Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1279results about "Granulation by material expression" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite proppant, composite filtration media and methods for making and using same

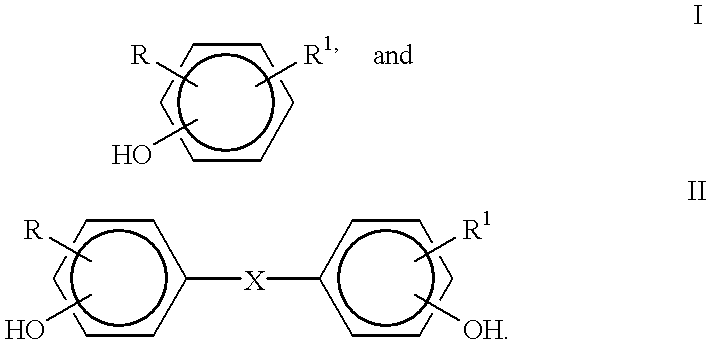

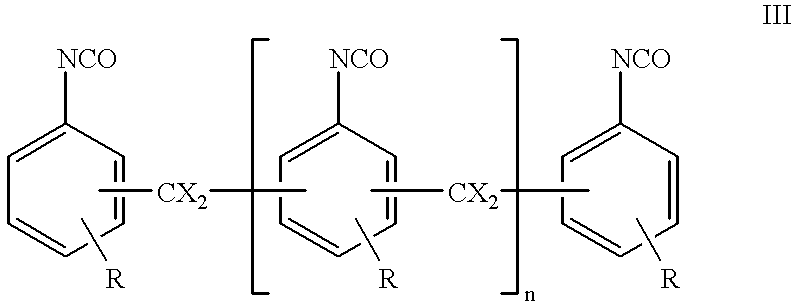

InactiveUS6632527B1Avoid condensationReduce molecular weightPretreated surfacesGlass/slag layered productsFiberFiltration

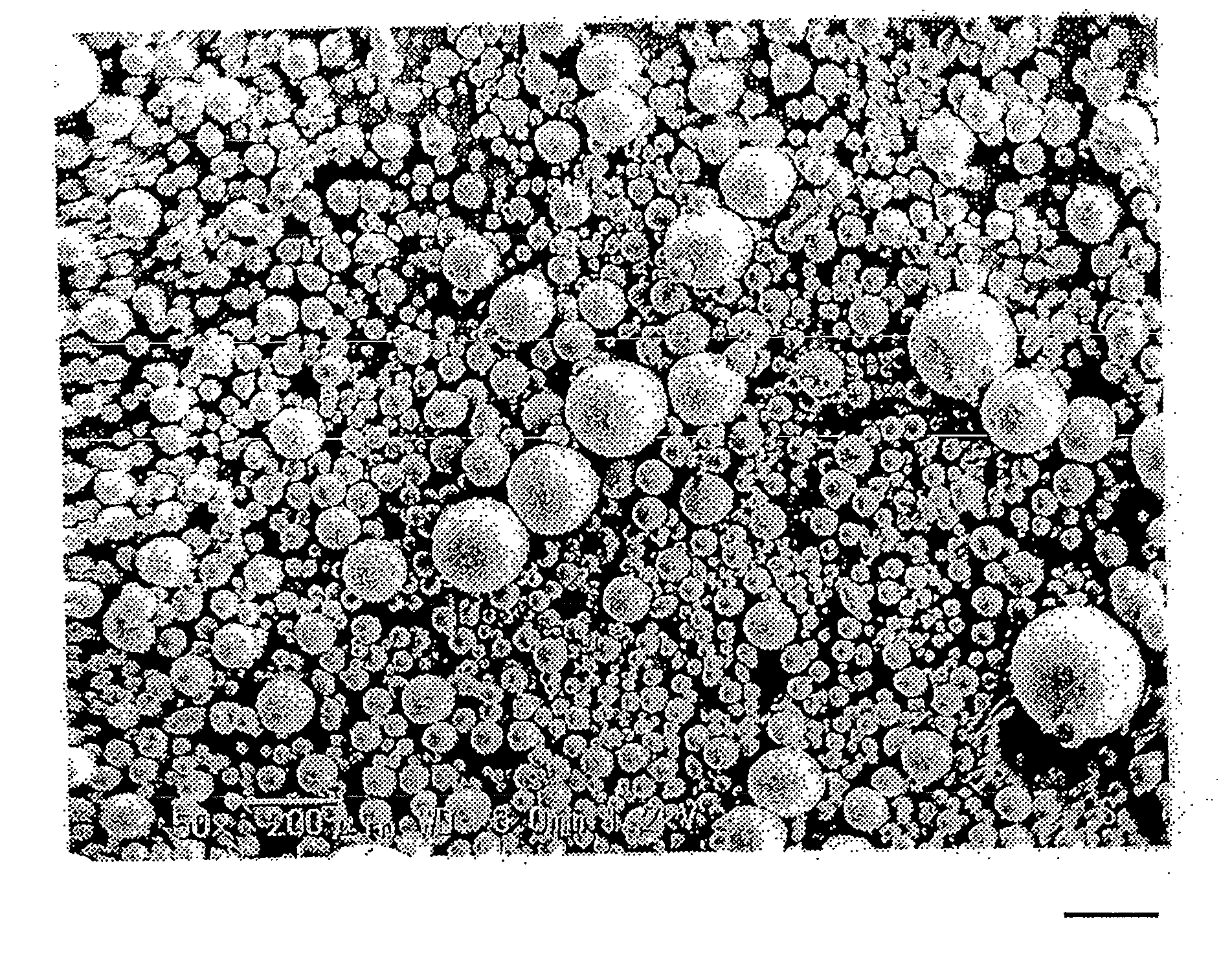

Composite particles made of a binder and filler material are provided for use in subterranean formations. The filler is finely divided mineral and optional fiber. The particles are proppants useful to prop open subterranean formation fractures. The particles are also useful for water filtration and artificial turf for sports fields. Methods of making the composite particles are also disclosed.< / PTEXT>

Owner:HEXION INC

Low density composite proppant, filtration media, gravel packing media, and sports field media, and methods for making and using same

InactiveUS6582819B2Low densityEasy to transportGranule coatingPretreated surfacesFiltrationArtificial turf

Low density composite particles made of a binder and filler material are provided for use in subterranean formations. The filler includes low density filler and optionally other filler. The binder includes a polymer and optionally cement. The particles may be employed as proppants useful to prop open subterranean formation fractures. The particles are also useful for gravel packing in subterranean formations, water filtration and artificial turf for sports fields. Methods of making the composite particles are also disclosed.

Owner:HEXION INC

Low density composite proppant, filtration media, gravel packing media, and sports field media, and methods for making and using same

InactiveUS20020048676A1Point becomes highImprove interfacial organic-inorganic adhesionPigmenting treatmentDead plant preservationFiltrationArtificial turf

Low density composite particles made of a binder and filler material are provided for use in subterranean formations. The filler includes low density filler and optionally other filler. The binder includes a polymer and optionally cement. The particles may be employed as proppants useful to prop open subterranean formation fractures. The particles are also useful for gravel packing in subterranean formations, water filtration and artificial turf for sports fields. Methods of making the composite particles are also disclosed.

Owner:HEXION INC

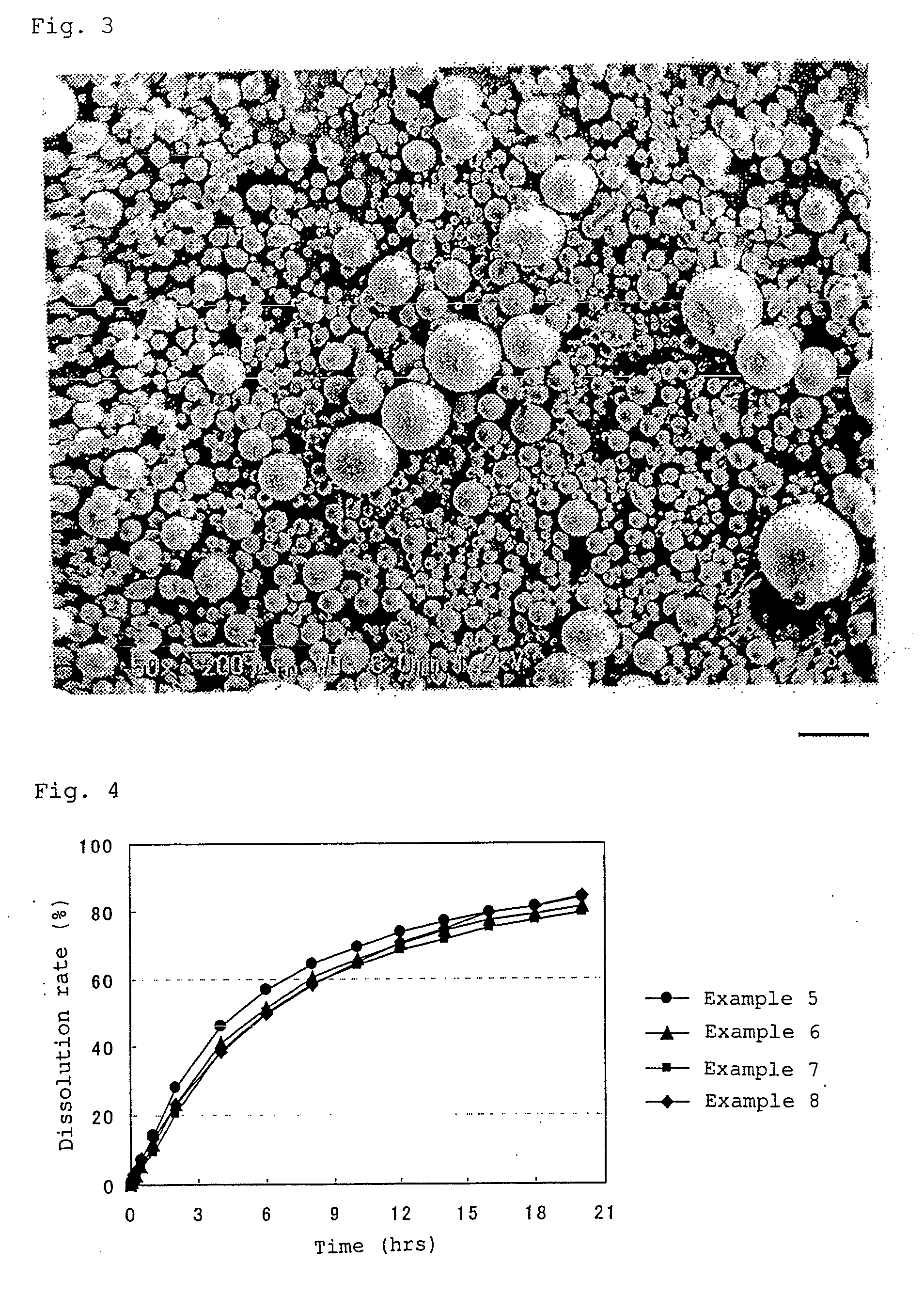

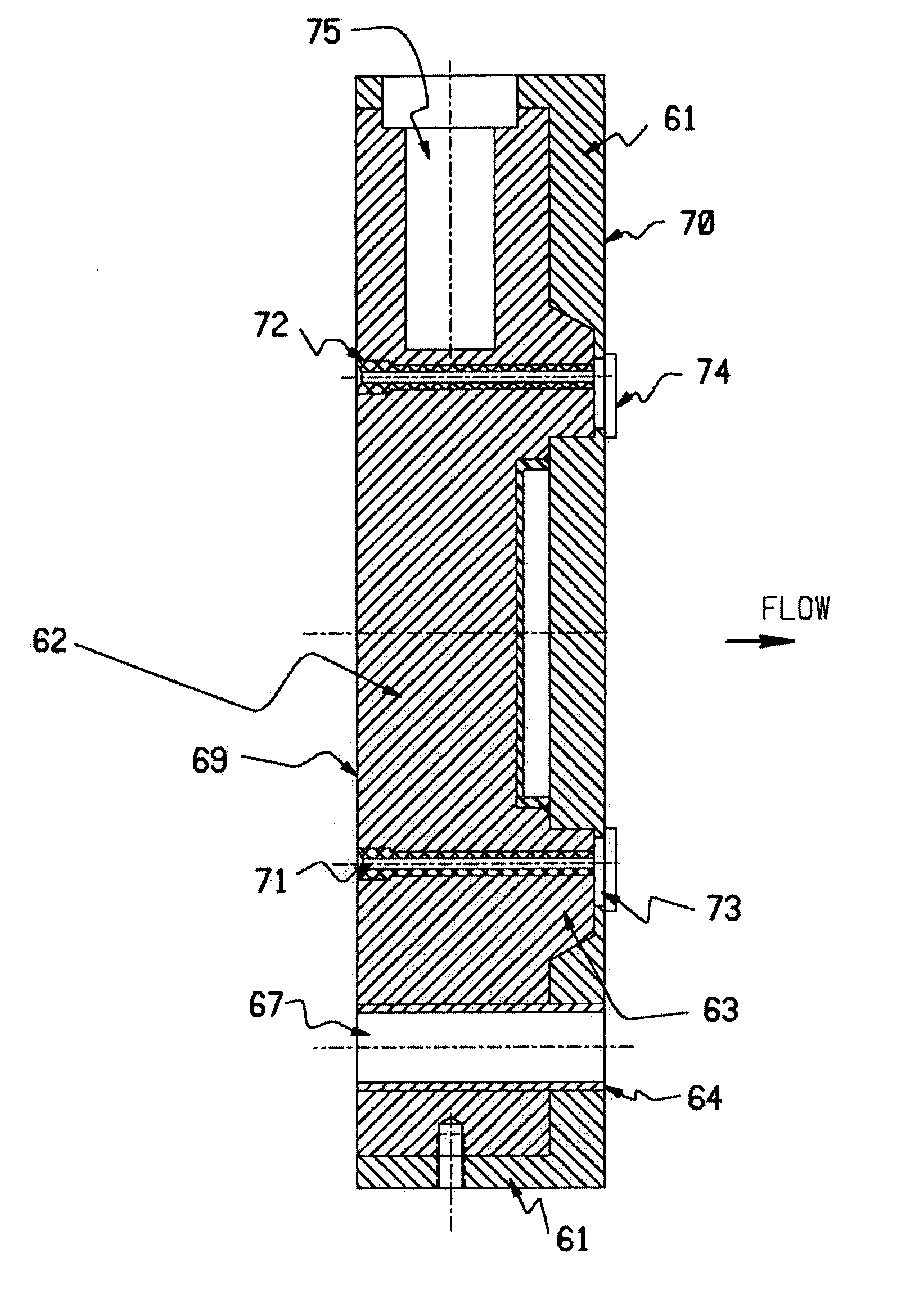

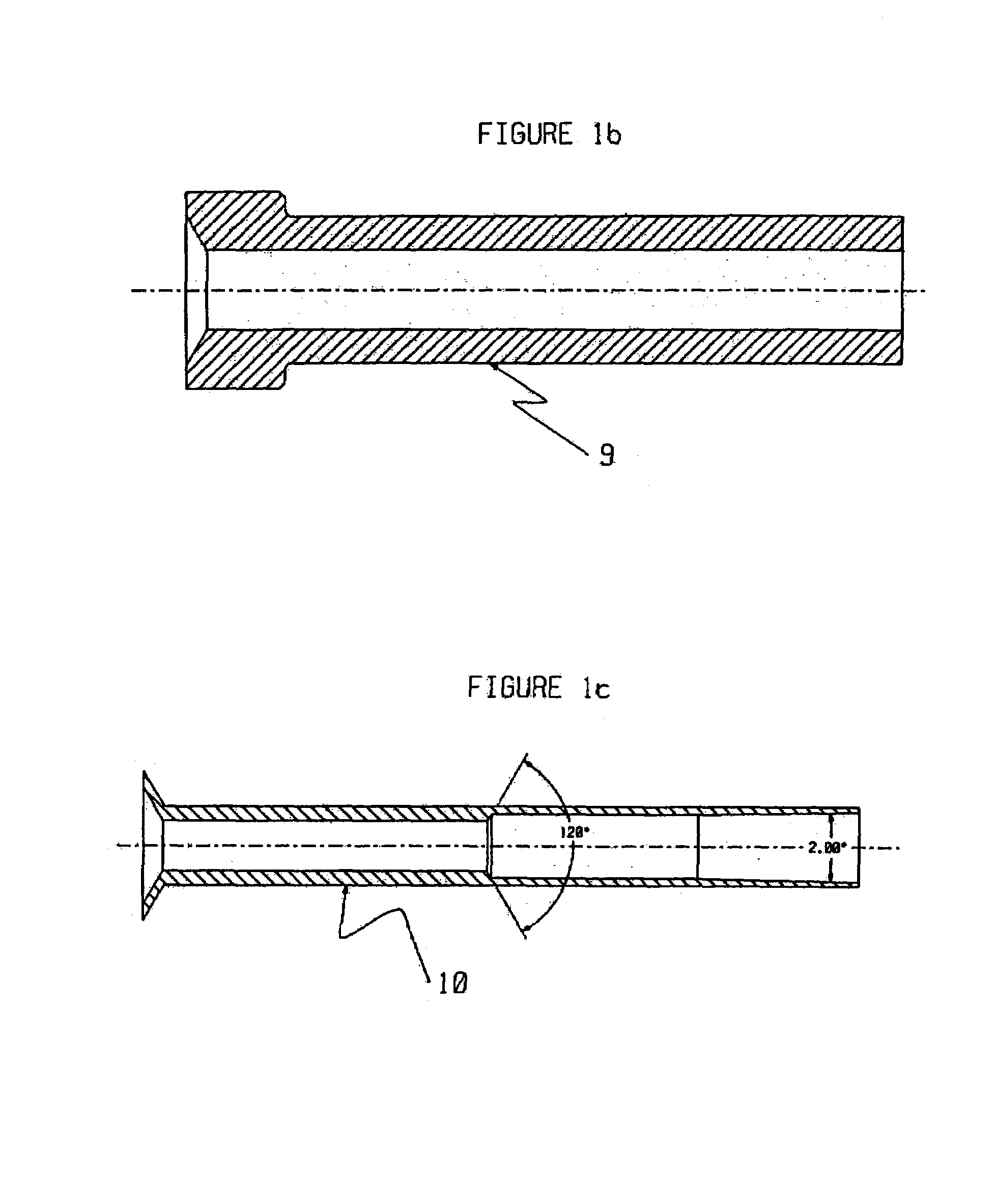

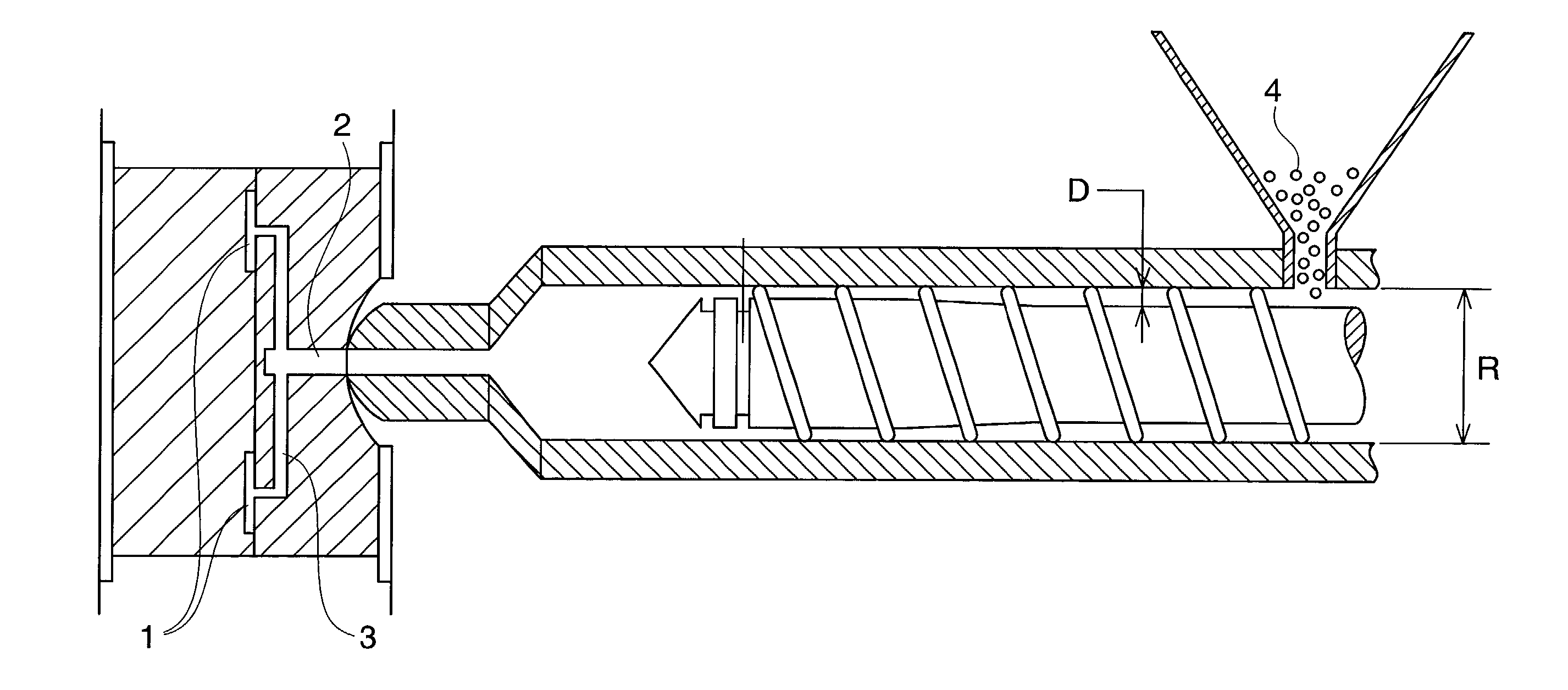

Method of producing drug-containing wax matrix particles, extruder to be used in the method and sustained-release preparation containing cilostazol

InactiveUS20090047357A1Easy to produceSolve low usagePowder deliveryBiocideSpray nozzleSustained-Release Preparations

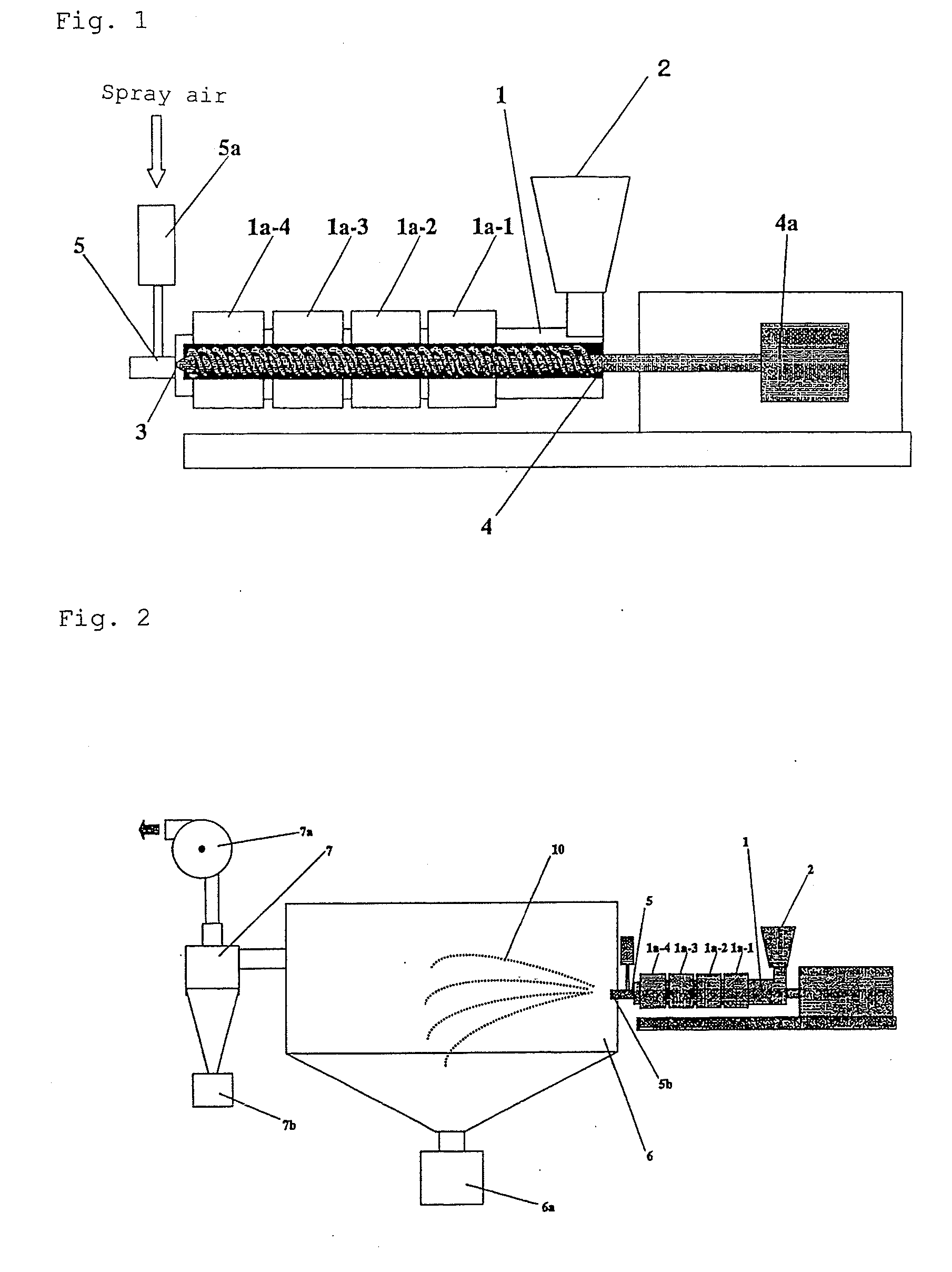

The present invention aims to provide a method for producing, by a simple method, drug-containing wax matrix granules, particularly drug-containing wax matrix granules having an average particle diameter of 1 mm or lower, while avoiding liquid blockage due to the recrystallization of a molten drug during the period from a melting step to a spray step.Drug-containing wax matrix granules having at least one wax and at least one drug are produced by the following steps (i) and (ii): (i) supplying the at least one drug and the at least one wax to an extruder in which the temperature of a barrel and the temperature of a die are adjusted to be higher than the melting point of the at least one wax; and (ii) while melting and kneading the at least one drug and the at least one wax in the extruder to give a molten kneaded drug and wax, spraying the molten kneaded drug and wax into an atmosphere having a temperature lower than the melting point of the wax from a spray nozzle directly mounted onto a die provided at a top end of the barrel of the extruder, thereby forming the mixture into granules.

