Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

739 results about "Tube bending" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tube bending is any metal forming processes used to permanently form pipes or tubing. Tube bending may be form-bound or use freeform-bending procedures, and it may use heat supported or cold forming procedures.

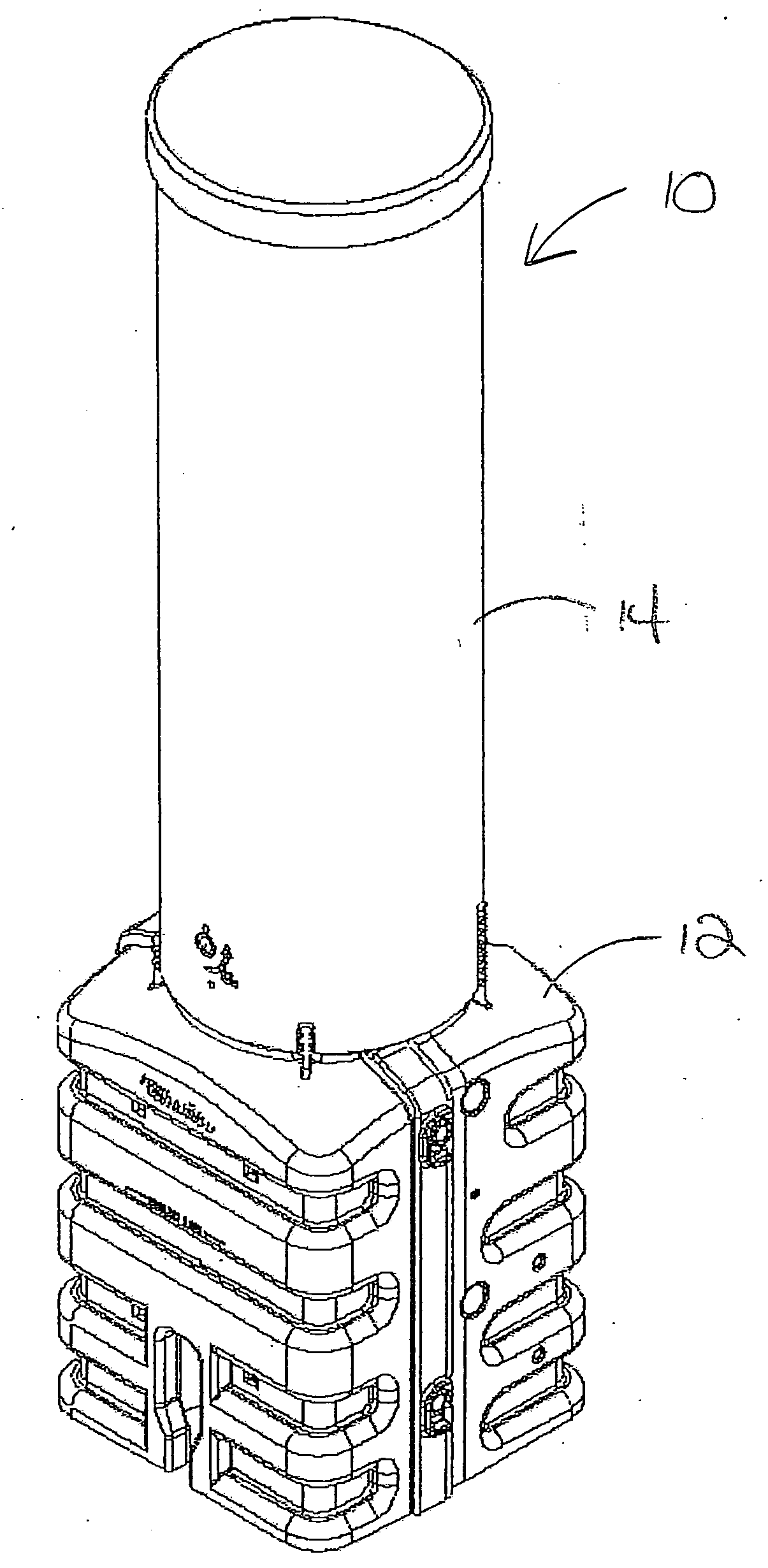

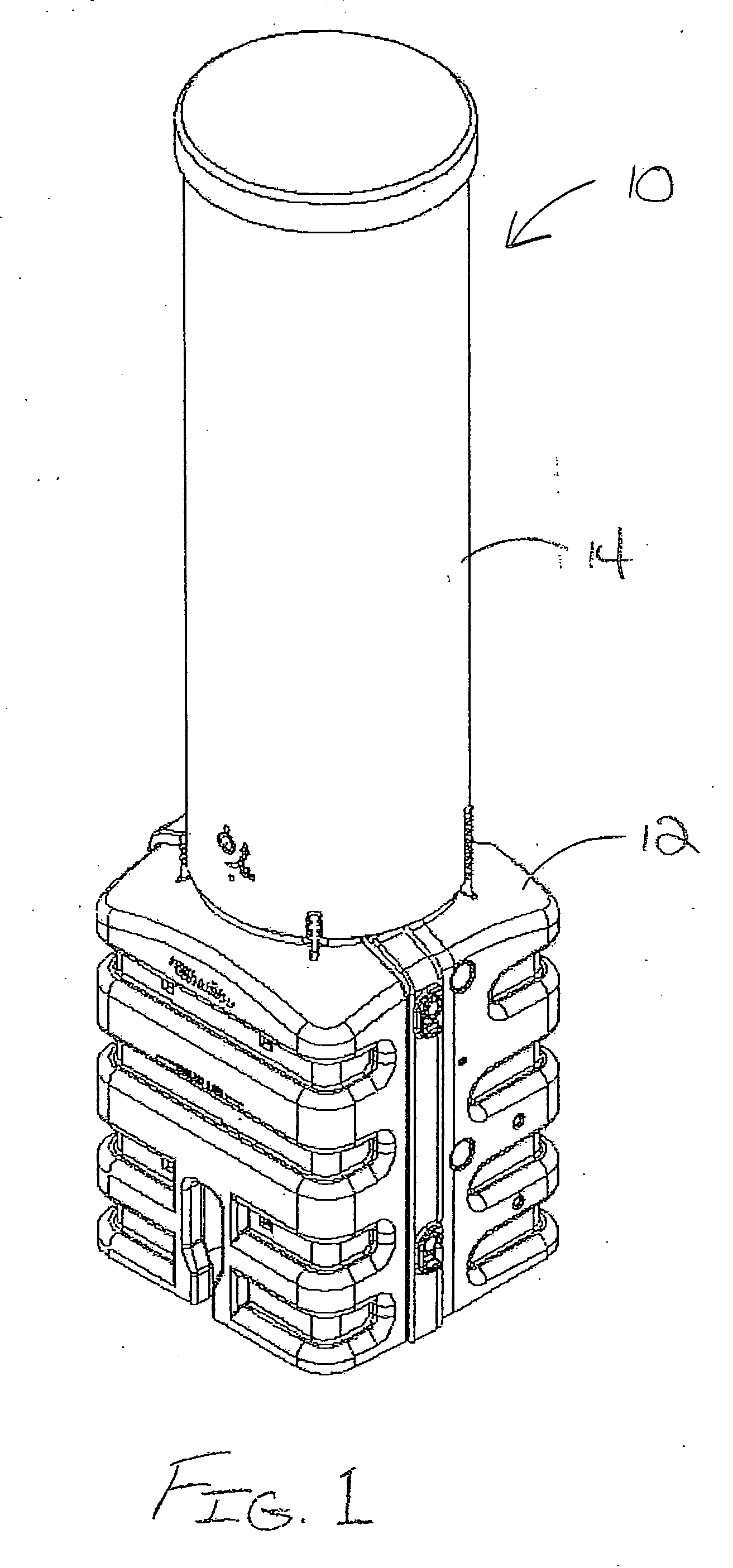

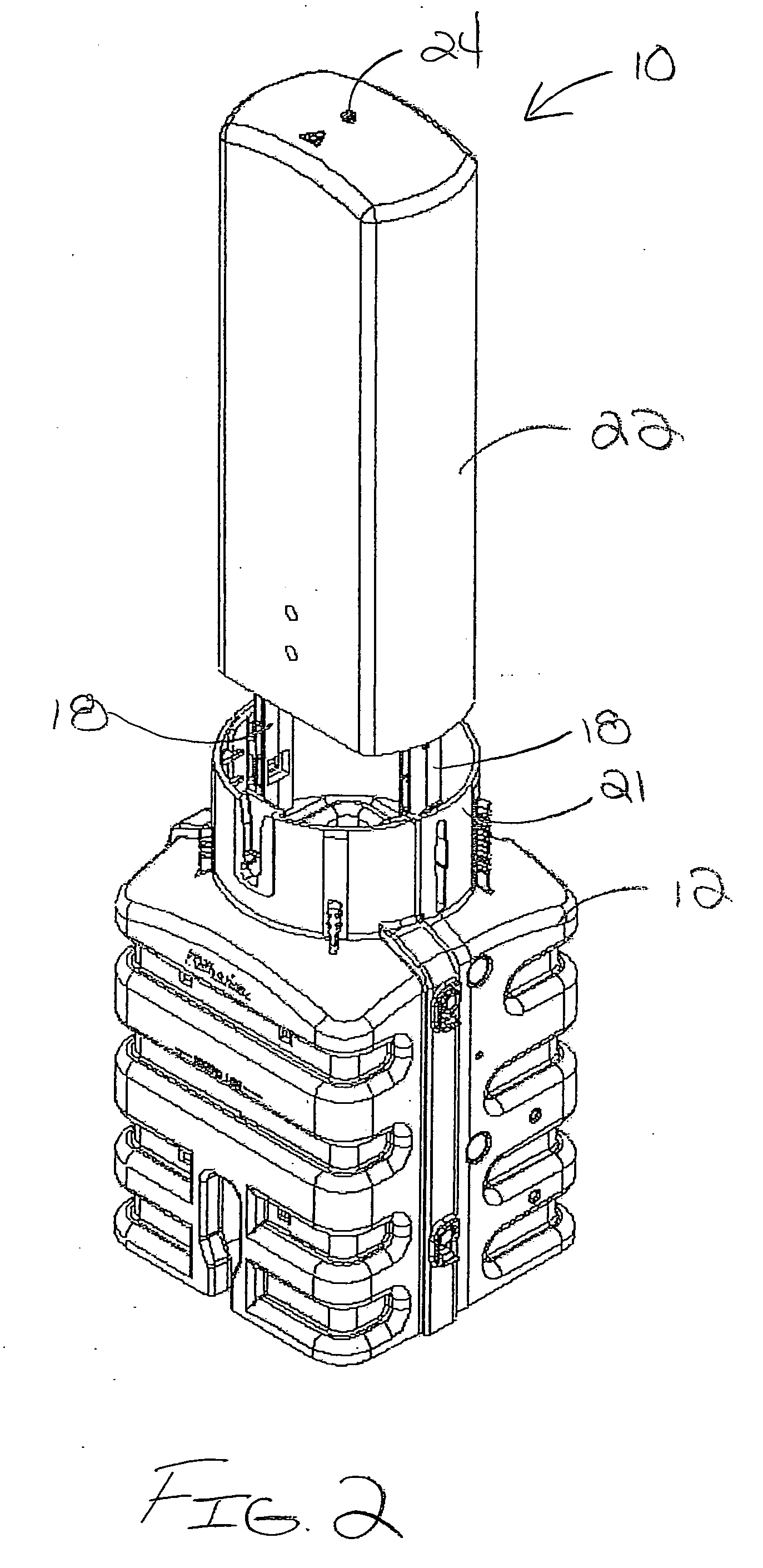

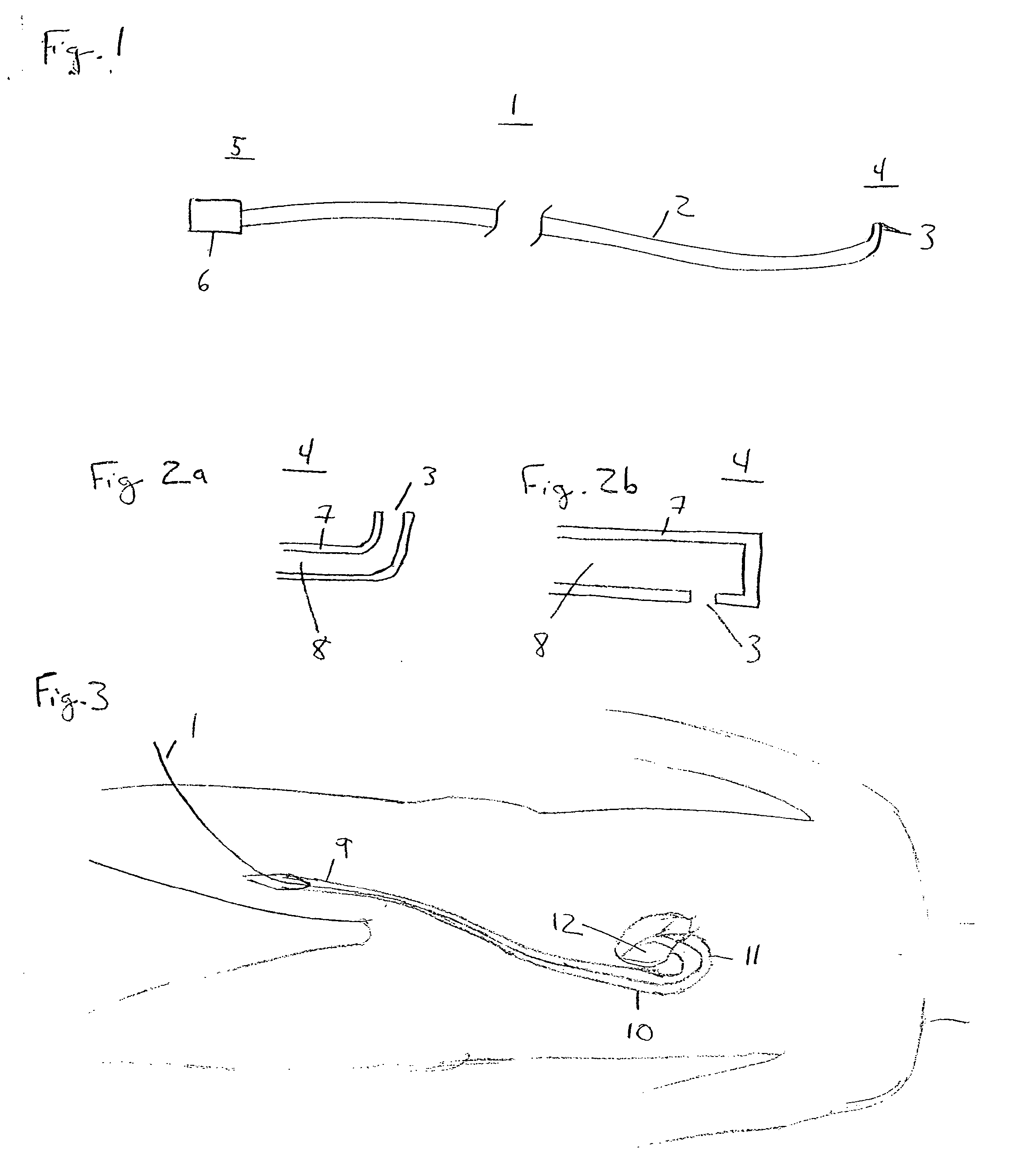

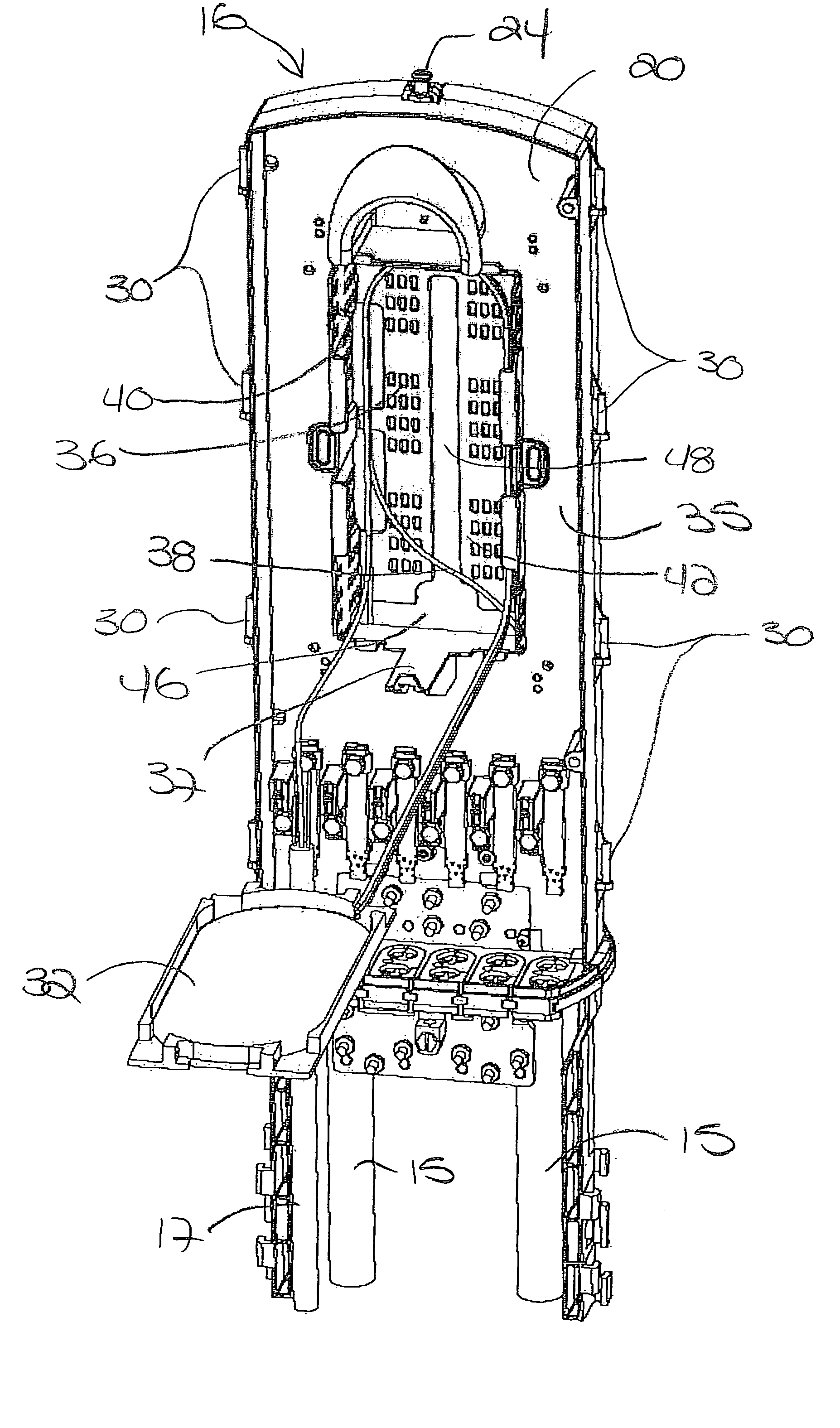

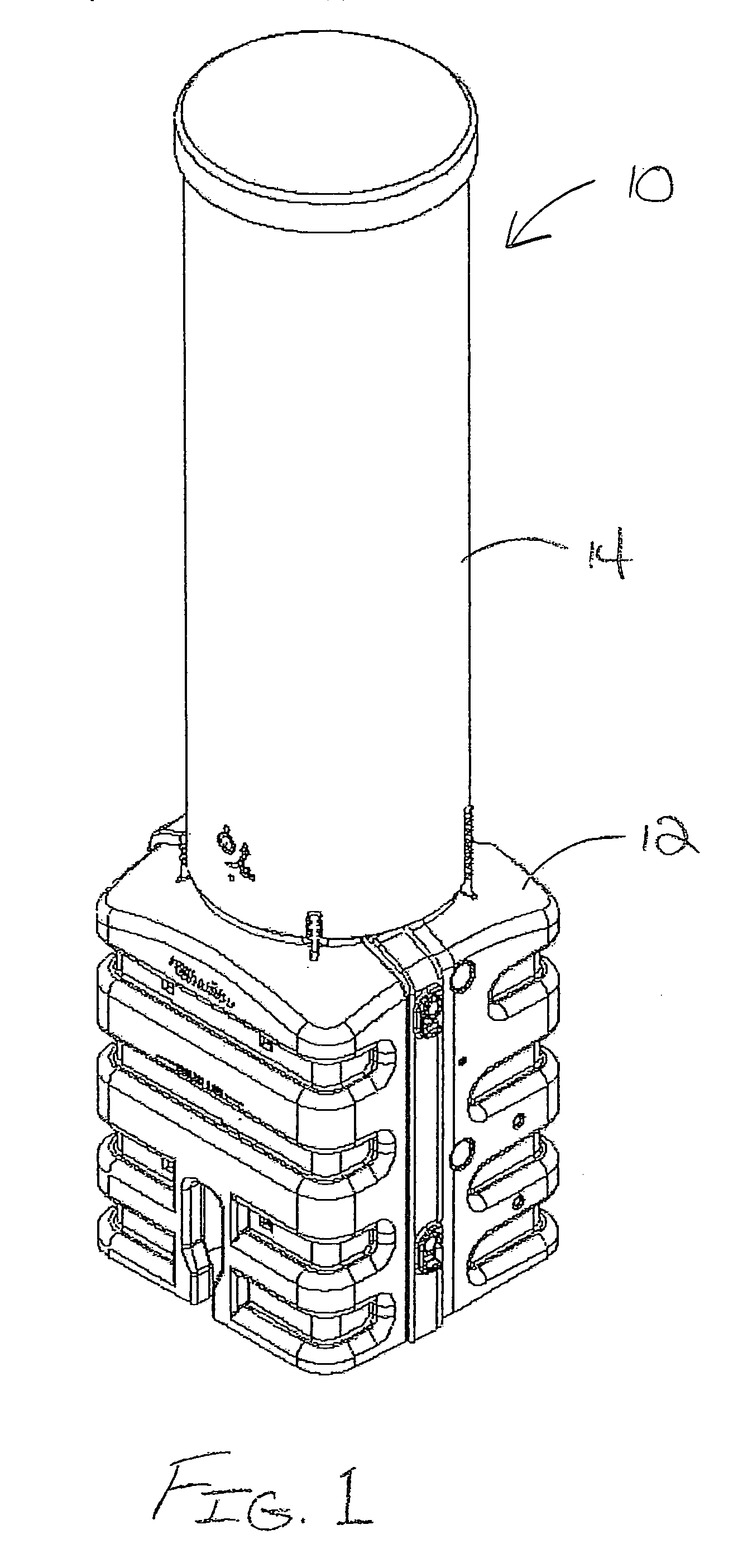

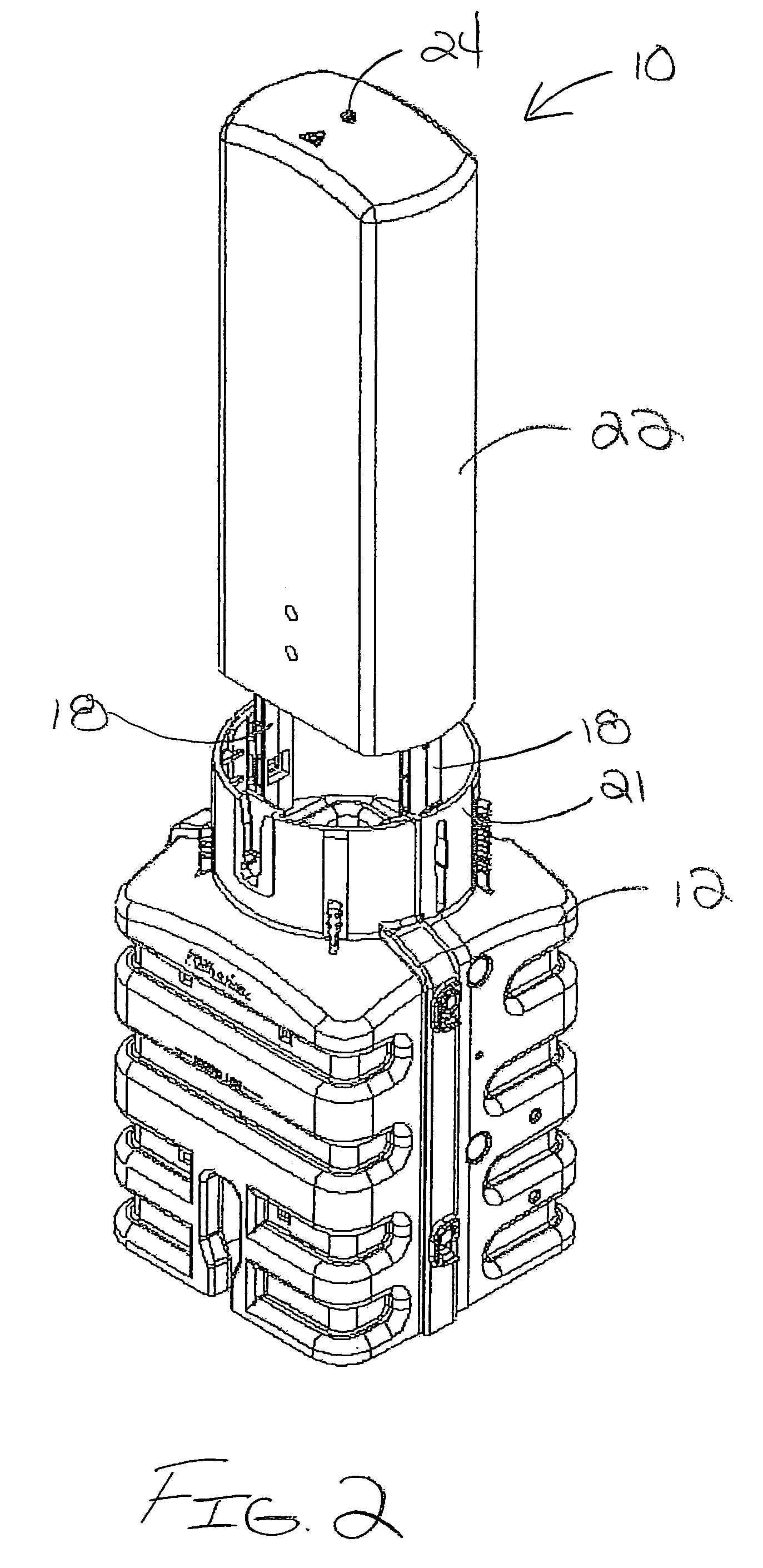

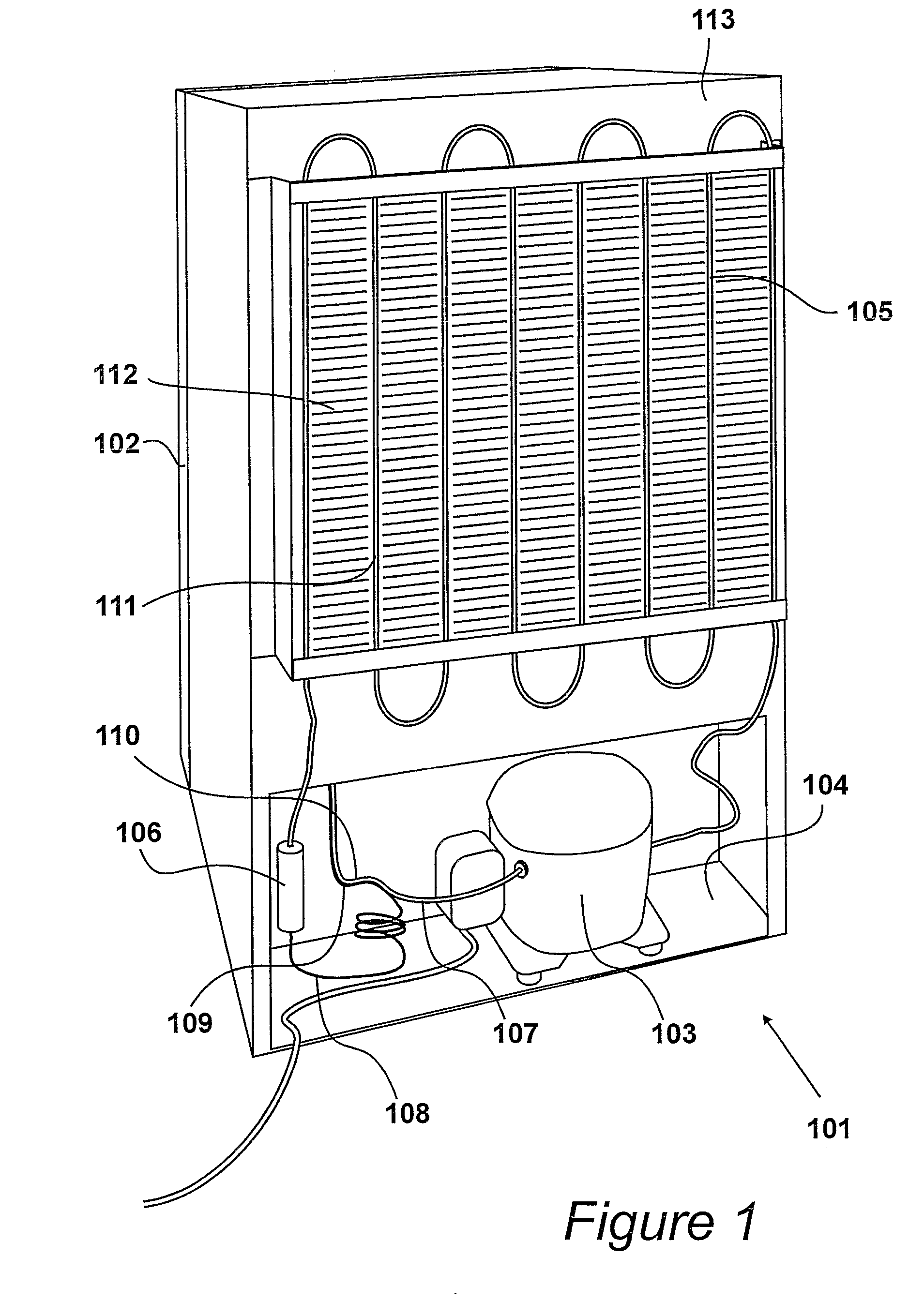

Fiber optic splice enclosure

A fiber optic splice enclosure for housing an interconnection contained in a splice tray between at least one optical fiber of a feeder cable and at least one optical fiber of a drop cable is provided. The optical fiber of the feeder cable is at least partially contained in a feeder cable buffer or transportation tube. The fiber optic splice enclosure includes a support frame arranged in the enclosure. The support frame includes a central office side and a drop side. A basket is arranged on the support frame for storing slack of a spliced buffer tube transitioning to the splice tray. The spliced storage arrangement is sized so as to be able to store slack of the spliced feeder cable buffer tube while maintaining a predetermined tube bend radius. A splice tray mounting arrangement is arranged on the drop side of the support frame for supporting the splice tray.

Owner:CHARLES INDS

Compact counterflow heat exchanger

InactiveUS20050217837A1Heat exchanger casingsStationary tubular conduit assembliesCounter flowEngineering

A geometric arrangement of components in a compact counter-flow heat exchanger that allows for either an increase in effectiveness at a set mass, or a reduction in heat exchanger mass at a set effectiveness, or a combination of the two. The geometric arrangement can be achieved by either tube bending at the level of piece part manufacture and subsequent care during the tube stacking process, or by elastic deformation of the tube stack at the time of bonding.

Owner:UNITED TECH CORP

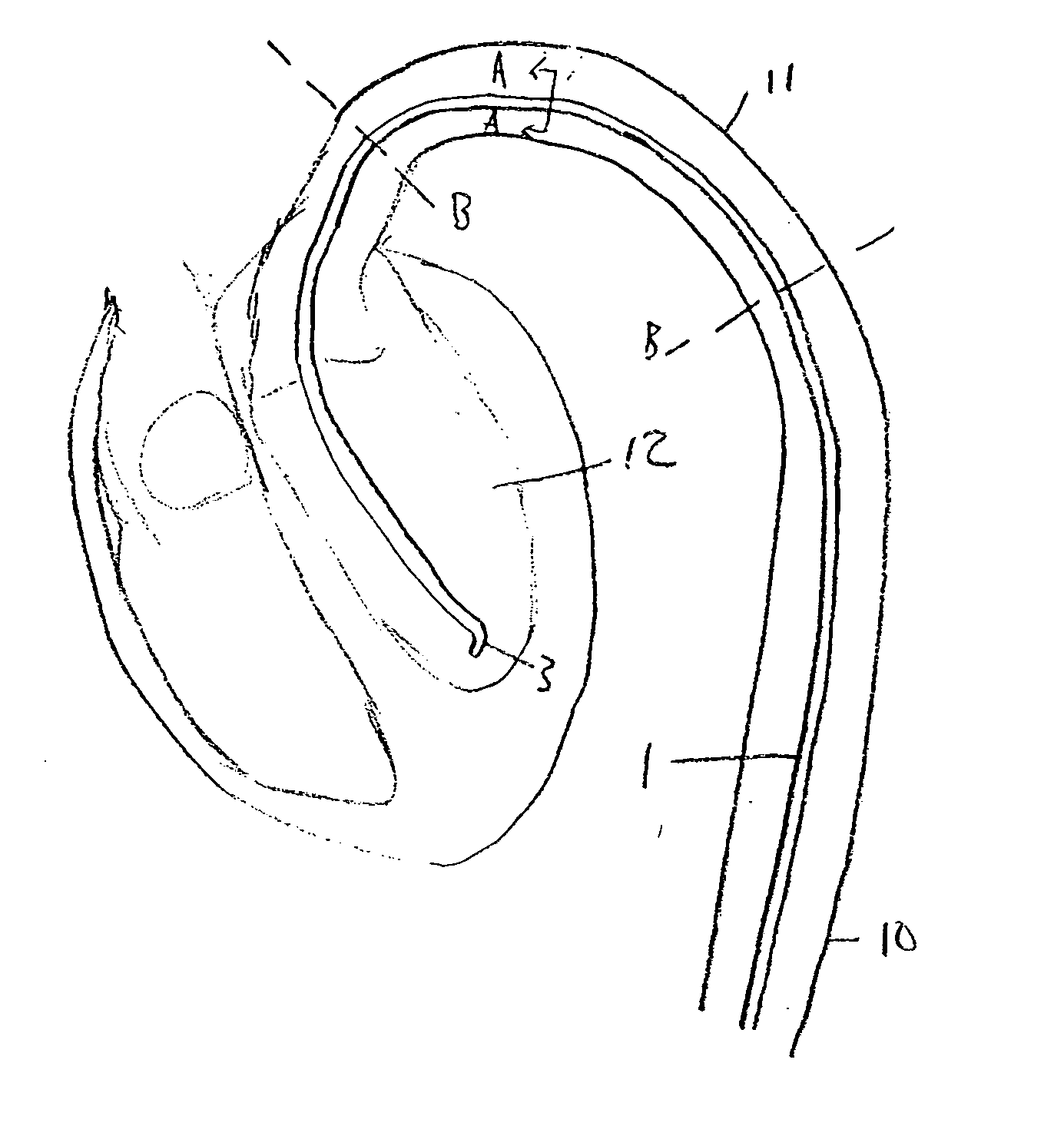

Medical device guidance from an anatomical reference

ActiveUS20050080429A1Rapid reliable determinationLow costEar treatmentSurgeryFluoroscopic imagingFluoroscopic image

A system and method for simply and reliably determining the location and orientation of a medical device within a patient's body. A medical device, such as a catheter, has bending indicators on or imbedded in its wall, and passes through an anatomical reference of known orientation relative to a target site within the patient. Information from the tube bending indicators permits determination of the orientation of a feature, such as an orifice, at the distal end of the medical device relative to the anatomical reference. From the known orientation of the anatomical reference, and information on the location and orientation of the distal end of the medical device obtained from fluoroscopic imaging from a single direction, the physician may reliably determine the orientation of the distal feature relative to the target site, eliminating the need for imaging from multiple directions.

