Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

152results about "Granulation with special binding agents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Soil conditioning agglomerates containing calcium

InactiveUS6936087B2High mechanical strengthGood curative effectBiocideCalcareous fertilisersParticulatesWater soluble

Mechanically strong, water-disintegrable agglomerates made from a particulate calcium source, a water-soluble binder and optionally containing a primary plant nutrient source and / or micronutrient source and a process for forming such agglomerates are disclosed. The agglomerates may be used as a soil liming agent and for introducing nutrient values into cultivated soil. Also disclosed is a method for introducing nutrient values into cultivated soil so as to inhibit leaching of the nutrient values from the soil and improve utilization of the nutrient values by plants grown in the soil.

Owner:MAGIC GREEN CORP

Polyvinyl butyral granular material for 3-D binder printing, production method and uses therefor

InactiveUS7402330B2Flat surfaceFiner and more detailed structureGranule coatingPretreated surfacesSurface layerMaterials science

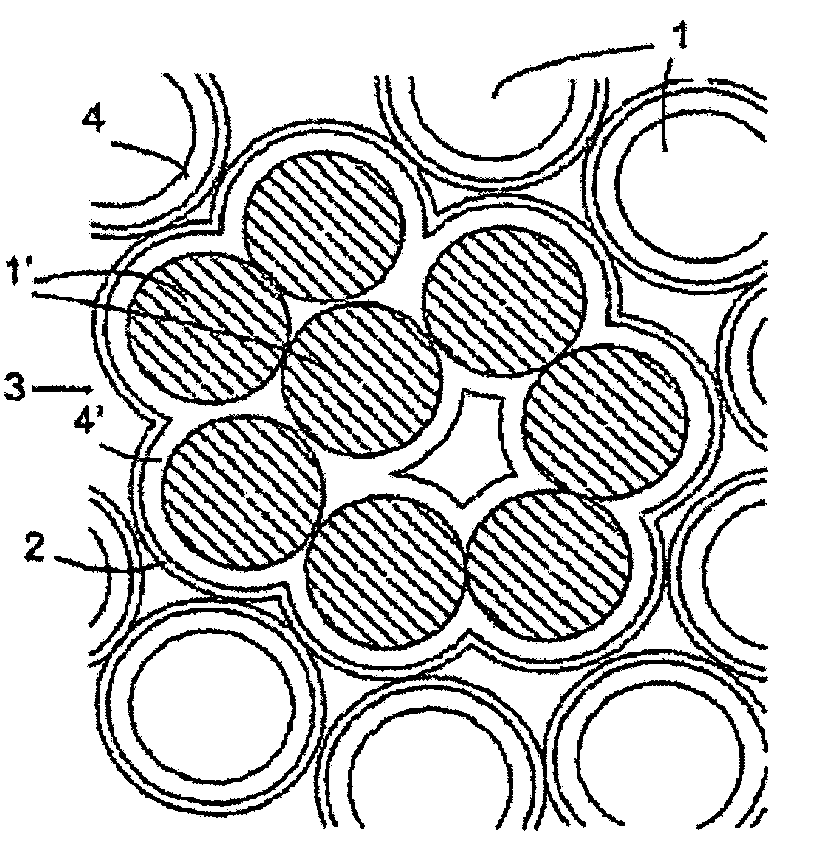

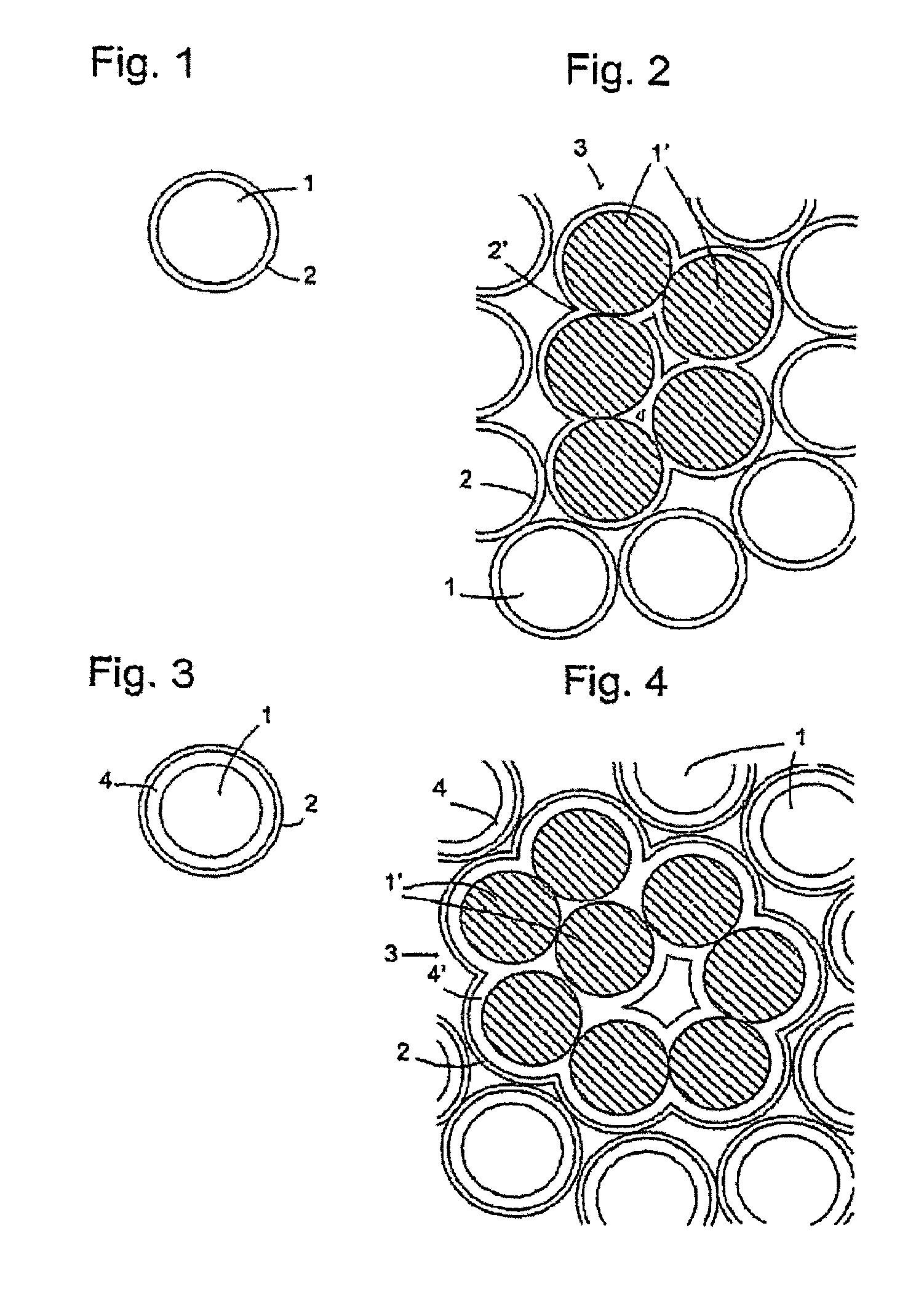

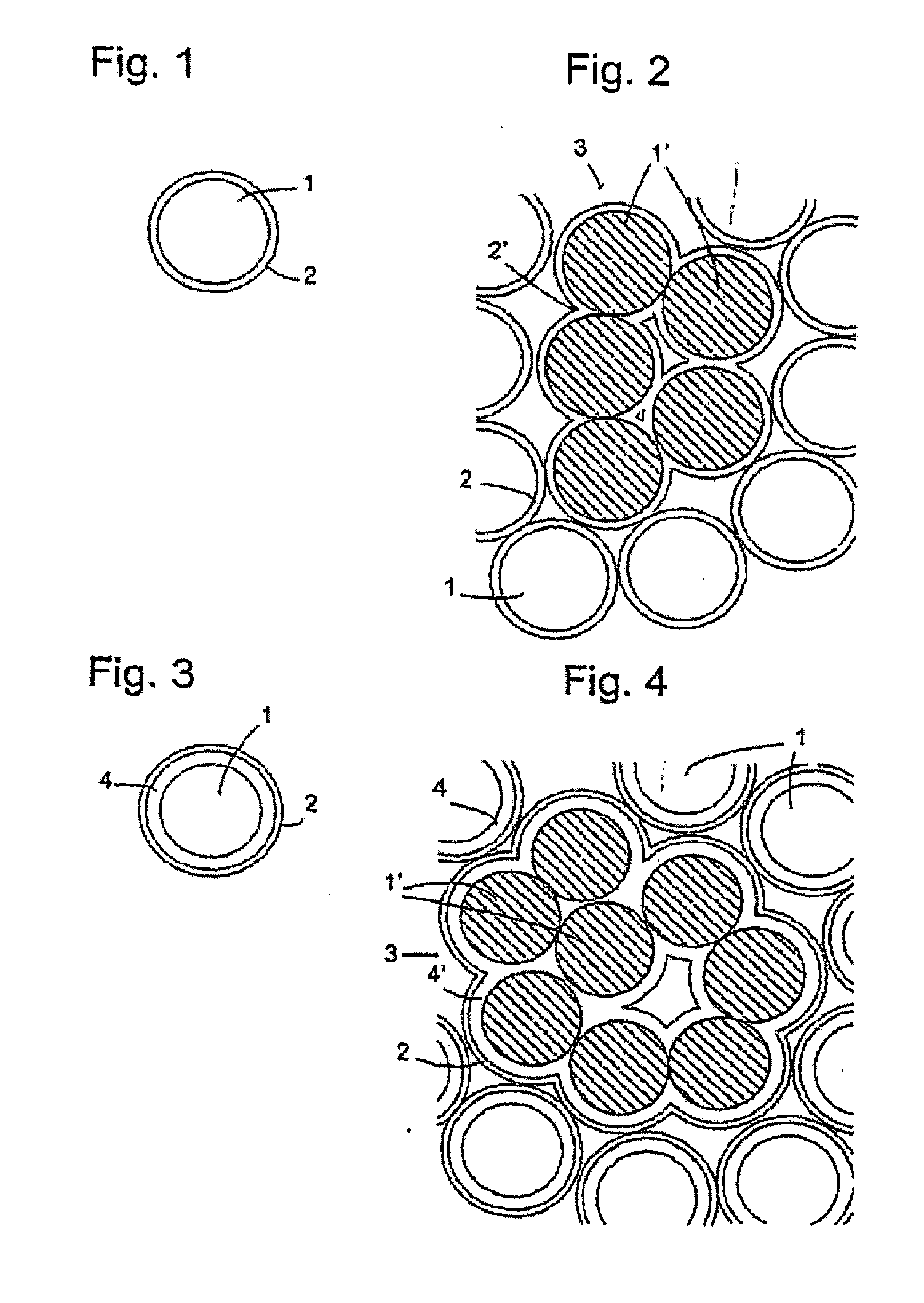

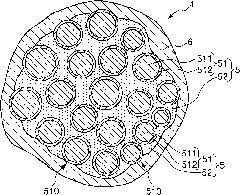

The invention relates to a granular material for 3D binder printing, said granular material consisting of particles provided with an externally non-polar surface layer (2). The invention also relates to a method for producing a granular material for 3D binder printing, whereby a surface layer (2) having a non-polar outer side is applied to initial particles (1), and to a method for producing an object consisting of the inventive granular material, according to which a layer of the inventive granular material is applied to a base, and pre-determined regions (3) of said layer are moistened with a binding fluid, said binding fluid being selected from fluids in which a surface layer of the particles of the granular material is soluble. The invention further realties to objects consisting of interconnected particles of the inventive granular material. The invention enables a very precise printing process.

Owner:VOXELJET AG

Technology for granulating powder

ActiveCN102107127ASimple processLow equipment requirementsGranulation with special binding agentsPrillAdhesive

Owner:SUNRESIN NEW METERIALS CO LTD XIAN

Granular material for 3d binder printing, production method and uses therefor

InactiveUS20050276976A1Extended service lifeFlat surfaceGranule coatingPretreated surfacesSurface layerMaterials science

The invention relates to a granular material for 3D binder printing, said granular material consisting of particles provided with an externally non-polar surface layer (2). The invention also relates to a method for producing a granular material for 3D binder printing, whereby a surface layer (2) having a non-polar outer side is applied to initial particles (1), and to a method for producing an object consisting of the inventive granular material, according to which a layer of the inventive granular material is applied to a base, and pre-determined regions (3) of said layer are moistened with a binding fluid, said binding fluid being selected from fluids in which a surface layer of the particles of the granular material is soluble. The invention further realties to objects consisting of interconnected particles of the inventive granular material. The invention enables a very precise printing process.

Owner:VOXELJET AG

Alumina-based catalyst for the treatment of gases containing sulphur compounds, use of these catalysts for the treatment and processes for treatment of the said gases

InactiveUS6080379AImprove performanceDispersed particle separationHydrogen sulfidesOrganic sulphur compoundSulphur compound

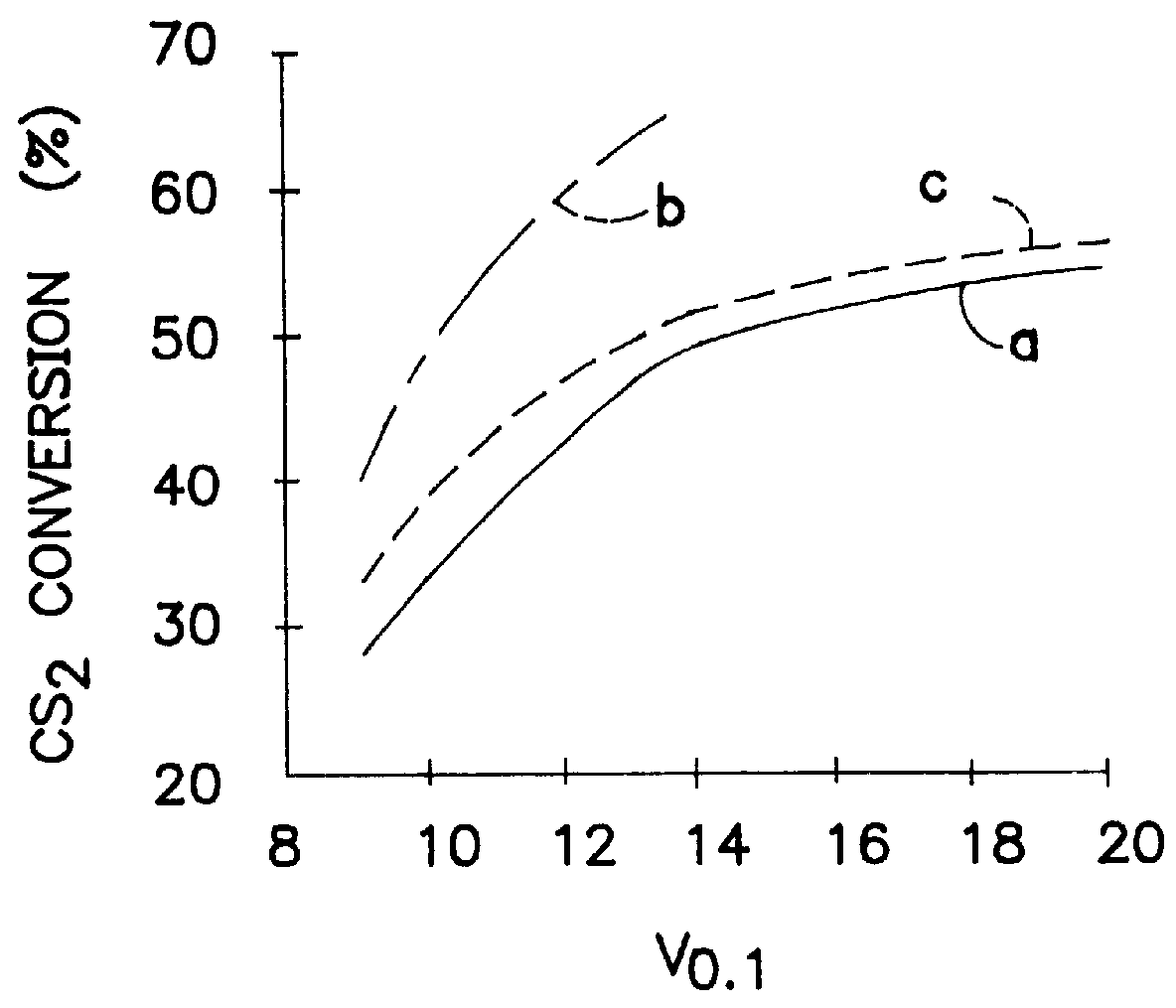

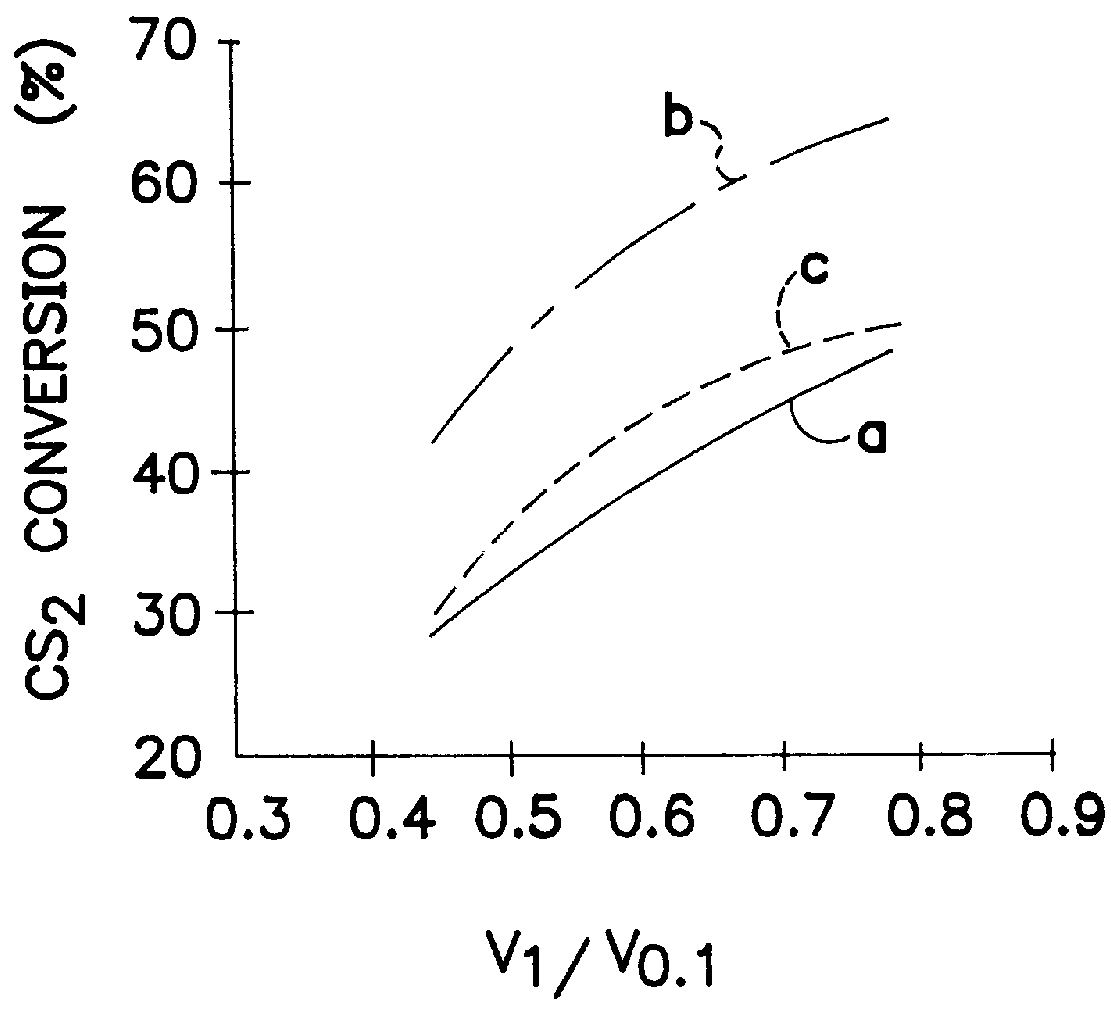

The invention relates to a catalyst for the treatment of gases containing sulphur compounds, using the Claus reaction or using hydrolysis, which is made up of alumina-based porous particles and characterized in that the cumulative volume created by all the pores whose diameter is greater than 0.1 .mu.m, V.sub.0.1, is greater than 12 ml / 100 g of catalyst and in that the cumulative volume created by all the pores whose diameter is greater than 1 .mu.m, V.sub.1, is such that the ratio V.sub.1 / V.sub.0.1 is higher than or equal to 0.65. This catalyst can be employed for the treatment of gases containing sulphur compounds by using the Claus reaction, or of gases containing organic sulphur compounds by using a hydrolysis reaction.

Owner:INST FR DU PETROLE

Controlled release cooling additive composition

InactiveUS6878309B2Consistent levelMaintain good propertiesBiocideWater softeningControlled releasePolymer coating

A controlled-release additive composition for use in aqueous systems. The composition comprises a core containing at least one additive component and a polymeric coating encapsulating said core. The controlled released cooling additive composition slowly releases the additive components to aqueous system, thereby delivering an effective concentration level of additive components over an extended period.