Owner:OTSUKA PHARM CO LTD

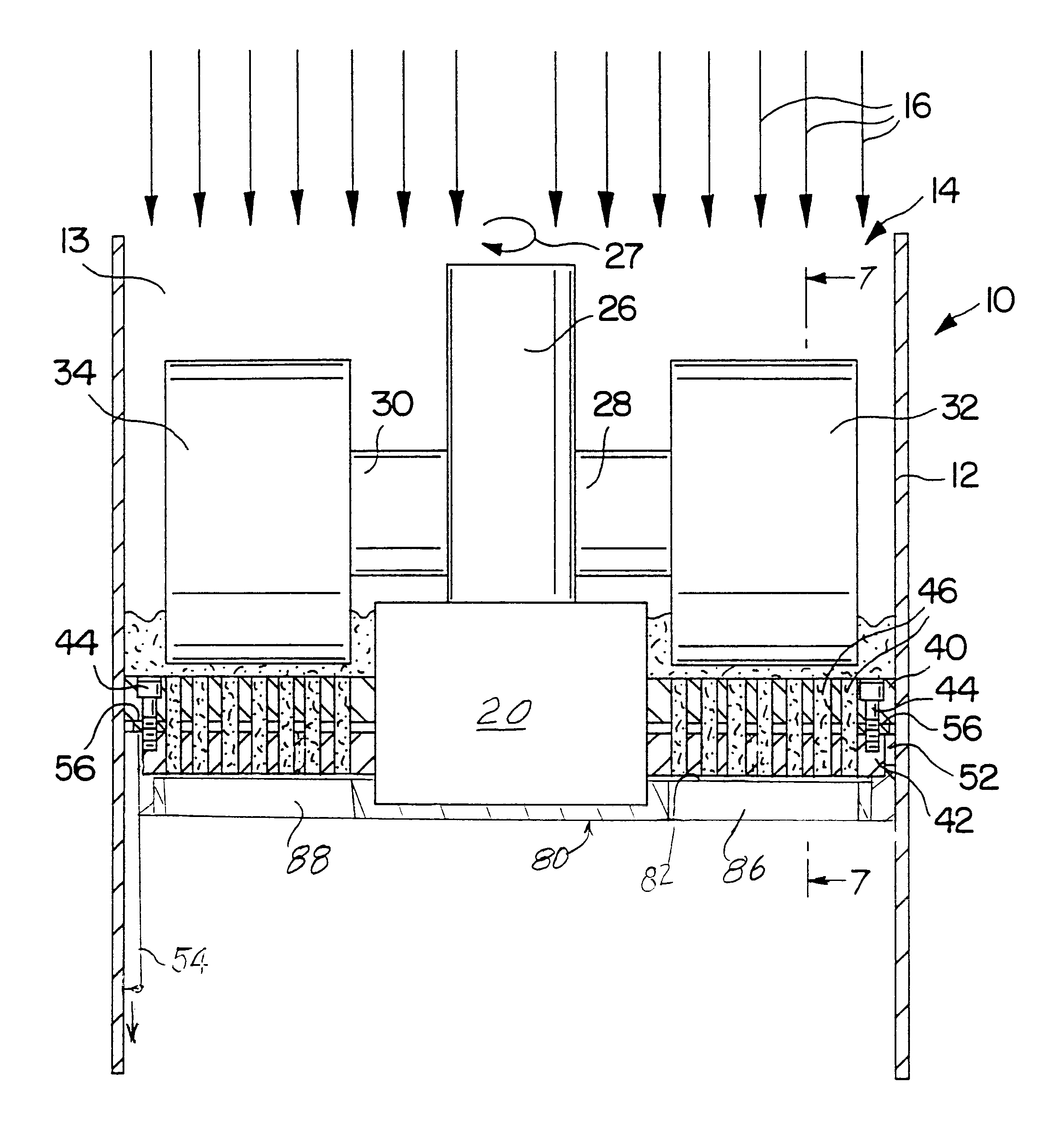

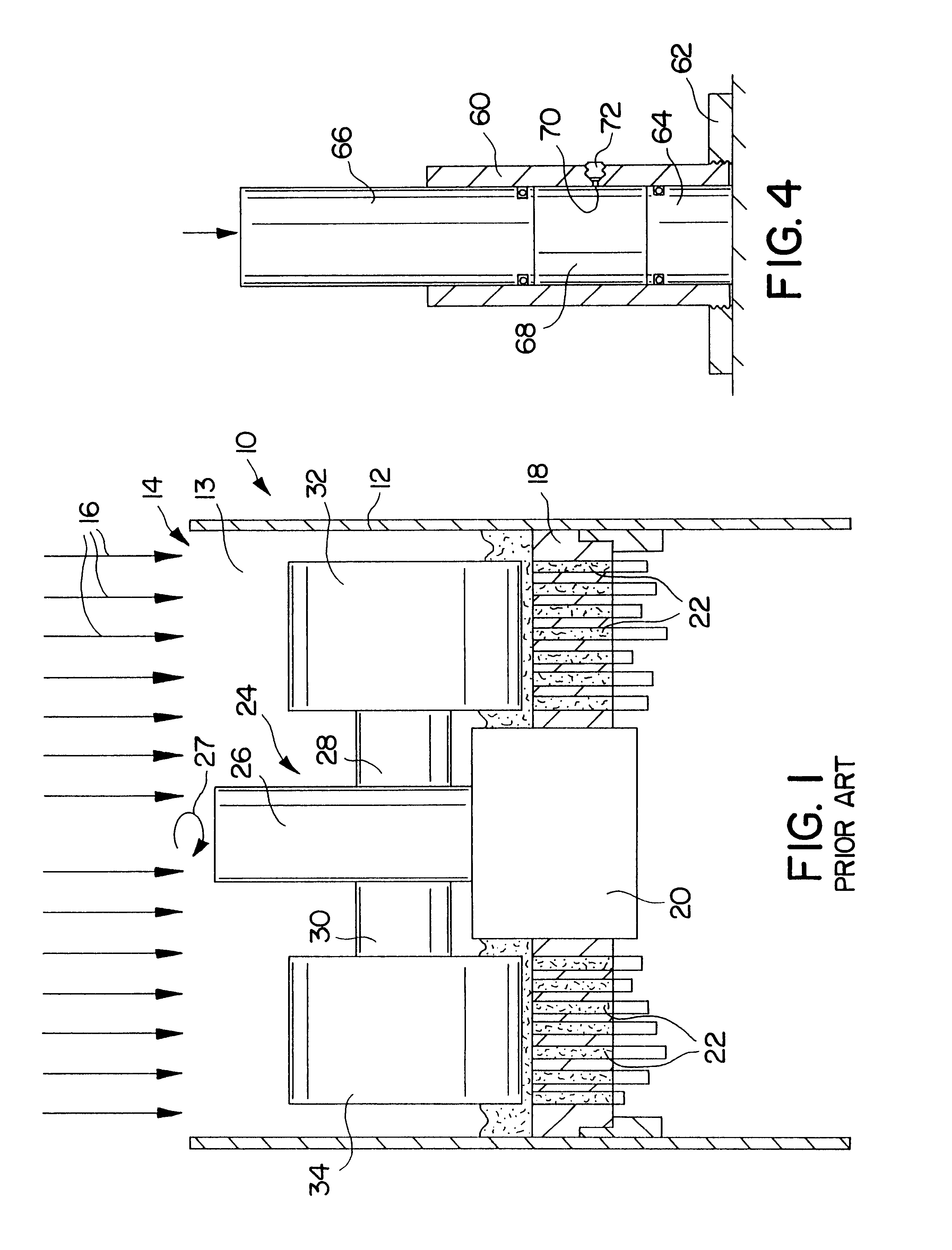

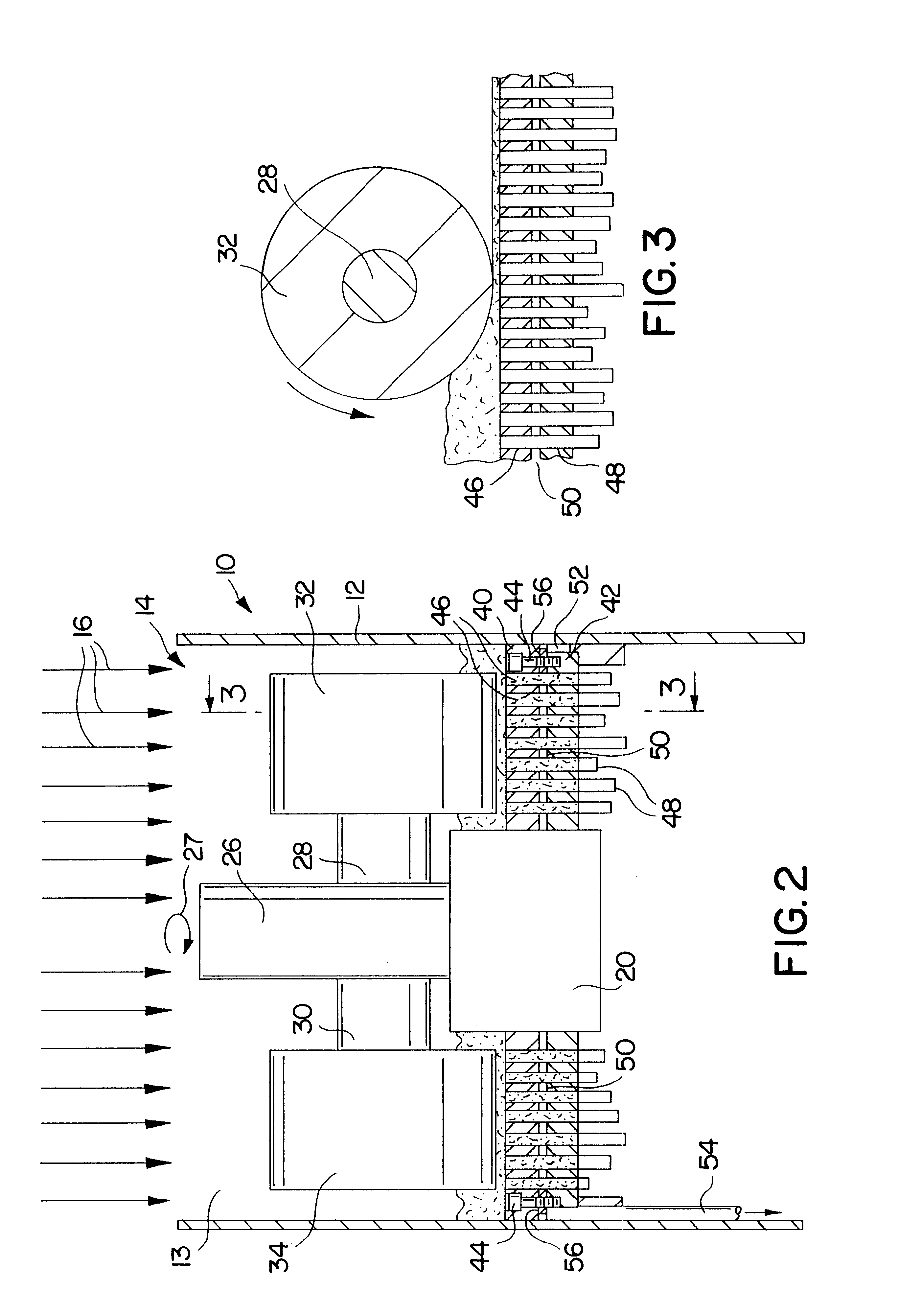

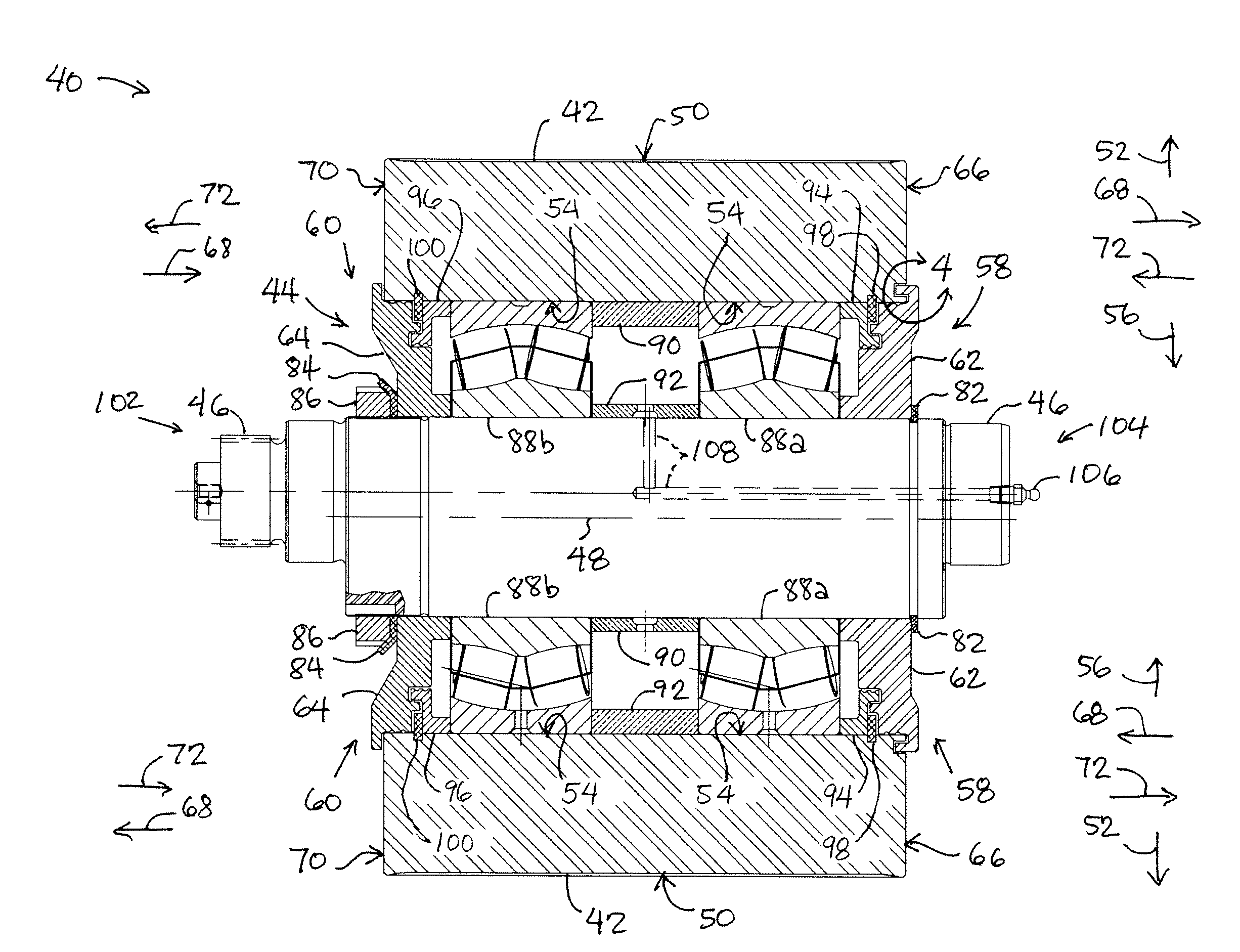

Polymer underwater pelletizer apparatus and process incorporating same

InactiveUS20050035483A1Minimizes potential for freezing of polymerEasy to moveMouldsConfectioneryThermoplasticUnderwater

Underwater melt pelletizer dies which have a highly thermally conductive pathway from their heating source to the vicinity of the polymer exit end of their die holes and have a thermally insulating material at that end of their die holes have improved operability and can pelletize thermoplastics which are otherwise difficult or impossible to pelletize with such an apparatus.

Owner:TICONA LLC

NANO particle/polyamide composite material, preparation method therefor, and use thereof

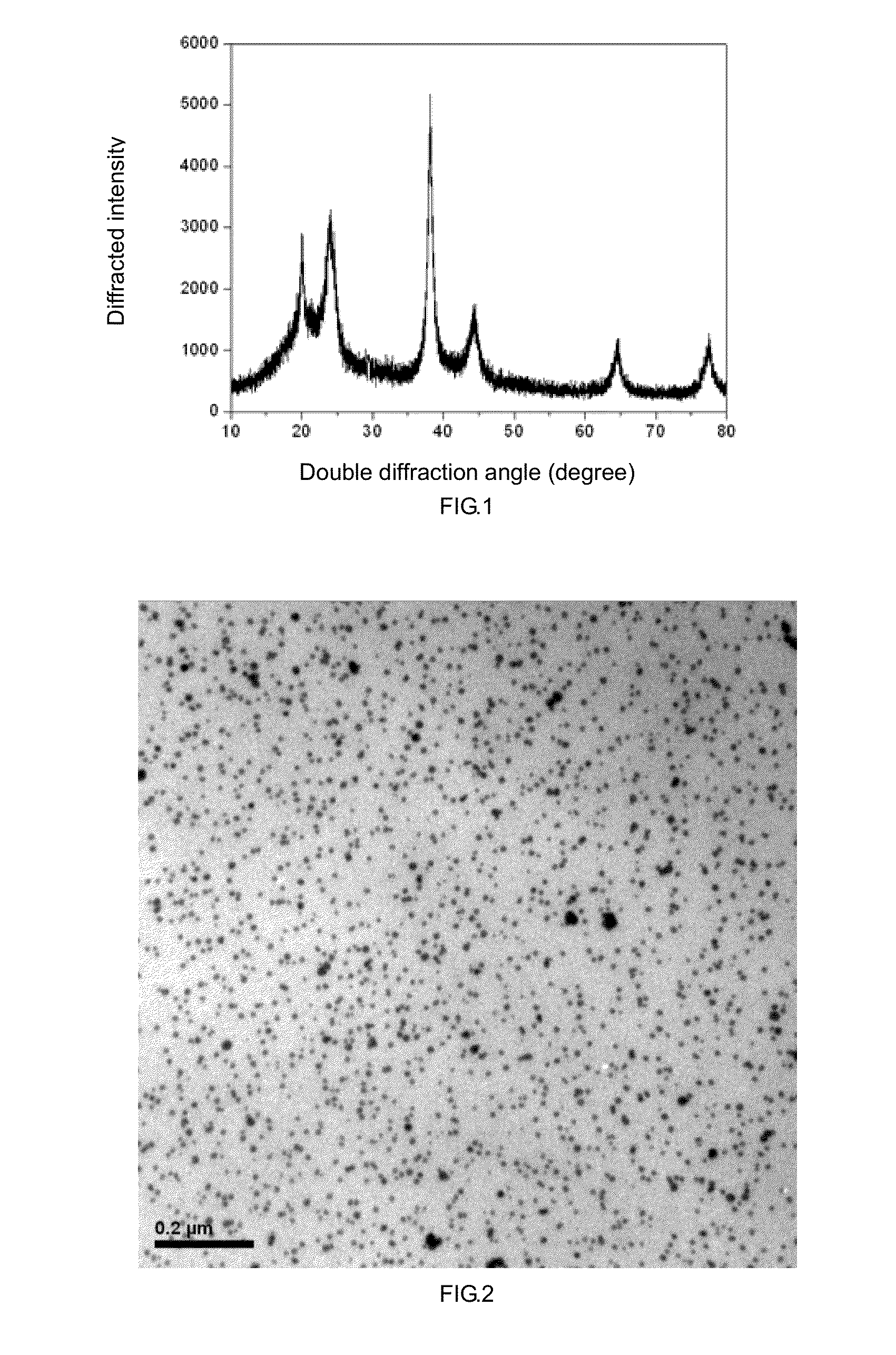

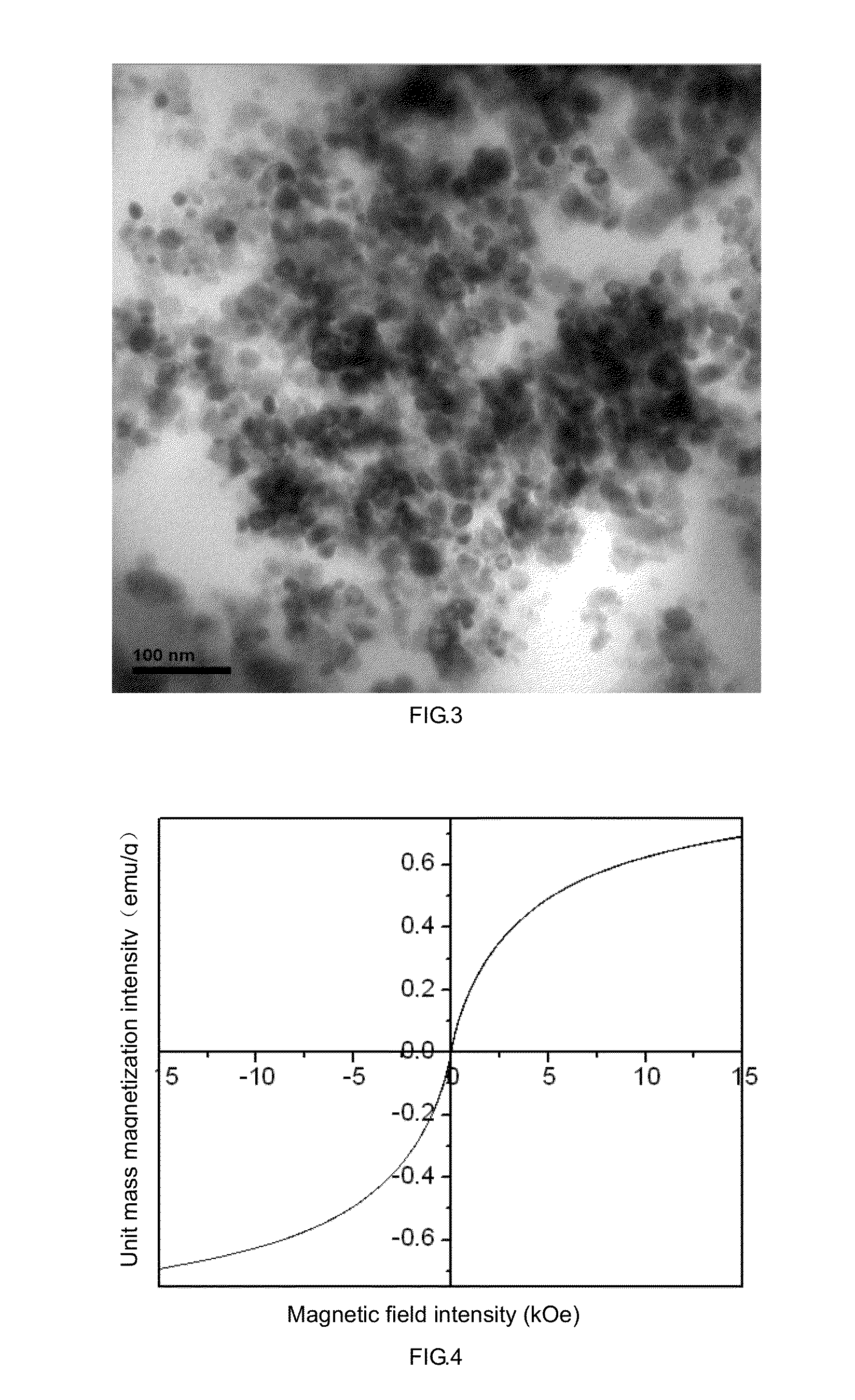

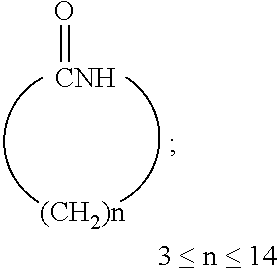

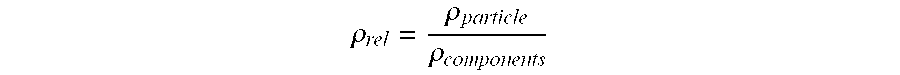

ActiveUS20140048738A1Improve mechanical propertiesEasy to moldNanotechInorganic material magnetismSynthesis methodsPolyamide

The present invention relates to the technical field of polymer composite material, and a nano particle / polyamide composite material, a preparation method therefor and a use thereof are disclosed. The nano particle / polyamide composite material comprises 0.01-99 parts by weight of inorganic nano particles and 1-99.99 parts by weight of a polyamide matrix. The preparation method for the nano particle / polyamide composite material of the present invention comprises hydrolysis polymerization or anionic polymerization. The nano particle / polyamide composite material of the present invention has the particular functions of nano materials, while having the advantages of the polymer matrix such as good mechanical performance and being easy for processing and molding. The nano particle is well dispersed in the polyamide matrix, is physically stable, and has a strong interaction at an interface between the nano particles and the polymer matrix, thus being useful as a structural material, a functional material and a polymer masterbatch. The cost of raw materials used in the synthesis method is low, the production apparatus is simple, and the route is green and environment friendly. Therefore, the method is applicable to large-scale industrial production.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Detergent particle

InactiveUS20030017959A1Resistance to crackingResistant to and fragmentationOrganic detergent compounding agentsNon-surface-active detergent compositionsParticulatesWater dispersible

The present invention relates to a water-soluble and / or water-dispersible particle comprising an active ingredient uniformly dispersed, preferably an enzyme, in a matrix comprising from 20-95% by weight of the particle of polyvinyl alcohol of a molecular weight of 10-30K daltons. The present invention further relates to a process to obtain a particle, to a detergent composition comprising the particle and to the use of particle to minimize, reduce or prevent the generation of dust while providing excellent cleaning on enzyme sensitive stains and soils and on particulate stains, improved thermostability and fabric softness performance.

