Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5694results about "Axial flow pumps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

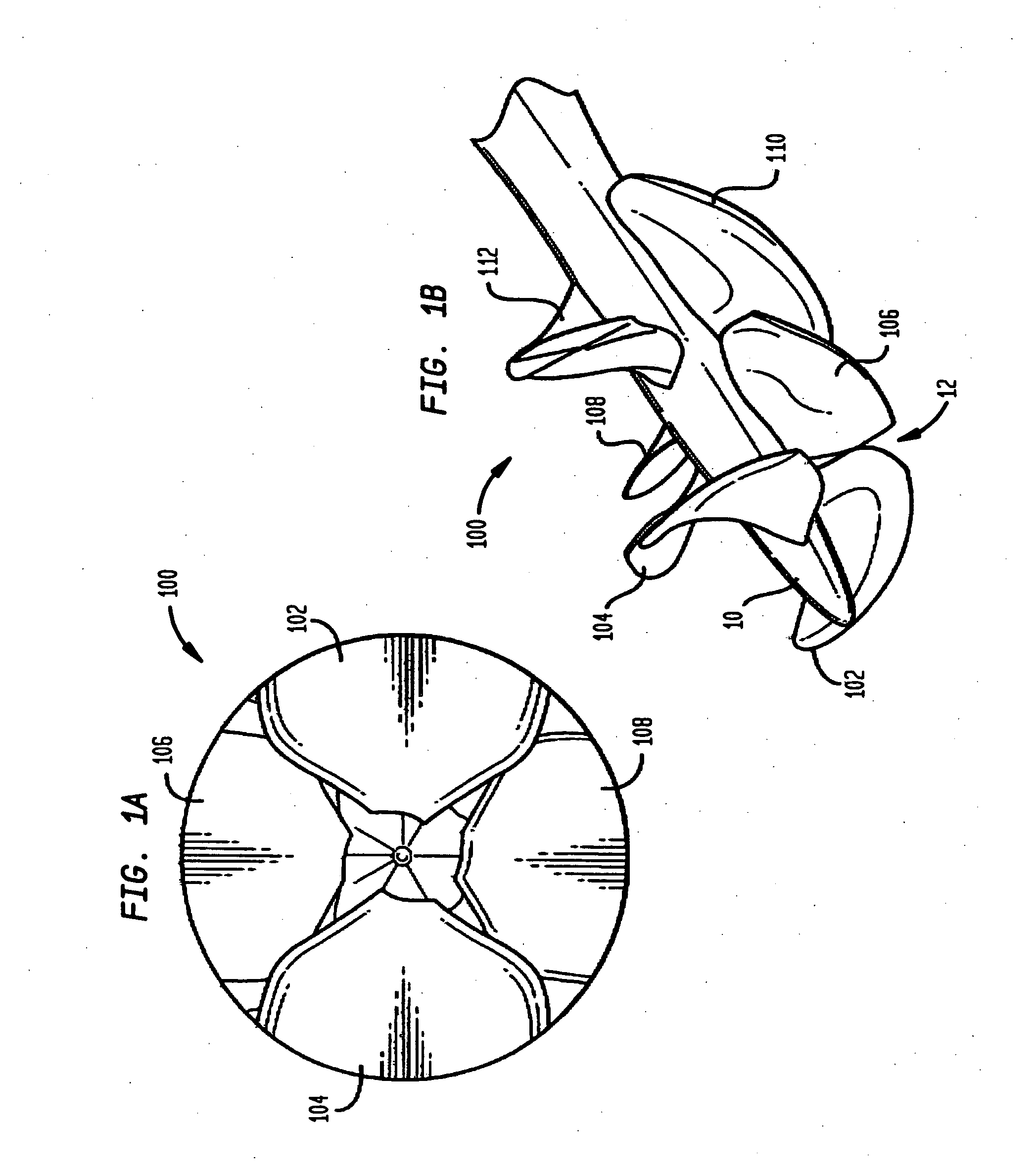

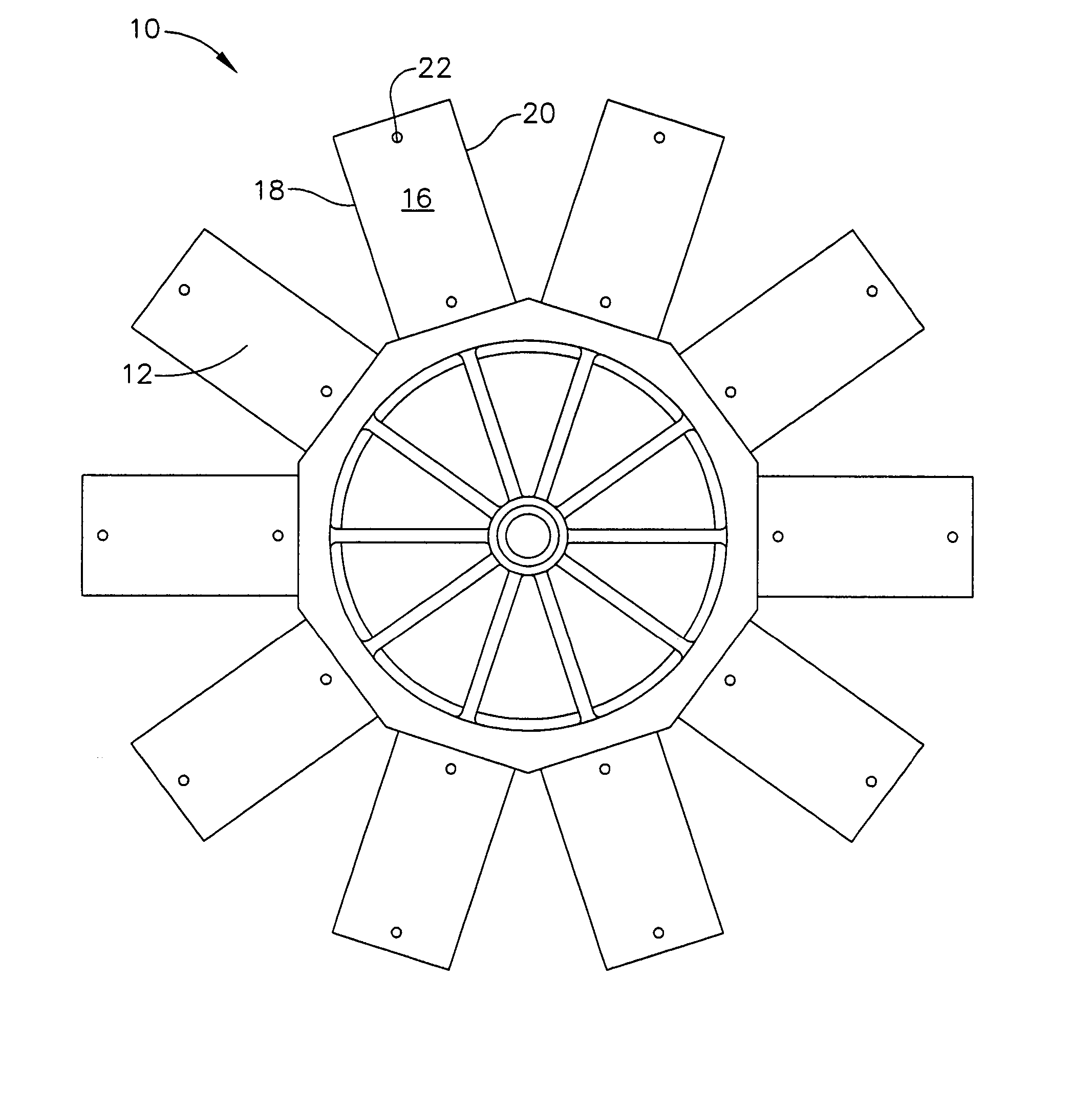

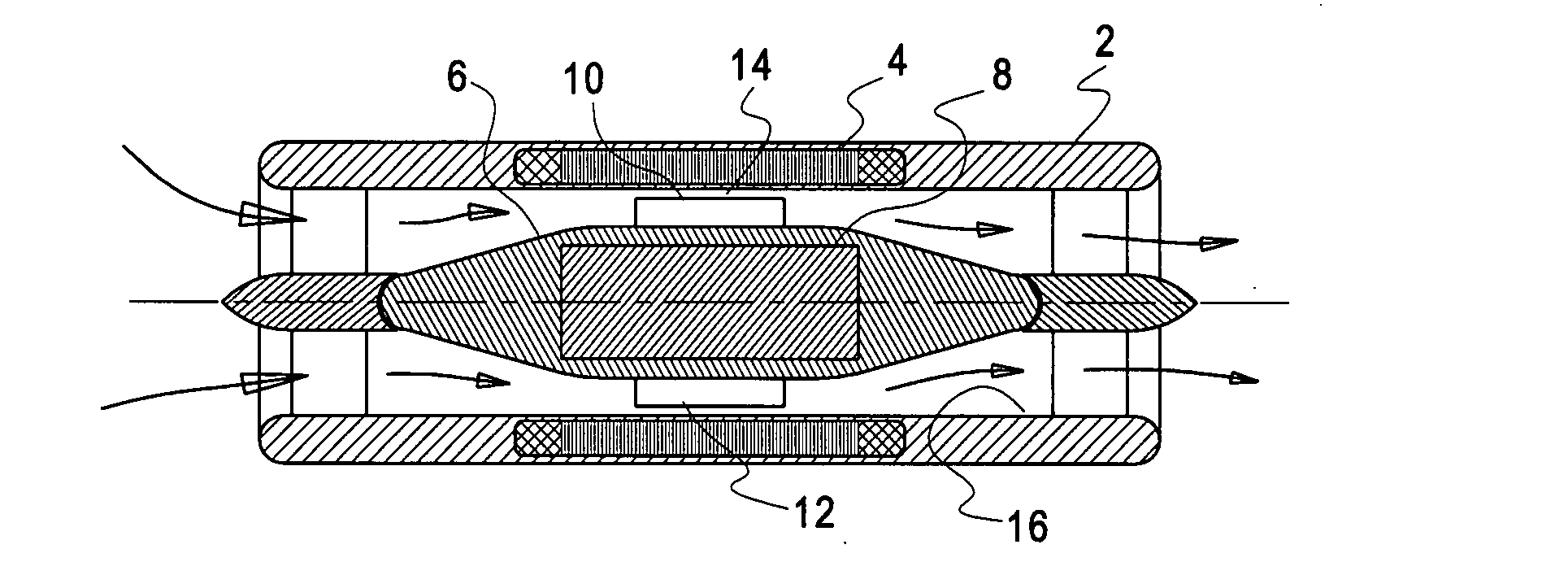

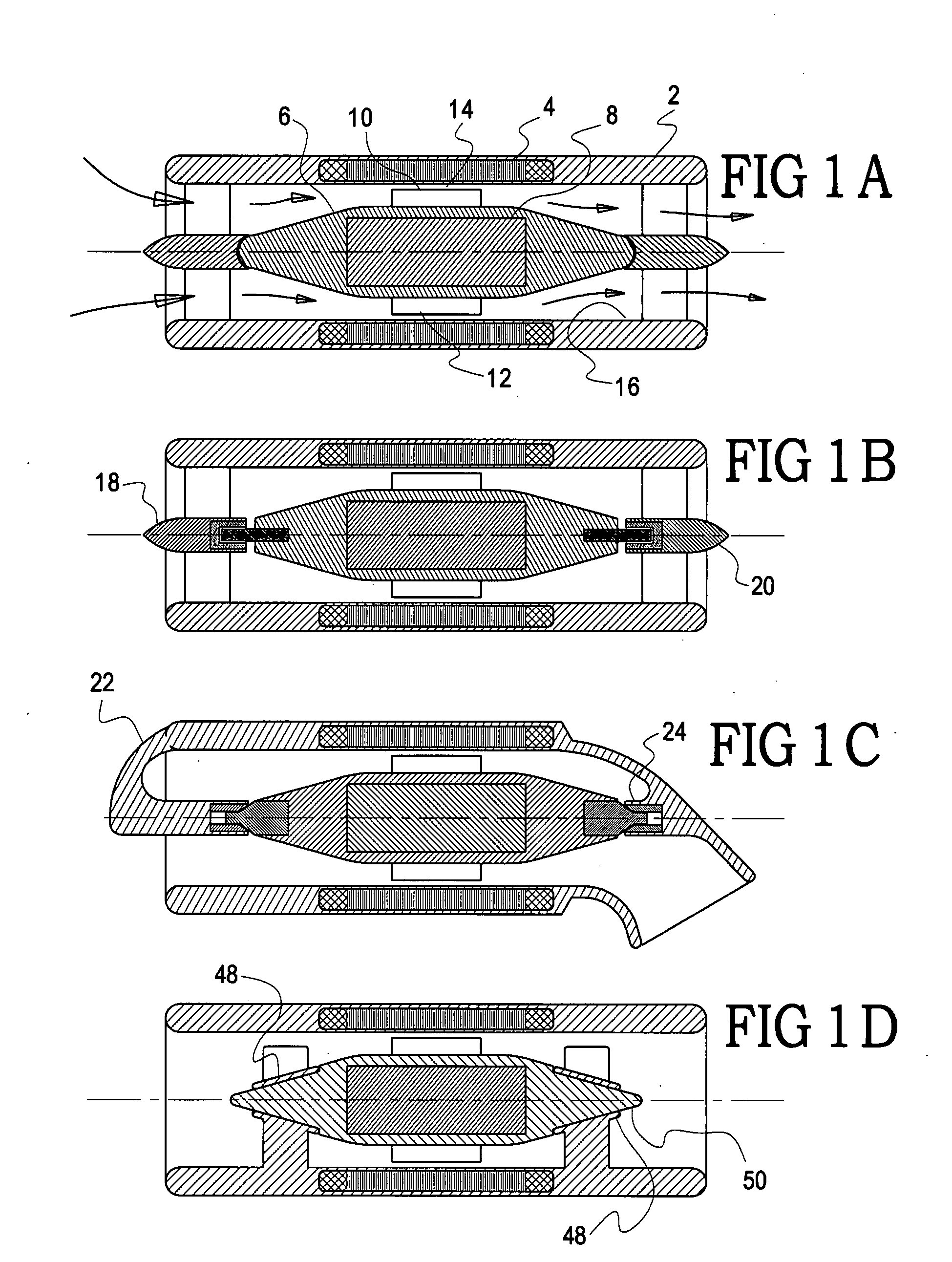

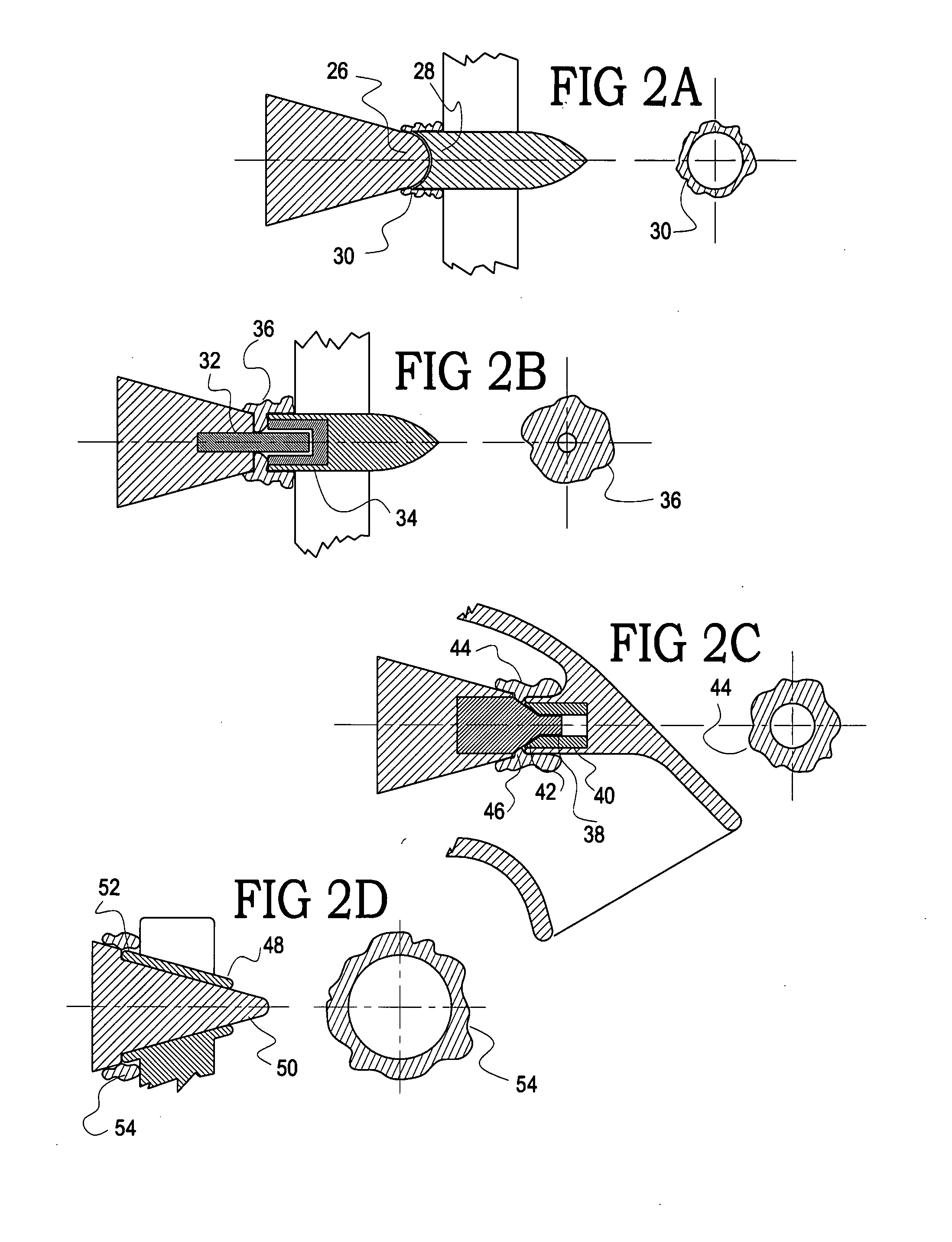

Expandable impeller pump

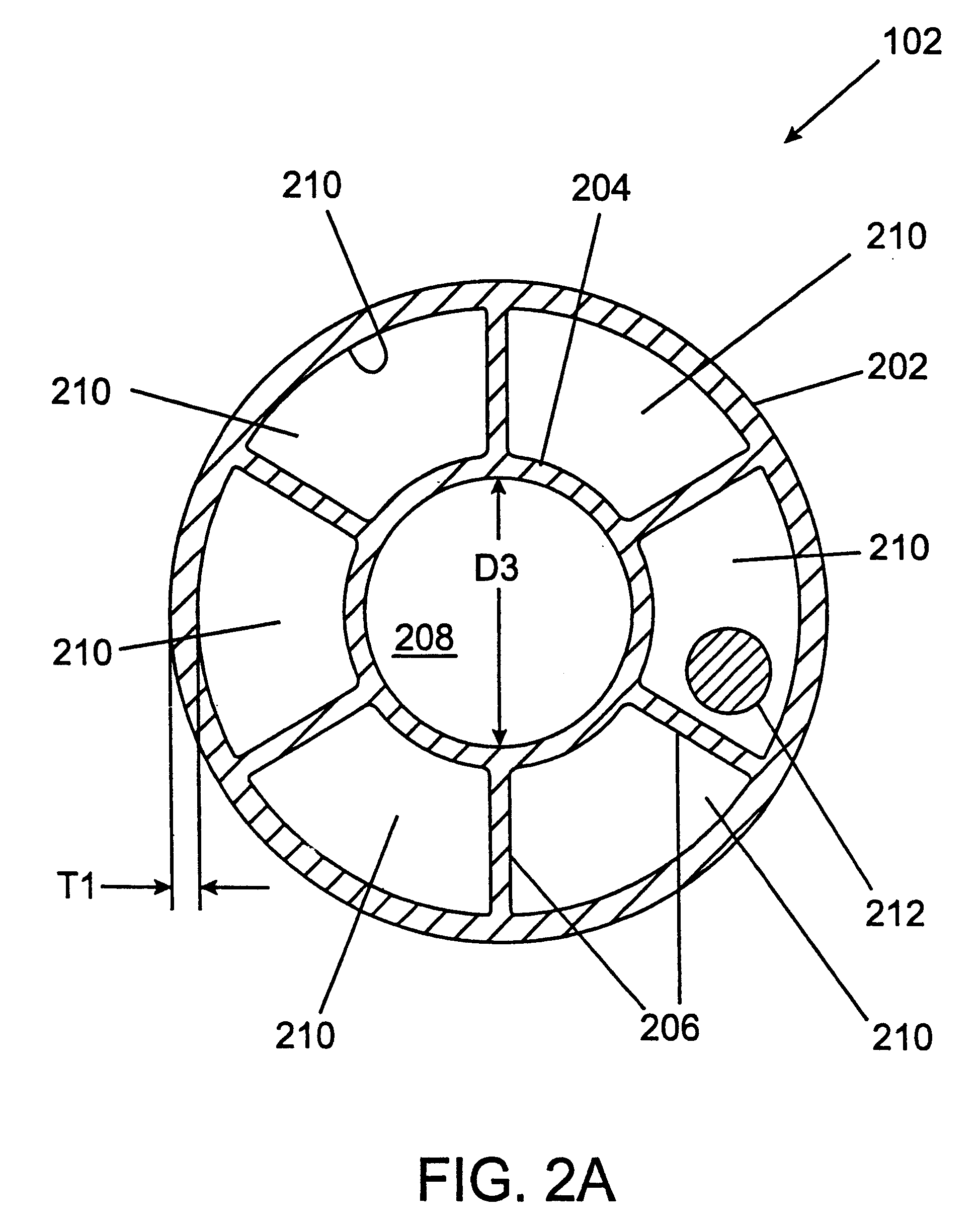

ActiveUS7393181B2Easy to compressReduced form requirementsPropellersEngine manufactureImpellerEngineering

