Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

66results about How to "Small working surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

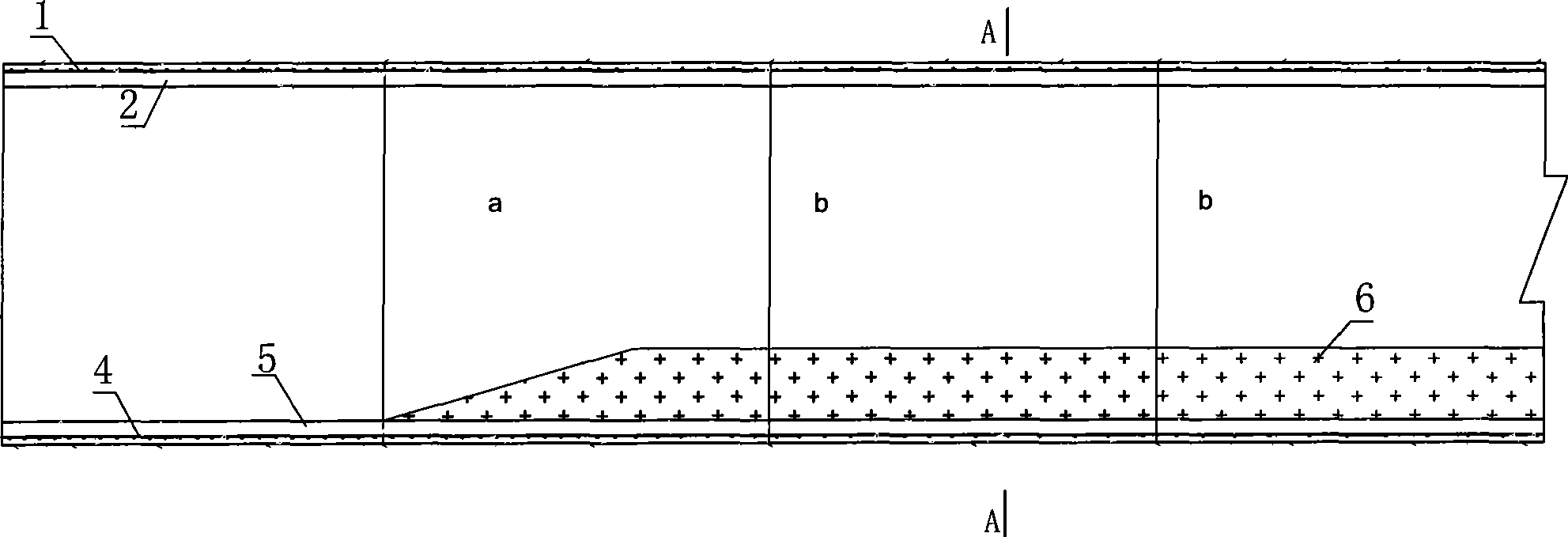

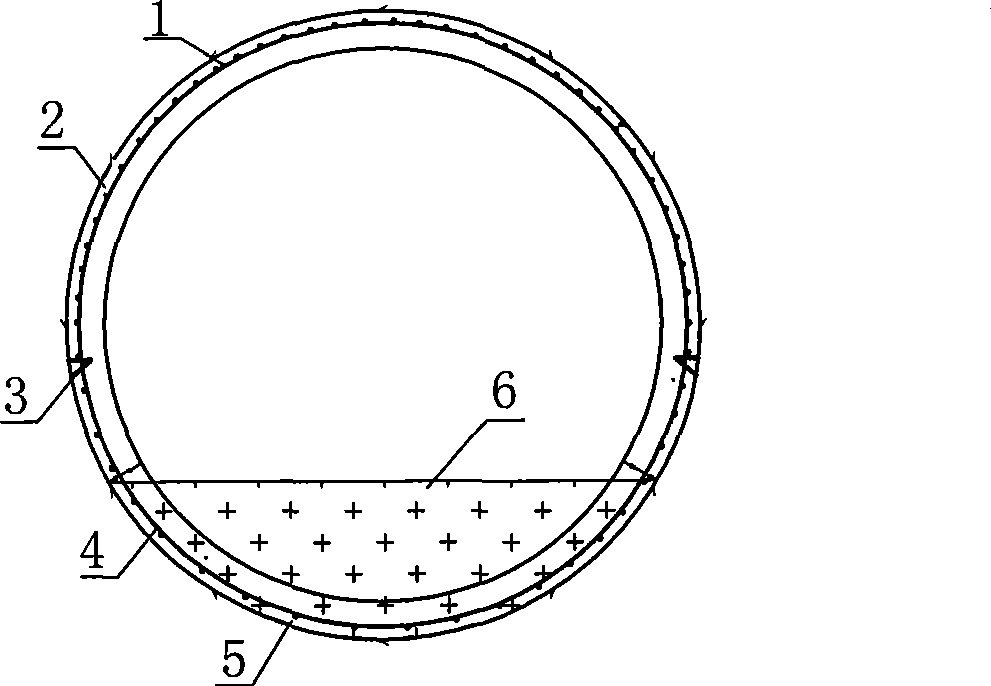

Synchronous grouting material used for tunnel and preparation method thereof

InactiveCN101928122AUnchangedImprove technical effectSolid waste managementCarboxymethyl celluloseHigh energy

The invention discloses a synchronous grouting material used for a tunnel and a preparation method thereof. The grouting material is the grout which is prepared by taking sediment grout as a main raw material, wherein the sediment grout comprises 30 to 65 percent of clay and fine sand totally and the weight ratio of soil to sand in the sediment grout is 0.1-0.18:1; and adding 80 to 120 kg of cement, 300 to 450 kg of coal ash, 200 to 500 kg of water or mud water and 3 to 10 kg of sodium carboxymethyl cellulose into per cubic meter of the sediment grout, wherein the grout density is between 1.85 and 2.05 g / cm<3> and the grout consistency is between 10.5 and 12 cm. In the preparation method, sediment and the mud water generated in a construction process are adopted as grouting materials, so that the sediment and the mud water can be changed into treasure from waste; and therefore, the preparation method has the characteristics of great reduction of the dosage of high-energy consumption cement, capability of working inside and outside tunnels, and convenient construction.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +2

Method for manufacturing roofing truss

The invention discloses a method for manufacturing roofing truss. The truss is constructed by truss nodes which are formed by assembling truss members by welding. The manufacturing steps are: decomposing an integral truss into the truss members in a computer, and manufacturing the truss members; manufacturing a bed-jig for assembling by welding; locating an upper chord, a lower chord and a taper transition section on the bed-jig, hoisting and locating brackets of sub-trusses and welding; hoisting and locating brackets of straight web members and welding; hoisting and locating brackets of slant web members, welding and measuring; hoisting and locating drawing plates, mounting stiffening plate, and welding; re-hoisting to the bed-jig for measuring and calibrating; marking out residual lines at the end parts and butting; and integrally assembly. The upper chord and lower chord in the invention adopts integral manufacturing, dispenses with intermediate inlaying web member, thus shortening distance between the upper chord and the lower chord, reducing assembly area and improving processing efficiency; the computer is adopted to collect coordinate data, thus ensuring preciseness of mounting and locating, reducing working hours, and increasing economic benefit.

Owner:JIANGSU HUNING STEEL MECHANISM

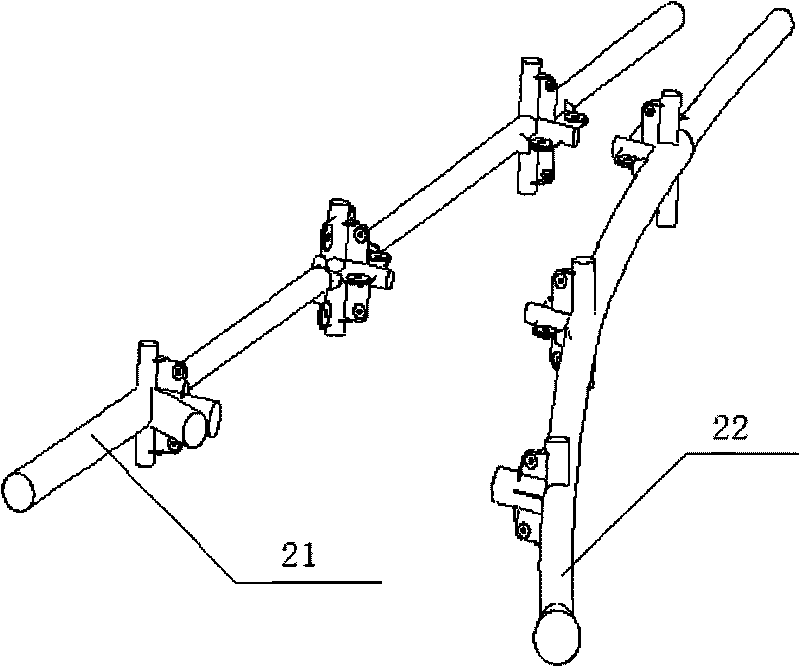

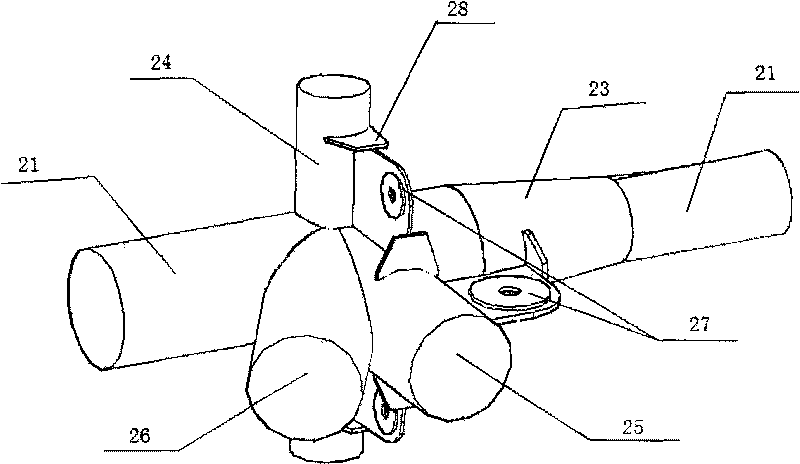

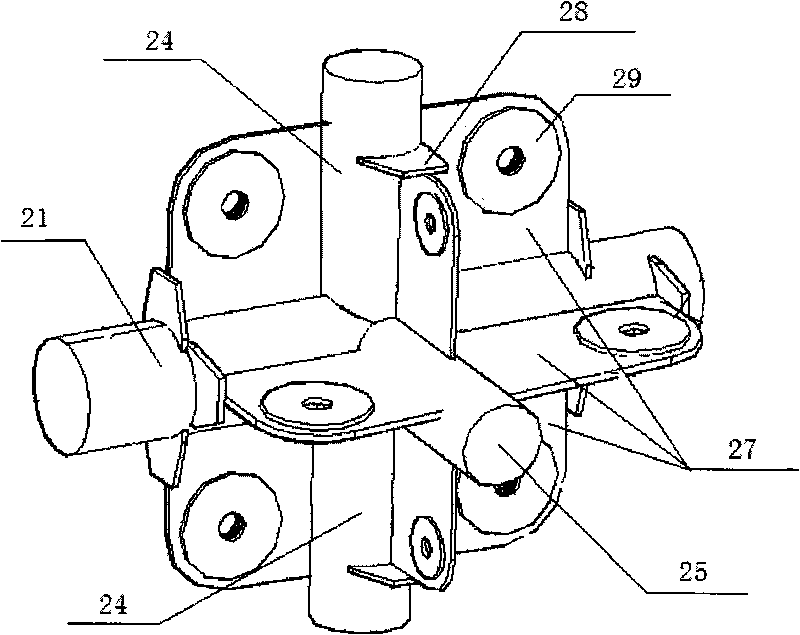

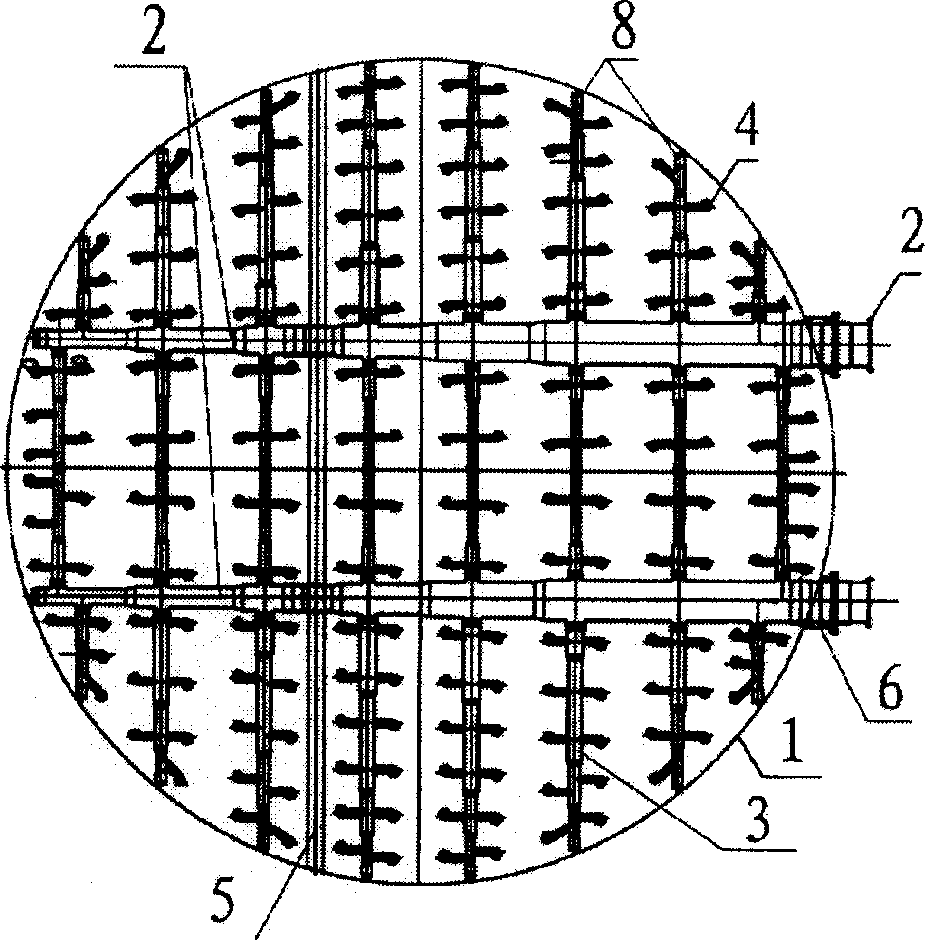

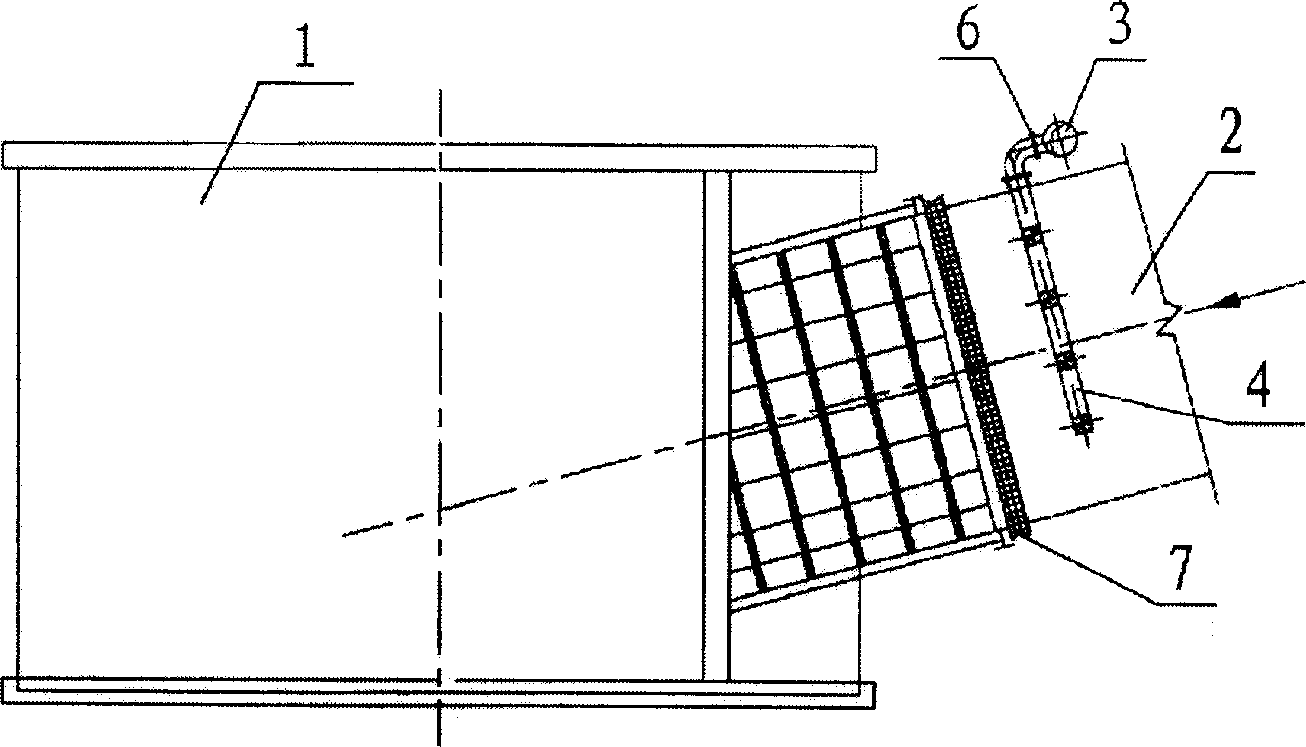

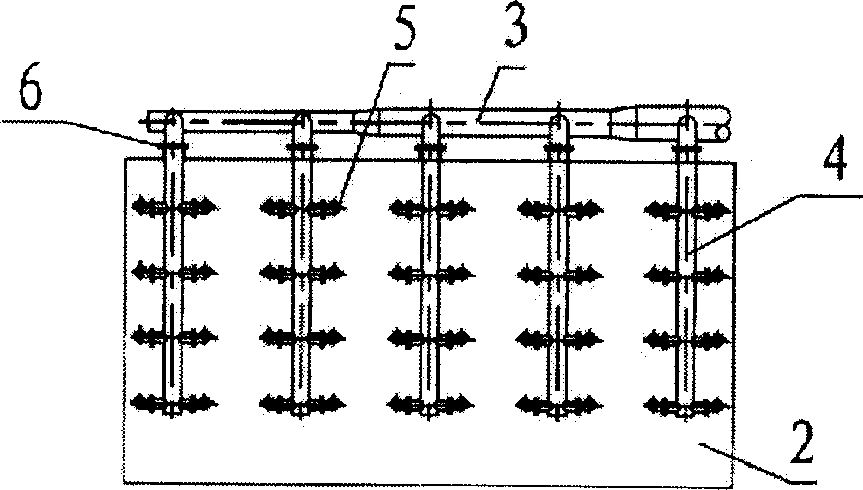

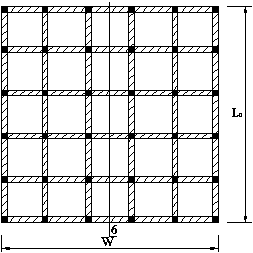

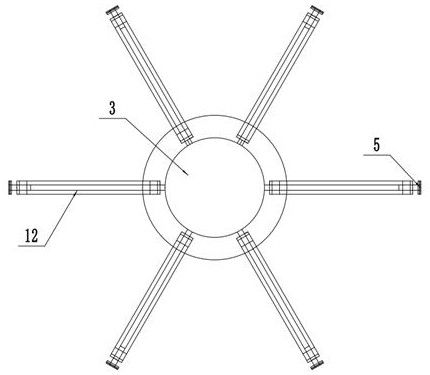

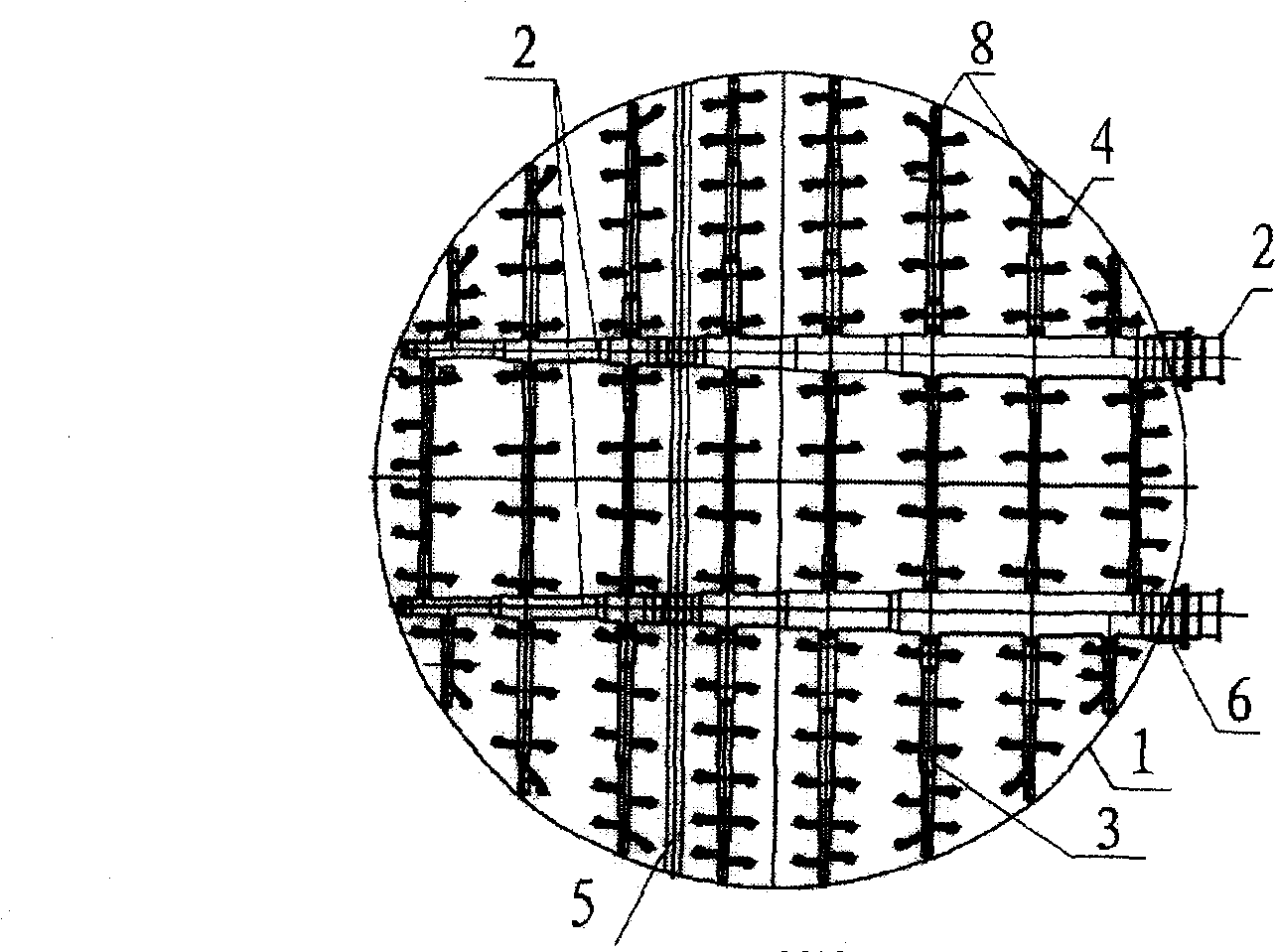

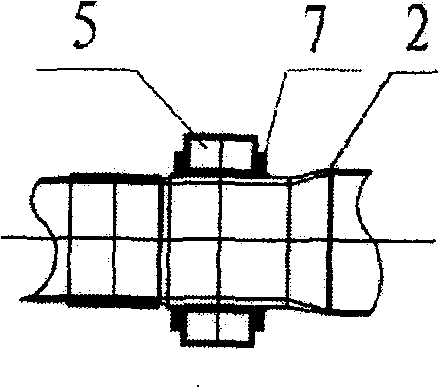

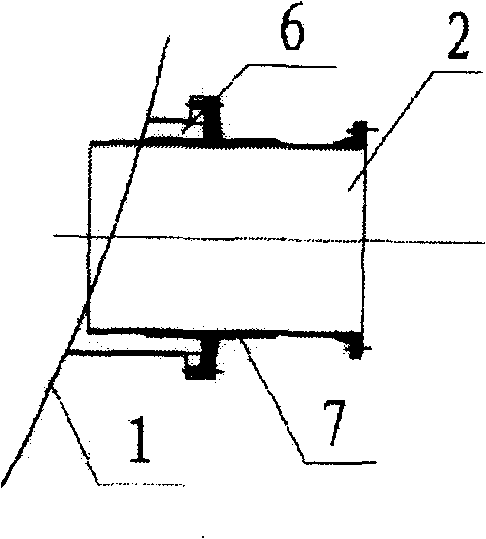

Circulating slurry sprinkling device for desulfurization of flue gas

ActiveCN1843580AReduce power consumptionReduce energy consumptionDispersed particle separationFlue gasSpray nozzle

