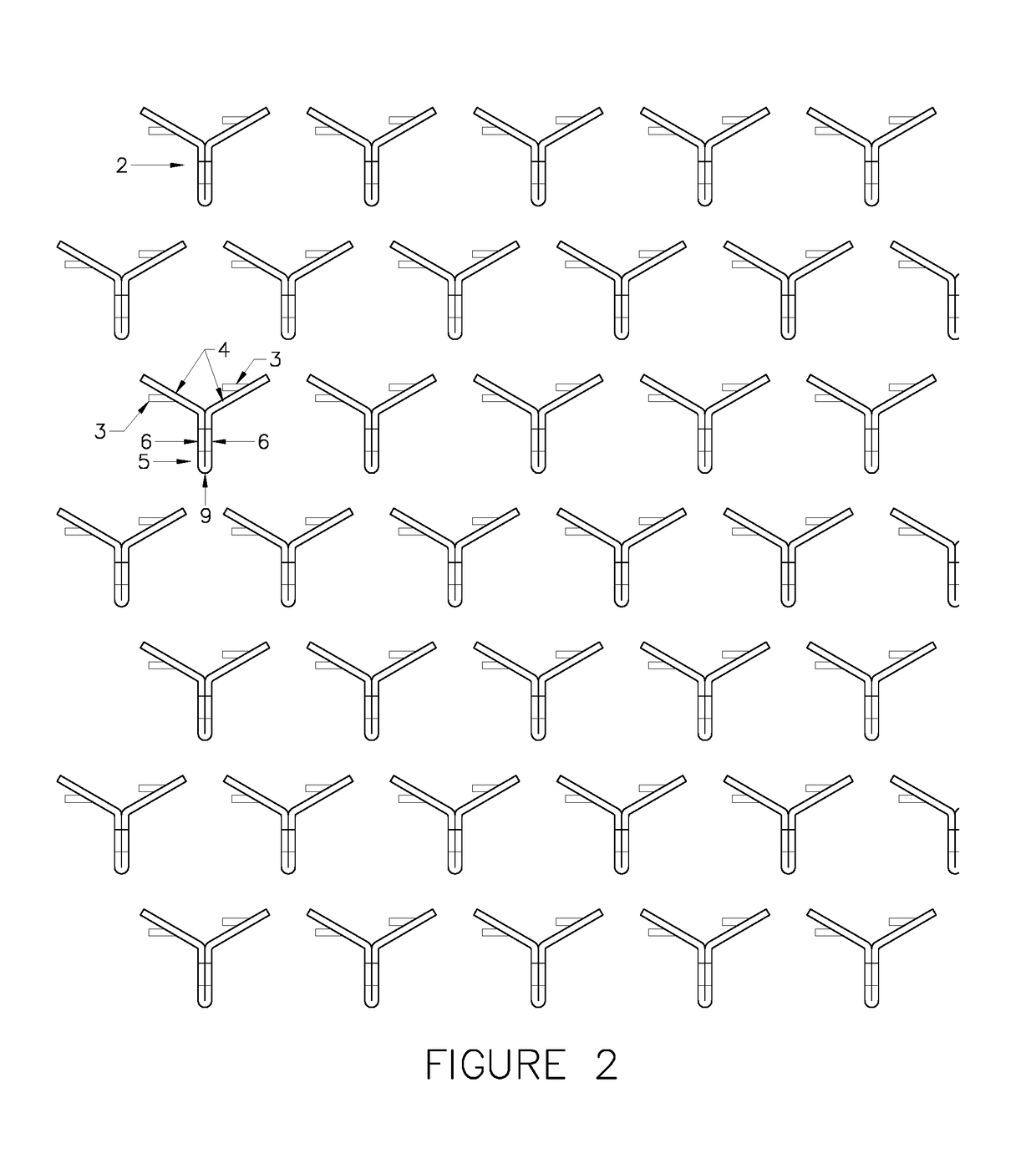

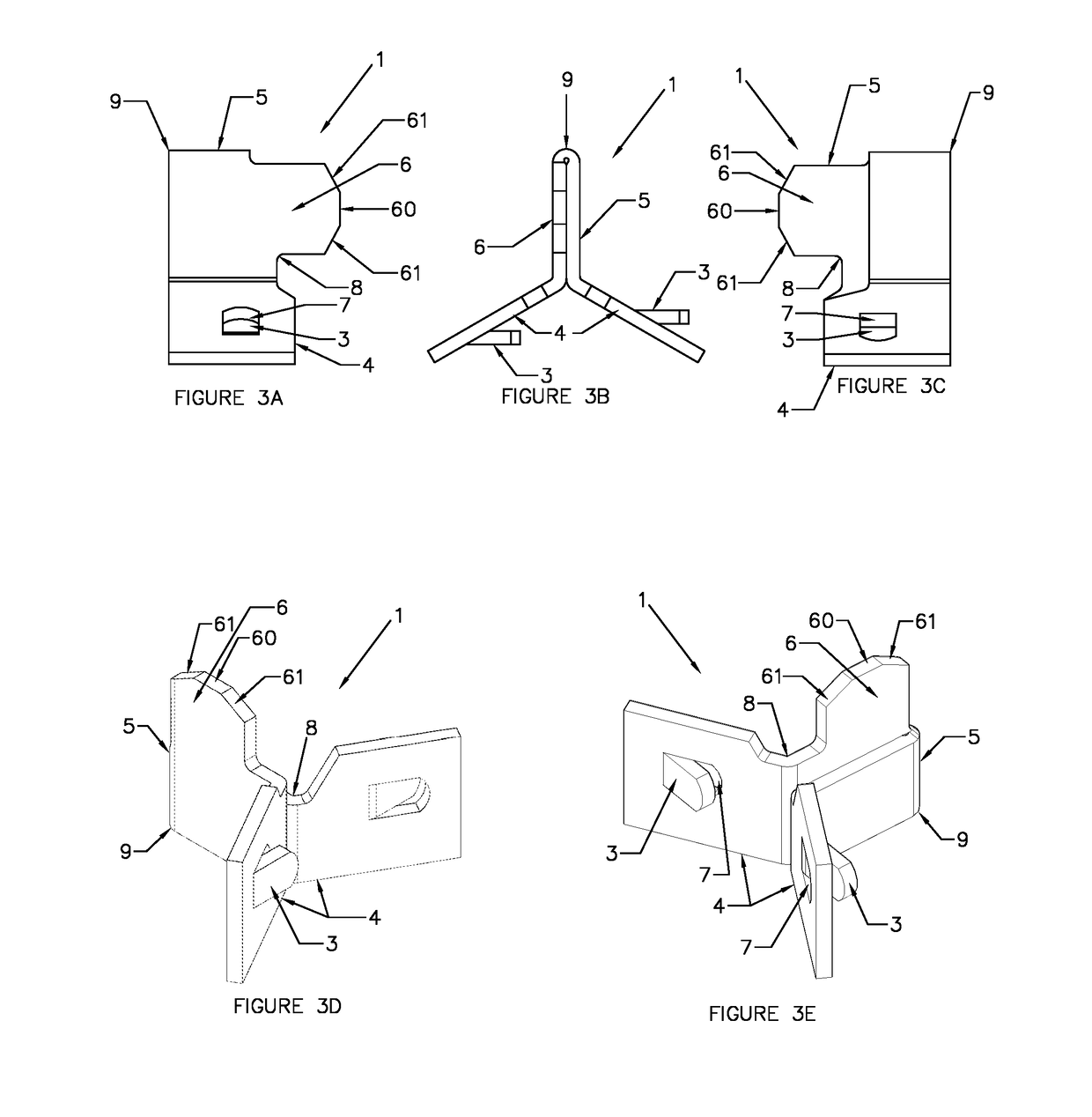

Refractory Anchor System

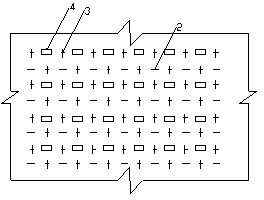

A Y-shaped refractory anchor, a plurality of Y-shaped refractory anchors, and a method of installing a plurality of Y-shaped refractory anchors in a hexagonal pattern is disclosed. The Y-shaped refractory anchor comprises a singular folded metal plate comprising a stem that comprises at least one triangular section to be welded to a backing surface and a folded stem base and a branch section comprising two branches, wherein the singular metal plate is folded together at the stem base, such that the stem of the Y-shaped anchor is twice as thick as the two individual branches.

Owner:JT THORPE & SONS INC

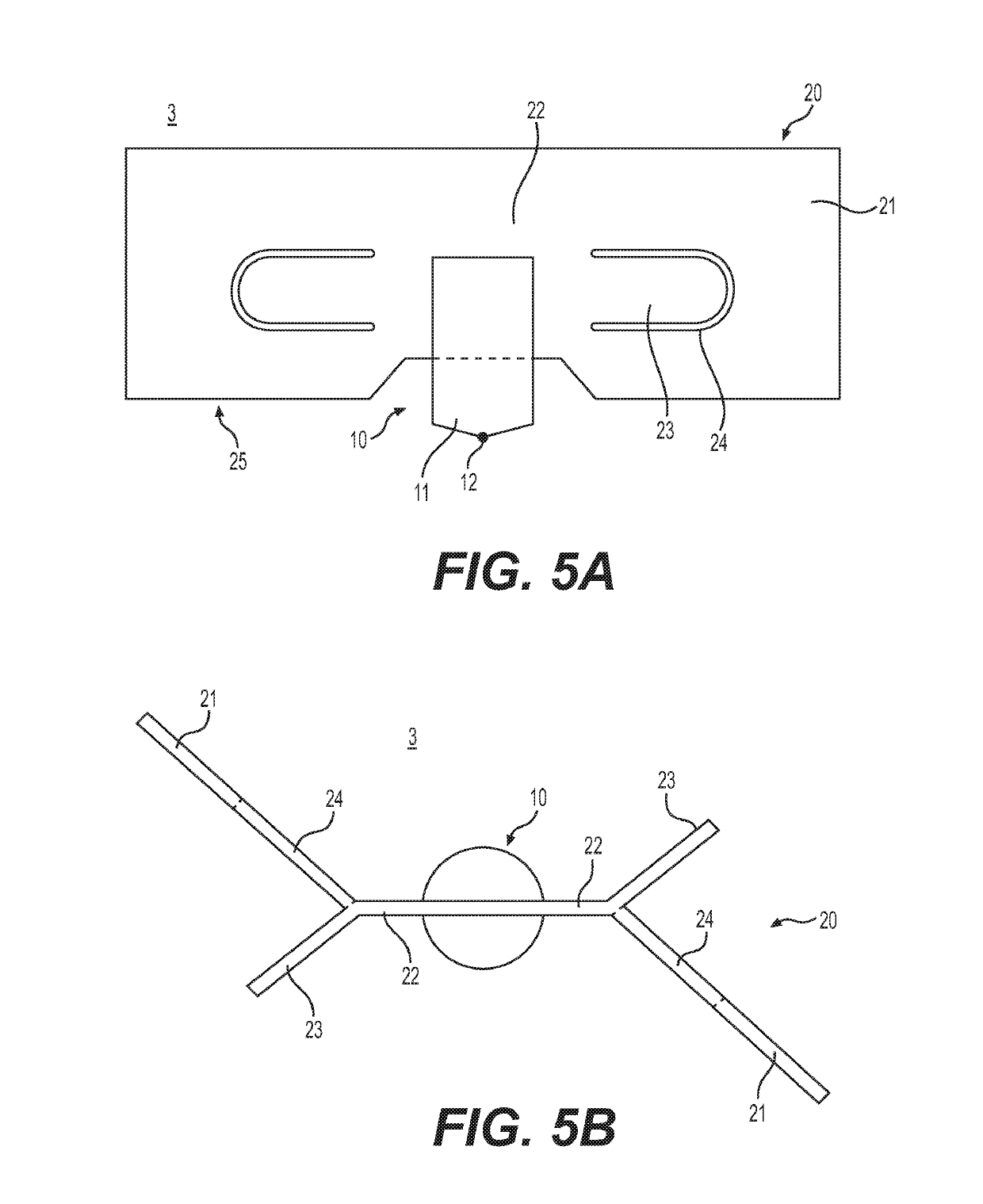

Refractory anchor assembly and method for installing the same

ActiveUS10352619B2Lining supportsChemical/physical/physico-chemical processesRefractoryBiomedical engineering

An anchor assembly for anchoring refractory materials within a vessel is disclosed that provides for a more reliable refractory anchor and resultant refractory lining system that is easier to install both in terms of the refractory lining and the anchor assembly itself when compared to prior art anchor assemblies. The anchor assembly includes a base pin assembly, and at least one anchor leg connected to and extending from the base pin assembly. The base pin assembly includes a mounting end formed on one end of the pin assembly adapted for securing the base pin assembly to the vessel. The mounting end has an electrical resistance contact point formed thereon. The electrical resistant contact point preferably has a flux material located thereon.