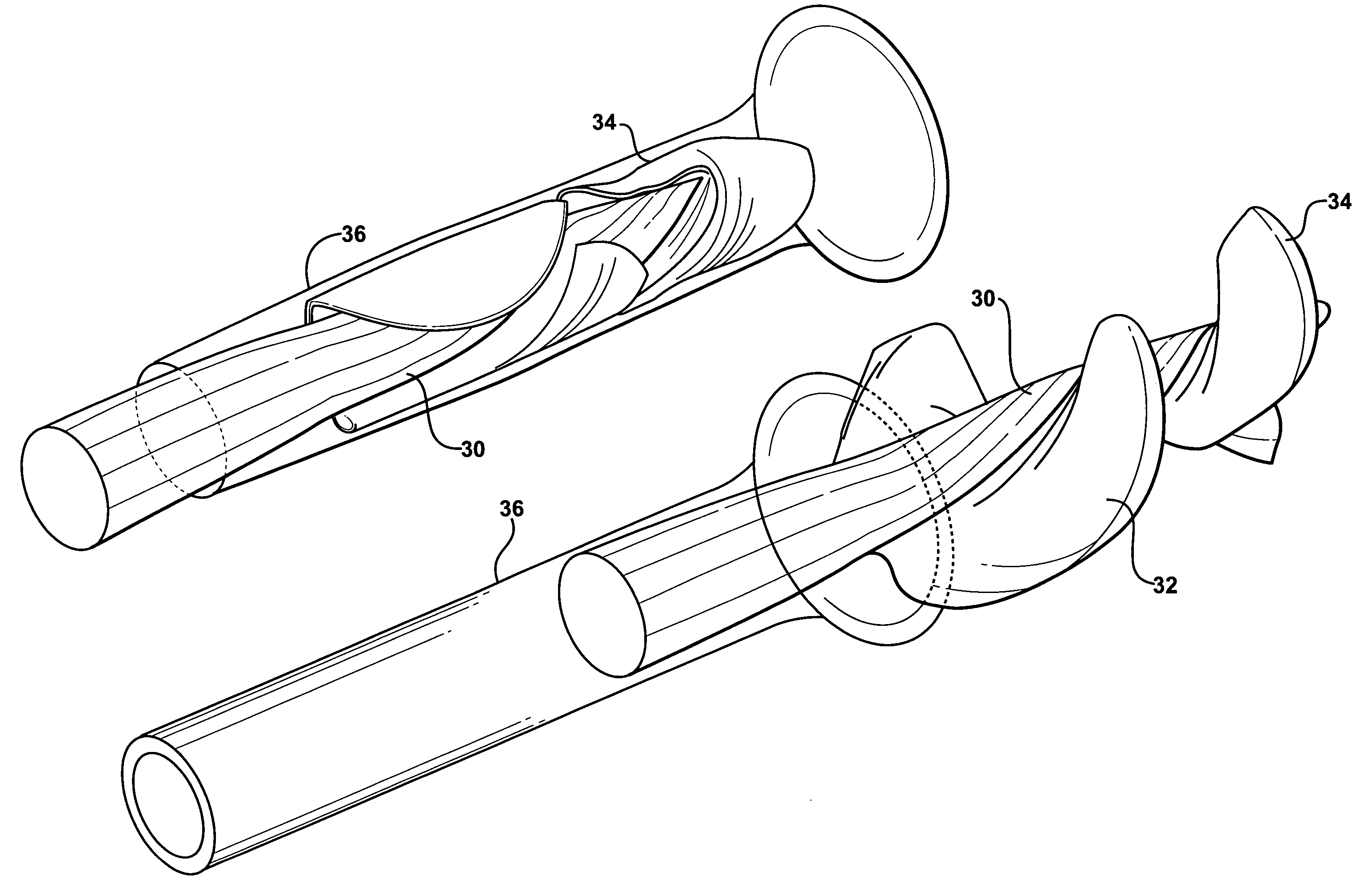

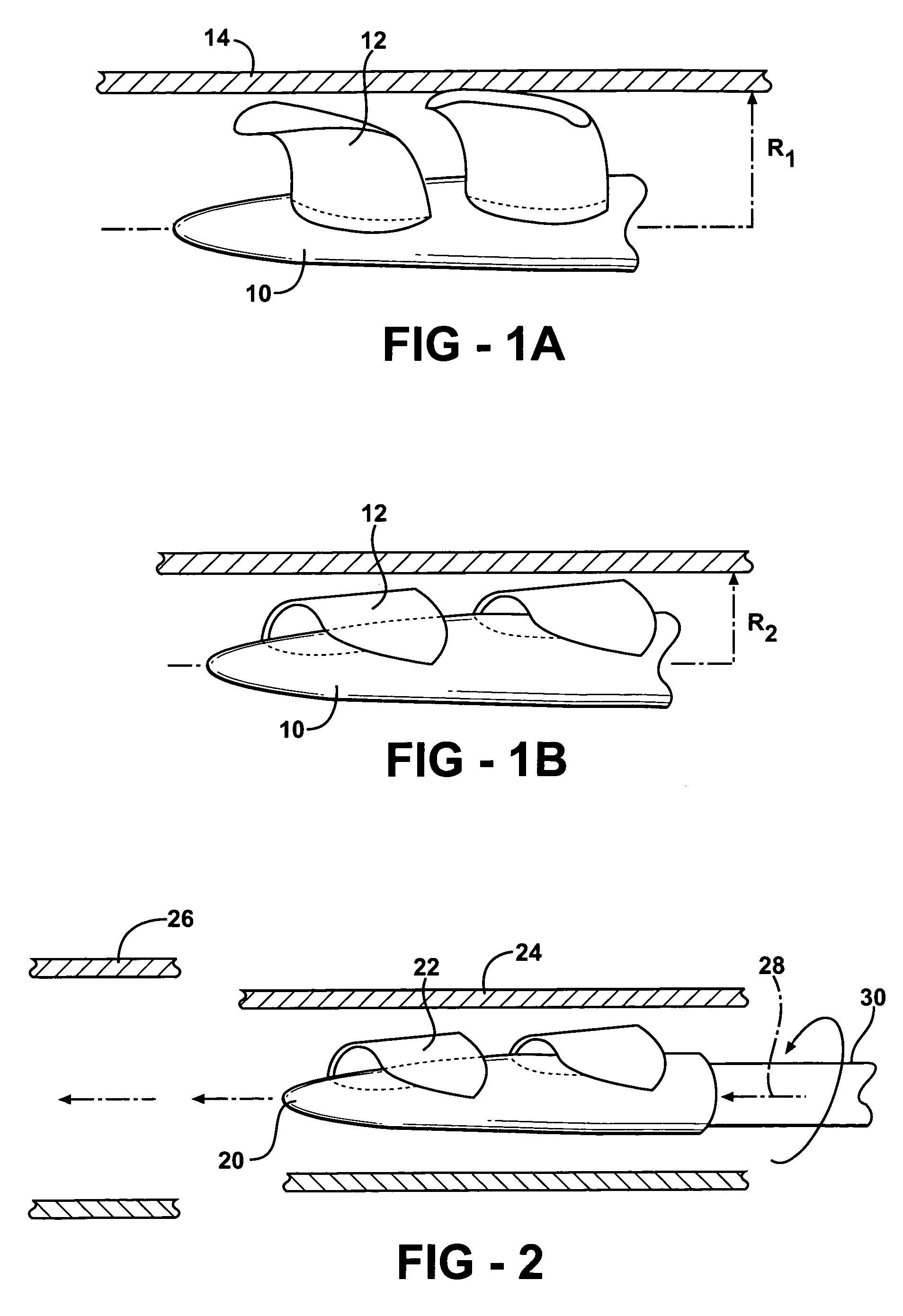

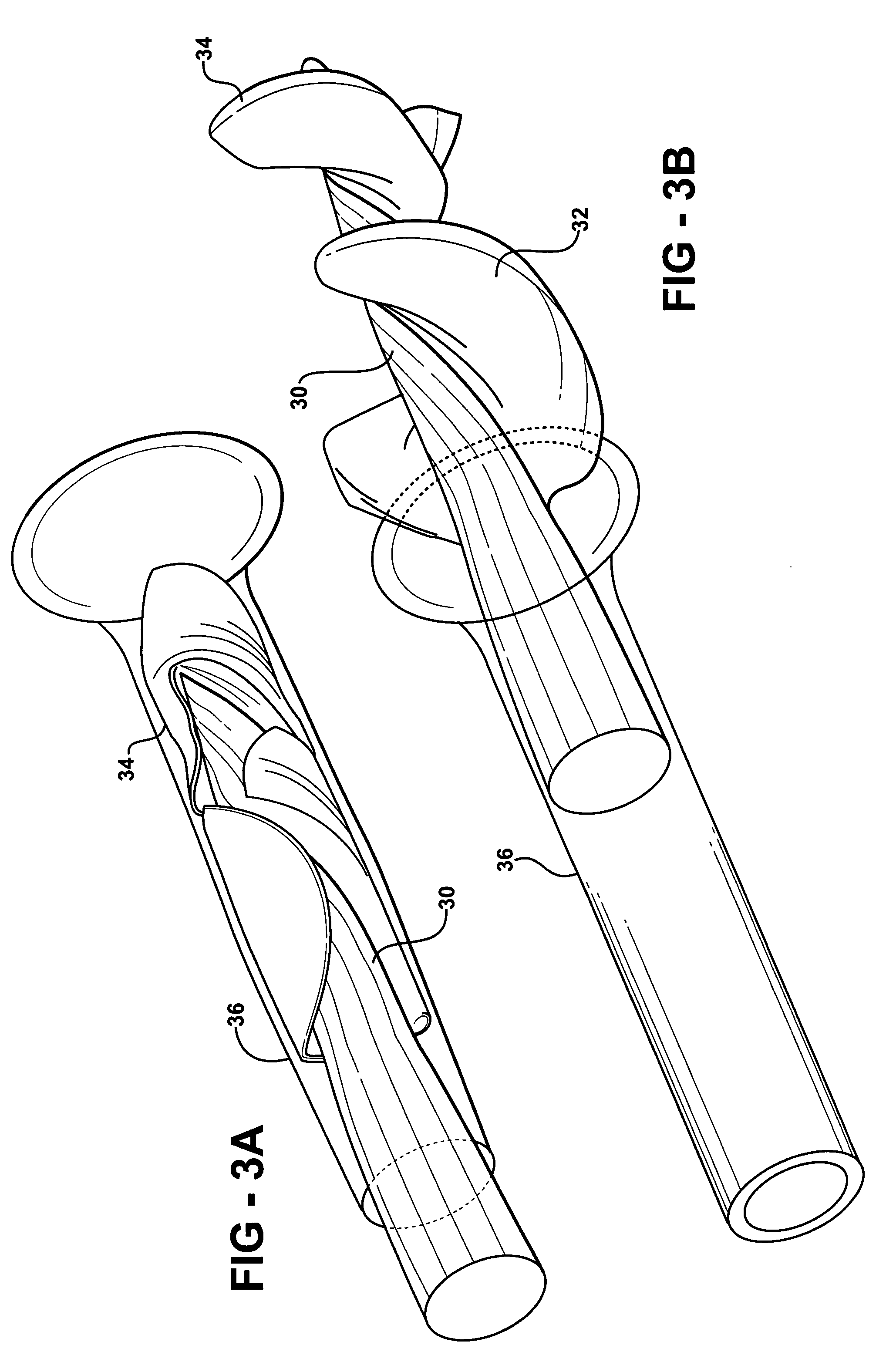

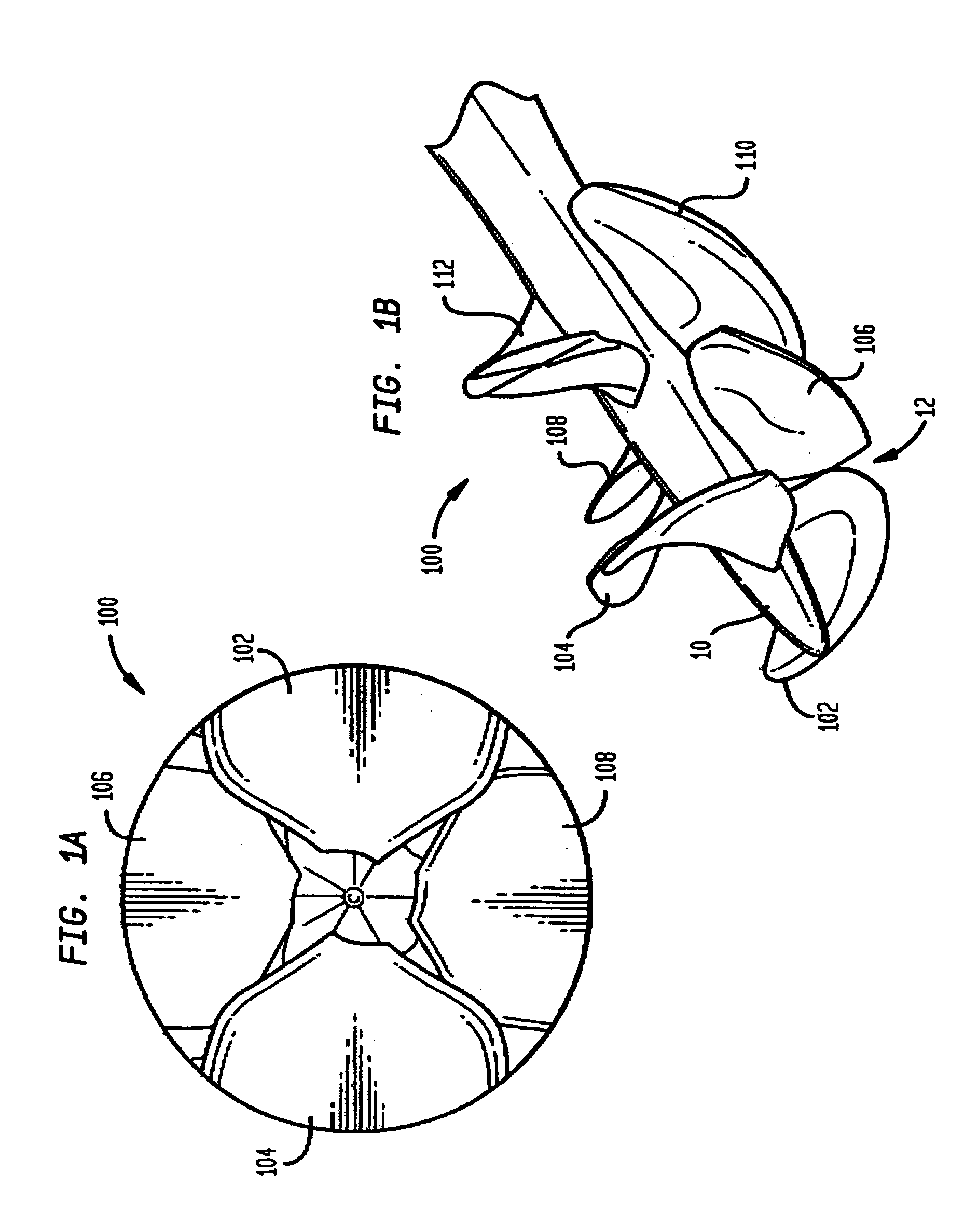

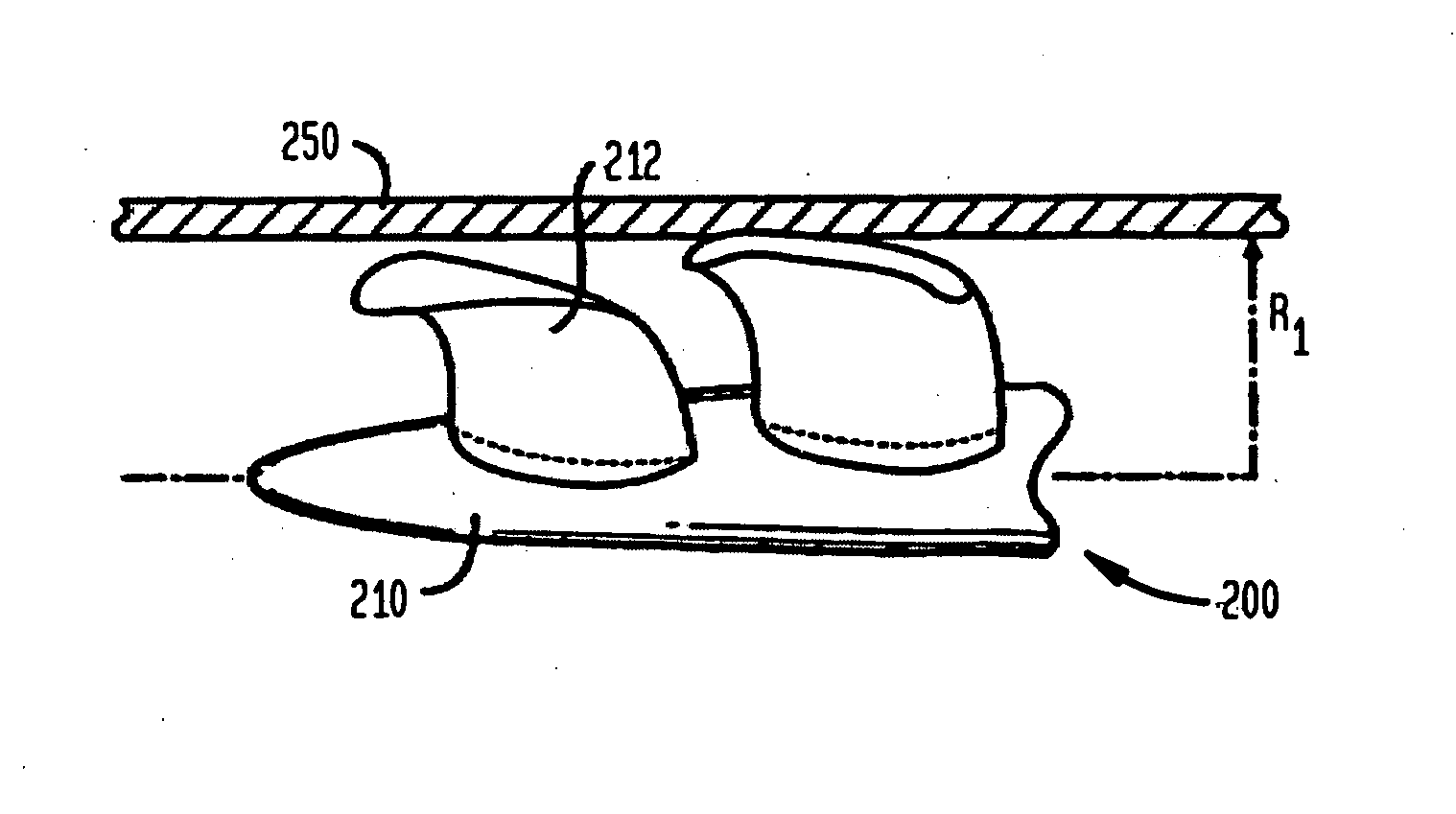

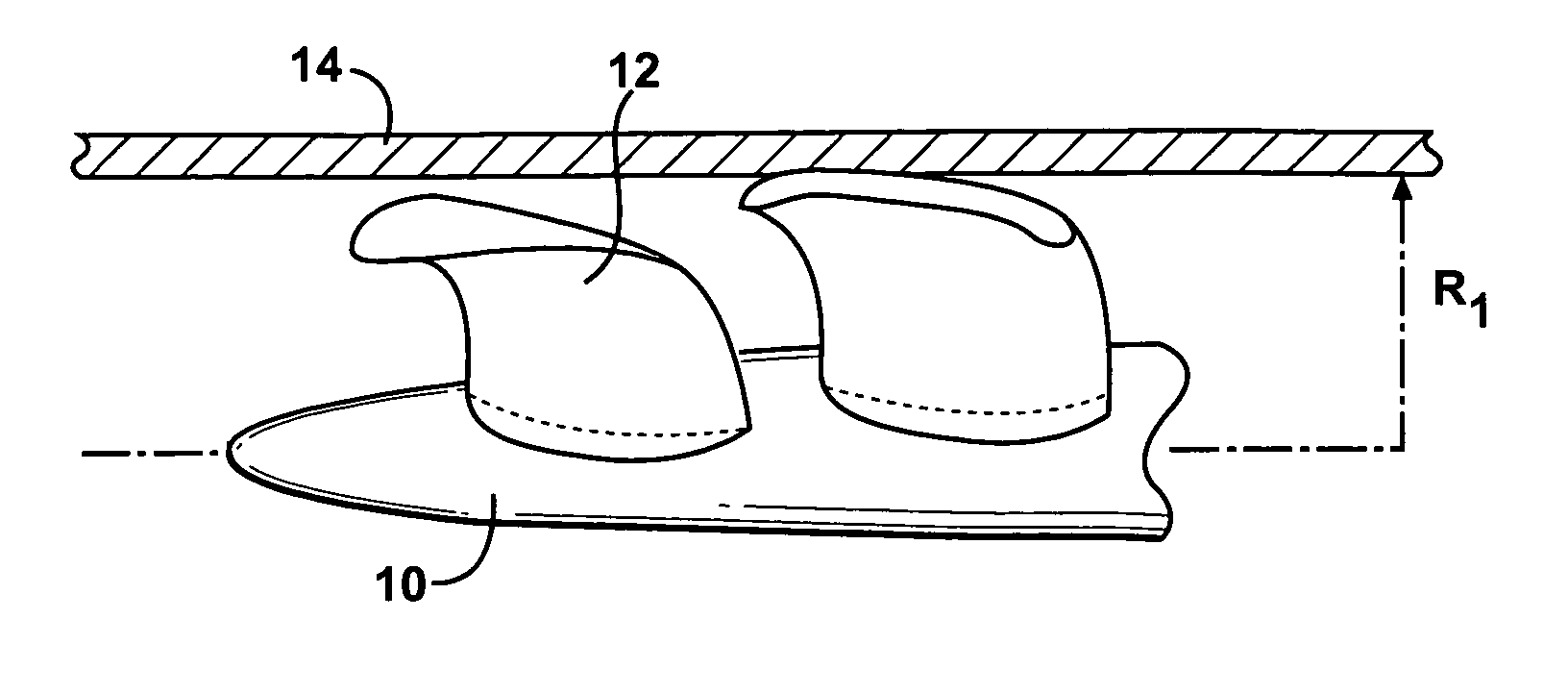

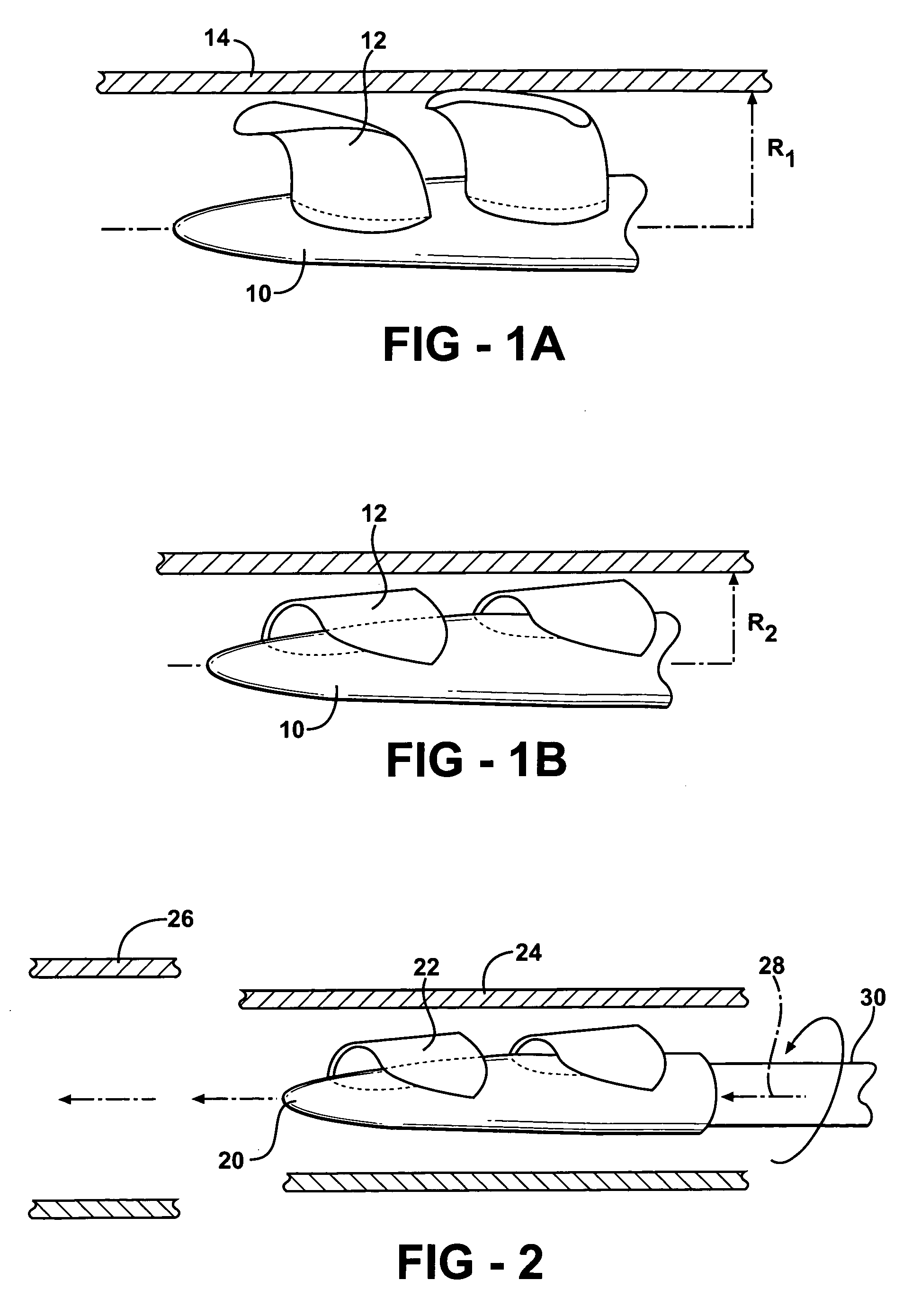

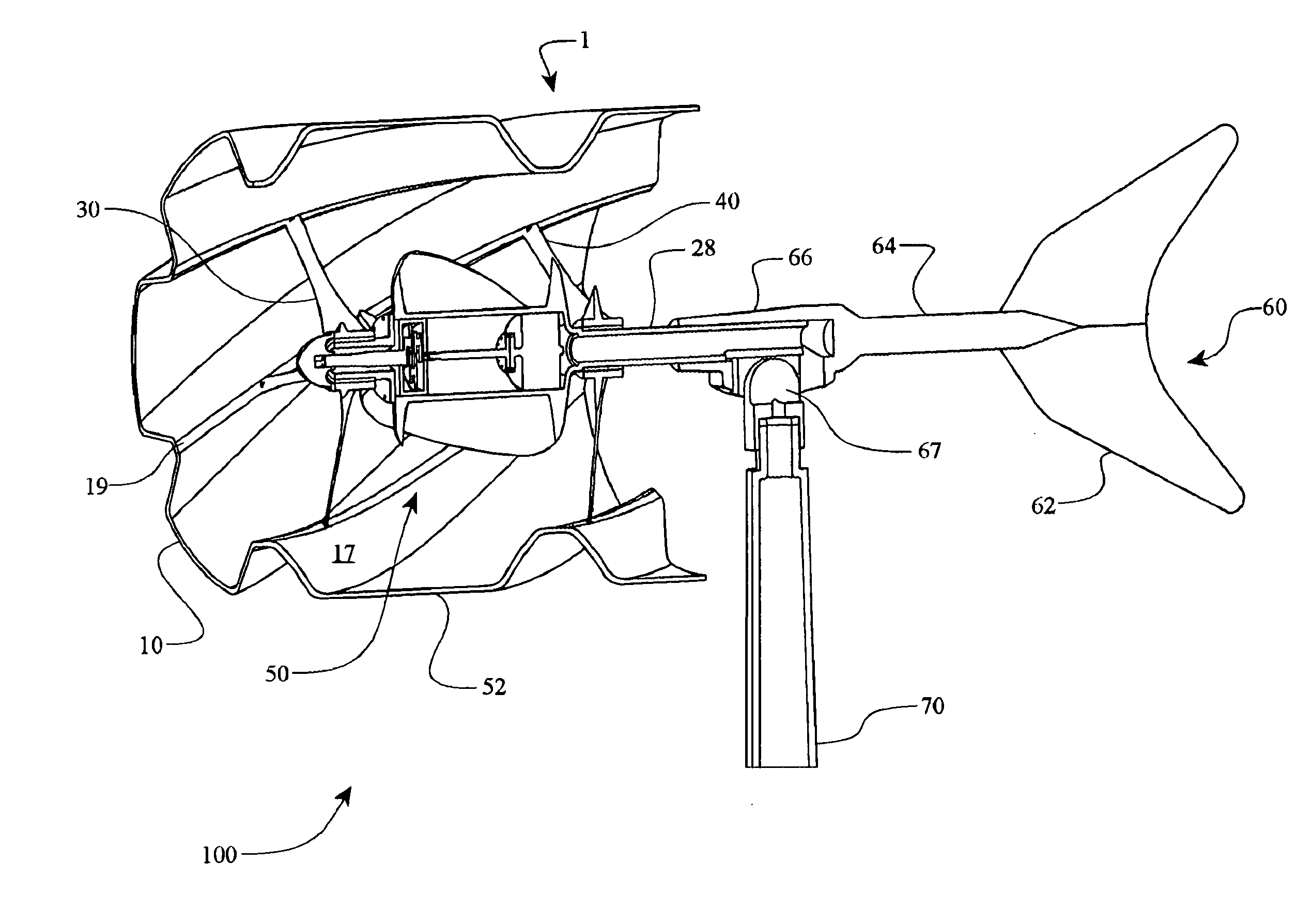

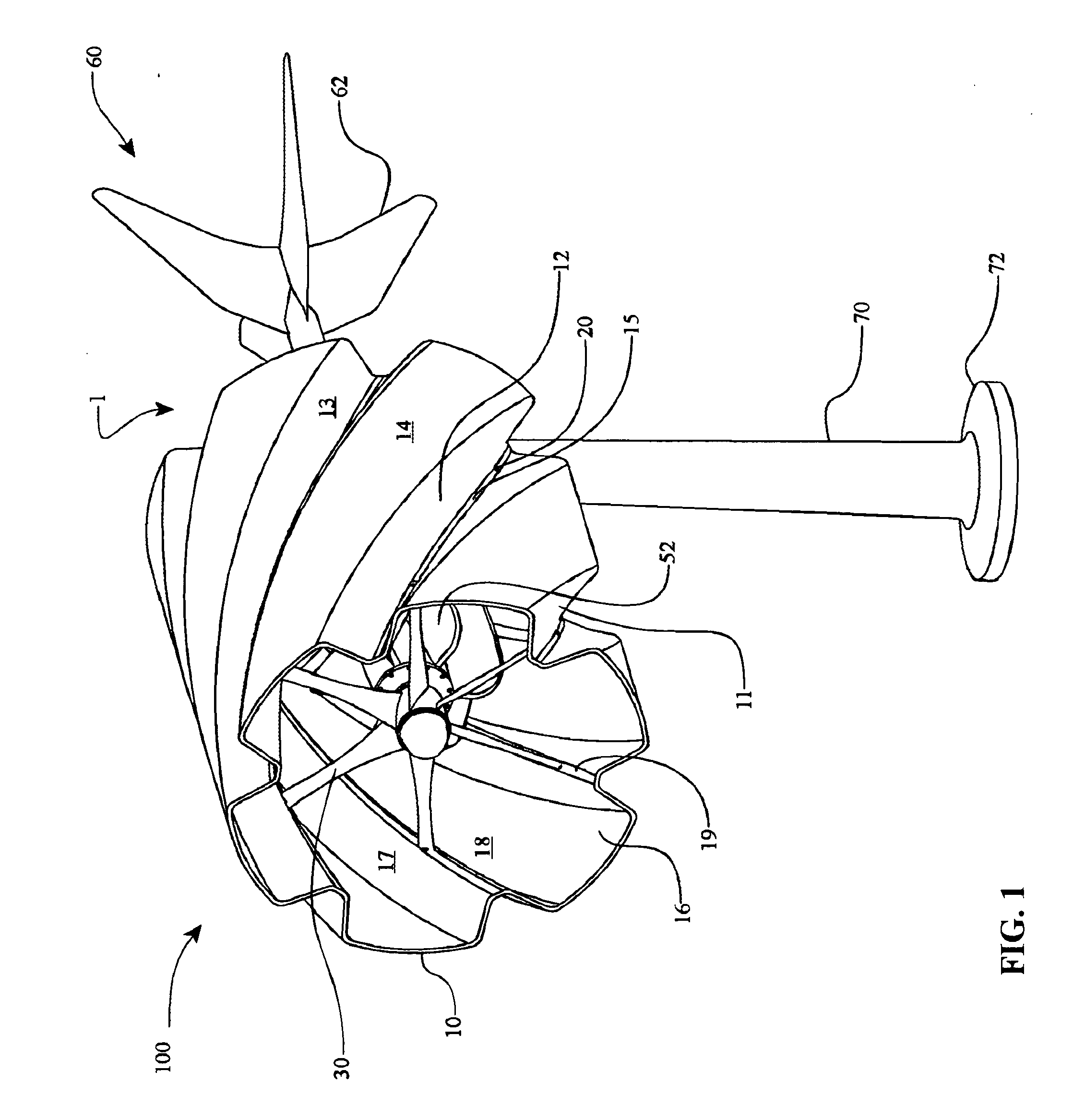

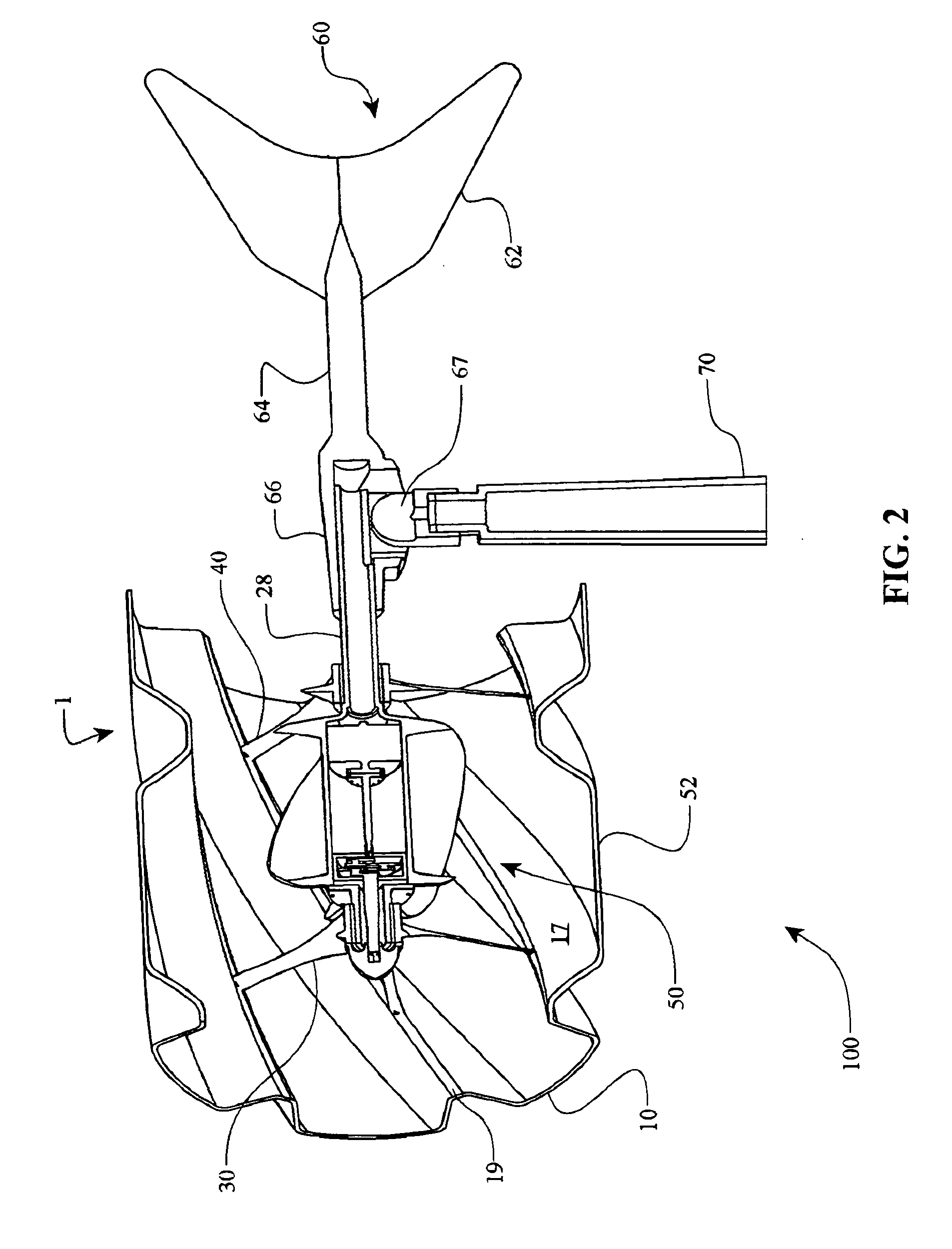

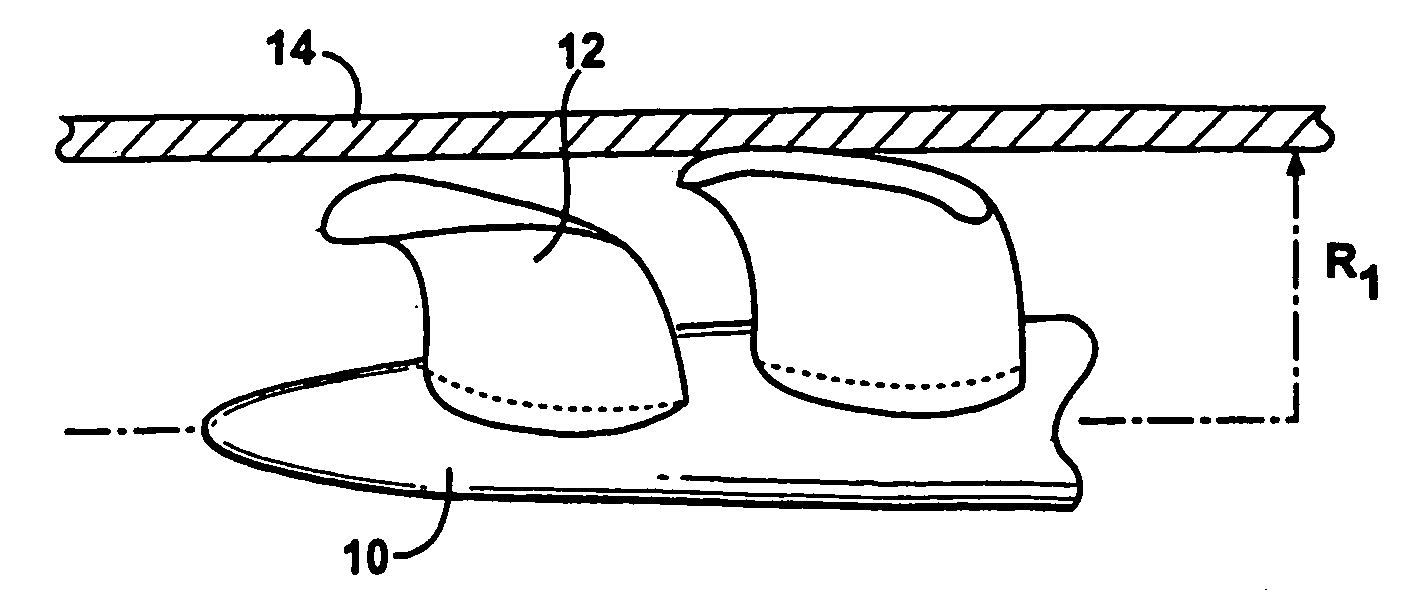

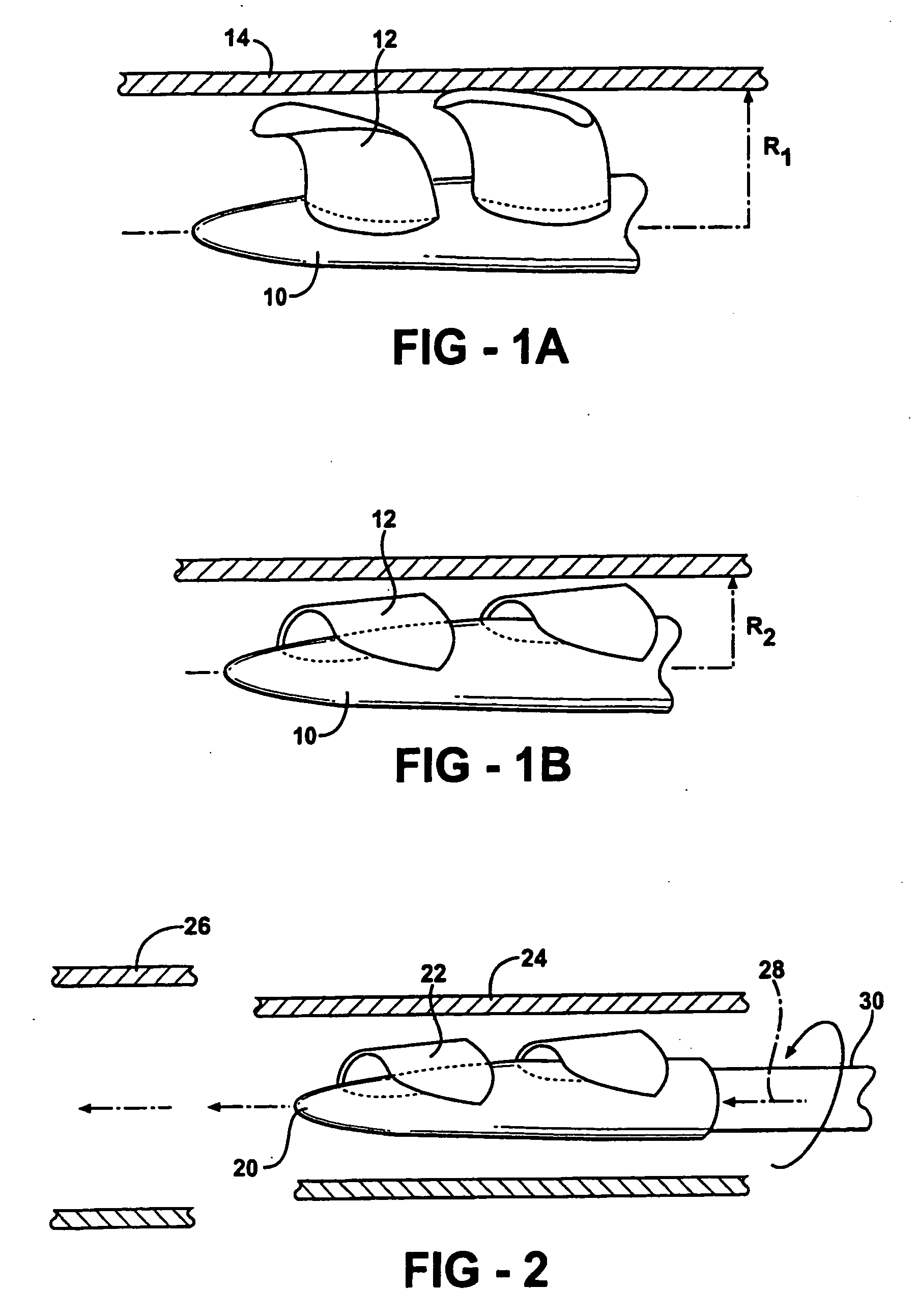

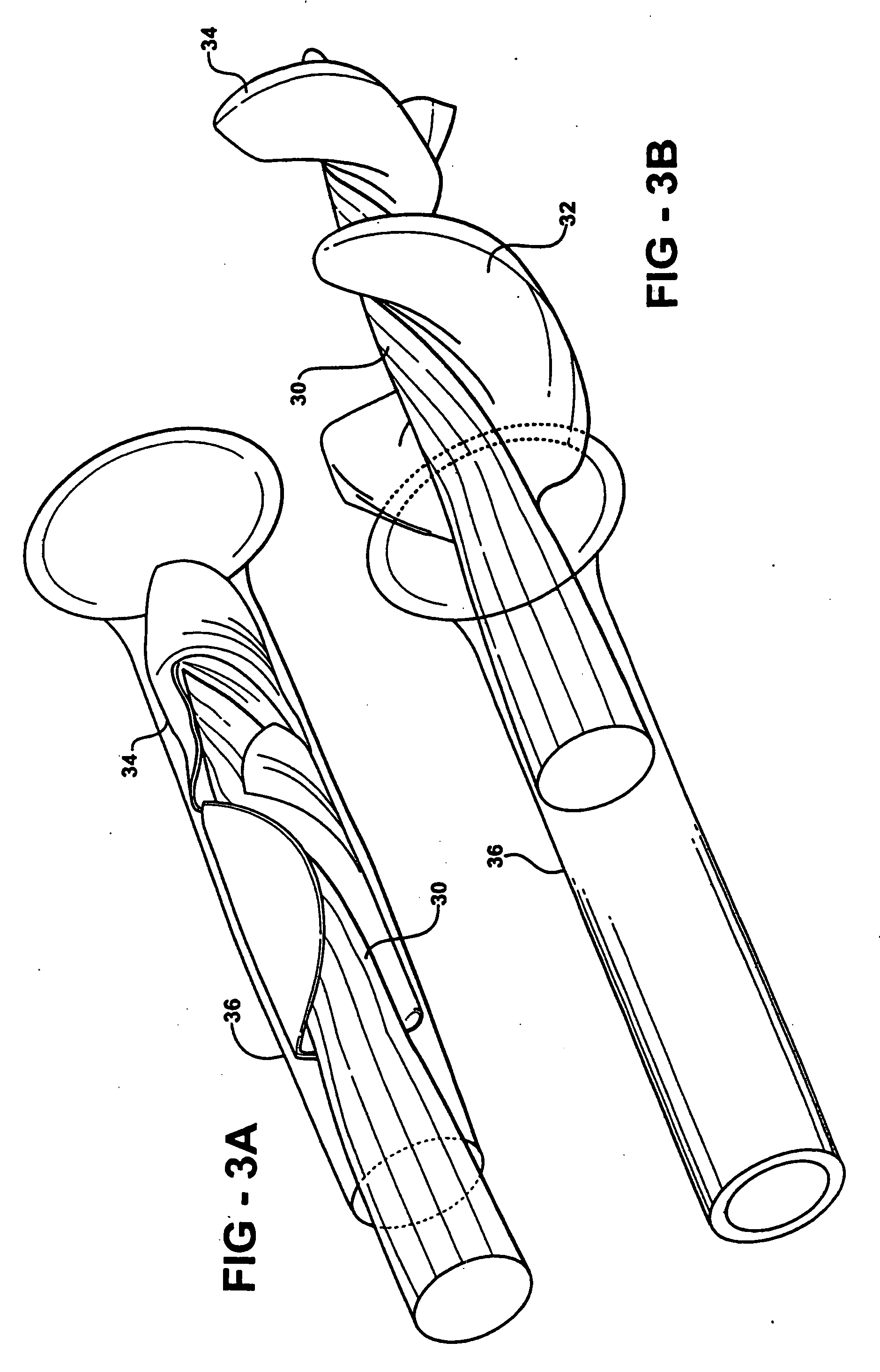

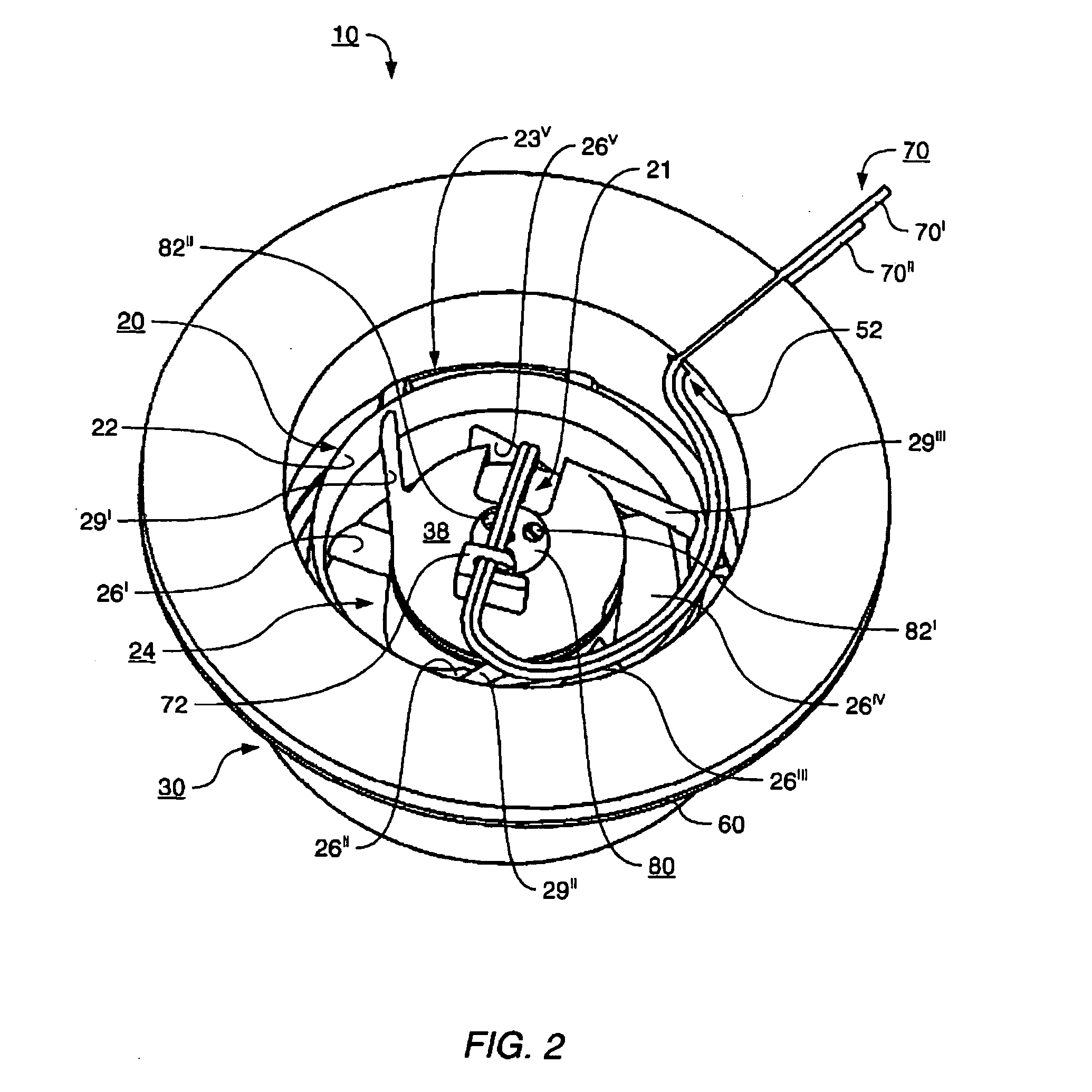

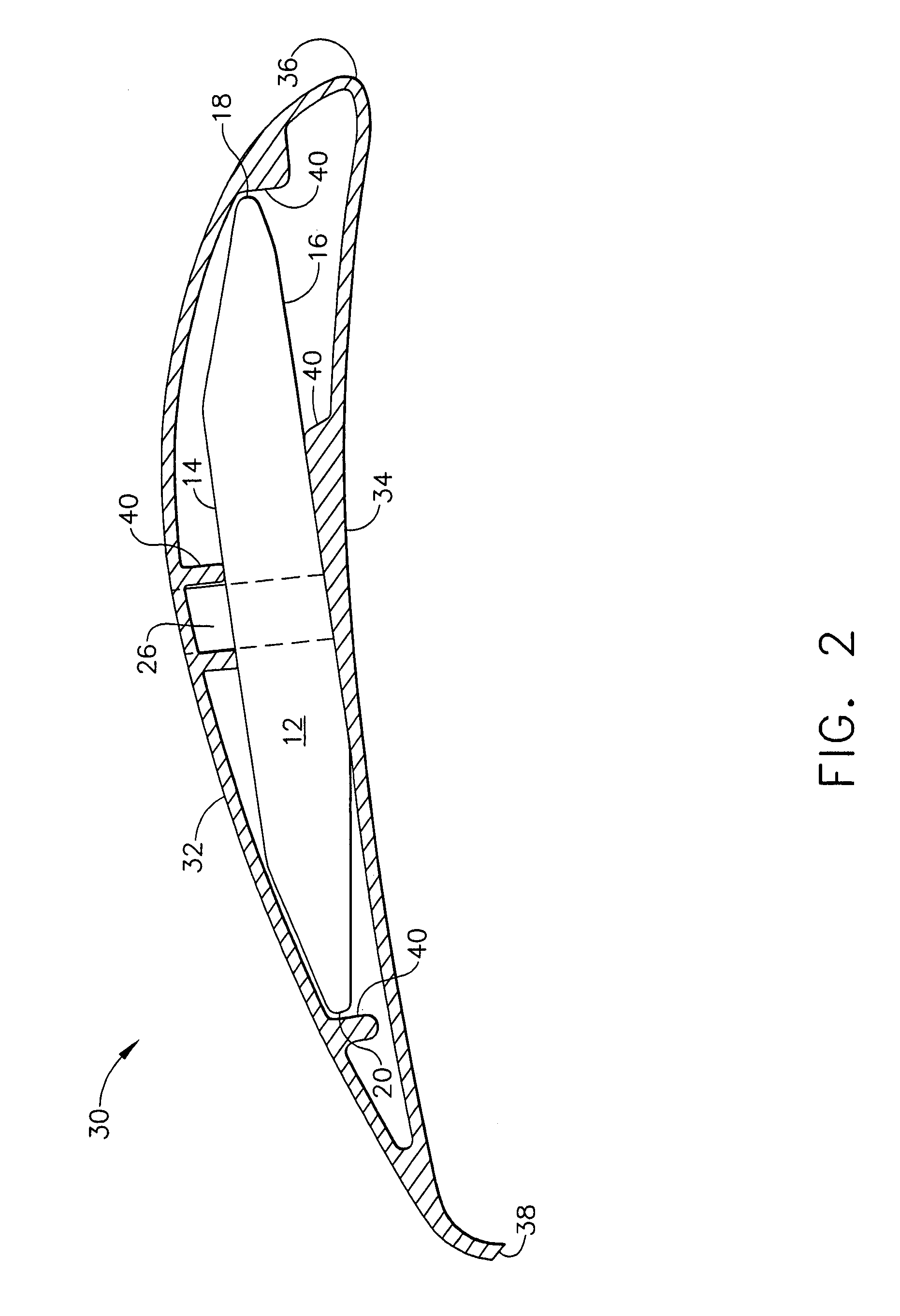

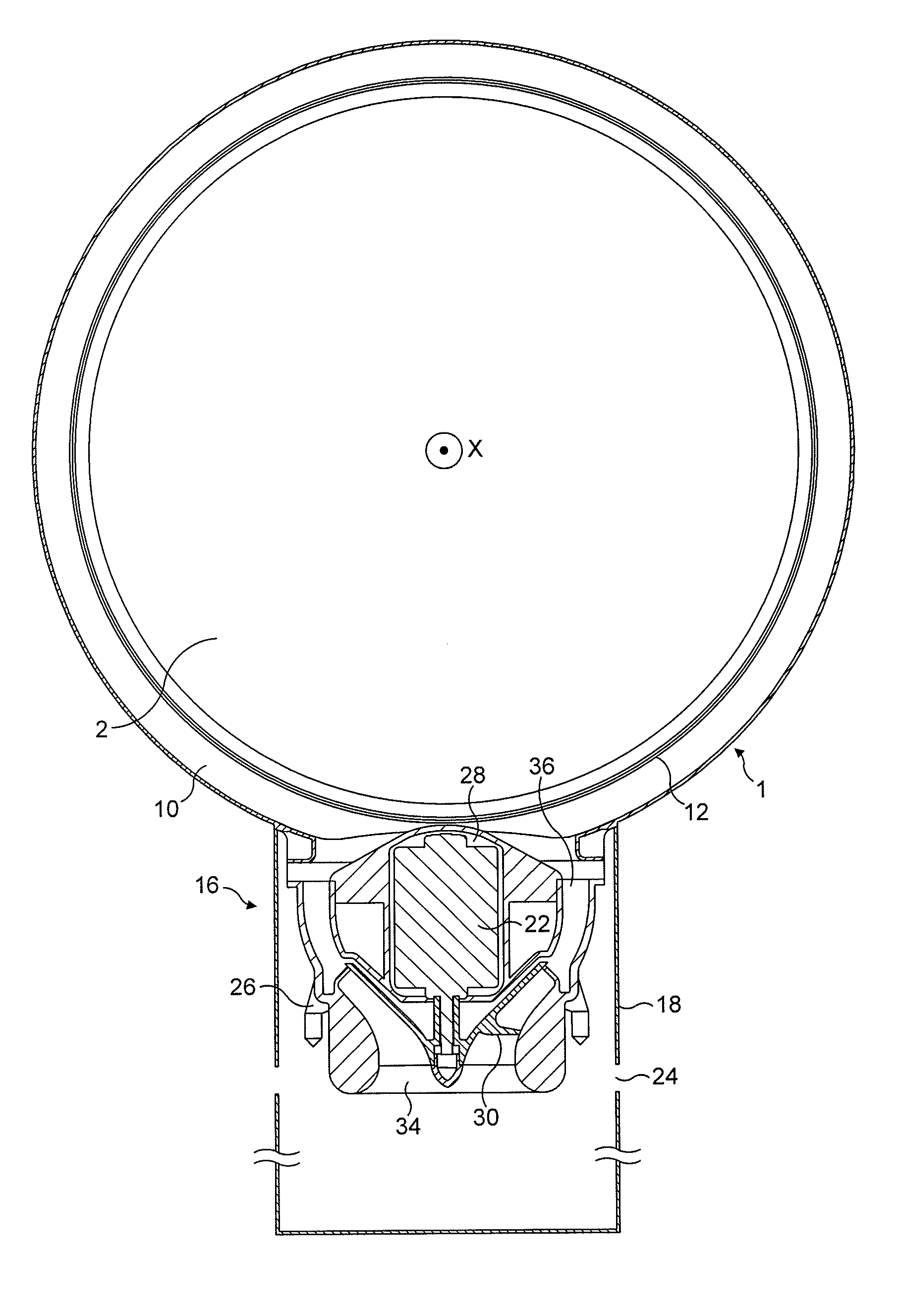

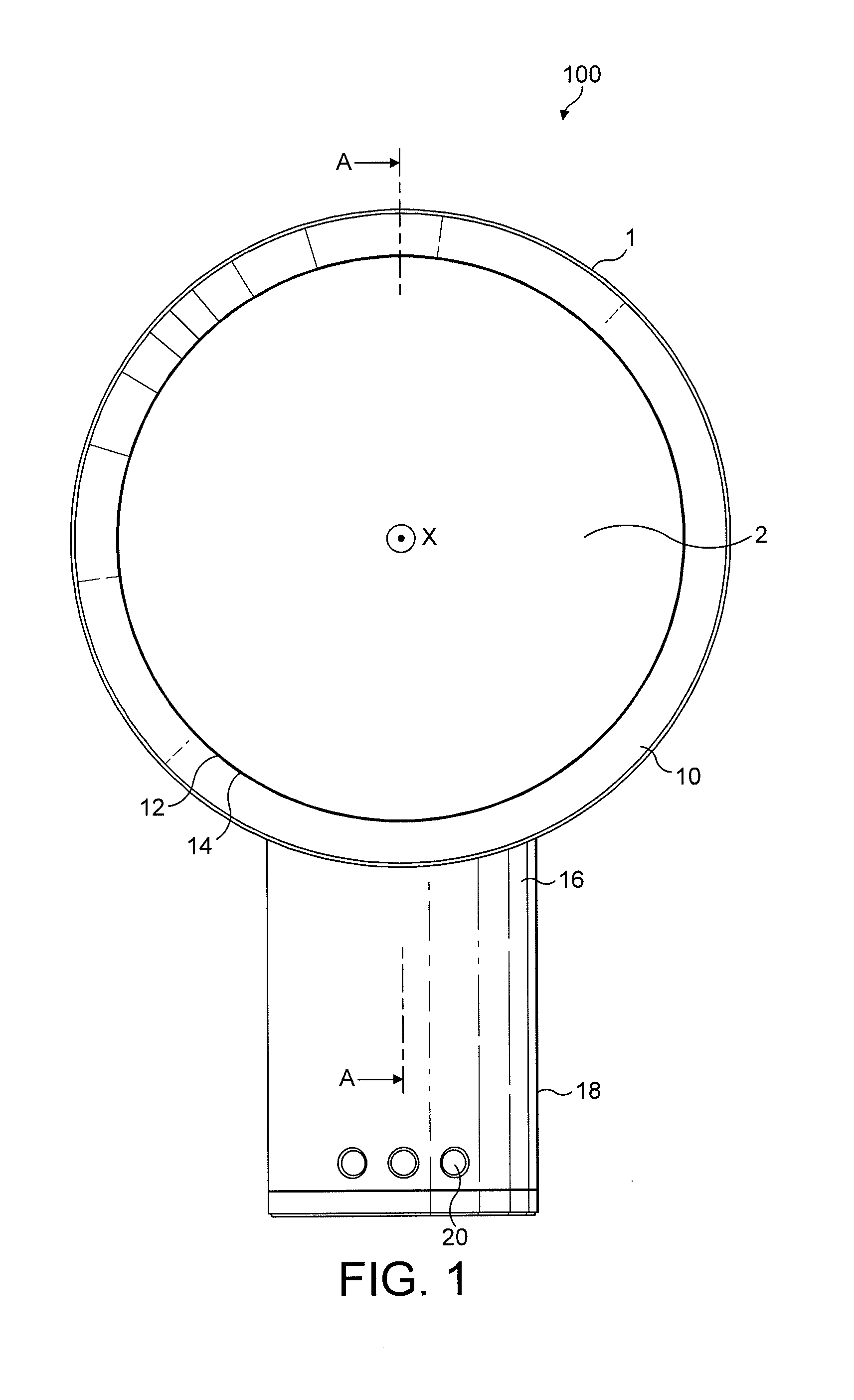

An impeller according to an example of the present invention comprises a hub, and at least one blade supported by the hub. The impeller has a deployed configuration in which the blade extends away from the hub, and a stored configuration in which the impeller is radially compressed, for example by folding the blade towards the hub. The impeller may comprise a plurality of blades, arranged in blade rows, to facilitate radial compression of the blades. The outer edge of a blade may have a winglet, and the base of the blade may have an associated indentation to facilitate folding of the blade.

