Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1943results about "Spacing mechanisms" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

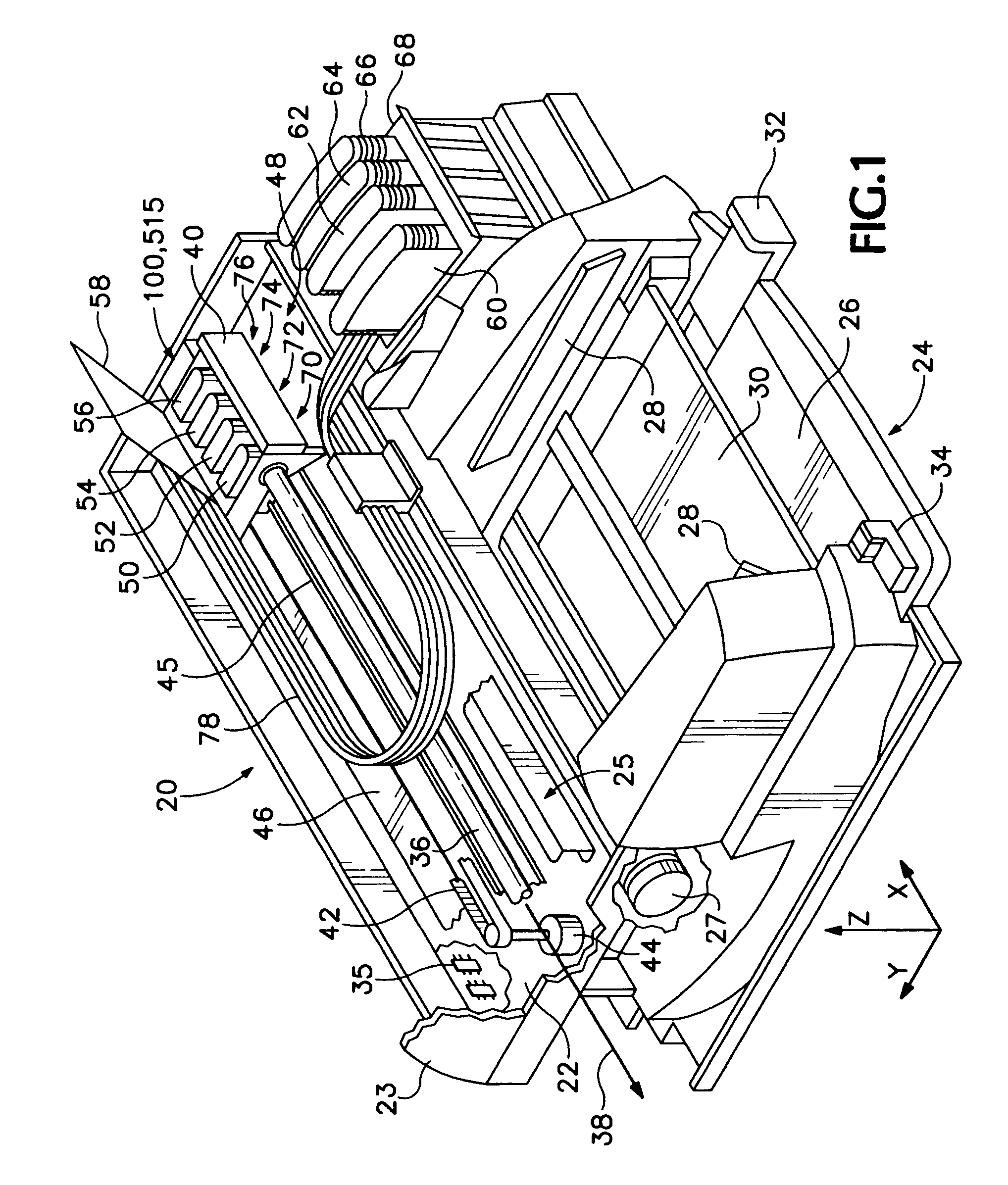

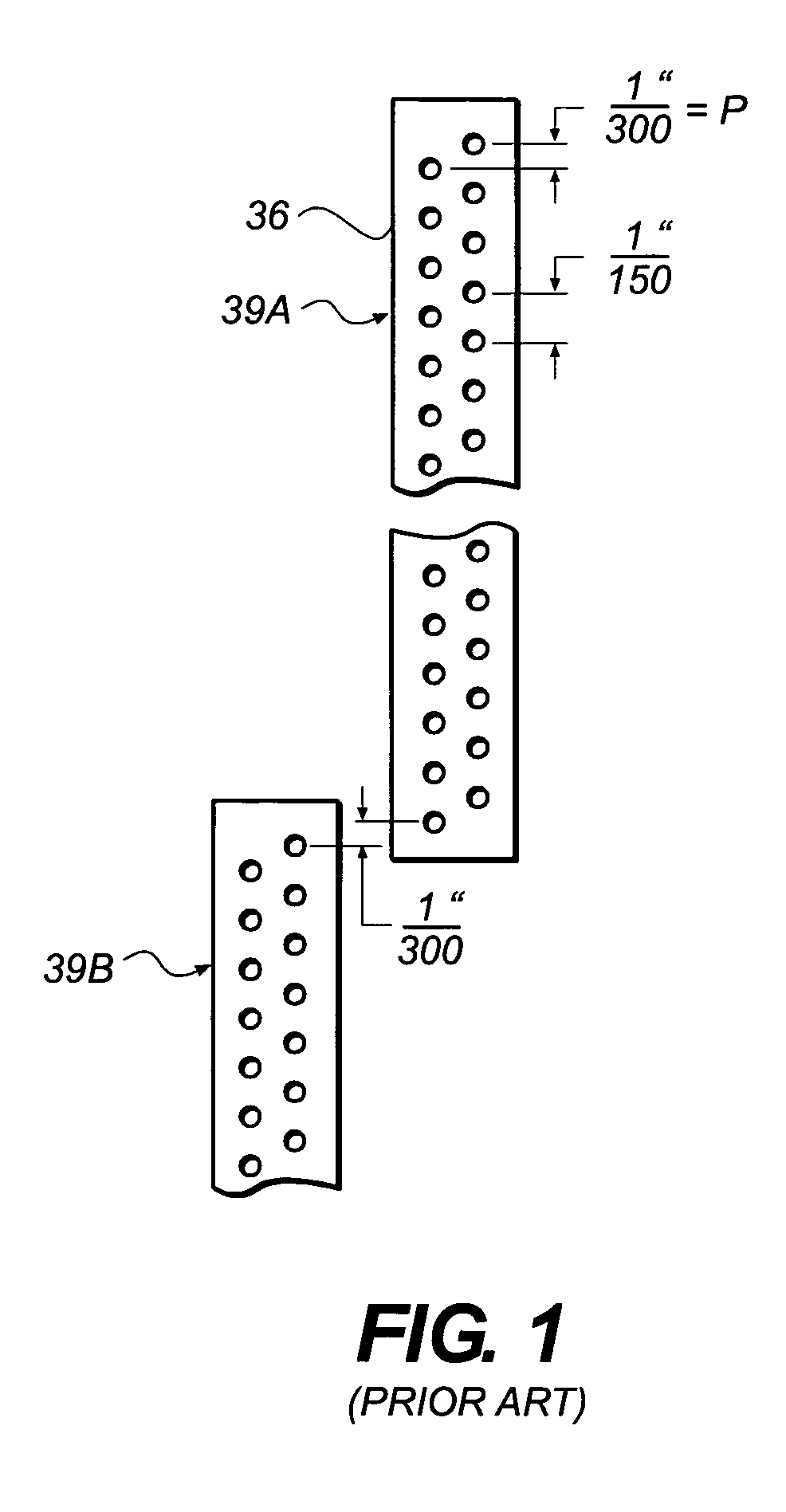

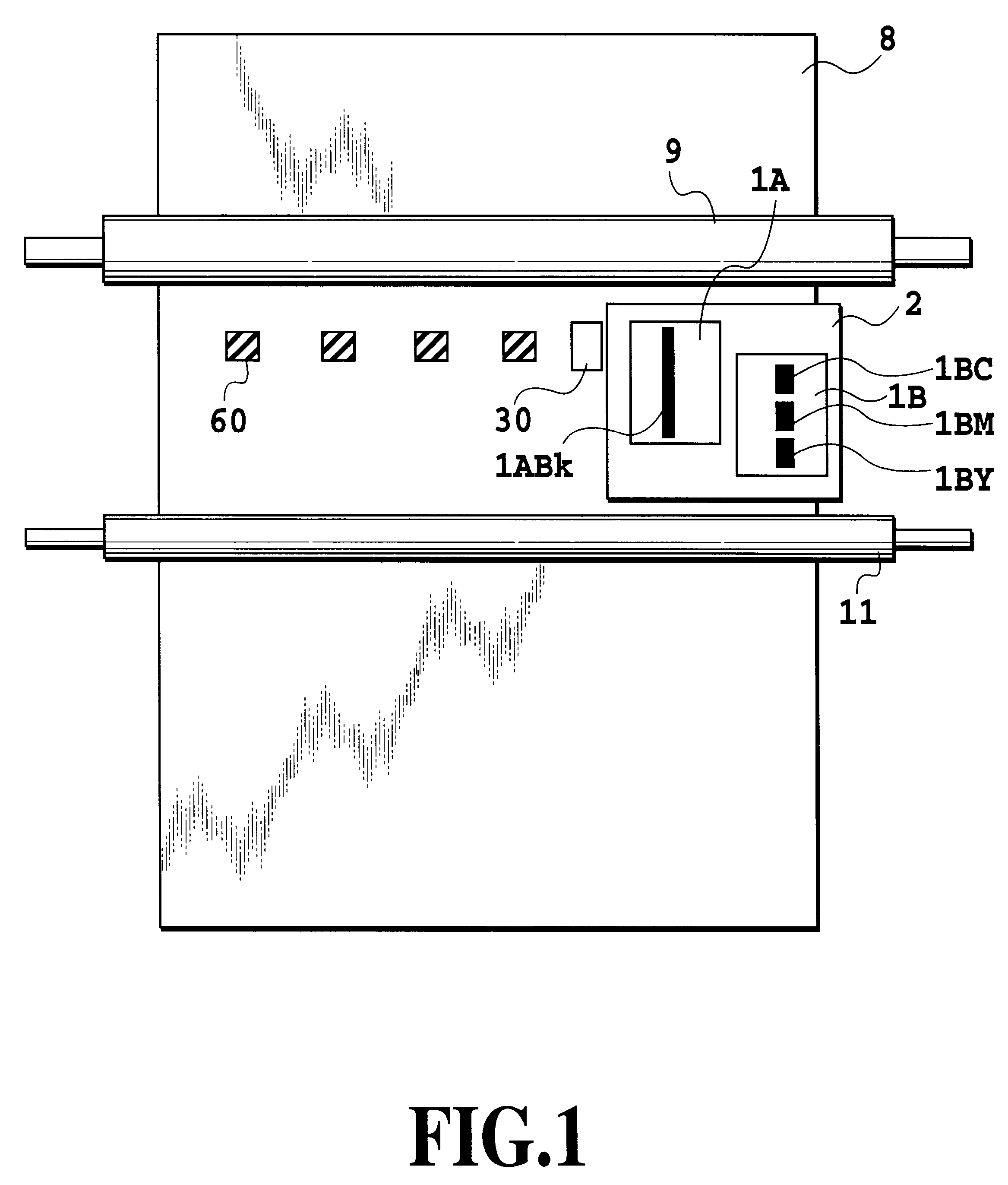

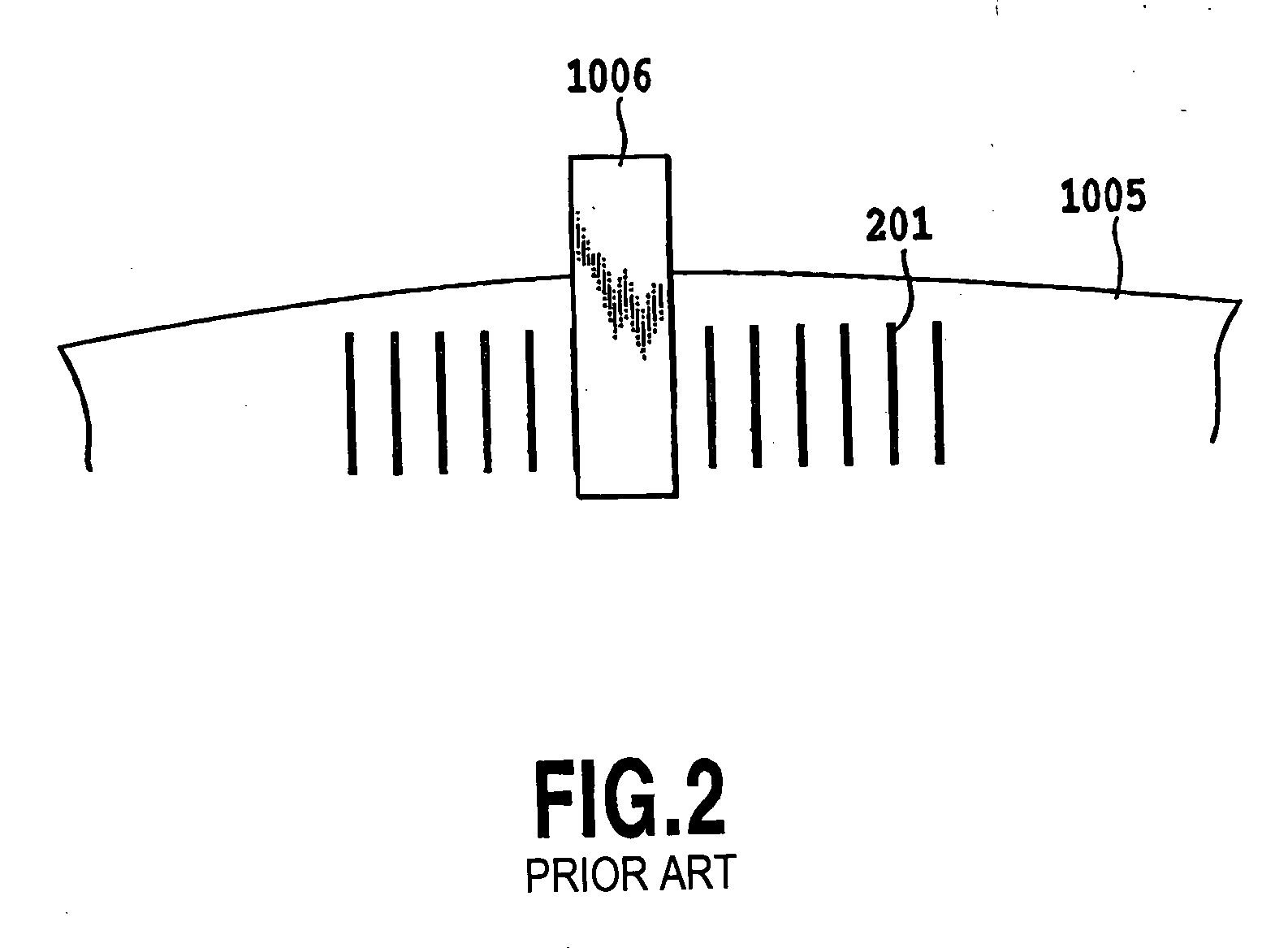

Method of aligning inkjet nozzle banks for an inkjet printer

InactiveUS20050083364A1Reduce Image ArtifactsDecreasing the required receiverSpacing mechanismsPower drive mechanismsComputer printingInk printer

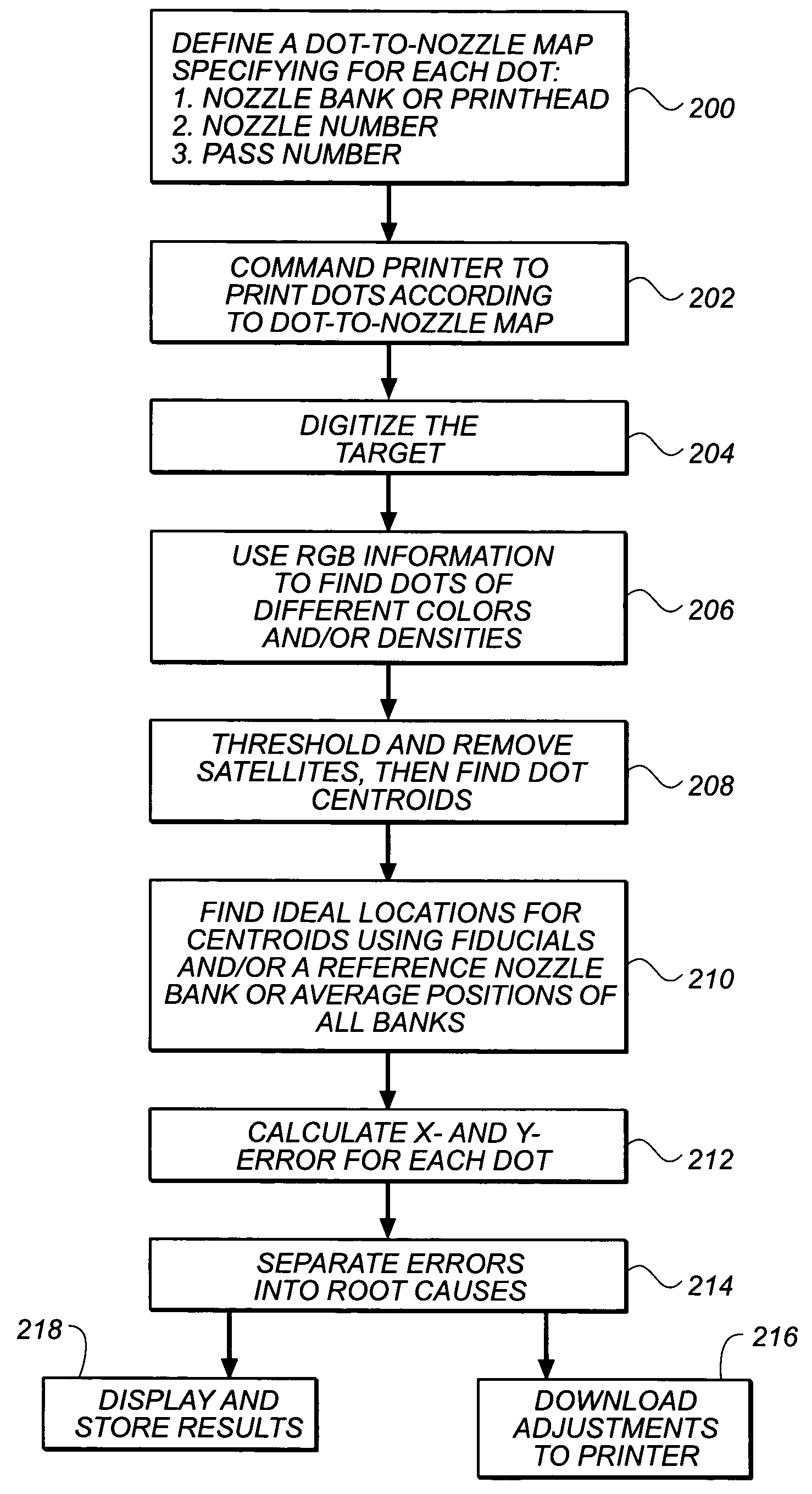

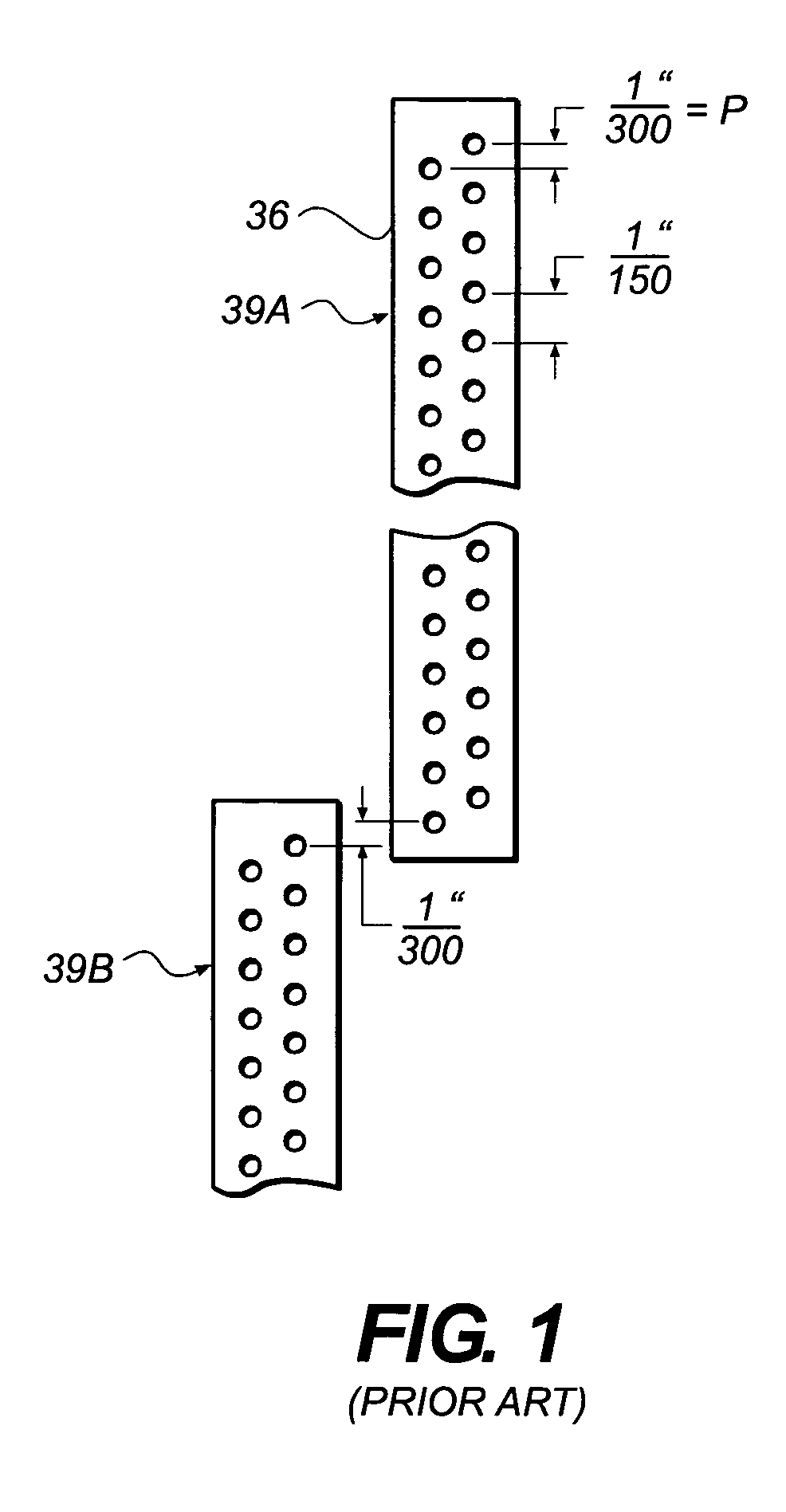

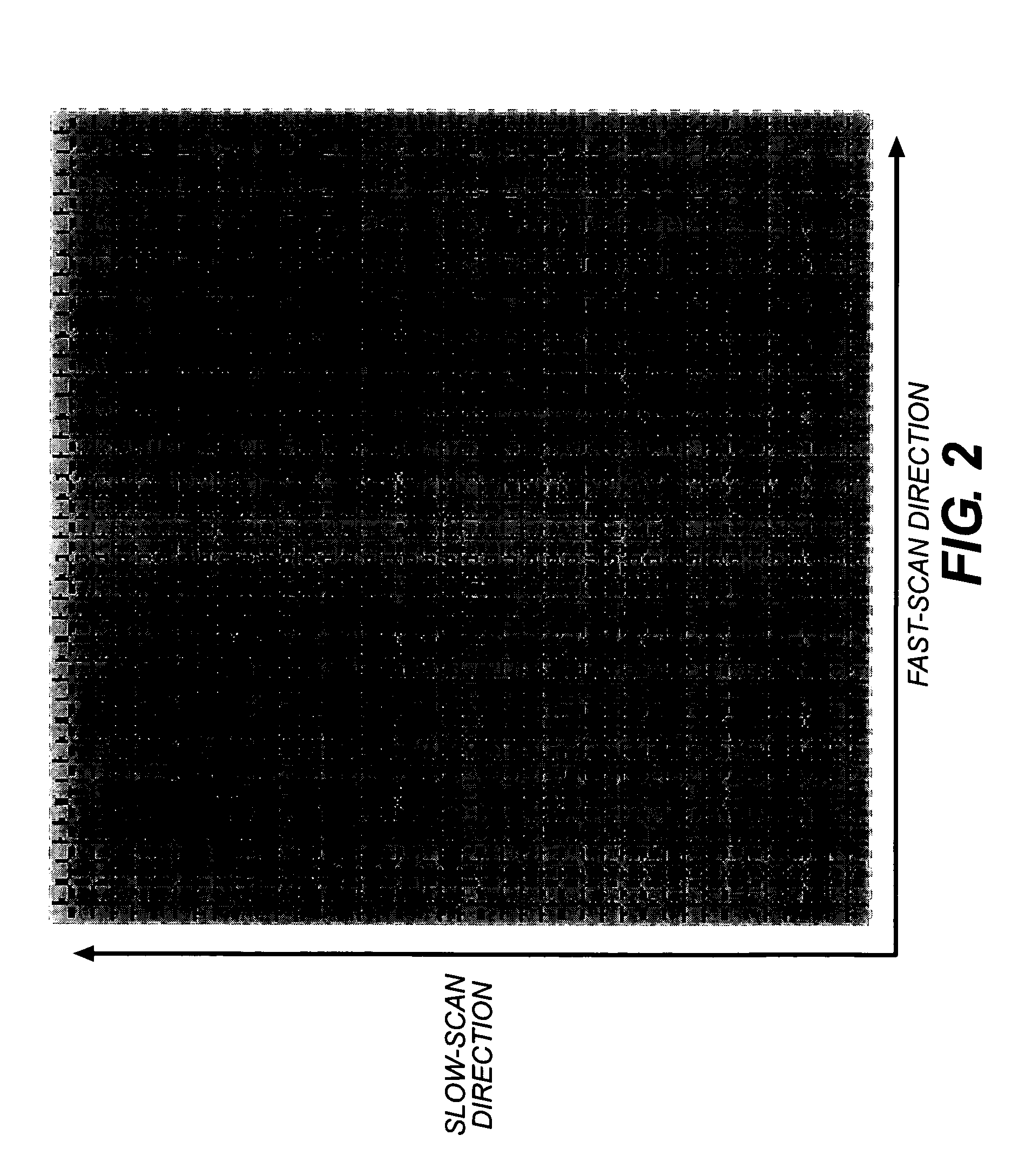

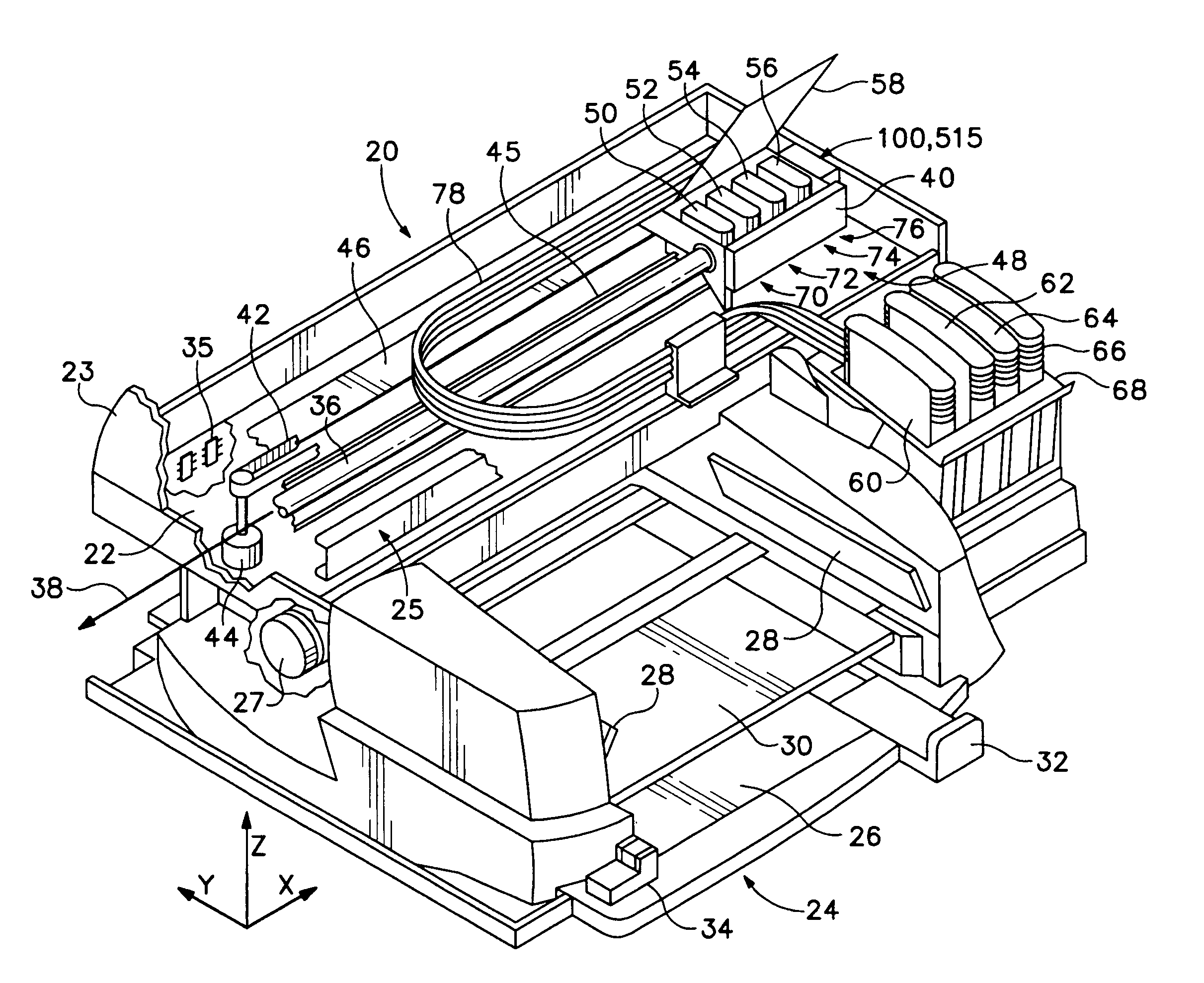

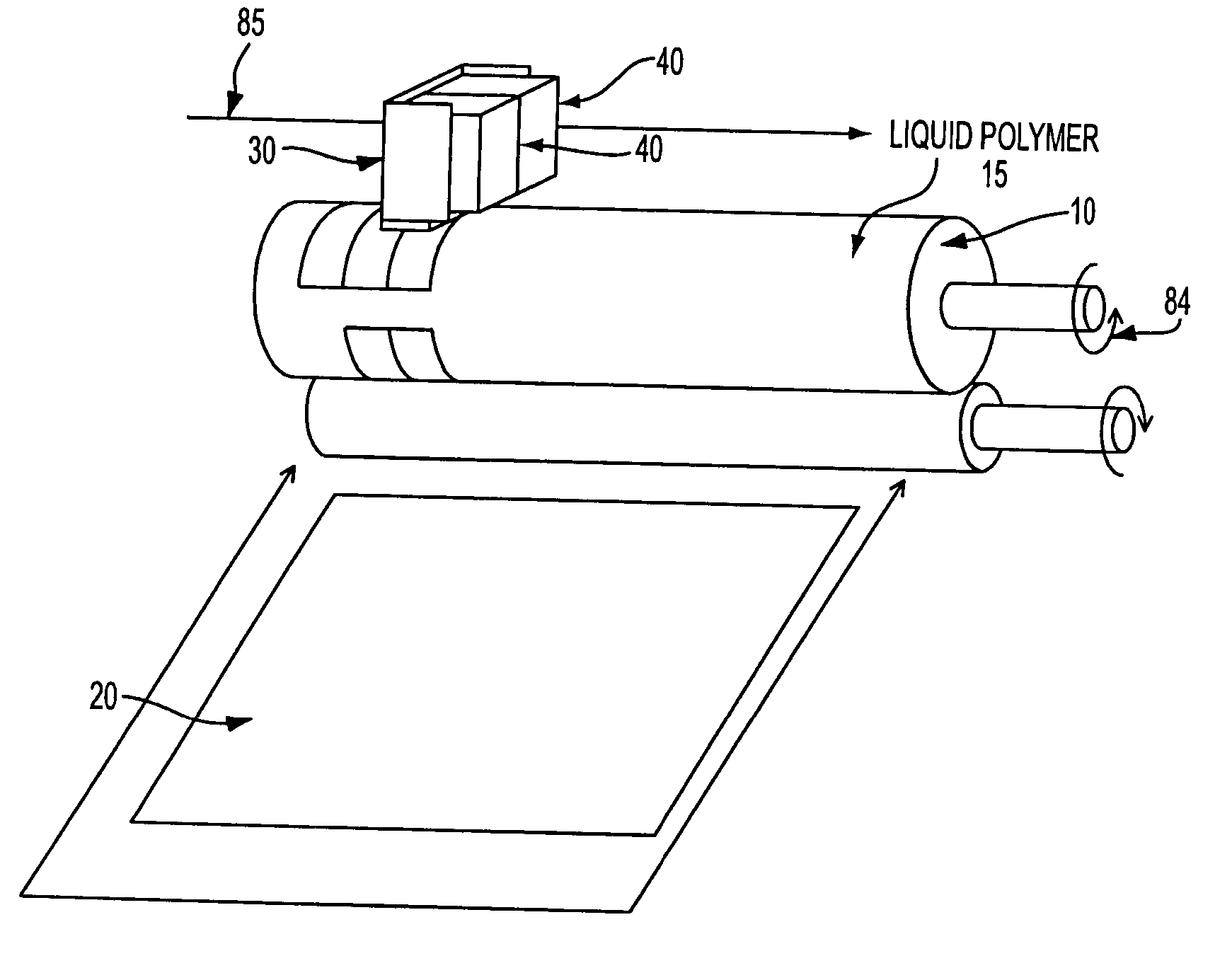

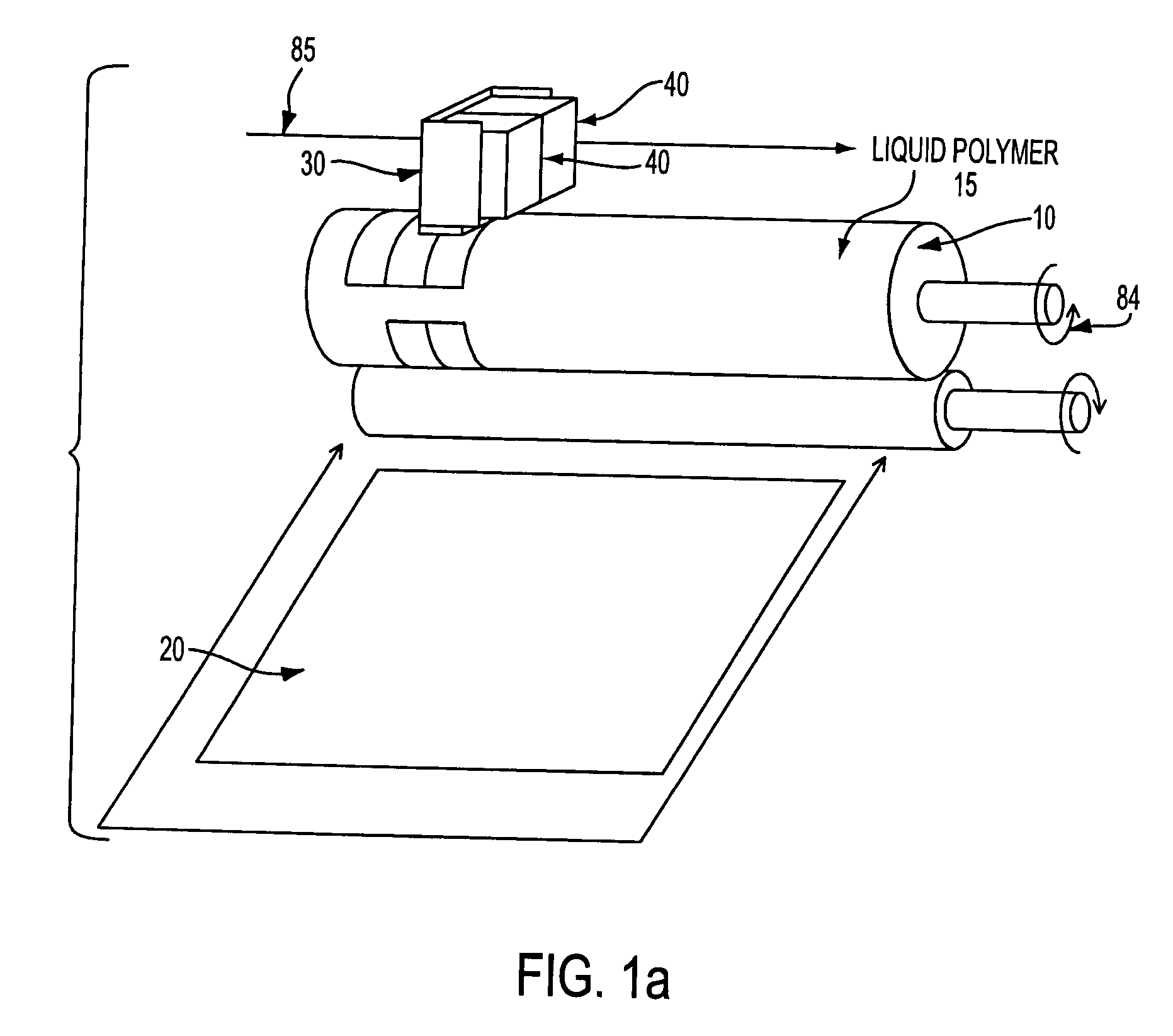

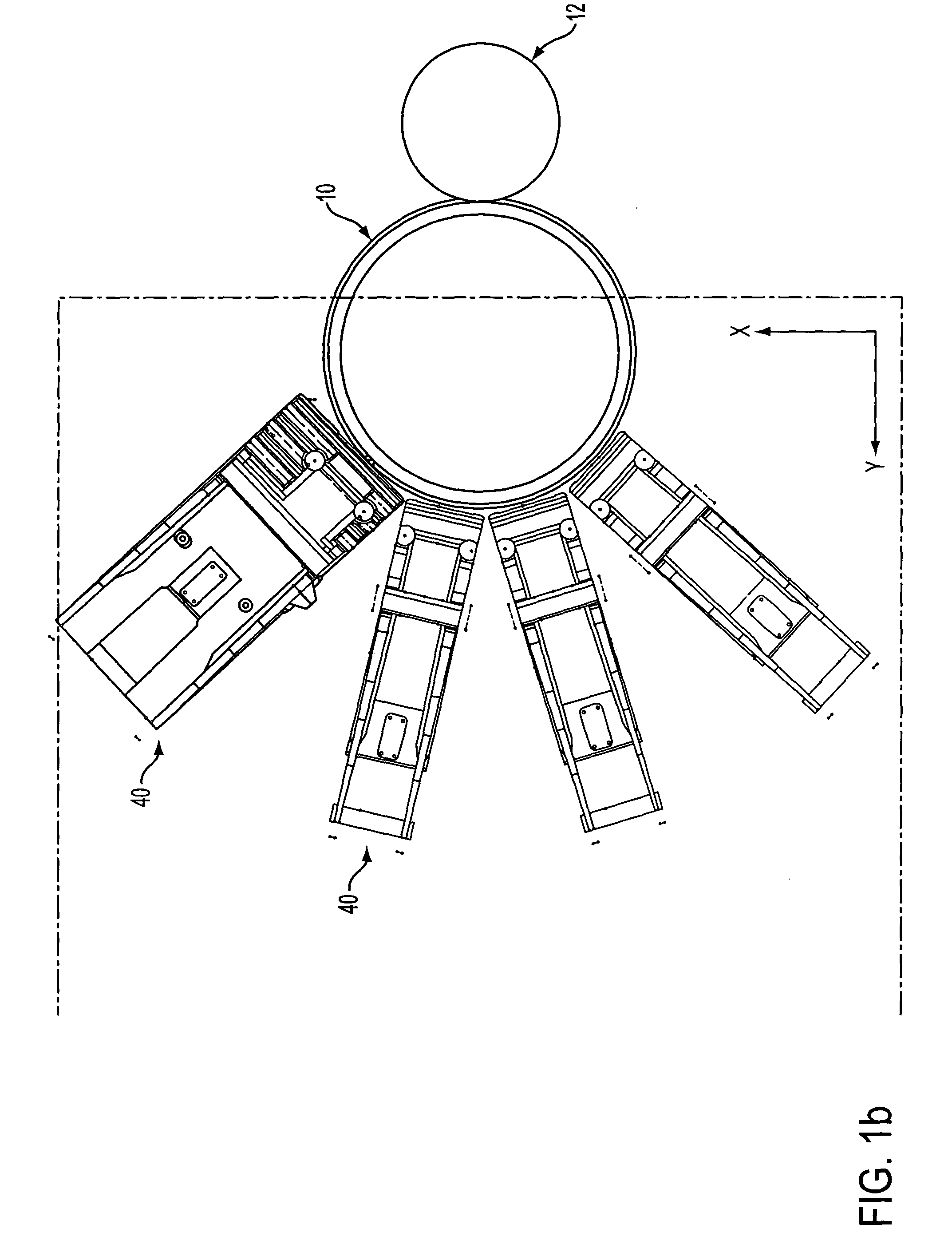

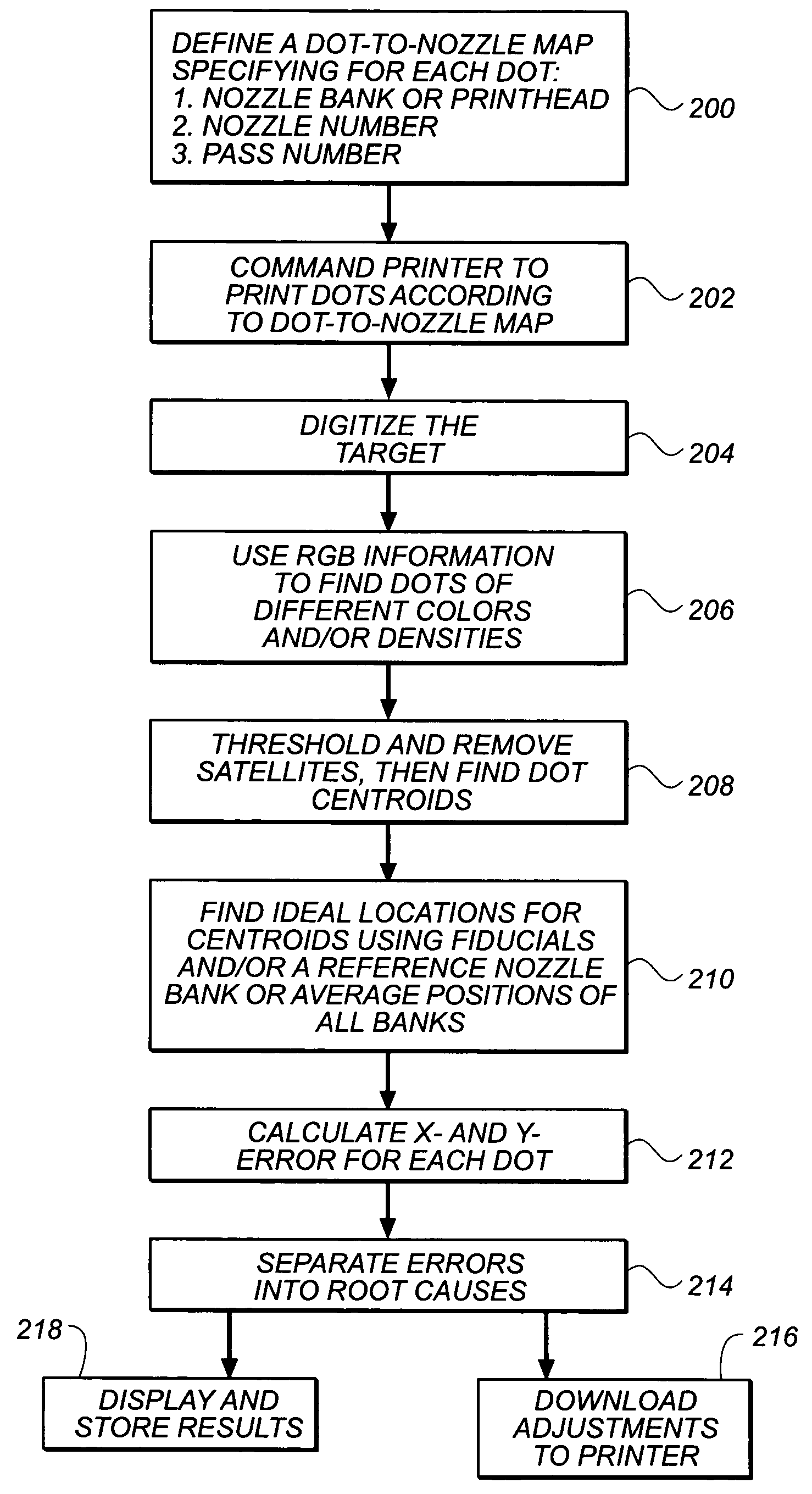

A method is provided for reducing image artifacts in printers that employ two or more printhead nozzle banks that must be aligned and registered with respect to each other either through adjustment of orientation and / or position of one nozzle bank relative to another or through selective control of actuation. In the method, discrete dots are printed by the nozzle banks upon a target receiver medium. Examination of the receiver medium or a reproduction thereof is made by a scanner and information regarding location of the dots is generated. From information regarding location of the dots a determination is made of error placement of the dots from ideal locations. Alignment of the nozzle banks are made in accordance with any errors determined in placement.