Owner:DOBER CHEMICAL CORPORATION

Dispersable thermoplastic mineral powder particle and preparing method thereof

ActiveCN1528809AGood dispersionReduce flyingInorganic pigment treatmentGranulation with special binding agentsThermoplasticMaterials science

The invention discloses a kind of mineral powder granules which are dispersive and have thermal plasticity. The mineral powder granules are made up of 95%-99.8% weight percentage mineral powder and 0.2%-5% weight percentage thermal plasticity binder. The mineral powder granules are easy to be dispersed, it can reduces the fluffy powder in use, decreases the harm to the environment and workers, at the same time, upgrades the quality of the products, it applies to plastic, rubber, paint field. The invention also discloses the manufacturing method of above mineral powder granules.

Owner:GUANGZHOU ECHOM SCI & TECH CO LTD

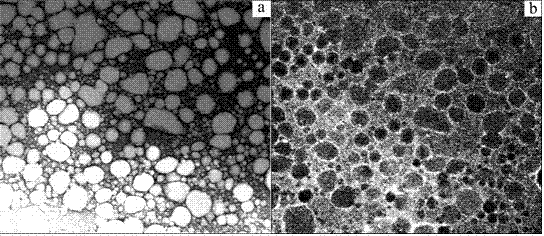

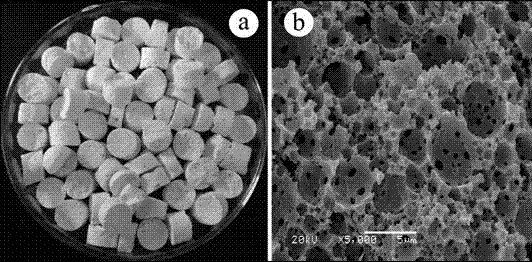

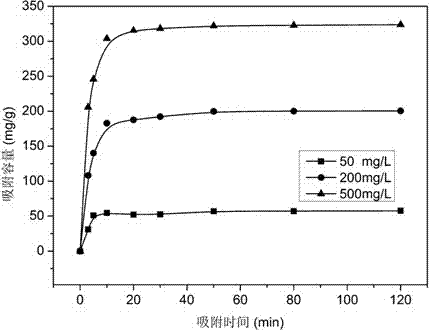

Porous foam body heavy metal adsorption material preparation method

ActiveCN104759265AImprove adsorption capacityEasy to useOther chemical processesContaminated soil reclamationFunctional monomerSoil treatment

The invention provides a porous foam body heavy metal adsorption material preparation method through a high internal-phase emulsion template method and belongs to the technical field of high-molecular materials. In the method, with water as a continuous phase, an organic solvent as an organic dispersed phase, a nonionic surfactant as an emulsion stabilizer, chitosan as a grafting framework and a polymerizable functional monomer as a grafting monomer, a white porous foam body material is prepared through the high internal-phase emulsion template method in the presence of an initiator and a crosslinking agent. An experimental result proves that the porous foam body heavy metal adsorption material not only contains abundant porous structures so that adsorption rate and capacity to heavy metal are greatly increased, but also has a quite excellent repeatable performance. Meanwhile, the material is in the form of a porous foam body so that the material is convenient to use and can be recycled when being used in heavy metal-polluted soil treatment.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