The invention relates to a smoke desulfuration cycle slurry spray device, which are layered in the adsorption tower. Each spray device is formed by at least two parallel spray main tube and the spray sub tubes branched from the spray main tube. The dual-direction ejectors that branched from the spray sub tubes are interlaced into mesh spray layer; two parallel spray main tubes are through the hole of support beam inside the adsorption tower, and horizontally fixed via single-beam support. The invention can solve the problems that not enough mixed between the smoke and cycle slurry; lower desulfuration effect; and easy abrasion and leakage at the interface between the spray tubes and the adsorption tower. The invention can be used in wet smoke desulfuration adsorption tower to utilize the limestone or lime slurry to adsorb the sulfur dioxide and sulfur trioxide.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG +1

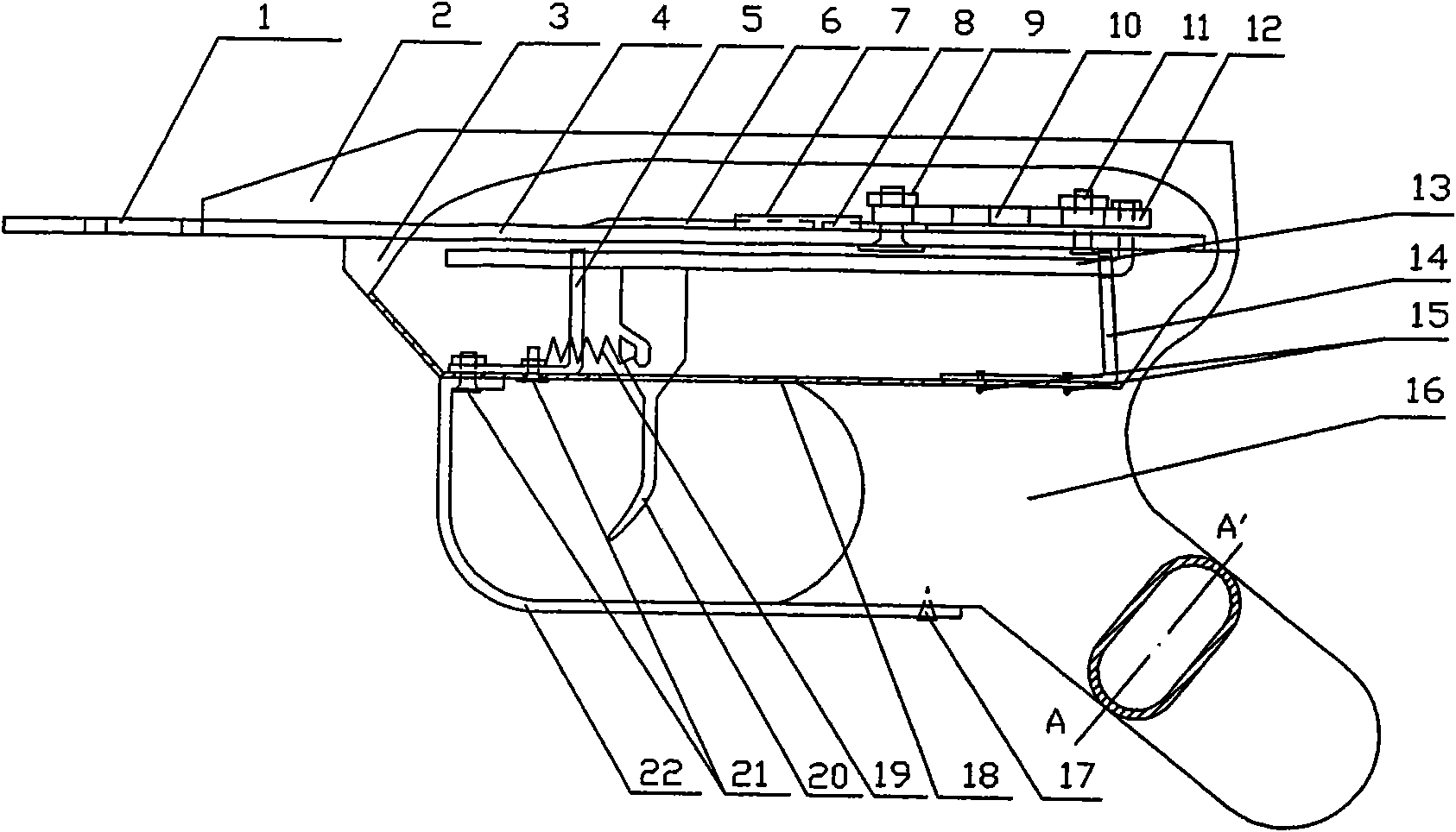

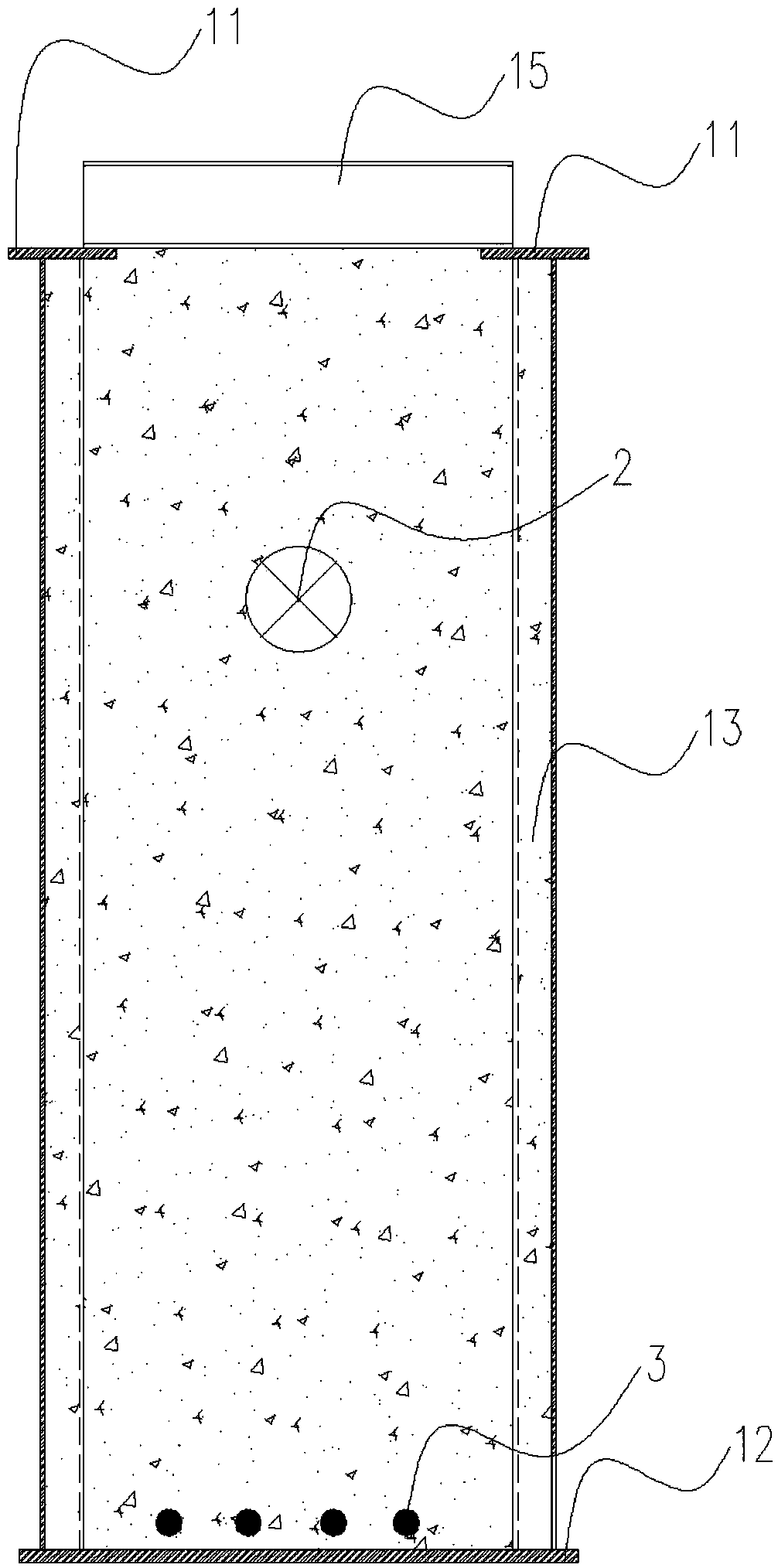

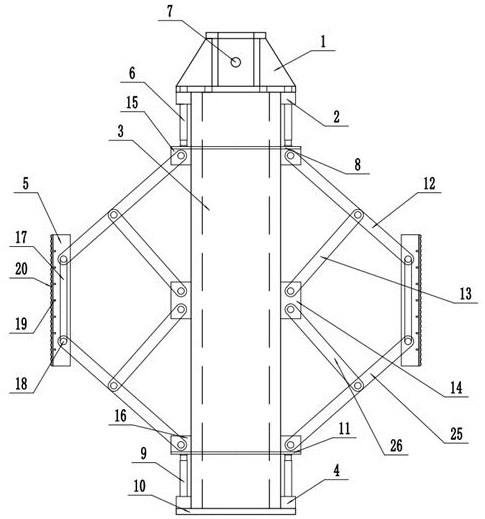

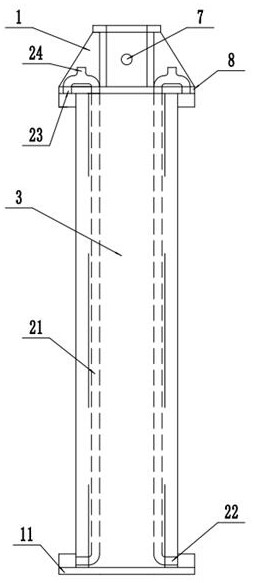

Vertical shaft construction device and method

The invention provides a vertical shaft construction device and a method, and belongs to the field of foundation engineering construction. The device comprises a ring beam, supports, a support system and floating prevention structures, wherein the ring beam is arranged in a soil body above a tunnel; the supports are applied to the side walls of a vertical shaft; the support system is a multilayer structure, and comprises a steel support structure and a middle separation plate structure arranged in the vertical direction; the support system is perpendicular to the length direction of the vertical shaft, and is fixedly connected with the supports at the two sides of the vertical shaft; and the floating prevention structures are positioned at the upper side and the left and right sides of the tunnel. The span of the vertical shaft is small, the device is provided with the multilayer support system, and the vertical shaft construction device is strong in structure, so that the pressure of soil bodies at the two sides of the tunnel can be preferably transferred, the interference on the soil bodies around the subway tunnel is little, and the swell quantity of the tunnel can be effectively controlled to satisfy the design requirement. In addition, the symmetric parallel operation can be adopted to synchronously construct and install the device on multiple working surfaces, so that the construction period is reduced.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD +1

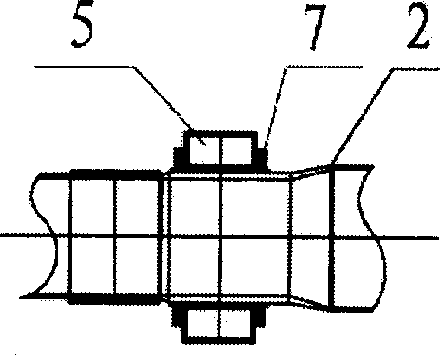

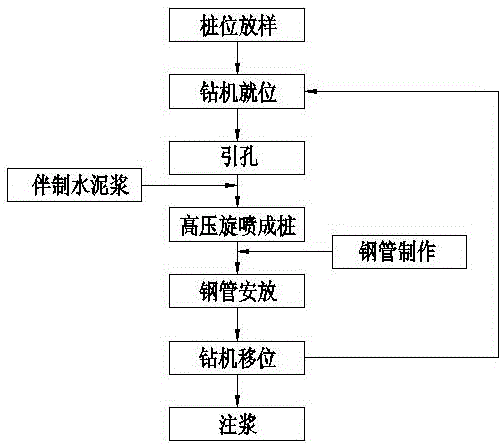

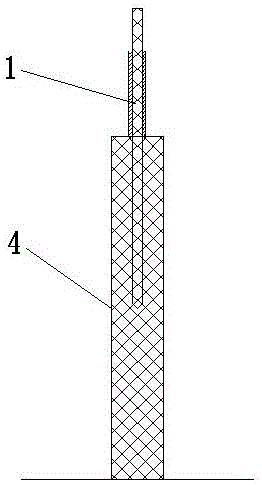

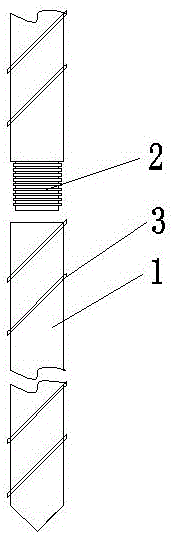

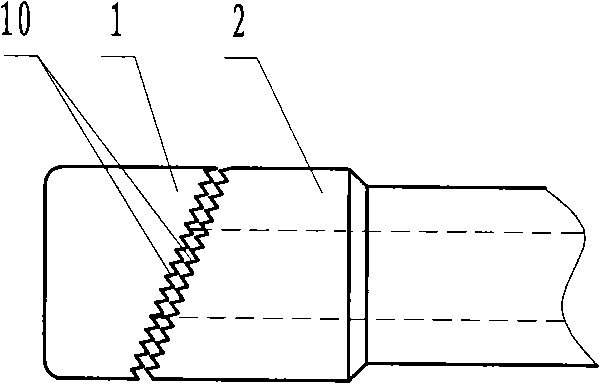

Rotary jet grouting bar inserting type mini pile construction method

InactiveCN106522213ASmall working surfaceImprove bearing capacityBulkheads/pilesArchitectural engineeringHigh pressure

The invention discloses a rotary jet grouting bar inserting type mini pile construction method. The rotary jet grouting bar inserting type mini pile construction method comprises the first step of pile position lofting, the second step of taking drilling machine into place, the third step of hole leading, the fourth step of cement paste mixing, the fifth step of high-pressure rotary jet grouting pile forming, the sixth step of steel pipe manufacturing, the seventh step of steel pipe placing, the eighth step of drilling machine translocating and the ninth step of grouting. The rotary jet grouting bar inserting type mini pile construction method has the beneficial effects that the working face is small, the requirement for the place height is low, the construction place is tidy and clean, the construction process is safe, accident potentials are low, the pile forming quality is good, the bearing force is relatively high, and the method is suitable for construction carried out on places like chemical plants where pipelines are complex, the place limiting conditions are high and the construction process safety requirements are strict. According to the construction method, high-pressure rotary jet grouting piles are adopted, steel pipes are embedded into pile holes, the outer wall of a pipe body of each steel pipe is spirally wound by round steel so that the frictional resistance of the side wall can be increased, and therefore the bearing force of a mini pile is improved. Symmetrical bevel connectors are formed in the bottom of a bottom pipe and are beneficial to sinking of the steel pipes, and the construction efficiency is improved.

Owner:浙江省岩土基础有限公司

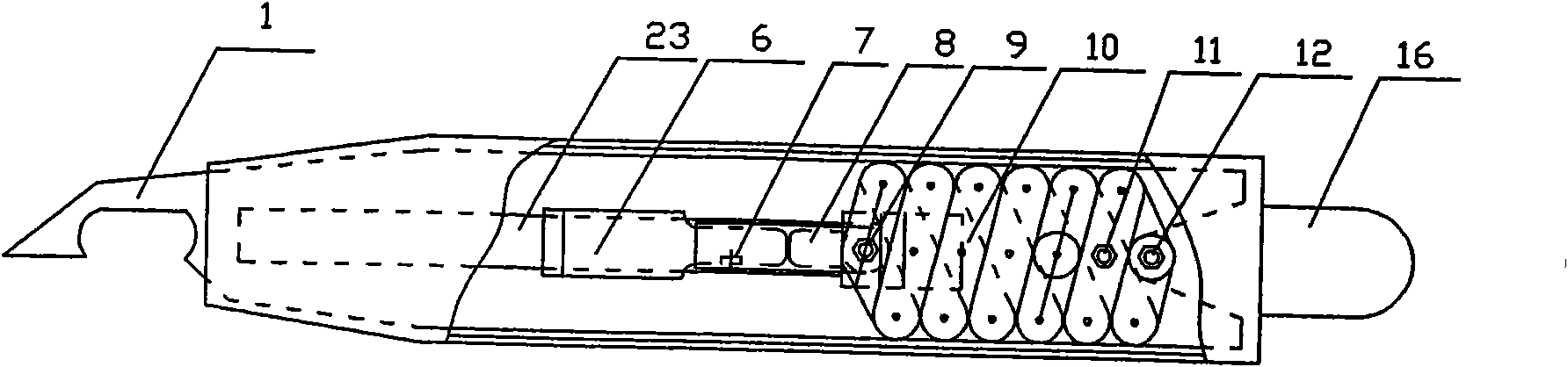

Zanthoxylum picker

The invention discloses a zanthoxylum picker comprising a picker body, a picker cover and a picker handle, wherein the picker cover is connected with the upper side of the picker body; and the picker handle is connected with the lower side of the picker body. The zanthoxylum picker is characterized in that the picker body is a hollow structure in the shape of an inverted trapezoid and is provided with a spanner hole at the lower part; an oriented plate is clamped between the picker body and the picker cover and is provided with a triangular fixed hook at the front end, a rectangle at the rear part and a rectangular opening in the middle; a cutter accelerator is installed on the oriented plate through a screw shaft, the front end of the cutter accelerator is connected with a cutter frame arranged in the rectangular opening of the oriented plate through a cutter frame coupler, and the rear end is connected with an elbow of a power driving rod; the power driving rod is installed in a front supporting frame and a rear supporting frame in the picker body, the lower side of the power driving rod is connected with a spanner passing through the spanner hole, and a tension spring is connected between the spanner and the front supporting frame and between the spanner and the rear supporting frame; and the front end of the cutter frame is provided with a blade. The picker has high picking speed and quality, low production cost and convenient popularization and application; in addition, three thorns are not easy to stab fingers.