Owner:EASTMAN KODAK CO

Early transparency detection routine for inkjet printing

InactiveUS20050073544A1Maximize useLow costSpacing mechanismsInvestigating moving sheetsSpecular reflectionComputer science

A system of classifying incoming media entering an inkjet printing mechanism identifies transparency media without requiring any special manufacturer markings. The media is first optically scanned using a blue-violet light at an initial intensity to obtain both diffuse and specular reflectance data. If useable, the data is compared with known values to classify the media so an optimum print mode tailored for the particular media is used. The early transparency detection system avoids time-consuming further steps trying to classify the media as photo media, plain paper, and the like, and facilitates fast printing of transparencies, which can be critical in the business environment when making last minute changes for a presentation. A printing mechanism constructed to implement this method is also provided.

Owner:HEWLETT PACKARD DEV CO LP

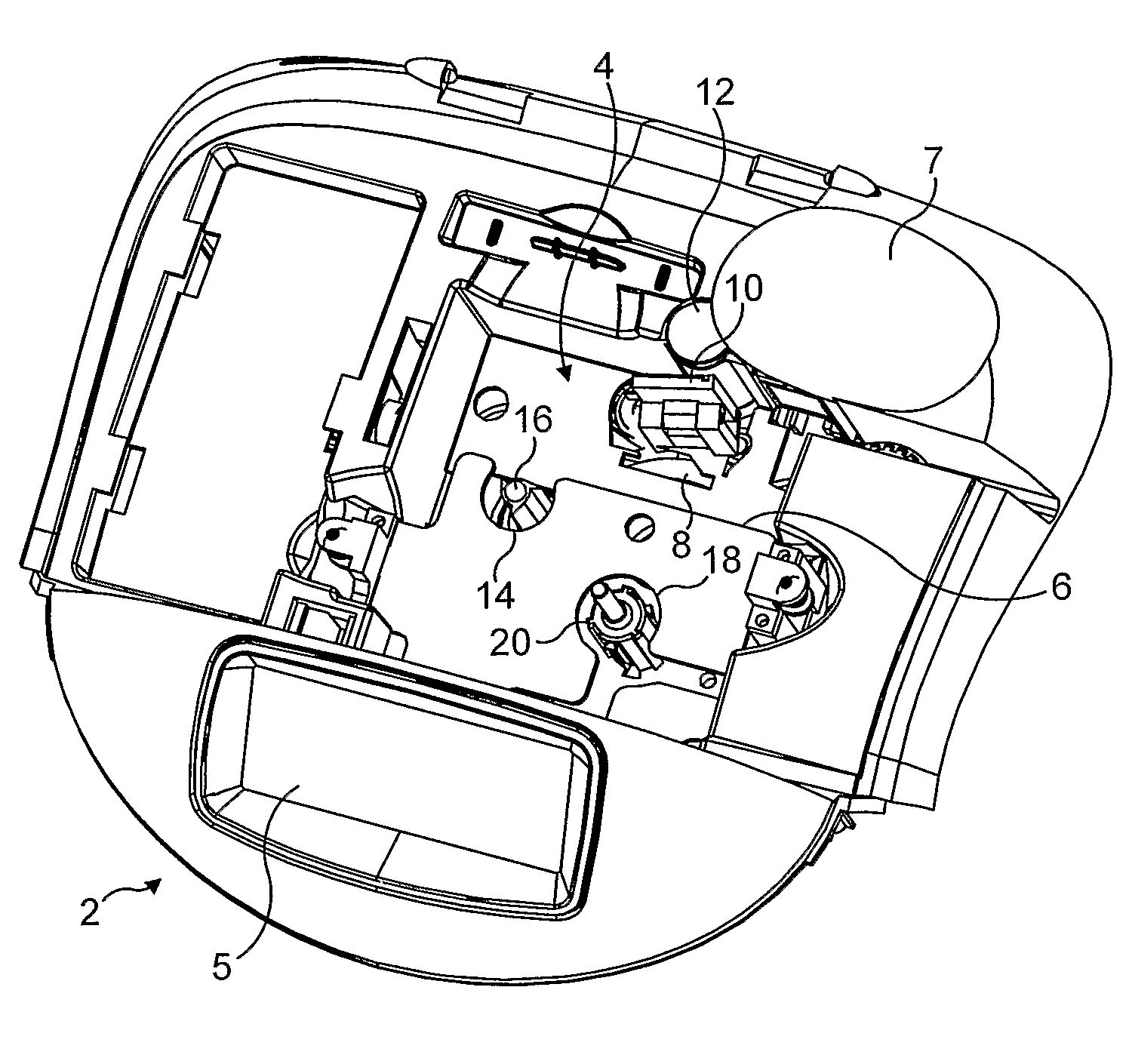

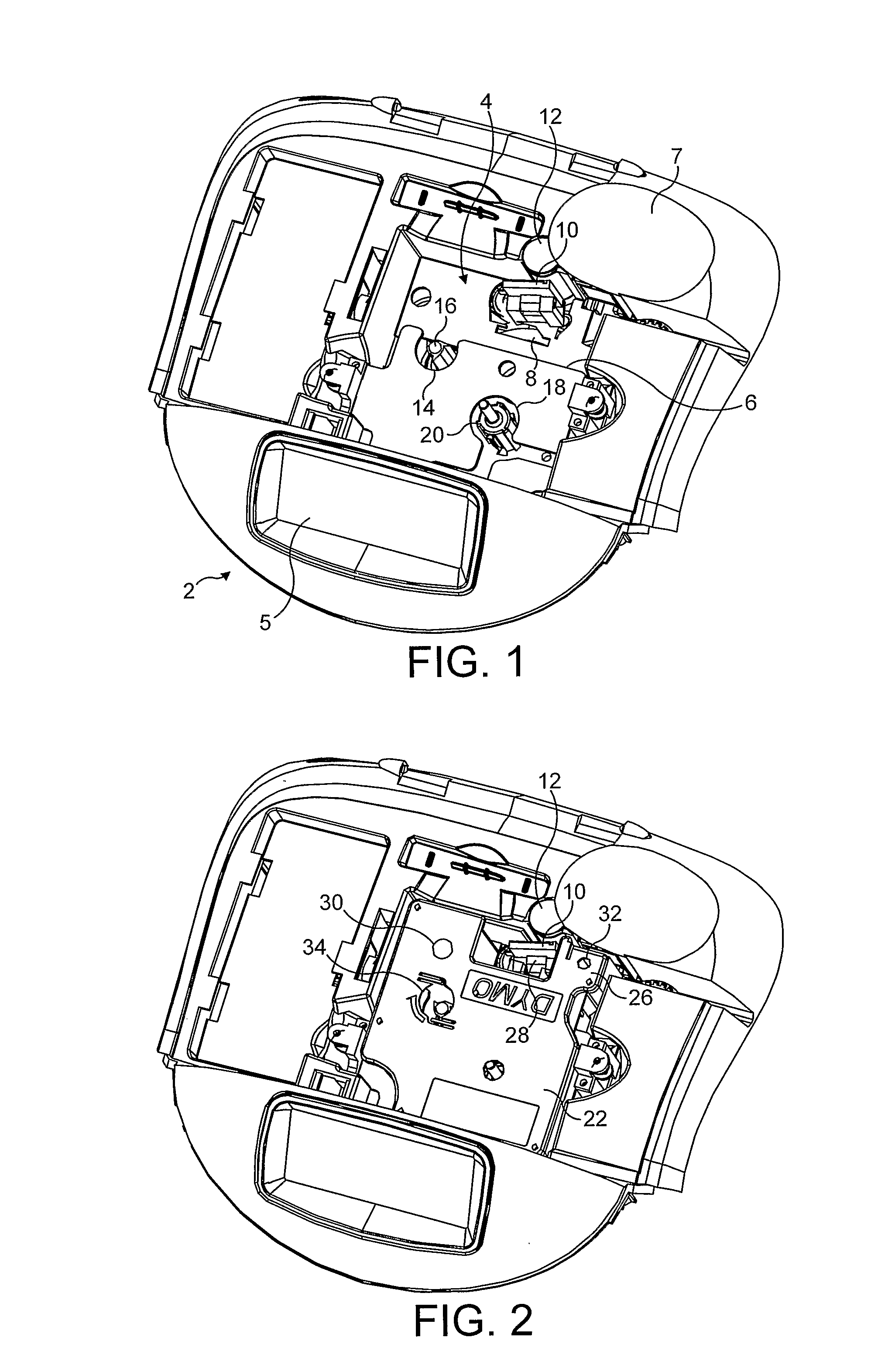

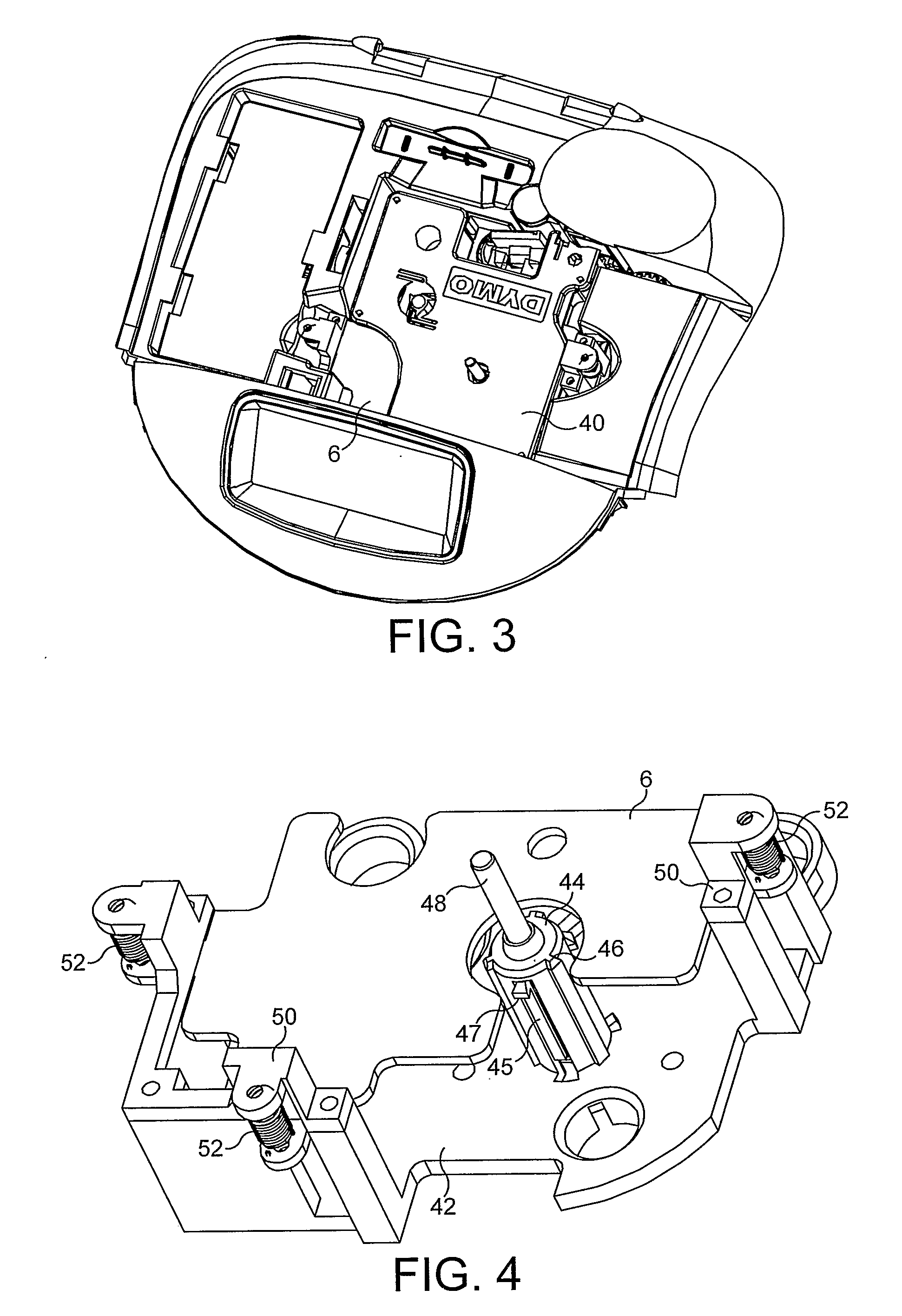

Cassette Locking and Ejecting Arrangement

InactiveUS20120170959A1Minimize movementHold steadyBuilding locksSpacing mechanismsLocking mechanism

A label printer comprising a cassette-receiving bay, the cassette-receiving bay having a base, a top opening opposite the base, and a locking mechanism extending from said base, the locking mechanism having a locking part, the locking part being movable in a first direction and biased in a second direction opposite to the first direction, the locking part having one or more projections such that a force thereon directed towards the base causes the locking part to move in the first direction and wherein said locking part is biased to move in the second direction when the force is removed.

Owner:DYMO (BVBA)