Owner:THE PROCTER & GAMBLE COMPANY

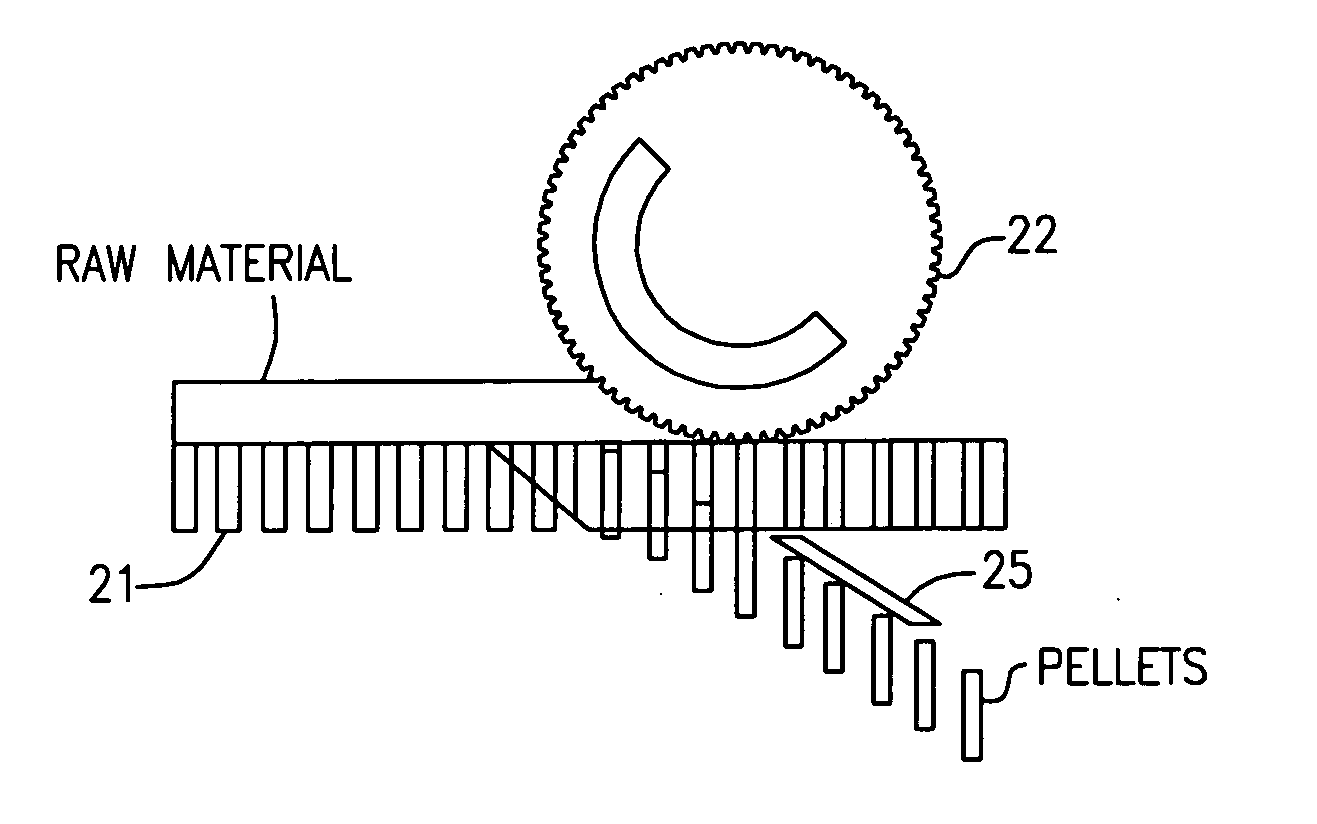

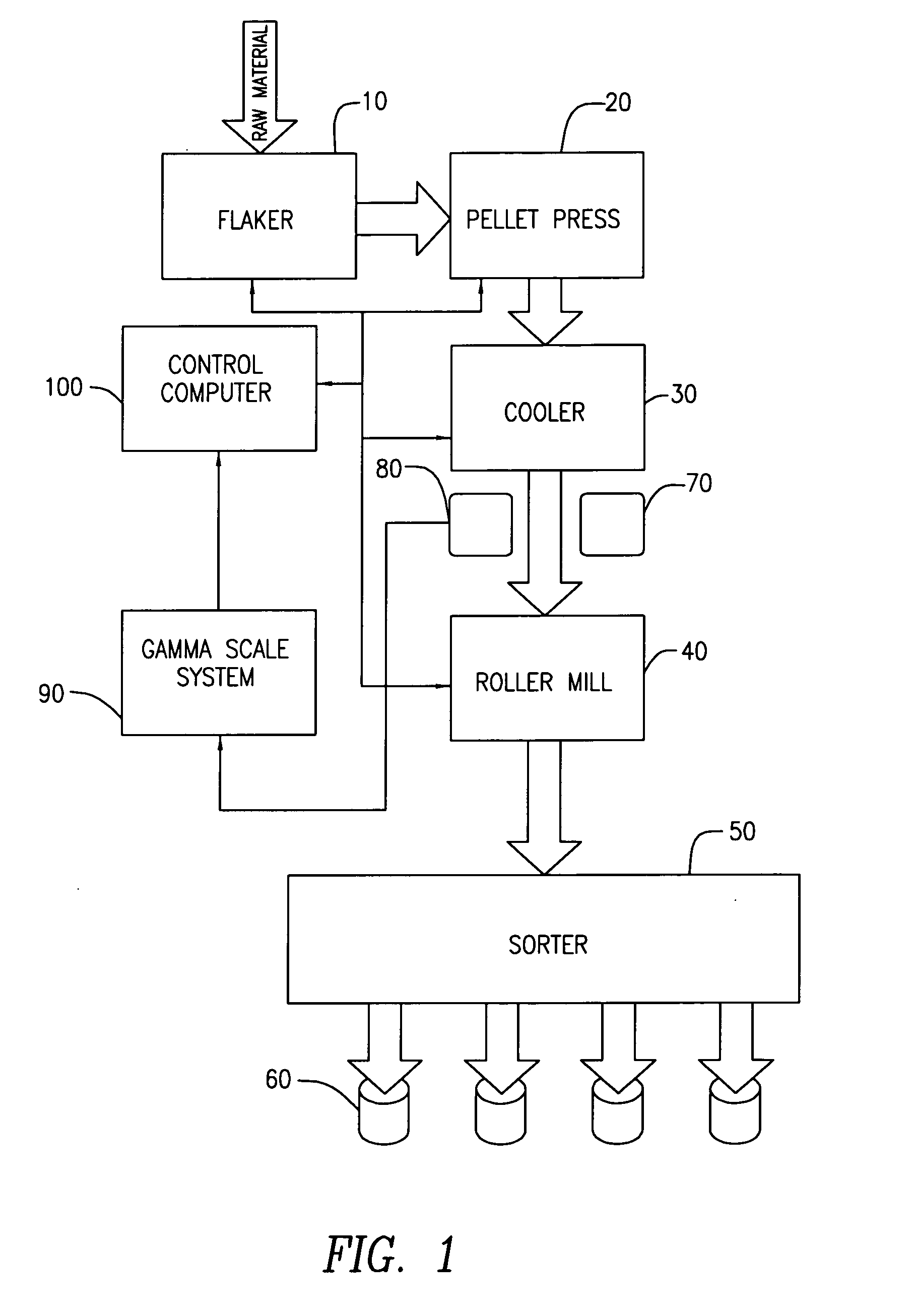

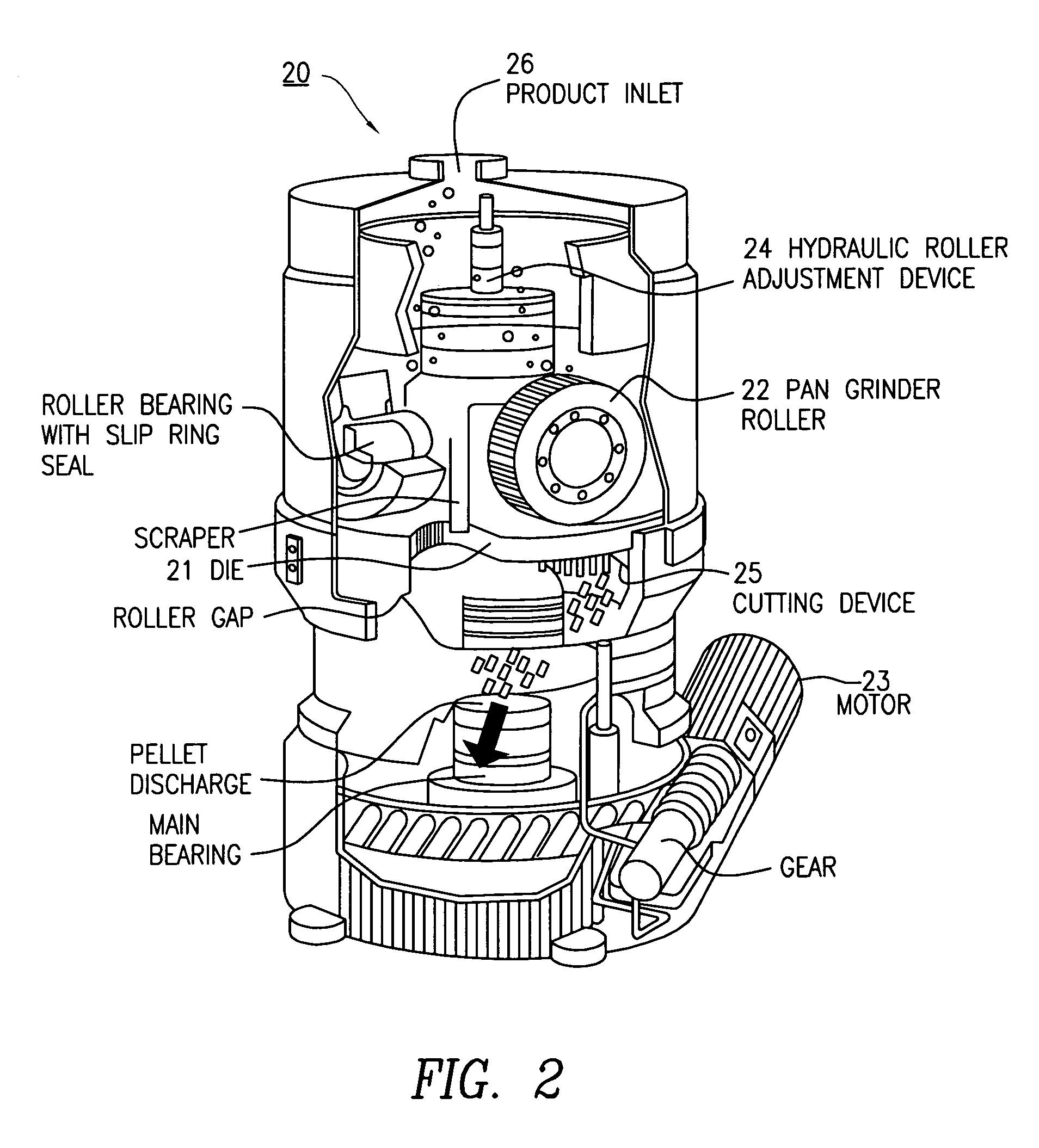

Pellet mill and method of making peanut hull granules

InactiveUS20050230872A1Minimizes of other wasteReduce energy costsConfectionerySweetmeatsEngineeringPeanut hull

To make peanut hull granules peanut shells are supplied to a flaker where the shells are flaked. The flaked shells are fed into a hydraulic pellet press where they are pressed into pellets using a horizontal die. The pellets are then cooled using cooler. The cooled pellets are processed by a roller mill that crumbles the pellets into granules.

Owner:AG FIBERS

Polymer underwater pelletizer apparatus and process incorporating same

InactiveUS7226553B2Minimizes potential for freezing of polymerEasy to moveMouldsConfectioneryThermoplasticUnderwater

Underwater melt pelletizer dies which have a highly thermally conductive pathway from their heating source to the vicinity of the polymer exit end of their die holes and have a thermally insulating material at that end of their die holes have improved operability and can pelletize thermoplastics which are otherwise difficult or impossible to pelletize with such an apparatus.

Owner:TICONA LLC

Apparatus for dewatering and pelletizing particulate fuel

An apparatus for pelletizing a feed material containing finely divided solids and water by compressing the feed material in the die cavities of a pellet mill and permitting excess water to escape from the material being compressed through at least one water escape opening in each die cavity.

Owner:ZITRON ZALMAN

Detergent particle

InactiveUS20050075261A1Minimize and reduce and prevent generation of dustEasy to cleanOrganic detergent compounding agentsTransportation and packagingParticulatesWater dispersible

The present invention relates to a water-soluble and / or water-dispersible particle comprising an active ingredient uniformly dispersed, preferably an enzyme, in a matrix comprising from 20-95% by weight of the particle of polyvinyl alcohol of a molecular weight of 10-30K daltons. The present invention further relates to a process to obtain a particle, to a detergent composition comprising the particle and to the use of particle to minimize, reduce or prevent the generation of dust while providing excellent cleaning on enzyme sensitive stains and soils and on particulate stains, improved thermostability and fabric softness performance.

Owner:BAECK ANDRE CESAR +2

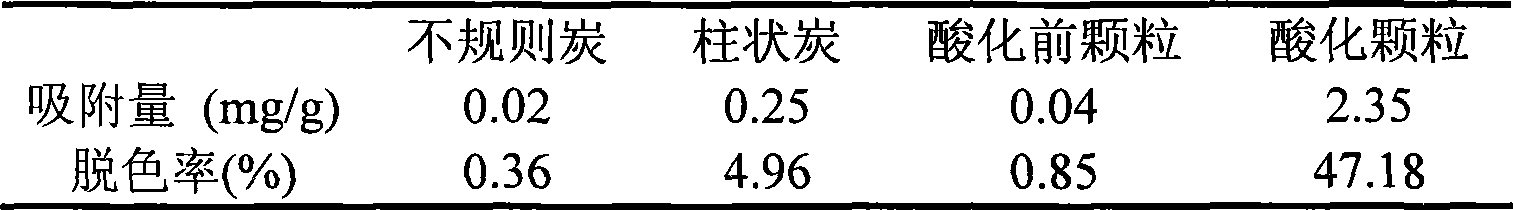

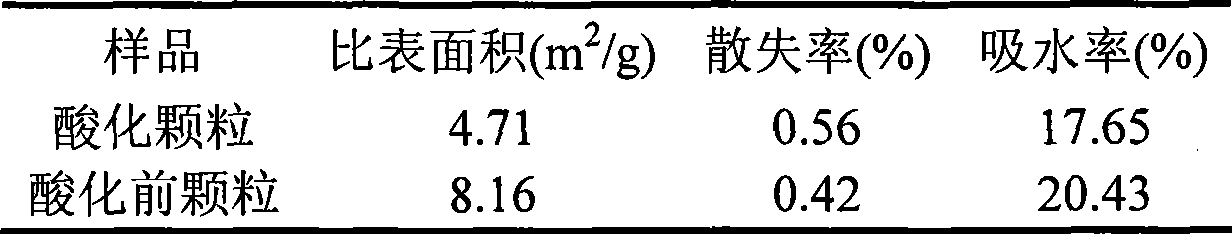

Preparation method of acidification sludge bentonite granules

InactiveCN101362073AReasonable designSimple processOther chemical processesGranulation by material expressionSodium BentoniteSludge

The invention relates to a preparation method of acidified sludge bentonite particles, pertaining to the technical field of environmental protection. Sludge and nano-bentonite powder are mixed together according to a certain ration, porous sludge bentonite particles are prepared by roasting under high temperature and the activity of the porous sludge bentonite particles is further modified by sulphuric acid to prepare the acidified sludge bentonite particles. The acidified sludge bentonite particles is yellow solid particles, with organic substance content reaching 165.788mg / g, specified surface area being 4.71m<2> / g, lost ratio being 0.56 percent and water absorptivity being 17.65 percent. The preparation method has the advantages of simple technology, economic efficiency, low cost, and the like, and the prepared acidified sludge bentonite particles have stable quality, uniform appearance and good absorptivity, thereby not only realizing the utilization of sludge as resource and the reduction of the pollution caused by the sludge, but also having wide application value in the aspect of decoloring processing of waste water produced in printing and dyeing, and realizing the purpose of treating waste by utilizing waste.

Owner:SHANDONG UNIV

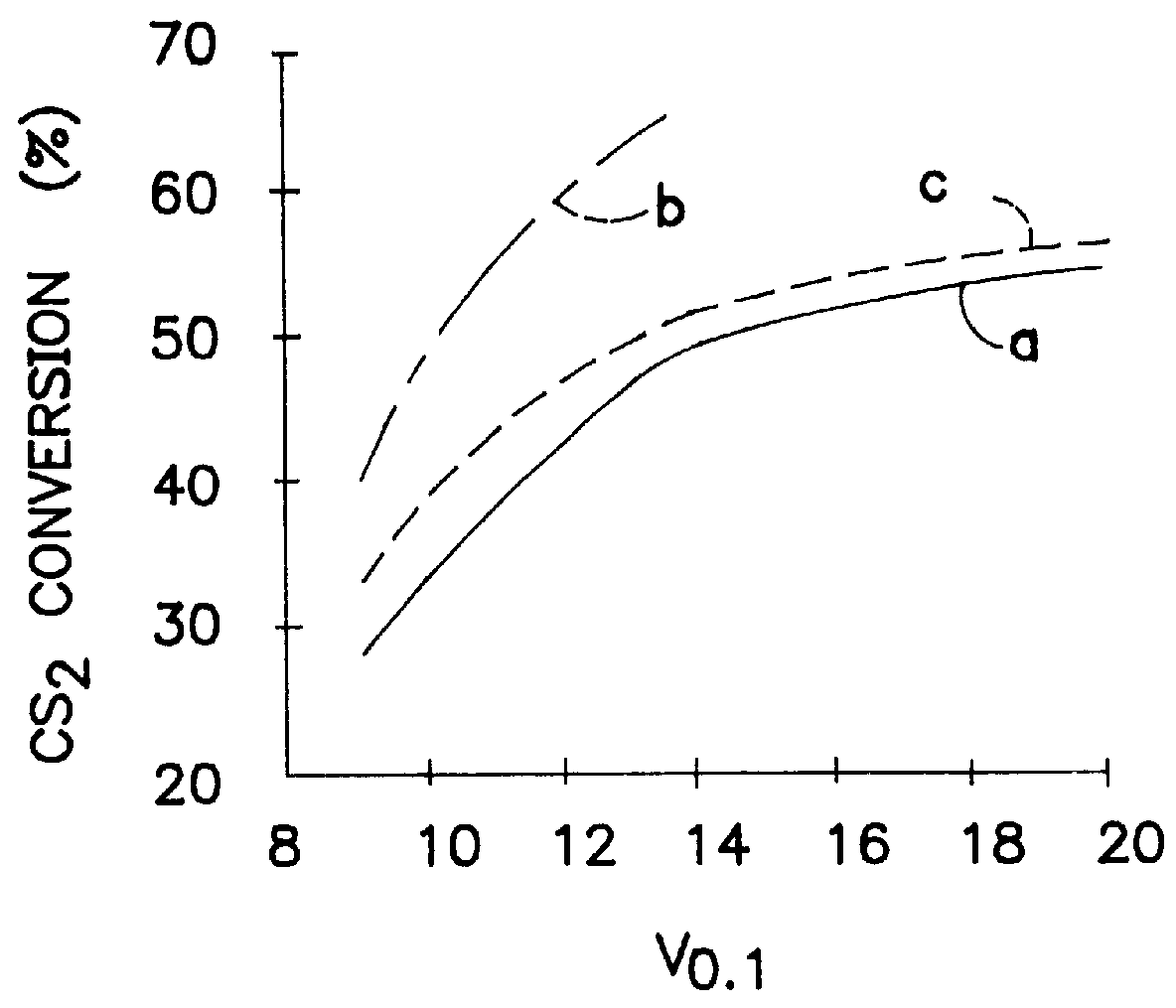

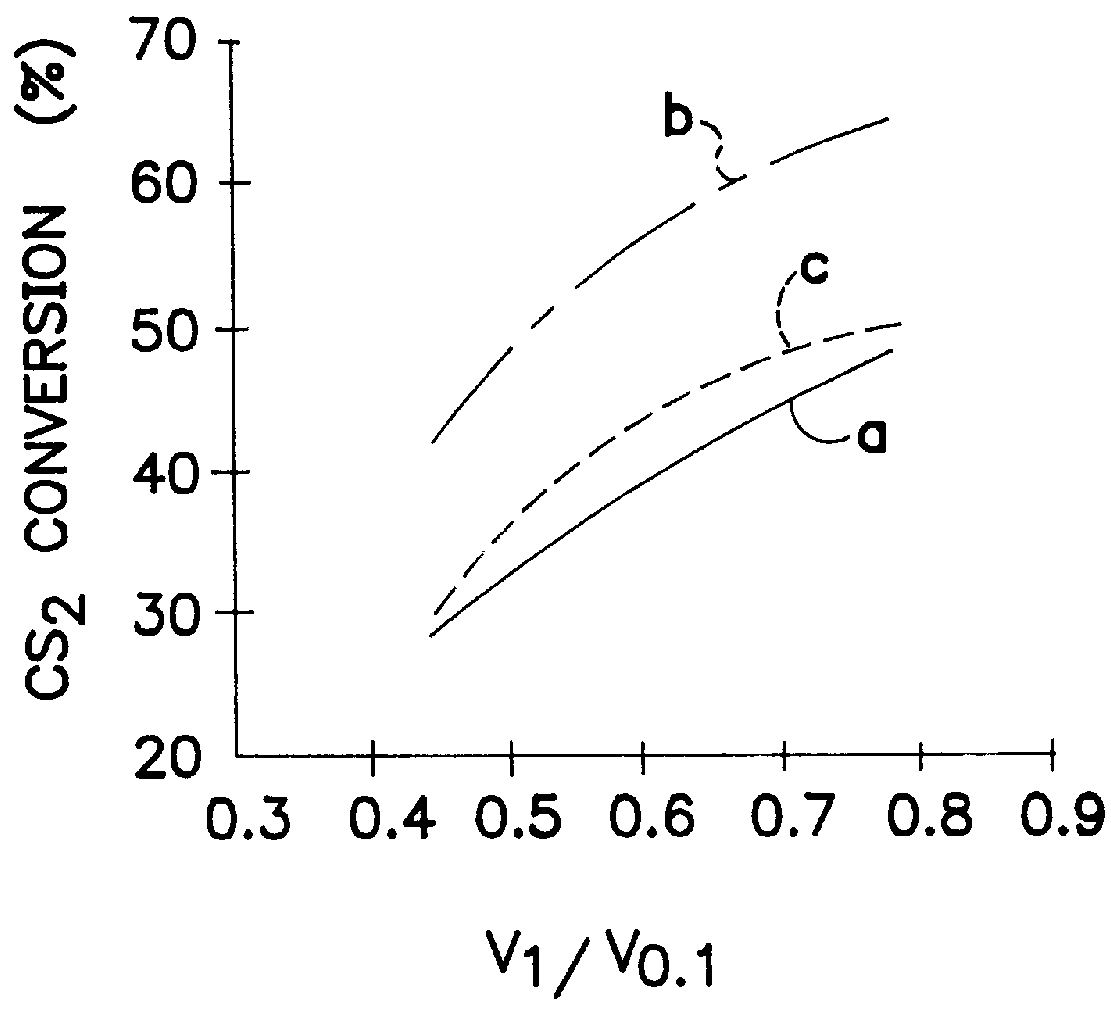

Alumina-based catalyst for the treatment of gases containing sulphur compounds, use of these catalysts for the treatment and processes for treatment of the said gases

InactiveUS6080379AImprove performanceDispersed particle separationHydrogen sulfidesOrganic sulphur compoundSulphur compound

The invention relates to a catalyst for the treatment of gases containing sulphur compounds, using the Claus reaction or using hydrolysis, which is made up of alumina-based porous particles and characterized in that the cumulative volume created by all the pores whose diameter is greater than 0.1 .mu.m, V.sub.0.1, is greater than 12 ml / 100 g of catalyst and in that the cumulative volume created by all the pores whose diameter is greater than 1 .mu.m, V.sub.1, is such that the ratio V.sub.1 / V.sub.0.1 is higher than or equal to 0.65. This catalyst can be employed for the treatment of gases containing sulphur compounds by using the Claus reaction, or of gases containing organic sulphur compounds by using a hydrolysis reaction.

