Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

942results about "Cylinder presses" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and apparatus for improving registration and skew end of line checking in production

System, method, article for determining registration and / or skew errors in a print medium with respect to a printing element includes a print medium including a two-dimensional pattern including a grid within a geometric shape. The grid has a plurality of vertical and horizontal lines, the intersection of each forming a cross-hair defining an X-Y positional data point; the collection of data points defining a data set. The geometric shape is in the form of a two-dimensional target having a plurality of concentric rings; an innermost one enclosing at least one of the X-Y positional data points in the data set. The printing element provides a marker onto the print medium. The positional location of the marker with respect to the one of the at least one enclosed X-Y positional data point defines a directional displacement vector for correcting registration and / or skew error between the print medium and the printing element.

Owner:INTERMEC IP CORP

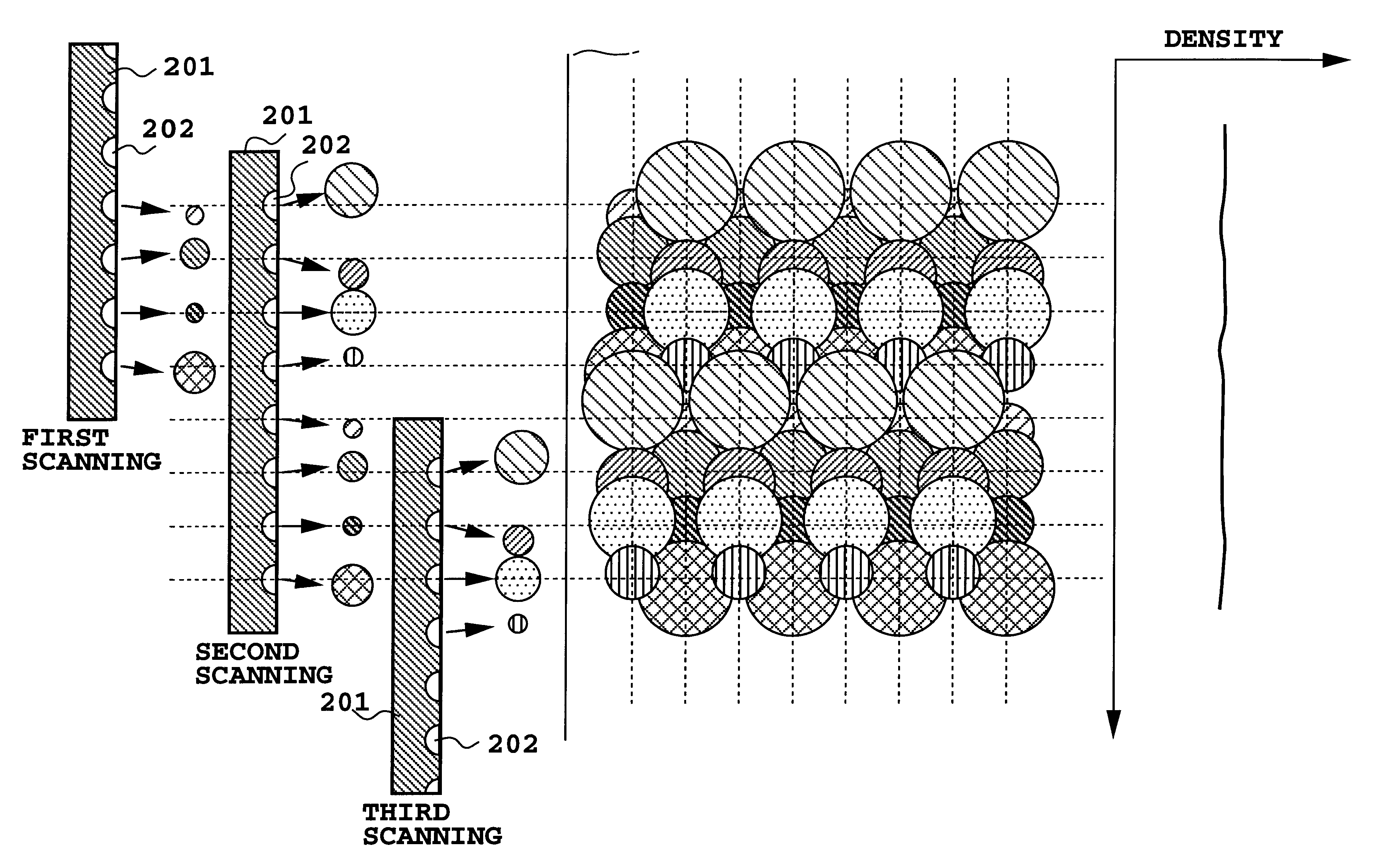

Adjustment method of dot printing positions and a printing apparatus

InactiveUS6257143B1Guaranteed uptimeLow costCylinder pressesPlaten pressesEngineeringPrinting registration

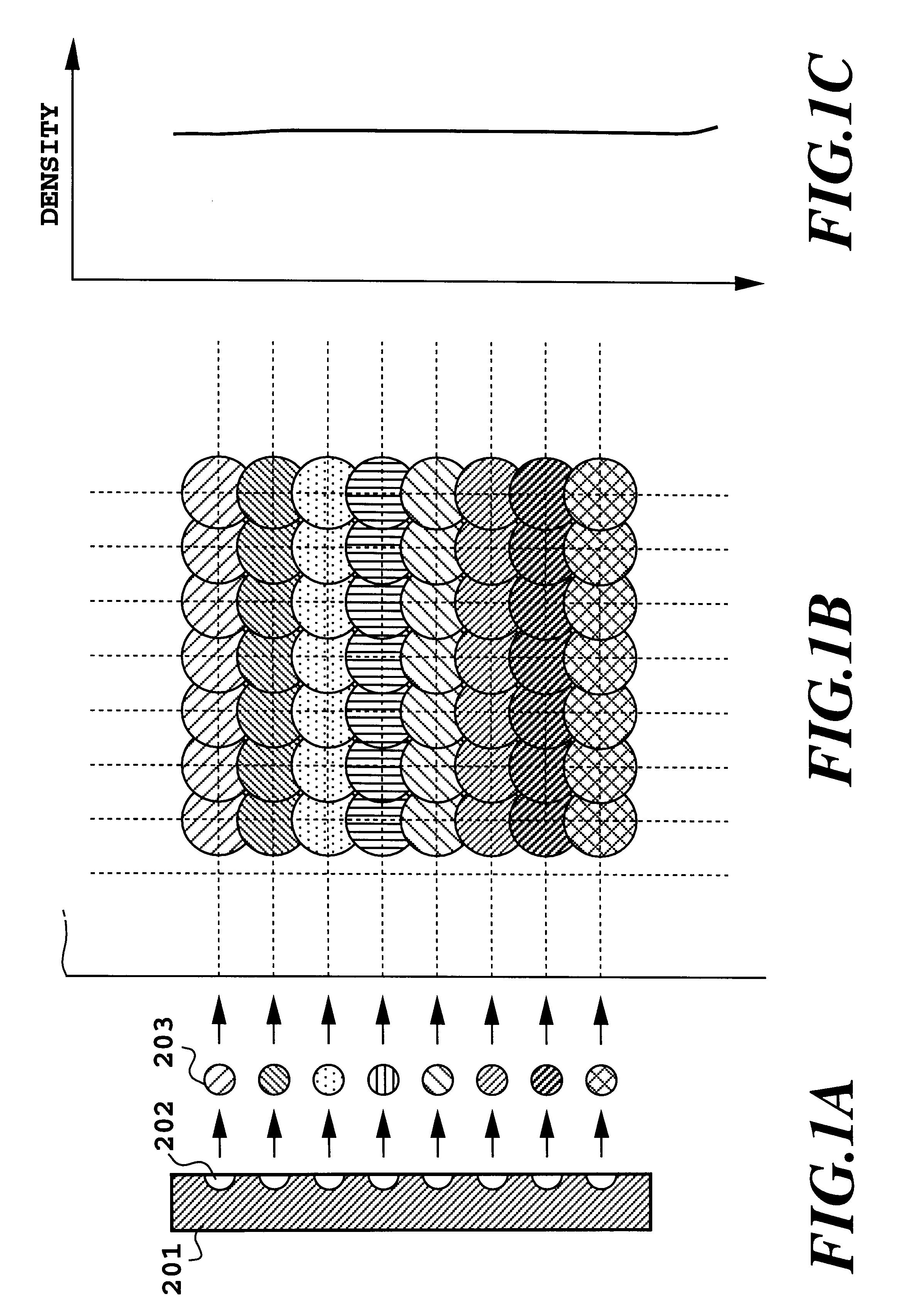

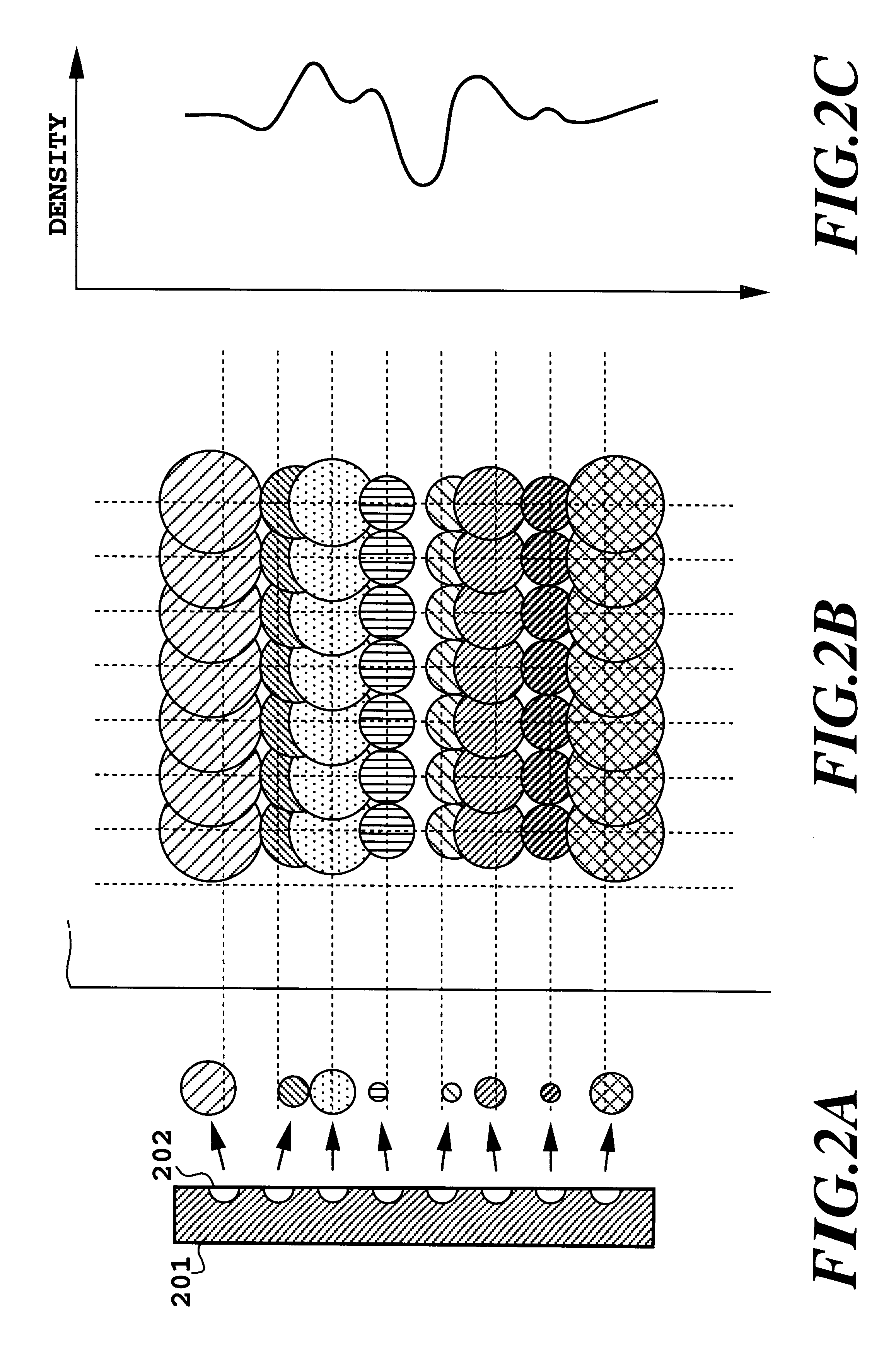

A plurality of patterns respectively having different area factor of dot formation area are formed by forward and reverse scanning printing of a print head, and then optical characteristics of the plurality of formed patterns are measured. A function representing the relationship between the printing position offset between the forward and reverse printings is determined from the optical characteristics. Then, respective pattern having a predetermined area factor of dot formation area is formed by means of forward and reverse scanning where the speed is differentiated according to the mode of a printing apparatus, and then the optical characteristics of this pattern is measured. By applying this measured optical characteristics to the function, an adjustment value of the dot formation position conditions between the forward and reverse scans is obtained for each mode. This makes it easy to perform printing registration in a printing apparatus in the case of printing by a forward and reverse scan of a printing head or in the case of printing by means of a plurality of printing heads. In this case, operations by a user etc. are also unnecessary and are easily performed.

Owner:CANON KK

All printed solar cell array

The present invention relates to a method for producing a photovoltaic novelty item. Conductive polymer solutions and semiconductive oxide dispersions are formulated into inks that are laid down on top of one another to produce voltage and current when exposed to light. In addition, these inks may be printed on novelty items, such as magazine advertisements or greeting cards, connecting to printed light emitting graphics.

Owner:ZEIRA EITAN C

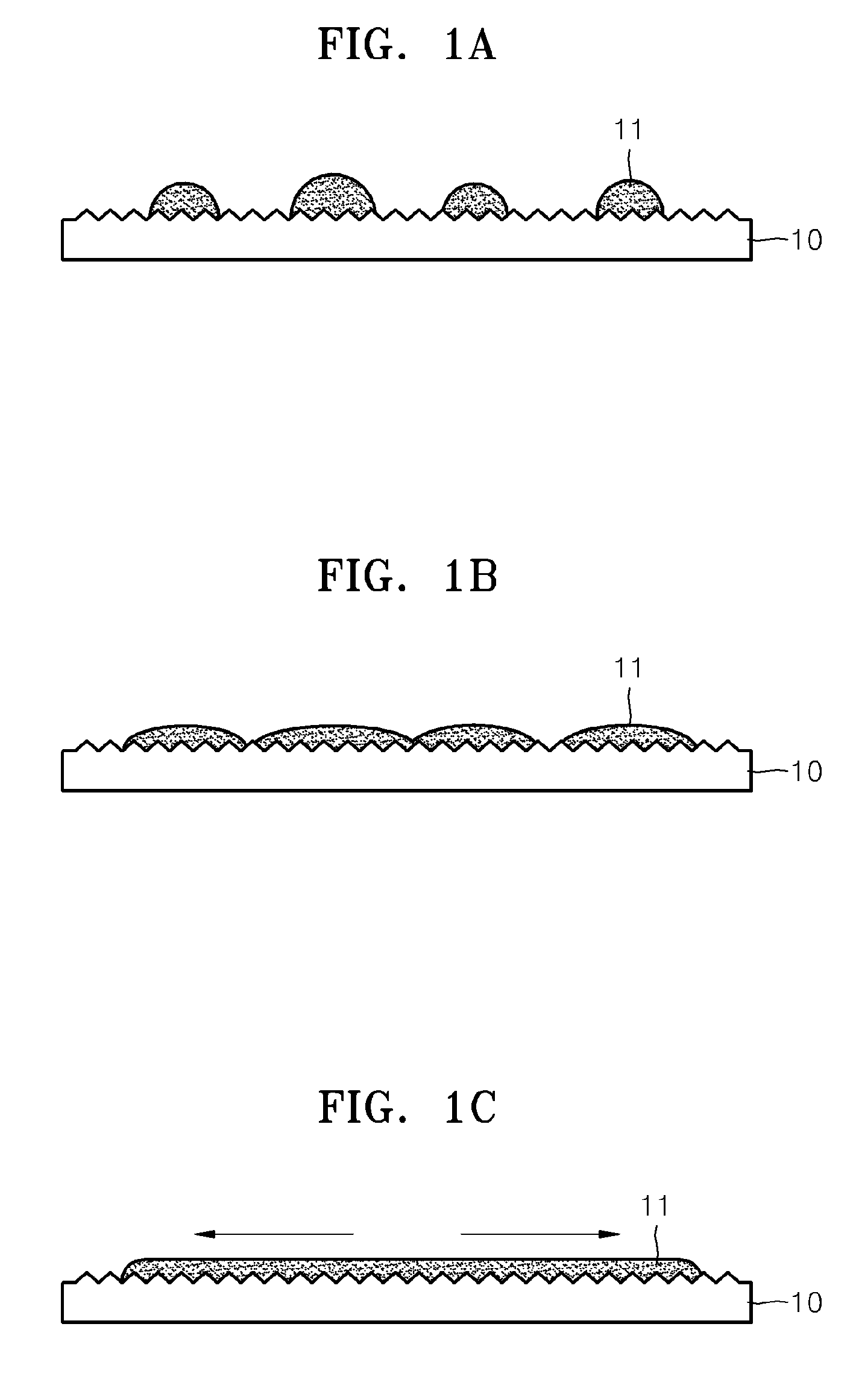

Electrode for secondary battery, manufacturing method thereof and secondary battery employing the same

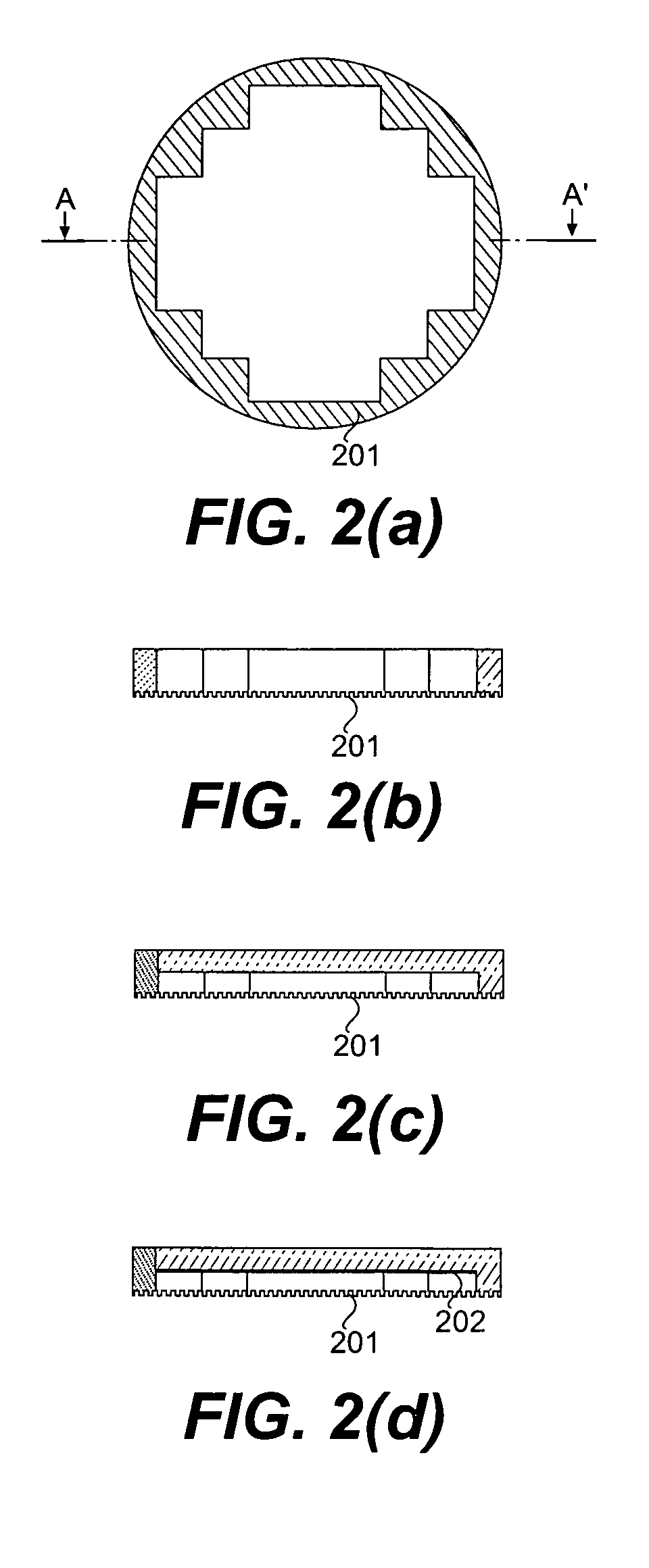

InactiveUS20090098457A1Improve thickness uniformityIncrease electrode capacityCylinder pressesPlaten pressesElectrical batterySurface roughness

Provided are an electrode for a secondary battery employing an active material layer having improved thickness uniformity by printing low-viscosity ink on the active material layer, a manufacturing method of the electrode, and a secondary battery having improved electrode capacity due to the employing of the electrode. The electrode includes a current collector, and an active material layer formed by printing ink having a viscosity not exceeding 500 mPa·s on the current collector and drying the current collector, wherein the current collector has a surface roughness (Ra) in a range from about 0.025 to 1.0 μm.