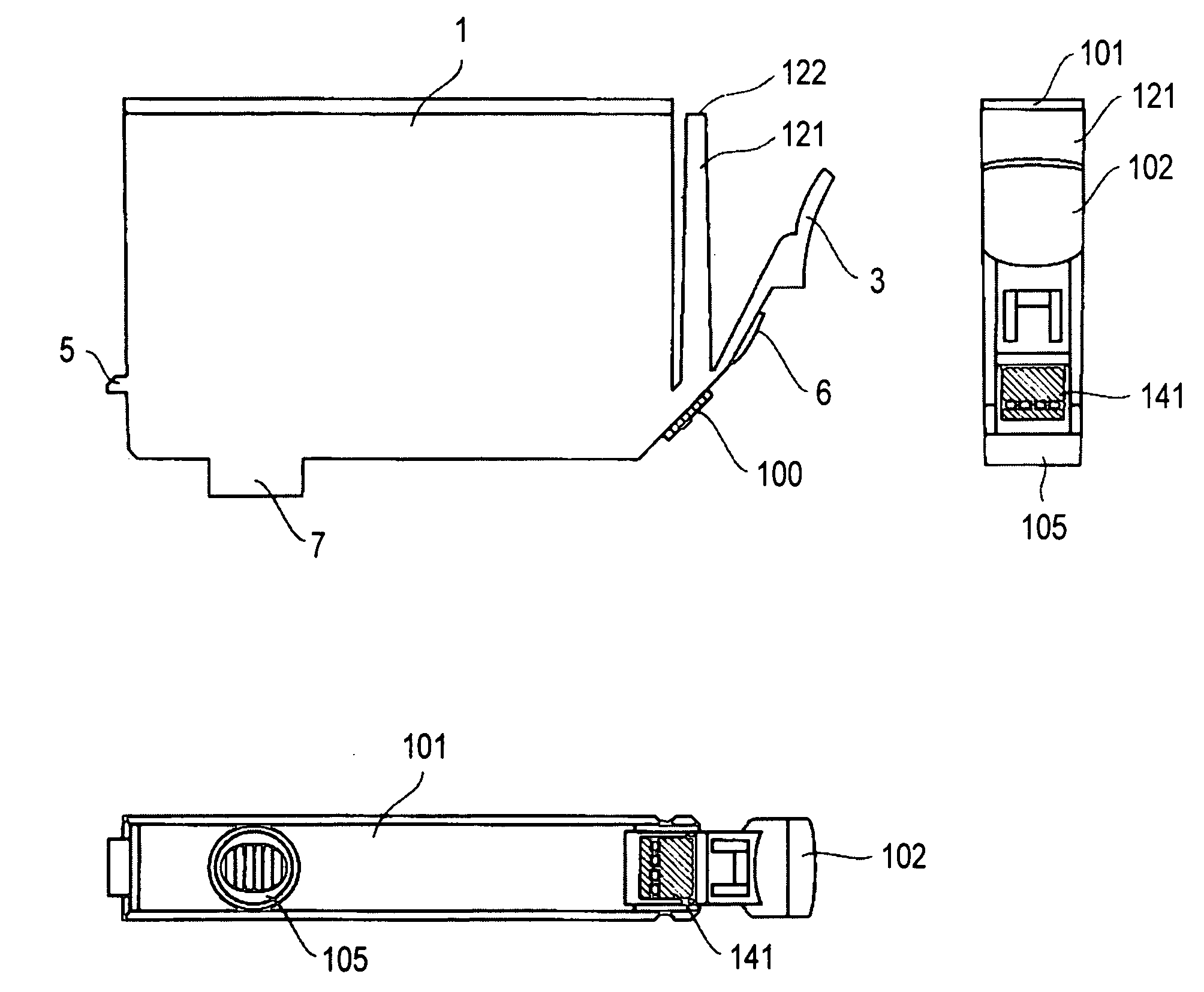

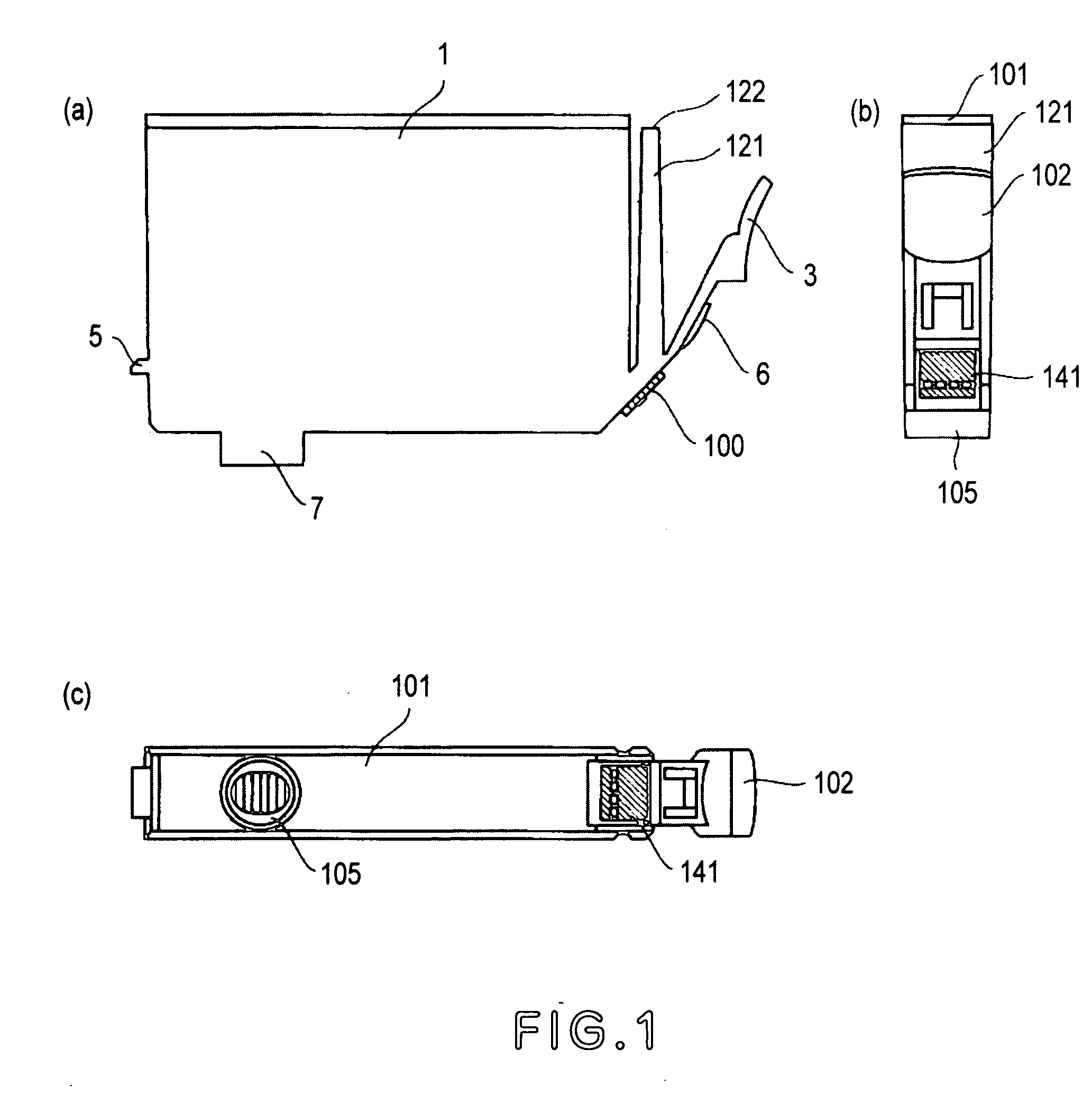

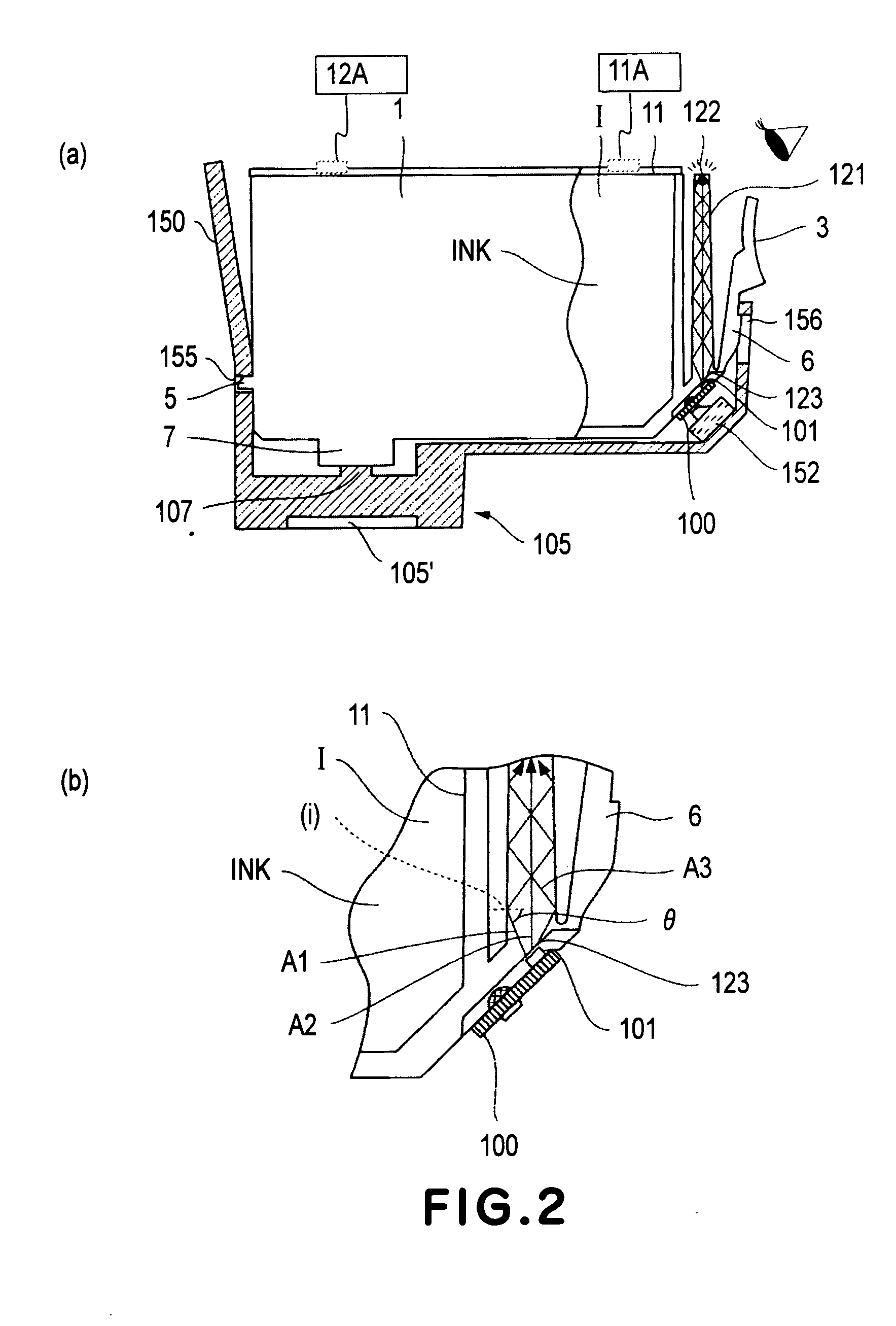

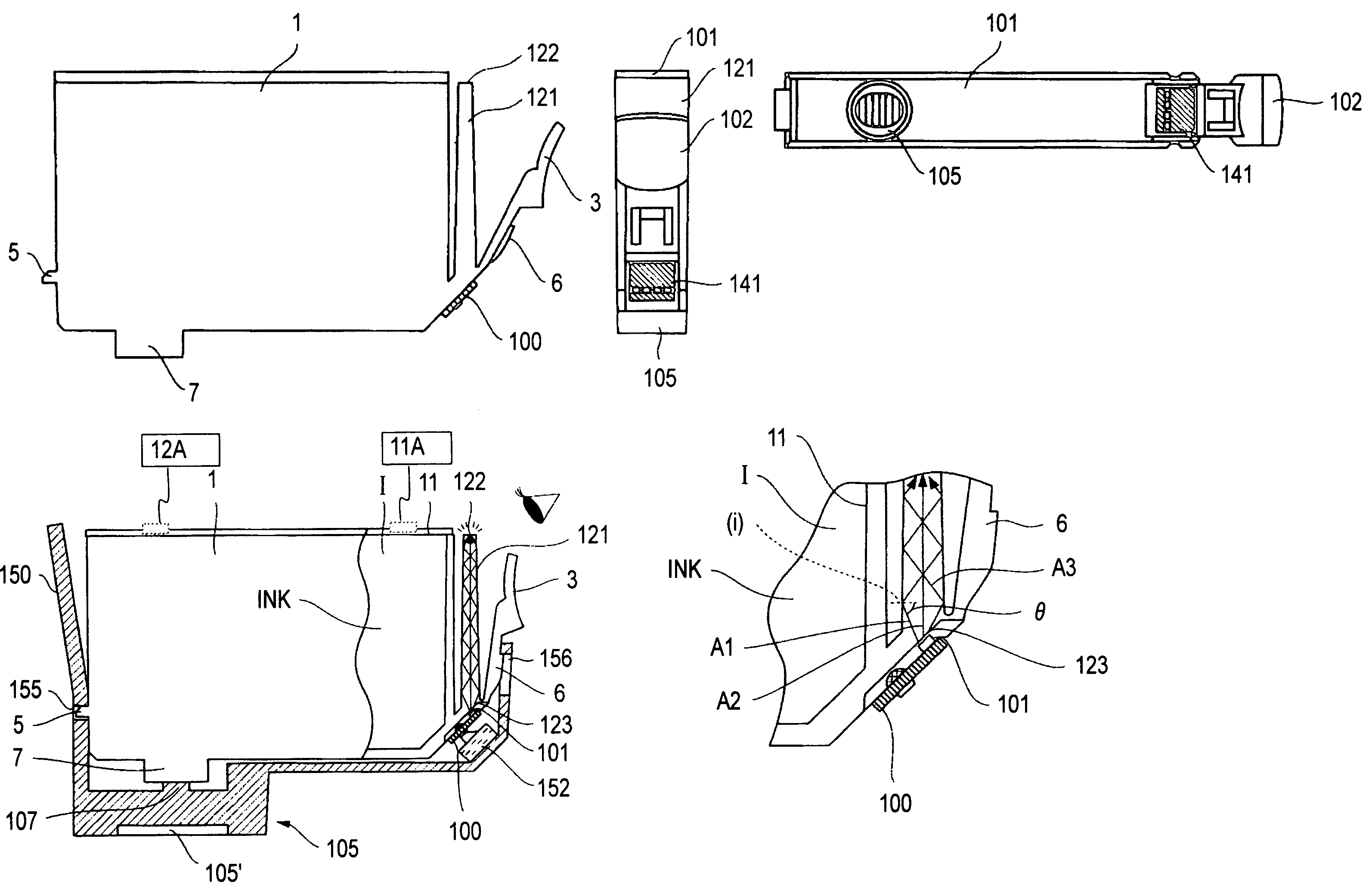

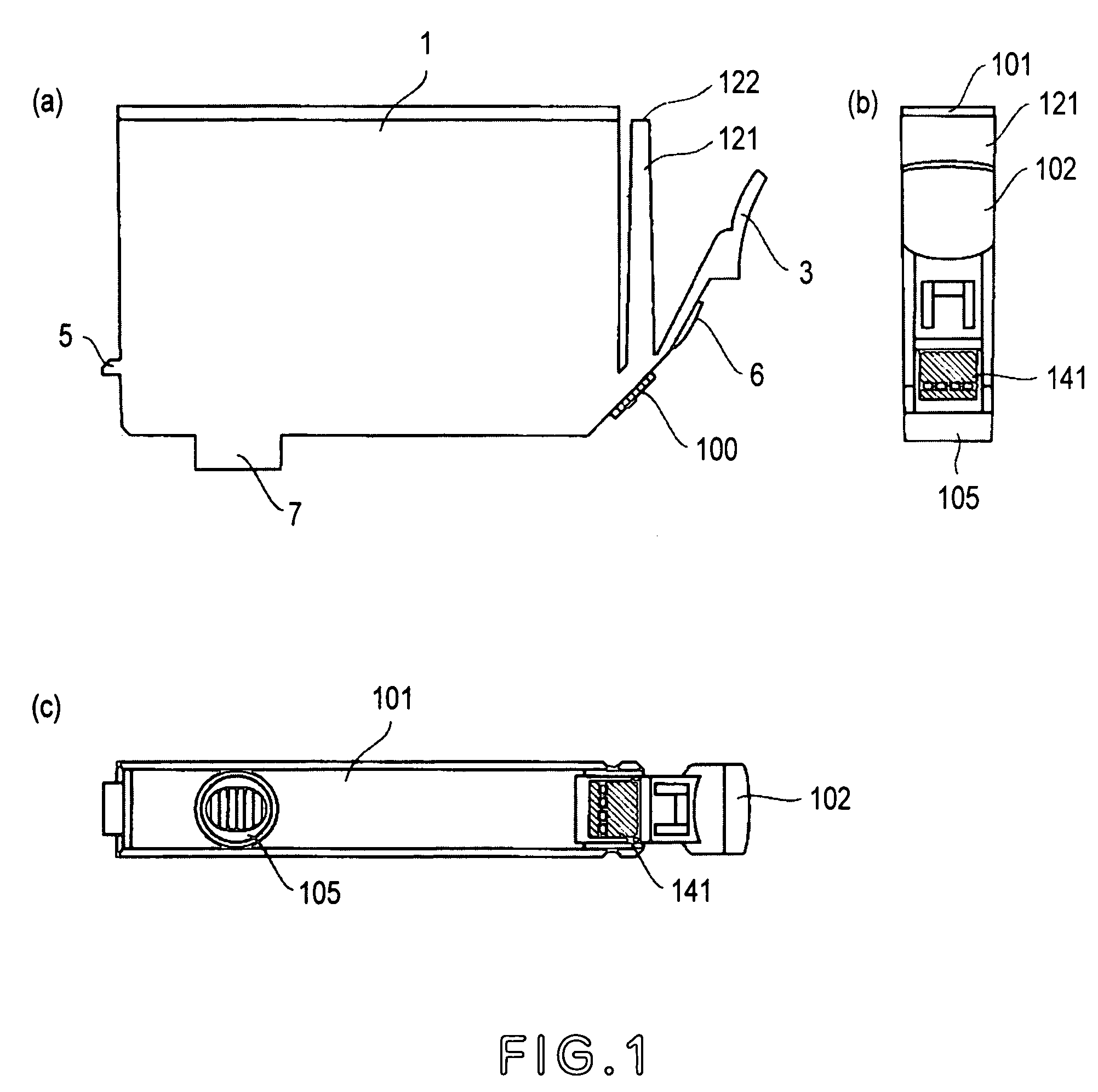

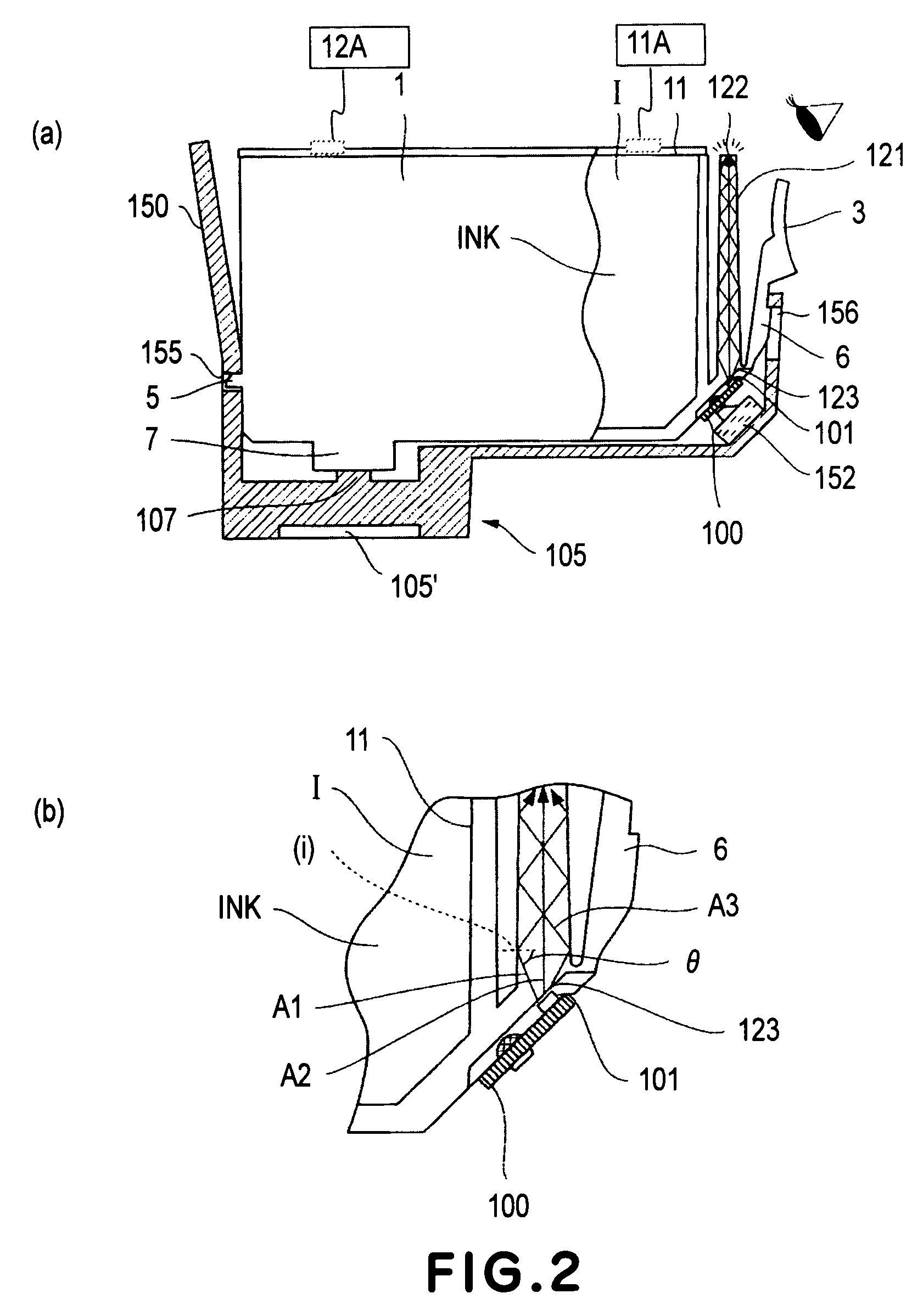

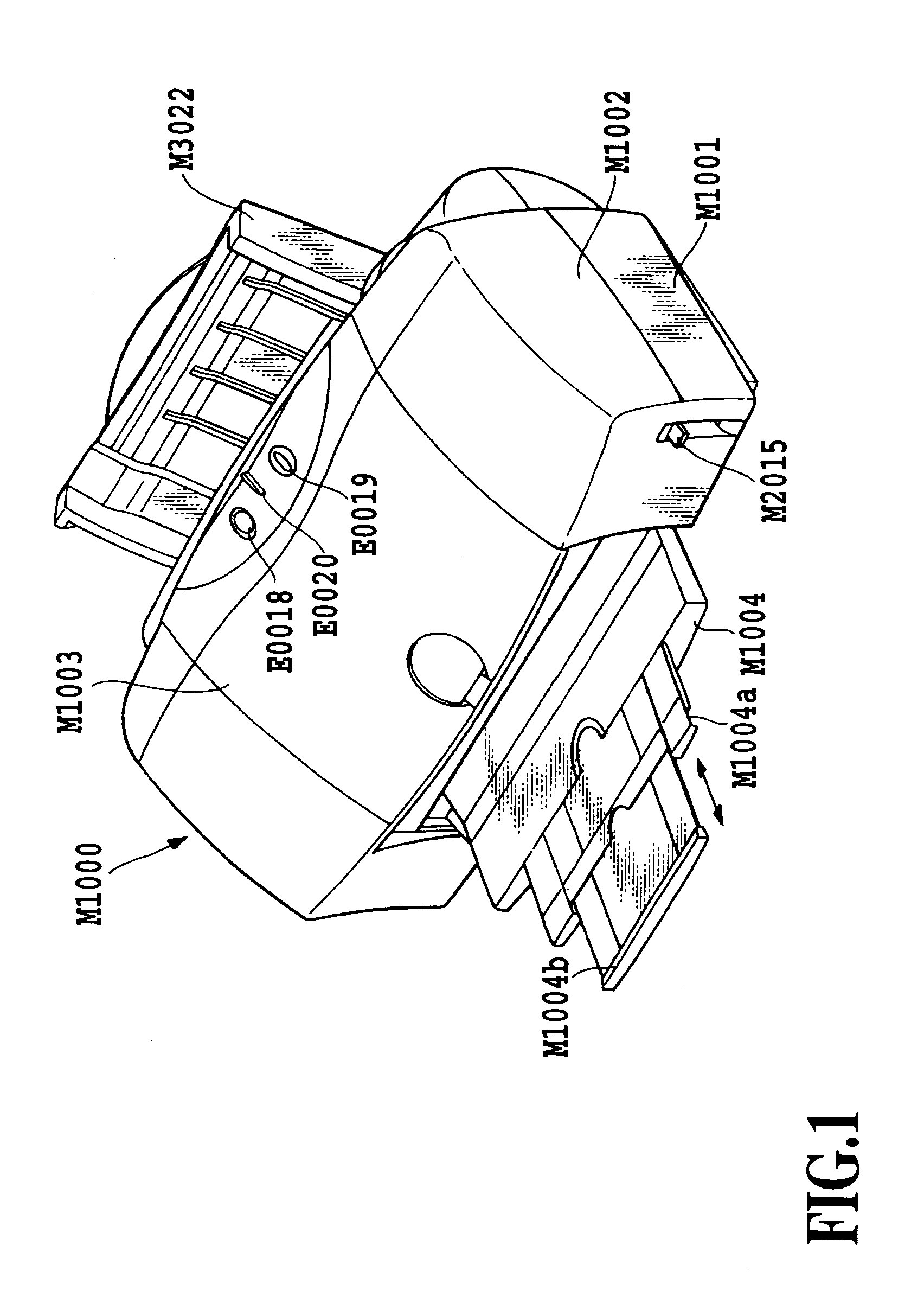

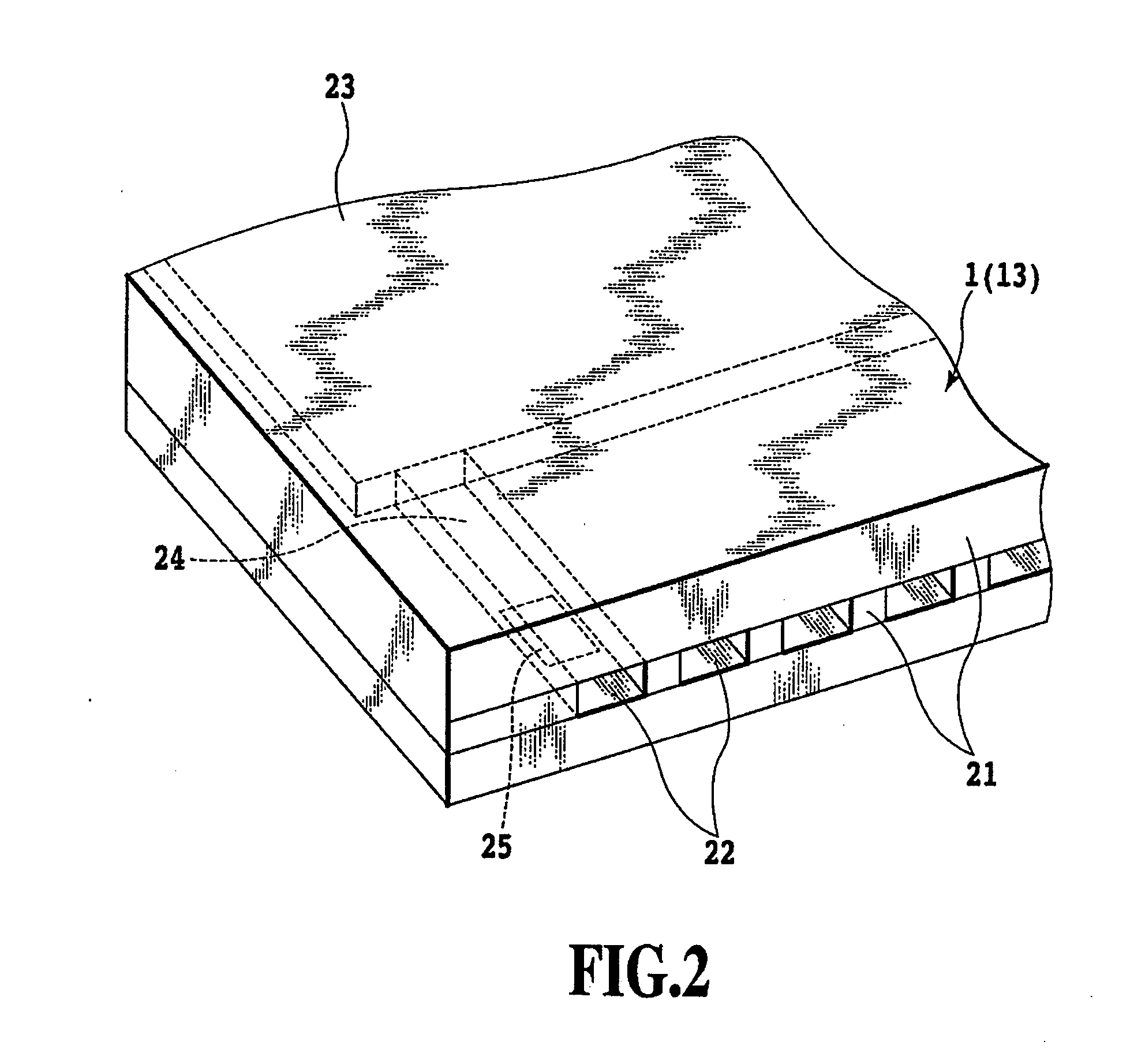

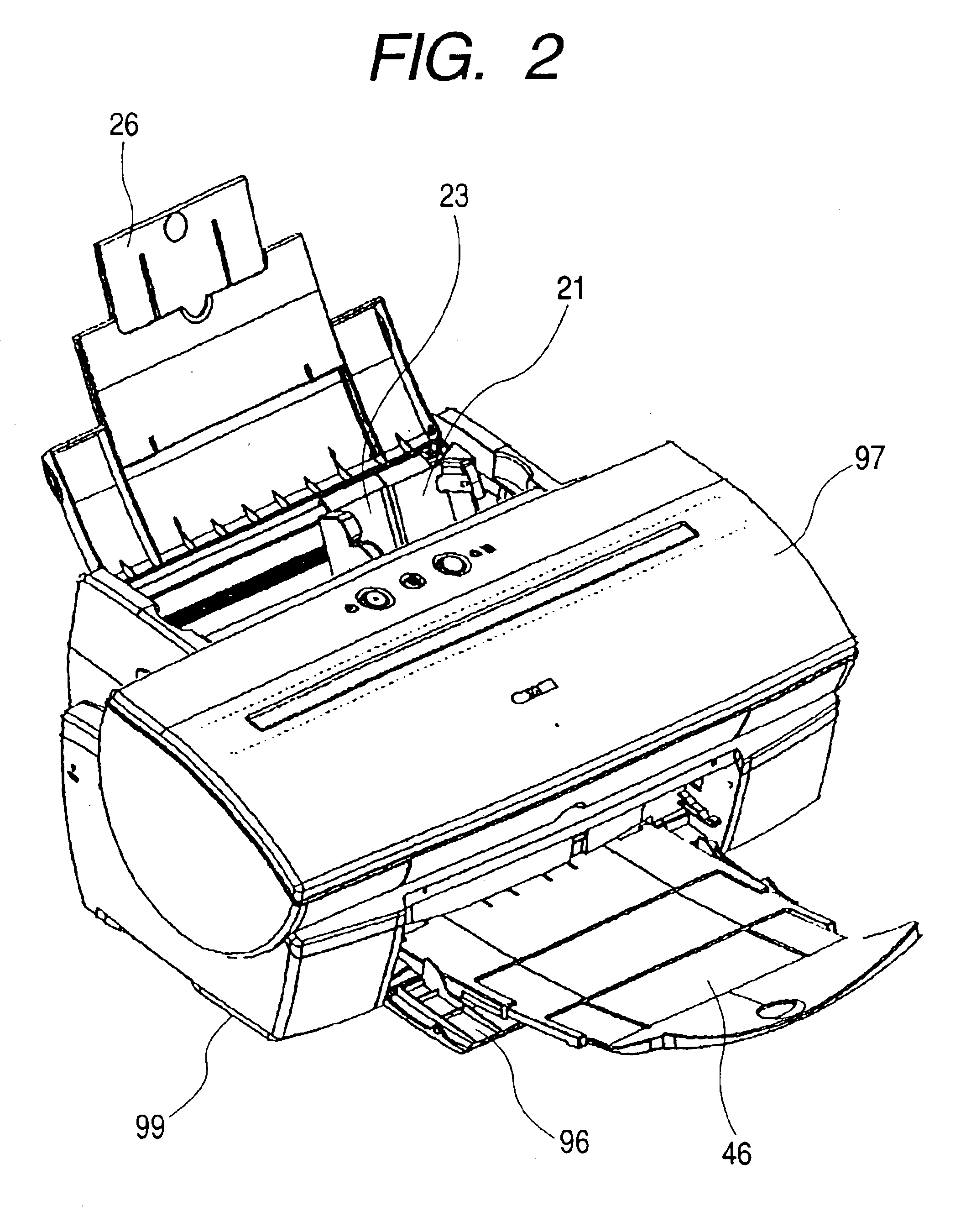

Liquid container and manufacturing method therefor

ActiveUS20050185034A1Optimization mechanismAccurate and reliable positioningSpacing mechanismsOther printing apparatusEngineeringMechanical engineering

Owner:CANON KK

Liquid container and manufacturing method therefor

ActiveUS7213914B2Operation to the mounting portionSimple and easySpacing mechanismsOther printing apparatusEngineeringLight-emitting diode

Owner:CANON KK

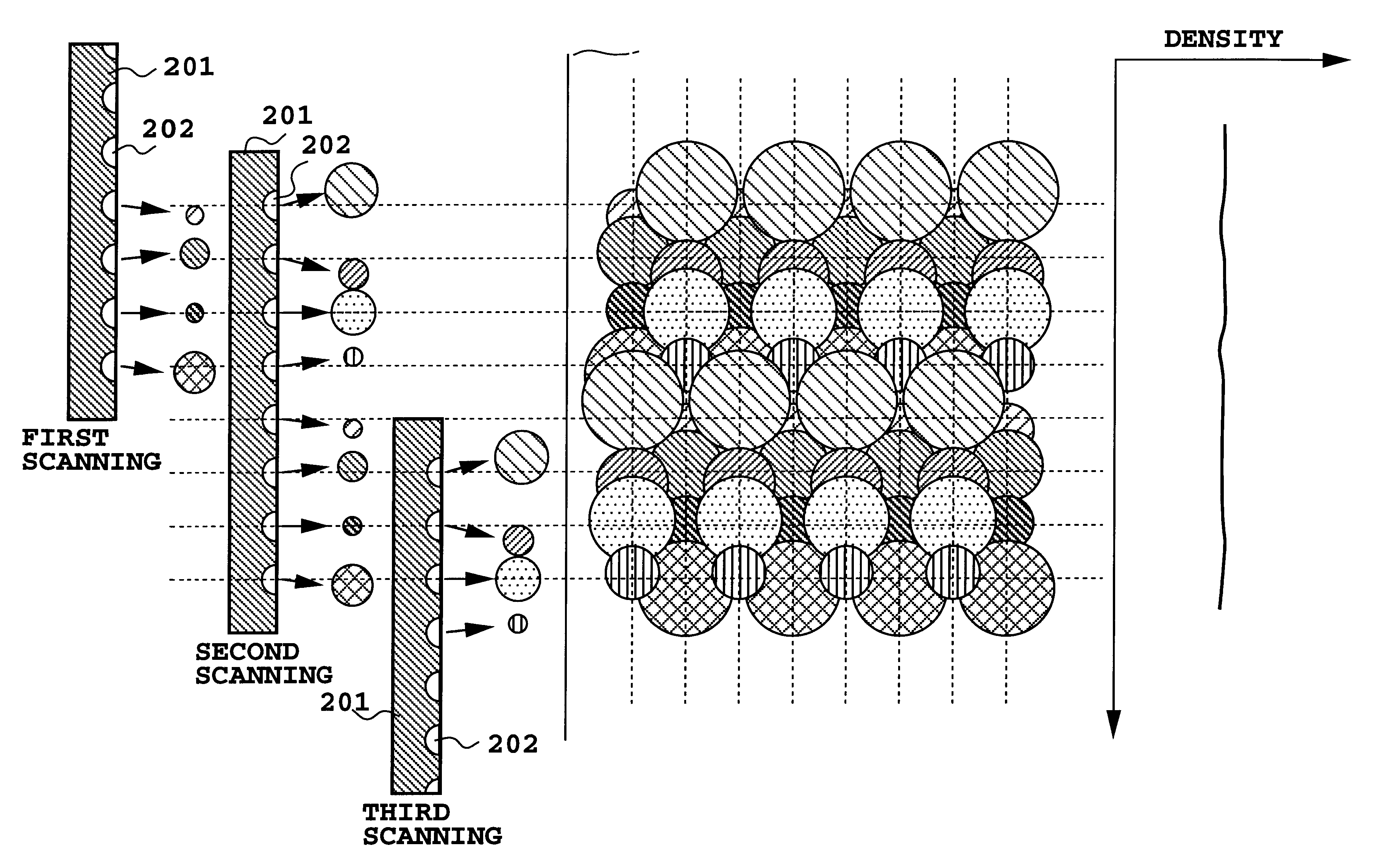

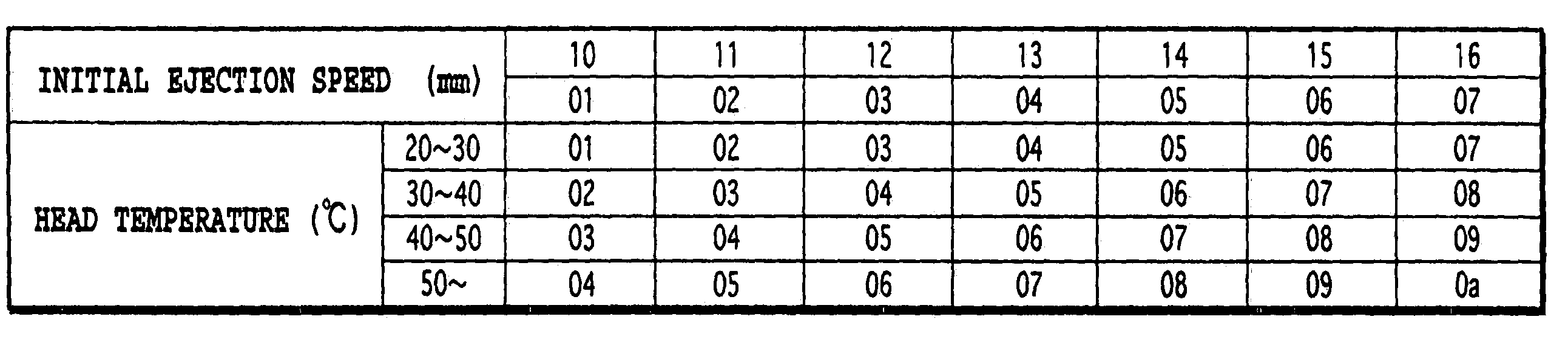

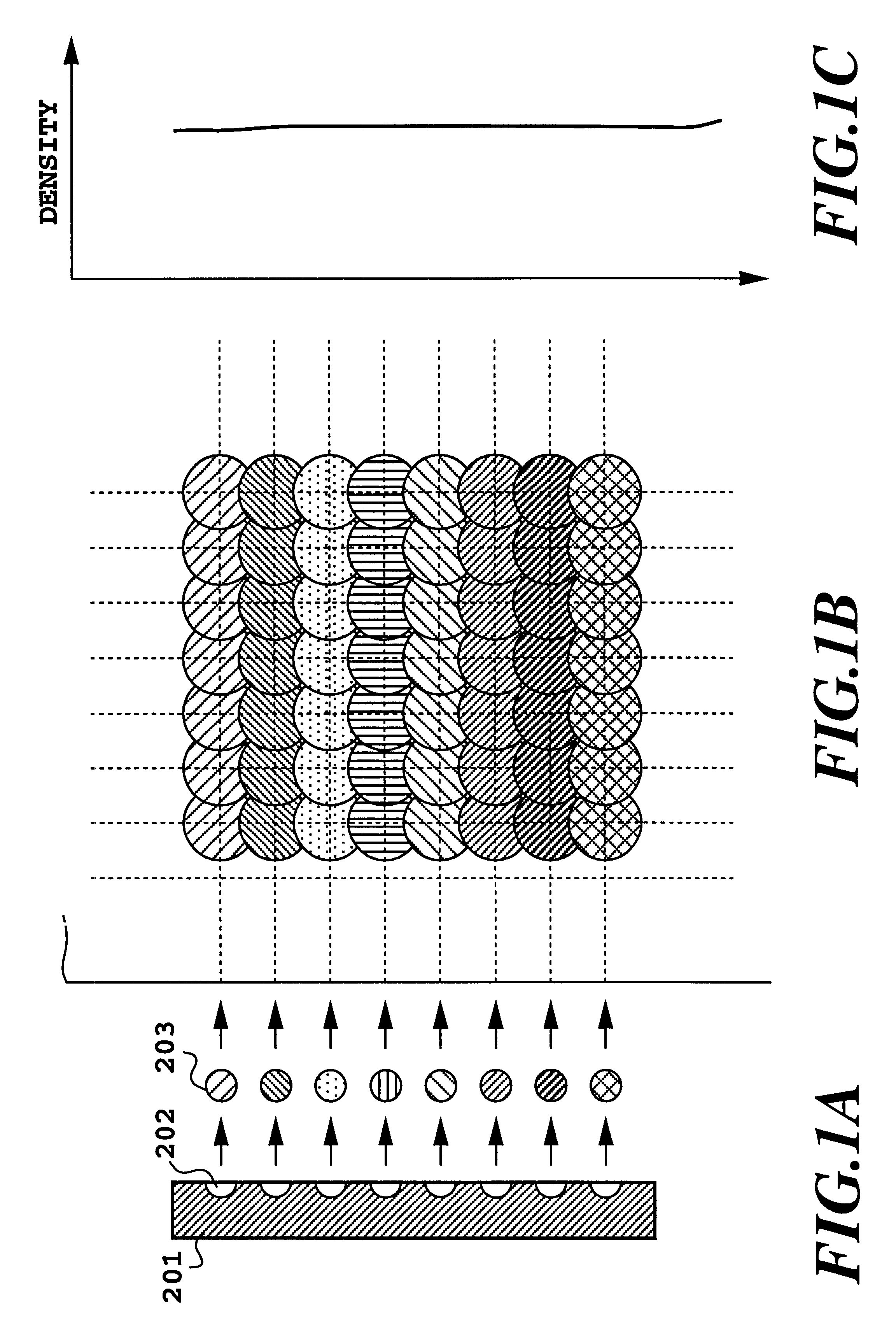

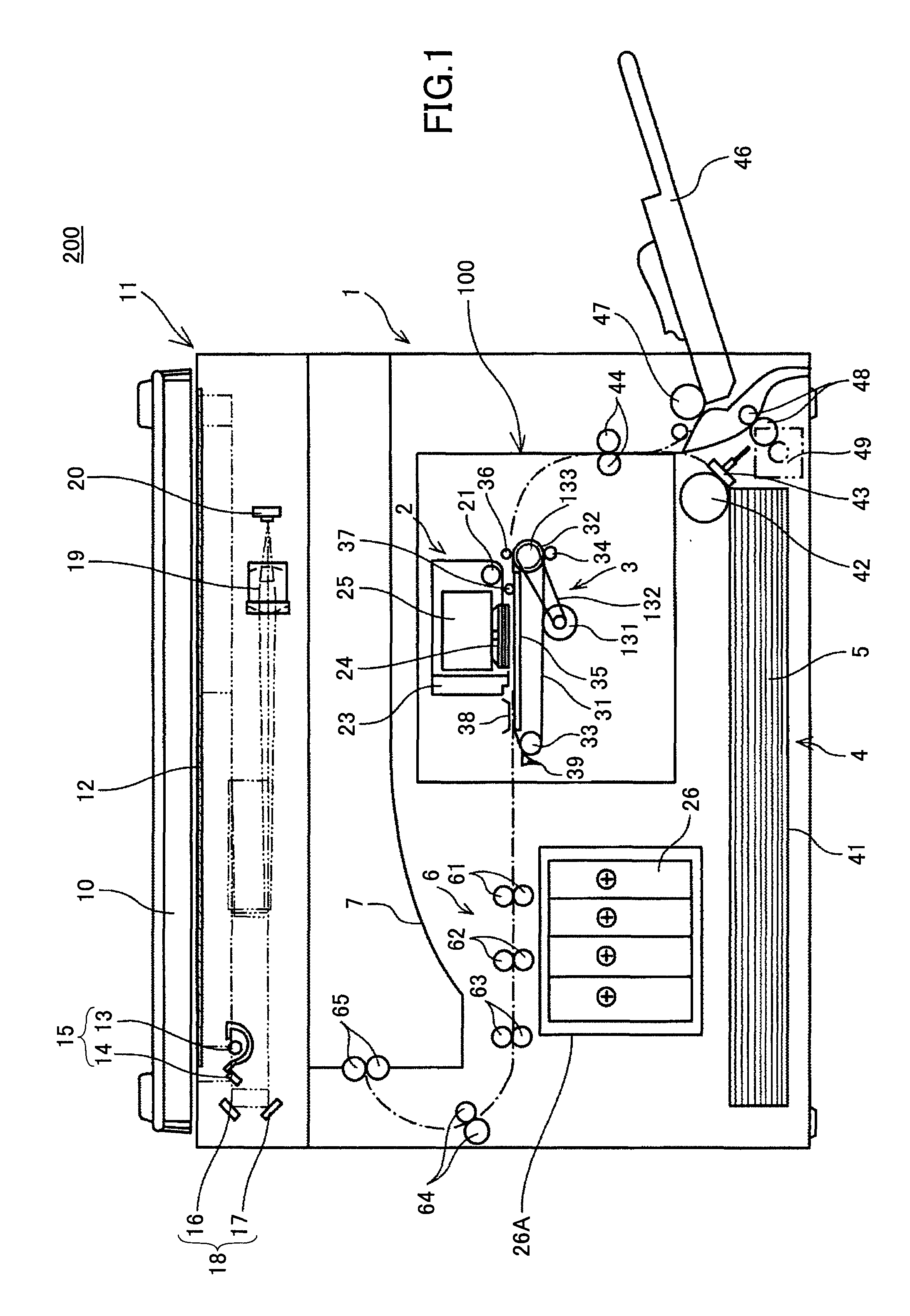

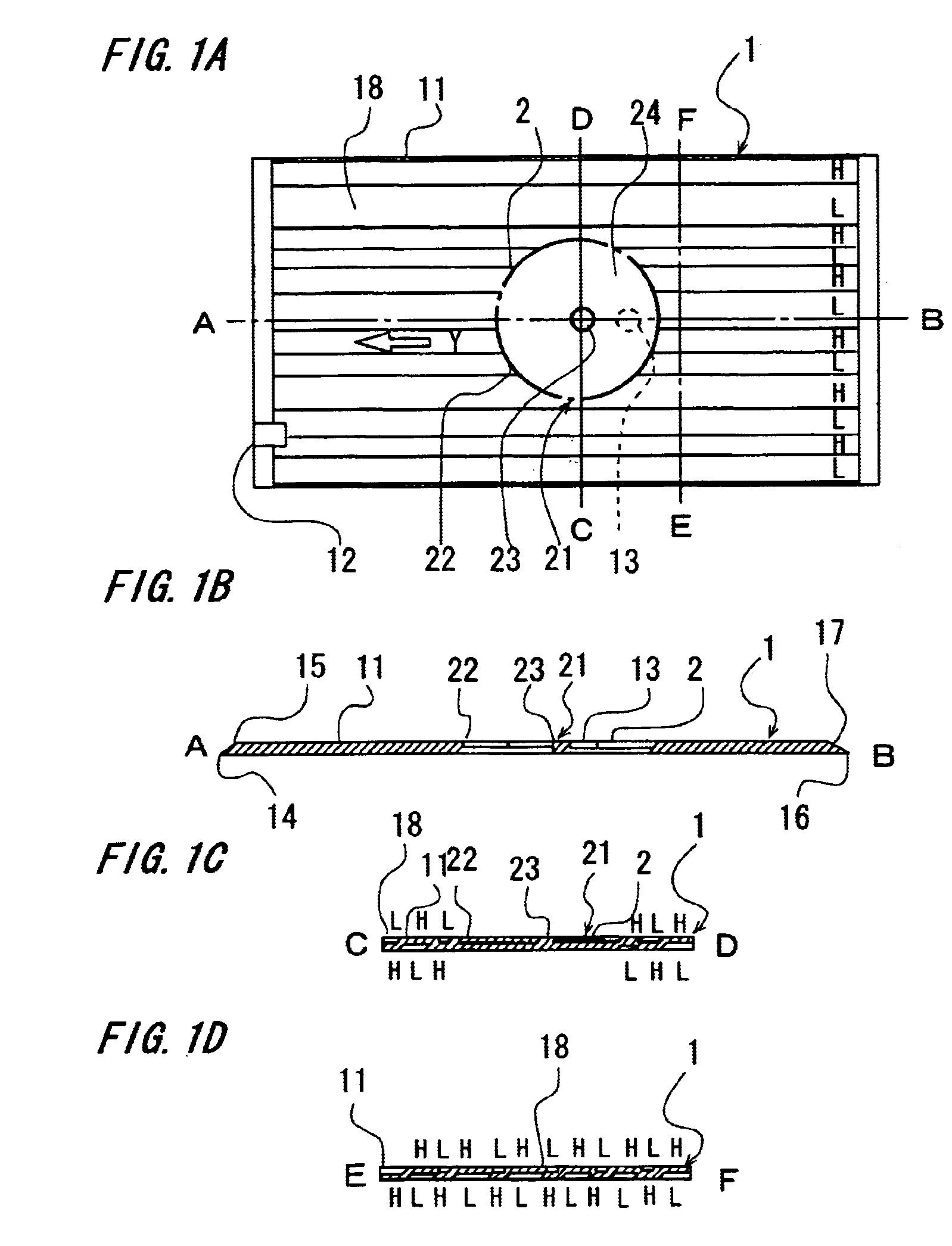

Adjustment method of dot printing positions and a printing apparatus

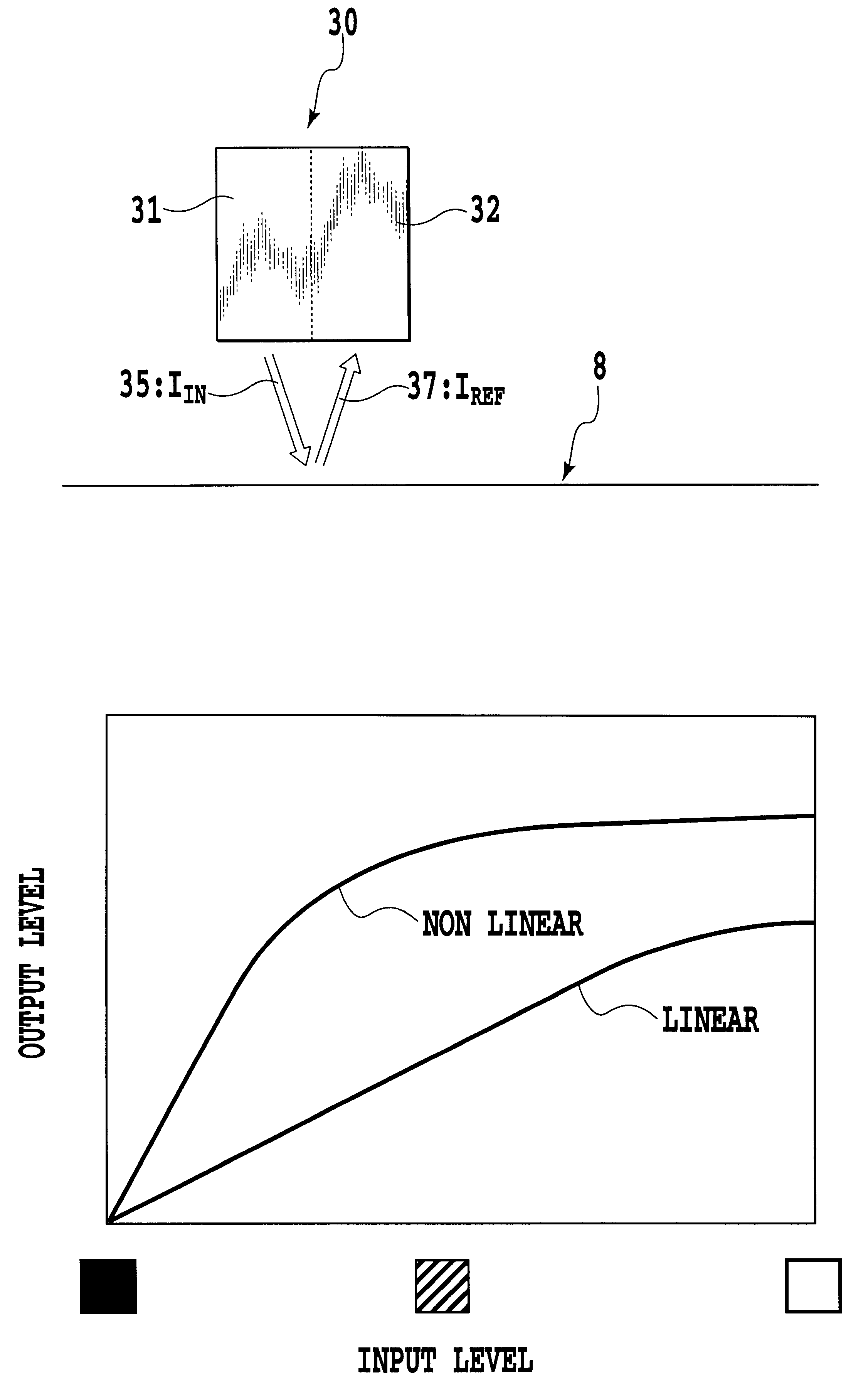

InactiveUS6257143B1Guaranteed uptimeLow costCylinder pressesPlaten pressesEngineeringPrinting registration

A plurality of patterns respectively having different area factor of dot formation area are formed by forward and reverse scanning printing of a print head, and then optical characteristics of the plurality of formed patterns are measured. A function representing the relationship between the printing position offset between the forward and reverse printings is determined from the optical characteristics. Then, respective pattern having a predetermined area factor of dot formation area is formed by means of forward and reverse scanning where the speed is differentiated according to the mode of a printing apparatus, and then the optical characteristics of this pattern is measured. By applying this measured optical characteristics to the function, an adjustment value of the dot formation position conditions between the forward and reverse scans is obtained for each mode. This makes it easy to perform printing registration in a printing apparatus in the case of printing by a forward and reverse scan of a printing head or in the case of printing by means of a plurality of printing heads. In this case, operations by a user etc. are also unnecessary and are easily performed.