Owner:BOSTON SCI SCIMED INC

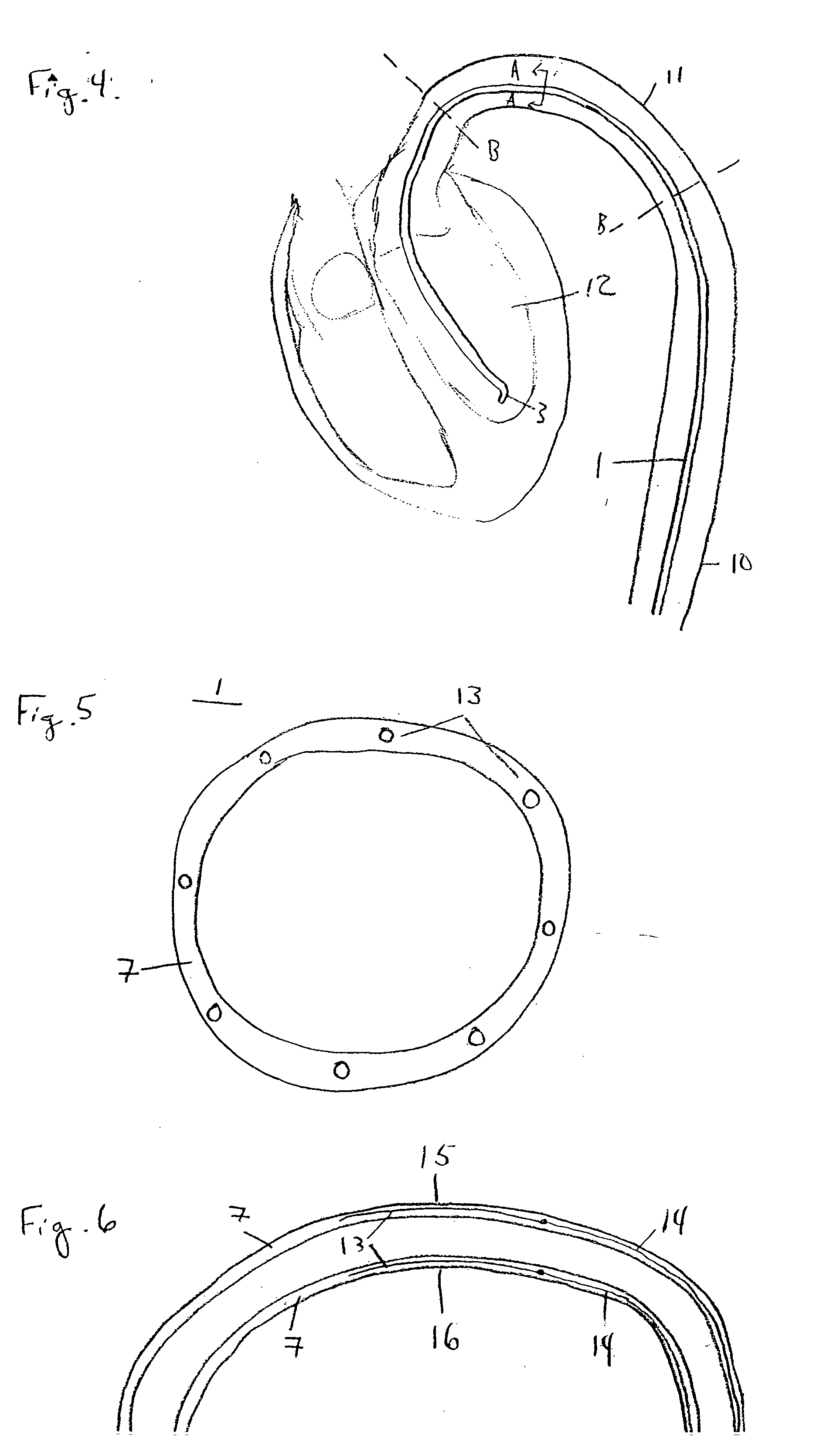

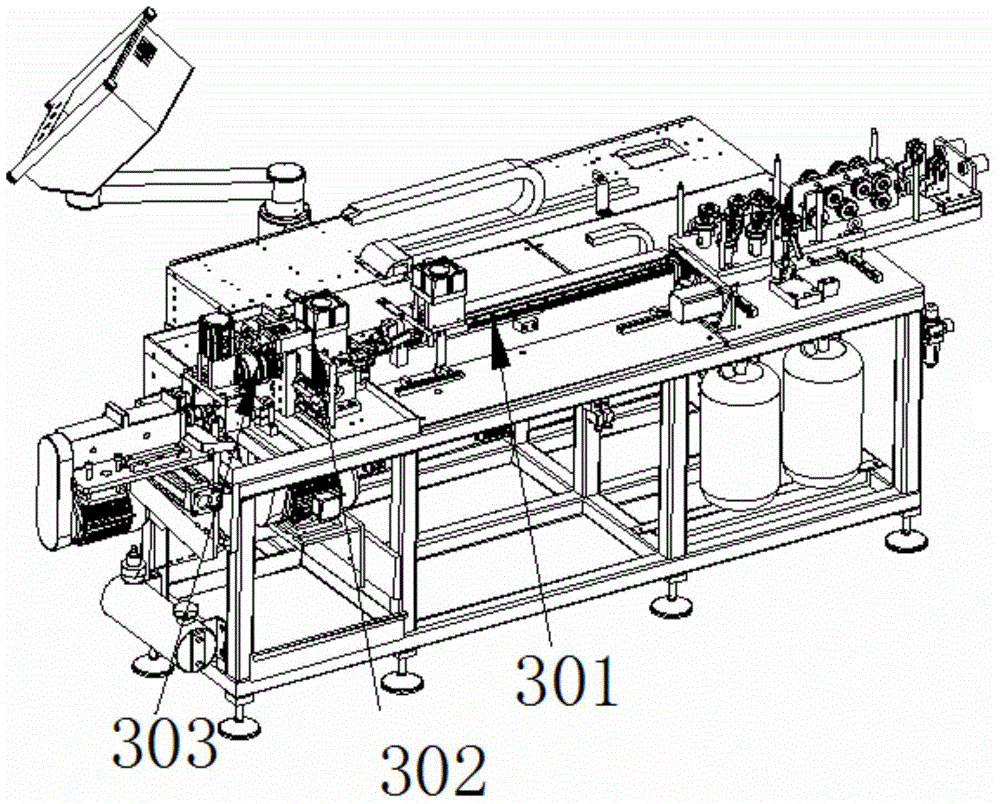

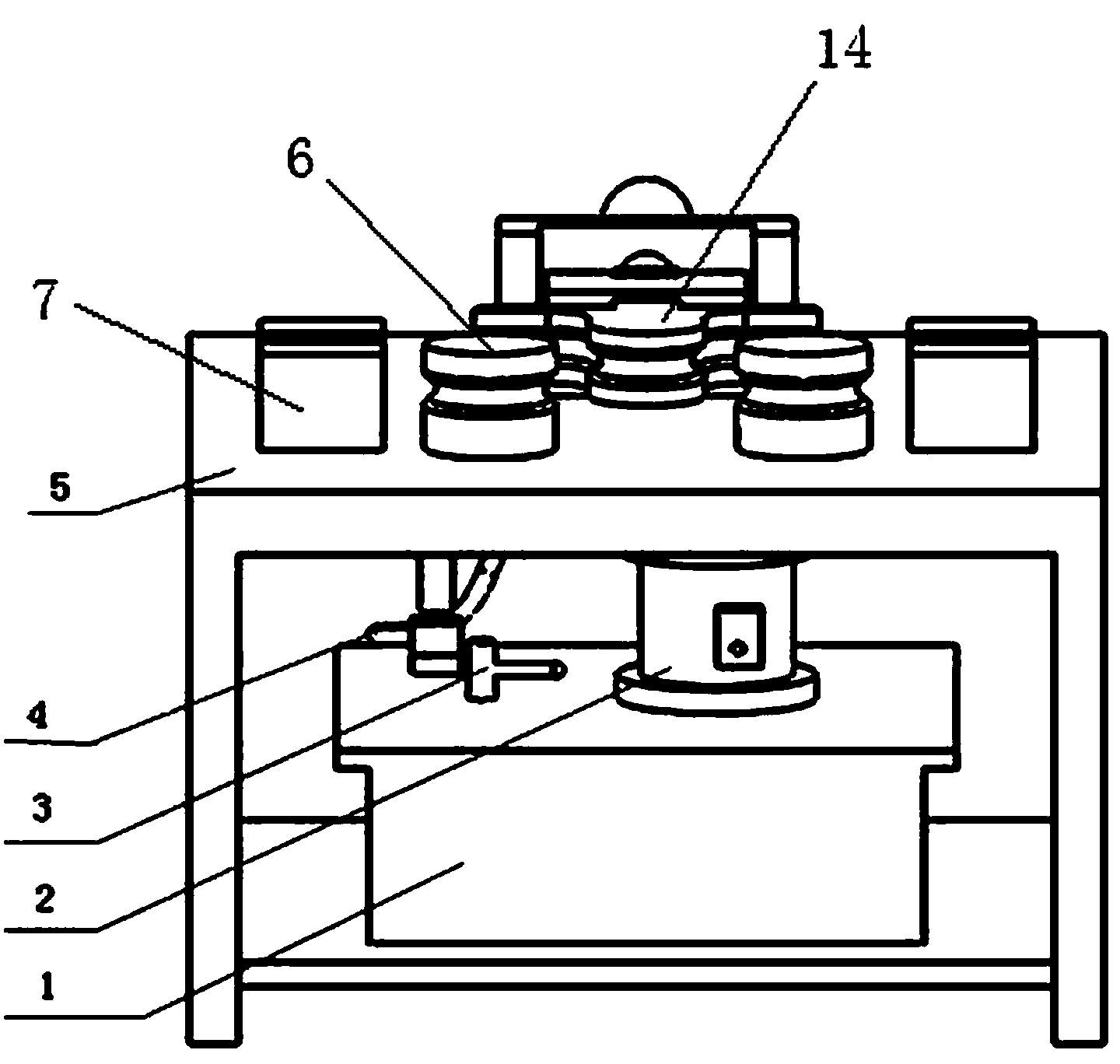

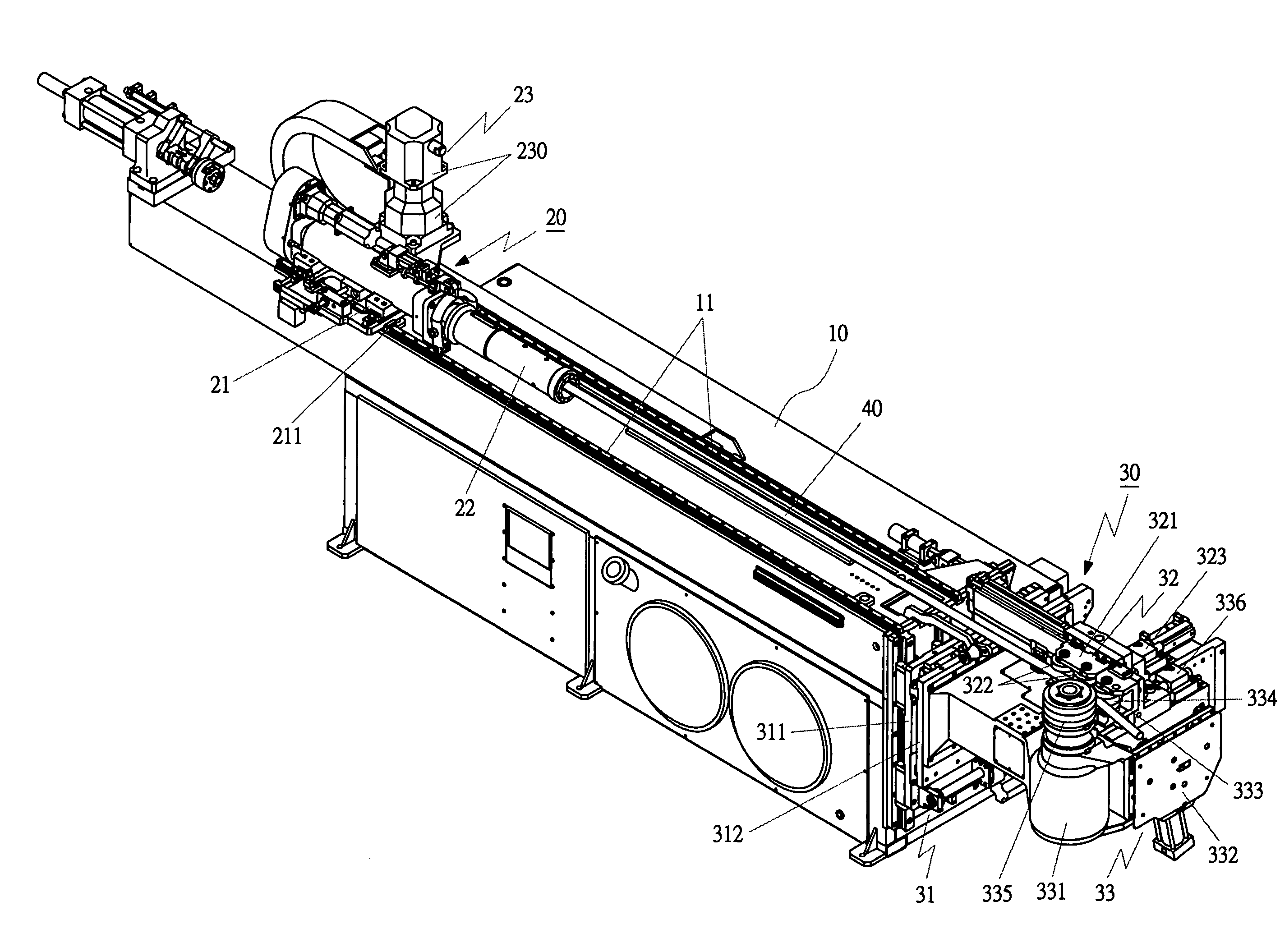

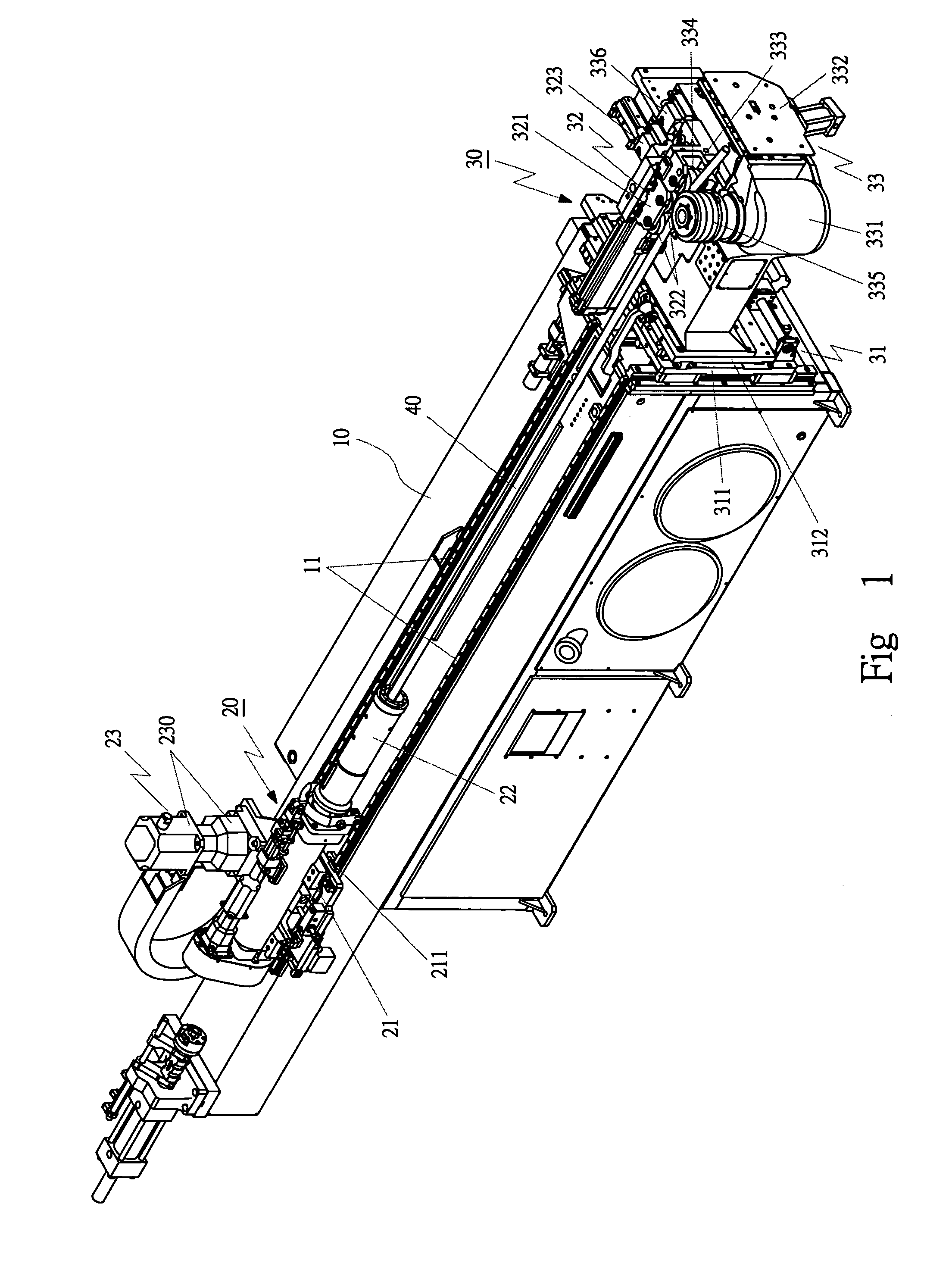

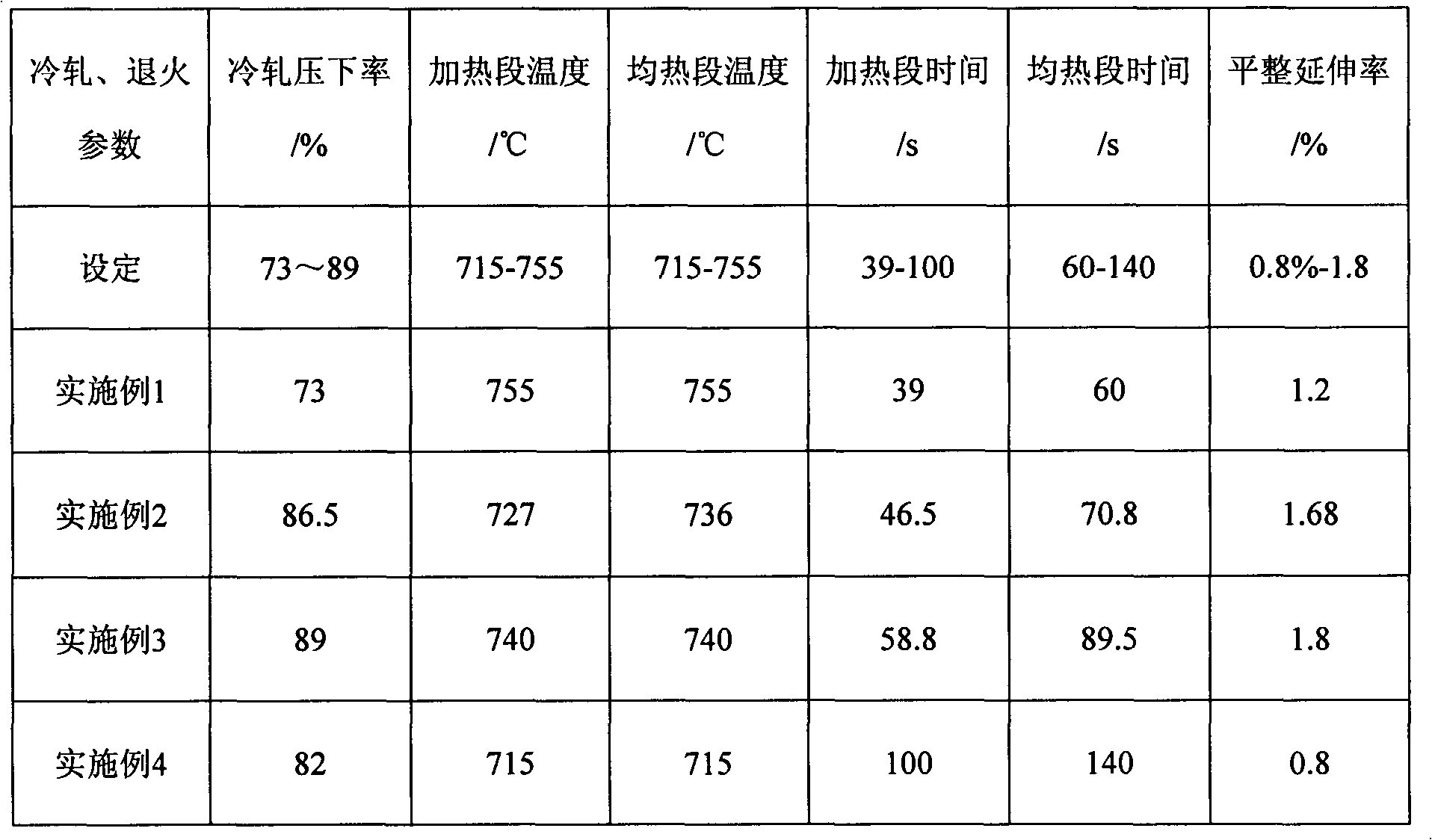

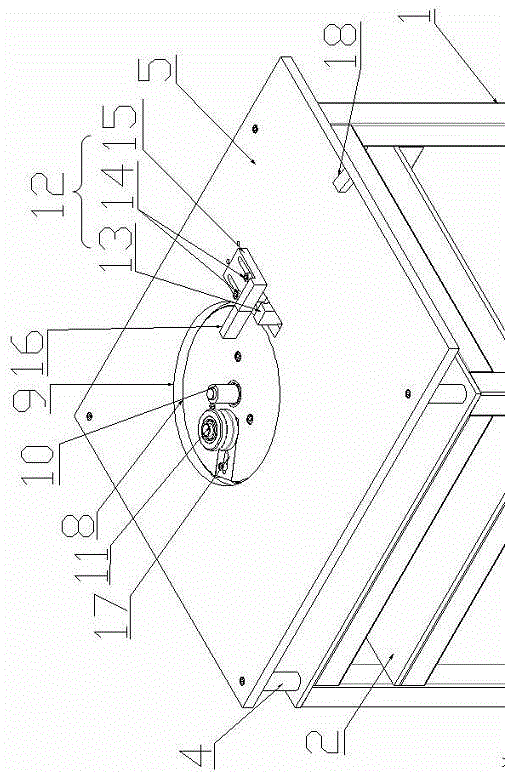

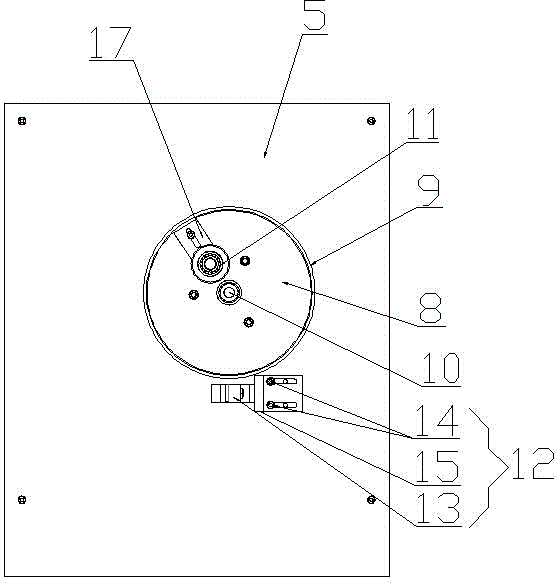

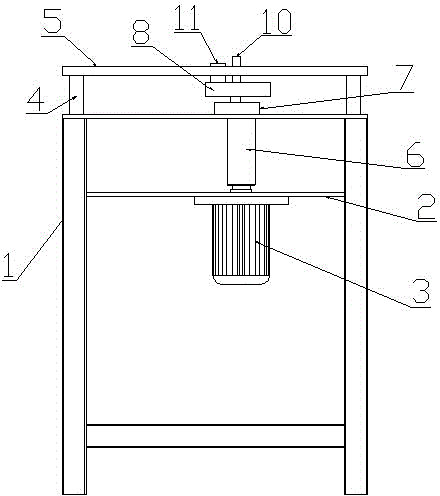

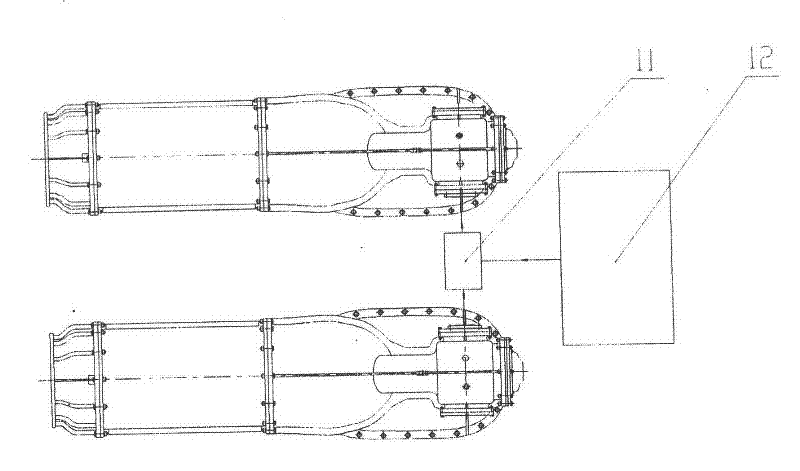

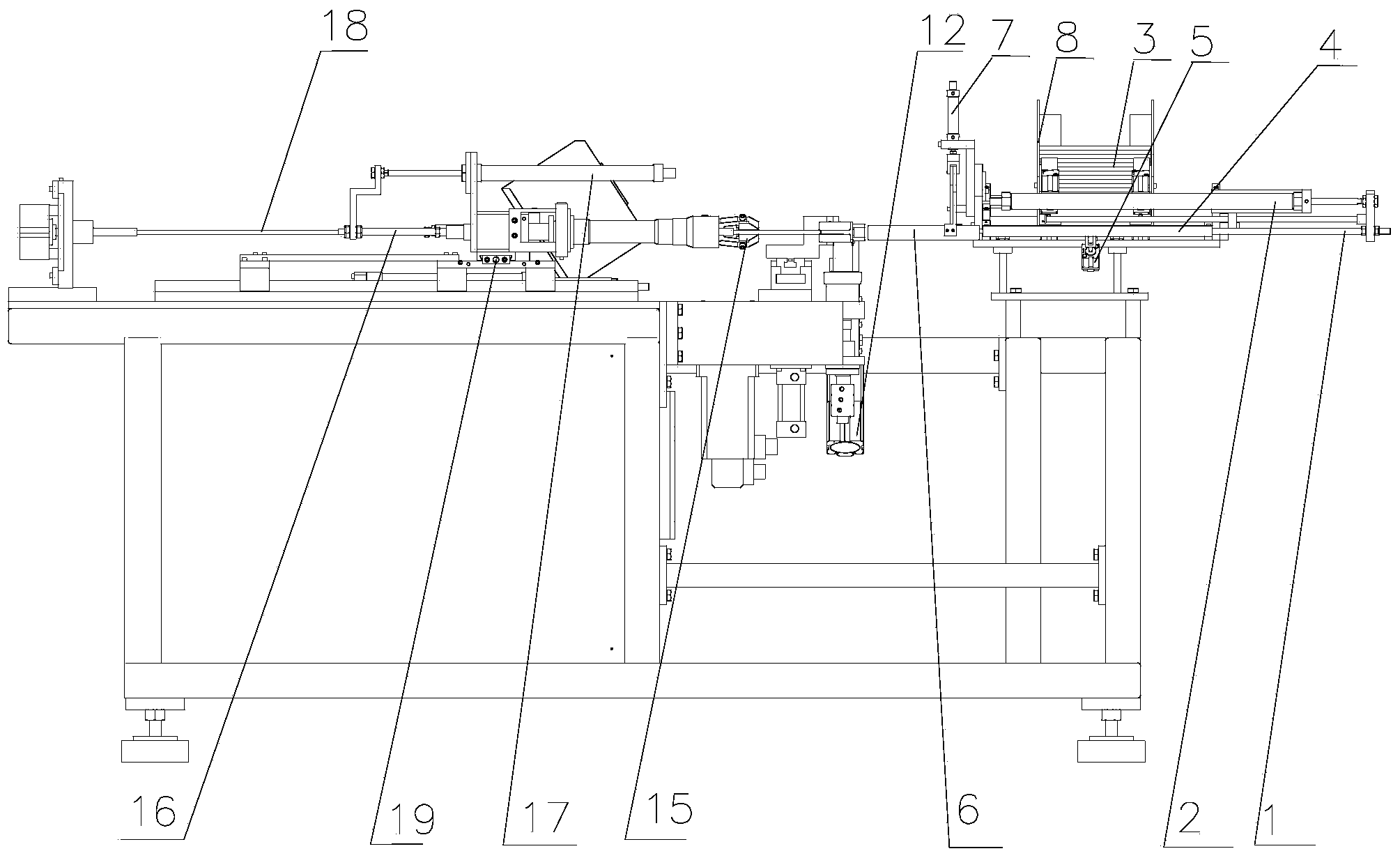

Laying-off, tube ending and tube bending integrated equipment

ActiveCN105149957AQuality assuranceGuaranteed accuracyOther manufacturing equipments/toolsAssembly lineEngineering

The invention discloses laying-off, tube ending and tube bending integrated equipment. The laying-off, tube ending and tube bending integrated equipment comprises a workbench. The laying-off, tube ending and tube bending integrated equipment further comprises a laying-off mechanism, a tube ending mechanism, a flaring / necking mechanism, a tube bending mechanism and a mechanical arm. The laying-off mechanism is used for conducting fixed-length laying-off on a workpiece and arranged on the workbench. The tube ending mechanism is used for conducting tube ending to the end portion of one end of the fixed-length workpiece and arranged in front of the laying-off mechanism in the advancing direction. The tube bending mechanism is used for bending the fixed-length workpiece. The flaring / necking mechanism is used for flaring or necking the end part of the other end of the fixed-length workpiece. The mechanical arm is used for assisting the conveying of the workpiece. The laying-off mechanism comprises a feeding device used for conducting fixed-length feeding and a cutting device used for conducting fixed-length cutting on the workpiece. The laying-off, tube ending and tube bending integrated equipment is simple in structure and suitable for processing of tubes with different sizes. Various processing such as cutting, laying-off, tube ending, hole shrinkage, hole chambering and tube bending can be conducted. The laying-off, tube ending and tube bending integrated equipment is suitable for assembly line production, and the processing efficiency and the processing precision are greatly improved.

