Apparatus for processing pipeline fitting and processing method thereof

A technology for processing devices and pipe fittings, which is applied to the processing equipment and processing fields of pipe fittings in air conditioners, can solve the problems of low utilization rate of raw materials, great influence on processing quality, large material turnover, etc., and achieves high utilization rate of raw materials, The effect of low processing cost and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

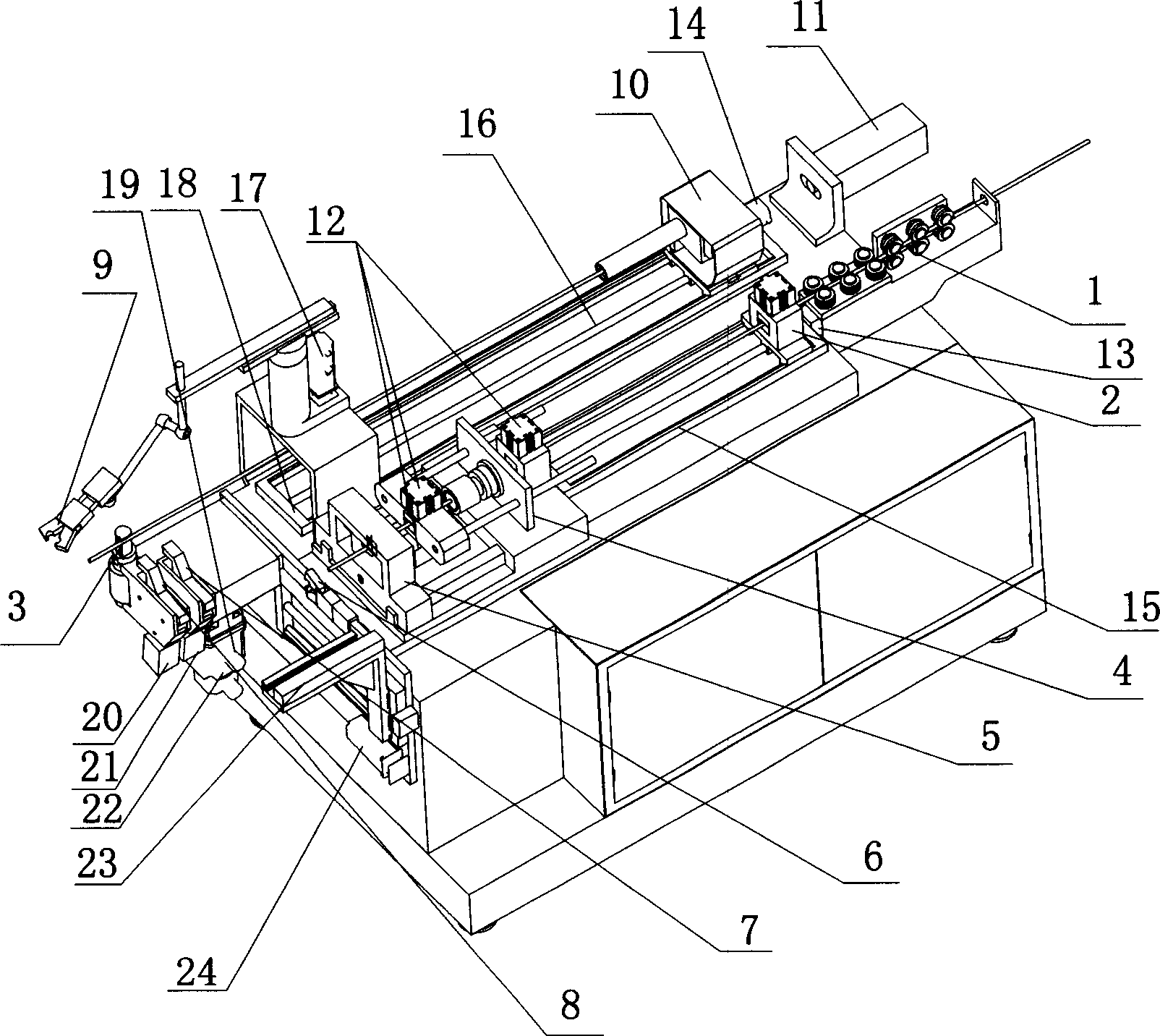

[0009] A processing device for pipe fittings, which includes a feeding device, a full-automatic pipe bending machine host, and a material unloading device; see figure 1 (feeding device and feeding basket are not shown in the figure), the main machine of the automatic pipe bending machine includes the forming part of the feeding pipe end, the feeding manipulator part and the pipe bending part, and the forming part of the feeding pipe end mainly includes the straightening device 1, the feeding Clamping cylinder 2, blanking and feeding screw assembly 15, copper pipe cutting and nozzle shaping device 4 and nozzle forming device 5; the bending part includes bending pipe clamping device 7, bending pipe profiling device 8, bending Pipe mold 3, bent pipe feeding trolley device 10 and bent pipe core pulling device 11, the unloading device includes unloading manipulator device 9 and unloading basket (not shown); the pipe fitting processing device also includes the above-mentioned movable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com