Owner:CANON KK

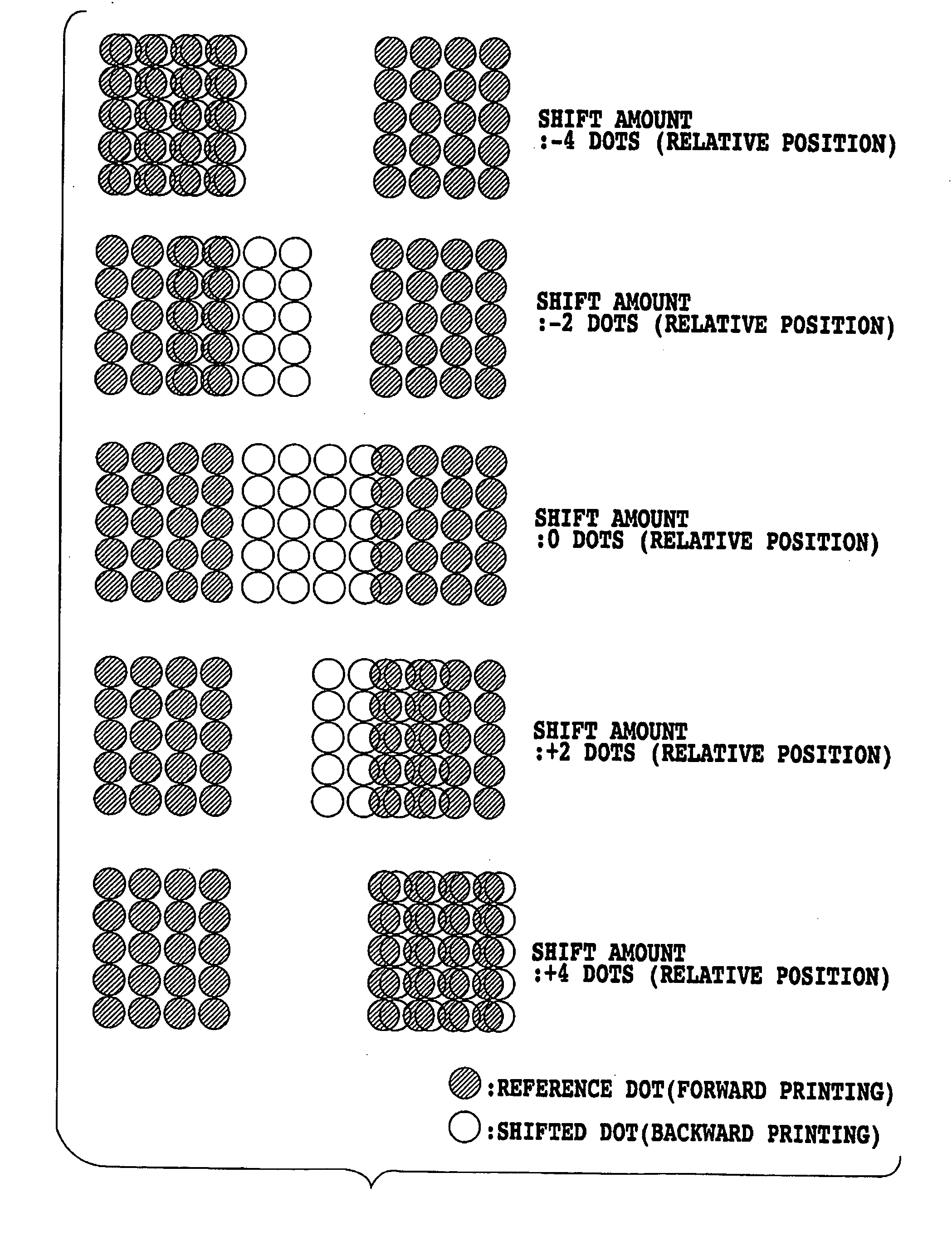

Adjustment method of dot printing positions and a printing apparatus

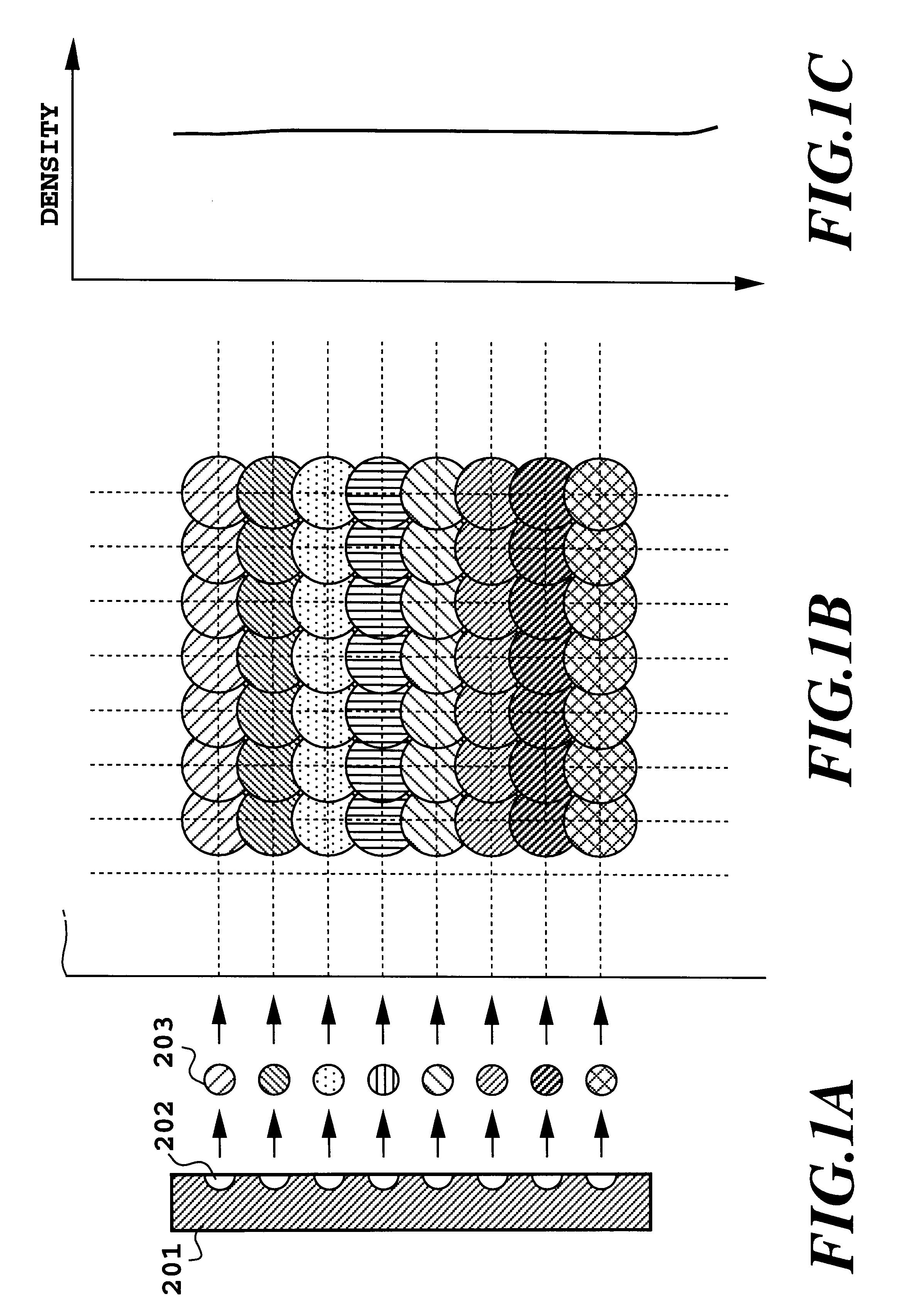

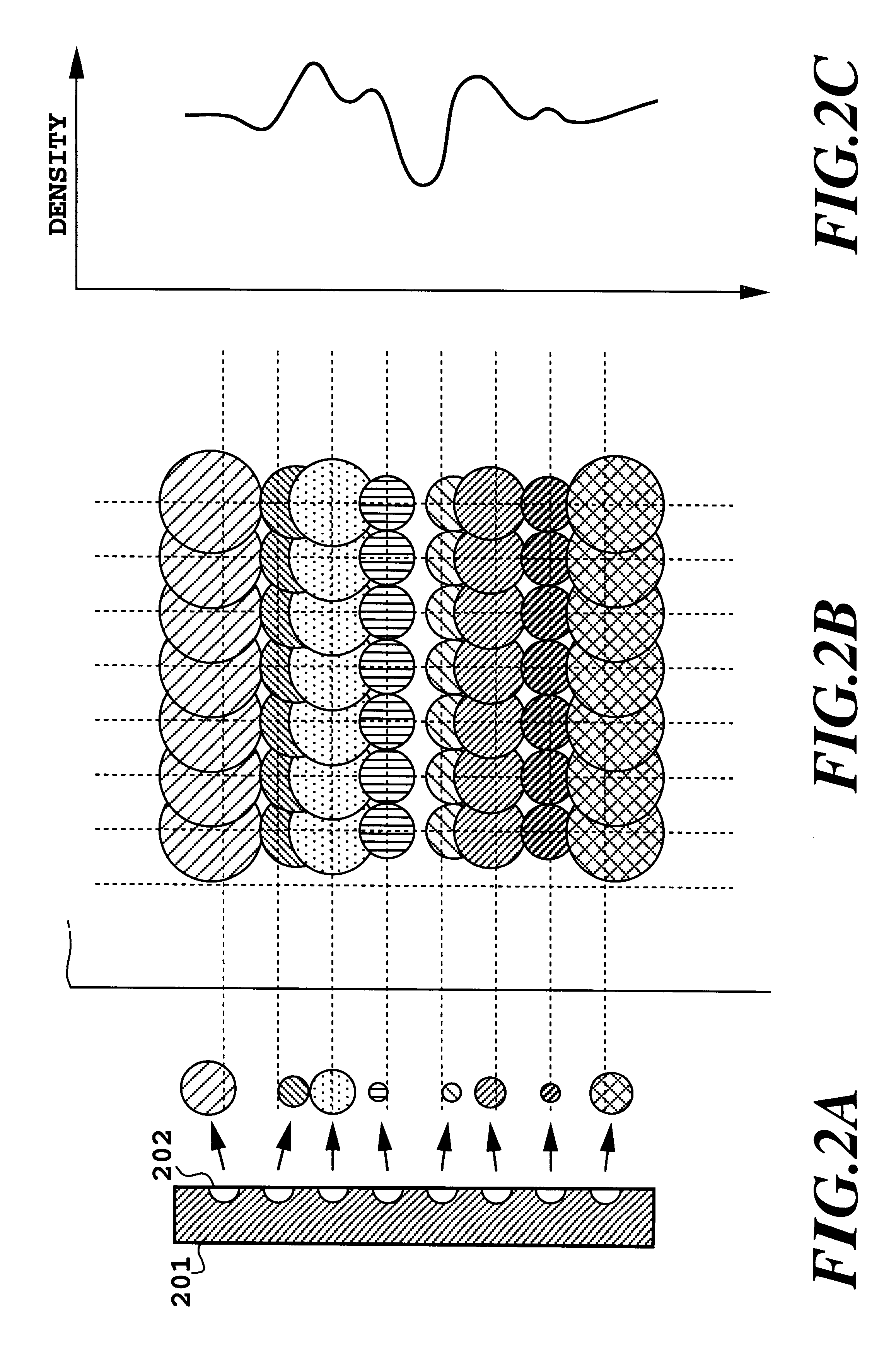

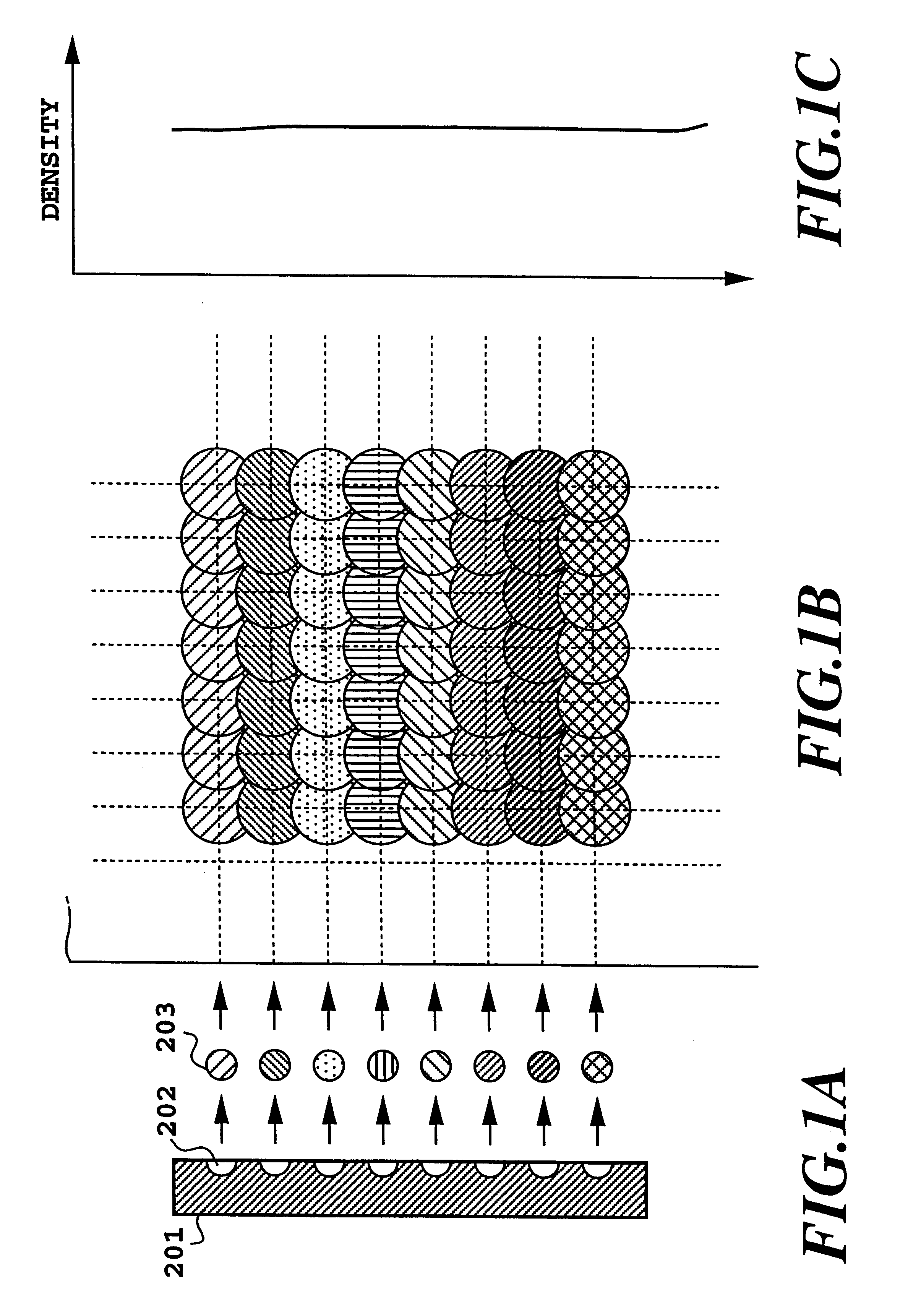

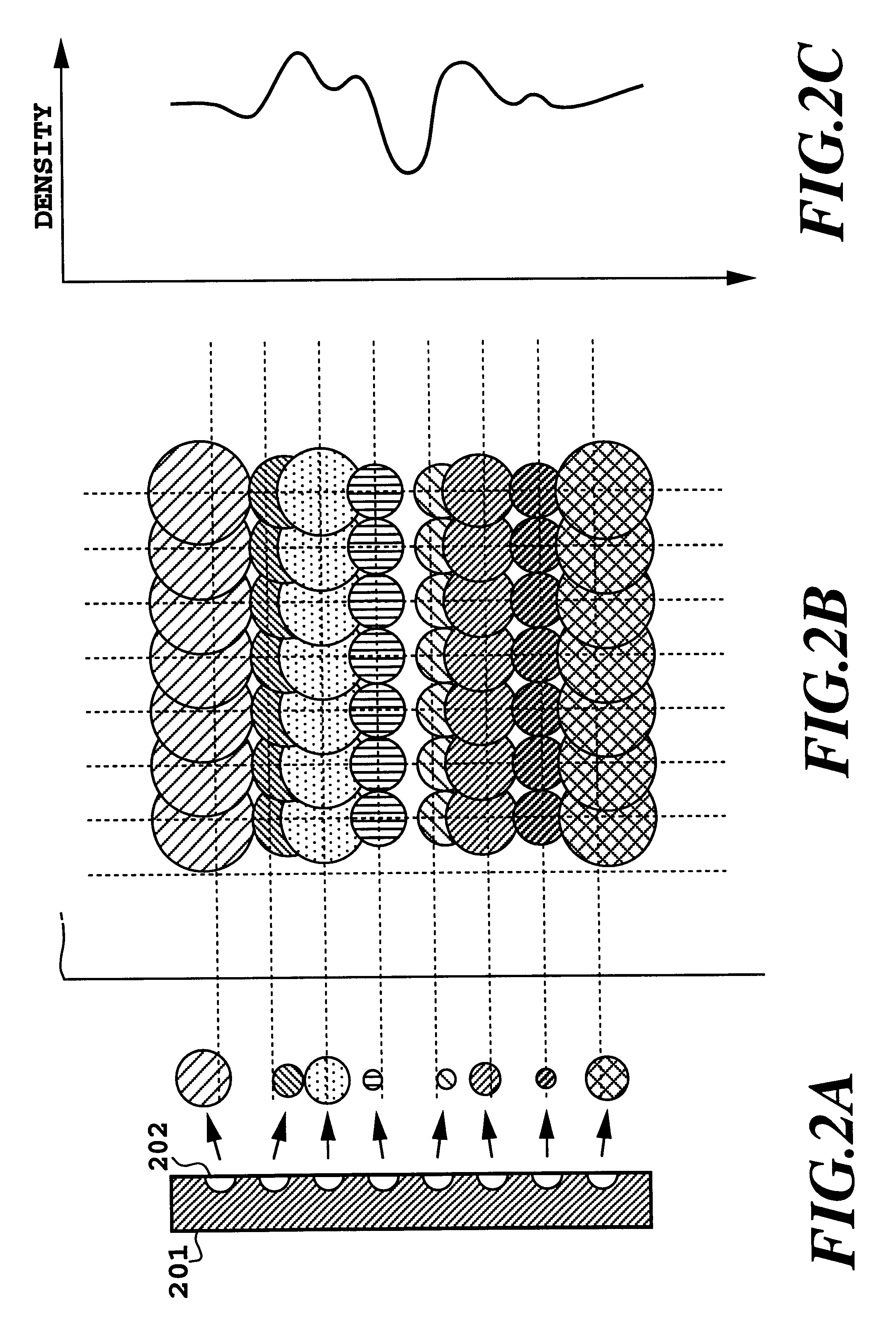

InactiveUS6532026B2Improve image qualityEasy to seeSpacing mechanismsOther printing apparatusPrinting registrationDensity change

In complementarily printing by bi-directional scannings of a head or by a plurality of print heads, first patterns and second patterns including reference dots for example, dots formed by a forward scan of the bi-directional scannings or by one of the plurality of print heads and dots each having the different direction of shifting of relative printing positions to the reference dots are printed in corresponding to the plurality of shifting amounts. These first and second patterns have the similar characteristics of a change in density. The difference is only that their characteristics in density change are inverted according to the direction of shifting. The intersection point of these two characteristics in density change is obtained as a position for adjustment where dot-formed positions match. This makes it easy to perform printing registration in a printing apparatus in the case of printing by a forward and reverse scan of a printing head or in the case of printing by means of a plurality of printing heads. In this case, operations by a user etc. are also unnecessary and are easily performed.

Owner:CANON KK

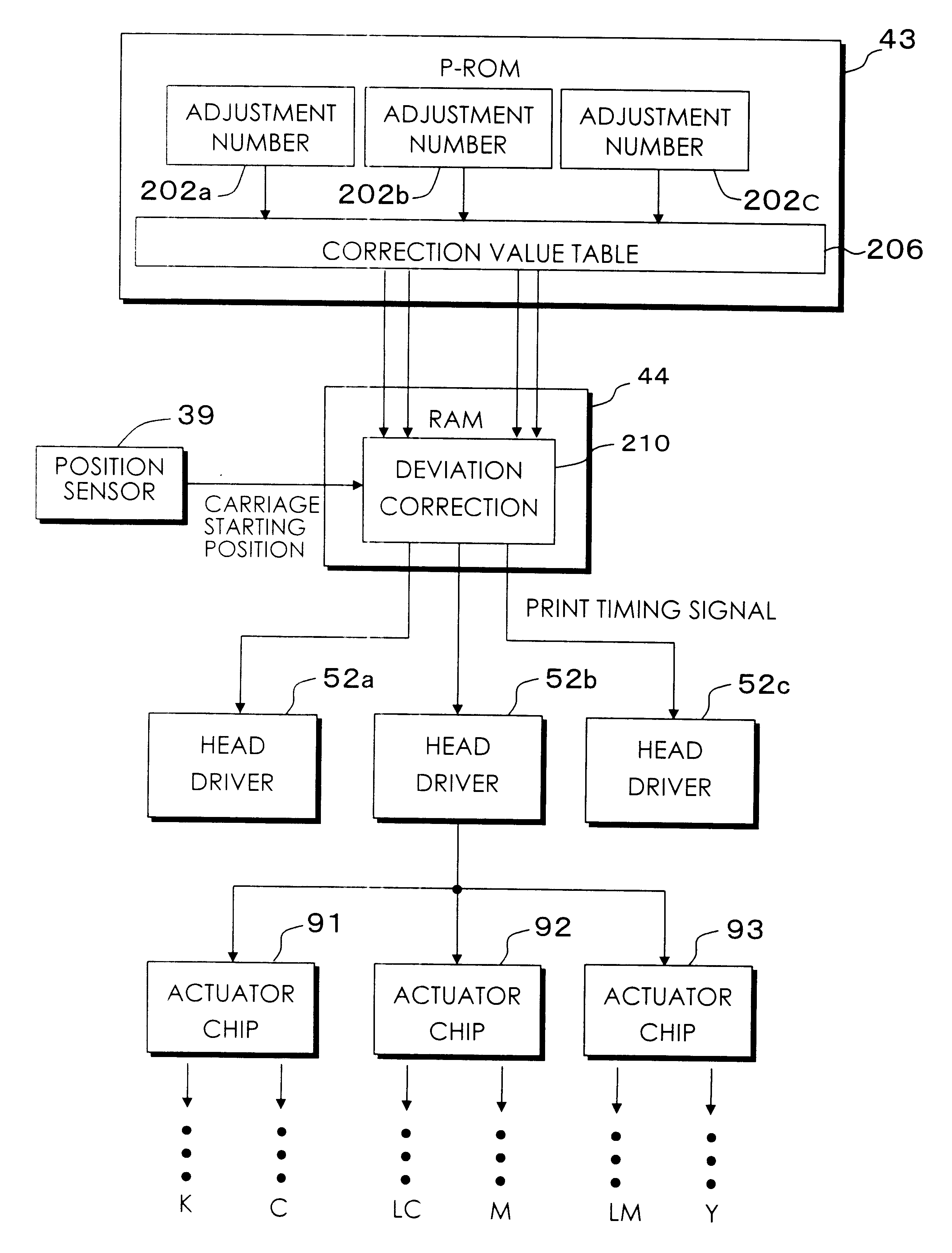

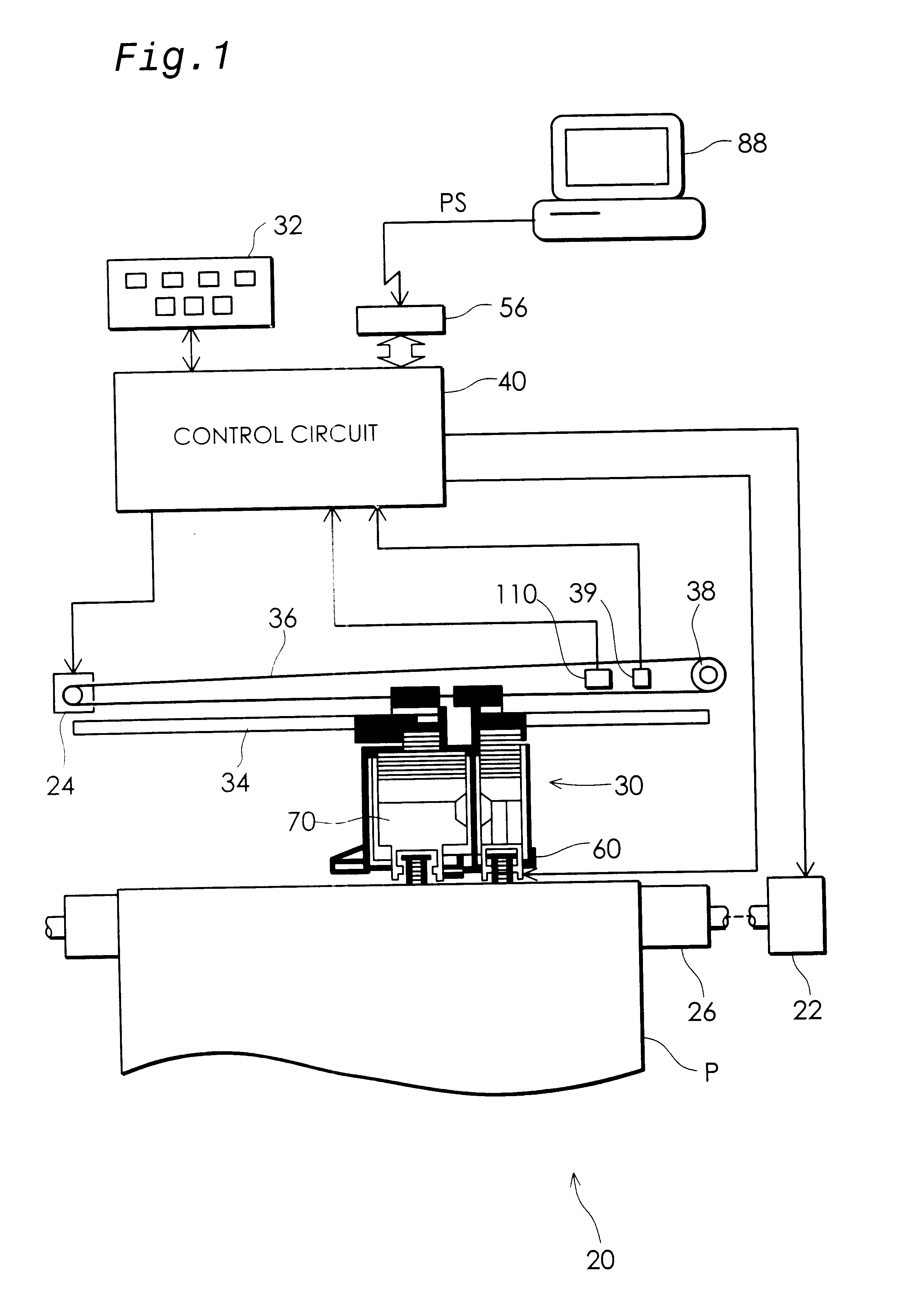

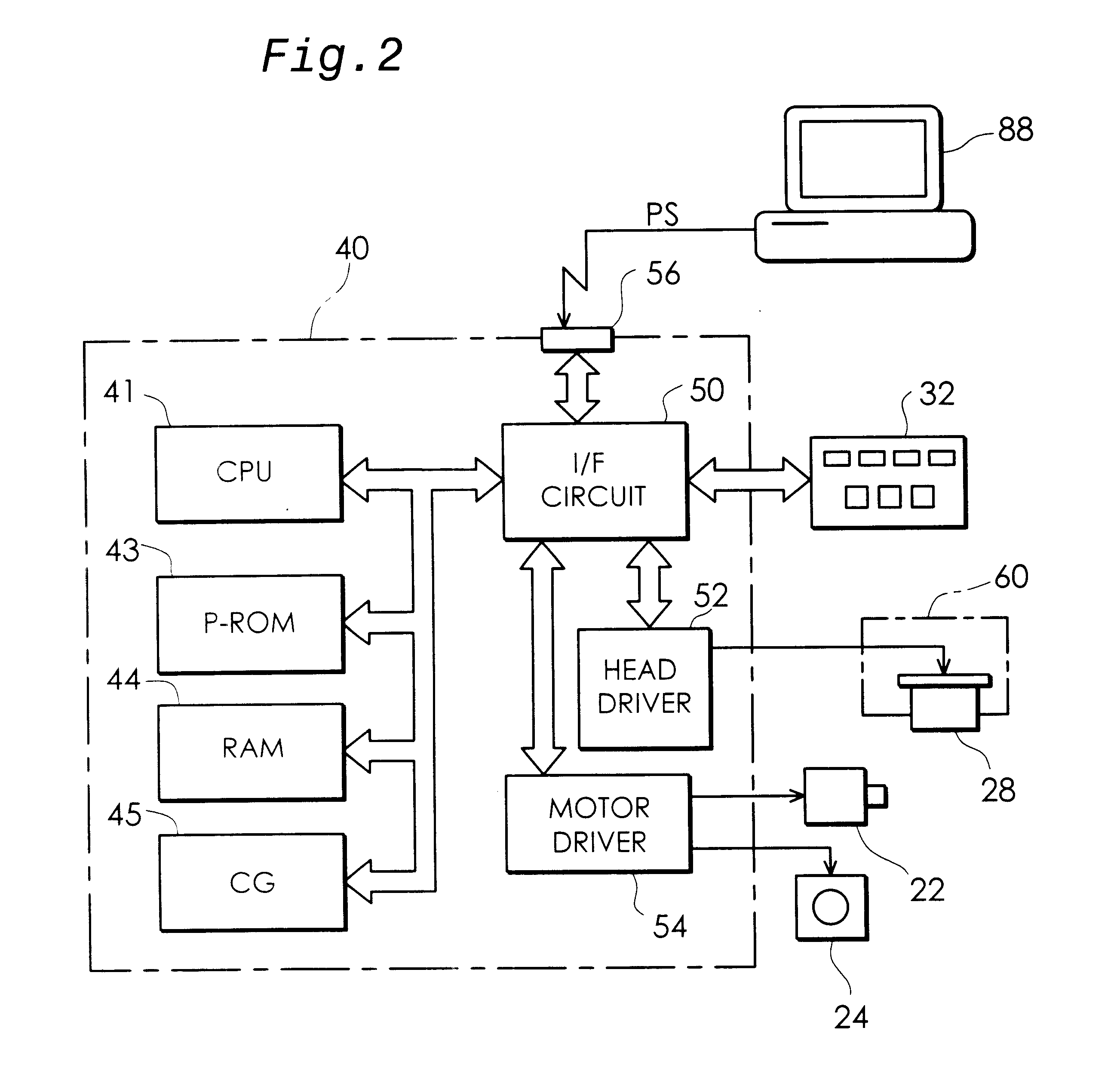

Positional deviation correction using different correction values for monochrome and color bi-directional printing

In monochrome printing mode, a first correction value is set for correcting printing positional deviation between ink droplets printed during forward and reverse main scanning passes. In color printing mode, a second correction value is set for correcting printing positional deviation between ink droplets printed during forward and reverse main scanning passes. An adjustment value is determined for reducing printing positional deviation during forward and reverse main scanning passes. For this, in monochrome printing mode the first correction value is used as an adjustment value, and in color printing mode at least a second correction value is used to determine an adjustment value. Following this, the adjustment value is used to adjust printing positions during forward and reverse main scanning passes.

Owner:SEIKO EPSON CORP

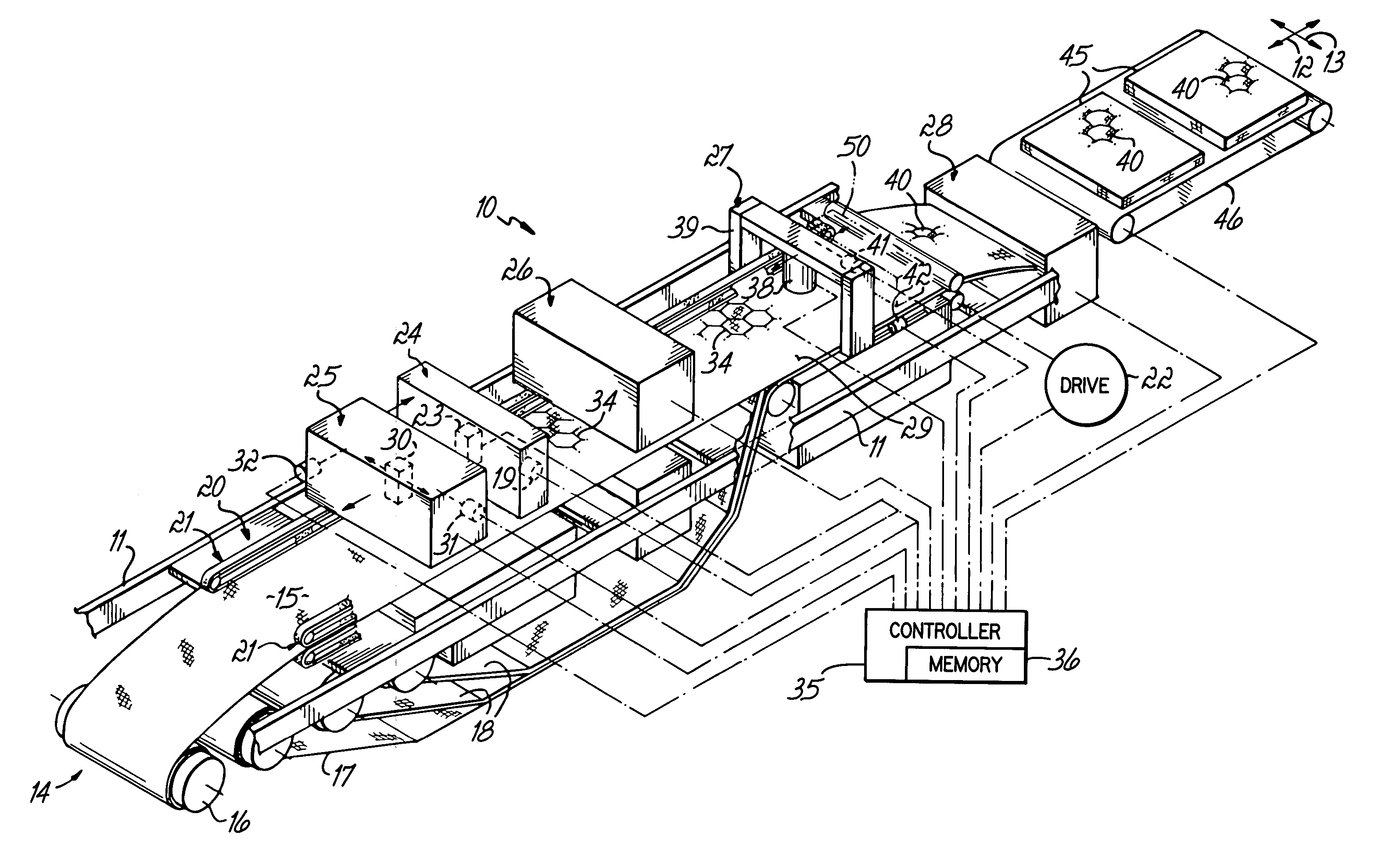

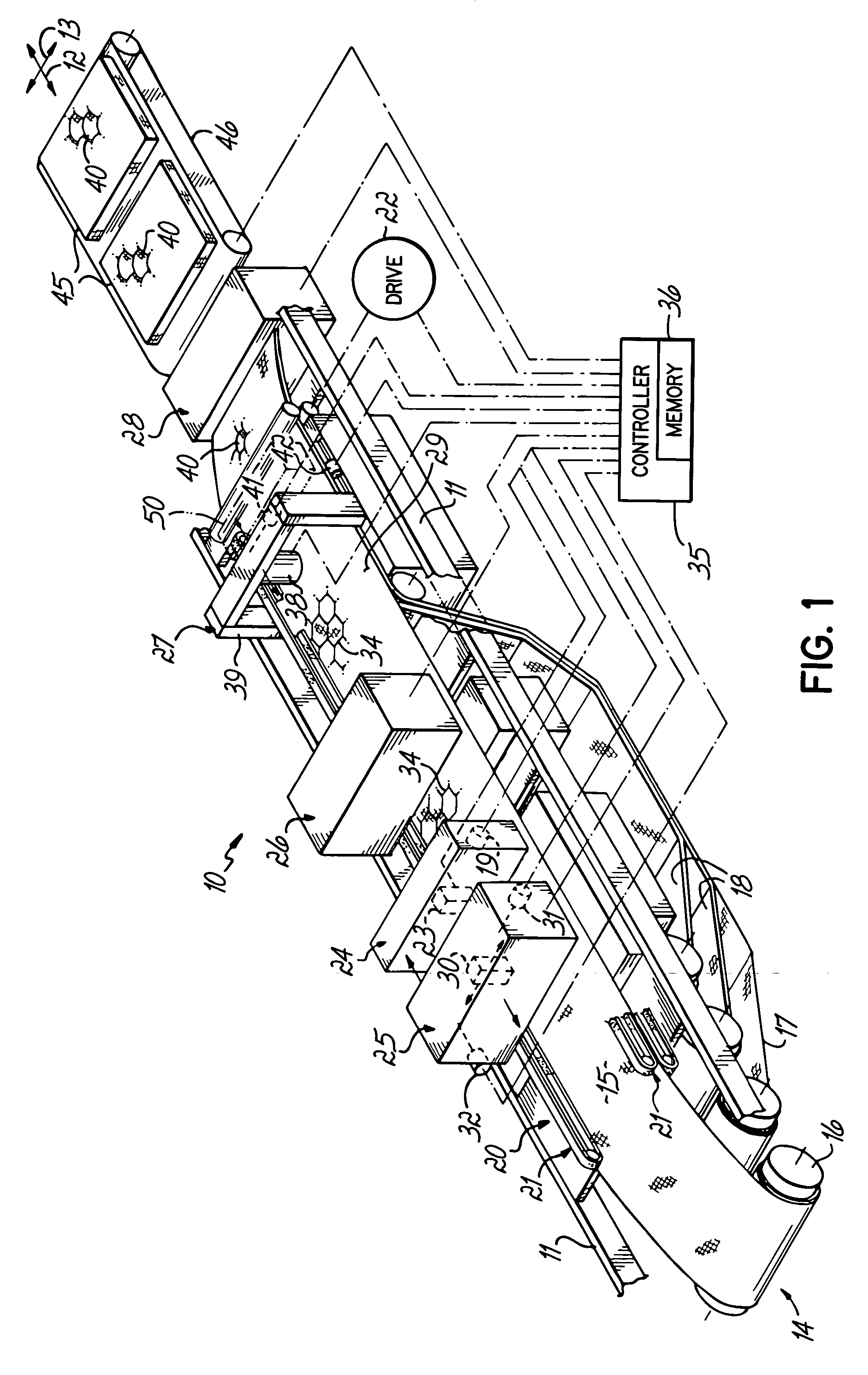

Apparatus and method for ink-jet printing onto an intermediate drum in a helical pattern

InactiveUS20050046651A1Improve printing qualityImprove throughputSpacing mechanismsOther printing apparatusImage transferImage manipulation

An apparatus and method for ink-jet printing onto an intermediate drum in a helical pattern while correcting for image skew and aliasing. A plurality of ink-jet print heads place an image on an intermediate drum, impervious to ink, in a helical patter. To compensate for helical printing, the image is altered by nozzle placement and image manipulation to correct for skewing errors, and thereafter, the nozzle timing is adjusted to correct for aliasing. The plurality of print heads move parallel to the axis of rotation of the drum while the drum is simultaneously rotating, causing the image to be placed in a helical pattern. Once the entire image is placed on the drum, paper is rolled against the drum under pressure and the image is transferred thereto.

Owner:FUNAI ELECTRIC CO LTD

Method of aligning inkjet nozzle banks for an inkjet printer

InactiveUS7073883B2Reduce Image ArtifactsDecreasing the required receiverSpacing mechanismsPower drive mechanismsComputer printingInk printer

A method is provided for reducing image artifacts in printers that employ two or more printhead nozzle banks that must be aligned and registered with respect to each other either through adjustment of orientation and / or position of one nozzle bank relative to another or through selective control of actuation. In the method, discrete dots are printed by the nozzle banks upon a target receiver medium. Examination of the receiver medium or a reproduction thereof is made by a scanner and information regarding location of the dots is generated. From information regarding location of the dots a determination is made of error placement of the dots from ideal locations. Alignment of the nozzle banks are made in accordance with any errors determined in placement.

Owner:EASTMAN KODAK CO

Adjustment method of printing positions, a printing apparatus and a printing system

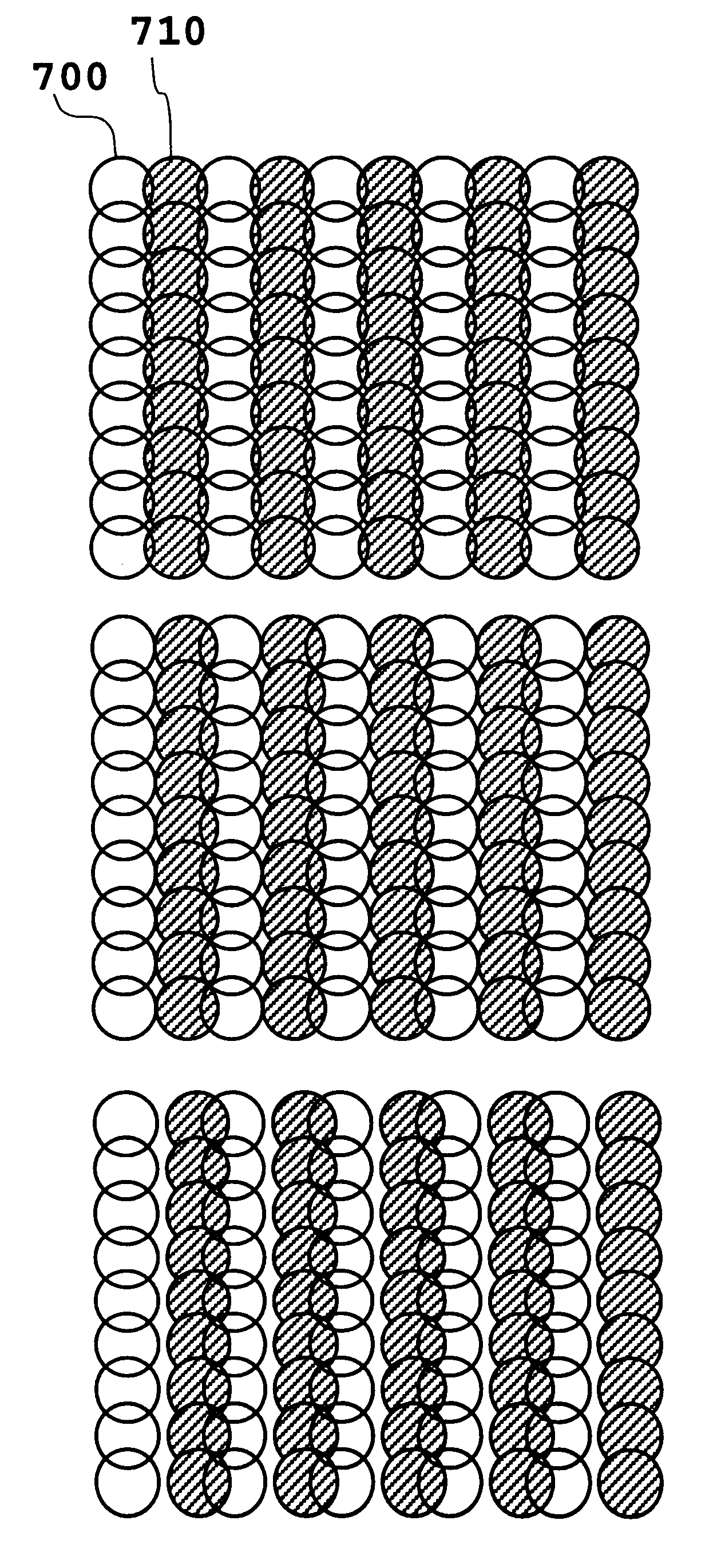

InactiveUS6960036B1High quality imagingPreventing Image Quality DeteriorationSpacing mechanismsGratingImage resolution

By using an ink jet head, which has for each color two parallel columns of nozzles arranged side by side in the main scan direction and shifted from each other by one-half the pitch at which the nozzles are arranged in each column, odd-numbered rasters and even-numbered rasters making up an image are printed by the two nozzle columns. The registration between the odd- and even-numbered rasters is secured during the printing to produce an image with high print quality. For that purpose, the ink ejection timing between the two raster groups is shifted by a predetermined interval to form a plurality of adjustment patterns; the adjustment patterns printed are checked and, according to the check result, an adjustment value for the ink ejection timing between the two ink nozzle columns is entered; and the entered adjustment value is stored to be reflected on the actual printing operation. To facilitate the adjustment pattern check, the plurality of adjustment patterns have a dot distribution with a blue noise characteristic at a resolution at which the printing apparatus can print.

