Electrical heating tube plane numerical controlled tube bending method and numerical controlled bending device using same

An electric heating tube and heating tube technology, applied in the field of numerical control bending devices, can solve the problems of high product defect rate, increased tooling equipment, low efficiency, etc., and achieve the effects of reducing product defect rate, simple structure, and lowering production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

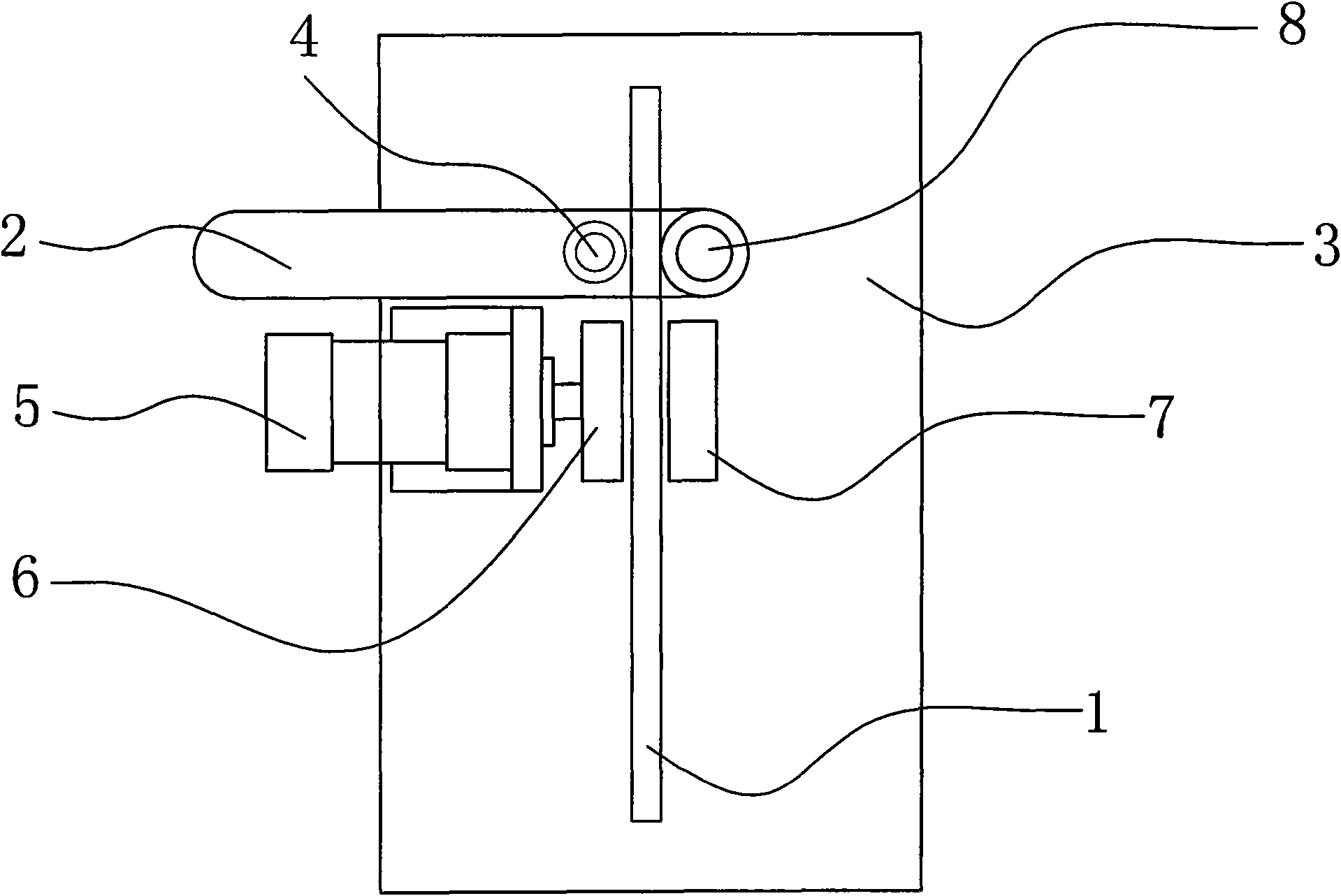

