Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

73 results about "Phosphonite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

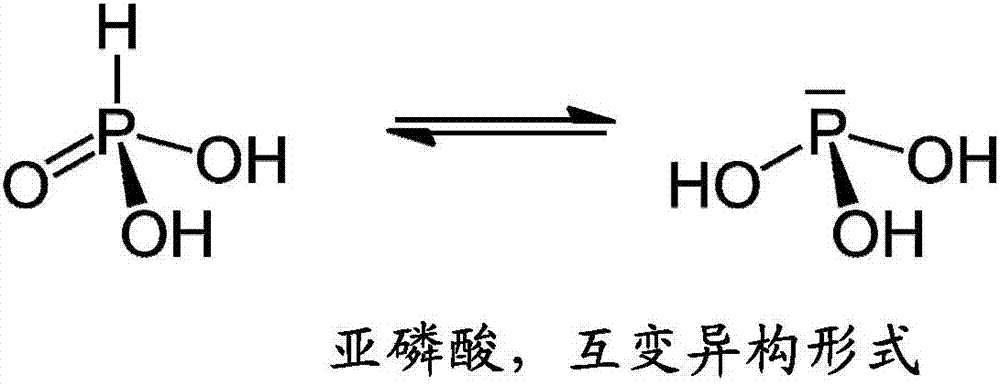

Phosphonites are organophosphorus compounds with the formula P(OR)₂R. They are found in some pesticides and are used as ligands.

Hydrocyanation process with reduced yield losses

ActiveUS20080015382A1Investment exemptionSelective and efficient and stableOrganic compound preparationPreparation by hydrogen cyanide additionHydrogenPhosphite ester

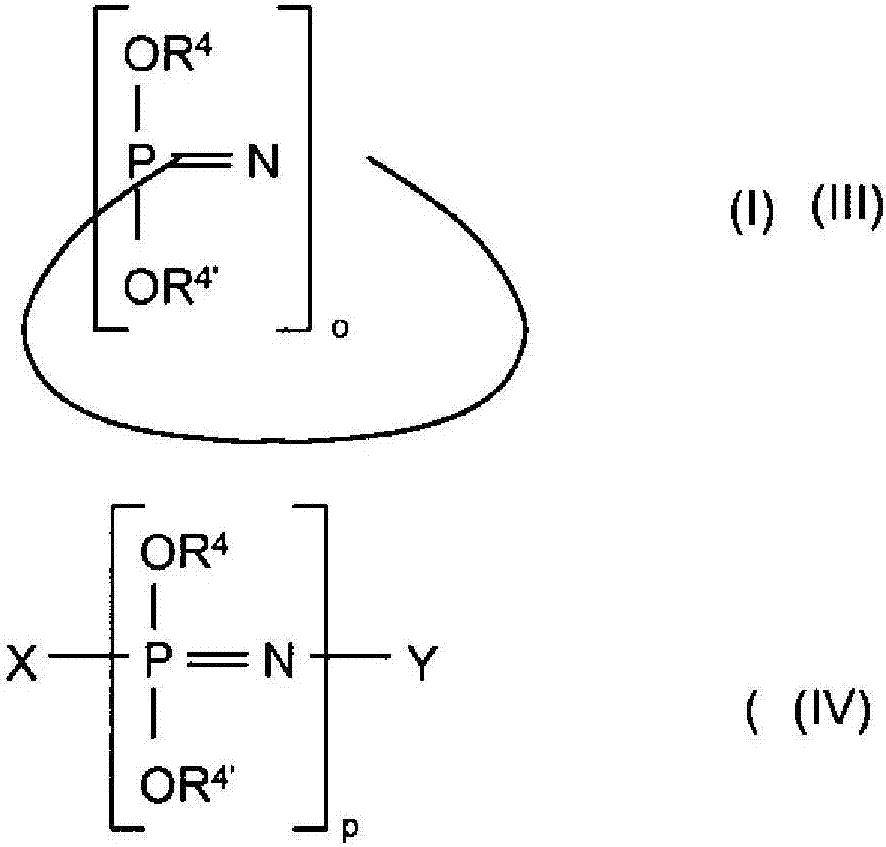

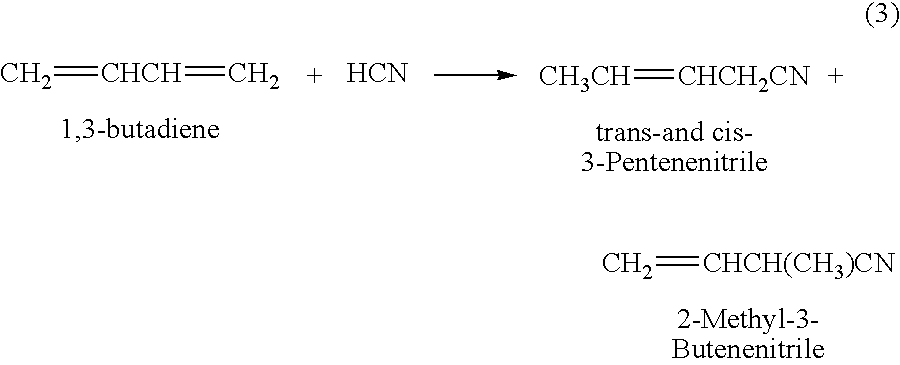

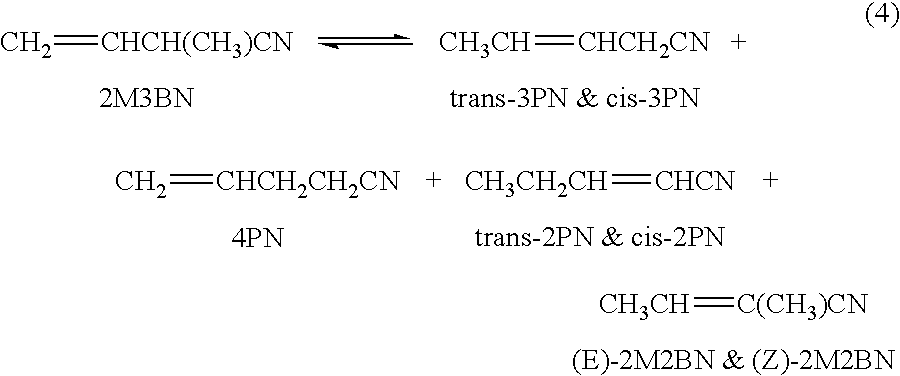

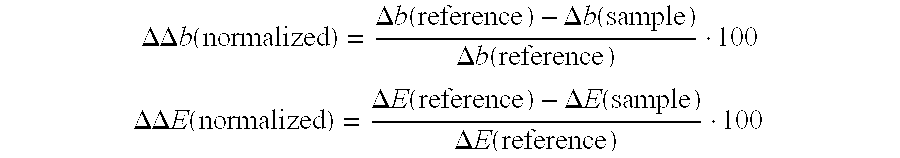

The invention provides a hydrocyanation process for the production of adiponitrile and other dinitriles having six carbon atoms, the process comprising:a) forming a reaction mixture in the presence of at least one Lewis acid, said reaction mixture comprising ethylenically unsaturated nitriles having five carbon atoms, hydrogen cyanide, and a catalyst precursor composition, by continuously feeding ethylenically unsaturated nitriles, hydrogen cyanide, and a catalyst precursor composition;b) controlling X and Z, wherein X is the overall feed molar ratio of 2-pentenenitriles to all unsaturated nitriles and Z is the overall feed molar ratio of hydrogen cyanide to all unsaturated nitriles, by selecting a value for X in the range from about 0.001 to about 0.5, and a value for Z in the range from about 0.5 / 1 to about 0.99 / 1, such that the value of quotient Q, whereinQ=X[(moles3PN+4PNinthefeed) / (molesallunsaturatednitrilesinthefeed)]-Zis in the range from about 0.2 to about 10, wherein 3PN is 3-pentenenitriles and 4PN is 4-pentenenitrile; andc) withdrawing a reaction product mixture comprising adiponitrile;wherein the ratio of the concentration of 2-pentenenitriles to the concentration of 3-pentenenitriles in the reaction mixture is from about 0.2 / 1 to about 10 / 1;wherein the catalyst precursor composition comprises a zero-valent nickel and at least one multidentate phosphorus-containing ligand;wherein the multidentate phosphorus-containing ligand is selected from the group consisting of a phosphite, a phosphonite, a phosphinite, a phosphine, and a mixed phosphorus-containing ligand or a combination of such members; andwherein the multidentate phosphorus-containing ligand gives acceptable results according to at least one protocol of the 2-Pentenenitrile Hydrocyanation Test Method.

Owner:INV NYLON CHEM AMERICAS LLC

Polylactic acid composition and molded article thereof

InactiveUS20110263762A1Improve thermal stabilityReduce heatGroup 5/15 element organic compoundsPhosphorous acidPolymer science

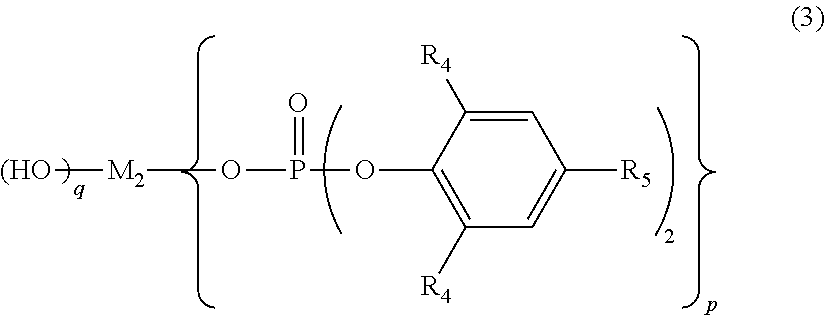

A composition comprising polylactic acid and having excellent heat stability, especially moist heat stability, and a molded article thereof.The composition comprises 100 parts by weight of a resin component (component A) which is composed of 5 to 100 wt % of polylactic acid (component A-α) and 95 to 0 wt % of a thermoplastic resin (component A-β), 0.001 to 5 parts by weight of a phosphono-fatty acid ester (component B), 0.01 to 5 parts by weight of a phosphate metal salt (component C), 0.001 to 2 parts by weight of at least one antioxidant (component D) selected from the group consisting of a phosphite-based compound, a phosphonite-based compound, a hindered phenol-based compound and a thioether-based compound, and 0.001 to 10 parts by weight of an end-sealing agent (component E).

Owner:TEIJIN KASEK KK +1

Polylactic acid composition

ActiveUS20120289625A1Improve heat stabilityImprove hydrolysis resistanceOrganic chemistryPlastic/resin/waxes insulatorsNitrogenPhosphite ester

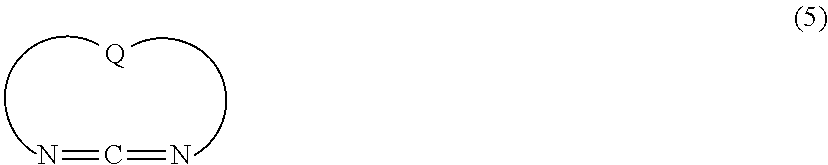

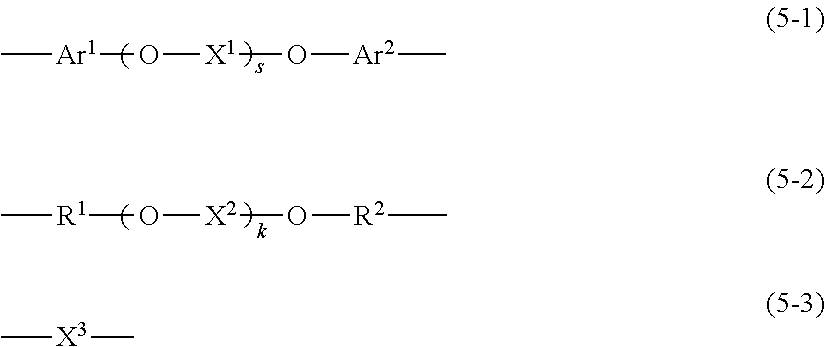

A resin composition which comprises polylactic acid, does not release an isocyanate group at the time of production and has excellent hydrolysis resistance and a low environmental burden.The resin composition comprises:(A) 100 parts by weight of a resin component (component A) containing polylactic acid (component A-α);(B) 0.001 to 10 parts by weight of a compound (component B) having one carbodiimide group and a cyclic structure in which first nitrogen and second nitrogen are bonded to each other via a bonding group, the cyclic structure consisting of 8 to 50 atoms; and(C) 0.001 to 2 parts by weight of at least one antioxidant (component C) selected from the group consisting of a hindered phenol-based compound, a phosphite-based compound, a phosphonite-based compound and a thioether-based compound.

Owner:TEIJIN LTD

Method for producing flame-resistant, non-corrosive and stable polyamide moulding compounds