Owner:CANON KK

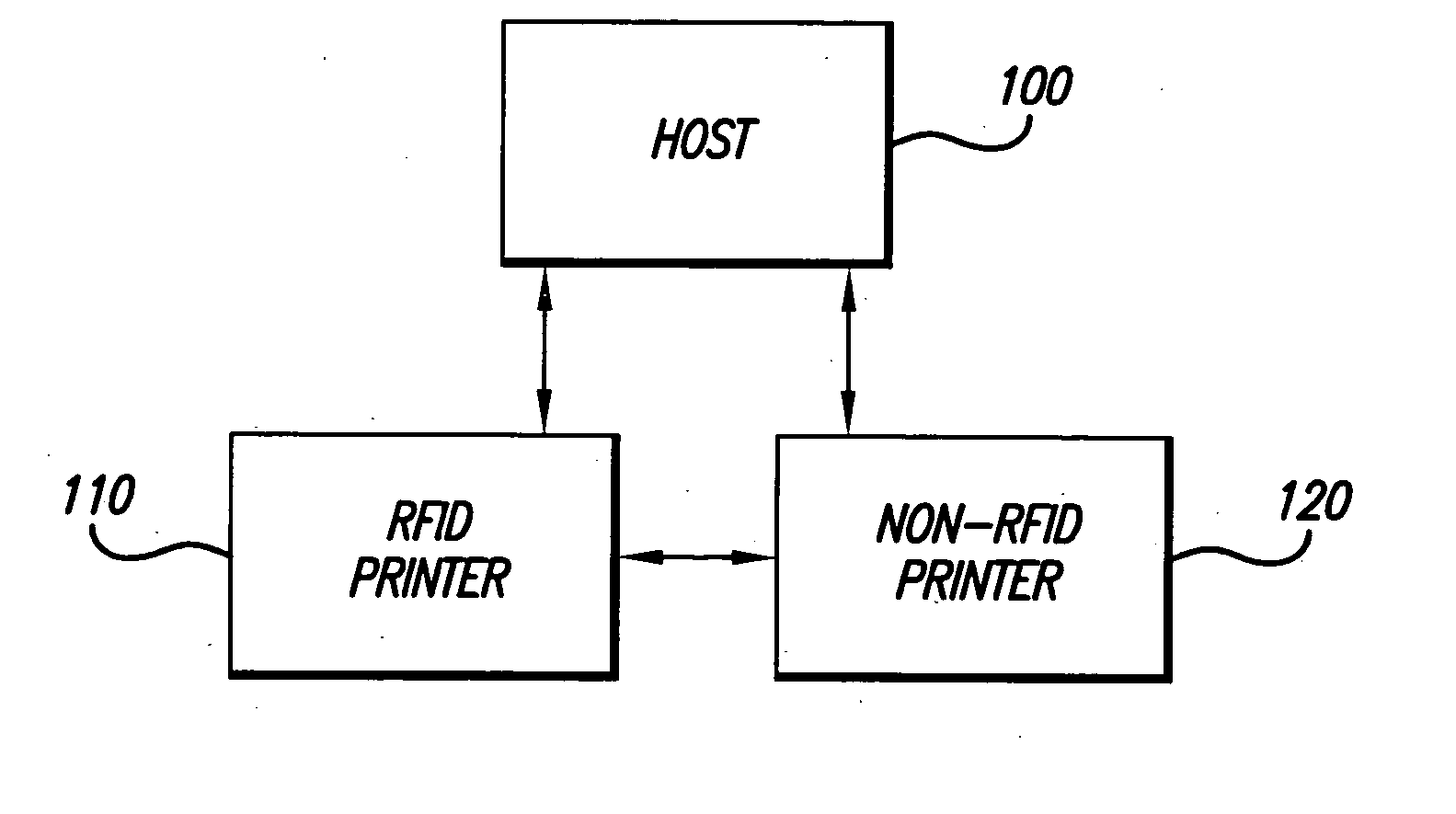

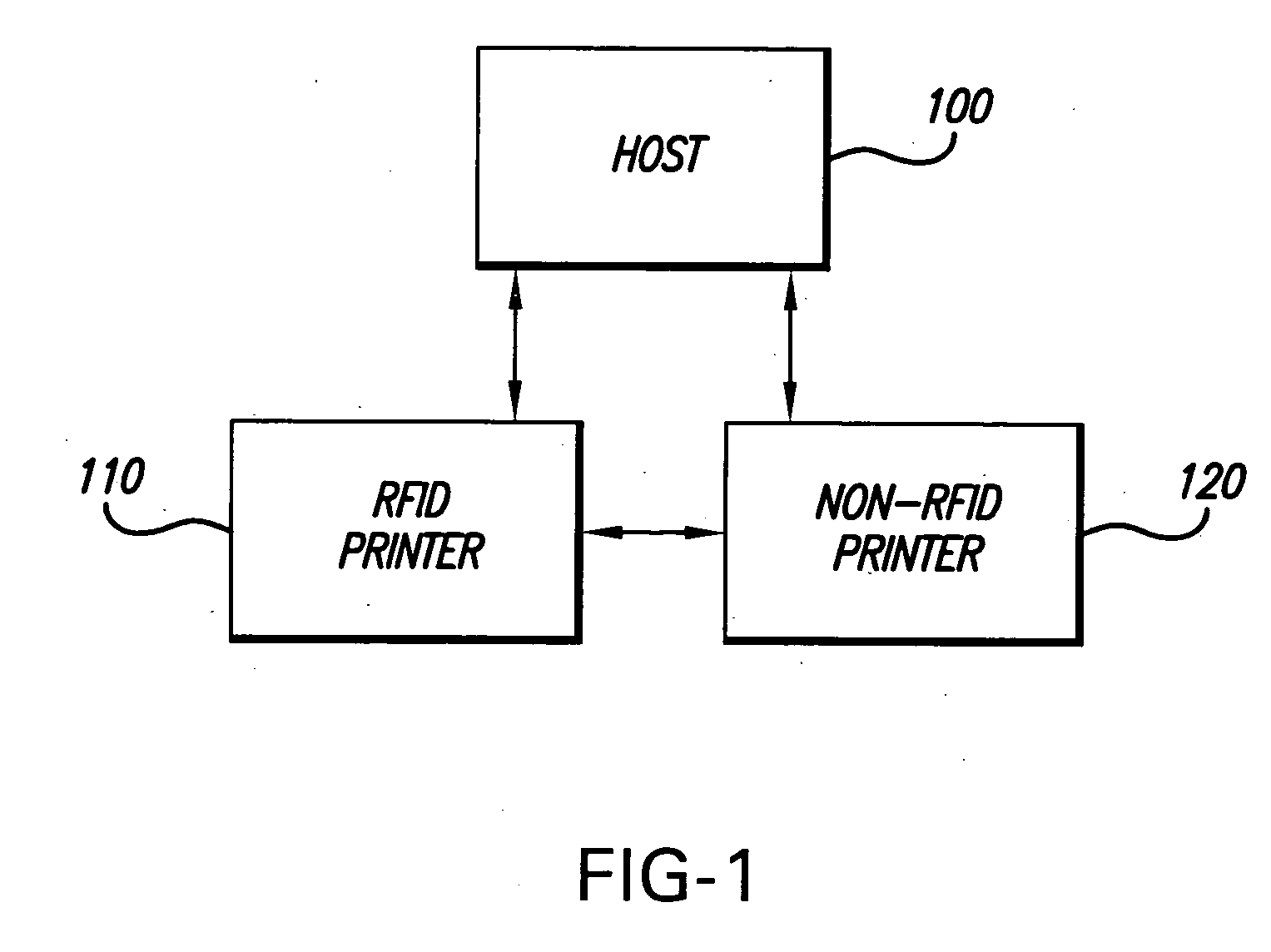

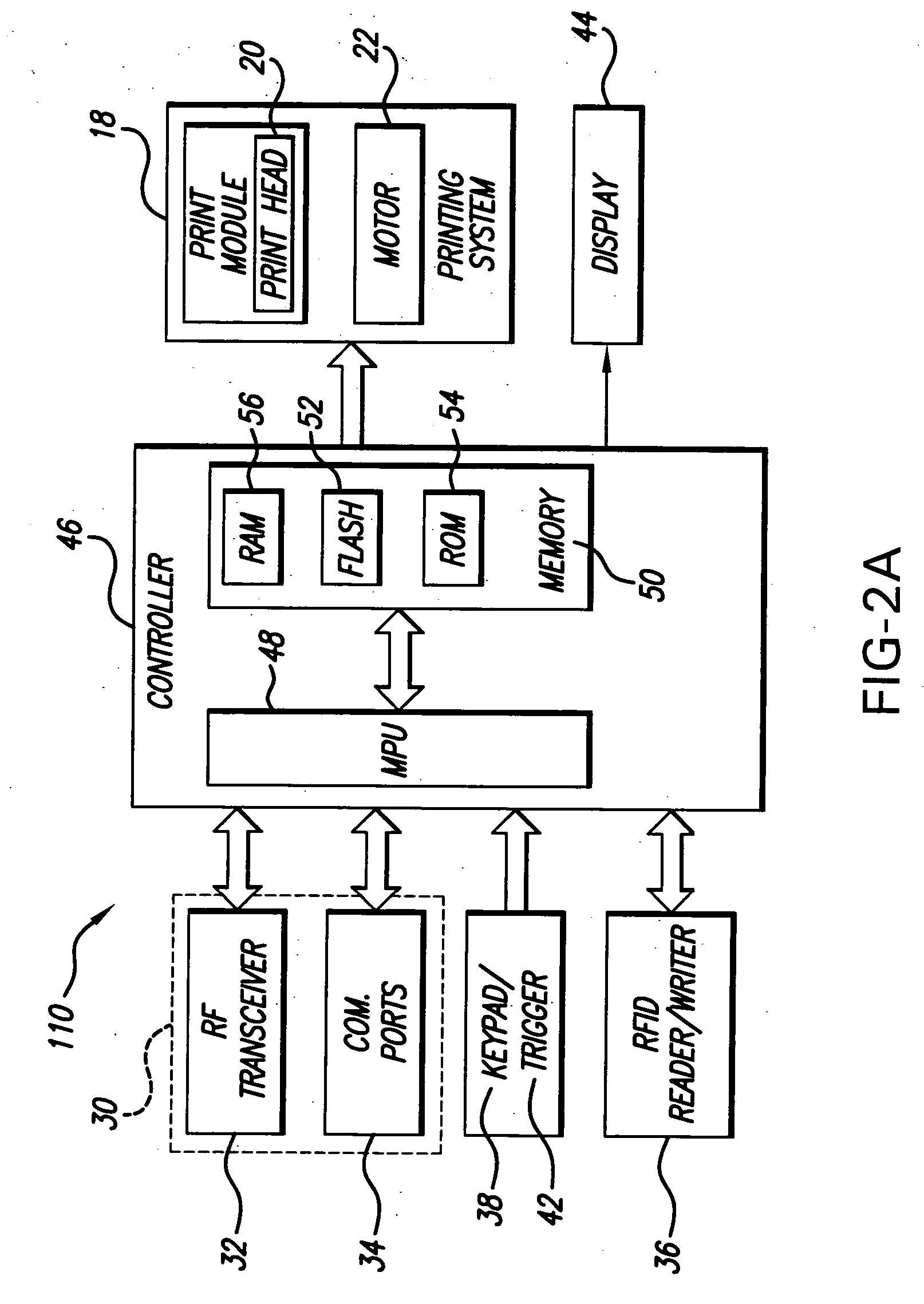

RFID printer system, method of printing and sets of record members

InactiveUS20060071063A1Not possibleInking apparatusTesting sensing arrangementsEngineeringTransponder

A system and method for printing both record members having RFID transponders disposed thereon and record members not having RFID transponders disposed thereon. In one embodiment, a RFID printer receives data to be printed on a record member and determines if the data includes RFID data to be written to a RFID transponder embedded on a record member. If the received data includes RFID data, the RFID printer prints a RFID record member according to the received data. If the received data does not include RFID data, the RFID printer transmits the data to a non-RFID printer for printing. In another embodiment, a non-RFID printer receives data to be printed on a record member and determines if the data includes RFID data to be written to a RFID transponder embedded on a record member. If the received data does not include RFID data, the non-RFID printer prints a record member according to the received data. If the received data does include RFID data, the non-RFID printer transmits the data to a RFID printer for printing. At least one set of RFID record members in a RFID web is written to and printed with data. At least one set of non-RFID record members in a non-RFID web is printed with the same data. The set(s) of RFID record members are associated with the set(s) of non-RFID members by the same indicium which is printed on at least one RFID record member and in at least one non-RFID record member having related data. When there are plural sets of RFID record members, wherein the sets of RFID record members have different data, and there are plural sets of non-RFID record members, wherein the sets of non-RFID record members have different data, and the data of the sets of RFID record members and the sets of non-RFID record members have related data, differing indicia are printed on at least one record member of each set to associate the sets of RFID and non-RFID record members.

Owner:AVERY DENNISON CORP

Calibration method for an optical sensor, an adjustment method of dot printing positions using the calibration method, and a printing apparatus

InactiveUS6474767B1Low costGuaranteed uptimeSpacing mechanismsOther printing apparatusPrinting registrationElectrical and Electronics engineering

In a complimentary printing by bi-directional scanning of a head or by a plurality of heads, a plurality of patterns in which a print start timing is shifted by a predetermined amount are printed with respect to a reference dot formed by the forward scan of the bi-directional scanning or by one of the plurality heads. In these patterns, an area factor by the dots formed by printing of the patterns is designed to be varied depending upon shifting amount. An average density is read from each of the plurality of patterns, optically. The timing at which the maximum one among average densities read from the patterns is obtained, can be set as the printing registration condition. Further, before the above reading operation, an optical sensor used for this operation is calibrated, for improving accuracies of the reading and the registrating. By these processings, printing registration between a forward and a reverse scan of a print head or printing registration between a plurality of print heads in a printing apparatus can be performed simply and with high accuracy.

Owner:CANON KK

Adjustment method of dot printing positions and a printing apparatus

InactiveUS6454390B1Low costGuaranteed uptimeSpacing mechanismsOther printing apparatusVolumetric Mass DensityEngineering

In a complimentary printing by bi-directional scanning of a head or by a plurality of heads, a plurality of patterns in which a print start timing is shifted by a predetermined amount are printed with respect to a reference dot, e.g. formed by the forward scan of the bi-directional scanning or by one of the plurality heads. In these patterns, an area factor by the dots formed by printing of the patterns is designed to be varied depending upon shifting amount. An average density is read from each of the plurality of patterns, optically. The timing at which the maximum one among average densities read from the patterns is obtained, can be set as the printing registration condition. Further, a processing including a coarse adjustment to a fine adjustment is performed in a series of algorithm. By these processings, printing registration between a forward and a reverse scan of a print head or printing registration between a plurality of print heads in a printing apparatus can be performed simply and with high accuracy, without operating by a user.

Owner:CANON KK

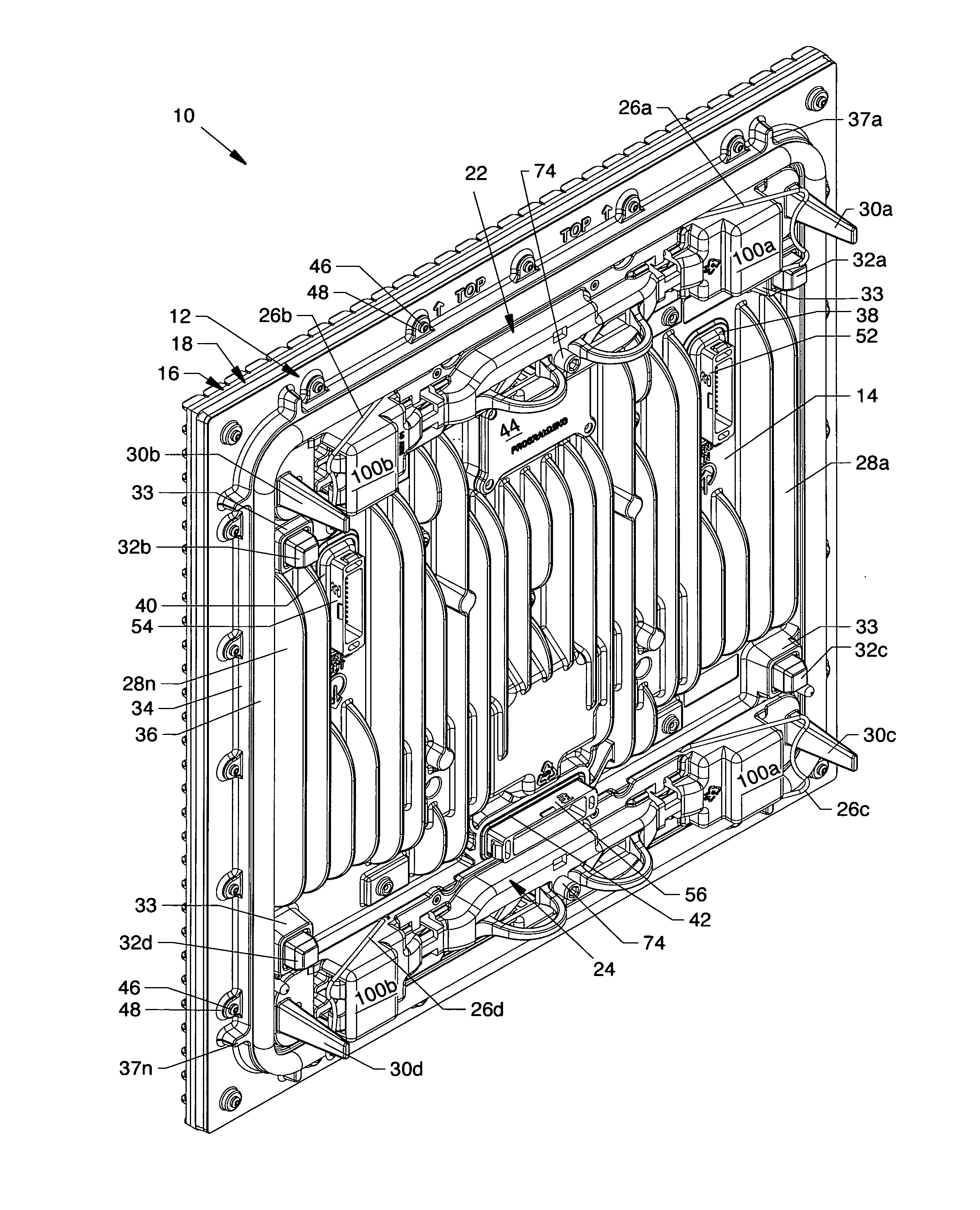

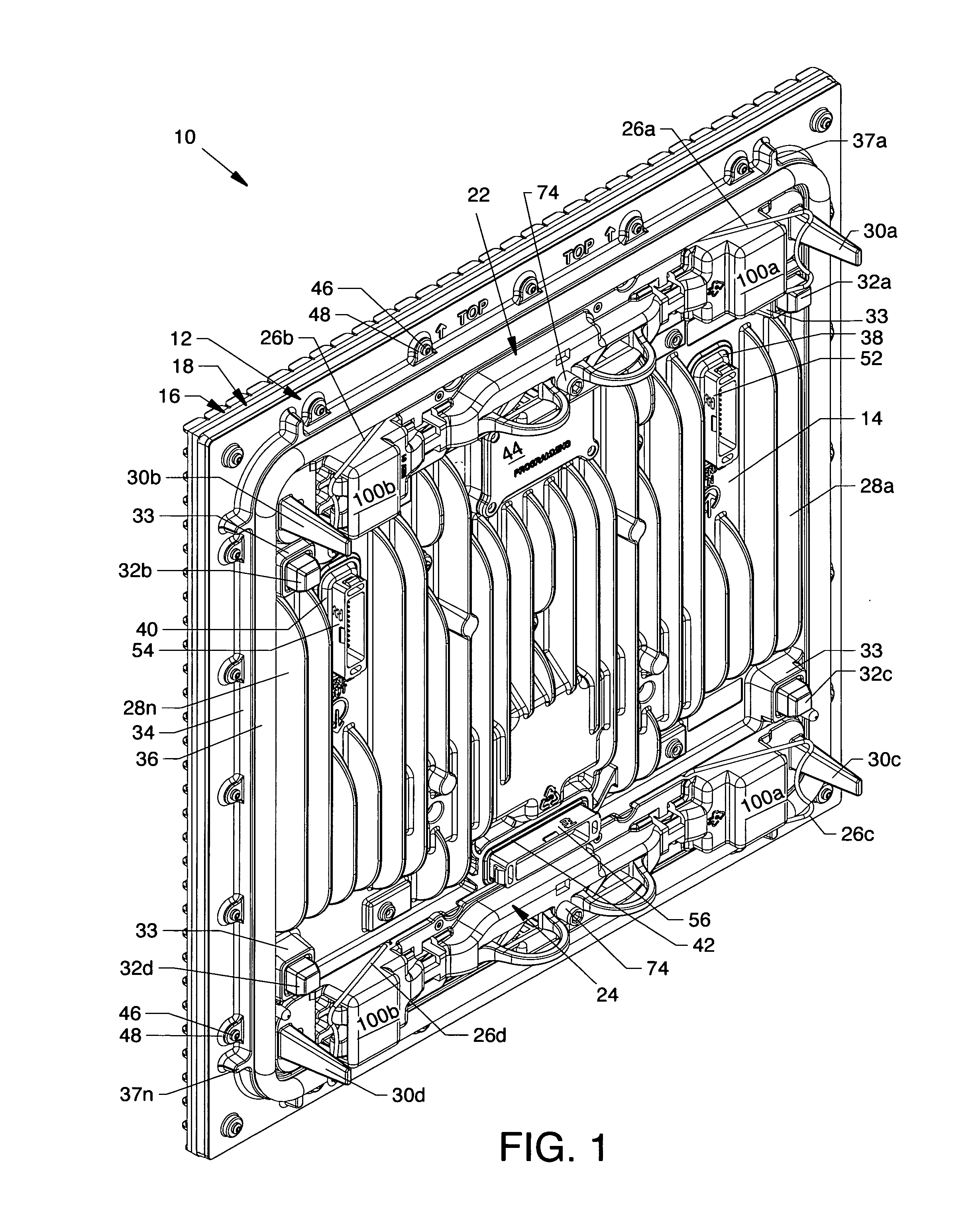

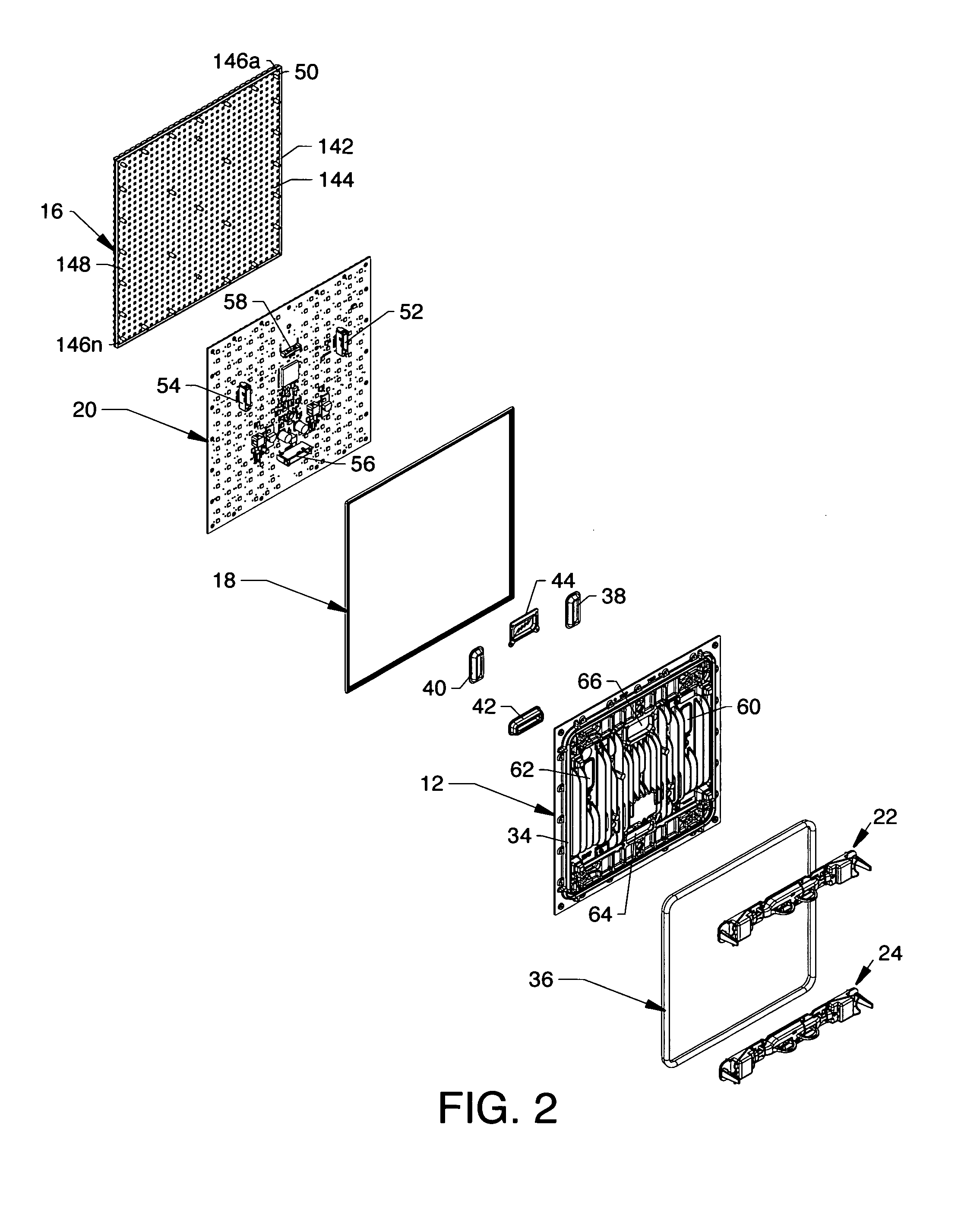

Multiple seal electronic display module having displacement springs

The present invention provides a multiple seal electronic display module having displacement springs for distributed use as major components of an electronic sign. Displacement springs are provided to displace the electronic display module from the front of an electronic sign mounting panel until latching mechanisms are properly actuated in order to secure the electronic display module to the electronic sign mounting panel and thus provide a visual clue indicating proper or improper securing. A configured front edge seal provides for multiple surface sealing of multiple components consisting of, but not limited to, a louver panel, an LED circuit board, and a housing. A rear seal is also provided to seal the rear of the electronic display module to the electronic sign mounting panel. Input and output signal jack base seals and a power jack base seal provide effective seals between the housing and the signal and power jacks.

Owner:DAKTRONICS

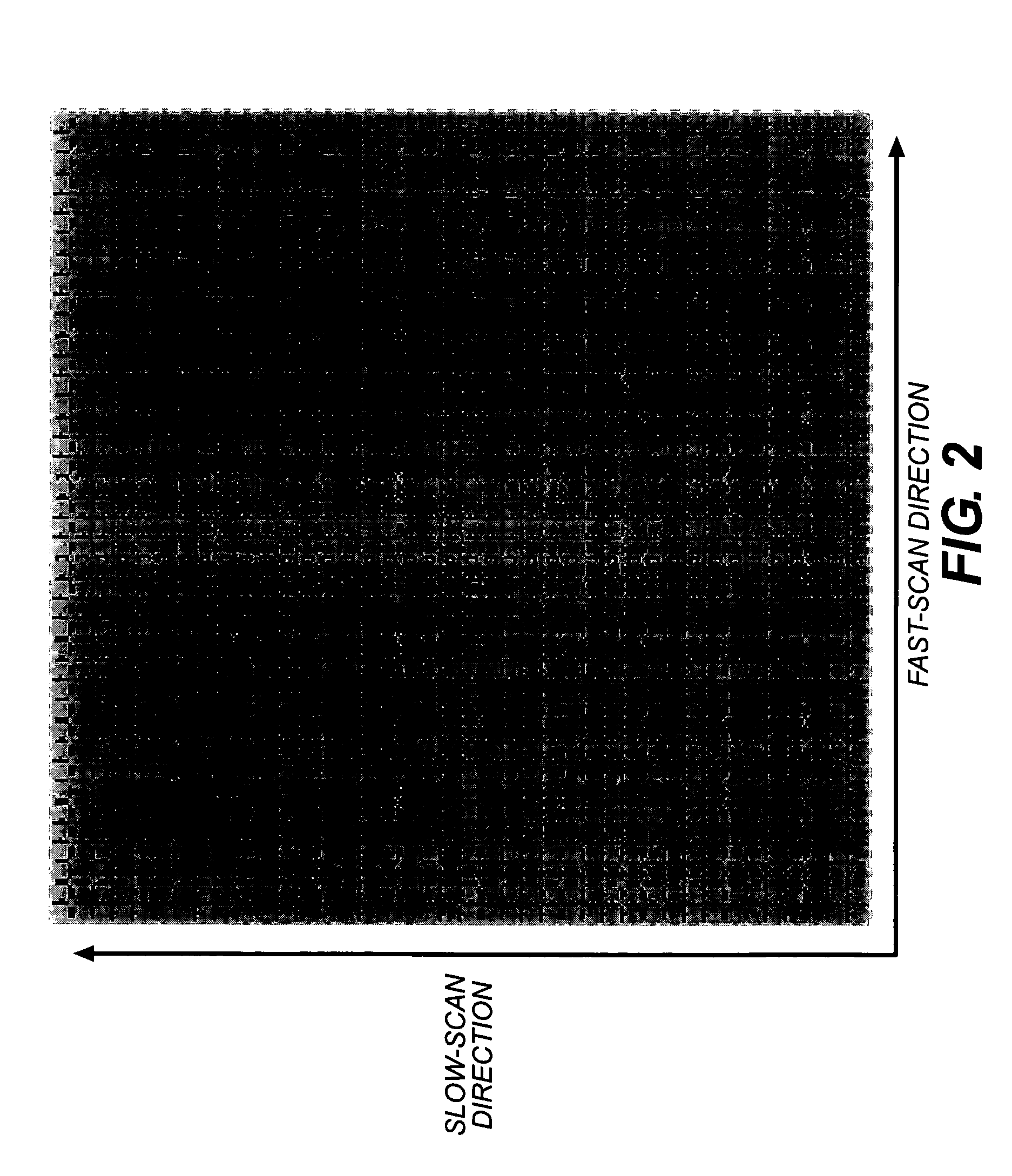

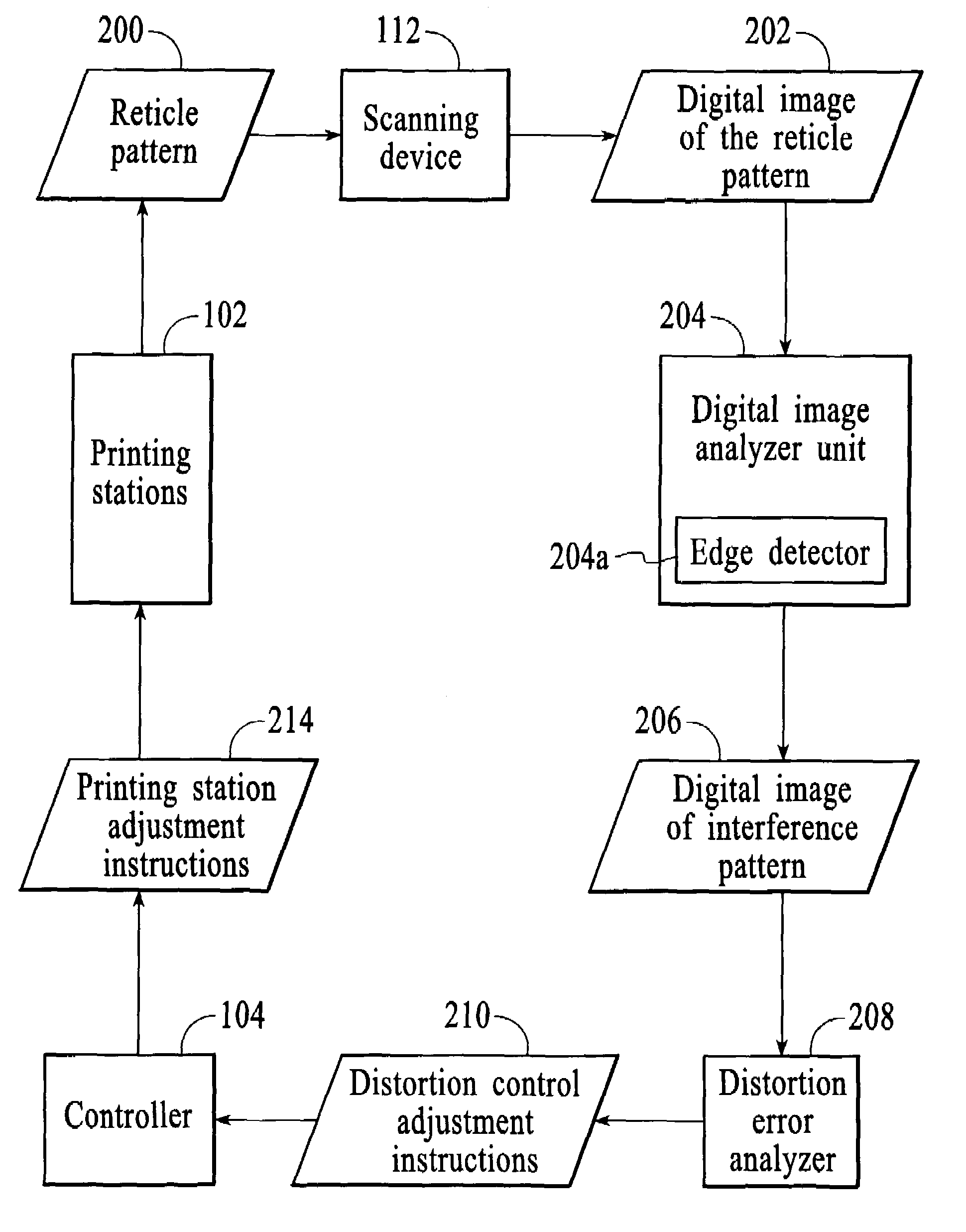

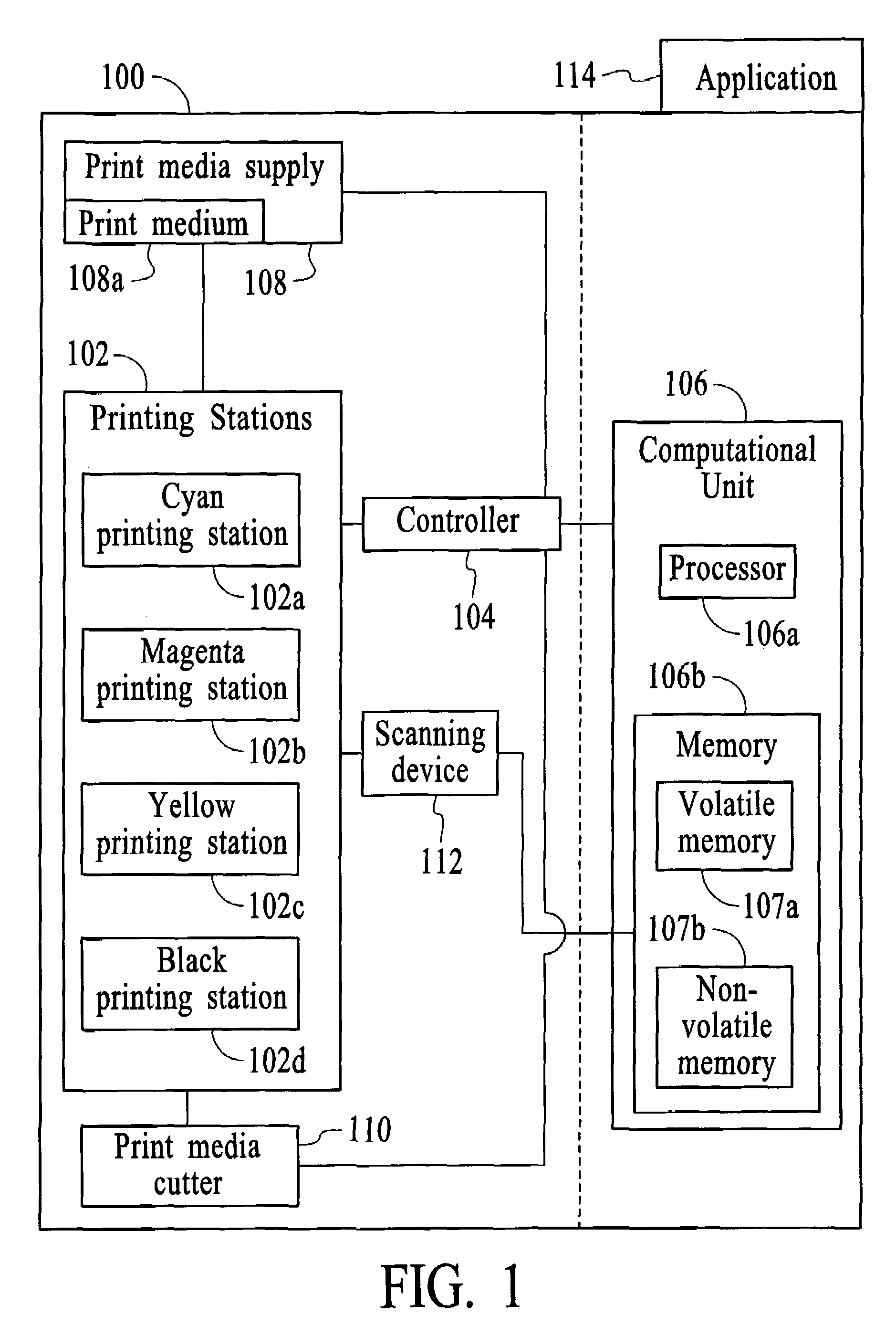

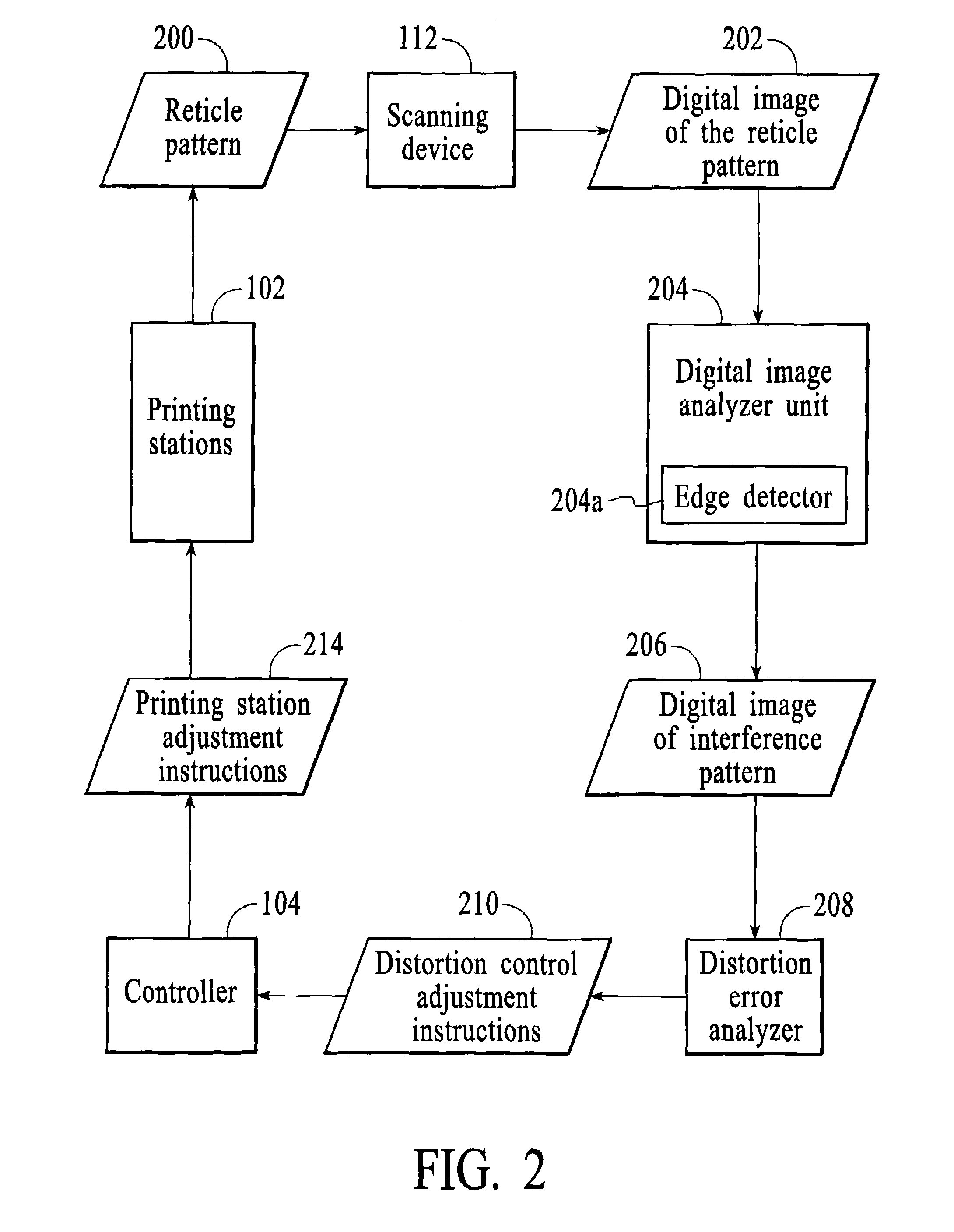

Method and system for minimizing the appearance of image distortion in a high speed inkjet paper printing system

ActiveUS6966712B2True colorPrecise registrationAddressographsPlaten pressesColor printingEngineering

A method and system for a printing device is disclosed. The method and system comprise printing a test pattern on a print medium and generating a digital image of the printed test pattern by an imaging device. The method and system include analyzing an interference pattern to measure for distortion of the print medium and calibrating the printing device based upon the measured distortion.In a preferred embodiment, the present invention utilizes the reticle patterns, which are printed in the margins of the paper, which are measured real-time during printing. The interference or Moiré patterns created by superimposed reticles may be used to measure image distortion, process direction misalignment, and misregistration caused by web distortion. The advantage of this invention is that image distortion compensation, RIP (Raster Image Processor) parameters, timing, or other printer characteristics may be adjusted on-the-fly in a closed feedback system, for high-speed textile or paper color printing, utilizing on-the-fly distortion or stretch measurement for accurate color and / or duplex images registration. In a duplex printer, automatic images alignment front-to-back is obtained by combining optically or logically the two images for the evaluation of interference patterns and amount of distortion in the process and scan direction.