Owner:SAMSUNG ELECTRONICS CO LTD

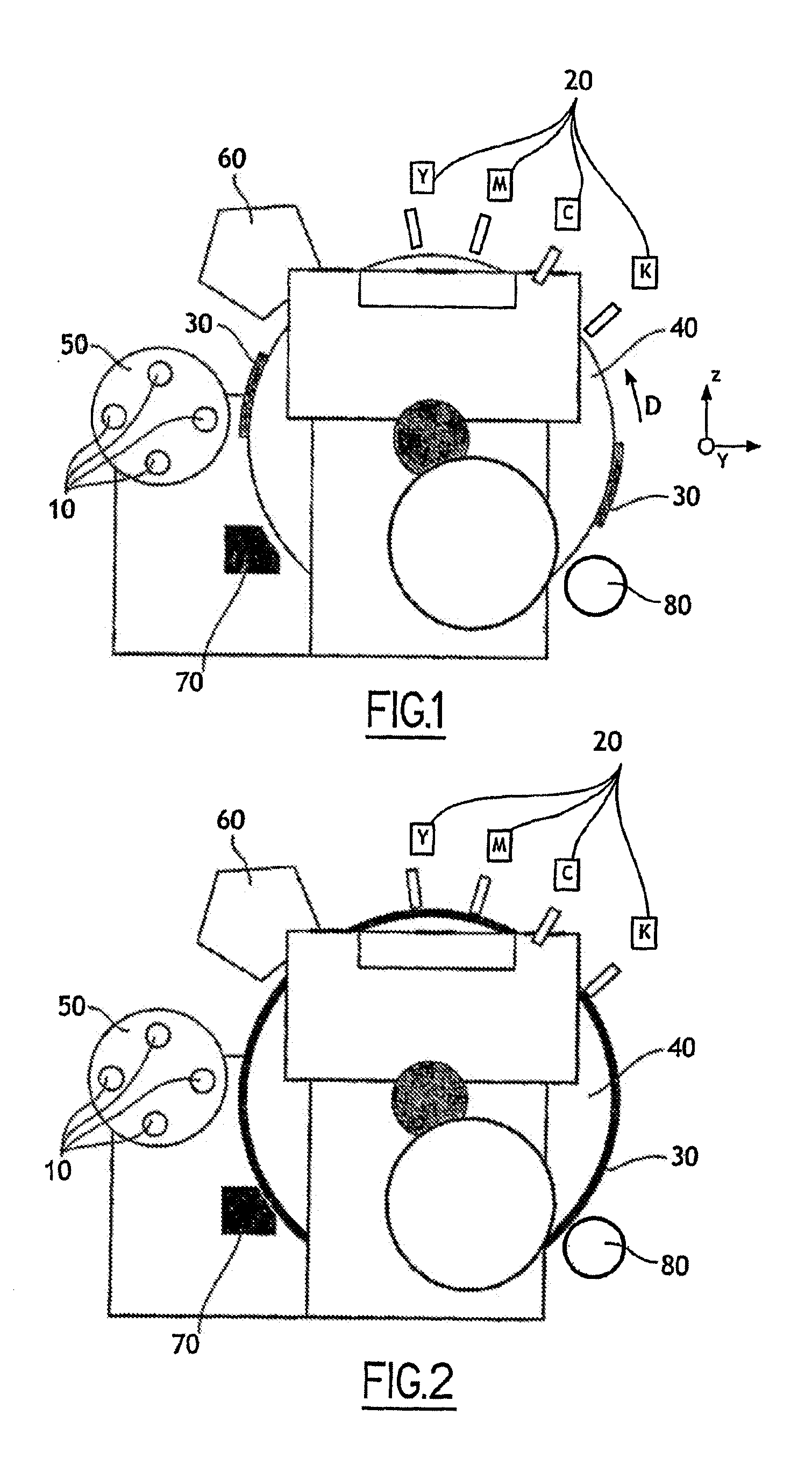

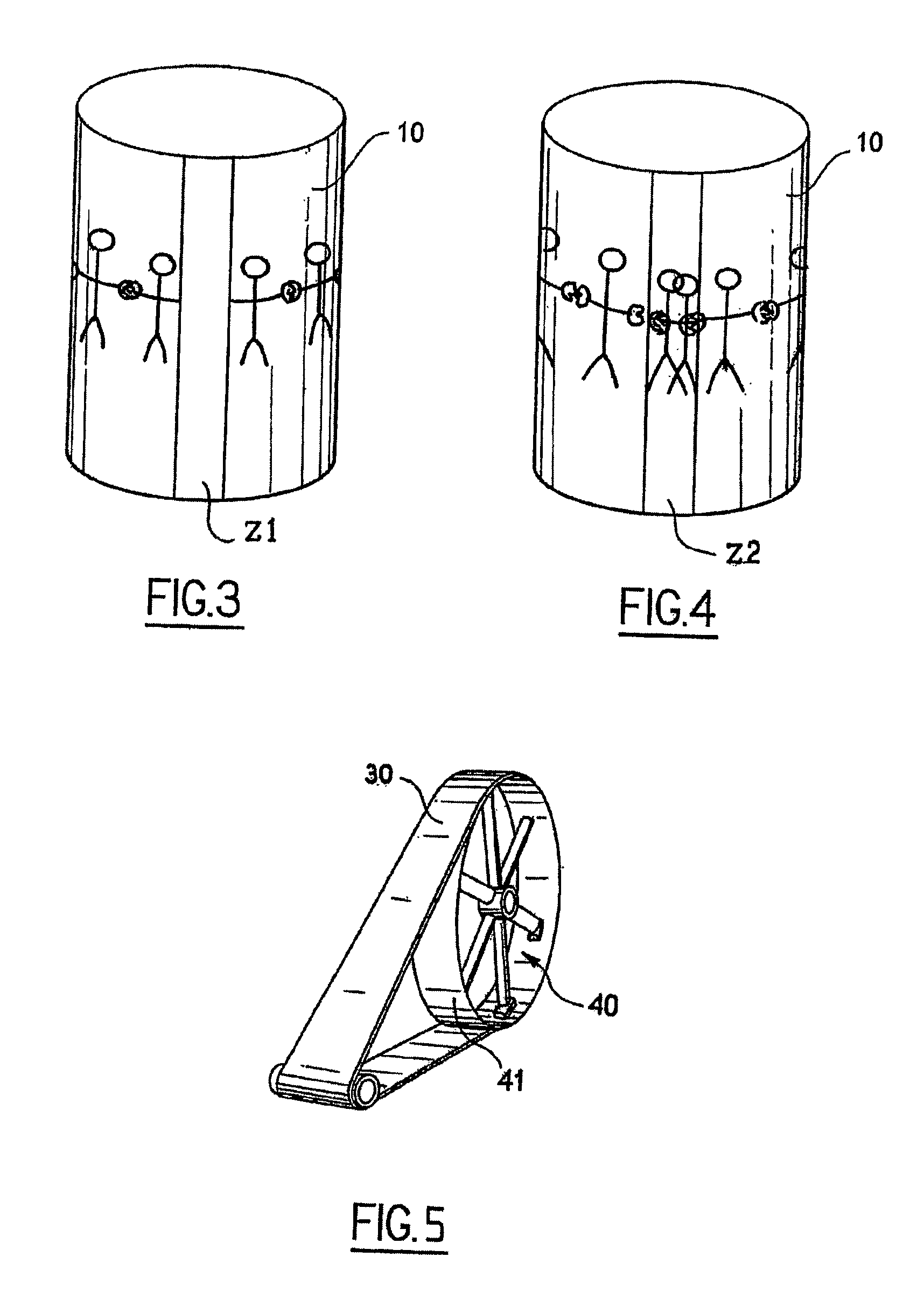

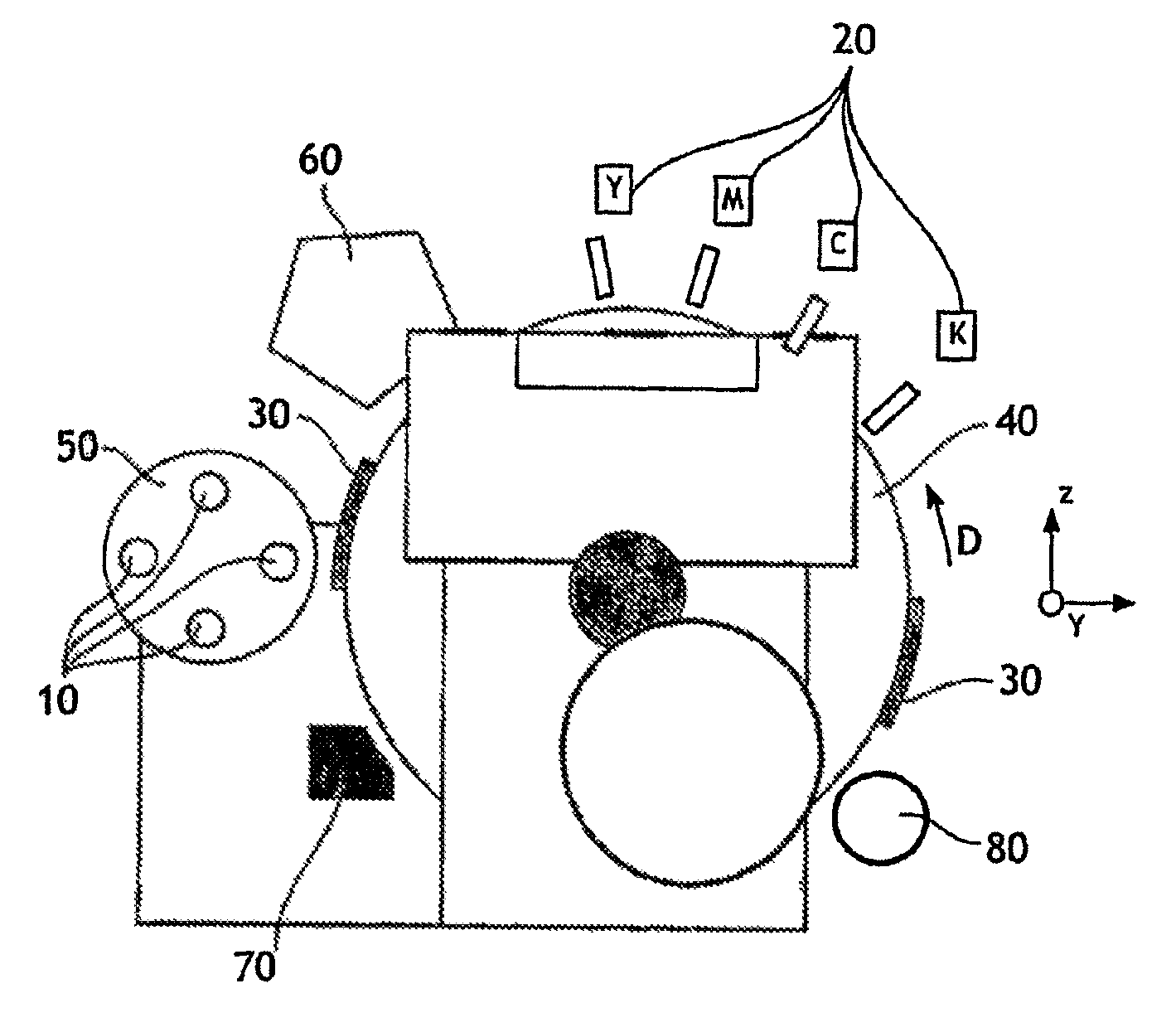

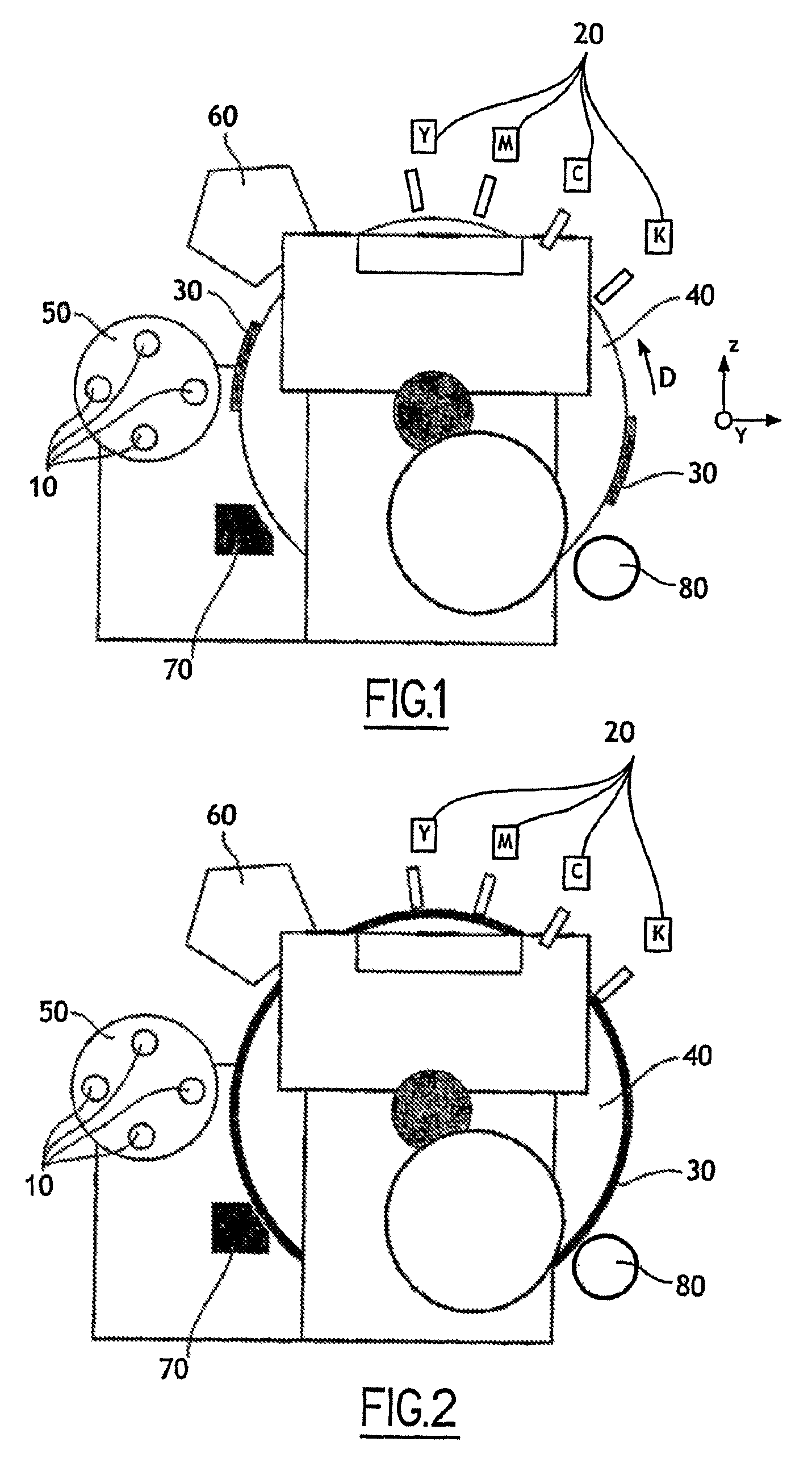

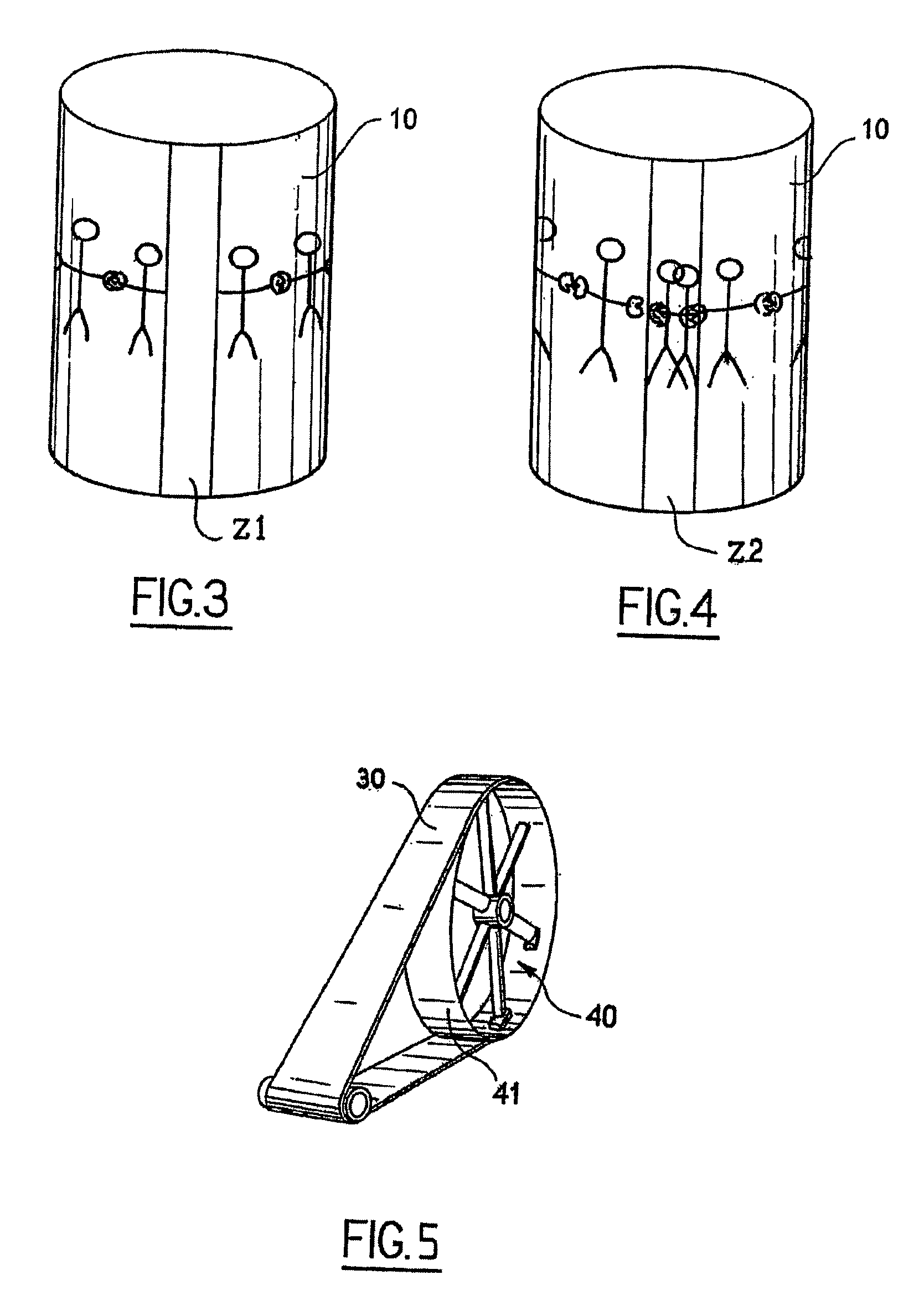

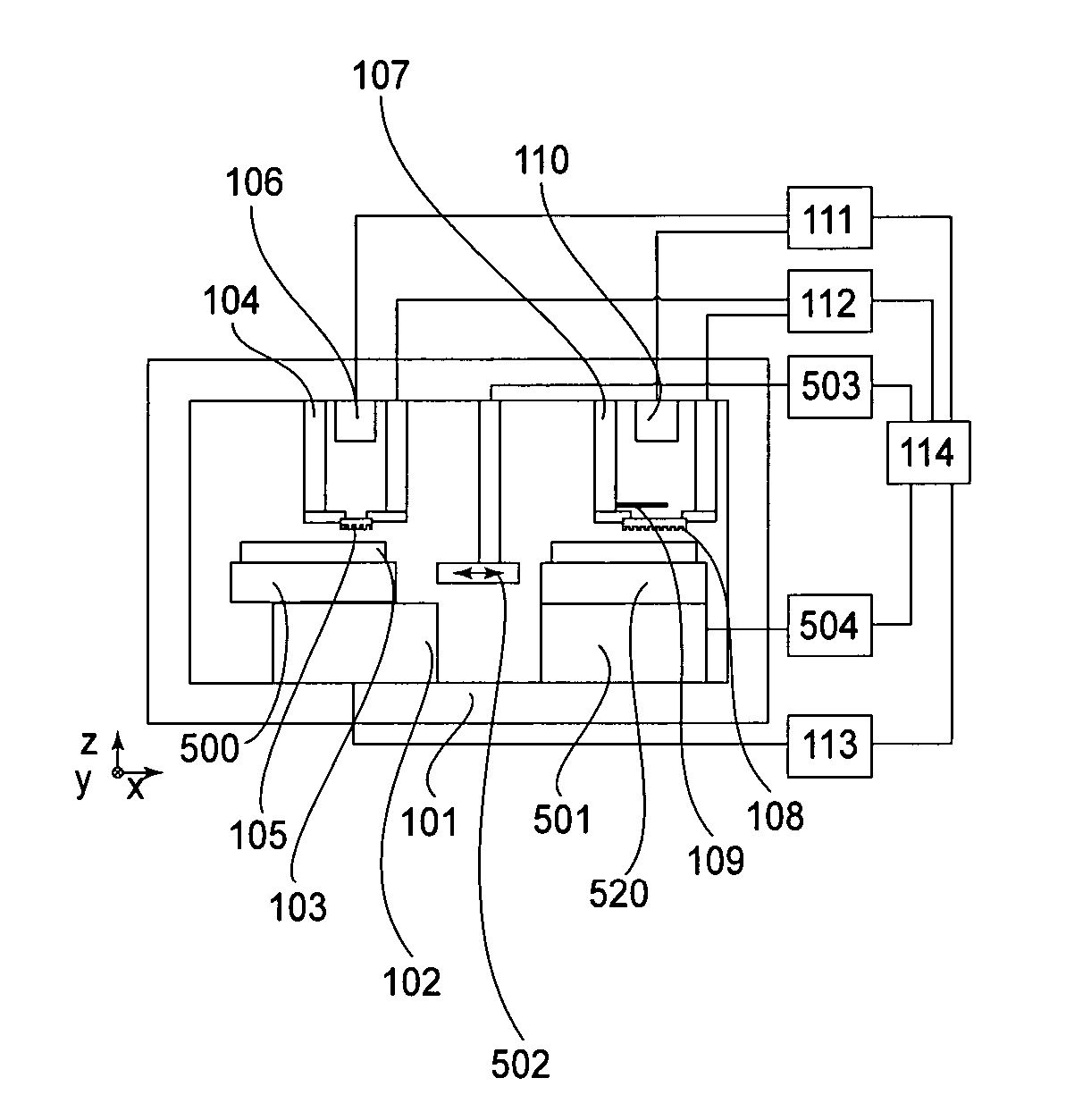

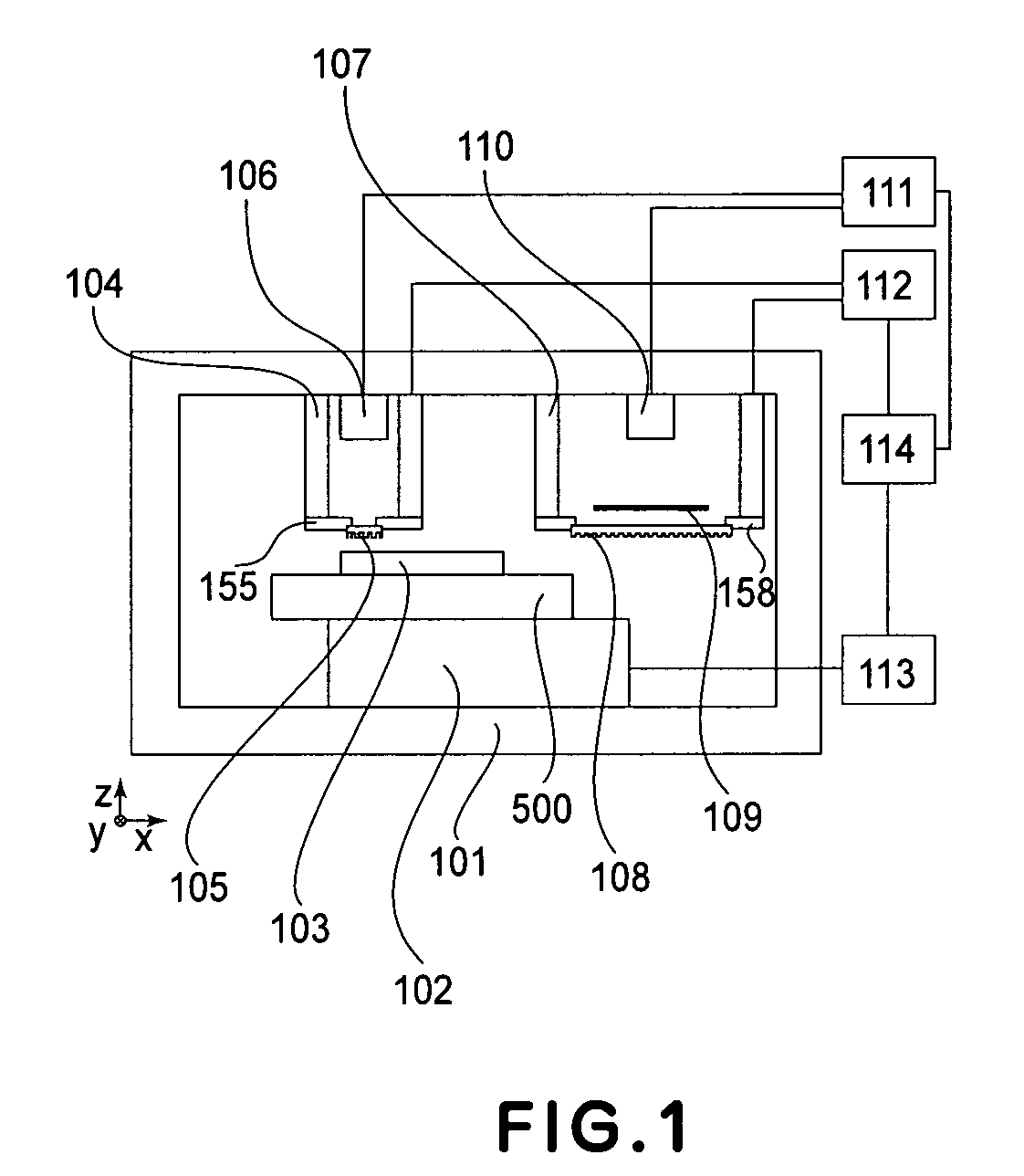

Device for printing by transfer onto a cylindrical printing medium

The invention relates to a device for printing by transfer onto a print support (10) comprising at least one blanket (30) driven in a sequential relative movement past a magazine (50) conveying the print supports (10), in which device the blanket (30) has a surface area greater than that of the print support (10), the device further comprising digital printing means (20) which print by spraying ink onto this blanket (30) over a variable area equal to that of the print support (10).

Owner:IMPIKA +1

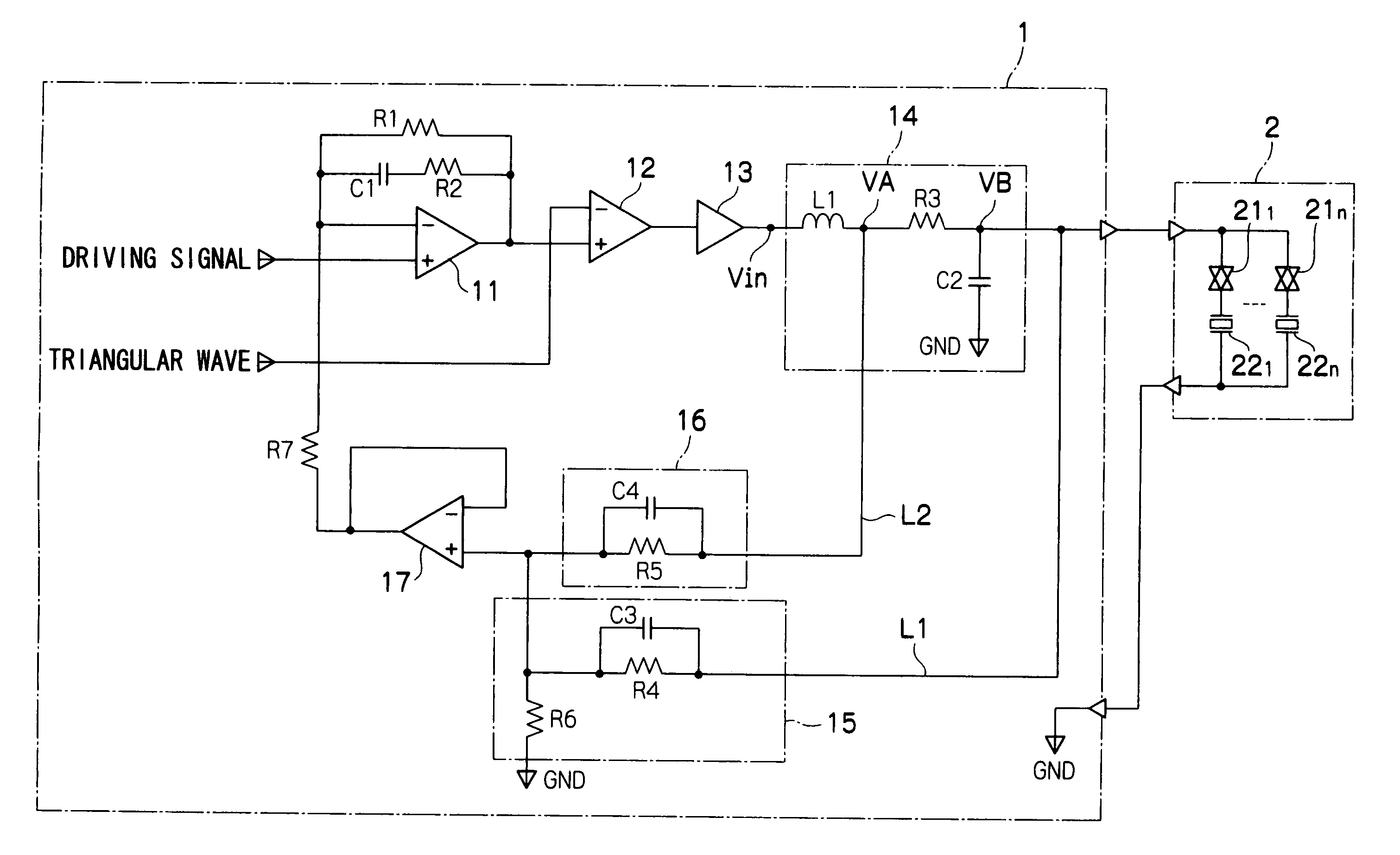

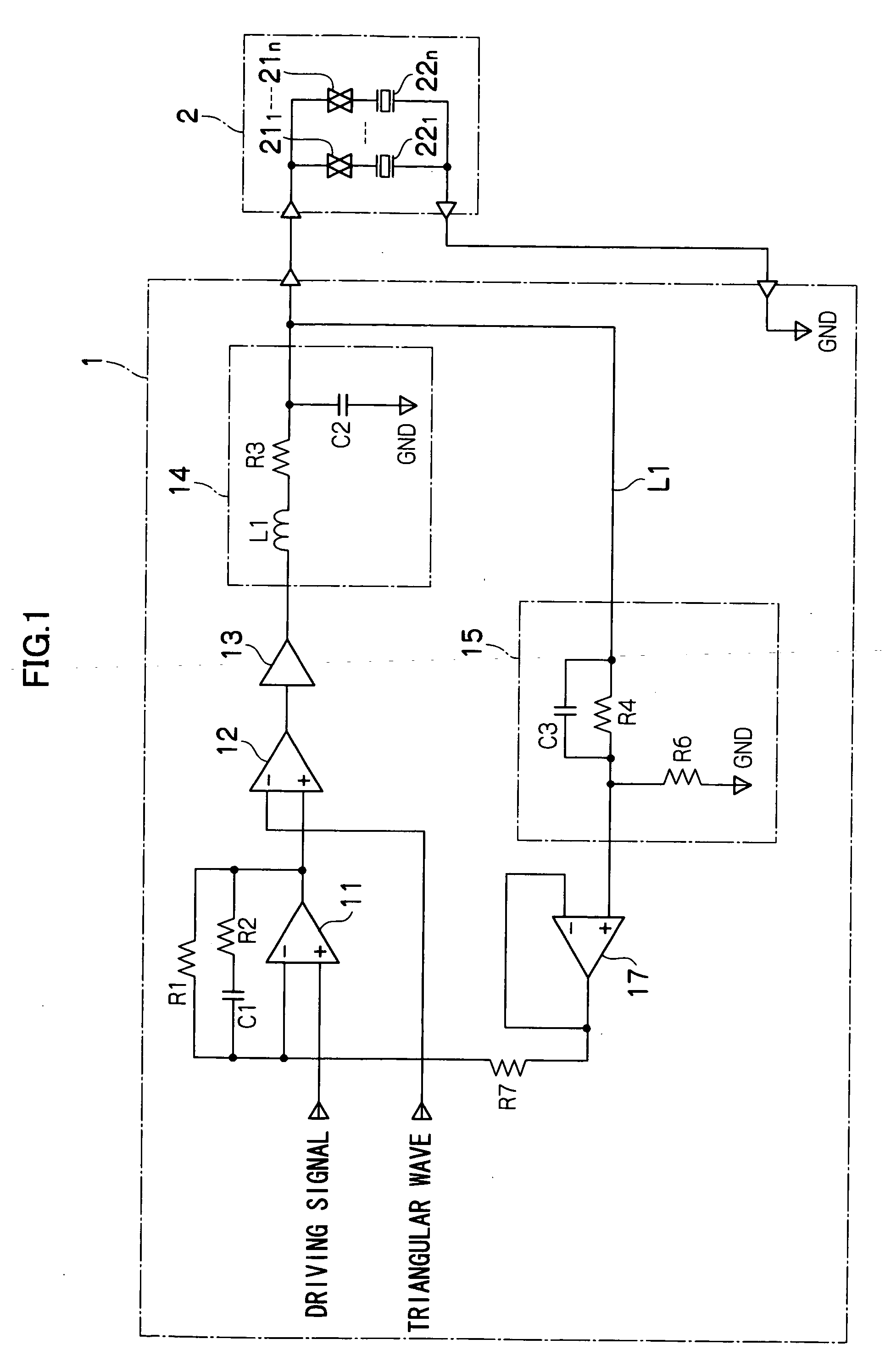

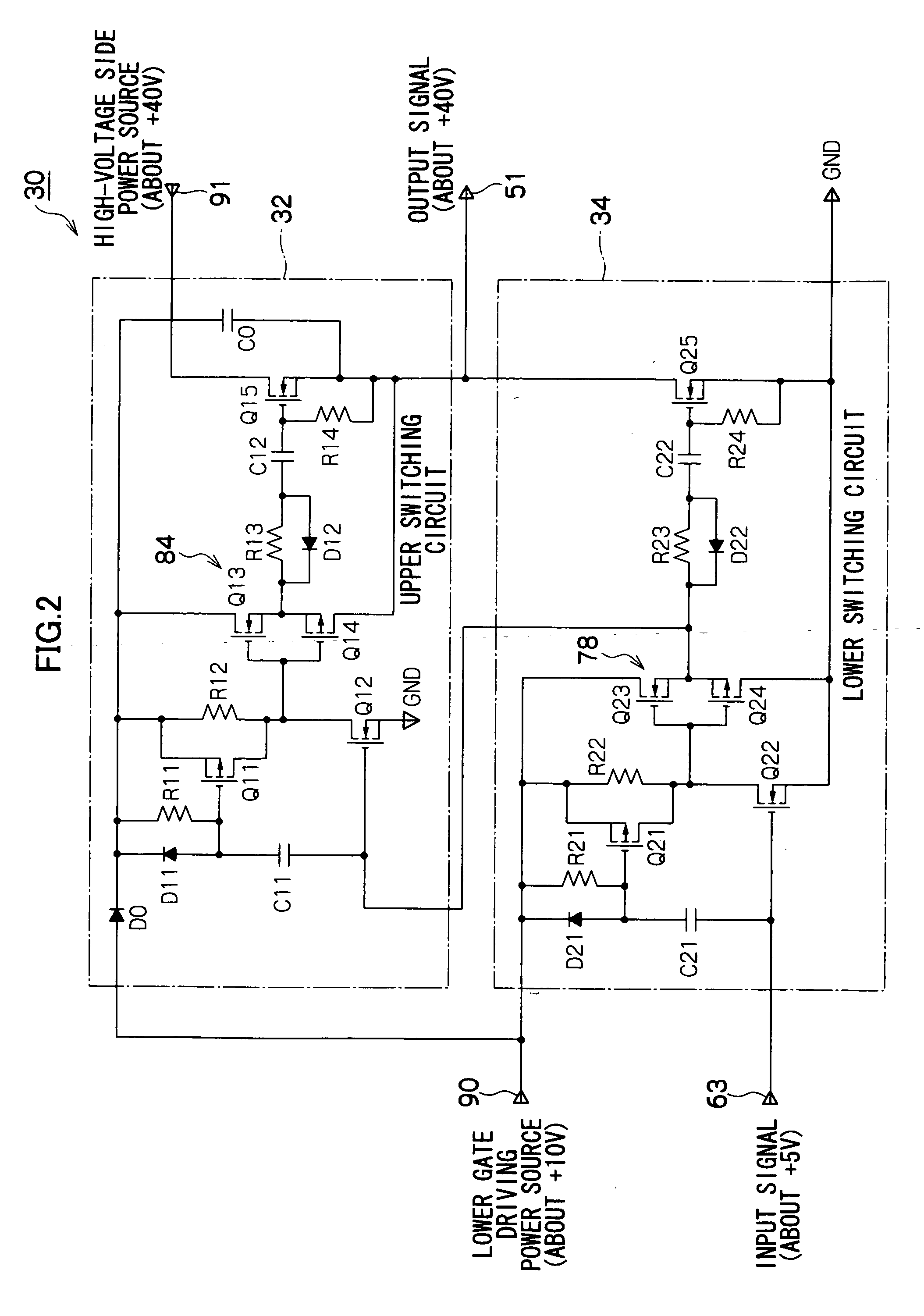

Capacitive load driving circuit and method, liquid droplet ejection device, and piezoelectric speaker driving device

InactiveUS20070079710A1Drive stabilityCylinder pressesPiezoelectric/electrostrictive transducersCapacitanceElectricity

There is provided a capacitive load driving circuit which applies a driving signal to a capacitive load. The driving circuit includes: an operational amplifier outputting a difference signal between signals from an inverting input terminal and a non-inverting input terminal, and setting a loop gain; a pulse width modulator pulse-width-modulating the difference signal outputted by the operational amplifier, and outputting resultant digital signal; a digital voltage amplifier amplifying a voltage of the digital signal; a first filter smoothing a digital signal from the digital voltage amplifier, and supplying a smoothed signal to the capacitive load as the driving signal; an impedance converting circuit converting an impedance of an output signal of the first filter; and a first feedback circuit feeding-back the driving signal, which is outputted from the first filter, to the inverting input terminal of the operational amplifier via the impedance converting circuit.