Owner:范万发

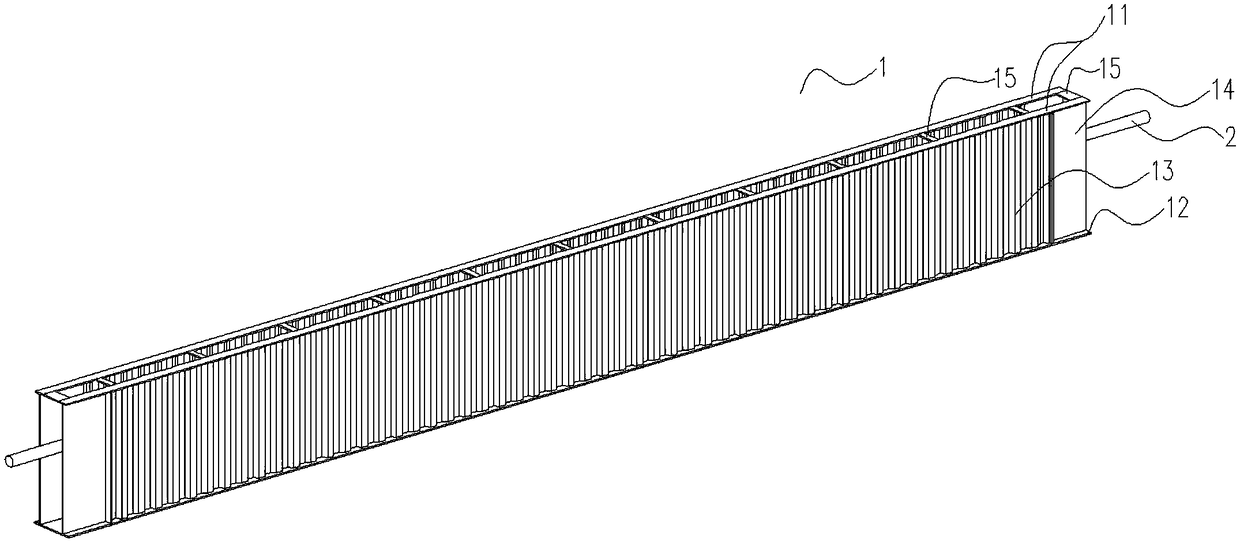

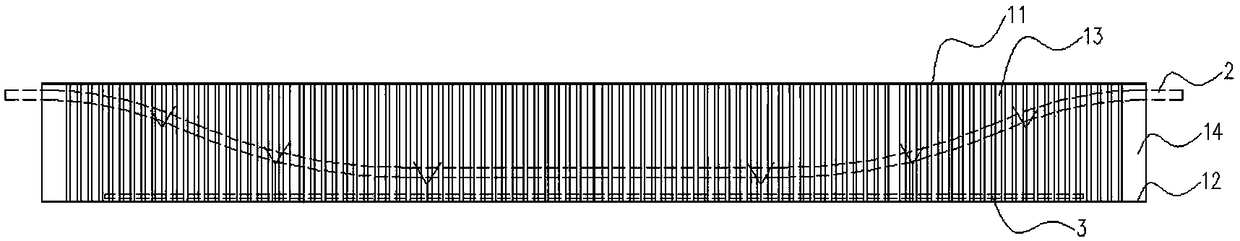

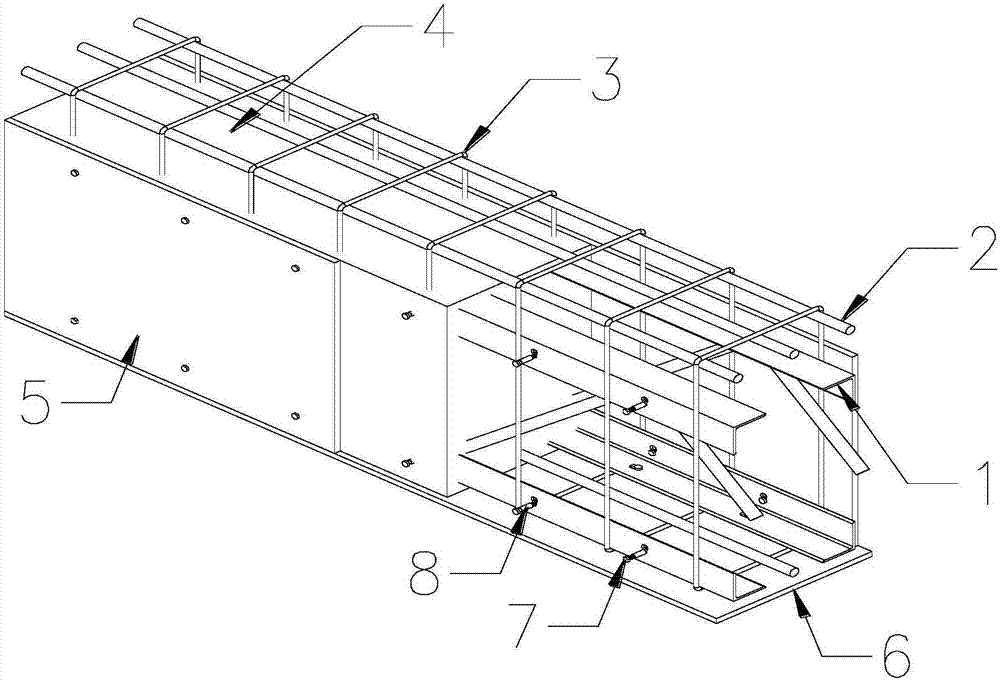

Steel corrugated shell and prestressed concrete composite beam and construction method thereof

PendingCN108316554AImprove shear resistanceImprove seismic performanceGirdersJoistsPre stressShock resistance

The invention provides a steel corrugated shell and prestressed concrete composite beam and a construction method thereof. The steel corrugated shell and prestressed concrete composite beam comprisesa steel corrugated shell, a prestressed steel strand and a concrete layer, wherein the steel corrugated shell comprises upper flanges, lower flanges, a corrugated web and an end web; the two upper flanges are arranged in parallel at left and right and are connected with each other by means of at least one upper flange connecting piece; the two lower flanges are arranged in parallel at left and right and are connected with each other by means of at least one lower flange connecting piece; the upper flanges and the lower flanges are arranged up and down in parallel; the corrugated web is arranged between the upper flanges and the lower flanges; the end web is arranged at the end of the corrugated web and is erected between the upper flanges and the lower flanges; the prestressed steel strandis arranged in the steel corrugated shell and passes through the steel corrugated shell along the length direction of the steel corrugated shell; the steel corrugated shell is internally filled withconcrete so as to form the concrete layer. The steel corrugated shell and prestressed concrete composite beam provided by the invention is good in shearing resistance, shock resistance and fire resistance, and is economical.

Owner:SHANGHAI OPEN STEEL JOIST

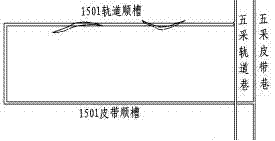

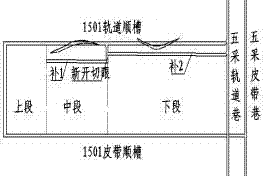

Complex geological condition fully-mechanized working face split-close type fault crossing method

InactiveCN107060759AReduce the degree of impactImprove resource recoveryUnderground miningSurface miningResource recoveryCoal

The invention provides a complex geological condition fully-mechanized working face spilt-close type fault crossing method, and relates to the field of coal mine production. The method comprises the steps: (1) building a roadway and bypassing a fault at the location near a track trough before the production of a working face; (2) removing equipment of a shrinking face when an upper working face is advanced to the fault while backstopping; (3) installing equipment at a new cut hole; (4) closing the face of the working face. According to the technical scheme, the method has the advantages that a guarantee is provided for the comprehensive and efficient advancement of the fully-mechanized working face; the coal resource recovery rate is increased; the additional construction costs of the moving expenses are reduced; the damage of the working face equipment caused by crossing fault is avoided; the coal heating value is ensured; the economic efficiency is improved; the practicality is good.

Owner:SHANDONG DONGSHAN XINYI COAL MINE CO LTD

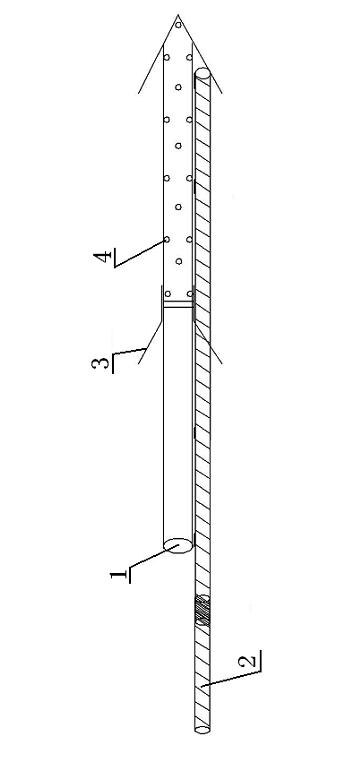

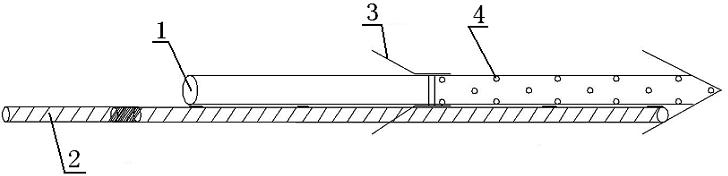

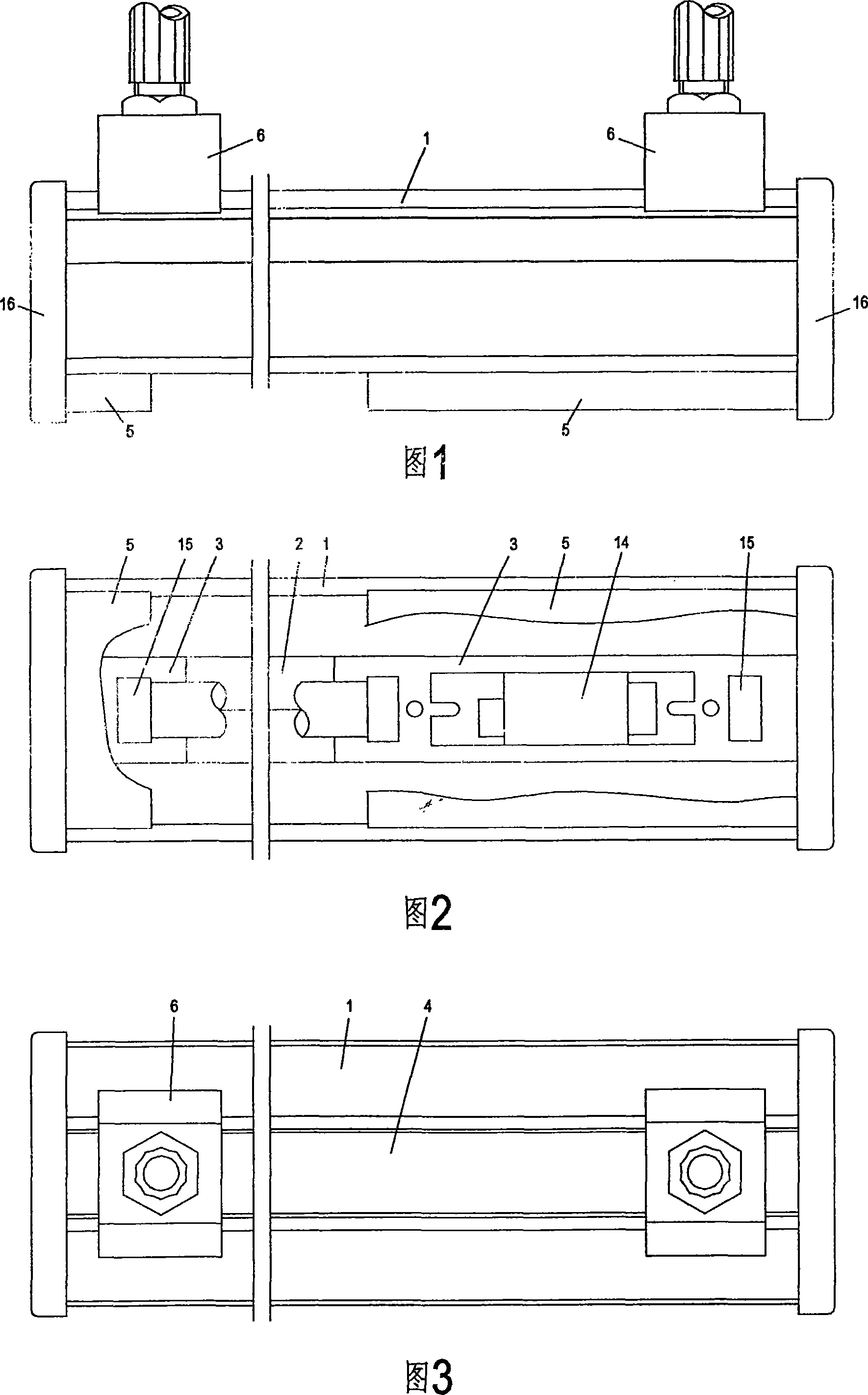

Steel tube locked anchor rod construction method

InactiveCN102660948AIncrease friction sectionTo achieve the purpose of one-time molding of groutingBulkheads/pilesPre stressSteel bar

The invention relates to a steel tube locked anchor rod construction method. The method comprises the following steps of: (1) deploying points by using a conventional method; (2) putting an anchor shank in place; (3) driving a guide steel tube in a steel tube locked prestressing anchor rod and a deformed steel bar anchor rod into soil at the deployed points to designed length by using the anchor shank; (4) mixing cement slurry; (5) injecting the cement slurry into the guide steel tube by an injection pump under the pressure of 0.5-3MPa, and stopping injecting the slurry when cement slurry flows out of a hole formed in the soil by the guide steel tube locked pretressing anchor rod; and (6) after the soil is solidified for seven days and the strength is above 75%, carrying out pull-push detection on the guide steel tube locked pretressing anchor rod, wherein the detection quantity is no less than 3% and the pull-push force is greater than a preset value. The method provided by the invention is simple in process and low in construction cost, and solves the problems admitted in the building industry that anchor rods and soil nails difficultly form holes in a soft ground, saturated soil, sand soil and silty clay in deep foundation pit support.

Owner:GANSU JIANGONG ENG CONTRACTING

Arrangement for sprinkling and pre-washing flue gas in entrance of flue gas-desulfurizing absorption tower

ActiveCN1843572AImprove desulfurization efficiencyReduce the number of runsDispersed particle separationLow loadFlue gas

The invention relates to a spray pre-washing device for treating the smoke at the inlet of smoke desulfuration adsorption tower. Said invention is arranged inside the inlet smoke channel of adsorption tower and separated by spray main tubes into spray sub-tubes; the spray sub-tubes are distantly connected to the injectors; the spray main tube is arranged above the ascending smoke chamber of smoke inlet; the spray sub-tubes are vertical to the direction of smoke and inserted into the smoke channel from the upper part of smoke channel; the injectors are uniformly connected to two sides of spray sub-tubes. The invention has the advantages that: via smoke pre-washing inside the smoke channel, it can improve the desulfuration efficiency of completed adsorption tower; and it can reduce the temperature in the pre-washing process on the completed or built adsorption tower, to reduce the number of spray layer with lower load to reduce the energy consumption.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG +1

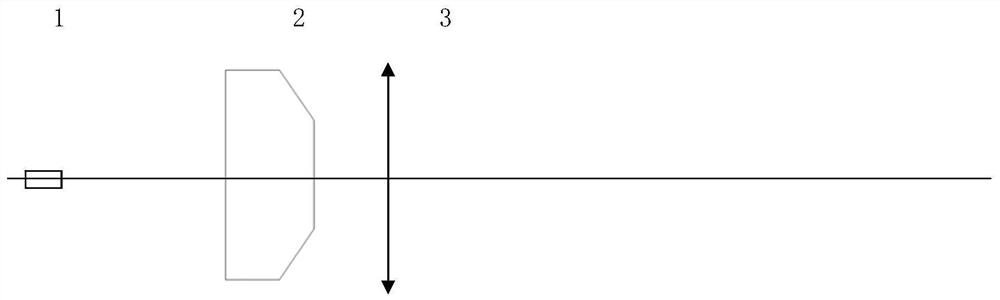

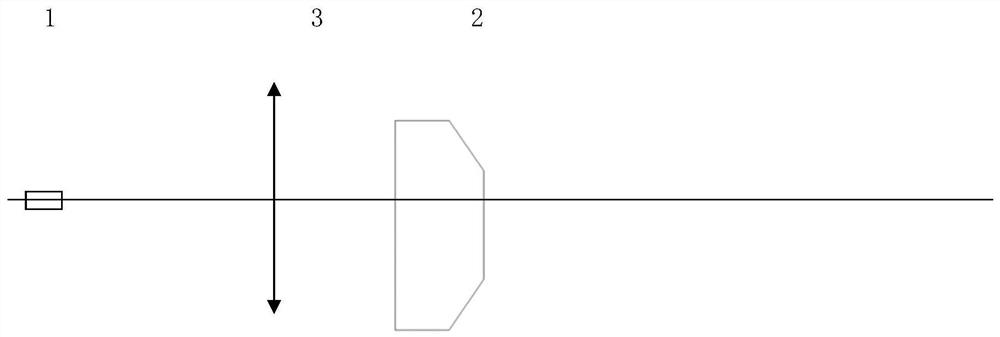

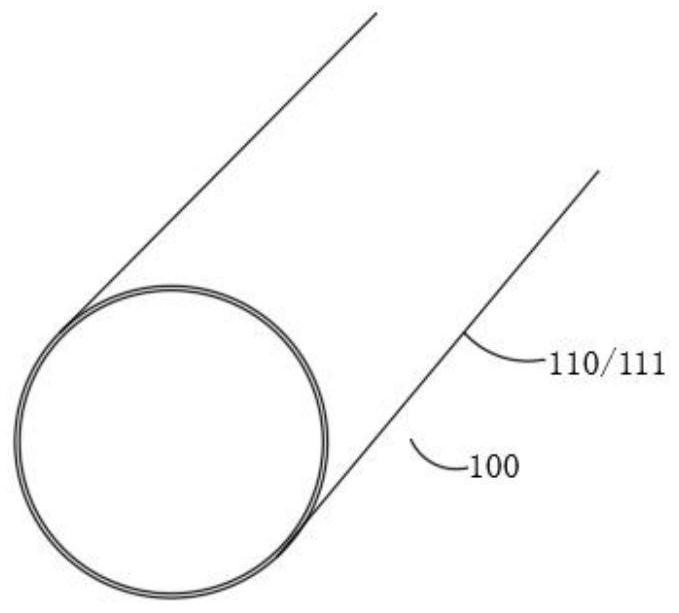

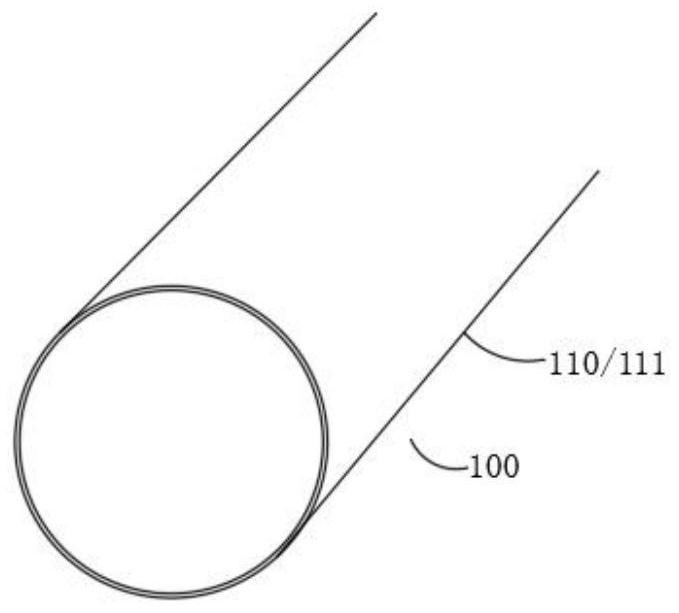

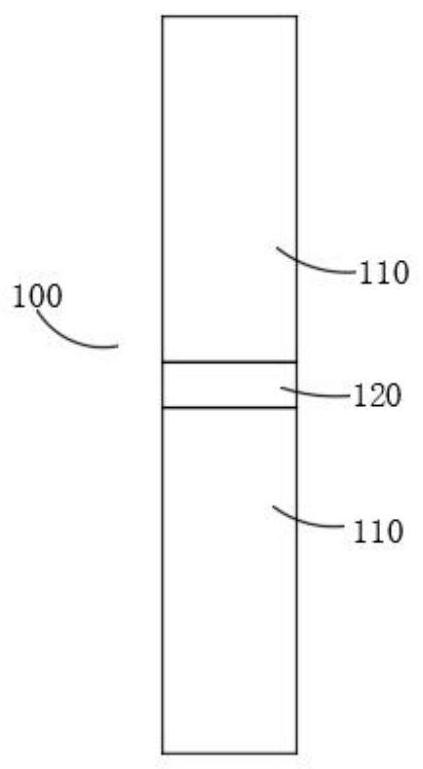

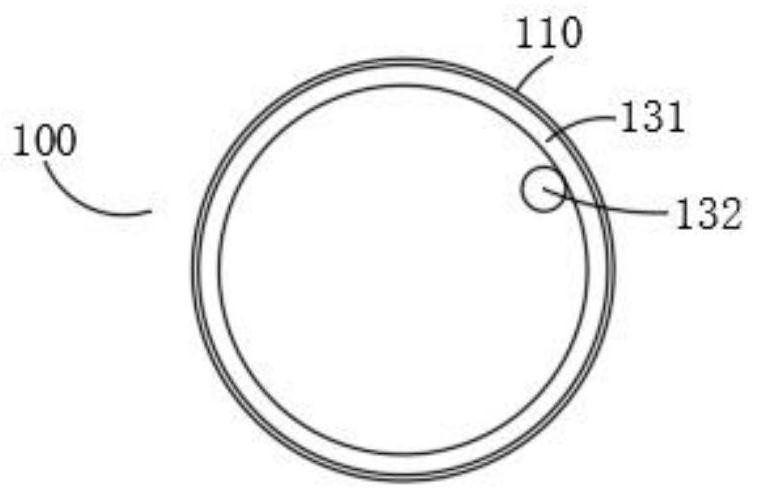

Optical system for forming point ring light spot

PendingCN113798662ASmall working surfaceReduce energy lossLaser beam welding apparatusOptical elementsOptical processingLight spot

The invention discloses an optical system for forming a point ring light spot. The optical system comprises an optical fiber, a frustum-shaped optical deflection element and an optical imaging system; the frustum-shaped optical deflection element and the optical imaging system are arranged on an optical fiber output light path, and the optical imaging system is arranged on the front side and / or the rear side of the frustum-shaped optical deflection element; and after light emitted by the optical fiber passes through a system composed of the frustum-shaped optical deflection element and the optical imaging system, a light spot of a point ring structure is formed on a certain surface. According to the optical system, various light spot structure requirements can be met, meanwhile, elements forming the system can be manufactured through a traditional optical processing technology, the manufacturing difficulty of the system is reduced, and then the manufacturing cost of the system can be greatly reduced.