Owner:RICOH KK

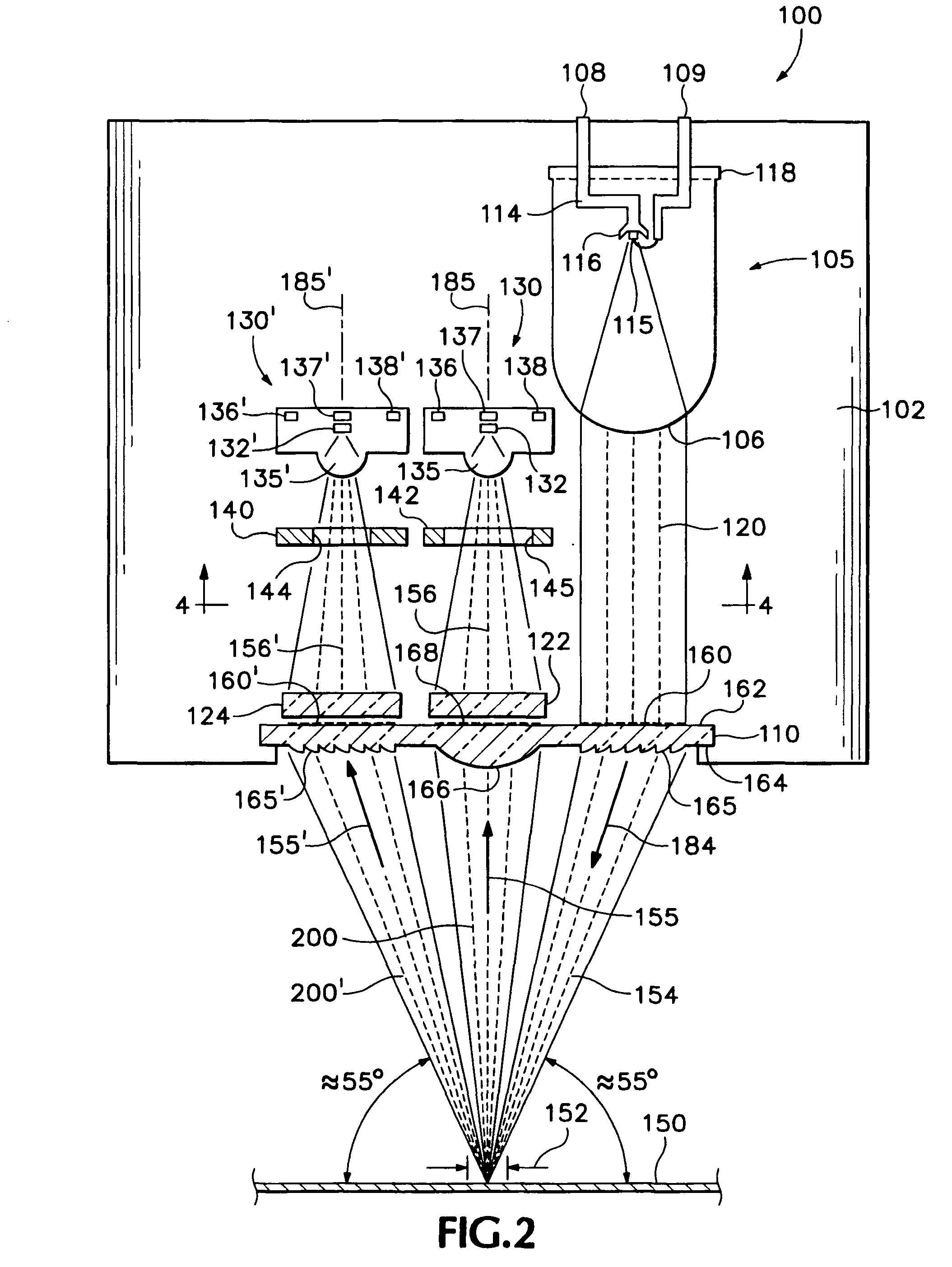

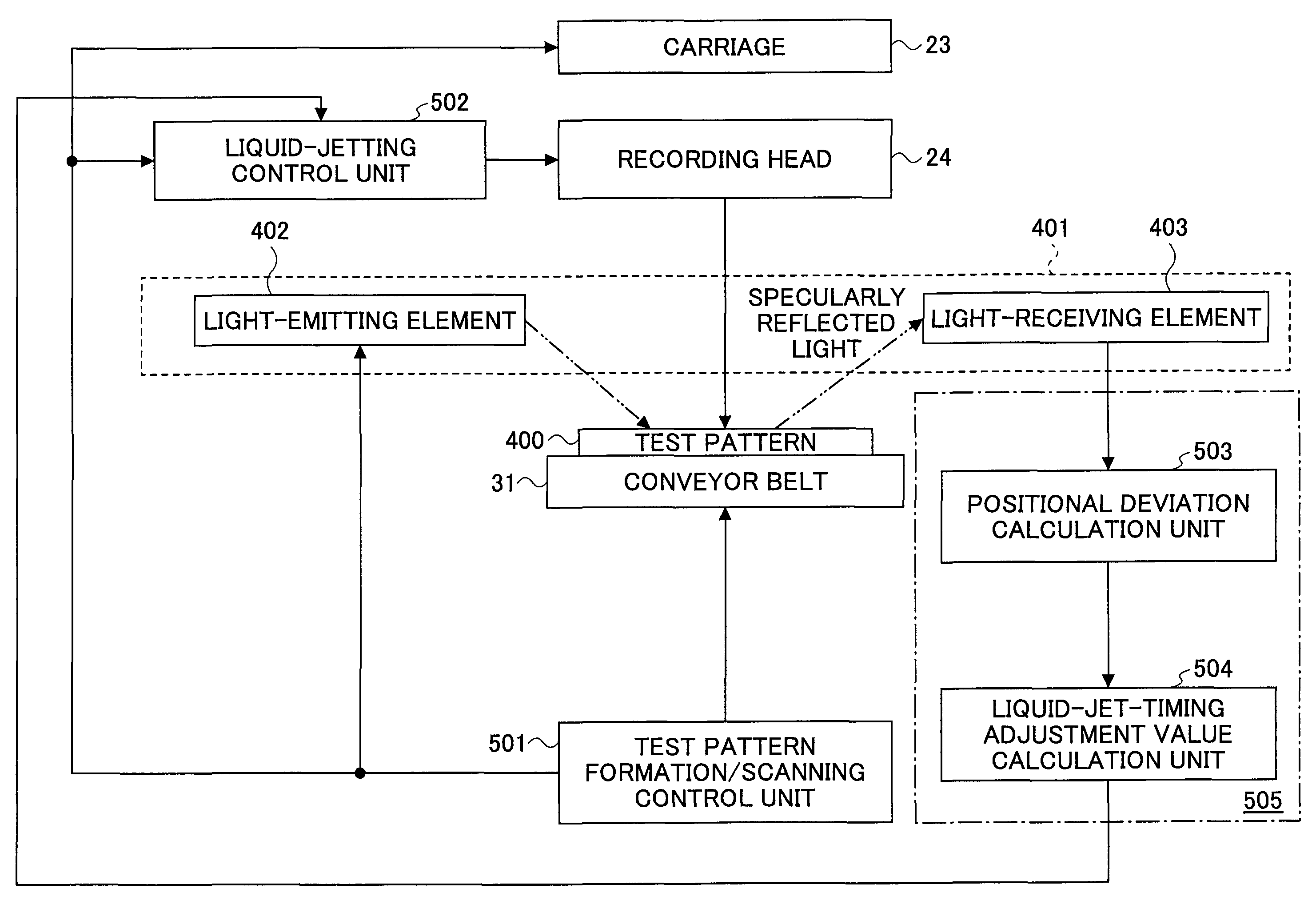

Liquid-jet device, image forming apparatus, and method for adjusting landing positions of liquid droplets

InactiveUS20080225068A1Solve or reduce one or more problemsSpacing mechanismsOther printing apparatusLiquid jetEngineering

A disclosed liquid-jet device includes a liquid-jet head configured to jet liquid droplets; a pattern formation control unit configured to control the liquid-jet head and thereby to form a test pattern composed of separate liquid droplets on a water-repellent part; a detecting unit including a light-emitting element configured to illuminate the test pattern on the water-repellent part and a light-receiving element configured to receive specularly reflected light from the illuminated test pattern and to output a detection signal proportional to the received specularly reflected light; and a landing position adjusting unit configured to adjust landing positions of the liquid droplets based on the detection signal from the light-receiving element.

Owner:RICOH KK

Adjustment method of dot printing position and printing system

ActiveUS20050052494A1Meet needsSpacing mechanismsOther printing apparatusUser needsArtificial intelligence

A print position adjusting method capable of executing dot adjust value calculation processing in ways that can meet diversified user needs of recent years, and a printing system that can realize the print position adjusting method are provided. Multiple kinds of dot adjust value calculation processing capable of acquiring an adjust value for aligning print positions are prepared, so that the user can select a desired one. With this arrangement, the user can execute the desired dot adjust value calculation processing as necessary.

Owner:CANON KK

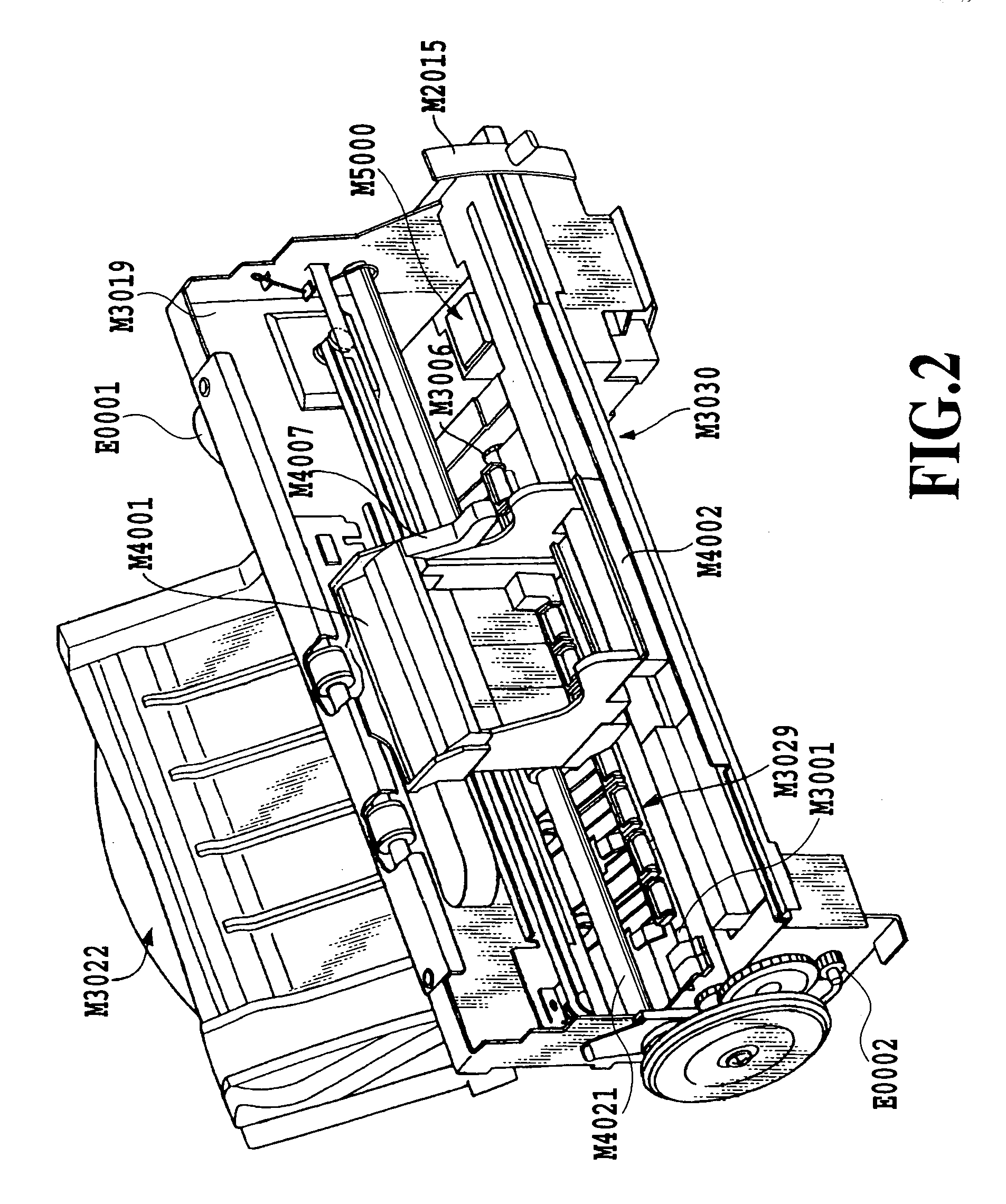

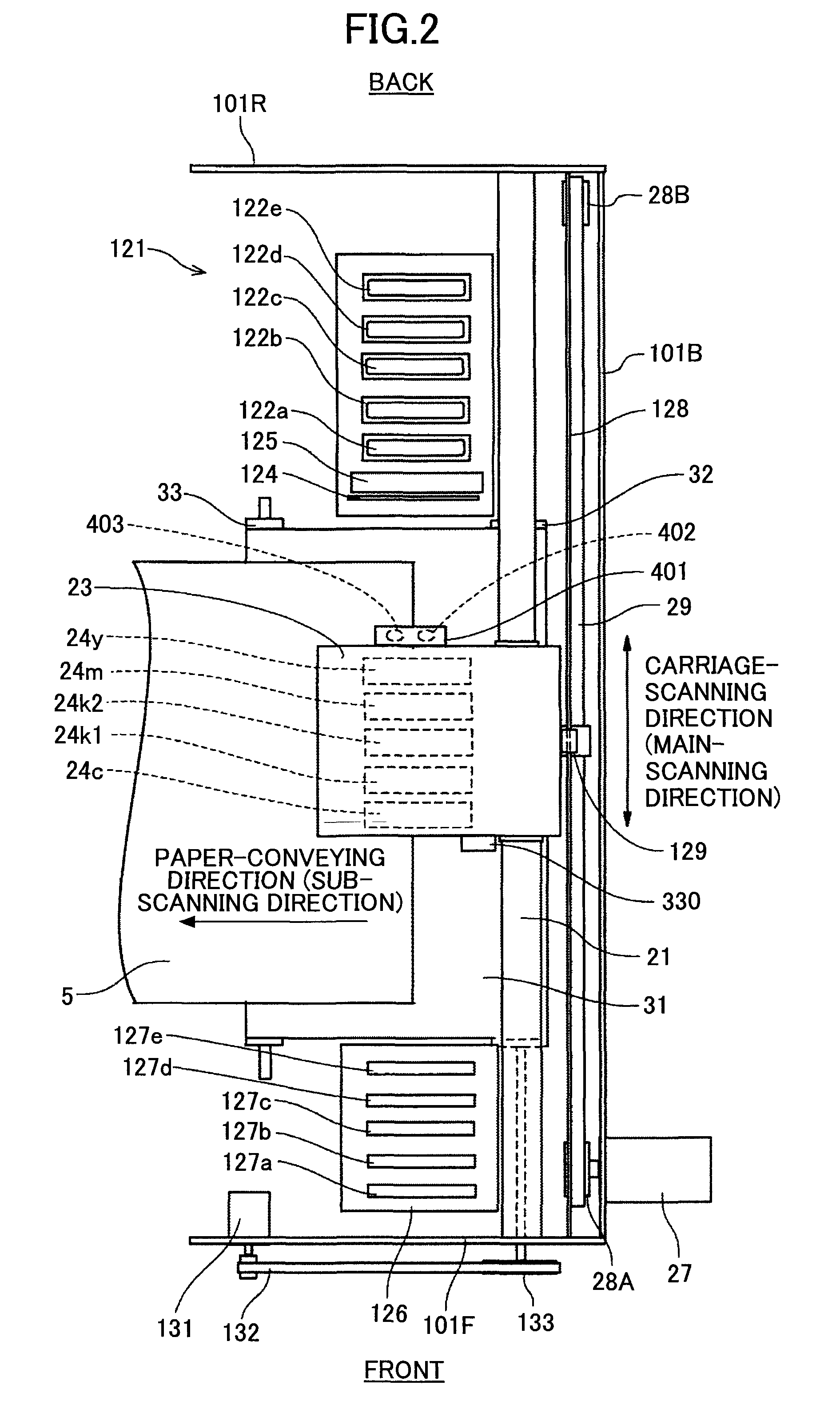

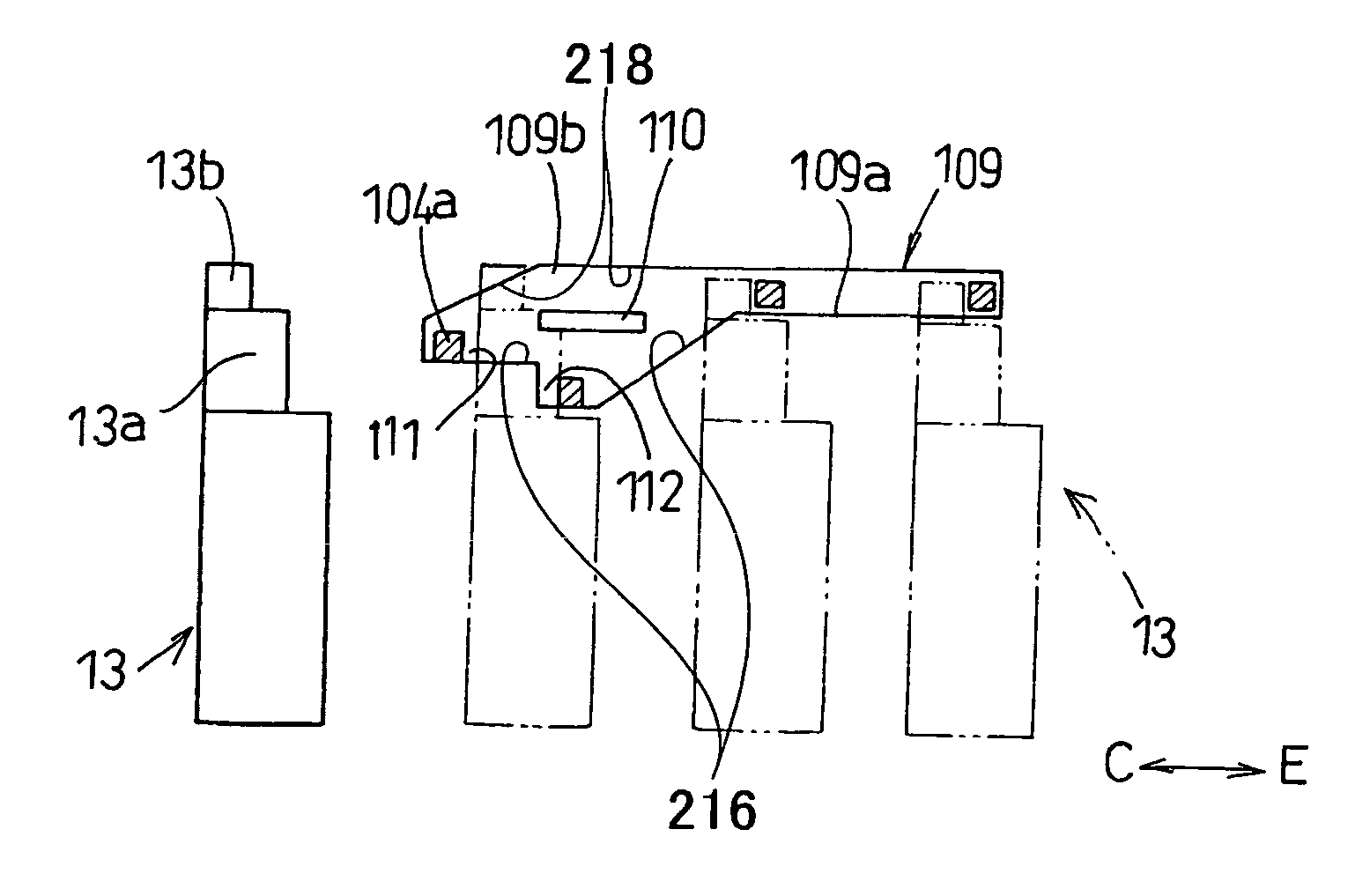

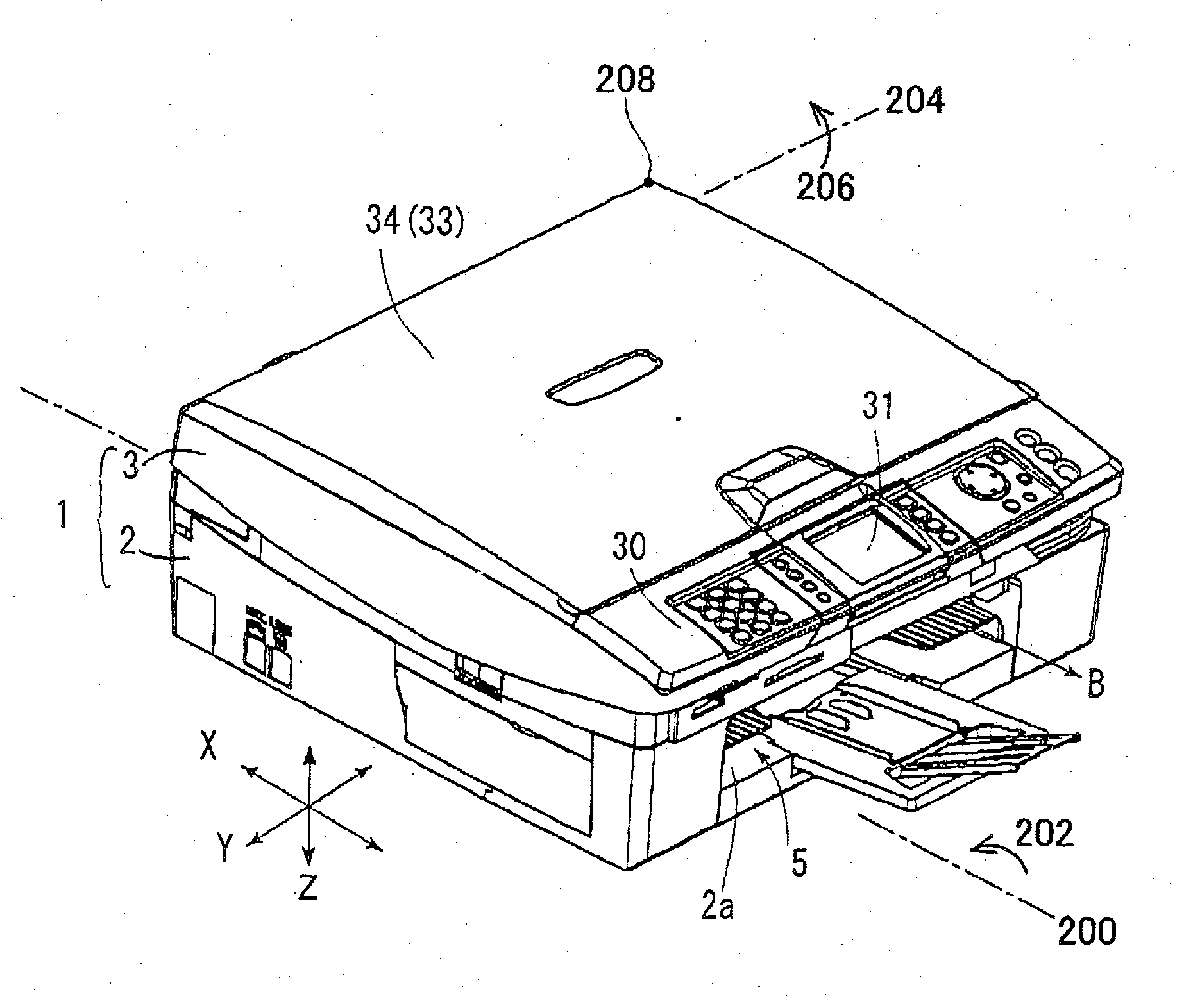

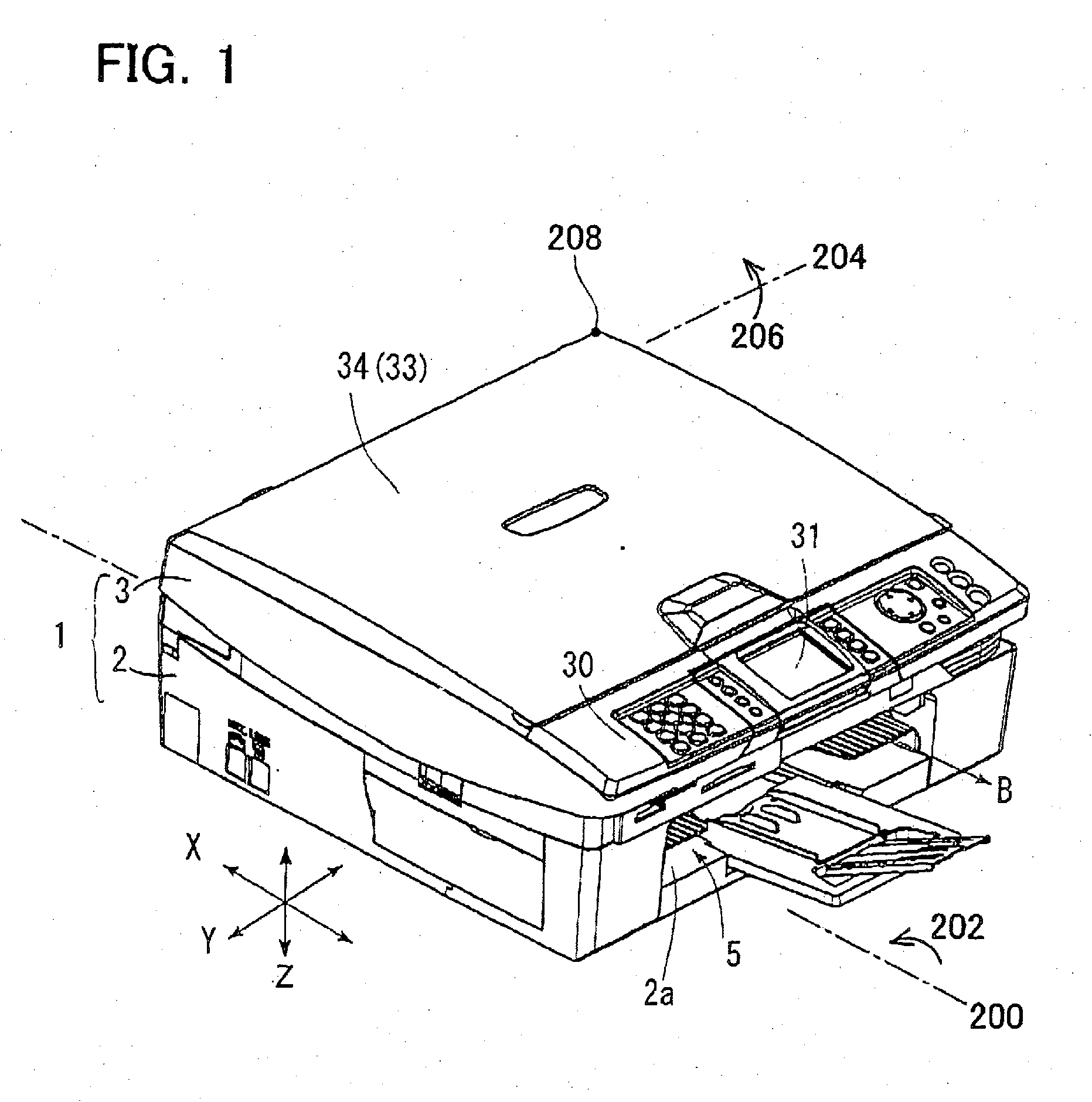

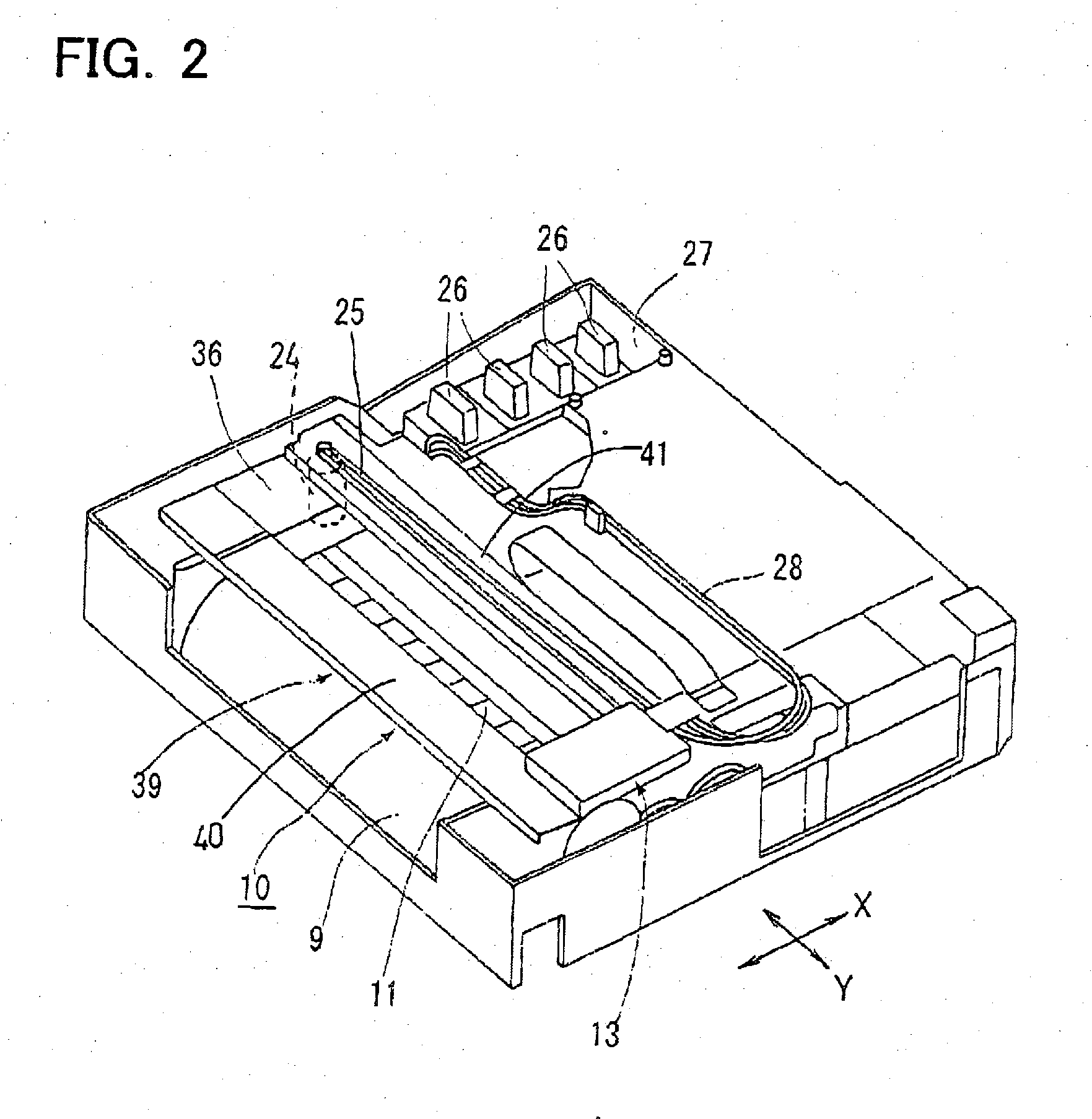

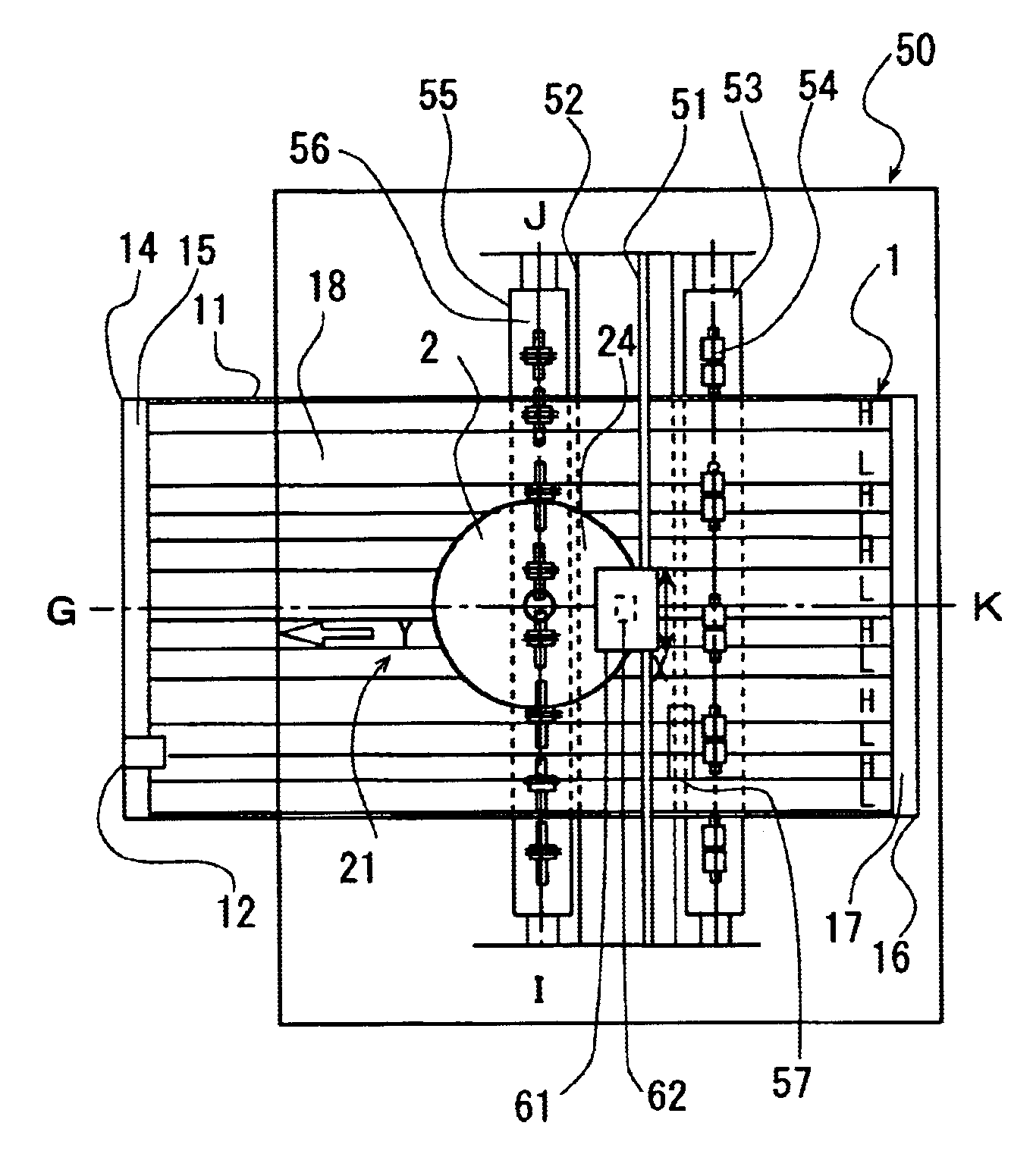

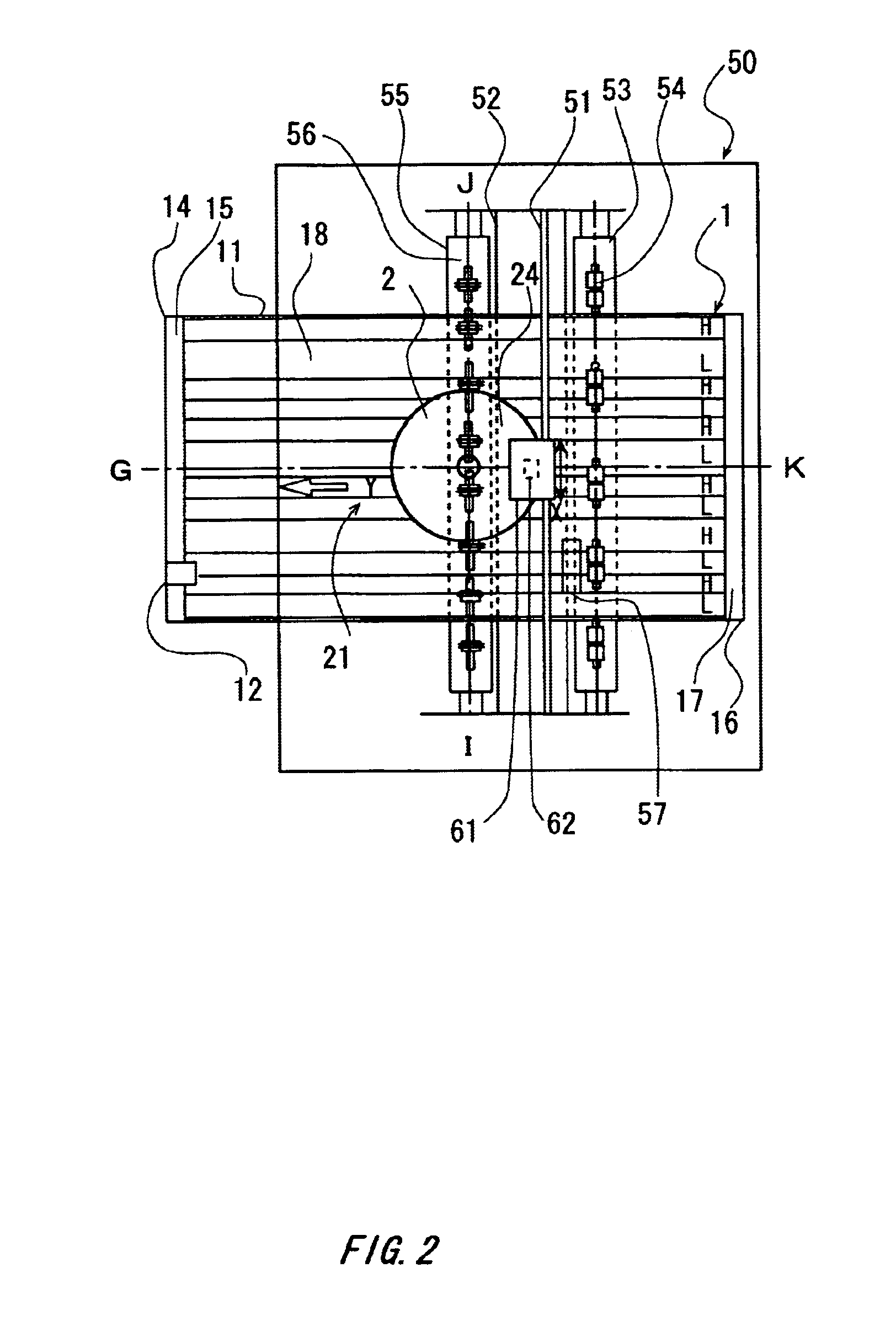

Printer with force transmitting path selecting mechanism

InactiveUS20070048058A1Promote quick completionReduce occasionSpacing mechanismsPower drive mechanismsEngineeringForce output

A printer has a carriage being movable between a first end and a second end of a reciprocating path; and a driving force transmitting path selecting mechanism provided at the second end of the reciprocating path. The selecting mechanism has: a common driving force outputting member; a plurality of force receiving members; a selecting member; and a position retainer for keeping the position of the selecting member. The selecting member connects the force outputting member to one of the plurality of force receiving members, and moves in association with the carriage when the carriage moves in a vicinity of the second end in a first direction extending from the first end to the second end. The position retainer keeps the position of the selecting member when the carriage moves in a second direction extending from the second end to the first end. The force receiving member connected to the force outputting member via the selecting member is selected in accordance with a movement of the carriage along the reciprocating path.