Owner:PENN STATE RES FOUND +2

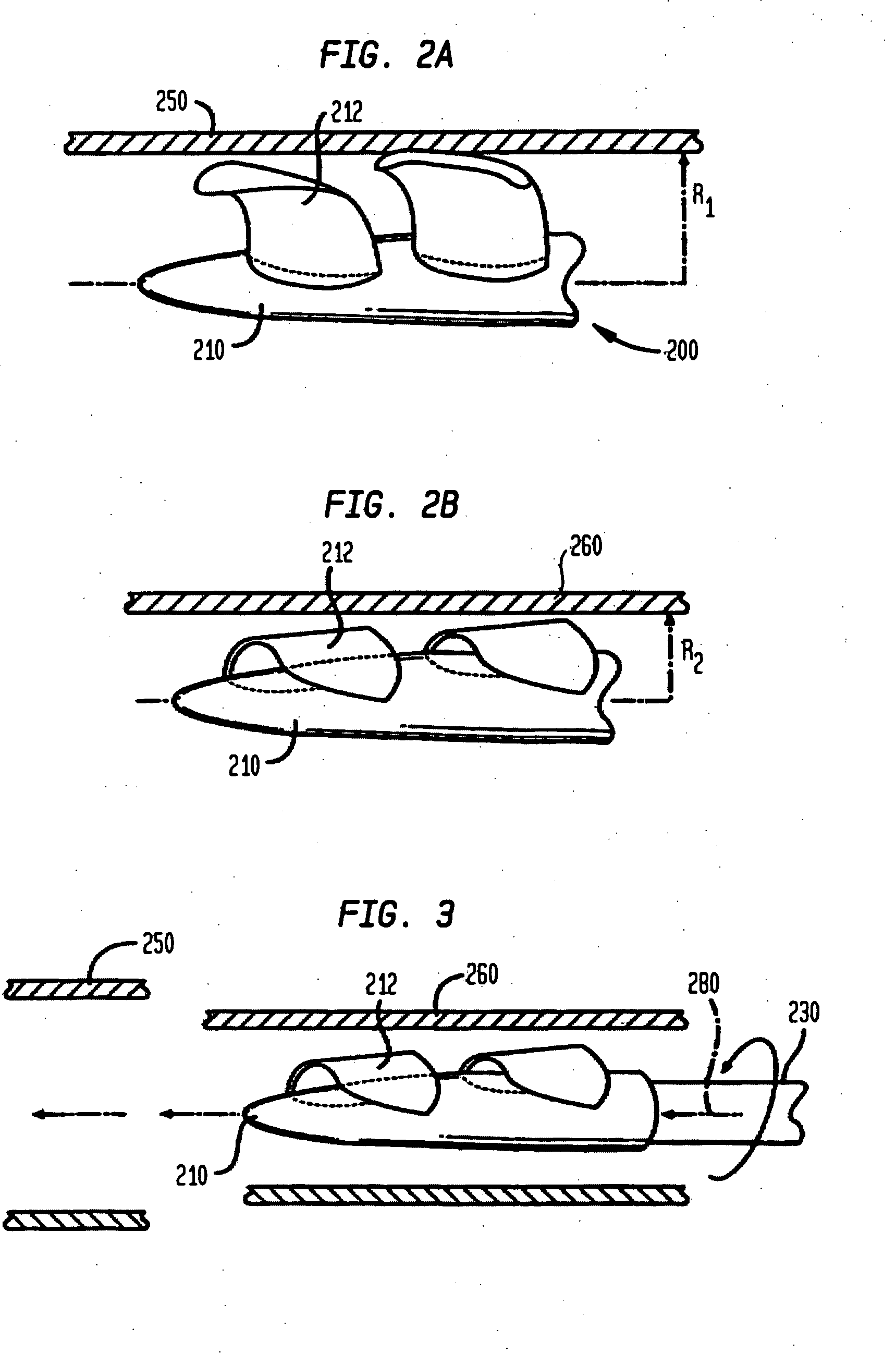

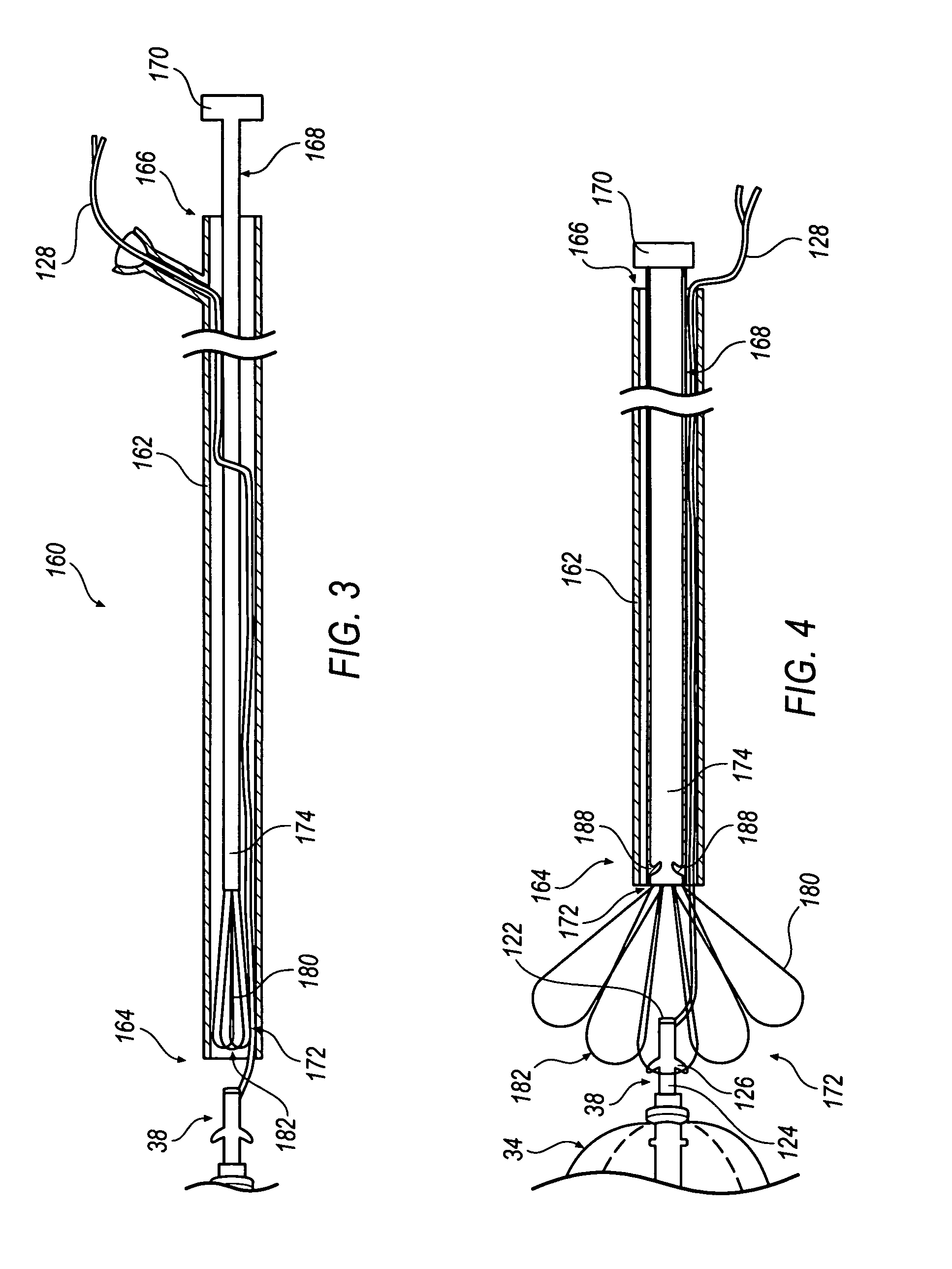

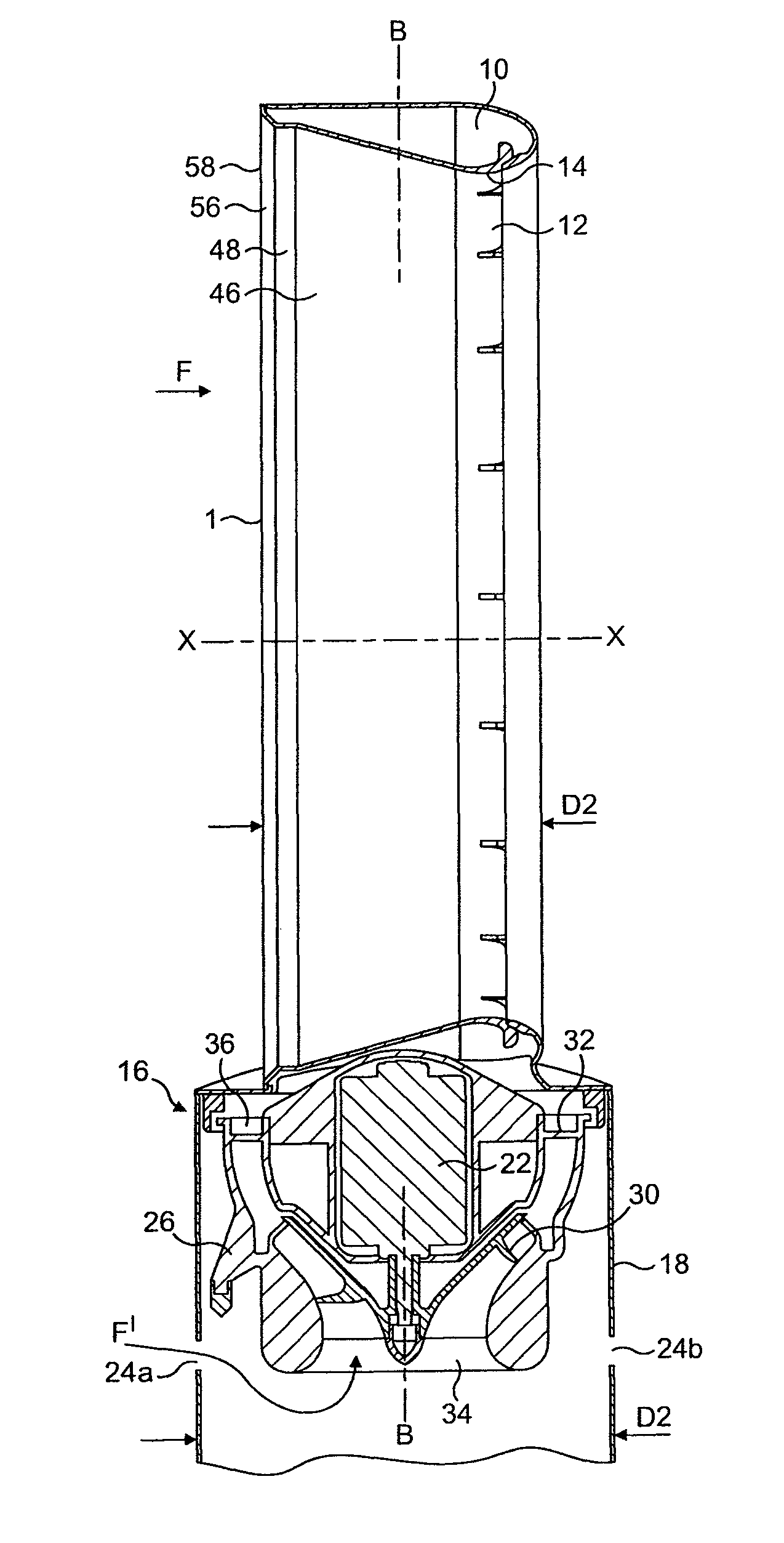

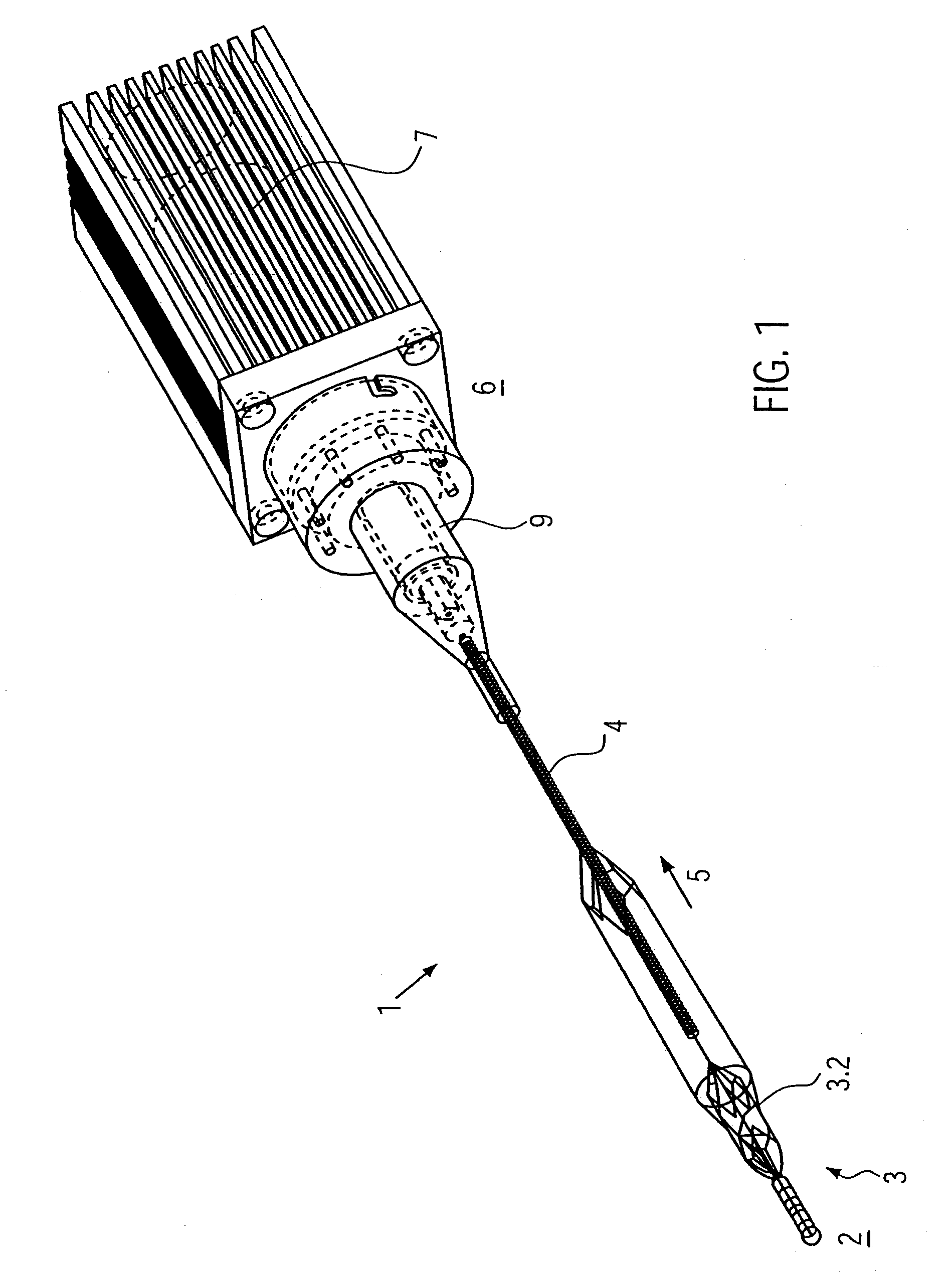

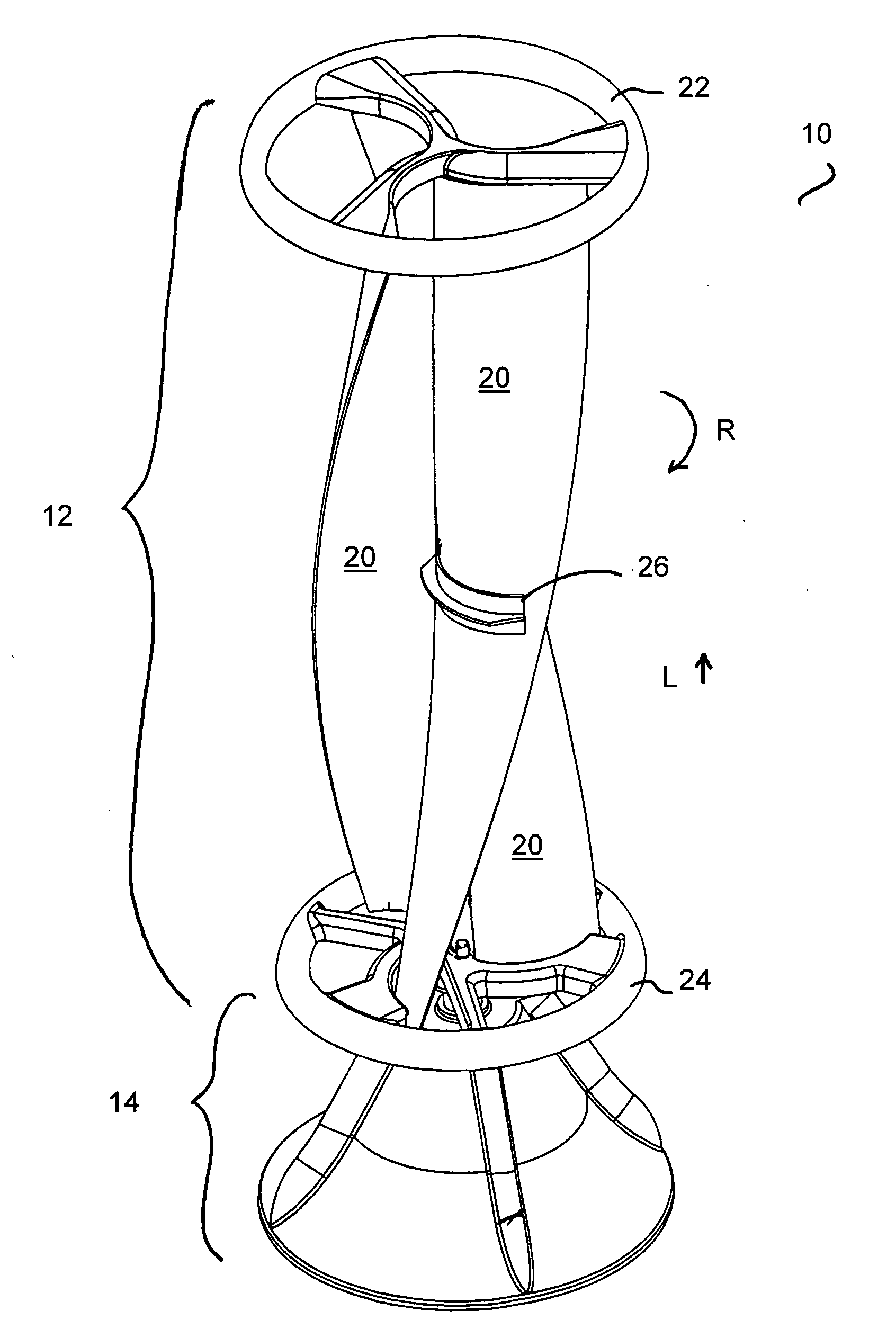

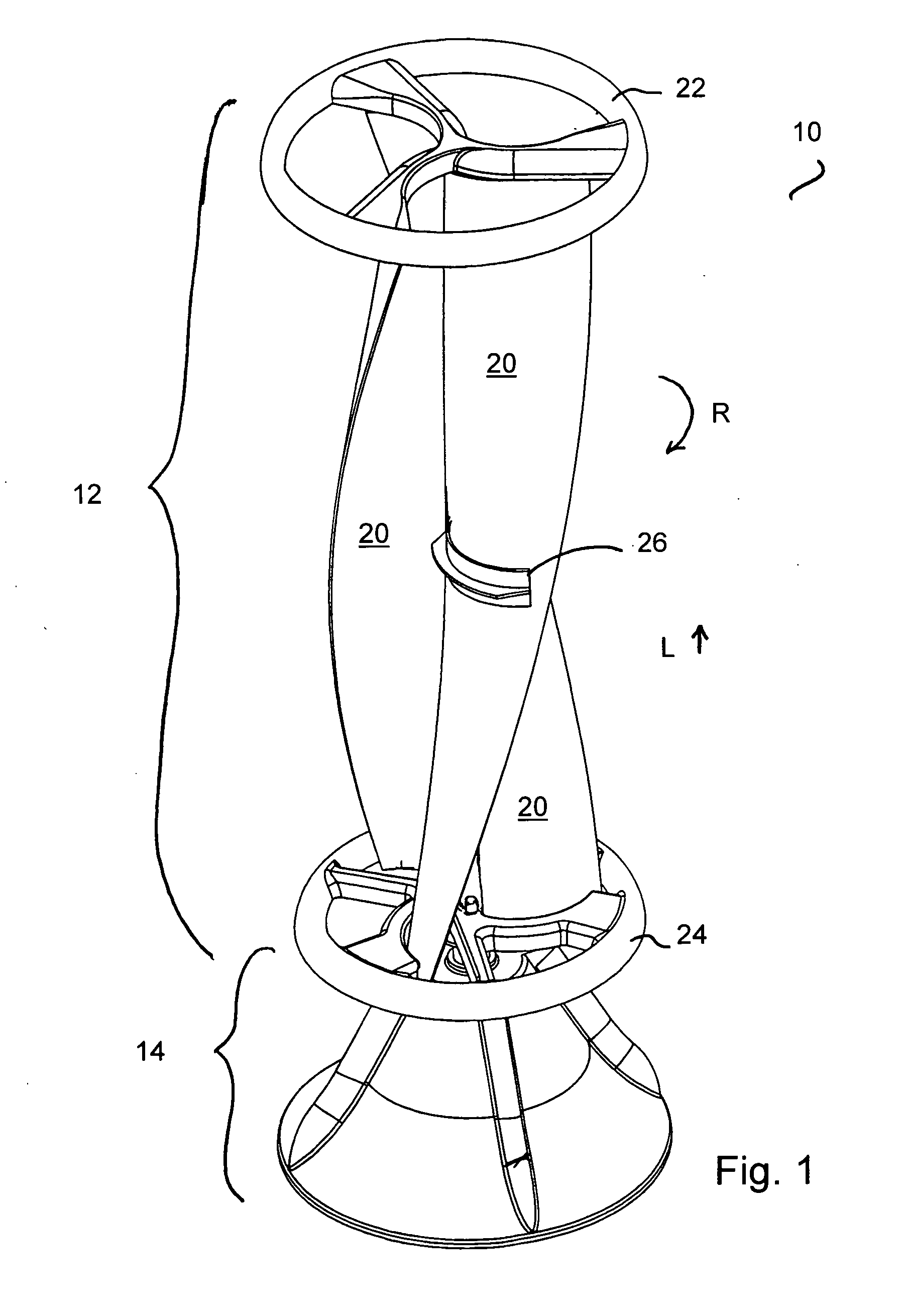

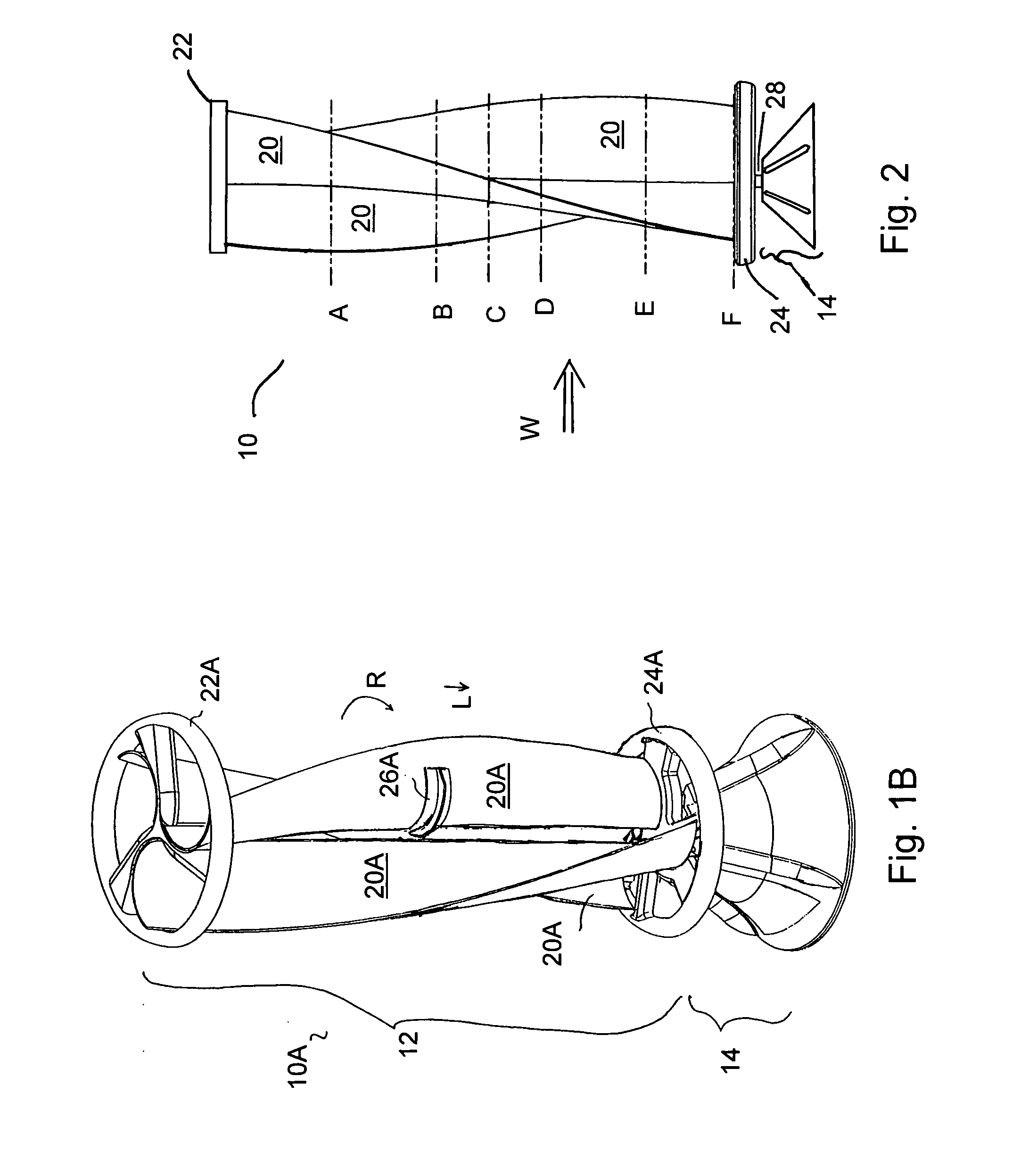

Heart assist device with expandable impeller pump

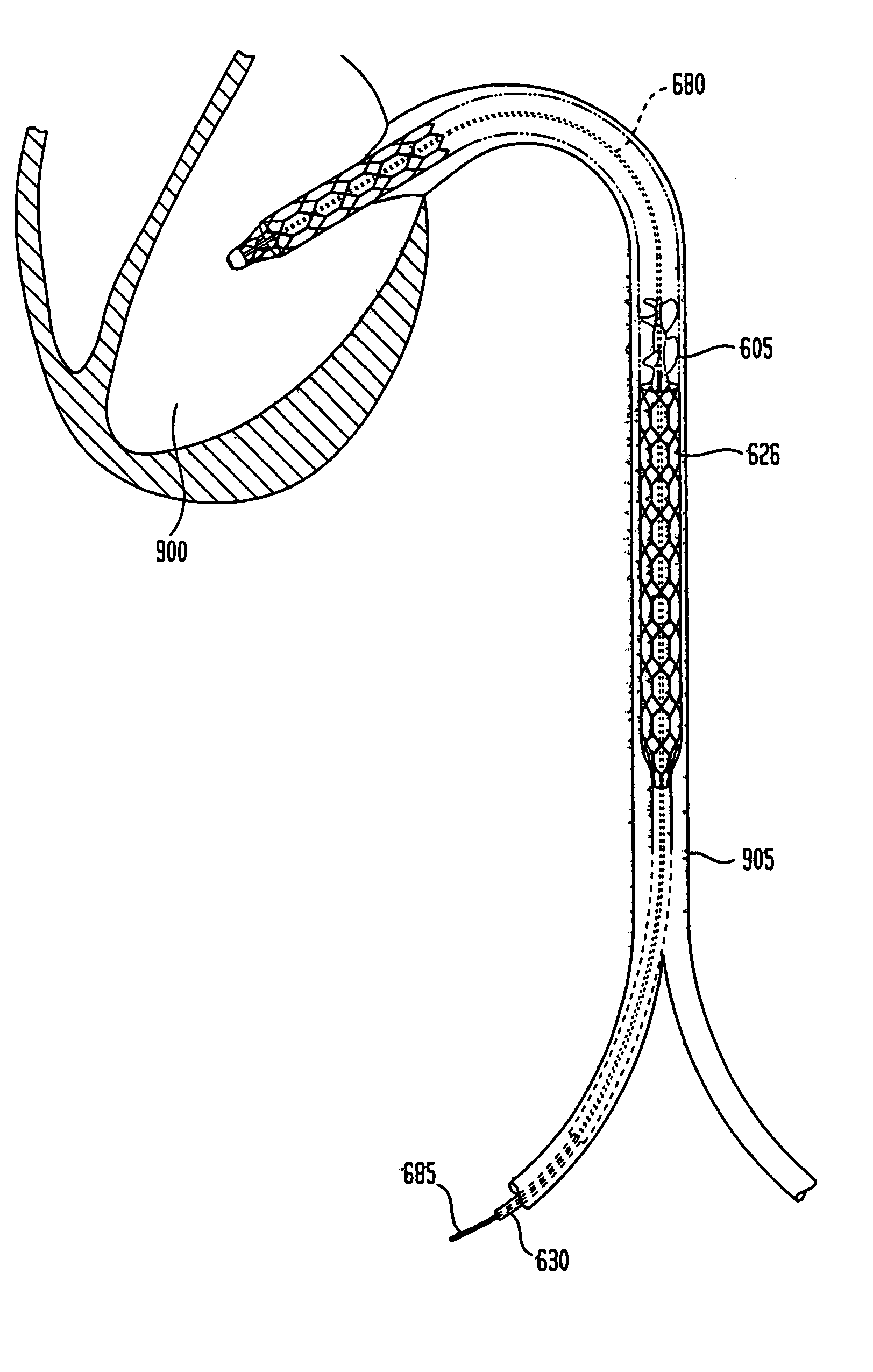

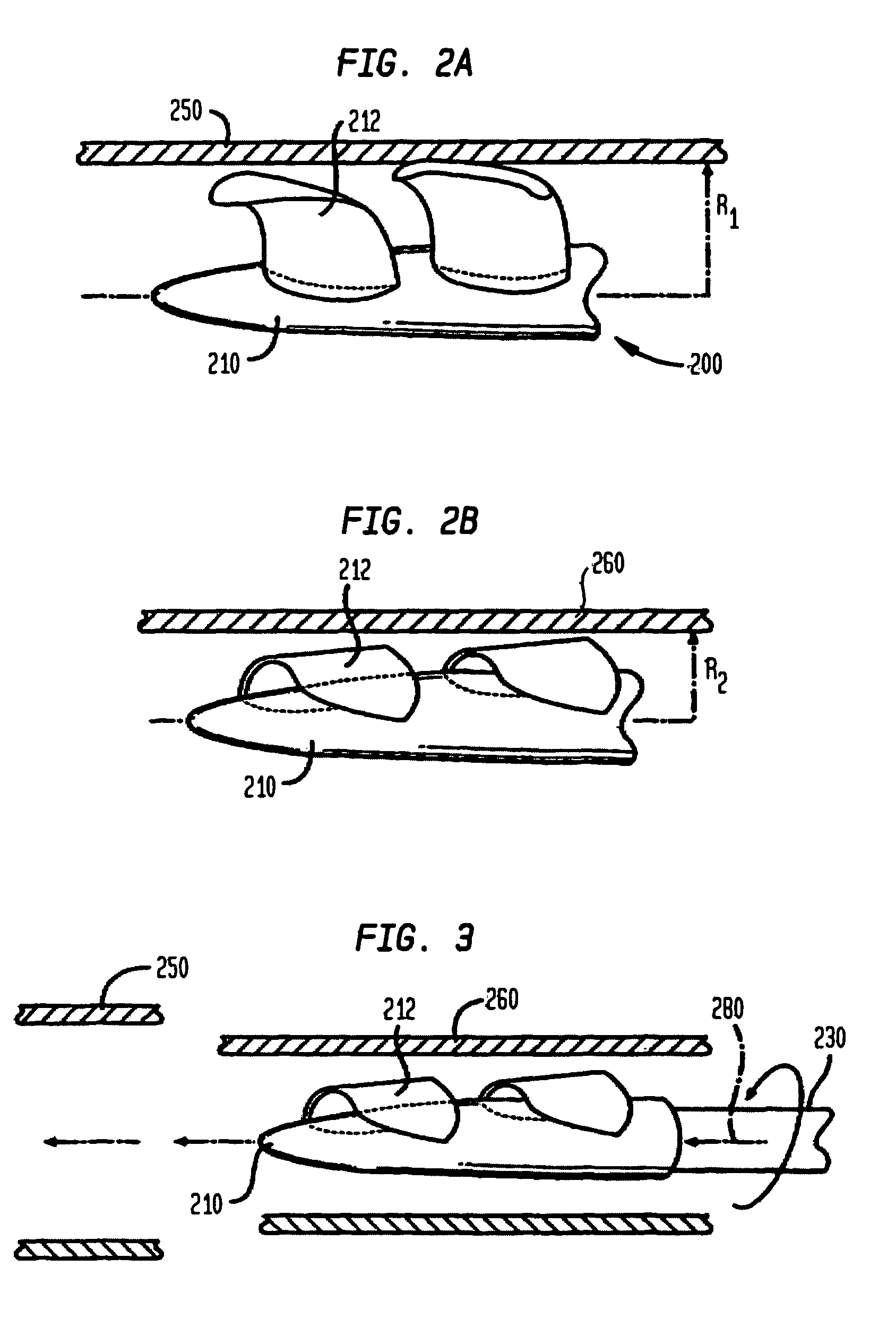

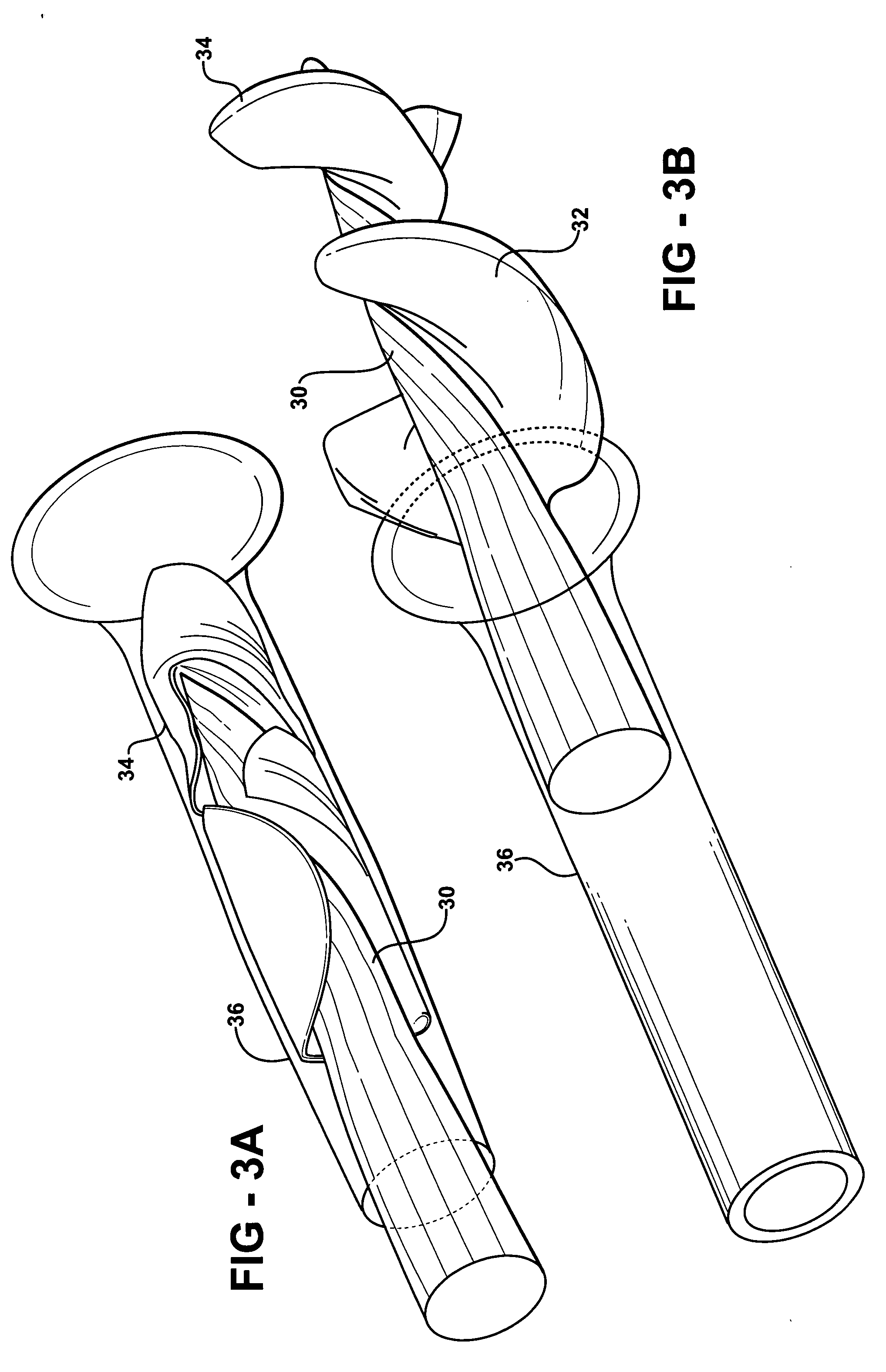

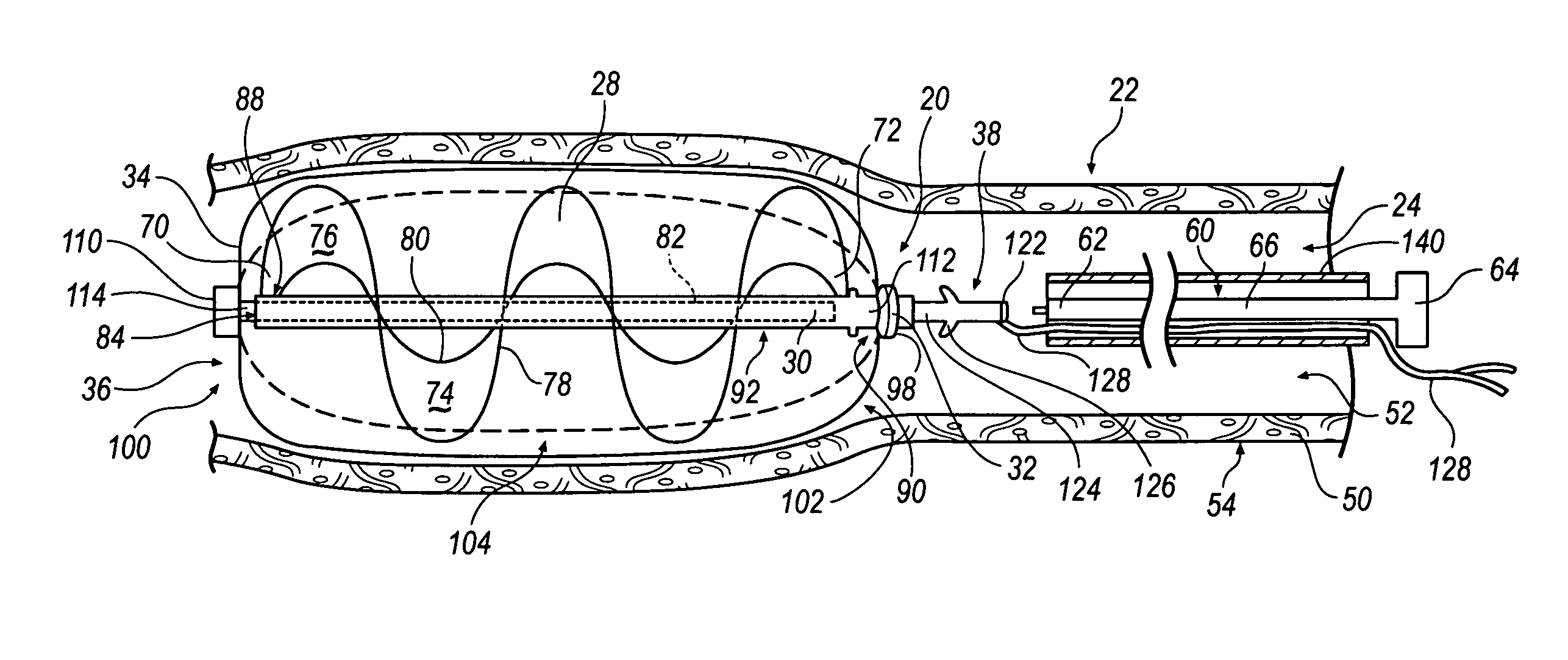

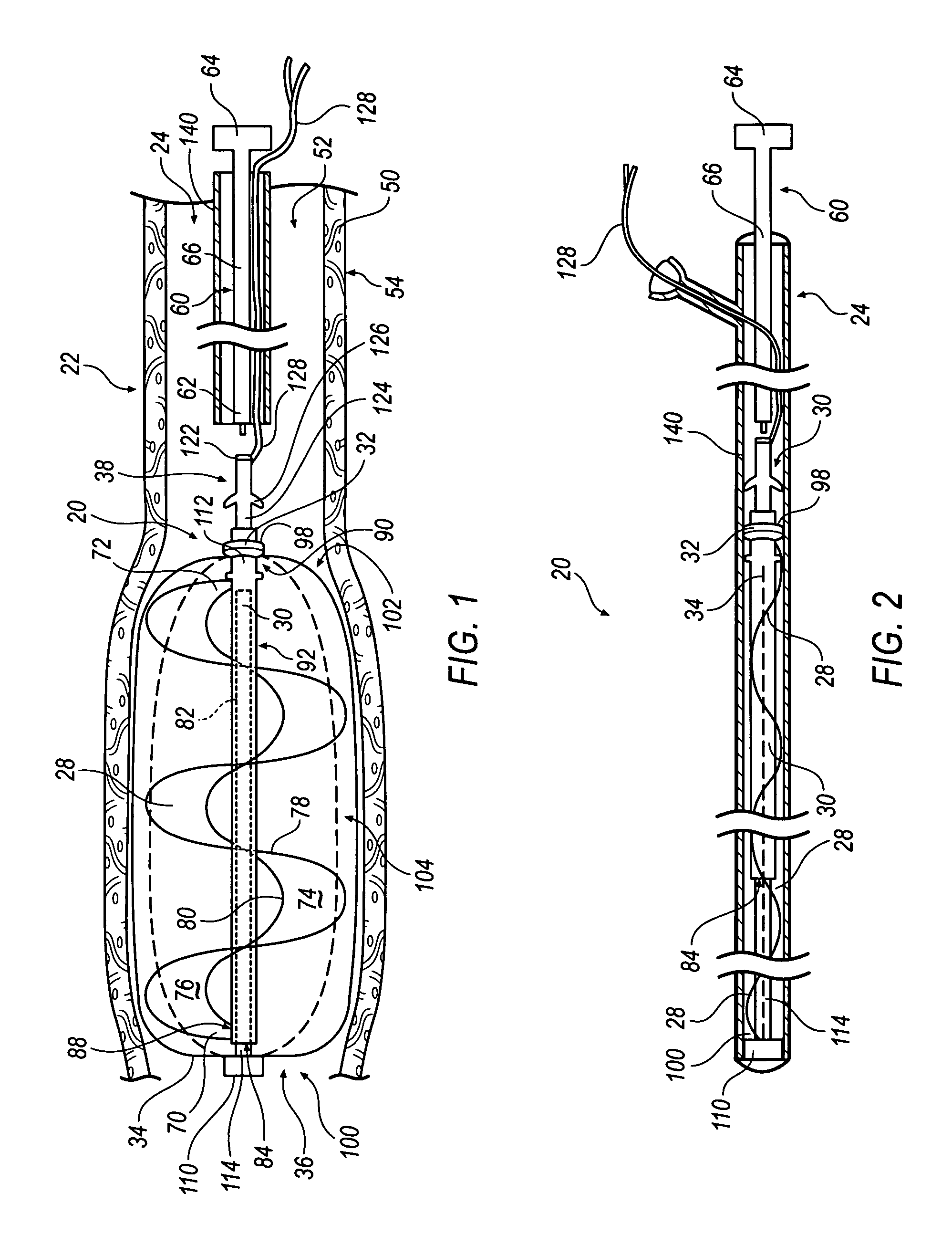

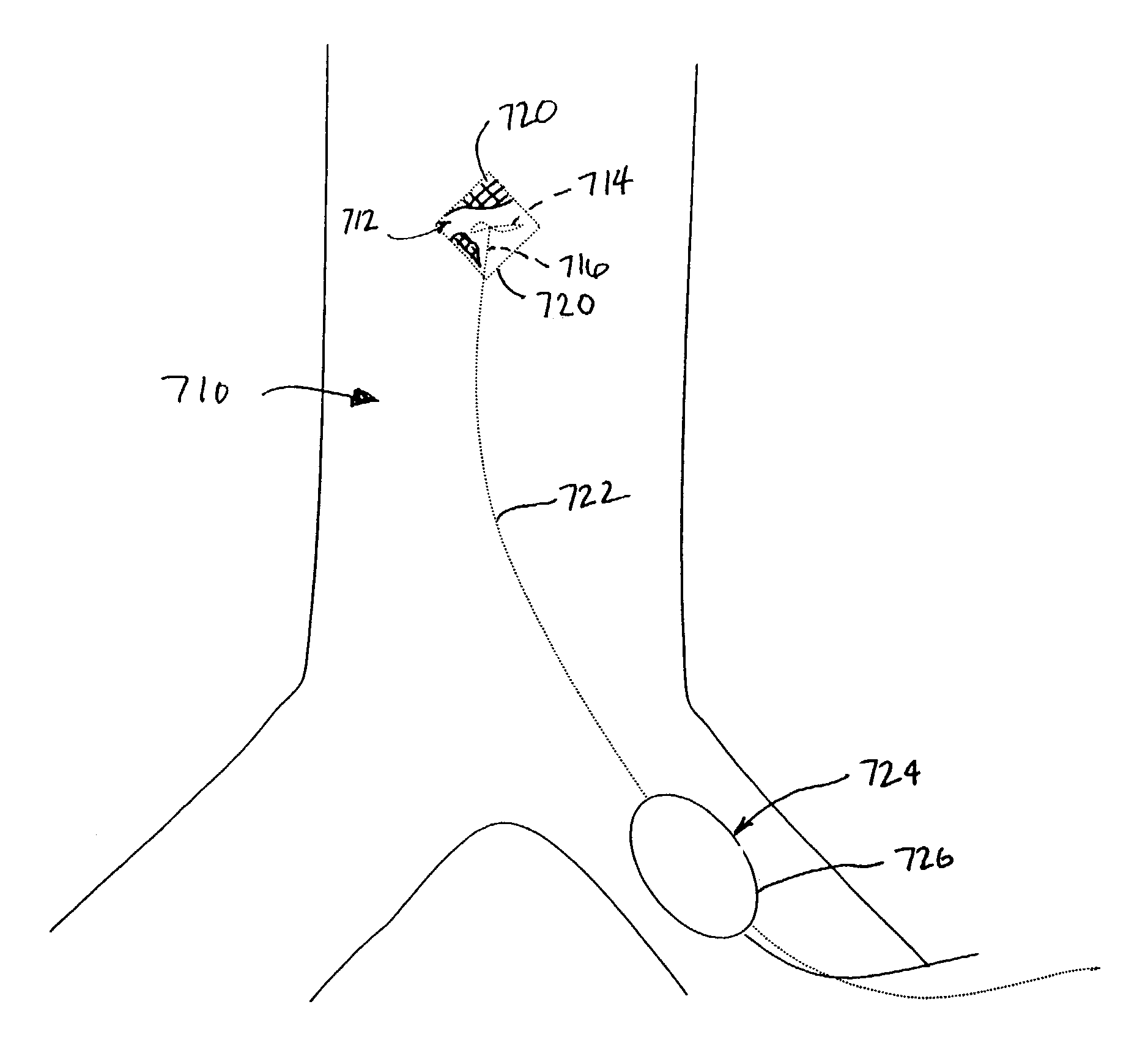

An impeller includes a hub and at least one blade supported by the hub. The impeller has a stored configuration in which the blade is compressed so that its distal end moves towards the hub, and a deployed configuration in which the blade extends away from the hub. The impeller may be part of a pump for pumping fluids, such as pumping blood within a patient. A blood pump may include a cannula having a proximal portion with a fixed diameter, and a distal portion with an expandable diameter. The impeller may reside in the expandable portion of the cannula. The cannula may have a compressed diameter which allows it to be inserted percutaneously into a patient. Once at a desired location, the expandable portion of the cannula may be expanded and the impeller expanded to the deployed configuration. A flexible drive shaft may extend through the cannula for rotationally driving the impeller within the patient's body.

Owner:PENN STATE RES FOUND +2

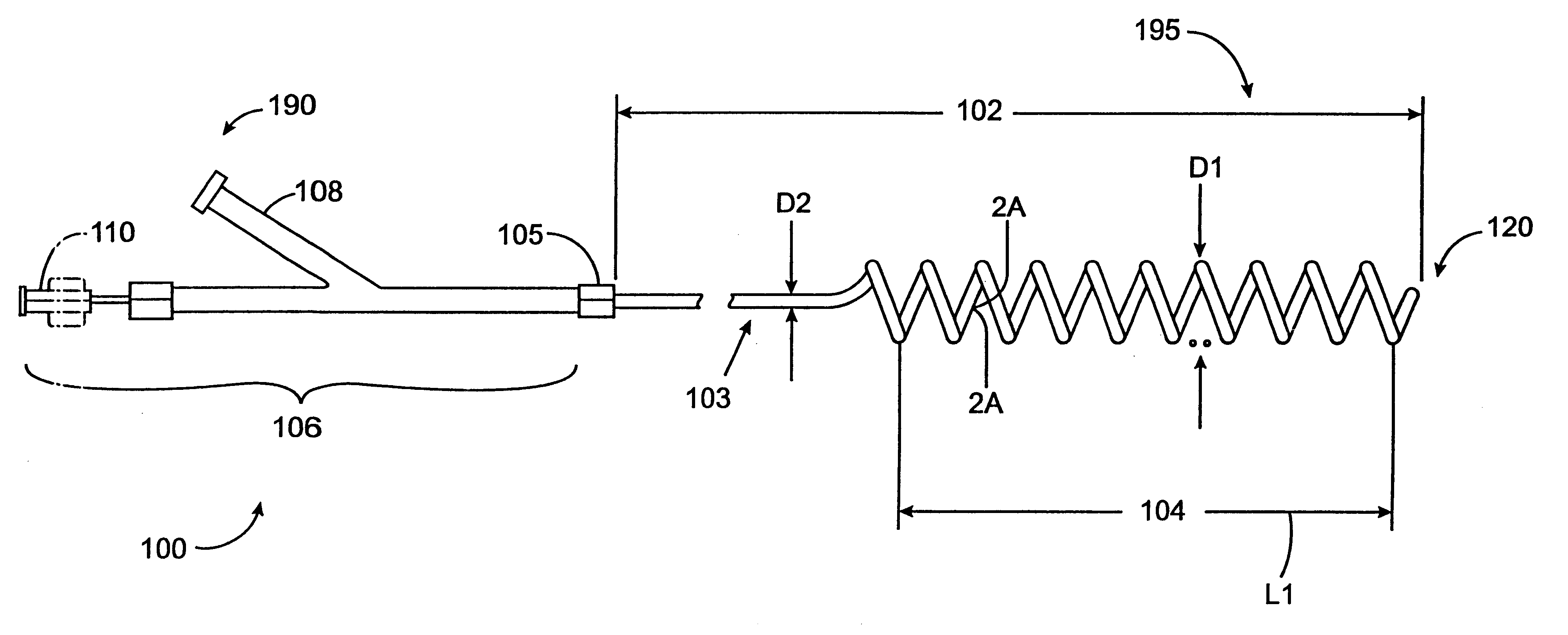

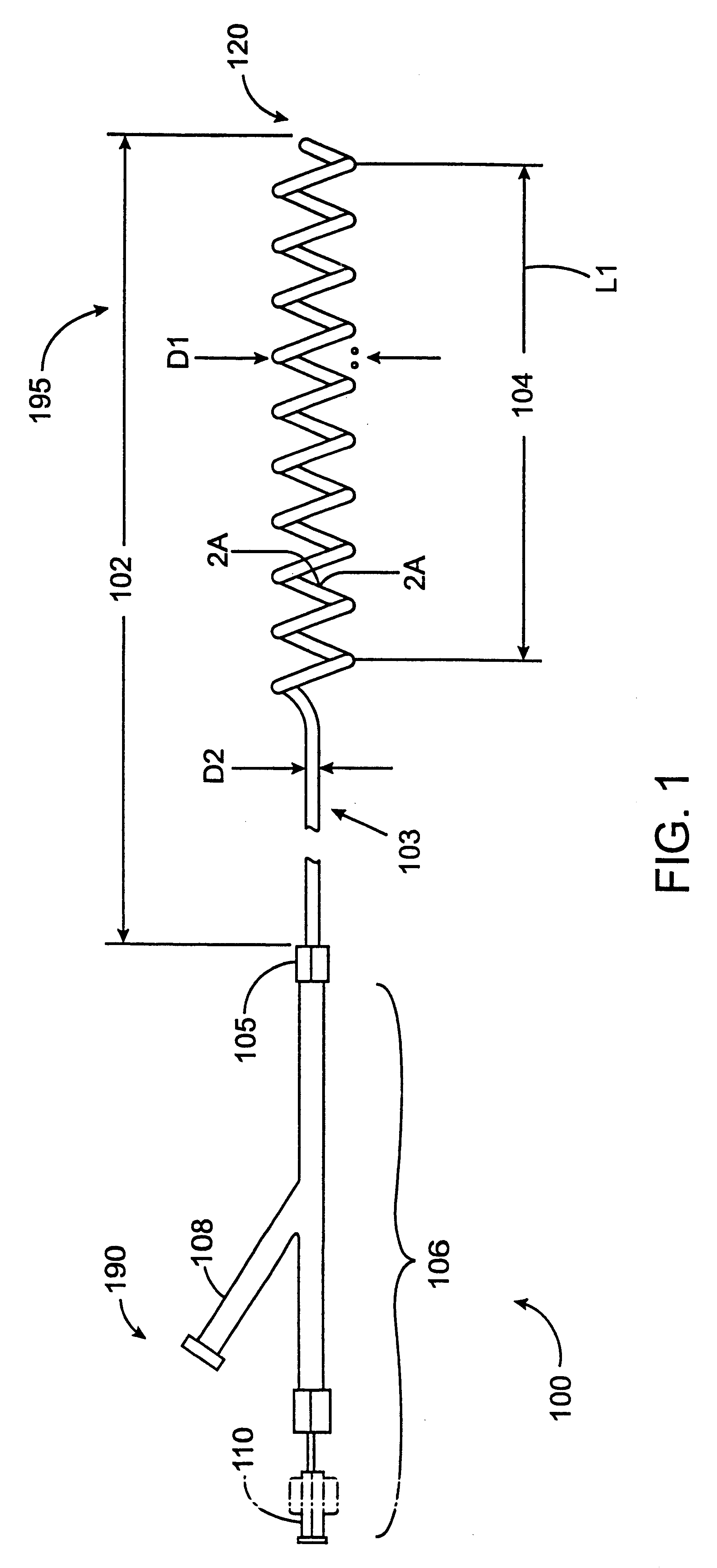

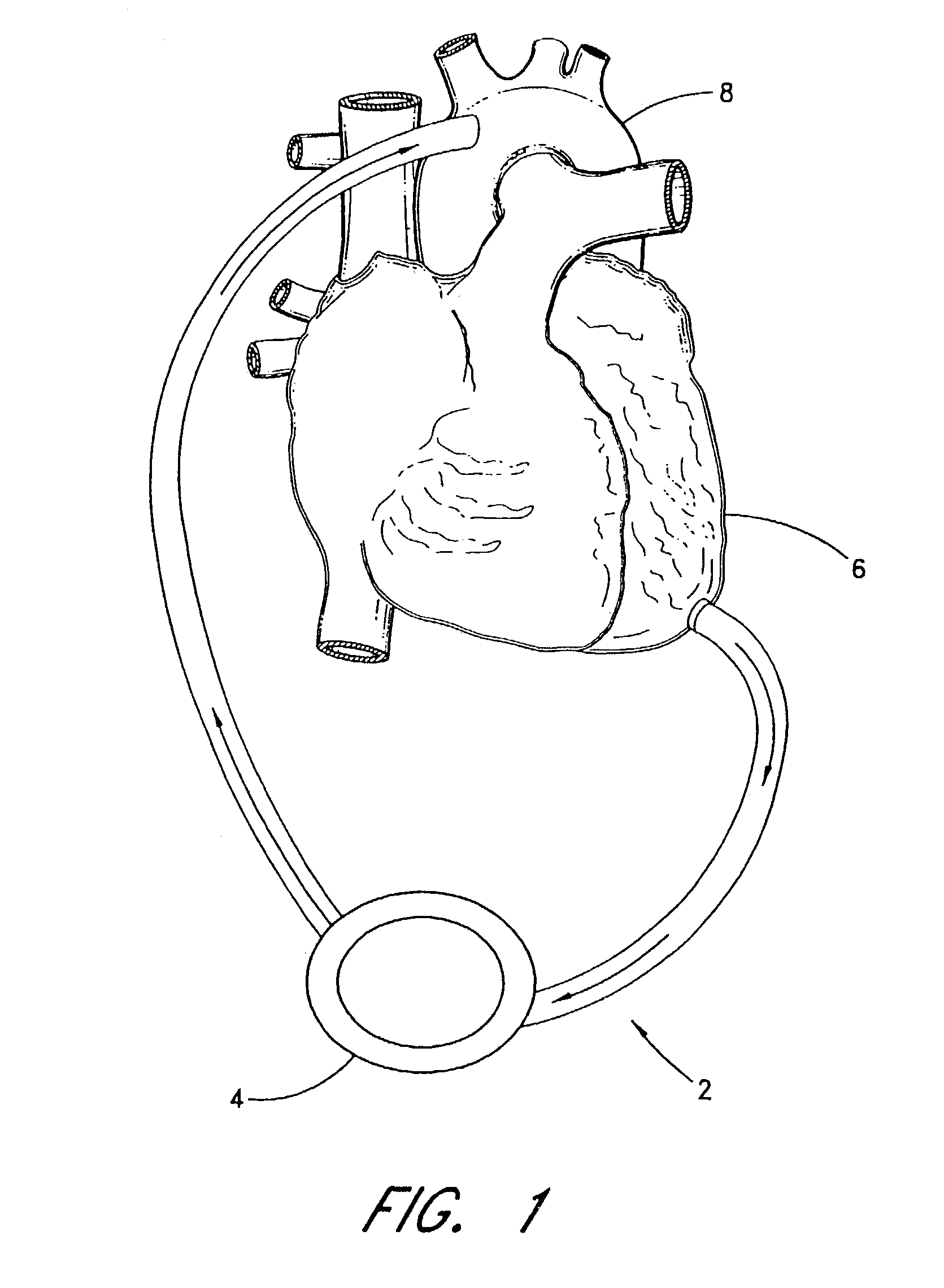

Catheter with coiled multi-lumen heat transfer extension

InactiveUS6287326B1Minimizing creationEasy to manufactureMulti-lumen catheterPump componentsMedicineInner loop

