Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1487 results about "Hindered amine light stabilizers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

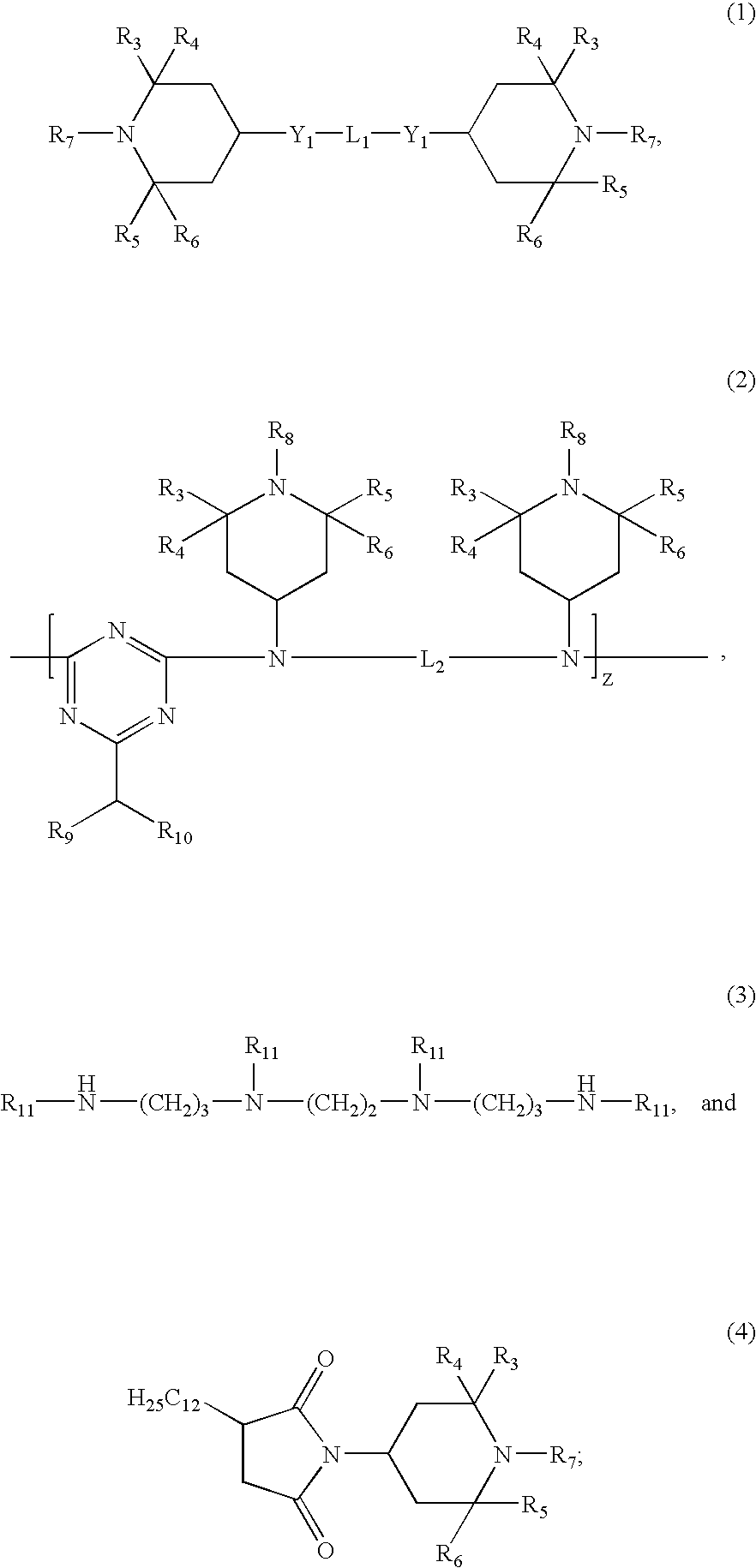

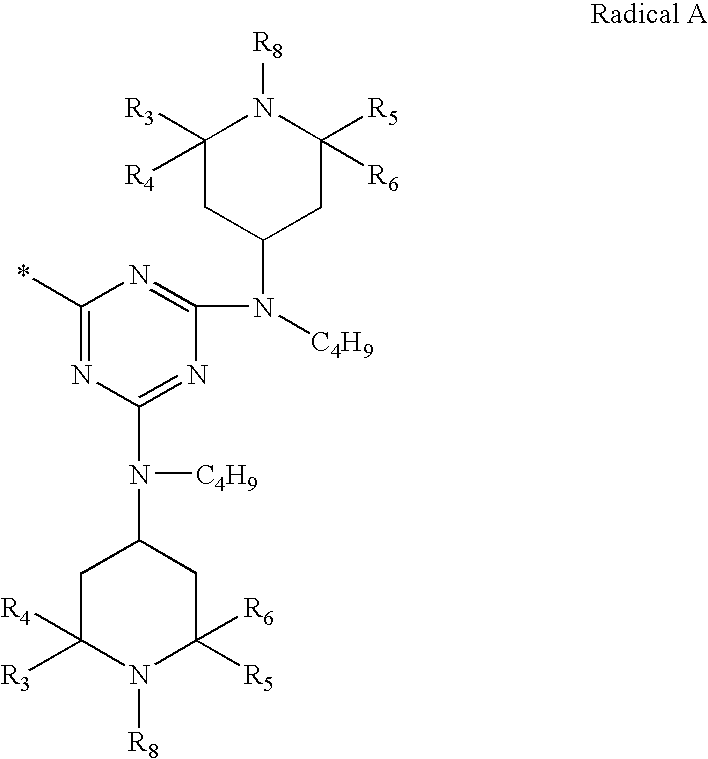

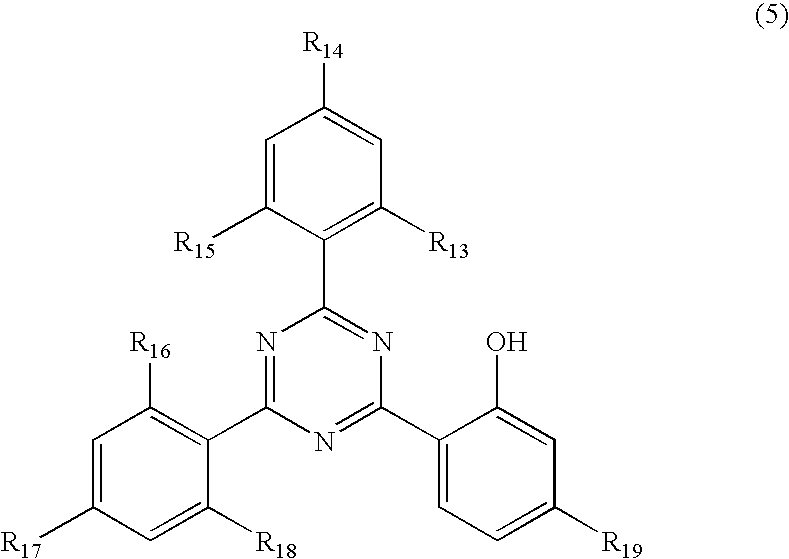

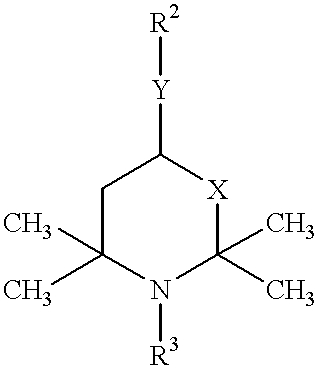

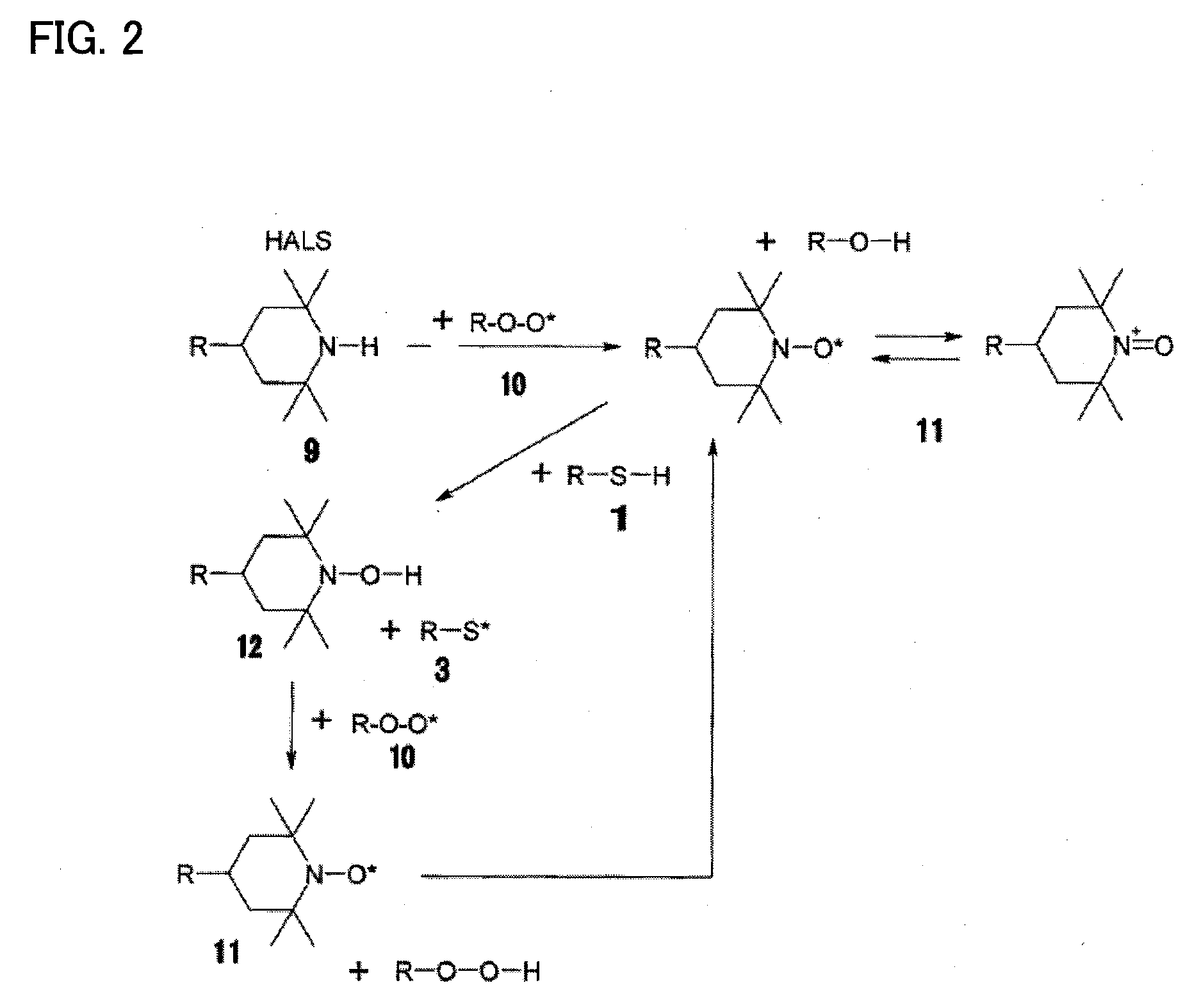

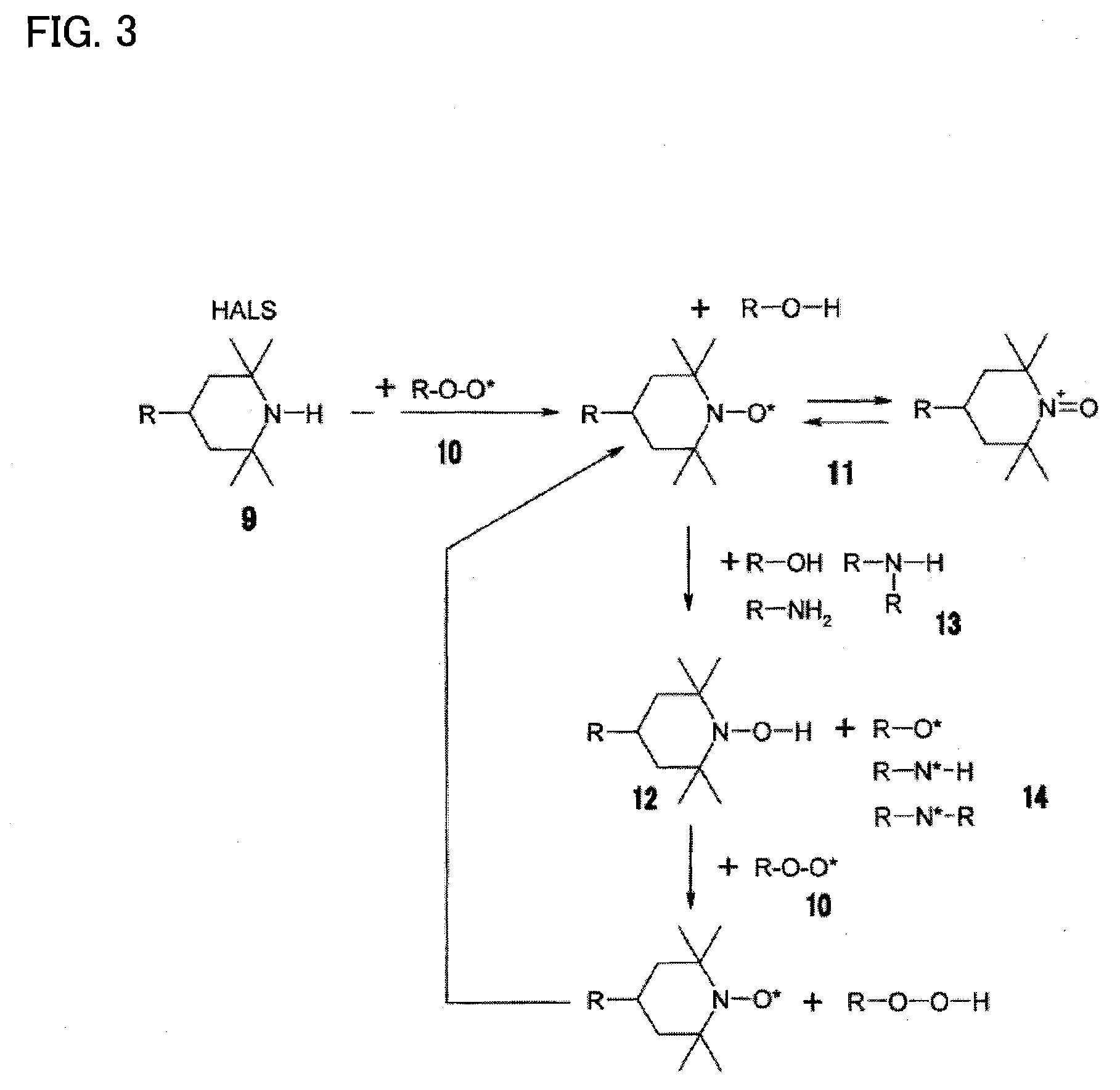

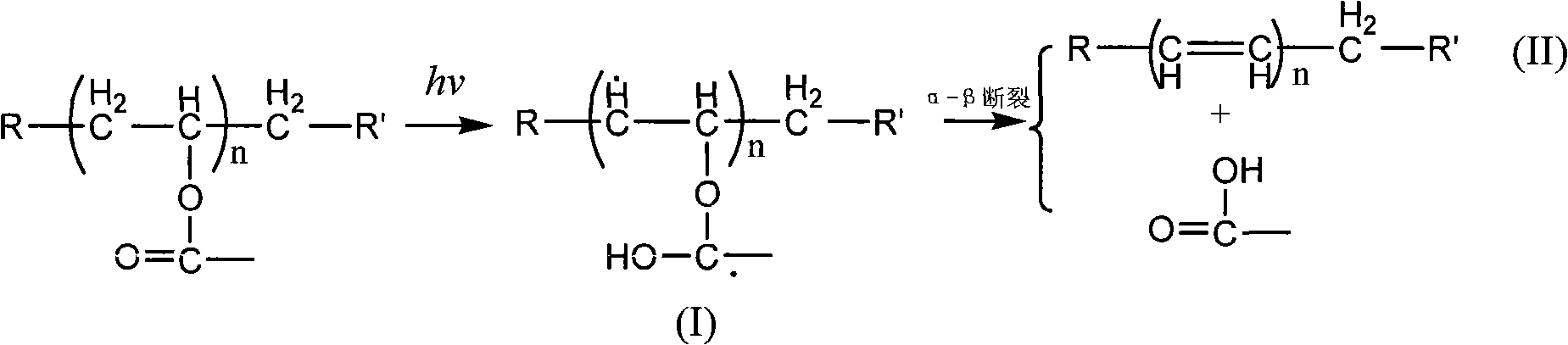

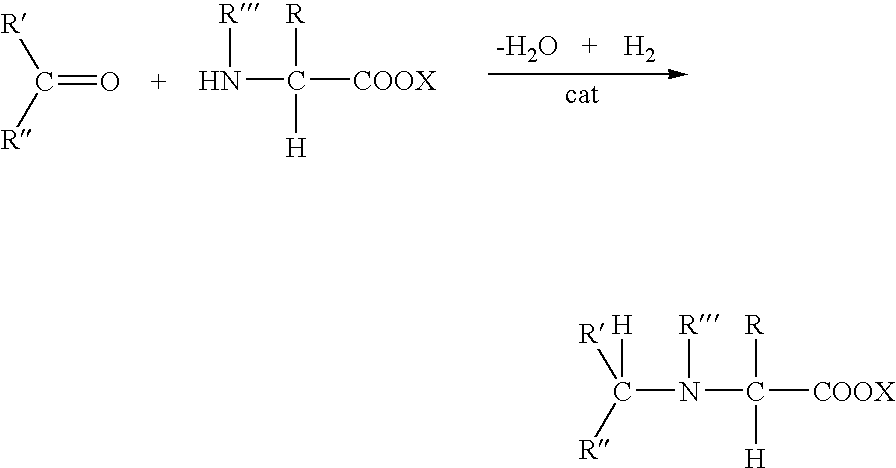

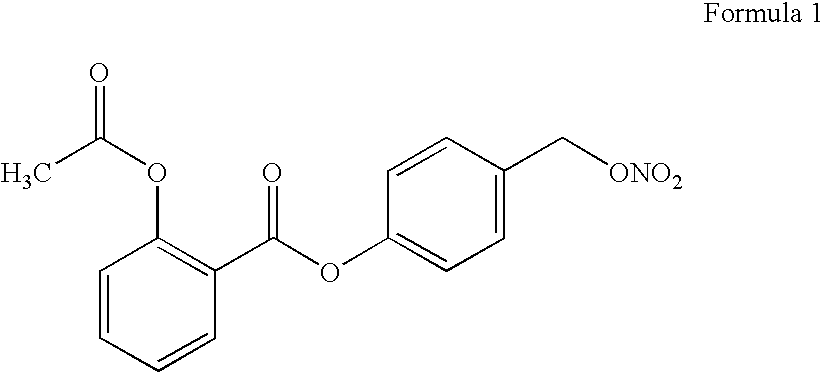

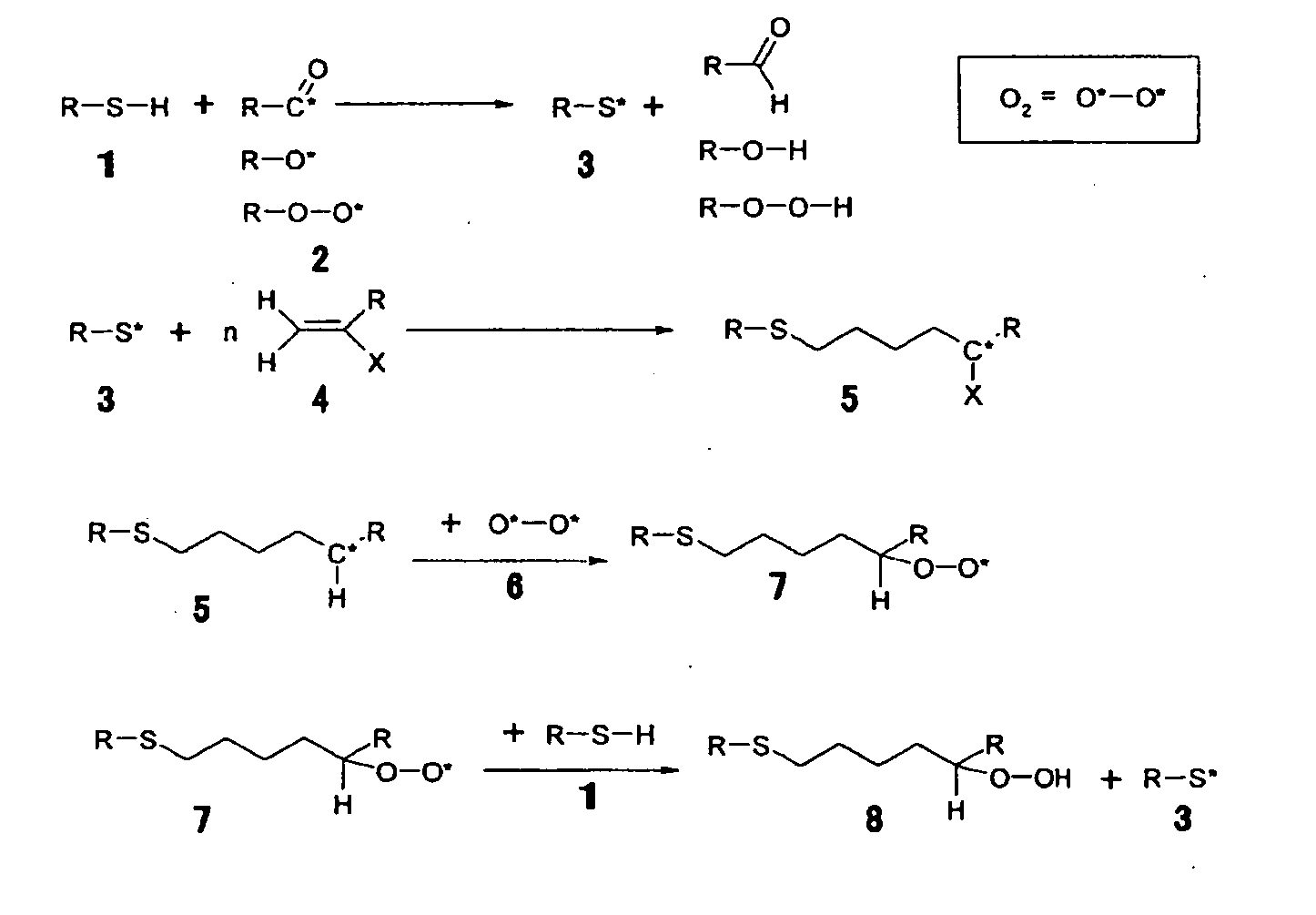

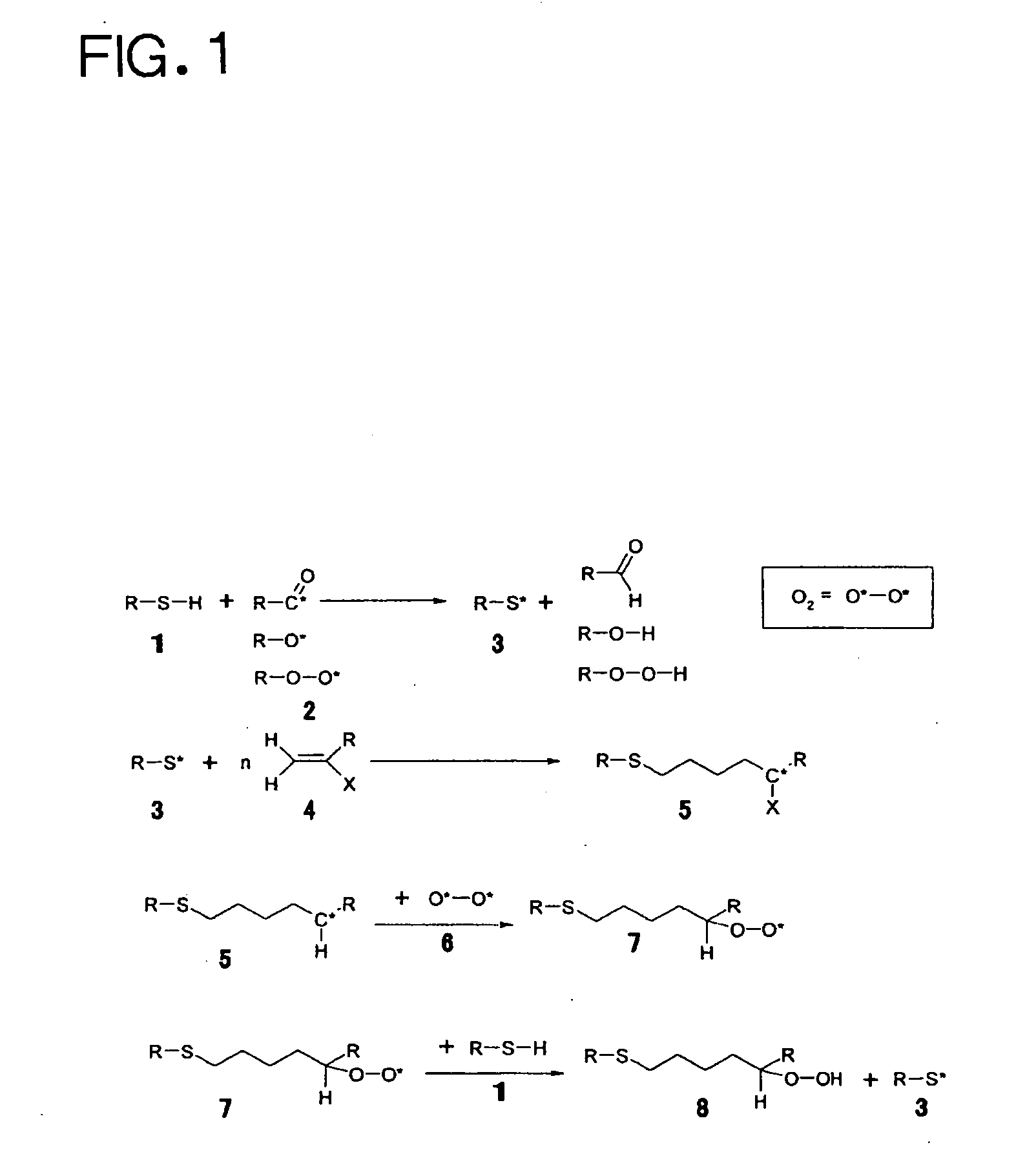

Hindered amine light stabilizers (HALS) are chemical compounds containing an amine functional group that are used as stabilizers in plastics and polymers. These compounds are typically derivatives of tetramethylpiperidine and are primarily used to protect the polymers from the effects of photo-oxidation; as opposed to other forms of polymer degradation such as ozonolysis. They are also increasingly being used as thermal stabilizers, particularly for low and moderate level of heat, however during the high temperature processing of polymers (e.g. injection moulding) they remain less effective than traditional phenolic antioxidants.

