Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1283results about "Granulation by pressing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

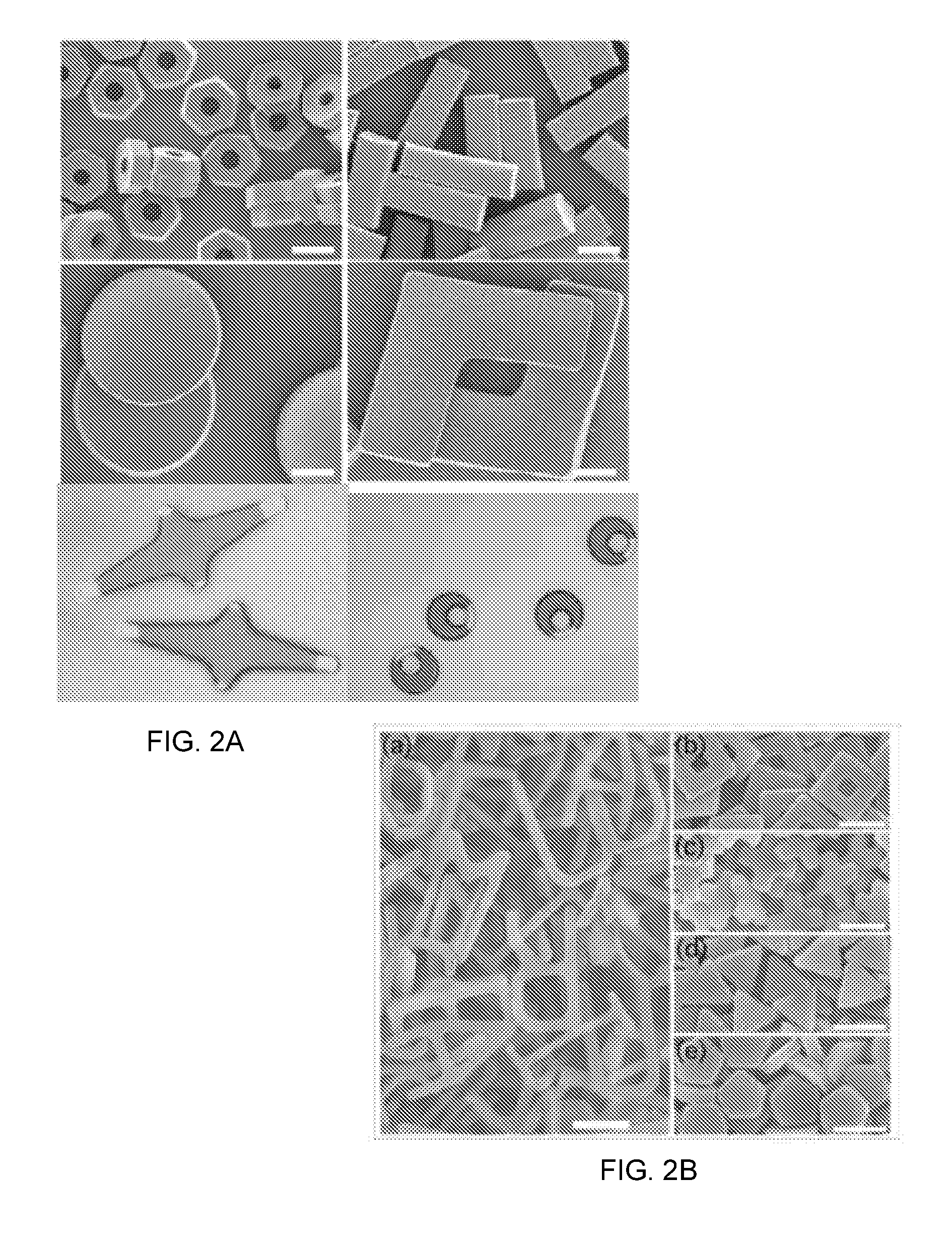

Shaped, fractured abrasive particle, abrasive article using same and method of making

ActiveUS20090169816A1Improve performanceLarge distributionPigmenting treatmentSpecial ornamental structuresPolymer chemistryAbrasive

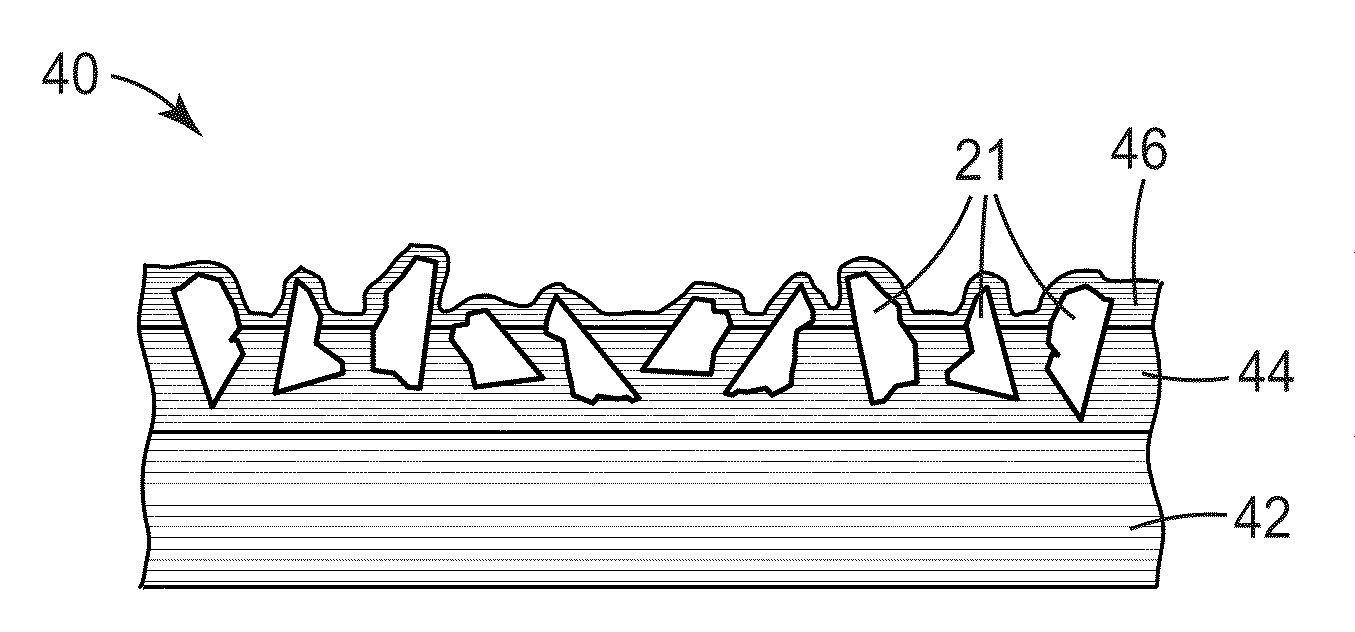

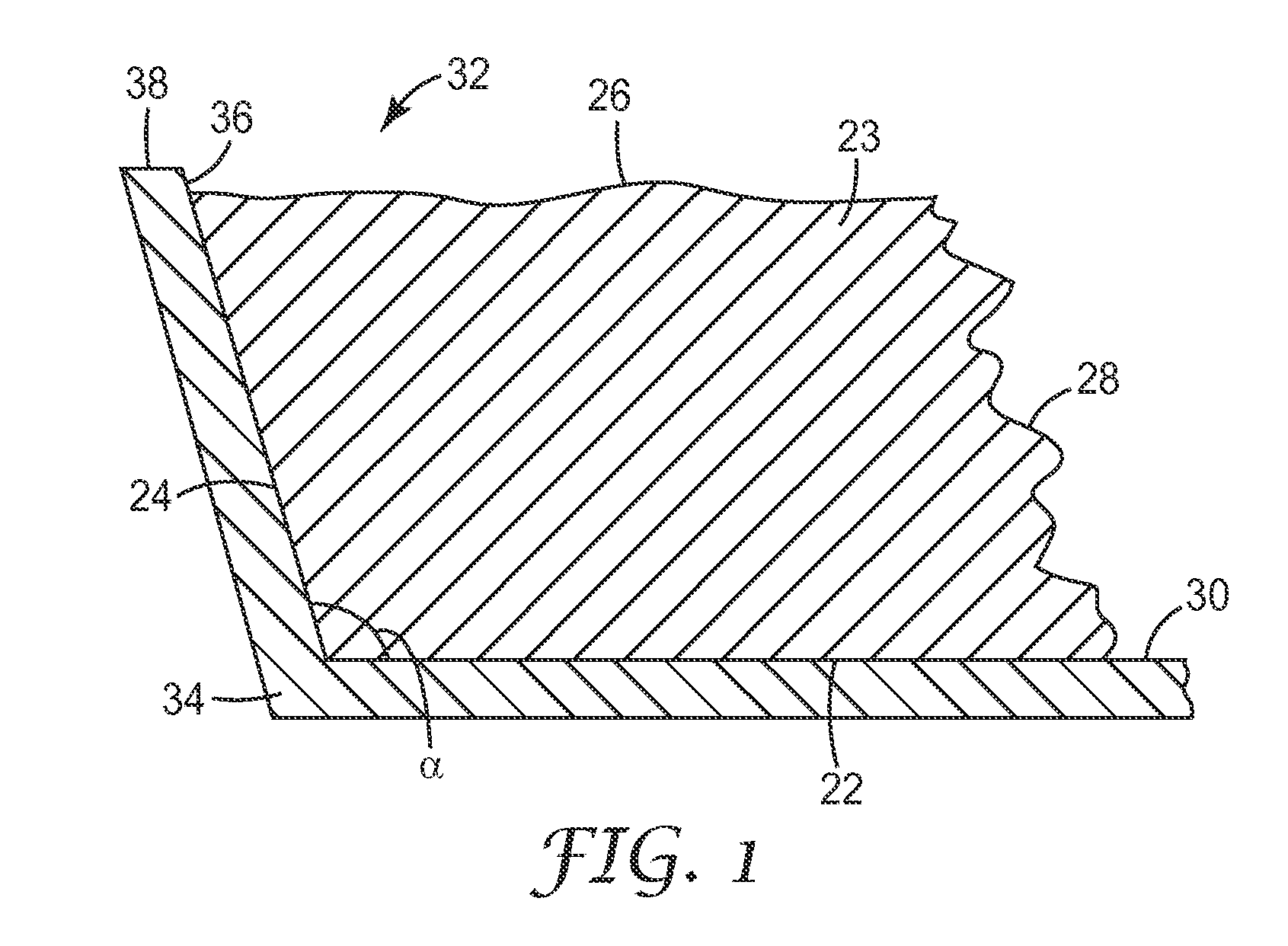

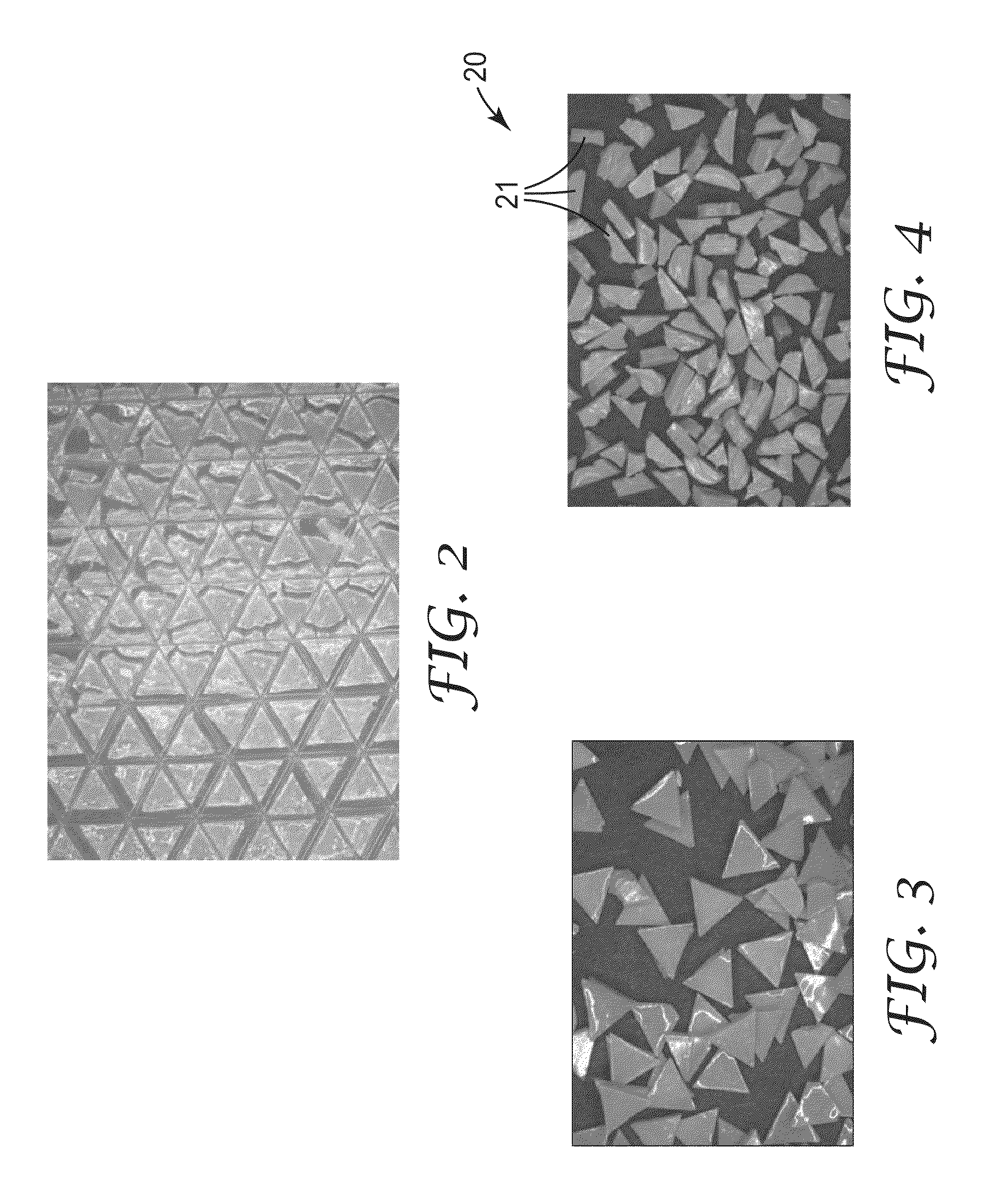

Precursor alpha alumina abrasive particles in a mold are subjected to a drying process that cracks or fractures at least a majority of the precursor abrasive particles into at least two pieces thereby producing abrasive shards having a smaller size than the mold cavity from which they were made. The smaller abrasive shards, once formed, could be reassembled like jigsaw puzzle pieces to reproduce the original cavity shape of the mold from which they were made. The cracking or fracturing of the precursor abrasive particles is believed to occur by ensuring that the surface tension of the abrasive dispersion to the walls of the mold is greater than the internal attractive forces of the abrasive dispersion as the abrasive dispersion is dried within the mold cavity.

Owner:3M INNOVATIVE PROPERTIES CO

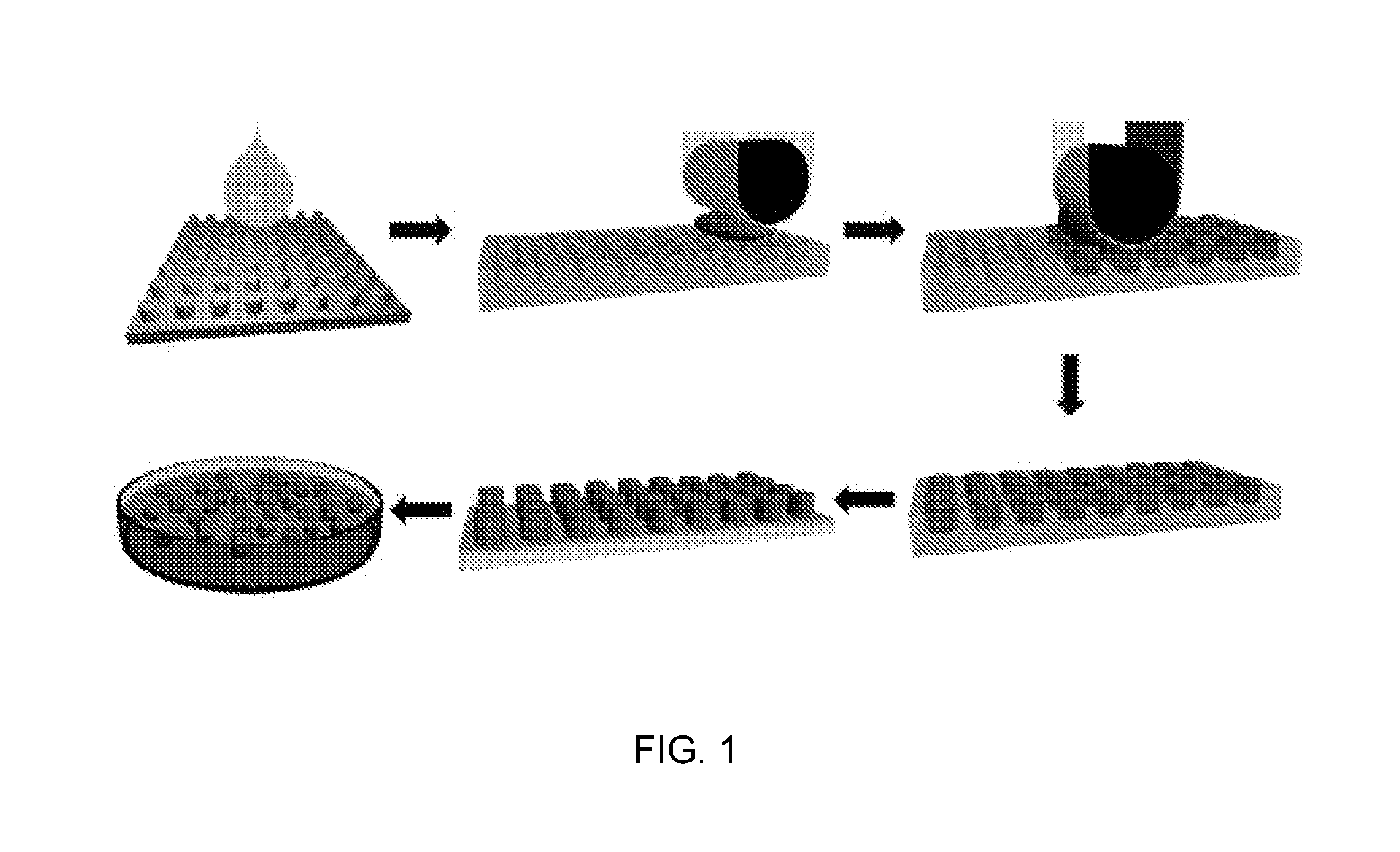

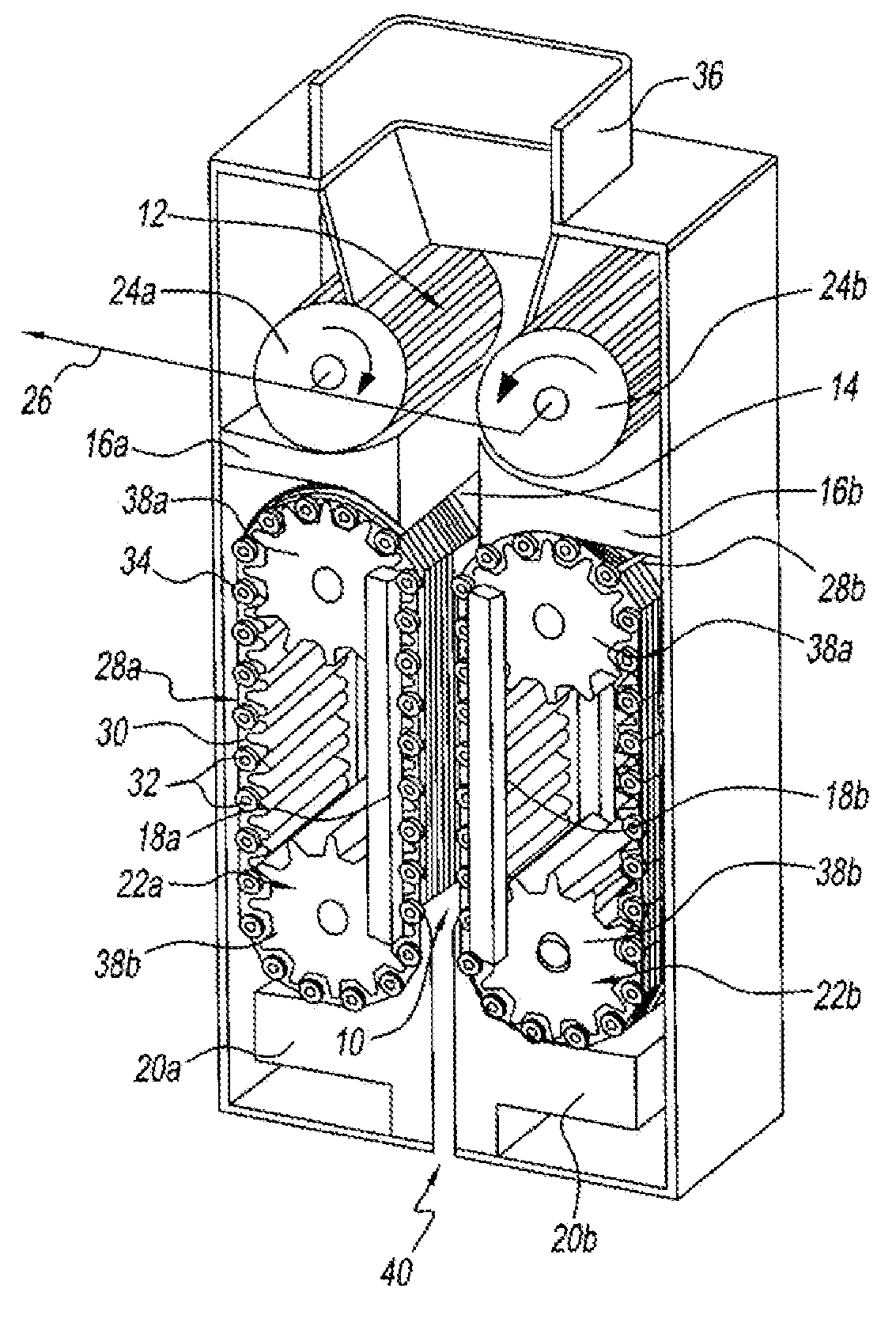

Granules, tablets and granulation

ActiveUS20080111269A1Quick cureEasy to assemblePowder deliveryElectrostatic separationMaterials scienceAirflow

The invention provides, inter alia, a method for producing granules from a powder, characterized in that a low compaction force is applied to the powder to produce a compacted mass comprising a mixture of fine particles and granules and separating fine particles from the granules by entraining the fine particles in a gas stream. Also provided are apparatus for use in the process and tablets formed by compression of the resultant granules.