Owner:浙江长兴和良智能装备有限公司

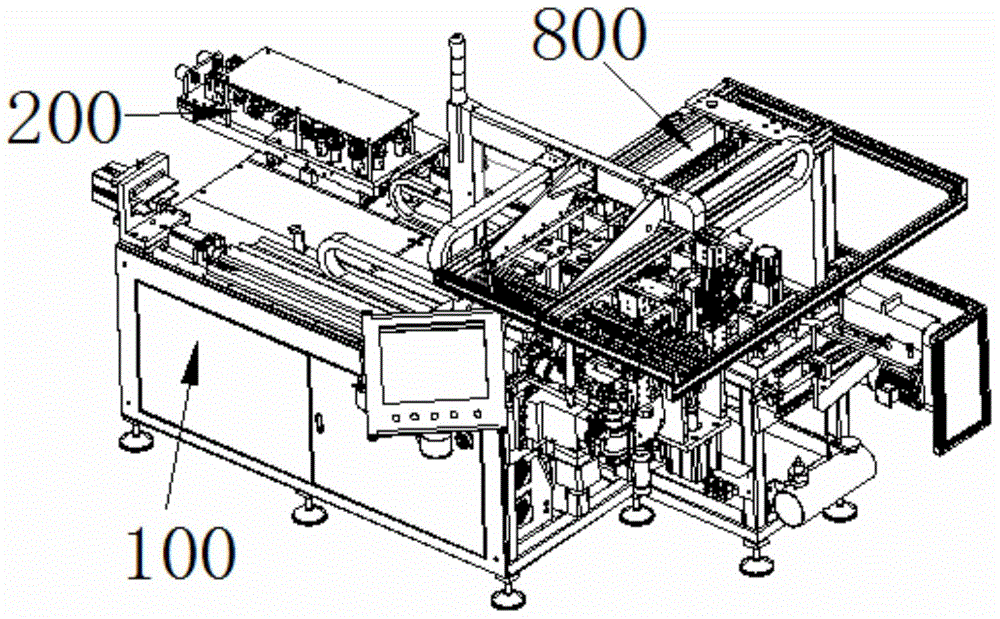

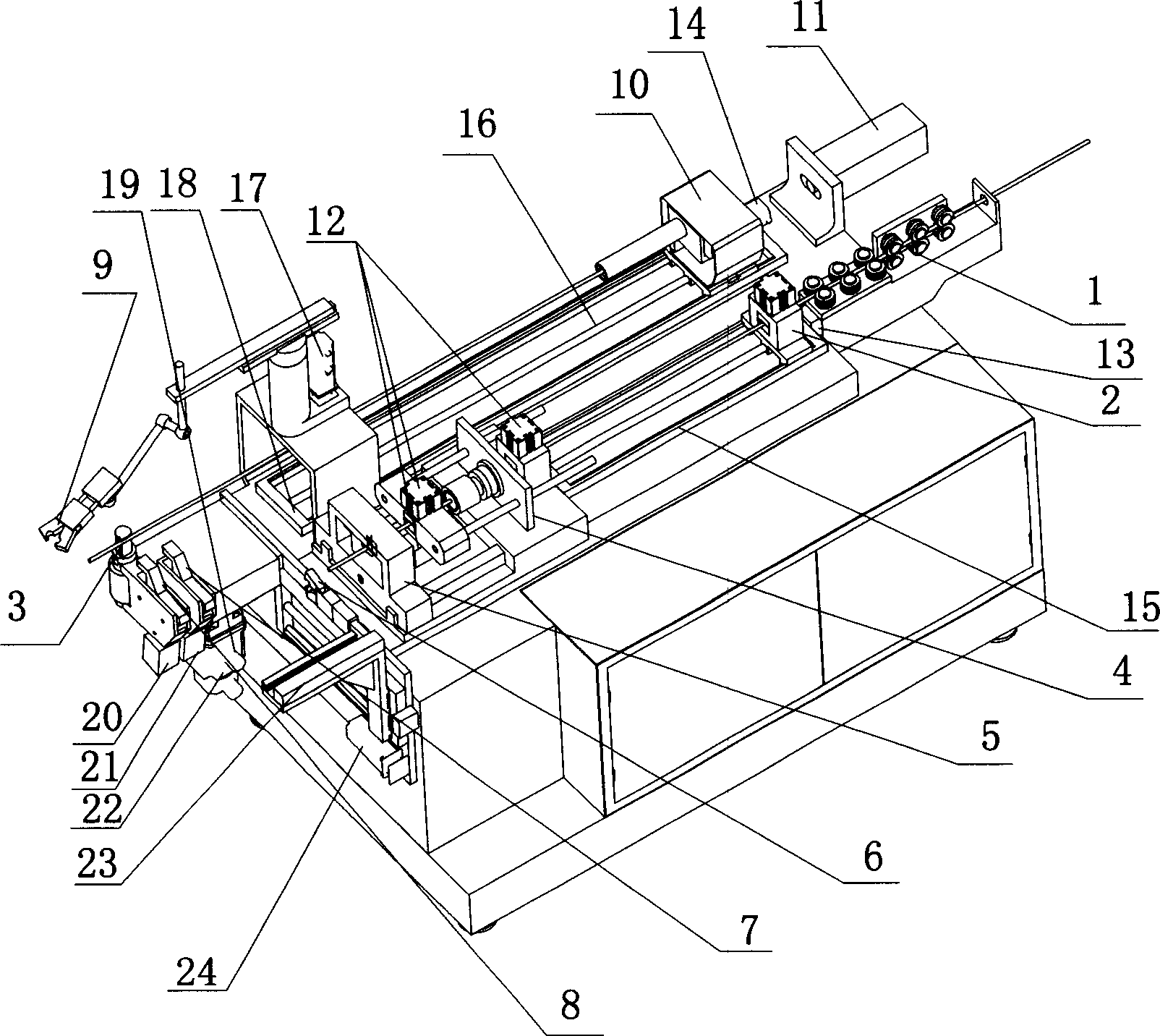

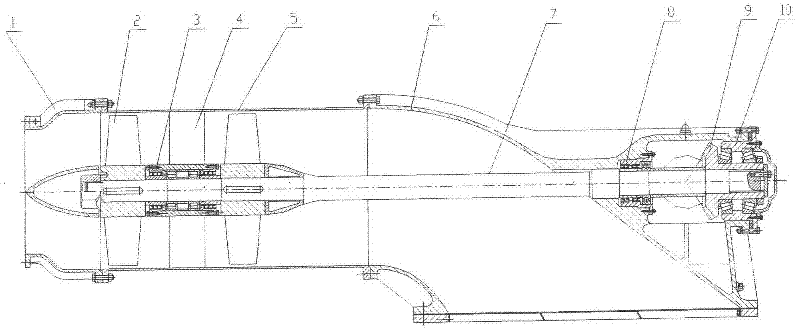

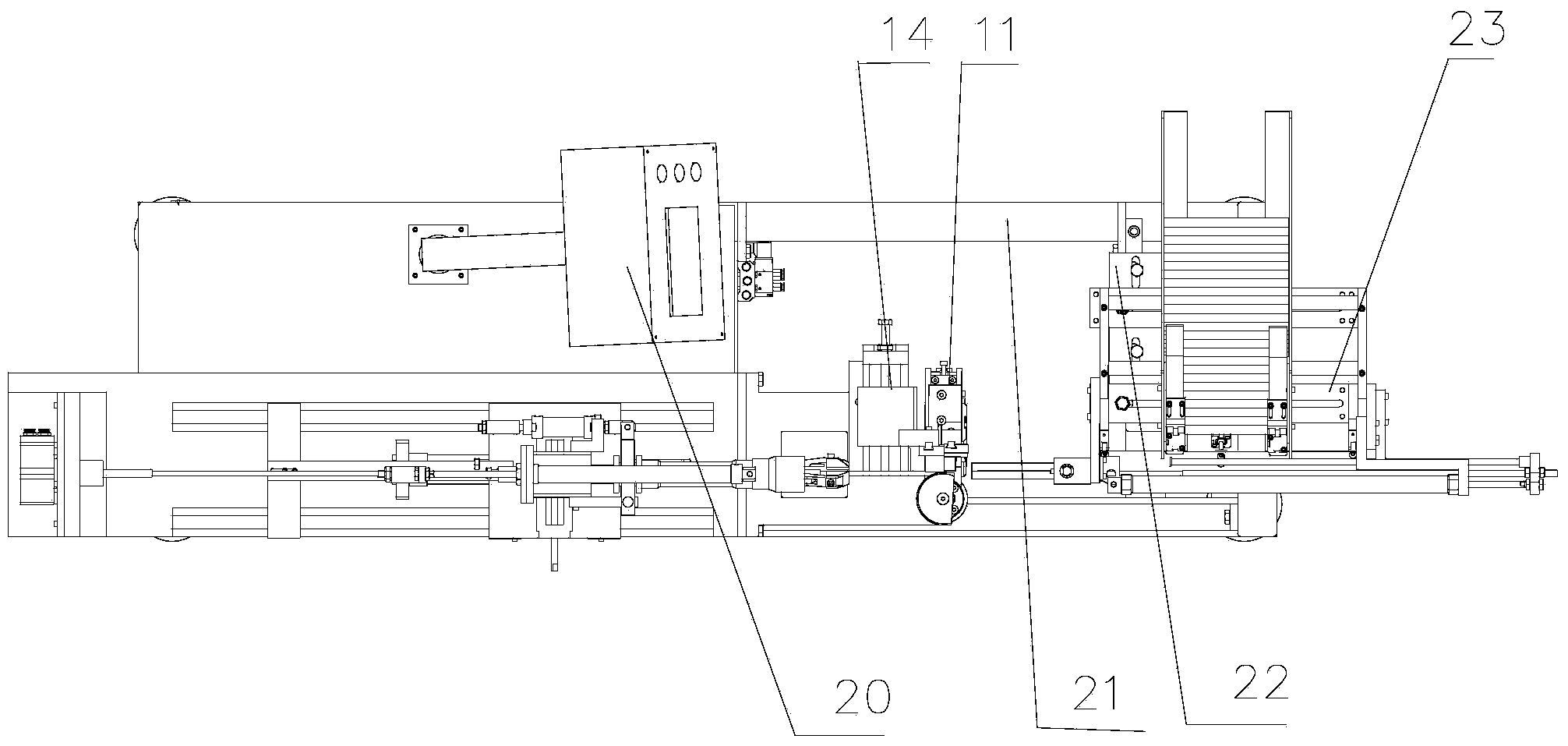

Apparatus for processing pipeline fitting and processing method thereof

A machine and technology for manufacturing the tube part used in air conditioner is disclosed. Said machine is composed of feeding unit, full-automatic tube bending unit and discharging unit. Said full-automatic tube bending unit consists of blanking and tube end shaping unit, feeding manipulator and tube bending unit. Said discharging unit comprises manipulator and discharging basket. Its advantages are high precision, automatization level and utilization rate of raw material.

Owner:GREE ELECTRIC APPLIANCES INC

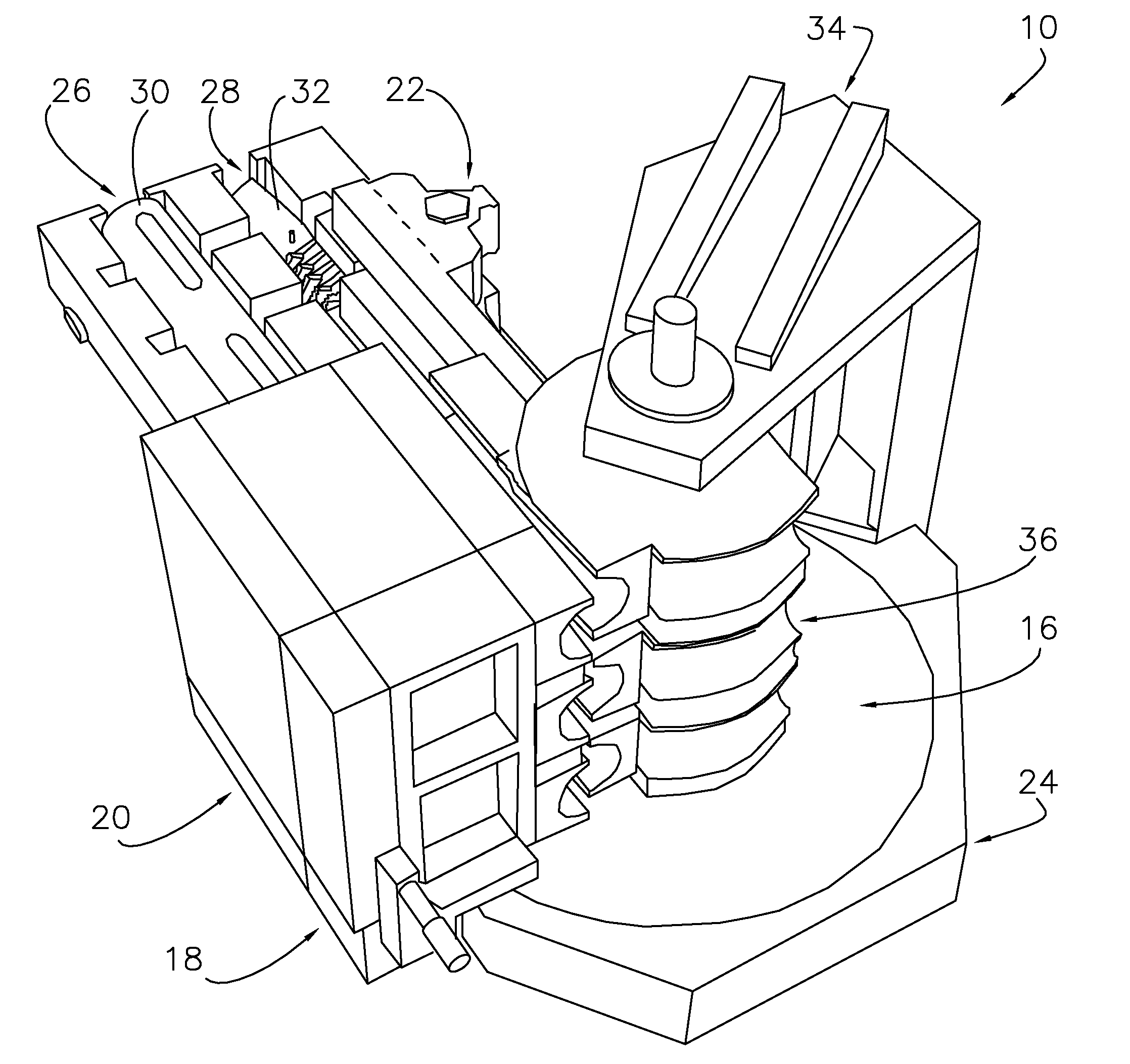

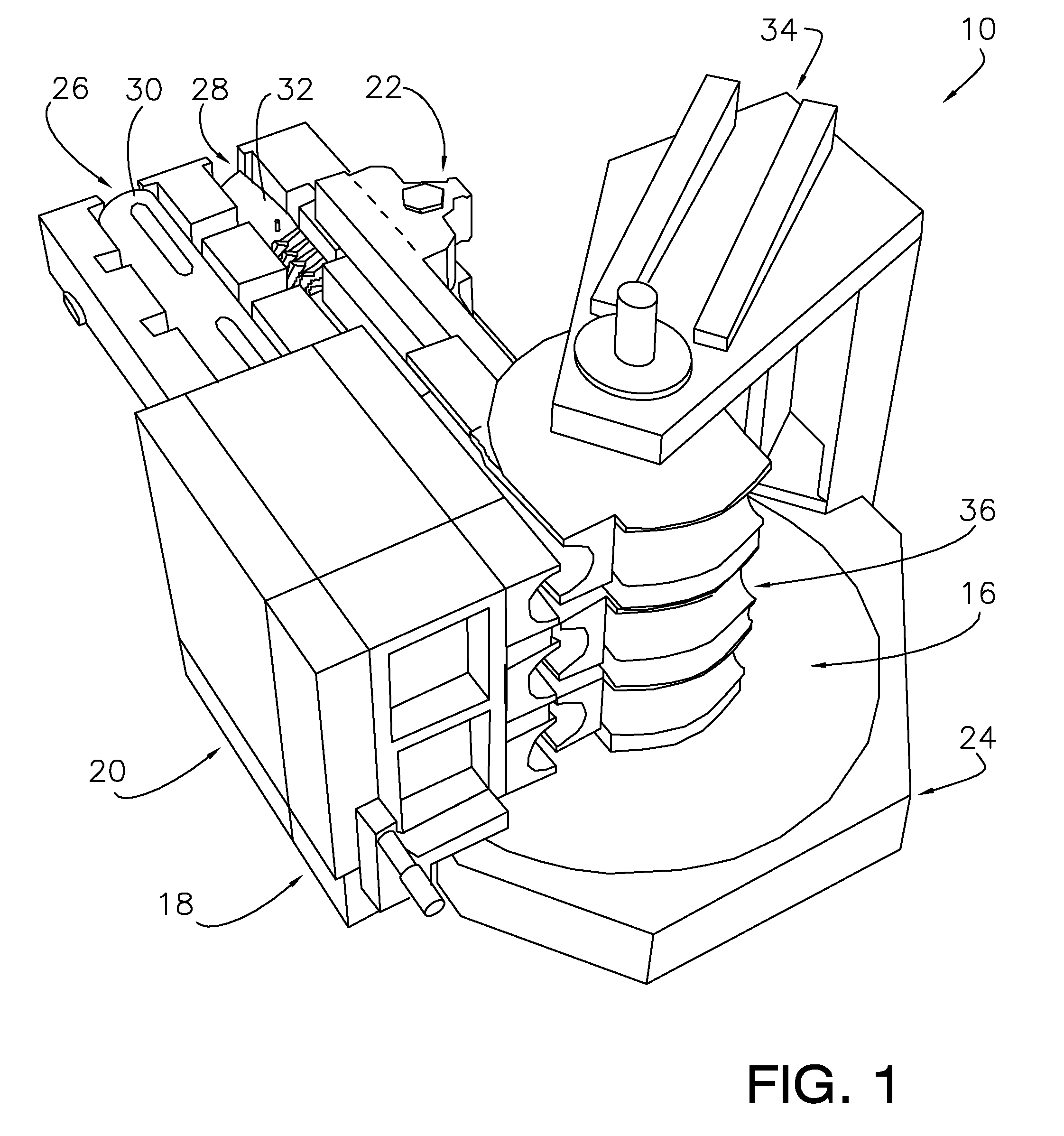

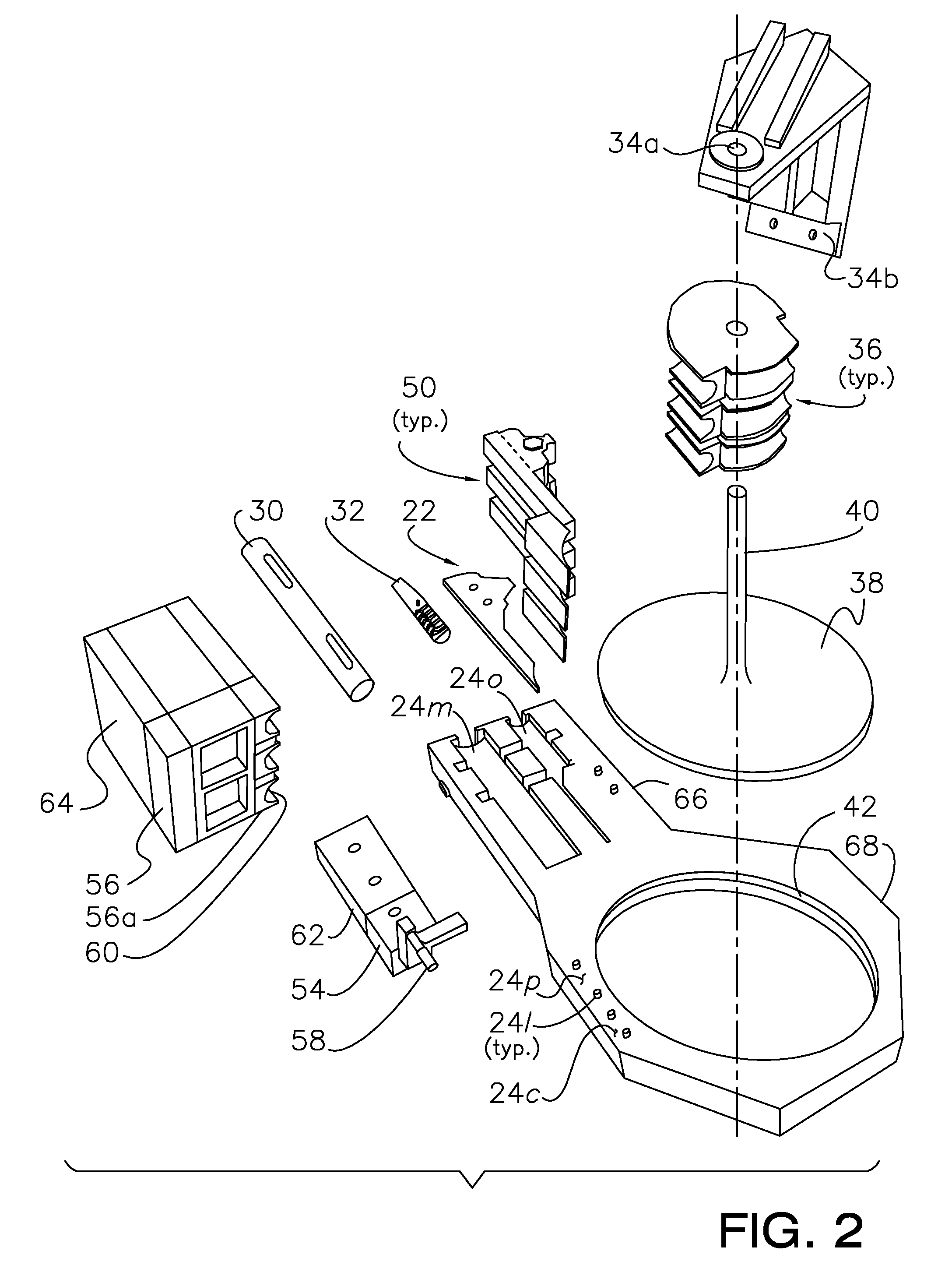

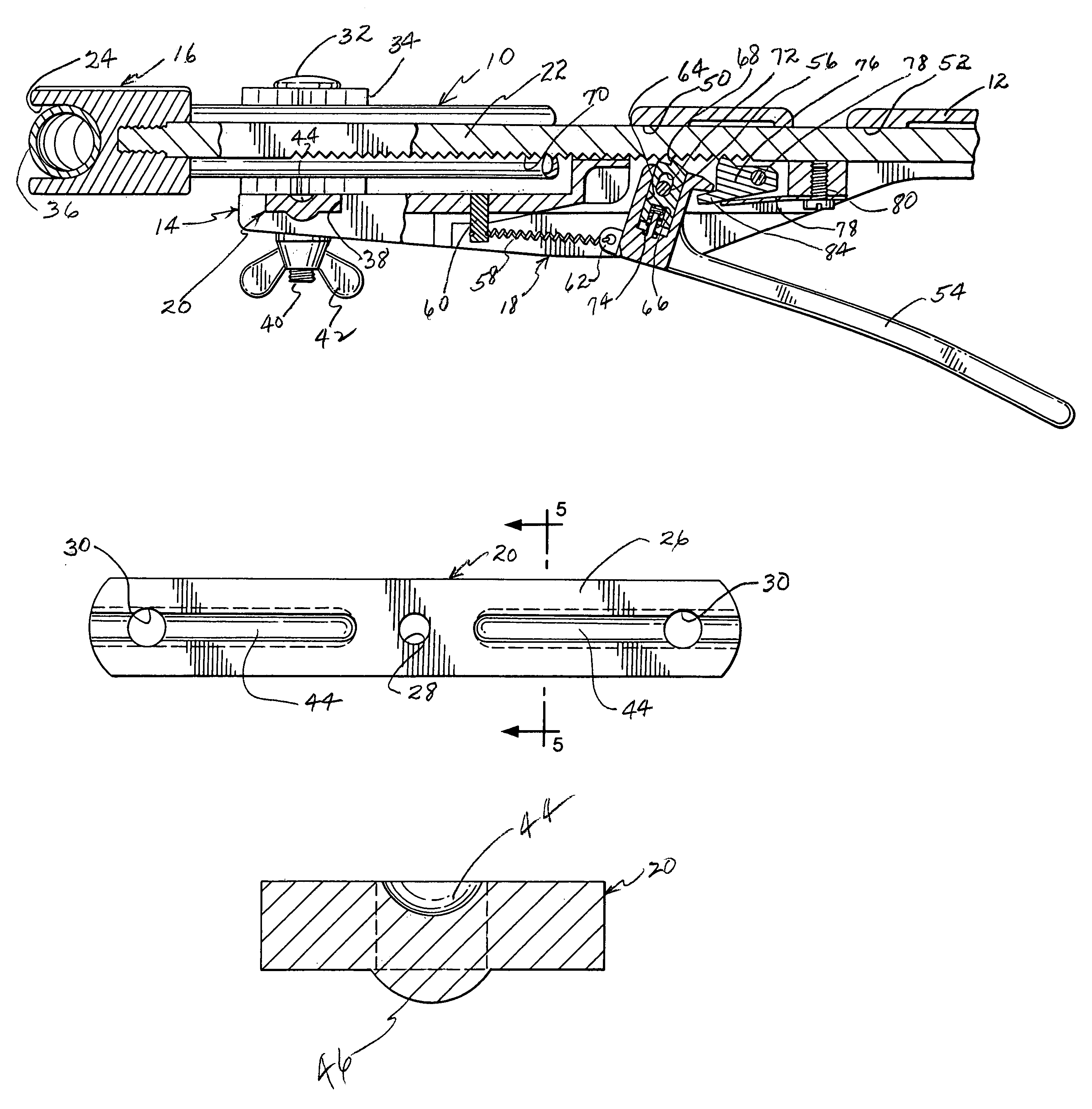

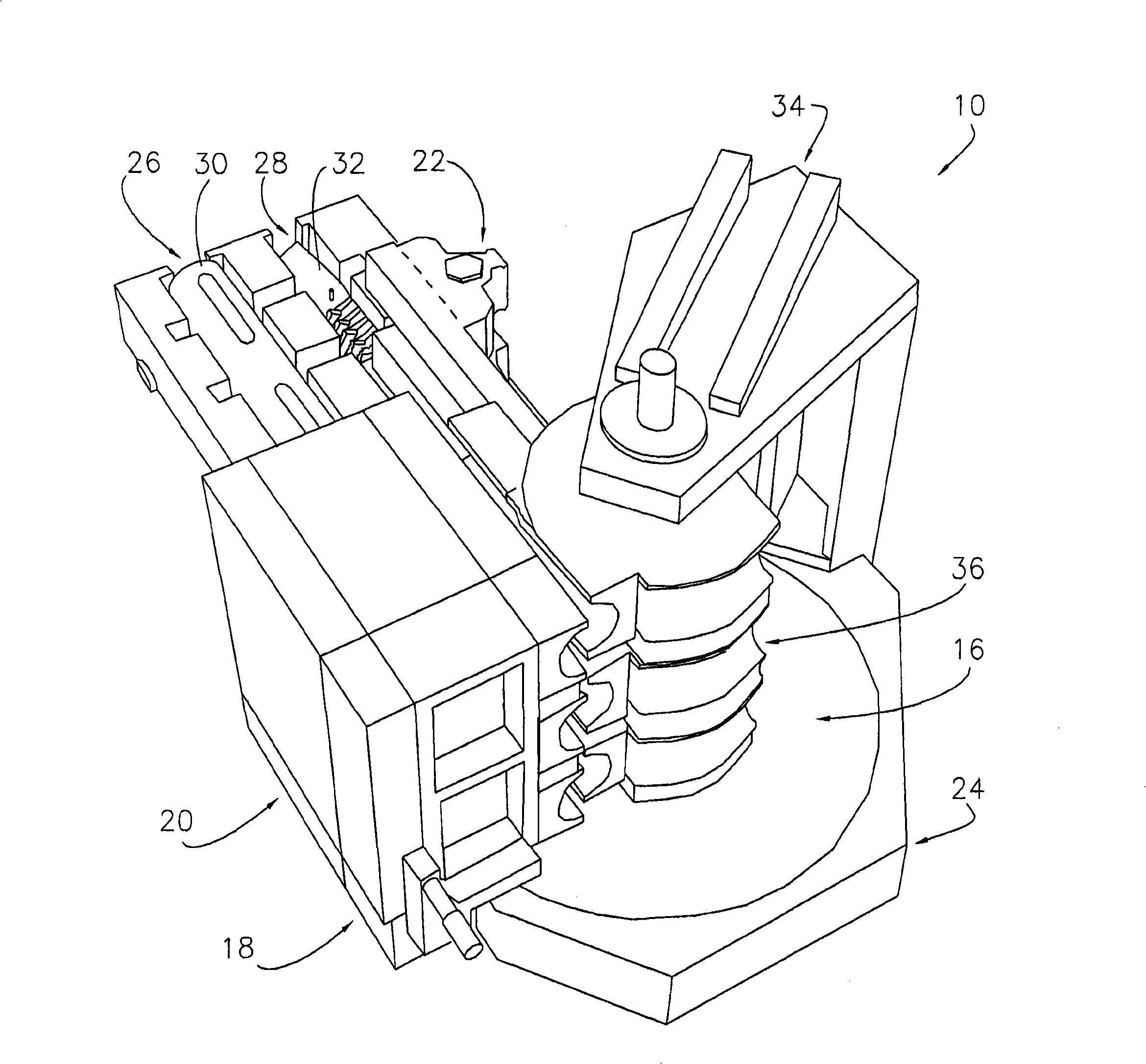

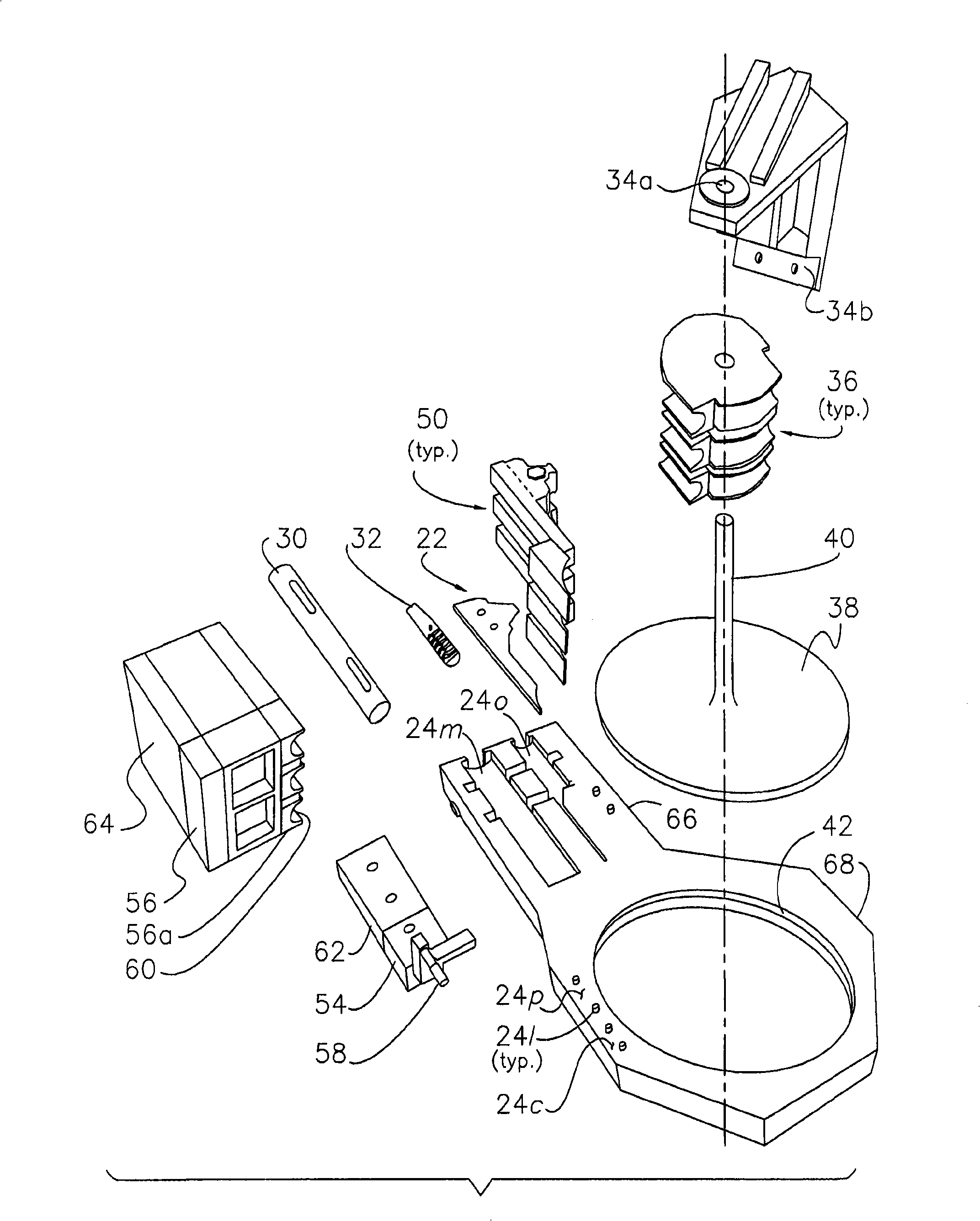

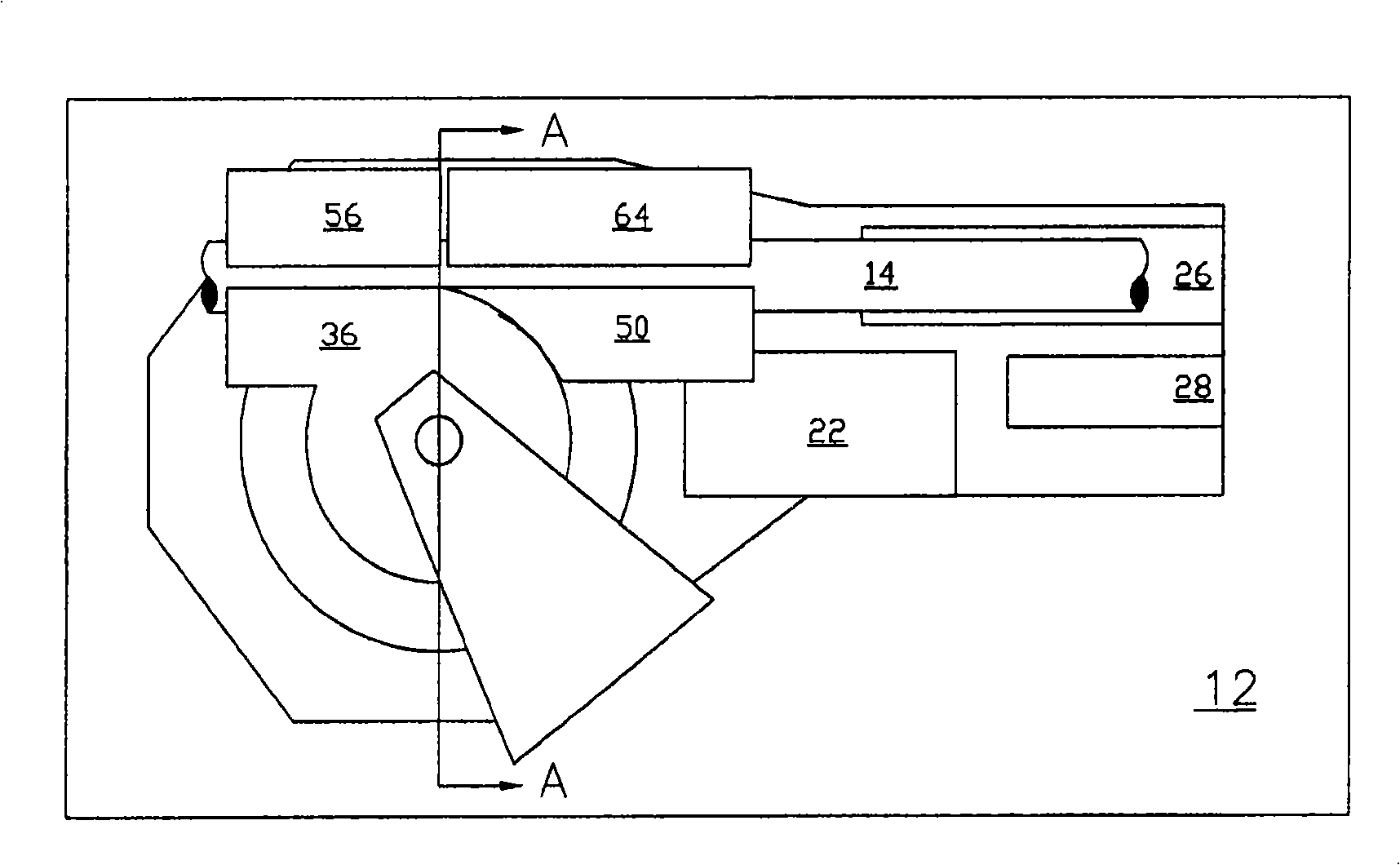

Quick change bend tooling bolster

A tube bending assembly adapted for use with a rotary draw bender, and preferably including a bend die mounting unit for securing a plurality of stacked bend dies drivenly coupled to the bender, a bend die tower unit for structurally supporting the bend die mounting unit, a wiper die mounting unit for securing a wiper die adjacent a selected bend die, a clamp die mounting unit for positioning and securing a clamp die, a pressure die mounting unit for securing a pressure die adjacent the clamp die, a mandrel saddle unit for positioning and enabling the utilization of a mandrel assembly, a collet saddle unit for positioning and enabling the utilization of a collet, and a bolster unit that interconnects the units, so as to present an integrated assembly capable of concurrent disconnection from and connection to the bender, and thereby reducing the tool set change-over period.