Owner:方笑尘

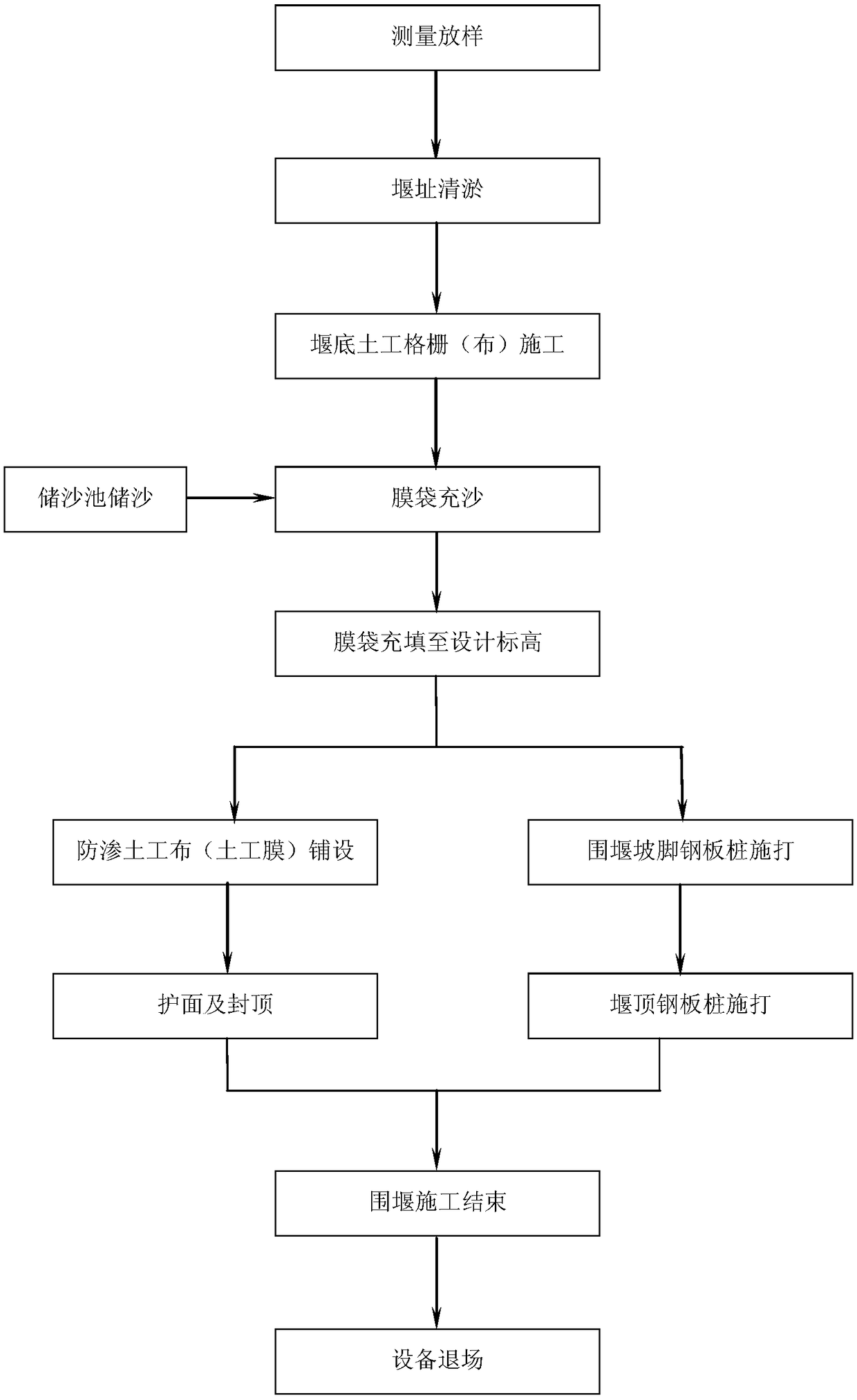

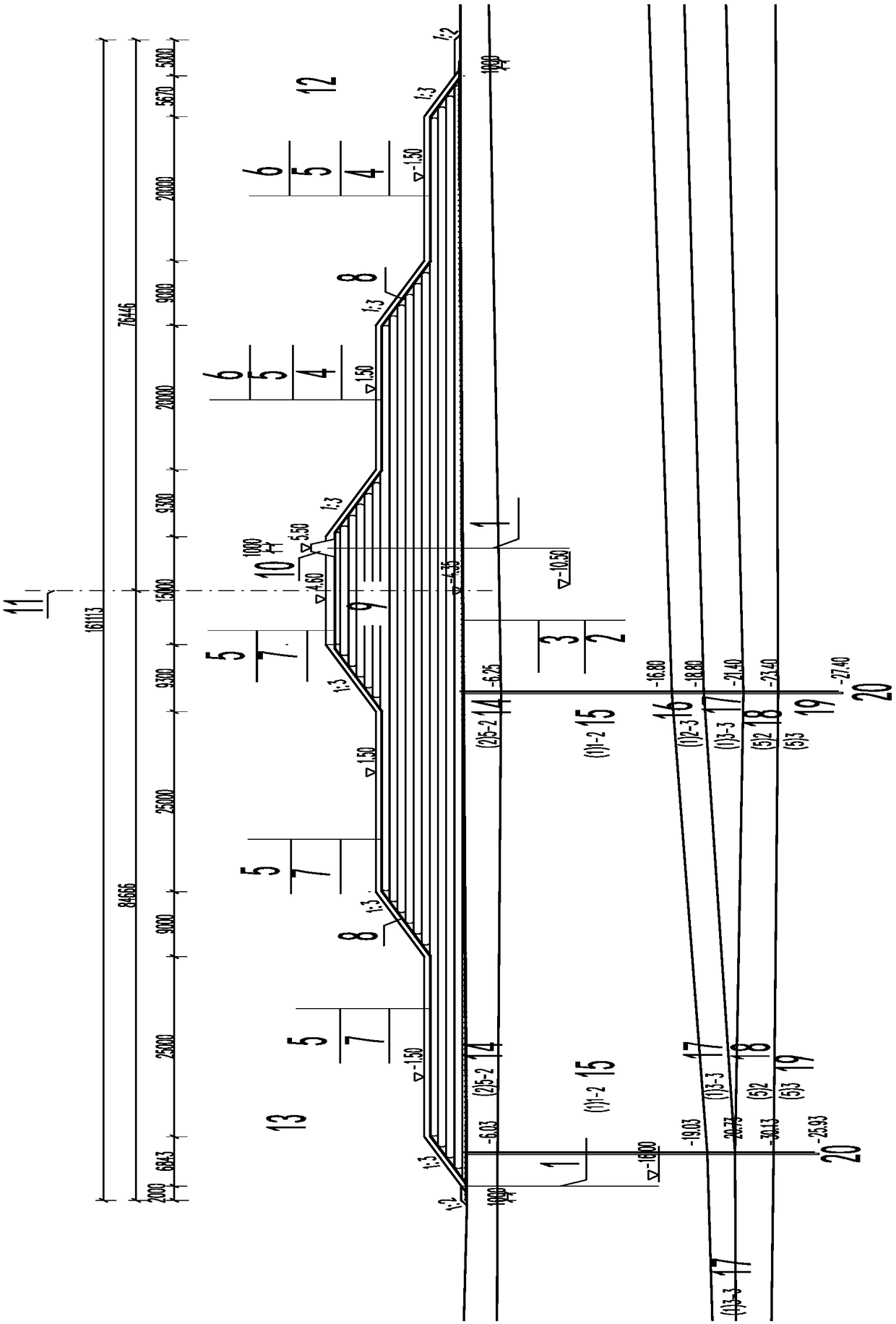

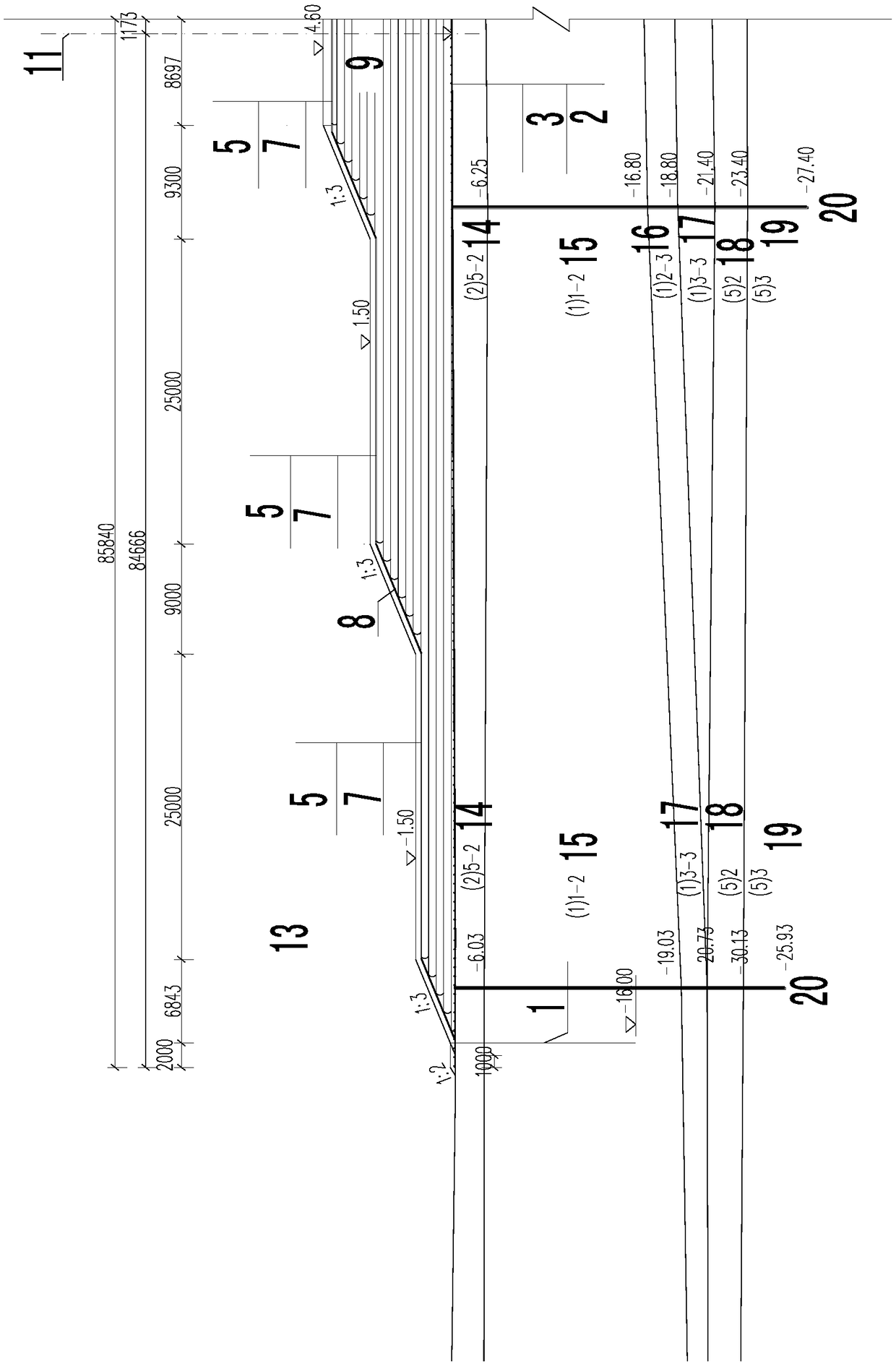

Structure of super-large cofferdam based on marine environment and construction process thereof

The invention discloses a construction process of a super-large cofferdam based on marine environment, which is characterized in that the cofferdam uses a sand washing film bag and a trapezoidal section structure. The width of the top of the cofferdam is about 15 meters, graded slope setting is carried out according to the height, and the slope of a upstream face is 1:3-1:4, the slope of a downstream face is 1:4, a steel plate pile water stop curtain is arranged on the top of the cofferdam, and a steel plate pile water stop curtain is arranged on the slope foot of the downstream face. The sandwashing film bag and the steel plate pile are combined in the process, and the process has the advantages that: the construction speed is fast, and the construction period can be shortened; the stability and durability are good, washing and flood can be resistant; due to the addition of the steel plate pile water stop curtain, the steel plate pile water stop curtain has higher rigidity and betteranti-seepage performance, and can achieve a good water-blocking effect; meanwhile, the cofferdam is convenient and fast to disassemble; and the steel plate pile can be used in a turnover way, so thatthe construction cost is reduced. The construction process of the super-large cofferdam based on the marine environment can provide reference basis and experience guidance for similar projects such as a water tunnel, a wharf cofferdam, a river-crossing bridge and the like.

Owner:中铁十八局集团第五工程有限公司 +1

High-speed construction method of tunnel lining concrete

InactiveCN101519970AIncrease profitOvercoming repeated removal of gravel materials and setting up construction roadsUnderground chambersTunnel liningRebarRapid construction

The invention provides a high-speed construction method of tunnel lining concrete. The method comprises the following steps: mounting umbrella arch reinforcement bars of the side wall first; removing ballast of tunnel soleplates; mounting reinforcement bars of the tunnel soleplates; pouring concrete of the tunnel soleplates; and pouring umbrella arch concrete of the side wall or pouring gross section concrete. The method has the advantages of improving the utilization ratio of the ballast road paved before excavating, reducing the working faces formed by repeatedly backfilling and removing the ballast road, overcoming the defects of repeatedly removing the ballast and paving a construction road, ensuring the simultaneous concrete construction of a plurality of working faces for the same tunnel lining, speeding up the construction of tunnel lining concrete and saving construction cost.