Stabilized aliphatic polyester compositions

Disclosed are stabilized aliphatic polyester compositions comprising an aliphatic polyester, a HALS, and a tris-aryl-S-triazine UV absorber that show low embrittlement, haze formation, and discoloration during weathering. Also disclosed are aliphatic polyester compositions comprising aliphatic polyester, a hindered amine light stabilizer, a triazine UV absorber, and a phosphite that exhibit low color prior to weathering but retain good clarity, color, and excellent impact strength after exposure to weathering conditions. The aliphatic polyester compositions may be used prepare shaped articles such as, for example, films, sheets, bottles, tubes, profiles, fibers, and molded articles.

Owner:EASTMAN CHEM CO

Thermoplastic resin compositions suitable for use in transparent laminates

InactiveUS20070289693A1Synthetic resin layered productsGlass/slag layered productsClear LayerPolymer science

The present invention is an improved polymeric resin composition comprising units derived from ethylene, from about 20 wt % to about 30 wt % units derived from an α,β-unsaturated carboxylic acid having from 3 to 8 carbons, and optionally an effective amount of at least one additive selected from the group consisting of hindered amine light stabilizers, UV light absorbers, and thermal stabilizers. Resins of the present invention are particularly suitable for preparing transparent laminates useful as glazing elements that provide a greater measure of safety than non-laminated glazing elements.