Owner:GM GLOBAL TECH OPERATIONS LLC

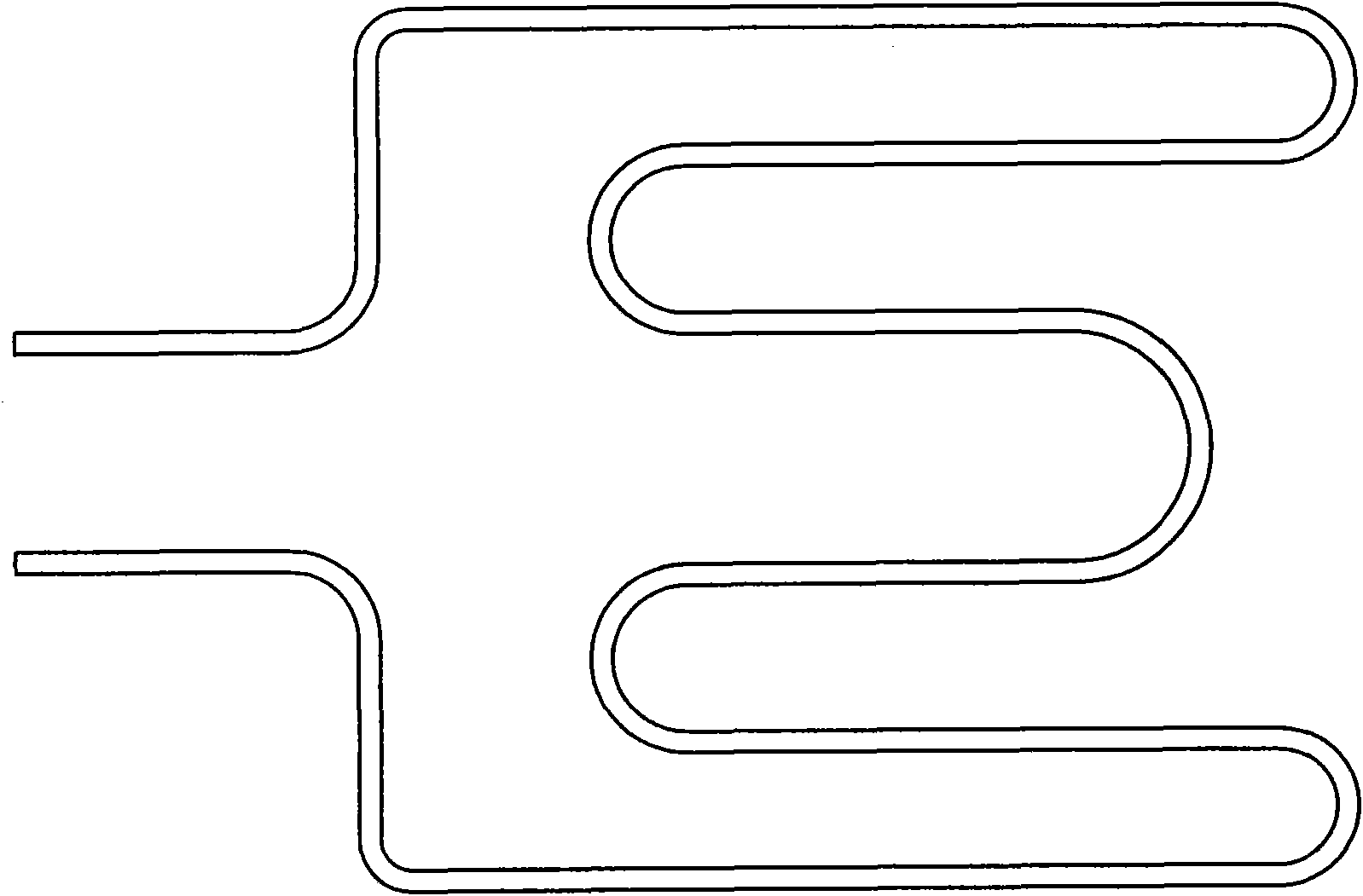

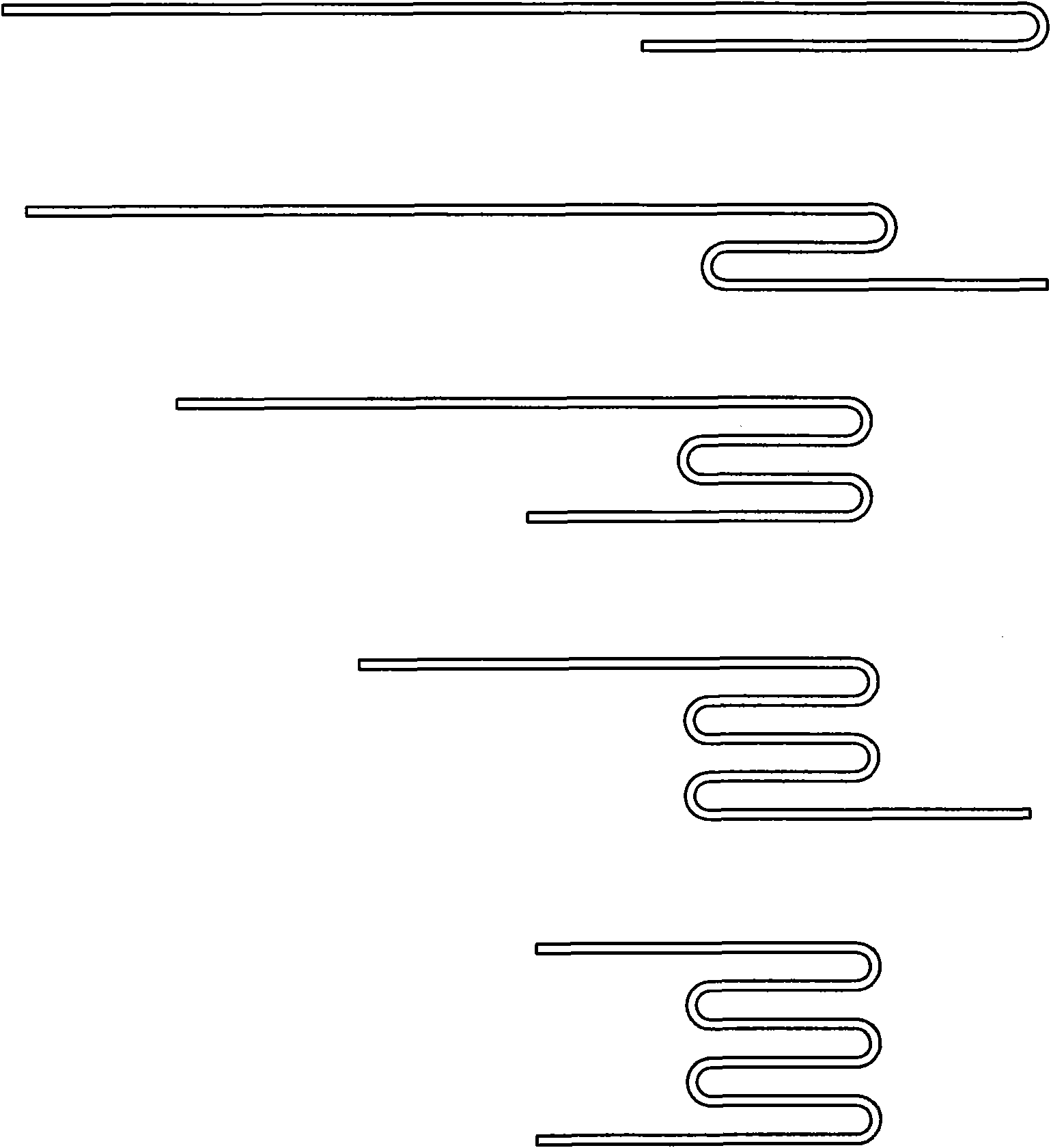

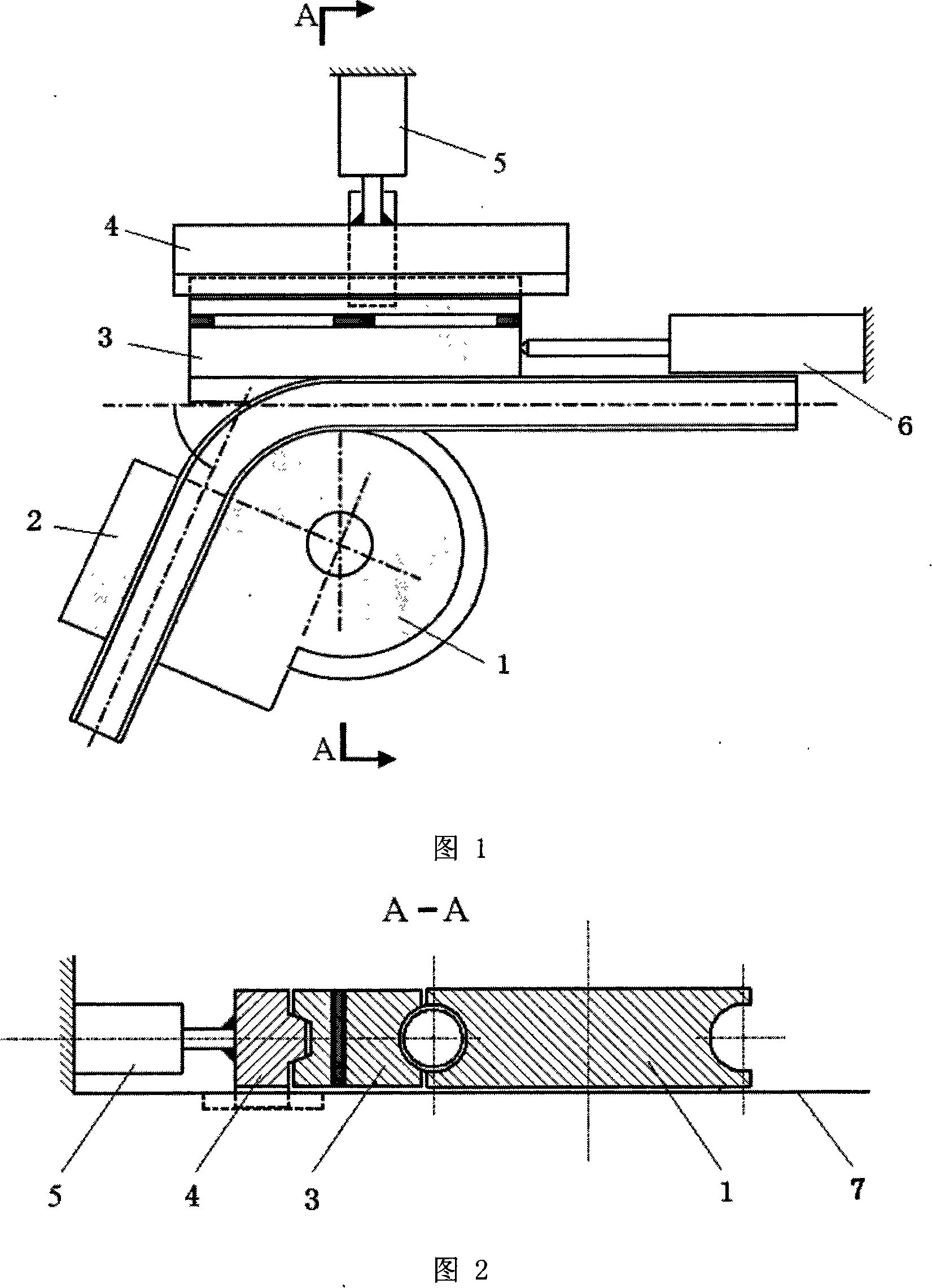

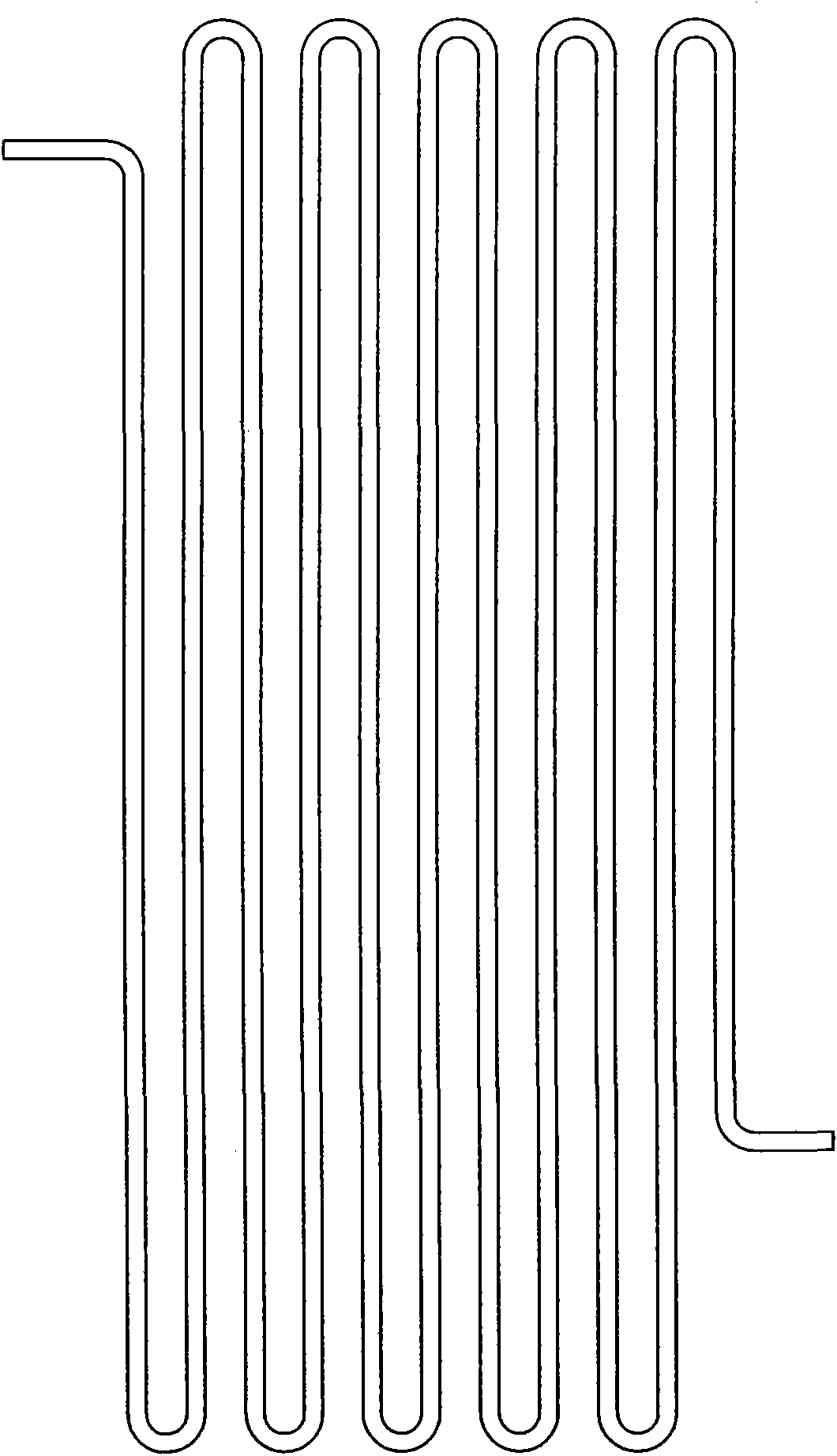

Electrical heating tube plane numerical controlled tube bending method and numerical controlled bending device using same

The invention relates an electrical heating tube plane numerical controlled tube bending method which comprises the technological processes of setting parameters, tube placing, tube fetching, and bending and forming, wherein the three processes of tube placing, tube fetching and bending and forming are repeated, and the parameters in a numerical controlled system are set so as to finish the wholeaction process. As the tube placing process, tube fetching process and the bending and forming process are adopted, the whole process needs no human intervention, and avoids the influence of human factors on the size, radius and angle of the bent product, thereby achieving the purposes of reducing the product fraction defective and production cost. Compared with the processing mode in the prior art, the method has the advantage of improving production efficiency; and compared with the existing processing equipment, a numerical controlled bending device adopted by the method has the advantagesof convenient operation and simple structure.

Owner:张明放

Tube bending forming processing device

InactiveCN101147934AImprove memory propertiesIncrease hydrostatic pressureShaping toolsHydraulic cylinderTangential force

The present invention discloses a bending forming processing equipment for pipe material. Said equipment includes the following several portions: bending die clamping die, pressing die, pressurizing plate, circumferential pressure-applying hydraulic cylinder, axial propulsion hydraulic cylinder and bending machine working table. The circumferential pressure-applying hydraulic cylinder pushing rod is rigidly connected with the pressurizing plate, the axial propulsion hydraulic cylinder pushing rod is flexibly connected with the pressing die end portion. The circumferential pressure-applying hydrautic cylinder can be used for driving said pressurizing plate to circumferentially apply pressure to the pipe material, and the axial propulsion hydraulic cylinder can be used for driving pressing die to apply tangential force to the pipe material, the bending die is fixed on the bending machine working table by means of bending centre, and bending die, pressing die and clamping die respectively have the groove fit with the outer diameter of said pipe material, the pressurizing plate is connected with the pressing die by means of dovelail groove, and the pressurizing plate also is connected with the bending machine working table by means of dovetail groove.

Owner:SHANGHAI JIAO TONG UNIV

Tube bending machine

ActiveCN104138943ANo impact damageGuaranteed service lifeShaping toolsMetal-working feeding devicesEngineeringTube bending

The invention relates to a tube bending machine. The tube bending machine comprises a rack, wherein a loading mechanism capable of outputting front-and-back linear displacement actions is arranged on the rack, a prop-bending die is in transmission connection with a power output end of the loading mechanism, two support wheels matched with the prop-bending die to bend corresponding metal tubes are also rotationally arranged on the rack, metal tube limiting mechanisms are arranged in positions, which are located on left and right sides of each support wheel, of the rack, each metal tube limiting mechanism is provided with a limiting channel which extends linearly and laterally and is penetrated through by the corresponding end of each metal tube, and the limiting channels are located on back sides of the corresponding support wheels respectively and provided with channel walls which are in stop fit with the corresponding ends of the metal tubes in the front-and-back direction and in sliding friction guide fit with the corresponding ends of the metal tubes bilaterally when the prop-bending die and the support wheels prop and press the metal tubes. The tube bending machine is not required to be manually held by an operator during usage and can bend R angles.

Owner:STATE GRID CORP OF CHINA +2

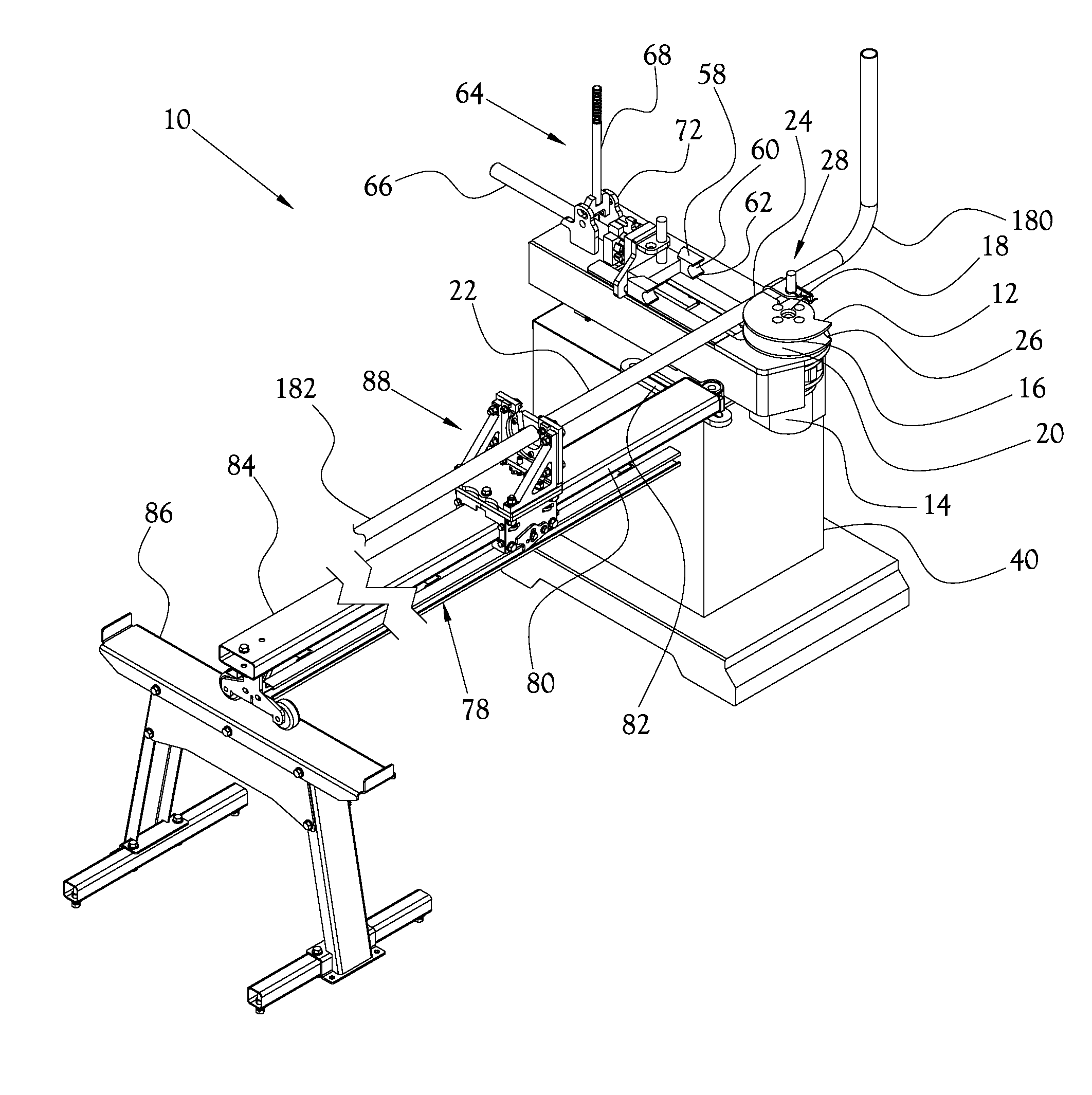

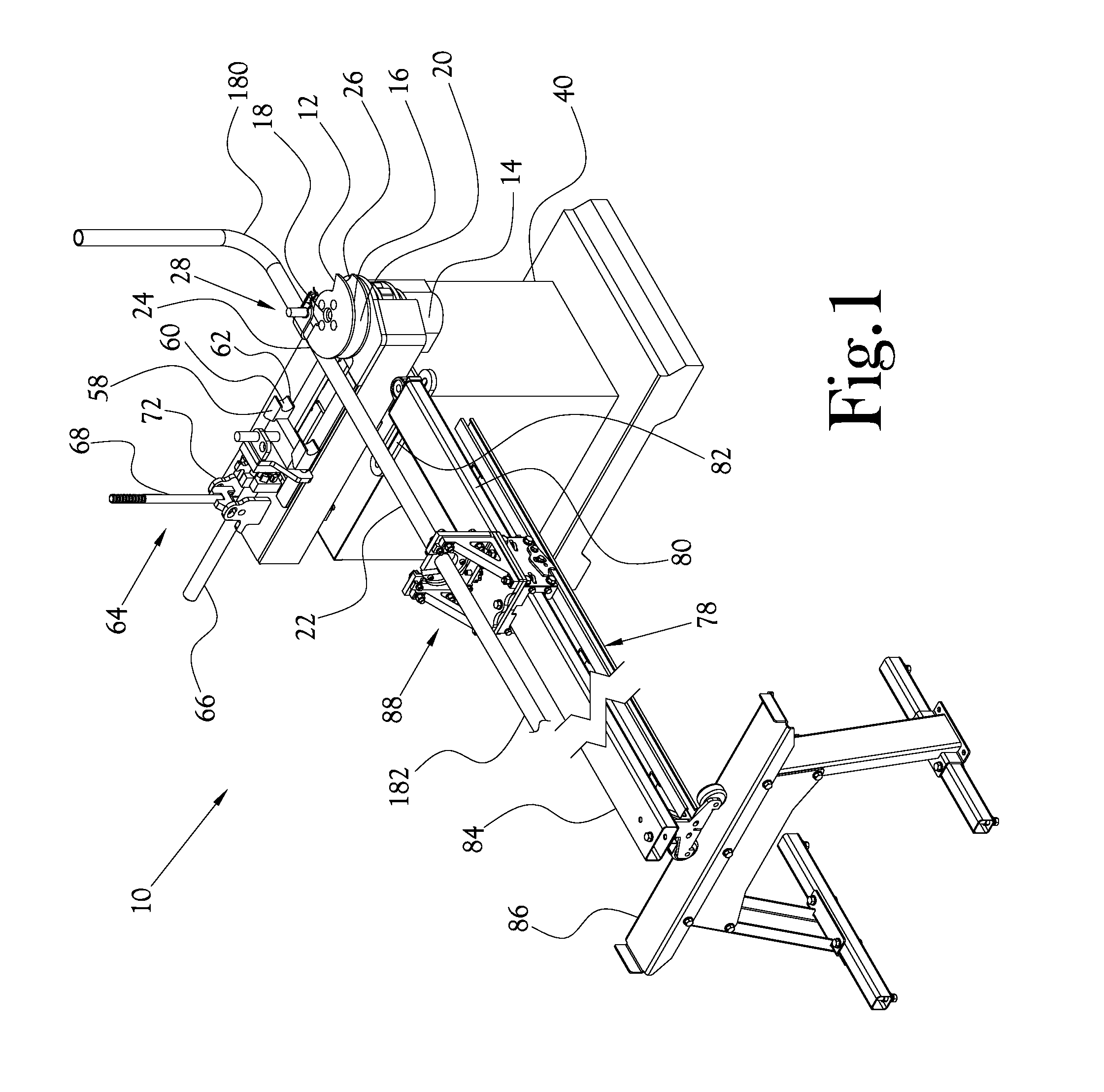

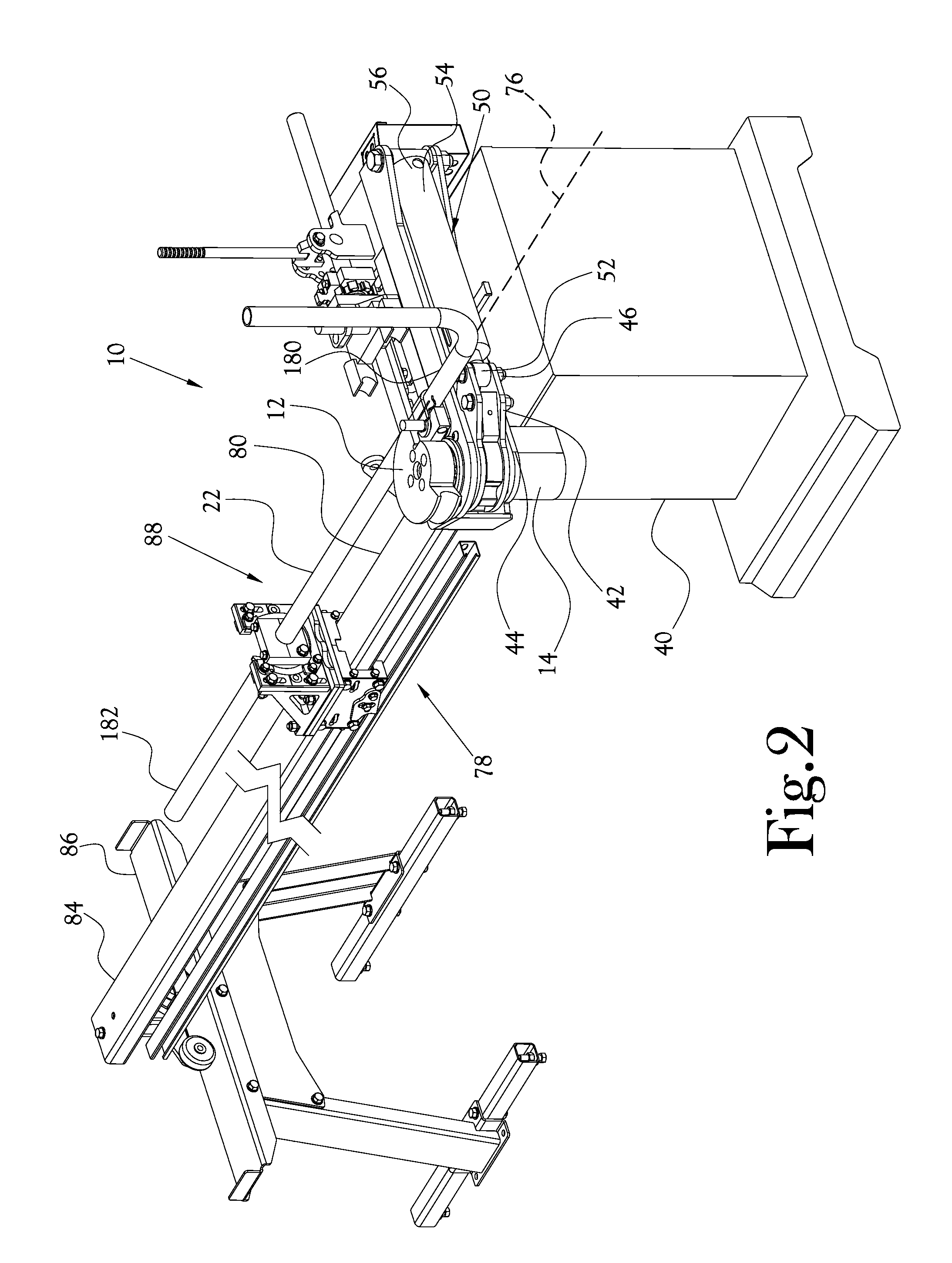

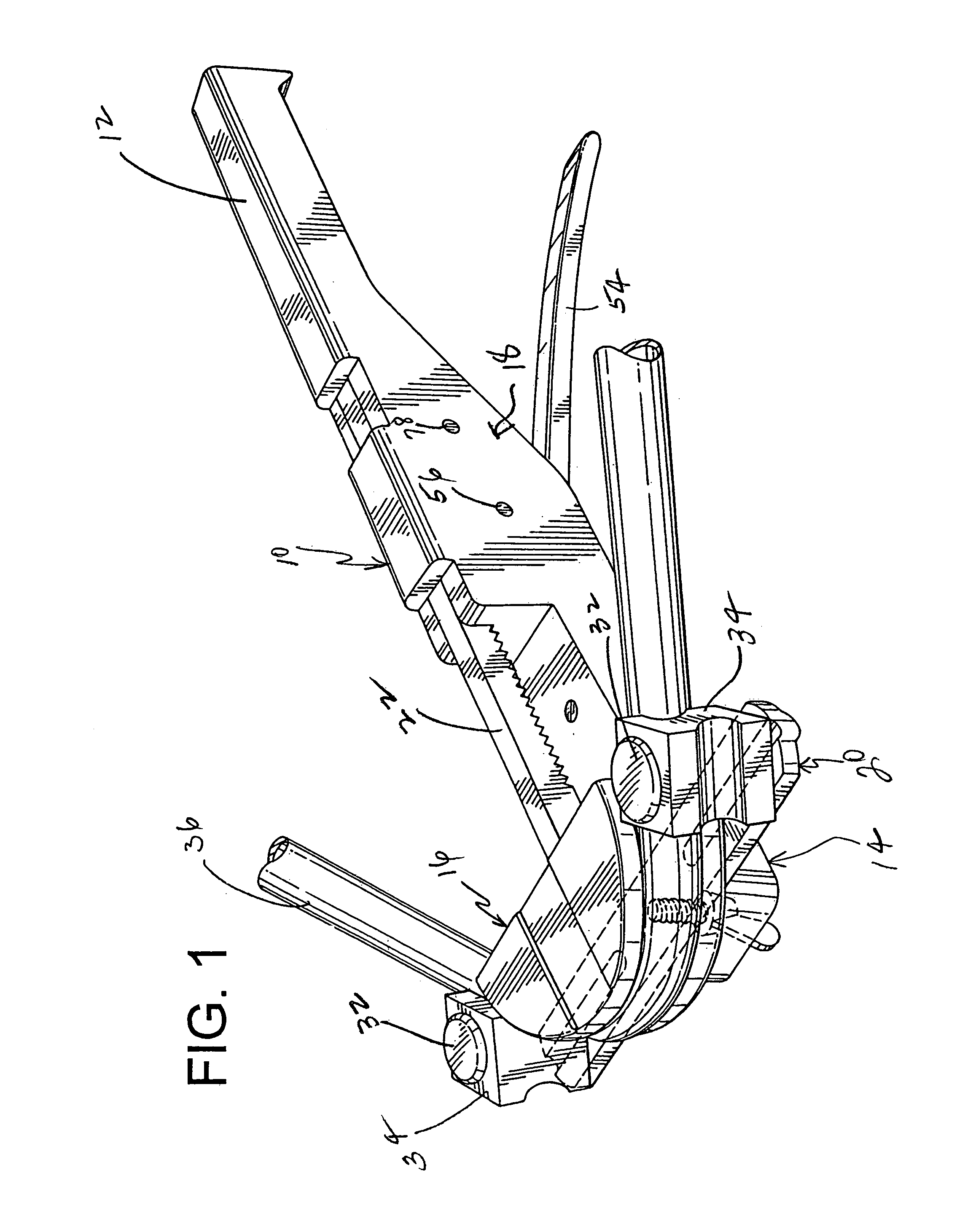

Tube Bending Machine With Reversible Clamp Assembly

A tube bending machine for bending a length of a tubular workpiece and an associated tube feeder assembly are disclosed. The tube feeder assembly has a carriage assembly slidably mounted along a rail. A clamp assembly is reversibly mounted to and carried by the carriage assembly. The clamp assembly is adapted to be releasably secured to the workpiece. The clamp assembly and carriage assembly are configurable to align the workpiece central axis along the rail, whereby sliding of the carriage assembly with the workpiece mounted in the clamp assembly carries the workpiece along the rail.