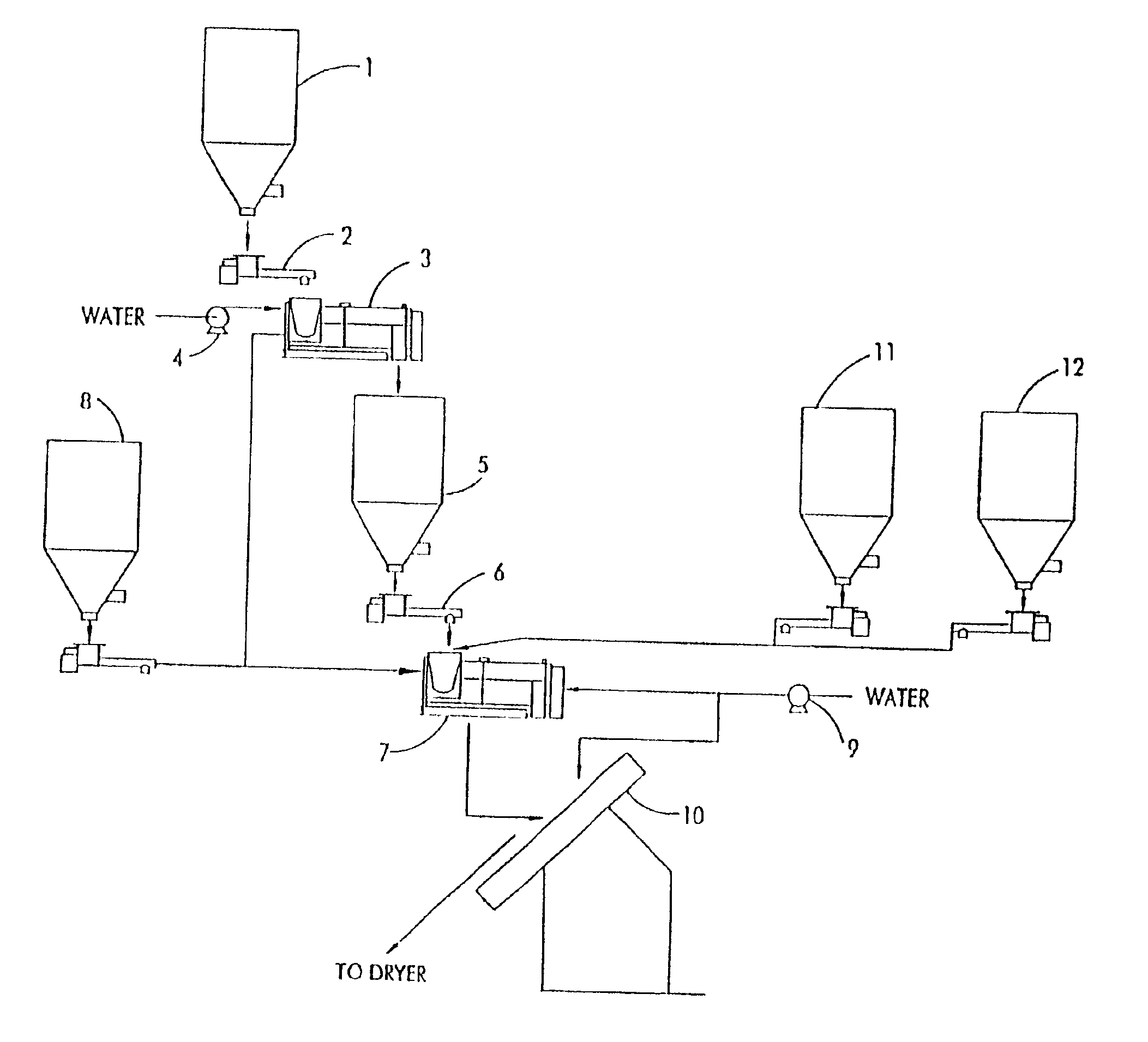

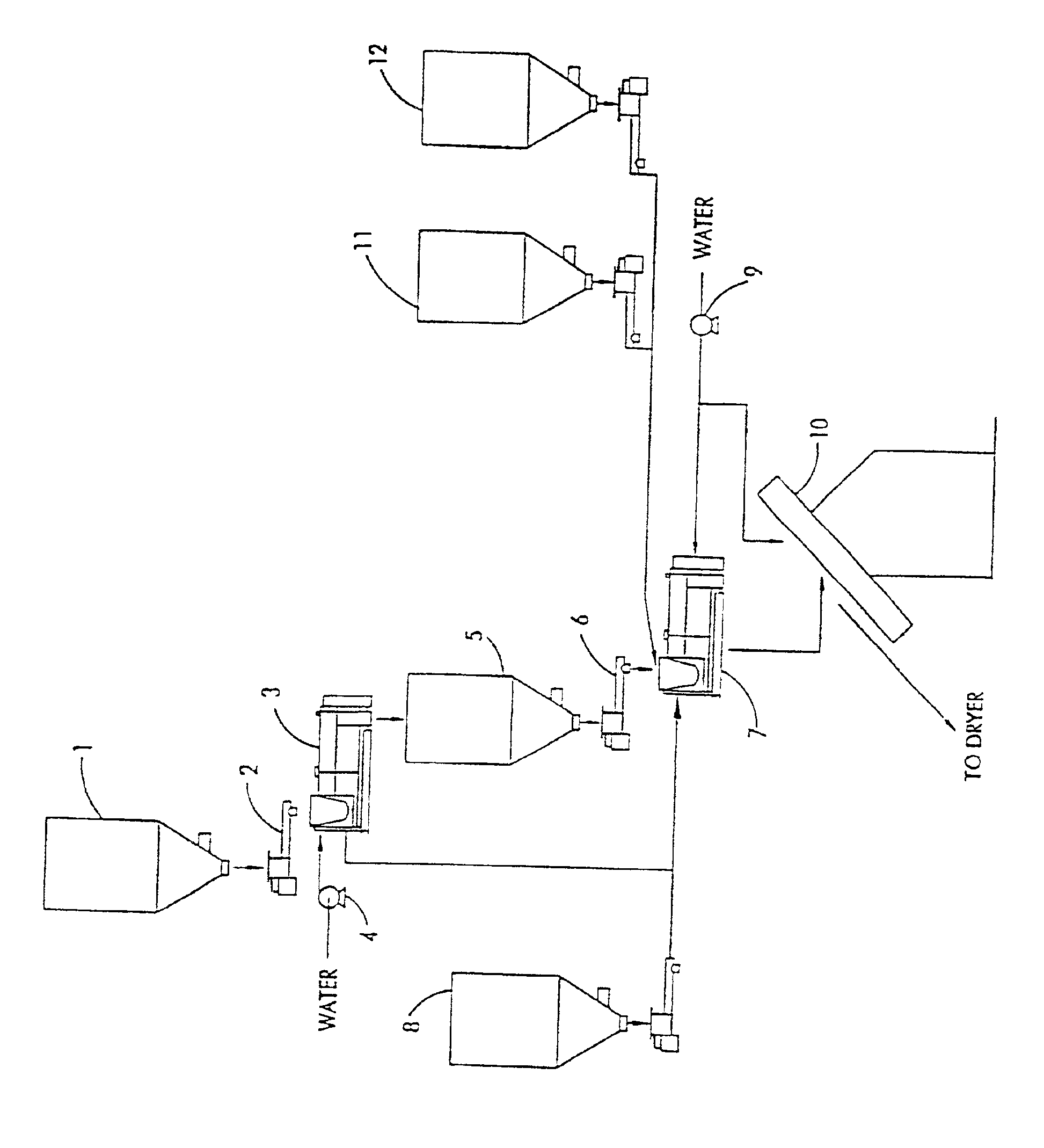

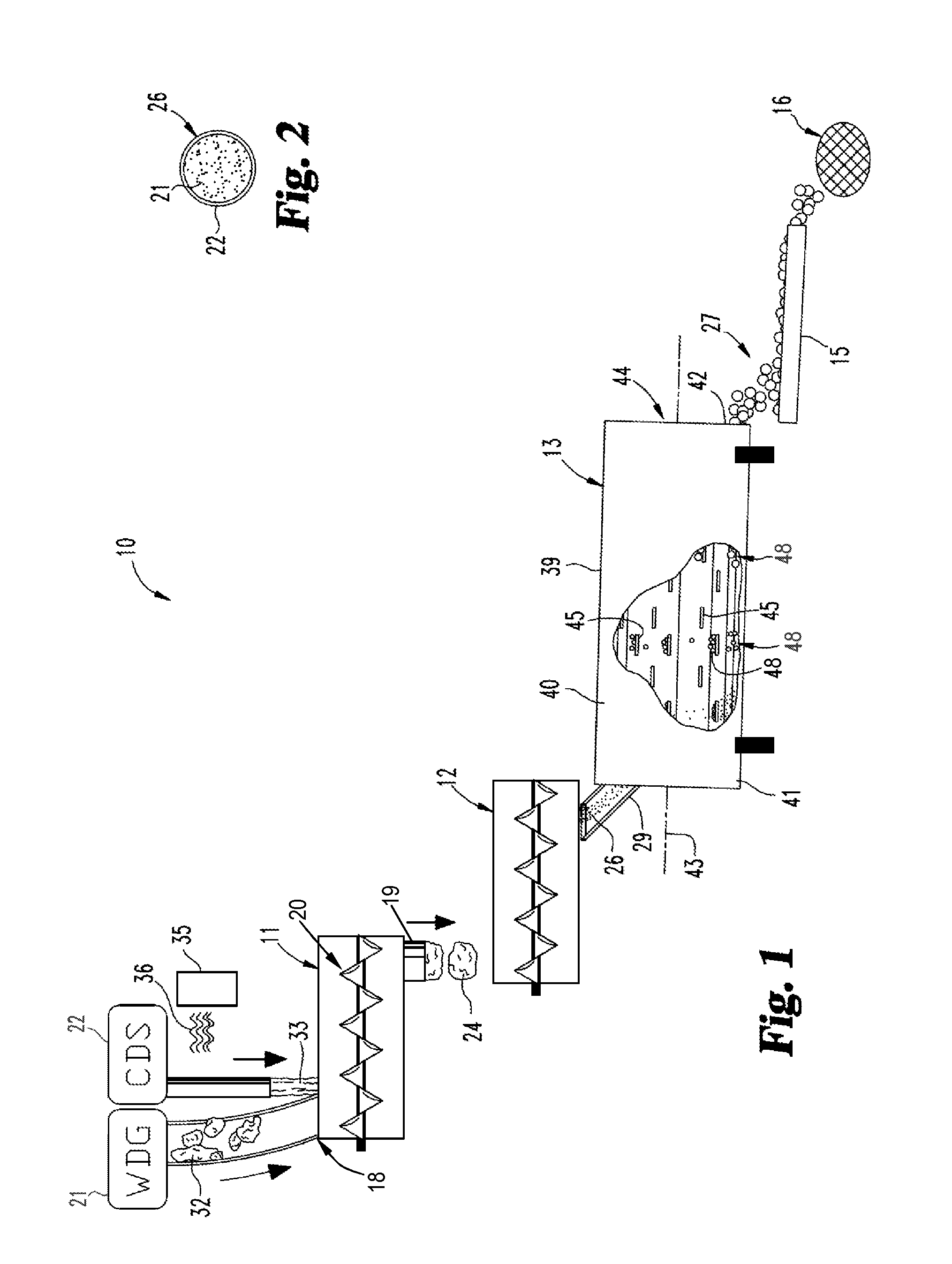

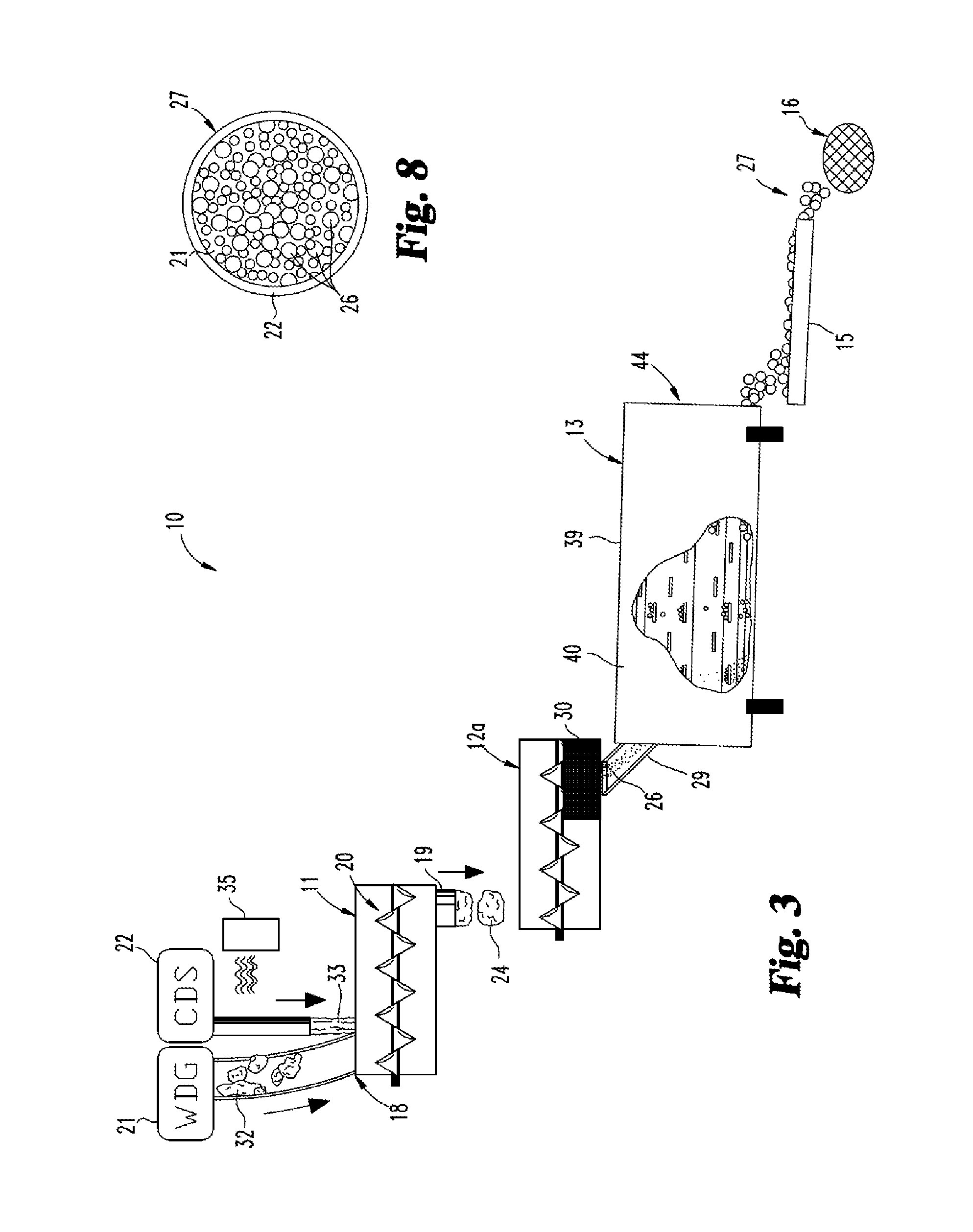

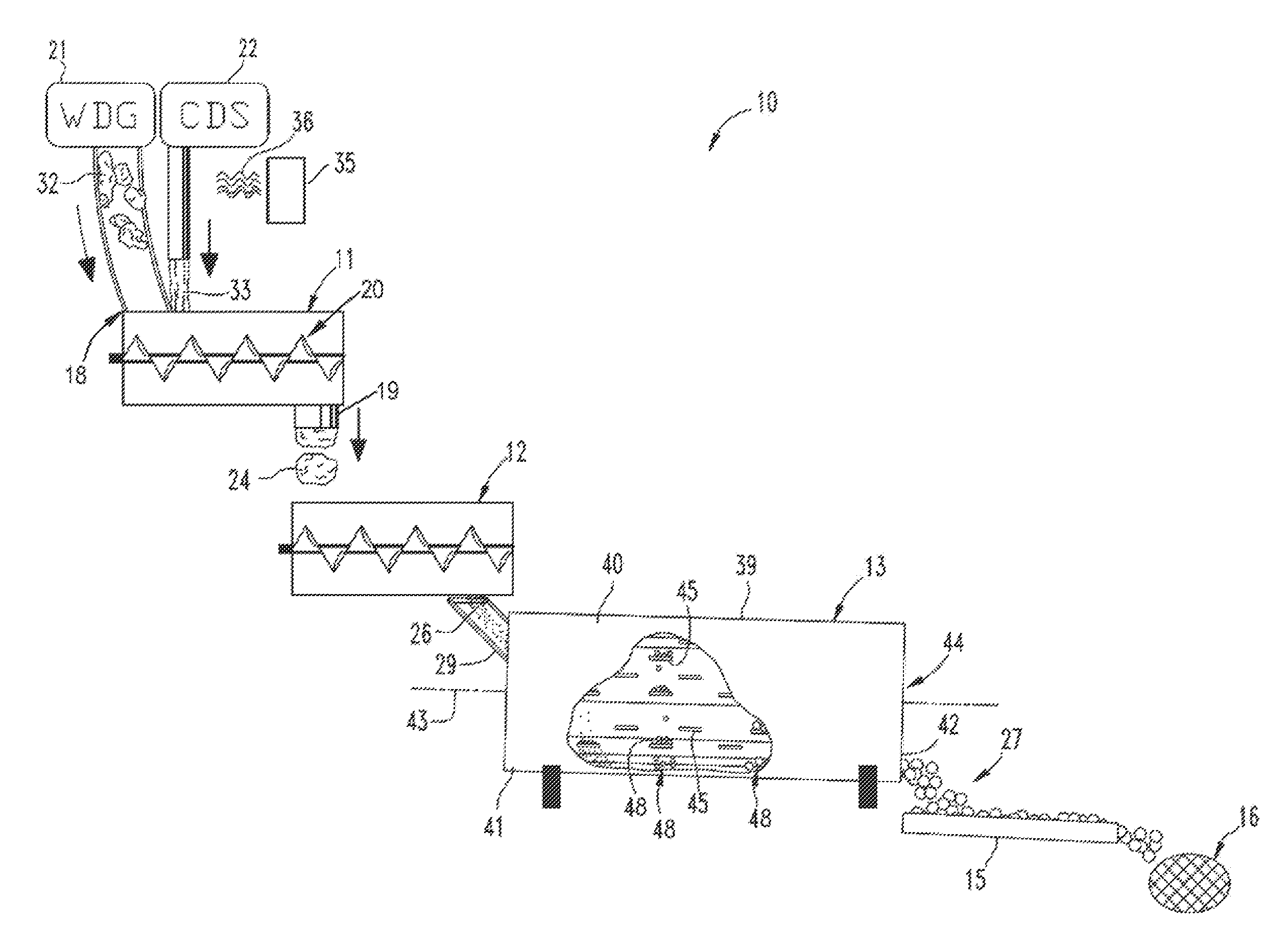

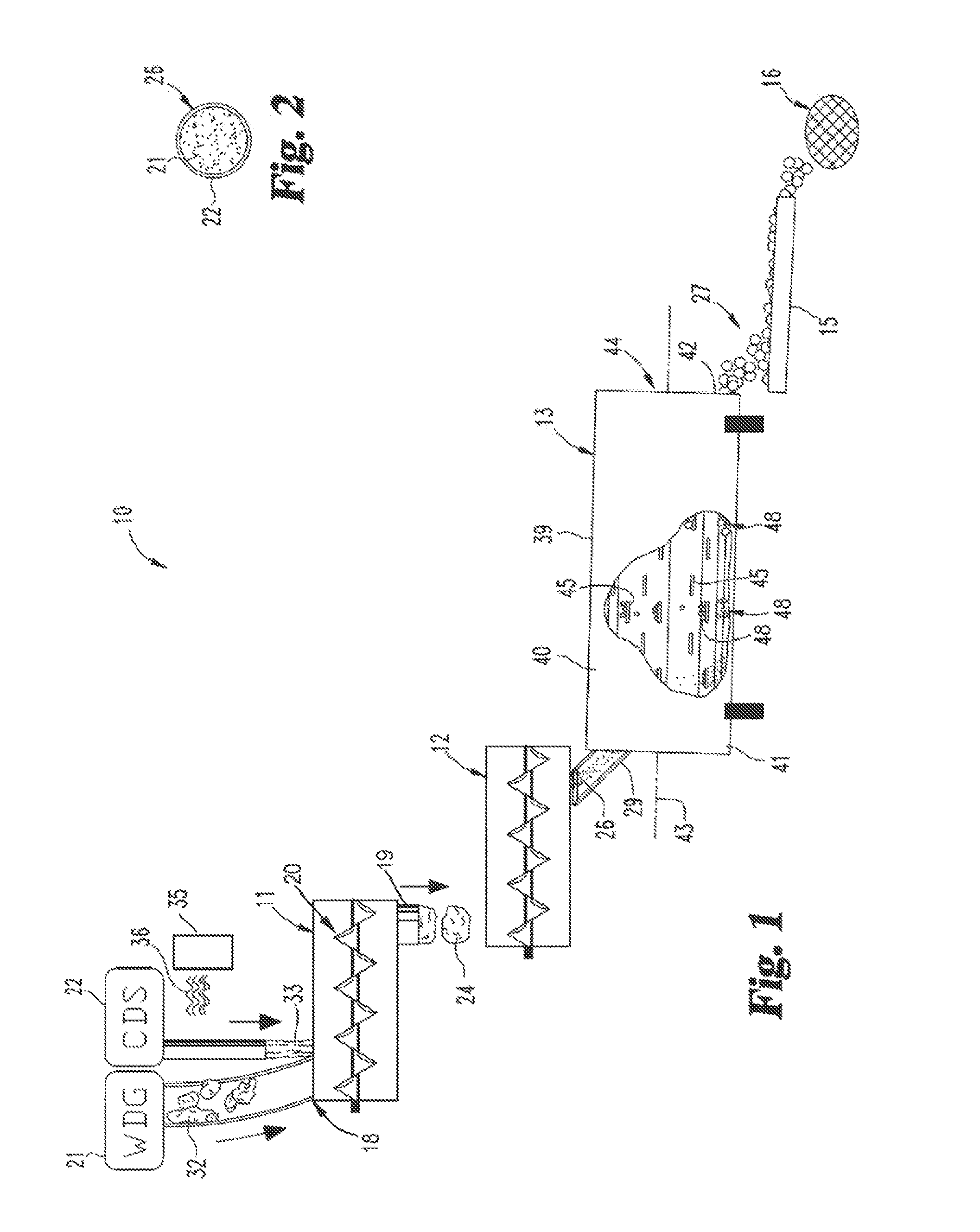

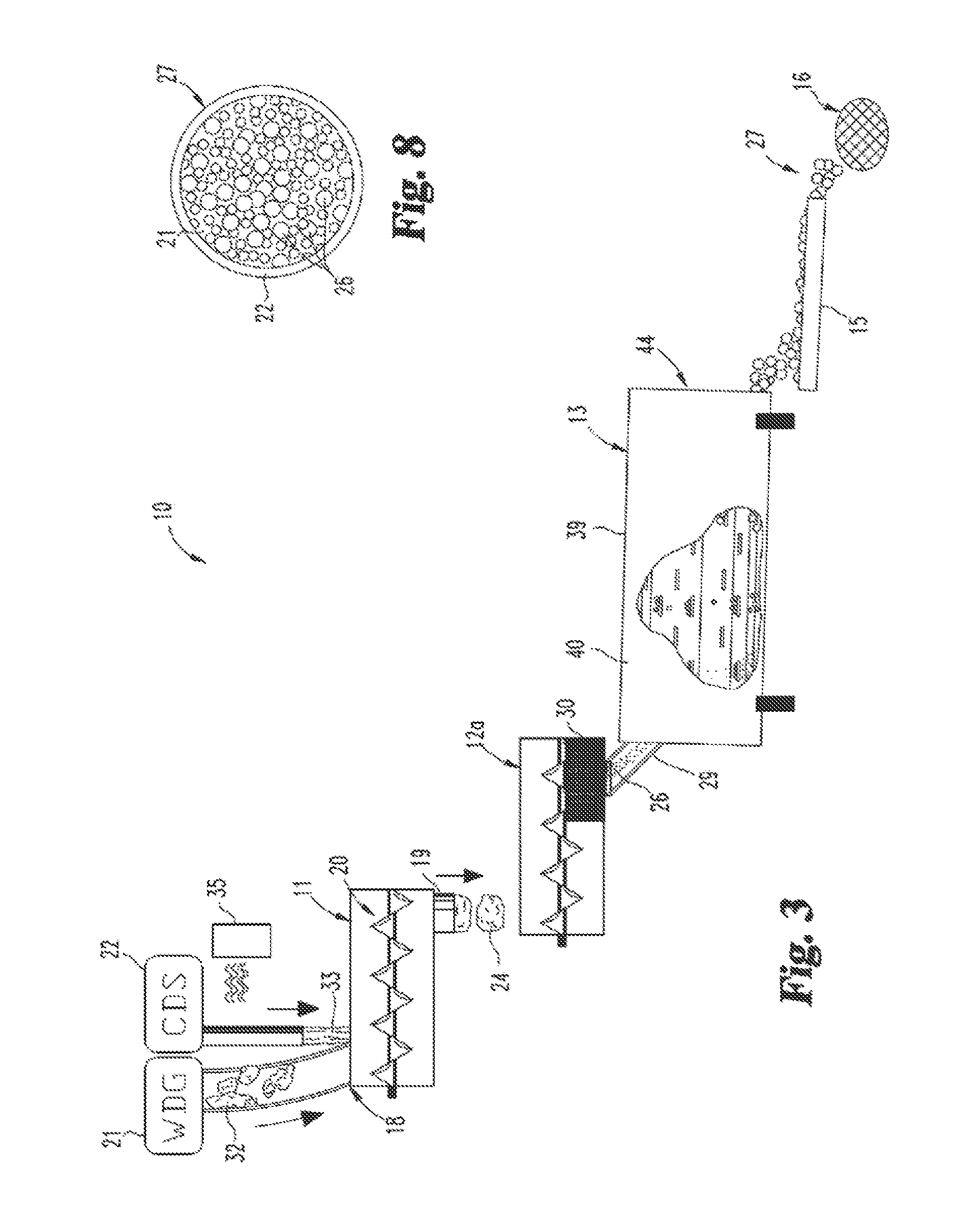

Apparatus and method for producing biobased carriers from byproducts of biomass processing

An apparatus for producing biobased carriers for dispersal of biological and chemical molecules includes a premixer having a first inlet, a first outlet, a cavity configured for receiving a wet coproduct and a binder through the first inlet, and a stirring apparatus within the cavity for premixing the wet coproduct and binder into a substantially homogeneous mixture; a high shear mixer having a housing, a drive apparatus and a high shear apparatus, the housing defining an opening, the drive apparatus being within the housing and for forcing the substantially homogeneous mixture from the premixer into the high shear apparatus, and the high shear apparatus including a rotor, a stator and a screen covering the opening and being for shear mixing the mixture including forcing the mixture through the screen and out of the housing in the form of nucleation enhanced particles; and an agglomerator having an interior chamber sized and configured to receive the nucleation enhanced particles from the high shear mixer and for transforming the nucleation enhanced particles into substantially spherical biomass pellets.

Owner:PURDUE RES FOUND INC

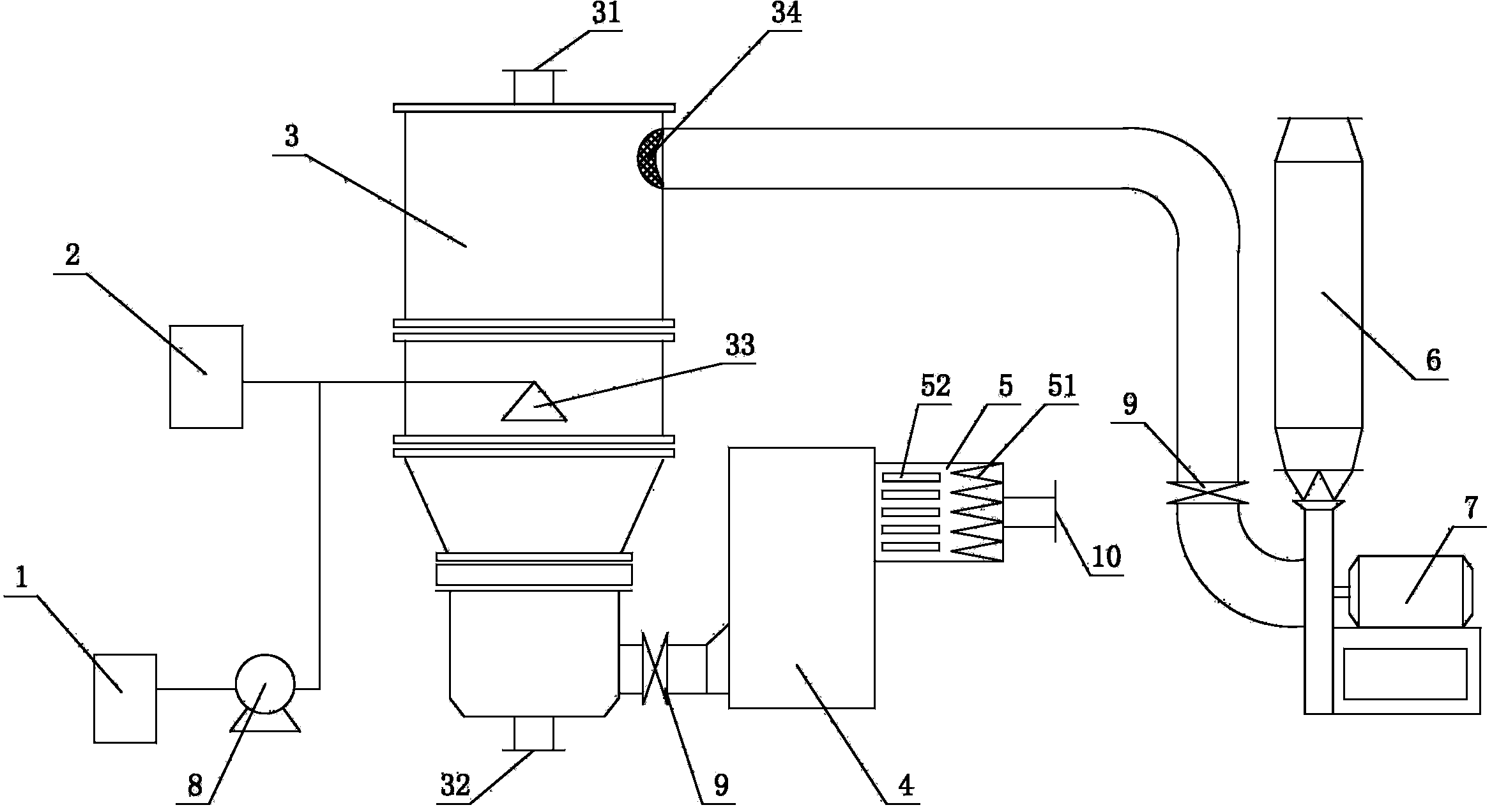

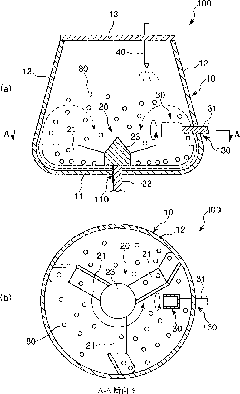

Fluid bed granulating drier and drying process thereof

InactiveCN104014278ANo flyingSimple structureDrying solid materials with heatChemical industryChemical industryGas compressor

The invention discloses a fluid bed granulating drier applied in various fields such as pharmacy, food, feeds, pigments and chemical industry and a drying process thereof. The fluid bed granulating drier comprises an adhesive tank, an air compressor and a fluid bed, wherein a hot air inlet is formed in the lower half part of the fluid bed and is connected with a heater; an air outlet of the fluid bed is connected with an exhaust fan via a pipeline; a filter is connected with the upper half part of the heater and is provided with an air inlet; filter cloth and a muffler are arranged at the air outlet of the fluid bed. The drier has a simple structure, is reasonable in design, completes the processes of mixing, granulating and drying in the same equipment, is quick in mass heat transfer, is operated at closed negative pressure, thus avoiding dust flying, is uniform in granules, does not have dead angles, is cleaned thoroughly, is free from cross pollution and is energy-saving and environment-friendly.

Owner:张家港市进润彩印包装有限公司

Apparatus and method for producing biobased carriers from byproducts of biomass processing

An apparatus for producing biobased carriers for dispersal of biological and chemical molecules includes a premixer having a first inlet, a first outlet, a cavity configured for receiving a wet coproduct and a binder through the first inlet, and a stirring apparatus within the cavity for premixing the wet coproduct and binder into a substantially homogeneous mixture; a high shear mixer having a housing, a drive apparatus and a high shear apparatus, the housing defining an opening, the drive apparatus being within the housing and for forcing the substantially homogeneous mixture from the premixer into the high shear apparatus, and the high shear apparatus including a rotor, a stator and a screen covering the opening and being for shear mixing the mixture including forcing the mixture through the screen and out of the housing in the form of nucleation enhanced particles; and an agglomerator having an interior chamber sized and configured to receive the nucleation enhanced particles from the high shear mixer and for transforming the nucleation enhanced particles into substantially spherical biomass pellets.