Owner:EI DU PONT DE NEMOURS & CO

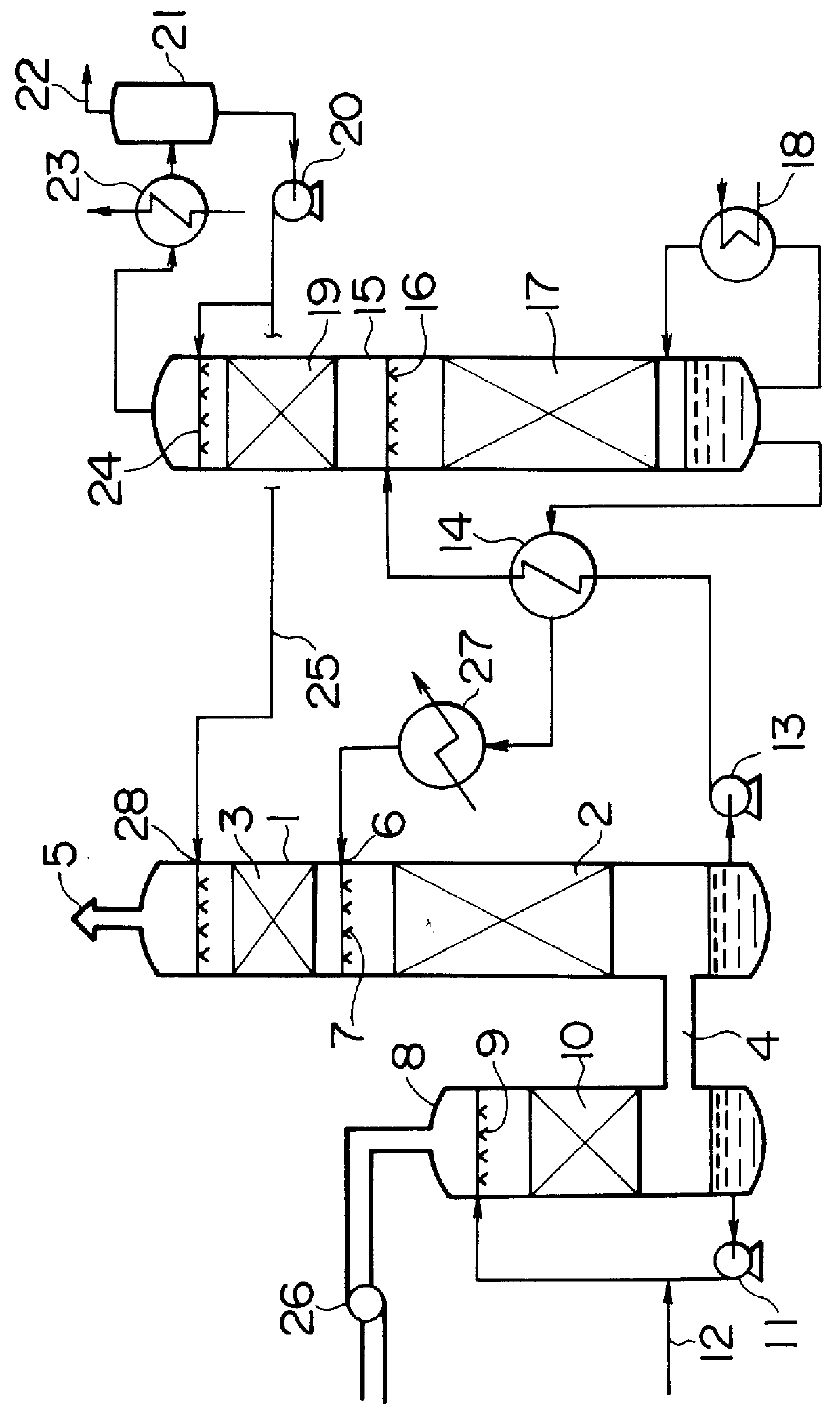

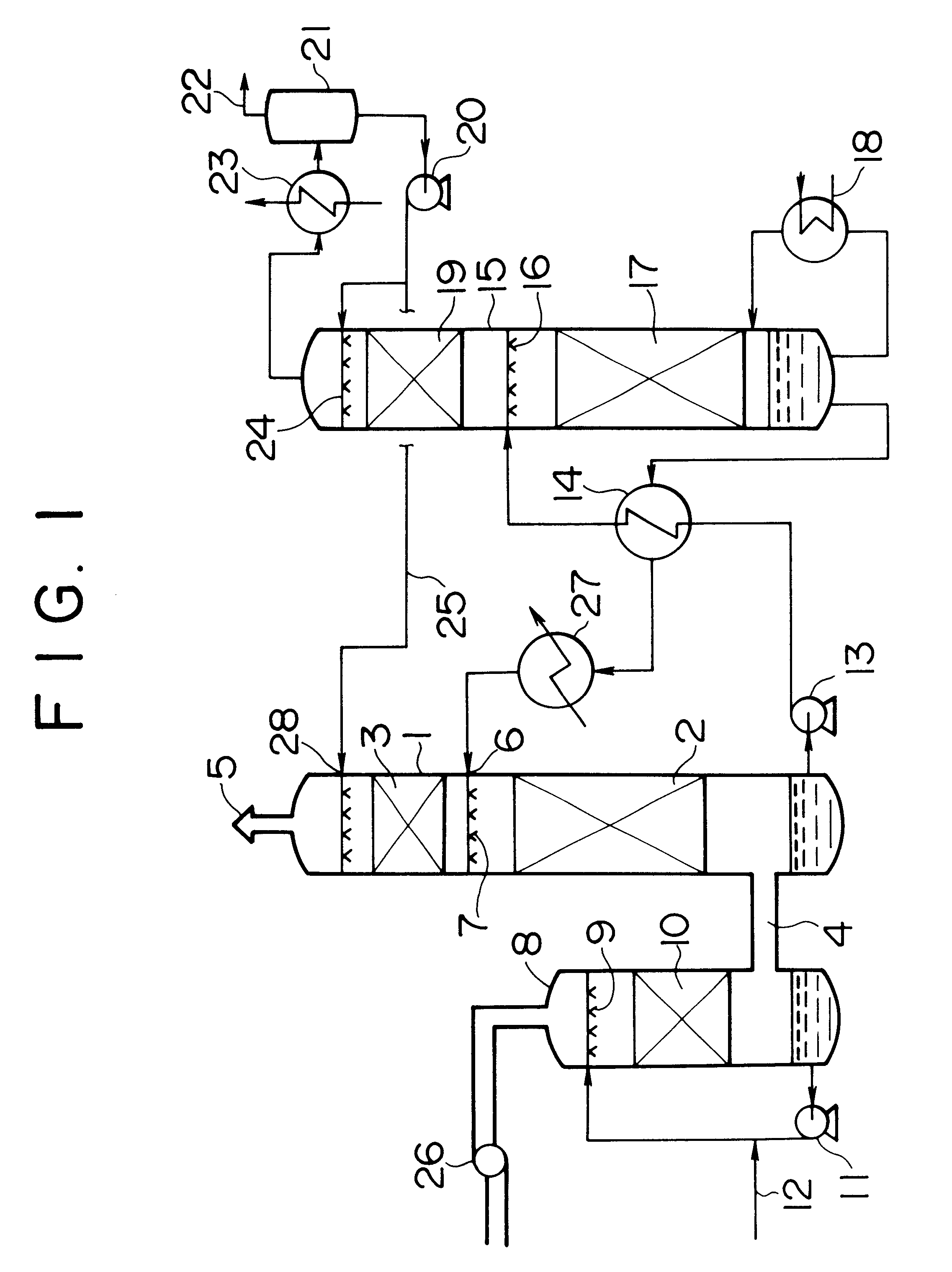

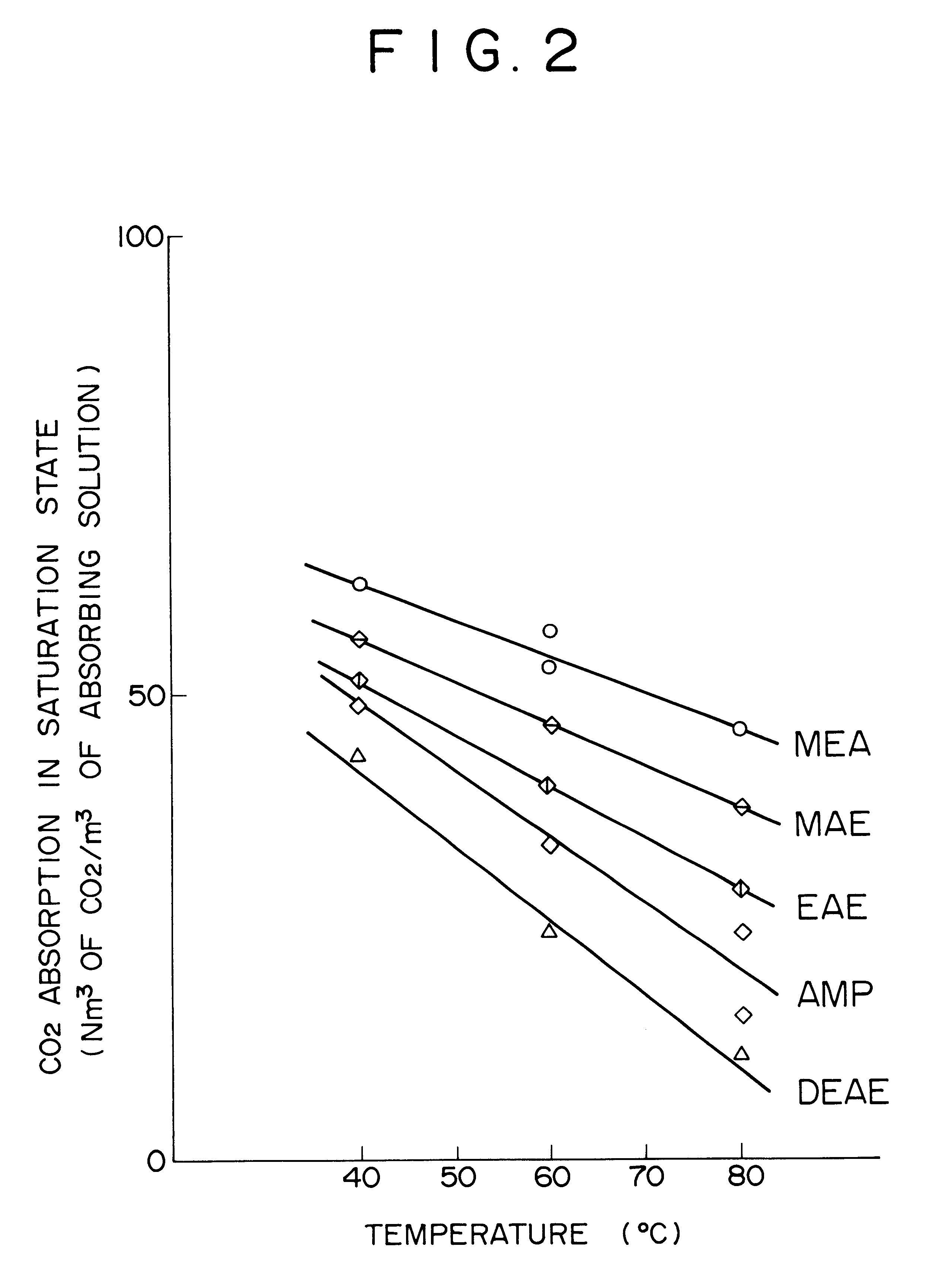

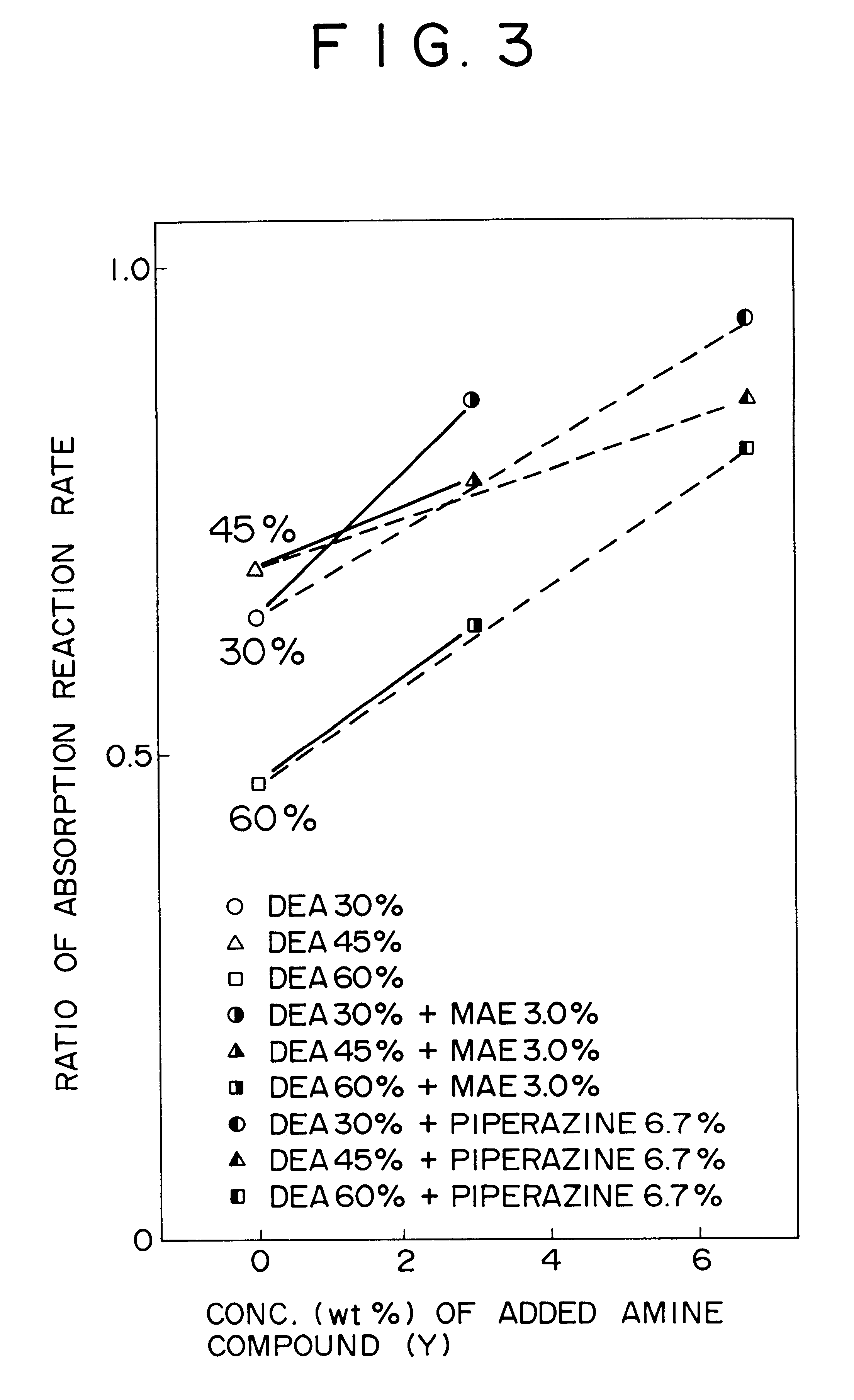

Method for removing carbon dioxide from combustion exhaust gas

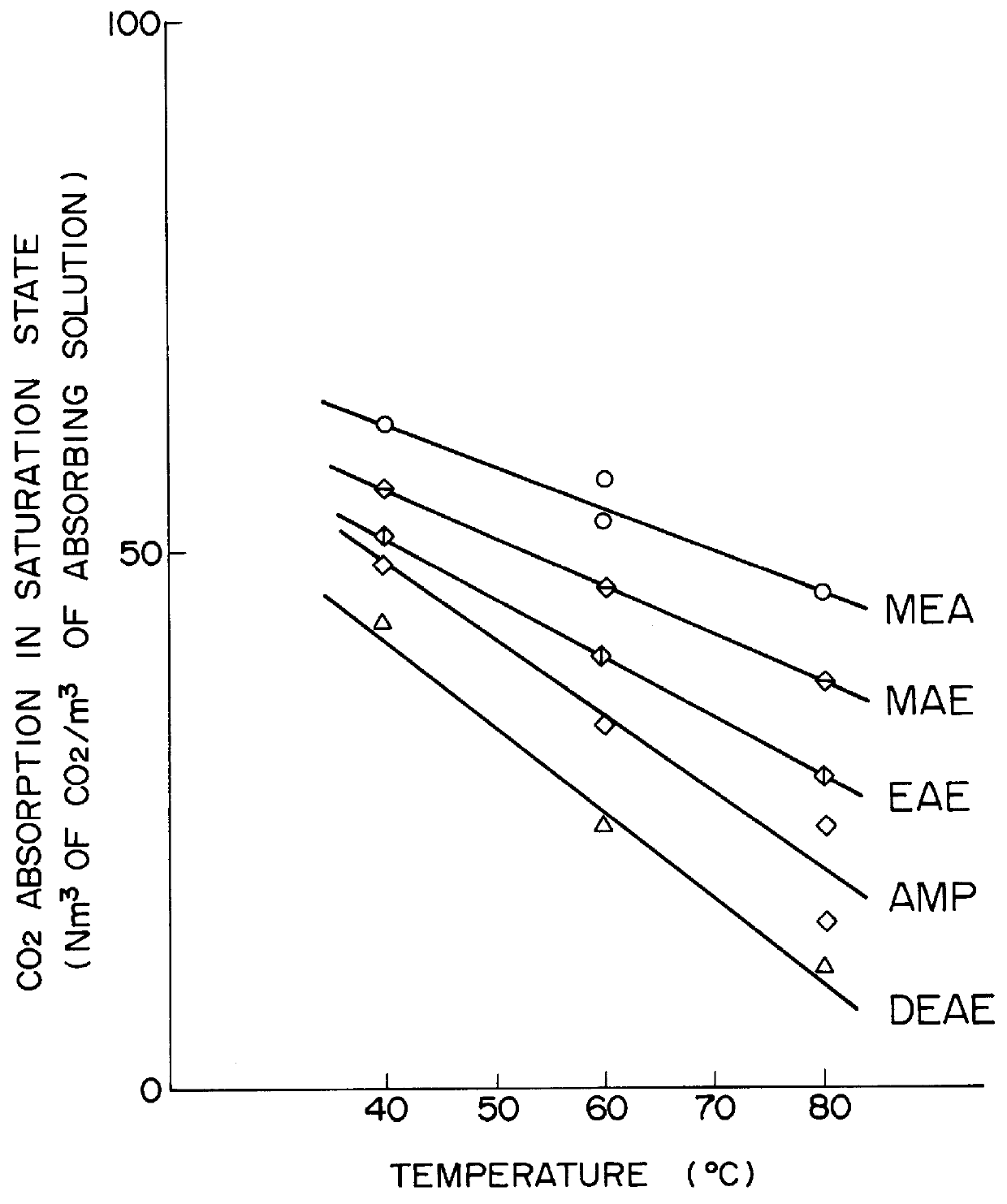

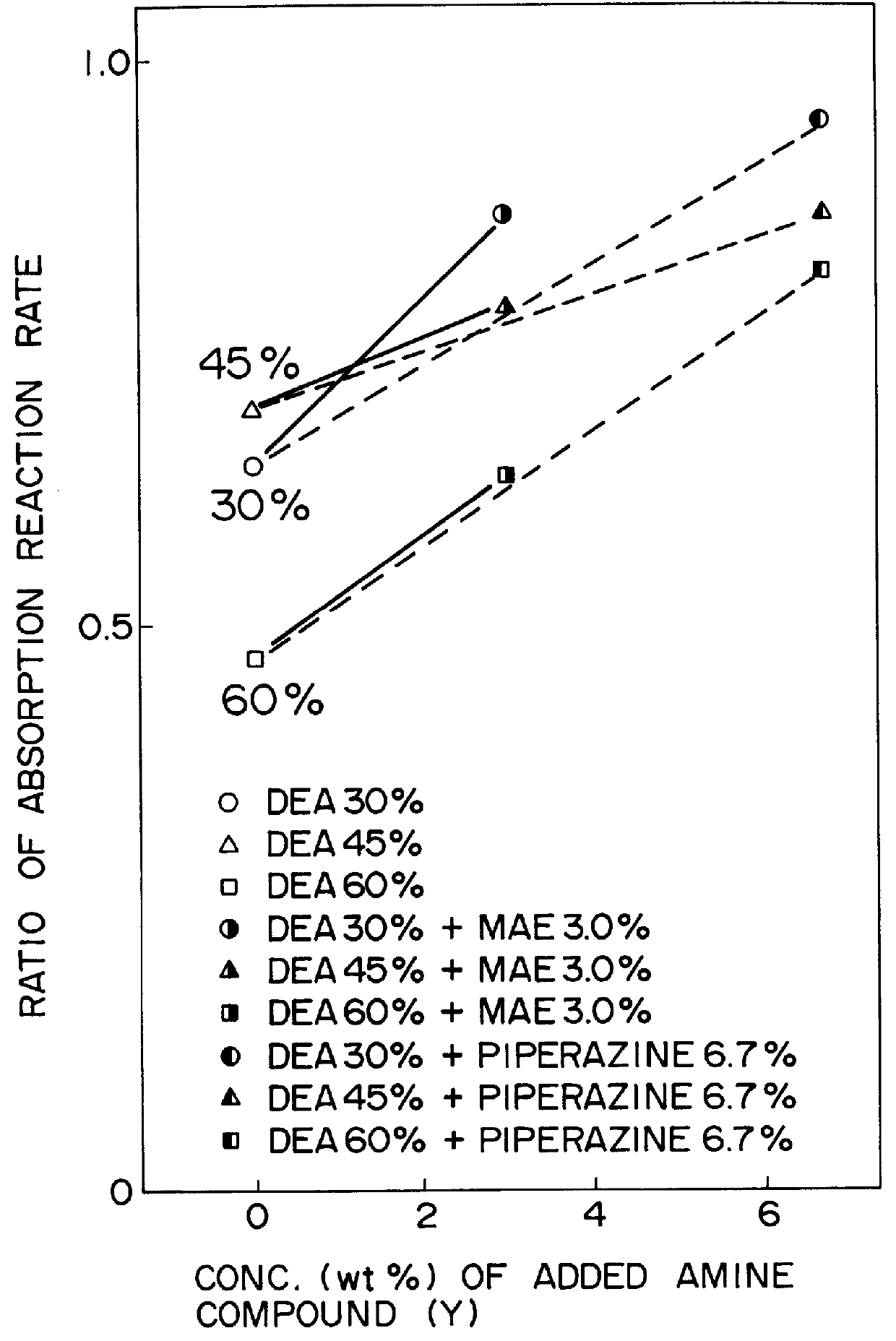

InactiveUS6036931AHigh absorption rateImprove absorption rateDispersed particle separationHydrogen sulfides2-methylaminoethanolMorpholine

There are disclosed a method for removing CO2 from a combustion exhaust gas which comprises the step of bringing the combustion exhaust gas under atmospheric pressure into contact with an aqueous solution of a hindered amine selected from the group consisting of 2-amino-2-methyl-1-propanol, 2-methylaminoethanol, 2-ethylaminoethanol and 2-piperidineethanol; and another method for removing carbon dioxide from a combustion exhaust gas which comprises the step of bringing the combustion exhaust gas under atmospheric pressure into contact with a mixed aqueous solution of 100 parts by weight of an amine compound (X) selected from the group consisting of 2-amino-2-methyl-1,3-propanediol, 2-amino-2-methyl-1-propanol, 2-amino-2-ethyl-1,3-propanediol, t-butyldiethanolamine and 2-amino-2-hydroxymethyl-1,3-propanediol; and 1-25 parts by weight of an amine compound (Y) selected from the group consisting of piperazine, piperidine, morpholine, glycine, 2-methylaminoethanol, 2-piperidineethanol and 2-ethylaminoethanol.