Owner:HUGHES JR ROBERT KYLE

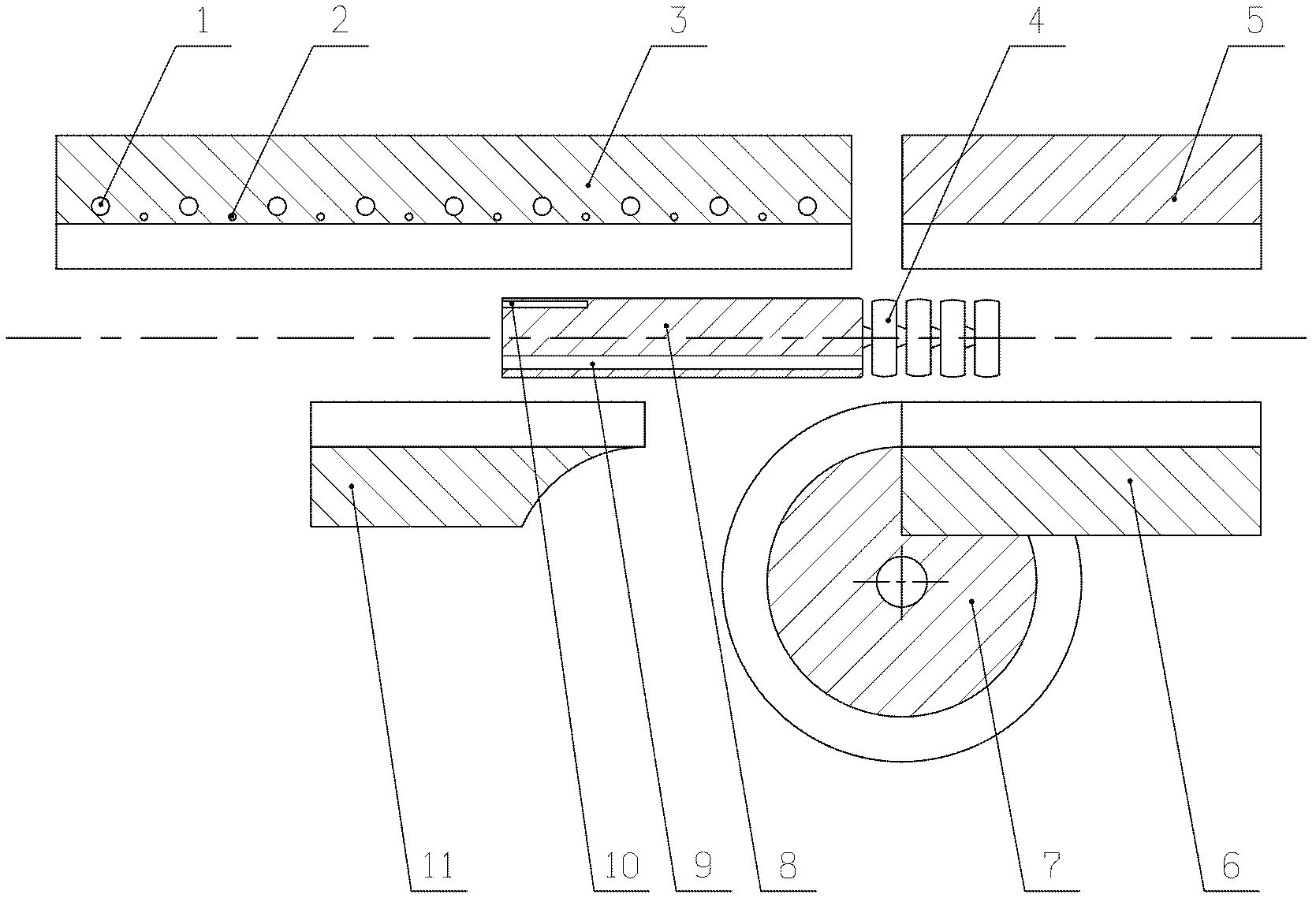

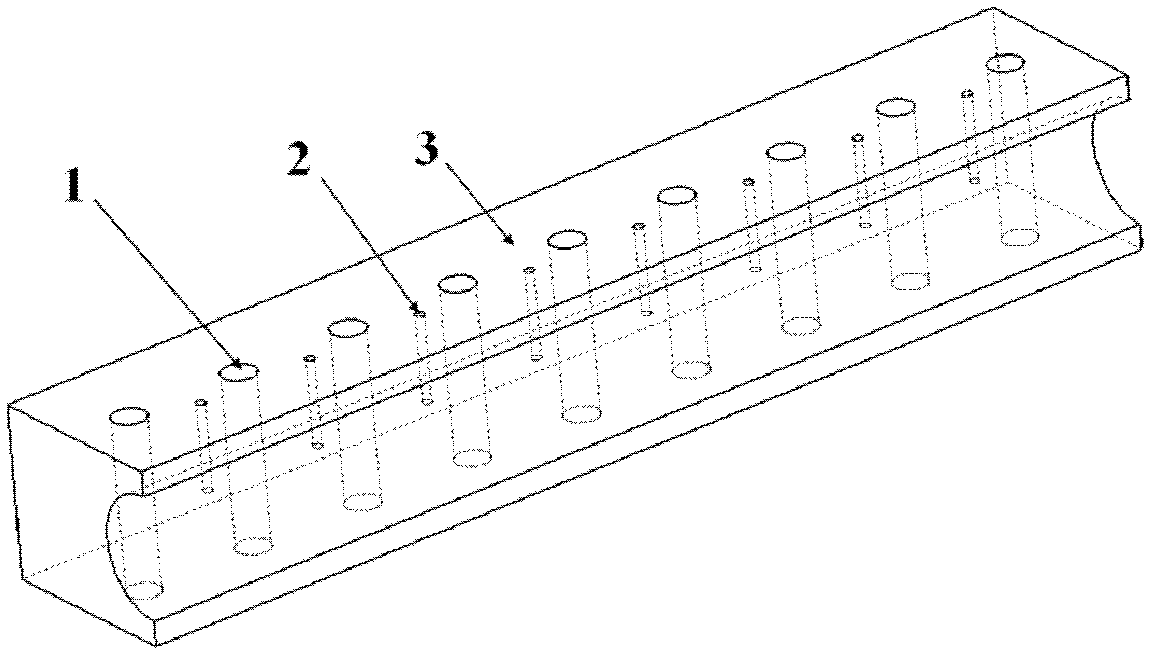

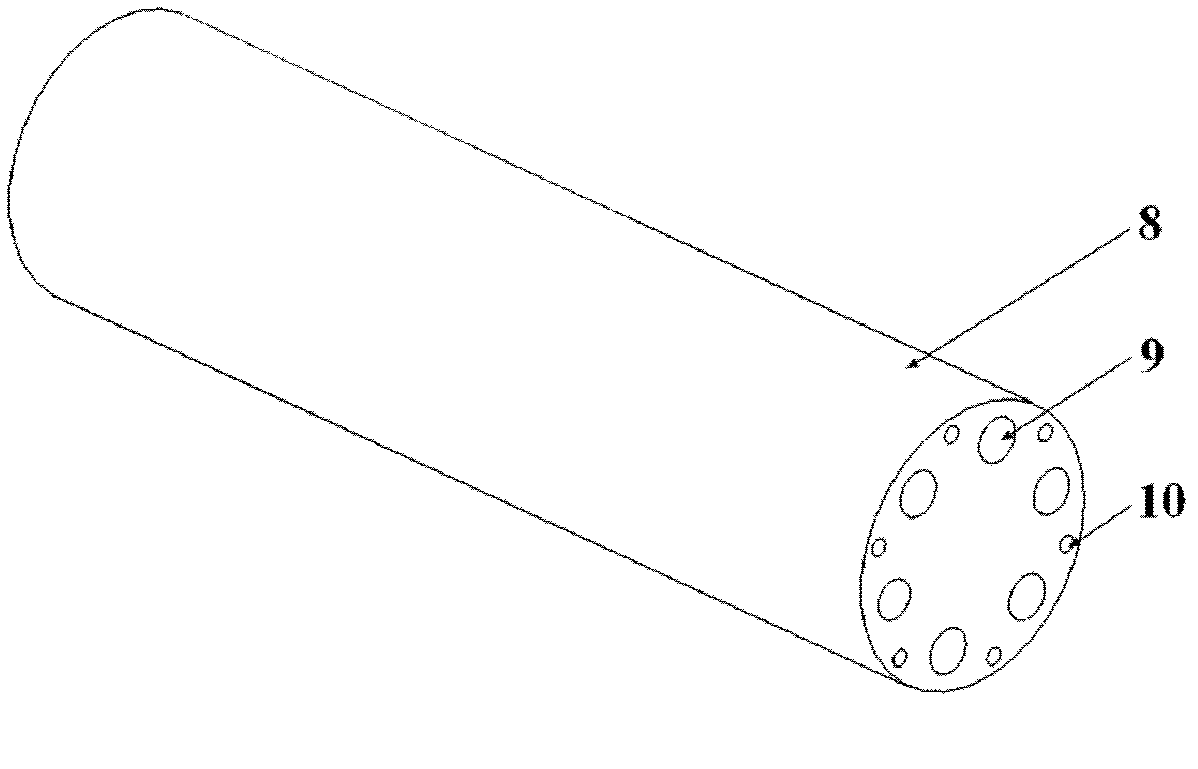

Numerical-control heating bending die and forming method for large-diameter thin-wall pure titanium tube

Disclosed are a numerical-control heating bending die and a forming method for a large-diameter thin-wall pure titanium tube. A plurality of pressure die heating holes are evenly distributed on the upper surface of a pressure die along the length direction of the pressure die, and a pressure die temperature measuring hole is arranged between each two adjacent pressure die heating holes. A plurality of mandrel heating holes and mandrel temperature measuring holes are circumferentially and evenly distributed on an end face of a mandrel, and one mandrel temperature measuring hole is positioned between each two adjacent mandrel heating holes. The pressure die heating holes and the mandrel heating holes are through holes, and the pressure die temperature measuring holes and the mandrel temperature measuring holes are blind holes. By determining a tube bending die, heat insulation of the die and a tube bender, bending speed, lubrication of the tube and the die, and heating and temperature control of the die, numerical-control heating bending of the thin-wall pure titanium tube with the diameter D larger than 40mm is realized, the problem of serious necking of the tube in a clamping area due to uneven heating temperature of the tube is avoided, excessive energy consumption for constant-temperature heating of the tube is reduced, the strength of a clamping end is ensured, and the bending yield of the tube is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Tube-bending device

InactiveUS6931908B1Improve performanceEliminate failure problemsForging/hammering/pressing machinesEngineeringTube bending

A tube-bending device including a frame having a reciprocably mounted anvil and a coacting crossbar with tube-restraining blocks, together with a ratchet mechanism for driving the anvil toward the blocks to perform tube-bending operations, wherein the crossbar is reinforced with reinforcing ribs to prevent failure.

Owner:MITSON KEN J

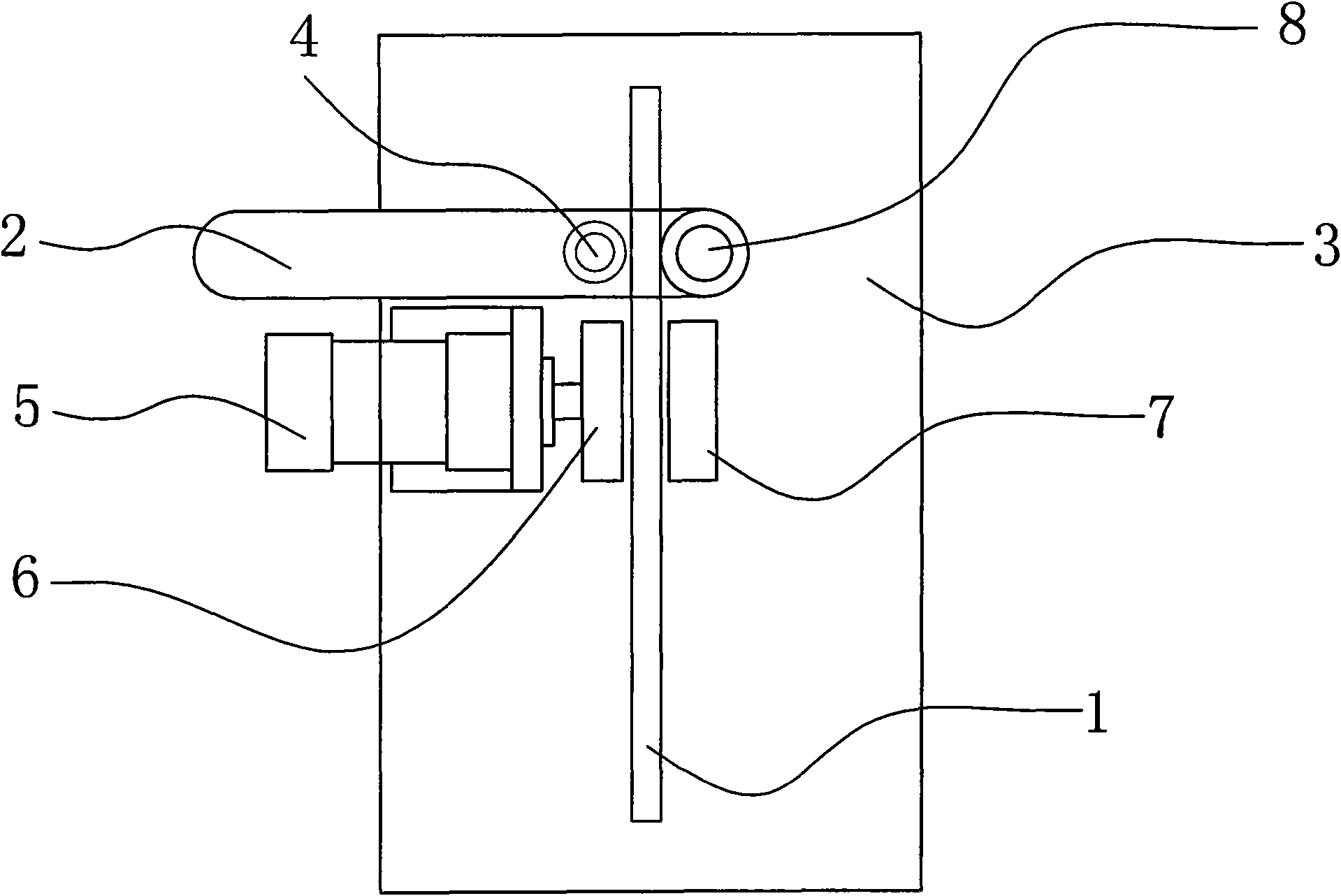

Tube bender

A tube bender includes a worktable, a rail on the worktable, a tube-pushing device and a tube-bending device. The tube-pushing device is positioned on the worktable, having a moving base and a clamper at one side of the moving device. The clamper clamps a tube being bent, and a push driver moves the moving base together with the tube work to a preset location. The tube-bending device consists of a base unit, a guide unit and a driving unit, and when the tube work is moved to the tube-bending device, it is bent by the tube-bending device, with a guide roller and a main roller sandwiching the tube for preventing the bent section of the finished tube from disfiguring.

Owner:YING HAN TECH CO LTD

Fiber optic splice enclosure

A fiber optic splice enclosure for housing an interconnection contained in a splice tray between at least one optical fiber of a feeder cable and at least one optical fiber of a drop cable is provided. The optical fiber of the feeder cable is at least partially contained in a feeder cable buffer or transportation tube. The fiber optic splice enclosure includes a support frame arranged in the enclosure. The support frame includes a central office side and a drop side. A basket is arranged on the support frame for storing slack of a spliced buffer tube transitioning to the splice tray. The spliced storage arrangement is sized so as to be able to store slack of the spliced feeder cable buffer tube while maintaining a predetermined tube bend radius. A splice tray mounting arrangement is arranged on the drop side of the support frame for supporting the splice tray.

Owner:CHARLES INDS

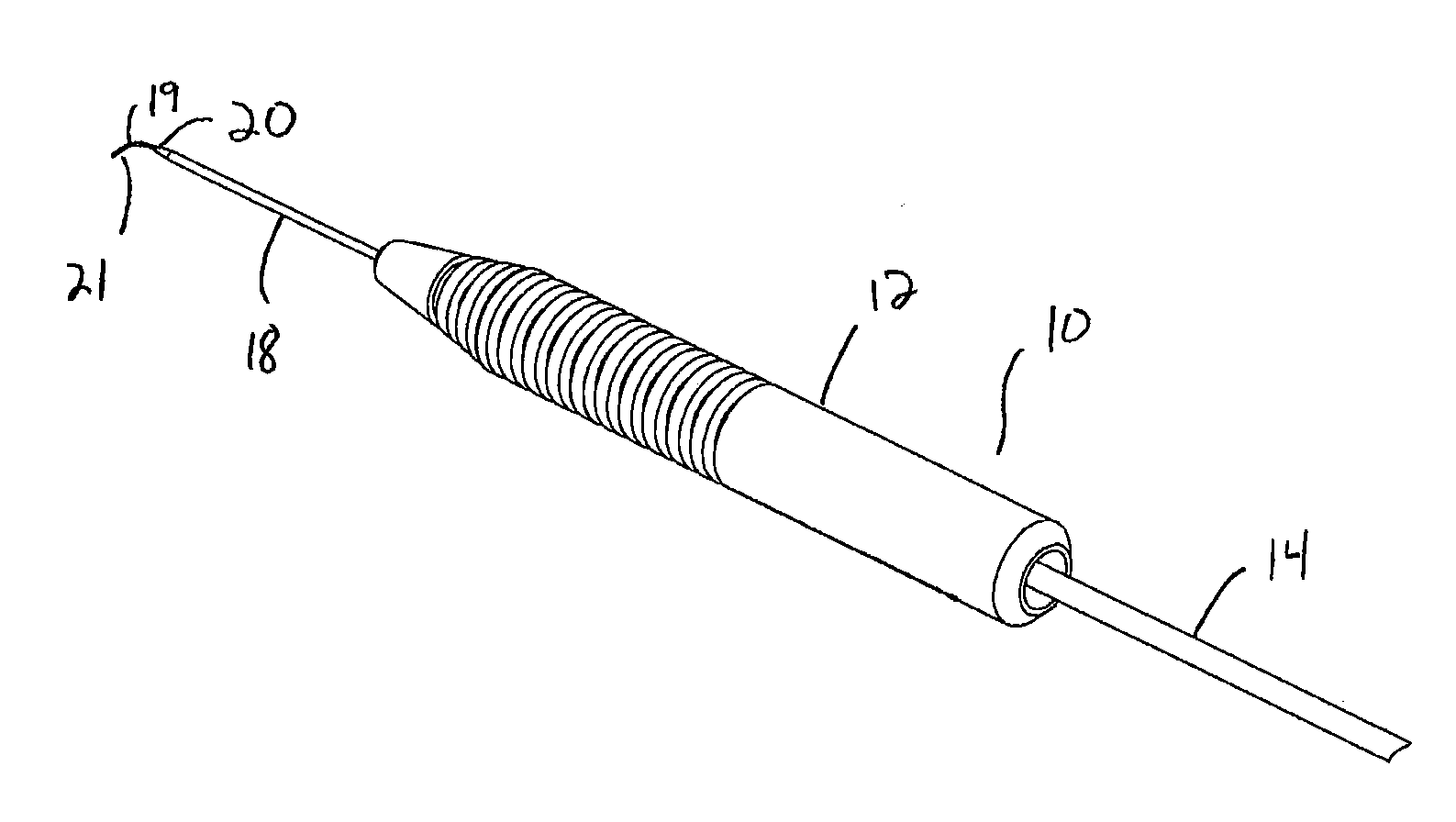

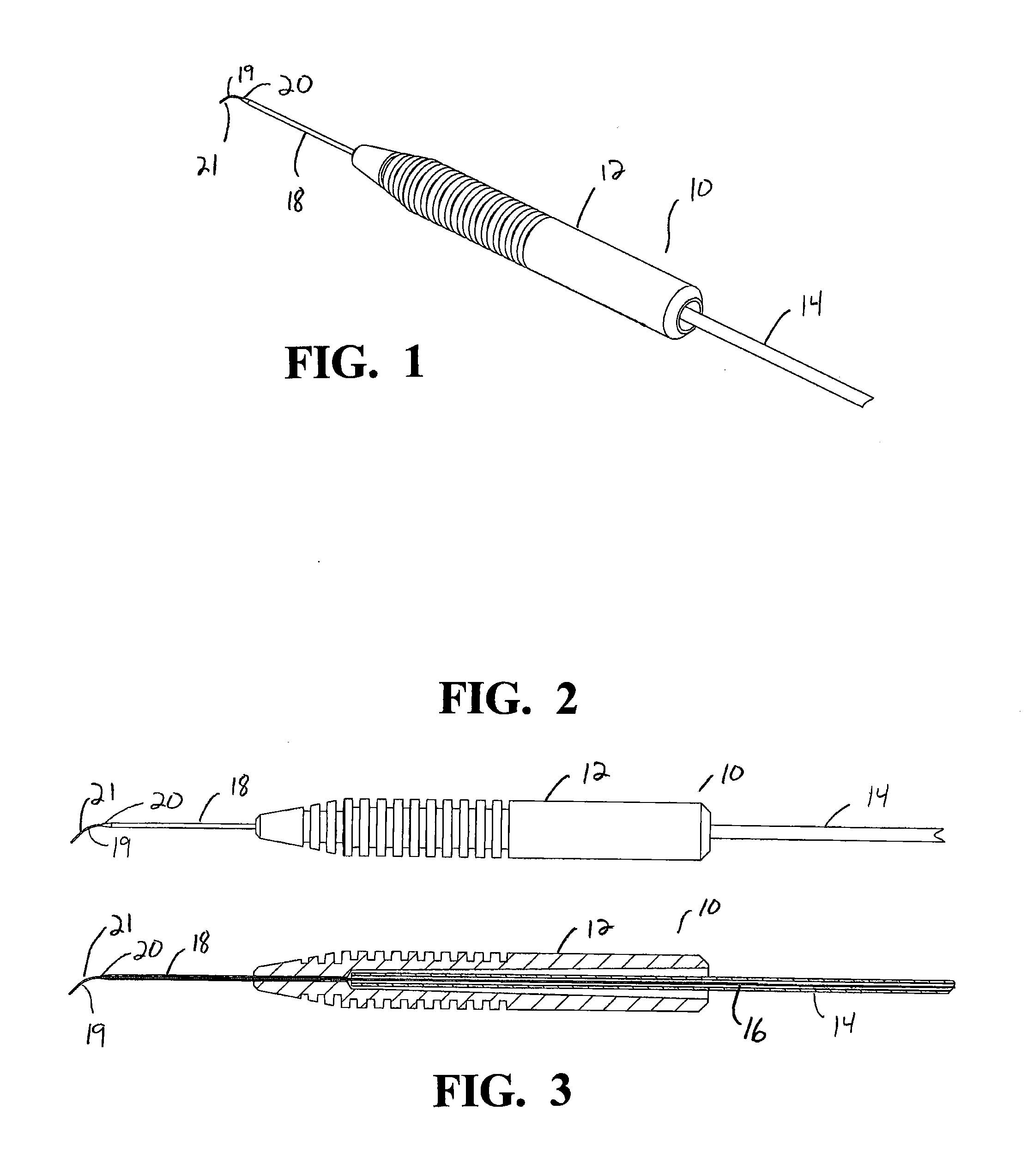

Flexible Surgical Probe

InactiveUS20090093800A1Lower insertion forceLarge treatment areaLaser surgeryDiagnosticsFiberLow insertion force

A probe having a flexible, small diameter fiber sheathed in a small diameter flexible tube comprising the distal tip of the probe. The small diameters of the fiber and tube allow the fiber to be bent in a tighter radius along essentially the entire length of the exposed portion of the fiber, with low tube bending forces during insertion, providing a compact design which eliminates the need for a straight distal portion. The small diameter tube also allows a greater wall thickness outer cannula to be used, thereby increasing instrument rigidity. This compact, rigid design with low insertion forces allows the fiber greater access to the internal posterior structures of the eye, while providing increased instrument rigidity for manipulation of the eye, as well as low insertion forces.

Owner:ALCON INC

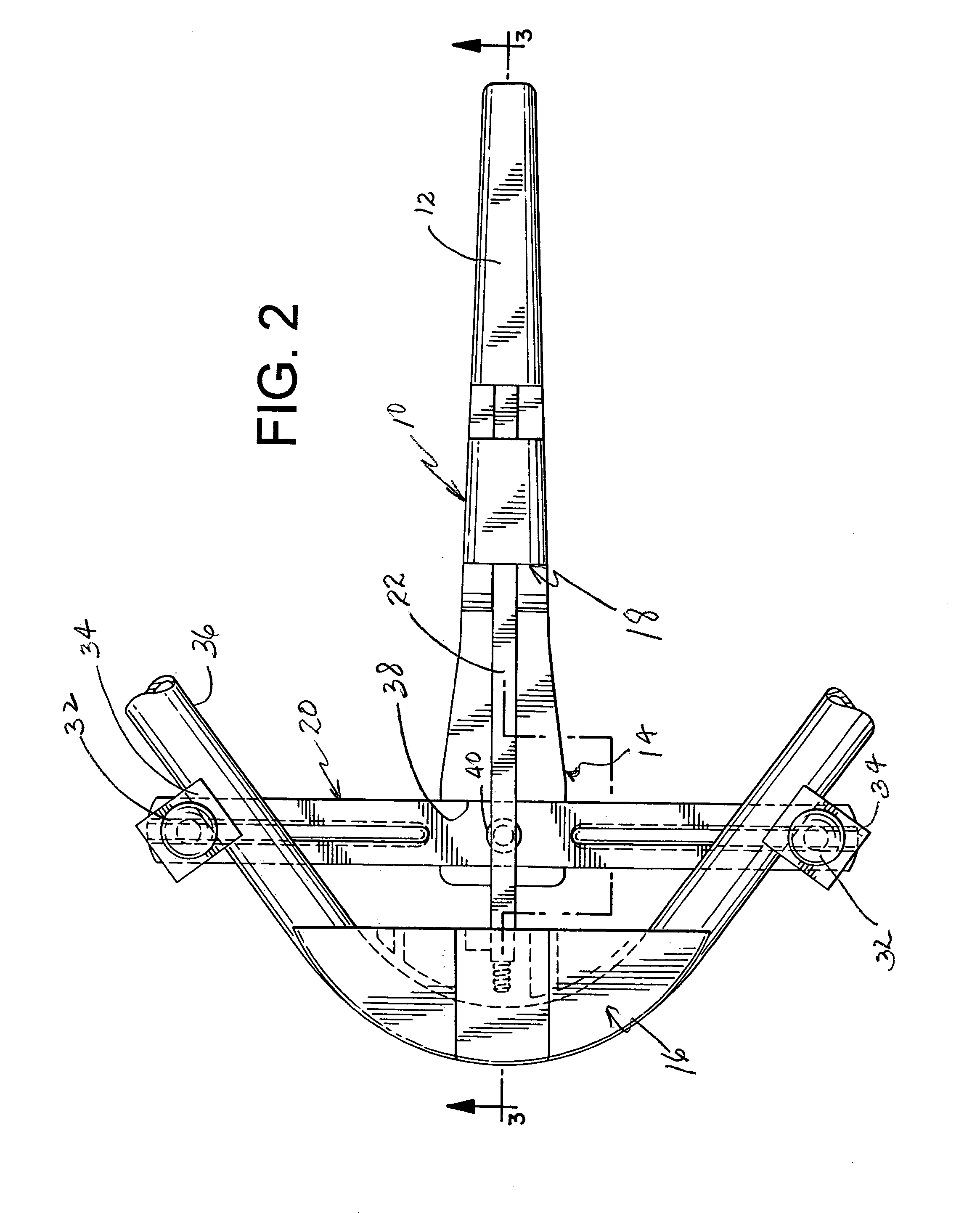

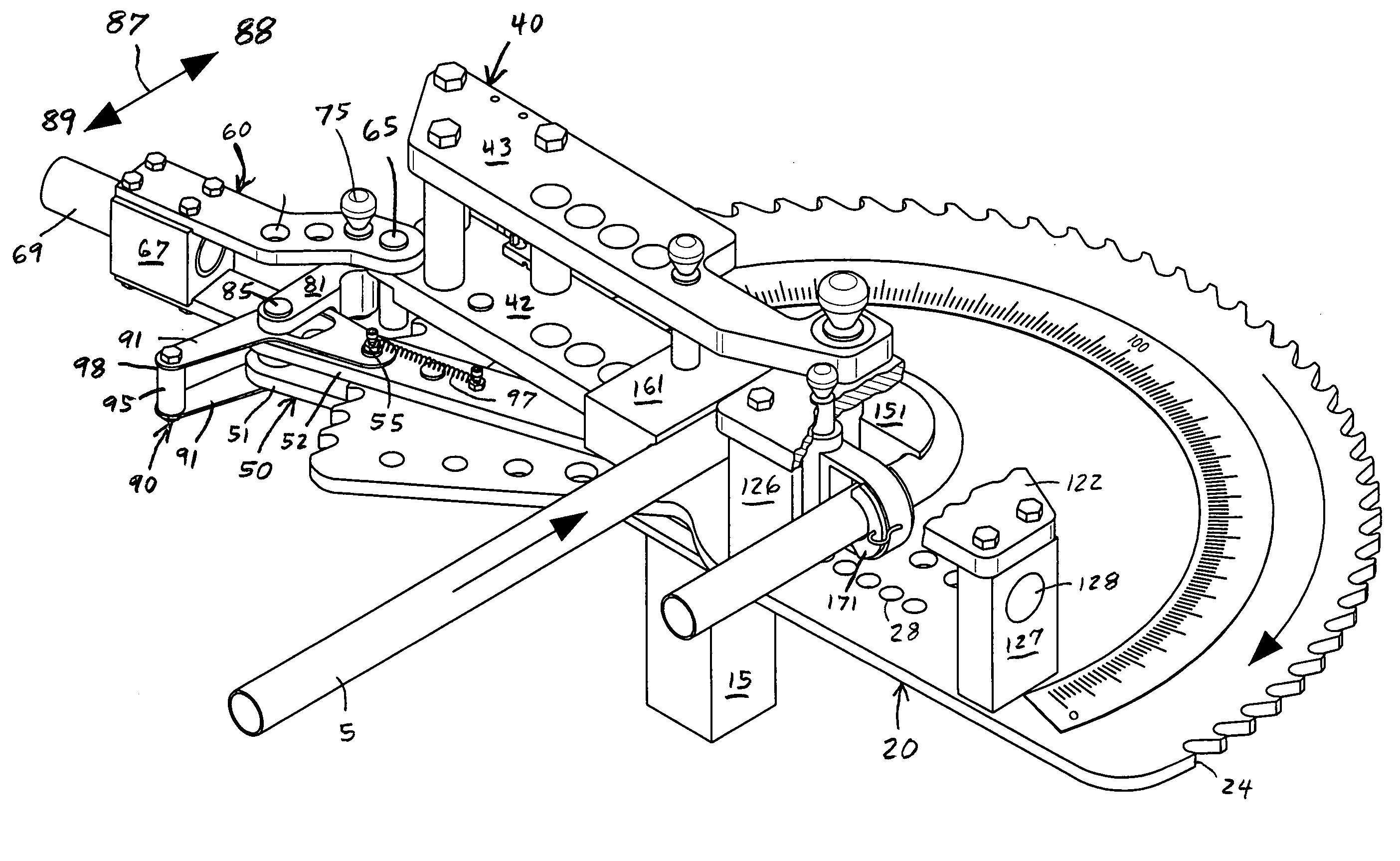

Tube bending machine

This invention is a manually operated tube bending machine with a power drive mechanism that is adjustably set to a desired bend speed. The bending machine includes a bending die, a counter die and a rotating hook die to form a desired bend into a tube or pipe. The tube bender includes a drive wheel with ratchet teeth around its perimeter. A drive pin grips one of the ratchet teeth. The drive pin is secured to a lever and torque bar. During each bending stroke, the lever and torque bar incrementally rotate the drive wheel a desired amount. The rotation of the drive wheel and hook die draw the tube through the bending and counter dies to bend the tube. An anti-spring back mechanism holds the position of the drive wheel while the power drive mechanism is advanced to grip the next ratchet tooth of the drive wheel.

Owner:JPW IND

Heat exchanger

InactiveUS20070215333A1Reduce hardnessEasy to bendMechanical apparatusFluid circulation arrangementWorking fluidTransfer system

A heat exchanger ( 301, 501, 601 ) comprising a first tube ( 107, 507, 607 ) for fluid transmission and a second tube ( 108, 508, 608 ) for fluid transmission within a heat transfer system that uses a working fluid which undergoes compression and evaporation. The first tube is placed in thermal contact with the second tube for a portion ( 109,110 ) of the respective lengths of the first tube and the second tube so as to allow an exchange of heat between the fluid within said tubes. The first tube ( 107, 507, 607 ) is constructed from steel alloy which has alloyed components to reduce the hardness of the steel to facilitate tube bending within a heat transfer system, thereby allowing the first tube to be constructed from the steel within the heat transfer system, in preference to copper.

