Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

504results about "Furnace cooling arrangements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

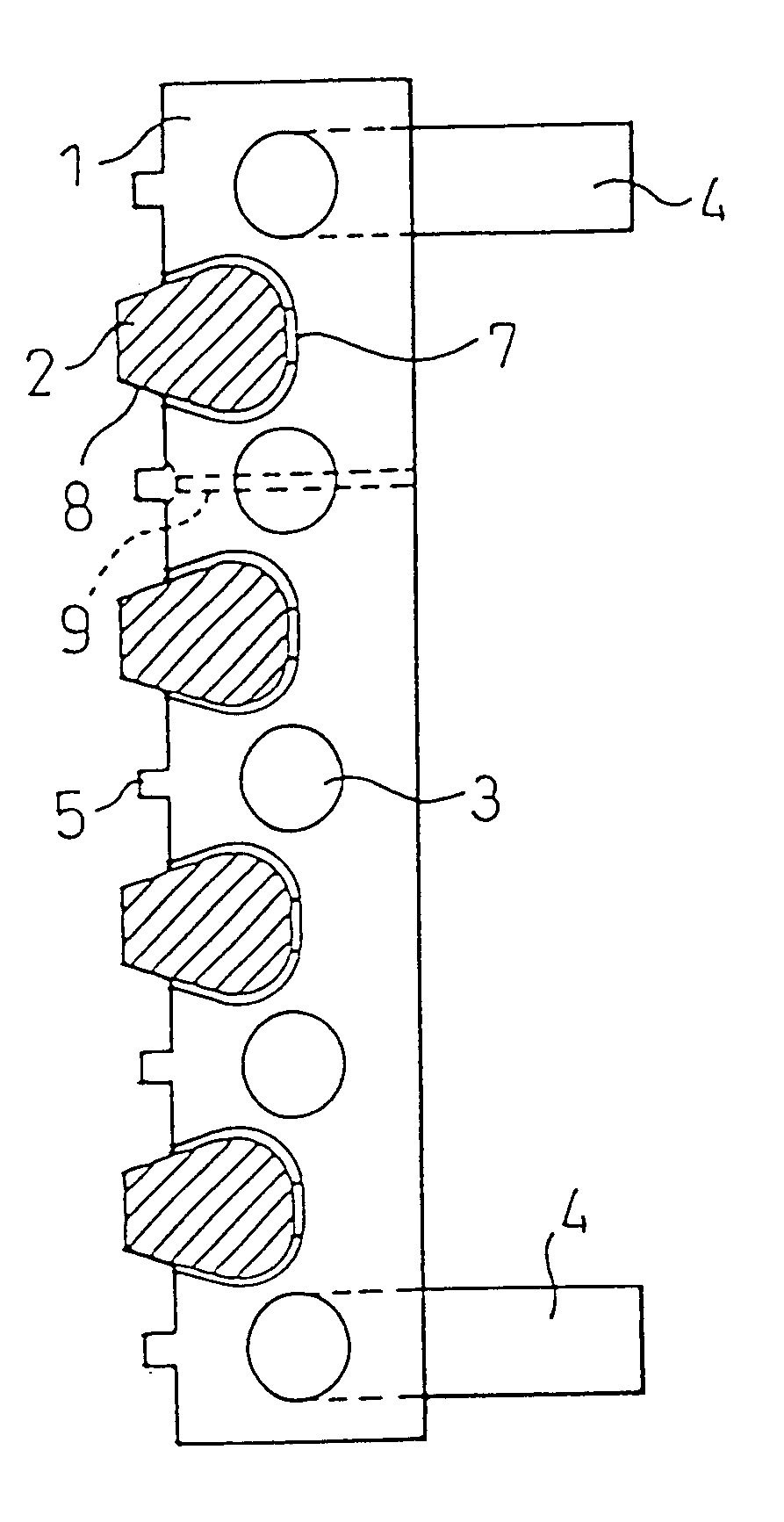

Interlocking floor brick for non-recovery coke oven

An improved non-recovery coke oven floor constructed of a single layer of refractory bricks including, for each oven sole flue, a pair of trunnion bricks and a center bridge brick spanning the width of the flue, having lower brick surfaces in the form of an arch, and joined end-to-end by a tapered tongue-and-groove joint disposed approximately perpendicular to the direction of a compression load transmitted by the center bridge brick to the trunnion bricks.

Owner:PENNSYLVANIA COKE TECH

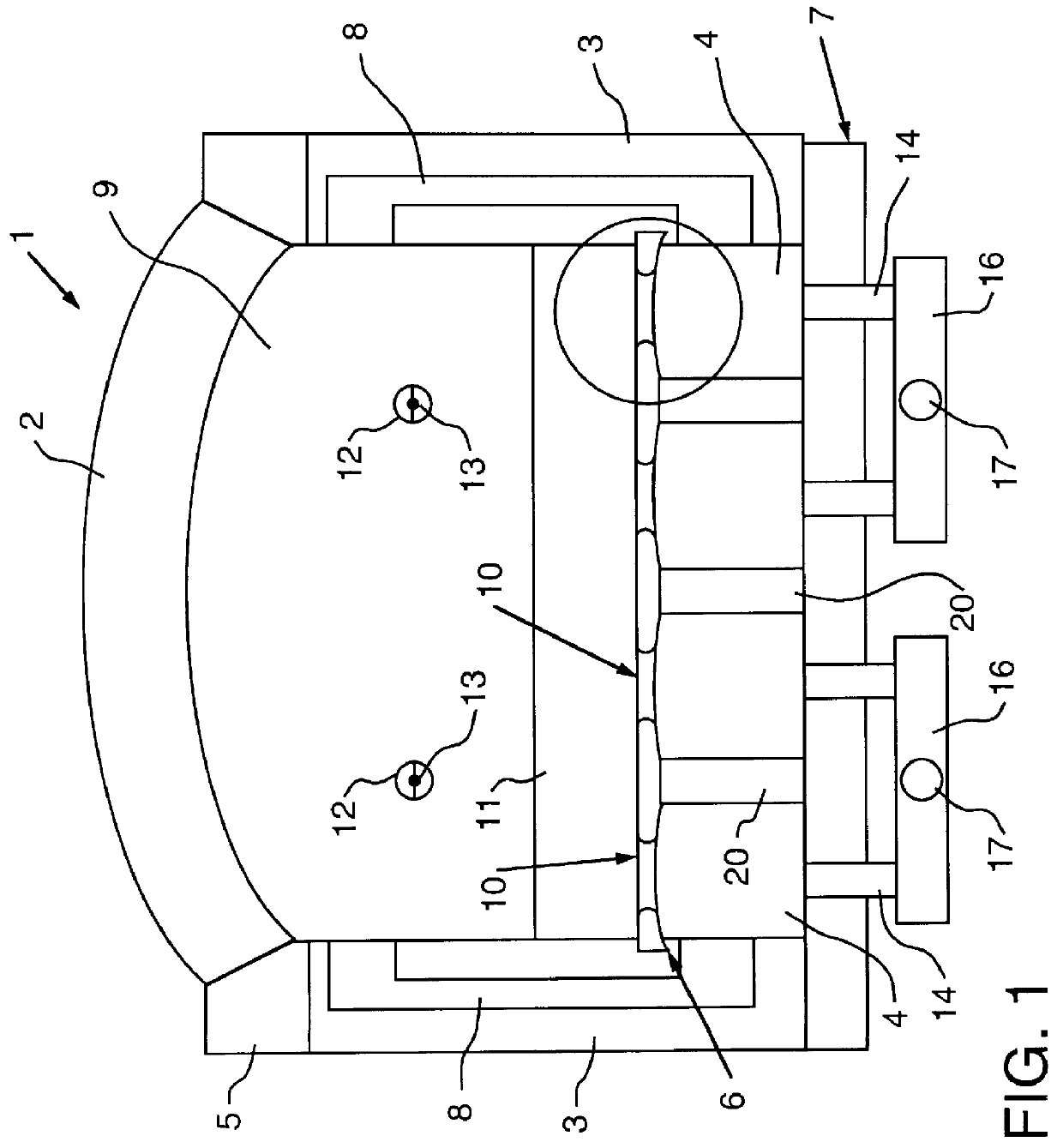

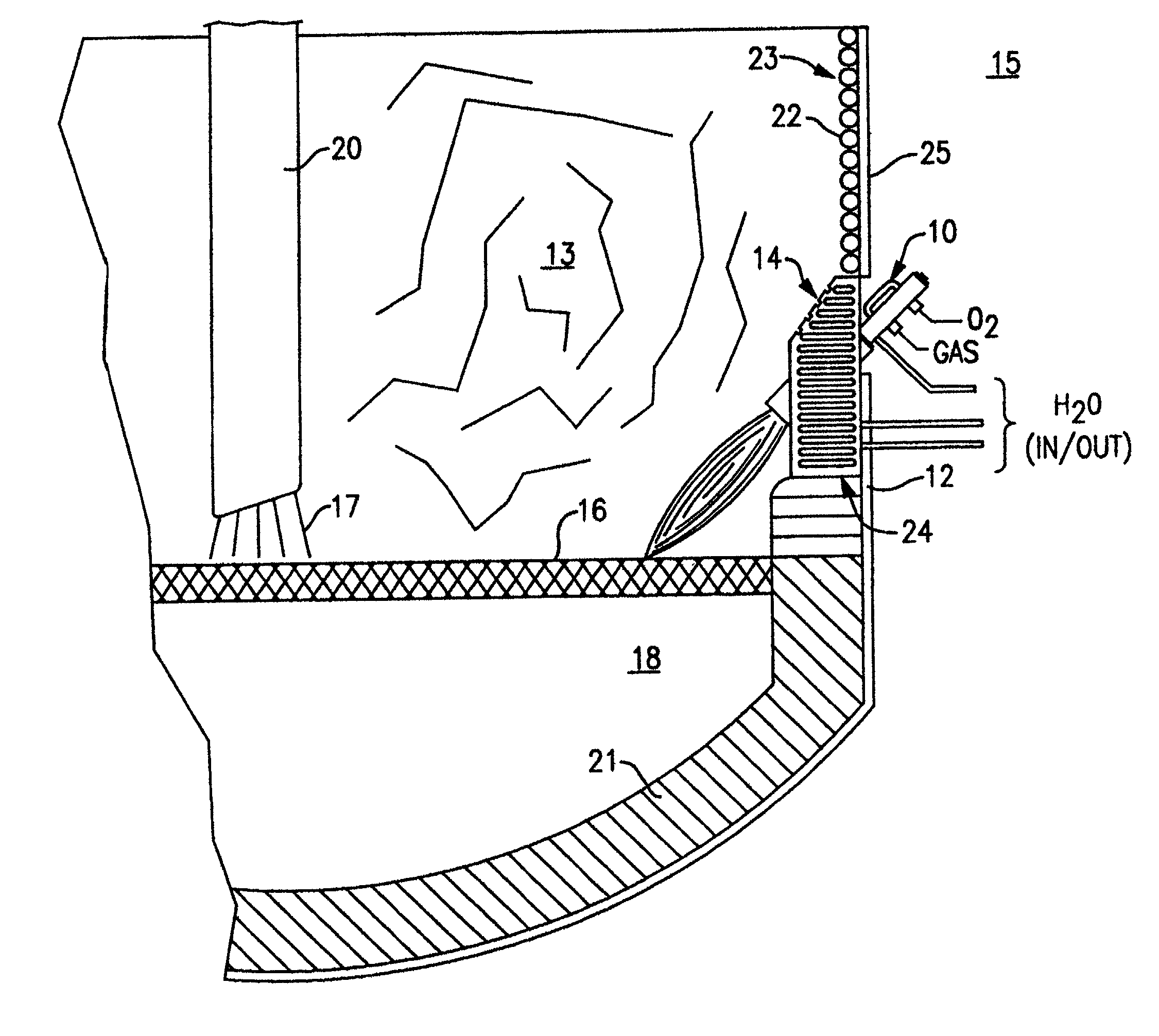

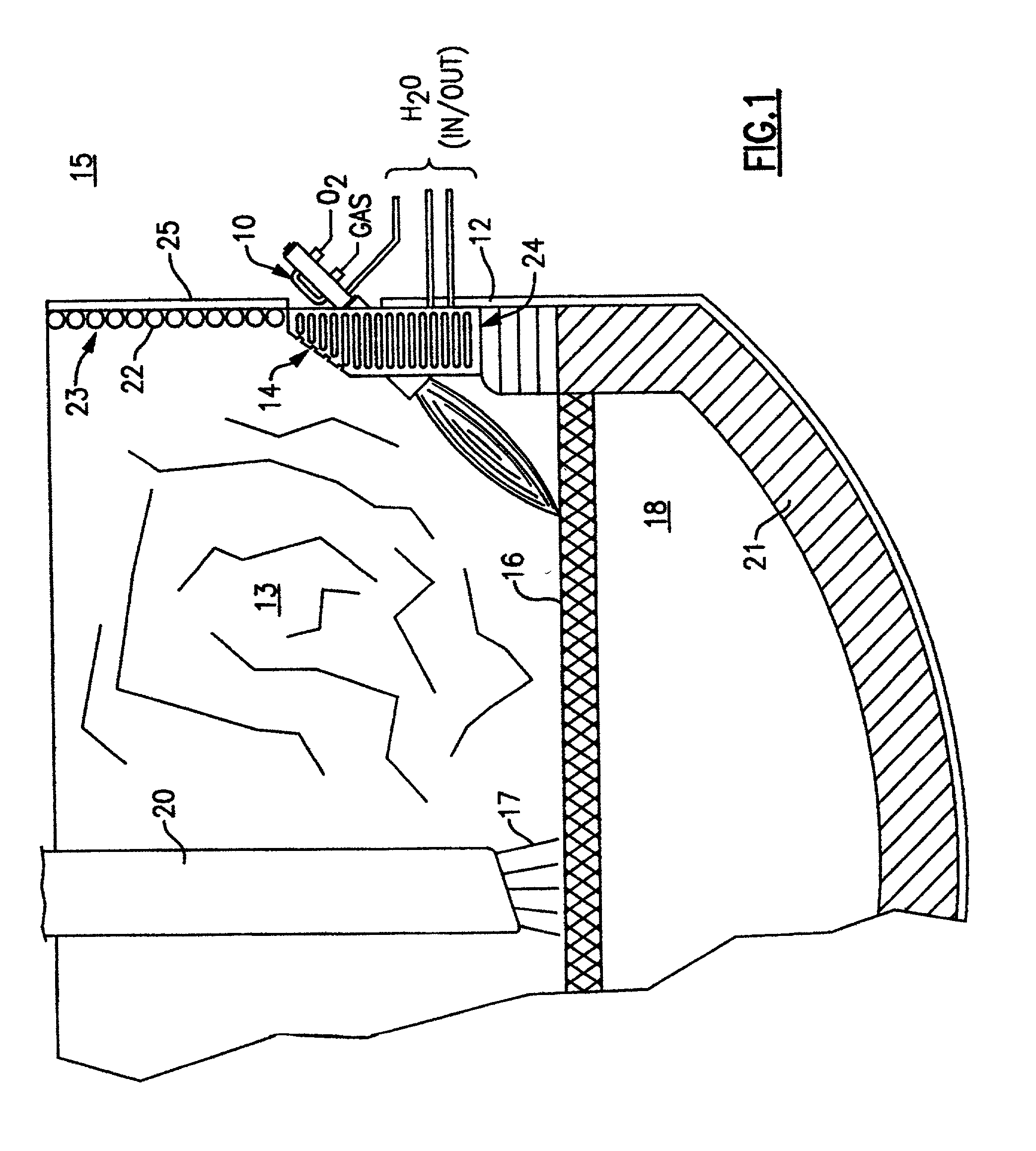

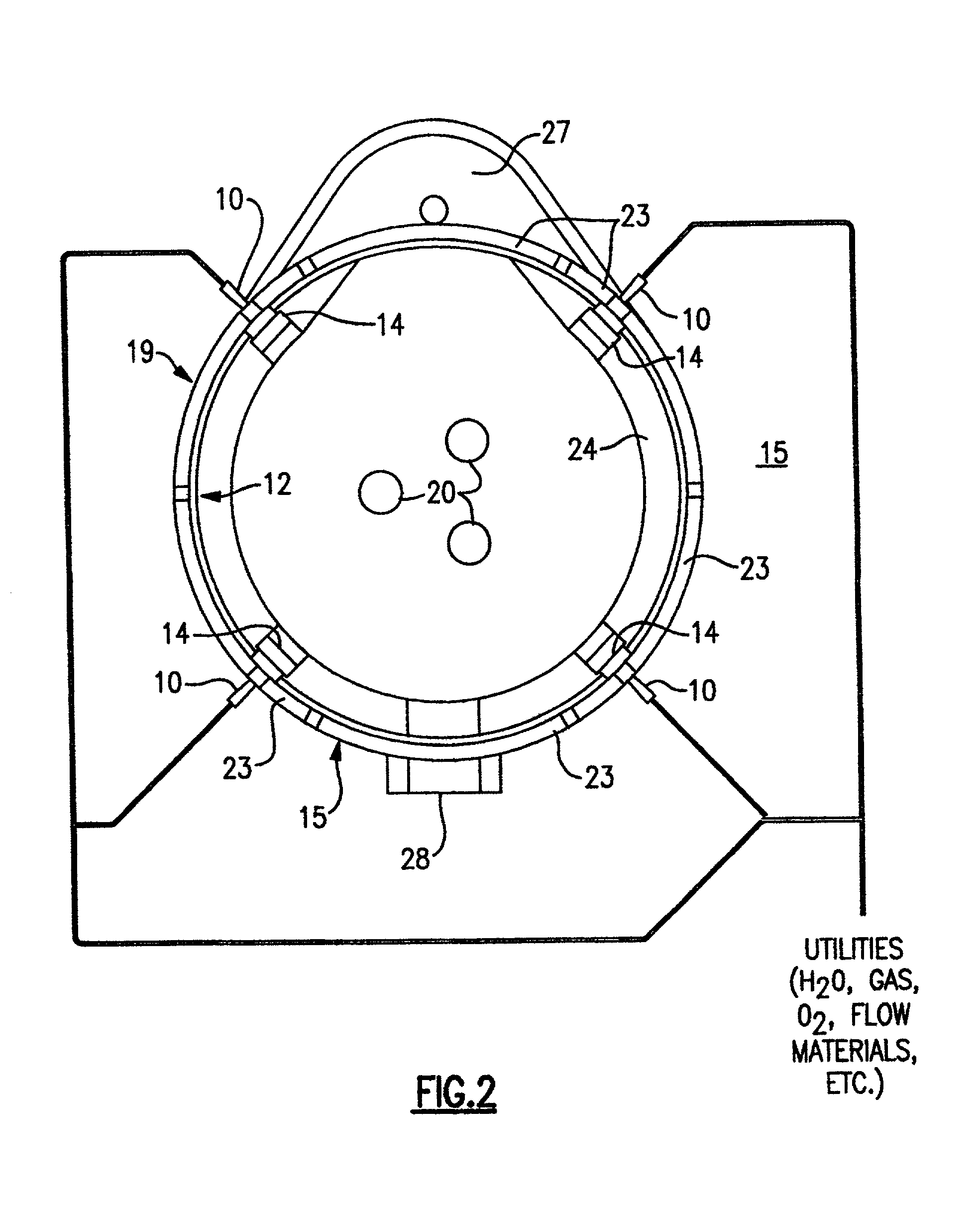

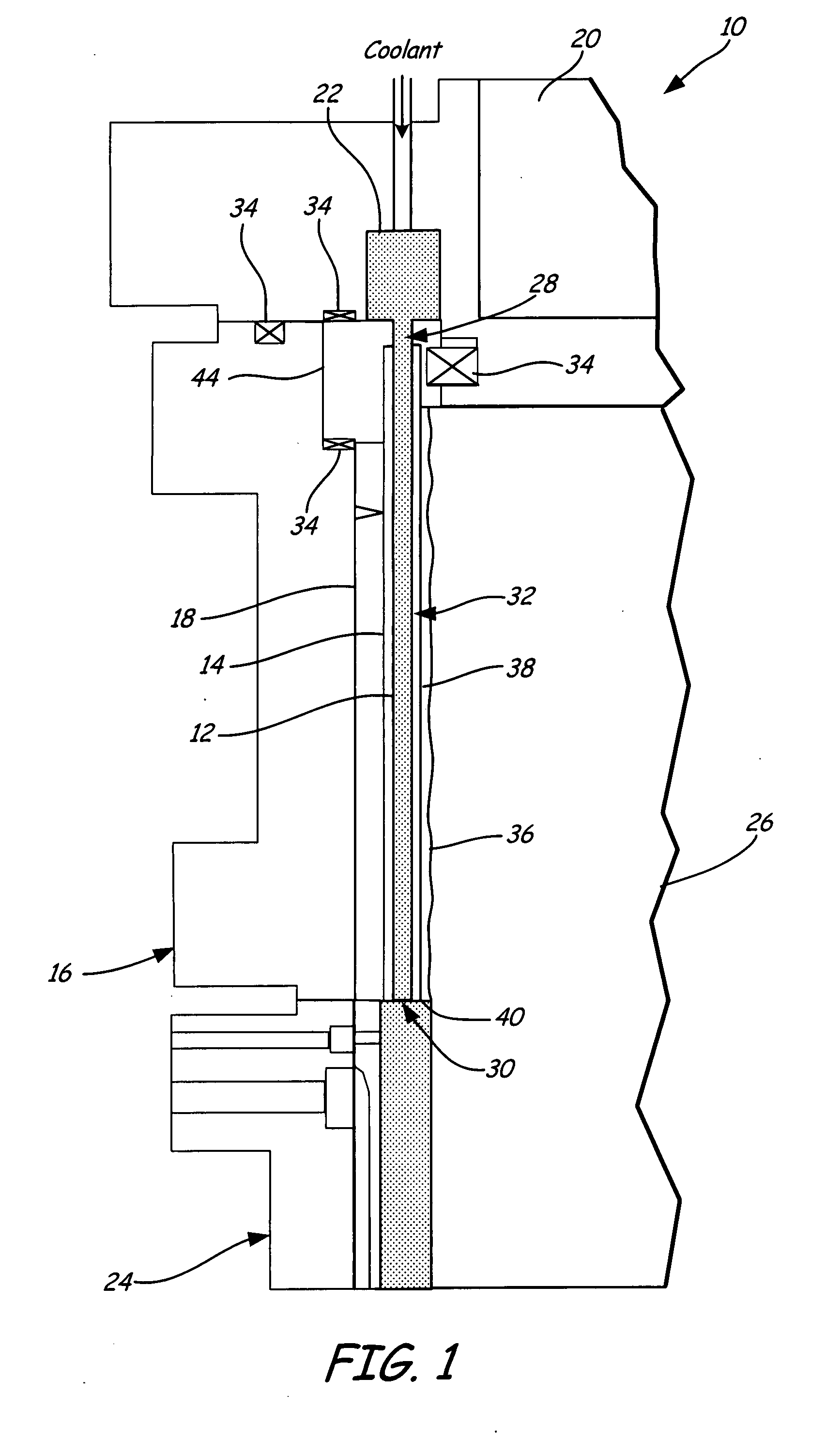

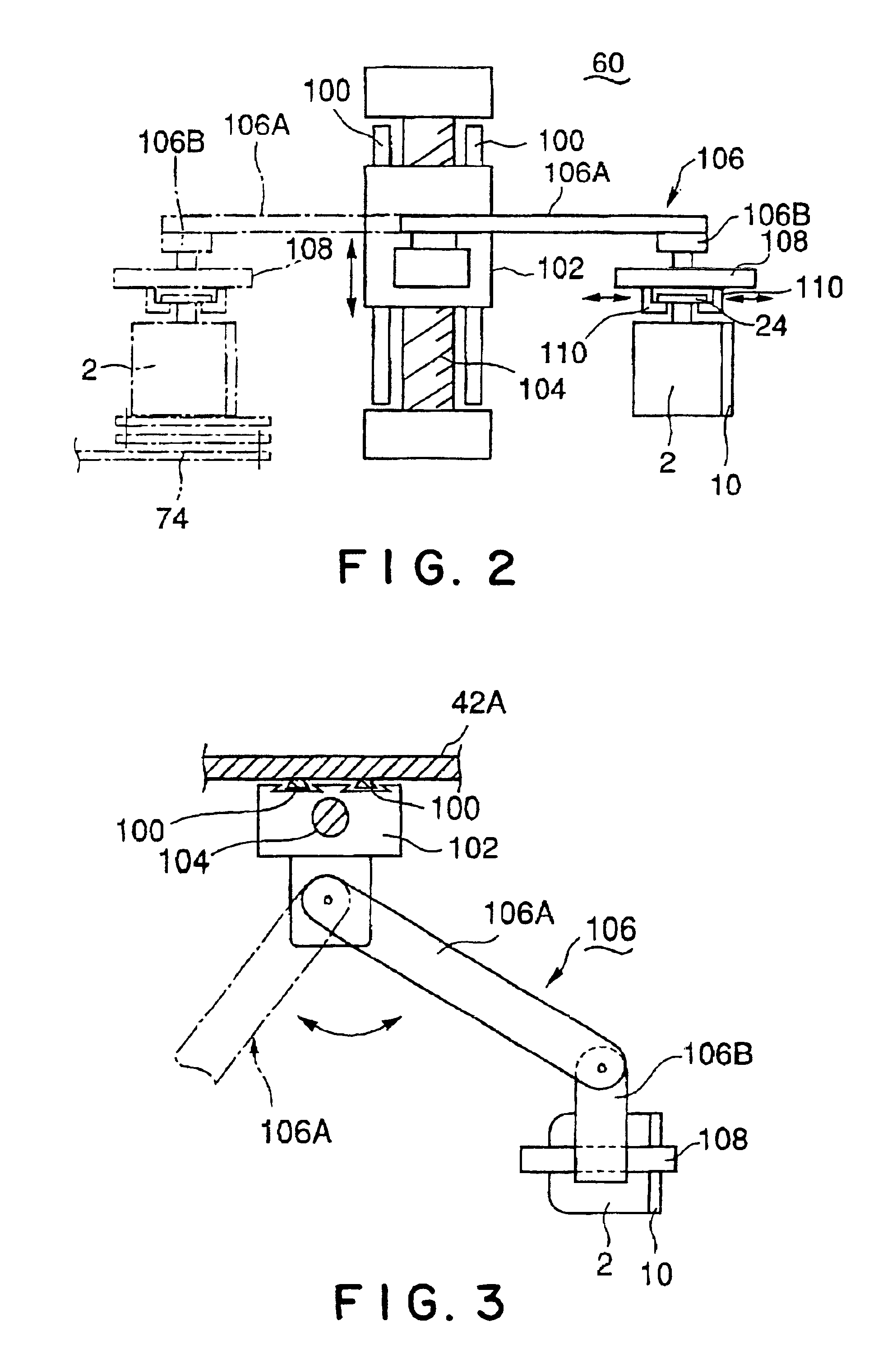

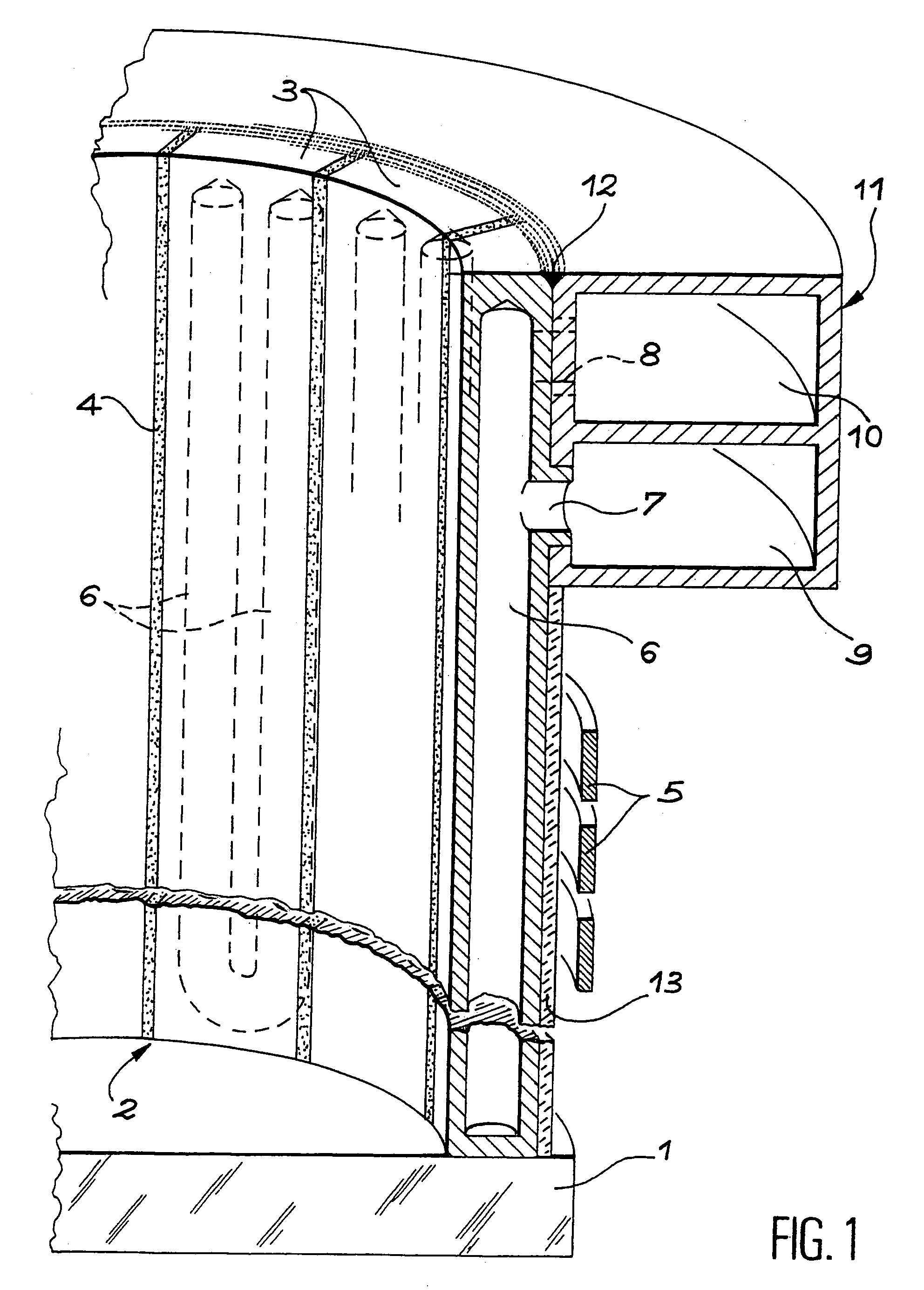

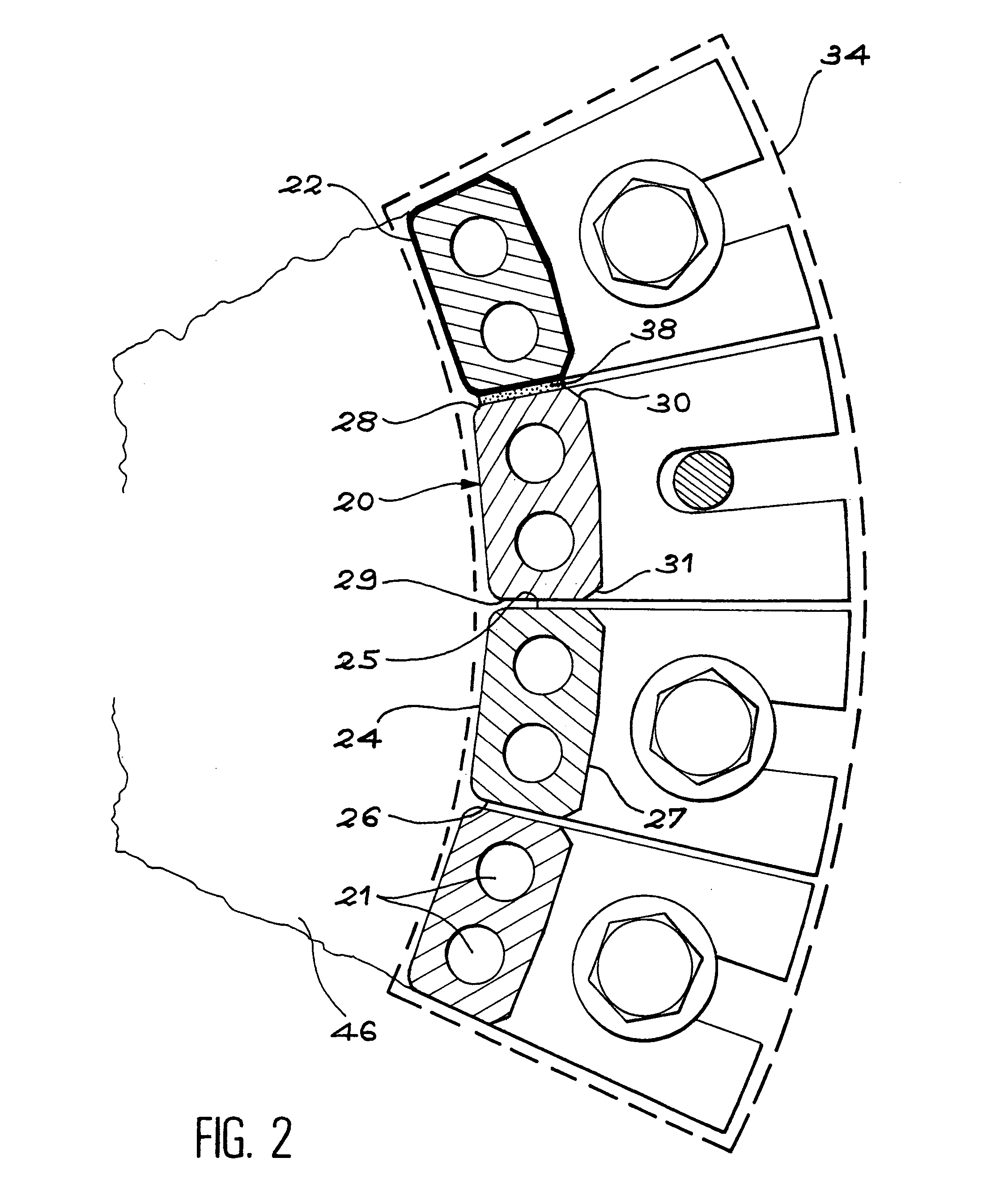

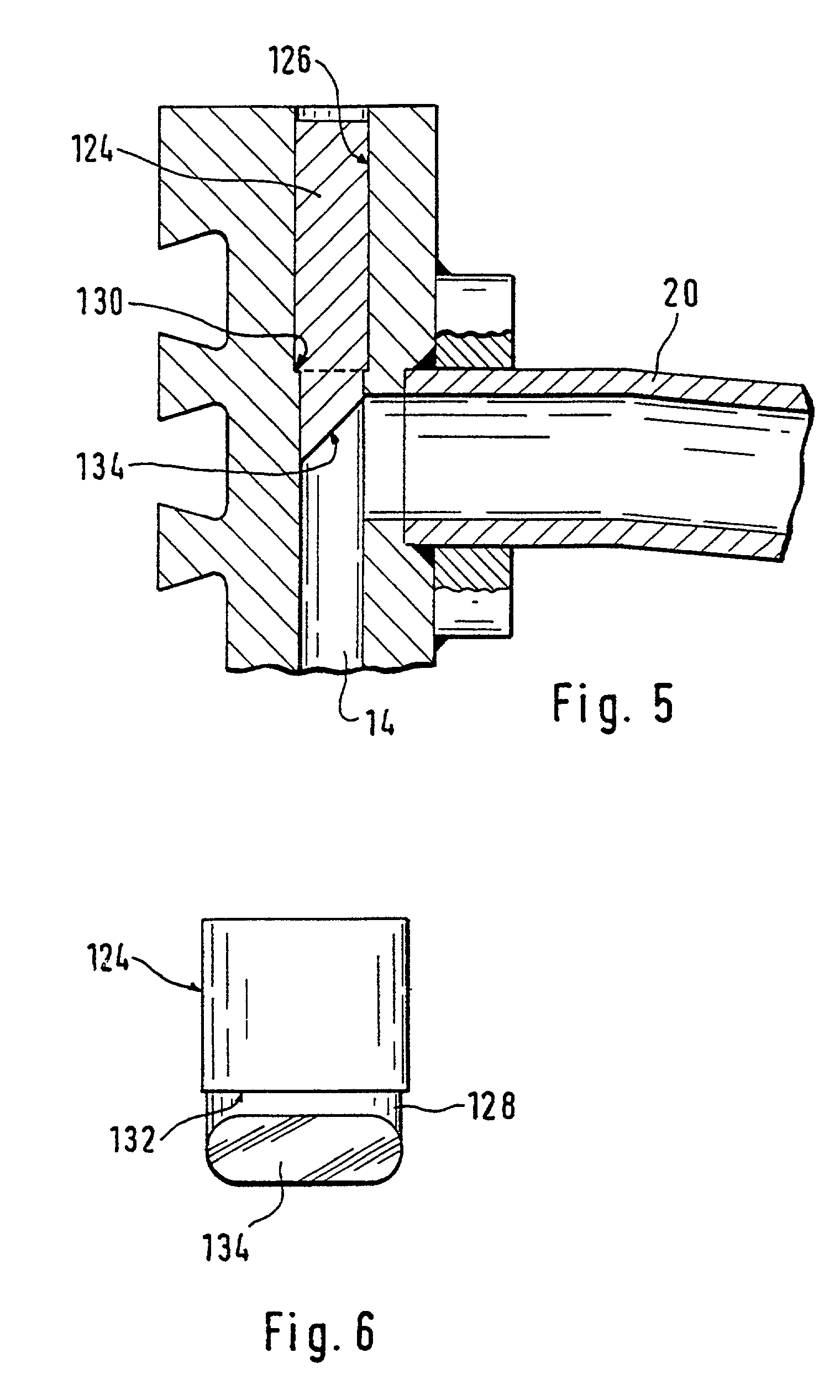

Mounting arrangement for auxiliary burner or lance

InactiveUS6614831B2Easy to produceImprove thermal conductivityElectric discharge heatingPeptide/protein ingredientsParticulatesElectric arc furnace