Owner:INST FR DU PETROLE

Formulation for inhalation

A dry powder composition comprising formoterol and a carrier substance, both of which are in finely divided form, wherein the formulation has a poured bulk density of from 0.28 to 0.38 g / ml is useful in the treatment of respiratory disorders.

Owner:ASTRAZENECA AB

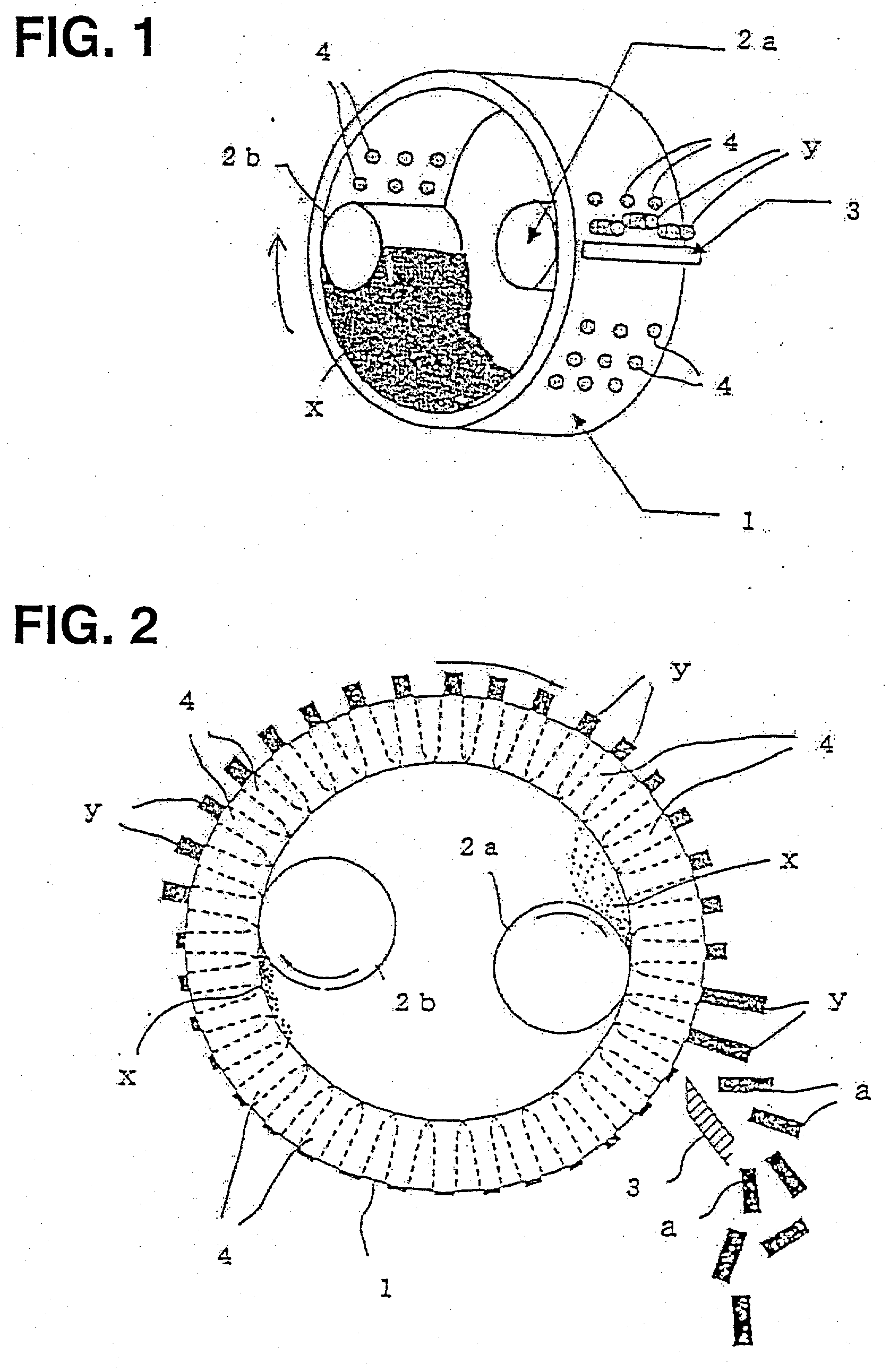

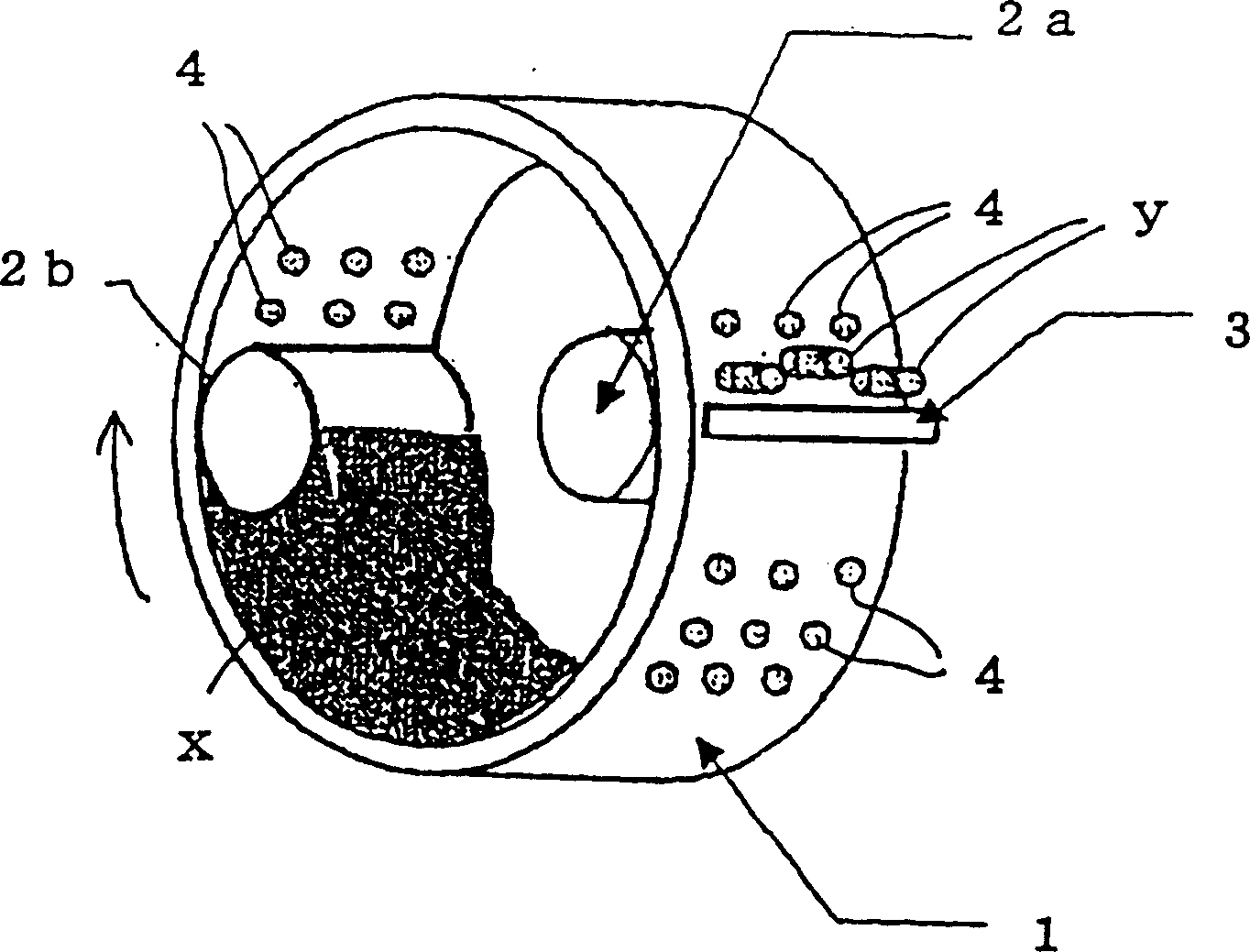

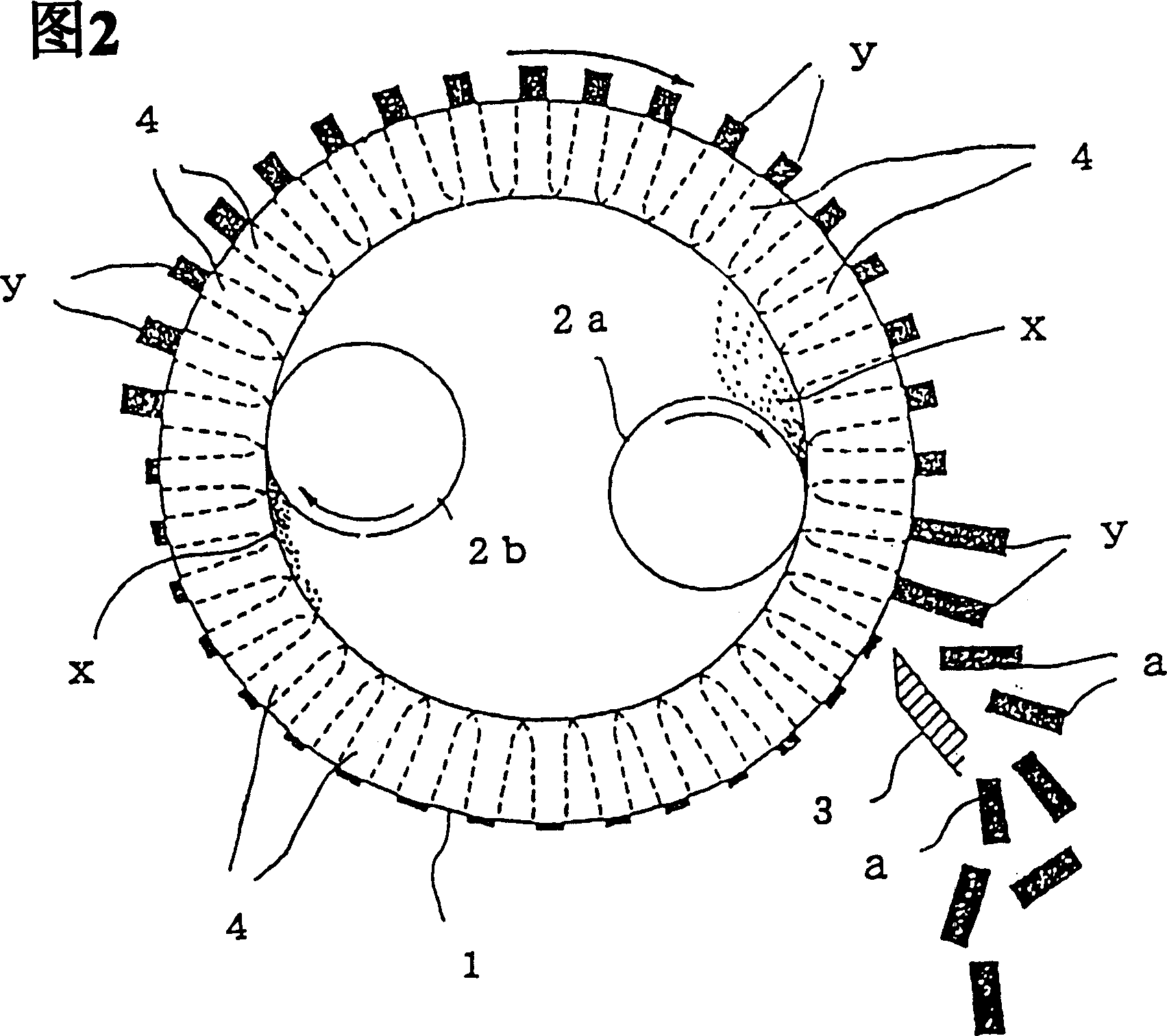

Pellets and method for producing the same

Waste plastics including solid plastics, thin plastics, and foamy plastics are fed into a ring die of an extrusion molding machine. The waste plastics are either semi-melted or melted, and are then extruded onto an outer circumferential surface the ring die through die cavities. Thus, granular plastic moldings are extruded onto the outer circumferential surface of the ring die through the die cavities, and are then cut or scraped from the outer circumferential surface of the ring die. The pellets have a melt-solidified surface, and have a strength sufficient to reach a predetermine zone in a raceway of a furnace and a grain diameter sufficient to be fed at a velocity higher than a limiting velocity thereof during injection to the furnace.