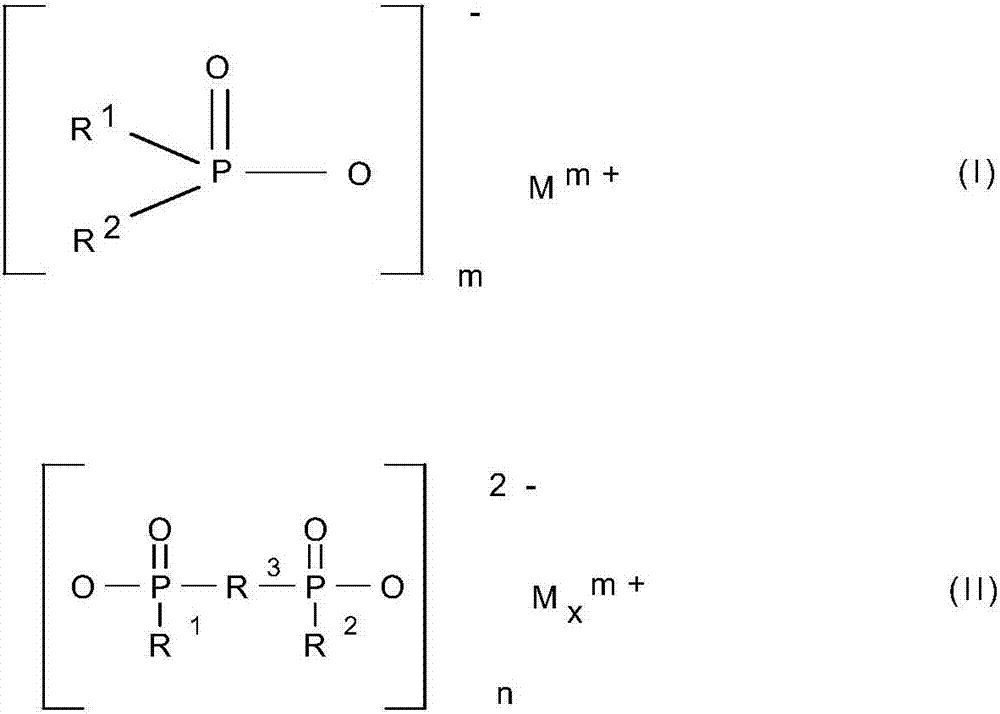

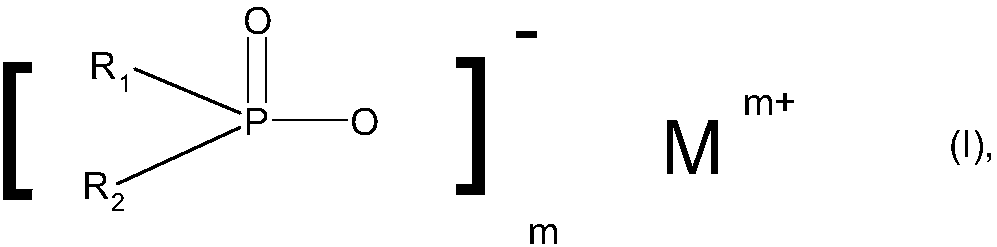

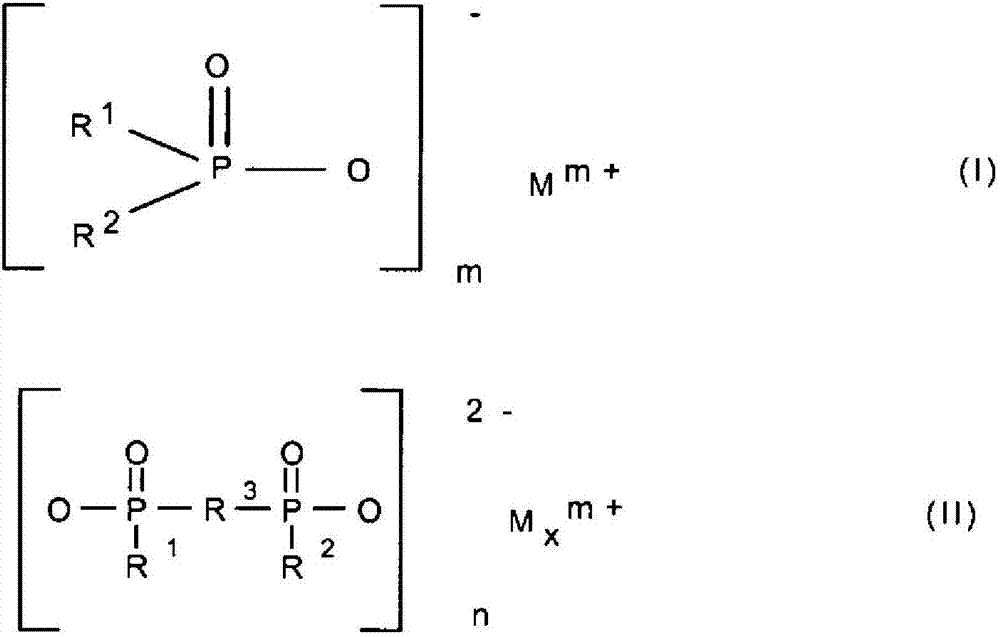

The invention relates to a method for producing flame-resistant, non-corrosive and stable polyamide moulding compounds. The aim of the invention is to use a mixture of several components as non-corrosive flame retardants. Said mixture comprises, as component A) 20 - 98 wt.% of a dialkylphosphinic acid salt of formula (I) (as shown in the description) and / or a diphosphinic acid salt of formula (II) (as shown in the description) and / or polymers thereof, wherein R1, R2 are the same or different and C1 -C6-alkyl are linear or branched; R3 represents C1-C10-alkylene, linear or branched, C6-C10-arylene, C7-C20-alkylarylene or C7-C20-arylalkylene; M represents Mg, Ca, Al, Sb, Sn, Ge, Ti, Zn, Fe, Zr, Ce, Bi, Sr, Mn, Li, Na, K and / or a protonated nitrogen base; m is 1 - 4; n is 1 - 4; x is 1 - 4, as component B) 1 - 80 wt.% of a salt of the phosphoric acid, having general formula (III) [HP(=O)O2]2-M m+, wherein M represents Mg, Ca, Al, Sb, Sn, Ge, Ti, Zn, Fe, Zr, Ce, Bi, Sr, Mn, Li, Na and / or K, as component C) 0.1 - 30 wt.% of an inorganic zinc compound, as component D) 0 - 30 wt.-% of a nitrogen-containing synergist and / or a phosphorous / nitrogen flame retardant, as component E) 0 - 3 wt.% of a phosphonite or a mixture of a phosphonite and a phosphite and as component F) 0 - 3 wt.-% of an ester or salt of long-chained aliphatic carboxylic acids (fatty acids), which comprise the typical chain lengths of C14 - C40, the total of the components always amounting to 100 wt.%.

Owner:CLARIANT PLASTICS & COATINGS LTD

Rare earth and calcium and zinc stabilizer for polychlorovinyl and its preparation

InactiveCN1583849AThe process is green and environmentally friendlyImprove stabilityZinc compoundsRare earth

Rare-earth and calcium and zinc stabilizing agent for polyethylene is produced by treating rare-earth and calcium and zinc compounds with surface modifying agent, and optimizing with polyethylene and anti-oxidating agent or / and organic tin compounds or organic phosphonite compounds or / and C8 - C22 metal saponified materials of calcium or zinc or magnesium or aluminum or / and ultraviolet absorber or / and urate or / and polyhydroxy esterified materials or / and polyethylene lubricant to be obtained. It has high quality and no toxicity, is produced with low cost and in a simple process.

Owner:GUANG DONG GUANG YANG HI TECH

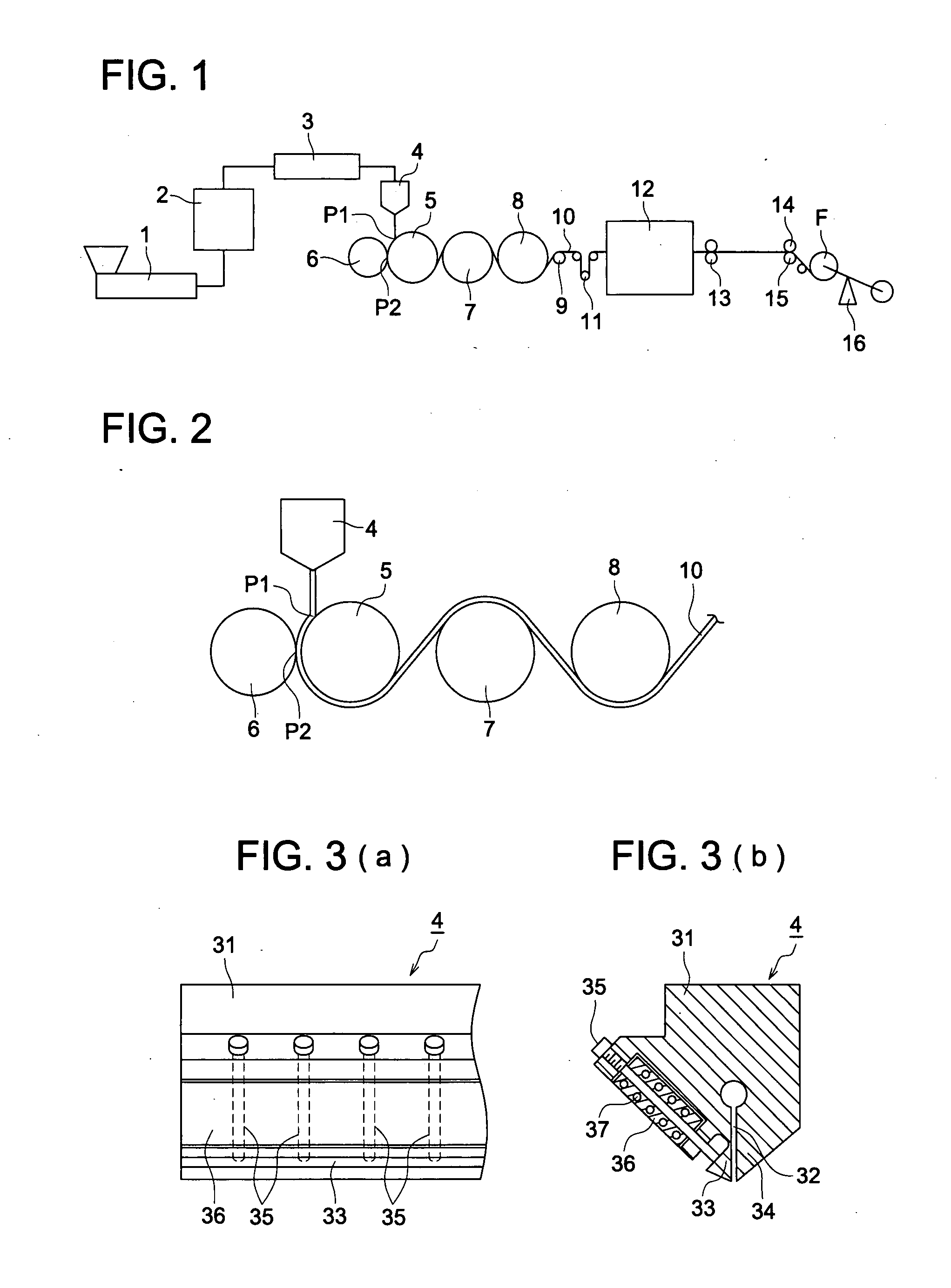

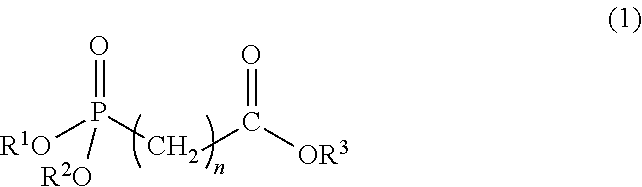

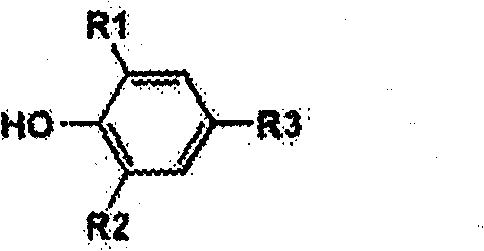

Manufacturing method of cellulose acylate film, cellulose acylate film, polarizing plate and liquid crystal display

InactiveUS20080057227A1Coloring deteriorationDeterioration in processingLiquid crystal compositionsPolarising elementsCelluloseO-Phosphoric Acid

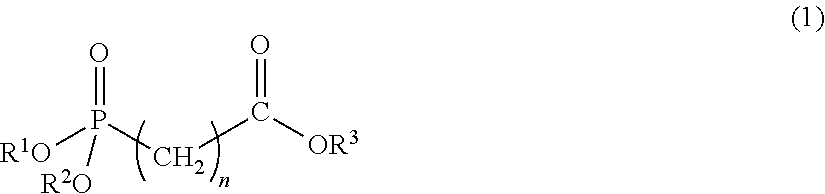

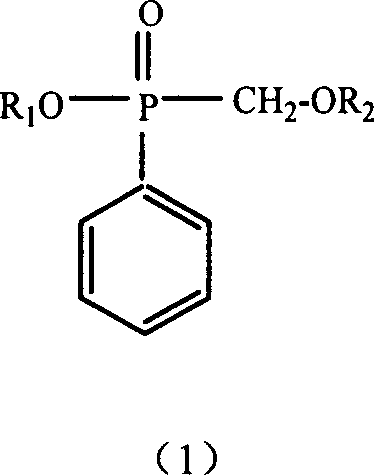

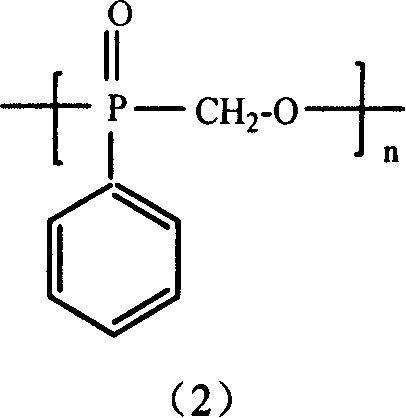

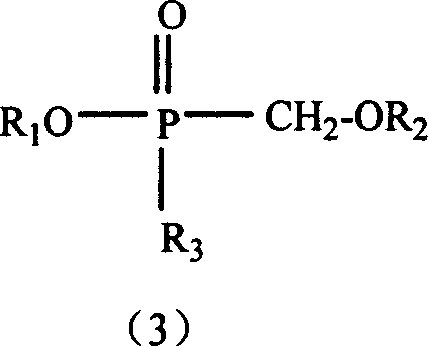

A cellulose acylate film manufacturing method based on melt-casting film formation technique, the comprising steps of: extruding a cellulose acylate film from a casting die, and sandwiching the cellulose acylate film between an elastically deformable touch roll and a cooling roll, wherein the cellulose acylate film includes at least one kind of compounds expressed by the following general formula (1) and at least one kind of phosphoric acid compounds selected from among phosphite, phosphonite, phosphinite and phosphane, wherein R11 through R16 each indicate a hydrogen atom or substituents.

Owner:KONICA MINOLTA OPTO

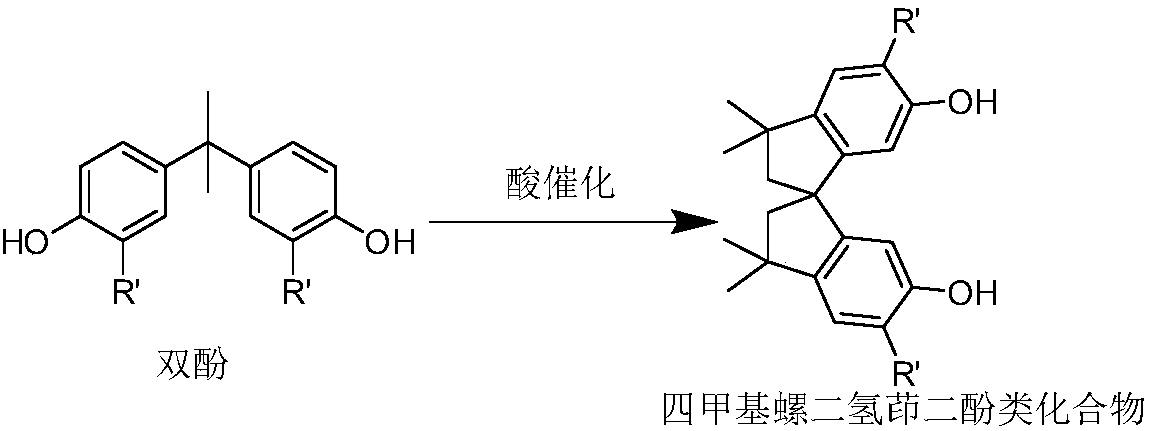

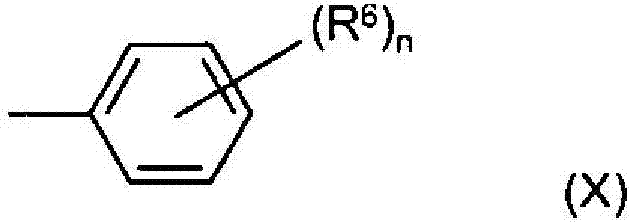

Monophosphine ligand based on tetramethyl spirobiindane skeleton, as well as intermediate, preparation method and application thereof