Owner:PURDUE RES FOUND INC

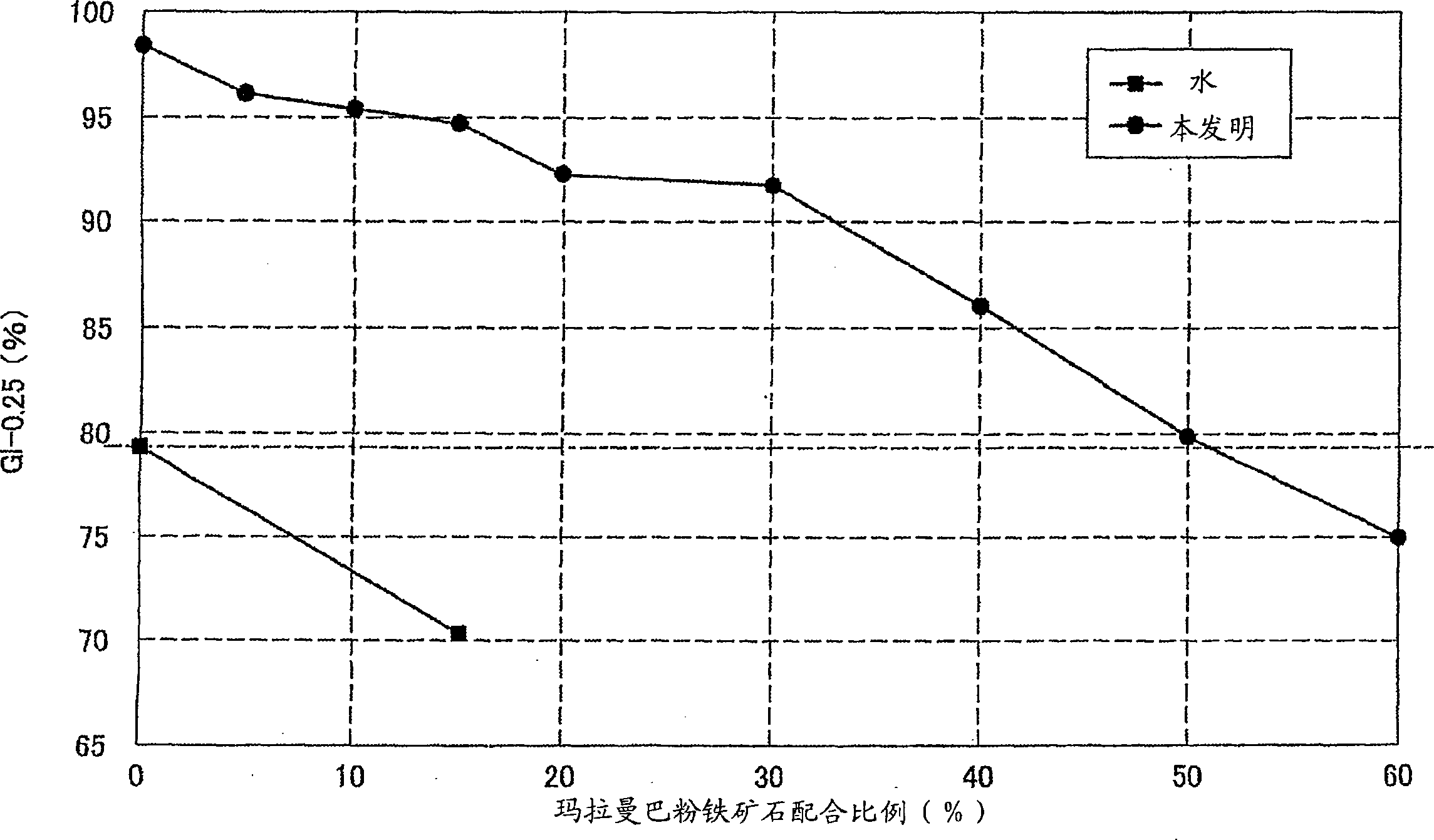

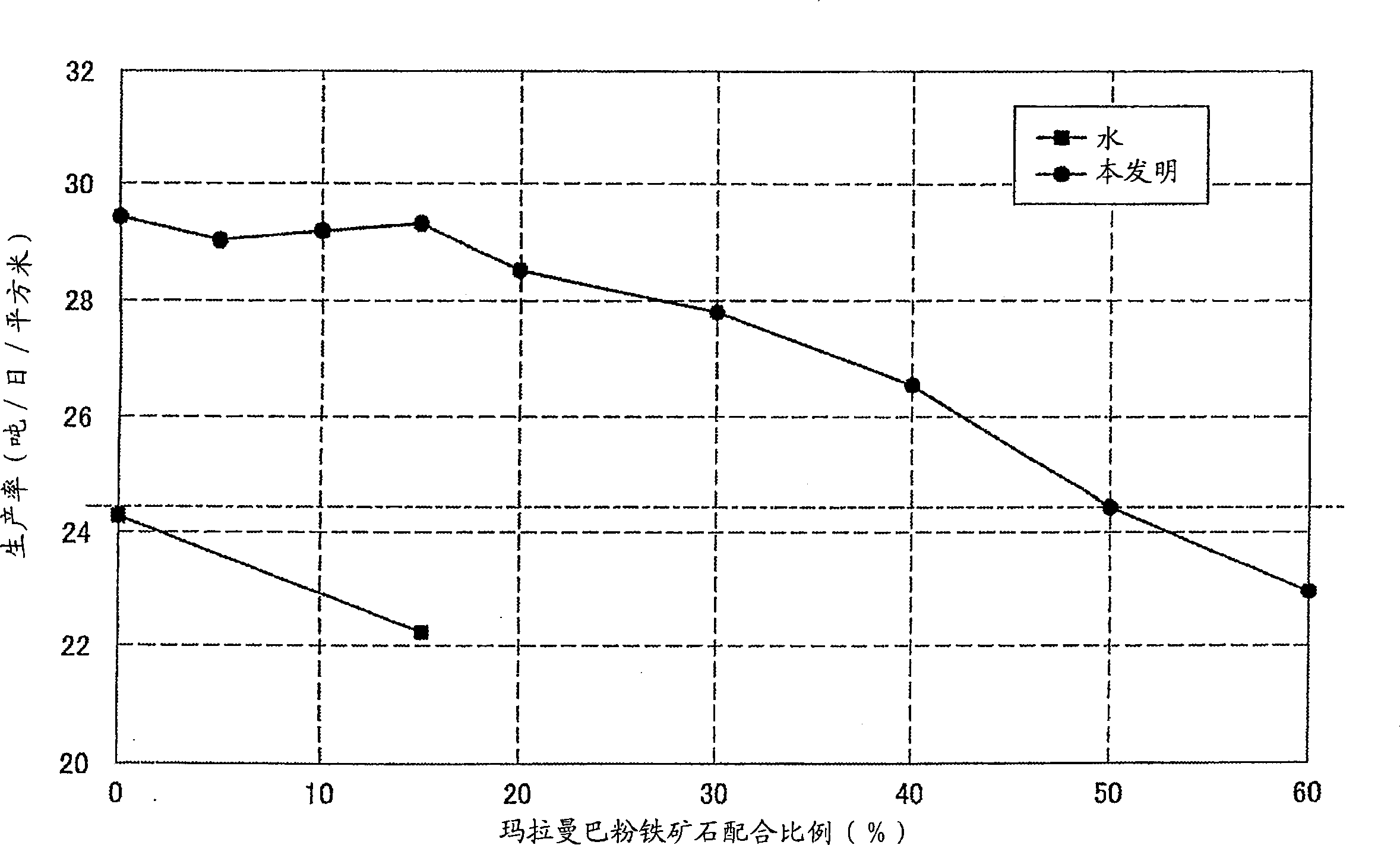

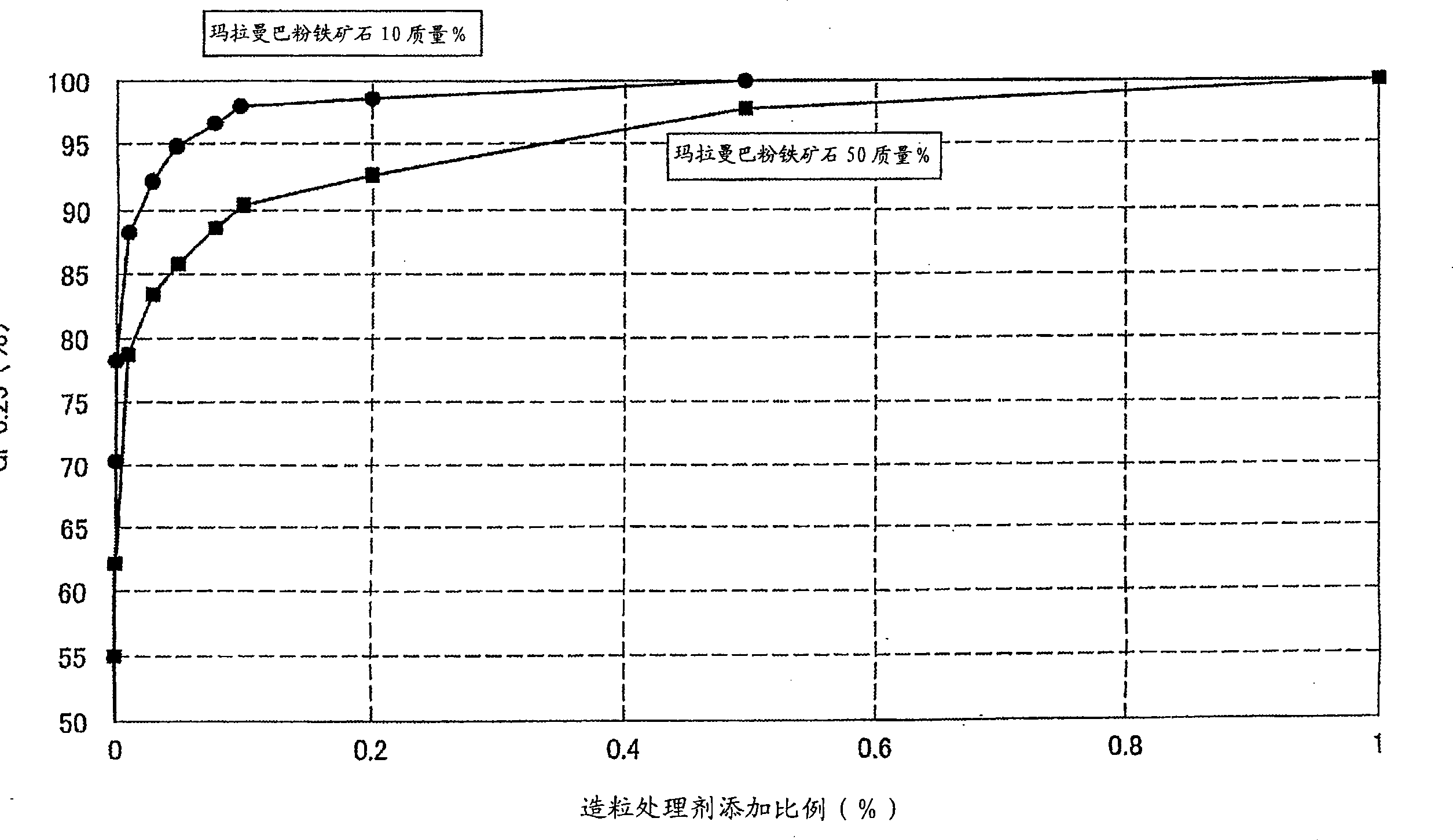

Method of granulating sintering material for iron manufacturing

A method of granulating a sintering material for iron manufacturing which contains a powdery iron ore, the method comprising a step which comprises diluting fine particles having an average particle diameter of 200 m or smaller beforehand with a solvent or part of the sintering material, adding the resultant mixture to the remaining sintering material, and granulating this mixture, the step being at least one step selected from the group consisting of the following (1), (2), and (3). A step which comprises diluting the fine particles with water so as to result in a slurry having a viscosity of 0.005 to 10 Pa.s, adding the slurry to a sintering material, and granulating the mixture. A step which comprises granulating beforehand the fine particles together with 13 to 60 wt.%, on a dry basis, of a sintering material containing iron ore as an essential component, adding the granules to the remaining sintering material, and granulating the mixture. A step which comprises mixing beforehand the fine particles with 0.3 to 10 wt.% of the sintering material on a dry basis, adding the mixture to the remaining sintering material, and granulating the mixture.

Owner:NIPPON STEEL CORP +1

Coating type slow-released granular pesticide

InactiveCN1358433AAchieve sustained releaseLow water solubilityBiocideAnimal repellantsSolubilityControlled release

The invention provides a mixed agrochemical granular agent capable of performing a controlled release of >=2 different kinds of agrochemical active ingredients having especially different solubility in water from each other and suitable for the treating method of seedling box of the rice at an individual eluting rate, and a method for producing the same. This controlled releasing mixed agrochemical granular agent is obtained by preparing a granulated material consisting of >=1 kind of agrochemical active ingredient having a high water solubility, an inorganic diluting carrier and a first thermoplastic material hardly soluble in water, setting the granulated material as an inner core and covering the surface of the core with a mixture of >=1 kind of agrochemical active ingredient different from the agrochemical active ingredients contained in the inner core and having a low water solubility, an inorganic diluting carrier and a second thermoplastic material hardly soluble in water to make an outer surface.

Owner:MITSUI CHEM INC

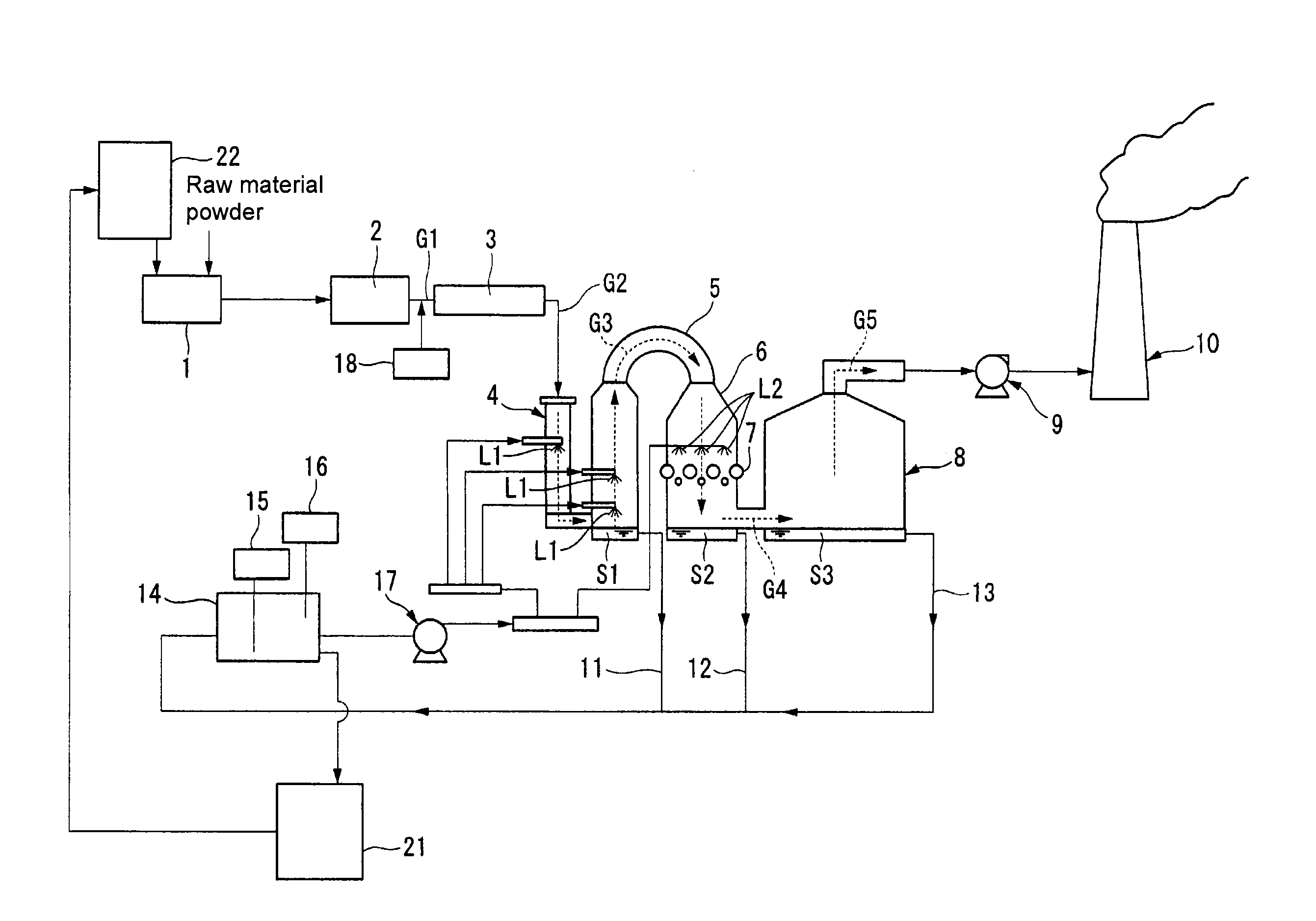

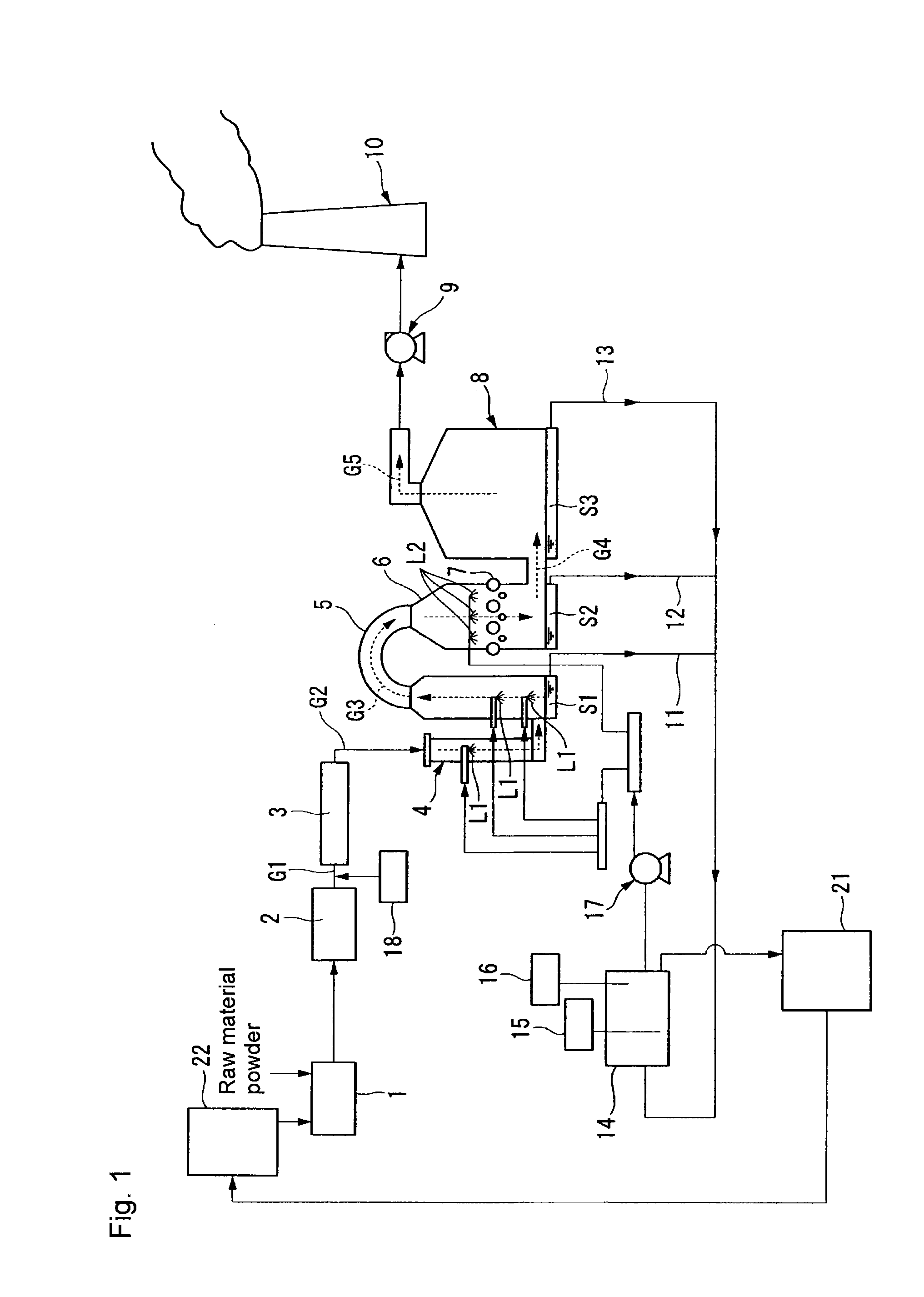

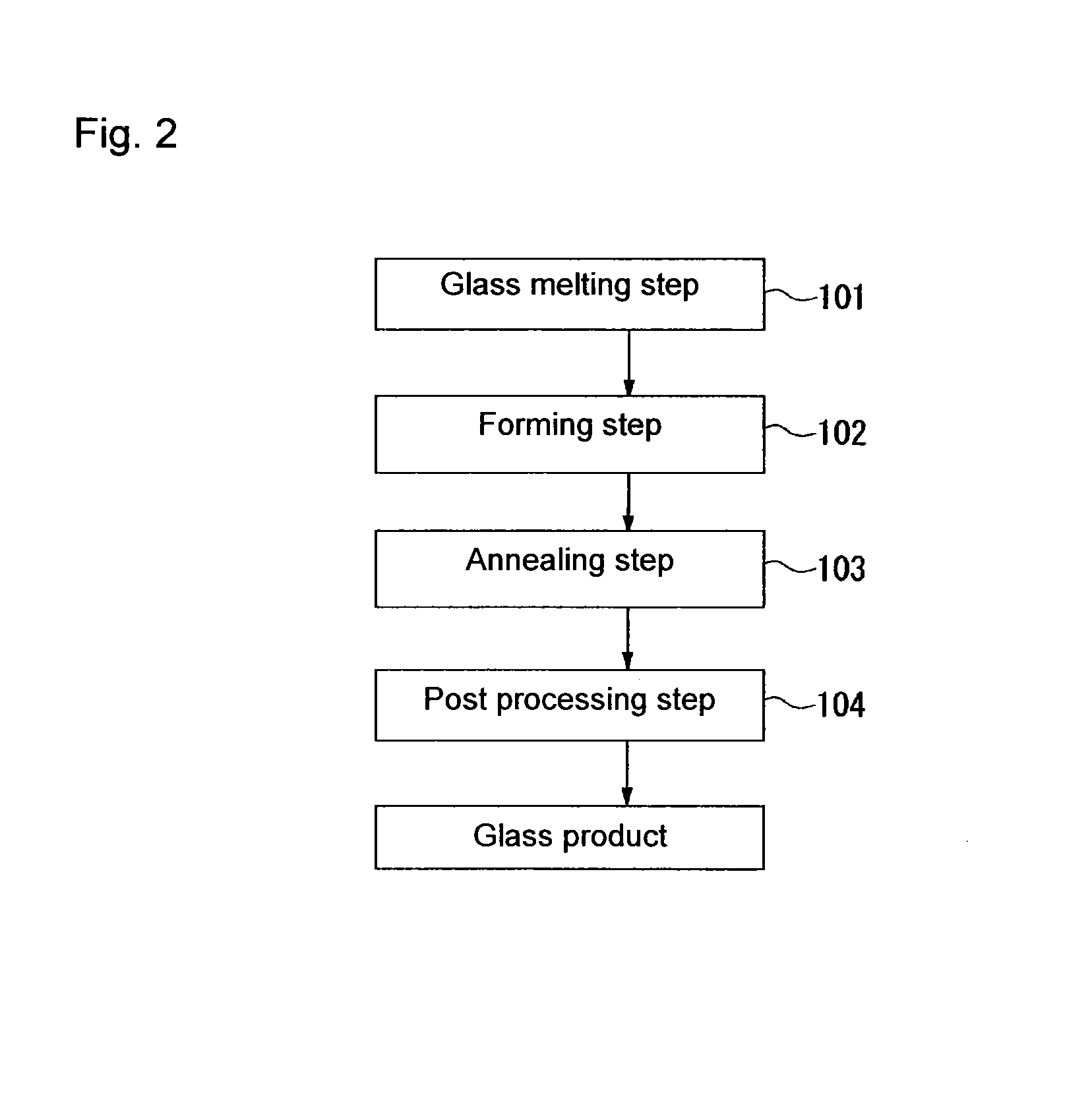

Process for producing granules, method for producing molten glass and method for producing glass product

ActiveUS20140075995A1Reduce the amount requiredLow production costGlass furnace apparatusDispersed particle separationAlkali freeSilicate glass

To provide a process for producing granules, wherein a component in an exhaust gas discharged from a glass melting furnace can be reused as a raw material for alkali-free glass, and a heating and drying step is not required for the reuse. Exhaust gas G1 formed in a process for melting a raw material of glass containing a boron component is brought in contact with contacting liquids L1 and L2 to obtain treated liquids S1, S2 and S3 having the boron component in the exhaust gas G1 dissolved therein; magnesium hydroxide is added to the mixture of the treated liquids in a treated liquid tank 14 to obtain a liquid containing a boron component and a magnesium component; by using the liquid, a granulation liquid is prepared; and in the presence of the granulation liquid, a raw material mixture for producing alkali-free borosilicate glass is granulated to produce granules.

Owner:ASAHI GLASS CO LTD

CuSn10 alloy injection forming method

The invention relates to an injection shaping method of CuSn 10 alloy, wherein said method comprises that: the diameter of CuSn 10 alloy is 6-50 mum; the adhesive is the polymer of ceresin wax PW, polyphenylacetylene PS, acetic acid ethyenyl ester polymer EVA, and geoceric acid SA. And the method comprises that: mixing and cubing the CuSn10 powder and adhesive at 55-66vol%, injecting and shaping; using solvent defatting method and thermal defatting method to remove adhesive to be sintered at 600-750Deg. C; at last, under reducing gas or inertia gas, sintering to obtain the final element. The invention can produce copper alloy element with complex shape and high quality with low cost.

Owner:UNIV OF SCI & TECH BEIJING

Long-acting plant composite fertilizer

InactiveCN1357519AIncreased fructose contentPrevention and suppression of pests and diseasesFertiliser formsGranulation with special binding agentsField experimentAdhesive

The long-acting composite plant fertilizer consists of green material including foxtail-like sophora herb, alfalfa, plant ash, plant oil residue and adhesive and based on the production of farmyard manure. Its production includes the processes of drying, crushing, sieving, mixing, extrusion, pelletizing, and stoving. Field experiment shows that it has obvious yield increasing effect on rice, wheat, corn, melons and fruits and can reduce plant diseases and insect pests effectively.