Owner:NIPPON KOKAN KK

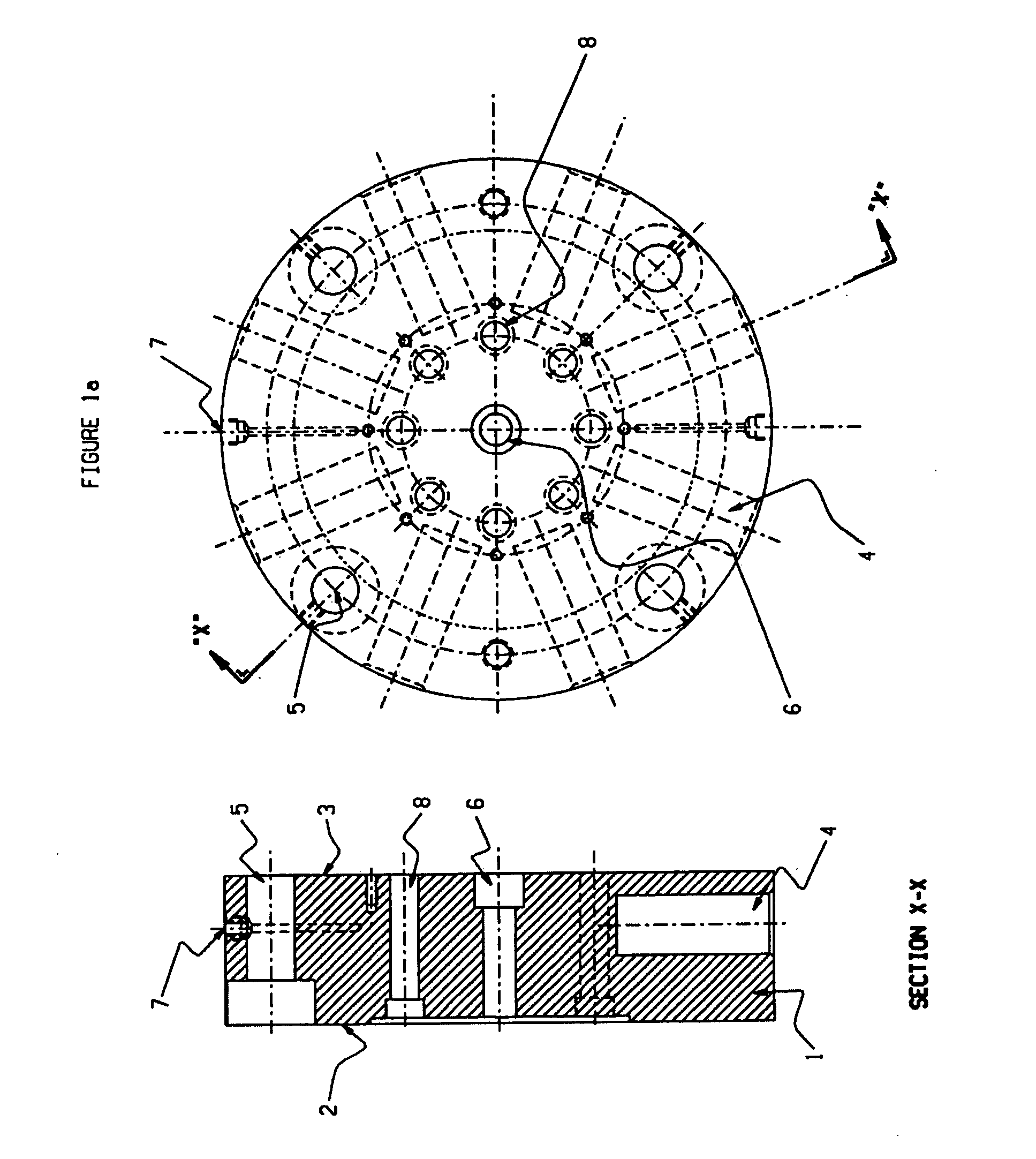

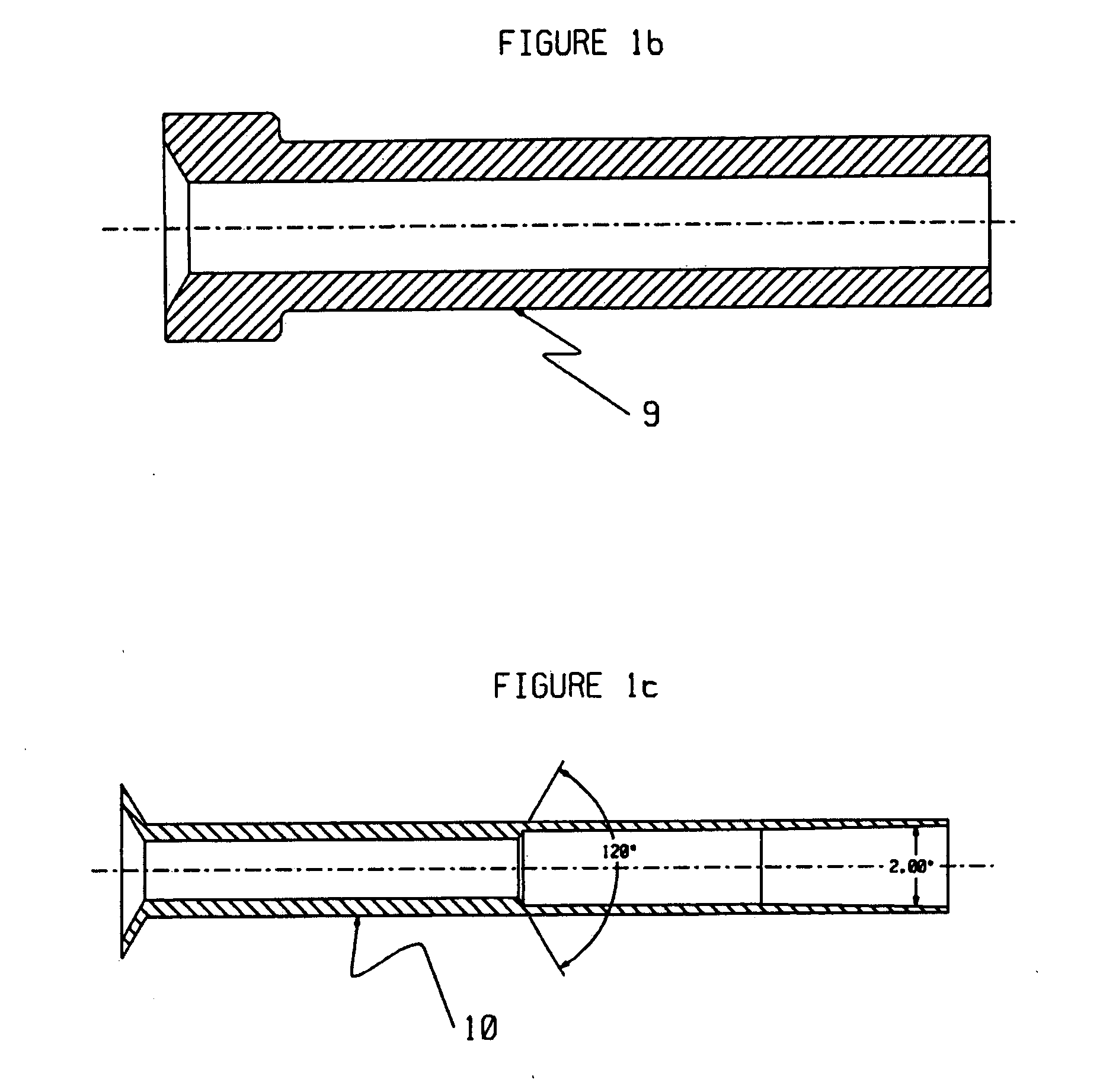

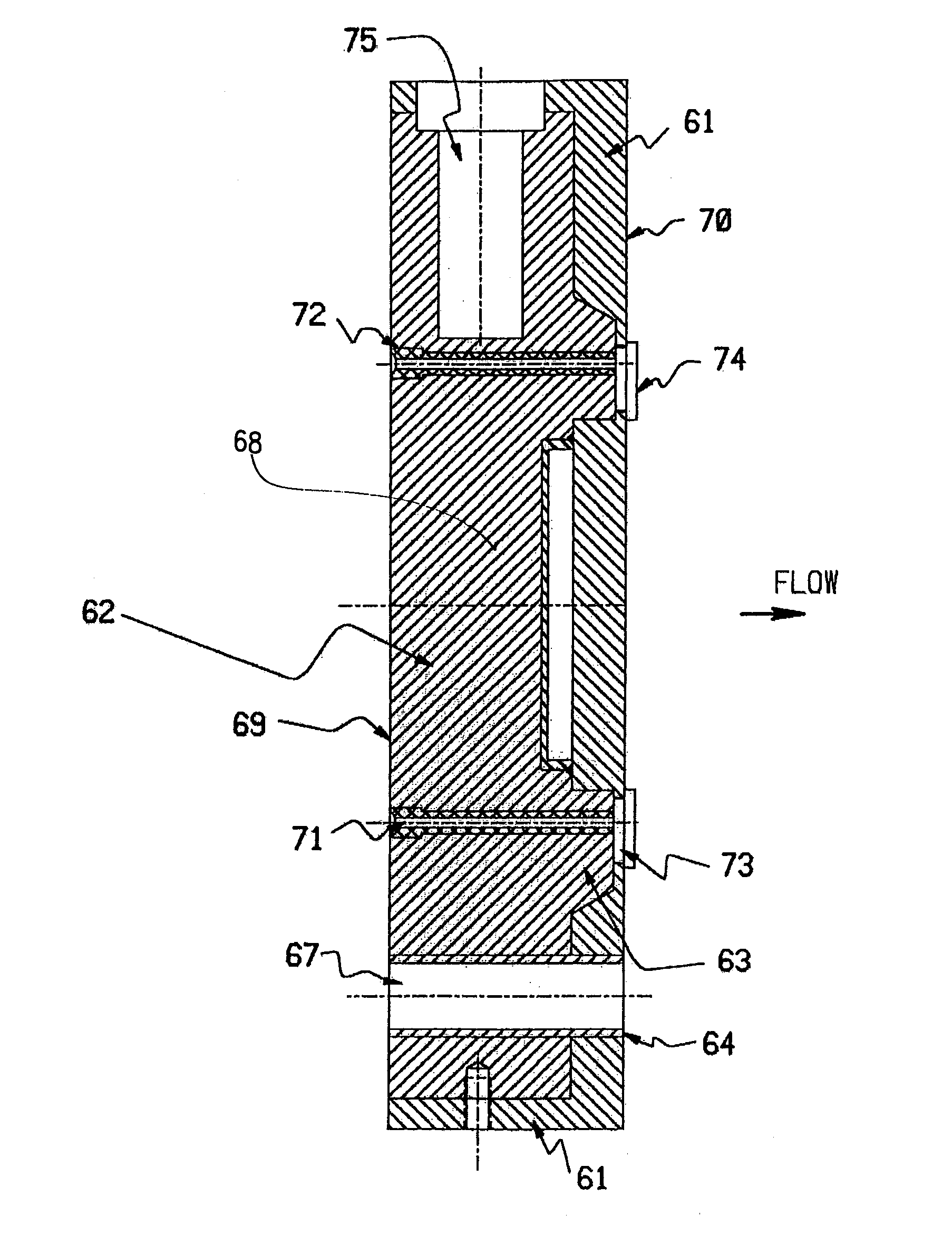

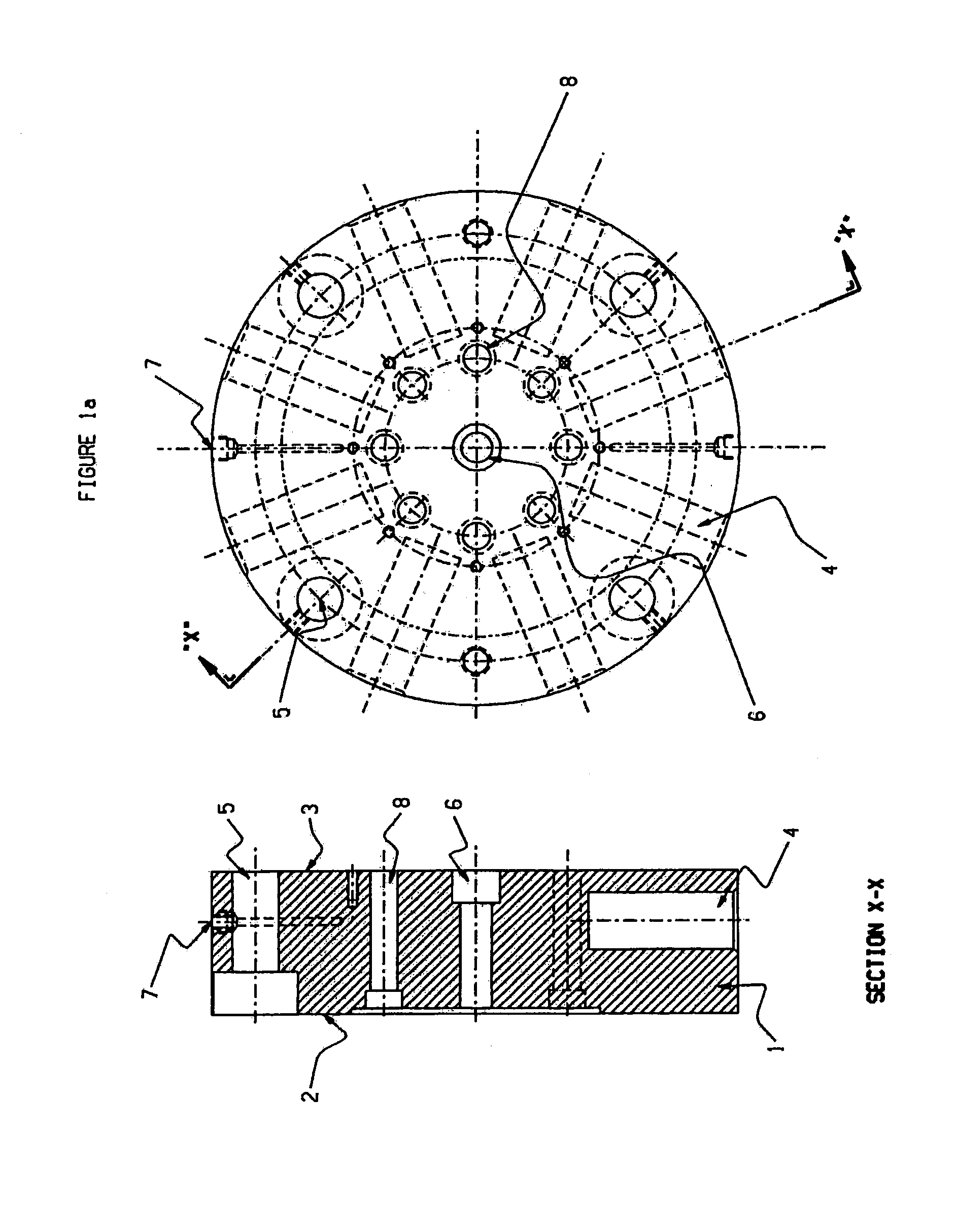

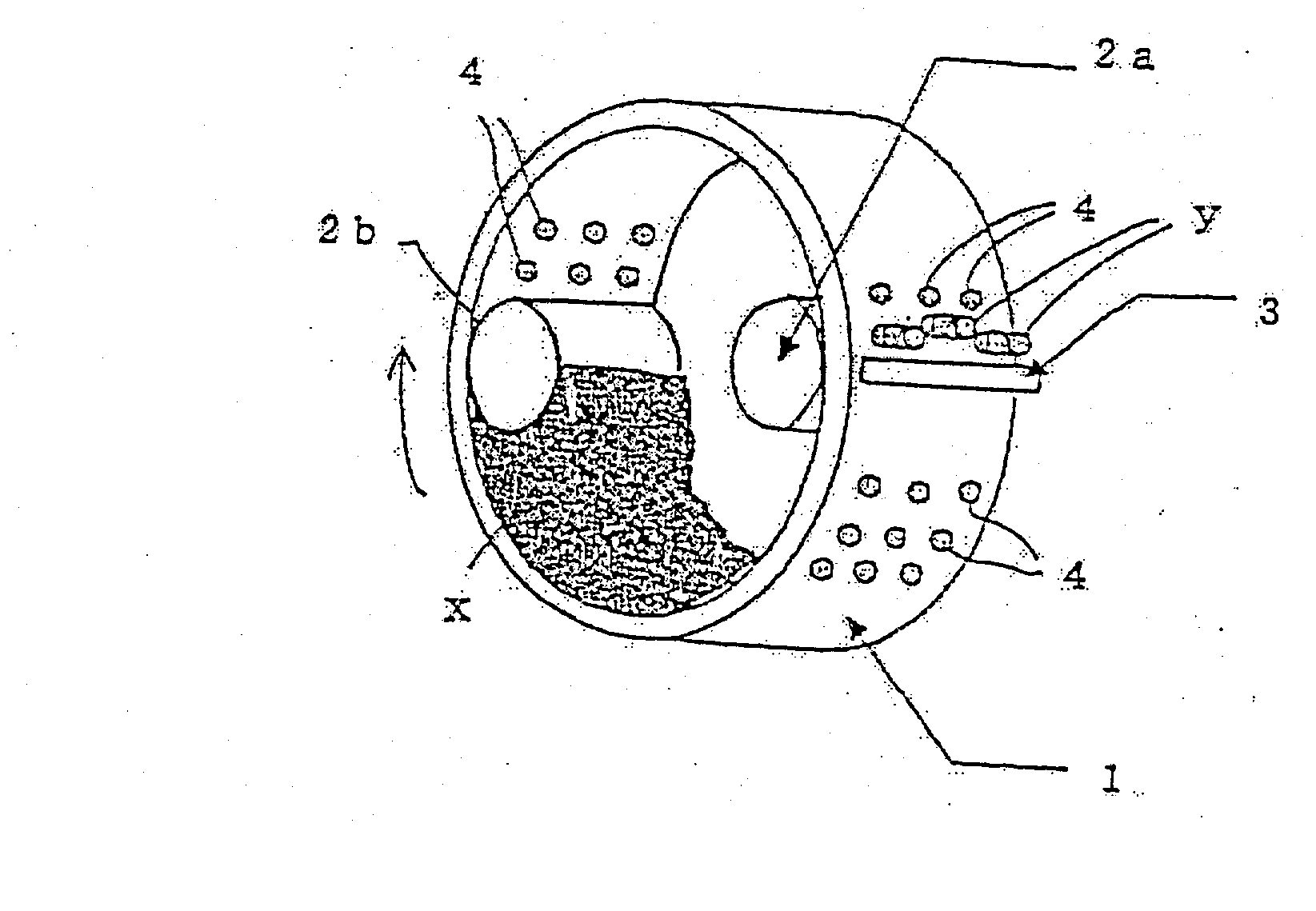

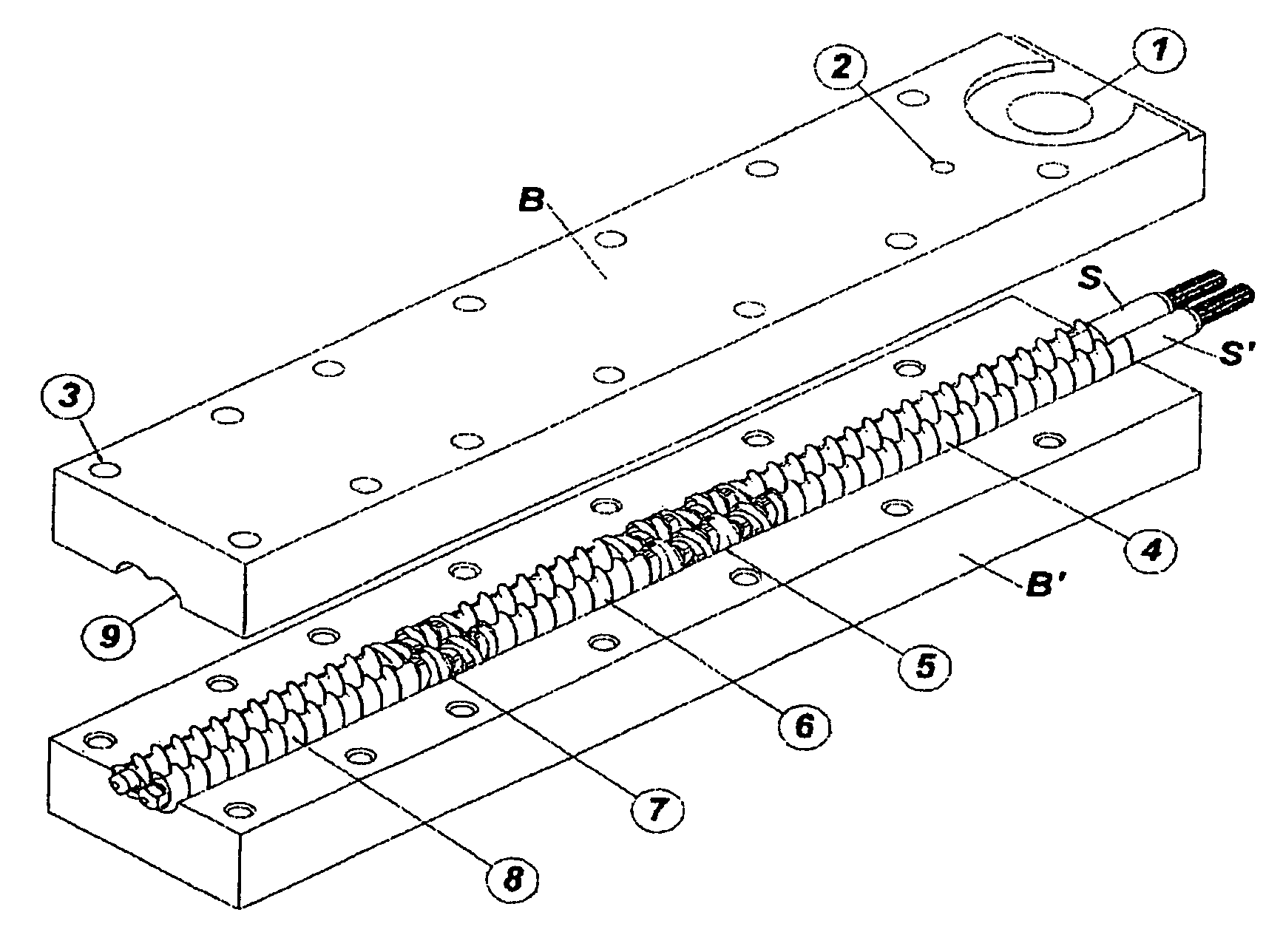

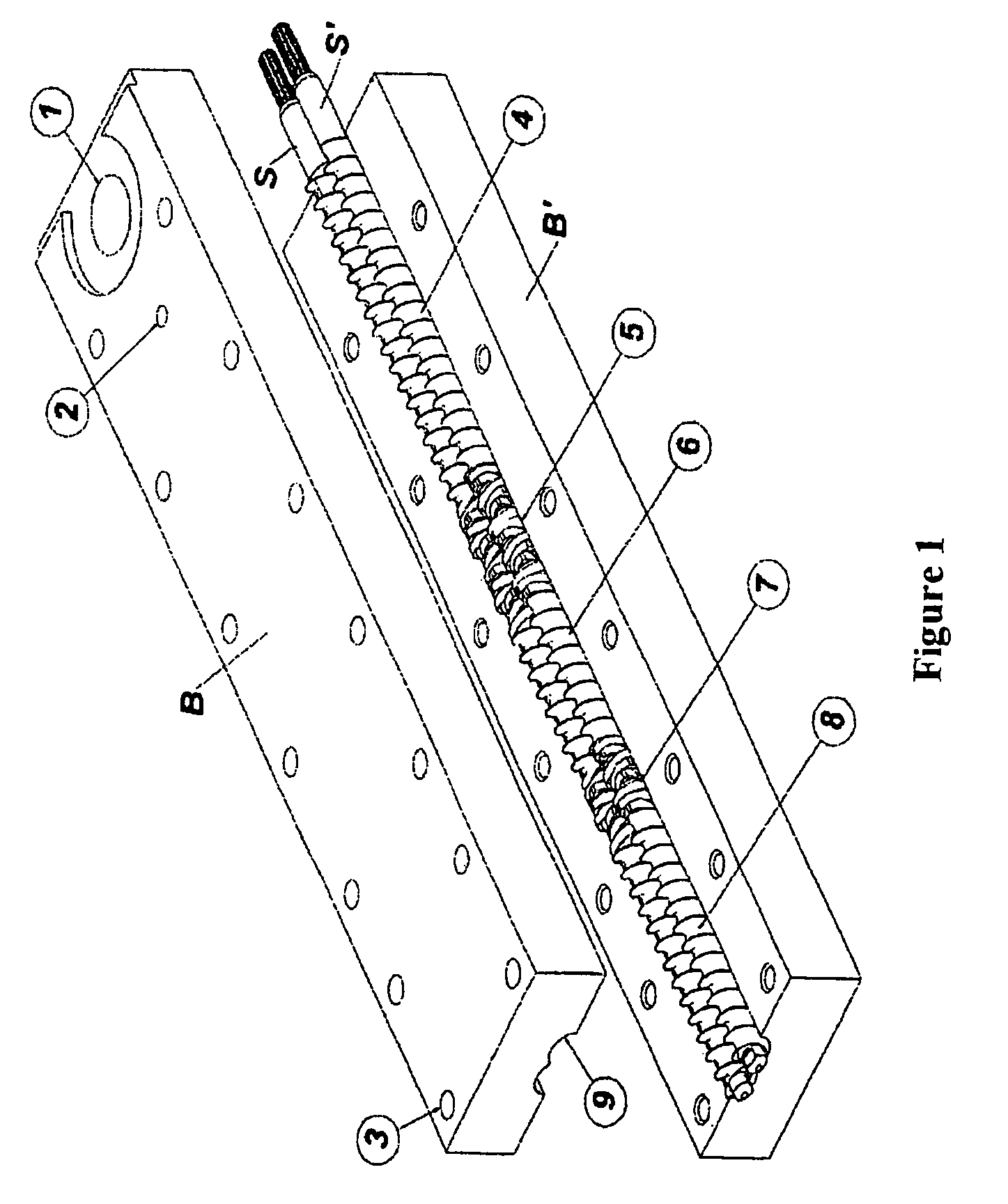

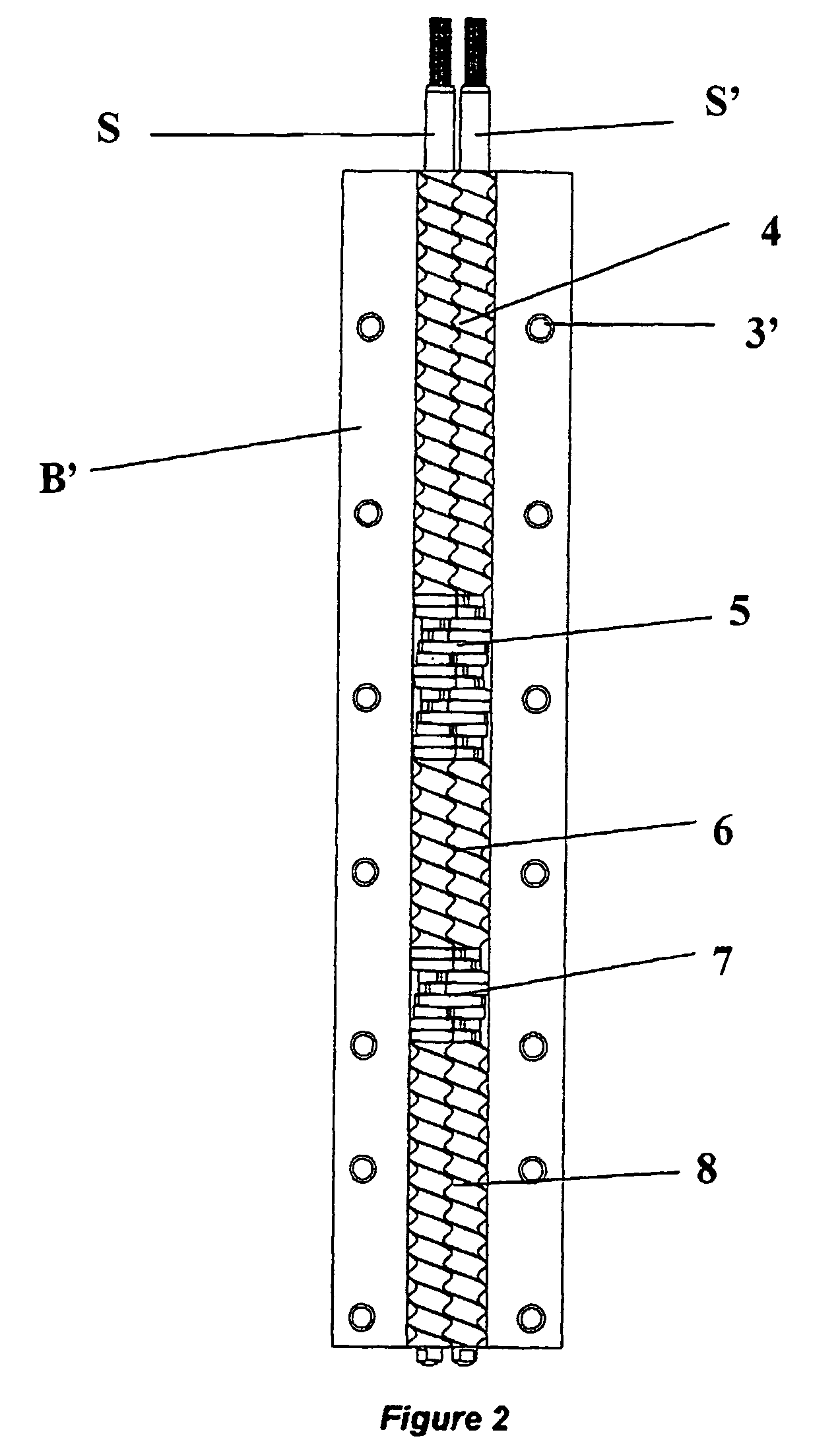

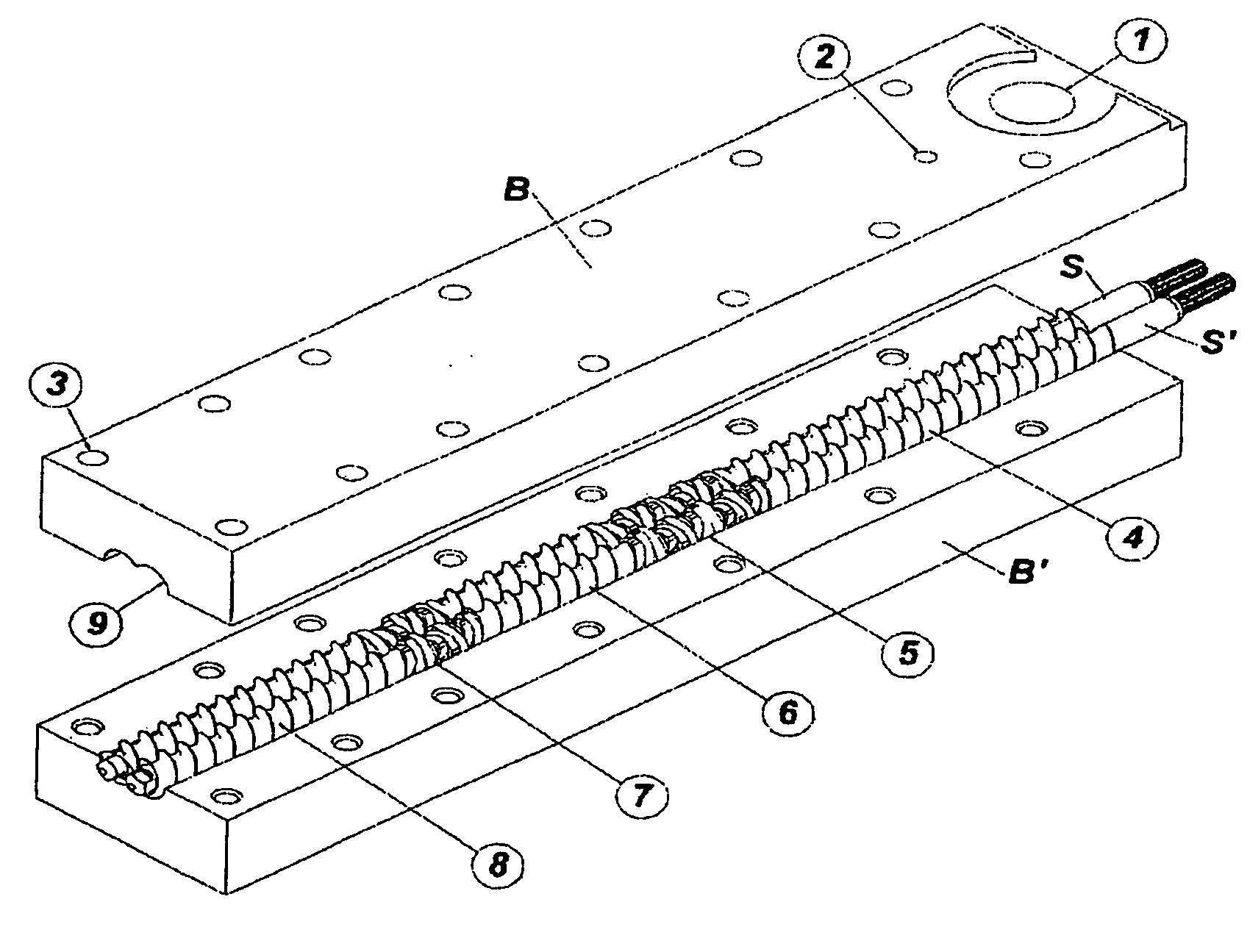

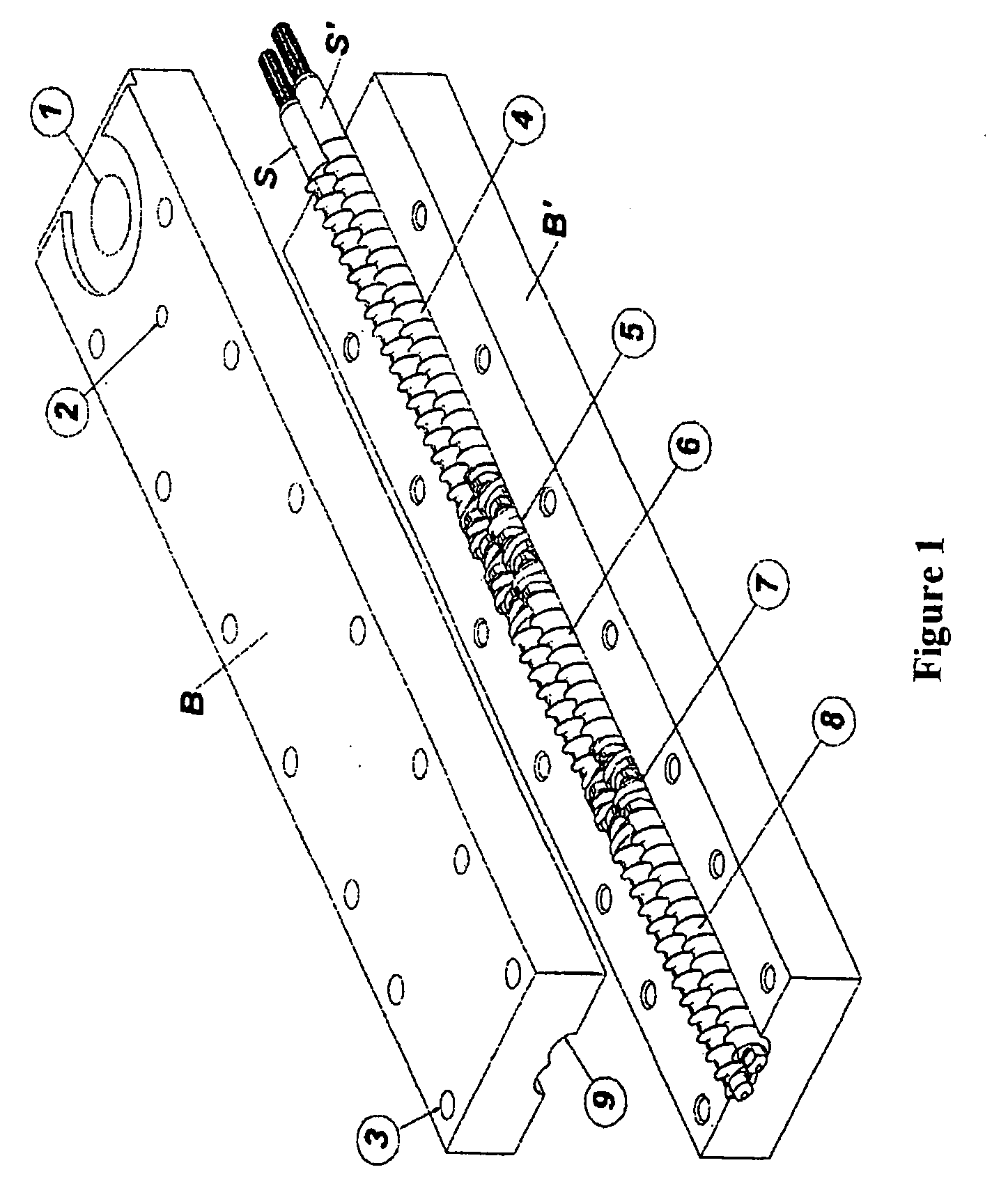

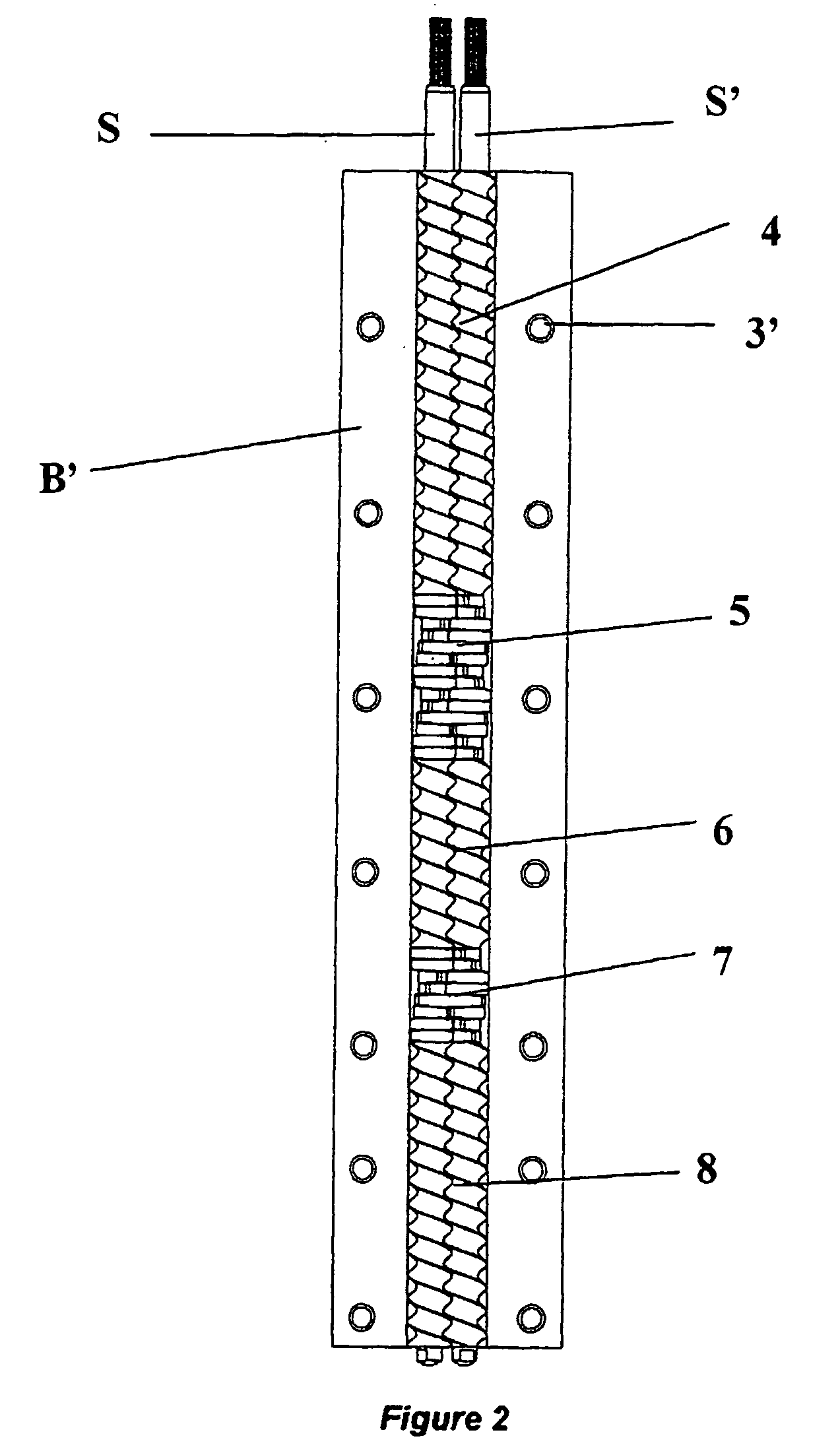

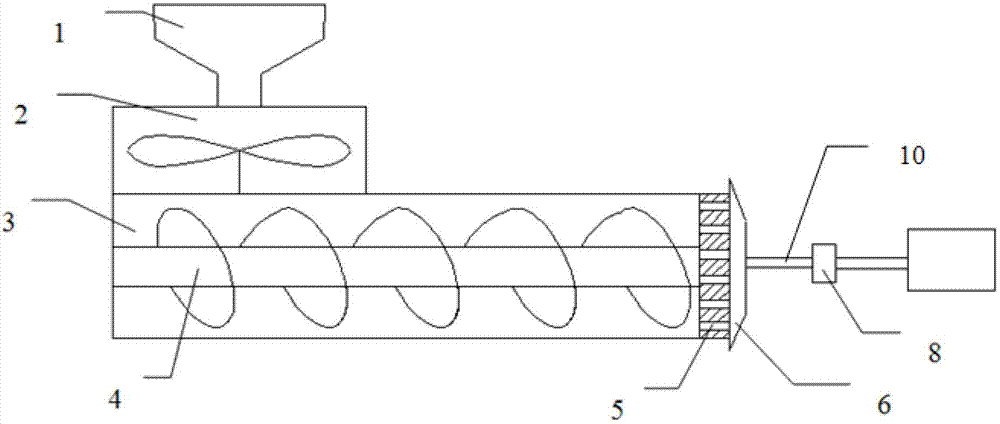

Process and apparatus for continuous wet granulation of powder material

ActiveUS7910030B2Simple processQuantity minimizationRotary stirring mixersFrozen sweetsEngineeringActive ingredient

An apparatus for wet granulating a powder material comprises: —a barrel having a granulation chamber and being provided with a first inlet (1) for receiving said powder material and for supplying it to said granulation chamber and with a second inlet (2) for receiving a granulating liquid and for supplying it to said granulation chamber, said granulation having an aperture (9) for discharge of granules from said barrel, and —a transporting means (S) for advancing said powder material toward the end of said granulation chamber while granulating it with the aid of said granulating liquid, said transporting means (S) comprising a first transport zone (4) at its rear end, an agglomeration zone (5) downstream from the first transport zone (4) and a second transport zone (8) at its front end, said first inlet (1) and said second inlet (2) being positioned above the first transport zone (4), wherein said