Owner:FUJIFILM BUSINESS INNOVATION CORP

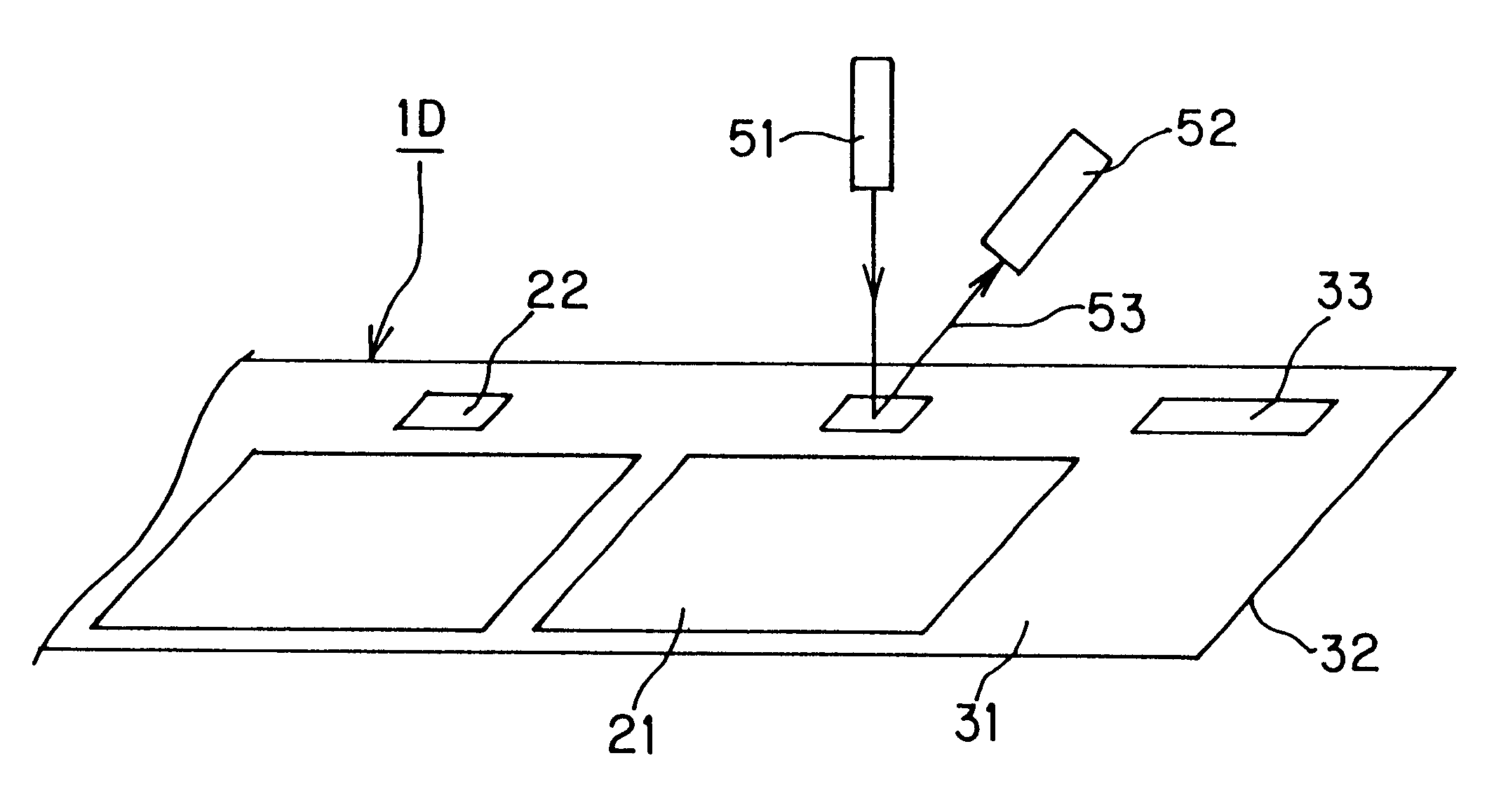

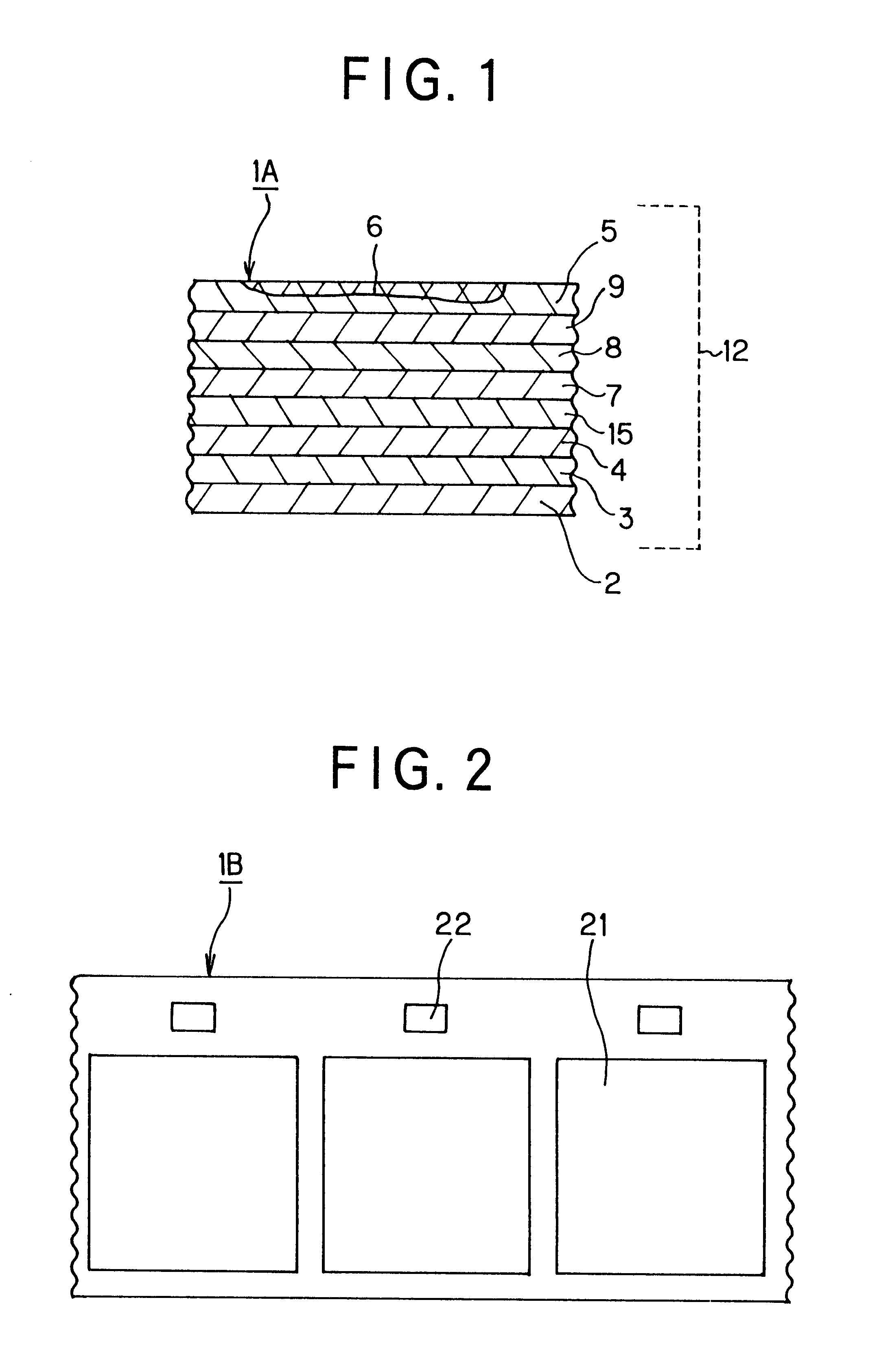

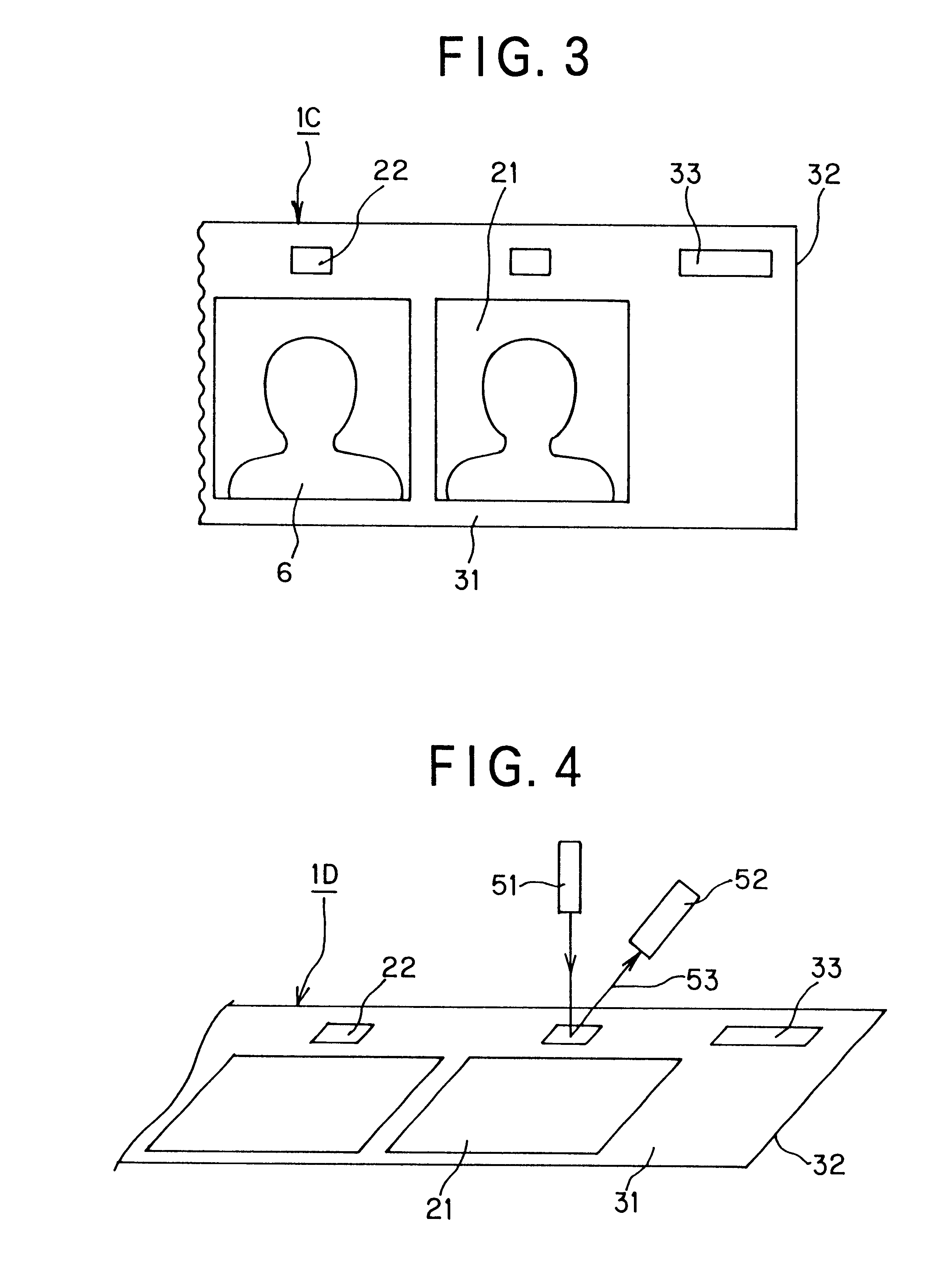

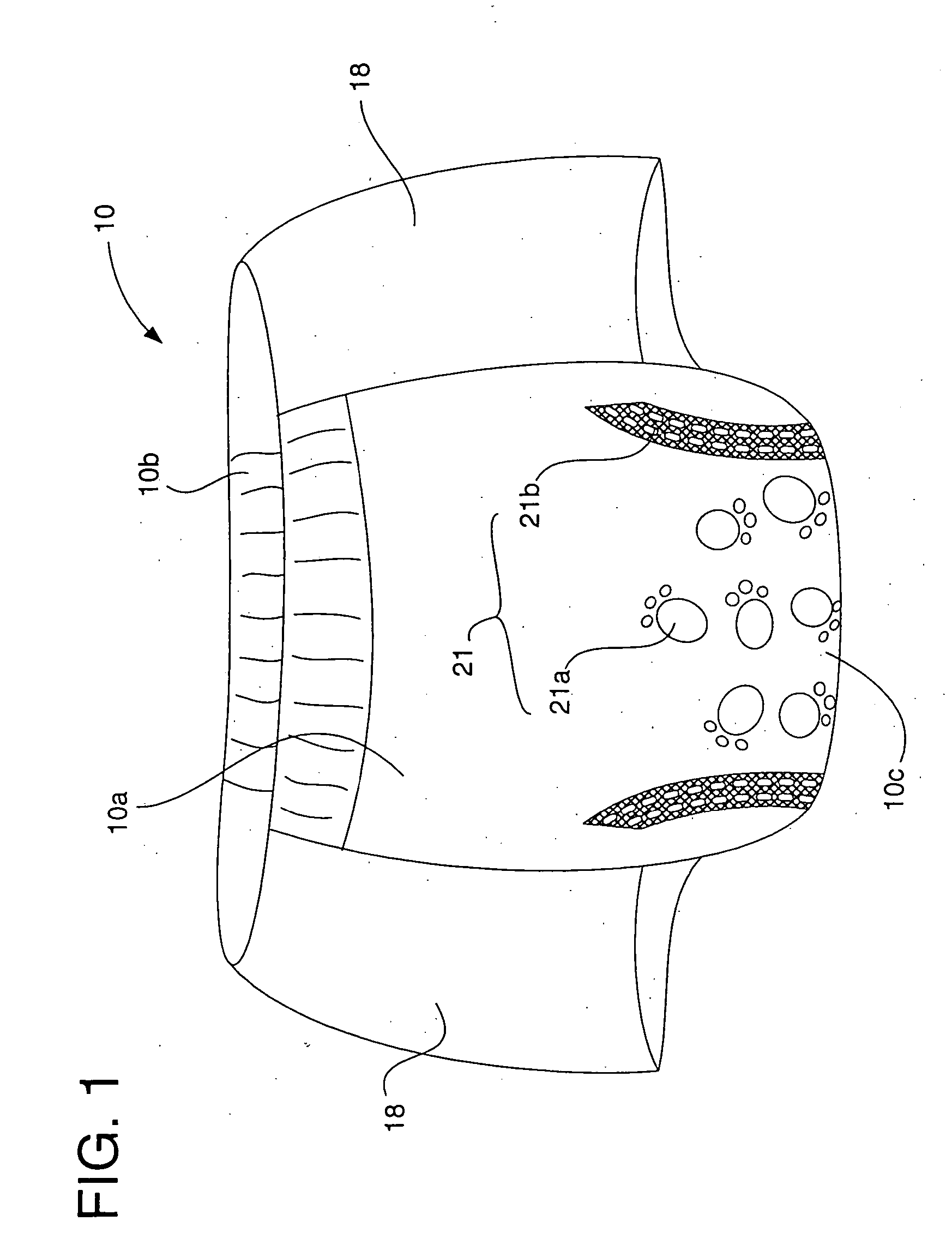

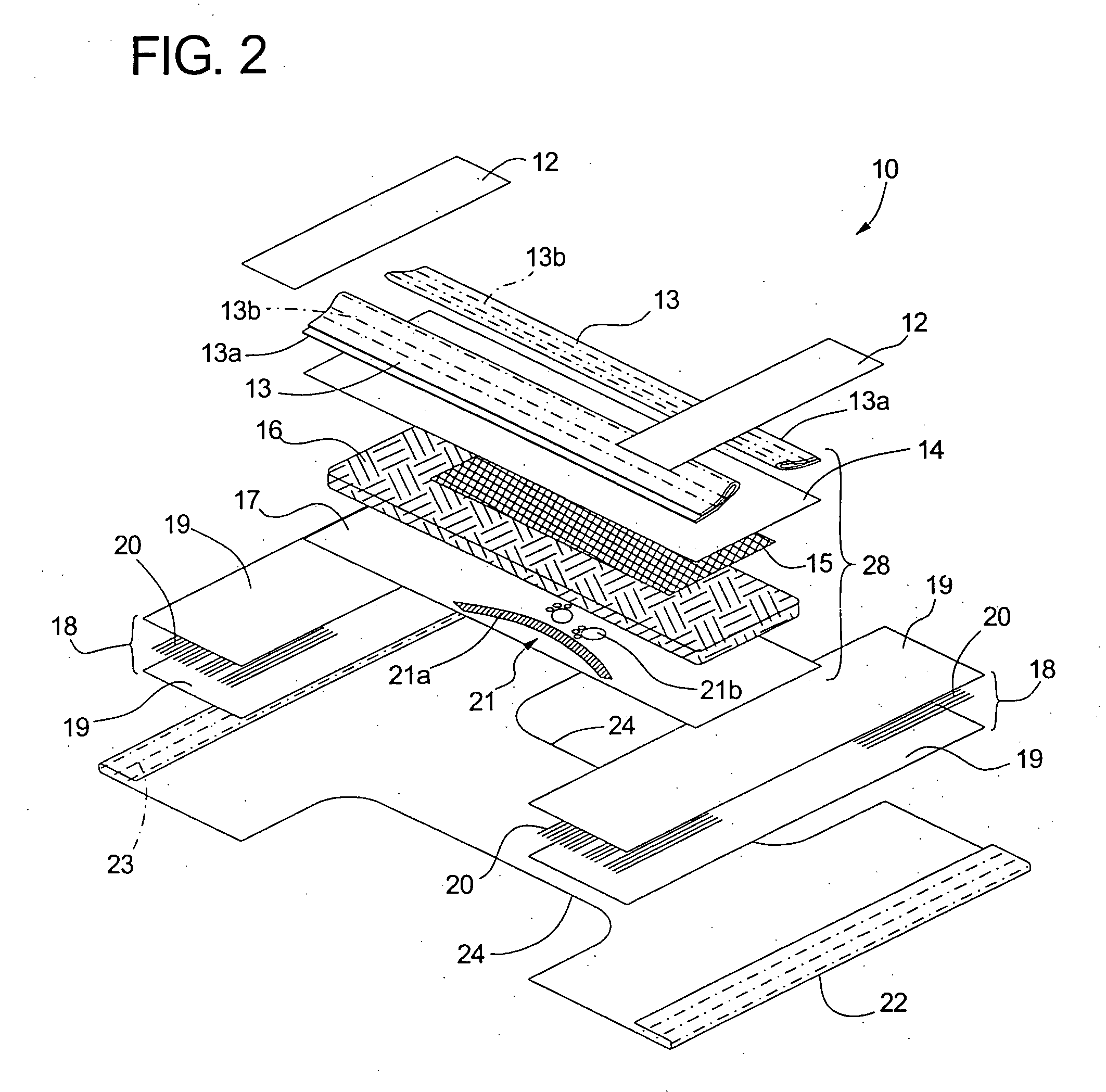

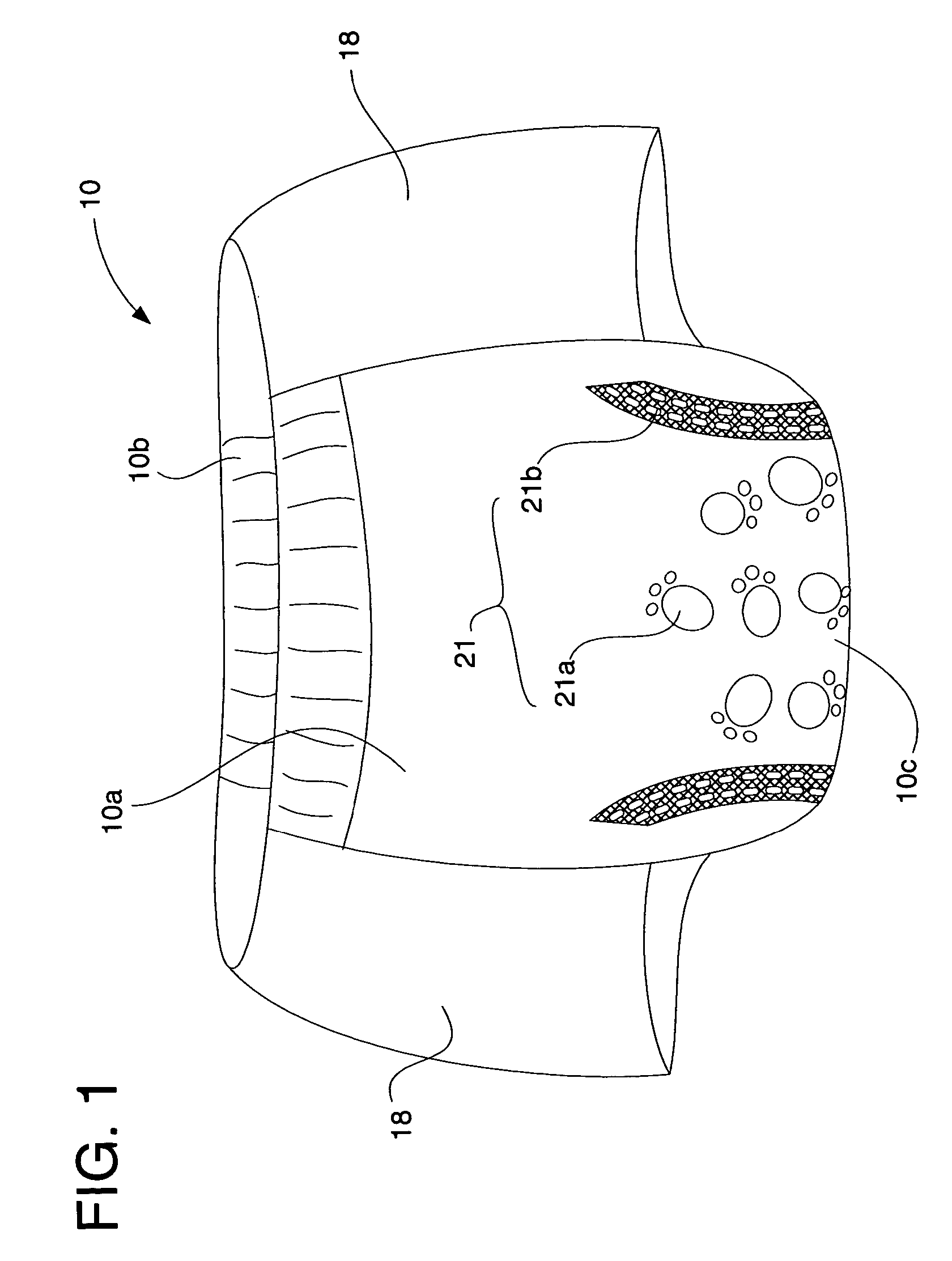

Intermediate transfer recording medium, method of forming print, and print

InactiveUS6308630B1Quality improvementSimple formatCylinder pressesPlaten pressesComputer scienceRecording media

An intermediate transfer recording medium is comprised by providing a transfer portion having a receptor layer on a substrate film. The transfer portion is printed with the image and thereafter transferred on a surface of a transfer-receiving material. In the first aspect of the intermediate transfer recording medium, the transfer portion is provided with plural hologram patterns 21 with a hologram mark 22 allocated to each the hologram pattern. According to the first aspect of the invention, since an image is formed on the receptor layer through positioning process using the hologram mark and then the transfer portion is transferred to the surface of the transfer-receiving material, no joint of a print plate appears in the hologram pattern and accuracy of transfer is remarkably excellent. On the other hand, In the second aspect of the intermediate transfer recording medium, peeling strength required to peel the transfer portion from the substrate film at the time when transferring the transfer portion to the transfer-receiving material is controlled in the range of 10 to 150 gf / inch. According to the second aspect of the invention, any transfer failure such as tail-extension or chip of the transfer portion is not caused.

Owner:DAI NIPPON PRINTING CO LTD

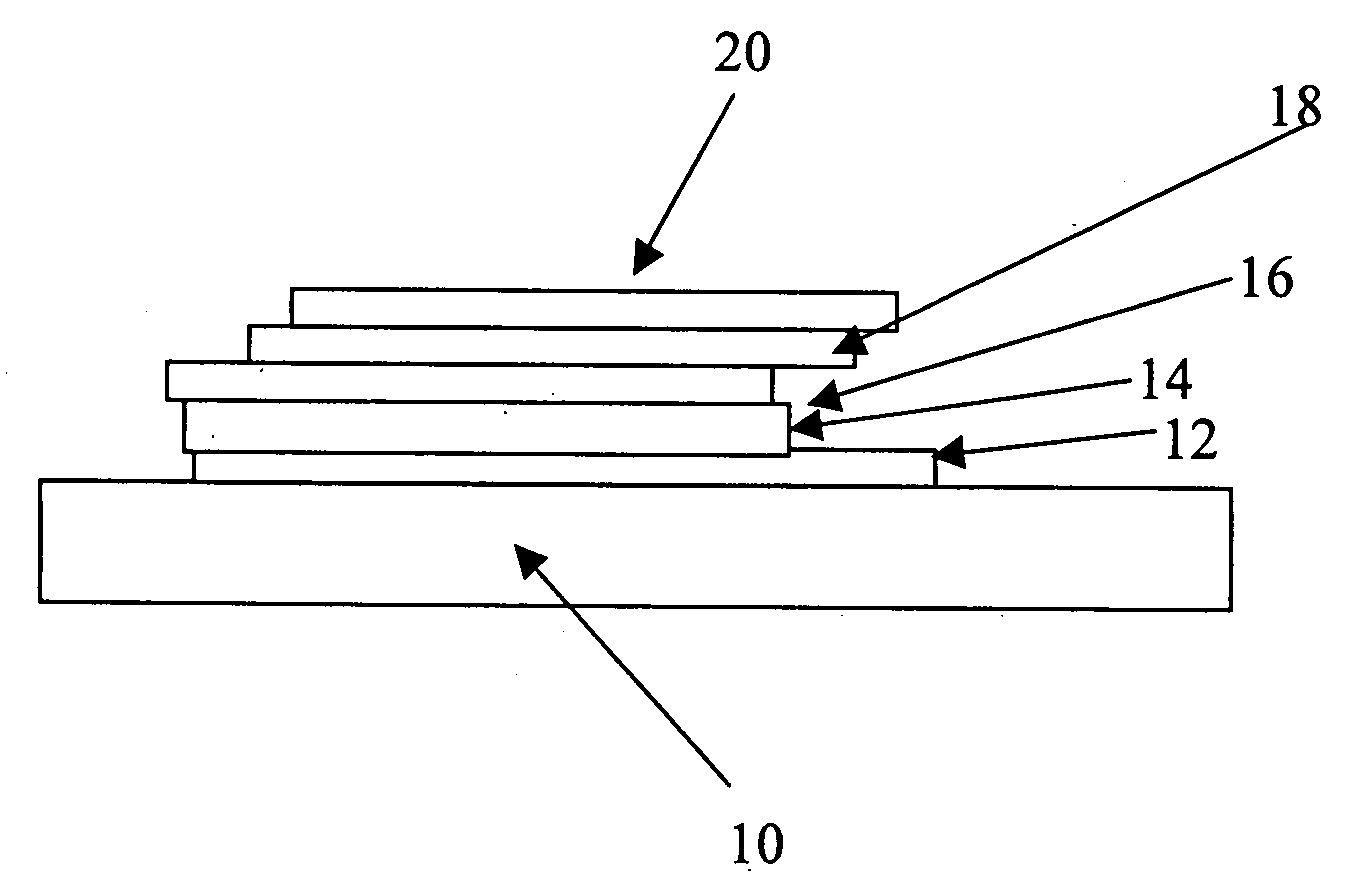

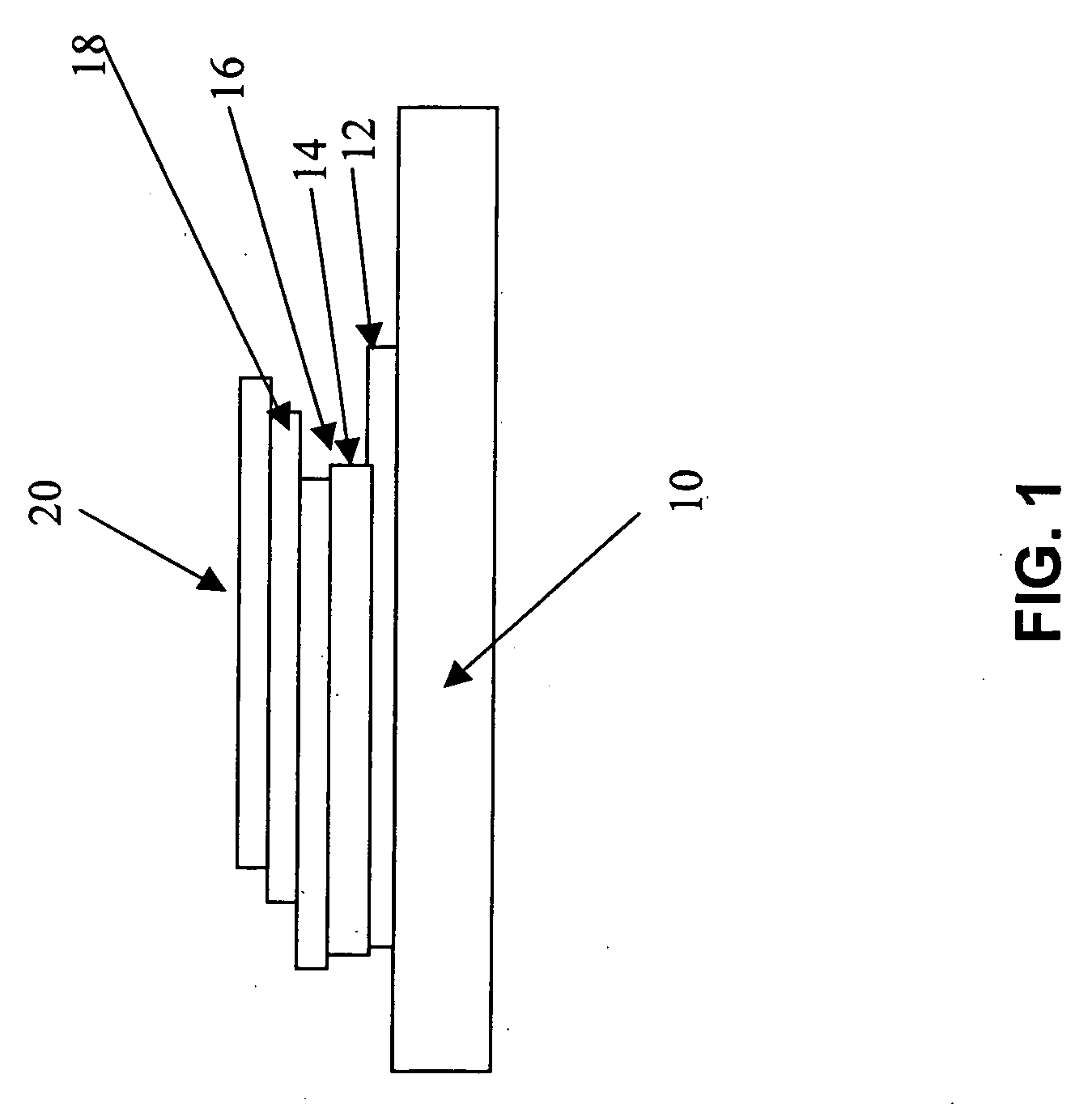

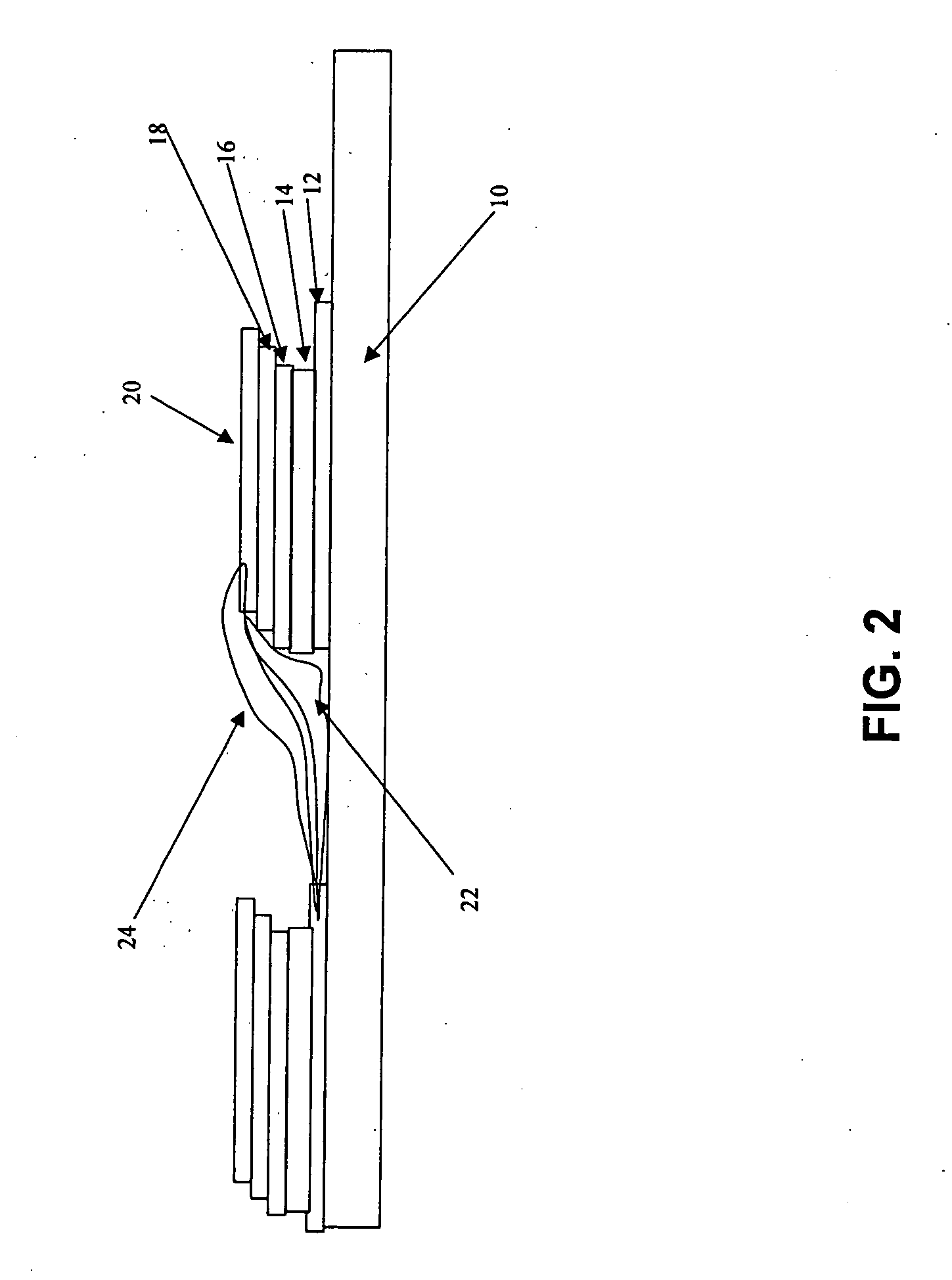

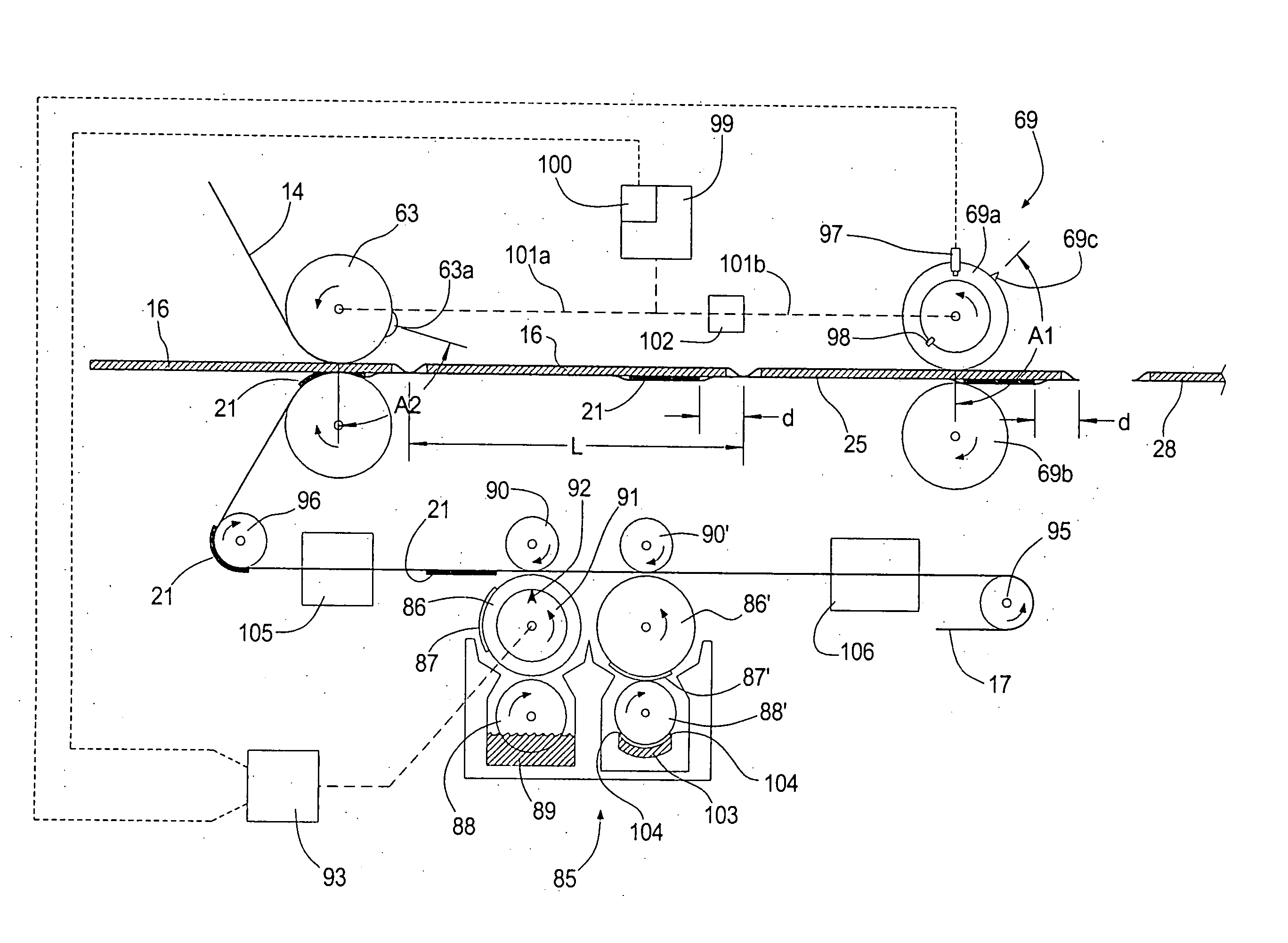

Device and method for printing by transfer onto a cylindrical printing medium

The invention relates to a device for printing by transfer onto a print support (10) comprising at least one blanket (30) driven in a sequential relative movement past a magazine (50) conveying the print supports (10), in which device the blanket (30) has a surface area greater than that of the print support (10), the device further comprising digital printing means (20) which print by spraying ink onto this blanket (30) over a variable area equal to that of the print support (10).