Owner:THE KANSAI ELECTRIC POWER CO +1

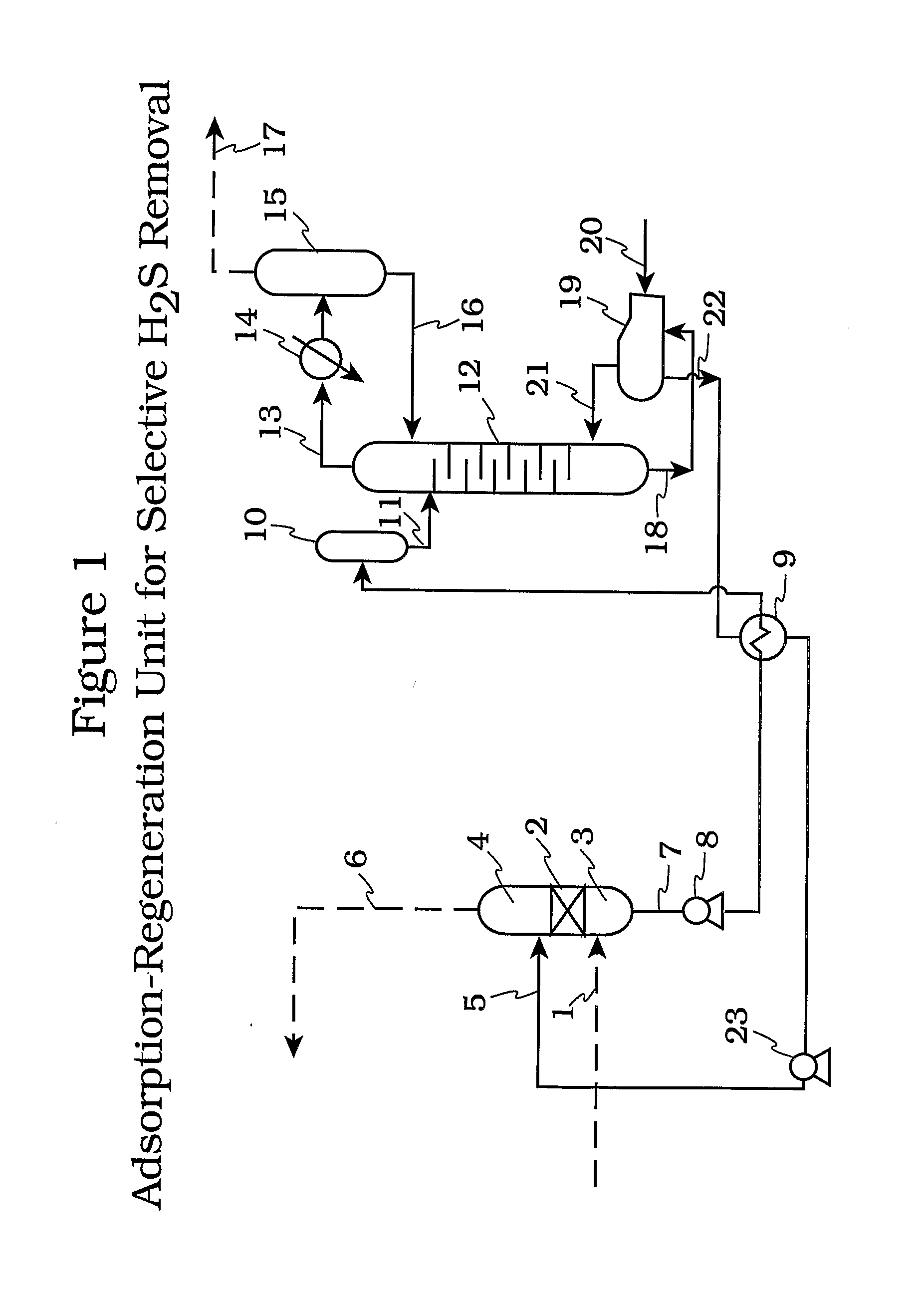

Absorbent composition containing molecules with a hindered amine and a metal sulfonate, phosphonate or carboxylate structure for acid gas scrubbing process

An acid gas absorbent comprising a metal sulfonate, phosphonate or carboxylate of a hindered amine and a process for the selective removal Of H2S as well as other acidic components such as carbon disulfide, carbonyl sulfide and oxygen and sulfur derivatives of C1 to C4 hydrocarbons from mixtures containing such acidic components and CO2 using said absorbent.

Owner:EXXON RES & ENG CO

Moisture curable polyolefin compositions

Owner:NIPPON YUNIKAA

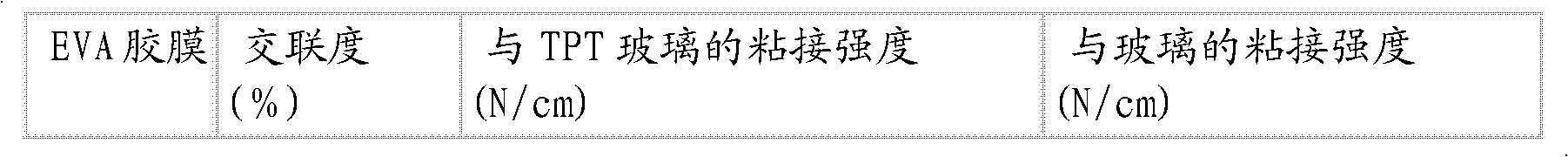

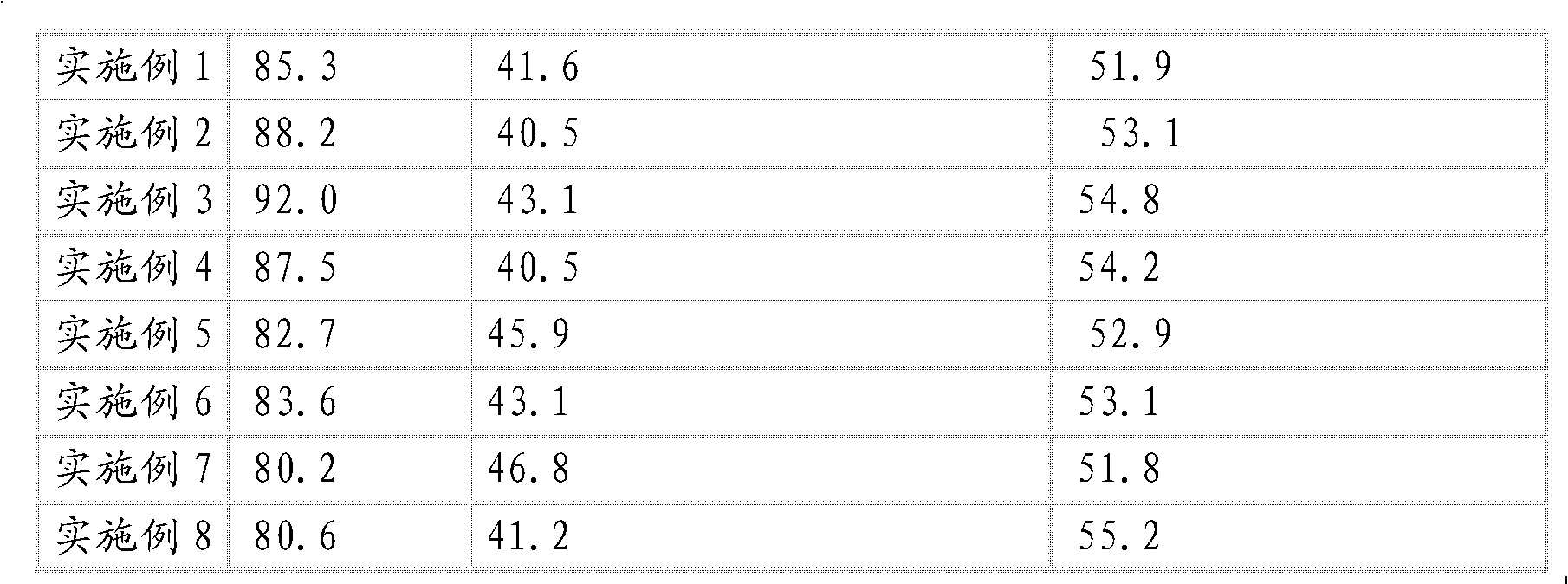

EVA (ethylene vinyl acetate) adhesive film for solar cells

InactiveCN102504715AFast curingIncrease productivityNon-macromolecular adhesive additivesFilm/foil adhesivesSolventHindered amine light stabilizers

The invention relates to an EVA (ethylene vinyl acetate) adhesive film for solar cells, which comprise ethylene vinyl acetate copolymer, silane coupling agent, cross-linked curing agent, cross-linking curing accelerator, thermal stabilizer, tackifier, antioxidant, ultraviolet absorbent, and hindered amine light stabilizer. Compared with the prior art and similar products, the EVA adhesive film for solar cells has great competition potential in terms of various indexes such as production formula, production process, properties and the like. A novel formula is used to prolong service life of the EVA adhesive film firstly, quick curing performance of the EVA adhesive film is improved so that production efficiency of cell package is benefited, using novel solvent to dissolve aids solves the quality problem caused by uneven mixing of the aids and particles in production, and by using the produced low-contraction-ratio EVA adhesive film, possibility of cell breakage in cell packaging can be lowered.

Owner:NINGBO HUAFENG PACKAGE

Method for removing carbon dioxide from combustion exhaust gas

InactiveUS6500397B1Improve absorption rateHigh absorption rateHydrogen sulfidesDispersed particle separation2-methylaminoethanolMorpholine

There are disclosed a method for removing CO2 from a combustion exhaust gas which comprises the step of bringing the combustion exhaust gas under atmospheric pressure into contact with an aqueous solution of a hindered amine selected from the group consisting of 2-amino-2-methyl-1-propanol, 2-methylaminoethanol, 2-ethylamino-ethanol and 2-piperidineethanol; and another method for removing carbon dioxide from a combustion exhaust gas which comprises the step of bringing the combustion exhaust gas under atmospheric pressure into contact with a mixed aqueous solution of 100 parts by weight of an amine compound (X) selected from the group consisting of 2-amino-2-methyl-1, 3-propanediol, 2-amino-2-methyl-1-propanol, 2-amino-2-ethyl-1, 3-propanediol, t-butyldiethanolamine and 2-amino-2-hydroxymethyl-1,3-propanediol; and 1-25 parts by weight of an amine compound (Y) selected from the group consisting of piperazine, piperidine, morpholine, glycine, 2-methylamino-ethanol, 2-piperidineethanol and 2-ethylaminoethanol.

Owner:THE KANSAI ELECTRIC POWER CO +1

Method for forming cured product from photocurable composition and cured product

InactiveUS20090093564A1Reduce energy consumptionReduce output powerImpression capsPretreated surfacesHydrogenHindered amine light stabilizers

A method for forming a cured product includes applying a photocurable composition to a base and irradiating the photocurable composition with light from a light source to cure the photocurable composition. The light source is at least one of a fluorescent lamp and a light-emitting diode. The photocurable composition contains a dendritic polymer, a polymerizable compound containing active hydrogen, a photopolymerization initiator, and a hindered amine light stabilizer.

Owner:SEIKO EPSON CORP

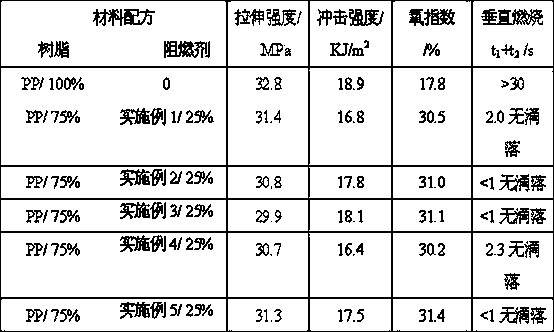

Composite flame retardant containing microcapsule-coated intumescent flame retardant and preparation method

InactiveCN103724666AHigh flame retardant efficiencyOvercome moisture absorptionPolymer scienceHindered amine light stabilizers

The invention belongs to the field of flame retardant materials, and particularly relates to a composite flame retardant containing a microcapsule-coated intumescent flame retardant and a preparation method. The composite flame retardant containing the microcapsule-coated intumescent flame retardant consists of the following components in percentage by mass: 60-94 percent of microcapsule intumescent flame retardant, 5-25 percent of flame-retardant synergist, 0.9-10 percent of smoke suppressant and 0.1-5 percent of hindered amine light stabilizer. The preparation method comprises the following steps: preparing the microcapsule-coated intumescent flame retardant; placing the microcapsule-coated intumescent flame retardant, the flame-retardant synergist, the smoke suppressant and the hindered amine light stabilizer into a high-speed mixer for mixing uniformly, and discharging to obtain the composite flame retardant containing the microcapsule-coated intumescent flame retardant. Multiple components in the composite flame retardant can play roles in retarding flame in a synergetic way, so that the flame retardance of a high polymer material is improved remarkably, the production of toxic and harmful smog in a burning process can be suppressed, and the flame retarding efficiency is increased greatly.

Owner:LIAONING TECHNICAL UNIVERSITY

Flame retardant compositions

Organic polymeric substrates, for example polyolefins such as polypropylene, can be made flame retardant by the incorporation of a synergistic mixture of (i.) a sterically hindered amine of the nitroxyl, hydroxylamine, alkoxyamine or hydroxyalkoxyamine class, and (ii.) a fluorinated polyolefin. Advantageously, a further flame retardant may be added, without the need of adding an antimony synergist. The compositions of the invention combine good flame retardant properties with light stability and good mechanical properties.

Owner:CIBA SPECIALTY CHEM CORP

Polyolefin-Based Crosslinked Articles

ActiveUS20090298964A1Excellent set propertyHigh tensile strengthImpression capsElectric discharge tubesElastomerFiber

Methods for making a crosslinked elastomeric composition and articles made of the same are provided. In at least one specific embodiment, an elastomeric composition comprising at least one propylene-based polymer is blended with at least one component selected from the group consisting of multifunctional acrylates, multifunctional methacrylates, functionalized polybutadiene resins, functionalized cyanurate, and allyl isocyanurate; and blended with at least one component selected from the group consisting of hindered phenols, phosphites, and hindered amines. The propylene-based polymer can include propylene derived units and one or more dienes, and have a triad tacticity of from 50% to 99% and a heat of fusion of less than 80 J / g. The blended composition can then be extruded and crosslinked. The extruded polymer can be crosslinked using electron beam radiation having an e-beam dose of about 100 KGy or less. The crosslinked polymers are particularly useful for making fibers and films.

Owner:EXXONMOBIL CHEM PAT INC

Energy ray-curable ink composition

ActiveUS20090197988A1Improve adhesionExcellent curabilityDuplicating/marking methodsInksHindered amine light stabilizers2,2,6,6-Tetramethylpiperidine

An object of the present invention is to provide an energy ray-curable ink composition which is excellent in curability and adhesion, and is also excellent in storage stability.The present invention relates to an energy ray-curable ink composition comprising a coloring material; a polyfunctional monomer having three or more ethylenical double bonds in one molecule as a polymerizable compound; an α-aminoalkylphenone-based compound and a thioxanthone-based compound as photopolymerization initiators; and a hindered amine-based compound having a 2,2,6,6-tetramethylpiperidinyl group as an antigelling agent.