Owner:ATACAMA LABS OY

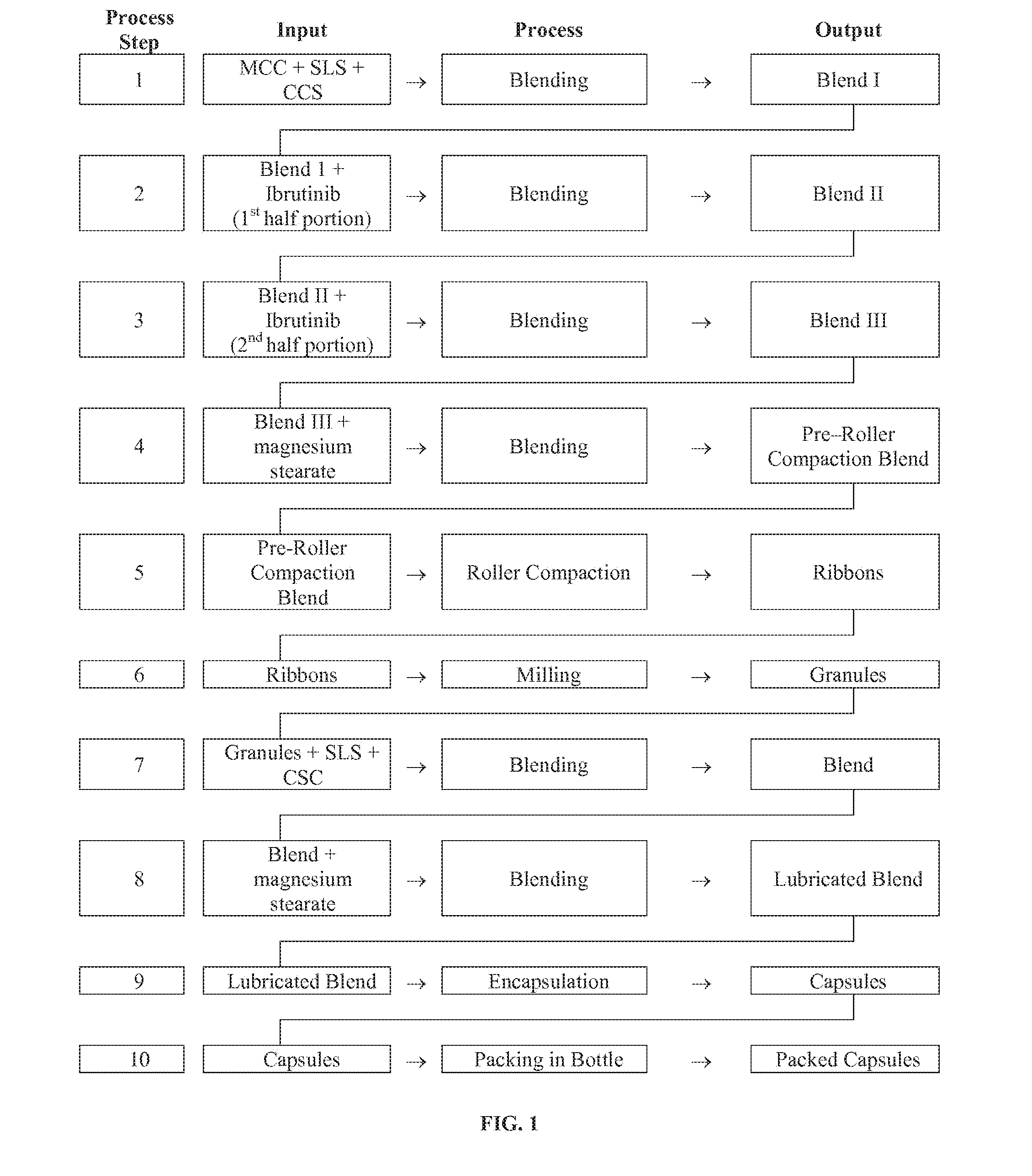

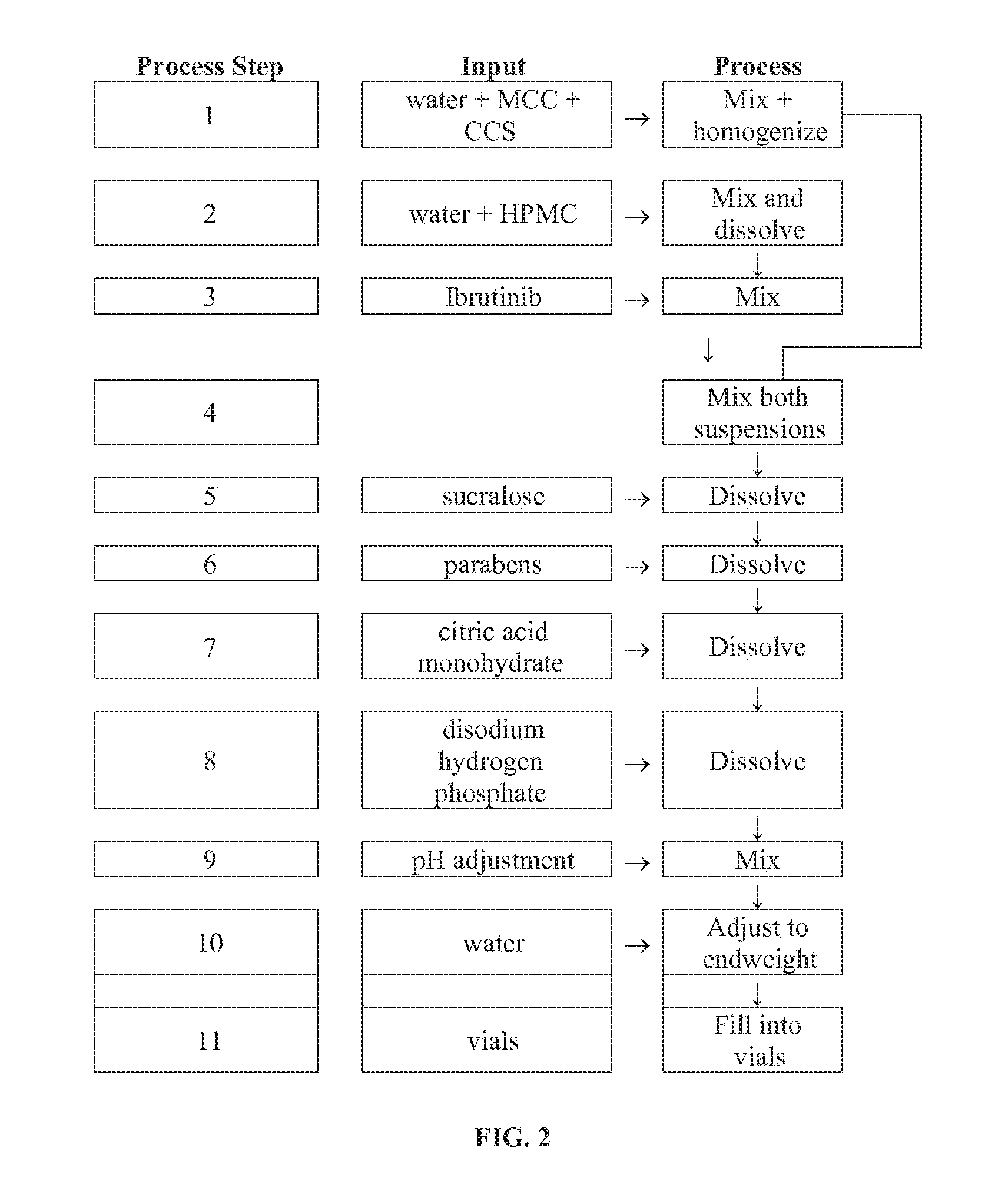

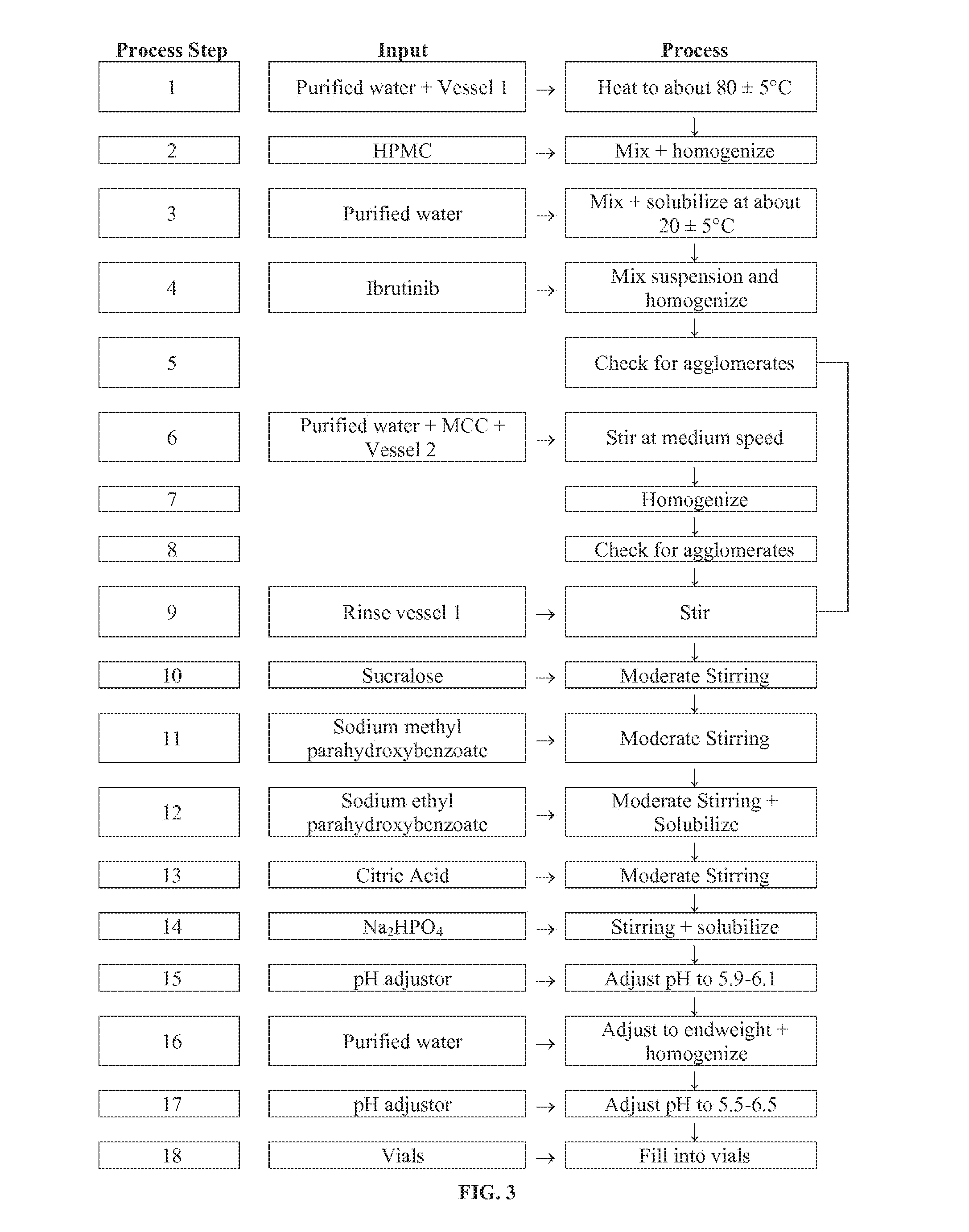

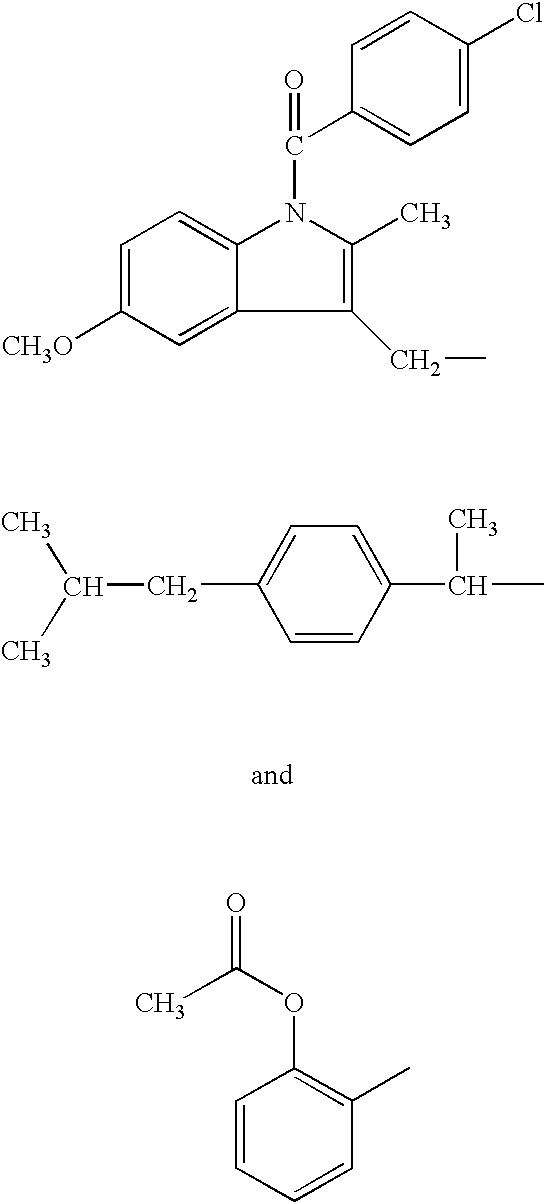

Compositions Containing Ibrutinib

InactiveUS20160287594A1Easy to sprinkleOrganic active ingredientsInorganic non-active ingredientsWaldenstrom macroglobulinemiaMetabolite

Discussed herein are pharmaceutical compositions containing Ibrutinib and processes for preparing them. The compositions may be utilized in the treatment of a variety of conditions including, without limitation, B-cell proliferative disorders such as non-Hodgkin lymphoma (diffuse large B cell lymphoma, follicular lymphoma, mantle cell lymphoma or burkitt lymphoma), Waldenstrom macroglobulinemia, plasma cell myeloma, chronic lymphocytic leukemia, lymphoma, or leukemia. These compositions are designed for oral ingestion. The compositions are contained within a capsule such as a standard or sprinkle or in a liquid formulation such as a suspension. In one embodiment, the pharmaceutical composition contains Ibrutinib, a salt, prodrug, or metabolite thereof, microcrystalline cellulose, croscarmellose sodium, sodium lauryl sulfate, and magnesium stearate. In another embodiment, the pharmaceutical composition contains Ibrutinib, a salt, prodrug, or metabolite thereof, microcrystalline cellulose, carboxymethylcellulose sodium, hydroxypropylmethylcellulose, citric acid monohydrate, disodium hydrogen phosphate, sucralose, sodium methyl parahydroxybenzoate, sodium ethyl parahydroxybenzoate, concentrated hydrochloric acid, sodium hydroxide, and water.