aperture (9) has a shape tightly fitting the terminal portion of the transporting means (S) for directly discharging said granules from the granulation chamber. The apparatus is useful for continuously wet granulating biologically-active ingredient formulations, chemicals, detergents and foodstuffs.

Owner:UNIV GENT

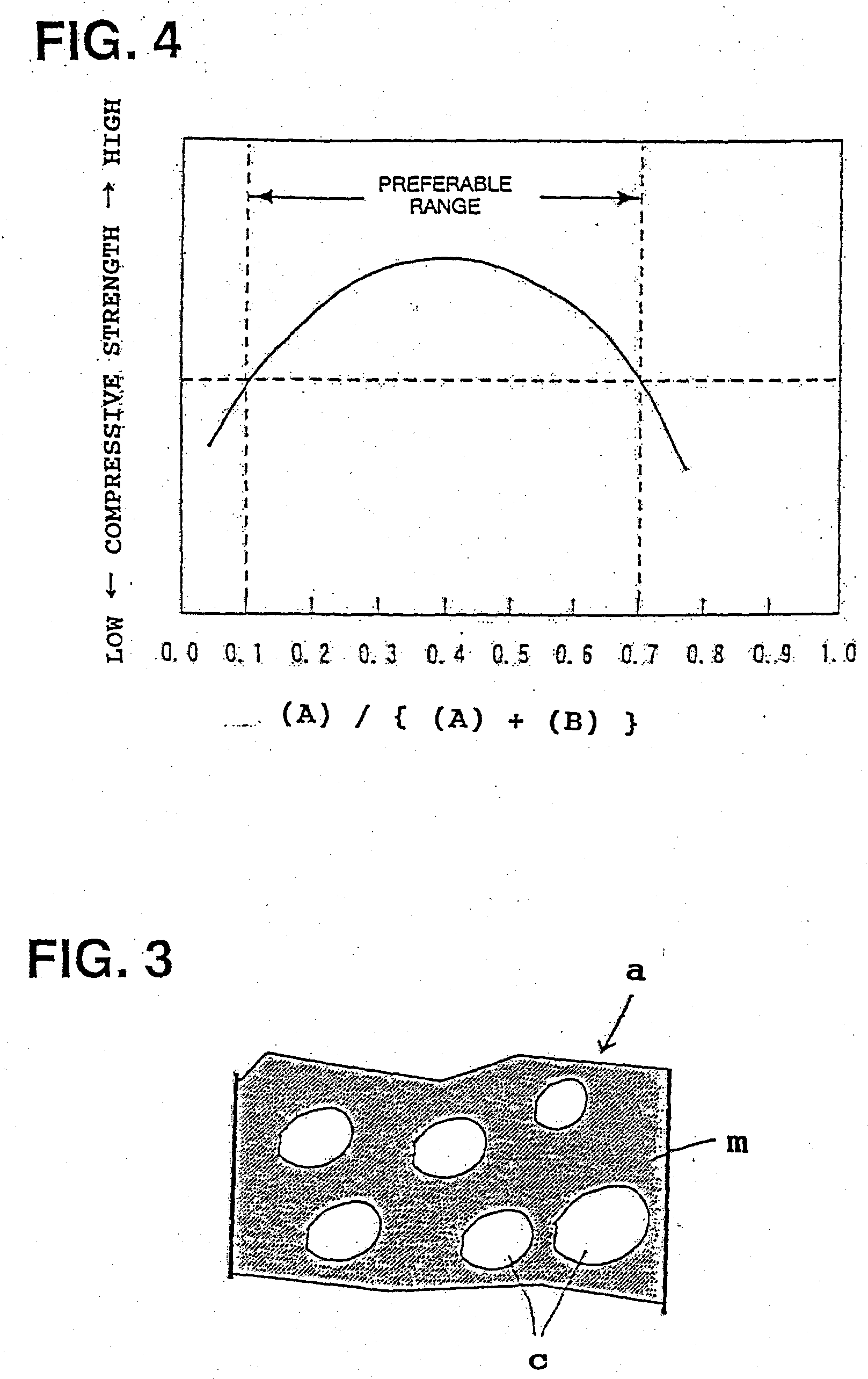

Granular pigments useful to color concrete

InactiveUS20040040469A1Readily and very rapidly dispersibleReduce responsibilityPigmenting treatmentGranulation by material expressionPigment granuleWater content

A method for the preparation of pigment granules includes mixing at least one pigment selected from the group consisting of iron oxide and chromium oxides with 1-25 wt. % water to form a damp powder. The damp powder is then pressure extruded through at least one die to form granules. The granules are then dried so that the final water content of the granules is less than about 1%, crumbled and sieved to form the final product.

Owner:ROCKWOOD PIGMENTS NA INC

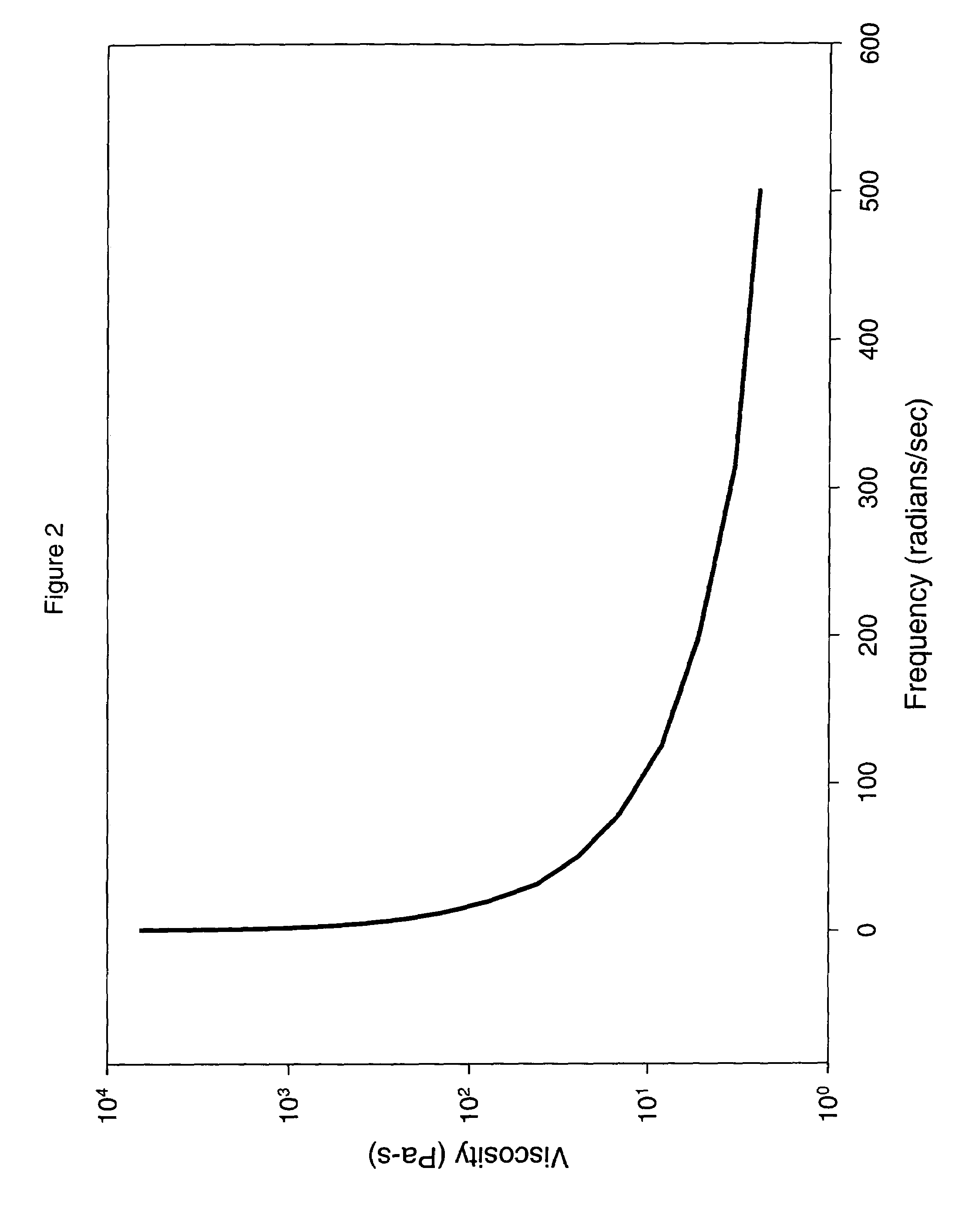

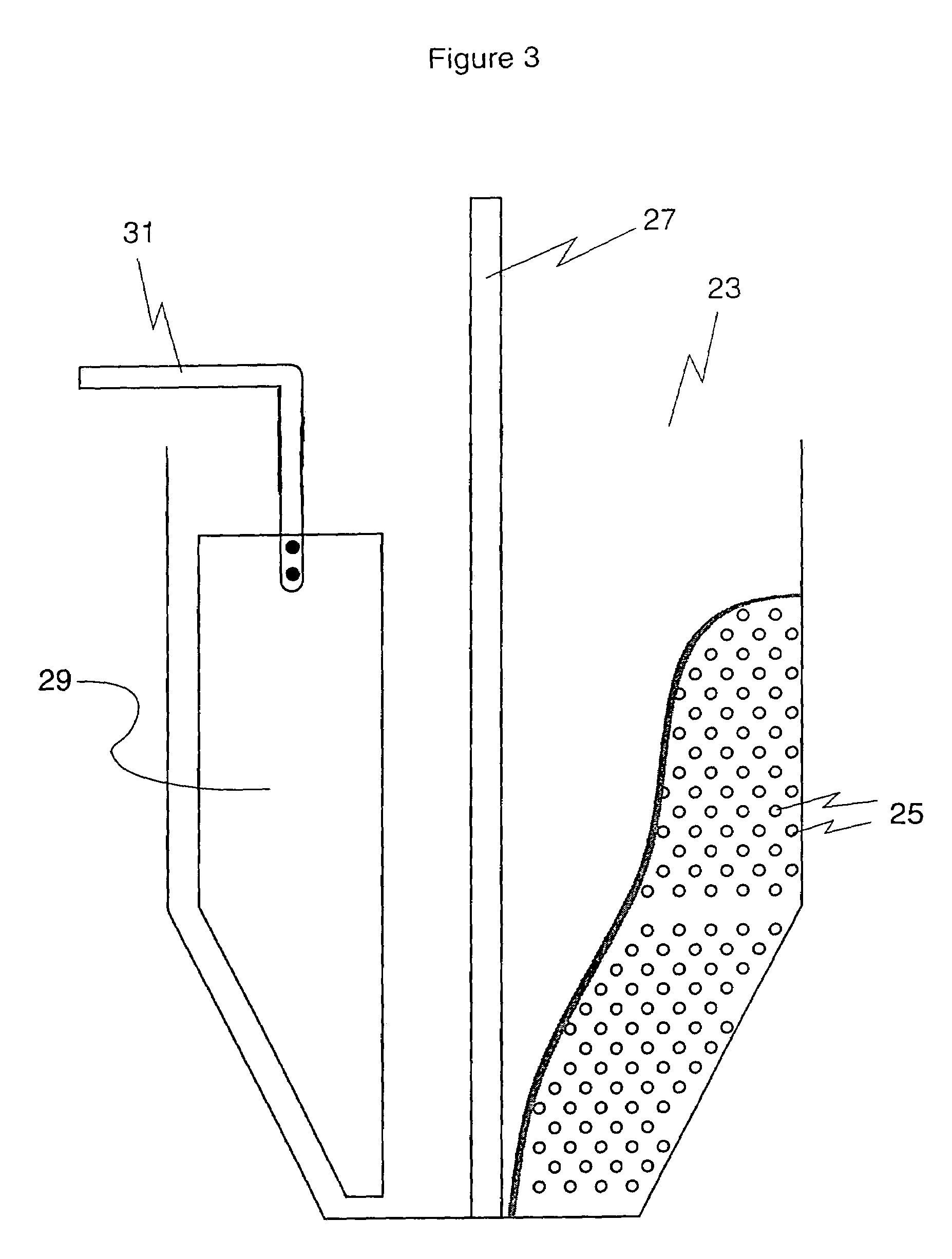

Prilling method

A prilling method comprising the steps of: providing a molten first component, mixing at least a second component with the molten first component, reacting the components to form a shear-thinnable mixture; and prilling the shear-thinnable mixture wherein the prilling comprises mechanically agitating in the prill head to shear thin the shear-thinnable mixture sufficiently to permit prilling. The inventive method can be used to produce fertilizer product comprising ammonium sulfate nitrate.