Owner:MAXELL HLDG LTD

Polyethylene crosslinkable composition

InactiveUS20020169238A1Plastic/resin/waxes insulatorsPower cables1,3,5-TriazineHindered amine light stabilizers

A composition comprising: (a) polyethylene; (b) as a scorch inhibitor, [1,3,5-tris(4-tert-butyl-3-hydroxy-2,6-dimethylbenzyl)-1,3,5-triazine-2,4,6-(1H,3H,5H)-trione]; (c) a thioester; (d) a hindered amine stabilizer; and (e) an organic peroxide.

Owner:UNION CARBIDE CORP

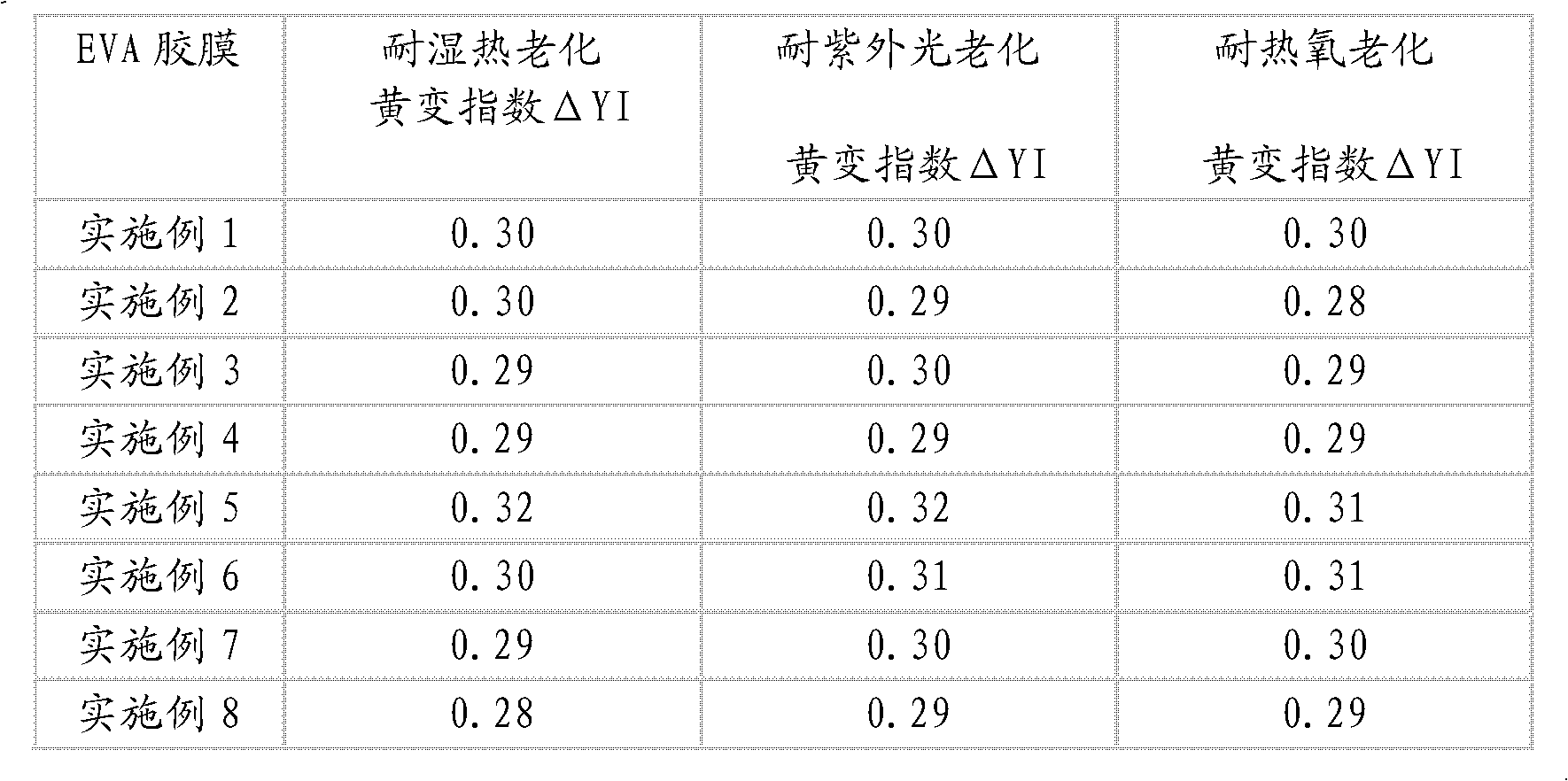

Novel EVA adhesive film

InactiveCN101353558AStrong free radical capture abilityGeneration of blockingFilm/foil adhesivesElectrical equipmentLight energyAdhesive

The invention provides an EVA adhesive film without adding uvioresistant absorbent, which is prepared mainly by the raw materials according to the mass ratio as follows: ethylene-vinyl acetate copolymer, 100 parts; peroxide type crosslinking agent 0.1 to 10 parts, phenolic or phosphite type antioxidant 0.05 to 5 parts; and hindered amine light stabilizer, 0.01 to 5 parts. As the ultraviolet absorbent is not used, the EVA adhesive film obtained does not produce ultra-violet cut-off, leads the solar modules to receive UV district light energy, thereby having higher photoelectric conversion efficiency and excellent uvioresistant anti-aging property, and guaranteeing the service life of PV modules.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

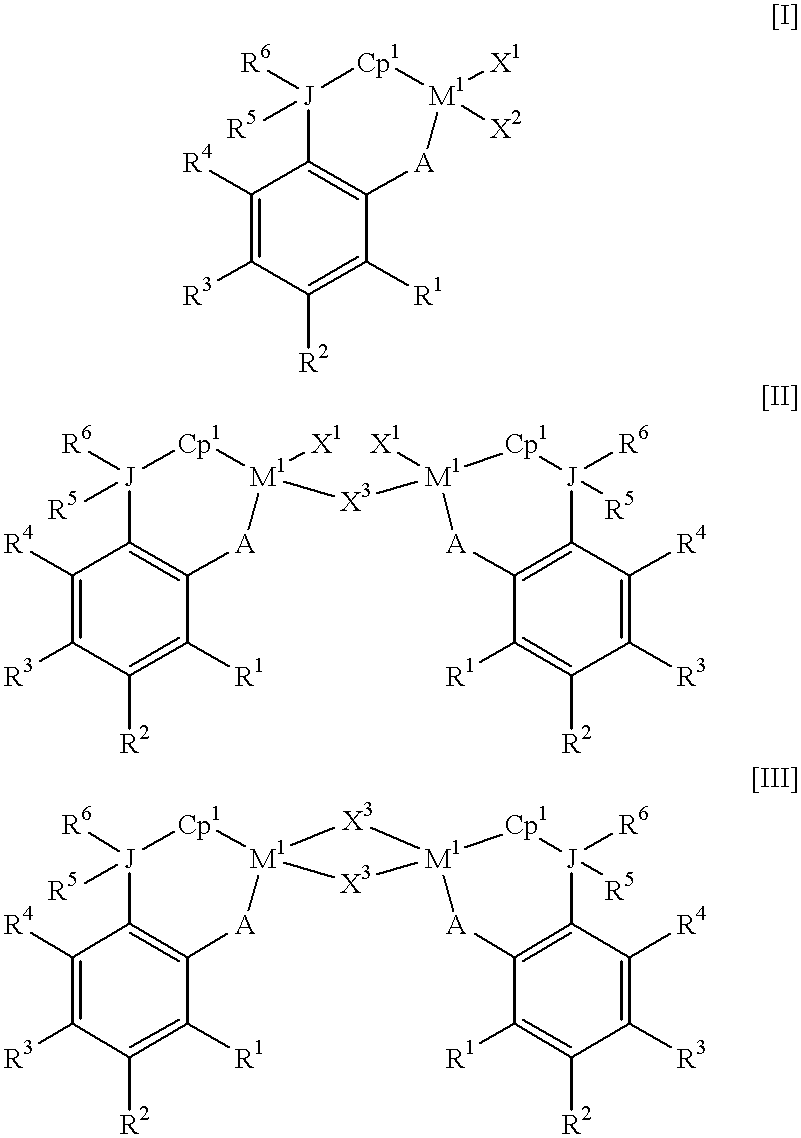

Propylene polymer, propylene block copolymer, process for preparing said polymer and said block copolymer, and propylene polymer composition

InactiveUS20020006993A1High crystallinityLong mesochainLayered productsPolymer scienceHindered amine light stabilizers

Disclosed are a propylene polymer having a high crystallinity of a boiled heptane-insoluble component contained therein, a high stereoregularity and an extremely long mesochain (continuous propylene units wherein directions of alpha-methyl carbons are the same as each other), and a process for preparing said polymer. Also disclosed are a propylene block copolymer containing a crystalline polypropylene portion having a high crystallinity of a boiled heptane-insoluble component contained therein, a high stereoregularity and an extremely long mesochain, and a process for preparing said copolymer. Further disclosed is a propylene polymer composition comprising the above propylene polymer or propylene block copolymer and at least one stabilizer selected from a phenol type stabilizer, an organophosphite type stabilizer, a thioether type stabilizer, a hindered amine type stabilizer and a metallic salt of higher aliphatic acid. The propylene polymer of the invention is excellent in rigidity, heat resistance and moisture resistance, and can be favorably used for sheet, film, filament, injection molded product, blow molded product, etc. The propylene block polymer of the invention is well-balanced between rigidity, heat resistance and moisture resistance, and can be favorably used for sheet, filament, injection molded product, blow molded product, etc. The propylene polymer composition of the invention has excellent properties of the propylene polymer or the propylene block copolymer, and moreover is excellent in heat stability during the molding stage, long-term heat stability and weathering resistance. The propylene polymer composition can be favorably used for sheet, film, filament, injection molded product, blow molded product, etc.

Owner:MITSUI CHEM INC

Aging-resistant EVA film adhesive for solar cell package and method for preparing same

InactiveCN1699458AImprove performanceImprove heat resistanceElectrical equipmentGlass/slag layered productsCross-linkAdhesive

The invention relates to an aging-resistant EVA film adhesive for solar cell package and method for preparation, wherein the preparation constituents include ethane-vinyl acetate copolymer (EVA), cross-linking and curing agent, ultraviolet light absorbent, anti-oxidant, and hindered amine light-stability agent. The preparation comprises the steps of mixing homogeneously, blending extrusion, flow casting the extrudate, cooling down, drawing, and winding.

Owner:SOUTH CHINA UNIV OF TECH

Cement products and methods of making and using the same

InactiveUS20090270527A1Reduce the amount requiredReduce eliminateImpression capsSurgical adhesivesHindered amine light stabilizersBone formation

Disclosed are cement products, methods of forming cement using the cement product, and methods of using the cement product in orthopedic and dental applications. Generally, the disclosed cement product includes a first component and a second component. The first component comprises a polymerizable resin comprising ethylenic unsaturated double bond, a suitable glycidyl group and / or a suitable isocyanate group. The second component includes a compound comprising more than one type of amine selected from the group consisting of primary amine, secondary amines, tertiary amines and quaternary amines. Alternatively, the second component includes a compound comprising a suitable mercapto (SH—) group, a hindered amine or a dimethylthiotoluenediamine (DMTDA). Optionally, the cement product includes a filler and / or a bioactive component to promote bone formation.