Owner:IMPIKA +1

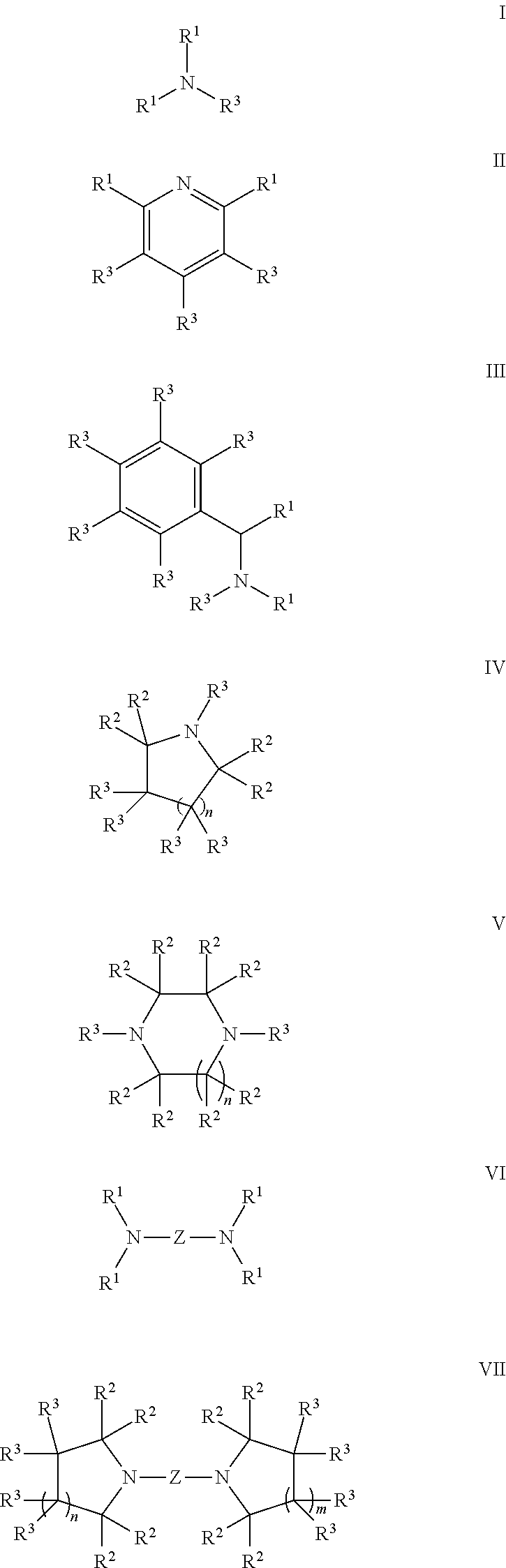

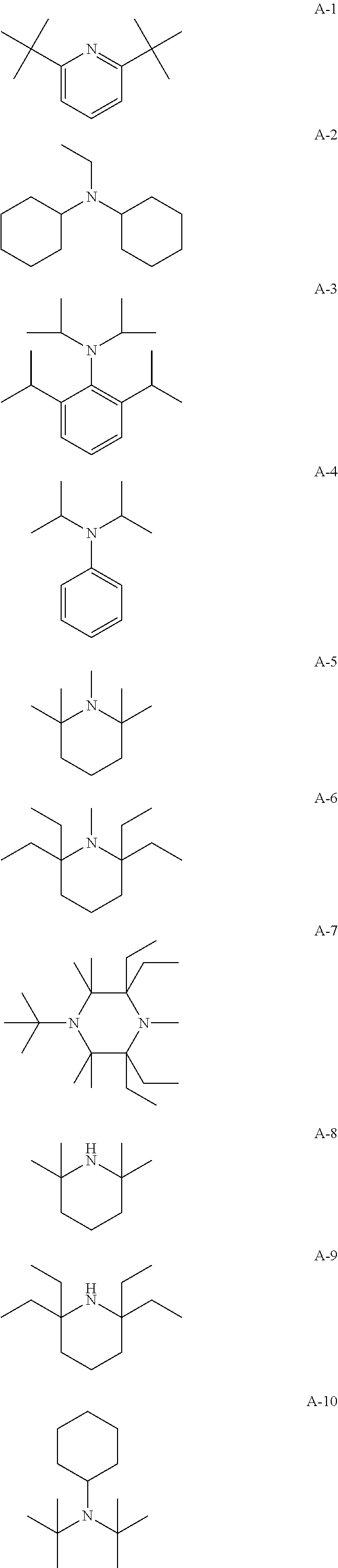

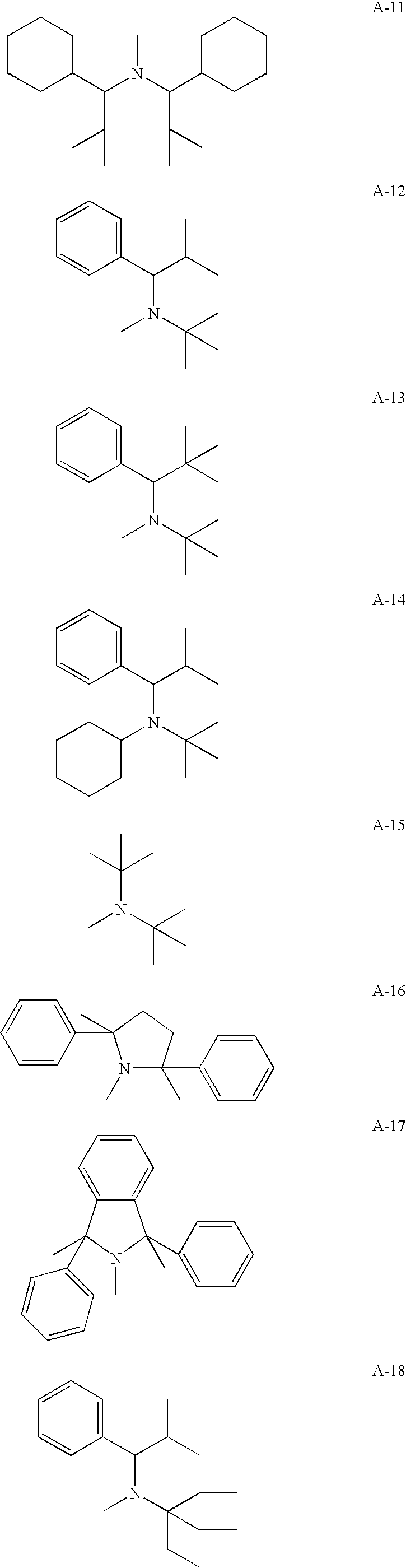

Radiation-curable polymerizable composition, ink composition, inkjet recording method, printed material, planographic printing plate, and method for forming planographic printing plate

InactiveUS7900558B2Cylinder pressesLiquid surface applicatorsPolymer scienceHindered amine light stabilizers

Owner:FUJIFILM CORP

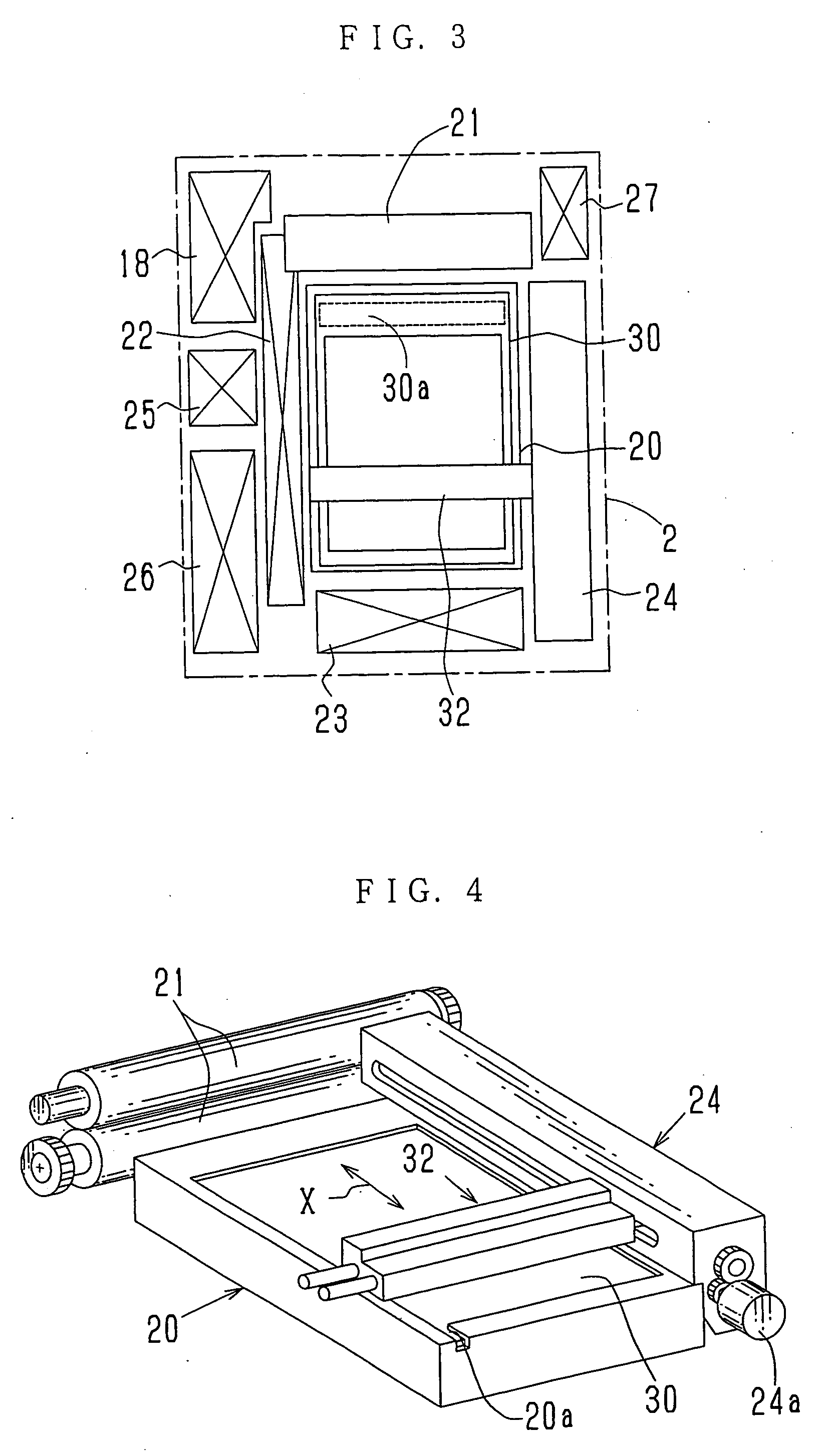

Process for producing member having pattern, pattern transfer apparatus, and mold

A pattern transfer apparatus is constituted by a first mold holding portion for holding a first mold for forming a pattern inside a peripheral area of a member and a second mold holding portion for holding a second mold for forming a pattern in the peripheral area of the member.

Owner:CANON KK

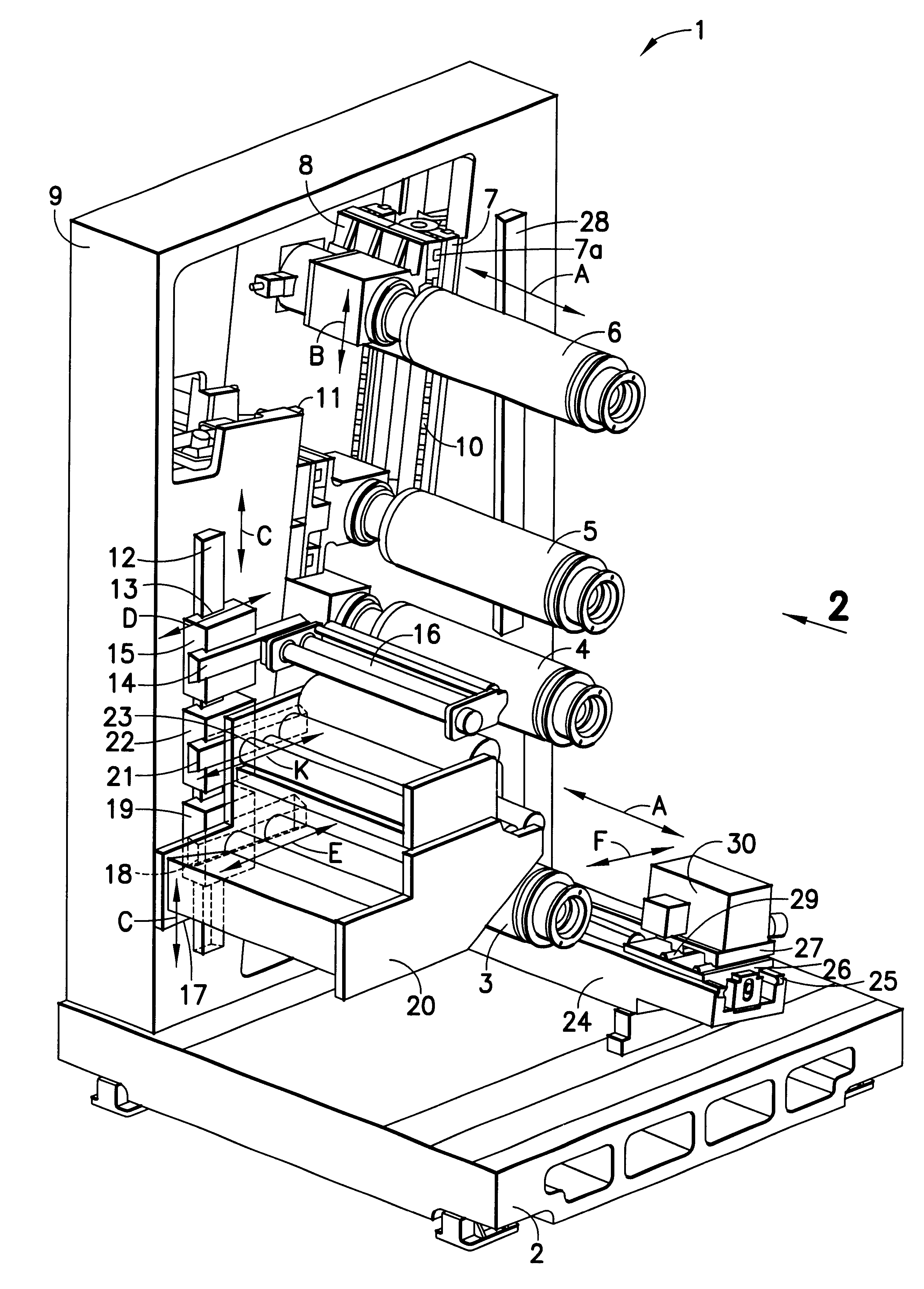

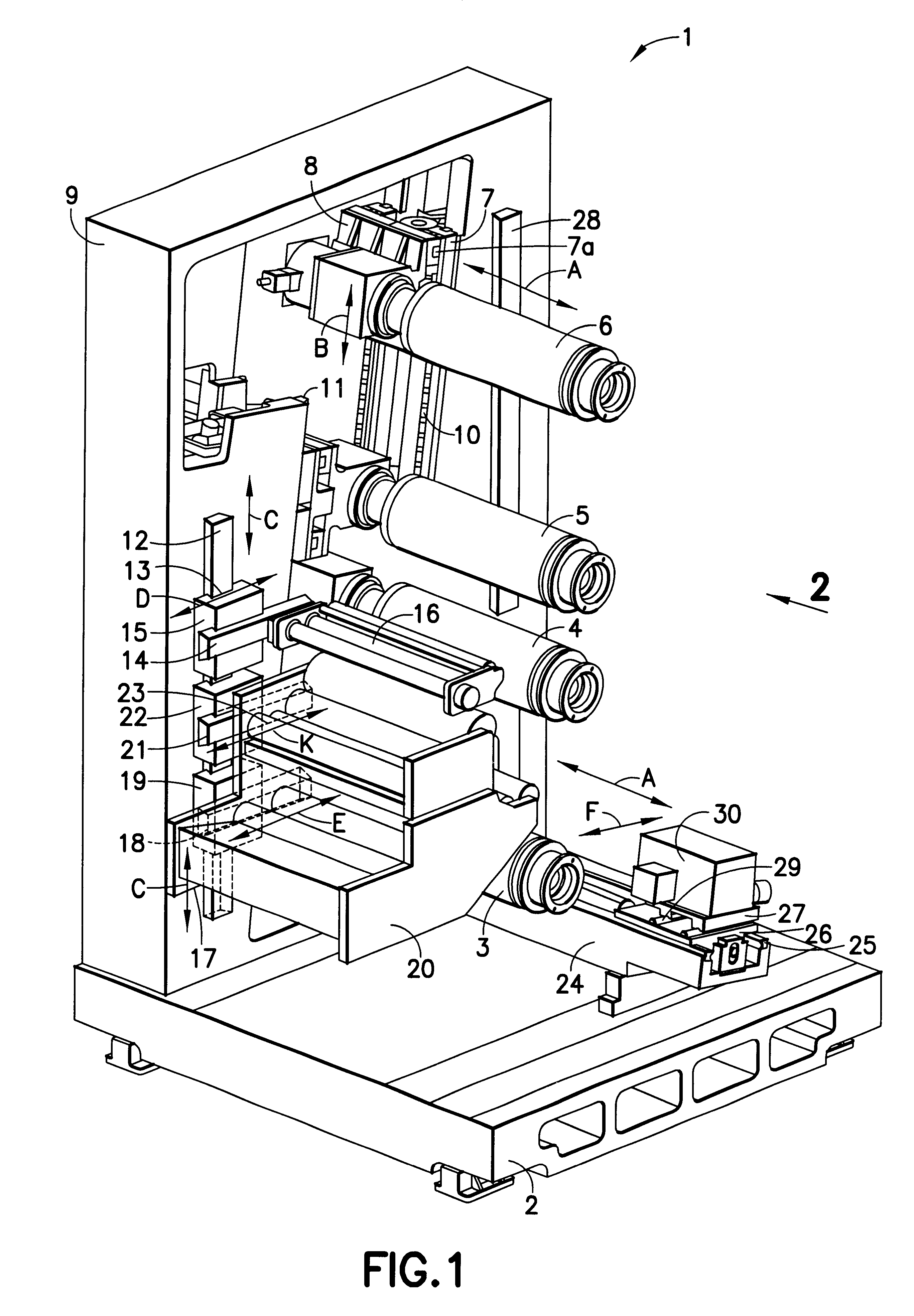

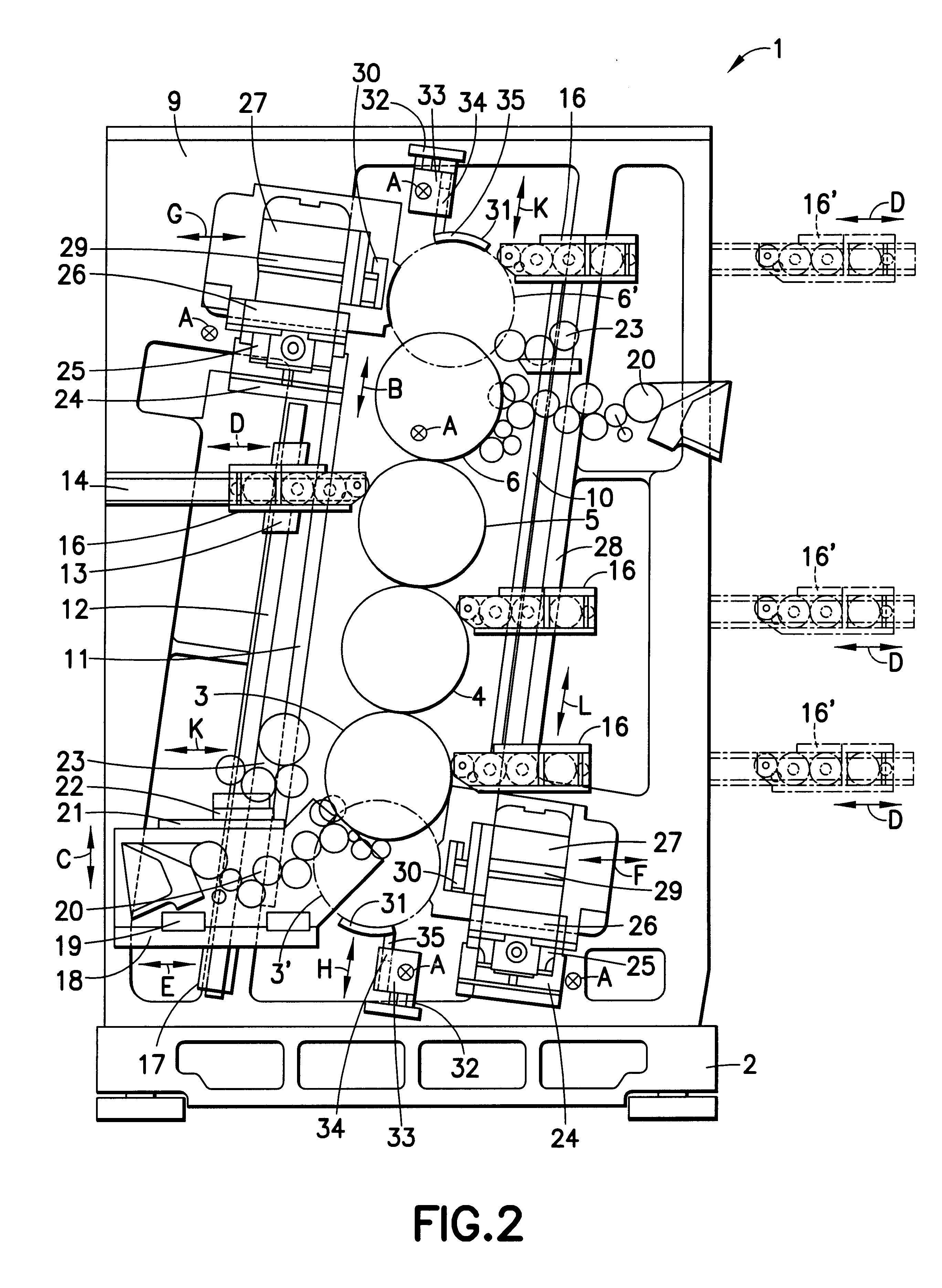

Printing unit for a rotary printing machine with cross slide

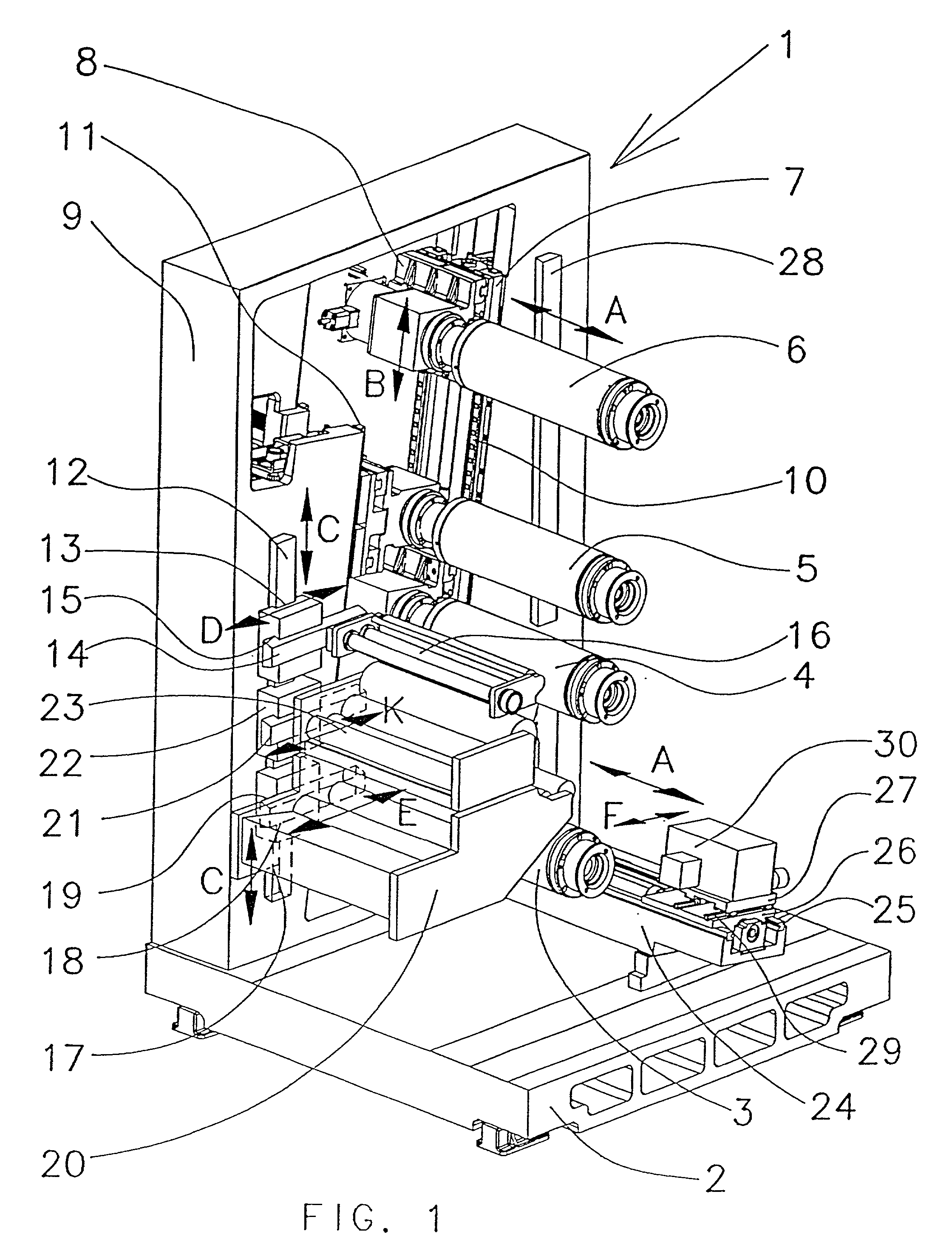

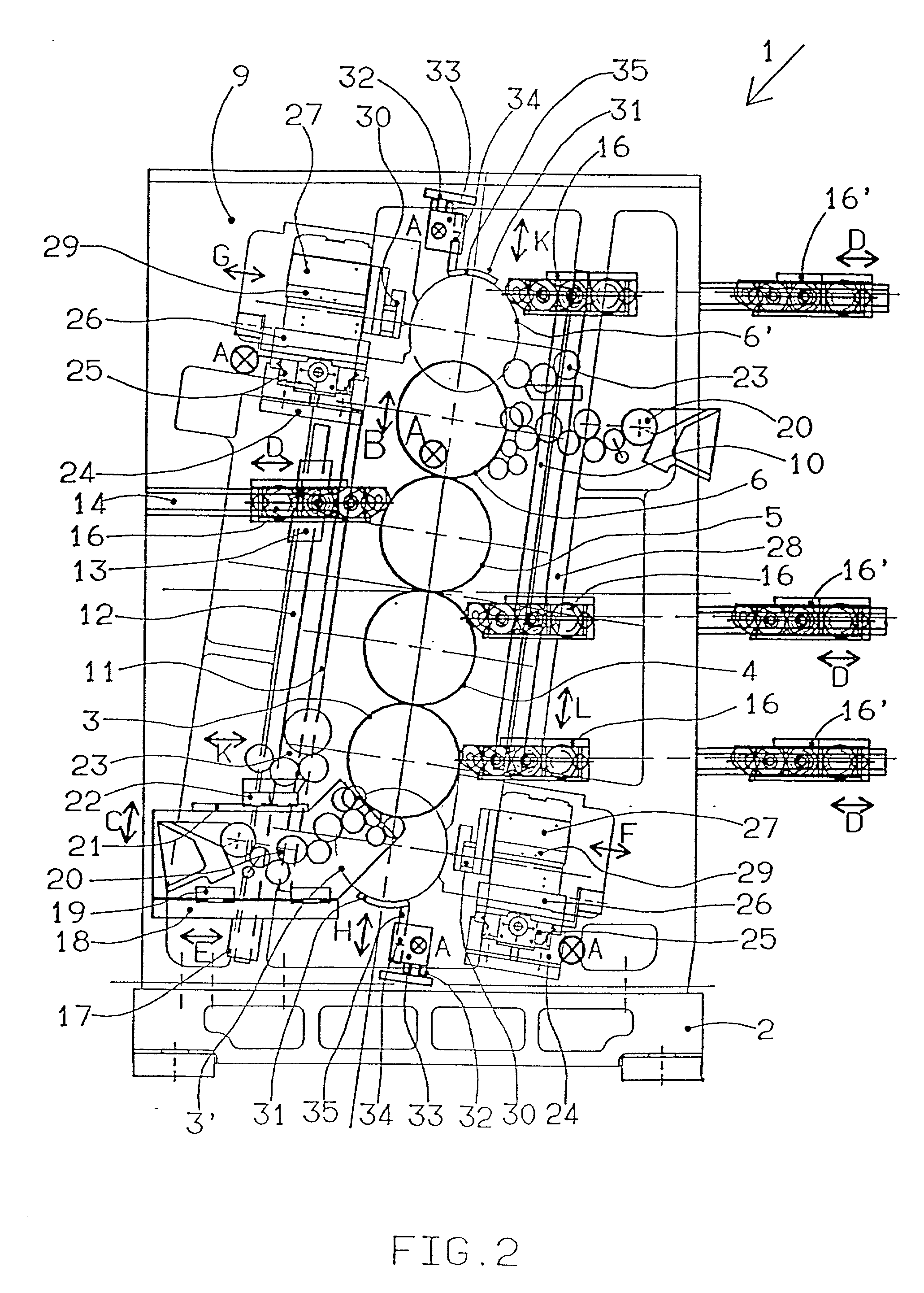

InactiveUS20010035104A1Long constructionEfficient introductionCylinder pressesAddressographsEngineeringPrinting press

Rotary printing machine with forme and impression cylinders for variable-format or variable-circumference printing and with service apparatus which are capable of being moved radially in relation to the printing-unit cylinders for throw-on or throw-off movements and in the axial direction of the cylinders or in the side-wall plane. The service apparatus and the printing-unit cylinders are arranged on cross slides which can each be moved in two directions relative to the printing-unit side wall.

Owner:MANROLANAD AG

Method of producing a high gloss coating on a printed surface

InactiveUS20030113466A1High coatingLow production costCylinder pressesTransfer printingPresent methodPaper sheet

The present invention is directed to a method for producing a high gloss coating on a printed surface. In the present method, an aqueous coating composition is deposited onto a surface to be printed using a blanket roller coating face which is a low energy, non-stick, smooth surface profile. In the present method, simultaneous with the deposition of aqueous coating onto a substrate, or shortly thereafter, pressure either alone or in combination with heat may be applied to the coating in order to create a substantially tack-free surface conforming to the surface of the coating face. By using a highly polished coating face, high gloss coatings may be readily obtained using this methodology in a number of traditional printing techniques including wet trap inline sheet-fed printing, heat-set offset printing, dry trap inline flexographic printing, offset web-fed printing and gravure printing. Coatings which are produced utilizing the present invention have high gloss values heretofore unobtainable using aqueous coating compositions.