Owner:JANSSEN PHARMA NV

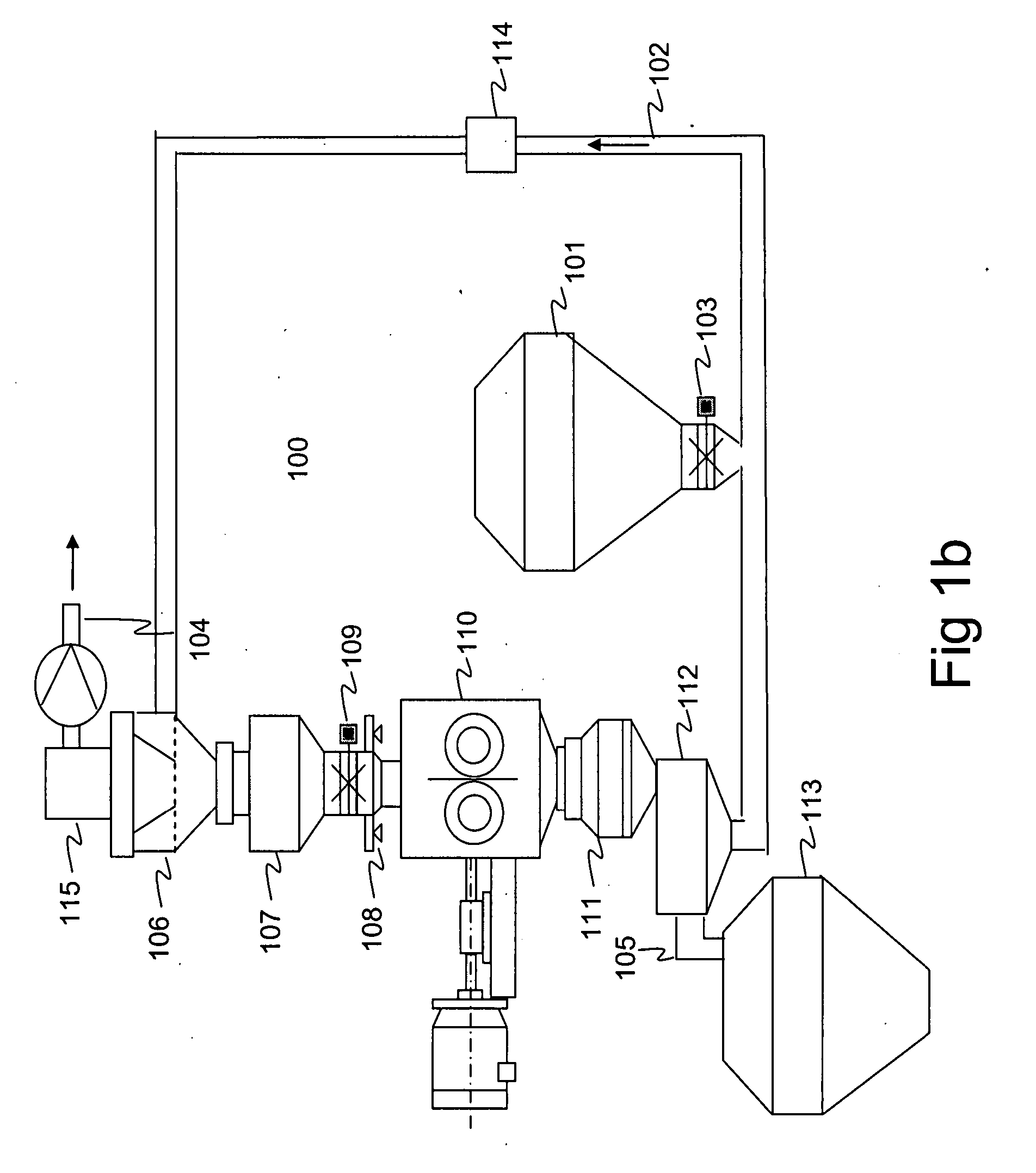

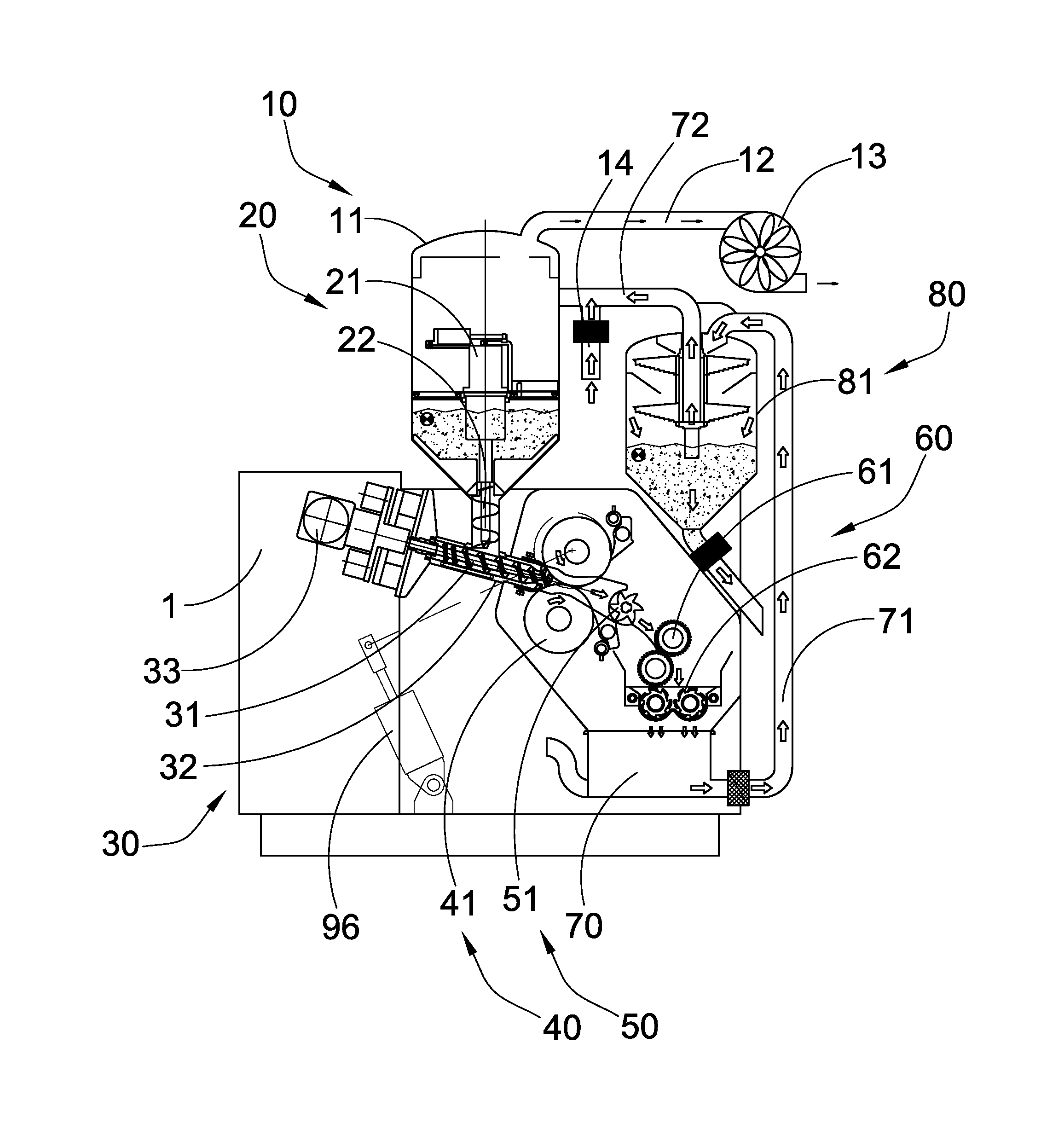

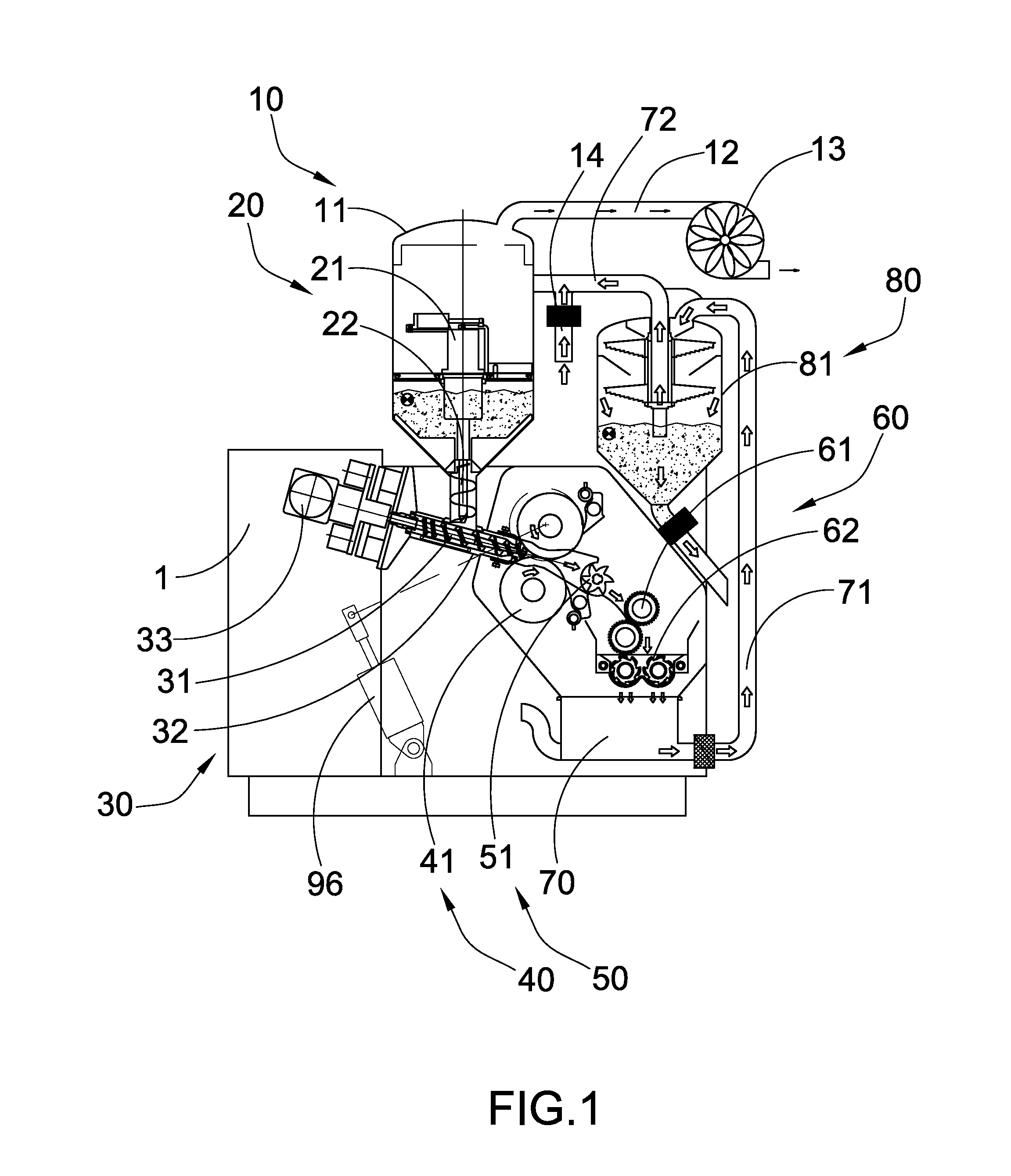

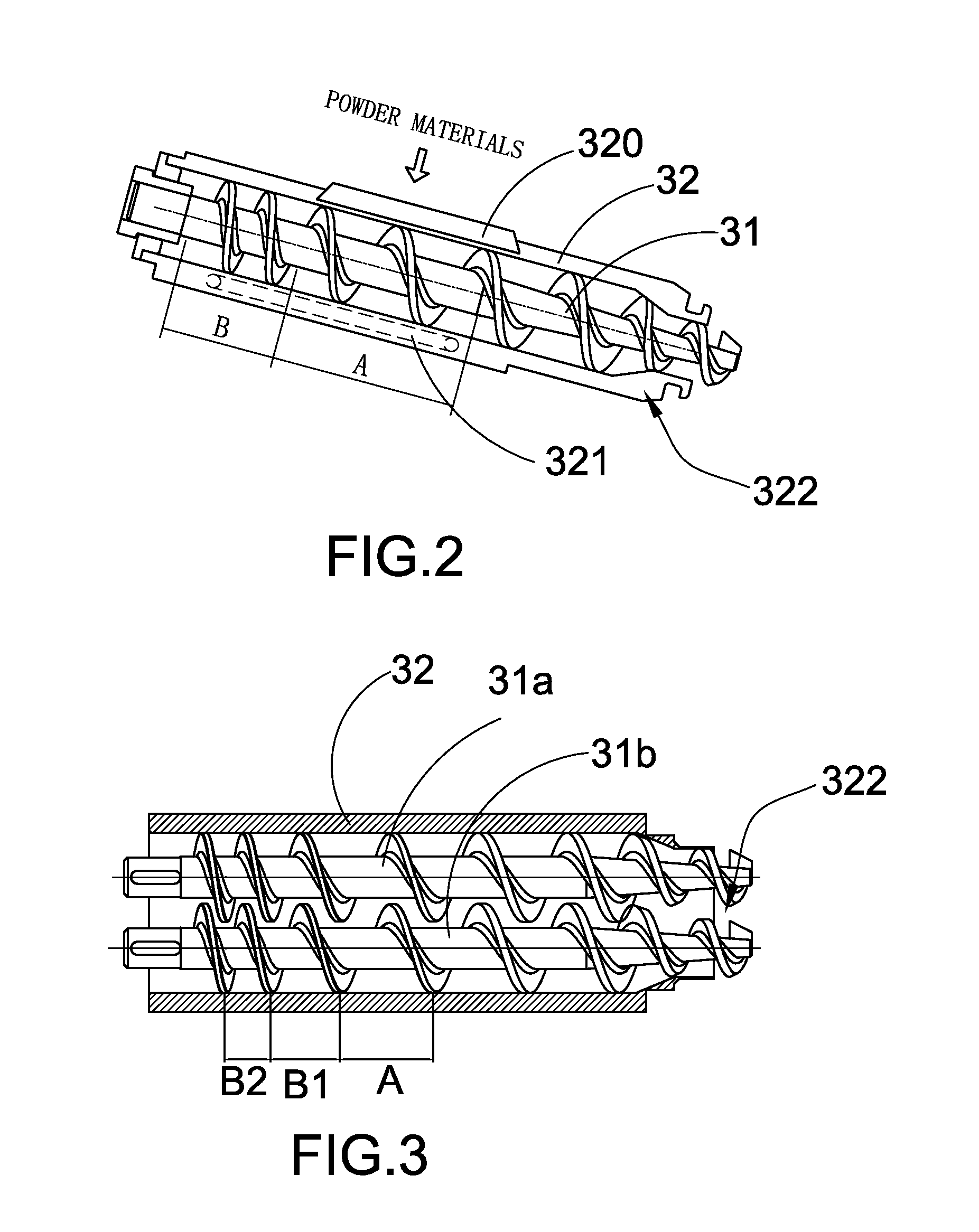

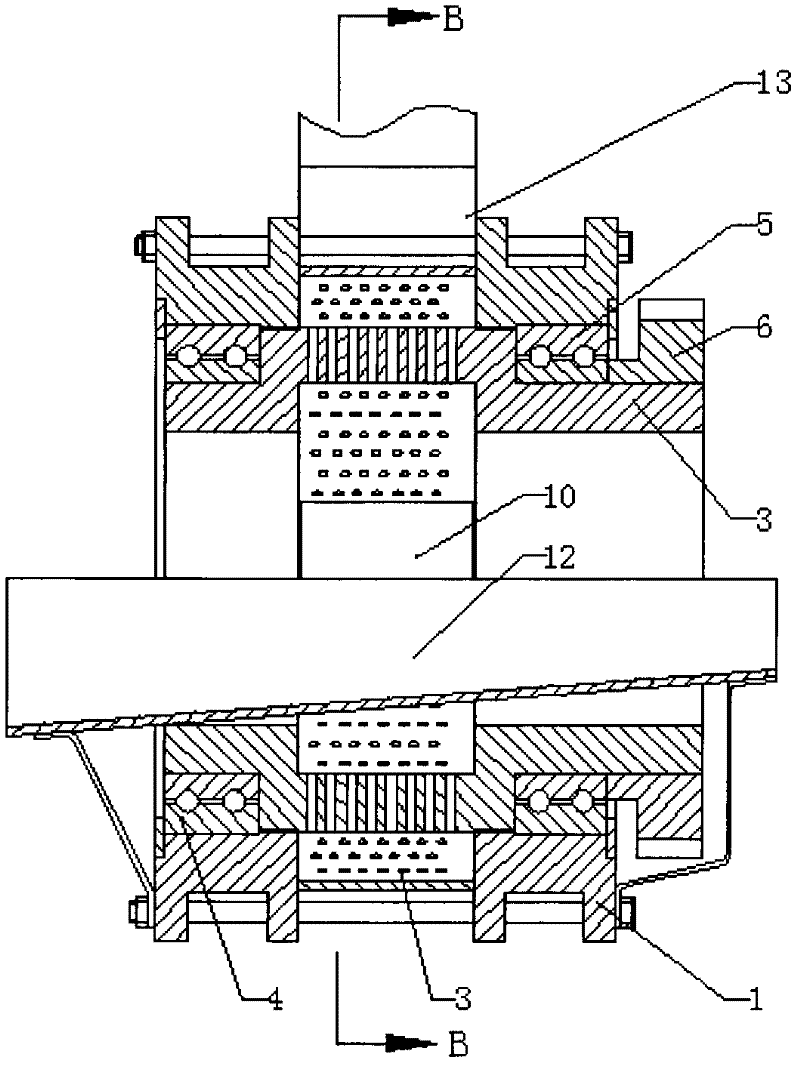

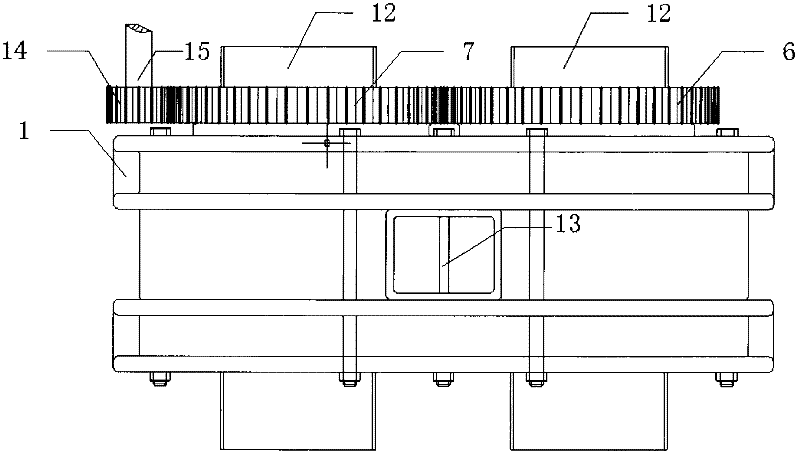

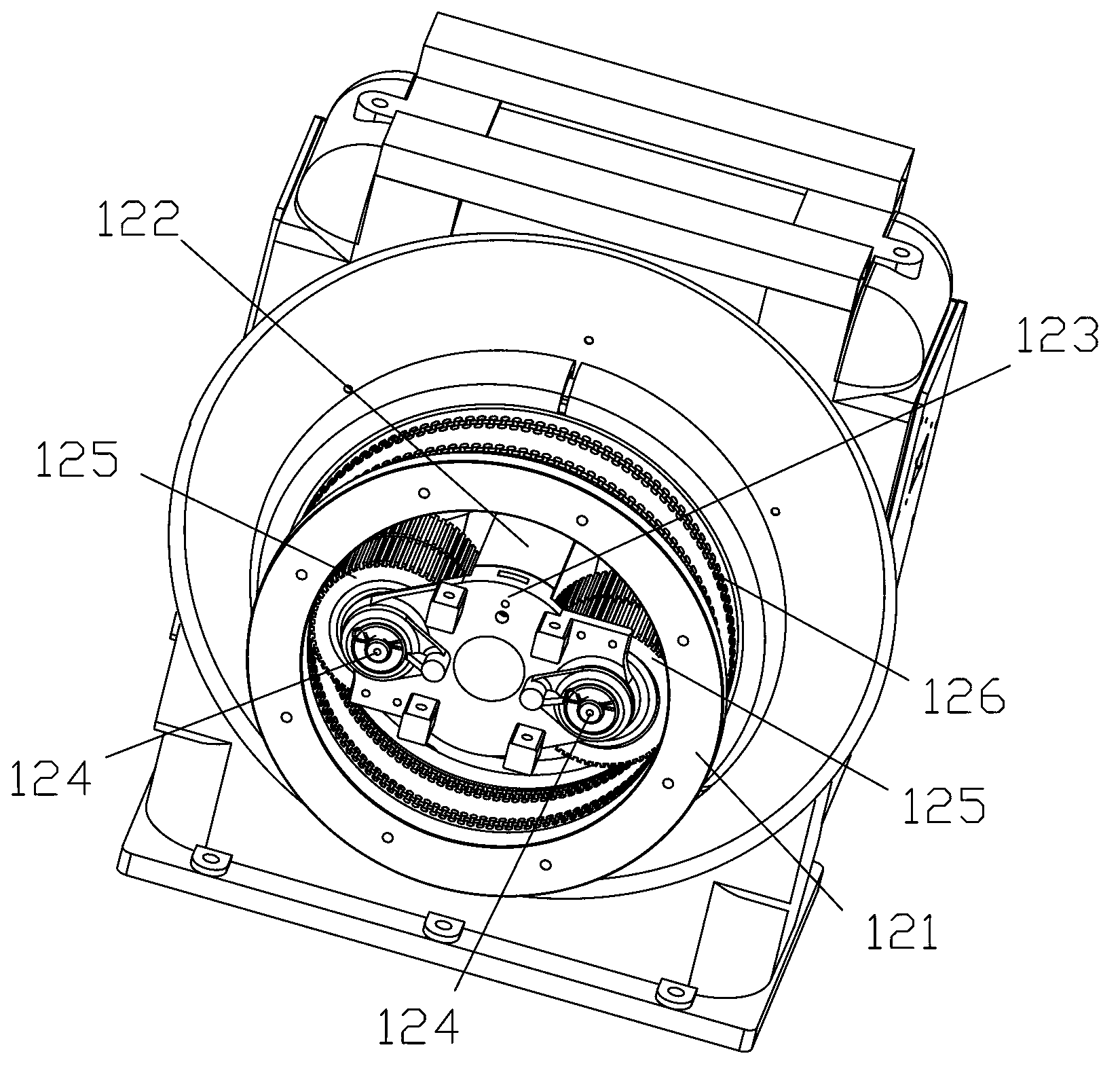

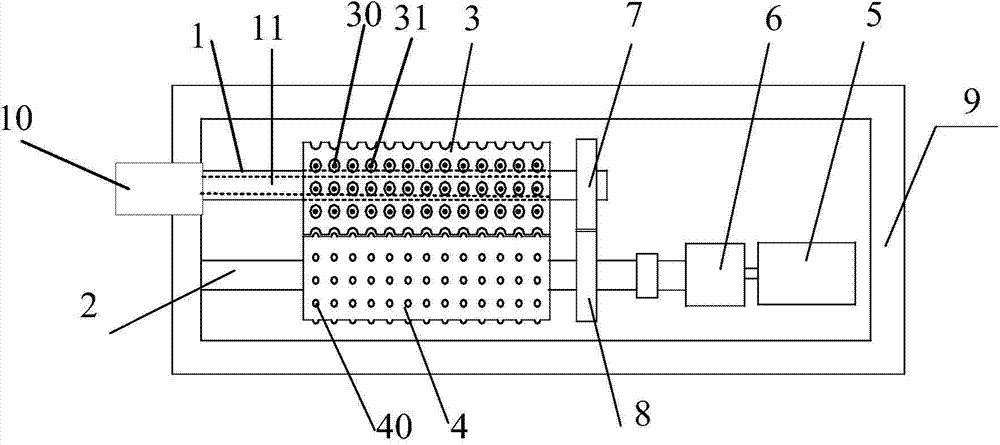

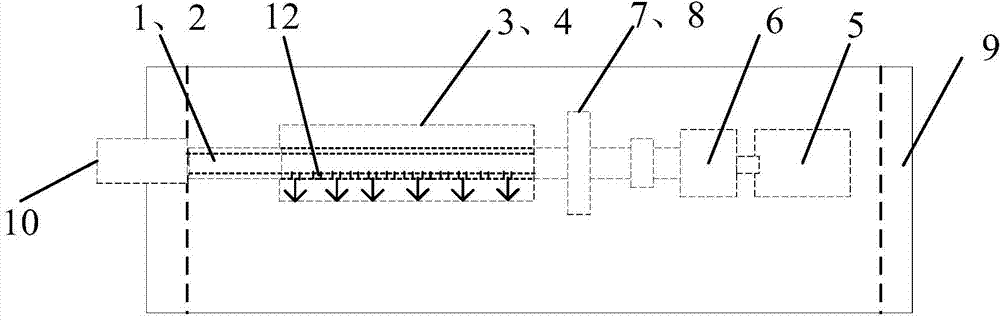

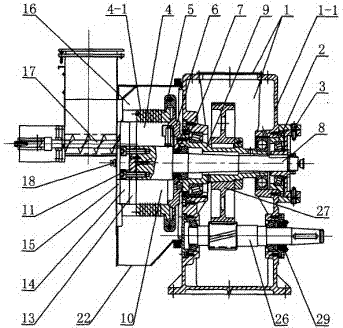

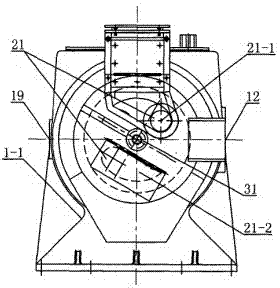

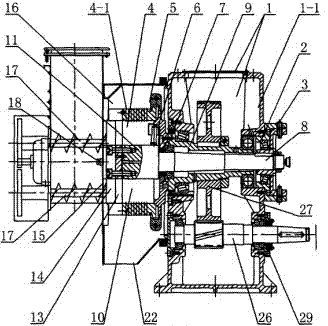

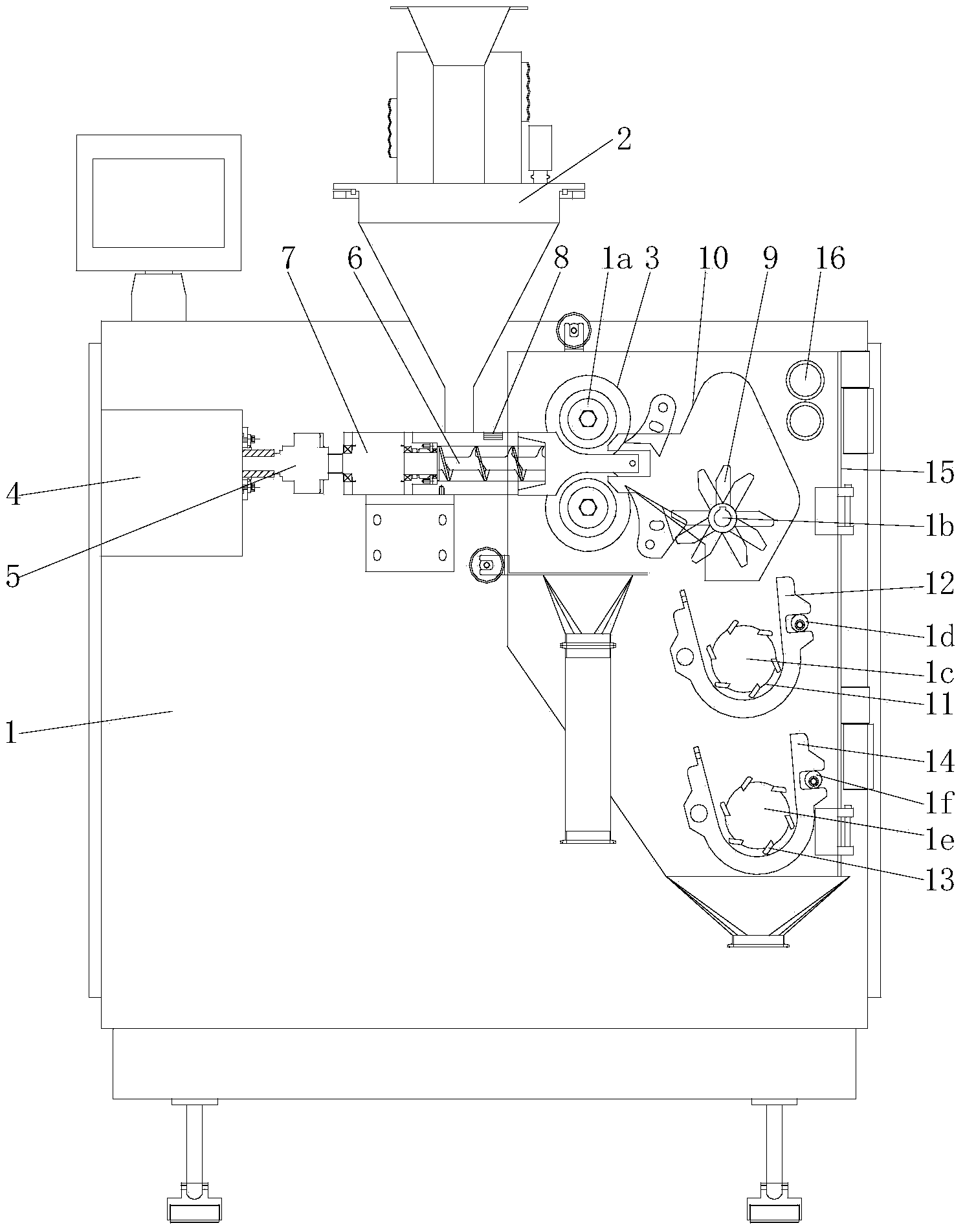

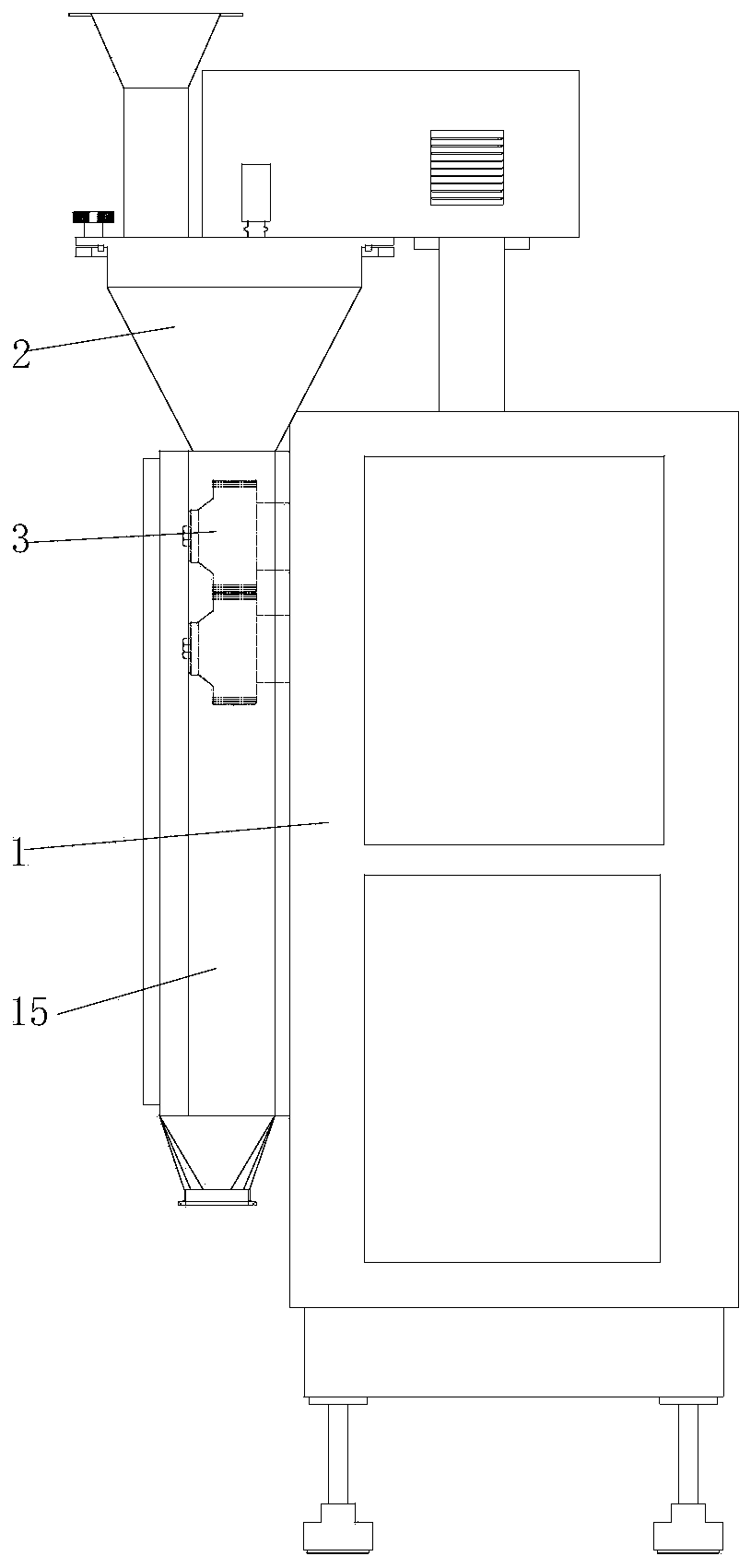

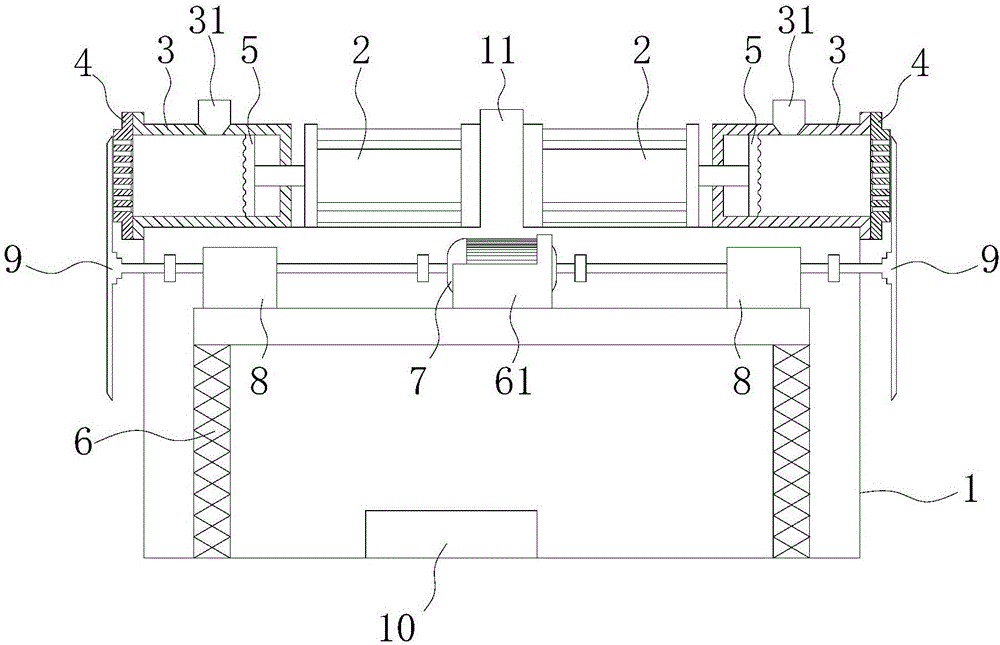

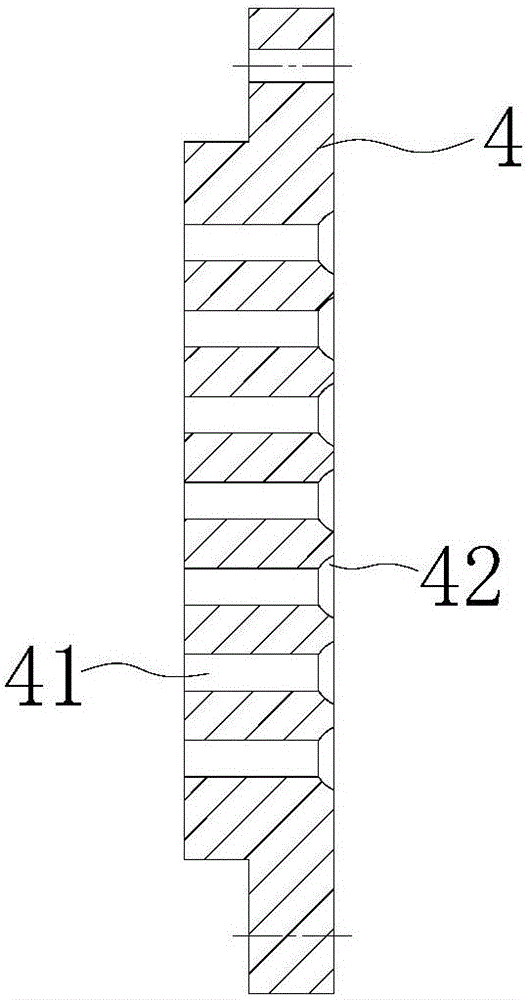

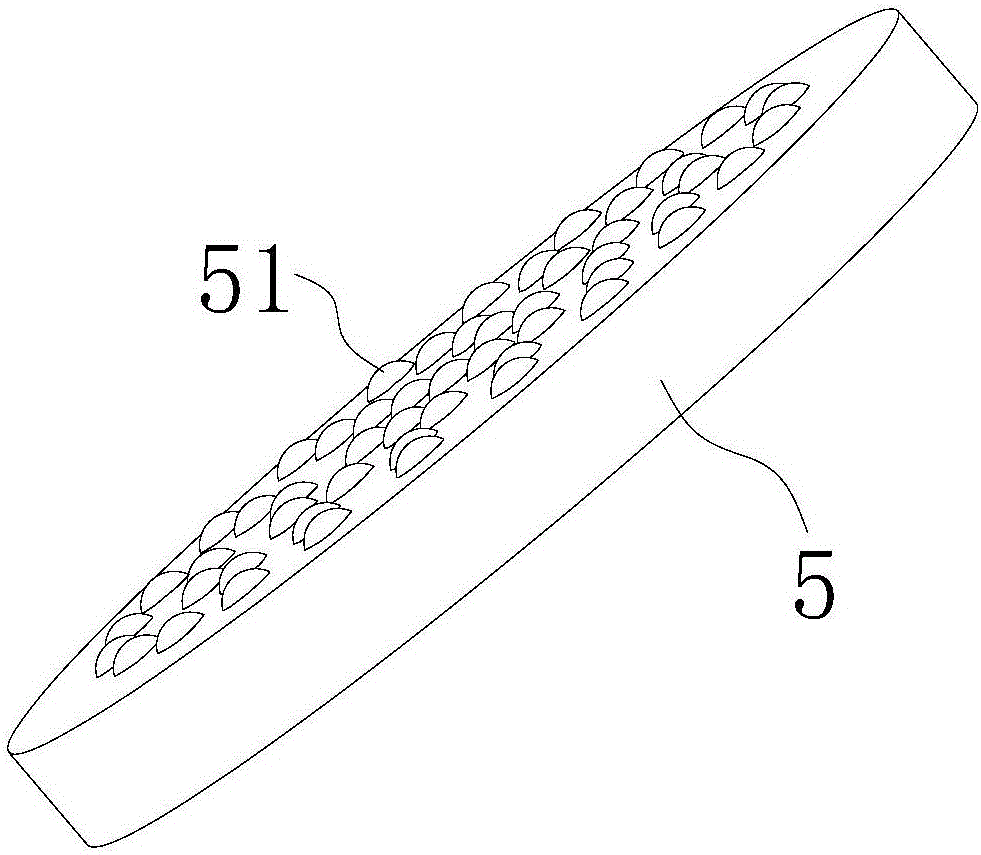

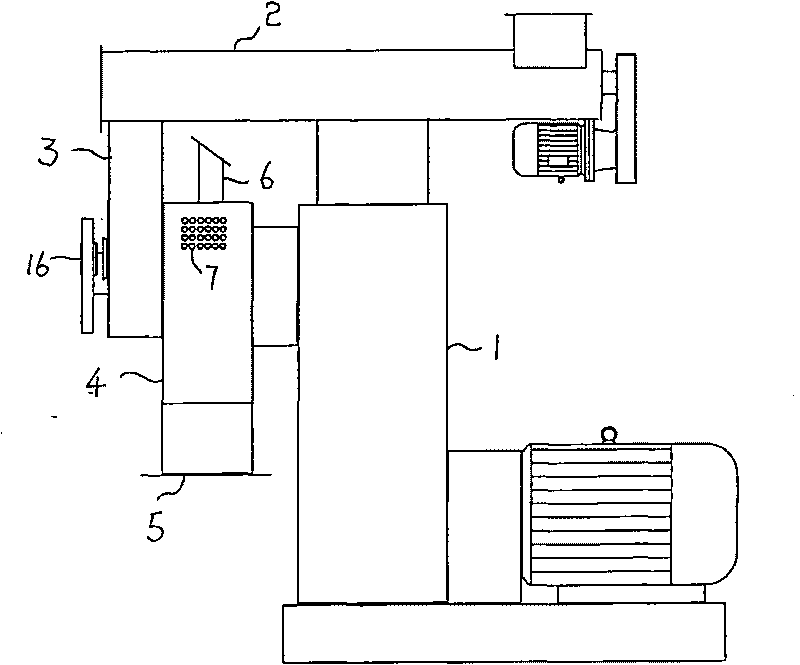

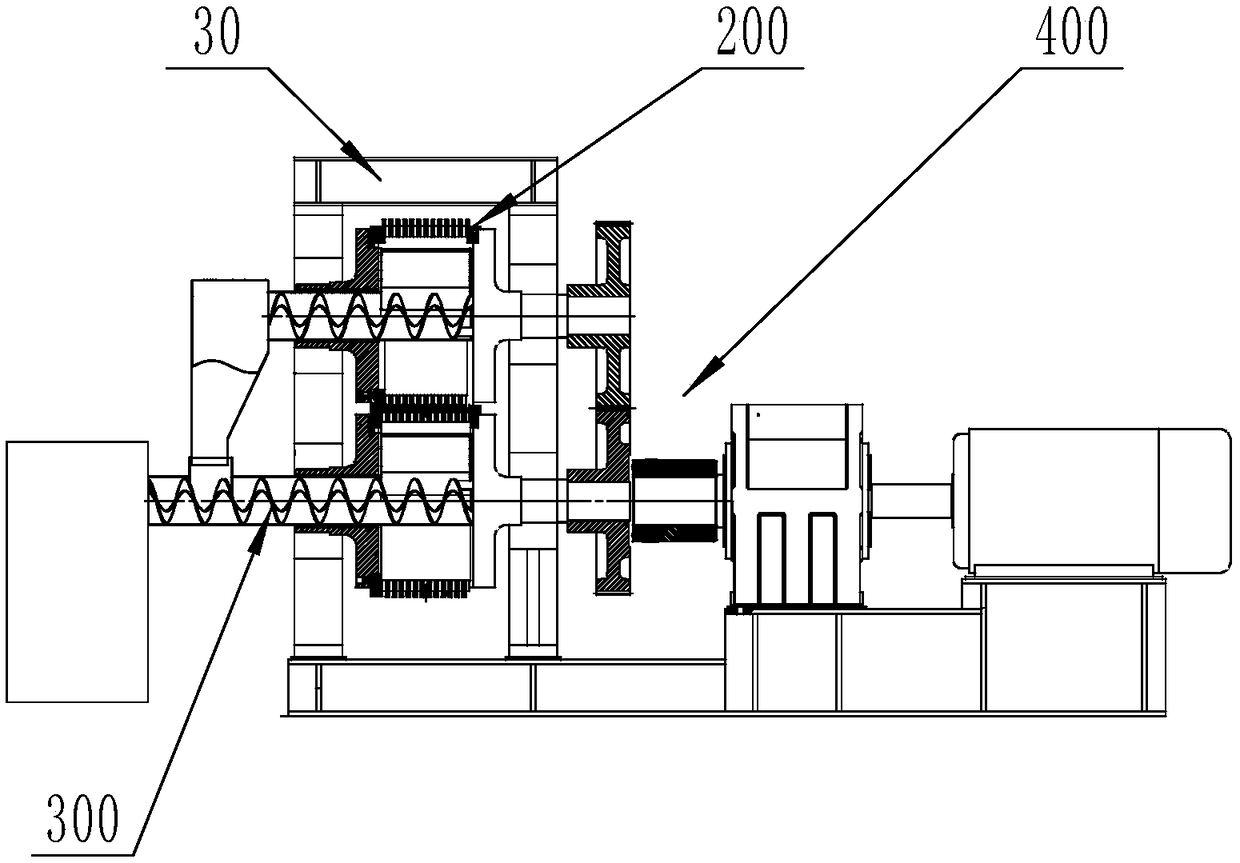

Dry Granulator

ActiveUS20150239152A1Compact structureImprove sealingDough homogenizationFrozen sweetsHardnessMaterials science

A dry granulator includes a feeding mechanism applied to suck powder materials into the material tanks; a vertical feeding mechanism to deliver the power materials to a bottom outlet of the material tank; a pressing mechanism to compress the powder materials into powder sheets with qualified hardness and thickness; an oblique feeding mechanism to deliver the powder materials to from the vertical feeding mechanism to the pressing mechanism; a crushing mechanism to crush the powder sheets into crushed powder sheets; a granulating mechanism to granulate the crushed powder sheet into finished particles products, so as to deliver to a collection storage; a sieving mechanism to separate the finished particle products with fine powders; a pressing wheel regulator applied to adjust an axial position of the lower and the upper pressing wheel; and a floating sealing device applied to provide a reliable sealing effect for the feeding mechanism.