Owner:PIONEER SURGICAL TECH INC

Radiation-curable polymerizable composition, ink composition, inkjet recording method, printed material, planographic printing plate, and method for forming planographic printing plate

InactiveUS7900558B2Cylinder pressesLiquid surface applicatorsPolymer scienceHindered amine light stabilizers

Owner:FUJIFILM CORP

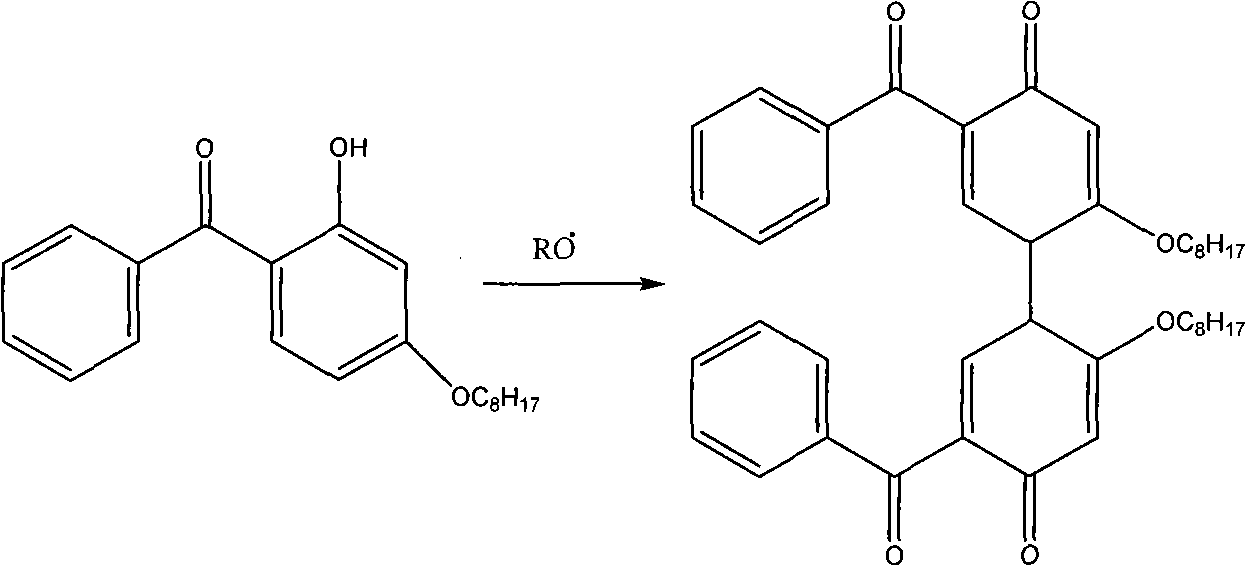

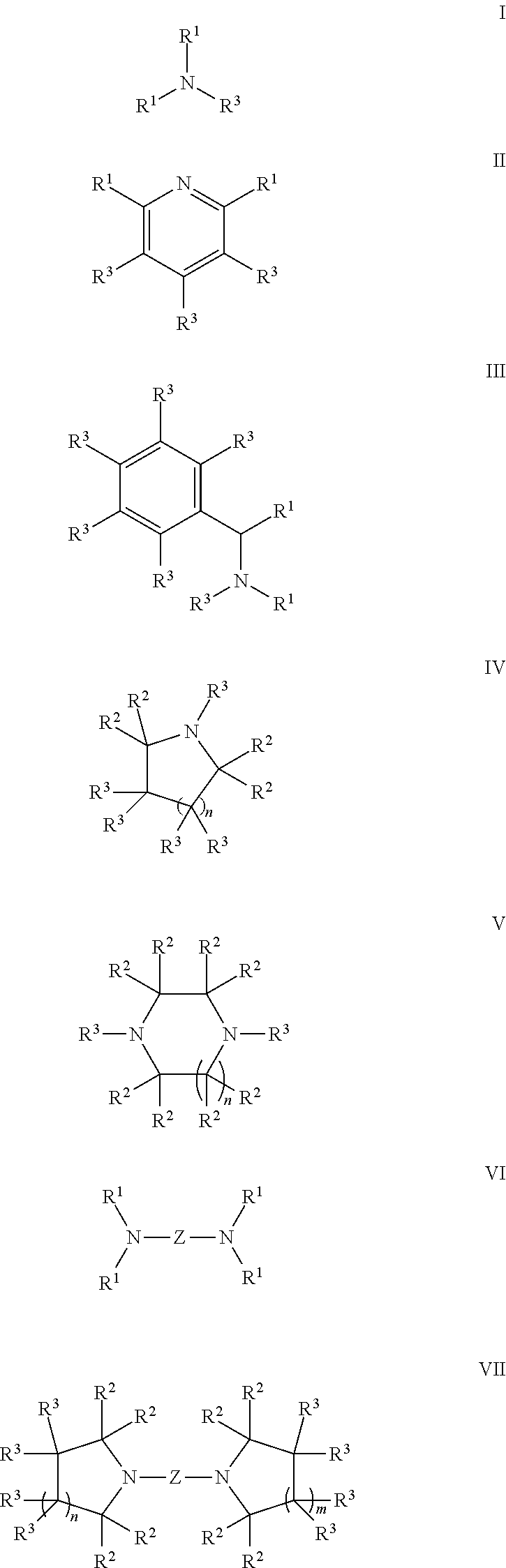

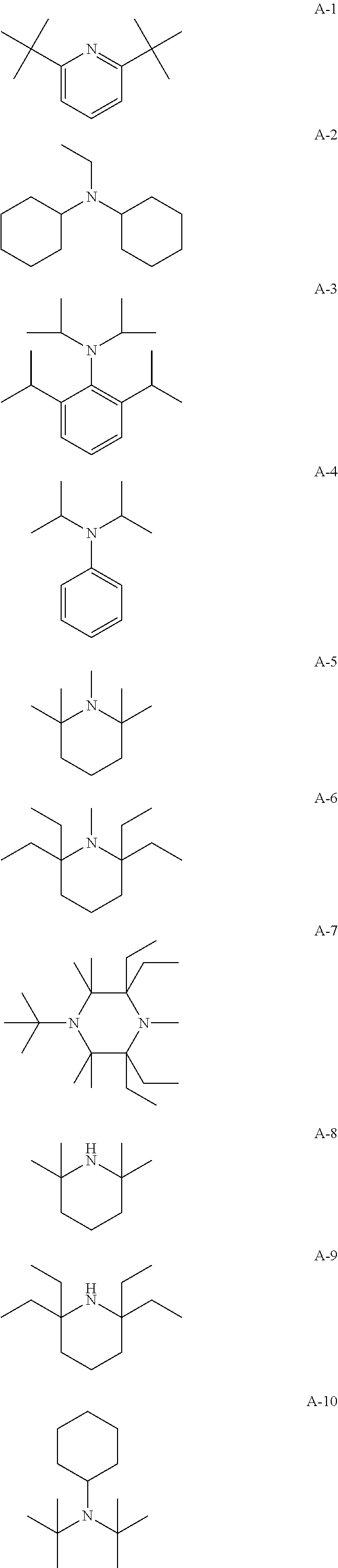

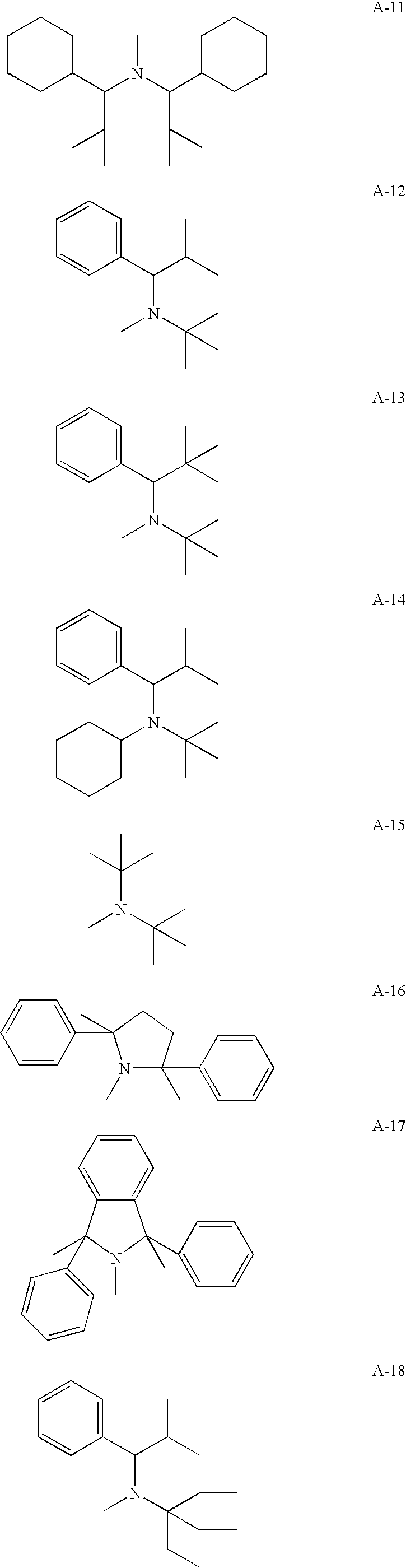

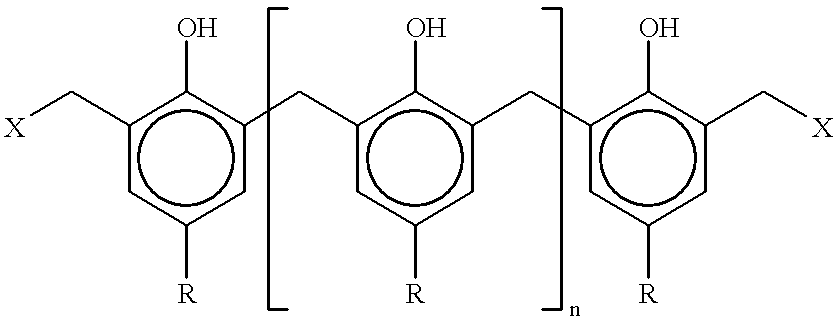

Synergistic additive system for the stabilization of polyamides

InactiveUS6063843AImprove efficiencyGroup 5/15 element organic compoundsMonocomponent polyamides artificial filamentGramHindered amine light stabilizers

Disclosed is a process for stabilizing polyamides against the damage effected by light, heat and / or oxidation while improving the differential dyeability, and processing stability therefore, comprising incorporating therein by melt-processing a synergistic additive system resulting in a uniform and intimate mixture with said polyamide, said additive system is selected from the group consisting of (I), (II) and (III) (I) is from 0.01% to 1% by weight of a sterically hindered phenylphosphonite (Ia) with from 0.05% to 5% by weight of oxanilide (Ib) or said (Ia) together with from 0.05% to 5% by weight of an aromatic di- or tri-carbonyl compound containing at least one, and preferably two hindered amine moieties (Ic); (II) is from 0.05% to 5% by weight of oxanilide (IIa) together with from 0.05% to 5% by weight of a aromatic di- or tri-carbonyl compound (IIb) containing at least one hindered amine moieties; (III) is from 0.01% to 1% by weight of a sterically hindered phenyl phosphonite (Ia), from 0.05% to 5% by weight of a oxanilide (Ib) and from 0.05% to 5% by weight of an aromatic di- or tri-carbonyl compound; wherein the percentages represent grams of additives used per hundred grams of polymer. Also disclosed are polyamide articles selected from the group consisting of molded articles, extruded articles and fibers, which optionally contain organic dyes, exhibiting outstanding color brightness and color stability.

Owner:CLARIANT FIANCE (BVI) LTD

Polyethylene crosslinkable composition

A composition comprising:(a) polyethylene;(b) as a scorch inhibitor, [1,3,5-tris(4-tert-butyl-3-hydroxy-2,6-dimethylbenzyl)-1,3,5-triazine-2,4,6-(1H,3H,5H)-trione];(c) a thioester;(d) a hindered amine stabilizer; and(e) an organic peroxide.

Owner:UNION CARBIDE CORP

Absorbent composition containing molecules with a hindered amine and a metal sulfonate, phosphonate or carboxylate structure for acid gas scrubbing process

Owner:EXXON RES & ENG CO

Pressure-sensitive adhesive composition

InactiveUS20050277729A1Improve responseNon-macromolecular adhesive additivesLayered productsInfraredHindered amine light stabilizers

A pressure-sensitive adhesive composition which comprises a pressure-sensitive adhesive polymer (A), a near-infrared absorbing dye (B), an ultraviolet absorber (C) and / or a hindered amine light stabilizer (D) is provided. The pressure-sensitive adhesive composition makes it possible to lessen deterioration of the near-infrared absorbing dye used by ultraviolet rays. Also, the composition is suited for use in forming pressure-sensitive adhesive layers and the like for sticking together laminar materials forming plasma displays and the like, can combine the functions of the respective layers in the plasma display front face plate in the pressure-sensitive adhesive layer formed, is capable of absorbing near-infrared rays as well as ultraviolet rays and, further, exhibits a color tone-adjusting function.

Owner:NIPPON SHOKUBAI CO LTD

Olefin-based copolymer composition

InactiveUS20020072561A1Film/foil adhesivesSynthetic resin layered productsHindered amine light stabilizersBenzotriazole

An olefin-based copolymer composition comprising the following component (a) in combination with any one component selected from the following components (b) to (i): (a): an olefin-based copolymer obtained by copolymerizing two or more olefins, wherein the olefins are selected from the group consisting of ethylene, propylene and alpha-olefins having 4 to 20 carbon atoms, and the total number of carbon atoms of the two or more selected olefins is 6 or more; (b): a crystalline alpha-olefin-based polymer comprising an alpha-olefin having 3 or more carbon atoms; (c): the following component (c-1) and / or component (c-2), (c-1): a block copolymer comprising (cH) a polymer block containing a vinyl aromatic compound and (cS) a polymer block containing a conjugated diene compound, (c-2): a hydrogenated product of the block copolymer recited in (c-1); (d): the component (b) in combination with an isobutylene-isoprene copolymer rubber and / or halogenated isobutylene-isoprene copolymer rubber; (e): the component (b) in combination with a tackifier resin; (f): the component (b), a component (f-1) which is an ethylene-propylene (non-conjugated diene) random copolymer rubber, and a component (f-2) which is an inorganic filler; (g): a component (g-1) and / or (g-2), (g-1): a benzotriazole light stabilizer having a benzotriazole skeleton and having a molecular weight of 100 to 5,000, (g-2): a hindered amine light stabilizer having a piperidyl group in its molecular skeleton and having a molecular weight of about 200 or more; (h): the component (f-1) in combination with the component (b) and / or an ethylene-based polymer having an ethylene content of 90 mol % or more; and (i): the component (b) and the inorganic filler (f-2).