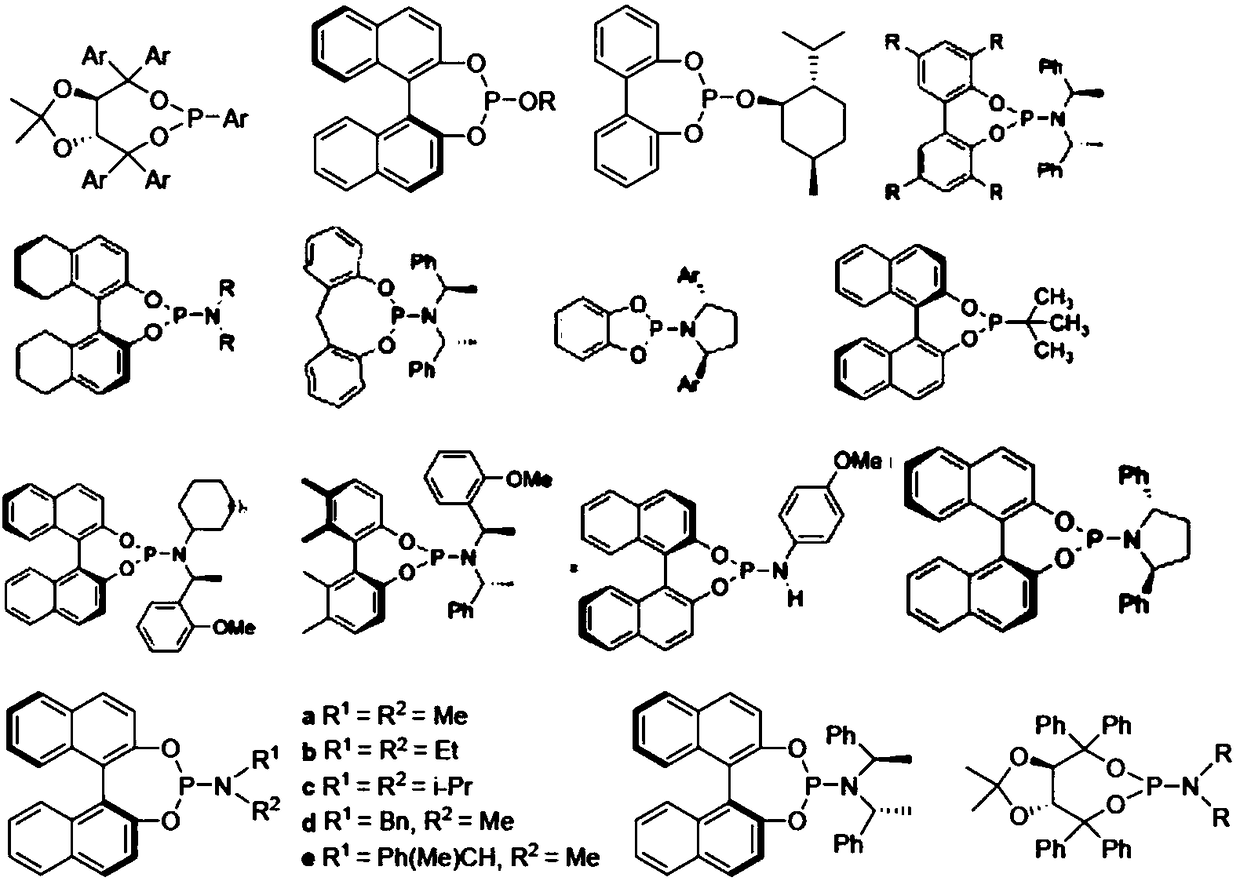

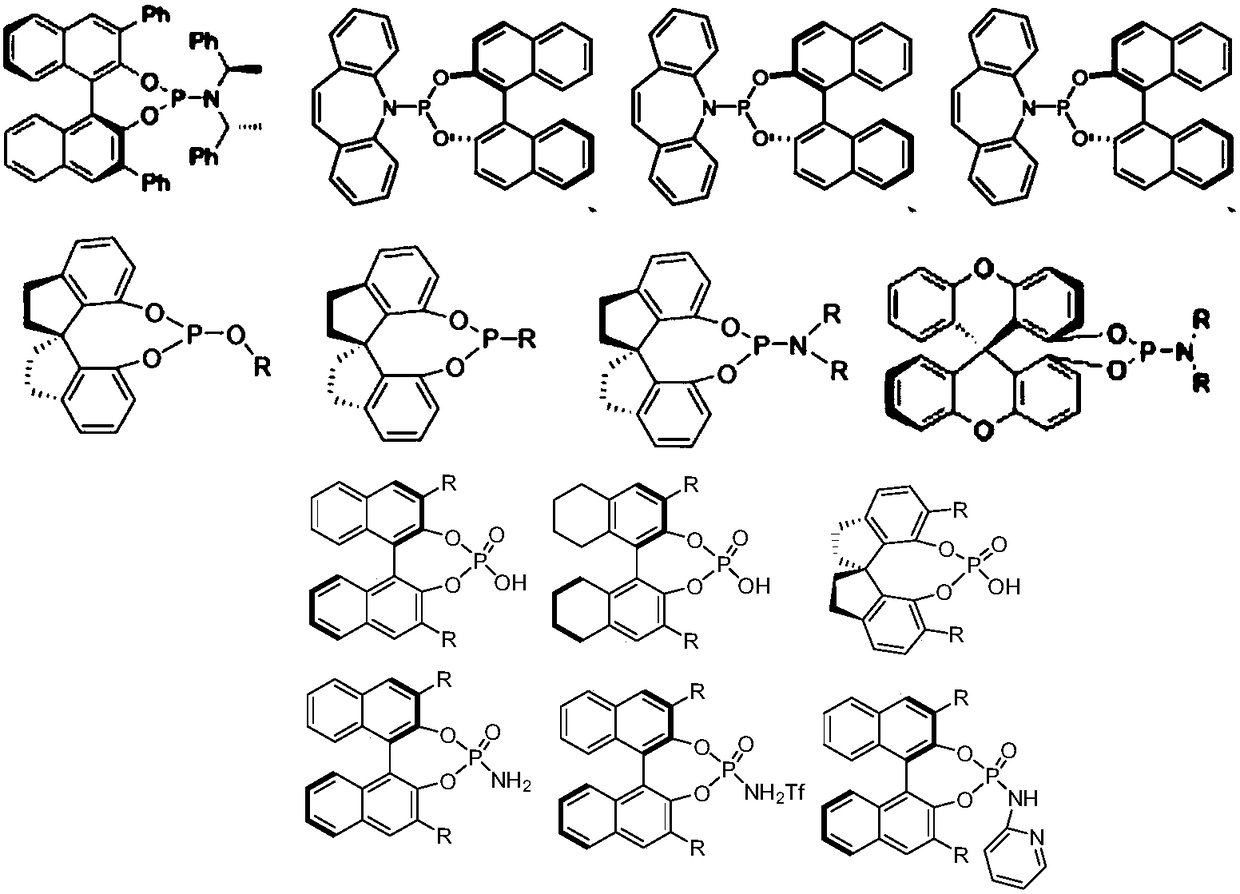

The invention discloses monophosphine ligand based on a tetramethyl spirobiindane skeleton, as well as an intermediate, a preparation method and application thereof. The monophosphine ligand adopts acompound with a structure as shown in a general formula I or I' or an enantiomer, a racemate or a diastereoisomer of the compound, and comprises phosphorous ester ligand, phosphorous ester ligand, phosphoramidite ester ligand, phosphoric acid and phosphamide. The monophosphine ligand takes a known 3, 3, 3', 3'-tetramethyl-1, 1'-spirobiindane-7, 7'-dimethyl aldehyde as a raw material, and is formedthrough a formula II which is taken as a preparation route of a key intermediate. The novel monophosphine ligand can serve as ligand to be used for organic reaction of metal catalysis or be directlyused for catalyzing the organic reaction, can particularly serve as chiral monophosphine ligand to be widely applied to multichiral catalytic reaction including asymmetric addition, asymmetric hydrogenation, asymmetric coupling and asymmetric allylic alkylation, and has economical practicability and an industrial application prospect.

Owner:ZHEJIANG UNIV

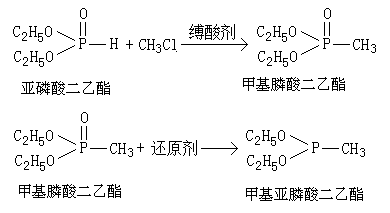

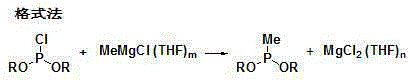

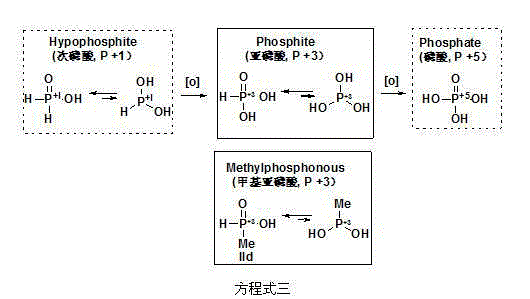

Synthetic method of diethyl methyl-phosphonite and glufosinate-ammonium

ActiveCN103319529AReduce manufacturing costReaction raw materials are cheap and easy to obtainGroup 5/15 element organic compoundsPhosphorous acidOrganic solvent

The invention discloses a synthetic method of diethyl methyl-phosphonite and glufosinate-ammonium. The synthetic method comprises the following steps: carrying out a reaction between diethyl phosphite and chloromethane gas in the presence of an acid binding agent to prepare diethyl methylphosphonite, and filtering after reaction, wherein the generated diethyl methylphosphonite exists in a filtrate; dropwisely adding an organic solvent, in which a reducing agent is dissolved, into the filtrate so as to reduce diethyl methylphosphonite into diethyl methyl-phosphonite, distilling a reaction solution after the reaction so as to obtain diethyl methyl-phosphonite, and preparing glufosinate-ammonium by using diethyl methyl-phosphonite as an intermediate. According to the invention, diethyl phosphite is used as a raw material; reaction raw materials are cheap and easily available; the reaction process is simple and easy to operate and is green and environmentally friendly; atom utilization rate is high; quality of the obtained product is good; yield is high; a new idea is provided for the synthesis of glufosinate-ammonium; preparation cost of glufosinate-ammonium is also reduced; and the synthetic method has wide application value.

Owner:SHANDONG WEIFANG RAINBOW CHEM

Multi-phase chiral metal catalyst and its production

InactiveCN101028604AHigh reactivityHigh selectivityCatalyst carriersOrganic-compounds/hydrides/coordination-complexes catalystsActive componentMetal catalyst

A multi-phase chiral metal catalyst used for preparing chiral aldehyde product by catalytic asymmetric hydroformylation of olefin is composed of the homogenous chiral ligand chosen from C-2 symmetric chiral biphosphine ligand, N-contained phosphinate type chiral ligand, biphosphinte-type ligand, etc, the active component chosen from Rh, Pt, Ru and Ir, and carrier. Its preparing process is also disclosed.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

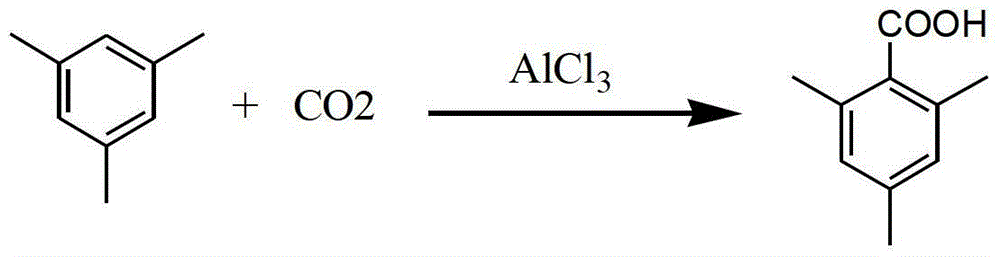

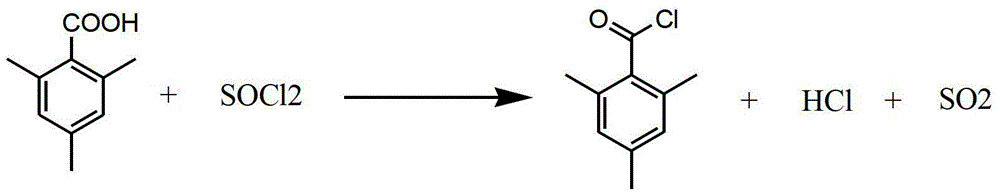

Preparation method of TPO-L photoinitiator

InactiveCN103333203AHigh yieldFast curingGroup 5/15 element organic compoundsWater circulationChloride

The invention relates to the technical field of TPO-L photoinitiators and particularly relates to a preparation method of a TPO-L photoinitiator, which comprises a stage of 2,4,6-trimethylbenzoyl chloride preparation and a stage of TPO-L photoinitiator production. According to the preparation method, 2,4,6-trimethylbenzoyl chloride which is used as the main raw material reacts with diethyl phenyl phosphonite, and then water circulation treatment is carried out to obtain the product; and the yield of the product is over 98%, the curing speed is high and the stability is good. Moreover, the method provided by the invention has a simple production technology, is easy to operate, has low requirements on the production equipment, reduces the production cost and hardly causes pollution.

Owner:NANTONG TAITONG CHEM TECH

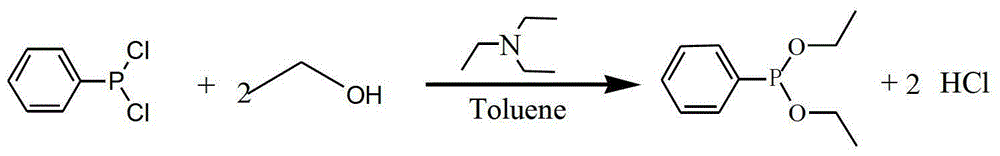

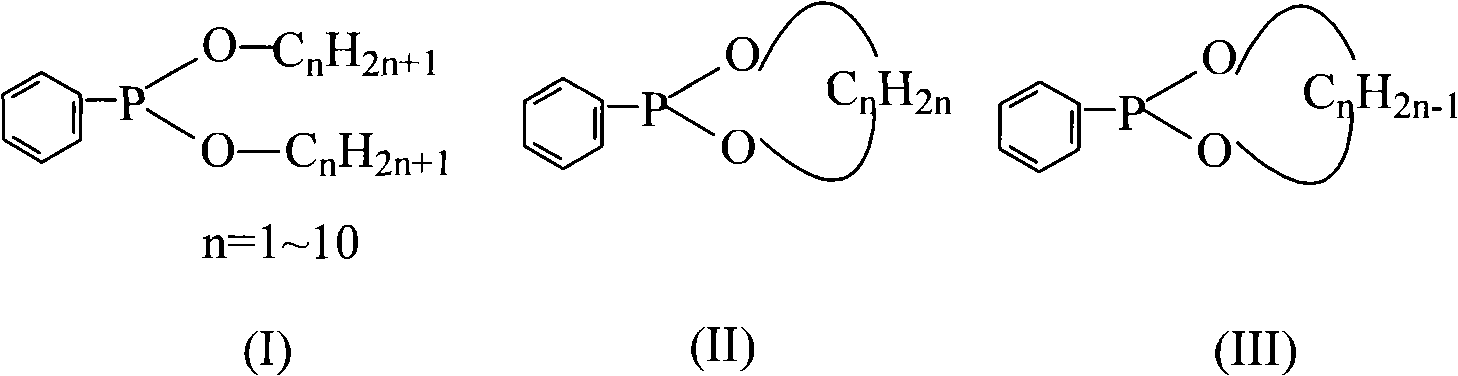

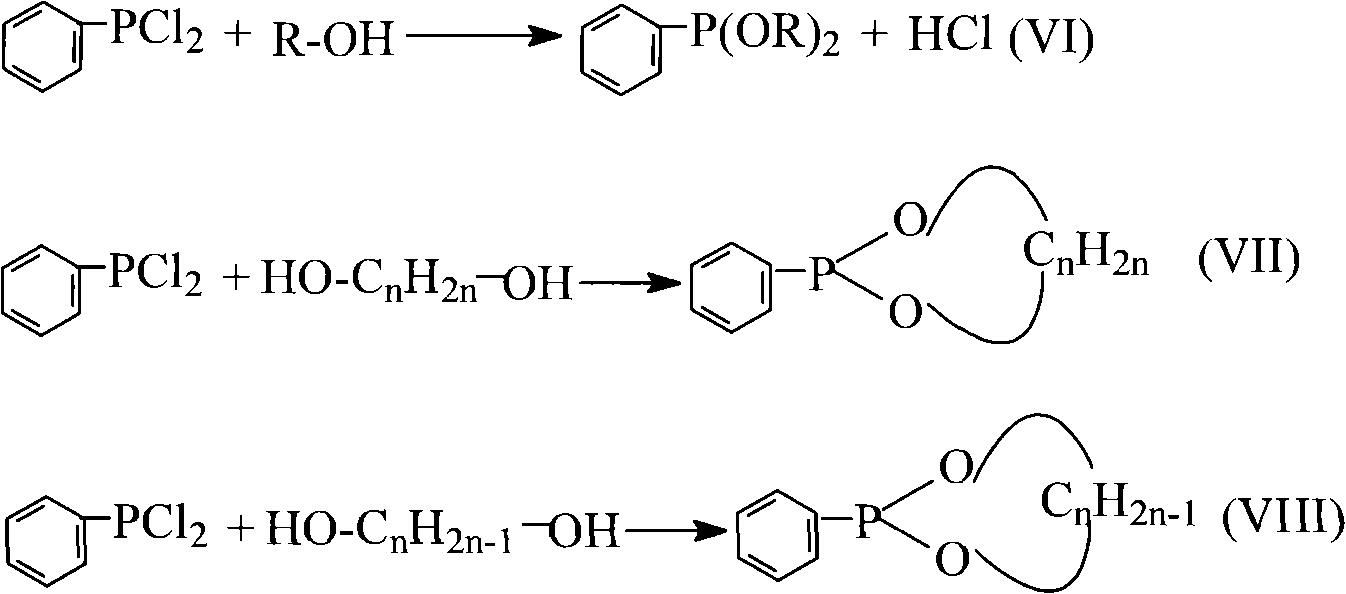

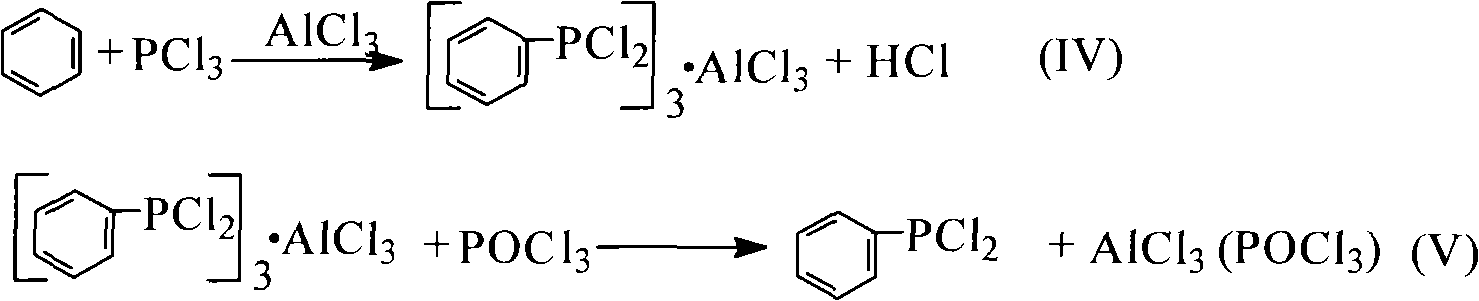

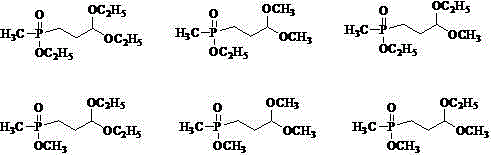

Method for preparing dialkyl phenyl-phosphonite

InactiveCN101538281ALow costReduce manufacturing costGroup 5/15 element organic compoundsAlcoholPhosphate

The invention relates to a method for preparing dialkyl phenyl-phosphonite which is a key intermediate of acyl phosphate photoinitiator. The method takes benzene, phosphorus trichloride and alcohol as main materials and synthesizes dialkyl phenyl-phosphonite through a two-step reaction. The method has the improvements that: in the second step of reaction, phenyldichlorophosphine reacts with the alcohol to synthesize the object under the condition of non-catalyst, the reaction temperature is controlled within 10 DEG C below zero to 10 DEG C, and phenyldichlorophosphine is dropwise added; and then the reaction is carried out under the condition of stirring at the temperature of 30 to 50 DEG C for 0.5 to 7 hours. The invention has the advantages of low cost, easy post treatment, high yield, and the like and is suitable for industrial production.