Owner:FRAZZITTA JOSEPH +1

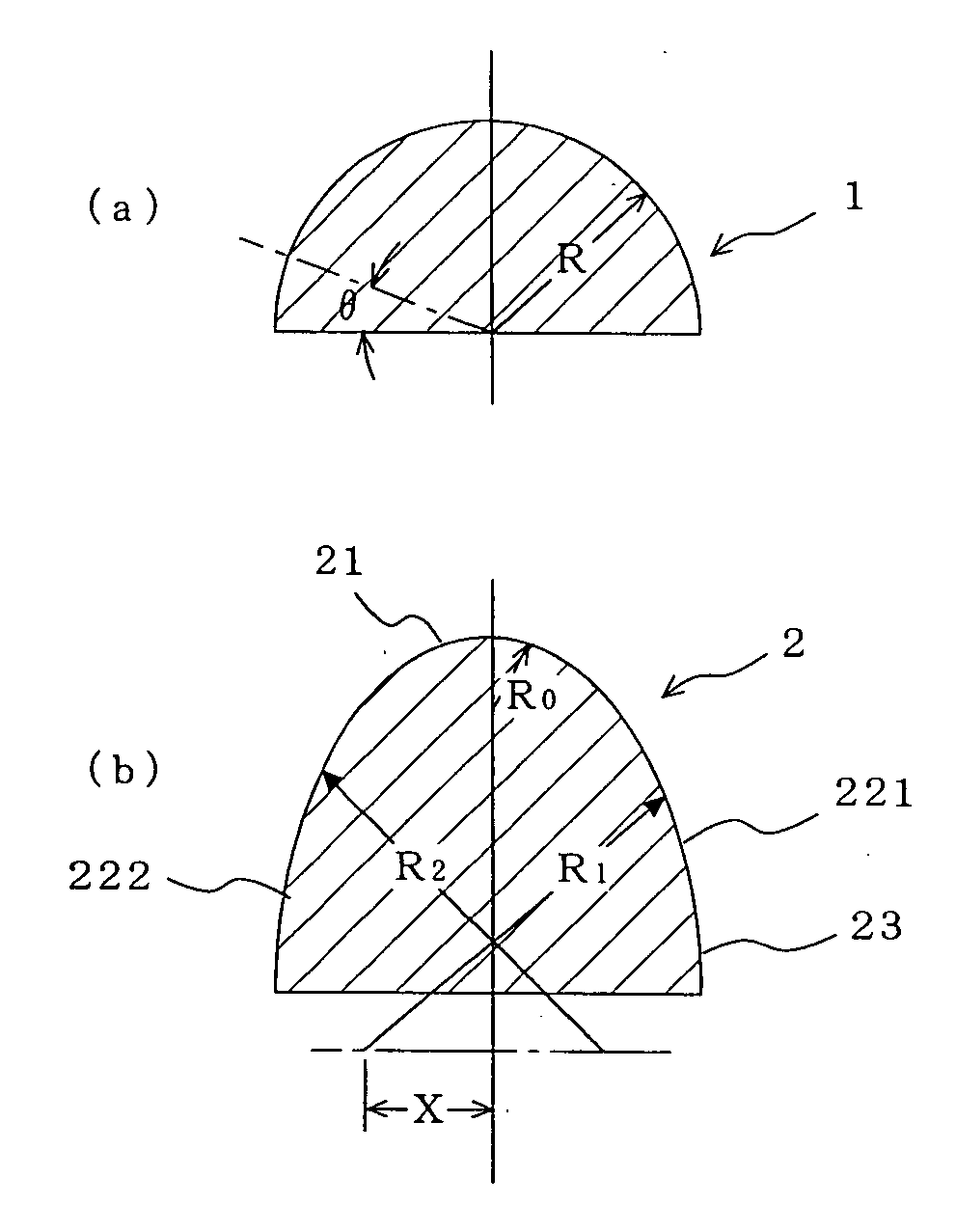

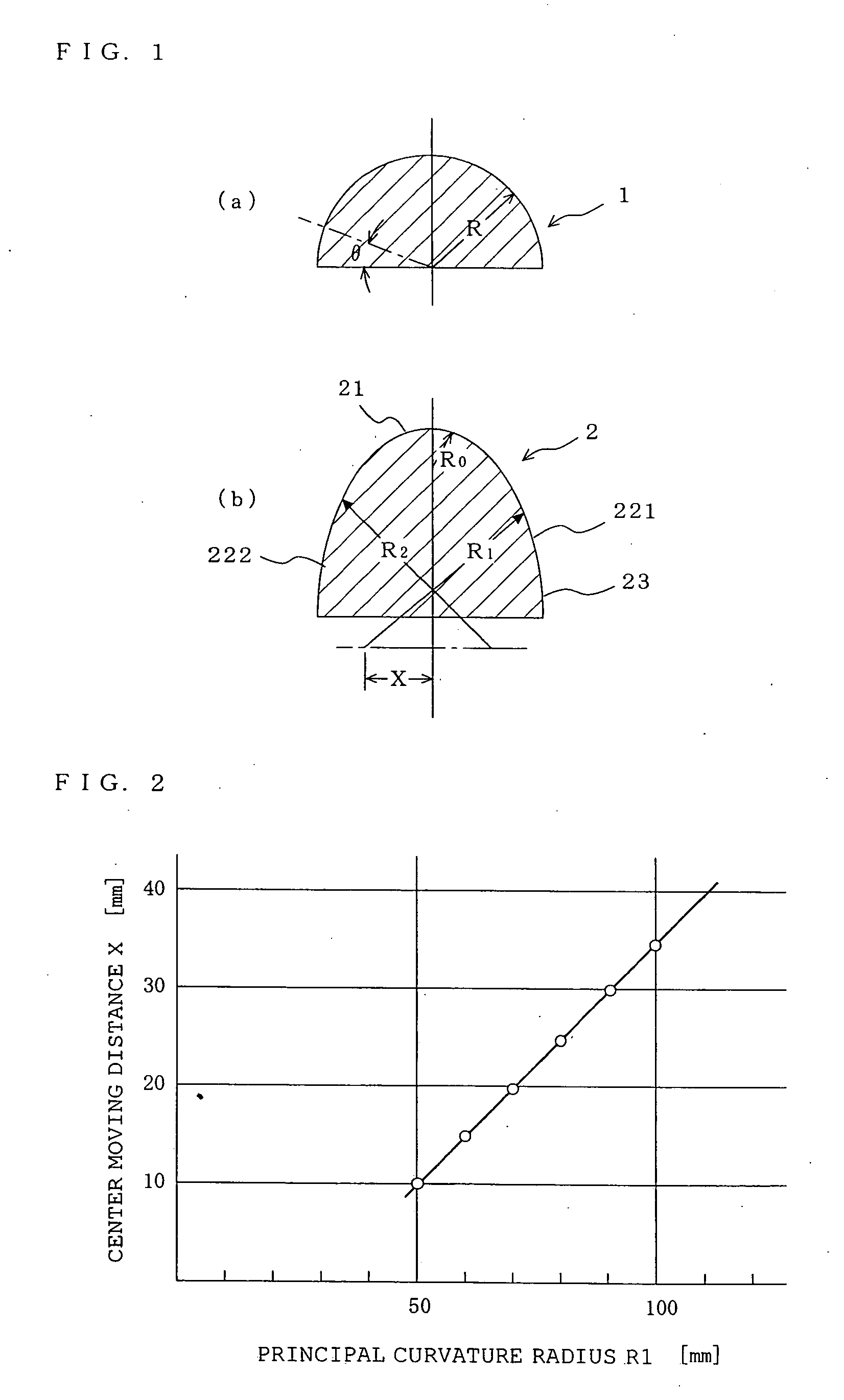

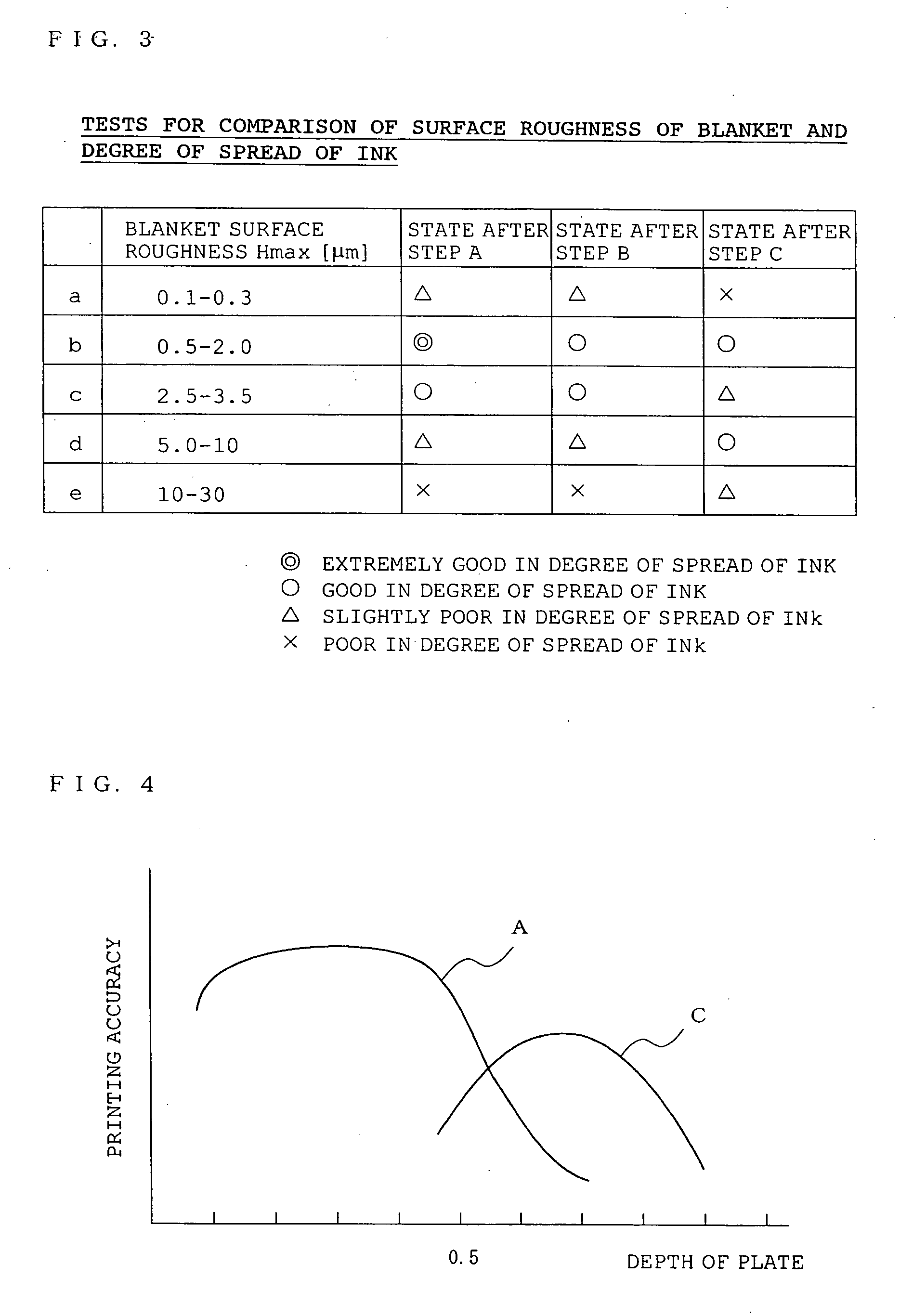

Method of Printing Curved Surface and Curved Surface Body Printed by Using Same

InactiveUS20080011177A1Accurate printingCylinder pressesPlaten pressesLetterpress printingEngineering

A curved surface printing method comprises a step of applying a printing ink to a raised portion of a letterpress printing original plate which is a planographic plate the raised portion of which is 0.1 to 50 μm high, a step in which an elastic blanket (2) of rubber or rubberish material having a curved surface (221, 222, 21) of a predetermined shape formed on a convex or concave surface of an object (1) to be printed and set in the same polarity direction as that of the convex or concave surface of the object (1) is pressed to the letterpress printing original plate placed in a fixed position and coated with the printing ink, and the printing ink is transferred to the curved surface (221, 222, 21) of the predetermined shape, and a step of moving the elastic blanket (2) to which the printing ink is transferred and which has curved surface (221, 222, 21) of the predetermined shape, bringing the elastic blanket (2) into contact with the curved surface of the object (1), and thus printing the object. A curved surface body printed by this method is also disclosed.

Owner:SHUHOU

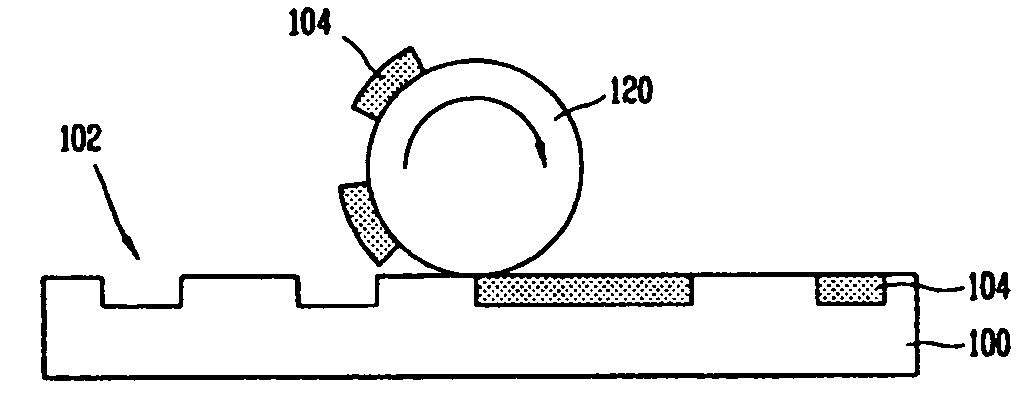

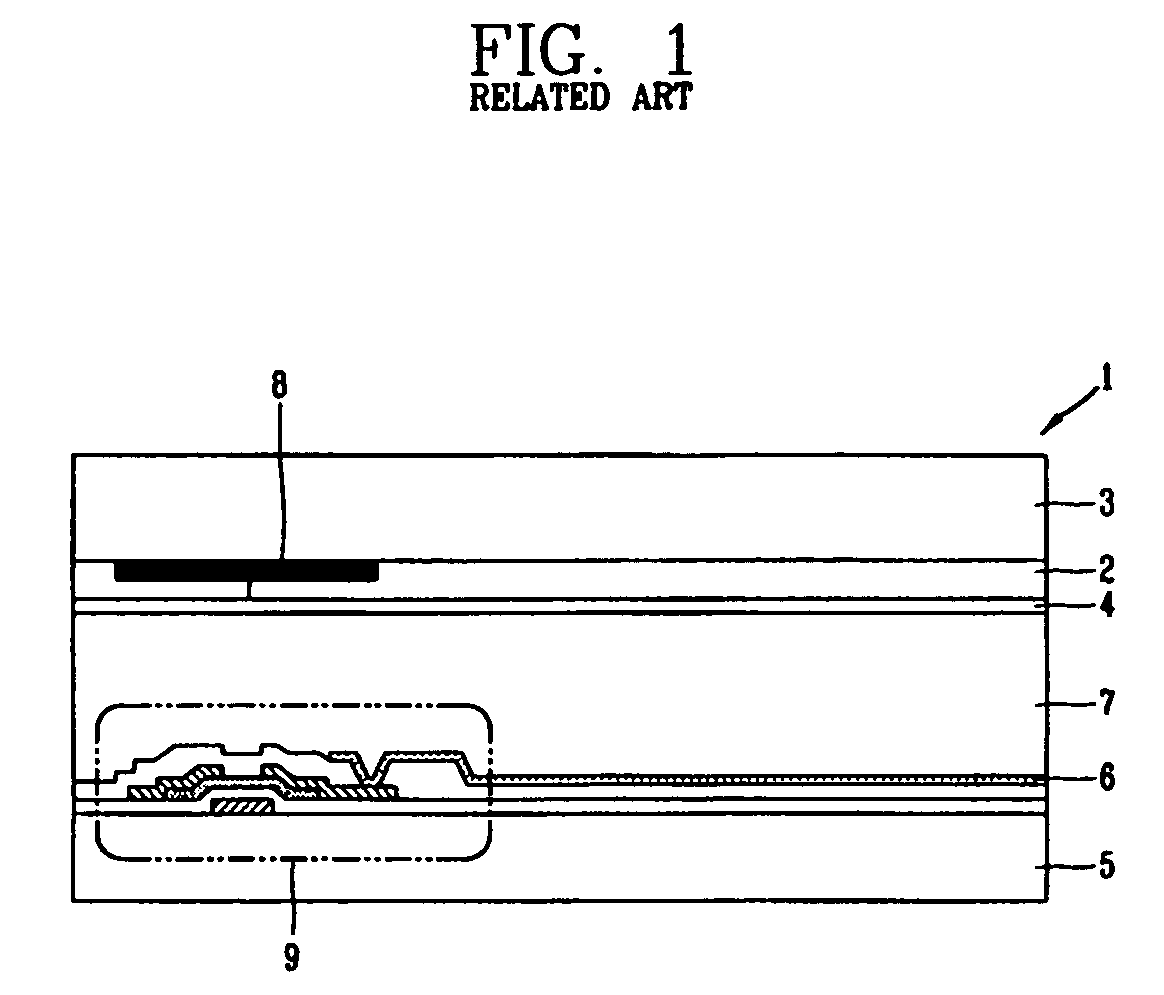

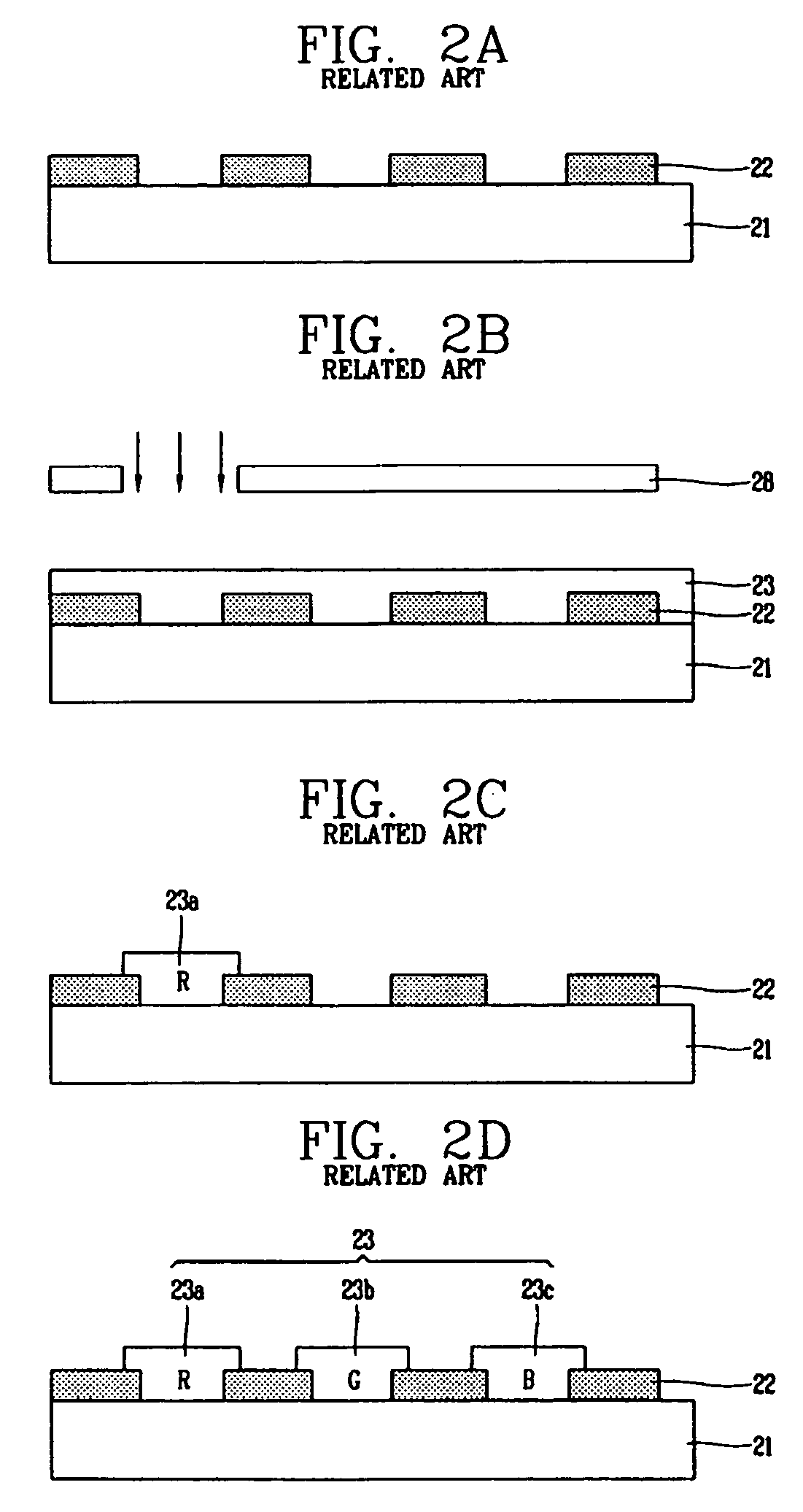

Method of fabricating color filter in display device

ActiveUS20040123753A1Cylinder pressesMechanical working/deformationLiquid-crystal displayDisplay device

A method of fabricating a color filter in a liquid crystal display device includes providing a plurality of clichés in which grooves are formed, filling color inks and a black resin in the grooves of the clichés, applying the color inks in the clichés onto a substrate to form a color filter, and applying a black resin in one of the clichés onto the color filter. The color inks and black resin are transferred to the clichés from an ink supply container via an ink supplying roller and from the clichés to the substrate via a printing roller.