Owner:BUNDY REFRIGERATION INT HLDG BV

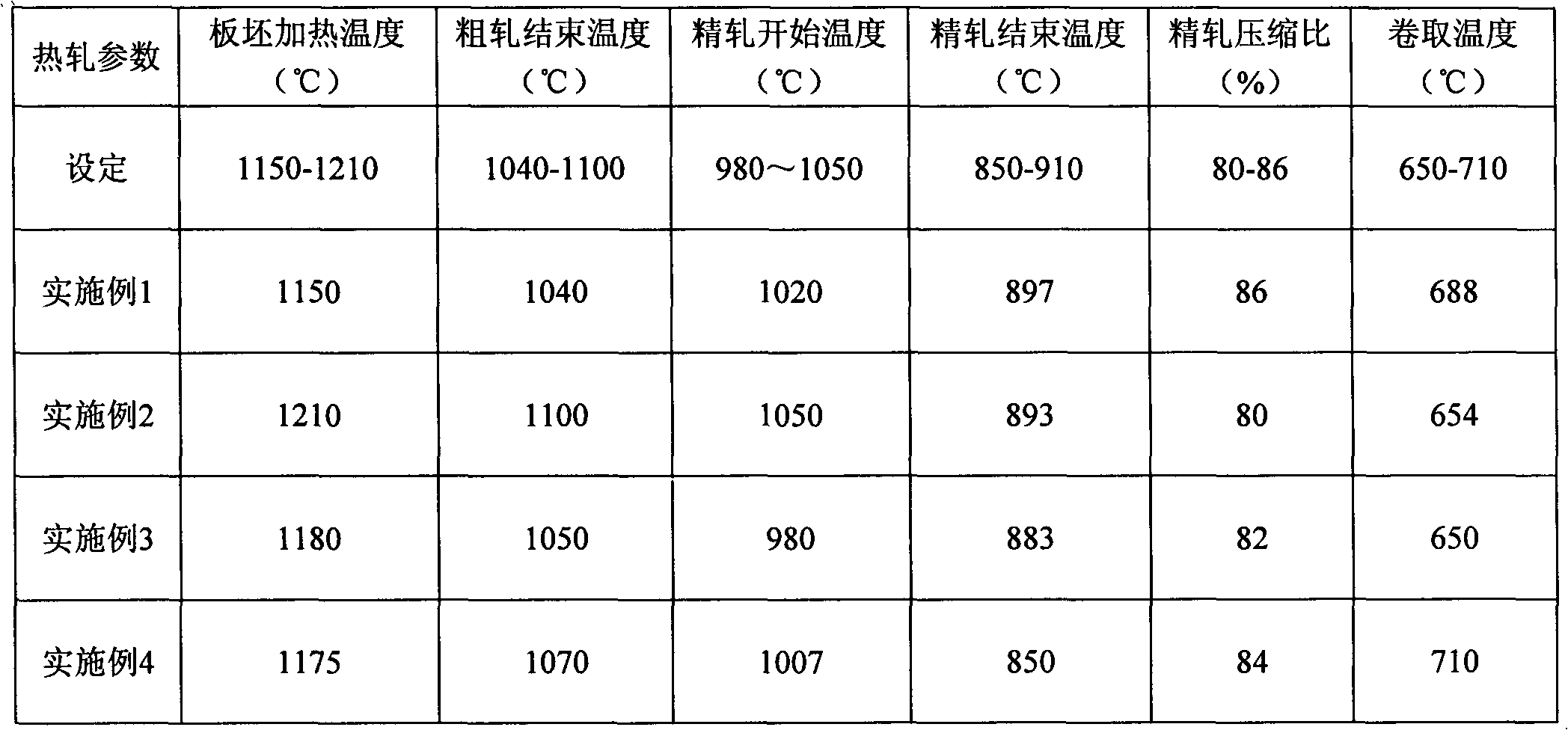

Cold-rolled steel strip for double-layer welded tube

ActiveCN102925794ALower yield strengthReduce hardnessTemperature control deviceControllabilityContinuous rolling

The invention relates to a cold-rolled steel strip, and especially relates to a cold-rolled steel strip for a double-layer welded tube and its manufacturing method to mainly solve technical problems comprising bad product yield and bad performance uniformity because of cover annealing generally adopted in the manufacturing of the double-layer welded tube. The chemical components of the cold-rolled steel strip for the double-layer welded tube comprise 0.015-0.054wt% of C, 0.034wt% or less of Si, 0.15-0.25wt% of Mn, 0.020wt% or less of P, 0.020wt% or less of S, 0.015-0.050wt% of Alt, and the balance Fe and inevitable impurity elements. In the invention, low carbon and low silicon are adopted, aluminum deoxidization is adopted as a crystal grain refinement element, and impurity form control, hot continuous rolling control cooling, continuous annealing temperature control and continuous flattening technologies are utilized to produce, so it is helpful for the guarantee of the yield strength, the percentage elongation after fracture and the hardness of the steel in prescribed requirement ranges. The cold-rolled steel strip makes the tube manufactured through using it have the advantages of good full-length performance uniformity, good roll bend formability, good tube barrel lap rebound controllability, good weldability, and good tube bending performance, and can guarantee the yield in the complete tube manufacturing flow.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

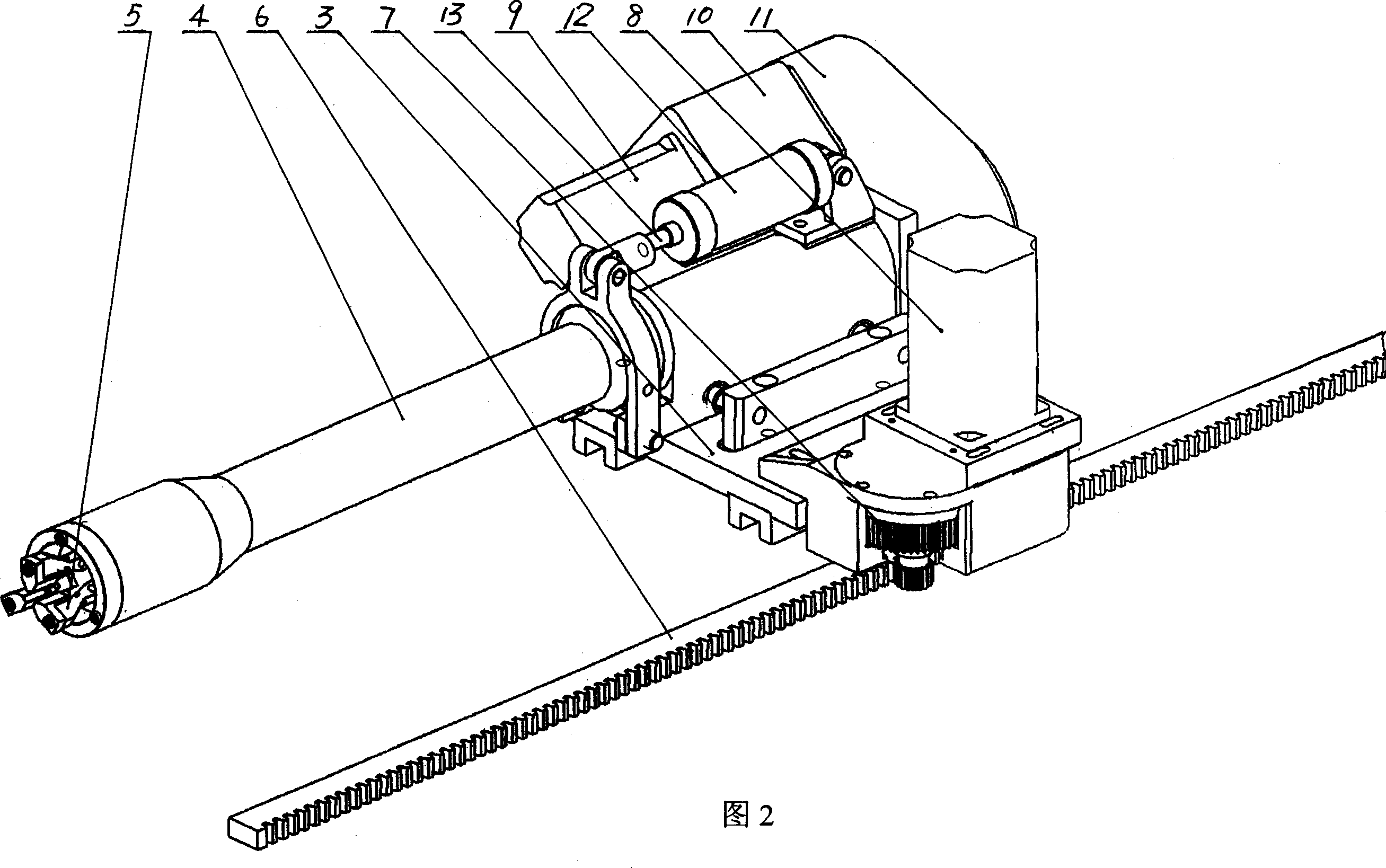

Material feeding pushing aid device for tube bending machine

InactiveCN1748891AHigh transmission precisionRealize constant power boost functionMetal-working feeding devicesPositioning devicesBogieAutomatic control

The material feeding push assister for tube bending machine includes feeding bogie on the tracks, pushing sleeve on the bogie and its driver, clamp in the end of the pushing sleeve and its driver, rack on one side of the tracks to mesh with the gear in the feeding bogie, servo motor connected to the gear via transmission unit, and automatic computerized controller connected with the servo motor. The present invention has simple structure, high transmission precision, constant force pushing of the fed material and high tube bending quality.

Owner:JIANGSU HEFENG MECHANICAL MAKING

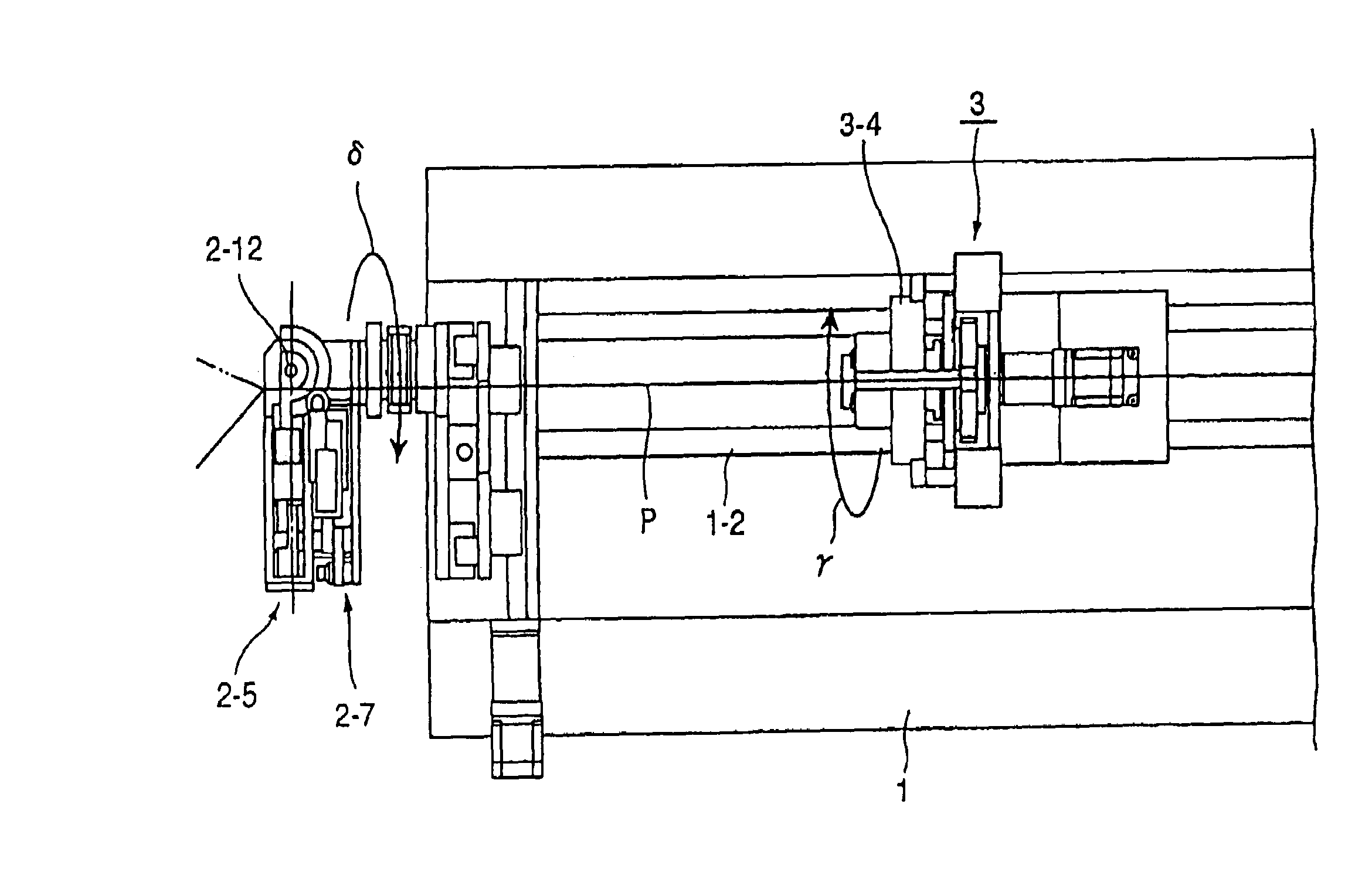

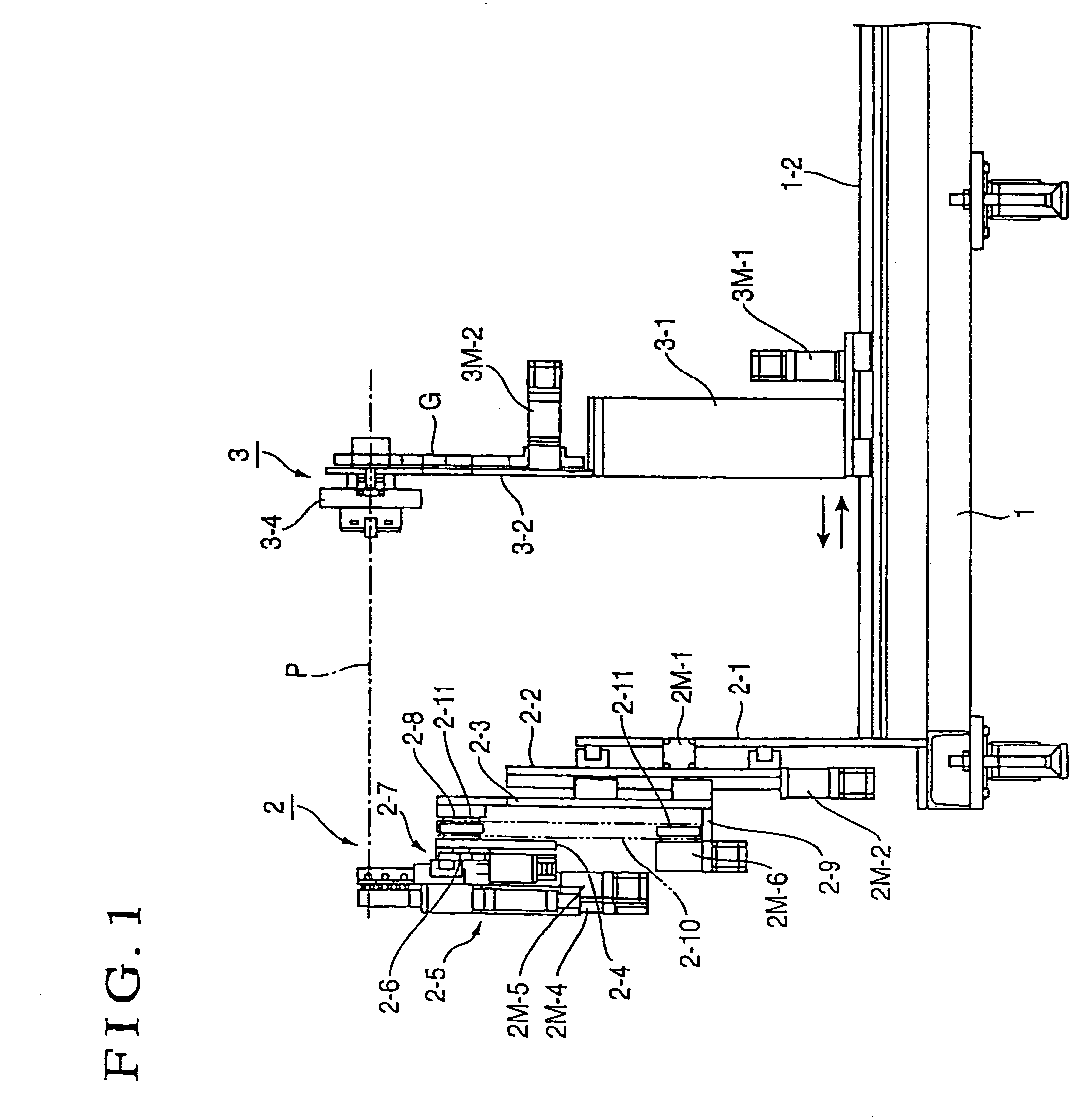

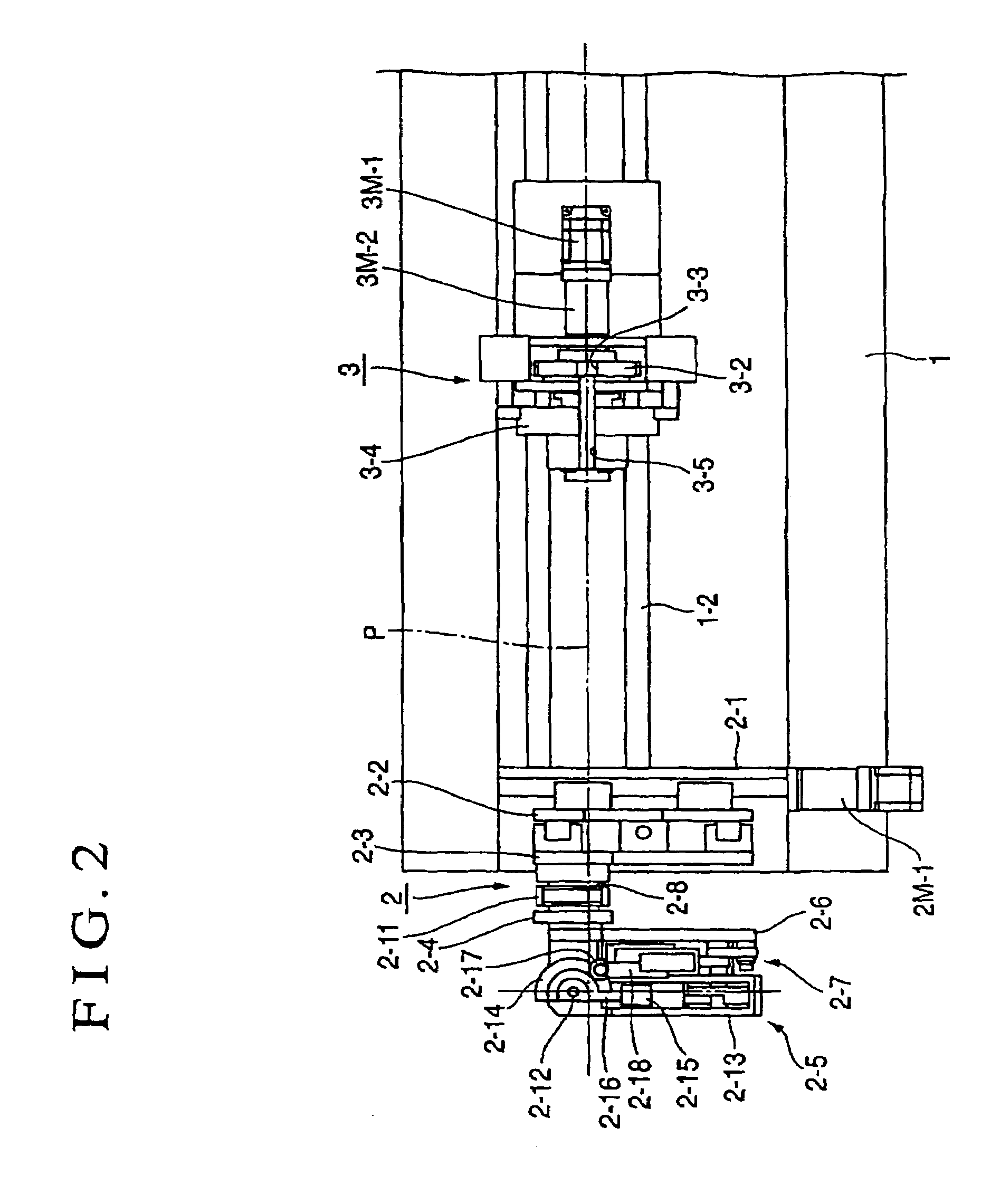

Bending device for tube

A tube bending device having draw-bending and compression-bending functions and capable of bending in all processes in a unit of device is provided. The device performing bending by rotating the tube at a predetermined angle with the tube pressured against a circumferential surface of a bending die, the device including a movable type of tube bending unit movable in a longitudinal direction of a tube to be processed or a fixed type of tube bending unit and a tube twisting unit for rotating the tube freely at a predetermined angle with a center of the tube being an axis core is characterized in that the tube bending unit has one or both of draw-bending and compression-bending functions and is provided rotatably in a vertical plane about an axis parallel to the axis core of the tube so that the displacement amount in a tube twisting operation can be reduced.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

Tube bending machine for air-conditioner heating tube

InactiveCN104607508ASimple structureEasy to operateMetal-working feeding devicesPositioning devicesTube bendingEngineering

The invention discloses a tube bending machine for an air-conditioner heating tube. A fixing shaft and an adjustable rotary column are arranged by arranging a rotary disc capable of rotating in order to fix one end of the heating tube, the other end of the heating tube is fixed through a fixing mechanism, an adjusting column of the fixing mechanism can adjust the position of a first adjusting block in order to adjust the distance between a fixing block and the first adjusting block to be suitable for different heating tubes, and then the tube can be bent by rotating the rotary disc. In addition, a locating block is arranged to locate the length of the heating tube, and a guide column is arranged to guide the heating tube. The tube bending machine is simple in structure and easy to operate, can flexibly adapt to bending different heating tubes, saves the production cost, improves production efficiency and is suitable for being applied to production.

Owner:WUHU HENGMEI ELECTRIC HEATING APPLIANCE

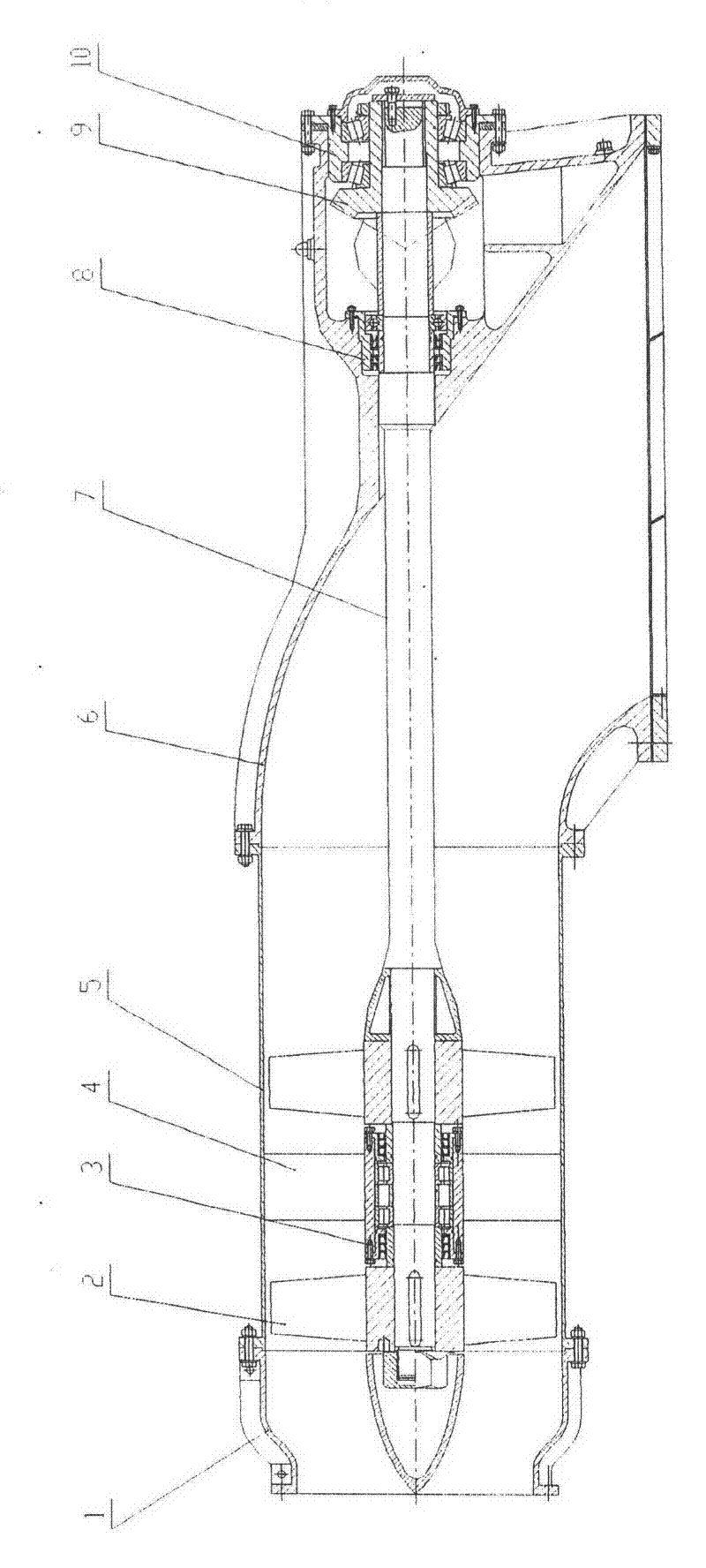

An axial flow water jet propulsion pump

InactiveCN102285441ASimple structureReduced axial dimension lengthPropulsive elementsAxial flow pumpsImpellerPush ups

The invention discloses an axial flow water jet propulsion pump. It includes a pump body, the pump body contains a cylindrical middle section, the front end and the rear end of the cylindrical middle section are respectively provided with a rectification spout and an inlet elbow, and an inner bearing seat is arranged in the cylindrical middle section. The inner bearing seat is coaxial with the cylindrical middle section, and guide vanes are connected between the periphery of the inner bearing seat and the inner wall of the cylindrical middle section. A pump shaft is arranged in the pump body, and the front end of the pump shaft passes through the inner bearing seat and protrudes in front of the inner bearing seat, and impellers are arranged on the pump shafts on both sides of the inner bearing seat. The rear end of the pump shaft passes out of the bend of the inlet elbow, and the rear end of the pump shaft is provided with a first outer bearing seat, and the rear end of the pump shaft penetrates into the first outer bearing seat. It is characterized in that a bevel gear is installed on the part of the pump shaft extending beyond the bend to the first outer bearing seat, and the diameter of the front end of the bevel gear is smaller than that of the rear end. The axial flow water jet propulsion pump has simple structure, short axial dimension, light weight and low manufacturing cost. Suitable for installation on ships to propel ships to sail.

Owner:中国人民解放军63983部队 +1

Quick changing bending machining pad pillow

A tube bending assembly adapted for use with a rotary draw bender, and preferably including a bend die mounting unit for securing a plurality of stacked bend dies drivenly coupled to the bender, a bend die tower unit for structurally supporting the bend die mounting unit, a wiper die mounting unit for securing a wiper die adjacent a selected bend die, a clamp die mounting unit for positioning and securing a clamp die, a pressure die mounting unit for securing a pressure die adjacent the clamp die, a mandrel saddle unit for positioning and enabling the utilization of a mandrel assembly, a collet saddle unit for positioning and enabling the utilization of a collet, and a bolster unit that interconnects the units, so as to present an integrated assembly capable of concurrent disconnection from and connection to the bender, and thereby reducing the tool set change-over period.