Owner:ADVANSIX RESINS & CHEM LLC

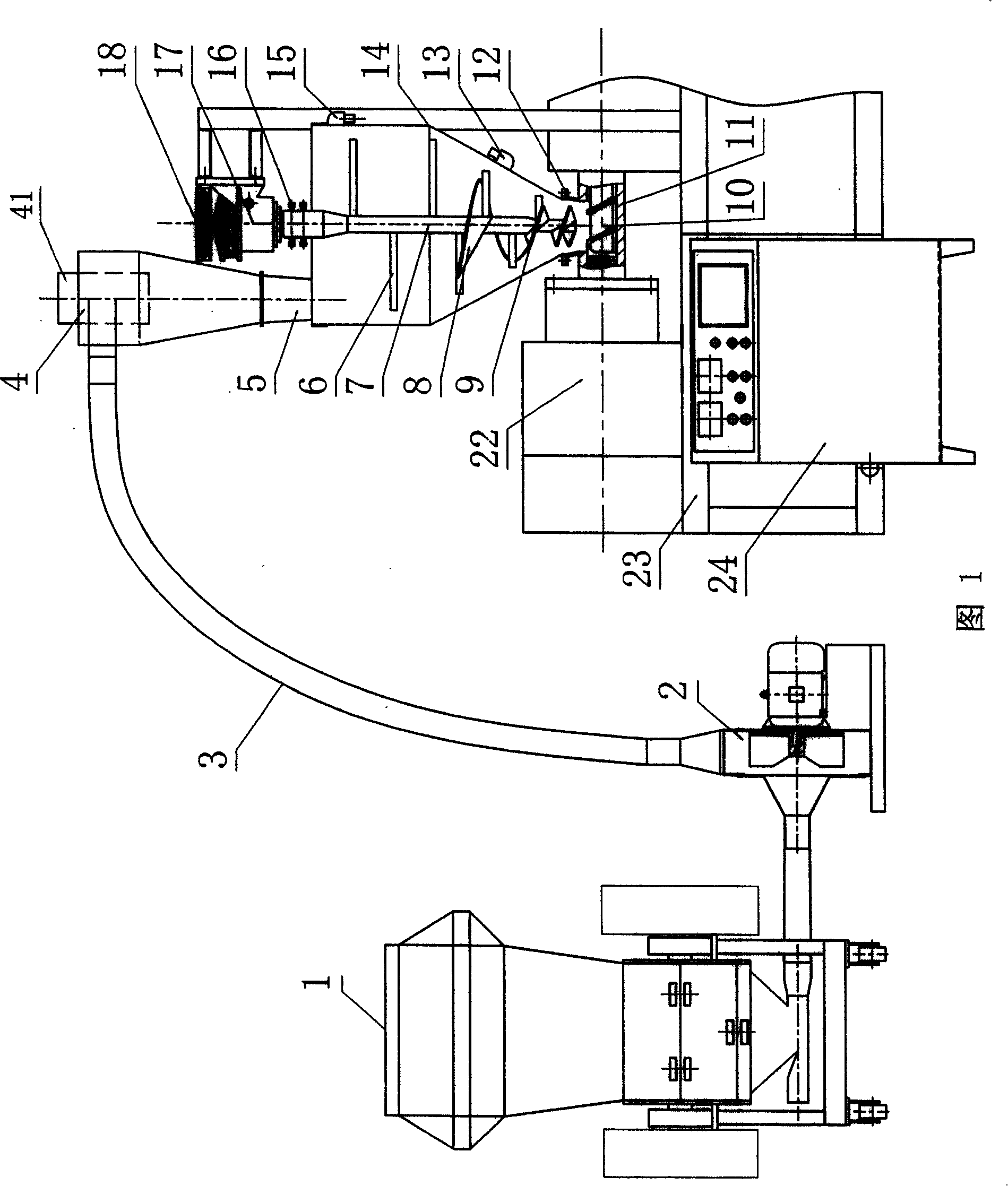

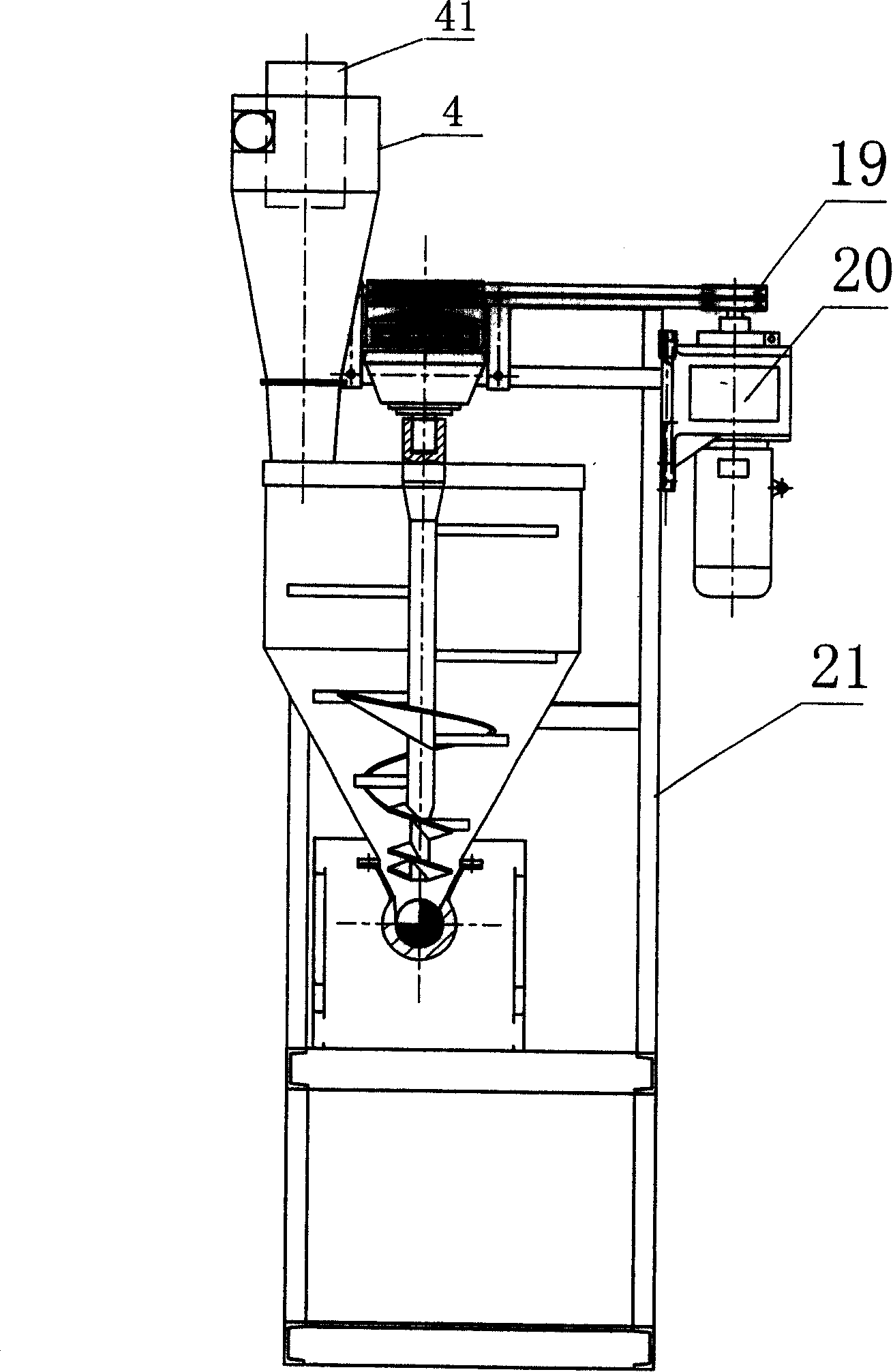

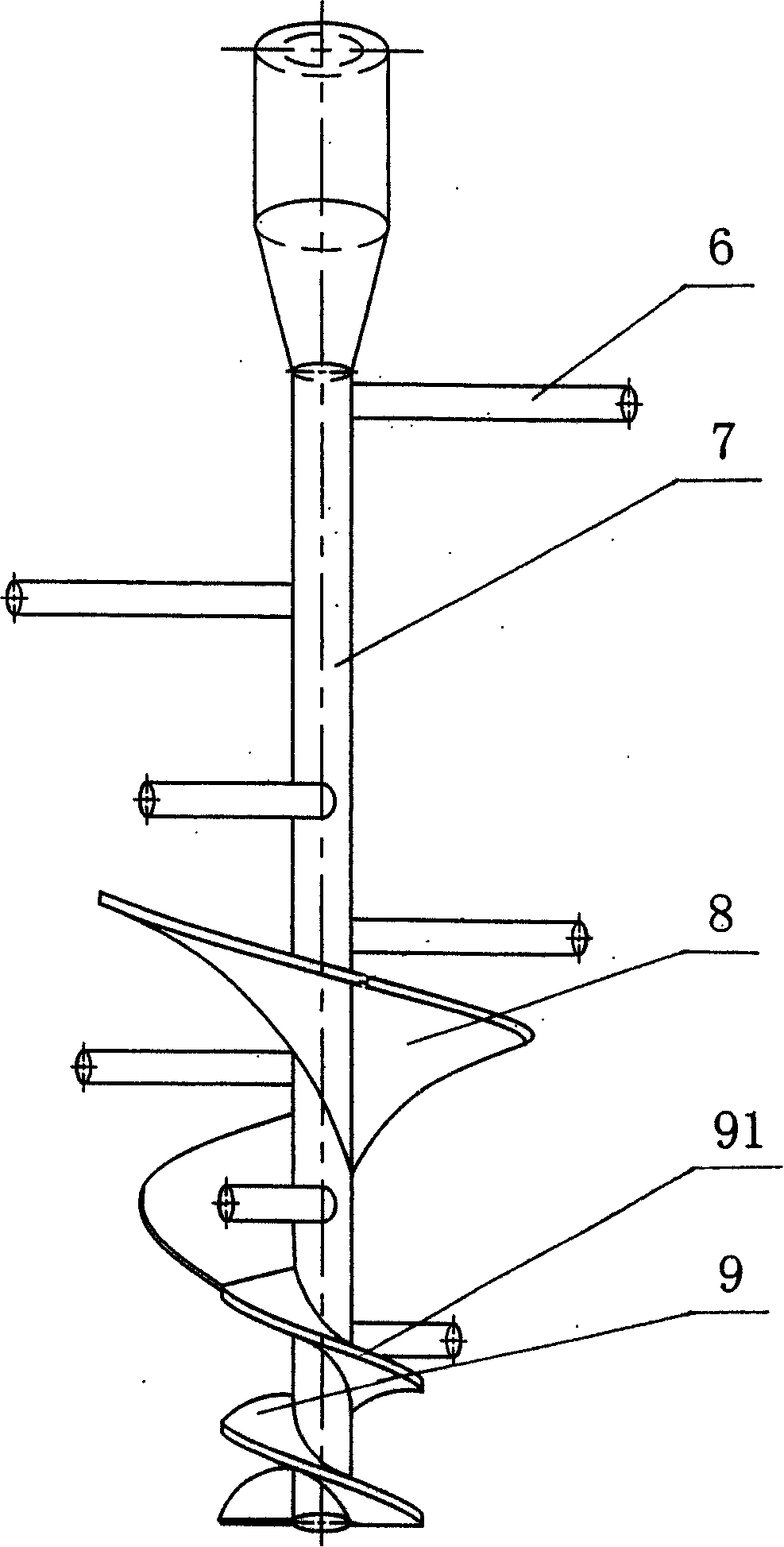

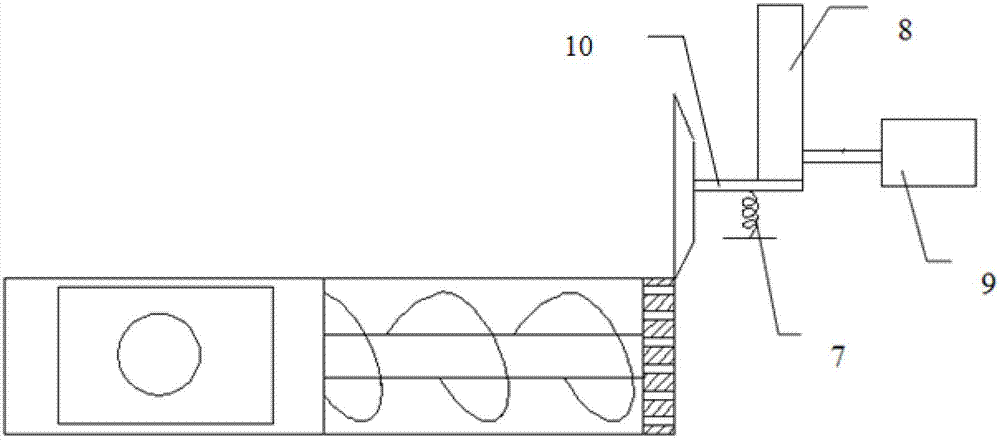

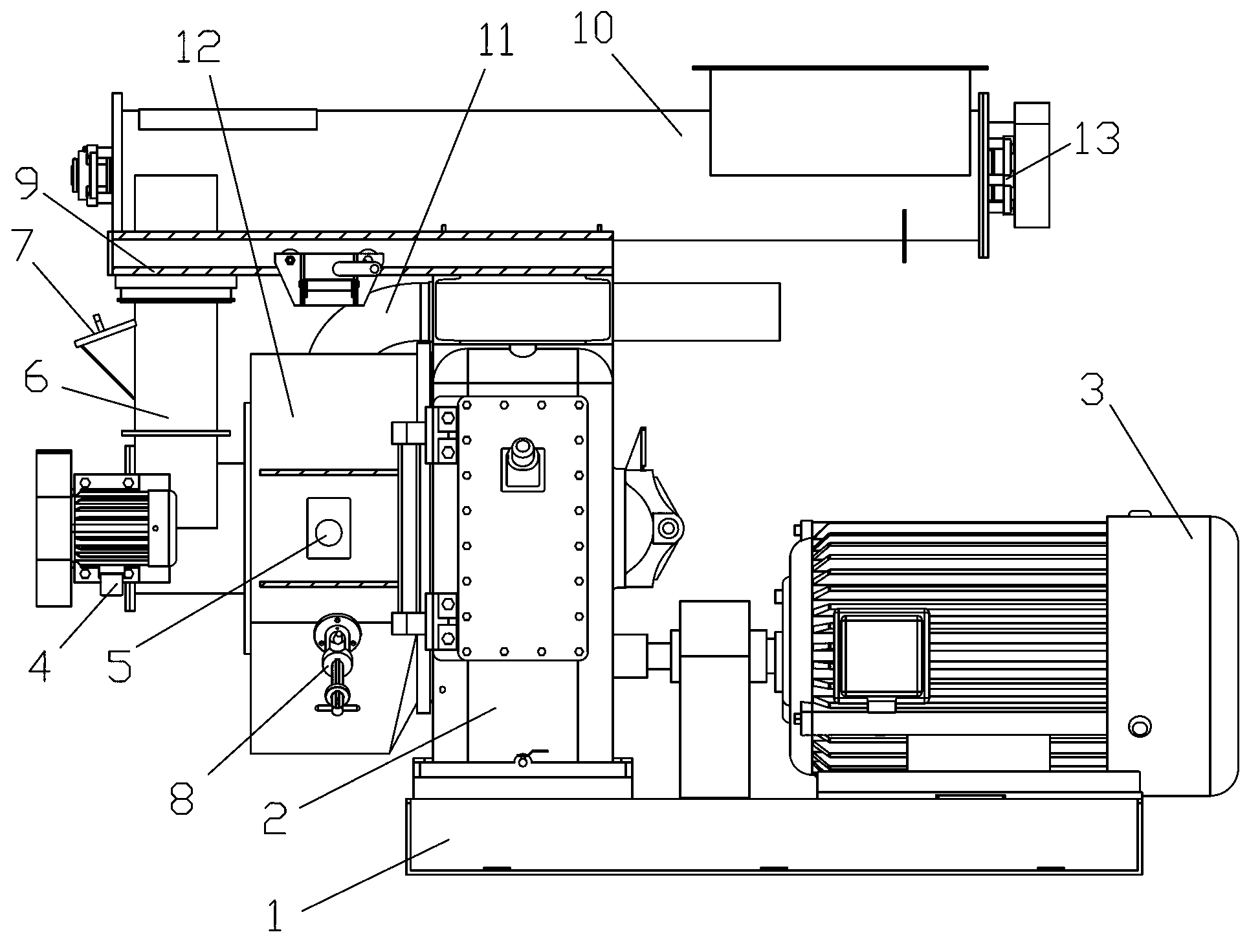

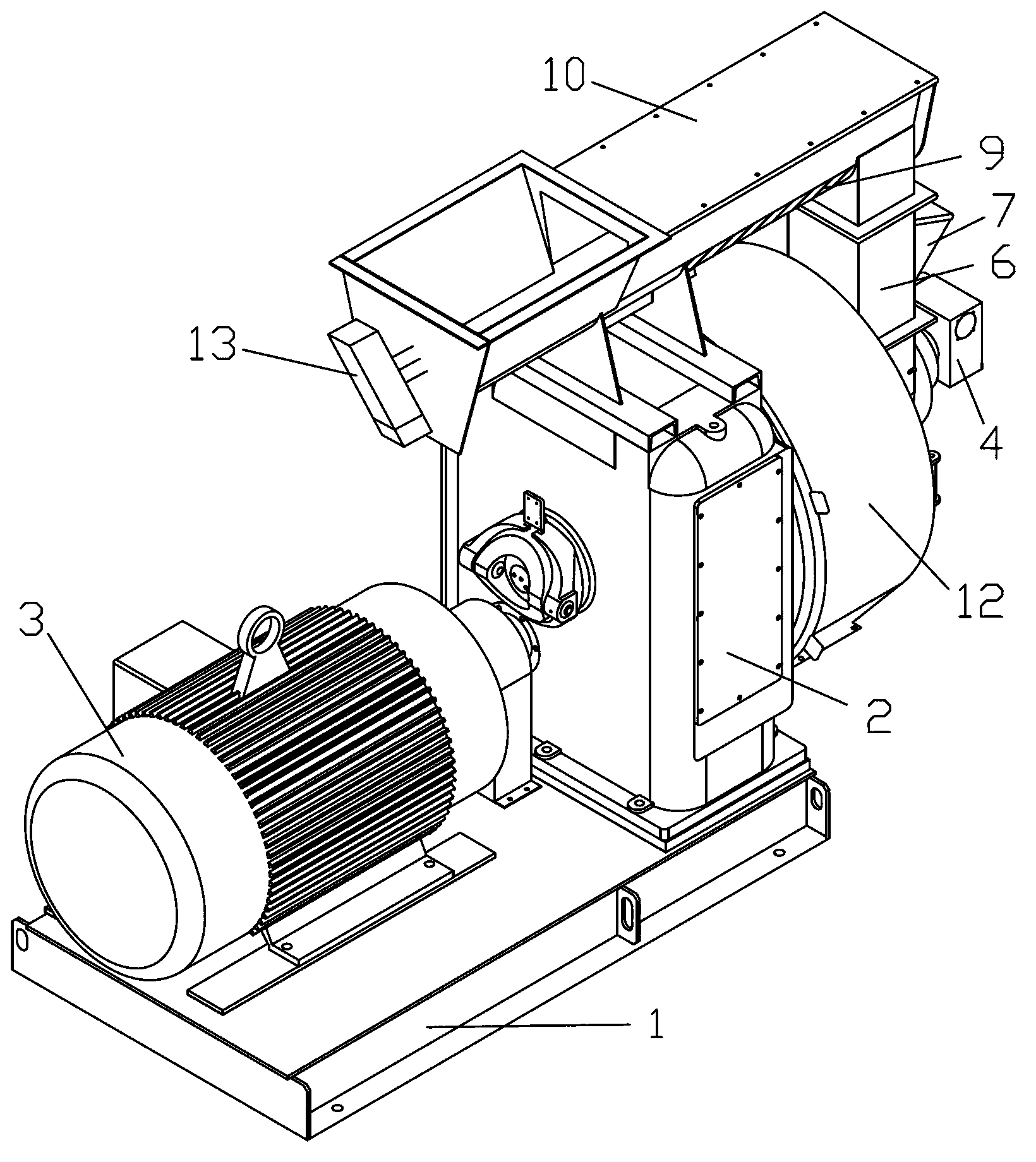

Material feeding system for granulator

InactiveCN101234316AReduce consumptionUniform size, plump and shinyGranulation by material expressionPressure transmissionHelical blade

The invention discloses a granulator feeding system. The material ground by a grinder is sent into a feeding tank which is provided with a sensor through a transmission pipe system, and then the material in the feeding tank is transmitted to a host screw through a stirring mechanism. The pipe system comprises a transmission fan which is connected with the outlet hopper of the grinder, a transmission pipe which is connected with the outlet of the transmission fan and a cyclone separator which is connected with the outlet of the transmission pipe; the stirring mechanism comprises a stirring section and a pressure transmission section; the stirring section is a material mixing rod which is arranged on the upper section of a center shaft, and the pressure transmission section is a structure combining the material mixing rod and a helical blade, which is arranged on the lower section of the center shaft. The helical blade comprises a helical expansion blade and a standard helical pressure plate which is arranged below the helical expansion blade; the front part of the standard helical pressure plate adopts double helix. The granulator feeding system has the advantages of reasonable structure, simple operation, uniform running, stability, reliability, high efficiency of extrusion pelletizing, reducing the production cost and saving energy consumption.

Owner:余姚市绿岛橡塑机械设备有限公司

Granular pigments useful to color concrete

InactiveUS6758893B2Readily and very rapidly dispersibleReduce responsibilityPigmenting treatmentGranulation by material expressionPigment granuleWater content

A method for the preparation of pigment granules includes mixing at least one pigment selected from the group consisting of iron oxide and chromium oxides with 1-25 wt. % water to form a damp powder. The damp powder is then pressure extruded through at least one die to form granules. The granules are then dried so that the final water content of the granules is less than about 1%, crumble and sieved to form the final product.

Owner:ROCKWOOD PIGMENTS NA INC

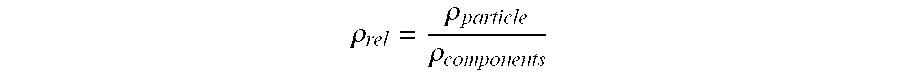

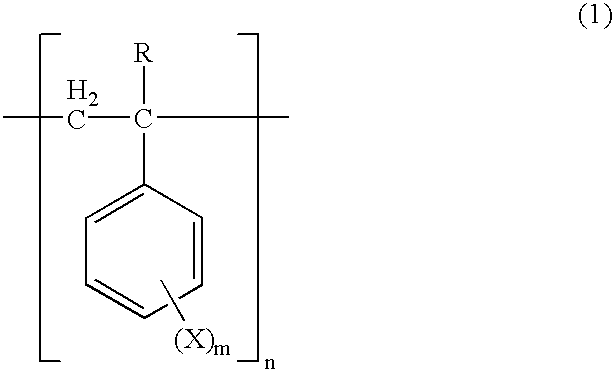

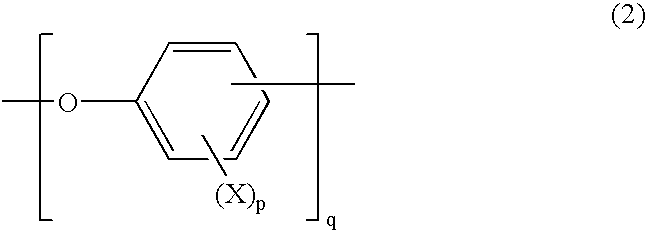

Polyamide resin pellet for a miniature part

InactiveUS20020115818A1Low water absorptionSmooth effectWorking-up pitch/asphalt/bitumen by chemical meansSynthetic resin layered productsShell moldingHeat resistance

A polyamide resin pellet for a miniature part, comprising a polyamide resin (A) whose melting point as measured by DSC is in the range of 280 to below 330° C., which has an average volume of 0.001 to 21 mm3, the average volume determined by randomly sampling 50 pellets, measuring the weight and specific gravity of each of the pellets and dividing the weight by the specific gravity. The polyamide resin pellet exhibits low water absorption and is excellent in moldability, mechanical strength characteristics and heat resistance. Further, it has specified average volume, configuration, average diameter and average length, so that, in an injection molding, plasticization is smoothly effected to thereby enable obtaining a molded item or article which exhibits low dispersion of weight and strength and has excellent hue. The polyamide resin pellet is especially suitable for use in a molding material for forming miniature parts for motor vehicles and electrical or electronic equipments.

Owner:MITSUI CHEM INC

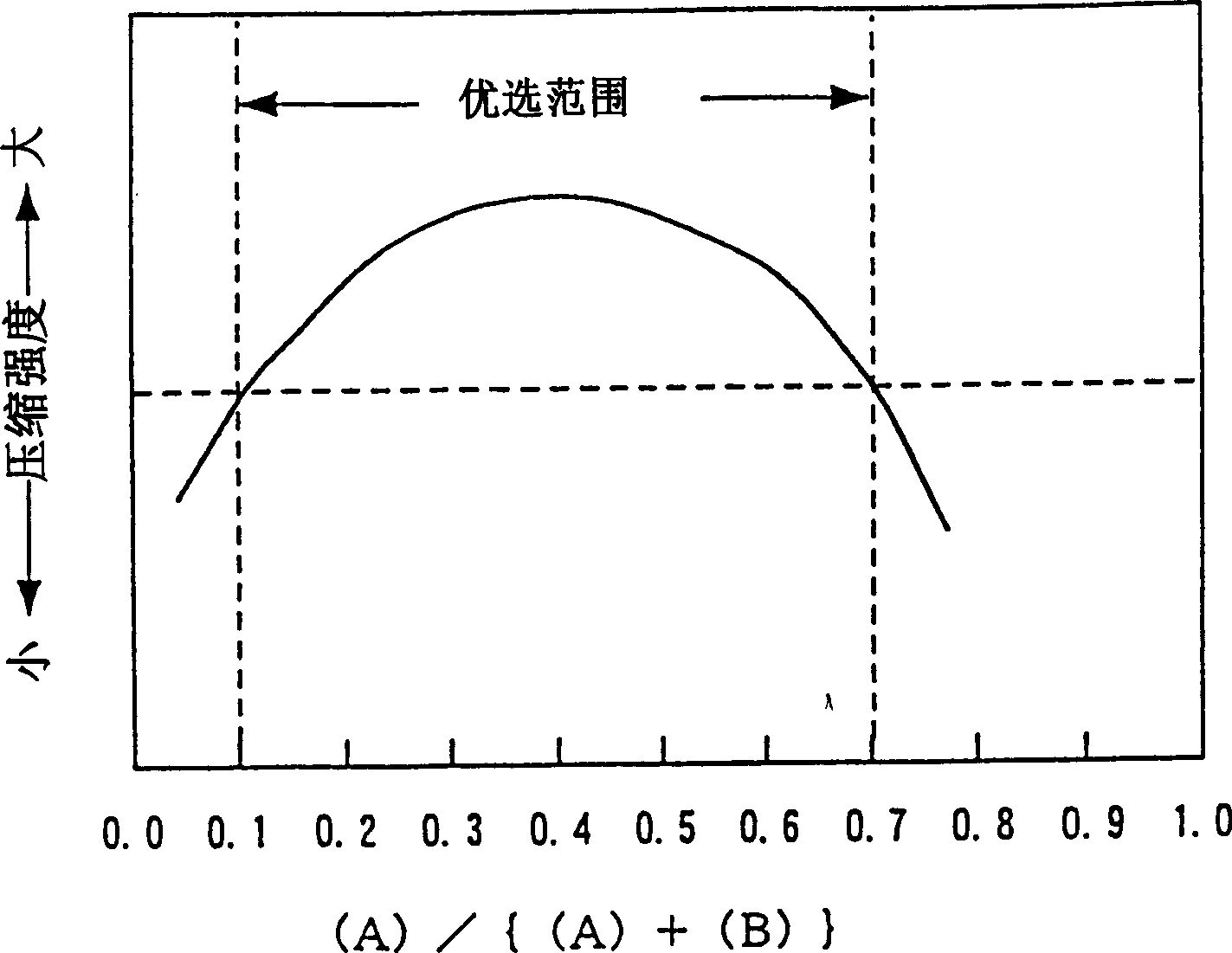

Preparation method of carrier-free talcum powder master batch

ActiveCN101792536ASolve pollutionSolve problems such as poor compatibilityGranulation by material expressionDiameter ratioDiluent

The invention relates to a talcum powder, in particular to a preparation method of carrier-free talcum powder master batch. The preparation method of the carrier-free talcum powder master batch comprises the following steps of: preparation of additive: mixing diluent and binding agent according to a certain proportion, wherein the diluent accounts for 90-99 percent, and the binding agent accounts for 1-10 percent; treatment of the talcum powder: stirring and mixing the mixed additive and talcum powder, wherein the additive accounts for 15-35 percent, and the talcum powder accounts for 65-85%; molding of the talcum powder: putting the mixed talcum powder into an extruder for extruding at the normal temperature, controlling the pelleting pressure to be 1-2 MPa, the diameter of the extruded granule to be 1-5mm and the length-diameter ratio to be 1-4; and drying the extruded granules at 120-180 DEG C for 0.5-1h, and obtaining the product, wherein the percent is weight percent. The preparation method has the advantages of solving the environment problem caused by rising powder in the using process of the traditional talcum powder.