Owner:XINJIANG TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

High-strength zeolite bead molding and method for producing the same

InactiveCN102177093AHigh strengthImprove wear resistanceOther chemical processesDispersed particle separationHigh intensityCompressive strength

Shaped beads formed from a zeolite and a clay binder by tumbling granulation is problematic in that the strength and abrasion resistance are poor. Shaped zeolite beads with an average diameter of 1.0 to 3.0 and having a compressive strength of 35 N or greater (particularly 70 N or greater) when hydrated and an abrasion resistance factor of 1.5% or less are obtained by subjecting a composition of at least 35 parts by weight of water per 100 parts by weight of zeolite and clay binder combined to tumbling granulation and then adding 4 parts by weight or less of clay binder per 100 parts by weight of the molding (excluding the water content), subjecting the product to tumbling granulation, drying and baking. Preferably the zeolite crystals used are 5 [mu]m or smaller; between 10 and 50 parts by weight of clay binder are used; and the same type of clay binder is used for molding and grading.

Owner:TOSOH CORP

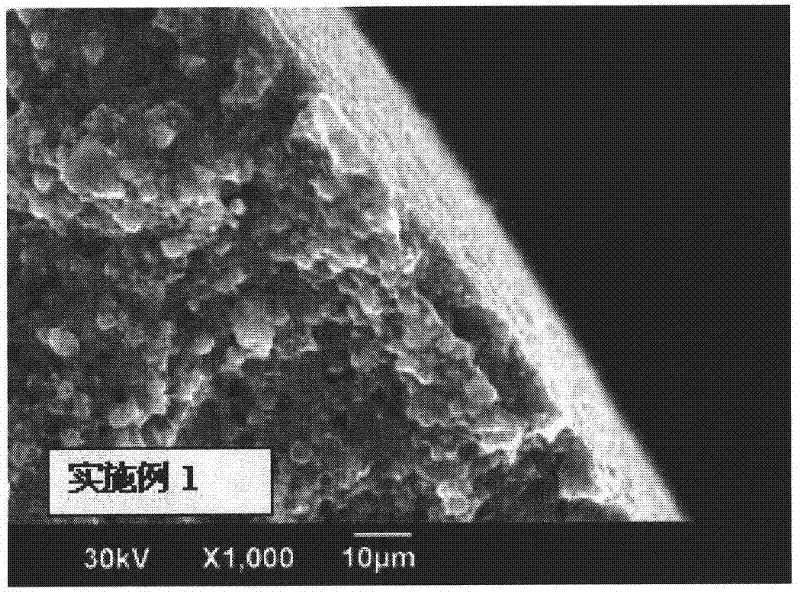

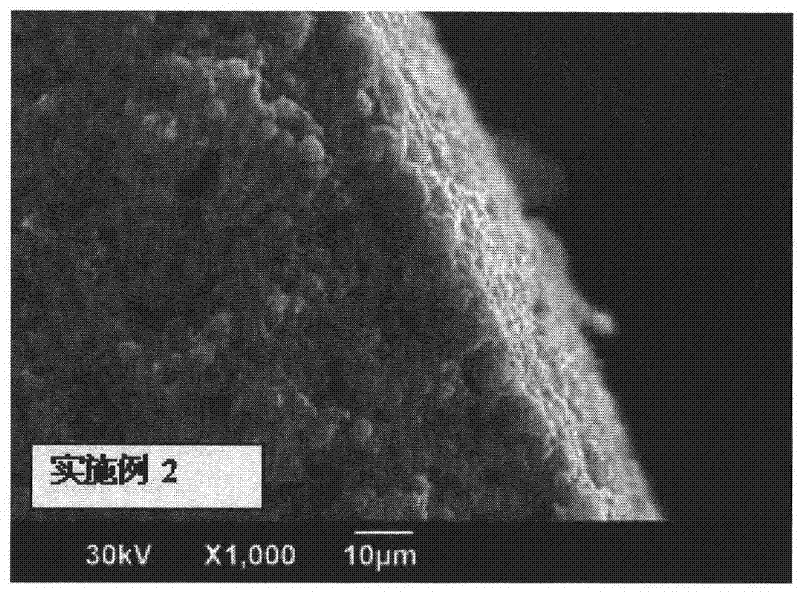

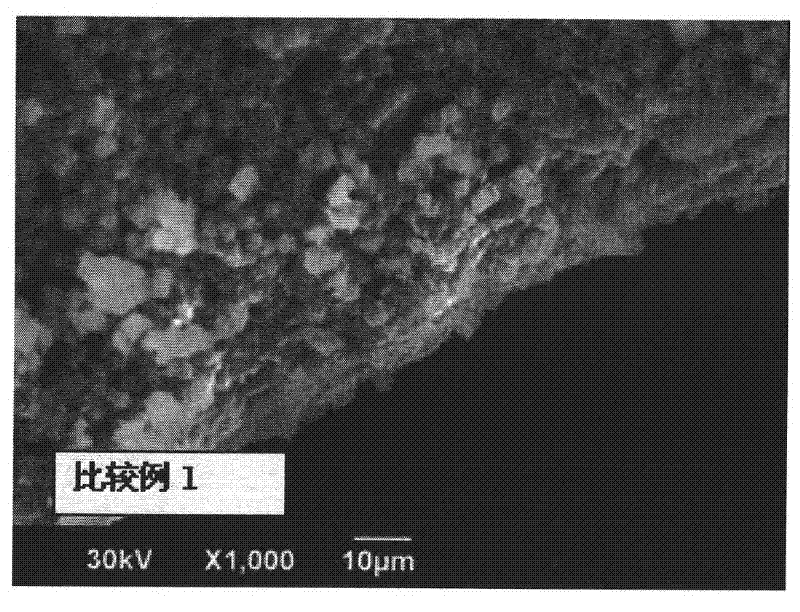

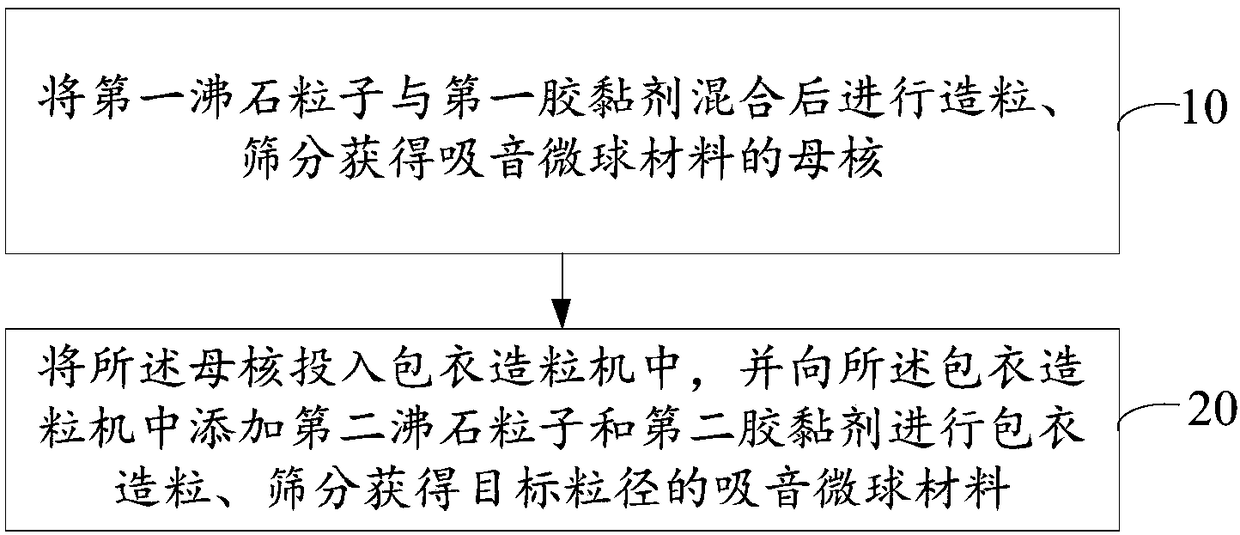

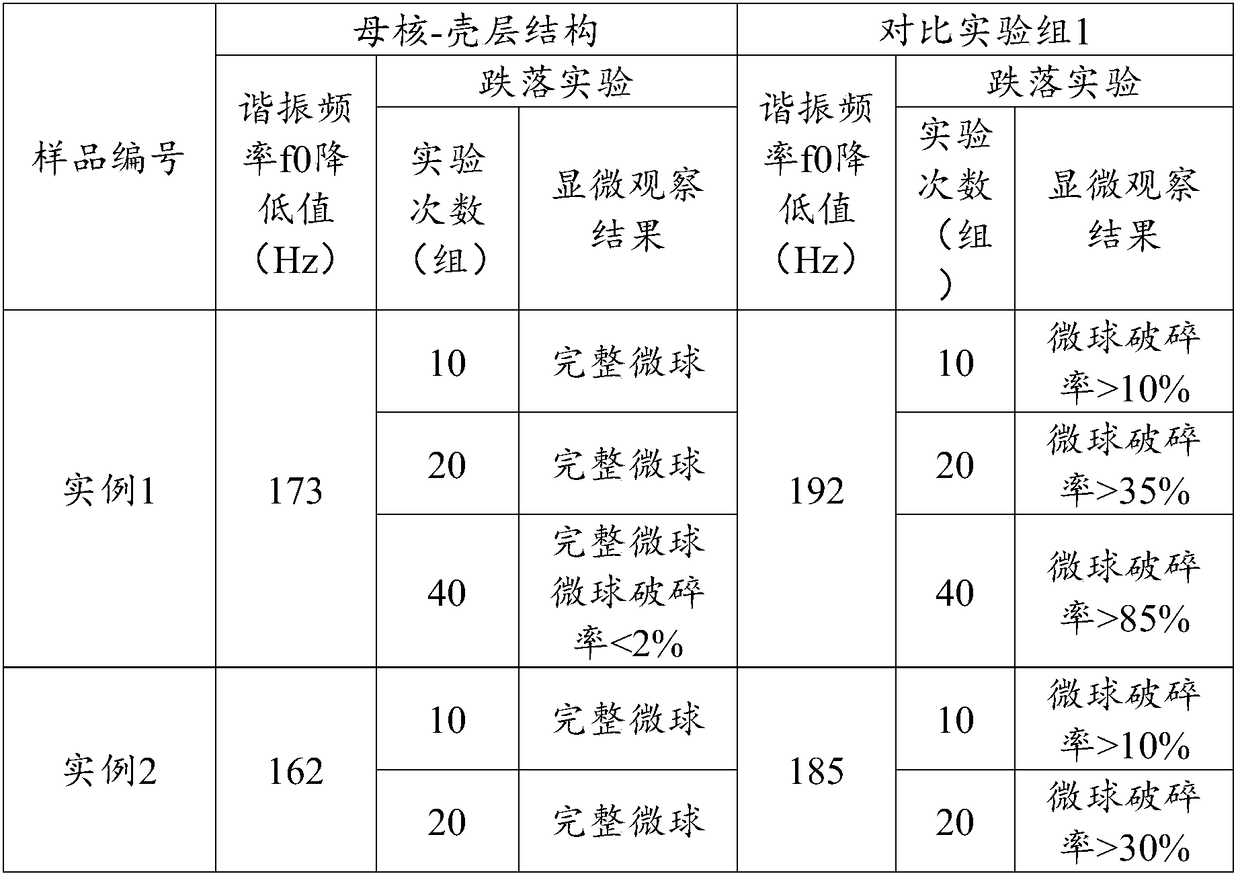

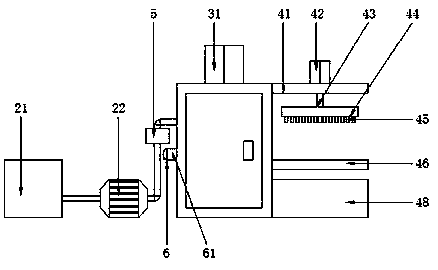

Sound adsorption microsphere material and preparation method thereof

ActiveCN108377456AImprove mechanical propertiesImprove impact toughnessElectrical transducersGranulation by liquid drop formationMicrosphereAdhesive

The invention relates to the technical field of the loudspeaker, especially a sound adsorption microsphere material and a preparation method thereof. The method comprises the following steps: mixing first zeolite particles and first adhesive, granulating and screening to acquire a mother nucleus of a sound adsorption microsphere material; putting the mother nucleus into a bed coating granulator, and adding the second zeolite particle and the second adhesive in the bed coating granulator to perform coating and granulating, thereby acquiring the sound adsorption microsphere material with the target grain size. Through the preparation method of the sound adsorption microsphere material provided by the invention, the precise control on the mother nucleus and coating in the porous zeolite soundadsorption microsphere in the size and adhesive content and like aspects can be realized by regulating the material proportion and process parameters of the mother nucleus and the coating liquid. Thesound adsorption microsphere material prepared through the method has the mother nucleus with low adhesive content, the whole adhesive content is reduced in comparison with the traditional method, and the sound adsorption microsphere material is provided with good acoustic performance.

Owner:深圳市大分子科技有限公司

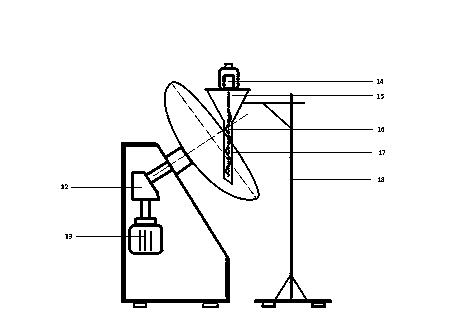

Granulation device for 4-tert-butylcatechol

ActiveCN108636293AEasy squeezeAvoid scatterGranulation by material expressionGranulation by pressingAdhesiveMaterial scattering

The invention discloses a granulation device for 4-tert-butylcatechol. The granulation device comprises a cabinet, an adhesion assembly, a pre-pressing assembly, a granulation assembly, a throttle assembly, a pushing assembly and a vibration assembly, wherein the adhesion assembly is mounted on one side of the cabinet; the pre-pressing assembly is mounted at the top of the cabinet; the granulationassembly is mounted on the other side of the cabinet; the pushing assembly and the vibration assembly are mounted in the cabinet; the adhesion assembly comprises a water tank, a water pump and an atomizer, the water tank is arranged on one side of the cabinet, and one side of the water tank is connected with one end of the water pump through a connecting pipe. The granulation device has the advantages that material extrusion is facilitated, and material scattering is prevented; materials are extruded repeatedly into blocks, and granule forming is facilitated; material pushing is facilitated;the materials are prevented from adhering to a fixed plate and are convenient to push; granulation is facilitated; flow rate of a liquid can be reduced, and the quantity of sprayed adhesive is reduced.

Owner:连云港腾宏科技化工有限公司

Calcium carbide slag powder and application thereof

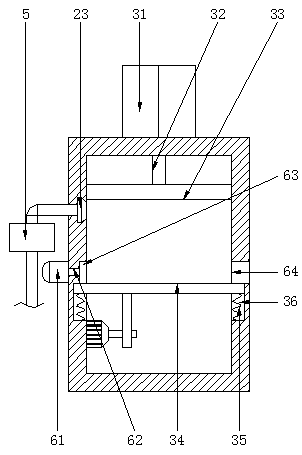

The present invention discloses a carbide slag powder curing material and the application of the same, which belongs to the waste slag utilizing technology of calcium carbide production. The carbide slag powder curing material is produced by proportioning mixing pelletization of carbide slag powder and dry powder industry adhesive. The carbide slag powder curing material can be used for producing qualified calcium carbide and cement by proportioning mixing with the charging for producing calcium carbide and the clinker for producing cement. The present invention also provides a dry material curing pelleter for producing carbide slag powder curing material, which comprises a motor, a gear-box, two extruding rollers and a screw device. In the present invention, the carbide slag is recovered so as to solve the problem of that the generated abundant dust and slag pollute environment and harm people health.

Owner:李建华

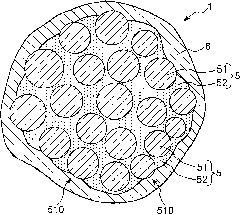

Granulated powder and method for producing granulated powder

ActiveCN102188933AAvoid disintegrationEasy to control supplyMetal-working apparatusThin material handlingSolubilityAcrylic resin

The invention provides a granulated powder and a method for producing granulated powder. The granulated powder includes secondary particles obtained by granulation such that a plurality of metal particles in a metal powder are bound to one another by an organic binder and an outer coating layer provided so as to cover the surfaces of the secondary particles. The outer coating layer is formed of a low water-soluble material having a lower water solubility than the organic binder. The material having a lower water solubility than the organic binder is preferably any of an organic amine or a derivative thereof, and an acrylic resin. Further, the outer coating layer is preferably at least partly in contact with the surfaces of the metal particles at an interface with the secondary particle.

Owner:SEIKO EPSON CORP

Granular polymer additives and their preparation

A compacted particulate polymer additive composition in a dry granular form formed from the following components: (a) at least one particulate organic phosphite, organic phosphonite, and / or organic phosphonate, and (b) one or more particulate polymer additives other than an organic phosphite, organic phosphonite, or organic phosphonate; wherein the particles of said composition are held together in compacted dry granular form exclusively or substantially exclusively by contact with dried surfaces of in situ desolvated particles from particles of one or more at least partially solvated components of (a), and optionally by contact with dried surfaces of in situ desolvated particles from particles of one or more at least partially solvated components of (b). Compositions of this type except that there is no component (b) are also described.