Owner:LG DISPLAY CO LTD

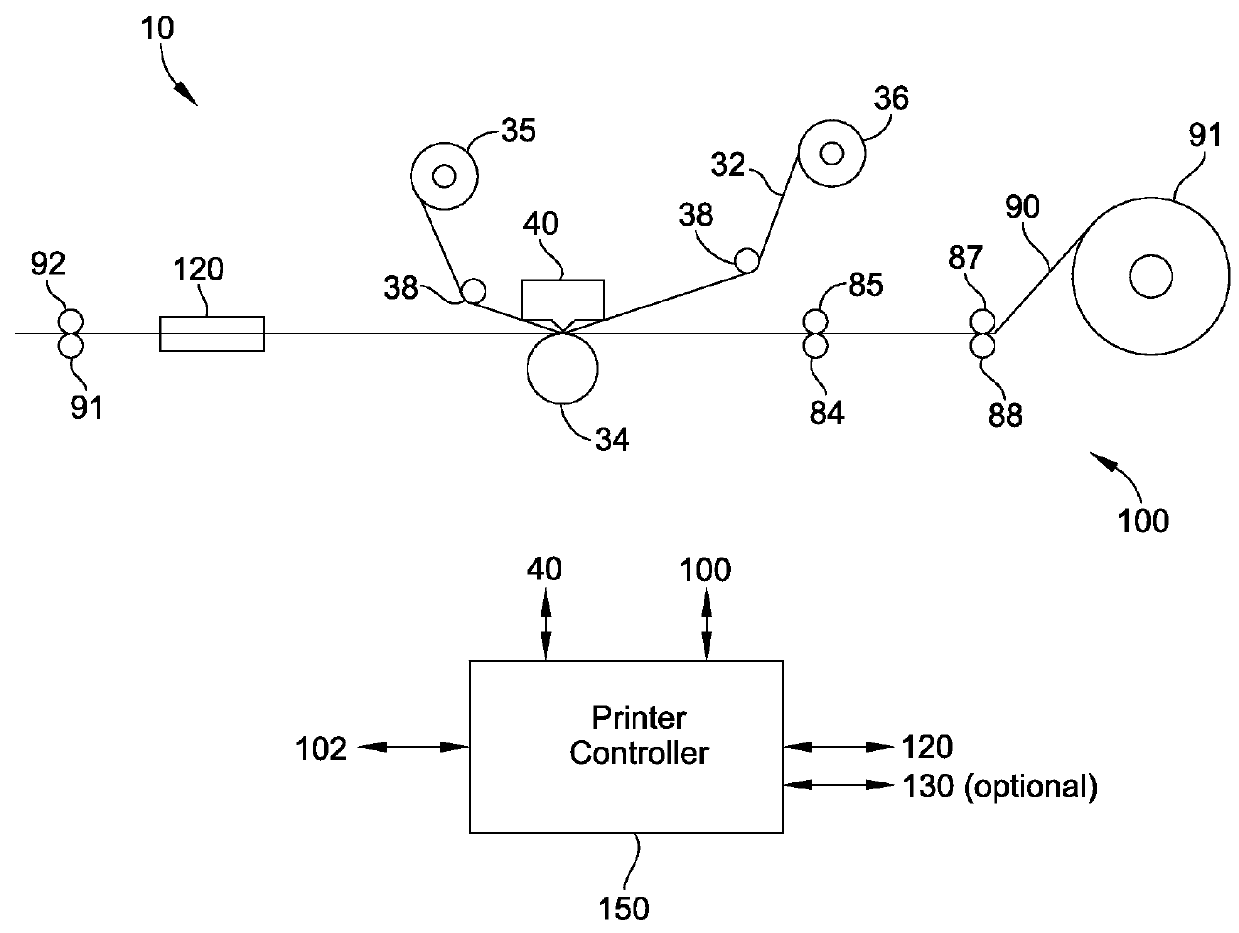

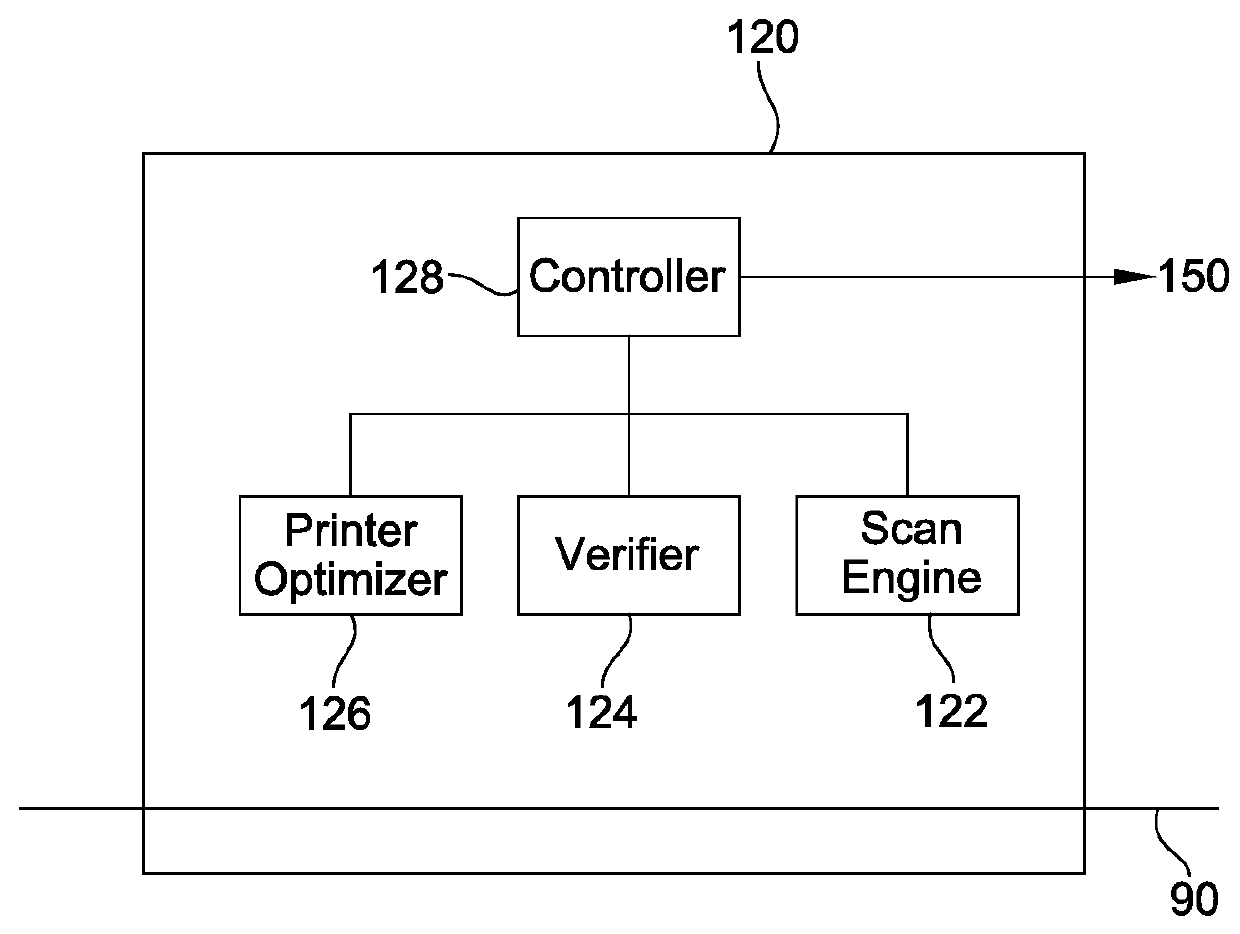

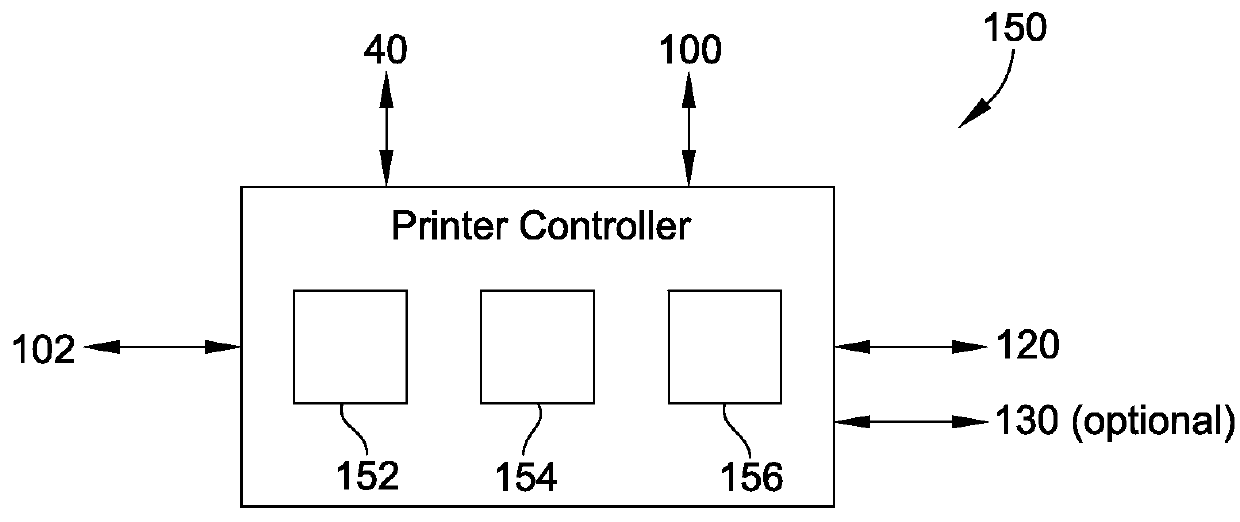

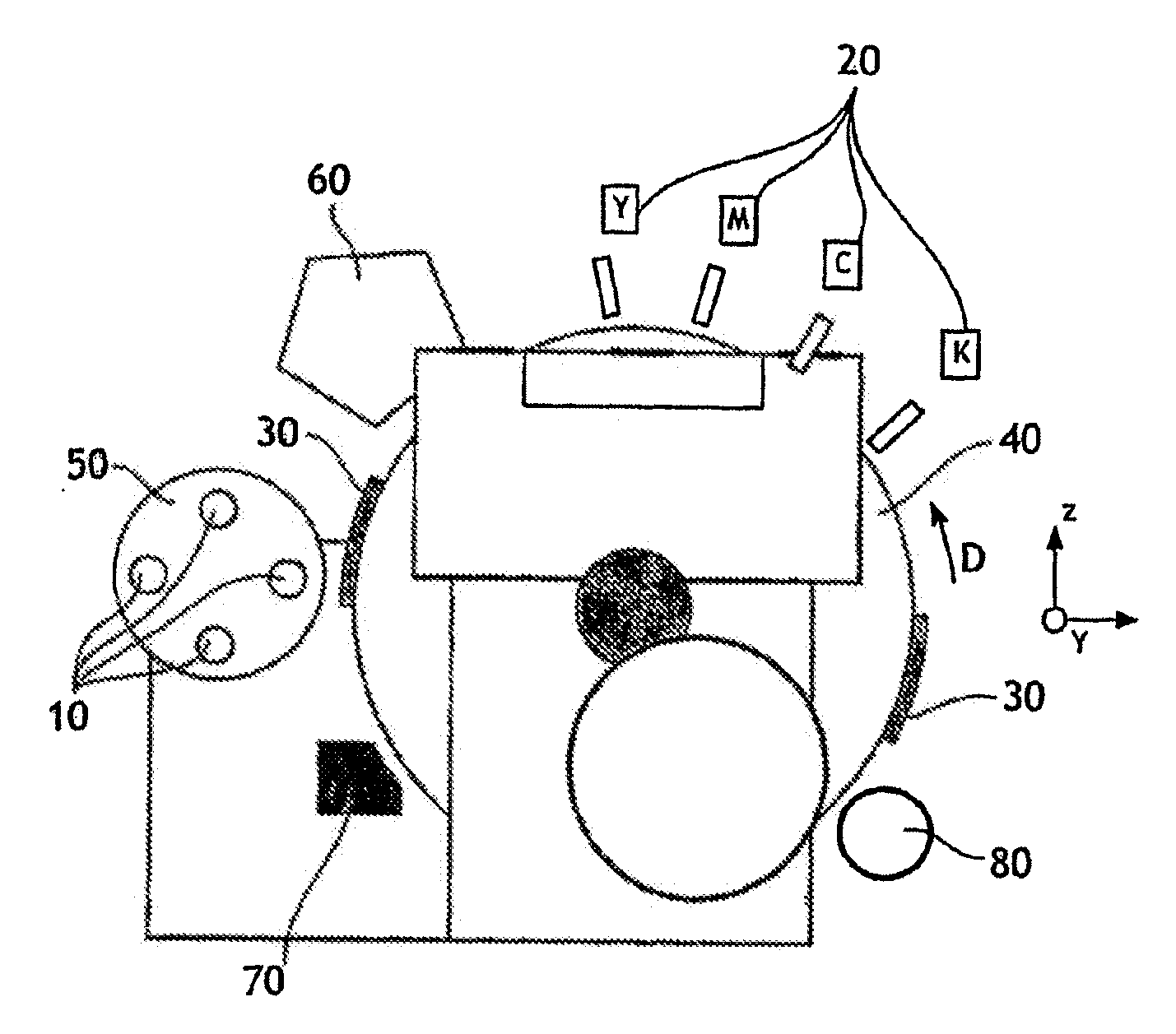

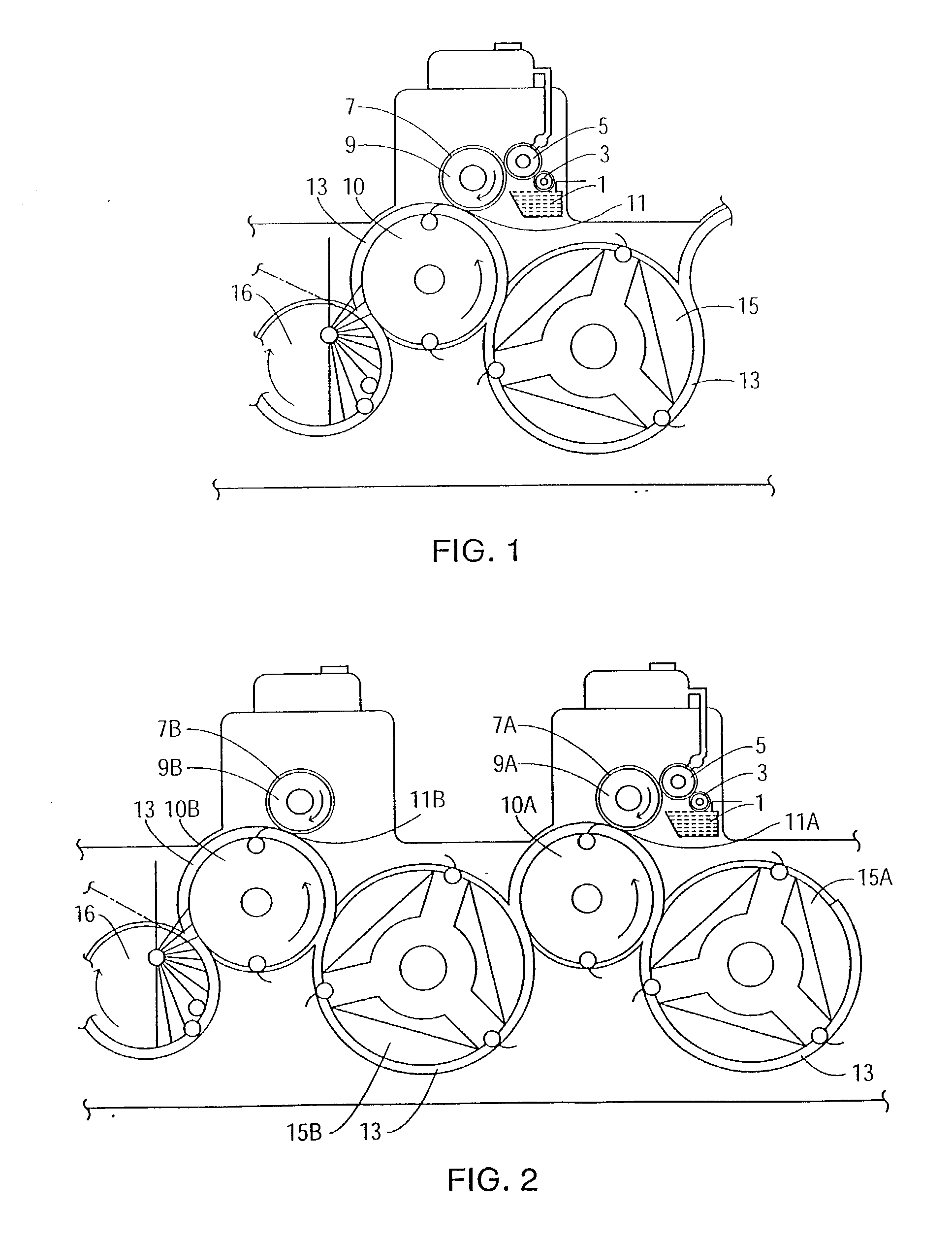

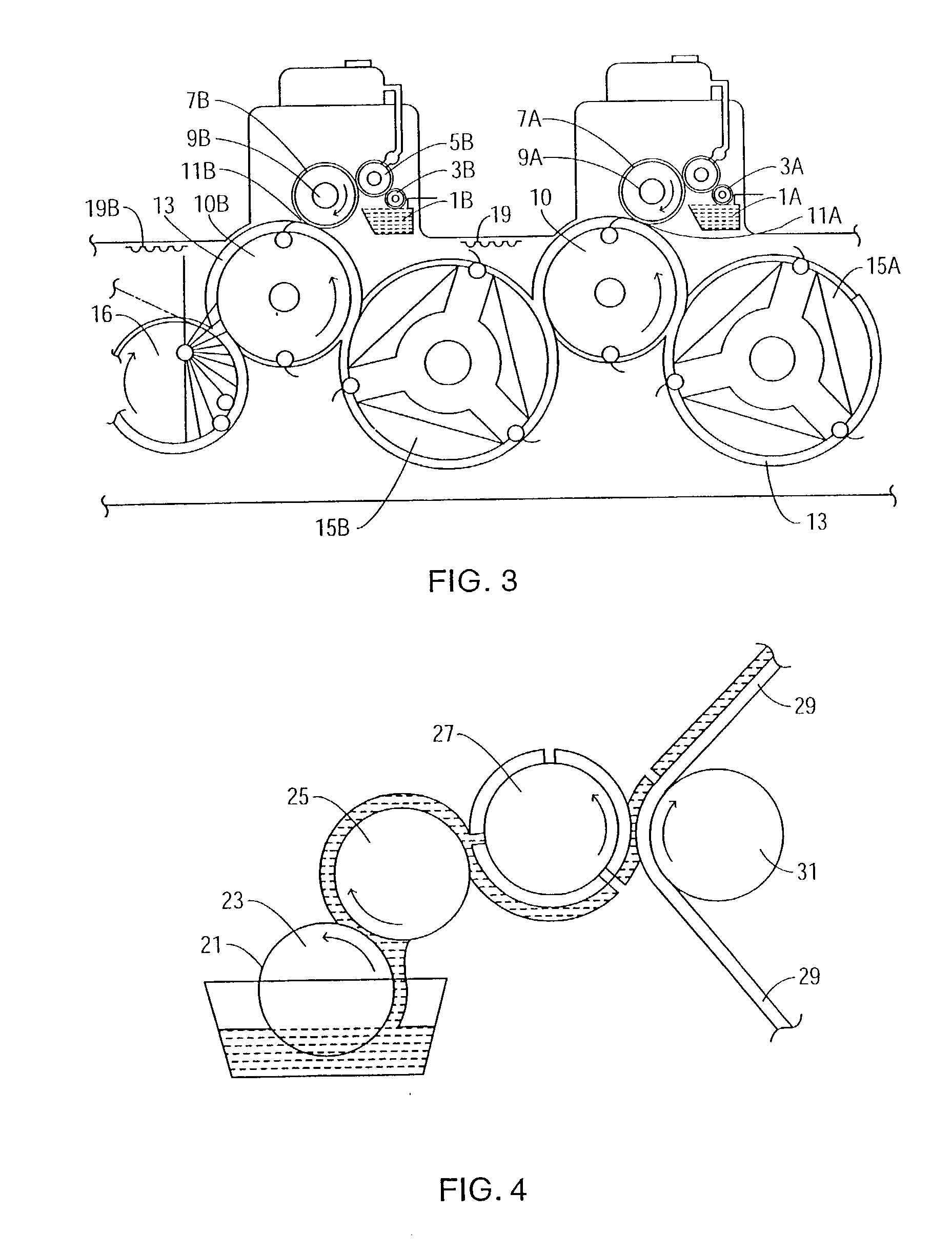

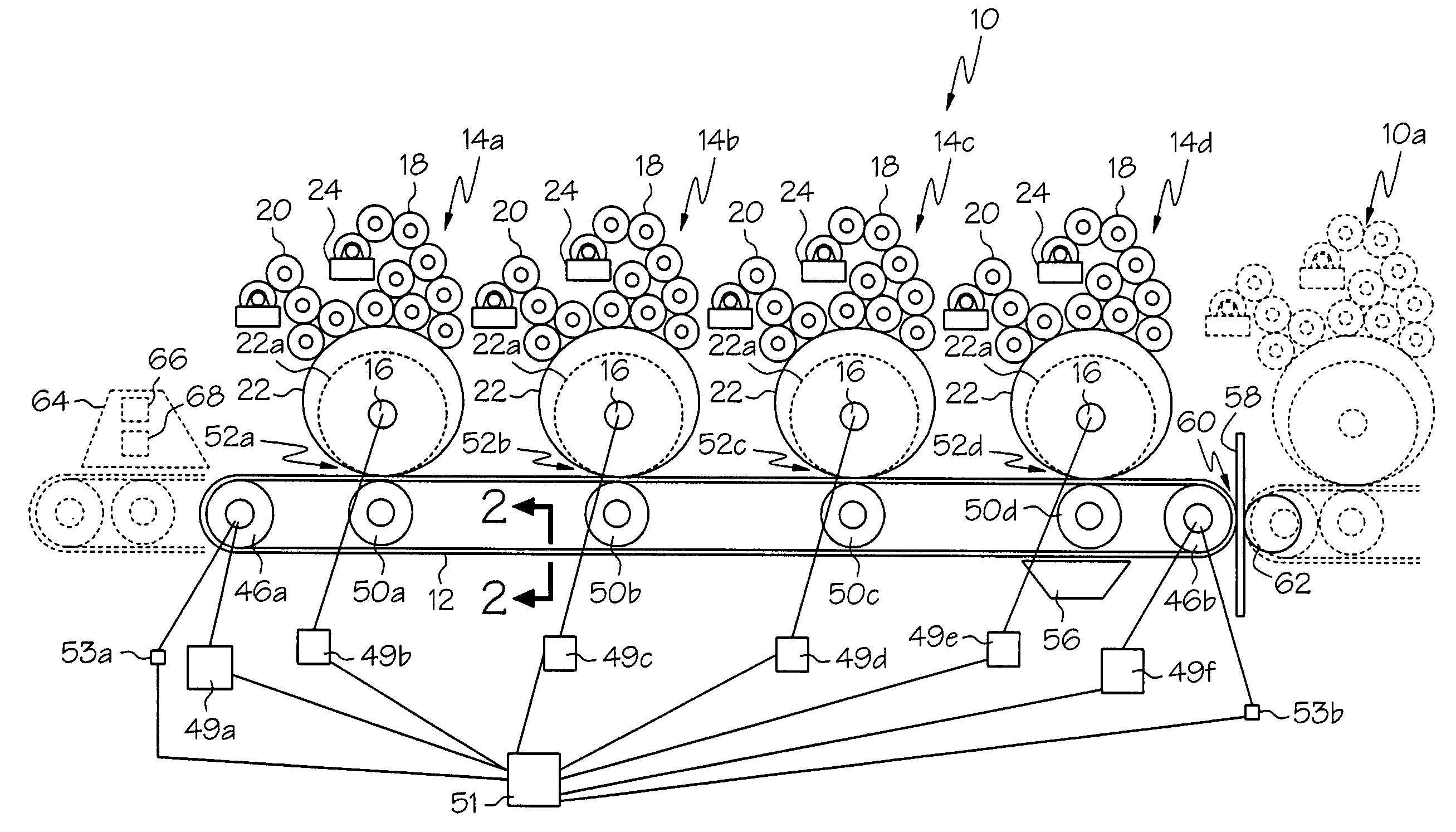

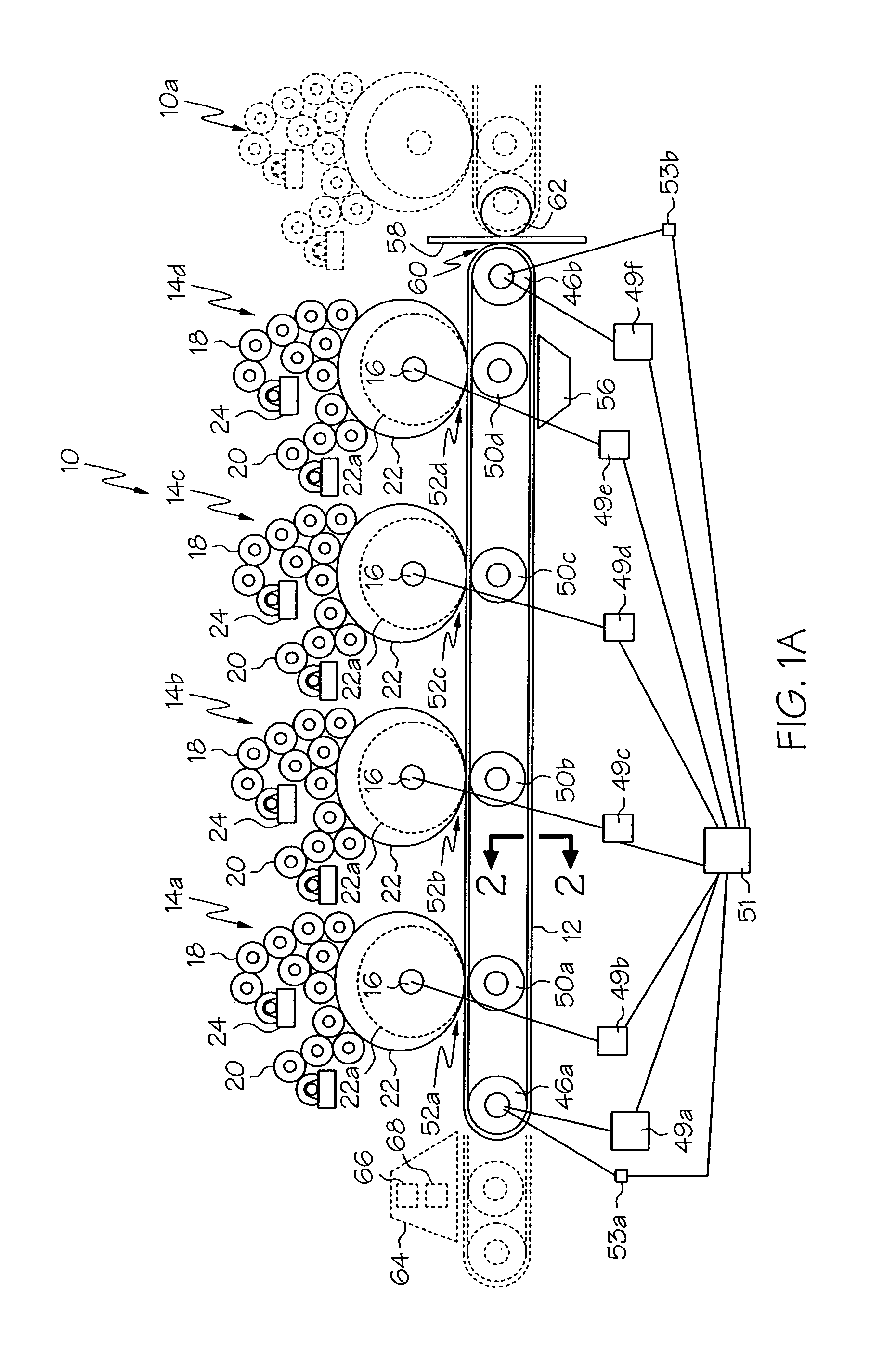

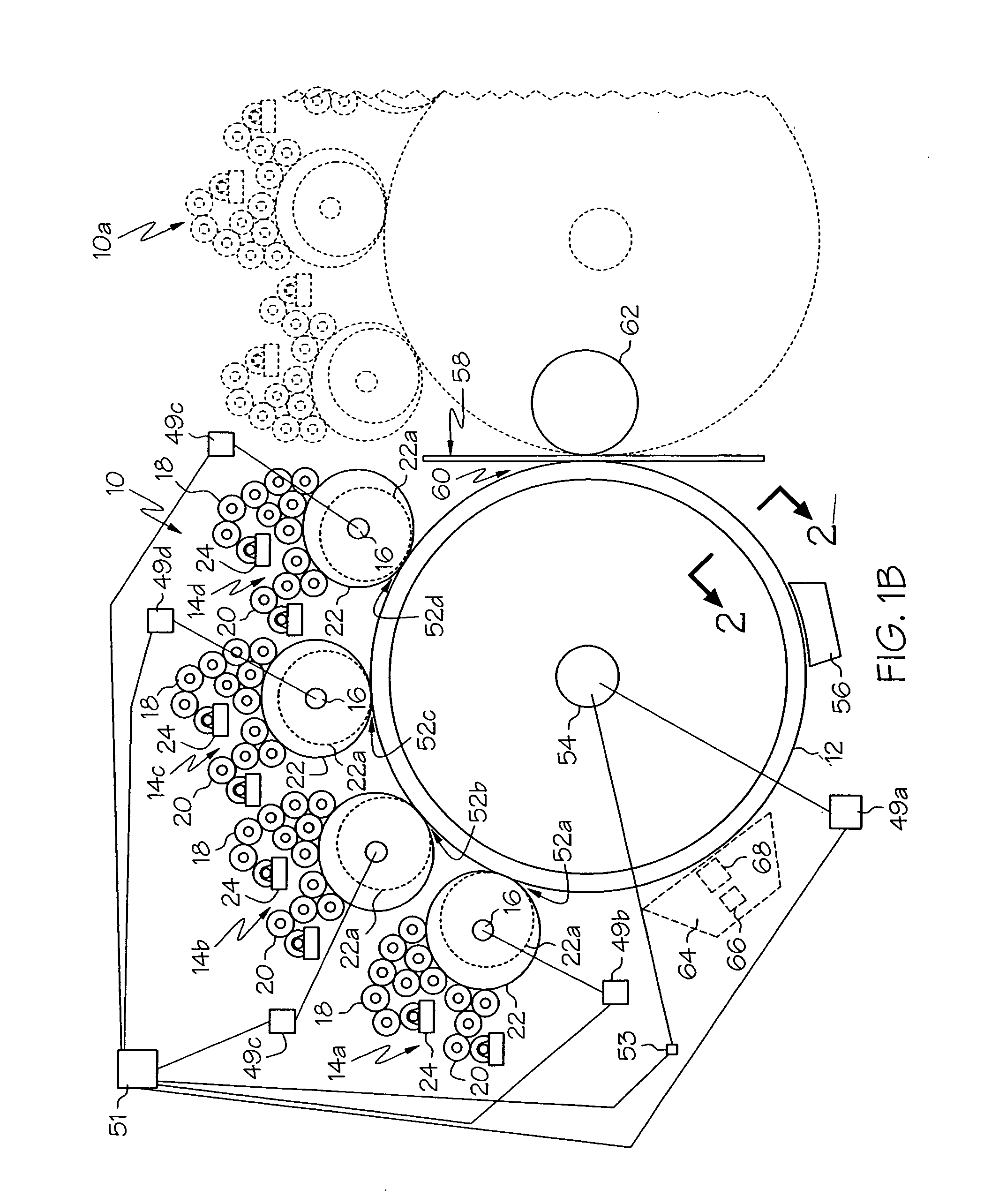

Variable cut-off offset press system and method of operation

InactiveUS7066088B2Aid in smooth operation of systemIncrease frictionCylinder pressesTransfer printingImage transferCleaning station

A variable cut-off offset press system and method of operation which utilizes a continuous image transfer belt is provided. The offset printing system comprises at least two plate cylinders adapted to have thereon respective printing sleeves. Each of the printing sleeves is adapted to receive colored ink from a respective ink source. An optional coating source may be provided to fully or partially coat the image transfer belt before inking. The system further comprises at least a impression cylinder, wherein the image transfer belt is positioned to contact each of the printing sleeves at respective nips formed between respective ones of the plate cylinders and the at least one impression cylinder. An image belt cleaning station adapted to remove residual ink or coating from the surface of the image transfer belt after image transfer of a multicolored image from the image transfer belt to a substrate is also provided.

Owner:DAY INT

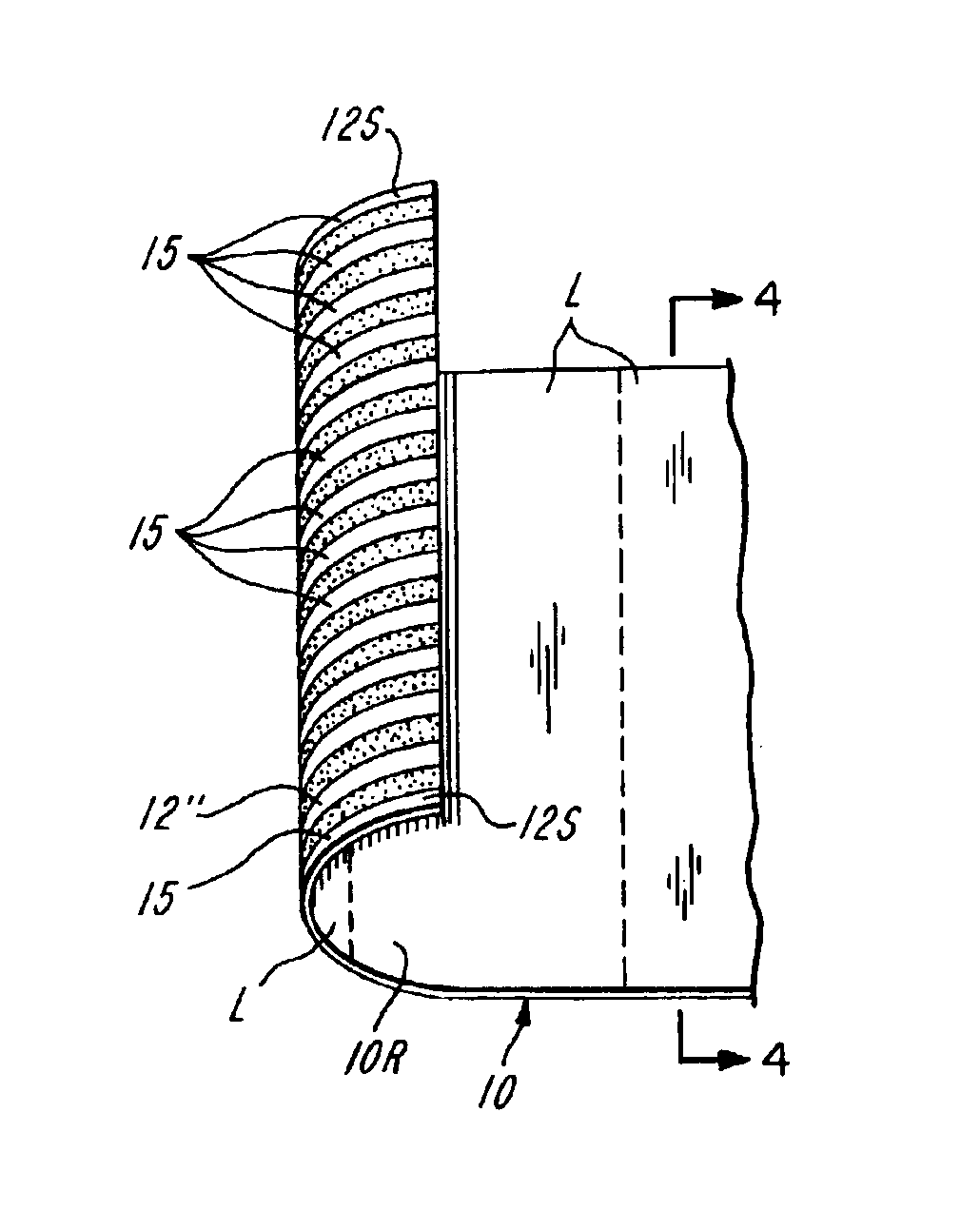

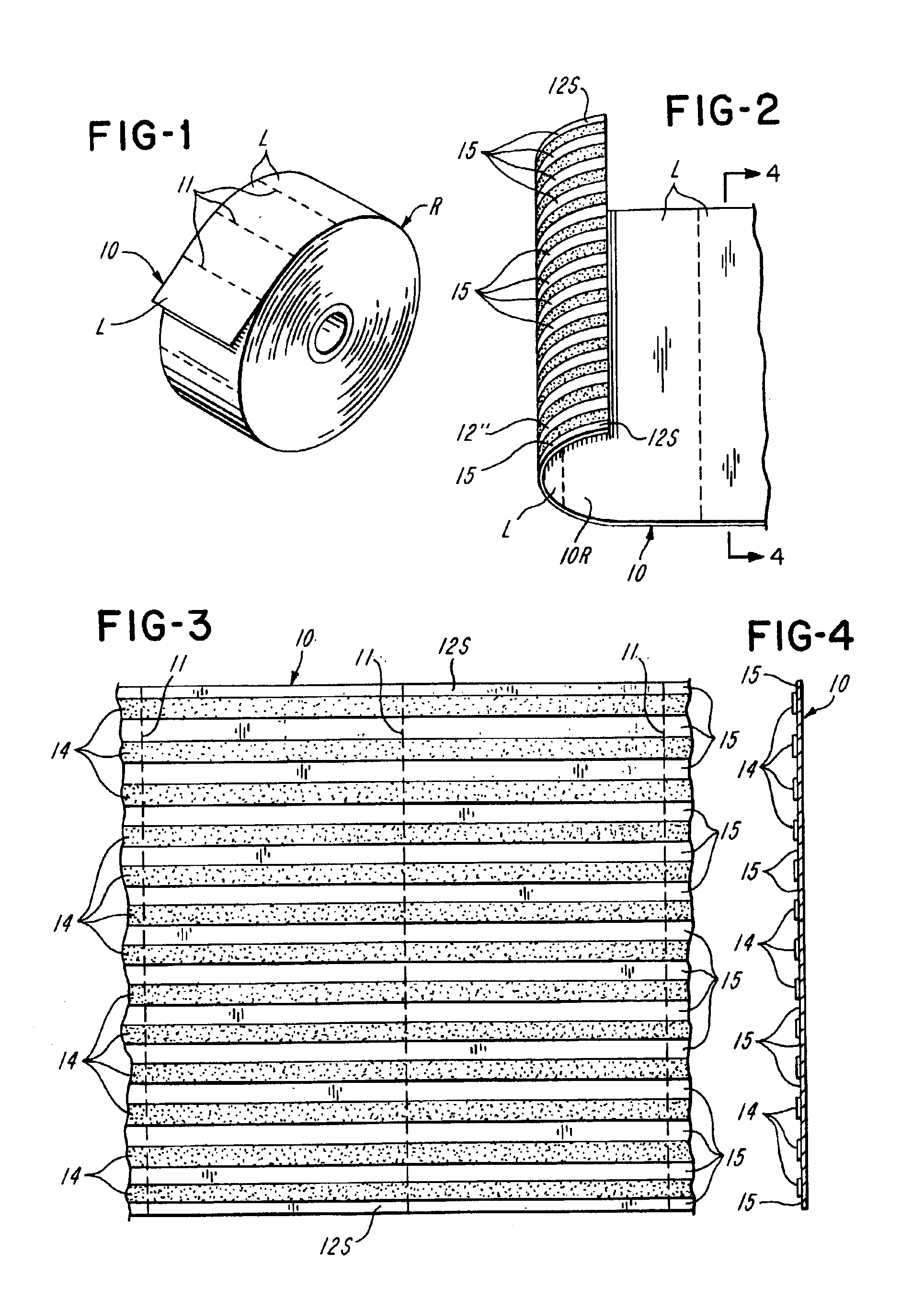

Method and system for handling a linerless label web

There is disclosed a linerless label web roll wherein the label web has a patterned coating of pressure sensitive adhesive on its underside between marginal side edges and at marginal side edges of the label web. The adhesive is provided in longitudinally extending laterally spaced stripes of adhesive with intervening adhesive-free zones. The label web can be supported and / or guided by support or guide elements which contact the adhesive-free zones in a suitable utilization device such as a printer or label applicator.