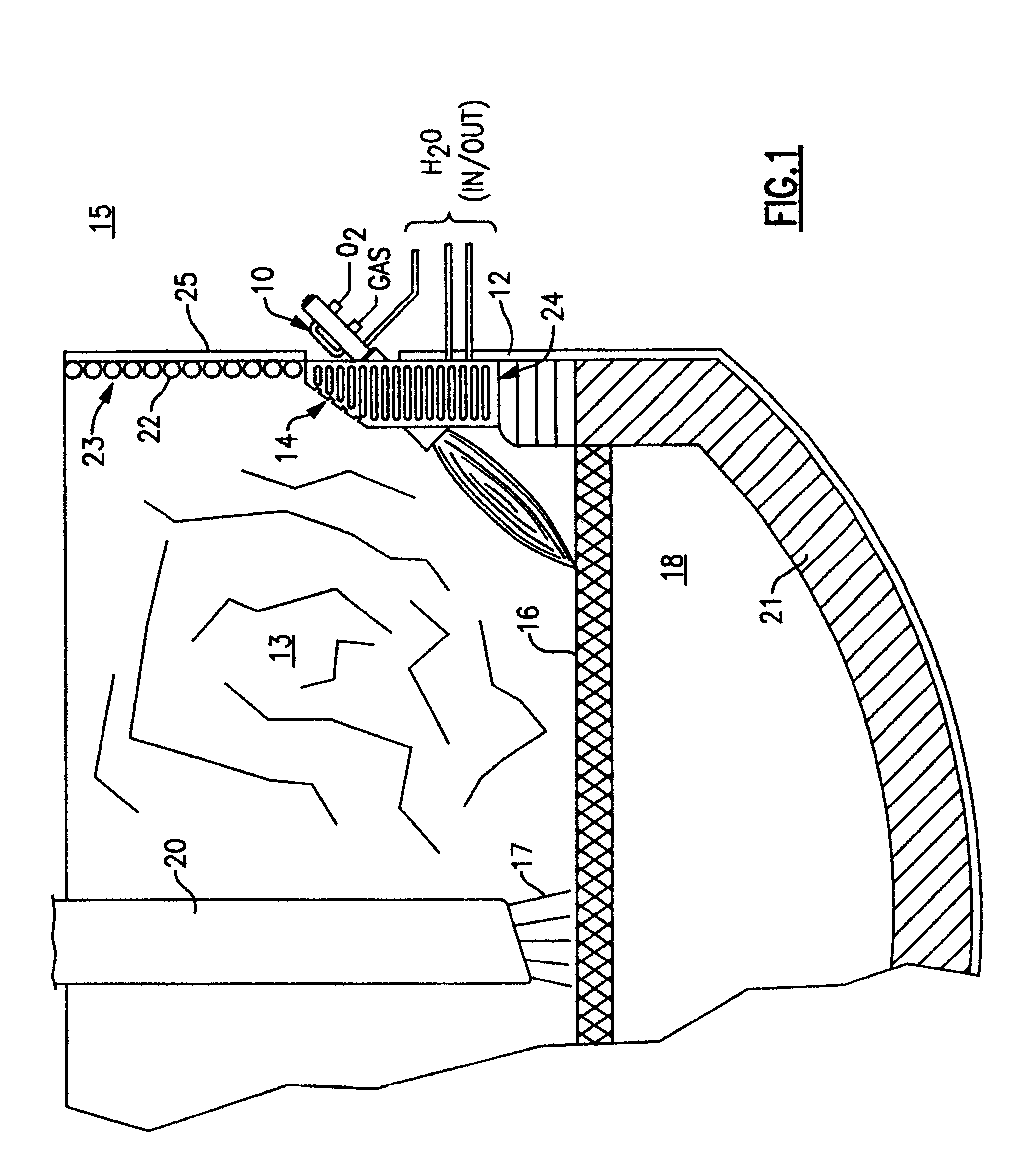

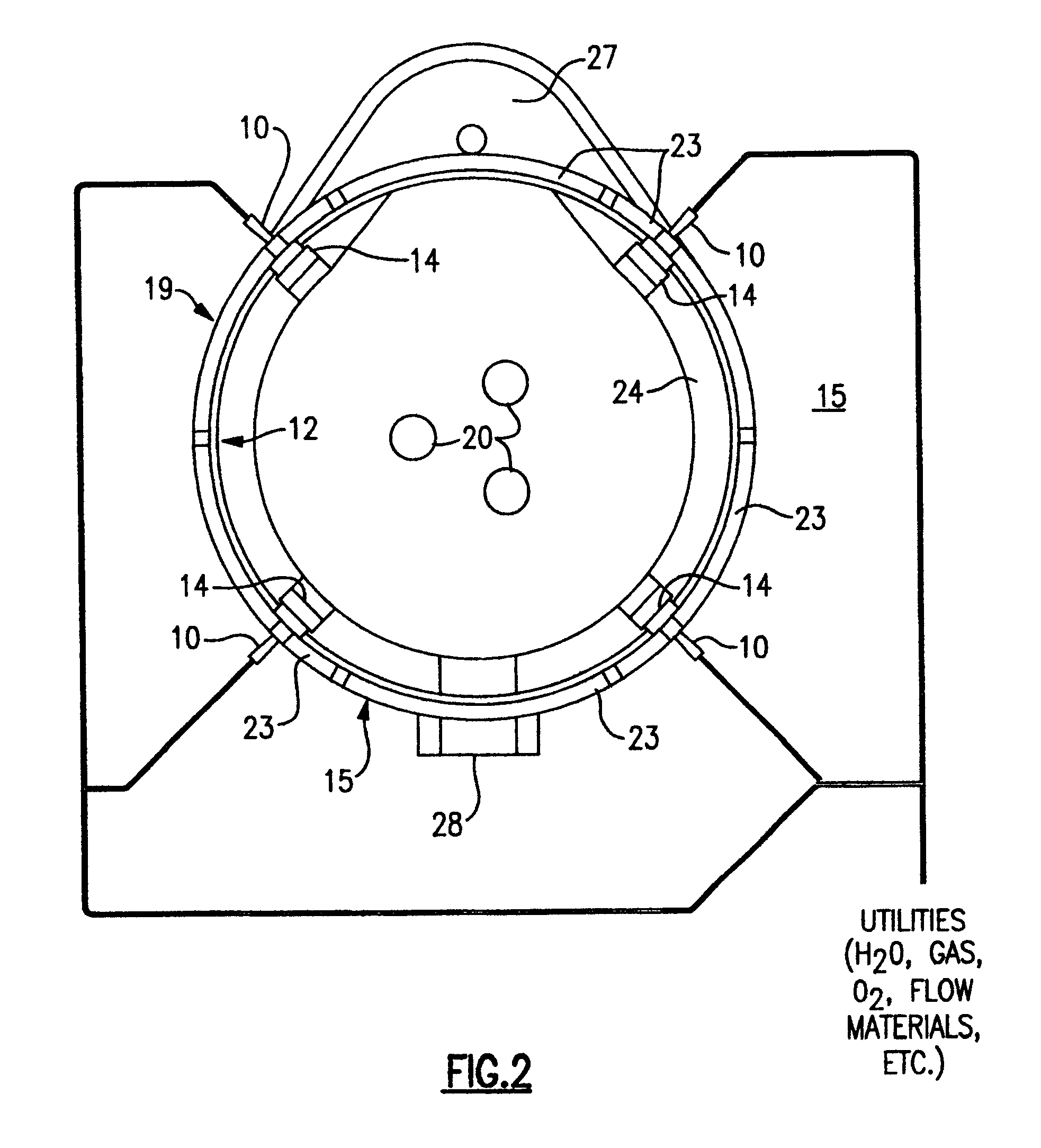

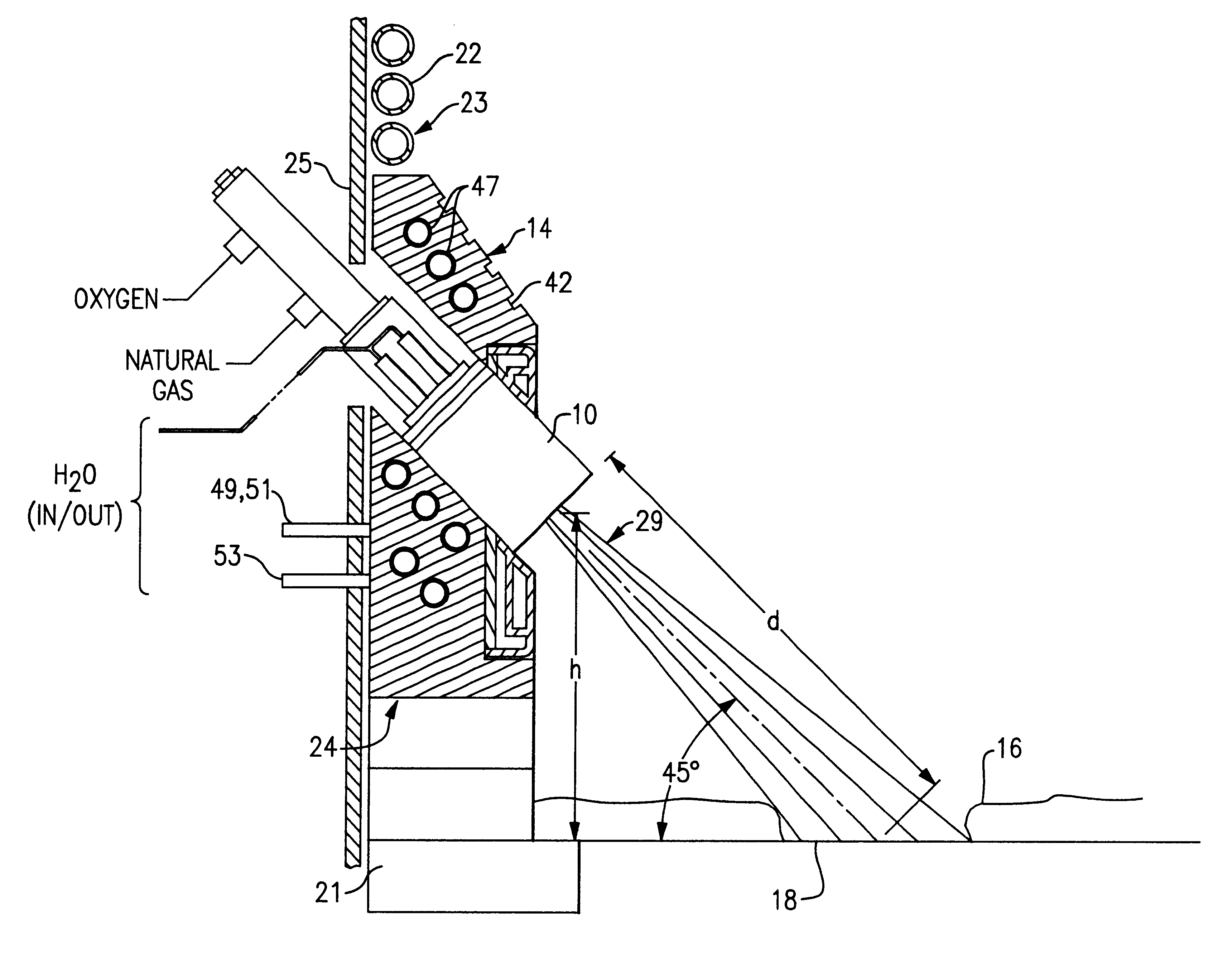

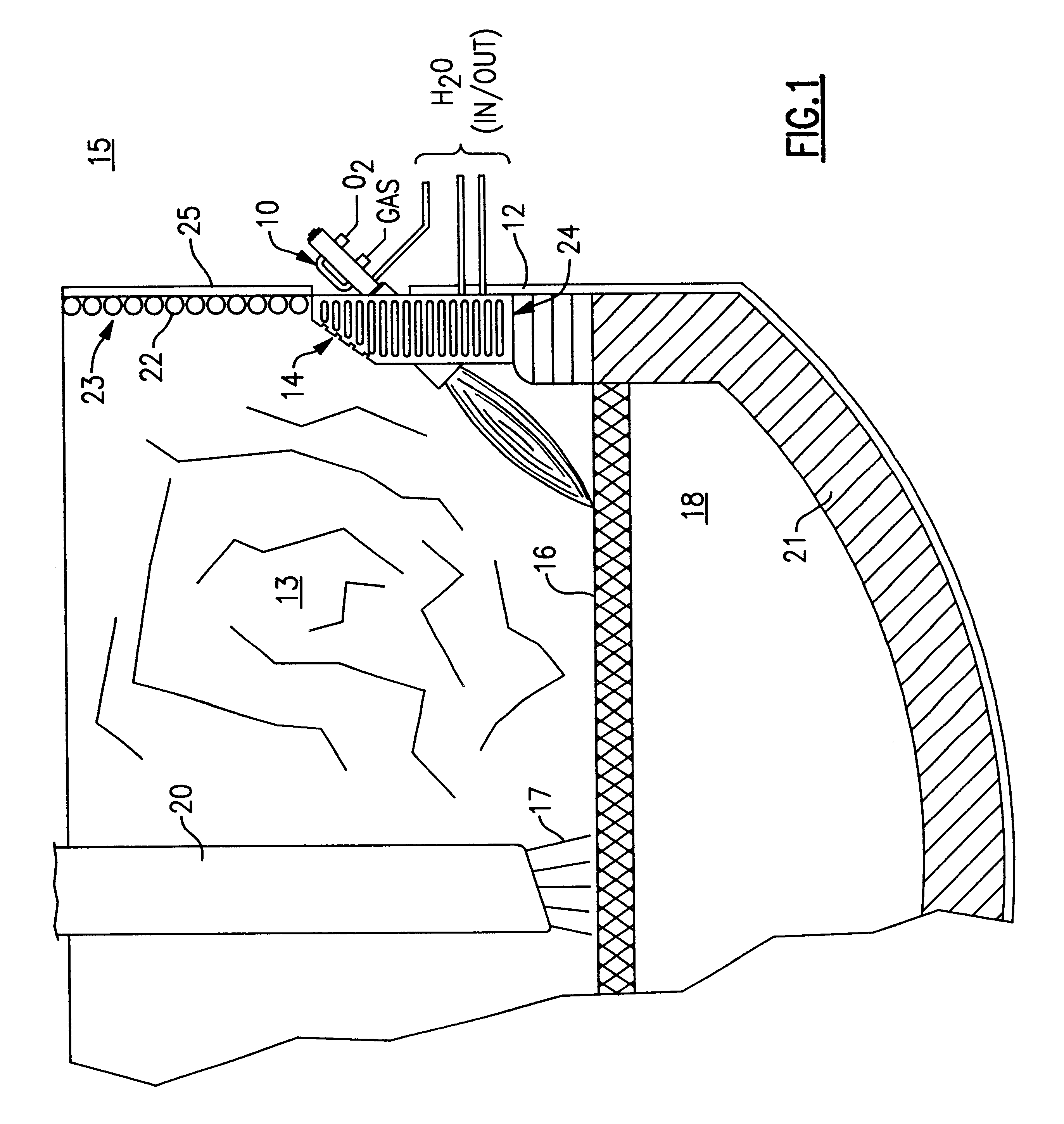

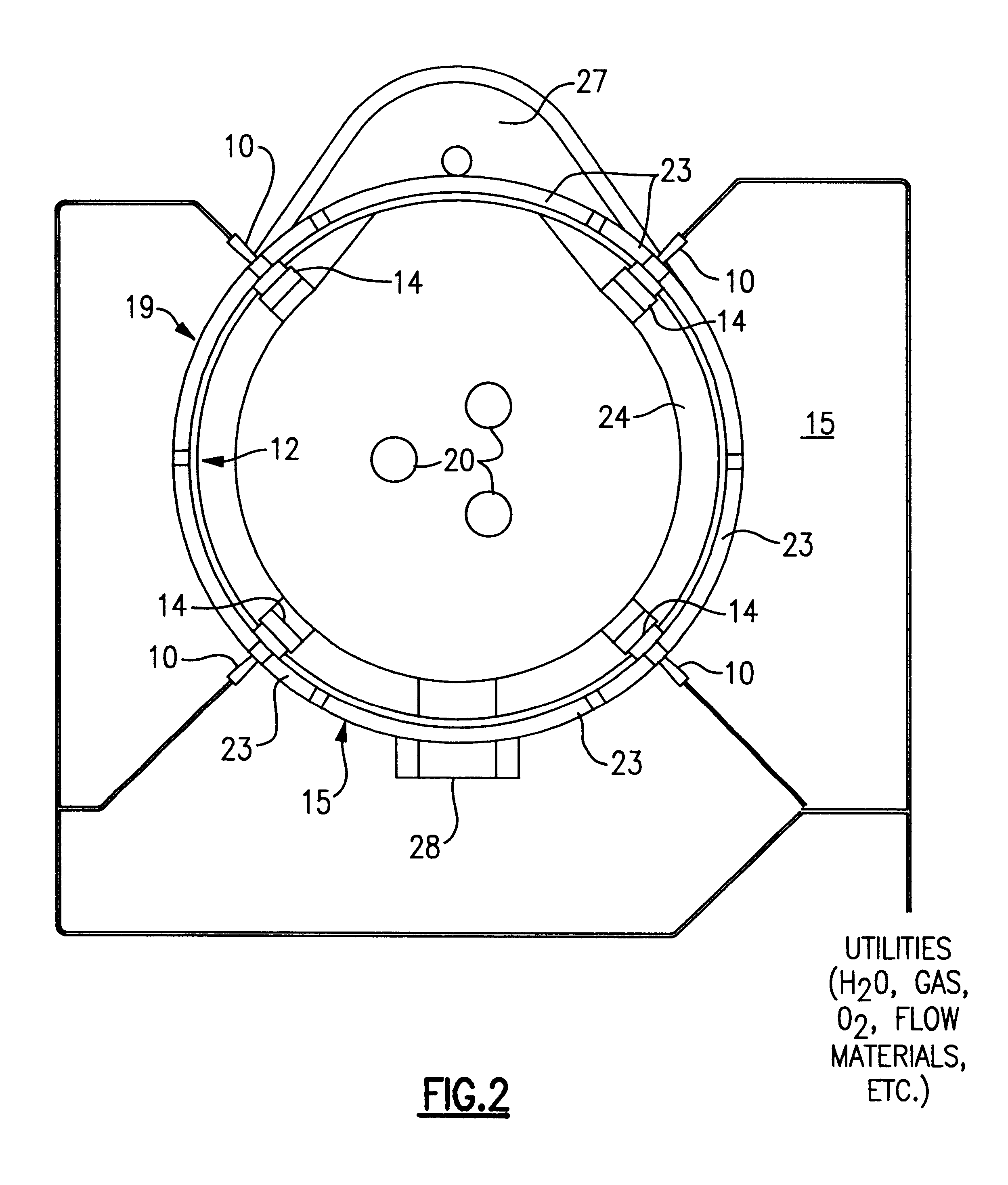

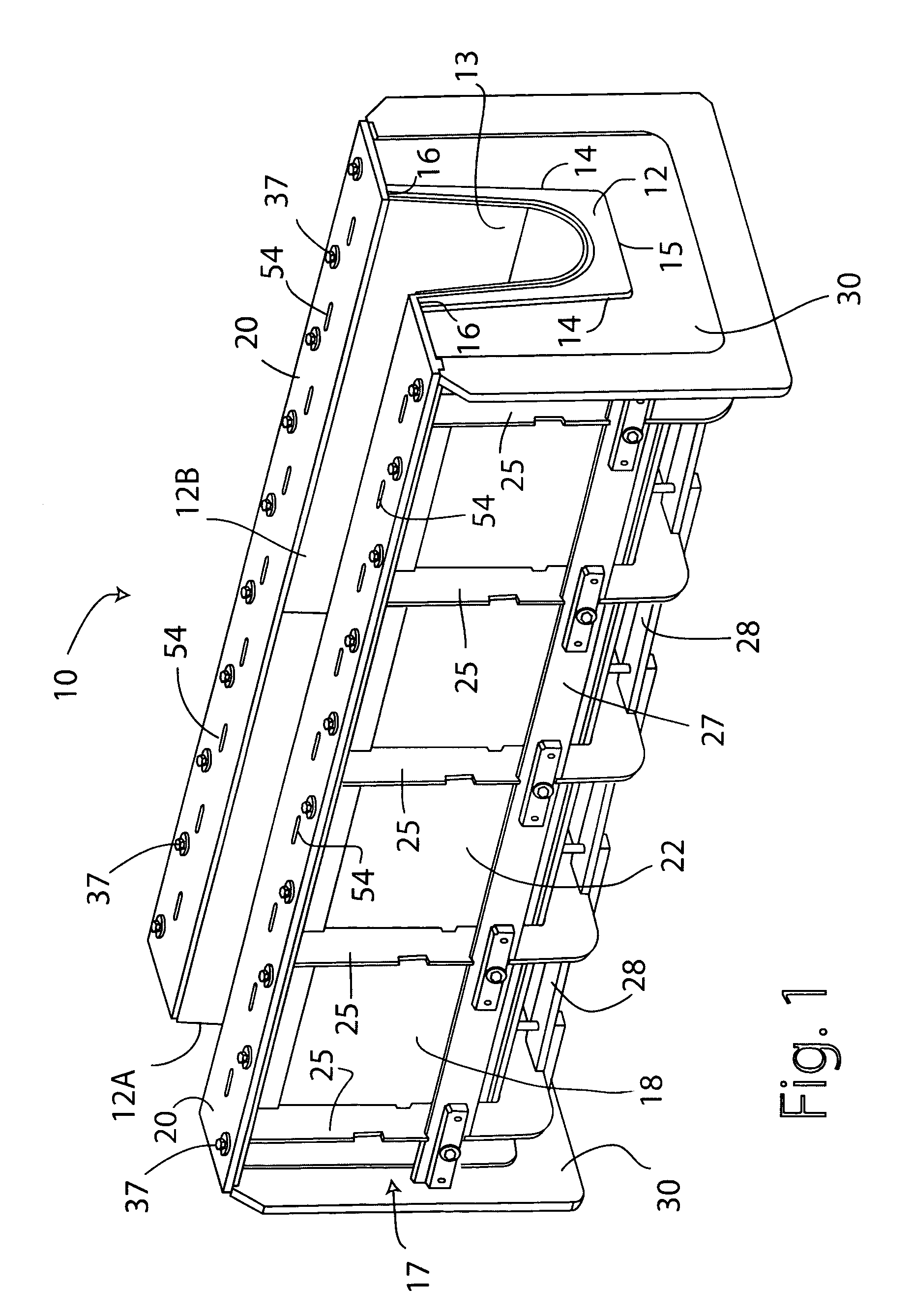

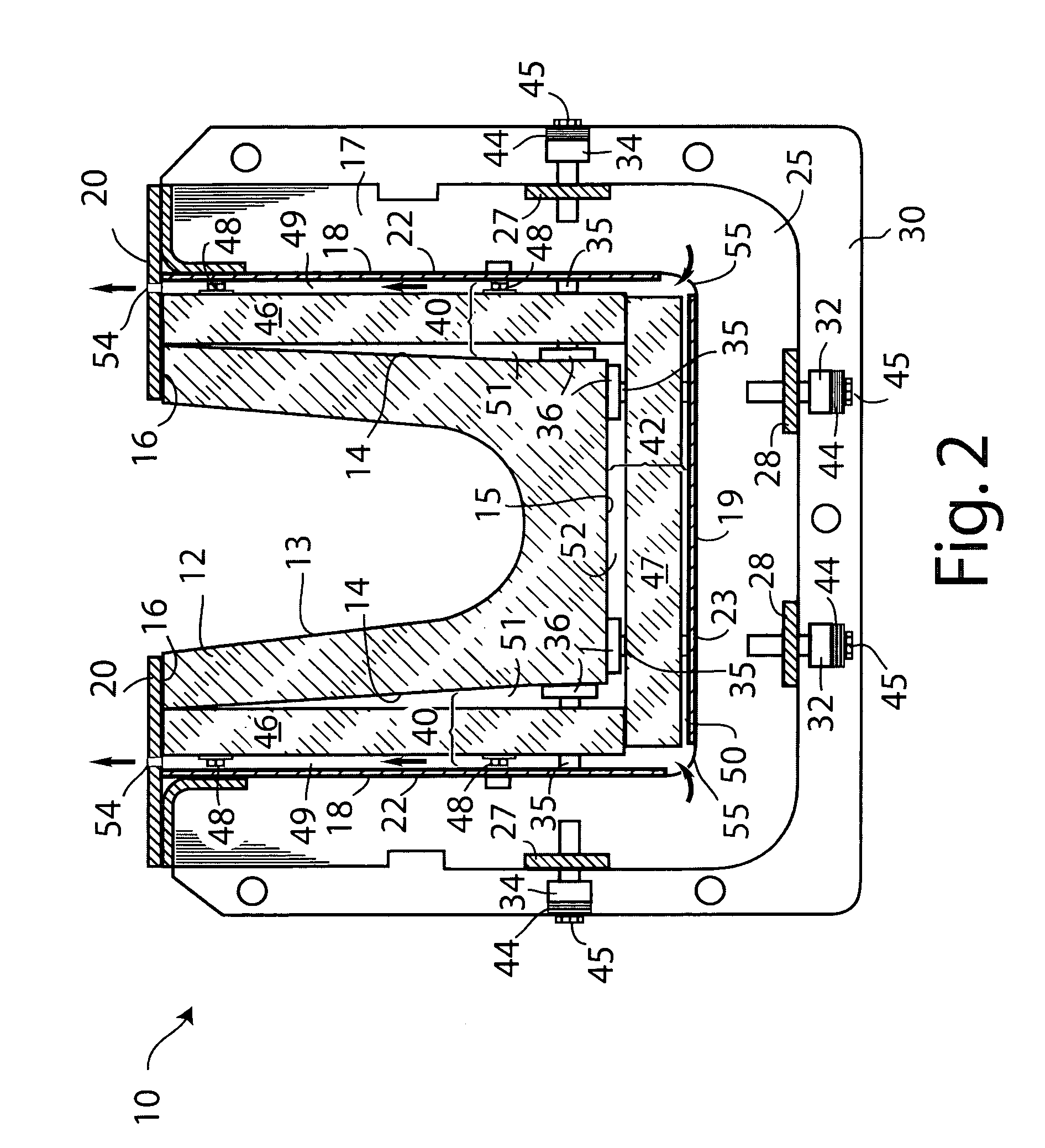

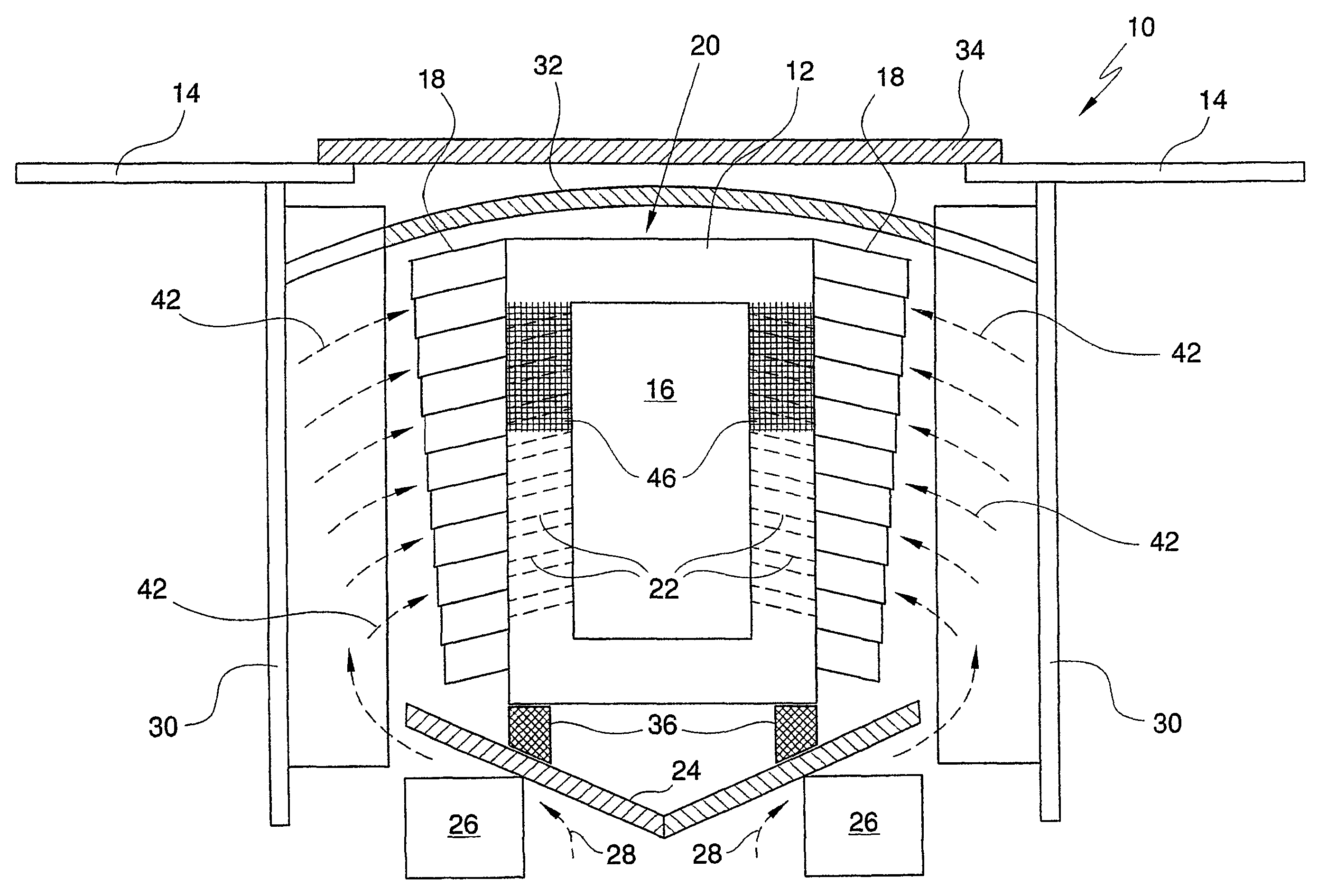

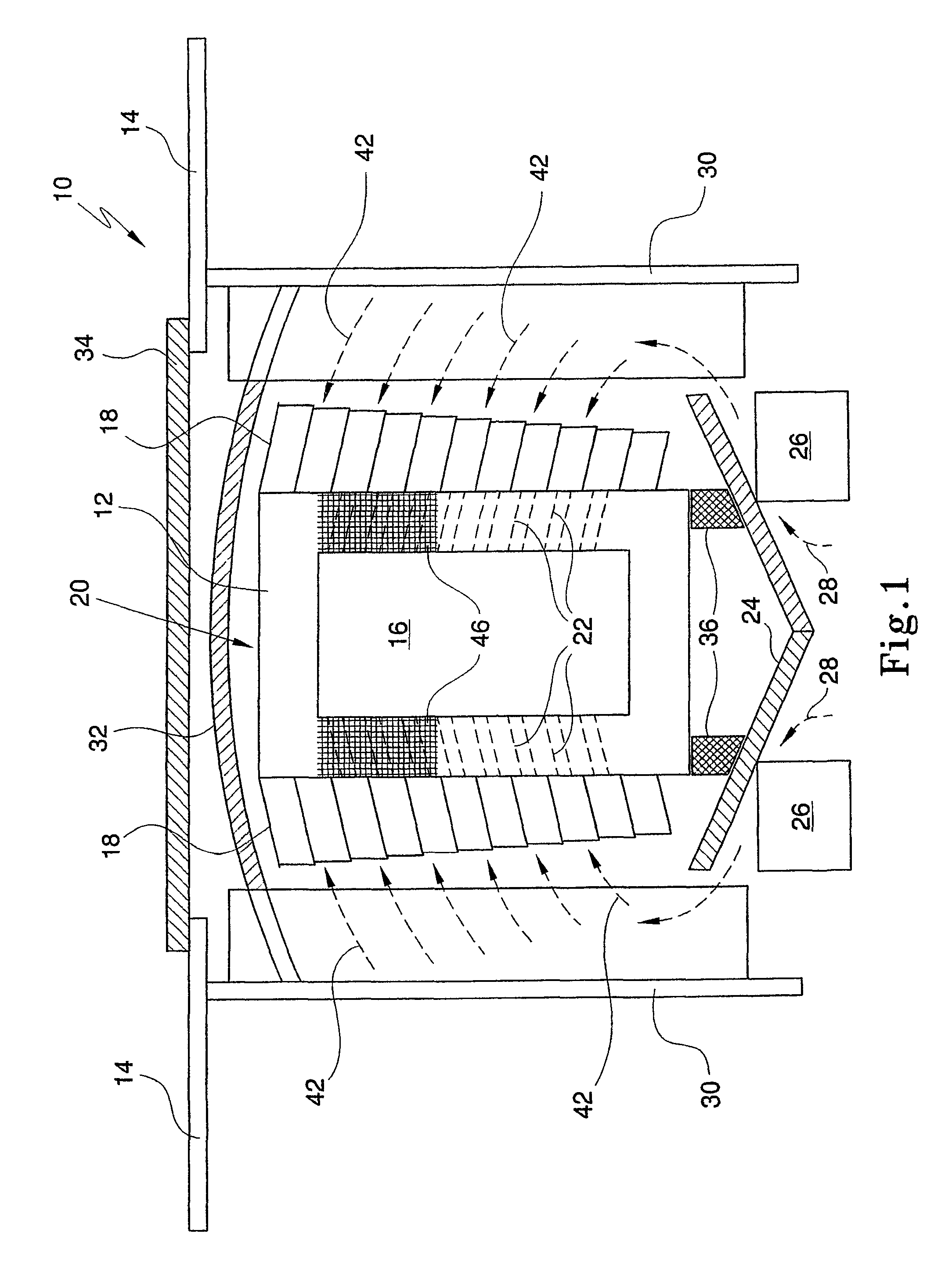

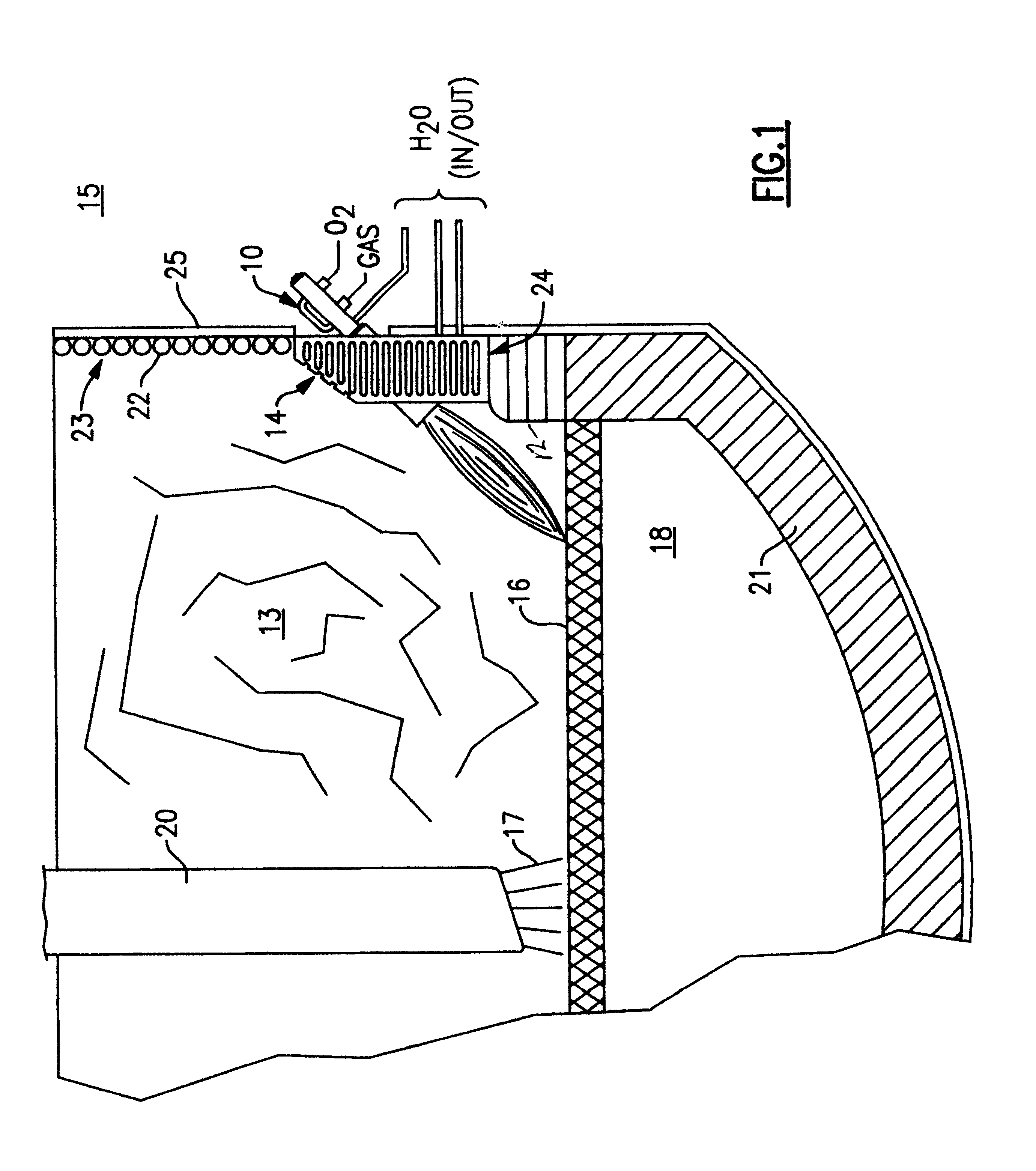

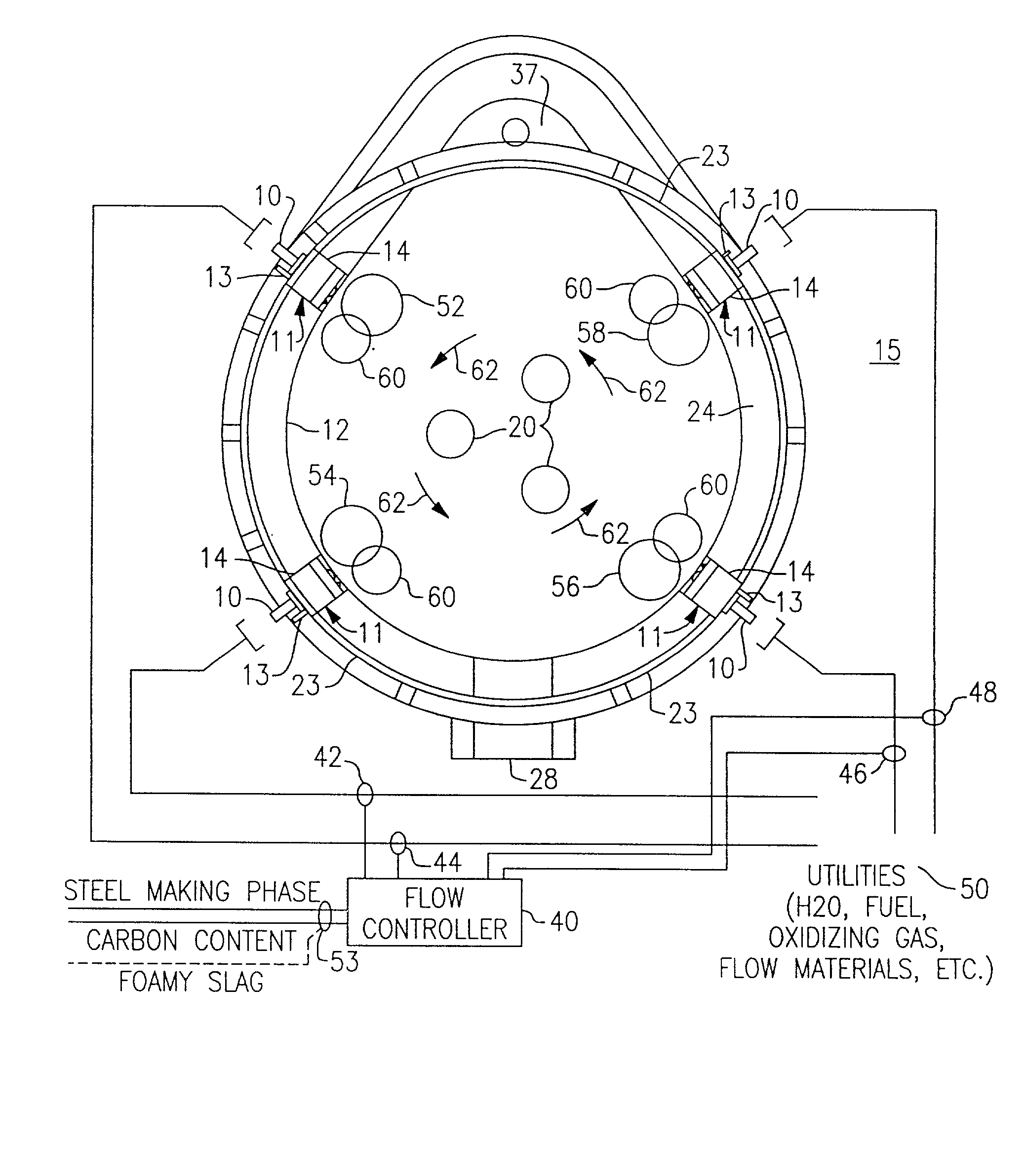

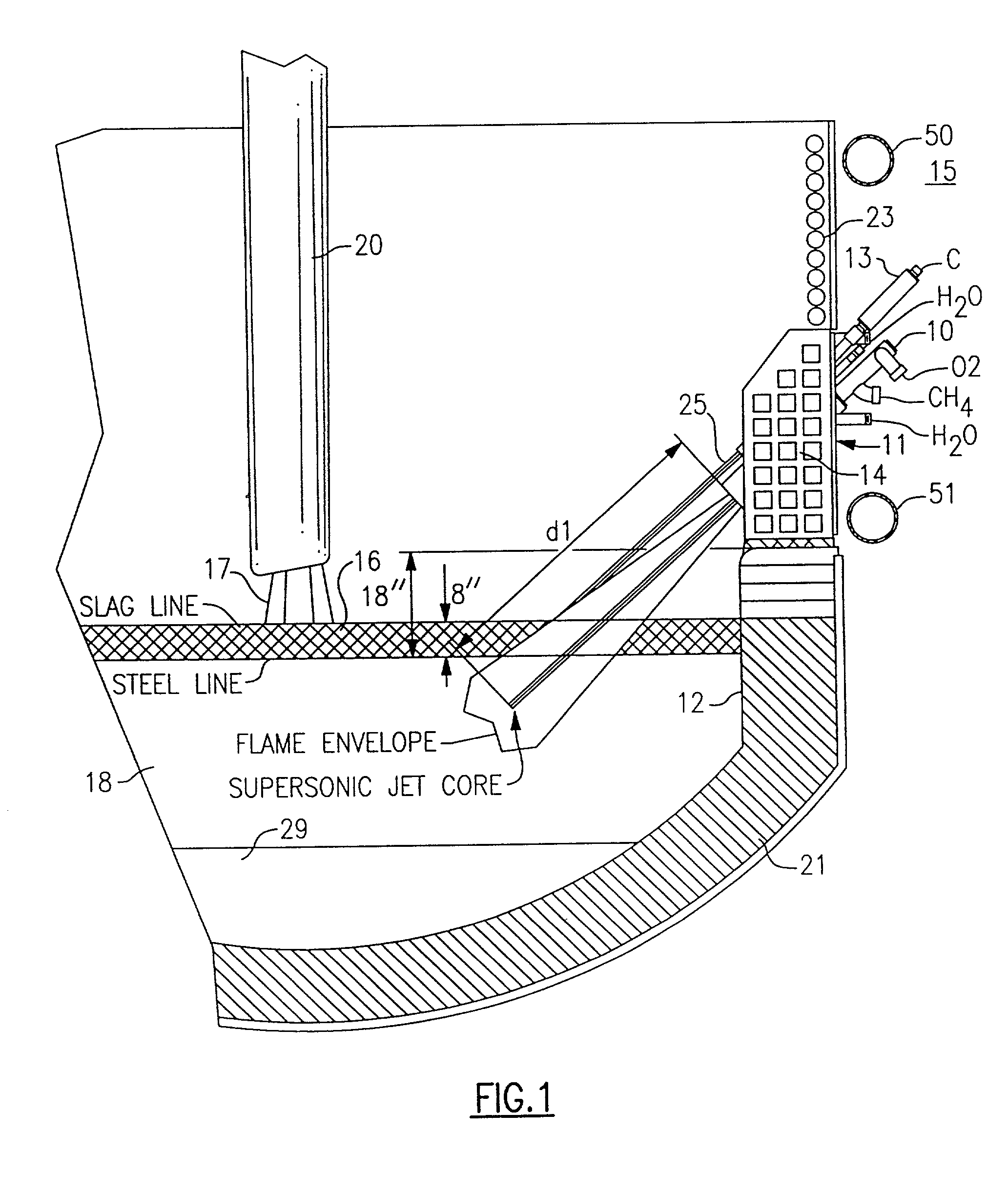

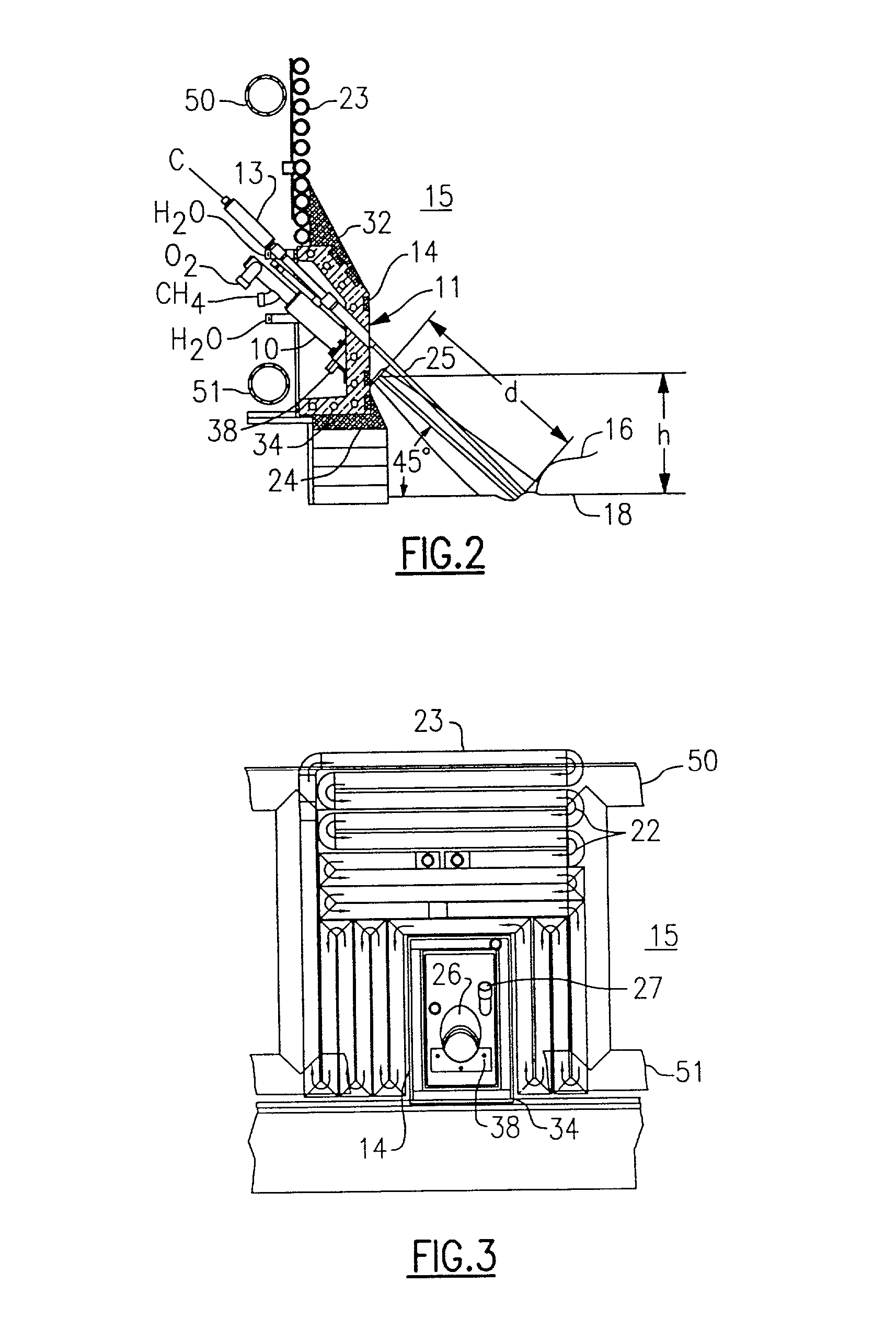

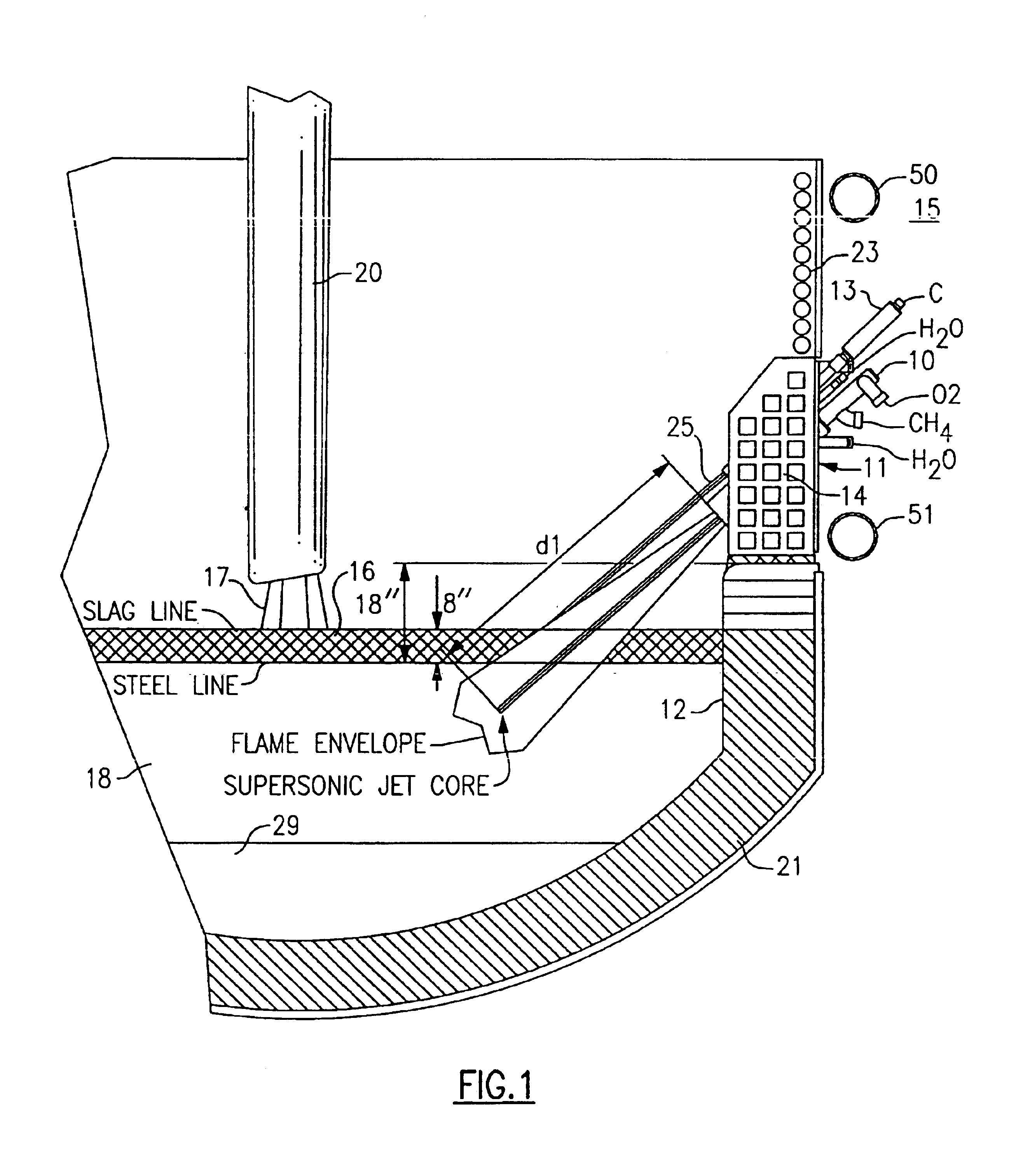

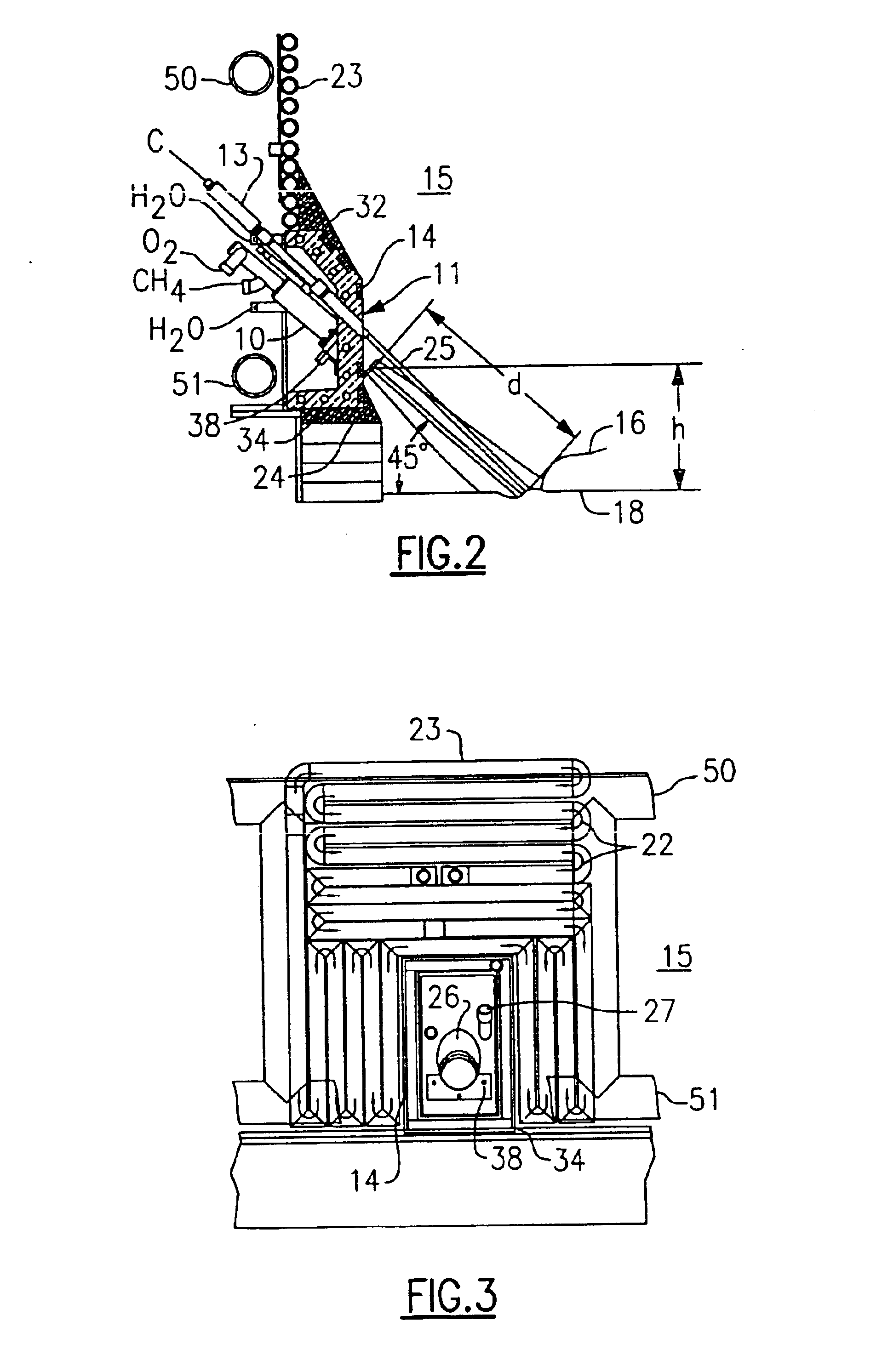

A mounting enclosure and an improved mounting arrangement for apparatus used in metal melting, refining and processing, particularly those apparatus adapted for steel making in an electric arc furnace, such as burners, lances and the like with supersonic oxygen lancing capability and injectors or the like for the introduction of particulate matter. The mounting enclosure is fluid cooled to survive the hostile environment of the electric arc furnace and is designed to occupy the step between the side wall and hearth of the furnace without any substantial change to the structure of the furnace. The mounting enclosure comprises a plurality of fluid cooling conduits surrounding an apparatus aperture and an injector aperture which are formed through the enclosure and adapted to mount an apparatus and an injector. The mounting arrangement includes utilizing the mounting enclosure to mount an apparatus with supersonic oxidizing gas lancing capability and an injector for particulate carbon in an electric arc furnace. Because the mounting enclosure is approximately the width of the step, the discharge openings of the apparatus and the injector are moved closer to the surface of the melt and toward the center of the furnace thereby providing increased efficiency. The discharge openings will now be extended to near the edge of the step so that the oxidizing gas flow pattern of the apparatus does not degrade the hearth material or other furnace equipment mounted nearby and the carbon flow pattern of the injector sufficiently agitates the slag to produce foaming.

Owner:PROCESS TECH INT

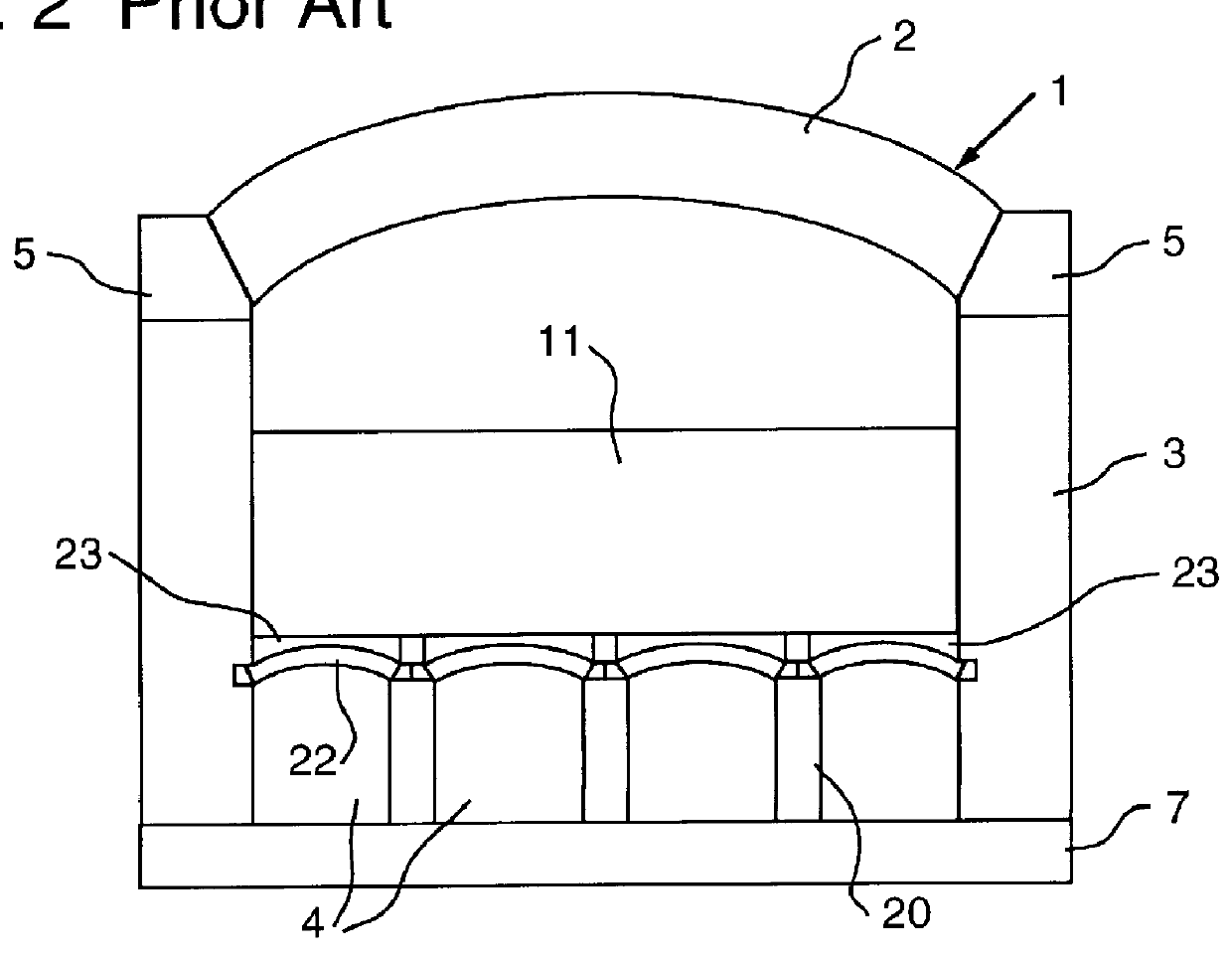

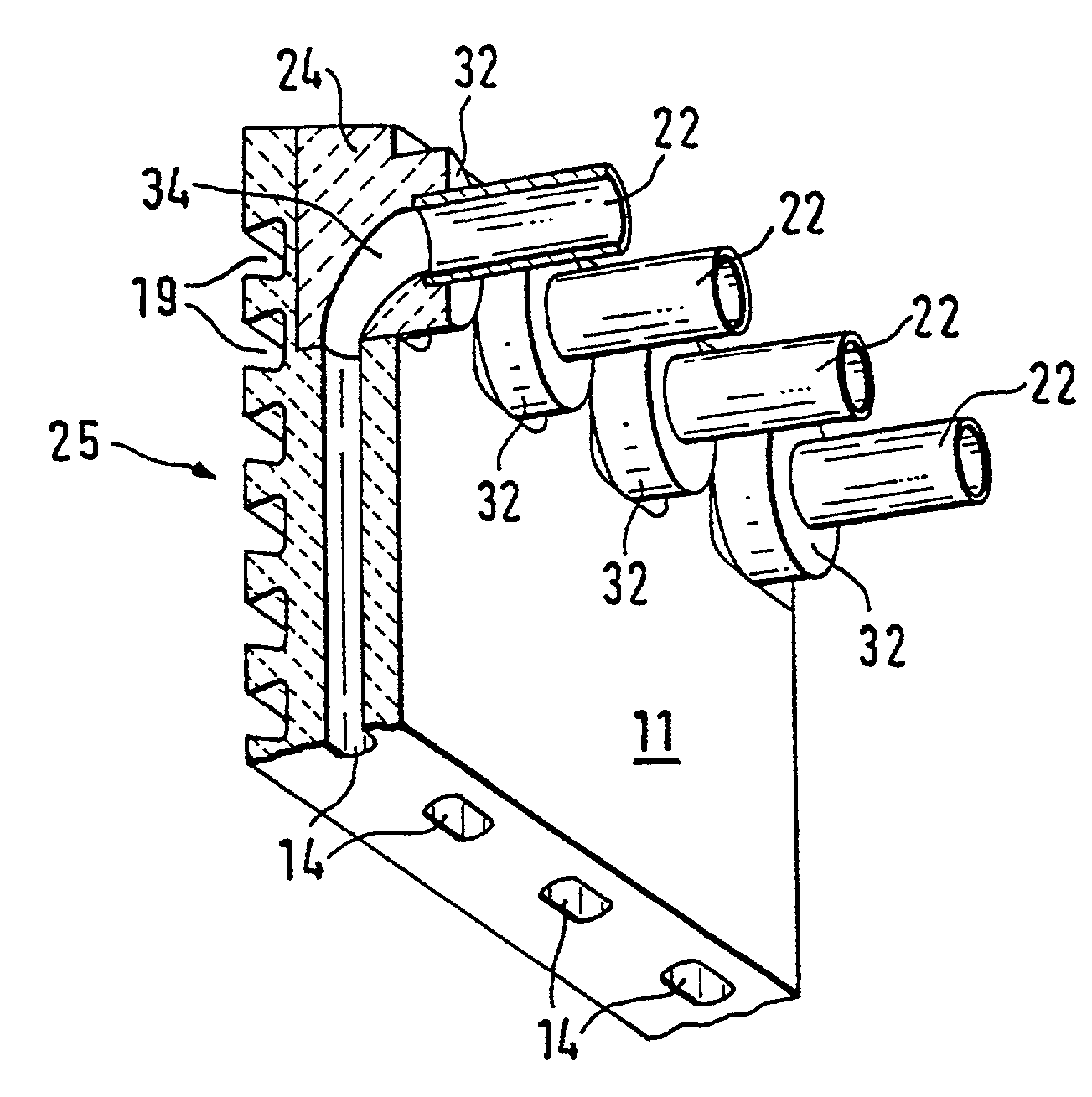

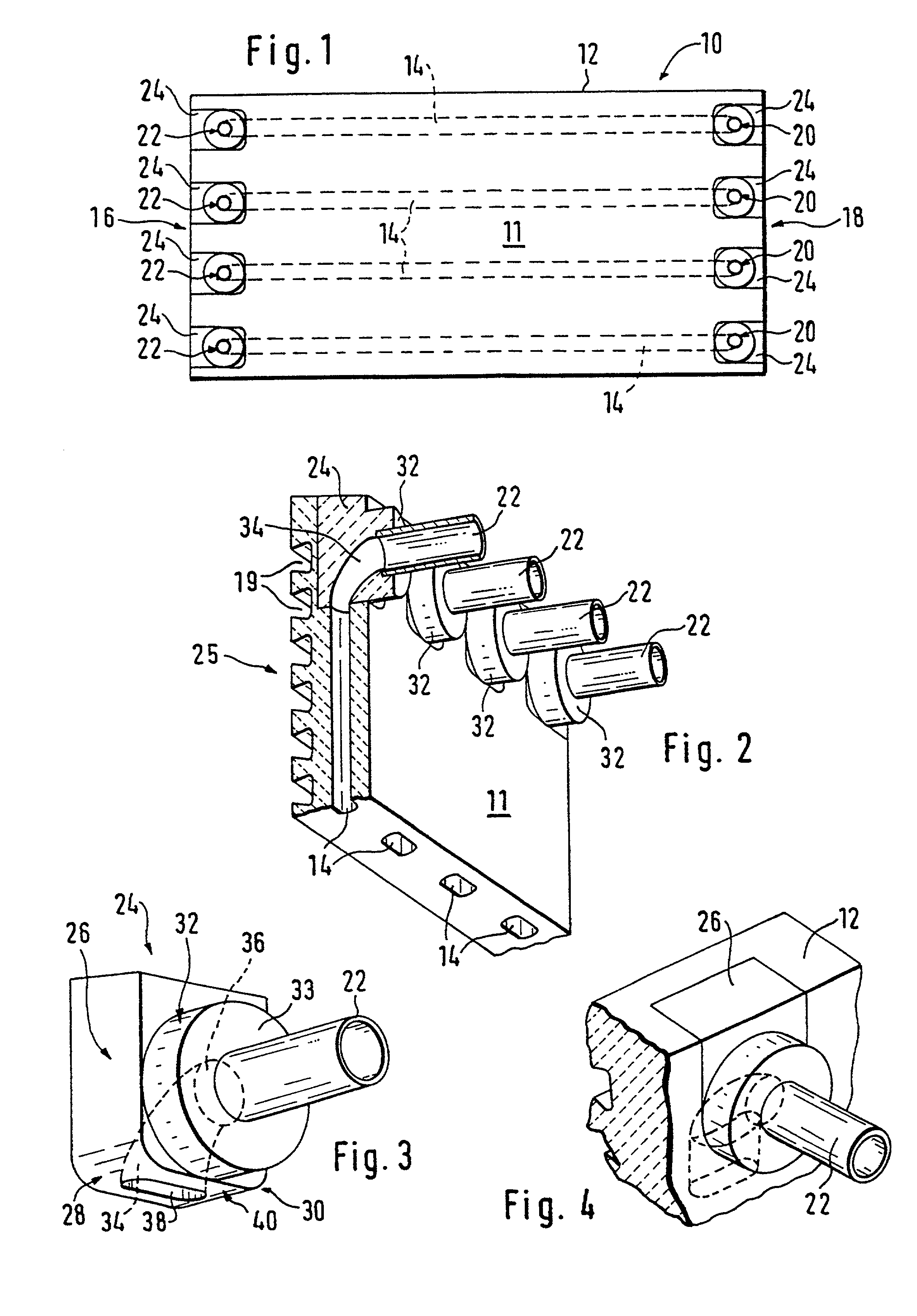

Mounting arrangement for auxiliary burner or lance

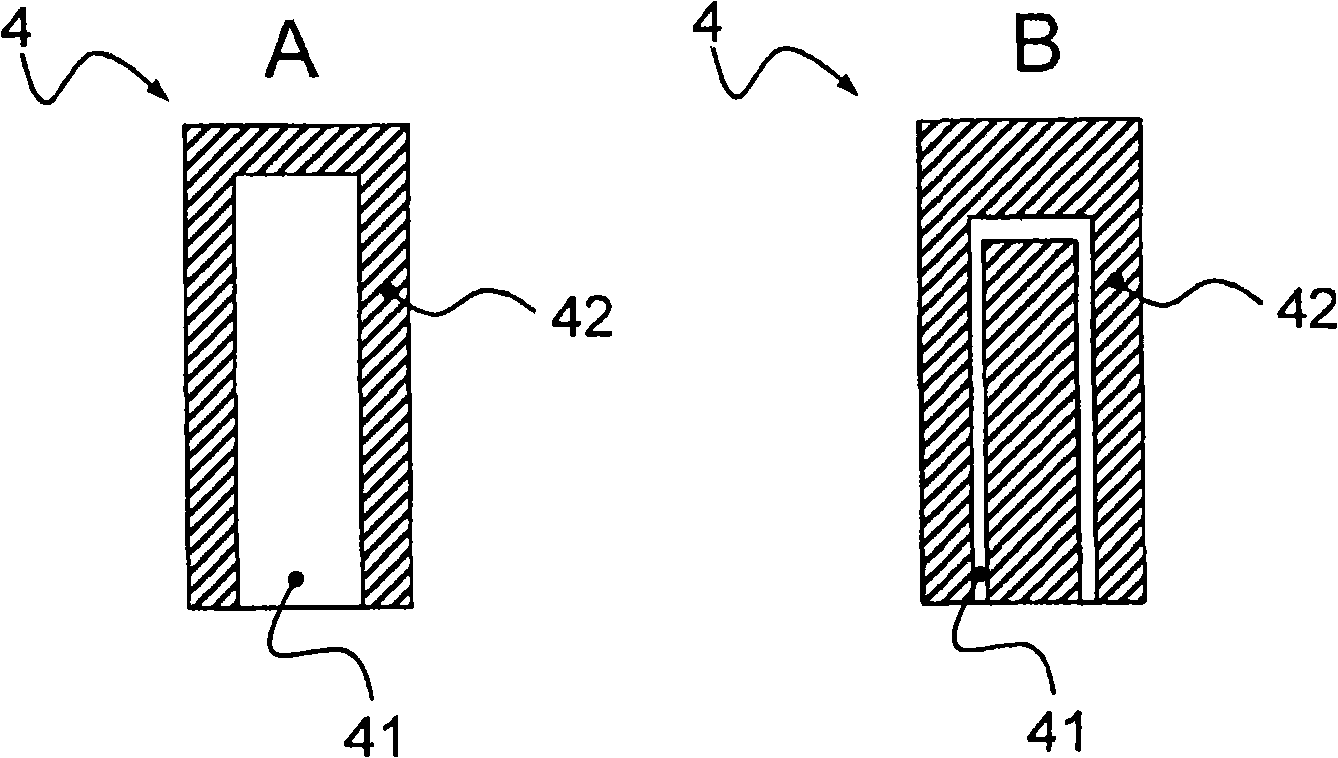

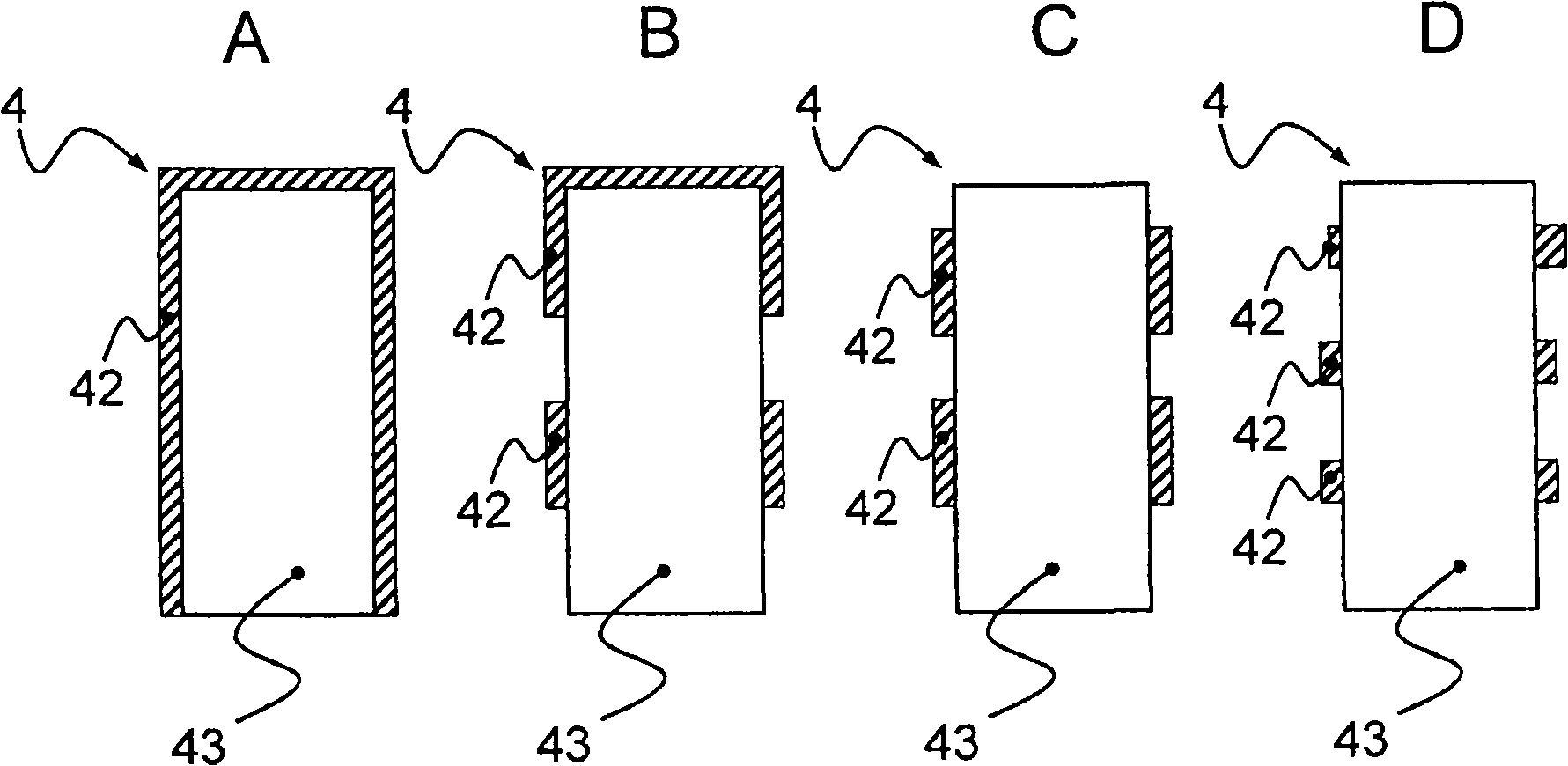

InactiveUS6289035B1Easy to produceImprove thermal conductivityElectric discharge heatingStirring devicesElectric arc furnaceCombustor

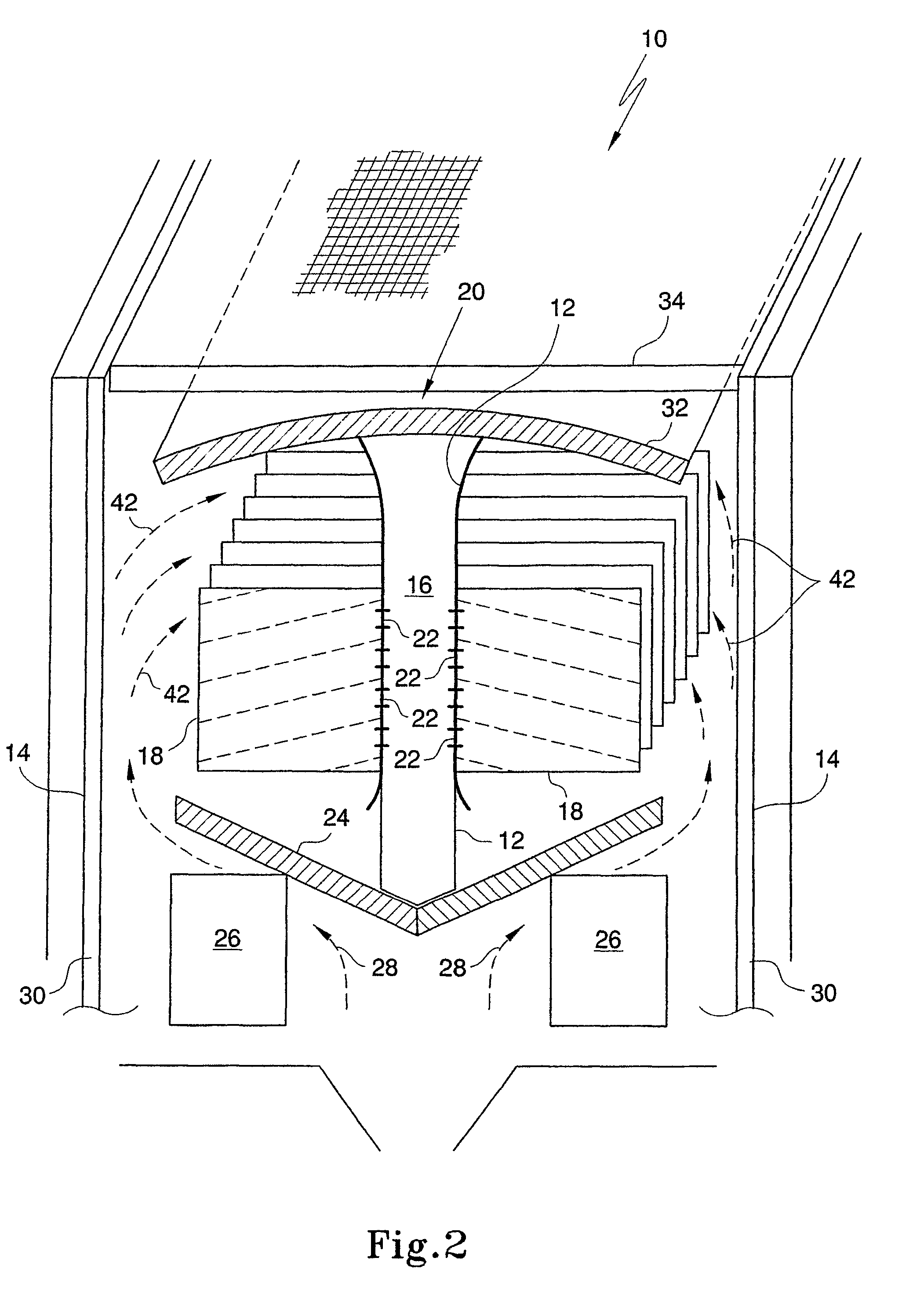