Owner:ALBEMARLE CORP

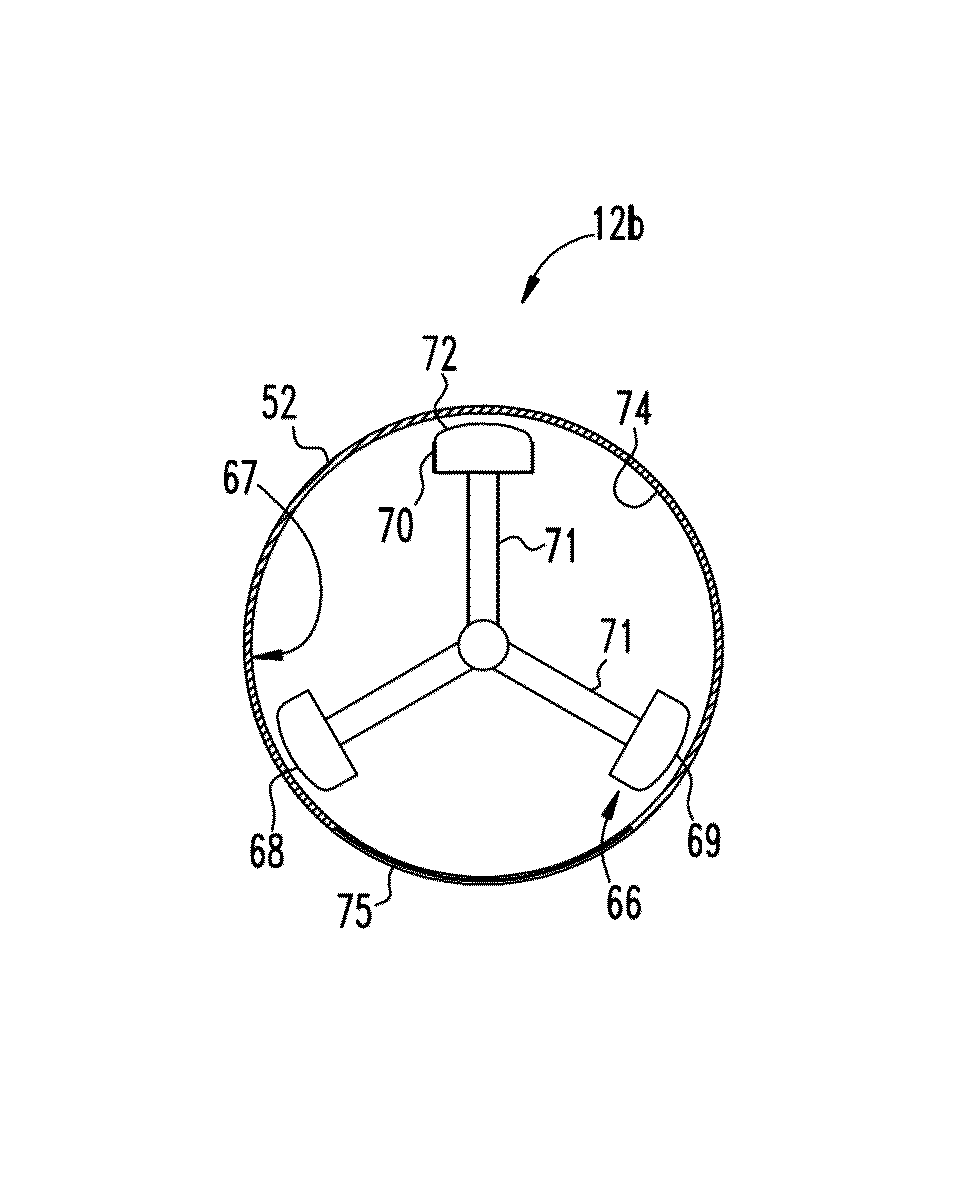

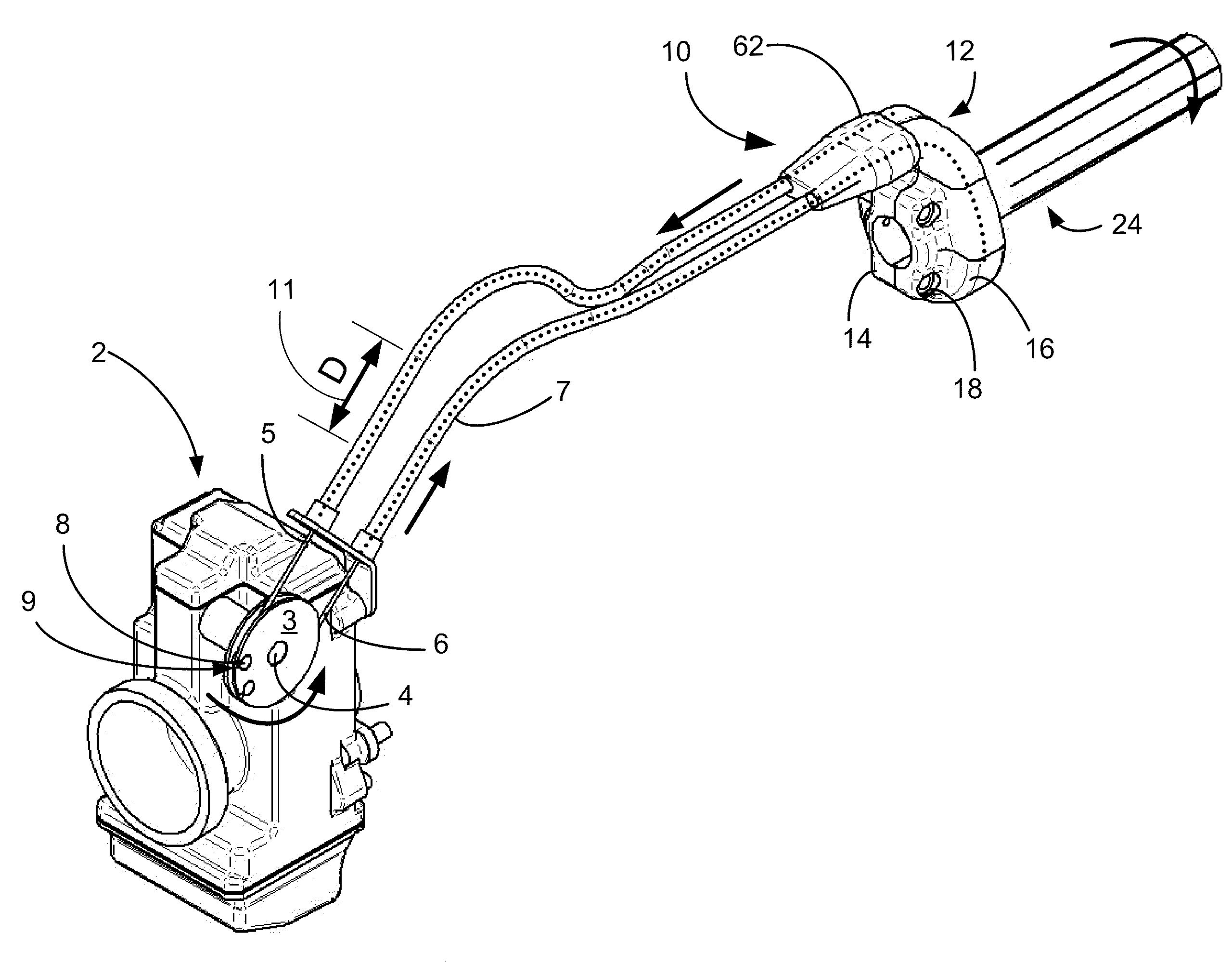

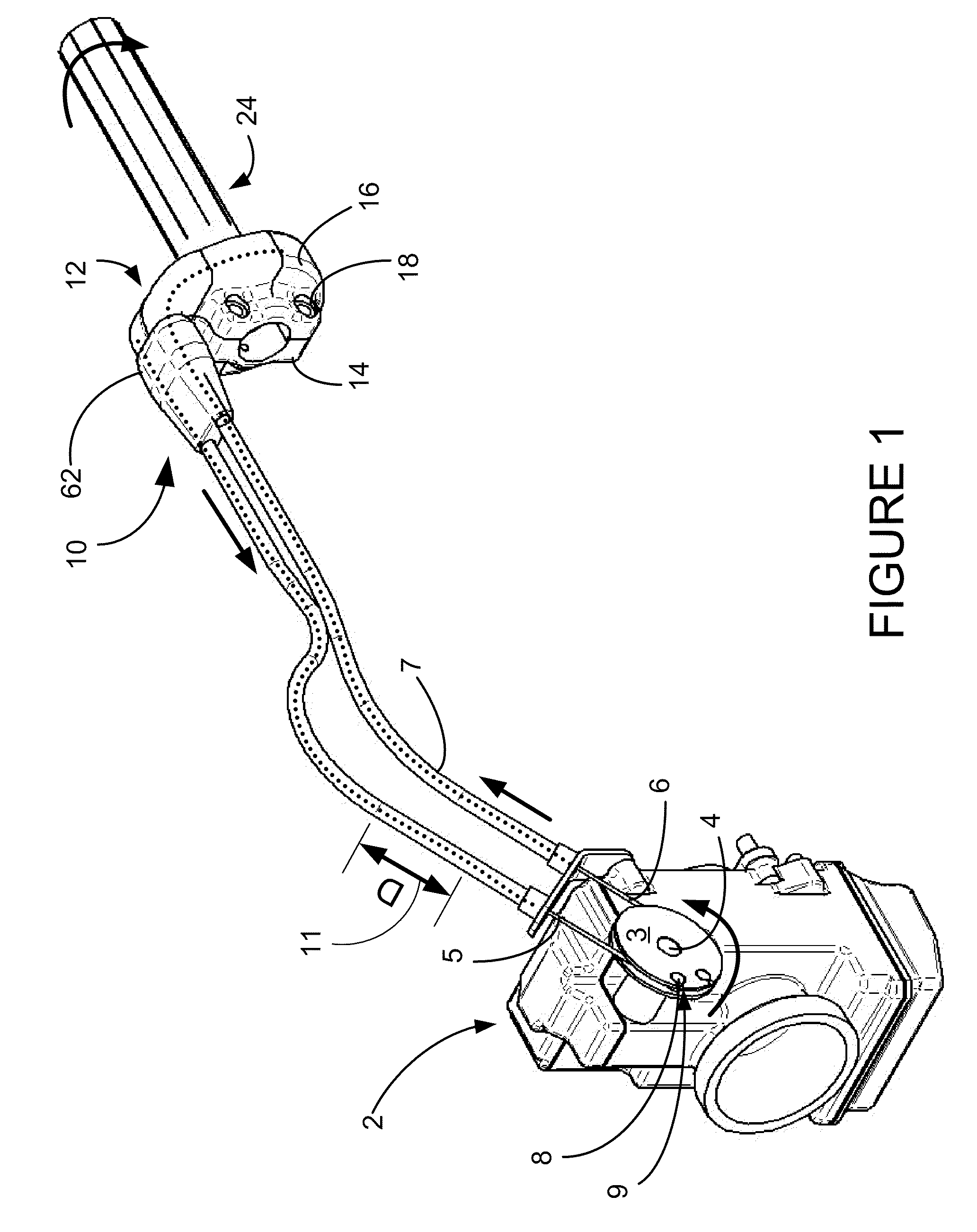

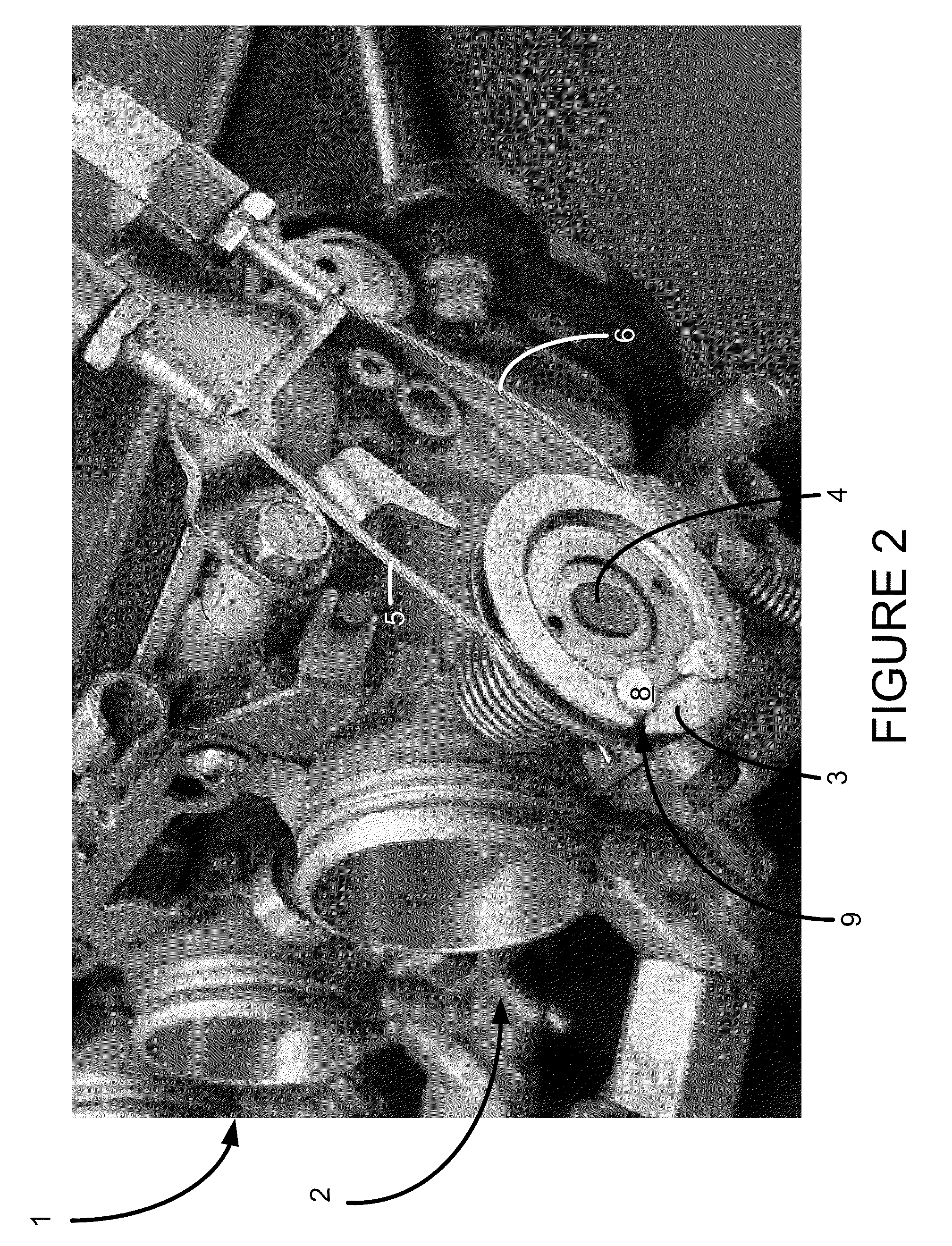

Variable rate push/pull twist throttle

A variable rate throttle for controlling a vehicle carburetor having control cables. The variable rate throttle includes a housing surrounding a cavity, a plurality of interchangeable throttle reels, each throttle reel having a different track radius, where a particular one of the throttle reels is positioned at a time in the cavity of the housing and which engages the control cables. A throttle handle engages the interchangeable throttle reel so that rotation of the handle causes rotation of the throttle reel and thus moves the control cables of the vehicle carburetor.

Owner:MOTION PRO

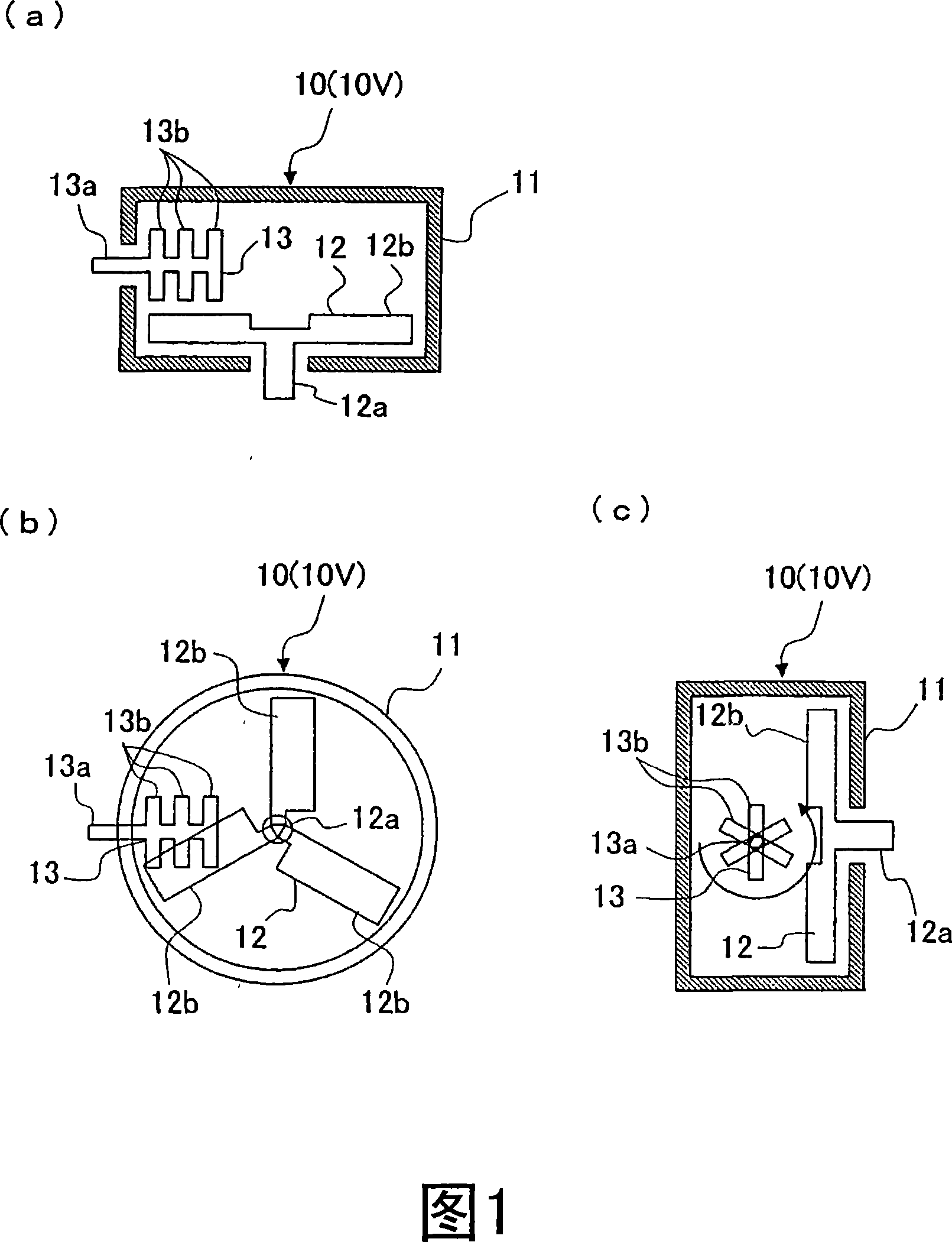

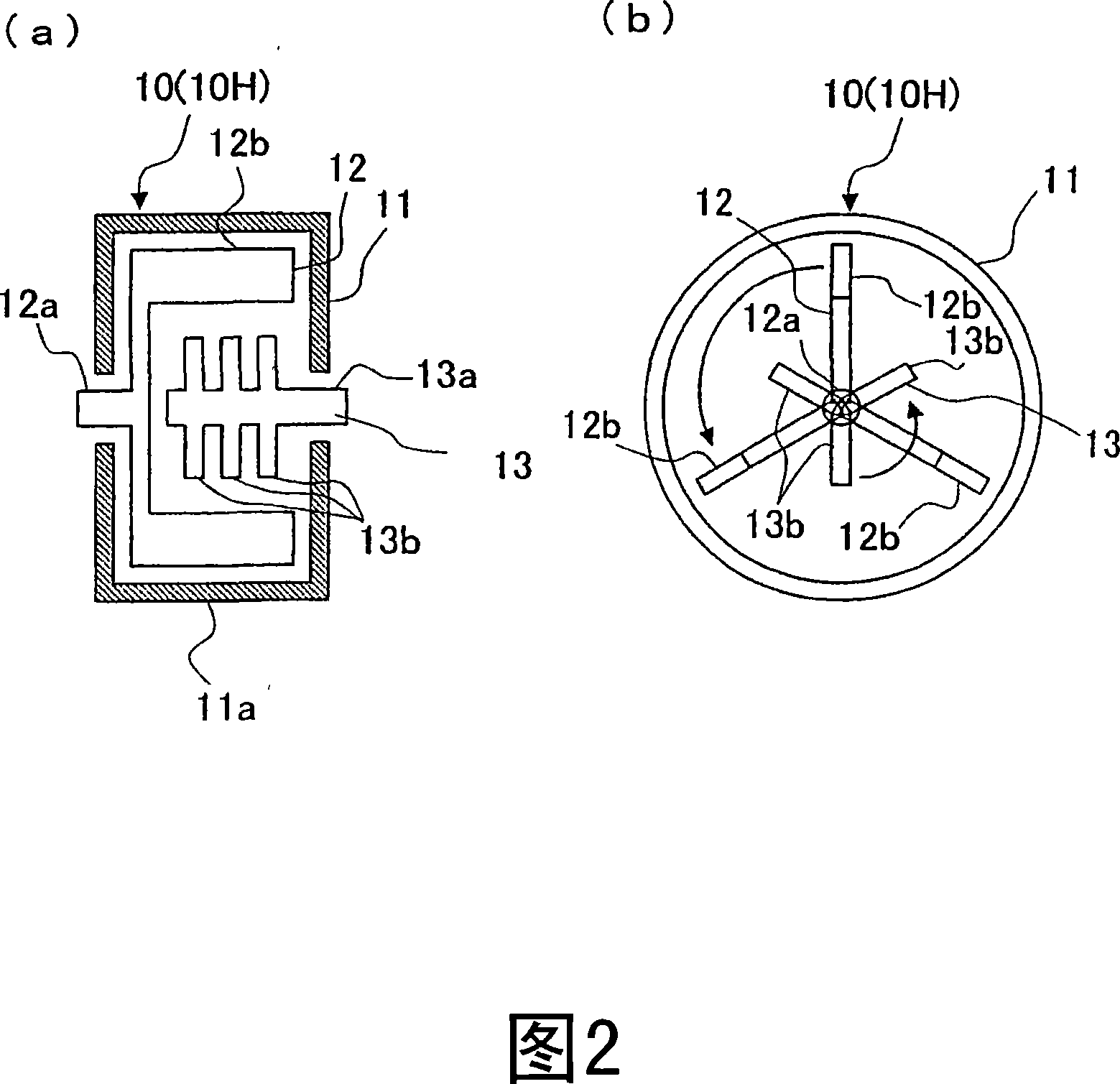

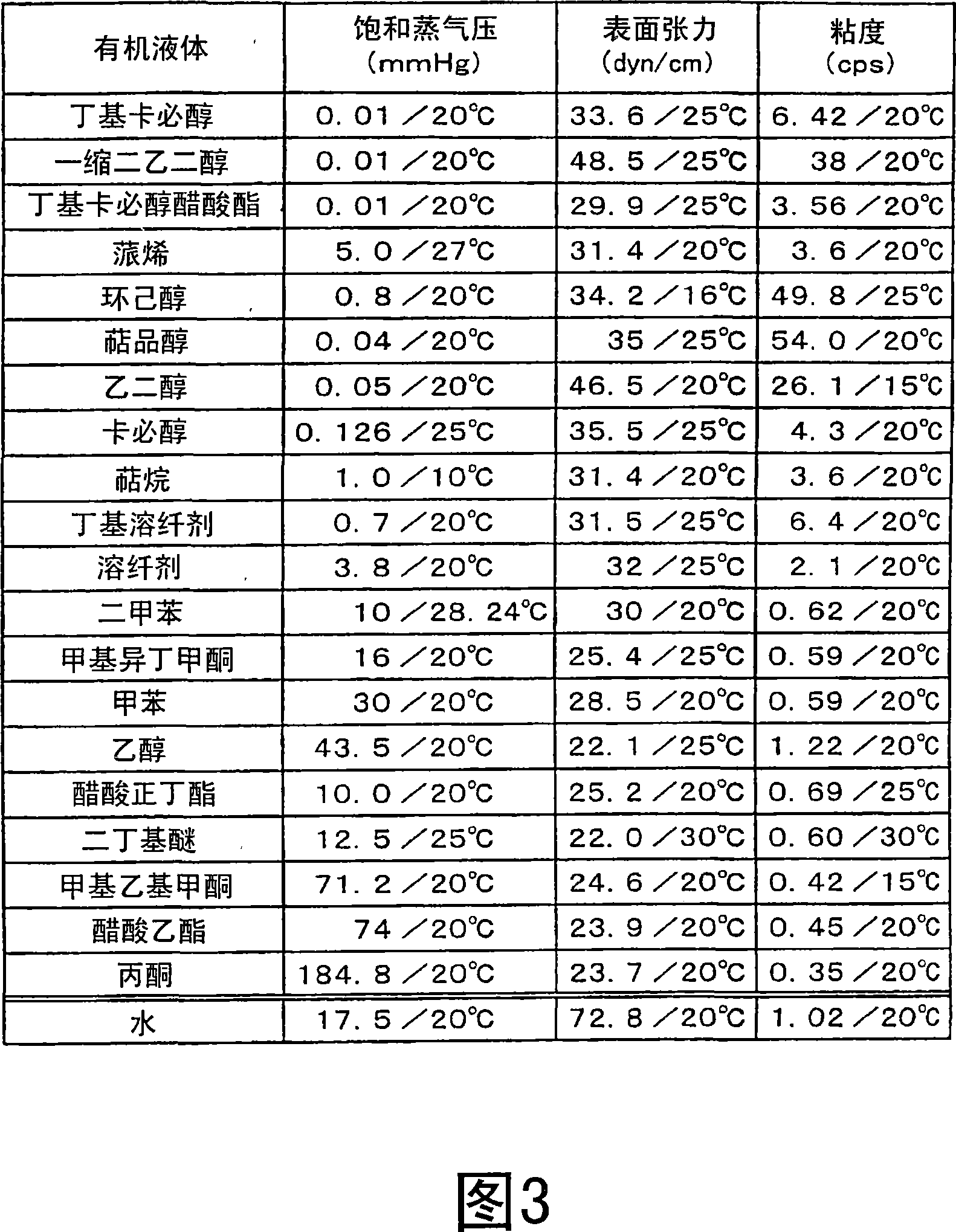

Method for producing raw material powder for rare earth sintered magnet, method for producing rare earth sintered magnet, granule and sintered article