A catheter includes a sealed multi-lumen heat transfer extension designed to internally circulate a coolant, and thereby cool tissue or fluid surrounding the catheter. The heat transfer extension includes a tube having a distally positioned region that coils about the tube's longitudinal axis. The tube houses multiple lumens running longitudinally along the tube. These lumens include one or more supply lumens and one or more return lumens. A distal fluid exchange reservoir resides at the tube's tip, for the purpose of redirecting fluid from the supply lumen(s) to the return lumen(s). The heat transfer extension may include a shape memory structure causing the heat transfer extension to vary its shape according to temperature. Namely, the extension assumes a coiled shape under predetermined shape-active temperatures, and it assumes a non-coiled shape under other predetermined shape-relaxed temperatures. The catheter also includes an interface having supply and return lines to provide coolant to the heat transfer extension, and remove coolant returning therefrom. To connect the supply / return lines with the supply / return lumens, the invention may include a fluid transfer housing. Optionally, one or more of the lumens may be configured as flow-through lumens to exchange fluids with the patient.

Owner:ZOLL CIRCULATION

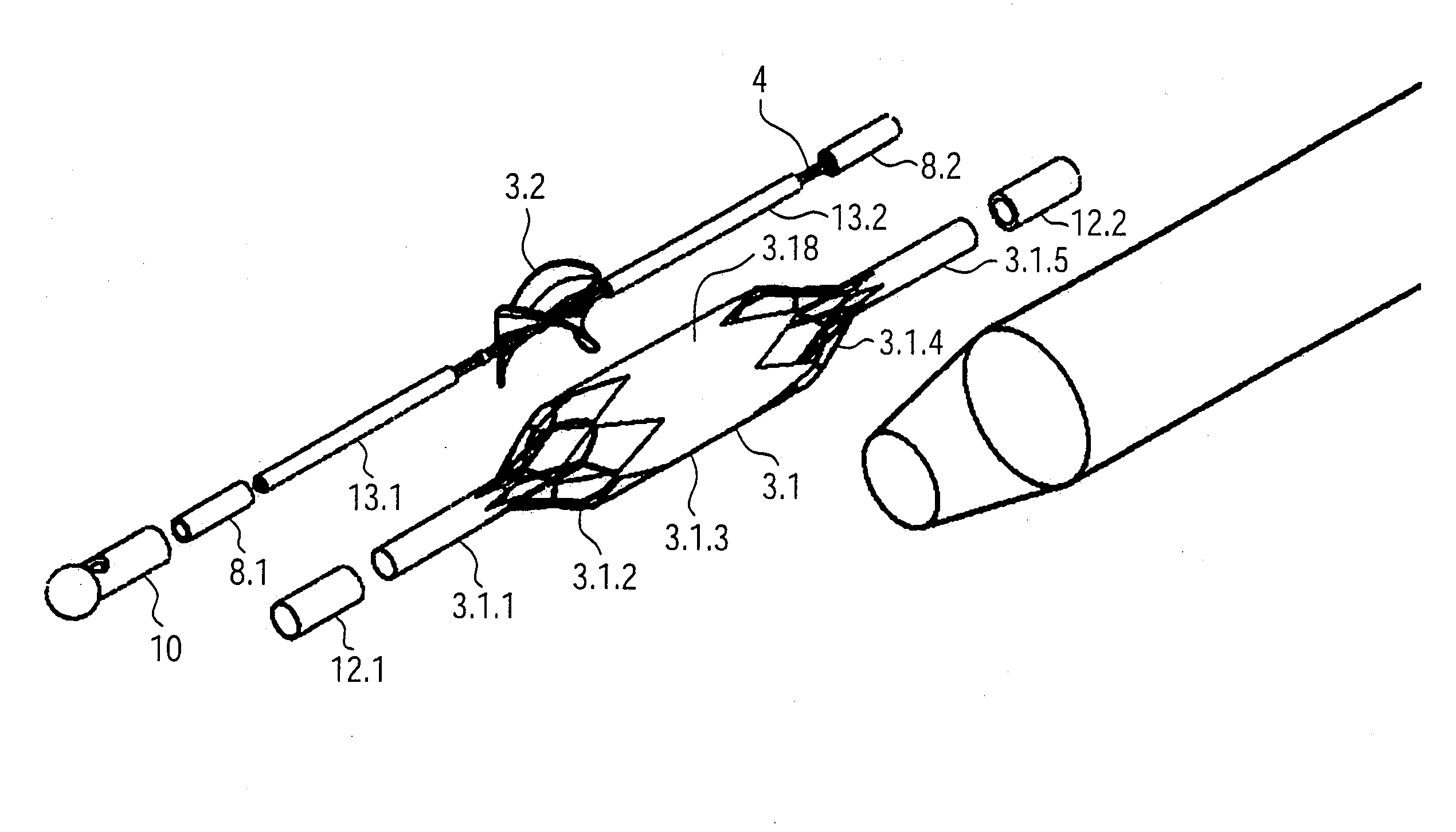

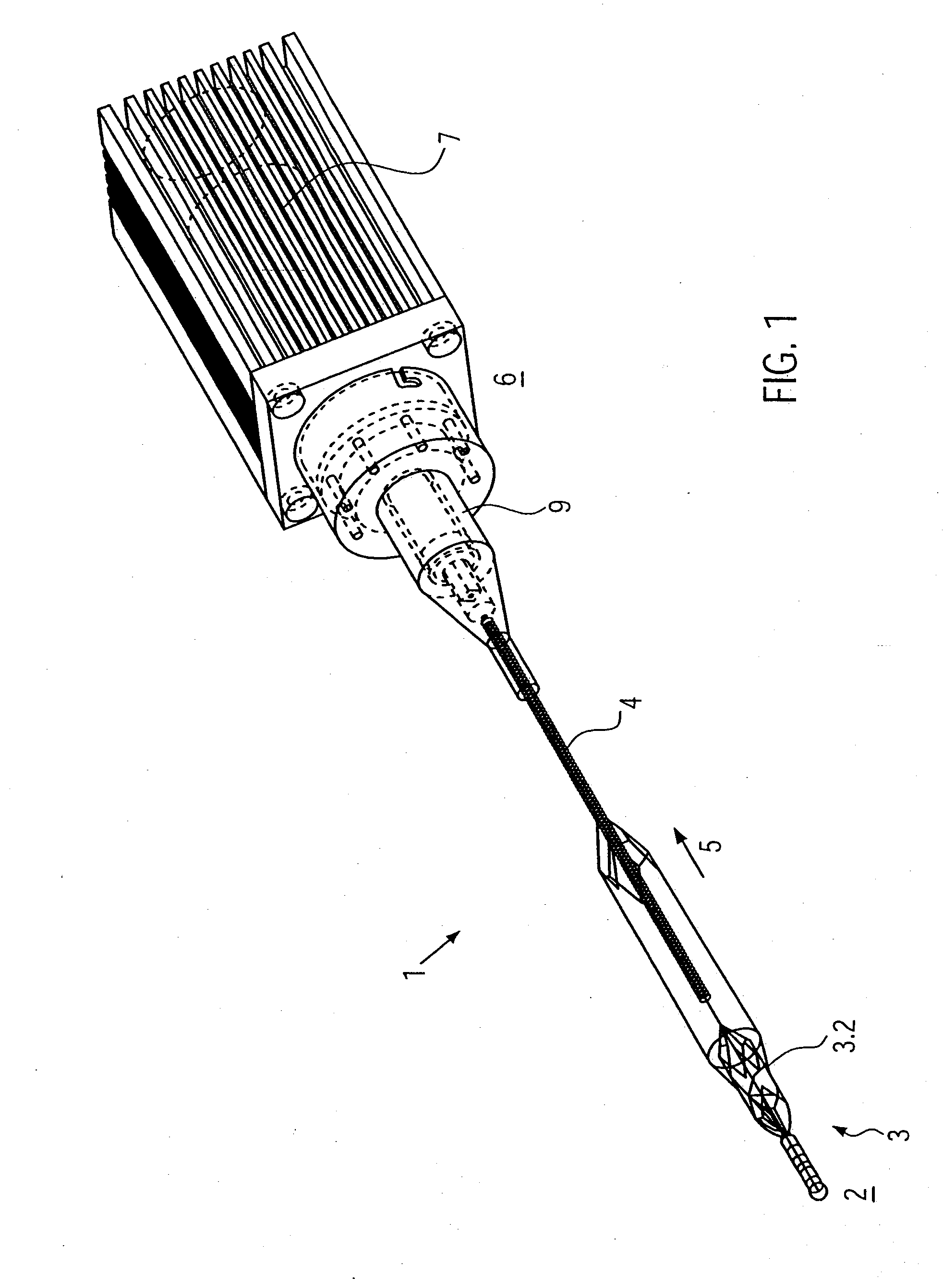

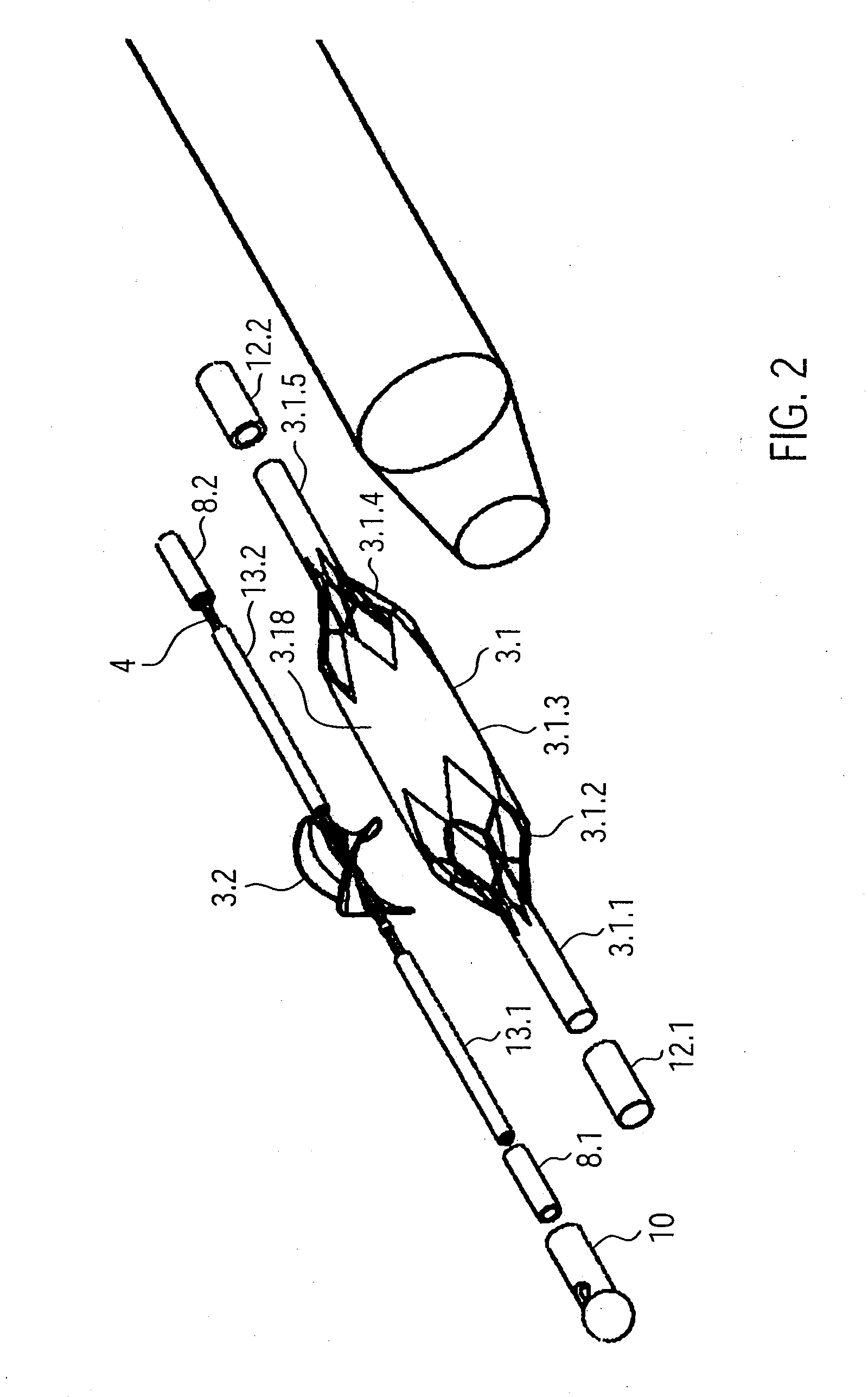

Catheter device

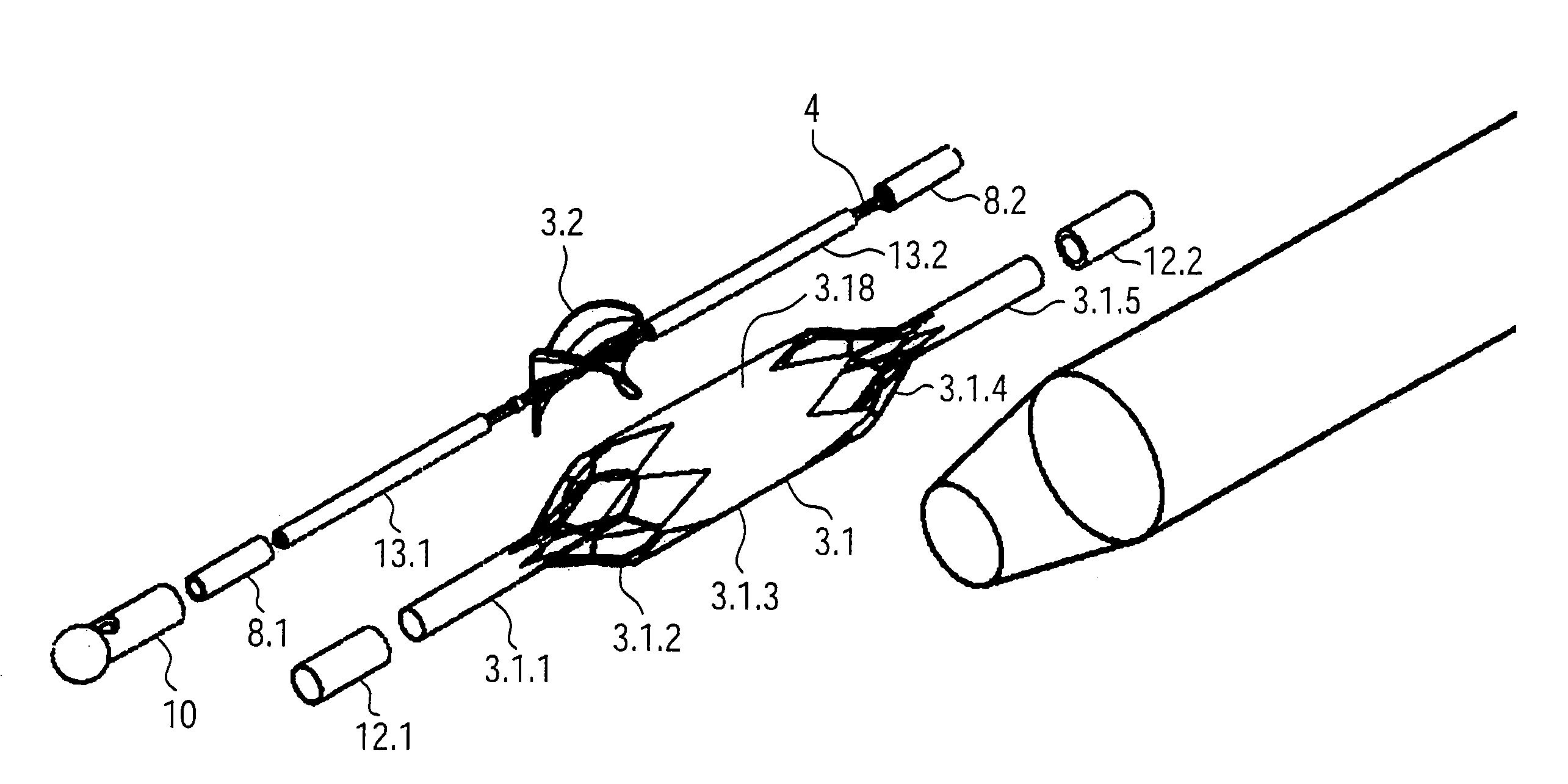

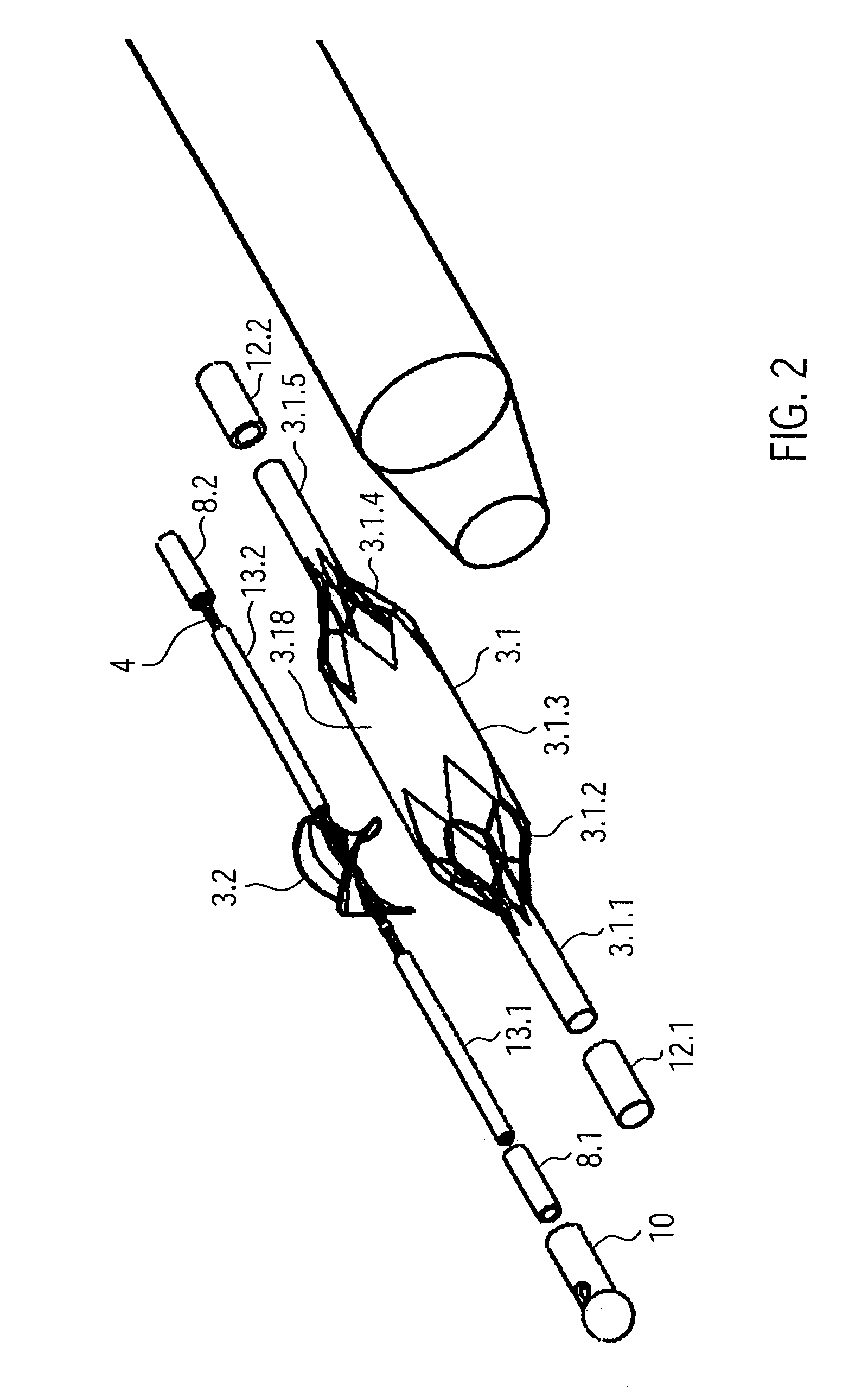

ActiveUS20090093796A1Maximum pump performanceImprove performancePump componentsSurgeryDrive shaftMechanical engineering

The catheter device comprises a drive shaft connected to a motor, and a rotor mounted on the drive shaft at the distal end section. The rotor has a frame structure which is formed by a screw-like boundary frame and rotor struts extending radially inwards from the boundary frame. The rotor struts are fastened to the drive shaft by their ends opposite the boundary frame. Between the boundary frame and the drive shaft extends an elastic covering. The frame structure is made of an elastic material such that, after forced compression, the rotor unfolds automatically.