Owner:SUMITOMO CHEM CO LTD

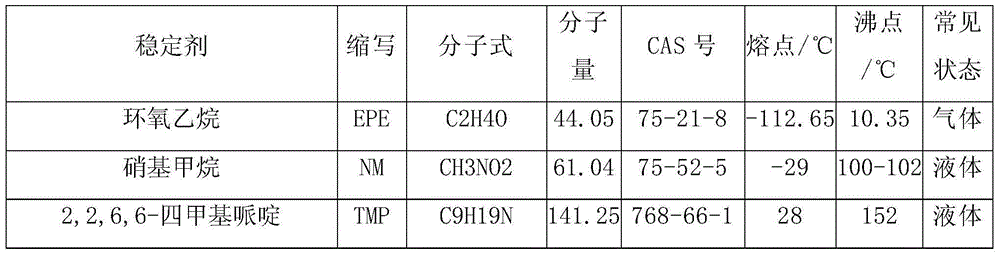

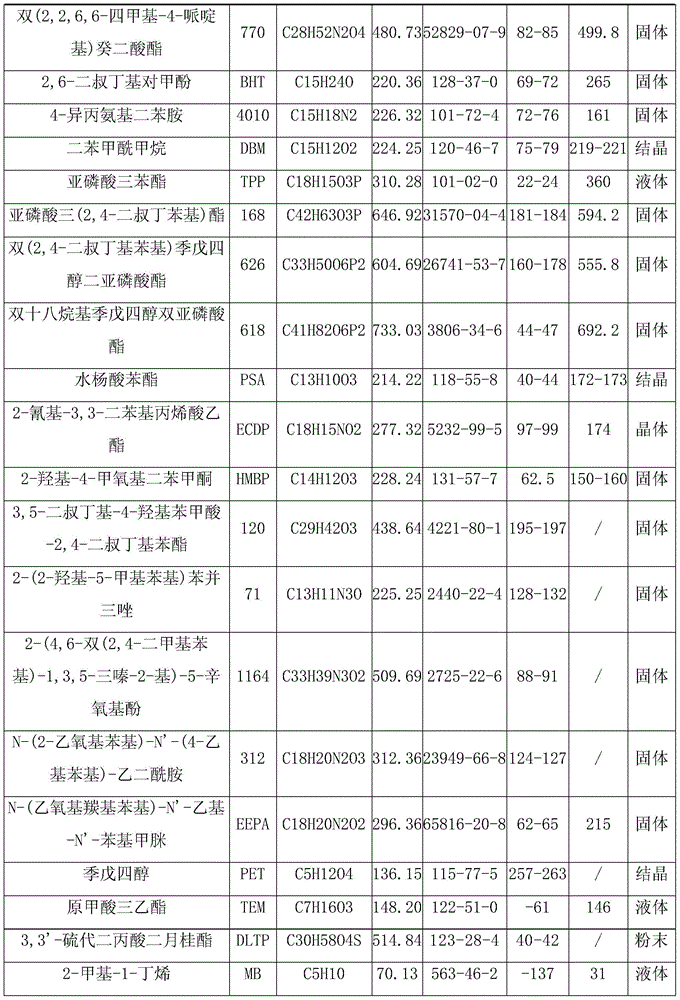

Composition containing HFC-161 and stabilizer

The invention discloses a composition containing HFC-161 and a stabilizer, wherein the stabilizer is selected from one or more of epoxy compound, nitro-compound, hindered amines, hindered phenols, secondary arylamines, beta-diketones, phosphite esters, salicylic acid esters, cinnamic acid esters, hydroxybenzophenones, hydroxybenzoic acids, hydroxylphenyl benzotriazoles, hydroxylphenyl triazines, oxanilides, formamidines, polyhydric alcohols, ortho-formates, organosulfur compounds, olefins, ethanol amines and fatty amines. The composition provided by the invention is capable of keeping a stable state in a long time under the coexistence of air or oxygen, and capable of being used as a heat transfer composition in the form of a liquid or a gas, a refrigerant, an aerosol propellant and the like.

Owner:SINOCHEM LANTIAN +2

Resin composition for reflector plate and reflector plate

InactiveUS20070161741A1Improve photostabilityImprove adhesionSpecial tyresSemiconductor devicesEpoxyHindered amine light stabilizers

Owner:MITSUI CHEM INC

Propylene polymer, propylene block copolymer, process for preparing said polymer and said block copolymer, and propylene polymer composition

InactiveUS6284857B1High crystallinityLong mesochainWeather resistanceHindered amine light stabilizers

Disclosed are a propylene polymer having a high crystallinity of a boiled heptane-insoluble component contained therein, a high stereoregularity and an extremely long mesochain (continuous propylene units wherein directions of alpha-methyl carbons are the same as each other), and a process for preparing said polymer. Further disclosed is a propylene polymer composition comprising the above propylene polymer and at least one stabilizer selected from a phenol type stabilizer, an organophosphite type stabilizer, a thioether type stabilizer, a hindered amine type stabilizer and a metallic salt of higher aliphatic acid. The propylene polymer of the invention is excellent in rigidity, heat resistance and moisture resistance, and can be favorably used for sheet, film, filament, injection molded product, blow molded product, etc. The propylene polymer composition of the invention has excellent properties of the propylene polymer or the propylene block copolymer, and moreover is excellent in heat stability during the molding stage, long-term heat stability and weathering resistance. The propylene polymer composition can be favorably used for sheet, film, filament, injection molded product, blow molded product, etc.

Owner:MITSUI CHEM INC

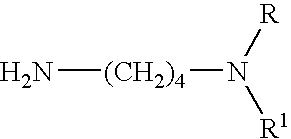

Hindered Amine Nitric Oxide Donating Polymers for Coating Medical Devices

Disclosed are hindered amine nitric oxide (NO) donating polymers for coating implantable medical devices. The polymers include sterically hindered secondary amines that do not react with monomer carbonyls or electrophilic alkenes, facilitating the synthesis of the NO donating polymers. The polymers are coated on implantable medical devices, providing anti-restenosis therapy by the release of NO at the implantation site.

Owner:MEDTRONIC VASCULAR INC

Photocurable ink composition, ink cartridge, inkjet recording method and recorded matter

InactiveUS20090110827A1Improve responseReducing ink viscosityInksGlass/slag layered productsHydrogenHindered amine light stabilizers

A photocurable ink composition includes a photoradical polymerization initiator, a compound having an active hydrogen-bearing functional group, and a hindered amine.

Owner:SEIKO EPSON CORP

Novel polyolefin packaging glue film composite and application thereof

ActiveCN102585731AExcellent mechanical impact modulusImprove aging resistanceNon-macromolecular adhesive additivesPhotovoltaic energy generationPolyolefinPolymer science

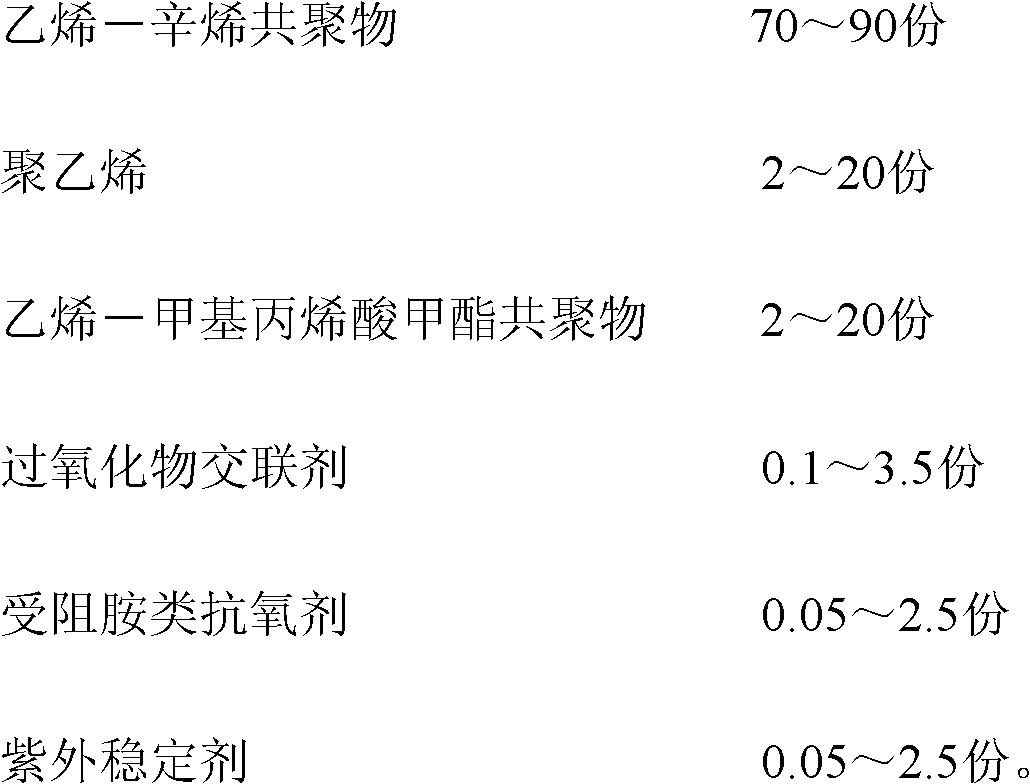

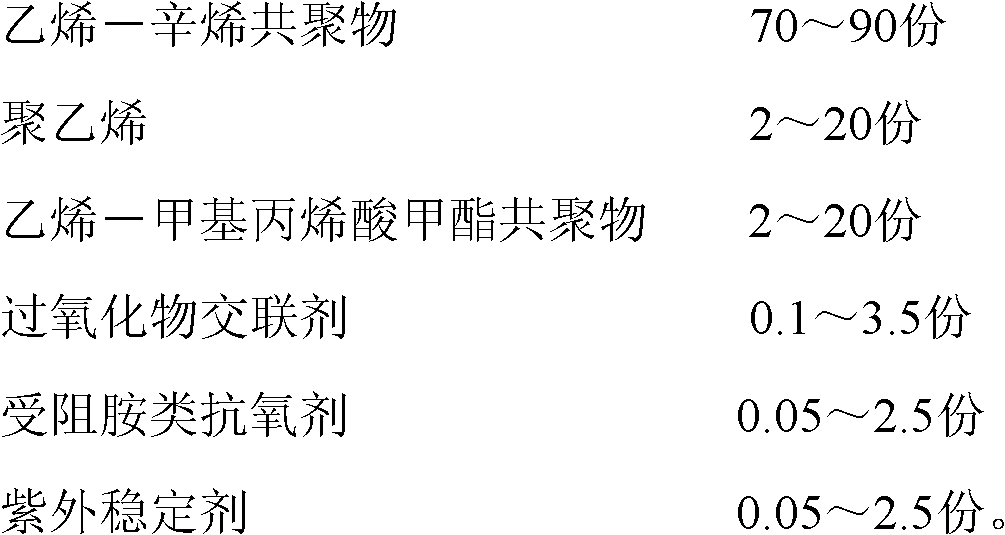

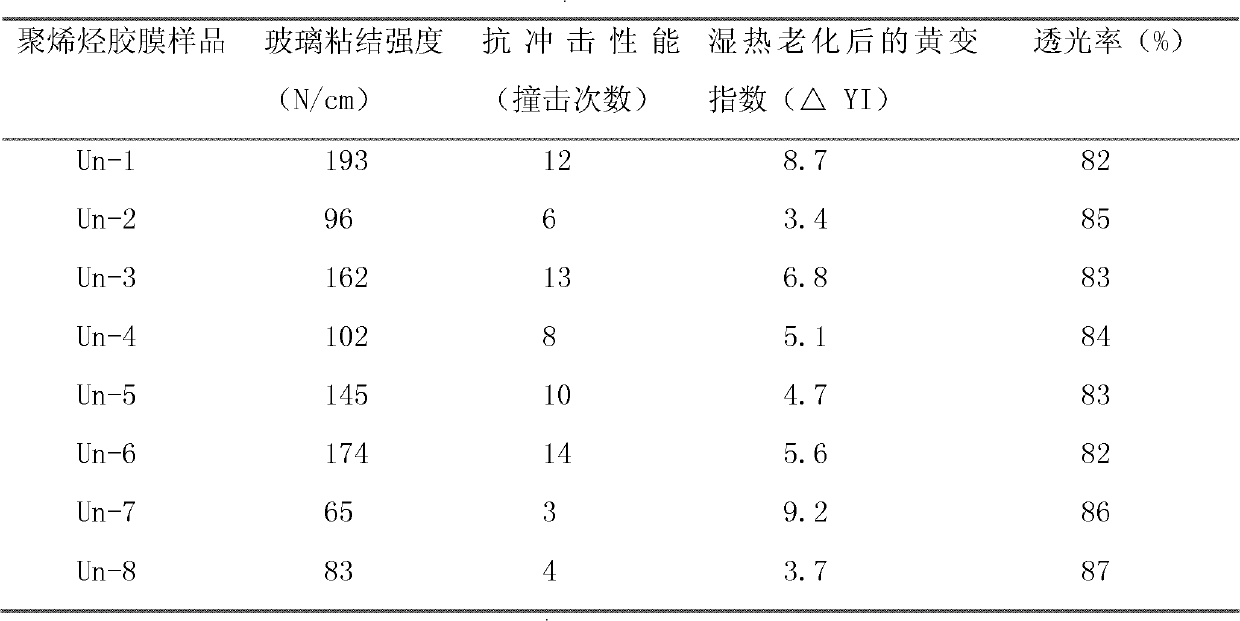

The invention discloses a novel polyolefin packaging glue film composite, which comprises the following components, by weight percentage, 70-90 parts of ethylene-octylene copolymer, 2-20 parts of polyethylene, 2-20 parts of ethylene-methyl acrylate, 0.1-3.5 parts of peroxide cross-linking agents, 0.05-2 parts of hindered amine antioxidants, and 0.05-2 parts of ultraviolet stabilizers. The polyolefin packaging glue film composite has excellent mechanical impact modulus and ageing-resistant performance and strong glass adhesion, simultaneously is convenient in machine-shaping, and can achieve on-line repairing and recycling of solar assemblies.

Owner:GUANGZHOU LUSHAN NEW MATERIALS +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com