Owner:BROTHER KOGYO KK

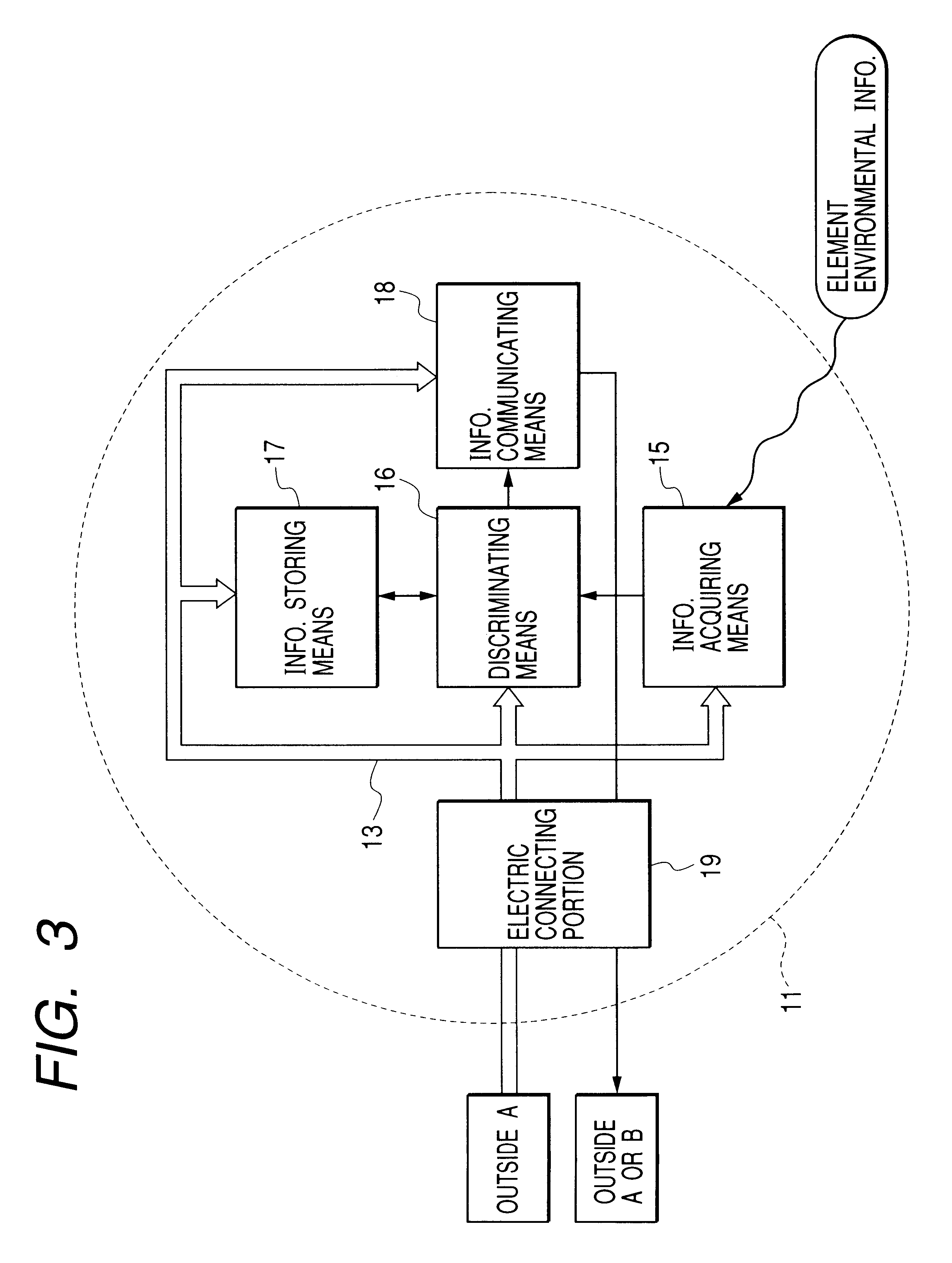

Ink tank and ink jet recording apparatus provided with the same

InactiveUS6685296B2Improve performanceEfficient determinationInking apparatusSpacing mechanismsEngineeringSemiconductor

An ink tank is provided which can efficiently perform detection of information in an ink tank such as an ink residual amount in the ink tank with a simple configuration in which it is unnecessary to set wiring or the like. A solid semiconductor element, which is provided with an acquiring unit for acquiring environmental information of the outside, an information storing unit, a discriminating unit for comparing acquired information and stored information to make a determination, and an information communicating unit for displaying the acquired information or communicating the acquired information to the outside, is embedded in an outer wall of an ink tank such that the solid semiconductor element is exposed to an internal side and an external side of the ink tank from the outer wall. The solid semiconductor element can perform supply of its operation energy or exchanges of signals in a non-contact state or by connecting with a terminal provided in a supporting portion or the like of the ink tank directly, thus, it is unnecessary to set wiring. In this case, the information acquiring means can be preferably disposed in the part of the solid semiconductor element exposed to the inside of the ink tank.

Owner:CANON KK

Printing apparatus and a printing registration method

InactiveUS6371592B1Avoid complex processLow costSpacing mechanismsOther printing apparatusEngineeringOperation mode

A construction of a printing apparatus wherein a printing registration with respect to forward and reverse scans of a printing head and a printing registration with respect to a plurality of printing heads are automatically carried out is realized without rendering the apparatus complex or causing its production cost to rise. To this end, the optical sensor for measuring patterns formed for use in printing registration is also used to serve other purposes such as a detection of a printing home position or a detection of a printing medium's end. Furthermore, by appropriately controlling a single optical sensor according to each of various intended purposes, the optimum characteristics are utilized in each respective operating mode. Because of the above, the addition of sensors to be used only for the purpose of printing registration and the accompanying rise of the print apparatus production cost are restrained.

Owner:CANON KK

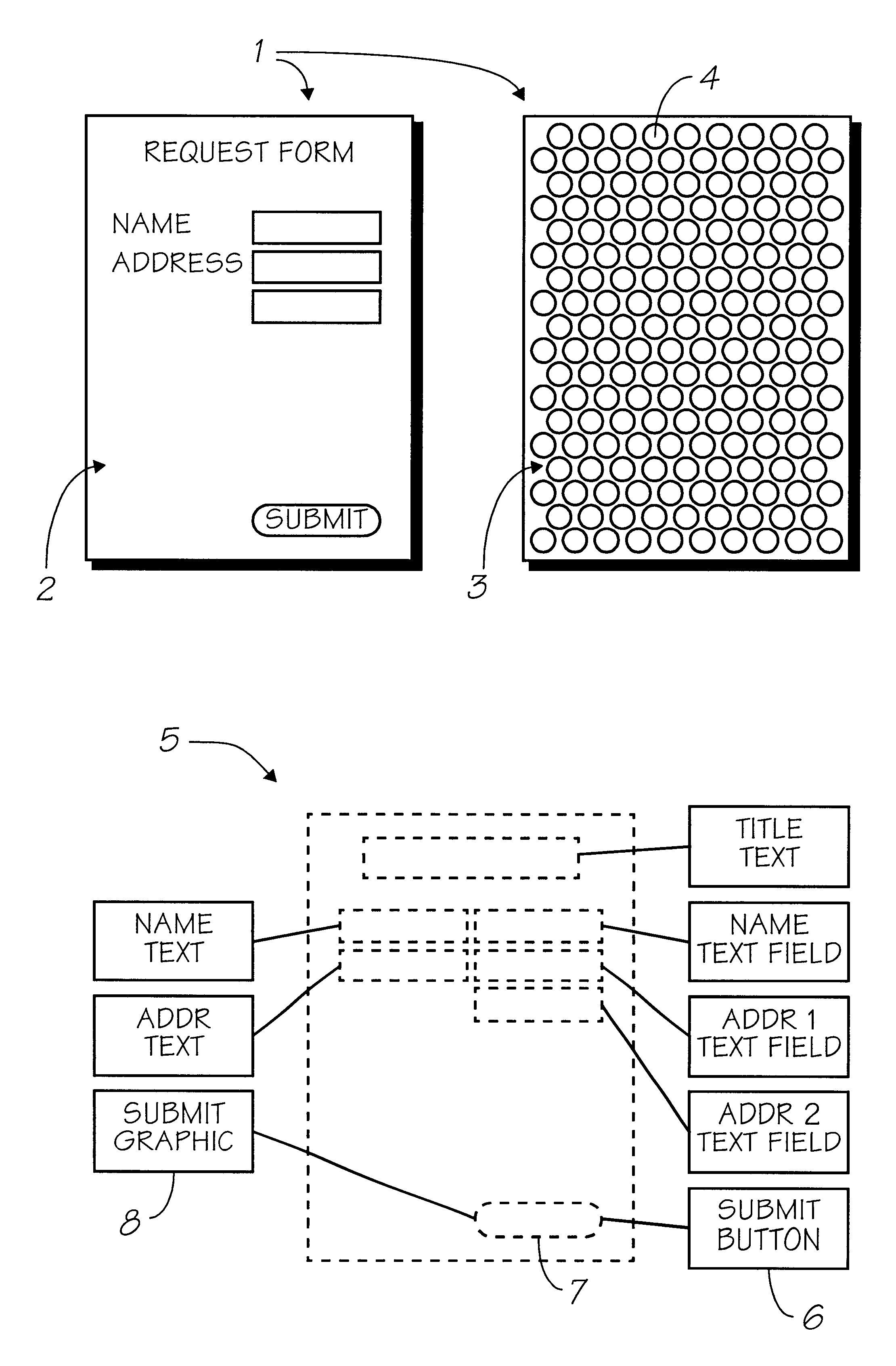

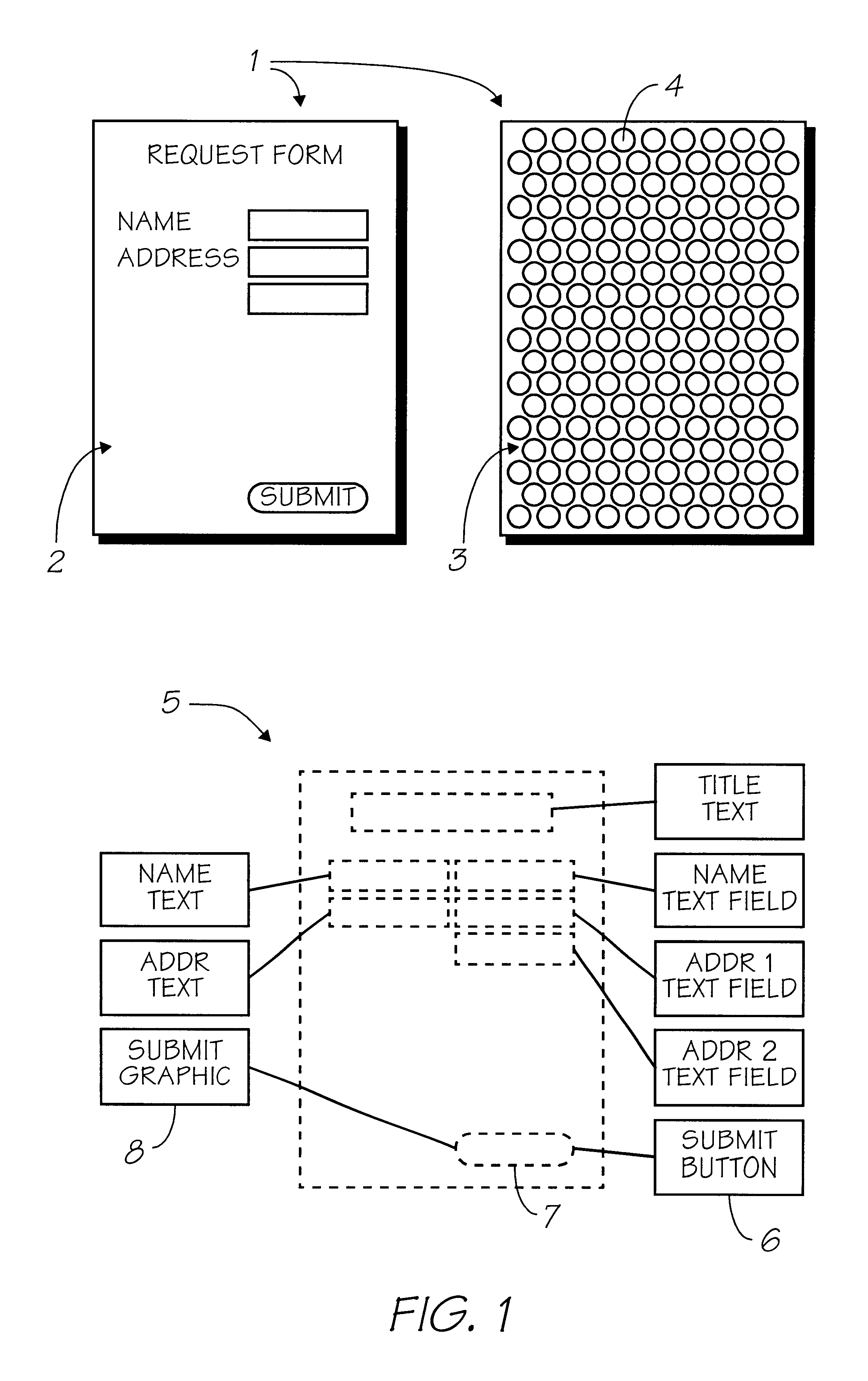

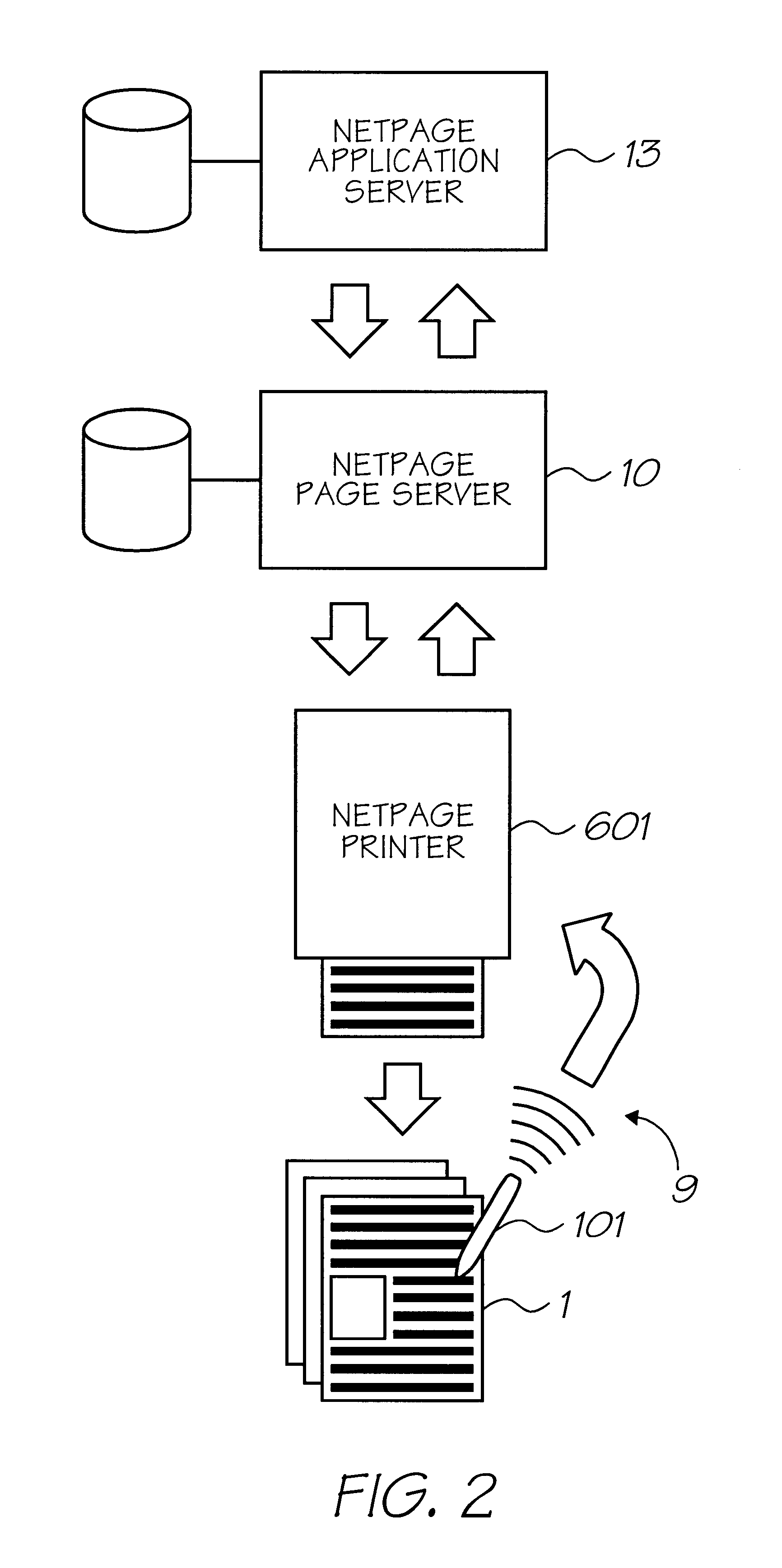

Method and system for composition and delivery of electronic mail

InactiveUS6816274B1Input/output for user-computer interactionCharacter and pattern recognitionComputer networkComputerized system

A method for composition and transmission of an electronic mail message including: printing a document to facilitate composition and transmission of the electronic mail message; composing the electronic mail message on the document utilizing a sensing device adapted to read coded data in the document; transmitting interaction data from the sensing device to a computer system, the interaction data representing interaction of the sensing device with the coded data to allow the message to be electronically captured in the computer system; and transmitting the message to at least one recipient address.

Owner:SILVERBROOK RES PTY LTD

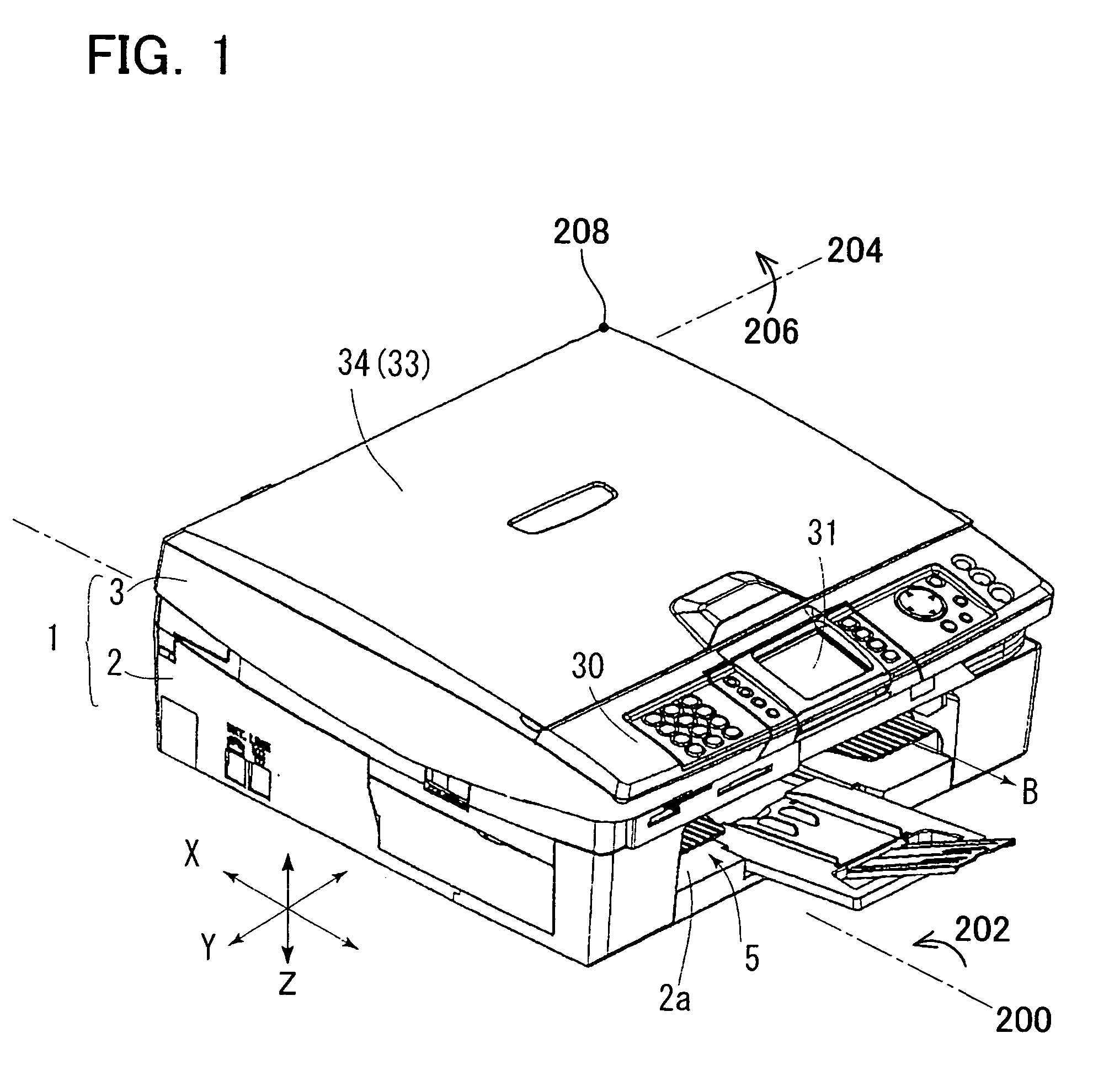

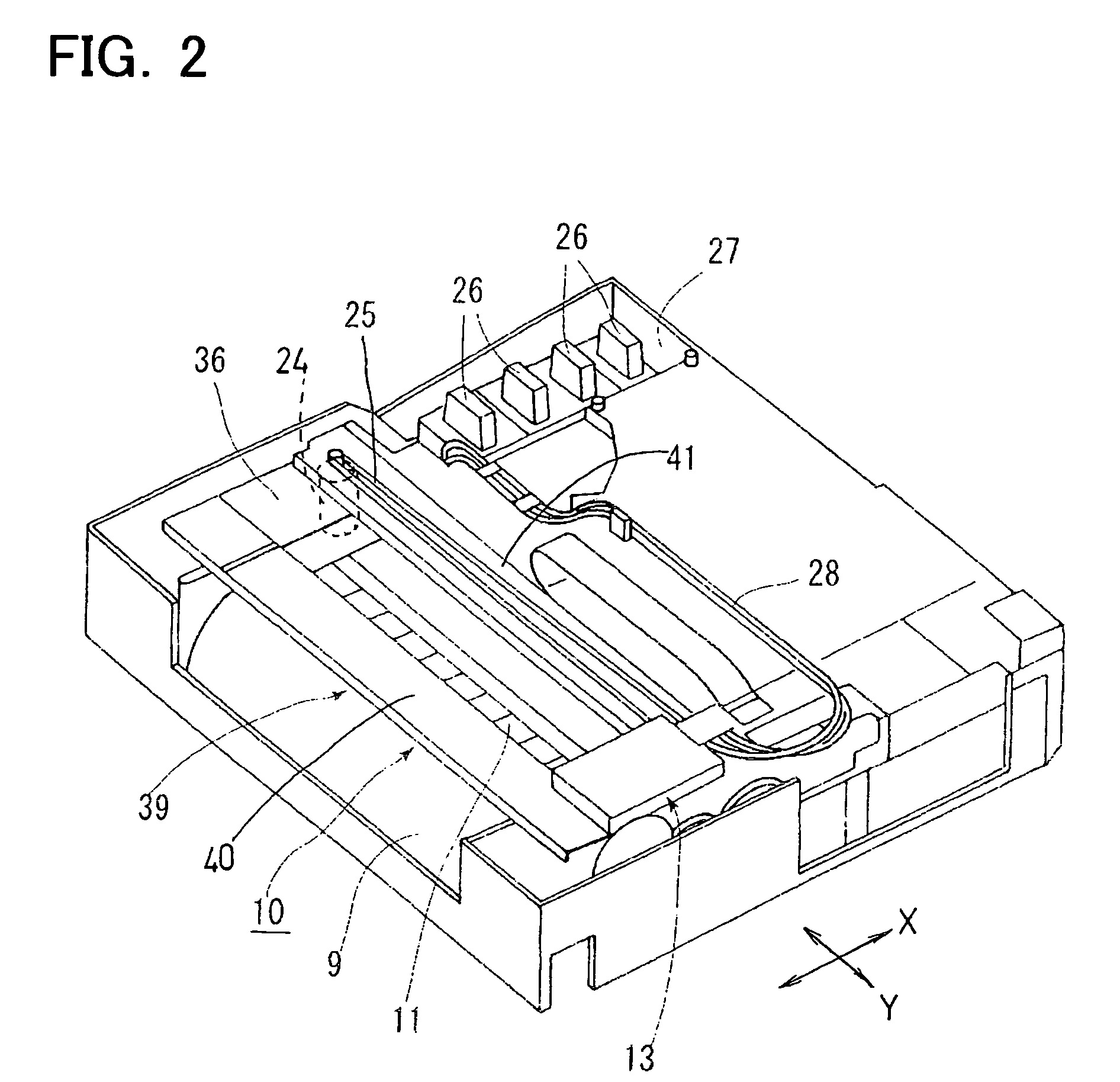

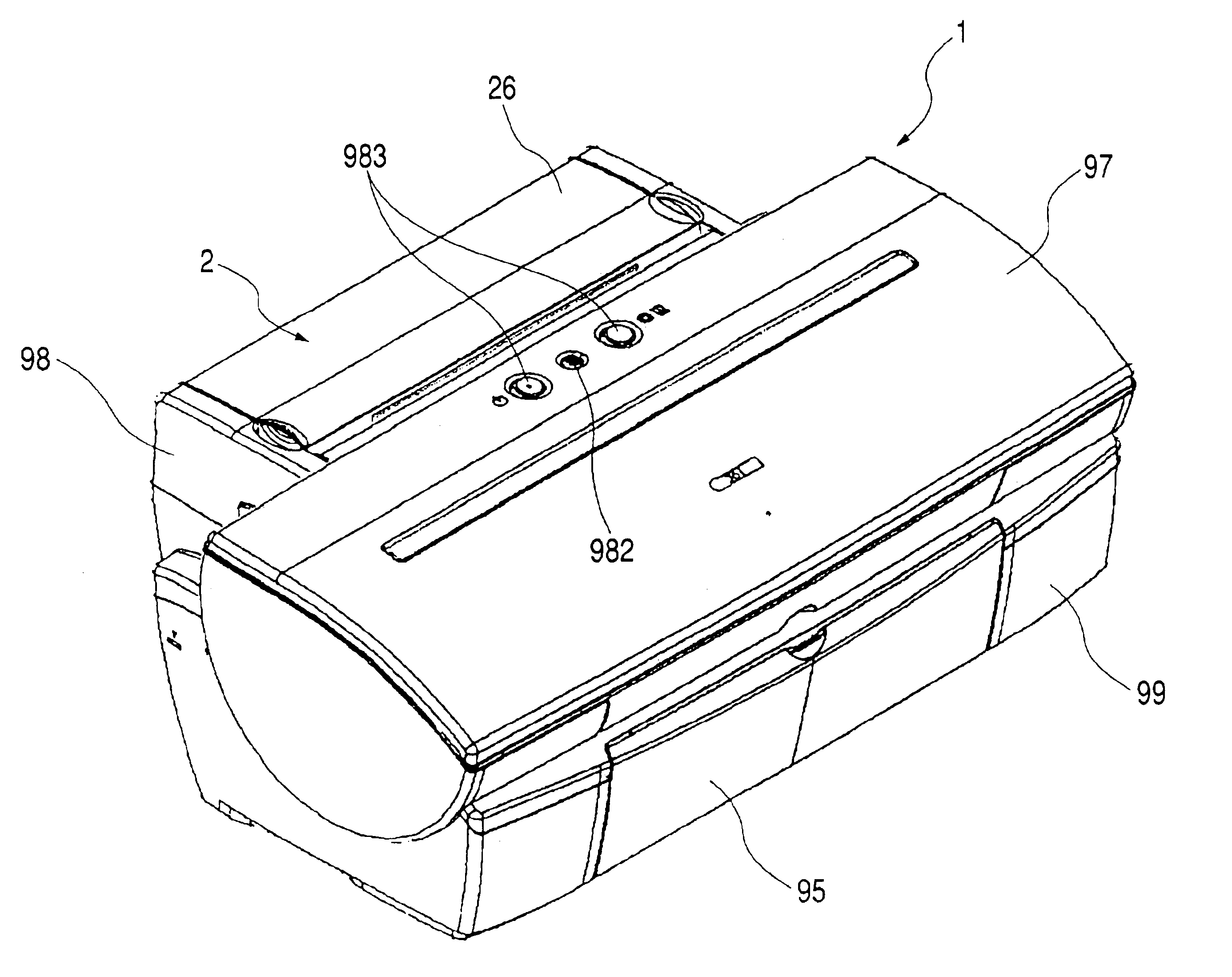

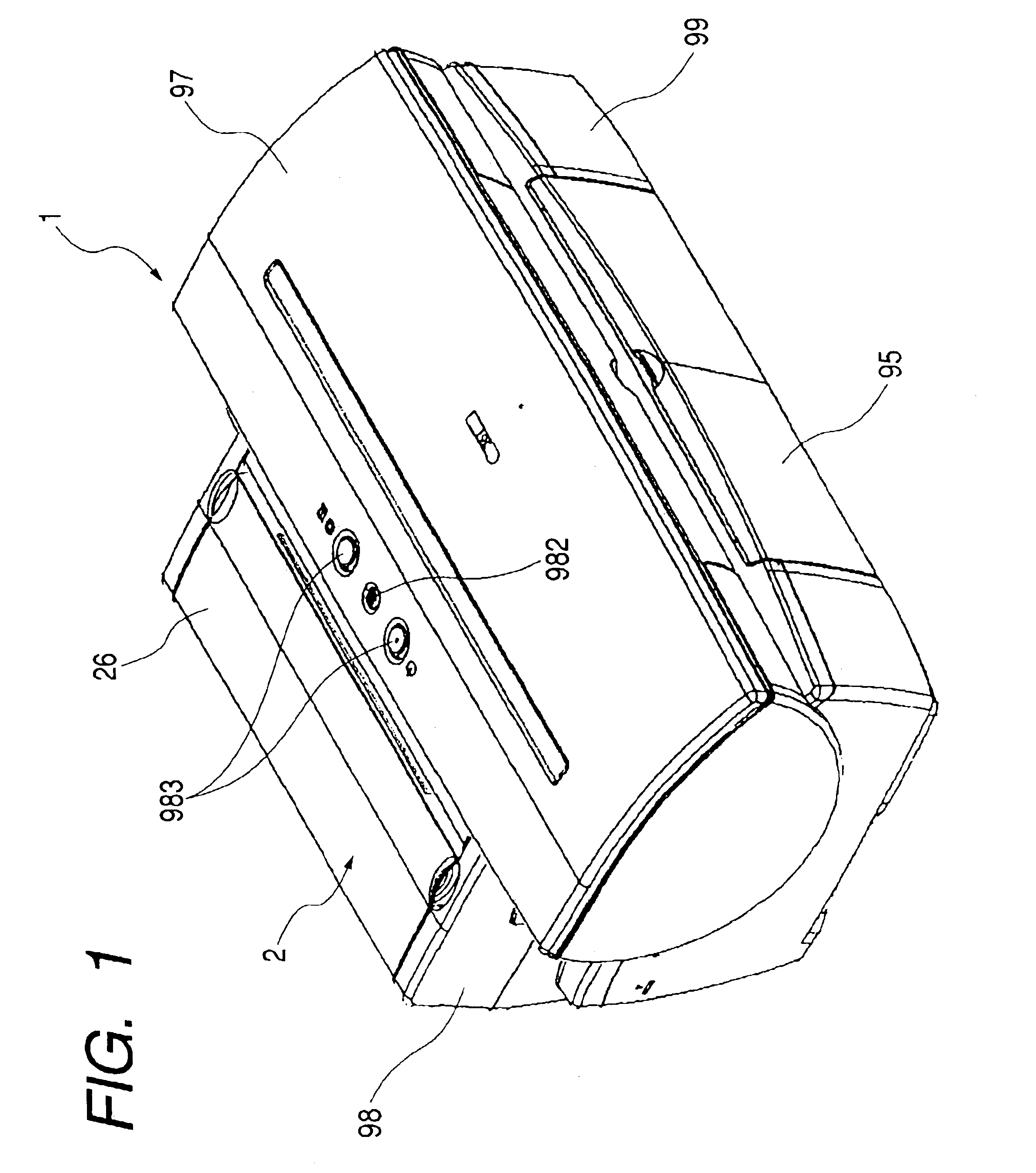

Printer with sheet sending mechanism

InactiveUS20070057447A1Increase speedSpacing mechanismsPower drive mechanismsEngineeringFeeding mode

A supply roller for sending a piece of sheet from pieces of sheets stacked within a cassette towards a sheet guide and a pair of feed-in rollers for sending the piece of sheet supplied from the sheet guide towards a printing region are provided within a printer. The pair of feed-in rollers has a feed-in drive roller driven by a motor and a feed-in driven roller driven by the feed-in drive roller. A sending speed of the pair of feed-in rollers is faster than a sending speed of the supply roller, and a sending force of the pair of feed-in rollers is stronger than a sending force of the supply roller. A controller of the printer controls the rotation of the supply roller and the pair of feed-in rollers according to a procedure that does not rely on a position of the sheet sent by the supply roller and the pair of feed-in rollers during the continuous feeding mode.

Owner:BROTHER KOGYO KK

Tray for transferring recording media, and recording apparatus

InactiveUS7101096B2Reduce noiseEfficient executionInking apparatusCharacter printing data arrangement from carrierReciprocating motionEngineering

A transferring tray for a printing apparatus for printing on one major surface of a recording media having disc shape, wherein the printing apparatus includes, a carriage having a printing head, reciprocating in a main scanning direction, a transferring unit transferring the recording media in a sub scanning direction, a detecting unit detecting the recording media being transferred by the transferring unit, and a recording unit printing on the one major surface of the recording media, the transferring tray including: a tray body having a rectangular plate shape made of a material which is not detected by the detecting unit; a detected portion formed on either one of two major surfaces of the tray body, being detectable by the detecting unit; and a mounting portion having a mounting recess such that the one major surface of the recording media comes up to substantially same level as one of the major surfaces of the tray body when the recording media is mounted on the transferring tray.

Owner:SEIKO EPSON CORP

Printer device alignment method and apparatus

InactiveUS6755499B2Highly suitableCharacter printing data arrangement from carrierError detection/correctionOffset distanceComputer printing

Owner:HEWLETT PACKARD DEV CO LP

Recording apparatus

InactiveUS6899474B2High-quality recordingEasy to implementInking apparatusSpacing mechanismsRecording headEngineering

To provide a recording apparatus for recording on a sheet by a recording head, including: a carriage for carrying the recording head and moving in a direction crossing a sheet transporting direction; a guide shaft for guiding a movement of the carriage; and a guide shaft lifting mechanism for changing a position in height of the guide shaft at three or more stages without changing a position of the guide shaft in the sheet transporting direction.