Owner:AIS AACHEN INNOVATIVE SOLUTIONS

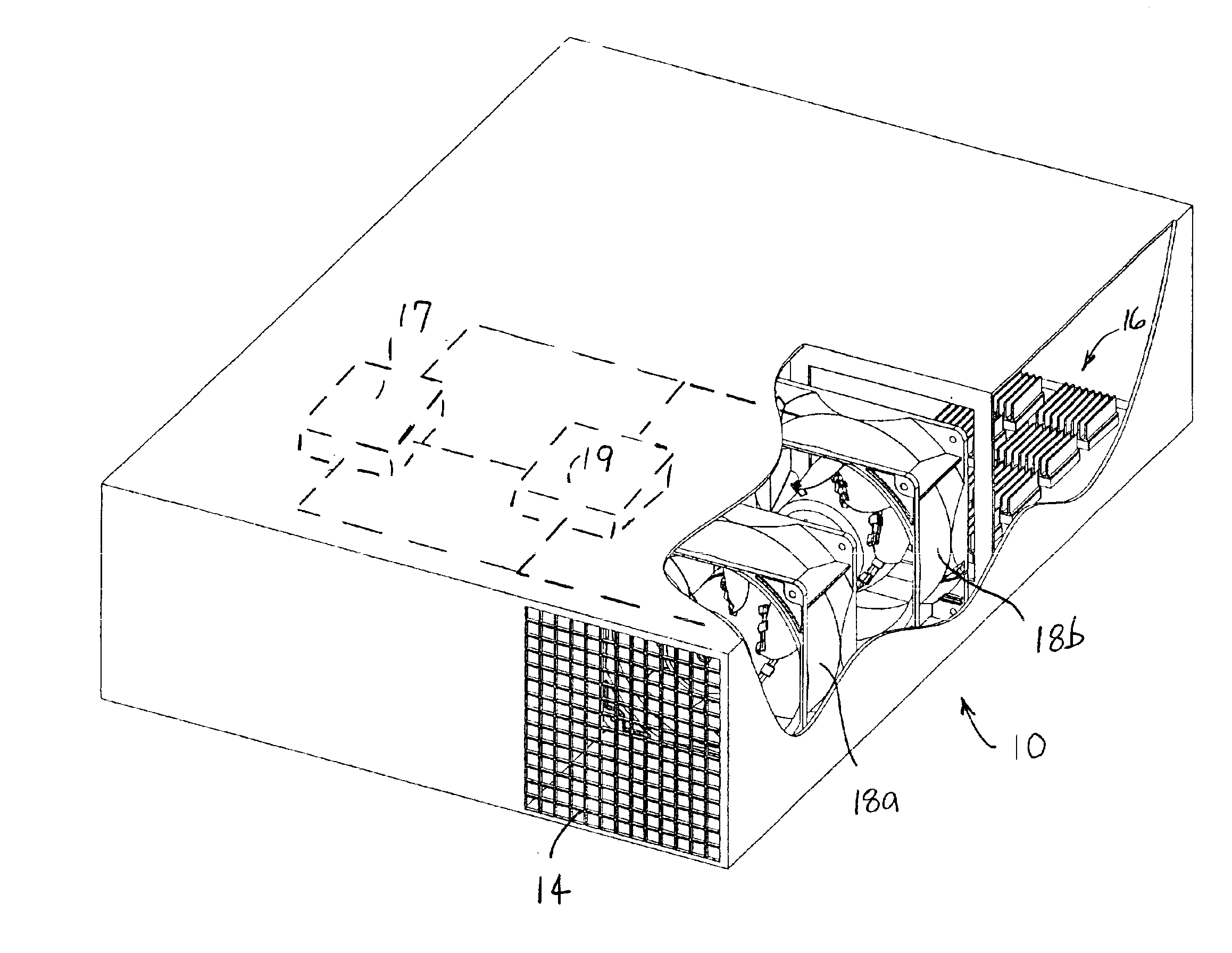

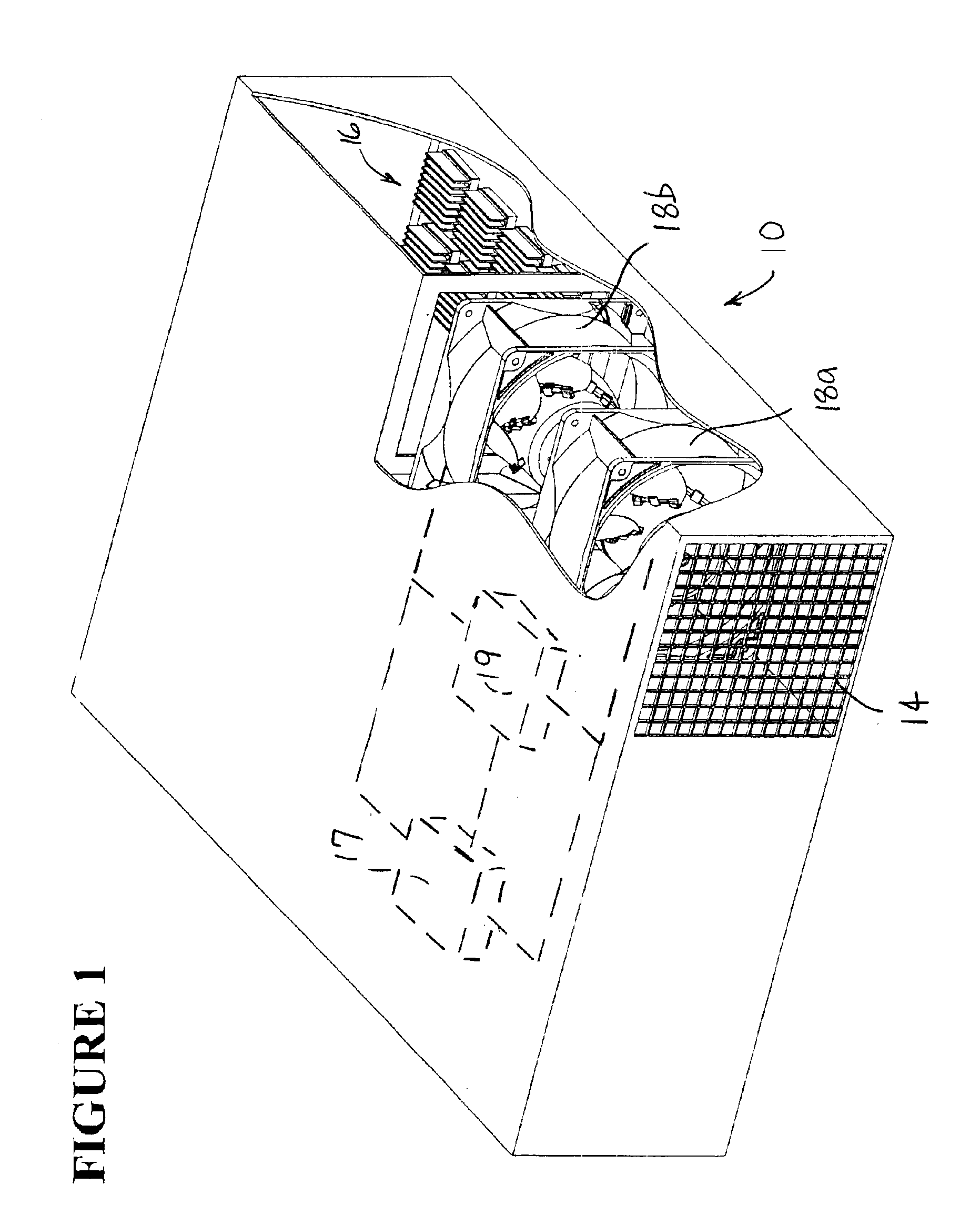

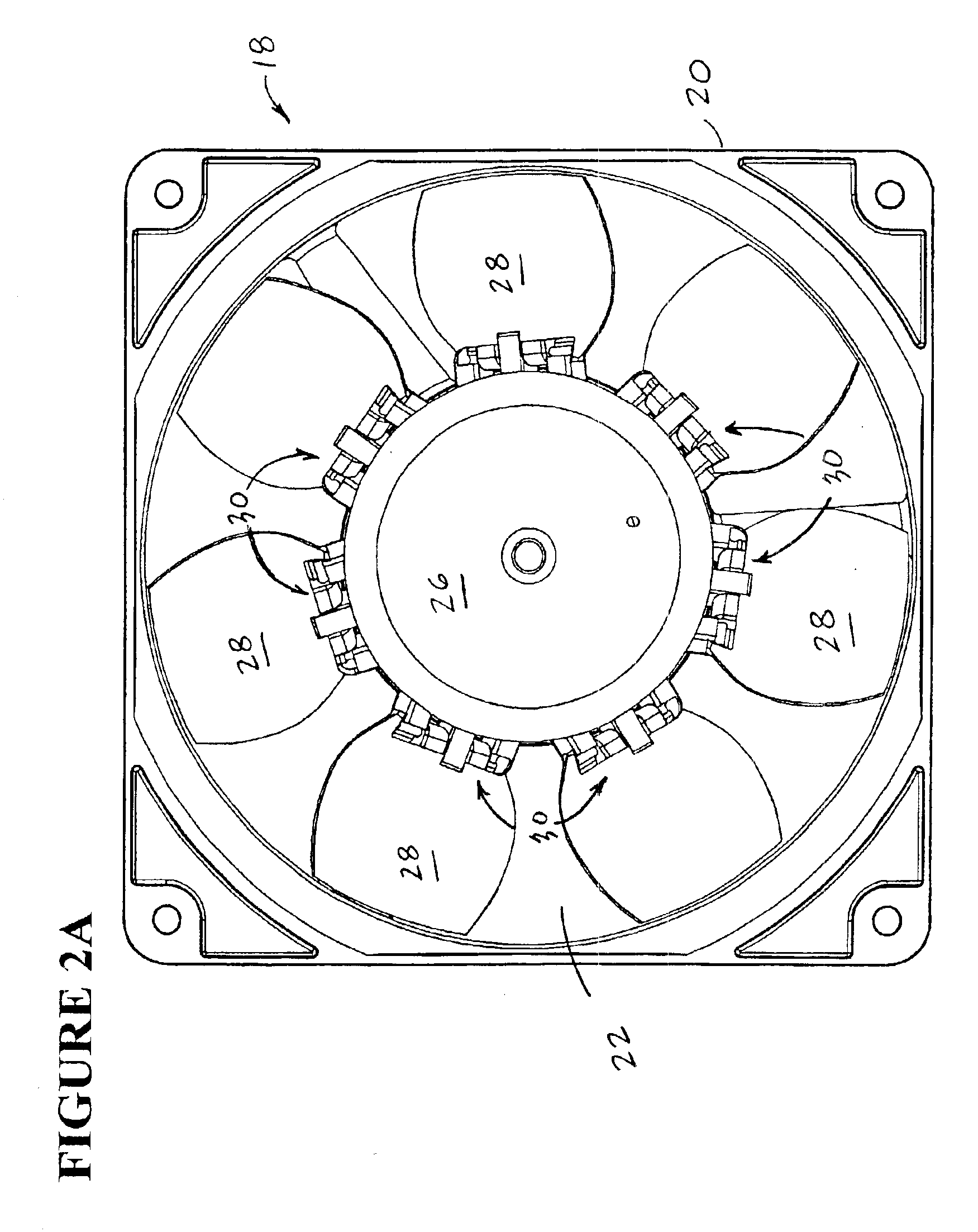

Fan with collapsible blades, redundant fan system, and related method

InactiveUS6860713B2Reduces fan inefficiencyPrevent undesirable blockagePropellersPump componentsFan bladeAirflow

A redundant fan system for a computer includes two fans installed in series with at least one of the fans having collapsible blades. A fan system of this type reduces the fan inefficiency caused when one fan in a series mounted pair is not operating, either because it is free-wheeling or in a locked rotor condition. When non-operational, the fan blades of the collapsible fan fold inward due to airflow generated by the operational fan over the collapsible blades. The ability of the blades to fold reduces the inefficiency of the operational fan, having less of an effect on fan life. Also, because the flow of air is less restricted, proper airflow can be maintained, thus preventing overheating of the computer.

Owner:NIDEC AMERICA CORP

Heart assist device with expandable impeller pump

An impeller includes a hub and at least one blade supported by the hub. The impeller has a stored configuration in which the blade is compressed so that its distal end moves towards the hub, and a deployed configuration in which the blade extends away from the hub. The impeller may be part of a pump for pumping fluids, such as pumping blood within a patient. A blood pump may include a cannula having a proximal portion with a fixed diameter, and a distal portion with an expandable diameter. The impeller may reside in the expandable portion of the cannula. The cannula may have a compressed diameter which allows it to be inserted percutaneously into a patient. Once at a desired location, the expandable portion of the cannula may be expanded and the impeller expanded to the deployed configuration. A flexible drive shaft may extend through the cannula for rotationally driving the impeller within the patient's body.

Owner:PENN STATE RES FOUND +2

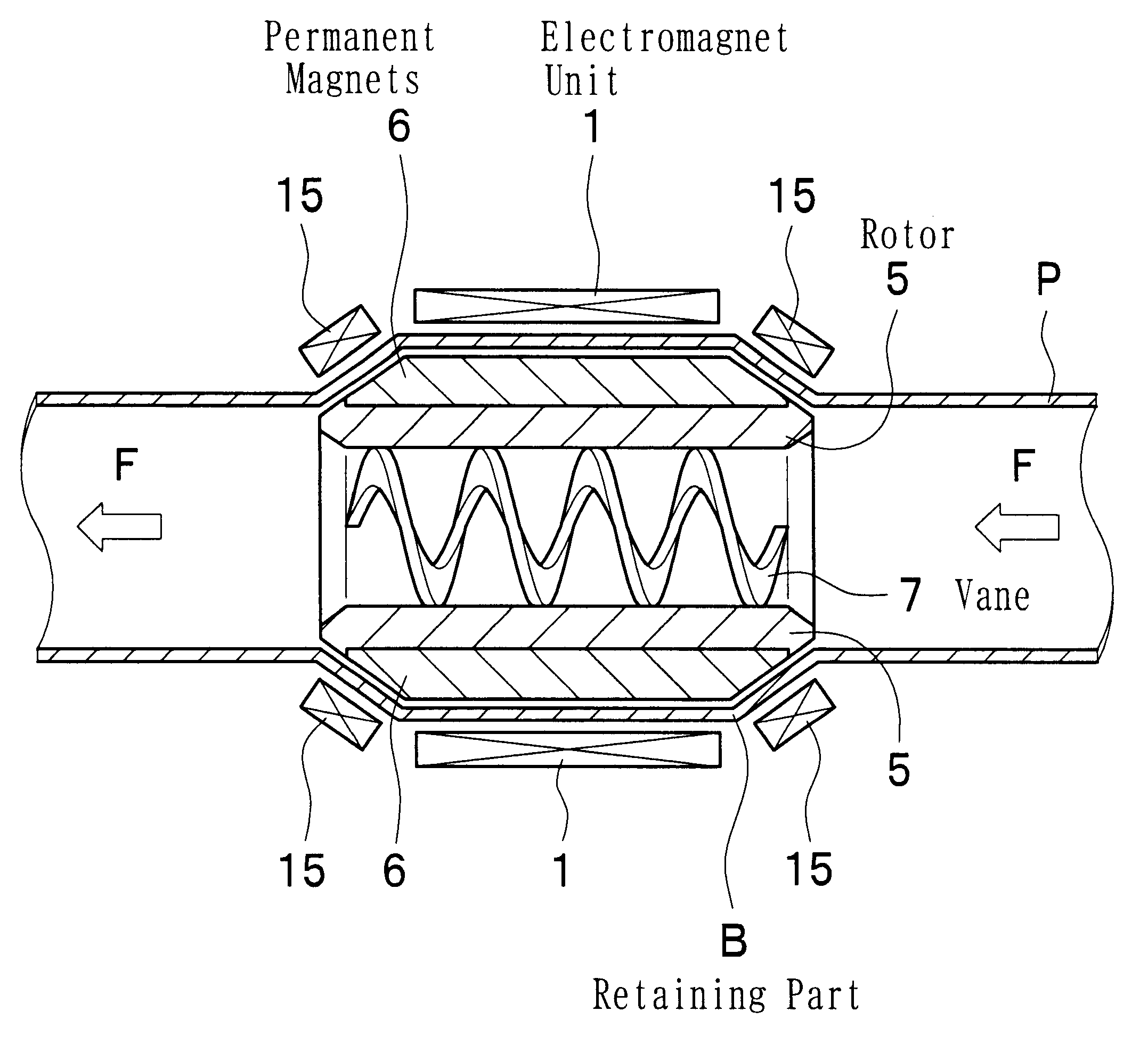

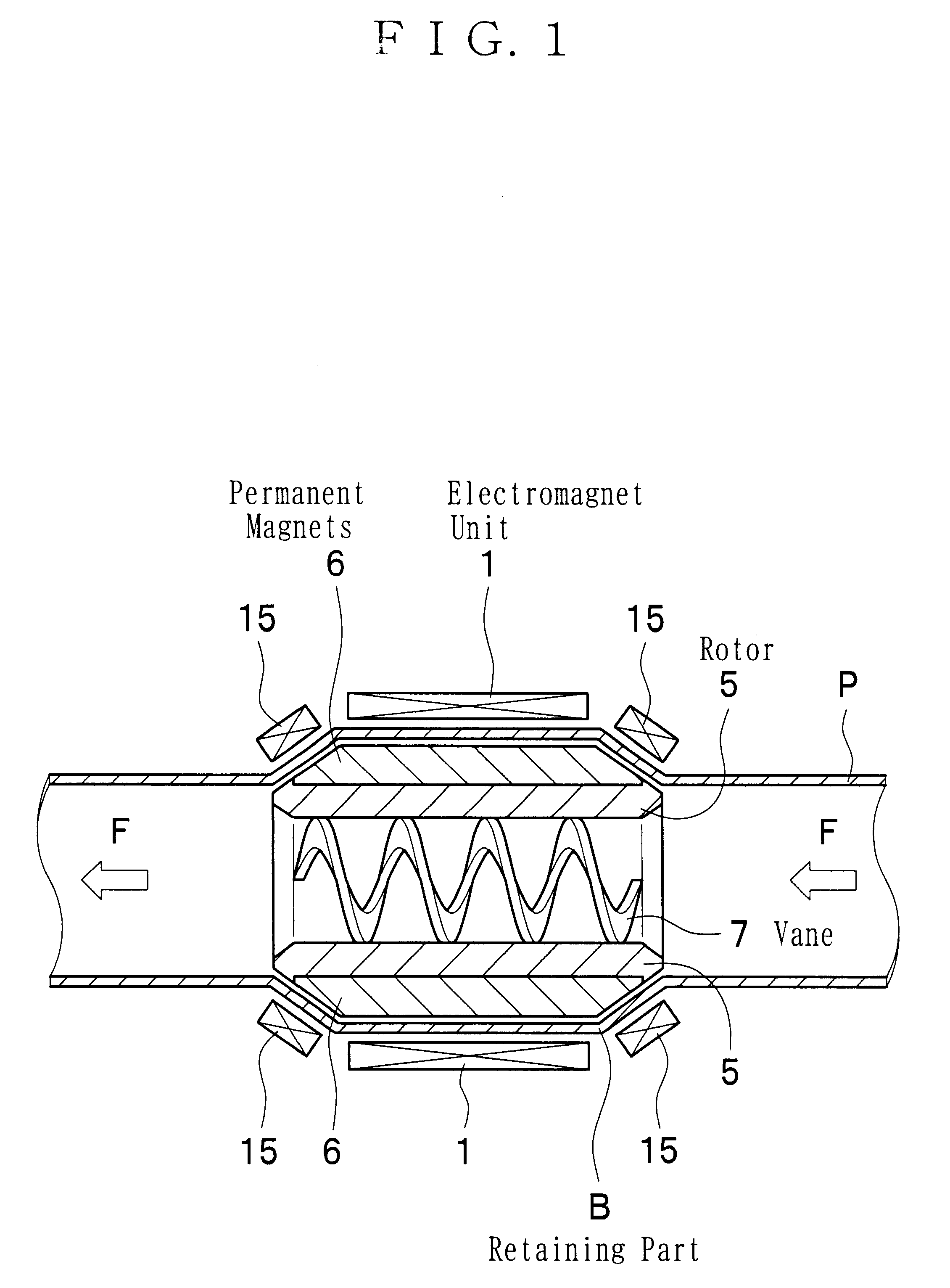

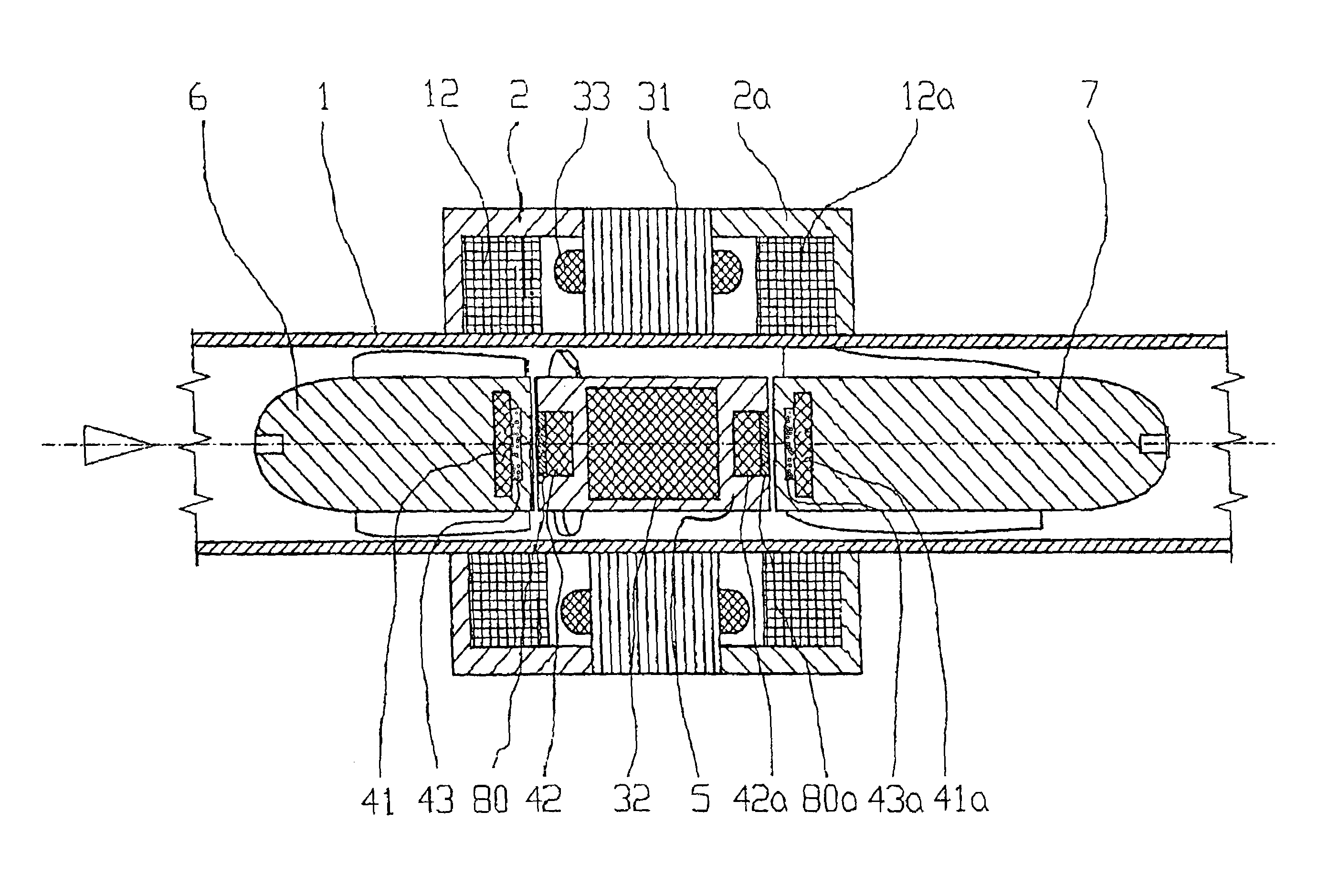

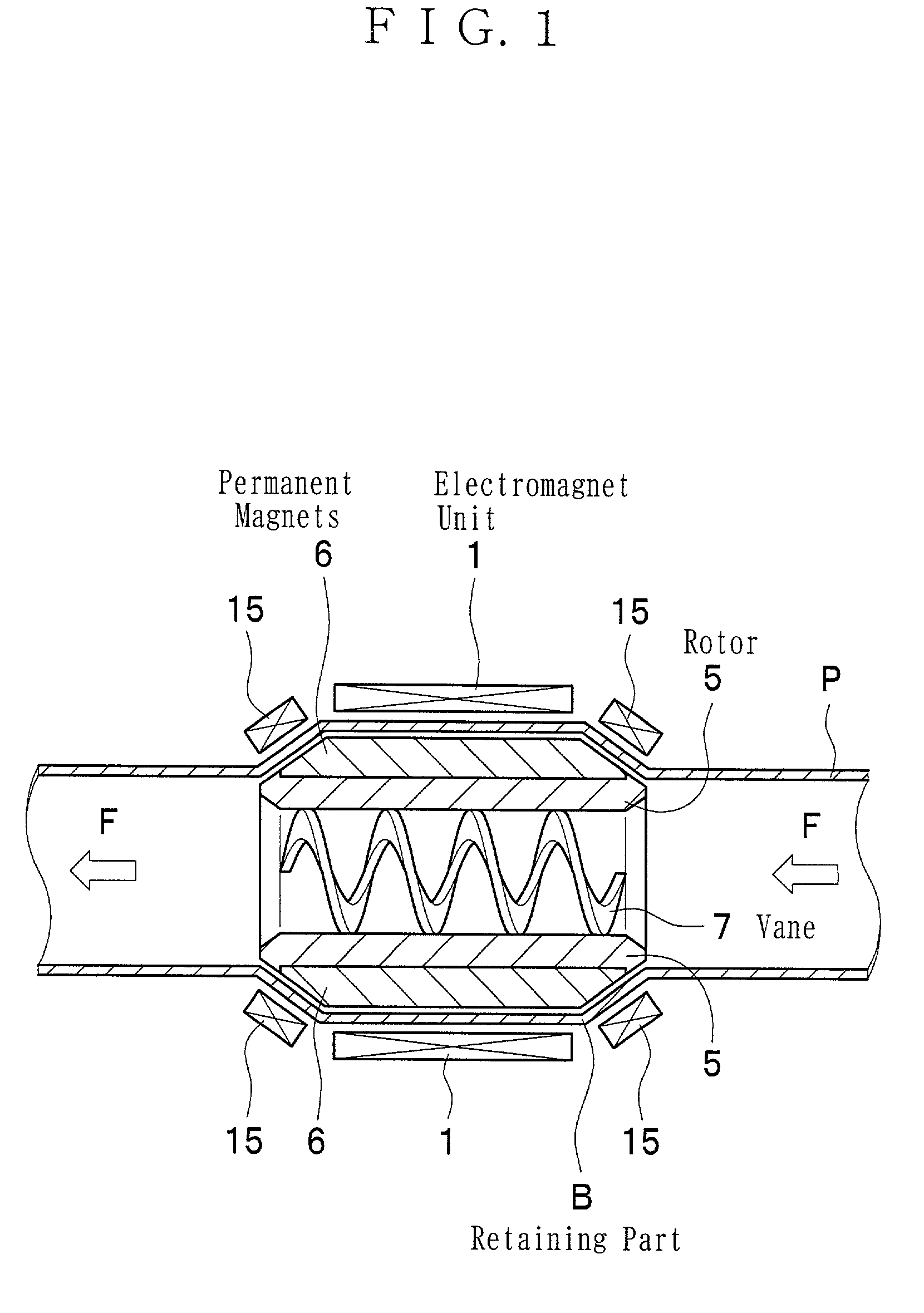

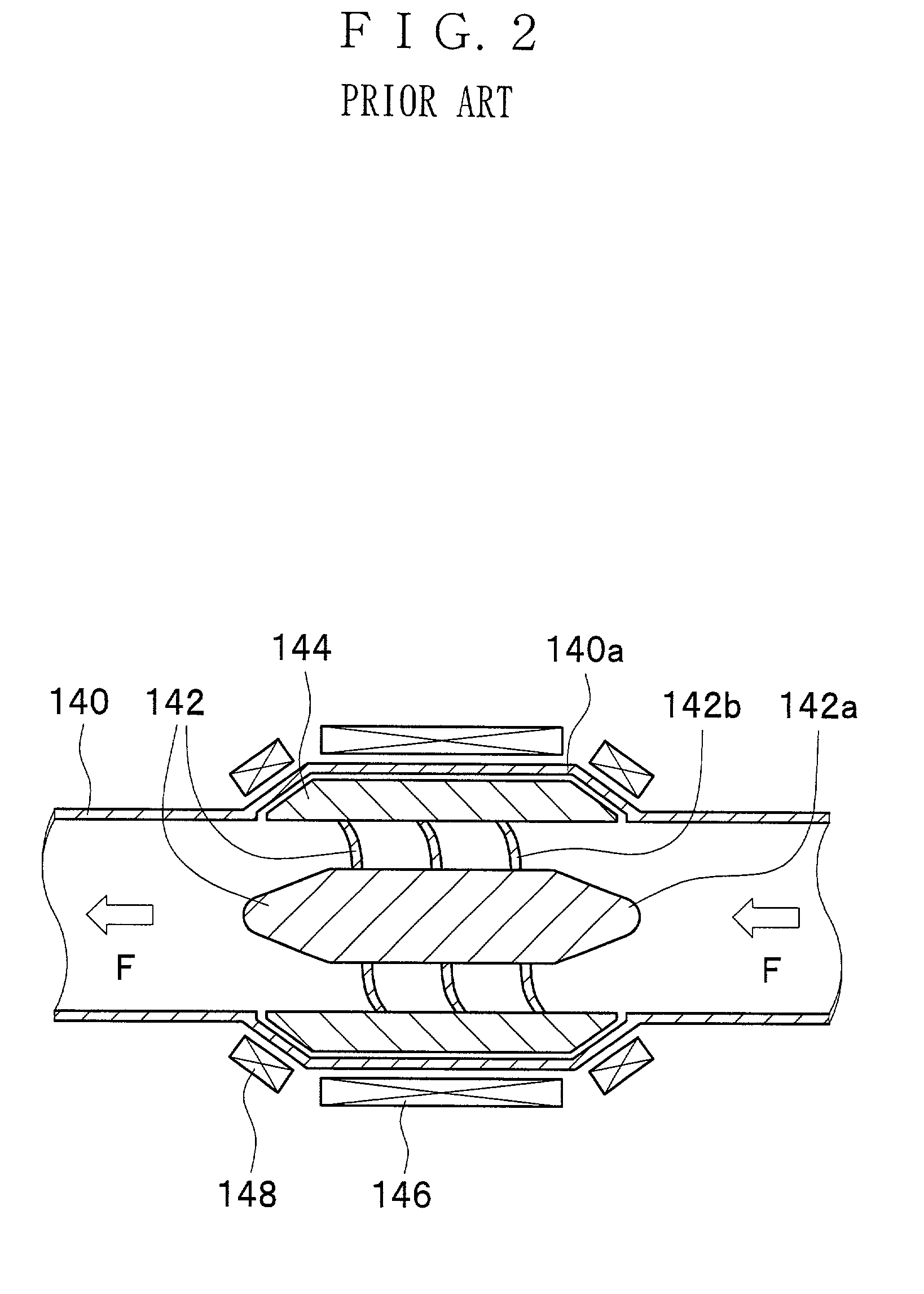

Magnetically driven axial-flow pump

A magnetically driven, axial flow pump comprises an electromagnetic unit arranged about the periphery of a pipe. A cylindrical rotor is accommodated within the pipe and is equipped with permanent magnets mounted on the periphery. A spiral, hollow vane is formed on an inner surface of the rotor by either casting or by cutting, such as with a NC machine, thus precluding the occurrence of gaps between the rotor and the vane. The lack of gaps within the pump makes the pump suitable for use as a blood pump.

Owner:NIPRO CORP

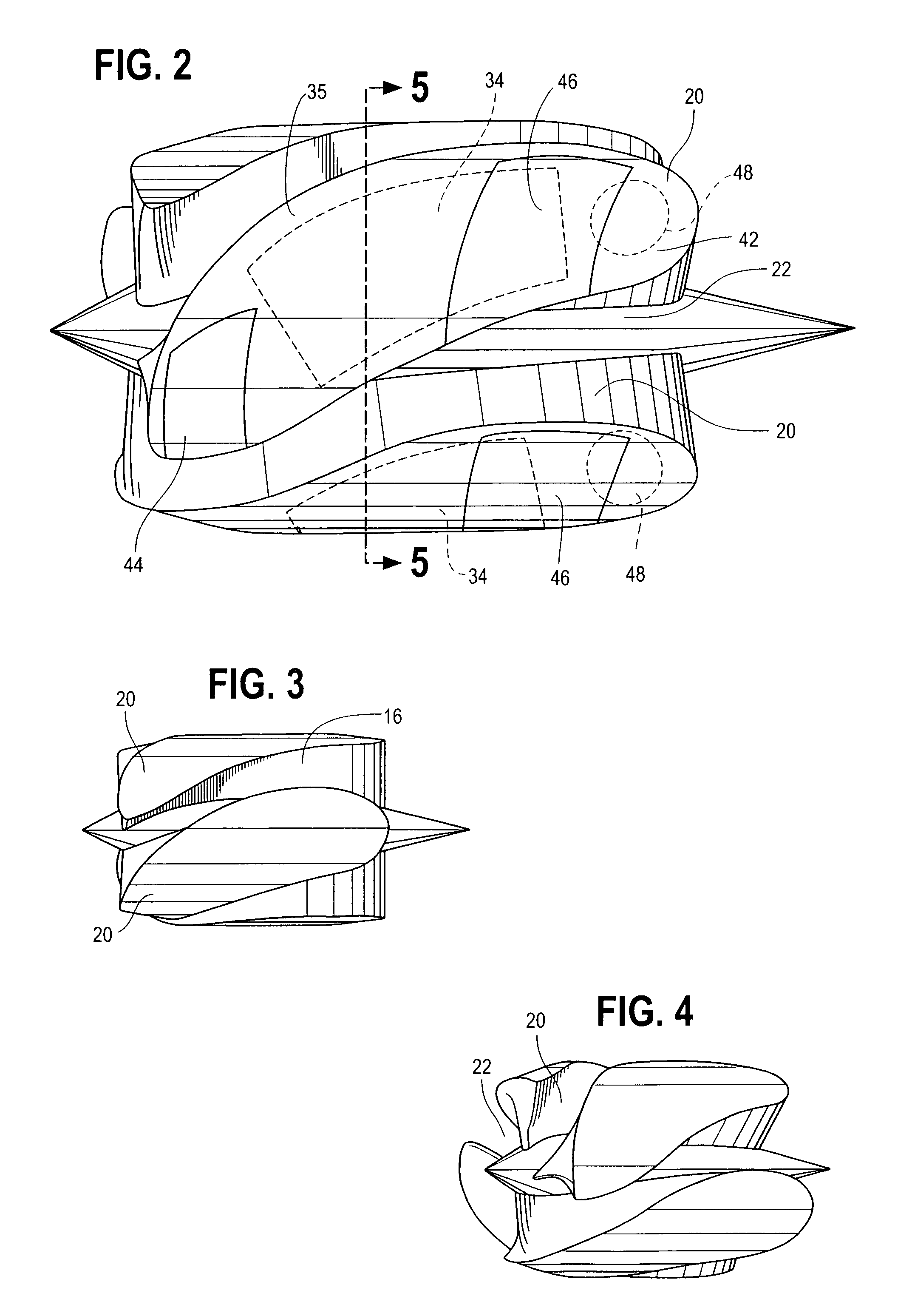

Expandable impeller pump

An impeller according to an example of the present invention comprises a hub, and at least one blade supported by the hub. The impeller has a deployed configuration in which the blade extends away from the hub, and a stored configuration in which the impeller is radially compressed, for example by folding the blade towards the hub. The impeller may comprise a plurality of blades, arranged in blade rows, to facilitate radial compression of the blades. The outer edge of a blade may have a winglet, and the base of the blade may have an associated indentation to facilitate folding of the blade.

Owner:PENN STATE RES FOUND +2

Fluid energy converter

Embodiments include apparatus and methods of fluid energy conversion. One embodiment relates to a tube for a fluid energy converter. The tube may include a generally cylindrical and hollow body having an interior surface, an exterior surface, and a longitudinal axis. Another embodiment includes a fluid energy converter having a longitudinal axis and a rotatable tube coaxial about the longitudinal axis. In some embodiments, the rotatable tube converts kinetic energy in a fluid into rotating mechanical energy, or converts rotating mechanical energy into kinetic energy in a fluid.

Owner:VIRYD TECH

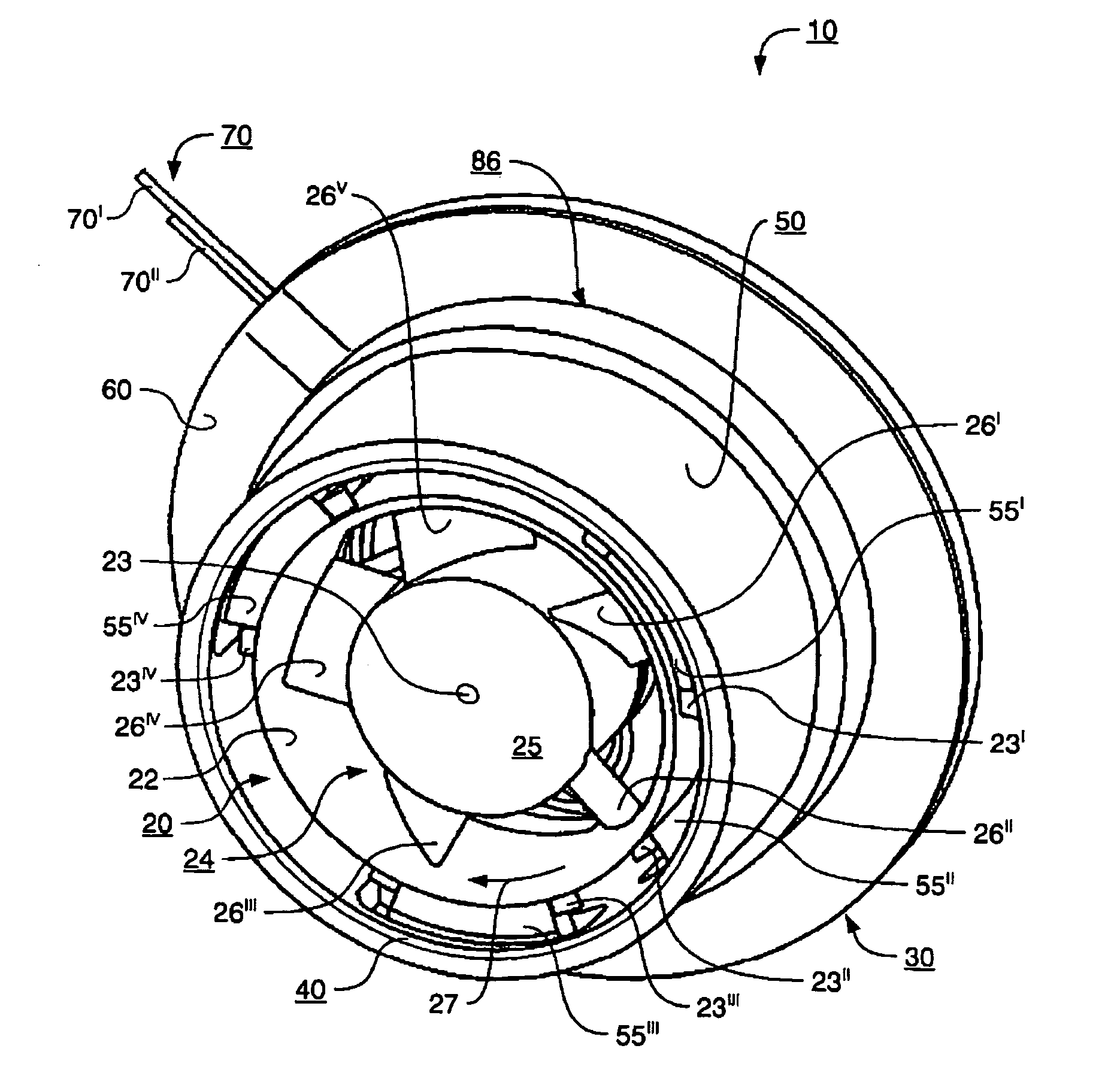

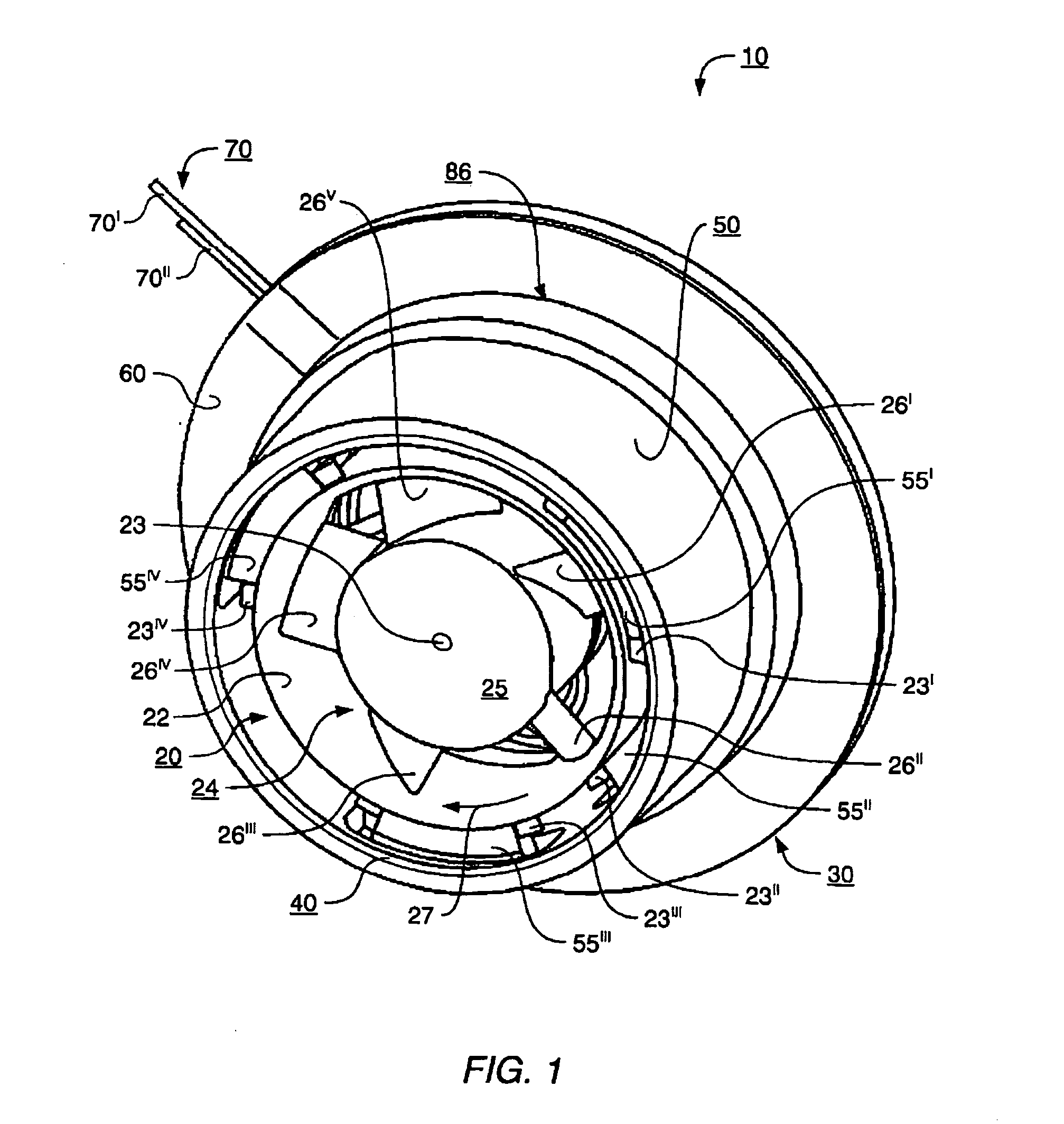

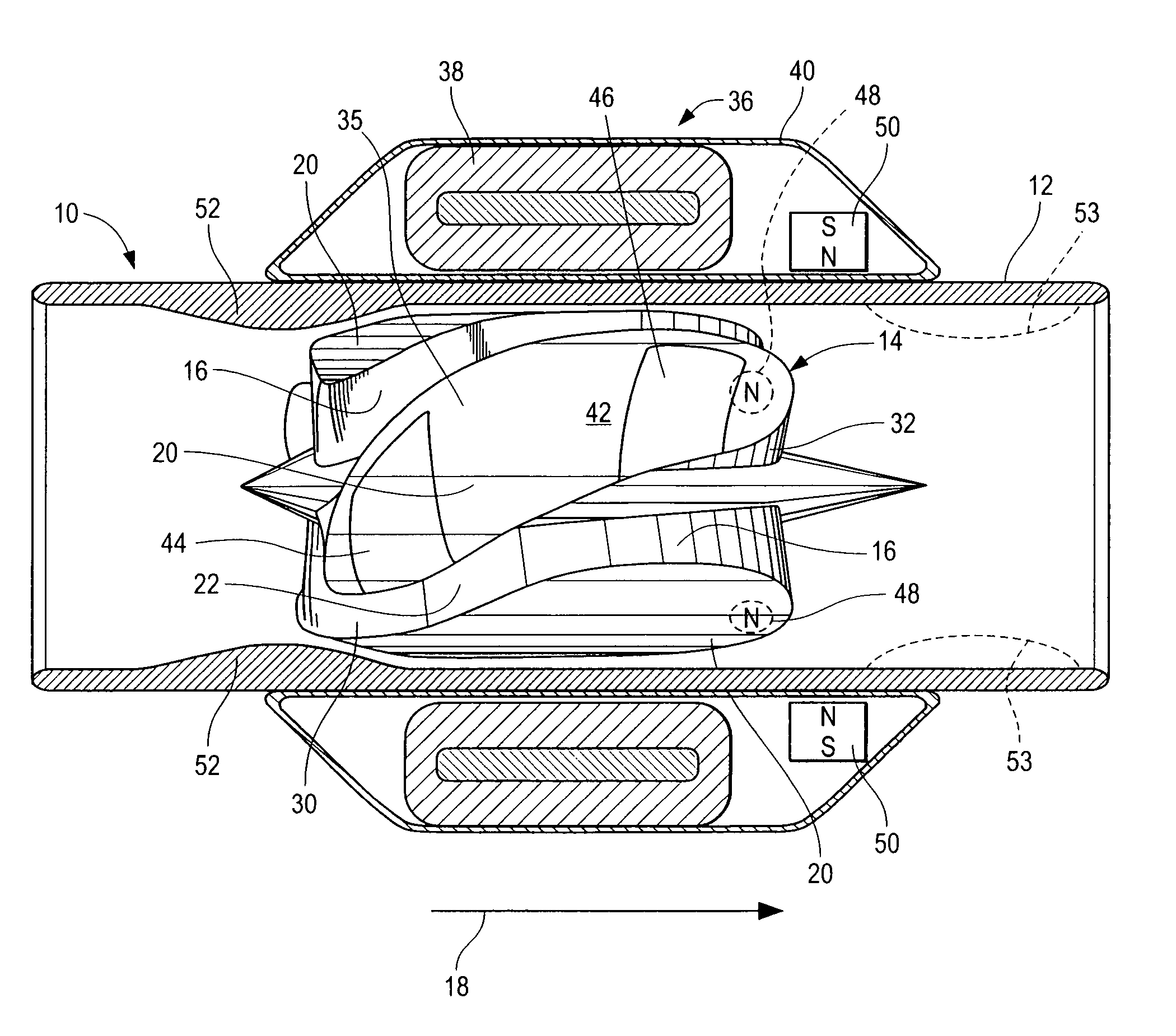

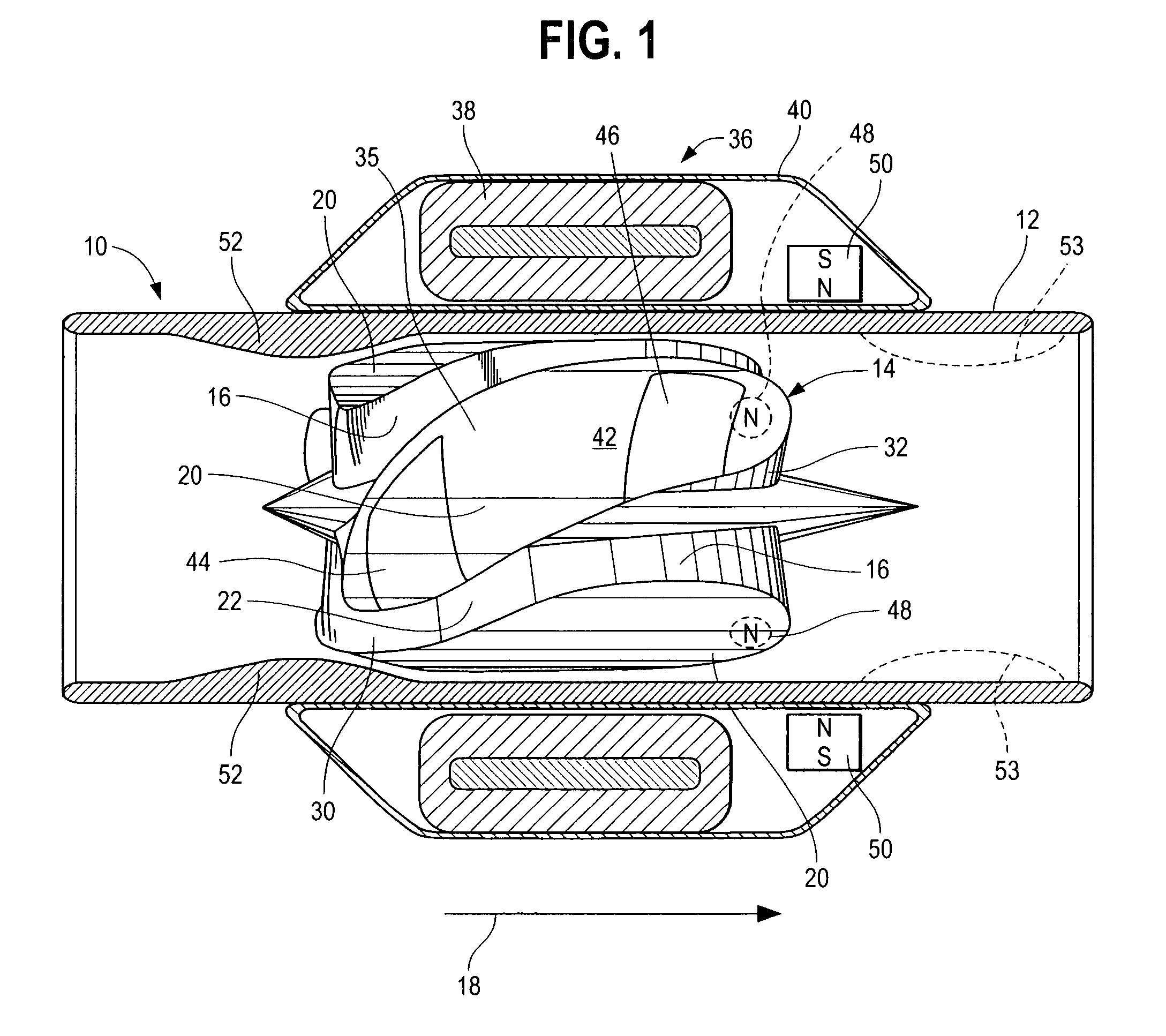

Expandable impeller pump

An impeller includes a hub, and a plurality of blades supported by the hub, the blades being arranged in at least two blade rows. The impeller has a deployed configuration in which the blades extend away from the hub, and a stored configuration in which at least one of the blades is radially compressed, for example by folding the blade towards the hub. The impeller may also have an operational configuration in which at least some of the blades are deformed from the deployed configuration upon rotation of the impeller when in the deployed configuration. The outer edge of one or more blades may have a winglet, and the base of the blades may have an associated indentation to facilitate folding of the blades.