ActiveCN1938115AGood removal effectReduced characteristicsTransportation and packagingMetal-working apparatusOrganic fluidRare earth

Owner:TDK CORPARATION

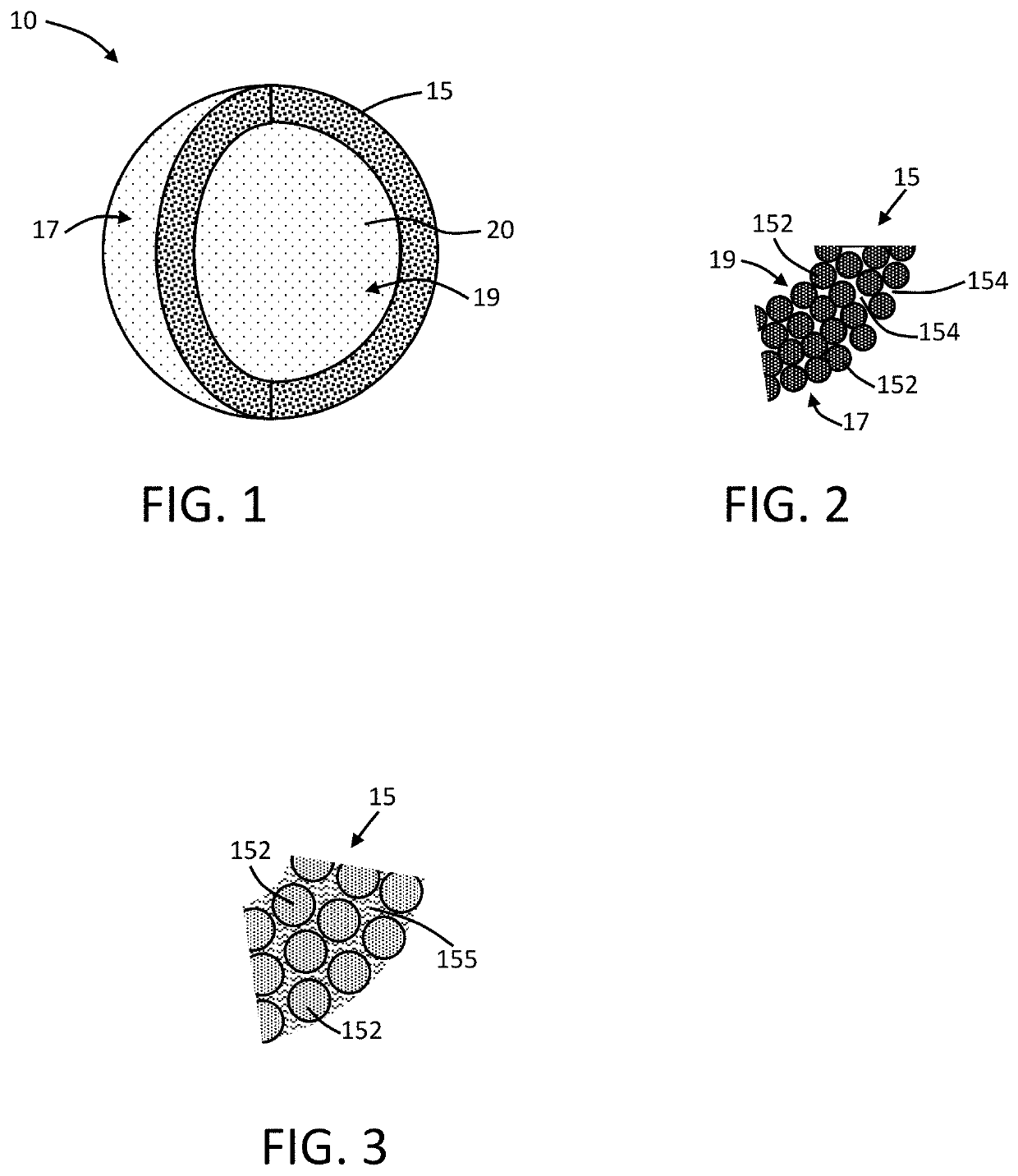

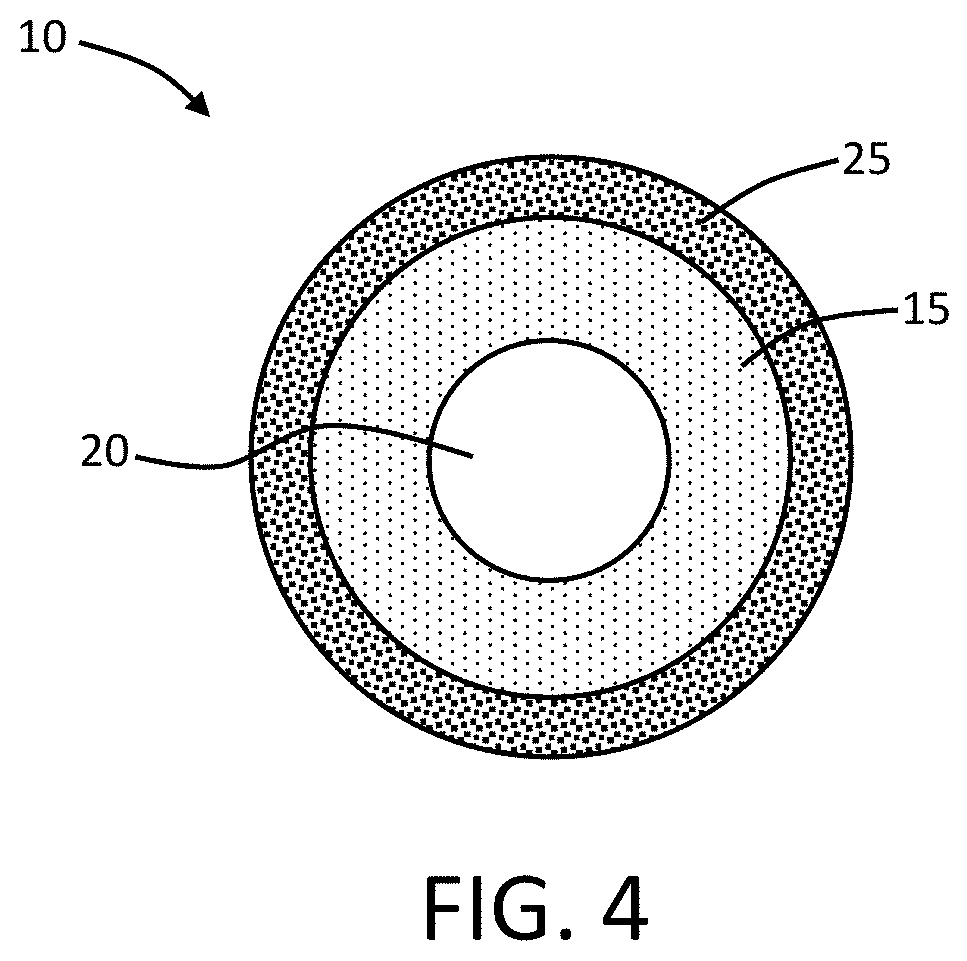

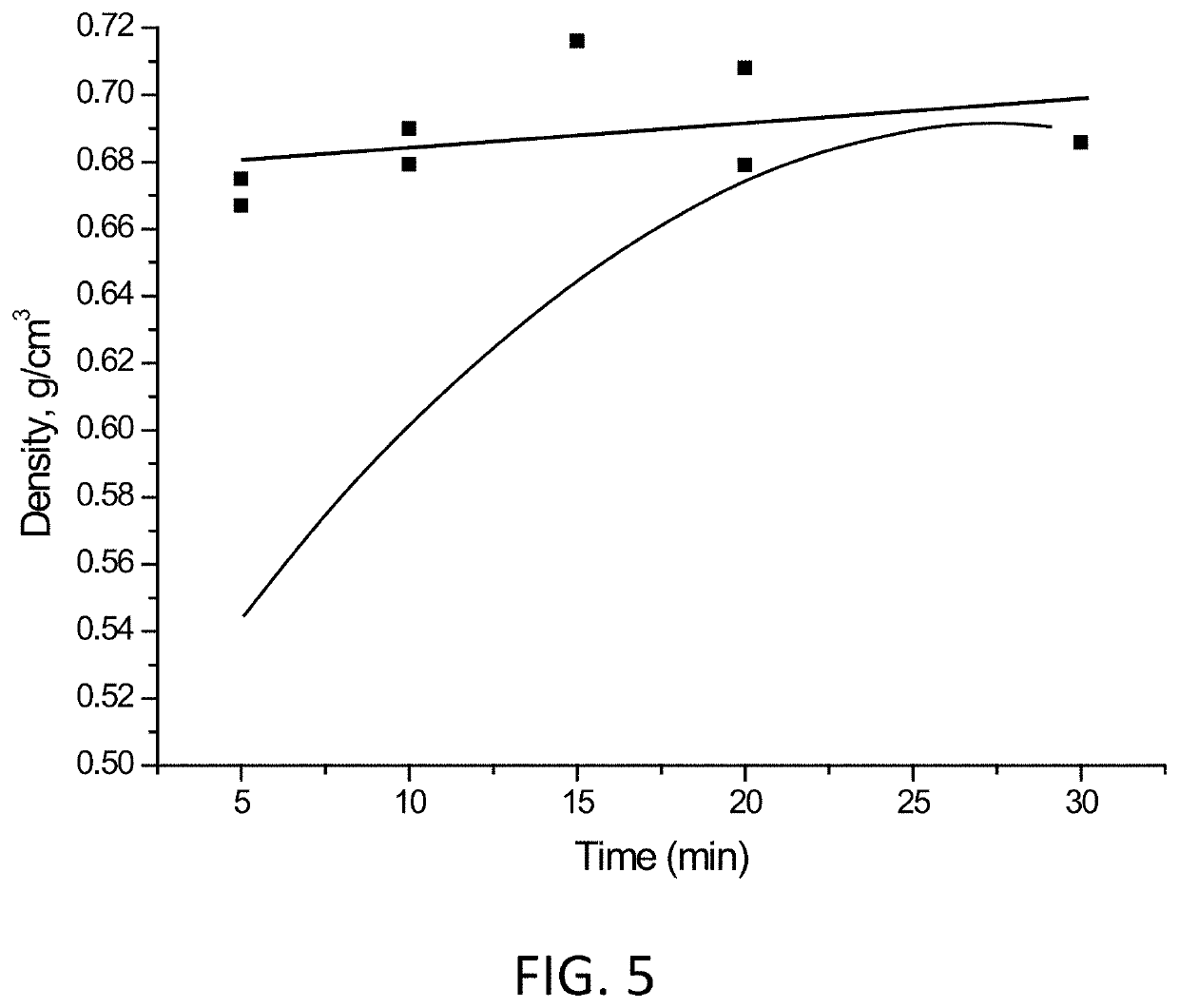

Hollow core granules, products incorporating the granules, and methods of preparing the granules

PendingUS20210237035A1Improve propertiesImprove performanceInorganic/elemental detergent compounding agentsCosmetic preparationsEngineeringBiology

The present disclosure relates to hollow core granules, products incorporating the hollow core granules, and methods of making the hollow core granules. The hollow core granules can comprise at least one wall surrounding a cavity that is devoid of any solid or liquid so as to define a hollow core, the at least one wall comprising a plurality of individual particles of at least one wall forming material, the plurality of individual particles sufficiently bound together so that the at least one wall is structurally self-sustaining. The hollow core granules further can include a binder material present in the at least one wall. The hollow core granules can be useful as a standalone material and / or may be useful in preparing a variety of products wherein the hollow core granules may be mixed or otherwise combined with further components. The disclosure further provides methods of making such hollow core granules.

Owner:CHURCH & DWIGHT CO INC

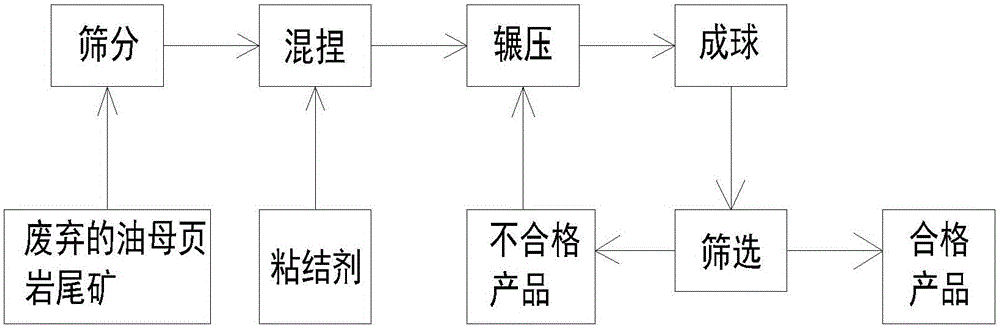

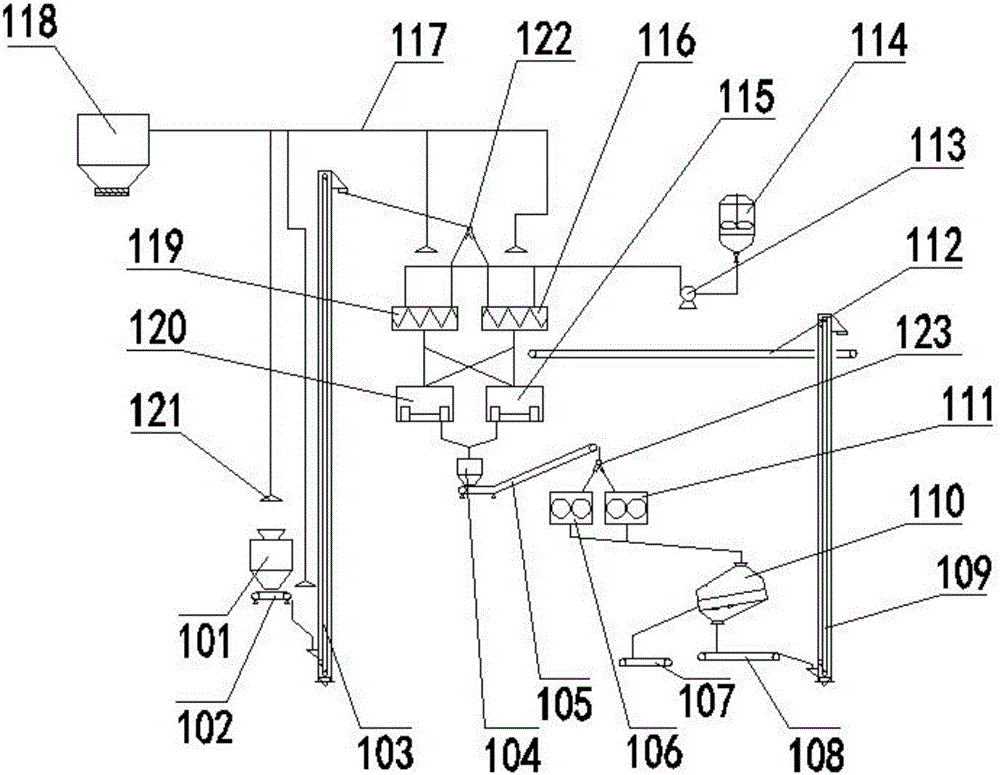

Granular oil shale pelletizing process and device

ActiveCN104998583AFacilitate continuous productionImprove adhesionSpecial form destructive distillationGranulation with special binding agentsBucket elevatorMetering pump

The invention provides a granular oil shale pelletizing process and device and belongs to the technical field of exhaust oil shale recycling. The granular oil shale pelletizing process comprises the steps of sieving, kneading, rolling, pelletizing and screening. The granular oil shale pelletizing device comprises a raw material bin, a first weighing belt conveyor, a first bucket elevator, a kneading machine, a wheel roller, a second weighing belt conveyor, a ball-pressing forming machine, a circular vibrating screen, a first belt conveyor, a second belt conveyor, a second bucket elevator, a binder agitation tank and a binder metering pump. According to the granular oil shale pelletizing process and device, through the kneading process, the rolling time is shortened, the energy consumption is reduced, the product quality stability is improved, and continuous production of the pelletizing device is facilitated; meanwhile, through re-rolling of rejected products, clearances caused during re-pelletizing are prevented, and the stability of the re-pelletized products is improved.

Owner:FUSHUN EAST CHINA ENERGY TECH R & D CO LTD

Method for granulating and forming silicon carbide fine powder and silicon carbide granule

InactiveCN102489218AFacilitate conductionImprove breathabilityGranulation with special binding agentsMass ratioEnergy consumption

The invention relates to a method for granulating and forming silicon carbide fine powder and a silicon carbide granule. The method comprises the following steps of: 1, selecting the silicon carbide fine powder; 2, preparing adhesive solution; 3, mixing the silicon carbide fine powder which is obtained in the step 1 and the adhesive solution which is obtained in the step 2 according to a mass ratio of 10: 1-2:1; and 4, granulating and forming the mixture which is obtained in the step 3 by using mechanical granulating equipment. The invention provides the method for granulating and forming the silicon carbide fine powder, which has the advantages that furnace jet and furnace explosion can be prevented, the utilization ratio of the silicon carbide fine powder is high, the energy consumption is low, the degree of the environment pollution is low and the operation is simple and convenient, and the silicon carbide granule.