Owner:EXXON RES & ENG CO

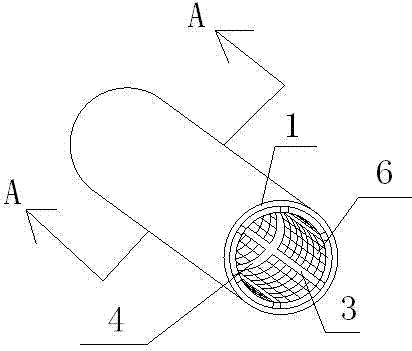

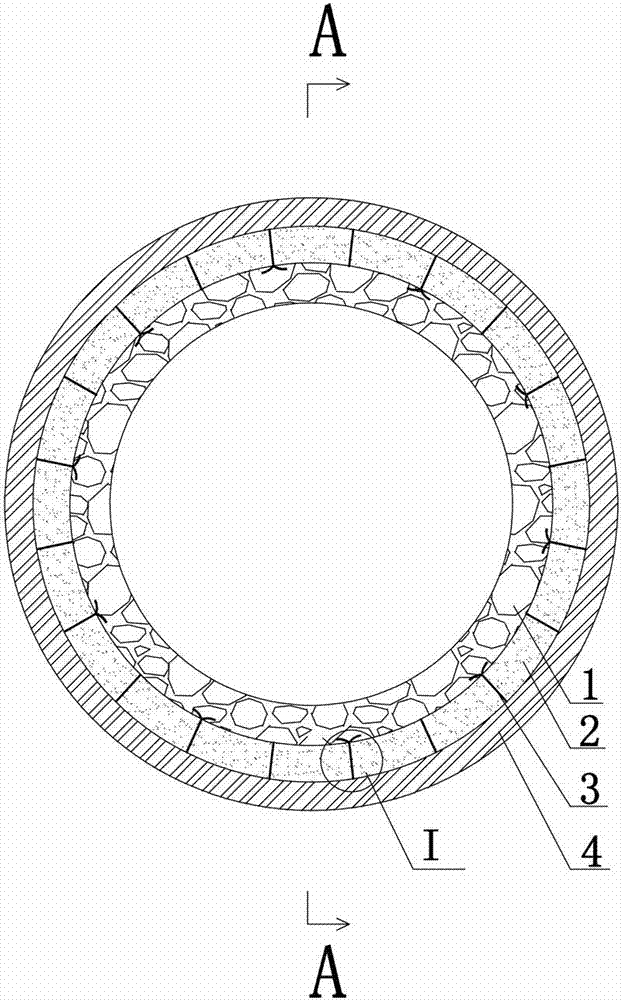

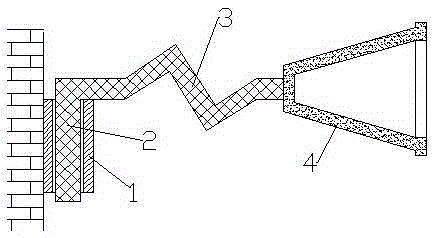

Fire-resistant liner for warm air pipeline and paving method thereof

InactiveCN102829634AImprove spray application efficiencyExtended service lifeLining supportsLinings repairFiberRefractory

The invention belongs to the technical field of fire-resistant material spraying and especially relates to a fire-resistant liner for a warm air pipeline and a paving method thereof. The fire-resistant liner comprises the warm air pipeline and is characterized by comprising a set of anchoring nails, a fire-resistant fiber felt and a spraying coating layer, wherein the anchoring nails are welded with an inner wall of the warm air pipeline; the fire-resistant fiber felt penetrates through the anchoring nails and is grafted with the inner wall of the warm air pipeline; and the spraying coating layer is sprayed and coated on the surface of the fire-resistant fiber felt. The structures, such as a fire-resistant stainless steel network and a quick clamping sheet, for fixing the fire-resistant fiber felt and the spraying coating layer during the paving process of the original fire-resistant liner for the warm air pipeline are omitted by the fire-resistant liner provided by the invention; the anchoring nails are used for fixing the fire-resistant fiber felt and the spraying coating; and under the condition of maintaining each performance index of the original fire-resistant liner, the spraying coating construction efficiency of the warm air pipeline is increased, the operation time is reduced and the service life of the warm air pipeline is prolonged.