Owner:ZHEJIANG FUTURE MACHINERY

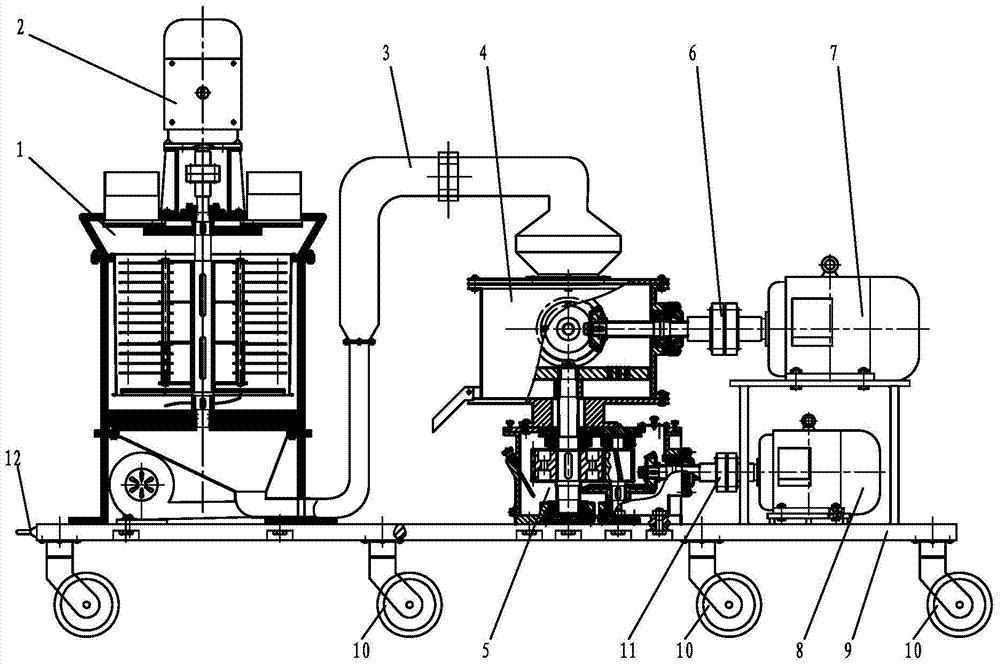

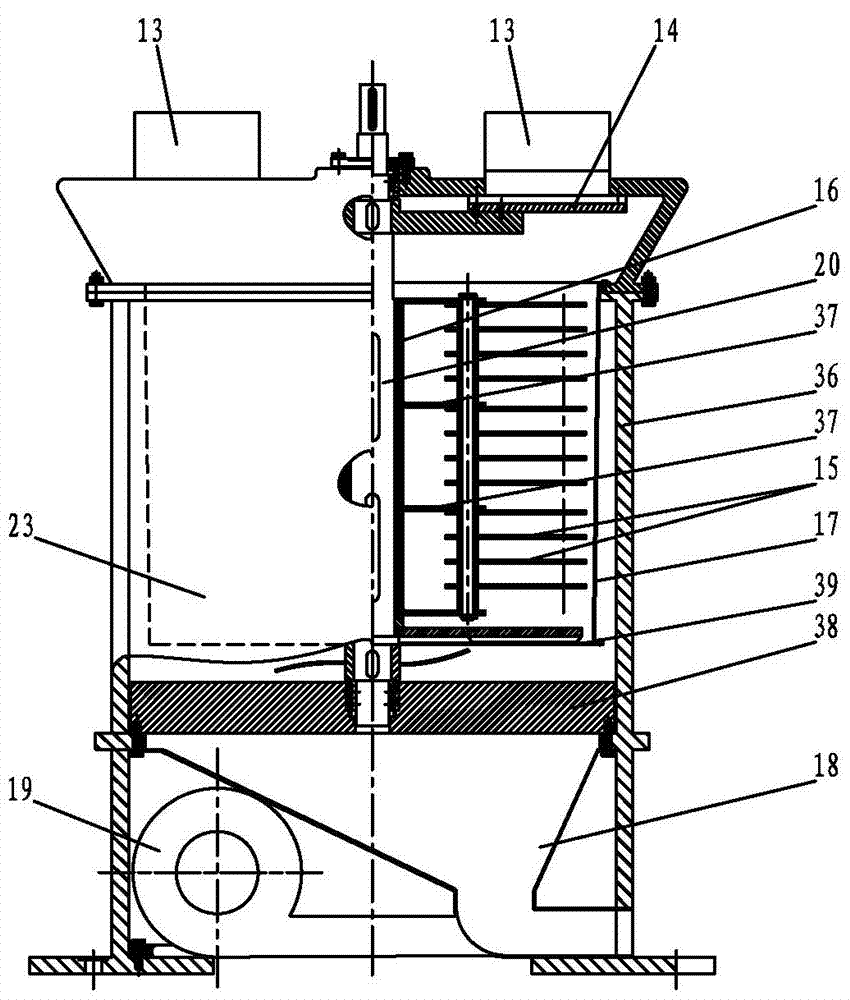

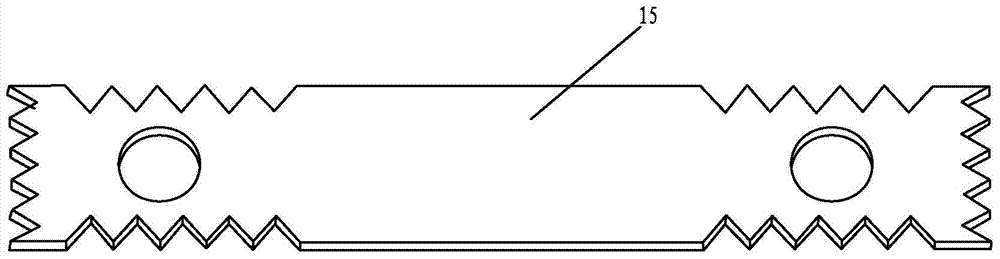

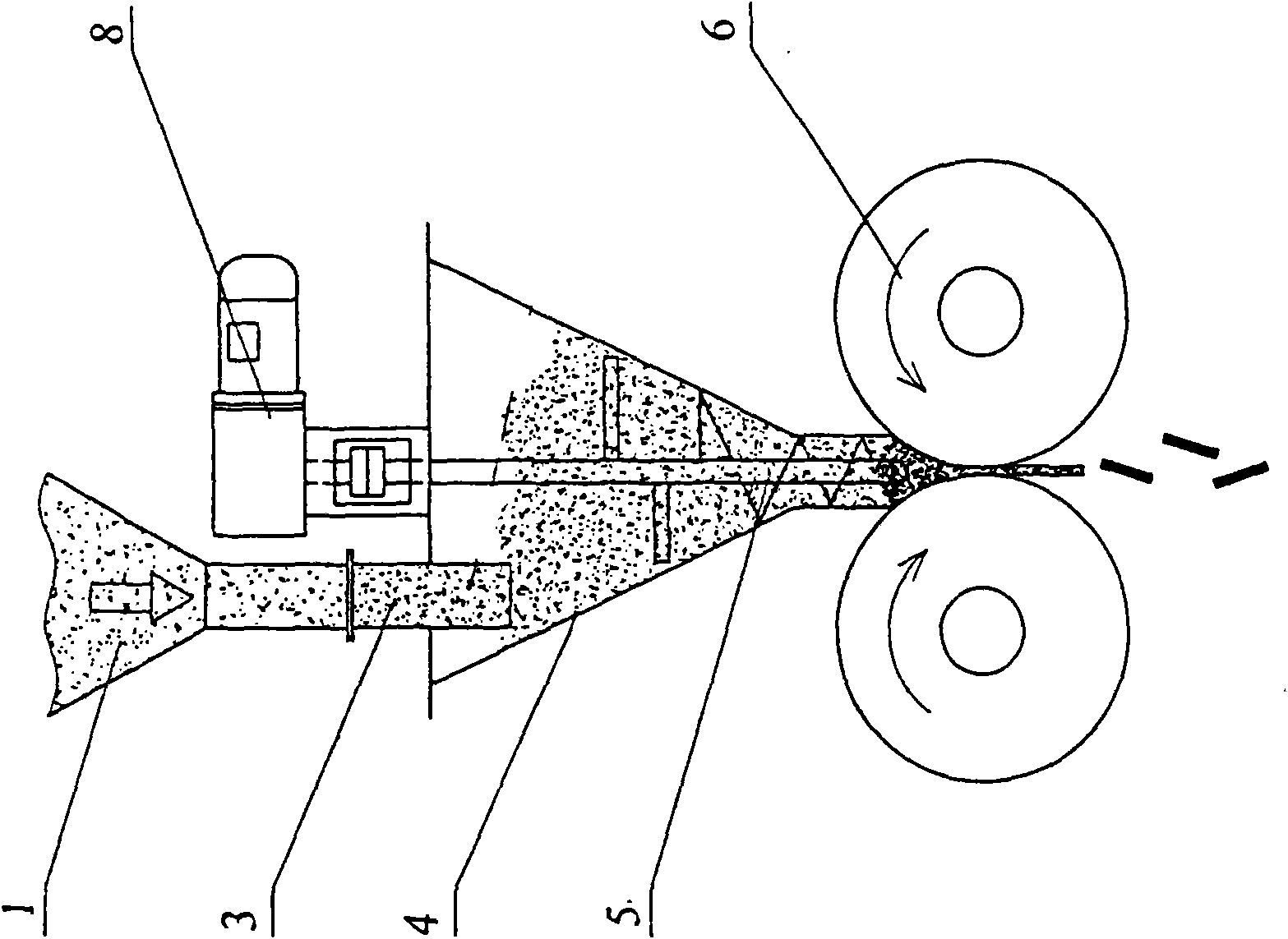

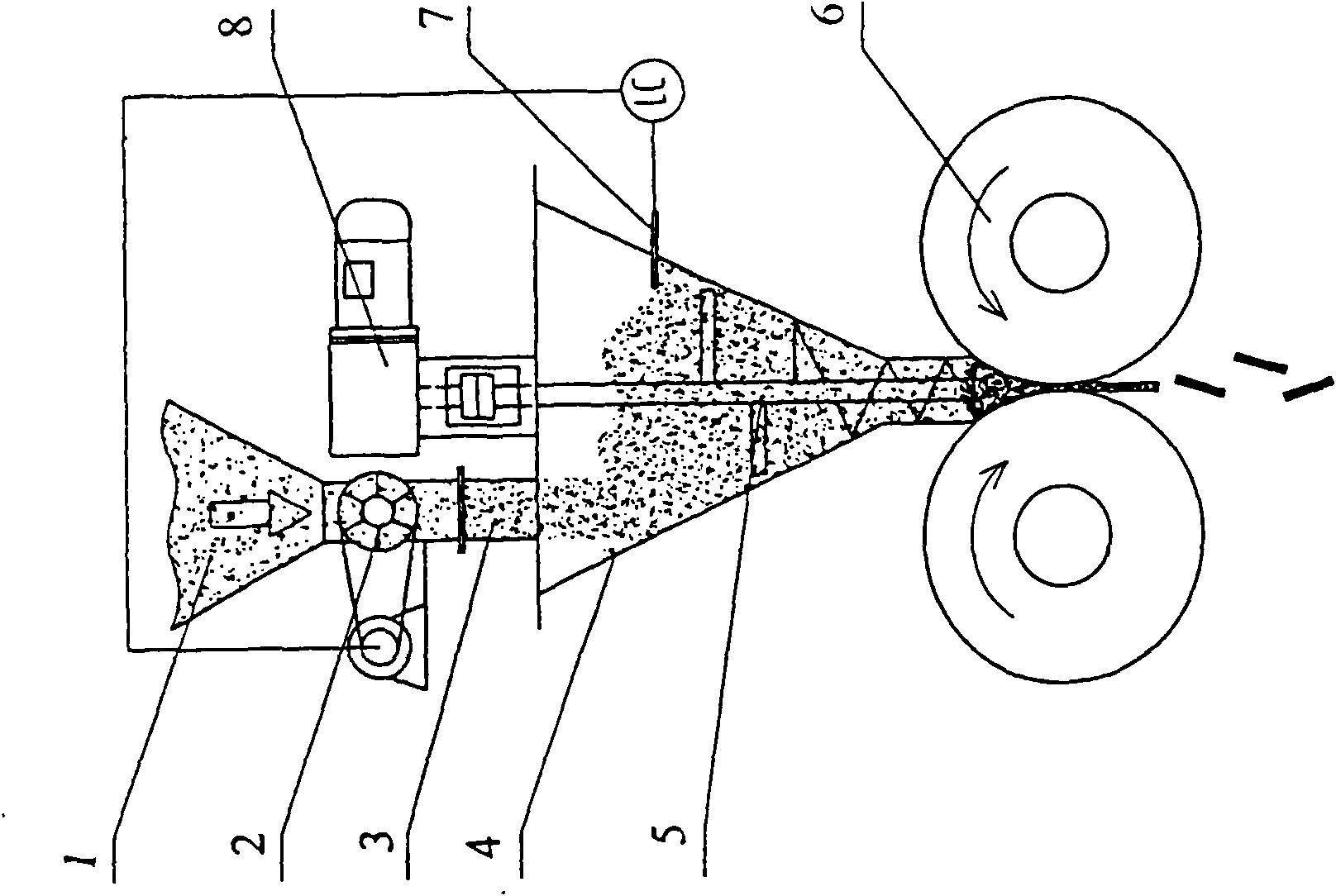

Biomass straw smashing and forming all-in-one machine

InactiveCN103495484ABig hitImprove crushing efficiencyGranulation by pressingGrain treatmentsWork cycleAir blower

The invention provides a biomass straw smashing and forming all-in-one machine, and relates to a straw smashing and forming device. The biomass straw smashing and forming all-in-one machine solves the problems that in an existing straw forming fuel production process, the straw smashing procedure and the compressing and compacting forming procedure are independently completed through a smashing device and a squeezing forming device respectively, the power consumption is high, the logistics cost is high, and the working cycle is long. The vertical smashing device and the squeezing forming device are arranged on a walking plate in parallel from front to back, walking wheels are arranged below the walking plate, a blade is arranged at the bottom of a feed port of the vertical smashing device, a main shaft of the smashing machine is sleeved with a sleeve, hammer carrier plates are arranged on the sleeve from top to bottom, a hammer set is arranged between every two adjacent hammer carrier plates in an annular mode, hammers of each hammer set are evenly arranged in the vertical direction, each hammer is of a multi-tooth-edge rectangular structure, an air blower is arranged at the bottom of a machine shell and communicate with a material storage hopper, and the material storage hopper is communicated with an inlet of the squeezing forming device through an air duct. The biomass straw smashing and forming all-in-one machine is used for smashing and forming biomass straw.

Owner:NORTHEAST FORESTRY UNIVERSITY

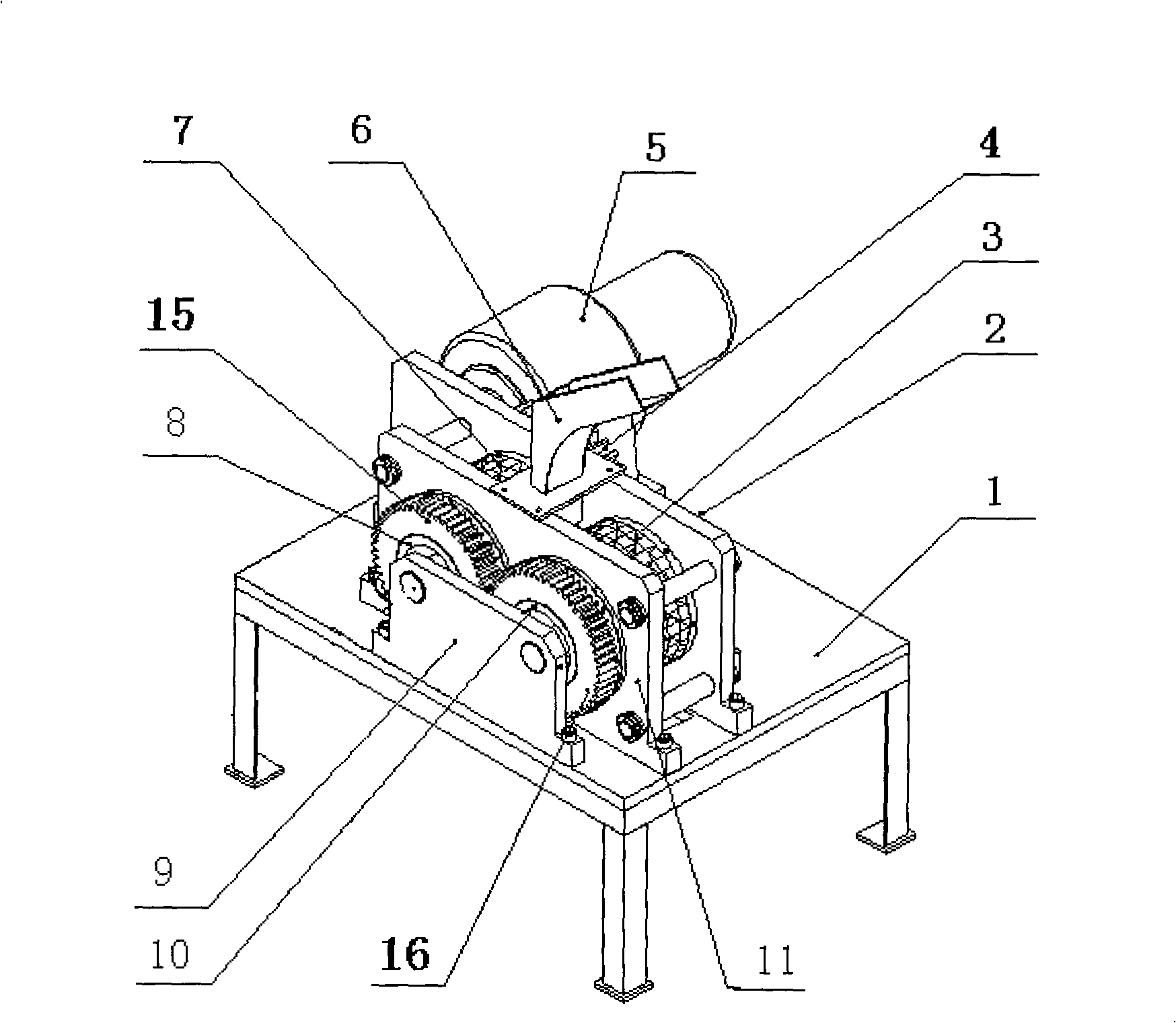

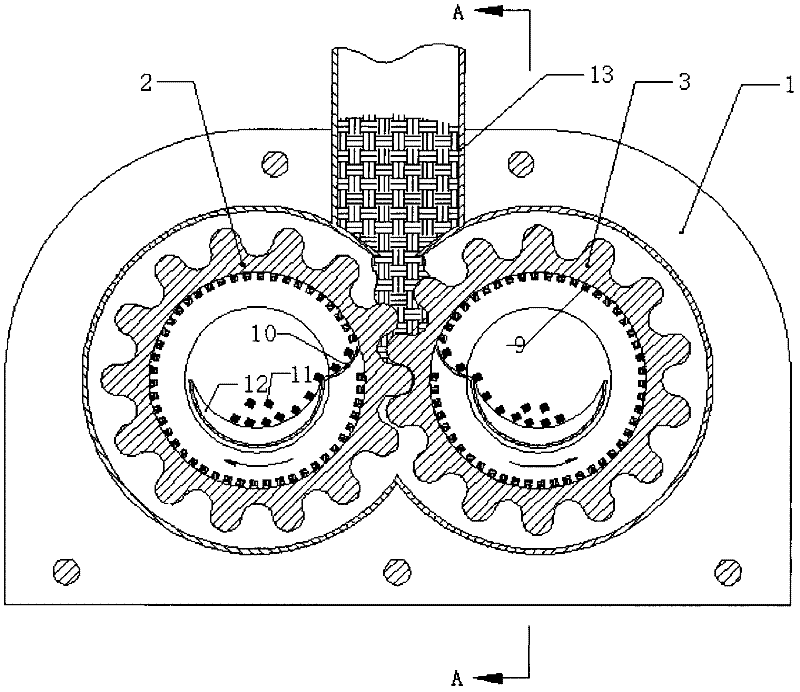

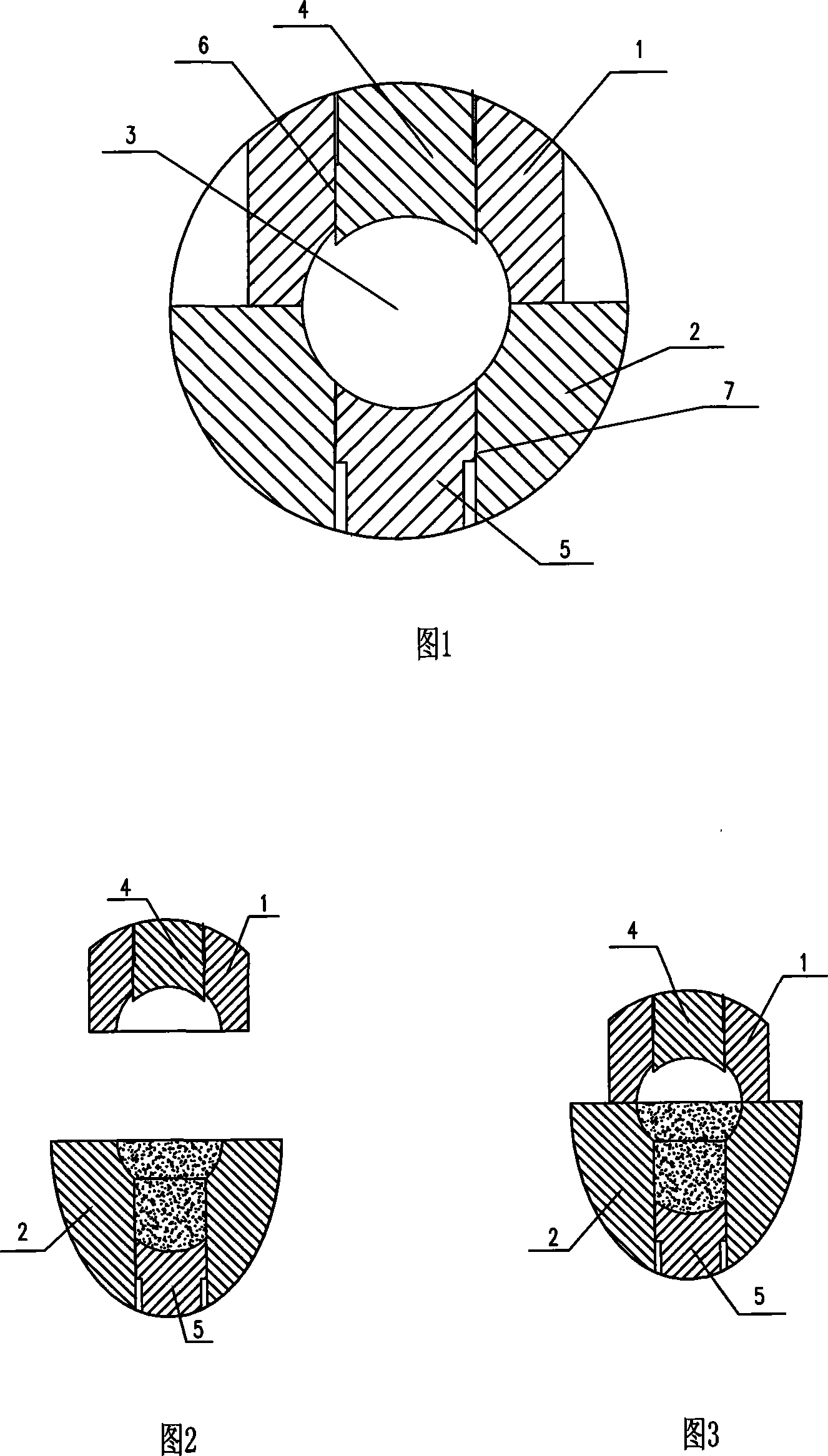

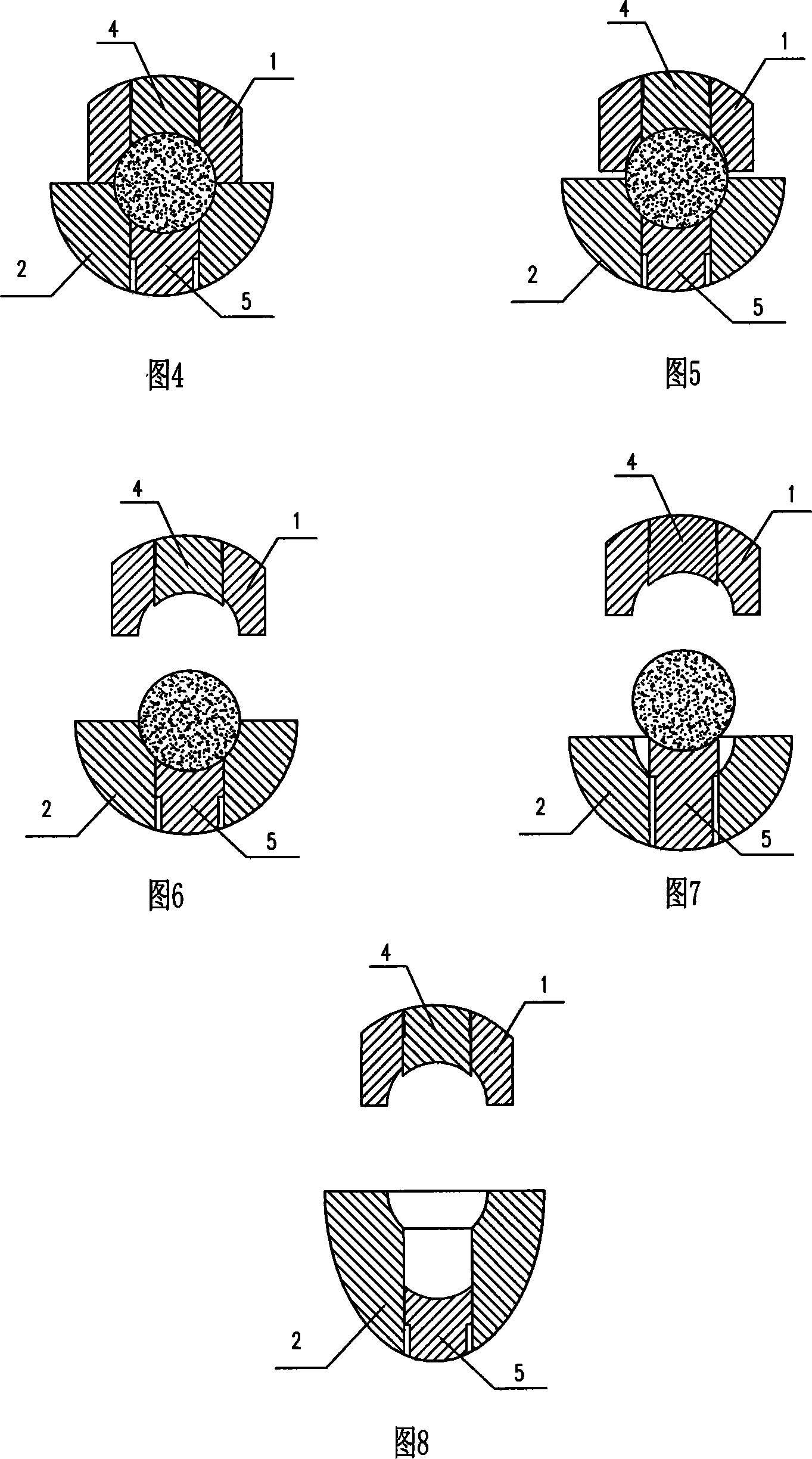

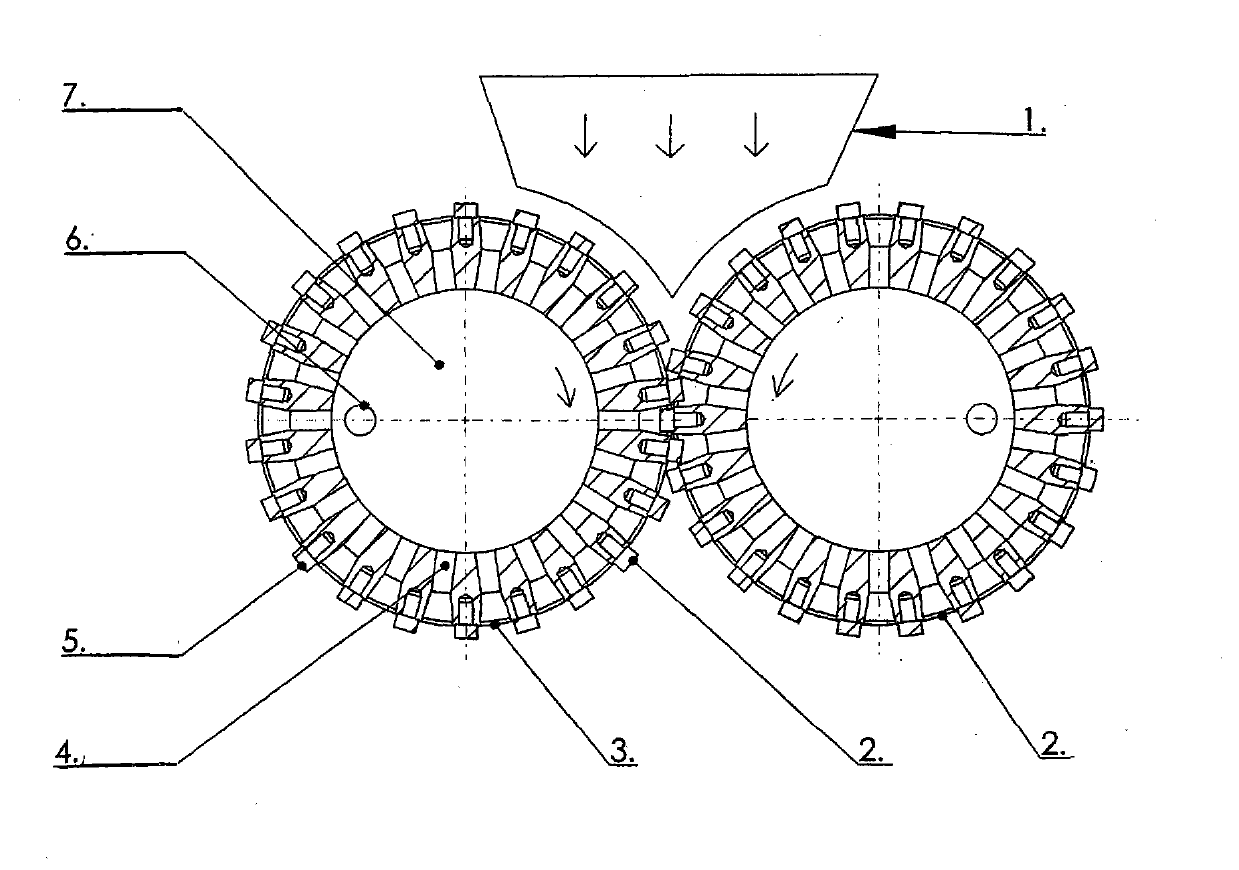

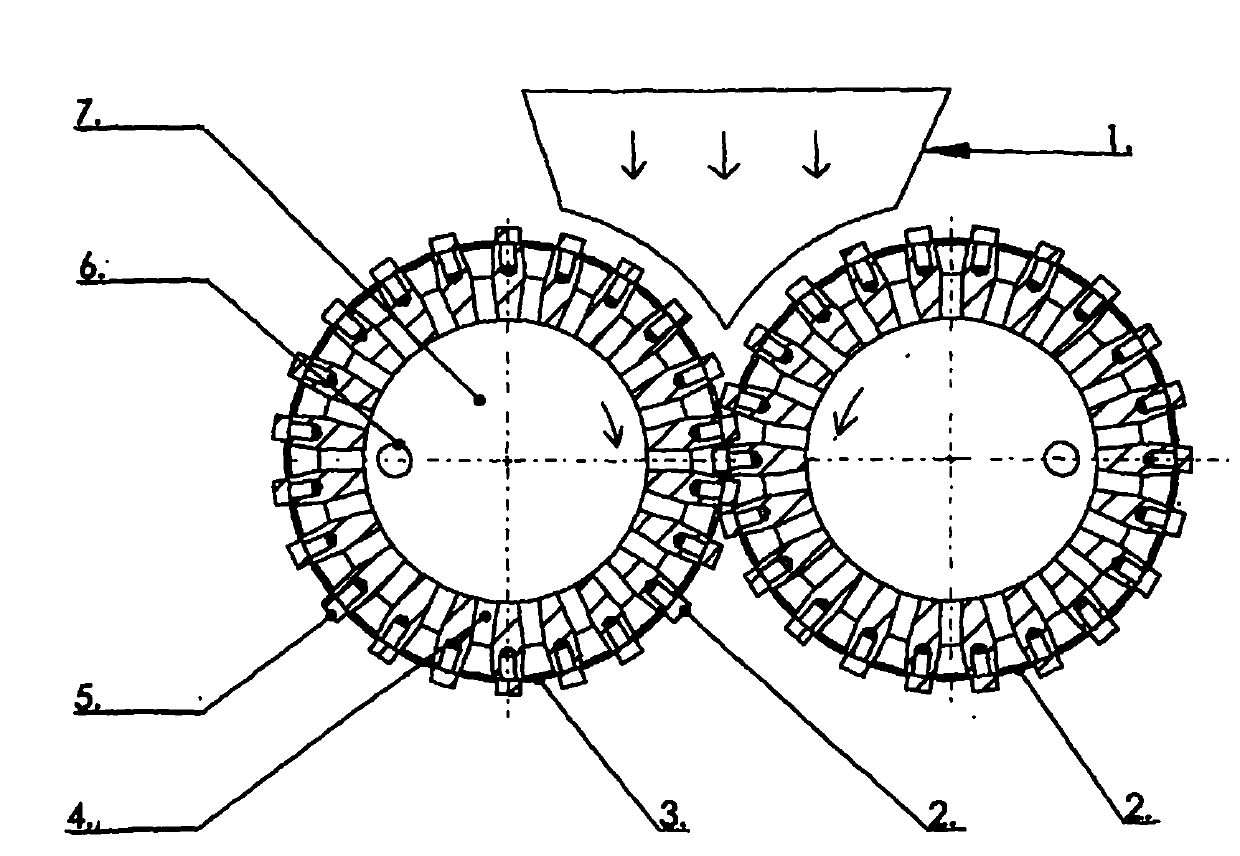

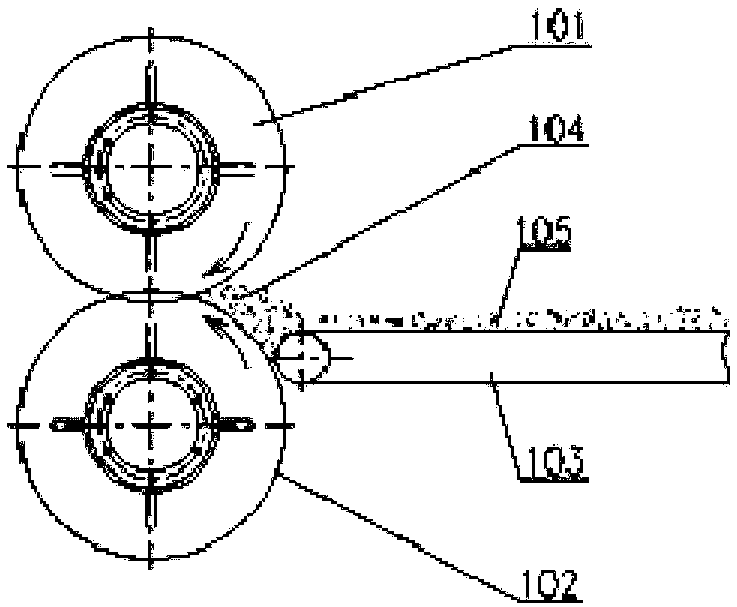

Lead disc granulator and design method thereof

ActiveCN101306471ASave energyReduce lossGranulation by pressingShaping pressEngineeringDesign methods

The invention belongs to a design method and a device for a machine carrying out granule cutting to soft metal in a cold state, in particular to a design method and a device relating to a lead cake granulator which squeezes a lead cake into granules via two squeezing rollers contra-rotating synchronously. A power mechanism is fixed on a machine frame (1) of the lead cake granulator adopted by the invention, and is in the transmission connection with a granule cutting mechanism via a transmission mechanism; the granule cutting mechanism is provided with the two squeezing rollers contra-rotating synchronously, and accidented and staggered dummy clubs and flutes are distributed on the arc surfaces of the squeezing rollers. The lead cake granulator can directly cut lead cakes into lead granules in the cold state, and the energy is saved, the lead material wastage is lowered, and the environmental pollution is reduced.

Owner:CECEP ENVIRONMENTAL PROTECTION EQUIP CO LTD

Biomass particle molding module and biomass particle molding machine

InactiveCN102248696AAchieve productionSimple structureGranulation by pressingShaping pressMolding machineEngineering

The invention provides a biomass particle molding module comprising a ring mold and a press roll, wherein particle molding holes are formed on the ring mold; ring mold engaging teeth are arranged on a pressing fit surface of the ring mold; press roll engaging teeth engaged with the ring mold engaging teeth are arranged on a pressing fit surface of the press roll; and the particle molding holes are positioned between the two adjacent ring mold engaging teeth. In the biomass particle molding module provided by the invention, the slipping phenomenon between the ring mold and the press roll in the material extruding process is avoided through the engaging fit between the ring mold engaging teeth and the press roll engaging teeth. The invention also provides a biomass particle molding machine on which the biomass particle molding module is arranged.