A mounting block and an improved mounting arrangement for apparatus used in metal melting, refining and processing, particularly those apparatus adapted to steel making in an electric arc furnace, such as burners, lances and the like with supersonic oxygen lancing capability. The mounting block is fluid cooled to survive the hostile environment of the electric arc furnace and is designed to rest on the step between the side wall and hearth of the furnace without any substantial change to the structure of the furnace. The mounting block comprises a plurality of fluid cooling conduits surrounding an aperture which is formed through the block and adapted to mount the apparatus. The mounting arrangement includes utilizing the mounting block to mount an apparatus with supersonic oxidizing gas or lancing capability in an electric arc furnace. The apparatus is mounted by passing it through an aperture in a water cooled side panel aligned with the mounting aperture in the mounting block. Because the mounting block is approximately the width of the step, the discharge opening of the apparatus is moved closer to the surface of the melt and toward the center of the furnace thereby providing increased efficiency. The discharge opening will now also extend past the inner edge of the step so that the oxidizing gas flow pattern does not degrade the hearth material and other furnace equipment mounted nearby.

Owner:PROCESS TECH INT

Molten metal containment structure having flow through ventilation

Exemplary embodiments of the invention provide a molten metal containment structure including a refractory molten metal containment vessel having an external surface, and a metal casing for the vessel having an internal surface at least partially surrounding the external surface of the vessel at a distance therefrom forming a spacing between the vessel and the casing. The spacing includes an unobstructed upwardly extending gap that is vented to the exterior of the structure by upper and lower openings in the casing. A layer of insulating material is preferably positioned in the spacing between the internal surface of the casing and the external surface of the vessel, with the layer of insulating material being narrower than the spacing at least at upwardly extending sides of the casing, thereby forming the unobstructed gap. The vessel may be a metal conveying trough, a housing for a metal filter, a container for a metal degasser unit, a crucible, or the like.

Owner:NOVELIS INC

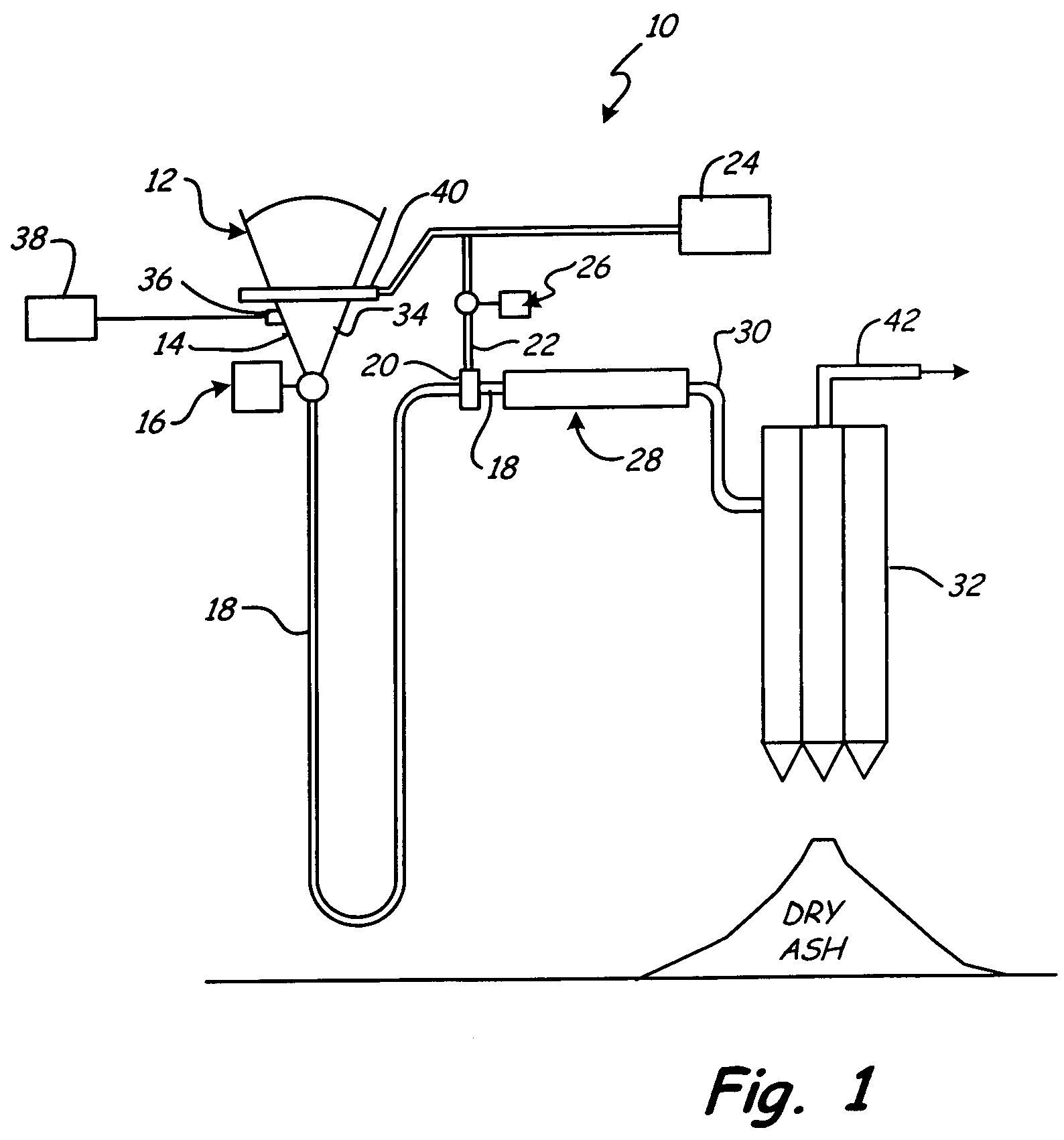

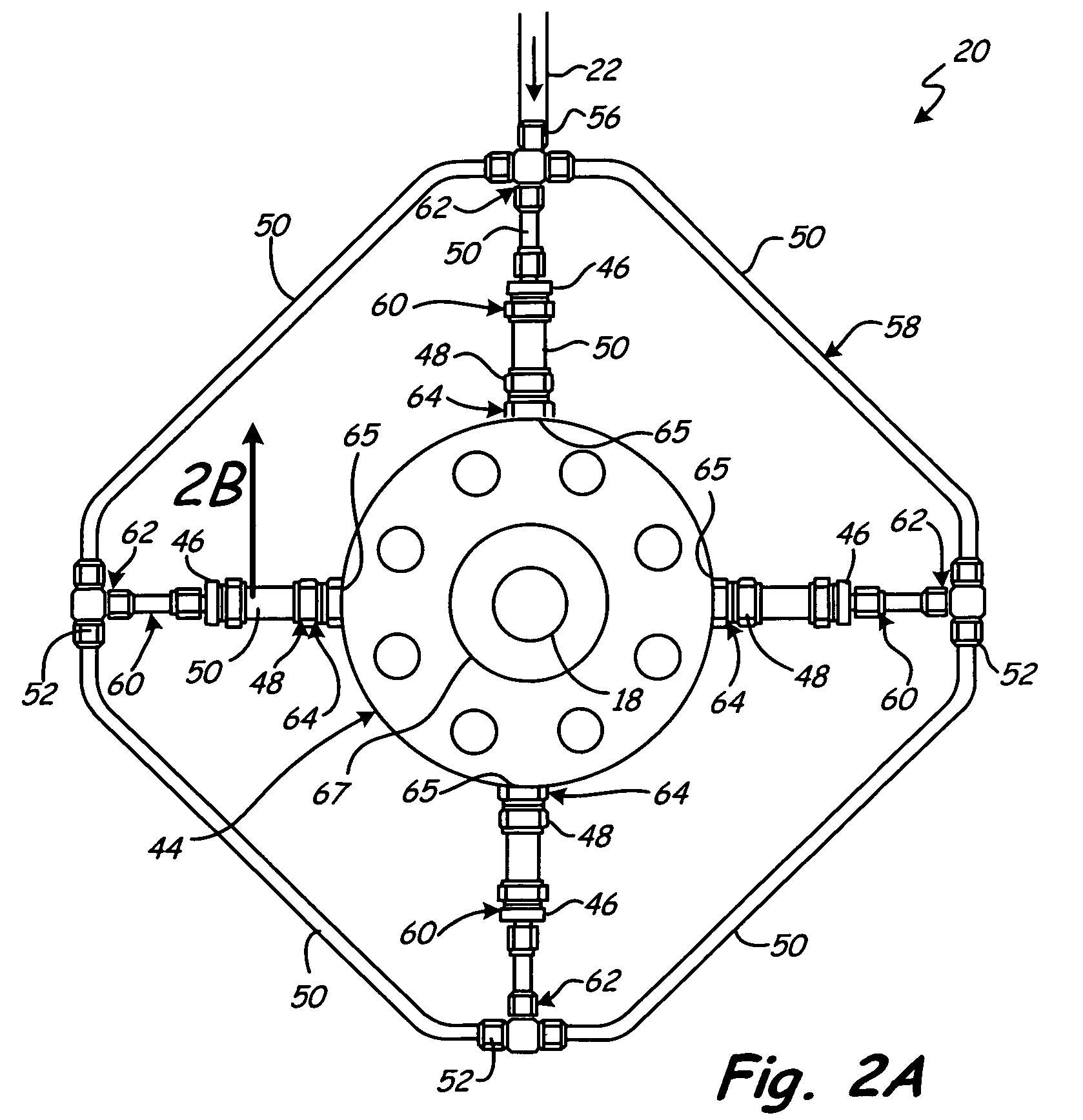

Continuous pressure letdown system

A continuous pressure letdown system connected to a hopper decreases a pressure of a 2-phase (gas and solid) dusty gas stream flowing through the system. The system includes a discharge line for receiving the dusty gas from the hopper, a valve, a cascade nozzle assembly positioned downstream of the discharge line, a purge ring, an inert gas supply connected to the purge ring, an inert gas throttle, and a filter. The valve connects the hopper to the discharge line and controls introduction of the dusty gas stream into the discharge line. The purge ring is connected between the discharge line and the cascade nozzle assembly. The inert gas throttle controls a flow rate of an inert gas into the cascade nozzle assembly. The filter is connected downstream of the cascade nozzle assembly.