Owner:ANSTEEL GRP MINING CO LTD

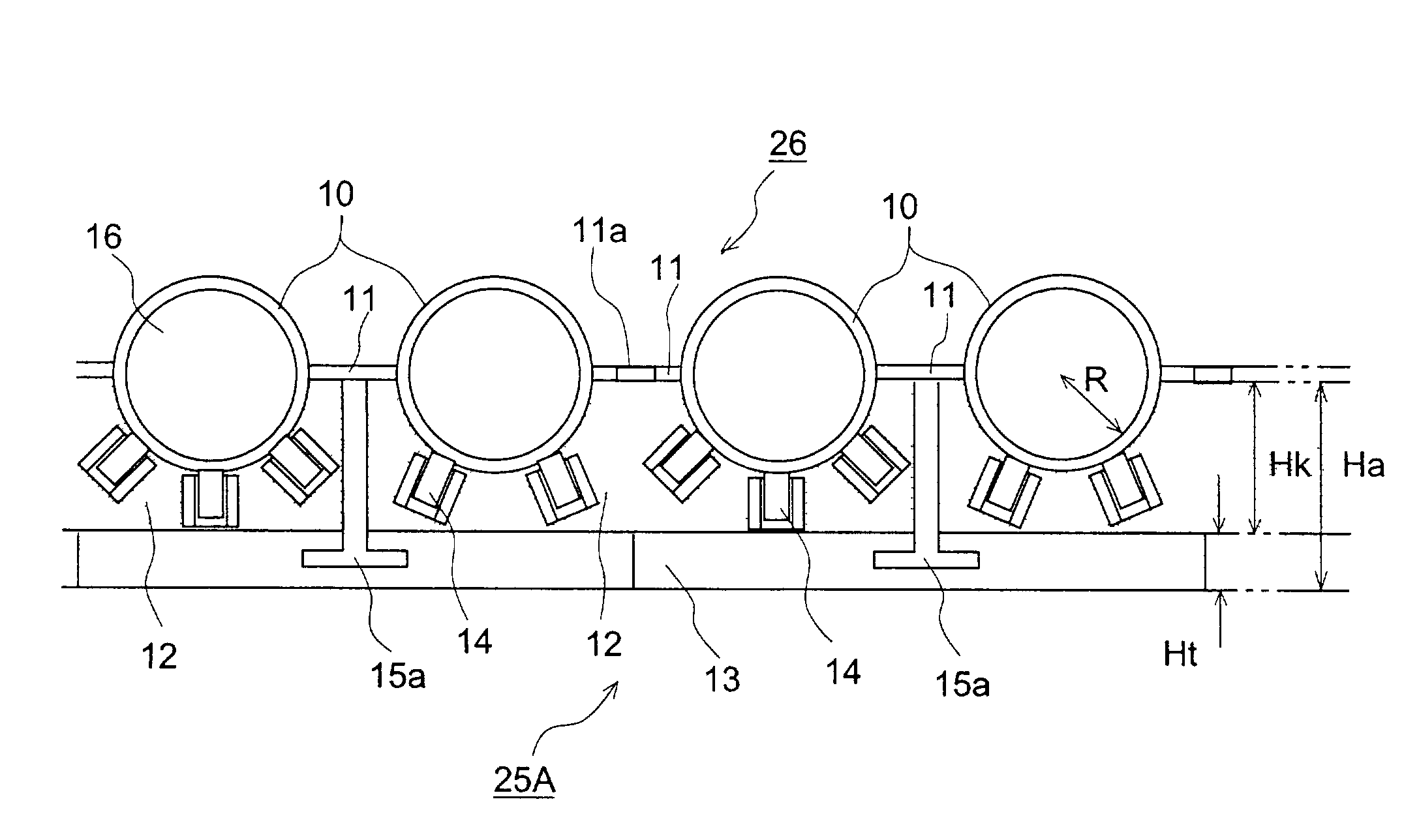

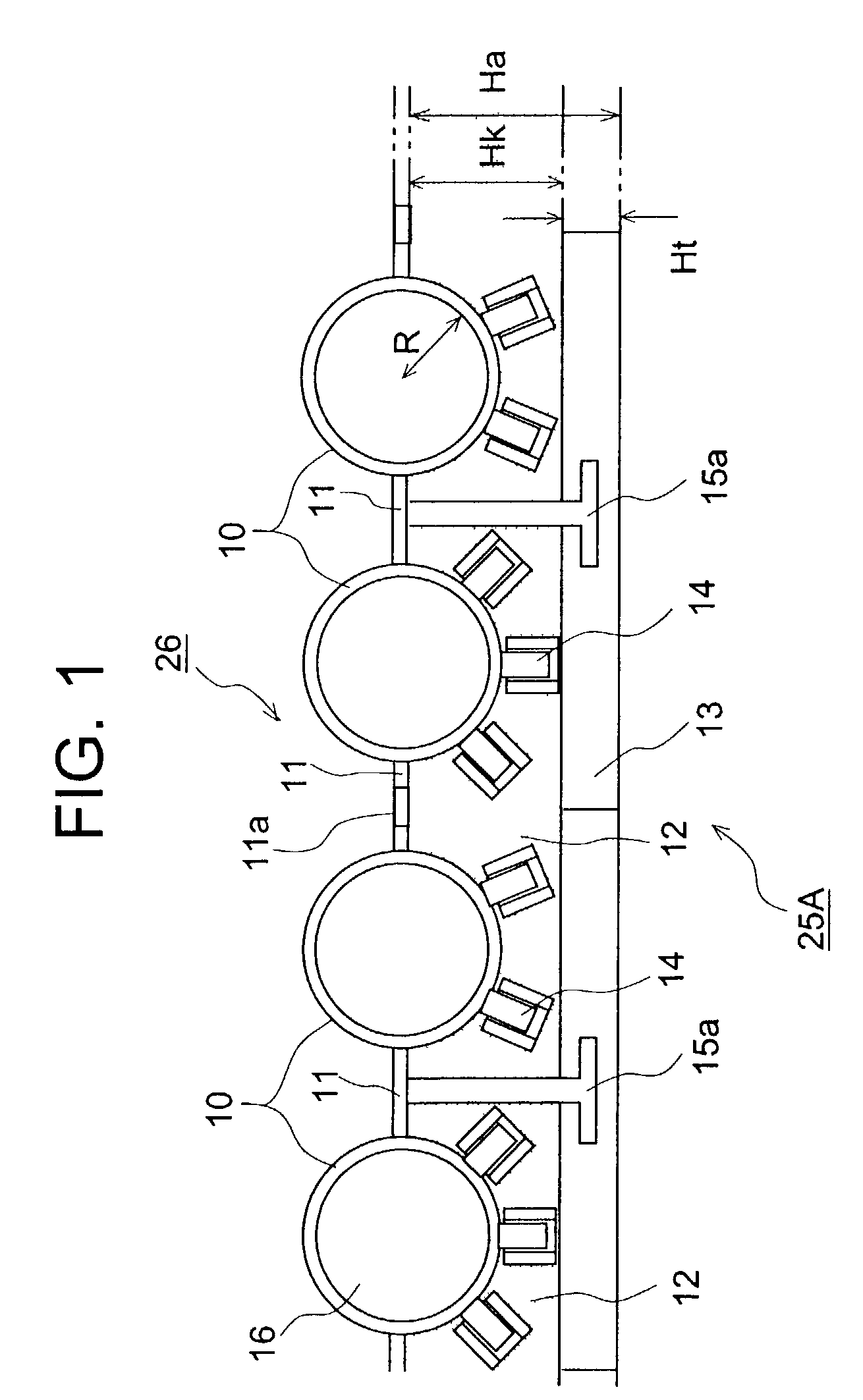

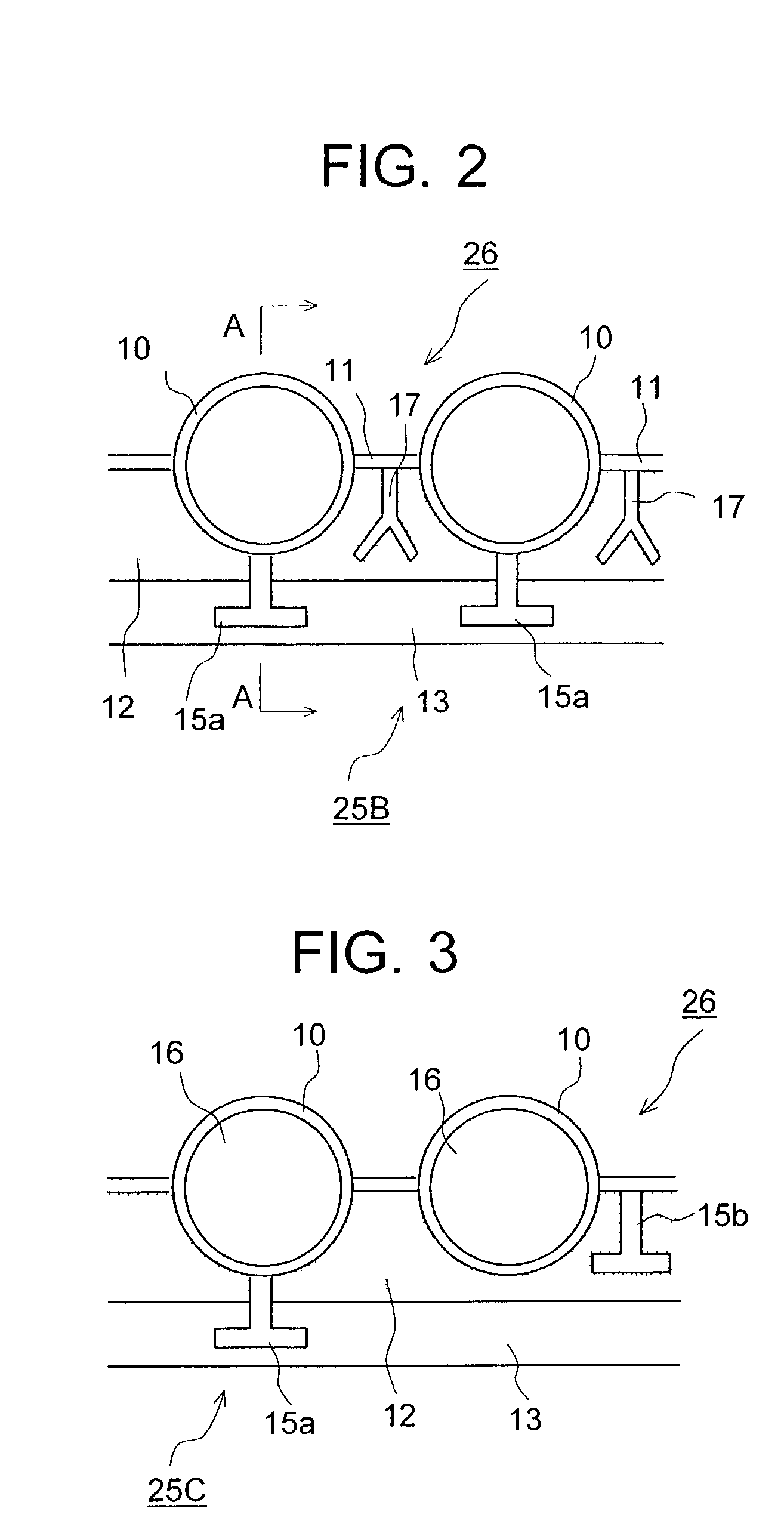

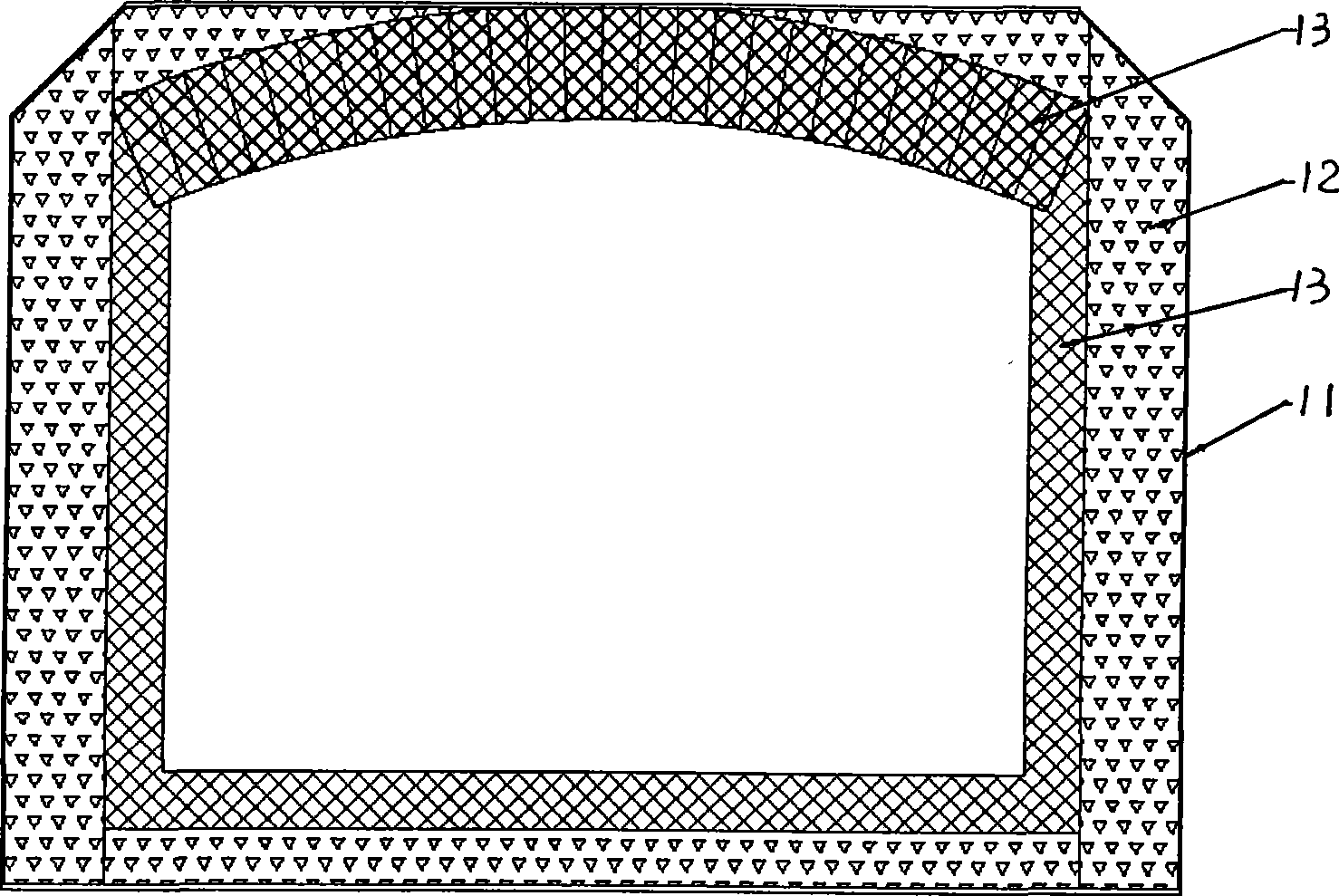

Fireproof structure and installation method for protecting water pipes

A fireproof structure protects water pipes with stable durability even in a high temperature gas environment. Even in a case where it falls off, it does not leave the water pipes suddenly exposed. The fireproof structure for protecting water pipes 25B installed on water pipe walls of a combustion gas side is configured by a double-layered structure made up of an outer layer water pipe protective structure facing towards the combustion gas side, which is fireproof tile 13, and an inner layer water pipe protective structure provided between the outer layer water pipe protective structure and the water pipes, which is fireproof castable 12. The thickness ratio between the castable 12 and the tiles 13 lies within the range of about 2:1 to 3:1, and the ratio between the thickness of the fireproof castable and the radius of the water pipe is set to 1+α:1, wherein the value of α ranges from approximately 0.1 to 0.3. The water pipes are equipped with hanging hooks 15a for tiles 13.

Owner:MITSUBISHI HEAVY IND LTD

Metallurgical Furnace

A metallurgical furnace including a refractory, which may include an inner layer, including bricks of a first type having a heat dissipation thickness, and bricks of a second type having a greater sacrificial thickness and protruding towards the furnace space. The furnace may include a force exerting member for contracting a segmented outer shell around the refractory, inward, as the refractory contracts when cooling. The force exerting member may include a tension member. The furnace may include a vertical compression member for exerting a compressive force upon the refractory, vertically compressing the refractory as it contracts. The furnace may include a cooling system, including a sleeve surrounding a layer of heated air, and air displacement members for displacing away the heated air. The furnace may include a roof, having suspension members extending therethrough, supporting an inner mesh, the inner mesh supporting insulating material. The furnace may also include an electrode seal having a plurality of shoes biased against the electrode(s).

Owner:JINZHOU TIANSHENG HEAVY IND

Refractory anchor

A monolithic refractory anchor which has a bridge portion and first and second V-shaped end portions attached to opposite ends of the bridge portion. The anchor has a pedestal located generally centrally of the anchor which extends below the bottom surfaces of the wing portions of the V-shaped sections, the pedestal forming a single welding attachment point for attachment, preferably by stud welding, to a metal substrate.

Owner:LANCLOS CHRISTOPHER P

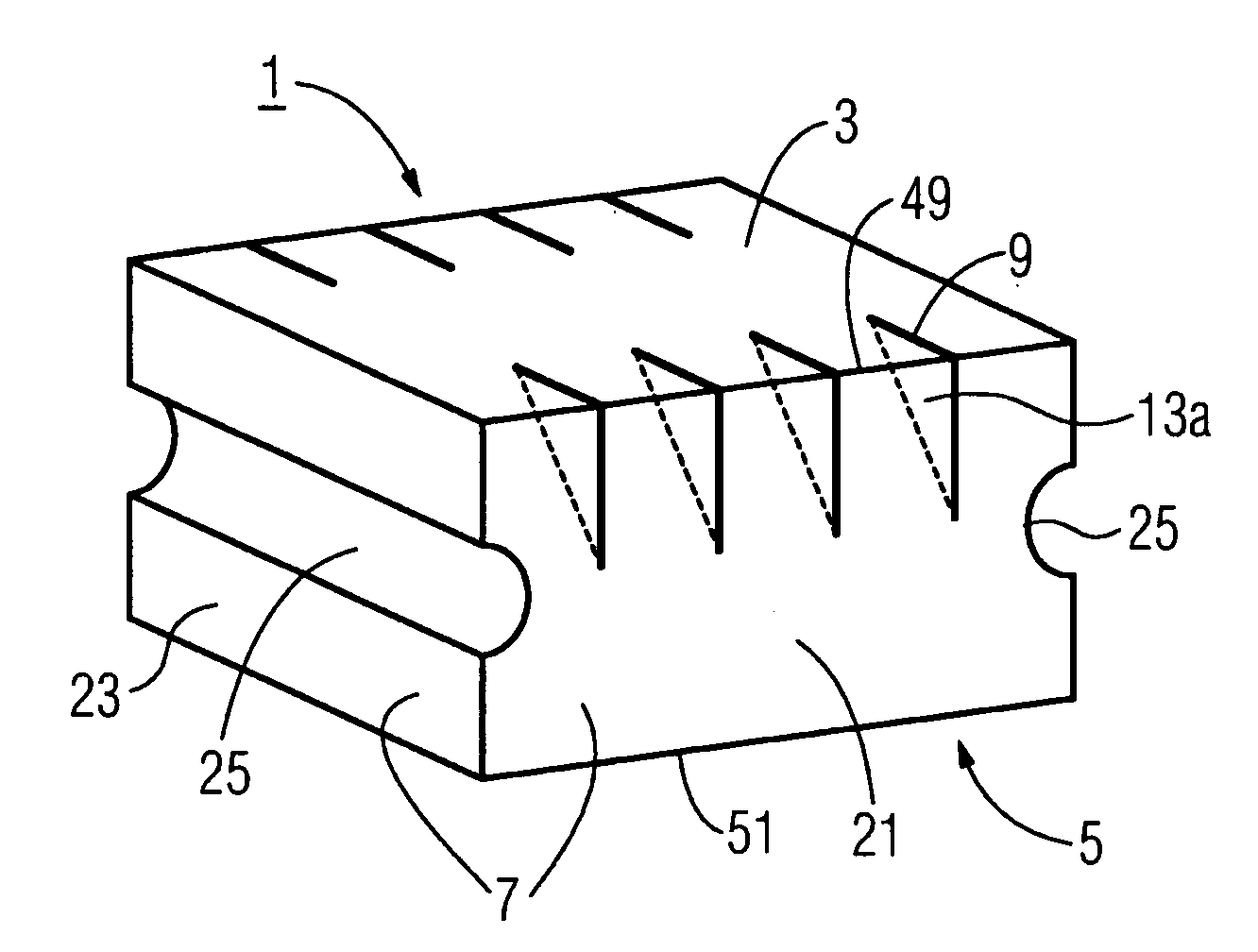

Combination anchoring piece with armor resistant to thermal stress

InactiveCN105403052AConducive to free expansionOffset stressLining supportsThermal expansionEngineering

The invention relates to an anchoring piece for a hearth, in particular to a combination anchoring piece with an armor resistant to thermal stress. A hollow hole is formed in a fixed bolt, and the fixed bolt is fixedly mounted on a furnace wall shell. A connecting piece is in an S-shaped bending structure, one end of the connecting piece is connected with a bolt, and the other end of the connecting piece is connected with a horn made of ceramics. The bolt is inserted into the hole of the fixed bolt, and the horn is in a hollow structure. The smaller head of the horn is connected with the connecting piece, and a step is arranged on the outer wall of the larger head of the horn. According to the combination anchoring piece, the bolt and the connecting piece are made of heat-resistant stainless steel materials, the bolt is inserted into the hole of the fixed bolt and can rotate, and the free expansion of a furnace wall is facilitated; the connecting piece is in the S-shaped bending structure, so that the stress caused by thermal expansion and cold contraction of the furnace wall is effectively neutralized; the horn is made of the ceramics, the thermal expansion and cold contraction of the horn are relatively little, and the corrosion resistance is good; the horn shape can keep the tensile force to the furnace wall, and the stability of the furnace wall is improved.

Owner:宜兴市炉顶密封工程有限公司 +1

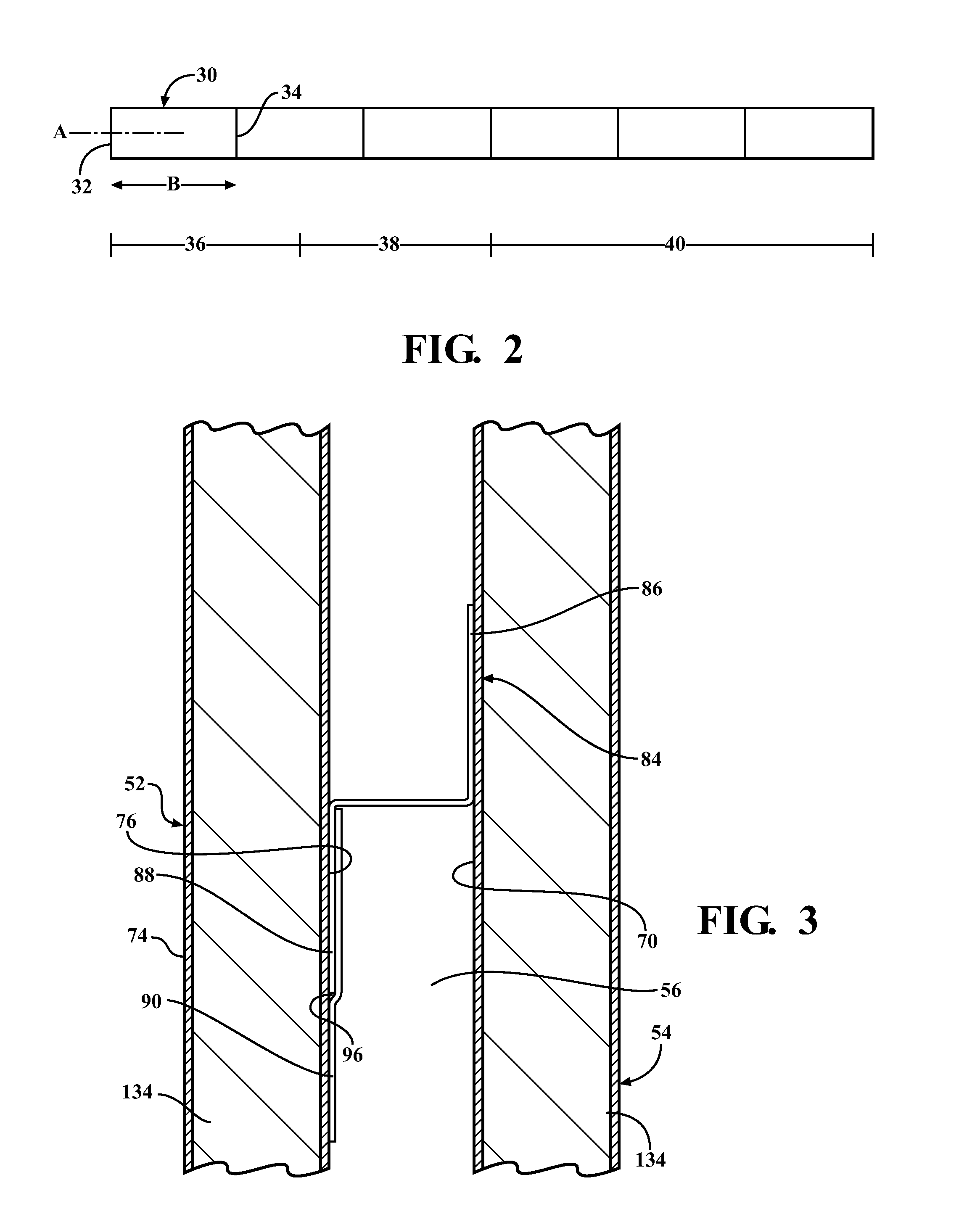

Heat shield element for lining a combustion chamber wall, combustion chamber and gas turbine

InactiveUS20090077975A1Short section lengthRisk of crack is greatContinuous combustion chamberLining supportsCombustion chamberMaterial Crack

The invention relates to a heat shield element for lining a combustion chamber wall, to a combustion chamber and to a gas turbine. The heat shield element comprises a hot side that can be exposed to a hot medium, a wall side opposite said hot side, and a peripheral side adjoining the hot side and the wall side and having a peripheral side surface. Relief slots are introduced into the material in an area of the heat shield element that is susceptible to material cracks induced by thermal stress, thereby limiting crack propagation.