Owner:YIWU ANDONG ELECTRICAL APPLIANCES

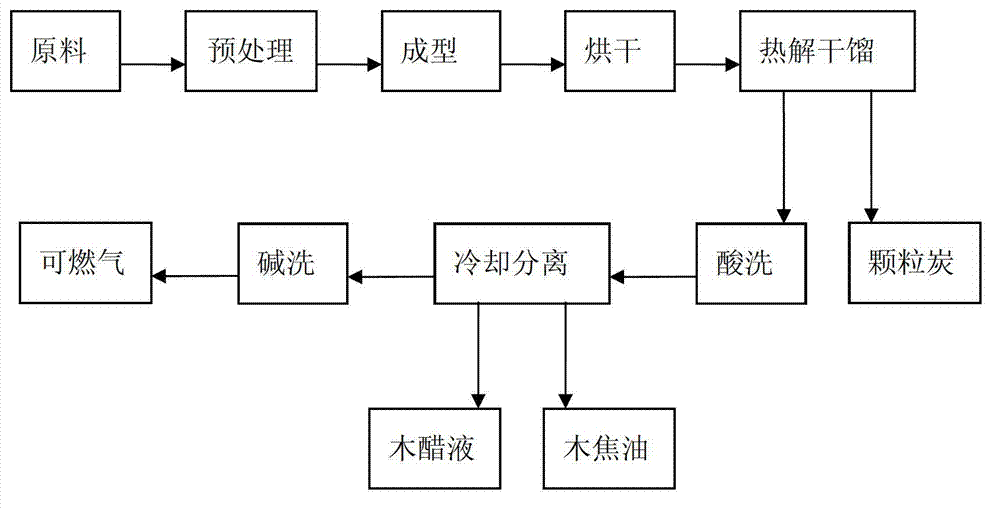

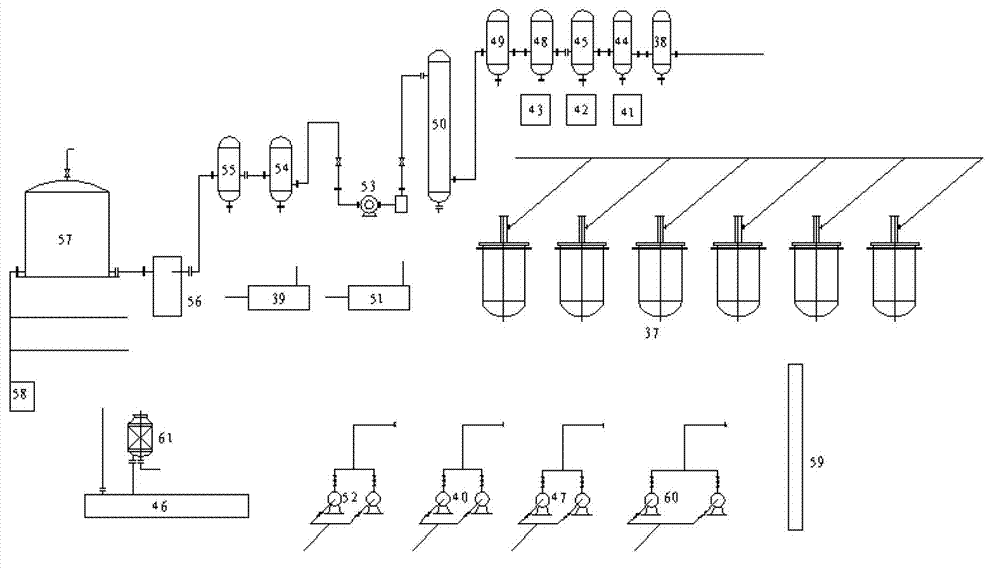

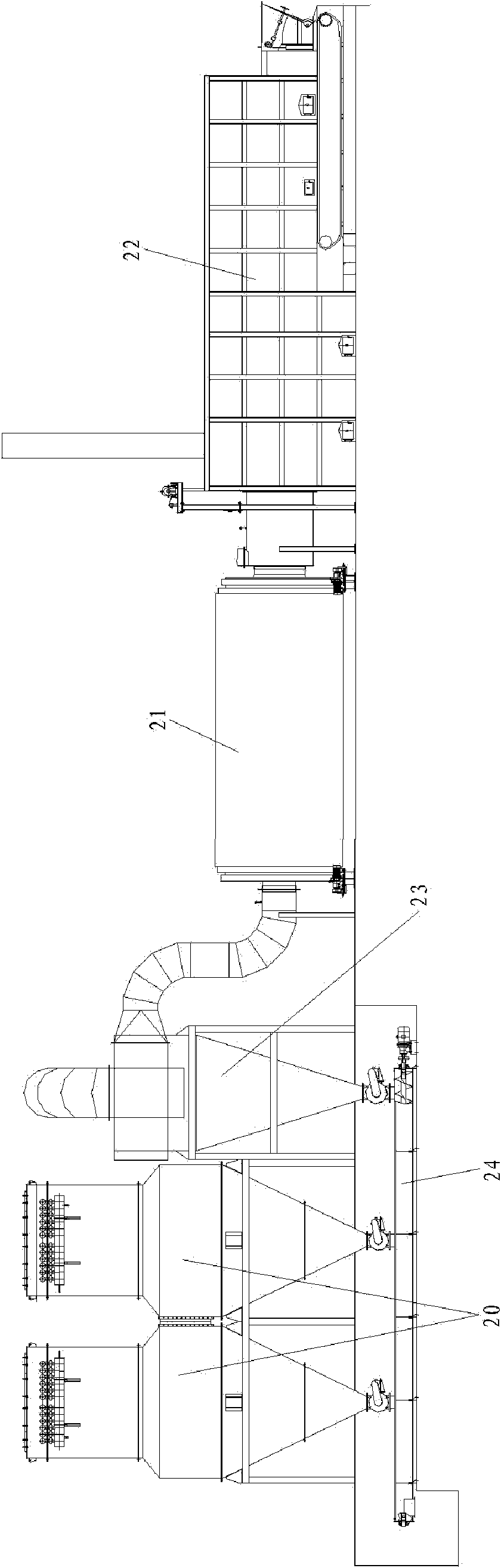

Process for industrially producing carbon, gas, oil and electricity through biomass energy forming and destructive distillation

ActiveCN102776009AReduce the chance of crackingExtended service lifeBiofuelsPyroligneous acid productionAcid washingMoisture

The invention discloses a process for industrially producing carbon, gas, oil and electricity through biomass energy forming and destructive distillation. The process comprises the following steps of: raw material pretreatment: crushing raw materials; forming: pressing the crushed raw materials into formed particles in a certain shape; drying: controlling the moisture content in the formed particles at 3%-5%; destructive distillation: thermo-chemically converting the dried formed particles into granular carbon, gas and liquid under the condition of air isolation or in the presence of little air; acid washing: performing acid washing on the gas produced through the destructive distillation; cooling and separation: cooling the acid-washed gas and performing gas-liquid separation on the gas and the condensed liquid, and then performing wood tar-pyroligneous separation on the cooled liquid; and alkali washing: performing alkali washing on the cooled gas. The process is capable of converting the biomass raw materials into high-grade good-quality fuels and industrial raw materials.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

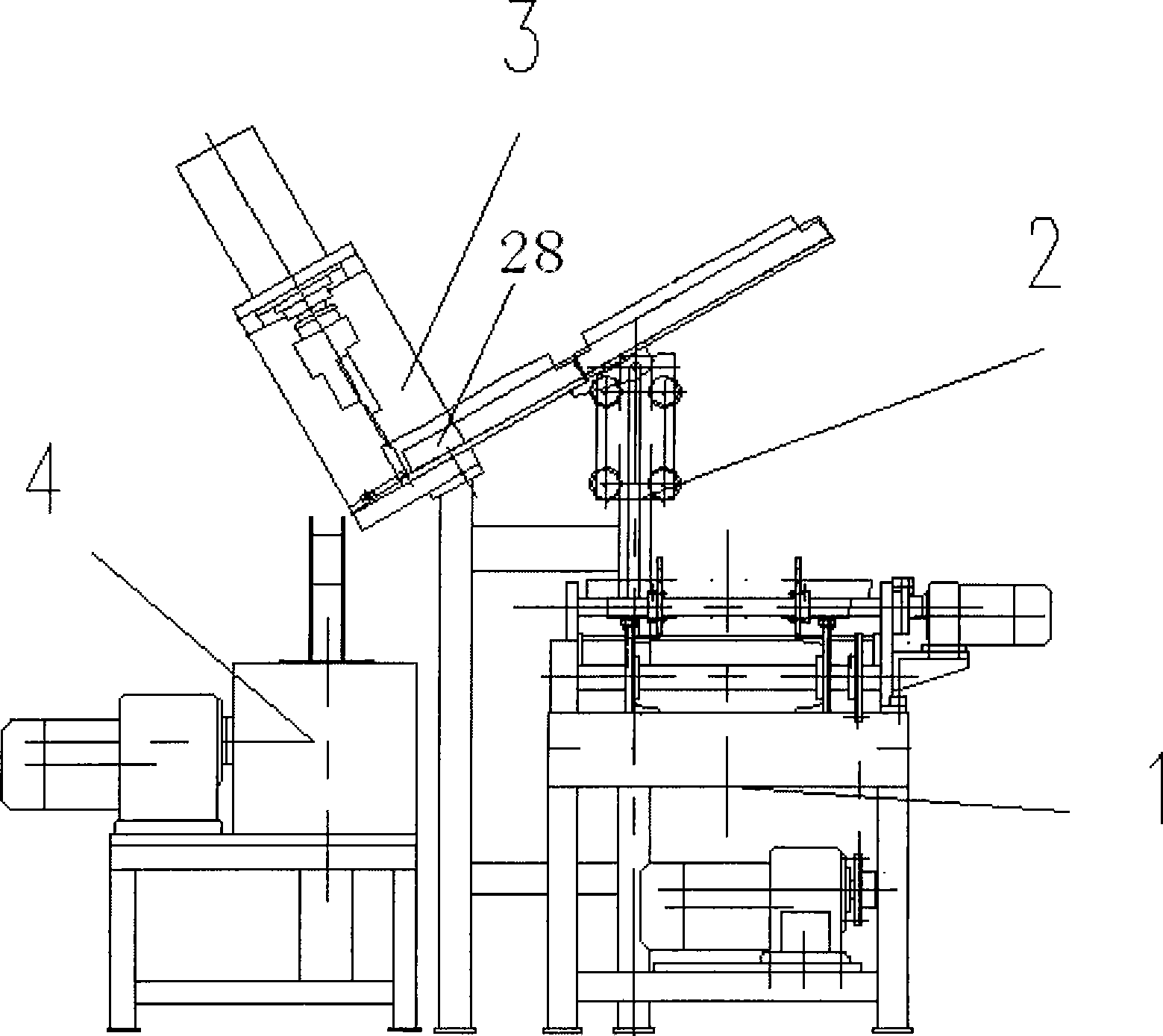

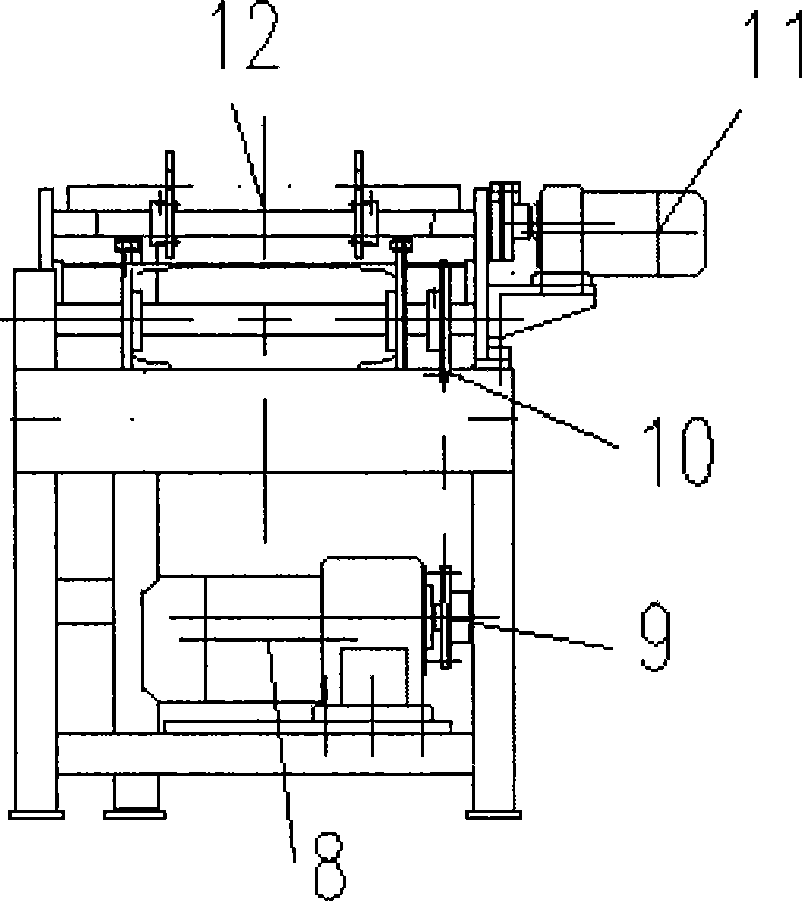

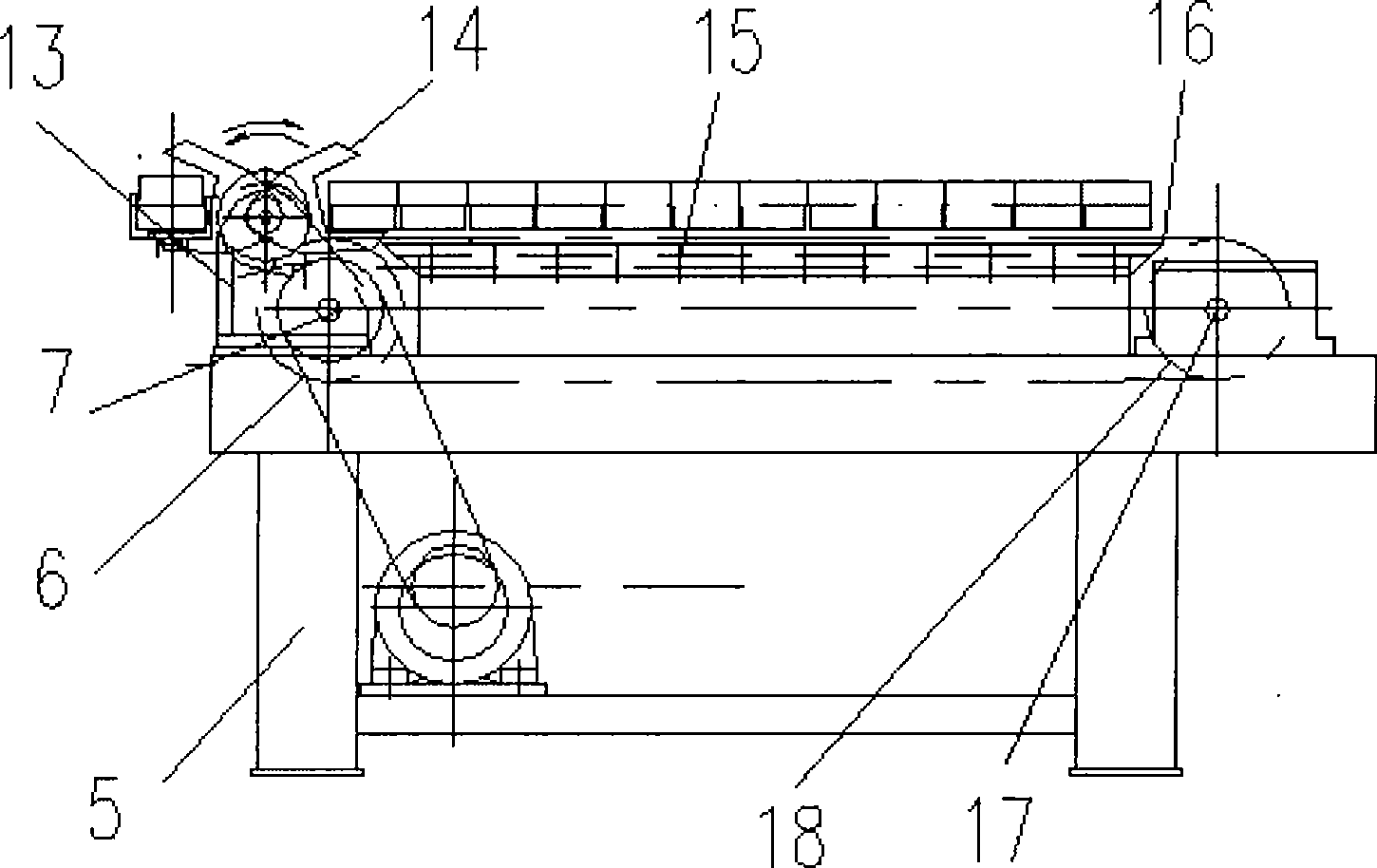

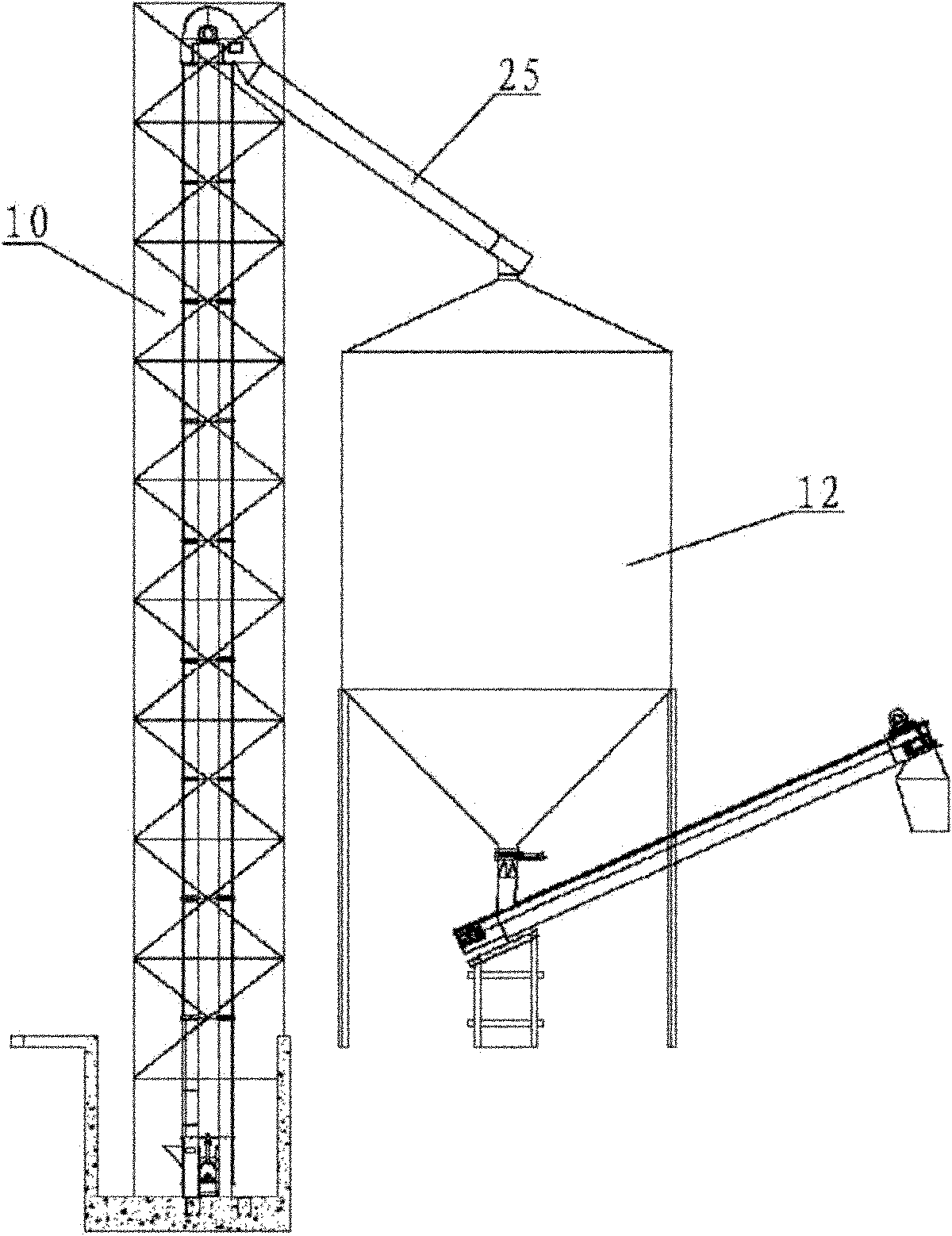

Lead bullion granulation automation line production process and apparatus

The invention belongs to a device through which a particle pipeline of soft metal is automatically divided in the cold state, in particular to a manufacturing method and device for lead ingot granulation automation line. The invention adopts the manufacturing method that lead ingot is transmitted to a lead ingot cake-cutting mechanism to cut lead ingot into cakes through a feeding mechanism, then the lead cakes are transmitted to a granulating machine to form particles, and the entire manufacturing process is automatically controlled. The invention relates to a manufacturing method and device for lead ingot granulation automation line, and an automatic lead ingot granulating manufacturing device mainly comprises a feeding mechanism, a lead ingot cake-cutting mechanism (3) and a granulating machine (4), wherein, a feed groove (22) of the feeding mechanism is butted with a lower anvil groove (28) of the lead ingot cake-cutting mechanism (3), and the lower anvil groove (28) of the lead ingot cake-cutting mechanism (3) is butted with a feed inlet of the granulating machine (4) so as to realize the full-automatic process that the lead ingot is transmitted into the lower anvil groove (28) of the lead ingot cake-cutting mechanism (3) through the feeding mechanism, the lead ingot is cut into lead cakes and transmitted into the feed inlet of the granulating machine (4) through the lead ingot cake-cutting mechanism (3), and the lead cakes are cut into granular lead through the granulating machine (4).

Owner:CECEP ENVIRONMENTAL PROTECTION EQUIP CO LTD

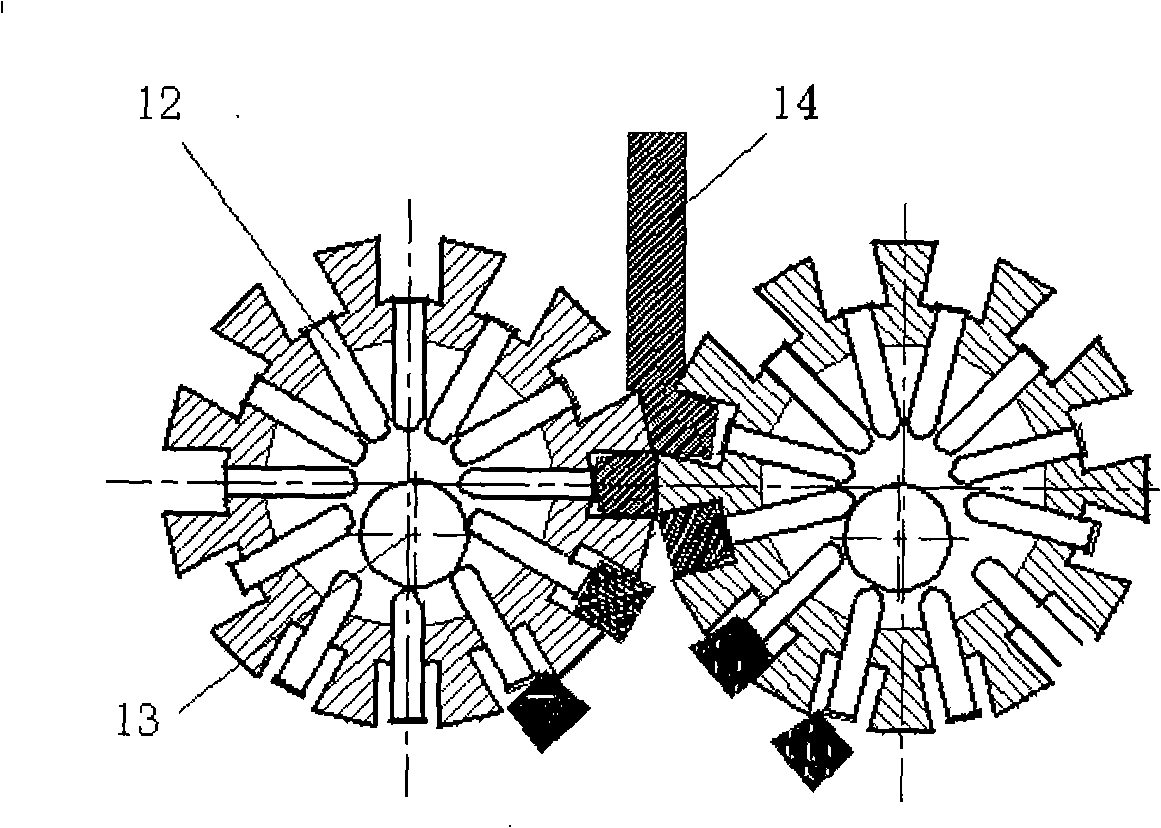

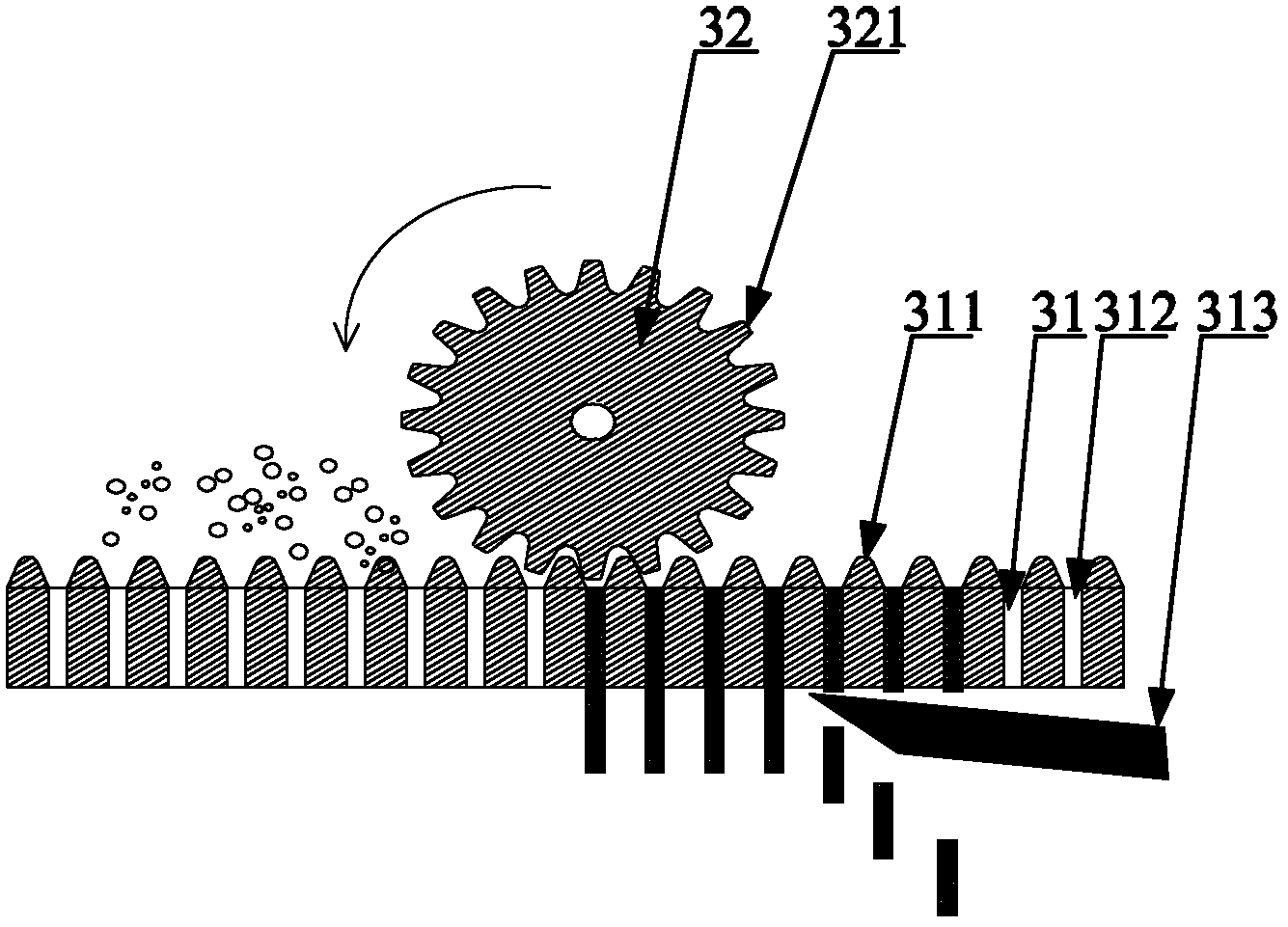

Gear type biomass fuel particle molding machine

InactiveCN102205217AIncrease productivityImprove work performanceGranulation by pressingShaping pressMolding machineMechanical engineering

The invention relates to a biomass curing molding device, which comprises gear type pair rollers, gears, bearings, cutting knives, a feed hopper, discharging hoppers and a housing; and is characterized in that tooth roots and tooth tips of the two gear type pair rollers intermesh and extrude materials for molding. The molding machine provided by the invention is mainly applied in the production of biomass molding particles and belongs to the biomass fuel particle molding machinery field.

Owner:谭定忠

Granulator

ActiveCN103055761ASmall working surfaceReduce wearGranulation by material expressionGranulation by pressingMechanical engineeringEngineering

The invention discloses a granulator comprising a base, a first motor, a second motor, a feeding device, a supply pipe, a feed pipe, a pressing device and a transmission device. The second motor conveys materials from the supply pipe to the feeding device, and then the materials enters the pressing device to be pressed through the feed pipe; power required by pressing is provided by the first motor and transmitted to the pressing device through the transmission device; the pressing device comprises a main shaft, a circular mould, a main shaft pressure plate connected with the main shaft, two press roller shafts which are arranged in parallel on the main shaft pressing plate, and four press rollers; each press roller shaft is provided with two press rollers, and a distance is left between the two press rollers on each press roller shaft; and six rows of mould holes are formed in the circular mould, every three adjacent rows of mould holes are in one group, and a distance is left between each two groups of mould holes and is equal to that between the two press rollers on each press roller shaft. The granulator is simple to operate, and has the advantages of high production efficiency, low energy consumption and long service life.