Owner:CHANGZHOU VOCATIONAL INST OF ENG

Flame-retardant polyamide compositions and use thereof

The invention relates to flame-retardant polyamide compositions containing a polyamide having a melting point of less than or equal to 290 DEG C as component A, fillers and / or reinforcing materials ascomponent B, phosphinic acid salt of formula (I) as component C, wherein R1 and R2 represent ethyl, M represents Al, Fe, TiOp or Zn, m represents 2 to 3, and p = (4 - m) / 2, a compound selected fromthe group of Al, Fe, TiOp or Zn salts of ethyl butylphosphinic acid, dibutylphosphinic acid, ethylhexylphosphinic acid, butylhexylphosphinic acid and / or dihexylphosphinic acid as component D, phosphonic acid salt of formula (II) as component E, wherein R3 represents ethyl, Met represents Al, Fe, TiOq or Zn, n represents 2 to 3, and q = (4 - n) / 2, a melamine polyphosphate having an average degree of condensation of between 2 to 100 as component F, a sterically hindered phenolic antioxidant as component G, and / or an organic phosphite and / or organic phosphonite as component H. The polyamide compositions can be used to produce fibers, films, and moulded bodies, in particular for applications in the electrical and electronics fields.

Owner:CLARIANT INT LTD

Synthesis and purification method of methyl phosphinate compounds

ActiveCN105131034AAvoid difficultyReduce production processGroup 5/15 element organic compoundsGrignard reagentCombinatorial chemistry

The invention relates to a synthesis and purification method of methyl phosphinate compounds. The method concretely comprises the following steps: adding brine to a solution containing a methyldialkyl phosphinate and magnesium chloride mixture in an inert solvent at a low temperature, and separating to obtain methylalkyl phosphinate or methyldialkyl phosphinate. The method solves the post-treatment and purification difficulties of a Grignard reagent method, and has the advantages of industrial production, effective reduction of the generation of methyl phosphonous acid, mild process conditions, and excellent reaction yield and product quality.

Owner:HEBEI VEYONG BIO CHEM

Polyamide composition and preparation method and application thereof

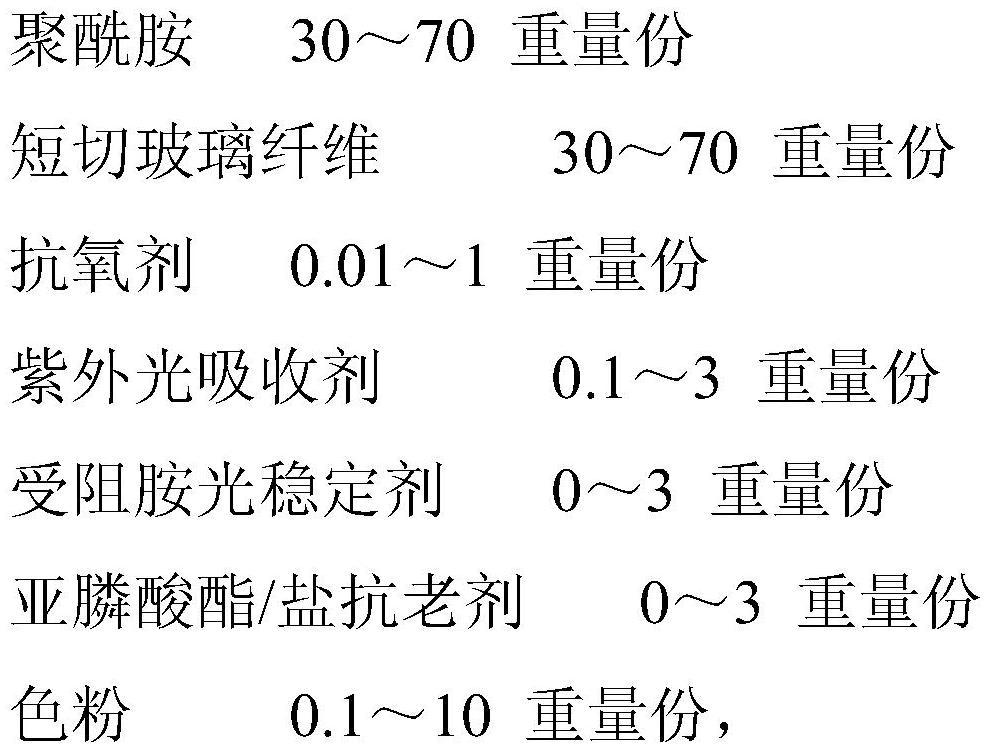

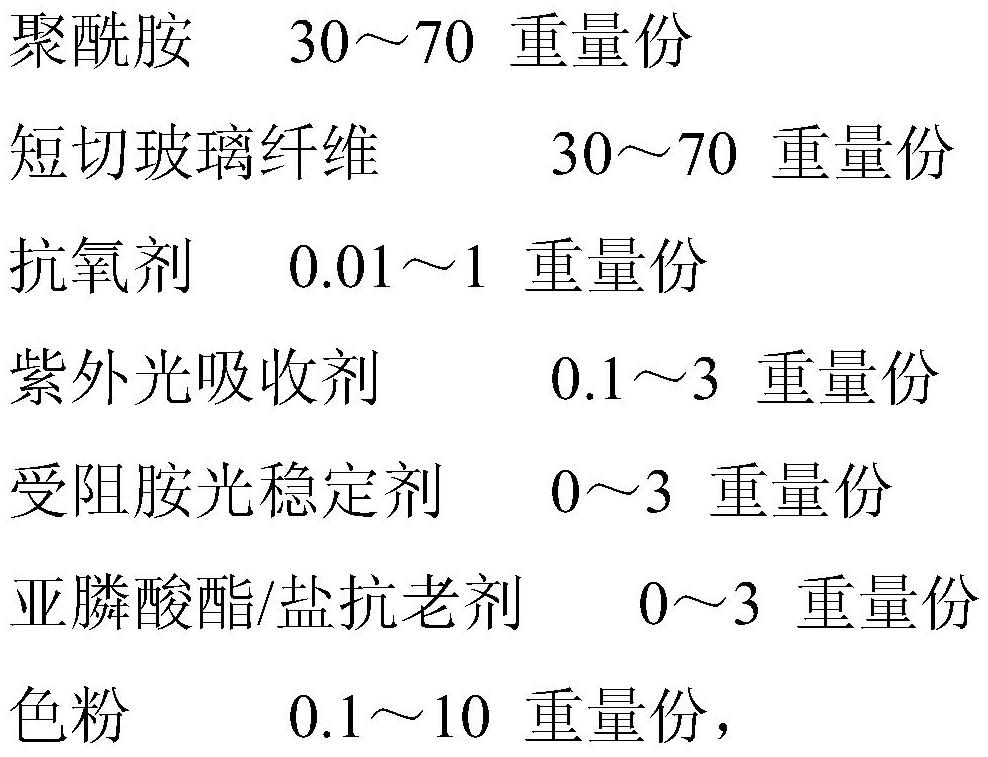

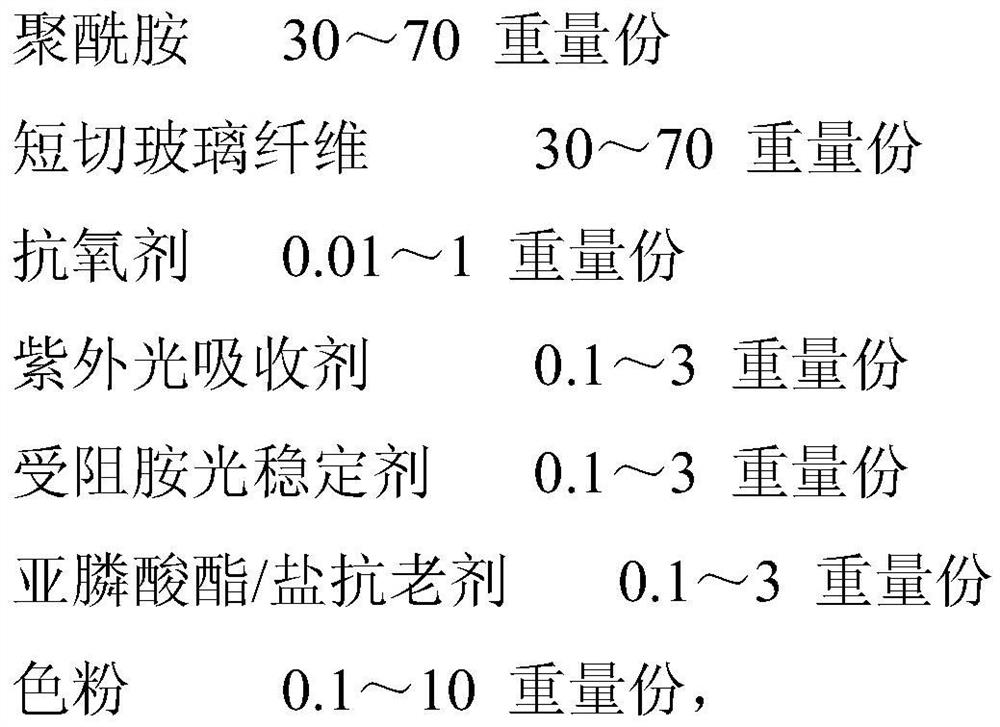

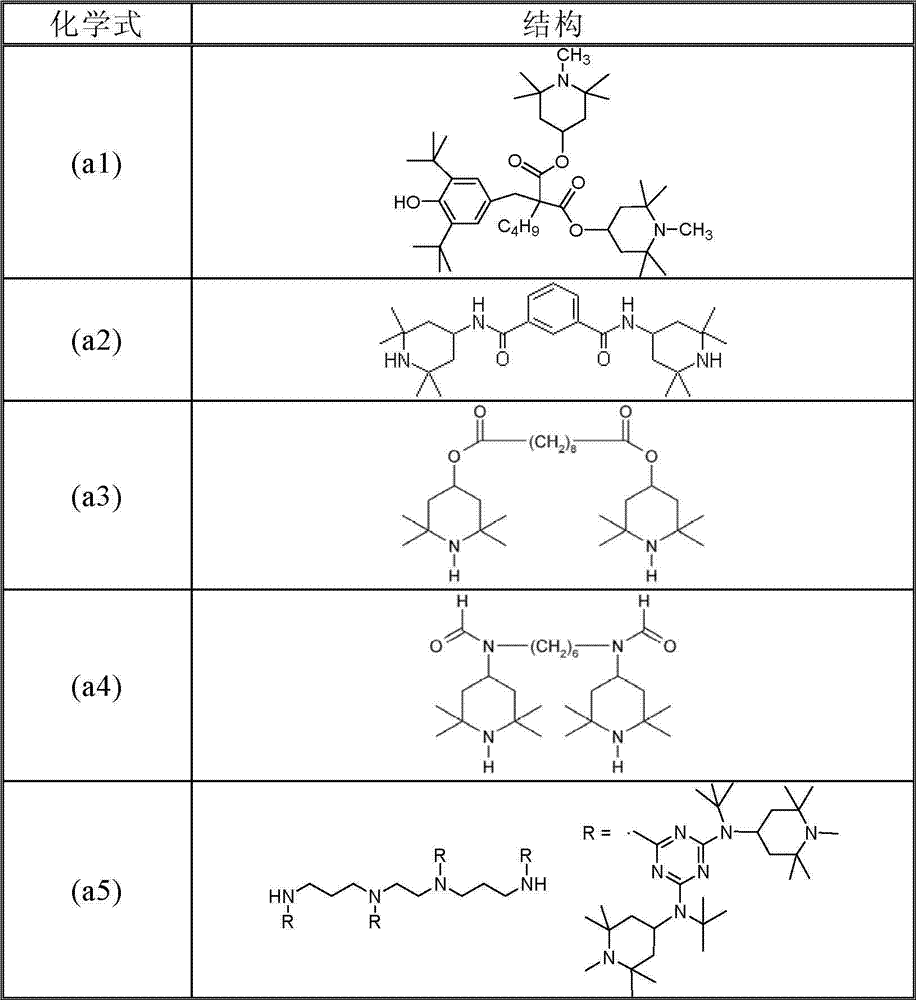

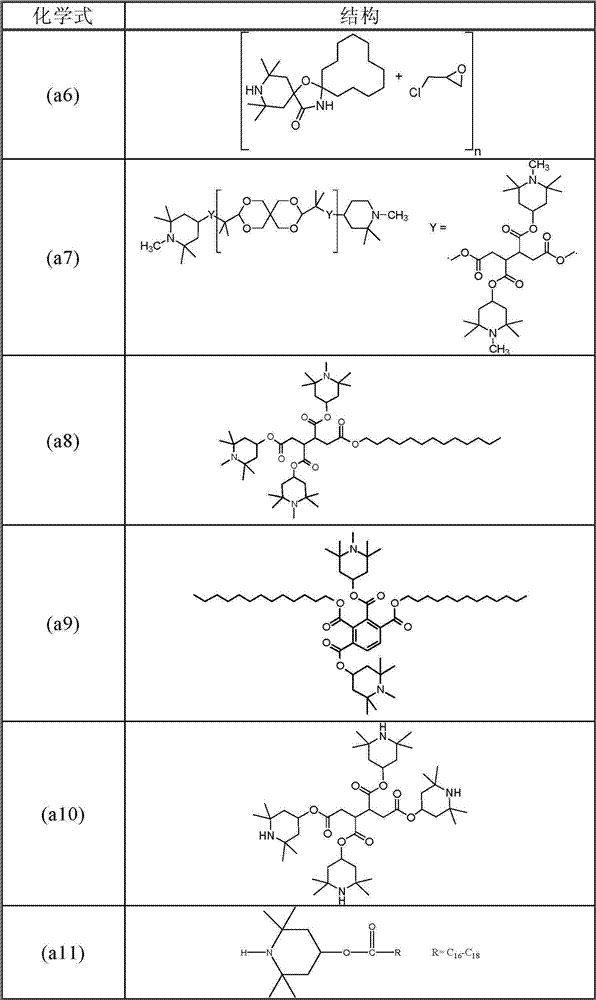

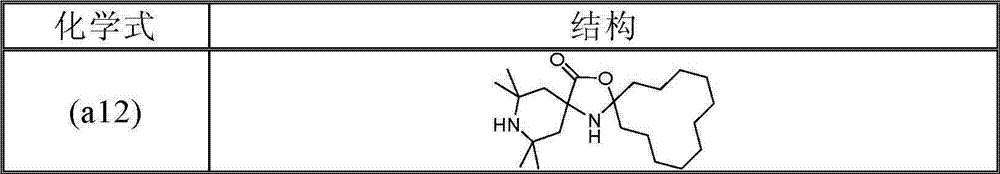

The invention relates to a polyamide composition as well as a preparation method and an application thereof. The invention provides a polyamide composition. The polyamide composition comprises the following components: 30-70 parts of polyamide; 30 to 70 parts of chopped glass fiber; 0.01 to 1 part of an antioxidant; 0.1 to 3 parts of an ultraviolet absorber; 0-3 parts of a hindered amine light stabilizer; 0-3 parts of a phosphite ester / salt anti-aging agent, and 0.1-10 parts of color powder; wherein the polyamide composition comprises at least one or two of the hindered amine light stabilizerand the phosphite ester / salt anti-aging agent. The polyamide composition disclosed by the invention can keep the initial color of the material under the dual effects of heating moisture absorption andultraviolet light, the color change is small, and the use experience of consumers on material appearance parts is improved.