Owner:SIEMENS AG

Modular paint oven using radiant and convection heat

Owner:GK LICENSING

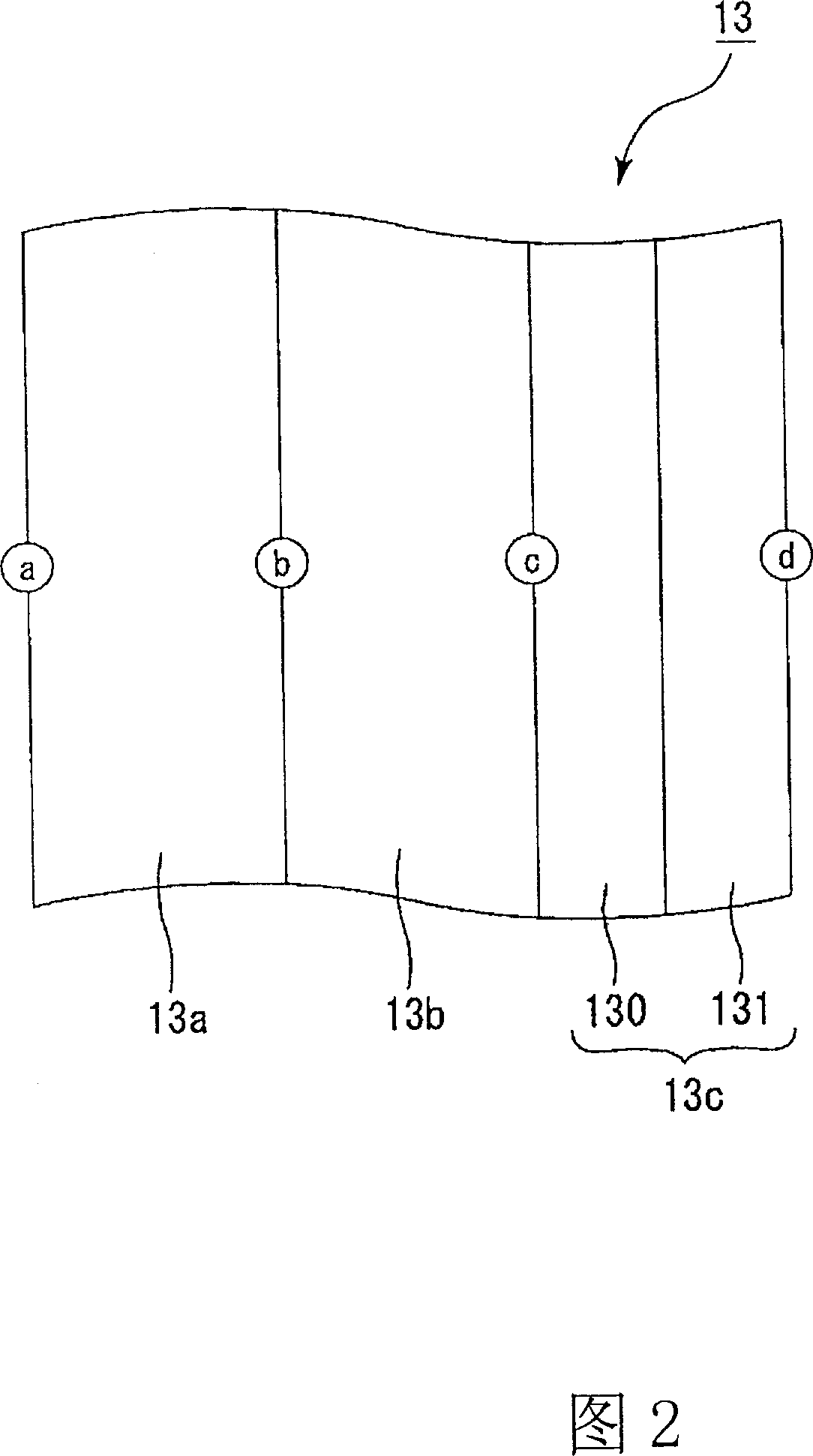

Firing kiln and process for producing ceramic member therewith

InactiveCN1973171AAvoid breakingAvoid crackingLining supportsMuffle furnacesLong term durabilityEngineering

A firing kiln that is free from any substantial drop of heat insulating performance of heat insulating layer, being free from any splitting into two parts or exfoliation of heat insulating layer, and that excels in long-term durability and heat efficiency. There is provided a firing kiln comprising a muffle formed so as to ensure a space for accommodation of moldings to be fired, a heater, or heating element functioning as a heater, disposed outside the muffle and multiple heat insulating layers disposed so as to enclose the muffle and the heater, characterized in that the heat insulating layers are made of carbon and fixed by means of holdbacks of carbon.