Owner:TC1 LLC +2

Heart failure/hemodynamic device

Owner:HRIDAYA

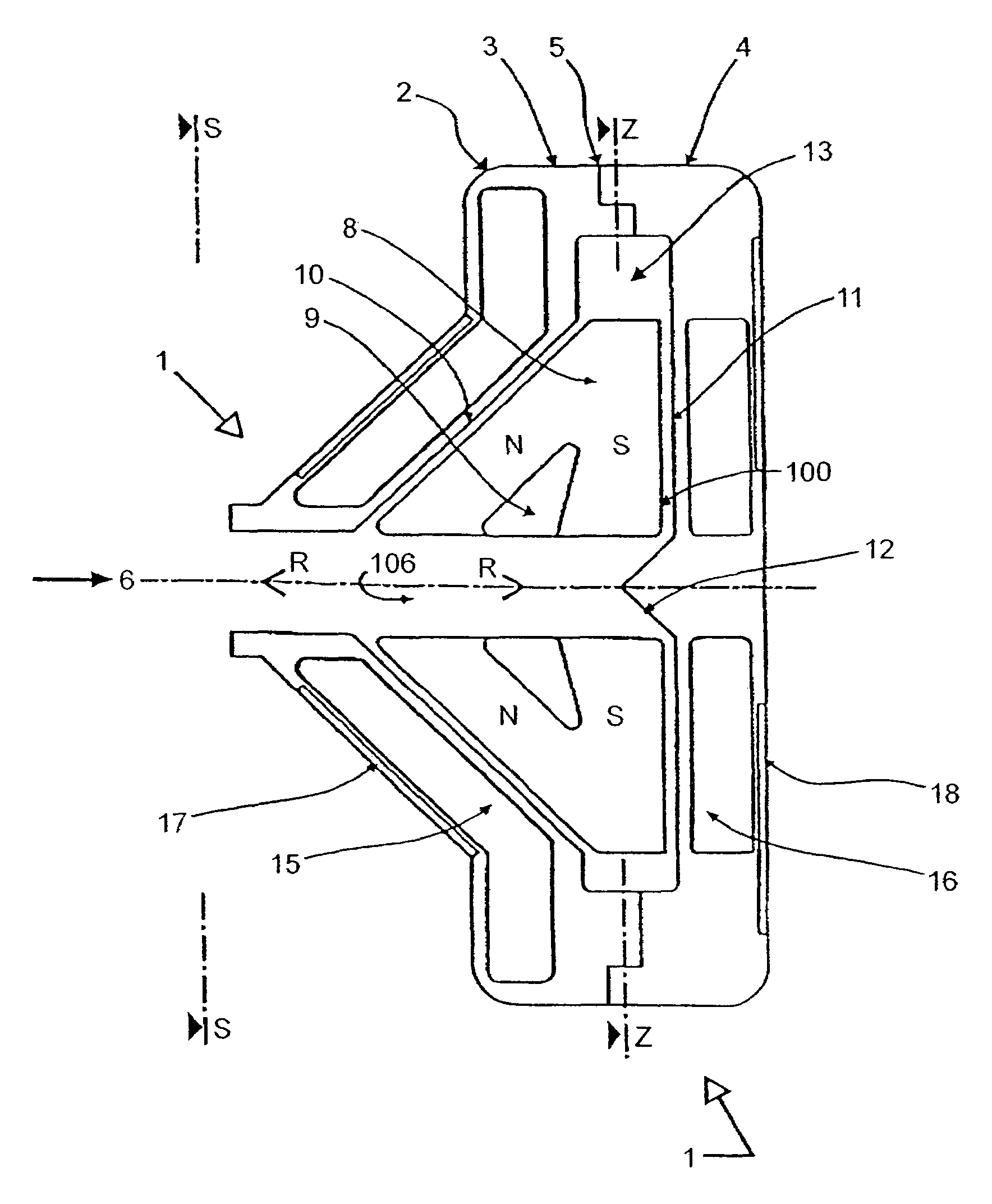

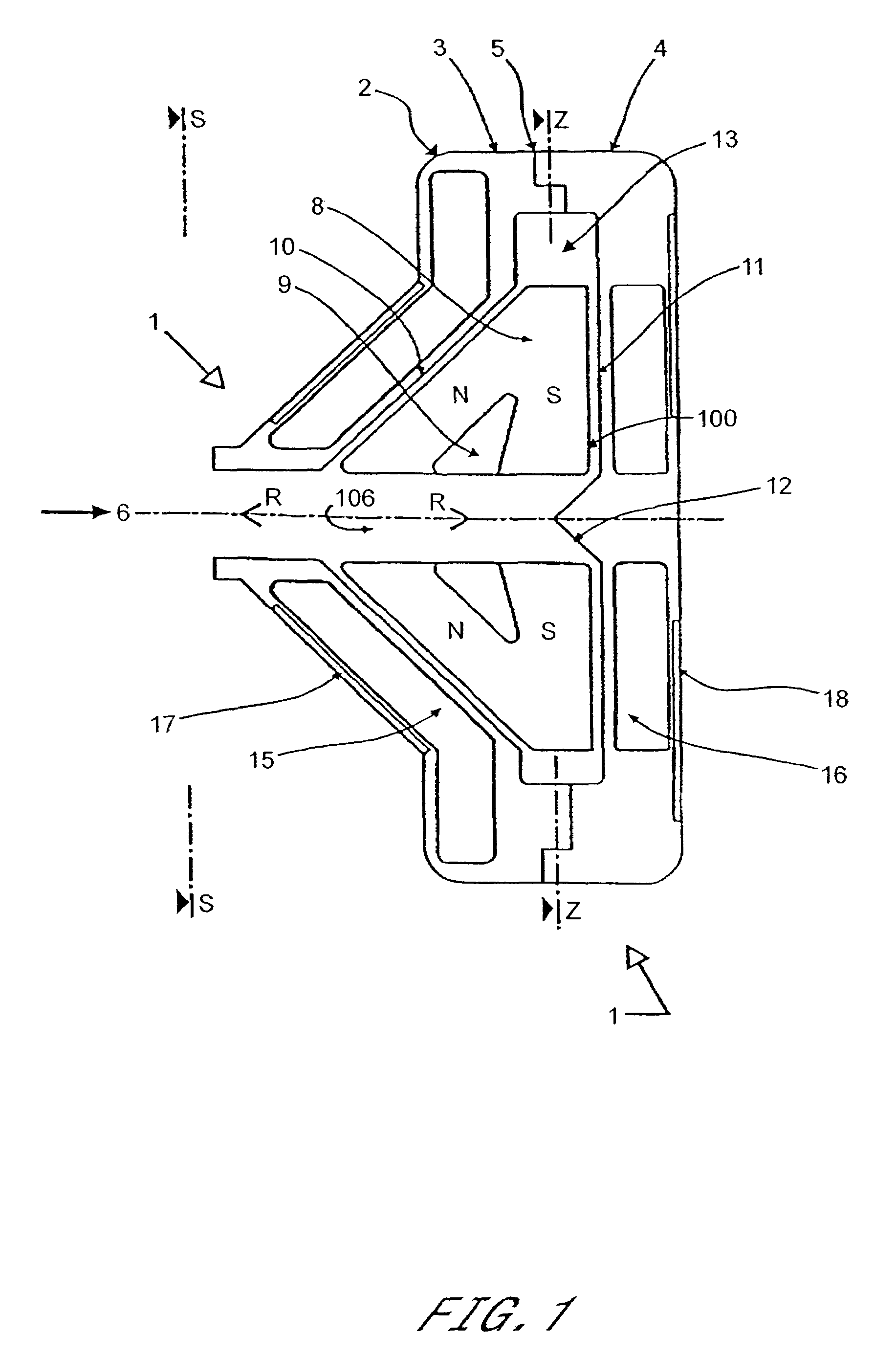

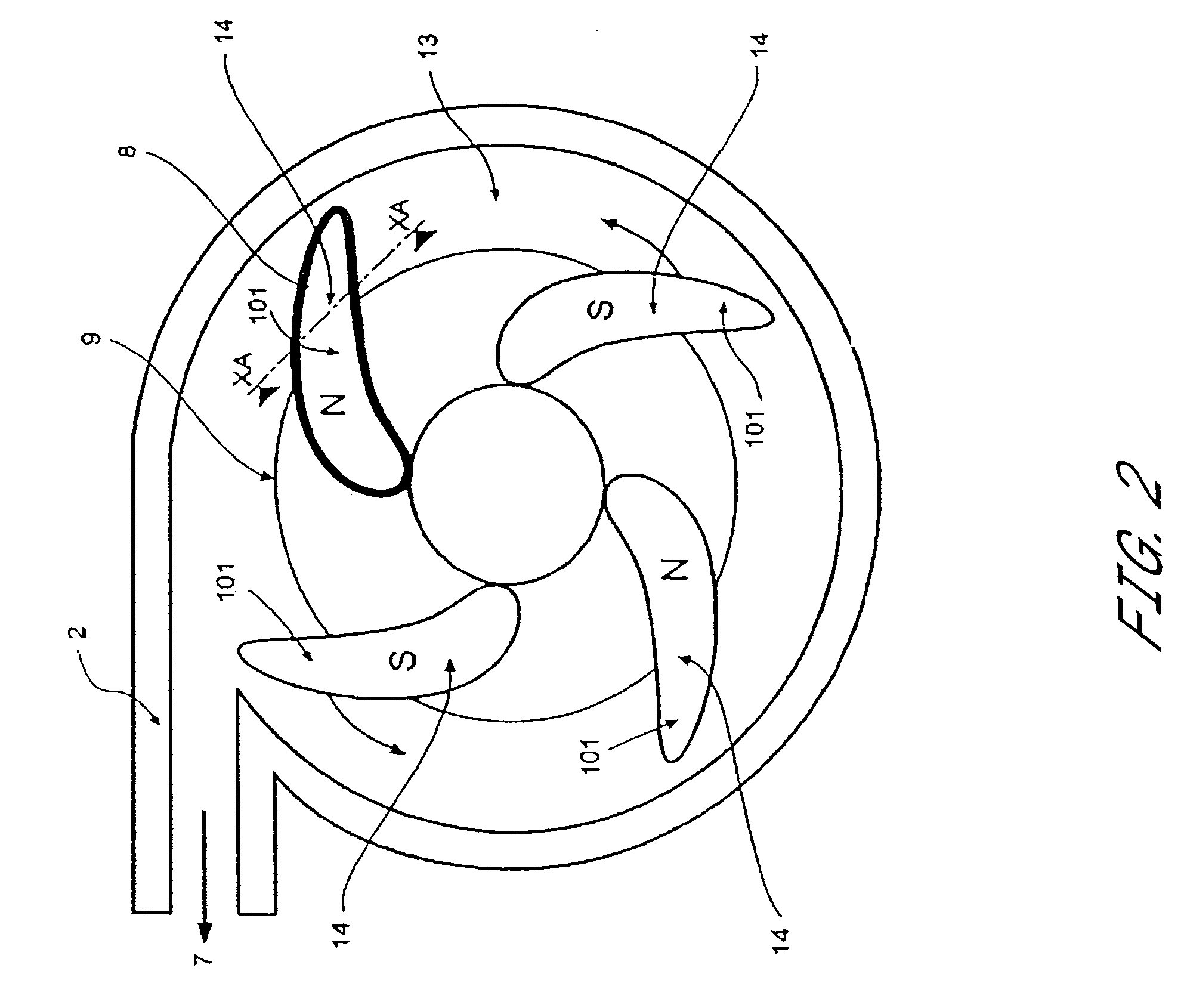

Rotary pump with exclusively hydrodynamically suspended impeller

A pump assembly 1, 33, 200 adapted for continuous flow pumping of blood. In a particular form the pump 1, 200 is a centrifugal pump wherein the impeller 100, 204 is entirely sealed within the pump housing 2, 201 and is exclusively hydrodynamically suspended therein as the impeller rotates within the fluid 105 urged by electromagnetic means external to the pump cavity 106, 203. Hydrodynamic suspension is assisted by the impeller 100, 204 having deformities therein such as blades 8 with surfaces tapered from the leading edges 102, 223 to the trailing edges 103, 224 of bottom and top edges 221, 222 thereof.

Owner:TC1 LLC +2

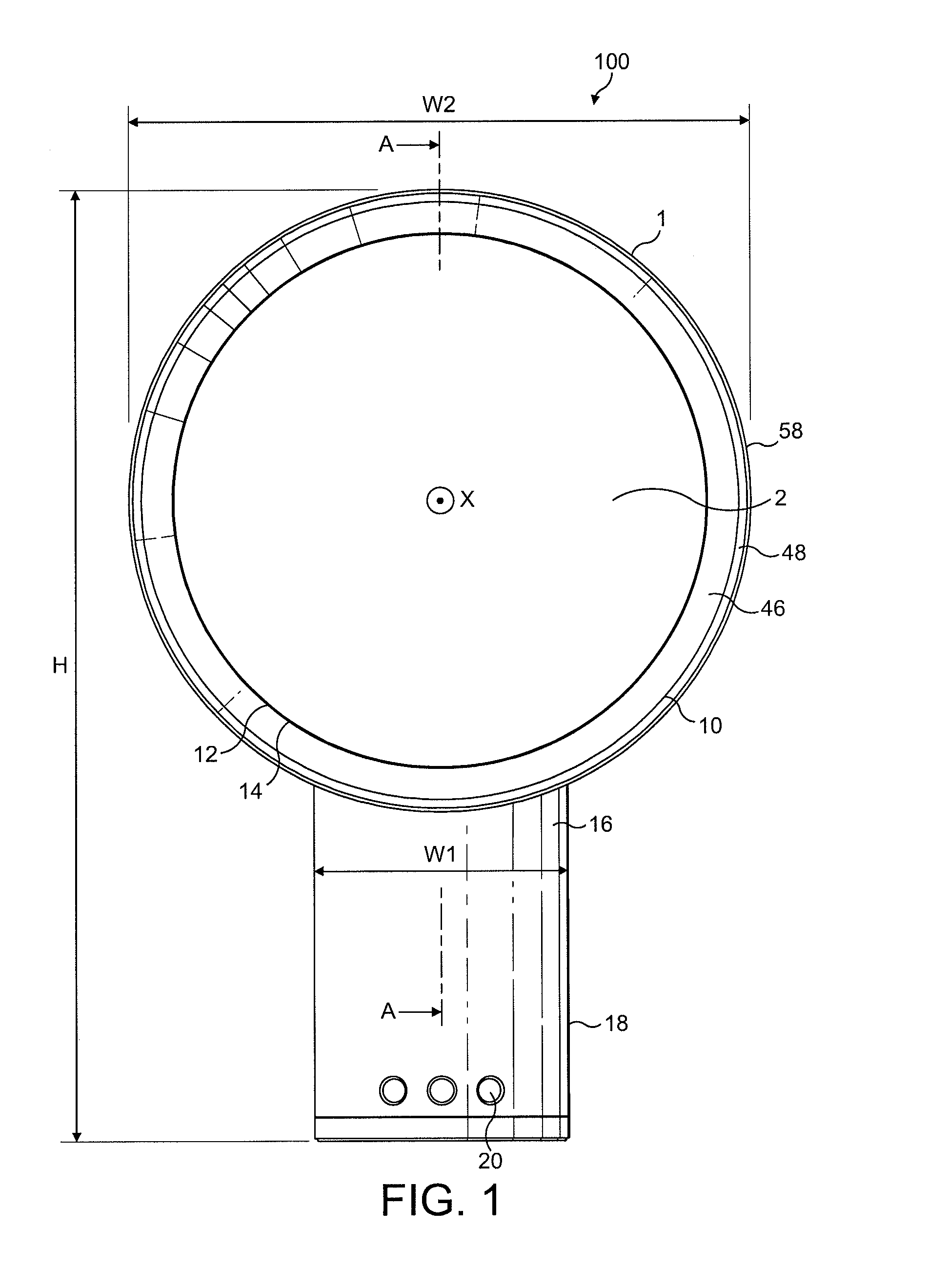

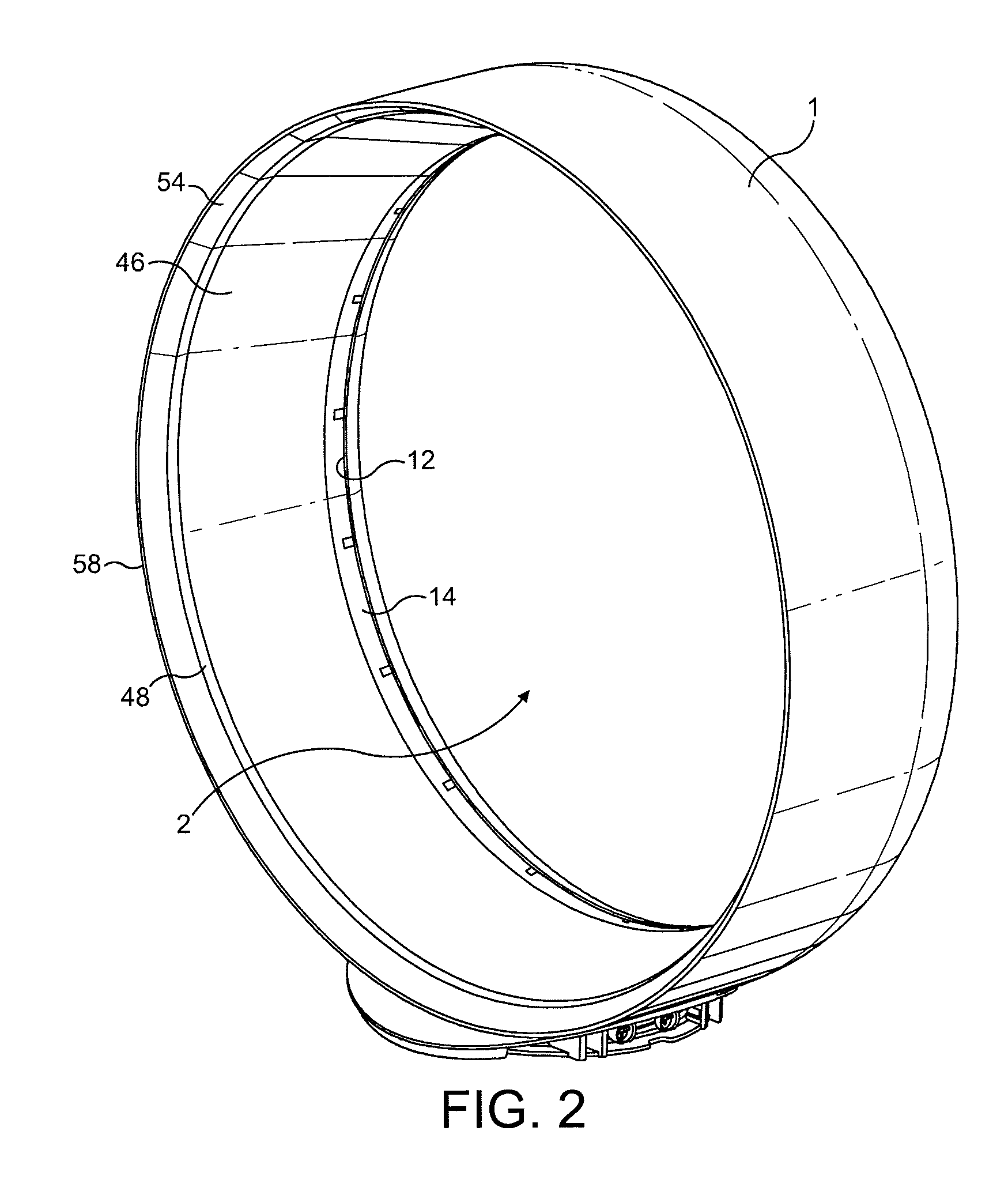

Fan

A fan assembly for creating an air current is described. The fan assembly includes a nozzle mounted on a base housing a device for creating an air flow through the nozzle. The nozzle includes an interior passage for receiving the air flow from the base, a mouth through which the air flow is emitted, the mouth being defined by facing surfaces of the nozzle, and spacers for spacing apart the facing surfaces of the nozzle. The nozzle extends substantially orthogonally about an axis to define an opening through which air from outside the fan assembly is drawn by the air flow emitted from the mouth. The fan provides an arrangement producing an air current and a flow of cooling air created without requiring a bladed fan. The spacers can provide for a reliable, reproducible nozzle of the fan assembly and performance of the fan assembly.

Owner:UNIVERSAL SAFETY RESPONSE INC +1

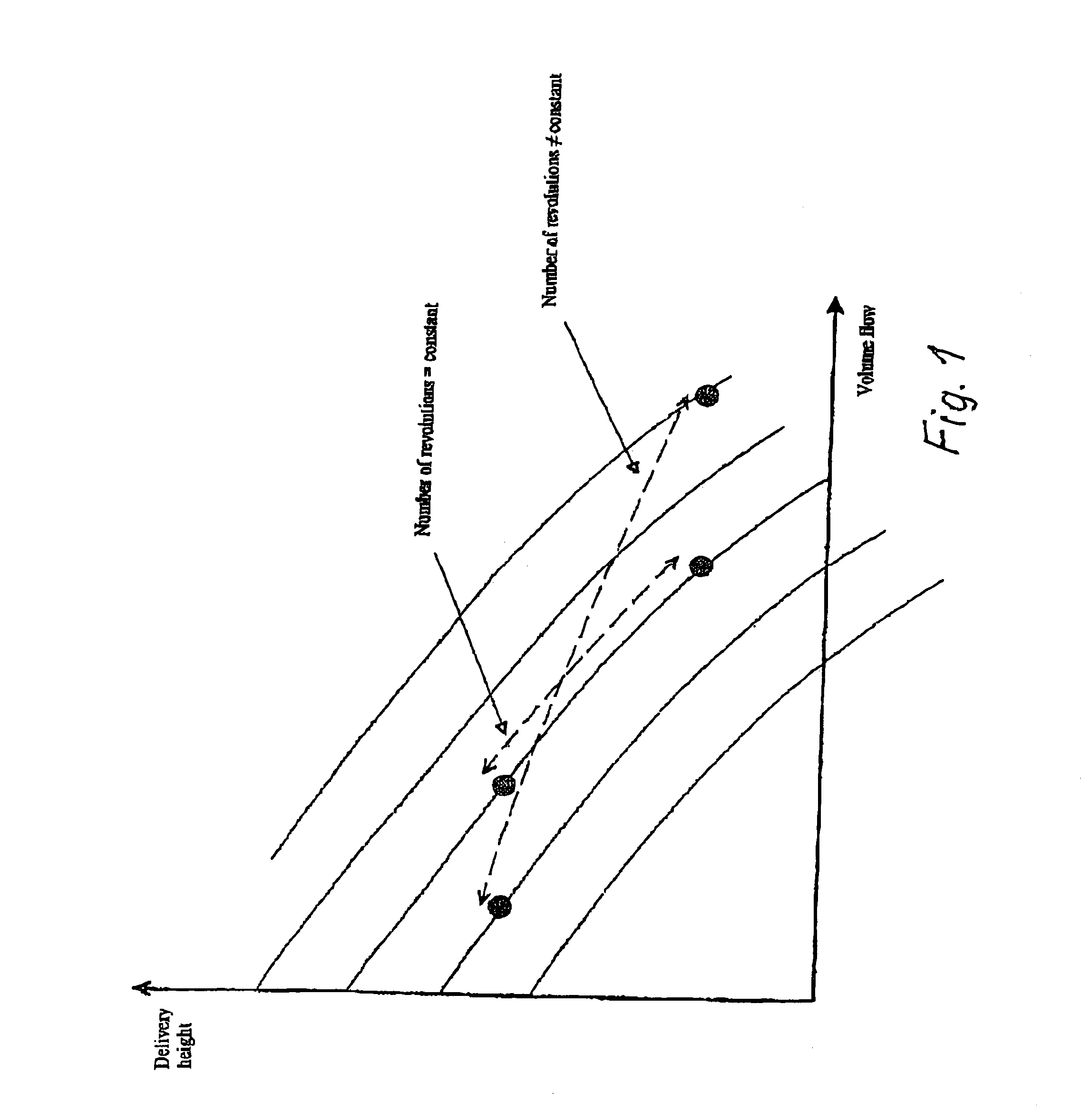

Method for controlling an assist pump for fluid delivery systems with pulsatile pressure

Method for controlling an assist pump for fluid delivery systems with pulsatile pressure. If for example a heart assist pump is driven with a constant number of revolutions, it is achieved, that the blood is also delivered through the assist pump, even when the heart chamber is in the decontraction phase. With the present method it is achieved, that an assist pump only acts supportingly in the pressure phase of the main pump, in such a way, that the pressure difference between the input side and the output side of the assist pump is continuously determined and the number of revolutions of the assist pump is controlled in such a way, that the determined pressure difference does not fall below a predetermined value and the rate of flow does not sink below zero.

Owner:BERLIN HEART GMBH

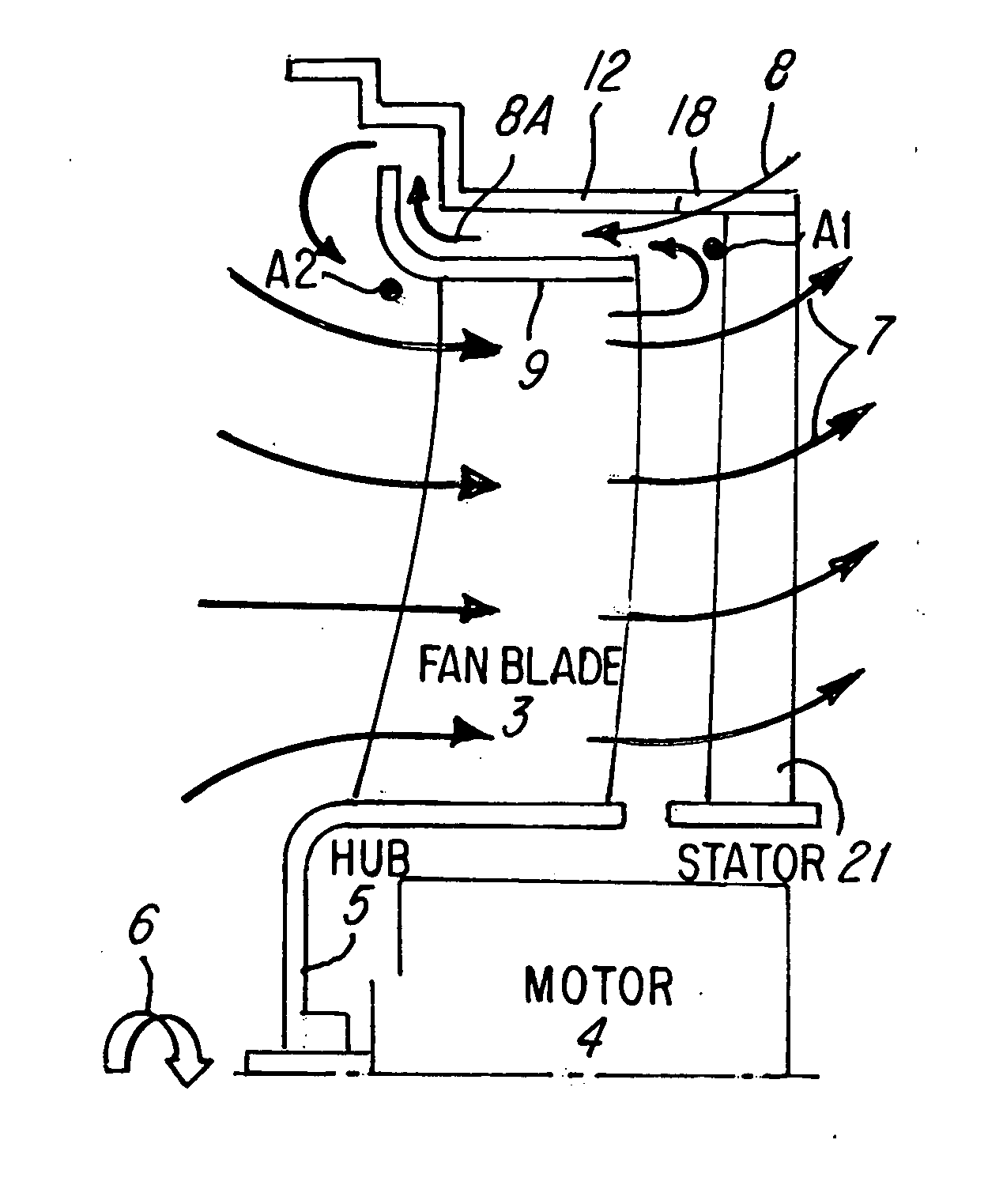

Fan unit having an axial fan with improved noise damping

ActiveUS20090191054A1Good noise cancelingCompact configurationPump componentsNon-rotating vibration suppressionMobile vehicleEngineering

Due to variations arising during manufacturing, axial fans often are slightly imbalanced, resulting in noise during operation, which is undesirable in many contexts, for example when the fan is used for ventilation purposes in a motor vehicle. A fan with improved vibration and noise damping can be achieved by elastically suspending the fan wheel within a first ring formed of a hard plastic, the first ring having a tubular extension formed of a softer plastic, and serving to mechanically connect the first ring to a surrounding annular carrier part. Optionally, the first ring and extension unit can include a spring element. Preferably, the first ring and tubular extension are produced by a multi-component forming technology such as two-plastic technology. The fan is preferably driven by an electronically commutated motor (ECM).

Owner:EBM PAPST ST GEORGEN & -

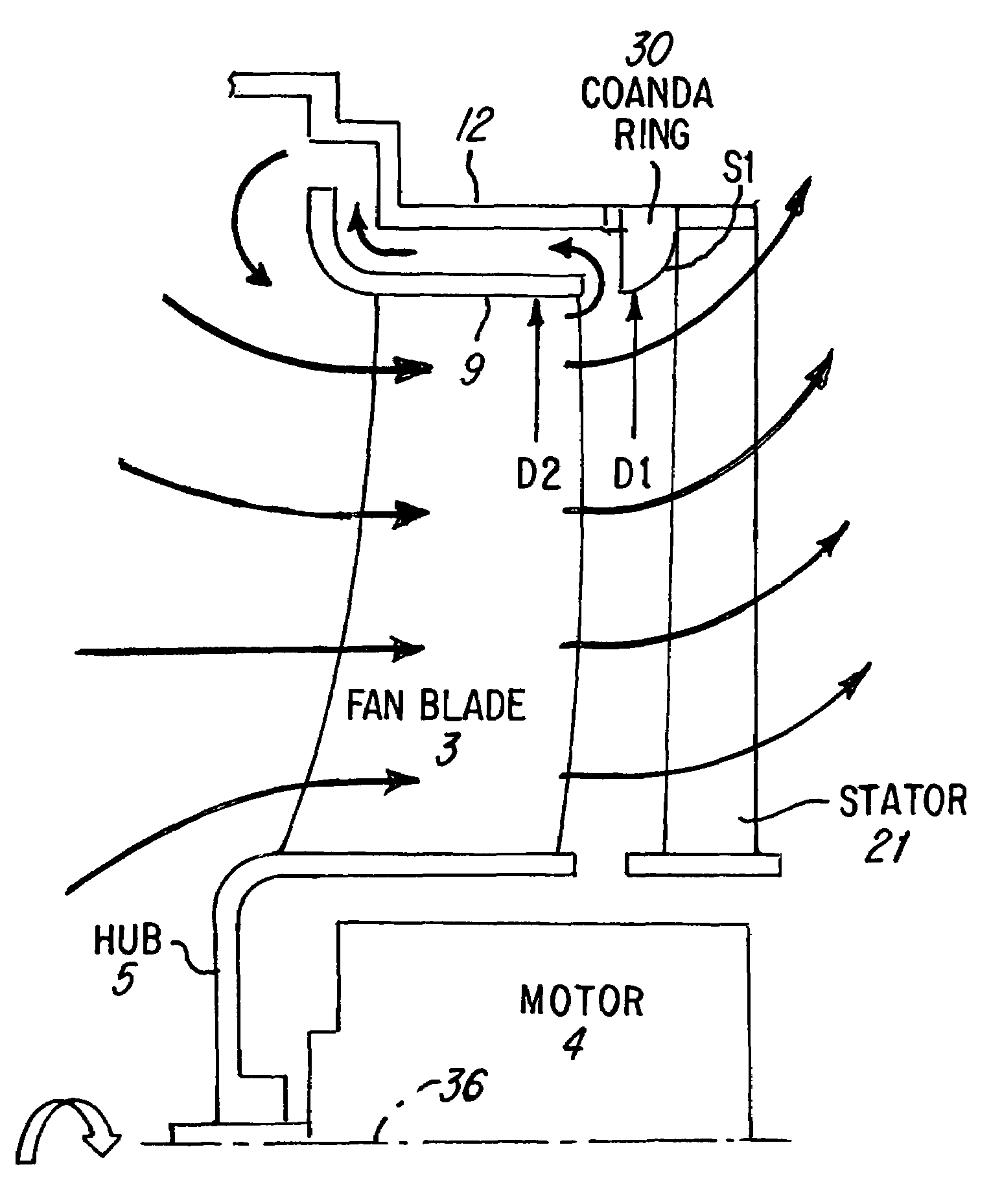

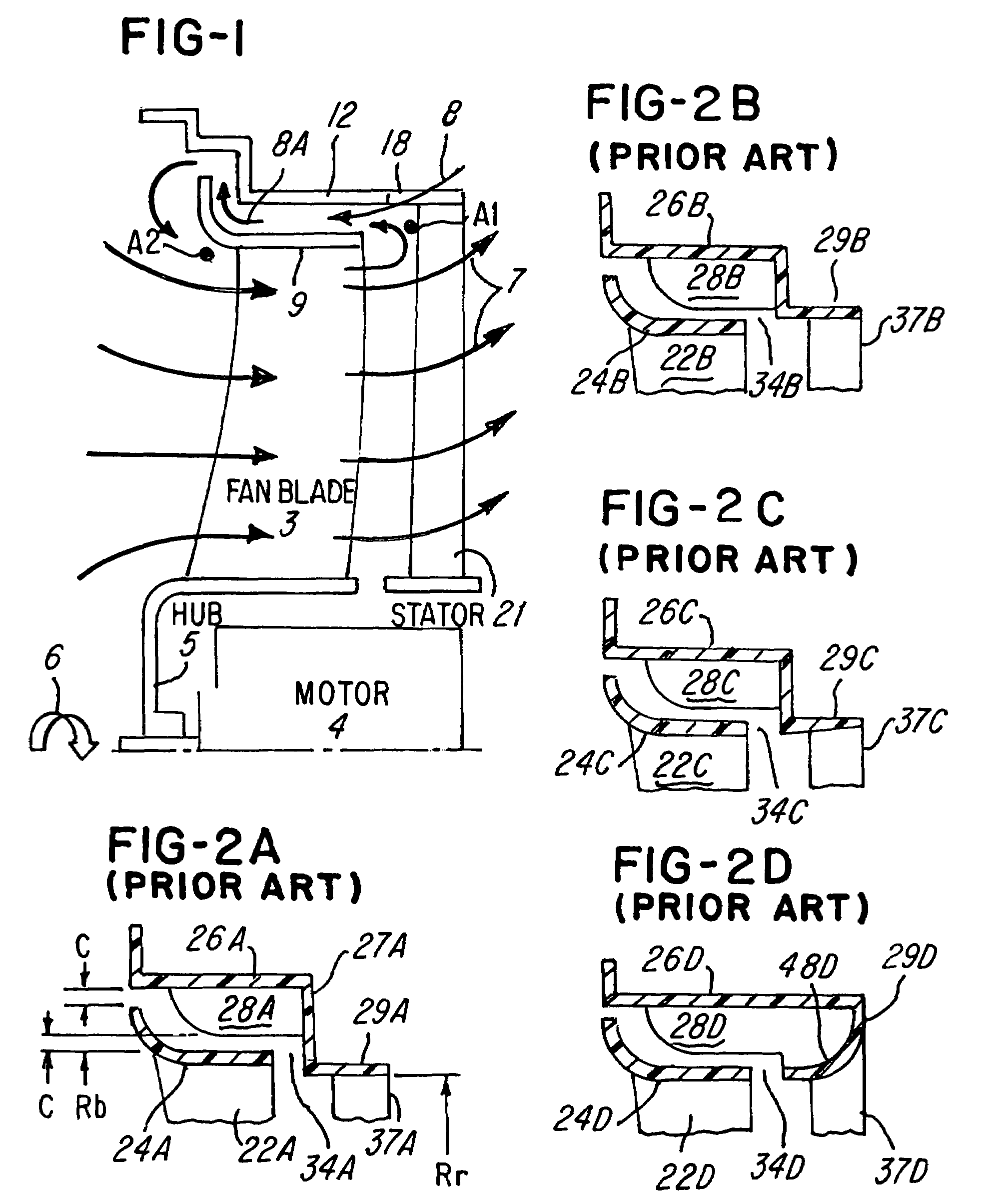

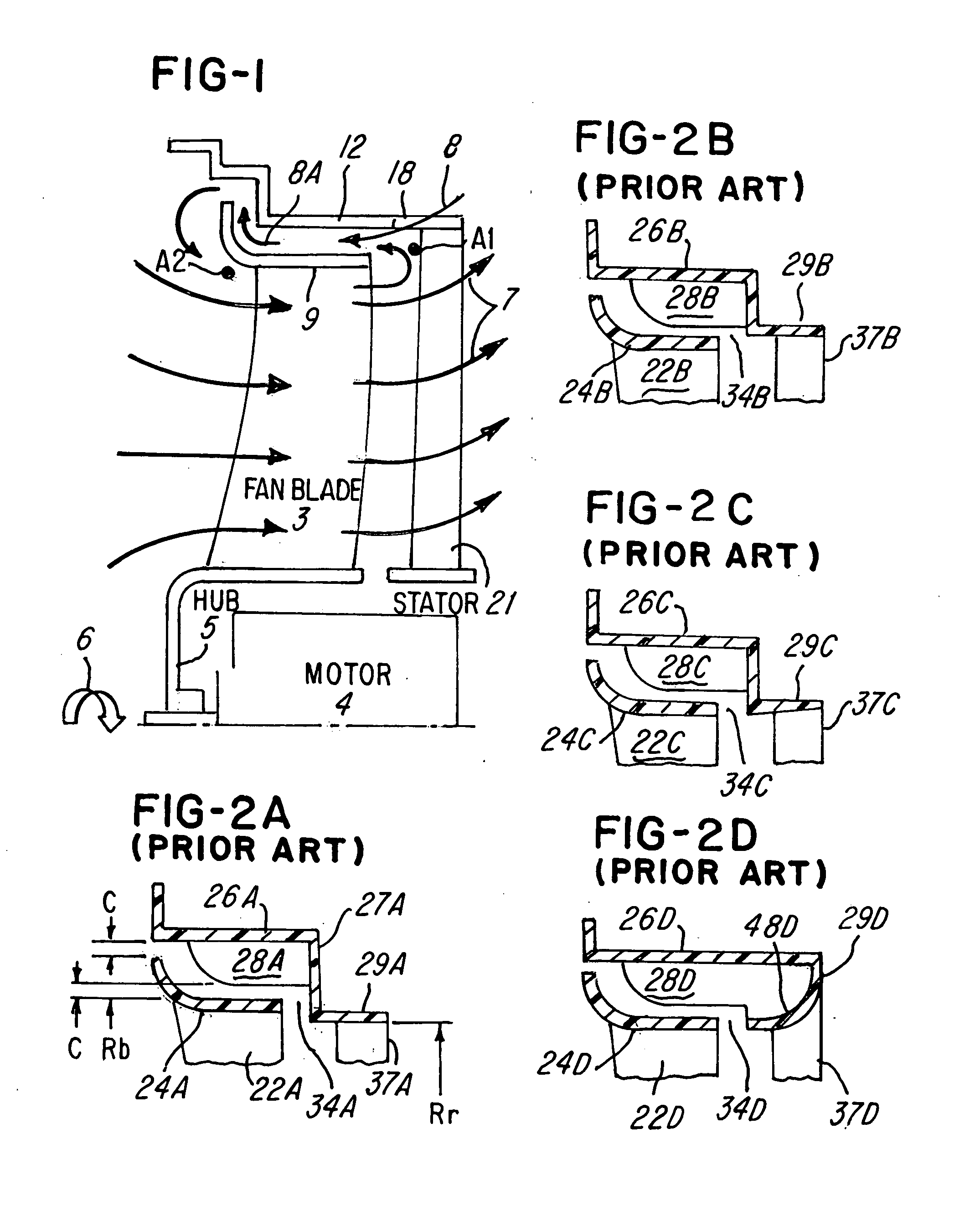

Cooling fan using Coanda effect to reduce recirculation

ActiveUS7478993B2Trend downIncrease the cross-sectional areaPump componentsReaction enginesEngineeringFan blade

Owner:VALEO INC

Catheter device

ActiveUS8439859B2Maximum pump performanceImprove performanceStarters with fluid-driven auxillary enginesHeart stimulatorsDrive shaftCatheter device

The catheter device comprises a drive shaft connected to a motor, and a rotor mounted on the drive shaft at the distal end section. The rotor has a frame structure which is formed by a screw-like boundary frame and rotor struts extending radially inwards from the boundary frame. The rotor struts are fastened to the drive shaft by their ends opposite the boundary frame. Between the boundary frame and the drive shaft extends an elastic covering. The frame structure is made of an elastic material such that, after forced compression, the rotor unfolds automatically.