Owner:艾曼斯(苏州)工程塑料有限公司

Thermoplastic resin composition for producing automobile exterior parts

To provide a resin composition having highly balanced properties of fluidity, impact resistance, dimensional stability, rigidity, heat-resistant rigidity, electrical conductivity, coating adhesion and appearance, which properties are required as a thermoplastic resin material for producing automobile exterior parts, and being excellent in retention stability, and a thermoplastic resin composition for producing automobile exterior parts obtained by molding the resin composition followed by electrostatic coating.A thermoplastic resin composition for producing automobile exterior parts, including the following components (A) to (H) in the following weight percentage ranges based on 100% by weight of the sum of the entire components constituting the composition: 18 to 80% by weight of component (A) which is a polyamide 6 resin having a viscosity number, as measured in accordance with ISO-307, of 80 to 120 ml / g and a ratio of a content of terminal carboxyl groups (unit: μeq / g) to a content of terminal amino groups (unit: μeq / g) of 2≦(terminal carboxyl group content / terminal amino group content)≦6; 5 to 25% by weight of component (B) which is a hydrogenated product of a block copolymer comprising a vinyl aromatic compound polymer block and a conjugated diene compound polymer block; 3 to 15% by weight of component (C) which is a graft-modified hydrogenated product of a block copolymer comprising a vinyl aromatic compound polymer block and a conjugated diene compound polymer block, said hydrogenated product being graft-modified with maleic anhydride in an amount of 2.6 to 5.0% by weight based on 100% by weight of said graft-modified hydrogenated product; 1 to 5% by weight of component (D) which is conductive carbon black having a BET specific surface area of not less than 600 m2 / g and a DBP oil absorption of not less than 300 ml / 100 g; 10 to 30% by weight of component (E) which is talc having an average particle diameter of 0.5 to 10 μm; 0.1 to 2% by weight component (F) which is a phosphonite compound; 0.5 to 5% by weight of component (G) which is an ethylene-vinyl alcohol resin; and 0 to 1% by weight of component (H) which is a pentaerythritol based phosphite.

Owner:DSM IP ASSETS BV

Flame-retardant polyamide composition

The invention relates to a flame-retardant polyamide composition containing as component A) 1-96 wt.% of one or more thermoplastic polyamides, as component B) 2-25 wt.% of a dialkylphosphinic acid salt of formula (I) and / or a diphosphinic acid salt of formula (II) and / or polymers thereof, wherein R1, R2 are the same or different and C1-C6 alkyl are linear or branched or H, R3 represents linear or branched C1-C10 alkylene, C6-C10 alkylene, C7-C20 arylalkylene or C7-C20 arylalkylene; M represents Mg, Ca, AI, Sb, Sn, Ge, Ti, Zn, Fe, Zr, Ce, Bi, Sr, Mn, Li, Na, K and / or a protonated nitrogen base; m is 1-4; n is 1-4; x is 1-4, as component C) 1-20 wt.% of a salt of the phosphoric acid, as component D) 1-20 wt.% of a phosphazene, as component E) 0-50 wt.% of a filling or reinforcing agent, as component F) 0-1 wt.% of a phosphonite or a mixture of phosphonite and a phosphite, and as component G) 0-1 wt.% of an ester or salt of long-chained aliphatic carboxylic acids (fatty acides), with the typical chain lengths of C14-C40, the total of the components always amounting to 100 wt.%.

Owner:CLARIANT INT LTD

Hydrocyanation process with reduced yield losses

ActiveUS7709674B2Yield lossInvestment exemptionOrganic compound preparationPreparation by hydrogen cyanide additionPhosphonitePhosphine

A hydrocyanation process produces adiponitrile and other dinitriles having six carbon atoms. The process involves forming a reaction mixture in the presence of at least one Lewis acid. The reaction mixture includes ethylenically unsaturated nitrites having five carbon atoms, hydrogen cyanide, and a catalyst precursor compositions. The reaction mixture is continuously fed while controlling the overall feed molar ratio of 2-pentenenitriles to all unsaturated nitriles and the overall feed molar ratio of hydrogen cyanide to all unsaturated nitrites. In the reaction product mixture, including adiponitrile, the ratio of the concentration of 2-pentenenitriles to the concentration of 3-pentenenitriles from about 0.2 / 1 to about 10 / 1. Included in the catalyst precursor composition is a zero-valent nickel and at least one multidentate phosphorus-containing ligand. The multidentate phosphorus-containing ligand may be a phosphite, a phosphonite, a phosphinite, a phosphine, and a mixed phosphorus-containing ligand or a combination of such members.

Owner:INV NYLON CHEM AMERICAS LLC

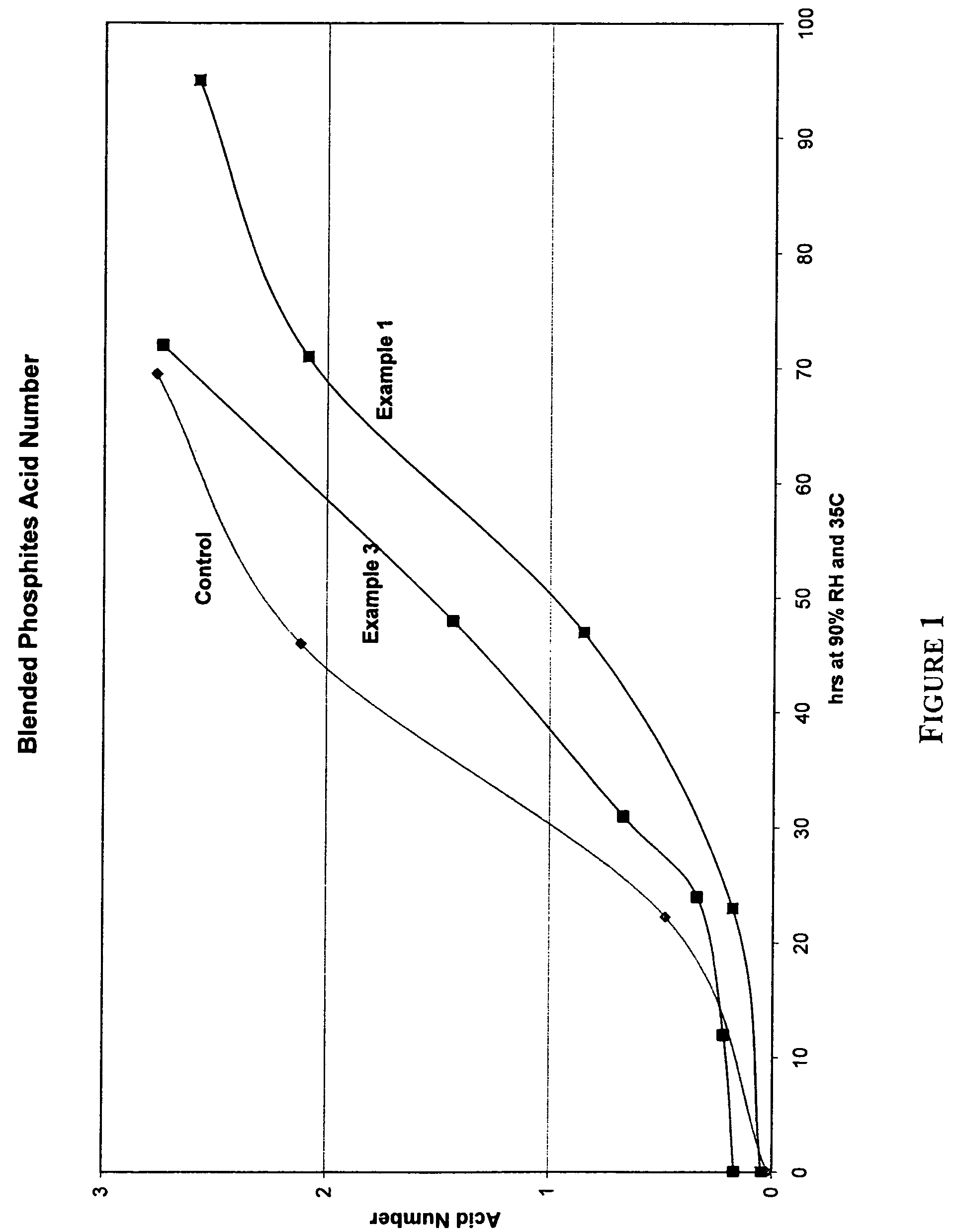

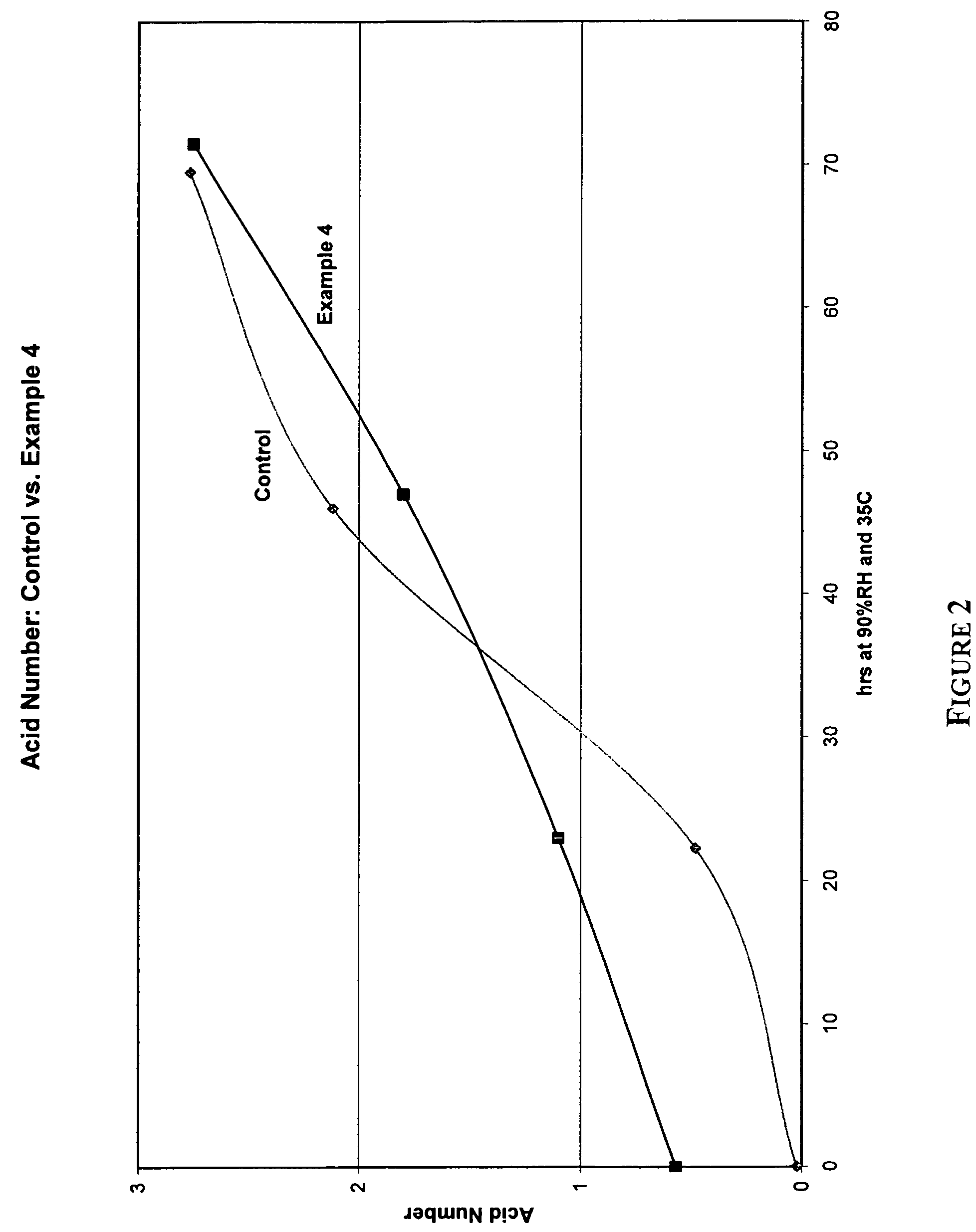

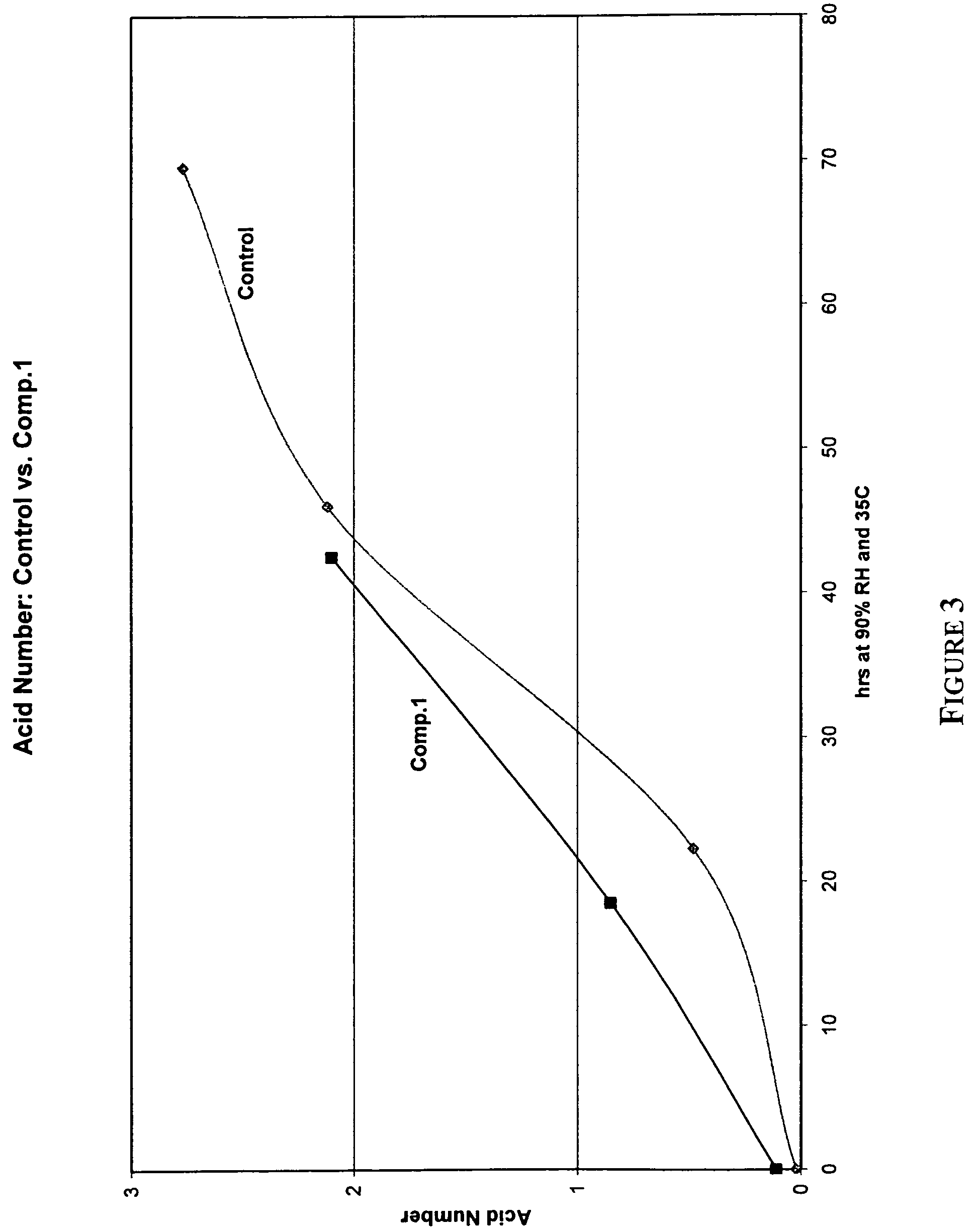

Granular polymer additives and their preparation

A compacted particulate polymer additive composition in a dry granular form formed from the following components: (a) at least one particulate organic phosphite, organic phosphonite, and / or organic phosphonate, and (b) one or more particulate polymer additives other than an organic phosphite, organic phosphonite, or organic phosphonate; wherein the particles of said composition are held together in compacted dry granular form exclusively or substantially exclusively by contact with dried surfaces of in situ desolvated particles from particles of one or more at least partially solvated components of (a), and optionally by contact with dried surfaces of in situ desolvated particles from particles of one or more at least partially solvated components of (b). Compositions of this type except that there is no component (b) are also described.