Owner:GAS TECH INST

Heat exchanger

ActiveUS7901617B2Lower overall pressure dropImprove heat transfer performanceBlast furnace detailsManufacturing convertersEngineeringCooling fluid

A heat exchanger 10 includes a conduit 12 for conveying cooling fluid relative to a body to be cooled. A heat transfer arrangement 62 is arranged in communication with an interior of the conduit 12, the heat transfer arrangement 62 and the conduit 12 together defining an assembly that is mountable adjacent the body to be cooled, convective heat exchange occurring, in use, due to movement of the cooling fluid relative to the body and the heat transfer arrangement 62 of the assembly and radiant heat exchange occurring between the body and at least part of the heat transfer arrangement 62 of the assembly.

Owner:ENPOT HLDG LTD

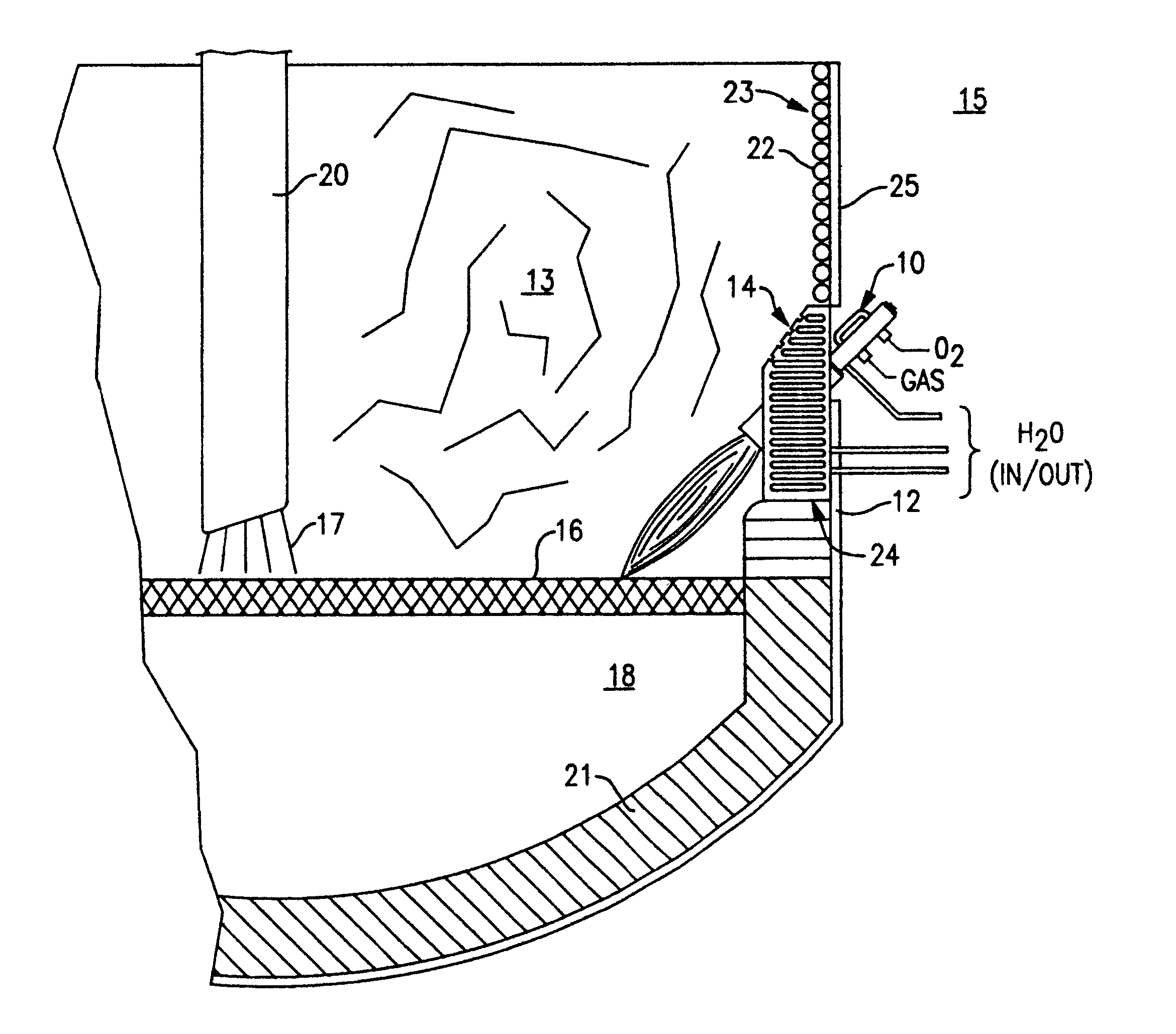

Method for melting and decarburization of iron carbon melts

InactiveUS6749661B2Shorten the construction periodHigh energyElectric discharge heatingStirring devicesElectric arc furnaceSlag

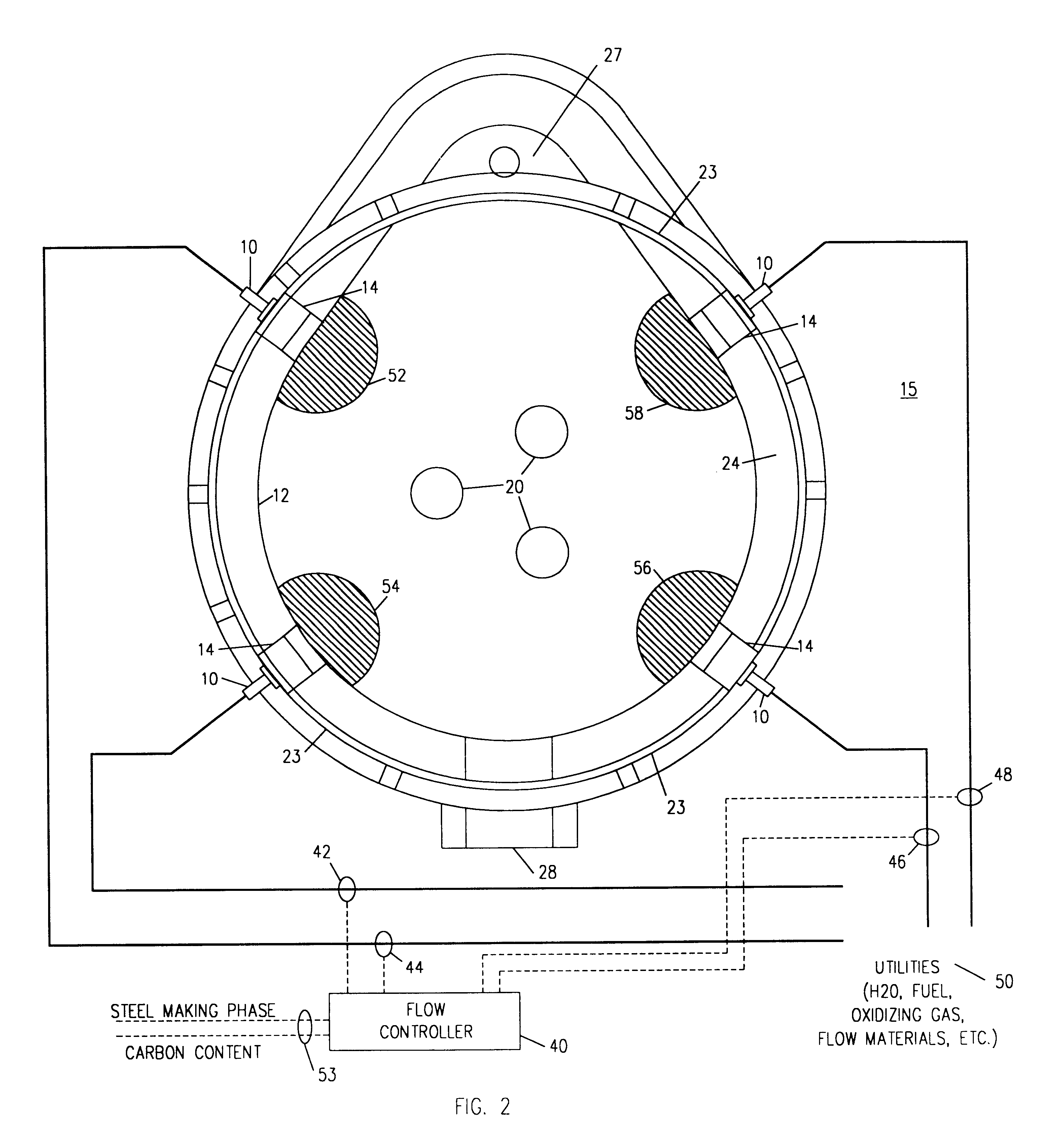

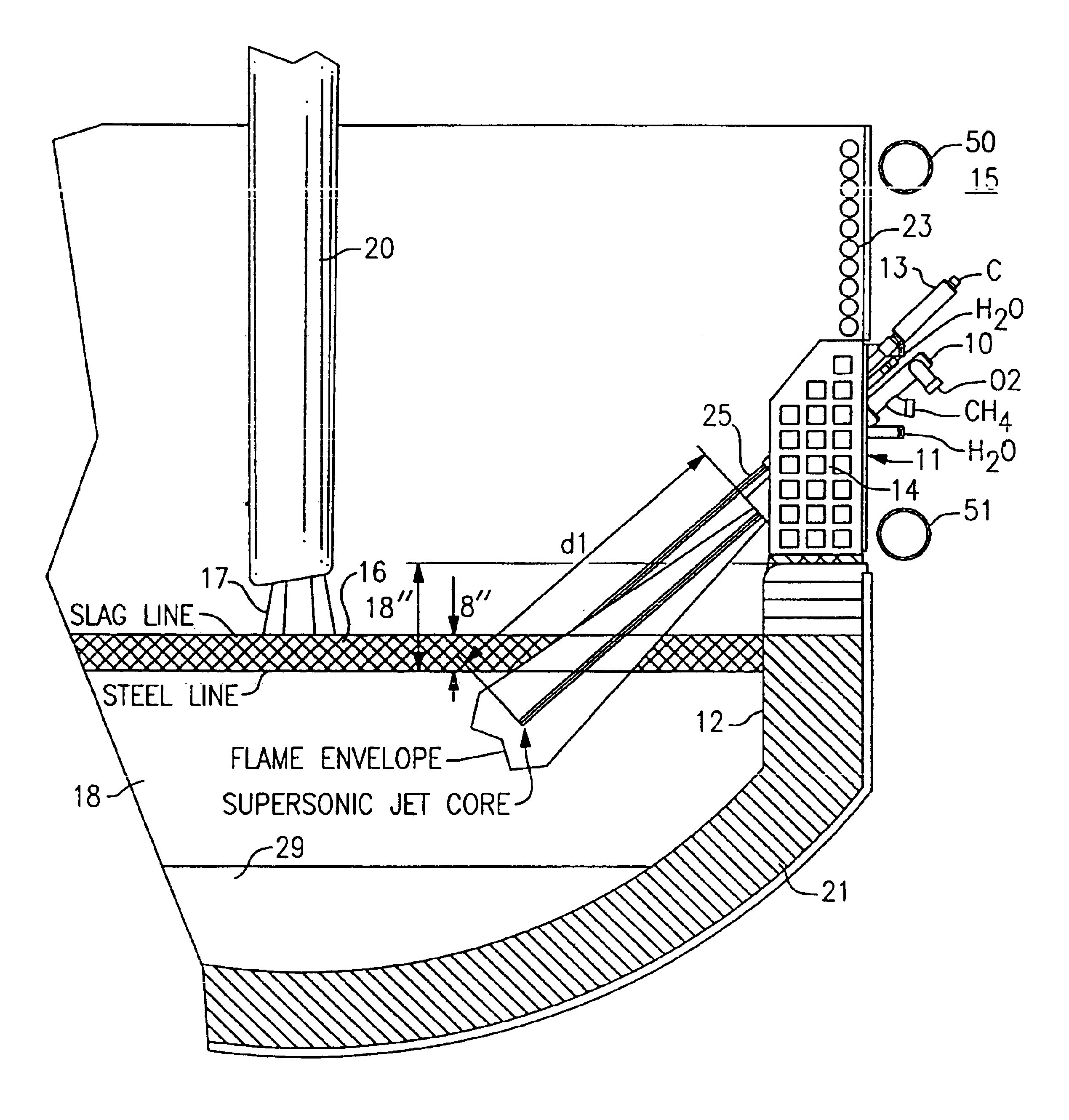

A method and an apparatus for advantageously introducing a flame and a high velocity oxidizing gas into a furnace for metal melting, refining and processing, particularly steel making in an electric arc furnace. The steel making process of an electric arc furnace is made more efficient by shortening the time of the scrap melting phase and introducing an effective high velocity oxidizing gas stream into the process sooner to decarburize the melted metal. In one implementation of an apparatus, improved efficiency is obtained by mounting a fixed burner / lance closer to the hot face of the furnace refractory at an effective injection angle. This mounting technique shortens the distance that the flame of the burner has to melt through the scrap to clear a path to the molten metal and shortens the distance the high velocity oxygen from the lance travels to the slag-metal interface thereby increasing its penetrating power. The method additionally includes supplying a plurality of reaction zones with the high velocity oxidizing gas to decarburize the melted metal. The plurality of reaction zones increases the surface area available for the reaction thereby allowing a more rapid rate of decarburization and a more homogenous metal bath. The reaction zones are supplied with the high velocity oxidizing gas according to an oxygen supply profile which is related to the carbon content of the metal bath. In this manner an optimal amount of oxygen can be introduced into the metal bath to shorten the decarburization process without producing excessive oxidation of the metal bath and excessive free oxygen in the furnace.

Owner:PROCESS TECH INT

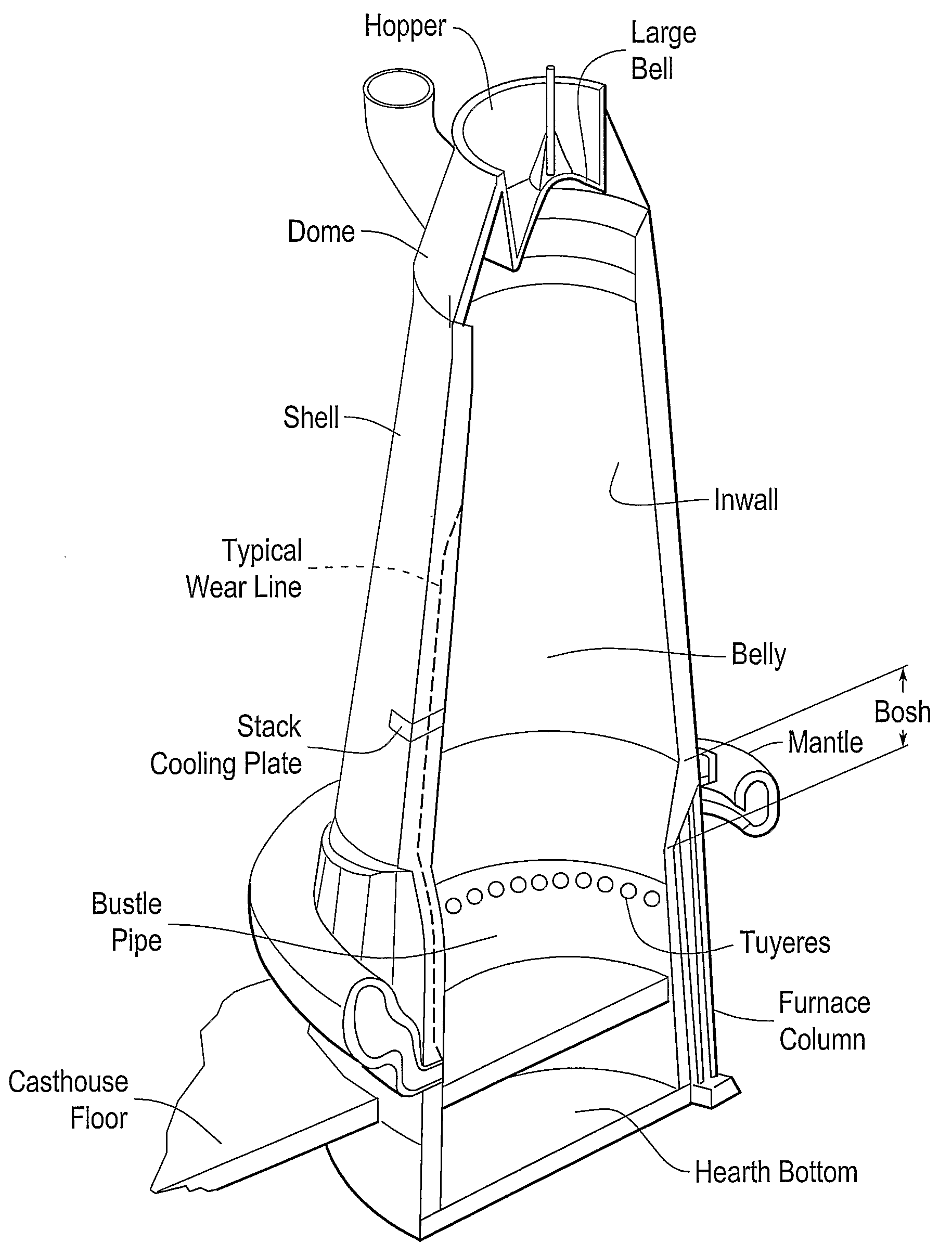

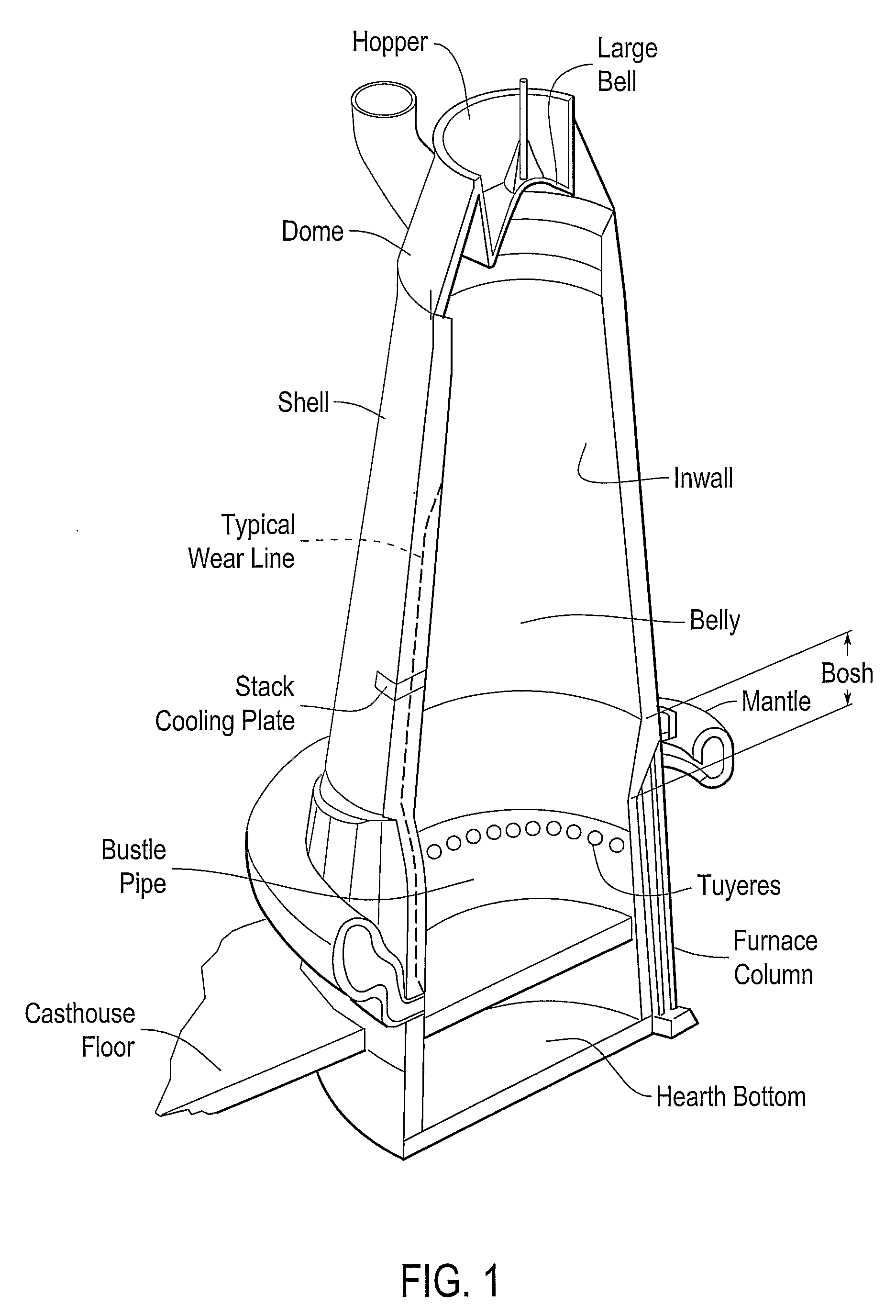

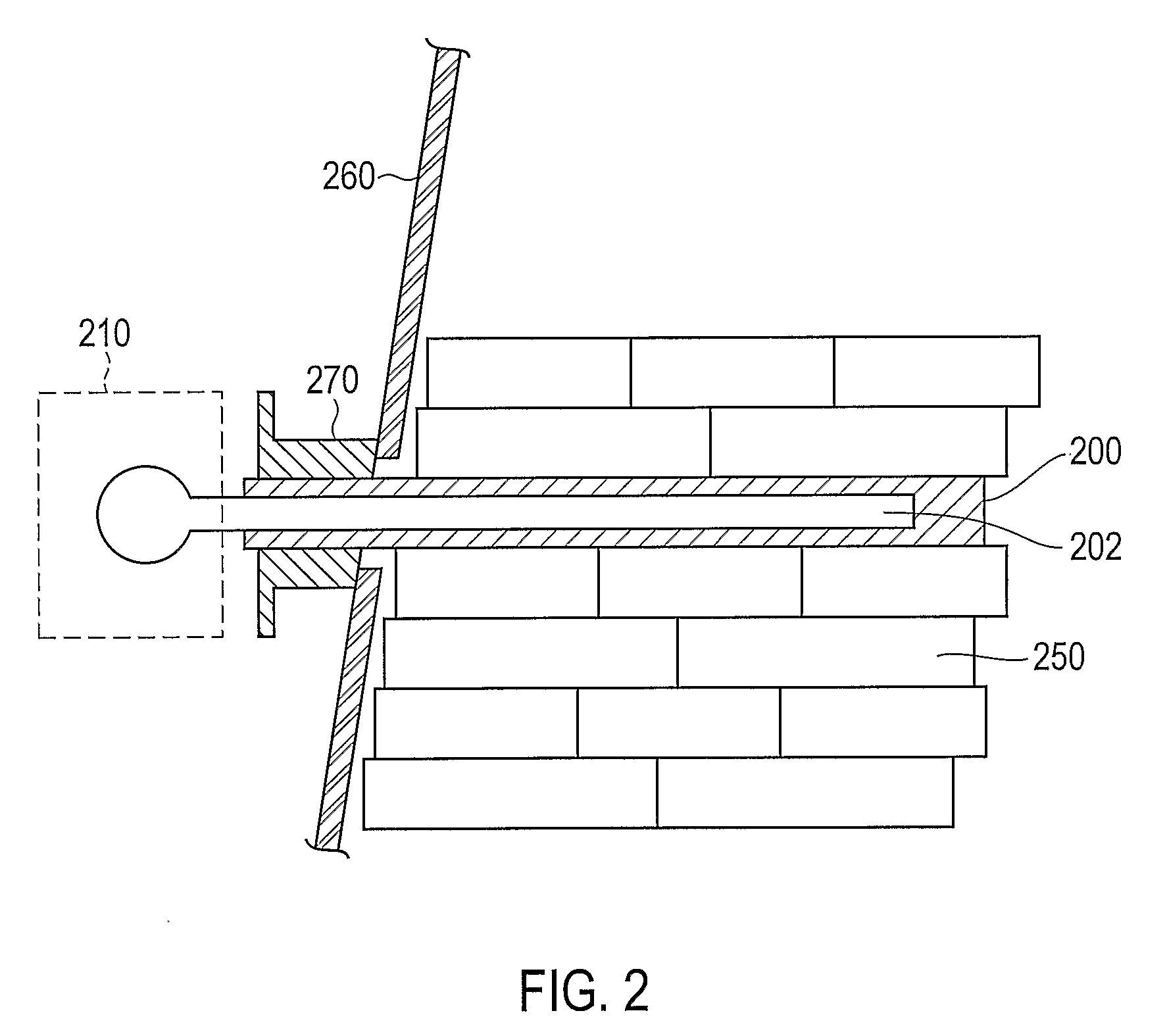

Systems and Methods of Cooling Blast Furnaces

InactiveUS20080111287A1Complicates designIncrease costBlast furnace detailsFurnace cooling arrangementsNuclear engineeringHeat pipe

Systems and methods provide a cooling device for a blast furnace that may prevent an excessive amount of coolant from entering the blat furnace and may be easily installed in a conventional blast furnace. Systems and methods may provide a cooling device for a blast furnace that may prevent an excessive amount of coolant from entering the blast furnace and may be simple and cost effective to manufacture. The end of a heat pipe (202) that is outside of the furnace may be configured to interact with a heat sink (210). The heat sink (210) may be for example, a separate amount of coolant that is circulated outside of the furnace, an evaporative cooling system, and / or any other system or method of cooling the heat pipe (202) that transfers heat from the heat pipe (202) to the heat sink (210). Because the coolant within the heat pipe (202) is sealed within the heat pipe (202), only the small, fixed amount of coolant that. is within the heat pipe (202) will enter the furnace should the cooling plate (200) rupture. Thus, substantial damage to the furnace, extensive repairs, and / or long periods of non-production may be avoided.

Owner:ANDCO METAL IND PROD

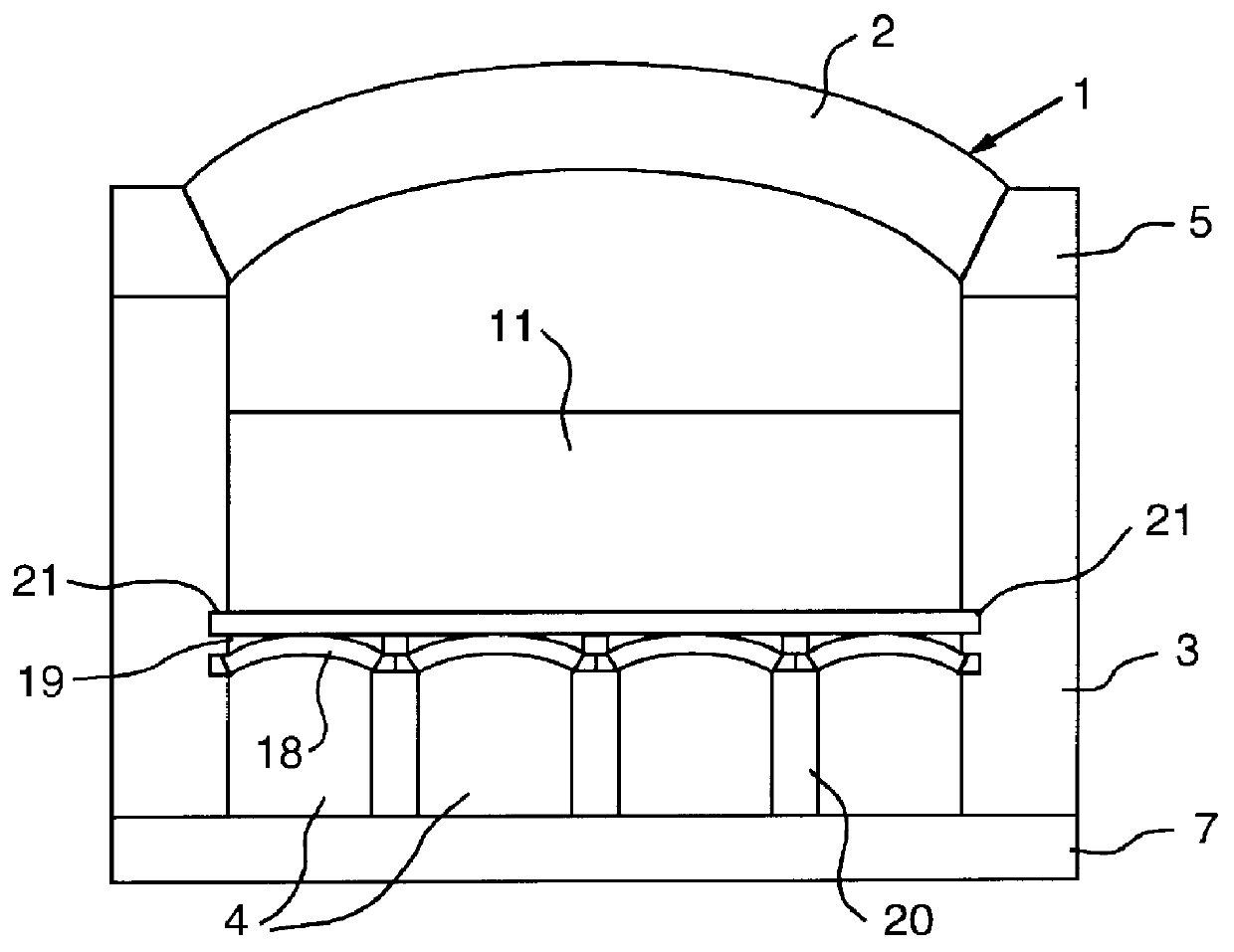

Mounting arrangement for auxiliary burner or lance

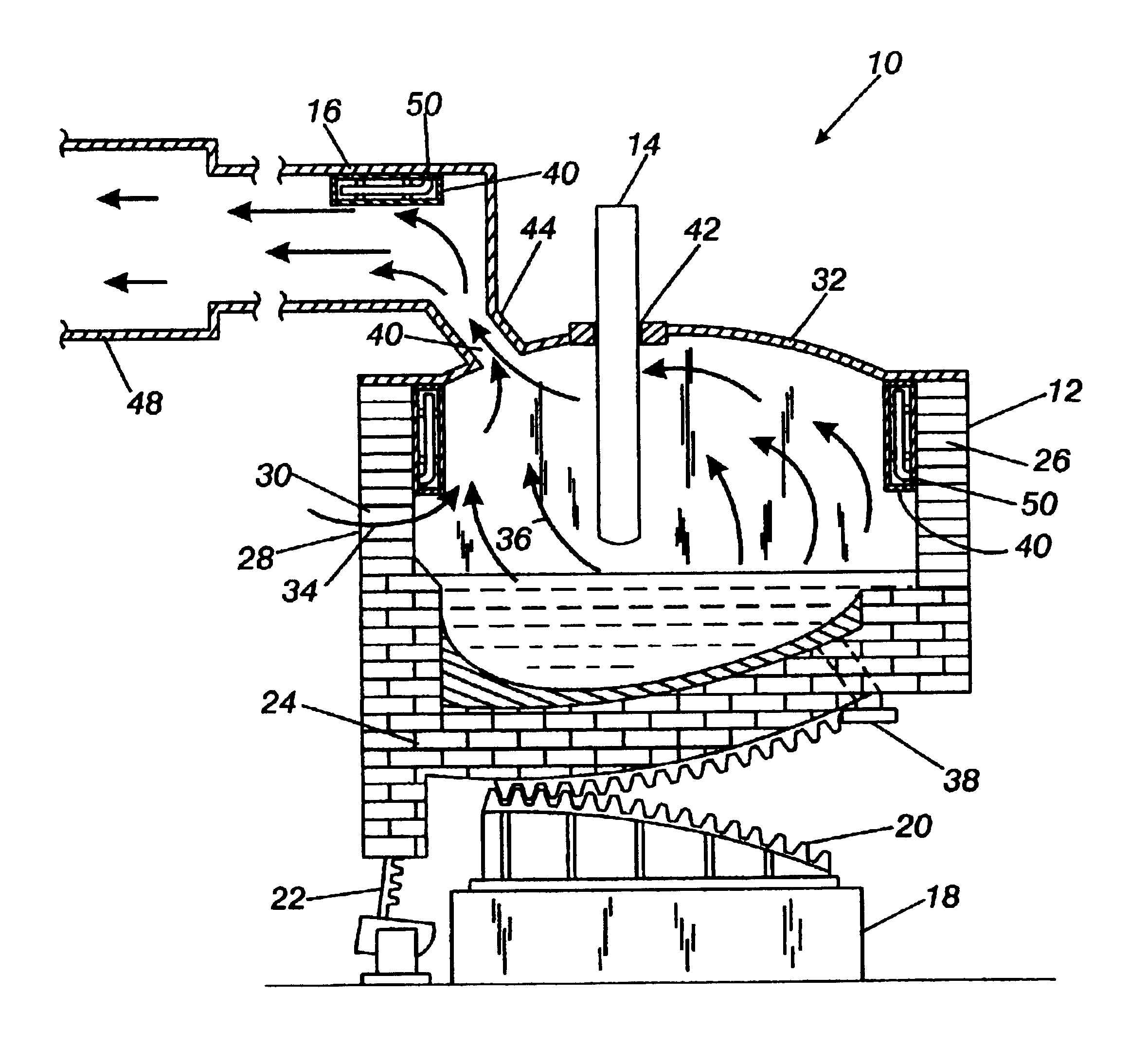

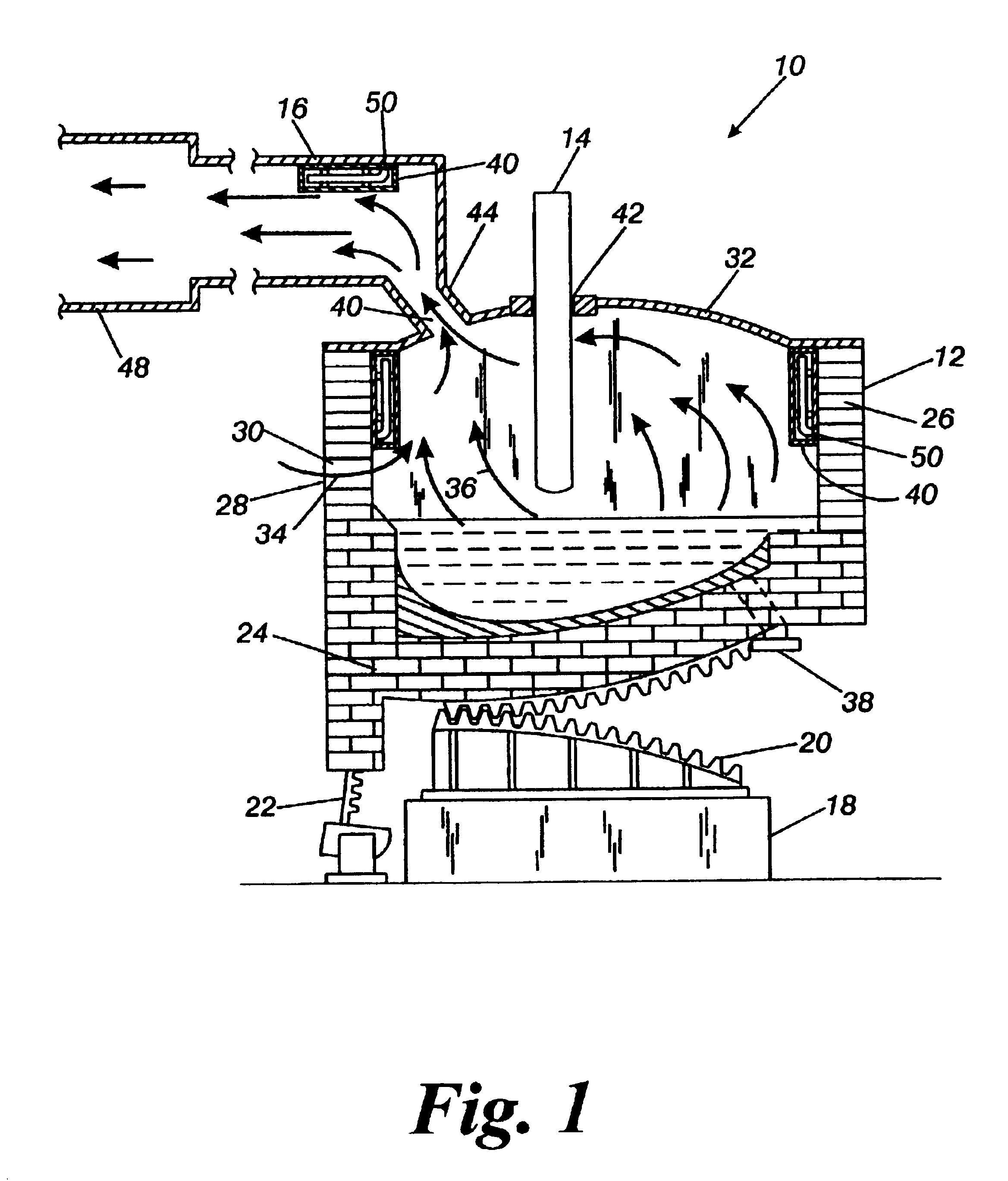

InactiveUS20020001332A1Easy to produceImprove thermal conductivityElectric discharge heatingPeptide/protein ingredientsParticulatesElectric arc furnace

A mounting enclosure and an improved mounting arrangement for apparatus used in metal melting, refining and processing, particularly those apparatus adapted for steel making in an electric arc furnace, such as burners, lances and the like with supersonic oxygen lancing capability and injectors or the like for the introduction of particulate matter. The mounting enclosure is fluid cooled to survive the hostile environment of the electric arc furnace and is designed to occupy the step between the side wall and hearth of the furnace without any substantial change to the structure of the furnace. The mounting enclosure comprises a plurality of fluid cooling conduits surrounding an apparatus aperture and an injector aperture which are formed through the enclosure and adapted to mount an apparatus and an injector. The mounting arrangement includes utilizing the mounting enclosure to mount an apparatus with supersonic oxidizing gas lancing capability and an injector for particulate carbon in an electric arc furnace. Because the mounting enclosure is approximately the width of the step, the discharge openings of the apparatus and the injector are moved closer to the surface of the melt and toward the center of the furnace thereby providing increased efficiency. The discharge openings will now be extended to near the edge of the step so that the oxidizing gas flow pattern of the apparatus does not degrade the hearth material or other furnace equipment mounted nearby and the carbon flow pattern of the injector sufficiently agitates the slag to produce foaming.