Owner:朱胜利

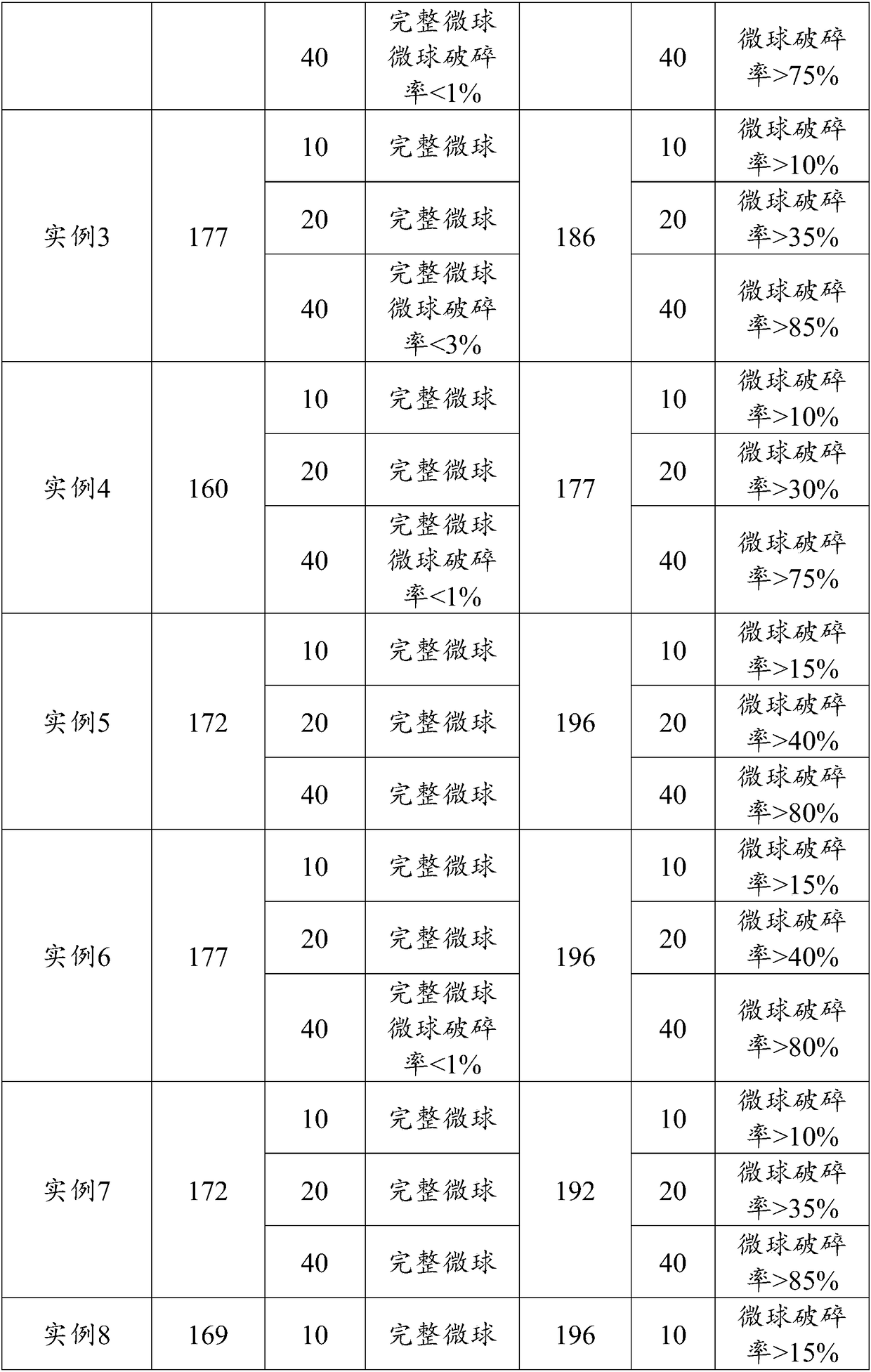

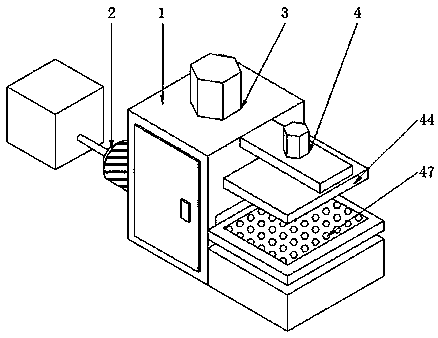

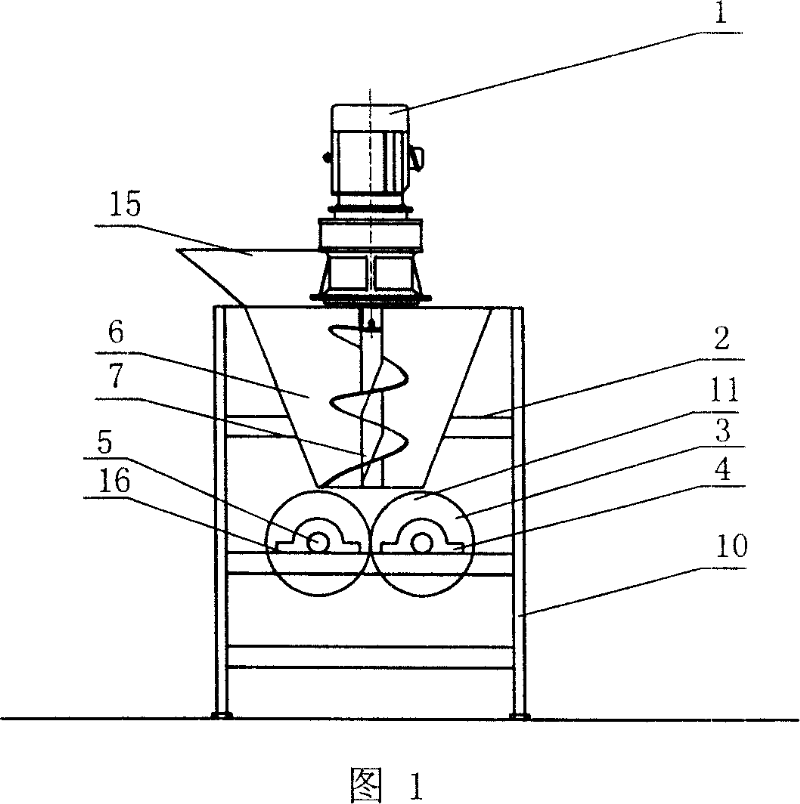

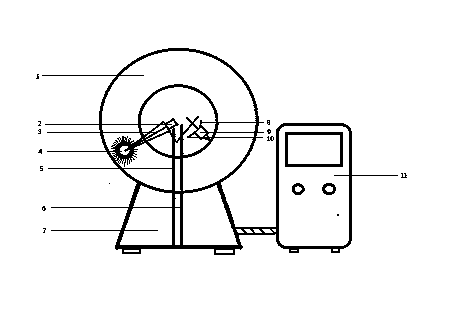

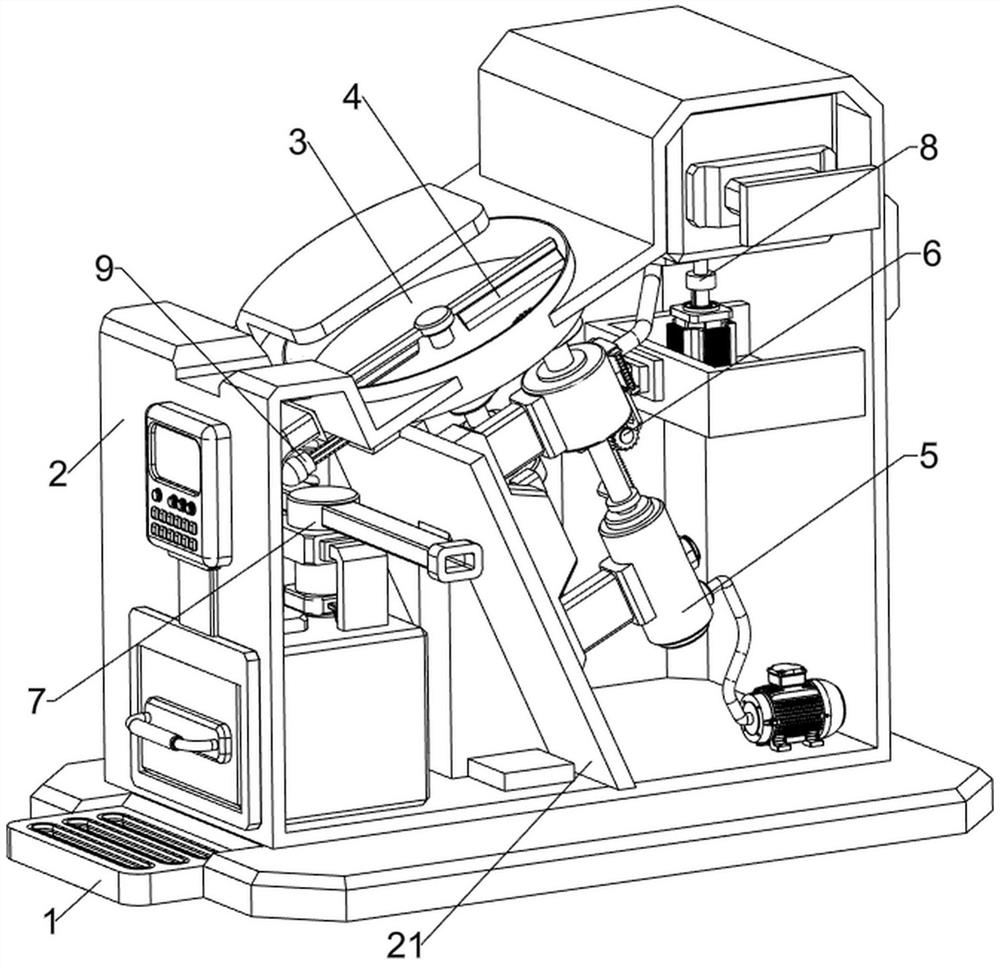

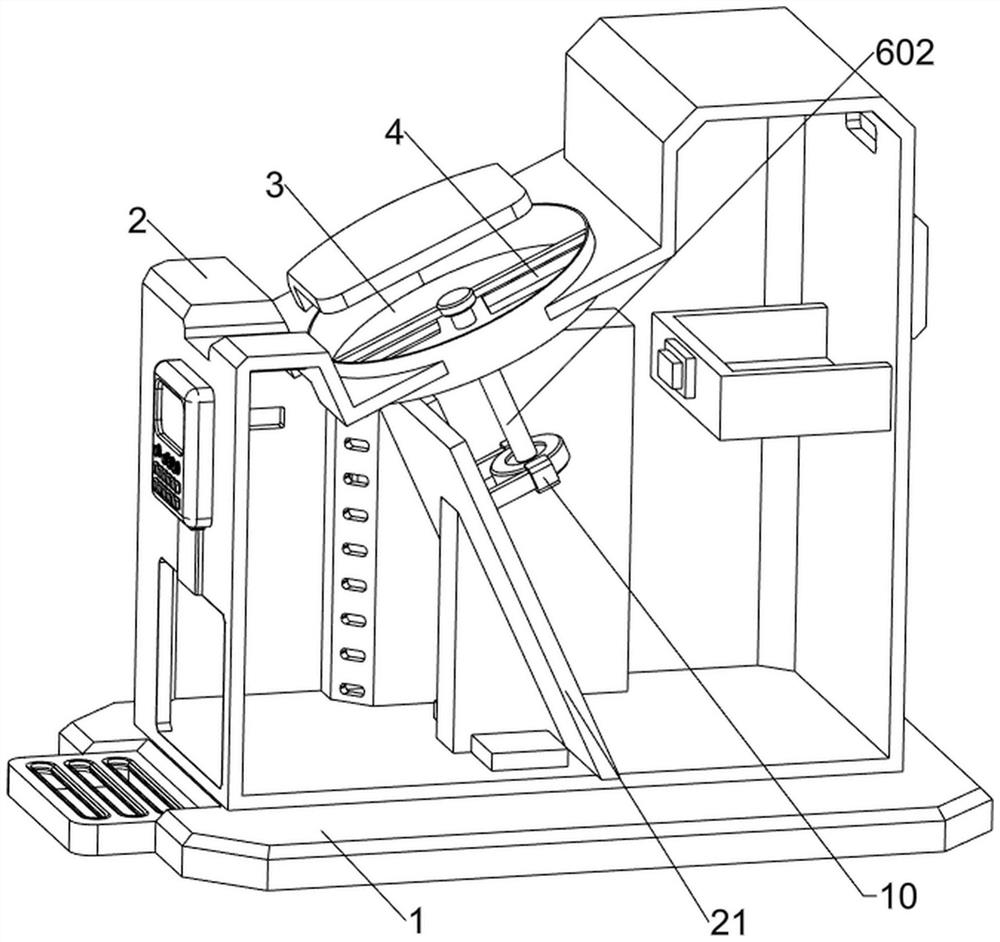

Spherical particle parent nucleus automatic preparation machine

InactiveCN103846049AAvoid cakingIncrease stickinessGranulation in rotating drumsGranulation with special binding agentsAdhesiveEngineering

A spherical particle parent nucleus automatic preparation machine is characterized by possessing a speed-adjustable rounding device, a binder spraying atomizing device, a powder quantitative supply device, a particle generating device and an automatic control device. The machine is capable of simulating the manual preparation process of the spherical particle parent nucleuses, and is especially suitable for spherical particle parent nucleuses prepared from powder with strong wettability, high viscosity and low auxiliary material ratio in medicinal, food and chemical raw materials. Prepared particles have the advantages of high finished product rate, high spherical degree, small particle size, narrow particle size distribution and the like.

Owner:SHANGHAI ZHANGJIANG ENG RES CENT OF MODERN PREPARATION TECH OF TRADITIONAL CHINESE MEDICINE

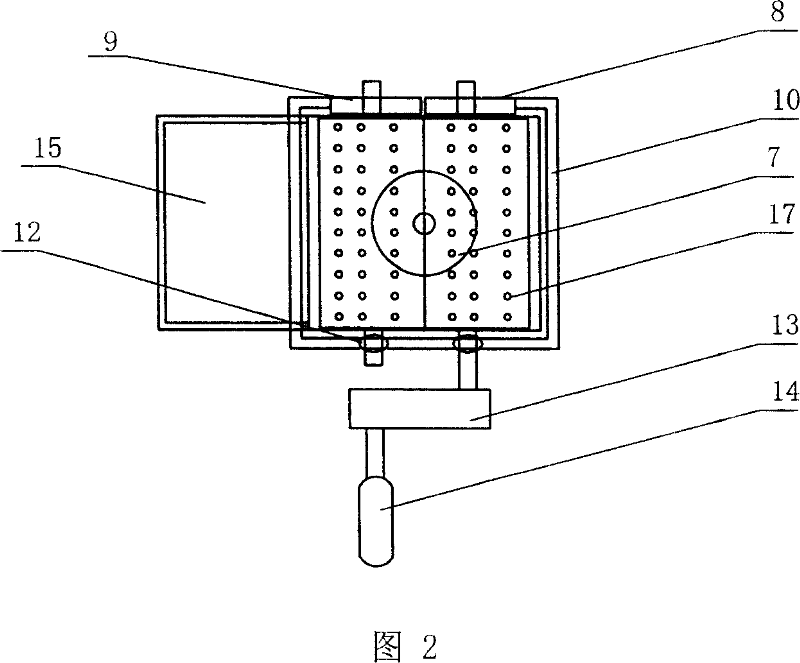

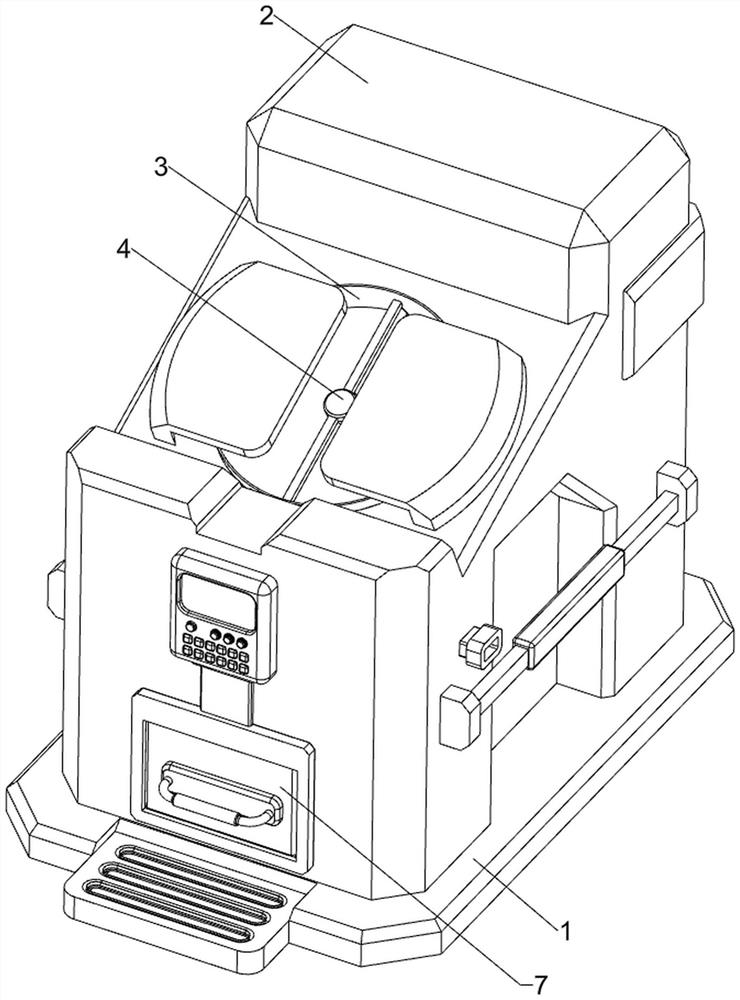

Hydraulic extrusion type activated carbon granulator

PendingCN113617289AAchieve the effect of automatic control of quantitative feedingDrying gas arrangementsMixer accessoriesActivated carbonEngineering

The invention discloses a hydraulic extrusion type activated carbon granulator. The invention aims to provide the hydraulic extrusion type activated carbon granulator which can prepare activated carbon through automatic hydraulic extrusion, automatically dry and collect the activated carbon, automatically control quantitative feeding, automatically knock a blanking pipe to shake off the activated carbon and automatically position a scraper. The hydraulic extrusion type activated carbon granulator comprises: a base, wherein the upper portion of the base is connected with a shell; a supporting plate, wherein the middle of the inner lower side of the shell is connected with the supporting plate; a granulation disc, which is connected to the middle of the upper part of the shell, wherein a plurality of through holes are uniformly formed in one side of the lower part of the granulation disc at intervals, and an opening is formed in one side of the granulation disc; and a discharging assembly, which is arranged on one side of the inner lower part of the shell and between the supporting plate and the granulation disc. The hydraulic extrusion type activated carbon granulator disclosed by the invention has the advantages of automatically drying and collecting activated carbon, automatically controlling quantitative feeding, automatically knocking a blanking pipe, shaking off attached activated carbon particles and automatically positioning the scraper.

Owner:新活力活性炭有限公司

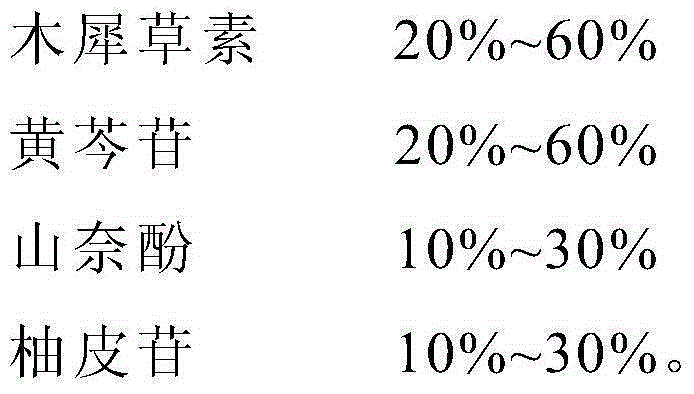

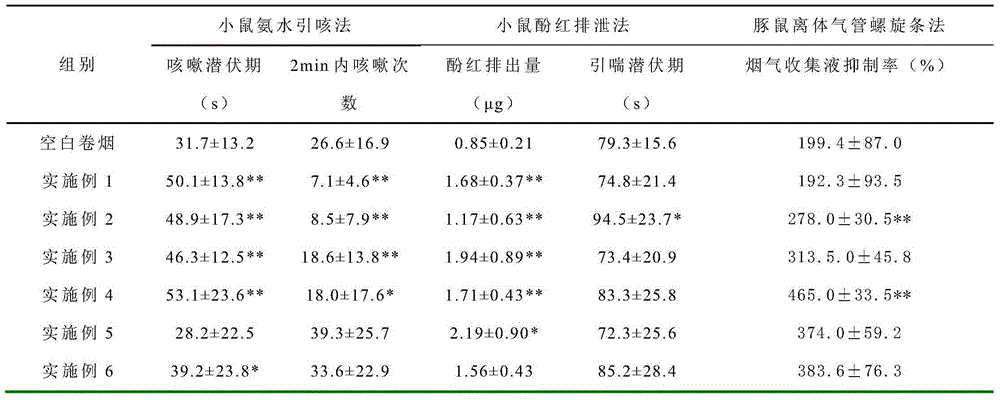

Plant flavone essence cigarette bead for cigarette, and preparation method and application thereof

ActiveCN105154227AGood natural gasComfortable SmellTobacco preparationEssential-oils/perfumesNaringinAdhesive

The invention discloses a plant flavone essence cigarette bead for a cigarette, and a preparation method and application thereof. The preparation method comprises the following steps: weighing an adhesive accounting for 0.1 to 1% of the weight of plant flavone essence; dissolving the adhesive with water and then adding dissolved adhesive into the plant flavone essence; extruding the obtained mixture with an extruder to obtain an elongated strip-like mixture; then rounding the mixture with a rounding machine; and carrying out drying so as to obtain the plant flavone essence cigarette bead. The plant flavone essence comprises, by weight, 20 to 60% of luteolin, 20 to 60% of scutelloside, 10 to 30% of kaempferol and 10 to 30% of naringin. The plant flavone essence cigarette bead has excellent natural smell and brings comfortable aromatic smell to a cigarette; when one smokes the cigarette, aroma components capable of improving aroma quantity and aroma quality are given out by substances in the cigarette bead through pyrolysis after combustion; and active components in the plant flavone essence cigarette bead enter the oral cavity of the human body with smoke in the cigarette, can directly act on the throat and exert good effect on improving comfortableness of the throat.

Owner:HUBEI CHINA TOBACCO IND +1

Popular searches

Animal corpse fertilisers Granulation in rotating dishes/pans Organic phosphatic fertilisers Phosphatic fertiliser granulation/pelletisation Ammonium salt fertilisers Cyanamide fertilisers Urea compound fertilisers Alkali orthophosphate fertiliser Ammonium orthophosphate fertilisers Energy based chemical/physical/physico-chemical processes

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com