Owner:CHINA GEZHOUBA GROUP CO LTD

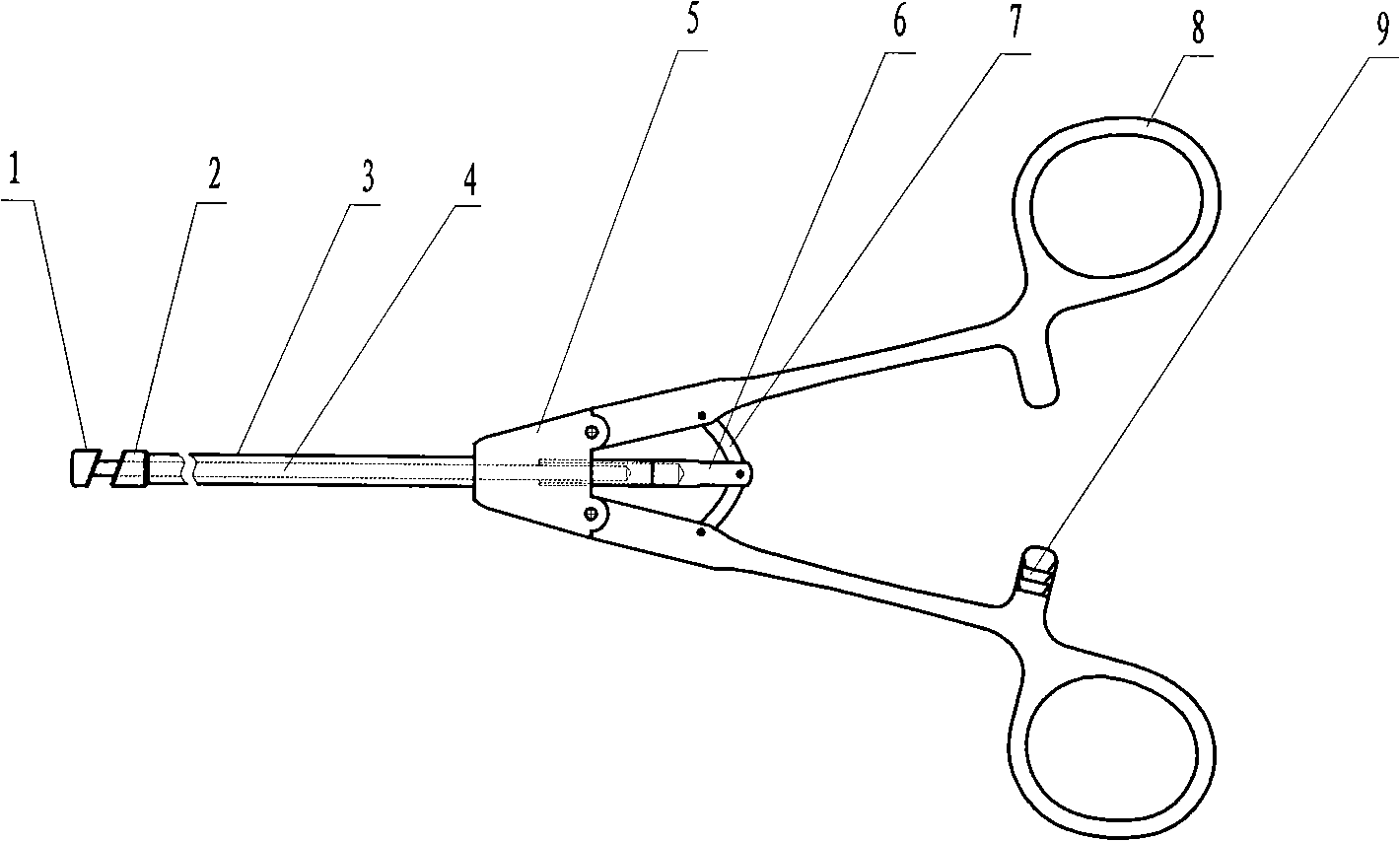

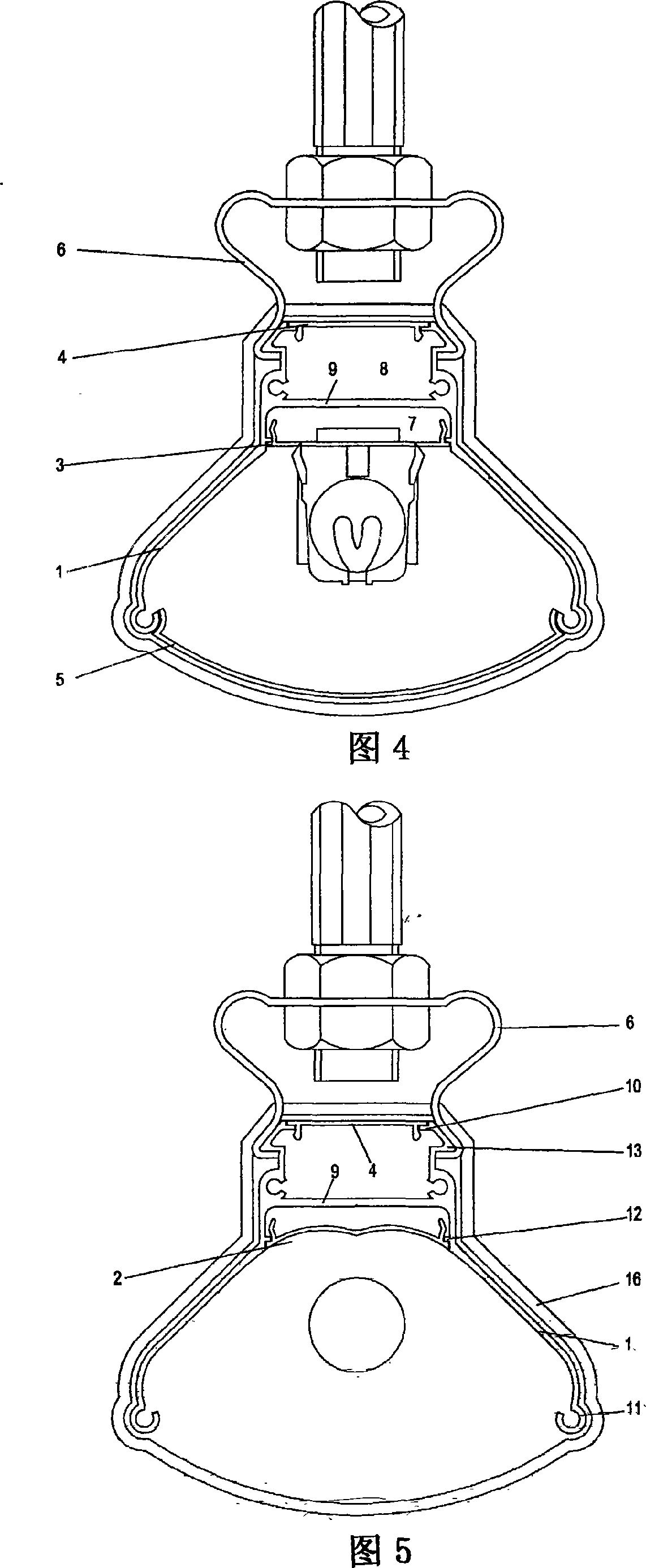

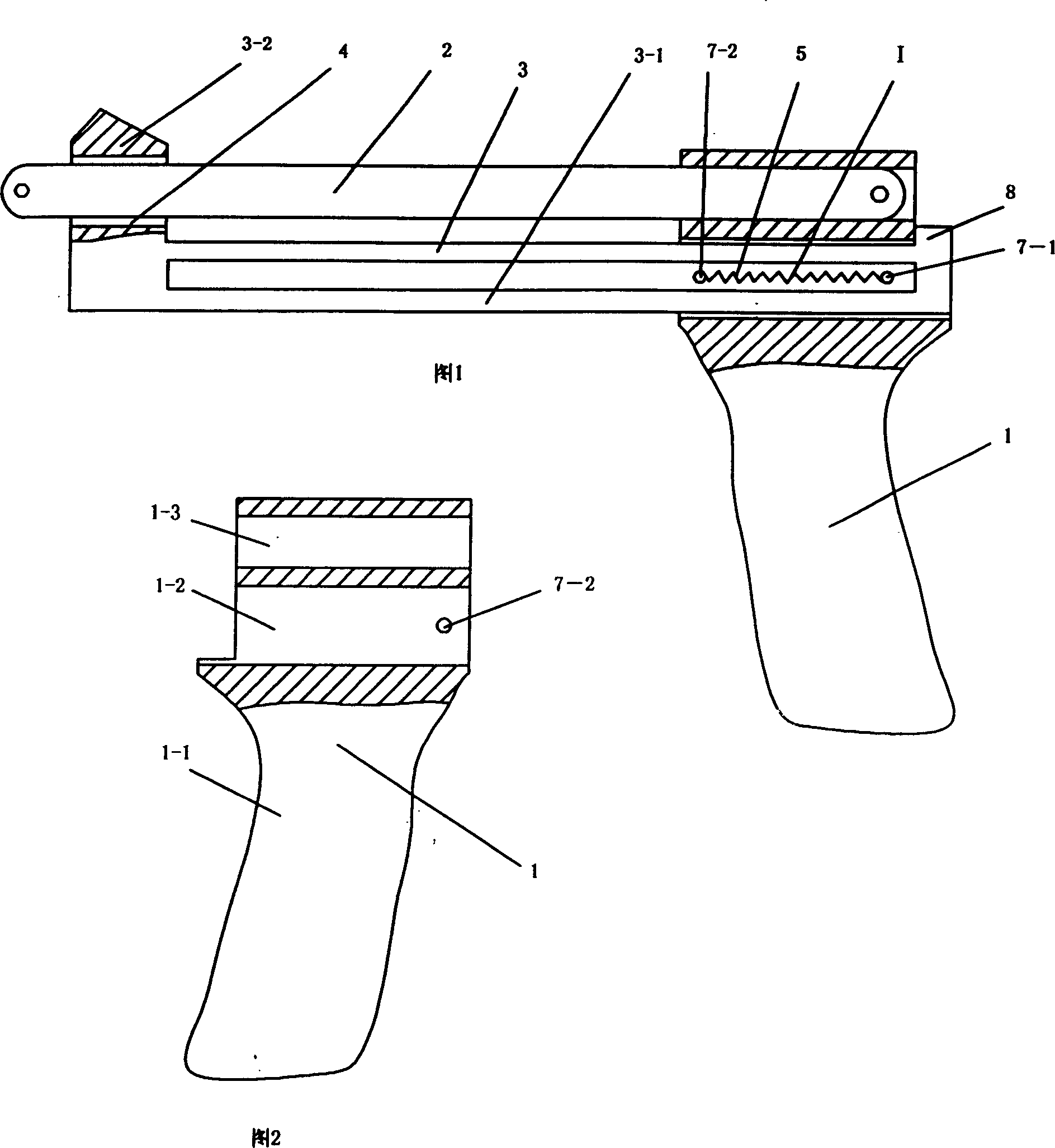

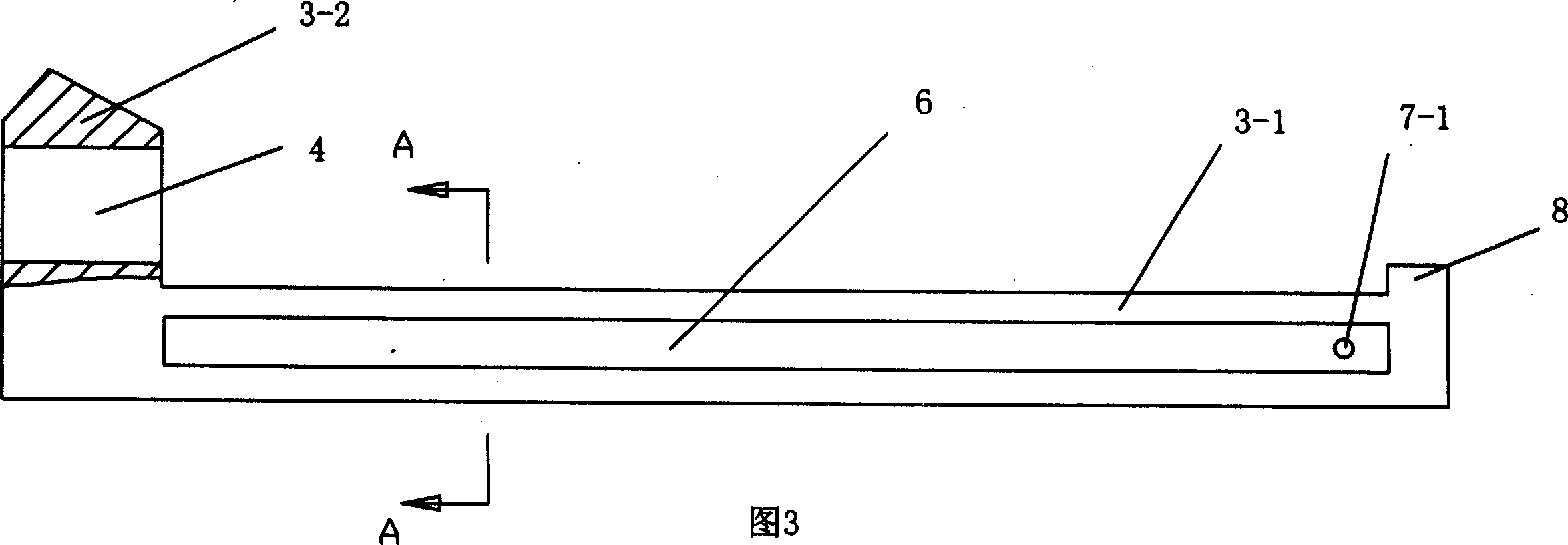

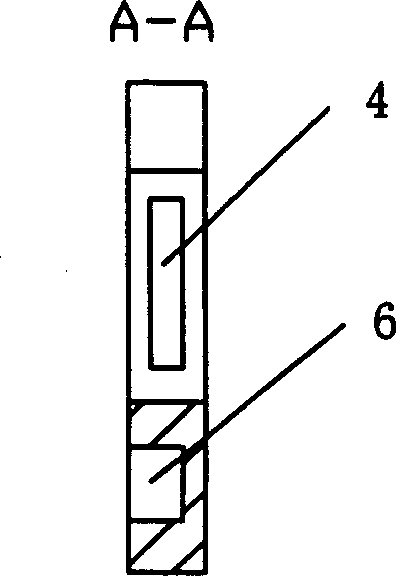

Fixed angle type needle holder

The present invention provides an angle fixing type needle holder for surgical operation, relating to medical instruments field, the needle holder comprises a needle holding body at front end and a hand-held operating handle (8) at rear end, the needle holding body comprises a couple of chucks (1) and (2) moving coaxially along a straight line, occlusal surfaces matching each other are provided between the chuck (1) and (2); an slope angle is formed between the occlusal surfaces and the principal axis of the needle holder; the chuck (2) is fixed on bottom of a hollow external tube (3), the chuck (1) is fixed on bottom of a pull rod (4) sleeved into the external tube (3) and movably connected to the external tube (3). According to the invention, the angle fixing type needle holder may alter holding angle of the needle in certain range such that the needle is hard to slidably drop or rotate in condition of small notch on body surface; and the needle holder may reliably suturing at deep position without damnifying tissue around.

Owner:华斌 +1

Bagged cement soil and its engineering application

The present invention discloses one kind of bagged cement soil and its engineering application. The bagged cement soil has the advantages of both cement soil and bagged soil, including wide material source and only needing small amount of cement and knitted bags; high compression strength of the structure up to 1 MPs; needing small work area and less disturbance on slope; no environmental pollution; low cost; needing no adhesive; etc.

Owner:XIANGTAN UNIV

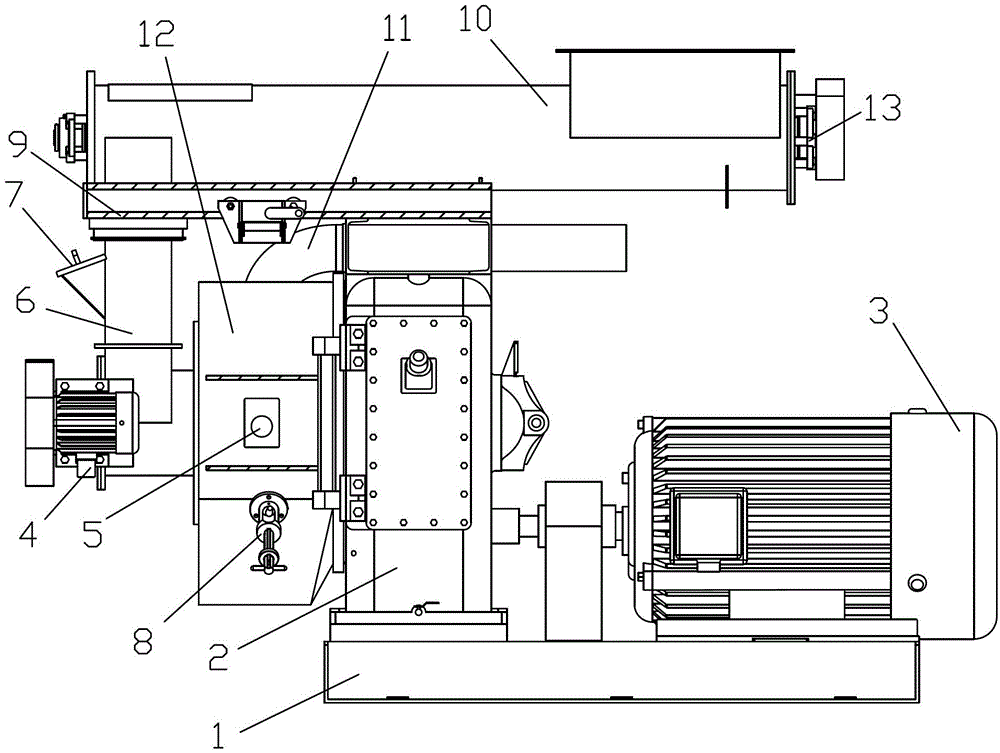

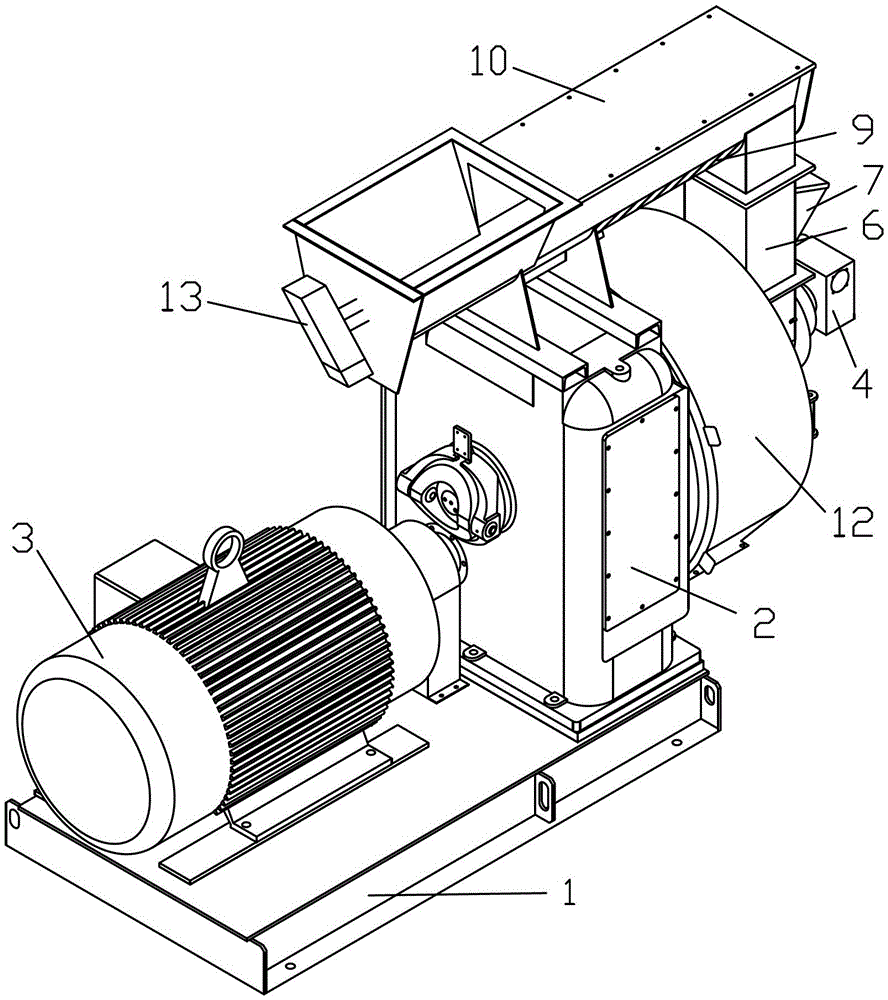

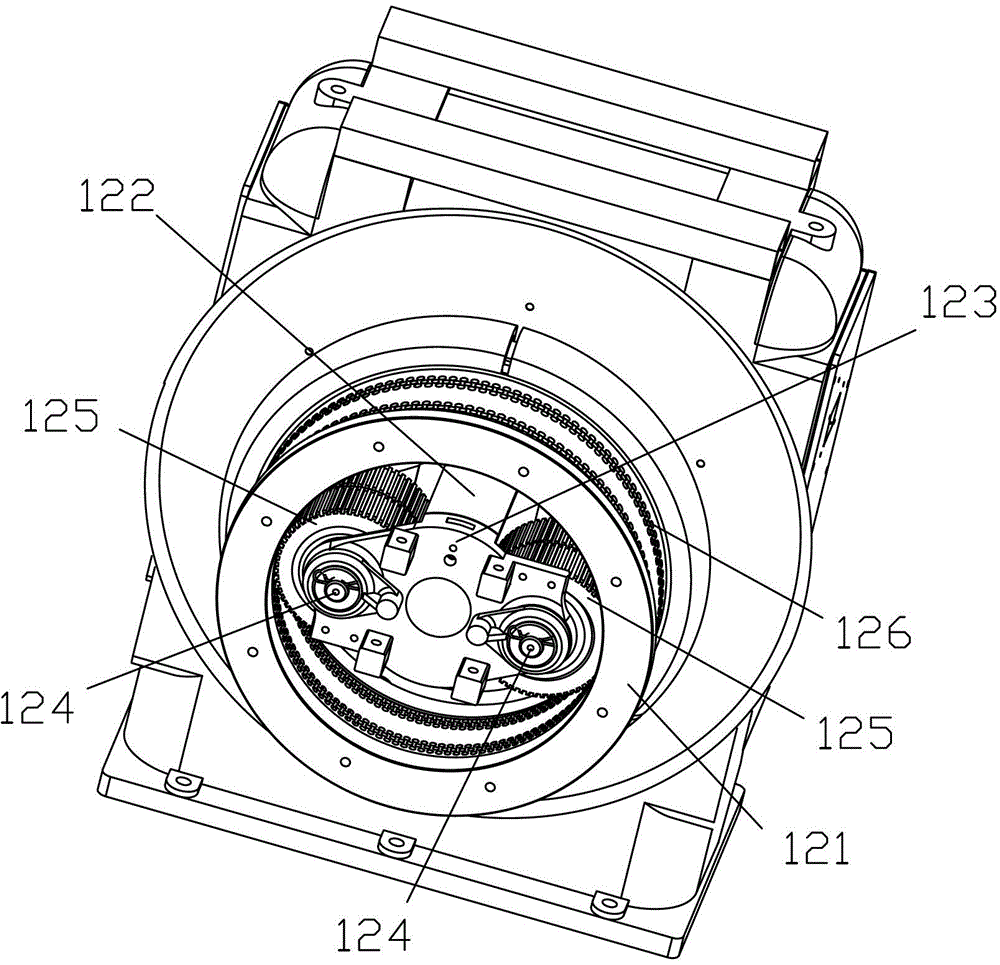

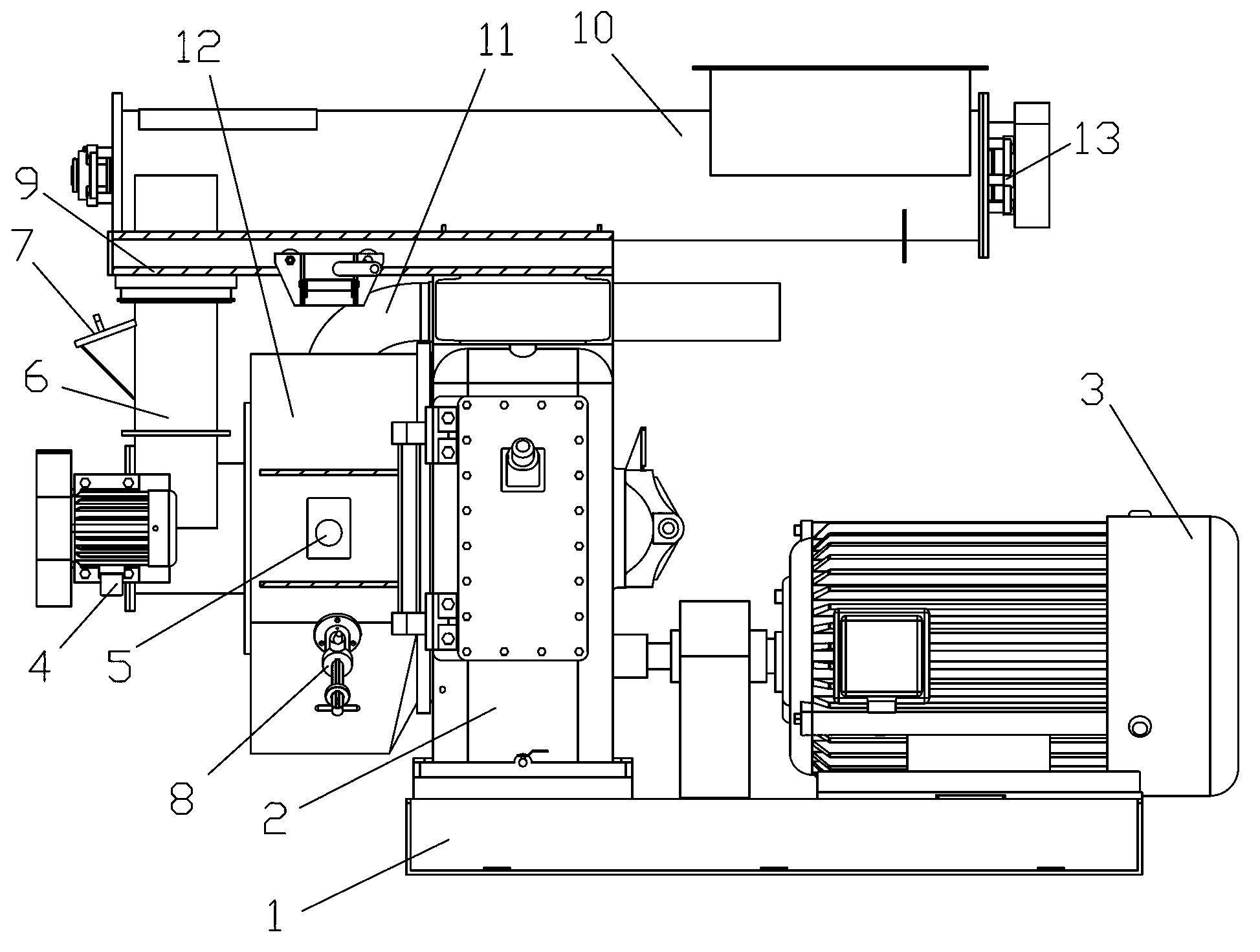

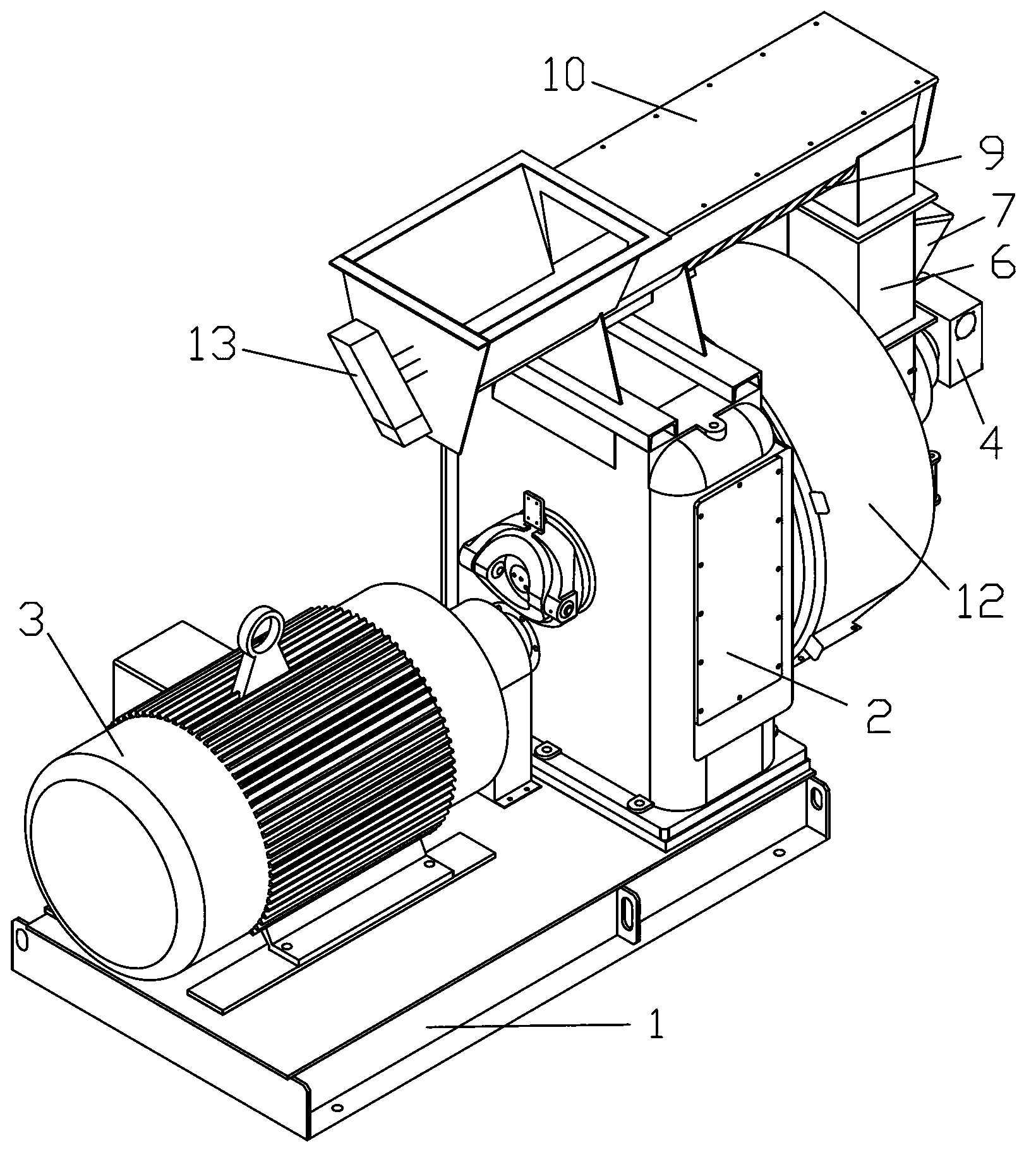

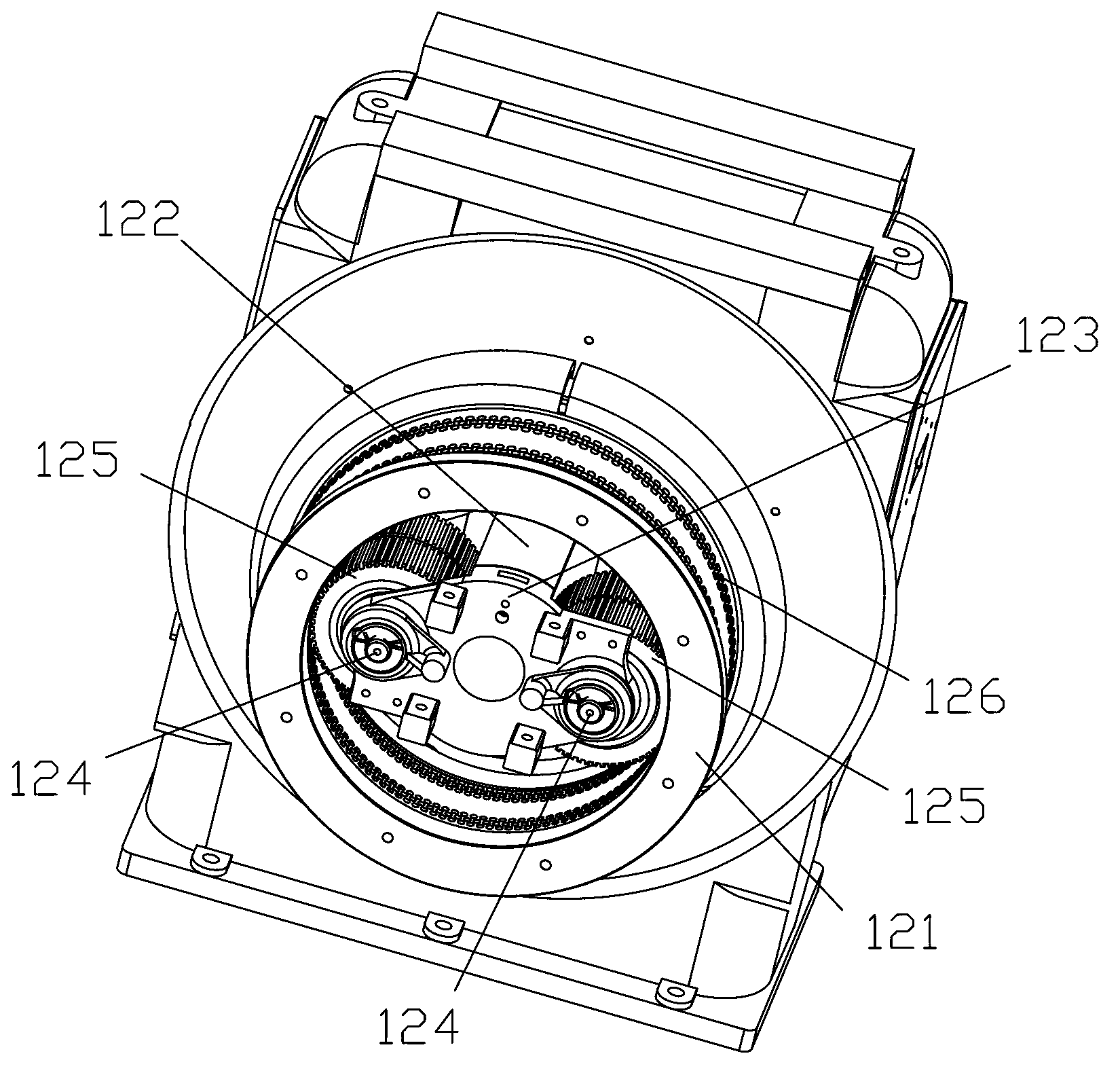

Granulator

ActiveCN103055761BEasy to operateIncrease productivityGranulation by material expressionGranulation by pressingEngineeringMechanical engineering