Owner:SHENYANG POLYTECHNIC UNIV +1

Process and apparatus for continuous wet granulation of power material

ActiveUS20060006258A1Quantity minimizationMinimize durationRotary stirring mixersFrozen sweetsEngineeringExtremity Part

An apparatus for wet granulating a powder material comprises:—a barrel having a granulation chamber and being provided with a first inlet (1) for receiving said powder material and for supplying it to said granulation chamber and with a second inlet (2) for receiving a granulating liquid and for supplying it to said granulation chamber, said granulation having an aperture (9) for discharge of granules from said barrel, and—a transporting means (S) for advancing said powder material toward the end of said granulation chamber while granulating it with the aid of said granulating liquid, said transporting means (S) comprising a first transport zone (4) at its rear end, an agglomeration zone (5) downstream from the first transport zone (4) and a second transport zone (8) at its front end, said first inlet (1) and said second inlet (2) being positioned above the first transport zone (4), wherein said aperture (9) has a shape tightly fitting the terminal portion of the transporting means (S) for directly discharging said granules from the granulation chamber. The apparatus is useful for continuously wet granulating biologically-active ingredient formulations, chemicals, detergents and foodstuffs.

Owner:UNIV GENT

Process for dispersing hot-melt adhesive fillers

InactiveCN101289599AReduce joinImprove product added valueNon-macromolecular adhesive additivesGranulation by material expressionLight whiteTalc

The invention relates to a method for dispersing hot-melt adhesive filler. The method comprises the following steps that: filler and other components of hot-melt adhesive are evenly mixed by granulation equipment; or part of the filler and other components of the hot-melt adhesive are evenly mixed and granulated by granulation equipment, and then the left over filler is evenly mixed with the granulated mixture. Other components of the hot-melt adhesive comprise main body resin, tackifying resin and a diluent agent; the filler comprises toner, flash powder, calcium carbonate, micro silicon powder, talc powder, white carbon black, light white carbon black, metal nitride, metal oxide and metal nitride or metal oxide; moreover, extruding granulation adopts a single screw extruder or a double screw extruder. The method has the advantages that: the addition of a poisonous and harmful dispersing agent is reduced to protect the environment; the filler is evenly mixed through a physical method, and manufacturing technique is simplified to reduce cost; and because a granular material contains less air volatile matter, the product is not easy to generate air bubbles, thereby ensuring product quality.

Owner:金尔升

Molded lump and production method therefor

Waste plastics containing solid plastics, slice plastics and foamed plastics are supplied into an annular die of a plastic extrusion device. The waste plastics are half-melted or melted and extruded from die holes to the annular die outer peripheral surface. The extruded plastic moldings are cut off or scraped off from the annular die outer peripheral surface. Each molded lump has a melt-solidified surface, a strength capable of reaching a preset area in a furnace raceway when blown into the furnace, and a grain size capable of providing velocities higher than a critical velocity.

Owner:JFE STEEL CORP

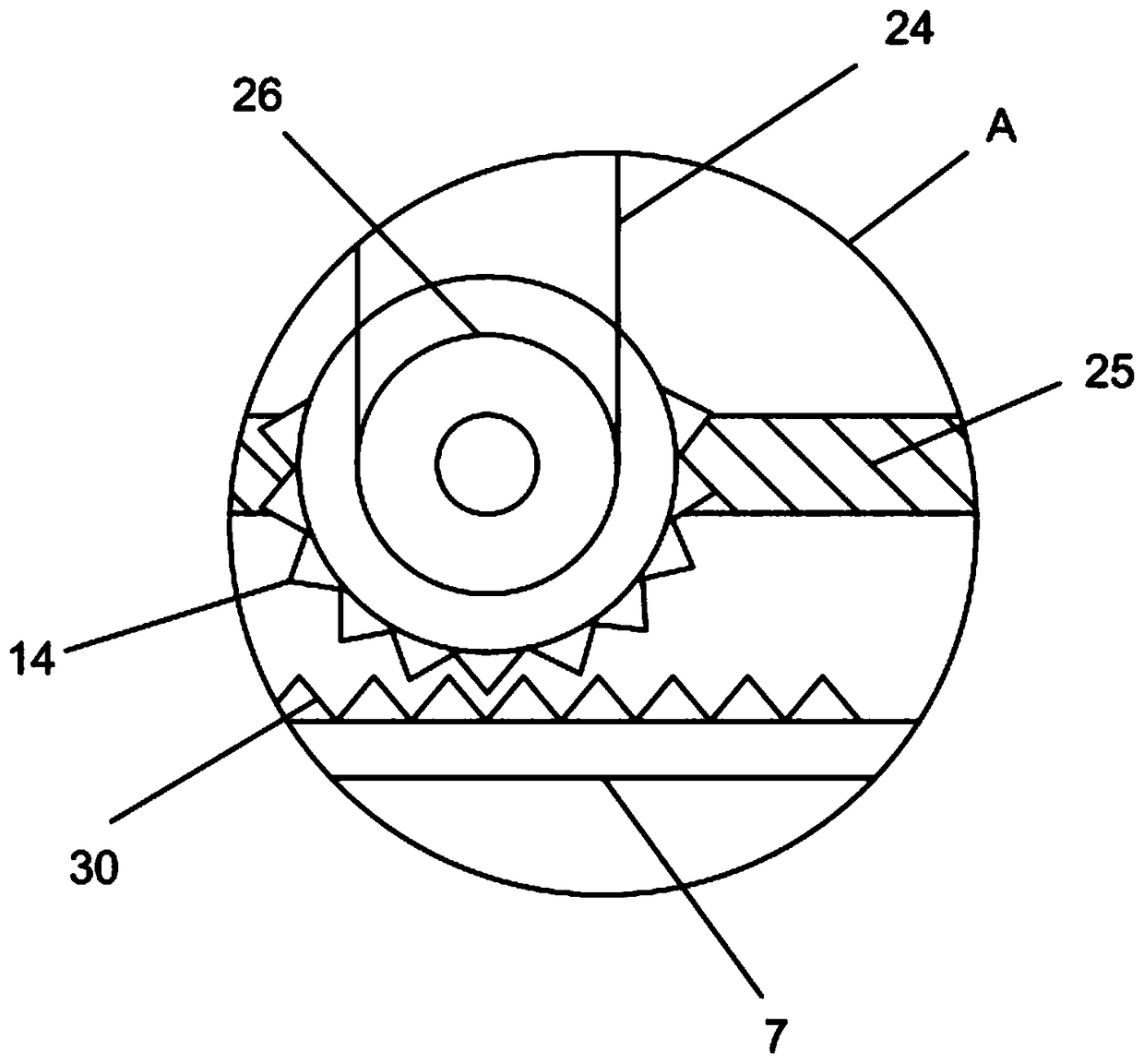

Pelletizer

InactiveCN103585928AEasy to use and flexibleEasy to replaceGranulation by material expressionAgricultural engineeringDrive motor

The invention provides a pelletizer. The pelletizer comprises a feeding tube, a stirring device, an extrusion device and a pelletizing device, which are successively connected. The pelletizing device comprises a pelletizing knife, a driving motor, a transmission rod, a reset spring and an eccentric wheel. The cut pelletizing knife is connected with the transmission rod; one end of the reset spring is fixed, and the other end is connected to the transmission rod; and the eccentric wheel is connected with the driving motor and in line contact with the transmission rod. The invention has the following beneficial effects: the pelletizing device is flexible and convenient for usage; an independent cutter head ensures that pelletized particles will not block the cutting tool; and the double-sided blade has the advantages of simple structure, convenient replacement, long service life and high production efficiency.

Owner:TIANJIN BAOTIAN AGRI MACHINERY SALES

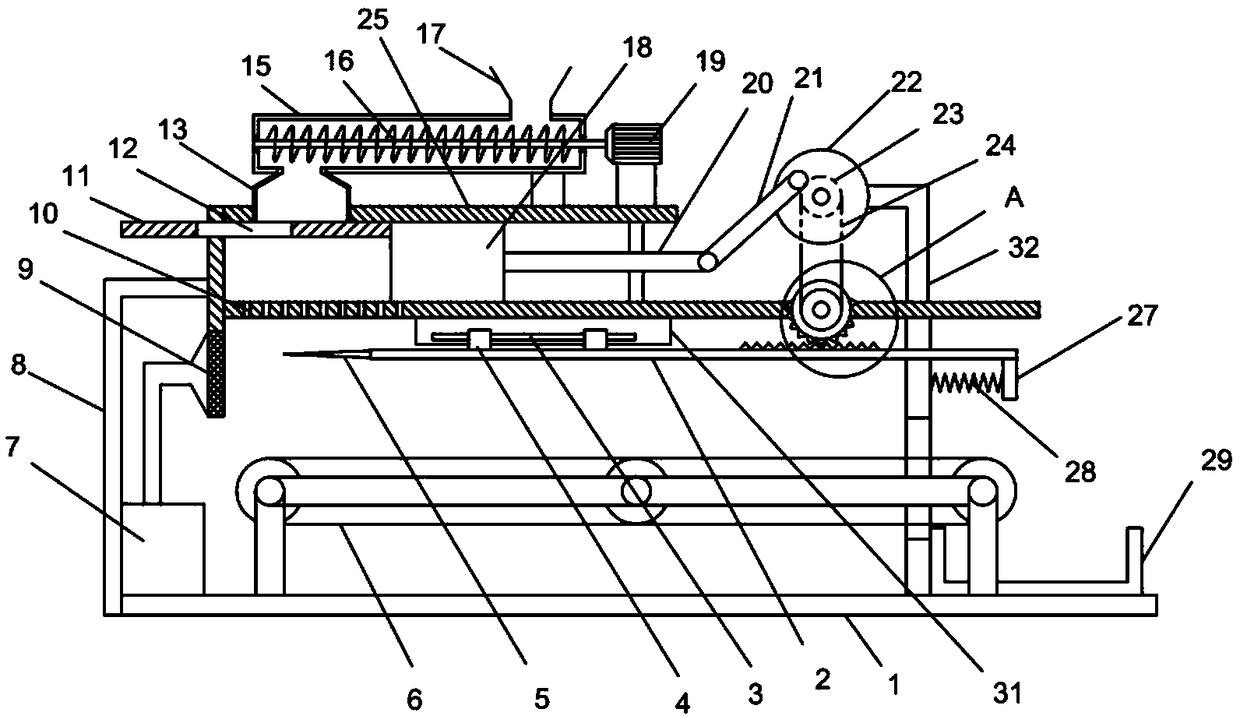

Feed extruding and granulating device for livestock feed processing

InactiveCN108654515AImprove the extrusion effectImprove work efficiencyFeeding-stuffGranulation by material expressionReciprocating motionEngineering

The invention discloses a feed extruding and granulating device for livestock feed processing. The feed extruding and granulating device is characterized in that a support rack is vertically fixedly mounted on a bottom plate, a limit extruding cylinder is fixedly mounted on the support rack, a slider is horizontally slidably arranged in the limit extruding cylinder, a slide plate is horizontally fixedly mounted at the left top end of the slider, the upper surface of the slide plate is abutted against the inner side of the limit extruding cylinder, and a feeding channel is vertically formed inthe slide plate; an air heater is fixedly mounted at the bottom of the bottom plate, and a collecting tank located at the right bottom of a conveying belt is fixedly mounted on the bottom plate. The feed extruding and granulating device has the advantages that feed intermittently enters the limit extruding cylinder is extruded into strip-shaped feed through extruding holes by the leftward and rightward reciprocating movement of the slider, and a good extruding effect and high work efficiency are achieved; the strip-shaped feed is repeated cut by a cutting blade which moves leftwards and rightwards in a reciprocating manner to achieve feed granulation, the feed is fast dried through hot air rightwards discharged by an exhaust mesh cover, feed adhesion is avoided, and the quality of feed granules is increased greatly.

Owner:HEFEI TOTEM LONG MACHINERY DESIGN CO LTD

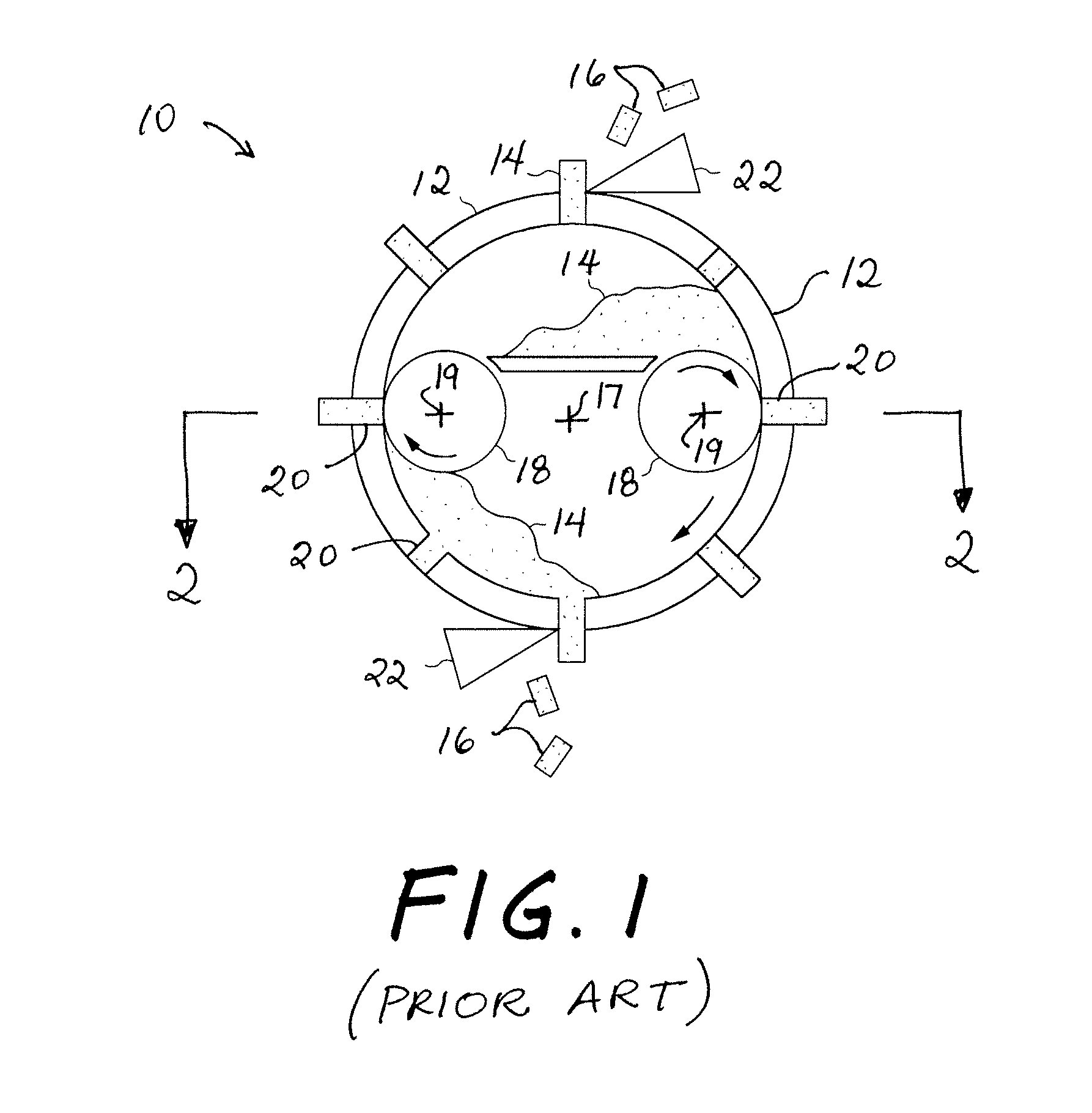

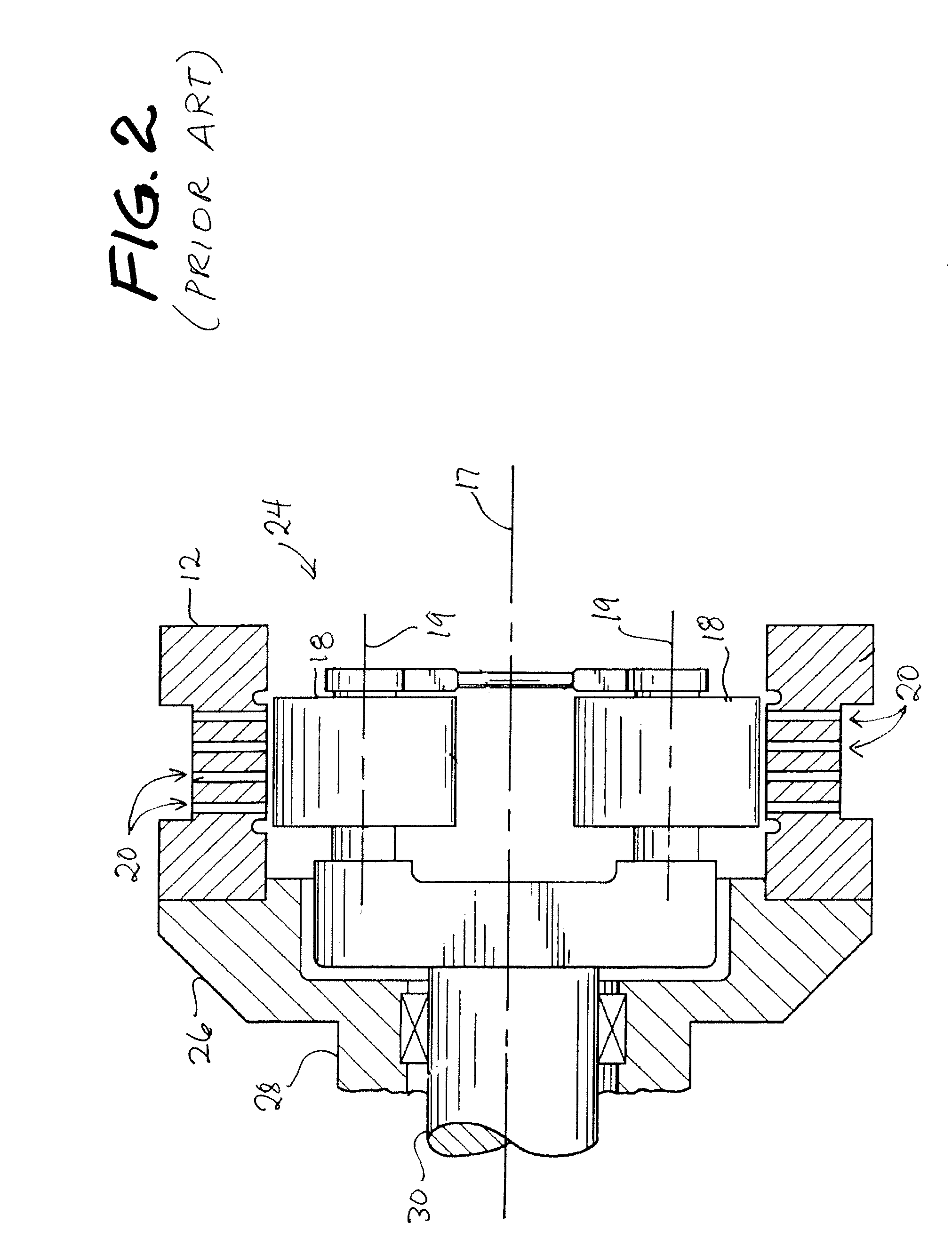

Roller for Pelleting Mill

A pellet mill includes a die carrying material to be extruded into pellets. The die rotates to bring the material toward rollers within the die. The rollers push the material through extrusion holes in the die. The rollers are mounted on and rotate about support shafts that are held stationary within the die. Sealing devices at the ends of the rollers prevent foreign material from interfering with bearings between the rollers and the support shafts. Each of the sealing devices include one or more sealing elements. The sealing elements may include a pair of mating grooves and protrusions.

Owner:ALLIS CARL R

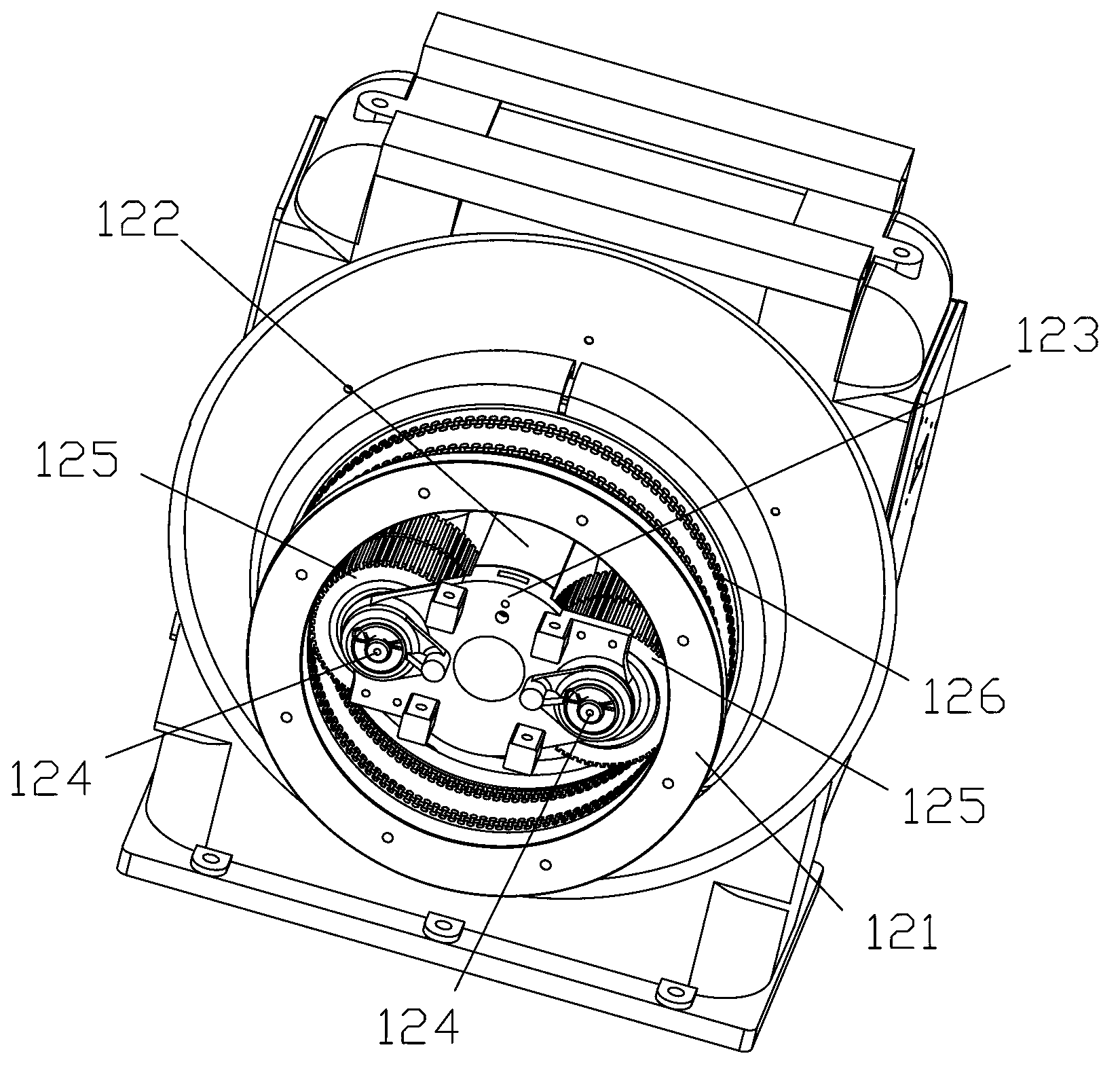

Granulator

ActiveCN103055761ASmall working surfaceReduce wearGranulation by material expressionGranulation by pressingMechanical engineeringEngineering

The invention discloses a granulator comprising a base, a first motor, a second motor, a feeding device, a supply pipe, a feed pipe, a pressing device and a transmission device. The second motor conveys materials from the supply pipe to the feeding device, and then the materials enters the pressing device to be pressed through the feed pipe; power required by pressing is provided by the first motor and transmitted to the pressing device through the transmission device; the pressing device comprises a main shaft, a circular mould, a main shaft pressure plate connected with the main shaft, two press roller shafts which are arranged in parallel on the main shaft pressing plate, and four press rollers; each press roller shaft is provided with two press rollers, and a distance is left between the two press rollers on each press roller shaft; and six rows of mould holes are formed in the circular mould, every three adjacent rows of mould holes are in one group, and a distance is left between each two groups of mould holes and is equal to that between the two press rollers on each press roller shaft. The granulator is simple to operate, and has the advantages of high production efficiency, low energy consumption and long service life.

Owner:JIANGSU JINWU MACHINERY CO LTD

Extrusion encapsulation of actives at an increased load, using surface active plant

ActiveUS20130243851A1Improve the level ofIncrease the maximum loadConfectionerySweetmeatsFlavorLoad following power plant

A glassy extrusion encapsulation composition and a method of making the composition are provided. The encapsulation composition comprises an encapsulate encapsulated in a glassy matrix comprising 0.5 to 12% by weight, based on the total weight of the glassy matrix, of at least one surface active plant extract, and 88 to 99.5% of at least one carbohydrate. The addition of a surface active plant extract to a carbohydrate matrix markedly increases the load of an encapsulate in the encapsulation composition. Such glassy matrices are useful for encapsulation of encapsulates, for example, flavors and medications. A food composition containing the encapsulation composition is also provided.

Owner:MCCORMICK & CO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com