Owner:ALBEMARLE CORP

Heat and light resistant polymer composition

The invention relates to a heat and light resistant polymer composition, specifically to a polymer composition containing at least one kind of polyester, at least one kind of hinderde-amine compound and at least one kind of trivalent phosphorus compound and an article such as an LED device, wherein the trivalent phosphorus compound is selected from the group containing phosphate ester, phosphinic acid ester and mixture thereof.

Owner:SOLVAY SPECIALTY POLYMERS USA LLC

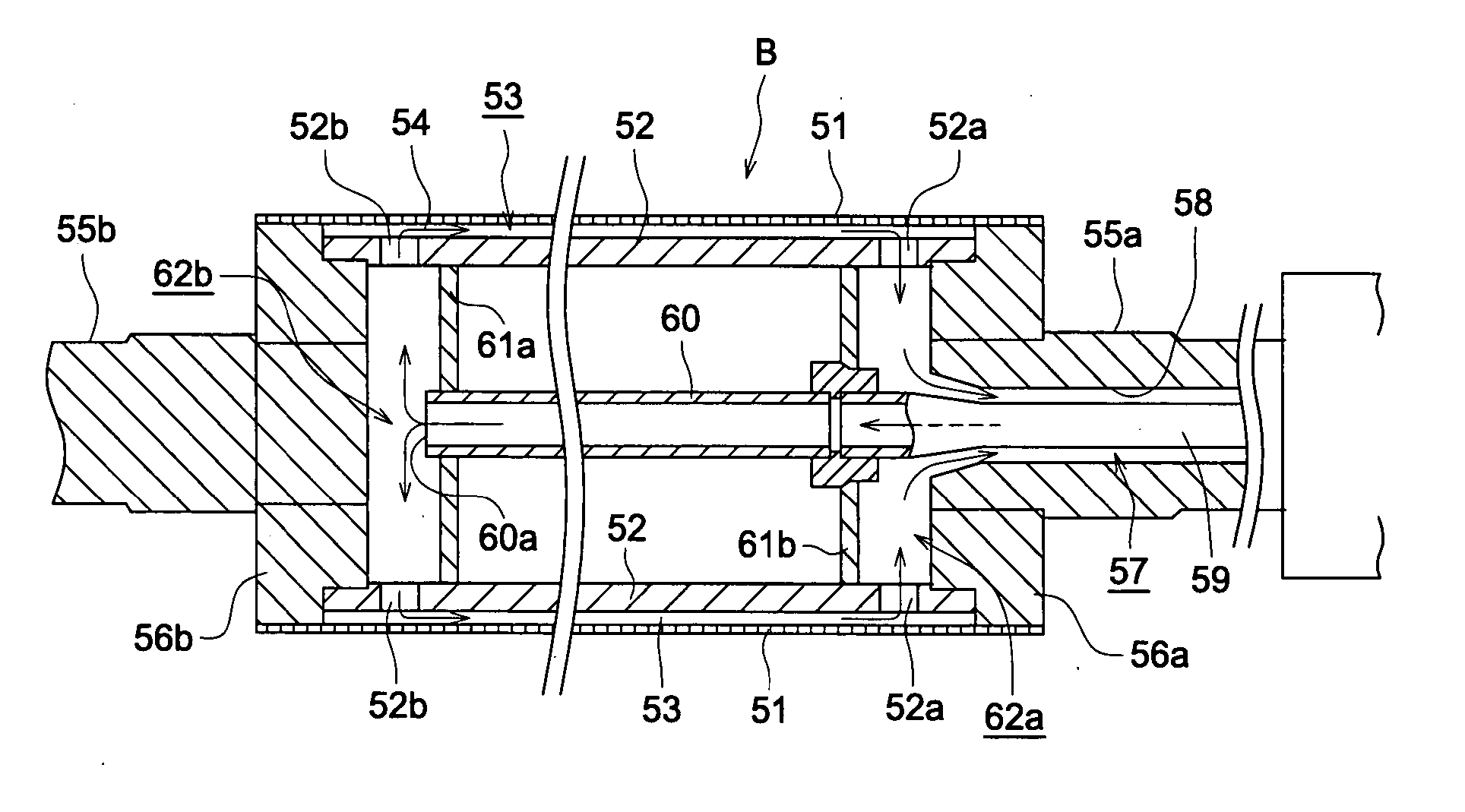

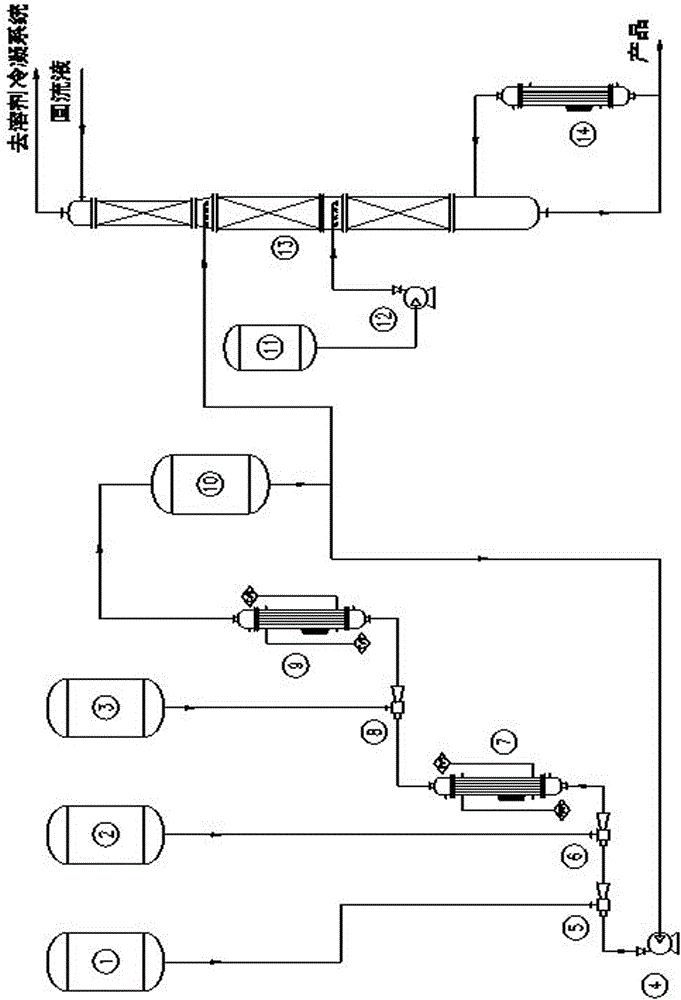

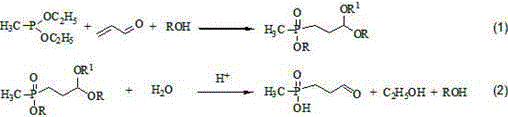

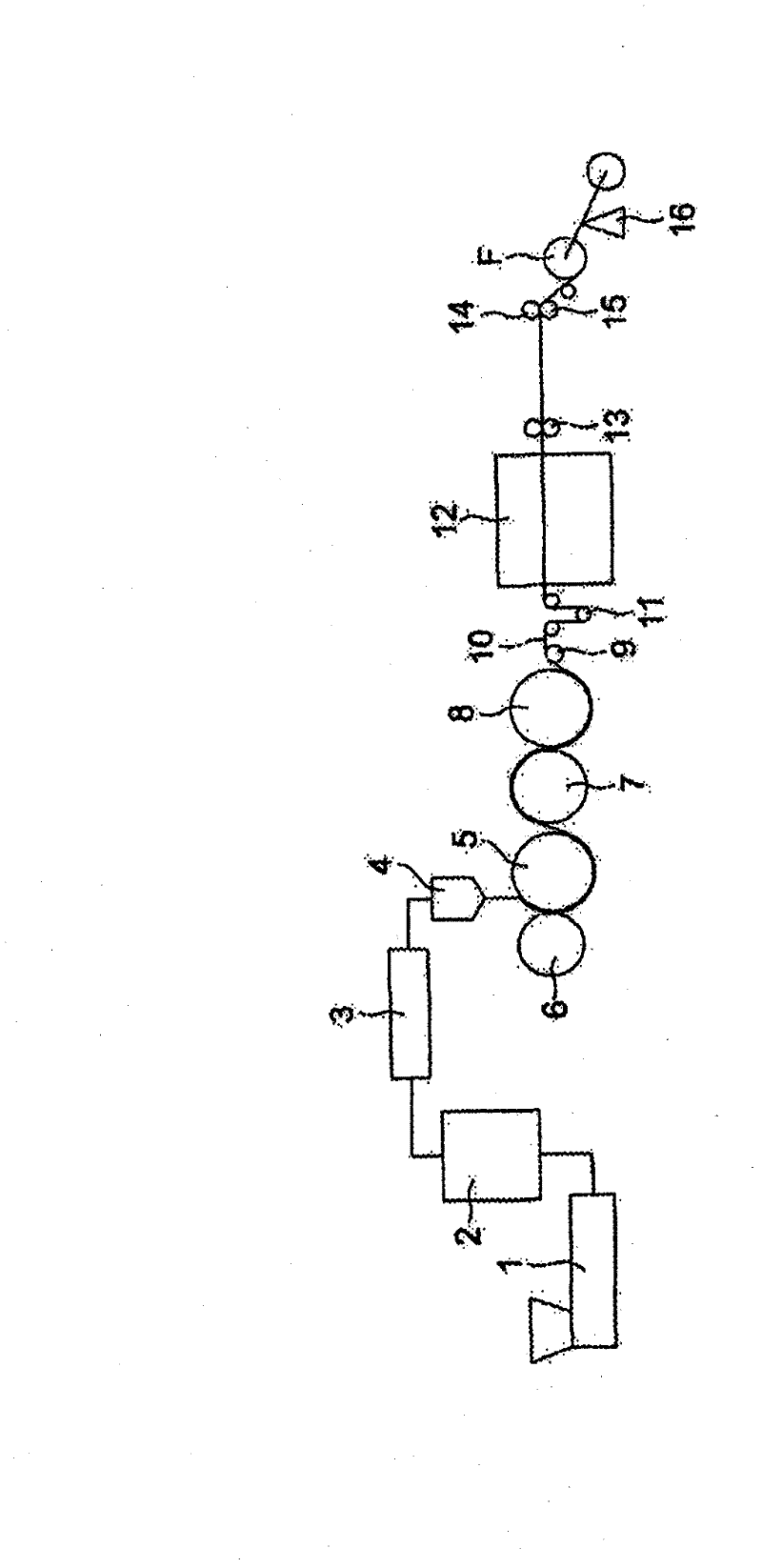

Technology and equipment for continuously producing 3-(methyl hydroxyl phosphonyl) propionaldehyde

ActiveCN105001259ATake away in timeImprove stabilityGroup 5/15 element organic compoundsAcyl groupPhosphonite

The invention discloses a technology and equipment for continuously producing 3-(methyl hydroxyl phosphonyl) propionaldehyde. The technology comprises the steps that the raw materials of diethyl methyl-phosphonite, acraldehyde and an alkyl alcohol are continuously added in a recycle tubular reactor to perform addition reaction, and an intermediate 1-dialkoxy-3-(alkoxy methyl phosphonyl) propane is prepared; then the prepared 1-dialkoxy-3-(alkoxy methyl phosphonyl) propane and dilute acid are simultaneously added in a reaction tower, and the product 3-(methyl hydroxyl phosphonyl) propionaldehyde is obtained at the column bottom. According to the technology and equipment, the continuous production of the 3-(methyl hydroxyl phosphonyl) propionaldehyde is achieved, the yield is large, the production cost is low, the automation degree is high, the operation is easy and convenient, the labor intensity is low, and the technology and equipment are more suitable for industrial production.

Owner:HEBEI VEYONG BIO CHEM

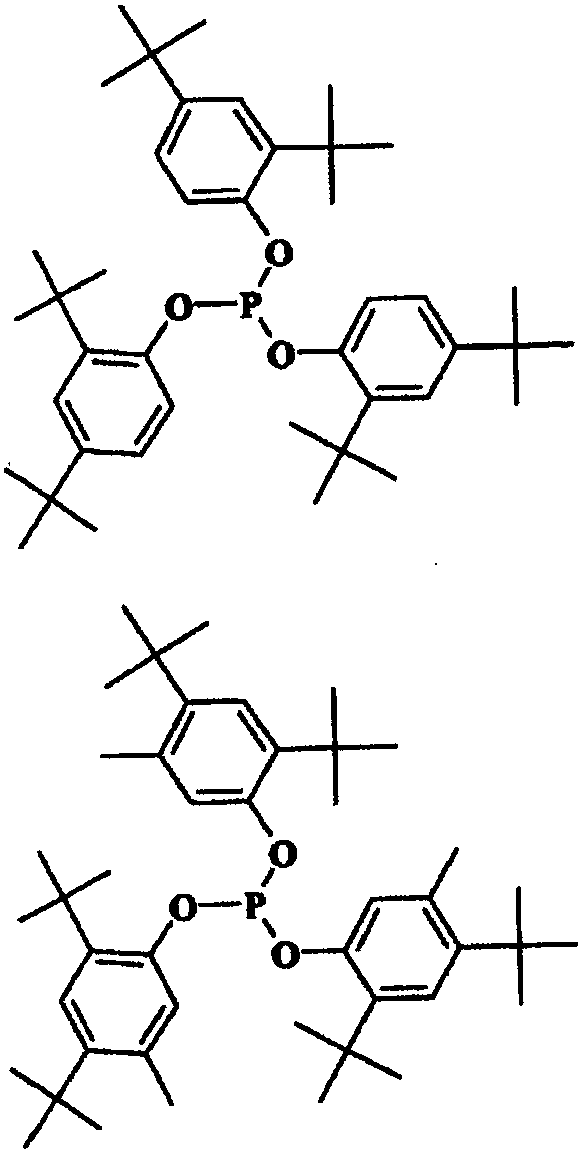

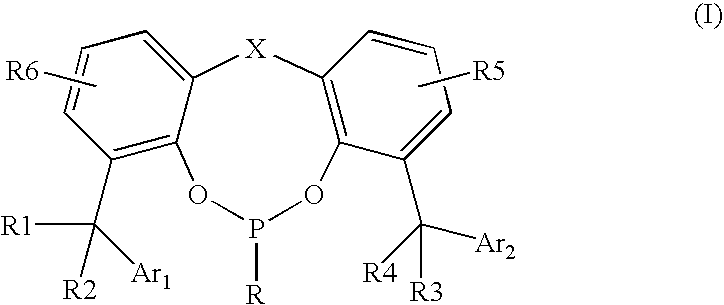

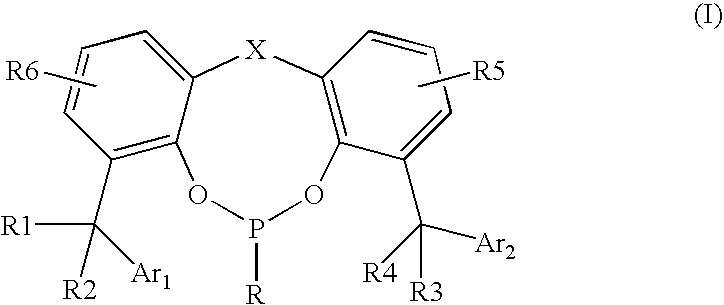

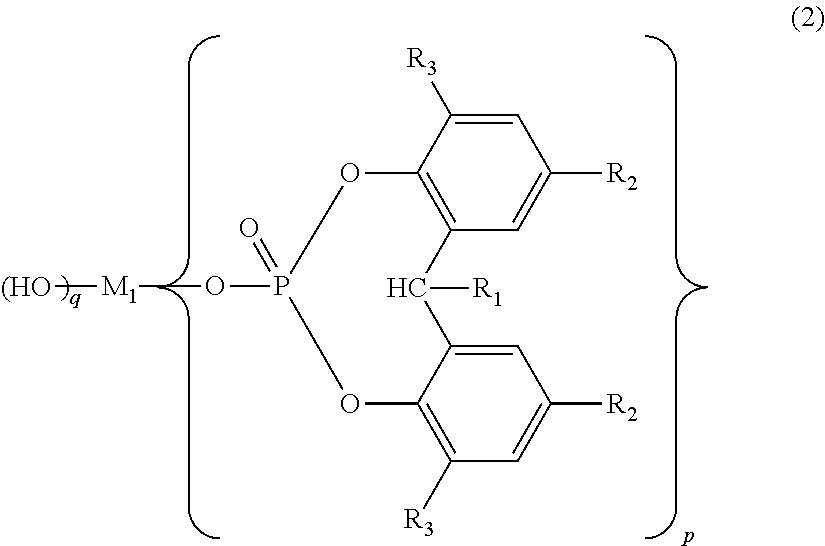

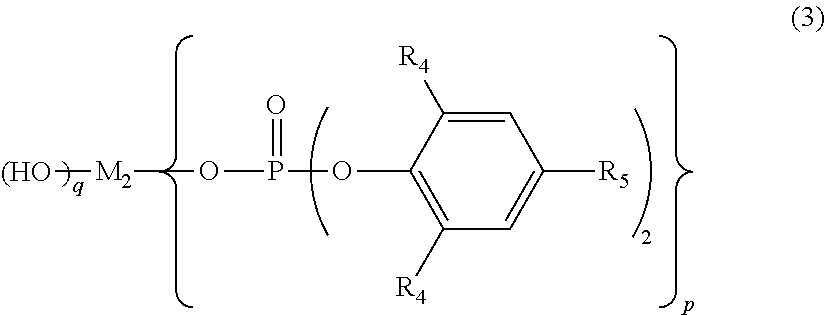

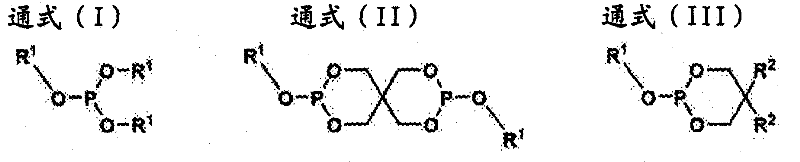

Phosphonite containing catalysts for hydroformylation processes

InactiveUS20090171122A1Increase Rh catalyst activityImprove catalytic stabilityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsArylPhosphonite

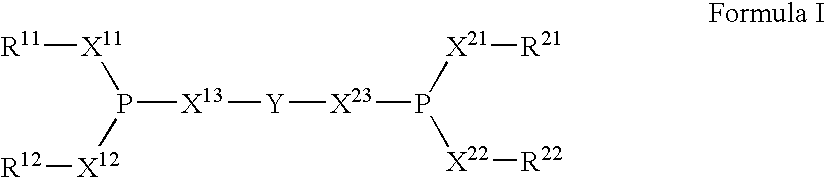

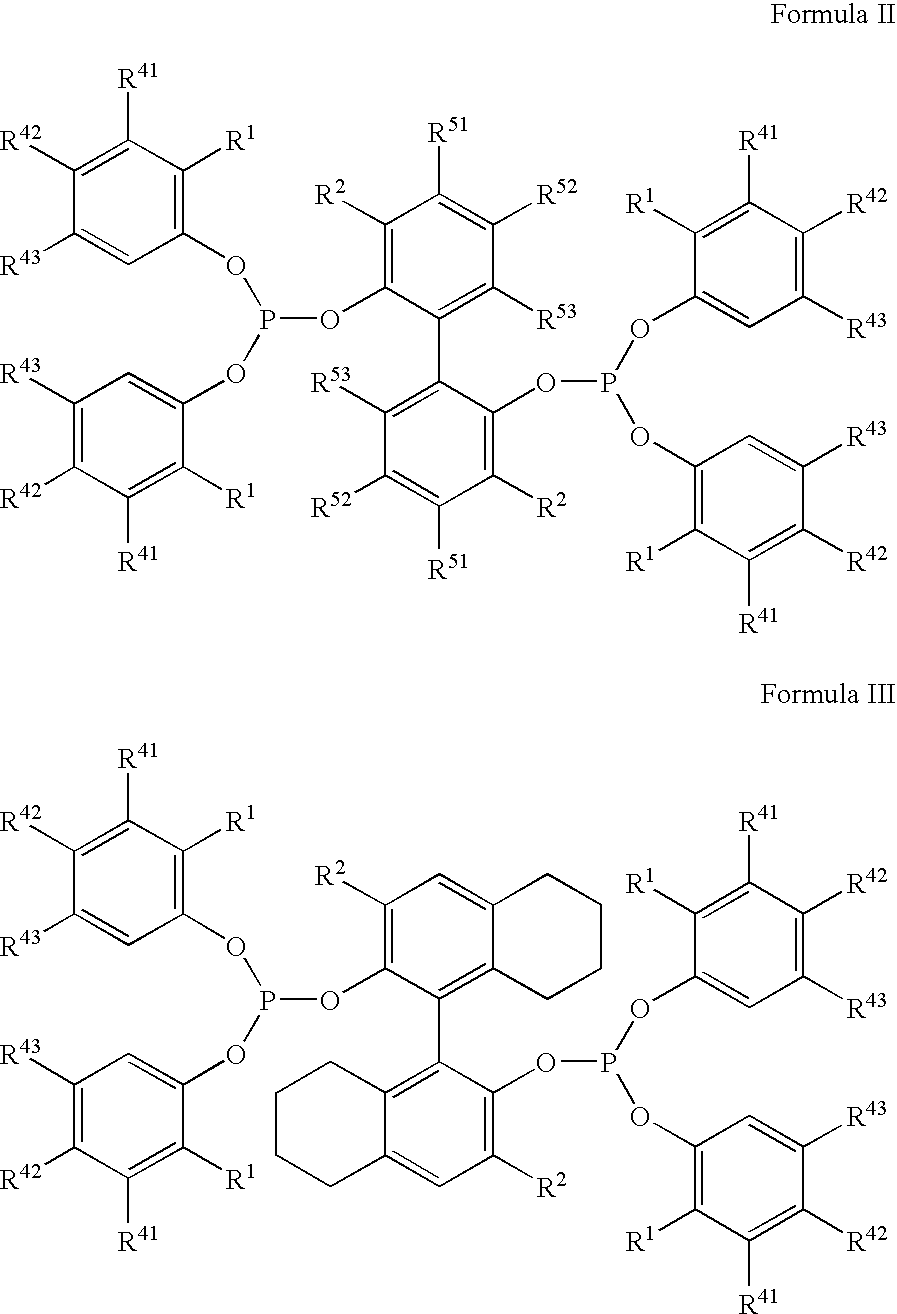

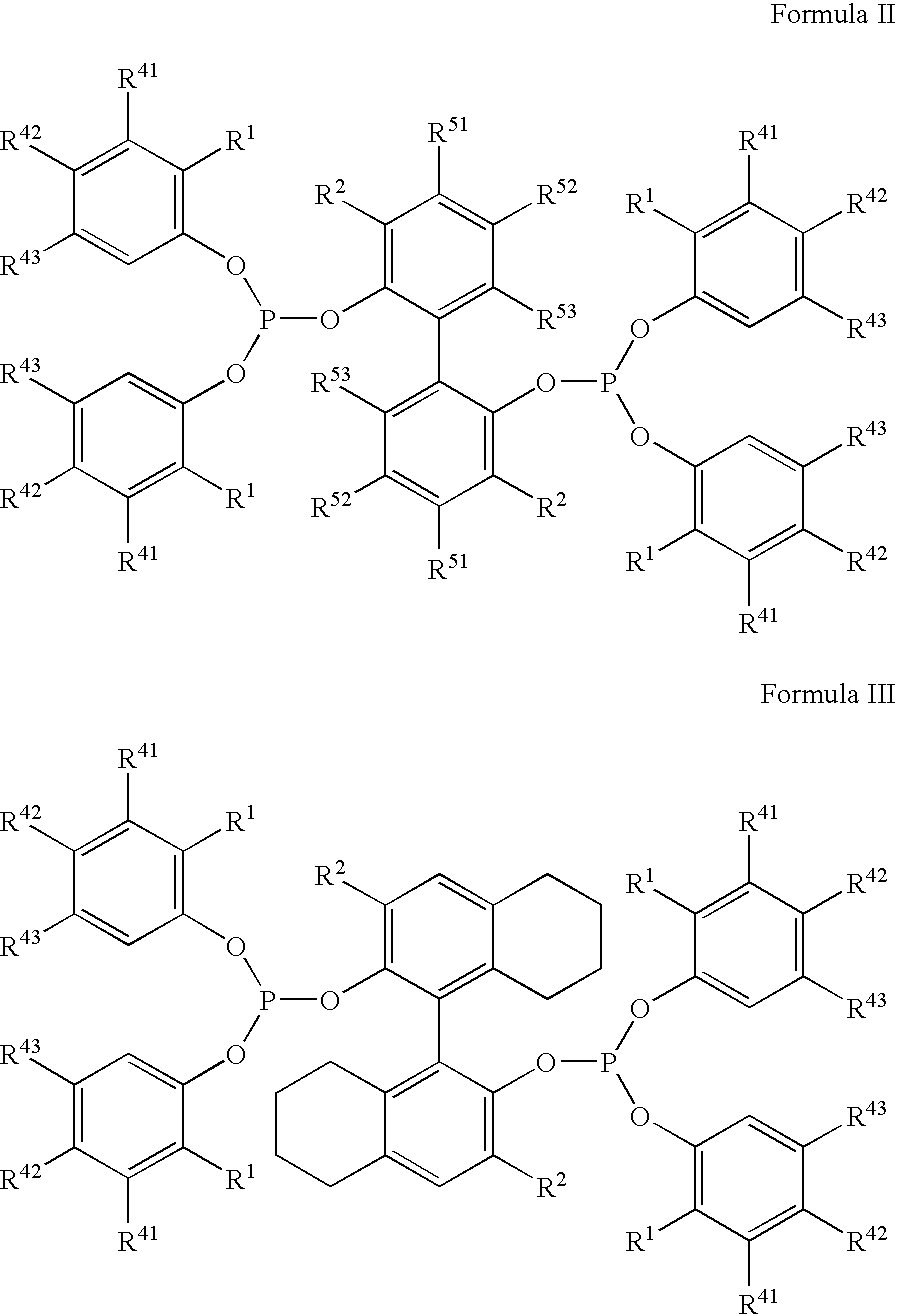

Novel trivalent organophosphonite ligands having the structure of general formula (I):wherein R is an alkyl or aryl group containing 1 to 30 carbon atoms; Ar1 and Ar2 are aryl groups containing 4 to 30 carbon atoms; R1 to R6 are H or alkyl or aryl hydrocarbon radicals containing 1 to 40 carbon atoms; and X is a connecting group or a simple chemical bond, were developed and found to be very active for hydroformylation processes for ethylenically unsaturated substrates. Catalyst solutions prepared from these ligands with a Rh metal show an unusual “ligand acceleration effect” for simple alkenes, i.e., the hydroformylation activity increases as the concentration of ligand increases, and are capable of producing linear or branched aldehydes under typical hydroformylation conditions.

Owner:EASTMAN CHEM CO

Method for the production of hydroxymethyl alkyl phosphinic acids and its ester thereof

InactiveCN1880324ARich and diverse sourcesThe synthesis process is green and environmentally friendlyGroup 5/15 element organic compoundsPolyesterPhosphonite

This invention provides modified method for producing hydroxymethyl-hydrocarbyl phosphinic acid and esterified compound thereof, comprising: hydrocarbyl-dichlorophosphine reacts with ethanol to prepare alkyl phosphonite, and then reacts with paraformaldehyde to prepare hydroxymethyl-hydrocarbyl phosphinic acid; hydrocarbyl phosphinic acid reacts with paraformaldehyde to prepare hydroxymethyl-hydrocarbyl phosphinic acid and then reacts with some diatomic alcohol for esterification. The esterified compound provided by this invention can be used as copolymerization combustion inhibitor of polyester.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Novel use of organic phosphonite

The invention discloses novel use of organic phosphonite, in particular use of the organic phosphonite as a corrosion inhibitor of titanium in sulfuric acid solution. The organic phosphonite may be one of amino trimethylene phosphonic acid and salts thereof, 1-hydroxy ethylidene-1,1-diphosphonic acid and salts thereof, [1,2-ethanediylbis(nitrilobis-(methylene))]tetrakis-phosphonic acid and salts thereof, diethylenetriaminepenta(methylene-phosphonic acid) and salts thereof, polyhydric alcohol phosphate ester, 2-hydroxyphosphonoacetic acid, hexamethylene diamine tetra(methylene phosphonic acid) and salts thereof, polyamino polyether methylene phosphonates, bis(hexamethylene triamine penta (methylene phosphonic Aacid)) and salts thereof, and phytic acid. The invention belongs to the technical field of metal material / chemical equipment anticorrosion. The corrosion inhibitor has a good corrosion inhibition effect on sulfuric acid under the condition of low dosage and has a high application value.

Owner:JIAYING UNIV

Scorch prevention in flexible polyurethane foams

InactiveUS20080048157A1Good foaming effectImprove stabilityImpression capsDentistry preparationsEpoxyAntioxidant

Compositions and methods for alleviating or preventing discoloration in flame-retarded flexible polyurethane foams, known as “scorching”, are provided. The anti-scorch compositions contain antioxidant agents combined with at least one, and preferably with two, additional compounds selected from β-diketone compounds, epoxy compounds, organic phosphites or phosphonites, and metal salts of carboxylic acids.