Owner:GM GLOBAL TECH OPERATIONS LLC

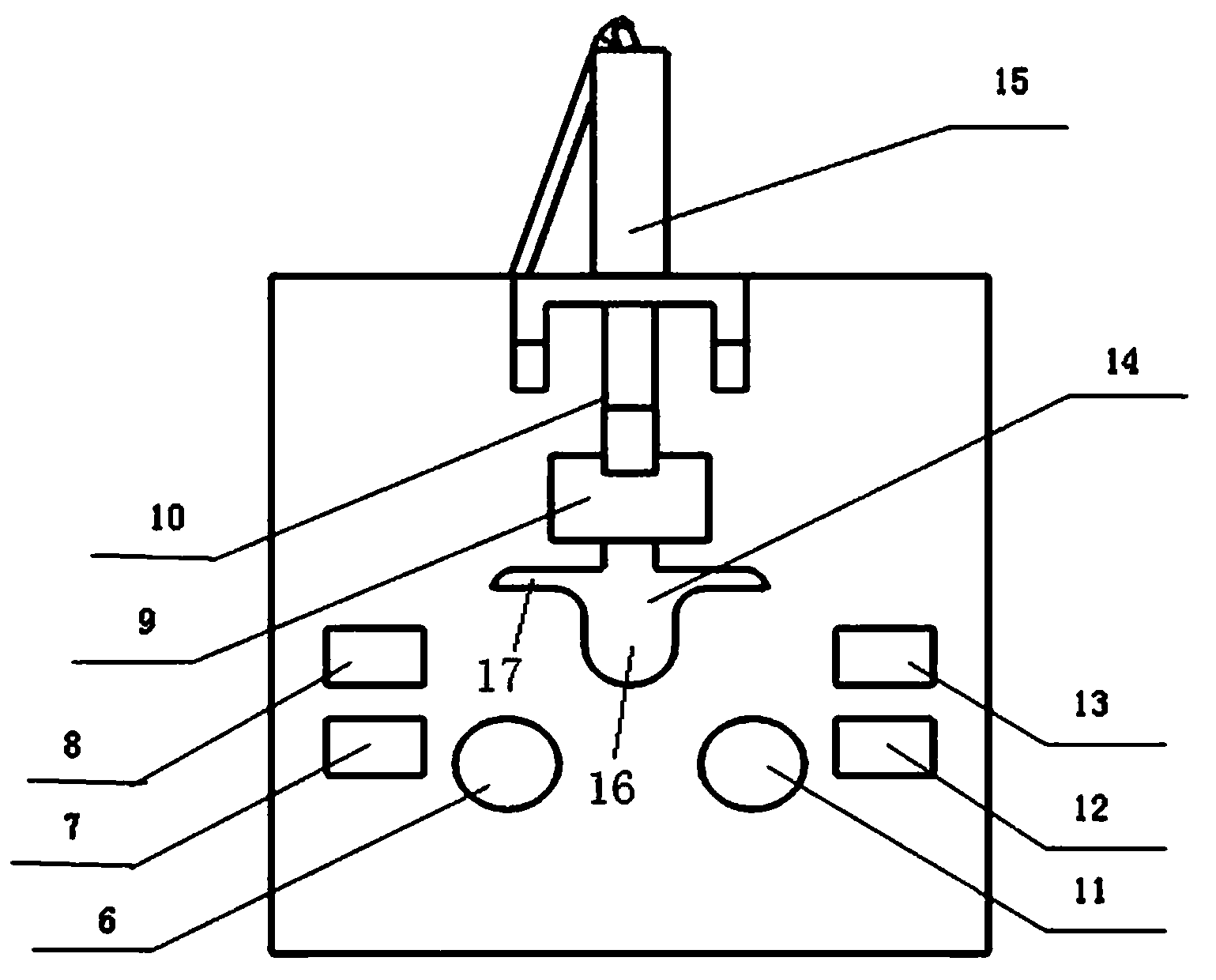

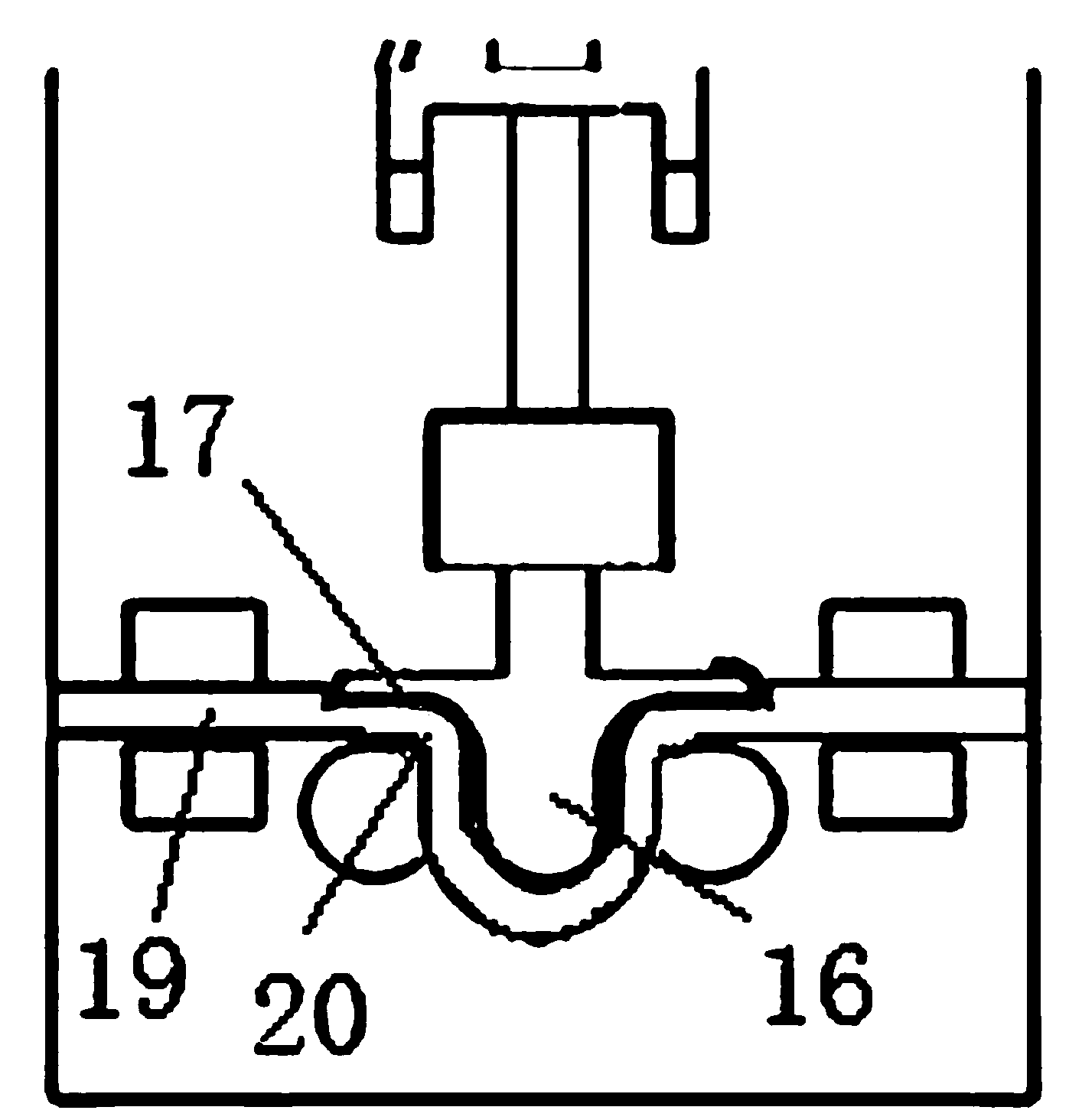

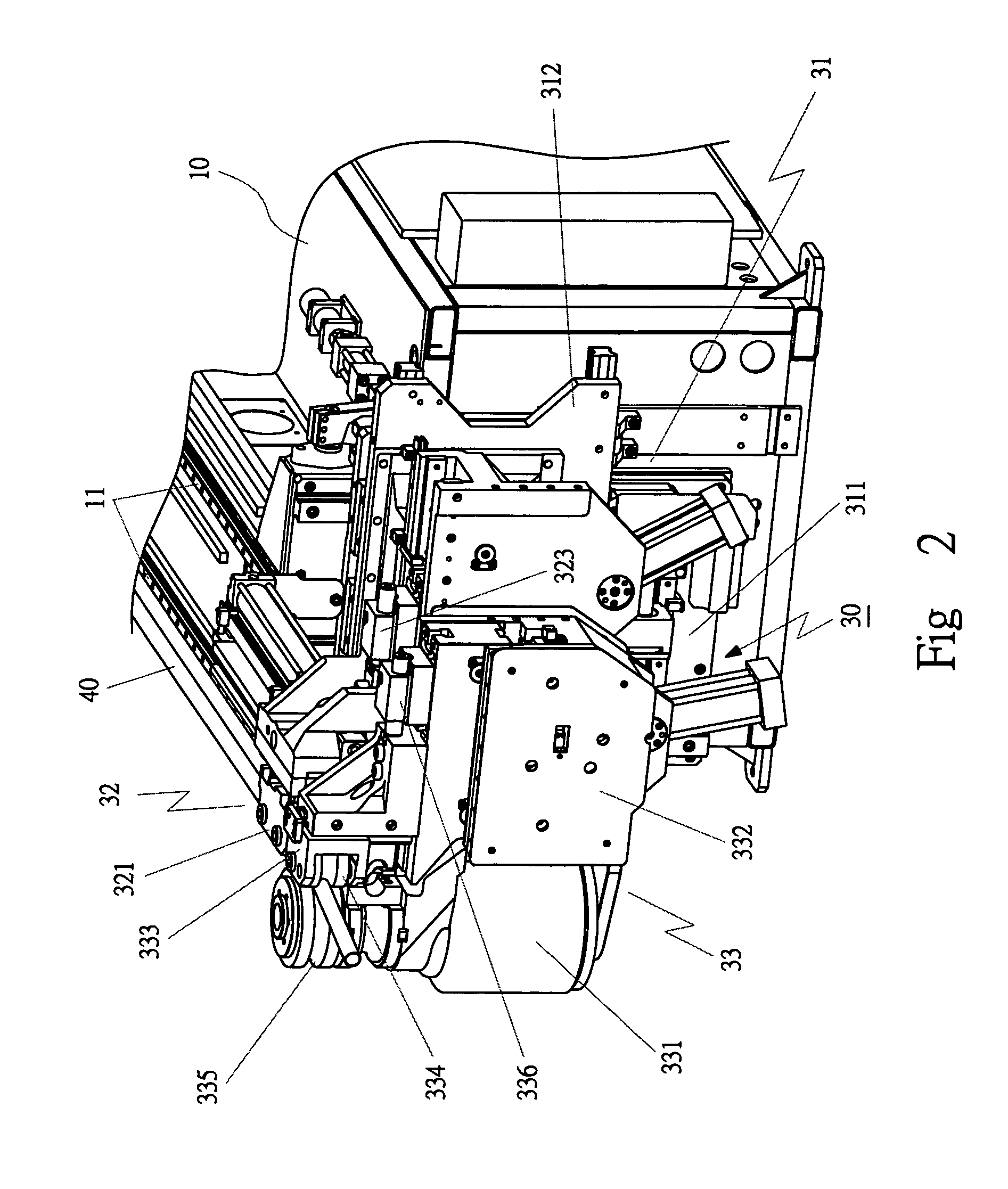

Tube bending machine and clamping mechanism thereof

The invention relates to a tube bending machine and a clamping mechanism thereof. The tube bending machine comprises: a heading mechanism installed on a bed piece along a metal tube transportation path, two boosting mechanisms, rotary structures and two clamping mechanisms, wherein when the metal tube is bent, the heading mechanism holds the metal tube and provides an axial driving force. One of the two clamping mechanisms protrudes under the metal pipe and clamps the metal tube from the side, and one of the two boosting mechanisms pushes against the metal tube. The clamping mechanism comprises: a side snap gauge, an elastic support rod and a boosting part. One side of the side snap gauge is hinged on the end part of the elastic support rod, and the other side thereof pushes against the boosting part. When the boosting part drives the side snap gauge and the elastic support rod to move toward the metal tube and the elastic support rod is blocked, the elastic support rod is elastically deformed along the axial direction, while the side snap gauge revolves around the end part of the elastic support rod under the impetus of the boosting part. The tube bending machine is capable of successively bending bilateral snake-like bends.

Owner:WISE WELDING TECH & ENG

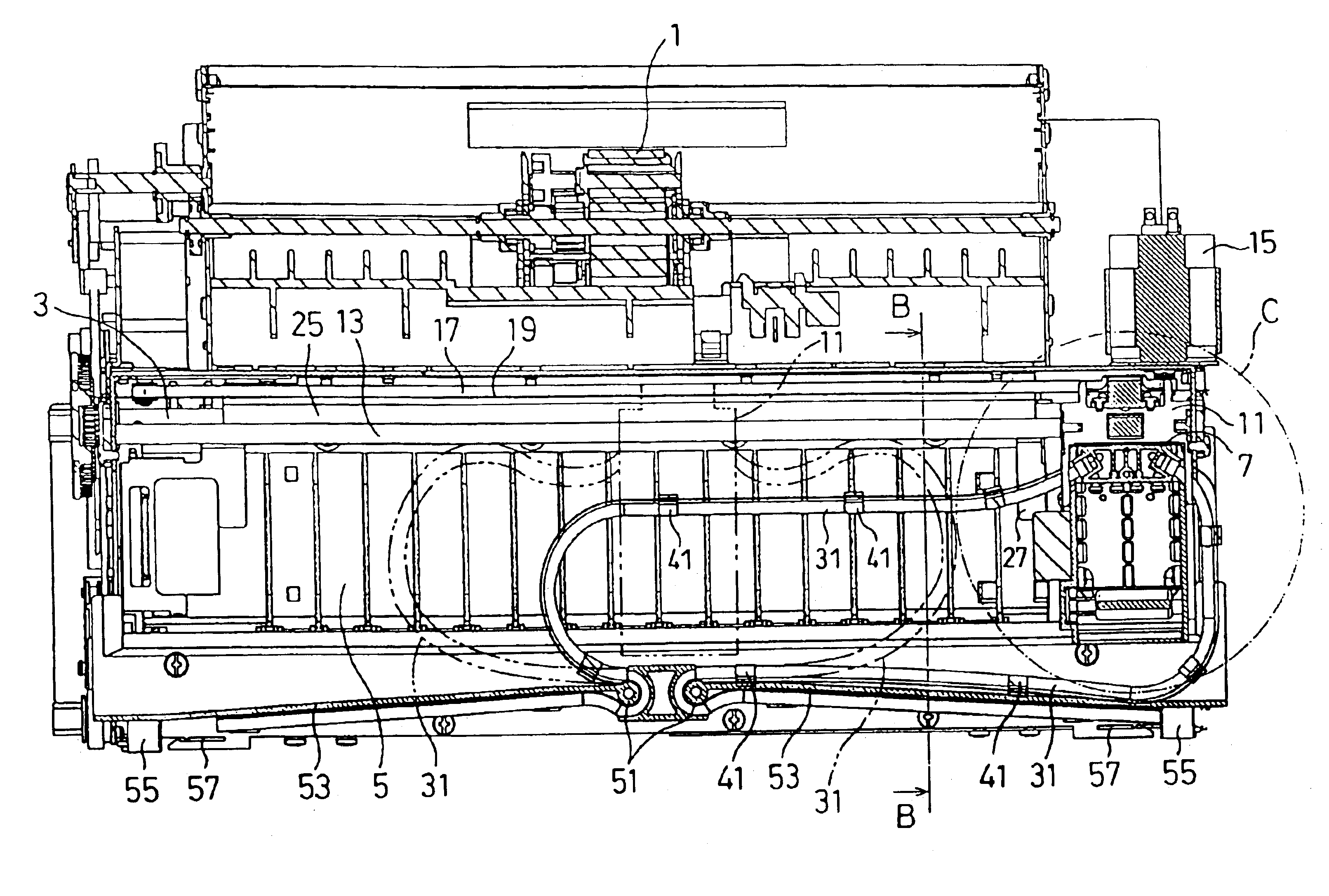

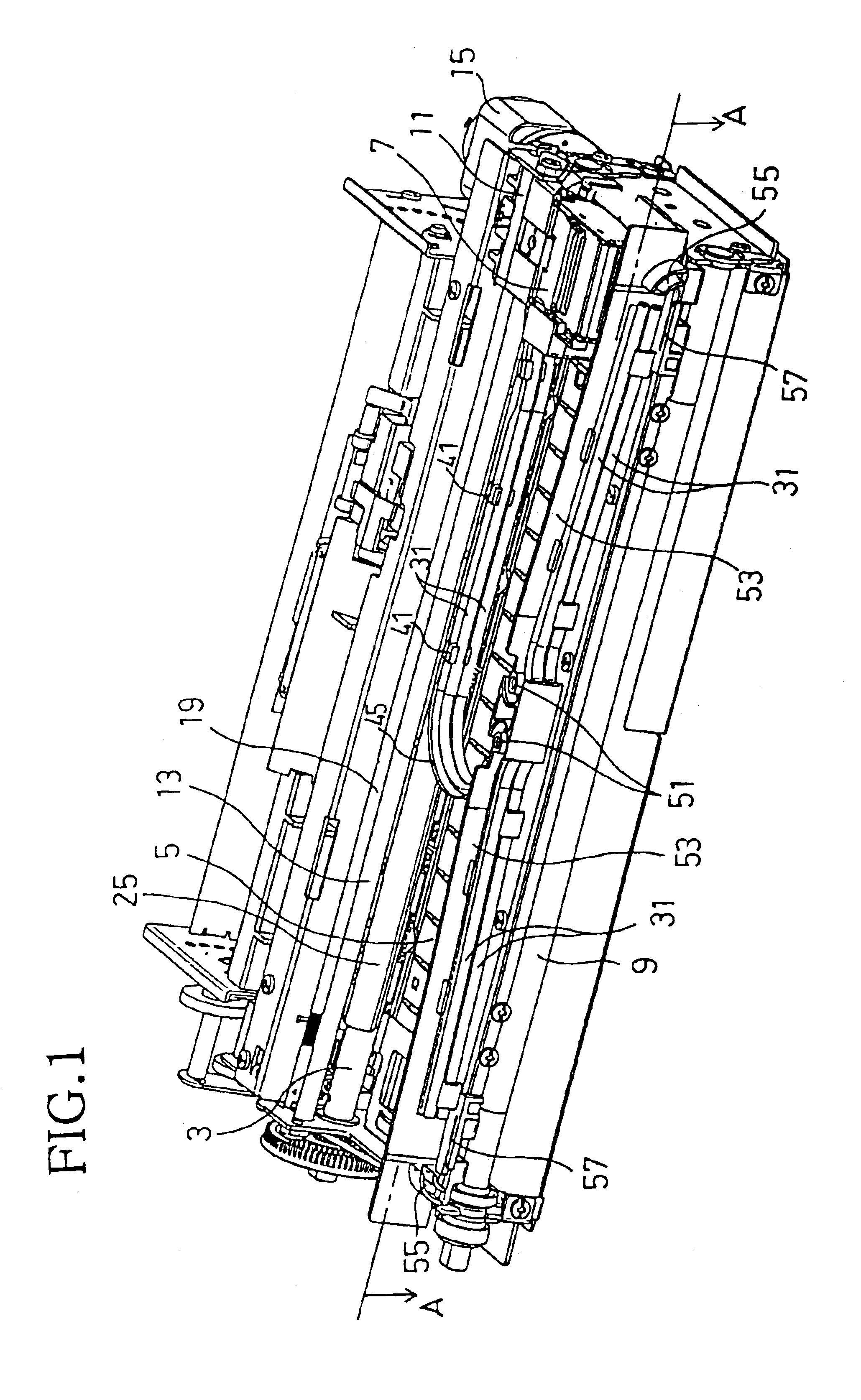

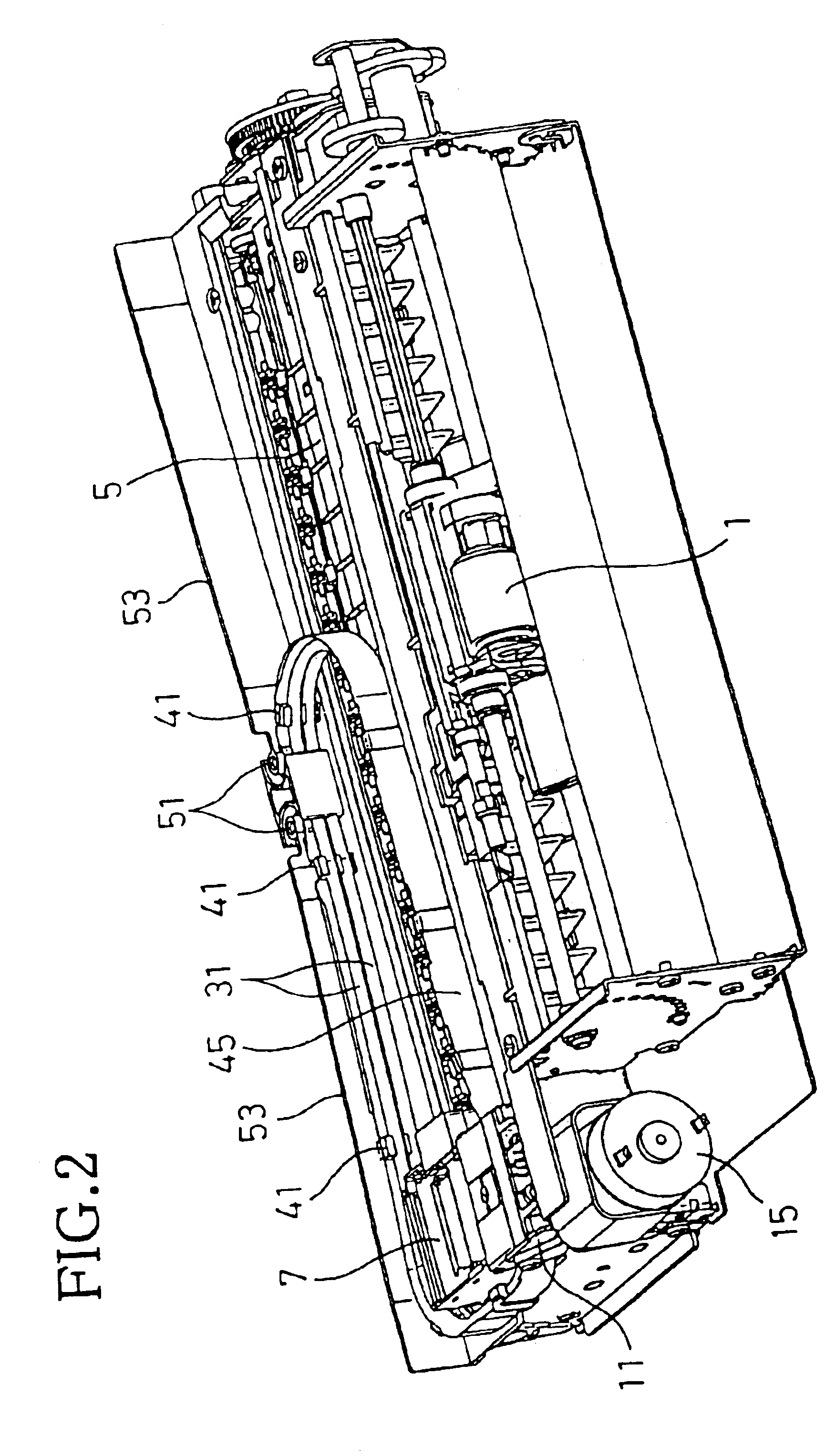

Ink jet printer

An ink jet printer includes an ink container supplying ink through a tube member to a separate print head to form an image. The ink jet printer also includes a guide rail to guide the print head, a transport roller to feed the recording medium, and a cover to prevent the tube member from contacting the roller. As the print head reciprocates in a width direction of a recording medium, the tube protruding from a surface of the print head on an end side in a moving direction thereof bends or flexes when the print head moves together with a carriage. The bending of the tube in the rearward direction is restricted by a tube band contacting the transport roller and cover. The cover and guide rail form a plane vertical to a platen at front faces of the cover and the guide. When the bending or movement of the tube is blocked or restricted by the vertical plane to a tube bending direction, the tube is not raised. Therefore, a resistance is not applied to the print head during the movement of the print head. Thus, the bending or movement of the tube can be restricted without providing a special device for the ink jet printer.

Owner:BROTHER KOGYO KK

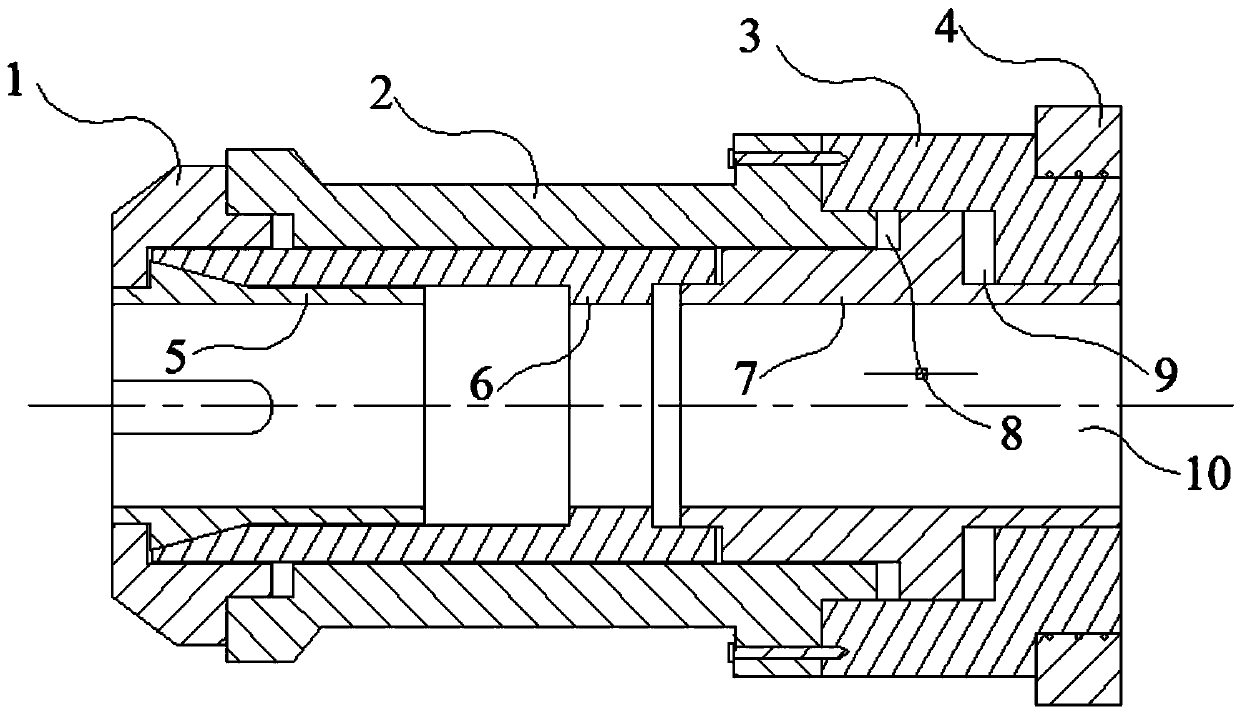

Inward-pushing-type clamping device of three-dimensional corner clamping tube in numerically-controlled tube bending machine

The invention discloses an inward-pushing-type clamping device of a three-dimensional corner clamping tube in a numerically-controlled tube bending machine, and belongs to the field of numerically-controlled tube bending machines. The inward-pushing-type clamping device comprises a flexible chuck, and further comprises a top end fixing sleeve, an outer fixing sleeve, a hydraulic outer cylinder, a bearing, an inward-pushing sleeve, a hydraulic inner cylinder, a first hydraulic cavity and a second hydraulic cavity. The top end fixing sleeve, the outer fixing sleeve, the hydraulic outer cylinder, the bearing, the flexible chuck, the inward-pushing sleeve, the hydraulic inner cylinder, the first hydraulic cavity and the second hydraulic cavity are respectively of a rotationally-symmetric structure, share the same central axis and internally forms a clamping inner cavity jointly. Due to the arrangement and assembling relationship of the components, when the inward-pushing-type clamping device clamps tubes, clamping force is easily controlled, tubes are not damaged, it is ensured that the inward pushing sleeve is steadily pushed to move and the flexible chuck is steadily pushed to contract in the clamping process, and the damage and skid, caused by uneven moving, of a workpiece are avoided.

Owner:ANHUI DEXI DHI TECH

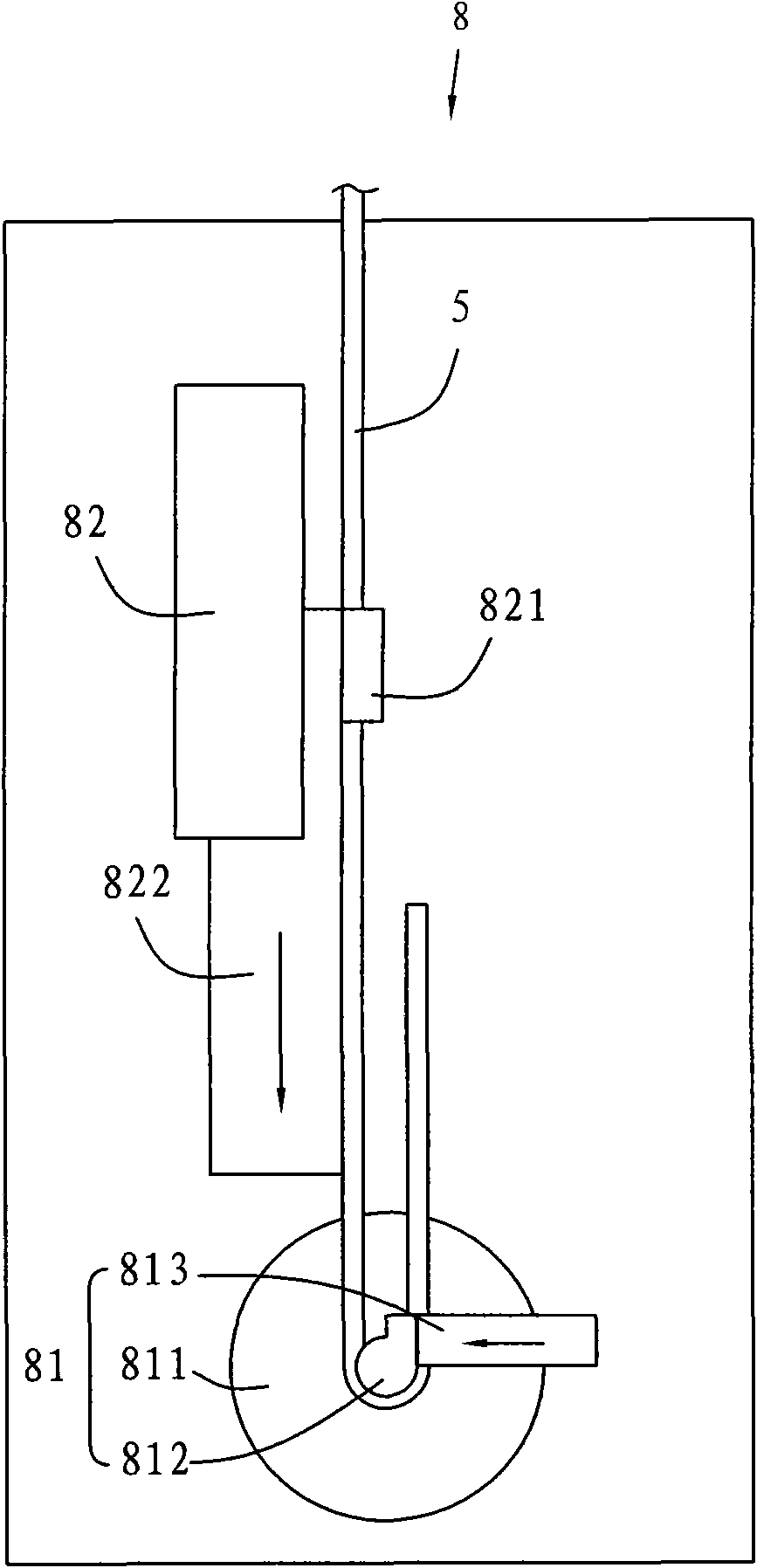

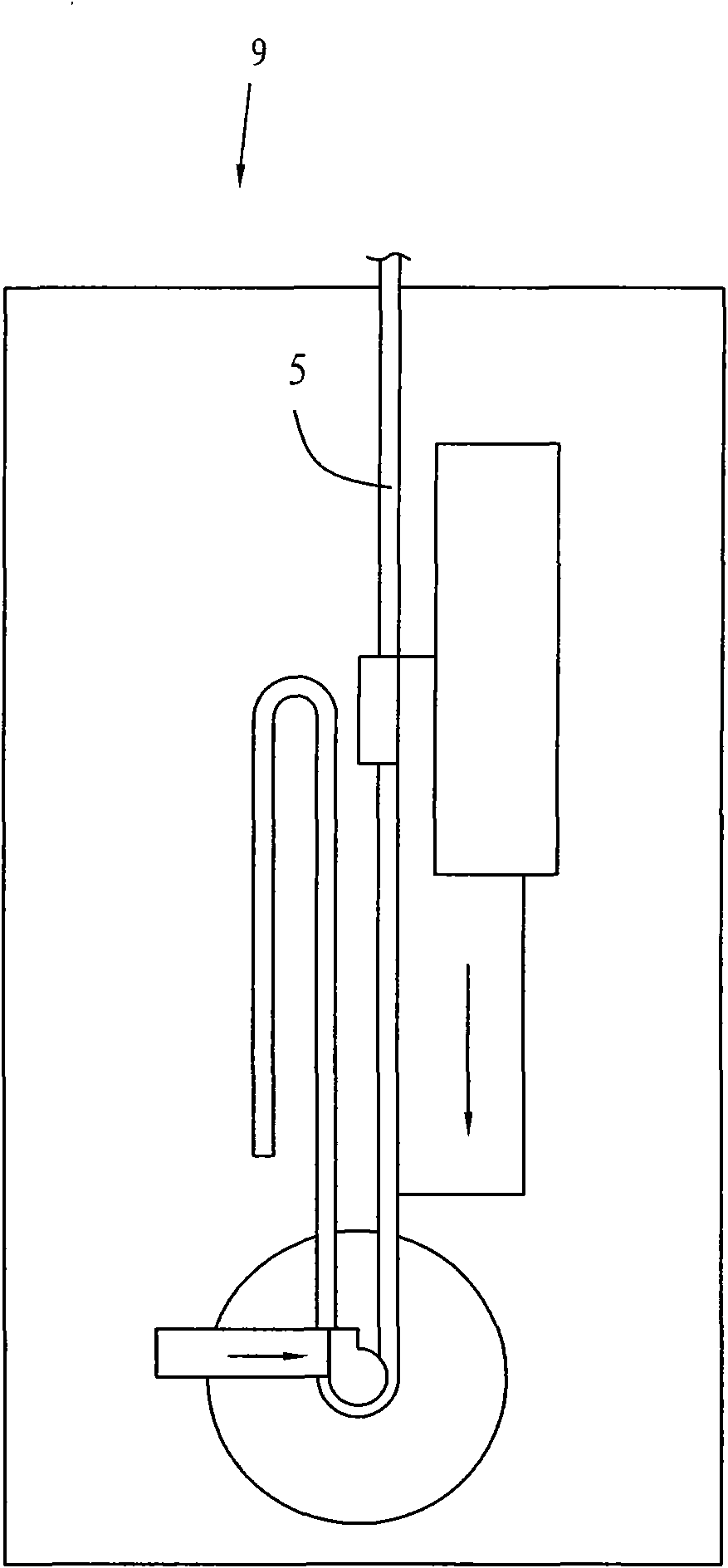

Automatic-feeding tube-bending machine

ActiveCN103586313ANo interferenceHigh degree of automationMetal-working feeding devicesPositioning devicesEngineeringTube bending

The invention discloses an automatic-feeding tube-bending machine. The automatic-feeding tube-bending machine comprises a feeding guide assembly, a tube-bending assembly and a material returning assembly. The feeding guide assembly comprises a material ejecting mechanism, a material supporting guide plate mechanism, a guide pipe mechanism, a discharging frame and a blanking mechanism. The tube-bending assembly comprises a clamping die used for clamping tube materials after feeding and a bending die which is driven by a driving mechanism to rotate around the clamping die and used for bending tubes. The material returning assembly comprises a mandrel, a material returning pipe and a driving mechanism. The automatic-feeding tube-bending machine is a full-automatic device capable of achieving automatic material supply, automatic material ejection, automatic tube bending, automatic tube-clamped feeding and automatic material returning. The automatic-feeding tube-bending machine is high in automation degree, capable of accurately and efficiently bending the tubes, ingenious in design, free of mutual interfere of all parts, and capable of being adjusted according to needs and change.

Owner:QINGDAO RENHAO MACHINERY MFG

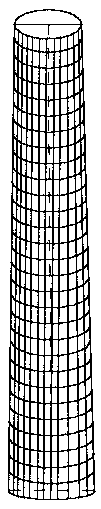

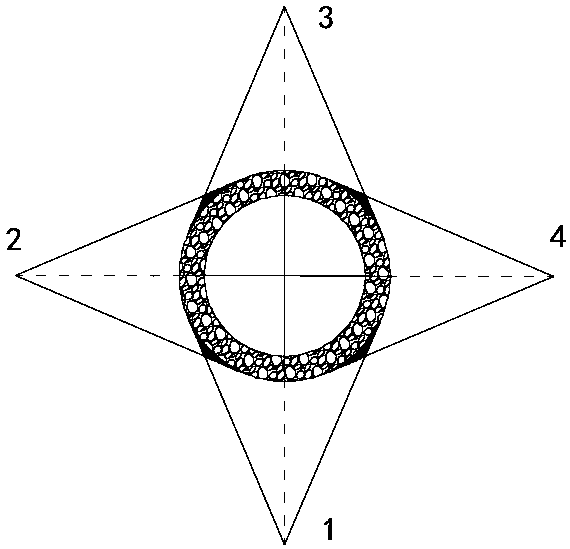

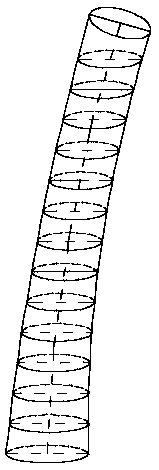

High tower tube bending degree detection method based on three-dimensional laser scanning

The invention belongs to the technical field of building deformation measurement and particularly relates to a high tower tube bending degree detection method based on three-dimensional laser scanning. The method comprises the steps of (1) arranging an instrument through retention points which are symmetrically arranged around a tower tube as a center, and obtaining point cloud data of a tower tube body, (2) constructing a tube body TIN model, selecting tower tube cross sections, and carrying out fitting of a tower tube central axis, (3) randomly selecting n points or selecting n points with a set interval along a counter-clockwise (or clockwise) direction at the edge perimeters of the cross sections and carrying out reduction of barycentric coordinates of the tower tube cross sections, and (4) calculating a tower tube bending displacement component, a bending displacement resultant and a bending average curvature according to an adjacent cross section through the obtained barycentric coordinates of the tower tube cross sections. According to the method, the disadvantages of difficult field operations, difficult precision control, time and labor consumption, poor accuracy of target data and a large data limitation in the traditional detection of a high tower tube bending degree are solved, the high tower tube bending degree detection can be rapidly and precisely realized, and the method has important practical significance for similar engineering detection and monitoring.