The invention discloses a granulator comprising a base, a first motor, a second motor, a feeding device, a supply pipe, a feed pipe, a pressing device and a transmission device. The second motor conveys materials from the supply pipe to the feeding device, and then the materials enters the pressing device to be pressed through the feed pipe; power required by pressing is provided by the first motor and transmitted to the pressing device through the transmission device; the pressing device comprises a main shaft, a circular mould, a main shaft pressure plate connected with the main shaft, two press roller shafts which are arranged in parallel on the main shaft pressing plate, and four press rollers; each press roller shaft is provided with two press rollers, and a distance is left between the two press rollers on each press roller shaft; and six rows of mould holes are formed in the circular mould, every three adjacent rows of mould holes are in one group, and a distance is left between each two groups of mould holes and is equal to that between the two press rollers on each press roller shaft. The granulator is simple to operate, and has the advantages of high production efficiency, low energy consumption and long service life.

Owner:JIANGSU JINWU MACHINERY CO LTD

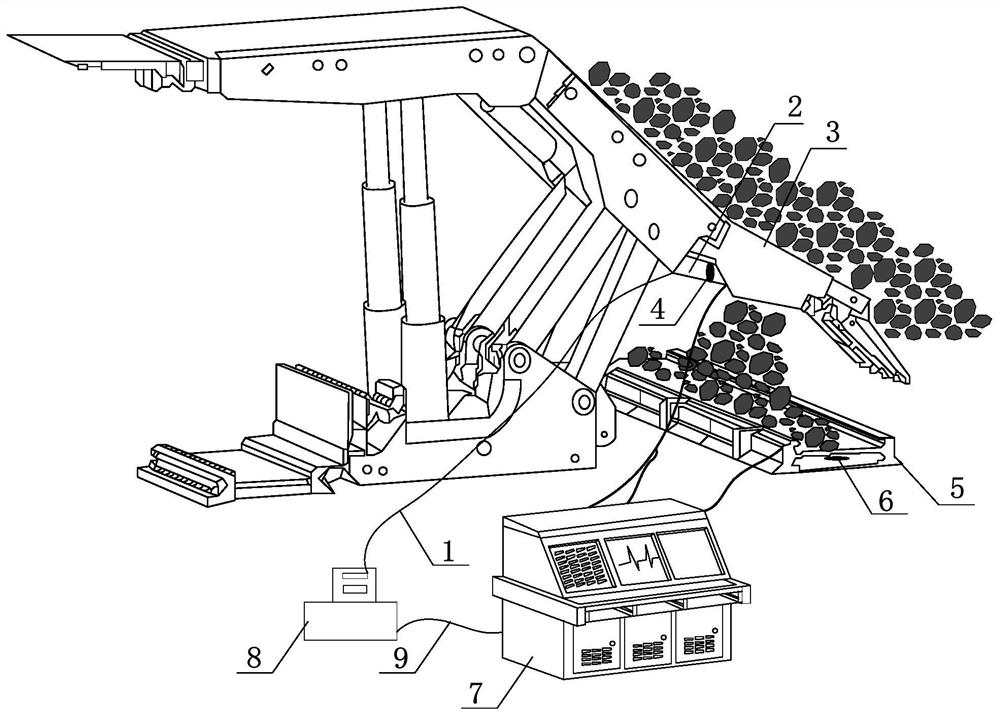

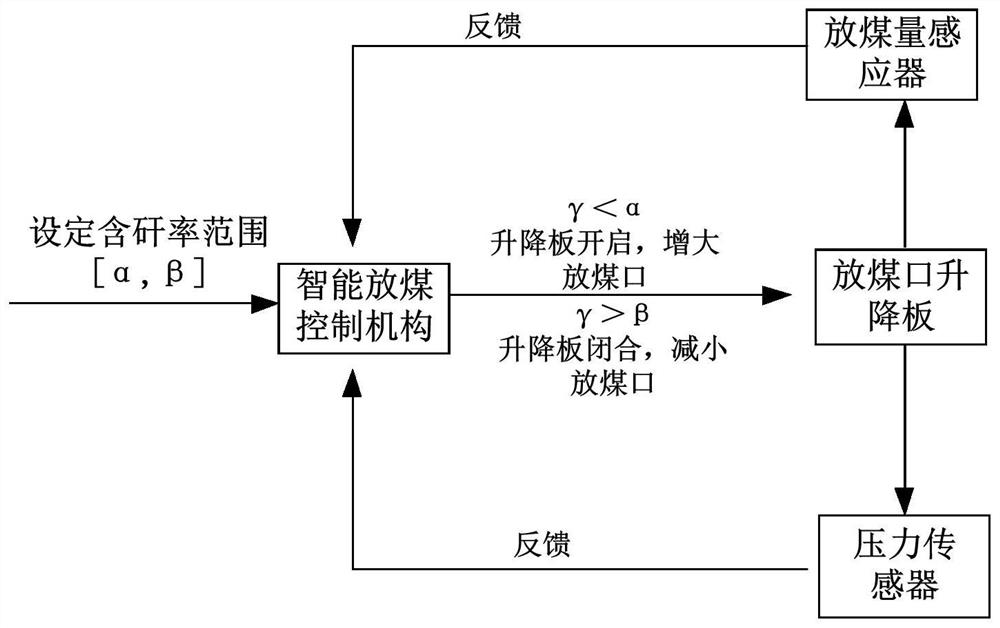

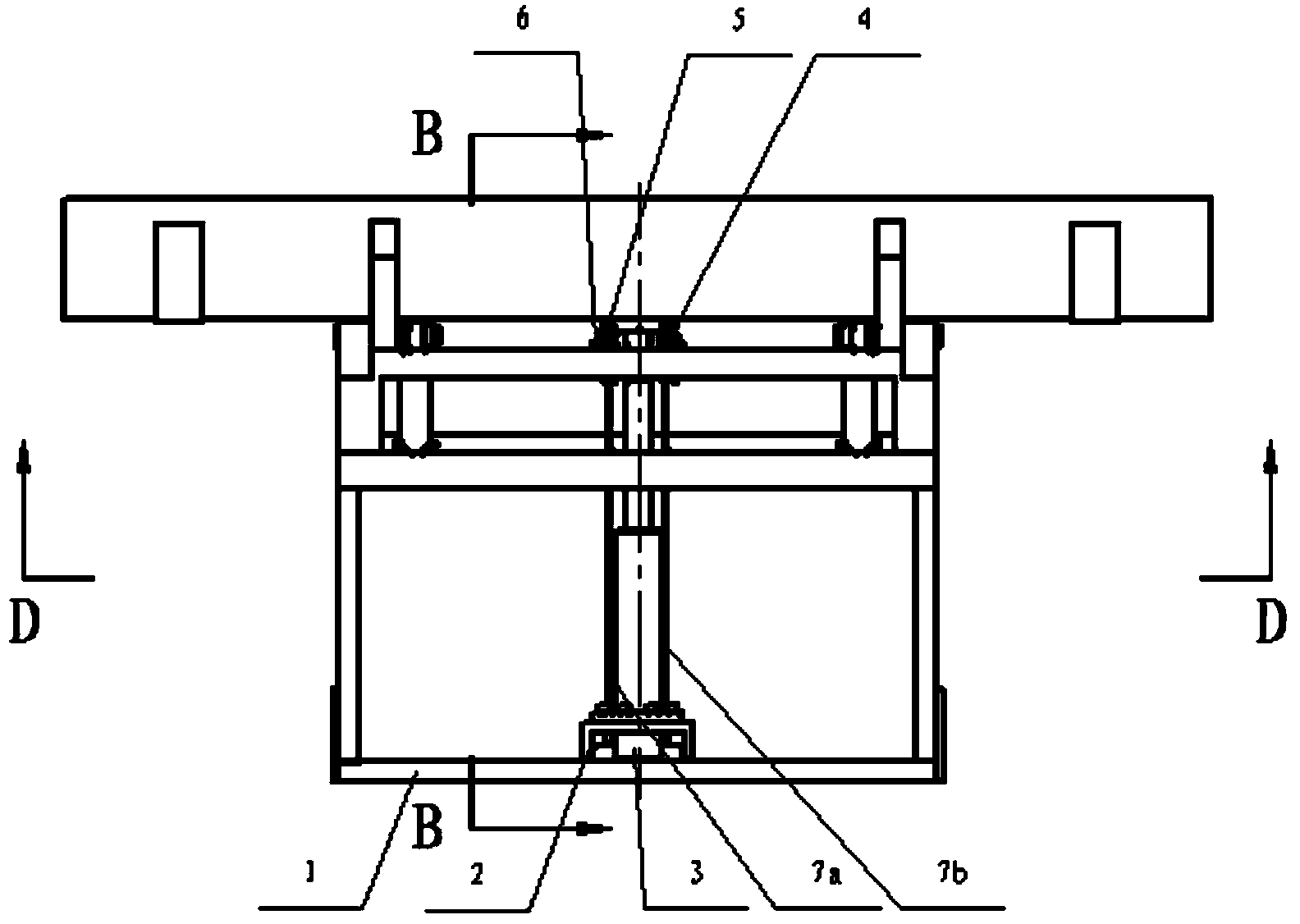

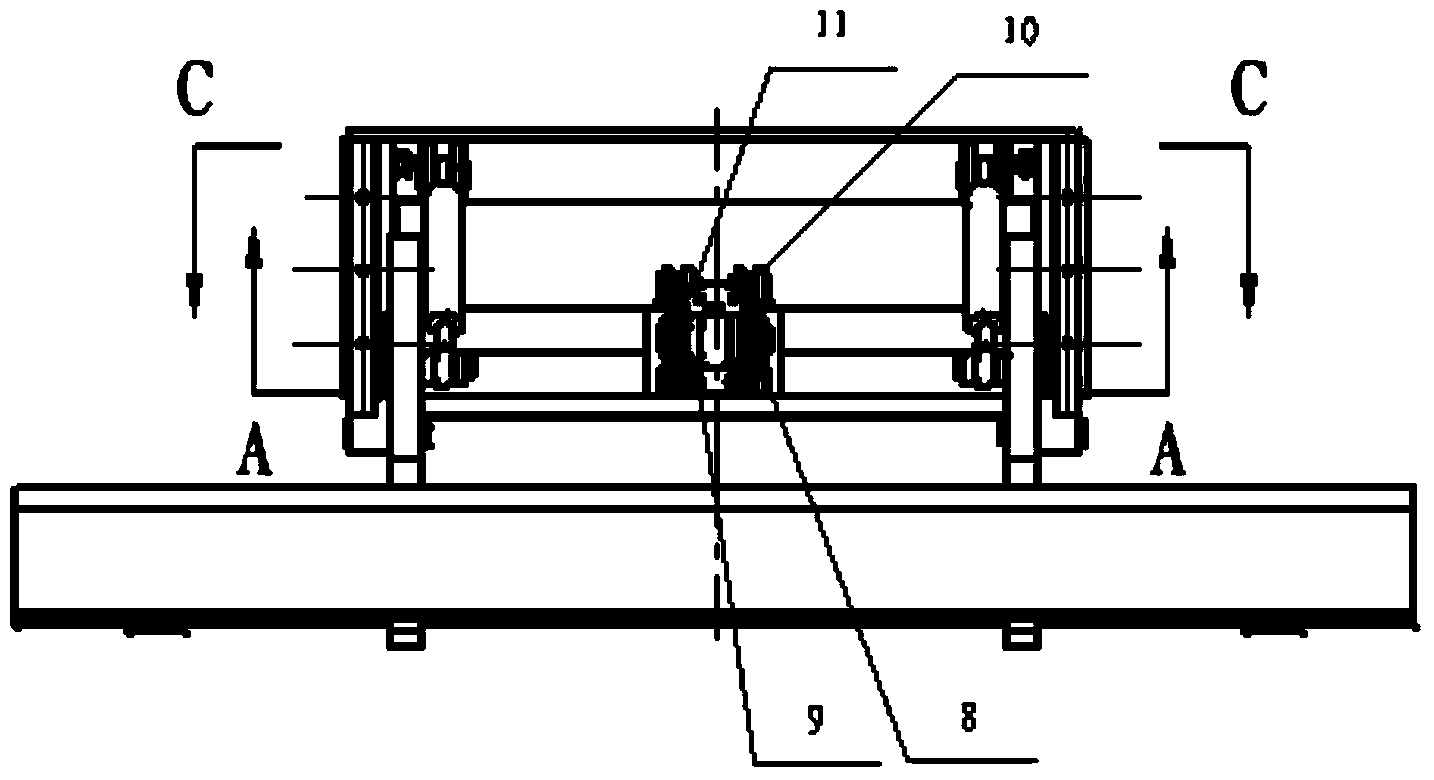

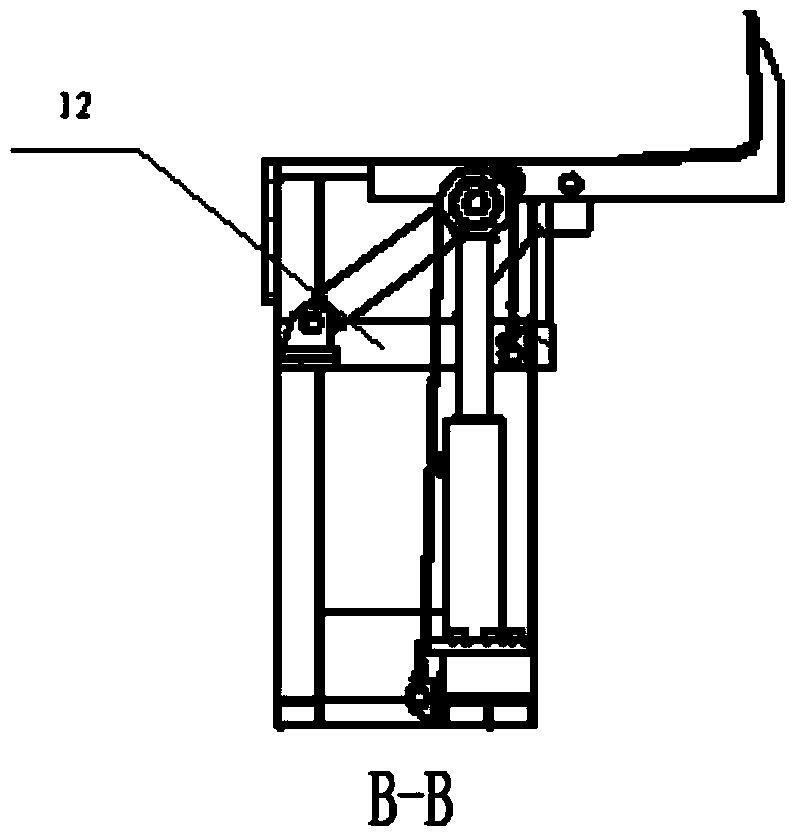

Intelligent coal control device and method for full-mechanized caving mining bracket of thick coal seam

InactiveCN111980739AImprove coal qualitySafe and efficient productionMine roof supportsUnderground transportControl systemStructural engineering

The invention provides an intelligent coal control device and method for a full-mechanized caving mining bracket of a thick coal seam, relates to the technical field of underground mining methods, andaims to solve the technical problems that a caving control system is complex in structure, is low in caving quality and the like. A caving control device comprises a caving mechanism, a coal carryingmechanism and a control mechanism, wherein the caving mechanism is arranged on the rear part of a full-mechanized caving hydraulic bracket, and comprises a hydraulic pipeline, a lifting movable column, a caving hole lifting plate and a caving amount inductor, and is used for controlling caving and monitoring the volume of outlet coal; the coal carrying mechanism is arranged below a hydraulic bracket, and comprises a scraping plate conveyor and a pressure sensor for conveying coal gangues and monitoring weight; and the control mechanism comprises a computer, an electric-hydraulic controller and a control cable for monitoring and judging caving quality and controlling caving. After coal refuse content is set by the device, monitored data of the caving amount inductor and the pressure sensorare combined to judge and regulate opening and closing of a caving hole. The device and the method provided by the invention further have the advantages of being simple in structure, flexible in operation, safe and efficient, and the like.

Owner:中煤能源研究院有限责任公司

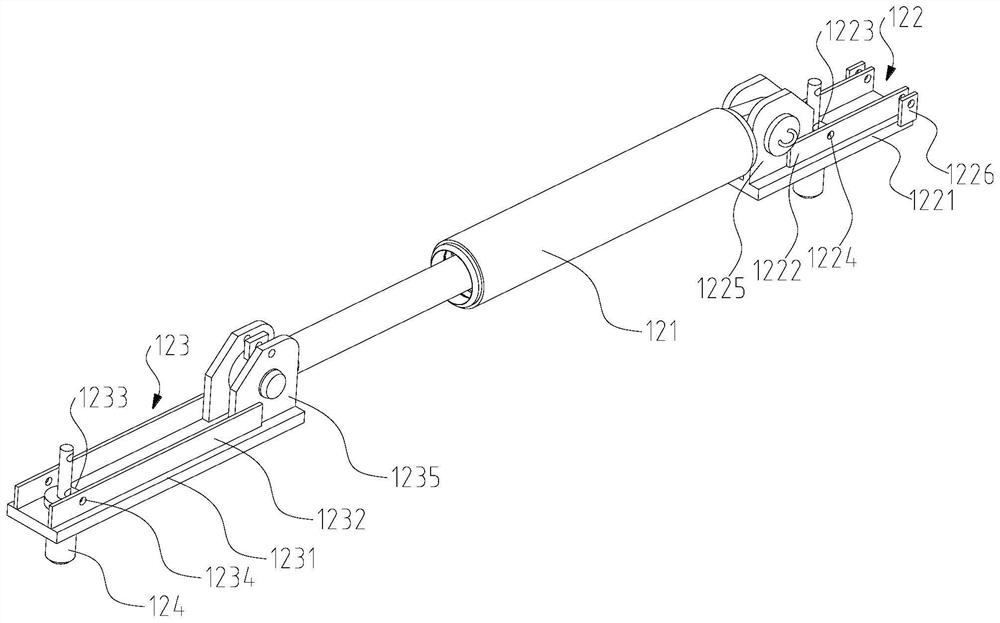

Automatic lifting device for drill pipes

The invention discloses an automatic lifting device for drill pipes. The automatic lifting device comprises a rack, a drill pipe lifting mechanism, a drill pipe bracket and a drill pipe pushing mechanism. By the aid of the automatic lifting device, the drill pipes can be pushed from one working platform to another working platform one by one. A cylinder barrel of a lifting cylinder is fixedly connected with the rack through a support; pulleys are connected with a piston rod of the drill pipe lifting cylinder through shaft hinging; two ends of each lifting steel wire rope are fixedly connected with a supporting frame and the rack respectively; turnover oil cylinders are hinged to the supporting frame and drill pipe forks respectively; the drill pipe forks are hinged to the supporting frame; and the supporting frame and the rack can slide relatively. According to the automatic lifting device for the drill pipes, the drill pipe lifting mechanism adopts a movable pulley structure, so that the lifting mechanism is effectively simplified, and the operation is simple. The drill pipe pushing mechanism adopts a link mechanism consisting of the oil cylinders and the drill pipe forks and is simple in structure, small in size and high in practicability.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