Owner:AVERY DENNISON CORP

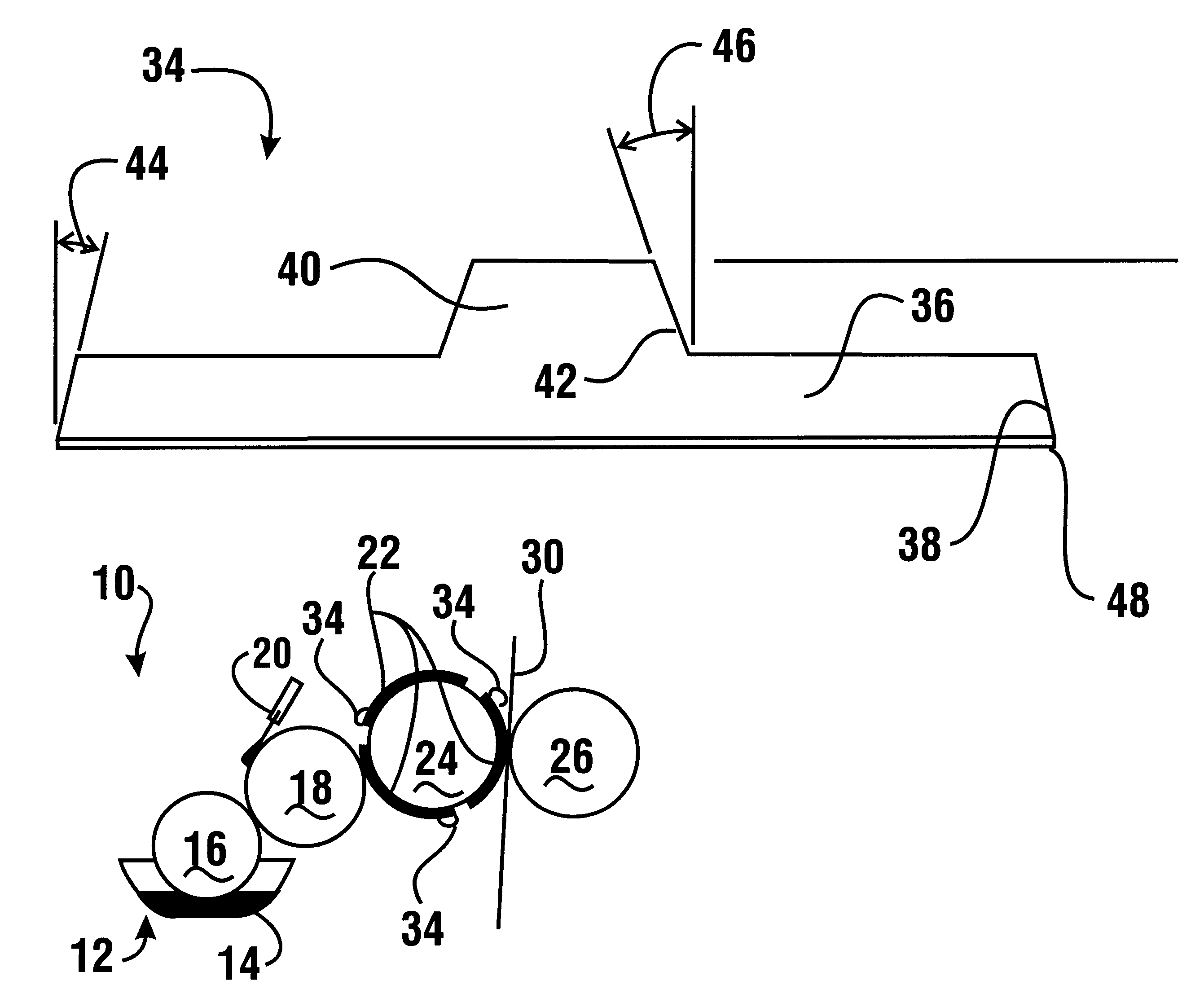

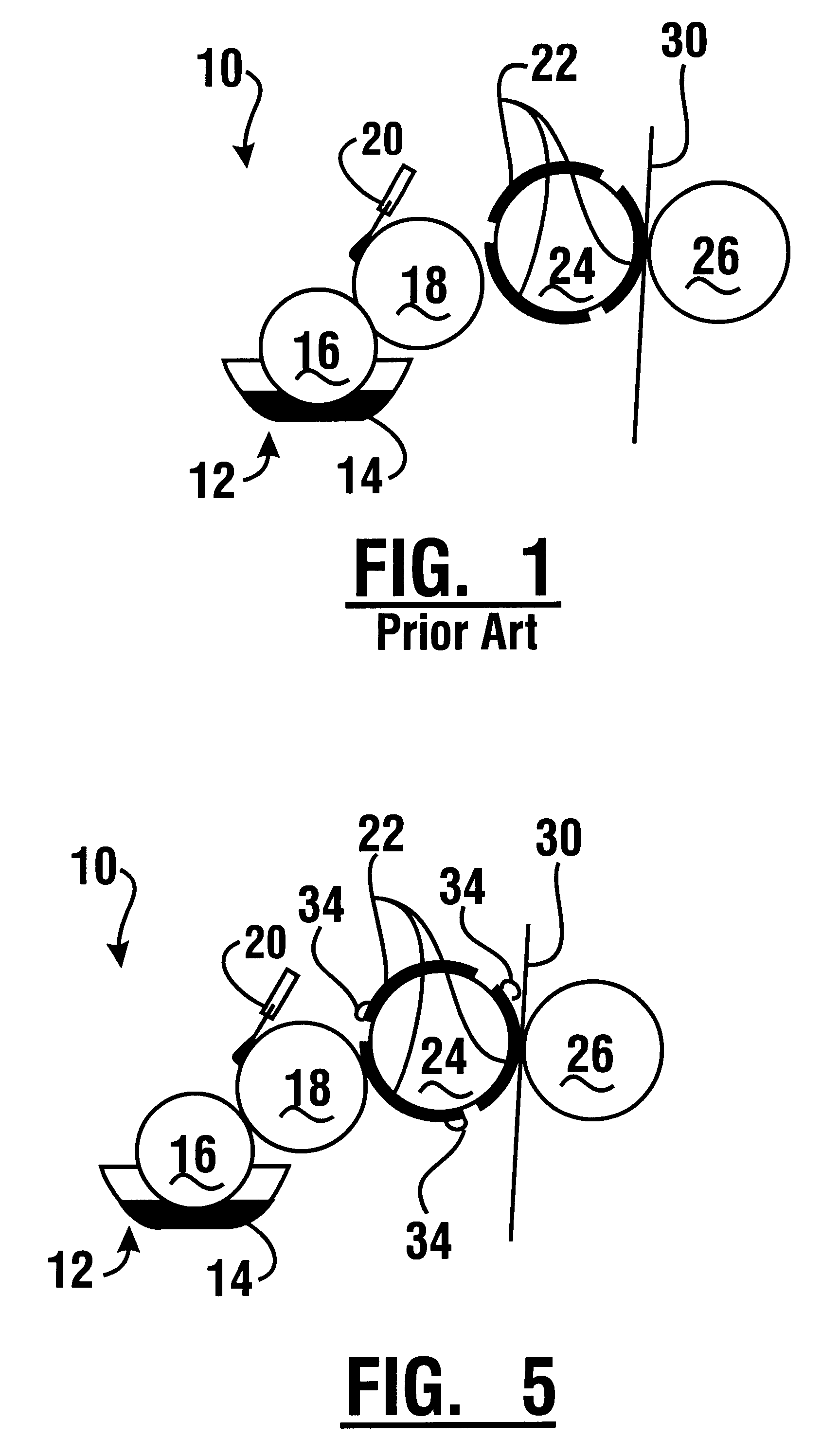

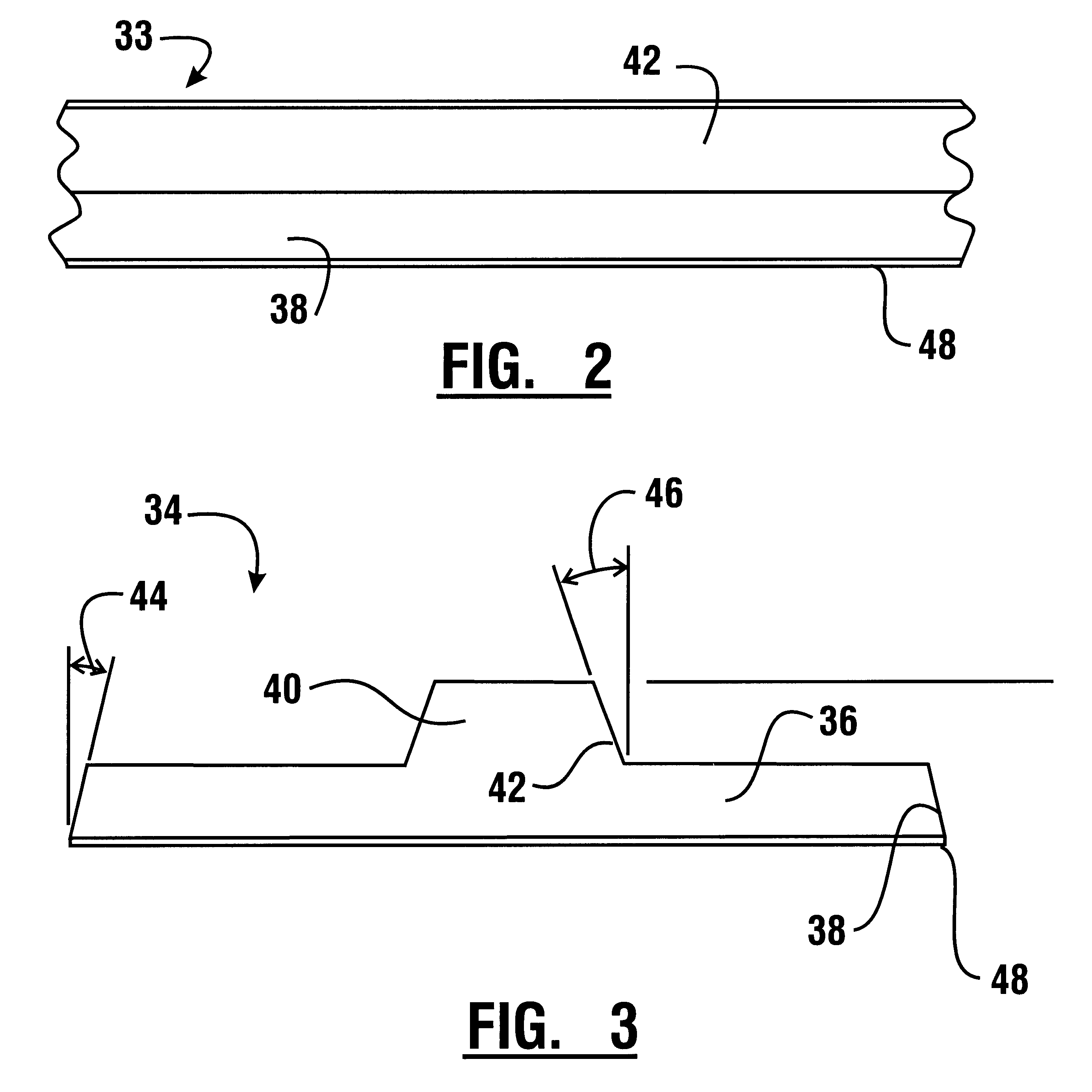

Flexographic printing apparatus and method

A pull band (34) is attached to a printing plate (22) in a flexographic printing operation to hold a flexible substrate (30) in a selected orientation for transfer of ink in a selected pattern. The pull band overcomes differences in friction between the printing plate and the substrate in areas of different amounts of ink to maintain the selected orientation. A specific length pull band may be selected and cut from a roll of pull band material. Pull bands may be attached parallel and perpendicular to the direction of rotation of the printing plate.

Owner:FEESLER DOUGLAS W

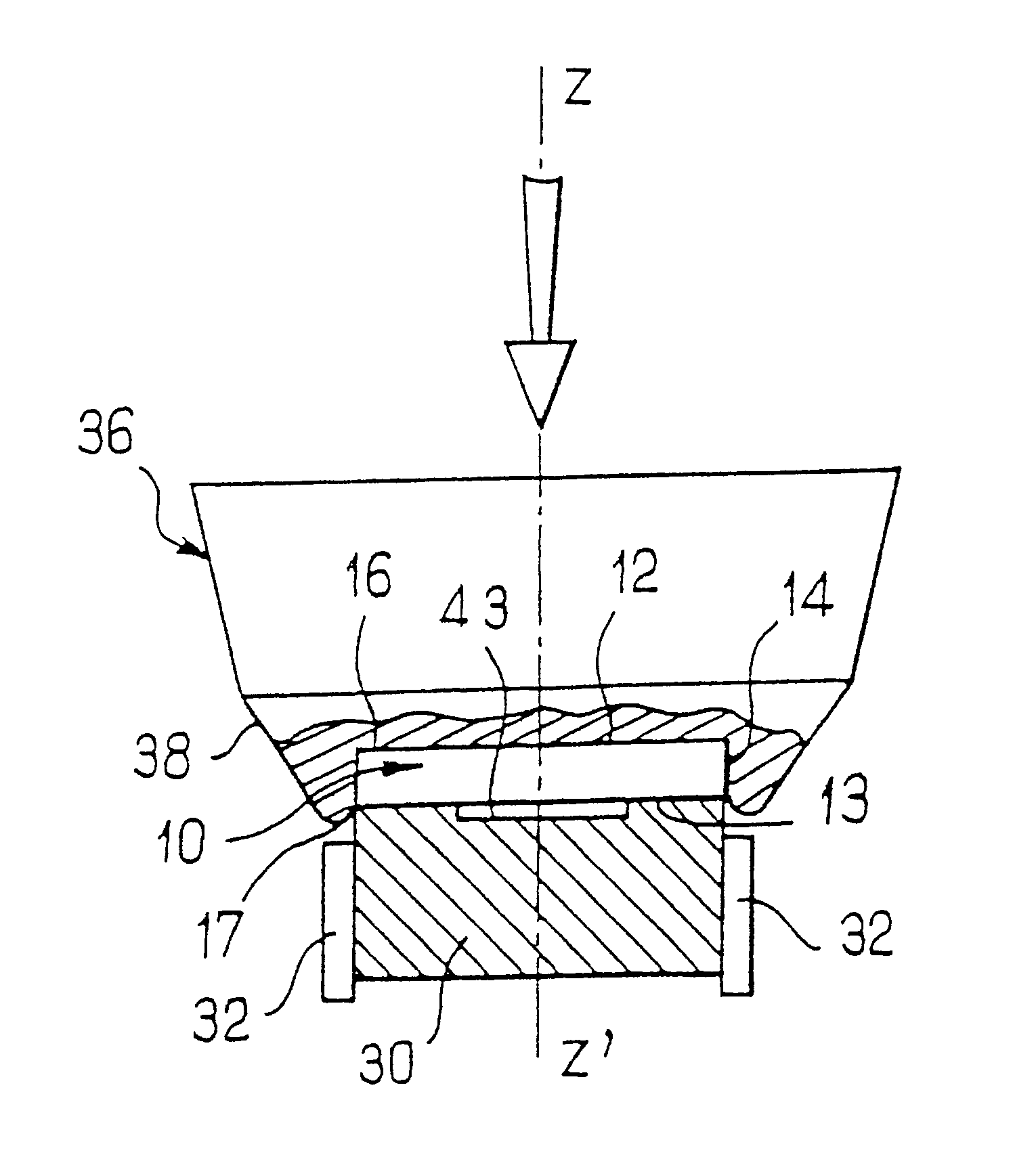

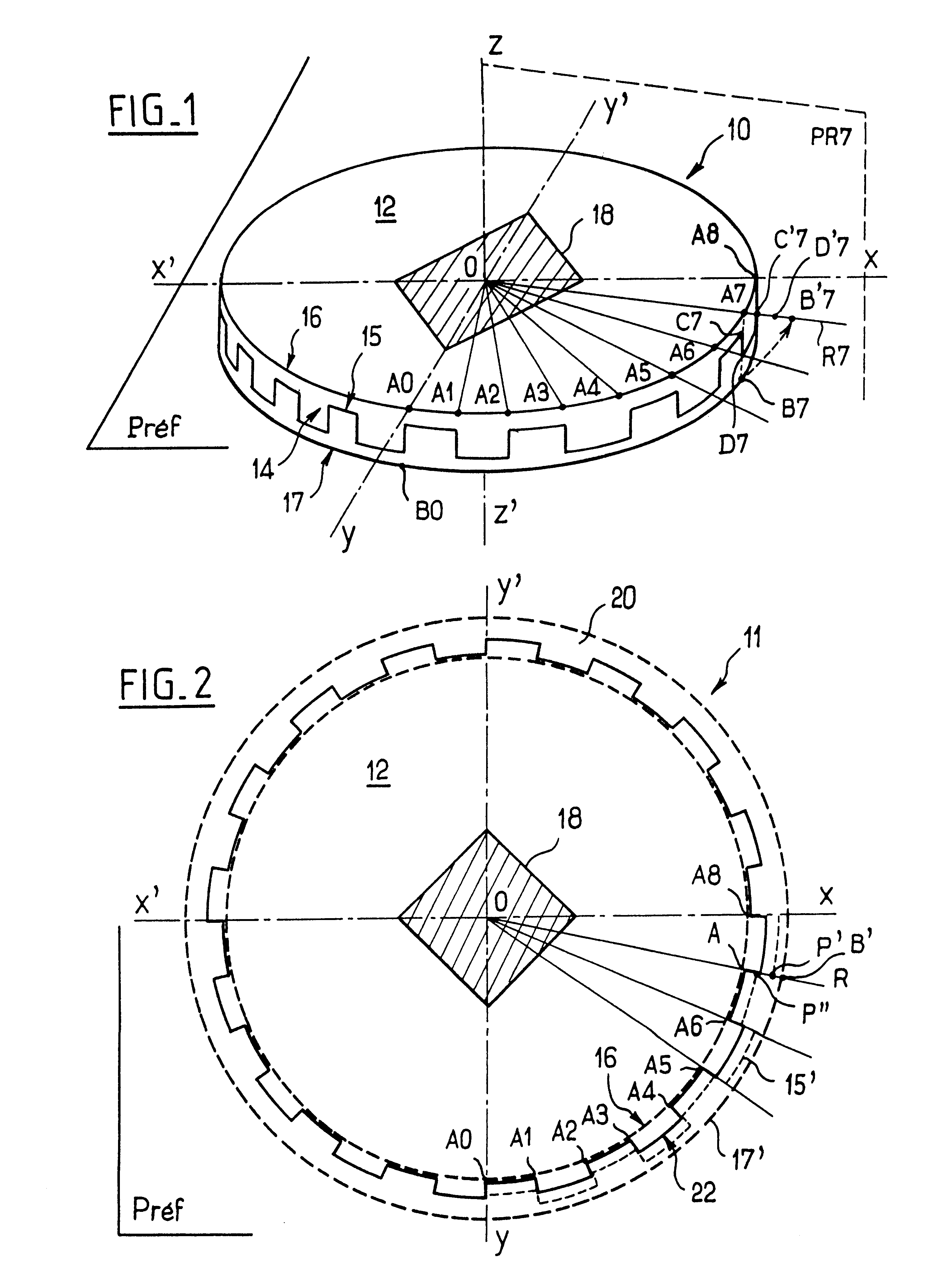

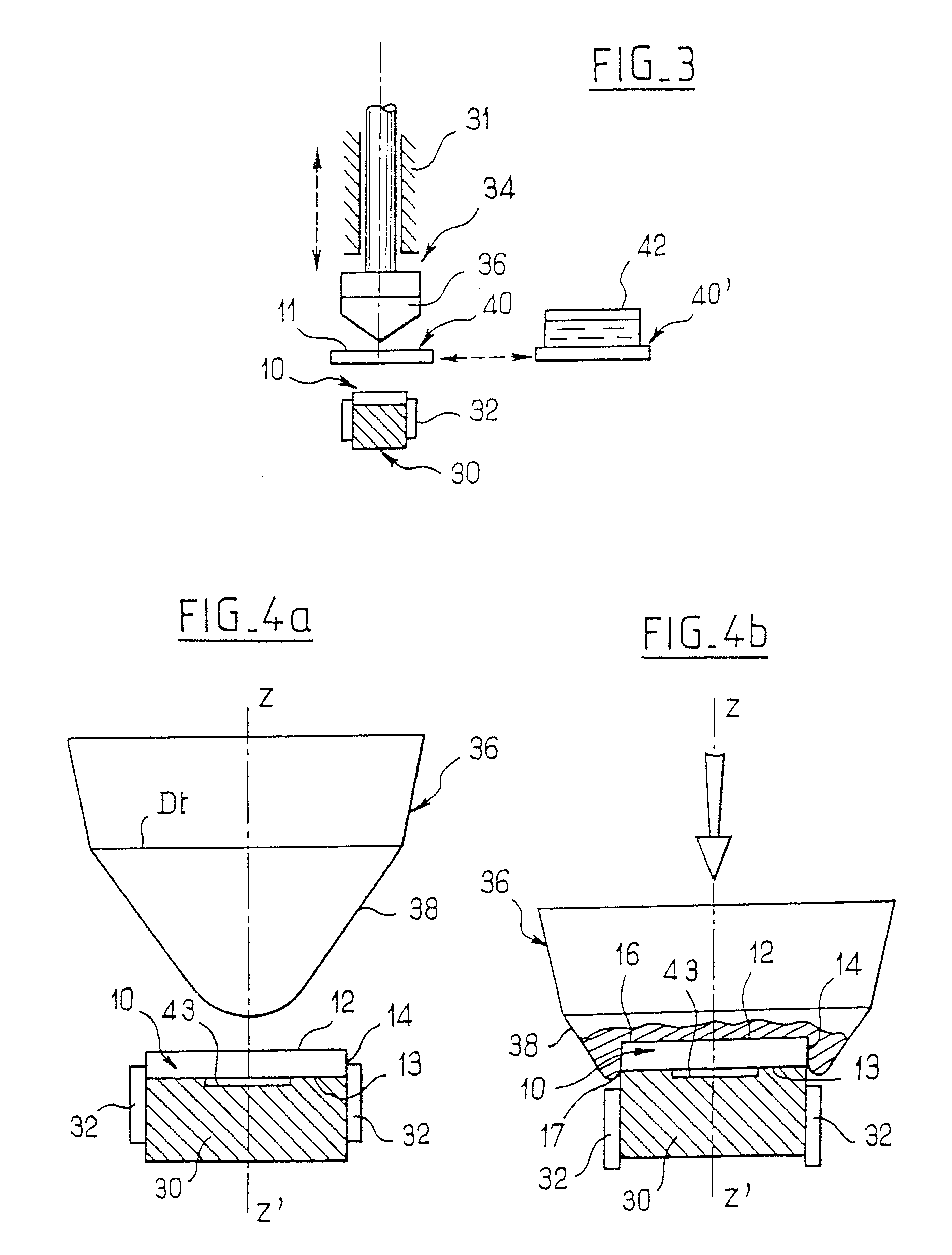

Method for marking a gaming disk by pad printing

A method for marking a side of a straight-sided chip with a decoration by pad printing. The method comprises providing an ink plate with an image defined by radially deformed representation of the decoration of the straight side of the chip in a ring-shaped zone, moving a pad coaxially into contact with the ink plate such that the image transfers to the pad, and moving the pad coaxially into contact with the chip such that the image transfers to the side of the chip.

Owner:GAMING PARTNERS INTERNATIONAL CORPORATION +1

System and method for incorporating graphics into absorbent articles

A method for incorporating graphics into absorbent articles. The method involving: providing a moving substrate to a print cylinder; sensing a line speed reference signal from a line speed target machinery component; rotating the print cylinder at a predetermined speed, based on the line speed reference signal, to thereby print a series of graphics on the moving substrate at a predetermined distance frequency; sensing a phase difference signal from a phase target machinery component; and setting an actual print cylinder phase angle, based on the phase difference signal, to approximate a predetermined phase angle to thereby position the series of graphics on the moving substrate at a series of desired graphics locations. A system for executing the method and garments produced from the method and system are also provided.

Owner:FIRST QUALITY RETAIL SERVICES

System and method for incorporating graphics into absorbent articles

A method for incorporating graphics into absorbent articles. The method involving: providing a moving substrate to a print cylinder; sensing a line speed reference signal from a line speed target machinery component; rotating the print cylinder at a predetermined speed, based on the line speed reference signal, to thereby print a series of graphics on the moving substrate at a predetermined distance frequency; sensing a phase difference signal from a phase target machinery component; and setting an actual print cylinder phase angle, based on the phase difference signal, to approximate a predetermined phase angle to thereby position the series of graphics on the moving substrate at a series of desired graphics locations. A system for executing the method and garments produced from the method and system are also provided.

Owner:FIRST QUALITY RETAIL SERVICES

Printing unit for a rotary printing machine with cross slide

InactiveUS6502509B2Long constructionEfficient introductionCylinder pressesAddressographsPrinting pressMechanical engineering

Rotary printing machine with forme and impression cylinders for variable-format or variable-circumference printing and with service apparatus which are capable of being moved radially in relation to the printing-unit cylinders for throw-on or throw-off movements and in the axial direction of the cylinders or in the side-wall plane. The service apparatus and the printing-unit cylinders are arranged on cross slides which can each be moved in two directions relative to the printing-unit side wall.

Owner:MANROLANAD AG

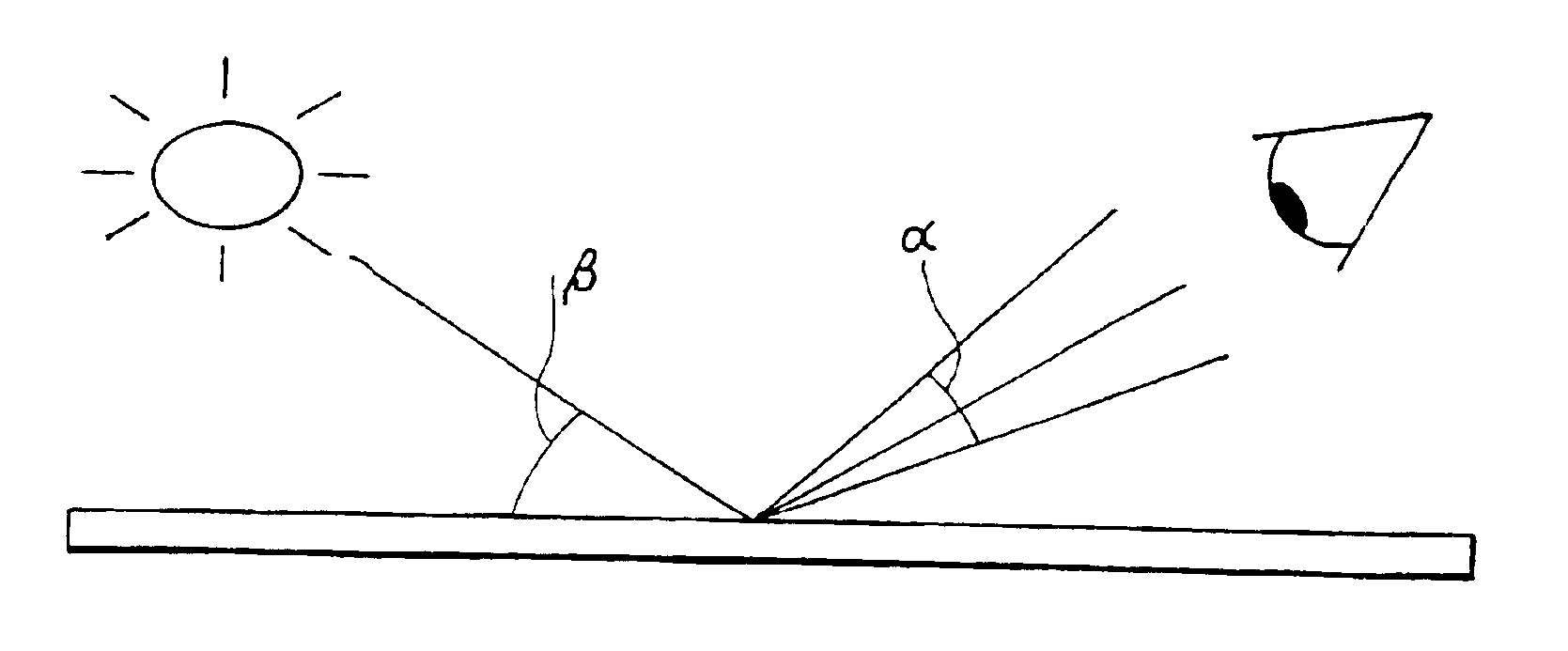

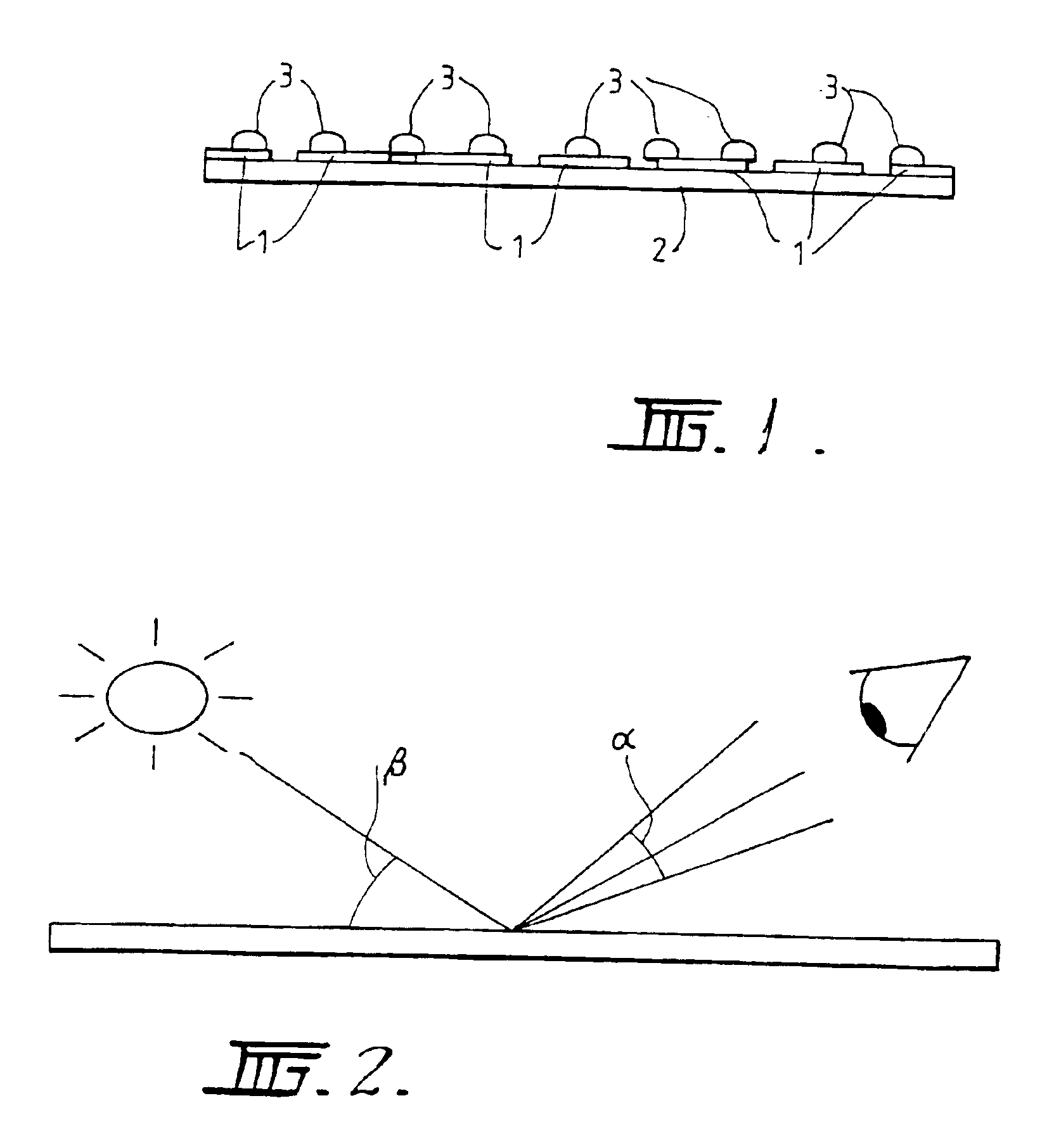

Security document with raised intaglio printed image

InactiveUS6905755B1Superior tonal effectHigh light transmittanceCylinder pressesDigitally marking record carriersMeasuring instrumentTransmittance

A security document or other device including a substrate (2), a smooth highly reflective layer (1) applied thereto and having a reflectivity of at least 60 gloss units, and a raised printed image (3) applied to said reflective layer by a printing process such as the gravure process, the raised printed image having a height of at least 10 microns and being printed using a translucent ink having a large value of 85 to 95 as measured on an XL 211 Hazegard haze measuring instrument, which render it substantially transparent or translucent while causing scattering of the light reflectance and transmittance in at least a partially specular manner. A method of producing a document is also disclosed.

Owner:NOTE PRINTING AUSTRALIA

Alkali resistant polymeric interlayers for lithoplates

Substrates for lithographic printing plate precursors and lithographic printing plate precursors are disclosed. The substrates comprise an aluminum or aluminum alloy support and the a layer of interlayer material on the support. The interlayer material is a co-polymer that comprise (1) acid groups and / or phosphonic acid groups, and (2) silyl groups substituted with three alkoxy and / or phenoxy groups. The lithographic printing plate precursors additionally comprise an imageable layer over the interlayer.

Owner:KODAK POLYCHROME GRAPHICS

Process for the offset printing of a catalytic species via a hydrophilic phase

An offset printing process comprising the steps of: applying a hydrophilic phase to a printing plate with or without an oleophilic phase, the hydrophilic phase comprising at least one catalytic species, and applying the hydrophilic phase applied to the printing plate to a receiving medium thereby realizing in a single step a functional pattern of the at least one catalytic species on the receiving medium, wherein, if the hydrophilic phase is applied with the oleophilic phase, the oleophilic and hydrophilic phases are either applied separately from an ink and a fountain medium or are applied together in the form of a single fluid ink, the single fluid ink consisting of a dispersing phase and a dispersed phase, and the hydrophilic phase is exclusive of an ionomer.

Owner:AGFA NV

Alkali resistant polymeric interlayers for lithoplates

Substrates for lithographic printing plate precursors and lithographic printing plate precursors are disclosed. The substrates comprise an aluminum or aluminum alloy support and the a layer of interlayer material on the support. The interlayer material is a co-polymer that comprise (1) acid groups and / or phosphonic acid groups, and (2) silyl groups substituted with three alkoxy and / or phenoxy groups. The lithographic printing plate precursors additionally comprise an imageable layer over the interlayer.

Owner:KODAK POLYCHROME GRAPHICS

Method for high definition dip transfer printing and article made according to method

Method for high definition printing to be dip transferred to a three-dimensional article comprises four color process printing a digital image from a digital image file onto a water soluble polymer film with solvent based ink to form a printed water soluble film and dip transfer printing the solvent based ink image through transcription on the surface of the article. The method is suitable for printing three-dimensional articles of a variety of shapes with high definition, photographic-quality images. The method is particularly suitable for decorating articles with complex images such as camouflage patterns.