Owner:BROMINE COMPOUNDS

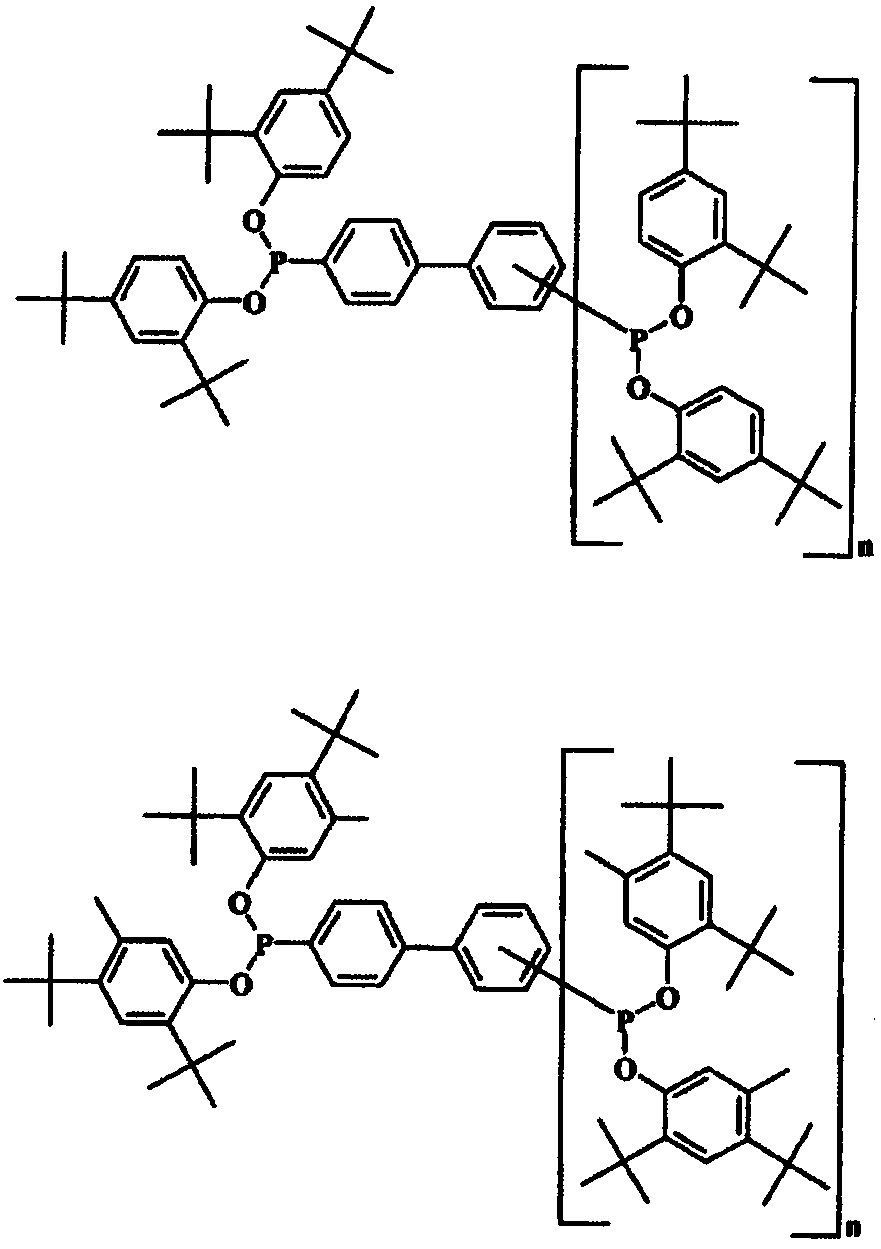

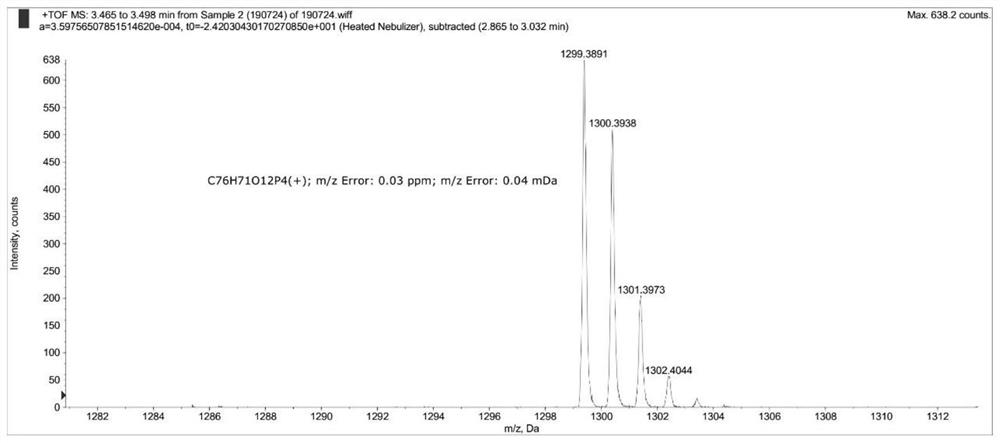

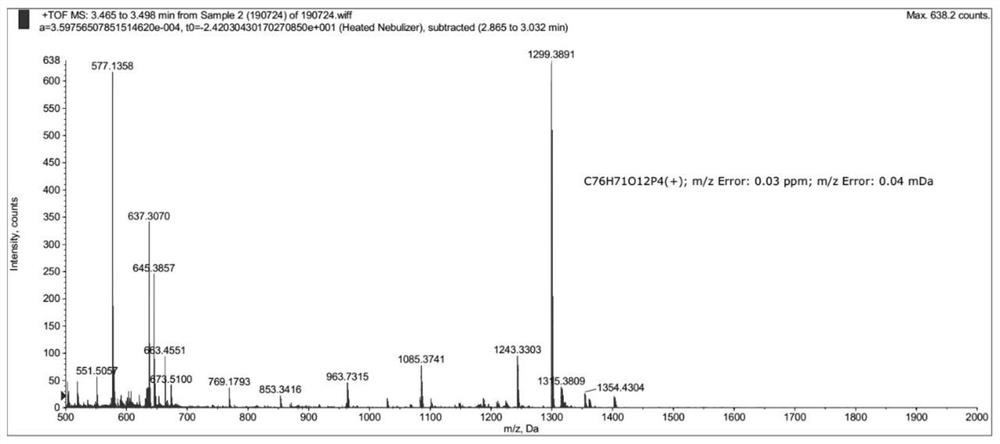

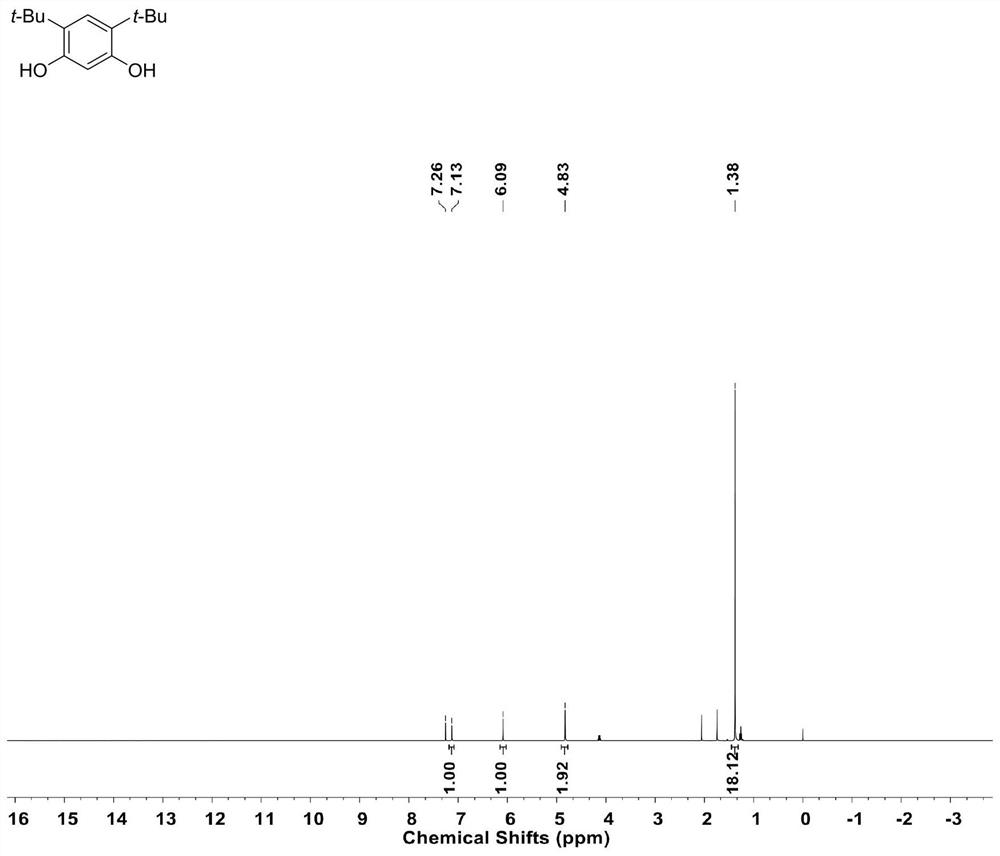

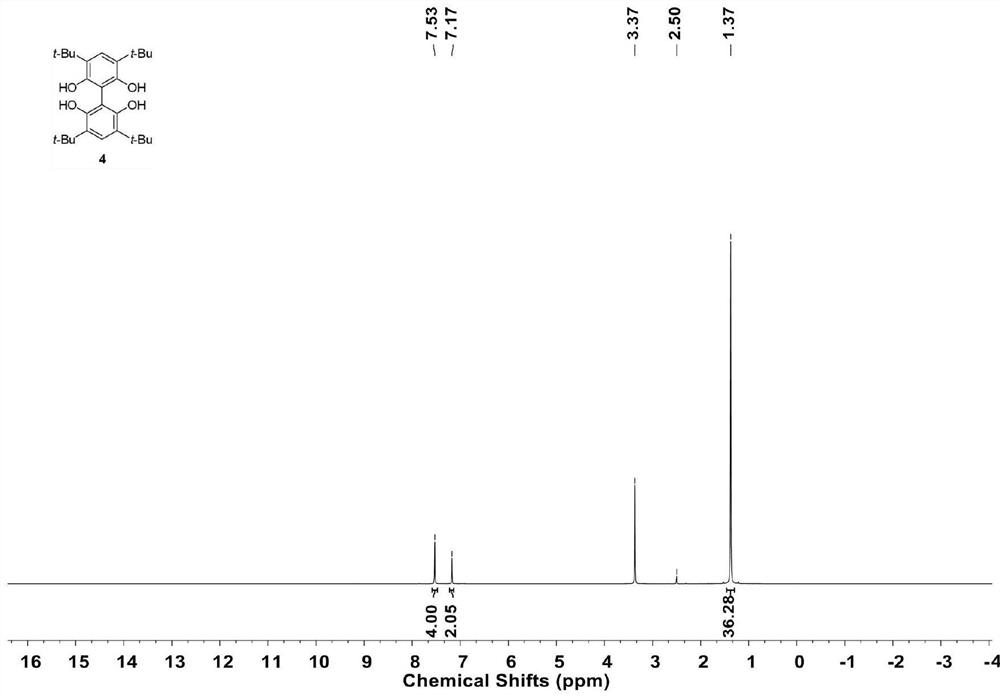

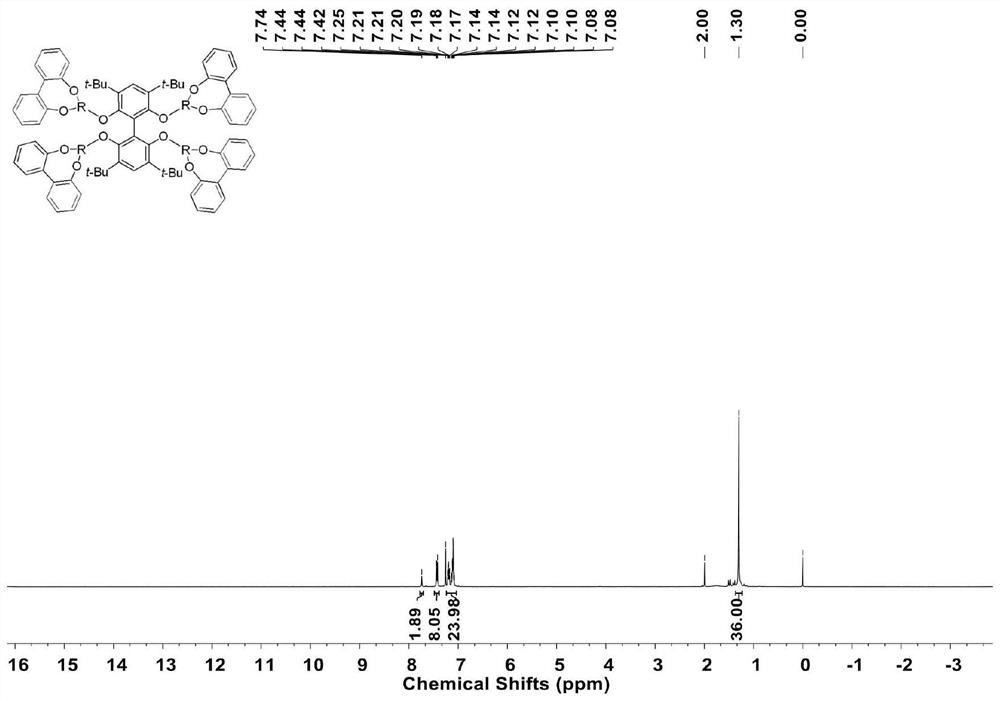

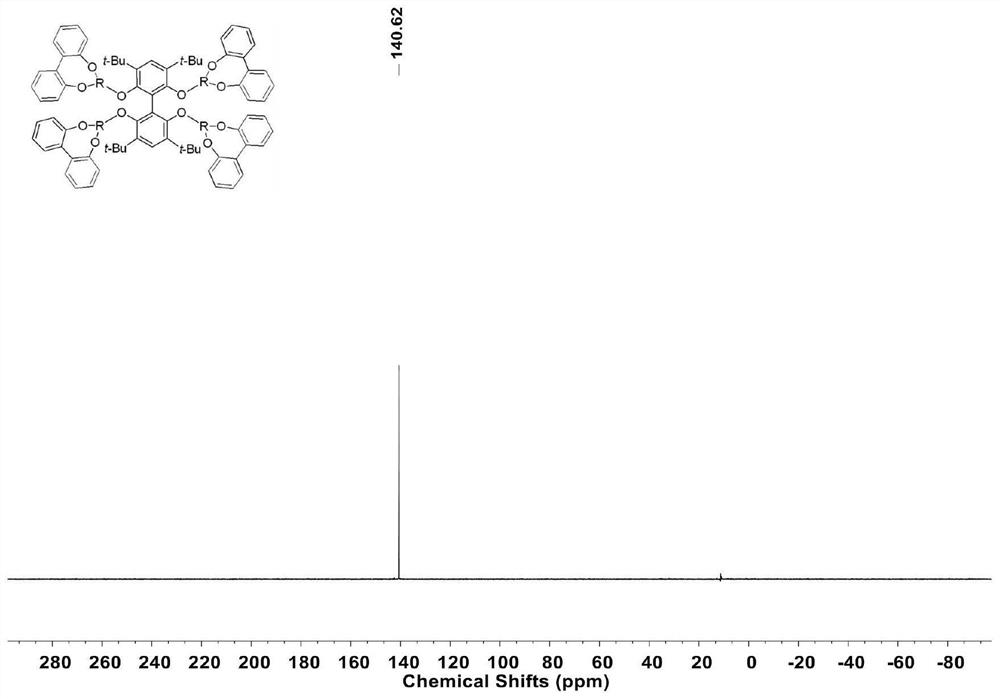

Preparation of novel biphenyl tetradentate phosphite ligand and application of novel biphenyl tetradentate phosphite ligand in mixed/etherified C4 hydroformylation reaction

PendingCN111909207AOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPerylene derivativesPhosphonite

The invention discloses a preparation method of a novel biphenyl tetradentate phosphite ligand 2, 2 ', 6, 6'-tetra [(1, 1 'biphenyl-2, 2'-diyl) phosphite]-3, 3 ', 5, 5'- tetra-tert-butyl -1, 1- 'biphenyl and derivatives thereof. The novel biphenyl tetradentate phosphite ligand has a structure as shown in general formula I, wherein a substituent R in the general formula I can be a cyclic phosphinestructure. Meanwhile, the invention discloses an application in a mixed / etherified C4 (butene) hydroformylation reaction system taking a novel biphenyl tetradentate phosphite ligand as a ligand.

Owner:广东欧凯新材料有限公司

Preparation method of biphenyl tetradentate phosphite ligand

PendingCN111909209AOrganic compound preparationGroup 5/15 element organic compoundsFormylation reactionPerylene derivatives

The invention discloses a preparation method of a novel biphenyl tetradentate phosphite ligand 2,2',6,6'-tetra [(1,1'-biphenyl-2,2'-diyl) phosphite]-3,3',5,5'-tetra-tert-butyl-1,1'-biphenyl and derivatives thereof. The novel biphenyl tetradentate phosphite ligand has a structure as shown in a general formula I, wherein a substituent R in the general formula I can be a cyclic phosphine structure. The novel biphenyl tetradentate phosphite ligand has good conversion rate and normal-to-isomeric ratio in a mixed / etherified C4 (butylene) hydroformylation reaction system.

Owner:广东欧凯新材料有限公司

Thermoplastic resin composition for producing automobile exterior parts

Owner:DSM IP ASSETS BV

Polylactic acid composition and molded article thereof

InactiveUS20140066555A1Improve thermal stabilityReduce heatGroup 5/15 element organic compoundsPhosphorous acidPolymer science

A method for producing a composition including polylactic acid and having excellent heat stability, especially moist heat stability, and a molded article thereof. The composition includes 100 parts by weight of a resin component (component A) which is composed of 5 to 100 wt % of polylactic acid (component A-α) and 95 to 0 wt % of a thermoplastic resin (component A-β), 0.001 to 5 parts by weight of a phosphono-fatty acid ester (component B), 0.01 to 5 parts by weight of a phosphate metal salt (component C), 0.001 to 2 parts by weight of at least one antioxidant (component D) selected from the group consisting of a phosphite-based compound, a phosphonite-based compound, a hindered phenol-based compound and a thioether-based compound, and 0.001 to 10 parts by weight of an end-sealing agent (component E).

Owner:TEIJIN LTD +1

Optical film, method for producing same, polarizing plate using same and liquid crystal display device

InactiveCN102186923AAvoid breakingNo light leakPolarising elementsNon-linear opticsCelluloseLiquid-crystal display

Disclosed is an optical film mainly composed of an acrylic resin and a cellulose ester resin. The optical film is prevented from breakage due to conveyance stress during melt film formation, and does not cause light leakage when used in a polarizing plate. Also disclosed is a polarizing plate using the optical film, and a liquid crystal display device. The optical film is characterized by containing an acrylic resin (A) and a cellulose ester resin (B), which are mixed at a mass ratio of from 50:50 to 95:5, and additionally containing a phosphorus additive selected from phosphinite, phosphonite and phosphite.

Owner:KONICA MINOLTA OPTO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com