Owner:IBIDEN CO LTD

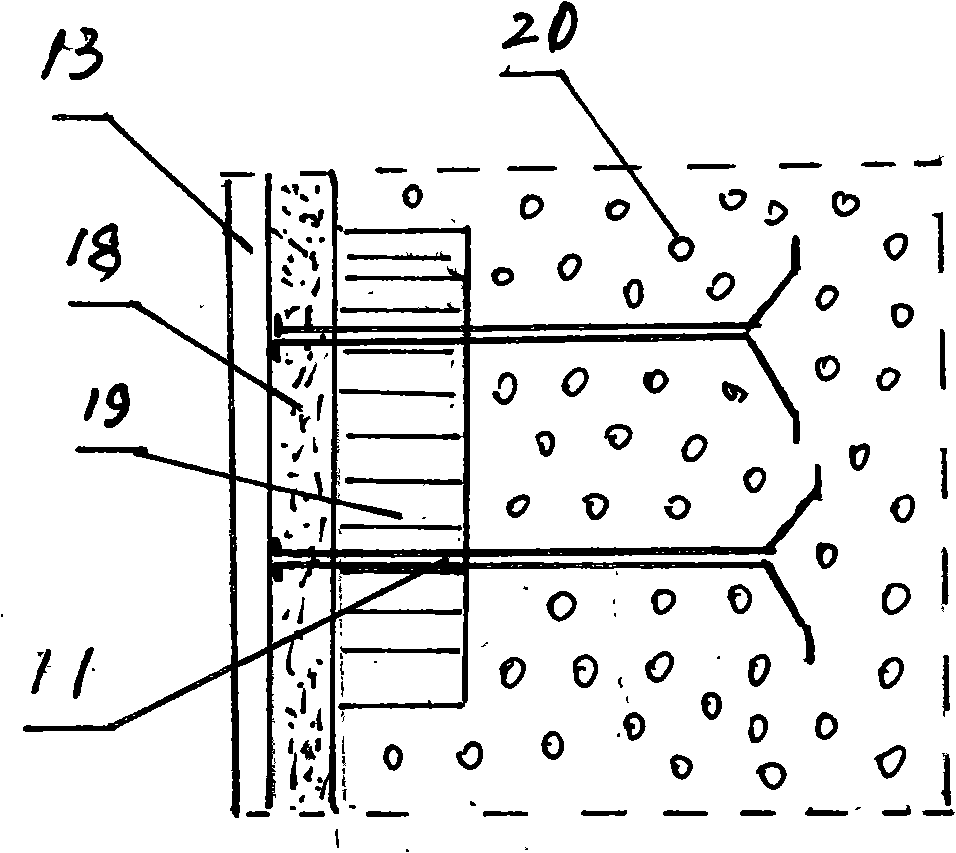

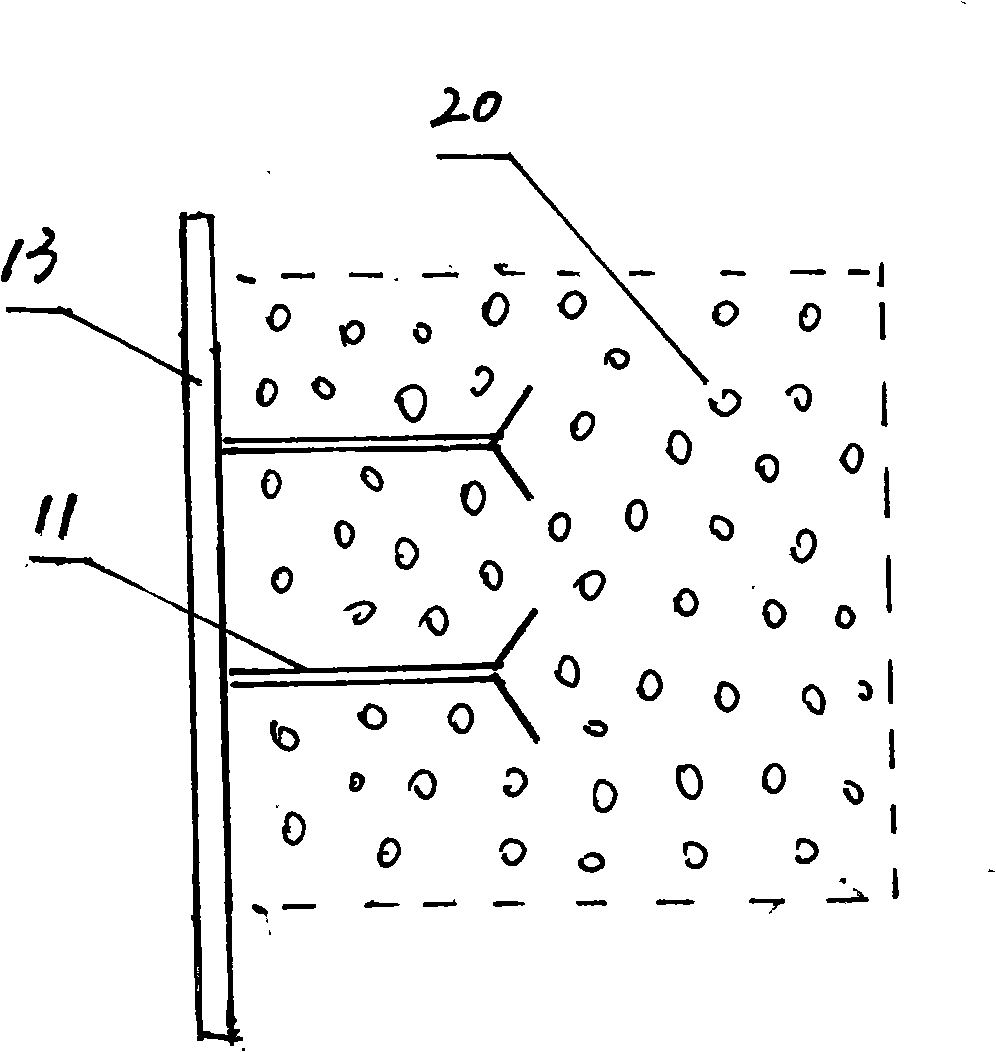

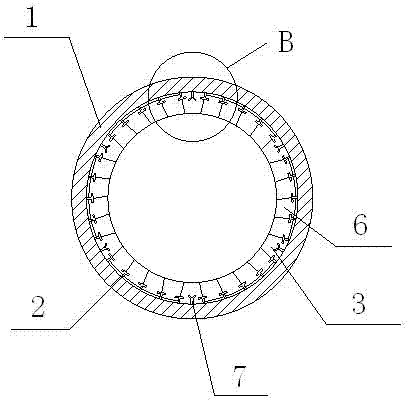

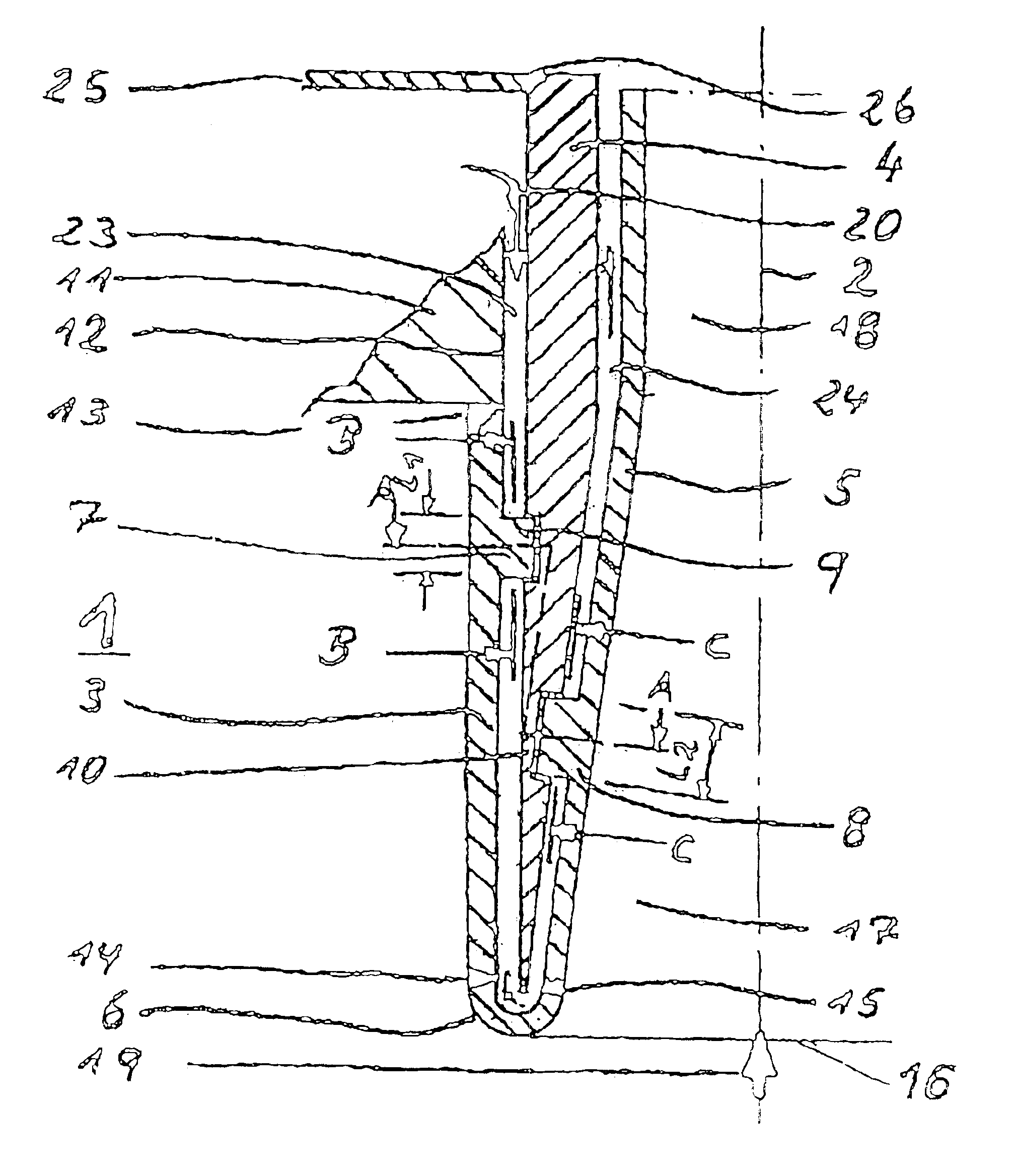

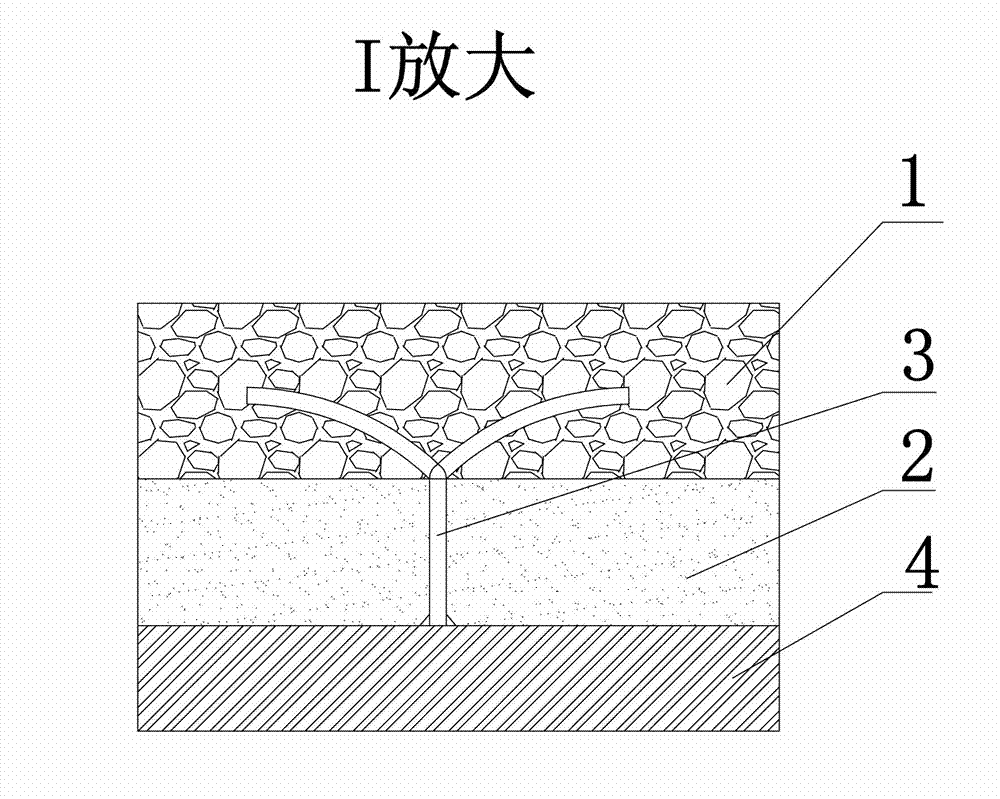

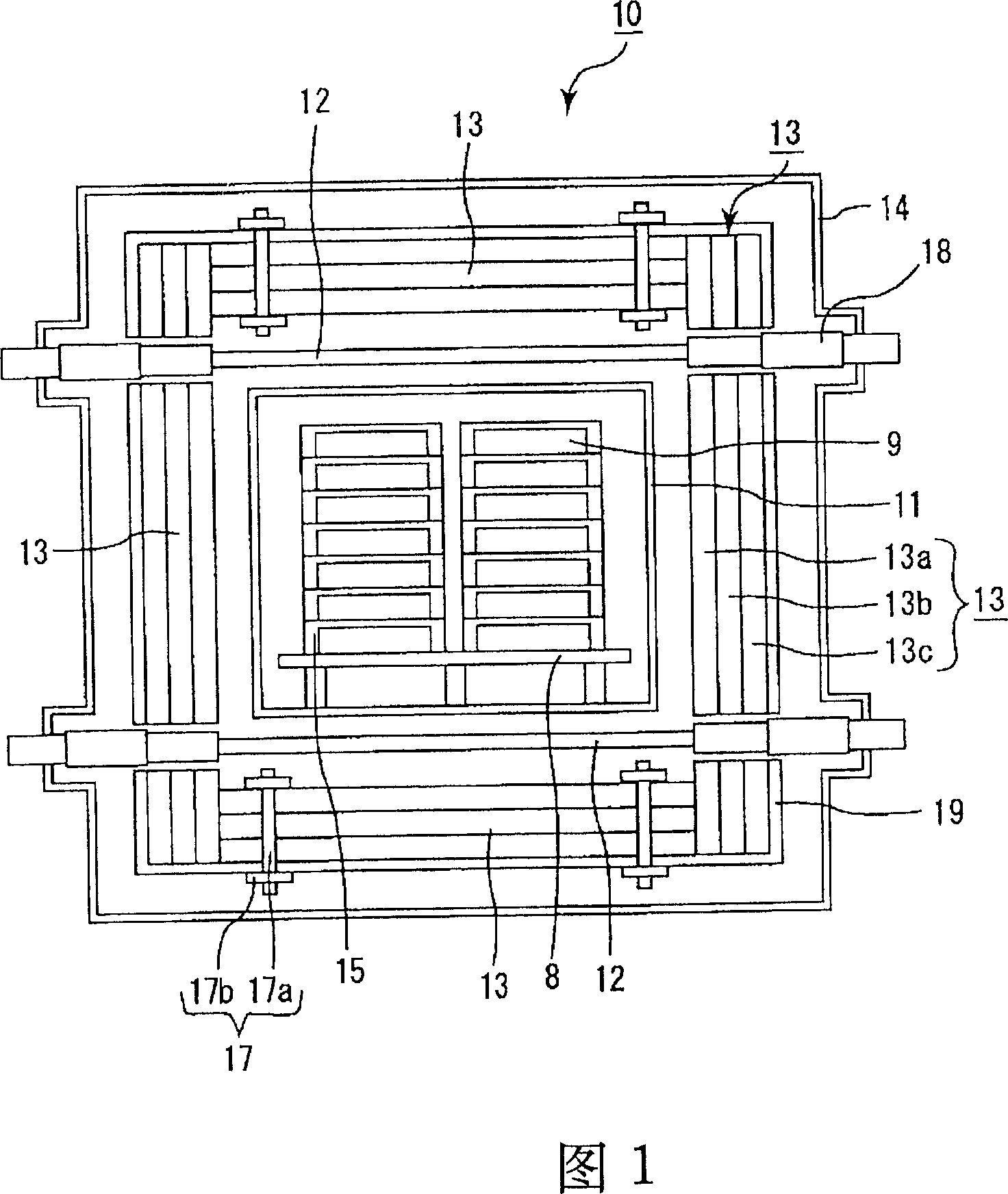

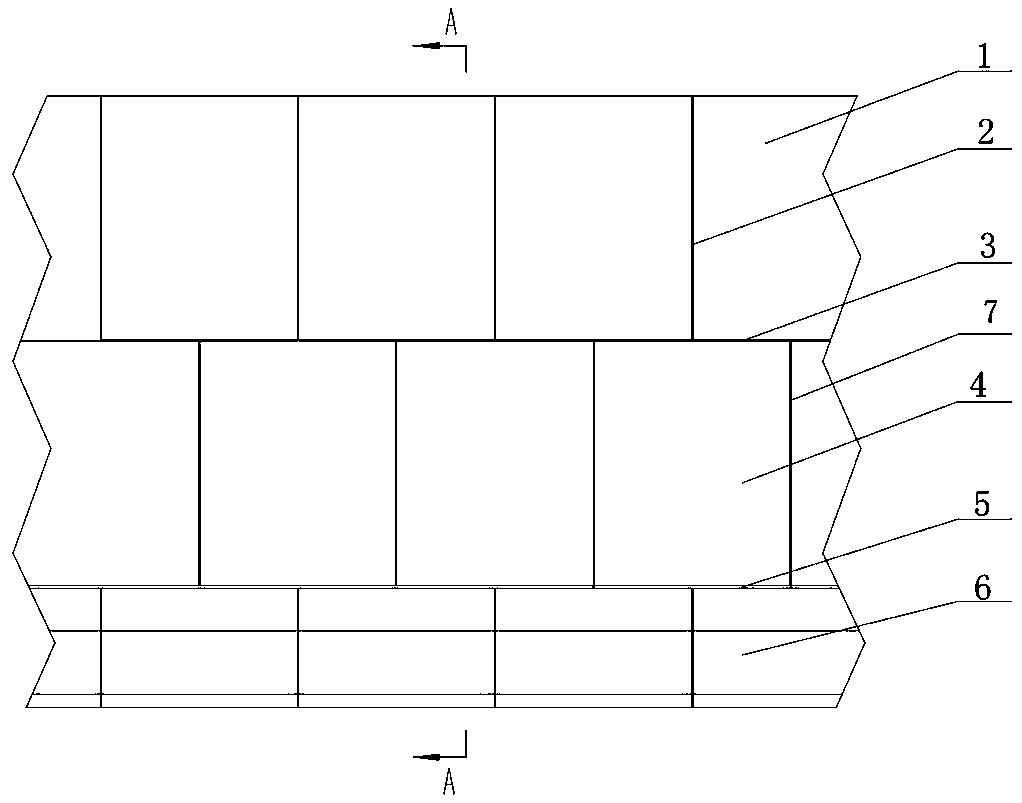

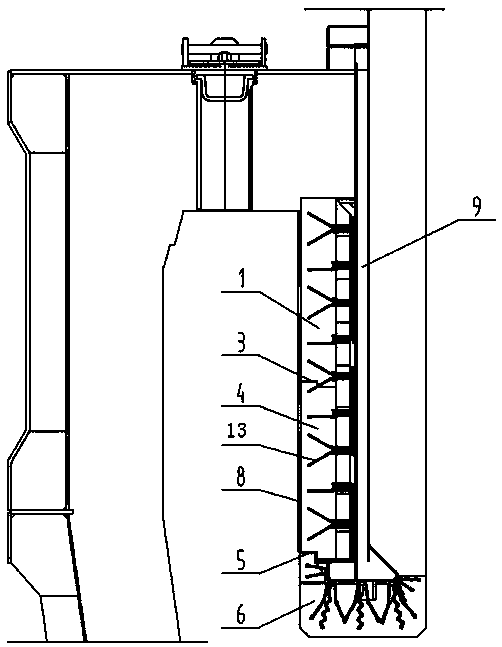

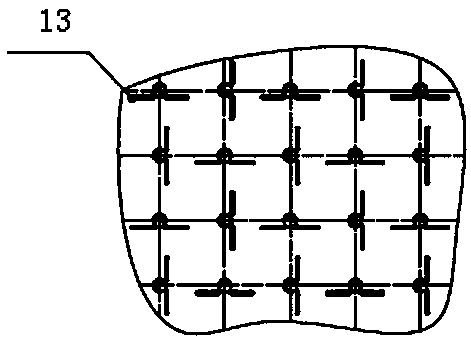

Mixed masonry method forrefractory material protective lining on outer side of hanging cylinder block

InactiveCN109798773AReduce mistakesSimplify the masonry processLining supportsLinings repairFiberRefractory

The invention relates to a mixed masonry method for a refractory material protective lining on the outer side of a hanging cylinder block, and belongs to the technical field of hanging cylinder type double-chamber vertical kiln production equipment. According to the technical scheme, the mixed masonry method includes the steps that (1) anchoring parts (13) are uniformly fixed to the outer side ofthe hanging cylinder block (9); (2) lower-layer castables (4) are pouredblock by block in the circumferential direction of the outer side of the hanging cylinder block (9) through a steel mold (10); (3) a second refractory ceramic fiber board (3) is laid on the lower-layer castables (4); (4) upper-layer castables (1) are poured on the lower-layer castables (4) block by block through the steel mold(10); and (5) fifth refractory ceramic fiber boards (8) are laid on the outer sides of the upper-layer castables (1) and the outer sides of the lower-layer castables (4). The mixed masonry method forthe refractory material protective lining on the outer side of the hanging cylinder block has the beneficial effects that errors caused by masonry can be reduced, the masonry process is simplified, and the problems that the hanging cylinder block is heated, expanded and deformed, and consequently a refractory material on an outer circle loosens and falls off can be solved.

