Tube bender

a tube bender and tube technology, applied in the field of tube benders, can solve the problems of not being so well qualified to produce perfect tubes, difficult to control the size of tubes after bending, and disqualified products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

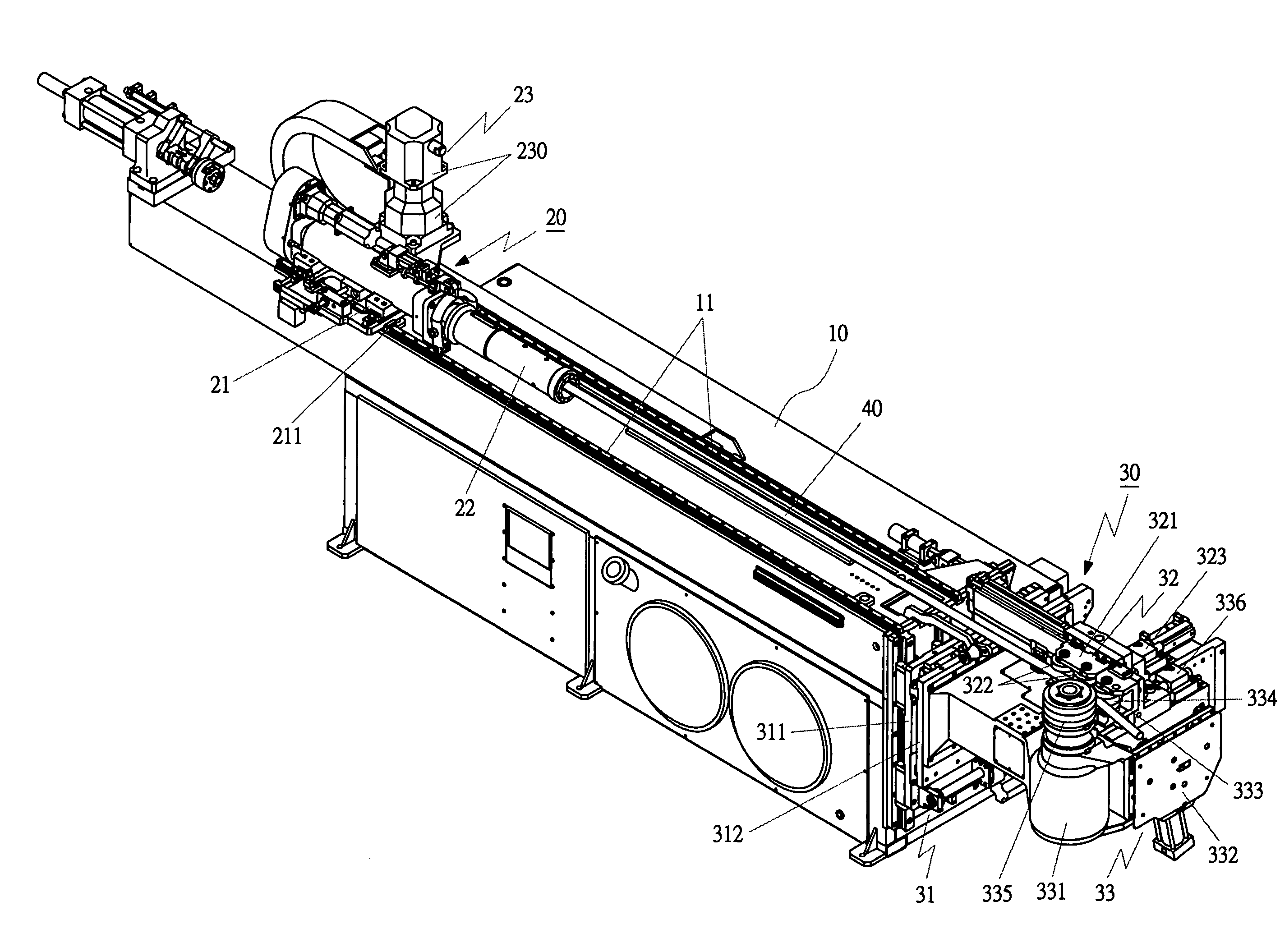

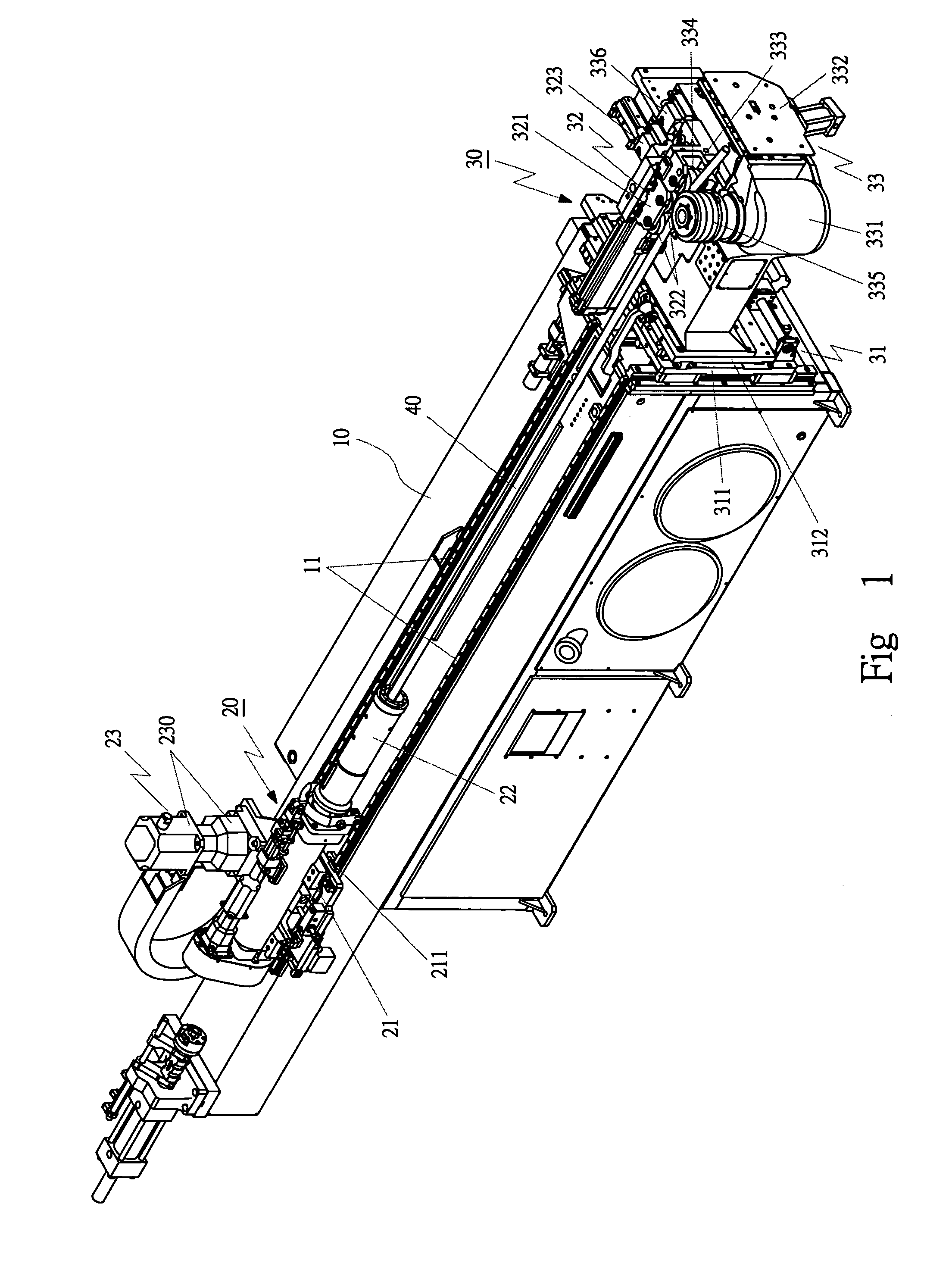

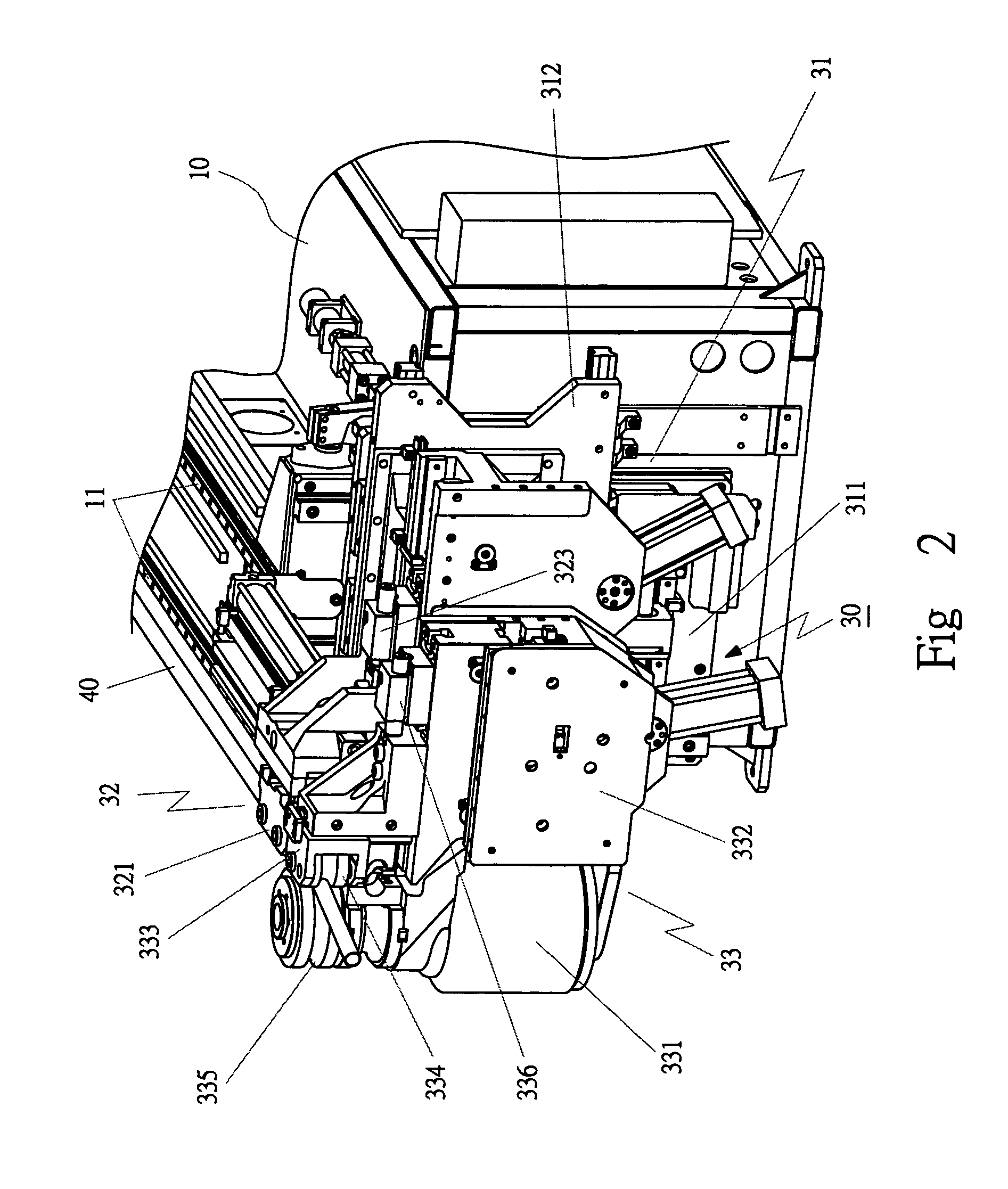

[0023]A first embodiment of a tube bender in the present invention, as shown in FIGS. 1, 2 and 3, includes a worktable 10, a tube-pushing device 20, and a tube-bending device 30 as main components combined together.

[0024]The worktable 10 has a number-style controlling device (not shown) belonging to a CNC number-style controlling system, and a rail 111 fixed on the worktable 10.

[0025]The tube pushing device 20 is positioned on the worktable 10, consisting of a moving base 21, a clamper 22, and a driver 23. The moving base 21 has a rail groove 211 symmetrically provided at two sides and connected with the rail 11 in a dovetail condition to let the moving base 21 to move smoothly on the rail 11. The clamper 22 is located at one side of the moving base 21, controlled by the controlling device for clamping and loosening a tube 40 being bent. The pushing driver 23 is connected with the moving base 21, consisting of a motor and a gear case 230, and using oil pressure or a threaded rod for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| speed | aaaaa | aaaaa |

| shape | aaaaa | aaaaa |

| force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com