Continuous production and apparatus for high-purity graphite carbon material

A technology of high-purity graphite and process method, which is applied in the field of coking industry, can solve the problems of low fixed carbon content, inability to meet production needs, and inability to meet needs, and achieve the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

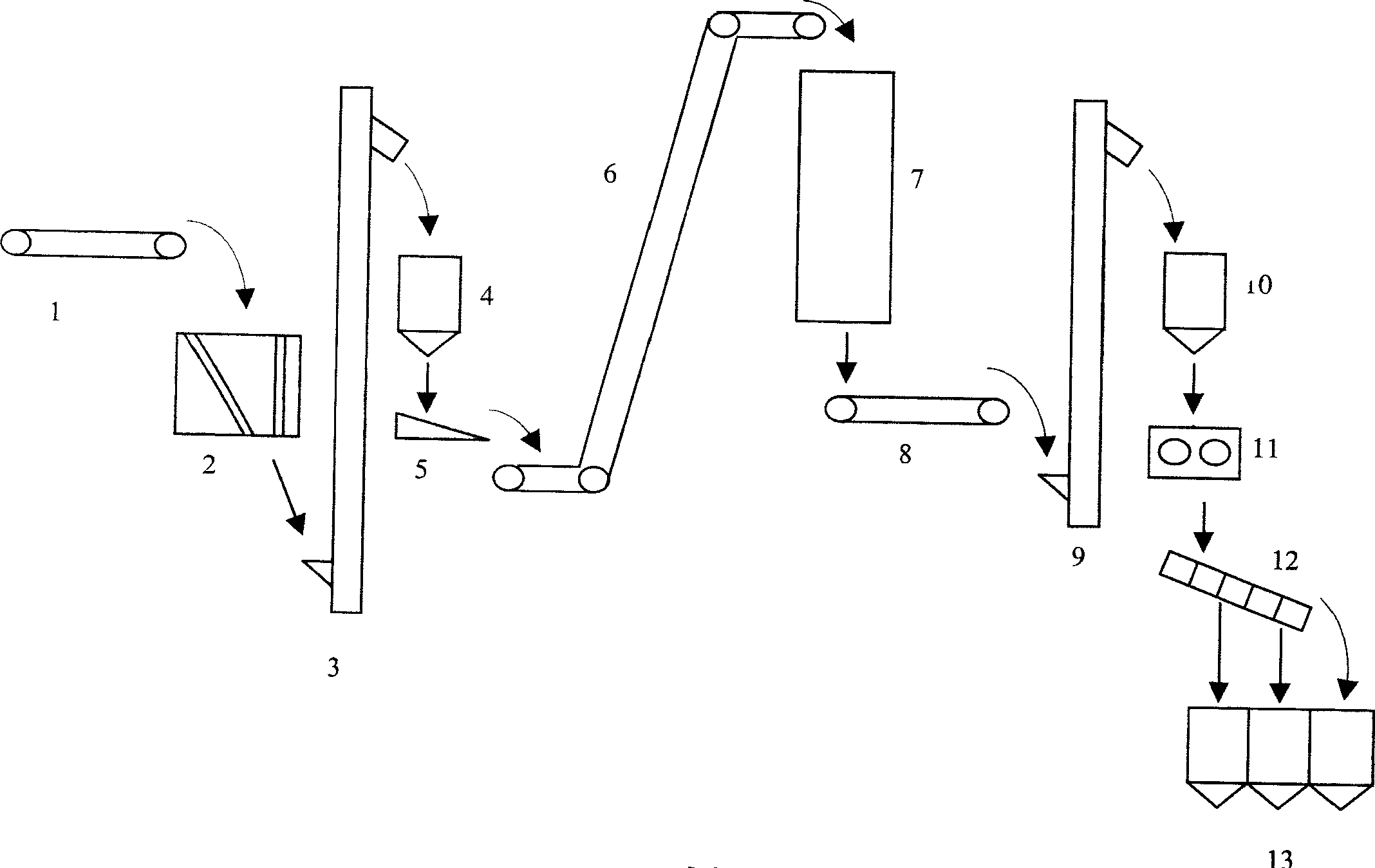

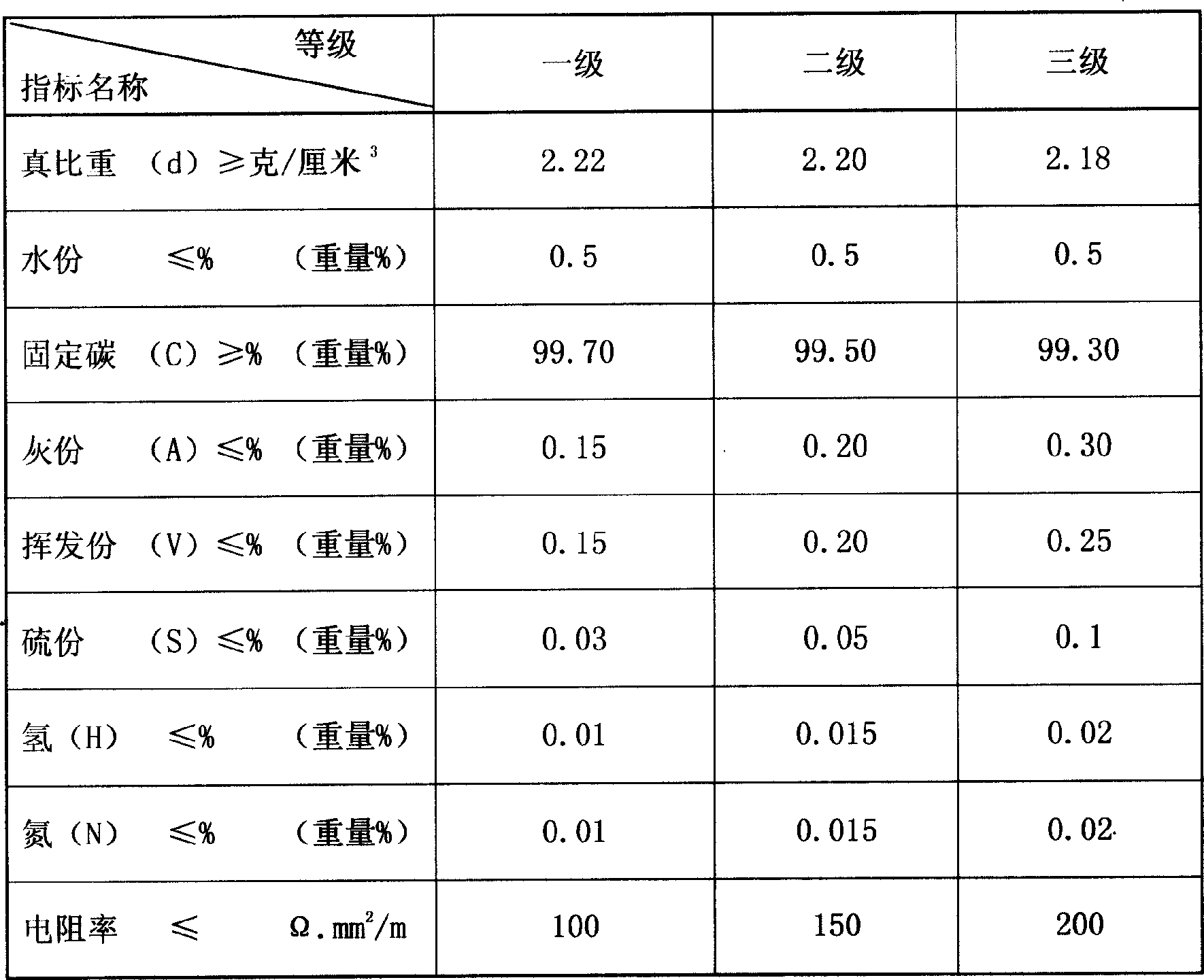

[0027] Embodiment 1 High-temperature calcination continuous airtight production of high-purity graphite carbon material

[0028] The production capacity is 1500 tons / year, the annual production time is 250 days, and the feed rate is 0.25 tons / hour.

[0029] Specifications of raw materials Calcined petroleum coke (% by weight) has 3% water, 98.81% fixed carbon on dry basis, 0.50% ash, 0.69% volatile matter, and 0.57% sulfur (S).

[0030] The main equipment adopts vertical calcining electric furnace, and the relevant equipment is listed in the following table:

[0031] Serial number Equipment name Specifications Quantity

[0032] 1 belt conveyor B500 1 set

[0033] 2 jaw crusher PEX-250×1000 1 set

[0034] 3 bucket elevator D250 1 set

[0035] 4 silos 20M 3 1 set

[0036] 5 Electromagnetic vibration feeder CZ3.00 1 set

[0037] 6 Large inclination belt conveyor DDJ II type B400, H80 1 set

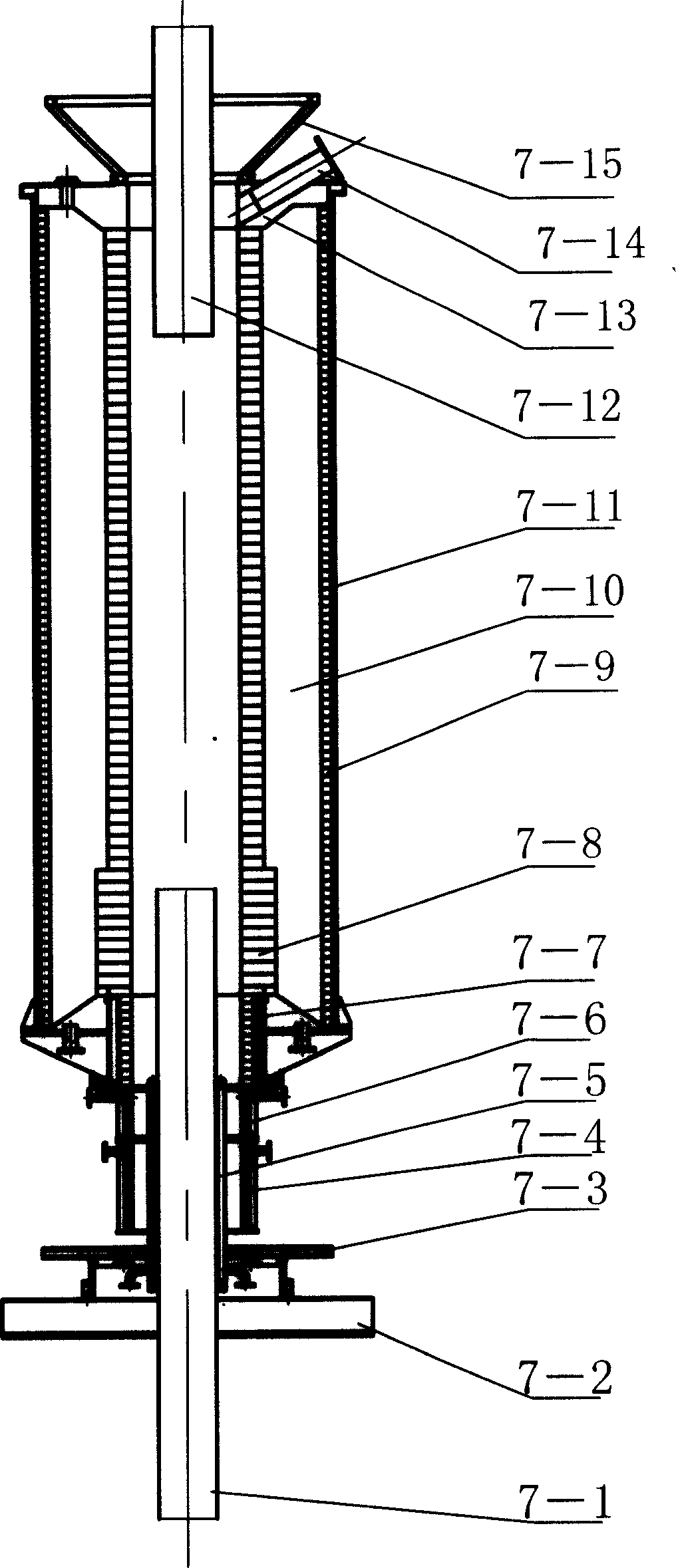

[0038] 7 Vertical Calciner Outer diameter×height φ2600×720...

Embodiment 2

[0054] Embodiment 2 High-temperature calcining continuous airtight production of high-purity graphite carbon material

[0055] The production capacity is 2100 tons / year, the annual production time is 250 days, and the feed rate is 0.35 tons / hour.

[0056] Specifications of raw materials Calcined petroleum coke (% by weight) contains 1.5% moisture, 98.78% fixed carbon on a dry basis, 0.53% ash, and 0.69% volatile matter; and 0.63% sulfur (S).

[0057] Main equipment and relevant equipment are the same as embodiment 1.

[0058] Process Control Parameters

[0059] 1. The crushing particle size of petroleum coke after calcining in the raw material system is controlled to be ≤55 mm, and the water content is controlled to be ≤1.5%;

[0060] 2. Calcination system Preheating temperature of vertical calcination electric furnace is 30-1800°C, preheating time is 2.1 hours, calcination temperature is about 2750°C, calcination time is 5.25 hours, cooling temperature is 230°C, cooling tim...

Embodiment 3

[0066] Embodiment 3 High-temperature calcination continuous airtight production of high-purity graphite carbon material

[0067] The production capacity is 2400 tons / year, the annual production time is 250 days, and the feed rate is 0.4 tons / hour.

[0068] Raw Material Specification Calcined petroleum coke (% by weight) moisture 3.2%, fixed carbon 98.75% on a dry basis, ash 0.56%, volatile matter 0.69%, and sulfur (S) 0.69%.

[0069] Main equipment and relevant equipment are the same as embodiment 1.

[0070] Process Control Parameters

[0071] 1. The crushing particle size of petroleum coke after calcining in the raw material system is controlled to be ≤55 mm, and the water content is controlled to be ≤3.2%;

[0072] 2. Calcination system Preheating temperature of vertical calcination electric furnace is 30-1800°C, preheating time is 1.84 hours, calcination temperature is about 2710°C, calcination time is 4.6 hours, cooling temperature is 245°C, cooling time is 2.15 hours, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com