Owner:唐山银色清源工程技术有限公司

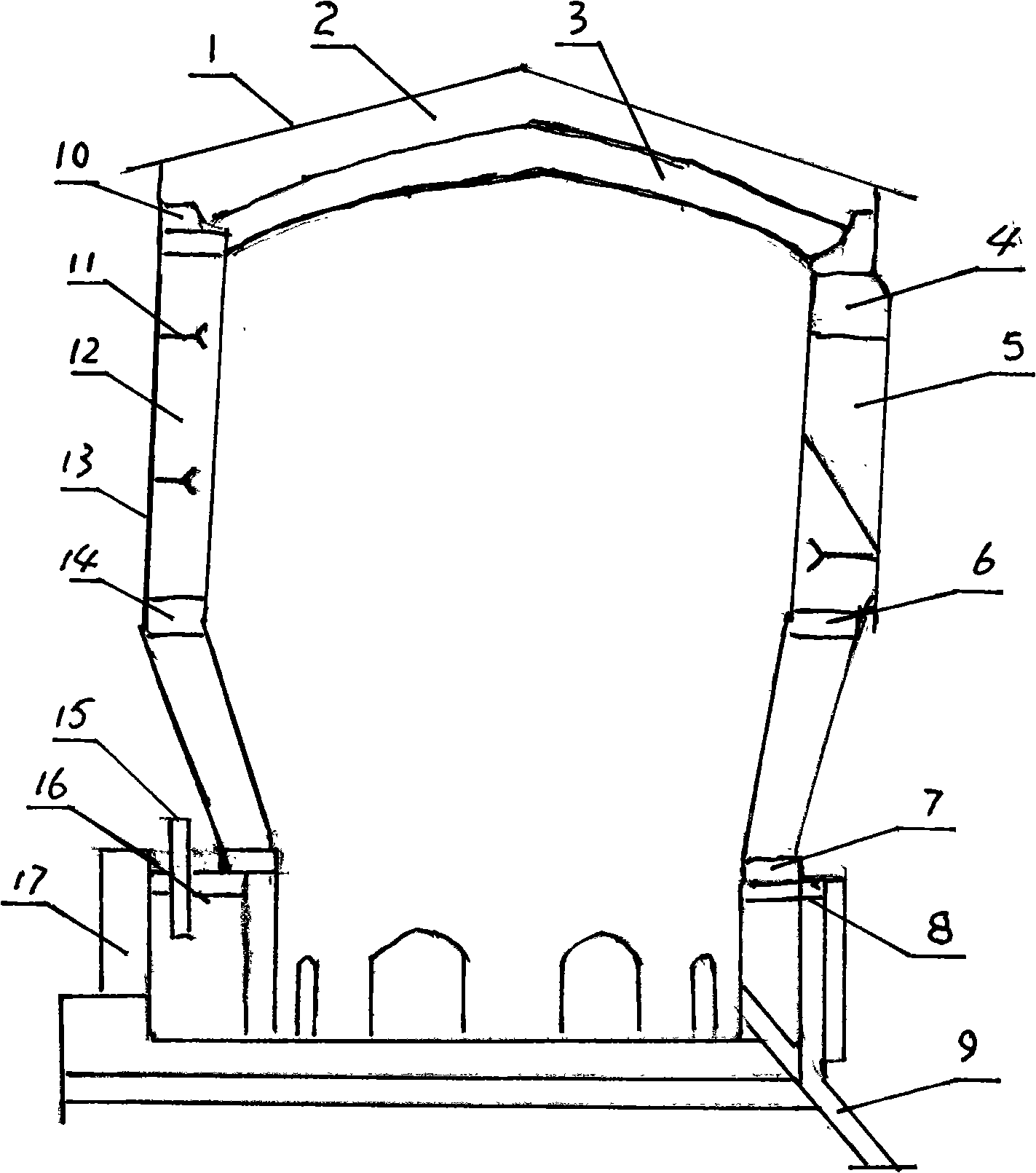

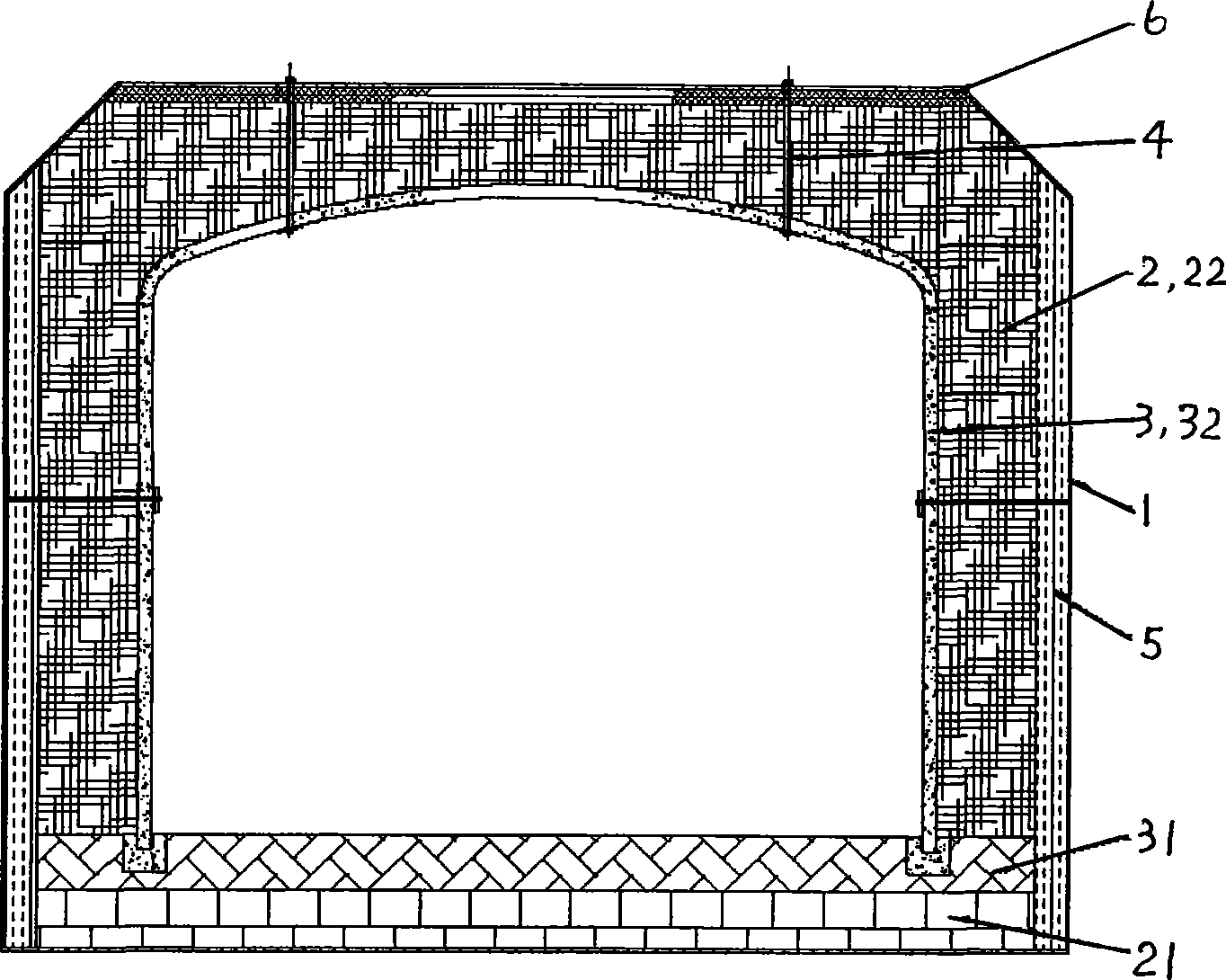

Industrial furnace liner

An industry furnace lining is arranged in the industry furnace shell and comprises an inner high temperature resistant layer and an outer heat-insulating layer, the bottom of the inner high temperature resistant layer is built by impervious bricks, a whole reverse U-shaped structural member made of high temperature resistant non-metal composite material is taken as an inner lining on the two sides and the top; the bottom of the outer heat-insulating layer is built by the insulating bricks, the two sides of the top of the outer heat-insulating layer are built by light high-alumina refractory fiber modules. The industry furnace lining of the invention has advantages of short furnace building period, low maintenance cost and long service life; and can implement the rapid temperature raising and descending of the furnace kiln.