Owner:PROCESS TECH INT

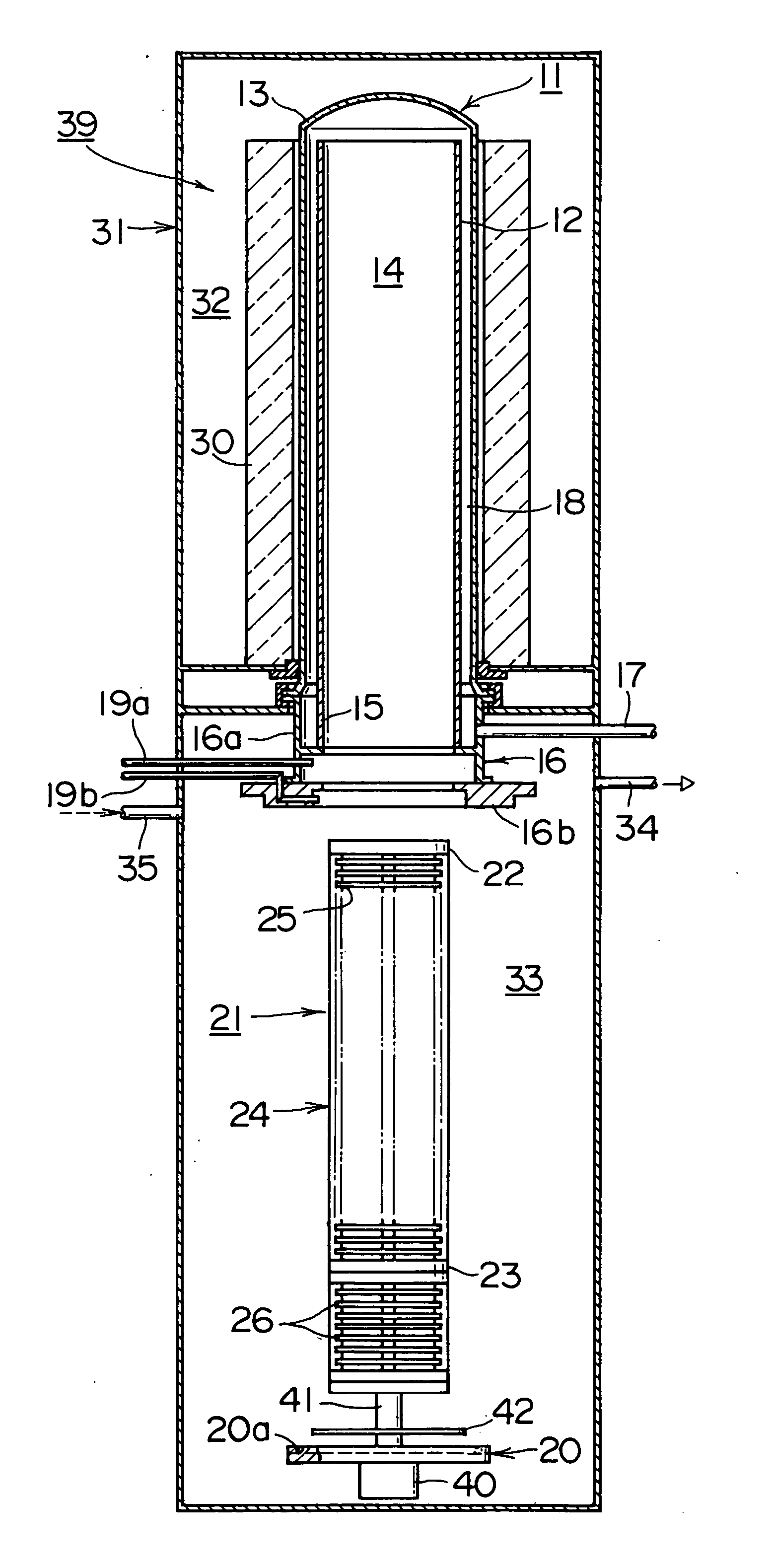

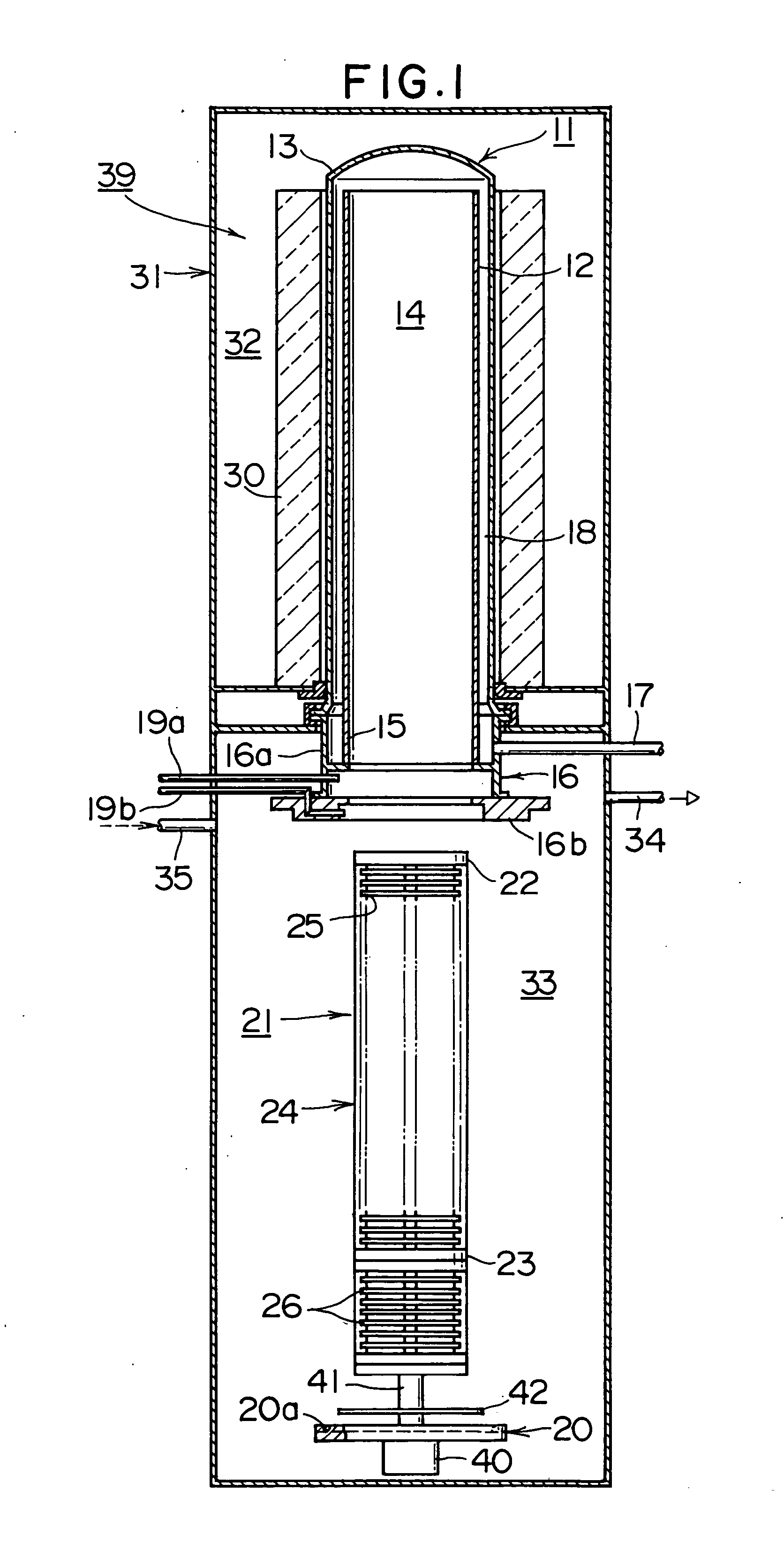

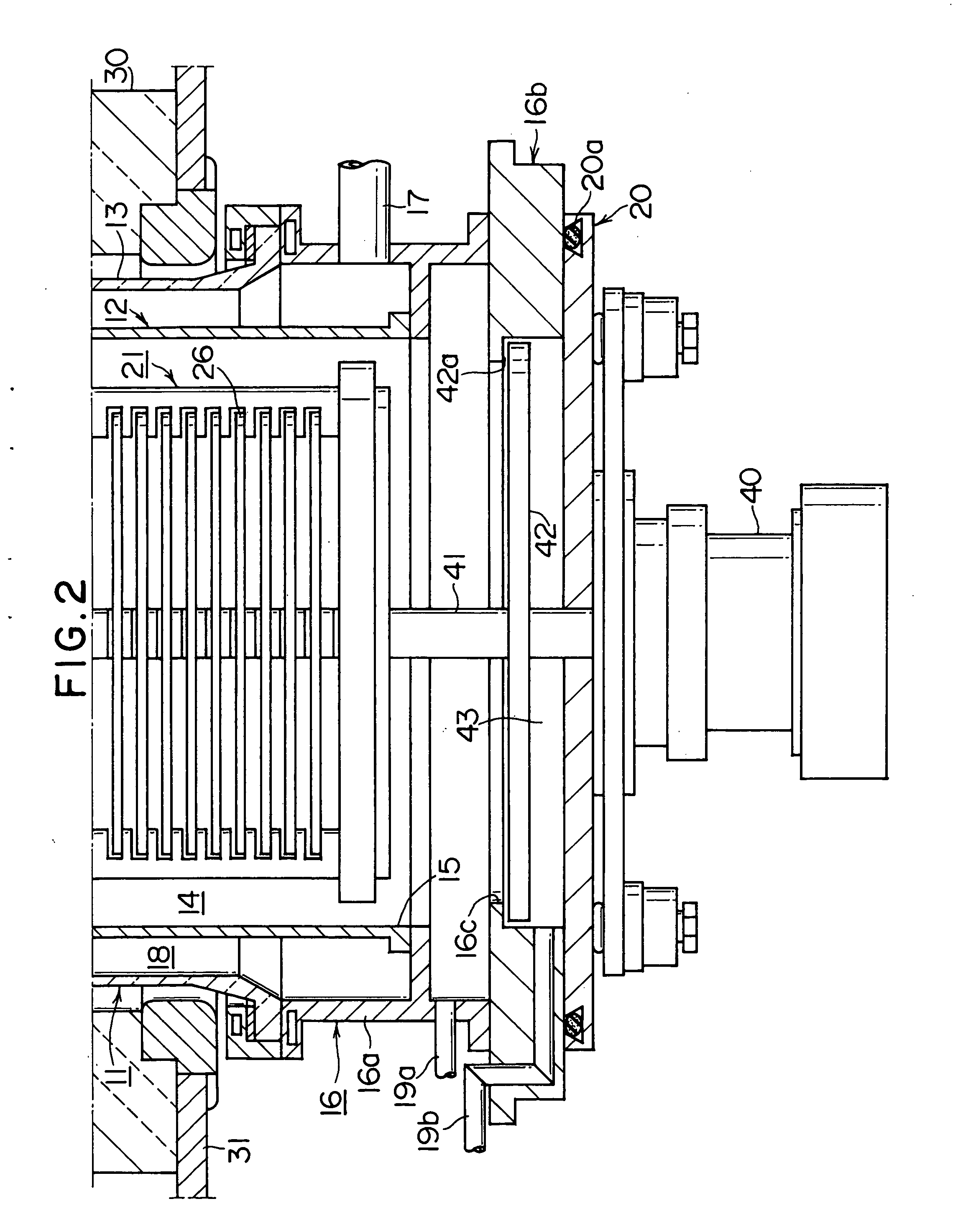

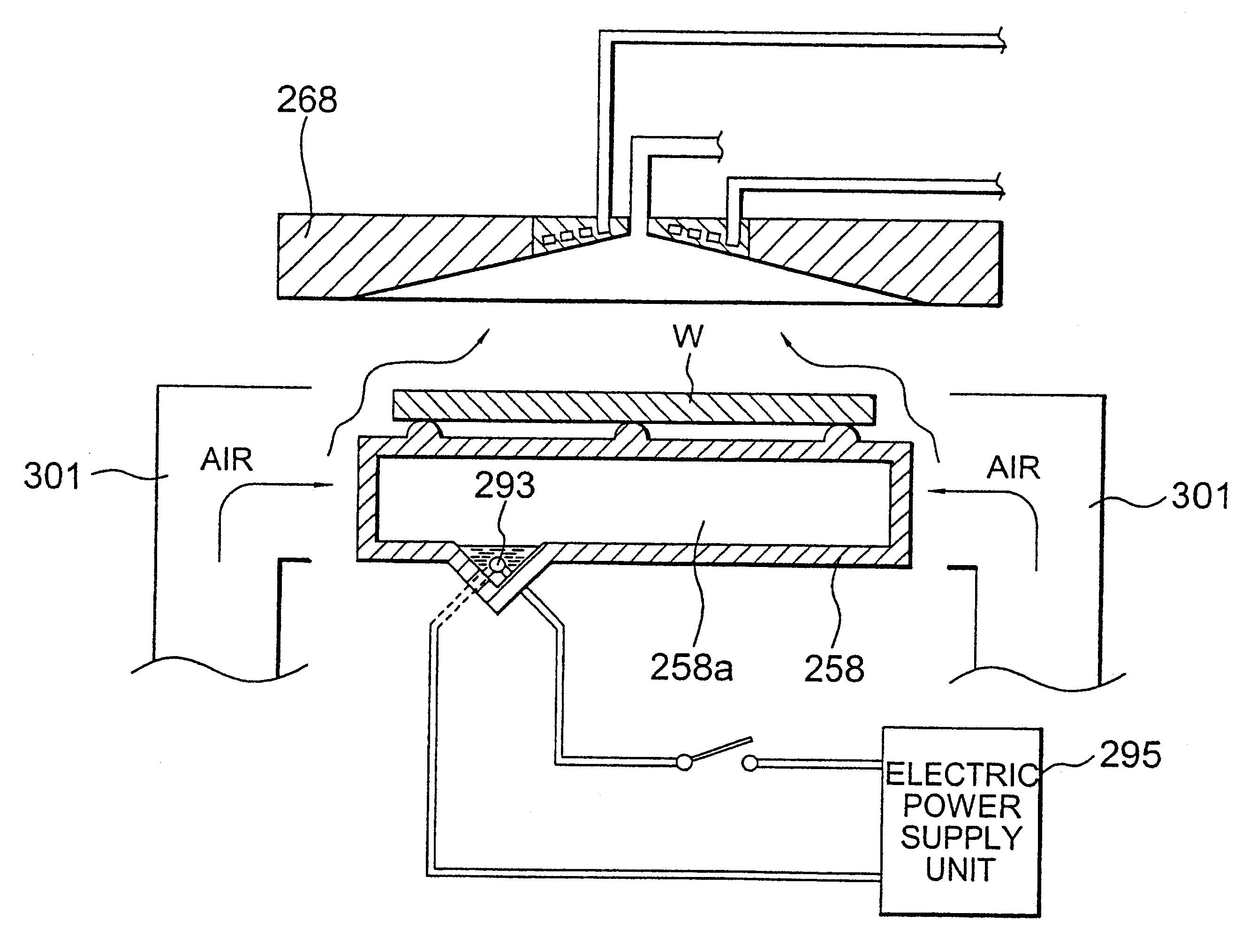

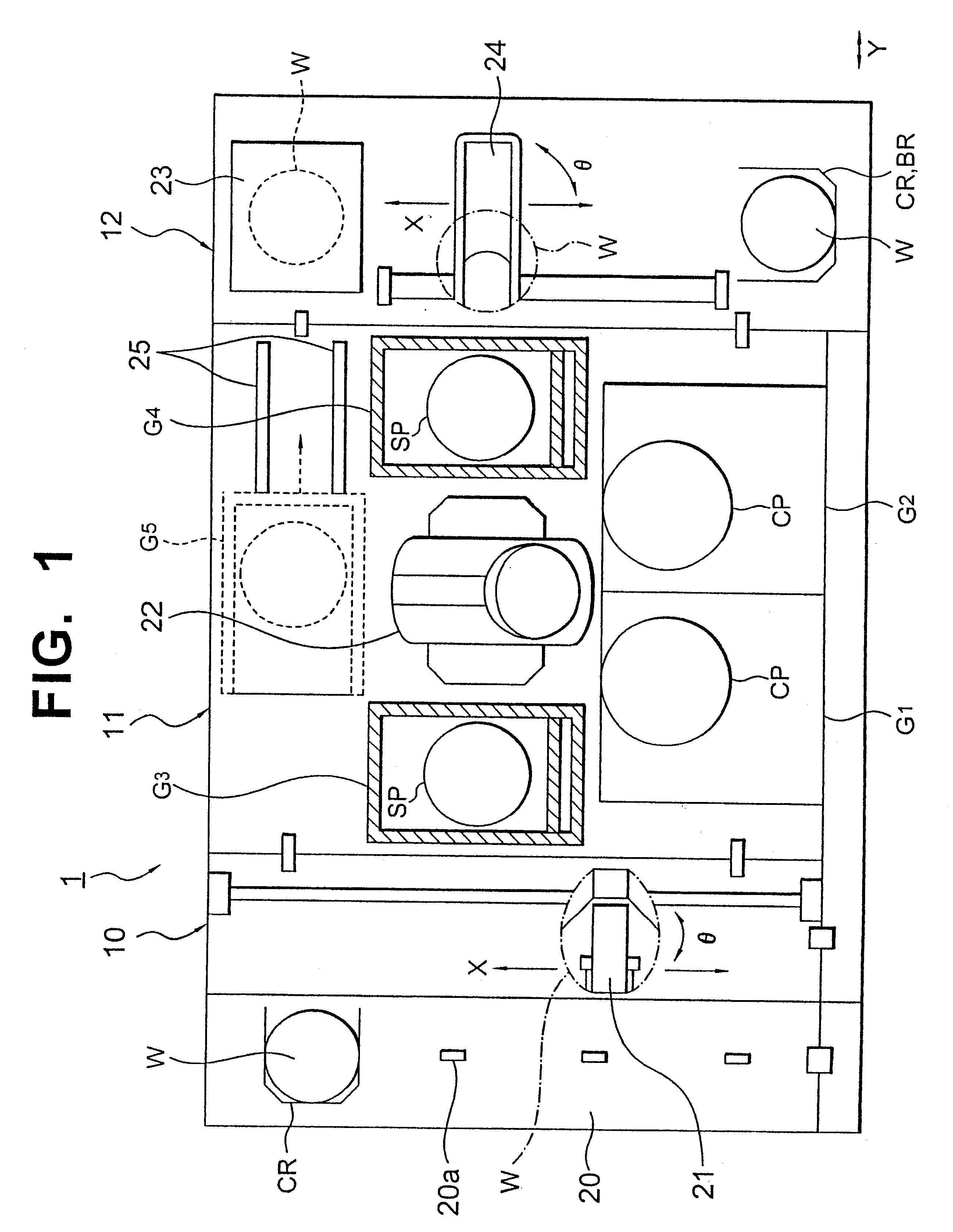

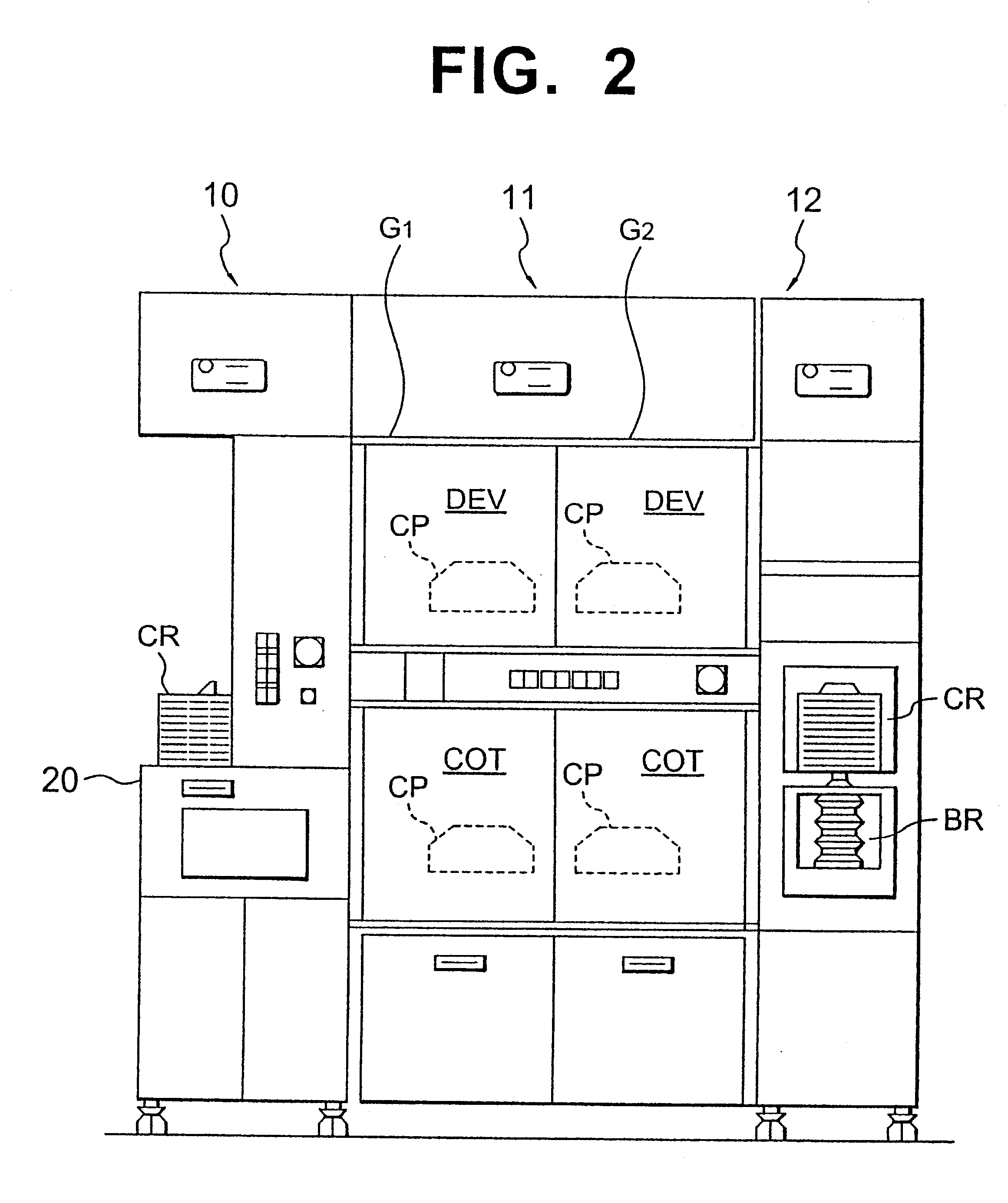

Substrate-processing apparatus and method of producing a semiconductor device

ActiveUS20060150904A1Avoid it happening againSemiconductor/solid-state device manufacturingCharge manipulationDevice materialEngineering

A CVD device has a reaction furnace (39) for processing a wafer (1); a seal cap (20) for sealing the reaction furnace (39) hermetically; an isolation flange (42) opposite to the seal cap (20); a small chamber (43) formed by the seal cap (20), the isolation flange (42), and the wall surface in the reaction furnace (39); a feed pipe (19b) for supplying a first gas to the small chamber (43); an outflow passage (42a) provided in the small chamber (43) for allowing the first gas to flow into the reaction furnace (39); and a feed pipe (19a) provided downstream from the outflow passage (42a) for supplying a second gas into the reaction furnace (39). Byproducts such as NH4Cl are prevented from adhering to low temperature sections such as the furnace opening and therefore the semiconductor device production yield is therefore increased.

Owner:KOKUSA ELECTRIC CO LTD

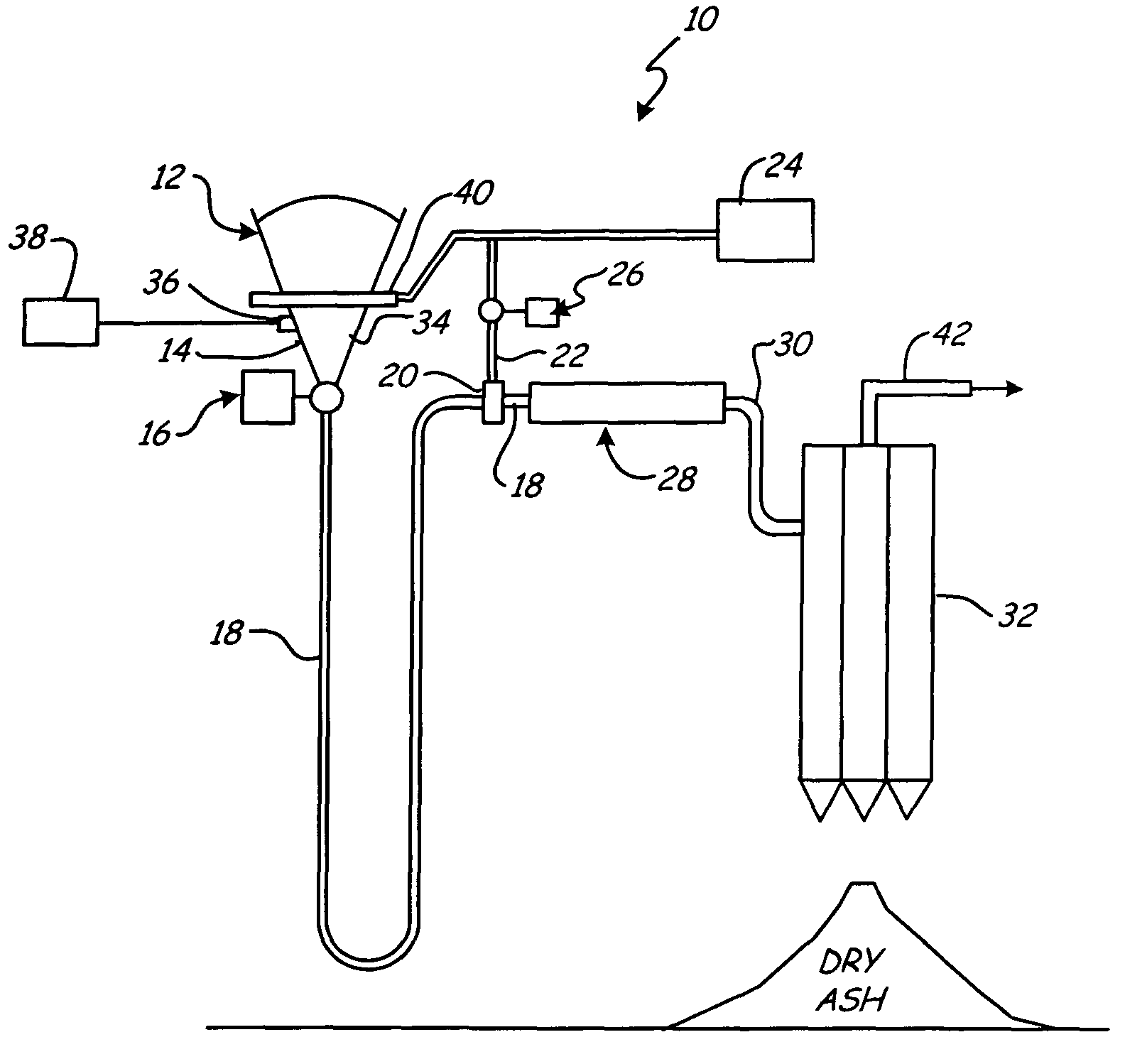

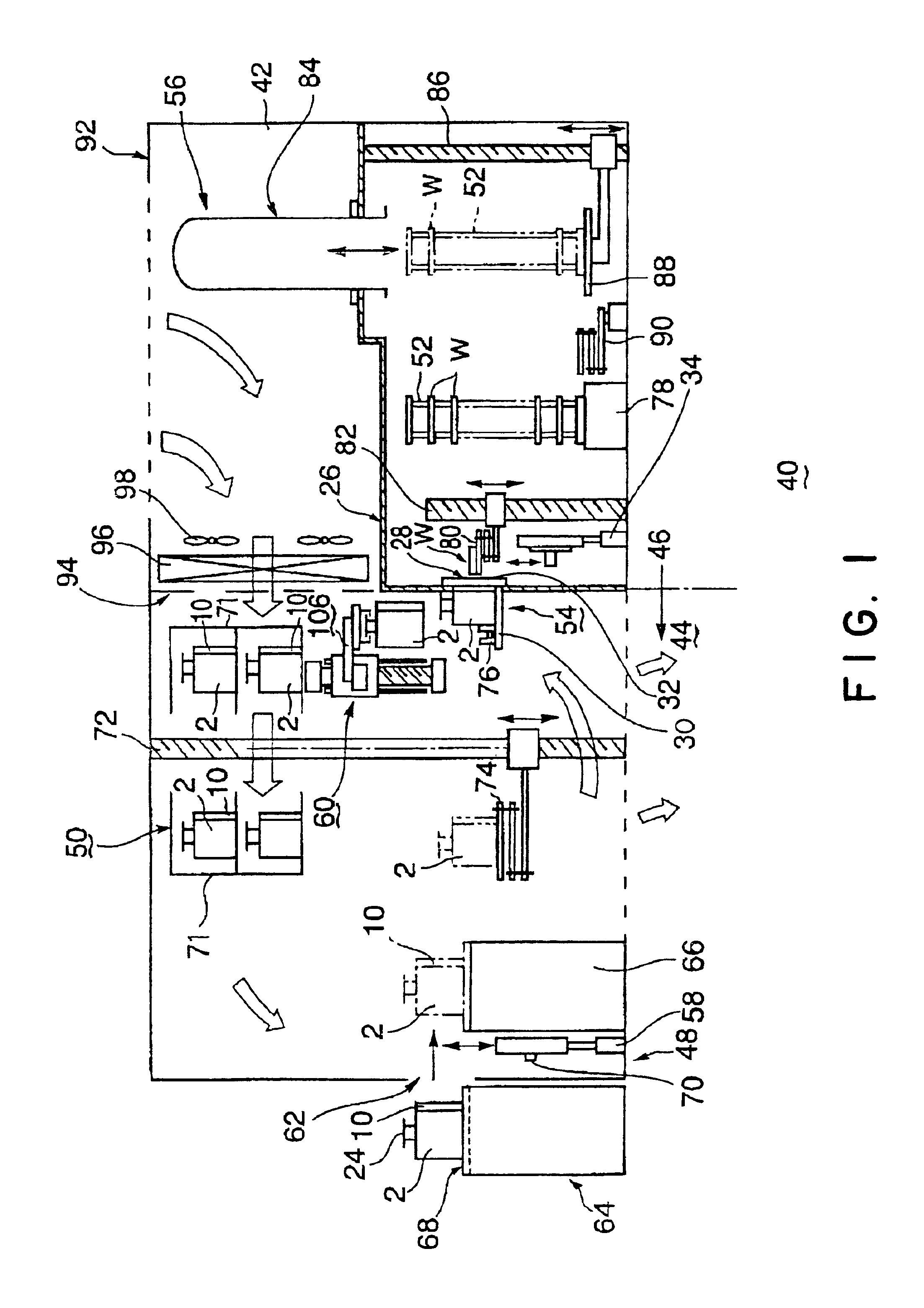

Method for particulate introduction for metal furnaces

InactiveUS20030000338A1Processing duration reducedReduce the amount of solutionElectric discharge heatingFurnace cooling arrangementsElectric arc furnaceSlag

A method and an apparatus for advantageously introducing a flame, a high velocity oxidizing gas, and a high velocity particulate flow into a furnace for metal melting, refining and processing, for example, steel making in an electric arc furnace. The steel making process of an electric arc furnace is made more efficient by shortening the time of the scrap melting phase, introducing a more effective high velocity oxidizing gas stream into the process sooner to decarburize the melted metal and introducing a more effective particulate injection to reduce FeO, form or foam slag and / or recarburize. Improved efficiency is obtained by mounting a fixed burner / lance and carbon injector lower and closer to the hot face of the furnace refractory at an effective injection angle. This mounting technique shortens the distance that the flame of the burner has to melt through scrap to clear a path to the molten metal, and shortens the distance the high velocity oxygen and high velocity particulates travel to the slag-metal interface. One method includes supplying a plurality of oxidizing reaction zones with the high velocity oxidizing gas to decarburize the melted metal and a plurality of particulate reaction zones with high velocity flows of particulate carbon for reducing FeO and / or forming foamy slag. The particulate reaction zones are located on the downstream side of the oxidizing gas reaction zones so as to minimize any effect of the reduction reaction on the decarburization reaction and to recover a part of the hot FeO produced in the oxidizing gas reaction zones.

Owner:PROCESS TECH INT

Method for particulate introduction for metal furnaces

InactiveUS6805724B2Processing duration reducedReduce the amount of solutionElectric discharge heatingFurnace cooling arrangementsElectric arc furnaceSlag

A method and an apparatus for advantageously introducing a flame, a high velocity oxidizing gas, and a high velocity particulate flow into a furnace for metal melting, refining and processing, for example, steel making in an electric arc furnace. The steel making process of an electric arc furnace is made more efficient by shortening the time of the scrap melting phase, introducing a more effective high velocity oxidizing gas stream into the process sooner to decarburize the melted metal and introducing a more effective particulate injection to reduce FeO, form or foam slag and / or recarburize. Improved efficiency is obtained by mounting a fixed burner / lance and carbon injector lower and closer to the hot face of the furnace refractory at an effective injection angle. This mounting technique shortens the distance that the flame of the burner has to melt through scrap to clear a path to the molten metal, and shortens the distance the high velocity oxygen and high velocity particulates travel to the slag-metal interface. One method includes supplying a plurality of oxidizing reaction zones with the high velocity oxidizing gas to decarburize the melted metal and a plurality of particulate reaction zones with high velocity flows of particulate carbon for reducing FeO and / or forming foamy slag. The particulate reaction zones are located on the downstream side of the oxidizing gas reaction zones so as to minimize any effect of the reduction reaction on the decarburization reaction and to recover a part of the hot FeO produced in the oxidizing gas reaction zones.

Owner:PROCESS TECH INT

Portable kiln

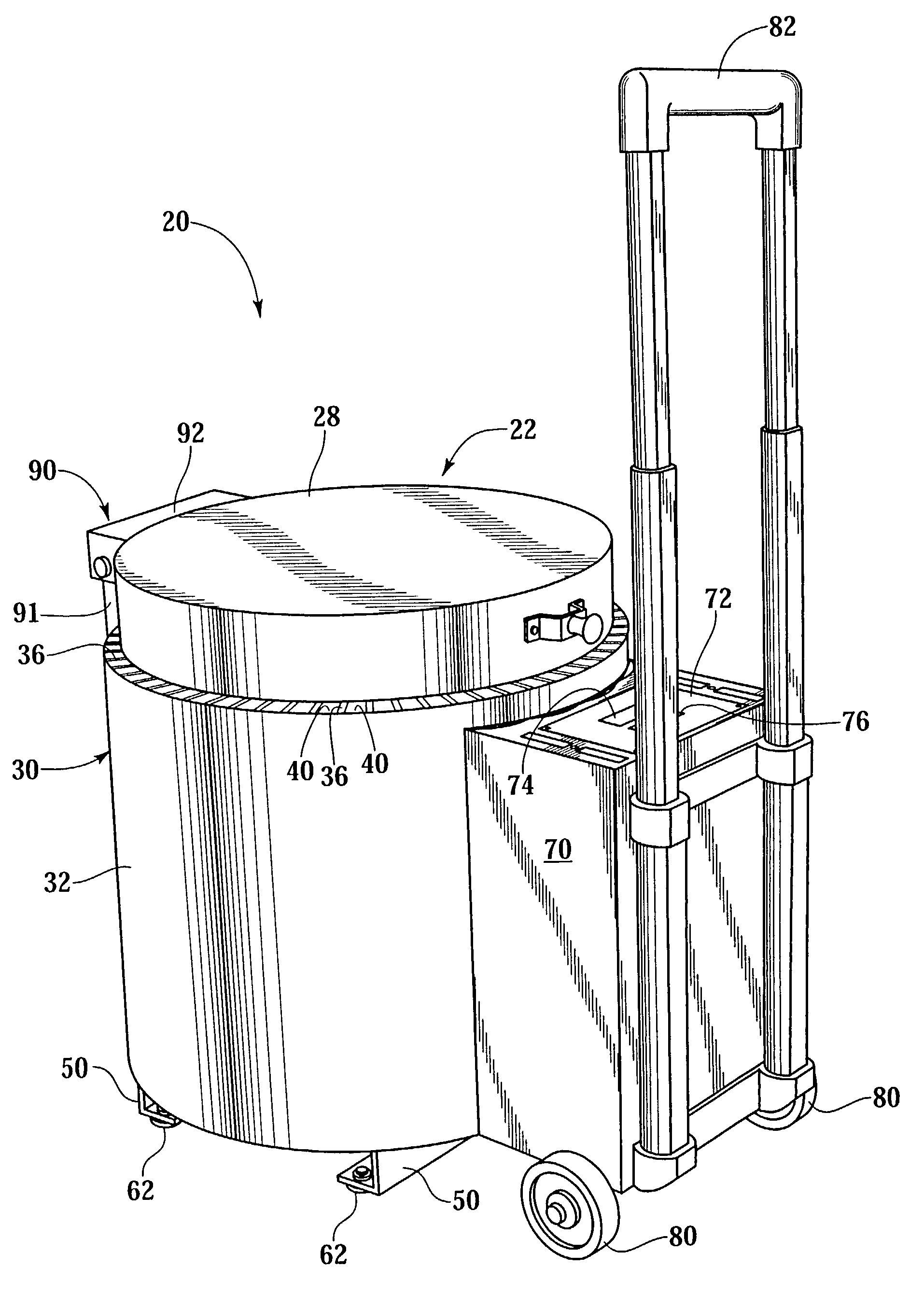

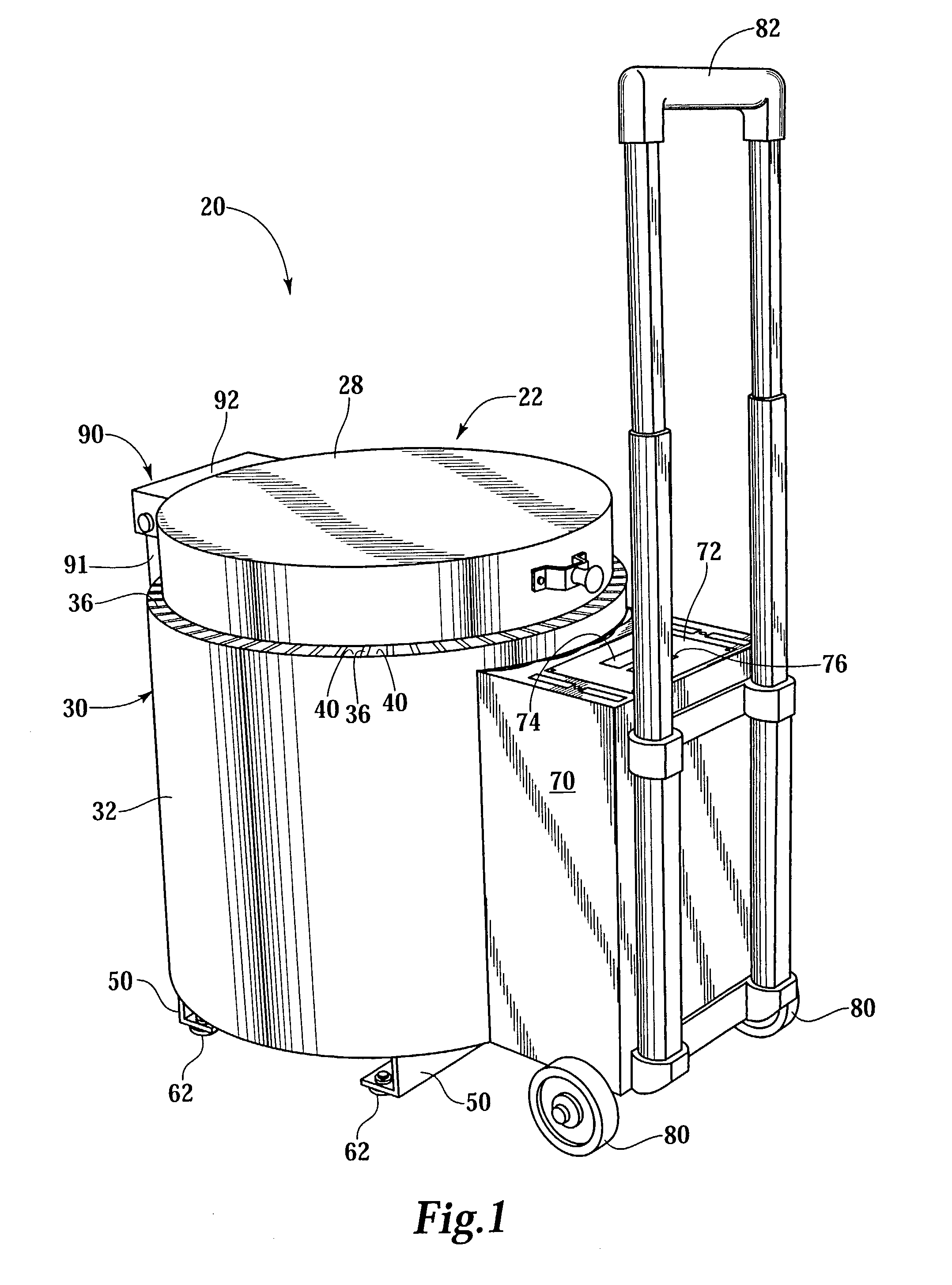

ActiveUS7458809B2Limited range of activitiesChamber furnacesFurnace cooling arrangementsEngineeringMechanical engineering

A portable kiln has a set of wheels, a handle and a platform base. The wheels and the handle are attached on a first side of the kiln so that the kiln can be tilted and rolled on the wheels using the handle. The platform base provides a spaced distance between the wheels and the floor when the kiln is sitting upright in an operational position. The kiln may also include a metal outer shell wrapped about an oven portion. The outer shell has a shell sidewall radially spaced from the oven portion sidewall, which forms an annular air channel between the outer shell sidewall and the oven portion. The outer shell has a C-shaped cross-section and it has upper and lower vent openings for the air channel. A hinge assembly allows a lid of the kiln to rest in an open position.