Owner:IMMERSION GRAPHICS CORP

Electronic still camera, instant printer and instant film

InactiveUS20050263026A1Easy constructionSimple mechanical structureCylinder pressesPlaten pressesLight beamStill camera

Owner:FUJIFILM CORP

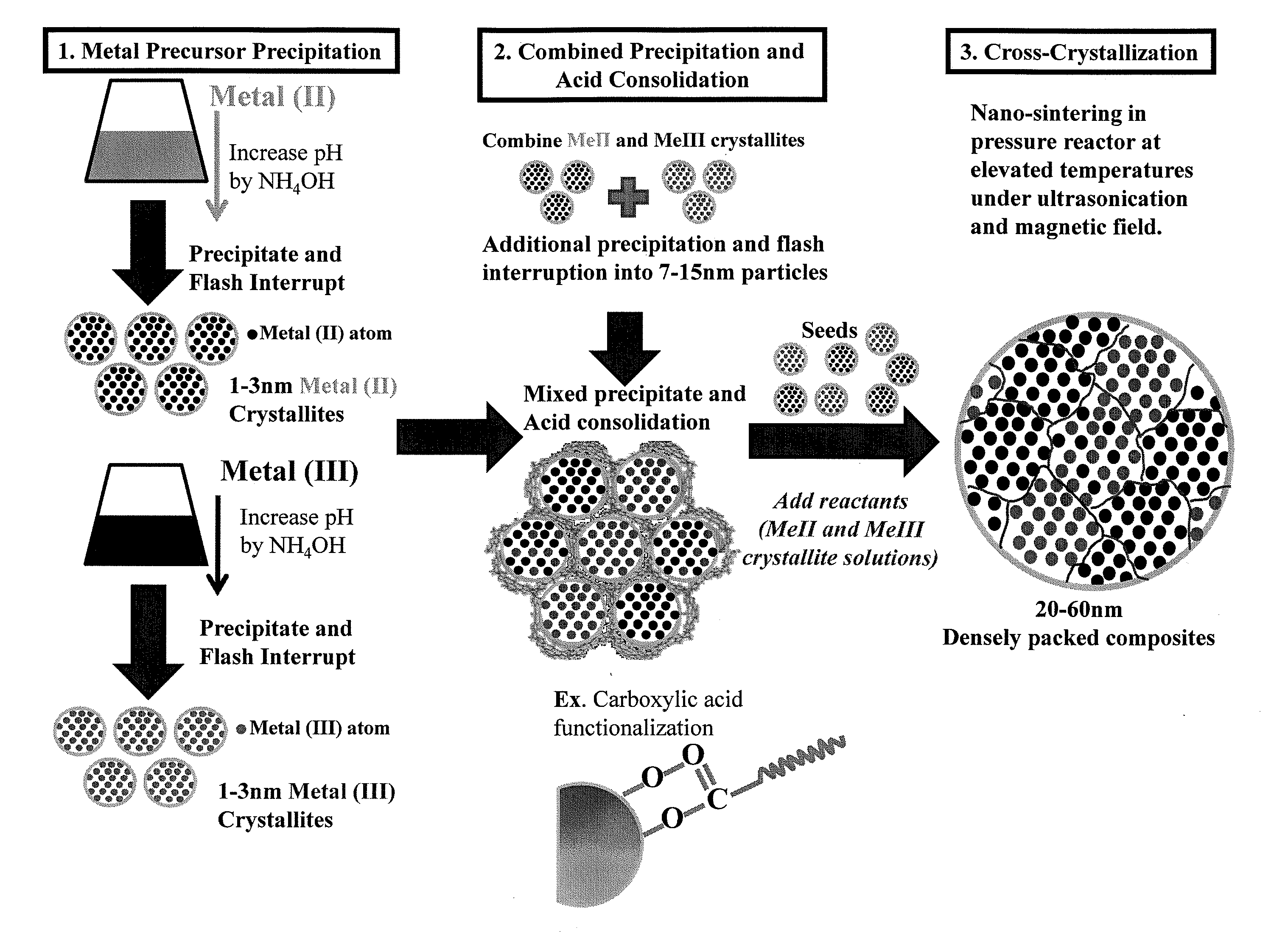

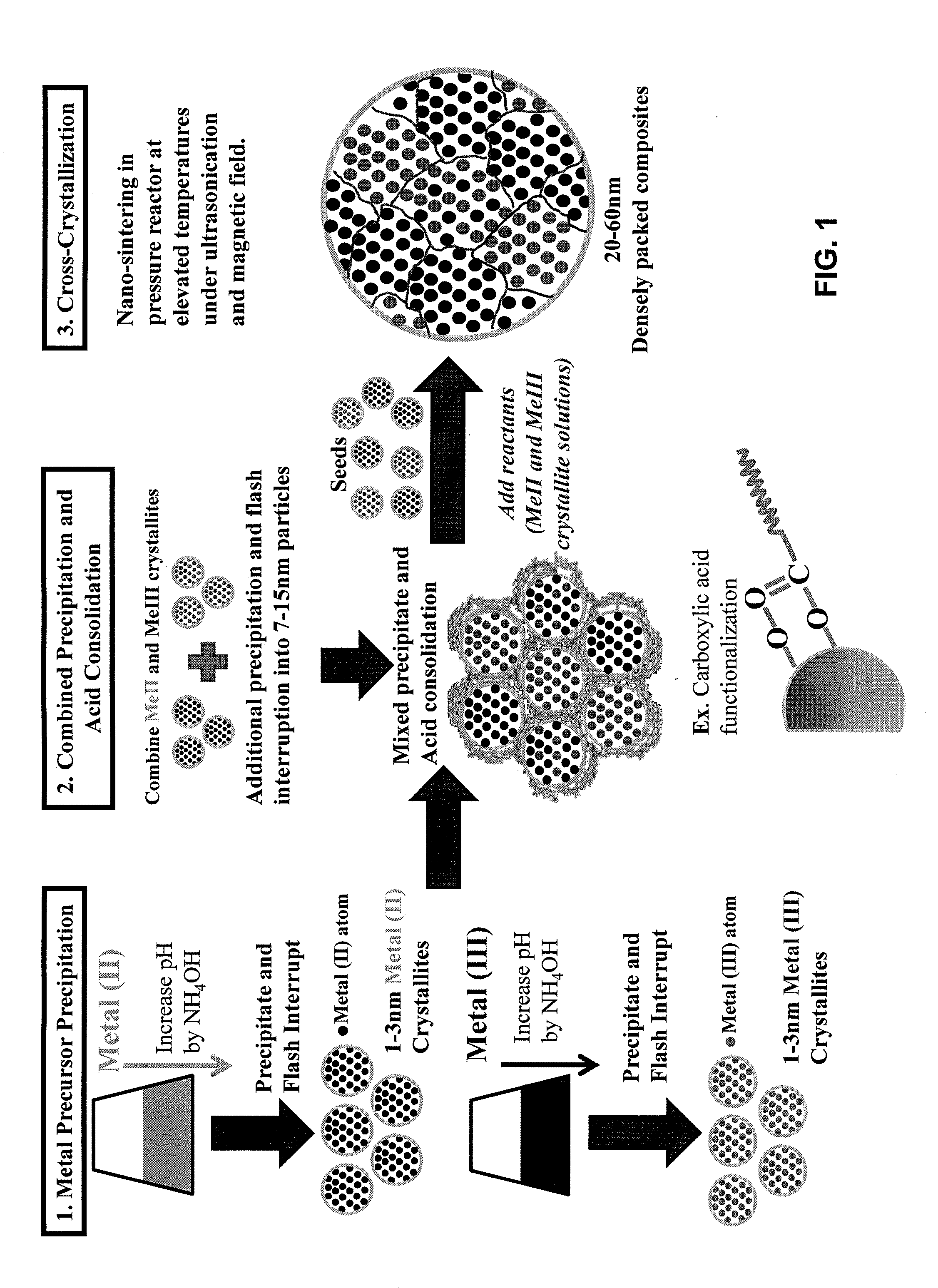

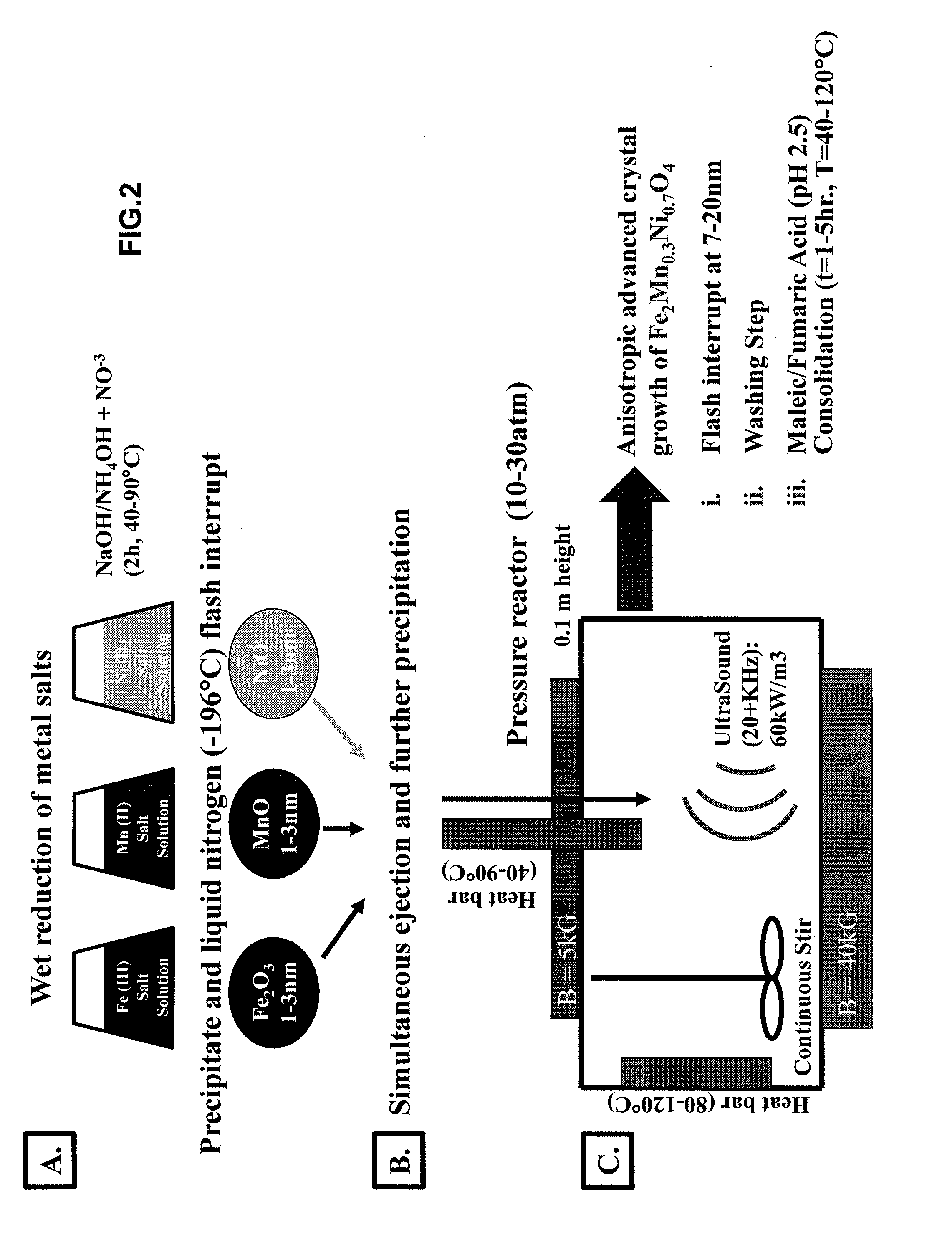

Magnetic fluid suitable for high speed and high resolution dot-on-demand inkjet printing and method of making

ActiveUS20120225264A1Increase printing speedImproved resolution characteristicCylinder pressesMaterial nanotechnologyRare earthOxidation state

A magnetic fluid composition include a suspension of nano-particles including cross-crystallized multi-metal compounds dispersed in a solvent, the cross-crystallized multi-metal compounds including at least two or more metals having different valencies or oxidation states, the metals selected from the group consisting of a monovalent metal (Me+), a divalent metal (Me2+), a trivalent metal (Me3+), a quadrivalent metal (Me4+) and a rare earth metal. The magnetic fluid having a viscosity and surface tension that permits dispensing from an inkjet printer at a rate of at least 2.5 m / s, at a resolution of at least 600 dpi, supporting jetting pulse frequencies of at least 15 KHz per nozzle (enabling high speed inkjet printing applications of at least 0.6 m / sec per individual nozzle row per print head), and enabling uninterrupted, industrial level print output of magnetic ink character recognition (MICR) code lines suitable for high speed magnetic data scanning per established industry regulations (ANSI X9).

Owner:VILLWOCK THOMAS

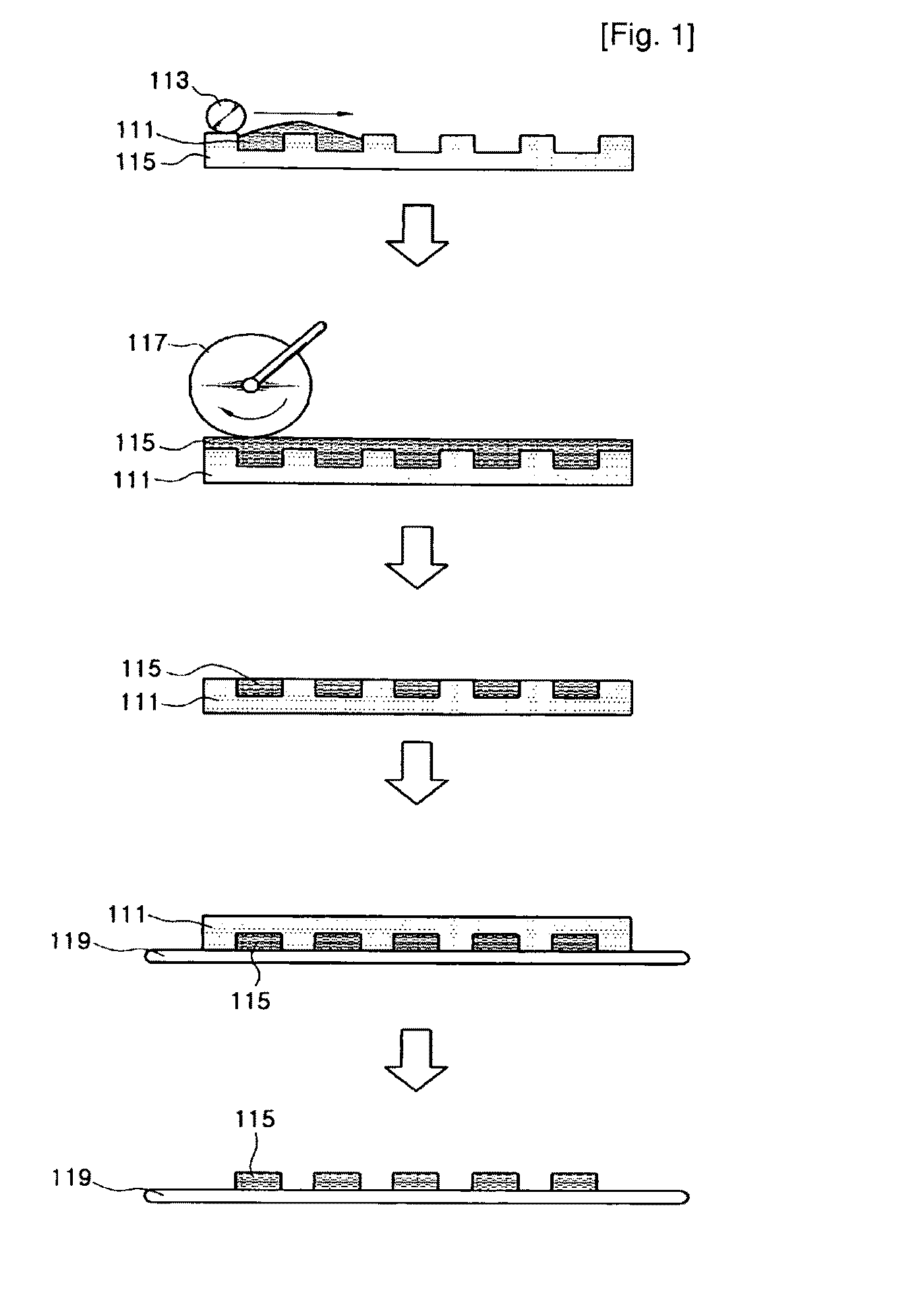

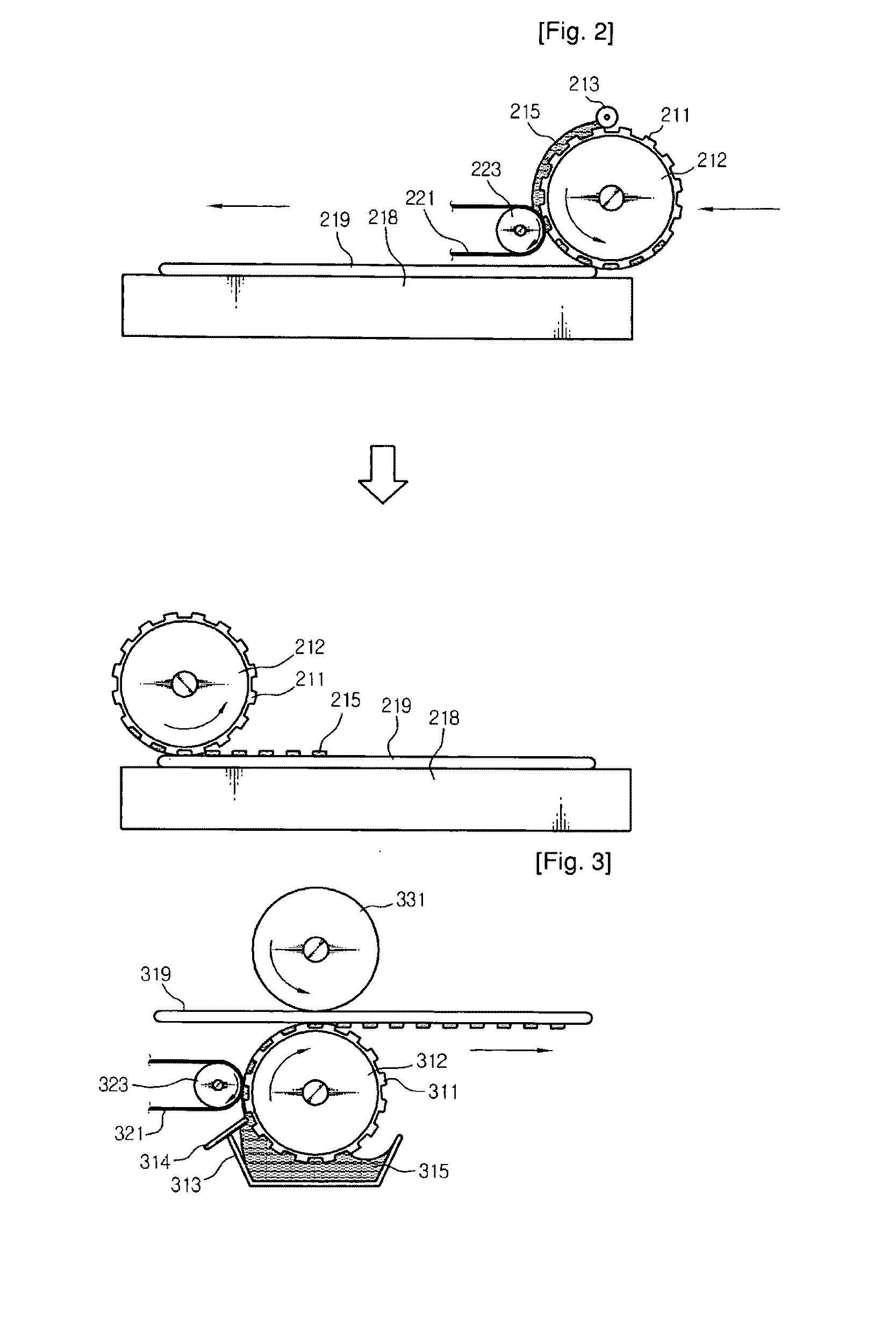

Method of printing fine patterns by intaglio printing and printing system for printing fine patterns by intaglio printing

InactiveUS20100089262A1Efficient removalQuality improvementCylinder pressesRotary intaglio printing pressSimple Organic CompoundsPolymer resin

A method of printing fine patterns prints a fine pattern on a substrate using an elastic mold with an intaglio pattern. This method includes applying a fine pattern printing ink to a surface of a patterned elastic mold; removing the ink applied to an embossed portion of the elastic mold by closely adhering an ink removing unit having a polymer resin or an organic compound with a surface energy from <a surface energy of the ink−2 erg / cm2> to <the surface energy of the ink+erg / cm> to the surface of the elastic mold and then detaching the ink removing unit therefrom; and closely adhering the elastic mold to a substrate to transcribe the printing ink thereto. This method allows forming a fine pattern with good quality since the ink applied to the embossed portion of the elastic mold may be effectively removed during a gravure process.

Owner:LG CHEM LTD

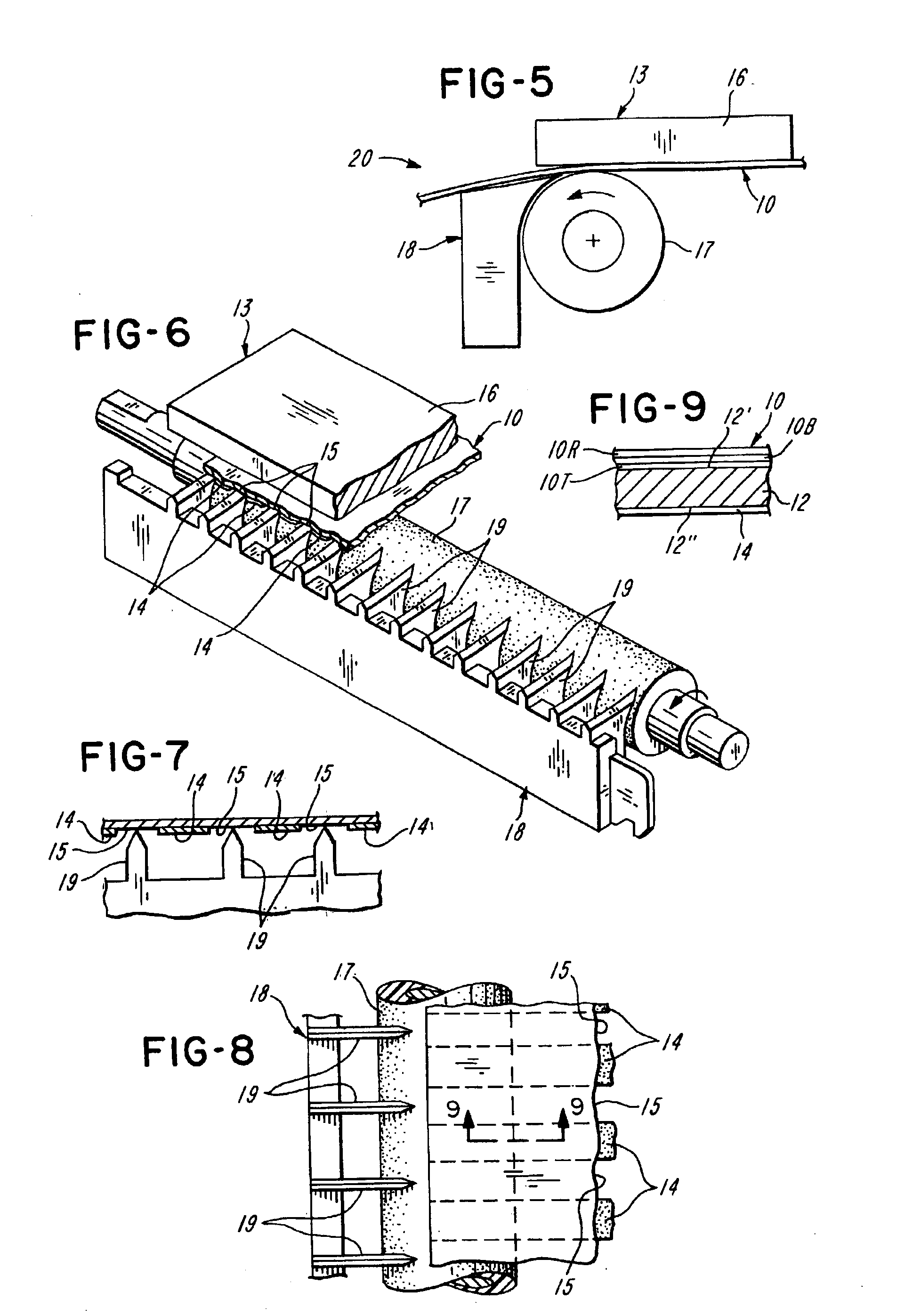

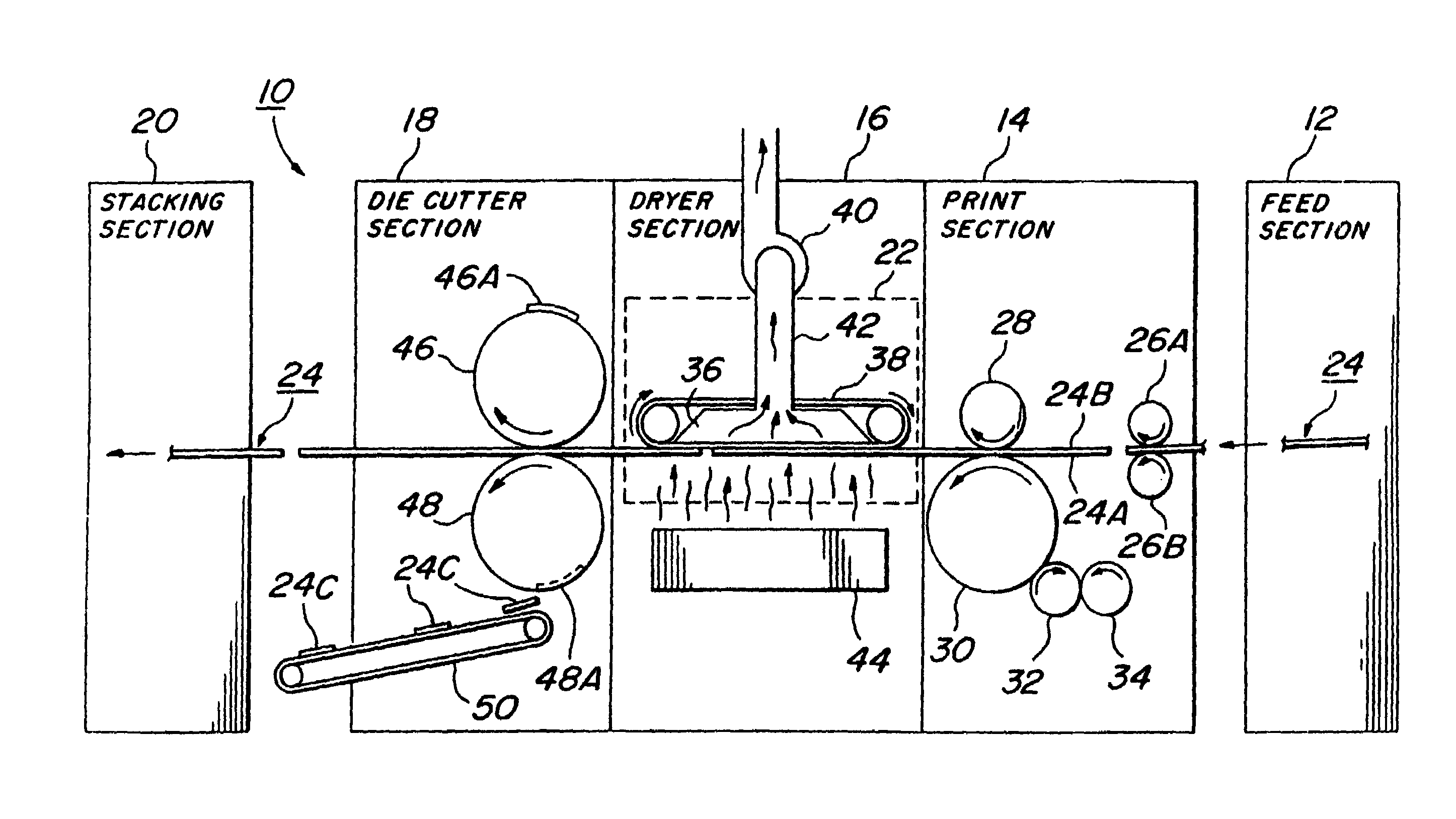

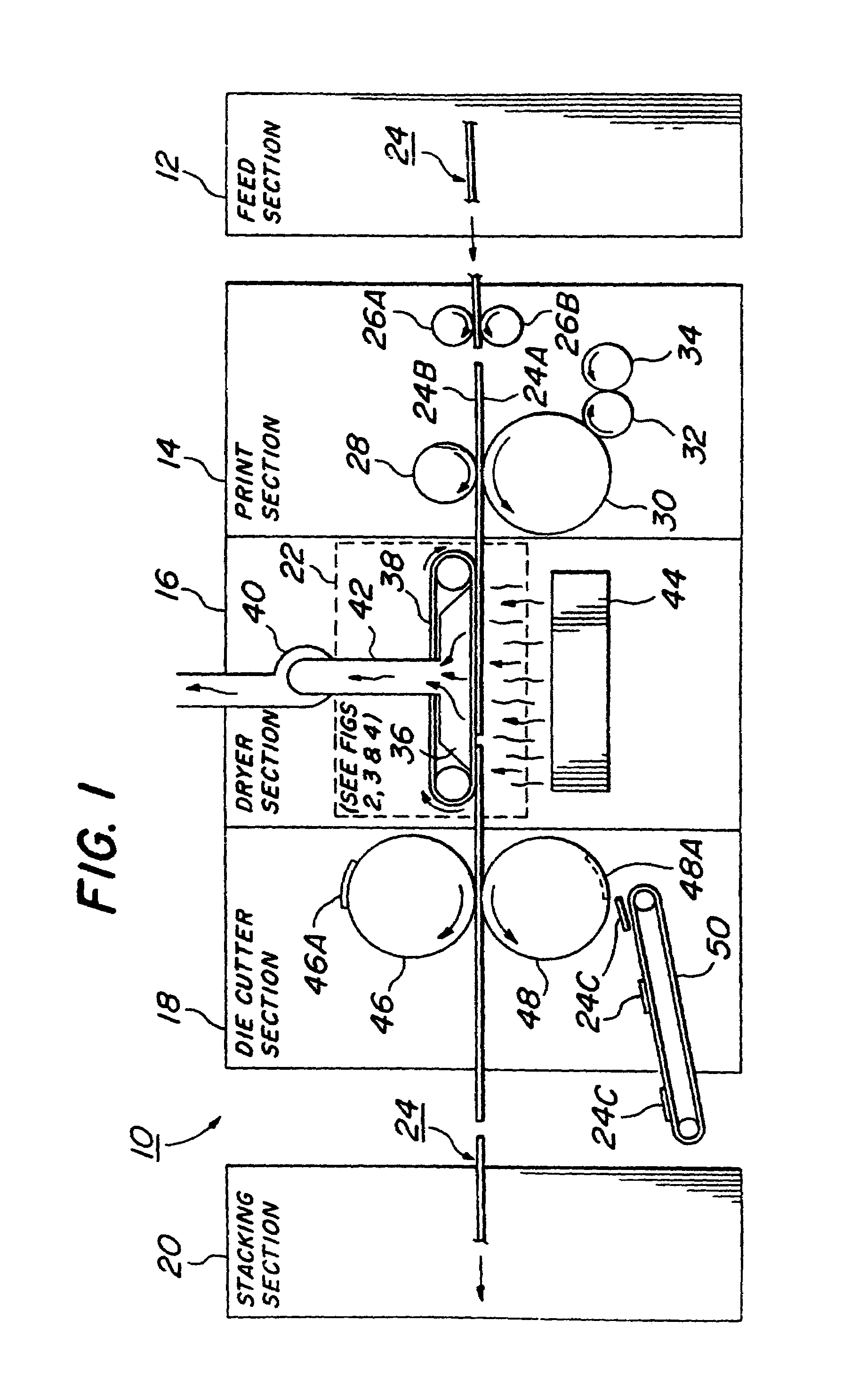

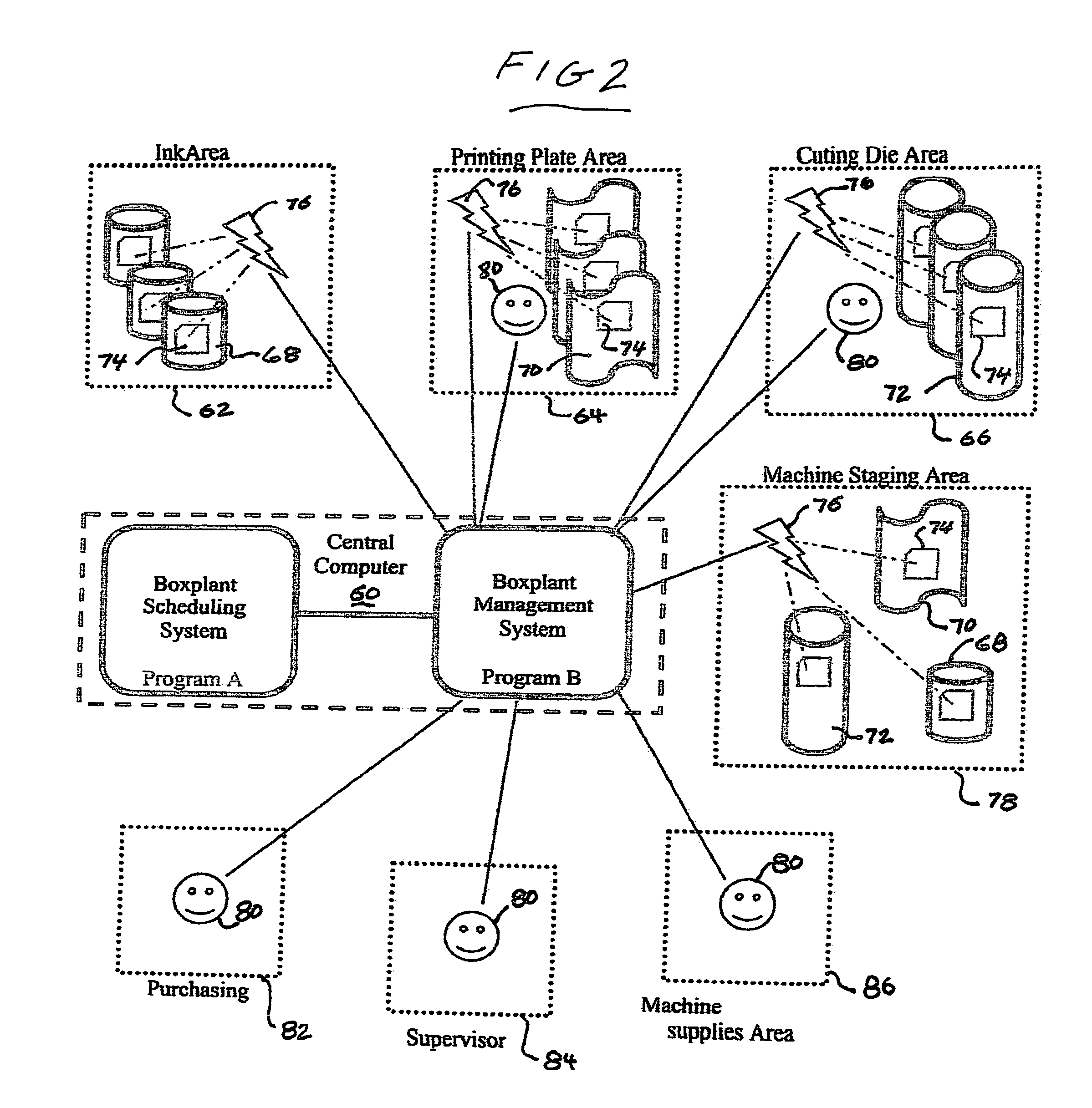

Method and apparatus for managing box-finishing machine

A computer network is used to manage and monitor operation of a box-finishing machine which prints information on and cuts or creases corrugated boards to be formed into boxes. The equipment used on the machine is provided with radio frequency information tags detected by an electronic reader which transmits the identification to a computer so that it can be determined by an operator that sufficient equipment is in storage and staging areas for use on the machine. Several computer terminals are provided at different areas throughout a plant so that access is easily provided to different personnel.

Owner:SUN AUTOMATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com