Owner:JIANGSU JINWU MACHINERY CO LTD

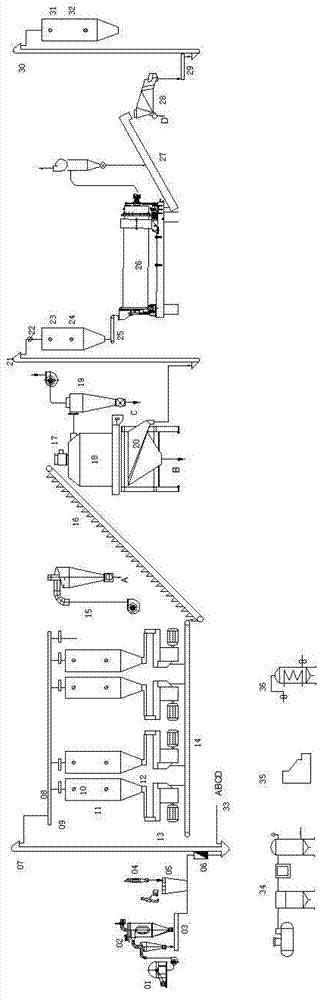

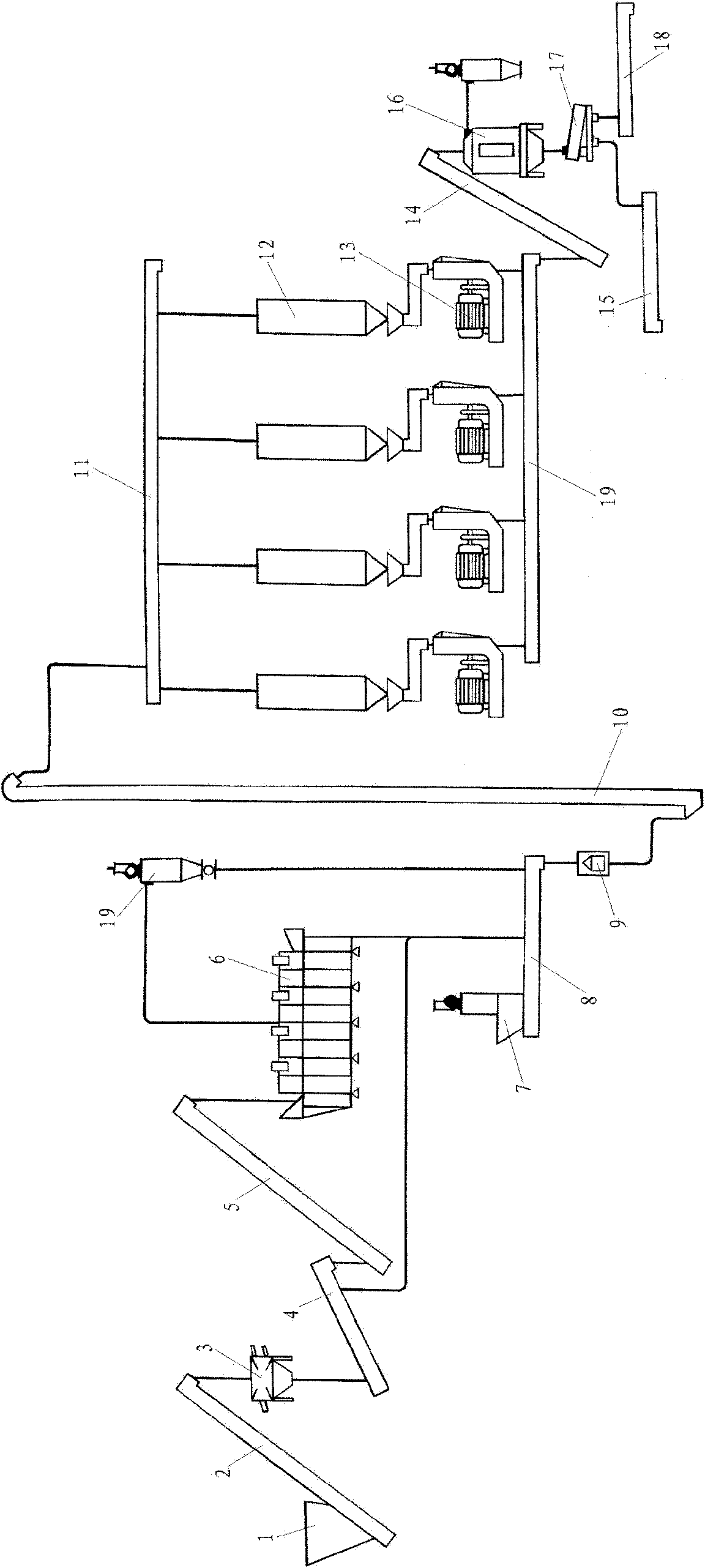

System for preparing biomass rod-shaped particles

The invention relates to a system for preparing biomass rod-shaped particles, which comprises a conveying device, a pre-cleaning screen, a drying system, a stock bin, a granulator, a cooling device and a vibration classifying screen, wherein the conveying device is used for conveying biomass materials or fuel; the pre-cleaning screen is used for screening and eliminating large biomass materials and impurities; the drying system is used for drying the biomass materials; the stock bin is used for storing the biomass materials and fuel or formed particles; the granulator is used for compressing the biomass materials into biomass particles; the cooling device is used for cooling the biomass particles; and the vibration classifying screen is used for screening the biomass formed particles according to the size. By using agriculture and forest wastes (such as stover, bagasse, rice chaff, bark, branches and sawdust) as the raw biomass materials and compressing the raw biomass materials into particles or rods by means of special forming equipment through crushing, extrusion, drying and other processes, the preparation system ensures that the particles or rods are about ten times higher in energy density as compared with the raw biomass materials not subjected to processing, facilitates the transportation and storage processes and achieves a high combustion efficiency.

Owner:SUZHOU DISEN BIOLOGICAL ENERGY

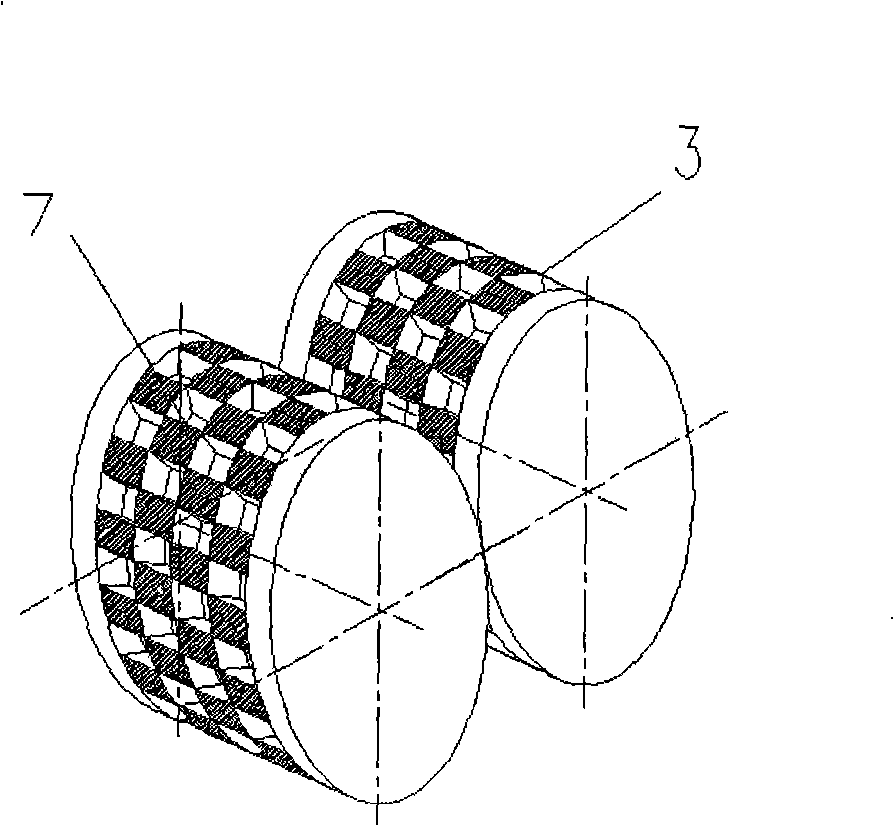

Internal air injection discharging double-roller granulator

ActiveCN103537226AWill not remainDoes not affect granulation efficiencyGranulation by pressingAir pumpEngineering

The invention discloses an internal air injection discharging double-roller granulator. A roller and a rotary shaft are hollow and are interconnected; one end of the hollow rotary shaft is connected with an air pump; a plurality of shaft air outlet holes are formed in one section, in the hollow roller, of the hollow rotary shaft; roller air outlet holes are formed in the bottom of a surface groove of the hollow roller; the roller air outlet holes are communicated with the hollow roller. Consequently, the airflow discharged by the air pump reaches the hollow roller through the hollow rotary shaft and is ejected out through the shaft outlet holes and the roller air outlet holes in turn, so that particles are separated from the groove in the surface of the roller and enter a collecting device; after granulating once by relatively squeezing the roller once, no particle remains on the surface, so that the next granulation efficiency or the next granulation quality is not affected.

Owner:WUHU 36 MACHINERY

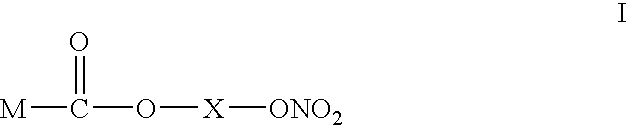

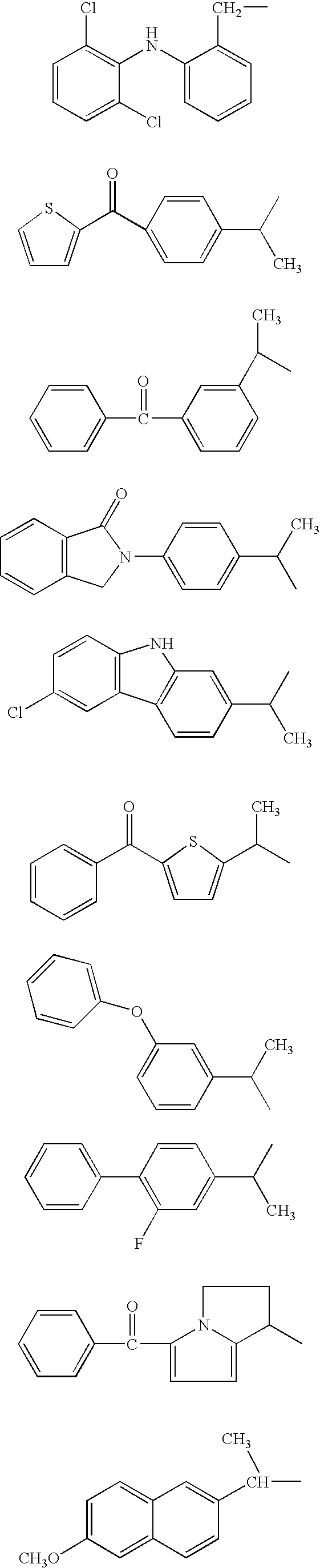

Non-donating nsaids adsorbed into carrier particles

The present invention relates to porous particles comprising one or more NO-donating Non Steroidal Antiinflammatory Compound(s) optionally mixed with one or more surfactant(s) and to new solid drug delivery composition comprising said particles optionally in combination with a second active drug. Futhermore, the invention relates to processes for producing said porous particles and solid drug delivery composition as well as the use of said composition in the manufacturing of a medicament. The No-donating NSAID may be in oily or melted form.

Owner:NICOX SA

Circular mold pelletizer

InactiveCN102784590AReduce bouncingExtended service lifeGranulation by pressingDrive wheelEngineering

The invention relates to a circular mold pelletizer and especially relates to a circular mold pelletizer for biomass pelletizing. The circular mold pelletizer comprises a main machine (1), a circular mold (4), a driving wheel (6), a main shaft (8), a main machine hollow shaft (9), a roller assembly (10), a main shaft pressing plate (13), slicers (28), a door cover (16), a gear shaft (26), forced feeders (17), feed inlets (21) and a discharge outlet (22). The circular mold pelletizer also comprises a division plate (14) and a door cover pressing plate (15), wherein the division plate (14) is connected to the main shaft pressing plate (13) at an end of the main shaft (8); the door cover pressing plate (15) is arranged at an inner side of the door cover (16); and the door cover pressing plate (15) and the division plate (14) are movably connected together. The circular mold pelletizer has the advantages that the circular mold pelletizer has a simple structure; a front end of the main shaft (8) is supported; the main shaft (8) moves up and down in a small range and has a long service life; raw material feeding is smooth; arch forming and material blocking are produced difficultly; adjustment of a roller-mold gap is convenient; and an overload protection capacity is strong.

Owner:LIYANG HUIDA MACHINERY

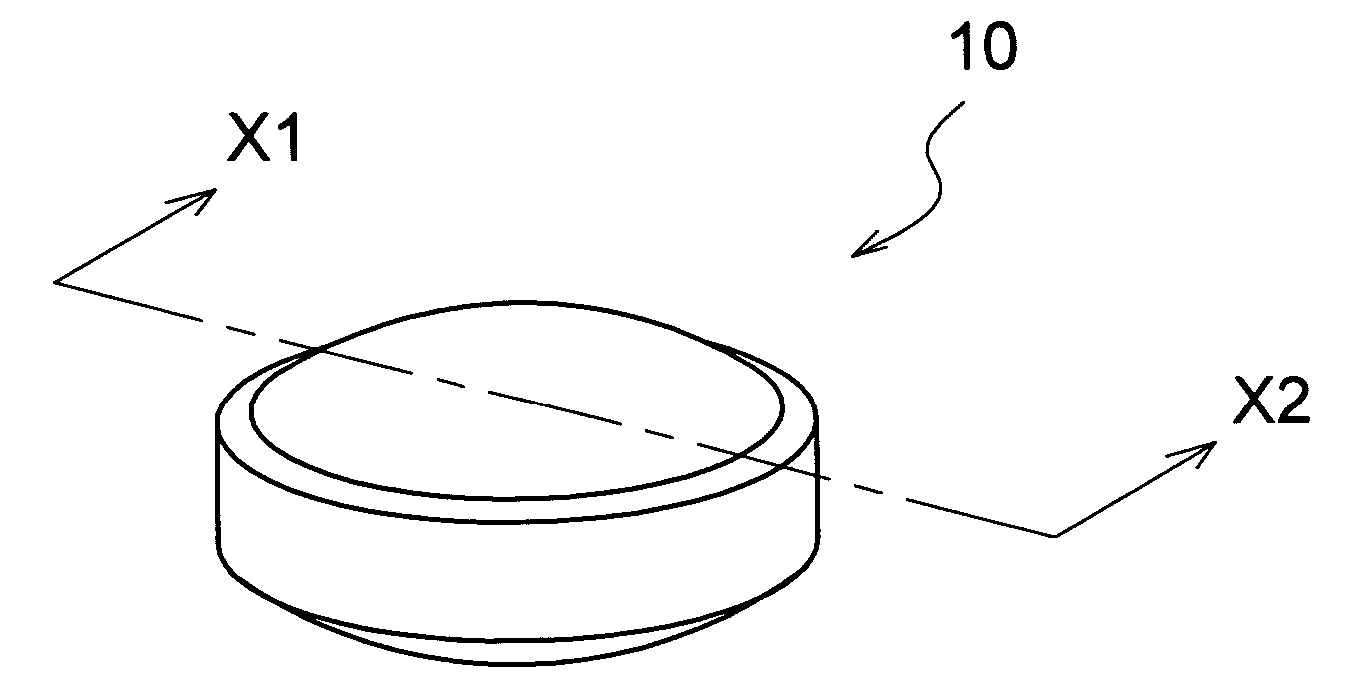

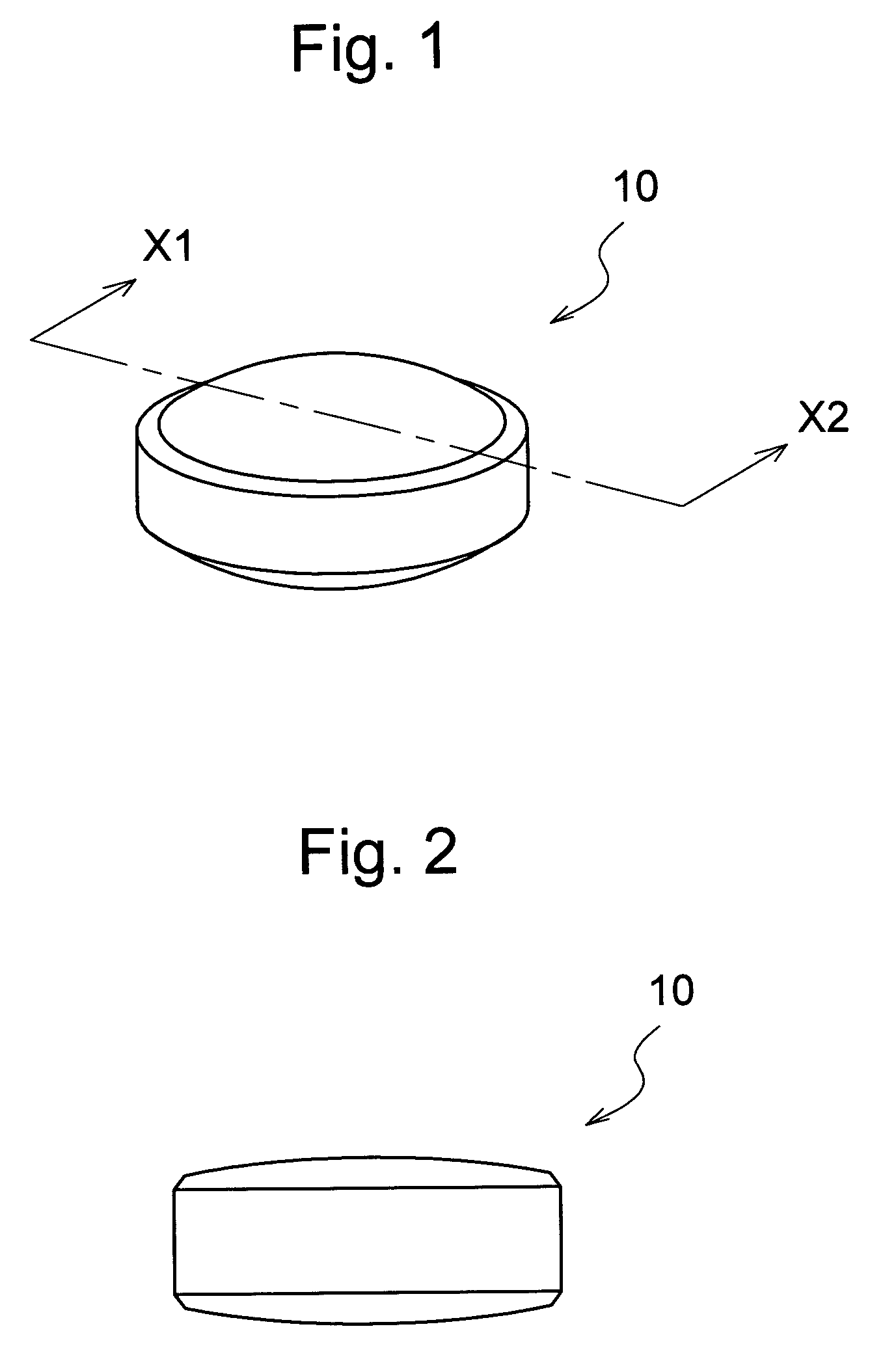

Animal litter and animal litter box using the same animal litter

InactiveUS20060027181A1Fast transferPrevent returnAnimal housingGranulation by pressingWide areaAdditive ingredient

A litter which has superior absorbency and deodorization capabilities, does not roll nor spread over a wide area easily, does not easily stick to the bottom of animals' feet, and is not easily carried out of the container when an animal enters or exits a container holding this litter is provided. By combining micronized resin or adhesive agent of which the main ingredient is silica sol to silica gel powder and compressing and molding, a litter which has superior absorbency and deodorization capabilities, does not roll nor spread over a wide area easily, does not easily stick to the bottom of animals' feet, and is not easily carried out of the container when an animal enters or exits a container holding this litter can be provided.

Owner:UNI CHARM CORP

Straw pelleting process

InactiveCN102764611ASimple granulation processHigh densityAnimal feeding stuffGranulation by pressingCompression moldingFiber

The invention belongs to the field of processing and application of straw and particularly relates to a straw pelleting process. The process mainly comprises the steps of 1), performing coarse grinding and feeding the ground straw into an ensiling pool to perform ensiling fermentation treatment; 2), drying to obtain ground straw with the water content of 9-15%; 3), performing fine grinding to obtain straw fiber with the particle size of 40-50 meshes per square inch and placing the straw fiber into a storage bin for storage through an air-assisted dust removal system; 4), pelleting, conveying the straw fiber to a ring die pelleting machine and performing compression molding by using a ring die and a compression roller to obtain rodlike straw particles with the density of 1-1.2g / cm3; and 5), performing cooling molding, placing the compressed straw particles into a cooler and cooling the straw particles to the room temperature through air cooling to obtain formed particles with smooth surfaces. According to the process, the straw is used fully, the pelleting effect is good, and the formed straw particles are smooth in surface and free from obvious cracks, are clean energy, can be used as base materials for culture of fungi or supplementary feed of livestocks and are convenient to popularize and apply in a large scale.

Owner:ZIBO SENYUAN STRAW ENERGY DEV

Granulated paper pad for pets and manufacturing method thereof

The invention provides a granulated paper pad for pets. The granulated paper pad is cylindrical, has the diameter of 3-7mm, the length of 3-20mm, the specific gravity of 320-550g / l and the natural water content being smaller than 7.5% and comprises the main components as follows: at least 70% of paper fiber and 10-20% of talcum powder or light calcium carbonate or kaolin. The manufacturing method of the granulated paper pad for pets comprises the following steps of uniformly crushing, grinding and forming, drying, screening and packing. Though the granulated paper pad for pets and the manufacturing method thereof disclosed by the invention, waste is fully utilized, energy is greatly saved, consumption is largely reduced, no emission and pollution exist in the production process, the liquid absorption amount is maximum compared with pet pads made from any textures, no pollution exists after the granulated paper pad is used, the used granulated paper pad can be directly putted into a sewer for degradation and never blocks the sewer, the opportunity of bacterial reproduction is reduced, the home environment is protected, and the health of persons and pets is strengthened. The granulated paper pad for pets does not have harm to the persons and the pets, is easy to store and is also clean; therefore, the problem that garbage is piled up at home after pads for pets are used, and damage and trouble caused by the persons sprinkling deodorizer for covering the excrement smell of the pets are completely solved.