Owner:HOHENSHELT

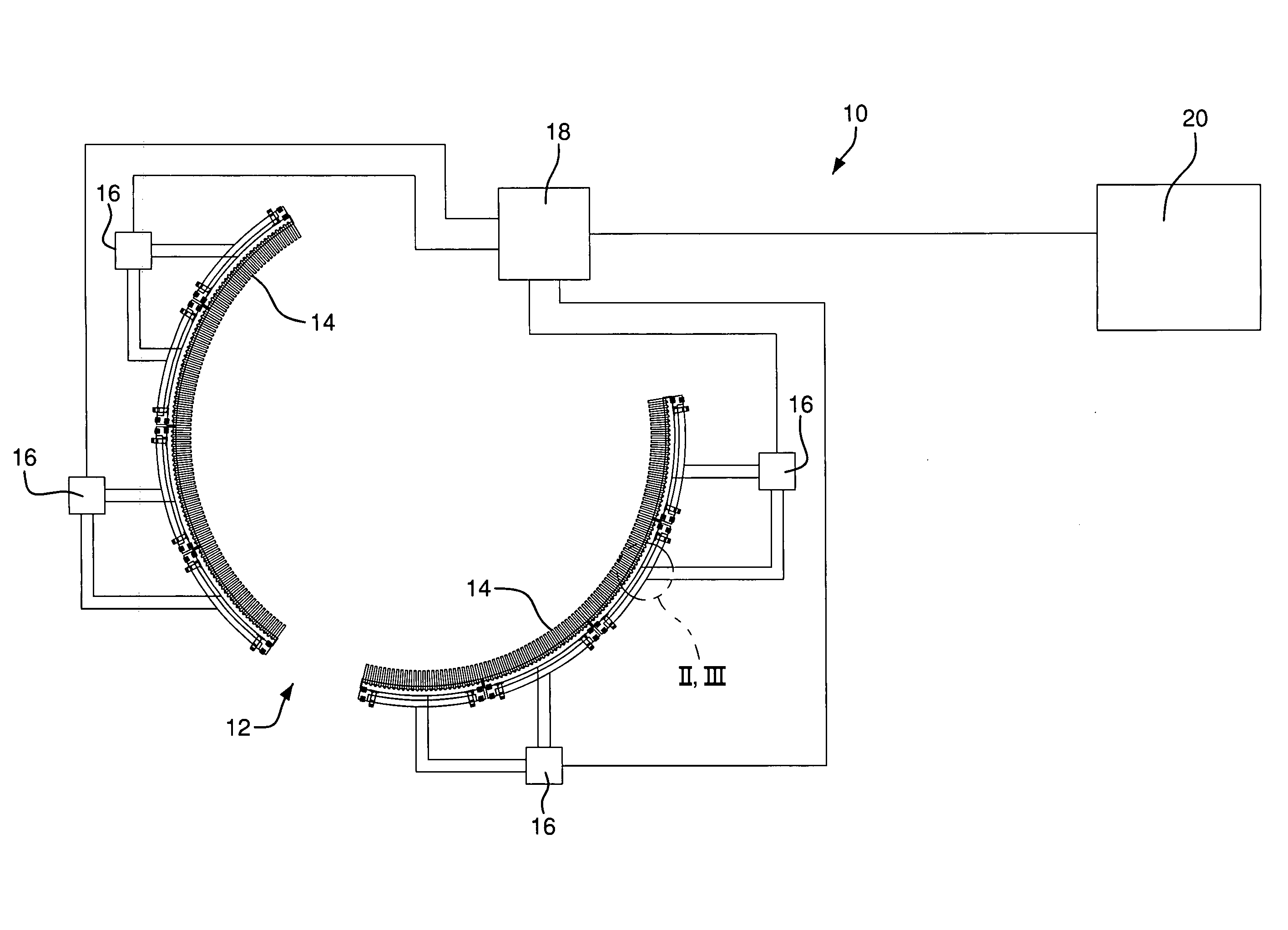

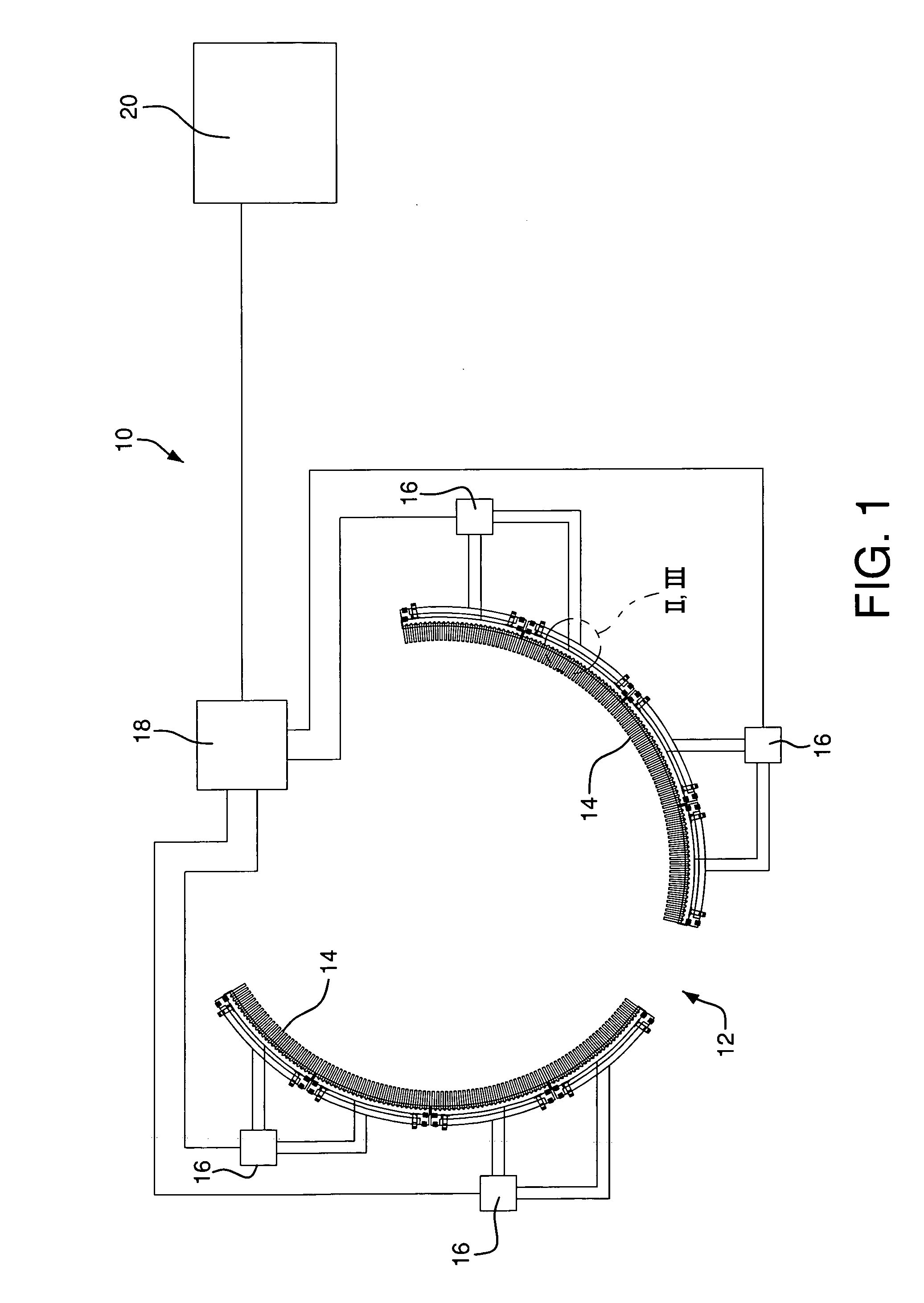

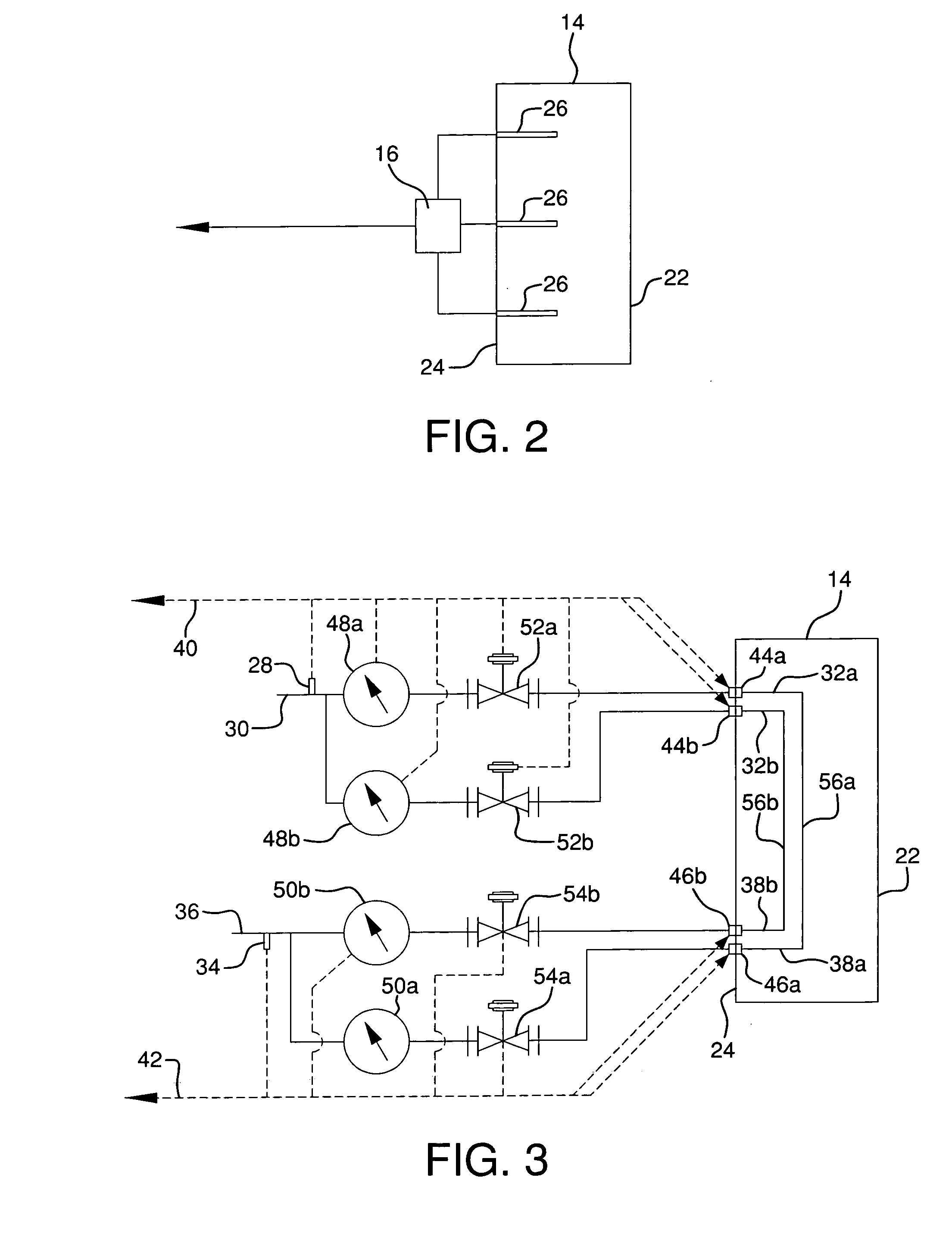

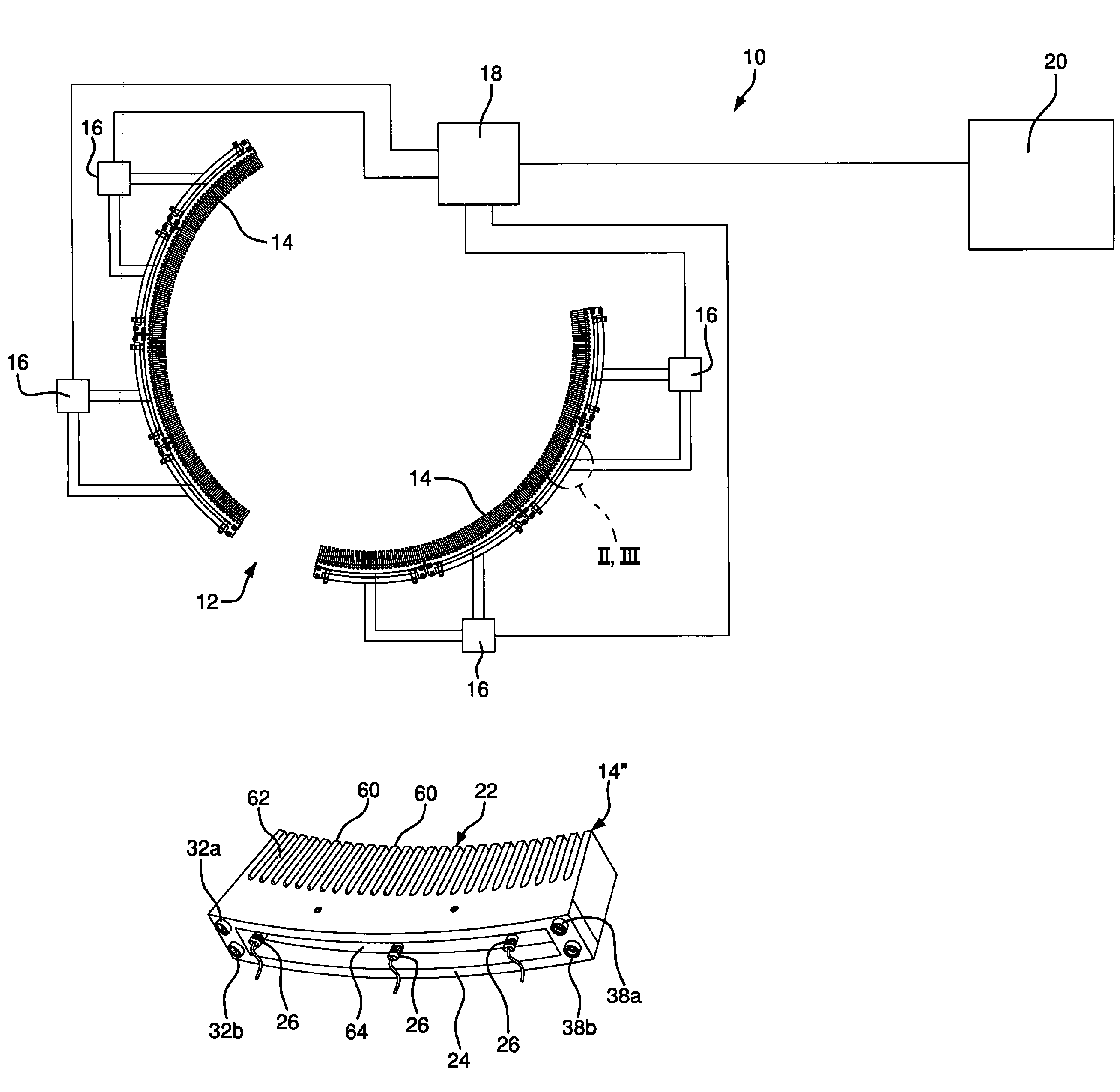

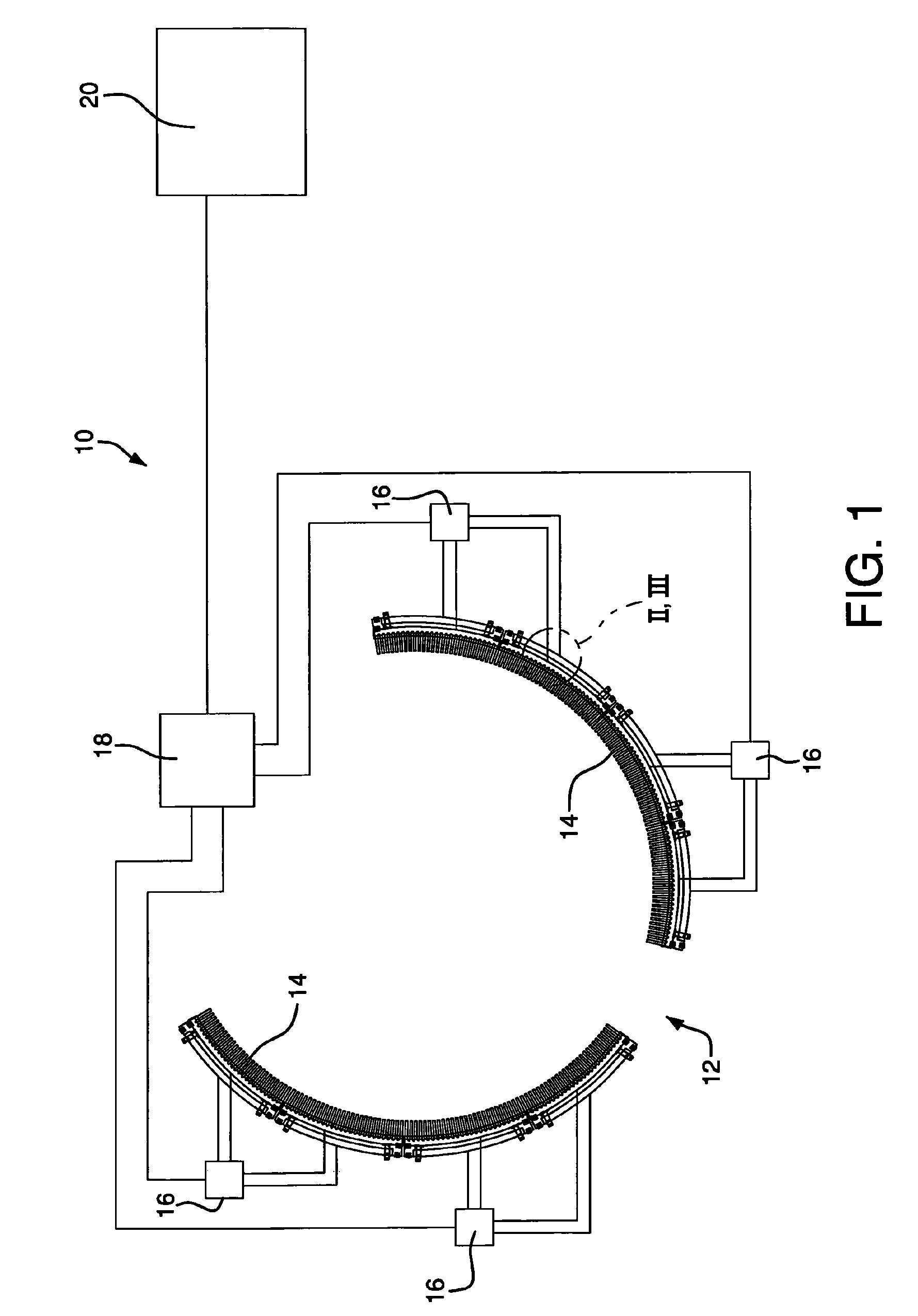

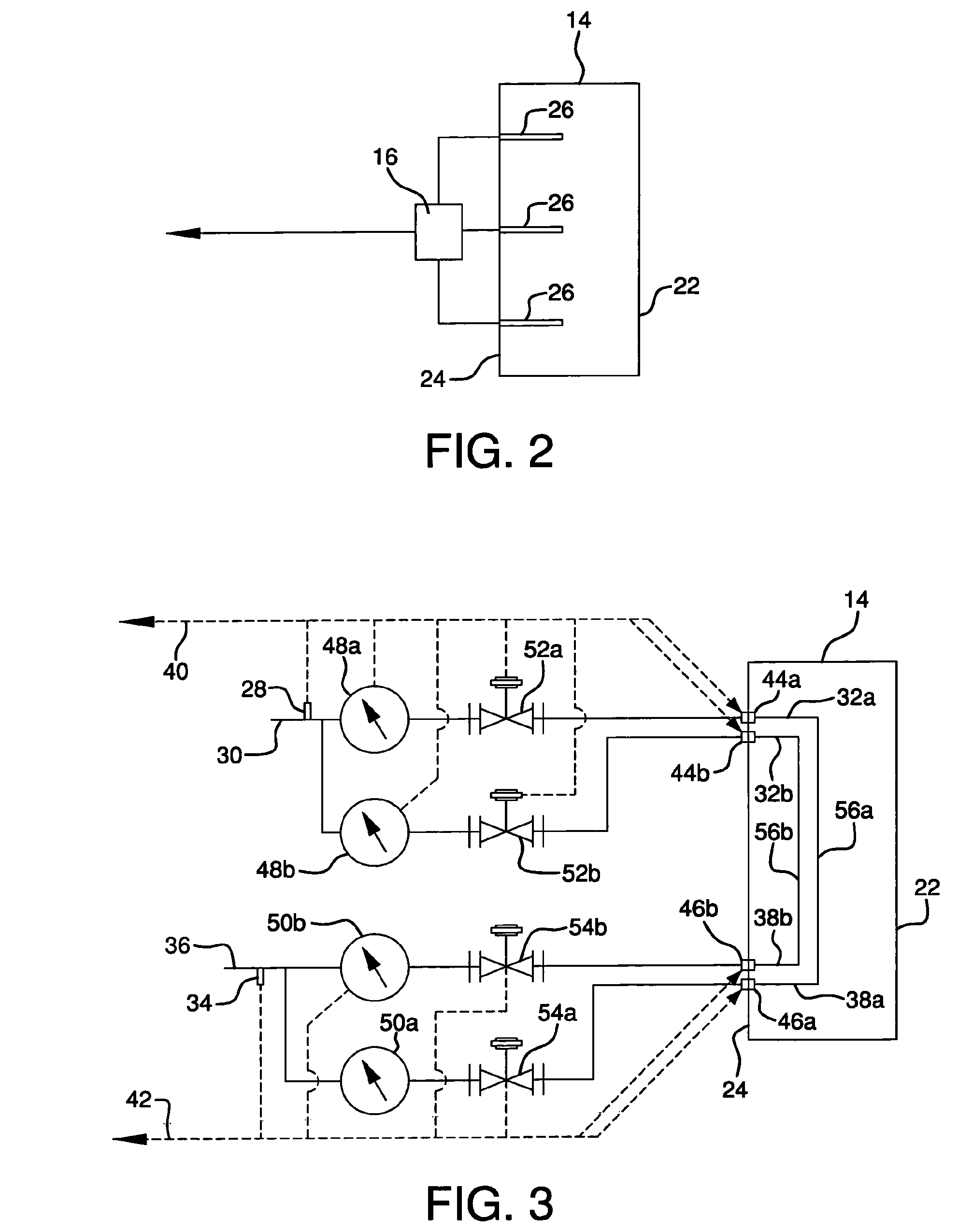

Furnace panel leak detection system

ActiveUS20090148800A1Detection of fluid at leakage pointFurnace cooling arrangementsElectric arc furnaceCoolant flow

A furnace panel leak monitoring and control system for fluid-cooled panels in high temperature industrial furnaces such as, for example, smelting furnaces, blast furnaces and electric arc furnaces. The system performs at least two and up four functions simultaneously. At minimum, the system includes one or more temperature sensors received within the body of the panel to monitor temperature within the metal of the panel itself, and pressure sensors installed proximate the inlet and outlet of each panel coolant fluid circuit, which circuits are preferably periodically automatically tested, to check for leaks in the coolant circuits. In addition, the system preferably includes temperature and flow sensors for monitoring the furnace panel coolant circuit(s) for temperature and flow fluctuations, respectively, which may be indicative of leaking cooling circuits. The system triggers visual and / or audible alarm means to alert a human operator of an apparent coolant fluid leak situation.

Owner:BERRY METAL

Casting method of cast steel cooling plate

InactiveCN101634520AImprove mechanical propertiesExtend your lifeFurnace cooling arrangementsProcess efficiency improvementCooling effectAlloy

The invention relates to a casting method of a cast steel cooling plate, which adopts a cast steel material to cast a cooling plate base body and a cooling water pipe. The casting method comprises the following steps: adding a slagging agent and a silicon iron alloy block in molten steel for casting steel; putting the cooling water pipe into a casting model, sheathing a pipe sleeve on the cooling water pipe and leading a liquid cold medium and a composite solid cooling medium to pass through the cooling water pipe; using molten steel for casting steel to cast the cooling plate base body, and casting the middle part of the cooling water pipe into the cooling plate base body; leading the casting model to be horizontal in the modeling process, leading a feeder head to be modeled lopsidedly toward one side and heightening one side of the feeder head of the model after the model is boxed; adopting an upper layer of inner sprue and a lower layer of lower sprue to carry out stepped casting so as to form sequential solidification; and cooling and disassembling the model. The casting method can effectively avoid the cooling water pipe from being penetrated in a fusing manner during the casting process, avoid air gaps from being generated between the base body and the cooling water pipe, avoids refusion and recrystallization, accurately realizes the microfusion of the outer surface of the cooling water pipe, prolongs the service life of the cooling plate, further prolongs the service life of a metallurgical high-temperature kiln, saves production cost and improves the cooling effect and the mechanical performance of the cast steel cooling plate.