Owner:POWERCHINA XIBEI ENG

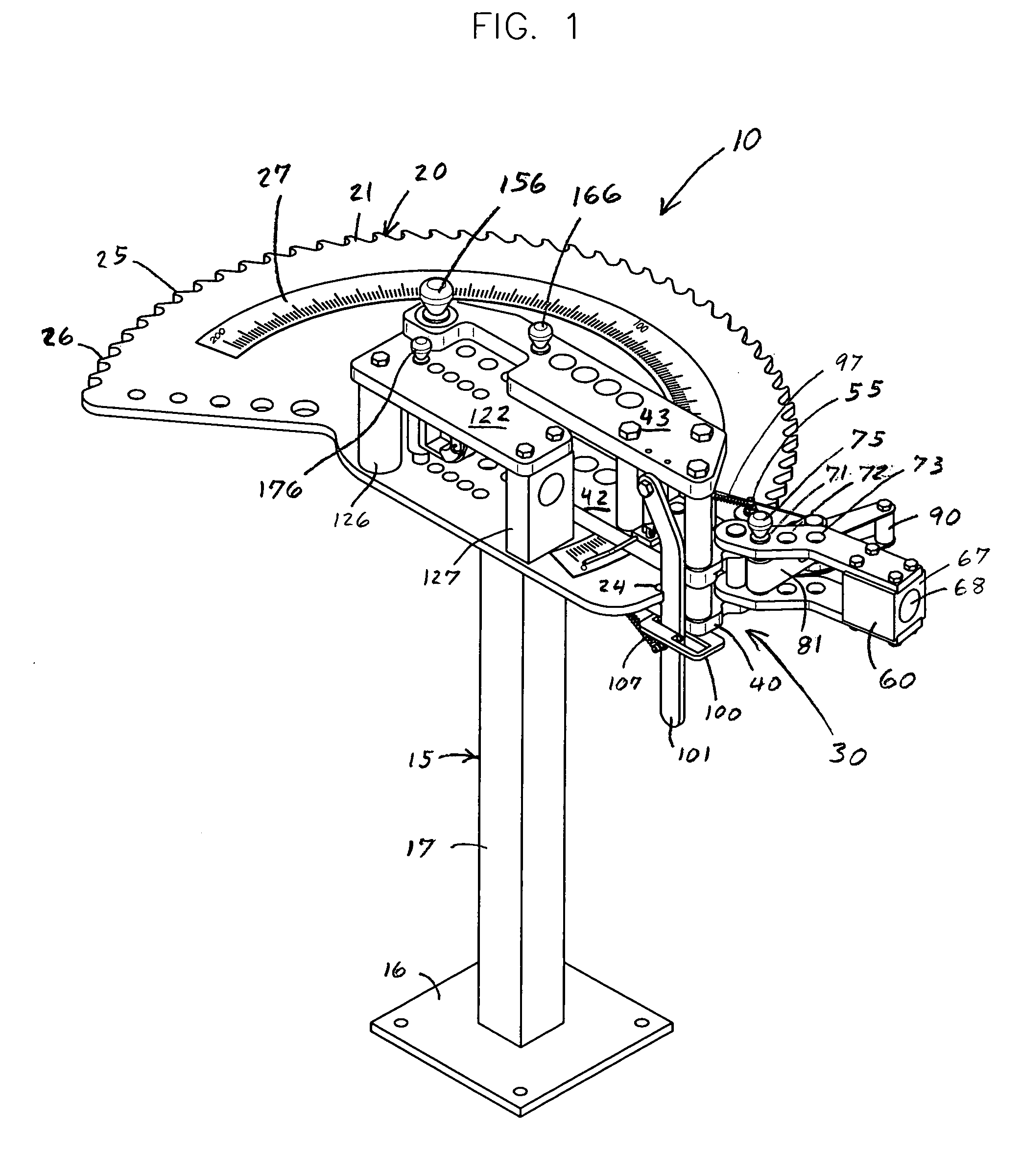

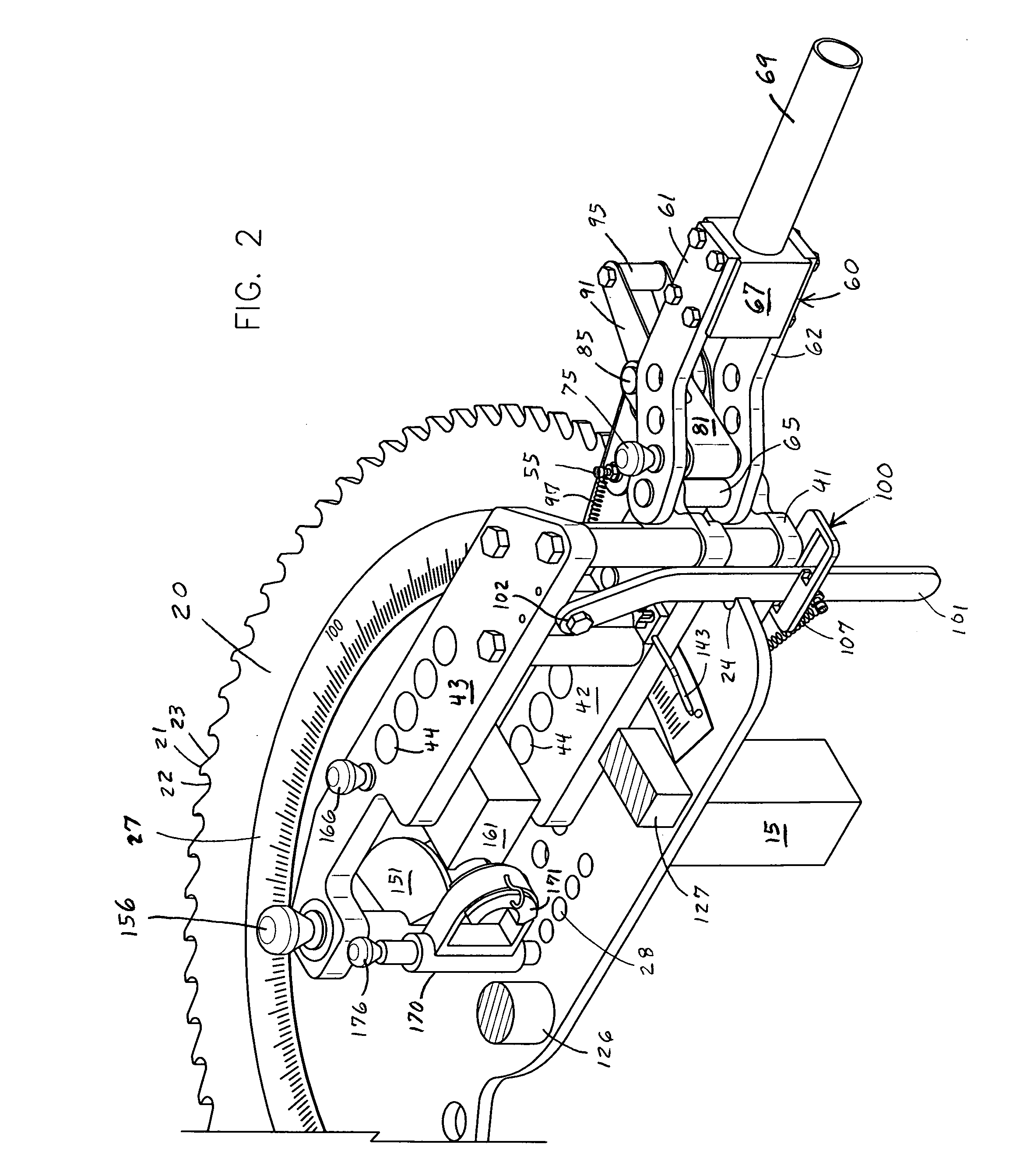

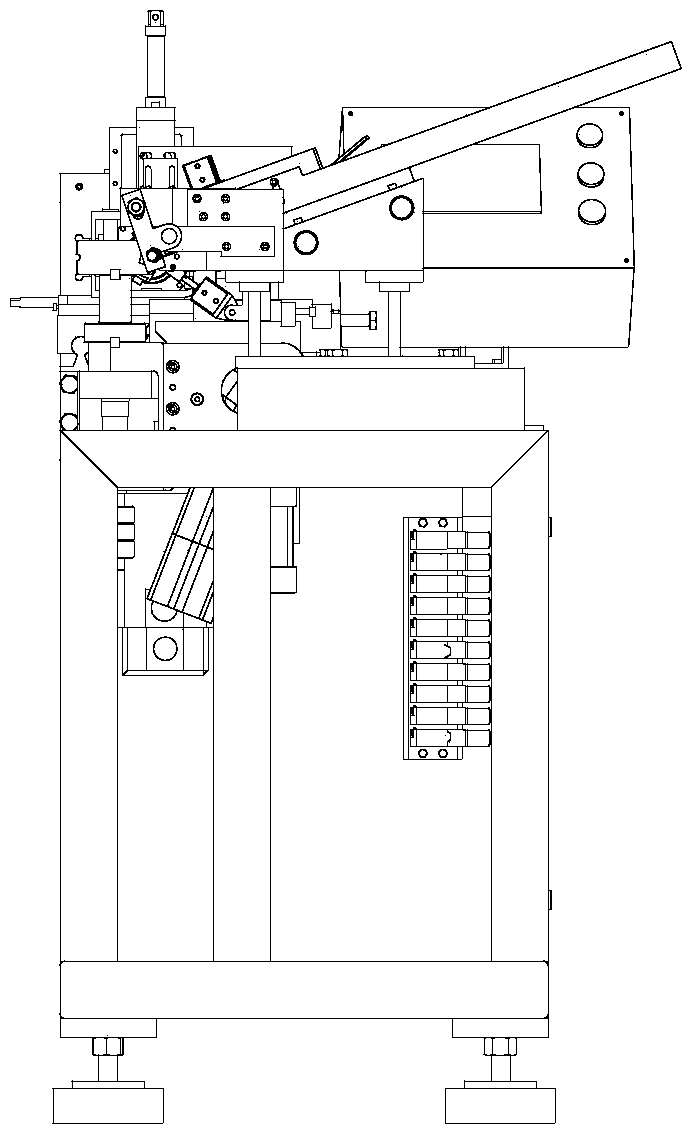

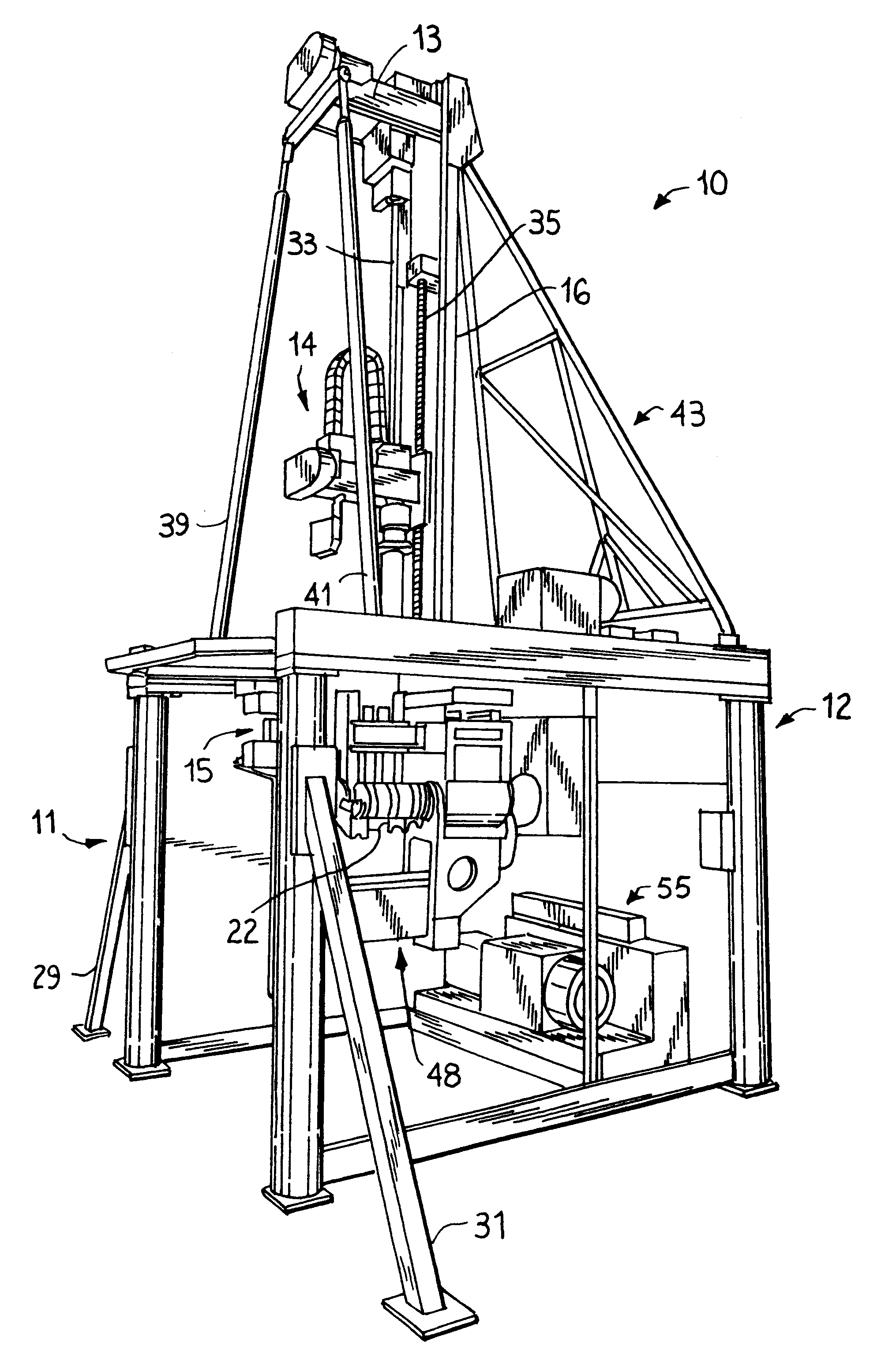

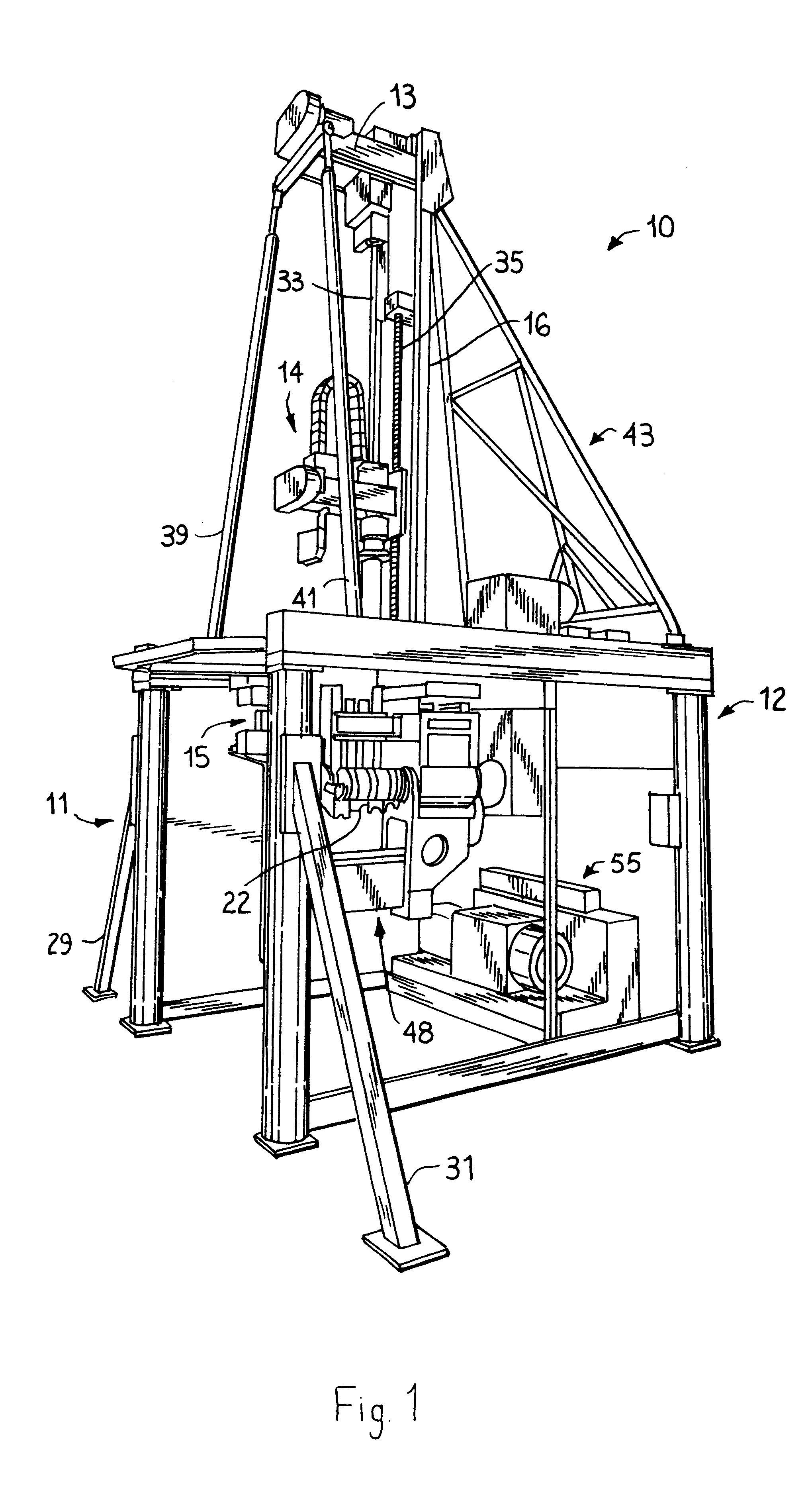

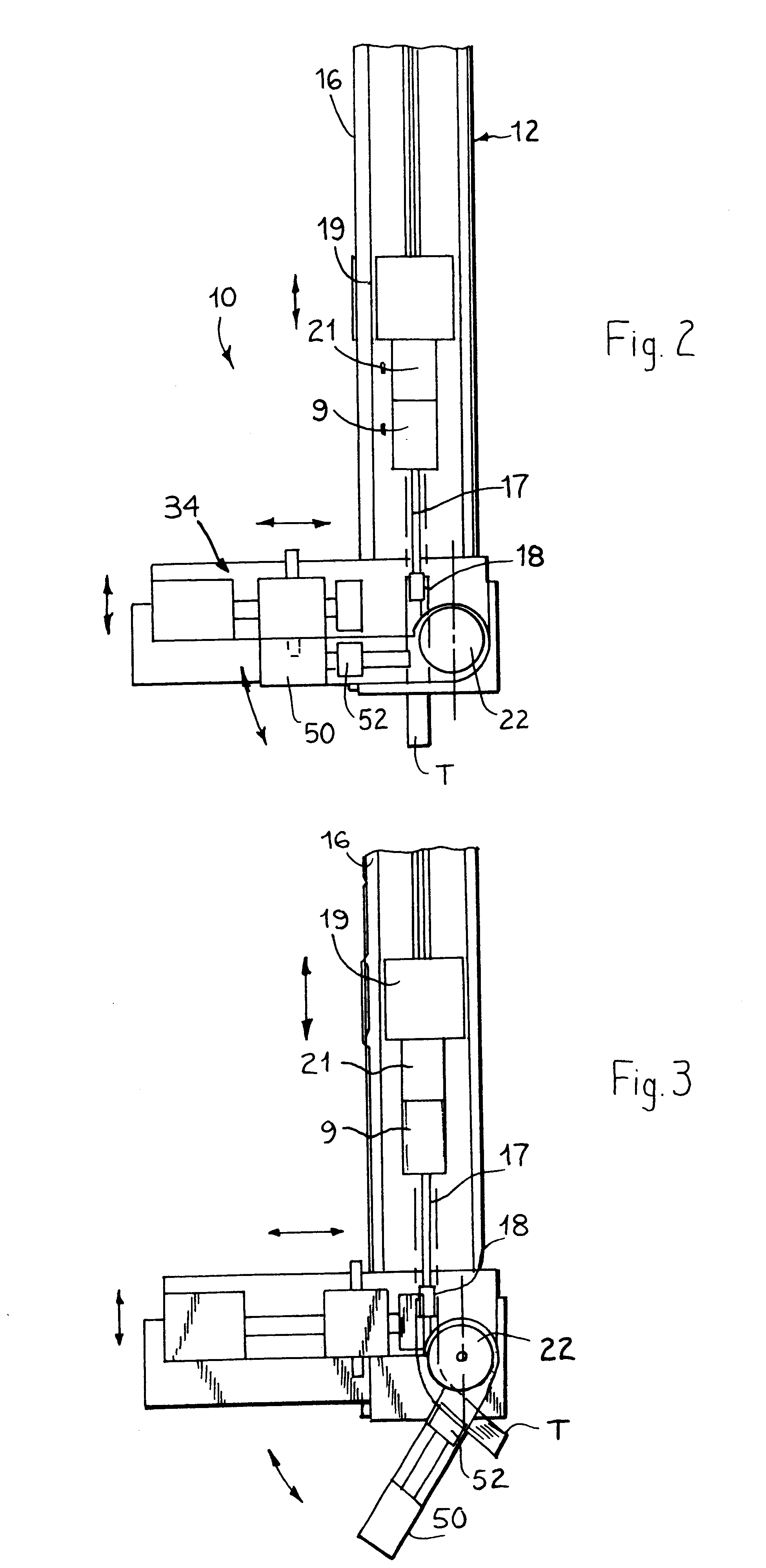

Vertically oriented apparatus for bending tubing, and method of using same

A vertically oriented tube bending apparatus includes a vertically oriented support frame, which takes up less floor space than the previously known tubing benders. A tube bending apparatus in accordance with the invention, generally, includes a support frame having a length, a width, and a height, wherein the greatest of these is the height. The apparatus further includes a tubing advance mechanism, attached to the support frame, for advancing a tubing workpiece along a substantially vertical path. A bend die is also provided which is rotatably attached to the support frame and pivotally movable about a pivot axis. The bend die has an outer side edge with an arcuate peripheral groove formed therein to receive a portion of a tubing workpiece. The apparatus also includes a pressure die movably attached to said support frame. The pressure die has a reciprocally movable first pressure applicator for applying pressure to a follower slide; and a follower slide which is slidably attached to said first pressure applicator. The follower slide includes an inner face having an arcuate cutout channel formed therein to receive a portion of a tubing workpiece therein substantially opposite the bend die. The apparatus also includes a bend arm assembly for bending a tubing workpiece against the bend die. The bend arm assembly is rotatably movable about the pivot axis of the bend die. The invention also encompasses a method of using the vertically oriented tubing bender to bend a piece of tubing stock.

Owner:ADAPTIVE MOTION CONTROL SYST

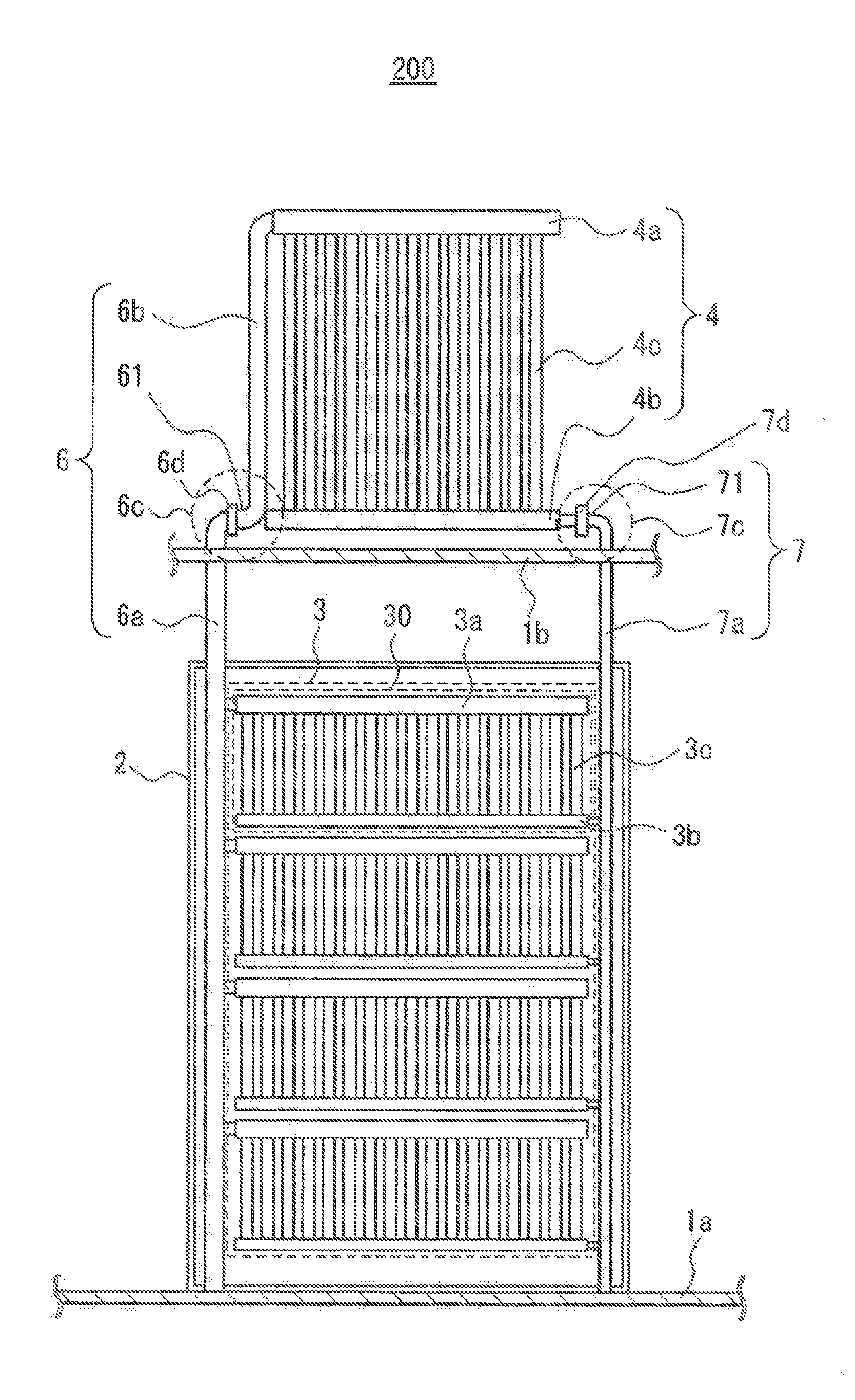

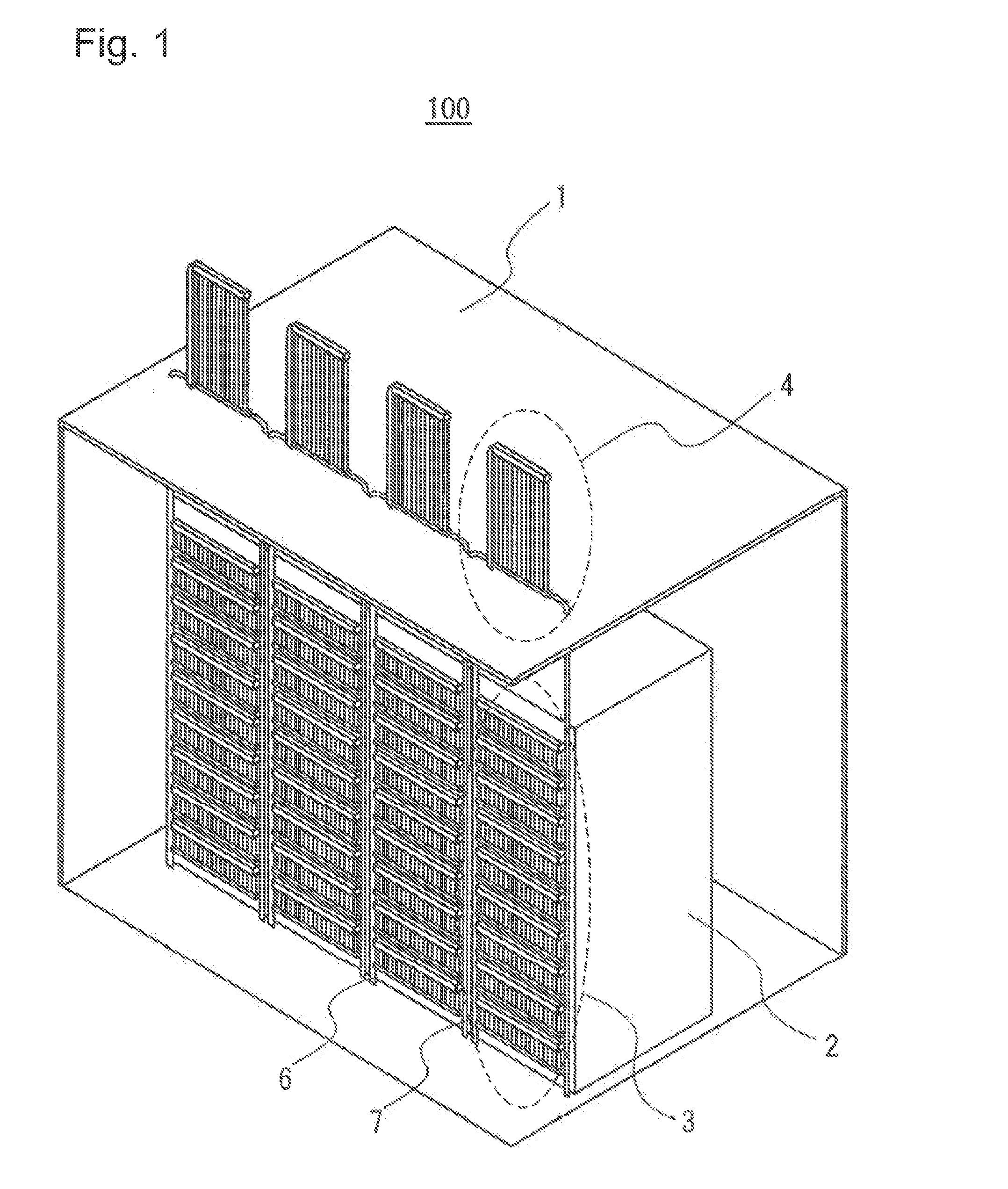

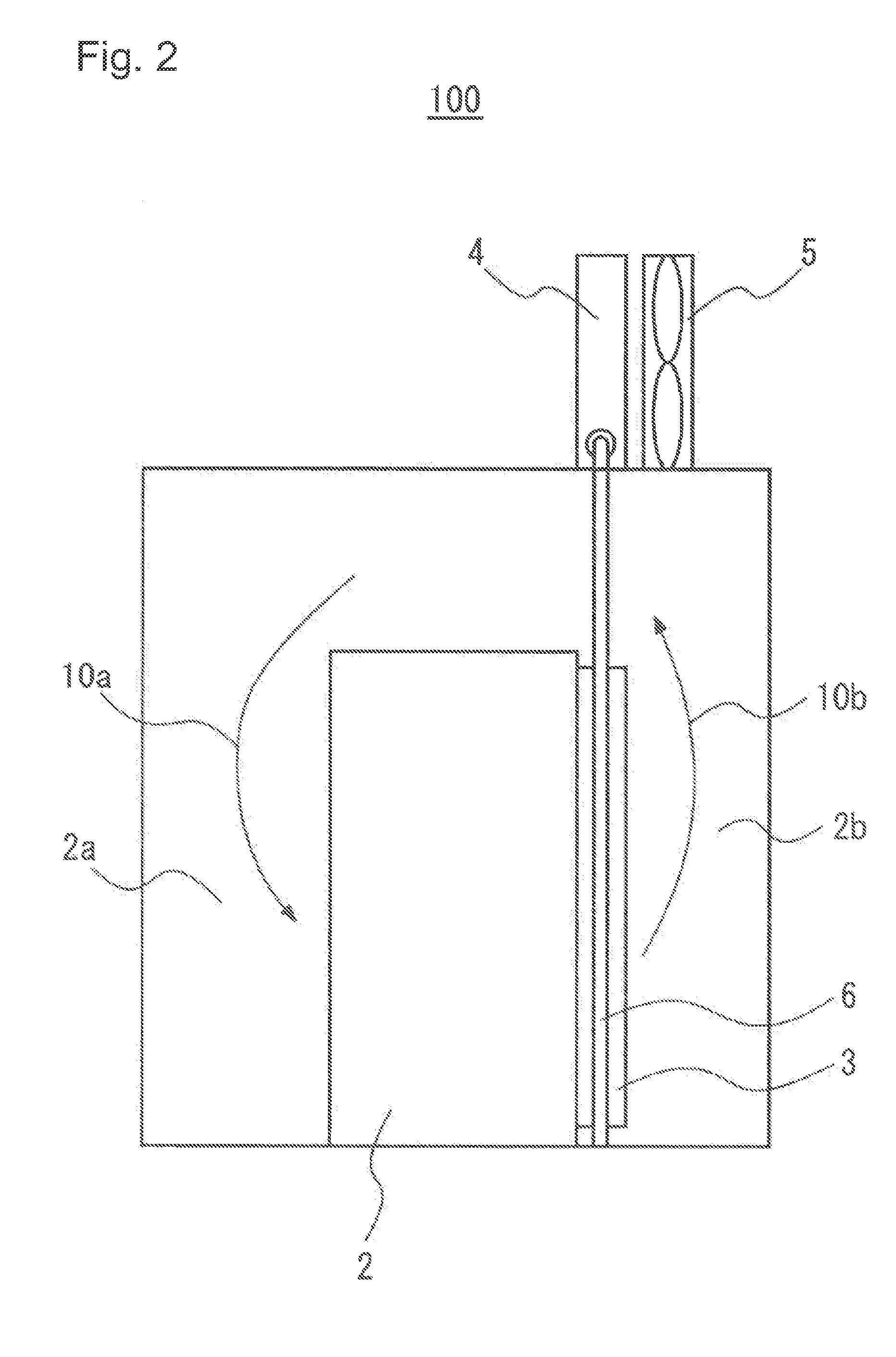

Electronic apparatus cooling system and electronic apparatus cooling system fabrication method

InactiveUS20160014933A1Good cooling propertiesDigital data processing detailsIndirect heat exchangersNuclear engineeringGas phase

[Problem]To provide an electronic apparatus cooling system having superior cooling characteristics and portability.[Solution] A rack 2 is installed within a container 1. A heat receiving apparatus 3 is disposed on a lateral face of the rack 2, and receives heat emitted within the rack 2 by a liquid-phase cooling medium gasifying and becoming a gaseous-phase cooling medium. A gaseous-phase tube 6 is disposed extending in plumb direction, and transports the gaseous-phase cooling medium from the heat receiving apparatus 3. A heat radiating apparatus 4 is disposed above the rack 2 outside the container 1, and radiates the heat which the heat receiving apparatus 3 has received by cooling the gaseous-phase cooling medium flowing from the gaseous-phase tube 6, making said gaseous-phase cooling medium into the liquid-phase cooling medium. A liquid-phase tube 7 transports the liquid-phase cooling medium from the heat radiating apparatus 4 to the heat receiving apparatus 3. The gaseous-phase tube 6 further comprises a gaseous-phase tube bend part 6c whereat cooling medium droplets, which arise from the condensation of the gaseous phase cooling medium as a result of the gaseous-phase tube 6 being exposed to the environment external to the container 1, are collected.

Owner:NEC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com