Owner:青岛正利纸业有限公司

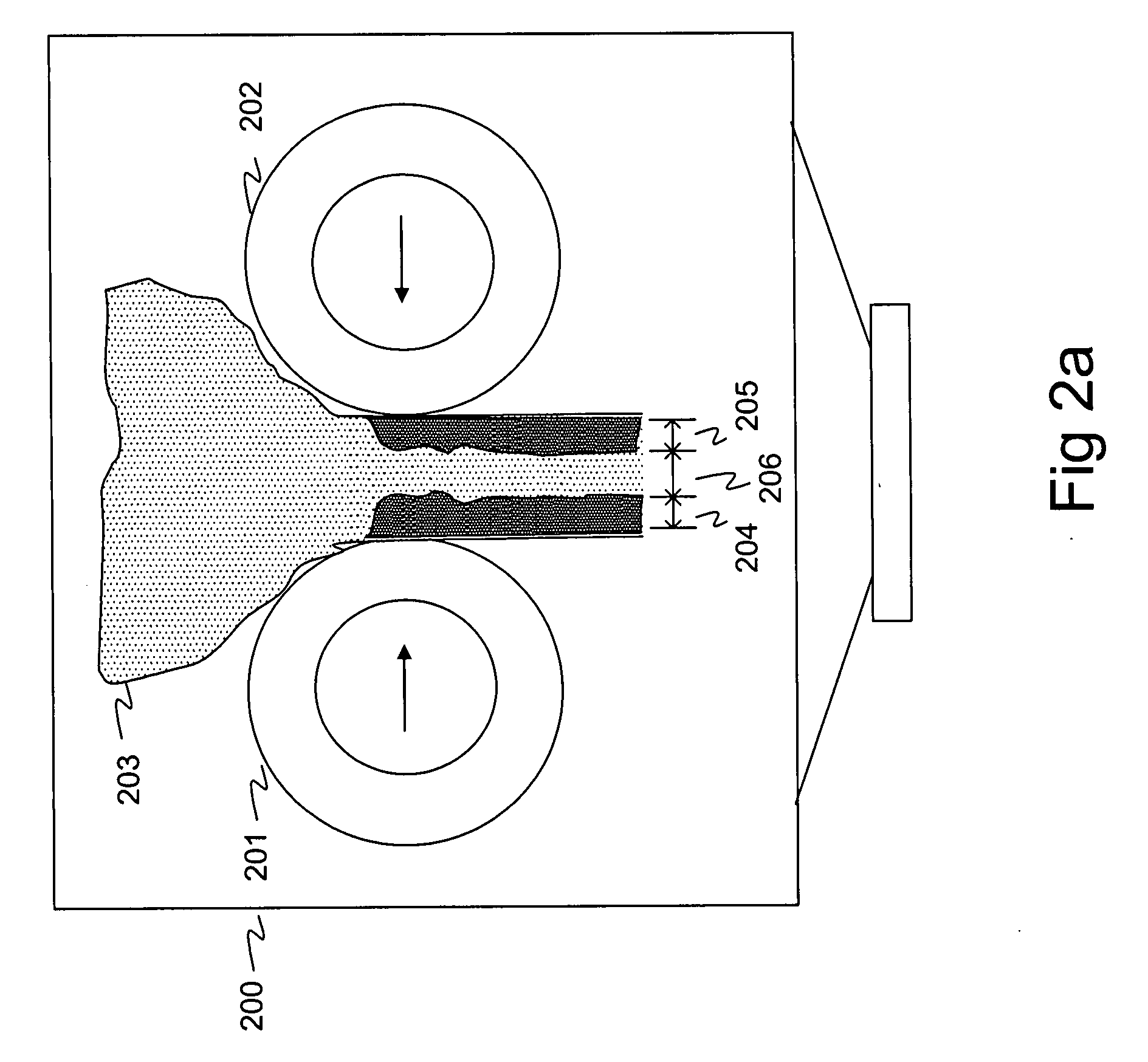

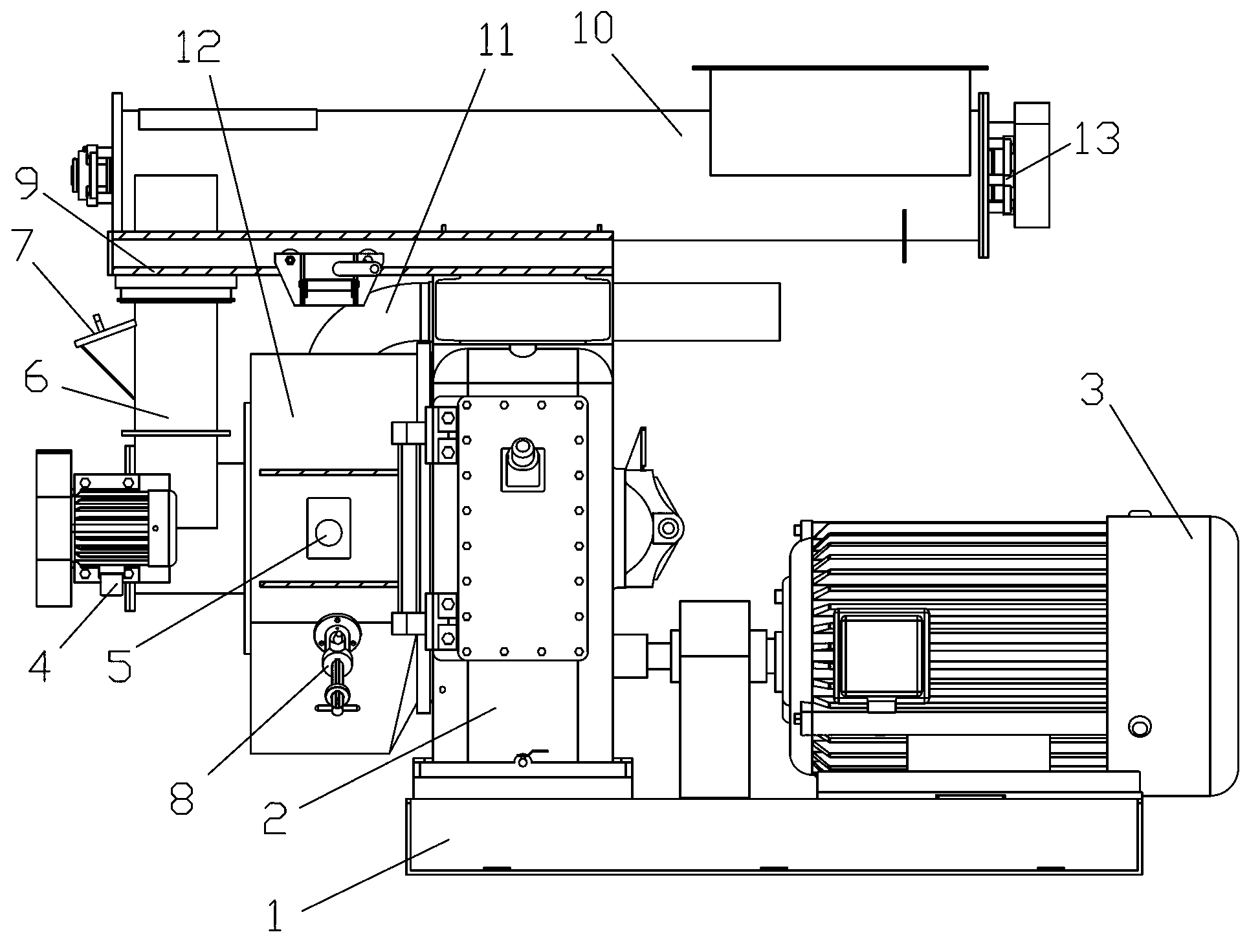

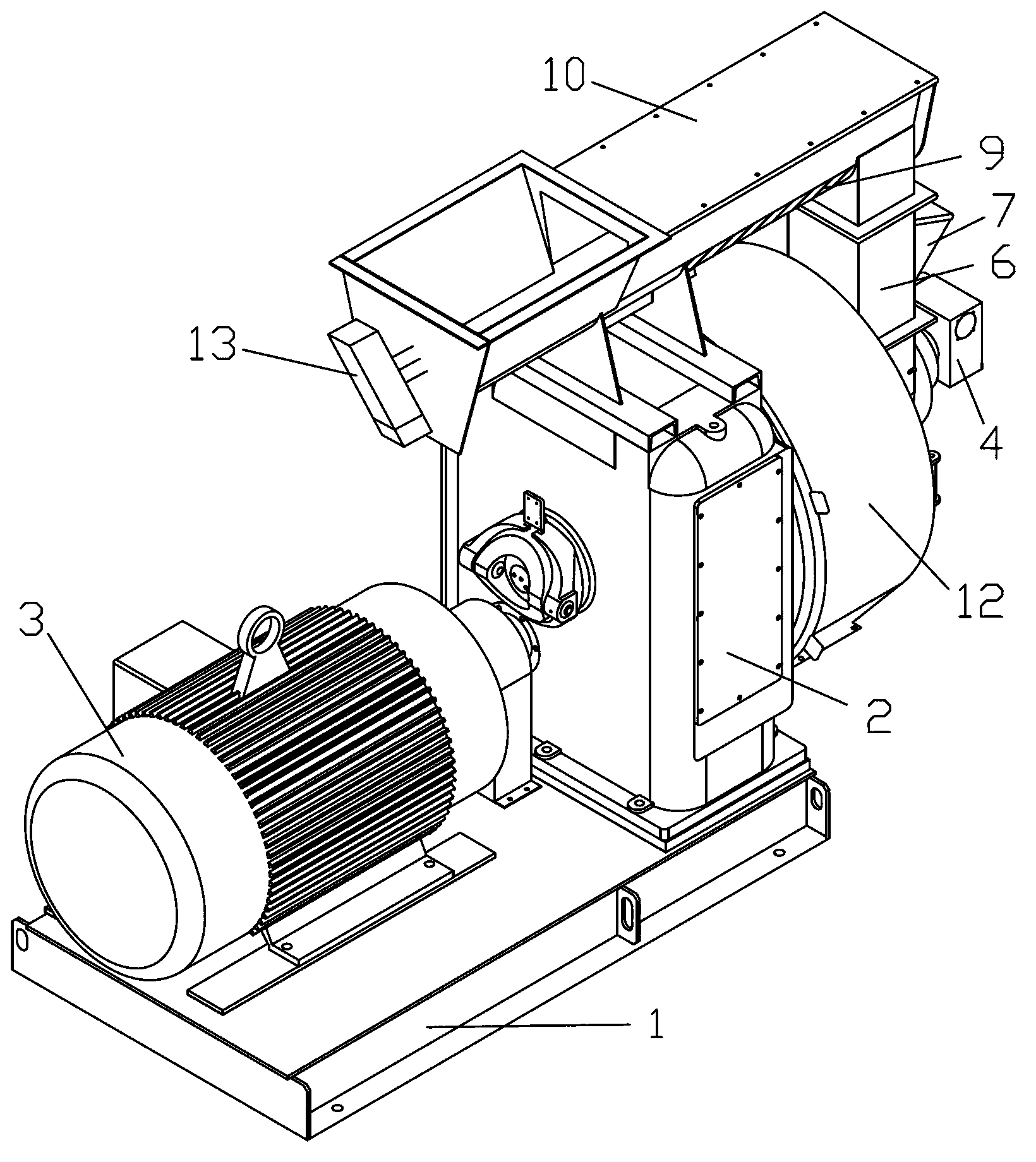

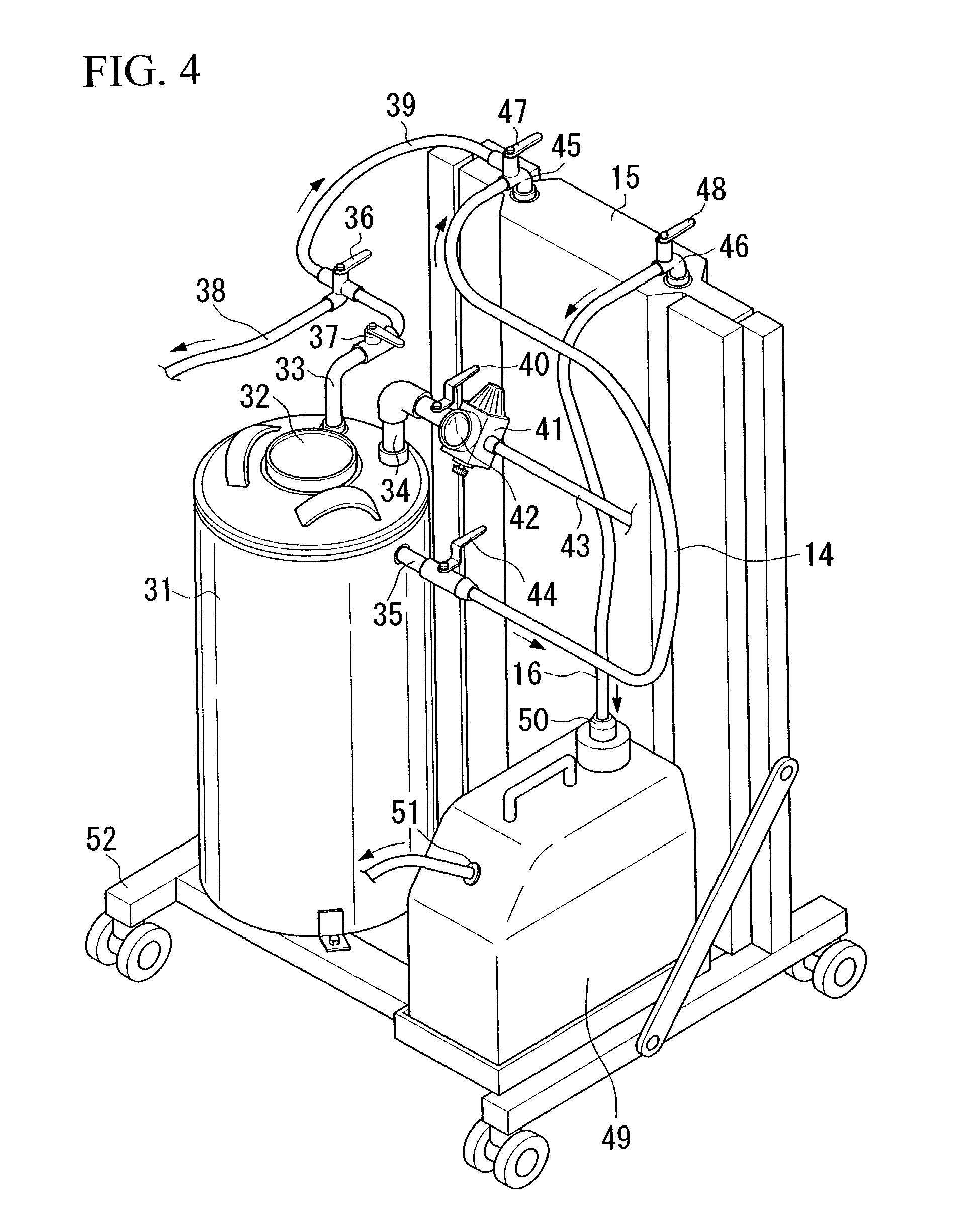

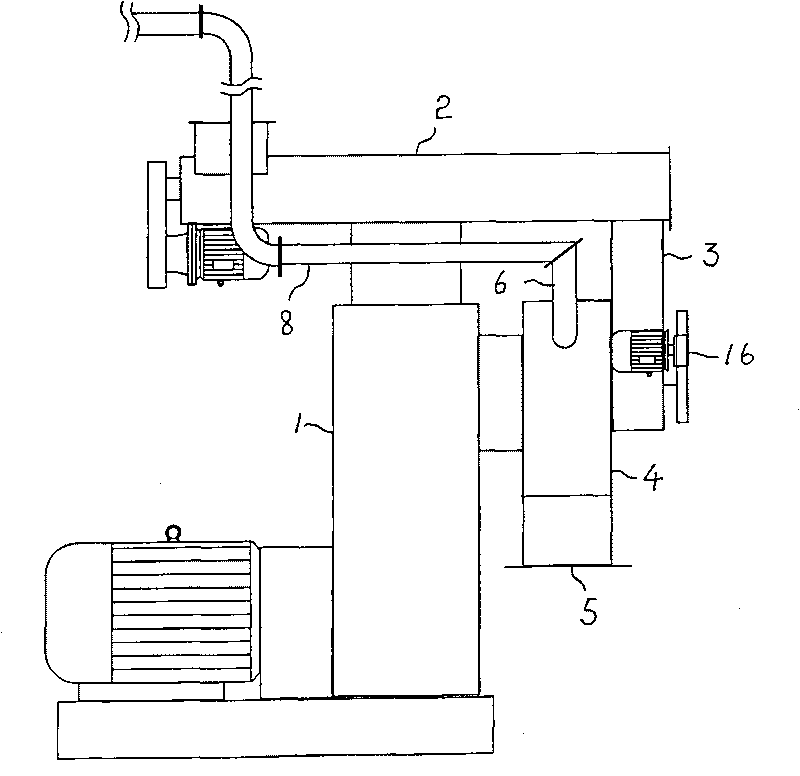

Double-roller type extruding and granulation device and granulation process flow thereof

ActiveCN101549269AImprove performanceReduce the overall heightGranulation by pressingPressure transmissionEngineering

The invention relates to a double-roller type extruding and granulation device and granulation process flow thereof. The device adopts the structure that a material level automatic constant pipe is inserted to the required depth in the hopper of a forced feeding machine and fixed, and the forced feeding machine is connected with a double-roller type extruding and granulator which is installed below the forced feeding machine. An intermediate bunker, a quantitative feeding device and a material level detecting device are not required. The device has the advantages that the property of unidirectional pressure transmission of solid powder is utilized, and the material level in the hopper of the forced feeding machine is ensured to be constant and always in optimum operating state through the material level automatic constant pipe in the position of a material inlet, therefore the stable performance of the double-roller type extruding and granulator is ensured. The problems that the traditional forced feeding machine detects the material level state by adopting a material level meter and realizes the constant material level in the hopper of the forced feeding machine by the complex way of adjusting the quantitative feeding device are avoided, the intermediate bunker, the quantitative feeding device, the level detecting device and the like required by the traditional way are omitted, the height of the factory building and the investment are greatly reduced, and the reliability is high.

Owner:南京三普造粒装备有限公司

Engineered Aerosol Particles, And Associated Methods

InactiveUS20120114554A1Extended stabilization timeMaterial nanotechnologySpraying apparatusNanoparticleNanometre

An engineered aerosol particle for use in aerosol applications is provided. The engineered aerosol particle comprises a fabricated nanoparticle body member being non-spherical. The fabricated nanoparticle body member is configured to provide at least one of auto-rotation, tumbling, or lift when entrained in an airstream to thereby increase settling time of the fabricated nanoparticle body member. An associated method is also provided.

Owner:LIQUIDIA TECH +1

External dry type granulator

ActiveCN103638874AIncreased production extrusion rateChange the defect on the exhaust problemGranulation by pressingEngineeringLubricant

The invention relates to an external dry type granulator. The granulator comprises a transmission case body, wherein a transmission mechanism is arranged in the transmission case body; a material feeding mechanism, which is vertically arranged along the transmission box body; and a pair of granulating rollers, which is horizontally arranged along the transmission case body, and also comprises a material pushing mechanism, wherein the material feeding mechanism, the granulating rollers, and the material pushing mechanism are all arranged on the exterior of the transmission case body, the material feeding mechanism is fixed on the transmission case body, and is above the material pushing mechanism, the material outlet of the material feeding mechanism is communicated with the material pushing mechanism, the material pushing mechanism is fixed on the outer wall surface of the transmission case body, the material outlet of the material pushing mechanism is arranged between the two granulating rollers, and the first output shaft in the transmission case body goes through the wall of the transmission case body and is connected to the granulating rollers. In the external dry type granulator, the transmission chamber is separated from the granulating chamber so as to avoid the material contamination caused by splashed lubricant.

Owner:CHANGZHOU WANJI DRYING ENG

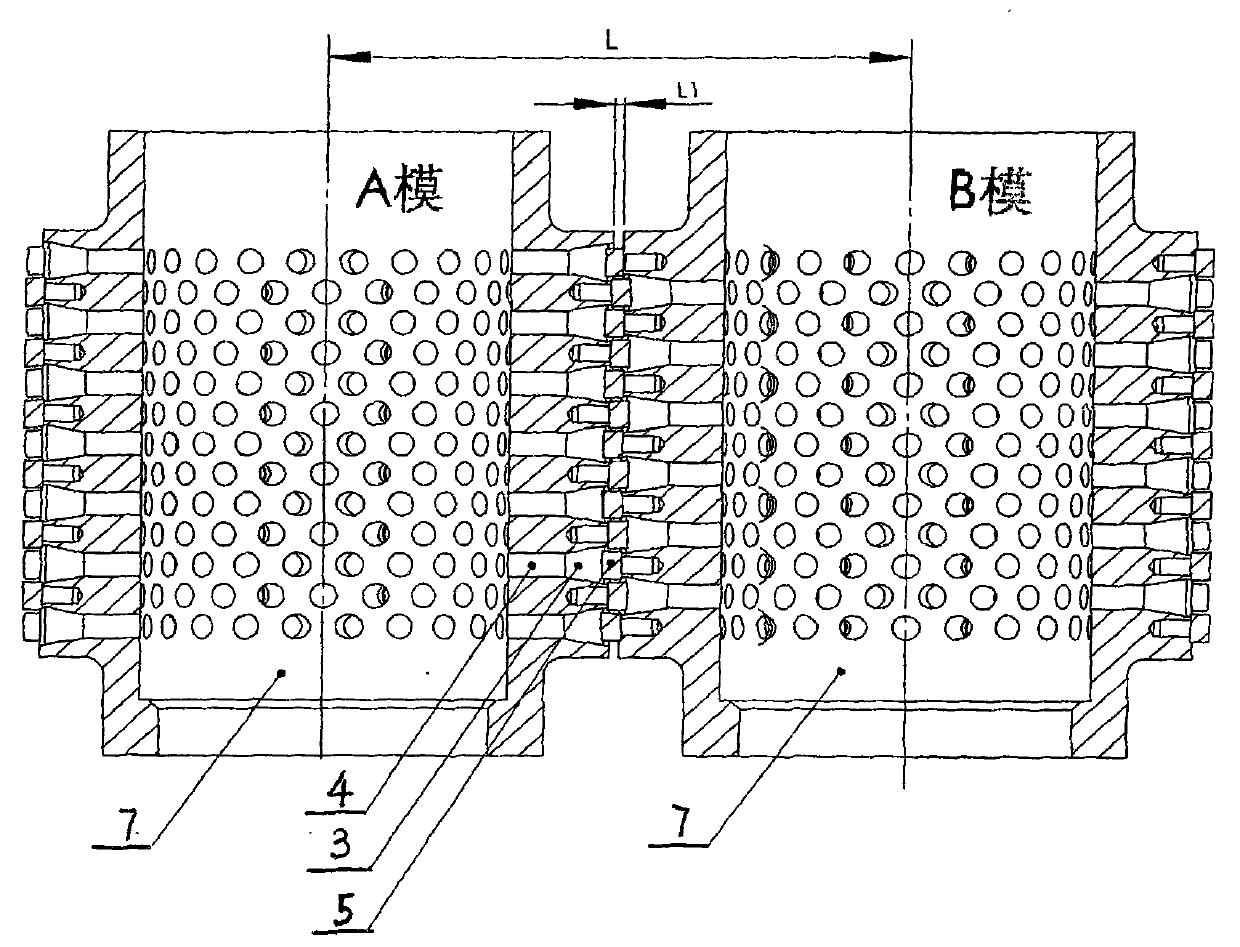

Pressing ball forming method and device

InactiveCN101125285ANot easy to produce dissectionNot prone to delaminationGranulation by pressingProcessing costSphericity

The present invention discloses a pressing ball molding method and device, comprising an upper die grid, a lower die grid, a global die cavity arranged between the upper die grid and the lower die grid, the characteristic technic proposal is that die cores are respectively arranged in the upper die grid and the lower die grid, the die core is movable arranged in the die grid, the global die cavity mainly consists of the upper die grid, the lower die grid and the die cores arranged in the die grids which are encircled, the connecting positions of the die cores and the die grid are provided with air-escape passages, compressing the powders which are sent into the die grid, by the vertical movement of the die grid corresponding to the die core, eliminating the air in the powders step by step, and pressing into a sphericity. The present invention has the advantages of high work efficiency, good presentation quality and low processing cost, has good value of market popularization.

Owner:房建春

Double-effect biomass fuel forming granulator

The invention discloses a double-effect biomass fuel forming granulator. The double-effect biomass fuel forming granulator includes a machine body, air cylinders, punching cylinders, fuel molding templates, puncher pins, a lifting platform, a double-shaft synchronous motor, transmissions and disc cutters; the middle of the upper end of the machine body is provided with a fixed block, the two sides of the fixed block are each fixedly provided with one air cylinder, the head end of a piston rod of each air cylinder is fixedly connected with one puncher pin, each puncher pin is connected with an inner cavity of the punching cylinder respectively, the output ends of the punching cylinder are fixedly connected with fuel molding templates, the lifting platform is arranged in the machine body and is provided with a motor fixing seat, the double-shaft synchronous motor is installed on the moto -fixing seat, two output shafts of the double-shaft synchronous motor are each connected with one transmission, and an output shaft of each transmission is connected with one disc cutter. The double-effect biomass fuel forming granulator is of a compact structure, greatly improves the production efficiency of forming biomass fuel particles and reduces the energy consumption of cutting.

Owner:海盐县吉能生物质燃料科技有限公司

Granular photocatalytic material, functional restoration method therefor, and apparatus for decomposing and removing toxic organic matter using the same

InactiveUS20030104930A1Increased durabilityIncrease surface areaPerfluorocarbons/hydrofluorocarbons captureGlass/slag layered productsPhoto irradiationPhysical chemistry

A granular photocatalytic material in the form of pellets or tablet is produced by compressing a photocatalyst mixture containing photocatalytic particles and a filler in air, a vacuum, or an inert gas at a temperature of 0 to 200.degree. C., a pressure of 500 to 6000 kg / cm.sup.2, and a pressing time of 0.01 to 60 seconds. An alkali slurry is applied on the surface of the granular photocatalytic material. A method of restoring a function of granular photocatalytic material comprises washing the surface of the granular photocatalytic material with the slurry or an alkali solution of sodium hydroxide An apparatus for decomposing and removing toxic organic matter comprises a means of bringing the granular photocatalytic material into contact with the toxic organic matter in a liquid or air, and a means of irradiating the granular photocatalytic material with light having a wavelength of 400 nm or less.

Owner:YAMAHA CORP

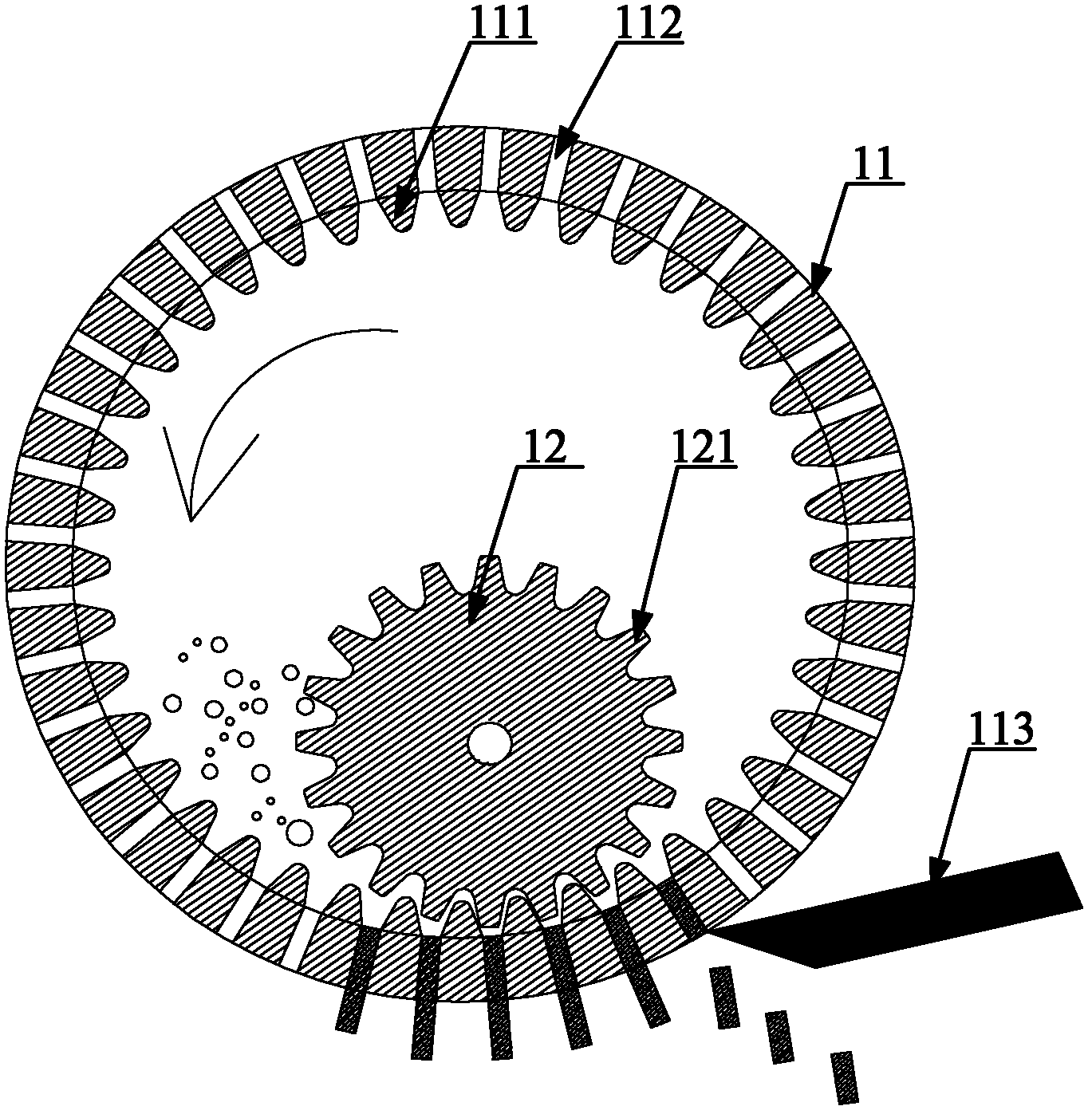

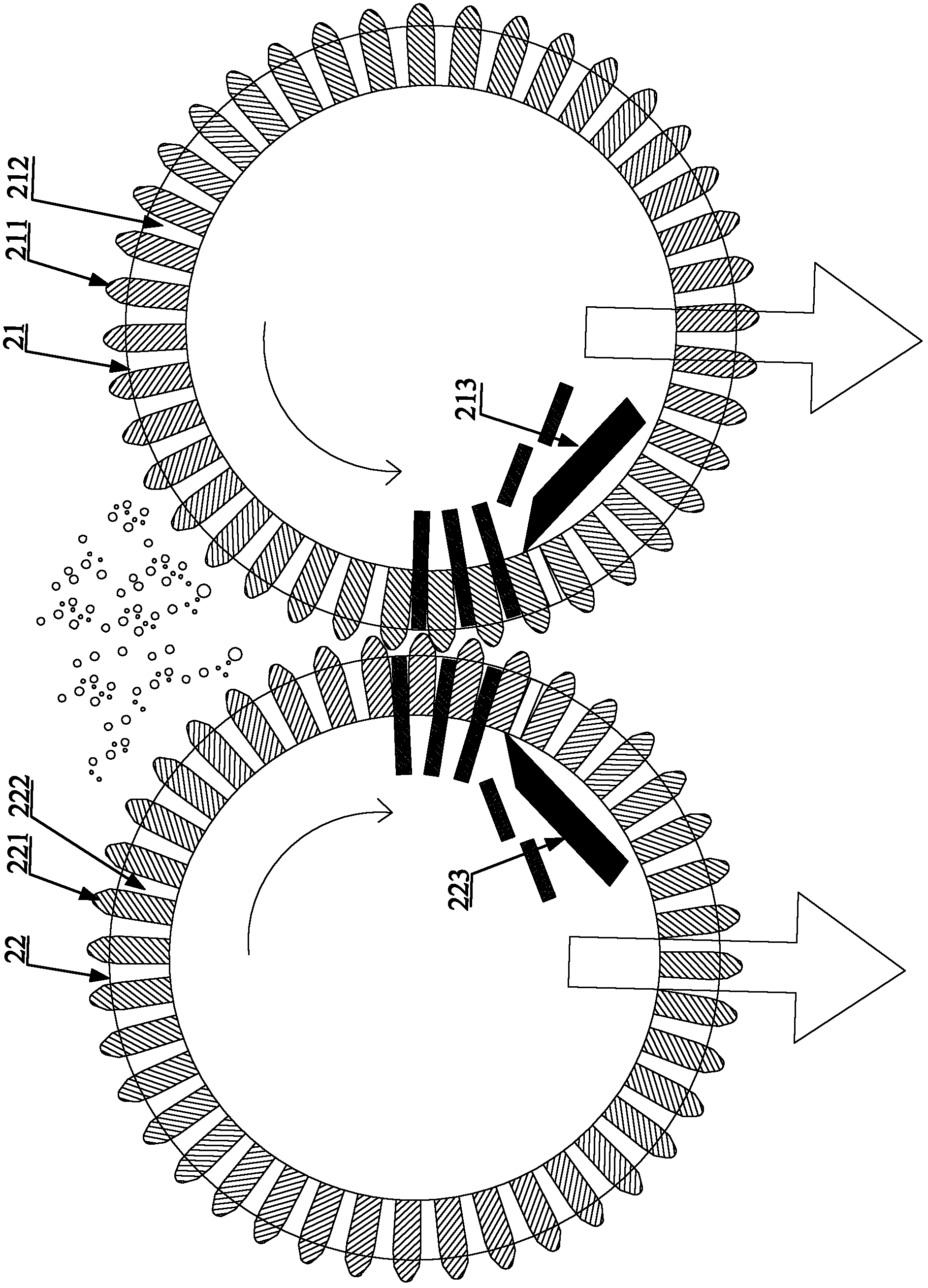

Biomass straw granulator

InactiveCN101947419AIncrease the forced mutual extrusion functionLow pellet priceGranulation by pressingShaping pressEngineeringMechanical engineering

The invention discloses a biomass straw granulator. The biomass straw granulator consists of rolling moulds; each rolling mould is uniformly provided with material extruding heads and shaped orifices; the material extruding heads are staggered with the shaped orifices; compression holes are formed on the heads of the shaped orifices; a discharging cavity is formed in the middle of the rolling mould; a cutter is arranged in the discharging cavity; and an extrusion head of a roller extends to the shaped orifice of the other roller, and an extrusion head of the other roller extends to the shaped orifice of the roller. The biomass straw granulator has the advantages of energy conservation, consumption reduction and improvement on work efficiency.

Owner:TIANJIN TESIDA BIOMASS ENERGY MACHINERY

Air-cooled dedusting system of biomass granulator

InactiveCN101700482AExtended service lifeIncrease productionDirt cleaningGranulation by pressingEngineeringProduct gas

An air-cooled dedusting system of a biomass granulator is used for forming air convection environment in a granulation room (4). The air-cooled dedusting system of the biomass granulator comprises the granulation room (4), of which the lower end is provided with a discharging opening (5); the air-cooled dedusting system of the biomass granulator is characterized in that the granulation room (4) is provided with at least one air opening, the air opening and / or the discharging opening (5) are connected to a blasting device or a drafting device. The inventive air-cooled dedusting system of the biomass granulator utilizes wind-force to produce air flow in the granulation room, can effectively temperature in the granulation room by the air-cooled form, realize cold pressing forming, and simultaneously dedust the fly ash and powder bits produced in the granulation process and recycle the discharged powder, thus saving cost, greatly enhancing service life of the granulator and yield of granulation, which is a significant renovation in the field of granulation.