Owner:AIS AACHEN INNOVATIVE SOLUTIONS

Fan blade modifications

Owner:DELTA T

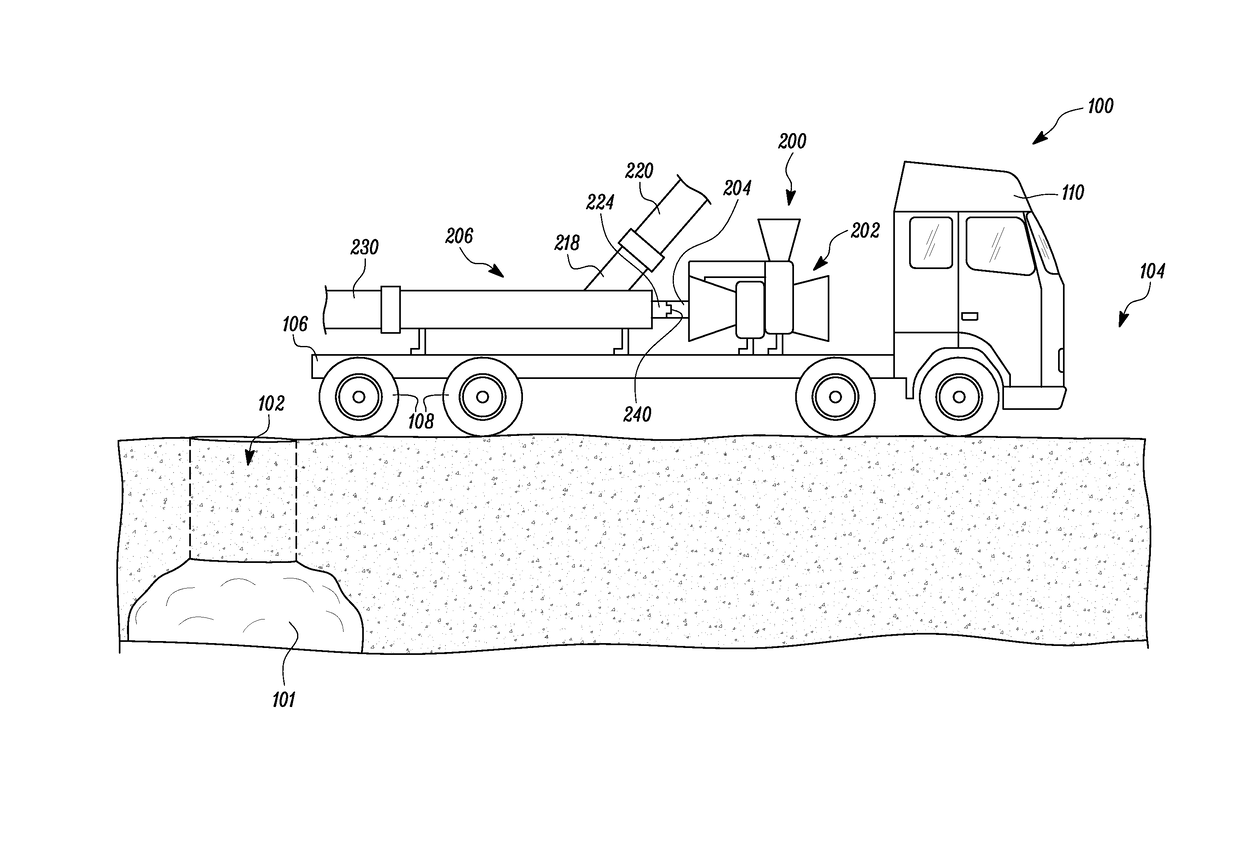

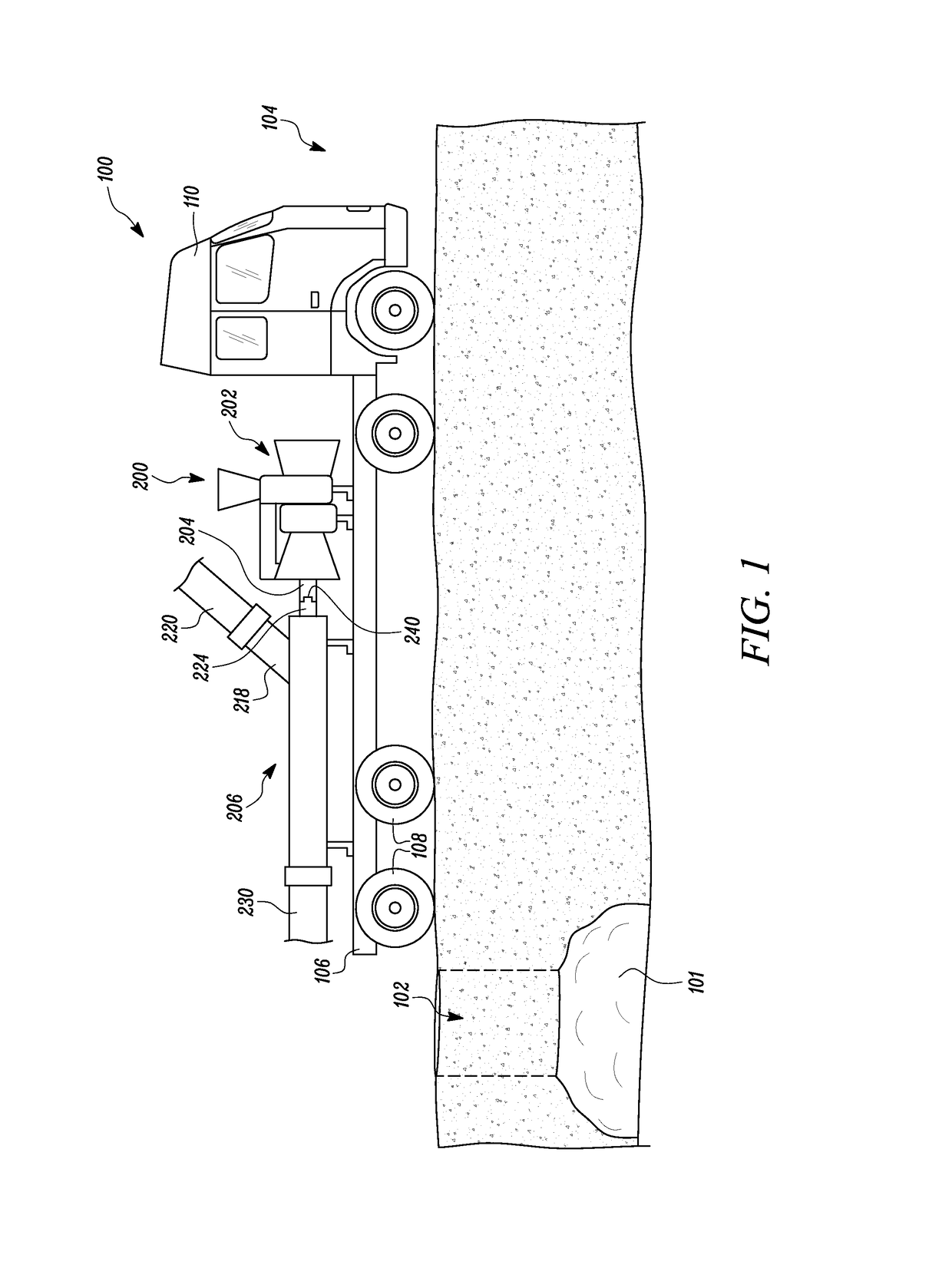

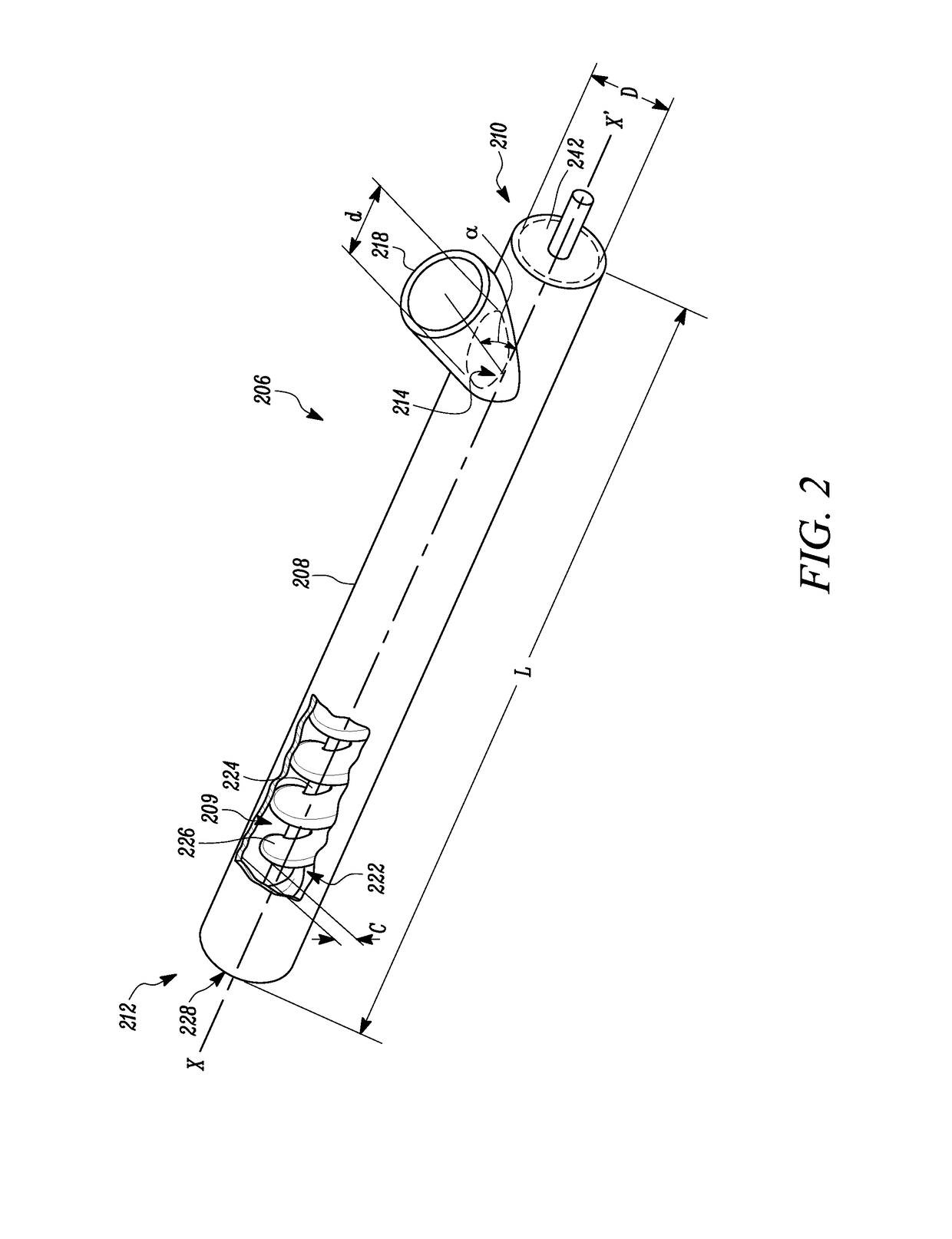

System and method for fracturing formations in bores

A system for fracturing a formation in a bore at a worksite is disclosed. The system includes a turbine. The system also includes a pump coupled to the turbine. The pump includes a housing member that is adapted to receive a fracturing fluid. The pump also includes an auger rotatably disposed within the housing member. The auger pressurizes the fracturing fluid at a desired pressure based on a speed of the turbine to supply a pressurized fracturing fluid to the bore. The auger includes a shaft coupled to the turbine and rotatable about a rotational axis. The auger also includes a helical blade disposed around the shaft.

Owner:CATERPILLAR INC

Fluid pump/generator with integrated motor and related stator and rotor and method of pumping fluid

InactiveUS7021905B2Small sizeReduce the number of partsGas turbine plantsRotary piston pumpsImpellerElectric machine

Owner:ADVANCED ENERGY CONVERSION

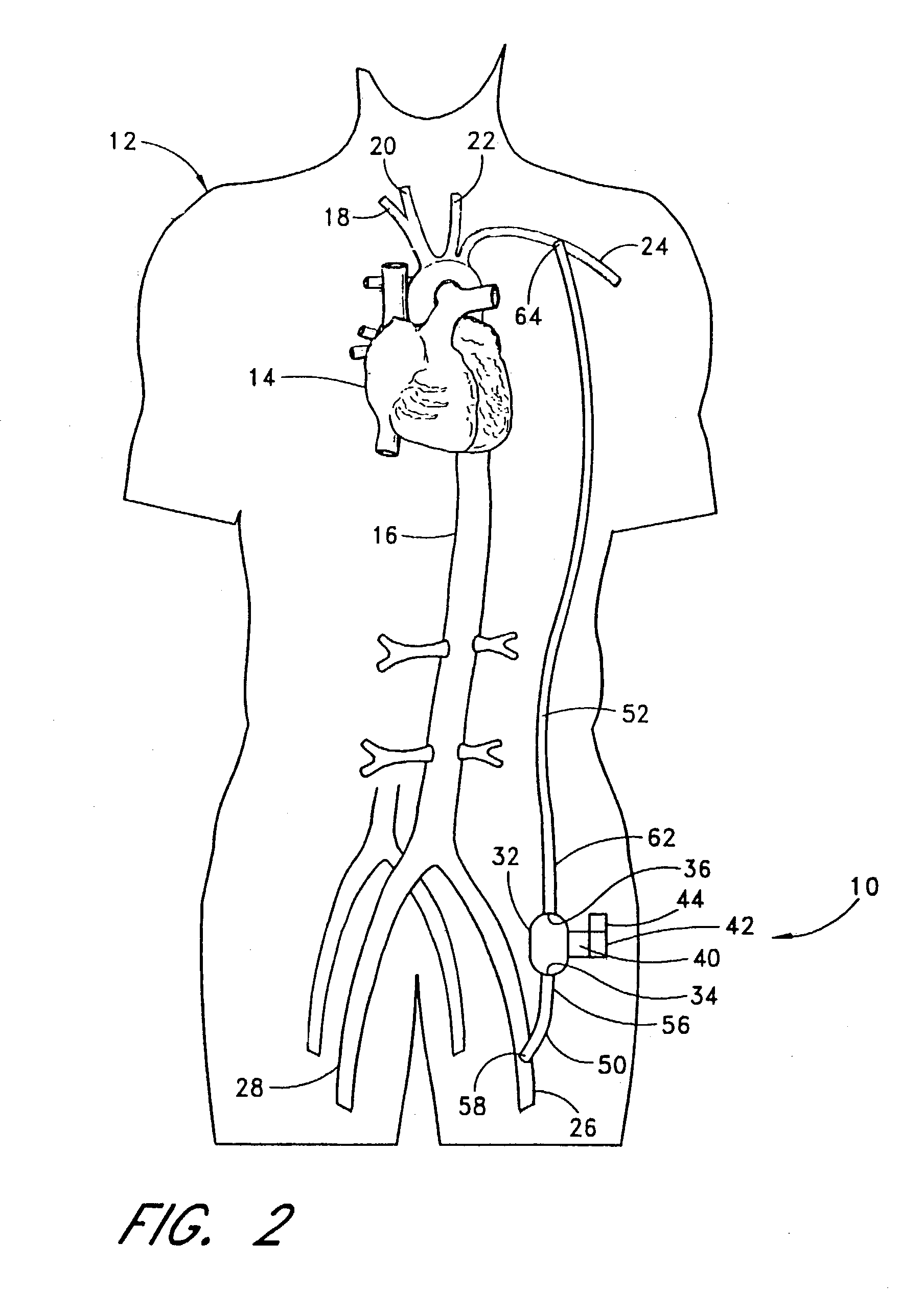

Implantable heart assist system and method of applying same

InactiveUS7125376B2RevitalizeReduce energy inputSpecific fluid pumpsOther blood circulation devicesAfterloadCatheter

An extracardiac pumping for supplementing the circulation of blood, including the cardiac output, in a patient without any component thereof being connected to the patient's heart, and methods of using same. One embodiment of the intravascular extracardiac system comprises a pump with inflow and outflow conduits that are sized and configured to be implantable intravascularly through a non-primary vessel, whereby it may positioned where desired within the patient's vasculature. The system comprises a subcardiac pump that may be driven directly or electromagnetically from within or without the patient. The pump is configured to be operated continuously or in a pulsatile fashion, synchronous with the patient's heart, thereby potentially reducing the afterload of the heart. In another embodiment, the system is positioned extracorporeally, with the inflow conduit and outflow conduit applied percutaneously to a non-primary vessel for circulating blood to and from the non-primary vessel or between the non-primary vessel and another blood vessel within the patient's vasculature.

Owner:TC1 LLC

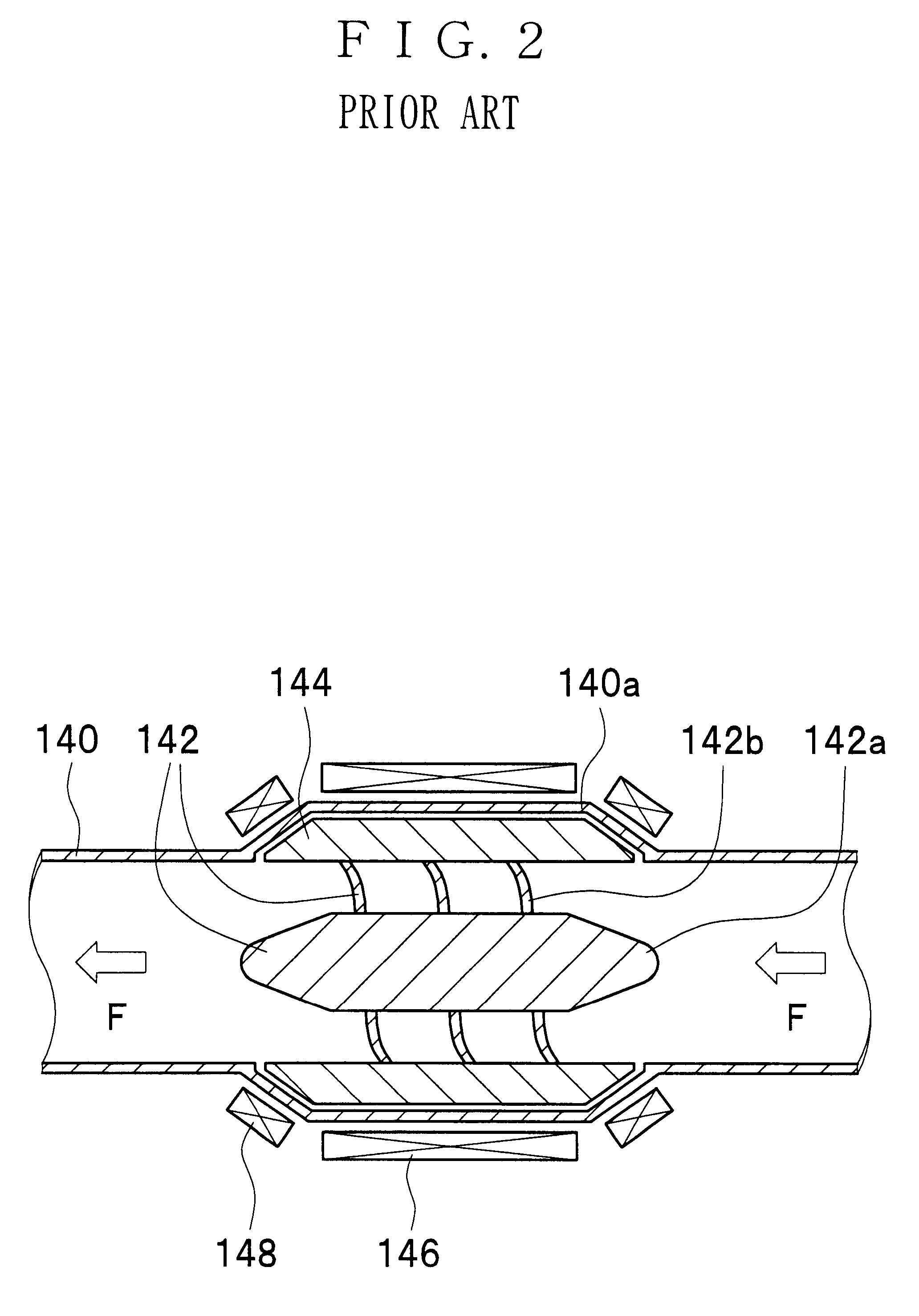

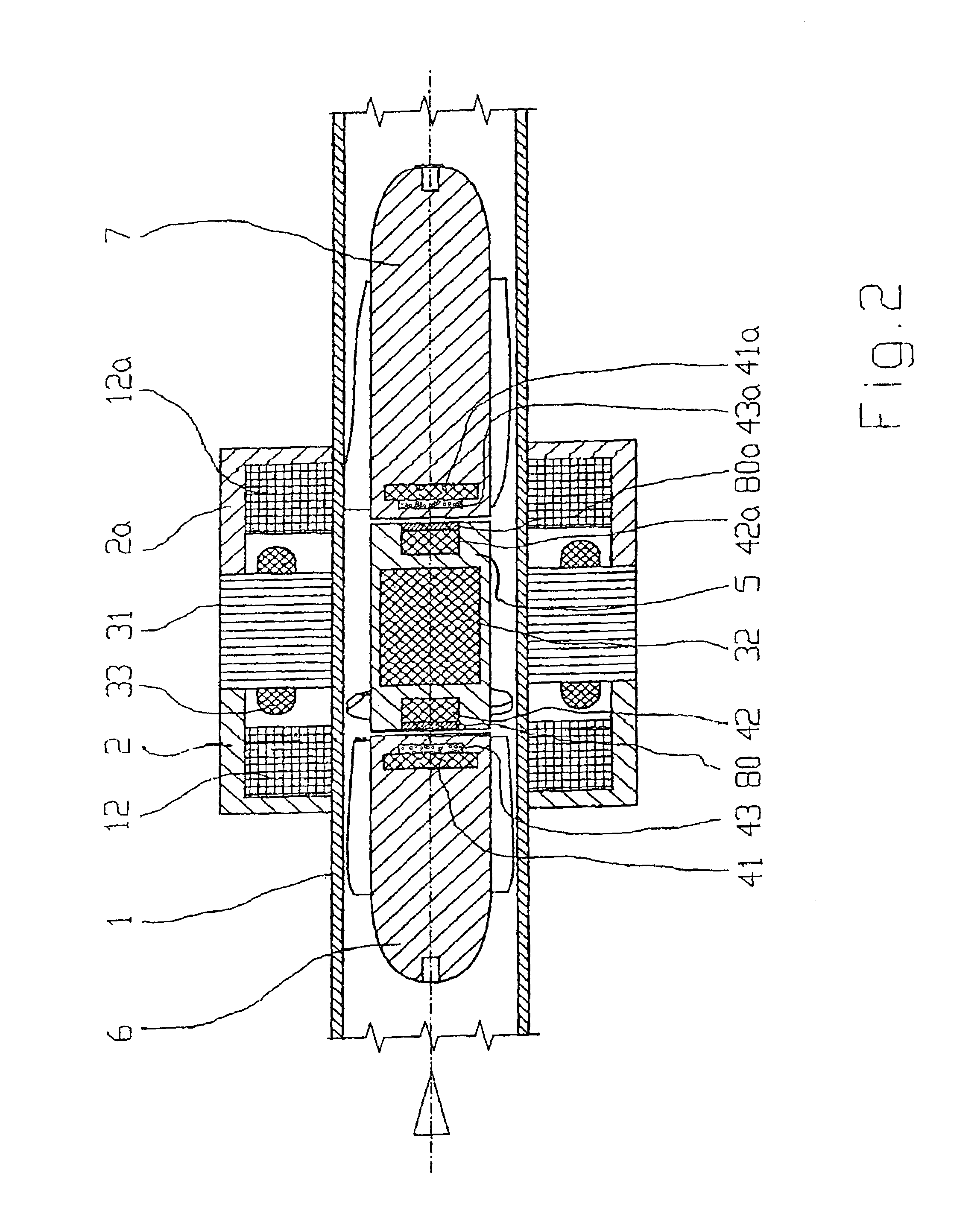

Magnetically driven axial-flow pump

A magnetically driven axial-flow pump comprising (i) an electromagnet unit 1 arranged about the periphery of a pipe "P", (ii) a cylindrical rotor 5 accommodated in the pipe "P", (iii) permanent magnets 6 mounted on the periphery of the rotor 5, and (iv) a spiral vane 7 formed on the inner surface of the rotor 5. A hollow is formed in the axial center portion of the vane 7. Because the rotor 5 and the vane 7 can be made as one piece with an NC machine, precluding the occurrence of gaps in the otherwise-inevitable joint between them, it is easy to make the rotor 5 and the vane 7. Because there are no gaps between the rotor 5 and the vane 7 as mentioned above and there is no object in contact with blood in the center portion of the vane, various germs do not enter blood, no thrombi are formed, blood tissues are not destroyed, and hence the pump is suitable as a blood pump.