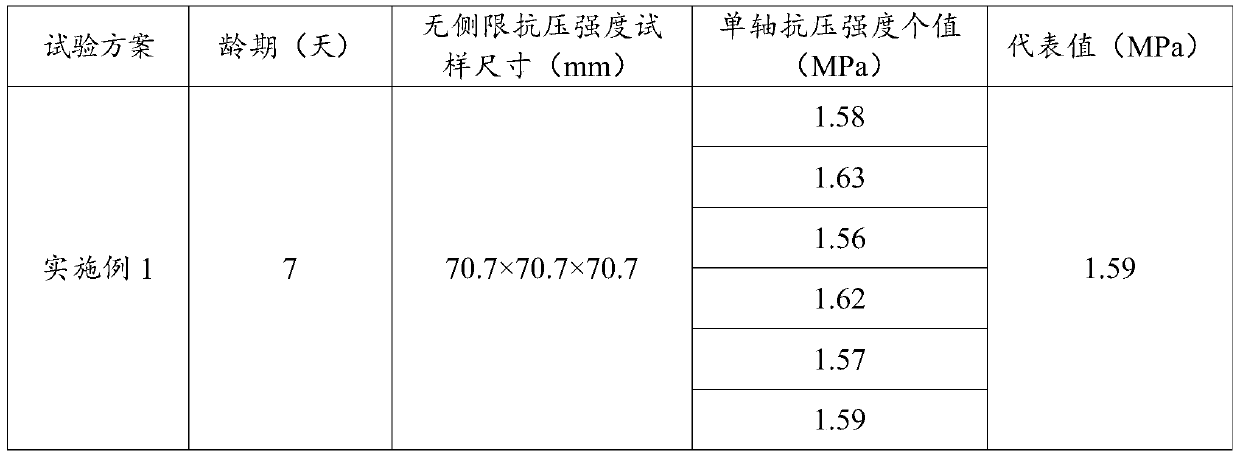

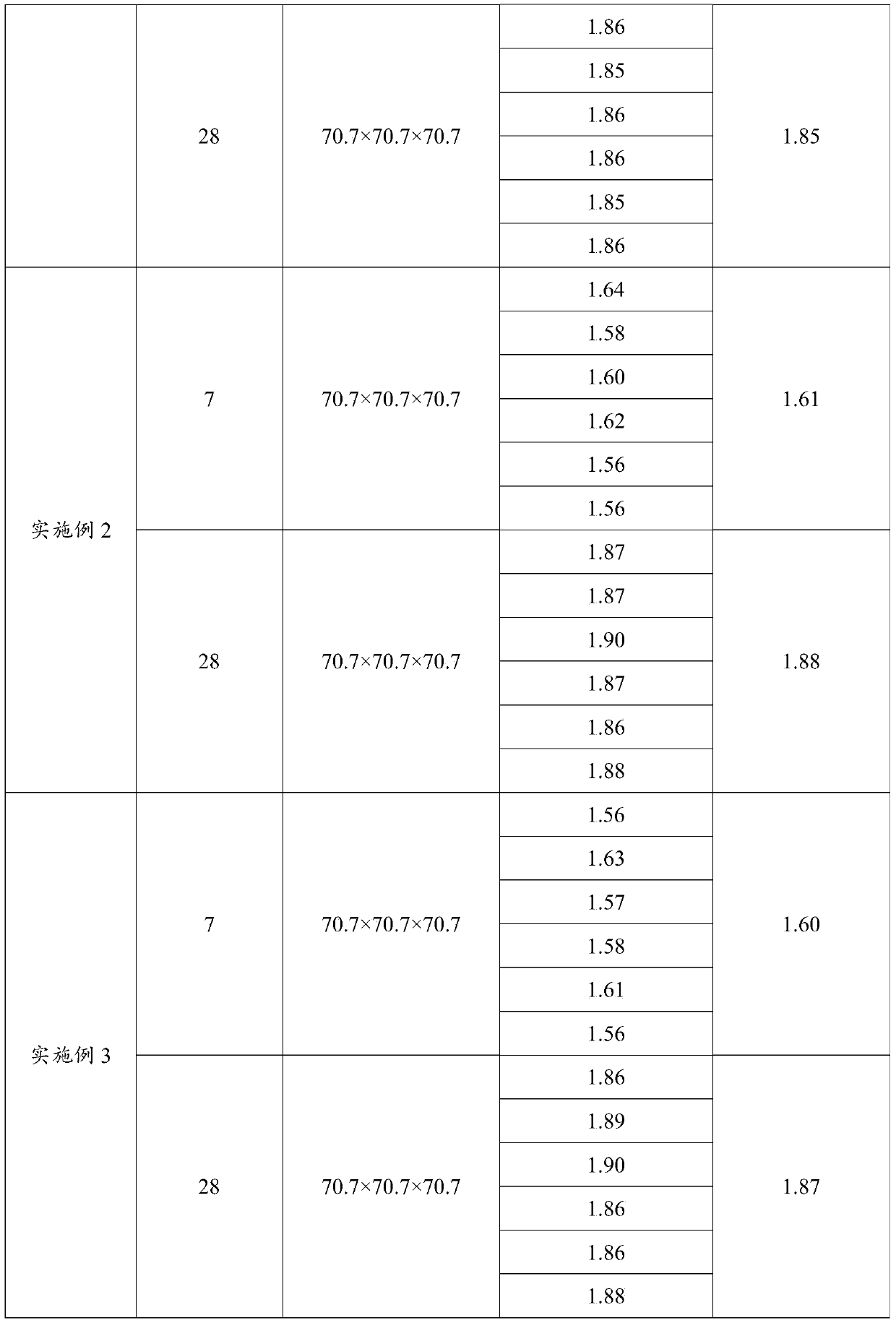

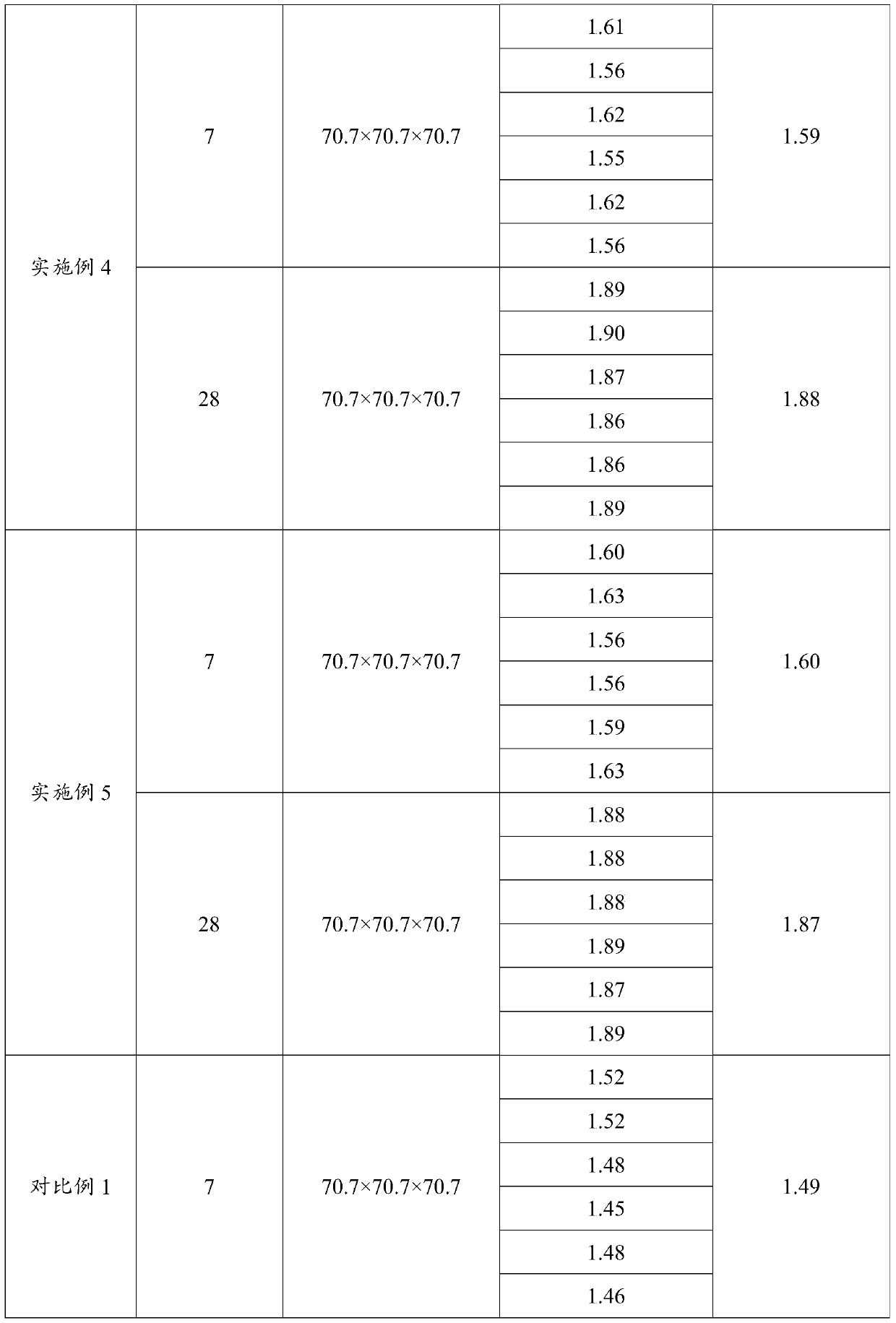

Early-strength cement soil as well as preparation method and application thereof

The invention discloses an early-strength cement soil as well as a preparation method and application thereof. The early-strength cement soil is composed of the following components in parts by weight: 23-25 parts of water, 65-75 parts of soil, 0.5-1 part of a quick-setting anti-permeability agent and 5.5-7 parts of cement, wherein the quick-setting anti-permeability agent is a mixed powder material of fly ash and water glass, and the mass ratio of the fly ash to the water glass is (90-95): (5-10). The early strength cement soil has the advantages of high early strength, short curing time, short construction period, extremely strong fluidity and self-sealing property, controllable construction quality and good impermeability.

Owner:THE QINGDAO ENG CO LTD OF CHINA RAILWAY NO 10 ENG GRP CO LTD +1

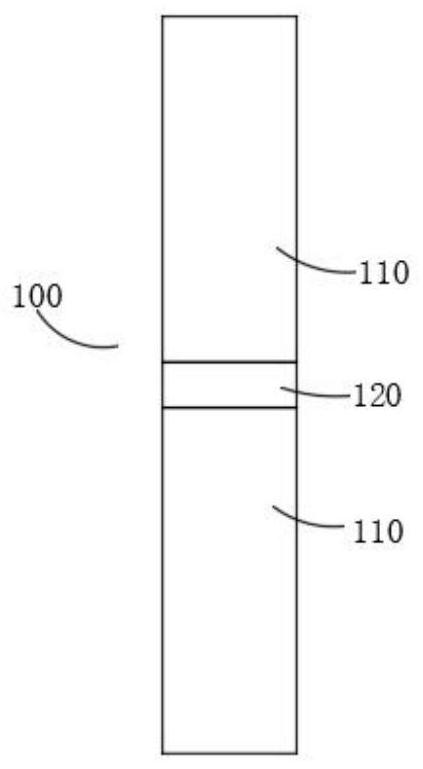

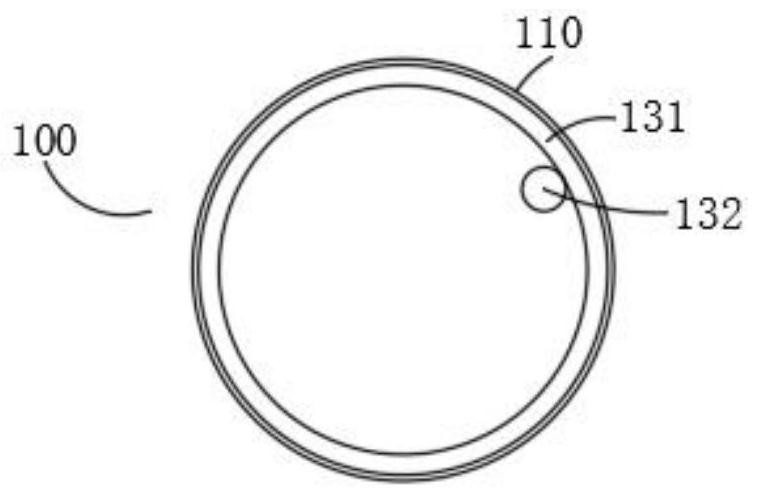

Filter element

PendingCN112237811AReduce areaSolve the costCombination devicesDispersed particle filtrationFiltrationEngineering

The invention discloses a filter element. The filter element is placed in a filter to be used for carrying out gas-solid separation filtration and / or liquid-solid separation filtration on an object tobe filtered during use; the filter element comprises at least two filter tubes which are arranged at intervals, and tube bodies of the filter tubes are formed by shaping metal or sheet-shaped materials taking the metal as a base body in a rolled mode and carrying out sealing processing on joints; the outer diameter of the tube body formed by rolling is only 20-200 mm, preferably 20-90 mm, furtherpreferably 20-60 mm, and further preferably 25-50 mm, and the outer diameter of the tube body formed by rolling is only 20-200 mm, preferably 20-90 mm; the lengths of the filter tubes range from 100mm to 5000 mm, preferably range from 100 mm to 3000 mm, further preferably range from 100 mm to 2000 mm, and further preferably range from 200 mm to 1500 mm. A plurality of small-diameter filter tubesare bundled, so the filtering area can be remarkably increased in a limited mounting space; the length of the filter element is reduced, so the blowback effect can be more uniformly distributed in the axial direction of the filter tubes. Therefore, the technical problems that in the prior art, a filter element is small in filtering area and poor in back flushing effectiveness are effectively solved.

Owner:CHENGDU INTERMENT TECH

Energy-saving classroom lamp

InactiveCN101109490AAchieve standardizationImprove efficiencyProtective devices for lightingLight fasteningsEngineering

Owner:SICHUAN XINDACHANG ELECTRIC & LIGHTING

Saw

InactiveCN1806984AAvoid breakingSmall working surfaceMetal sawing devicesMechanical engineeringCircular segment

The invention discloses a saw. The current saw comprises a saw frame and a saw blade composed by a bow back of the saw and a handle. When there is barrier, or the cutting depth is beyond the length between saw blade and bow back of the saw, the sow can't be used. The said saw comprise saw frame, saw blade and slipping strip. The slipping strip comprises long side and short side, and they form L shape. The long side is connected with saw frame through resetting-mechanism, and the on the short side there is mouth to prevent flexibility. One end of saw blade is connected with saw frame, and the other end of saw blade is free end. The invention has the advantages of reasonable structure, little operating area, wide sphere of application and strong intensity.

Owner:洪传

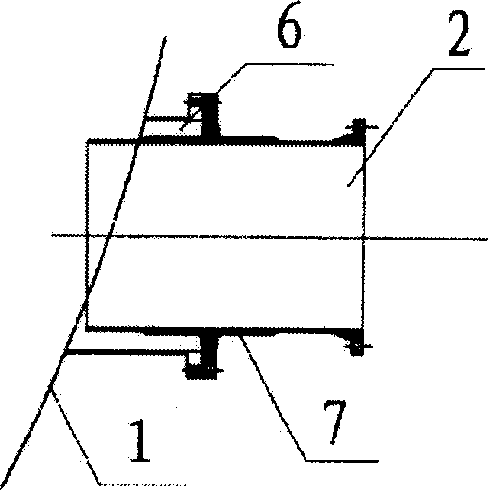

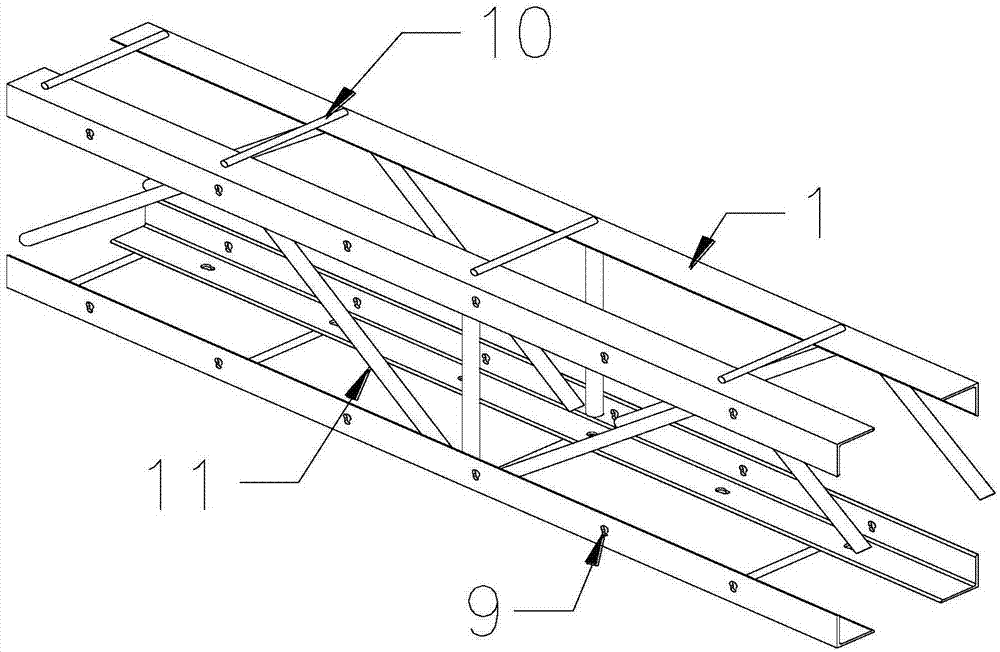

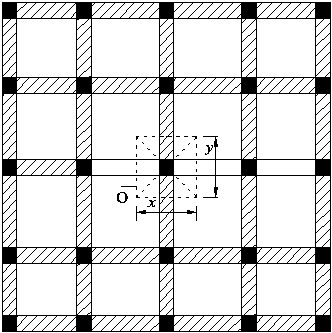

Floor surface structure assembled with internal keels and external formworks

A floor surface structure assembled with internal keels and external formworks comprises the side formworks, the bottom formwork, the structural steel keels, hoops, main bars, sleeves, connecting bolts and the like. According to the floor surface structure assembled with the internal keels and the external formworks, the structural steel keels are utilized to construct a truss to serve as a stress structure in the construction stage to bear the load of the construction stage; in the structure using stage, stress steel bars equivalently serving as a structure structural beam participates in the structural whole stress; and meanwhile, a certain number of connecting holes are pre-punched in the side walls of the internal keels in the length direction according to a certain modulus, the formworks, the internal keel truss, steel bar frameworks and the like are connected into a whole through the connecting bolts in the construction stage so as to form a stable system with the closed side and bottom faces, and thus pouring of concrete is facilitated.

Owner:SHANGHAI OPEN STEEL JOIST

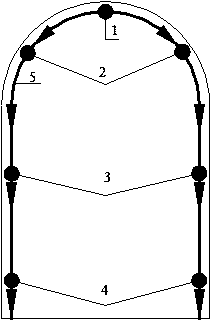

Spray anchor net hanging construction method capable of being used for roadway surrounding rock support

InactiveCN110685721AFlexibleHigh hanging net areaUnderground chambersTunnel liningArchitectural engineeringRock bolt

The invention relates to a roadway construction method, particularly relates to a spray anchor net hanging construction method capable of being used for roadway surrounding rock support, and solves the net hanging problem of steel plastic grilles in roadway engineering. The method comprises the following steps that the flatness of surrounding rock is determined, loose broken stones on the surfaceof the surrounding rock are cleared, the width of the steel plastic grilles is determined, drilling is carried out, the steel plastic grilles are laid sequentially and symmetrically according to the sequence of an arch crown, an arch waist, a side wall and a footing, an anchor rod is installed, the installation quality is checked, and hanging supplementing is carried out. Through the net hanging method, the roadway construction working face is saved, the roadway net hanging efficiency is improved, the labor intensity of construction personnel is reduced, the stability of the roadway surrounding rock is guaranteed, and the safety and high efficiency of roadway excavation are ensured.

Owner:张军贤 +1

Filter

PendingCN112237810AReduce areaSolve the costCombination devicesDispersed particle filtrationProcess engineeringControl theory

The invention discloses a filter. The filter comprises a filter structure, and the filter structure comprises at least two filter elements which are arranged at intervals; the filter element comprisesat least two filter tubes which are arranged at intervals, and tube bodies of the filter tubes are formed by shaping metal or a sheet-shaped material taking the metal as a base body in a rolling manner and performing sealing processing on joints; and the outer diameter of the pipe body formed by rolling is only 20-200 mm. The bundled filter element formed by bundling a plurality of small-diameterfilter tubes is adopted, so that the filtering area can be remarkably increased; for a filter with a large size, the weight of a single filter element can be reduced by adopting a plurality of cluster type filter elements while a high filtering area is ensured, and the installation is simplified; for a filtering structure needing a large number of filter tubes, a plurality of cluster type filterelements are respectively mounted, so that a relatively uniform blowback effect can be ensured. Therefore, compared with the prior art, the filter has the advantages that a larger filter area can be achieved, and the problems of installation and blowback after the filter pipes are bundled are solved.