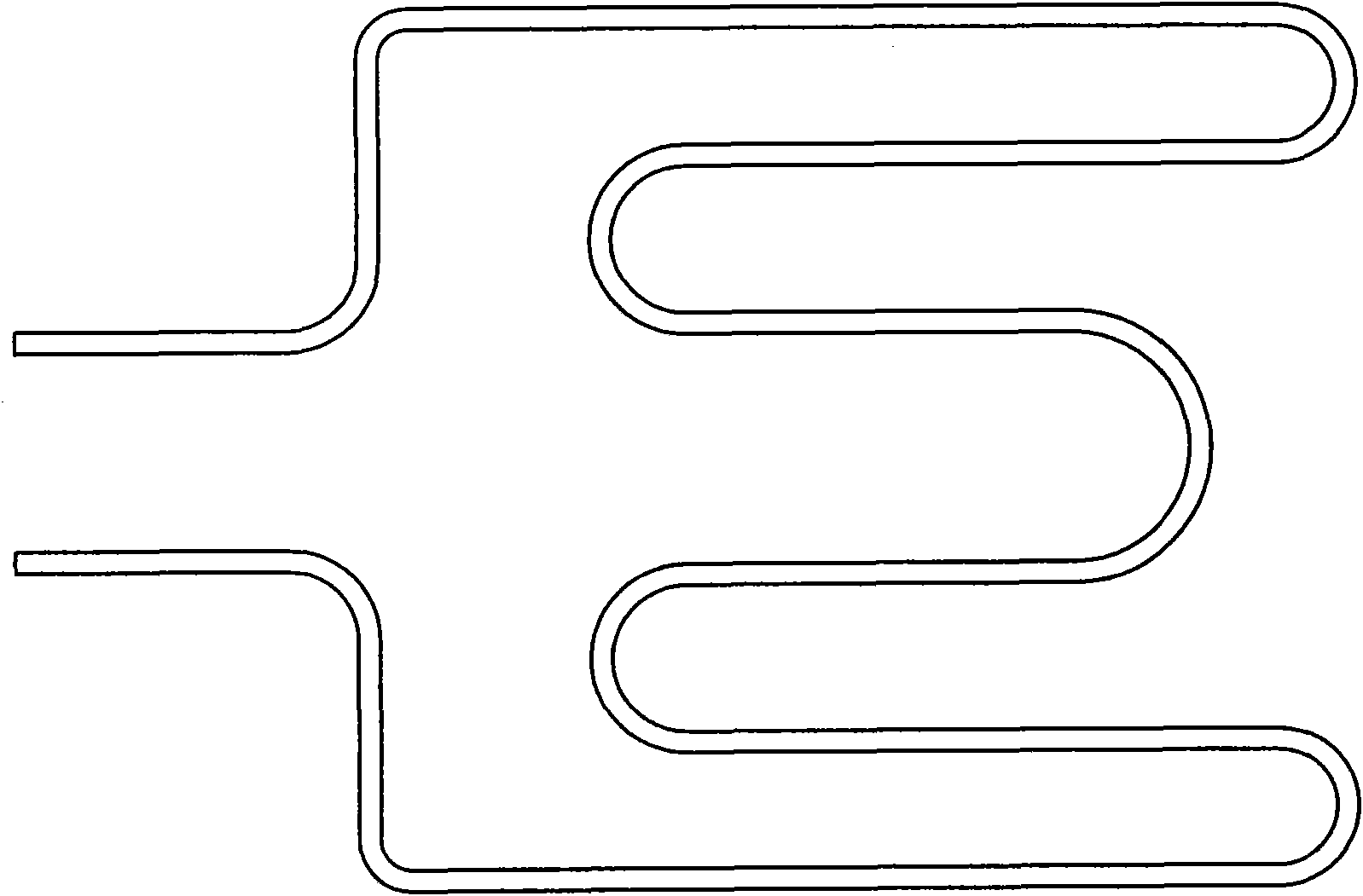

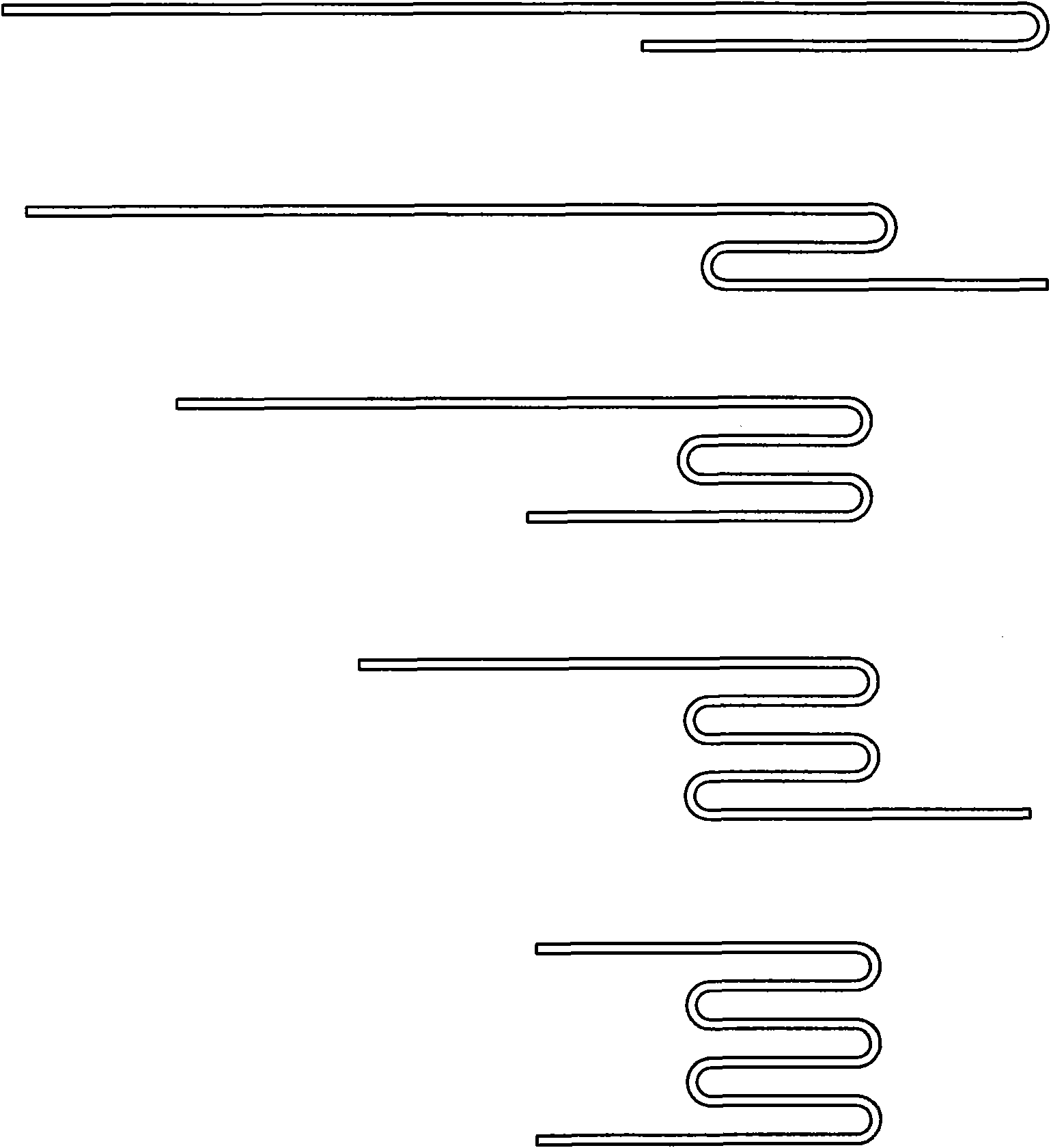

[0026] Please refer to Figure 2 to Figure 6 As shown, the following combines a specific electric heating tube plane numerical control bending method, and its technological process is:

[0027] Parameter setting: first, input the pre-set parameters into the drive control system according to the specified requirements.

[0028] Pipe laying process: first put the straight heating pipe into two sets of clamping molds, and the heating pipe is placed in the center of one side.

[0029] Pipe taking process: open the automatic button set in the main frame, the first bending clamping mechanism 9 automatically clamps the heating tube, the feeding clamping mechanism 10 clamps the heating tube, and moves to the set bending position, after the first bending clamping mechanism 9 is released, the second bending clamping mechanism 11 clamps the heating tube and sends it to the bending machine head.

[0030] The first bending clamping mechanism 9 only clamps the heating tube, and its mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com