Owner:NIPRO CORP

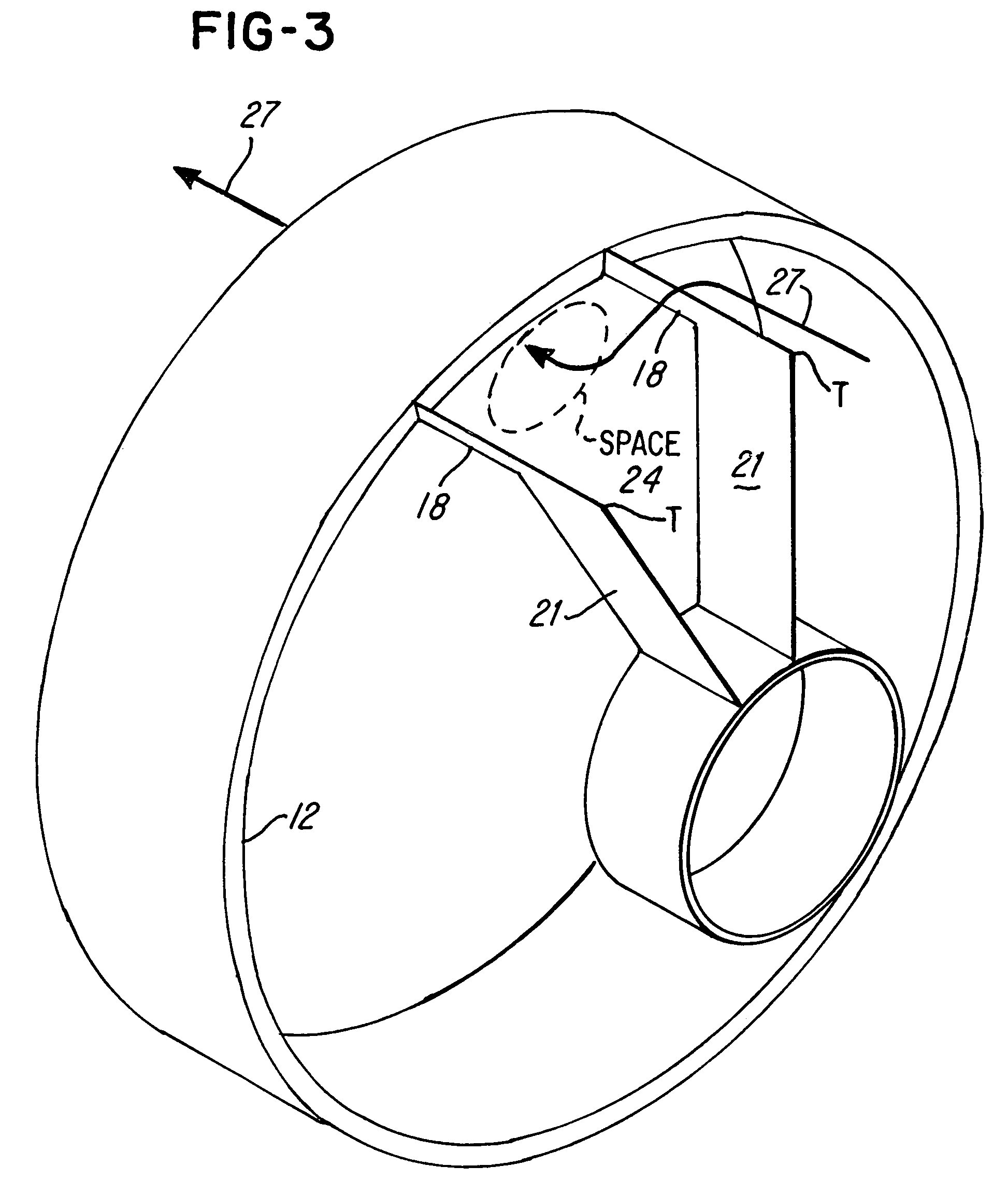

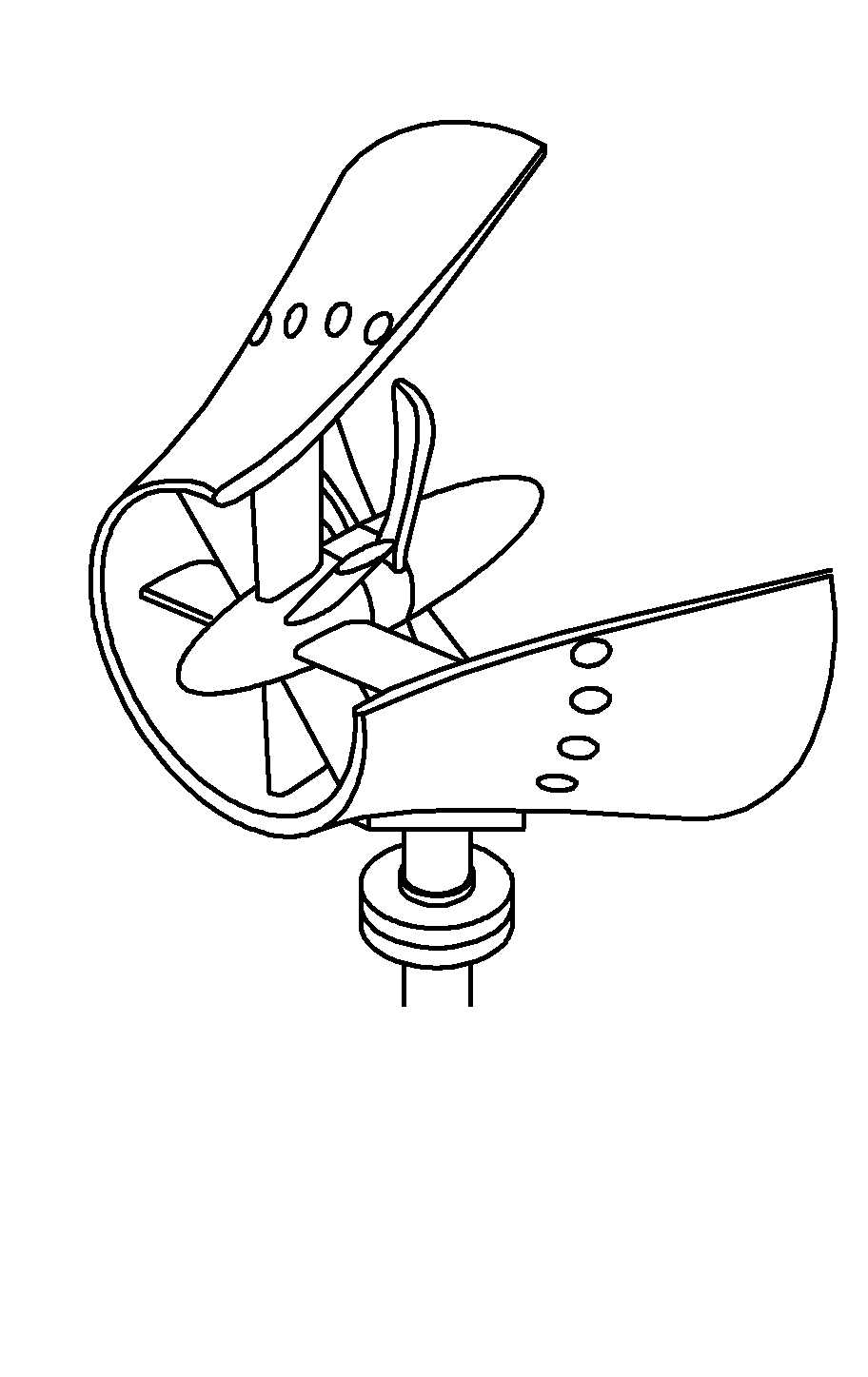

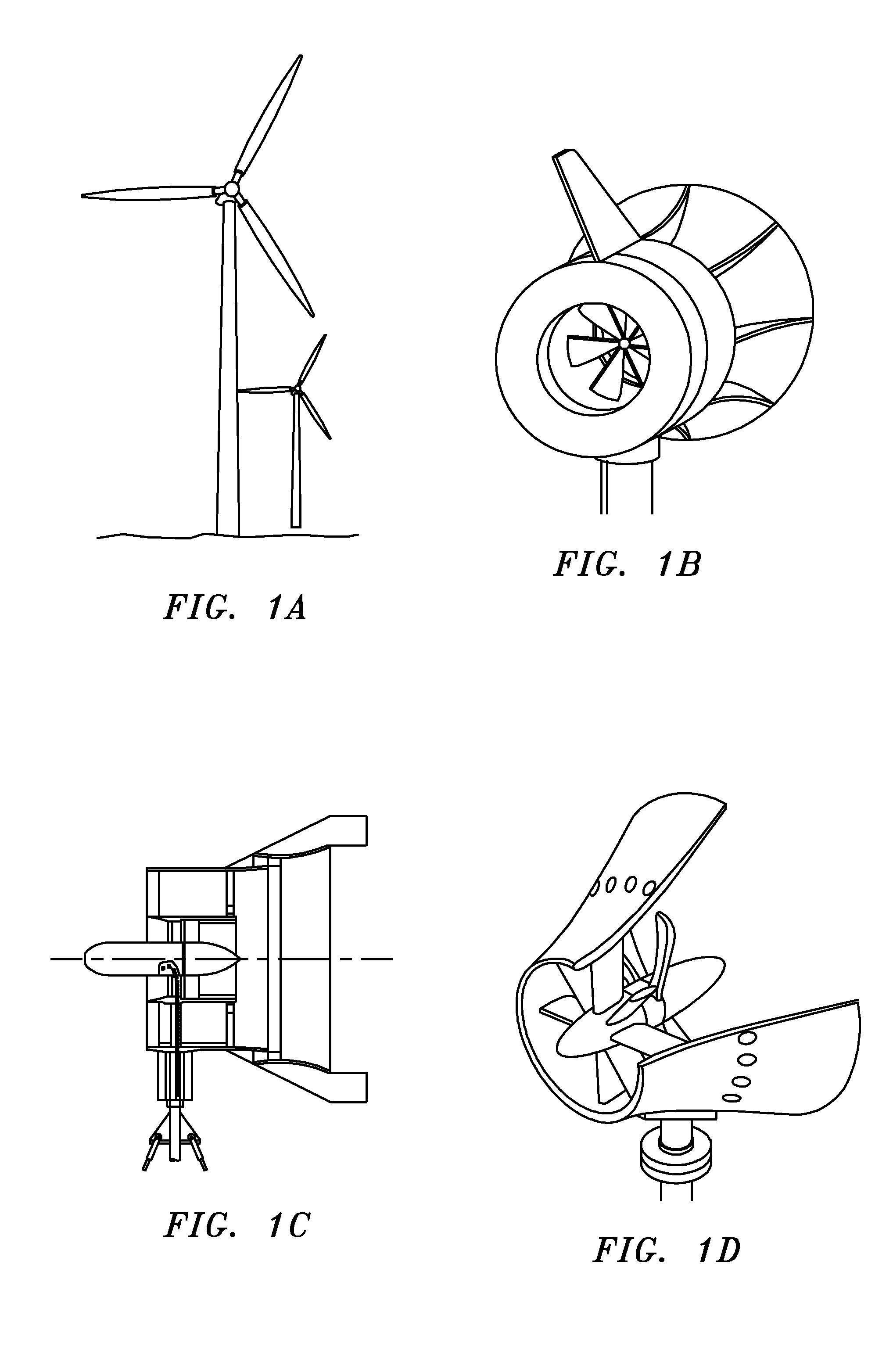

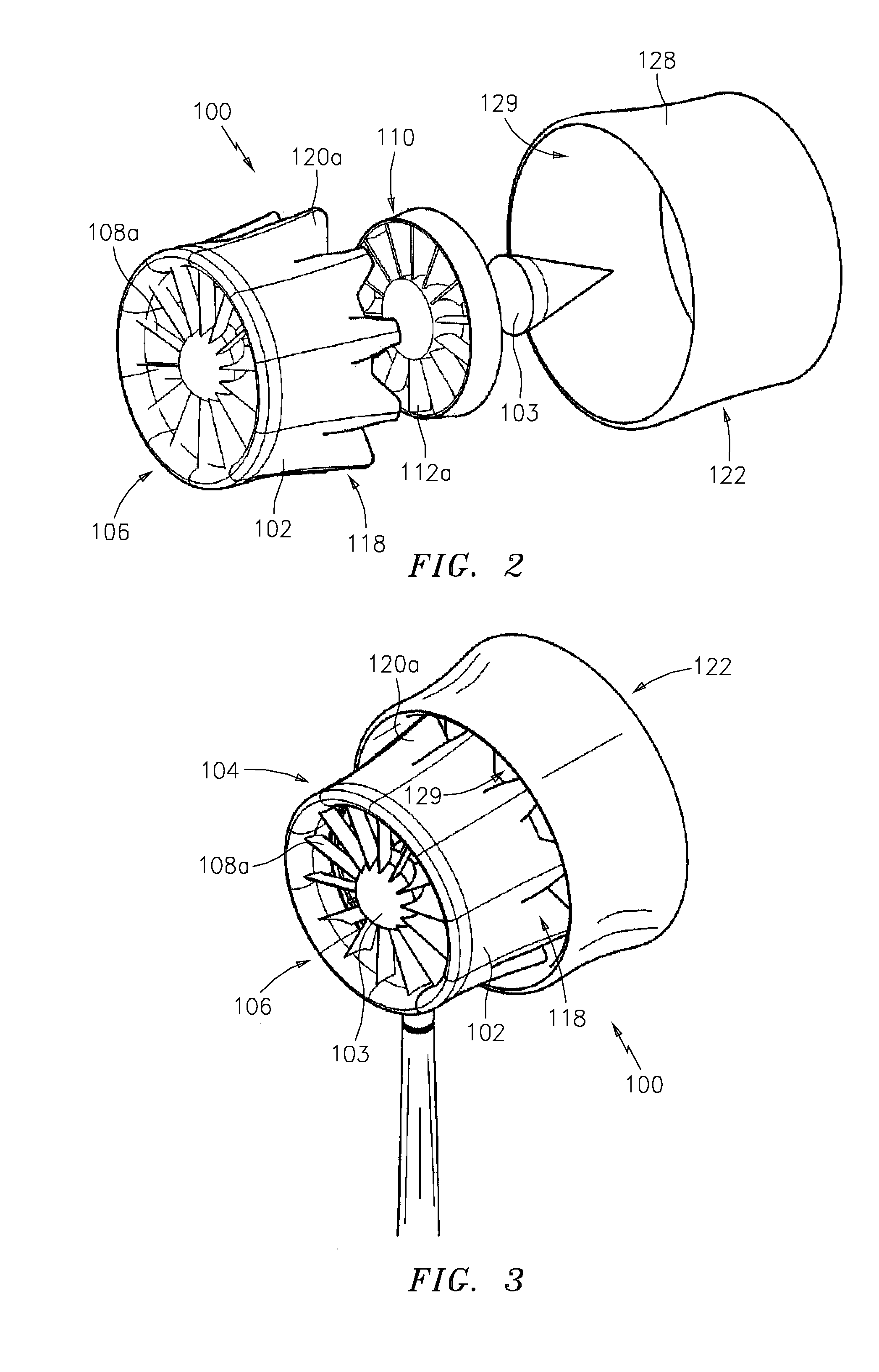

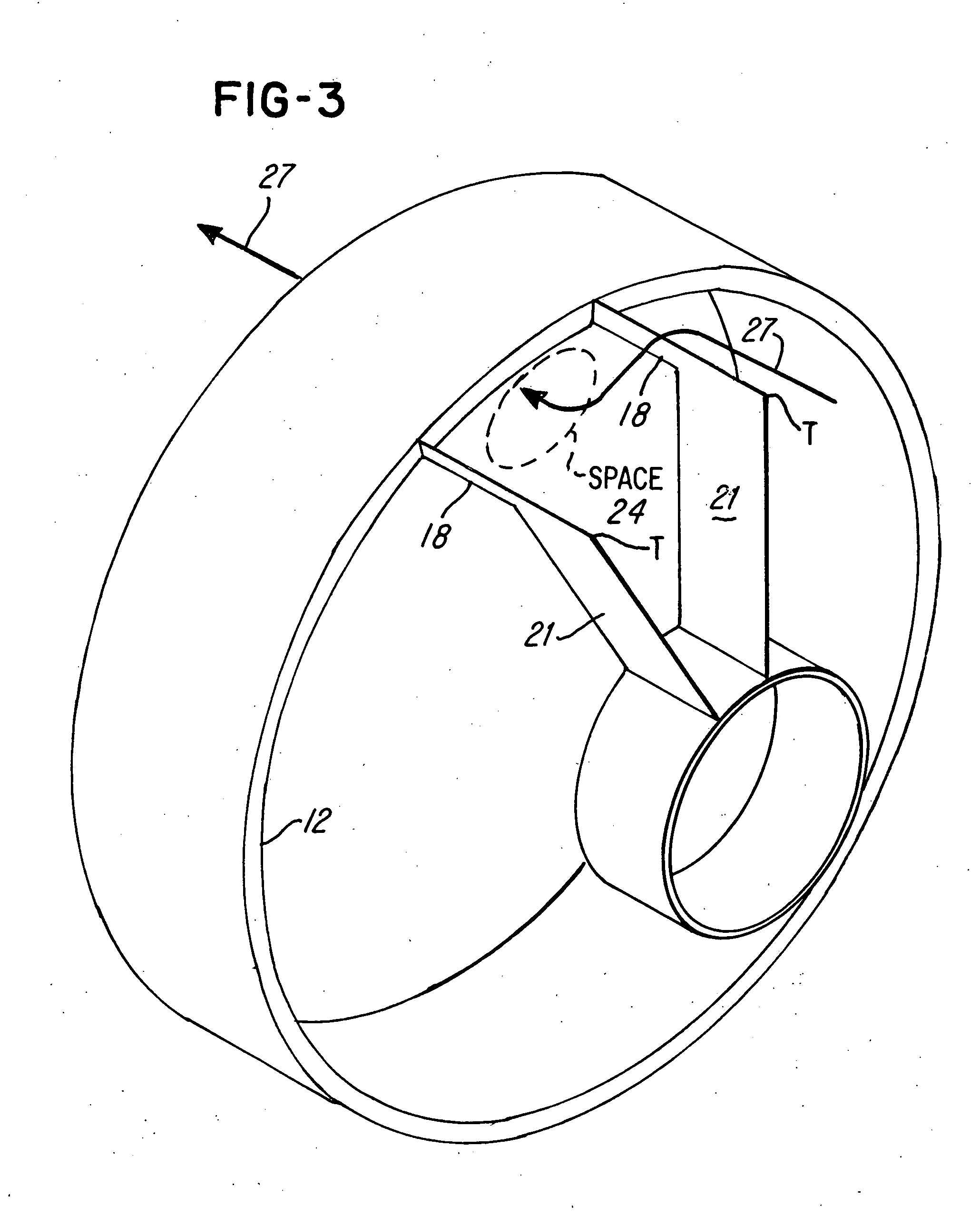

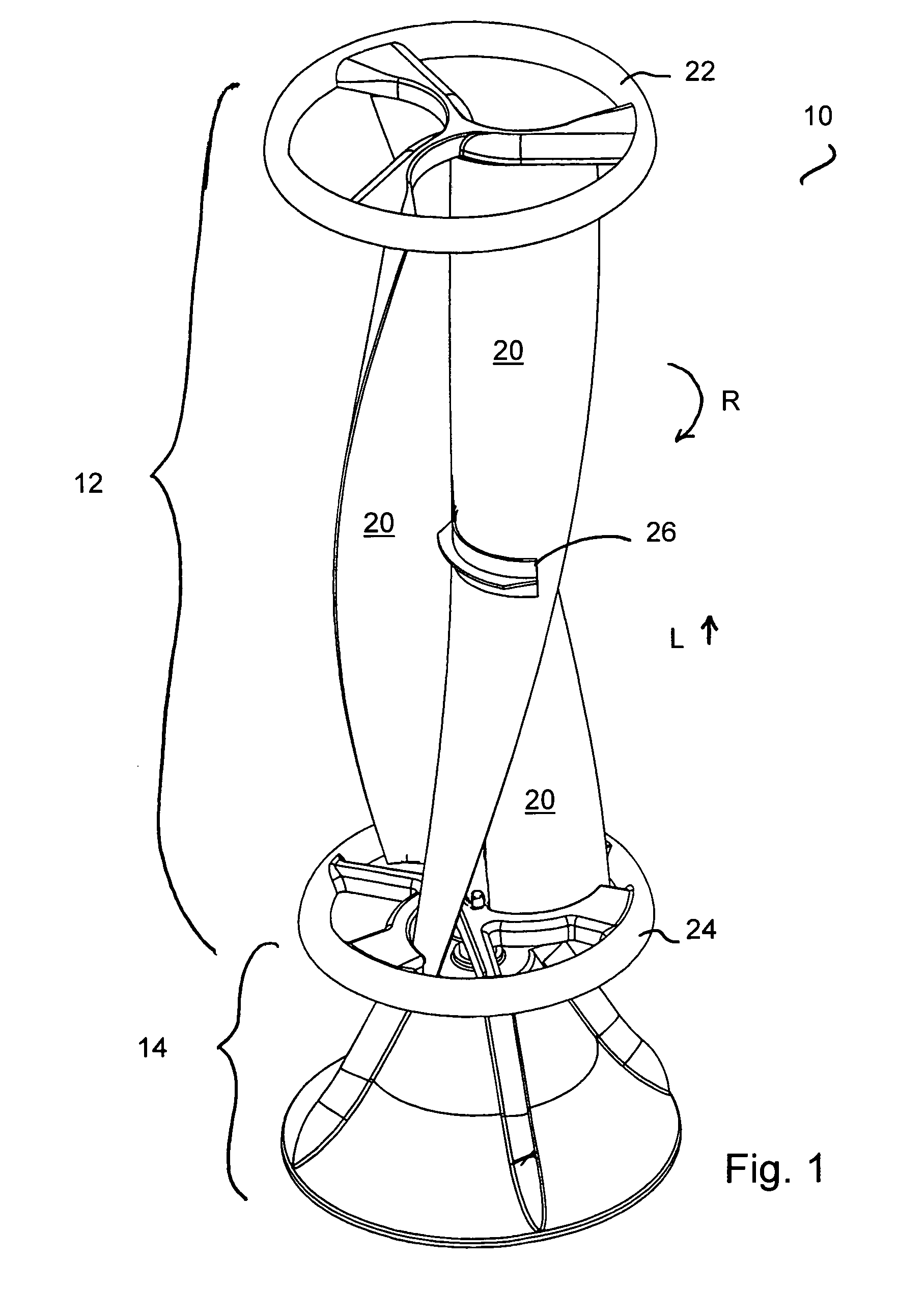

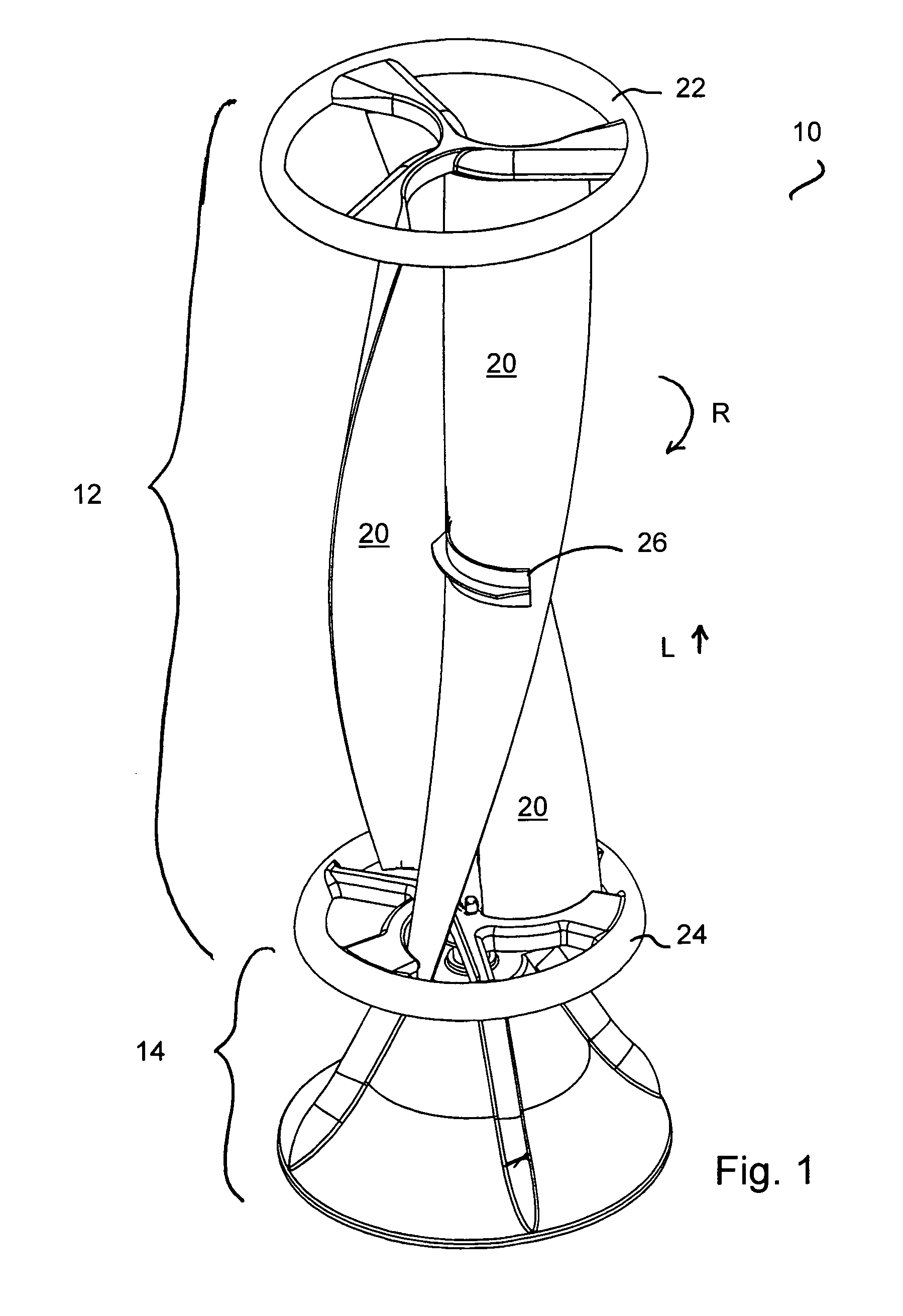

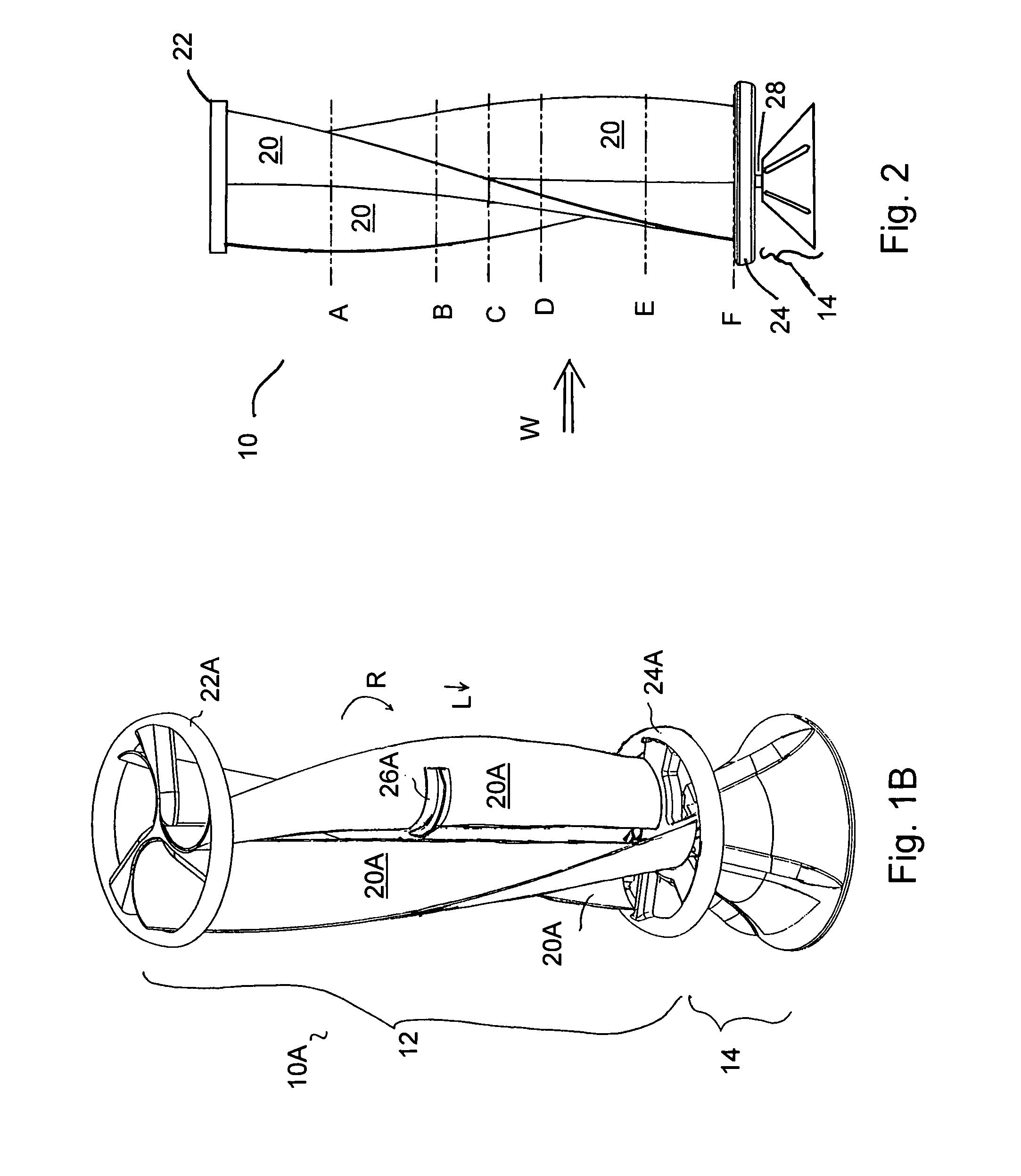

Wind turbine with mixers and ejectors

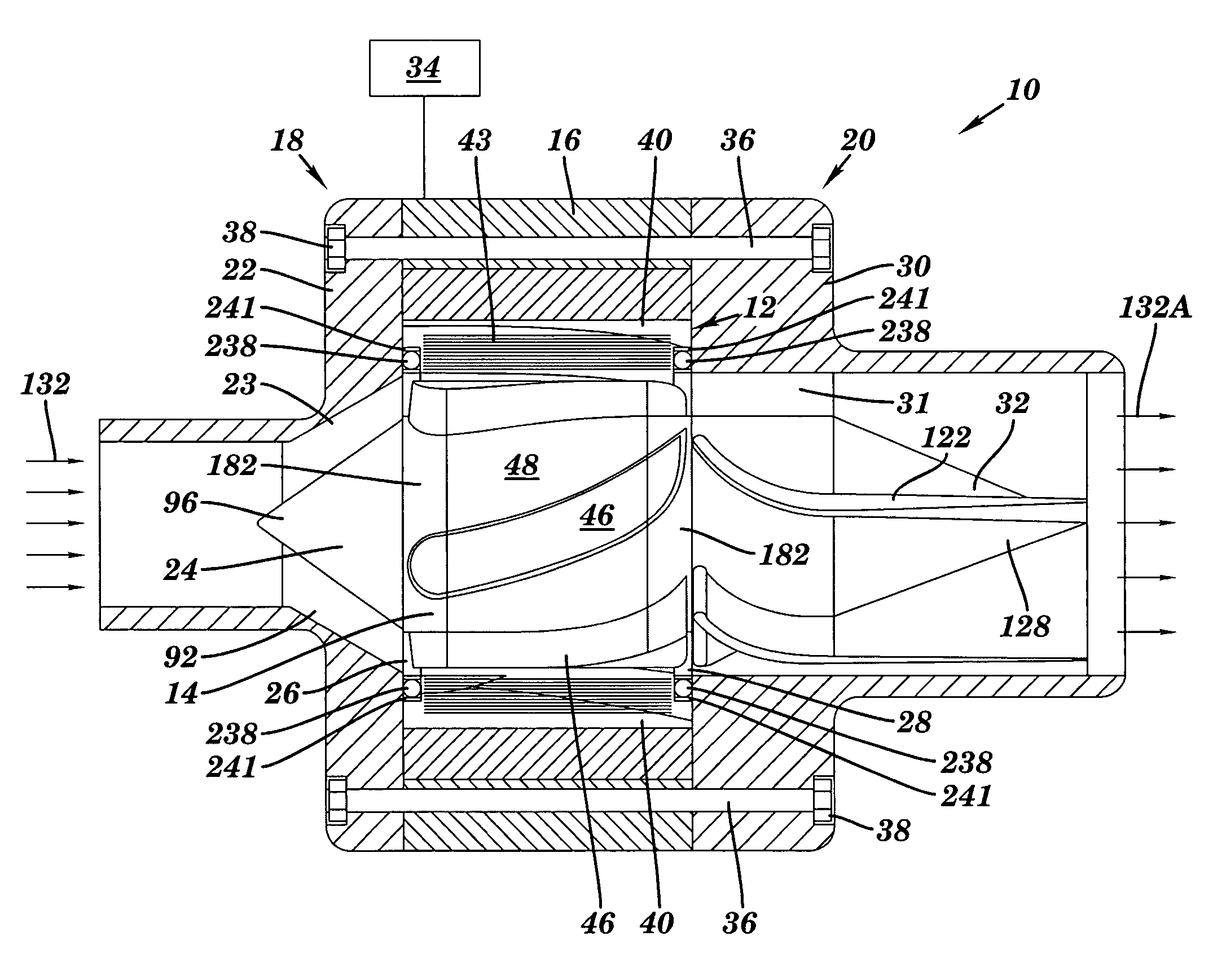

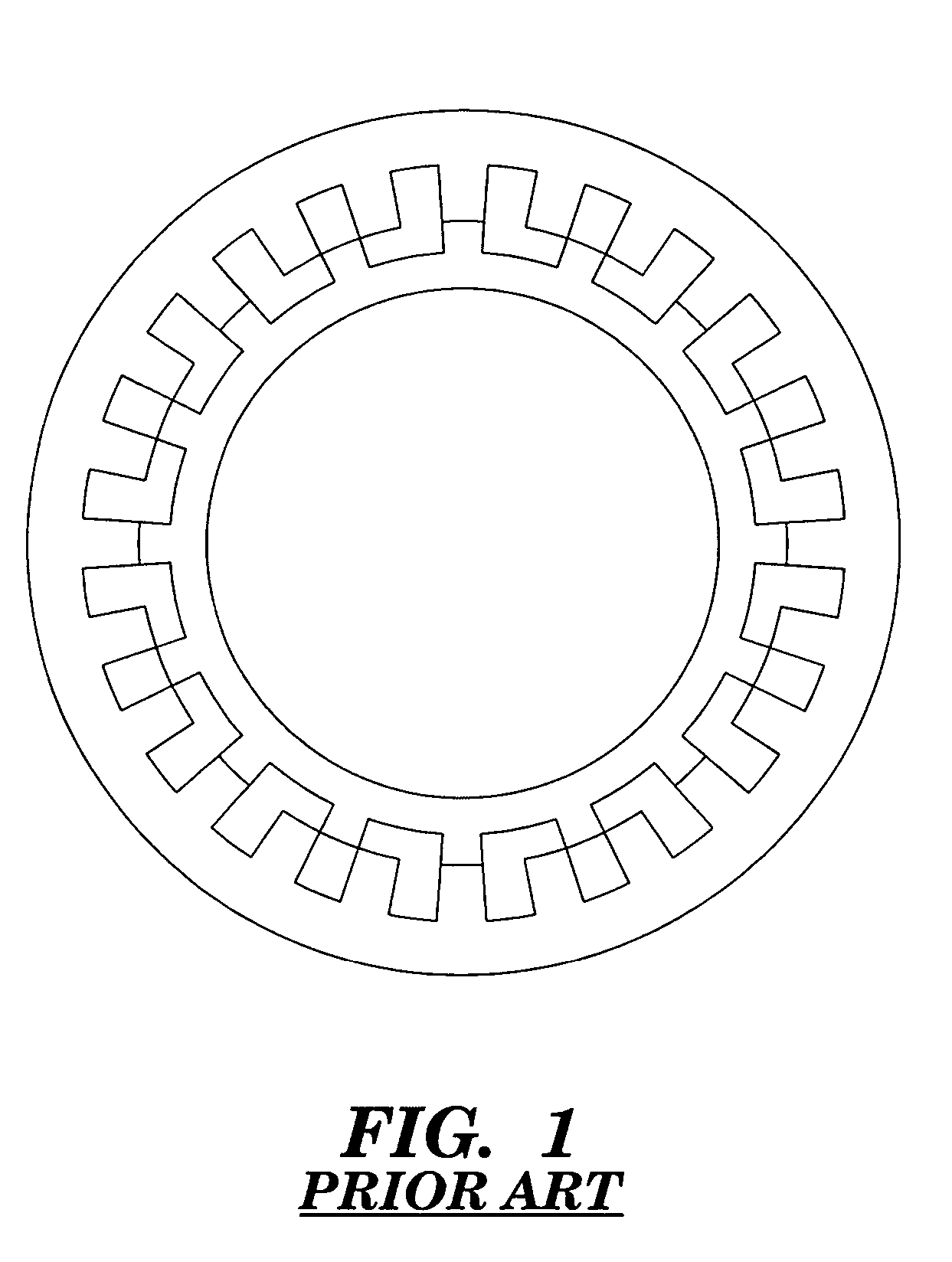

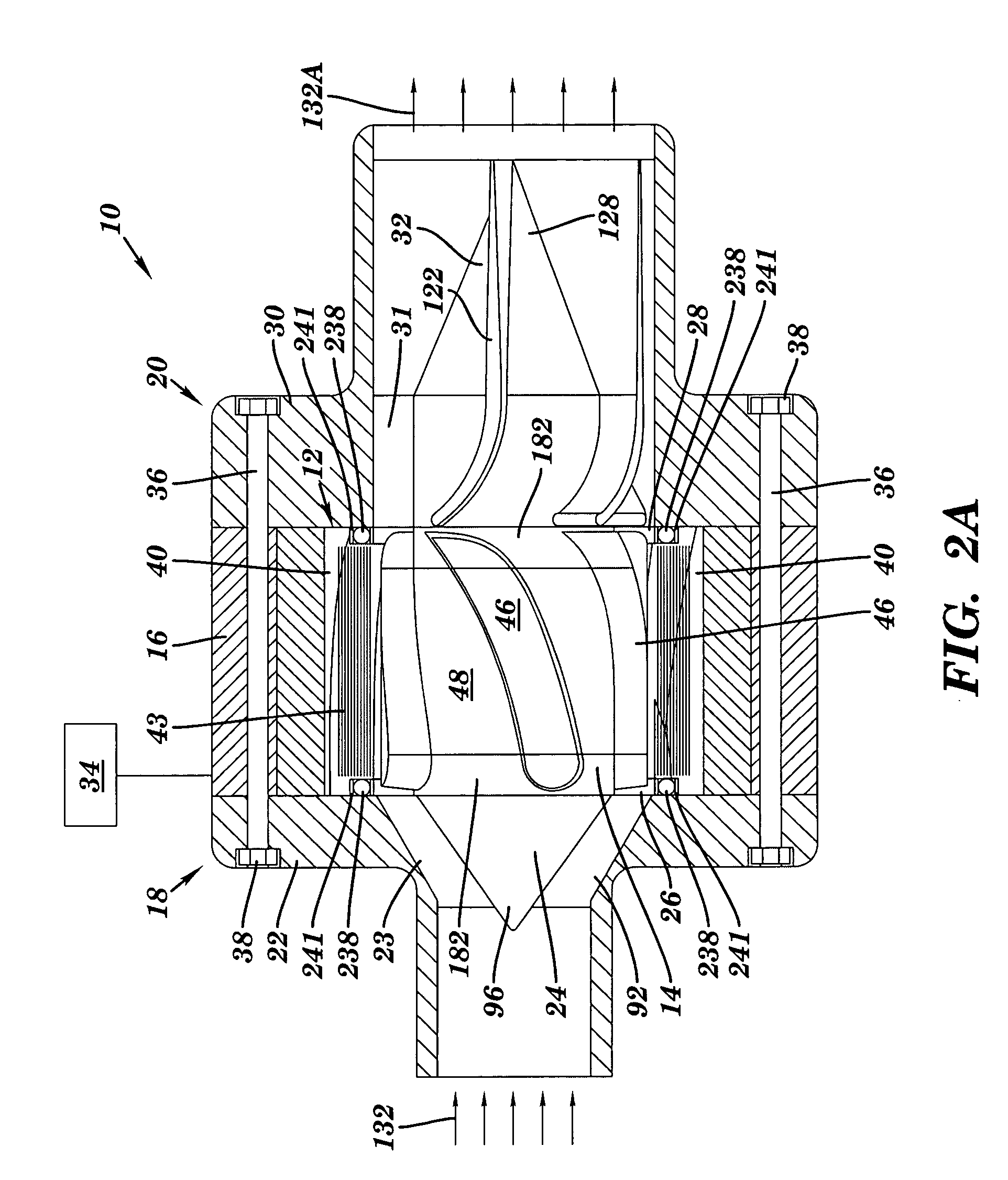

A Mixer / Ejector Wind Turbine (“MEWT”) system is disclosed which routinely exceeds the efficiencies of prior wind turbines. In the preferred embodiment, Applicants' MEWT incorporates advanced flow mixing technology, single and multi-stage ejector technology, aircraft and propulsion aerodynamics and noise abatement technologies in a unique manner to fluid-dynamically improve the operational effectiveness and efficiency of wind turbines, so that its operating efficiency routinely exceeds the Betz limit. Applicants' preferred MEWT embodiment comprises: an aerodynamically contoured turbine shroud with an inlet; a ring of stator vanes; a ring of rotating blades (i.e., an impeller) in line with the stator vanes; and a mixer / ejector pump to increase the flow volume through the turbine while rapidly mixing the low energy turbine exit flow with high energy bypass wind flow. The MEWT can produce three or more time the power of its un-shrouded counterparts for the same frontal area, and can increase the productivity of wind farms by a factor of two or more. The same MEWT is safer and quieter providing improved wind turbine options for populated areas.

Owner:FLODESIGN WIND TURBINE

Cooling fan using coanda effect to reduce recirculation

ActiveUS20070224044A1Increase the cross-sectional areaTrend downPump componentsReaction enginesFan bladeAerospace engineering

Owner:VALEO INC

Fan

A fan assembly for creating an air current includes a bladeless fan assembly including a nozzle and a device for creating an air flow through the nozzle. The nozzle includes an interior passage and a mouth receiving the air flow from the interior passage. A Coanda surface located adjacent the mouth and over which the mouth is arranged to direct the air flow. The fan provides an arrangement producing an air current and a flow of cooling air created without requiring a bladed fan, that is, the air flow is created by a bladeless fan.

Owner:DYSON TECH LTD

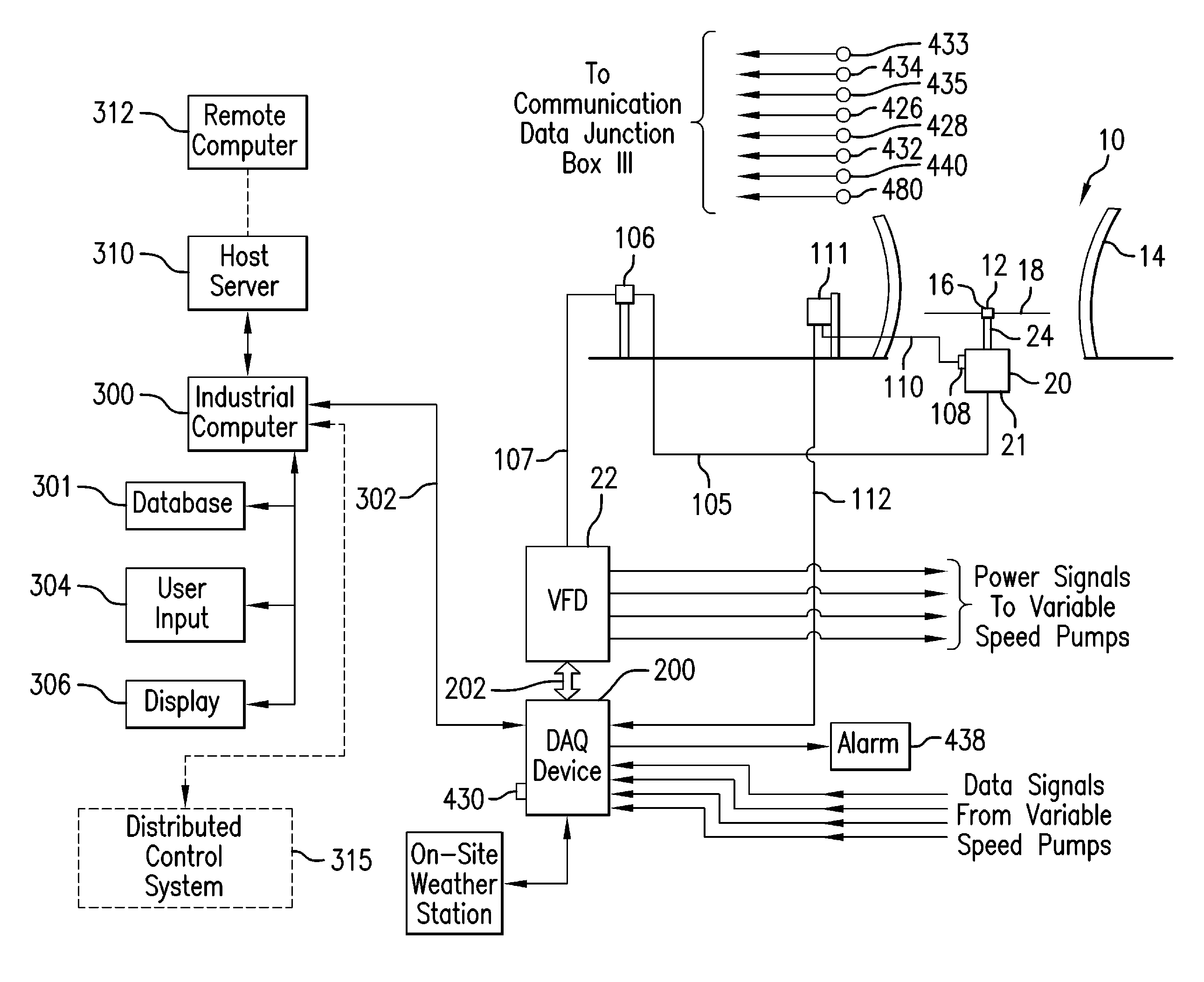

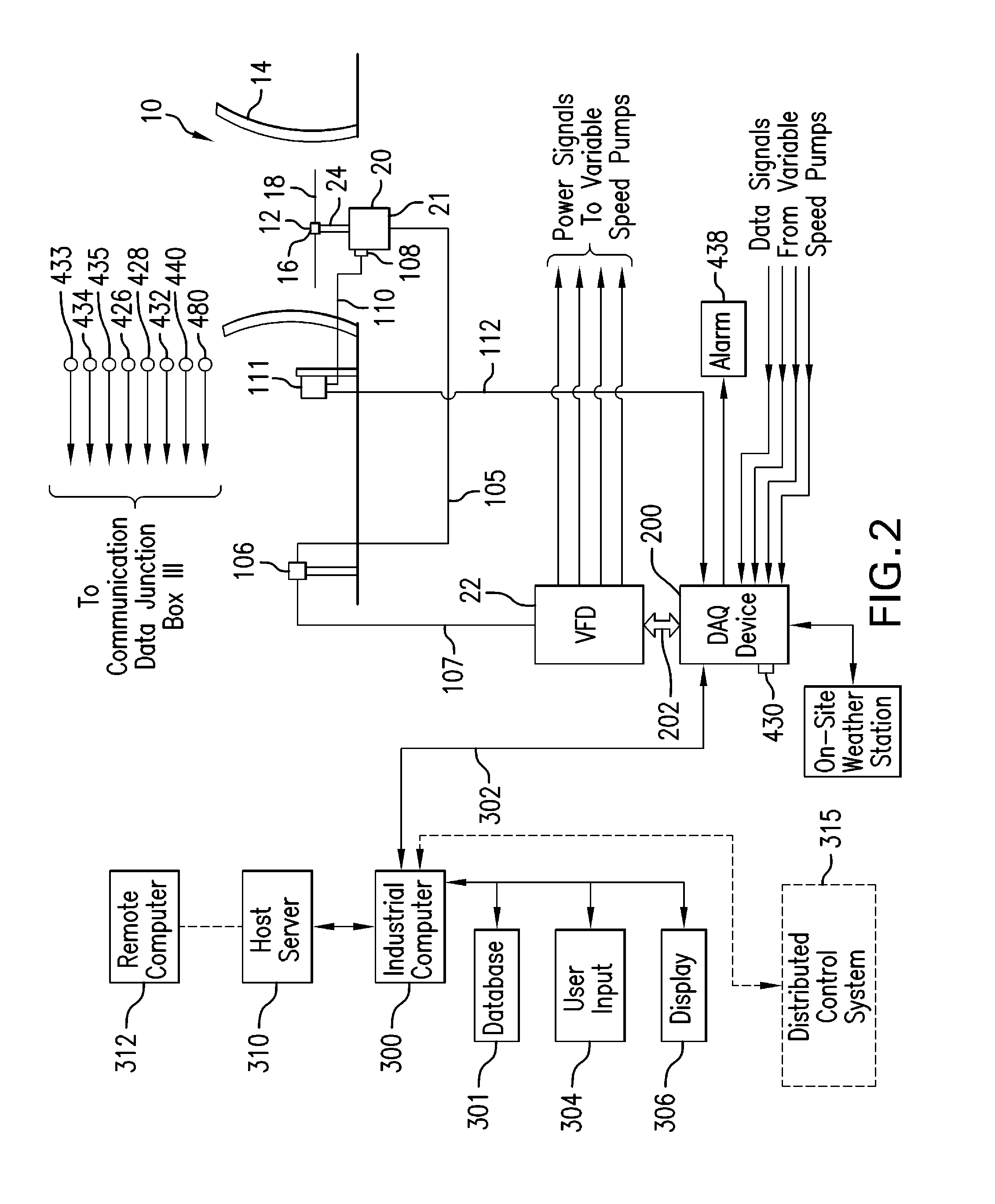

Direct drive fan system with variable process control

ActiveUS20140244051A1System smoothReduce vibrationTransportation and packagingEngine fuctionsCooling towerHigh torque

The present invention is directed to a direct-drive fan system and a variable process control system for efficiently managing the operation of fans in a cooling system such a as wet-cooling tower or air-cooled heat exchanger (ACHE), HVAC systems, mechanical towers or chiller systems. The present invention is based on the integration of key features and characteristics such as tower thermal performance, fan speed and airflow, motor torque, fan pitch, fan speed, fan aerodynamic properties, and pump flow. The variable process control system processes feedback signals from multiple locations in order control a high torque, variable speed, permanent magnet motor to drive the fan. Such feedback signals represent certain operating conditions including motor temperature, basin temperature, vibrations, and pump flow rates. Other data processed by the variable process control system in order to control the motor include turbine back pressure set-point, condenser temperature set-point and plant part-load setting. The variable process control system processes this data and the aforesaid feedback signals to optimize the operation of the cooling system in order to prevent disruption of the industrial process and prevent equipment (turbine) failure or trip. The variable process control system alerts the operators for the need to conduct maintenance actions to remedy deficient operating conditions such as condenser fouling. The variable process control system increases cooling for cracking crude and also adjusts the motor RPM, and hence the fan RPM, accordingly during plant part-load conditions in order to save energy.

Owner:PRIME DATUM

Helical wind turbine

InactiveUS7344353B2Efficient captureLower resistanceWind motor controlPump componentsLinear configurationWing configuration

A vertical axis wind turbine wherein the blades of the rotor section of the wind turbine comprise at least sections wherein the blades have a non-linear configuration in the “z” axis. In a preferred embodiment, the blades of the rotor section have a linear trailing edge with a non-linear, and preferably helical, surface configuration. This particular design allows the blades to provide both a rotational force and a positive or negative lift component. Further, the blades define an open area in the center of the rotor section through which air flow can pass in order to create a vertical vortex of air. As such, a more efficient vertical axis wind turbine provided.

Owner:ARROWIND CORP

Multiple rotor, wide blade, axial flow pump

InactiveUS7972122B2Simple procedureReduce patient surgical traumaPump componentsBlood pumpsAxial-flow pumpImpeller

A blood pump comprises a pump housing; a plurality of rotors positioned in said housing, each rotor comprising an impeller having a hydrodynamic surface for pumping blood; and a motor including a plurality of magnetic poles carried by each impeller, having motor stators, each including electrically conductive coils located adjacent to or within the housing. At least one of the rotors is adopted to rotate clockwise, and at least one of rotors is adopted to rotate counterclockwise. By this means, stator or stationary blades between the rotors may not be needed.

Owner:HEARTWARE INC

Helical wind turbine

InactiveUS20060257240A1Efficient captureLower resistancePump componentsWind motor controlLinear configurationSpecial design

A vertical axis wind turbine wherein the blades of the rotor section of the wind turbine comprise at least sections wherein the blades have a non-linear configuration in the “z” axis. In a preferred embodiment, the blades of the rotor section have a linear trailing edge with a non-linear, and preferably helical, surface configuration. This particular design allows the blades to provide both a rotational force and a positive or negative lift component. Further, the blades define an open area in the center of the rotor section through which air flow can pass in order to create a vertical vortex of air. As such, a more efficient vertical axis wind turbine provided.

Owner:ARROWIND CORP

Blood pump bearings with separated contact surfaces

ActiveUS20080269880A1Precise functionPrevent thrombusPump componentsBlood pumpWear resistantThrombus

Rotary hydrodynamic blood pumps have been used to treat over a thousand patients. The Jarvik 2000 has supported a patient for seven years and uses blood immersed bearings washed by high flow to avoid excessive thrombus formation. This permits the pump to be very simple and small. Nonetheless, the present Jarvik 2000 bearings and all other mechanical blood immersed bearings of the prior art have a supporting structure that predisposes to thrombus adjacent to the bearings. The present invention provides a bearing structure that eliminates this predilection site for thrombus formation, and may provide indefinite thrombus free operation. The rotor of the preferred embodiment includes a tapered hub fabricated of wear resistant material supported by three posts at each end of the rotor, upon which the rotor rotates. Blood washes the unobstructed spaces between the posts to prevent the accumulation of a torus of thrombus that could enlarge excessively.

Owner:JARVIK ROBERT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com