Owner:CHENGDU INTERMENT TECH

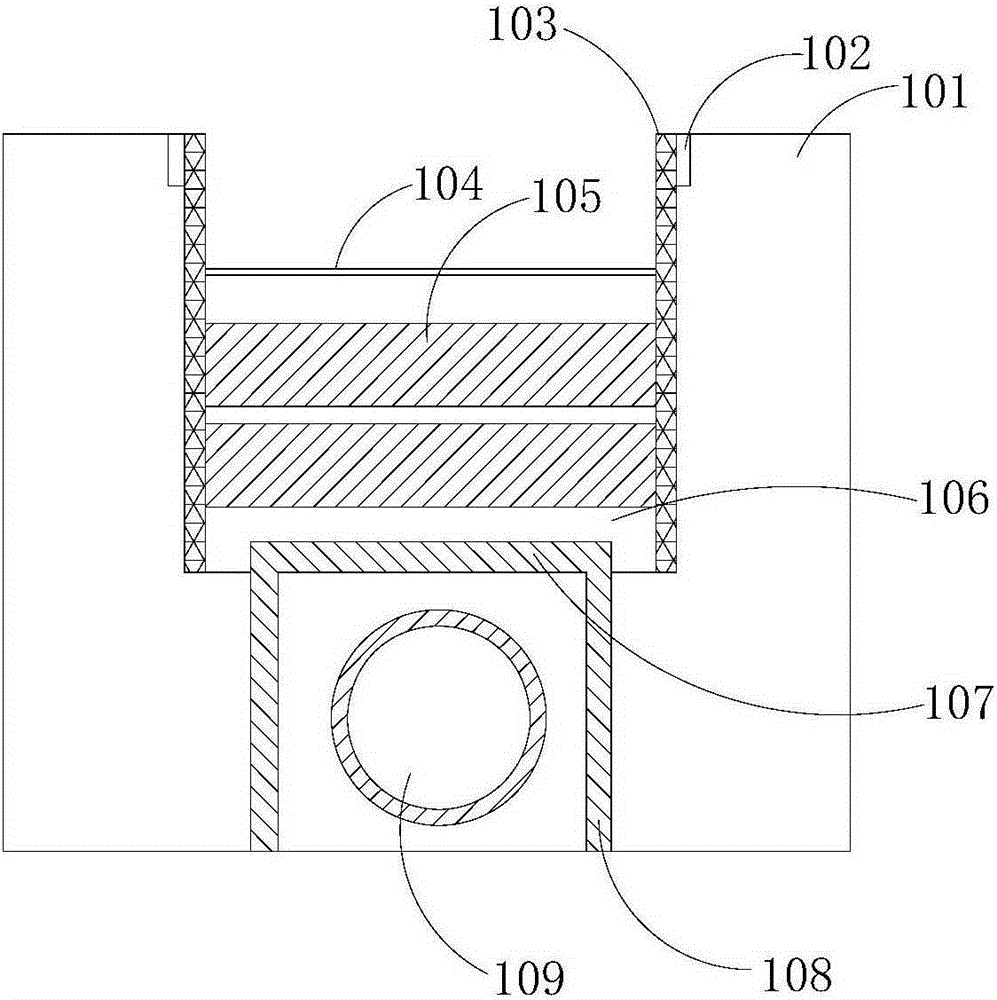

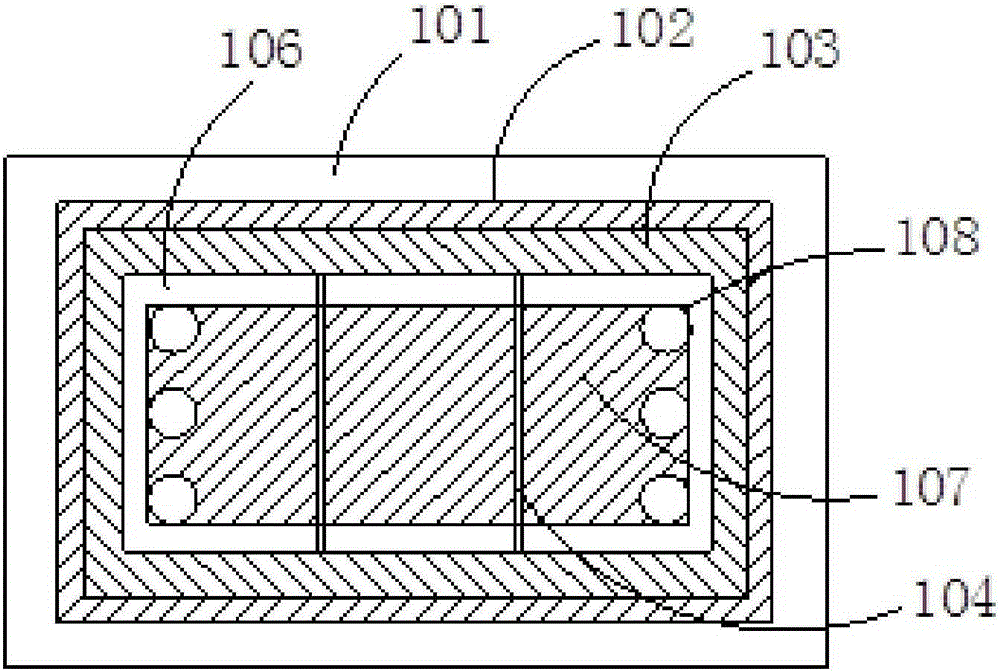

Granulator

InactiveCN103263876AEasy to operateIncrease productivityGranulation by pressingEngineeringMechanical engineering

The invention discloses a granulator which comprises a base, a first motor, a second motor, a feeding device, a feeding pipe, a conveying pipe, a pressing device and a transmission device, wherein the second motor is used for conveying materials to the feeding device from the feeding pipe, then the materials enter the pressing device through the conveying pipe to be pressed; power required by pressing is provided by the first motor, and is transmitted to the pressing device through the transmission device; the pressing device comprises a main shaft, a circular mould, a main shaft pressing plate connected with the main shaft, two roll pressing shafts arranged on the main shaft pressing plate in parallel, and four pressing rolls; and two pressing rolls are arranged on each roll pressing shaft, spacing is set between the two pressing rolls on each roll pressing shaft, six rows of mould holes are formed in the circular mould, and every three adjacent rows of mould holes form one group, and spacing is set between two groups of mould holes. The space between the two groups of mould holes is equal to the spacing between the pressing rolls on each roll pressing shafts. The granulator disclosed by the invention is simple to operate, high in production efficiency, low in energy consumption and long in service life.

Owner:JIANGSU JINWU MACHINERY CO LTD

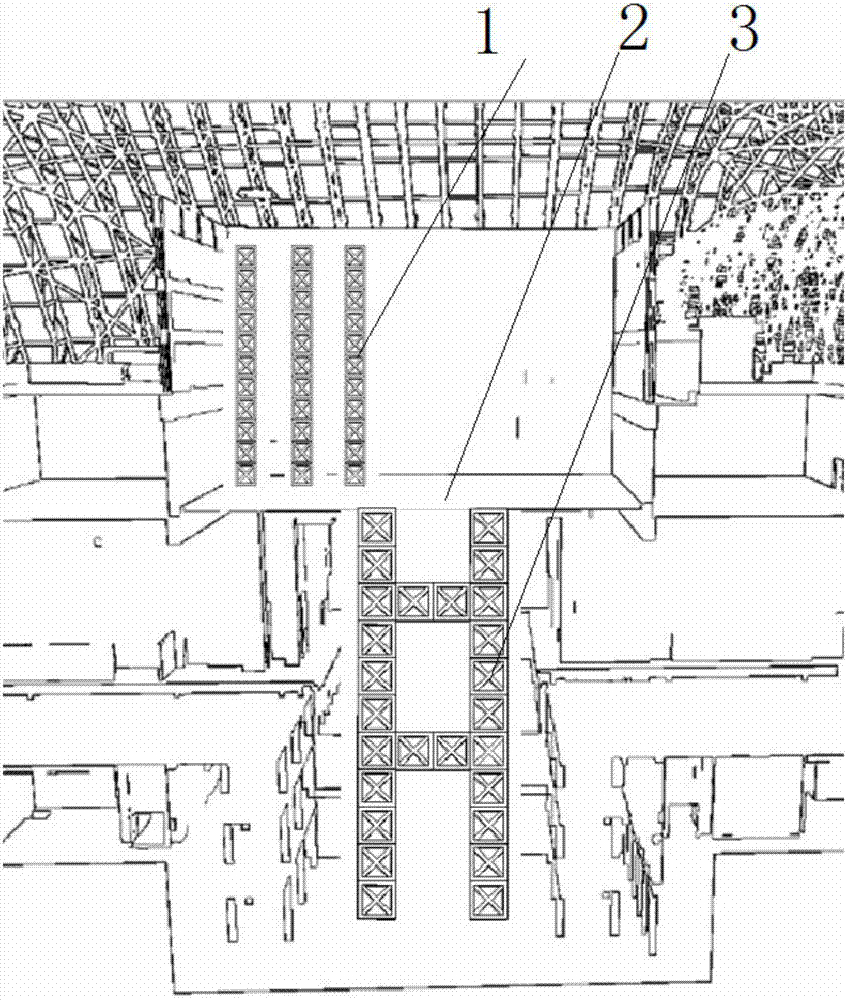

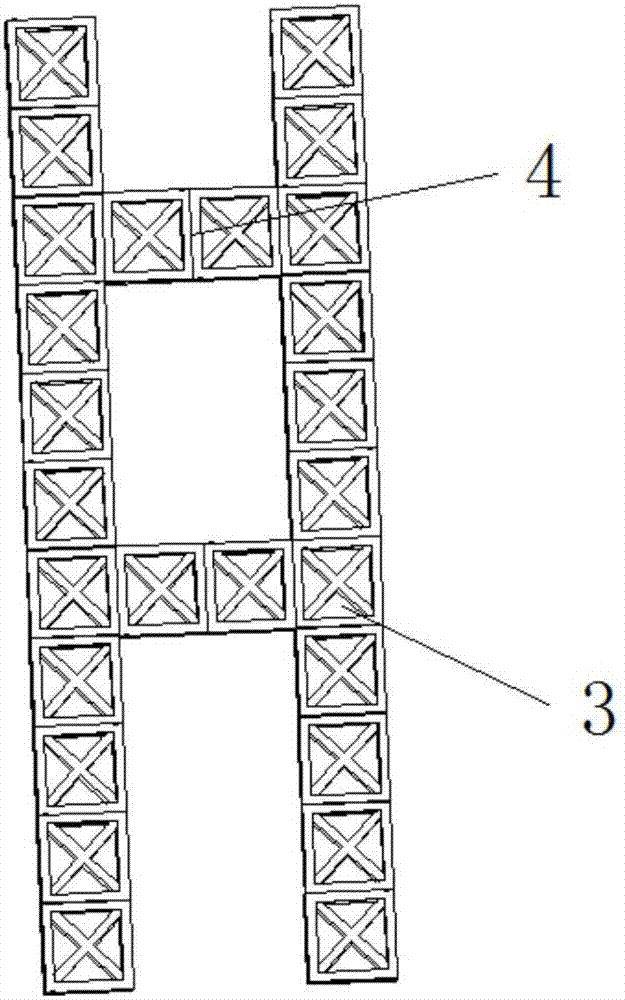

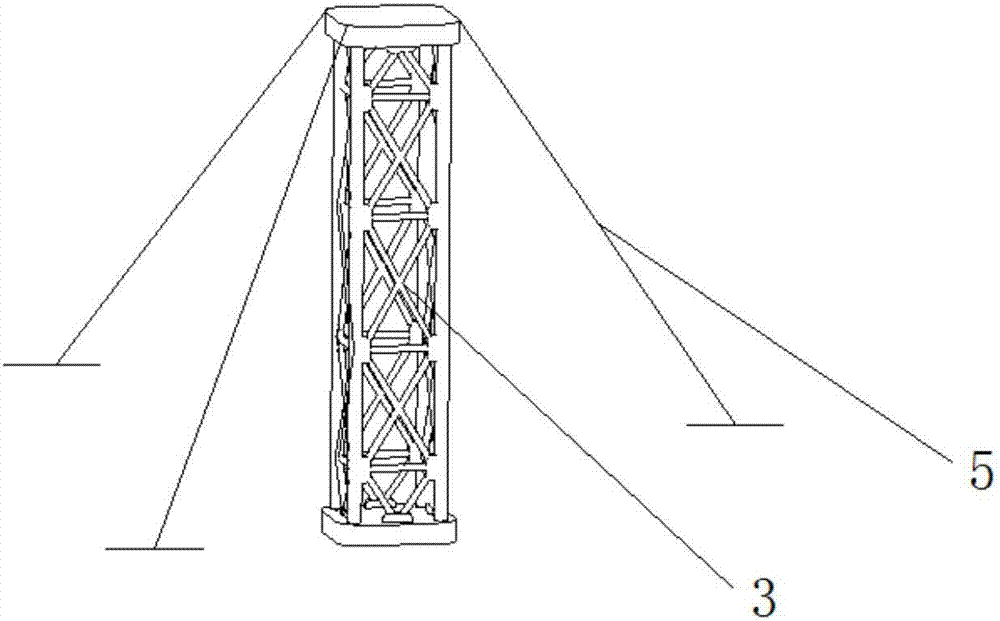

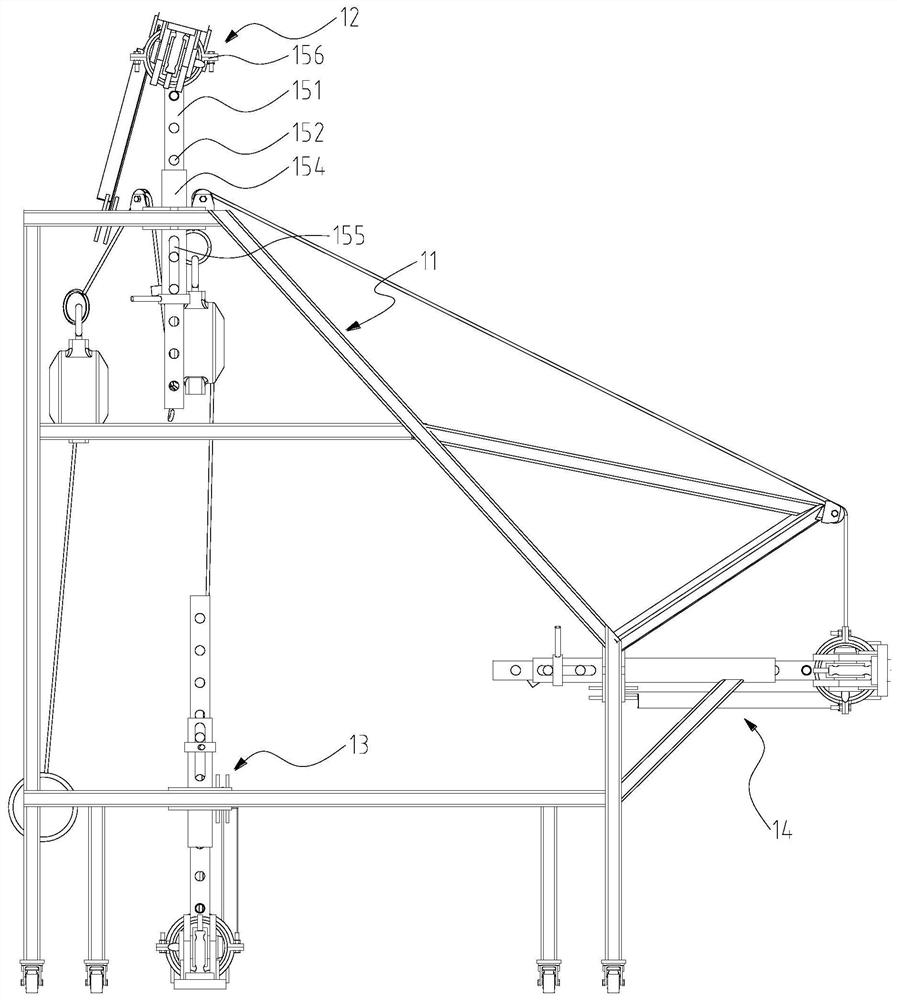

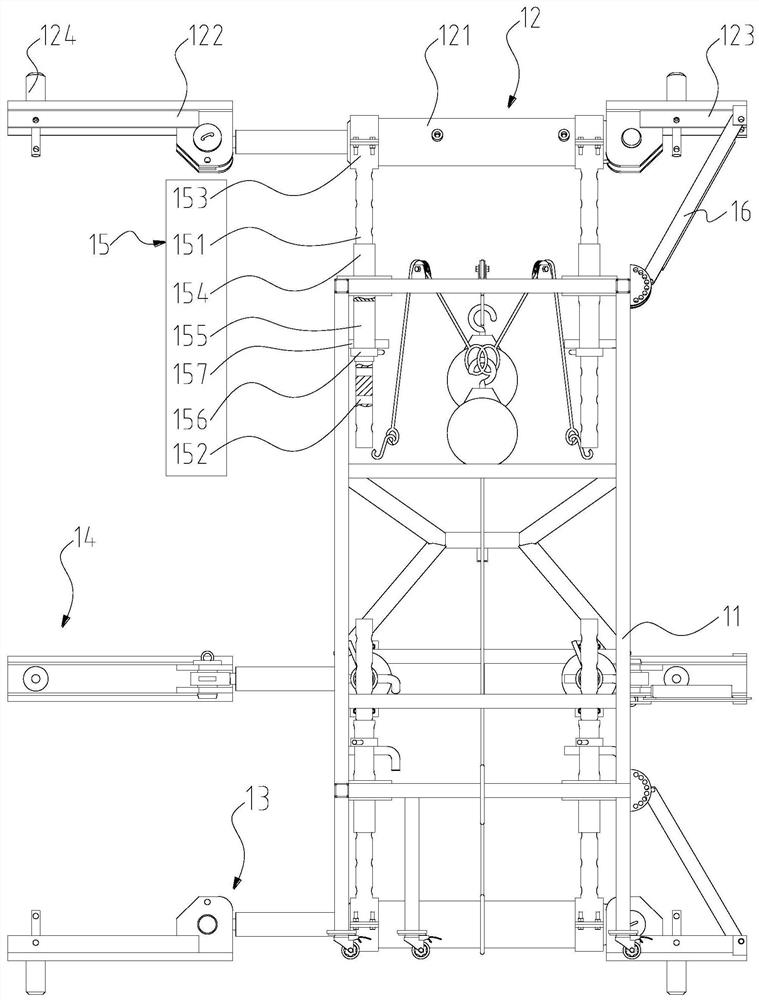

Installation support structure for theater main stage steel beam and construction method of structure

InactiveCN107476614AEasy to operateGuaranteed stabilityBuilding material handlingTheatresSupporting systemConcrete beams

The invention discloses an installation support structure for a theater main stage steel beam. The installation support structure comprises a first support system, a switching platform and a second support system, wherein the first support system comprises a plurality of first latticed columns and transverse supporting beams, the first latticed columns are vertically and fixedly arranged on the ground, and the transverse supporting beams are supported by the first latticed columns and horizontally and fixedly arranged on the top surfaces of the first latticed columns; the switching platform is laid and fixed to a supporting table surface formed by the transverse supporting beams and longitudinal concrete beams; the second support system comprises second latticed columns, the second latticed columns are arranged on the switching platform and support the steel beam in the sectional installation of the steel beam, and the purpose of installing the steel beam in a section-by-section unloading and propelling mode is achieved. The installation support structure is suitable for construction of a multi-layer ultra-high hanging type steel structure which is large in span and large in lower support height, has few working faces and has high installation precision requirements.

Owner:NANJING CHINA CONSTR CHEM EQUIP MFG

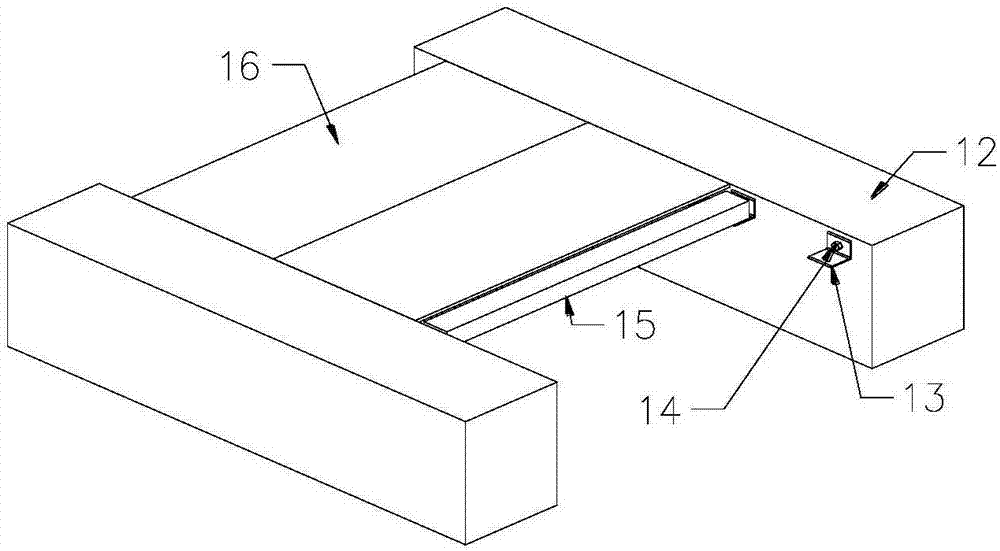

Prefabricated pipe gallery, prefabricated pipe gallery assembly stand and assembly method

ActiveCN111424708BPlay a reinforcing roleReduce weightArtificial islandsUnderwater structuresArchitectural engineeringStructural engineering

The assembled pipe gallery, the assembly platform of the assembled pipe gallery and the assembly method of the present invention belong to the field of pipe gallery construction, and the purpose is to solve the problem of inconvenient construction of the pipe gallery. The prefabricated pipe gallery includes a base with slide rails and a pipe gallery body supported on the slide rails; the pipe gallery body is assembled by butt joints of N sections of pipe gallery segments along the longitudinal direction, between the pipe gallery body and the U-shaped base Concrete is poured in between. The prefabricated pipe gallery is easy to manufacture and environmentally friendly. The assembly platform of the assembled pipe gallery includes an adjustment platform located on the outside of the lower section of the pipe gallery section for adjusting the section of the lower section of the pipe gallery section, and an adjustment platform located in the inner cavity of the section of the pipe gallery section for tensioning two adjacent sections of the pipe gallery Segmental tensioning platform; the assembled platform has a simple structure and a small size of the tensioning platform, which can be used in the inner cavity of the section of the pipe gallery to avoid occupying the construction space, and is especially suitable for the construction of the pipe gallery project with a small construction space . The assembling method effectively saves the construction space, saves the working surface and shortens the construction period.

Owner:CHINA 19TH METALLURGICAL CORP

Connecting device for burying pile casing and construction method

InactiveCN112442990AControl verticalityControl precisionBulkheads/pilesRobotic armStructural engineering

The invention discloses a connecting device for burying a pile casing and a construction method. The connecting device comprises a connector connected with a rotary drilling rig, an oil pump cylinderlocated in the pile casing is connected to the lower portion of the connector, a first hydraulic oil pump and a second hydraulic oil pump are arranged at the upper end and the lower end of the oil pump cylinder correspondingly, a first tray moving in the axial direction of the oil pump cylinder is arranged at the bottom of the first hydraulic oil pump, a second tray moving in the axial direction of the oil pump cylinder is arranged at the top of the second hydraulic oil pump, a plurality of mechanical arms arranged in the radial direction of the oil pump cylinder are arranged between the firsttray and the second tray, and supporting plates abutting against the inner wall of the pile casing are arranged at the ends, away from the oil pump cylinder. When the first tray and the second tray move close to each other, the mechanical arms drive the supporting plates to expand in the radial direction, and when the first tray and the second tray move away from each other, the mechanical arms drive the supporting plates to contract in the radial direction.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

Circulating slurry sprinkling device for desulfurization of flue gas

ActiveCN100450587CReduce power consumptionReduce energy consumptionDispersed particle separationFlue gasSpray nozzle

The invention relates to a smoke desulfuration cycle slurry spray device, which are layered in the adsorption tower. Each spray device is formed by at least two parallel spray main tube and the spray sub tubes branched from the spray main tube. The dual-direction ejectors that branched from the spray sub tubes are interlaced into mesh spray layer; two parallel spray main tubes are through the hole of support beam inside the adsorption tower, and horizontally fixed via single-beam support. The invention can solve the problems that not enough mixed between the smoke and cycle slurry; lower desulfuration effect; and easy abrasion and leakage at the interface between the spray tubes and the adsorption tower. The invention can be used in wet smoke desulfuration adsorption tower to utilize the limestone or lime slurry to adsorb the sulfur dioxide and sulfur trioxide.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com