Owner:SHANGHAI HUISEN MTH INDAL FURNACES

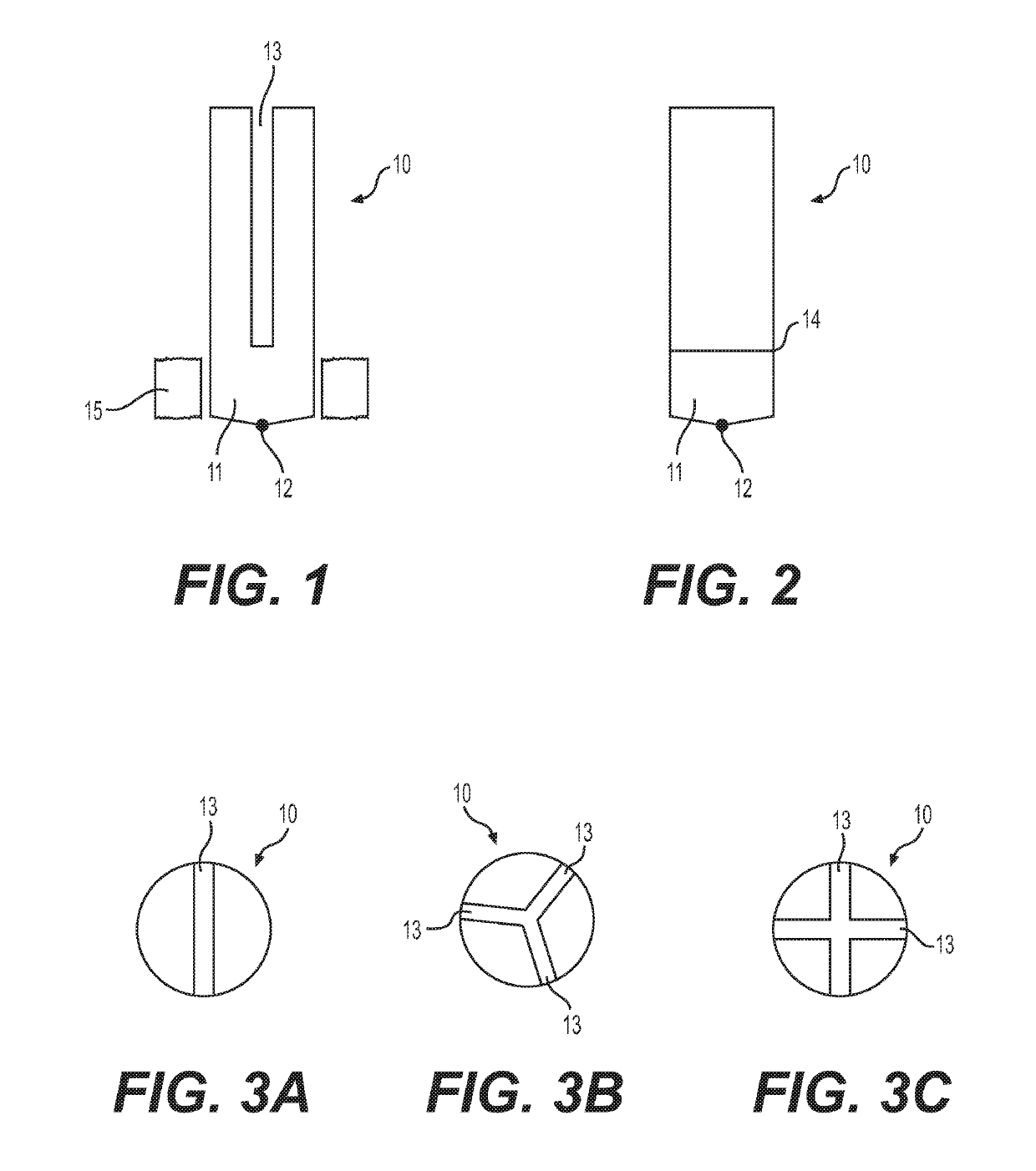

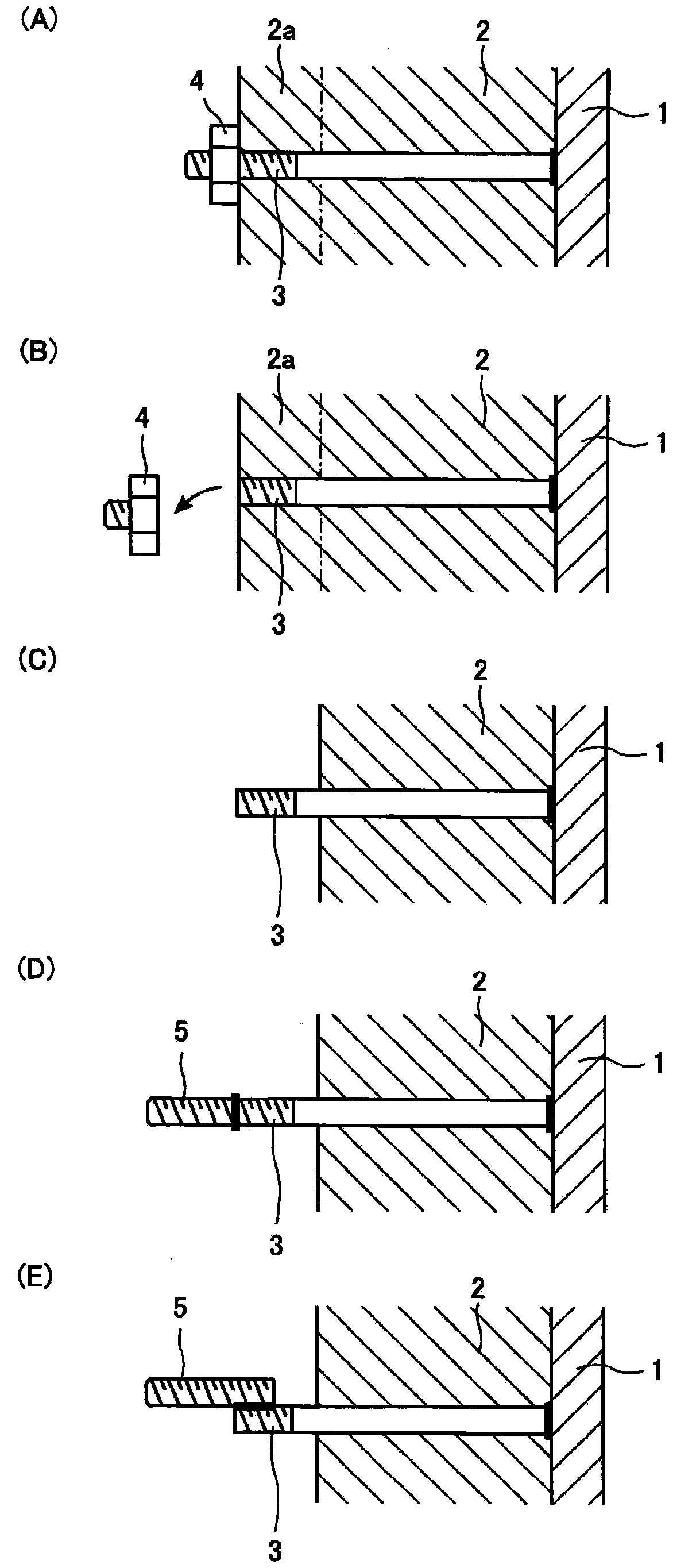

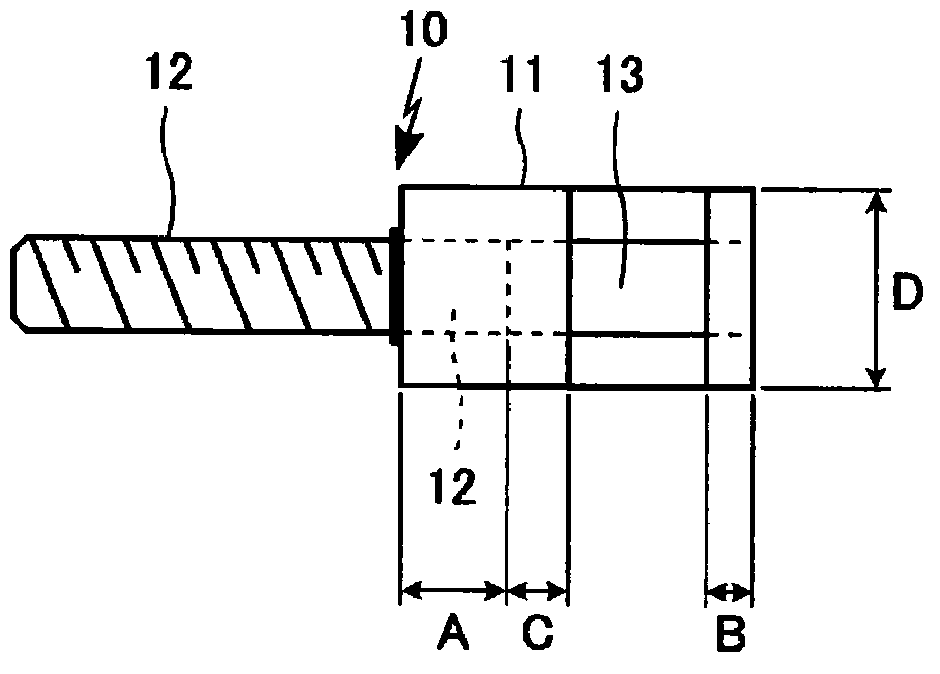

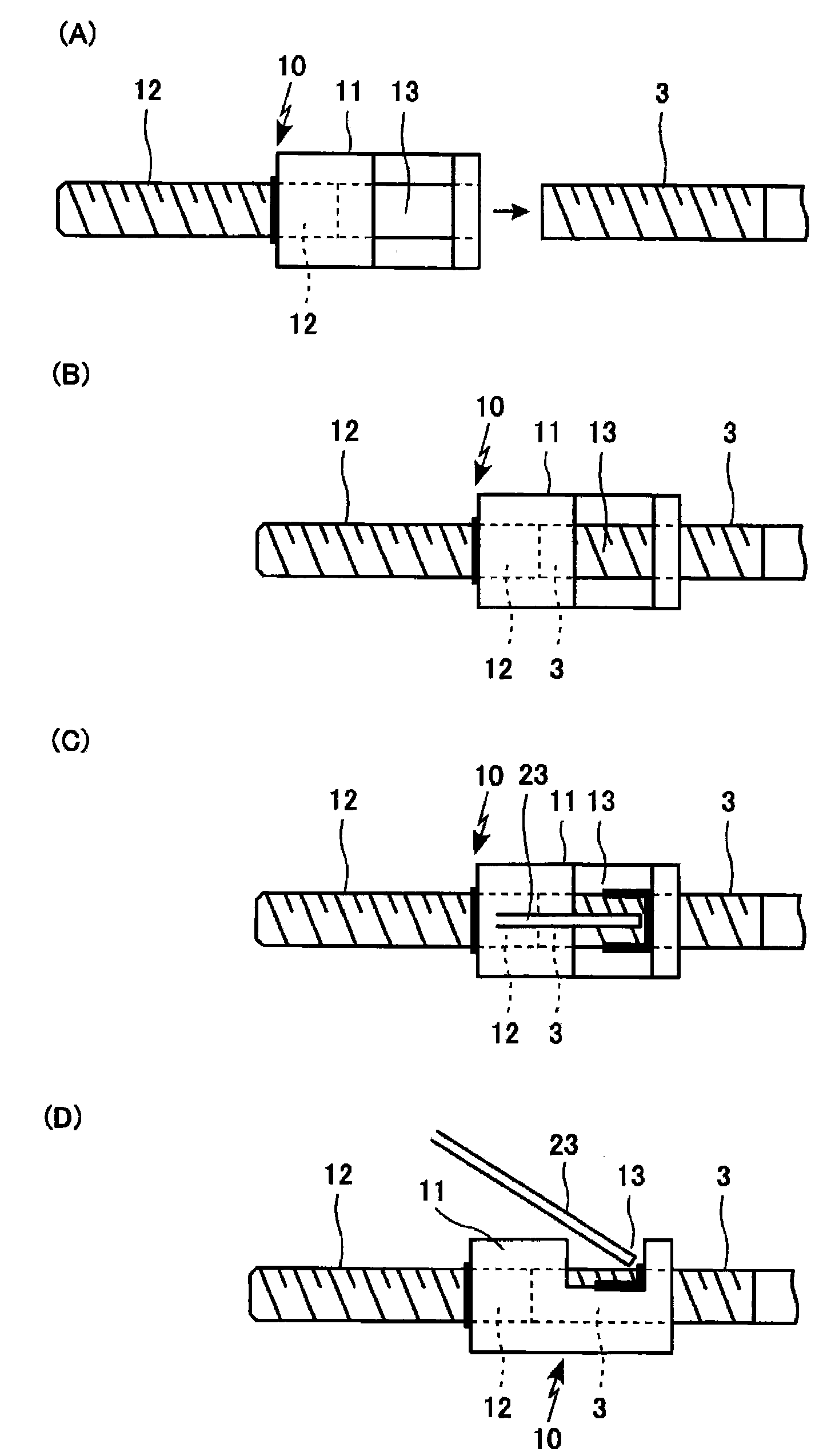

Stud bolt connecting member and industrial furnace inner face repair method

InactiveCN104395620AEasy to installSimple and suitable replacementLining supportsLinings repairEngineeringRepair method

The present invention addresses the problem of easily and suitably performing, in a short time, repair work on an industrial furnace inner face using a stud bolt connecting member that connects to a stud bolt when repairing the inner face of an industrial furnace on which a lining material is mounted by the stud bolt, which is provided on the inner face of the furnace wall, passing through the lining material. To repair an inner face of an industrial furnace on which a lining material (2) is mounted on the inner face of the furnace wall (1) by a stud bolt (3) provided on the inner face of the furnace wall passing through the lining material that contains at least an insulating material, a stud bolt connecting member (10) has a connecting cylindrical portion (11) through which the distal end of a stud bolt is inserted and a bolt portion (12) projecting from the distal end of the connecting cylindrical portion and is provided with an opening (13) for welding the stud bolt to the connecting cylindrical portion.

Owner:CHUGAI RO CO LTD

Anchoring method of kiln liner of cylindrical rotary thermal equipment

Provided is an anchoring method of a kiln liner of cylindrical rotary thermal equipment. Three kinds of metal anchoring parts of different shapes are manufactured, refractory building block anchoring bricks with convex grooves and concave grooves are designed and manufactured, fixing anchoring force is exerted on the root of the kiln liner, stabilizing anchoring force is exerted on the middle of the kiln liner, pulling anchoring force is exerted on the upper portion of the kiln liner, and the anchoring points at the root of the kiln liner are at least 1.5 times those of the middle or the upper portion of the kiln liner. Four kinds of metal anchoring parts and the anchoring bricks made of refractory building blocks exert anchoring force on the root, the middle and the upper portion of the kiln liner, long-term stable anchoring is formed in the kiln liner of the rotary thermal equipment from normal temperature to high temperature more than 1400 DEG C, sliding and displacement of the kiln liner are solved effectively, combination intensity of the kiln liner and the inner wall of a furnace body is enhanced, the kiln liner is prevented from falling off or being damaged, the service life of the kiln liner is prolonged, the number of maintenance times is reduced, cost is saved, and the utilization rate of the equipment is improved.

Owner:洛阳市洛华粉体工程特种耐火材料有限公司

Sidewall with buckstay for a metallurgical furnace

A sidewall for a metallurgical furnace and a metallurgical furnace having the same are described herein. In one example, a sidewall of a metallurgical furnace is provided that includes an outer wall, a hot plate and a buckstay. The hot plate is coupled in a spaced apart relation to the outer wall. The buckstay is mechanically coupled to the outer wall and the hot plate. The buckstay includes a buckstay web extending from a buckstay flange. The buckstay web includes a first end coupled to the buckstay flange, and a second end mechanically and movably coupled to the hot plate.