Owner:CANON KK

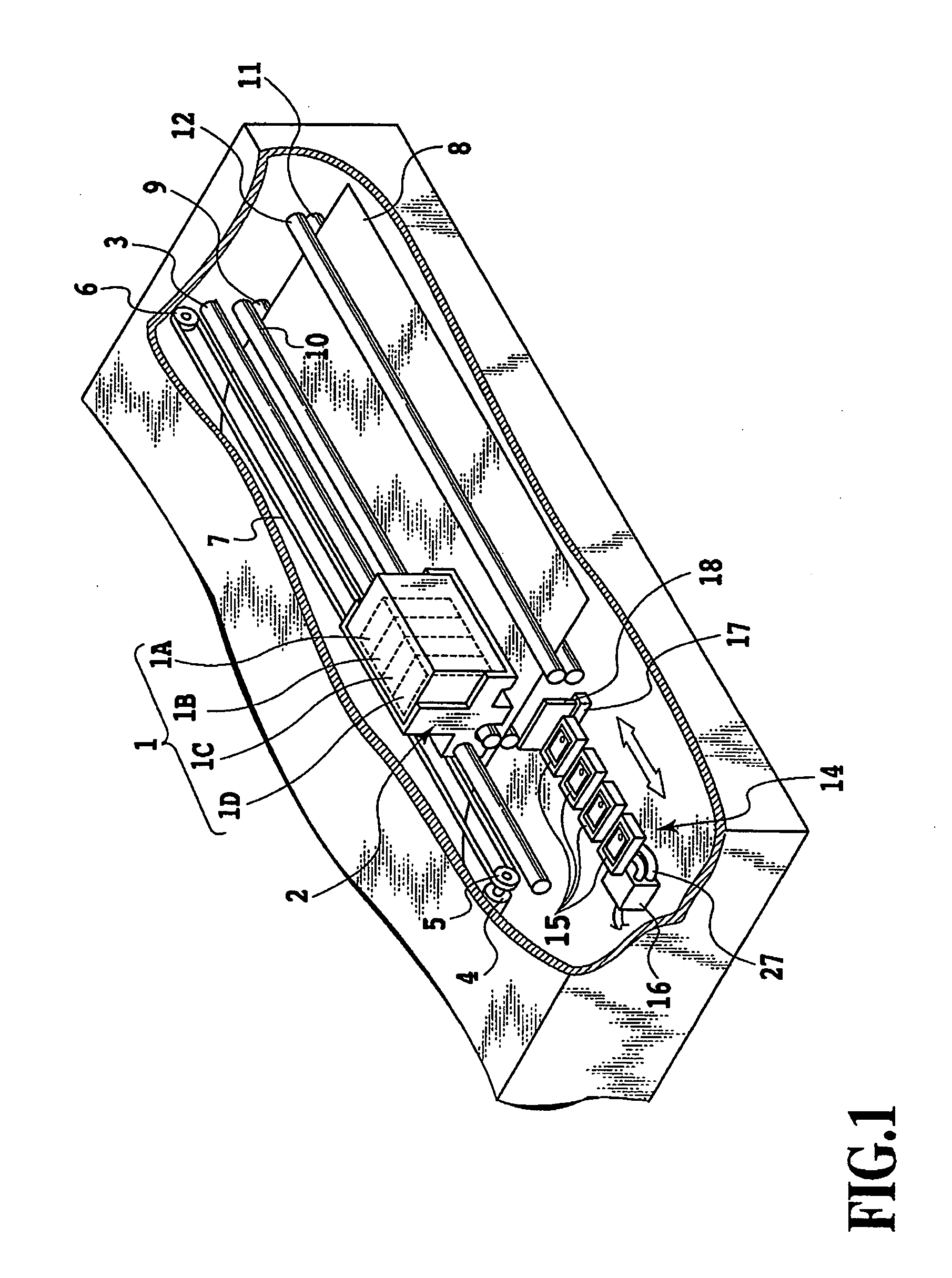

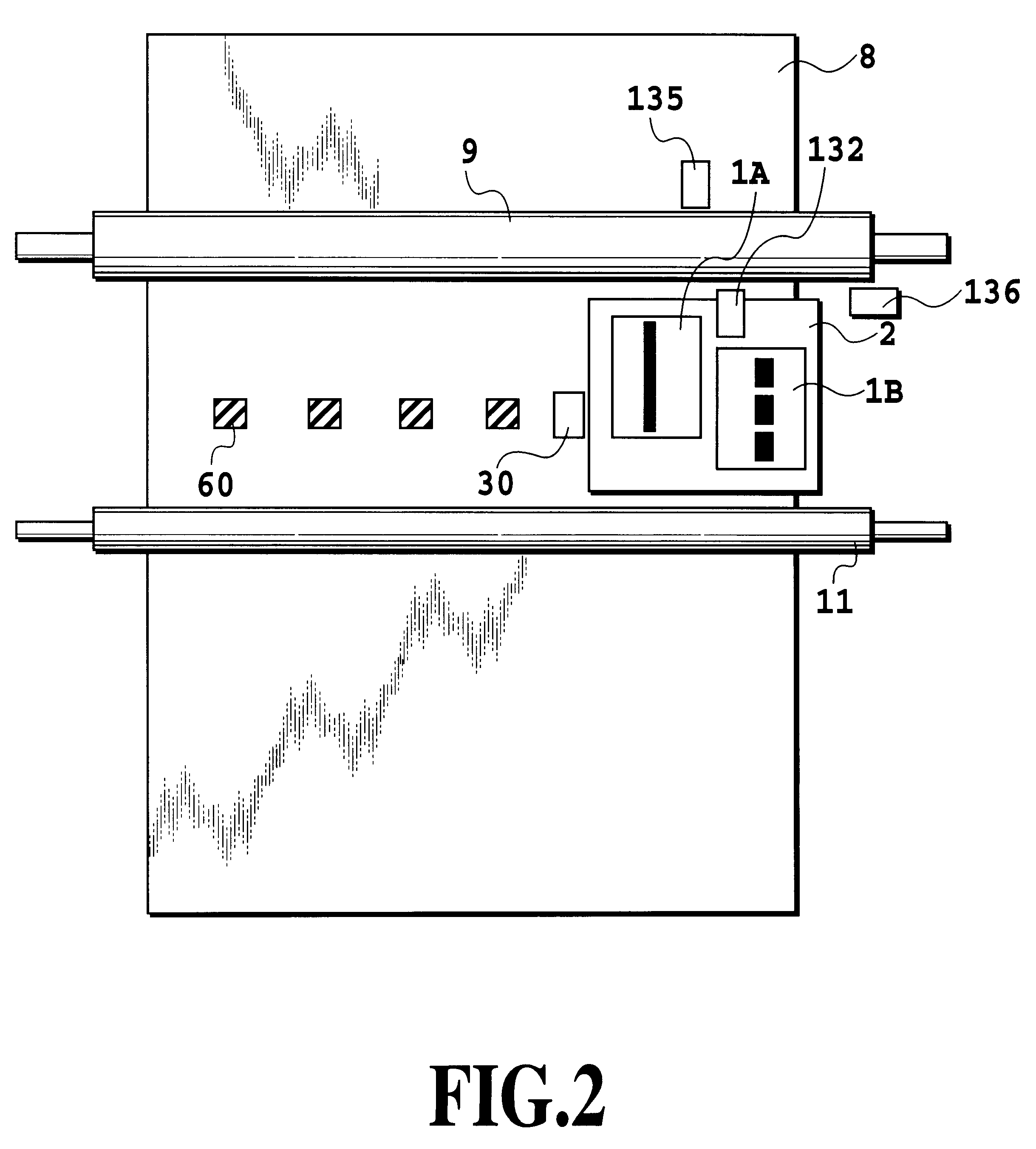

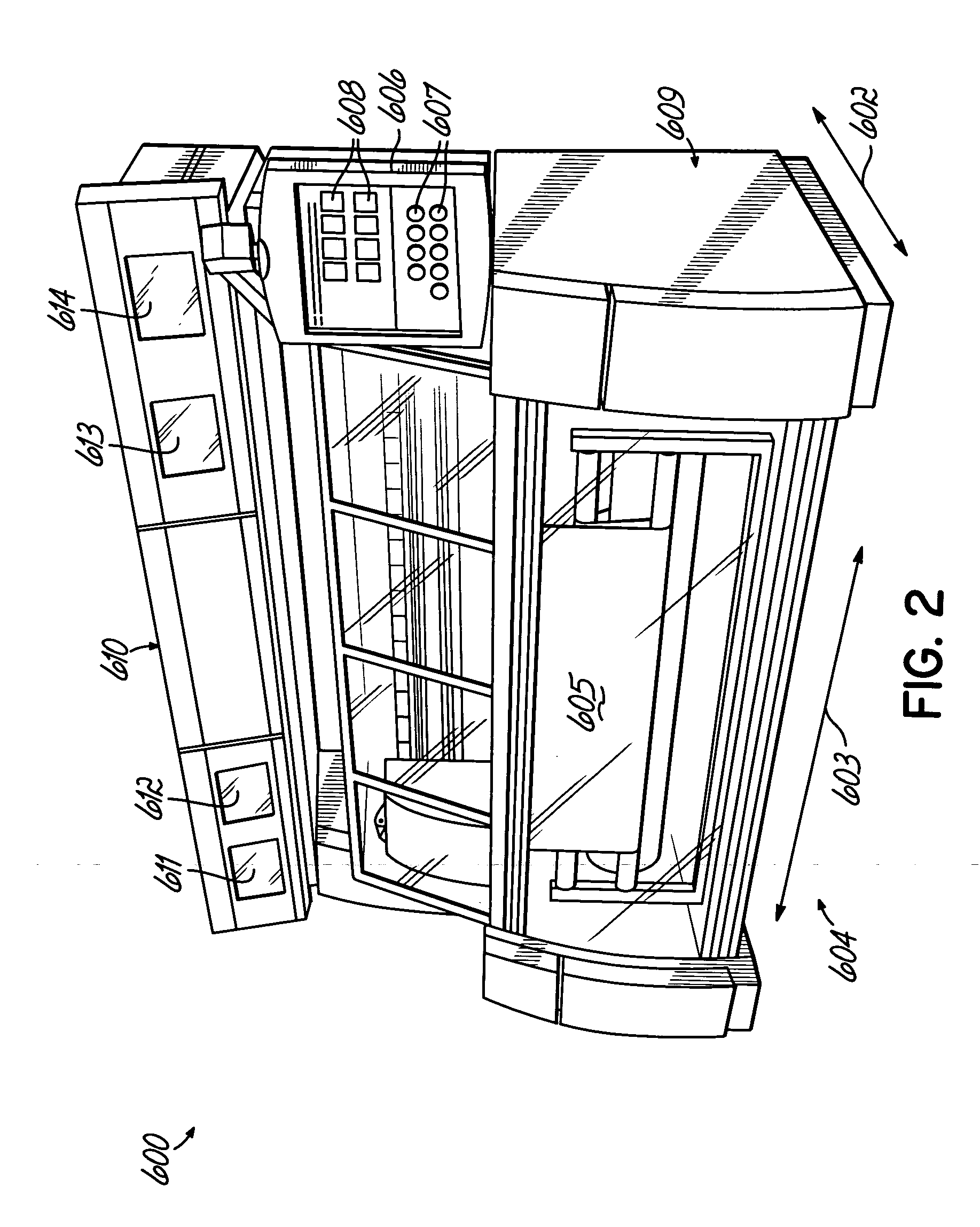

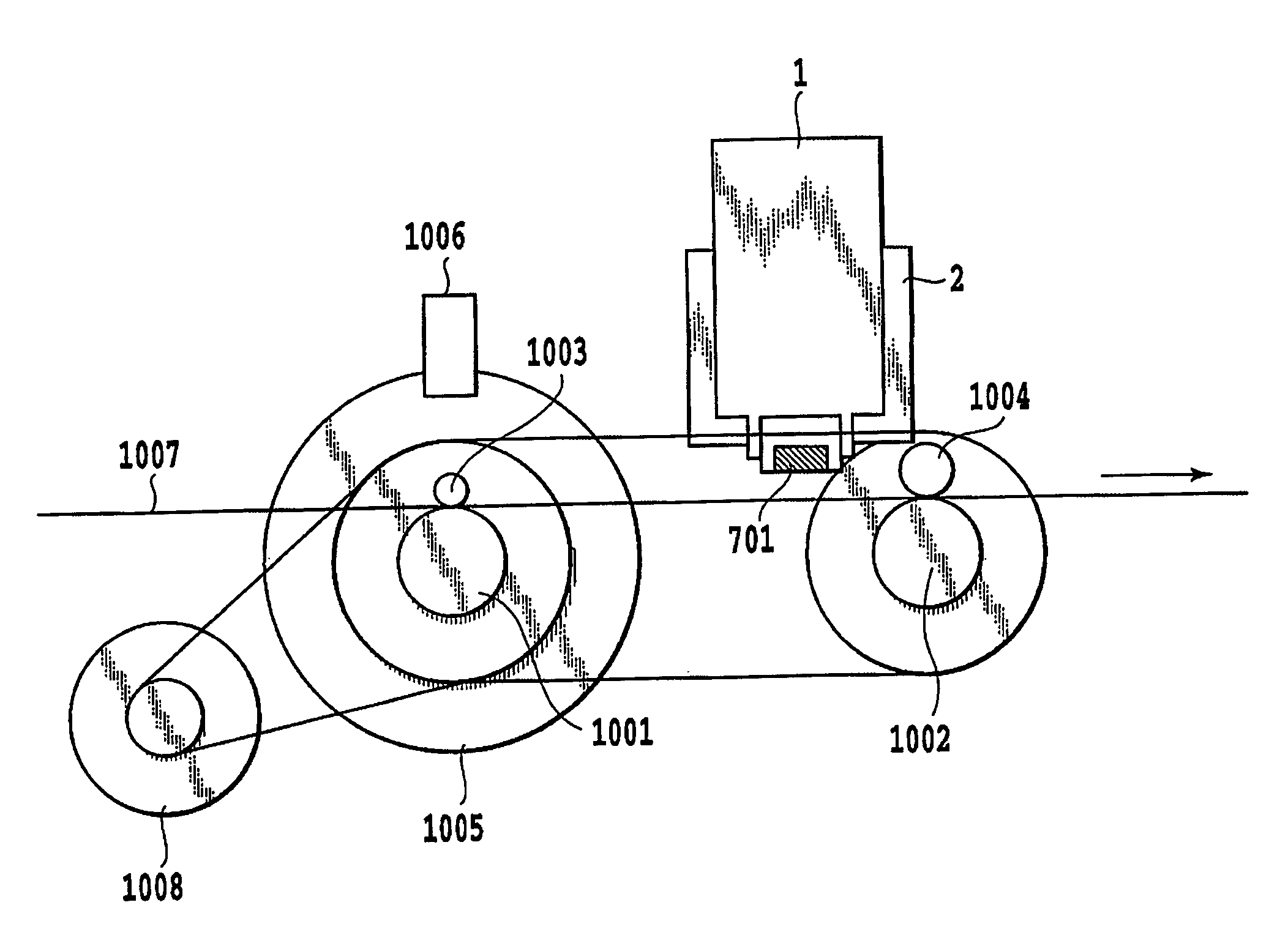

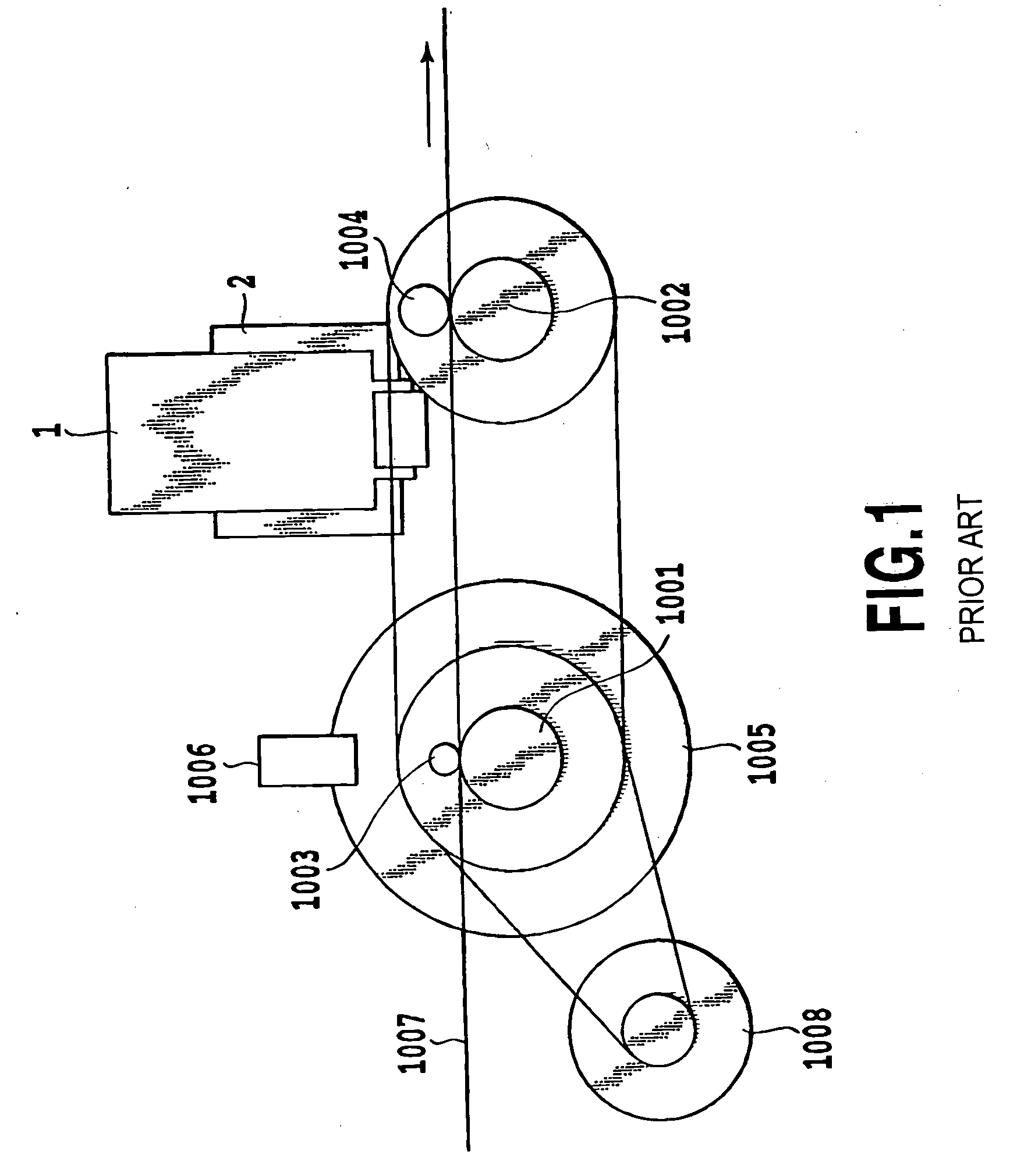

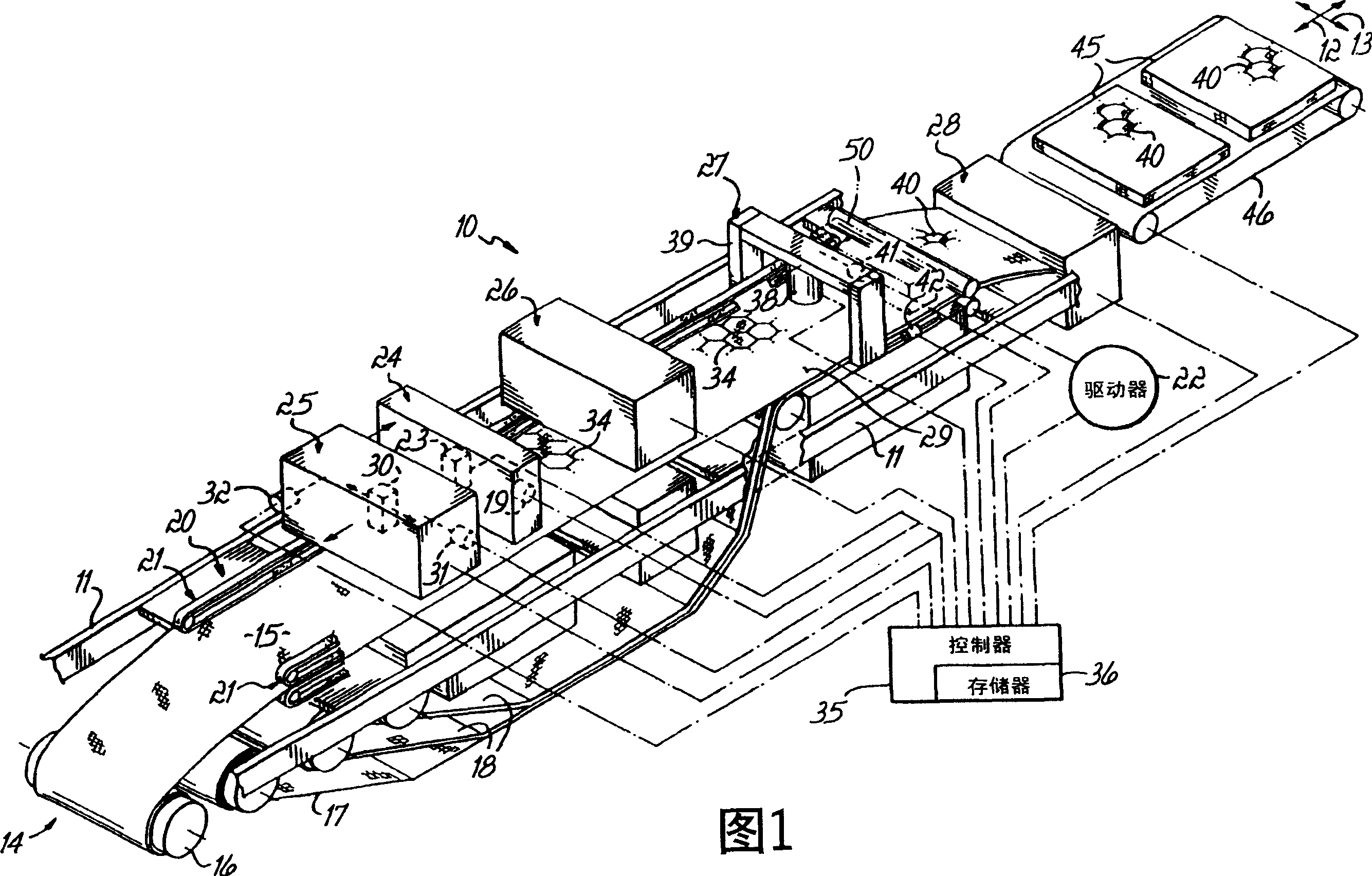

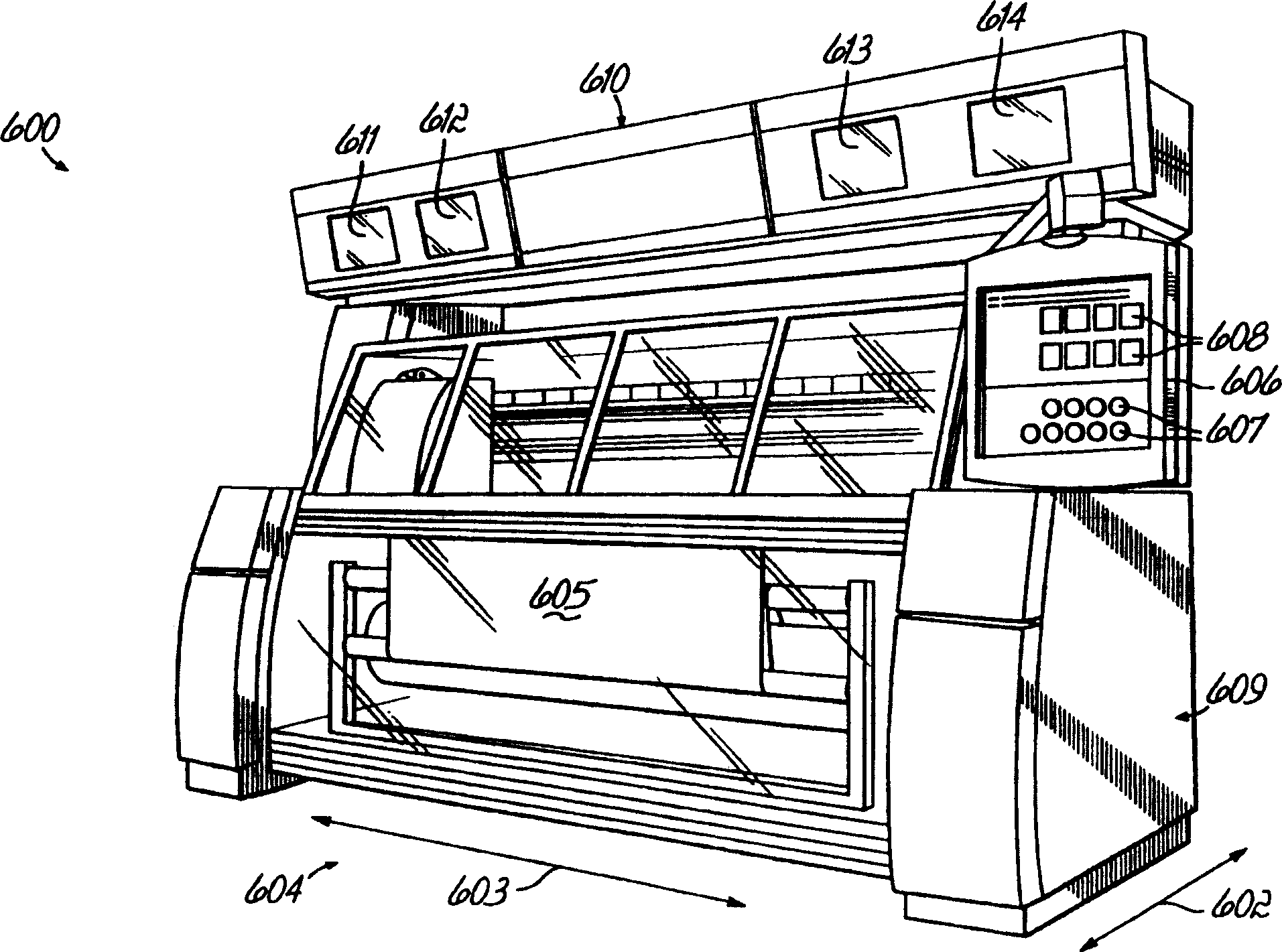

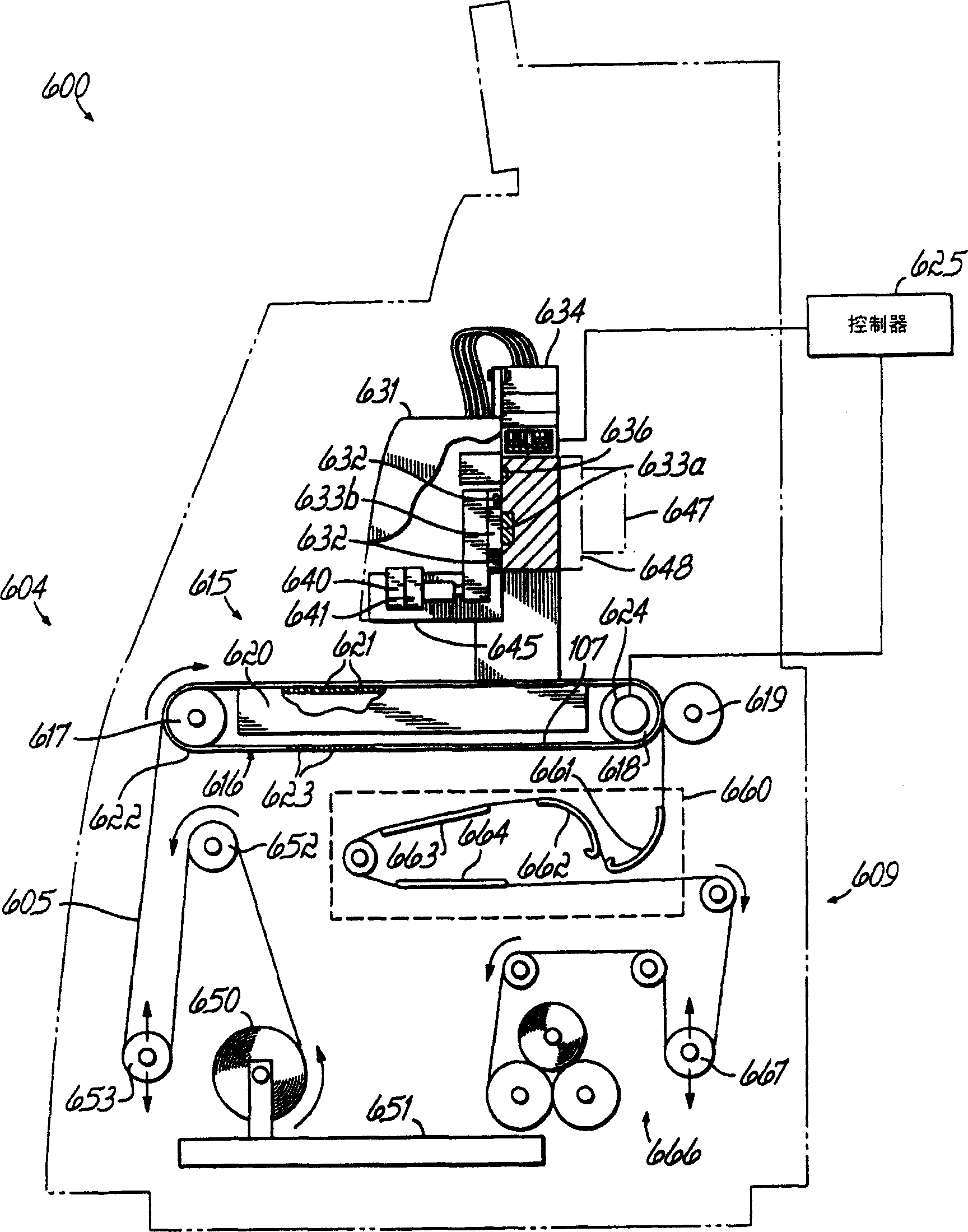

Method and apparatus for ink jet printing

InactiveUS20050174412A1Efficient curingHigh color saturation potentialDuplicating/marking methodsSpacing mechanismsPolyesterPorous substrate

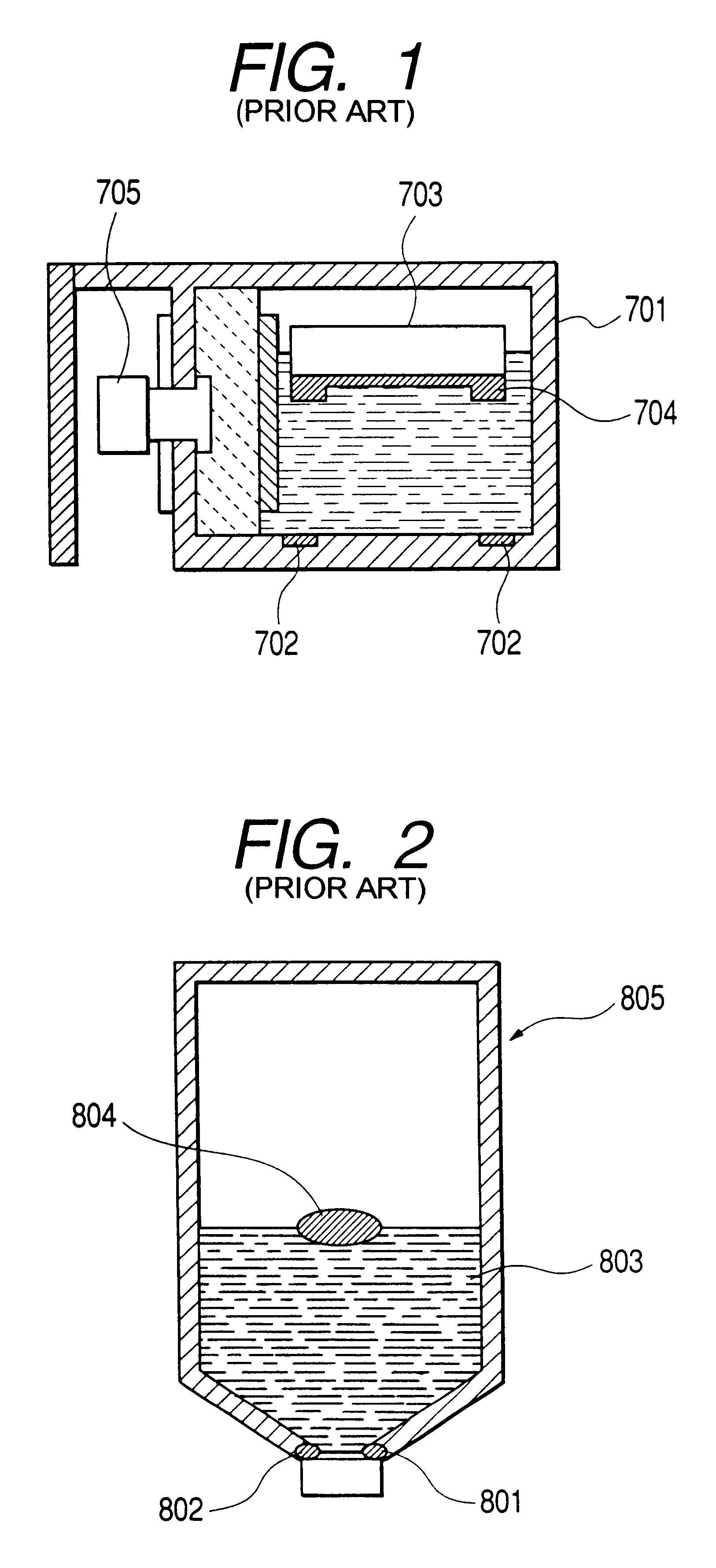

Ink jet printing is provided on large area substrates such as wide width textile webs. The printheads are driven by linear servo motors (633) across a bridge (630) that extends across the substrate. The timing of the jetting of the ink is coordinated with the motion of the printheads (640,641), so that the heads can be rapidly moved and the ink can be jetted while the printheads are accelerating or decelerating as they move on the bridge. Preferably, ultraviolet (UV) light curable ink is jetted and first partially cured with UV light (645,646) and then subjected to heating to more completely reduce uncured monomers of the ink on the substrate. Preferably, the heat is applied by contacting the substrate with a heated plate (661,662). Ink jet printing is provided using ultraviolet (UV) light curable or other curable composition or stable or other printable substance. In certain embodiments the UV ink has a dye-component therein. The ink is jetted onto a substrate, the composition is cured, then heated to set the dye. Sublimation dye-based UV ink printing onto polyester is preferred. A release layer of protective material (702,704), such as a TEFLON film or sheet, covers a substrate support (705,706). A porous substrate to be printed, such as a textile material (711), is supported on or above the support. Ink is jetted onto the substrate, with some of the ink passing through pores in the substrate and landing on the protective material. UV curable ink is preferably used and is exposed by UV light from a UV light curing head, which solidifies the ink on the substrate. The UV curing light has a long enough focal length to focus on the surface of the substrate and also, where it passes through pores in the substrate, on ink on the protective material, thereby solidifying the ink on the protective material. When the substrate is removed from the support, the solidified ink on the protective material may be wiped from the protective material. The protective material may be a coating on the support over which the substrate slides or a belt that moves with the substrate. A textile substrate may be preconditioned by singeing or shaving to remove fuzz from the fabric that could clog the printheads. A printhead cleaning station is also provided.

Owner:L & P PROPERTY MANAGEMENT CO

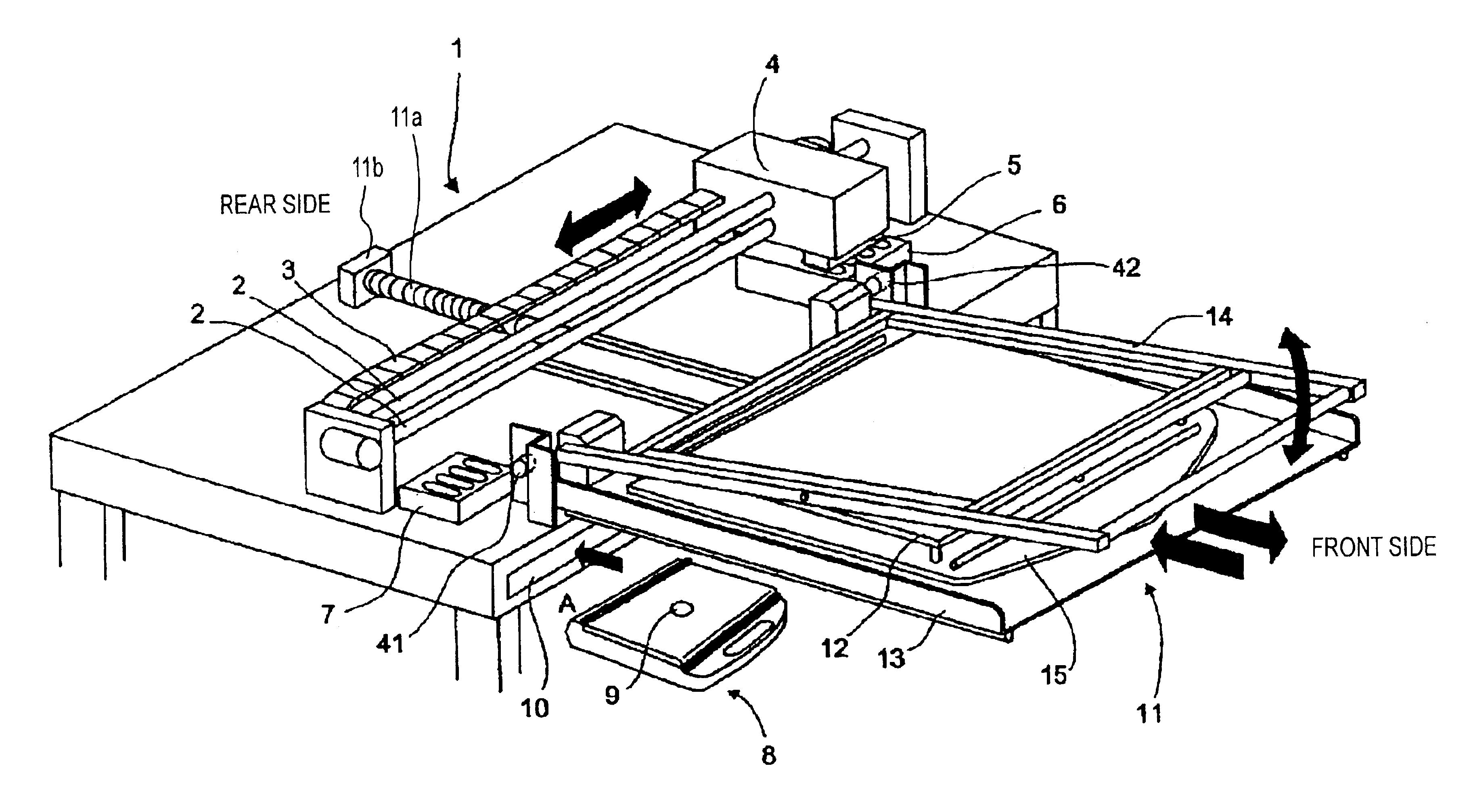

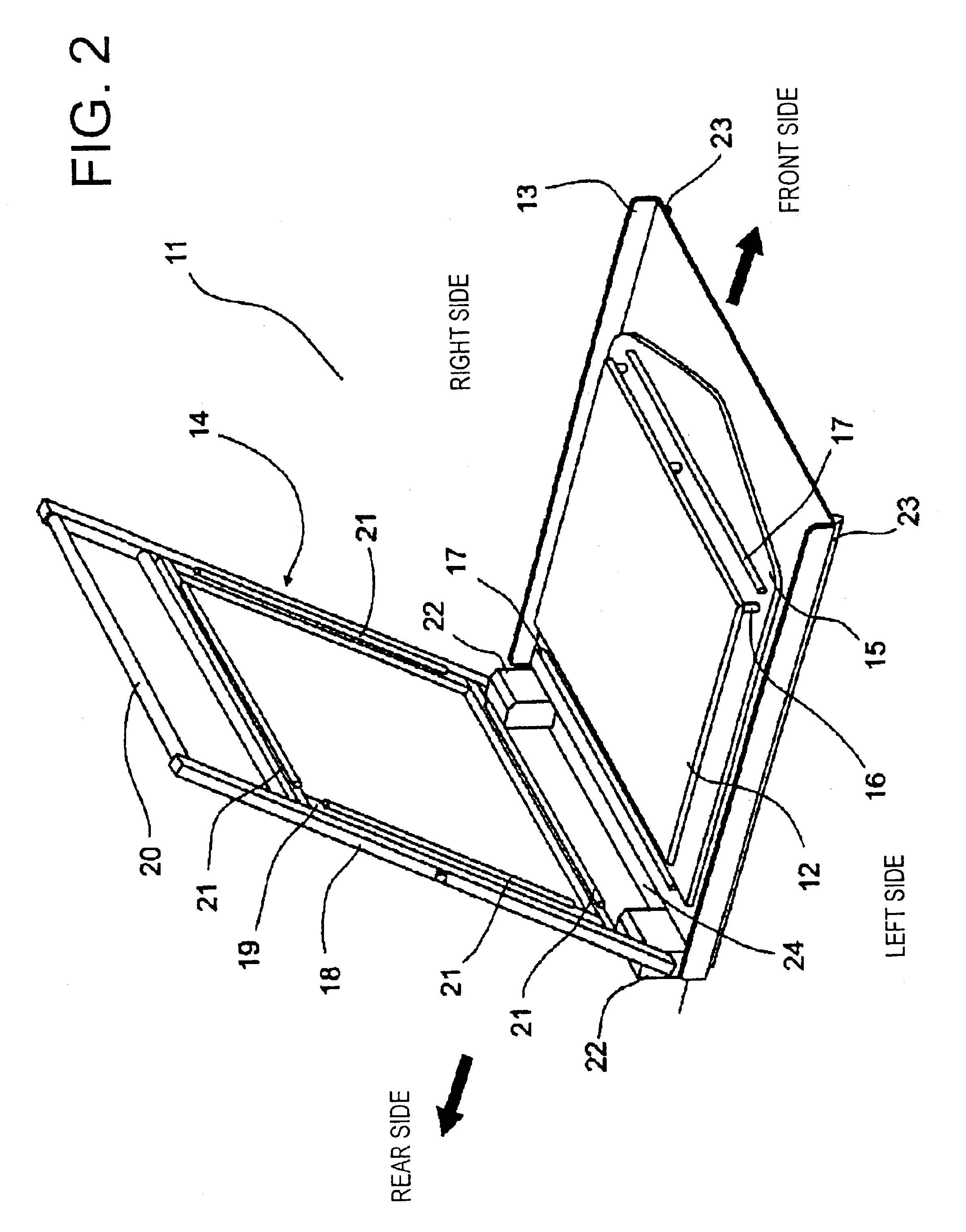

Platen device for holding workpiece in ink-jet printer

InactiveUS6908190B2Easy to set upMinimize permeation of inkInking apparatusPlaten pressesMechanical engineeringInkjet printing

Owner:BROTHER KOGYO KK

Printing apparatus with first and second measuring means for obtaining a conveying amount of a printing medium

ActiveUS7104710B2Eliminate errorsIncrease speedSpacing mechanismsOther printing apparatusProcess engineeringMechanical engineering

Owner:CANON KK

Method and apparatus for ink jet printing

InactiveCN1678458AEliminate cloggingImprove reliabilityDuplicating/marking methodsSpacing mechanismsPorous substratePolyester

Ink jet printing is provided on large area substrates such as wide width textile webs. The printheads are driven by linear servo motors (633) across a bridge (630) that extends across the substrate. The timing of the jetting of the ink is coordinated with the motion of the printheads (640, 641), so that the heads can be rapidly moved and the ink can be jetted while the printheads are accelerating or decelerating as they move on the bridge. Preferably, ultraviolet (UV) light curable ink is jetted and first partially cured with UV light (645, 646) and then subjected to heating to more completely reduce uncured monomers of the ink on the substrate. Preferably, the heat is applied by contacting the substrate with a heated plate (661, 662). Ink jet printing is provided using ultraviolet (UV) light curable or other curable composition or stable or other printable substance. In certain embodiments the UV ink has a dye-component therein. The ink is jetted onto a substrate, the composition is cured, then heated to set the dye. Sublimation dye-based UV ink printing onto polyester is preferred. A release layer of protective material (702, 704) such as a TEFLON film or sheet, covers a substrate support (705, 706). A porous substrate to be printed, such as a textile material (711), is supported on or above the support. Ink is jetted onto the substrate, with some of the ink passing through pores in the substrate and landing on the protective material. UV curable ink is preferably used and is exposed by UV light from a UV light curing head, which solidifies the ink on the substrate. The UV curing light has a long enough focal length to focus on the surface of the substrate and also, where it passes through pores in the substrate, on ink on the protective material, thereby solidifying the ink on the protective material. When the substrate is removed from the support, the solidified ink on the protective material may be wiped from the protective material.

Owner:L & P PROPERTY MANAGEMENT CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com