Owner:江苏联兴成套设备制造有限公司

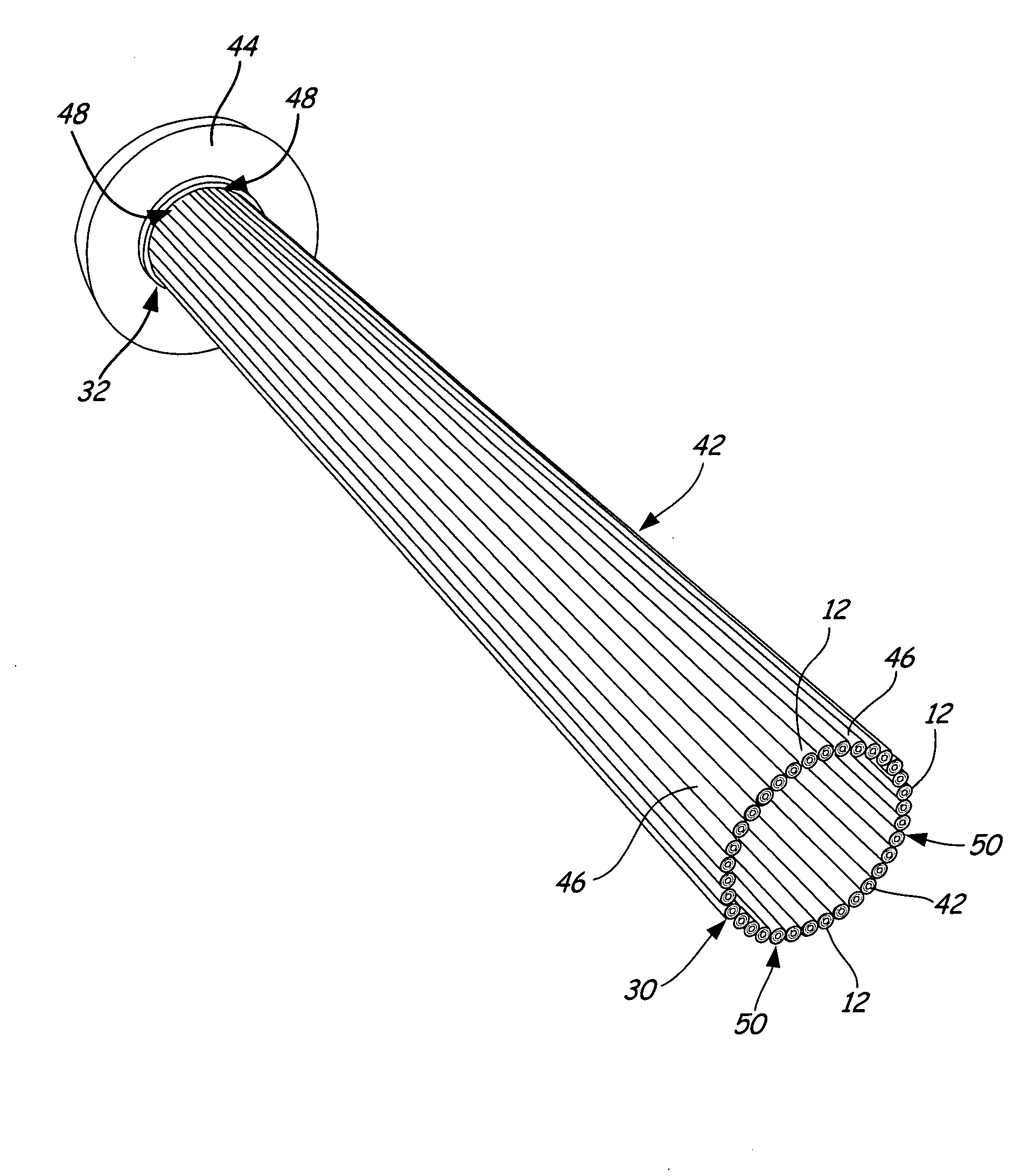

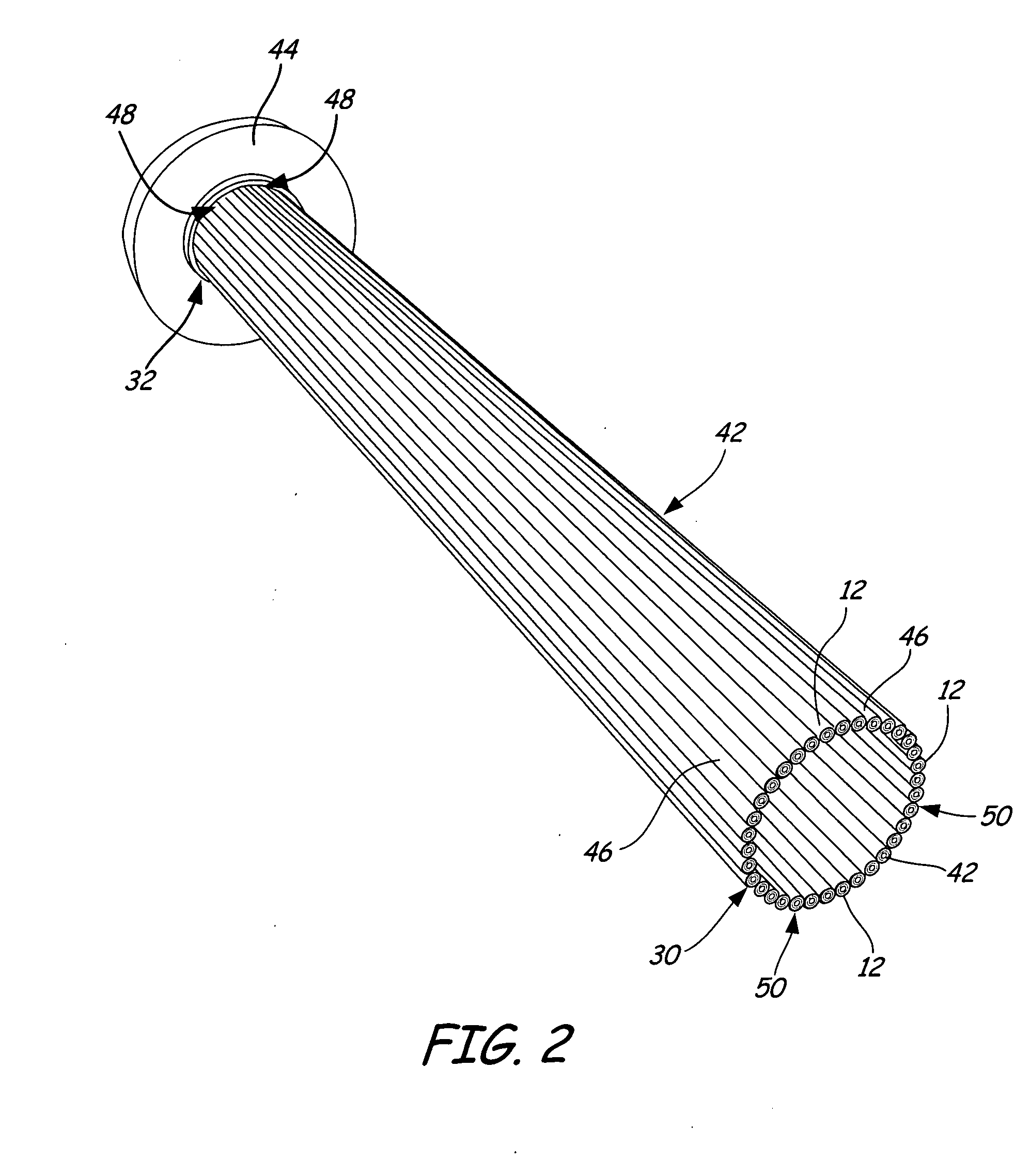

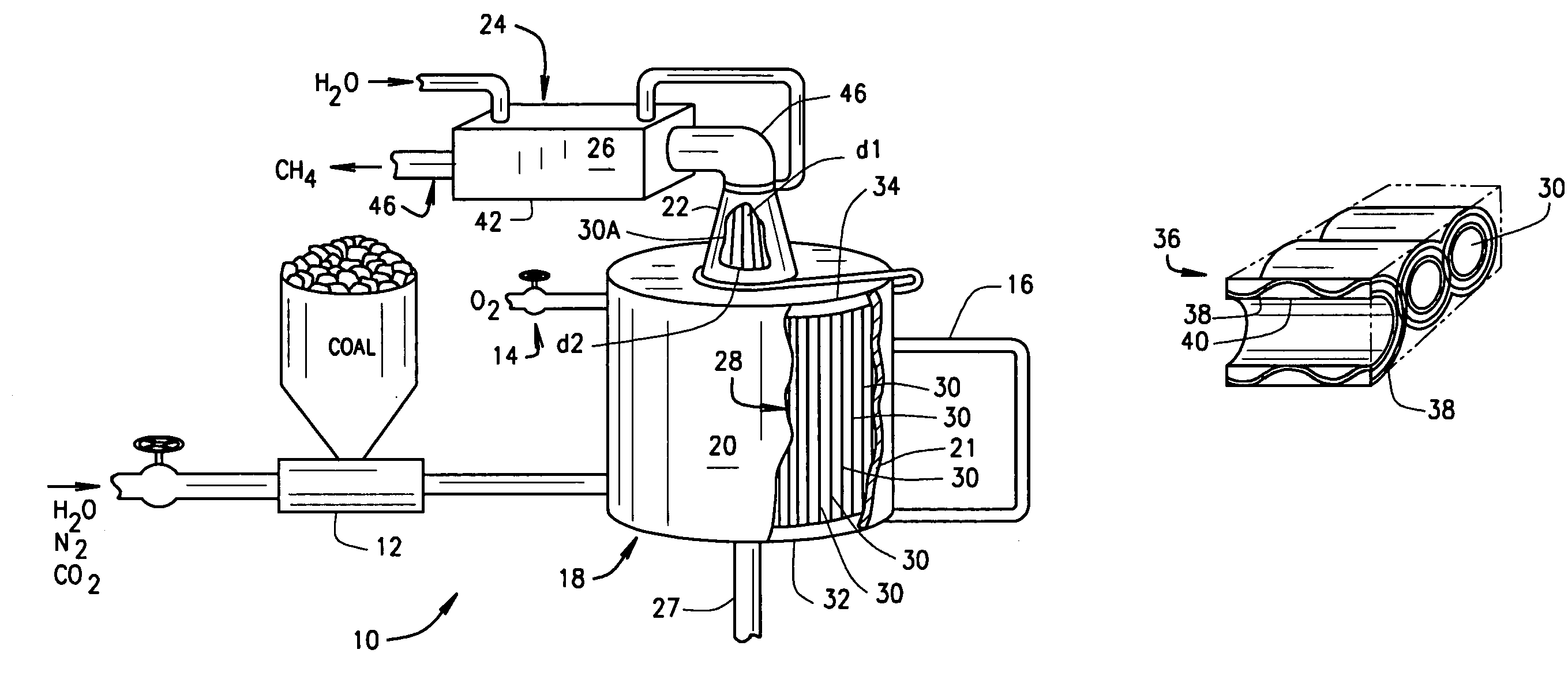

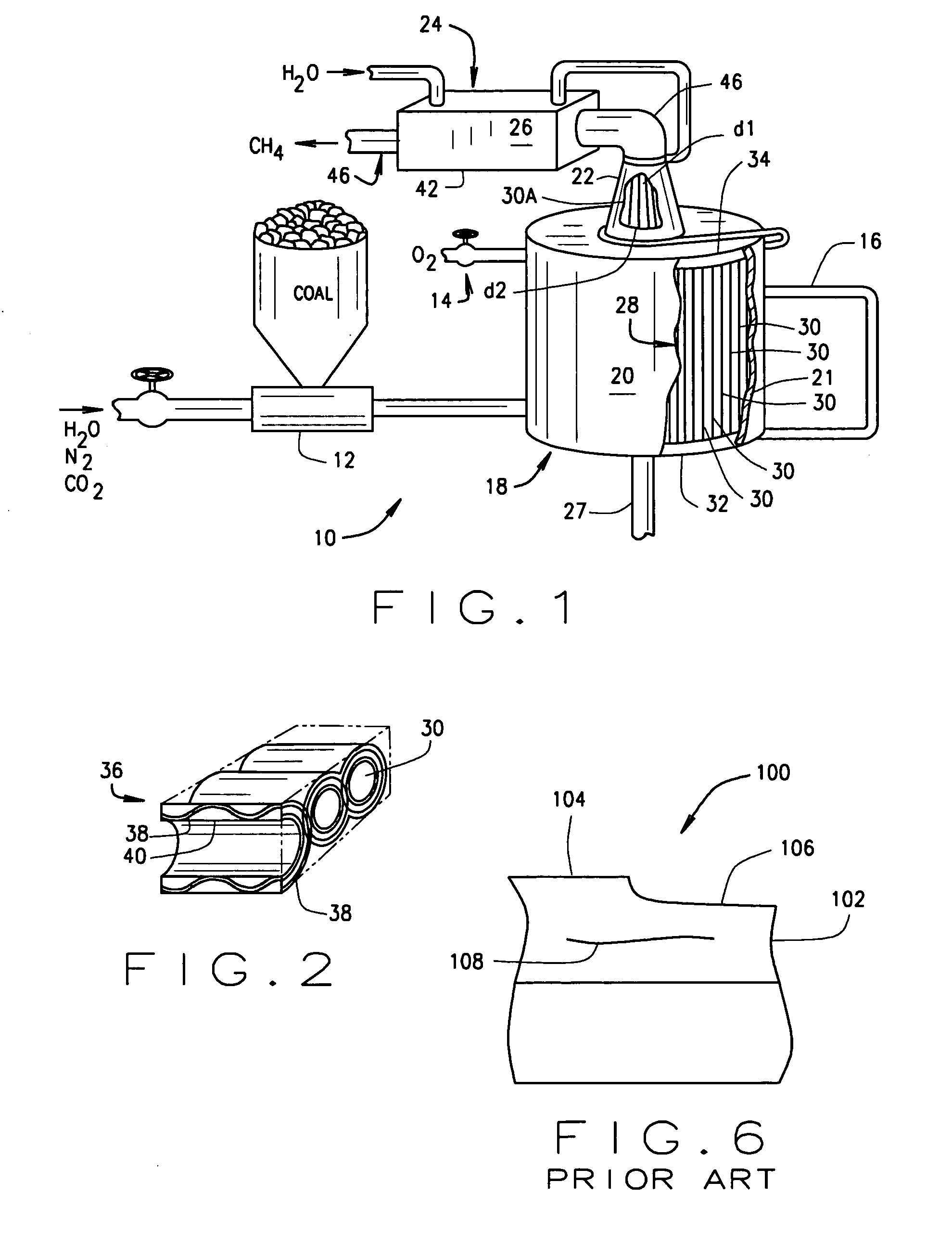

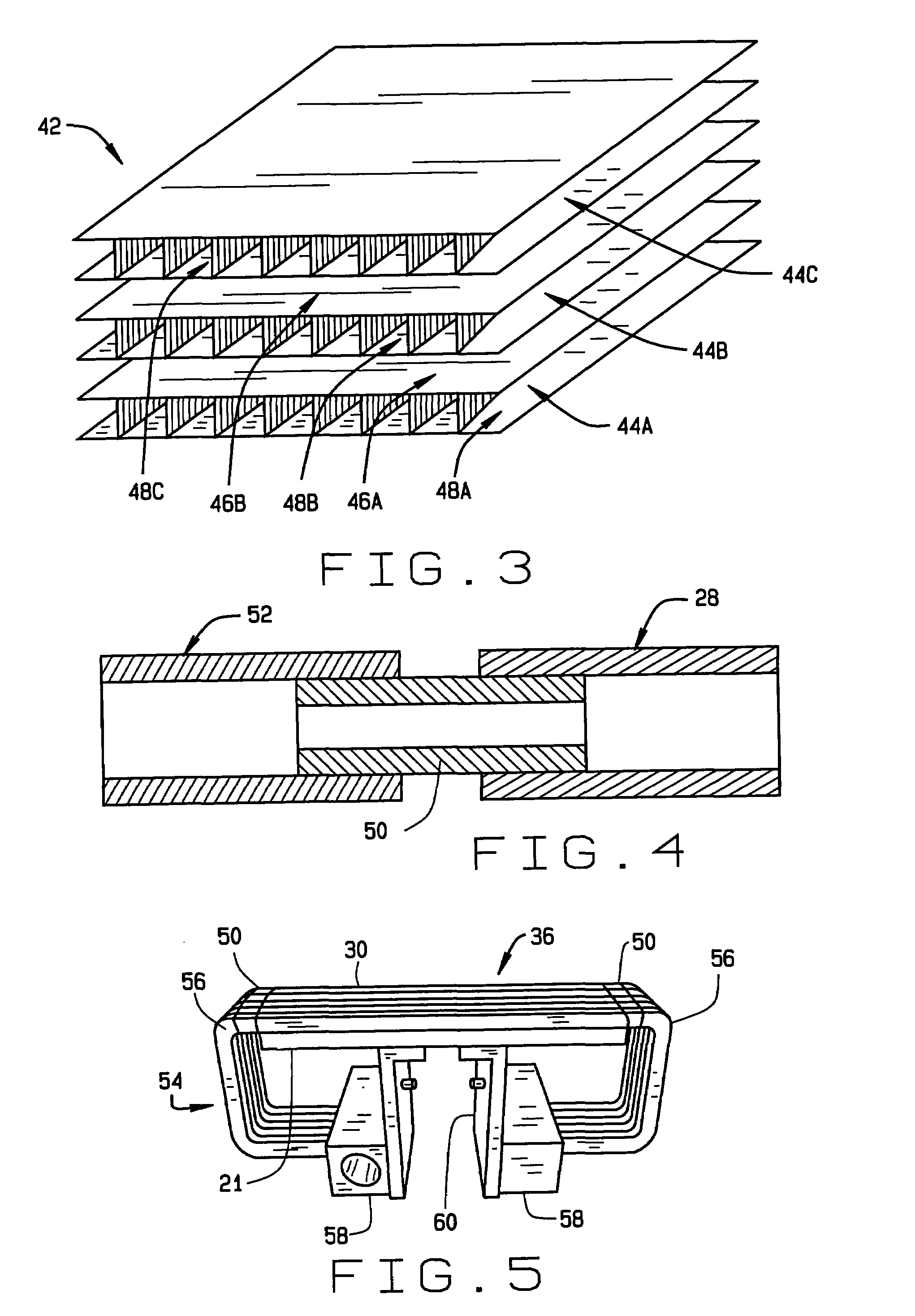

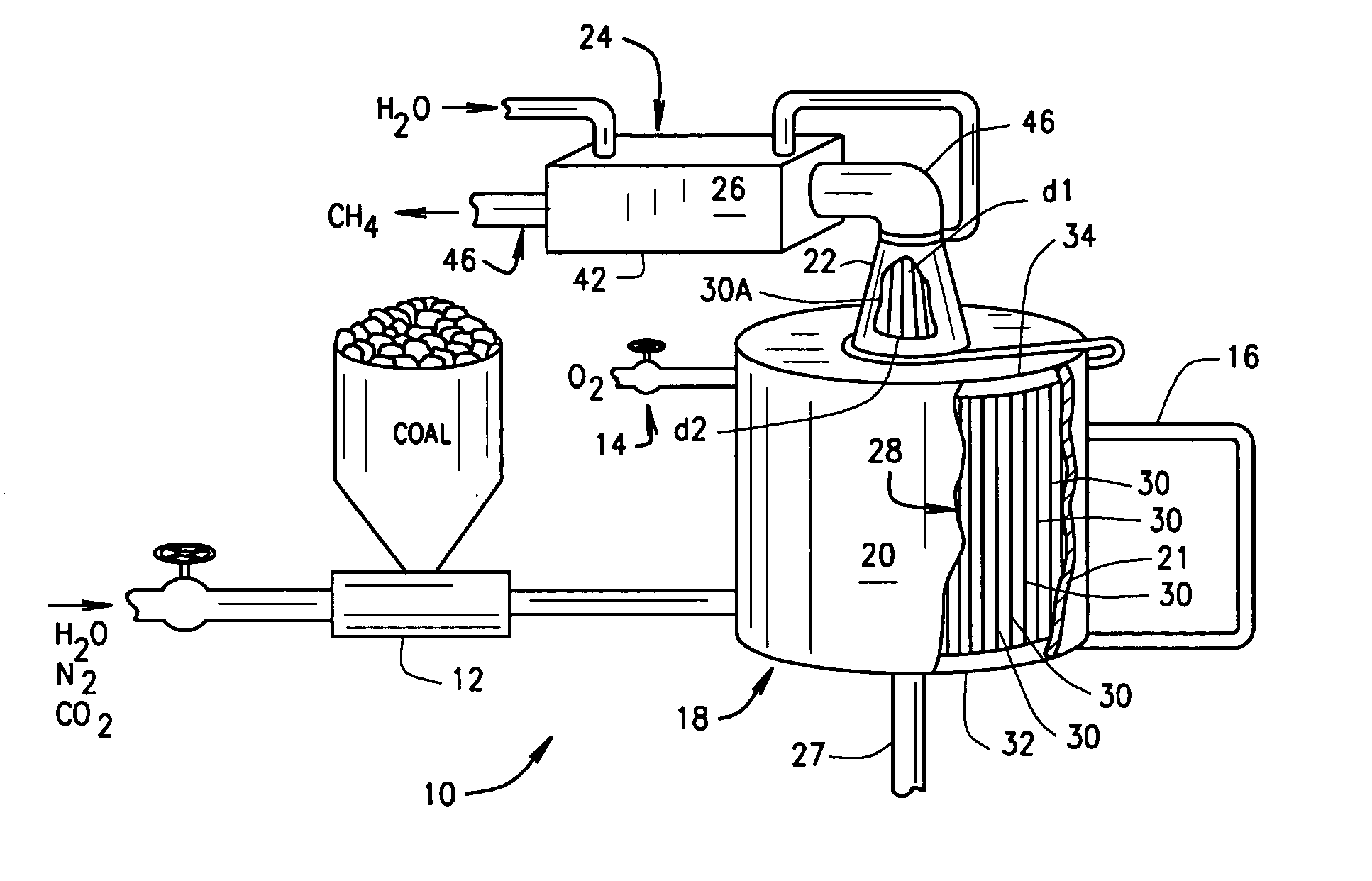

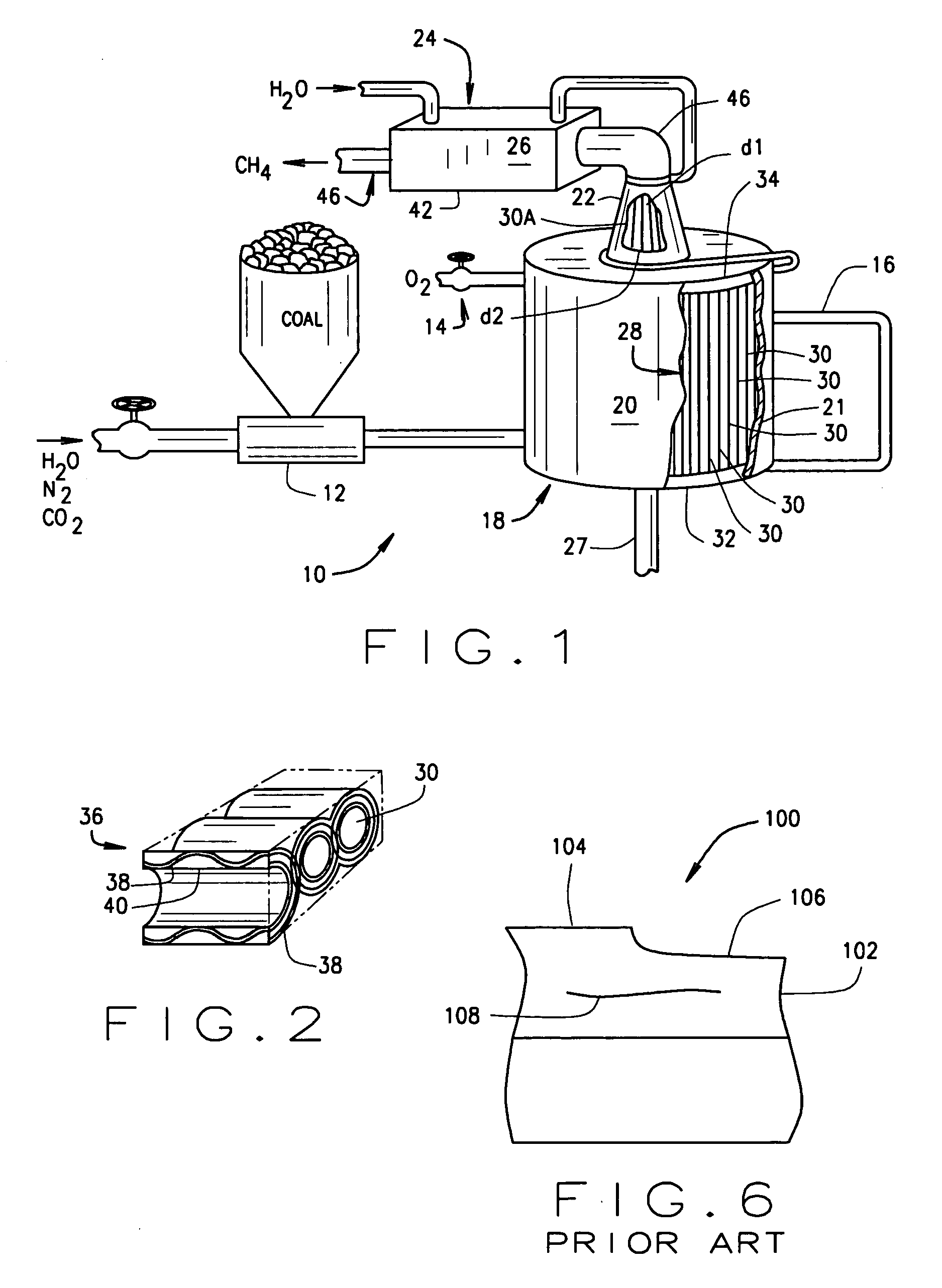

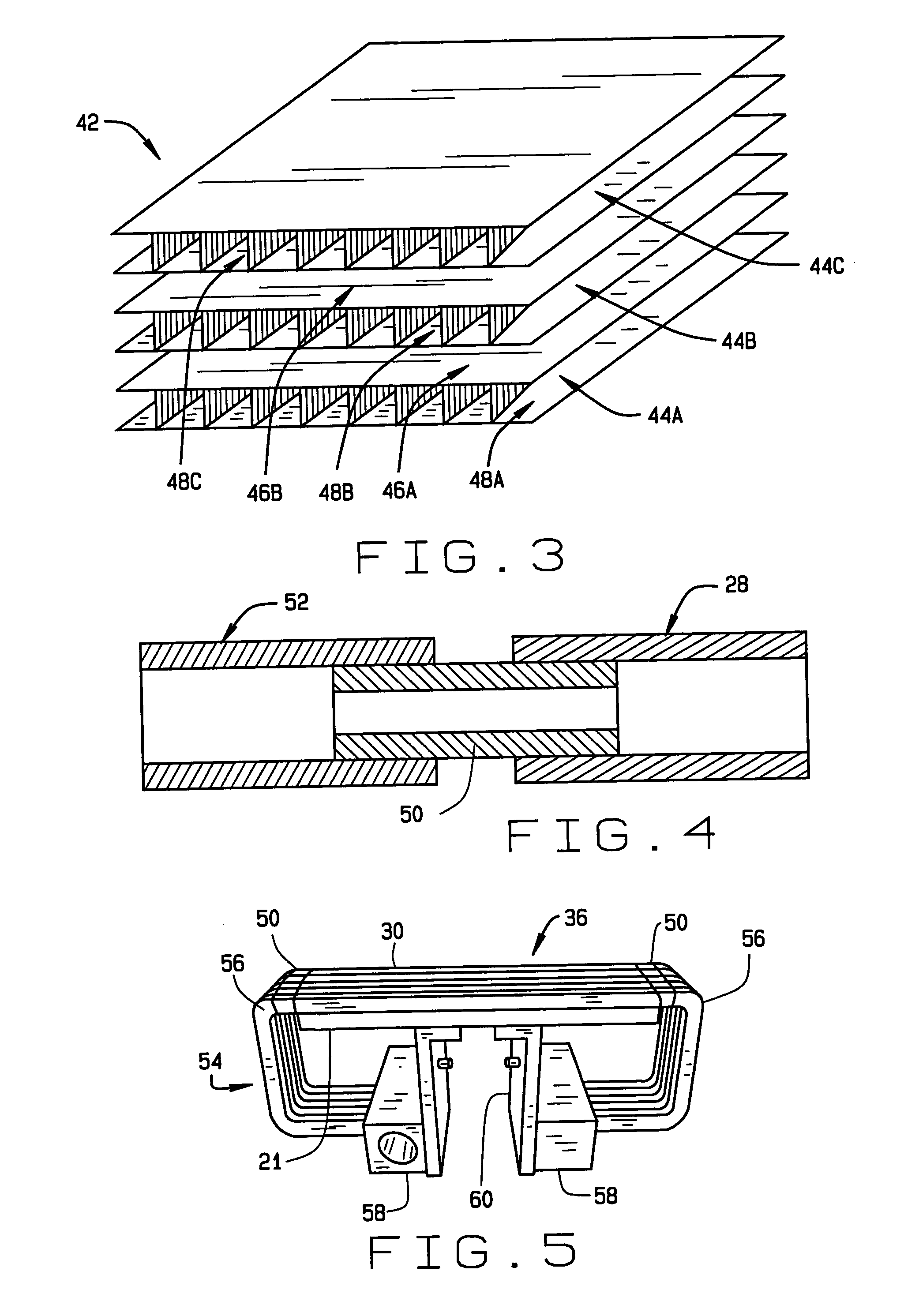

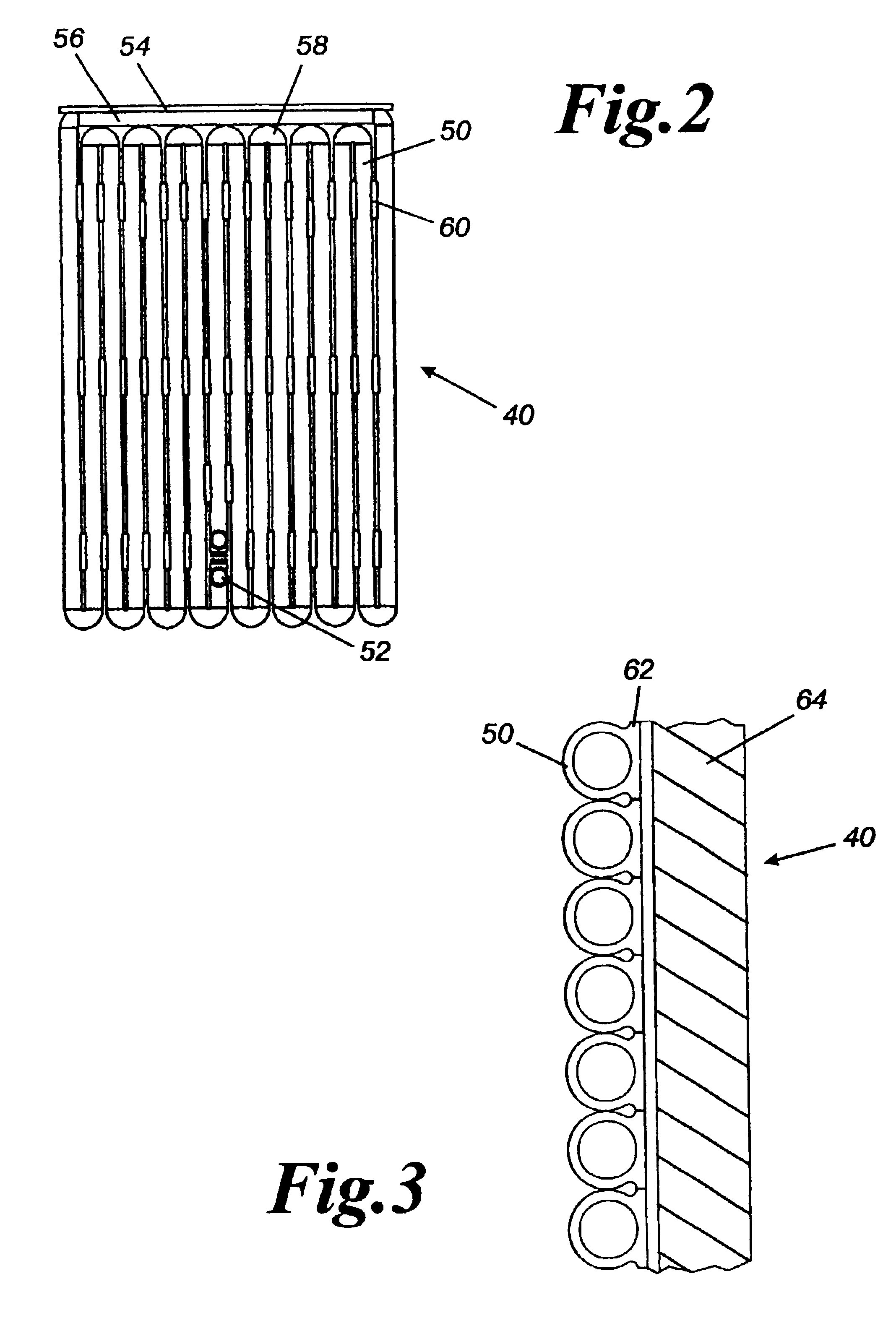

Regeneratively cooled synthesis gas generator

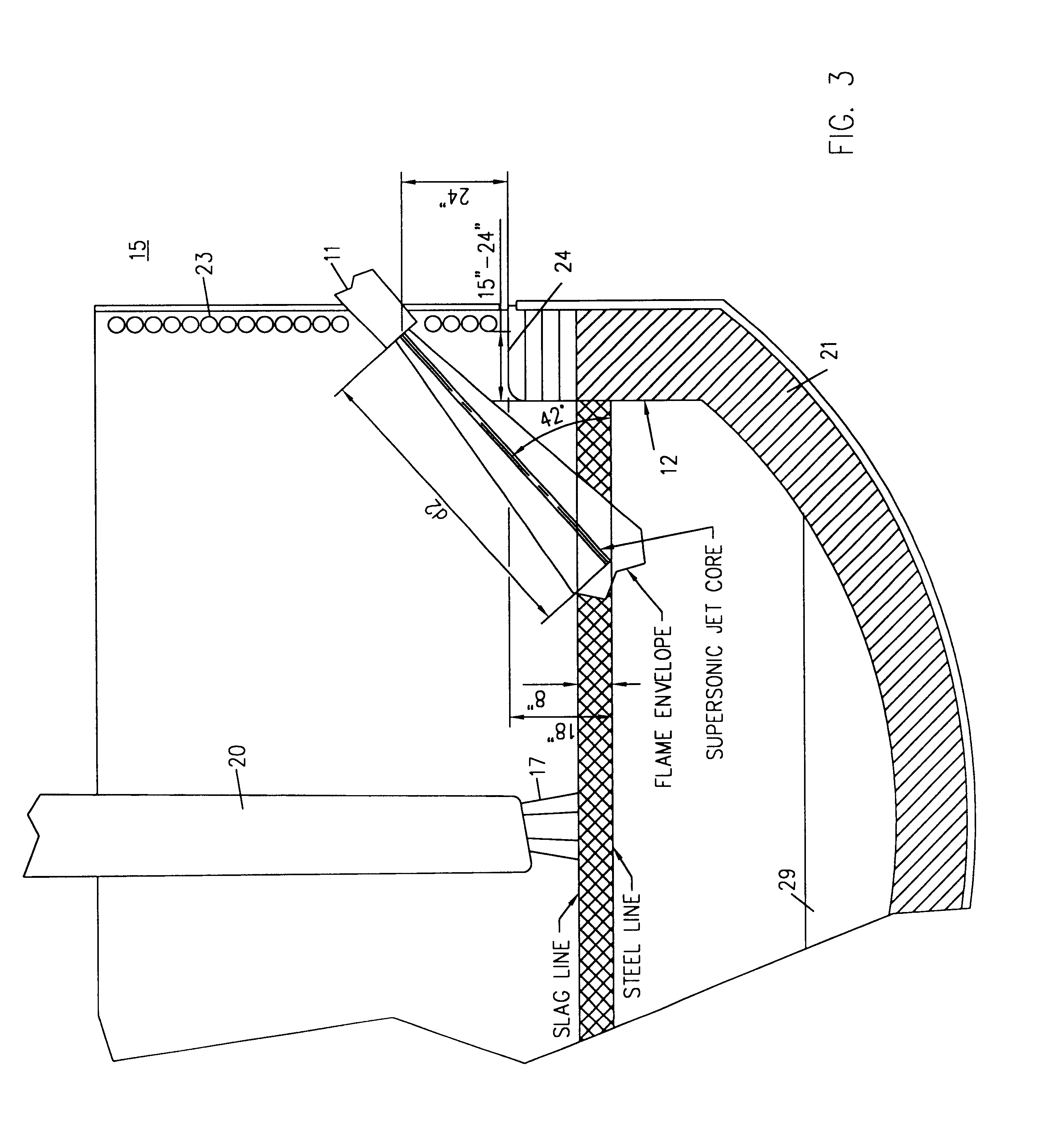

InactiveUS6920836B2Low costImprove reliabilityGasifier mechanical detailsCorrosion preventionYarnFiber

A coolant liner for a carbonaceous fuel (coal or petcoke) gasification vessel including a ceramic composite panel and a method of cooling a vessel. The panel includes at least two layers of woven yarns of fibrous material and walls extending between the layers. Accordingly, the layers and the walls define coolant channels that extend in a warp direction. Moreover, one of the layers may be less than about 0.08 inches thick. Materials used to create the composite panel may include alumina, chromia, silicon carbide, and carbon. Additionally, the liners may be shaped in an arc or have coolant channels which vary in diameter in the warp direction. Additionally, the liner may abut a structural closeout of the vessel. The coolant liner provides a significantly more durable component than previously employed liners and is especially well suited to demanding service environments.

Owner:GAS TECH INST +1

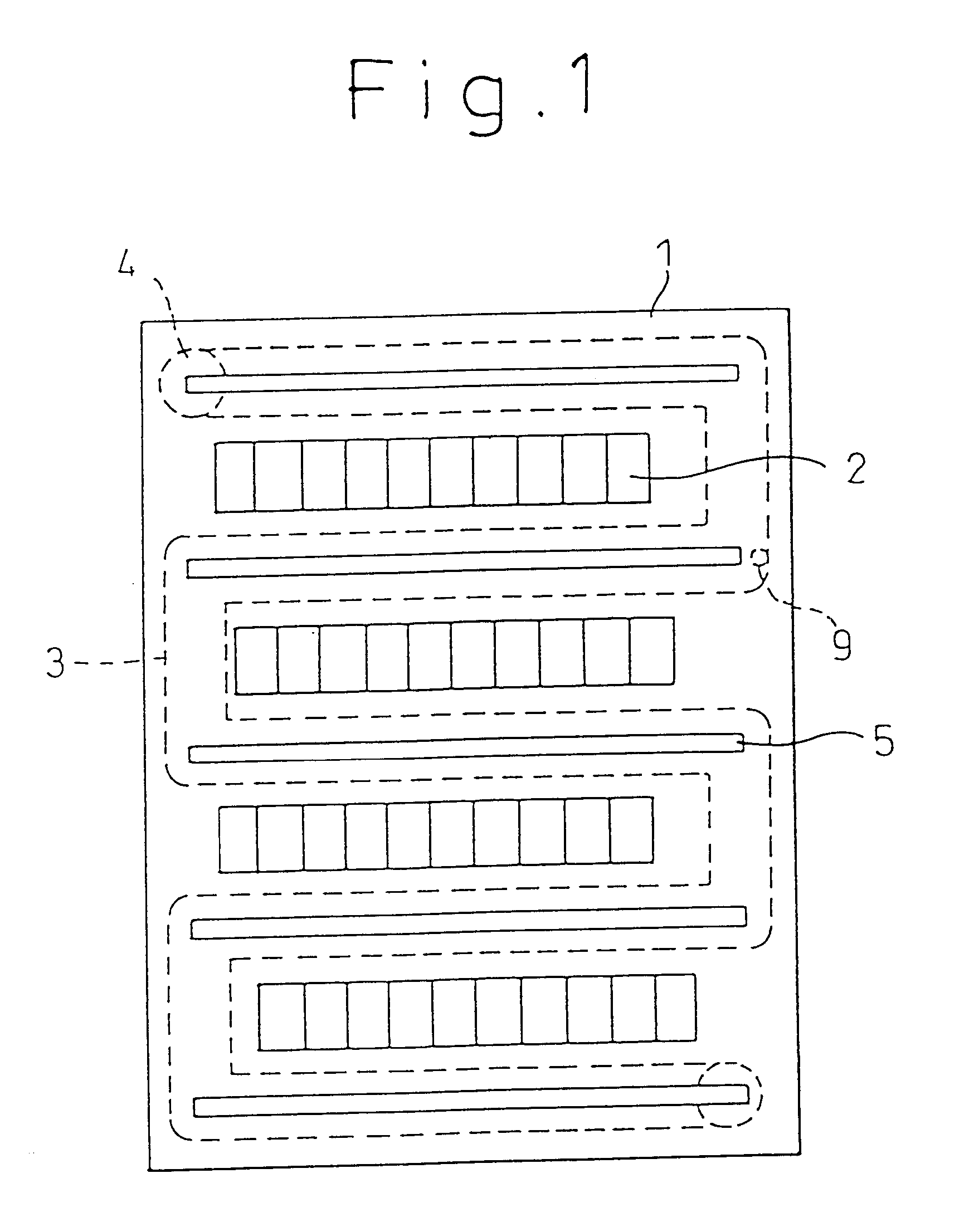

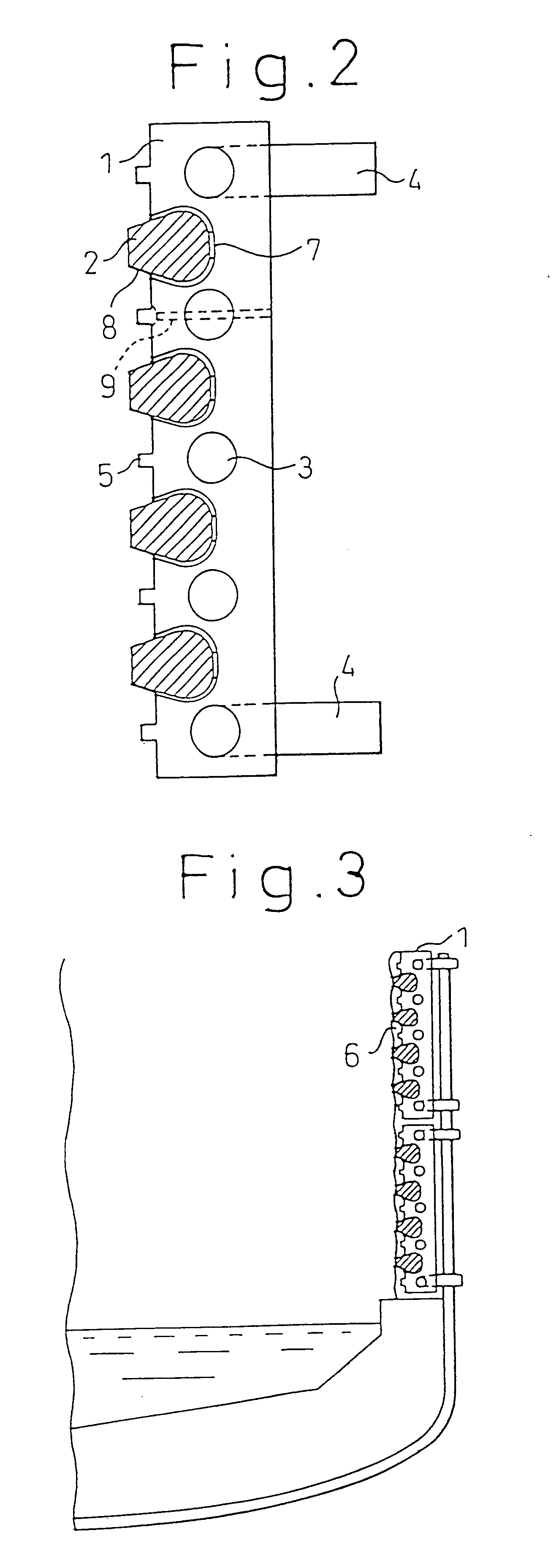

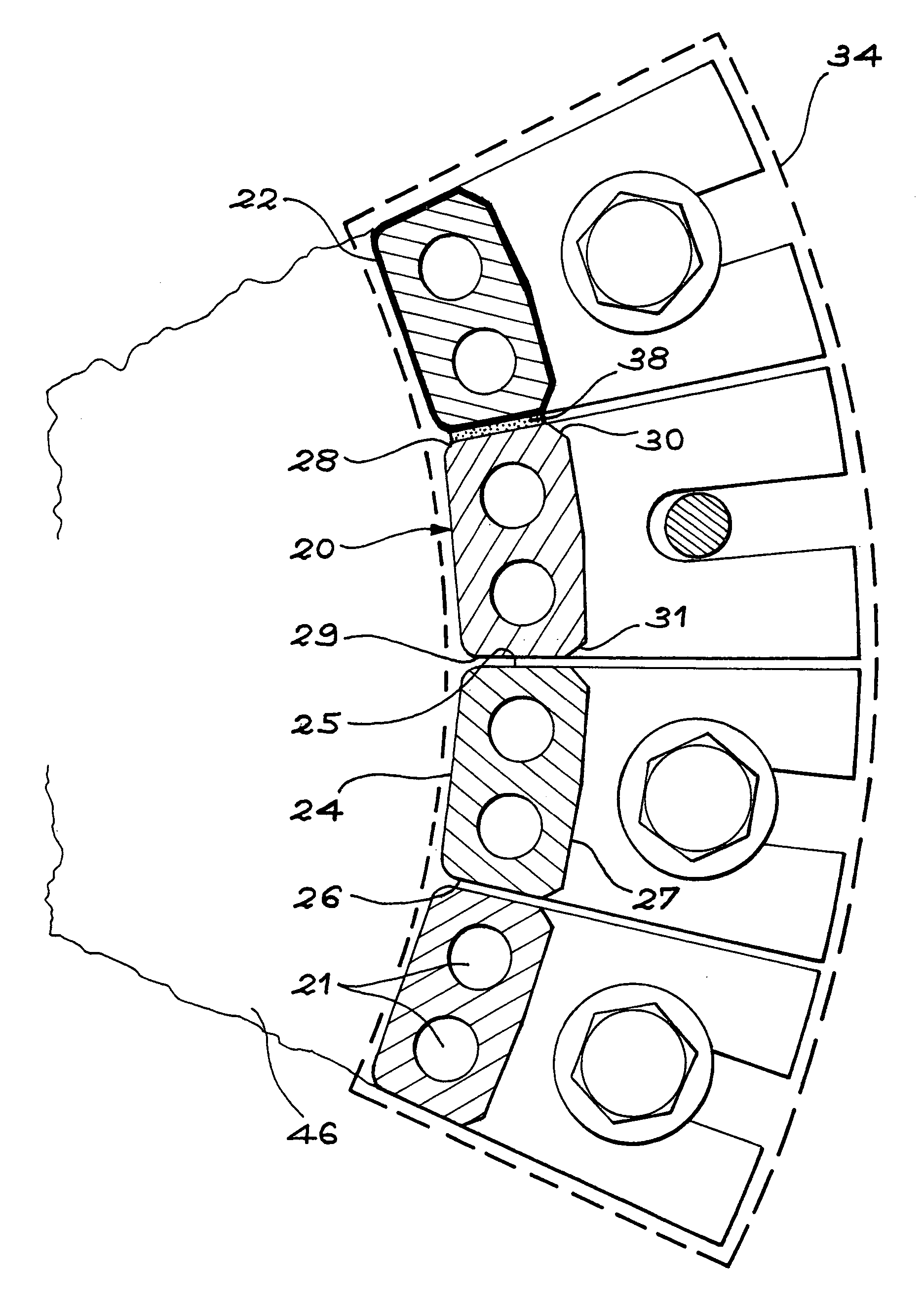

Water-cooling panel for furnace wall and furnace cover of arc furnace

A water-cooled panel for the furnace wall and furnace roof of an electric-arc furnace is integrally fabricated of refractory bricks arrayed on the furnace inner wall in multiple regularly spaced rows to be exposed at the end surfaces and cooling water pipes installed between the rows of refractory bricks (2). A furnace exterior side of the refractory bricks and a furnace interior side of a cooling water pipe are overlapped in a vertical direction of the water-cooled panel, and the cooling water pipe is provided in between an upper and lower side of refractory bricks.

Owner:NIPPON STEEL CORP

Regeneratively cooled synthesis gas generator

InactiveUS20050072341A1Low costImprove reliabilityGasifier mechanical detailsFurnace cooling arrangementsYarnFiber

A coolant liner for a carbonaceous fuel (coal or petcoke) gasification vessel including a ceramic composite panel and a method of cooling a vessel. The panel includes at least two layers of woven yarns of fibrous material and walls extending between the layers. Accordingly, the layers and the walls define coolant channels that extend in a warp direction. Moreover, one of the layers may be less than about 0.08 inches thick. Materials used to create the composite panel may include alumina, chromia, silicon carbide, and carbon. Additionally, the liners may be shaped in an arc or have coolant channels which vary in diameter in the warp direction. Additionally, the liner may abut a structural closeout of the vessel. The coolant liner provides a significantly more durable component than previously employed liners and is especially well suited to demanding service environments.

Owner:GAS TECH INST +1

Heat treatment apparatus

InactiveUS6450803B2Uniform heat treatmentEasy to controlSpadesMuffle furnacesEngineeringHeat treated

A heat treatment table is divided into two or more regions, a heater is disposed for each region. On a predetermined portion of the heat treatment table, a plurality of sensors are disposed separately each other. A relation between temperatures of the respective portions on the heat treatment table and temperatures detected by the sensors is grasped in advance, thereby enables to surmise a temperature of the respective portion of the heat treatment table from the temperature detected by the sensors. In the case of an wafer being actually treated by placing on the heat treatment table, the temperatures detected by the sensors are observed, from these detected temperatures, the temperatures of the respective portions on the heat treatment table, that is, temperatures affecting the wafer, are surmised.