Owner:溧阳市华生机械厂

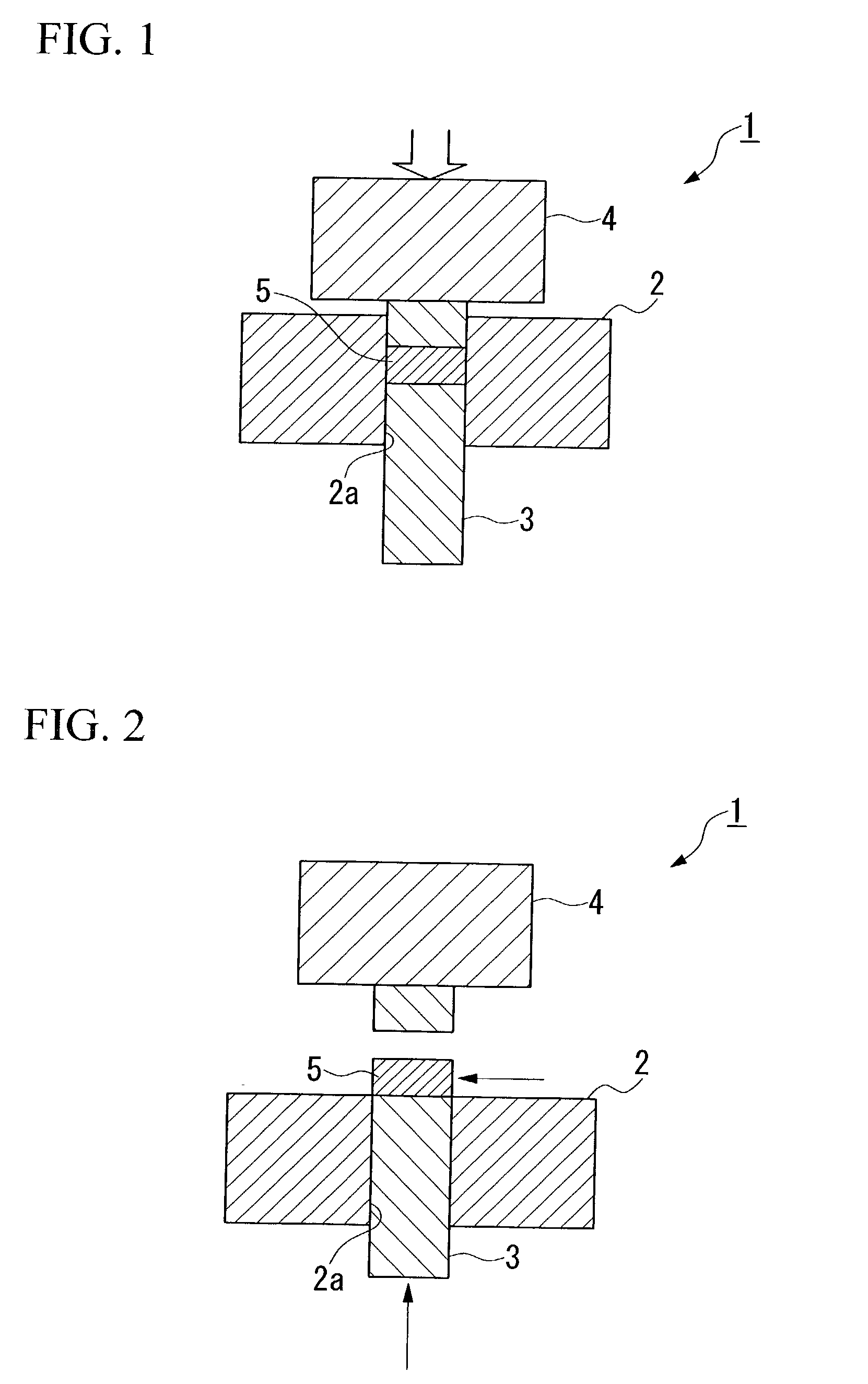

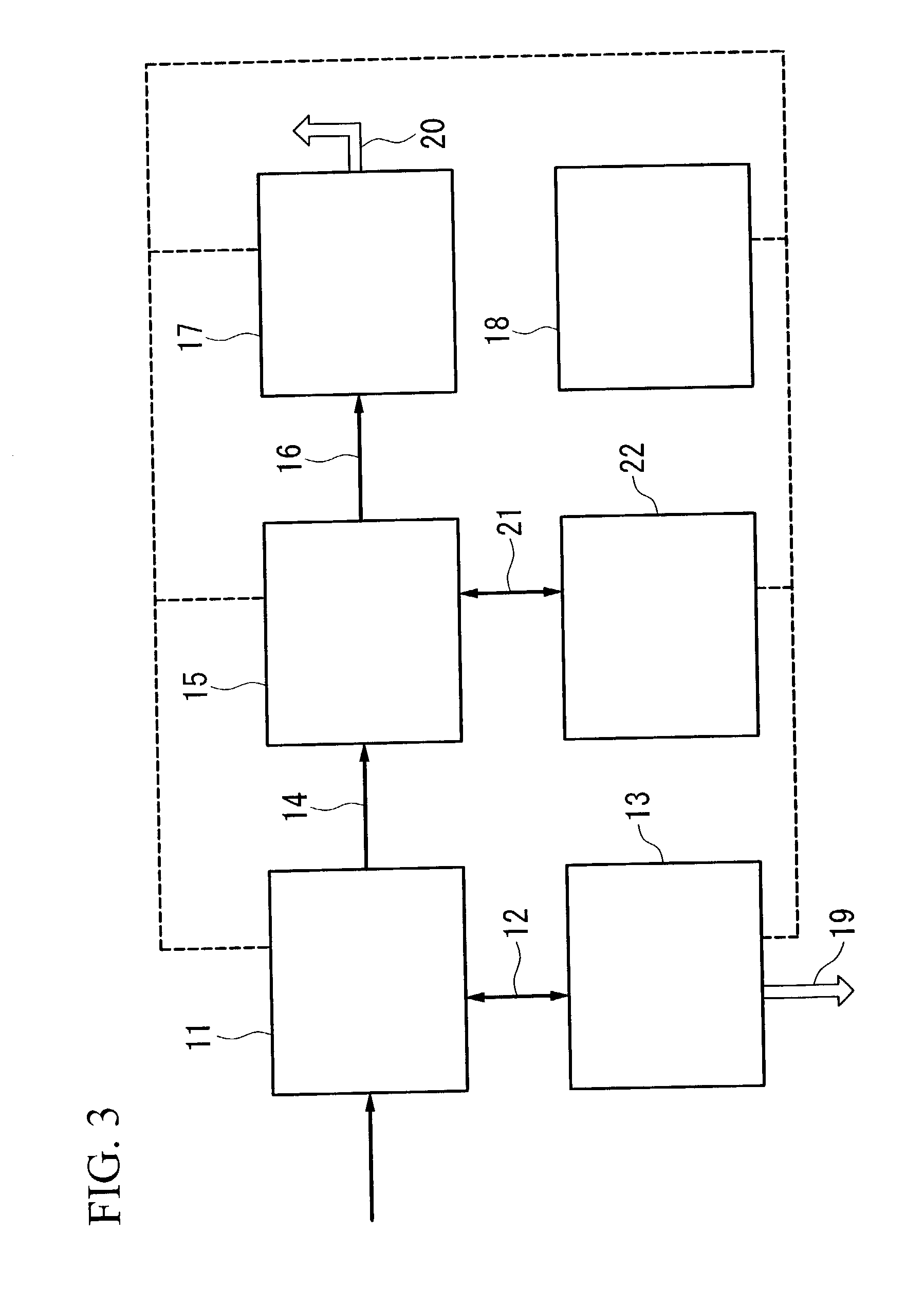

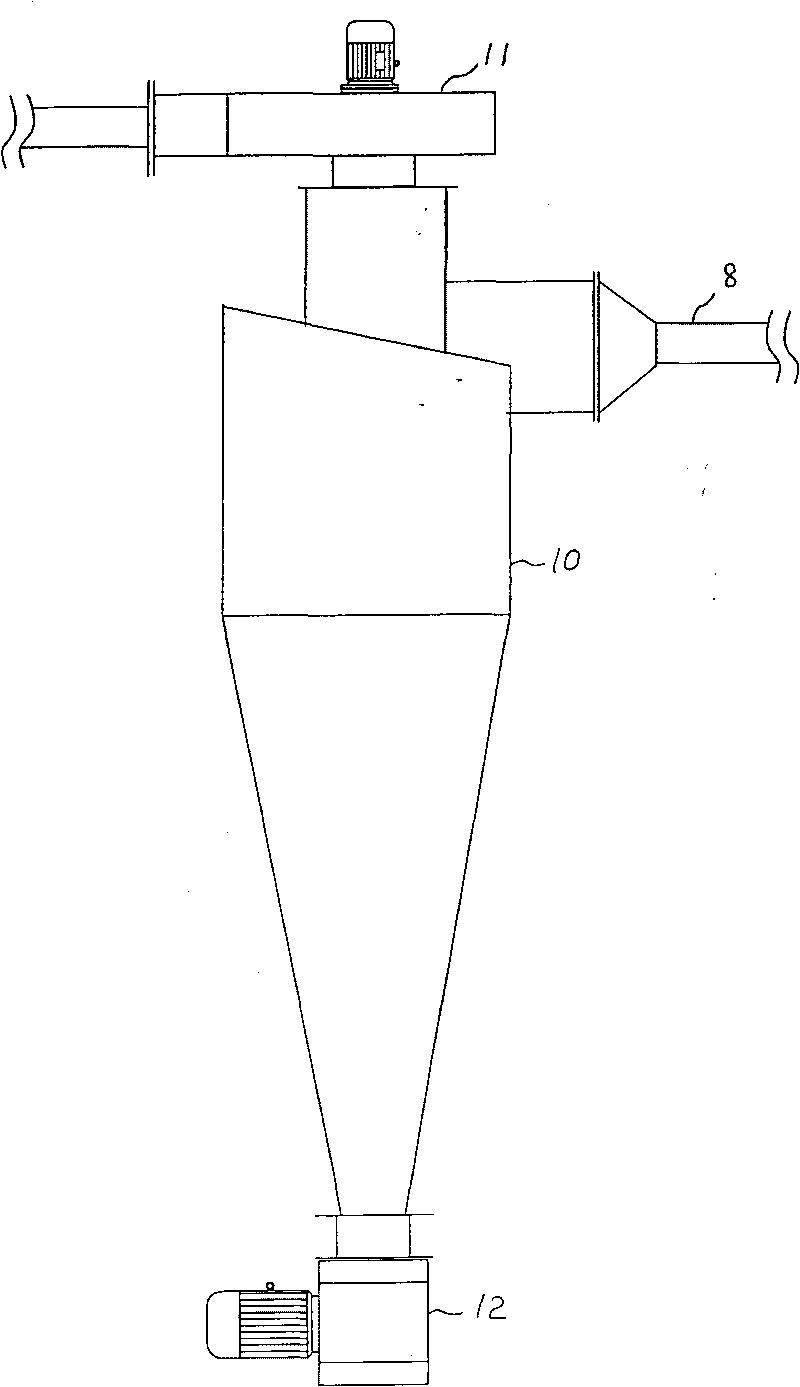

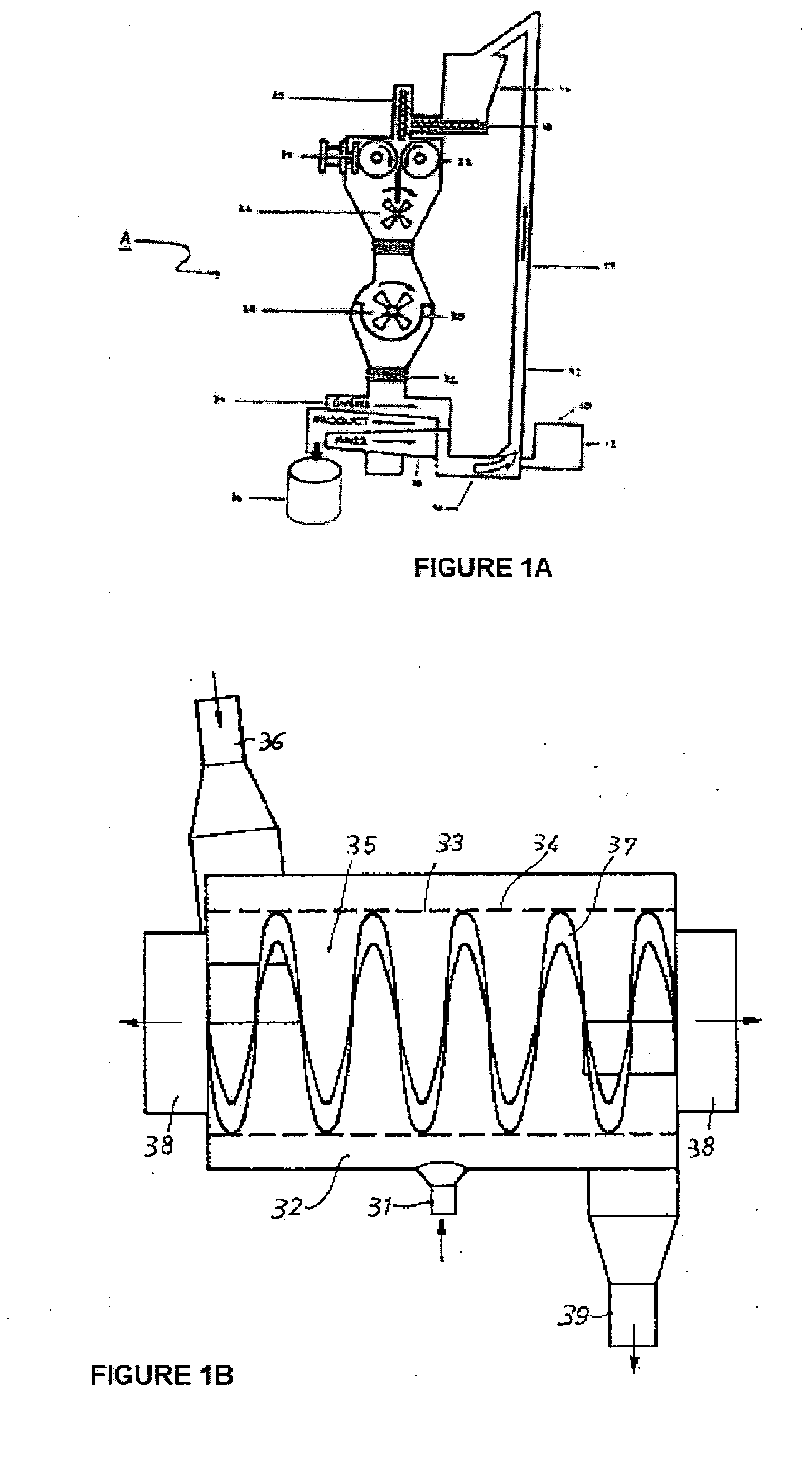

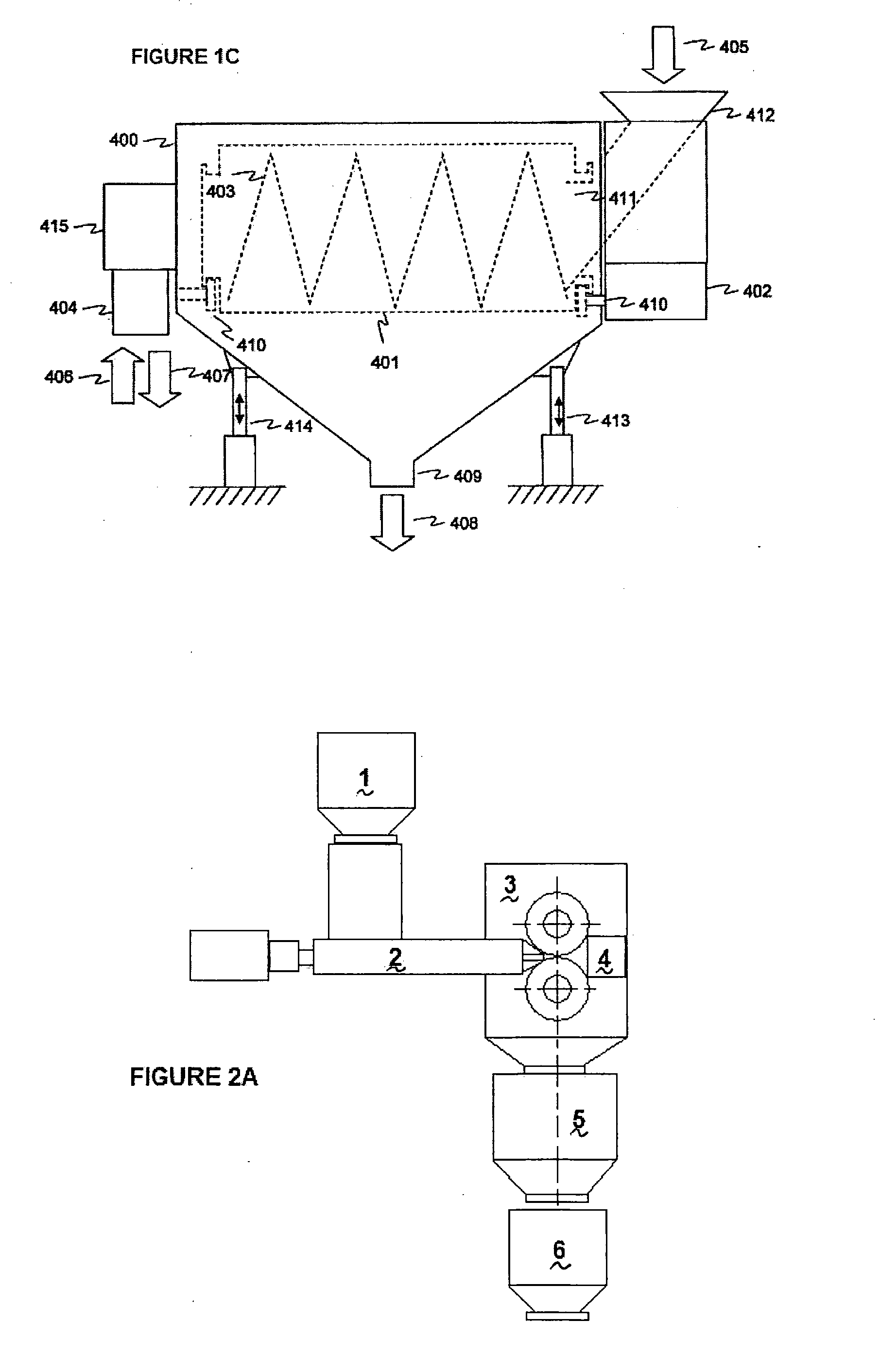

Dry granulation in a gas stream

ActiveUS20110220745A1Improve product qualityGood compensationGas current separationPharmaceutical product form changeCycloneCyclonic separation

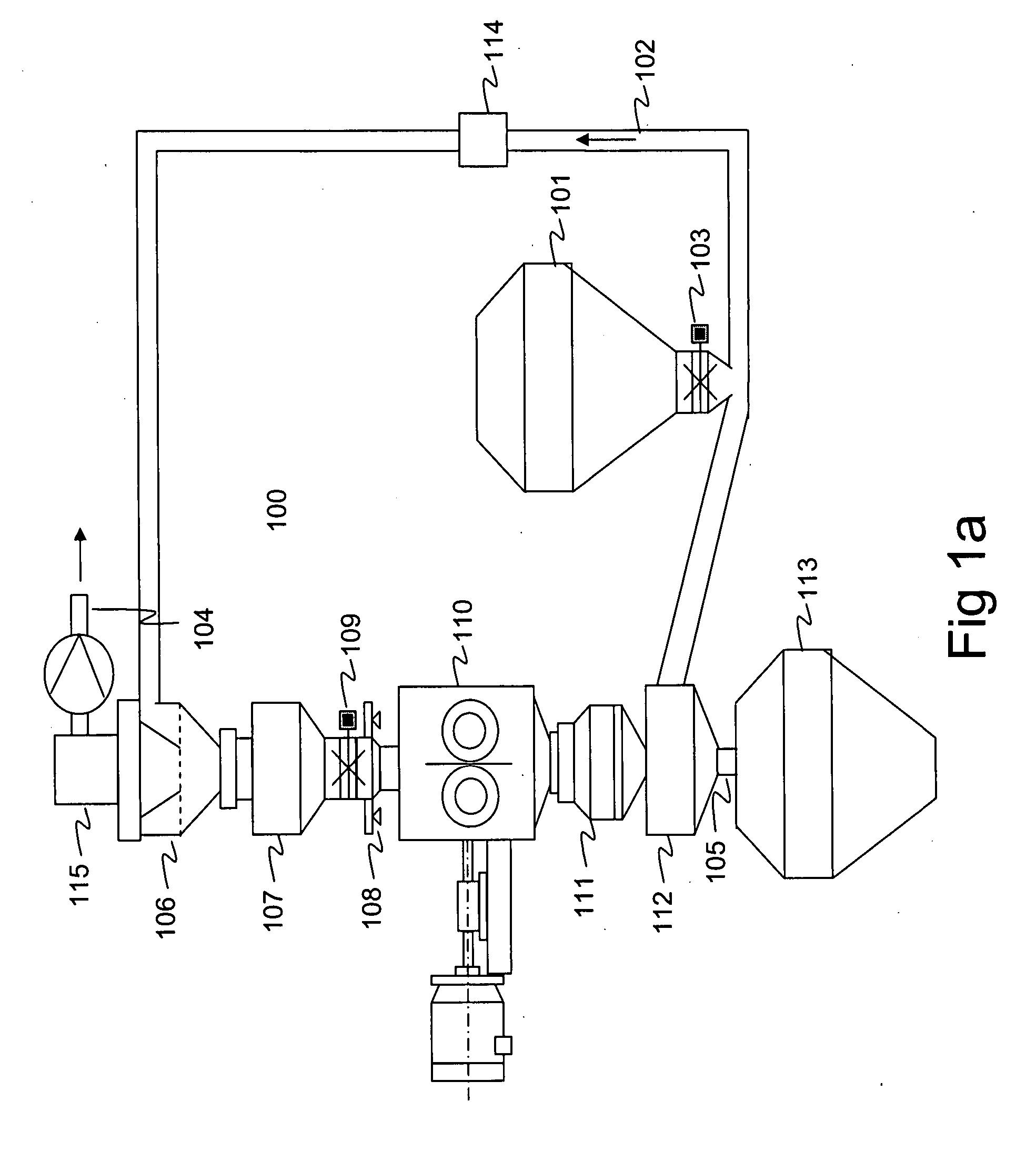

An apparatus wherein the gas enters from an opening 4 located in a part of a compaction chamber 3 and is dragged through a granulator 5, a fractioning device 12, a special cyclone 11 and a filter system 8A to a suction fan, which creates a gas stream. In such apparatus the bulk to be compacted 1, the fine particles to be compacted again and the compacted bulk have the same flow direction than the carrier gas. Due to its complete or partial impermeability, the structure of the apparatus makes also possible the use of a gas different from normal air. This is important when the bulk is sensible to oxygen.

Owner:POLIBIOTECH

Method for preparing biomass pellet fuel by mulberry branch fermentation wastes

InactiveCN104845696AGood technical effectImprove molding rateBiofuelsSolid fuelsWoody plantCaloric values

The invention discloses a method for preparing biomass pellet fuel by mulberry branch fermentation wastes. The method comprises the following steps of crushing the mulberry branch fermentation wastes into 1 to 3mm, and crushing the woody plant leftovers into 3 to 6mm; uniformly stirring and mixing 5 to 40 parts of mulberry branch fermentation waste powder and 60 to 95 parts of woody plant leftover powder, heating and drying to the 14 to 25% of water content, and sending the dried material into a press roll type annular die to form. The method has the advantages that by mixing the mulberry branch fermentation wastes with low caloric value and the woody plant leftovers with high caloric value, the biomass raw material can be formed under the condition of lower aperture and length ratio of the annular die, the abrasion of the annular die is reduced, and the forming rate, product density, durability and lower caloric value of the pellet fuel can be effectively improved.

Owner:GUANGXI ACAD OF SCI +1

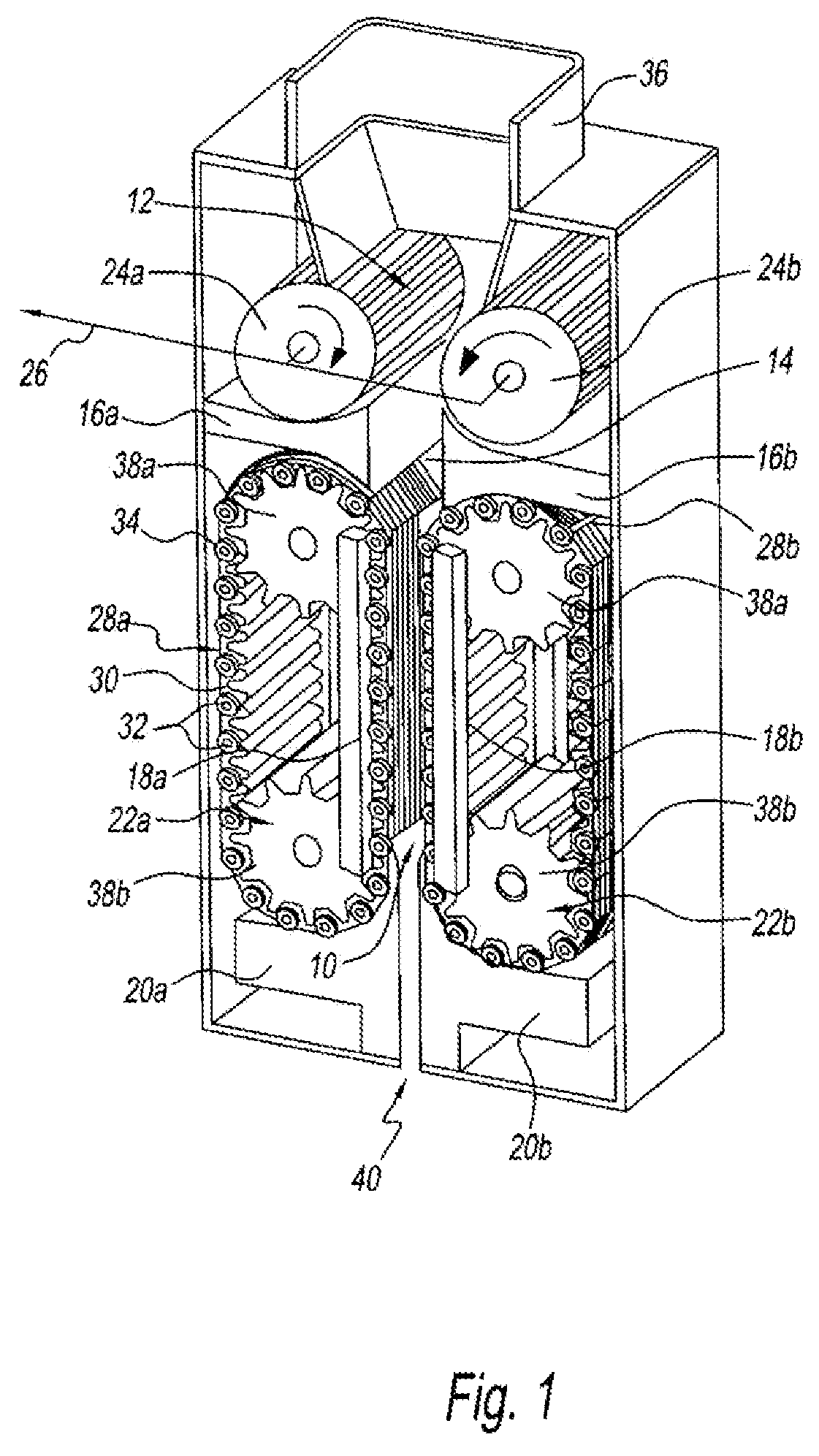

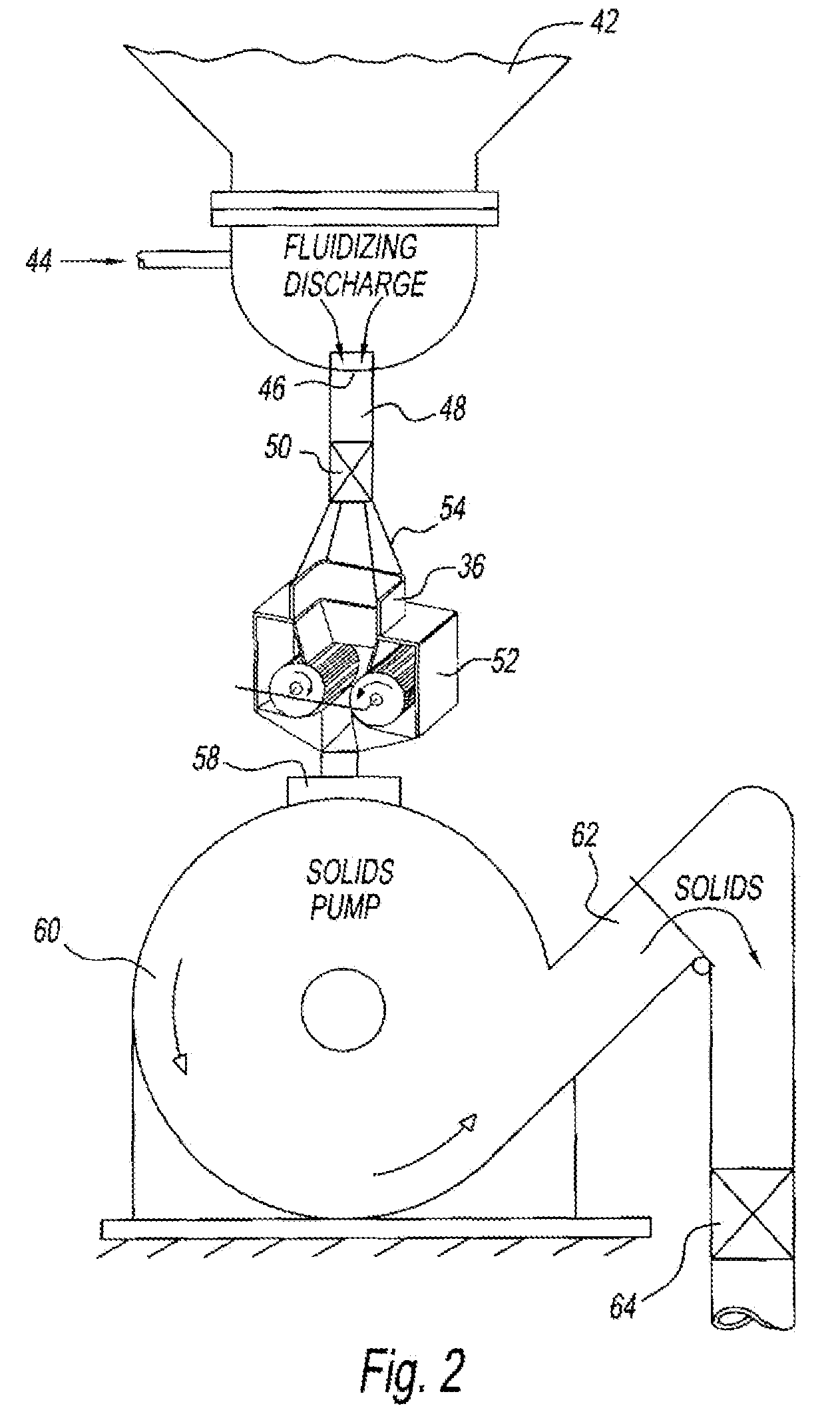

Active solids supply system and method for supplying solids

A solids supply systems having a solids deaeration zone and a solids pump zone, and to methods for supplying the solids e.g., pulverized dry coal, to an application, e.g., gasification process. The solids deaeration zone includes a roller system containing a plurality of porous roller assemblies, or a belt system containing a plurality of porous belt assemblies. The solids deaeration zone is operable to deaerate and convey the solids to the solids pump zone. In the solids deaeration zone, the solids become sufficiently compacted prior to and upon entry into the solids pump zone to be effectively conveyed through the solids pump zone.

Owner:EXXON RES & ENG CO

Granulator

PendingCN109433105AStop fallingIncreases chances of trapping materialGranulation by pressingEngineeringCo extrusion

The invention discloses a granulator. The granulator comprises a feeding device, wherein the feeding device comprises an upper hollow die roll, a lower hollow die roll and a conveying mechanism; the upper hollow die roll and the lower hollow die roll are engaged with each other to form a bell-mouthed feeding region; and the conveying mechanism is in contact with the lower hollow die roll, and a wrap angle is formed between the conveying mechanism and the lower hollow die roll, so that a material which is flattened under co-extrusion of the lower hollow die roll and the conveying mechanism is conveyed to the bell-mouthed feeding region. The flattened material is uniformly and orderly conveyed to the bell-mouthed feeding region, and when the material is extruded, the conveying mechanism canfurther stop dropping of the material. The probability of clamping the material by the lower hollow die roll is increased, and therefore, the granule forming rate is increased. By a wrap angle type feeding mechanism, the mounting height of a feeding system can be reduced, and a feeding condition is convenient to observe.

Owner:JIANGSU SANY ENVIRONMENTAL TECH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com