Owner:SYST SPRAY COOLED

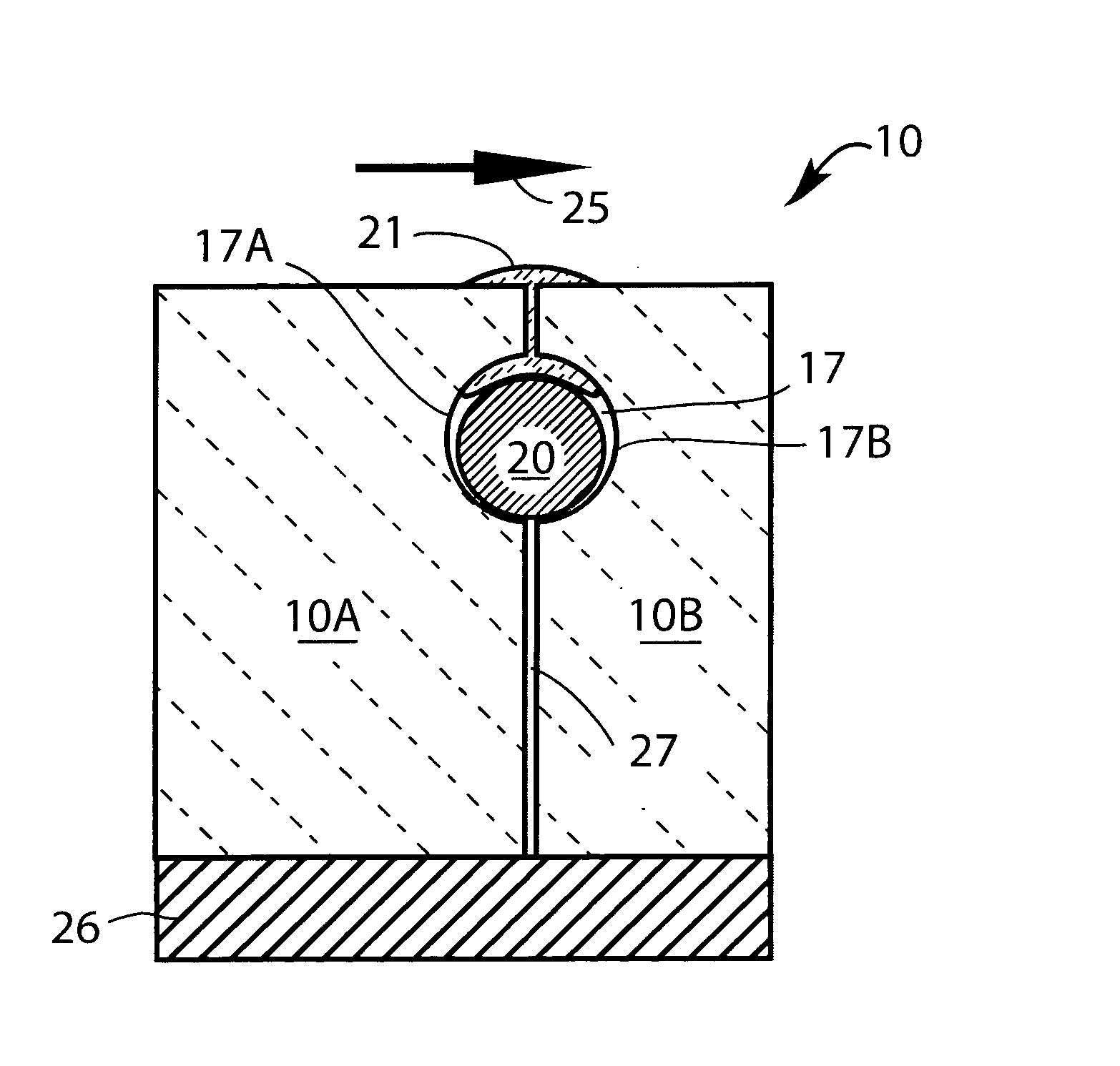

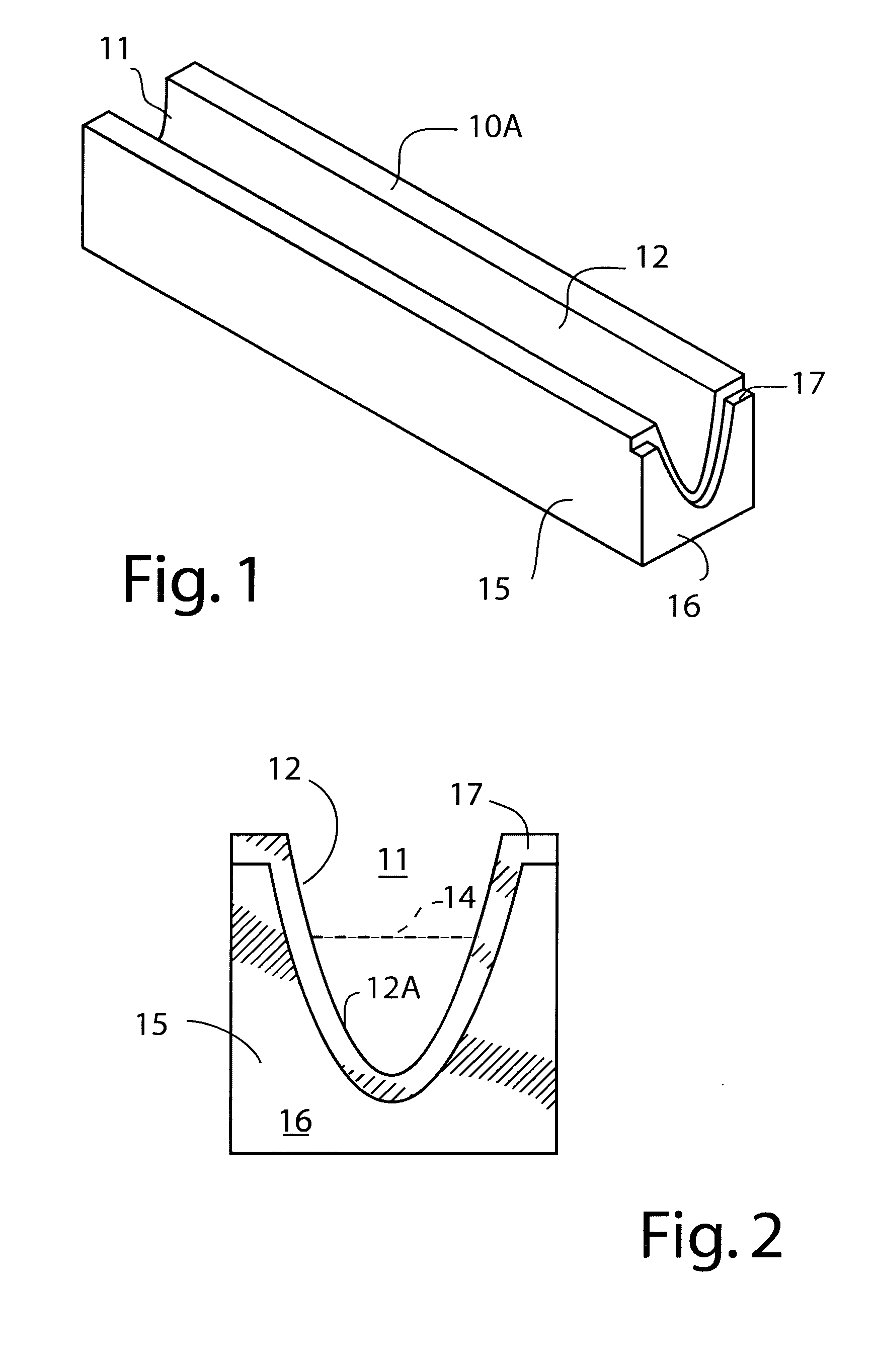

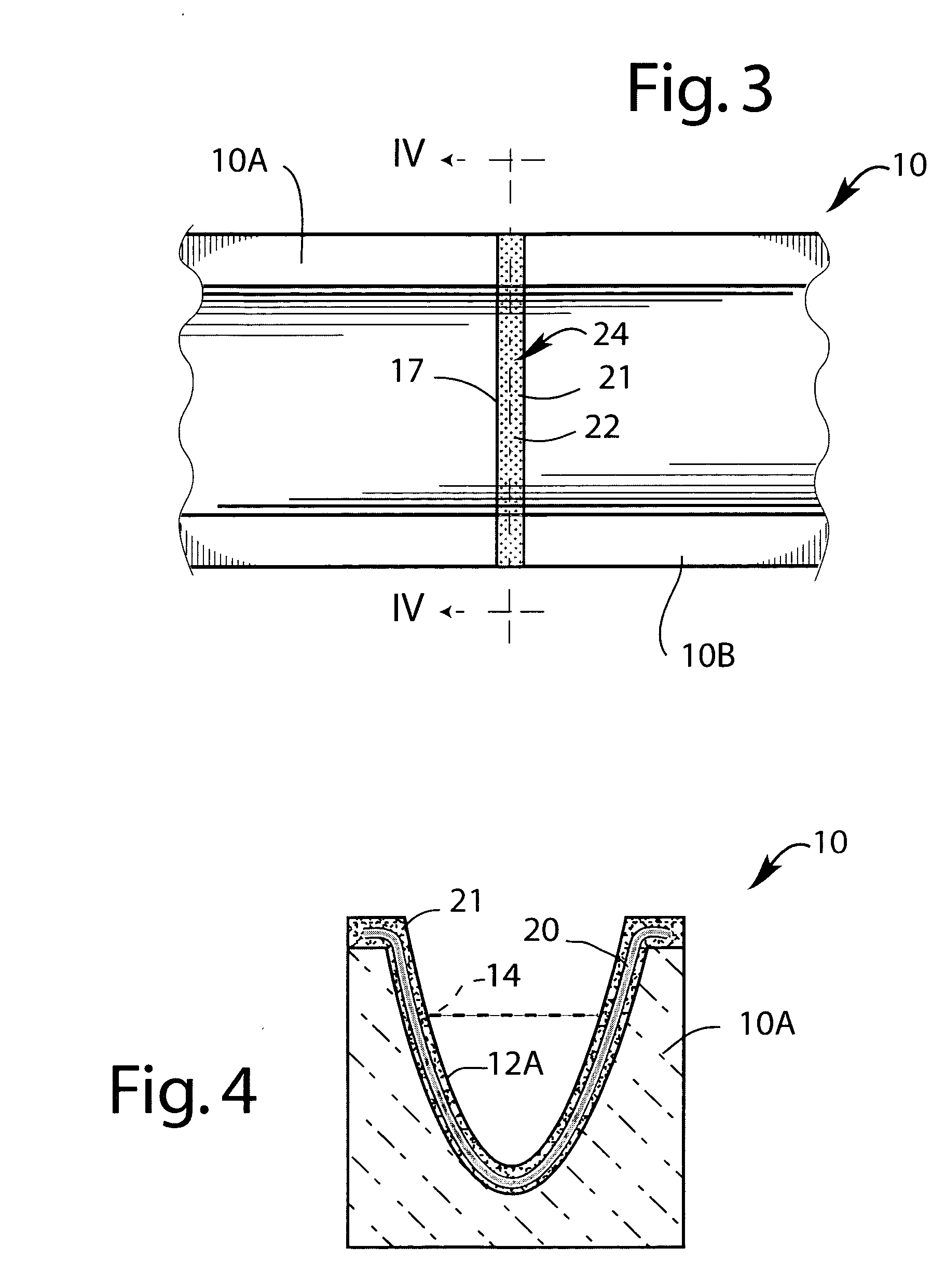

Method of forming sealed refractory joints in metal-containment vessels, and vessels containing sealed joints

An exemplary embodiment of the invention provides a method of preparing a reinforced refractory joint between refractory sections of a vessel used for containing or conveying molten metal, e.g. a metal-contacting trough. The method involves introducing a mesh body made of metal wires into a gap between metal-contacting surfaces of adjacent refractory sections of a vessel so that the mesh body is positioned beneath the metal conveying surfaces, and covering the mesh body with a layer of moldable refractory material to seal the gap between the metal-contacting surfaces. Other embodiments relate to a vessel formed by the method and a vessel section with a pre-positioned mesh body suitable for preparing a sealed joint with other such sections.

Owner:NOVELIS INC

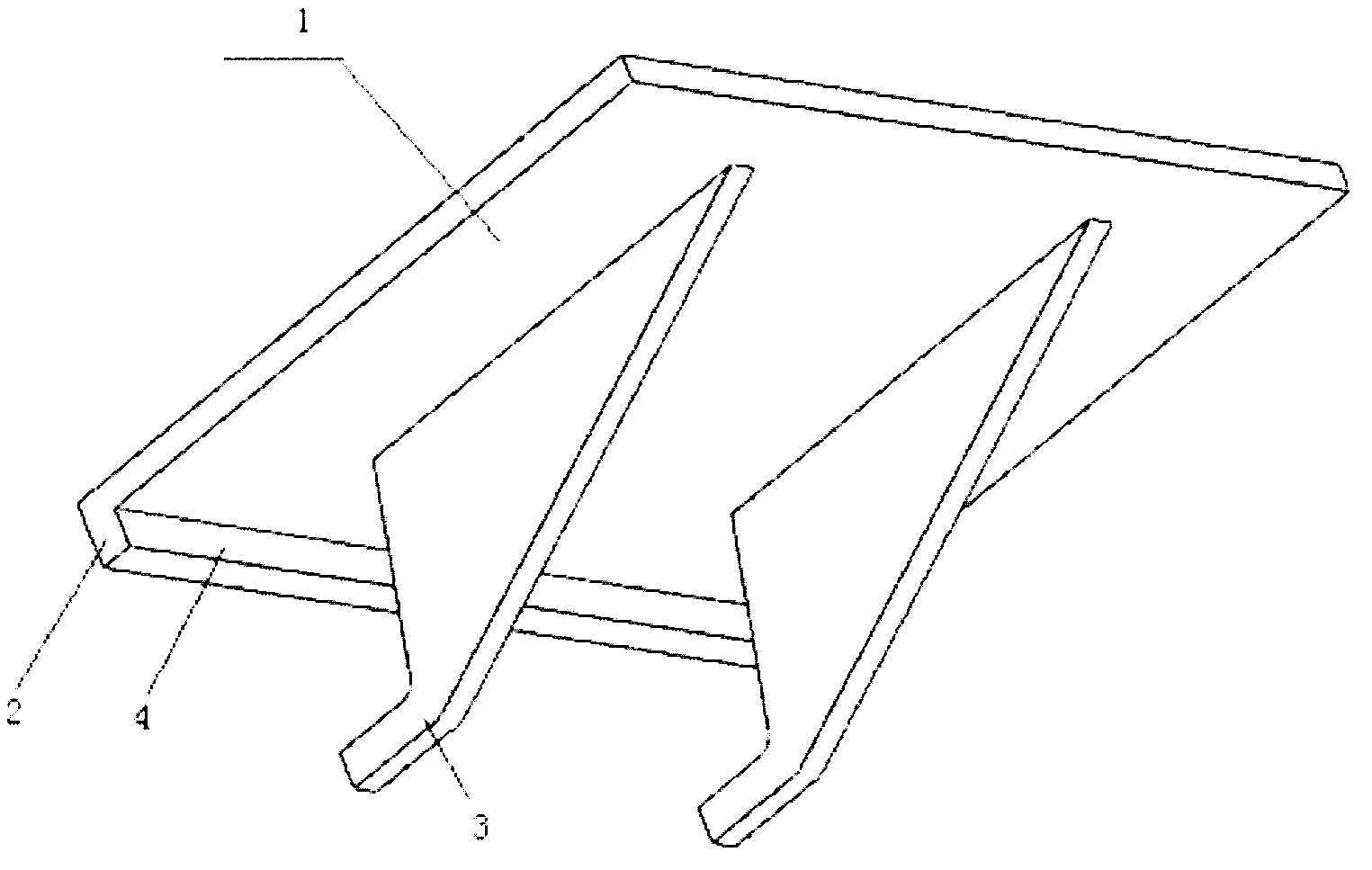

Heating furnace brick holding frame structure

The invention discloses a heating furnace brick holding frame structure which comprises a brick holding plate, a brick pulling rod and a heating furnace wall plate. The brick pulling rod is in a strip-shaped structure. The cross-section of the strip-shaped structure is F-shaped. Two shorter sides parallel to each other of the F-shape cross section are connected with the heating furnace wall plate. The brick holding plate comprises a plate body and a support. A bending portion towards the reverse surface of the plate body is arranged on one edge of the plate body. The support is connected with the reverse surface of the plate body. The support is L-shaped. One side of the L-shaped support is connected with the plate body. The bending portion of the plate body is fastened on the longer side of the L-shaped support. The other side of the L-shaped support directs toward the bending portion and abuts against the heating furnace wall plate. Due to the structure of the heating furnace brick holding frame, the heating furnace brick holding frame structure can be manufactured in a casting mode and applied to various heating furnaces. In this way, novel alloy materials can be selected to use, and heat-resistant property of the heating furnace brick holding frame structure is improved.

Owner:LIYANG HENGXIANG SPECIAL STEEL MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com