Owner:TOKYO ELECTRON LTD

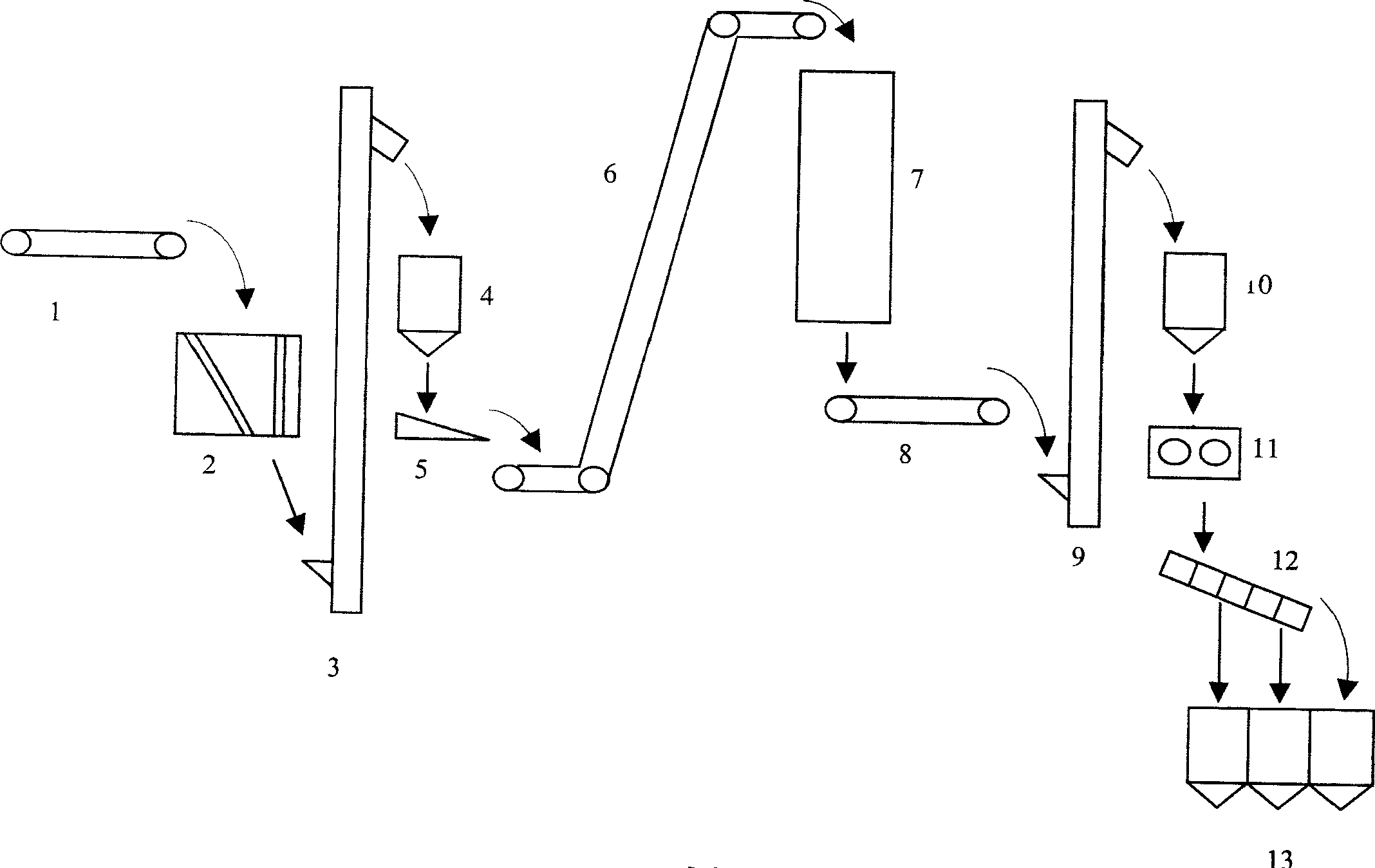

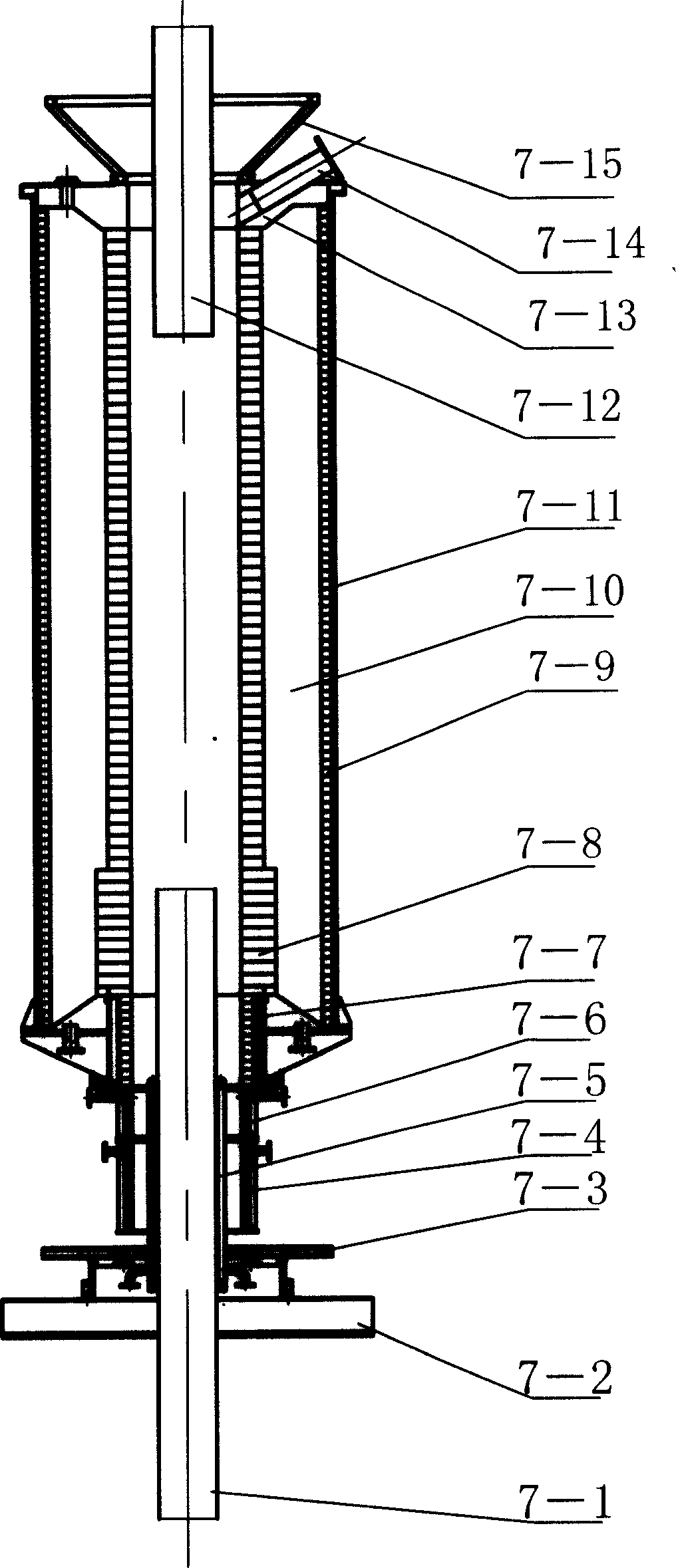

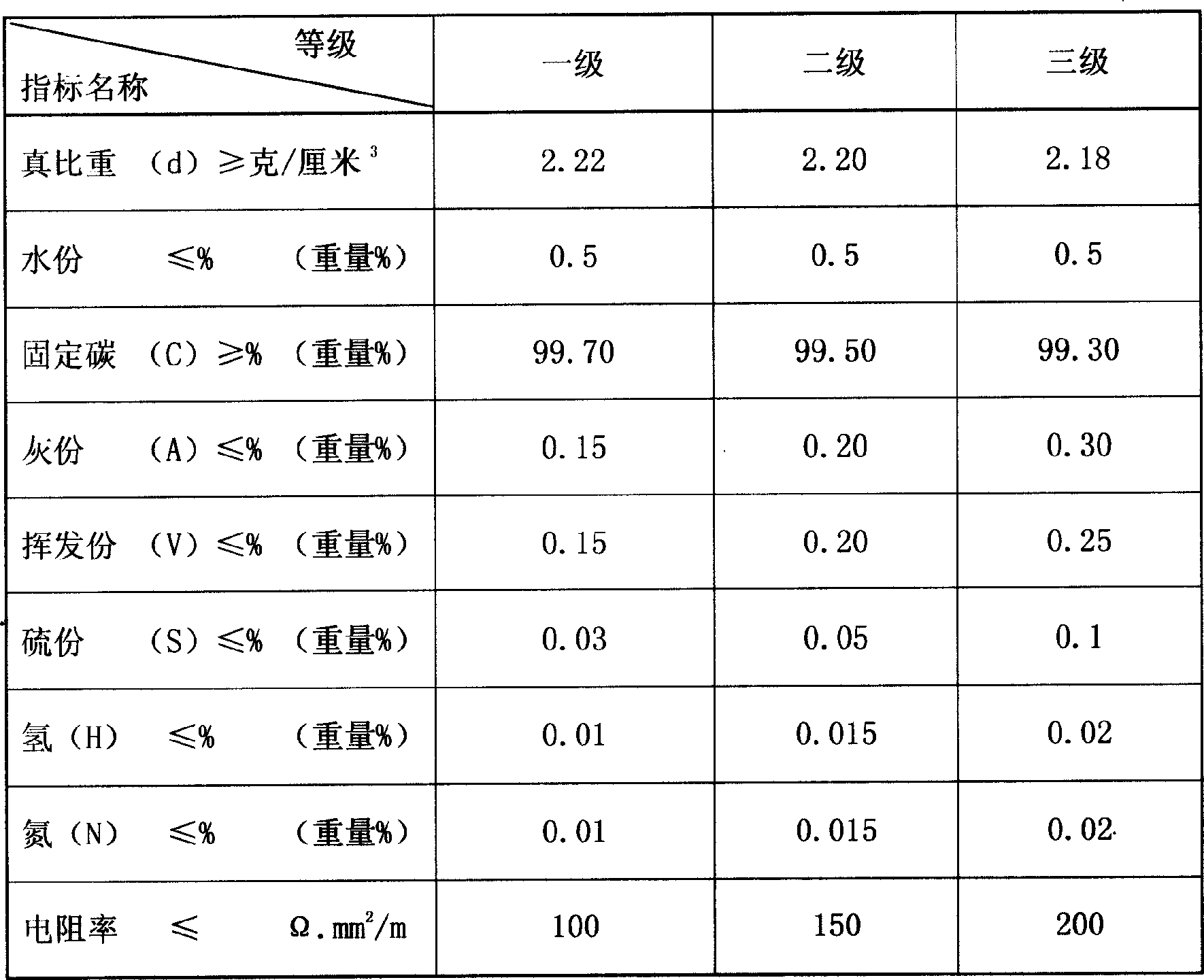

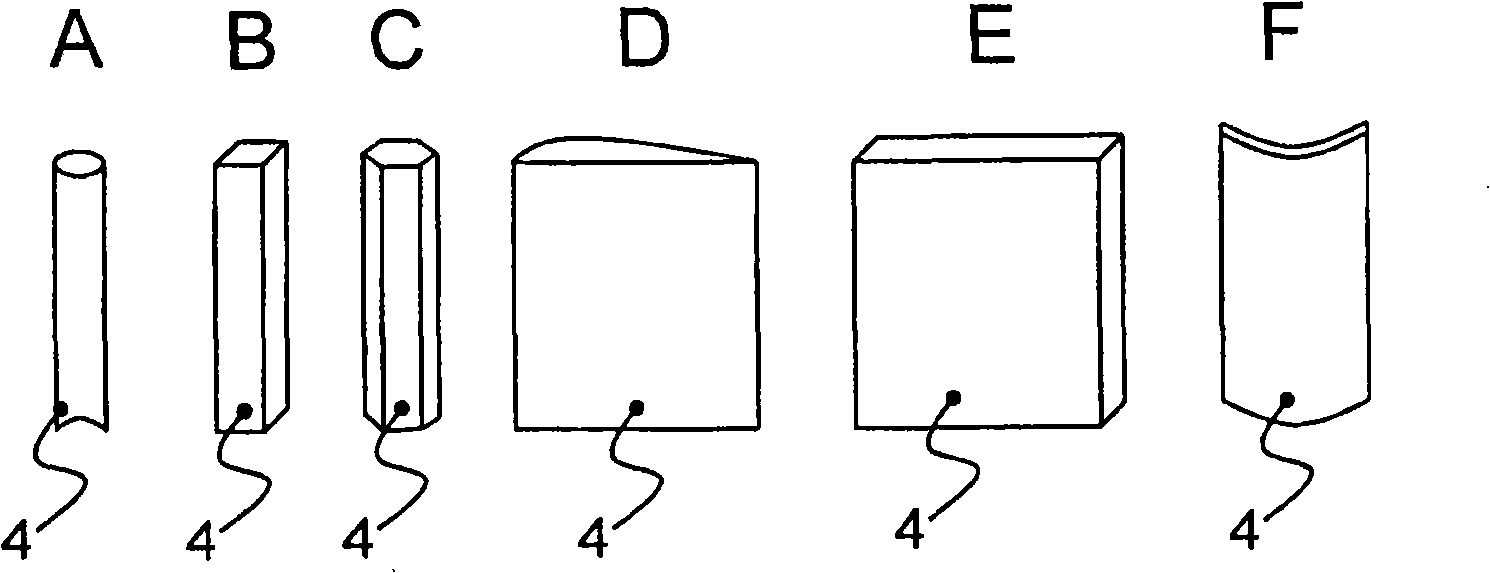

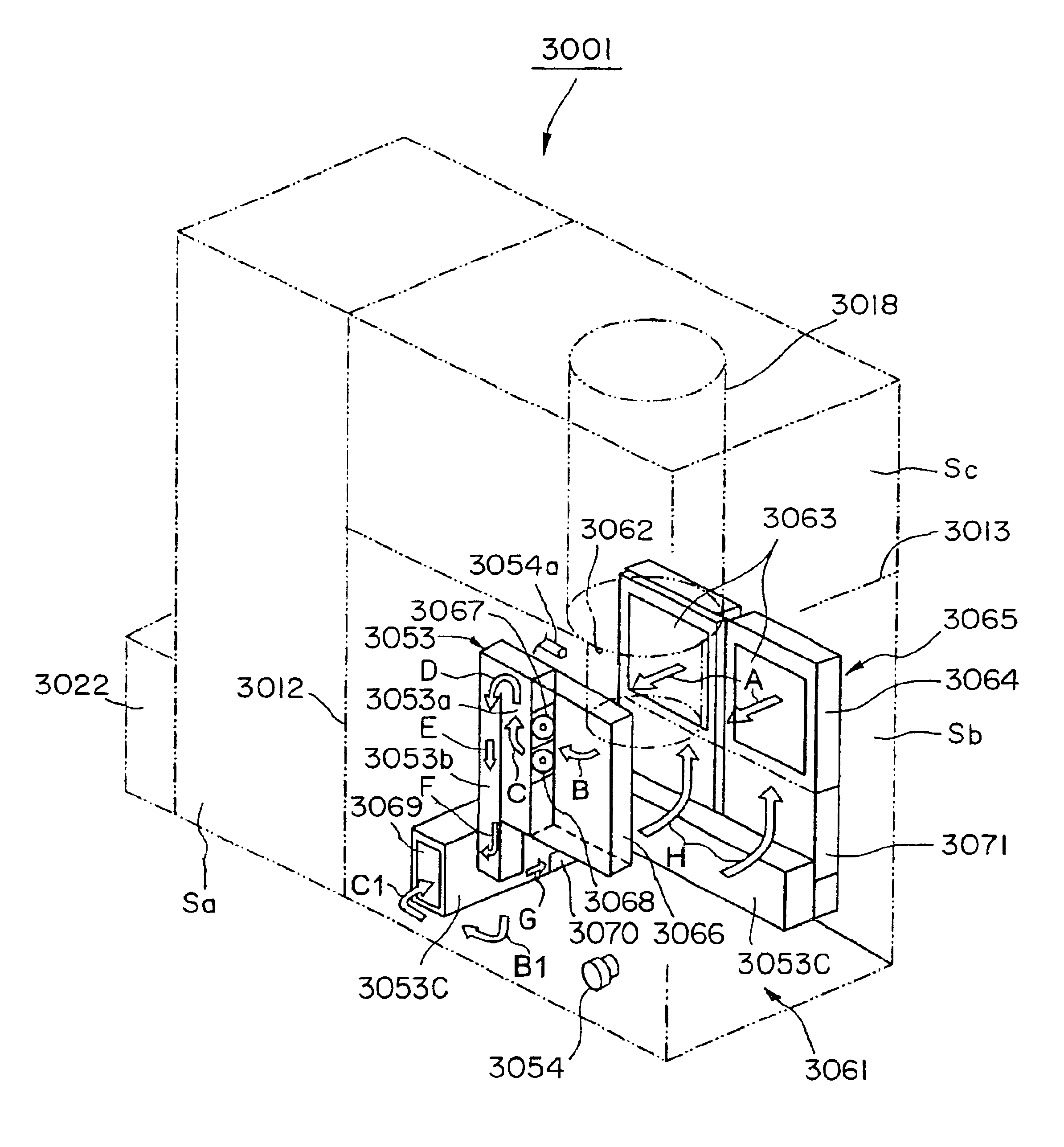

Continuous production and apparatus for high-purity graphite carbon material

ActiveCN1613756ASolve ultra-high temperature resistanceSolve insulation problemsFurnace cooling arrangementsFurnace coolingRefractoryGraphite

A production of high-purity graphitic carbon material and its apparatus are disclosed. The process involves raw material system, roasting system and post-treating system: 1) breaking forged petroleum coke by raw material system with grain size up to 0-60 mm and controlling water content <=5%; 2) delivering the treated material into vertical roasting electric furnace and high-temperature treating, preheating, purifying and graphitizing under high-temperature, controlling temperature at 1800-3000deg.C, cooling and discharging at 50-250deg.C with 6-21 hrs; and 3) breaking and screening discharged material by post-treating system with grain size up to 0-50 mm, classifying and packing. The vertical roasting electric furnace consists of upper and lower electrode, supporting frame, material disc, the third cooling section, electrode cooling cover, furnace core carbon fireproof material, furnace casing, furnace lid , smoke conduit, and bucket.

Owner:JIANGSU SURUN HIGH CARBON

Method for temperature manipulation of a melt

InactiveCN101405231AIncrease temperatureReduce the temperatureOhmic-resistance electrodesTank furnacesElectrical resistance and conductanceElectrical resistivity and conductivity

A method and device are disclosed for temperature manipulation of a melt even with conductivity below 10<-1> O <-1>cm<-1>, thus permitting refining of the melt at temperatures above 1700 DEG C. According to the method for temperature manipulation of a melt (16), in particular, in a refiner unit, the melt (16) is heated at least by ohmic resistance heating, at least two electrodes (4) are arranged in the melt (16) and at least a part of the melt (16) is cooled. The device (1) for temperature manipulation and / or refining and / or purification and / or homogenisation of a melt (16) comprises at least one arrangement for accommodating melt material (36, 16), defining an inner chamber and at least two electrodes (4) for ohmic resistance heating of the melt (16), wherein the electrodes (4) project into the inner chamber of the arrangement in particular of the vessel (2).

Owner:SCHOTT AG

System and method for steel making

InactiveUS6890479B2Improve conductivityHigh hardnessTuyeresBlast furnace detailsProduction rateAlloy

A metallurgical furnace, which includes a furnace shell, an exhaust system, and a gas cleaning system, further includes a plurality of improved pipes and fume ducts throughout to increase operational life and productivity. The pipes and fumes ducts are comprised of an aluminum-bronze alloy which provides enhanced properties over prior art materials including thermal conductivity, modulous of elasticity and hardness. The use of the alloy also minimizes maintenance requirements of the pipes and fume ducts, thereby extending their operational life. In operation, gases formed from smelting or refining are evacuated from the furnace shell through the exhaust system into the gas cleaning system. The gases, as well as the system, are water cooled by way of the plurality of pipes displaced throughout.

Owner:AMERIFAB INC

Furnace panel leak detection system

ActiveUS7832367B2Detection of fluid at leakage pointFurnace cooling arrangementsElectric arc furnaceStress sensors

A furnace panel leak monitoring and control system for fluid-cooled panels in high temperature industrial furnaces such as, for example, smelting furnaces, blast furnaces and electric arc furnaces. The system performs at least two and up to four functions simultaneously. At minimum, the system includes one or more temperature sensors received within the body of the panel to monitor temperature within the metal of the panel itself, and pressure sensors installed proximate the inlet and outlet of each panel coolant fluid circuit, which circuits are preferably periodically automatically tested, to check for leaks in the coolant circuits. In addition, the system preferably includes temperature and flow sensors for monitoring the furnace panel coolant circuit(s) for temperature and flow fluctuations, respectively, which may be indicative of leaking cooling circuits. The system triggers visual and / or audible alarms to alert a human operator of an apparent coolant fluid leak situation.

Owner:BERRY METAL

Heat treatment system and a method for cooling a loading chamber

InactiveUS7059849B2Efficient solutionSimple structureWorkpiece holdersMuffle furnacesThroatNuclear engineering

Owner:TOKYO ELECTRON LTD

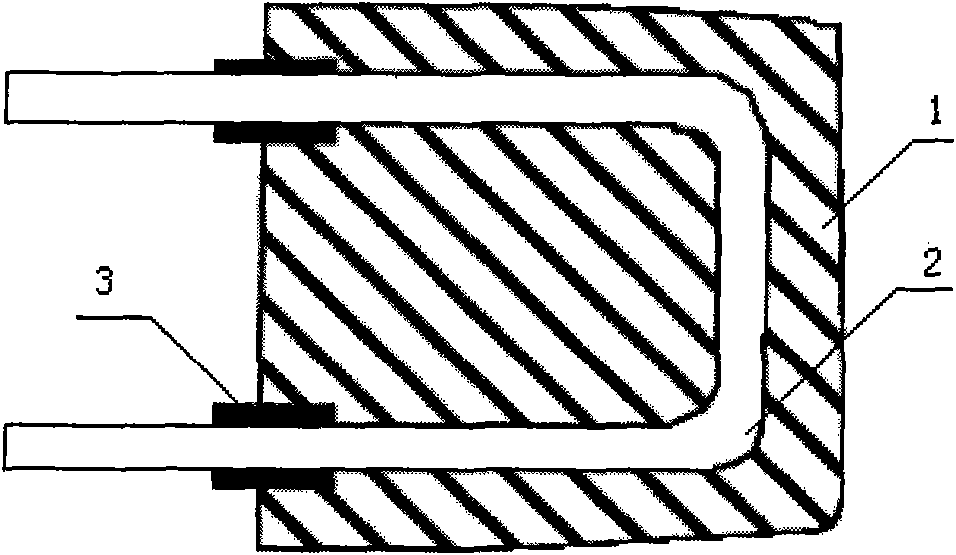

Core-type furnace

InactiveUS6996153B2Perfect electric protectionImprove protectionFurnaces without endless coreFurnace cooling arrangementsCeramic coatingEngineering

Vertical segments of a side wall of a crucible for an induction furnace are assembled at an adjustable, invariable position by screws screwed into tapped holes of a flange common to all segments. A precise assembly is thus obtained producing no deformation and no internal stresses. The segments are coated with a ceramic coating for their protection and to prevent formation of electric arcs. Junction edges of faces are rounded to achieve the same effect. Water cooling boxes of the lower furnace hearth are similarly constructed. The apparatus can, as an example, be applied to vitrification techniques.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +2

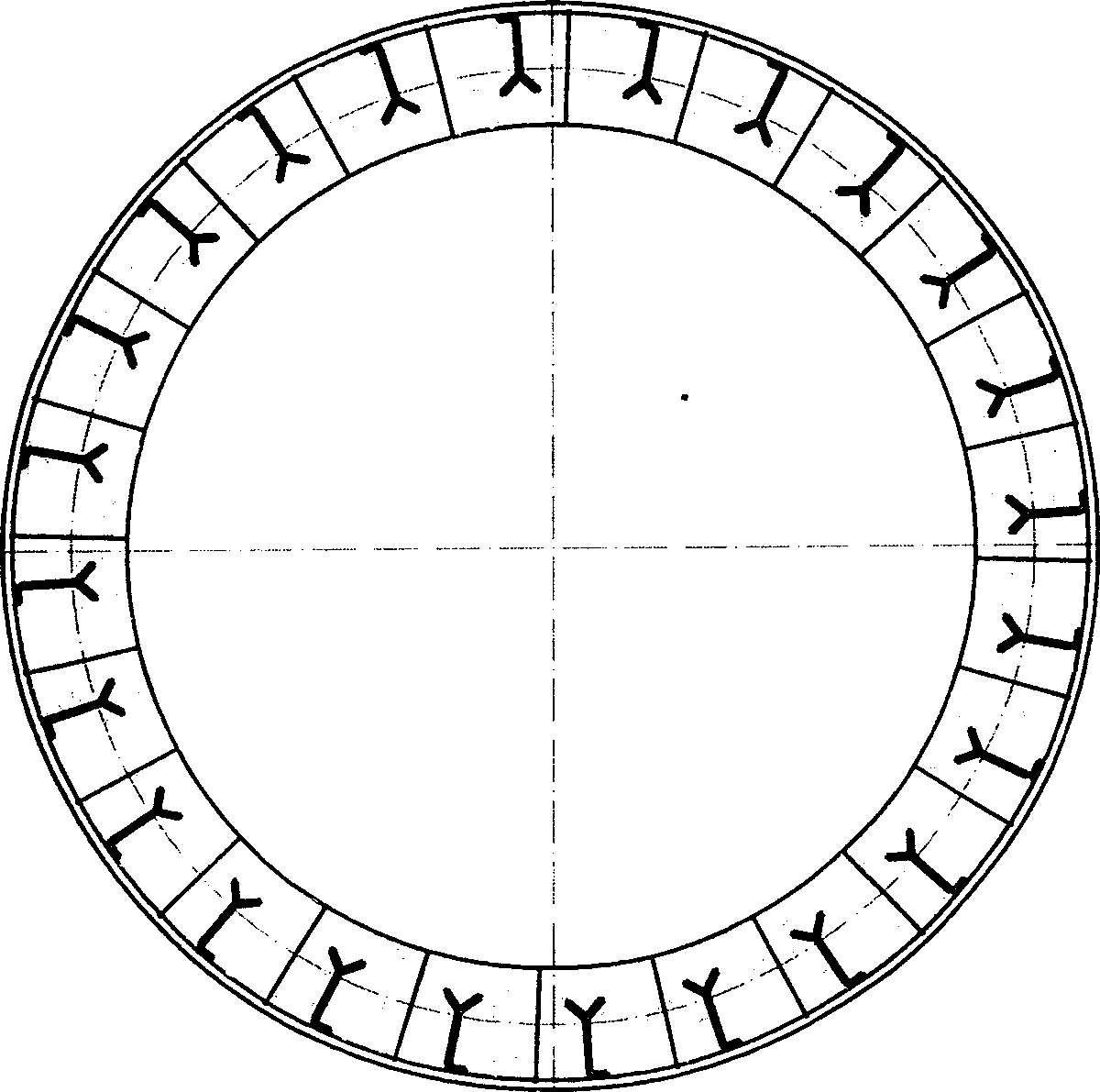

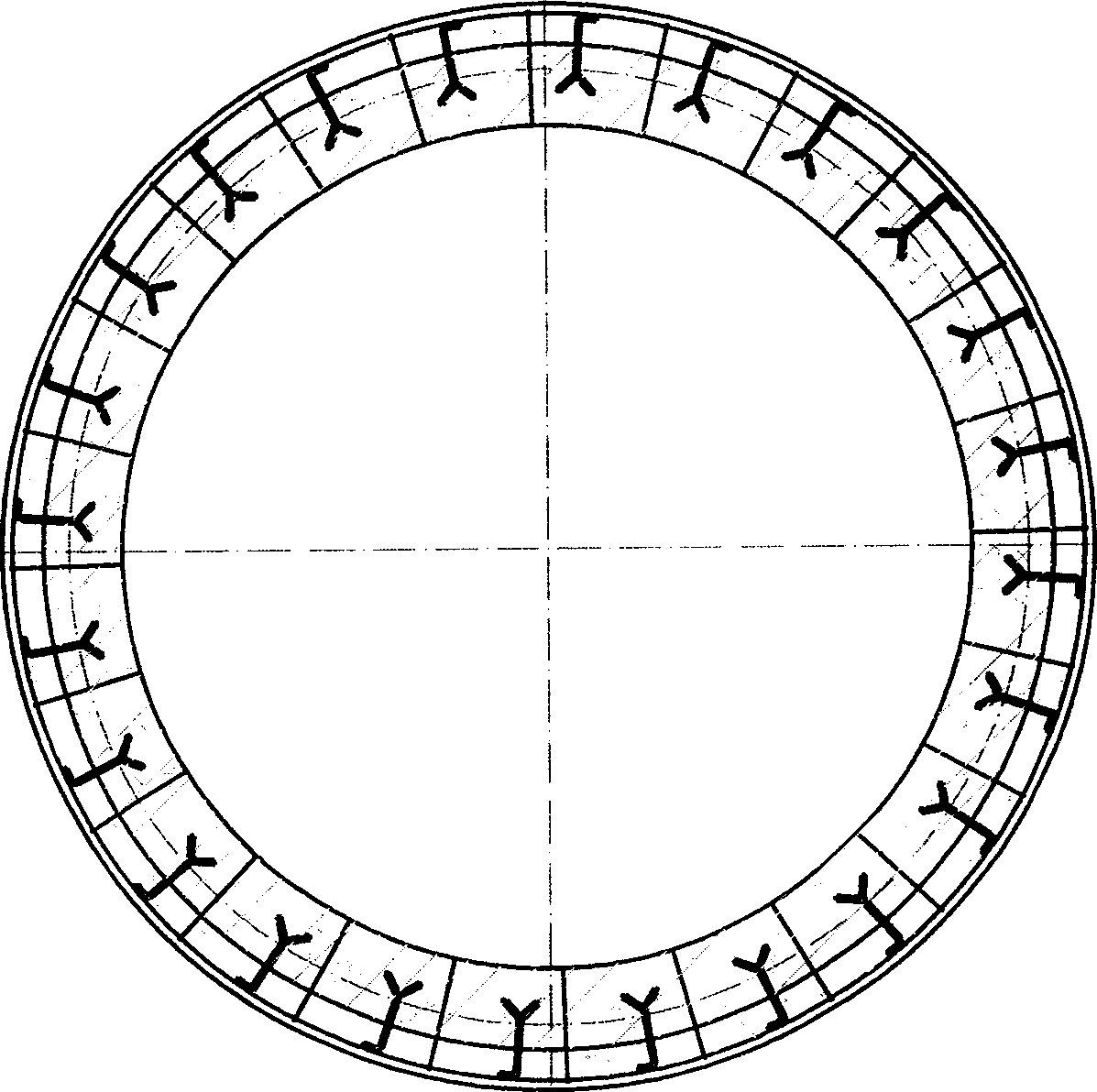

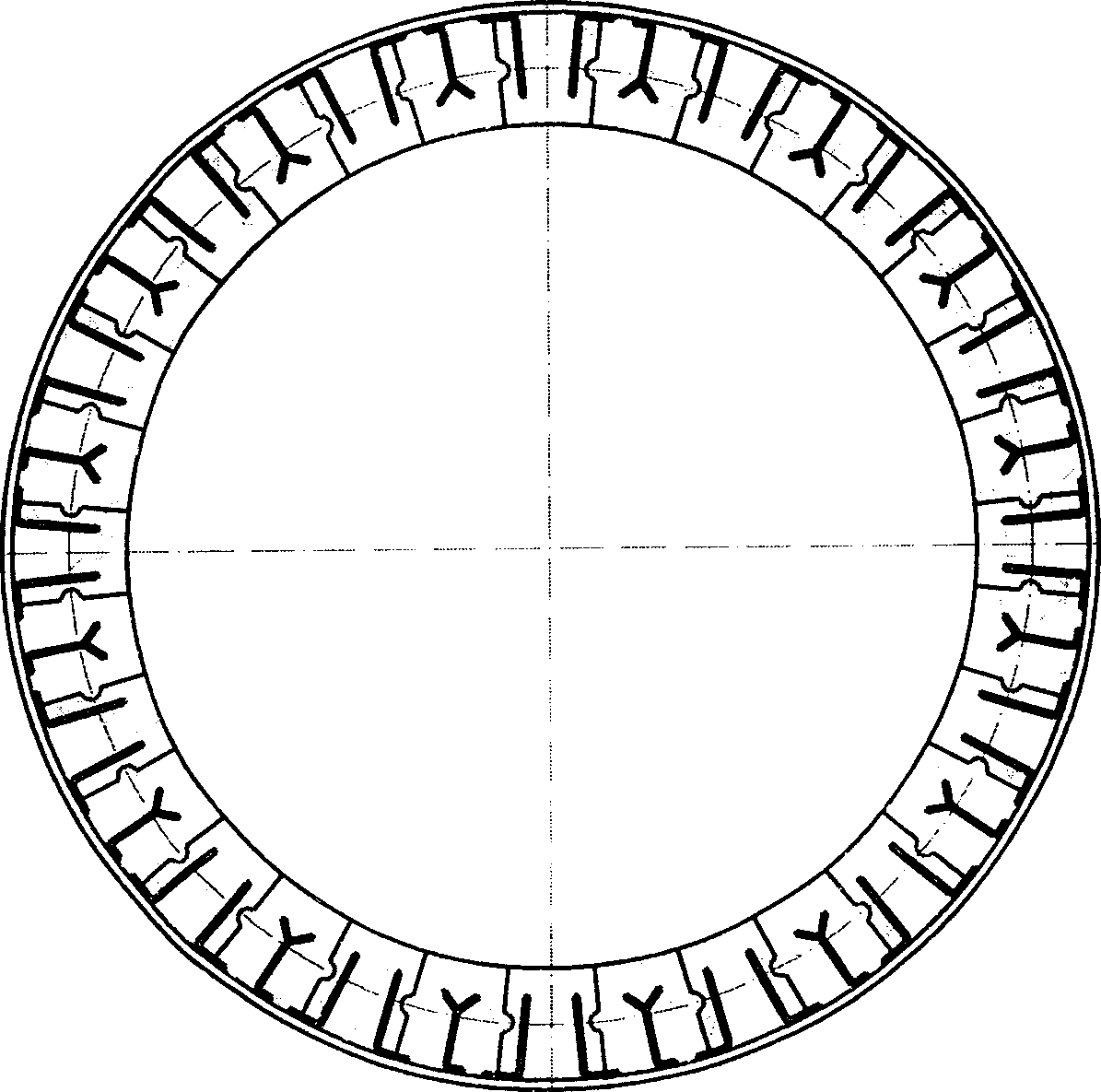

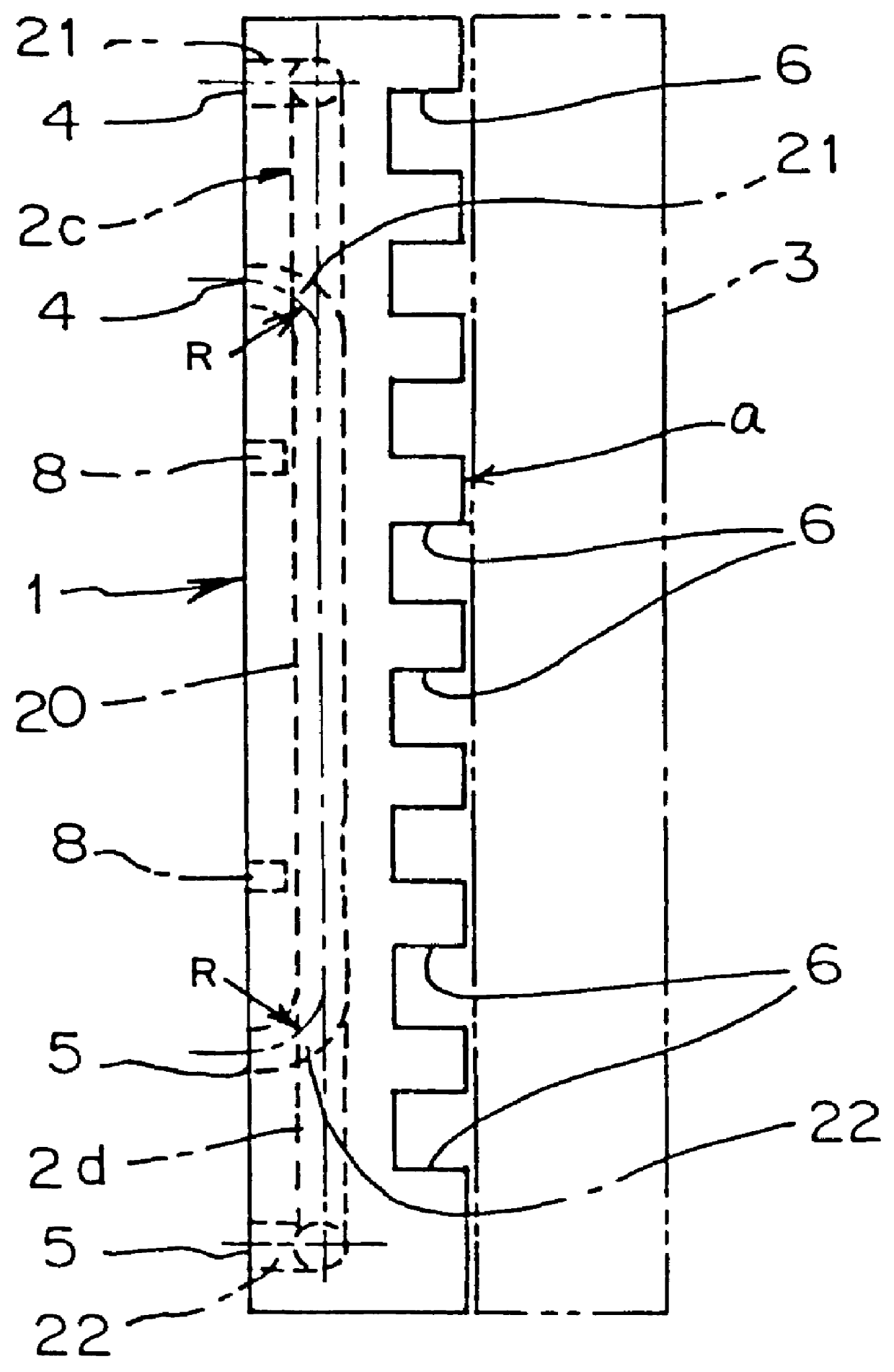

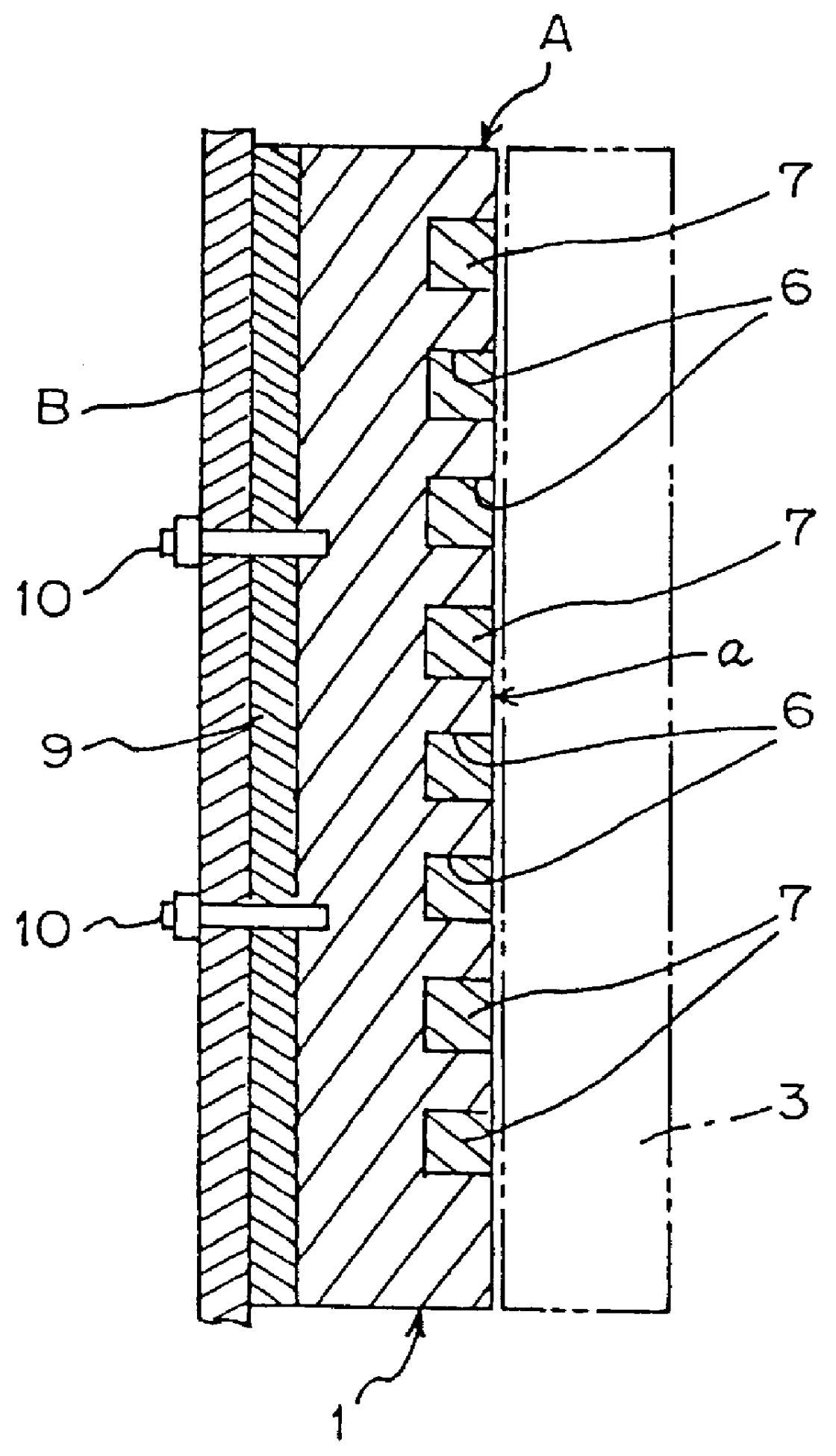

Cooling panel for a furnace for producing iron or steel

InactiveUS7549463B1Pressure loss becomes excessiveReduce total pressure lossMetal-working apparatusCooling devicesSteelmakingCopper

Owner:PAUL WURTH SA

Rotary kiln casting material prefabricated sections and method for making same

InactiveCN1670457AShorten the timeSave materialRotary drum furnacesFurnace cooling arrangementsEngineeringLight quality

This invention relates to a rotary kiln cast material precast block. It is compounded by high temperature proof outer layer and light quality heat insulation and preservation inner layer. Anchoring inner tendon is set between the two layers; an arc groove is set on both lateral faces of the precast block. The rotary kiln cast material precast block in this invention can also be consisted by high temperature proof outer layer and anchoring inner tendon, anchoring inner tendon is set in high temperature proof outer layer and an arc groove is set on both lateral faces of the precast block. This invention also provides a method of manufacturing the above precast block. The problem of difficult processing of inner liningof rotary kiln, long consumption time, high labor intensity, expensive cost of erecting framework is solved. And the problem of short life, high failure rate, no long time stable running in production running is also solved.

Owner:张继枢

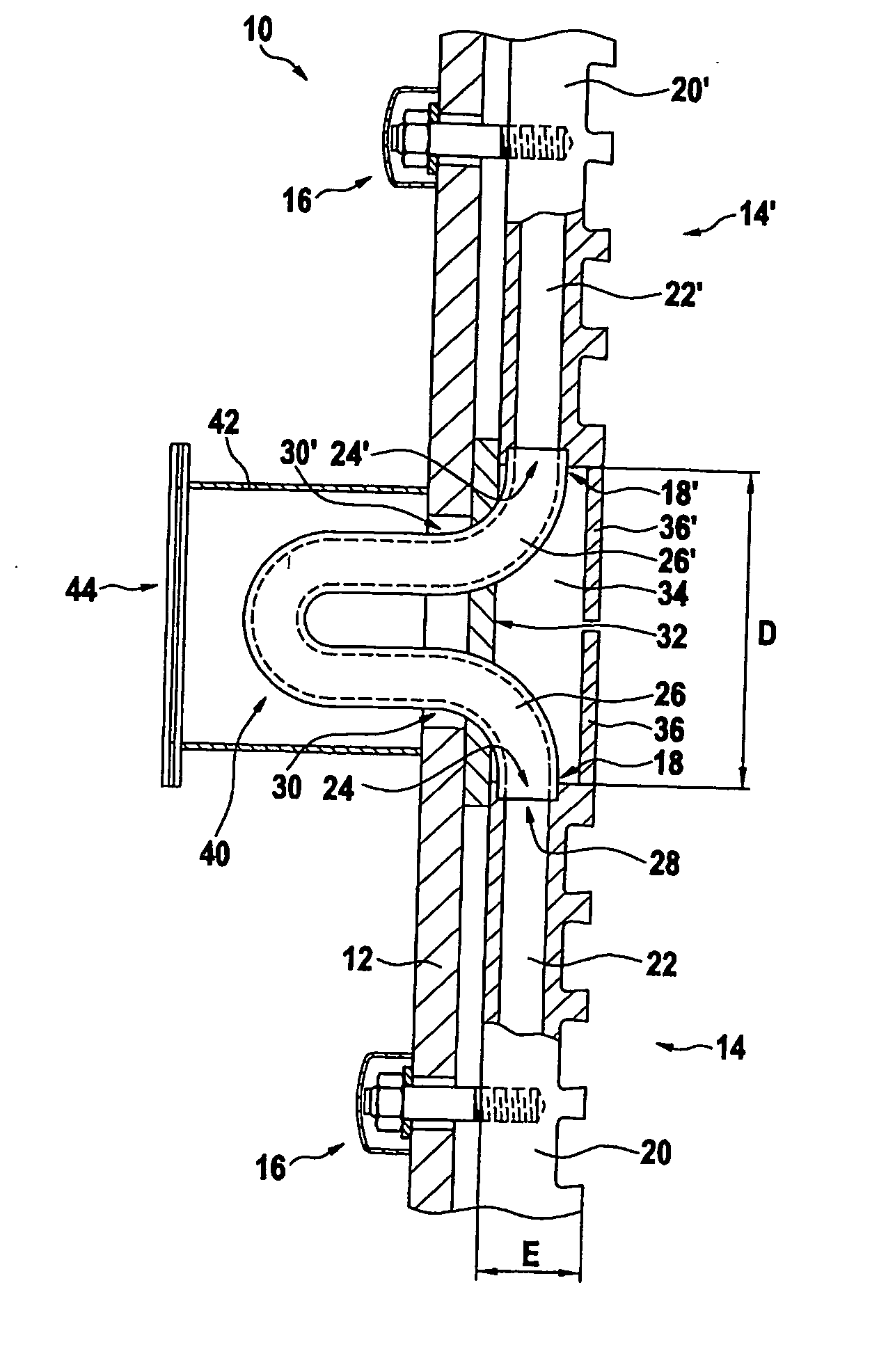

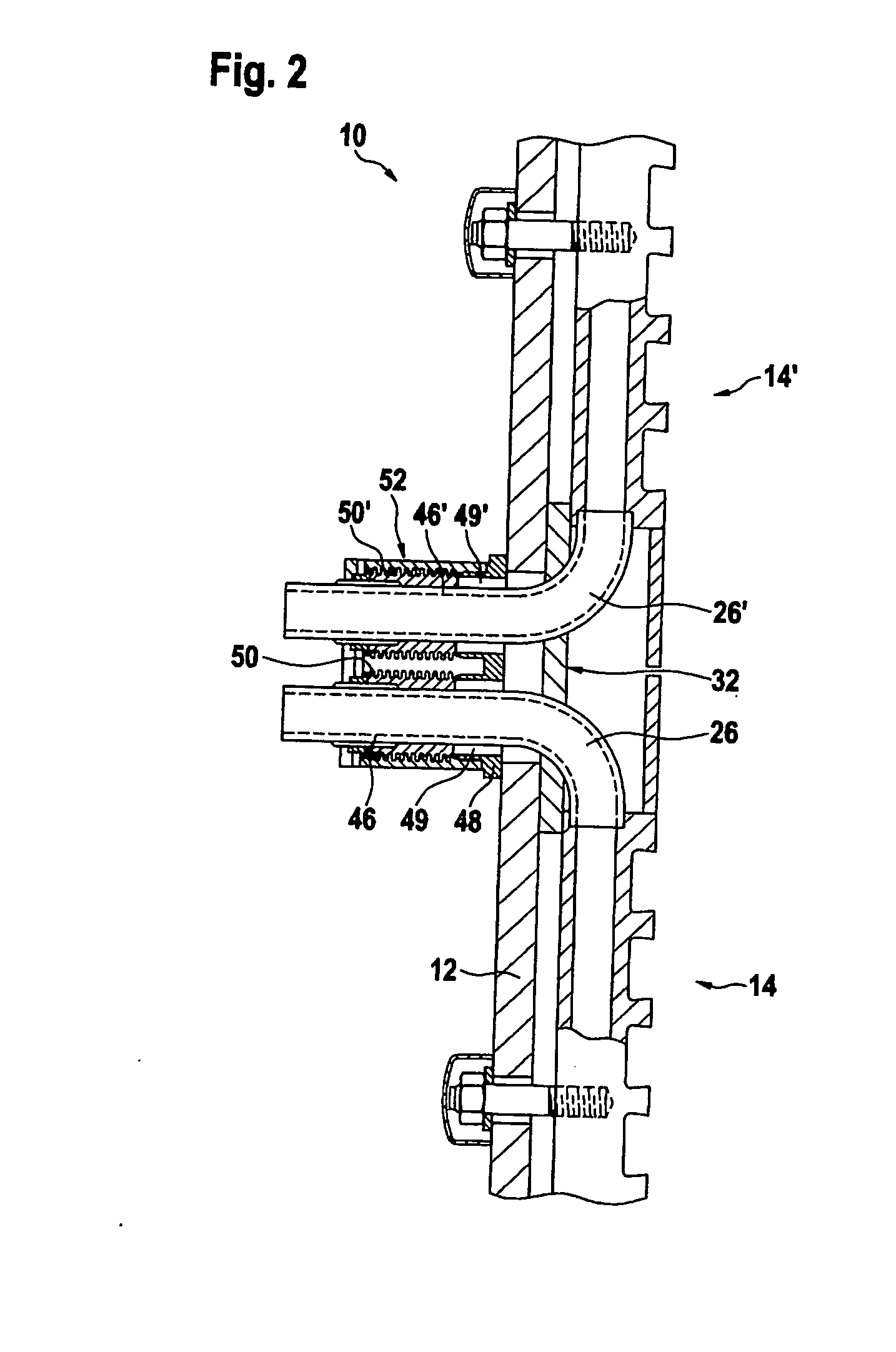

Cooled furnace wall

InactiveUS20060208400A1Save a lot of timeEliminate needBlast furnace detailsManufacturing convertersEngineeringTube bending

A cooled furnace wall comprises a furnace shell with an inner and an outer side and cooling plates lining the inner side of the furnace shell. Each of the cooling plates has a plate body and protruding connection pieces for supplying the cooling plate with a coolant. The furnace shell has connection openings therein for interconnecting the connection pieces of adjacent connection plates from the outer side of the furnace shell. At least one of the connection pieces is formed by a tube bend that protrudes from an edge face of the plate body and that has a connection end to extending through one of the connection openings in the furnace shell.

Owner:PAUL WURTH SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com